Patents

Literature

448 results about "Camber angle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

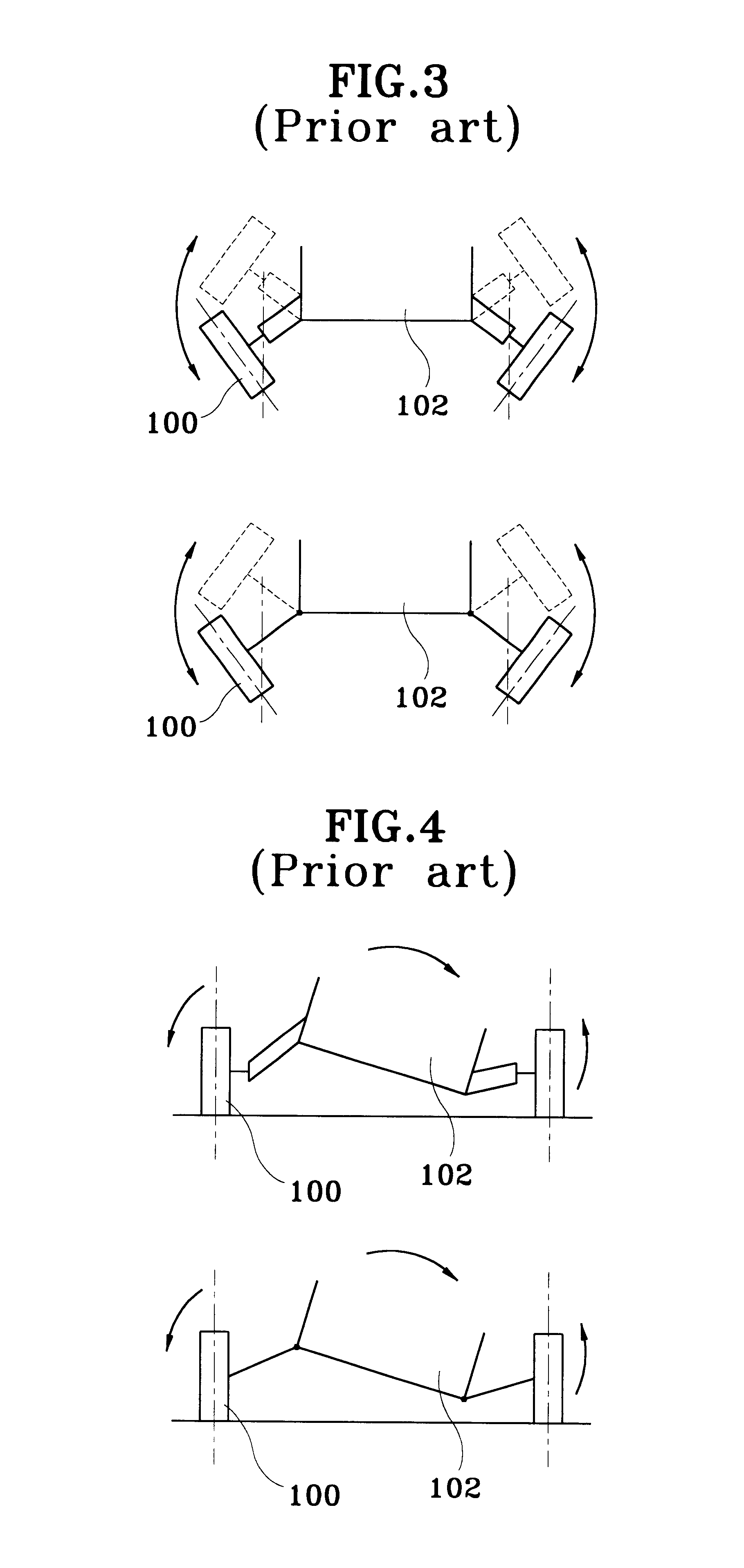

Camber angle is the angle made by the wheels of a vehicle; specifically, it is the angle between the vertical axis of the wheels used for steering and the vertical axis of the vehicle when viewed from the front or rear. It is used in the design of steering and suspension. If the top of the wheel is farther out than the bottom (that is, away from the axle), it is called positive camber; if the bottom of the wheel is farther out than the top, it is called negative camber.

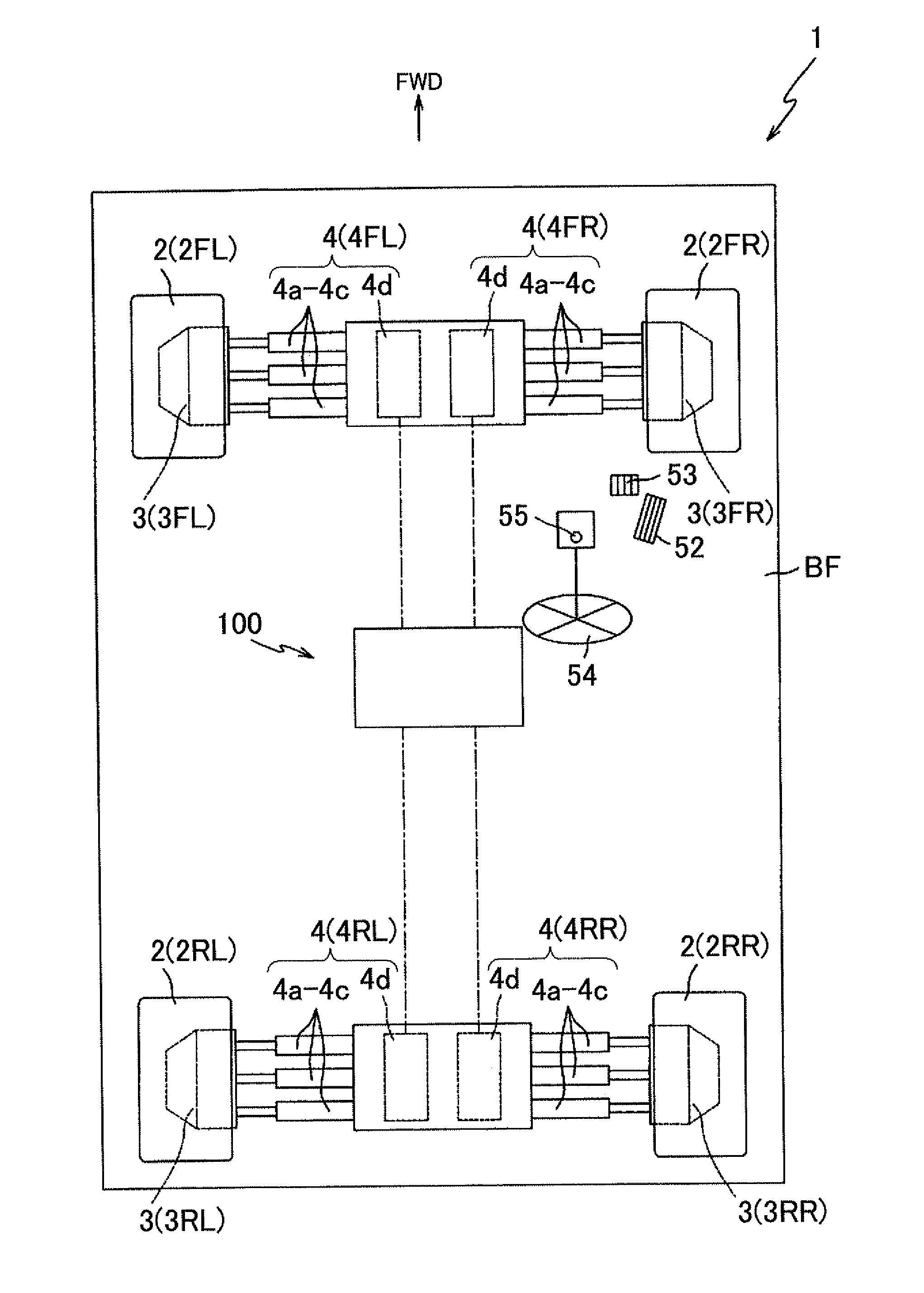

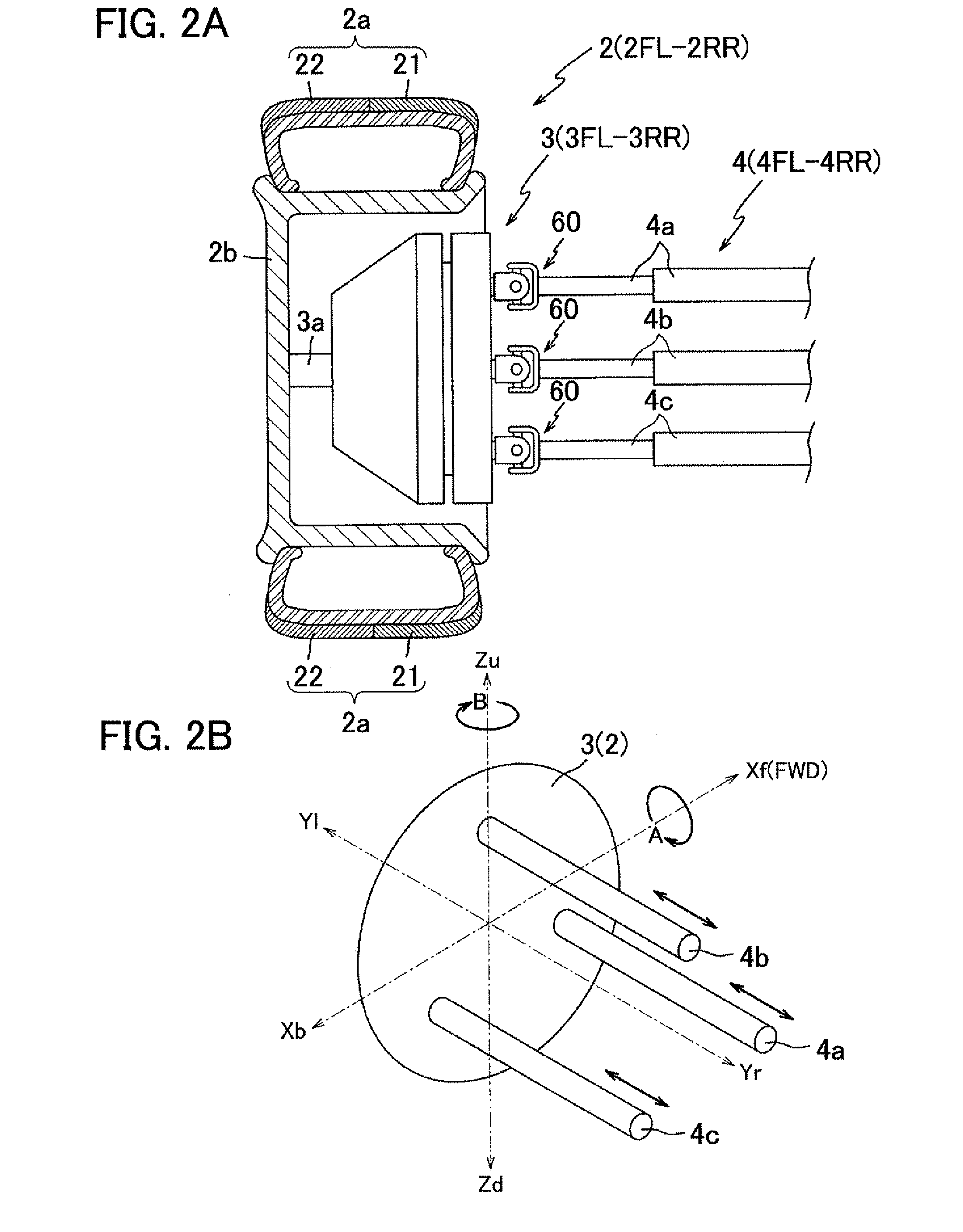

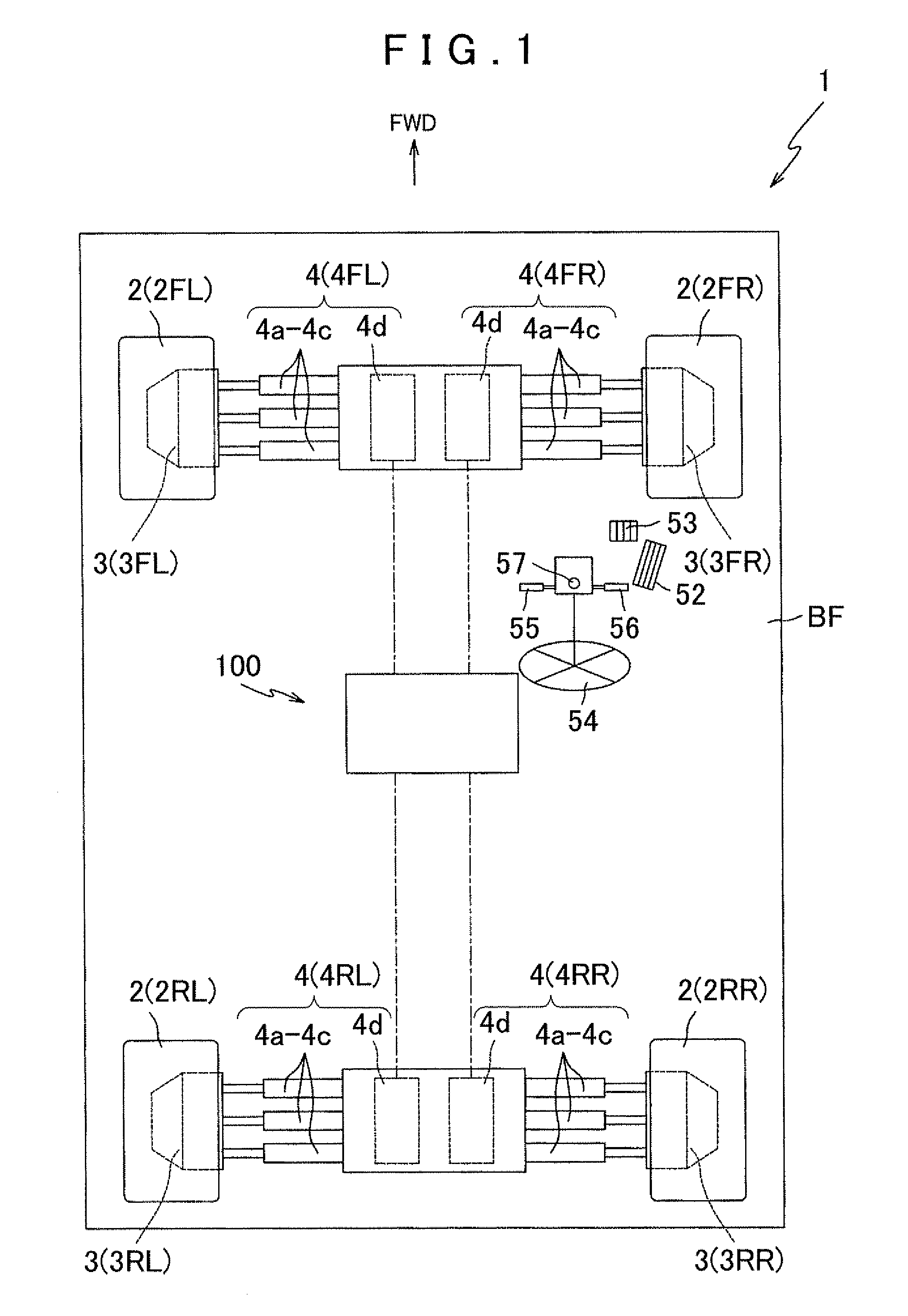

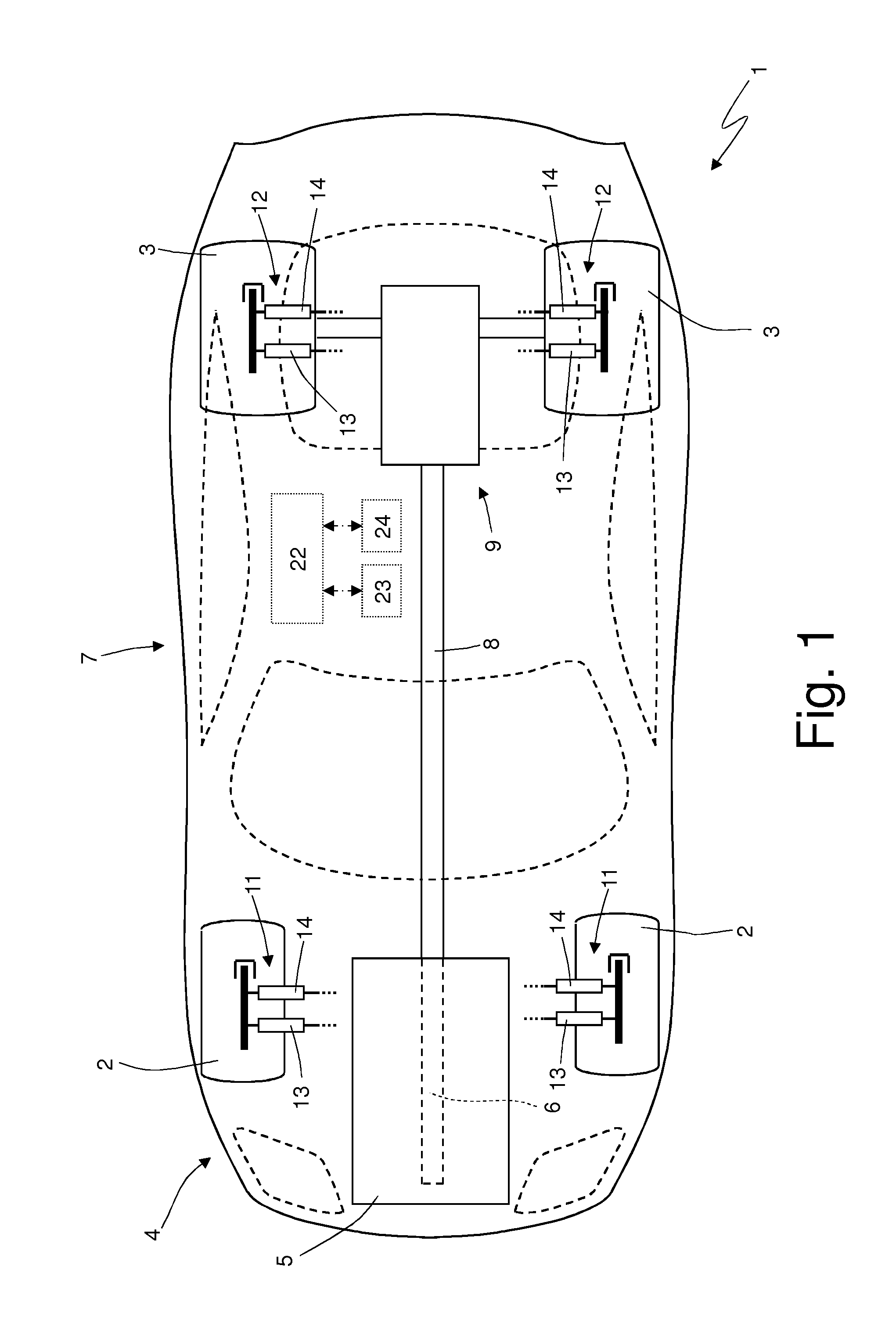

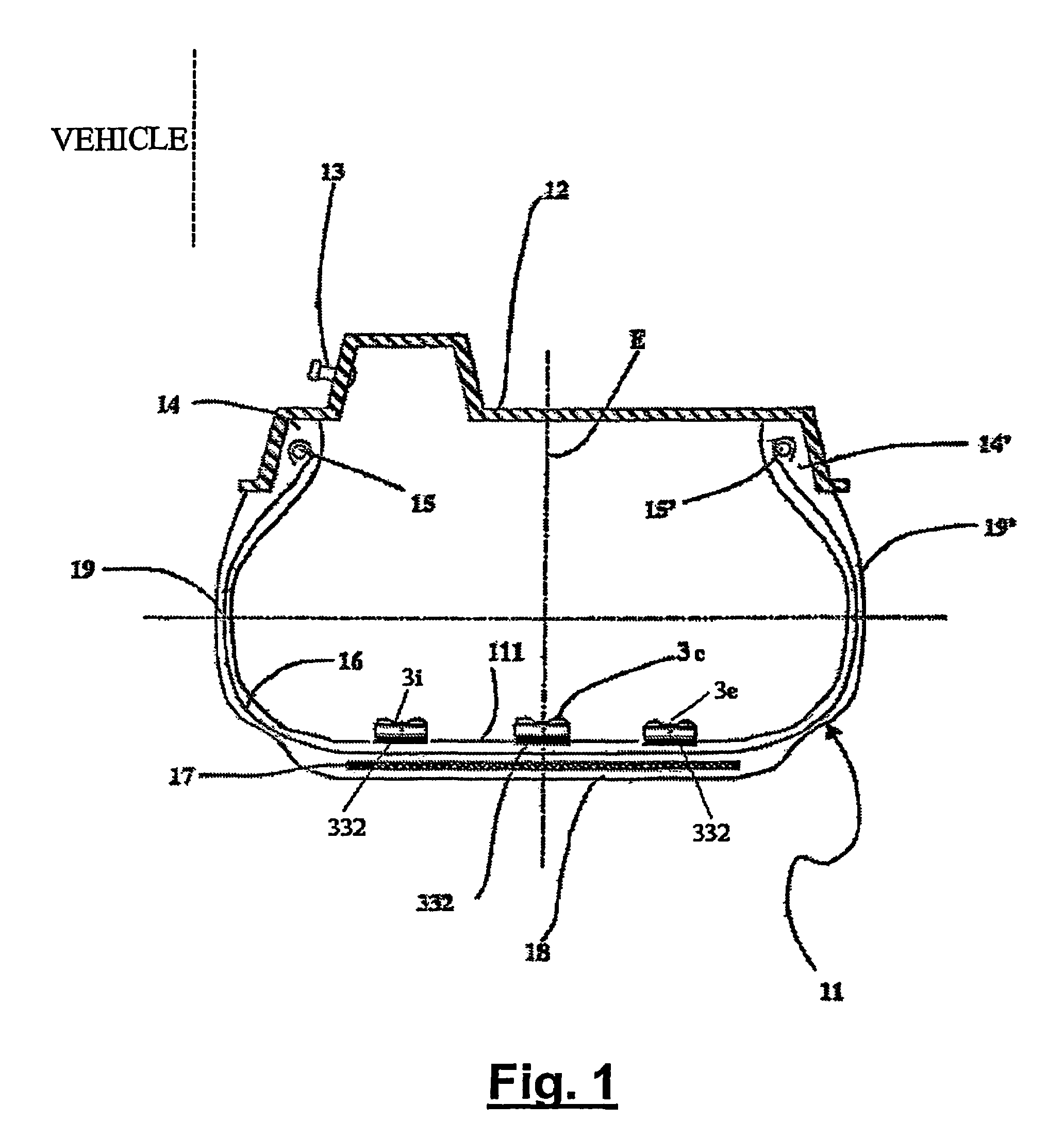

Camber angle controlling device

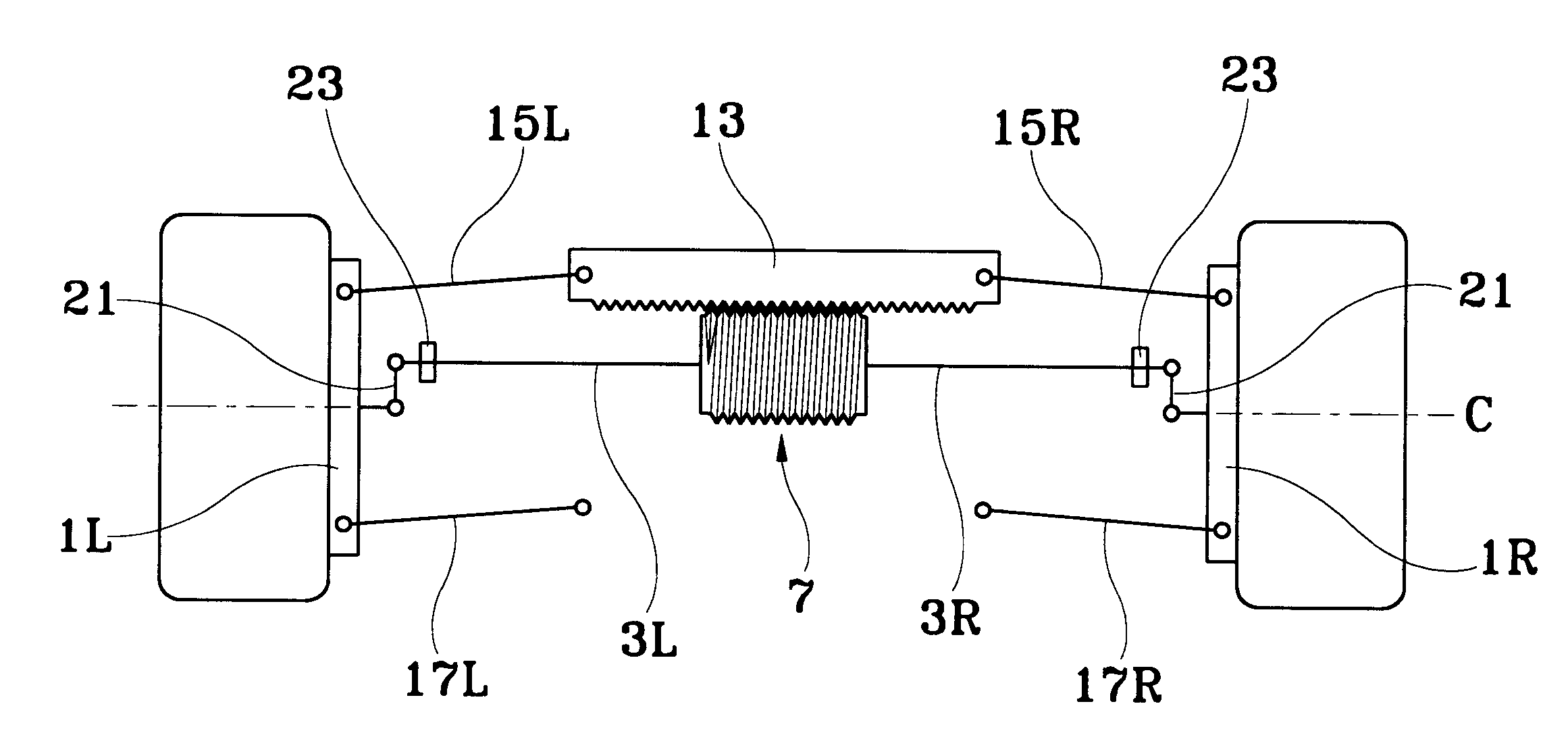

InactiveUS20100217491A1Improve gripIncrease clamping forceDigital data processing detailsSpecial tyresRolling resistanceCamber angle

A camber angle applying device is controlled to adjust the camber angle of wheels to a predetermined value. Therefore, the characteristics (or a high gripping property) of a high gripping force and the characteristic (or a low rolling resistance) of a small rolling resistance can be separately used as the performance of the wheels. By utilizing the high gripping property of the wheels, therefore, a vehicle is enabled to reduce its energy consumption, while retaining its running characteristics (such as a turning performance, an accelerating performance or a braking performance), by utilizing the rolling resistance of the wheels. Moreover, the camber angle applying device is controlled to reduce the rolling resistance of the wheels, so that the energy loss to occur in the wheels during running can be reduced to further reduce the energy consumption of the vehicle.

Owner:EQUOS RES

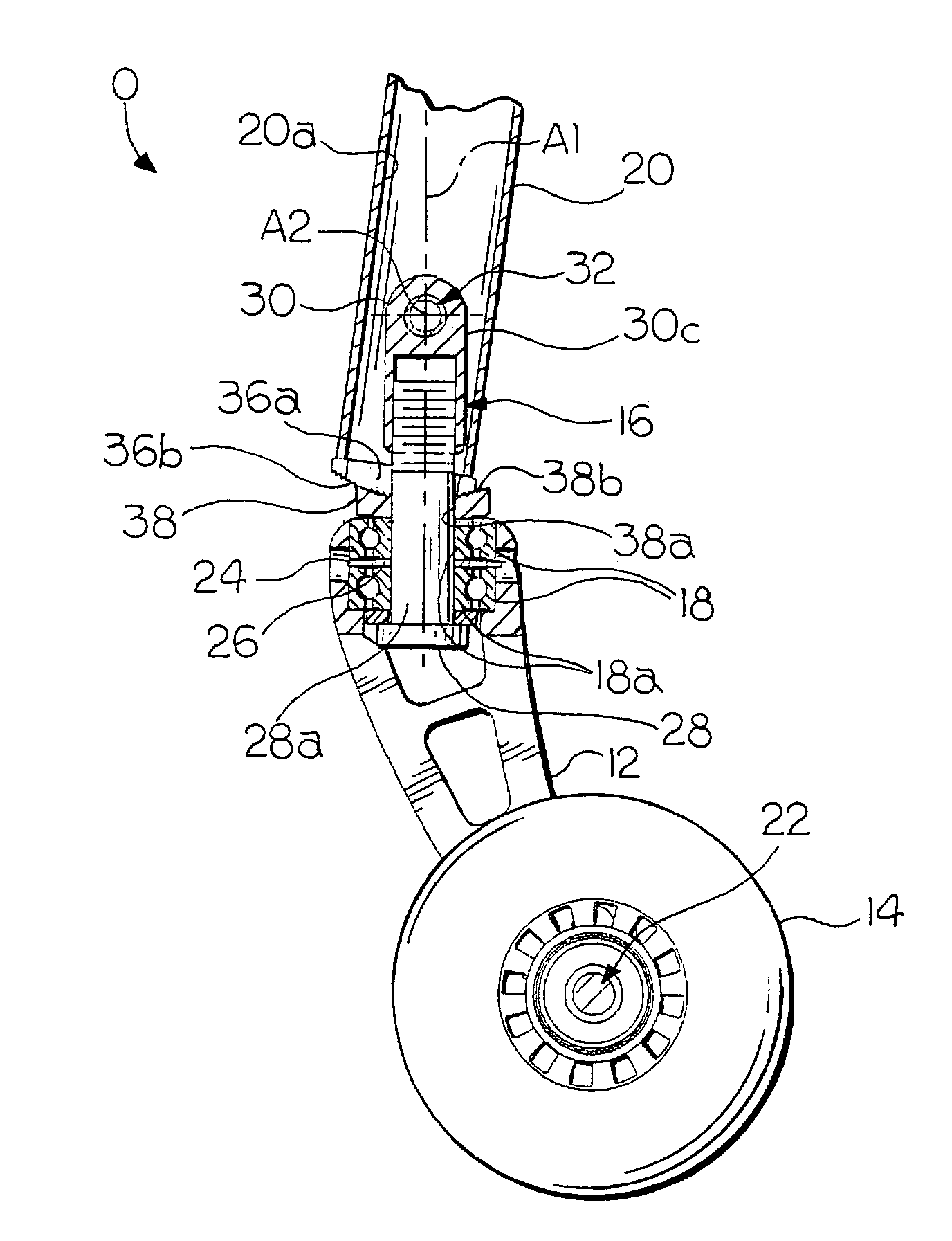

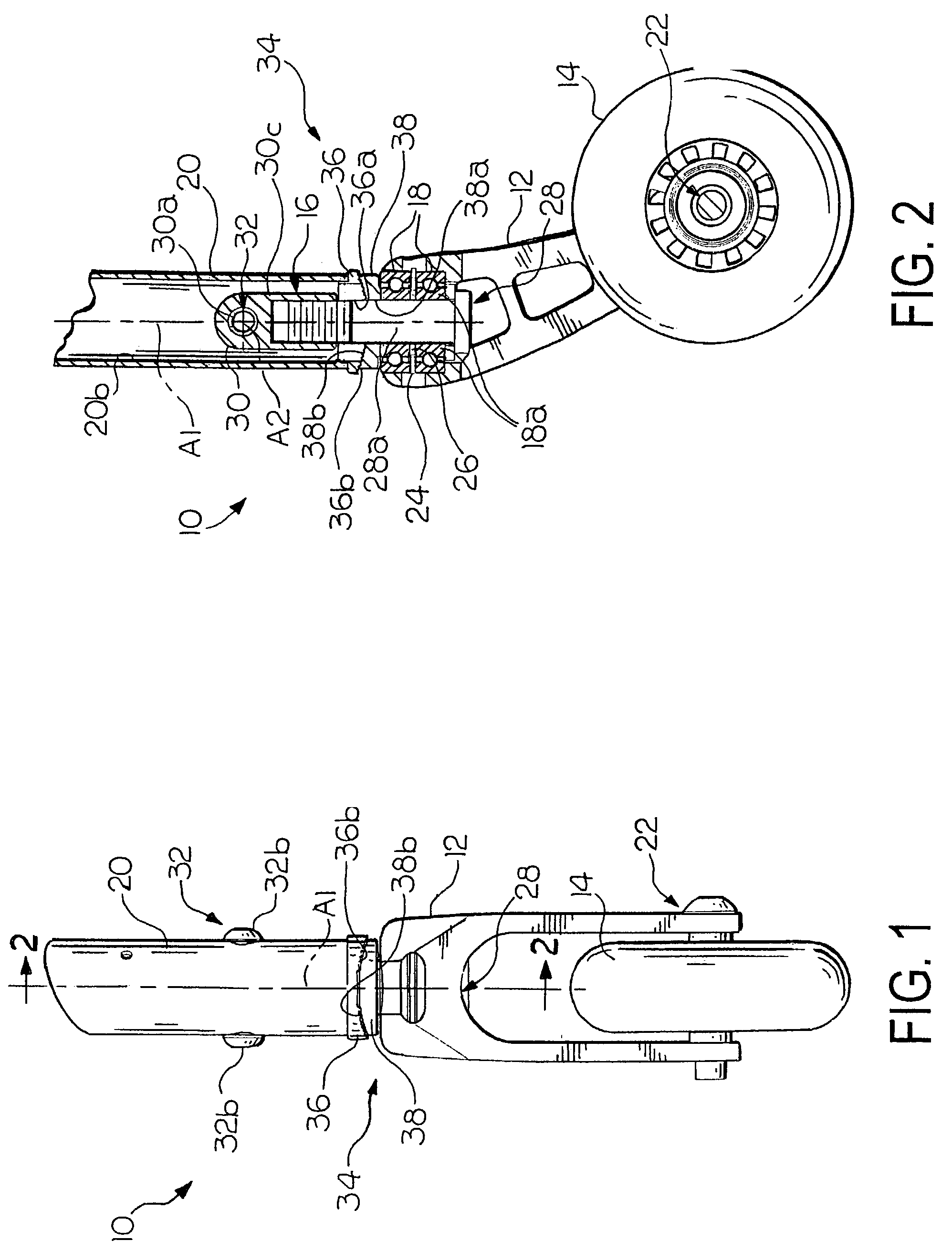

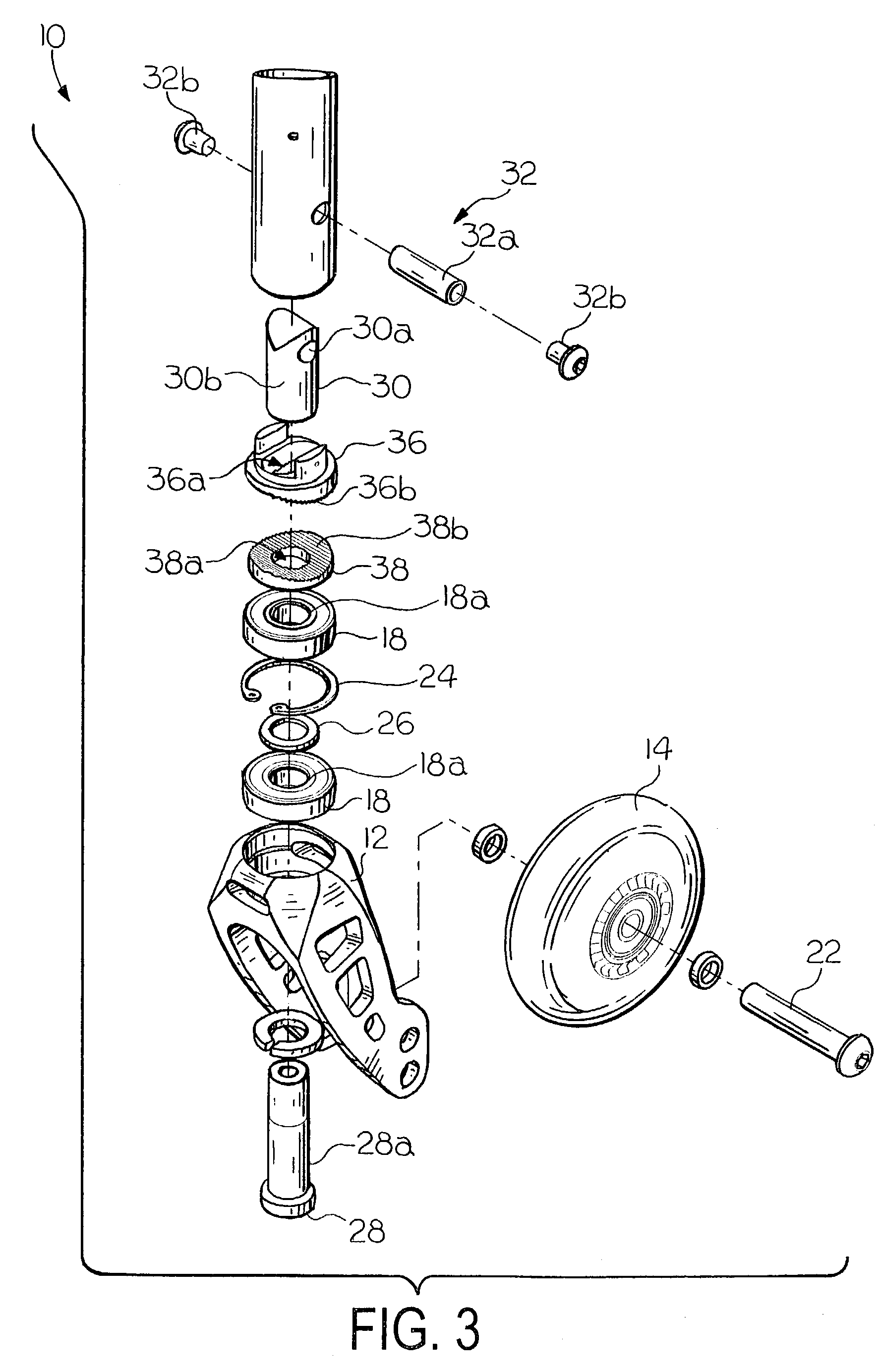

Adjustable wheel assembly

An improved wheel assembly comprises a caster fork, a caster wheel rotatably supported by the caster fork, and a caster swivel post defining an axis about which the caster fork rotates. The caster swivel post is being adapted to rotate about a pivot axis within a cylindrical housing. Alternatively, the wheel assembly has an adjustable axle for varying the camber angle of a wheel. The wheel assembly comprises a housing and an axle supported by the housing. The axle in turn rotatably supports a wheel. The axle is adapted to rotate about a pivot axis within a cylindrical housing.

