Patents

Literature

219results about How to "Improve wetting performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

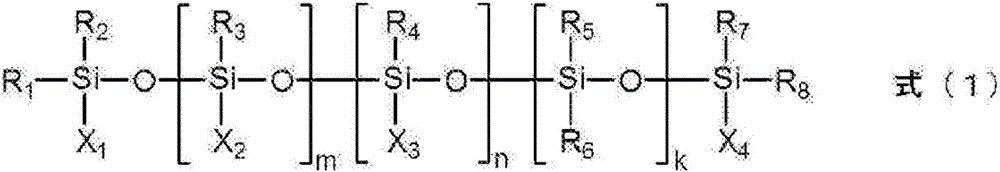

Tire

InactiveUS20110112212A1Reduce fuel consumptionImprove performance on iceSpecial tyresPolymer sciencePolymer chemistry

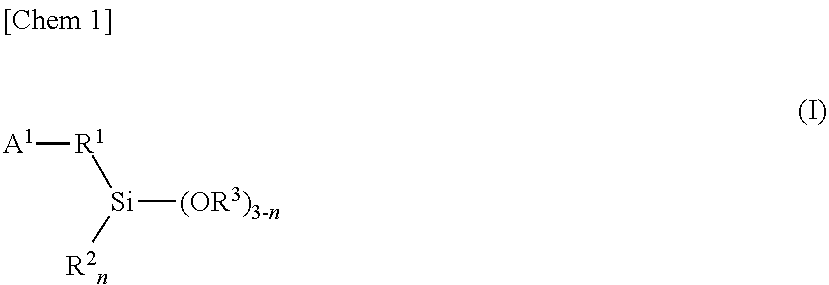

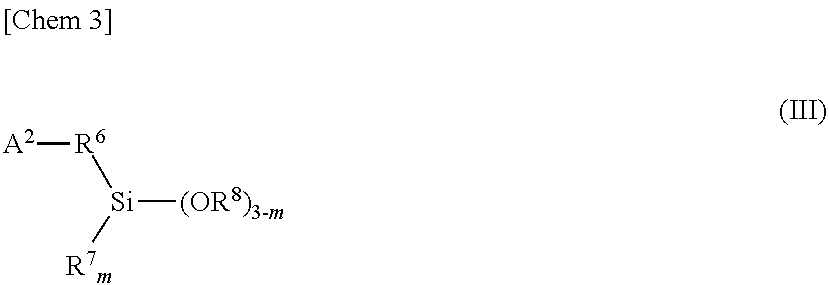

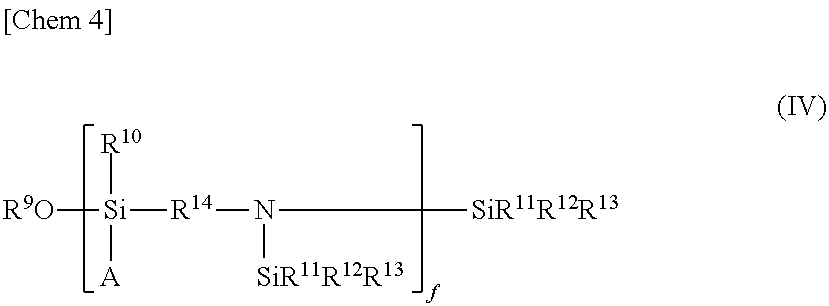

Provided is a tire using a rubber composition, in which: the rubber composition contains a rubber component and a filler; the rubber component contains (A) a modified conjugated diene polymer and (B) a modified conjugated diene-aromatic vinyl copolymer; a modifying agent used for each of the component (A) and the component (B) includes (C) a hydrocarbyloxysilane compound containing a nitrogen atom and a silicon atom or (D) a hydrocarbyloxysilane compound containing a silicon atom; a combination of an unmodified conjugated diene polymer and the modifying agent, and a combination of an unmodified conjugated diene-aromatic vinyl copolymer and the modifying agent include any one of the following items 1 to 3: 1: the conjugated diene polymer and the component (C), and the conjugated diene-aromatic vinyl copolymer and the component (D); 2: the conjugated diene polymer and the component (D), and the conjugated diene-aromatic vinyl copolymer and the component (C); and 3: the conjugated diene polymer and the component (C), and the conjugated diene-aromatic vinyl copolymer and the component (C); and the filler contains silica and carbon black at a mass ratio of 10:90 to 80:20, the tire having good low fuel consumption, good on-ice performance, good wet performance, and good dry performance.

Owner:BRIDGESTONE CORP

Pnuematic tire

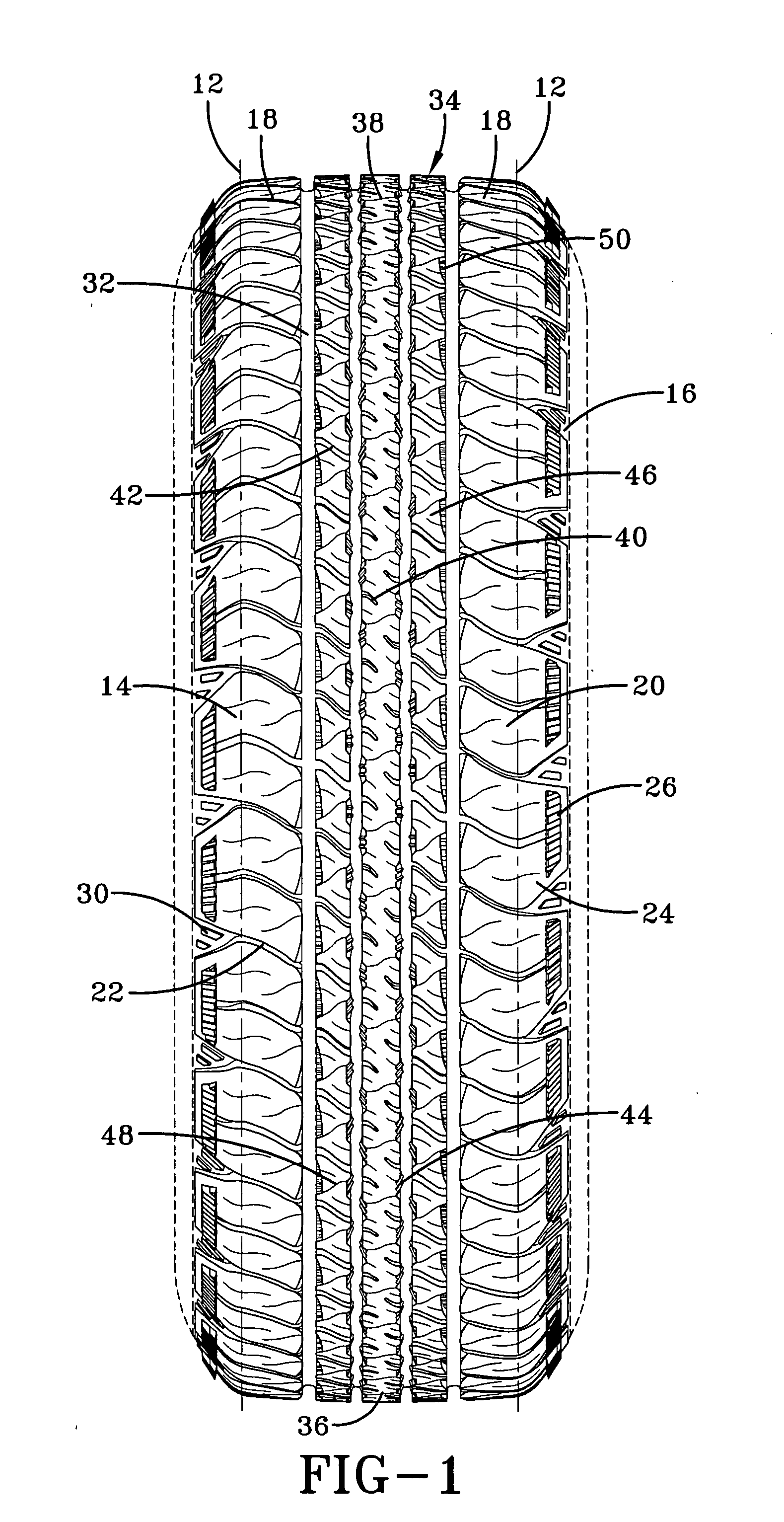

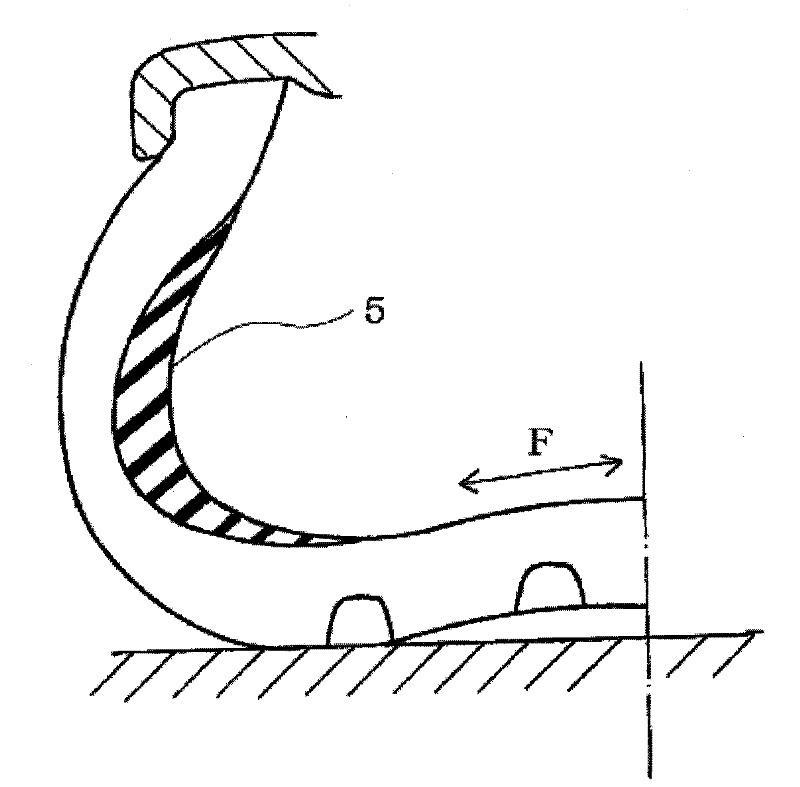

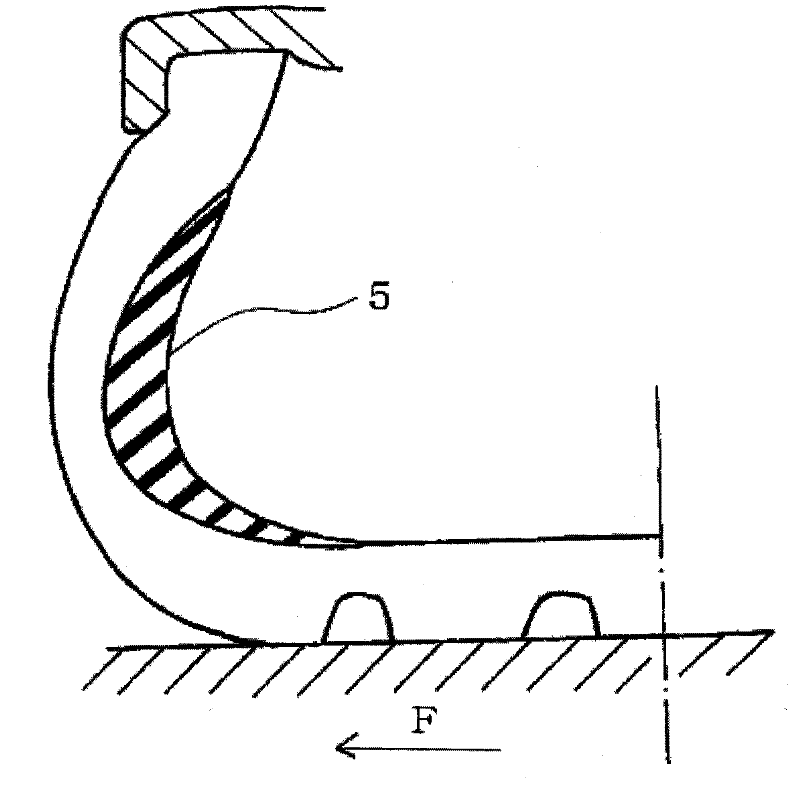

InactiveUS20080271827A1Great tractionImprove wetting performanceTyre tread bands/patternsNon-skid devicesGround contactEngineering

The tire has a ground contacting tread portion, the tread comprising at least one straight circumferentially extending groove. The groove defines one lateral side and a lateral boundary of a plurality of tread elements. At least one tread element has a chamfer within the tread element and inward of the lateral boundary of the tread element. The chamfer extends in the circumferential direction of the tire and has an inclined radially outer surface. The chamfer has at least one traction element in the radially outer surface, the indentation extending radially inward of the radially outer surface of the chamfer.

