Patents

Literature

741results about How to "Large pores" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silicon nitride powder, silicon nitride sintered body, sintered silicon nitride substrate, and circuit board and thermoelectric module comprising such sintered silicon nitride substrate

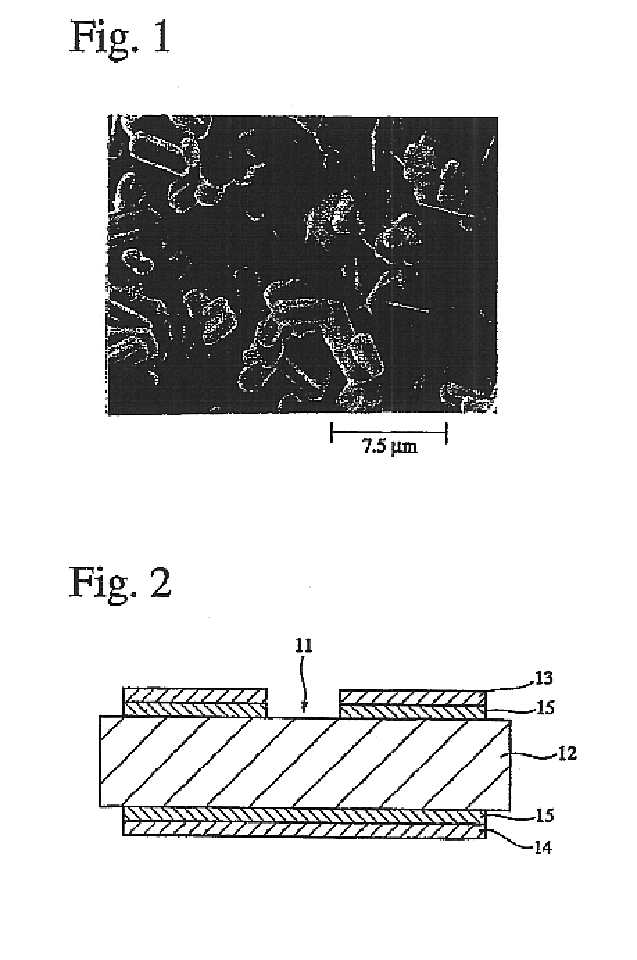

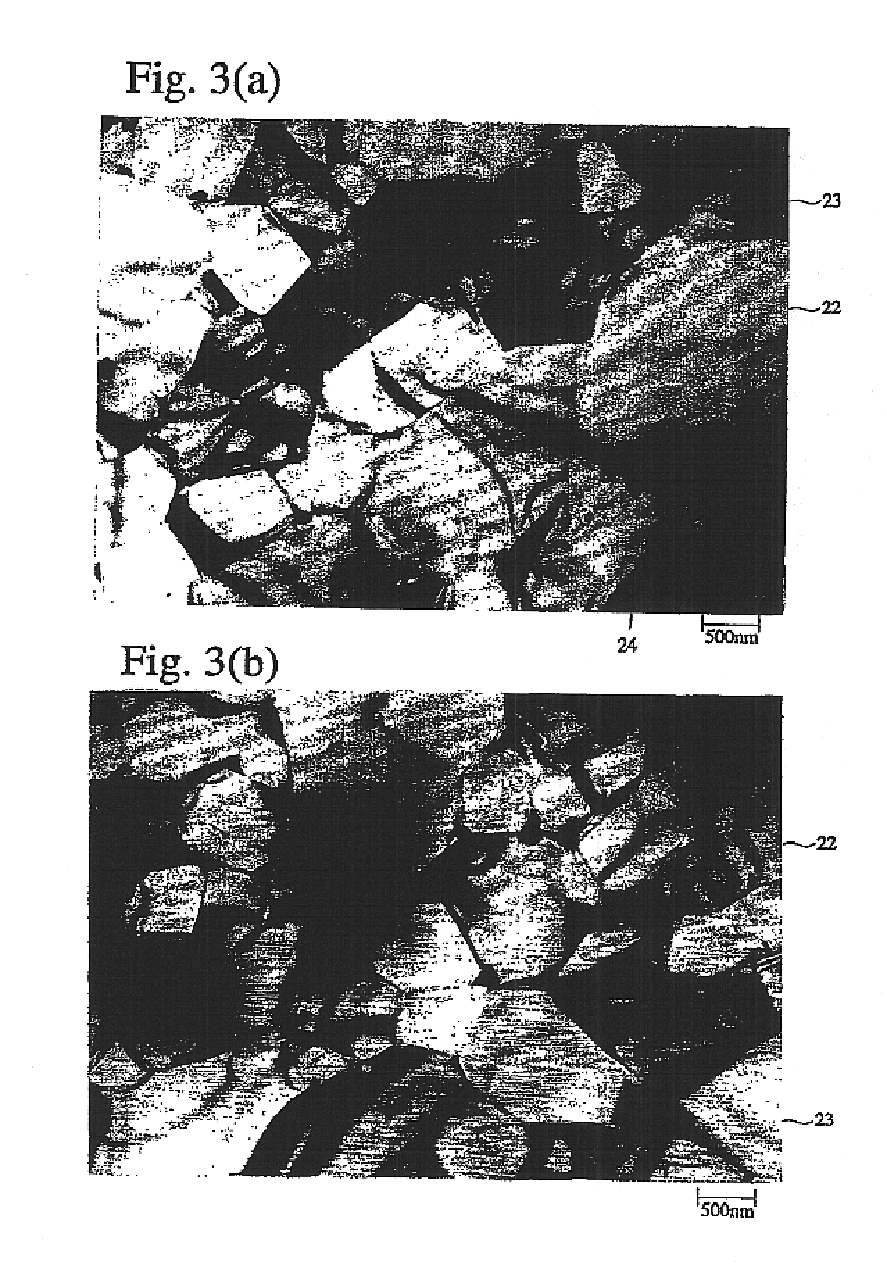

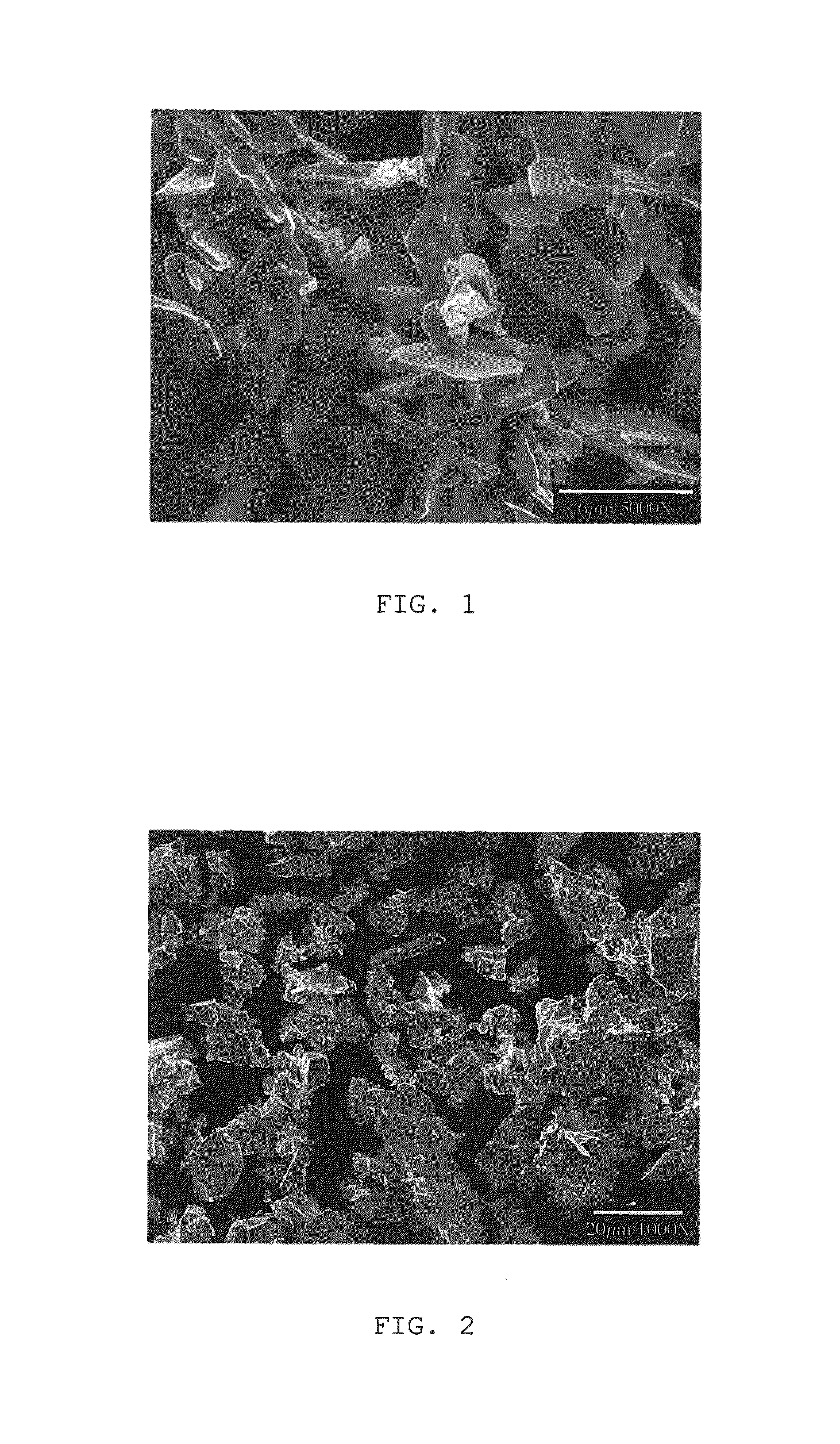

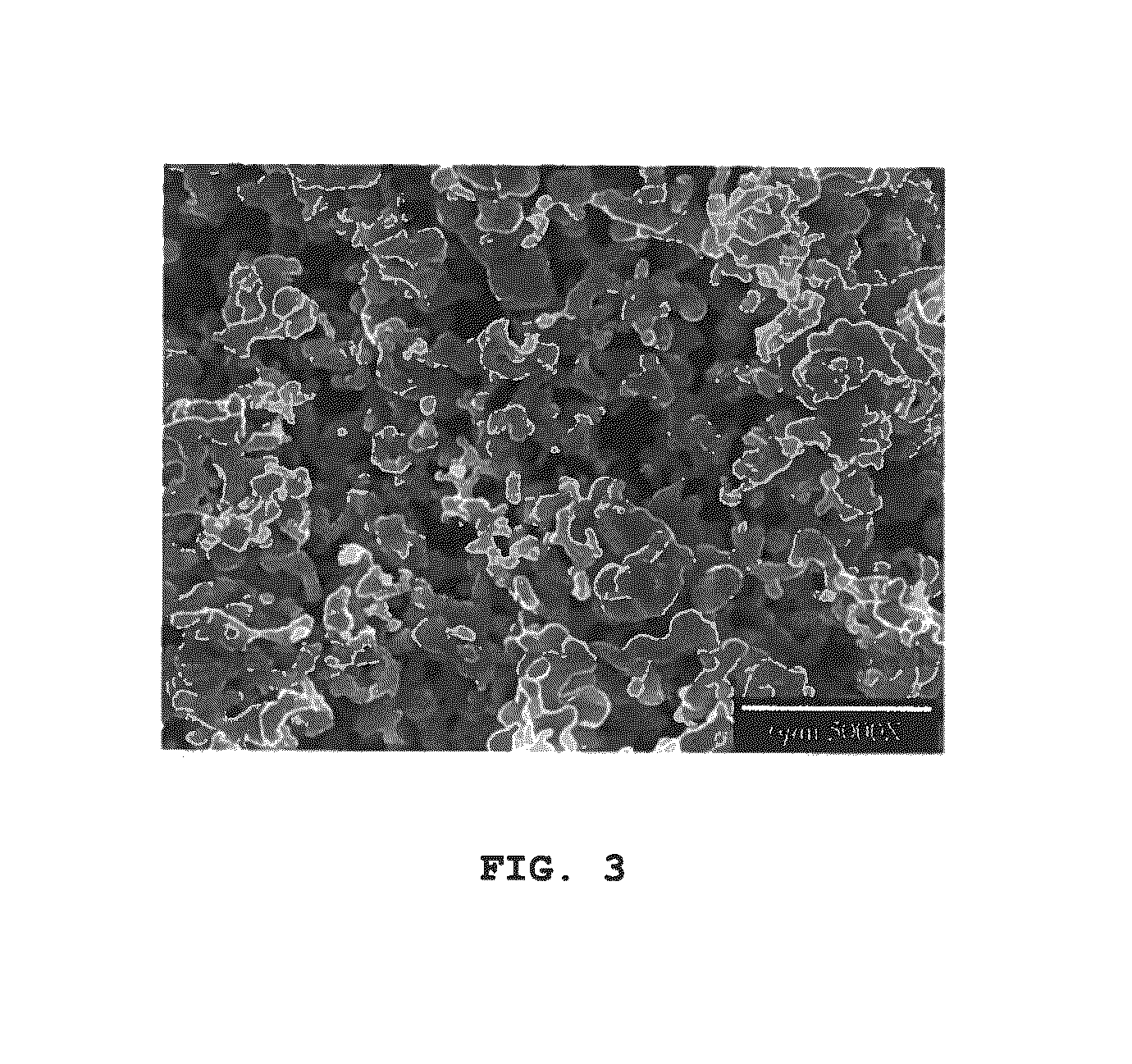

InactiveUS6846765B2High mechanical strengthImprove thermal conductivityNitrogen compoundsSemiconductor/solid-state device detailsRare-earth elementNitrogen atmosphere

A silicon nitride sintered body comprising Mg and at least one rare earth element selected from the group consisting of La, Y, Gd and Yb, the total oxide-converted content of the above elements being 0.6-7 weight %, with Mg converted to MgO and rare earth elements converted to rare earth oxides RExOy. The silicon nitride sintered body is produced by mixing 1-50 parts by weight of a first silicon nitride powder having a particle ratio of 30-100%, an oxygen content of 0.5 weight % or less, an average particle size of 0.2-10 μm, and an aspect ratio of 10 or less, with 99−50 parts by weight of α-silicon nitride powder having an average particle size of 0.2-4 μm; and sintering the resultant mixture at a temperature of 1,800° C. or higher and pressure of 5 atm or more in a nitrogen atmosphere.

Owner:HITACHI METALS LTD

Massive bodies containing free halogen source for producing highly converted solutions of chlorine dioxide

InactiveUS7182883B2Increase conversion rateImprove permeabilityBiocideOrganic chemistryHalogenLiquid water

A massive body, e.g., a tablet, for producing a solution of chlorine dioxide when the massive body is added to liquid water. The massive body comprises a metal chlorite such as sodium chlorite, an acid source such as sodium bisulfate and a source of free halogen such as the sodium salt of dichloroisocyanuric acid or a hydrate thereof. The concentration of free halogen in the solution will be:(a) less than the concentration of chlorine dioxide in said solution on a weight basis and the ratio of the concentration of chlorine dioxide to the sum of the concentrations of chlorine dioxide and chlorite anion in said solution is at least 0.25:1 by weight; or(b) equal to or greater than the concentration of chlorine dioxide in said solution on a weight basis and the ratio of the concentration of chlorine dioxide to the sum of the concentrations of chlorine dioxide and chlorite anion in said solution is at least 0.50:1 by weight.