Owner:SUNRISE MEDICAL (US) LLC

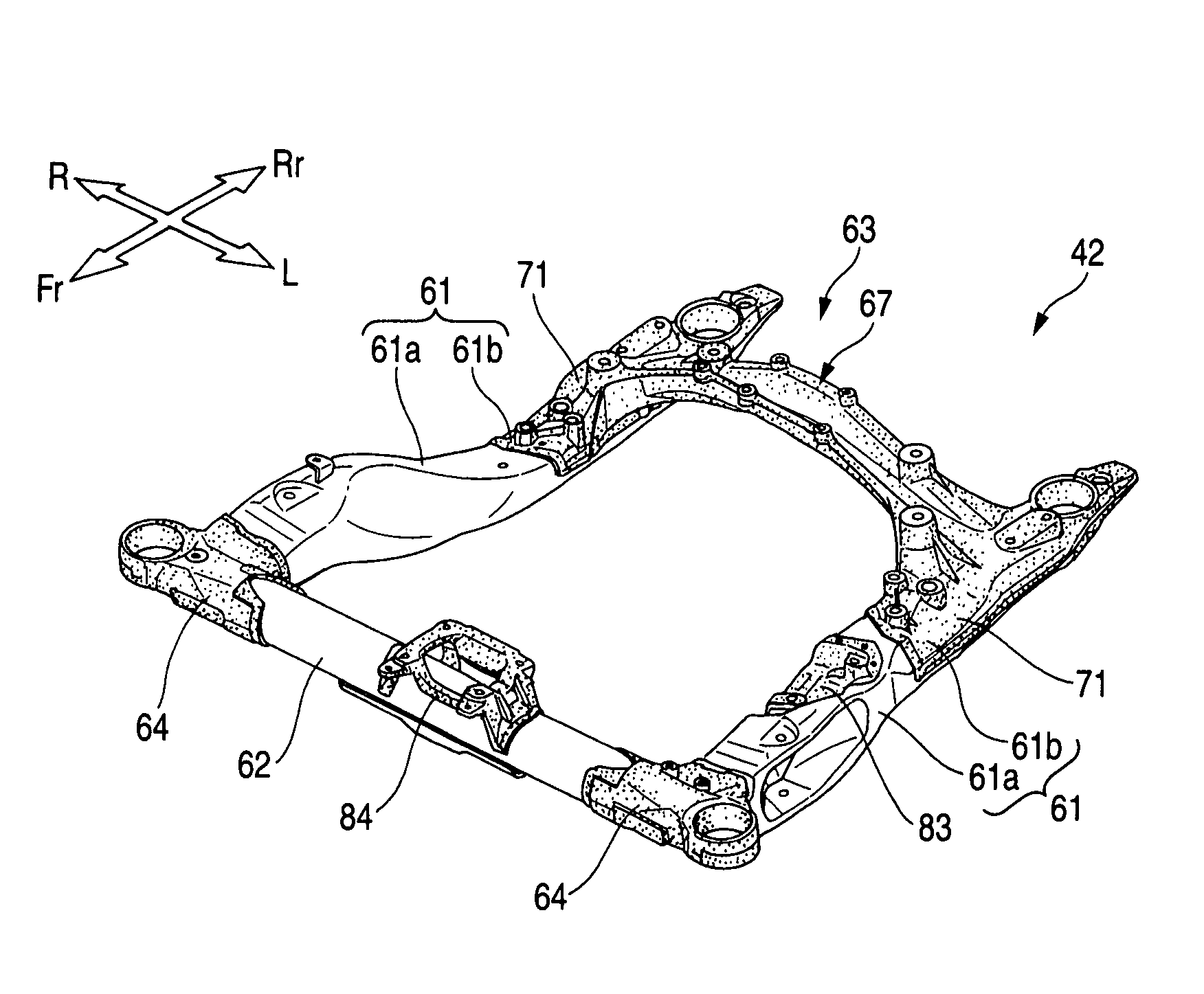

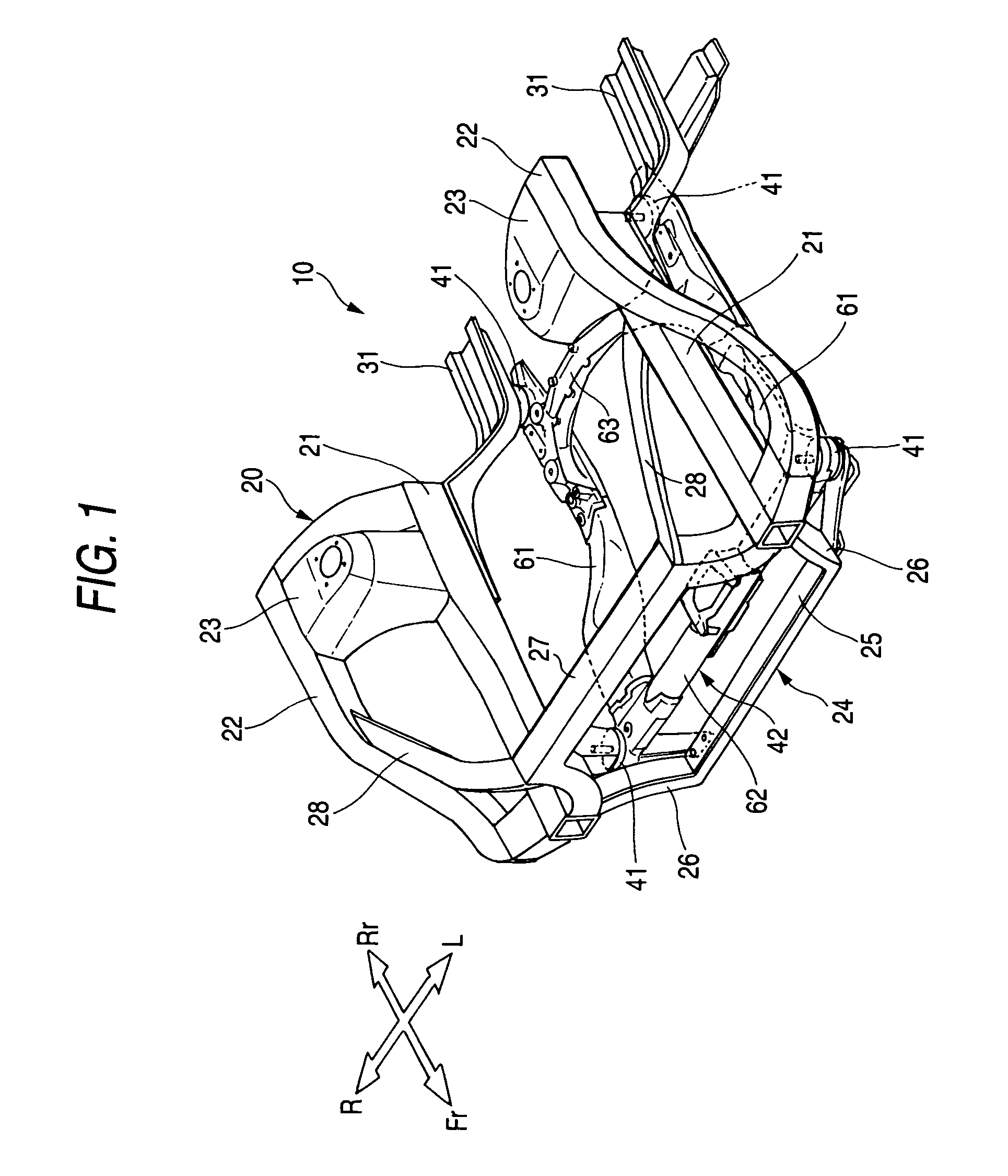

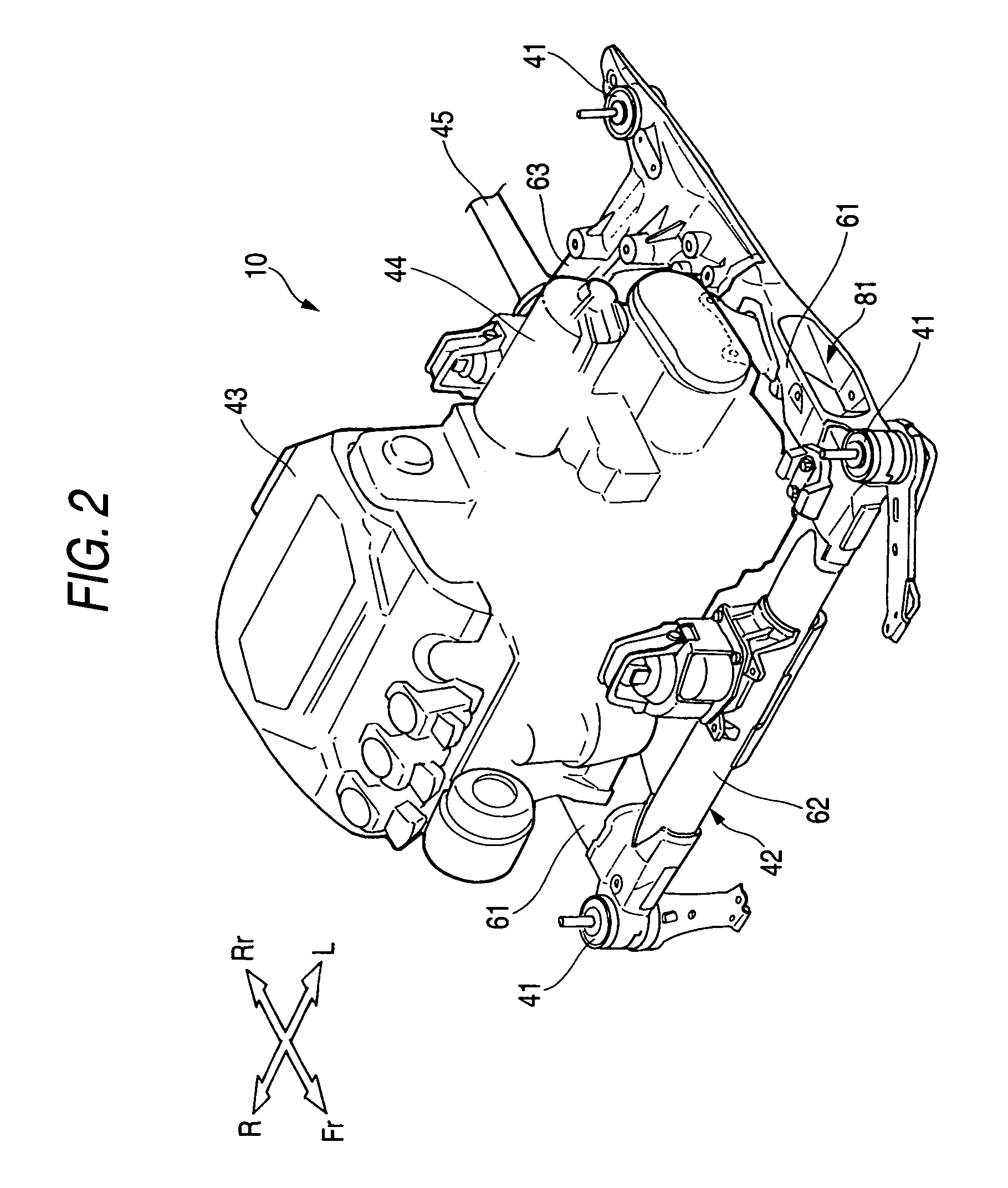

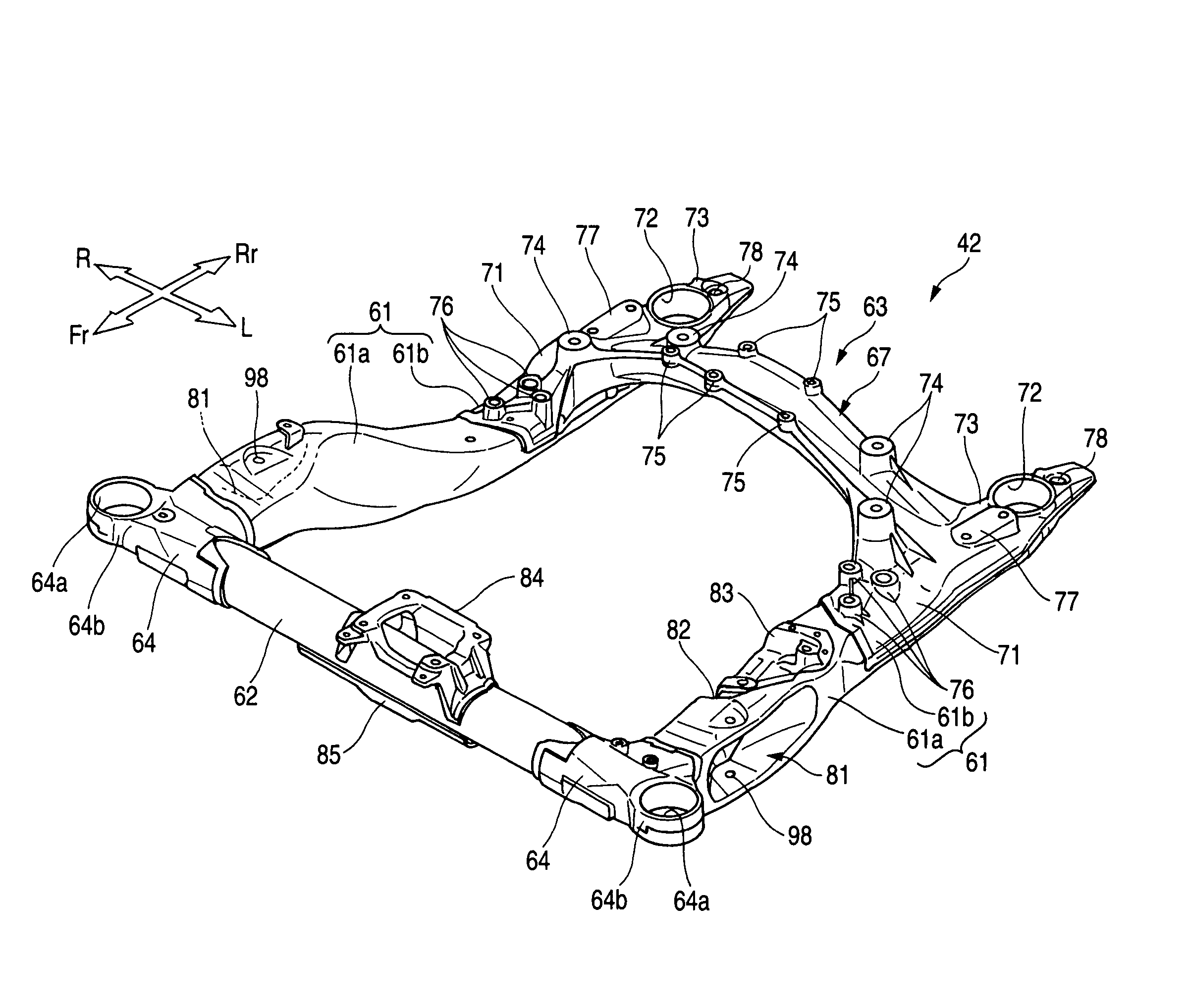

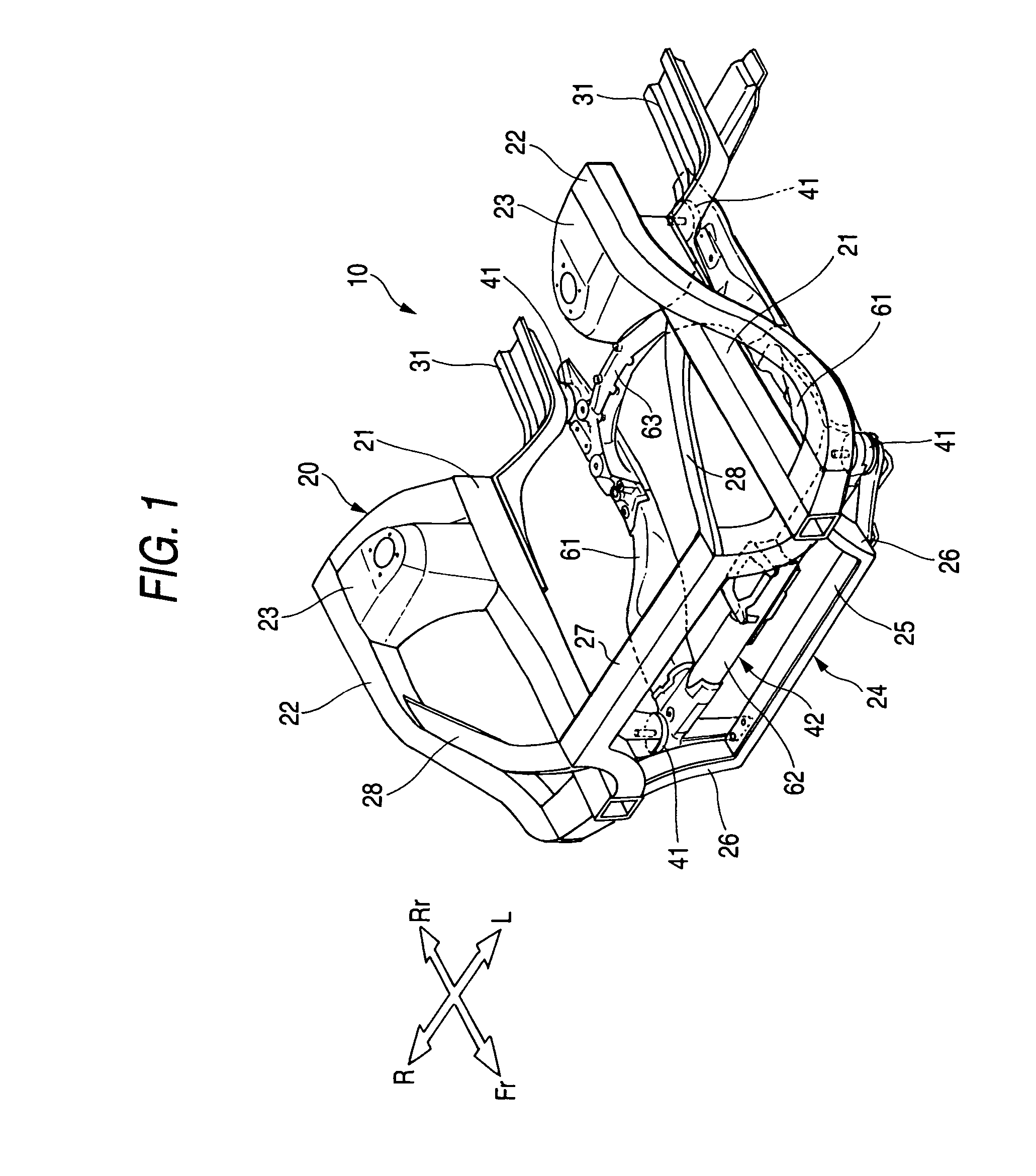

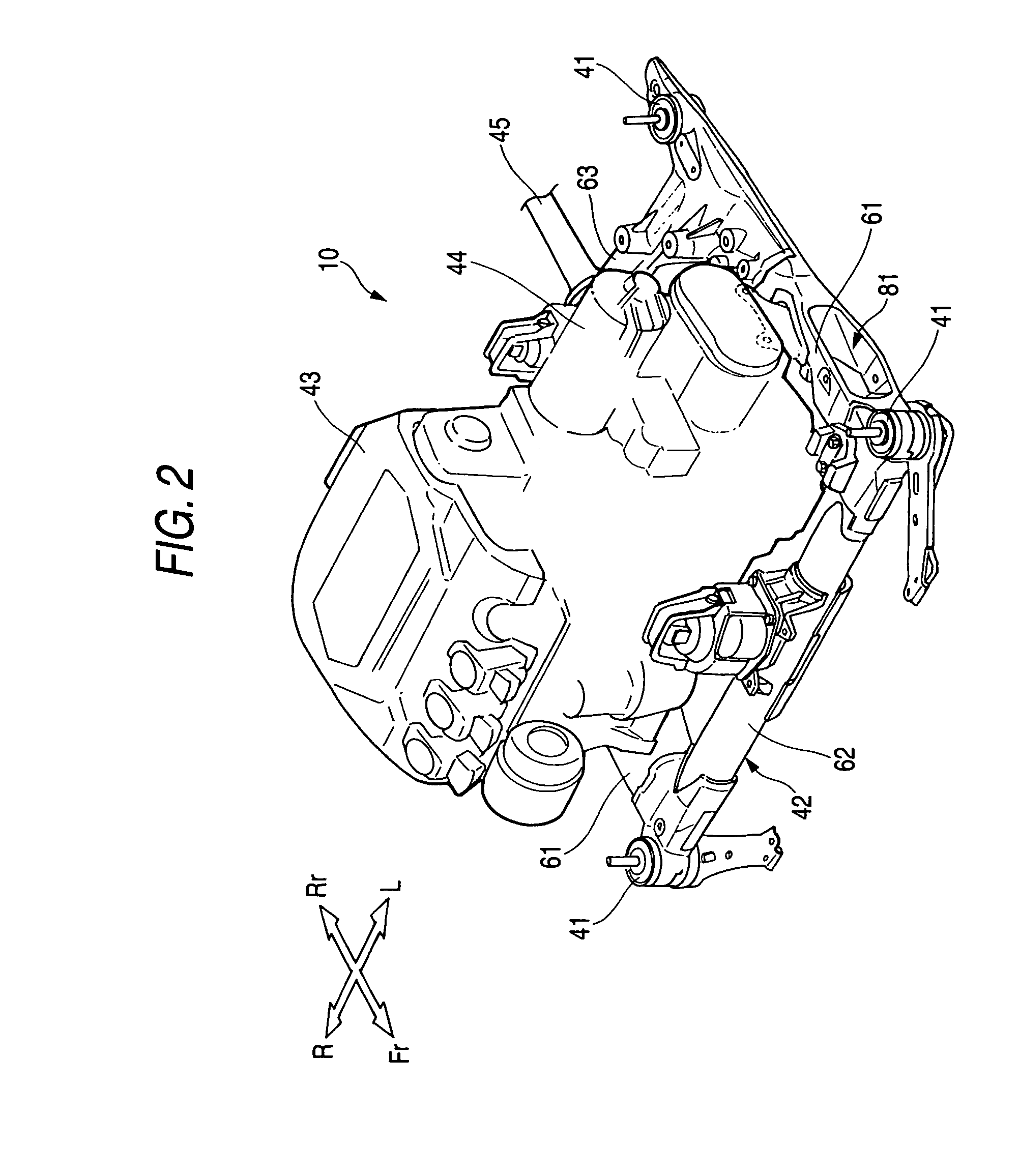

Body frame structure

InactiveUS7520514B2Improve transmission performanceMaintain performanceUnderstructuresSuperstructure subunitsVehicle frameCamber angle

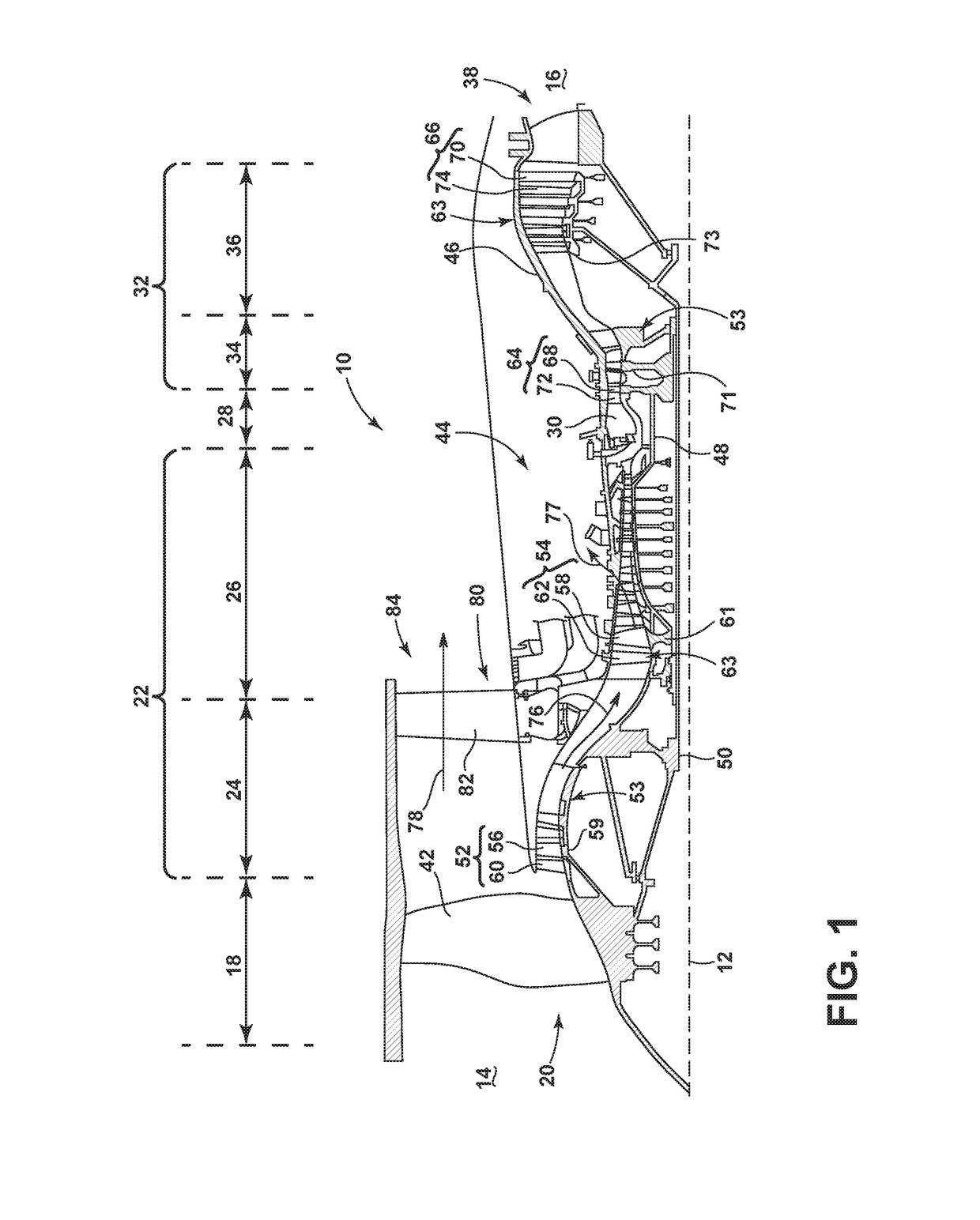

A front subframe 42 is formed of an aluminum alloy into a frame that is formed substantially into a shape of parallel crosses or into a rectangular shape and is made up of left and right front joint portions 64, 64 and left and right rear joint portions 71, 71 which are disposed at corners of the frame that is formed substantially into the shape of parallel crosses or the rectangular shape, and left and right longitudinal members 61, 61, and front and rear cross members 62, 67 which connect the joint portions 64, 64, 71, 71 together. The left and right front joint portions 64, 64 and the left and right rear joint portions 71, 71 are formed of an aluminum alloy die-cast product, whereas the left and right longitudinal members 61, 61 are formed of an aluminum alloy wrought product. In addition, connecting locations 76 . . . of a camber angle adjusting mechanism 157 are formed of an aluminum alloy die-cast product. Additionally, a rear cross member compound 63 is formed of an aluminum alloy die-cast product.

Owner:HONDA MOTOR CO LTD

Body frame structure

InactiveUS20070169982A1Improve transmission performanceMaintain performanceUnderstructuresSteering partsCamber angleDie casting

A front subframe 42 is formed of an aluminum alloy into a frame that is formed substantially into a shape of parallel crosses or into a rectangular shape and is made up of left and right front joint portions 64, 64 and left and right rear joint portions 71, 71 which are disposed at corners of the frame that is formed substantially into the shape of parallel crosses or the rectangular shape, and left and right longitudinal members 61, 61, and front and rear cross members 62, 67 which connect the joint portions 64, 64, 71, 71 together. The left and right front joint portions 64, 64 and the left and right rear joint portions 71, 71 are formed of an aluminum alloy die-cast product, whereas the left and right longitudinal members 61, 61 are formed of an aluminum alloy wrought product. In addition, connecting locations 76 . . . of a camber angle adjusting mechanism 157 are formed of an aluminum alloy die-cast product. Additionally, a rear cross member compound 63 is formed of an aluminum alloy die-cast product.

Owner:HONDA MOTOR CO LTD

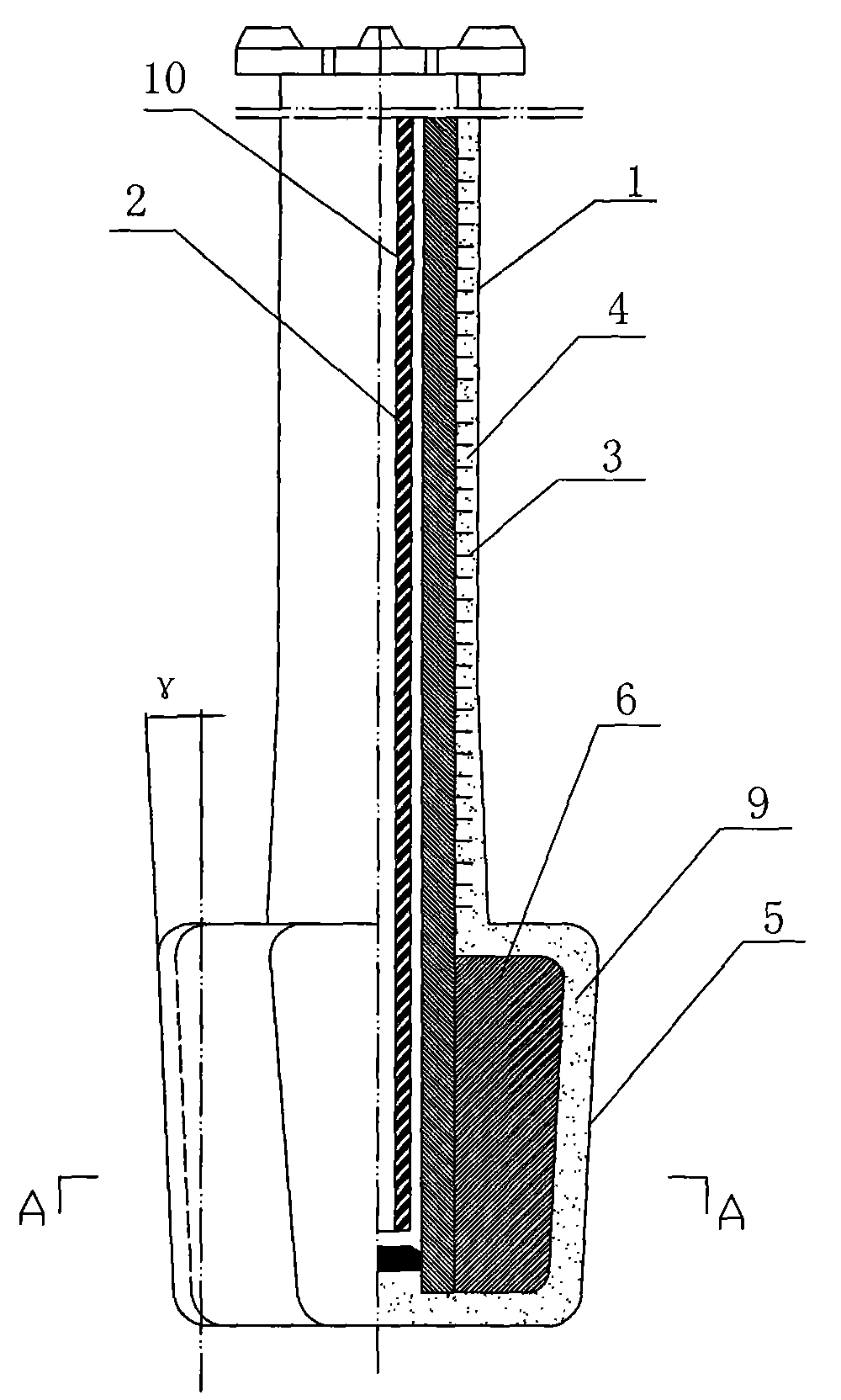

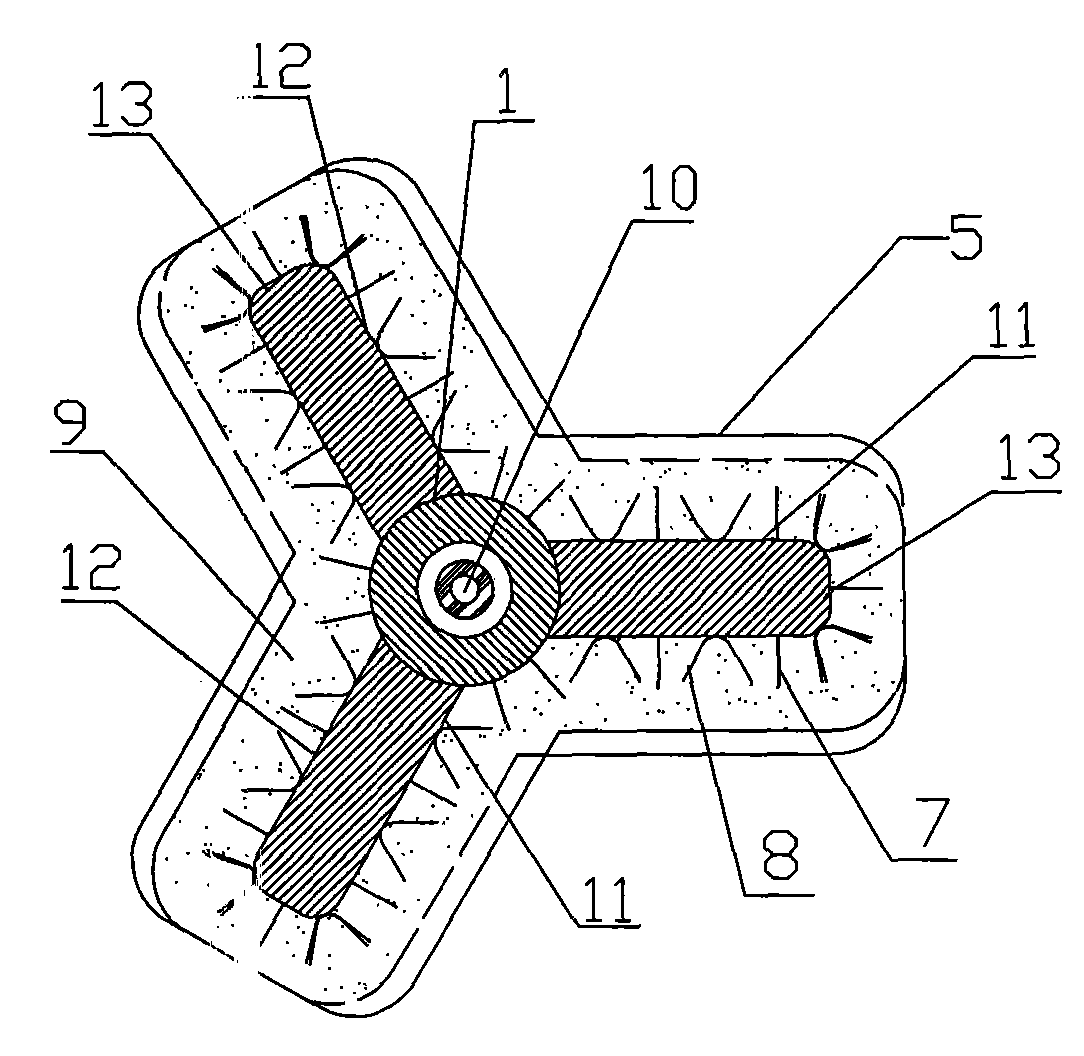

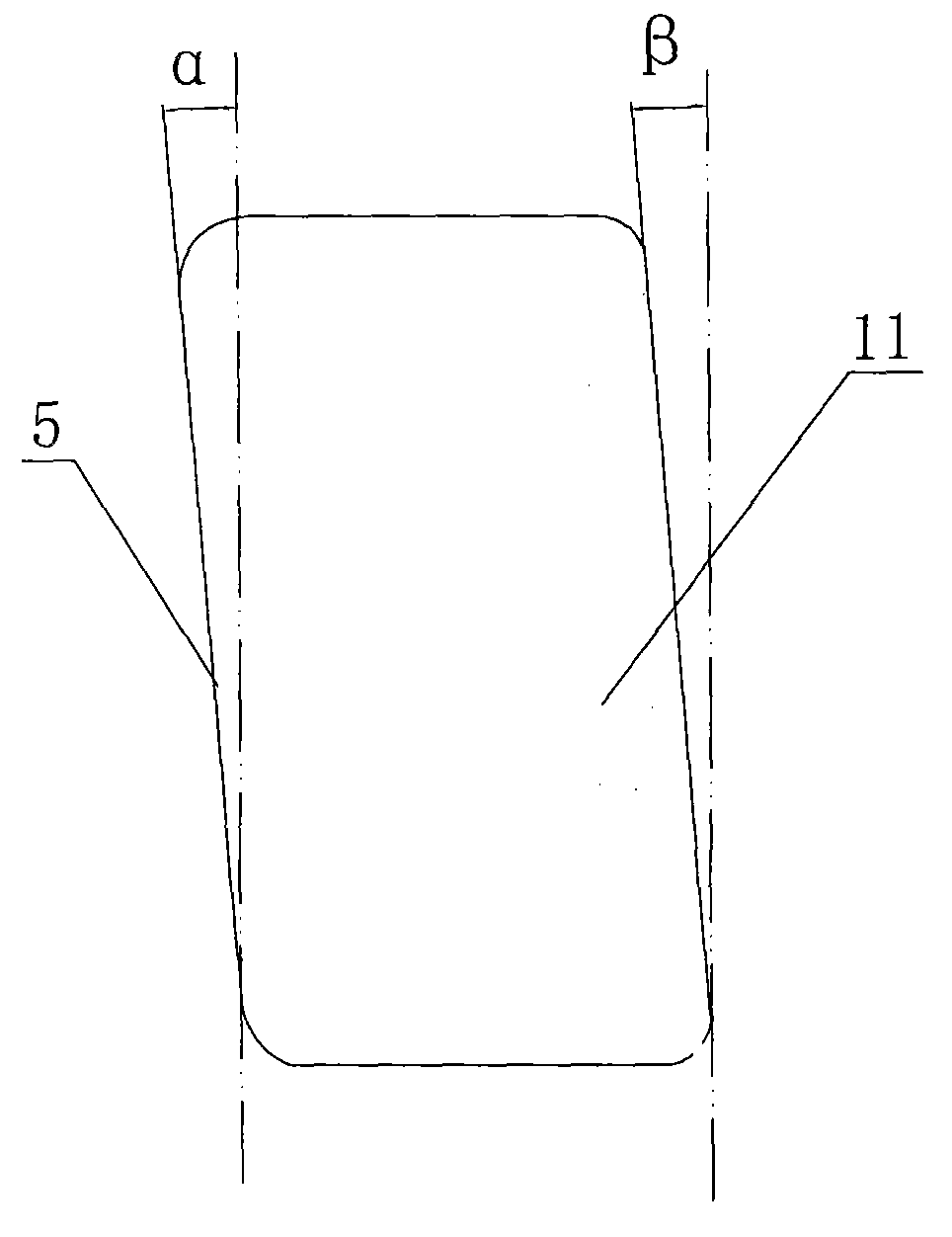

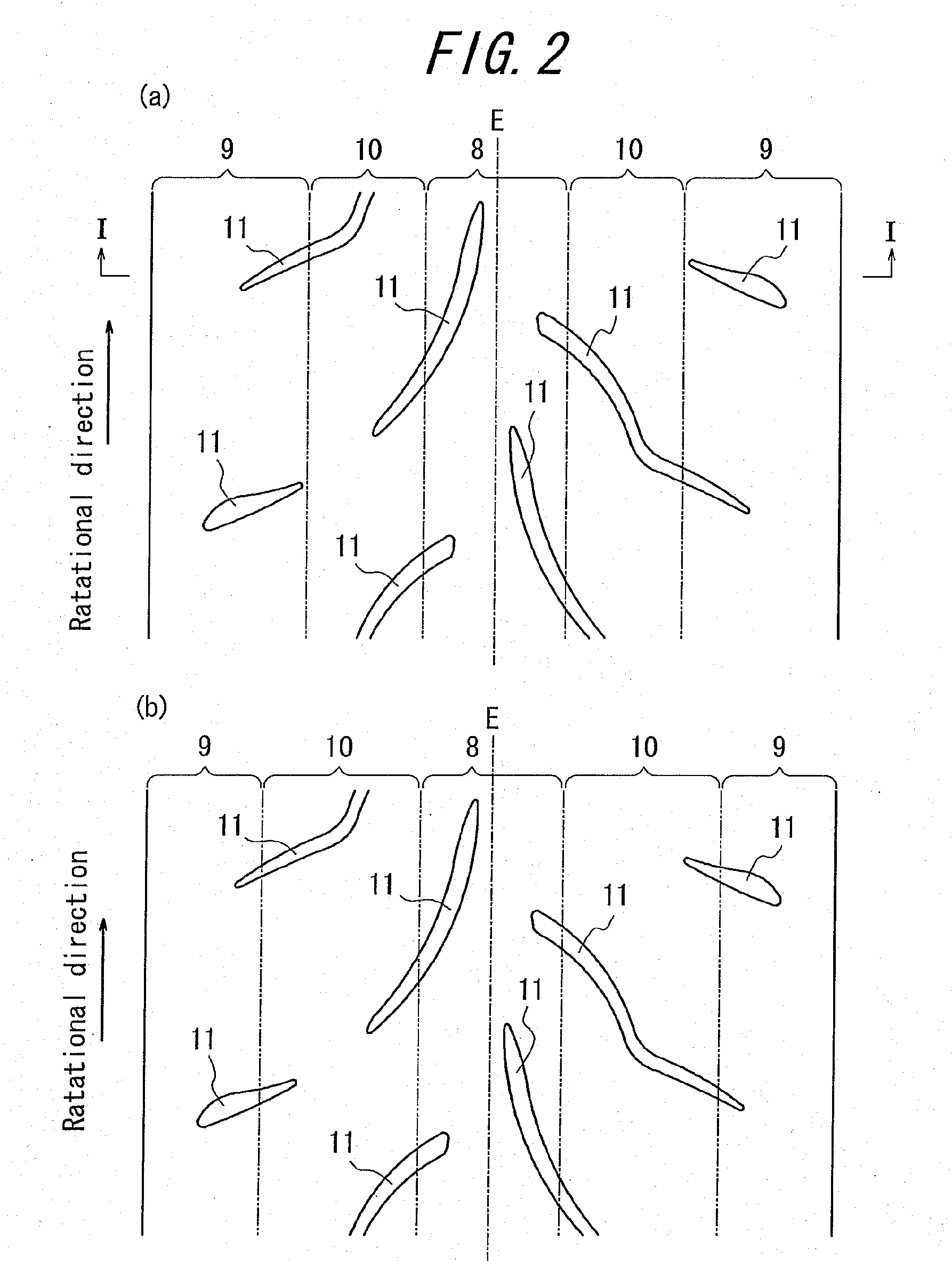

Stirrer for desulphurization of molten iron

The invention relates to a stirrer for external stirring desulphurization of molten iron before converter steelmaking, aiming at solving the existing deficiencies at present that slags among mixing blades are numerous, large intensity of vortex at the bottom of the metal opposing side of the mixing blades is disadvantageous to the discharging of the involved desulphurization slags. The invention comprises the following measures: the stirrer for desulphurization of molten iron is composed of a metal core 2, a V-shaped rivet firmware 3, a refractory liner 4, a metal chip 6, a V-shaped rivet firmware 7, a double V-shaped rivet firmware 8, a refractory liner 9 and an air cooling tube 10; the metal core 2, the V-shaped rivet firmware 3 and the refractory liner 4 constitute a rotation axis 1; the metal chip 6, the V-shaped rivet firmware 7, the double V-shaped rivet firmware 8, the refractory liner 9 and the air cooling tube 10 constitute mixing blades 5; three mixing blades 5 above the rotation axis 1 are evenly distributed; the front rake angle alpha of the inclined plane from bottom to top of the metal facing water surfaces 11 of the mixing blades 5 is 4.1-30 degrees, the front rake angle beta of the inclined plane from bottom to top of the metal opposing surfaces 12 is 0.1-30 degrees, the camber angle gamma of the inclined plane from bottom to top of the outside surface 13 is 4.1-15 degrees. In the invention, slags among the mixing blades are small, the dynamic condition for stirring desulphurization is excellent, the service life is long and the structure is simple.