Owner:MORRISON ANDREW EDWARD +4

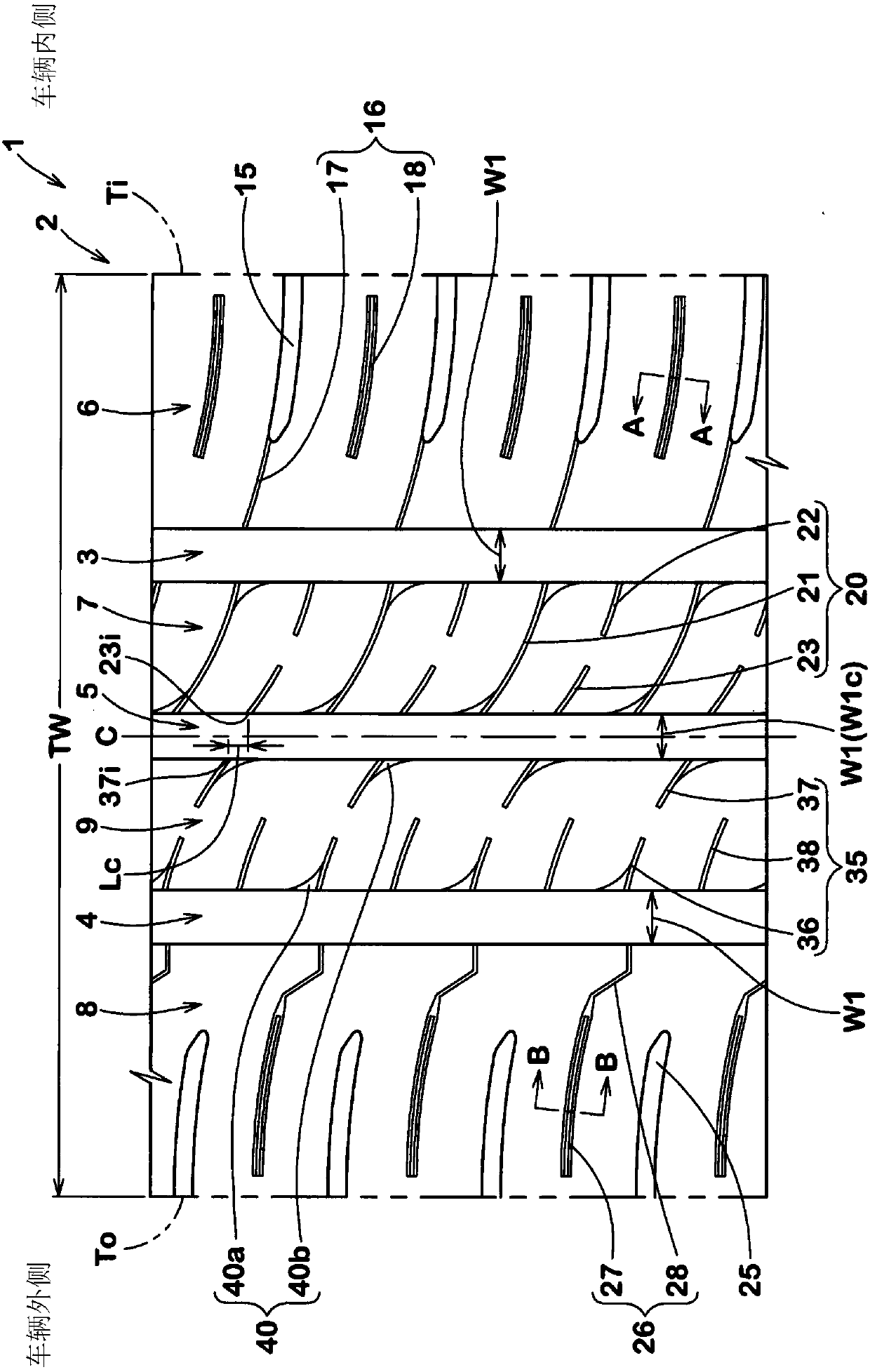

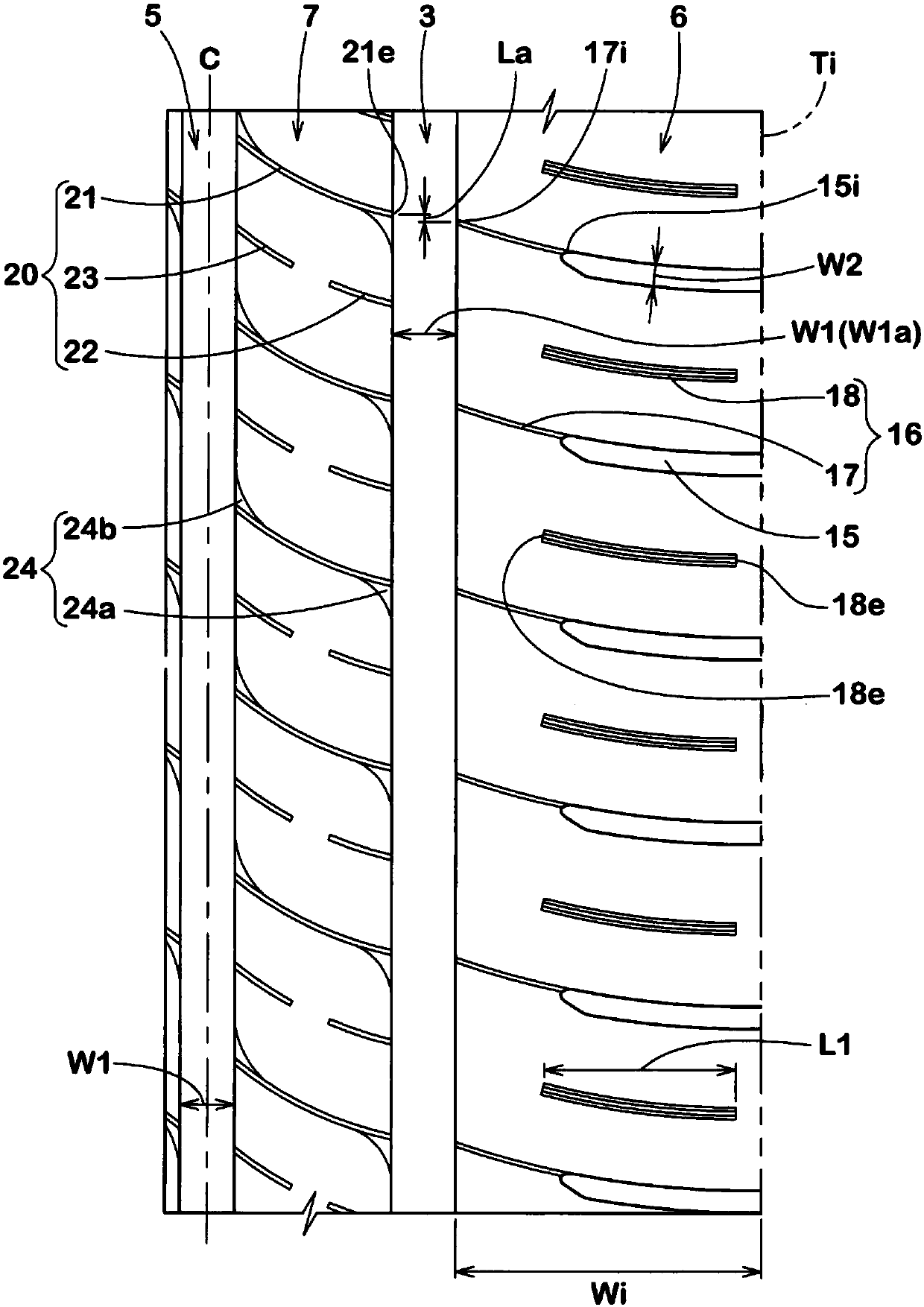

Pneumatic tire

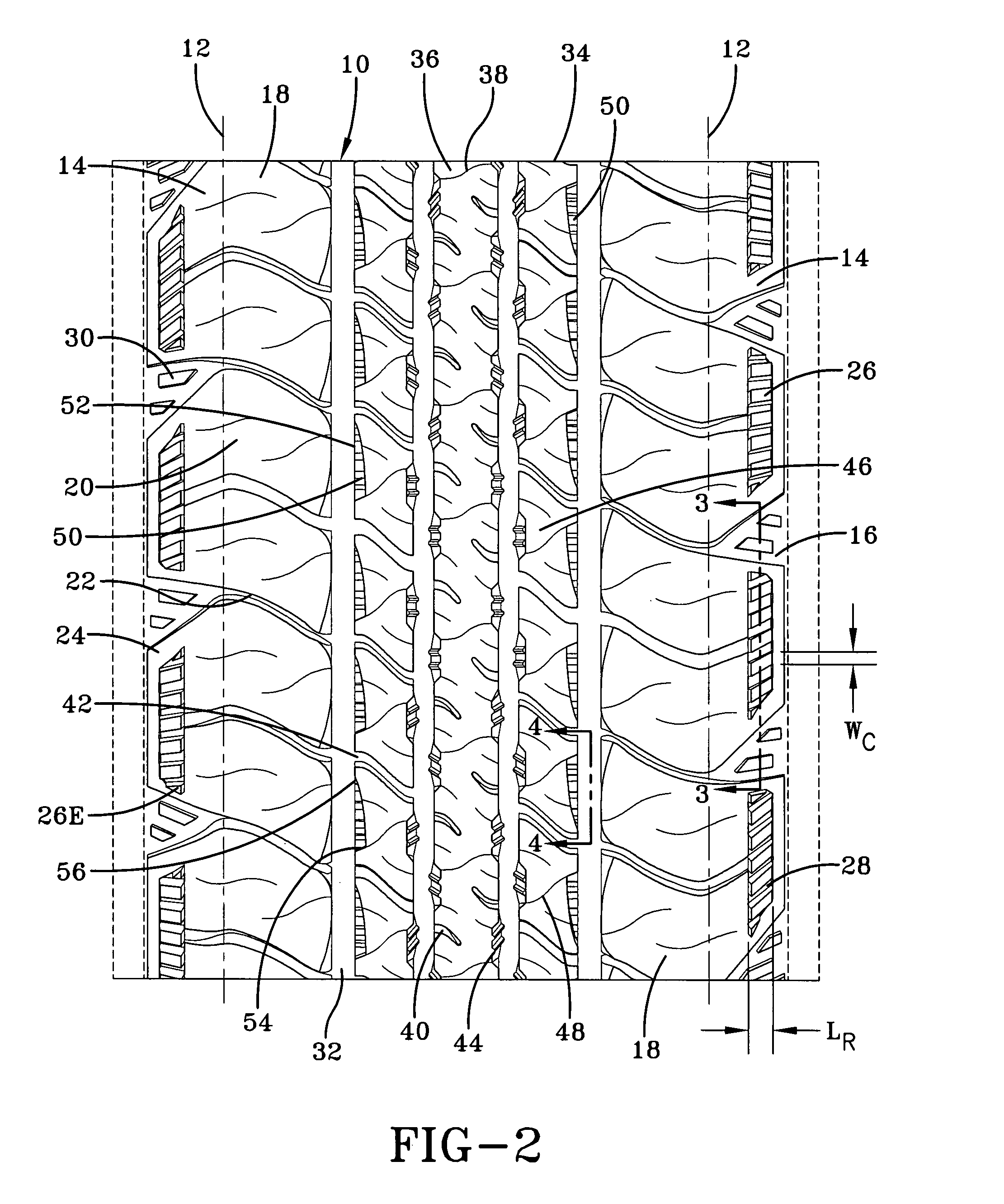

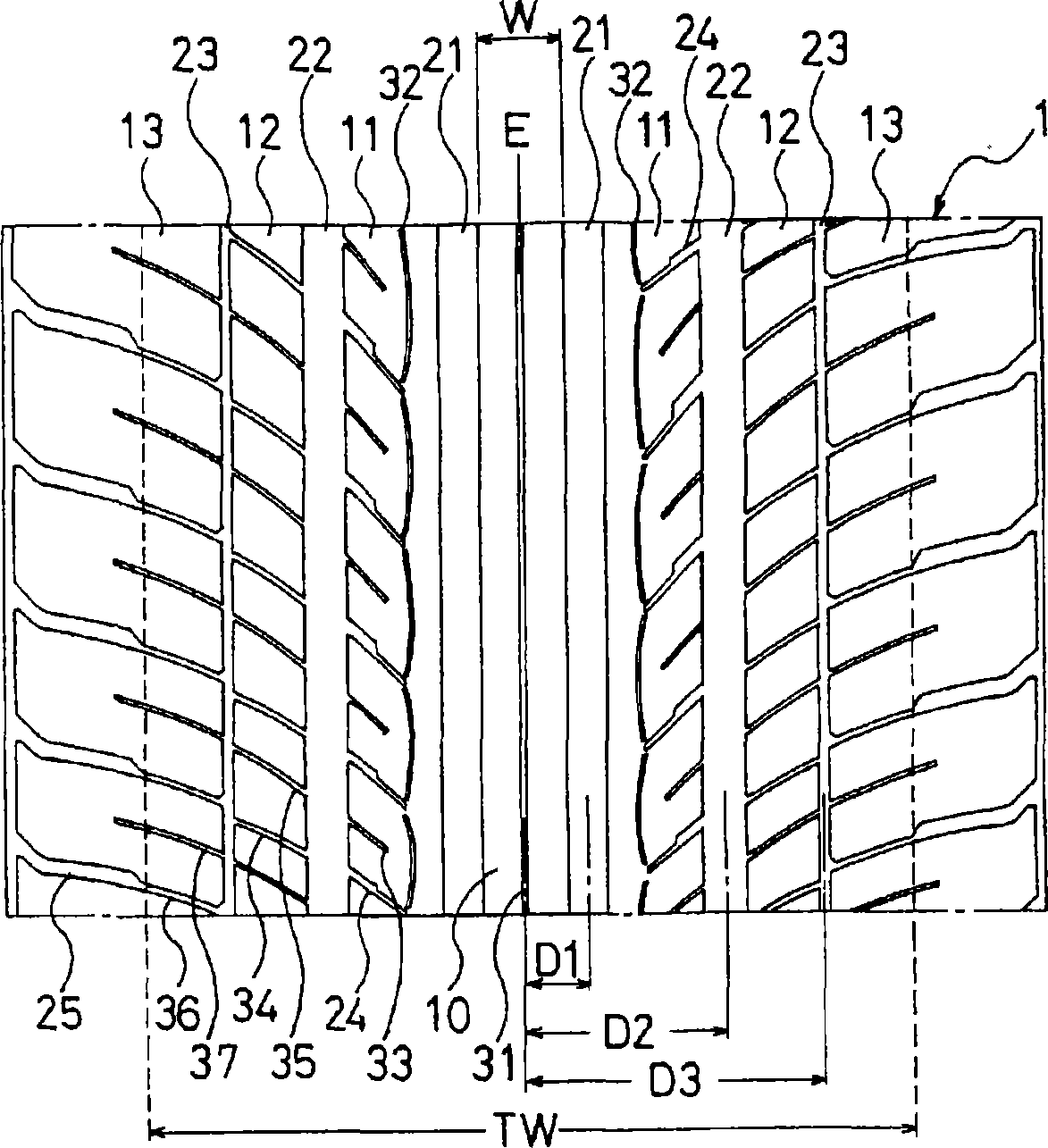

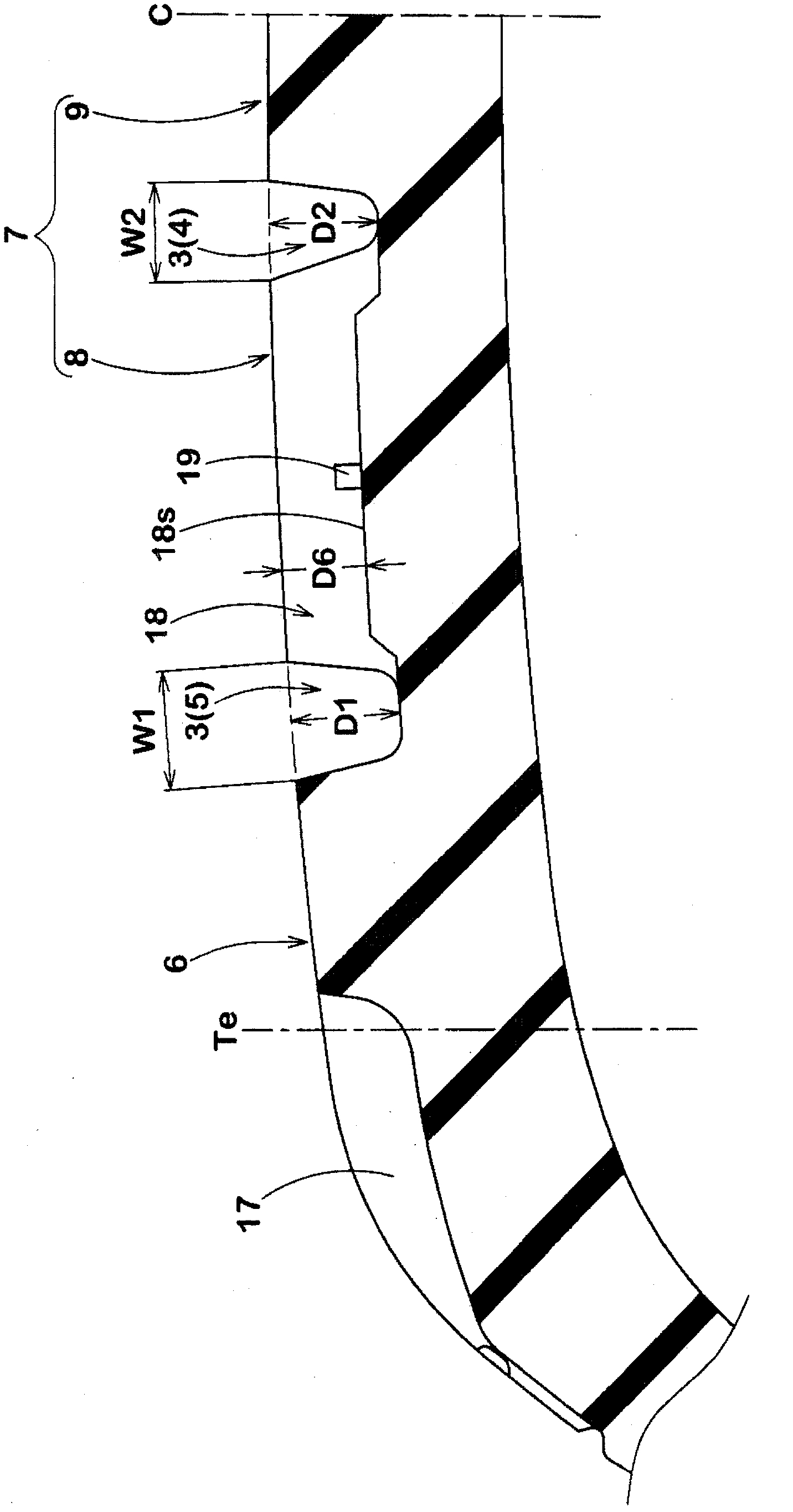

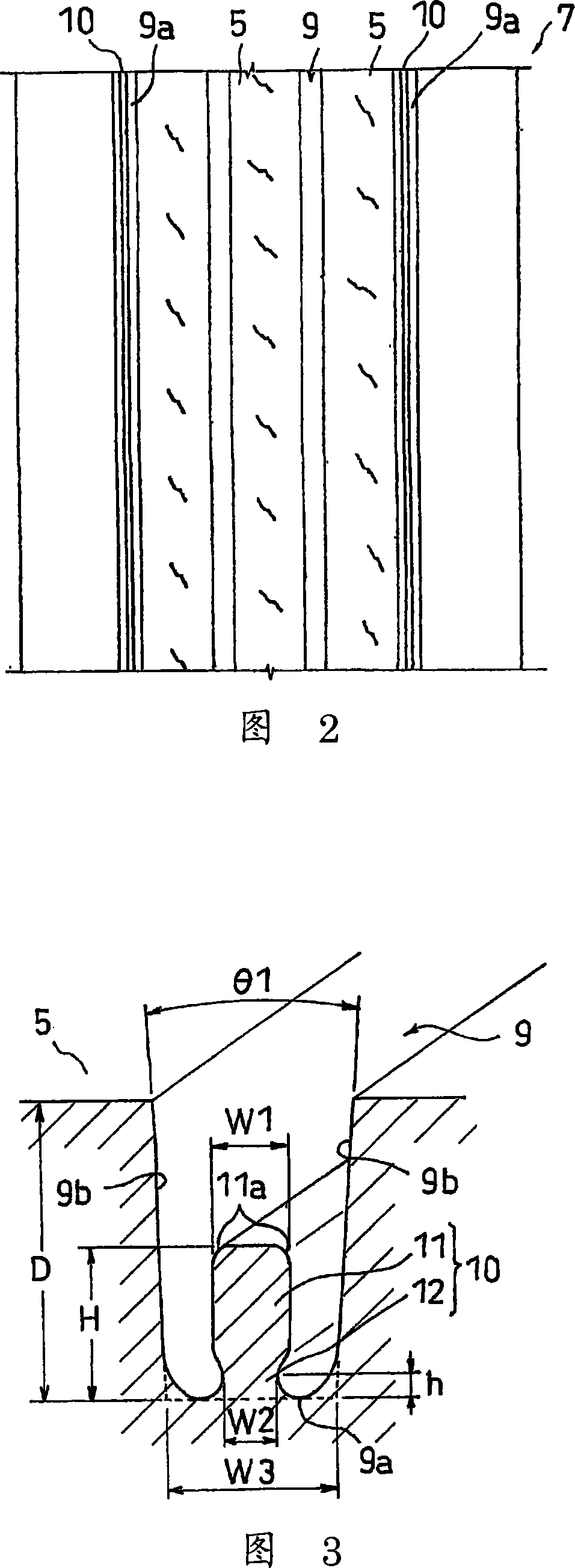

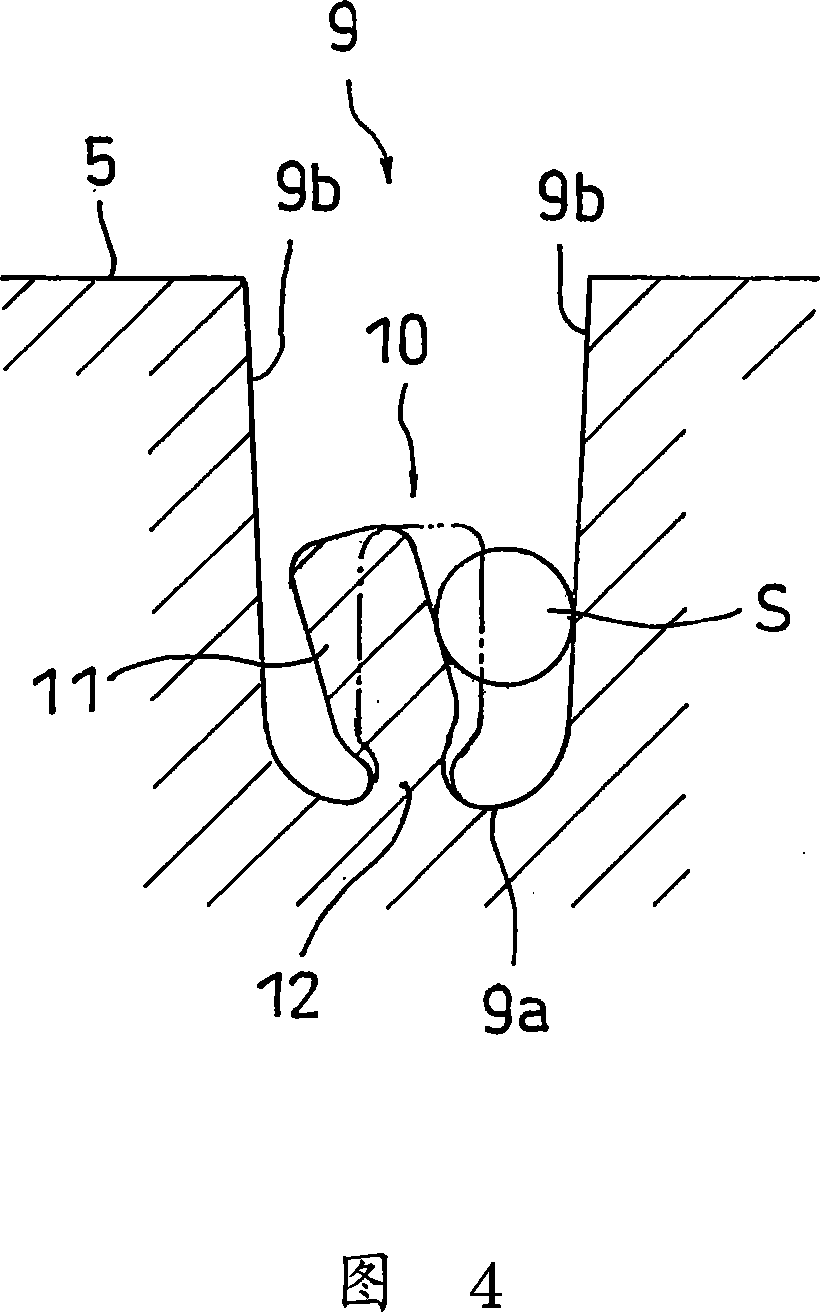

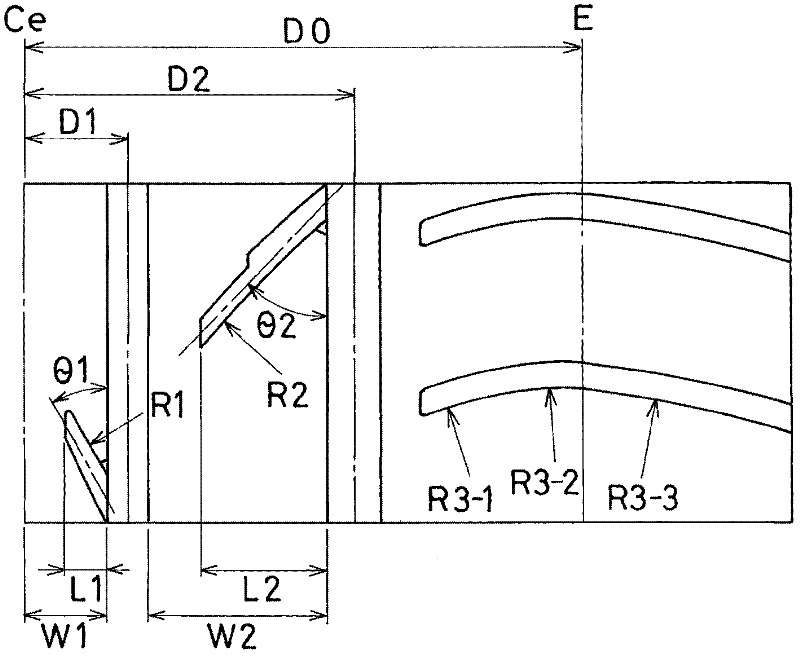

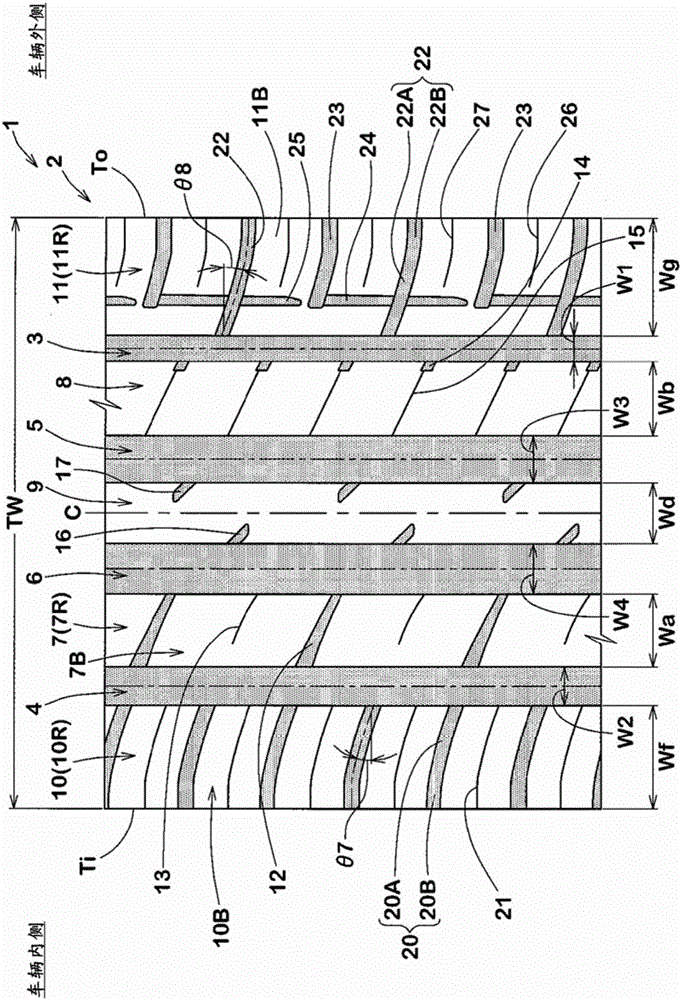

InactiveCN1867464AImprove wetting performanceImprove noiseTyre tread bands/patternsEngineeringOperational stability

A pneumatic tire capable of simultaneously achieving wet performance and noise performance while enhancing driving stability. The pneumatic tire has a rib-like land portion extending in the circumferential direction of the tire, in the central portion of the tread; a left and right pair of first grooves extending in the circumferential direction of the tire while being next to both sides of the rib-like land portion; and a left and right pair of first land portions extending in the circumferential direction of the tire while being next to the outsides of the first grooves. Narrow grooves extending in the circumferential direction of the tire are provided in the rib-like land portion. Further, lug grooves and zigzag narrow grooves are provided in the first land portions, where the lug grooves do not communicate with the first grooves and incline relative to the tire equator, and the undulating or zigzag narrow grooves extend in the tire circumferential direction. The minimum distance (W2) between an undulating or zigzag narrow groove and the outer side wall of a first land portion is set 60-70% of the width (W1) of the first land portion, and the amplitude (W3) of the undulating or zigzag narrow groove is set 5-12% of the width (W1) of the first land portion.