Owner:ENGELHARD CORP

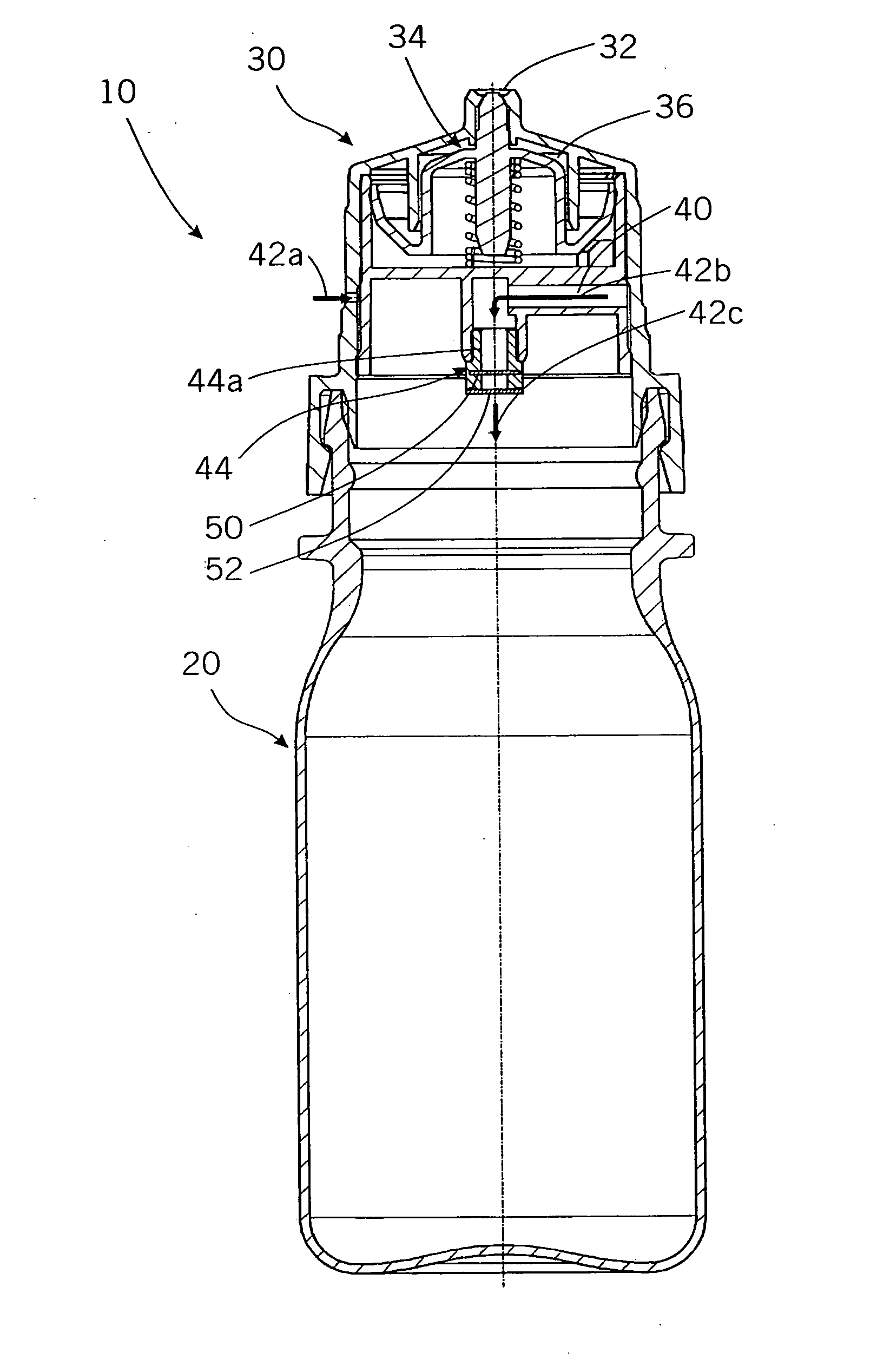

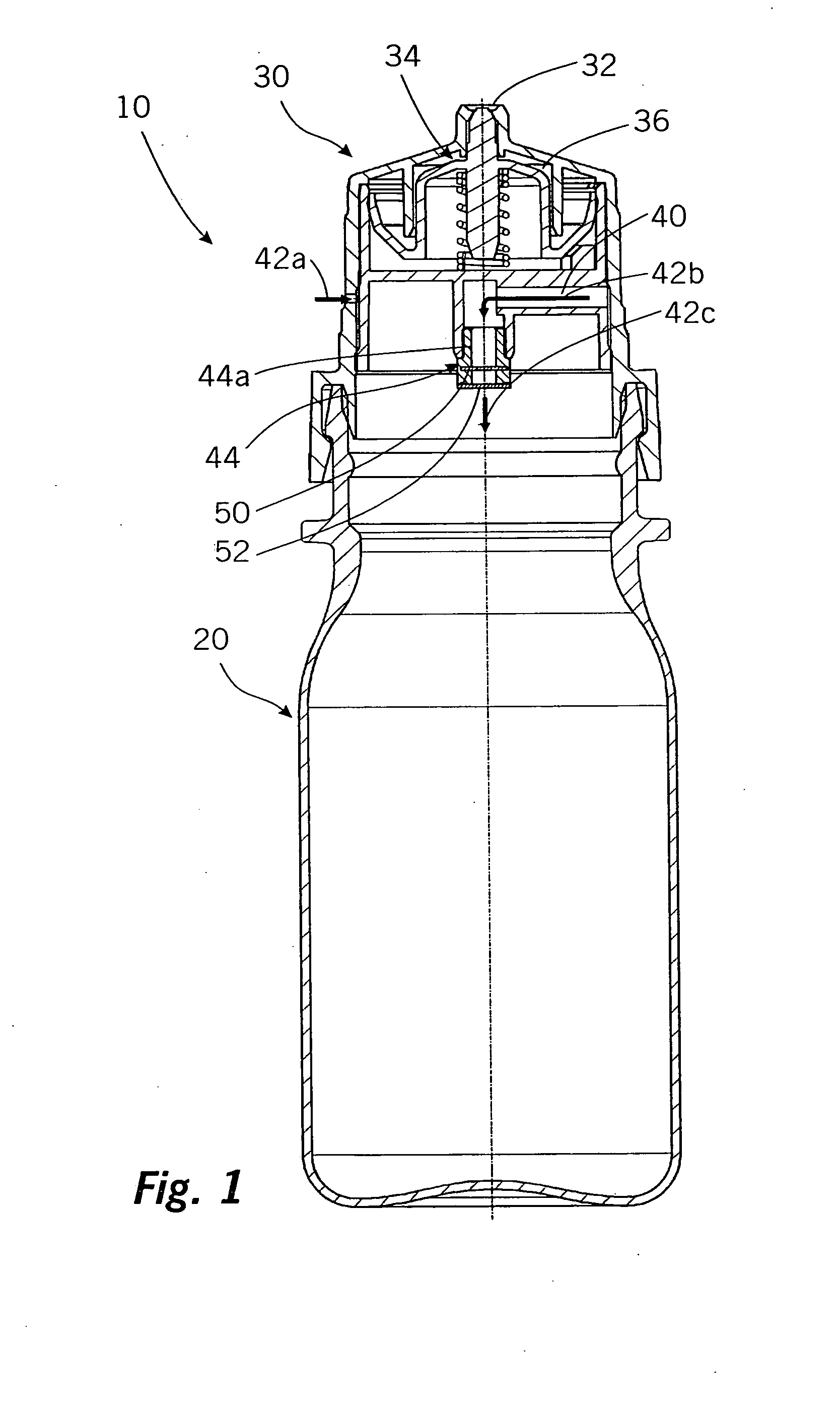

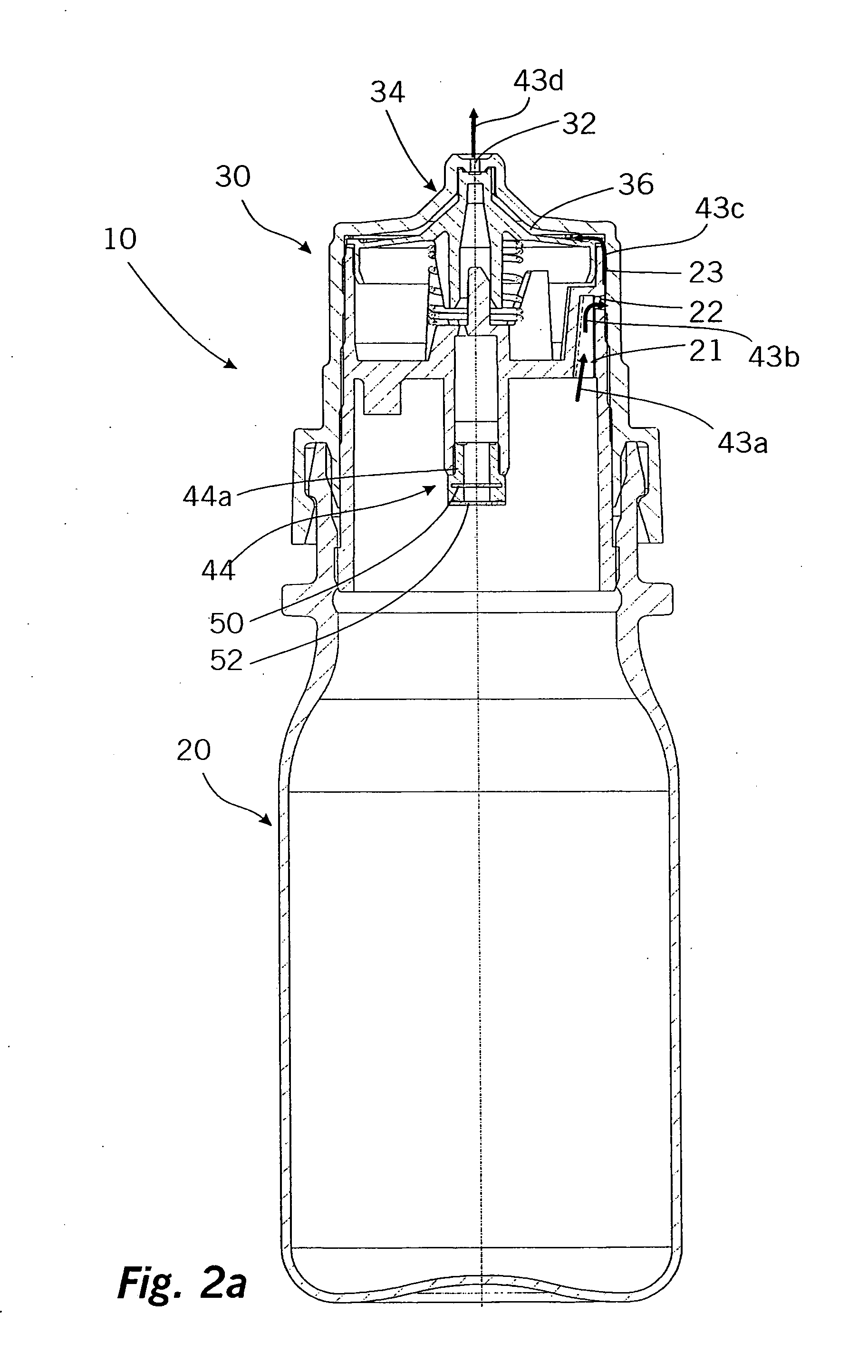

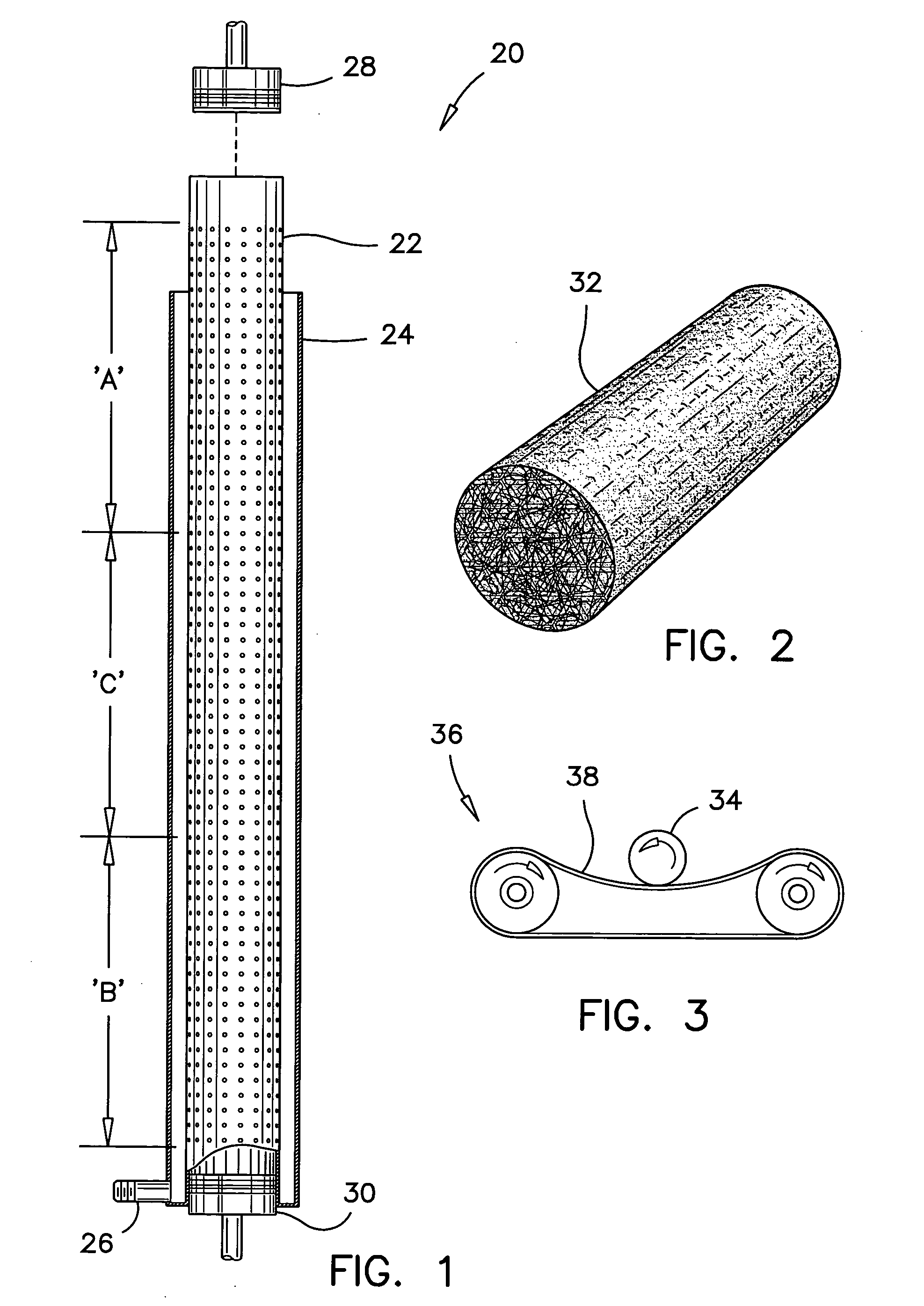

Dispensing device

ActiveUS20090294347A1Reduce pressureLarge poresPharmaceutical containersMedical packagingLiquid mediumEngineering

The invention relates to a dispensing device for a liquid medium, having a medium reservoir for accommodating the medium, having a dispensing opening for dispensing the medium from the medium reservoir, and having a pressure-equalizing channel which opens out into the medium reservoir and has a microbiologically active filter arrangement inserted therein.According to the invention, the filter arrangement has a liquid filter oriented in the direction of the medium reservoir and a bacteria filter oriented away from the medium reservoir.

Owner:APTAR RADOLFZELL

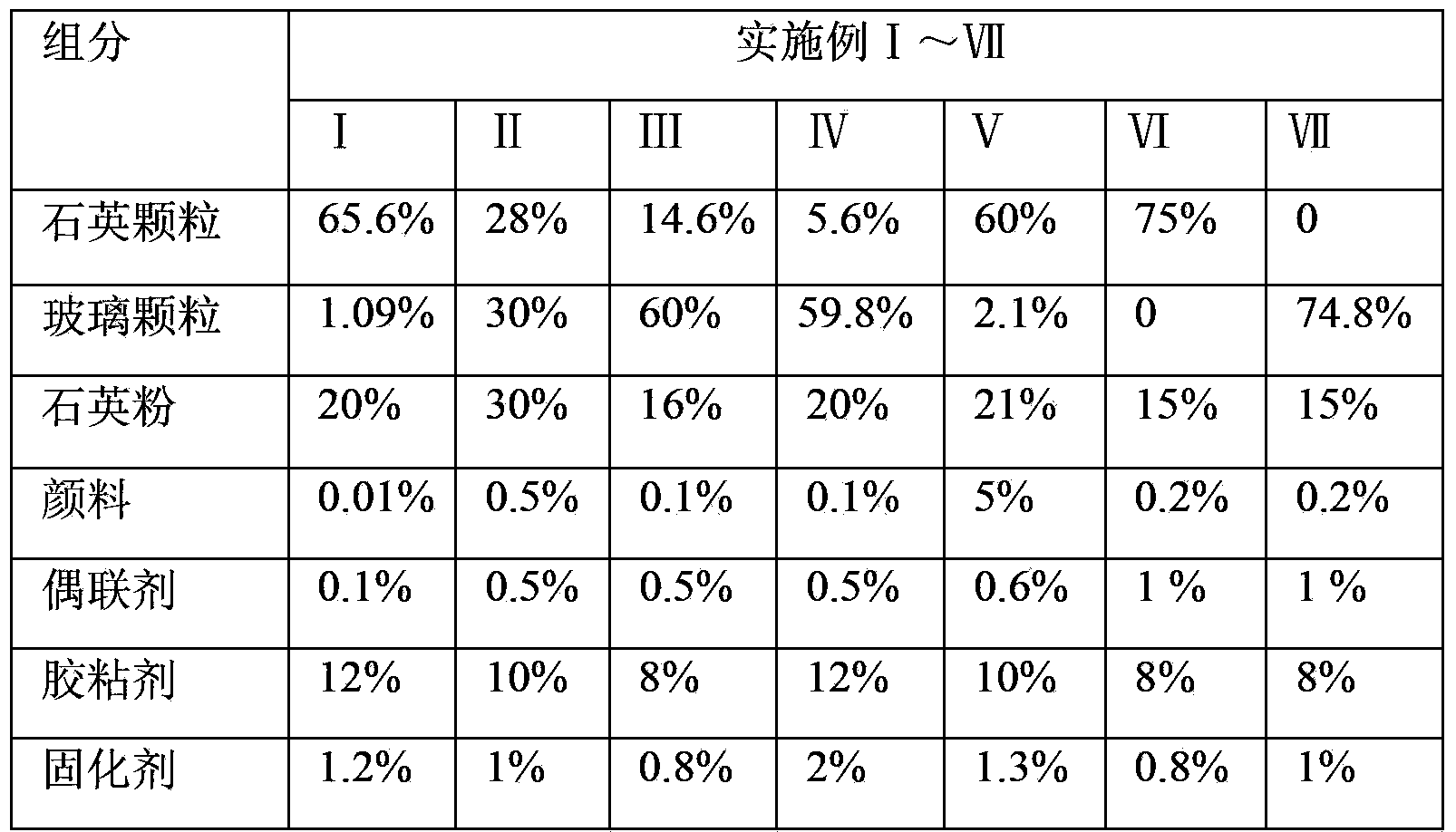

High-impact toughness man-made quartzite slab and preparation method thereof

The invention provides a high-impact toughness man-made quartzite slab and a preparation method thereof. The man-made quartzite slab comprises the following components in percentage by weight: 58-75 percent of particle raw materials, 15-33 percent of quartz powder, 0.01-10 percent of paint, 0.1-1 percent of coupling agent, 8-12 percent of adhesive and 0.8-2 percent of curing agent, wherein the particle raw materials are quartz particles, glass particles, or a mixture of the two. The man-made quartzite slab provided by the invention has the characteristics of low probability of cracking and deformation, and the like.

Owner:GUANGDONG BANNER NEW MATERIAL TECH

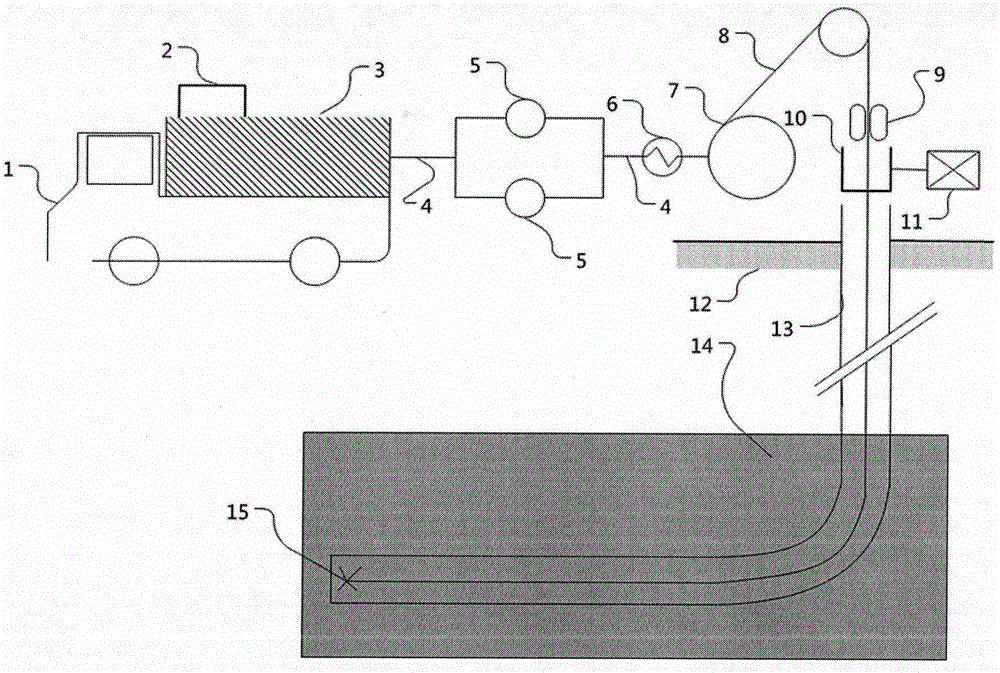

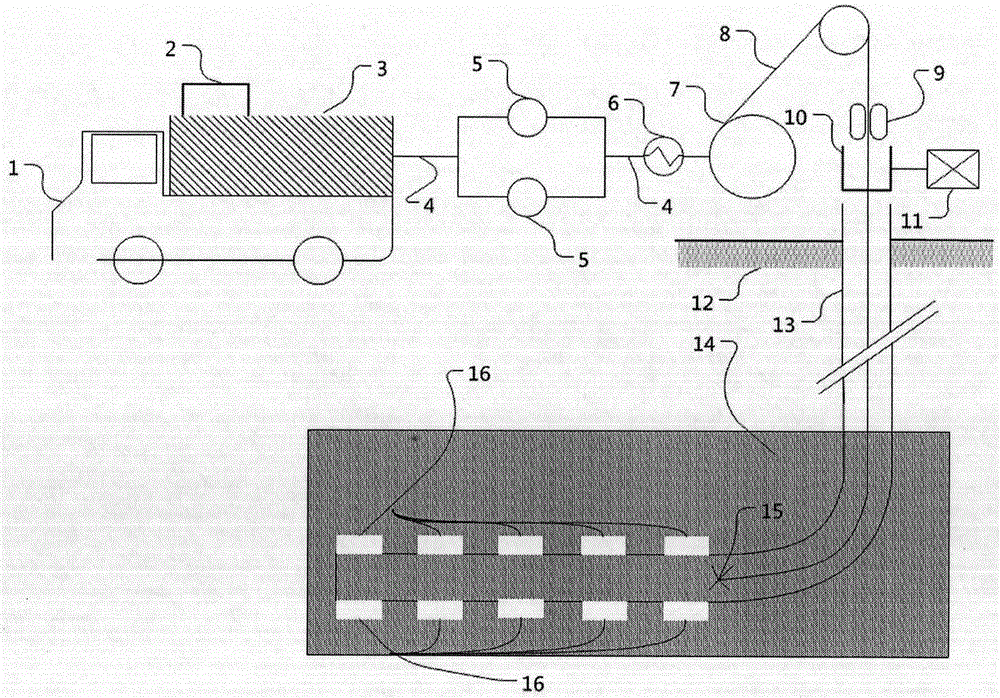

Coalbed methane horizontal well supercritical CO2 jet flow cavity construction and multi-segment synchronous deflagration fracturing method

InactiveCN105625946AAids in stress unloadingImprove permeabilityLiquid/gas jet drillingFluid removalHigh energyHigh pressure

The invention relates to a coalbed methane horizontal well supercritical CO2 jet flow cavity construction and multi-segment synchronous deflagration fracturing method. The method comprises the following steps: completing coalbed methane horizontal well drilling, introducing a coiled tubing into an supercritical CO2 rotary jet flow rock-breaking device to the bottommost end of a shaft, and performing pore broadening on the shaft by using an underground supercritical CO2 rotary jet flow rock-breaking device in order to form a cylindrical pore which is 1.0-1.5 meters in diameter and is 2-4 meters in length underground; after first-segment pore broadening is finished, lifting a rotary jet-flow tool to perform second-segment pore broadening work and so forth to finish pore broadening work of all well segments, wherein the segment distances are 80-100 meters; putting a solid explosive into a pore broadening cavity by using the coiled tubing after finishing pore broadening, and introducing a screen pipe; lastly, pressurizing by using a ground high-pressure CO2 pump to ignite the explosive, and mixing generated high-energy gas with a supercritical CO2 fracturing coalbed. By adopting the method, a plurality of complex volume cracks can be generated in the coalbed, explosive fracturing contributes to coalbed stress unloading after pore broadening, and the coal rock permeability can be improved effectively, so that the yield of a coalbed methane horizontal well is improved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

