Patents

Literature

154 results about "Niti alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The NiTi alloy is used in orthodontics for wires. Andreasen and his colleagues introduced the alloy to orthodontics, and a wire (now named Nitinol Classic) was marketed in the late 1970s by Unitek Corporation (now 3M Unitek). Andreasen and Morrow 28 cite several earlier studies from this group.

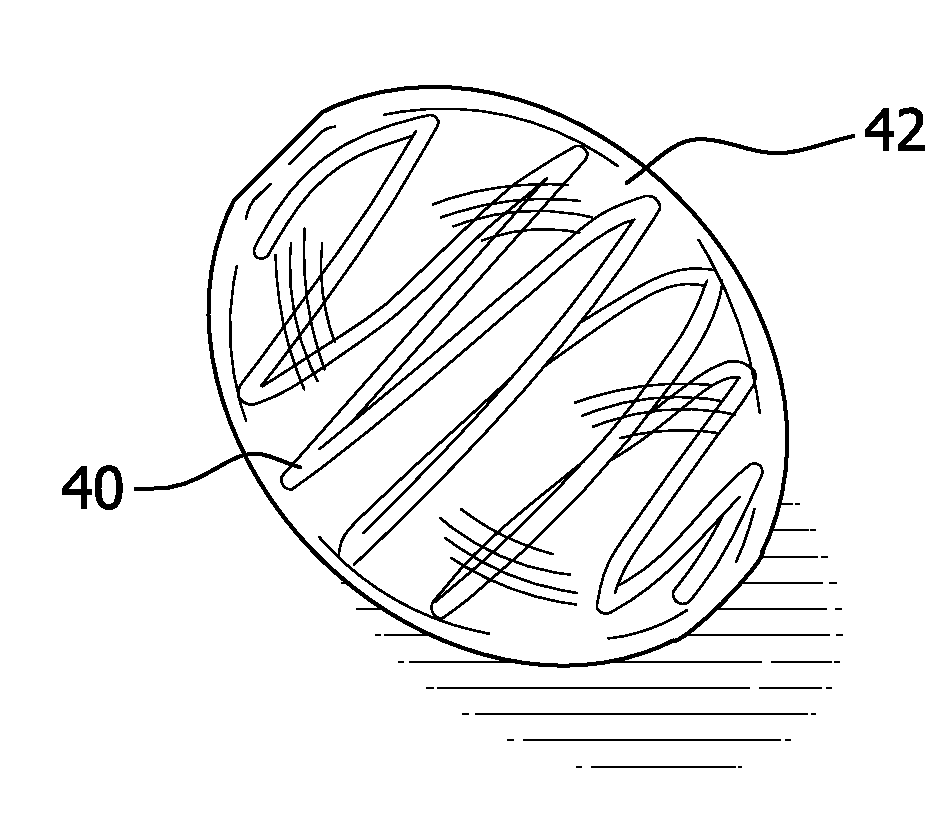

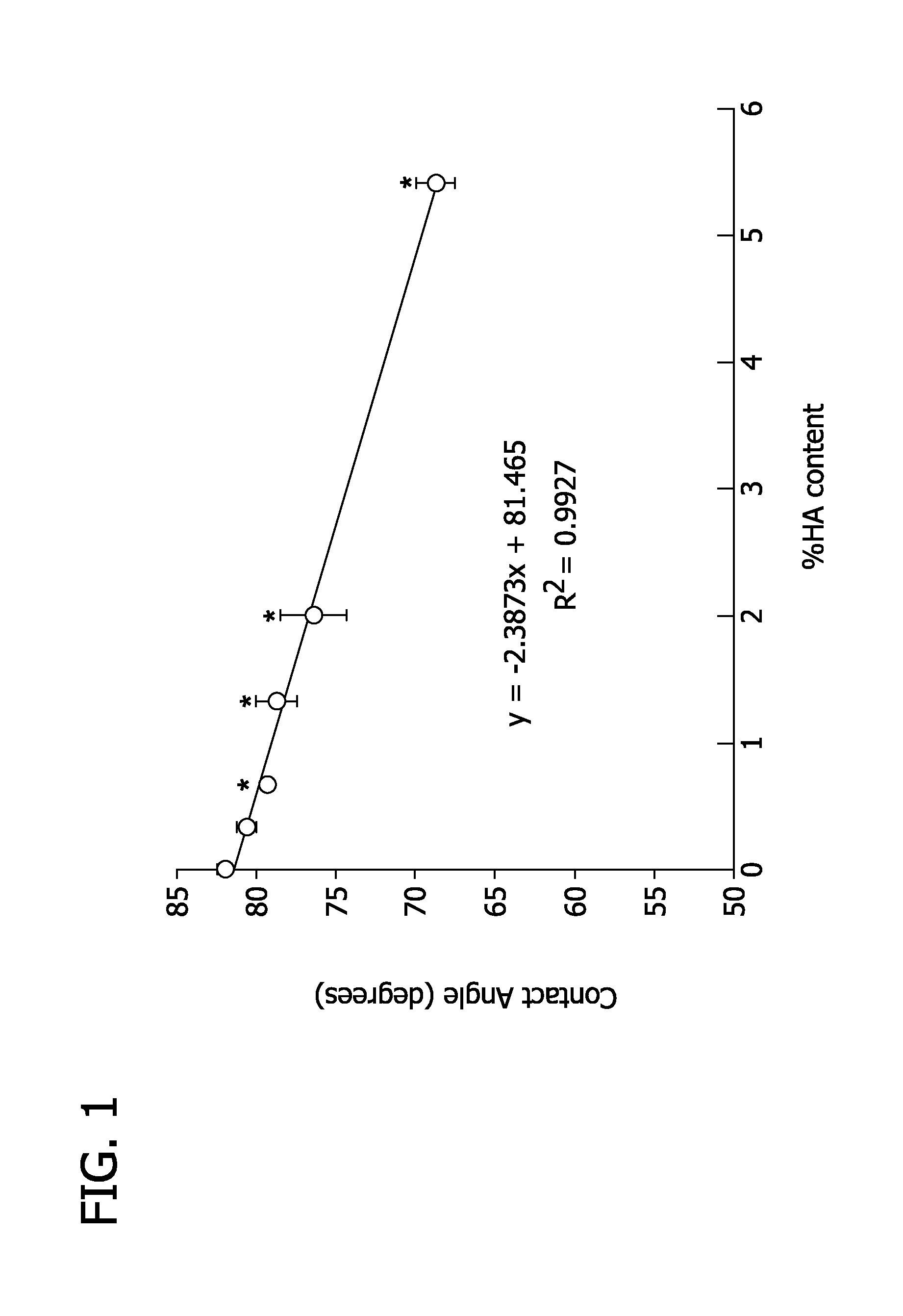

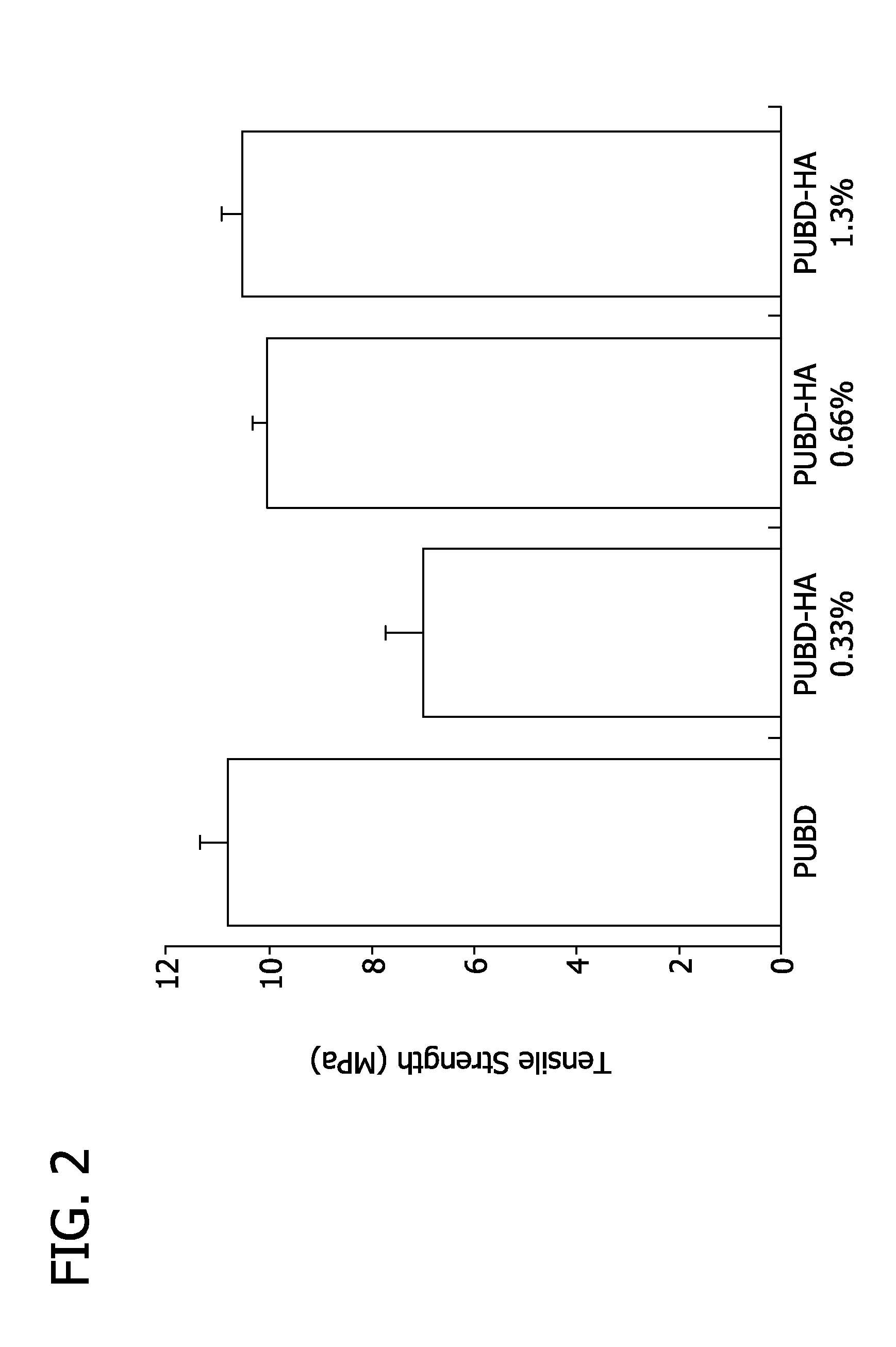

Aneurysm occlusion device containing bioactive and biocompatible copolymer shell and biocompatible metallic frame member

An endovascular device for occluding a vascular aneurysm is disclosed. The device includes a polymeric shell member that, in one embodiment, may be constructed from a bioactive and biocompatible polyurethane-diol-glycosaminoglycan copolymer, and a biocompatible metallic frame member. The copolymer is sufficiently flexible and strong for endovascular delivery into a vascular aneurysm and for use as a polymeric shell for receiving the biocompatible metallic frame member. The biometallic frame member may include one or more components constructed from a NiTi alloy.