Owner:THE YOKOHAMA RUBBER CO LTD

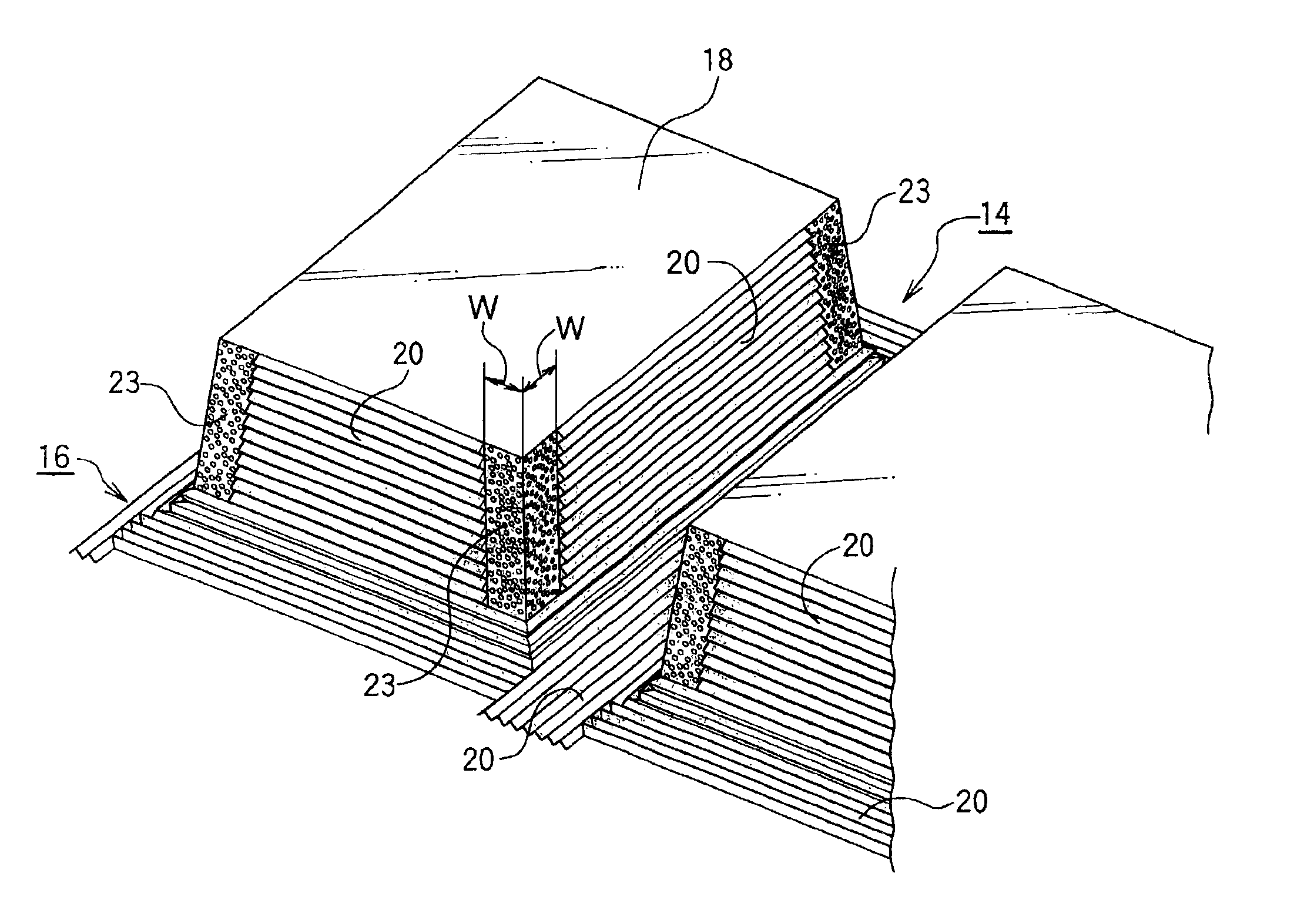

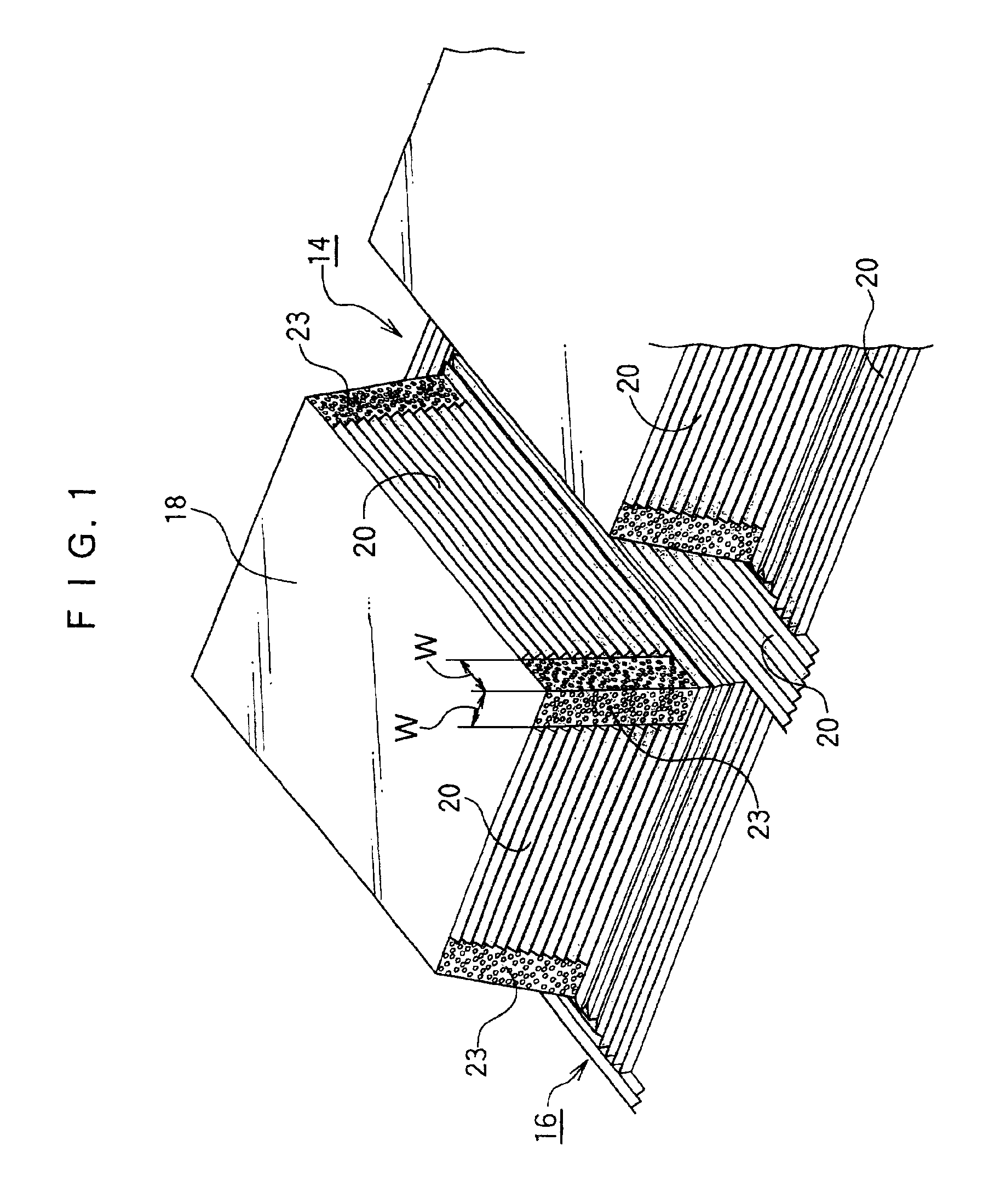

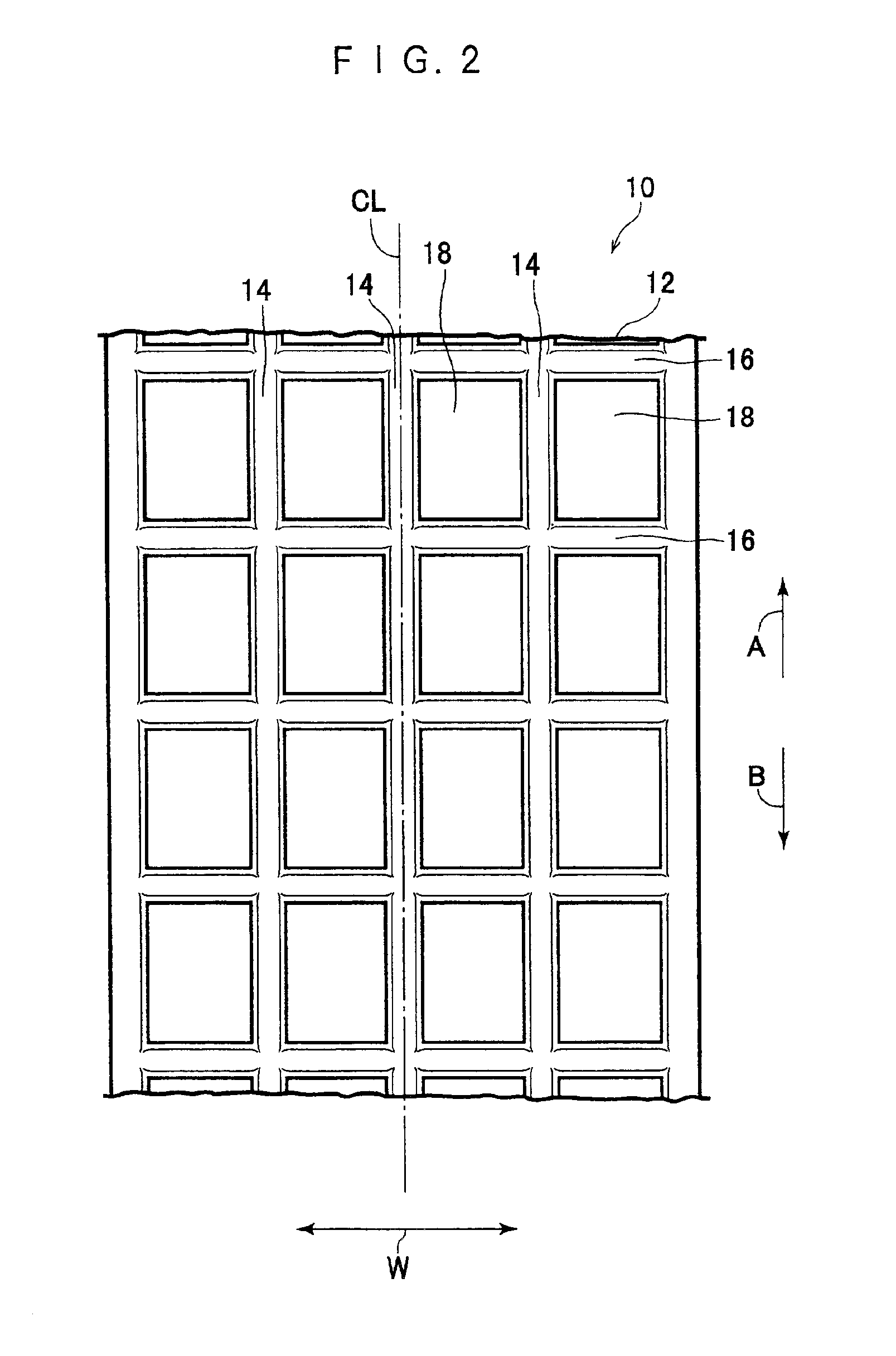

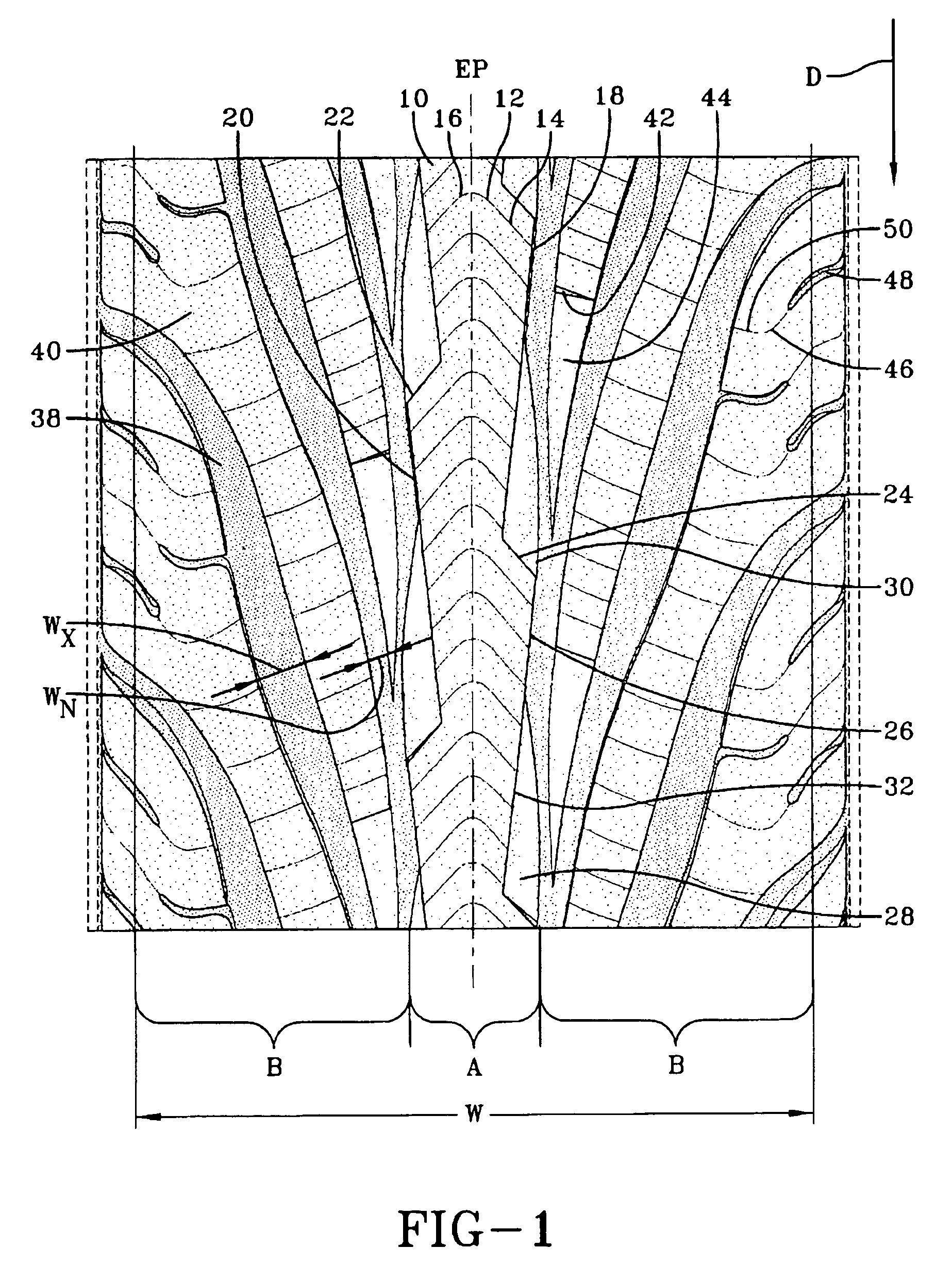

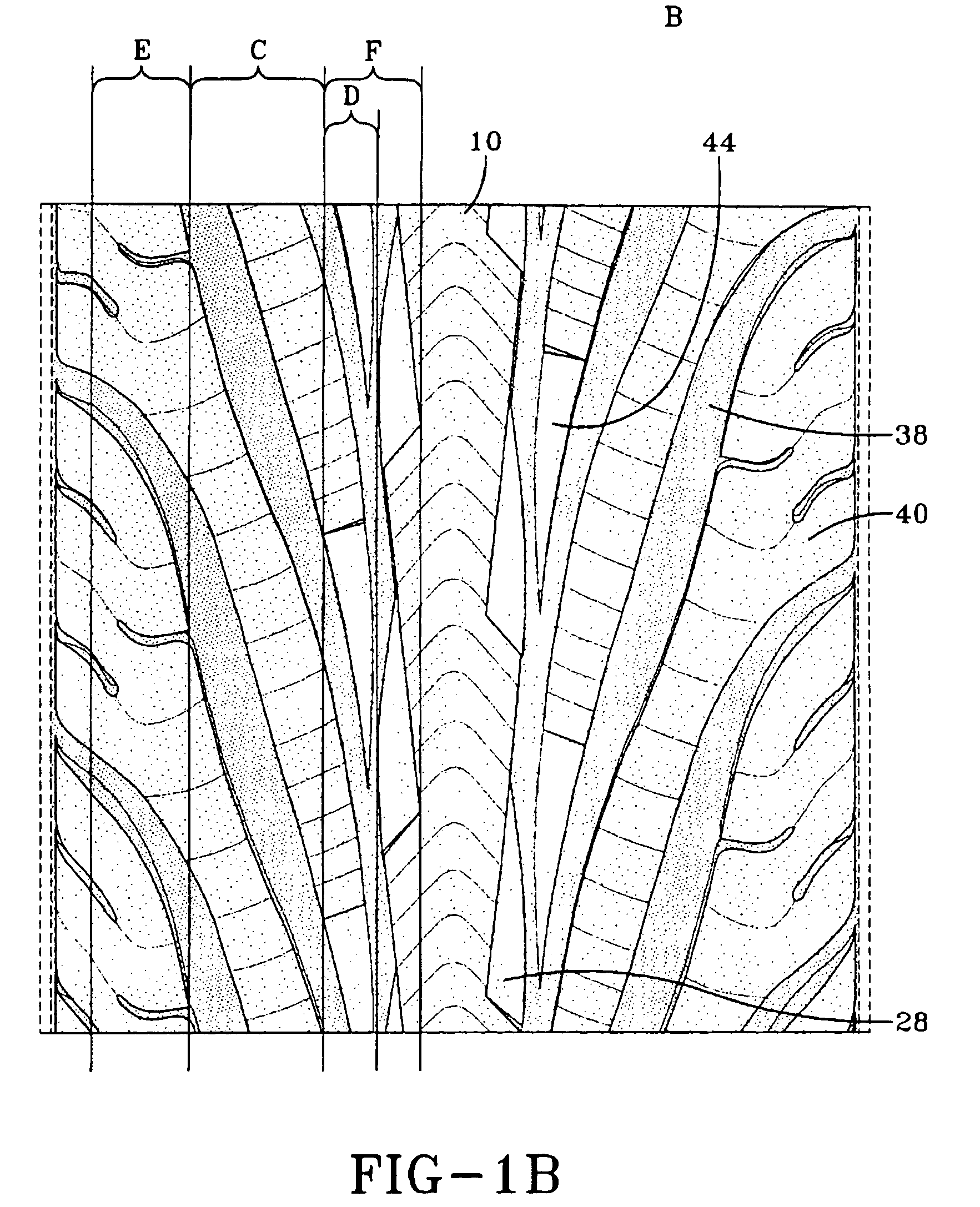

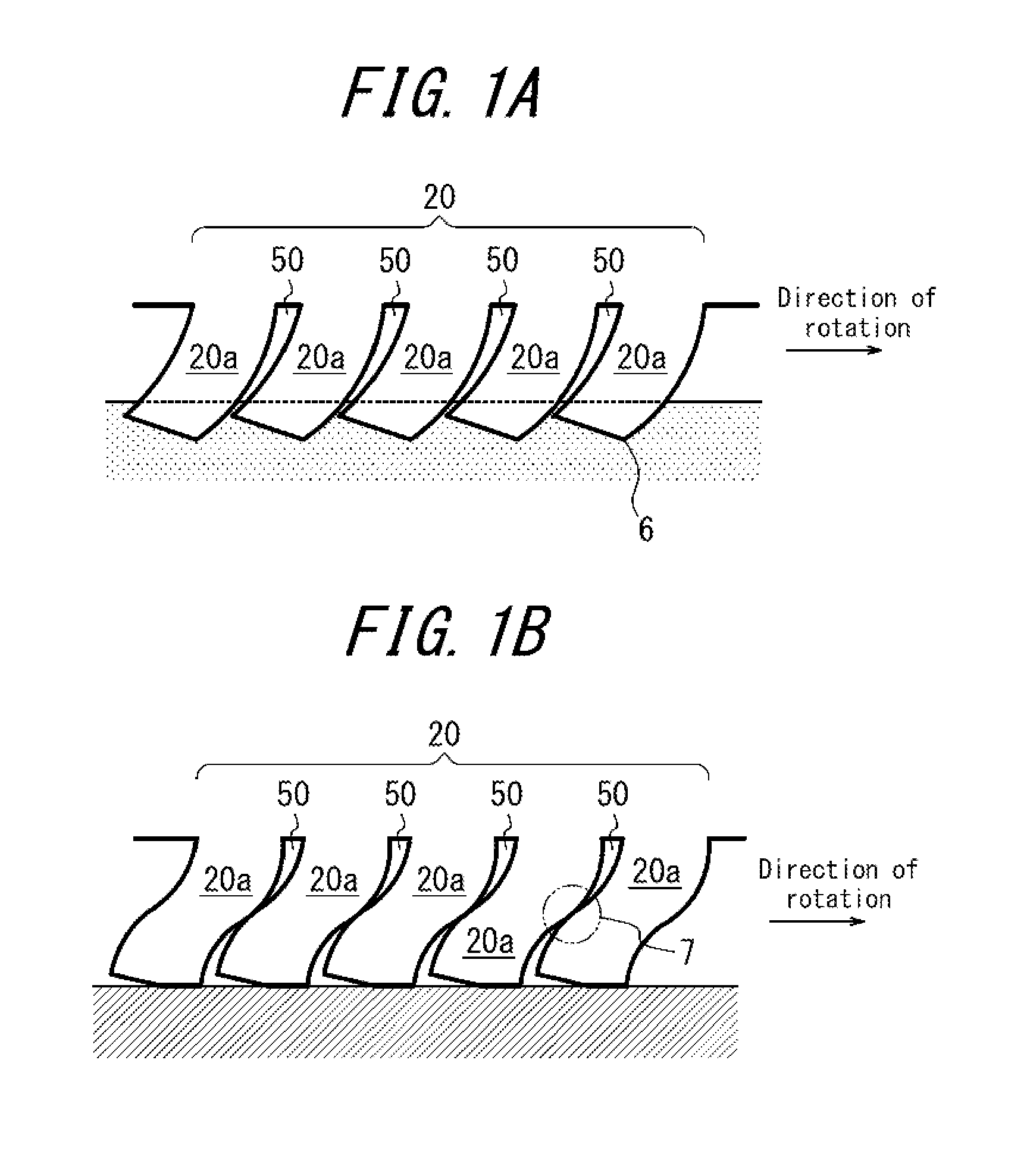

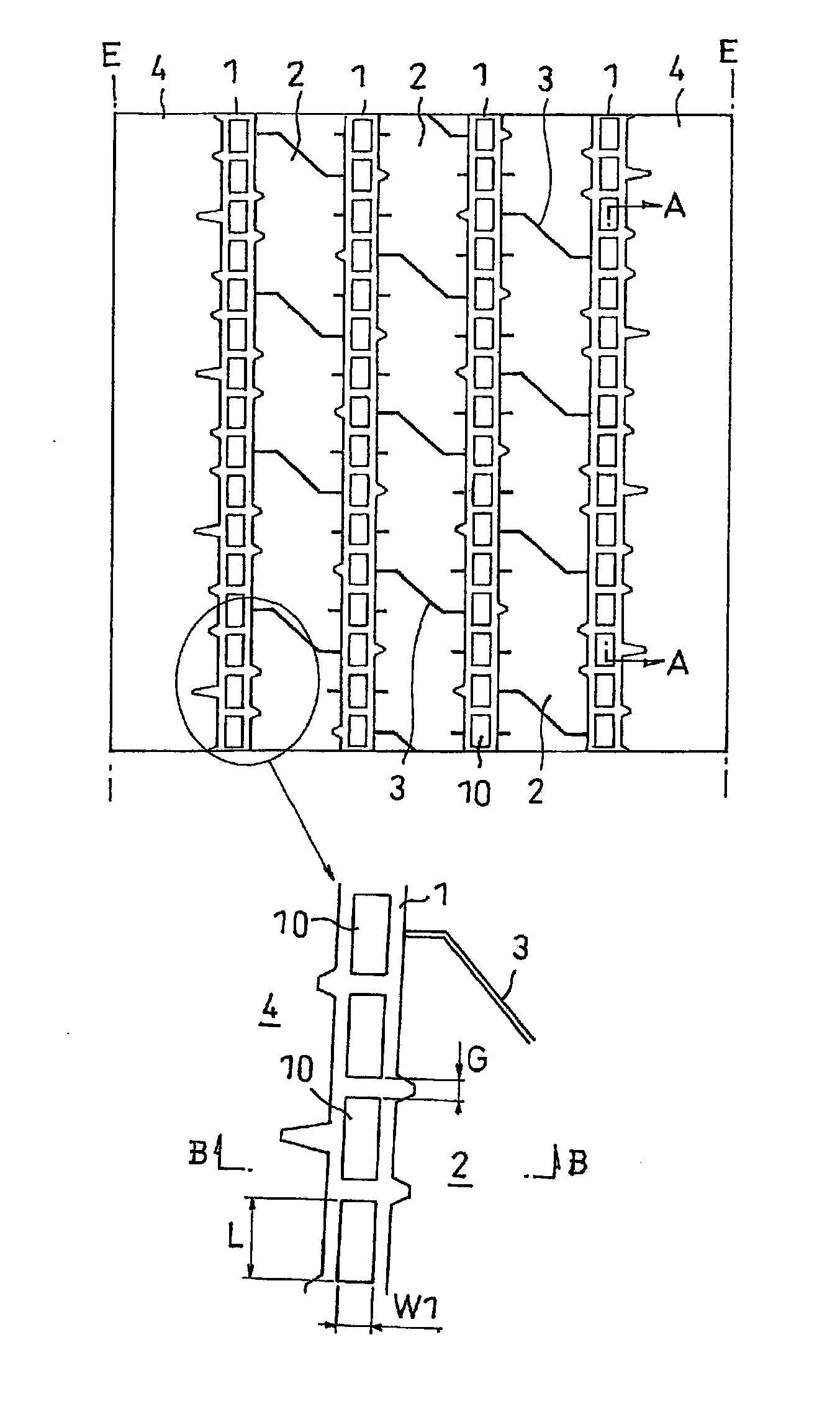

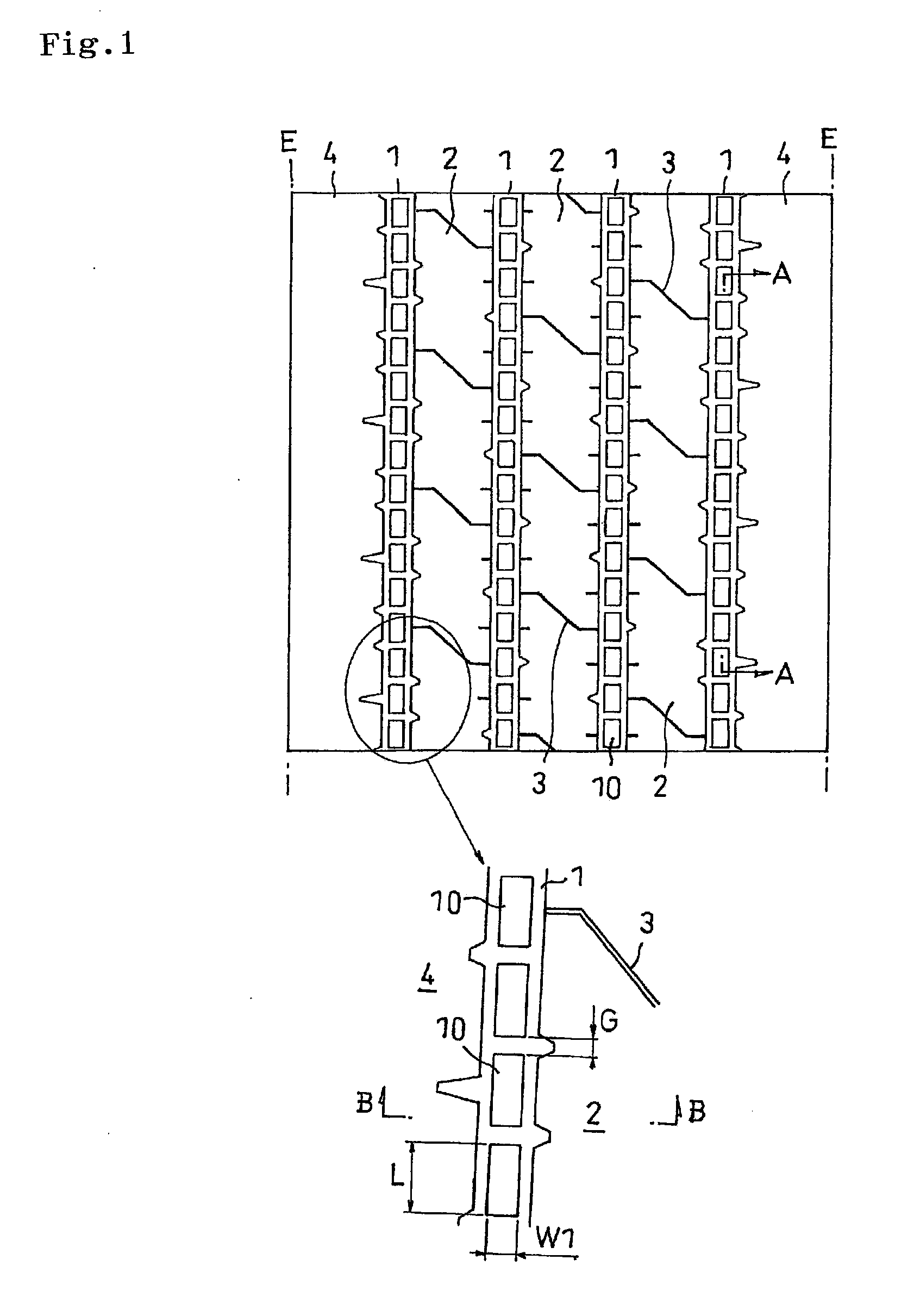

Tire having longitudinally extending smaller grooves formed in the walls of a groove

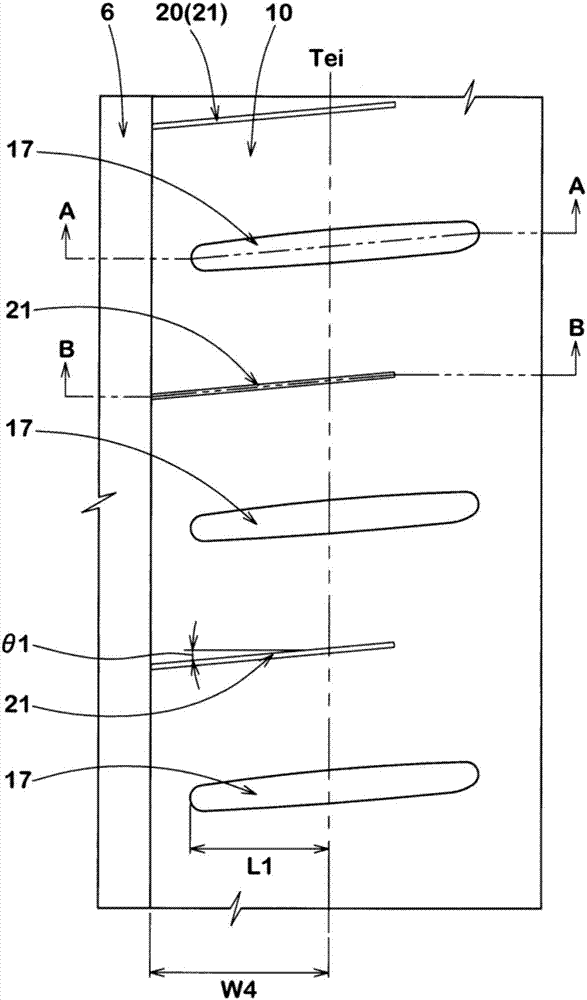

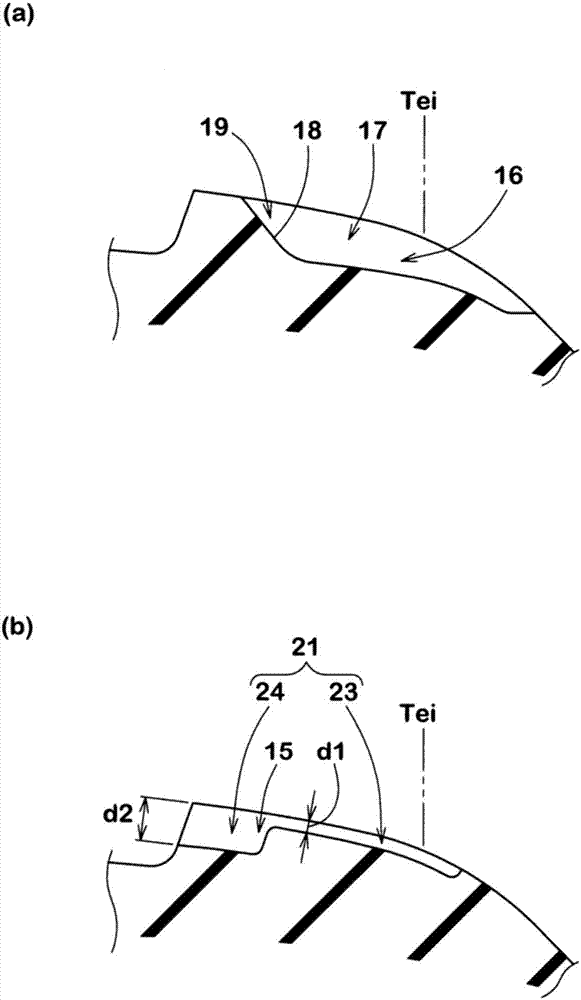

InactiveUS6866076B2High rateImprove wetting performanceTyre tread bands/patternsNon-skid devicesTransverse grooveWater flow

A tire capable of reducing a resistance to a fluid in a groove to improve the wet performances. By forming smaller grooves (or riblets 20) having a depth set within a range of 0.01 to 0.5 mm at a pitch within a range of 0.01 to 0.5 mm in the walls of a circumferential groove and a transverse groove, more specifically, the resistance to the water flowing in the groove is reduced to improve the drainage efficiency of the groove. By arranging a turbulence generating zone having a number of pointed projections at the groove side faces at the confluence between the circumferential groove and the transverse groove, on the other hand, there is suppressed the separation of the water flow in the vicinity of the confluence. With these constructions, it is possible to improve the wet performances of the tire better than the prior art.

