A kind of magnetite-intelligent graphite composite phase conductive concrete

A technology of conductive concrete and magnetite, applied in the field of conductive concrete, can solve the problems of reducing the strength of concrete, reducing the resistance value, reducing the strength of components, etc., and achieving the effect of improving the strength of concrete, improving the strength of concrete and excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

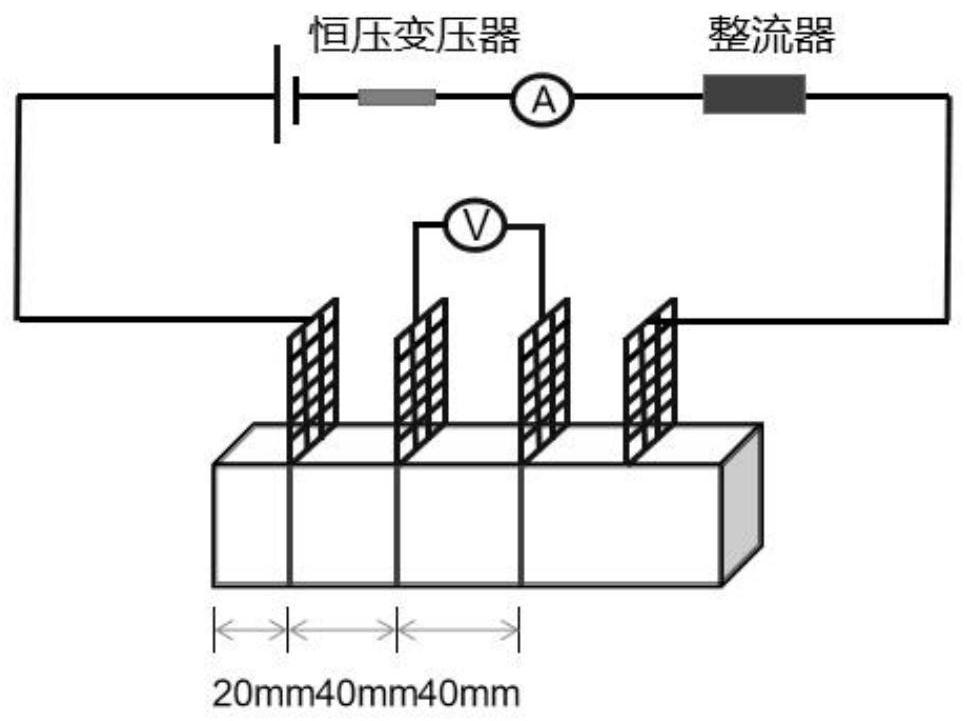

Method used

Image

Examples

Embodiment 1

[0083] The method for preparing conductive concrete that neither uses alkali excitation nor ultrasonic vibration wrapping technology is characterized in that: in parts by weight, the composition and content of the concrete are respectively:

[0084] Ordinary Portland cement: 1 part

[0085] Primary fly ash: 0.1 parts

[0086] River sand: 0.77 parts

[0087] Stones: 2.14 parts

[0088] Superplasticizer: 0.03 parts

[0089] Magnetite sand: 0.52 parts

[0090] Graphite: 0.06 parts

[0091] Water: 0.44 parts.

[0092] The preparation method comprises the following steps:

[0093] (1) According to the number of weights, the above-mentioned raw materials are divided into six groups, the first group is magnetite sand: 0.52 parts, and the second group is graphite: 0.06 parts. The third group is ordinary portland cement: 1 part, primary fly ash: 0.1 part, river sand: 0.77 part. The fourth group is water: 0.44 parts and superplasticizer: 0.03 parts. The fifth group of stones: 2...

Embodiment 2

[0099] The conductive concrete prepared only by alkali excitation technology and the preparation method thereof are characterized in that, in parts by weight, the composition and content of the concrete are respectively:

[0100] Ordinary Portland cement: 1 part

[0101] Primary fly ash: 0.1 parts

[0102] River sand: 0.77 parts

[0103] Stones: 2.14 parts

[0104] Superplasticizer: 0.03 parts

[0105] Sodium hydroxide: 0.00176 parts

[0106] Magnetite sand: 0.52 parts

[0107] Graphite: 0.06 parts

[0108] Water: 0.44 parts.

[0109] The preparation method comprises the following steps:

[0110] (1) According to the number of weights, the above-mentioned raw materials are divided into six groups, the first group is magnetite sand: 0.52 parts, and the second group is graphite: 0.06 parts. The third group is ordinary portland cement: 1 part, primary fly ash: 0.1 part, river sand: 0.77 part. The fourth group is water: 0.44 parts, sodium hydroxide: 0.00176 parts and supe...

Embodiment 3

[0116] The preparation method of conductive concrete prepared only by ultrasonic vibration wrapping technology is characterized in that: in parts by weight, the composition and content of concrete are respectively:

[0117] Ordinary Portland cement: 1 part

[0118] Primary fly ash: 0.1 parts

[0119] River sand: 0.77 parts

[0120] Stones: 2.14 parts

[0121] Superplasticizer: 0.03 parts

[0122] Magnetite sand: 0.52 parts

[0123] Graphite: 0.06 parts

[0124] Water: 0.44 parts.

[0125] Silane coupling agent KH-560: 0.00018 parts.

[0126] The preparation method comprises the following steps:

[0127] (1) According to the number of weights, the above-mentioned raw materials are divided into six groups, the first group is magnetite sand: 0.52 parts, and the second group is graphite: 0.06 parts. The third group is ordinary portland cement: 1 part, primary fly ash: 0.1 part, river sand: 0.77 part. The fourth group is water: 0.44 parts and superplasticizer: 0.03 parts. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com