Coalbed methane horizontal well supercritical CO2 jet flow cavity construction and multi-segment synchronous deflagration fracturing method

A technology for horizontal wells and coalbed methane, applied in drilling equipment and methods, drilling with liquid/gas jets, mining fluids, etc., can solve the problems of difficult formation of network fractures, polluted coal seams, long construction period, etc., and increase production , Improve the permeability of coal body and the effect of improving the permeability of coal rock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] Coalbed methane horizontal well supercritical CO provided by the invention 2 The method of jet cavity creation and multi-stage synchronous deflagration fracturing may include the following specific steps:

[0028] 1. Lower into the rotary jet device

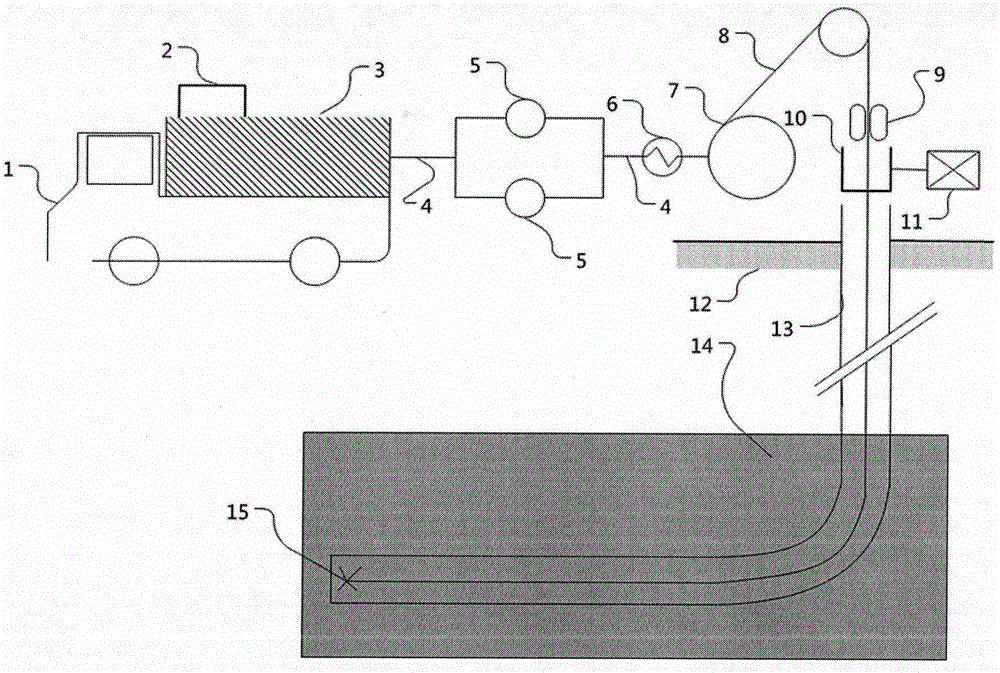

[0029] figure 1 Shown is supercritical CO 2 Schematic diagram of the rotary jet device entering the well. Supercritical CO 2 The rotary jet device 15 is connected to the coiled tubing 8, passes through the coiled tubing injection head 9, the wellhead device 10 and the wellbore 13 are lowered into the bottom of the well.

