Tire structure with shape memory alloy

A technology of memory alloys and tires, which is applied to tire parts, reinforcement layers of pneumatic tires, transportation and packaging, etc., can solve problems such as lack of research, improve rolling resistance performance, increase ride comfort, and increase envelopment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

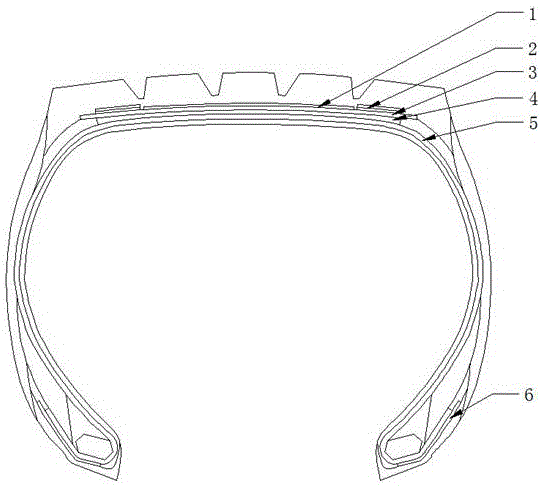

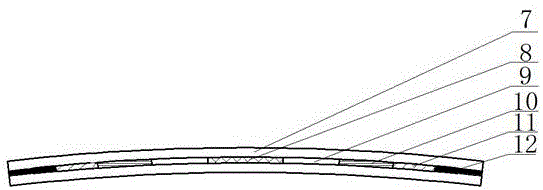

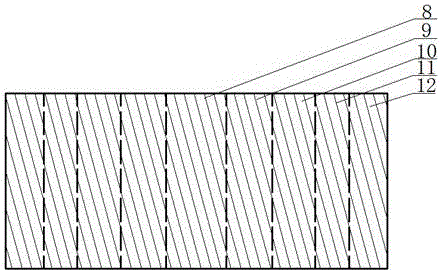

[0025] Such as figure 1 and figure 2 As shown, a tire structure using shape memory alloys, including the first belt layer 4, the second belt layer 3, the third belt layer 1, the zeroth belt layer 2, and the carcass layer 5 and reinforcement layer 6;

[0026]The first belt layer 4, the second belt layer 3, the third belt layer 1, the zeroth belt layer 2, the carcass layer 5 and the reinforcement layer 6 are covered by rubber on the outside and curtains on the inside. The second belt layer 3 includes ordinary cords and shape memory alloy cords, and the proportion o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com