Owner:武汉钢铁有限公司 +1

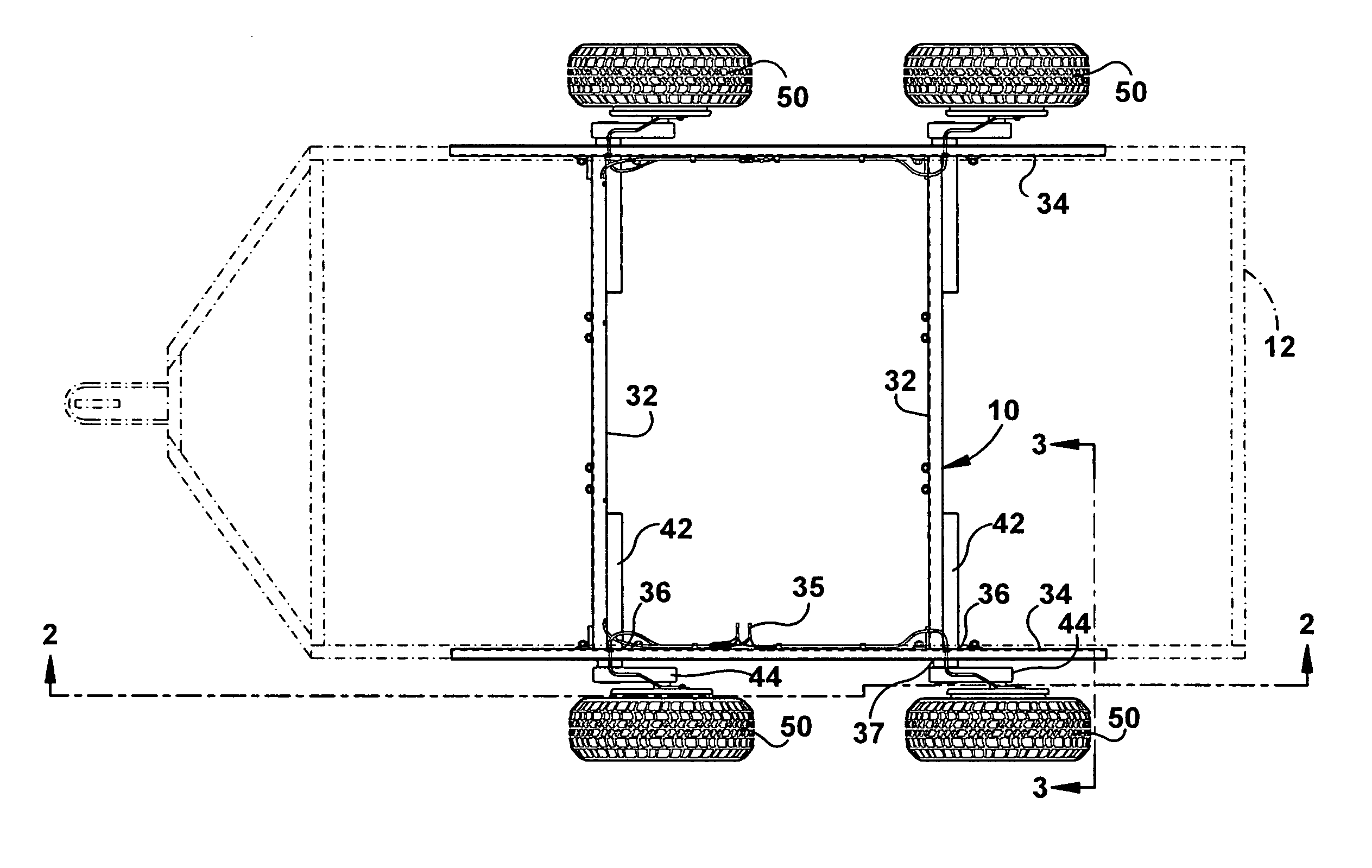

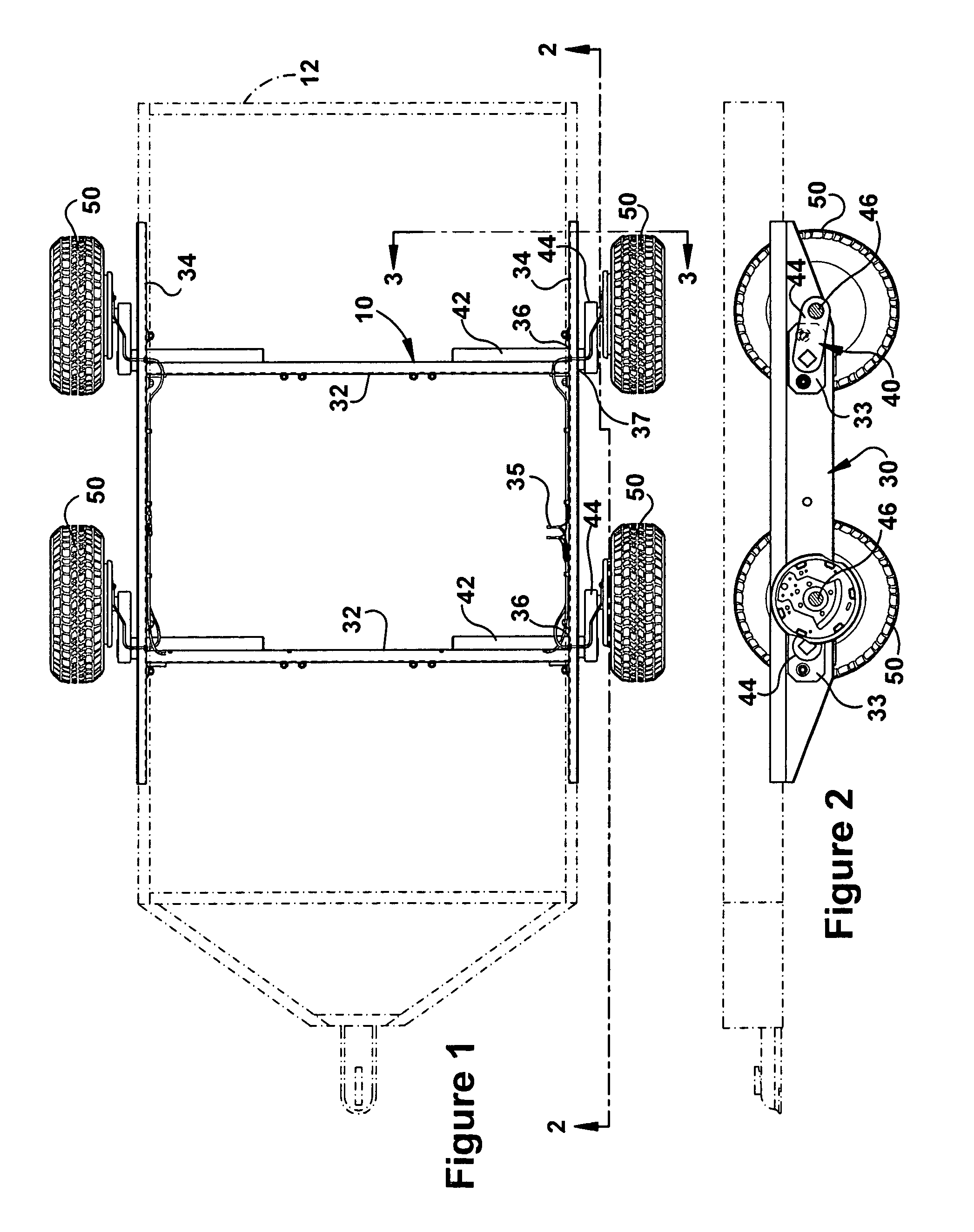

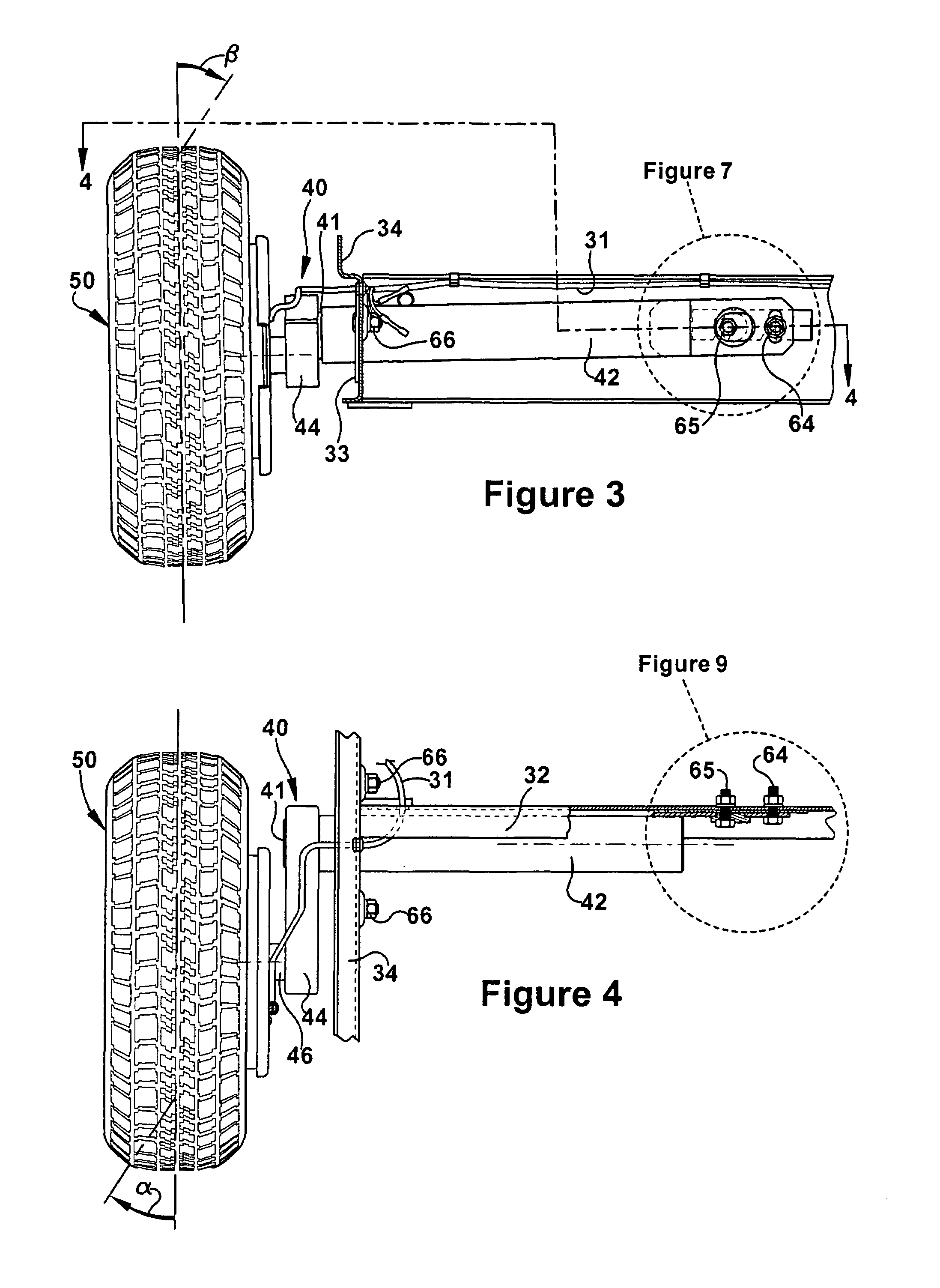

Trailer sub-frame assembly

A sub-frame assembly for use with a vehicle having wheels such as a trailer is provided. The sub-frame assembly comprises two or more frame members, one or more cross members, and two or more stub torsion axle assemblies. Each of the stub torsion axle assemblies have a torsion arm, a spindle extending from the torsion arm for mounting one of the wheels, and a distal end extending from the stub torsion axle assembly for mounting to the frame assembly. The frame assembly may further comprise one or more shim plates for reception between the cross member and the distal end of the stub torsion axle assembly for allowing adjustment of the toe angle of the wheel assembly. In addition, the stub torsion axle assembly may be rotatably mounted to the cross member whereby the camber angle of the wheel assembly may be adjusted.

Owner:DEXTER AXLE CO

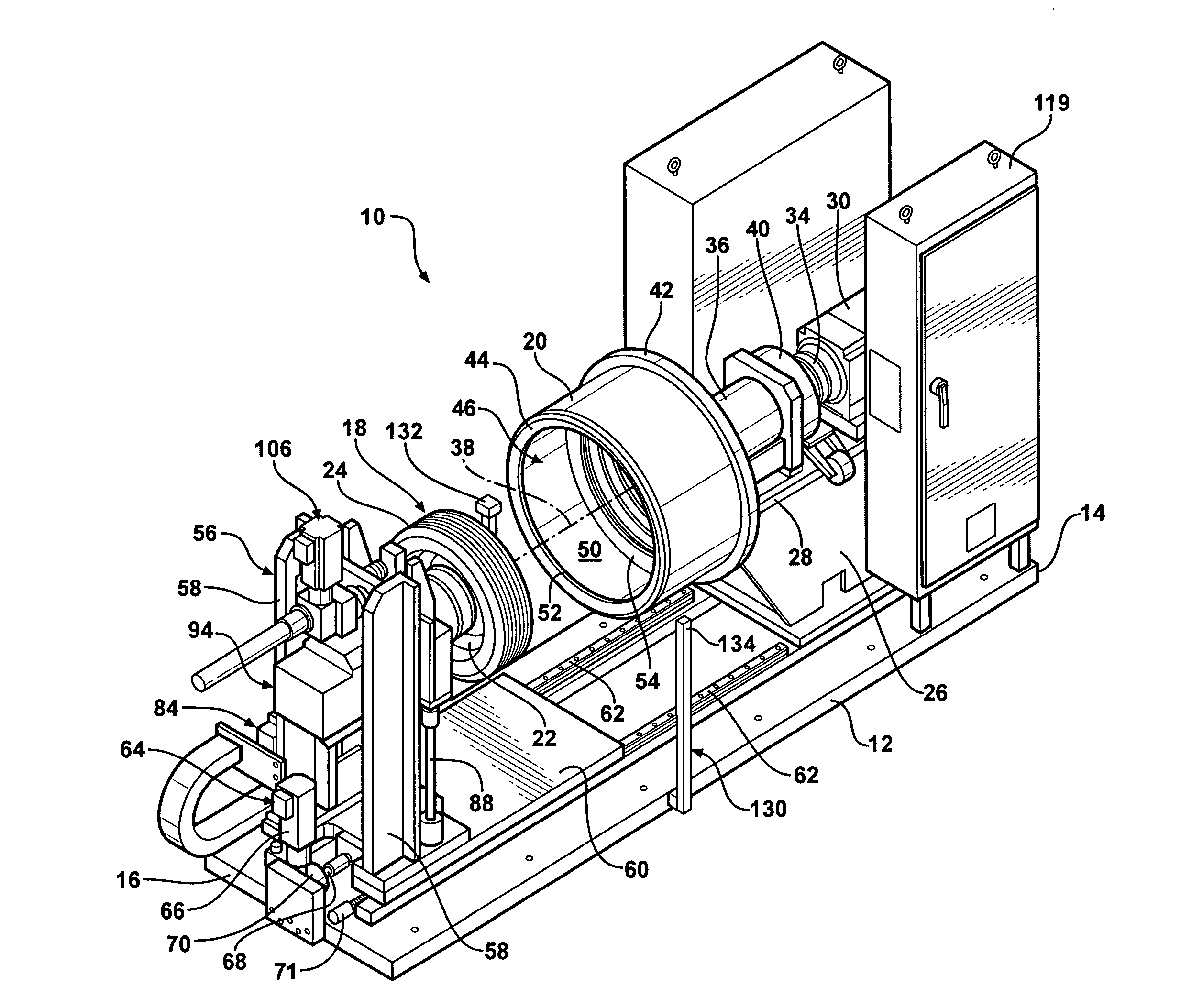

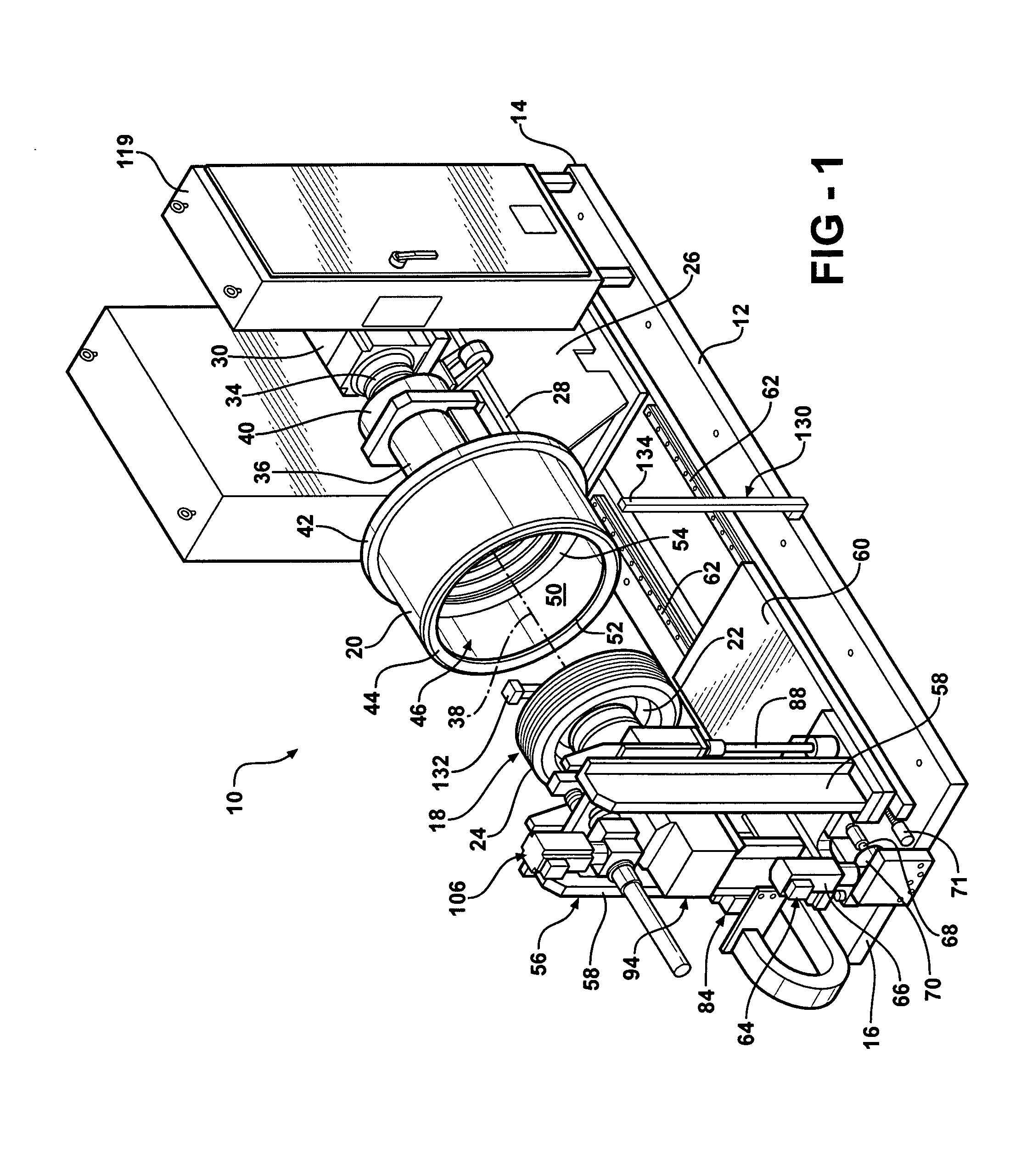

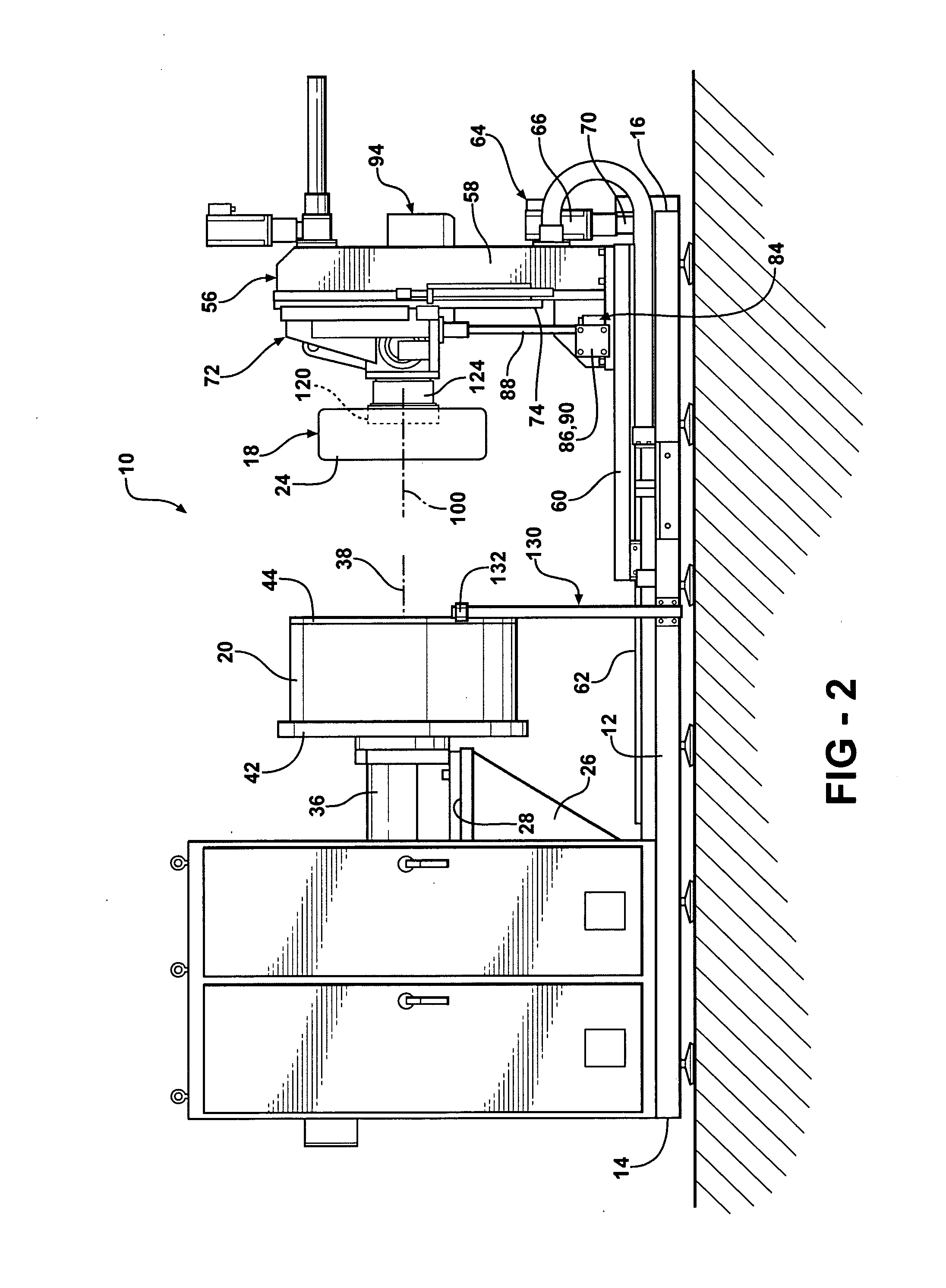

Biaxial wheel test assembly

A wheel test assembly for testing a wheel-and-tire assembly includes a drum operatively mounted to a base for rotation of the drum. The drum includes an inner circumferential surface. A tailstock assembly is slidably coupled to the base for movement in a lateral direction relative to the drum. A support assembly is slidably coupled to the tailstock assembly for movement in a vertical direction for positioning the wheel-and-tire assembly into rolling contact with the inner circumferential surface of the drum. A spindle assembly is pivotally coupled to the support assembly to adjust a camber angle of the wheel-and-tire assembly. The wheel-and-tire assembly is mounted to the spindle assembly for rotation of the wheel-and-tire assembly.

Owner:LINK ENG

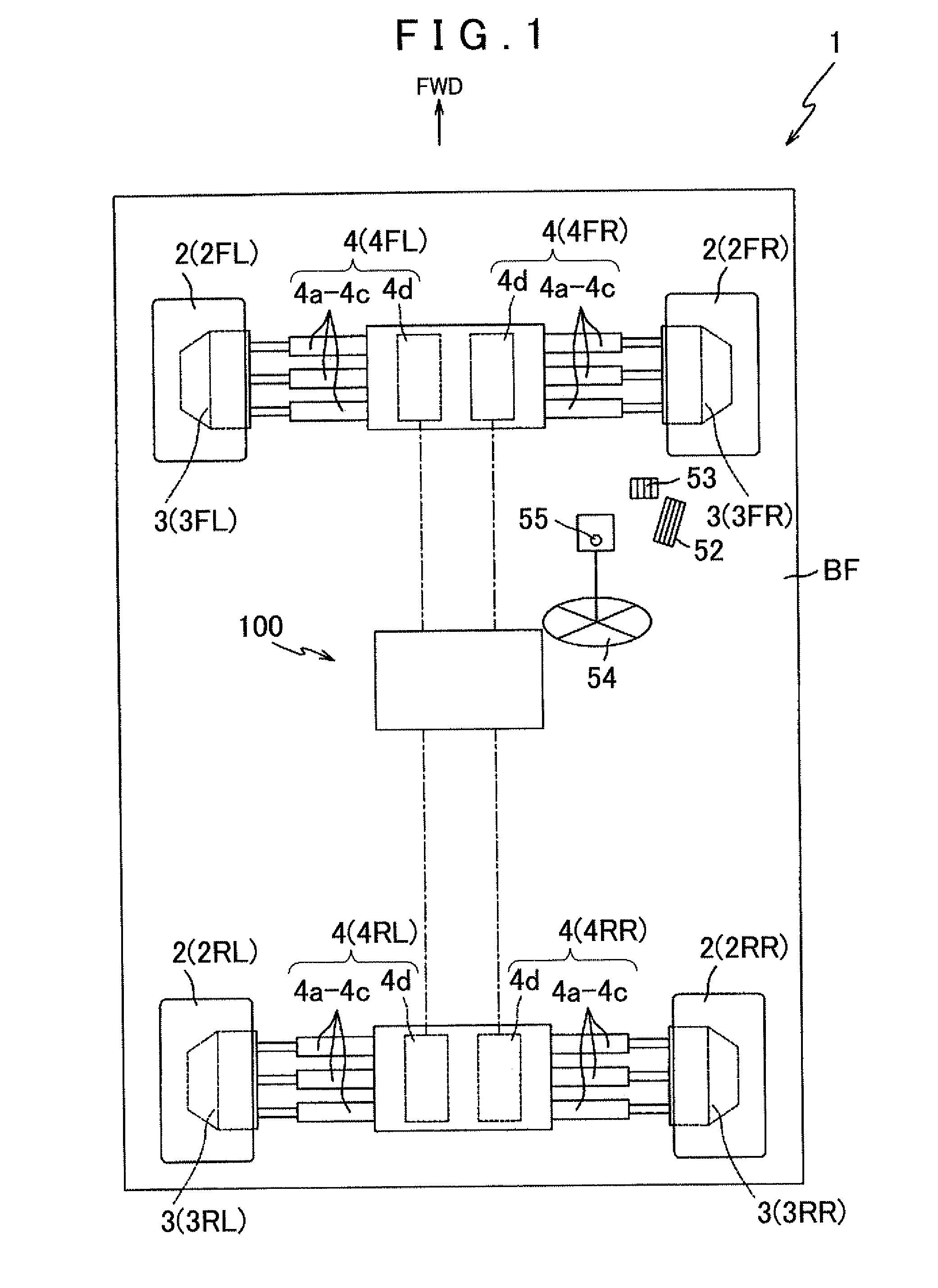

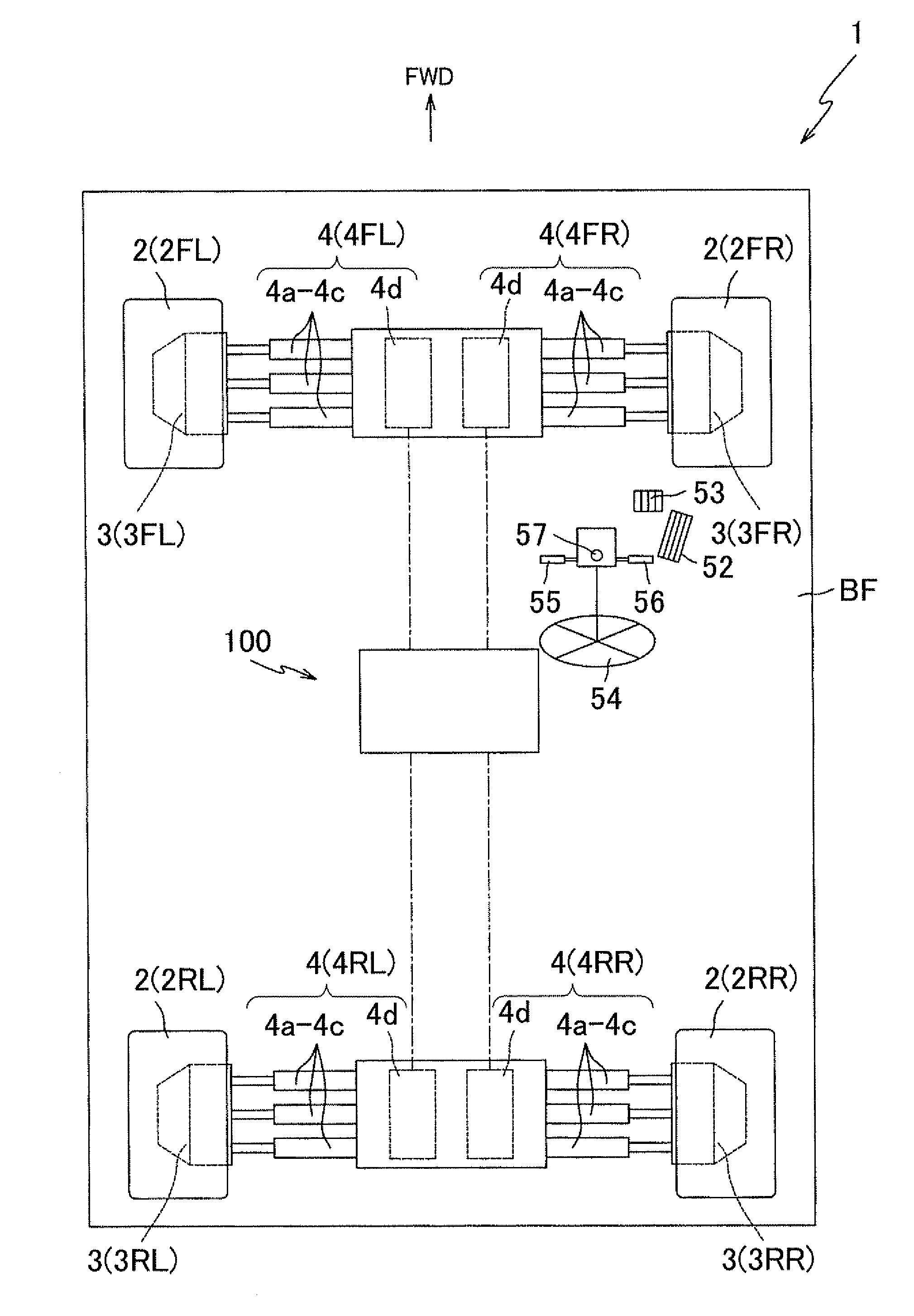

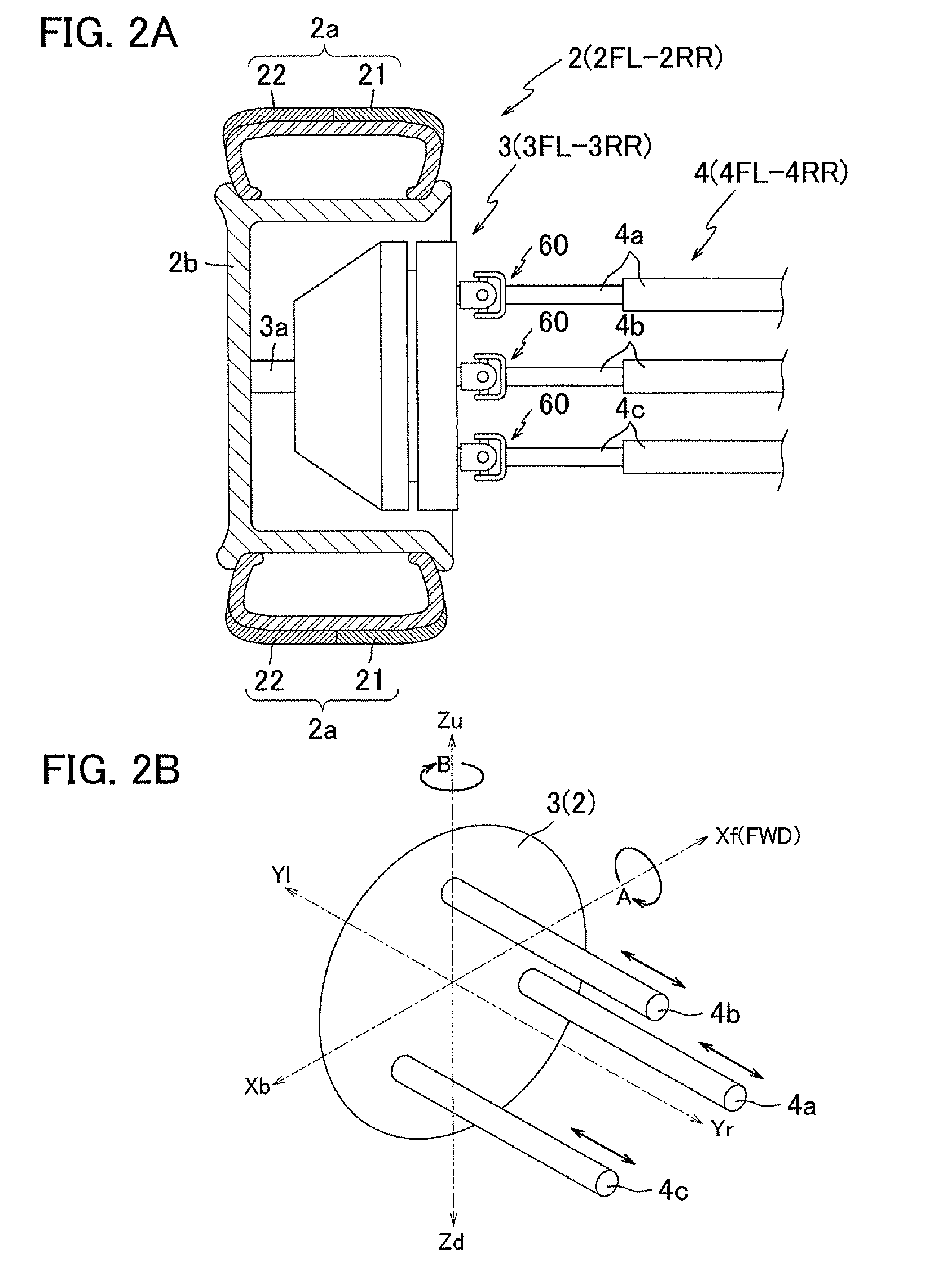

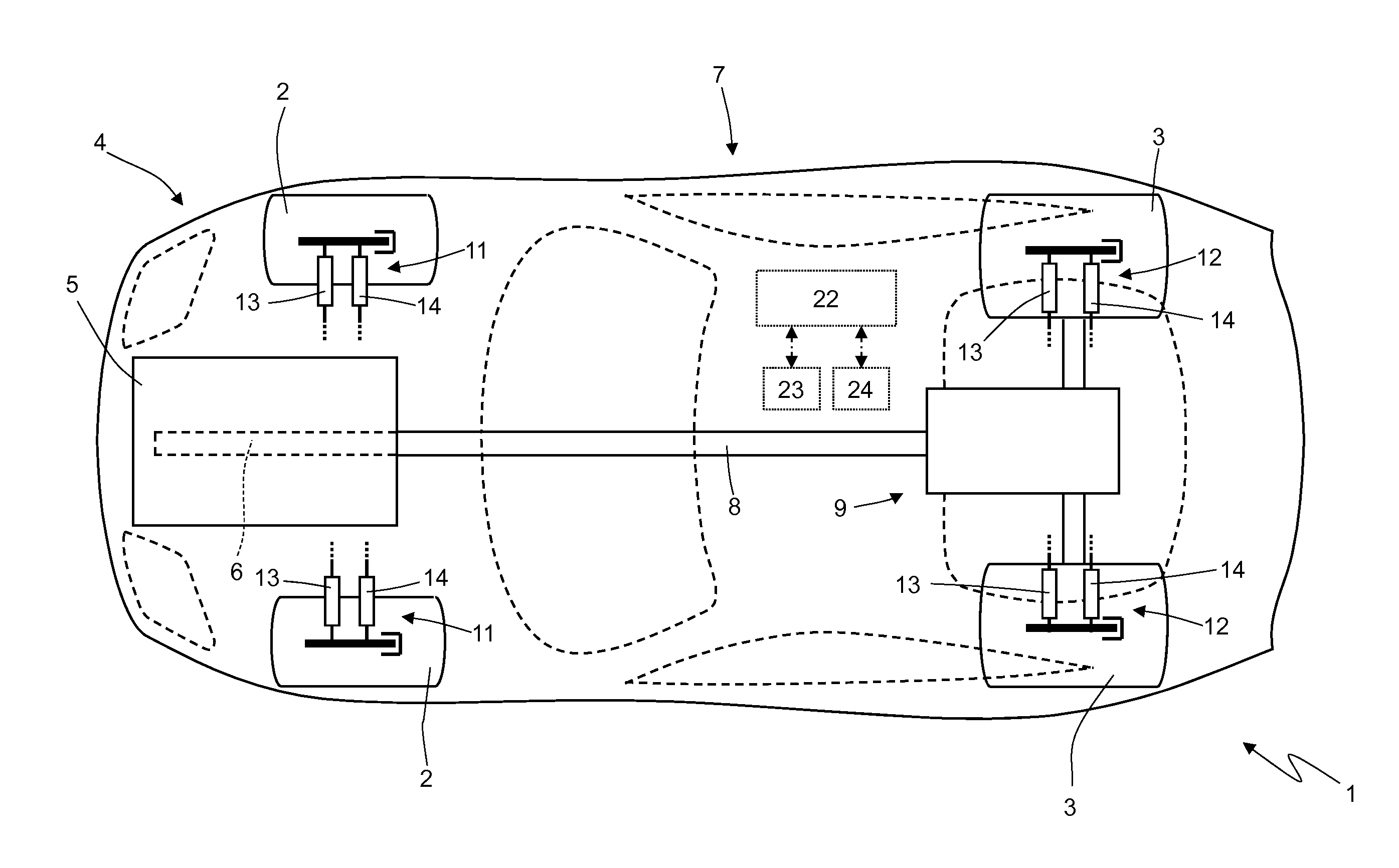

Vehicle control device

ActiveUS20100023213A1Increase contactImprove compatibilityDigital data processing detailsRoad vehicles traffic controlGround contactRolling resistance

A vehicle control device which can at least provide compatibility between a high grip performance and fuel efficiency or compatibility between quietness and fuel efficiency is provided. When a camber angle of a wheel 2 is adjusted to a negative camber, ground contact in a first tread 21 is increased and ground contact in a second tread 22 is decreased. Accordingly, the high grip performance or the quietness is provided. On the other hand, when the camber angle of the wheel 2 is adjusted to a positive camber, the ground contact in the first tread 21 is decreased and the ground contact in the second tread 22 is increased. Accordingly, a rolling resistance becomes low, and fuel saving is achieved. In this manner, by adjusting the camber angle of the wheel 2, the compatibility can be provided between conflicting performances of the high grip performance or the quietness and the fuel saving.

