Patents

Literature

1081 results about "Wheelbase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

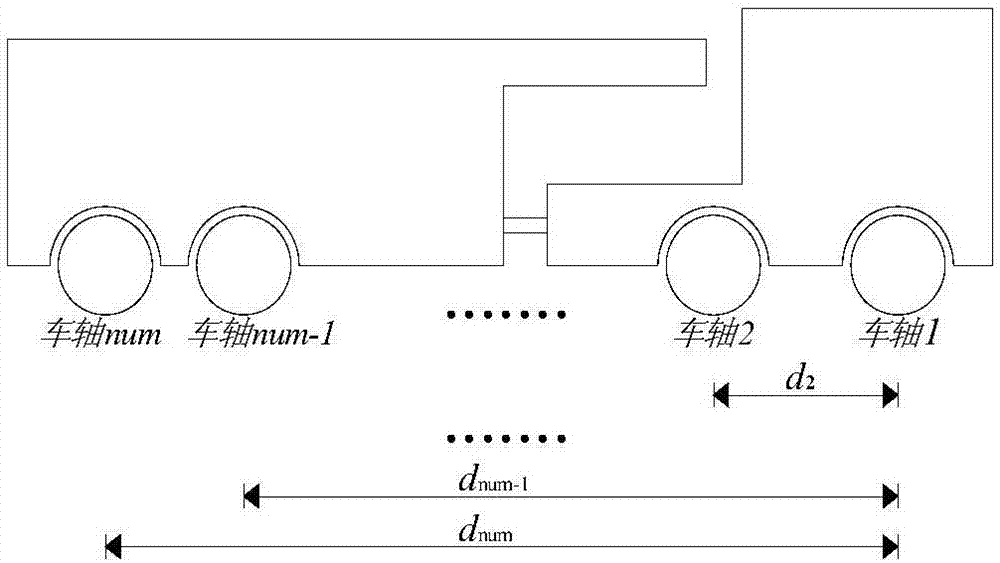

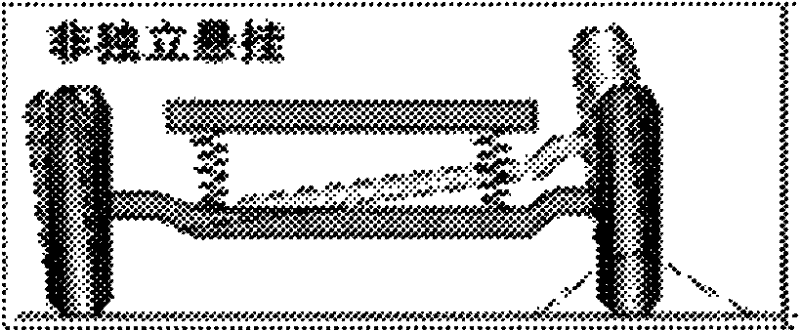

In both road and rail vehicles, the wheelbase is the distance between the centers of the front and rear wheels. For road vehicles with more than two axles (e.g. some trucks), the wheelbase is the distance between the steering (front) axle and the centerpoint of the driving axle group. In the case of a tri-axle truck, the wheelbase would be the distance between the steering axle and a point midway between the two rear axles.

Apparatus for assisting steering of vehicle when backing

InactiveUS7295227B1Easy to moveDigital data processing detailsAnti-collision systemsDriver/operatorImaging processing