Owner:WISCONSIN ALUMNI RES FOUND

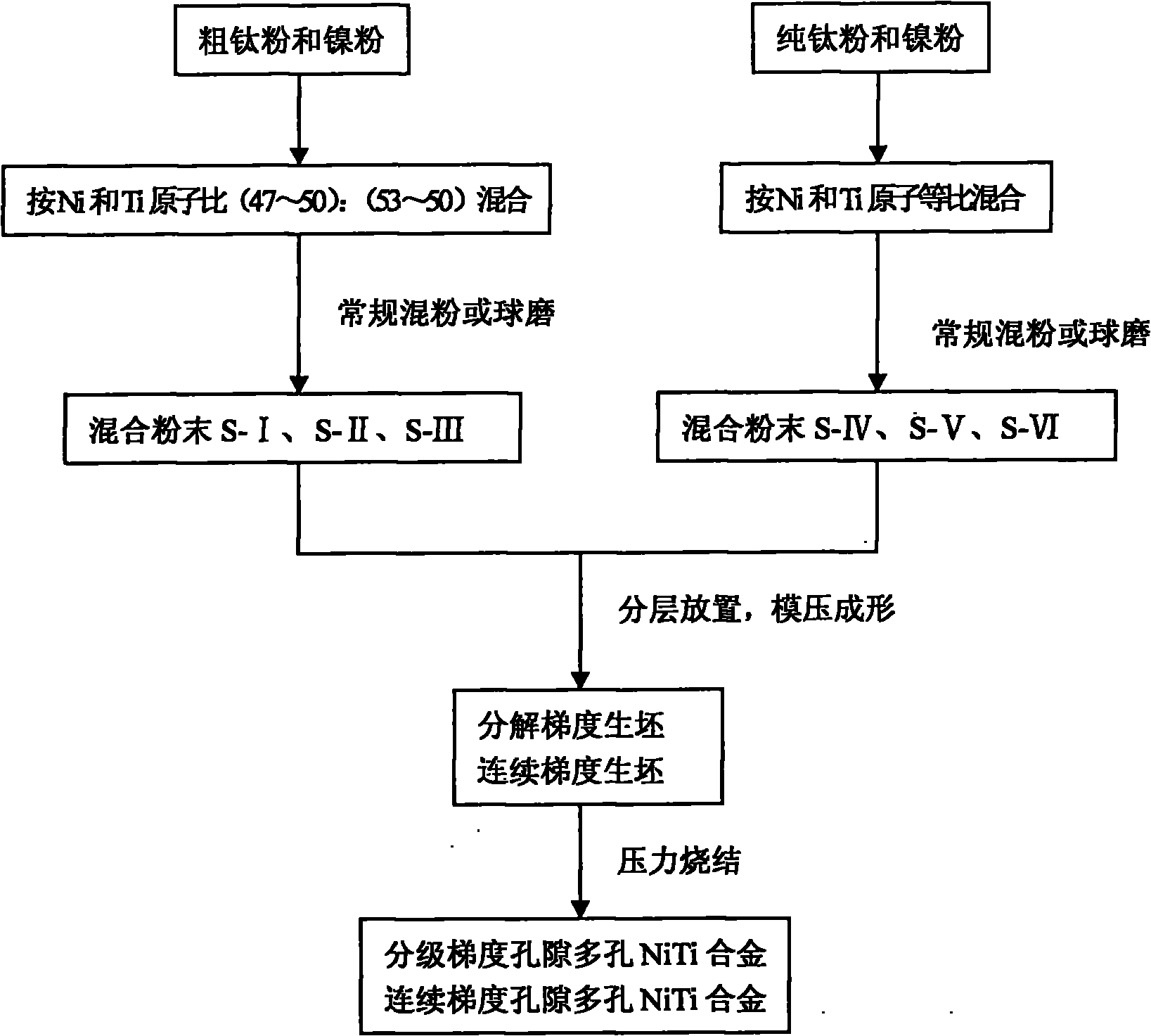

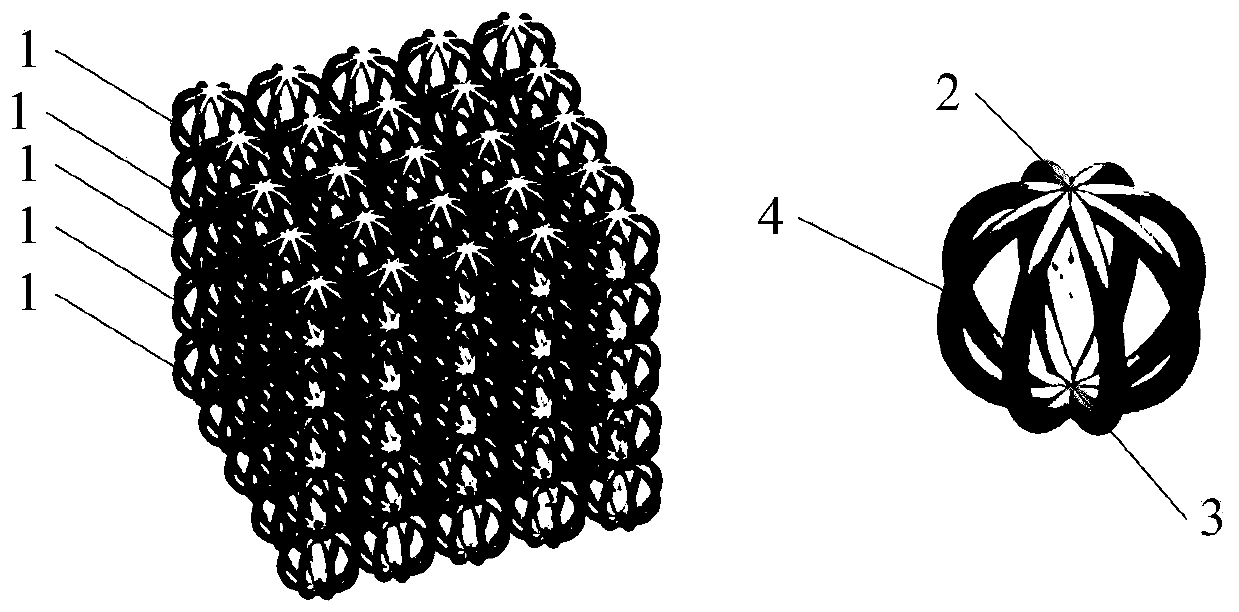

Method for preparing super-elastic gradient-porosity porous NiTi alloy

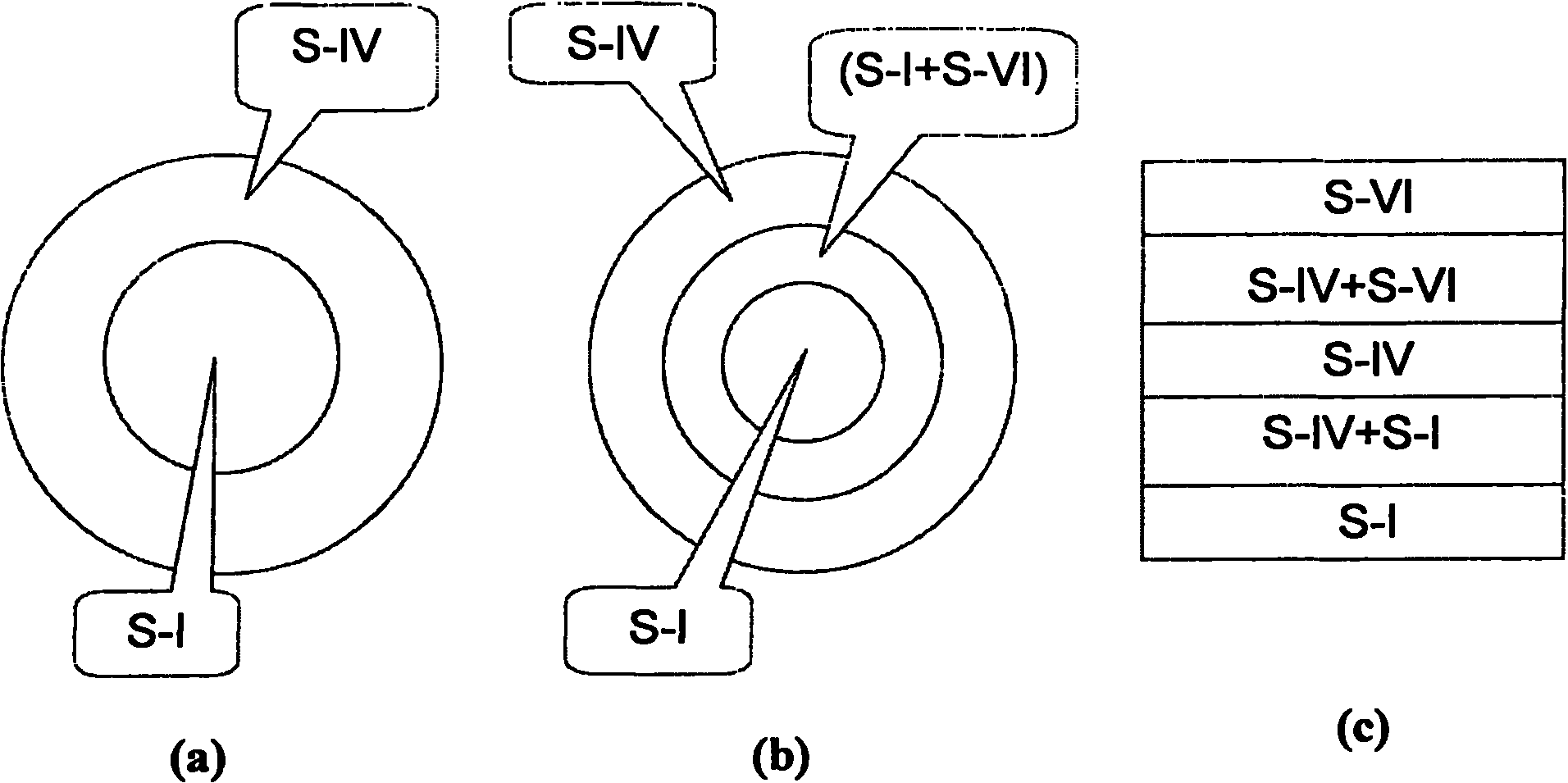

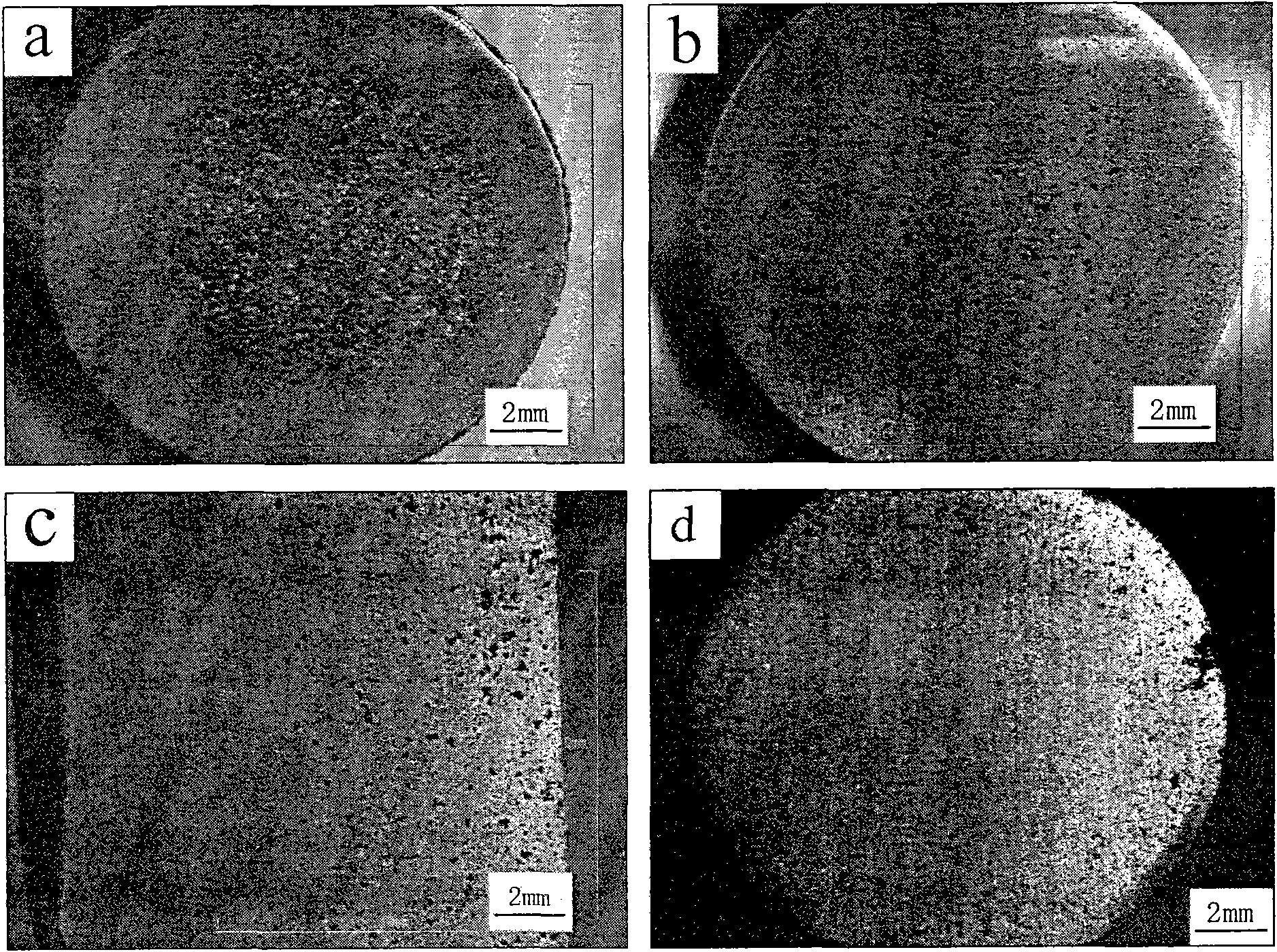

The invention discloses a method for preparing a super-elastic gradient-porosity porous NiTi alloy, which comprises the following steps of: (1) mixing coarse titanium powder and nickel powder in an atomic ratio of (47-50):(53-50), numbering the mixed powder as S-I, S-II and S-III in turn according to the difference of particle sizes of the nickel powder, uniformly mixing pure titanium powder and nickel powder in the same atomic ratio of Ti to Ni, and numbering the mixed powder as S-IV, S-V and S-VI in turn according to the difference of particle sizes of the nickel powder; (2) dividing a mold into 2 to 5 layers along the radial or axial direction of the mold, and performing compression molding to obtain layered green body of the gradient-porosity porous NiTi alloy; and (3) sintering the green body in a sintering furnace in the atmosphere of protective gases to obtain the porous NiTi alloy in different gradient pore distribution. The porous NiTi shape memory alloy is suitable for tissue ingrowth and has good mechanical property.

Owner:SOUTH CHINA UNIV OF TECH

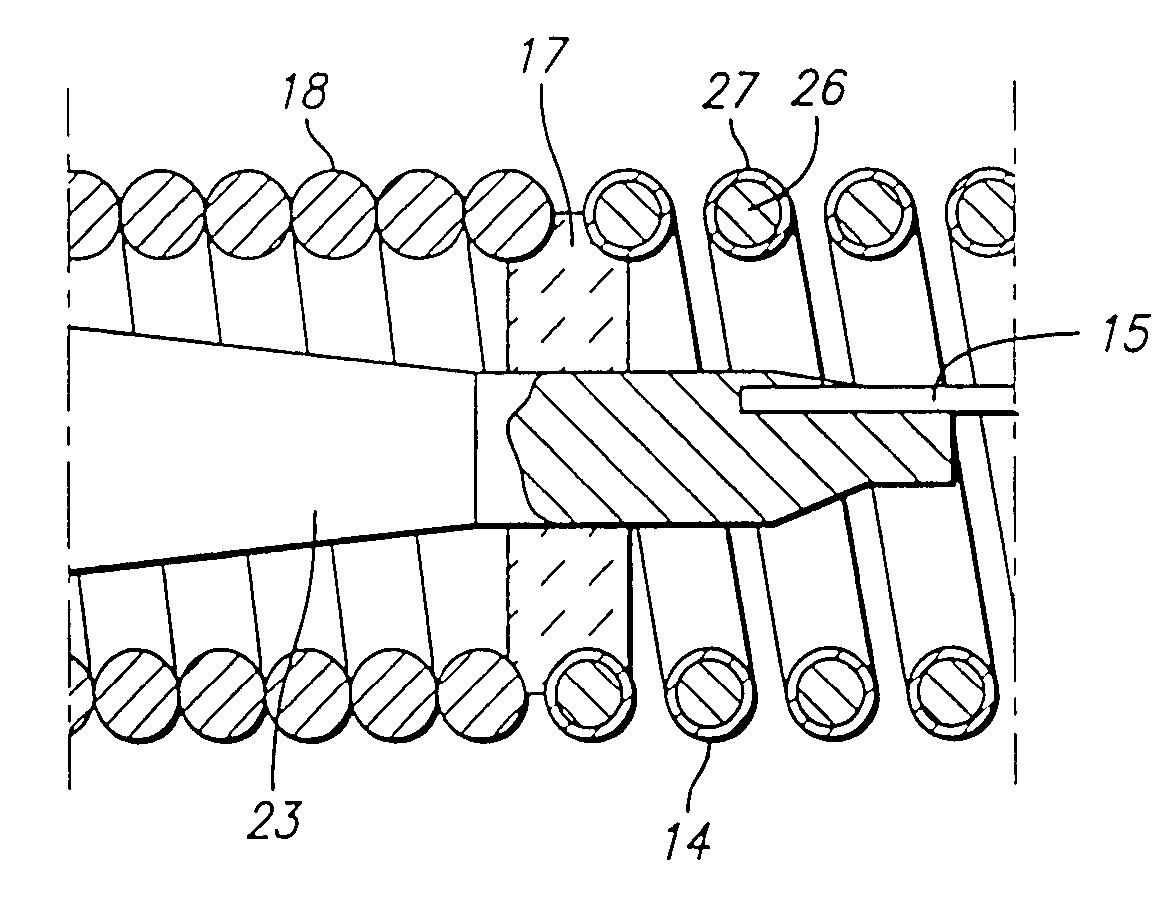

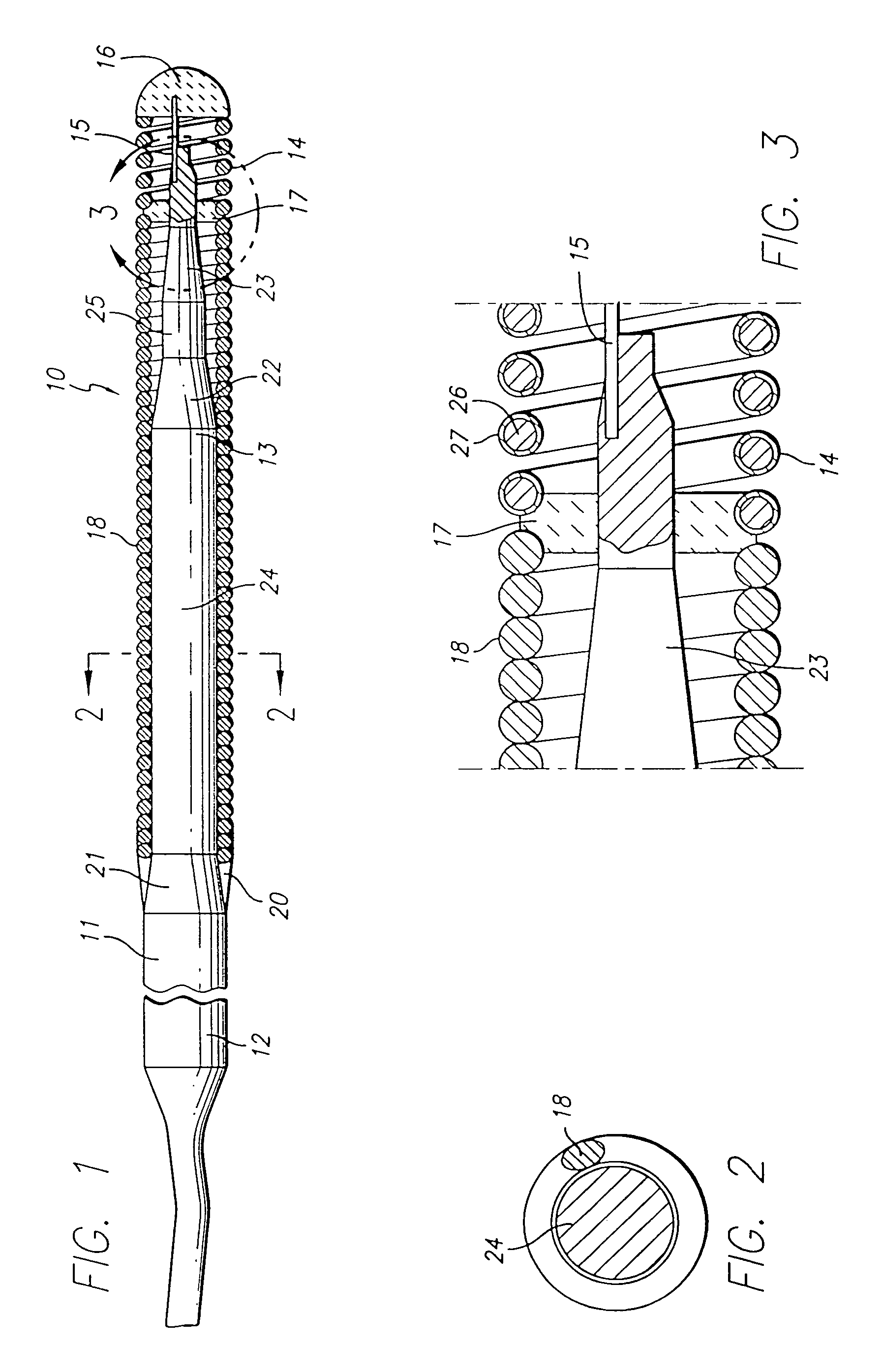

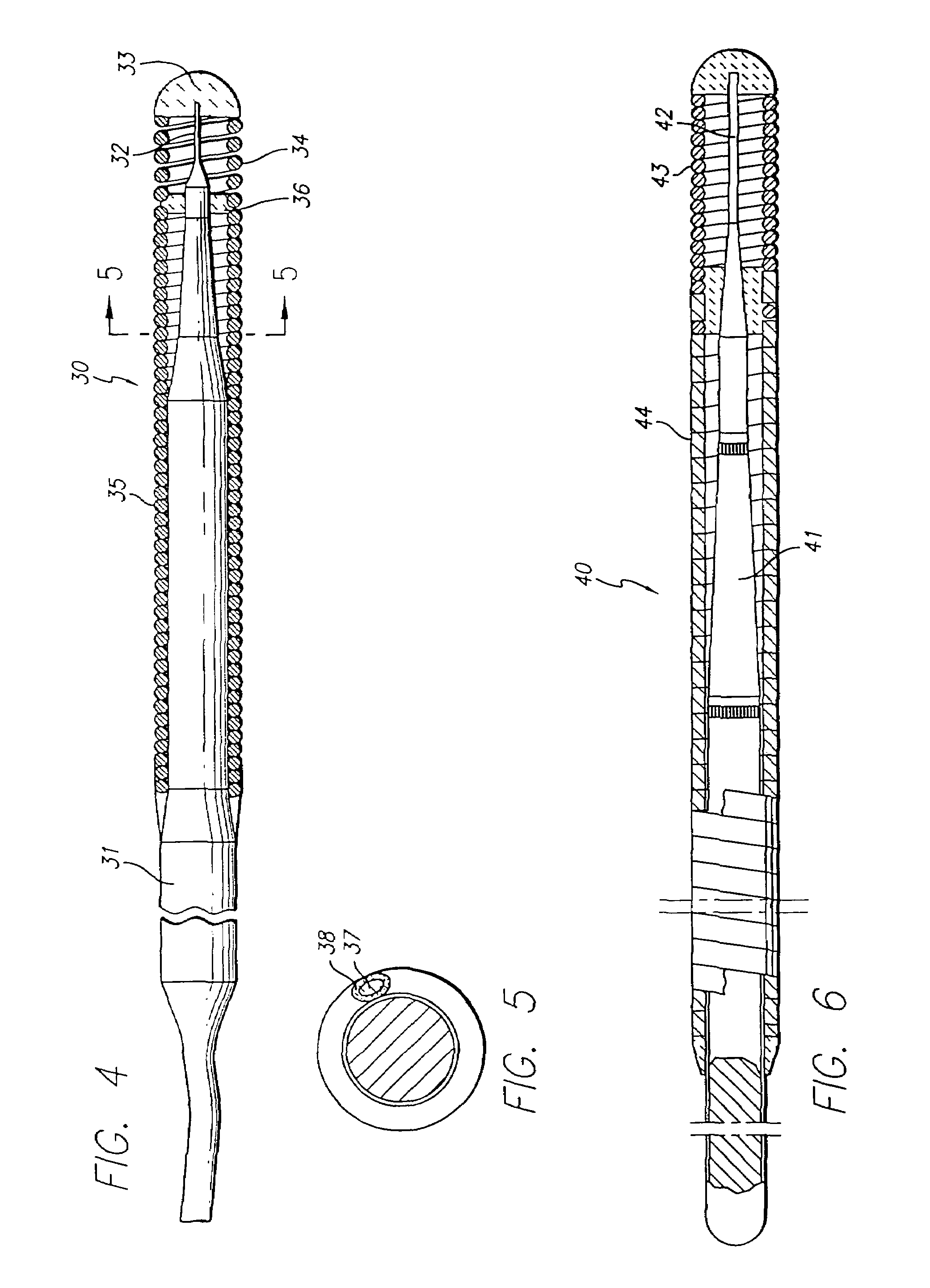

Process for providing composite radiopaque intracorporeal product

The invention is directed to a guidewire having a distal flexible member, such as a helical coil, which is formed with at least one highly radiopaque component and at least one high strength component. In a presently preferred embodiment, the highly radiopaque component is at least 10% and less than about 60% of the transverse cross-section of the flexible member, preferably at least 20% but less than 40%. The highly radiopaque component may be formed of radiopaque material such as platinum, gold, iridium and the like and the high strength component may be formed of a material such as tantalum, stainless steel, NiTi alloys, Co—Cr—Mo alloys and the like.

Owner:ABBOTT CARDIOVASCULAR

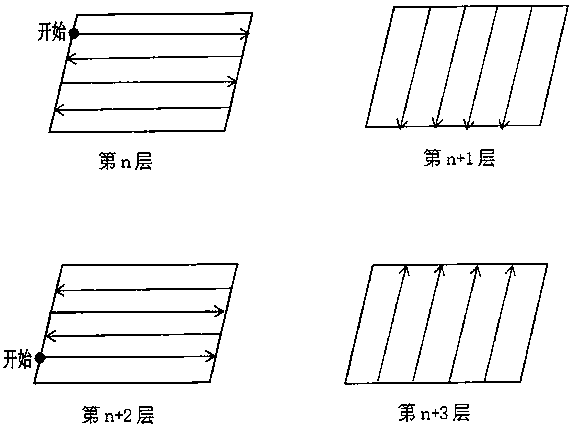

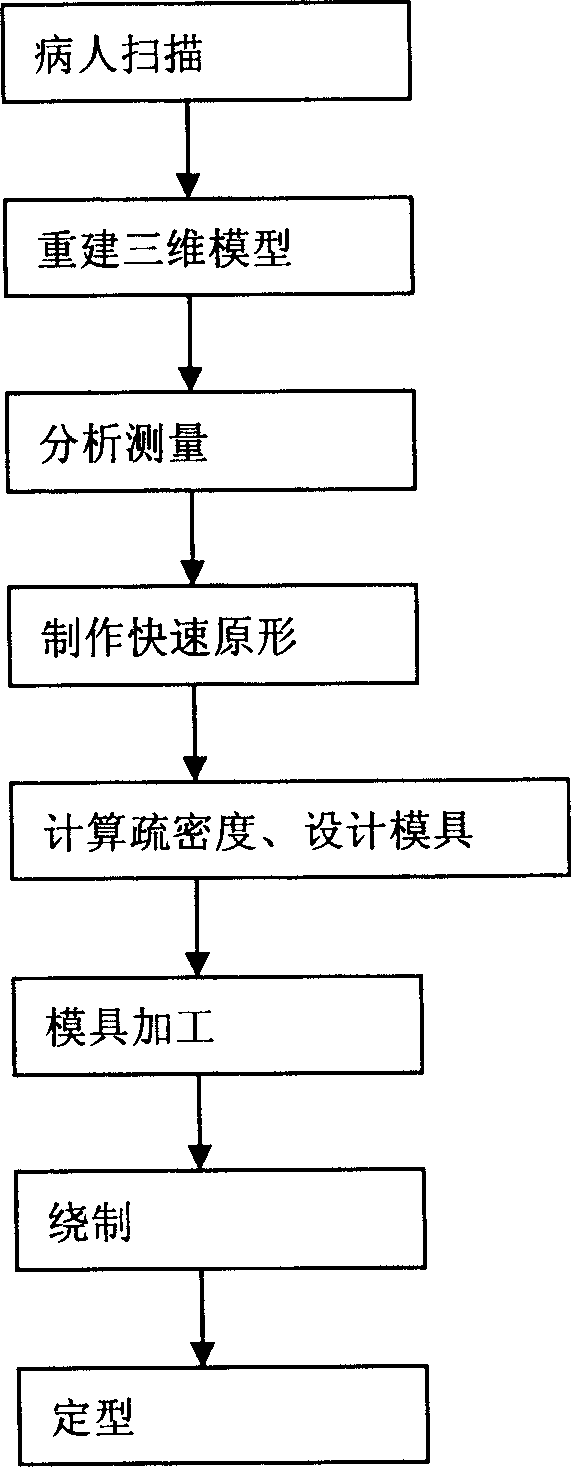

Method for forming complex NiTi alloy component through additive manufacturing

InactiveCN108393492APlay a cooling roleImprove bindingAdditive manufacturing apparatusIncreasing energy efficiencyNiti alloyNumerical control

The invention discloses a method for forming a complex NiTi alloy component through additive manufacturing. According to the method, a metal base plate is installed at the bottom of a forming chamber,the forming chamber is filled with high-purity argon beforehand to make the oxygen content in the forming chamber smaller than 60 microliter per liter, a selective laser melting technology is utilized to form the complex NiTi alloy component, layer-by-layer laser cladding is realized through the numerical control program of each layer to finally obtain a three-dimensional metal part, and the problem that the complex NiTi alloy component with good mechanical property cannot be made with a common smelting method or a powder metallurgy method in the prior art is solved. With the method for forming a complex NiTi alloy component through additive manufacturing, the various complex NiTi alloy components with cambered surfaces, complex inner chambers and the like are quickly formed without any special molds or any special tools, and the made components are good in interlayer combination, simple in technology, and short in manufacturing period, and has the characteristics of being high in density, accuracy, metal powder utilization rate and the like.