Owner:EQUOS RES

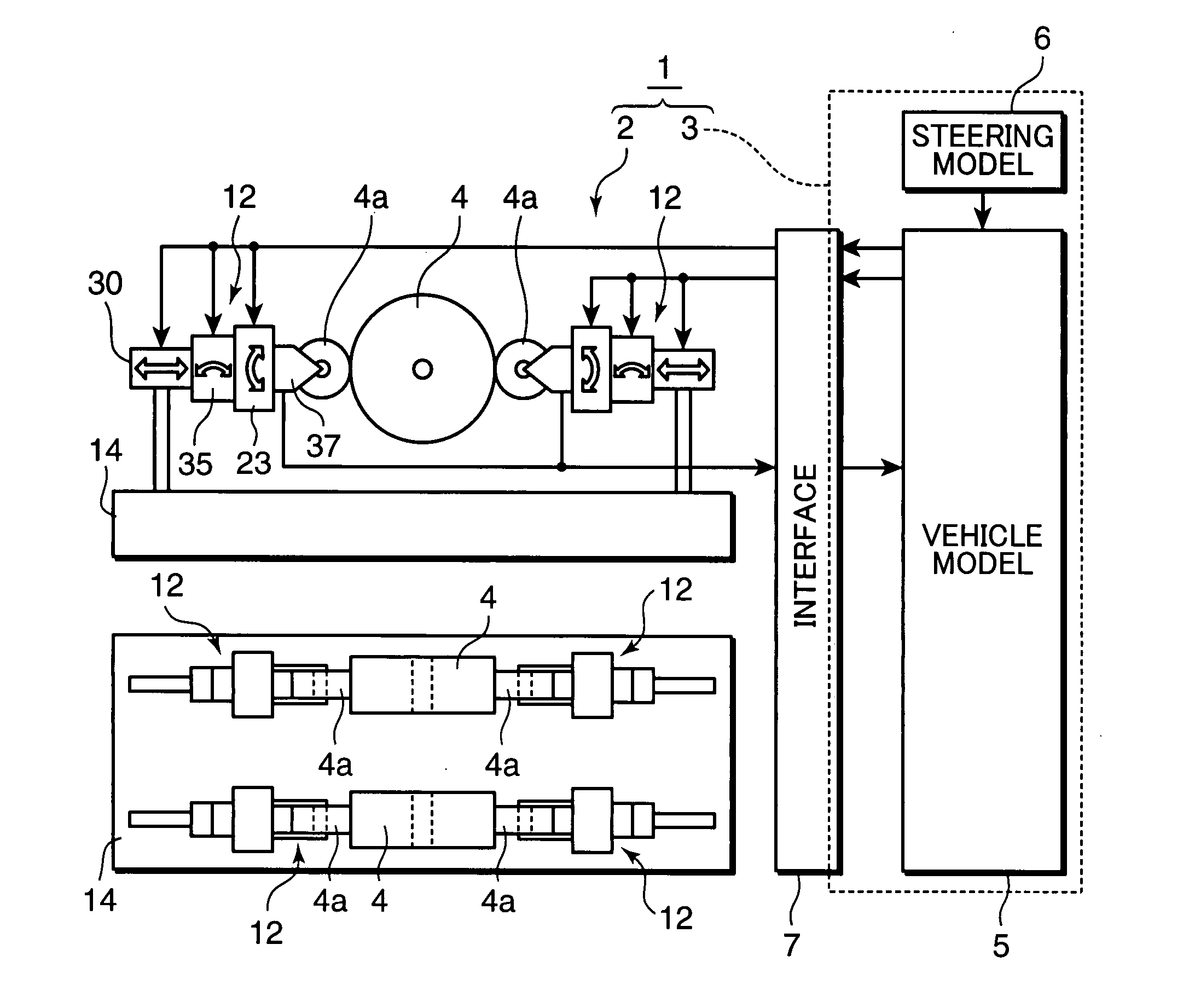

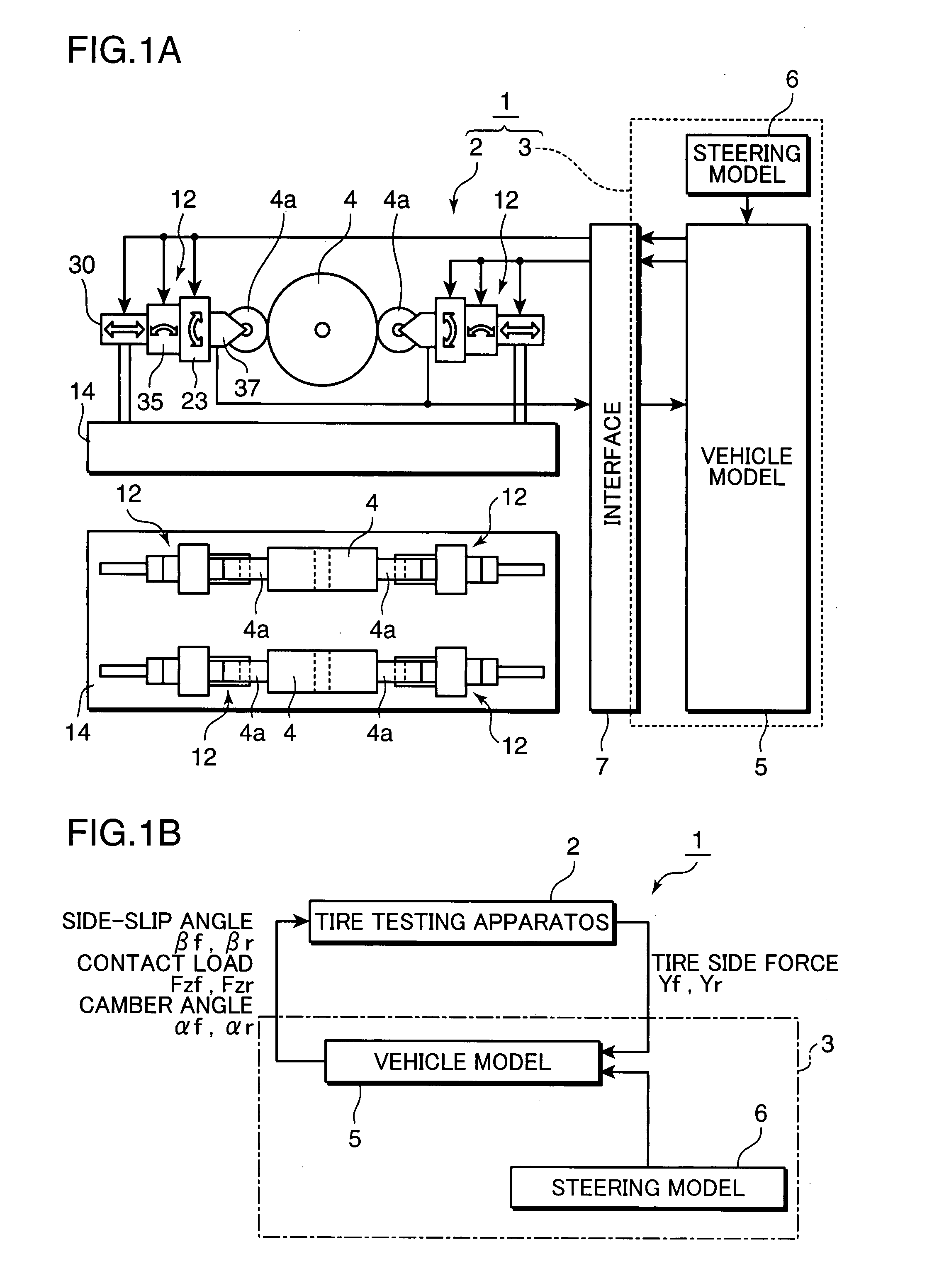

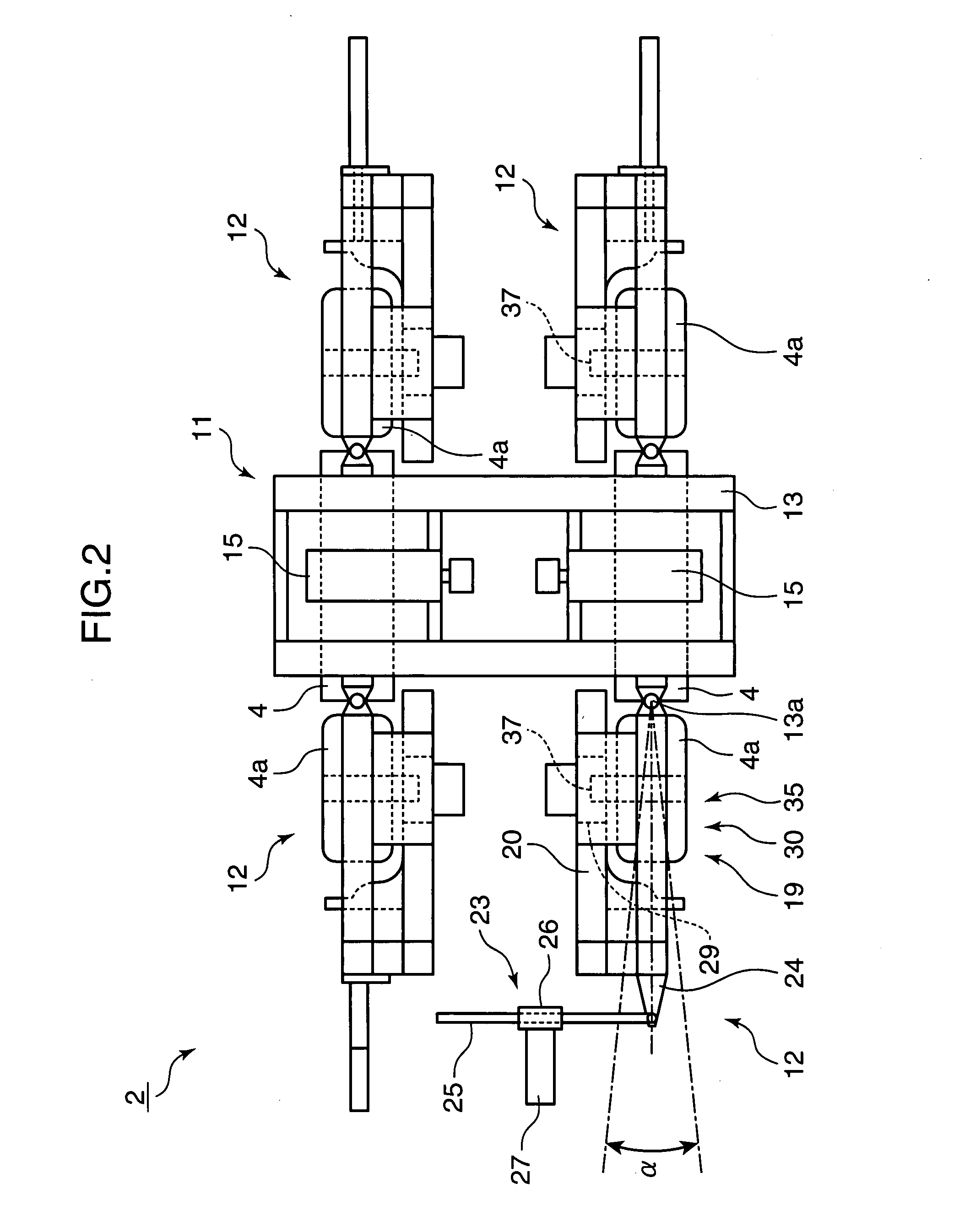

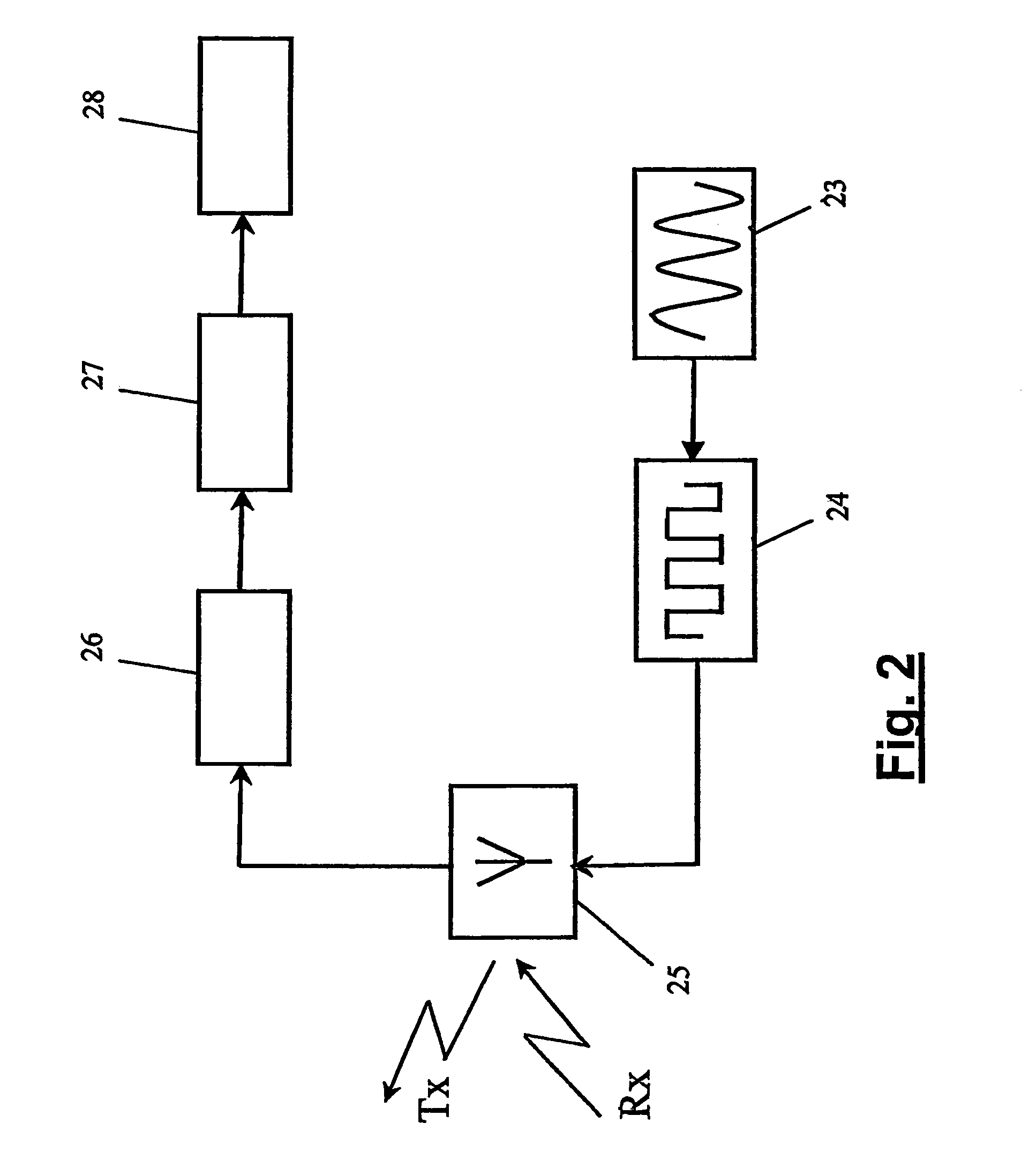

Tire Hil Simulator

InactiveUS20070256484A1Hand manipulated computer devicesInflated body pressure measurementSteering angleCamber angle

A tire HIL simulator is provided which is capable of, in a testing apparatus where a vehicle model is incorporated into a tire testing apparatus, reproducing the behavior of a tire which corresponds to the three-dimensional behavior of a vehicle, even if a three-dimensional vehicle model is used. As a device for resolving this, this tire HIL simulator includes a tire testing apparatus 2 and a controller 3 connected mutually. The tire testing apparatus 2 conducts a running test on a tire 4a using a mimic road surface body 4, and includes a side force measuring device 37 for measuring a tire side force and each actuator which gives a contact load, a side-slip angle and a camber angle, respectively. The controller 3 sets a steering angle and a tire side force from the side force measuring device 37 as an input value and calculates the three-dimensional motion of a vehicle using a vehicle model 5, and based on this calculation result, outputs each command value for the contact load, the side-slip angle and the camber angle to each actuator of the tire testing apparatus 2.

Owner:KOBE STEEL LTD +1

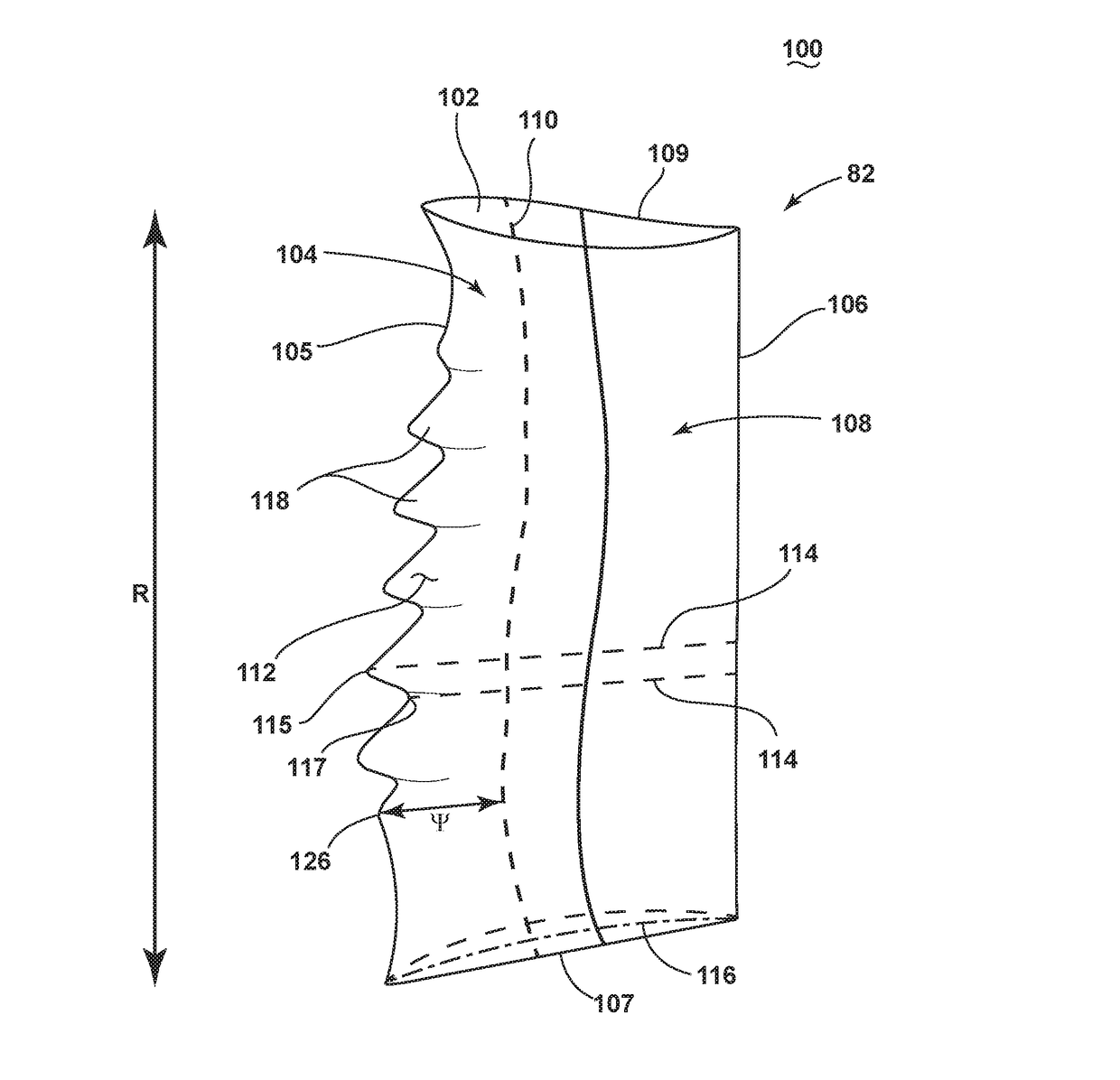

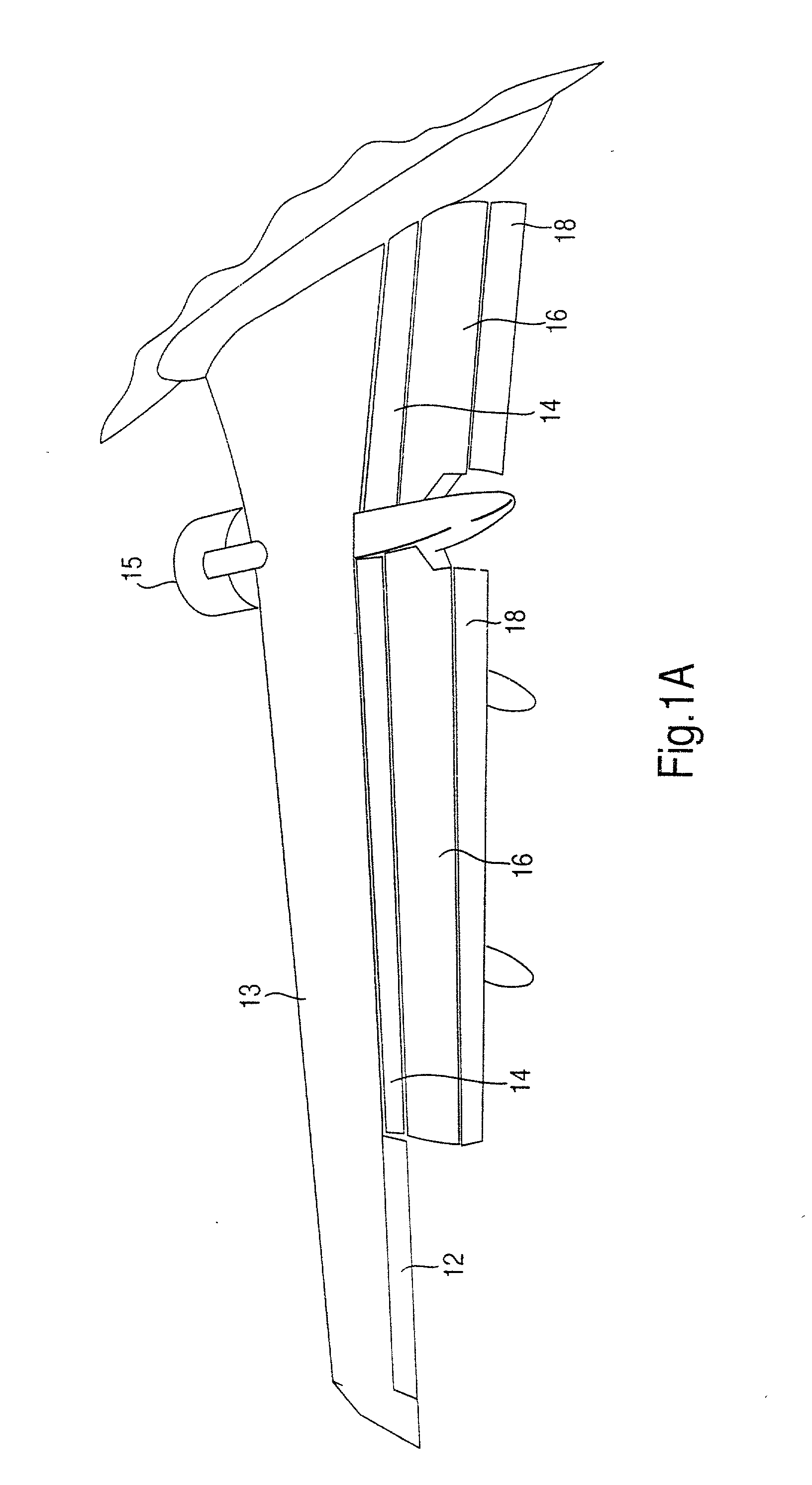

Airfoil assembly with leading edge element

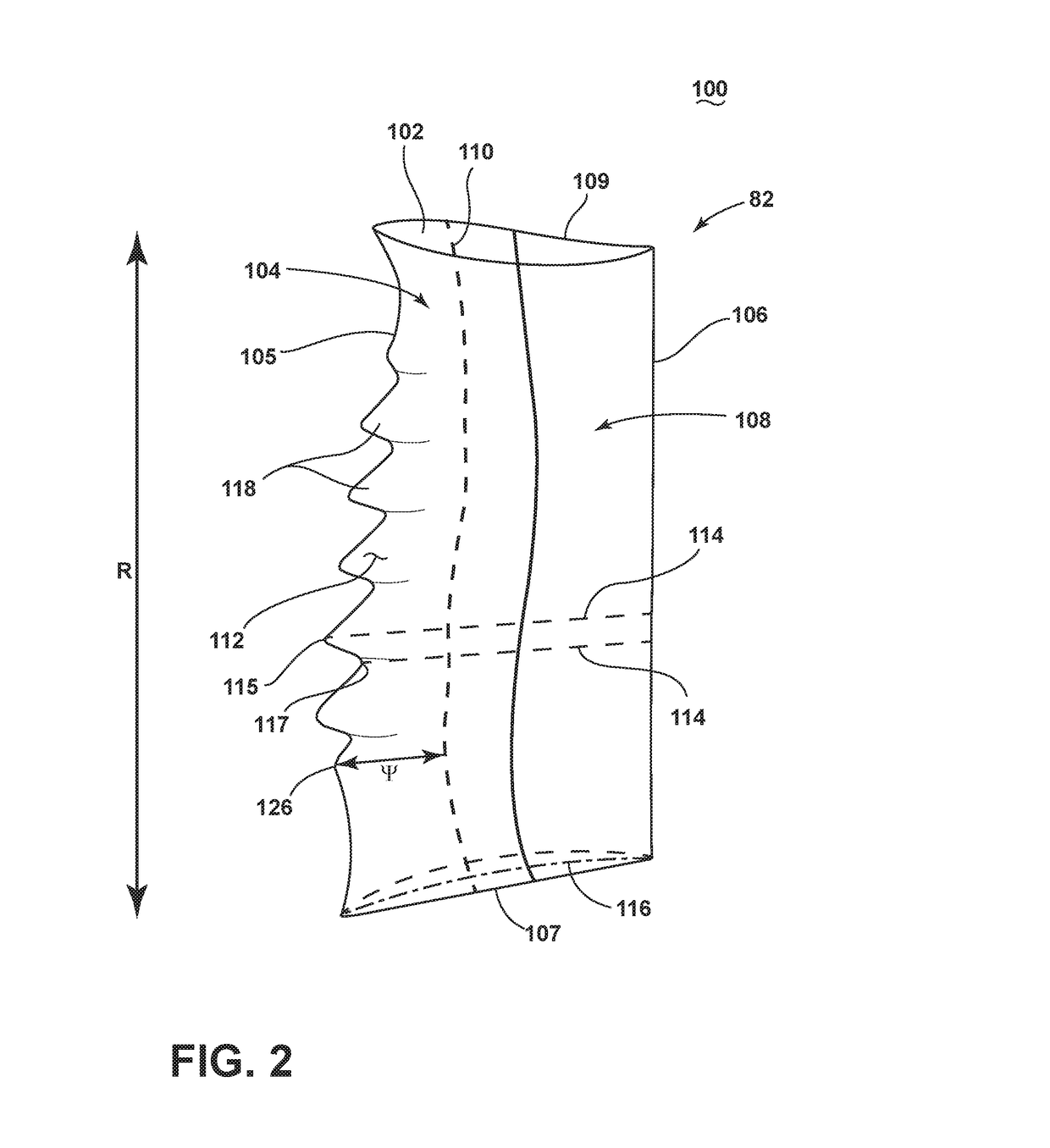

An airfoil assembly including a composite body having a mounting edge and a trailing edge which is secured to a leading edge element defining a 3-D leading edge geometry with both chord and camber variation.

Owner:GENERAL ELECTRIC CO

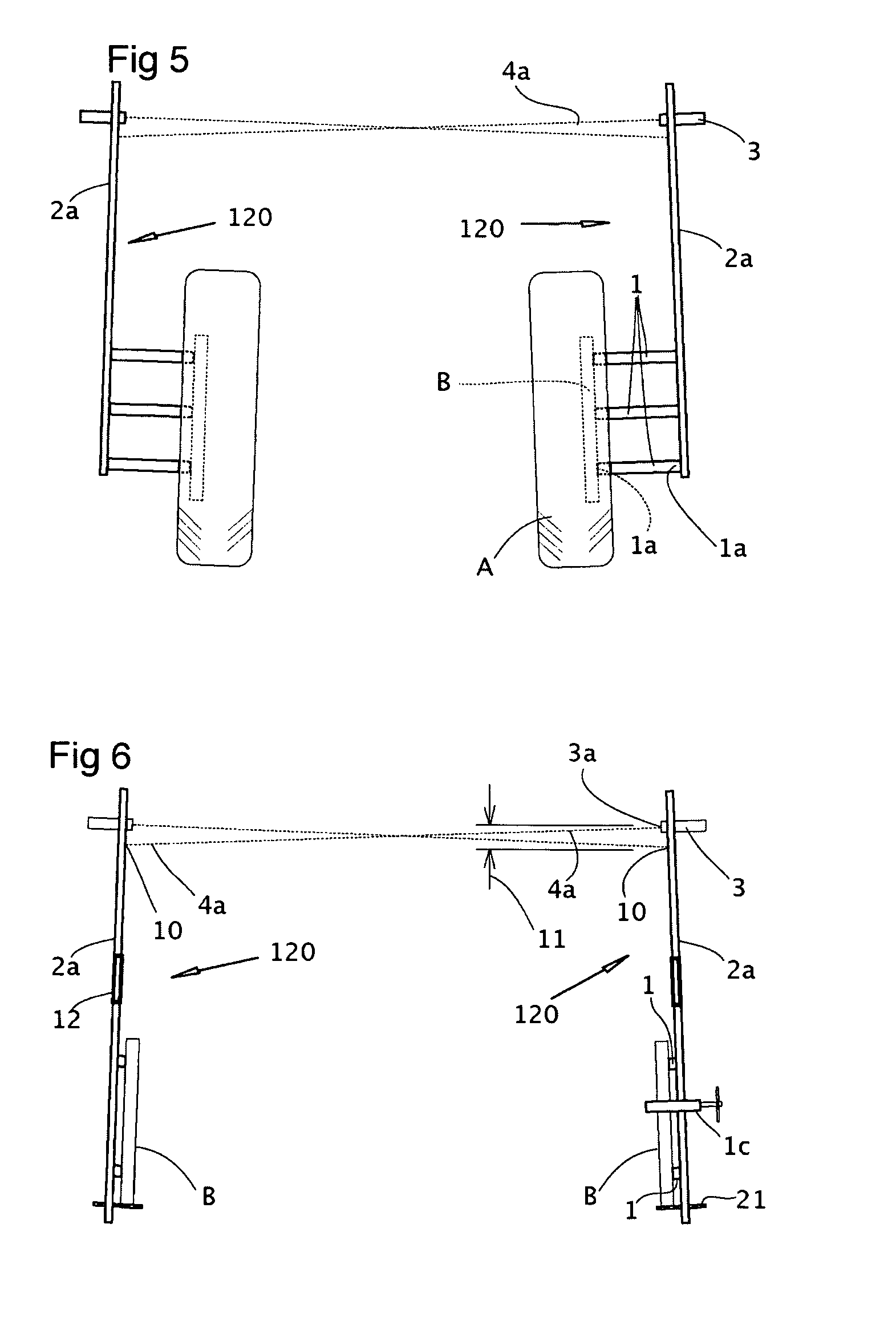

Method for reducing fuel consumption in aircraft

InactiveUS20020005461A1Increase arcIncreasing chordAircraft controlEfficient propulsion technologiesFlight control surfacesPush pull

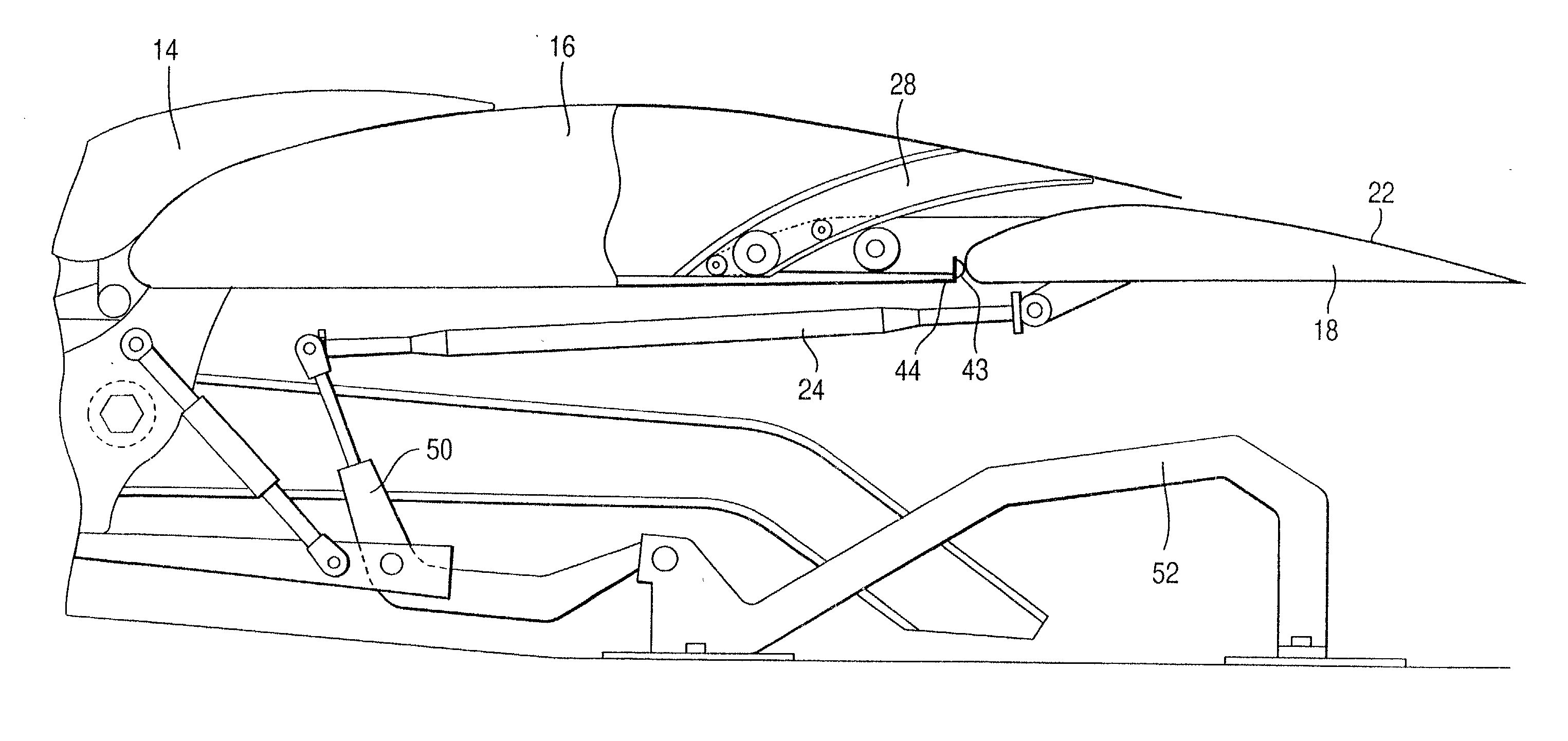

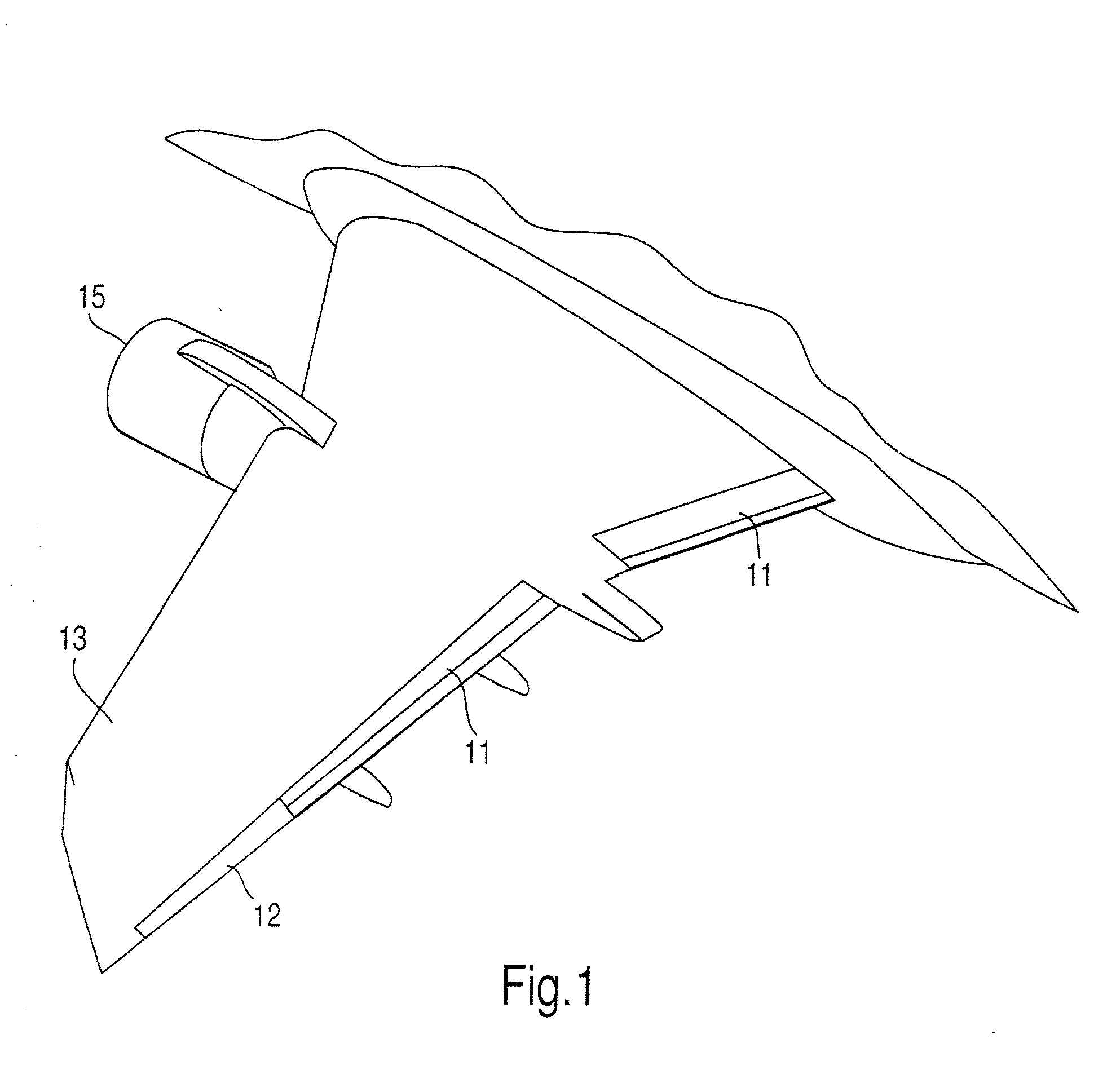

A method and means are provided for increasing the aerodynamic efficiency of an airfoil employed by an aircraft. The method utilizes the primary flight control surfaces (11) (12) contiguous to the airfoil's trailing edge and relocates these devices to novel positions (21) (23) resulting in an expanded cord and enhanced camber for the aircraft wing (13). Self-adjusting push-pull rods (25) (60) replace conventional solid rods (24) where necessary in combination with a re-rigging of the flight control surfaces (11) (12) to predetermined positions (21) (23). Any voids created by this modification between the shared upper and lower fluid flow surfaces of the aircraft wing (13) and its flight control surfaces (11) (12) are eliminated through the installation of appropriate structure (40) or seal (43). Thus the aircraft wing (13) retains a unique geometric profile as a usual configuration.

Owner:AEROTECH SERVICES +1

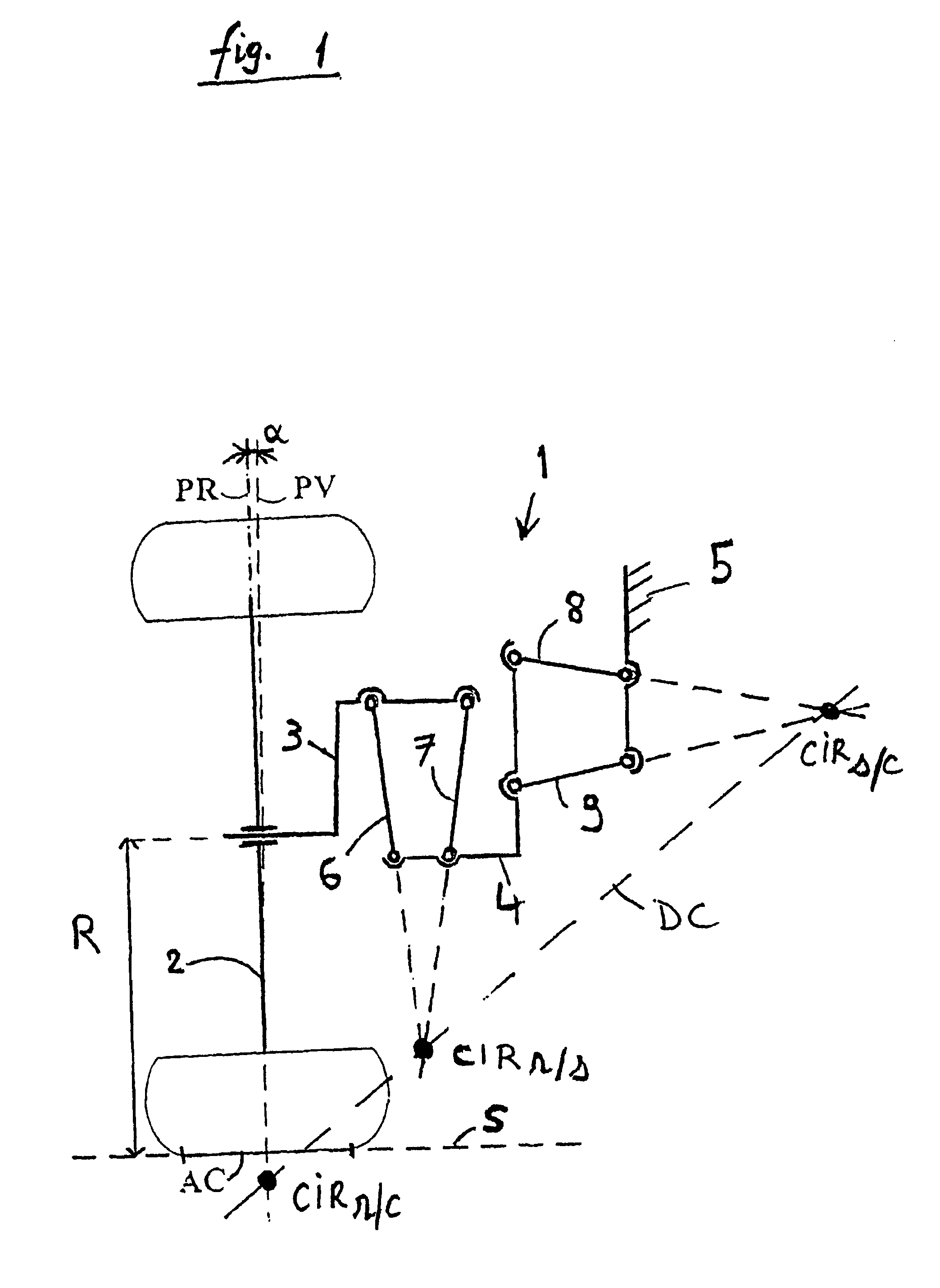

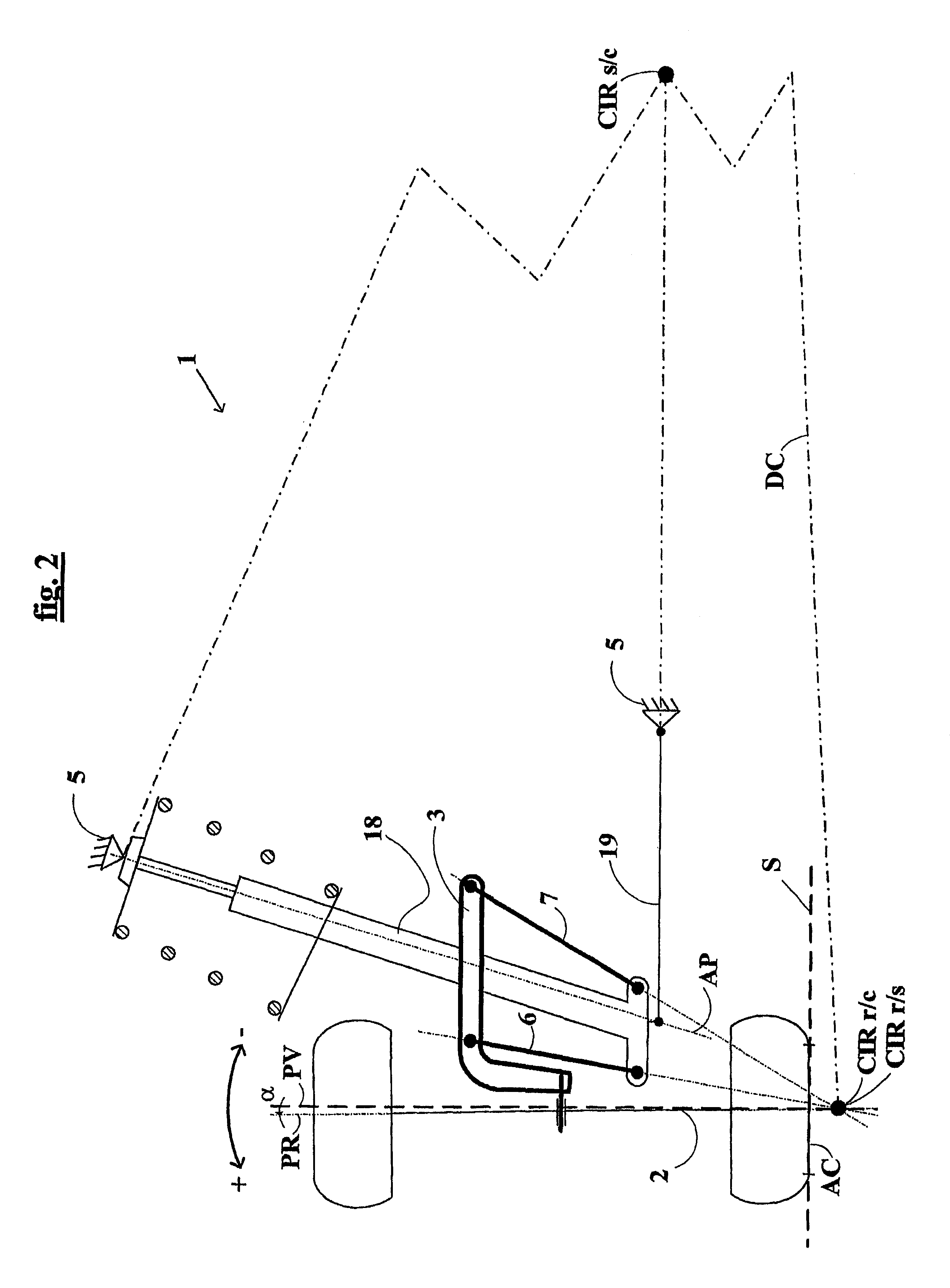

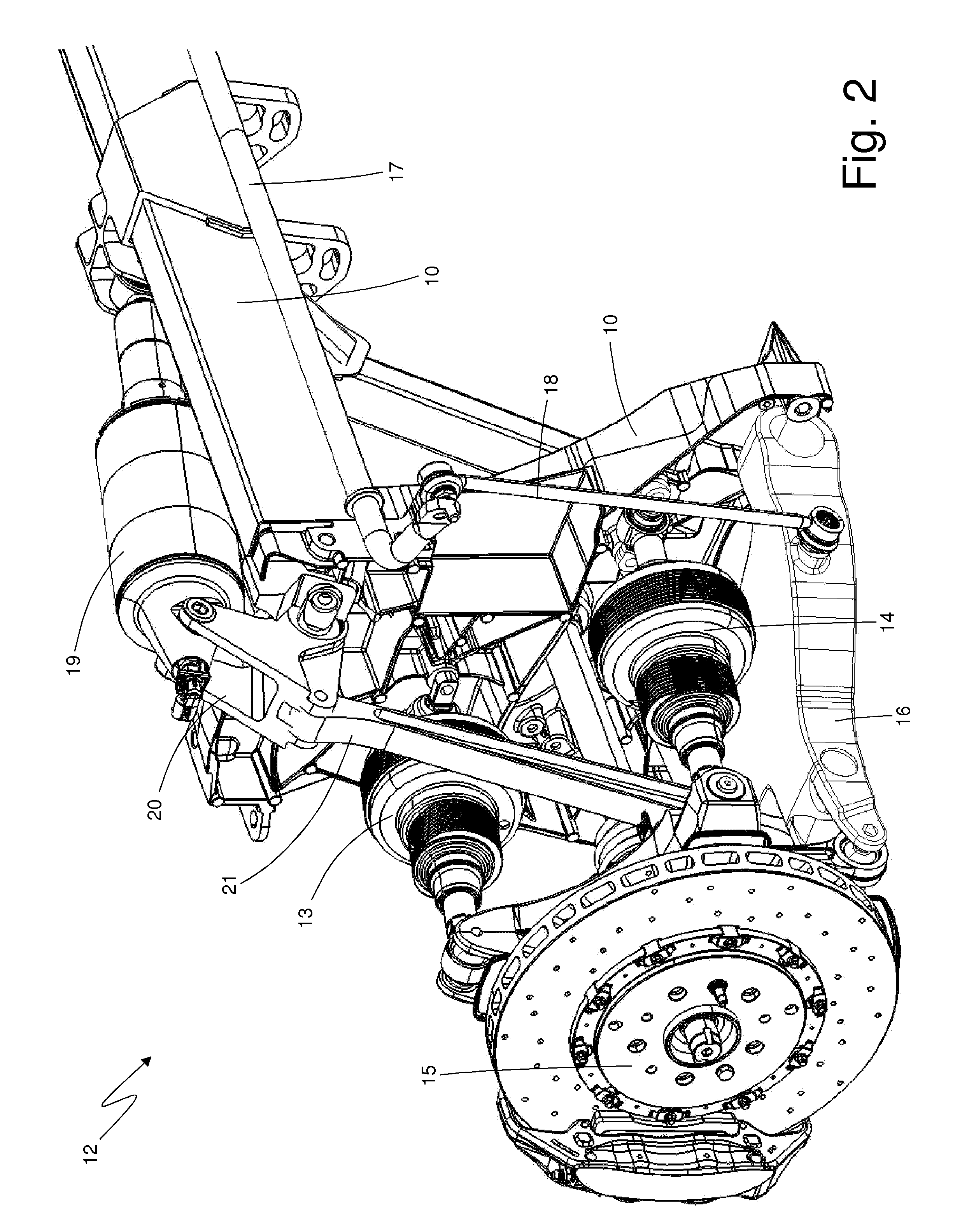

Vehicle suspension with camber control

InactiveUS6688620B2Limit track variationLimit energy necessarySteering partsResilient suspensionsGround contactCamber angle

A vehicular suspension device comprises a wheel carrier which is articulated relative to the suspension elements. This connection is provided by rigid connection rods. This additional degree of freedom permits variation of the camber angle independently of the suspension spring movement and of the deformations of its elements. The variation of the camber is preferably controlled by the forces sustained by the wheel in the ground contact area of the tire. This is obtained by a configuration in which the movements of the wheel relative to the body of the vehicle allow an instantaneous center of rotation which is situated beneath the plane of the ground.