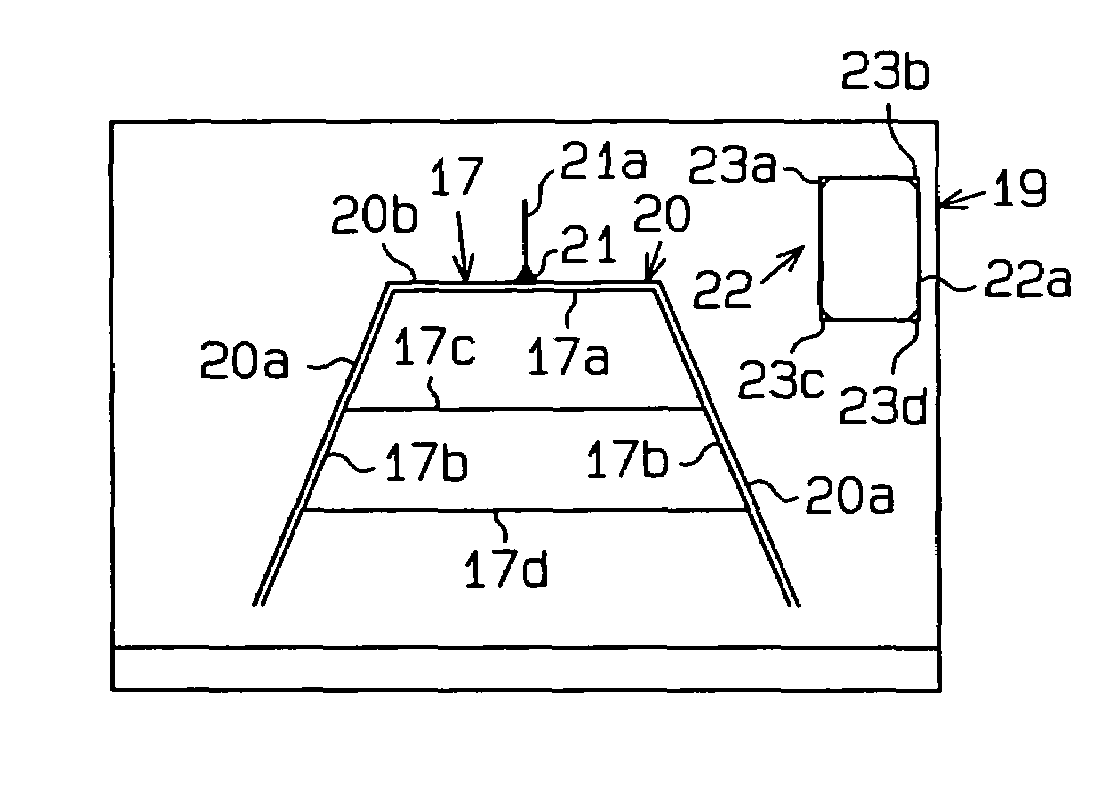

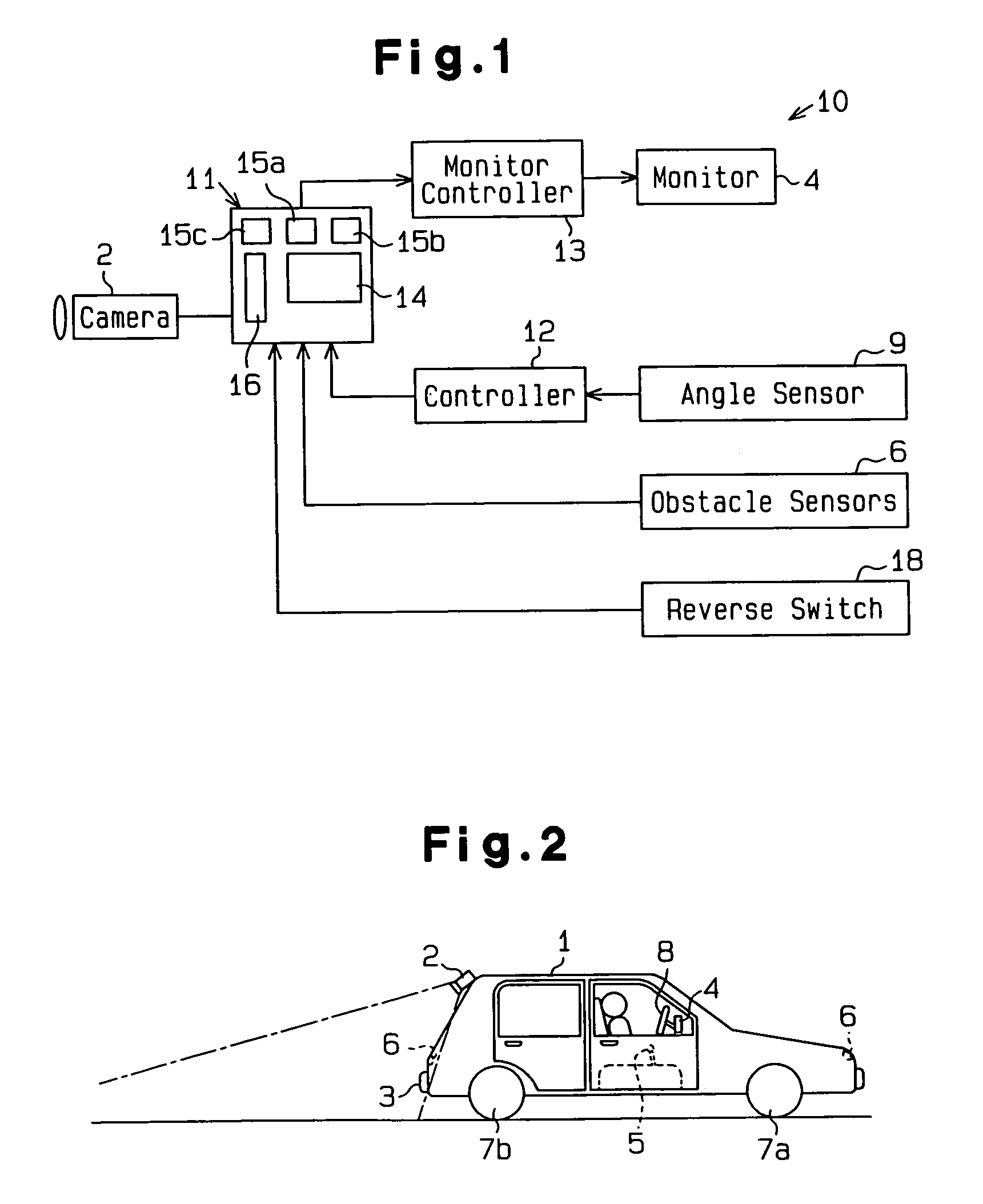

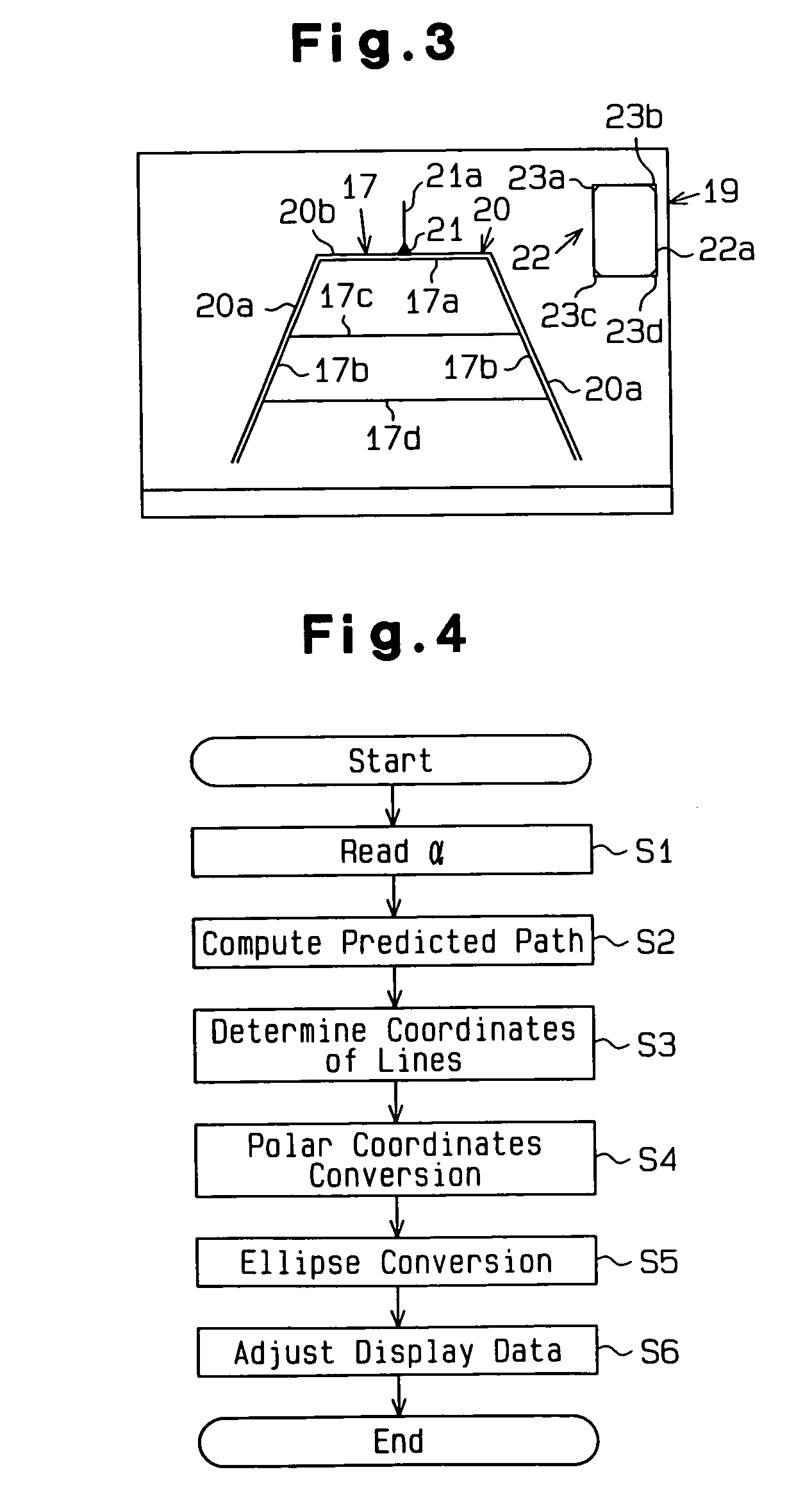

A steering assist apparatus that assists a driver when backing a vehicle in an S-shaped path or parallel parking. The apparatus displays guidance marking on a monitor screen and the driver refers to the guidance marking, which permits the driver to easily back the vehicle to a desired position. The apparatus includes a camera, a monitor, an angle sensor, obstacle sensors, an image processing unit, a controller and a monitor controller. The image processing unit computes the predicted path of the vehicle at the current wheel angle. The monitor shows an image captured by the camera. The image processing unit generates data representing a guidance marking based on the predicted path and superimposes the marking on the monitor screen. The location of the marking on the screen is determined based on the current wheel angle. The marking represents part of the predicted path. Specifically, the marking matches the width of the vehicle. In the monitor screen, a marking is separated from the rear bumper of the vehicle by a distance corresponding to the wheelbase of the vehicle.