Owner:JILIN UNIV

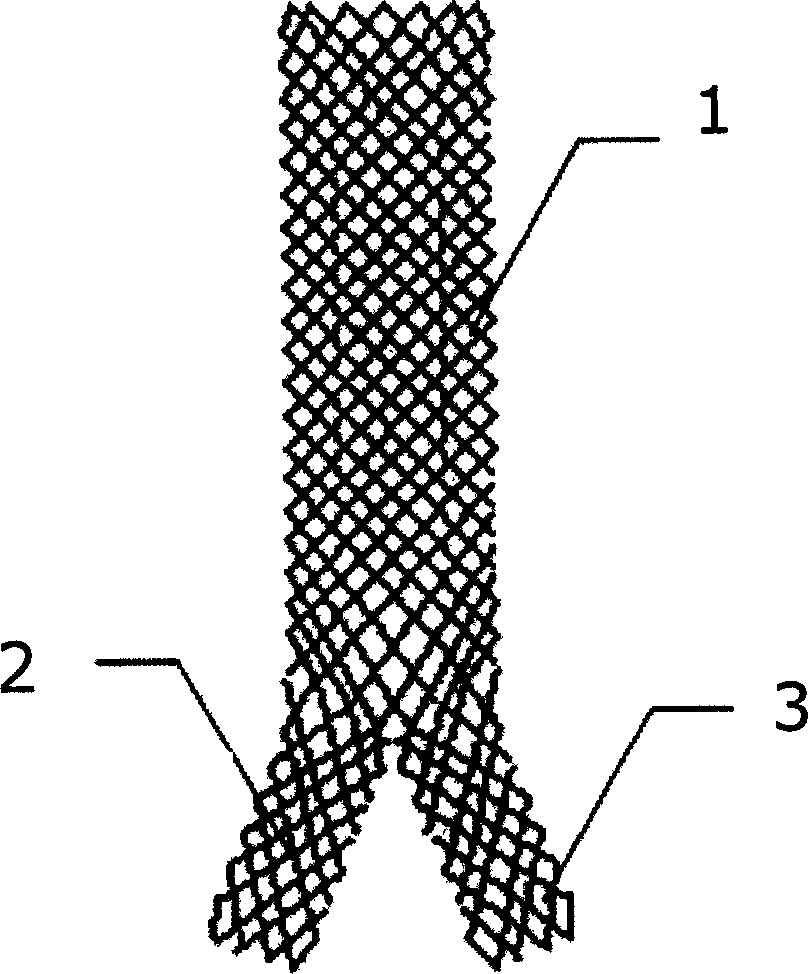

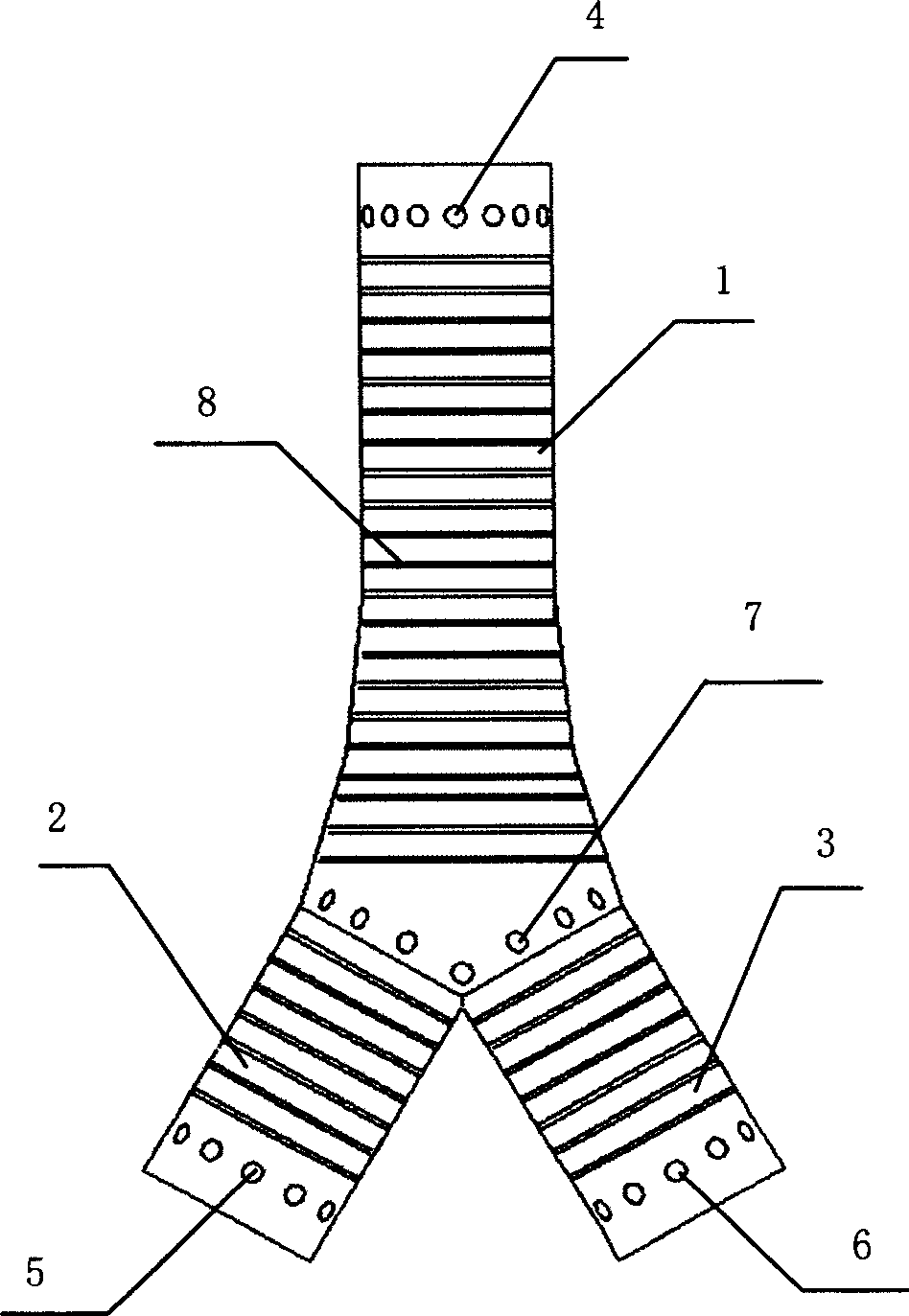

Y-shaped Ni-Tialloyed tracheal net braided support and its mfg. method

InactiveCN1833620AAvoid multiple implantsPrevent diseaseStentsTubular organ implantsNiti alloyNuclear medicine

A braided Y-shaped reticular scaffold for trachea is composed of a main body and two branches to form a Y shape. It is made up of NiTi-alloy wire through CT or MRI scanning to obtain the image of the narrow tranches part, measuring and analyzing its length, internal diameter and the included angle between two branches, preparing mould, and braiding.

Owner:SHANGHAI JIAO TONG UNIV

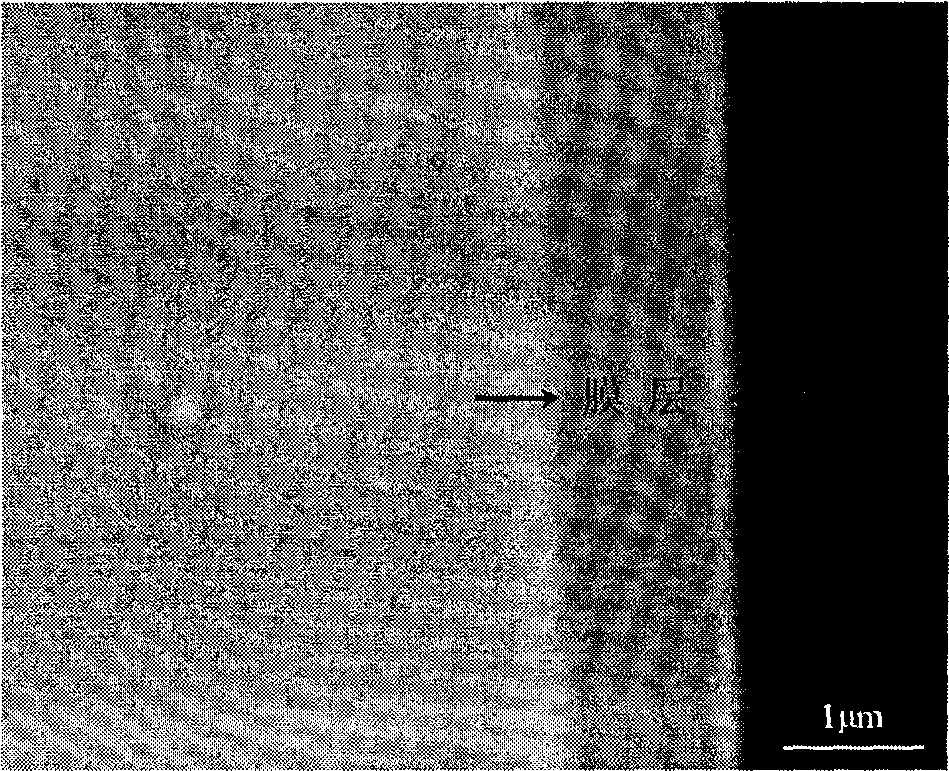

Method for preparing diamond-like coating on surface of biological medical NiTi alloy

InactiveCN101532122AReduce the probability of activationThe original adsorption ratio is largeVacuum evaporation coatingSputtering coatingNiti alloyFilm base

The invention discloses a method for preparing a diamond-like coating on the surface of biological medical NiTi alloy. The method comprises the following steps that: a pre-treated basal body is put on a rotary hack lever of electrical arc reinforced magnetron sputtering ion filming equipment, and a planar C target is arranged on the inner wall of a furnace body in a mode of planar target; a vacuum chamber is introduced into argon gas to clean the vacuum chamber and the pre-treated basal body; the surface of the basal body is plated with a Ti base layer after cleaning, and a TiC transition layer is prepared; and the diamond-like coating is prepared and obtained on the TiC transition layer on the surface of the basal body. For the diamond-like coating prepared by the method, the hardness reaches 25 to 30Gpa, the film base binding force reaches 48 to 60N, and the corrosion resisting property is obviously better than that of the NiTi alloy; moreover, the method can obviously improve the mechanical and biological properties of the biological medical NiTi alloy.

Owner:XI AN JIAOTONG UNIV

Shape memory alloy sealing gasket and production technology thereof

InactiveCN102409197AUnder high pressureGuaranteed anti-agingFlanged jointsNiti alloyShape-memory alloy

The invention discloses a shape memory alloy sealing gasket. The sealing gasket is characterized in that the material comprises the following components in parts by weight: 53.25-58.42 parts of Ni, 41.63-45.82 parts of Ti, 0.1-0.2 part of Al, 0.01-0.03 part of Cu and 0.015-0.12 part of V. The shape memory alloy sealing gasket utilizes the superelasticity and shake-suction performance of the NiTi alloy and has the advantages of good compression elasticity, corrosion resistance, fatigue resistance, high pressure resistance and good safe reliability.

Owner:NANJING UNIV OF TECH

Chemical process of preparing bioactive hydroxy apatite layer on the surface of NiTi alloy

InactiveCN1417378AUniform thicknessExcellent adhesionMetallic material coating processesProsthesisNiti alloySimulated body fluid

The present invention discloses a chemical process of preparing bioactive hydroxyapatite layer on the surface of NiTi alloy. The NiTi alloy matrix is first polished, cleaned and dried; then acid and alkali treated, dried and precalcified in Na2HOP4 and Ca(OH)2 solution; and finally processed in simulating body fluid to grow hydroxyapatite naturally. The present invention is characterized by the said treating liquid, which is mixed acid of HCl, H2SO4 and H2O in the ratio of 1 to 1 to 0-4 30-65 % concentration HNO3 water solution and used in treatment at 20-60 deg.c for 1-24 hr; and the alkali solution of 1-5 M concentration sodium hydroxide solution at 40-150 deg.c used in soaking for 1-24 hr. The present invention has the advantages of low acid and alkali treating temperature, matrix withshape memory effect and surface bioactivity and capable of being implanted into body to induce the formation of hydroxyapatite, etc.

Owner:TIANJIN UNIV

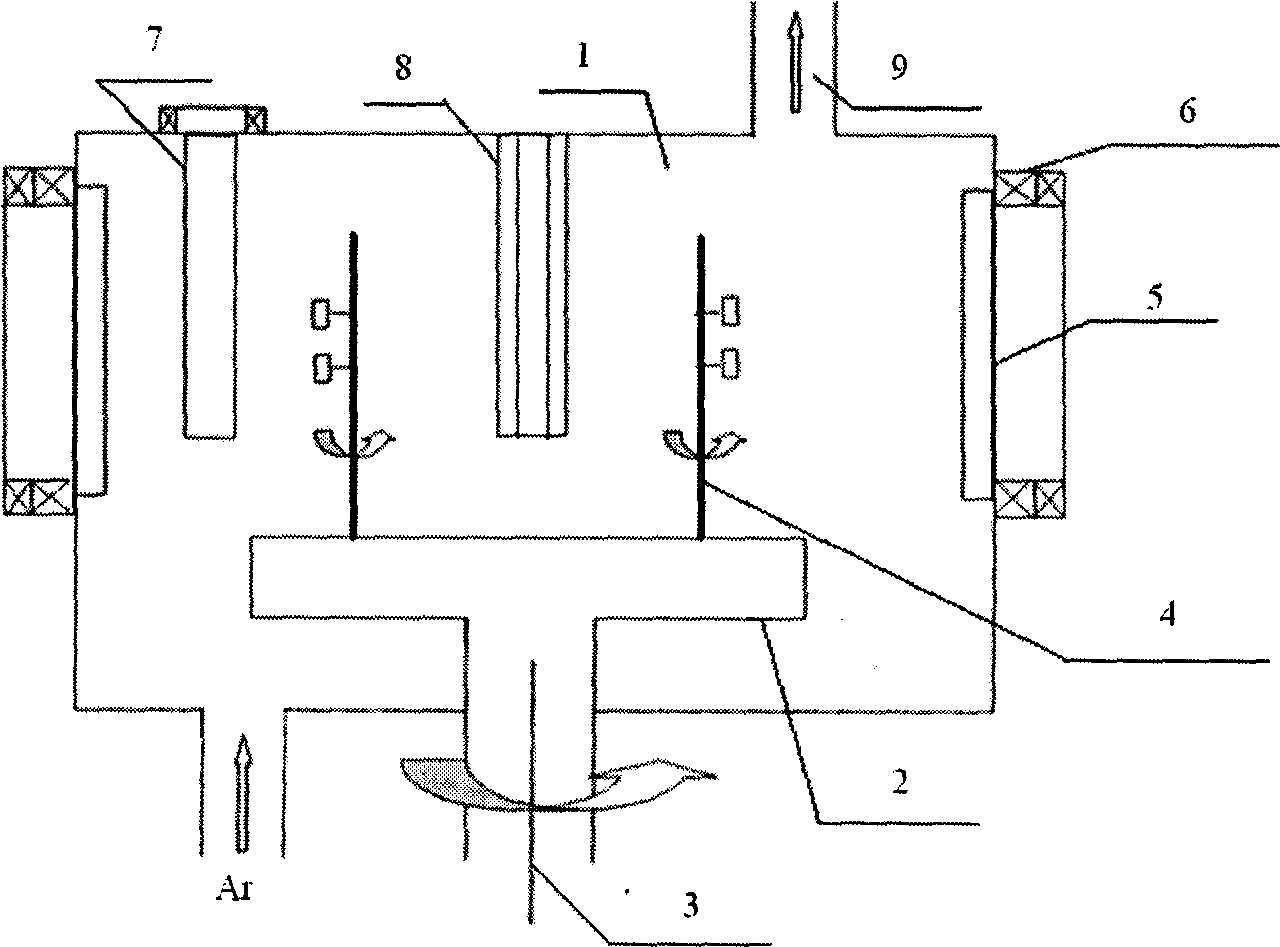

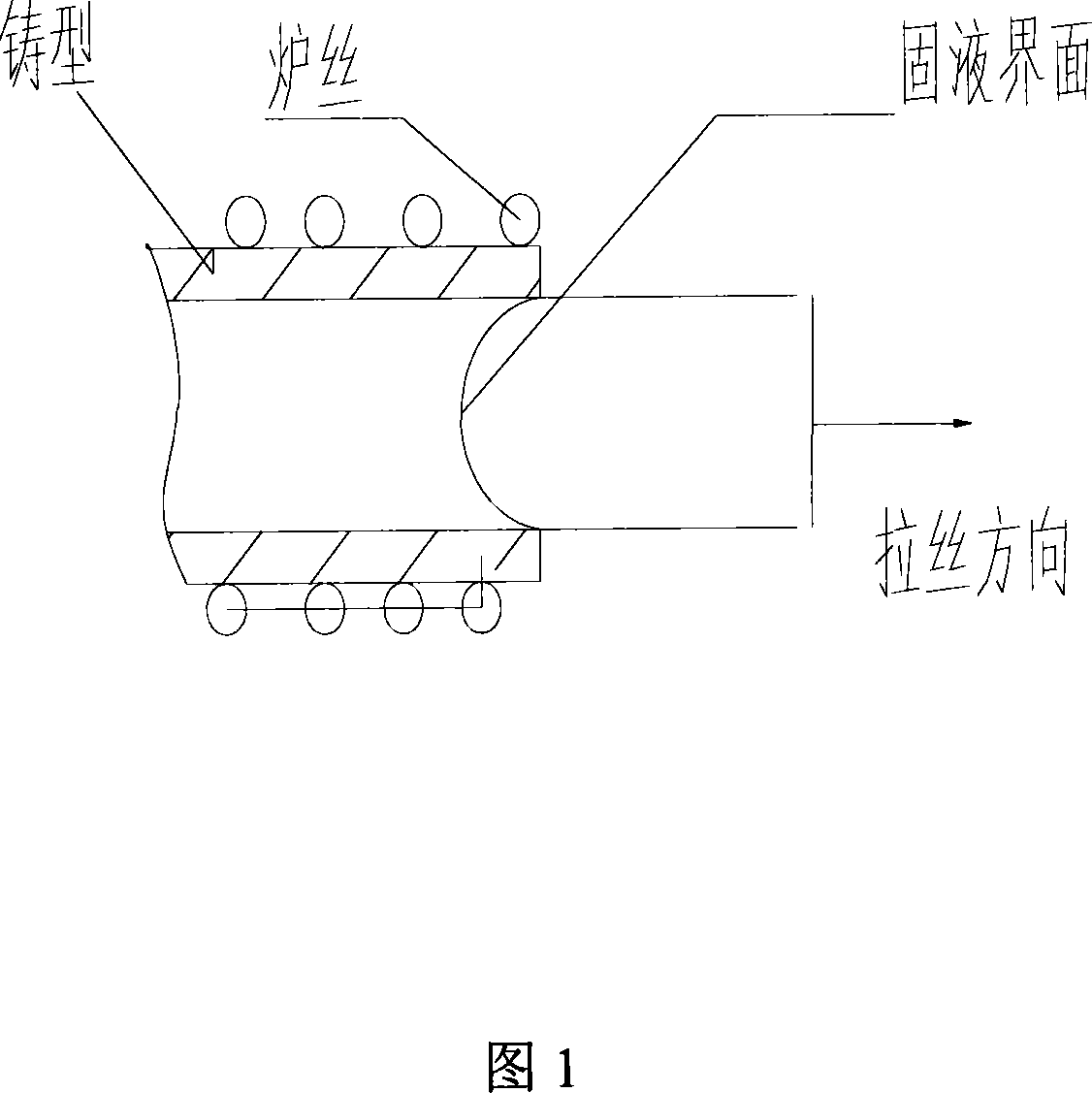

Copper-aluminum-manganese-beryllium memory superelasticity alloy and producing method thereof

A super-plastic memory alloy of Cu-Al-Mn-Be and its production are both disclosed herewith. It contains Al 8-14%, Mn 3-22%, Be 0.2-0.6%, and balanced with Cu, produced by: smelting in a continuous casting resistance furnace in presence of Ar with -0.04--0.1Mpa to obtain ingots, drawing into wires or plates or sections, at 30mm / min minus or plus 5mm and mouth temperature of 1020 deg.C minus or plus 10 deg.C, with distance between the mouth and cooling water of 100L / h minus or plus 50L / h, and heat treating. It has 10-30% specific elongation and 6-25% super-elasticity higher than traditional NiTi alloy.

