Inorganic material surface biological method

An inorganic material and biological technology, applied in metal material coating technology, ion implantation plating, coating, etc., can solve problems such as weak binding force, poor biochemical effect, and weakened biomolecular activity, and achieve strong binding force, The effect of uniform modification and accelerated healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

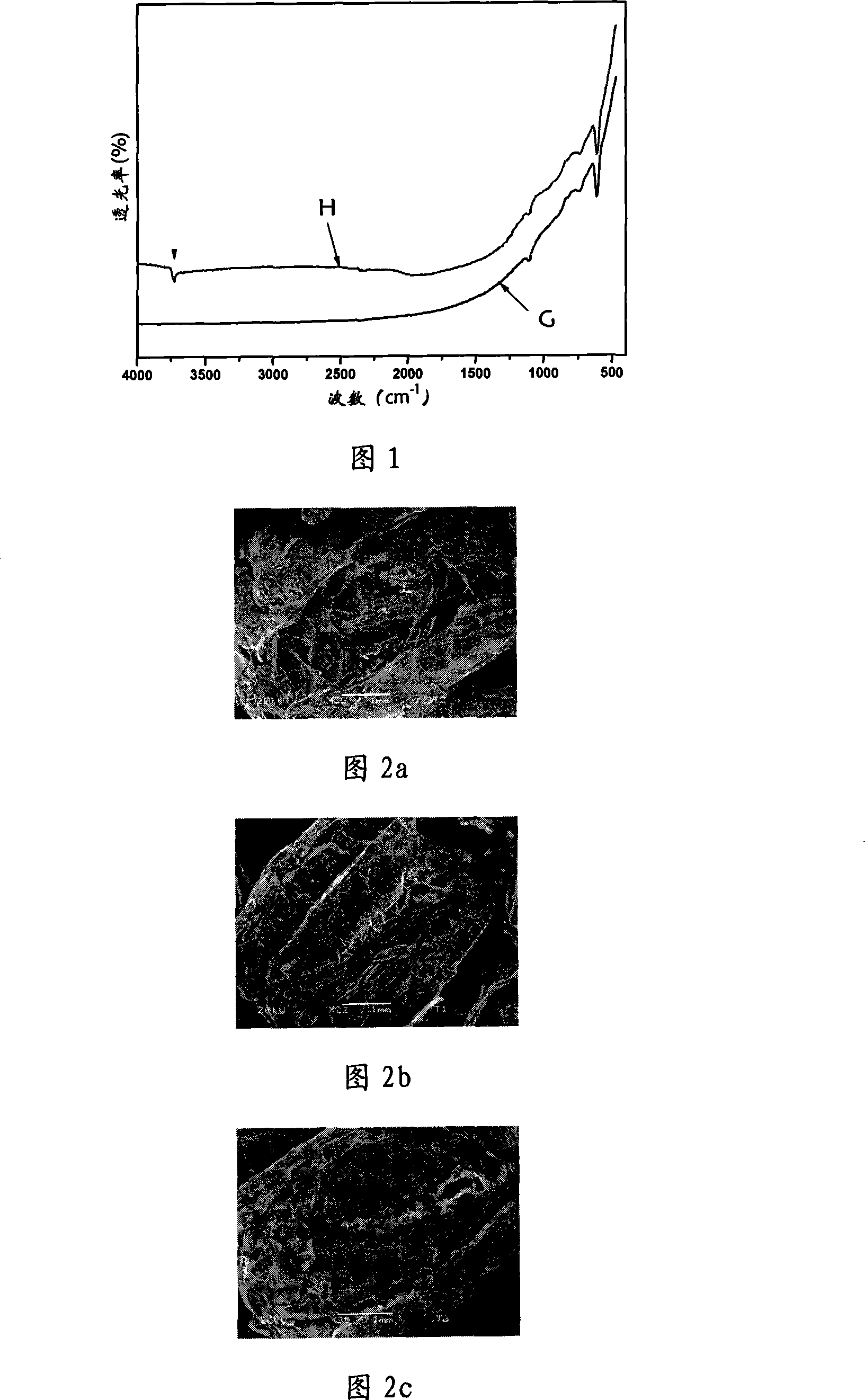

[0023] These 8 embodiments are all coated with tantalum oxide film on the surface of inorganic materials, then generating hydroxyl groups on the tantalum oxide film, and finally covalently grafting albumin; all are carried out according to the following operation steps:

[0024] A. Sputtering coating, using the existing unbalanced magnetron sputtering technology to sputter on the surface of inorganic materials to form a tantalum oxide film.

[0025] The specific operation steps are as follows:

[0026] TaO thin films were prepared by unbalanced magnetron sputtering device. This embodiment adopts the existing unbalanced magnetron sputtering device, including: workbench (sample stage), four sputtering target stages, pulse or DC power supply, workpiece, changeover switch, gas cylinder, bias power supply and heating device .

[0027] Cleaning: First, install the metal tantalum target on the target stage of the unbalanced magnetron sputtering equipment, place the workpiece on the...

Embodiment 1-8

[0039] Examples 1-8, the more specific operation during covalent grafting is: first prepare the albumin solution with distilled water, and then add an appropriate amount of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide in sequence hydrochloride (EDC), N-hydroxysuccinimide (NHS) and 2-morpholineethanesulfonic acid (MES) to activate the albumin surface. Immerse the inorganic material treated in step B into the albumin solution and seal it, place it in a constant temperature water bath (can be shaken) for a fixed set time, and take it out. After the physical adsorption layer on the surface of the workpiece is removed by ultrasonic cleaning, it is dried and stored for use.

Embodiment 9-16

[0041] Embodiments 9-16 are the same as Embodiments 1-8 respectively, except that in step A, the target used for sputtering coating is titanium metal, so that a titanium oxide film is formed on the surface of the inorganic material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com