Owner:BRIDGESTONE CORP

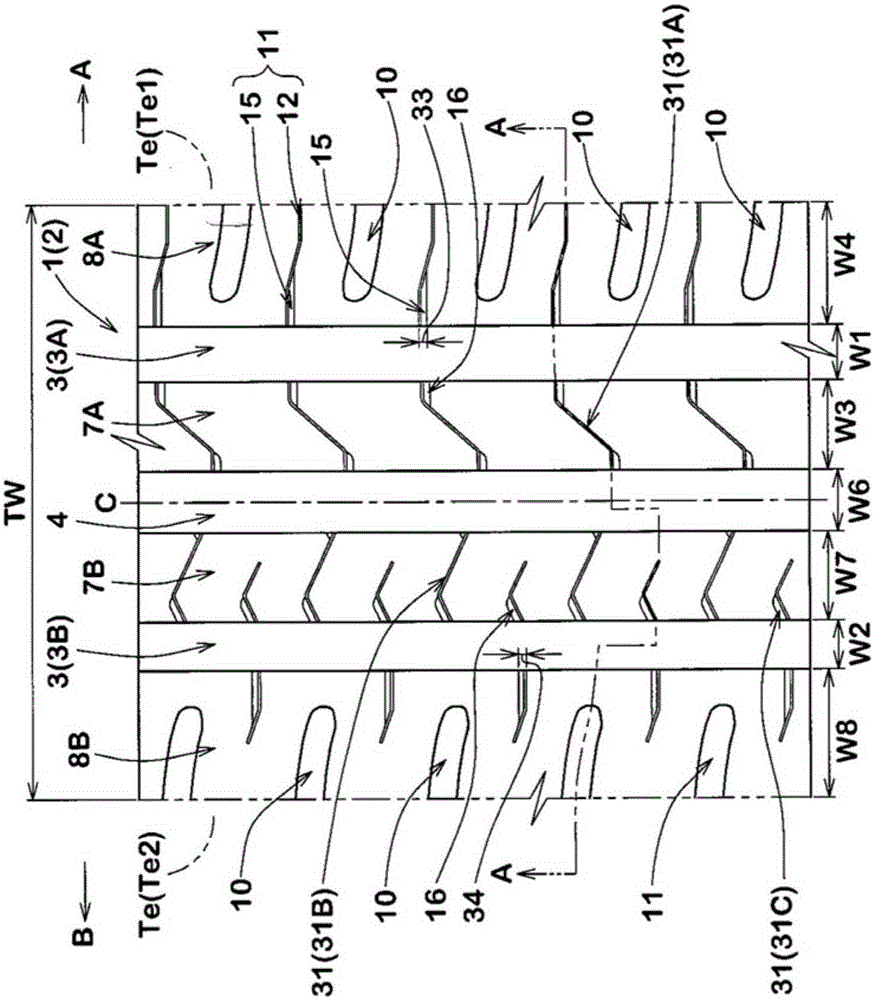

Pneumatic tire

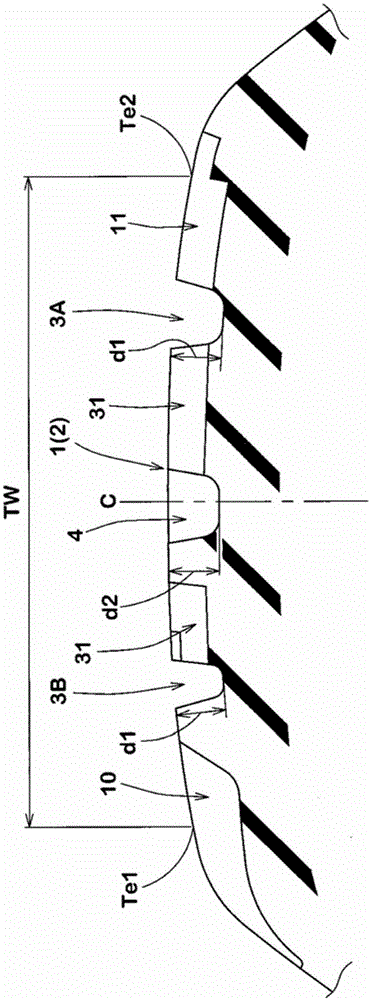

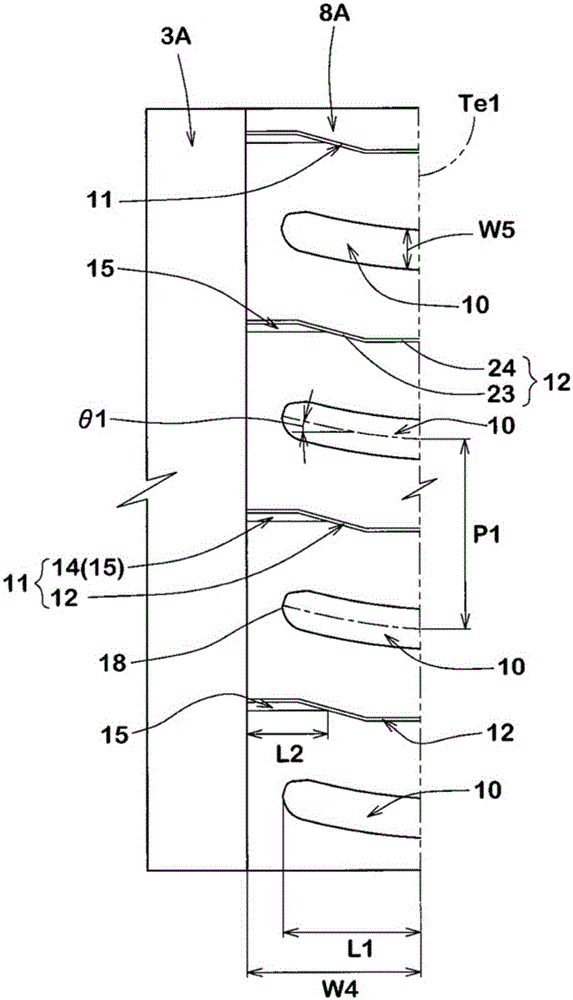

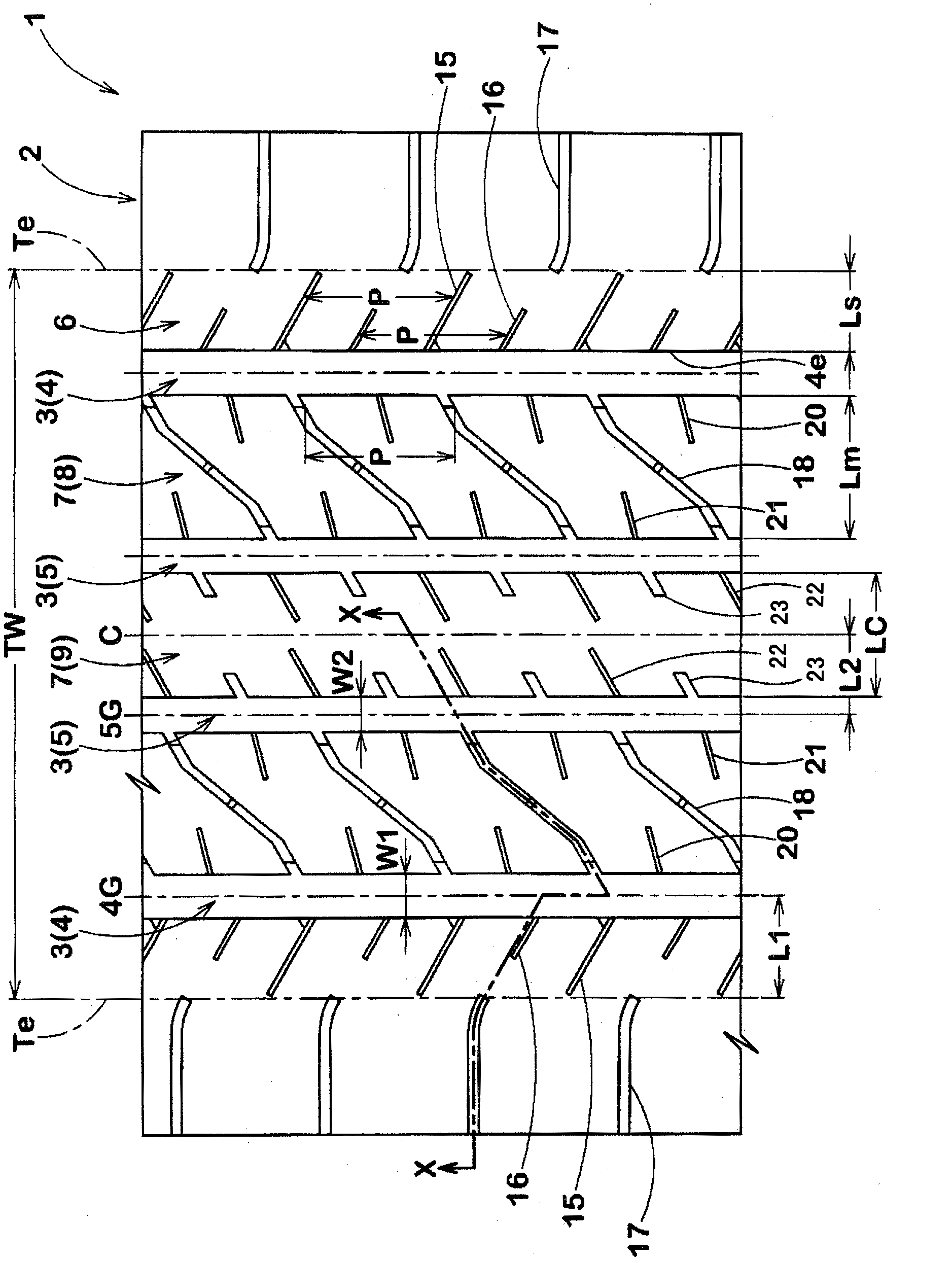

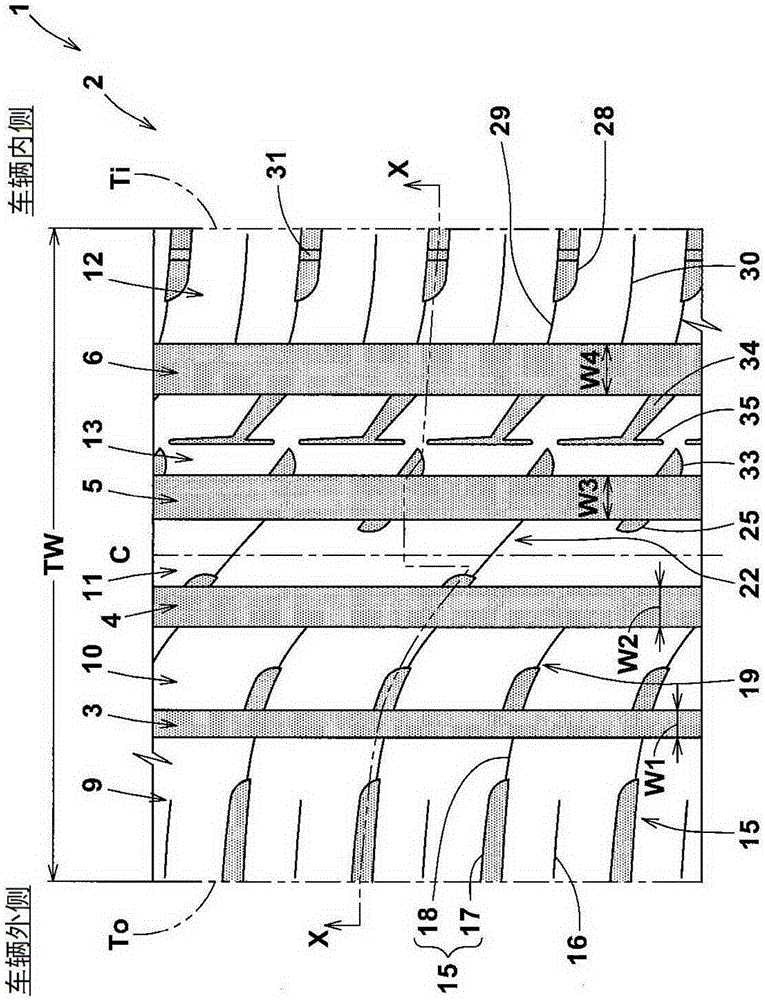

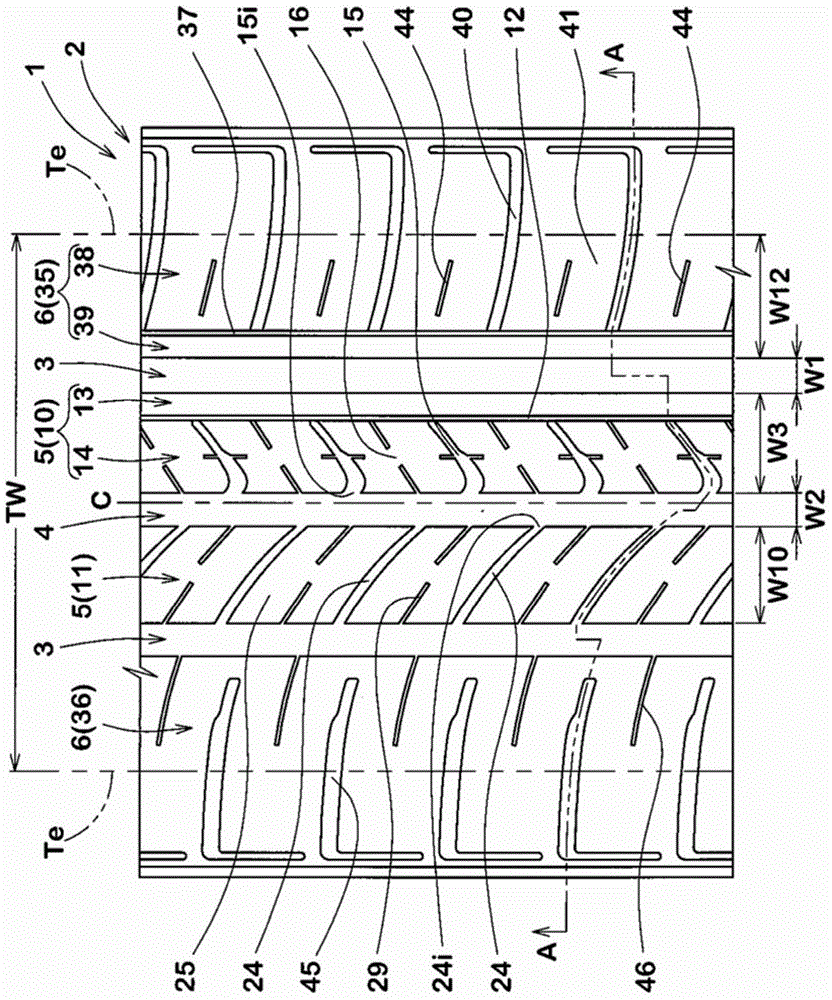

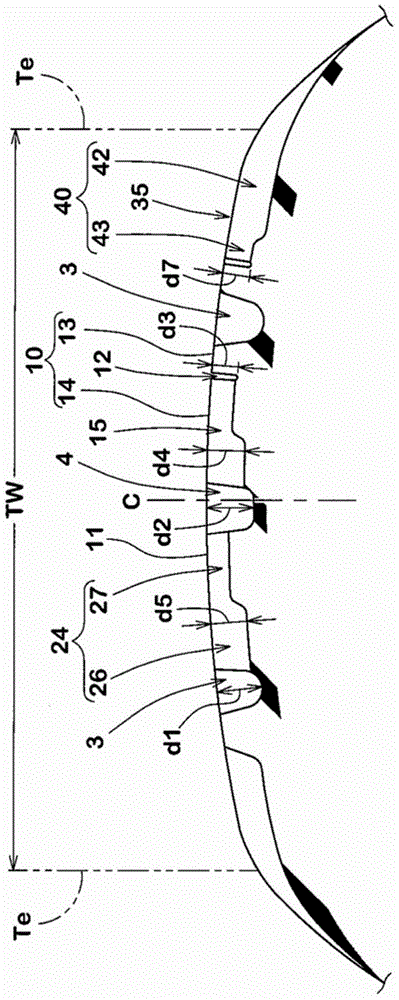

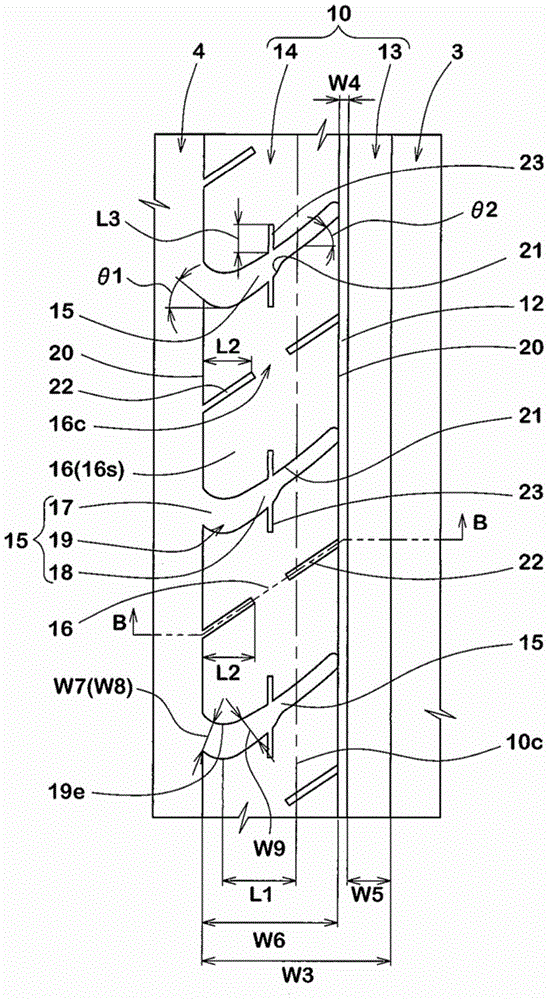

ActiveCN105564160AGood drainageWater drift suppressionTyre tread bands/patternsEngineeringRoad surface

A pneumatic tire (1) comprises a tread portion (2) having an inboard tread edge (Tel) to be positioned towards the center of a vehicle body, and an outboard tread edge (Te2) to be positioned away from the center of the vehicle body. The tread portion (2) is provided with an inboard shoulder main groove (3A), an outboard shoulder main groove (3B) and a center main groove (4) to define an inboard shoulder land region (8A) and an inboard middle land region (7A). The width W1 of the inboard shoulder main groove (3A) is more than the width W2 of the outboard shoulder main groove (3B) and in a range of from 9.0 % to 10.0 % of the tread width (TW). The ratio W4 / W3 of the width W4 of the inboard shoulder land region (8A) to the width W3 of the inboard middle land region (7A) is in a range of from 1.3 to 1.4. The inboard shoulder land region (8A) is provided with shoulder lateral grooves (10) extending axially inwardly from the inboard tread edge (Tel) to terminate within the inboard shoulder land region (8A). The ratio W5 / P1 of the width w5 of the shoulder lateral grooves (10) to an arrangement pitch P1 of the shoulder lateral grooves (10) is in a range of from 0.18 to 0.25.

Owner:SUMITOMO RUBBER IND LTD

Pneumatic tire

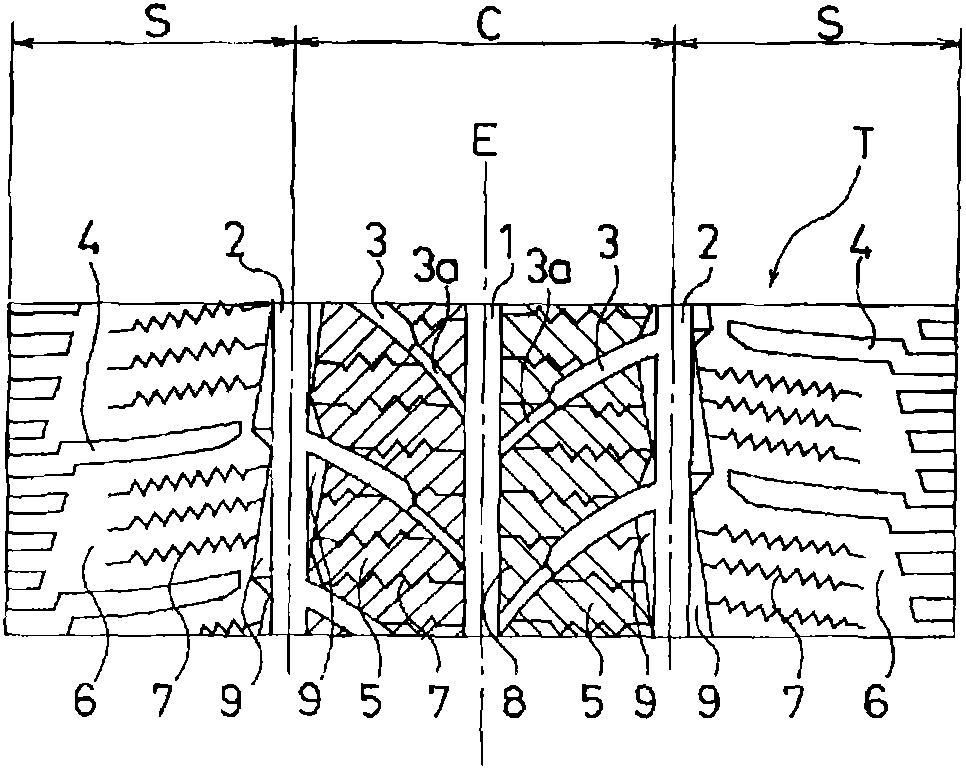

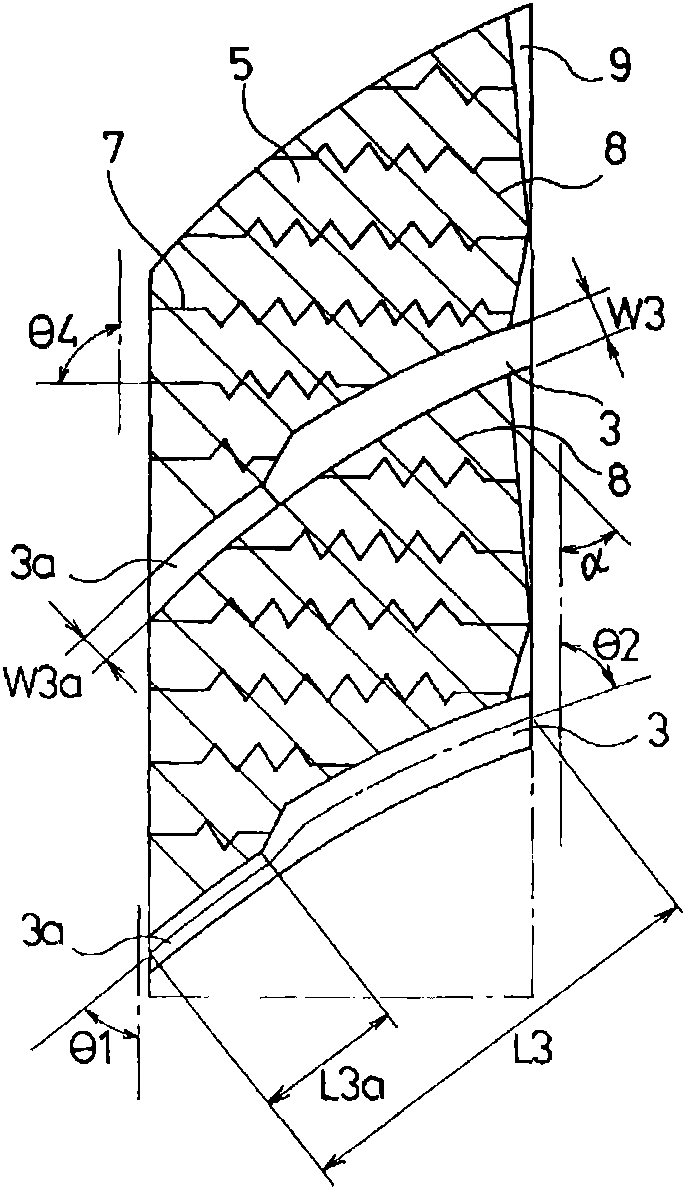

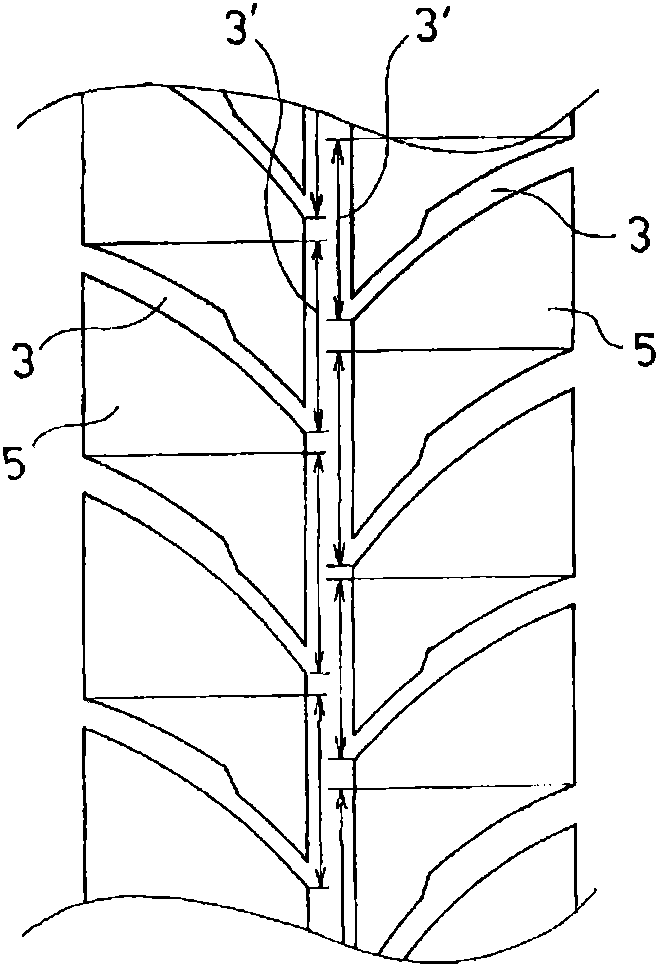

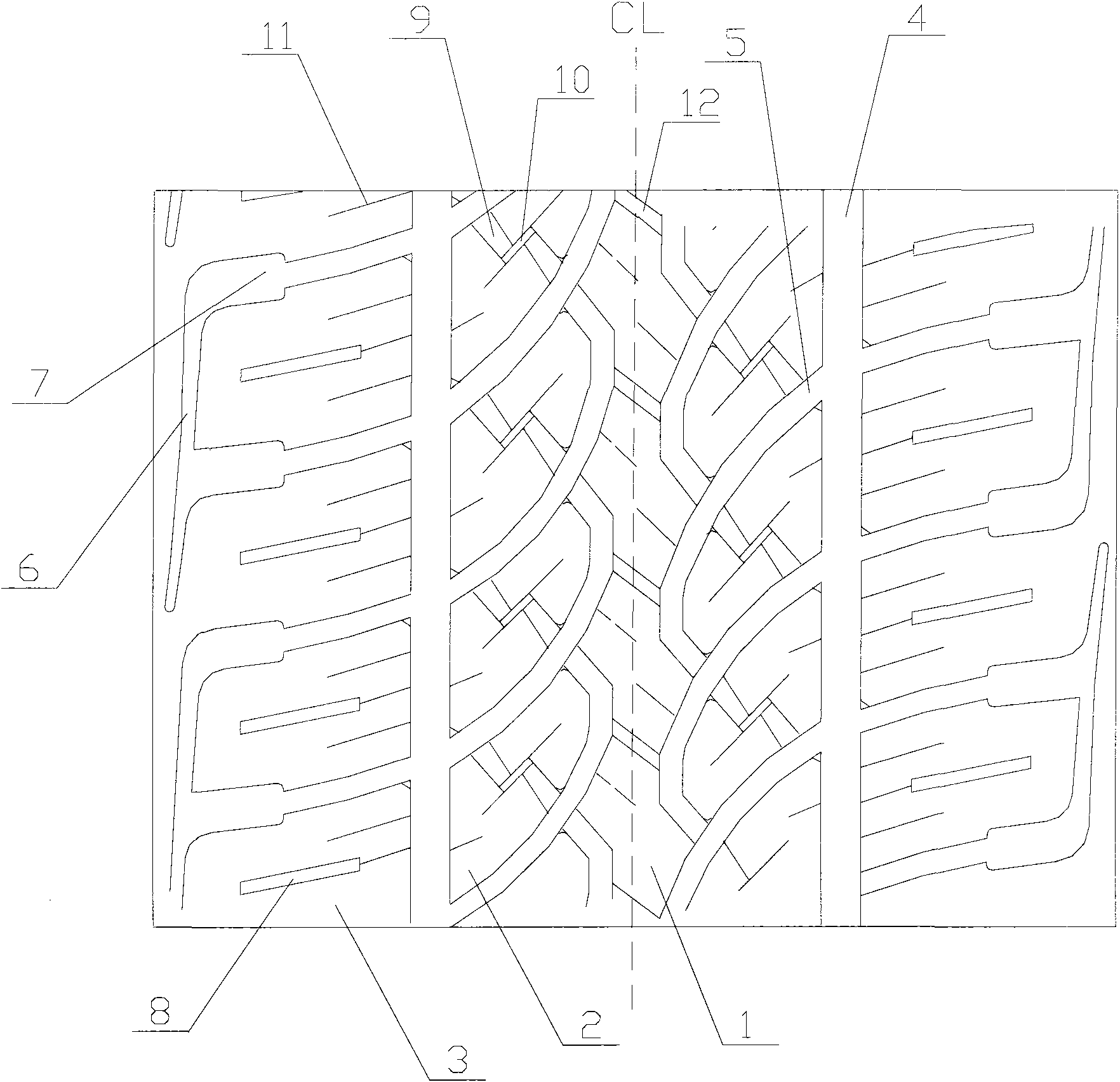

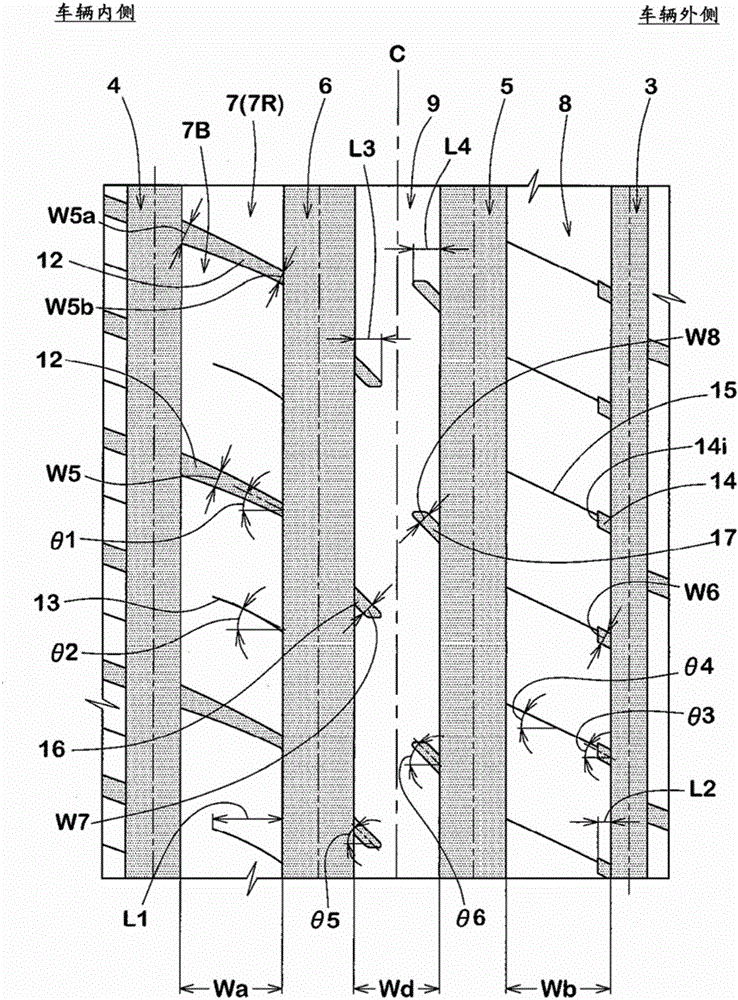

ActiveCN102310723AImprove wetting performanceImprove snow performanceSpecial tyresTyre tread bands/patternsAcute angleTransverse groove

The invention provides a pneumatic tire, which has directional patterns and achieves improved wet performance, snow performance and nonuniform wear resistance. The central portion (C) of the pneumatic tire is divided into multiple pattern blocks (5) via a central main groove (1), outer main grooves (2) and transverse grooves (3). Meanwhile, the strip-shaped patterns (5) at the tire shoulder portion (S) is provided with shoulder pattern grooves (4). The patterns of the pneumatic tire are directional patterns. The transverse grooves (3) are formed at two sides of the central main groove (1) in the tire width direction and is reversely inclined relative to the tire equator, wherein the central inclined angle Theta1 of the transverse grooves (3) is an acute angle. Meanwhile, the transverse grooves (3) are formed at two sides of the central main groove (1) in the tire width direction and the tire circumferential direction in a staggered manner such that the circumferential portion (3') formed by upward projection of the transverse grooves (3) in the tire circumferential direction is provided at the periphery of the tire. In addition, sipes (7) are provided at the pattern blocks (5) and the strip-shaped patterns (6).

Owner:THE YOKOHAMA RUBBER CO LTD

Pneumatic tire

InactiveCN101678722AImprove performance on iceGuaranteed drainage functionTyre tread bands/patternsEngineeringRoad surface

A pneumatic tire achieving good on-ice performance and good wet performance at the same time is provided. A pair of first main grooves extending in the circumferential direction of the tire is provided in the center region of a tread. A pair of second main grooves extending in the circumferential direction of the tire is provided on both the outer sides of the pair of first main grooves. First luggrooves and second lug grooves are alternately arranged in the circumferential direction of the tire such that the first lug grooves extend inward in the lateral direction of the tire from each shoulder end of the tread and communicate with the corresponding one of the first main grooves and further such that the second lug grooves extend inward in the lateral direction of the tire from the shoulder end of the tread and do not communicate with the corresponding one of the first main grooves. A center rib is arranged to extend between the pair of first main grooves. A shoulder block row composed of blocks is arranged between each second main groove and the corresponding one of the shoulder ends, and an intermediate shoulder block row composed of blocks is arranged between the second main groove and the adjacent one of the first main grooves. In the intermediate shoulder block row are arranged long blocks having a circumferential length equivalent to the length of two blocks of the shoulder block row.