Owner:江阴鑫裕装潢材料有限公司

Medical tectorial membrane shaped radiation NiTi alloy endovascular stent

InactiveCN101161297AShort doubling timeRestore proliferative abilityStentsSurgeryTectorial membraneNiti alloy

The present invention belongs to the technique category of the medical instrument, relates to a tectorial conformal radiate NiTi alloy vascular inner rack which is implanted to the blood vessel of the human body. To settle the problems of that the existing vascular inner rack can not restrain the growth of the tumour and the thrombus is easy to form, etc., the bracket used by the invention is self-expanding NiTi alloy vascular inner rack, a layer of polycarbonate type polyurethane membrane is covered at the inner wall, the antineoplastic medicine is spraying-coated to the inner surface of the membrane, and the active particles which are used for the inner radiating of the tumour are inserted at the outer bracket of the membrane according to the conformal property. The NiTi alloy vascular inner rack applied by the invention can effectively expand and support the blood vessel; the novel film forming material polycarbonate type polyurethane has an excellent bioavailability; the active particles for the conformal radiotheraphy outside the membrane are inserted to the bracket with a simple and convenient double-buckle mode, the growth surround the blood vessel area is effectively restrained and the radioactive side injury of the normal tissue is reduced. The invention has the advantages of easy making, low cost, strong innovation and wide market prospect.

Owner:李楠

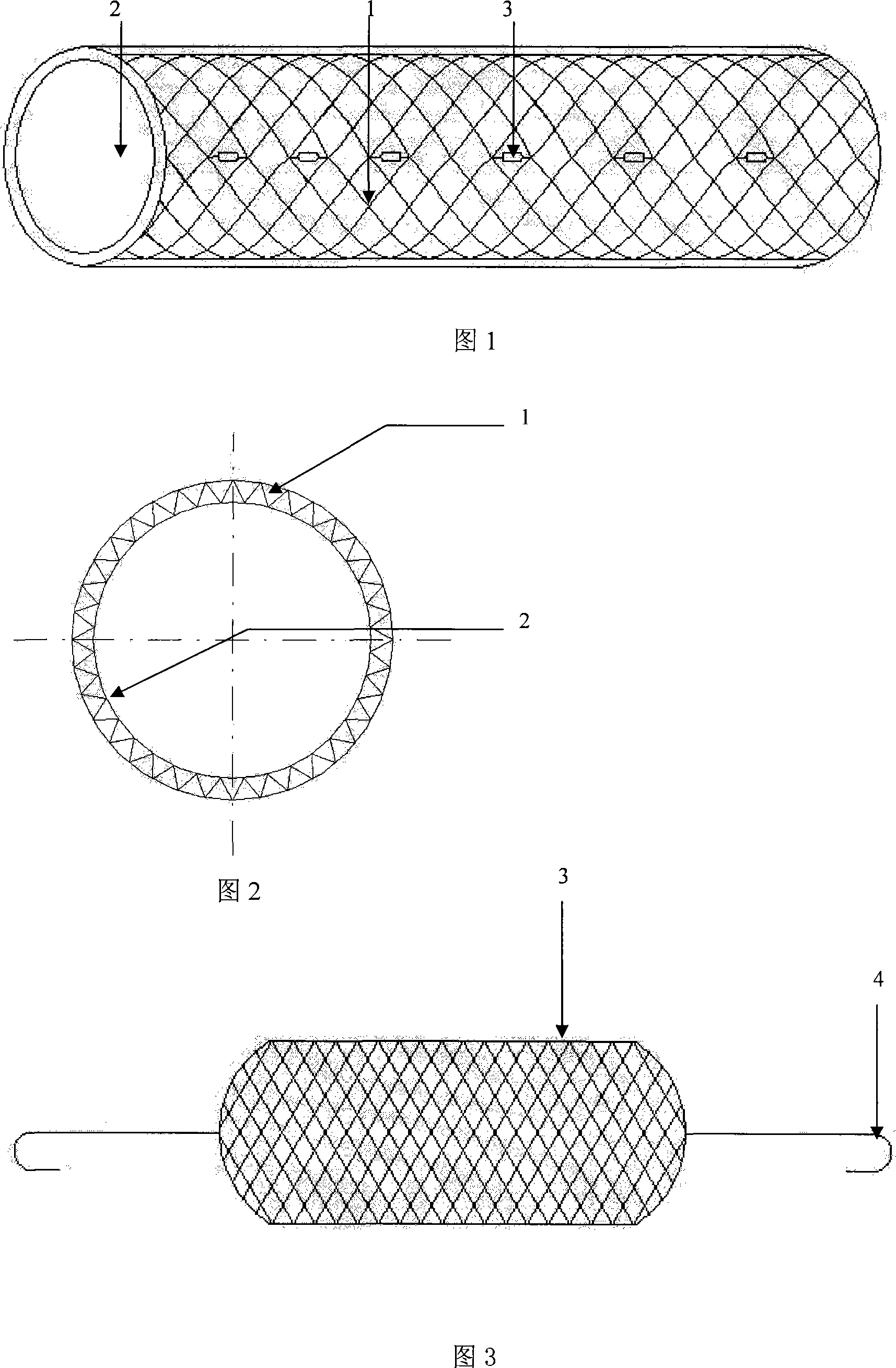

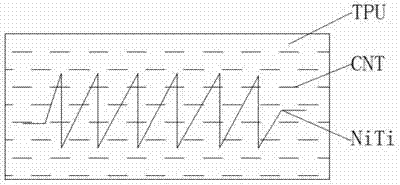

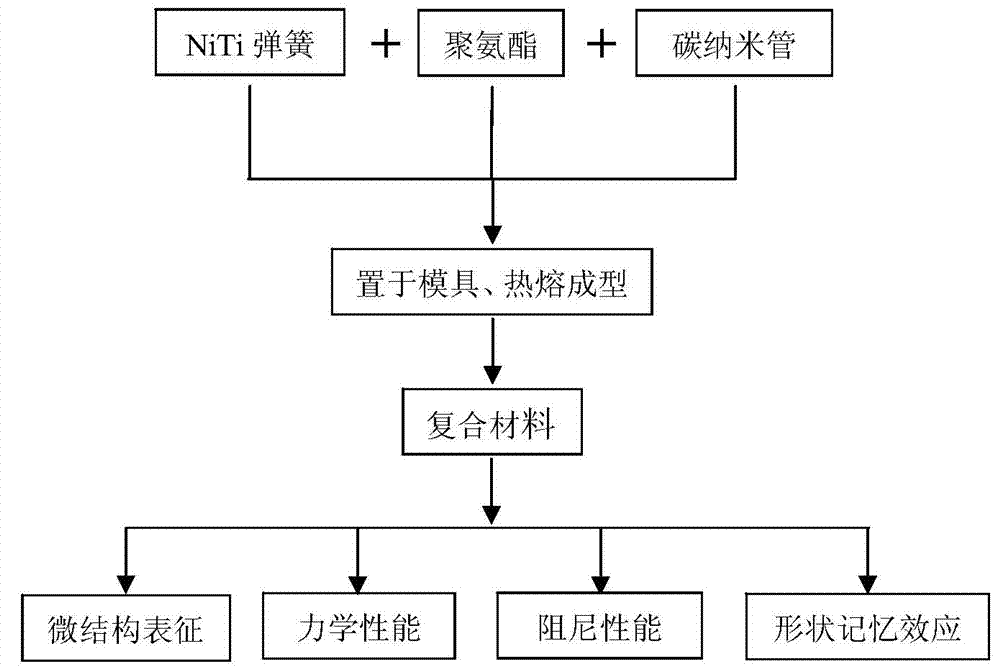

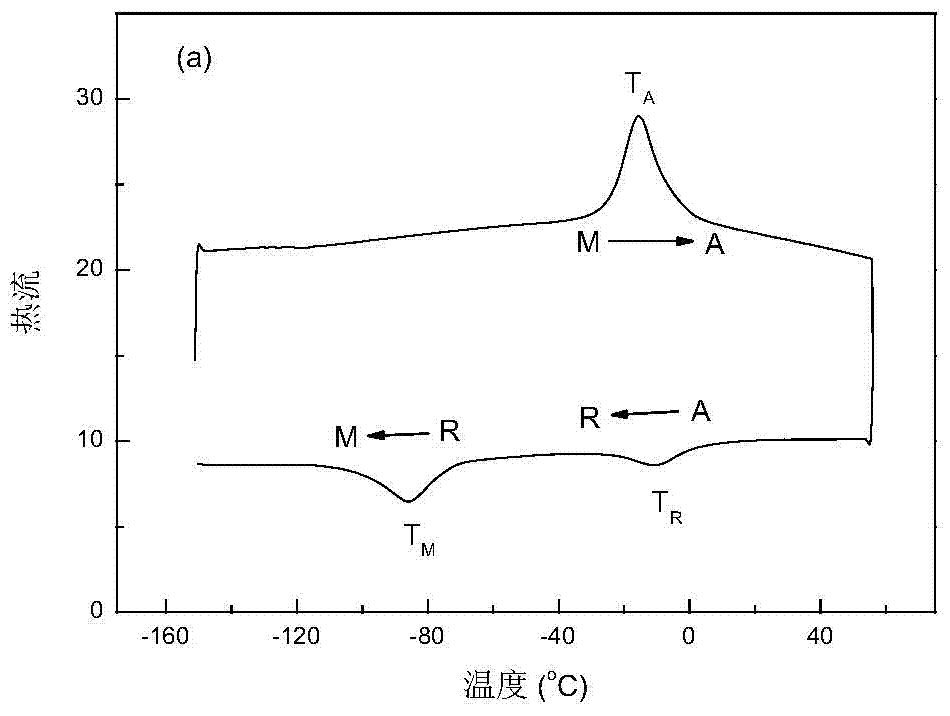

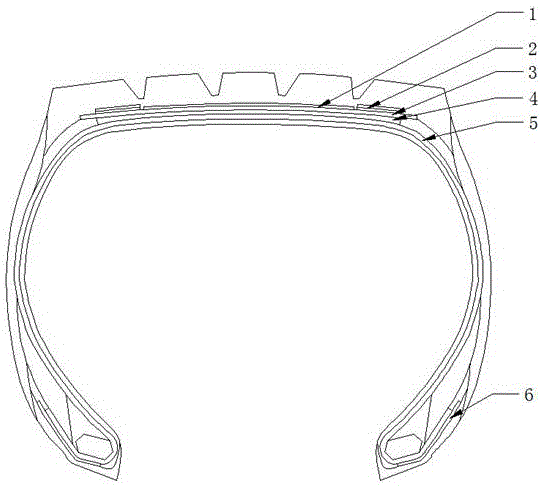

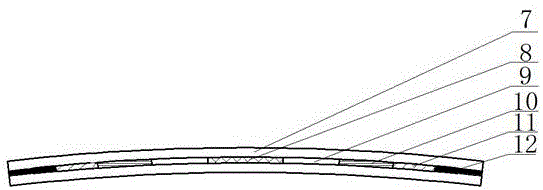

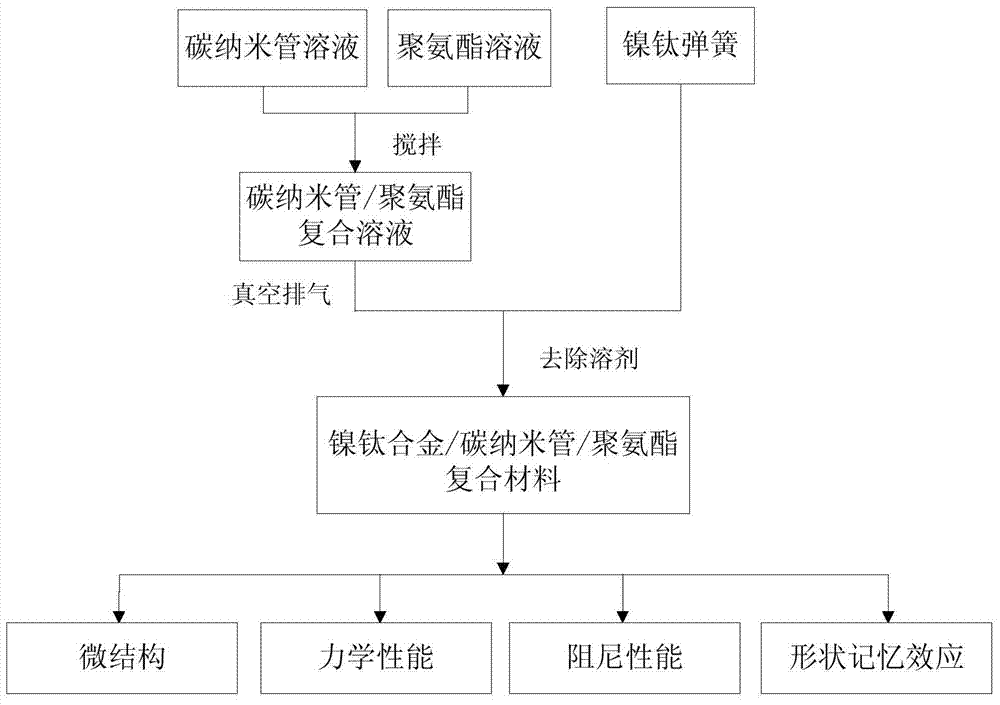

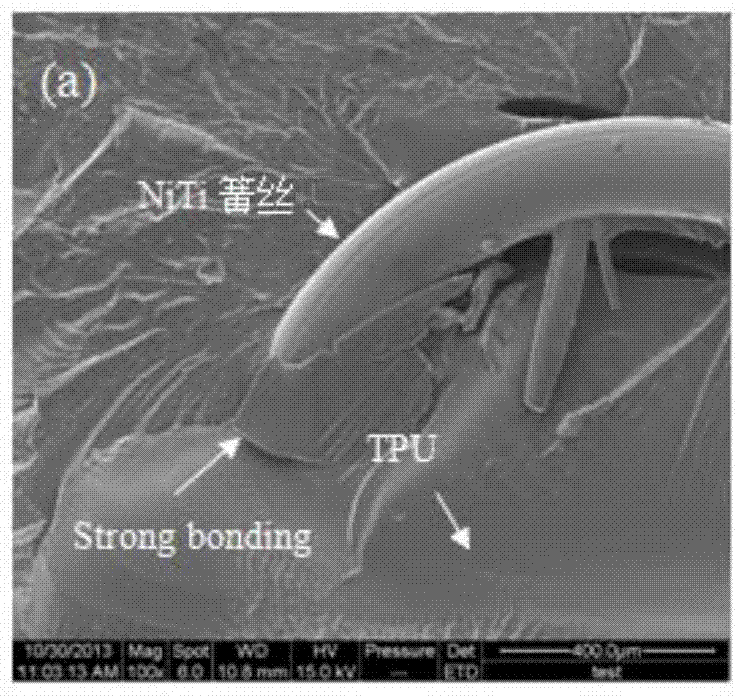

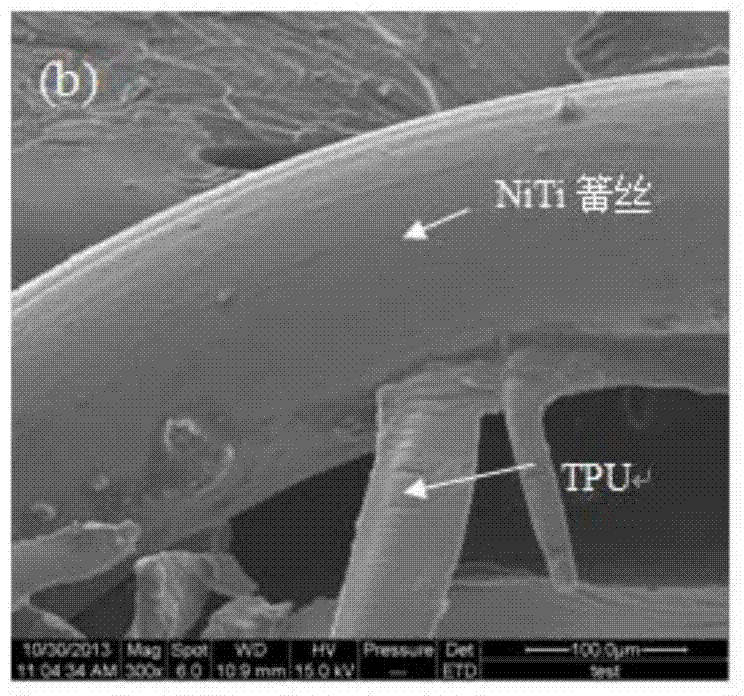

Polyurethane composite material doped by nickel-titanium memory alloy and carbon nanotube and preparation method thereof

The invention provides a polyurethane composite material doped by a nickel-titanium memory alloy and carbon nanotube, and a preparation method thereof. The preparation method comprises the following steps: (1) winding NiTi alloy wires around a spring winding machine to form a spring structure; (2) subjecting the obtained spring to a thermal treatment with a temperature of 400 to 500 DEG C; (3) mechanically stirring and mixing carbon nanotubes and polyurethane elastomer particles; (4) painting a demoulding agent on the inner surface of a mould; (5) placing the mixture obtained in the step (3) into the mould, melting the mixture at a temperature of 190 to 220 DEG C, and moulding; (6) evenly placing the NiTi alloy springs on the layer prepared in the step (5), then dispersing the mixture of carbon nanotubes and polyurethane elastomer around the NiTi springs until the springs are totally covered; (7) finally carrying out composite material melting and moulding in an air blast constant temperature oven. The prepared material is a damping intelligent composite material having a shape memory effect, is capable of adapting to the environmental and temperature changes, and can be applied to the vibration damping field.

