High-impact toughness man-made quartzite slab and preparation method thereof

An artificial quartz stone, high-impact technology, applied in the field of artificial quartz stone plate and preparation, can solve the problems of poor impact toughness, deformation, material cracking, etc., and achieve the effect of high elongation at break, high density and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

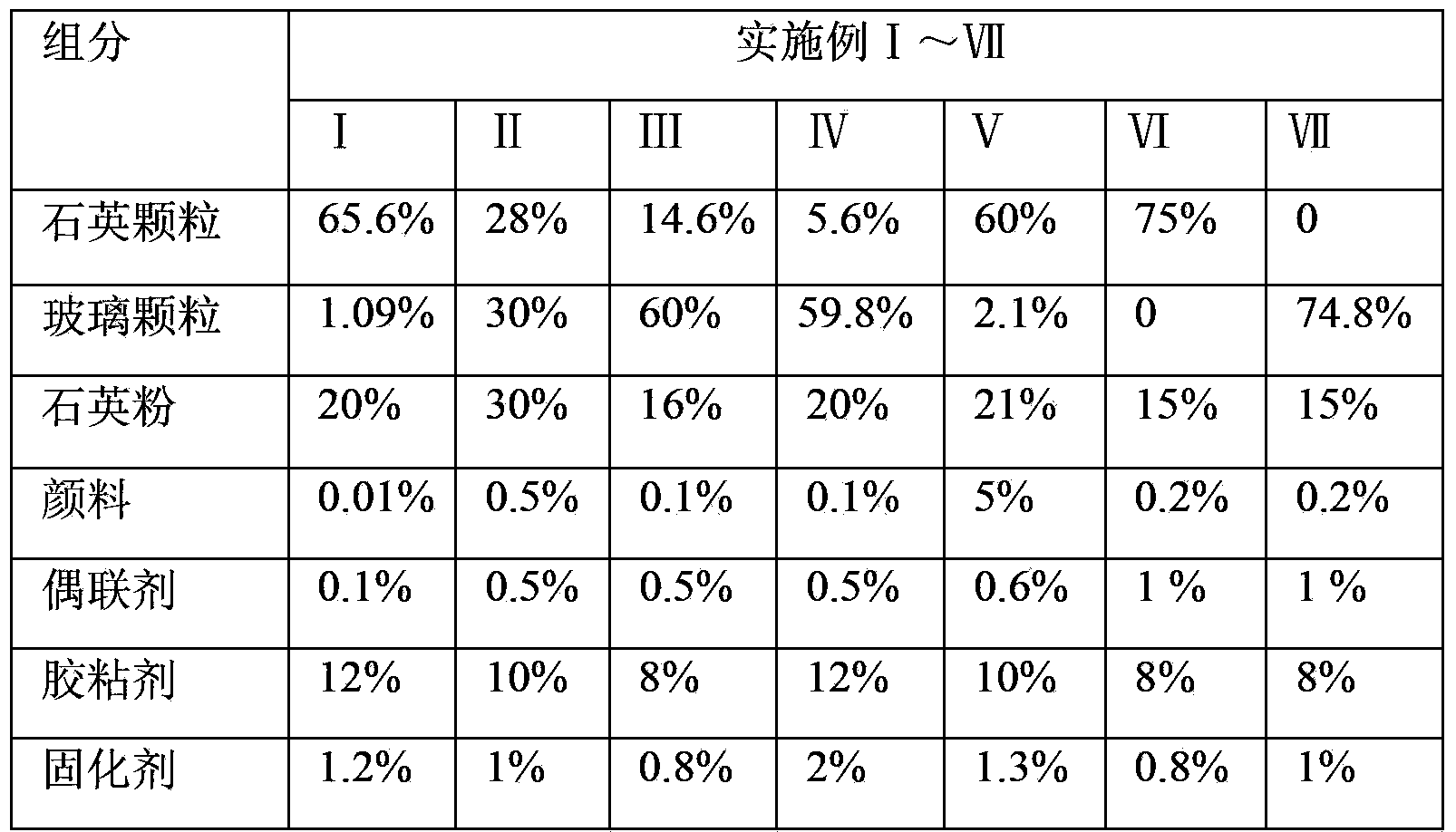

[0046] A high-impact toughness artificial quartz stone plate is prepared according to the following steps:

[0047] (1) Weigh each component according to the formula of Example III corresponding to Table 1 below, wherein the particle size of quartz particles is 5-10 mm, the particle size of glass particles is 5-10 mm; the particle size of quartz powder is 0.1-0.18 mm mm and microneedle-like and spherical-like quartz powder; the coupling agent is a silane coupling agent; the adhesive is a flexible unsaturated polyester resin with a solid content of ≥65% and a viscosity of 0.5-1Pa·s (25°C ), acid value 15-26mgKOH / g, Barcol hardness of pure resin cast body ≥ 45°, elongation at break > 3.0%, bending strength ≥ 120Mpa, heat distortion temperature ≥ 60°C, impact strength ≥ 90Mpa; curing agent is peroxide tert-Butyl Benzoate.

[0048] (2) Pour the raw materials weighed in step 1 into a double planetary mixing tank for stirring, the stirring frequency is 50-55Hz, and the stirring tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com