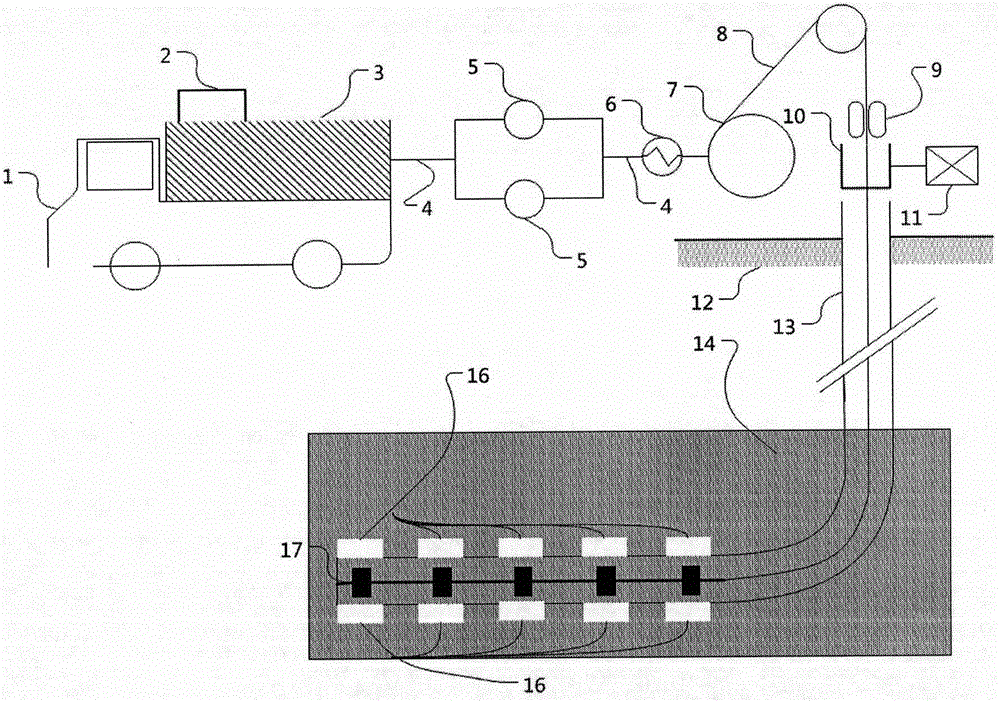

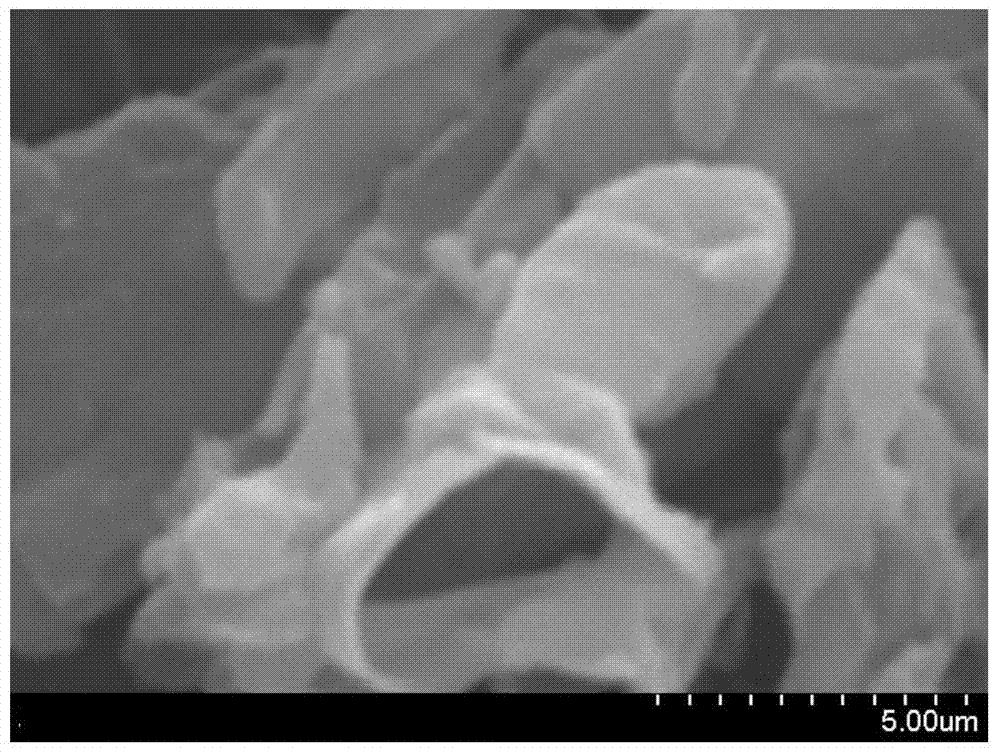

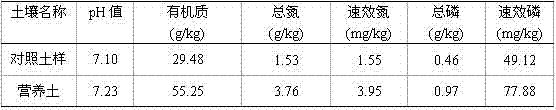

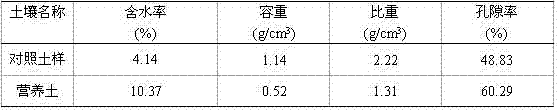

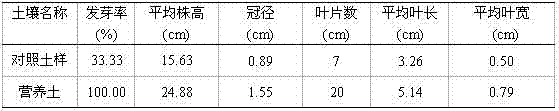

Soil improvement agent and improvement method of heavy metal lead-contaminated soil

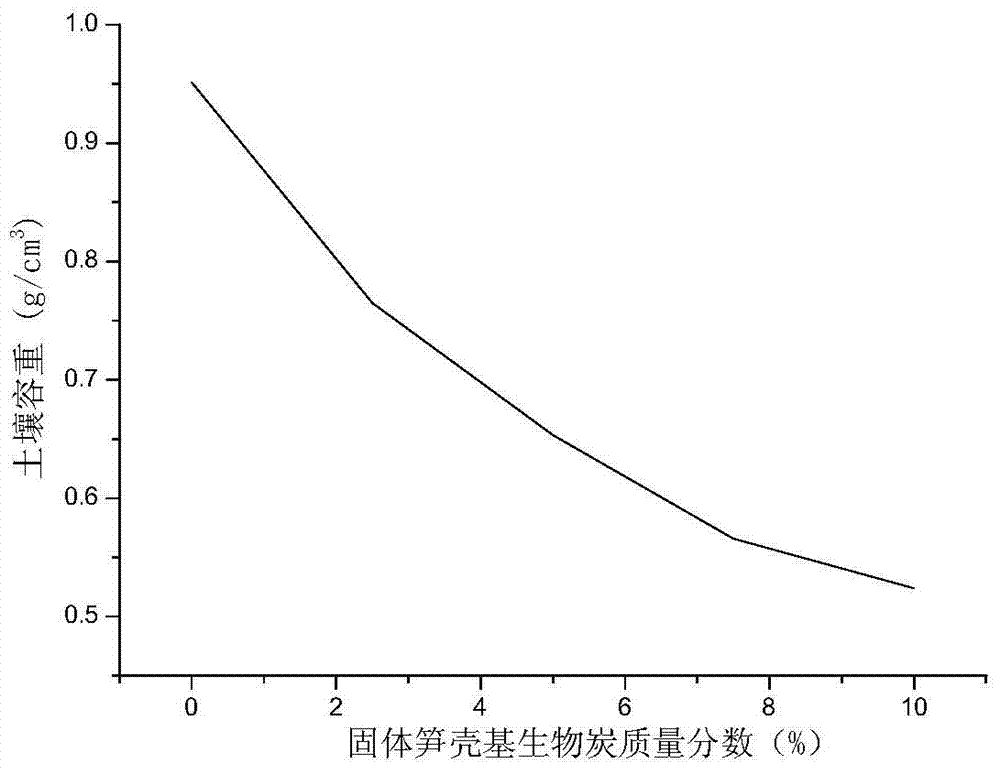

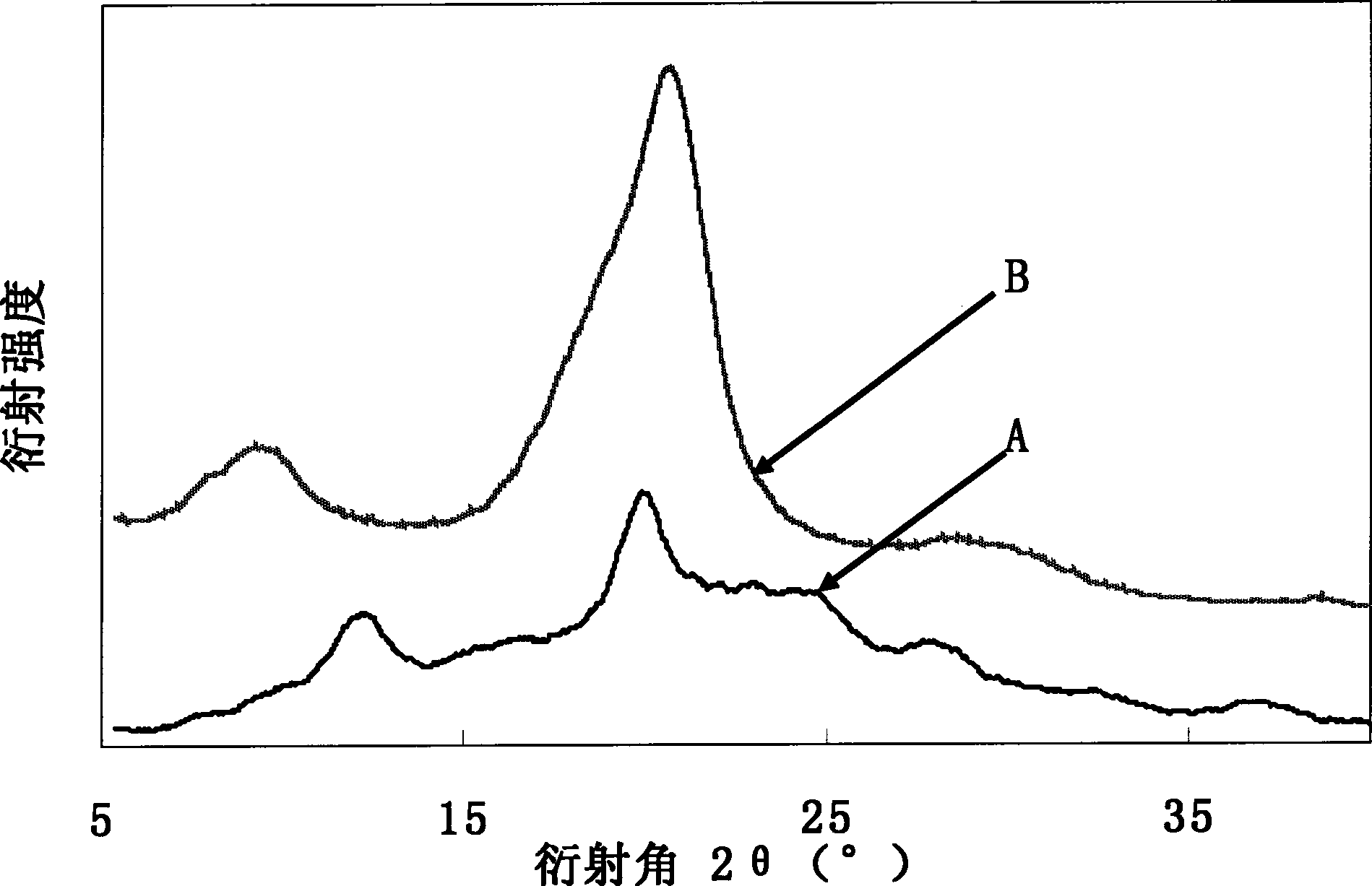

InactiveCN103484125AWeaken the poisonImprove water and fertilizer retention capacityContaminated soil reclamationOrganic fertilisersBiomassContaminated soils

The invention discloses a soil improvement agent and improvement method of heavy metal lead-contaminated soil, relating to a soil improvement agent. The soil improvement agent is solid bamboo shoot shell-based biochar, and elements obtained by isolating oxygen at 400 DEG C and pyrolyzing for 30 minutes include C, H, N, K, P, Mg, Ca, Si and O. The soil improvement agent is prepared by the steps of cleaning, drying and grinding a bamboo shoot shell, and putting into a pyrolyzing furnace; isolating oxygen at 380-420 DEG C and pyrolyzing for 20-40 minutes; drying, pre-charring and charring the biomass bamboo shoot shell to obtain solid bamboo shoot shell-based biochar. The improvement method comprises the steps of adding 2.5-10% of the soil improvement agent by mass into the heavy metal lead-contaminated soil; adding water to 70% of the saturation moisture capacity of the field oil; covering with a film to prevent water loss; forming air ports in the film at an interval of 5cm; adding water every 2-3 days to supplement the lost water; culturing, taking out the product and performing air drying to obtain improved soil.

Owner:XIAMEN UNIV

Organic substrate suitable for planting vegetables, melons and fruits and preparation method thereof

ActiveCN101891511ALarge focal porosityLarge coke porosity (75%-85%) and many poresBio-organic fraction processingOrganic fertiliser preparationInsect pestWater Hyacinths

The invention discloses an organic substrate suitable for planting vegetables, melons and fruits and a preparation method thereof. The preparation method is characterized by comprising the following steps of: mixing the following materials in percentage by weight: 30 to 40 percent of water hyacinth, 20 to 35 percent of sawdust, 10 to 20 percent of biomass char, 10 to 20 percent of wormcast, 0.3 to 1.1 percent of beneficial microflora, and 0.8 to 1.7 percent of nonmetallic mineral, and stirring the materials by using water with an EC value of less than 150US.cm<-1>; fermenting for 48 hours in a storeroom at the temperature of between 20 and 28 DEG C, and composting for 25 to 30 days at the temperature of between 40 and 90 DEG C so as to prepare the organic substrate. The organic matrix hasthe advantages of rich nutrition, strong air permeability, low cost, and capacities of improving the plant yield and quality and reducing the plant diseases and insect pests.

Owner:李学麒

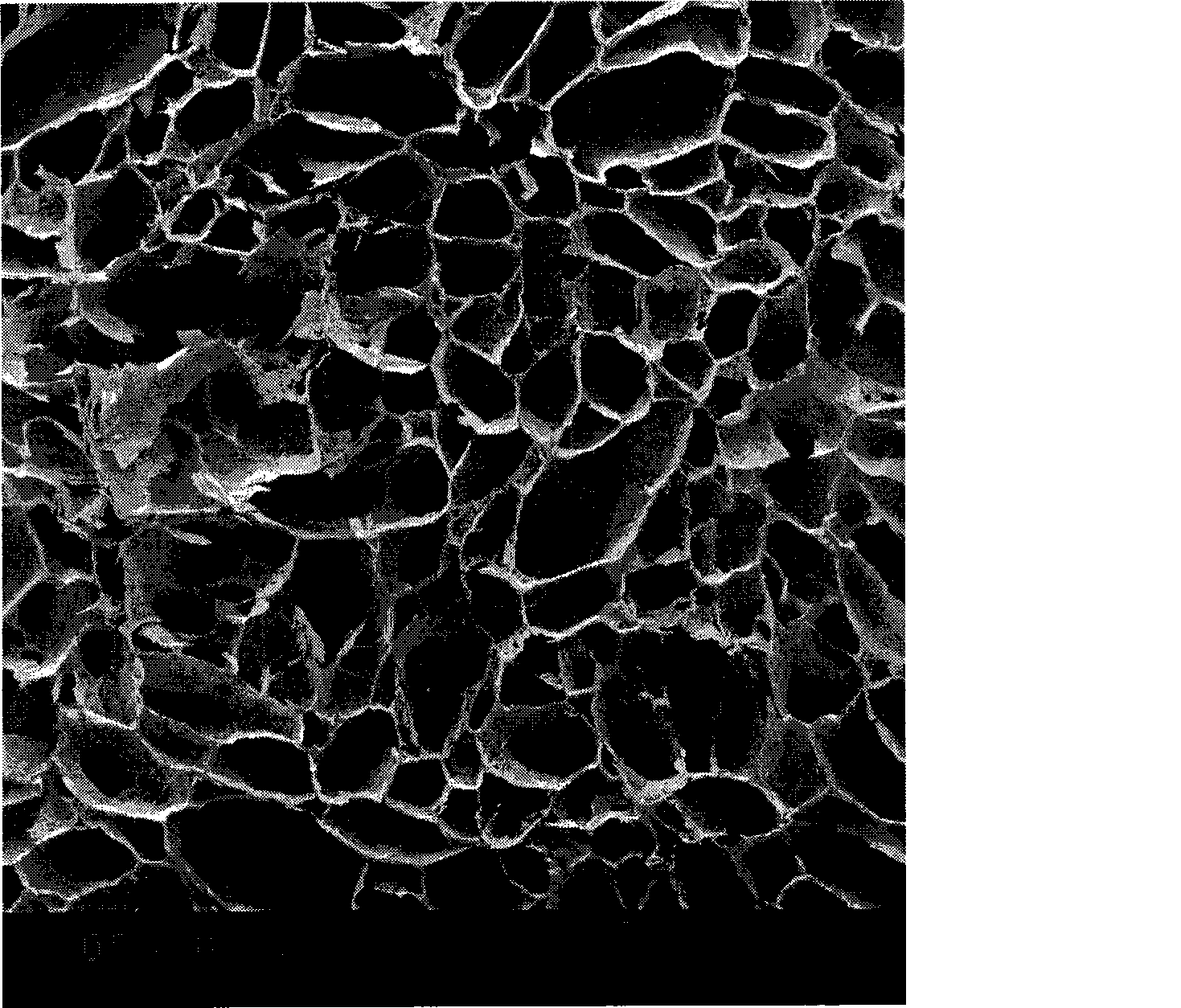

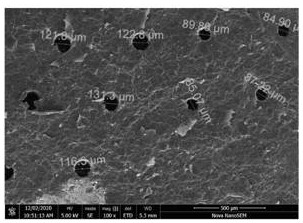

Silk fibroin porous three-dimensional material and preparation method thereof

The invention relates to a porous material and a preparation method thereof, in particular to a technology in which silk fibroin is taken as a raw material to prepare porous three-dimensional materials. In the method, silk fibroin solution is injected into a metal mould, 1-24 hours of quick freezing is carried out on the solution at the low temperature of minus 10-minus 80 DEG C, thus obtaining afrozen body; the frozen body is preserved at the temperature of minus 5-minus 25 DEG C for 2-60 days, thus obtaining frozen crystalline solid; then the frozen crystalline solid is thawed and dried, thus obtaining the silk fibroin porous three-dimensional material. The silk fibroin of the porous material is fibroin I type crystal structure, therefore, the silk fibroin is insoluble in water and canbe completely degraded in a while and is finally degraded into nonpoisonous amino acid; the material of the invention has mutual run-through pores with aperture of 10-500 microns; the pores and pore diameter are relatively large, thus being suitable for growth of cells; meanwhile, in the process of preparation, no chemical cross linking agent, foaming agent or denaturing agent are needed, thus retaining fine biocompatibility of the silk fibroin.

Owner:苏州盛泽科技创业园发展有限公司

Filter material of tefloncomposite membrane

ActiveCN1565713AHigh strengthLarge circulationSemi-permeable membranesSynthetic resin layered productsDimethyl formamidePolyvinylidene fluoride

The invention relates to polytetrafluoroethylene (PTFE) composite film filtering materials for air filtering industry. The polytetrafluoroethylene composite film filtering materials comprise the following components: fiberglass as basement film; polytetrafluoroethylene as surface film; and adhesive agent which is one of polysulfone, nylon 66 and polyvinylidene fluoride fibre for binding the fiberglass and polytetrafluoroethylene; pore-forming material which is one of metal salt KI and NH#-[4]Cl; solvent which is one of dimethyl acetamide, dimethyl formamide and N-methyl pyrrolidone. The content (by weight) of macromolecular compound and pore-forming material is: 5% to 30% of macromolecular compound, 5% to 15% of pore-forming material. The fiberglass and polytetrafluoroethylene composite materials can improve filtration efficiency and have improved hydrophobicity, high-temperature resistance and corrosion resistance.

Owner:SHANGHAI FILTER

Graphene foam film enhanced heat-conducting gasket and preparation method thereof

PendingCN113290958ALarge poresHigh porosityLamination ancillary operationsLaminationAdhesive cementPolymer science

The invention discloses a graphene foam film enhanced heat-conducting gasket and a preparation method thereof. The graphene foam film enhanced heat-conducting gasket comprises a plurality of layers of graphene foam films and adhesives filled in the graphene foam films and among the layers, and the graphene foam films account for 60-95 wt% of the total weight of the heat-conducting gasket. The graphene is arranged in the heat-conducting gasket in the thickness direction, and the gasket has good heat-conducting performance in the thickness direction; besides, the combination of the graphene foam film and the adhesive has good compressibility and compression resilience, and the application thermal resistance is small.