Owner:THE YOKOHAMA RUBBER CO LTD

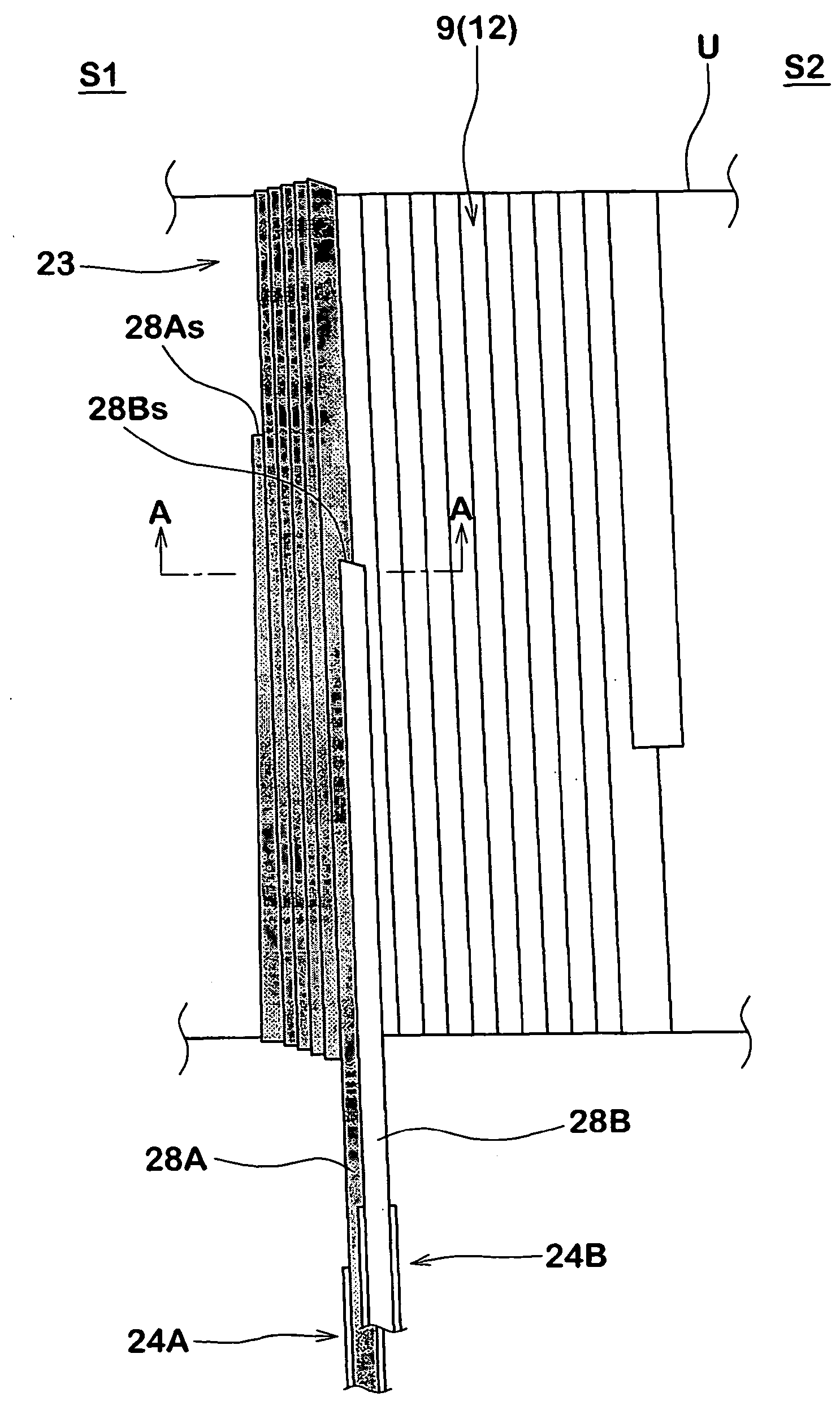

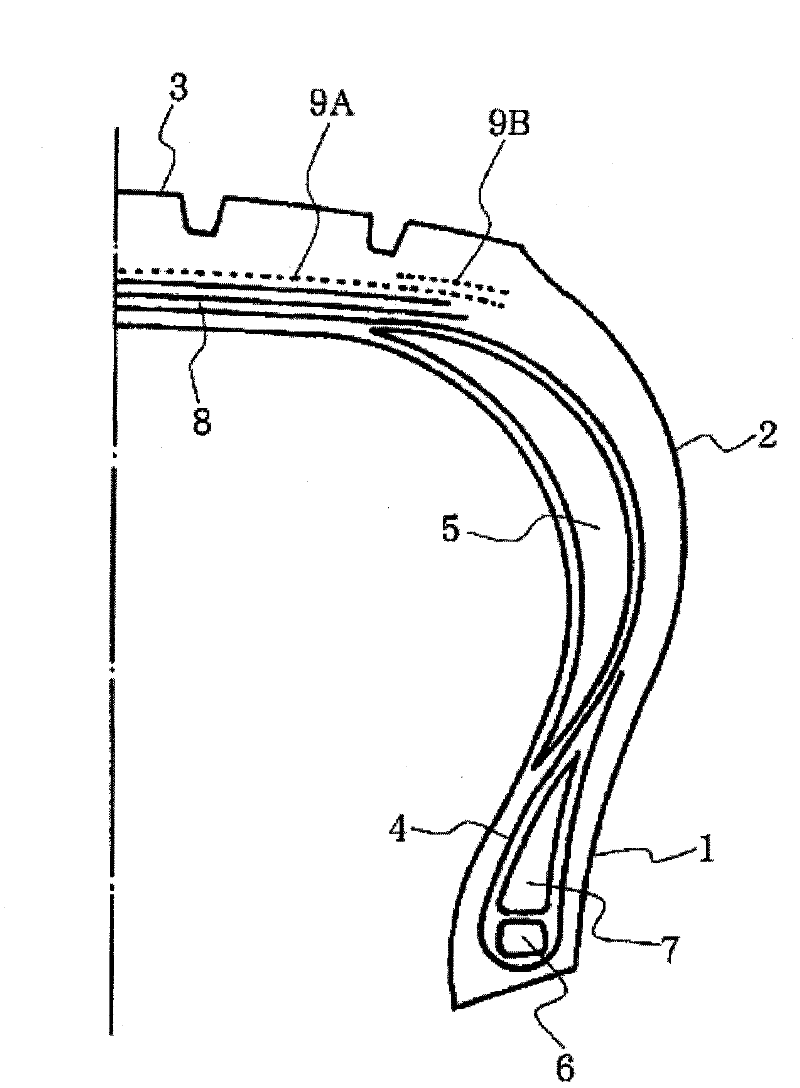

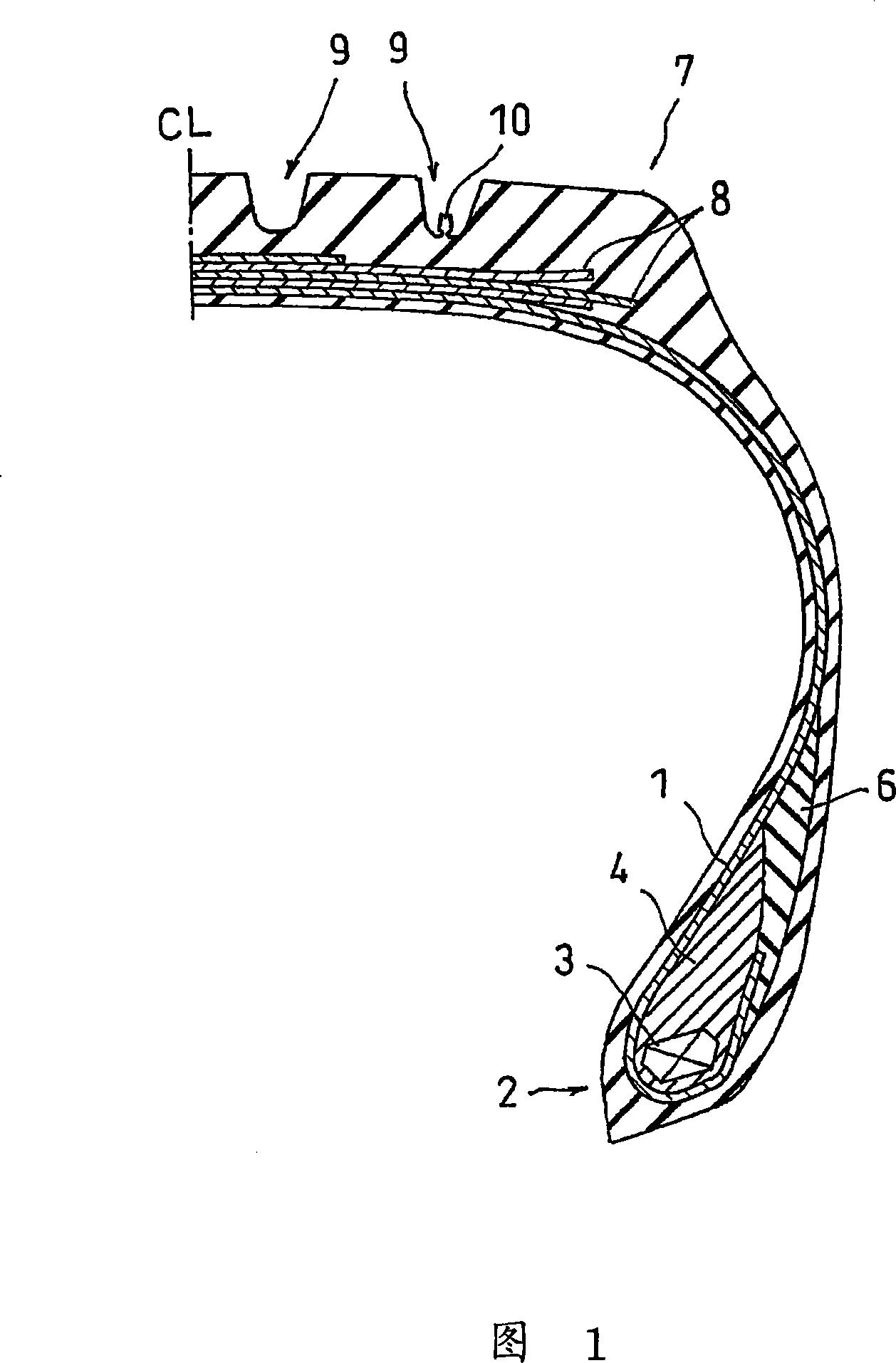

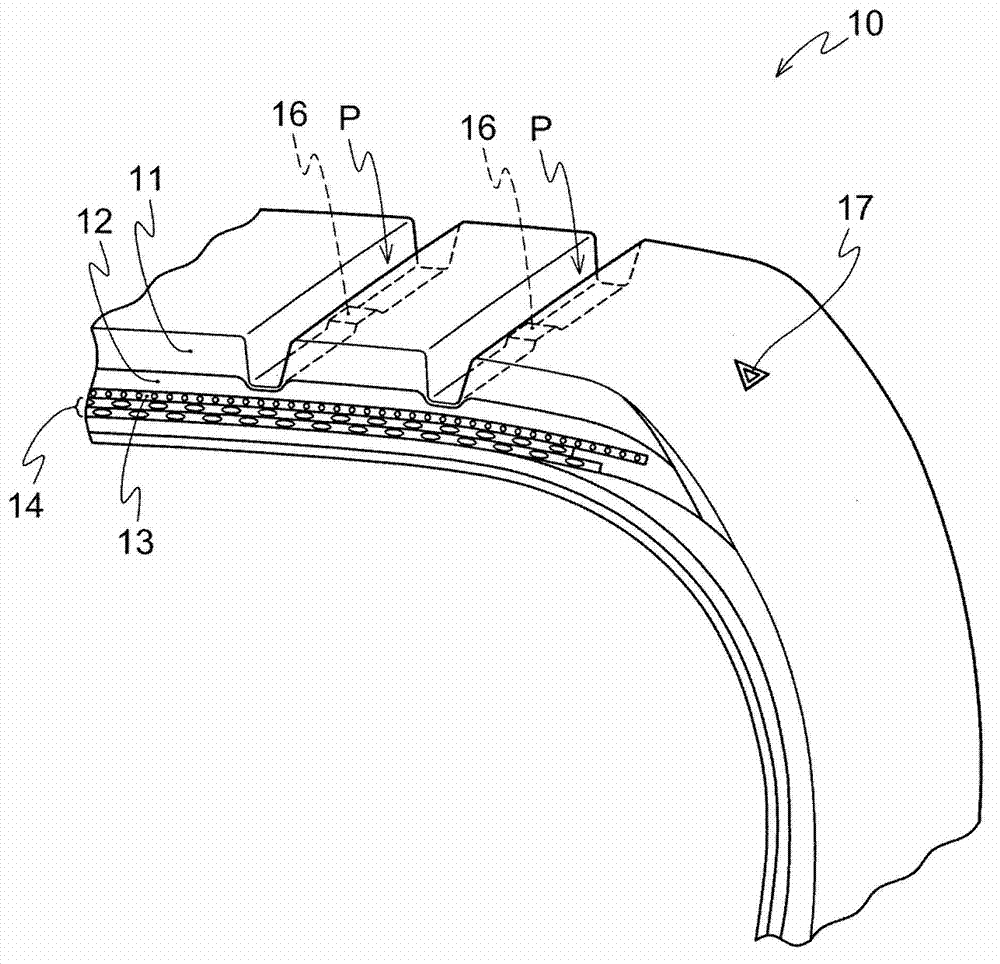

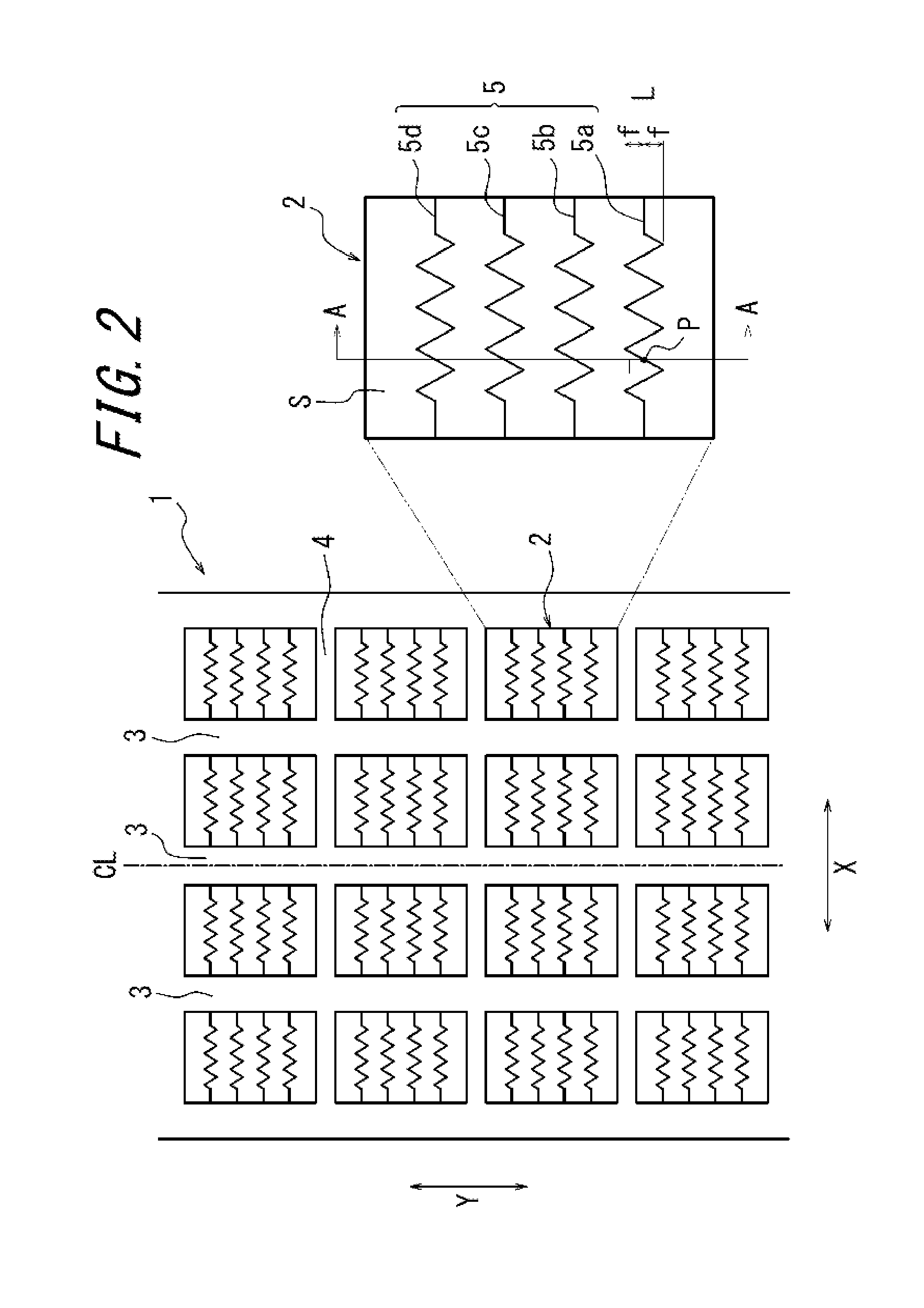

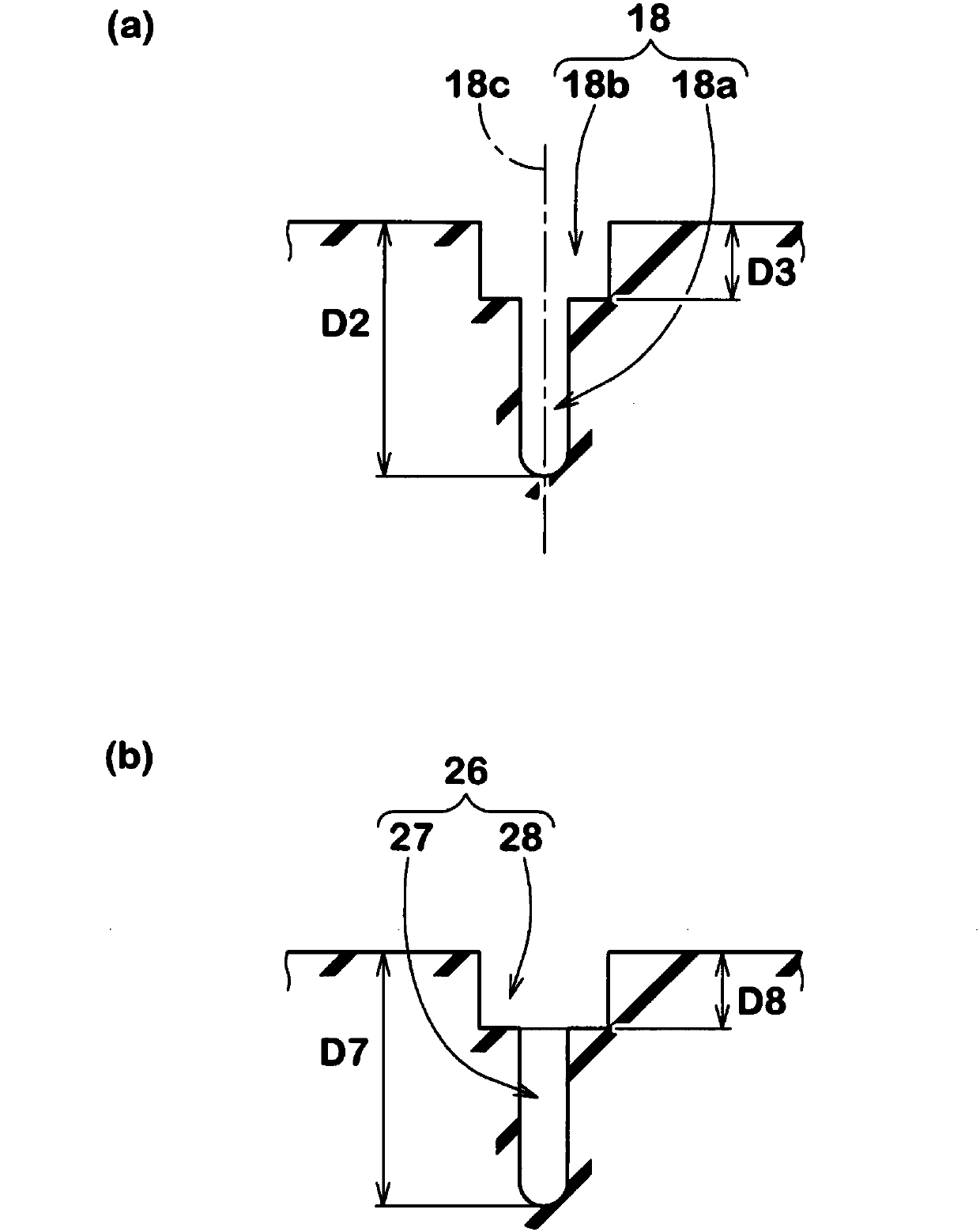

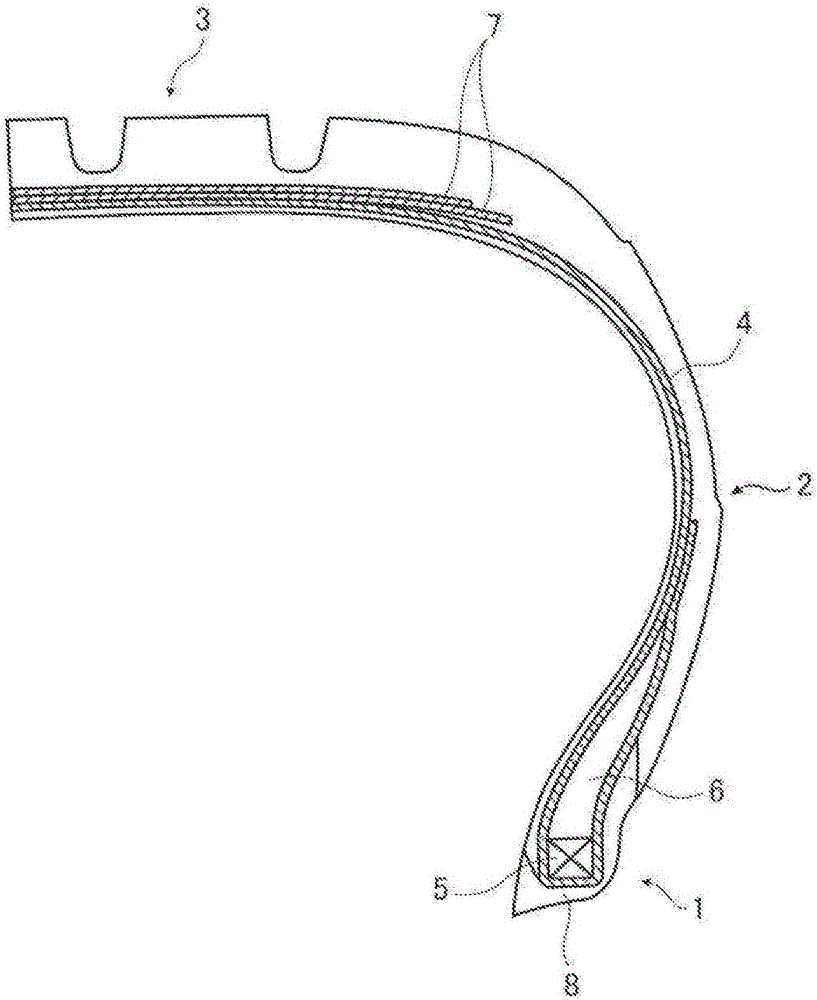

Producing method of pneumatic tire

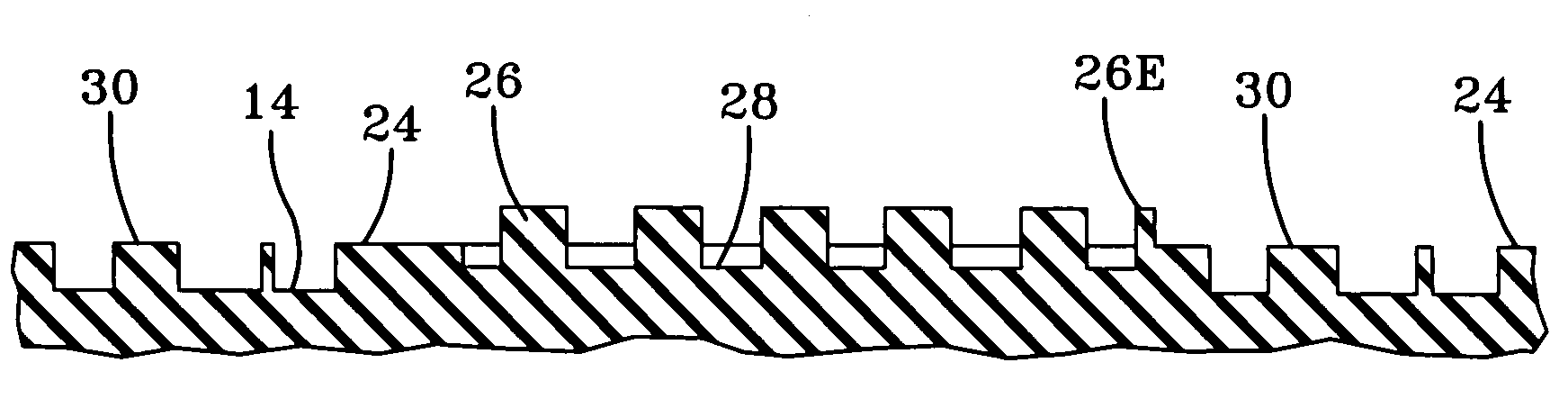

It is an object of the invention to provide a producing method of a pneumatic tire capable of discharging static electricity of a vehicle to a road surface. A producing method of a pneumatic tire for producing the pneumatic tire in which its tread portion includes a conductive inner conductive portion which is in conduction with a rim when the rim is assembled, and an annular cap rubber portion whose inner peripheral surface is in contact with the inner conductive portion and whose outer peripheral surface comes into contact with a road surface. The producing method comprising a cap rubber forming step for forming a cylindrical unvulcanized cap rubber portion by spirally winding a ribbon-like unvulcanized rubber strip 28 around a center shaft of a substantially cylindrical to-be-wound body 23, wherein the cap rubber forming step includes a simultaneous winding step for simultaneously winding the non-conductive rubber strip 28A and the conductive rubber strip 28B around the to-be-wound body by using applicators 24A and 24B for guiding the rubber strips 28A and 28B.

Owner:SUMITOMO RUBBER IND LTD

Pneumatic tire

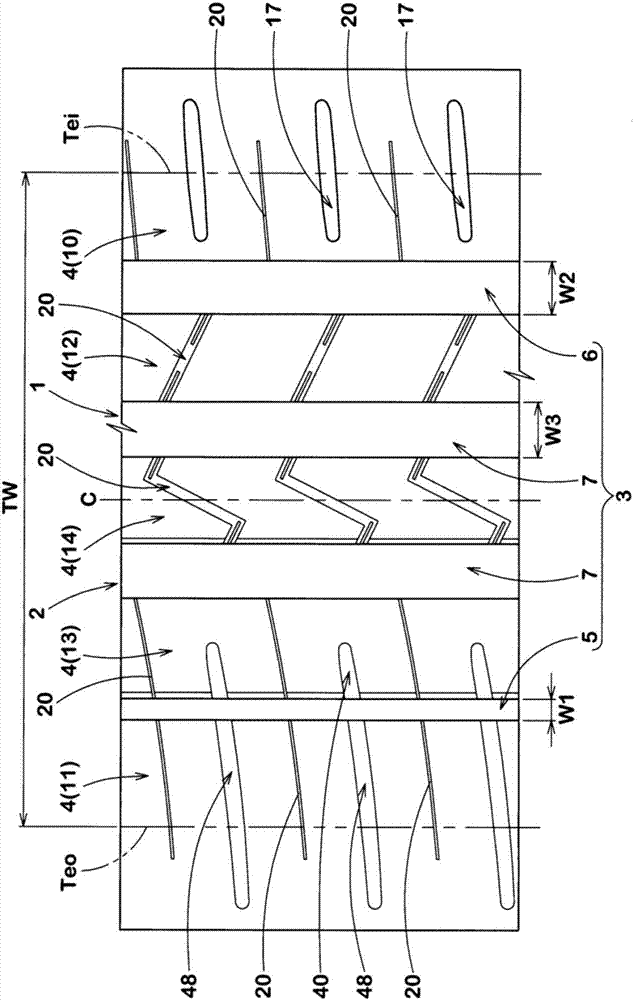

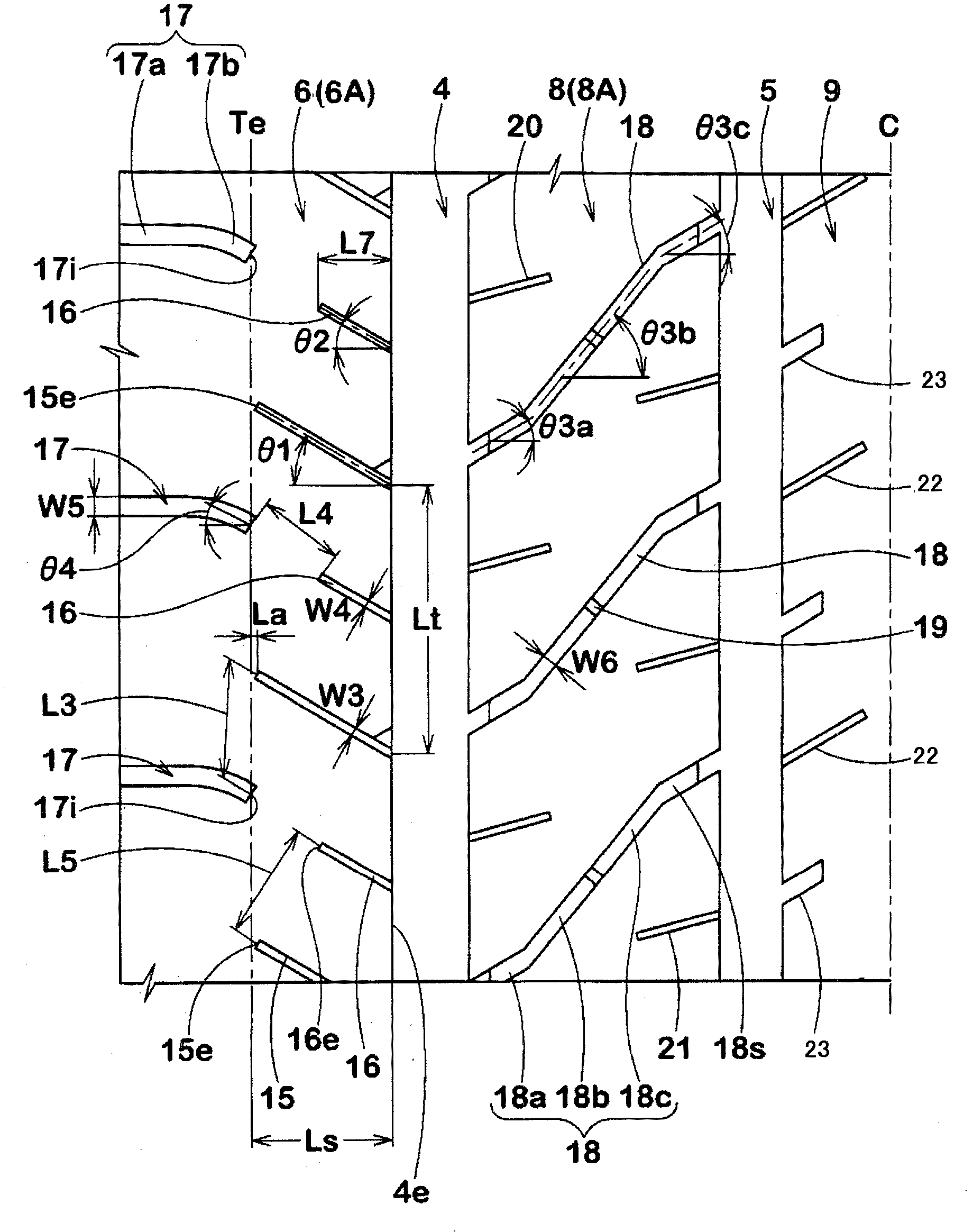

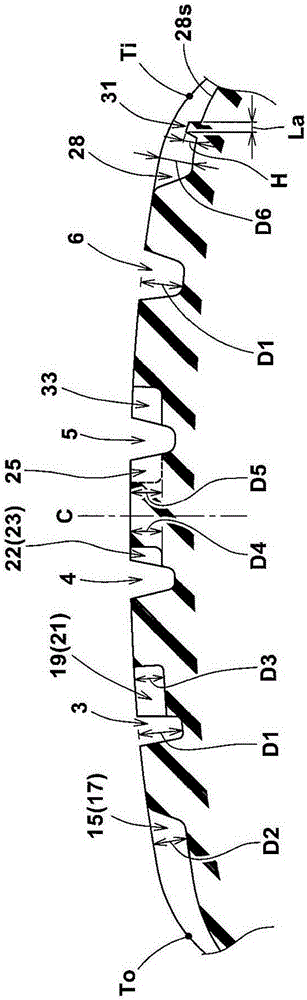

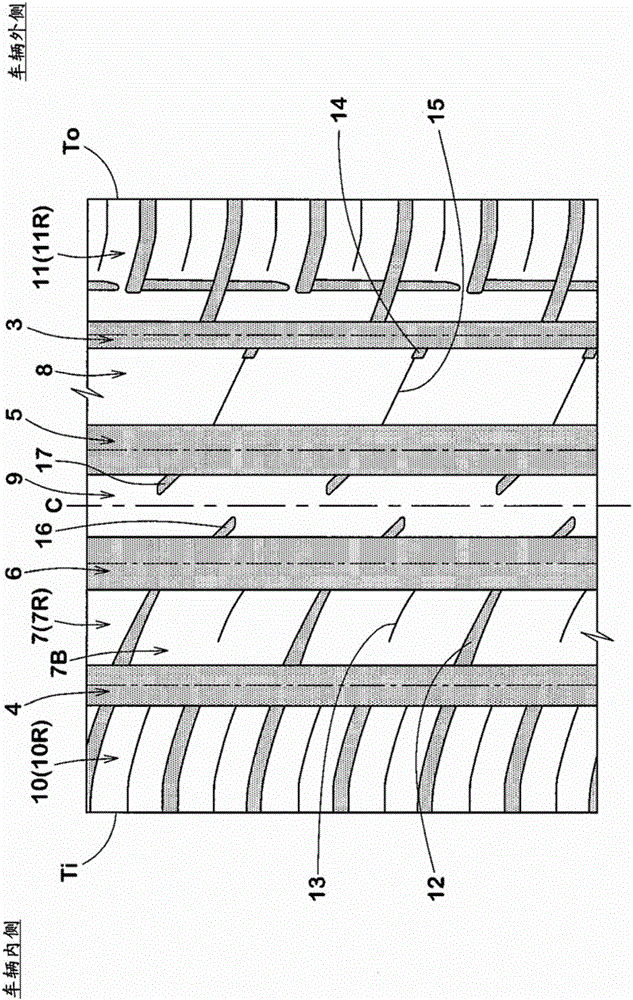

ActiveCN107150556ASuperior Wetland PerformanceExcellent handling stabilityTyre tread bands/patternsEngineeringMechanical engineering

A pneumatic tire comprises a tread portion 2 having an outside tread edge Teo and an inside tread edge Tei to be positioned outside and inside, respectively, with respect to a vehicle. The tread portion 2 is axially divided into land regions 4 by four main grooves 3 including an outside shoulder main groove 5, an inside shoulder main groove 6 and two crown main grooves 7. The outside shoulder main groove 5 has a width smaller than the inside shoulder main groove 6 and the crown main grooves 7. The land portions 4 include an inside shoulder land region 10 provided with inside shoulder lateral grooves 17. Each of the land regions 4 is provided with sipes 20 each extending across the entire width of the land region and having a width less than 3 mm.