Owner:TOYOTA IND CORP

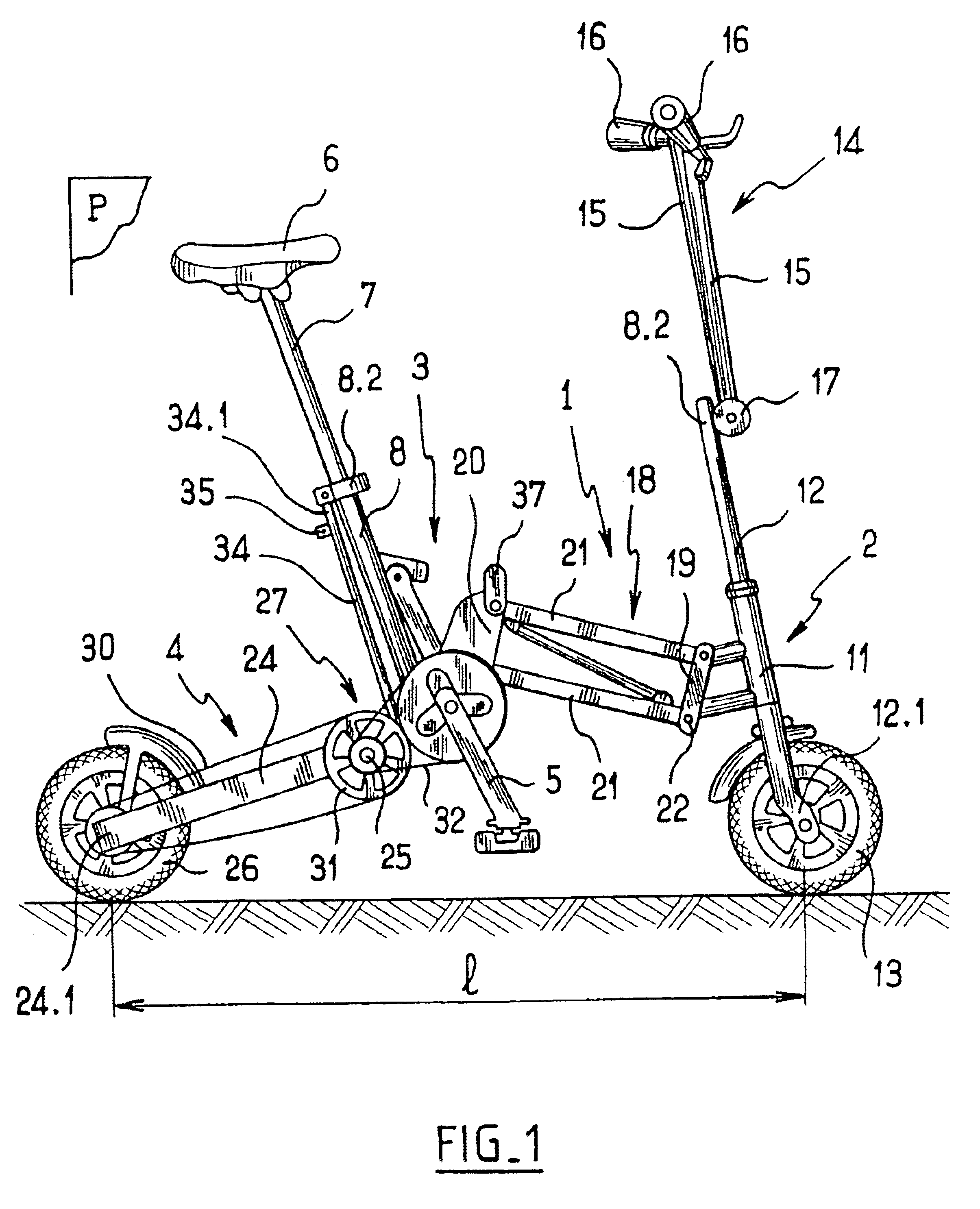

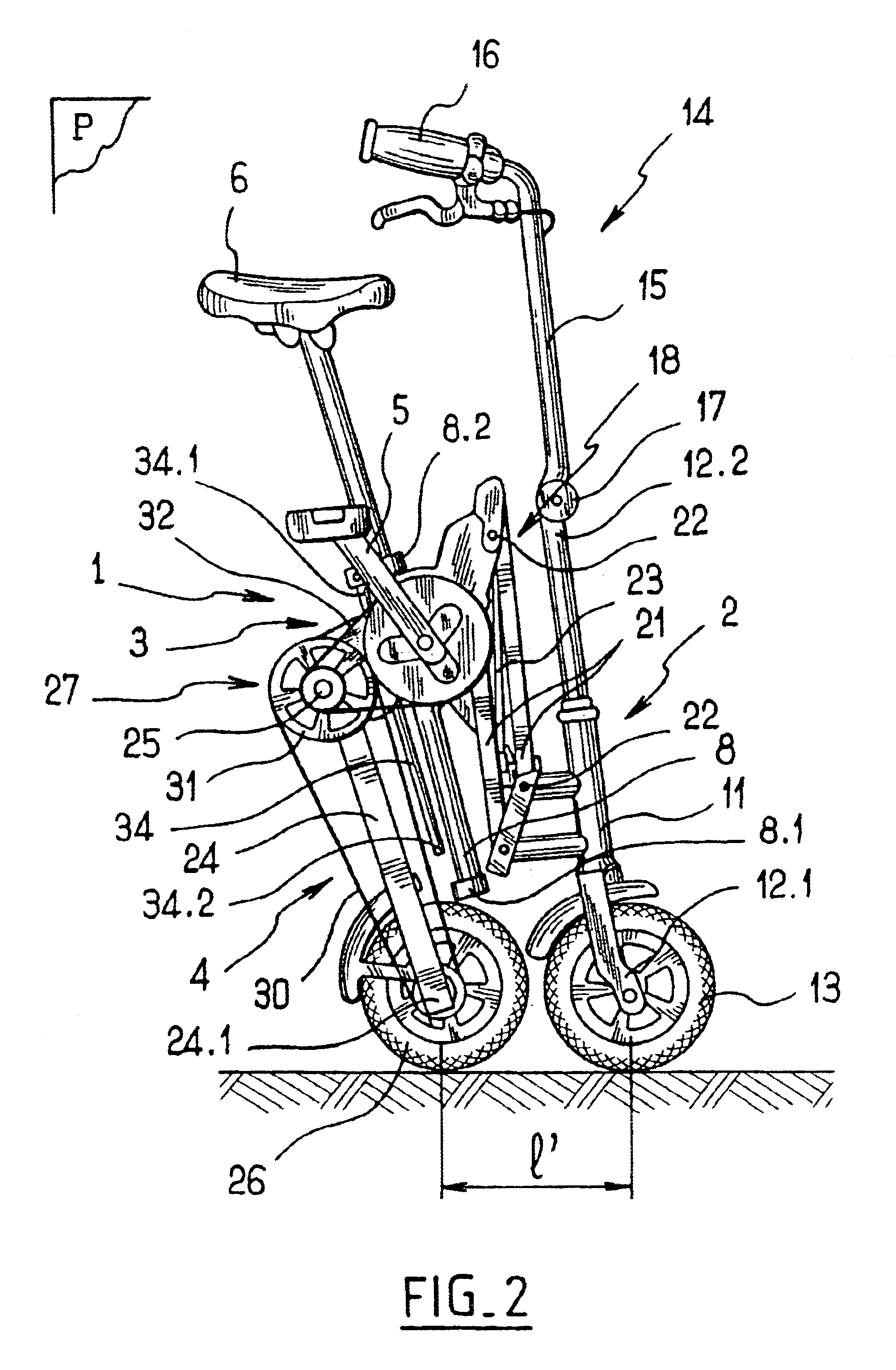

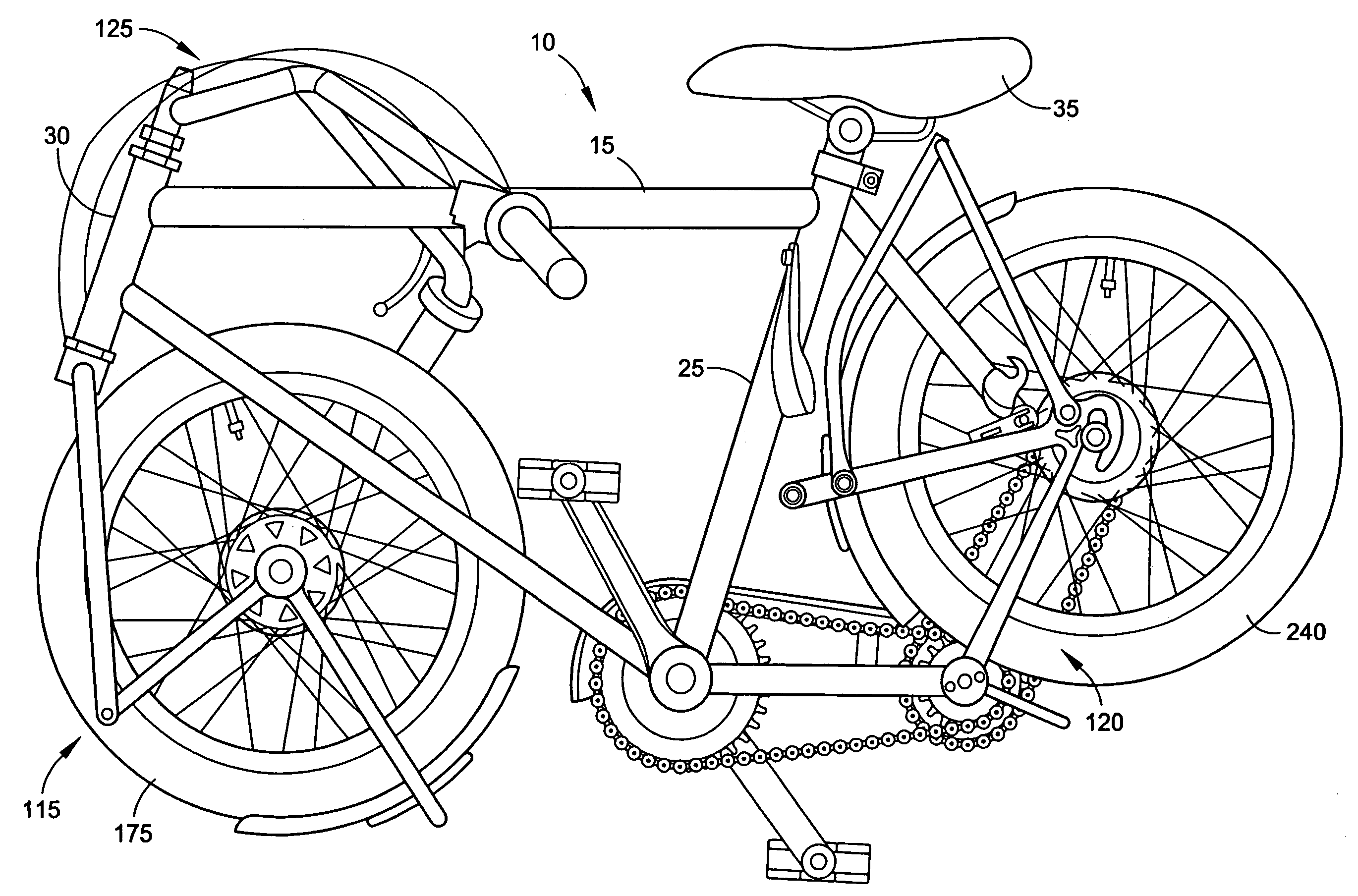

Folding bicycle

InactiveUS6799771B2Length of connection can be constantSimple structurePassenger cyclesWheel based transmissionCrankEngineering

