Method and device for wheel camber adjustment

a technology for camber adjustment and wheel camber, which is applied in the direction of pivoted suspension arms, transportation and packaging, construction cranes, etc., can solve the problems of unfavorable driving behavior of the vehicle, unfavorable driver manual camber adjustment, and adjustment of camber angl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

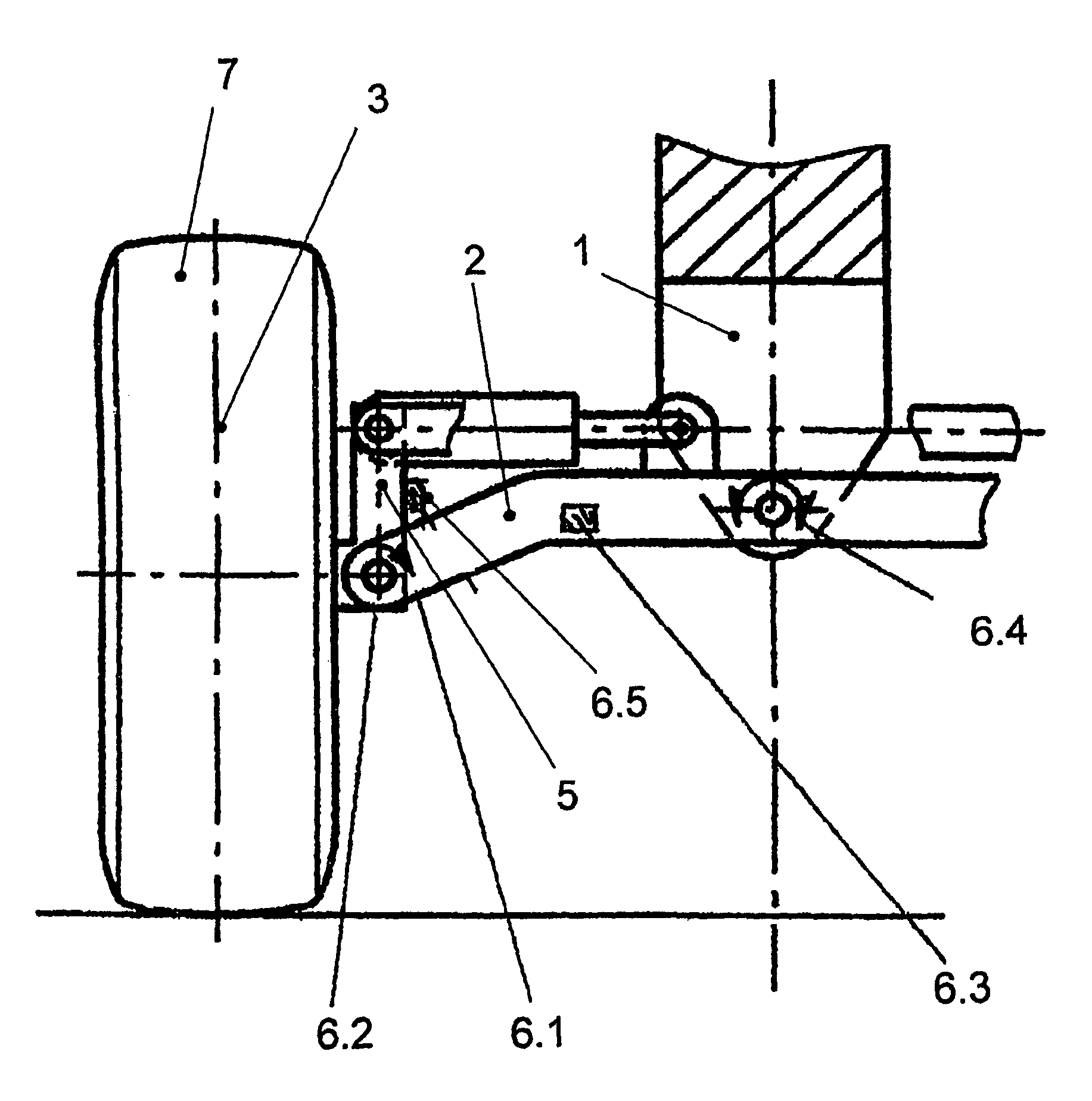

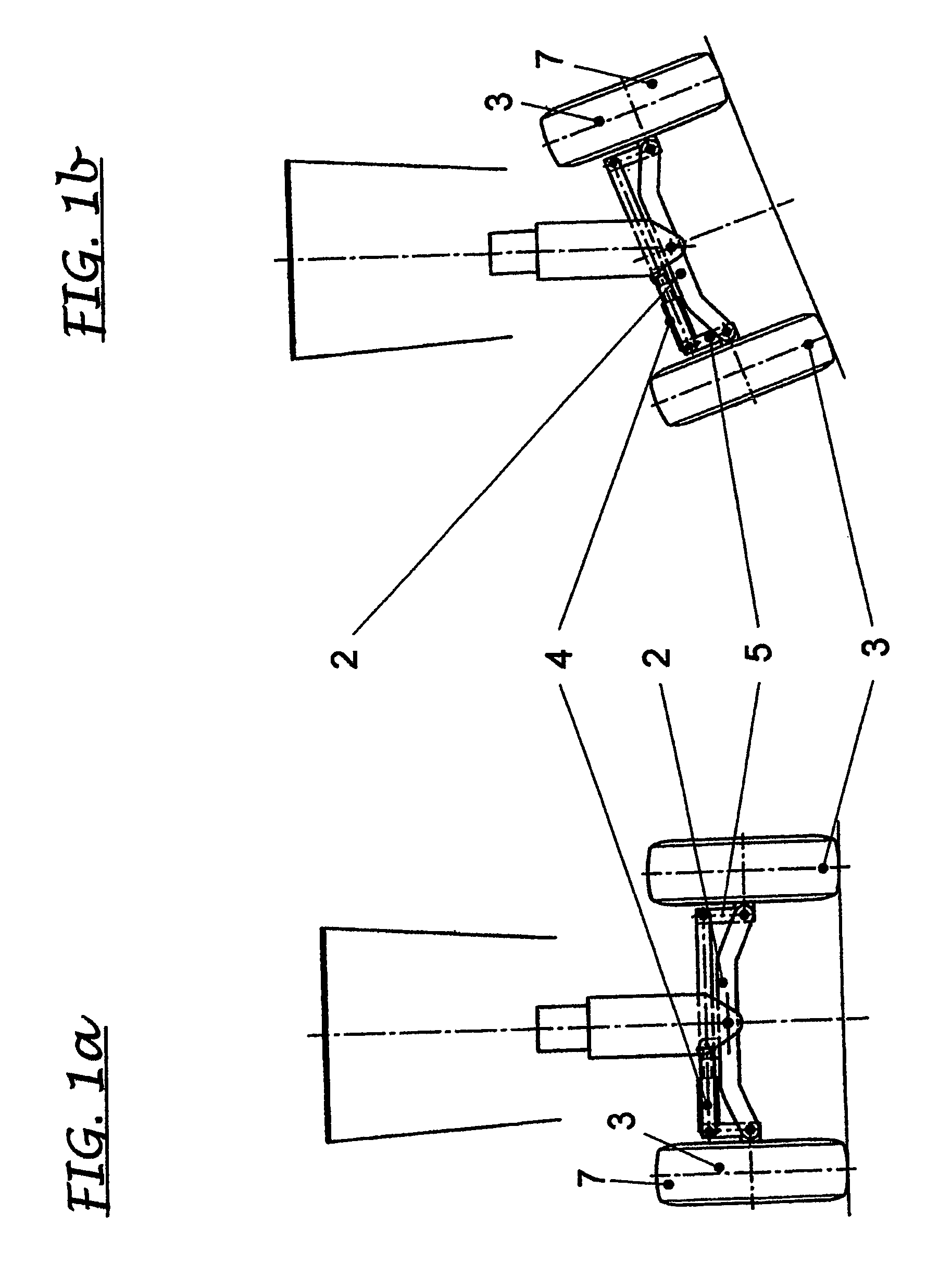

[0026]FIG. 1a and FIG. 1b illustrate the camber adjustment system in accordance with the present invention. In this case, the camber angle is adjusted manually by means of a camber cylinder 4, which is mechanically connected to a wheel pivot unit 5. The wheel pivot unit 5 is moved by the extension and retraction of the camber cylinder 4 and the relative angle between the wheel plane 3 of the vehicle wheel and the perpendicular of the carriageway is thus changed. The camber cylinder 4 has a releasable connection with the front axle 2 and is arranged in parallel to the latter and to the carriageway. If there is a terrain-dependent inclination of the carriageway, the front axle 2 and the camber cylinder 4 arranged in parallel to it will follow the inclination of the carriageway. The camber cylinder 4 and the wheel pivot unit 5 are at right angles to each other in the case of both a flat and an inclined carriageway. The camber angle is the same in both cases.