Owner:SUMITOMO RUBBER IND LTD

Inflation tire

InactiveCN102649389AImprove impactImprove rigidityTyre tread bands/patternsRoad surfaceWear resistance

The invention discloses an inflation tire, which can be used to maintain the sideslipping performance, the performance on wet road surfaces of the vehicle, and to improve the heal-and-toe wear resistance performance of the vehicle. The inflation tire (1) is provided with a plurality of grooves(3) of a pair of tire shoulder main grooves(4). A land part width (Ls) of a tire shoulder land part(6) is 10 to 15% of a tire surface grounding width (TW). The tire shoulder land part (6) is provided with a first tire shoulder horizontal groove (15), which extends from the part close to the tire surface grounding end (Te),and is inclined at an angle of 10 to 35 degrees relative to the tire shaft; a second tire shoulder horizontal groove (16), which is inclined from the part between the first tire shoulder horizontal grooves (15, 15) at an angle of 10 to 35 degrees towards the axial direction of the tire, and can form a terminal on the tire shaft more close to the inner side than the first tire shoulder horizontal groove(15); a third tire shoulder horizontal groove (17), which is inclined from the outer side of the tire surface grounding end (Te) of the tire shaft towards the inner side of the tire shaft, and can form a terminal close to the tire surface grounding end(Te).

Owner:SUMITOMO RUBBER IND LTD

Pneumatic tire

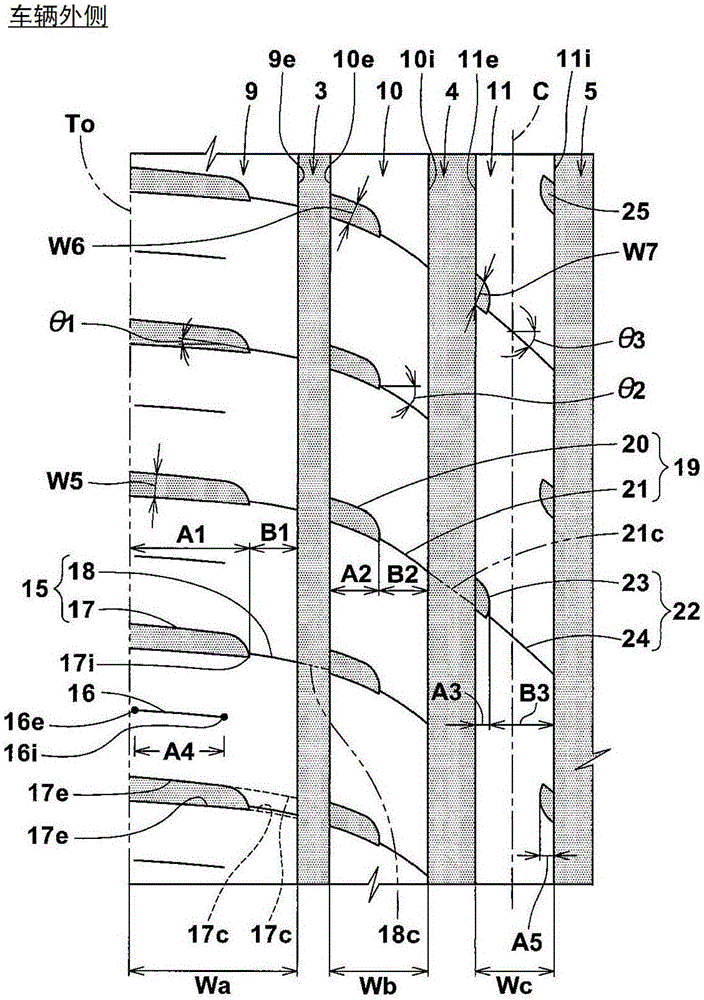

ActiveCN105620205AHigh circumferential stiffnessImprove wetting performanceTyre tread bands/patternsEngineeringWear resistance

To provide a pneumatic tire that exhibits well-balanced enhancement of wear resistance while maintaining high wet performance. [Solution(s)] On the tread 2, a pneumatic tire 1 is provided with a first tread edge (To), main grooves each extending continuously in a tire circumferential direction, land sections bordered by the main grooves, and lateral grooves crossing through the land sections. The land sections include a first land section 9 having the first tread edge (To) and provided with first lateral grooves 15, a second land section 10 adjacent to the inner side of the first land section 9 and provided with second lateral grooves 19, and a third land section 11 adjacent to the inner side of the second land section 10 and provided with third lateral grooves 22. Lateral grooves (15, 19, 22) each include an outer portion that extends from the first tread-edge (To) side land periphery and a sipe portion that is connected to the outer portion. Tire axial lengths (A1) 1 / 4 (A3) of outer portions and tire axial lengths (B1) 1 / 4 (B3) of sipe portions are specified at their respective values.

Owner:SUMITOMO RUBBER IND LTD

Rubber composition and pneumatic tire using the same

InactiveCN1922258AImprove liquidityGood dimensional stabilitySpecial tyresTyre beadsPolymer scienceSilicon dioxide

A rubber composition which comprises (i) a conjugated diene based rubber gel exhibiting a toluene swelling index of 16 to 70, (ii) a diene based rubber such as natural rubber, a polyisoprene rubber, an aromatic vinyl-conjugated diene copolymer rubber and / or a polybutadiene rubber, and optionally (iii) carbon black and / or silica; and (a) a pneumatic tire using the above composition in a high hardness reinforcing layer extending along a tire side wall from a bead section, which is improved in the fluidity and dimensional stability in extruding molding, with the retention of satisfactory hardness of a high hardness reinforcing rubber, (b) a pneumatic tire using the above composition in both end portions of an extruded tire tread, which is improved in its processability and dimensional stability in extruding molding, with the retention of flex fatigue characteristics in both end portions of a tread, and (c) a pneumatic tire using the above composition as an under tread having a thickness of 1.5 to 6 mm, which has a relatively thick under tread exhibiting a high elastic modulus and is excellent in processability and driving stability.

Owner:THE YOKOHAMA RUBBER CO LTD +1

Run-flat tire

InactiveCN102056754AExcellent run-flat performanceExcellent high-speed straight running stabilitySpecial tyresPneumatic tyre reinforcementsWire rodDynamic storage

Provided is a run-flat tire which has an excellent run-flat performance as well as a high high-speed straight running stability in the non-punctured state, a high steering stability on both of a dry road surface and a wet road surface and a good fuel efficiency. A run-flat tire which comprises at least two cross belt layers formed by rubberizing a steel cord and a tread rubber located successively, wherein a reinforcing rubber is provided inside a carcass. The above-described steel cord has a single twisted structure or a core / single layered sheath structure consisting of 6 to 10 steel strands having a strand diameter of 0.10 to 0.20 mm. The density of the implanted steel cords is 40 cords / 50 mm or more and the distance between the adjacent steel cords in the belt layer is 0.3 mm or longer. Moreover, the dynamic storage modulus E' (MPa) at 30 DEG C of the tread rubber and tand at 60 DEG C of the same respectively satisfy the relationships represented by the formulae: 5.0<=E' and 0.050<=tand<=0.240.

Owner:BRIDGESTONE CORP

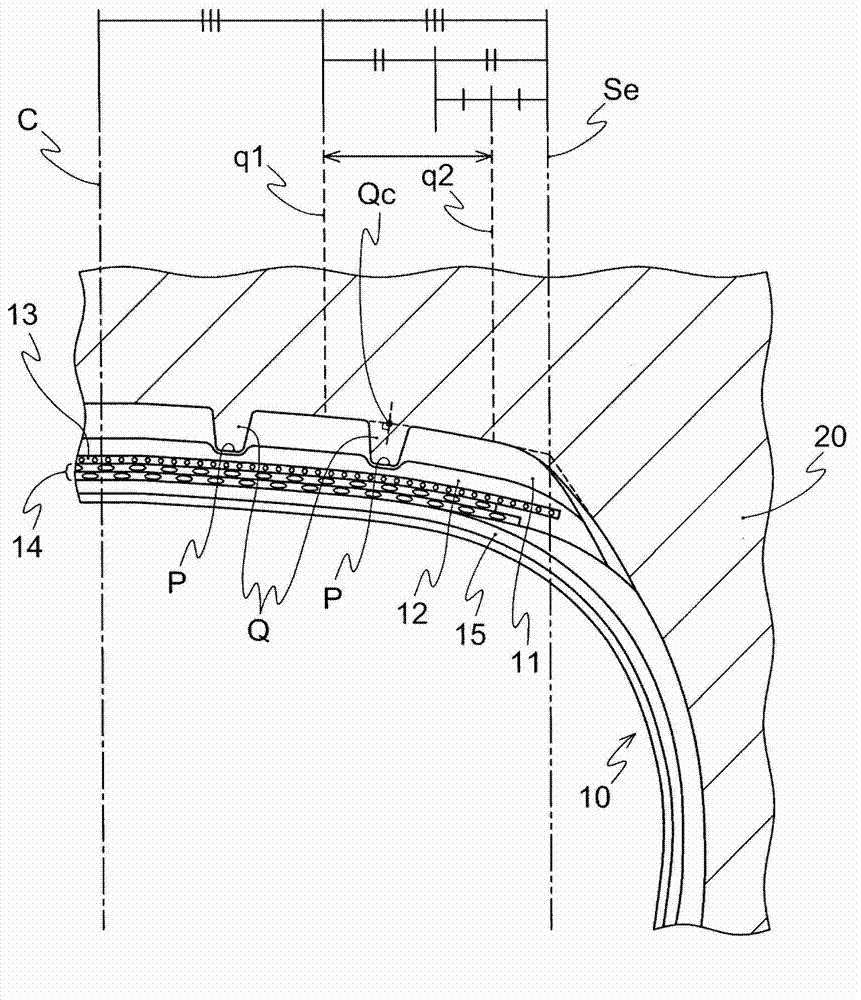

Pneumatic tire and tire mold

InactiveCN101157325AIncrease volumeEnsure normal drainageTyresTyre tread bands/patternsEngineeringRestoring force

PROBLEM TO BE SOLVED: To provide a pneumatic tire capable of suppressing damage such as a channel bottom crack by effectively enhancing a stone non-biting property. ŽSOLUTION: At the channel bottom 9a of a circumferential groove 9 formed on the tread surface, a protrusion 10 is formed extending along the extending direction of the circumferential groove 9. The protrusion 10 comprises a head top 11 protruding toward the outer periphery of the tire and a base 12 having a width narrower than that of the head top 11 and connecting the head top 11 and the channel bottom 9a. When a small stone is bitten, the head top is tilted around the base 12 and the protrusion 10 is totally deflected and deformed, thereby generating a reaction force based on a deformation restoring force. Ž

Owner:TOYO TIRE & RUBBER CO LTD

Inflatable tire

ActiveCN103242578AImprove rolling resistanceImprove wetting performanceSpecial tyresRolling resistance optimizationLanding performanceRolling resistance

The object of the invention is to provide an inflatable tire with good rolling resistance, wet land performance and wear-resistance, wherein the generation of groove cracks on the surface of the tire is inhibited. The inflatable tire is an inflatable tire with a surface, and the surface comprises a drive surface and a base part. The drive surface is prepared by a rubber combination for the drive surface, and the rubber combination comprises a preset amount of silicon dioxide that has a 70-300m2 / g BET specific surface area, a preset amount of carbon black and / or inorganic filler, and 0.5-5 parts in weight of release agent, wherein the release agent comprises at least one of a group that consists of fee fatty acid metal salt, fatty acid amides and amide ester. The base part is prepared by a rubber combination for the base part, and based on the weight parts, the rubber combination comprises a preset amount of carbon black and / or silicon dioxide that has a 70-300m2 / g BET specific surface area.

Owner:SUMITOMO RUBBER IND LTD

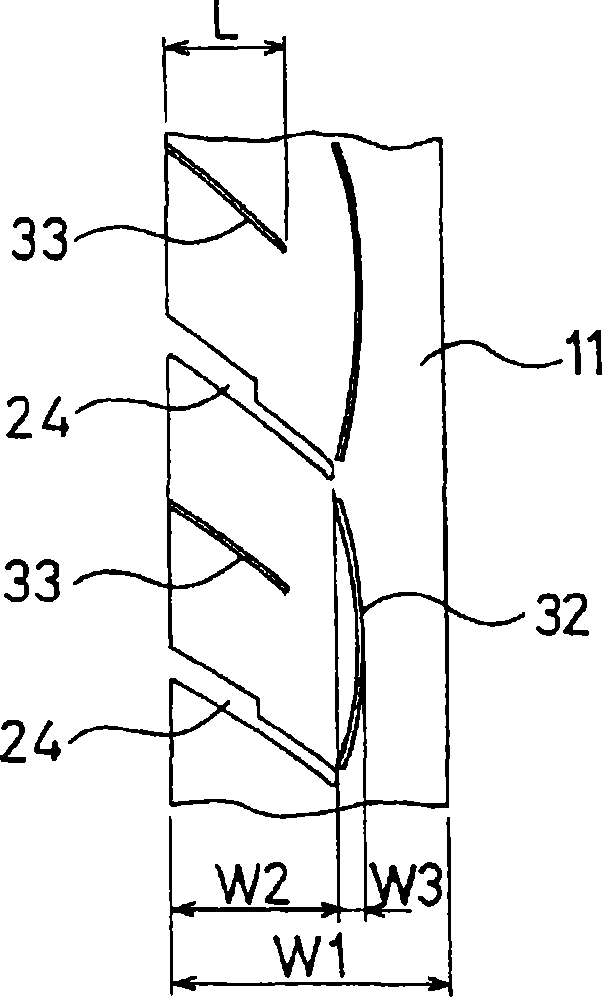

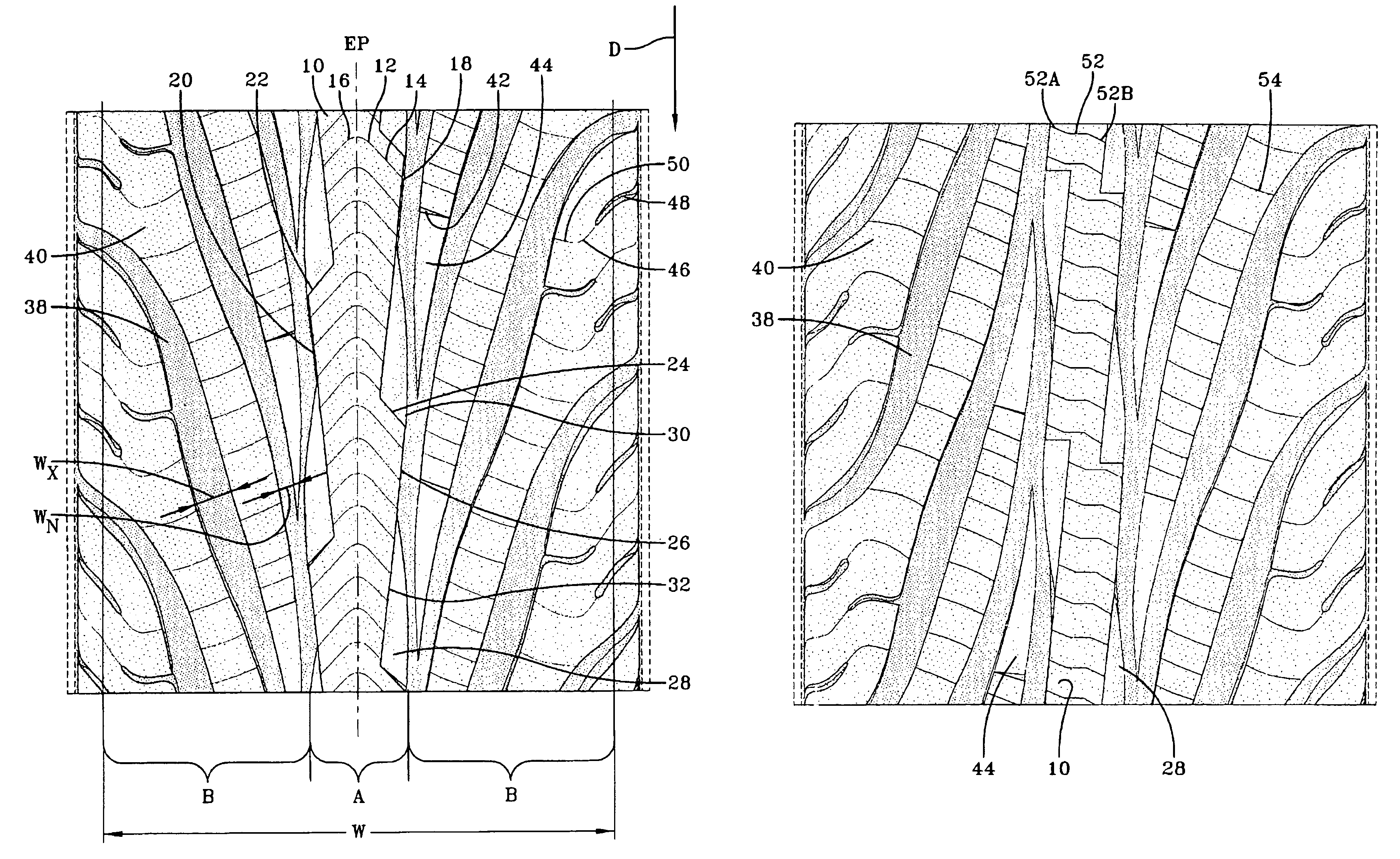

Pneumatic tire having tread with axially adjacent block chamfer and rib chamfer

ActiveUS7143798B2Improve tractionExcellent wet performanceTyre tread bands/patternsNon-skid devicesEngineeringHigh density

A tire tread for a pneumatic tire has a center rib and a series of steeply slanted grooves in each side region of the tread, the circumferentially adjacent grooves form blocks extending through the tread side regions. The center rib has a serrated configuration along each lateral side and a supporting chamfer extending from each serration point. Adjacent to each rib chamfer is a chamfer extending from the axially innermost point of the rib at the junction of two adjacent steeply slanted grooves. The rib is provided with high density siping. The tread blocks are siped wherein the siping density decreases from the tread center to the tread shoulders.

Owner:THE GOODYEAR TIRE & RUBBER CO

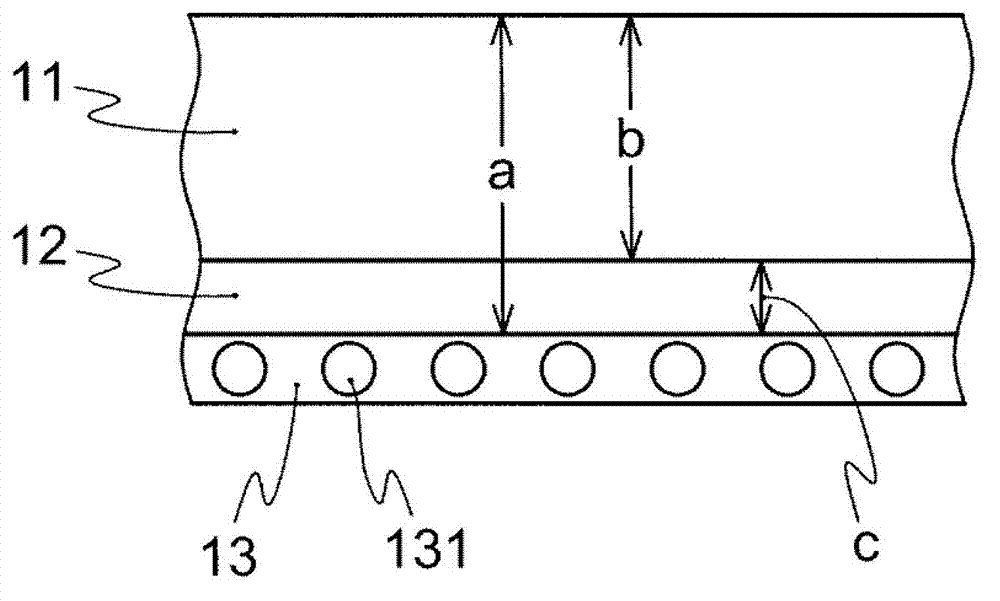

Preparation method of structure and function integrated neutron absorbing material

InactiveCN109852850AImprove distribution uniformityHigh densityShieldingStructure and functionBoron carbide

The invention relates to a preparation method of a structure and function integrated neutron absorbing material. The method prepares the structure and function integrated neutron absorbing material byadopting a powder metallurgy method through such processes as burdening, ball milling, molding, sealing, compactness, hot rolling and annealing with boron carbide powder, nanometal oxides, aluminum and alloy powder as raw materials. The structure and function integrated neutron absorbing material prepared by the method is excellent in component uniformity, high in compactness, high in heat conductivity and excellent in mechanical performance.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS +2

Preparation method of copper-zinc-iron ternary alloy chemical plating layer on surface of aramid fiber

InactiveCN104088138AHigh surface energyImprove wetting performancePhysical treatmentFibre typesChemical platingSurface modification

The invention discloses a preparation method of a copper-zinc-iron ternary alloy chemical plating layer on the surface of aramid fiber. The preparation method comprises the following steps: carrying out surface modification on aramid fiber; carrying out low-concentration colloid palladium treatment; and carrying out a copper-zinc-iron ternary alloy chemical plating process. The preparation method has the beneficial effects that an environment-friendly glyoxylic acid chemical plating process is used to realize co-deposition of a copper-zinc-iron ternary alloy; the plating layer is composed of following components in percentage by mass: 85%-90.5% of copper, 1.0%-3.0% of iron, 0.5%-1.5% of zinc and the balance of carbon and oxygen; through detection, the surface resistance of the plating layer keeps below 50m(omega) / sq; an adhesive tape method is used for determining the binding force between the plating layer and fabric fibers and the weight loss ratio is less than 0.1%; the plating layer is bright and a microstructure is uniform; the plating layer can resist atmosphere corrosion and meets the requirements of electric conduction, electromagnetic shielding, static electricity prevention and the like.