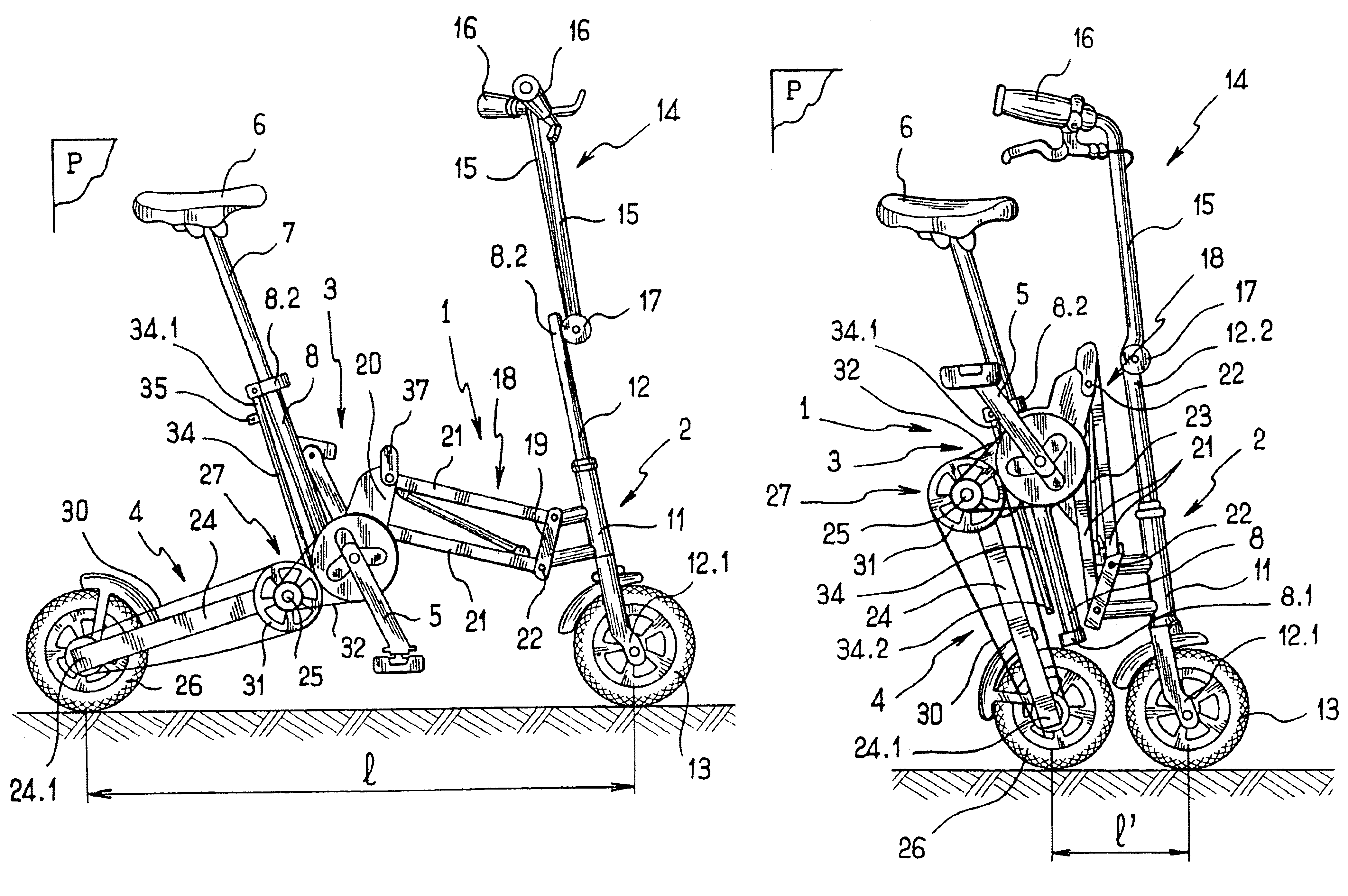

A folding bicycle comprises a frame including a front part whereon is mounted pivoting a steering rod having a lower end provided with a first wheel and an upper end provided with a handlebar, a rear part whereon is mounted a second wheel, and a central part whereon are mounted a saddle and a crankset connected to the rear wheel by transmission elements, such that the saddle, the crankset, the steering rod, the front wheel and the rear wheel are substantially contained in a common plane when the bicycle is unfolded. The frame includes elements articulating the front part and the rear part to the central part to reduce the bicycle wheelbase associated with elements for maintaining at least the front wheel and the rear wheel in the plane.