Owner:CHANGZHOU FUXI TECH CO LTD

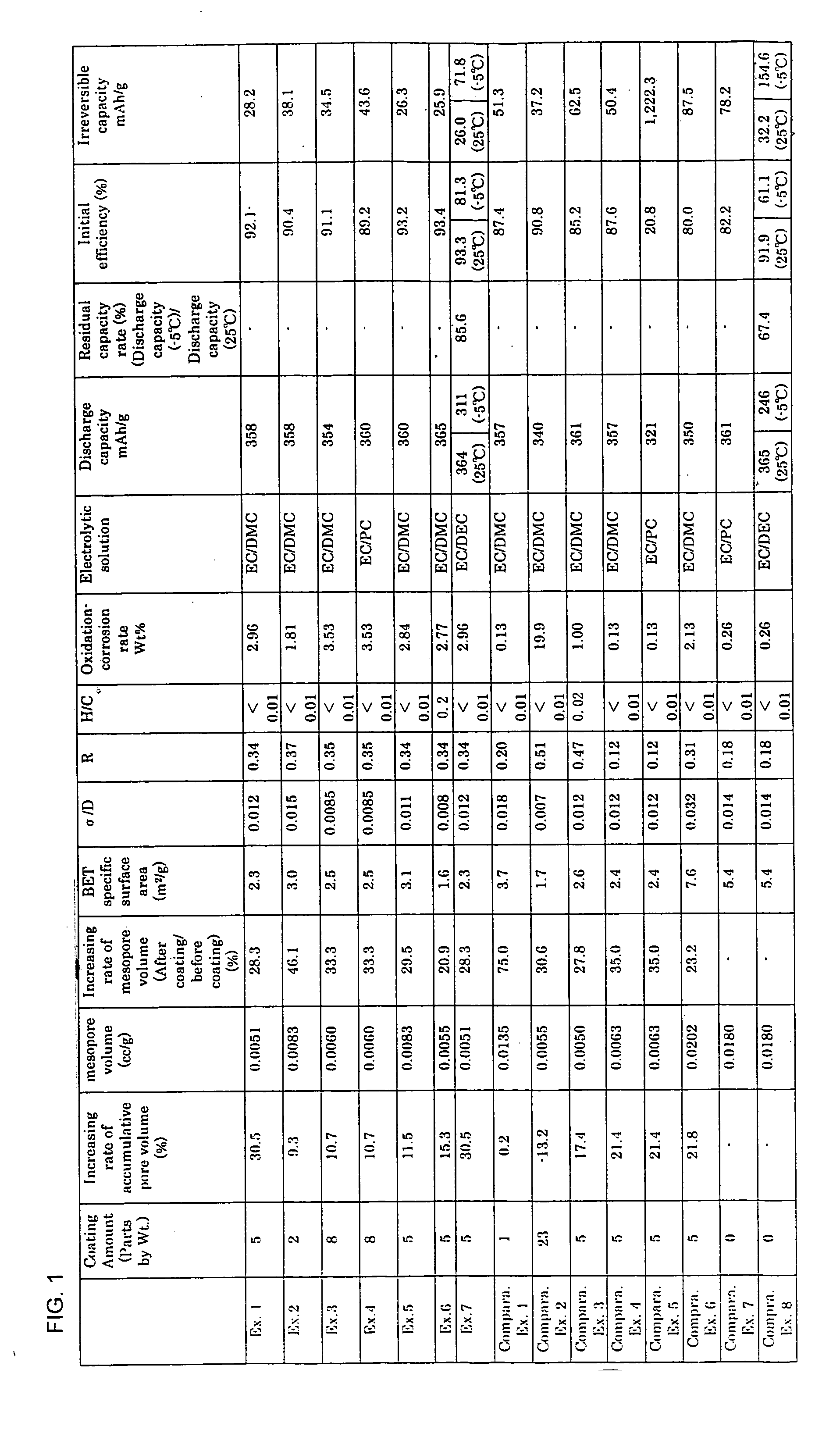

Negative electrode material for lithium ion secondary battery

InactiveUS20050158550A1Good effectTrimming is irreversibleSynthetic resin layered productsCellulosic plastic layered productsLaser scatteringLithium

The invention provides an anode material for lithium ion secondary battery using a coated graphite powder as a raw material. The coated graphite powder is coated with carbonized material of thermoplastic resin of a carbonization yield of not more than 20 wt % in a proportion of not more than 10 parts by weight the carbonized material per 100 parts by weight graphite powder. The graphite powder as coated with thermoplastic resin increases 5% or more in accumulative pore volume of the graphite powder having a pore size of 0.012 μm to 40 μm as measured by a mercury porosimeter method, as compared with the graphite powder before coated with the thermoplastic resin. The coated graphite powder has a mesopore volume defined by IUPAC of 0.01 cc / g or less as calculated with the BJH method as viewed from desorption isotherm, which is also equal to 60% or less of the pore volume of the graphite powder before coated with the thermoplastic resin, an average particle size ranging from 10 μm to 50 μm, as measured by a laser-scattering-particle-size-distribution measuring device, and a ratio of standard deviation to the average particle size (σ / D) of 0.02 or less.

Owner:TOYO TANSO KK

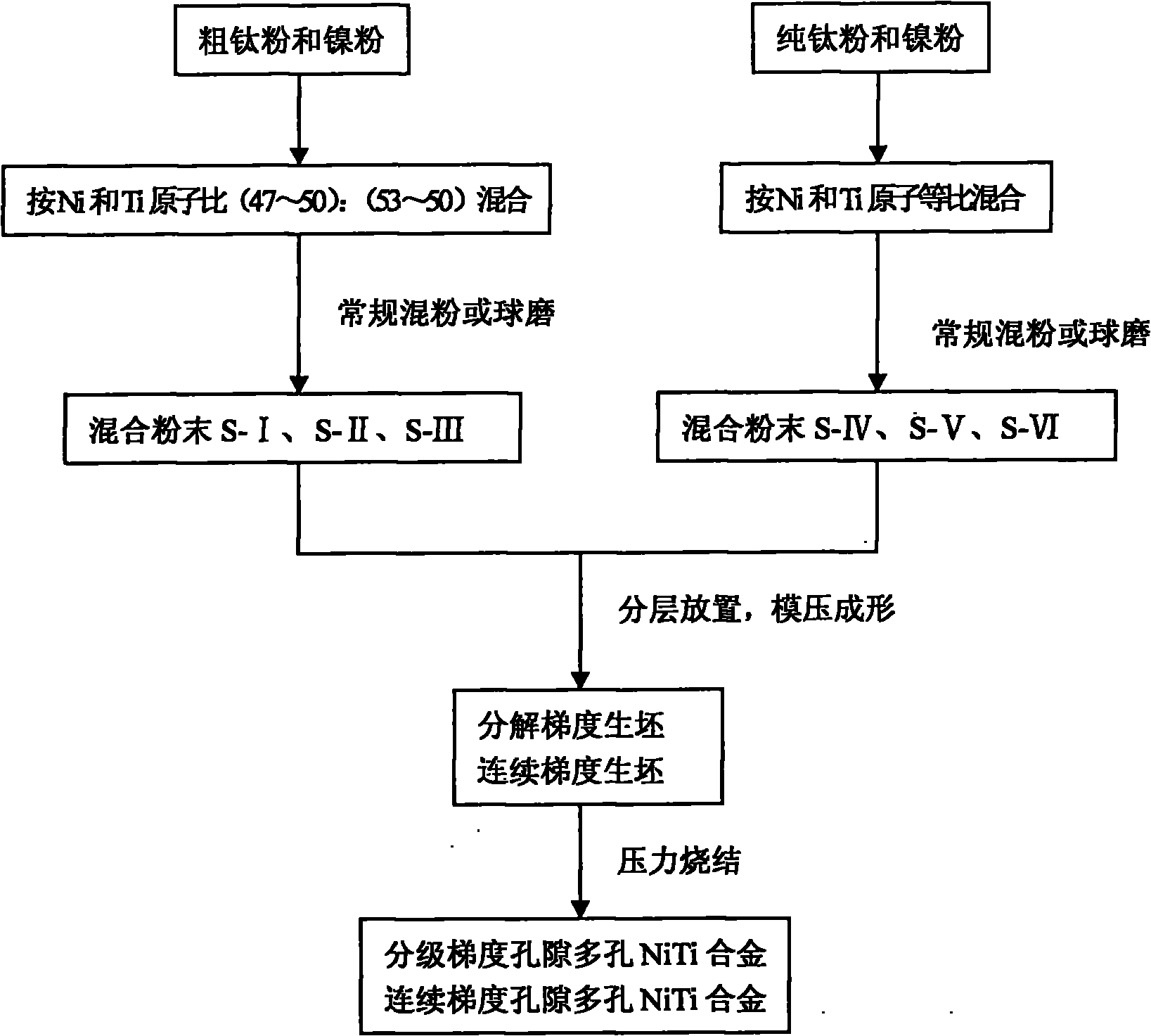

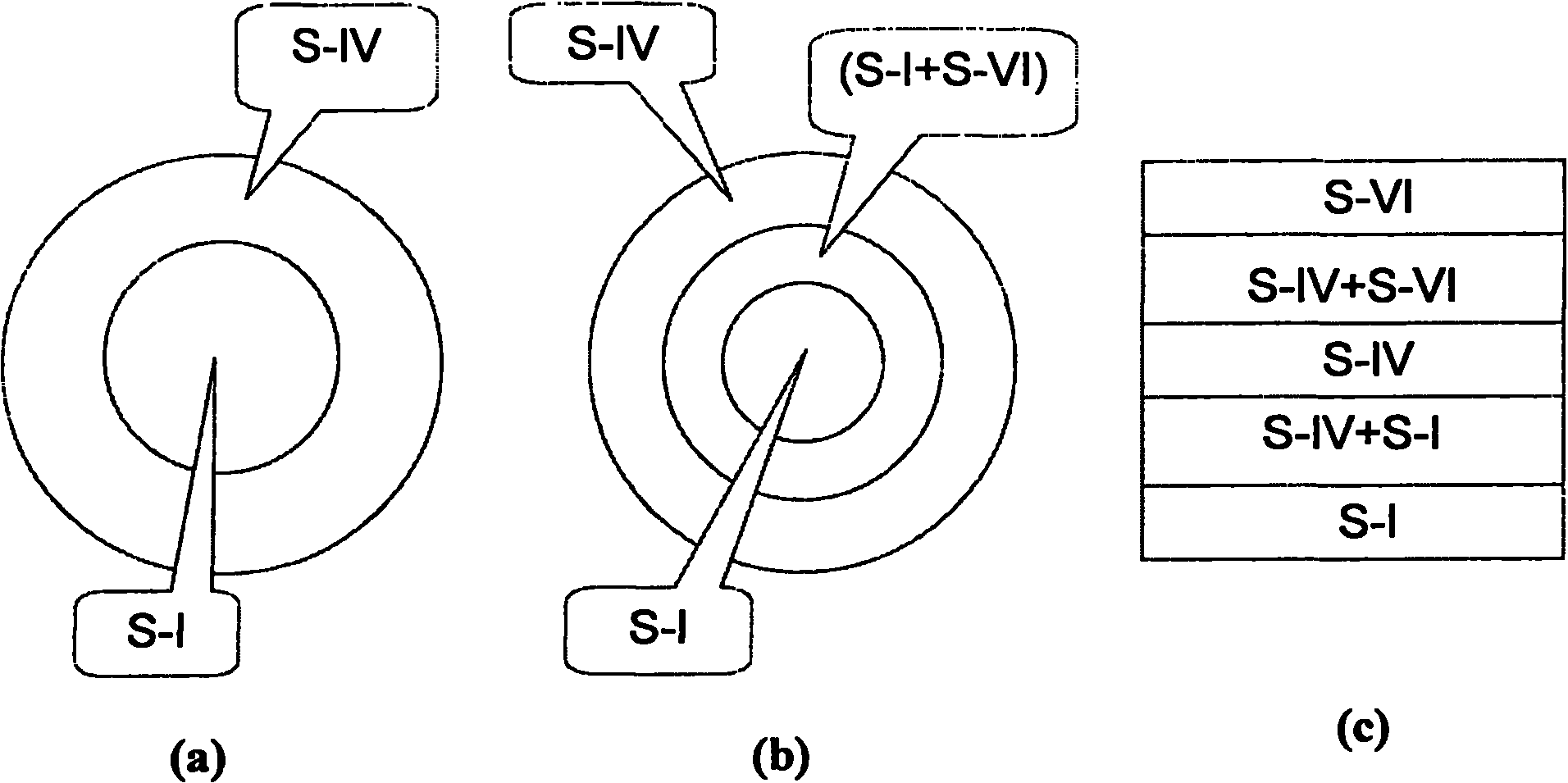

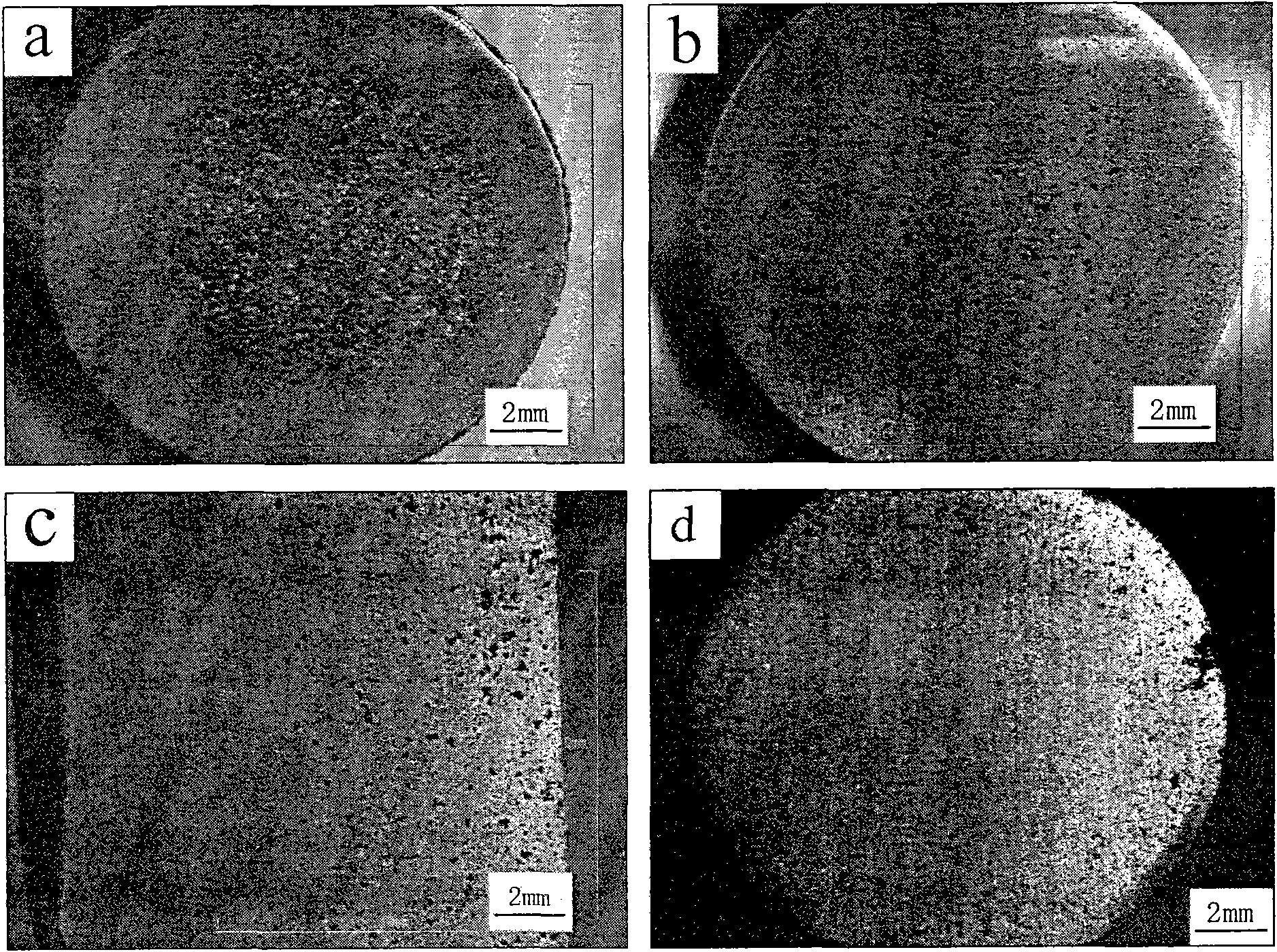

Method for preparing super-elastic gradient-porosity porous NiTi alloy

The invention discloses a method for preparing a super-elastic gradient-porosity porous NiTi alloy, which comprises the following steps of: (1) mixing coarse titanium powder and nickel powder in an atomic ratio of (47-50):(53-50), numbering the mixed powder as S-I, S-II and S-III in turn according to the difference of particle sizes of the nickel powder, uniformly mixing pure titanium powder and nickel powder in the same atomic ratio of Ti to Ni, and numbering the mixed powder as S-IV, S-V and S-VI in turn according to the difference of particle sizes of the nickel powder; (2) dividing a mold into 2 to 5 layers along the radial or axial direction of the mold, and performing compression molding to obtain layered green body of the gradient-porosity porous NiTi alloy; and (3) sintering the green body in a sintering furnace in the atmosphere of protective gases to obtain the porous NiTi alloy in different gradient pore distribution. The porous NiTi shape memory alloy is suitable for tissue ingrowth and has good mechanical property.

Owner:SOUTH CHINA UNIV OF TECH

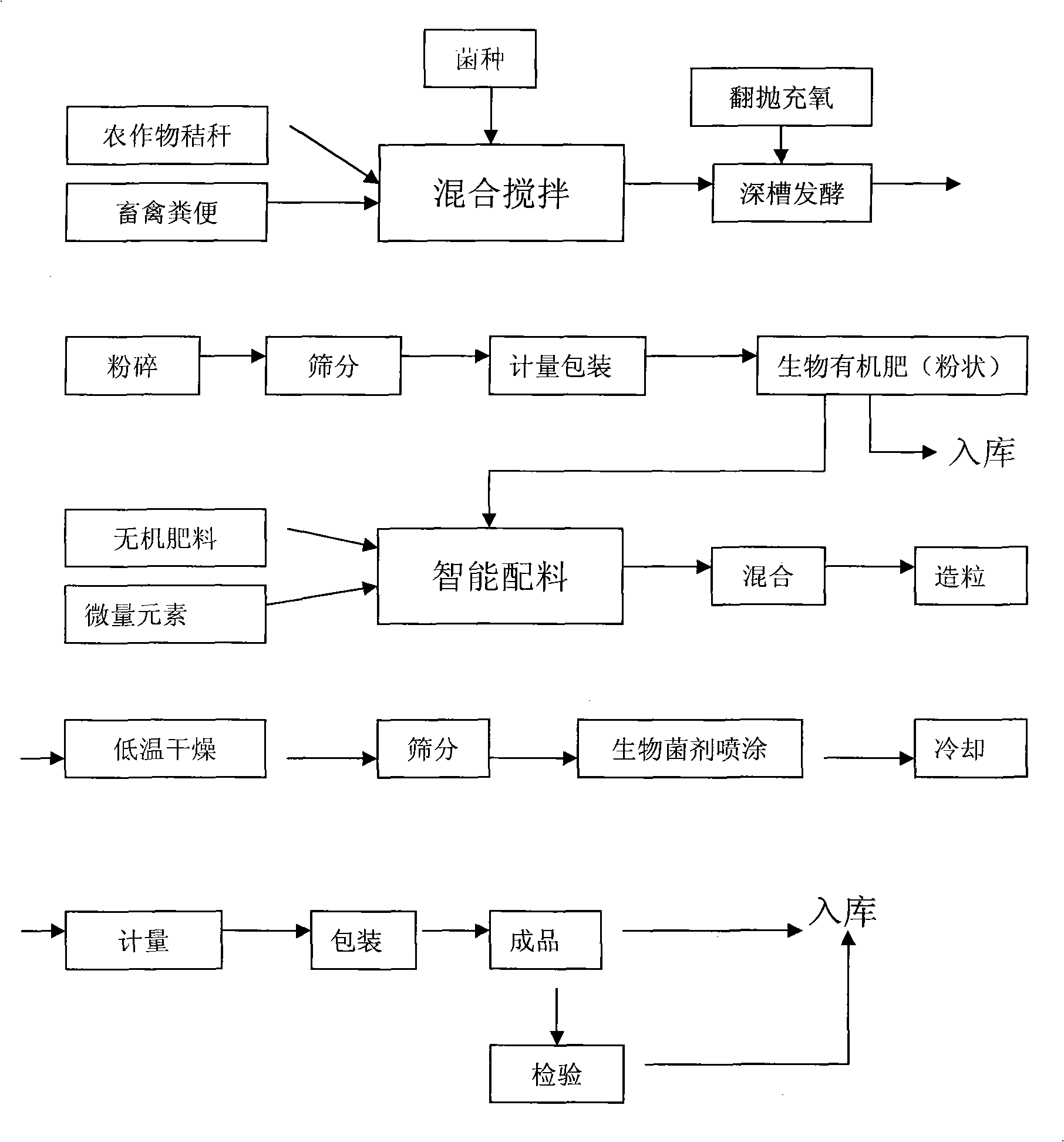

Production process of biological-organic-inorganic ternary compound fertilizer

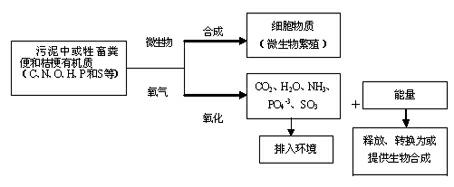

InactiveCN101676243AShorten the decay cycleReduce nutrient lossBio-organic fraction processingOrganic fertiliser preparationChemistryOrganic component

The invention provides a production process of a biological-organic-inorganic ternary compound fertilizer which is prepared by the following steps: mixing crop stalks, such organic components as livestock manures and active biological agents, regulating the carbon nitrogen ratio from 26 to 35, PH from 5.5-8.2 and moisture from 40% to 65% according to the organic matter contents of the crop stalksand the livestock manures, fermenting the mixture at minus15-75 DEG C for 20-50 days and ensuring the living bacteria count to be 0.03-0.2 billion / g, carrying out turning and oxygenating, fermenting in deep tanks and grinding on the mixture to prepare the biological organic fertilizers, mixing the biological organic fertilizers with the inorganic fertilizers and trace elements and simultaneously adopting the low-temperature drying process after extruding granulation and the biological agent spraying and cooling technology. The method can greatly shorten the decay period, ensure little nutrientloss and little generating capacity of sour gases in the processes of fermentation and decay and complete decay and fermentation, can enhance the stress resistance of the crops, ensure obvious disease-resistant effects and high survival rates of specific functional bacteria and has wide application. Through field contrast tests, both the production and income are increased by 10-25% by applying the biological organic fertilizer.