Owner:MICHELIN RECH & TECH SA

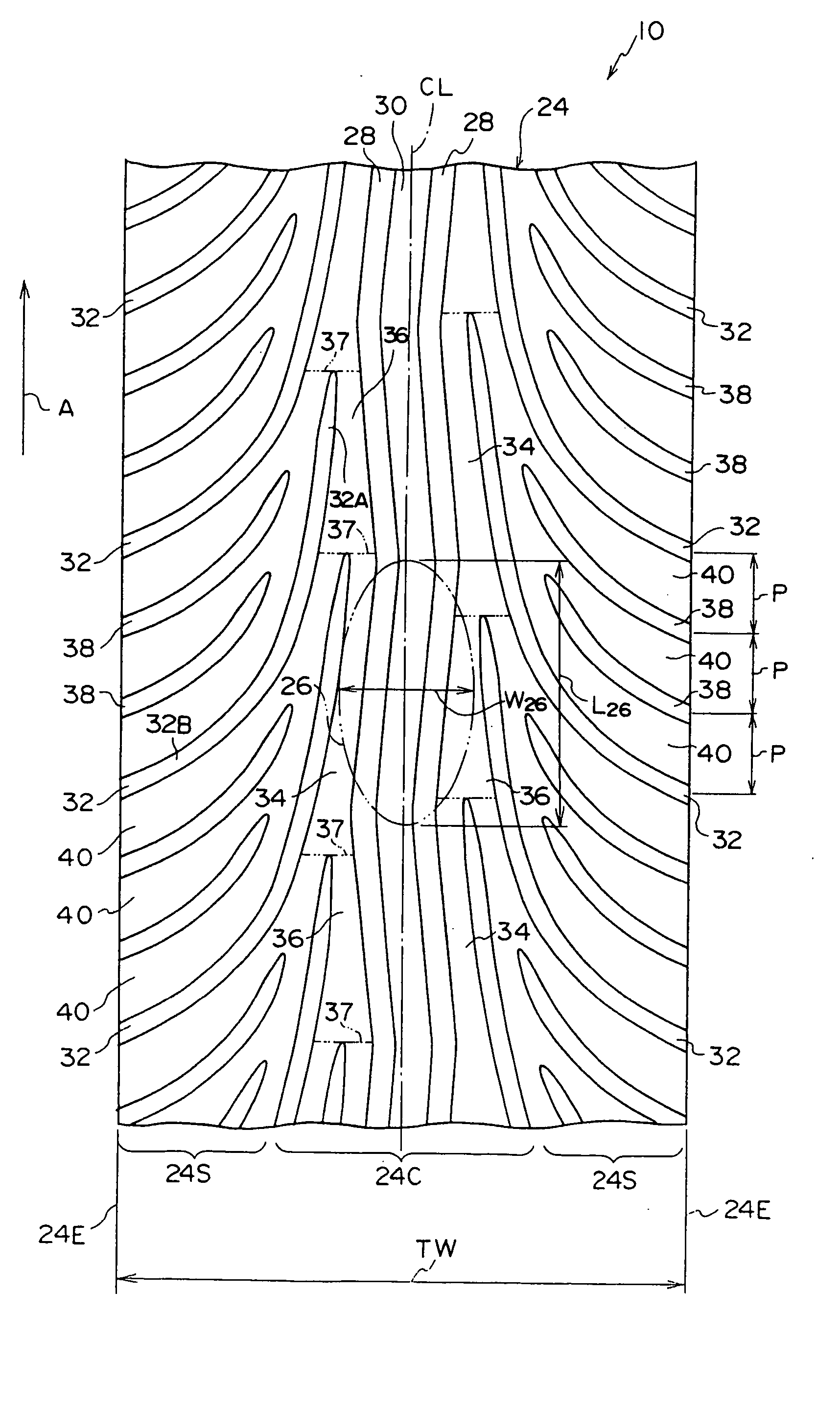

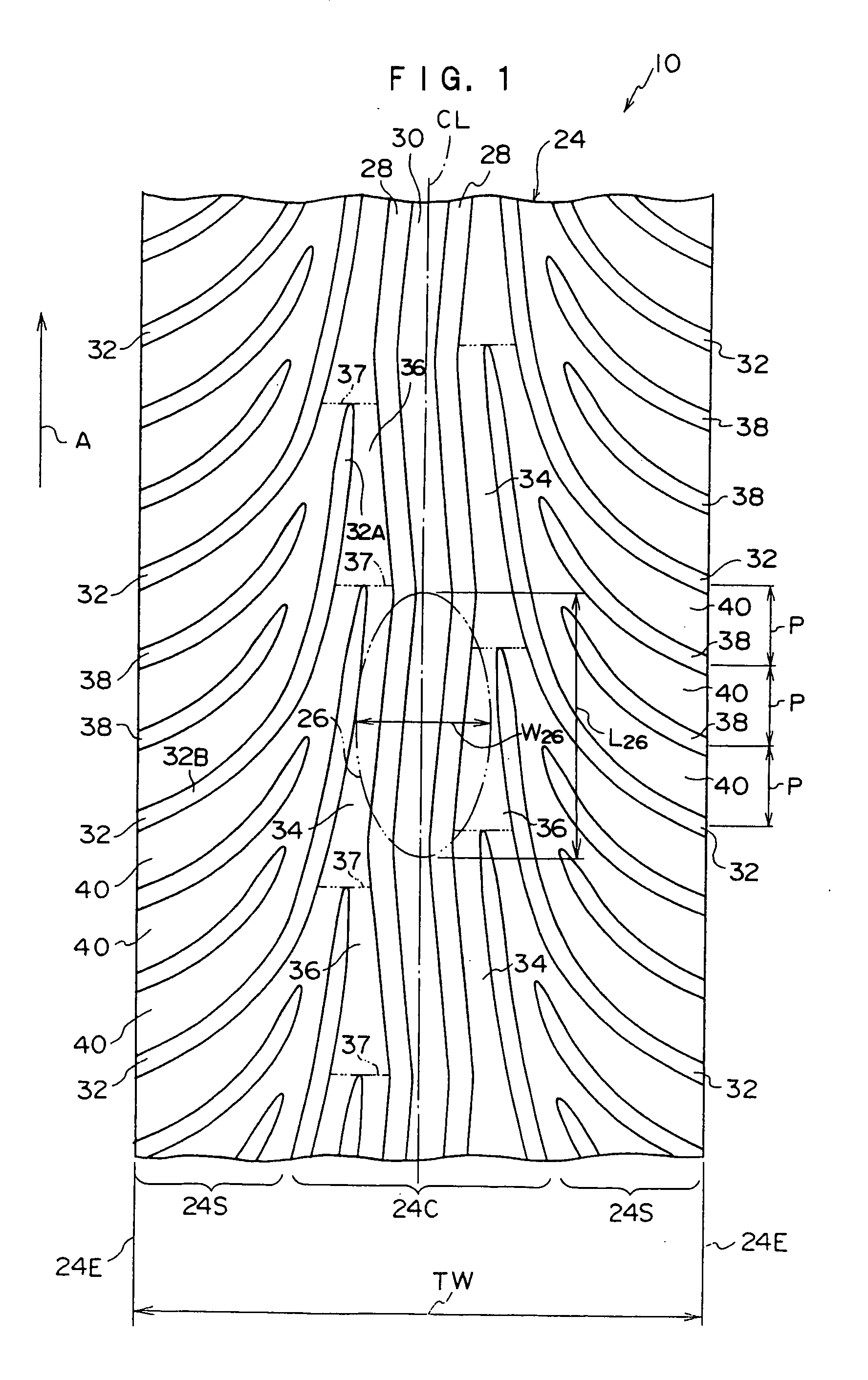

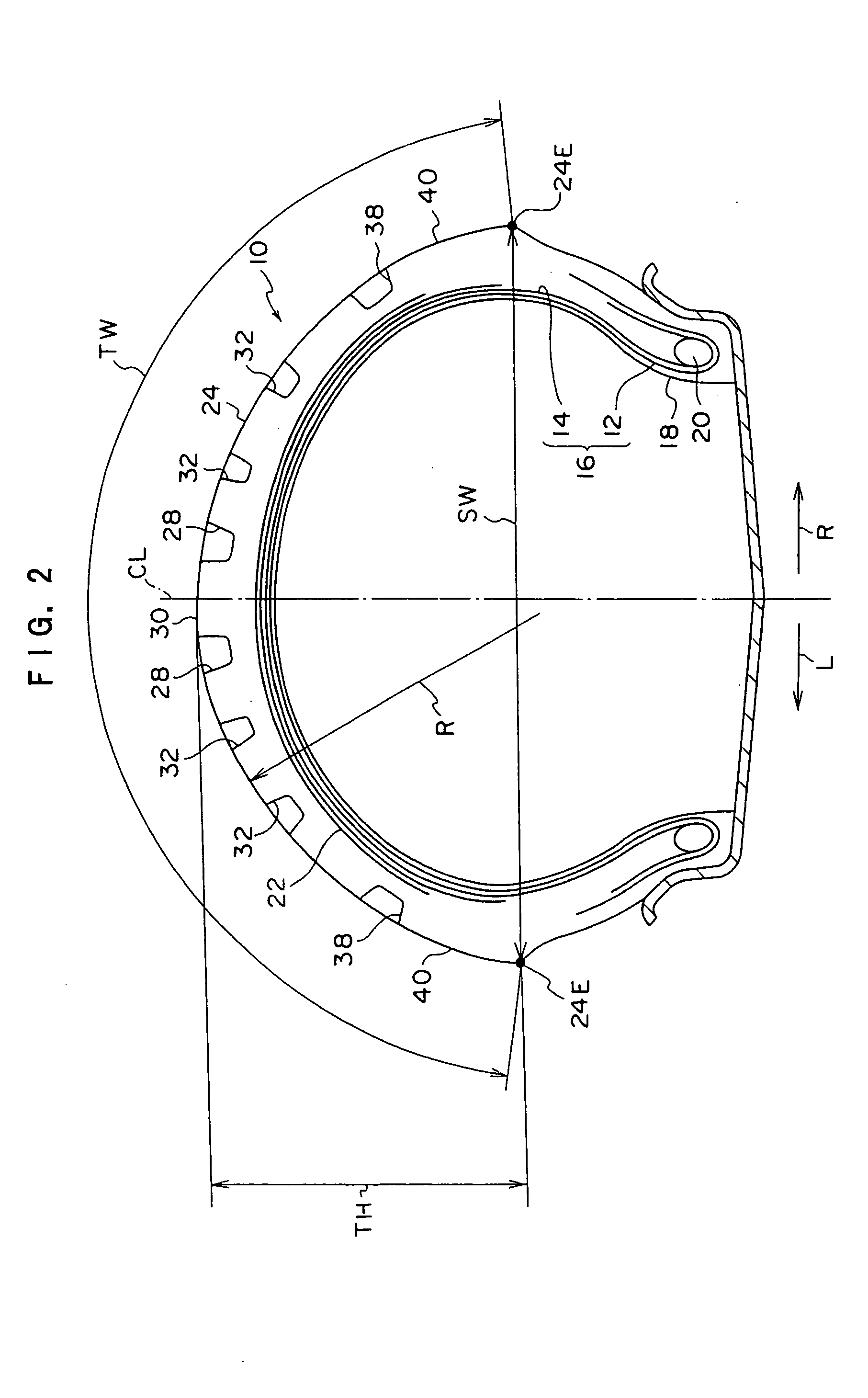

Pneumatic tire for motorcycle

ActiveUS20050115653A1Rigidity levelDeterioration of drainage due to a change of groove depth can be preventedMotorcycle tyresTyre tread bands/patternsCamber angleEngineering

To provide a pneumatic tire for a motorcycle in which both wear resistance and wet steering stability can be attained. Since a pair of zigzag circumferential direction grooves 28 are positioned at the center of a tread central region 24C and has an amplitude, even when a certain camber angle is exceeded, an occurrence of a sudden separation of the zigzag circumferential direction groove 28 from a road-contact surface 26 can be prevented, whereby deterioration of wet steering stability can be suppressed. When the camber angle increases, water in a road-contact surface 26 is drained by inclining grooves 32 which are arranged at an external side of the zigzag circumferential direction groove 28. Since sharp inclining groove portions 32A of the inclining grooves 32 are positioned in the tread central region 24C, and no lug groove components are employed, circumferential direction rigidities of land portions in the tread central region 24C are high and exhibits excellent wear resistance. Since loose inclining groove portions 32B and sub-inclining grooves 38 of the inclining grooves 32 are positioned in tread side regions 24S, rigidities of land portions 40 resisting to inputs at the time of a large camber angle are high, and accordingly, wear resistance is high.

Owner:BRIDGESTONE CORP

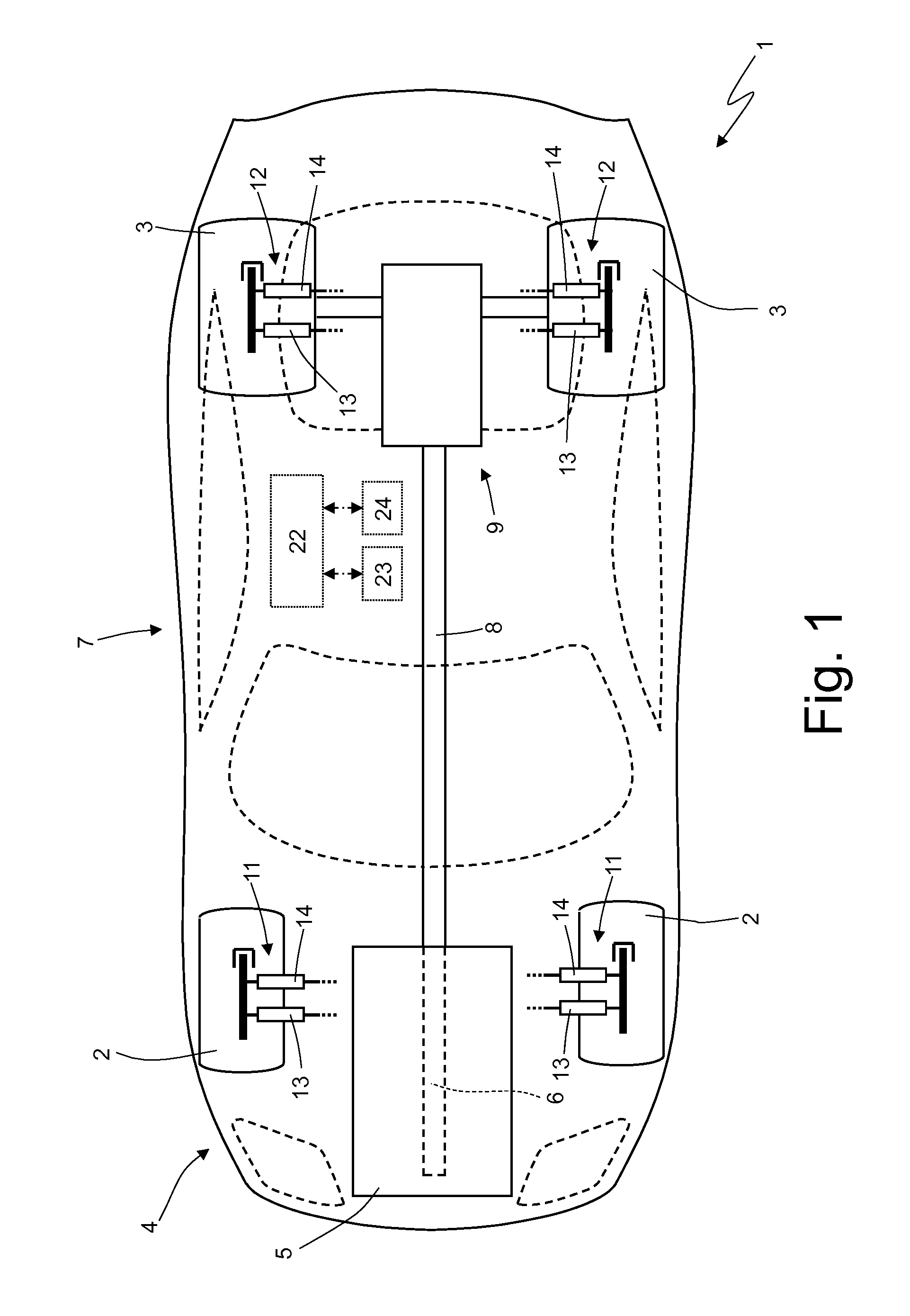

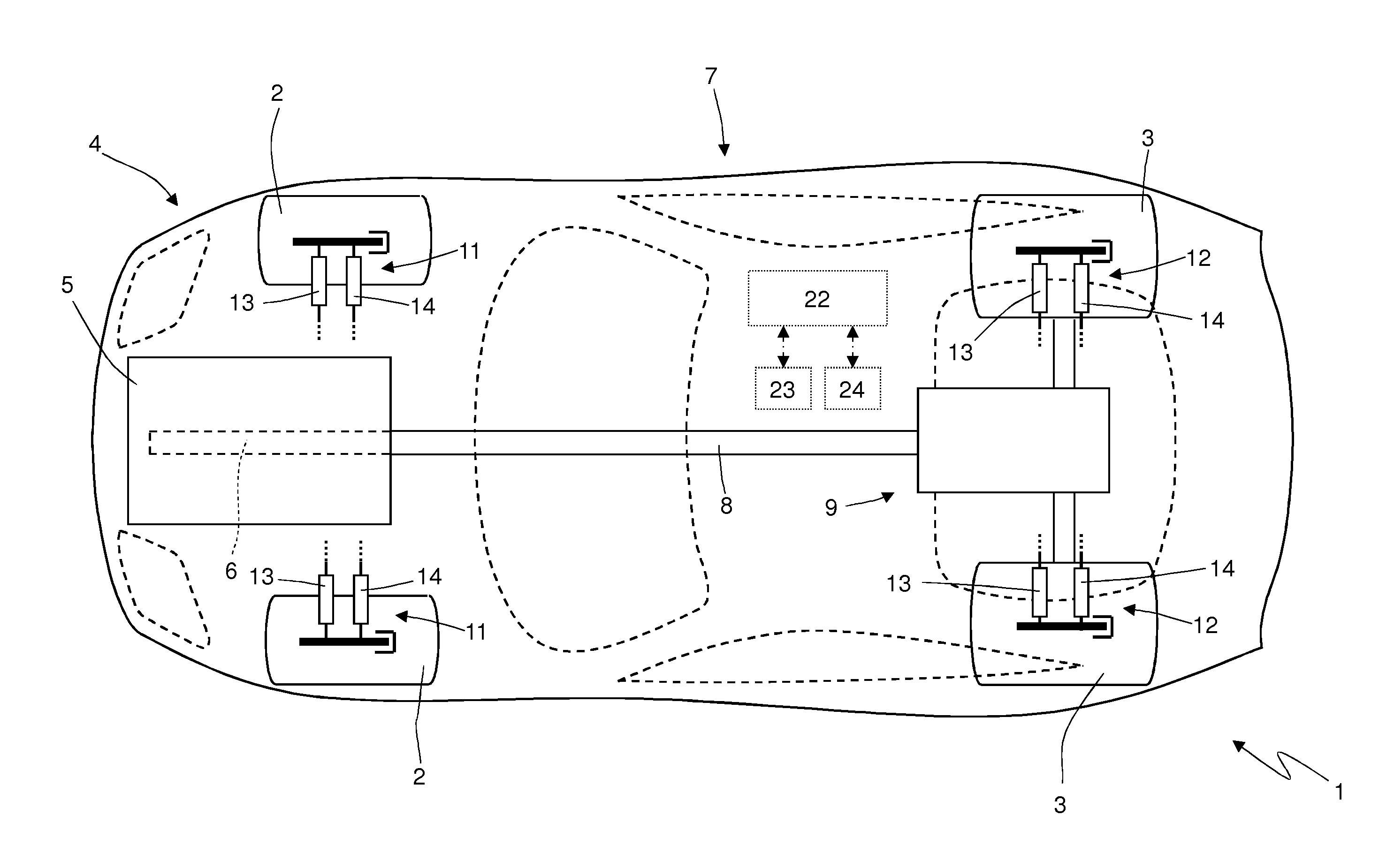

Control method of an active suspension of a car

ActiveUS20130197756A1Easy and cost-effectiveDigital data processing detailsAnimal undercarriagesCamber angleSlip angle

A control method for an active suspension of a vehicle, wherein the determination of an optimal camber angle of the active suspension includes the steps of: estimating the slip angle of the wheel of the active suspension; estimating the vertical force which weighs on the wheel of the active suspension; estimating the transverse force which is transferred to the ground by the wheel of the active suspension as a function of the slip angle of the wheel of the active suspension and as a function of the vertical force which weighs on the wheel of the active suspension; and determines the optimal camber angle as a function of the transverse force which is transferred to the ground by the wheel of the active suspension.

Owner:SPAN FERRARI SPA

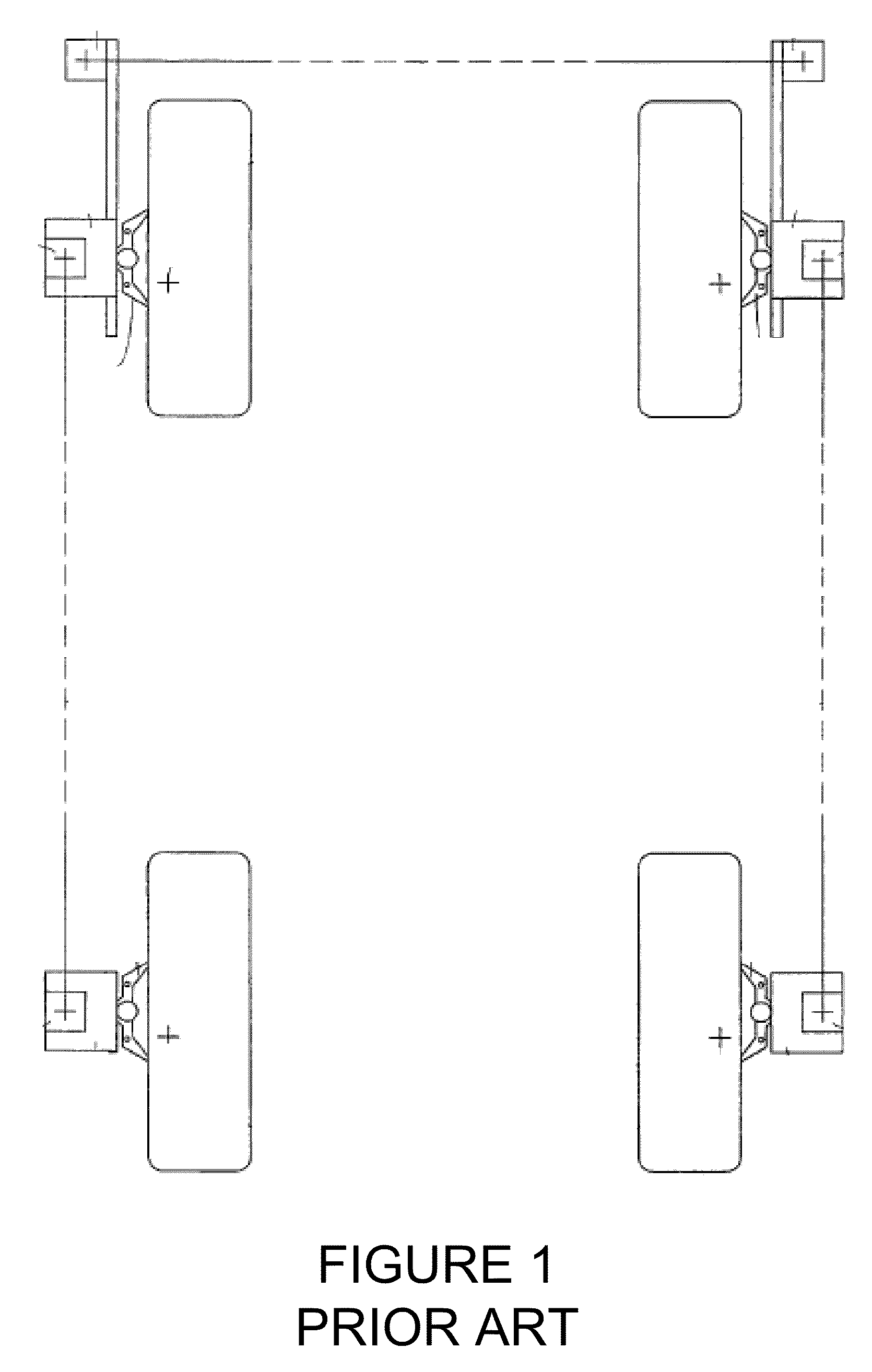

Wheel alignment gauge

InactiveUS20060185180A1Accurately indicatedAngles/taper measurementsUsing electrical meansEngineeringSpoke

The present invention is a wheel alignment gauge for checking the ‘toe’ and ‘camber’ of the wheels. The gauge can be used with the vehicle on the ground. The gauge uses three identical magnet-ended extension rods which are inserted through the vent holes or spokes of the wheels. The rod's inboard ends magnetically attach to the disc brake rotor surface leaving the outboard ends clear of the vehicle's wheel and bodywork. Flat plates rest on the ground and magnetically attach to the outboard ends to create a plane parallel to the rotor and wheel. Laser-ended alignment arms magnetically attach to the plates, are level, and have forward ends that extend beyond the front of the vehicle allowing the lasers to project ate target sheets centered on the lasers. Each arm also has a perpendicular location arm that contacts the front of the wheel (or rotor when the wheels are removed). The laser's dots provide a off-center measurement, which, along with the arm's spacing, one can calculate the trigonometric SINE of the wheel's angle. The gauge can be quickly changed from vertical to horizontal for camber or toe measurements respectively. If adjustment is required, the vehicle is raised on its suspension, the wheels are removed and the gauge re-attached to locate on the rotors to direct alignment adjustments.

Owner:MACKELVIE WINSTON

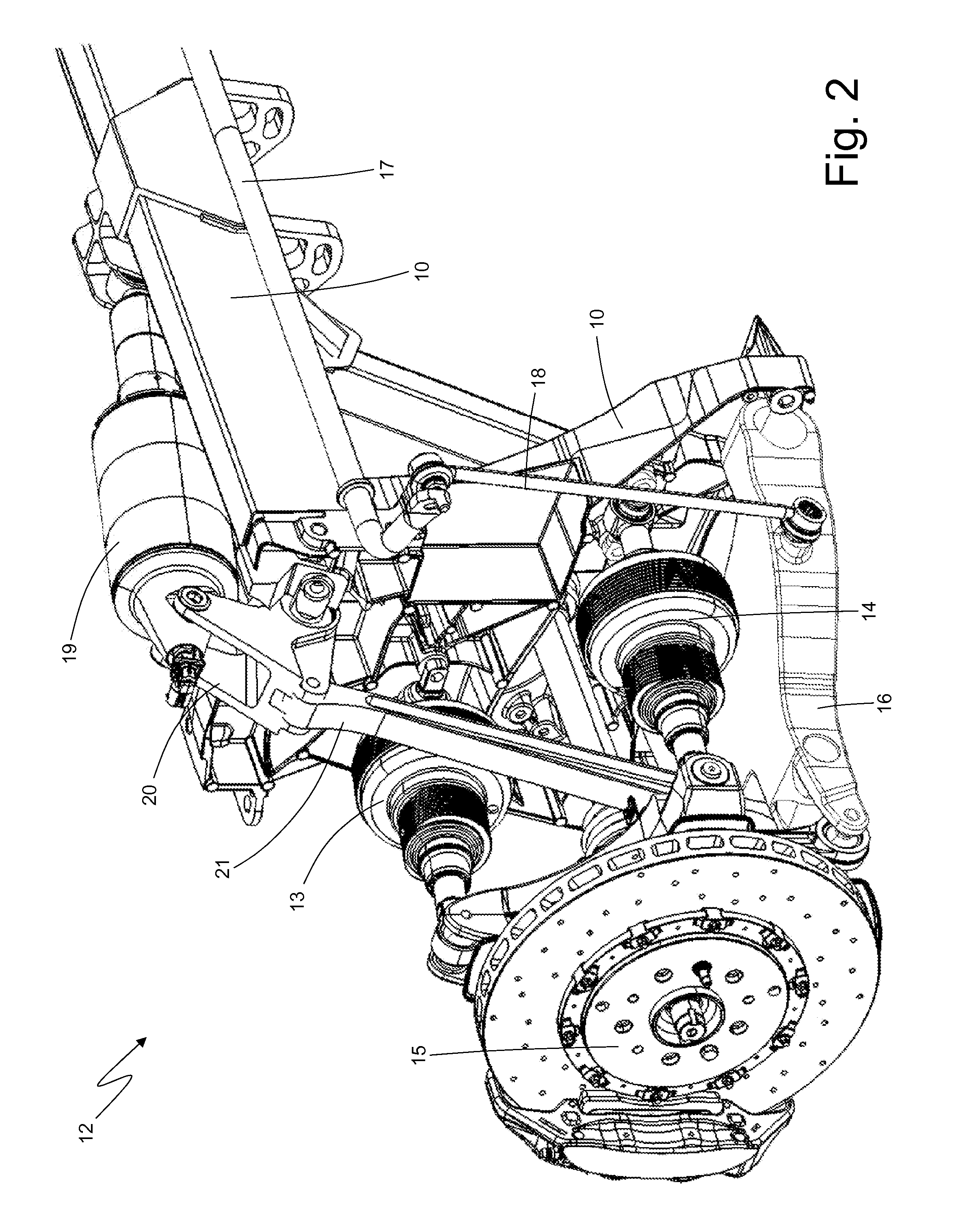

Method to control toe angle and camber angle in active rear suspensions of cars

ActiveUS20130190980A1Easy and cost-effectiveDigital data processing detailsAnimal undercarriagesCamber angleControl theory

A control method of the toe and camber angles of rear active suspensions of a vehicle; the control method includes the steps of:detecting when the vehicle follows a curved trajectory; conferring negative toe angles combined with zero camber angles to the rear active suspensions, when starting the curved trajectory and when the vehicle enters the curved trajectory; and conferring positive camber angles combined with negative toe angles to the rear active suspensions, while following the curved trajectory and when the vehicle is inscribed in the curved trajectory.

Owner:SPAN FERRARI SPA

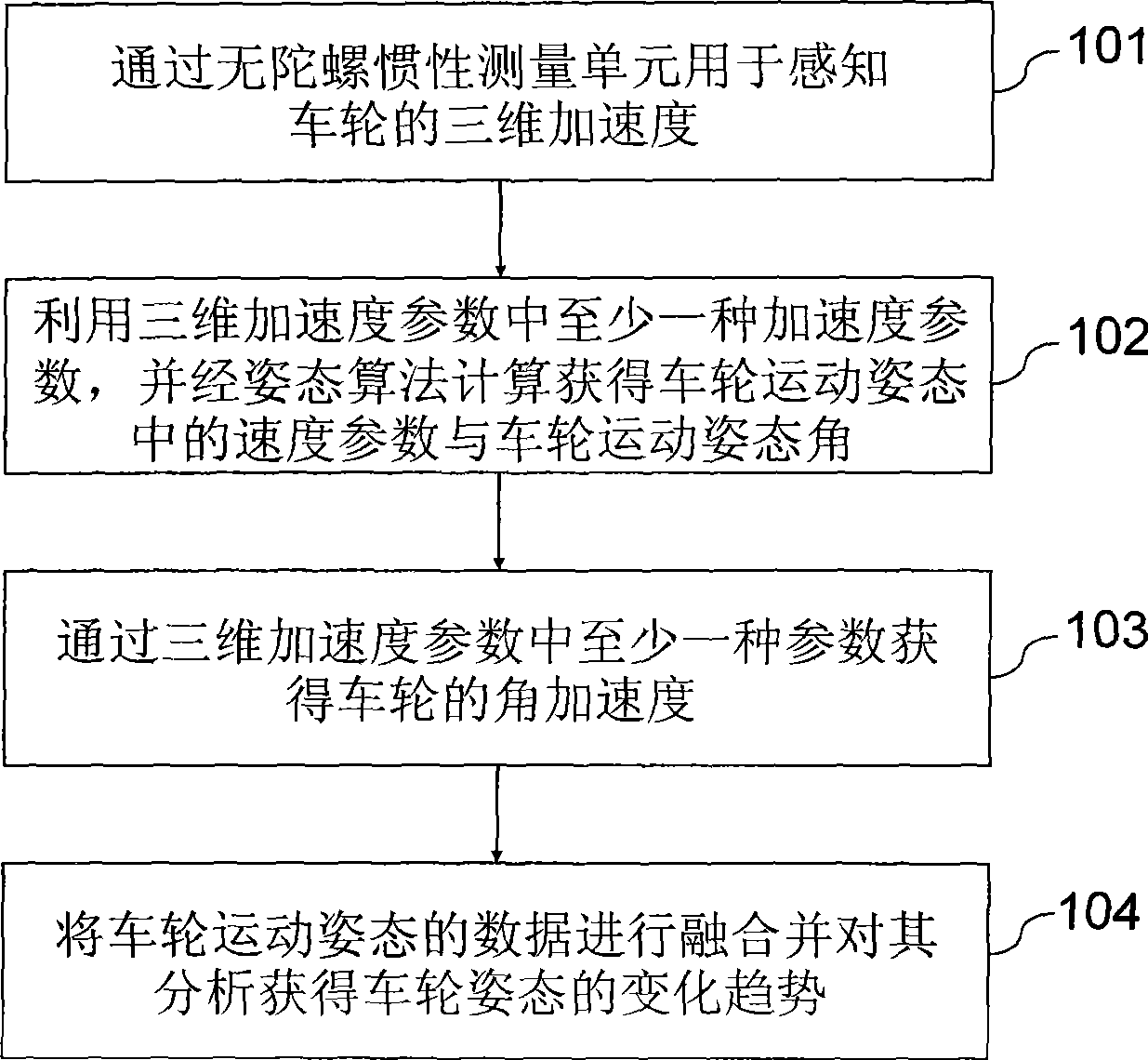

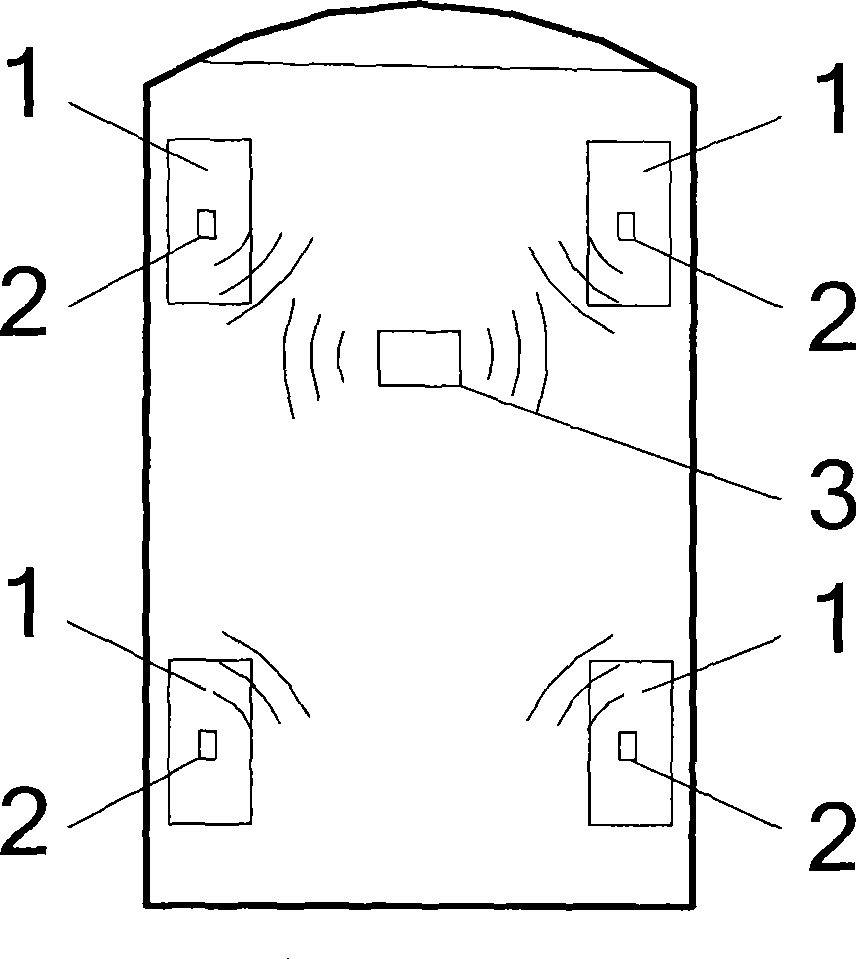

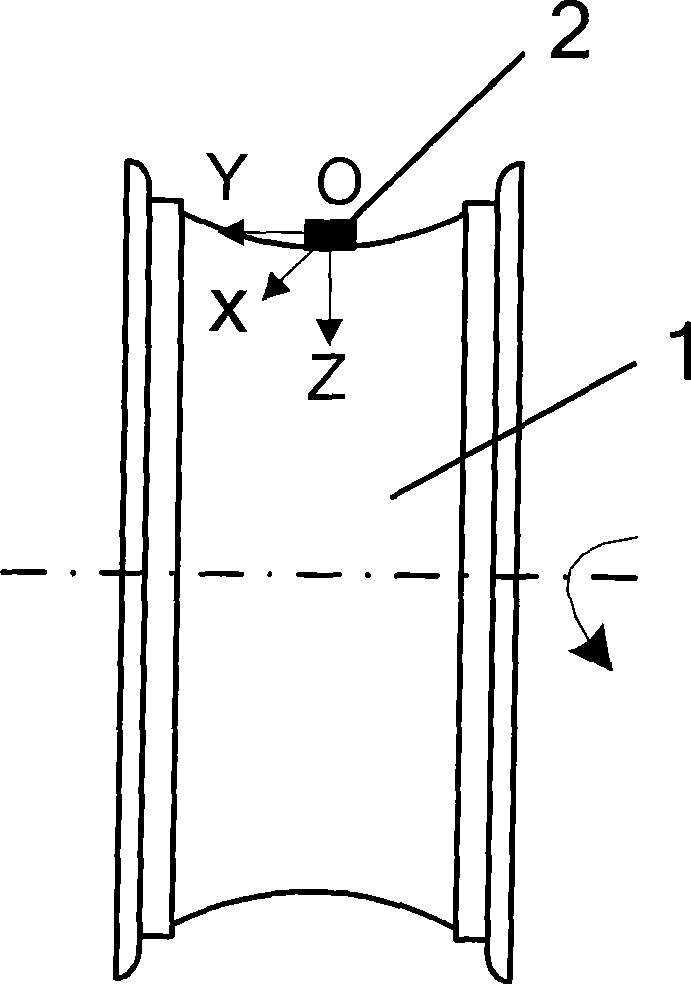

Wheel-loaded intelligent sensing wheel movement attitude monitoring method

InactiveCN101498621ASports attitude monitoringAdd prediction functionTyre measurementsVehicle wheel testingSimulationAngular acceleration

The invention discloses a movement posture monitoring method based on a wheeled intelligent sensing wheel, which comprises the following steps: an equatorial plane of a hub of each wheel of a vehicle is provided with a top-free microinertia measuring unit, sensing signals are conditioned, digitized and calculated by a posture algorithm way, and main movement posture parameters of the wheels are obtained; the main movement posture parameters of the monitored wheels comprise tangential acceleration, sideward acceleration, acceleration centripetal, advance speed, side velocity, angular acceleration, camber angles, slip angles, heading angles, and the like; after the parameters are inosculated and analyzed through a plurality of sending data, the movement safety condition of the wheels such as the unbalanced degree, looseness, fly off, slippage, and the like of wheels can be monitored and actively estimated, thereby being favorable for preventing and reducing the occurrence of traffic accidents.