Owner:黑龙江恒河沙科技开发有限公司

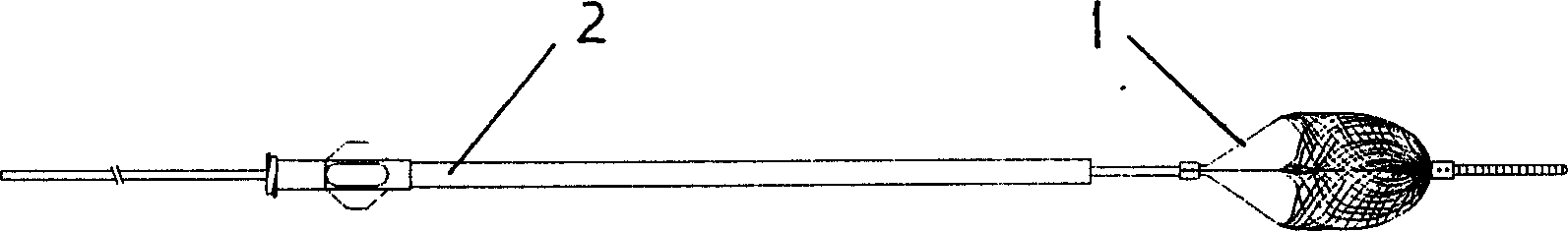

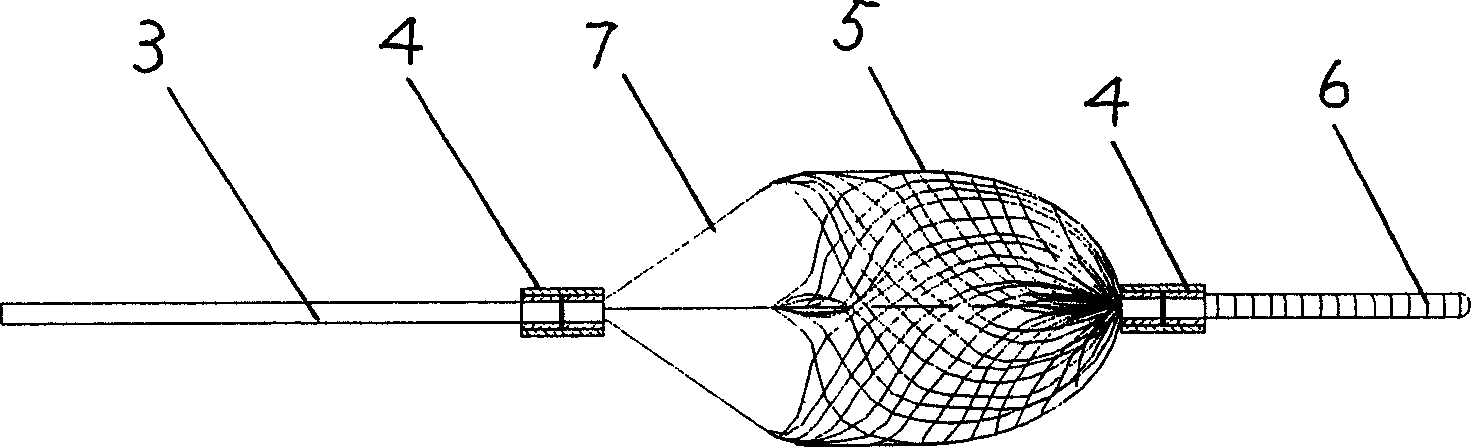

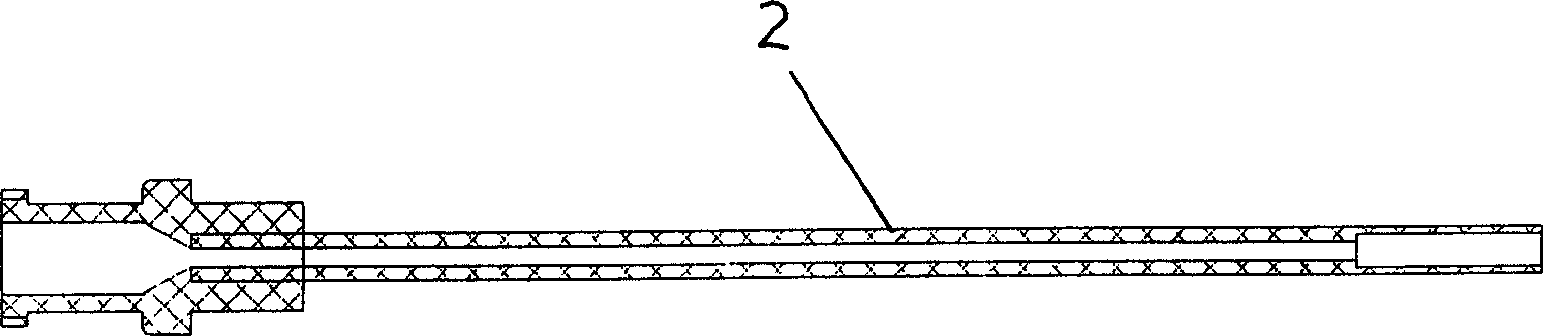

Far end protecting device and its preparing method

InactiveCN1663536ASmall form factorThe procedure is safe and effectiveSurgeryCatheterNiti alloyEngineering

The invention discloses one kind of remote end protector and its preparing method. The technique problem to be solved is that collecting solid particle during operating, permitting the flow of blood, and decreasing outline size of protector. The remote end protector in this invention has filter, which is a basket with netting of contracting radial, setting godet bar along axial line, near end leg of basket with netting connects to godet bar, far end connects to godet head. The preparing method is that: 1. knitting mesh duct with NiTi alloy wire and platinum wire, holding at temperature 450~550deg.C; harnessing spring casing pipe to stainless steel wire or NiTi wire; 2. welding casing pipe and godet head, godet bar and casing pipe together. Compared with existing technique, the filter of remote end protector in this invention is basket with netting that can shrink into transport pipe along radian, decreases outline size of remote end protector, can be used to small blood vessel and serious stenotic pathological changes, brings more safe and efficiency for operation, particularly fits conveying to far end of target blood vessel by duct.

Owner:STARWAY MEDICAL TECH

Method for preparing organic film on surface of NiTi alloy

ActiveCN102211077AGood biocompatibilityNo change in propertiesPretreated surfacesSpecial surfacesNiti alloyOrganic film

The invention relates to an organic film-based NiTi alloy surface modification method, and belongs to the field of metal material surface modification. The method comprises the following steps of: irradiating a preprocessed NiTi alloy by using 60Co at room temperature, immersing in a mixed solution of H2O2 and H2SO4 for activation, performing silanization by using vinylsilane, irradiating by using gamma-rays of the 60Co, and grafting organic monomer or polymer to obtain the organic film on the surface of the NiTi alloy. The organic film prepared on the surface of the NiTi alloy can be prepared into a biological material with high biocompatibility through a molecular design; the film is bound with the surface of the NiTi alloy in a form of covalent bond, and the binding force is large; the grafting ratio of the reaction is controlled by adjusting parameters such as irradiation dose, dose rate, organic monomer or polymer concentration and the like, and the performance of the organic film on the surface of the NiTi alloy is improved; the adopted mutual irradiation grafting method is easy and convenient to implement, the utilization rate of radiation energy is high, a chemical initiator is not needed to be added, and the product is pure; meanwhile, materials can be sterilized in the irradiation process, and biomedical materials are convenient to use.

Owner:BEIJING RADIATION APPL RES CENT +1

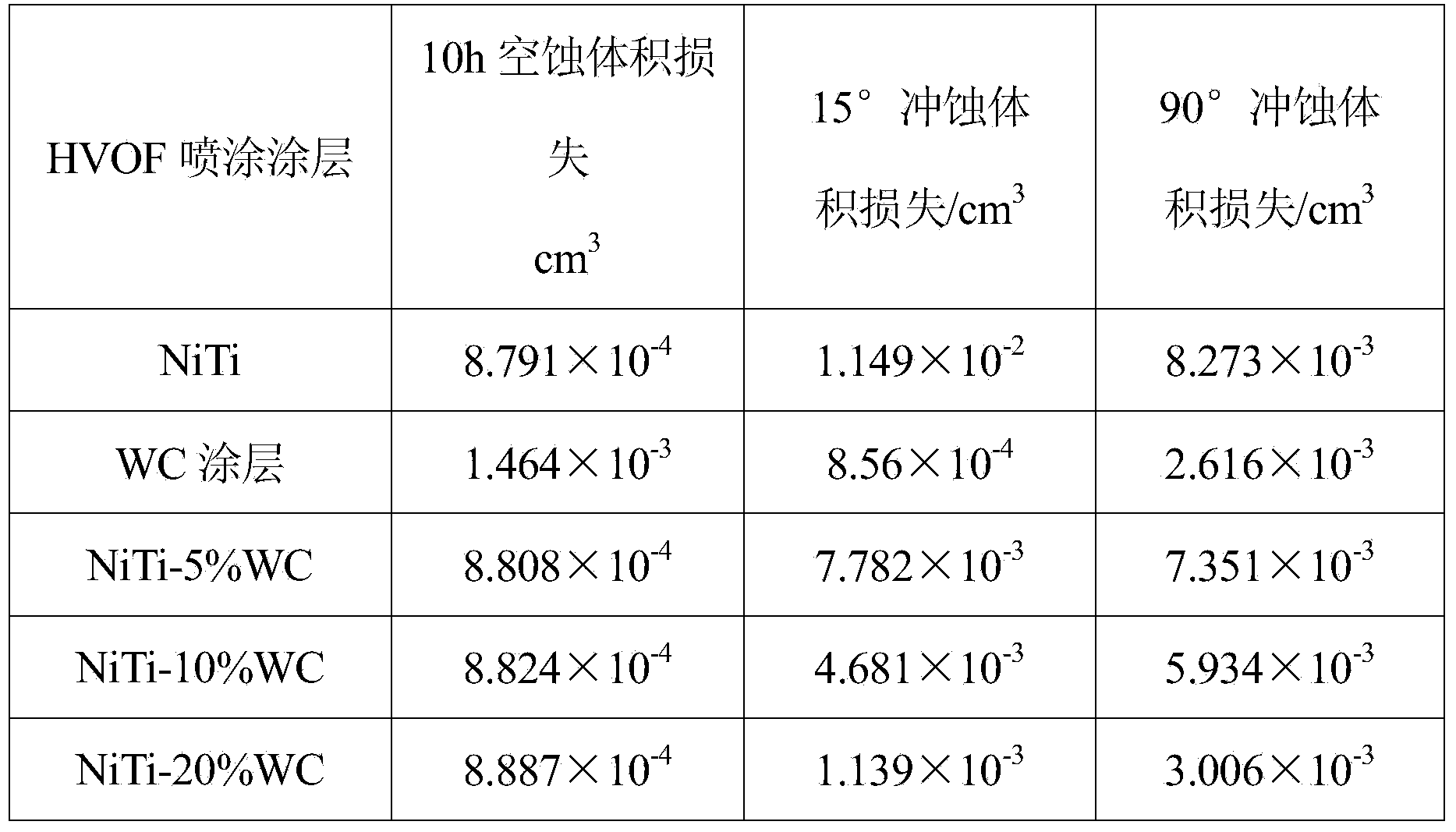

Coating material with abrasion-resistant and cavitation-damage-prevention functions and preparation method thereof

InactiveCN103962548AHas anti-cavitation propertiesHigh hardnessMolten spray coatingPressure inorganic powder coatingNiti alloyCavitation

The invention discloses a coating material with abrasion-resistant and cavitation-damage-prevention functions and a preparation method thereof. The coating material is a composite coating powder material of a NiTi matrix phase enhanced by WC hard-phase particles, the WC hard-phase particles account for, by weight, 1-50% of the composite coating powder material, the NiTi matrix phase is an NiTi intermetallic compound of a B2 phase structure, the grain size of the WC hard-phase particles is at the nanometer lever less than100 nanometers or at the submicron level less than 1 micrometer and the WC hard-phase particles are evenly distributed in the NiTi intermetallic compound matrix phase in a dispersing mode. In the preparation method, the mechanical ball milling technology is used for realizing alloying or an atomization granulating technology is used for preparing the coating material, and the grain size of prepared powder is 5-100 micrometers; the powder maintains the cavitation-damage-prevention performance of NiTi alloy and meanwhile has the excellent abrasion-resistant performance of WC. Coatings coated with the powder do not need thermal treatment.

Owner:HUANENG POWER INTERNATIONAL +1

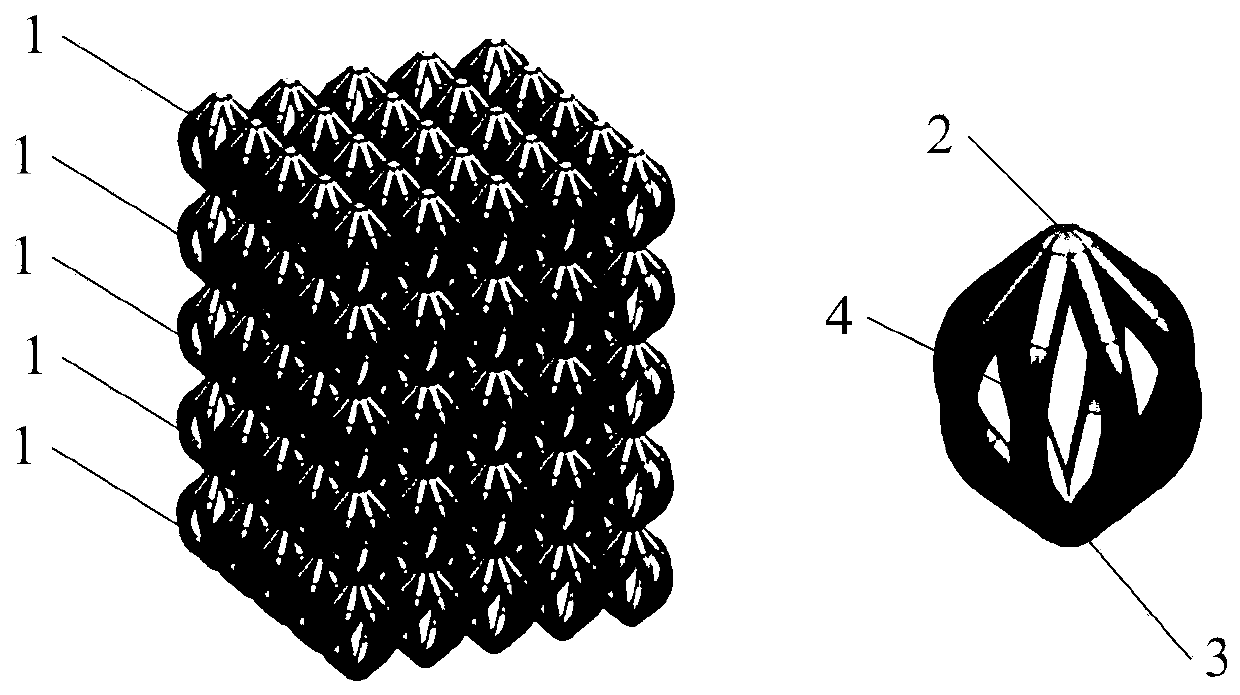

Recoverable energy absorption structure and preparation method thereof

InactiveCN110792721AHigh forming precisionImprove forming efficiencyAdditive manufacturing apparatusVibration suppression adjustmentsNiti alloyEnergy absorption

The invention discloses a recoverable energy absorption structure and a preparation method thereof. The recoverable energy absorption structure comprises a plurality of energy absorption layers whichare sequentially stacked from top to bottom, wherein each energy absorption layer comprises a plurality of energy absorption units; each energy absorption unit comprises a plurality of elastic connecting pieces; the upper ends of the elastic connecting pieces are connected with an upper connecting point; the lower ends of the elastic connecting pieces are connected with a lower connecting point; agap is formed between the parts, except the two ends, of every two adjacent elastic connecting pieces; and the elastic connecting pieces are made of NiTi alloy. According to the recoverable energy absorption structure, the problem that a traditional energy absorption structure cannot be repeatedly used is solved, and the mechanical property of the structure is improved; the preparation method canbe used for preparing the energy absorption structure which can be repeatedly used, and the prepared energy absorption structure has good mechanical property; and the preparation method can give consideration to the mechanical property and the preparation efficiency of the energy absorption structure.

Owner:INST OF MACHINERY MFG TECH CHINA ACAD OF ENG PHYSICS

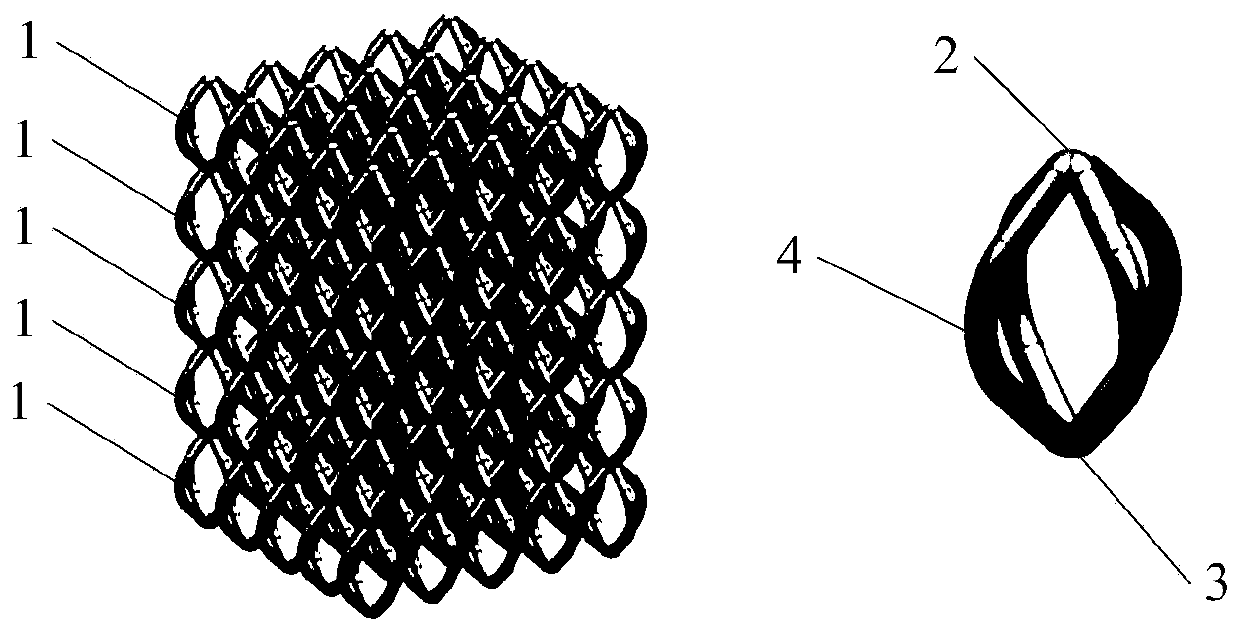

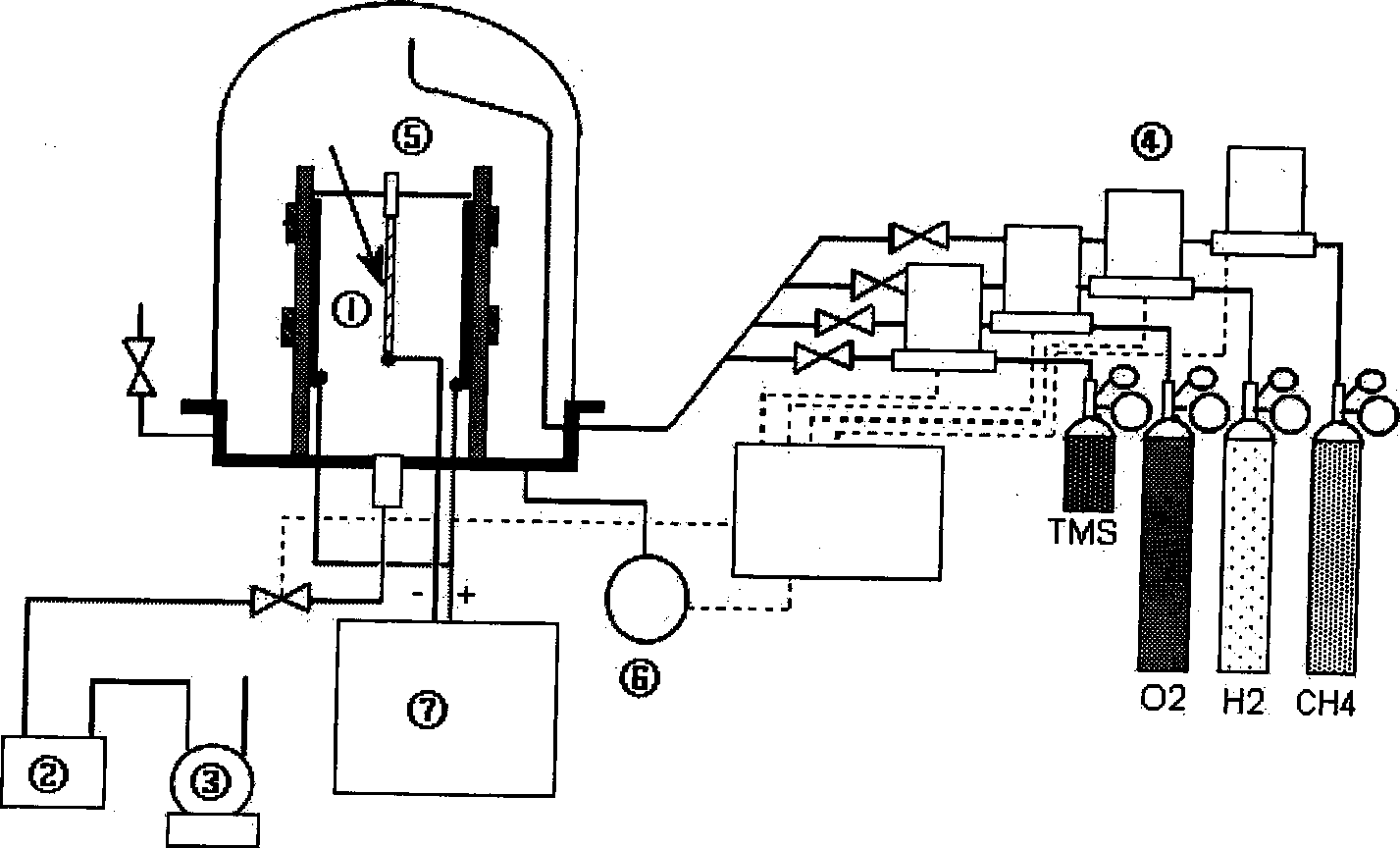

Nano coating combined with micropore surface method for modifying endovascular stent

The invention provides an endovascular stent modification method with the combination of a nanometer coating and a microporous surface, which comprises the steps of: forming micropores on the surface of an implantable medical device, namely an NiTi alloy or 316L stainless steel endovascular stent, preparing a layer of SiOx: H nanometer coating on the surfaces of the micropores, ensuring that the stent can be quickly endothelialized after implanted into a human body and has good blood compatibility and corrosion resistance, and selecting a trimethyl silane (TMS) monomer or mixed gas of the trimethyl silane monomer and oxygen O2 as reaction gas aerated for preparing the nanometer coating, or orderly aerating the TMS, CH4 and O2 gas monomers respectively. The stent modified by the method can be quickly endothelialized after implanted into a pathological change position, and effectively reduce the formation of thrombus; and the biocompatibility (such as corrosion resistance, and the like) of the stent is obviously superior to that of an unmodified stent, so that the incidence rate of ISR is reduced after the sent is implanted through surface modification technology based on stents which have come into the market.