Owner:辽宁元亨生物科技有限公司

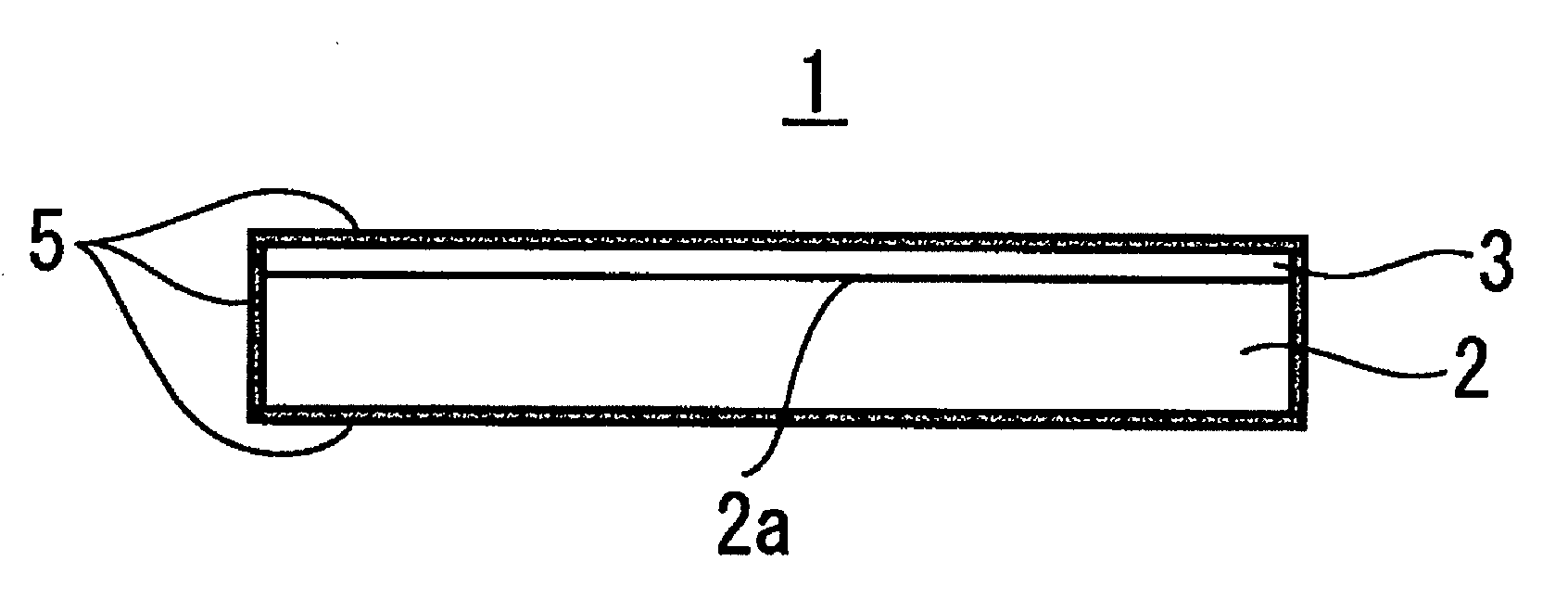

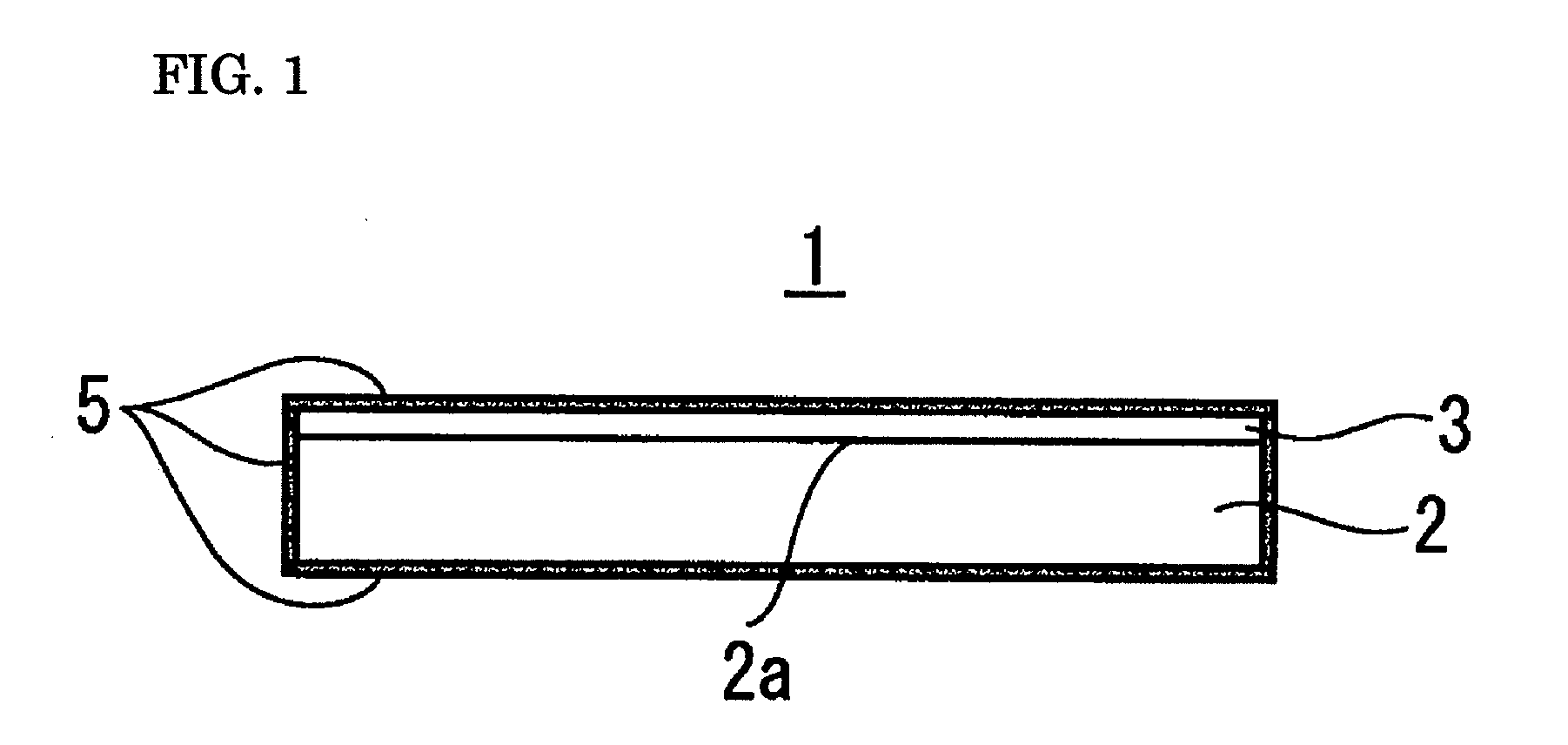

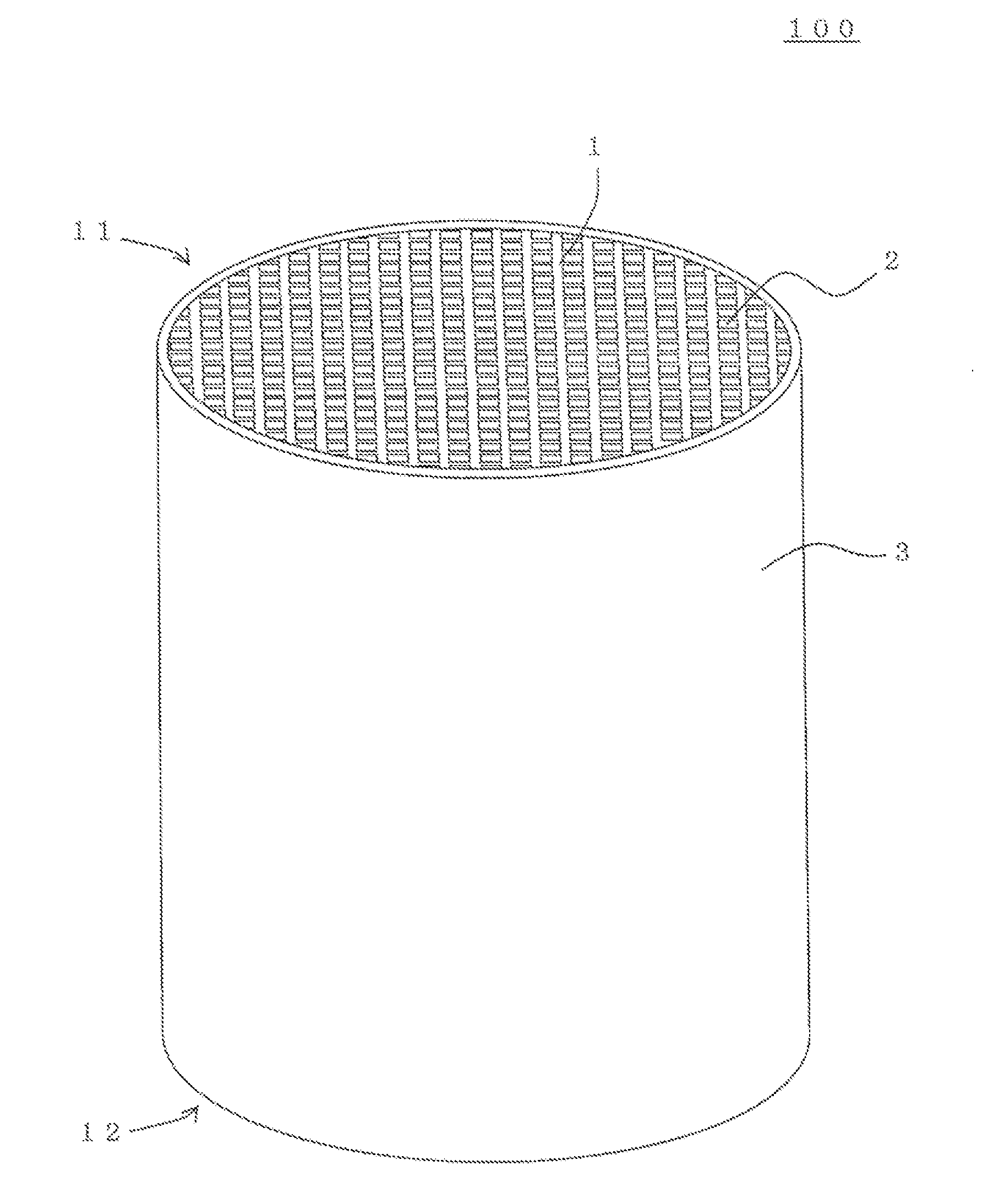

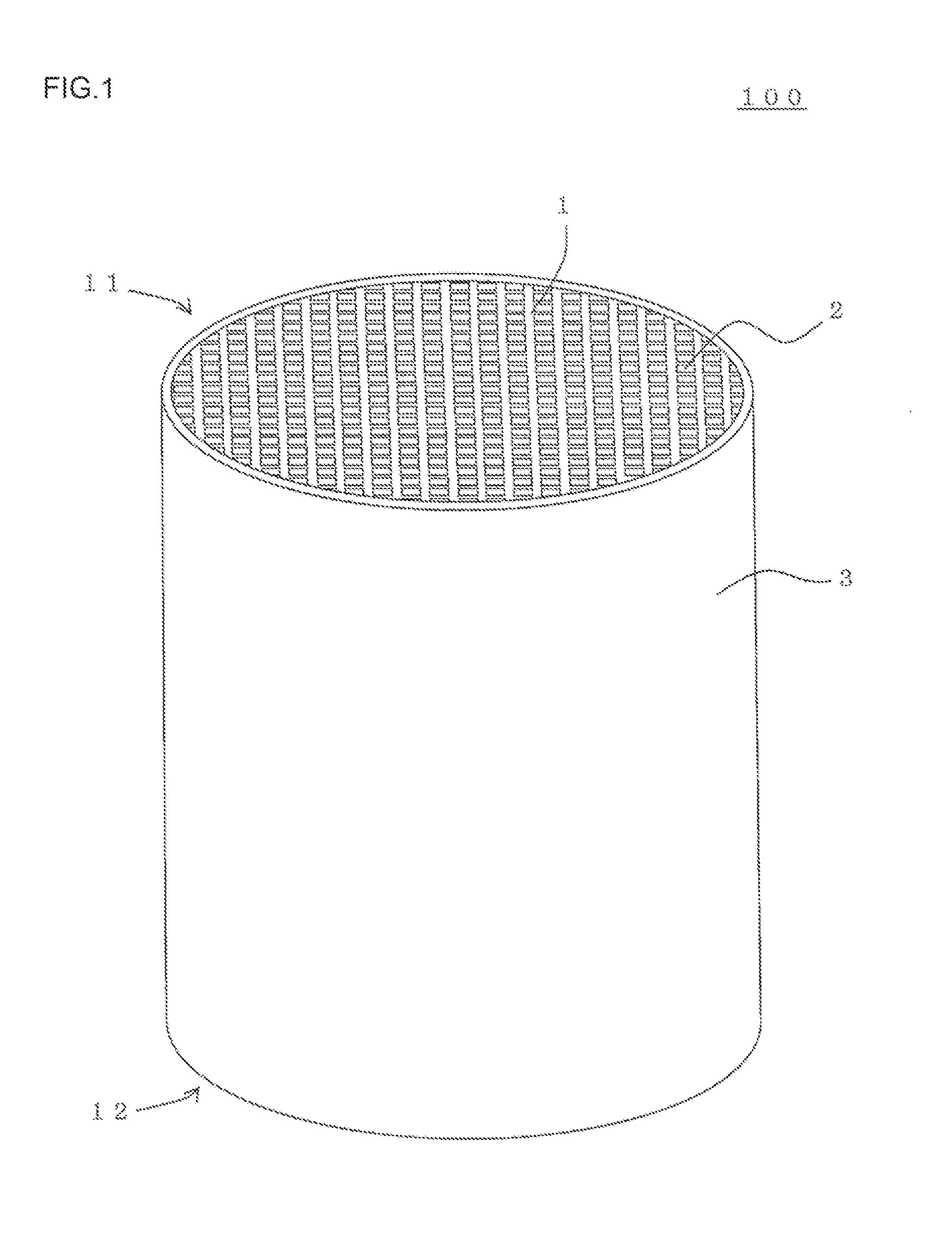

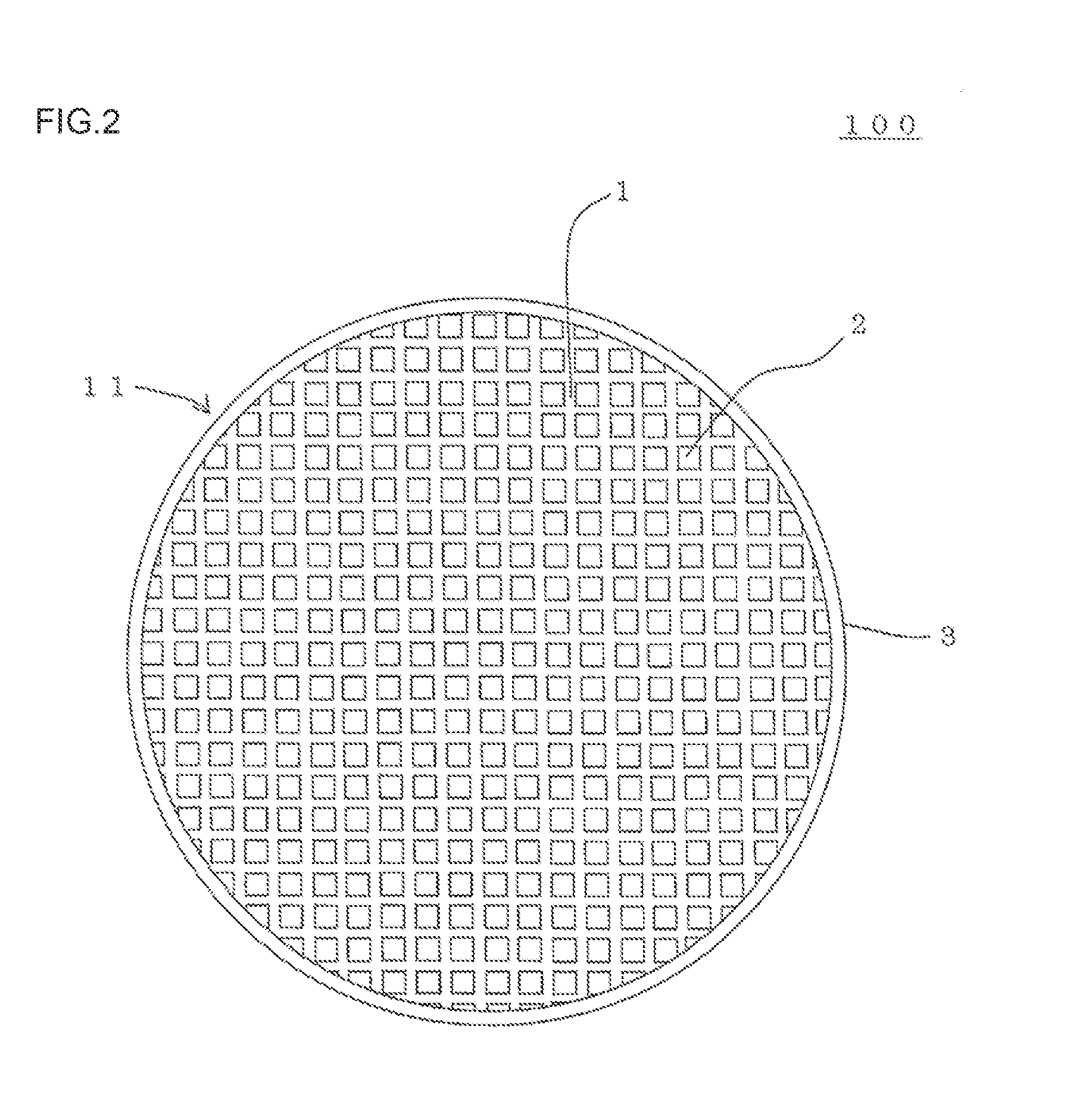

Porous multilayer filter and method for producing same

InactiveUS20110052900A1Large poresReduce thicknessMembranesSemi-permeable membranesFiberHydrophilization

Provided is a porous multilayer filter which can trap ultrafme particles and in which permeability is high and treatment can be performed at a high flow rate. A porous multilayer filter is characterized by including a support layer 2 composed of a porous expanded PTFE sheet, and a filtration layer 3 composed of a porous expanded PTFE sheet which is different from that of the support layer 2, wherein at least a liquid-to-be-treated inflow surface of the filtration layer 3 is subjected to hydrophilization treatment, the filtration layer 3 and the support layer 2 are fusion-bonded to each other at a boundary therebetween to form a multilayer structure, pores of the support layer 2 three-dimensionally communicate with pores of the filtration layer 3, and pores surrounded by a fibril skeleton of the filtration layer 3 are smaller than pores of the support layer 2.

