Pneumatic tire

A technology of pneumatic tires and tires, applied in tire parts, tire tread/tread pattern, transportation and packaging, etc., can solve problems such as water drift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

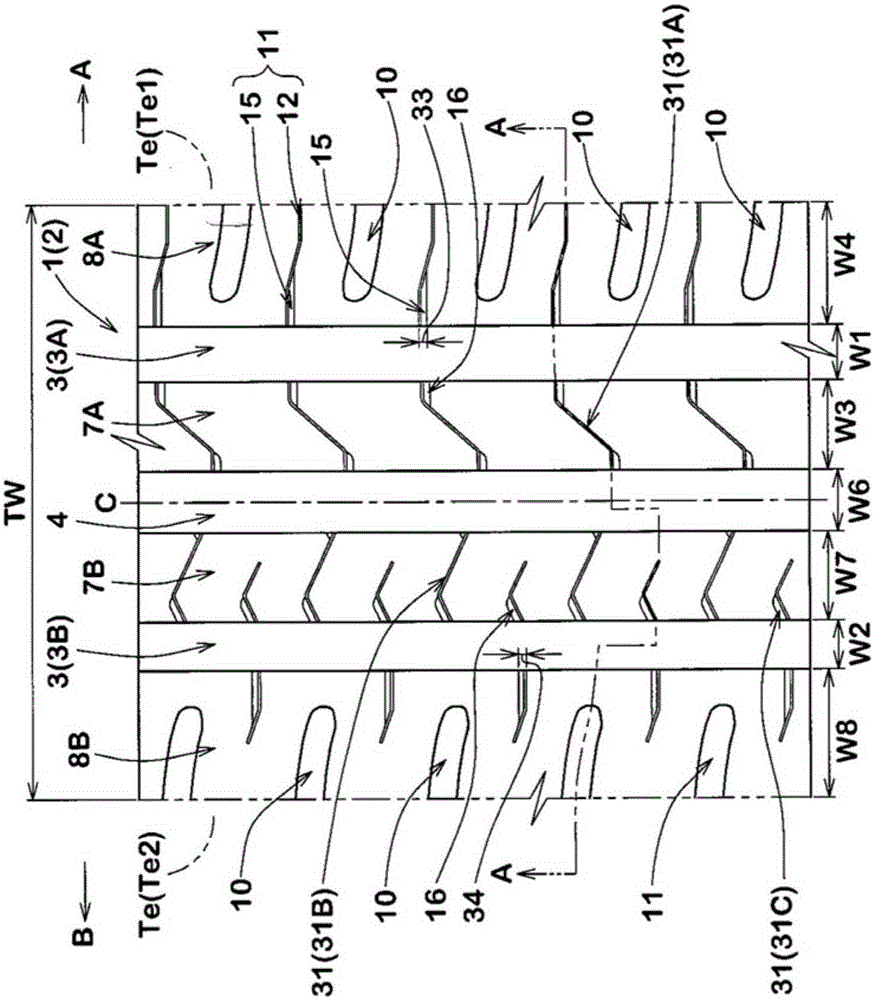

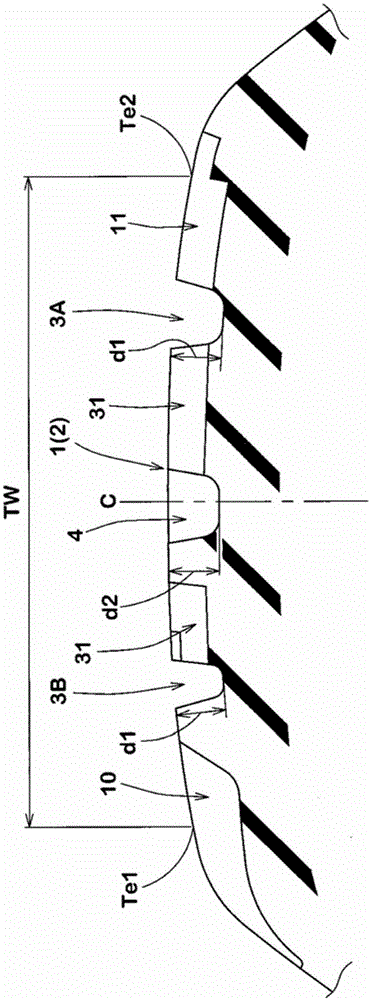

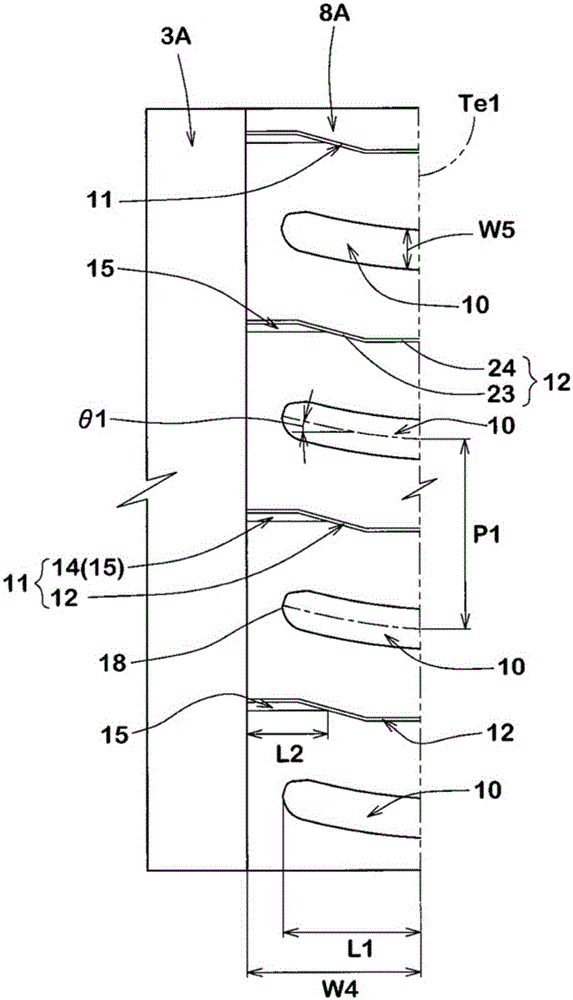

[0097] Prototyped according to the specifications in Table 1 with figure 1 Pneumatic tires of size 165 / 70R14 with the basic tread pattern in As Comparative Example 1, such as Figure 8 As shown, a pneumatic tire in which the groove width W1 of the inner shoulder main groove 3A is smaller than the groove width W2 of the outer shoulder main groove 3B and in which the shoulder lateral groove 10 communicates with each shoulder main groove was trial-produced. The handling stability and wet road performance of each test tire were tested on a dry road surface. The general specifications and test methods of each test tire are as follows.

[0098] Mounting rim: 14×5J

[0099] Tire internal pressure: 230kPa

[0100]

[0101] The steering stability when the following test vehicles were driven on an asphalt circuit course was evaluated based on the driver's sensory experience. The results are expressed by taking the result of Comparative Example 1 as 100. As a result, the larger th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com