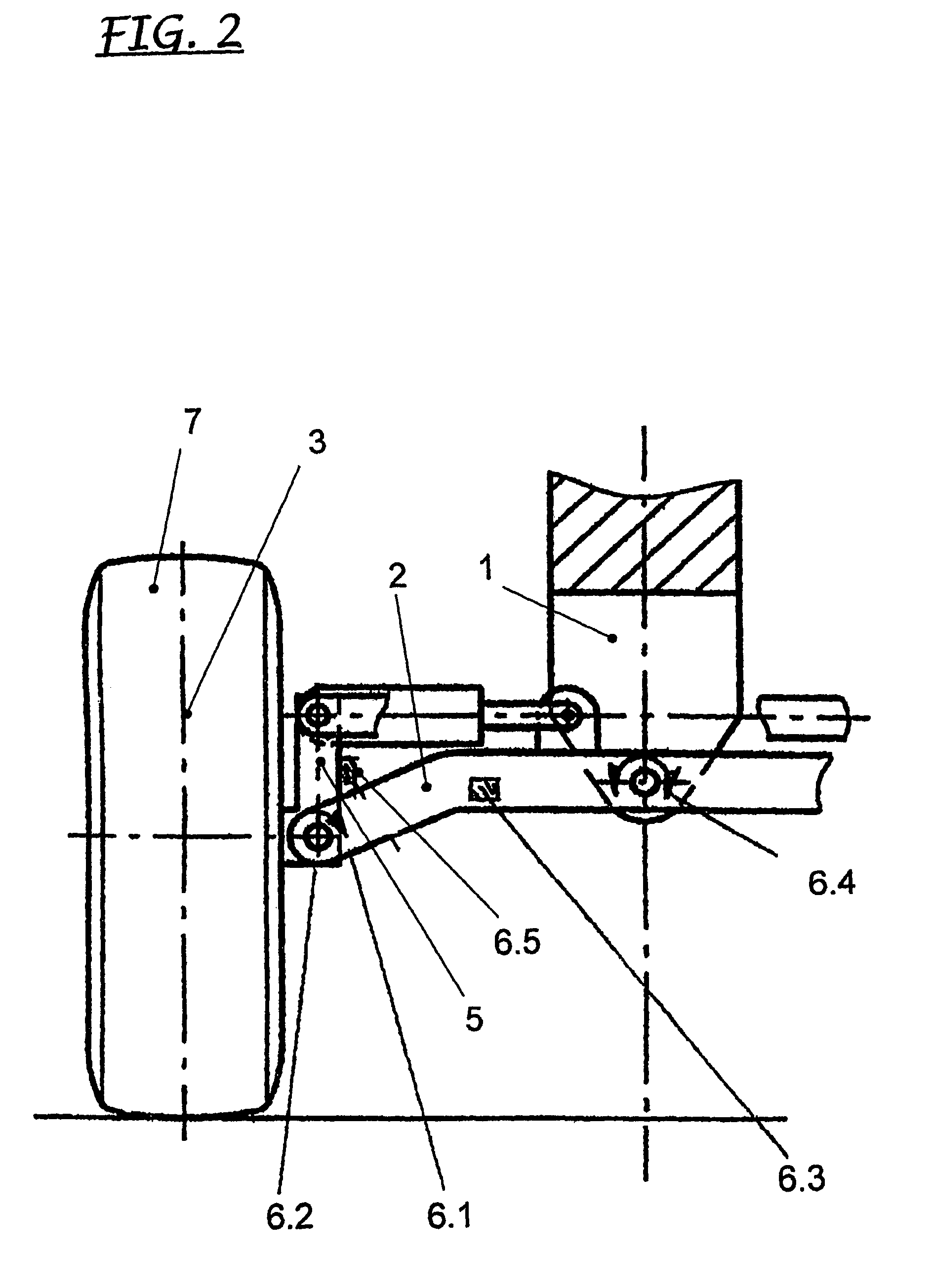

[0027]FIG. 2 shows the advan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com