[0030] 2. Multi-stage reaming

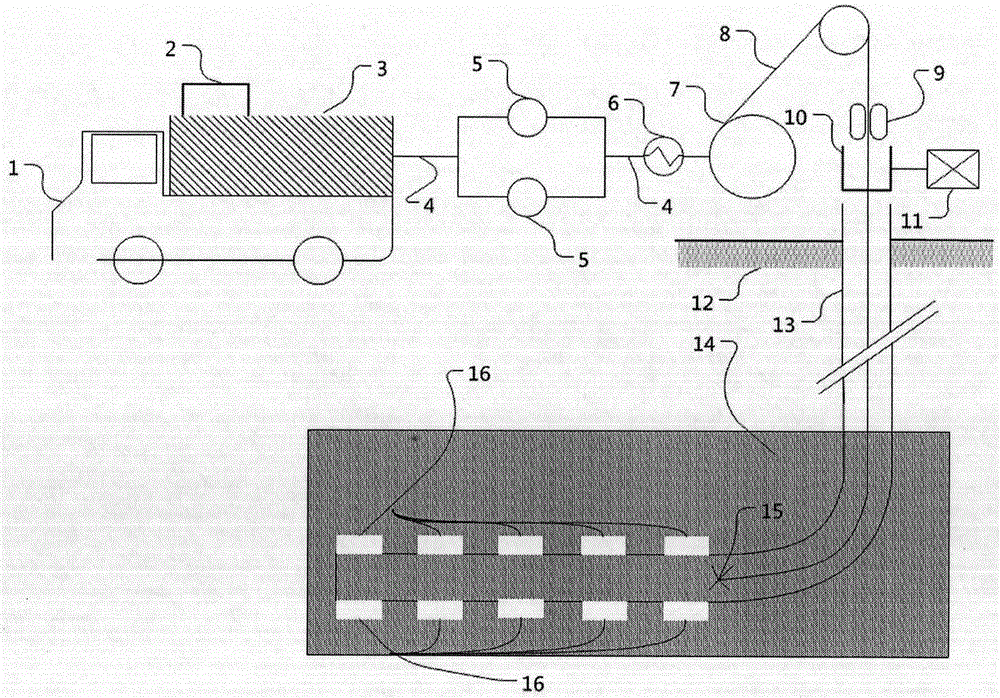

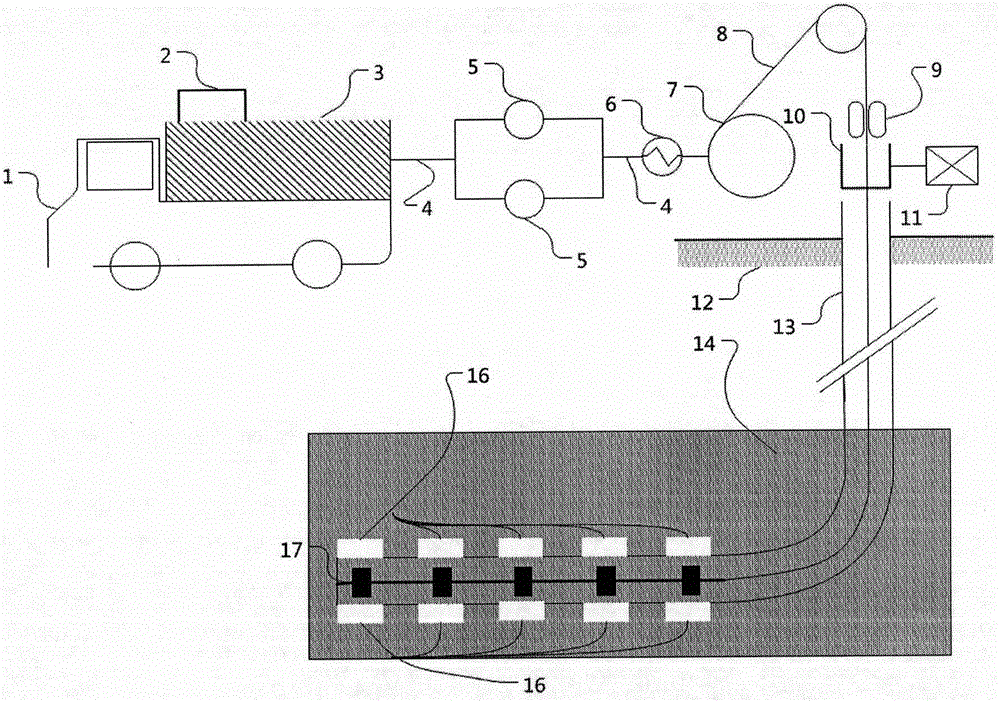

[0031] figure 2 Shown is a schematic diagram of supercritical carbon dioxide rotating jet multi-stage reaming.

[0032] Liquid CO 2 By CO equipped with vehicle-mounted refrigerating unit 2 2 Tanker 1 transport, the transport pressure is controlled at 4-5MPa, and the temperature is controlled at -10°C-5°C.

[0033] CO 2 Liquid CO in storage tank 3 2 It is transp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com