Owner:MOBIKY

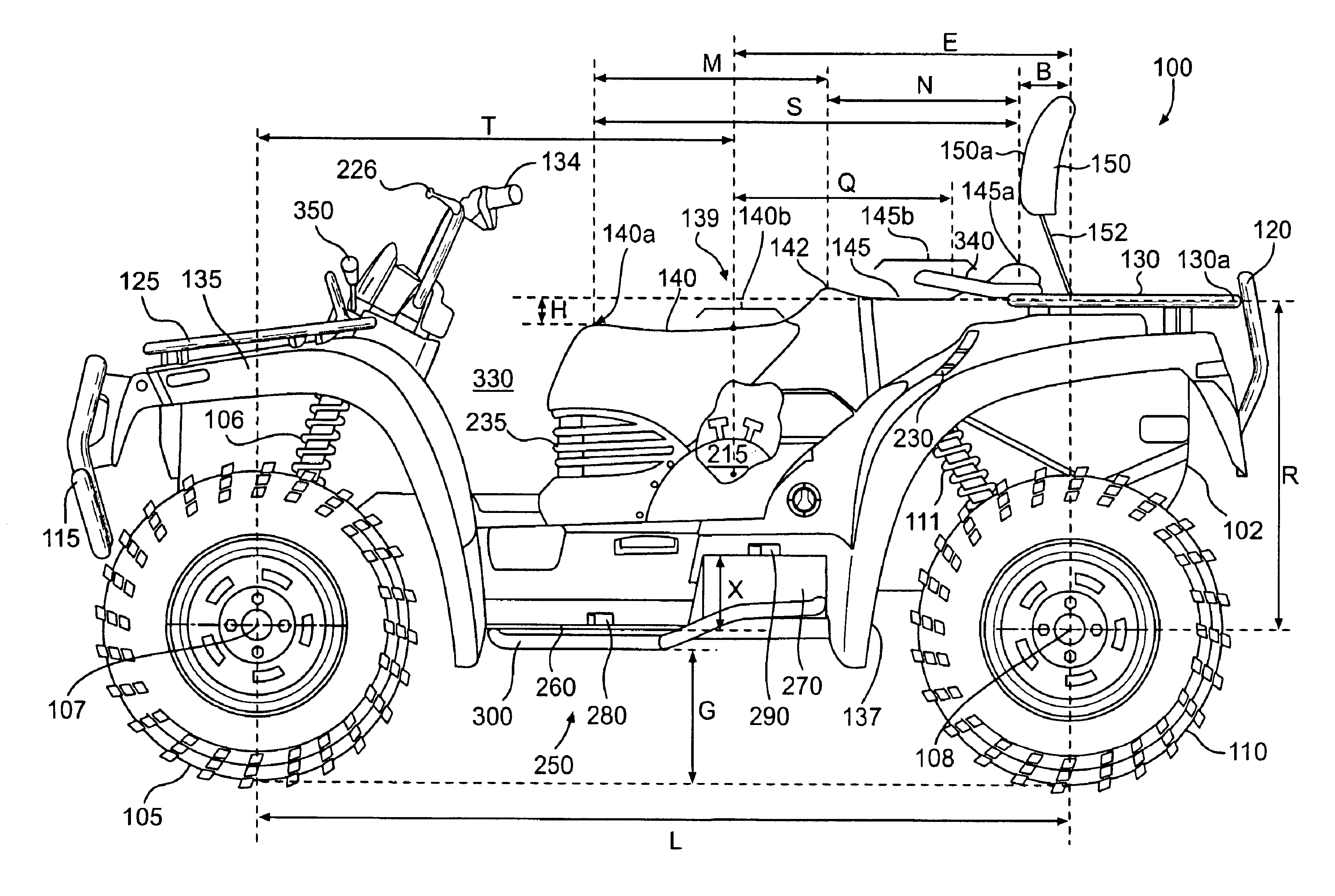

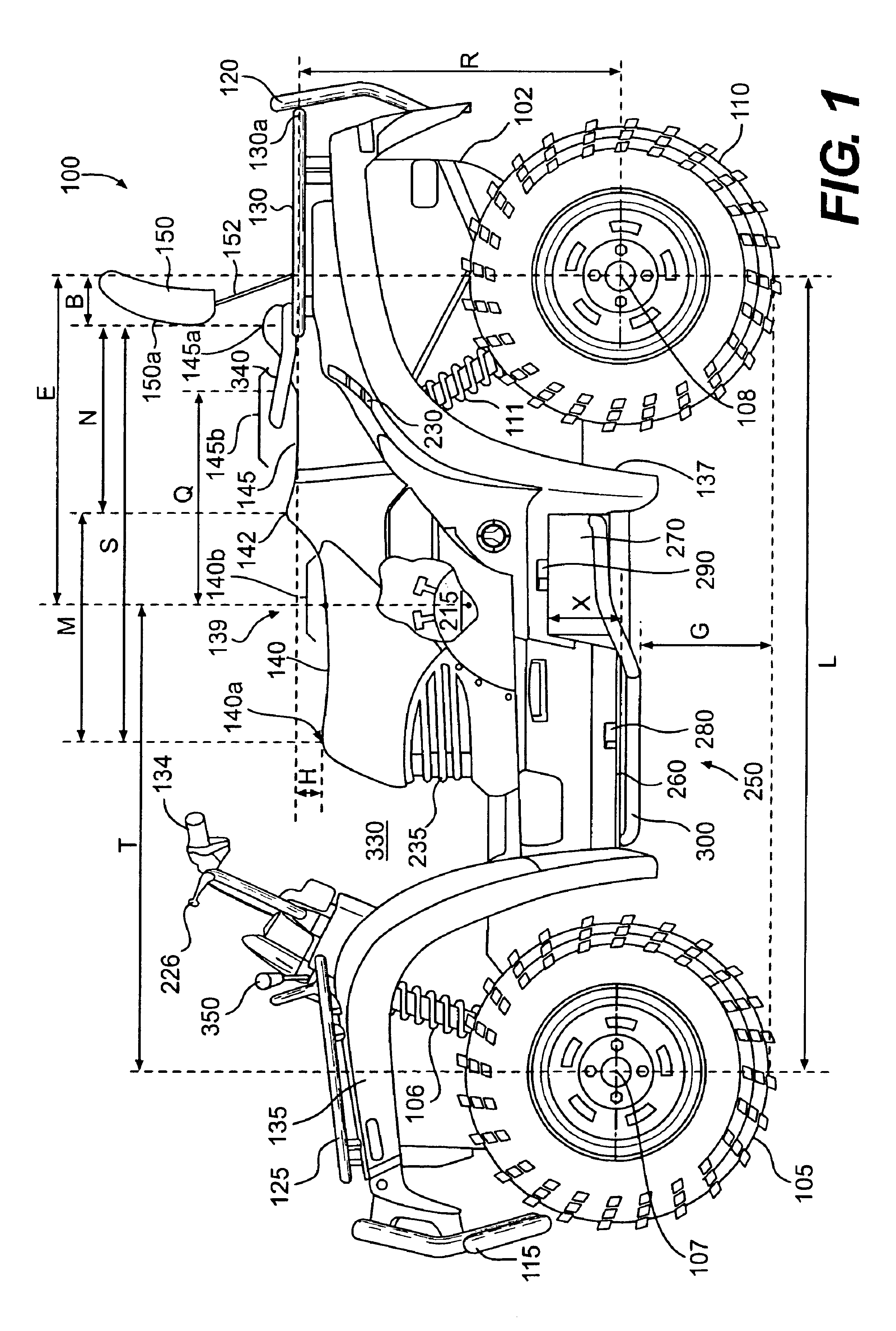