Owner:SUMITOMO ELECTRIC FINE POLYMER INC

Production method and application of sandy land conditioner made from bentonite

ActiveCN102656971AWell mixedPromote production and incomeClimate change adaptationOrganic fertilisersAlkali soilEngineering

The invention discloses a production method and application of sandy land conditioner made from bentonite. The production method and application include the steps of firstly, purifying and modifying bentonite, and adding special additive to produce sandy land conditioner; secondly, manually or mechanically evenly scattering the sandy land conditioner to sandy soil surface of leveled sandy land, dry farmland or arid farmland; thirdly, using a rotary tiller to perform rotary tillage so as to evenly mix the sandy land conditioner and the sand soil inside topsoil; and fourthly, fully irrigating with water to enable the sandy land conditioner to absorb water and turn adhesive so that the sandy land conditioner is well combined with the sand soil to form soil aggregates, thereby achieving water saving, water holding, fertilizer holding, wind proofing and sand stabilization and increasing yield of planted crops. The sandy soil conditioner is mainly used for modifying sand soil, dry farmlands and arid farmlands, and can also be used for modification of saline-alkali soil, impoverished soil, yellow mud soil and easily caking soil, desertification control and various sand stabilizing projects. The sandy land conditioner is more effective in application to rice planting.

Owner:郝国成

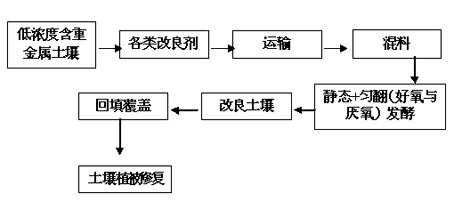

Method for comprehensively utilizing low-concentration heavy metal-containing soil improvement and repairing damaged soil by plants after detoxification of contaminated field

InactiveCN102319726AQuality improvementSimple structureContaminated soil reclamationSludgeAdditive ingredient

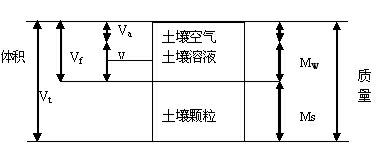

The invention relates to a method for comprehensively utilizing low-concentration heavy metal-containing soil improvement and repairing damaged soil by plants after detoxification of a contaminated field. The method comprises the following steps of: conveying of low-concentration soil after heavy metal-containing soil is detoxified, sludge and pulverized fuel ash; principal fermentation, mixing of various ingredients; primary fermentation; static state of post-fermentation (secondary fermentation); uniform turning (aerobic and anaerobic) fermentation; conveying of improved soil; and vegetation repairing (woody and herbaceous plants) planting for the contaminated soil. In the method, a modifier is added for modification, so that the content of heavy metals in the soil is reduced, the structure and pores of the damaged soil are repaired, and the permeation and air permeability of the soil are improved; and organic matters and other noxious matters in sludge and soil are decomposed and degraded in a certain condition by utilizing microbes in the sludge to reduce volume weight and compactness, so that the improved soil forms a substance similar to humus soil to serve as a biochemical process of the improved soil and fertilizer. According to the method, the planted vegetation growing environment of the land which uses the improved soil as a soil base material is ensured, so that the waste is used to treat waste, and the comprehensive utilization is improved.

Owner:姜桂荣 +1

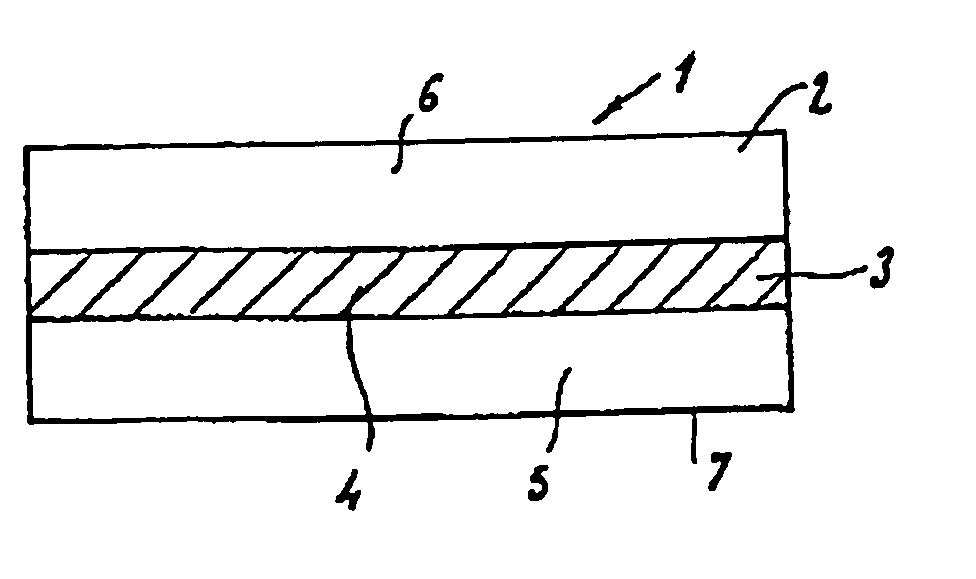

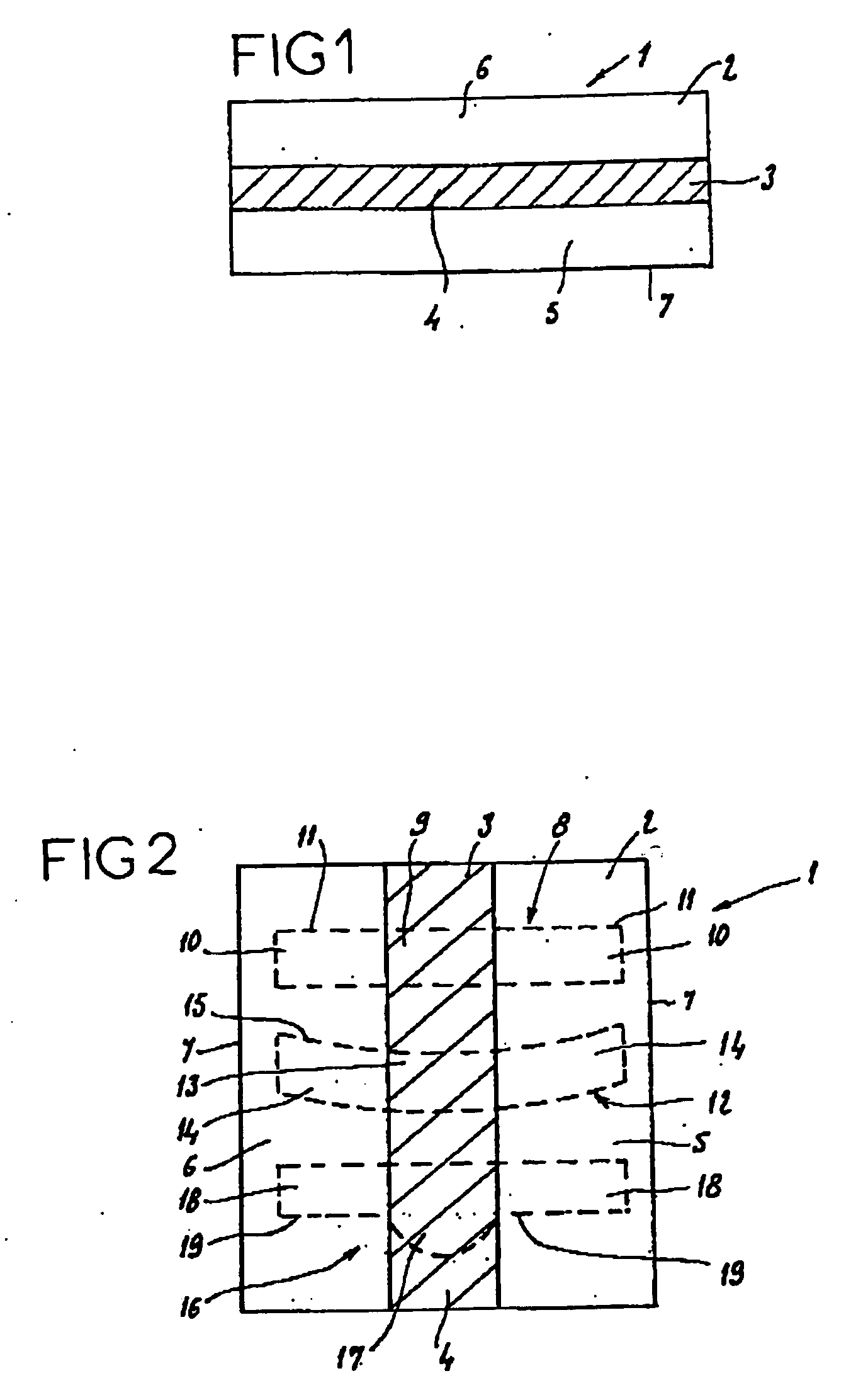

Intermediate composite part for forming reinforcement prosthesis

The present invention relates to an intermediate composite part (1) designed for forming a composite reinforcement prosthesis and comprising: i) a porous textile support (2) which includes an arrangement of threads each composed of at least one filament of nonabsorbable polymer material, said textile support defining the free edge or edges (7) of the part, and ii) a hydrophilic absorbable material (3) covering said textile support, at least on one side of the latter, extending across the surface of what is called a protected zone (4) and creating, on each side of the latter, two unprotected zones (5, 6) of the textile support which are limited by said free edges and are devoid of any of said absorbable material. It also relates to a process for preparing such a part.

Owner:SOFRADIM PROD SAS

Ceramic membrane support and preparation method thereof

The invention discloses a ceramic membrane support and a preparation method thereof. The support is prepared from the following materials by mass: 50 to 80% of alpha-alumina, 10 to 30% of a compound of silicon, 1 to 10% of a sintering aid and 3 to 15% of a binder and a pore forming agent. The preparation method provided in the invention mainly comprises the steps of formation of green bodies and sintering. According to the invention, alumina and a silicon-containing inorganic substance or organic matter are used as reaction components for manufacture of a mullite support, which enables a composition to have reduced volume and increased pore; the support prepared thereafter has high porosity and strength. According to the invention, cheaper alumina and lower sintering temperature can be employed for preparation of the support, which enables preparation cost for the support to be reduced.

Owner:SANDA FILM SCI & TECH XIAMEN

Method for producing mulberry stamen tea

InactiveCN1647674AIncrease productionQuality improvementPre-extraction tea treatmentTea substituesBudBlood sugar

The present invention discloses the preparation process of mulberry stamen tea. The mulberry stamen tea is prepared with tender bud as the waste from mulberry garden management as main material and through deactivating enzyme, kneading, drying and other steps, and the drying step may be completed in different temperatures so as to form different types of mulberry stamen tea. The mulberry stamen tea is dark green, scented, sweet, mellow and nutritious, and has the health effects of diuresis, lowering blood pressure, reducing blood sugar, etc.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

Biological soil remediation agent and method for remediating soil

InactiveCN105618478AImprove the growing environmentEffective passivationContaminated soil reclamationSoil remediationBiology

The invention discloses a biological soil remediation agent which is prepared by mixing a solid passivator and a microbic solution according to the volume-weight ratio of 1:(15-30) (L / kg). The solid passivator comprises the following ingredients in percent by mass: 50-60 percent of clay carrier, 15-30 percent of diatomite, 10-15 percent of humic acid and 10-20 percent of charcoal. The microbic solution comprises a non-spore forming bacterium and streptomyces microflavus. The biological soil remediation agent can be used for remediating a soil ecosystem, improving the crop growth environment, effectively passivating heavy metal pollutants, such as lead, and reducing the availability for plants.

Owner:NANJING GAIA BIOLOGICAL ENG CO LTD

Honeycomb structure and honeycomb catalyst body

ActiveUS20130059724A1Suitable for usePromote absorptionMolecular sieve catalystsDispersed particle filtrationPore diameterPeak value

Partition walls are provided with small pores and large pores, a porosity of the partition walls is from 50 to 70%, a porosity of the large pores of the partition walls is 30% or larger, a ratio of a total volume of the small pores to a total volume of the large pores is 20% or larger, and in a graph showing a pore diameter distribution of the partition walls, the pore diameter at a maximum peak value of the large pores is from 20 to 200 μm, and the pore diameter at a maximum peak value of the small pores is from 0.1 to 8 μm. Furthermore, a value obtained by dividing a porosity value (%) of the large pores by a thickness value (μm) of the partition walls is 0.2 or larger in a honeycomb structure.

Owner:NGK INSULATORS LTD

Water-insoluble silk fibroin porous material and preparation method thereof

The invention discloses a water-insoluble silk fibroin porous material and a preparation method thereof. The preparation method comprises the following steps of: adding one or more kinds of salt solution into silk fibroin solution, mixing the solution uniformly and then injecting the mixture into a metal die, freezing the mixture for 24 hours at the temperature of between 10 DEC below zero and 80 DEG C below zero, performing freeze drying on the mixture, and treating the mixture at the temperature of between 4 and 120 DEG C under the environment with the humidity of 30 to 98 percent to form the water-insoluble silk fibroin porous material. The solution loss rate of the water-insoluble silk fibroin porous material in 37 DEG C water for 24 hours is below 2 percent, and the material can be fully degraded into no-toxicity amino acid; the material has large holes and apertures, and is suitable for the growth of cells; and meanwhile, any chemical cross-linking agent, foaming agent or denaturing agent and the like does not need to be added during preparation, so good biocompatibility of the silk fibroin is kept, and the silk fibroin can be used for wound recovery materials for cell culture, skin, bones and gristles and medicinal release-controlled materials for temporary coverage, tissue isolation and hemostasis and the like.

Owner:SUZHOU UNIV +1

Fire log made of recycled materials and a method and an apparatus for manufacturing the same

The fire log comprises an organic fibre base that is over-saturated with vegetable cooking oil. The vegetable oil is contained and sealed therein by a casing made of the vegetable wax. More specifically, the fire log is over saturated with 65%-75% by weight of vegetable oil. The vegetable oil is used vegetable cooking oil. The organic fibre base represents about between 20%-30% by weight and consists of compressed paper-based products such as cardboard, newsprint and recyclable paper. The vegetable wax casing represents about between 1-5% of its weight. In another aspect of the present invention, the organic fibre base is made of broken fibres and interstices, and the vegetable oil is infused therein while these fibres are dilated from their natural states. In yet another aspect, the organic fibre base is formed in a perforated cylinder whereby a bark-like appearance is imprinted on its surface.

Owner:BONNELL RICKARD CARLA +1

Composite fertilizer-keeping nutrient soil prepared from biogas residues and biogas liquids and preparation method thereof

InactiveCN102219595AIncrease moisture contentImprove fat retention capacityBio-organic fraction processingClimate change adaptationPorosityFermentation

The invention provides a method for preparing composite fertilizer-keeping nutrient soil by using biogas residues and biogas liquids. The method comprises the following steps: mixing the biogas residues, sawdust, bone meal, soil, potassium permanganate, ferrous sulfate and an inorganic fertilizer, and smashing the mixture; and adding the biogas liquids in the mixture for evenly stirring, and carrying out anaerobic fermentation for 20-30 days at the room temperature so as to obtain the composite fertilizer-keeping nutrient soil prepared from the biogas residues and biogas liquids. The composite nutrient soil has the characteristics that loading is low, the volume weight is low, and the porosity is large; nutrient components are comprehensive and delayed-acting and quick-acting nutrient components are contained simultaneously; the fertilizer-keeping effect is good, the times of fertilizing and watering are decreased, the watering is carried out once each half month, and the fertilizer is applied once each year; the application range is wide, and the composite nutrient soil can be used in roofs, courtyards and potting flowers and plants; and the cost is low. Most of the raw materialsfor the composite nutrient soil are agricultural solid wastes, and the preparation process is simple.

Owner:KUNMING UNIV OF SCI & TECH

Plant nutrient substrate special for promoting plant growth

ActiveCN103651072AReduce alkalinityImprove water retentionCultivating equipmentsSoilless cultivationGrowth plantAlkalinity

The invention provides a plant nutrient substrate special for promoting plant growth. The raw material components of the plant nutrient substrate include organic composts, turfy soil, wood powder, peanut shells, polyacrylamide soil conditioners, Chinese herbal medicine nutritional agents and antalkalies. Due to the fact that the polyacrylamide soil conditioners, the antalkalies and the Chinese herbal medicine nutritional agents are added, plant growth ecological concrete has the water absorption function, the water retention function, the fertilizer maintenance function, the soil structure improving function and the like, and the difficult problem that concrete is not suitable for growth of most plants due to the fact that the concrete is too high in alkalinity is solved.