Owner:SHANDONG JIANZHU UNIV

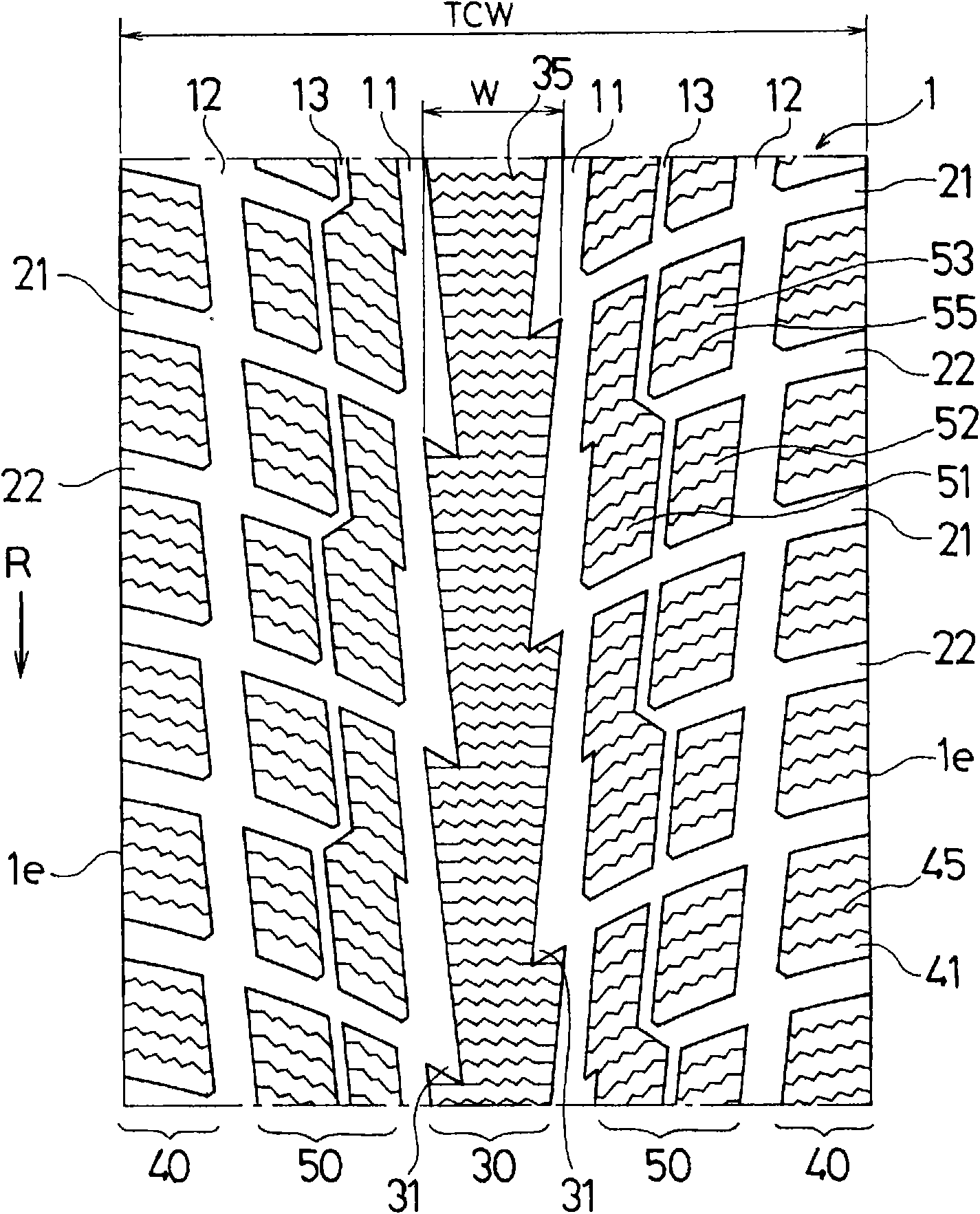

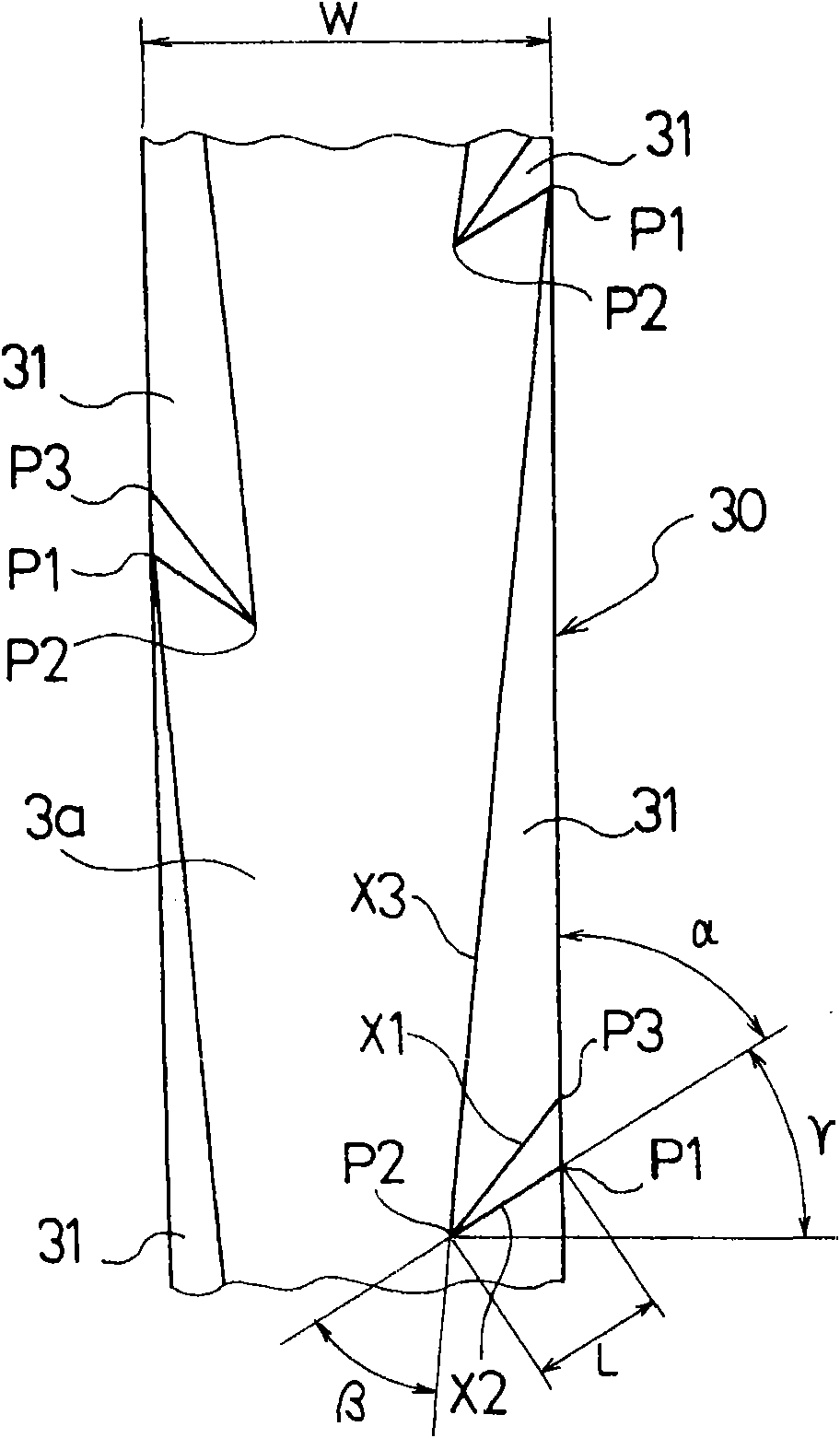

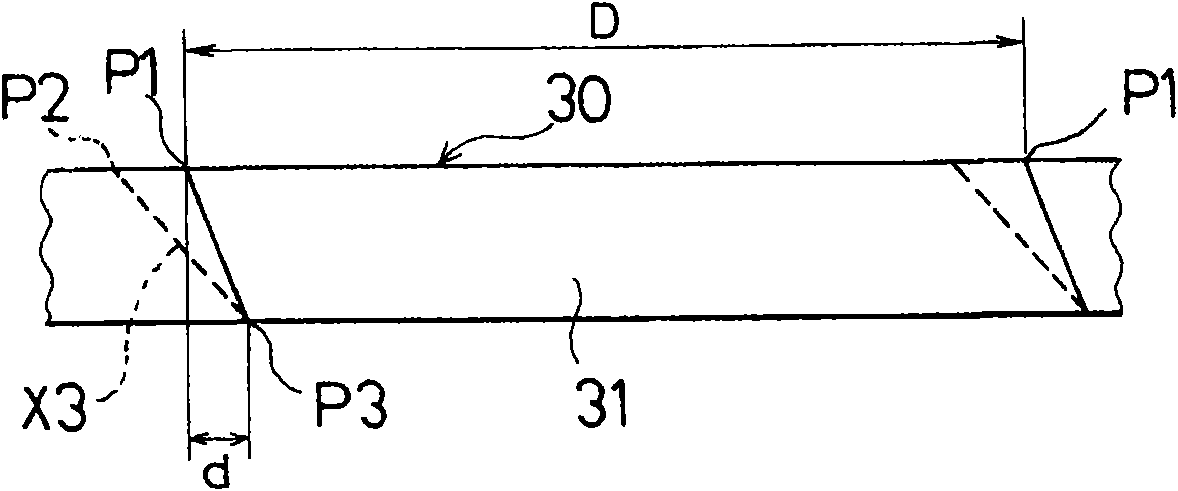

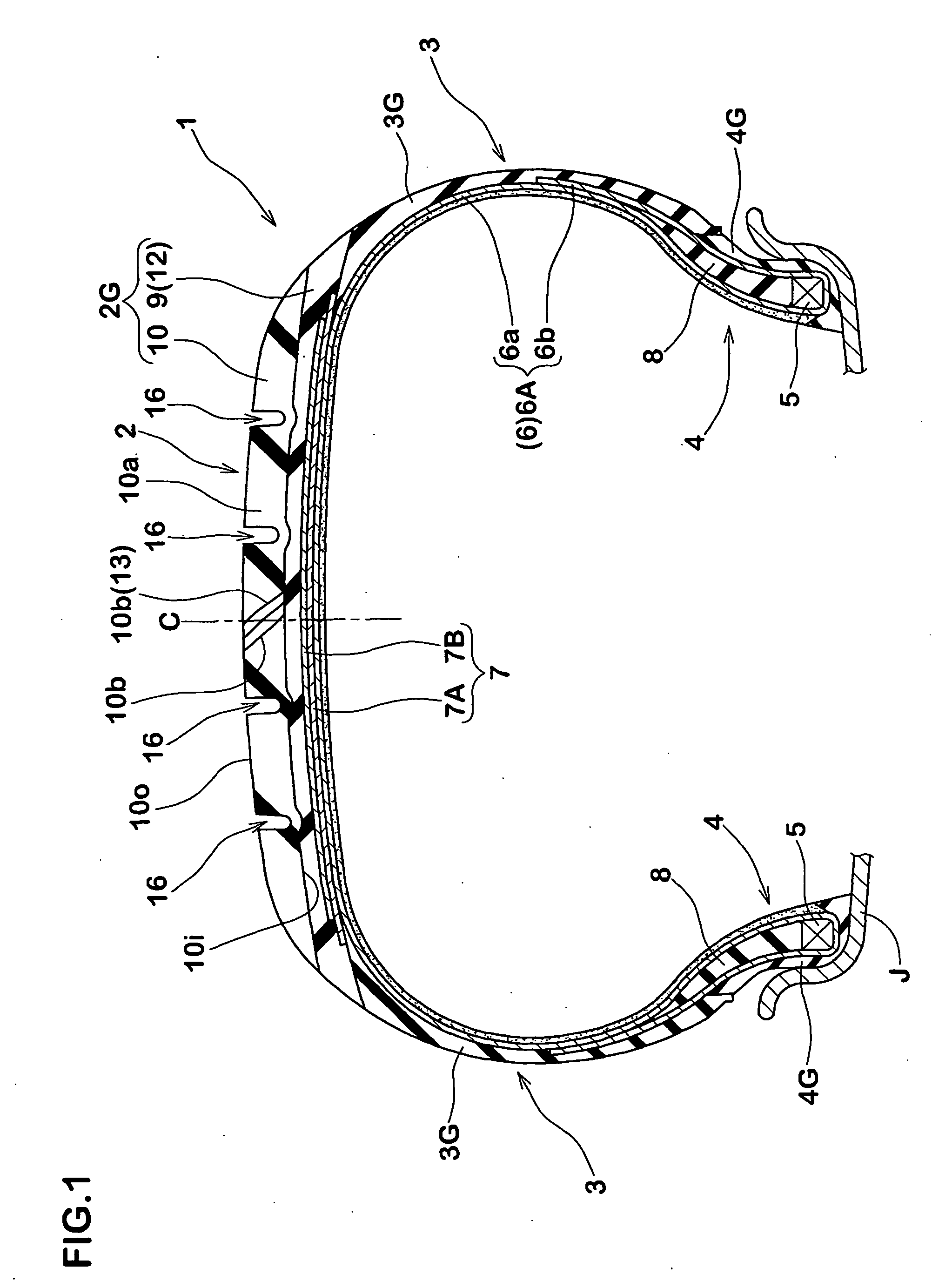

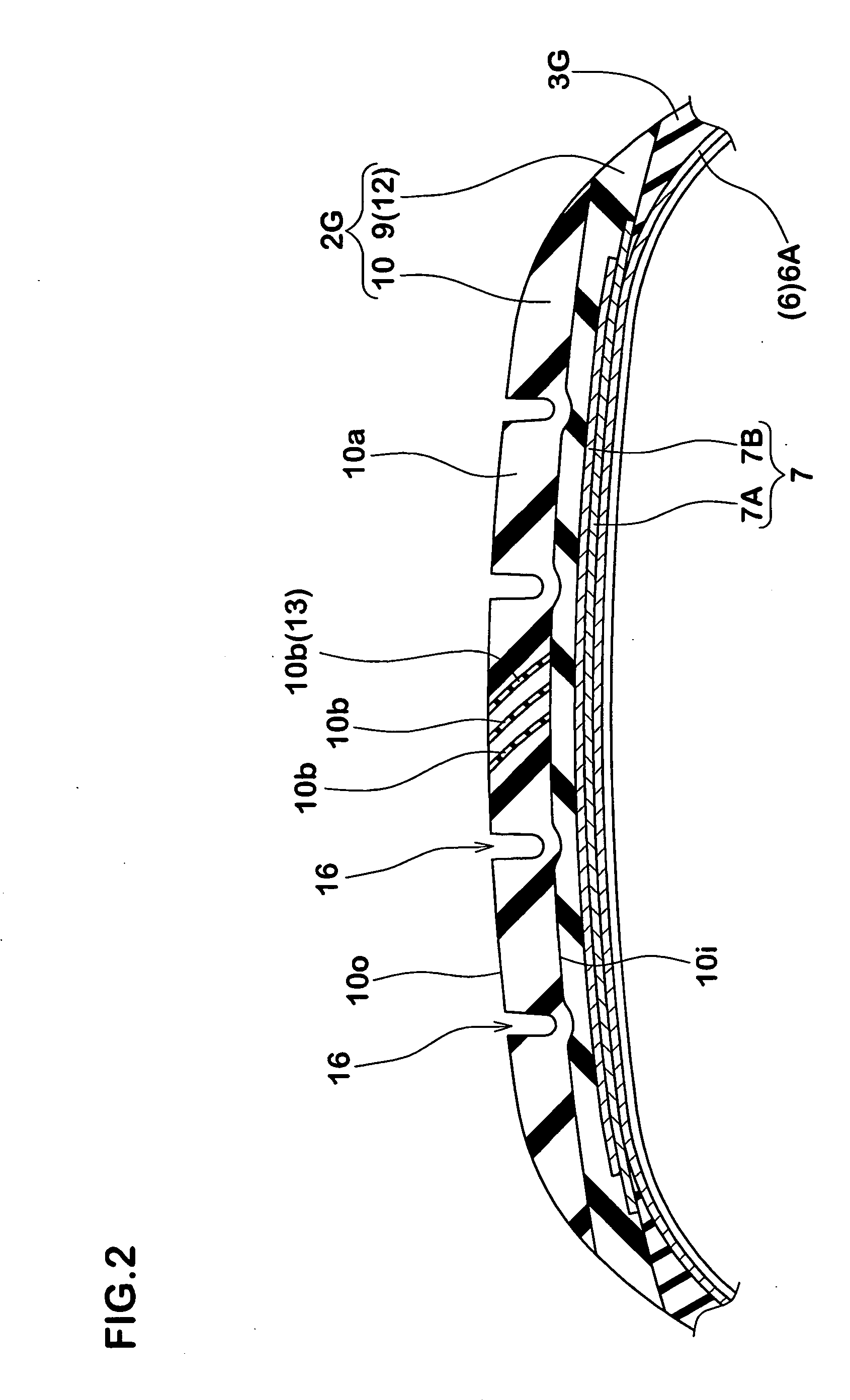

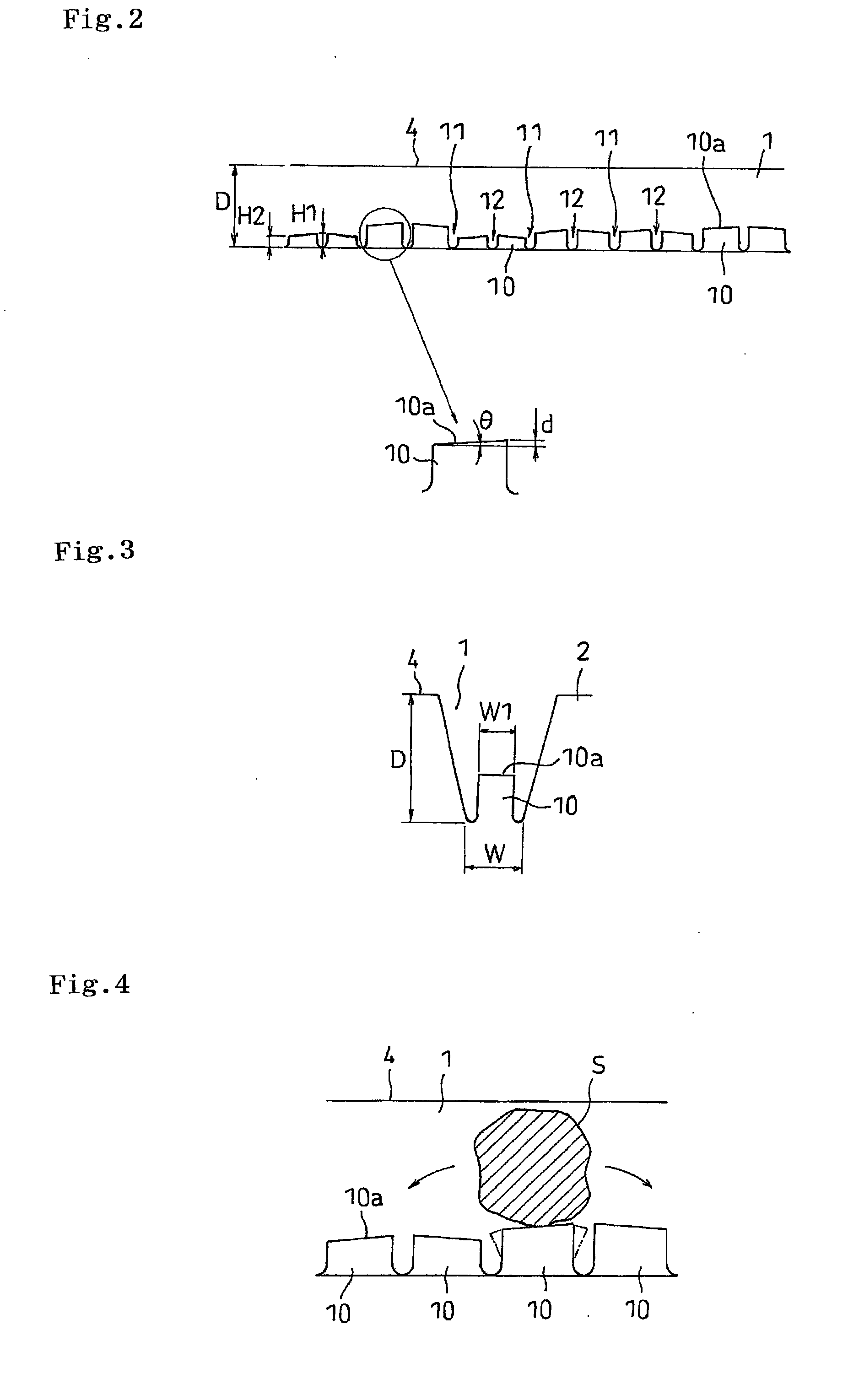

Pneumatic tire

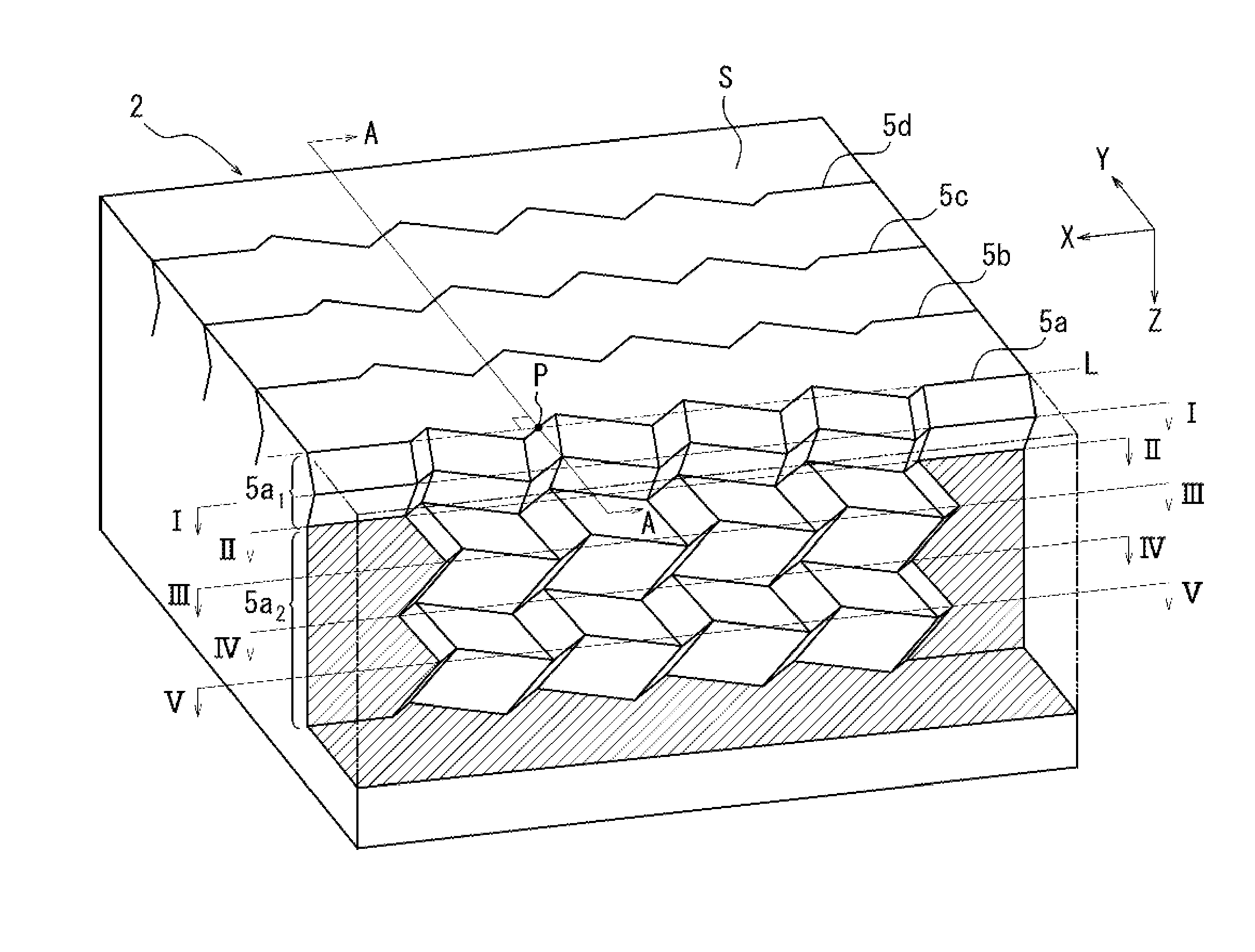

ActiveUS20140299245A1Keep dryImprove wetting performanceTyre tread bands/patternsNon-skid devicesEngineeringDepth direction

Provided is a pneumatic tire including a land portion provided with a sipe, which is capable of simultaneously providing snow performance, dry performance, and wet performance all at high level in a single land portion. The pneumatic tire includes a land portion 2 on a tread portion. The land portion 2 is provided with a sipe 5 having amplitude in a tire circumferential direction and extending in a tire width direction. In a depth direction extending from a land portion surface S toward an inner side in a tire radial direction, sipe 5 includes: a land portion's surface-side part 5a1 bent toward tire circumferential direction from land portion surface S; and a land portion's bottom-side part 5a2 bent in a direction different from a direction of land portion's surface-side part 5a1 or bent toward tire circumferential direction by a displacement different from a displacement of land portion's surface-side part 5a1.

Owner:BRIDGESTONE CORP

Pneumatic Tire

InactiveUS20100212793A1Reduce car exterior noiseReduce marginTyre tread bands/patternsNon-skid devicesEngineeringMechanical engineering

A pneumatic tire has a main groove extending along a tire circumferential direction in a tread surface. A plurality of projections having different heights are provided in a groove bottom of the main groove in such a manner that an outer peripheral surface is inclined so as to repeat trough portions depressed to an inner side in a tire diametrical direction and peak portions protruding to an outer side in the tire diametrical direction along the tire circumferential direction.

Owner:TOYO TIRE & RUBBER CO LTD

Pneumatic tire

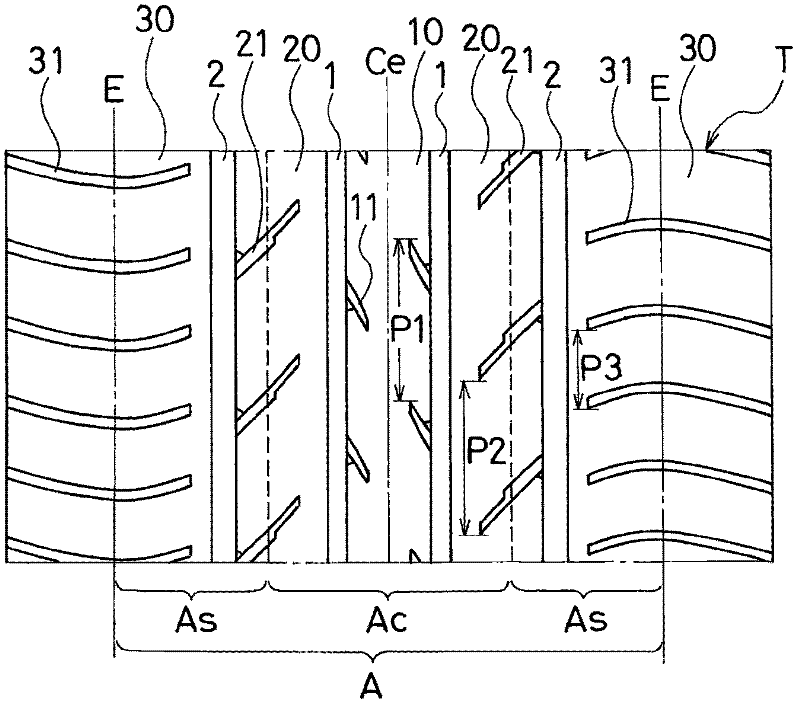

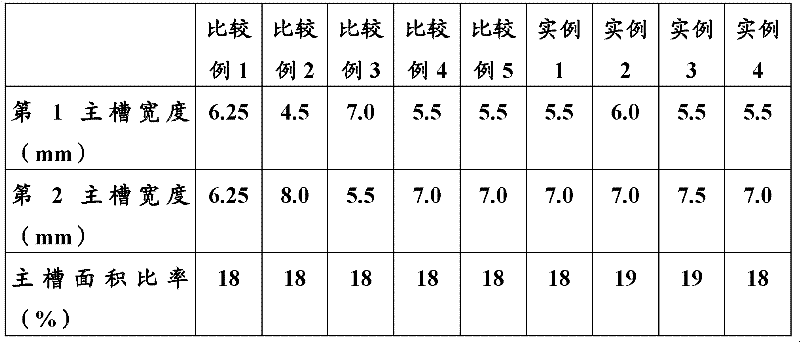

ActiveCN102632772ASuppress pass toneLower pass toneTyre tread bands/patternsRolling resistance optimizationEngineeringArea ratio

The present invention provides a tire which is provided with central side main grooves (1,1) and tire shoulder side main grooves (2,2) at a tire surface part T. Central strip-shaped patterns (10) are curved between the main grooves (1,1), and central strip-shaped patterns (20) are curved between the main grooves (1,2), wherein, on the central strip-shaped patterns (10) and the central strip-shaped patterns (20), a plurality of tread grooves (11,21) which are terminated in the strip-shaped patterns are formed according to a mode that the groove width reduces gradually in a process of approaching the central side. The distance between the central position of the tire surface part (T) and the center of the main groove (1) is set to 15%-25% of the distance between the central position and a grounding end. The distance between the central position of the tire surface part (T) and the main groove (2) is set to 60%-80% of the distance between the central position and the grounding end. The width of the main groove (1) is set to 70%-90% of the width of the main groove (2). The total area of the main groove (1) and the main groove (2) is set to 15%-25% of the area of the grounding area (A) in the tire surface part (T). The groove area ratio of a central area (Ac) is set to be smaller than that of a tire shoulder area (As).

Owner:YOKOHAMA RUBBER CO LTD

Tire tread of sedan meridian tire

ActiveCN101607512ASufficient braking forceImprove maneuverabilityTyre tread bands/patternsTire beadCentral line placement

The invention relates to a sedan tire structure, in particular to a tire tread pattern structure of a sedan tire. The tire tread of the sedan meridian tire comprises central pattern blocks, lateral pattern blocks and tire shoulder pattern blocks, wherein the central pattern blocks are the longitudinal pattern blocks; the lateral pattern blocks and the tire shoulder pattern blocks are regularly arranged on the left side and the right side of the central pattern blocks from inside to outside in sequence; the central pattern blocks are positioned on the central line position of the tire tread; the same arched pattern ditch is spaced between the central pattern blocks and the lateral pattern blocks, between the two adjacent lateral pattern blocks, and between the two adjacent tire shoulder pattern blocks respectively; an inclined lateral pattern ditch is spaced between the two adjacent central pattern blocks; and a longitudinal circumferential pattern ditch is spaced between the lateral pattern blocks and the tire shoulder pattern blocks. The tire tread of the tire adopts mixed patterns, and has the advantages of sufficient braking force, good control performance and elegant appearance.

Owner:QINGDAO YELLOWSEA RUBBER

Pneumatic tire

A pneumatic tire (1) has a tread pattern capable of improving wet performance and steering stability in a well balanced manner. An inboard middle land portion (7) is provided with inboard middle axial grooves (12) connecting between an inboard shoulder main groove (4) and an inboard crown main groove (6) and inclined at 20 to 30 degrees. An outboard middle land portion (8) is provided with outboard middle semi-blind grooves (14) extending axially inwardly from a outboard shoulder main groove (3), and outboard middle sipes (15) extending from the axially inner ends of the outboard middle semi-blind grooves (14) to the outboard crown main groove (5). The outboard middle semi-blind grooves (14) and the outboard middle sipes (15) are inclined at 20 to 30 degrees. A center land portion (9) is provided with inboard crown semi-blind grooves (16) extending from the inboard crown main groove (6), and outboard crown semi-blind grooves (17) extending from the outboard crown main groove (5).