Owner:CHONGQING UNIV

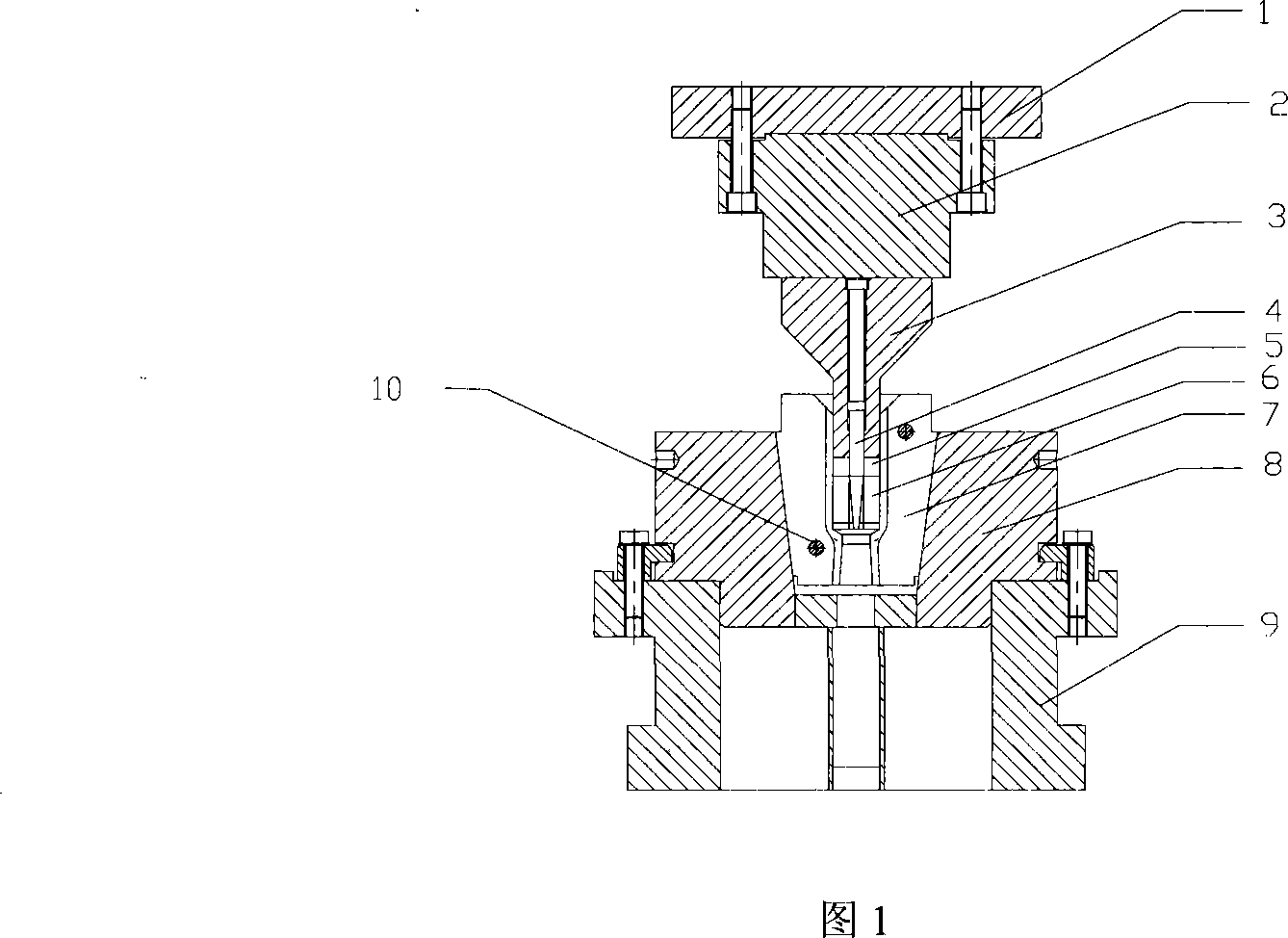

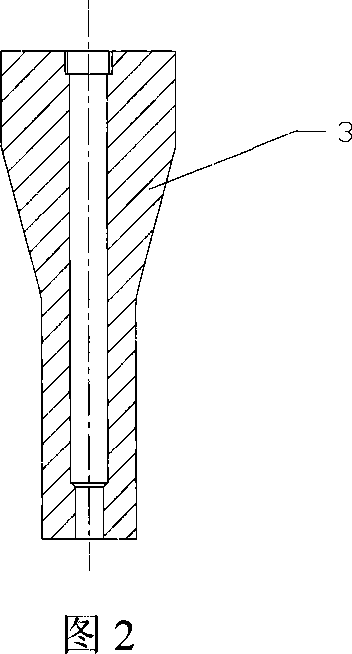

High rate NiTi alloy pipe blank hot extruding mold

The present invention relates to hot extruding technology, and is especially one kind of hot extruding mold for extruding NiTi shape memory alloy pipe blank to form. The technological process includes the steps of: smelting, forging, machining extruded blank, preheating the extruded blank, painting lubricant to the extruded blank, heating the extruded blank to 960-1130 deg.c under inert gas protection and maintaining for 20-30 min, preheating mold, painting lubricant to the mold, hot extruding in speed of 400-500 mm / s, and annealing. The extruding mold is split combined cavity mold, and has simple replacement and long service life. The present invention has the advantages of material utilizing rate up to 89 %, high quality of microscopic pipe blank structure, long mold life, high heating temperature, low production cost and simple process and apparatus.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

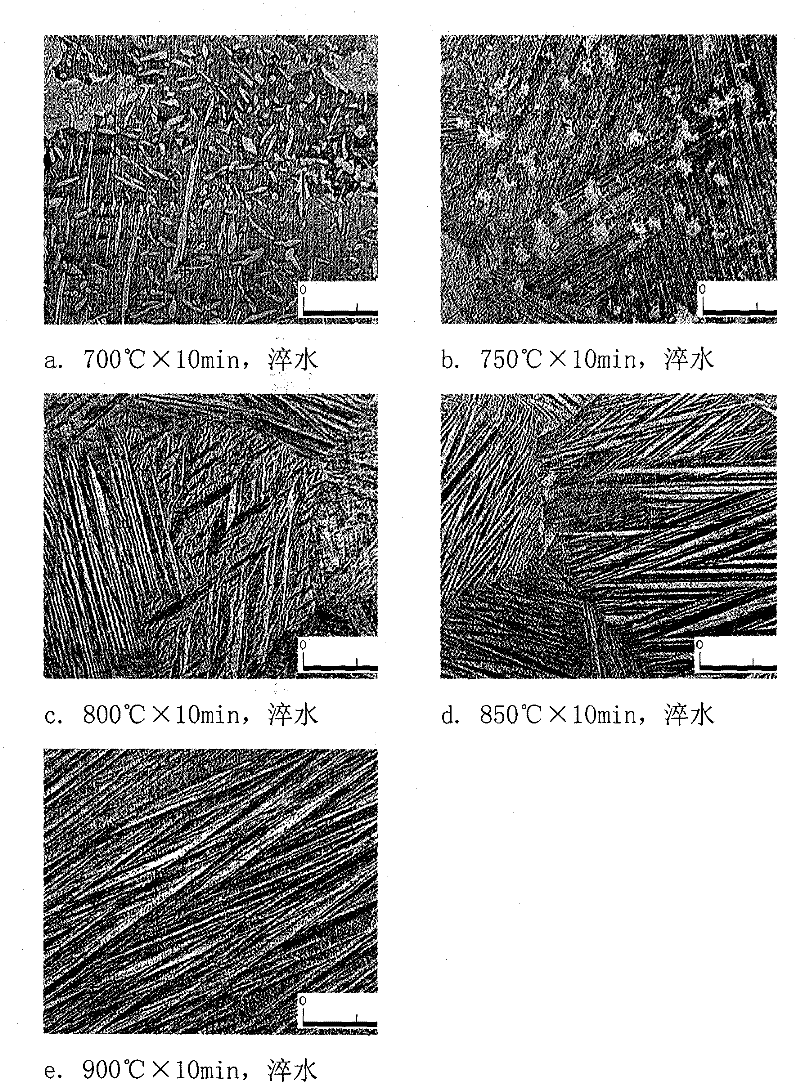

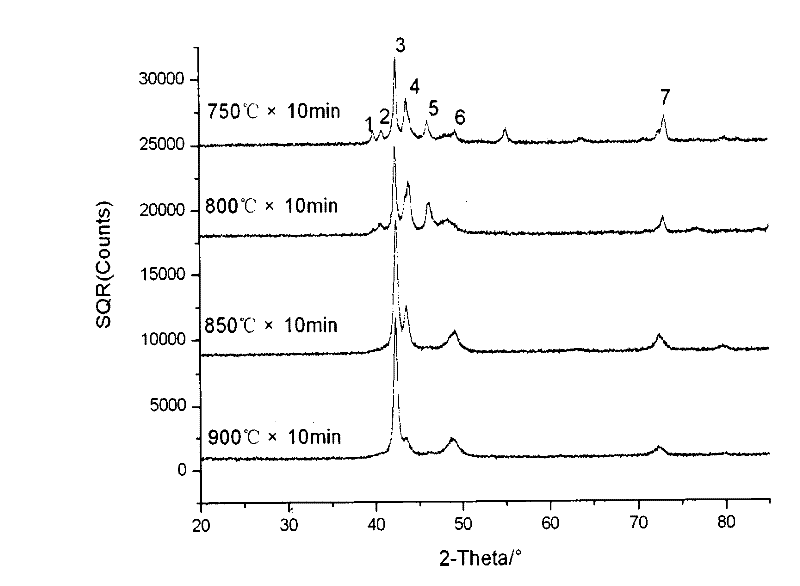

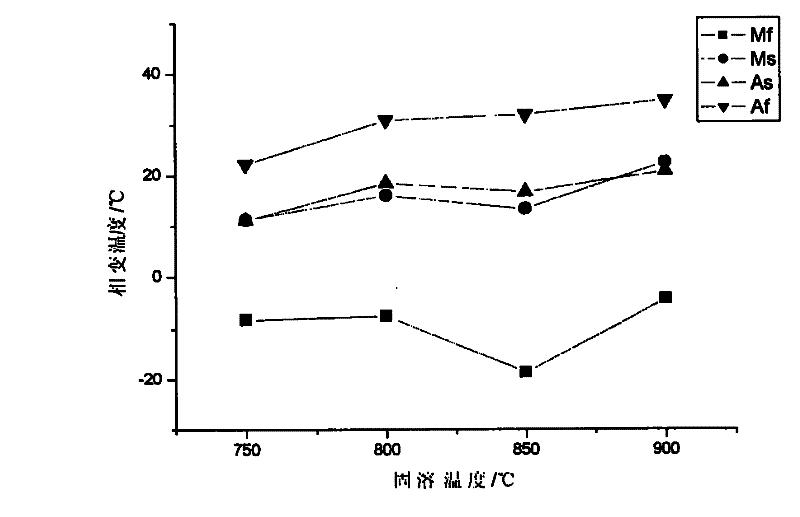

High-performance copper-based shape memory alloy material

The invention relates to a high-performance copper-based shape memory alloy material, which is characterized by consisting of copper, zinc, aluminum, trace elements and a mixed solvent. A preparation method of the high-performance copper-based shape memory alloy material comprises the following steps of: homogenizing the raw materials at 600-700 DEG C, then preserving the temperature for 1h and cooling along with a furnace; carrying out solid solution treatment on raw materials at 700-900 DEG C for 10-20min and then hardening; ageing for 20-50min at 100-150 DEG C; and then carrying out cold rolling processing, wherein the rolling pass working rate is 10-40 percent. The practical shape memory alloy material with high performance cost, provided by the invention, realizes the large-scale production so as to replace the conventional NiTi alloy material; and in price, compared with the NiTi memory alloy, the copper-based memory alloy has significant market competition advantage.