Owner:青岛中科坤泰装配建筑科技有限公司

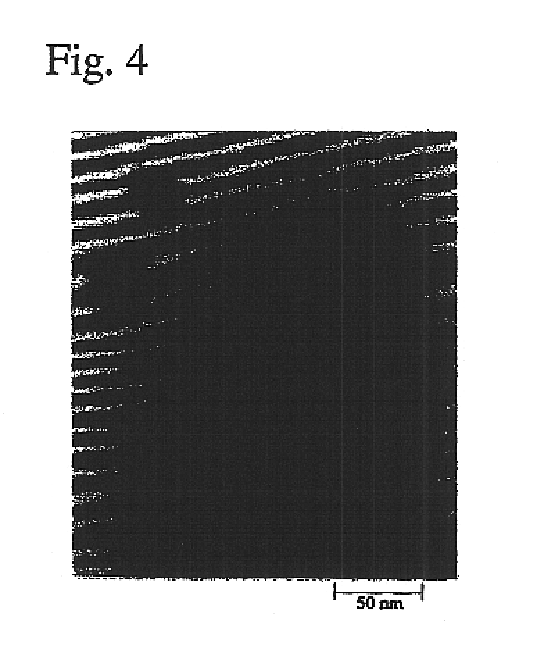

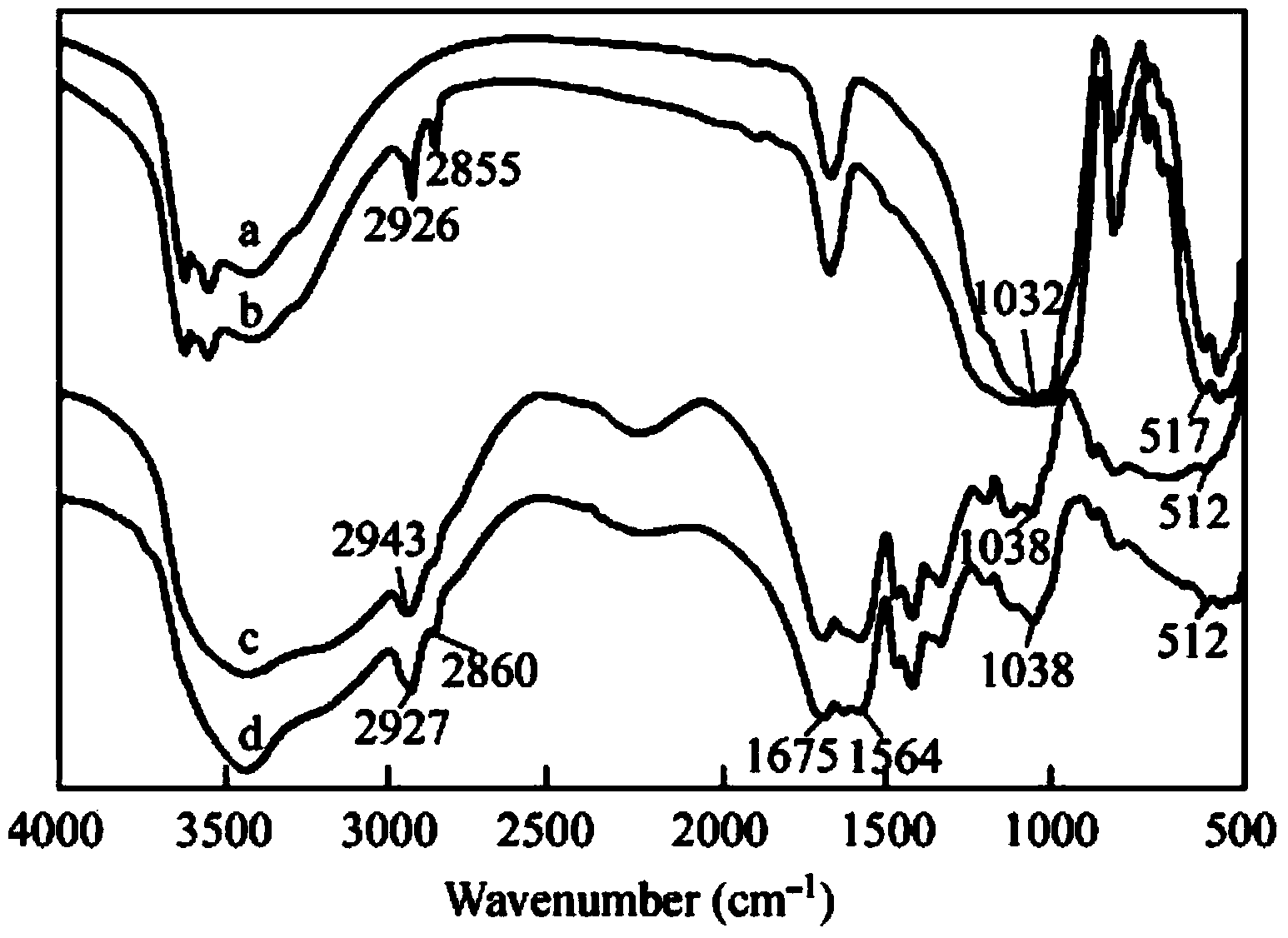

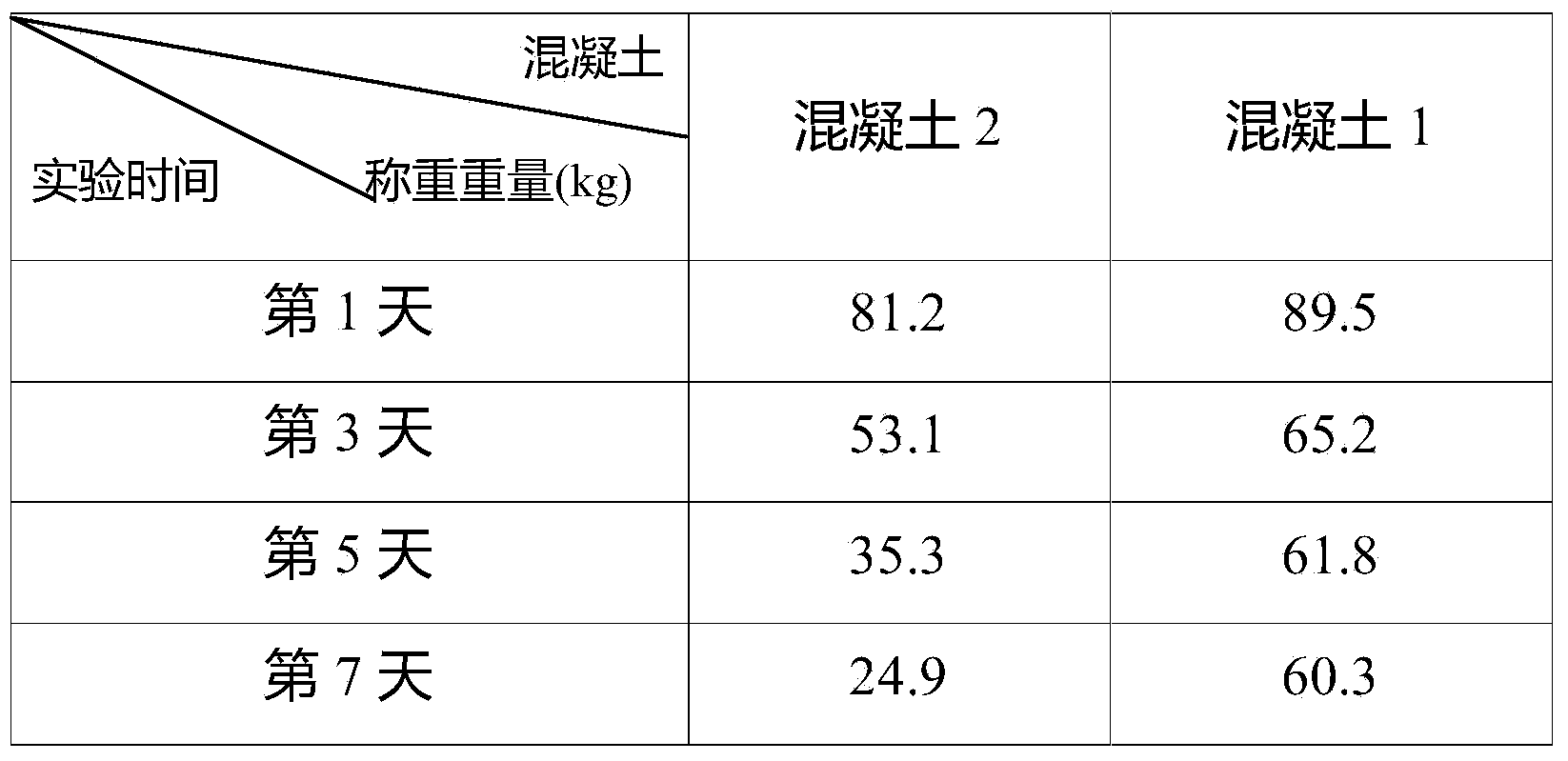

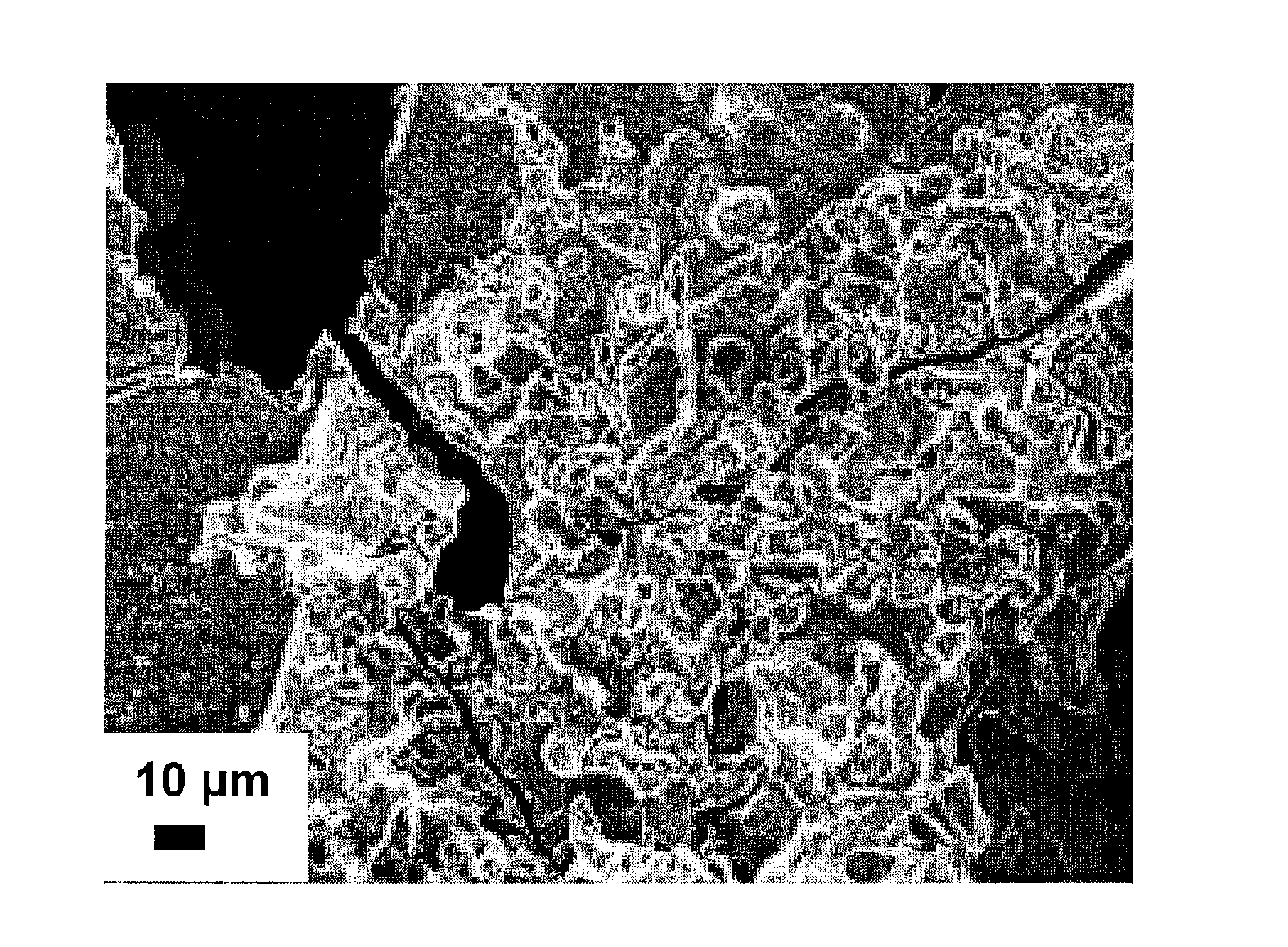

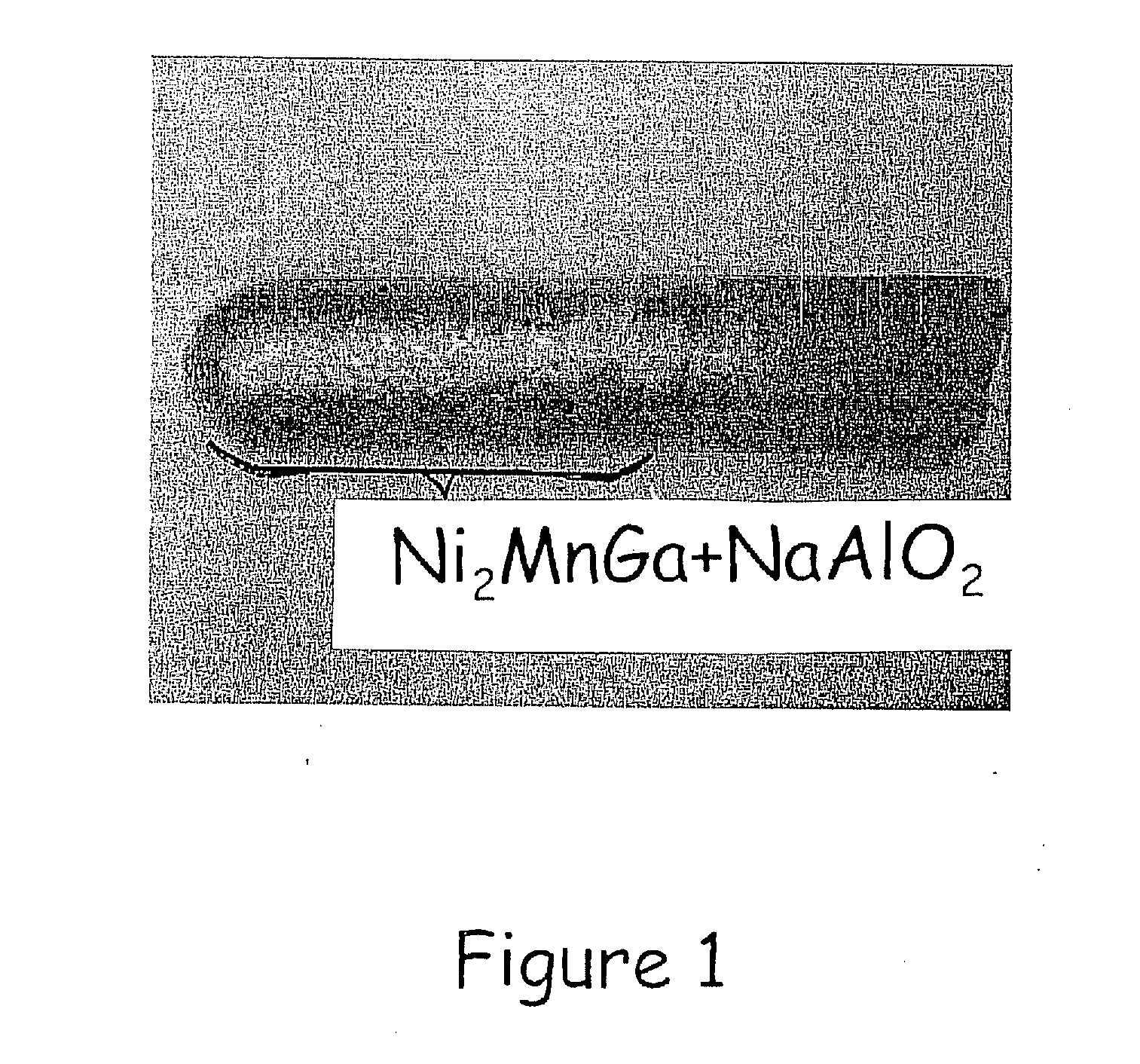

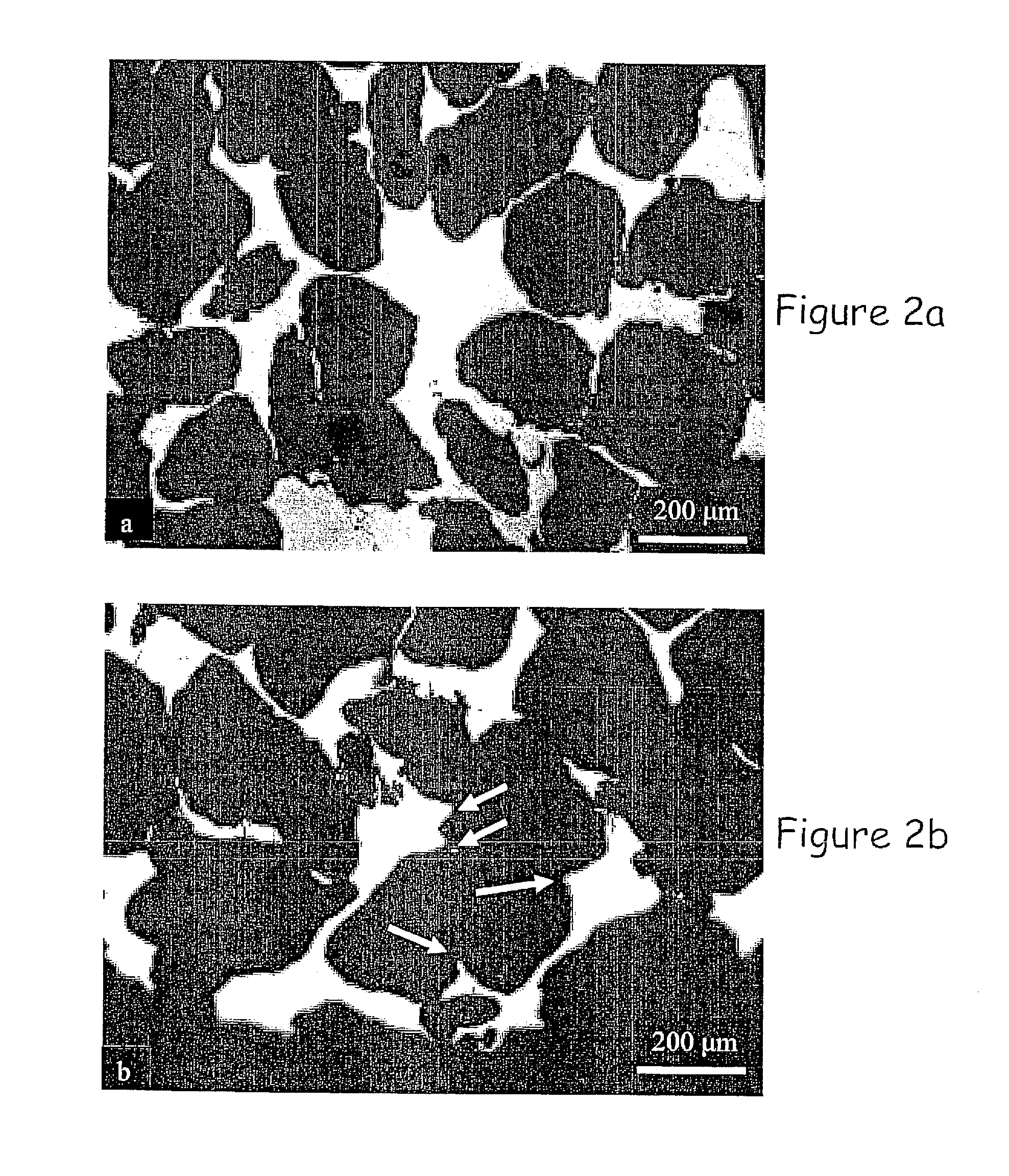

Polycrystalline foams exhibiting giant magnetic-field-induced deformation and methods of making and using same

ActiveUS20110064965A1Reduce constraintsLarge poresInorganic material magnetismThin material handlingAlloySingle crystal

Magnetic materials and methods exhibit large magnetic-field-induced deformation / strain (MFIS) through the magnetic-field-induced motion of crystallographic interfaces. The preferred materials are porous, polycrystalline composite structures of nodes connected by struts wherein the struts may be monocrystalline or polycrystalline. The materials are preferably made from magnetic shape memory alloy, including polycrystalline Ni—Mn—Ga, formed into an open-pore foam, for example, by space-holder technique. Removal of constraints that interfere with MFIS has been accomplished by introducing pores with sizes similar to grains, resulting in MFIS values of 0.12% in polycrystalline Ni—Mn—Ga foams, close to the best commercial magnetostrictive materials. Further removal of constraints has been accomplished by introducing pores smaller than the grain size, dramatically increasing MFIS to 2.0-8.7%. These strains, which remain stable over >200,000 cycles, are much larger than those of any polycrystalline, active material.

Owner:NORTHWESTERN UNIV +1

Transition metal oxide-aluminosilicate purification media

InactiveUS7288498B1Reduced activityExtended service lifeWater/sewage treatment by irradiationOther chemical processesMicroorganismMetal

The invention, in its various embodiments, relates to a medium for purifying fluids, particularly consumable fluids like air and water, by removing organic materials from the fluids by contacting the fluids with a combination of extremely small diameter transition metal oxide and an aluminosilicate having relatively large pores. In addition, contact of the fluids with the purification medium can also significantly reduce the level of microorganisms existing in the fluid, providing another purification benefit.