Owner:SUMITOMO RUBBER IND LTD

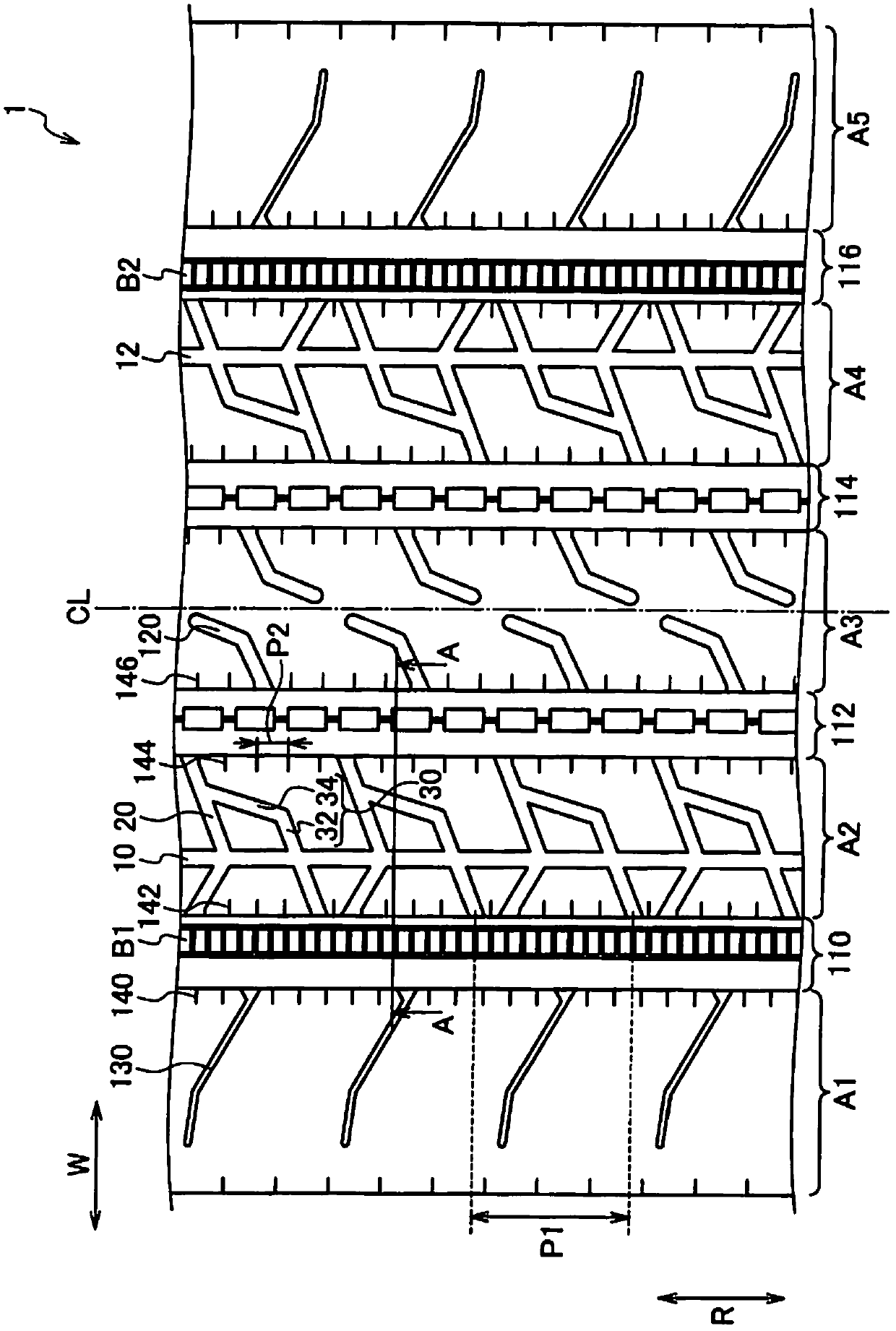

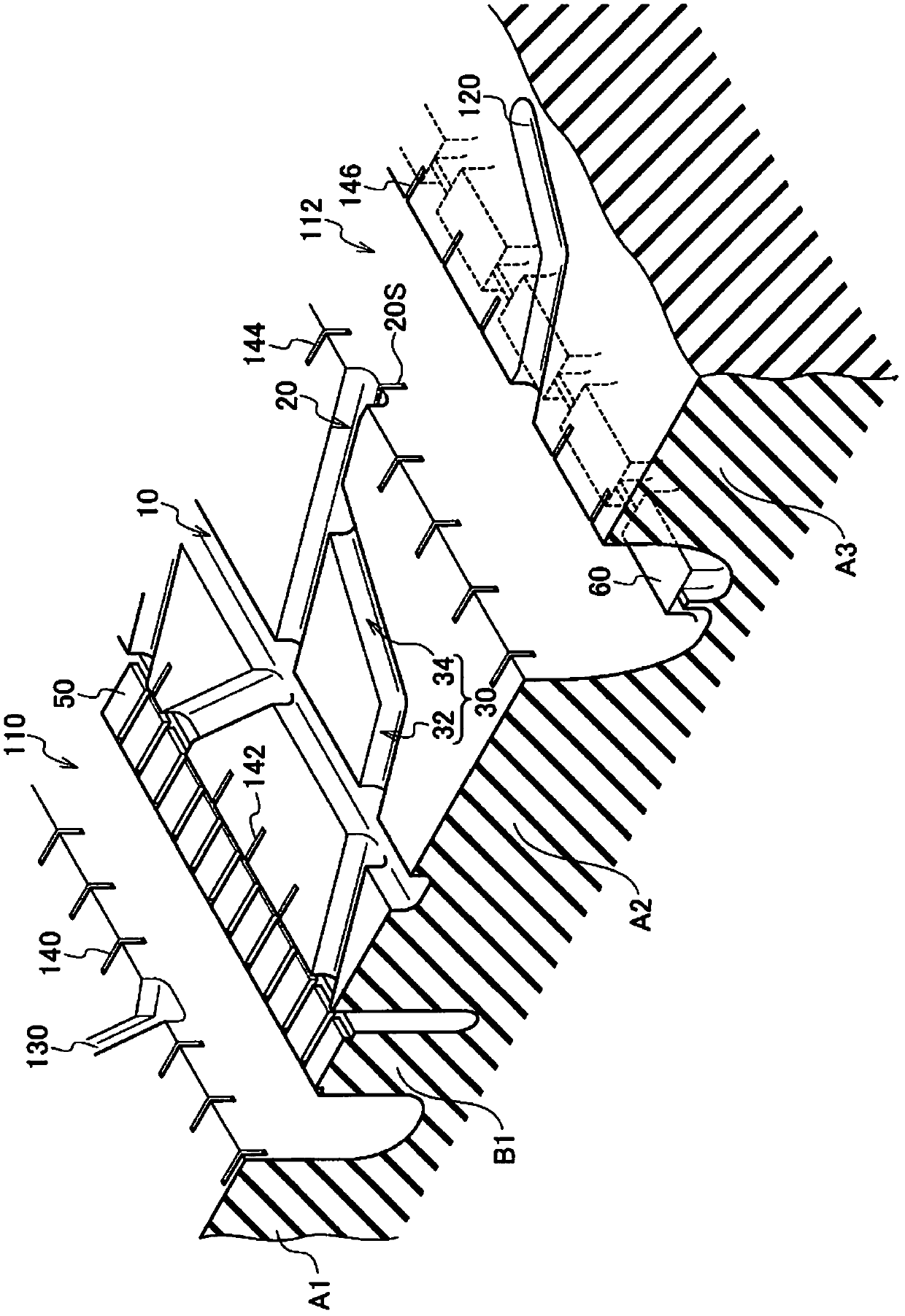

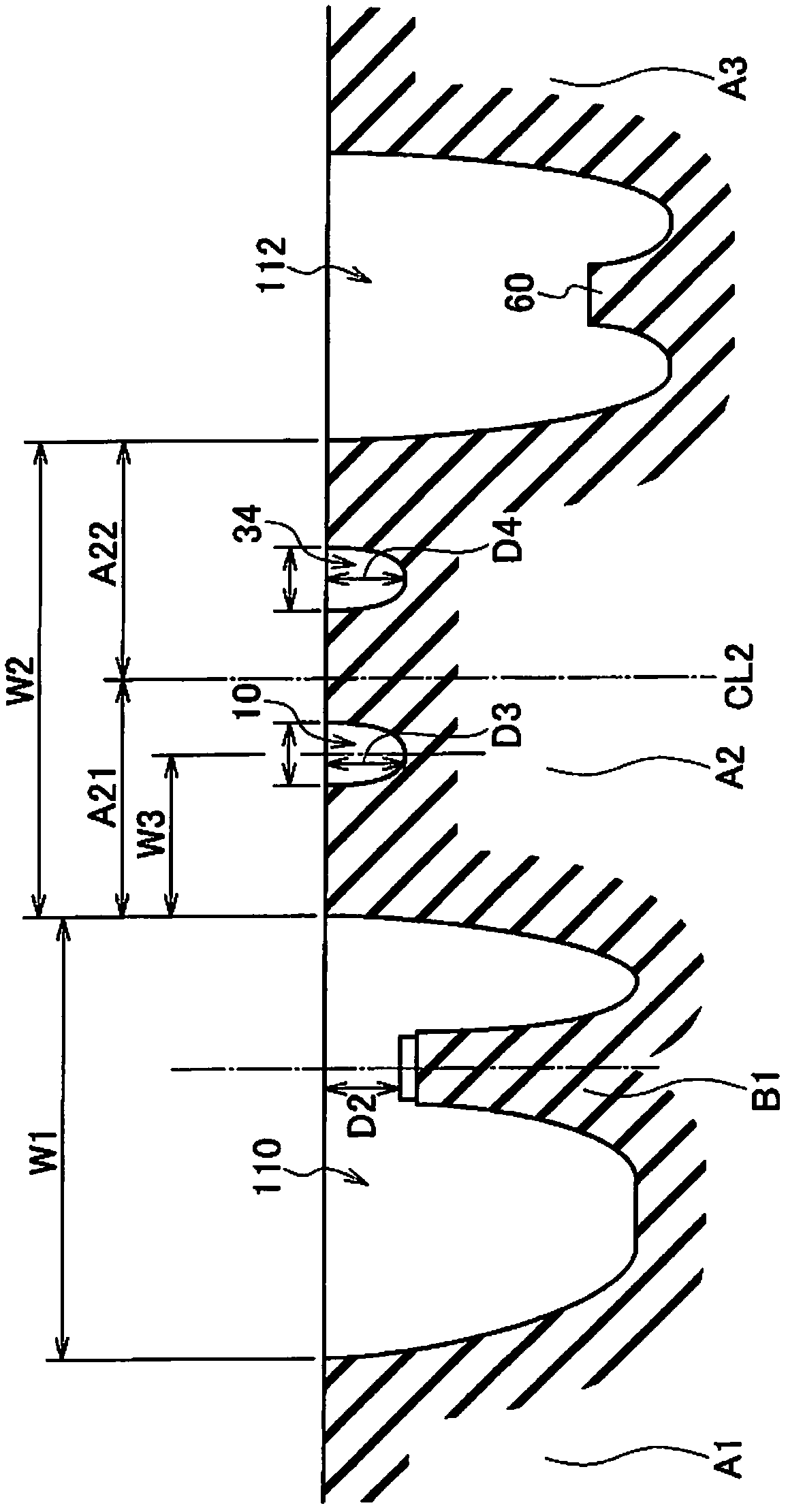

Heavy duty tire

InactiveCN102802966AInhibits uneven wearImprove wetting performanceHeavy duty tyresHeavy duty vehicleEngineeringHeavy duty

The invention provides a heavy duty tire, comprising: a shoulder rib (A1) (shoulder rib (A5)) which is provided to a tread shoulder section; a second rib (A2) (second rib (A4)) which is adjacent to the shoulder rib (A1) with a circumferential groove (110) (circumferential groove (116)) interposed therebetween and is provided further toward the tire equator side than the shoulder rib (A1); and an uneven wear absorbing rib (B1) (uneven wear absorbing rib (B2)) provided within the circumferential groove (110) and located further toward the inside in the tire radial direction than the tread surfaces of the shoulder rib (A1) and of the second rib (A2). Circumferential narrow grooves (10, 12) having a smaller width than the circumferential grooves (110, 116) are formed in the second ribs (A2, A4). Each circumferential narrow groove (10, 12) is formed in such a manner that, when the tire is mounted on the vehicle, the circumferential groove (10, 12) is located on the outer side of the tire with reference to the center of the second rib (A2, A4) in the tread width direction.

Owner:BRIDGESTONE CORP

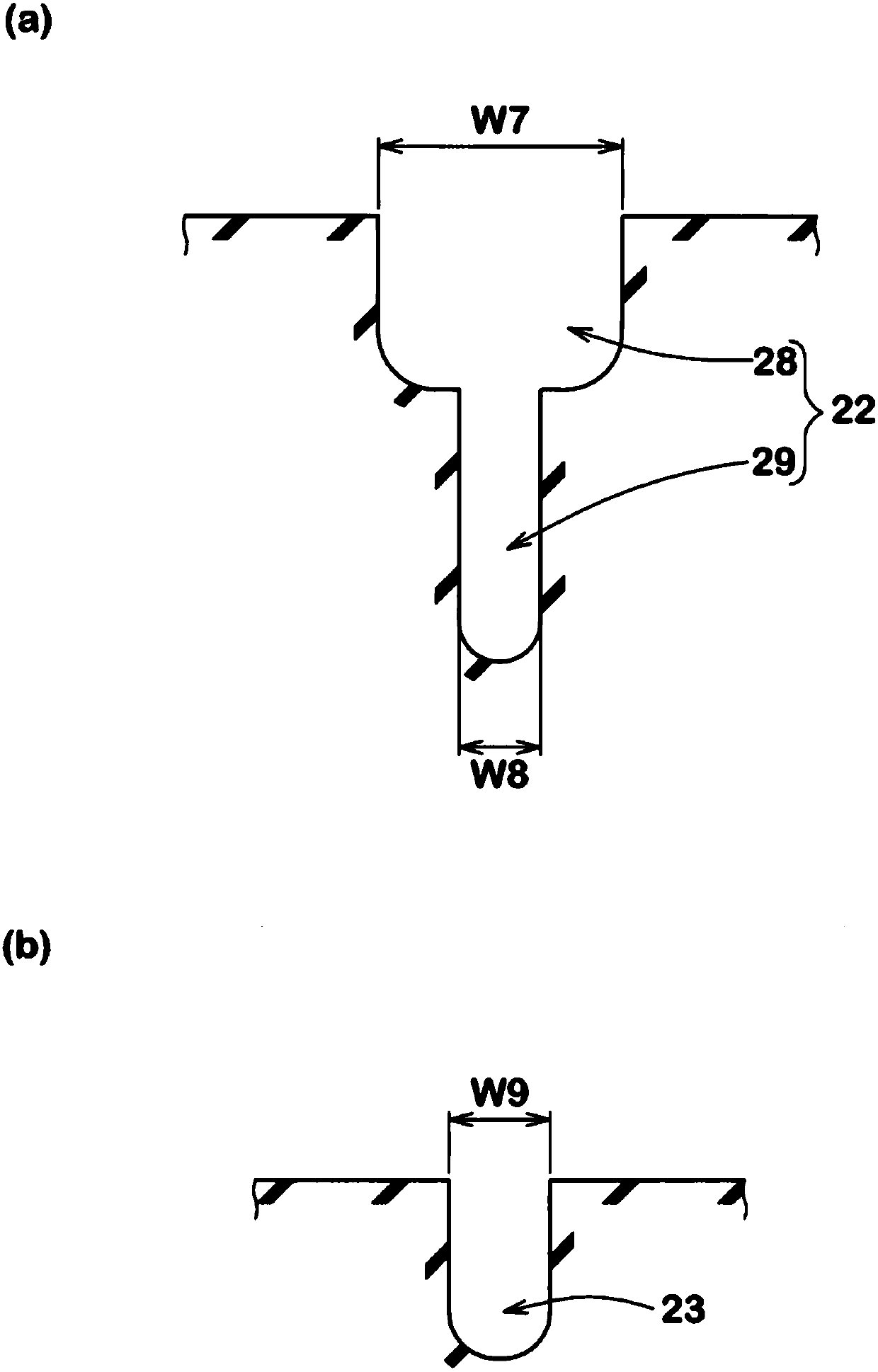

Tire

ActiveCN107867124AReduce rigidityImprove wiping effectTyre tread bands/patternsMechanical engineeringTread

The present invention provides a tire in which wet performance can be improved without sacrificing steering stability. A tire (1) has designated installation direction on a vehicle. An outboard shoulder land region (8) is provided with outboard shoulder sipes (26). The outboard shoulder sipe (26) comprises a deep bottom part (27) and a shallow bottom part (28) with a depth smaller than the deep bottom part (27). The shallow bottom part (28) comprises a first part (30) extending axially inwardly from the axially inner end (27i) of the deep bottom part (27) towards a tire equator C, a second part (31) extending axially outwardly from the outboard shoulder main groove (4) to wards an outboard tread edge (To), and a third part (32) connecting the first part (30) and the second part (31). The first part (30), the second part (31) and the third part (32) have different angles with respect to the tire axial direction.

Owner:SUMITOMO RUBBER IND LTD

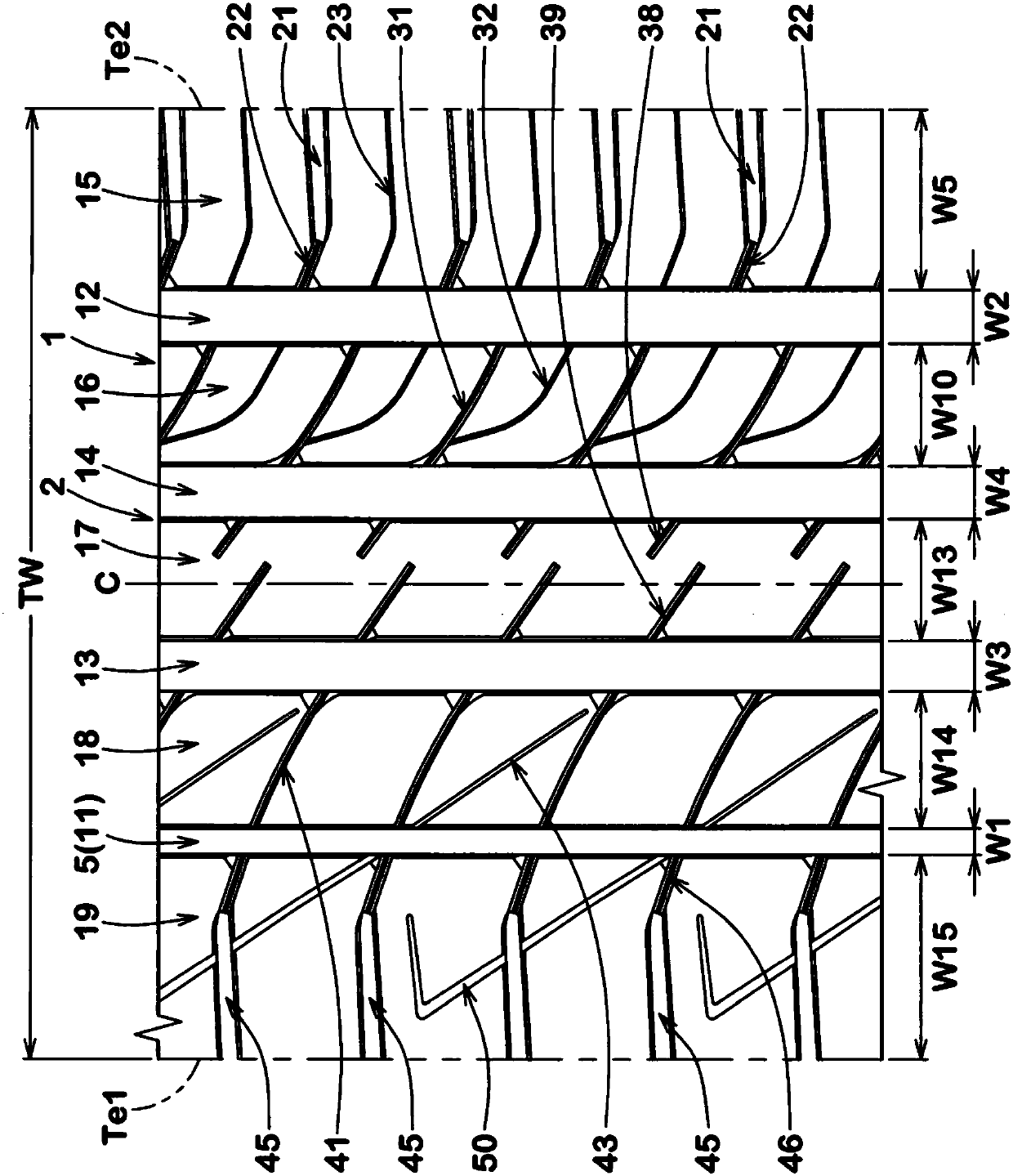

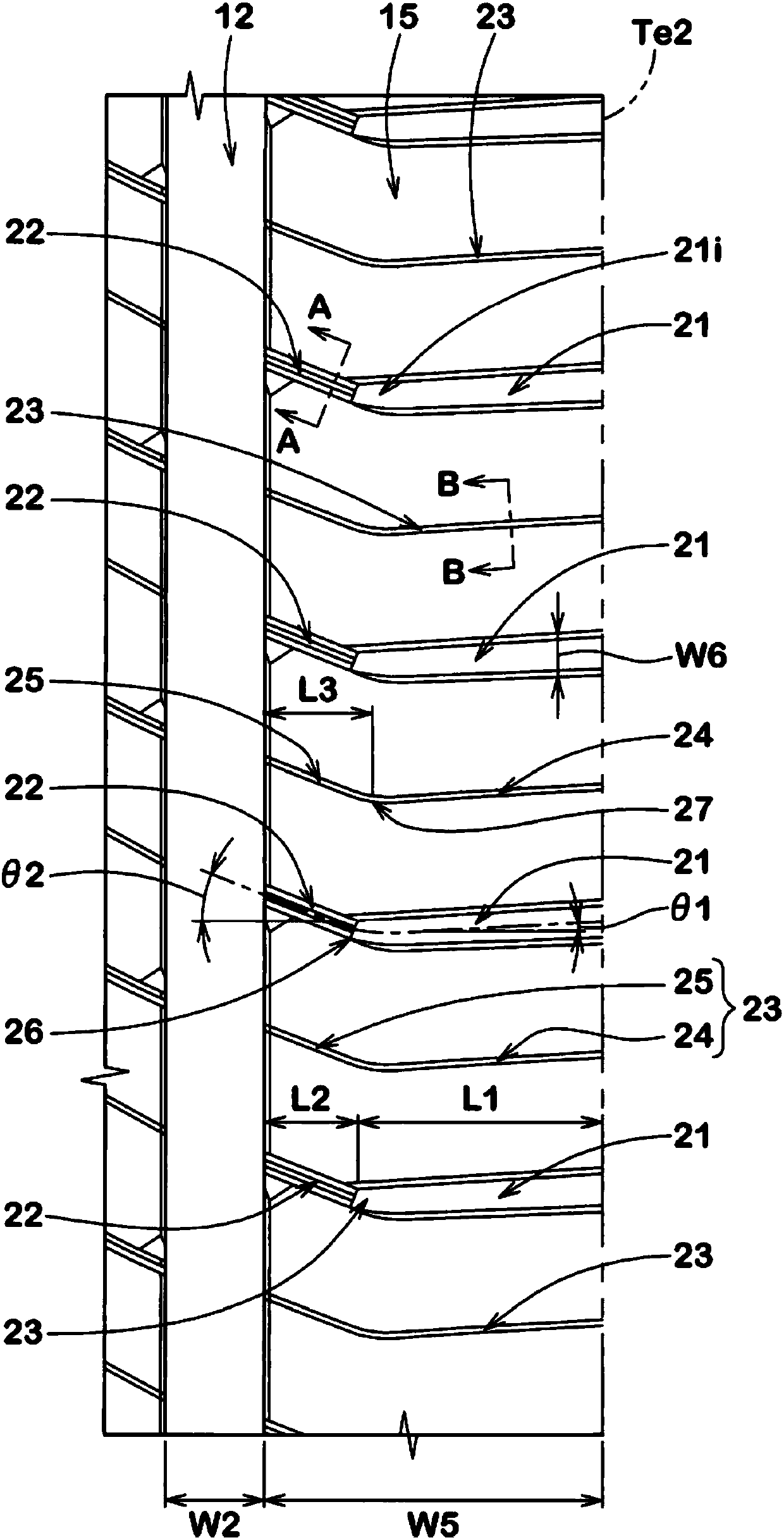

Pneumatic tire

ActiveCN107813661AImprove rigidityImprove performanceTyre tread bands/patternsEngineeringFlexion angle

The invention aims to provide a pneumatic tire, which has excellent wetland properties and operation stability. A pneumatic tire 1 comprises a tread portion 2 having an outboard tread edge Te1 to be positioned away from the center of a vehicle body and an inboard tread edge Te2 to be positioned close to the center of the vehicle body. The tread portion 2 is provided with an inboard shoulder main groove 12, and an inboard shoulder land region 15 between the inboard shoulder main groove 12 and the inboard tread edge Te2. The inboard shoulder land region 15 is provided with inboard shoulder rug grooves 21, connecting sipes 22, and inboard shoulder sipes 23. The inboard shoulder sipe 23 is made up of a straight outer part 24 extending from the inboard tread edge Te2 toward the axially inside,and a straight inner part 25 extending to the inboard shoulder main groove 12 at a flexion angle with respect to the outer part 24. The axial length of the inner part 25 is more than the axial lengthof the connecting sipe 22.

Owner:SUMITOMO RUBBER IND LTD

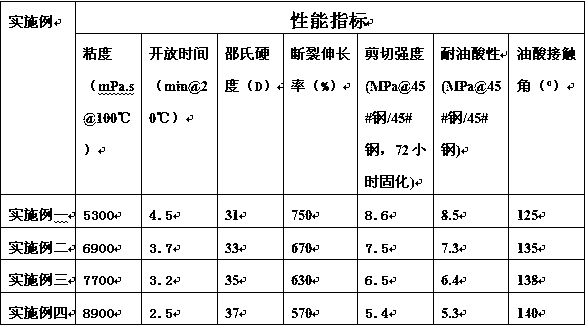

Moisture-curing polyurethane hot melt adhesive with excellent oil resistance and preparation method of moisture-curing polyurethane hot melt adhesive

InactiveCN109679559AImprove oil resistanceImprove compatibilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesFunctional monomerChemistry

The invention discloses a moisture-curing polyurethane hot melt adhesive with excellent oil resistance and a preparation method of the moisture-curing polyurethane hot melt adhesive. The moisture-curing polyurethane hot melt adhesive is characterized by being prepared from 1-35 parts of polyether diols, 1-40 parts of liquid polyester diols, 1-60 parts of crystalline polyester diols, 1-45 parts ofa polyacrylic acid fluorine-containing copolymer, 1-50 parts of isocyanate, 0.1-2 parts of a catalyst, 0.1-3 parts of an antioxidant and 0.1-4 parts of a silane coupling agent. Poly(dodecafluoroheptylmethacrylate-random-methyl methacrylate-random-octadecyl methacrylate-random-hydroxyethyl methylacrylate) is synthesized firstly and added to a polyurethane prepolymer reaction, a hydroxy-containingacrylic acid functional monomer enables the polyacrylic acid fluorine-containing copolymer to partially participate in the polyurethane prepolymer synthesis reaction, a fluorinated acrylate copolymerchain segment is introduced, by means of an efficient synergistic effect of the formula, the hot melt adhesive shows better compatibility, composition and content of other raw materials are further adjusted, and therefore, oil resistance of the polyurethane hot melt adhesive is improved.

Owner:SHUNDE POLYTECHNIC

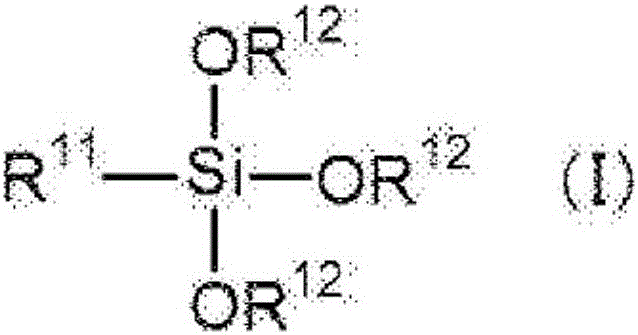

Rubber composition for tires, and pneumatic tire

ActiveCN106795337AReduce resistanceIncrease resistanceSpecial tyresRolling resistance optimizationPolymer scienceRolling resistance

The present invention addresses the problem of providing: a rubber composition for tires which, when made into a tire, exhibits excellent wet performance, excellent low rolling resistance, and excellent steering stability; and a pneumatic tire in which said rubber composition for tires is used. This rubber composition for tires includes: a diene-based rubber; silica; a silane coupling agent; a fatty acid metal salt; and a prescribed alkyl trialkoxysilane. The diene-based rubber includes at least 60 mass% of a modified conjugated diene-based rubber, and includes at least 30 mass% of a specific conjugated diene-based rubber corresponding to a portion or all of the modified conjugated diene-based rubber. The average glass transition temperature of the diene-based rubber is -45 to -20 DEG C. The specific conjugated diene-based rubber is produced using a specific production method, and has an aromatic vinyl unit content, a vinyl bond content, and a weight average molecular weight which are within prescribed ranges.

Owner:THE YOKOHAMA RUBBER CO LTD

Pneumatic tire

ActiveCN104097461AImprove wet performanceImprove Noise PerformanceTyre tread bands/patternsEngineeringGroove width

The present invention relates to a pneumatic tire that exhibits excellent noise performance while maintaining wet performance. Each of the shoulder and center grooves (3, 4) has a groove width (TW) set in range of 7 to 9% of width of the tread footprint. Middle land sections (5) include an outer middle land portion (10) divided by a middle narrow groove (12) into a first outer middle land portion (13) and a second outer middle land portion (14). The first outer middle land portion is bar-shaped. A plurality of outer side cross trenches (15) are arranged on the second outer middle land portion (14). Each of outer middle lateral grooves (15) includes a first portion (17) and a second portion (18) having the opposite inclination to the inclination of the first portion (17), and a connection portion (19) between the first portion (17) and the second portion (18). The connection portion (19) is positioned on a center main groove (4) side with respect to the center point of the outer middle land portion (10) in the tire axial direction.

Owner:SUMITOMO RUBBER IND LTD

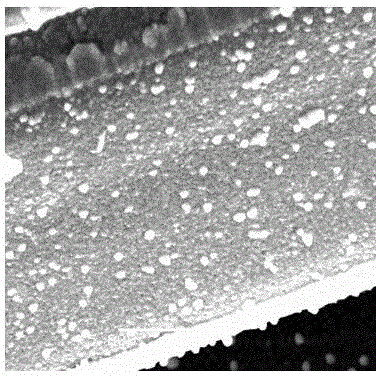

Welding method of WP/Al composite material and Al2O3 ceramic

ActiveCN104741808AImprove wetting performanceReduces the chance of void formationWelding apparatusZincCeramic

The invention provides a welding method of a Wp / Al composite material and Al2O3 ceramic. The welding method comprises the following steps: (1) the surface of the Wp / Al composite material is grinded, deoiled and polished, and is washed by de-ionized water; (2) the treated Wp / Al composite material is put into zinc galvanizing liquid to perform the zinc galvanizing pretreatment; (3) a metal deposition layer with a thickness of 0.5-2 microns is sputtered on the surface of the Wp / Al composite material by a magnetron sputtering method; and (4) the Al2O3 ceramic plated with an Au layer on the surface, an Au-Sn solder and the Wp / Al composite material having the metal deposition layer and obtained in the step (2) are stacked in sequence, and are put in a vacuum sintering furnace to perform the vacuum welding; the welding temperature is 310-350 DEG C; the insulating time is 3-10 min; and the products are discharged from the furnace after the temperature is reduced below 50 DEG C. The welding method effectively solves the problem of weak wettability of the Wp / Al composite material and the brazing solder with high volume fraction; and the composite material and the Al2O3 ceramic are formed to effective welding after the welding.

Owner:GRIMAT ENG INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com