Owner:SOUTH CHINA UNIV OF TECH

Method and system for determining a cornering angle of a tyre during the running of a vehicle

A method and a system for determining a cornering angle of a tyre fitted on a vehicle during running of the vehicle on a rolling surface. The tyre has an equatorial plane. In the method, the length of the contact region between the tyre and the rolling surface is estimated, the length being measured at a distance from the equatorial plane; the load exerted on the tyre is estimated; a camber angle to which the tyre is subjected, is estimated; and the cornering angle is derived from the camber angle, tyre load and contact region length.

Owner:PIRELLI TYRE SPA

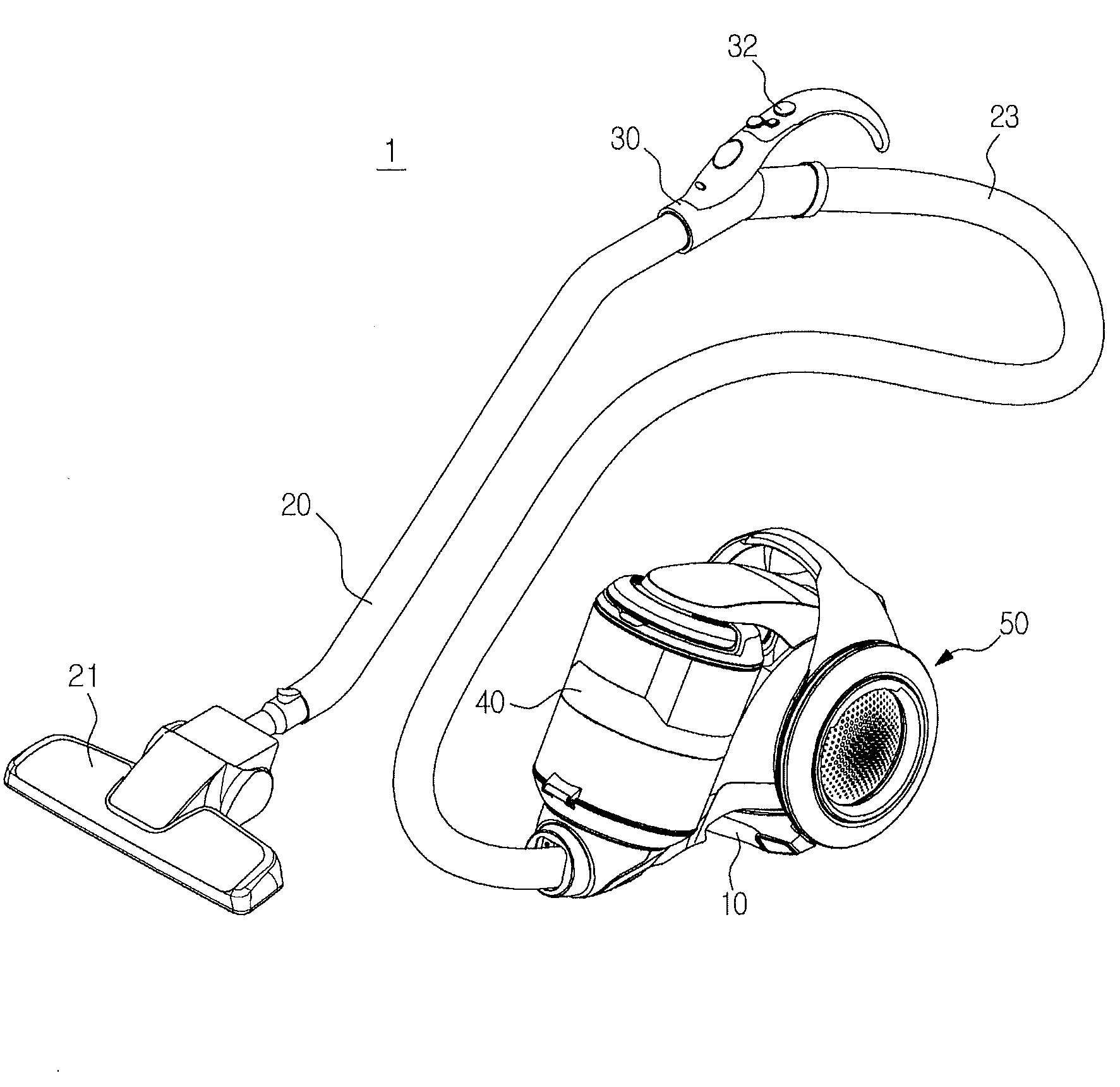

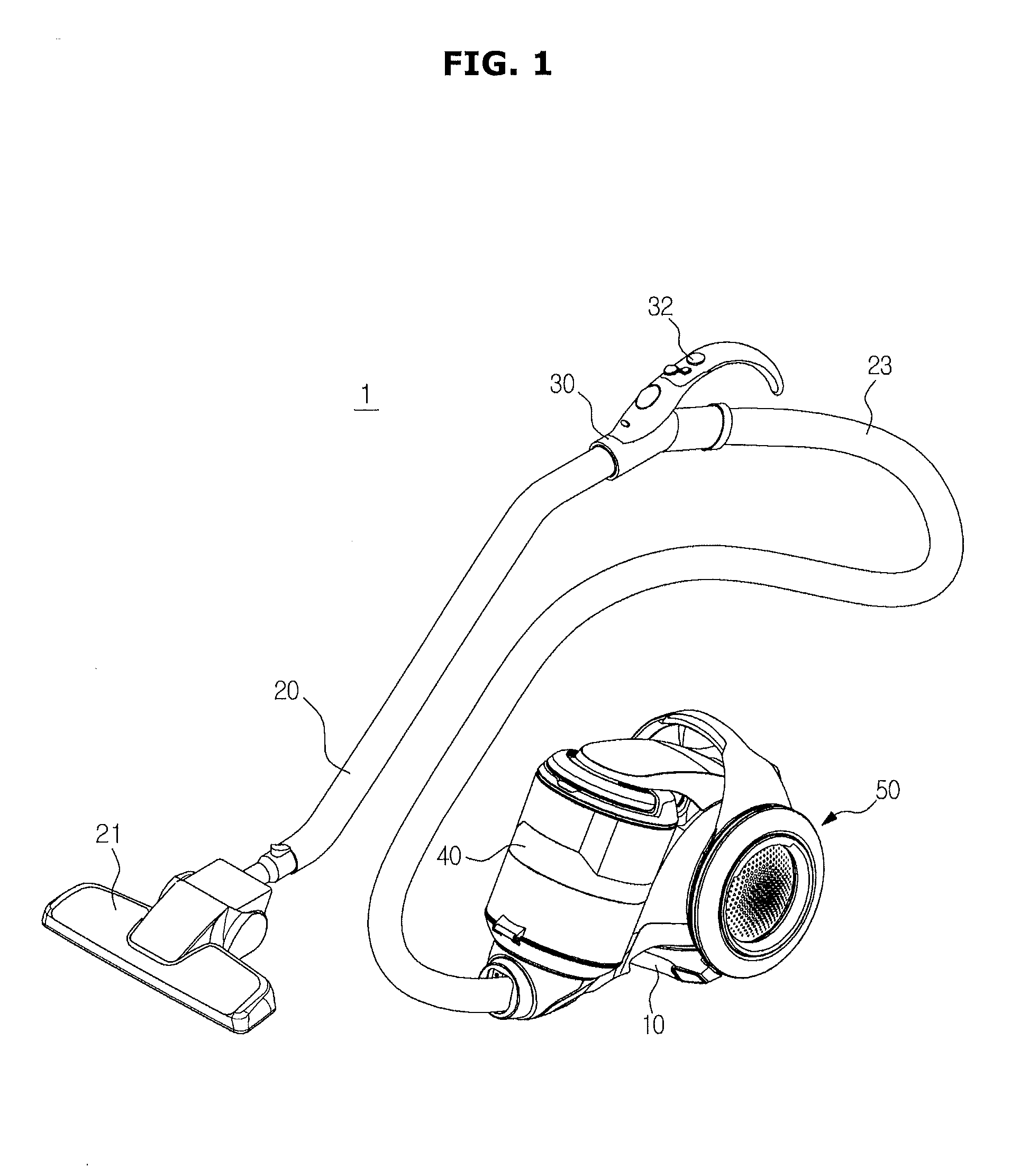

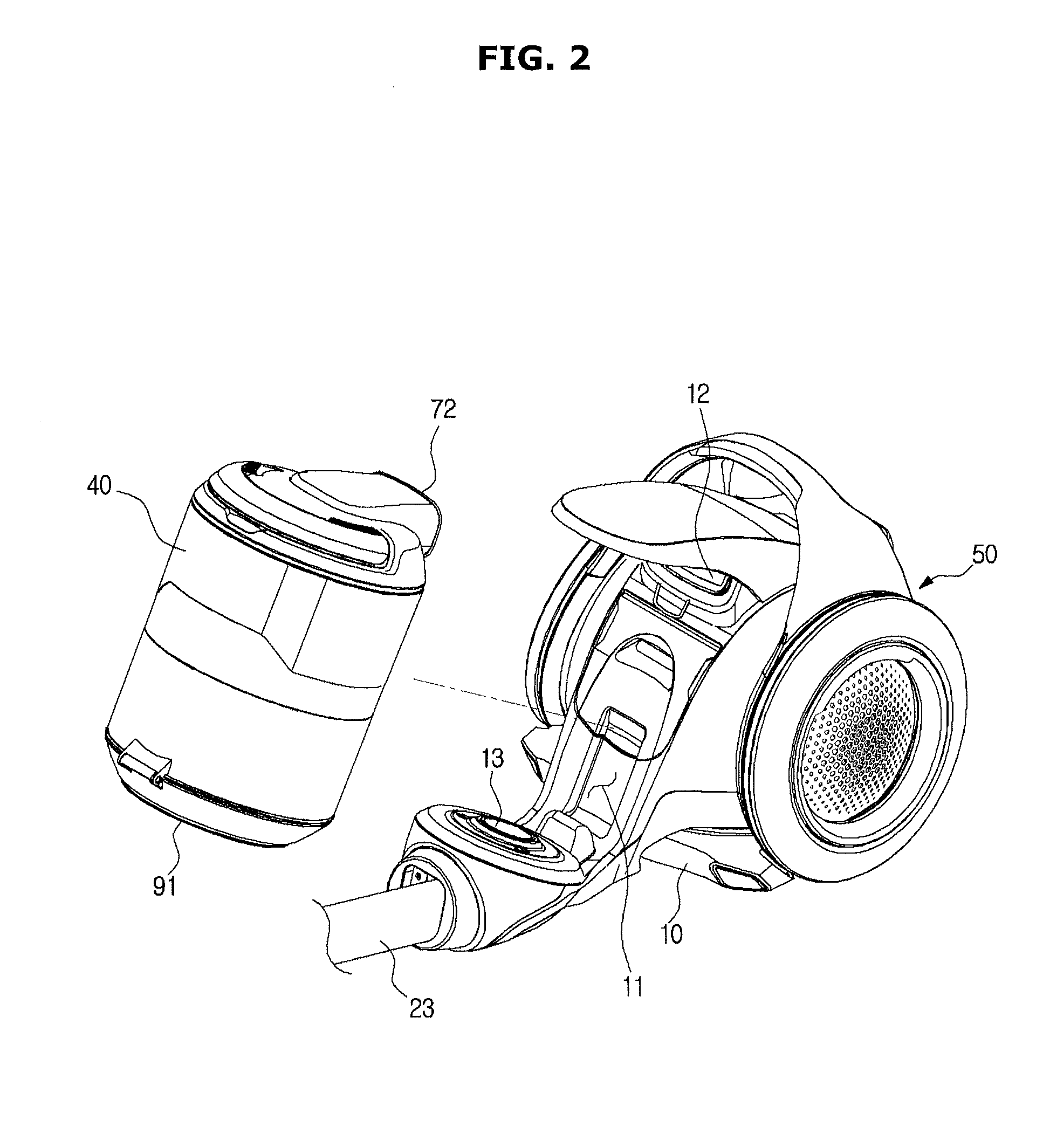

Vacuum cleaner

ActiveUS20140359967A1Improve straight mobilityImprove mobilityCleaning filter meansMechanical cleaningEngineeringCamber angle

A vacuum cleaner includes a main body including a fan motor to generate suction force, a suction unit connected to the main body to suction foreign matter from a surface to be cleaned in a state of contacting the surface, a dust collector separatably mounted to the main body to separate and collect dust from air suctioned by the suction unit, and a wheel assembly to move the main body, wherein the wheel assembly includes frames provided at a lower part and left and right sides of the main body and wheels rotatably mounted to the frames provided at the left and right sides of the main body, each wheel having a negative camber angle.

Owner:SAMSUNG ELECTRONICS CO LTD

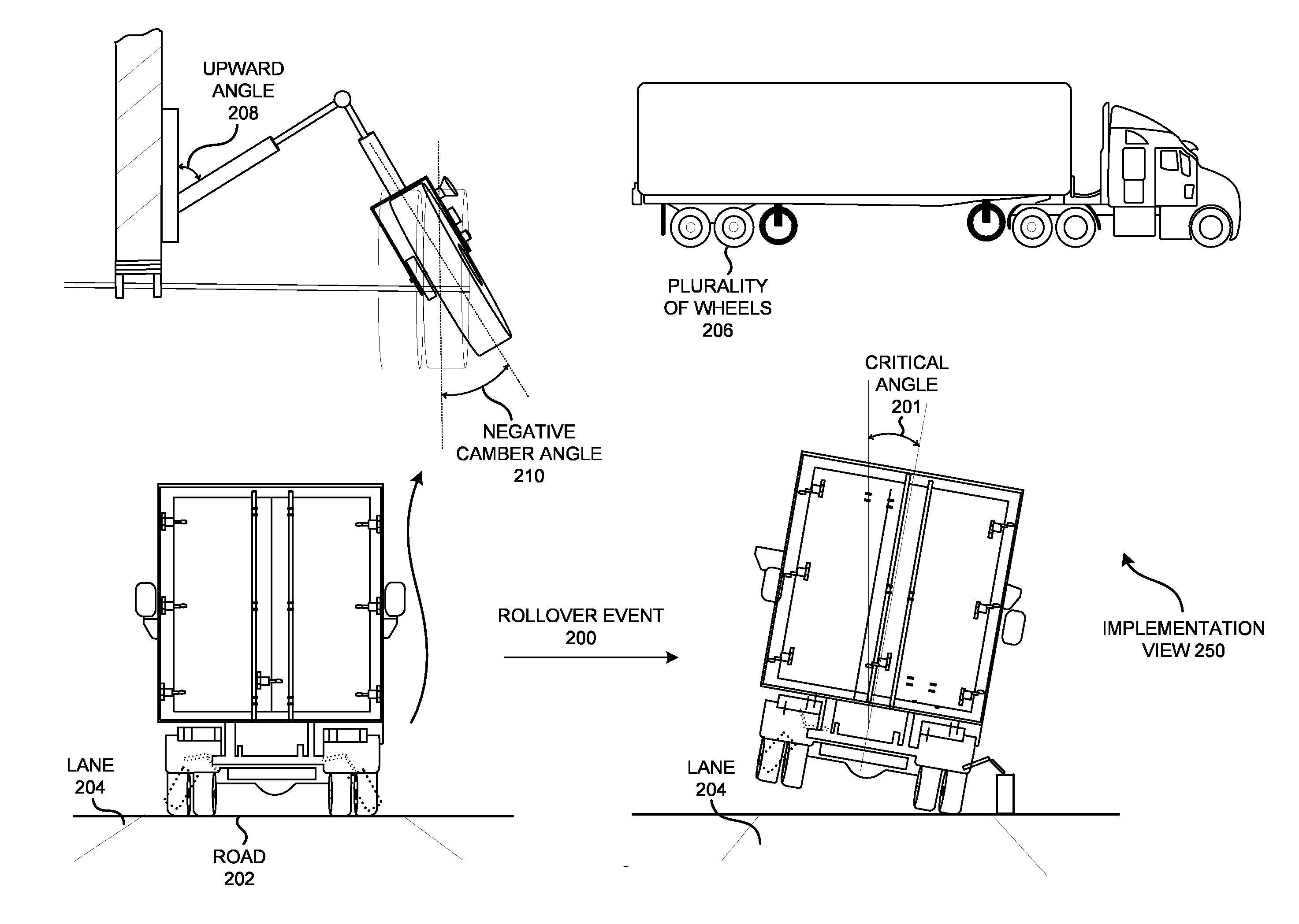

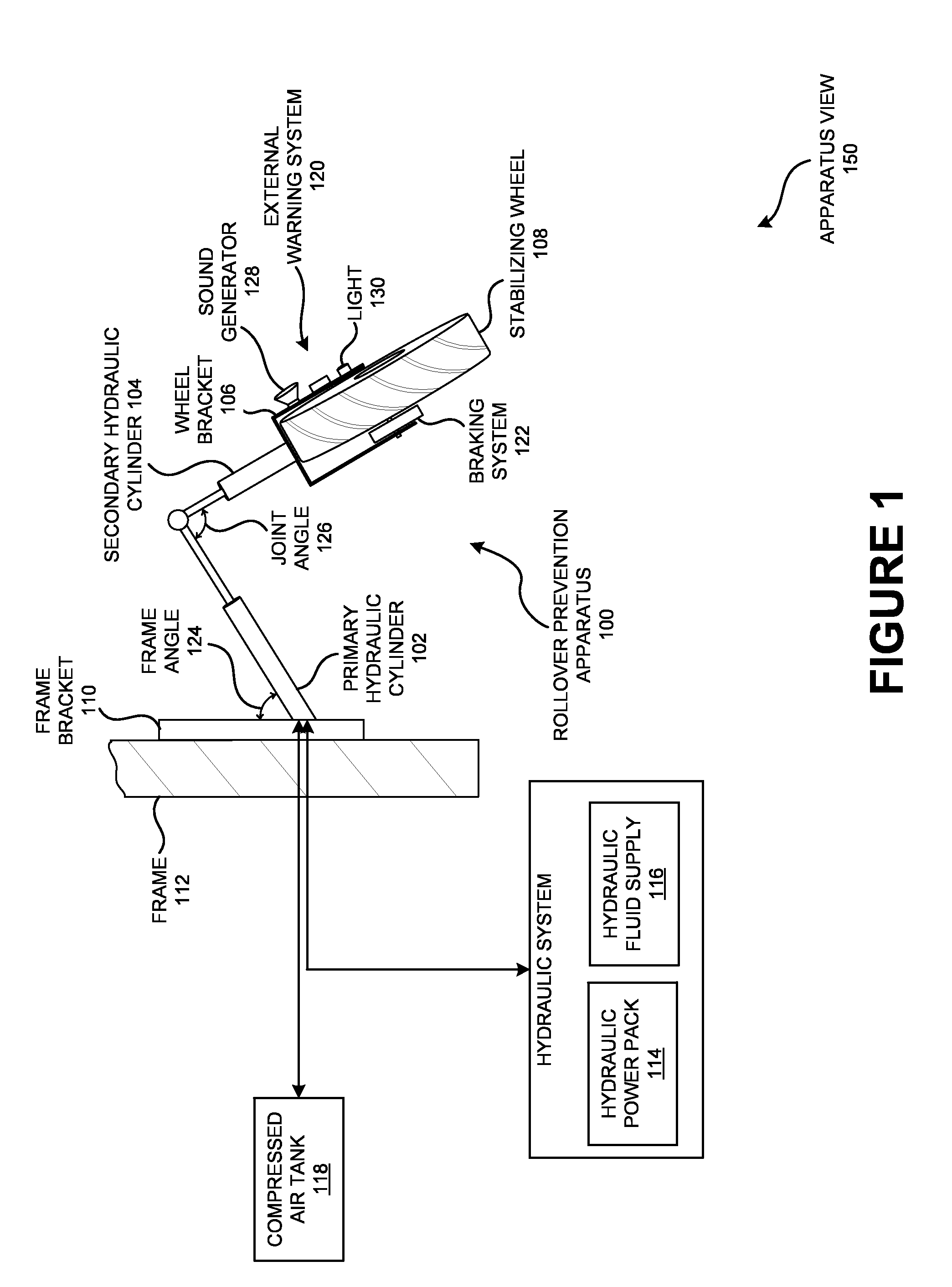

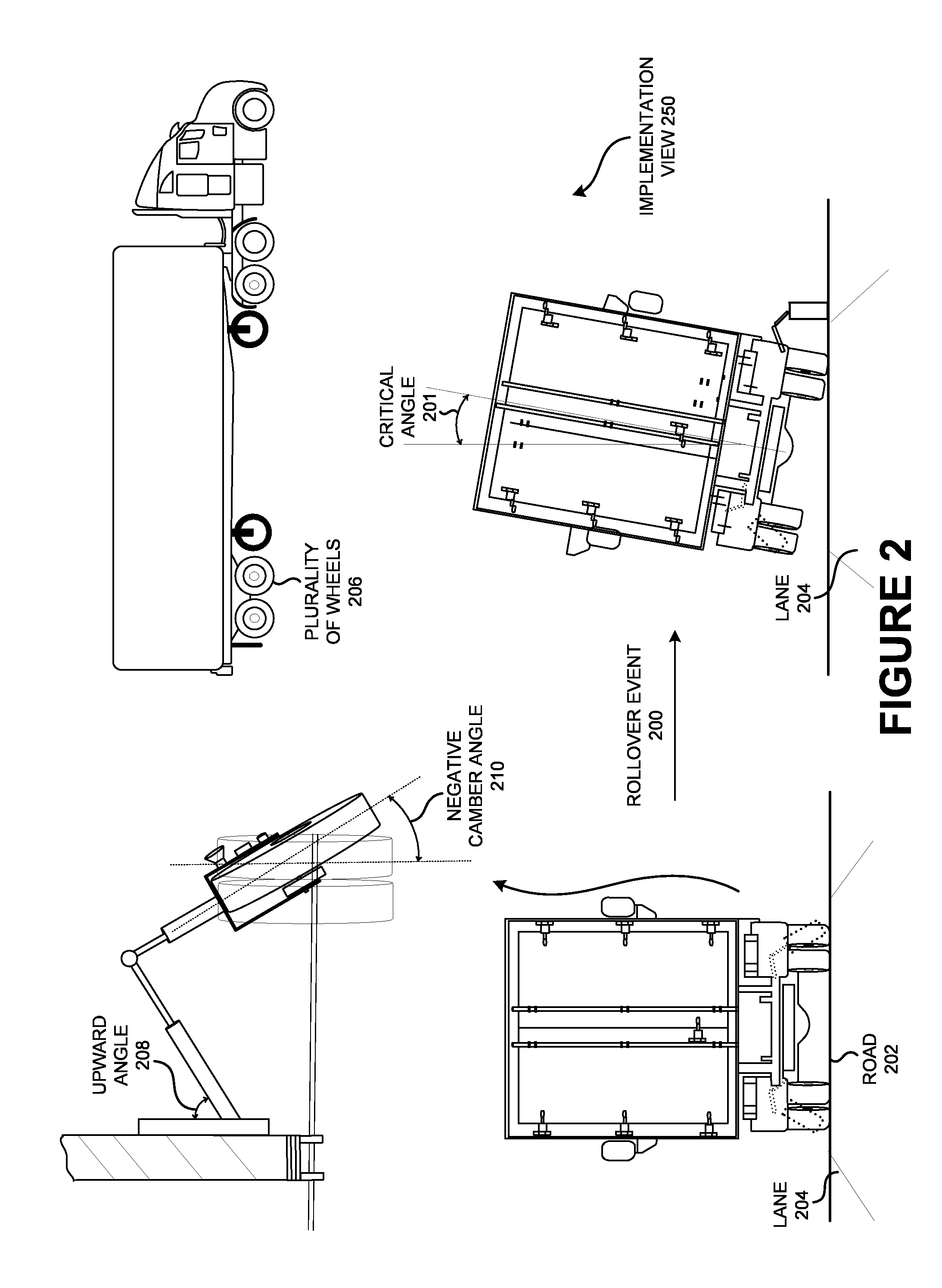

System, method, and apparatus to prevent commercial vehicle rollover

ActiveUS20150239409A1Prevent rolloverDigital data processing detailsPedestrian/occupant safety arrangementHydraulic cylinderRollover

A rollover prevention apparatus includes a primary hydraulic cylinder attached to a frame bracket, a secondary hydraulic cylinder attached to the primary hydraulic cylinder and a wheel bracket. The rollover prevention apparatus includes a stabilizing wheel affixed to the wheel bracket. The stabilizing wheel is substantially in line with a plurality of wheels affixed to the frame while the primary and secondary hydraulic cylinders are retracted, the line being substantially perpendicular to the primary and secondary hydraulic cylinders. The stabilizing wheel has a negative camber angle with respect to the plurality of wheels while the primary and secondary hydraulic cylinders are retracted. A rollover event may be averted by extending the primary and secondary hydraulic cylinders such that the stabilizing wheel makes contact with a road without substantially leaving a lane, and using the secondary hydraulic cylinder to push against the road until the rollover event has been averted.

Owner:MOUSA ISAM

Spectacle lens

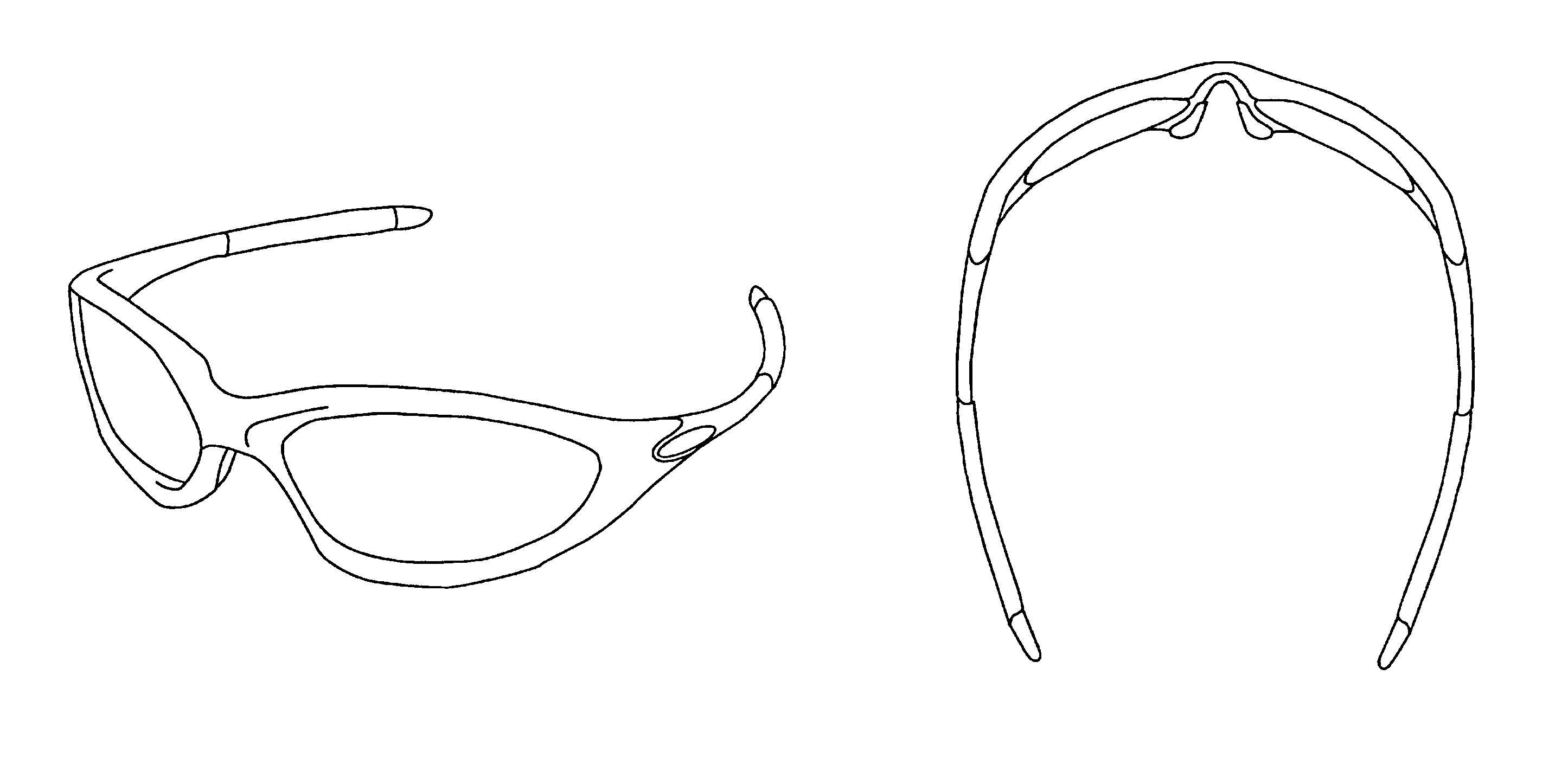

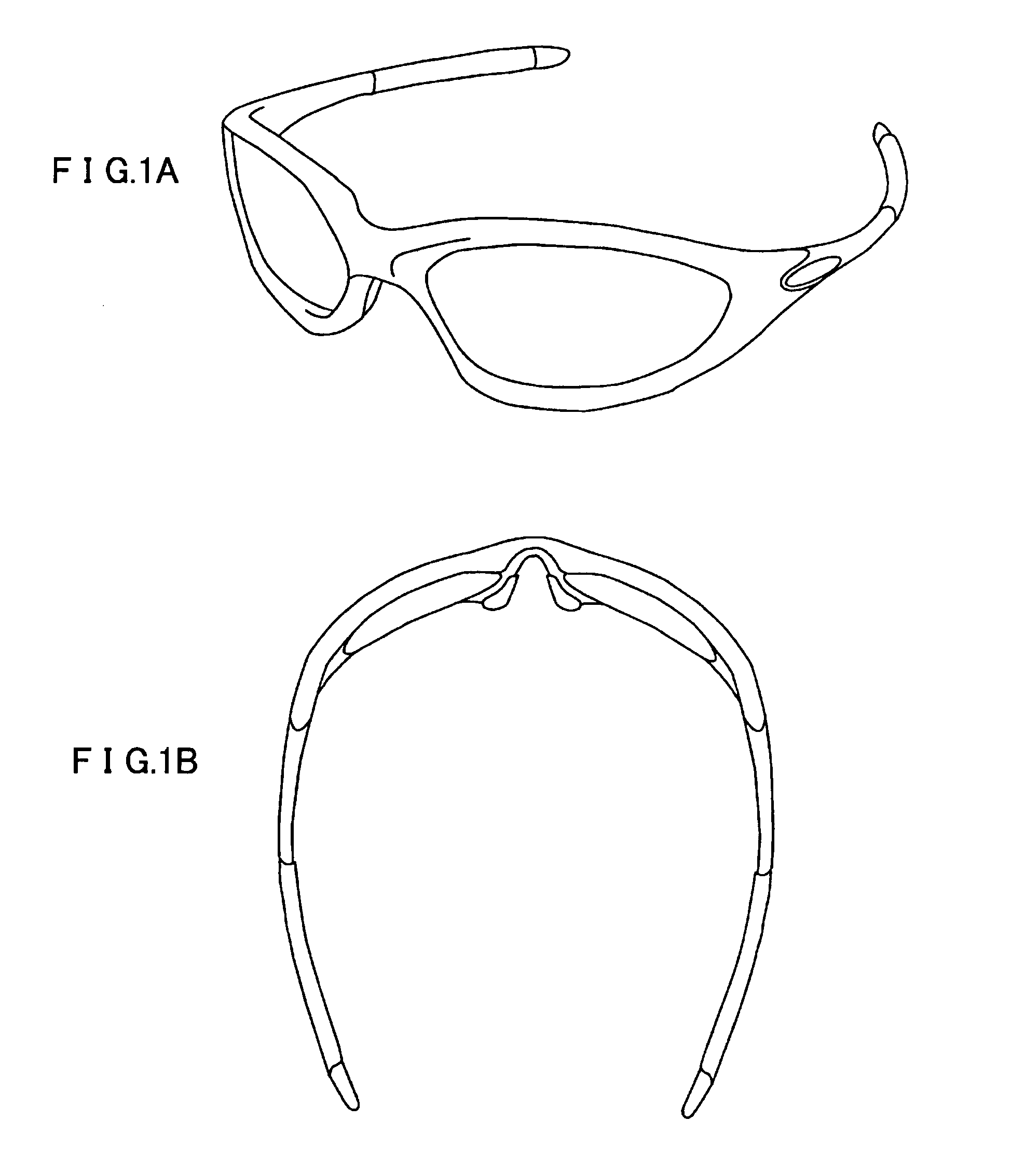

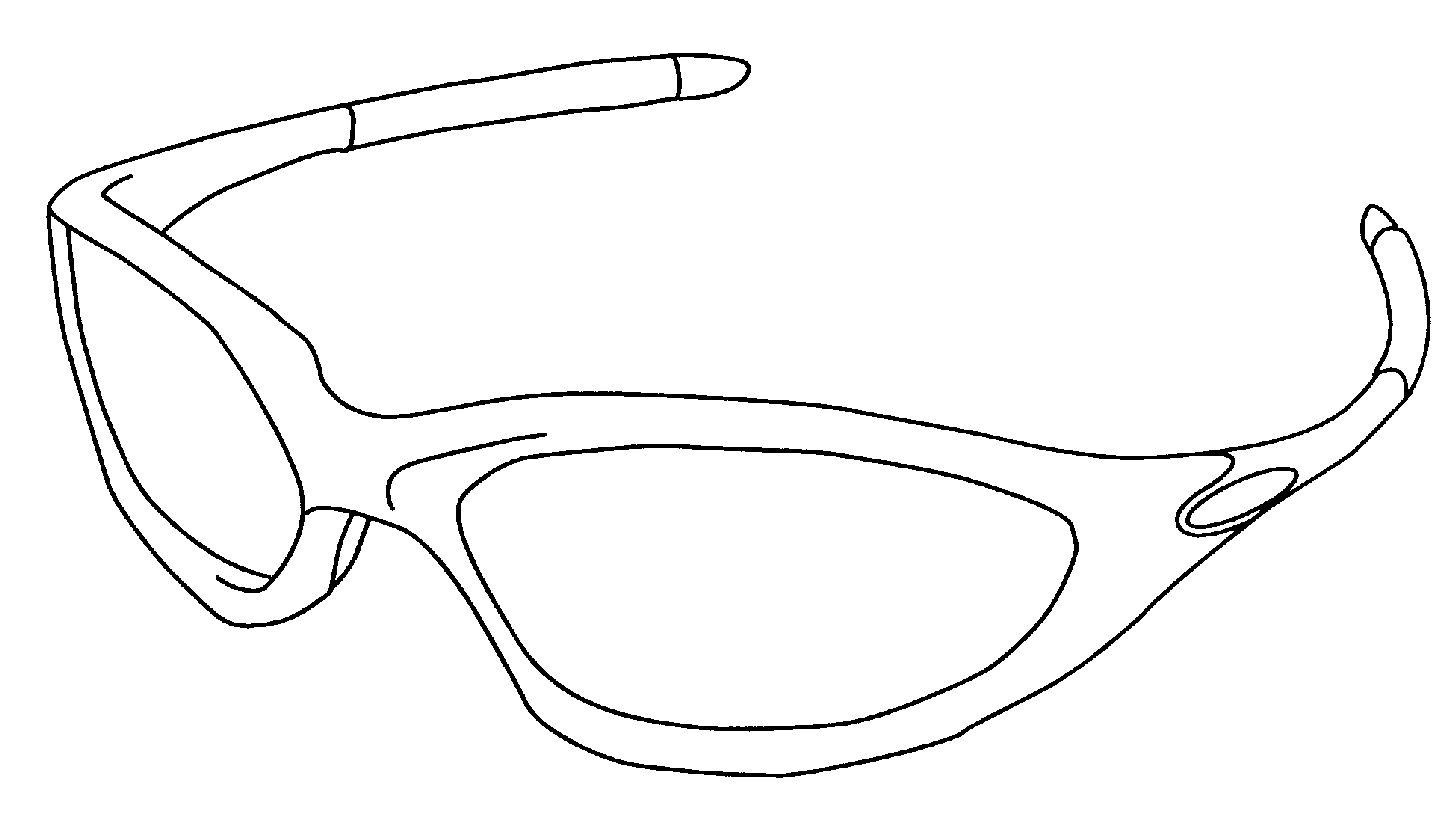

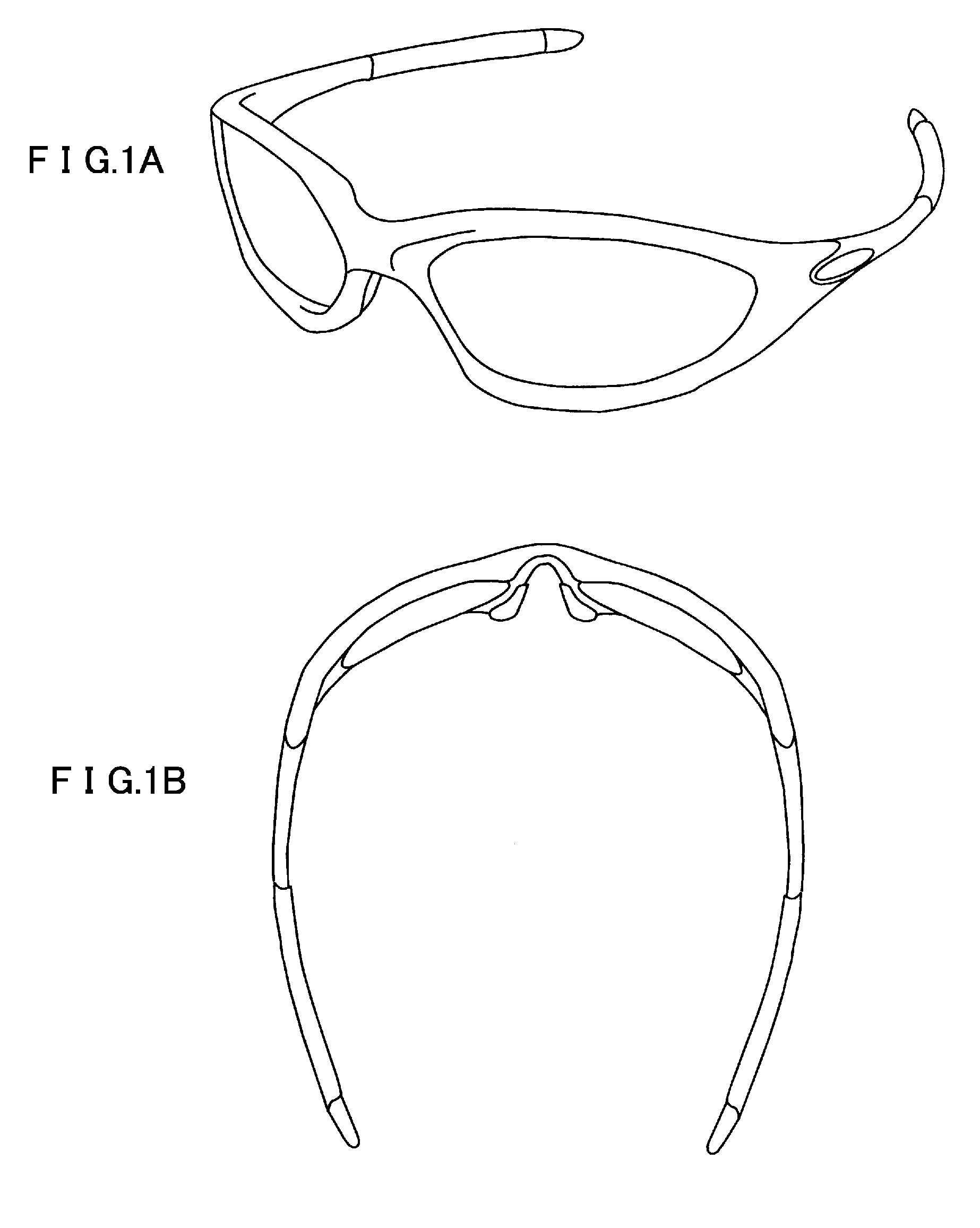

ActiveUS7070274B2Satisfactory performanceEye diagnosticsNon-optical partsUses eyeglassesEyeglass lenses

To provide a spectacle lens that is designed optically to suit a spectacle frame with a large camber angle such as a wraparound type spectacle frame. A spectacle lens that is mounted in a spectacle frame with a camber angle of 200° or more, in which cylindrical power for offsetting astigmatic aberration, which is caused by the camber angle at a design reference point, is added to a refractive surface on an object side or a refractive surface on an eye side, prismatic power for offsetting prismatic effect, which is caused by the camber angle at the design reference point, is added to the refractive surface on the object side or the refractive surface on the eye side, and aspherical surfaces different from each other on a nose side and an ear side are formed on the refractive surface on the object side or the refractive surface on the eye side.