Owner:ANHUI FENGHUI METAL

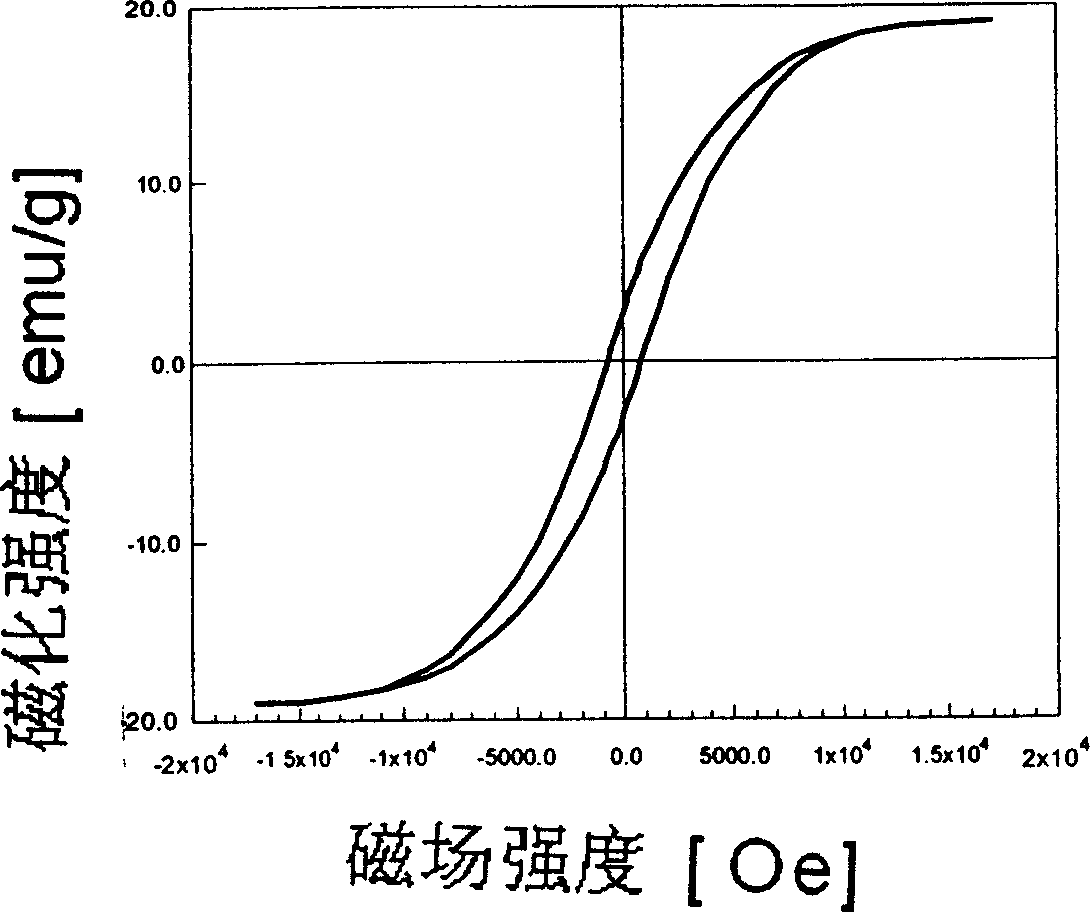

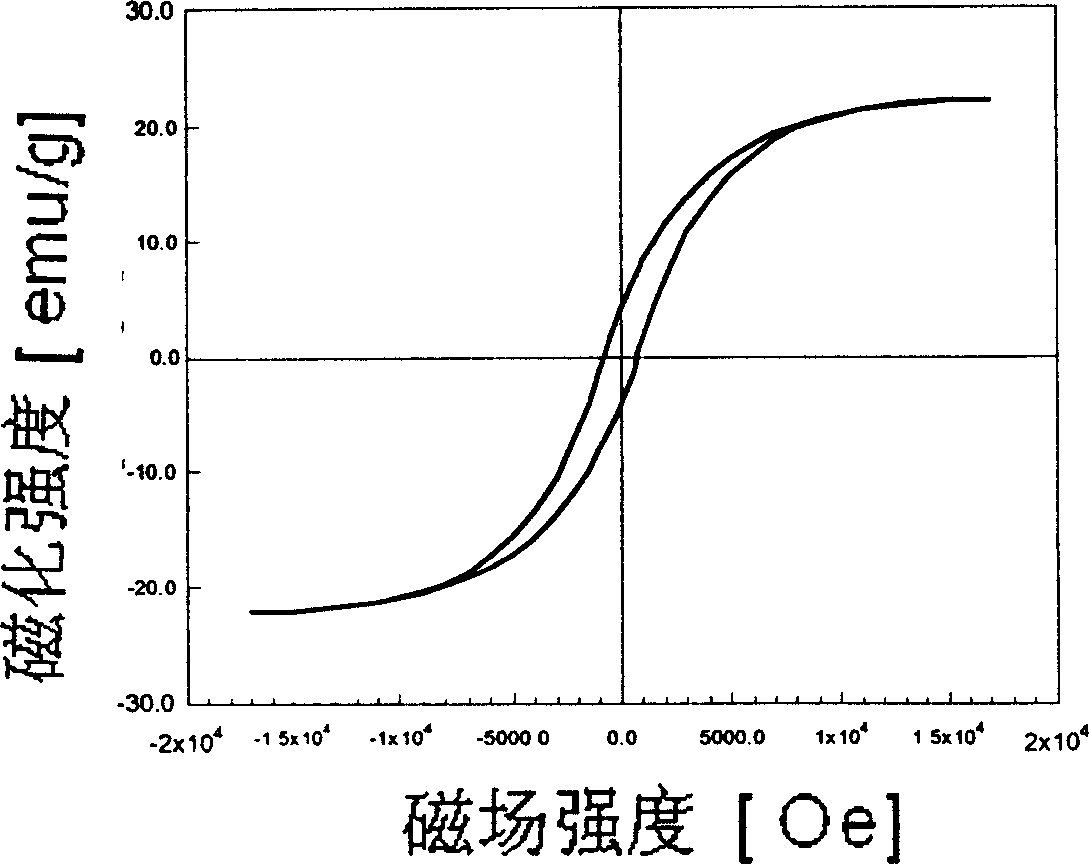

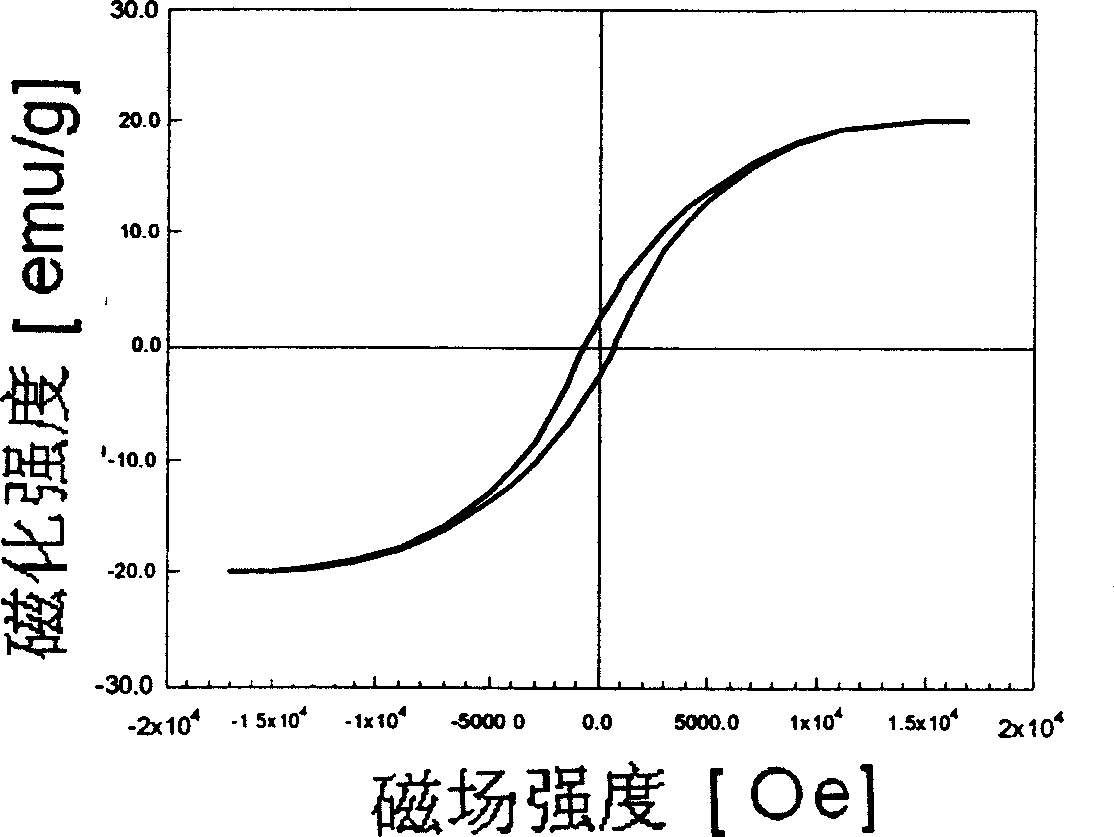

Plating liquid for nickel-titanium alloy to coat nickel, cobalt and tungsten through chemical technology and technique method

InactiveCN1661131AGood magnetic coverageLiquid/solution decomposition chemical coatingNiti alloyChemical plating

A plating liquid for chemically plating the magnetic NiCoW film on the surface of NiTi alloy is an aqueous solution containing nickel sulfate, cobalt sulfate, sodium tungstate, sodium hypophosphite, sodium citrate and ammonium sulfate. Its chemical plating process includes such steps as alkali washing of said surface of NiTi alloy, acid washing, sensitizing, activating, immersing it in said plating liquid and chemical plating. The plated product can be used as the medical magnetic scaffold for physiotherapy and chemicotherapy.

Owner:TONGJI HOSPITAL ATTACHED TO TONGJI MEDICAL COLLEGE HUAZHONG SCI TECH +1

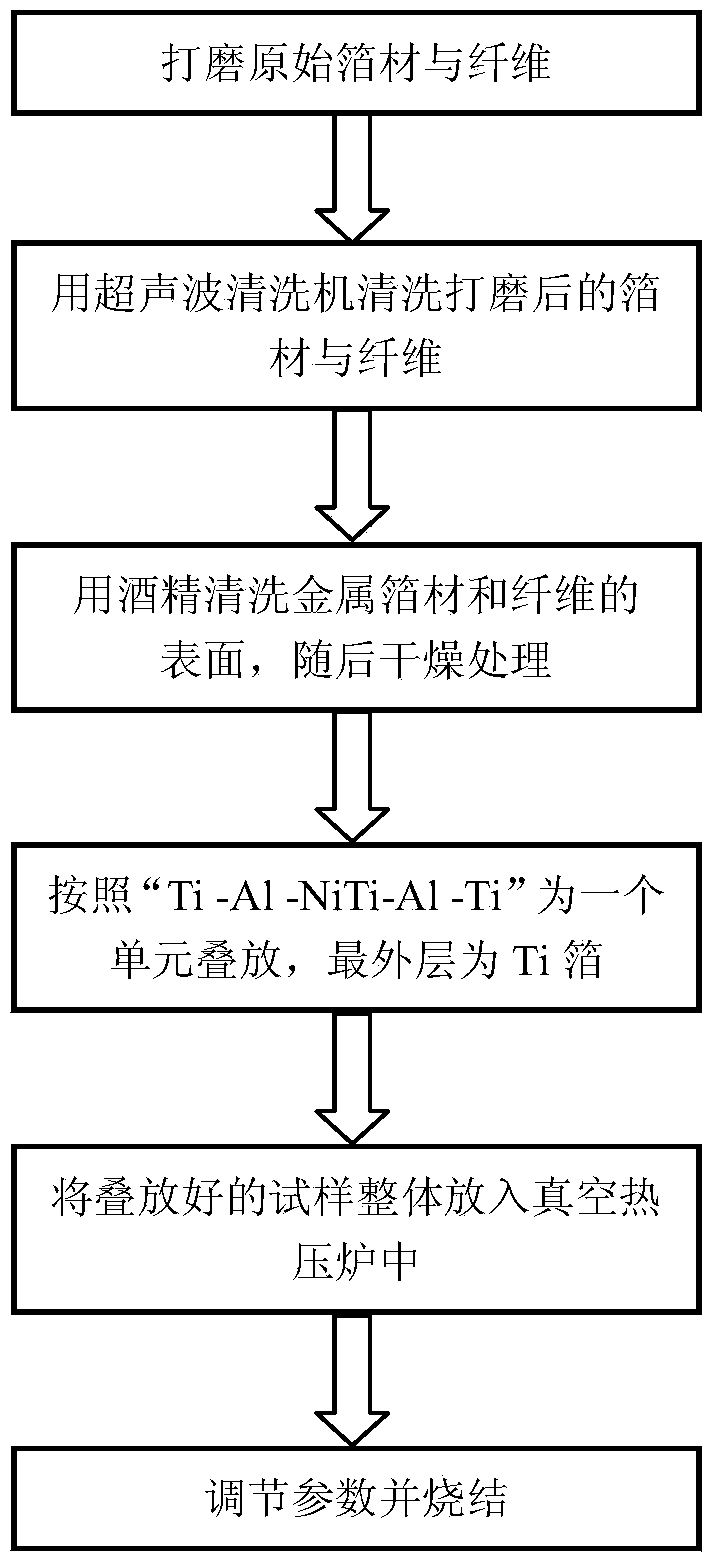

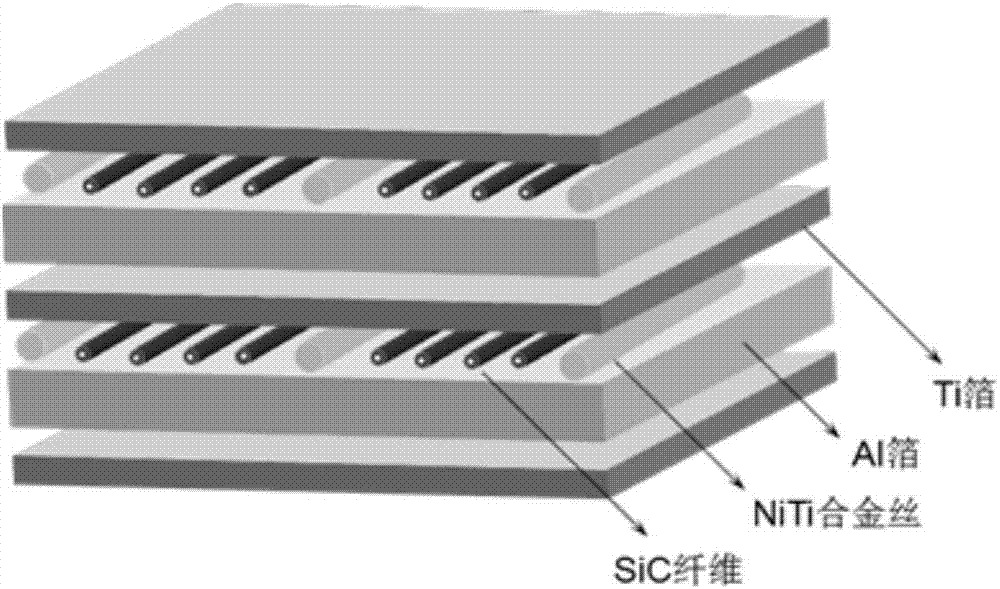

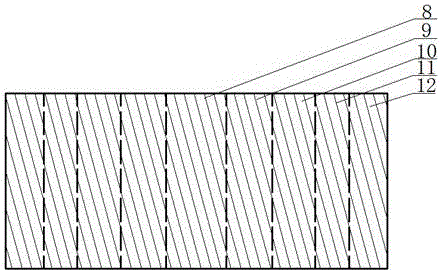

Preparation method of NiTi fiber reinforced intermetallic compound-based laminar composite material for vibration and noise reduction

ActiveCN104099540ASpecial high energy-absorbing laminated structureImprove performanceNiti alloyStructure function

The invention provides a preparation method of a NiTi fiber reinforced intermetallic compound-based laminar composite material for vibration and noise reduction. The preparation method comprises the steps of polishing Ti foils, Al foils and NiTi alloy fibers by use of abrasive paper to remove oxide layers, next, cleaning by use of an ultrasonic cleaner and then cleaning by use of alcohol, drying, stacking by the unit of Ti foil-Al foil-NiTi fibers-Al foil-Ti foil with the Ti foils as the outmost layers, and putting the entire stacked material in a vacuum hot pressing furnace for sintering. The prepared fiber reinforced laminar composite material is highly damped (the loss modulus can be 3500MPa under the conditions of a temperature ranging from a room temperature to 50 DEG C and 1Hz, and the loss modulus can be 4100MPa under the conditions of the same temperature range and 20Hz) and has high strength (the compressive strength can be 1400MPa), and therefore, the prepared fiber reinforced laminar composite material is a high-performance structure-function integrated composite material.

Owner:HARBIN ENG UNIV

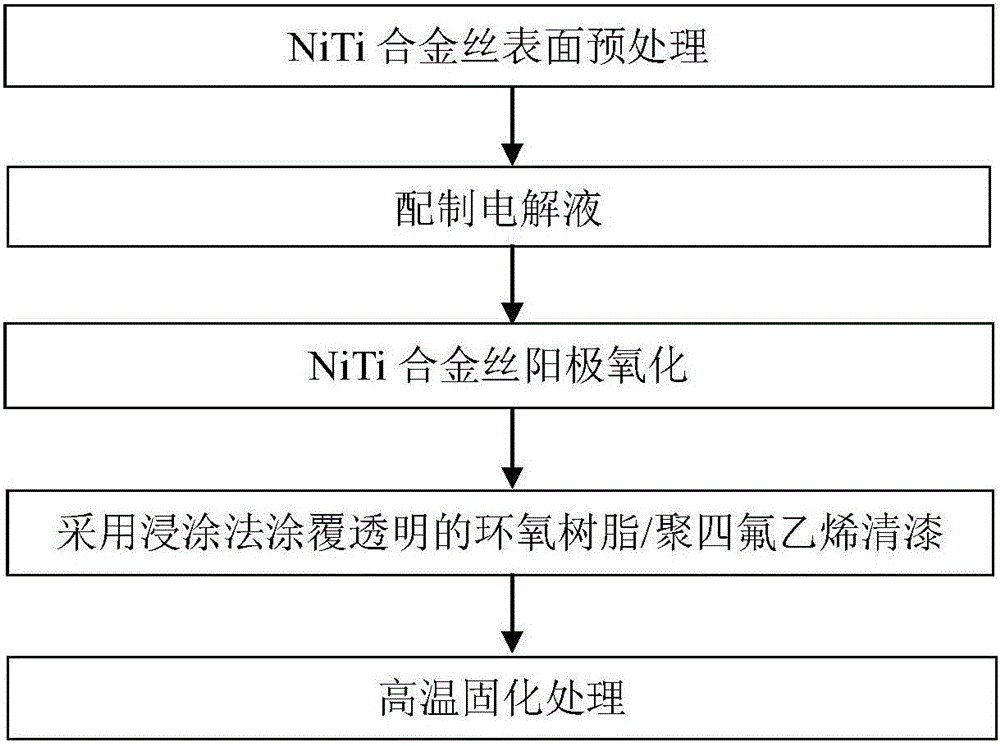

Preparation method of NiTi alloy tooth arch wire for orthodontics

InactiveCN105019001AImprove mechanical propertiesGood biocompatibilityArch wiresAnodisationNiti alloyEpoxy

The invention discloses a preparation method of a NiTi alloy tooth arch wire for orthodontics. The preparation method comprises the steps of: 1) surface pretreatment of a NiTi alloy wire; 2) preparation of electrolyte; 3) anodizing of the NiTi alloy wire; 4) coating of transparent epoxy resin / polytetrafluoethylene varnish by a dip coating method; and 5) high-temperature curing treatment and final obtaining of the NiTi alloy tooth arch wire having invisible double-layer protection. Compared with a traditional method, the preparation method can effectively prevent such problems as nonuniform dispersion of TiO2 pigment in organic high molecular emulsion and reduction of coating mechanical performance and corrosion resistance caused by TiO2; and in addition, the method has such advantages as low cost and adaptation to batch production.

Owner:XIAN UNIV OF TECH

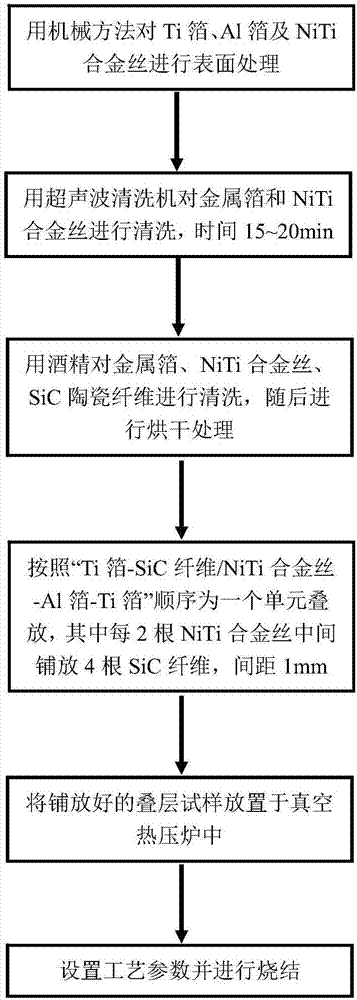

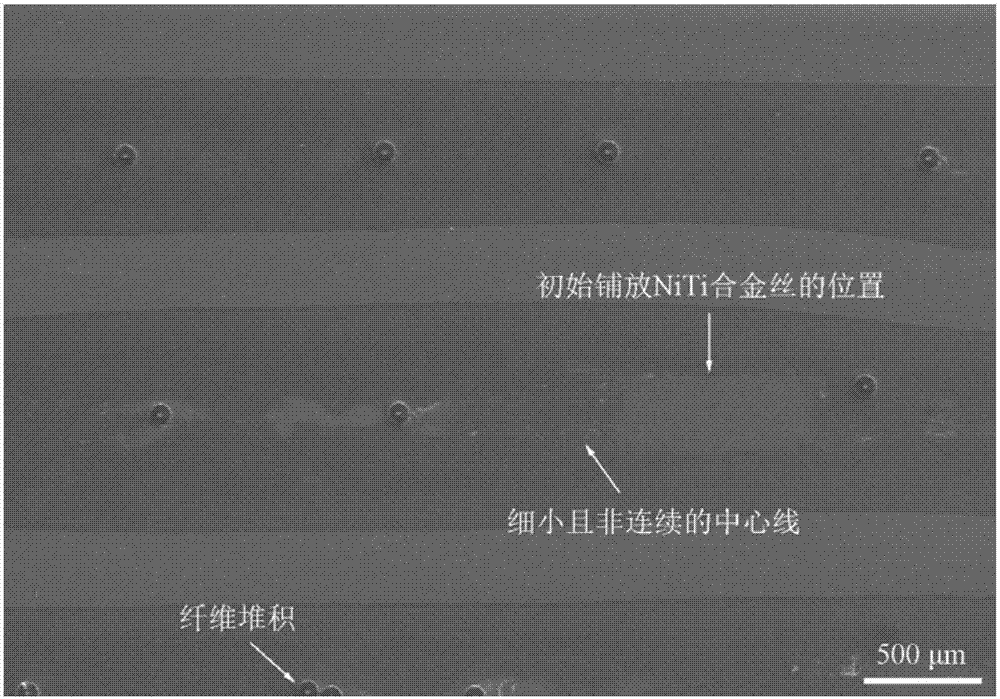

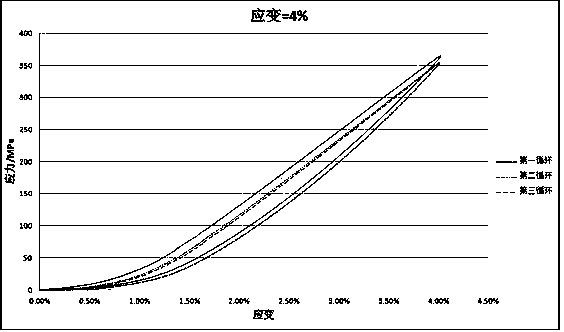

Method for improving titanium-aluminum laminated composite material structure and improving mechanical performance

The invention provides a method for improving a titanium-aluminum laminated composite material structure and improving mechanical performance. Tungsten core SiC ceramic fibers are pre-treated, and NiTi alloy wires, Ti foil and Al foil are subjected to ultrasonic cleaning; the Ti foil, the tungsten core SiC ceramic fibers, the NiTi alloy wires and the Al foil serve as a unit to be stacked according to the sequence of the Ti foil, the tungsten core SiC ceramic fibers, the NiTi alloy wires, the Al foil and the Ti foil, the four SiC fibers are placed between every two NiTi alloy wires, the interval is 1 mm, and the upper surface and the lower surface are both the Ti layers; and sintering is conducted on the unit through a vacuum hot pressing device. According to the method for improving the titanium-aluminum laminated composite material structure and improving the mechanical performance, through the design principle that nickel and titanium elements in the NiTi wires easily react with aluminum elements under the low temperature to form inter-metallic compounds, the SiC fibers and the NiTi alloy wires are simultaneously introduced into inter-metallic compound layers through the vacuum hot pressing sintering method, the SiC fibers serve as reinforcing bodies, introduction of the NiTi alloy wires aims to remove inter-metallic compound layer center lines through the sufficient diffusion reaction mechanism of the NiTi alloy wires and Al, and the SiC fiber / base body interface is improved, so that the mechanical performance of a composite material is improved.

Owner:HARBIN ENG UNIV

Preparation method of porous NiTi alloy

A preparation method of a porous NiTi alloy includes the steps as follows: Ni powder and Ti powder are mixed in mole ratio, after a process control agent is added to Ni / Ti mixed powder, ball milling and screening are performed, and Ni / Ti ball-milled powder is obtained; Ni / Ti degreased powder is obtained under vacuum heating; the Ni / Ti degreased powder and the Ni / Ti mixed powder are mixed, and Ni / Ti working powder is obtained; the Ni / Ti working powder is contained in a steel cylinder and compacted through vibration, then redundant space in the steel cylinder is filled with steel sheets, the endopening of the steel cylinder is sealed and welded, and a steel capsule containing the Ni / Ti working powder is prepared; the steel capsule is arranged in a heating furnace and is heated at the constant heating speed, when the temperature of the steel capsule is changed suddenly, the steel capsule is taken out of the furnace rapidly, is immersed in water for cooling and is removed after being cooled, and the porous NiTi alloy is obtained. The porous NiTi alloy prepared with the method is high in porosity, uniform in hole diameter, high in phase purity and excellent in mechanical property and super-elasticity, the pore shape is close to the spherical shape, and the alloy can be used as an implant material for the human body hard tissue.