Owner:KINETICO

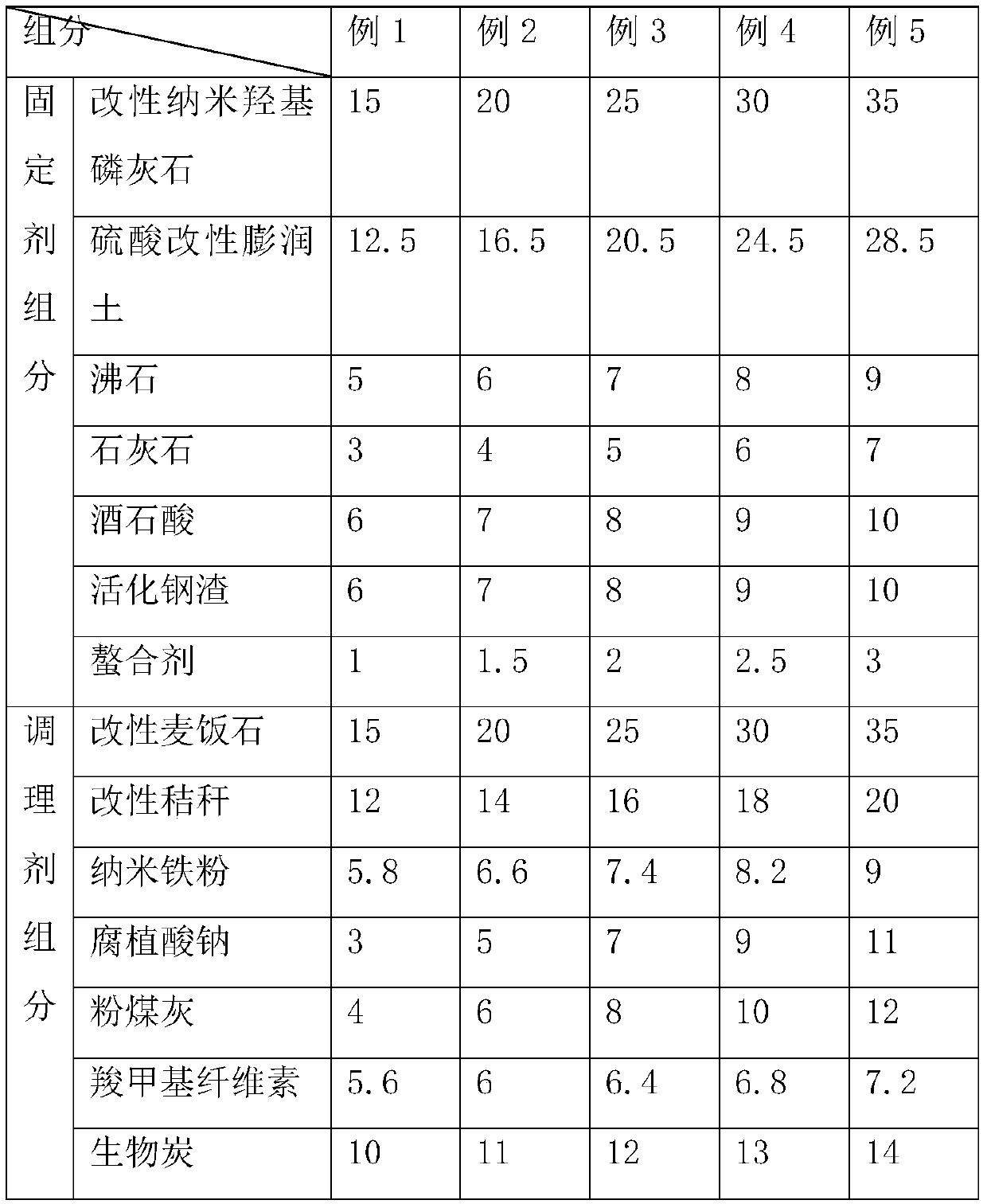

Heavy metal contaminated soil remediation agent and preparation method and application method thereof

PendingCN111100652AImprove curing effectAvoid leachingAgriculture tools and machinesContaminated soil reclamationCelluloseMetal contamination

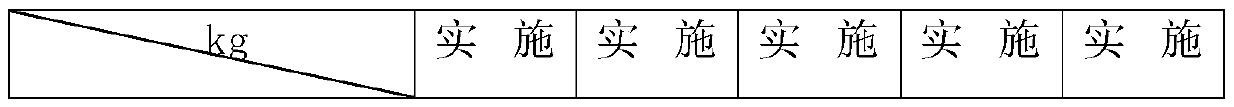

The invention discloses a heavy metal contaminated soil remediation agent as well as a preparation method and an application method thereof. The heavy metal contaminated soil remediation agent comprises a fixing agent component and a conditioner component in a mass ratio of 1: (2-3). The curing agent component is prepared from the following components in parts by weight: 15 to 35 parts of modifiednano-hydroxyapatite, 12.5 to 28.5 parts of sulfuric acid modified bentonite, 5 to 9 parts of zeolite, 3 to 7 parts of limestone, 6 to 10 parts of tartaric acid, 6 to 10 parts of activated steel slagand 1 to 3 parts of a chelating agent. The conditioner is prepared from the following components in parts by weight: 15 to 35 parts of modified medical stone, 12 to 20 parts of modified straw, 5.8 to9 parts of nano iron powder, 3 to 11 parts of sodium humate, 4 to 12 parts of fly ash, 5.6 to 7.2 parts of carboxymethyl cellulose and 10 to 14 parts of charcoal. The heavy metal contaminated soil remediation agent has the advantage of a good removal effect and remediation effect on divalent heavy metal ions such as copper, zinc, chromium and nickel.

Owner:卢再亮

Anodic oxidation dyeing process for multi-blind hole aluminum extruded section product

The invention relates to an anode oxidating dyeing technique of aluminium extruded section product with a plurality of blind holes which has steps as follows: loading, removing oil, washing with clean water, washing and spraying, corrupting with alkali, washing with clean water, washing and spraying, cleaning with ultrasonic, washing with pure water, anode oxidating, cleaning, cleaning and spraying, washing with pure water, processing before dyeing, washing with pure water, dyeing, washing with pure water, closing with nickel salt, cleaning and spraying, washing with pure water, drying in vacuum. The technique changes oxidating film hole by using increase of oxidating temperature and electrolyte concentration for enhancing the film absorption ability to dye; a processing agent before dyeing can avoid poor dyeing effect caused by acid sewage flow in hole, screw hole of the anode oxidating product efficiently, and control poor dyeing effect, white point, color mistiness with flow hanging shape caused by residual medicinal liquor flow in dyeing by increasing dyeing ability of dye; replacement of dyeing agent can greatly increase stability of dyeing and prolong working life of dye, and increase absorption ability of the oxidating film to dye.

Owner:SHANGHAI REAL INDAL

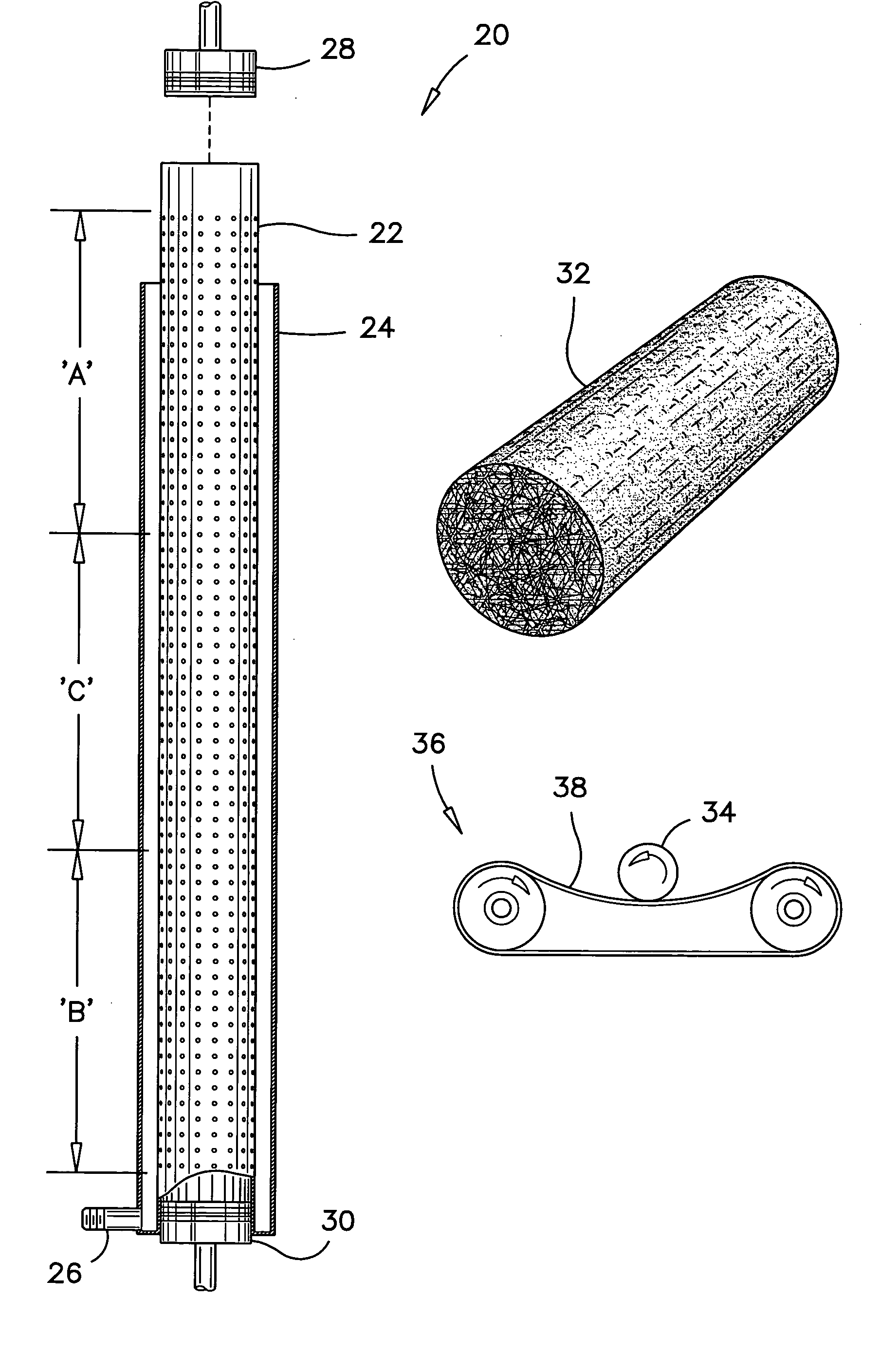

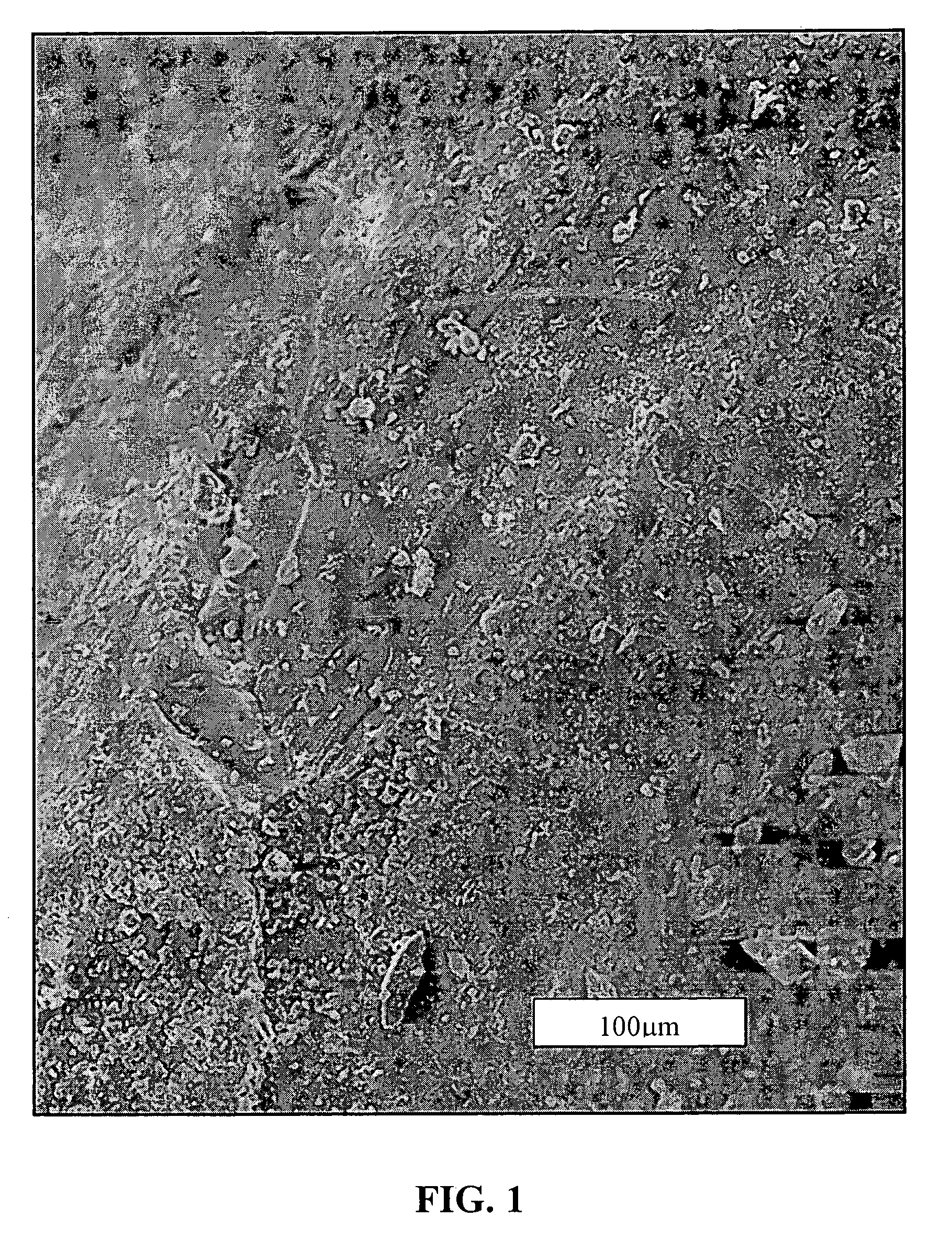

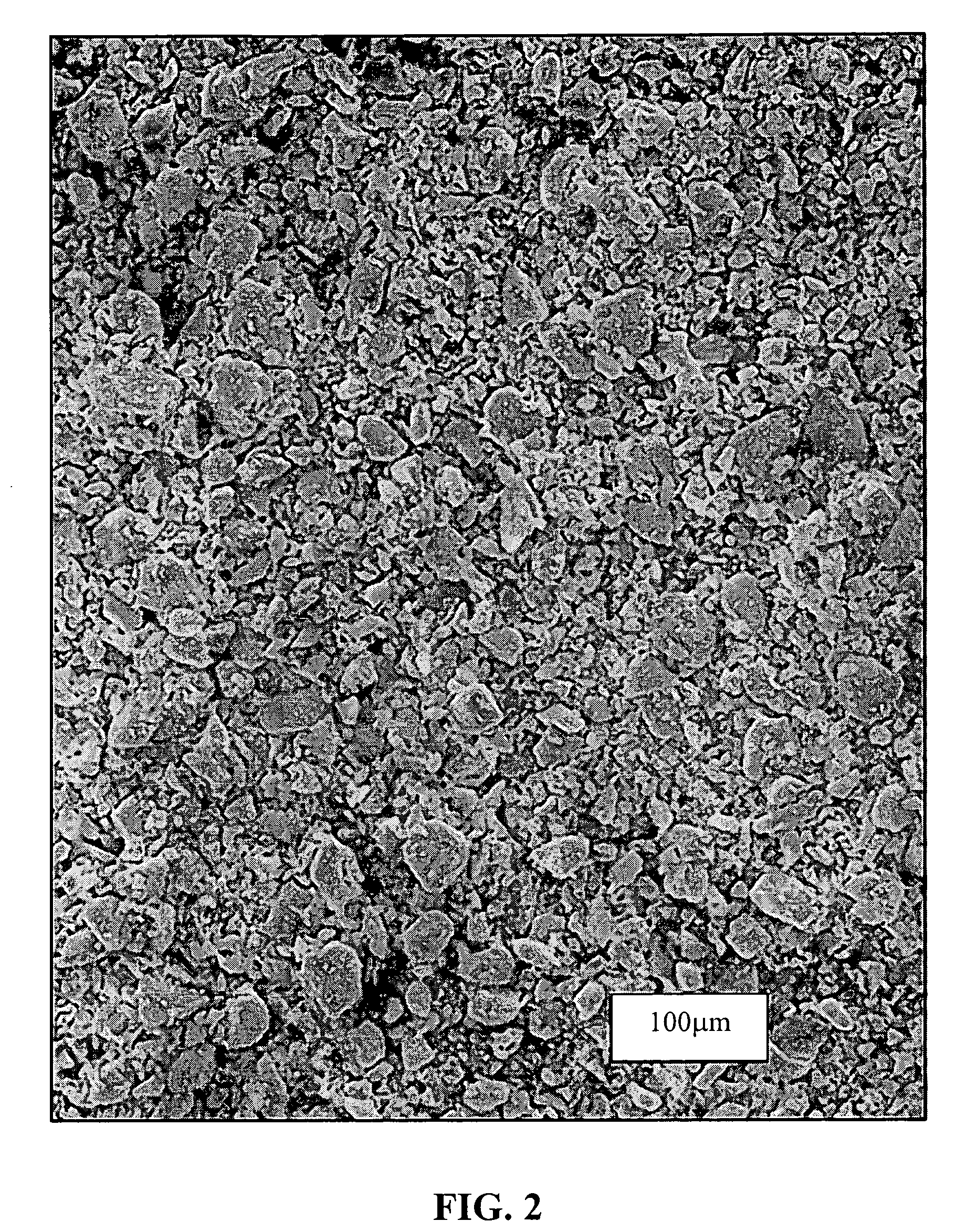

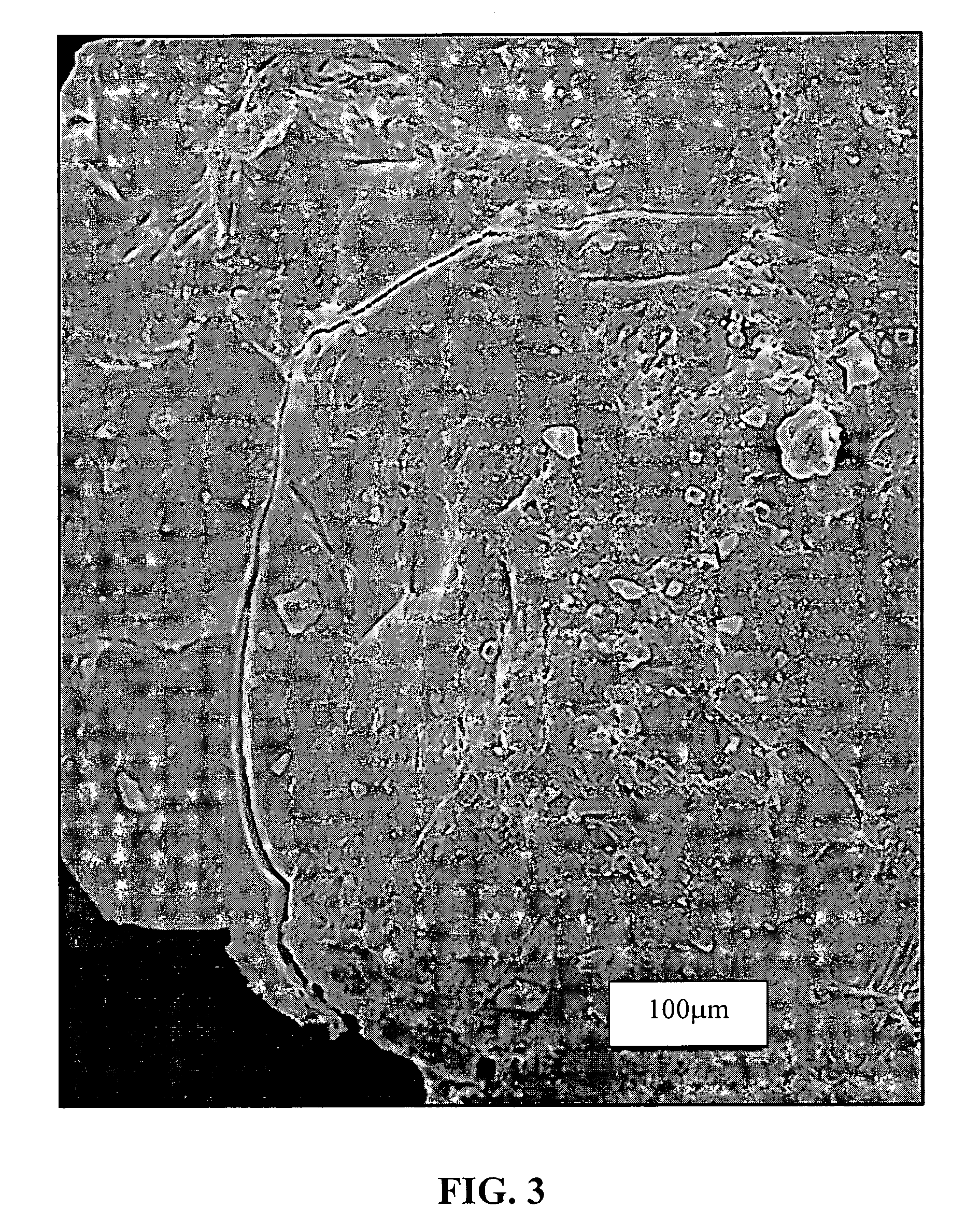

High voltage tantalum anode and method of manufacture

ActiveUS9312075B1Refining issueIncrease capacitanceLiquid electrolytic capacitorsTransportation and packagingFiberPorosity

Tantalum powders produced using a tantalum fiber precursor are described. The tantalum fiber precursor is chopped or cut into short lengths having a uniform fiber thickness and favorable aspect ratio. The chopped fibers are formed into a primary powder having a controlled size and shape, narrow / tight particle size distribution, and low impurity level. The primary powder is then agglomerated into an agglomerated powder displaying suitable flowability and pressability such that pellets with good structural integrity and unifrom pellet porosity are manufacturable. The pellet is sintered and anodized to a desired formation voltage. The thusly created capacitor anode has a dual morphology or dual porosity provided by a primary porosity of the individual tantalum fibers making up the primary powder and a larger secondary porosity formed between the primary powders agglomerated into the agglomerated powder.

Owner:WILSON GREATBATCH LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com