Owner:HOYA LENS MFG PHILIPPINES

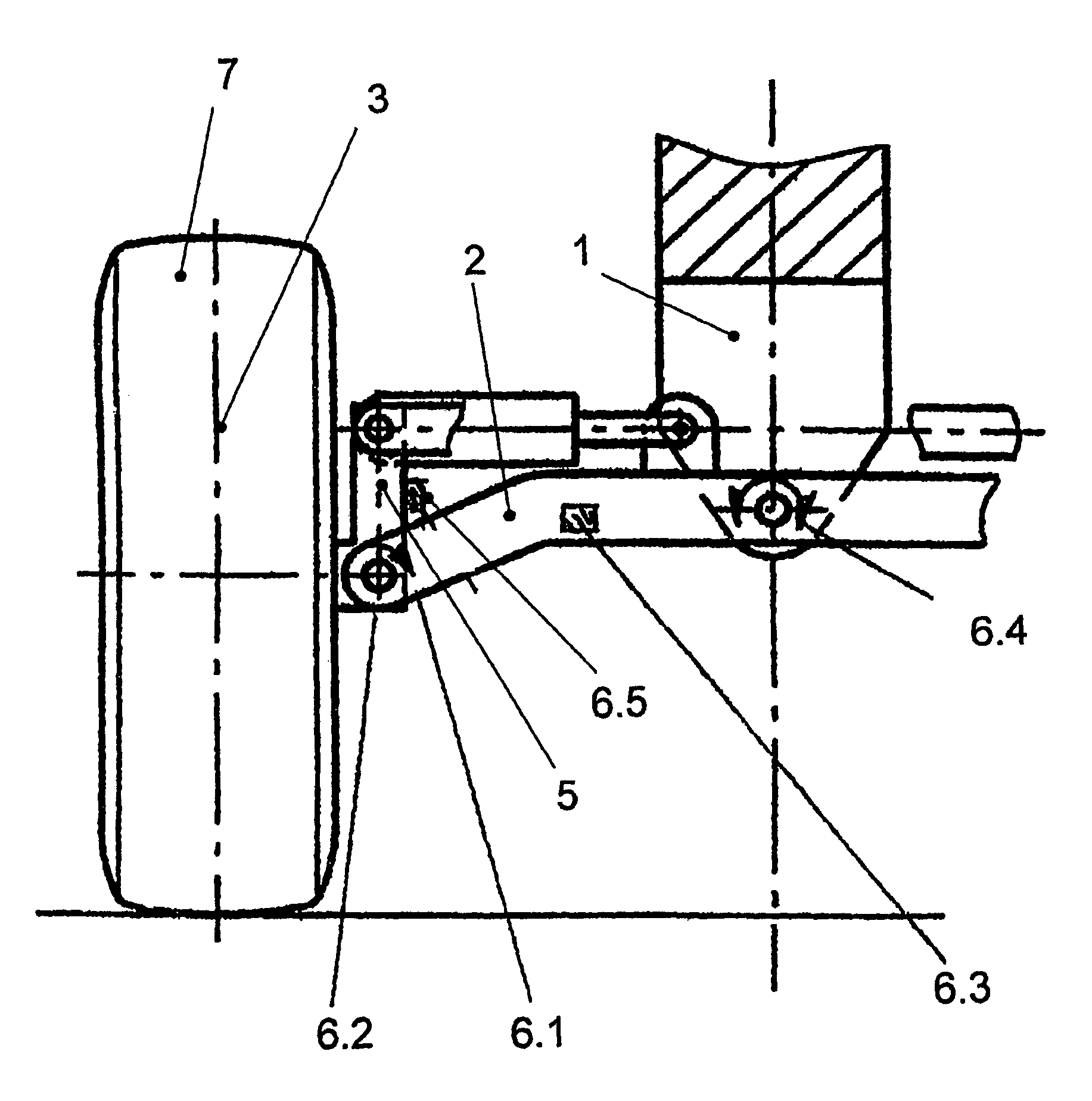

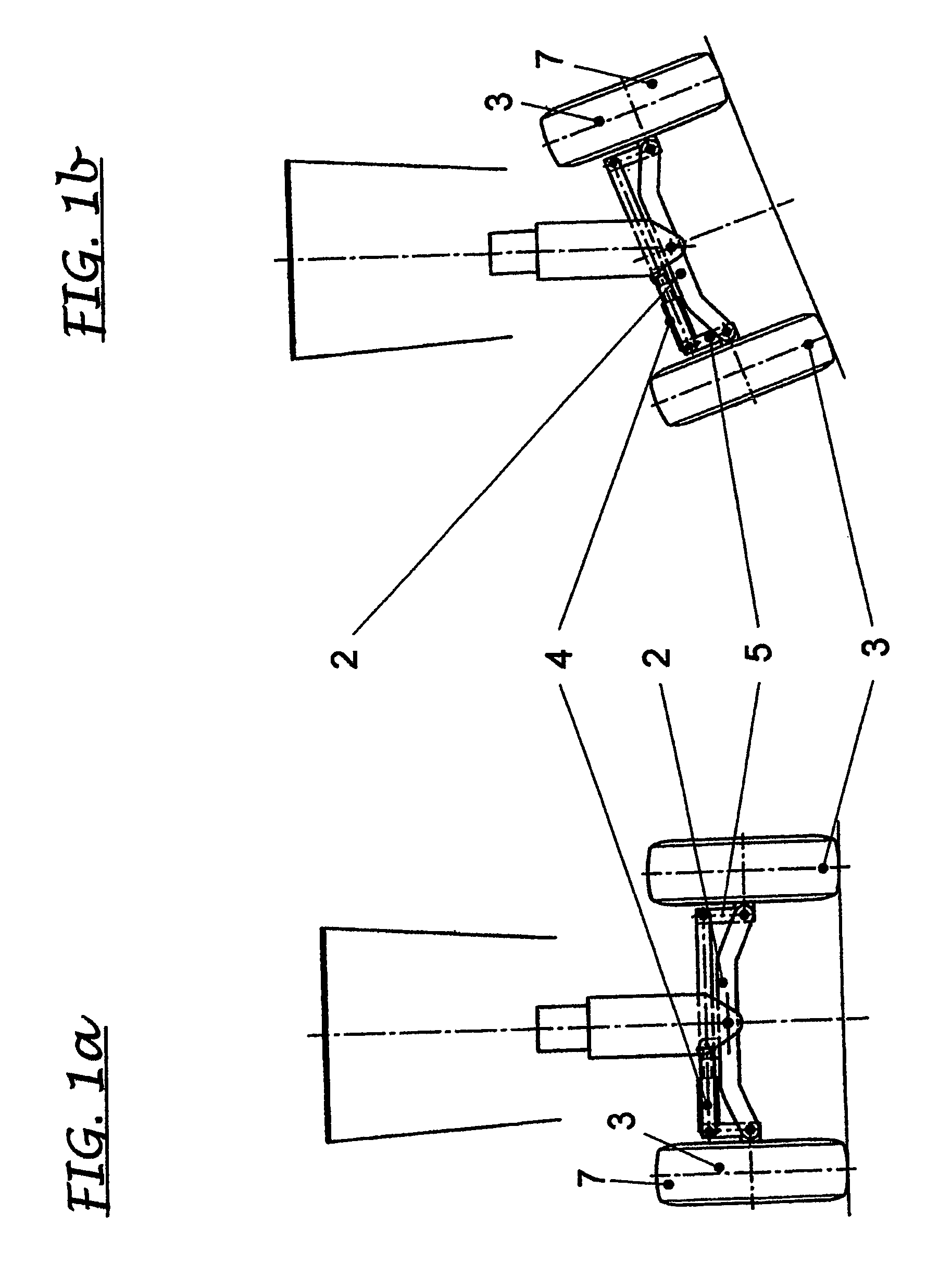

Method and device for wheel camber adjustment

InactiveUS7673883B2Strong constructionAgricultural vehiclesInterconnection systemsCamber angleCommercial vehicle

The invention concerns a method and a device for the adjustment of wheel camber in commercial vehicles, particularly wheeled construction vehicles used for earthworks, particularly on uneven ground. The camber angle is set inventively and automatically by means of a camber cylinder and a wheel pivot unit, as a function of at least one of the driving parameters. For this purpose, the driving parameters, e.g. the axle swing angle, the steering lock angle, the lateral force on the vehicle wheels on the front axle and the absolute inclination of the construction vehicle are detected by sensors, the output signals of which are fed to an electronic control unit as input parameters. The camber angle sets itself as a function of the setting signal from the electronic control unit by means of a camber cylinder and a wheel pivot unit, in accordance with specified control strategies. As well as the self-setting wheel camber adjustment system, the camber cylinder is embodied so that it can still be operated manually.

Owner:CNH BAUMASCHEN

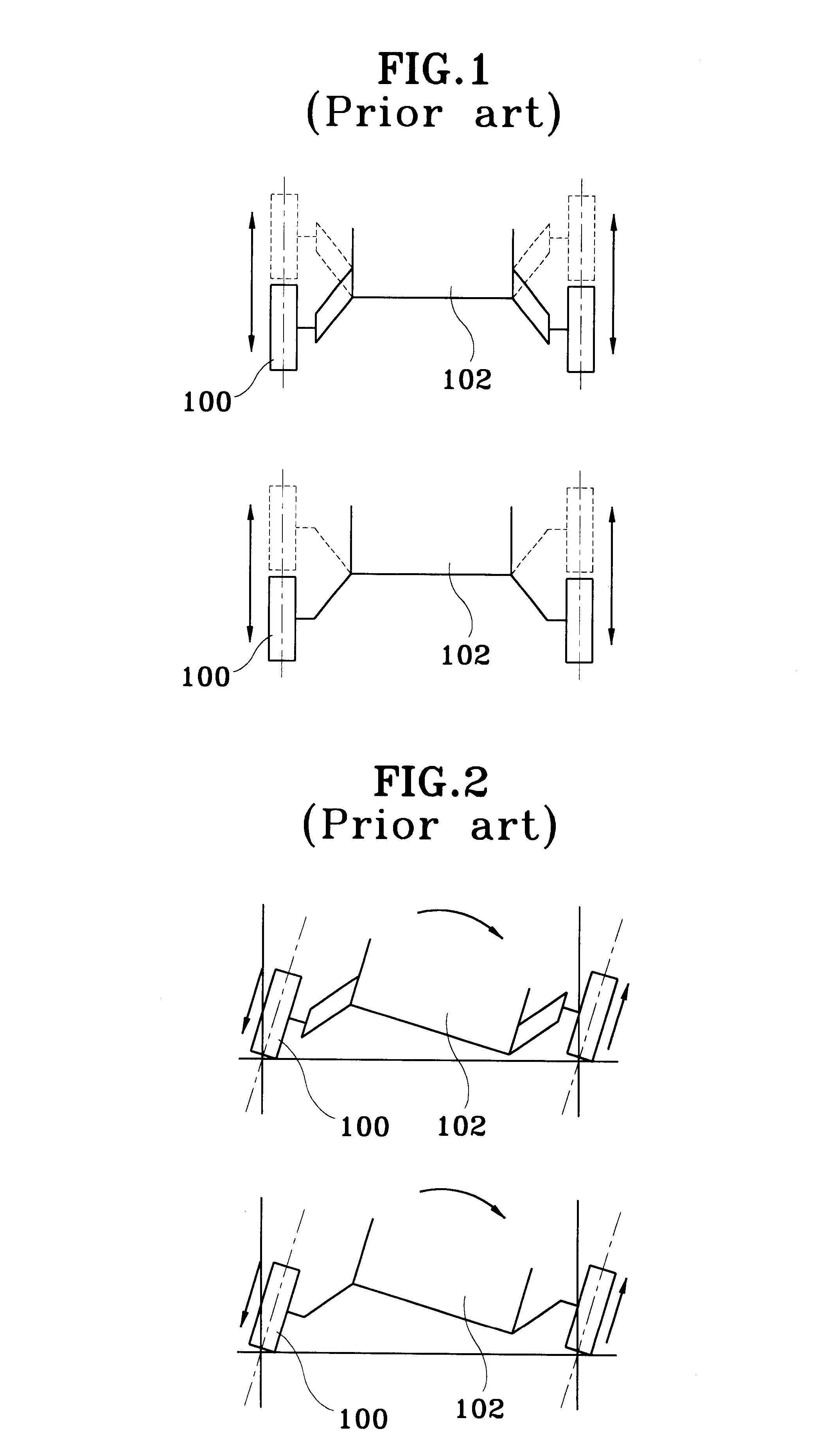

Camber control suspension

The invention relates to a camber control suspension of a vehicle that can form a stable camber angle even at the time when the vehicle rolls as well as when bumping and rebounding, including a camber control rack and camber control links which function to control camber of wheels by stopping or moving according to the vertical motion of both wheels. As a result, a most stable ground contact state of the tires at all times is achieved to sufficiently enhance the groiund contact force of the tires at any running state of the vehicle.

Owner:HYUNDAI MOTOR CO LTD

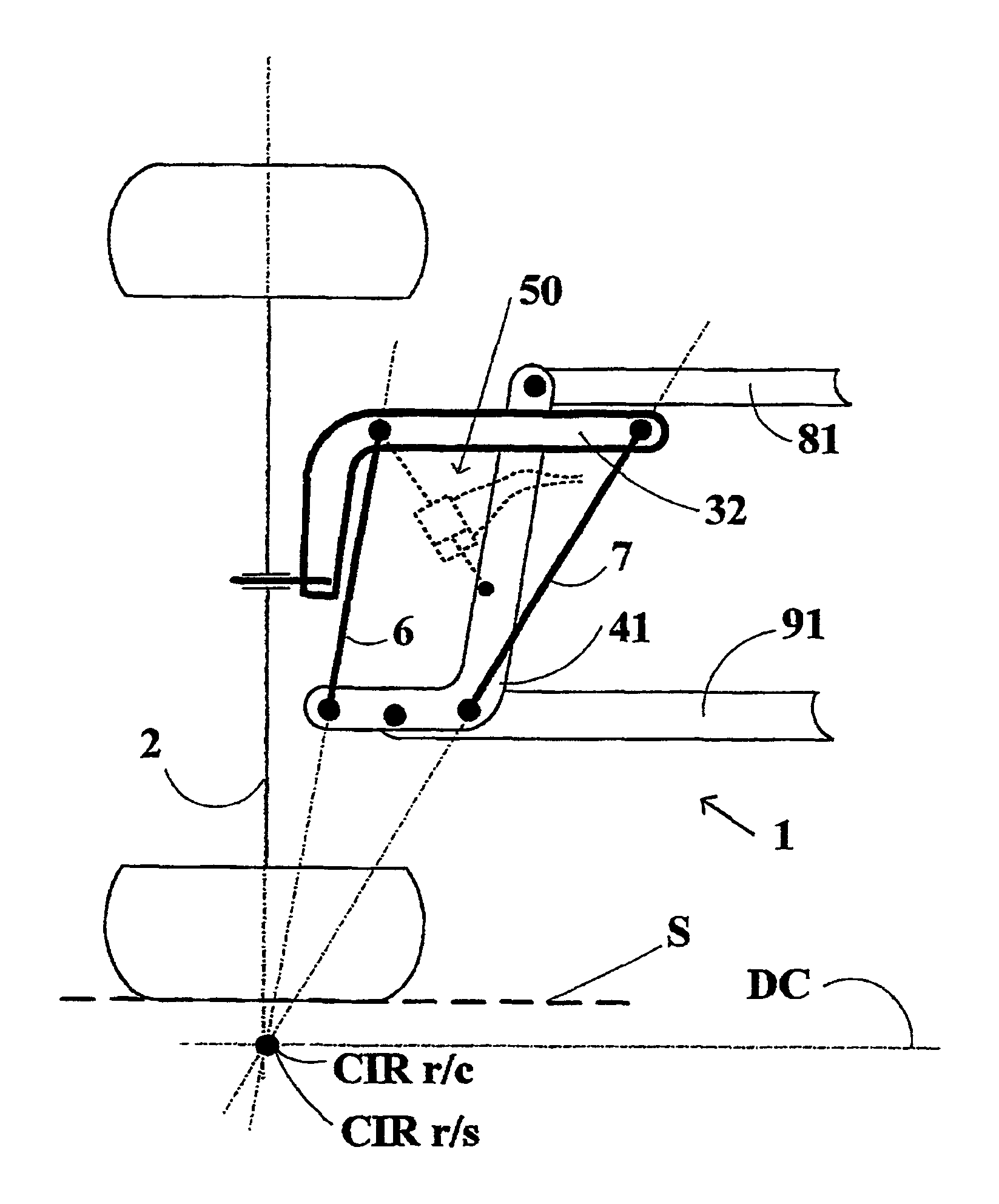

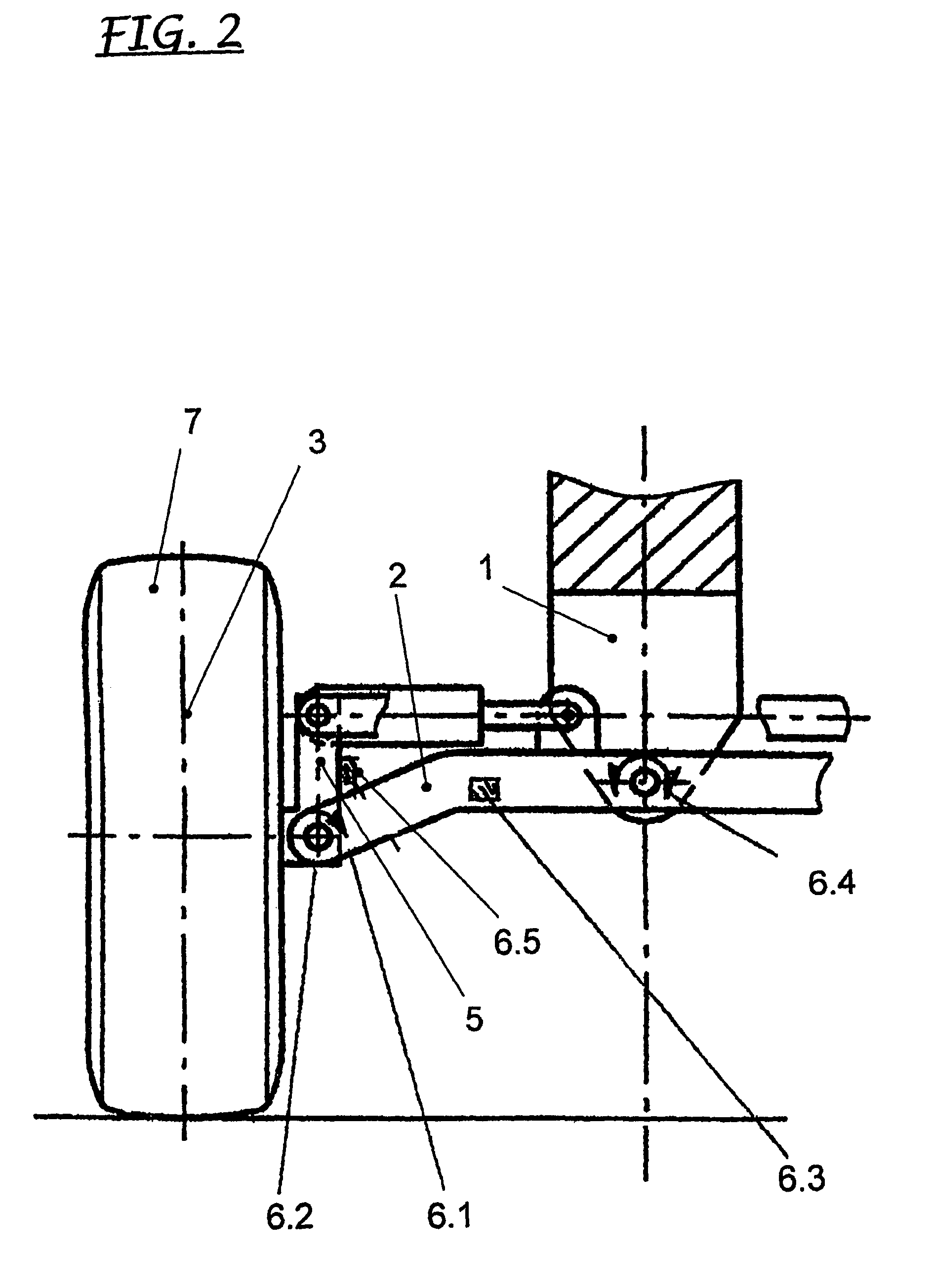

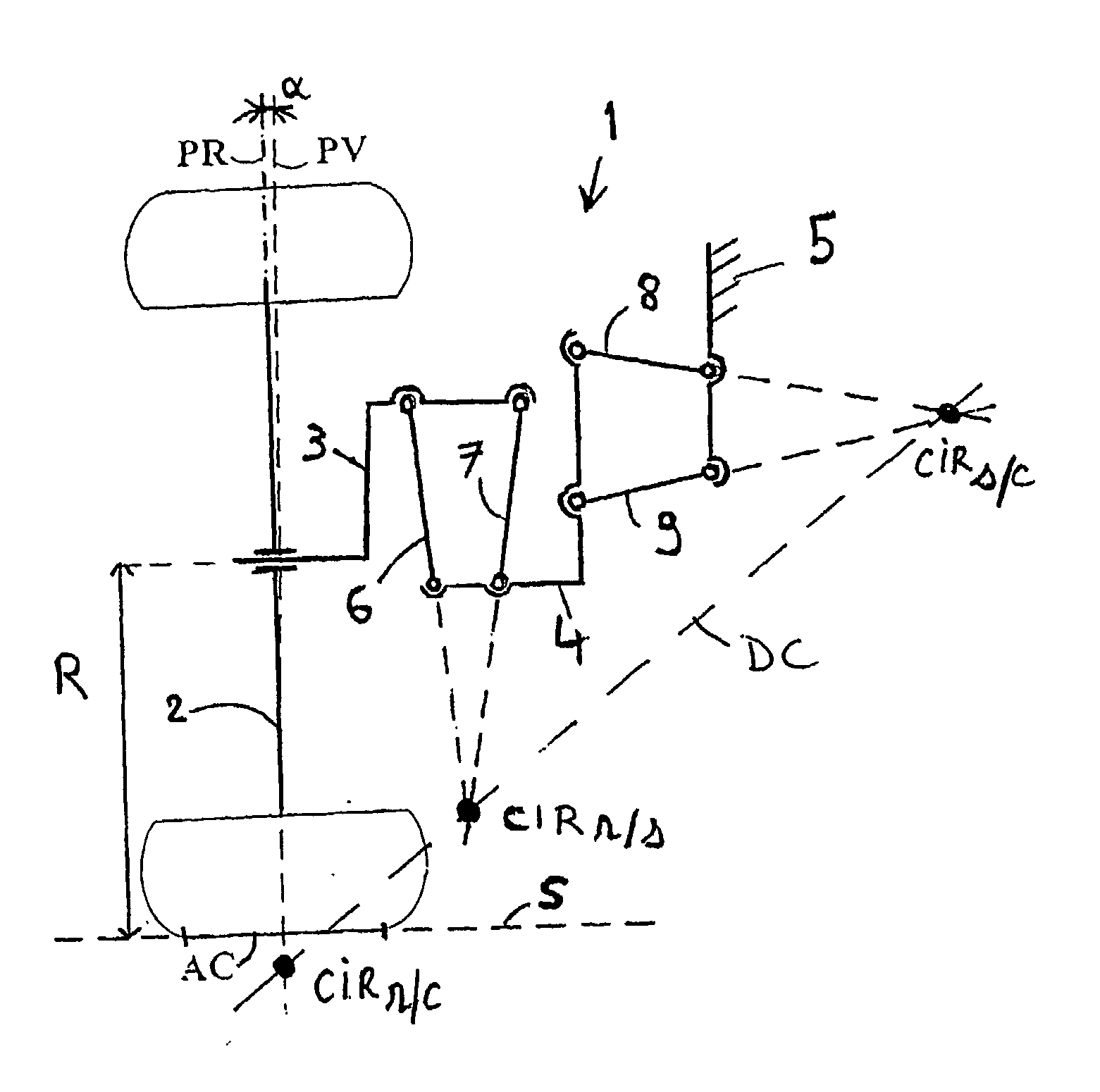

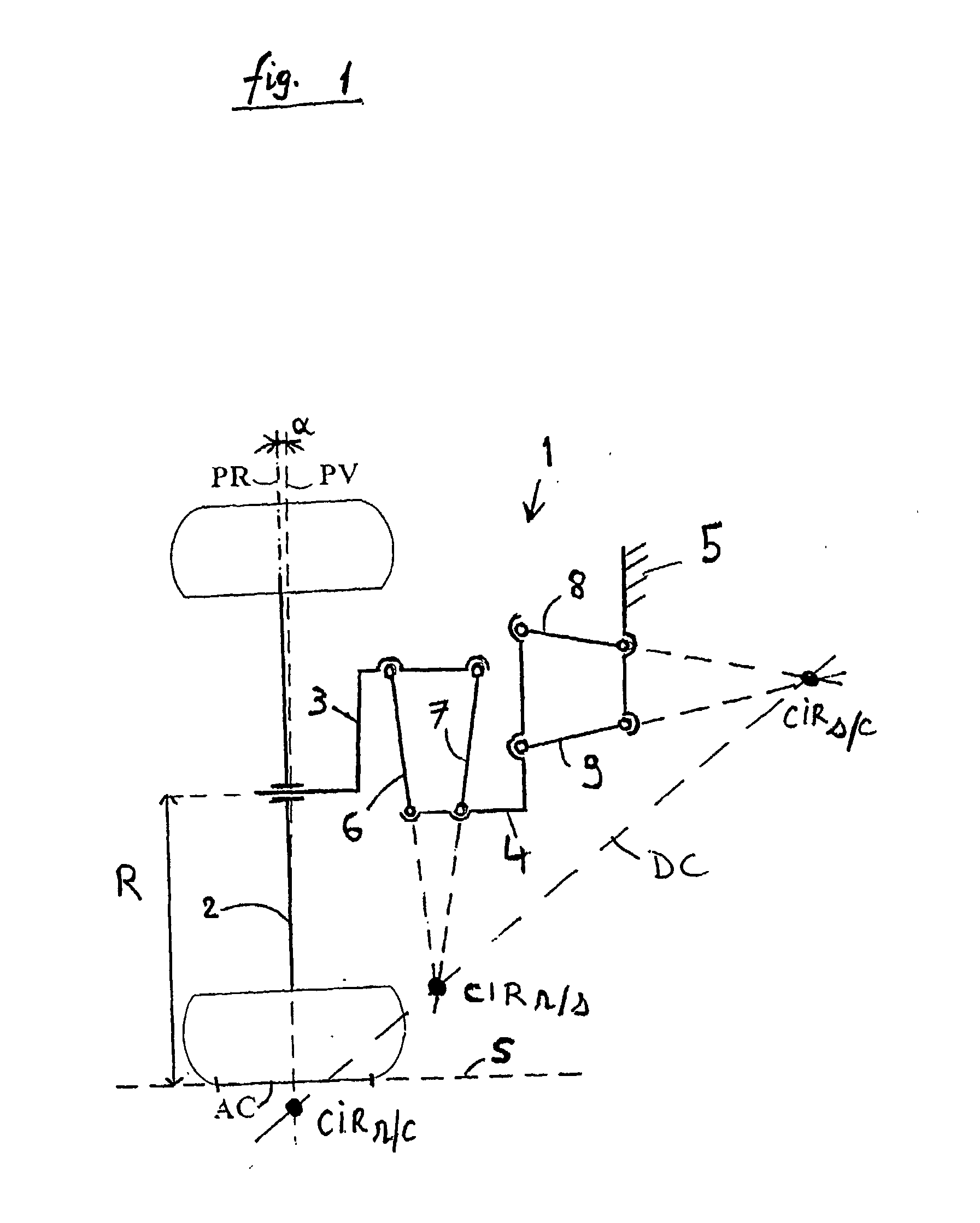

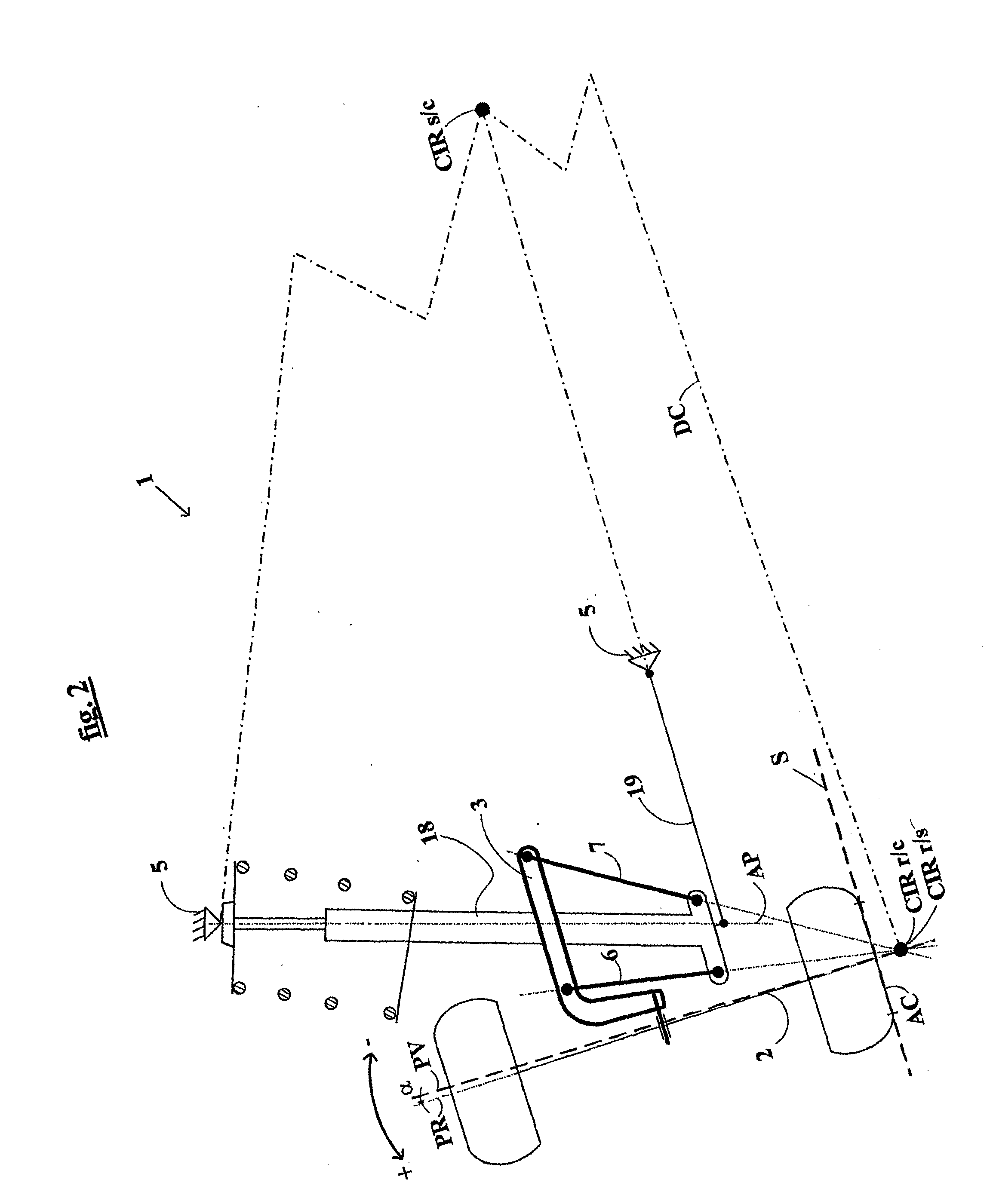

Wheel support device and suspension device comprising the said support device

A vehicular suspension device (1) comprises a wheel carrier (31) which is articulated relative to the suspension elements (18, 19). This connection is provided by rigid connection rods (6, 7). This additional degree of freedom permits variation of the camber angle (alpha) independently of the suspension spring movement and of the deformations of its elements. The variation of the camber is preferably controlled by the forces sustained by the wheel (2) in the ground contact area (AC) of the tire. This is obtained by a configuration in which the movements of the wheel (2) relative to the body (5) of the vehicle allow an instantaneous center of rotation (CIR r / c) which is situated beneath the plane of the ground (S).

Owner:MICHELIN RECH & TECH SA

Spectacle Lens

ActiveUS20050225719A1Satisfactory optical performanceSatisfactory performanceEye diagnosticsNon-optical partsEyeglass lensesCamber angle

To provide a spectacle lens that is designed optically to suit a spectacle frame with a large camber angle such as a wraparound type spectacle frame. A spectacle lens that is mounted in a spectacle frame with a camber angle of 200° or more, in which cylindrical power for offsetting astigmatic aberration, which is caused by the camber angle at a design reference point, is added to a refractive surface on an object side or a refractive surface on an eye side, prismatic power for offsetting prismatic effect, which is caused by the camber angle at the design reference point, is added to the refractive surface on the object side or the refractive surface on the eye side, and aspherical surfaces different from each other on a nose side and an ear side are formed on the refractive surface on the object side or the refractive surface on the eye side.

Owner:HOYA LENS MFG PHILIPPINES

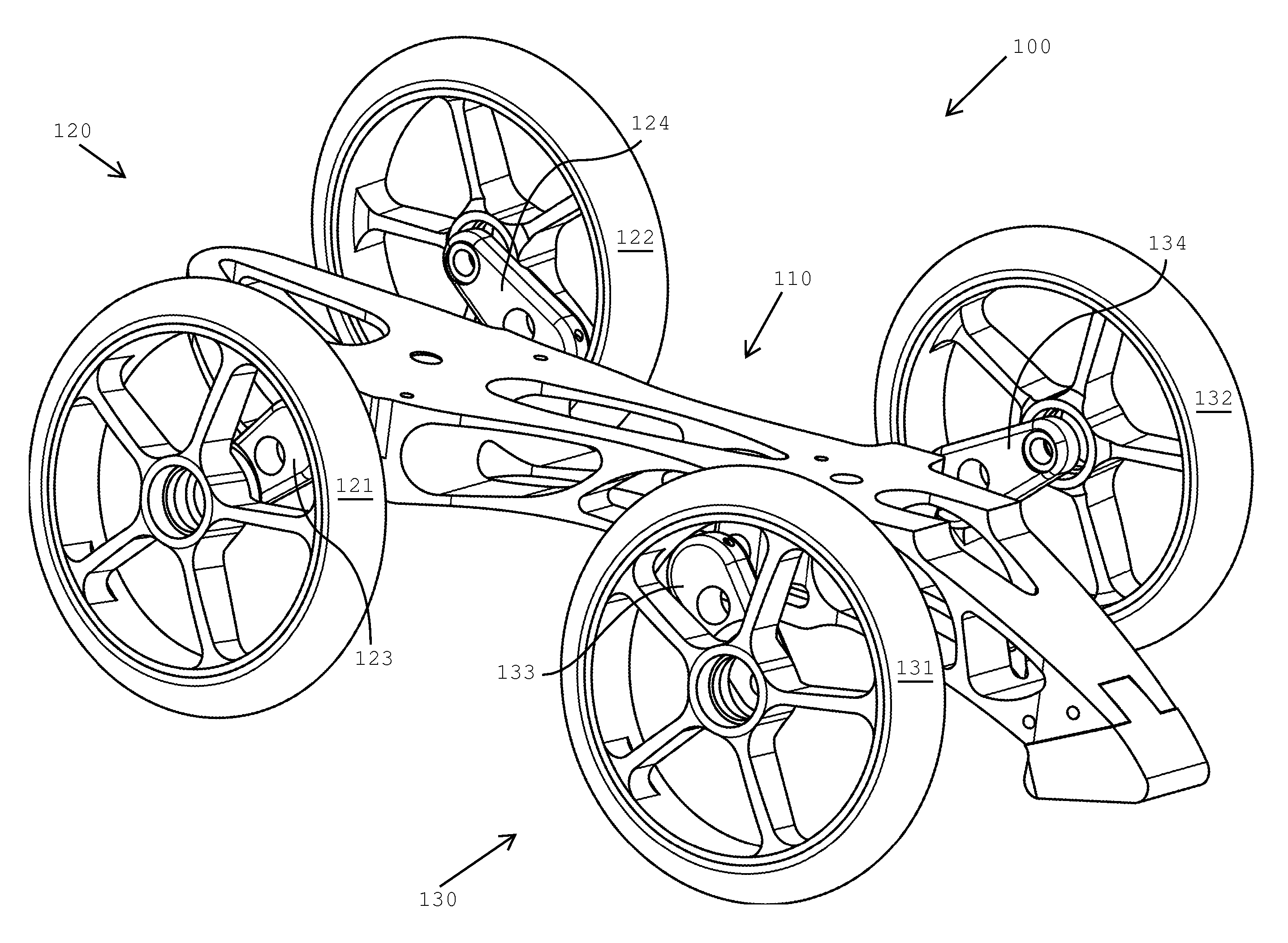

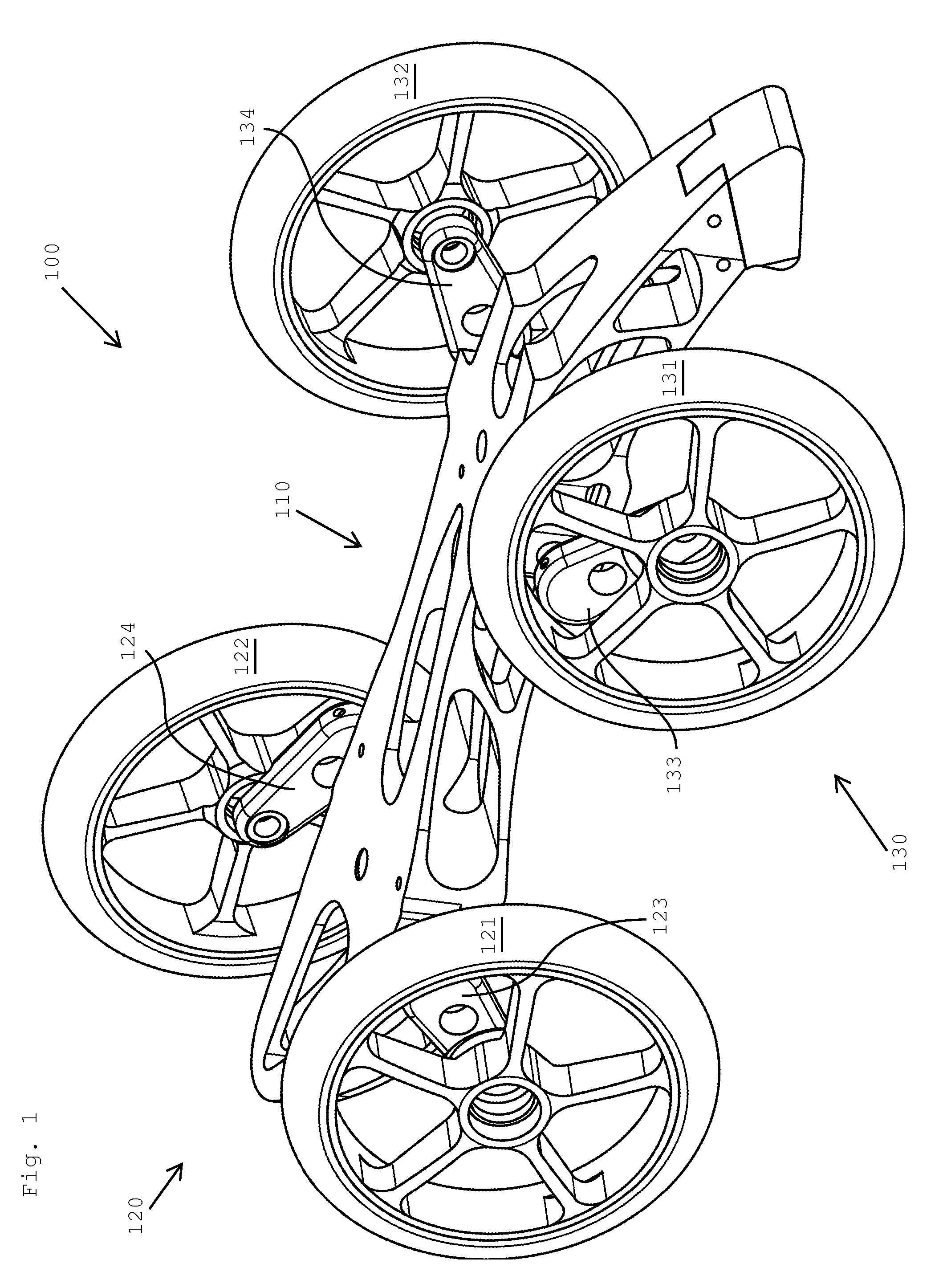

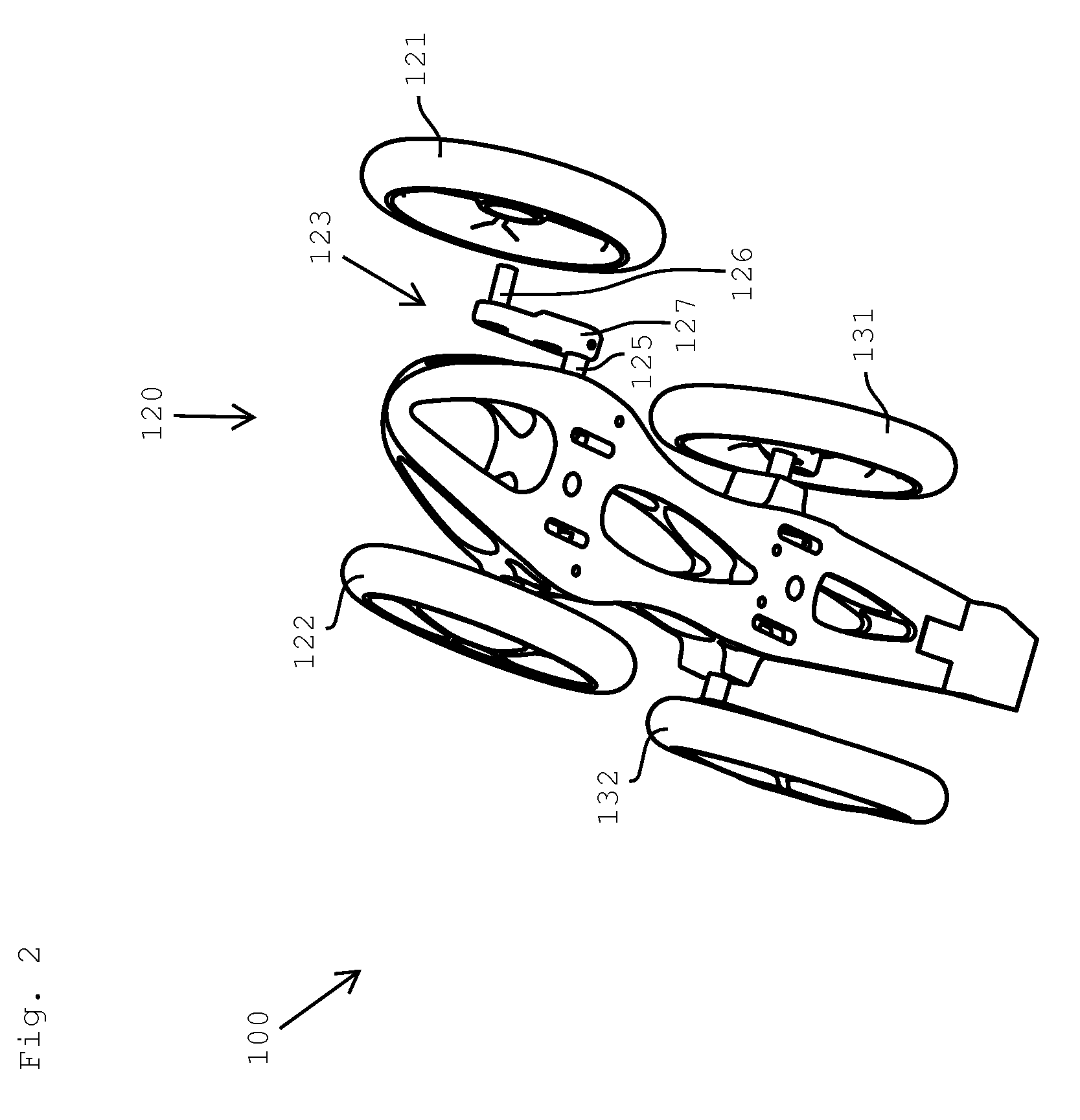

Lean-to-Turn Wheeled Device

InactiveUS20100044981A1Improve cornering performanceOvercomes shortcomingSkatesSkate-boardsCamber angleMechanical engineering

A wheeled device having pairs of wheels positioned on opposite sides (e.g. skateboard or “quad” skate) that includes a base and at least one turnable wheel assembly. A turnable wheel assembly includes two wheels having negative camber angle, and is configured such that the axles of the wheels can pivot about an axis disposed substantially perpendicular to the direction of travel. This configuration is conducive to the use of large wheels.