Owner:GUANGDONG INST OF NEW MATERIALS

Tire structure with shape memory alloy

ActiveCN105034703AImprove rolling resistanceIncrease envelopePneumatic tyre reinforcementsStress concentrationTire bead

The invention discloses a tire structure with shape memory alloy. In the tire structure, a shape memory alloy, such as NITI alloy and the like, is employed as the cord wires inside a belted layer rubber sheets in a certain arrangement manner instead of a steel wire tire cord material in a certain ratio, , so that force distribution on tire tread and tire shoulder is improved by means of a negative thermal expansion behavior and a two-way shape memory effect of the shape memory alloy, thereby reducing steel wire stress at the end of the belted layer in the tire. The tire structure with the shape memory alloy is reduced in strain energy density at the tire shoulder of the tire, is reduced in tire use temperature and is reduced in tire shoulder crack. Meanwhile, the tire structure can enhance the stress on steel wires at the tire tread, so that a tire is improved in rolling resistance performance and service life synergistically. The tire structure can also improve stress concentration at a tire bead.

Owner:SHANDONG LINGLONG TIRE

Method for preparing NiTi spring/carbon nano-tube/polyurethane composite material

The present invention provides a method for preparing a NiTi spring / carbon nano-tube / polyurethane composite material. The method comprises: (1) respectively dissolving carbon nano-tubes and polyurethane elastomer particles in an organic solvent, and adding the carbon nano-tube solution to the polyurethane elastomer solution in a dropwise manner, wherein the carbon nano-tube content is 0.1-1 wt%; (2) placing the mixed solution obtained in the step (1) in a vacuum drying oven to exhaust gas, wherein the temperature is maintained at 70-100 DEG C, and the time is 0.5-1.5 h; (3) placing a NiTi alloy spring into acetone, and carrying out ultrasonic cleaning; (4) slowly embedding the NiTi alloy spring into the mixed system obtained in the step (2); and (5) removing the solvent in an air blasting constant temperature oven, wherein the temperature is maintained at 70-100 DEG C, the molding time is 24-48 h, and the product is obtained after the solvent is completely removed. According to the present invention, the method has characteristics of simple preparation process, good moldability and low cost; and the prepared composite material exhibits good damping property and good shape memory recovery property.

Owner:黑龙江恒和沙科技开发有限公司

Method for preparing colorful titanium dioxide film on surface of porous NiTi alloy at low temperature

InactiveCN102168242ANot easy to peel offNot easy to fall offSolid state diffusion coatingNiti alloySand-paper

The invention discloses a method for preparing a colorful titanium dioxide film on a surface of porous NiTi alloy at low temperature, comprising the following steps: 1. carrying out preprocessing, deoiling, SiC sand paper grinding, mechnical polishing and electrochemical polishing on the surface of the porous NiTi alloy; 2. carrying out hydrothermal treatment on the preprocessed porous NiTi alloy in a high-pressure hydrothermal kettle containing deionized water, wherein the deionized water is 30-70% by volume of the high-pressure hydrothermal kettle, the hydrothermal treatment temperature is 200-300 DEG C, and the processing time lasts for 8-12 hours; and 3. washing, naturally drying or drying at the temperature of 50-80 DEG C, thus obtaining the porous NiTi alloy provided with the colorful titanium dioxide film. the preparation method is simple, ensures low cost, is not influenced by the shape of the porous NiTi alloy, ensures no environment pollution, and can be used for repair and replacement on hard tissues such as bones, joints, artificial fangs and the like, and the bright color of the film can play roles in identification and attractiveness.

Owner:NANCHANG HANGKONG UNIVERSITY

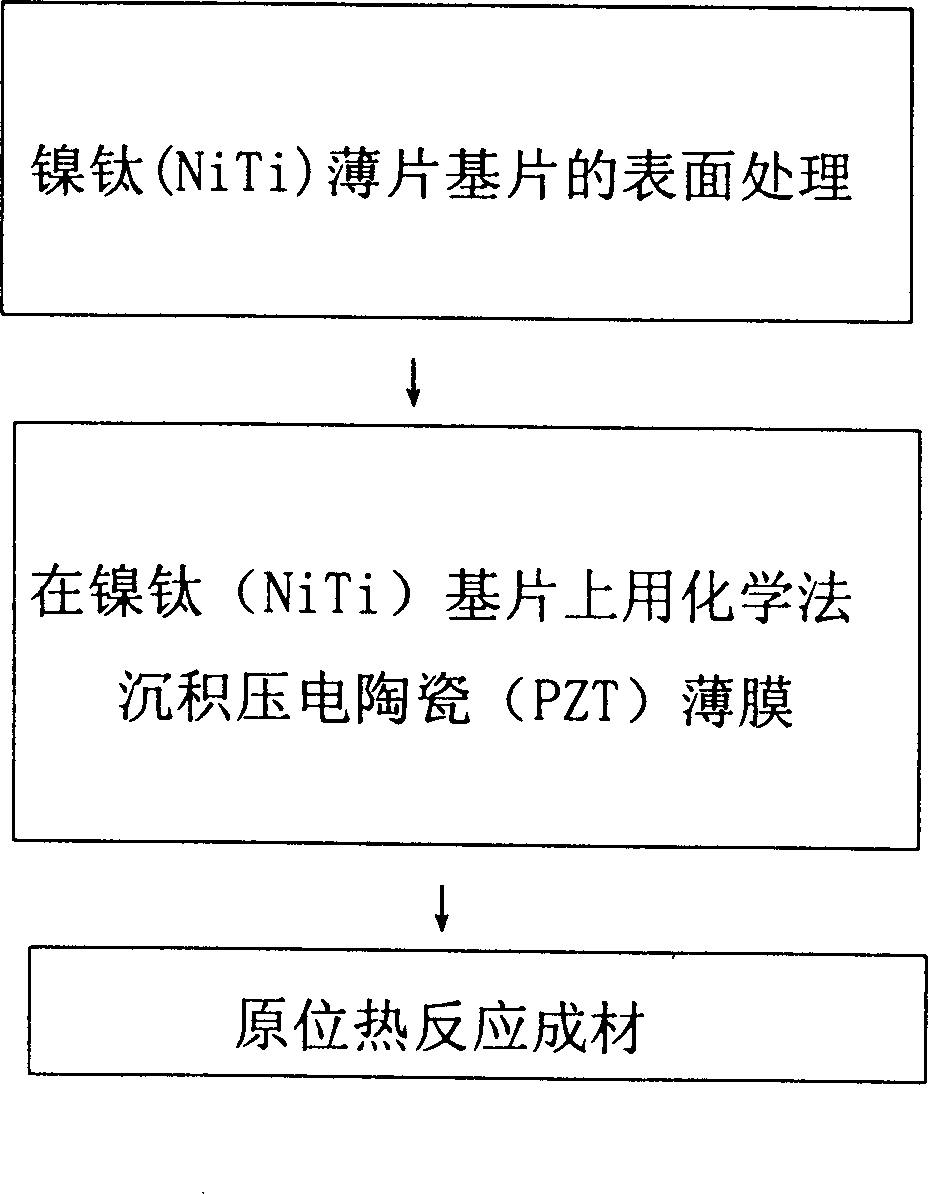

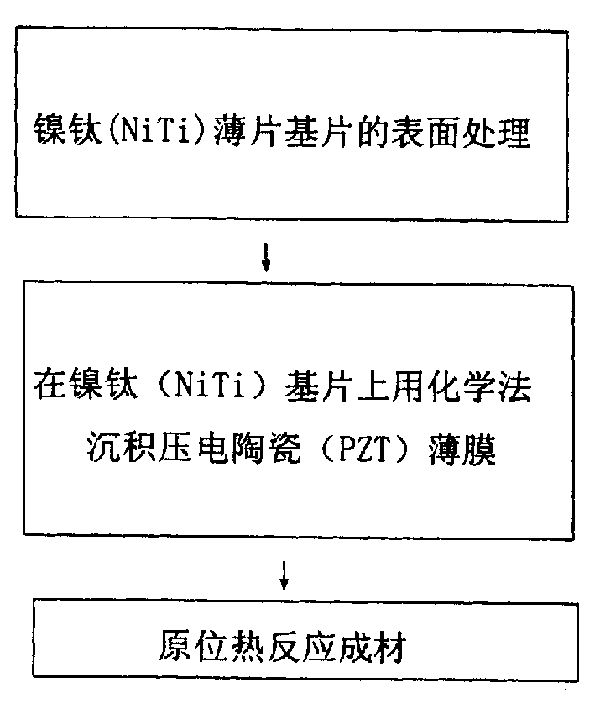

Nickel titanium memory alloy and piezoelectric ceramic hetero three step compounding technology

InactiveCN1411080ASolve the problem of interface combinationPiezoelectric/electrostrictive device manufacture/assemblyChemical vapor deposition coatingNiti alloyElectricity

A heterogeneity three-step complex technology of NiTi memory alloy and piezoelectric ceramics (PZT) includes the following three steps: 1. surface process of NiTi substrate 2. depositing PZT film on NiTi substrate by chemical method 3. formation by in-situ thermal-response, the above mentioned three steps are on air environment and heated with normal furnace with the following advantages: 1. obtaining transition layer of TiO2 ceramic layer and NiTi alloy zone by insitu thermal-response by which to solve the problem of combination of interfaces between NiTi and PZT 2. getting a new functional composite material eg. intelligent damped material.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Anti-thrombosis and anti-infection titanium alloy implantation instrument with alveolate porous structure

ActiveCN109730802AExcellent super hemophobic performanceAvoid stickingStentsHeart valvesNiti alloyMicro nano

The invention relates to an anti-thrombosis and anti-infection titanium alloy implantation instrument with an alveolate porous structure and belongs to the technical field of surface modification of metal materials. According to the method, a traditional femtosecond laser shaping mode is replaced with a femtosecond laser dual-pulse mode, correspondingly a local instantaneous electronic state of amaterial is adjusted and controlled, and different micro-nano composite structures can be prepared. Through dynamic regulation and control of electrons, the unique alveolate porous structure is finally processed. According to the structure, the static contact angle between the structure and fresh rabbit blood is 143.4 degrees + / - 2.6 degrees, and the rolling angle is 8.5 degrees + / - 2 degrees. Because a fluorinated material has low surface energy, certain frictional resistance and excellent bactericidal and antithrombotic capability, by conducting fluorination treatment on a NiTi alloy surfaceof the alveolate porous structure, a super blood dispersing surface is obtained, wherein the static contact angle between the super blood dispersing surface and the fresh rabbit blood is 167.3 degrees + / -3.2 degrees, and the rolling angle of the super blood dispersing surface is 1.6 degrees + / - 0.3 degree; meanwhile, the obtained surface also has excellent antibacterial performance. The method isapplicable to the surfaces of titanium alloy materials different in size and shape.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

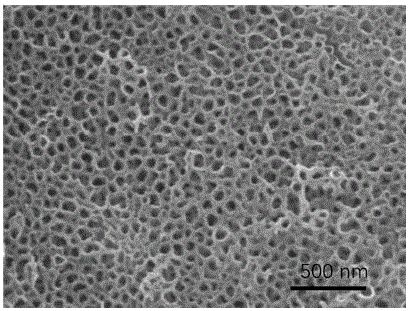

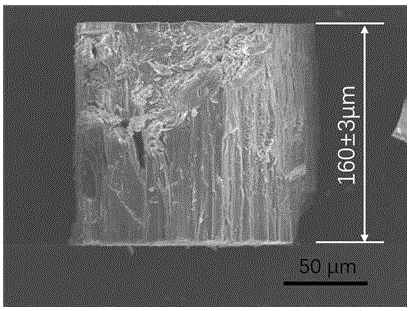

Method of preparing ultra-long Ni-Ti-O nano tube on surface of NiTi alloy

The invention discloses a method of preparing an ultra-long Ni-Ti-O nano tube on the surface of NiTi alloy, belongs to the technical field of preparing nano materials and relates to a novel preparation method for a Ni-Ti-O nano tube. The method comprises the following steps: firstly, carrying out grinding and polishing pretreatment on an NiTi alloy specimen, then soaking the pretreated NiTi alloy specimen into a glycol electrolyte containing HCl and H2O, and preparing the Ni-Ti-O nano tube on the surface of the NiTi alloy specimen by adopting an anodic oxidation method. According to the method, by optimizing the preparation technology, the length of the nano tube can be up to 160 microns, thus the method has a wide application prospect in the field of supercapacitors, sensors, electro-catalysis, biomedicines and the like.

Owner:TAIYUAN UNIV OF TECH

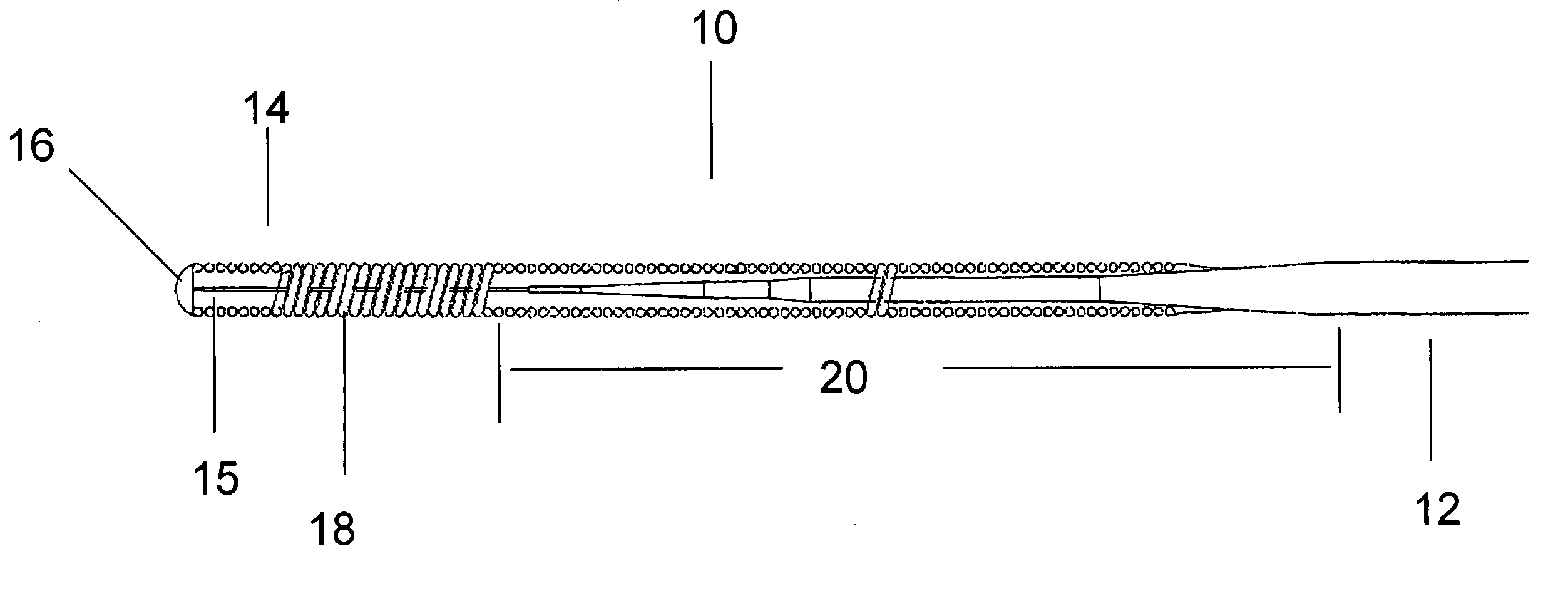

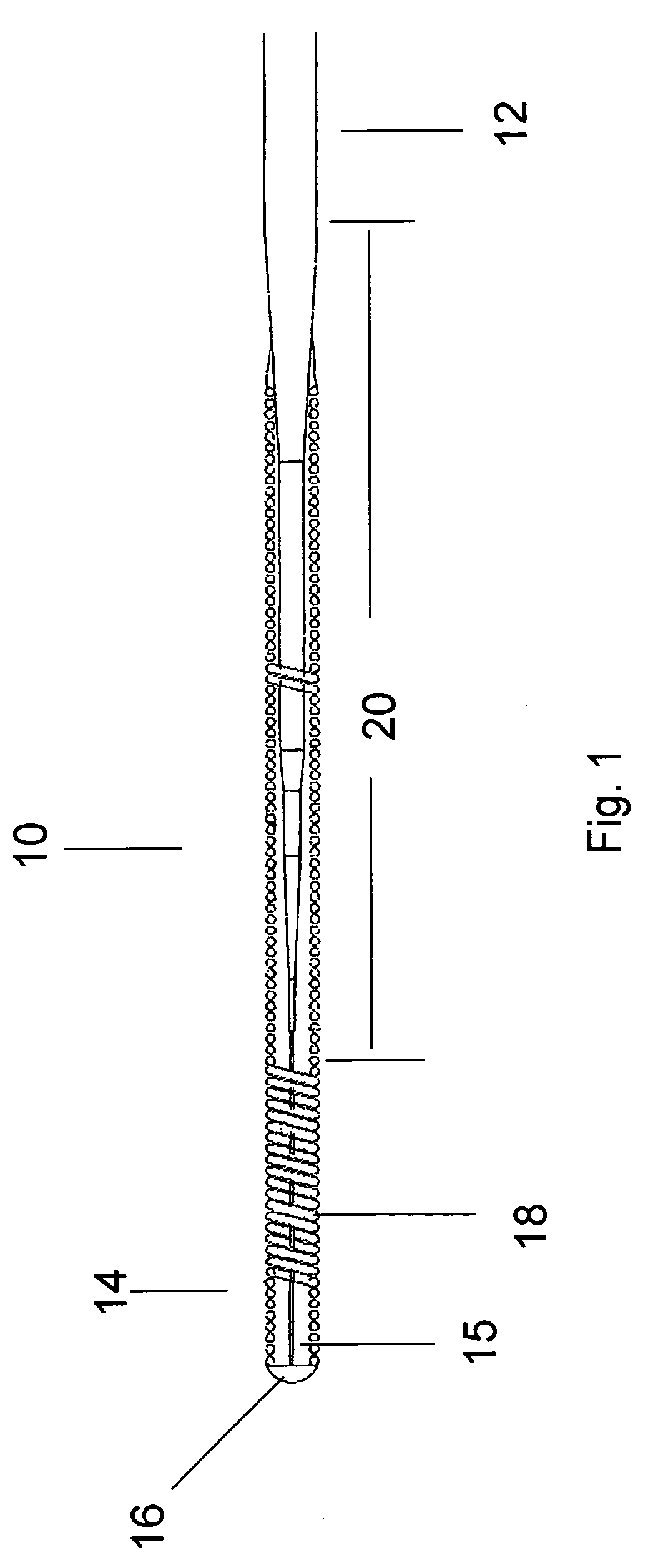

Titanium molybdenum alloy guidewire

InactiveUS20060089568A1High springbackHigh flexabilityGuide wiresDiagnostic recording/measuringNiti alloyTitanium

A guidewire for medical use such as in vascular and nonvascular systems. The guidewire made from a titanium molybdenum alloy wire with a composition of approximately 78% titanium 11.5% molybdenum 6% zinc and 4.5% tin by weight such that it is softer than stainless steel guidewires and stiffer than NiTi alloy guidewires. The distal end of the guidewire is of a smaller diameter and softer than the proximal end and fitted with a coil for springiness such that the distal end will bend when encountering curves in the body passageways. The distal tip may be heat treated for a gradient of softness with the distal tip being the softest. The distal end may also be tapered to provide an additional gradient of softness. A distal tip on the distal end of the guidewire protects the wall of the passageway from being punctured as the guidewire travels through the passageway. The resulting guidewire has properties between those of stainless steel guidewires and NiTi alloy guidewires for better torsion and stiffness characteristics.

Owner:MX MEDICAL +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com