Owner:CHEN SHANE

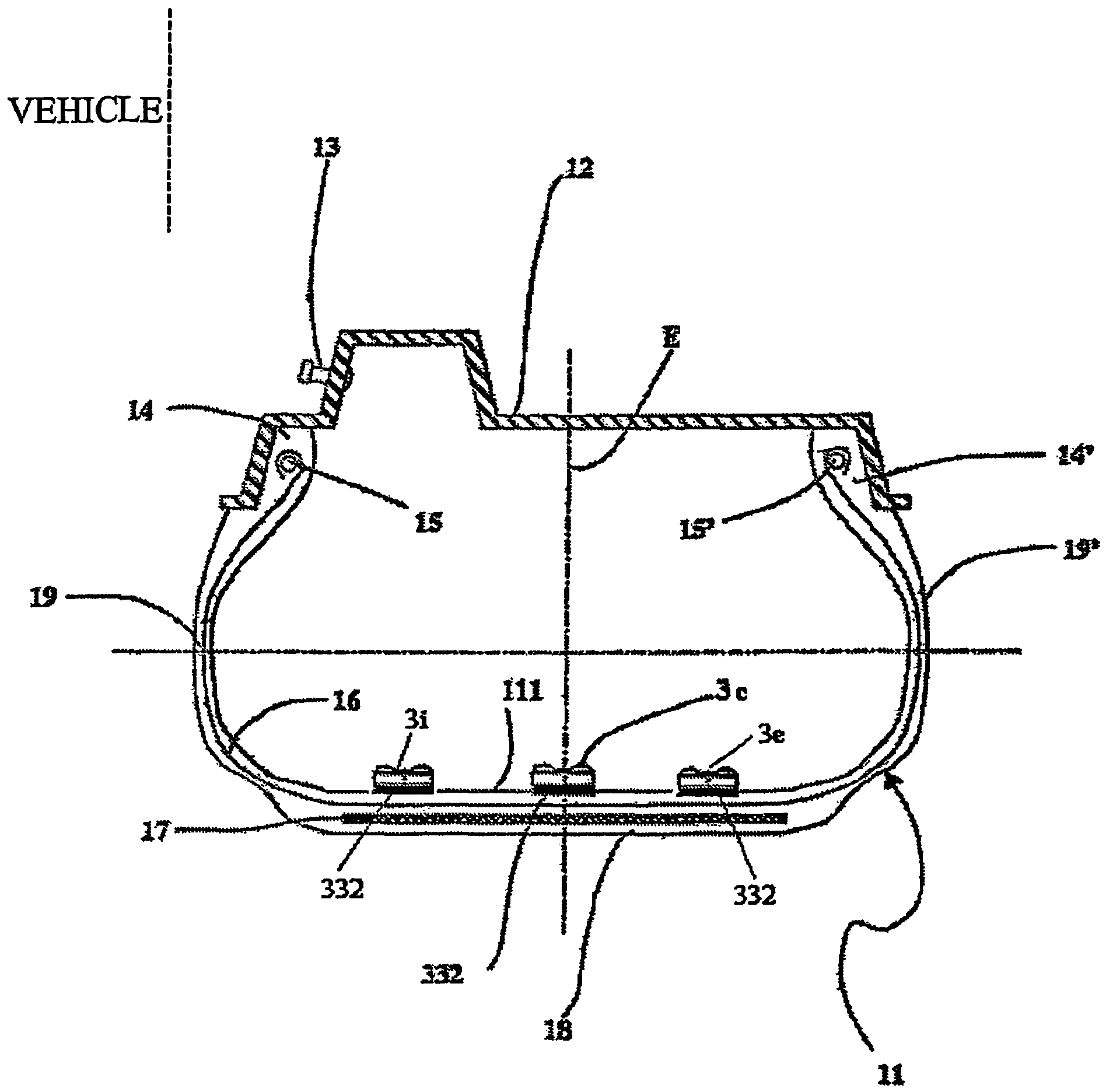

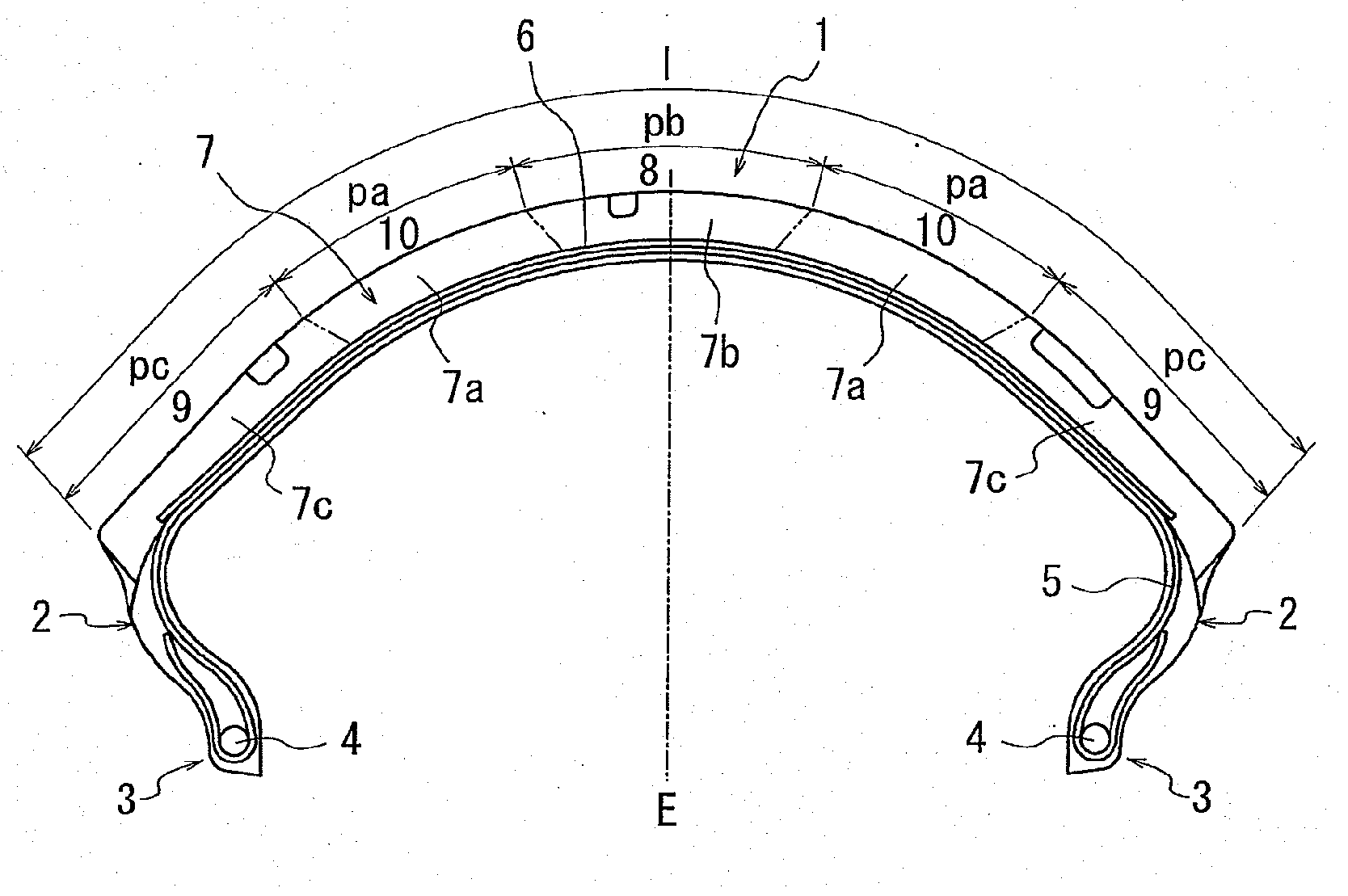

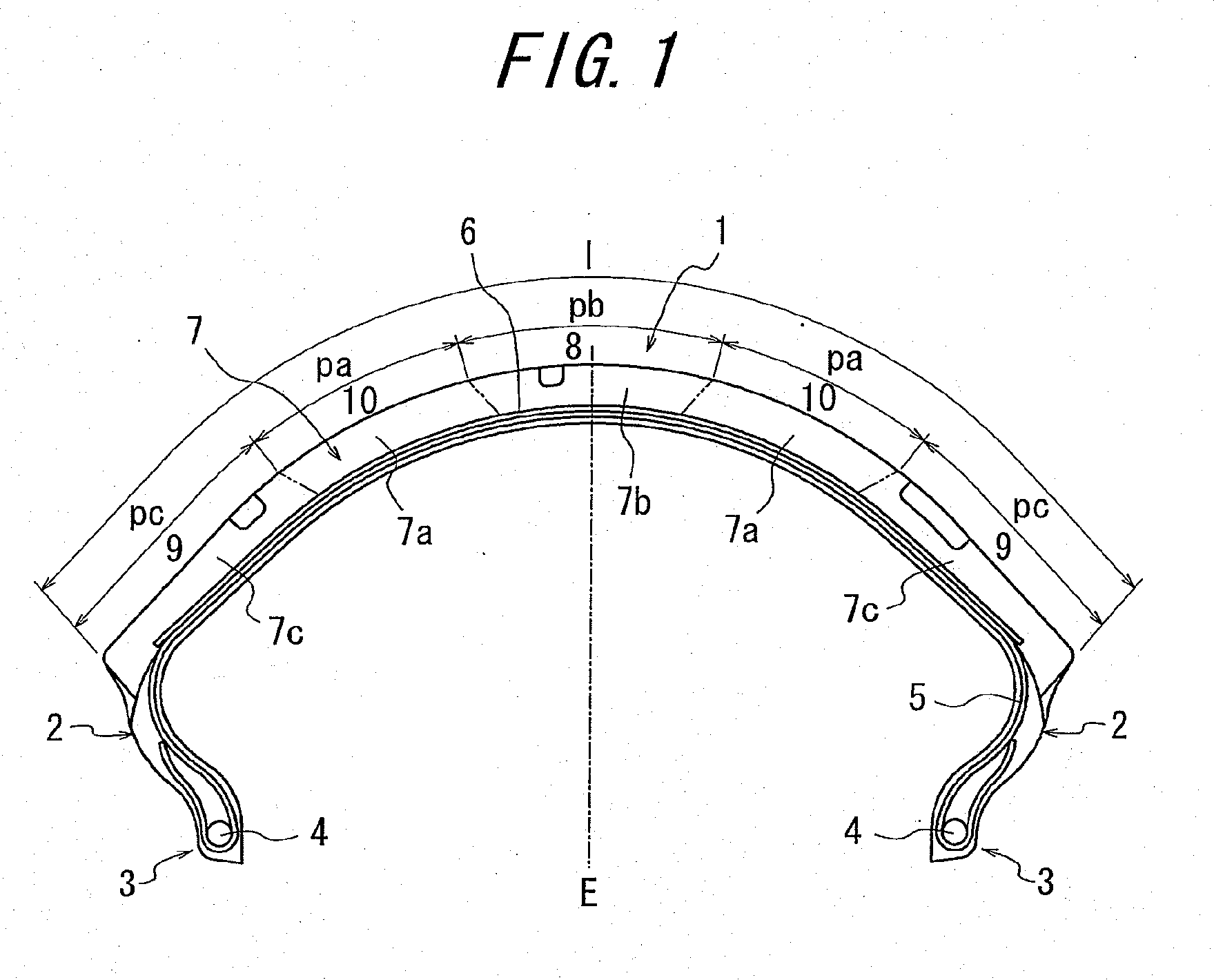

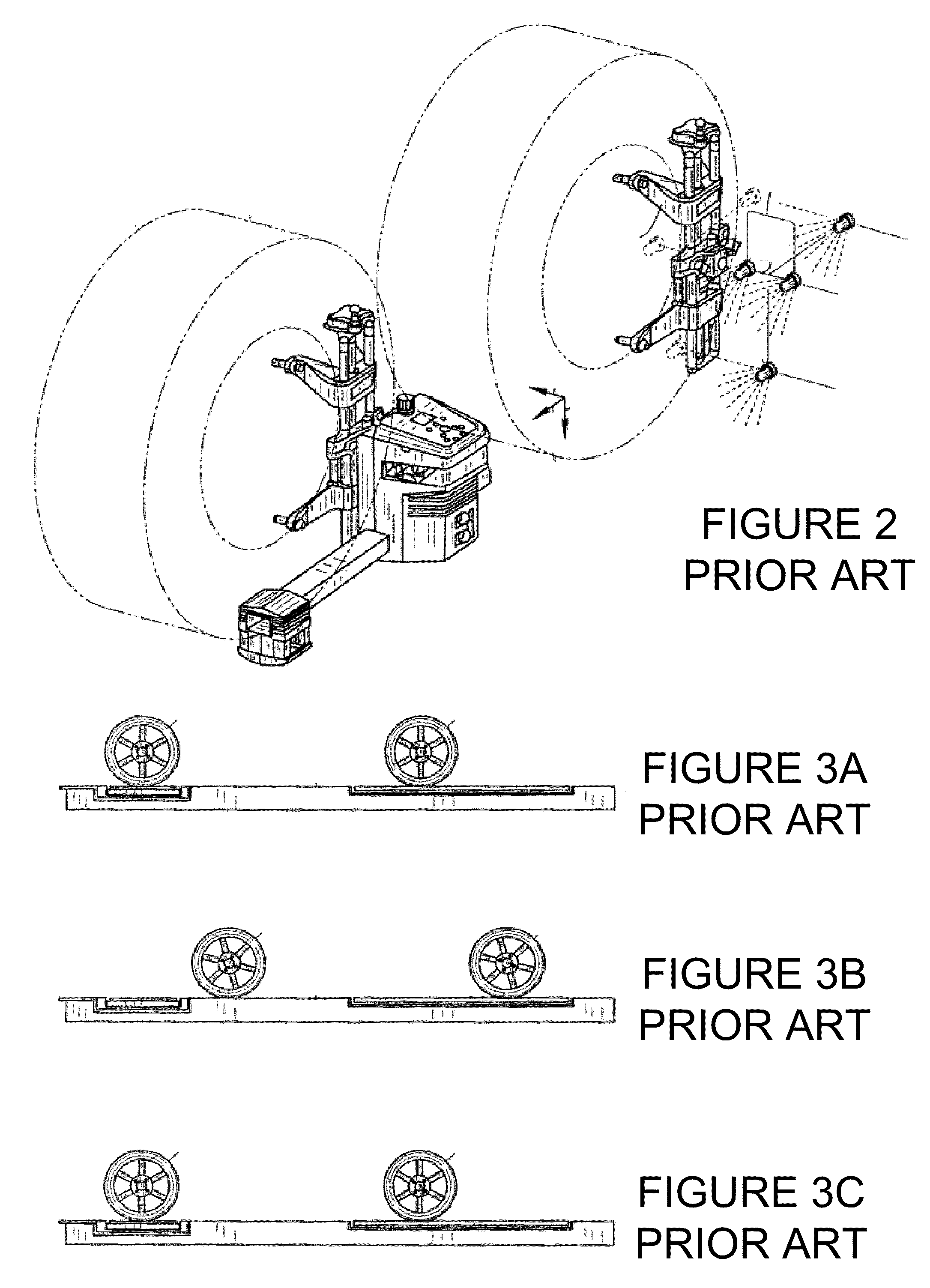

Pneumatic tire for motorcycle

ActiveUS20100193095A1Effective forceStrong lateral forceMotorcycle tyresTyre tread bands/patternsGround contactCamber angle

The present invention provides a pneumatic tire for motorcycle, in which driving properties and braking properties when a moderate camber angle is imparted to the tire on a dry road surface are improved without deteriorating stability in running, relatively large lateral force is reliably generated, and excellent wet performance is demonstrated without deteriorating dry performance of the tire, so that stable running is constantly enabled. The pneumatic tire for motorcycle, comprises: a tread portion 1 containing tread rubber 7 having a layered structure including at least one layer; a pair of sidewall 2 portions extending on the inner side in the radial direction and provided continuous with respective side portions of the tread portion 1; and bead portions 3 provided continuous with the inner peripheral sides of the respective sidewalls 2, wherein a ground contact region of the tread portion 1 is constituted of five regions consisting of: a center region 8 including the tire equatorial plane E; a pair of shoulder regions 9 including ground contact ends of the tread; and a pair of intermediate regions 10 located between the center region 8 and the respective shoulder regions 9, 100% modulus at the room temperature (25° C.) of intermediate tread rubber 7a provided across the entire part of each intermediate region 10 is set larger than each of 100% modulus of center tread rubber 7b provided across the entire part of the center region 8 and 100% modulus of shoulder tread rubber 7c provided across the entire part of each shoulder region 9, and a negative ratio in the ground contact region of the tread is set so as to gradually increase from the respective shoulder regions 9 toward the center region 8.

Owner:BRIDGESTONE CORP

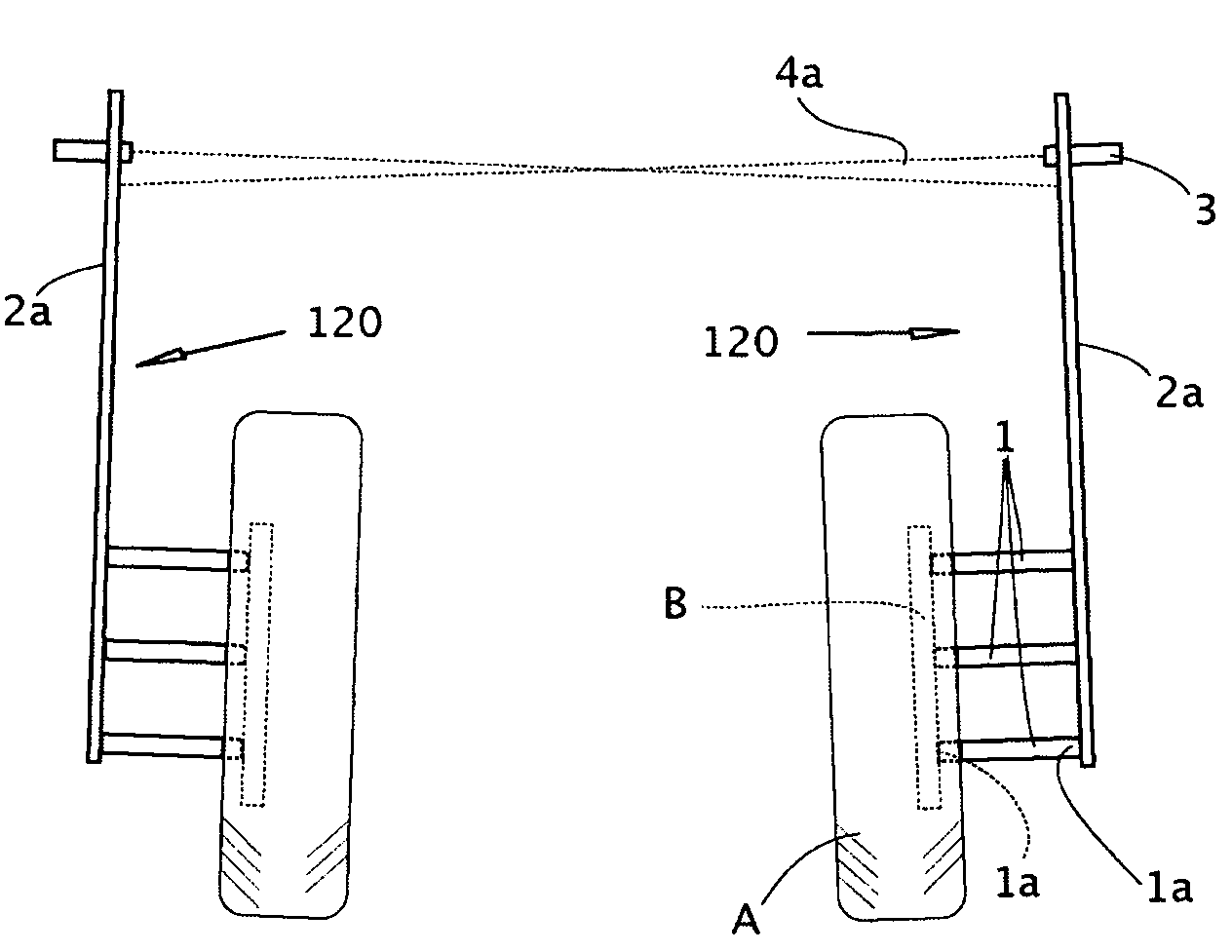

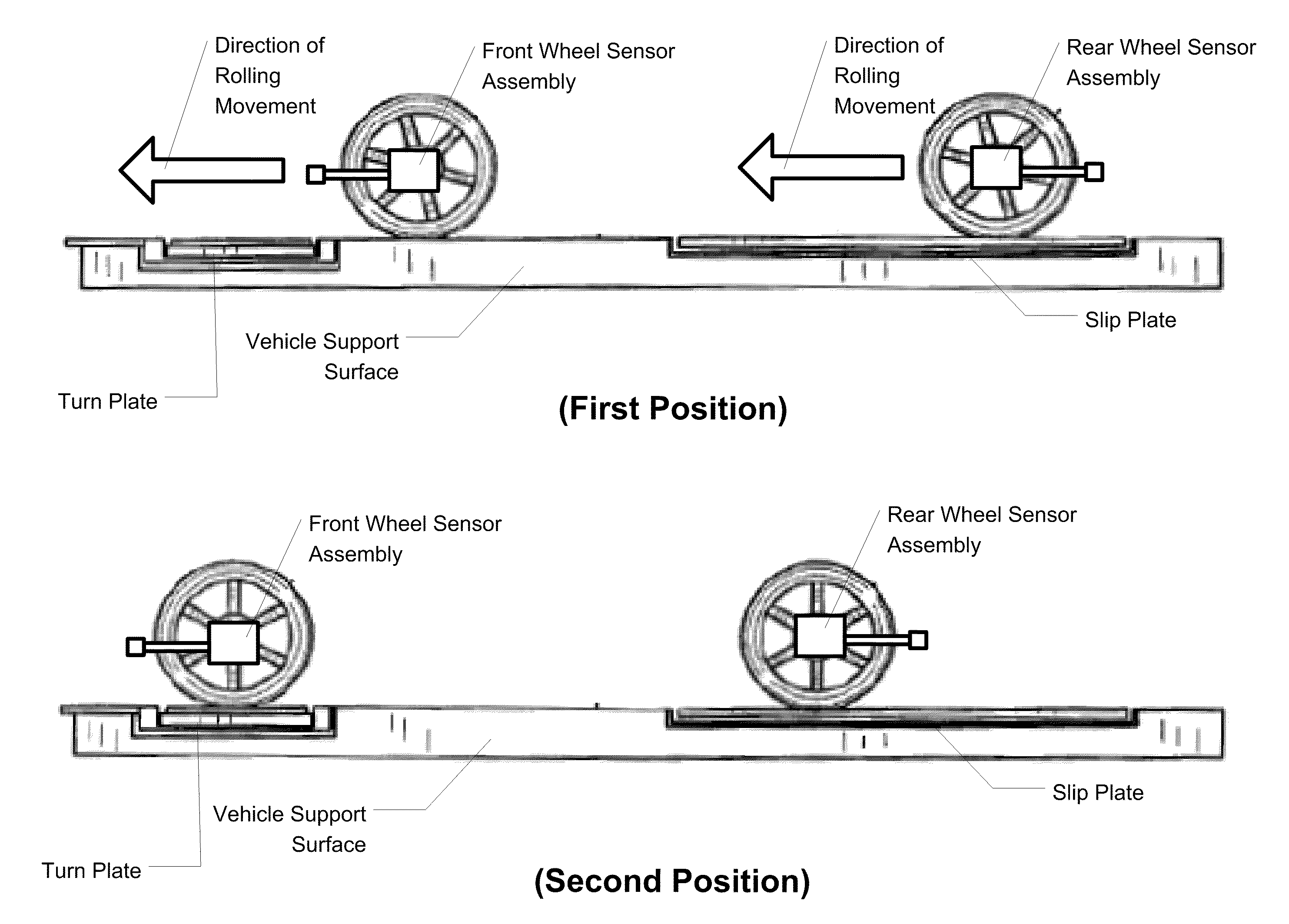

Method for rolling compensation with wheel-mounted sensors

A method for compensating axial misalignment between wheel-mounted alignment sensors and an axis of rotation for an associated wheel. The method compensates sensors mounted to each wheel of a vehicle simultaneously, without requiring jacking of the vehicle wheels above a supporting surface, and which only requires wheel rotational movement over an arc of 60 degrees or less. The method utilizes measurements of a change in a wheel toe angle and measurements of a change in a wheel camber angle, during a measured rotational movement of the wheel, to identify sinusoidal variation in the respective toe and camber angles during the wheel's rotational movement, from which a measure of axial misalignment between the wheel-mounted alignment sensor axis of rotation and the wheel axis of rotation is identified.

Owner:HUNTER ENG

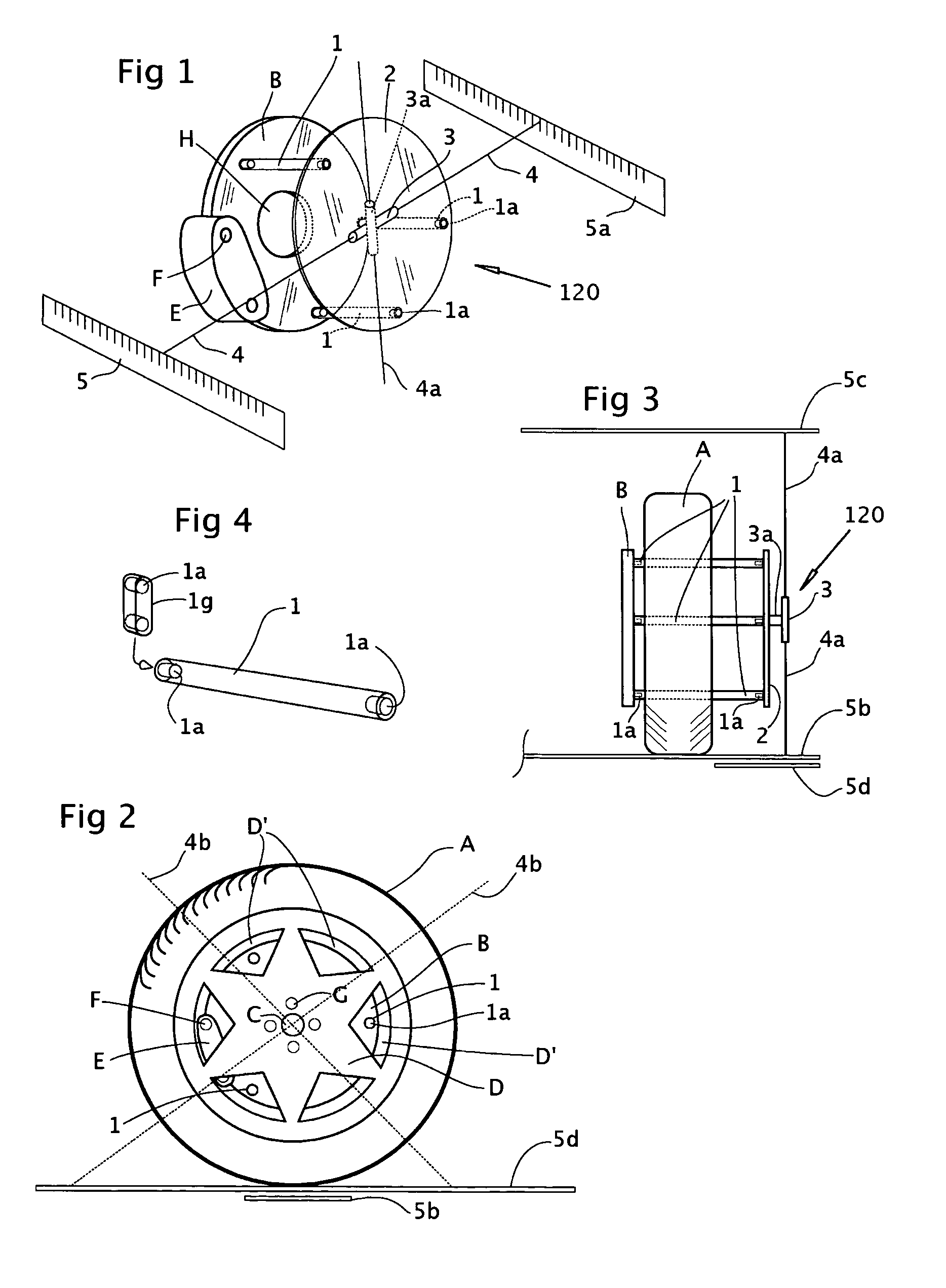

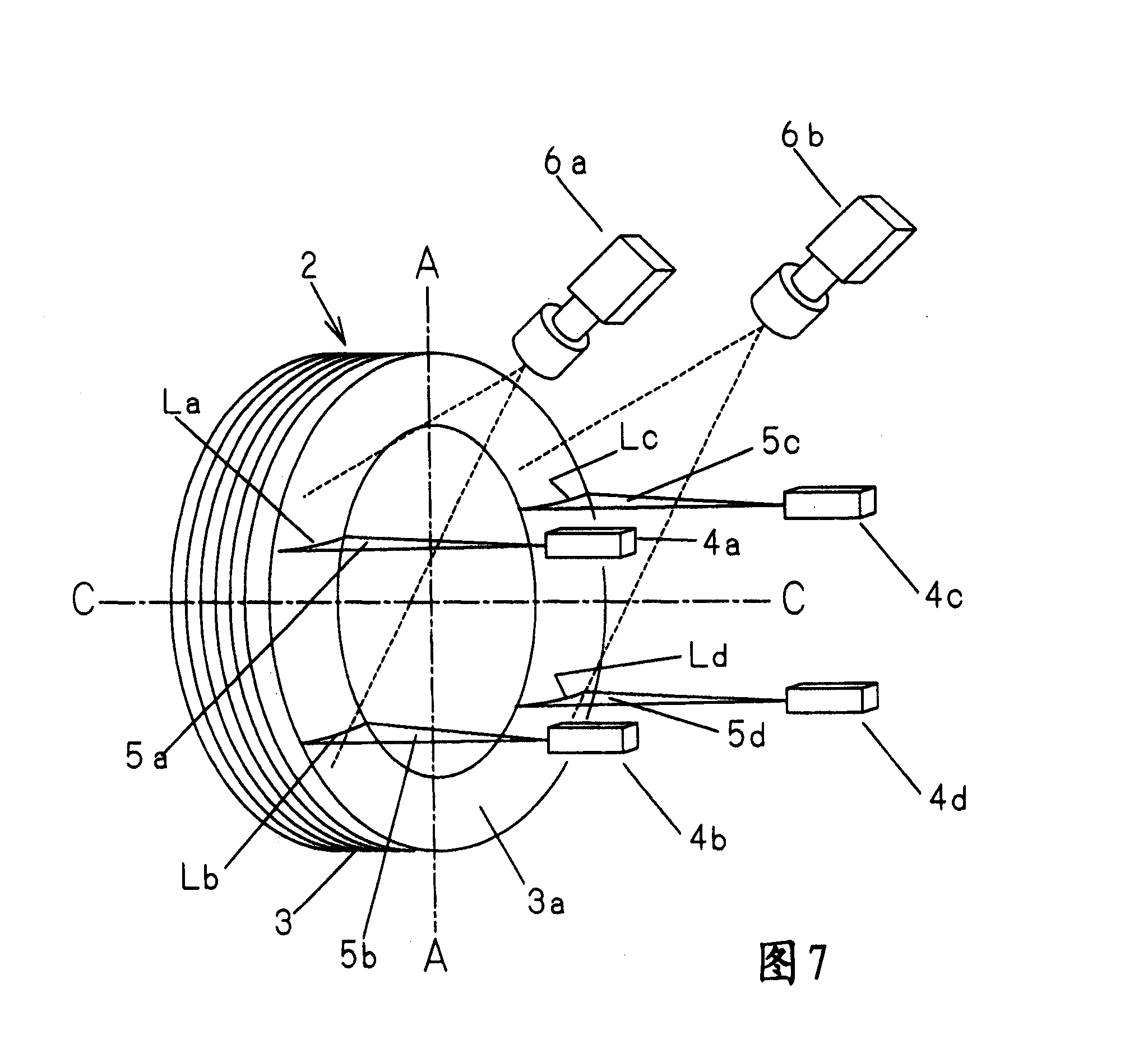

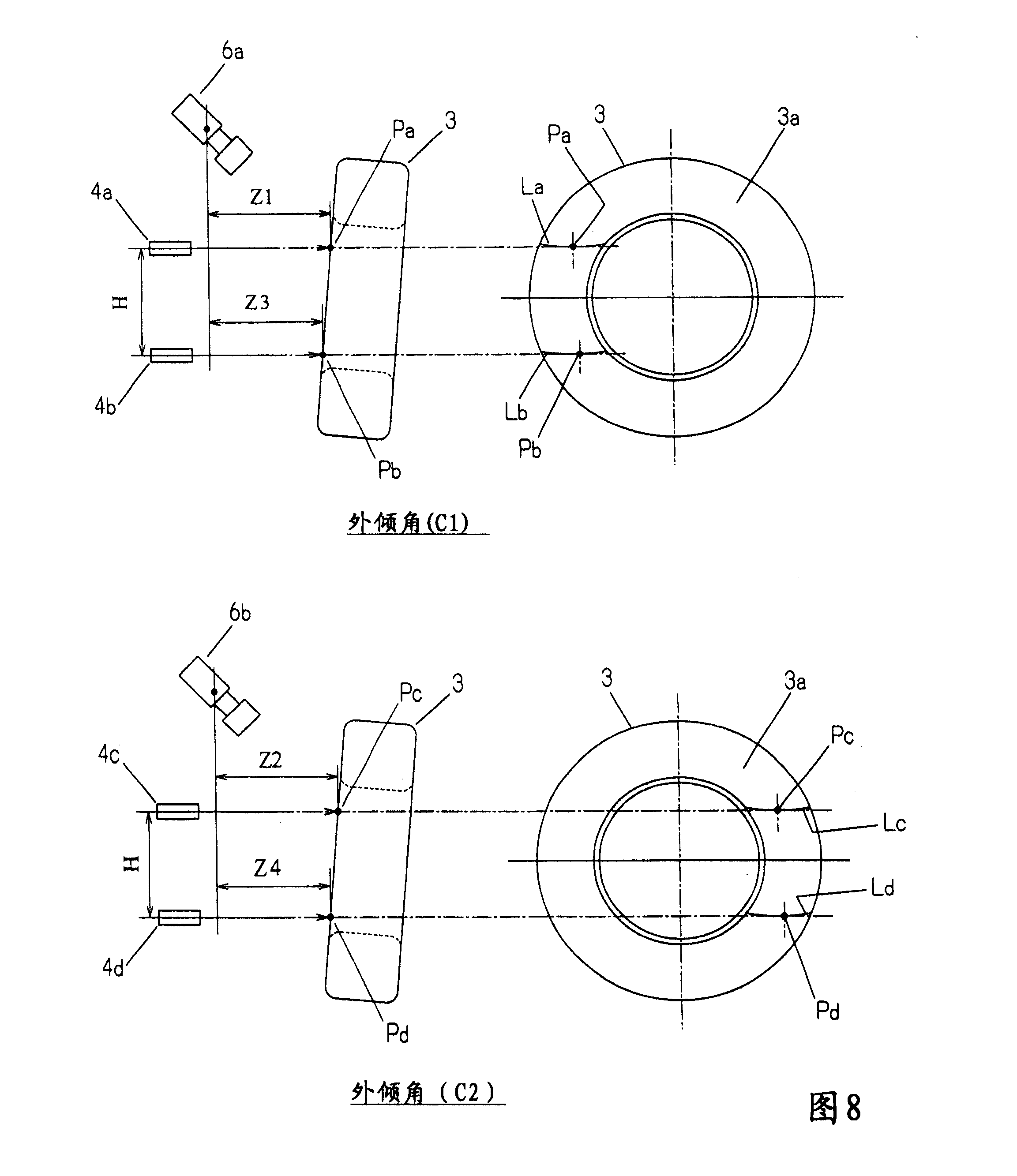

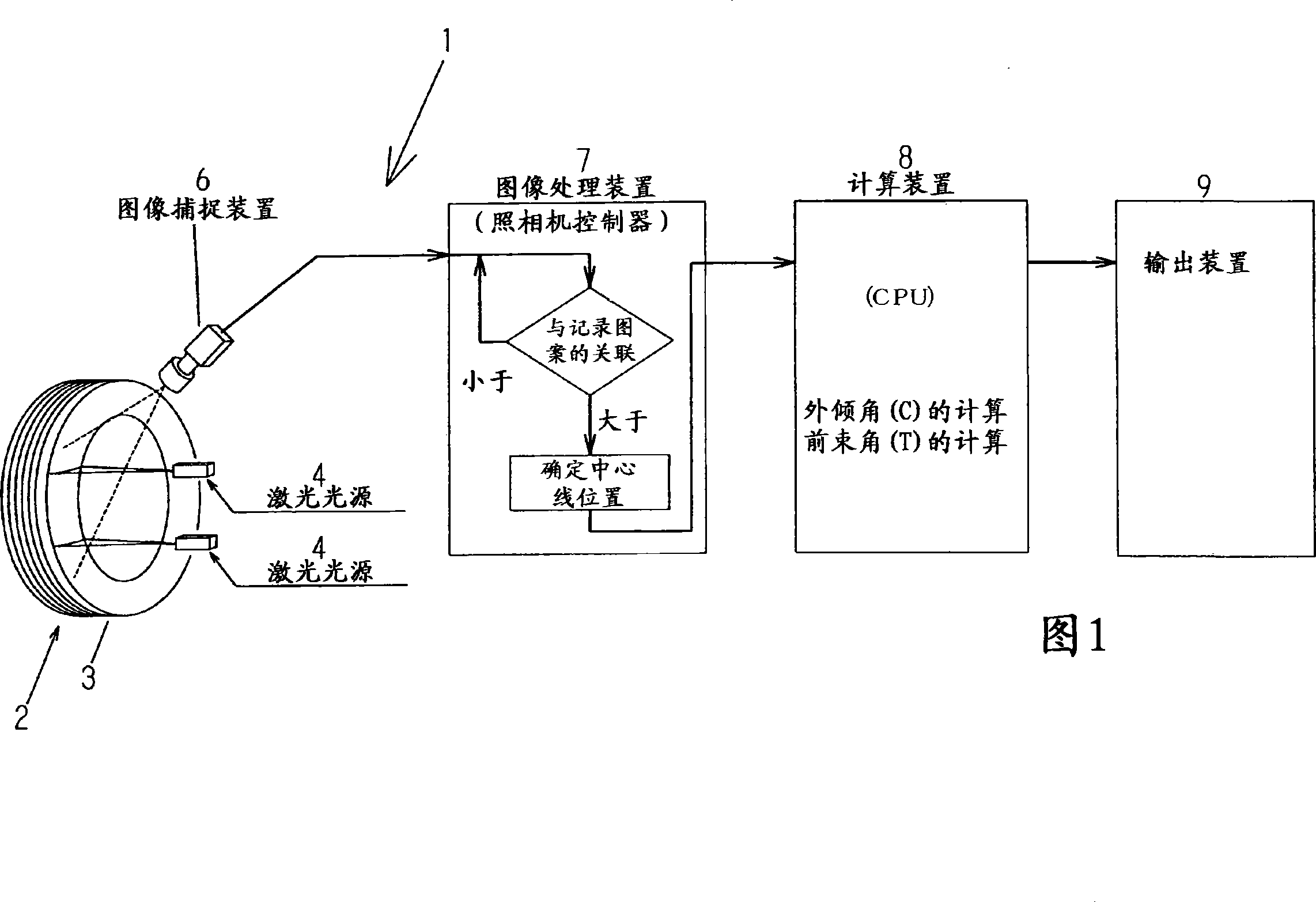

Wheel positioning measuring device

The invention relates to a non-contact type wheel positioning and measuring device, which has a simple structure and can measure the toe-in angle and the camber angle with high accuracy. The device comprises a pair of laser sources used for horizontally emitting a beam of laser to the side of the wheel, the pair of laser sources are vertically arranged and separated from each other so as to form two vertical and mutually separated illuminating outline patterns; a pattern catching device which is arranged at the outer side of the laser sources and at a same face with the laser sources so as to catch the outline patterns which is taken as the measured images; an image processor which is used for determining and recording the midline position data of each illuminating outline pattern, the midline position data are images caught by the image catching device and comprise outlines, and each prior recorded image which comprises outline pattern, compared with the caught images, the selected recorded images which comprise the outline patterns have a certain degree of or higher relativity; and a calculating device which gains the position of the wheel through calculating the recorded midline position data.

Owner:YASAKA SEIKI

Self compensation floating swing arm independent suspension system

ActiveCN102363408AIdeal handlingIdealized securityInterconnection systemsResilient suspensionsAnti-roll barCamber angle

The invention provides a self compensation floating swing arm independent suspension system, comprising a self compensation floating swing arm independent suspension device and a centrifugal force control scissors-type anti-roll bar device. The two mechanisms can be used in combination or independently and are applicable to both front wheels and rear wheels. The self compensation floating swing arm independent suspension system guarantees that wheels perform line bounce along a vertical direction of a car body on various kinds of road surfaces when a car runs at a low speed or at a high speed or makes turns and guarantees maximum contact area between the wheels and the road surfaces, with the parameters of king pin angle, toe-in angle, camber angle, wheel track, and axle base being maintained the same as original parameters; and, when the car makes turns, the centrifugal force control scissors-type anti-roll bar device works automatically, offsets a roll force with a force equal to the roll force in magnitude and opposite to the roll force in direction, and enables the car body to lower automatically, thereby improving anti-roll capacity and realizing idealization of controllability, safety, stability and comfort of the car. The self compensation floating swing arm independent suspension system has a simple structure, excellent performance, and low cost, and is easy to realize.

Owner:侯贺

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com