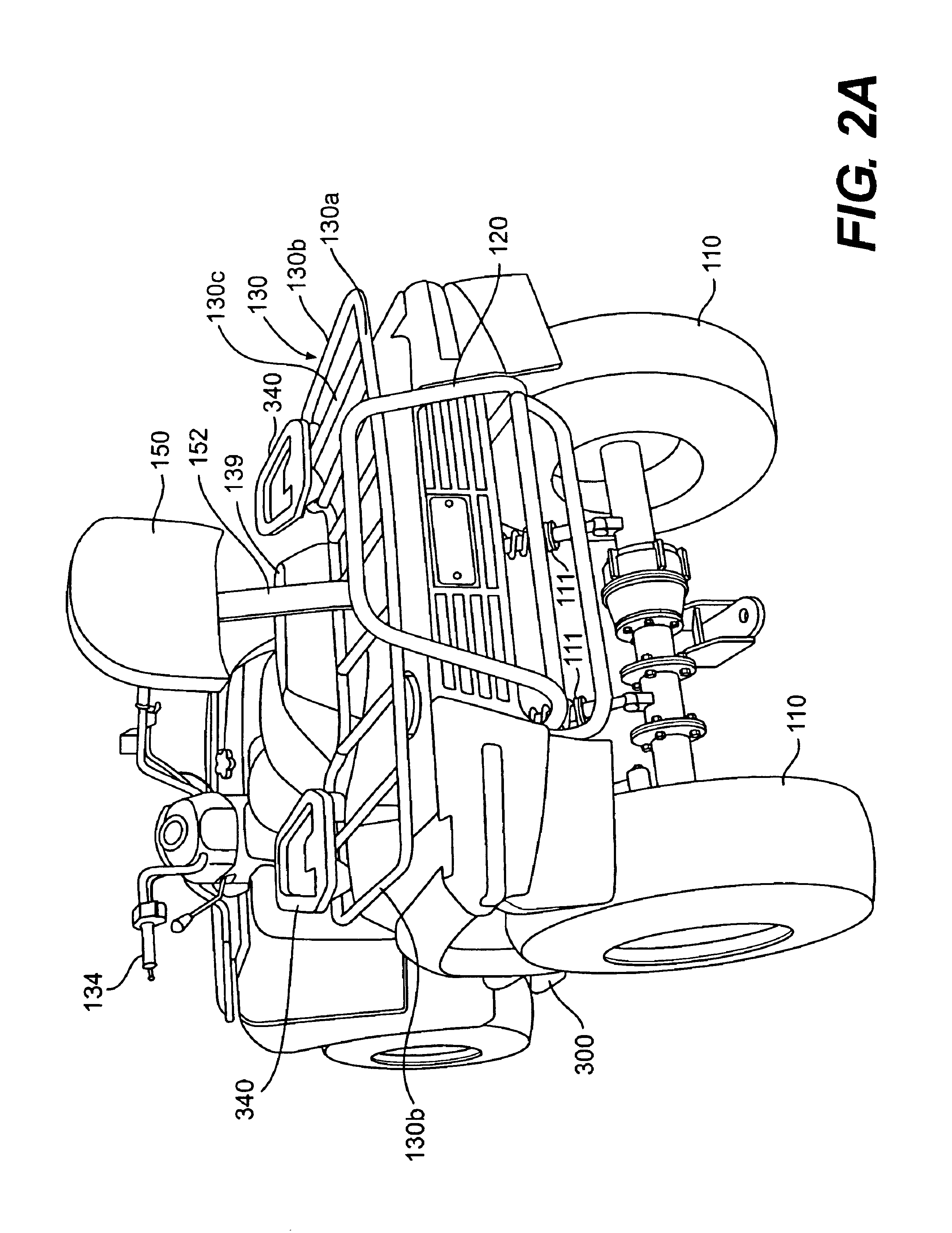

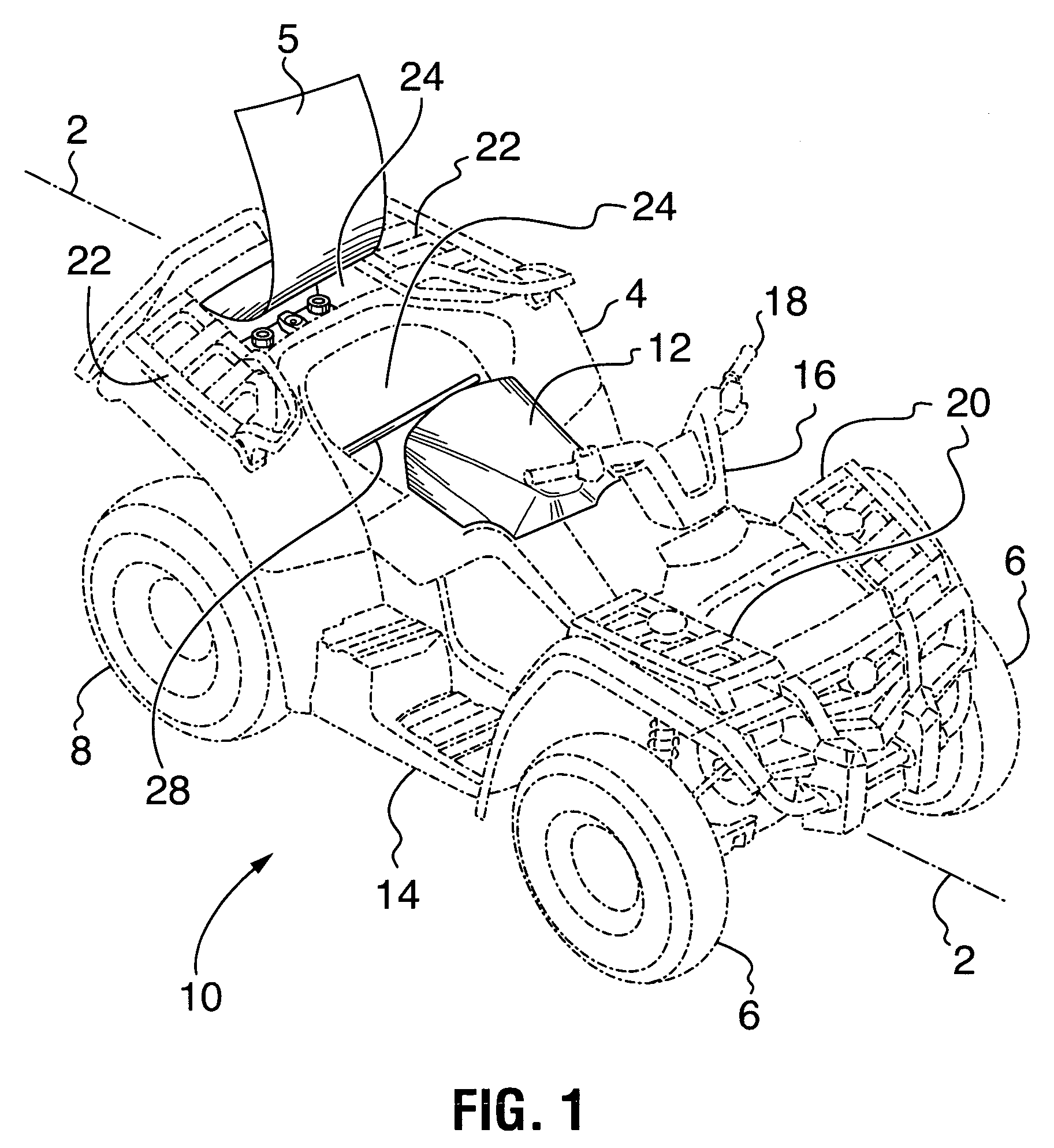

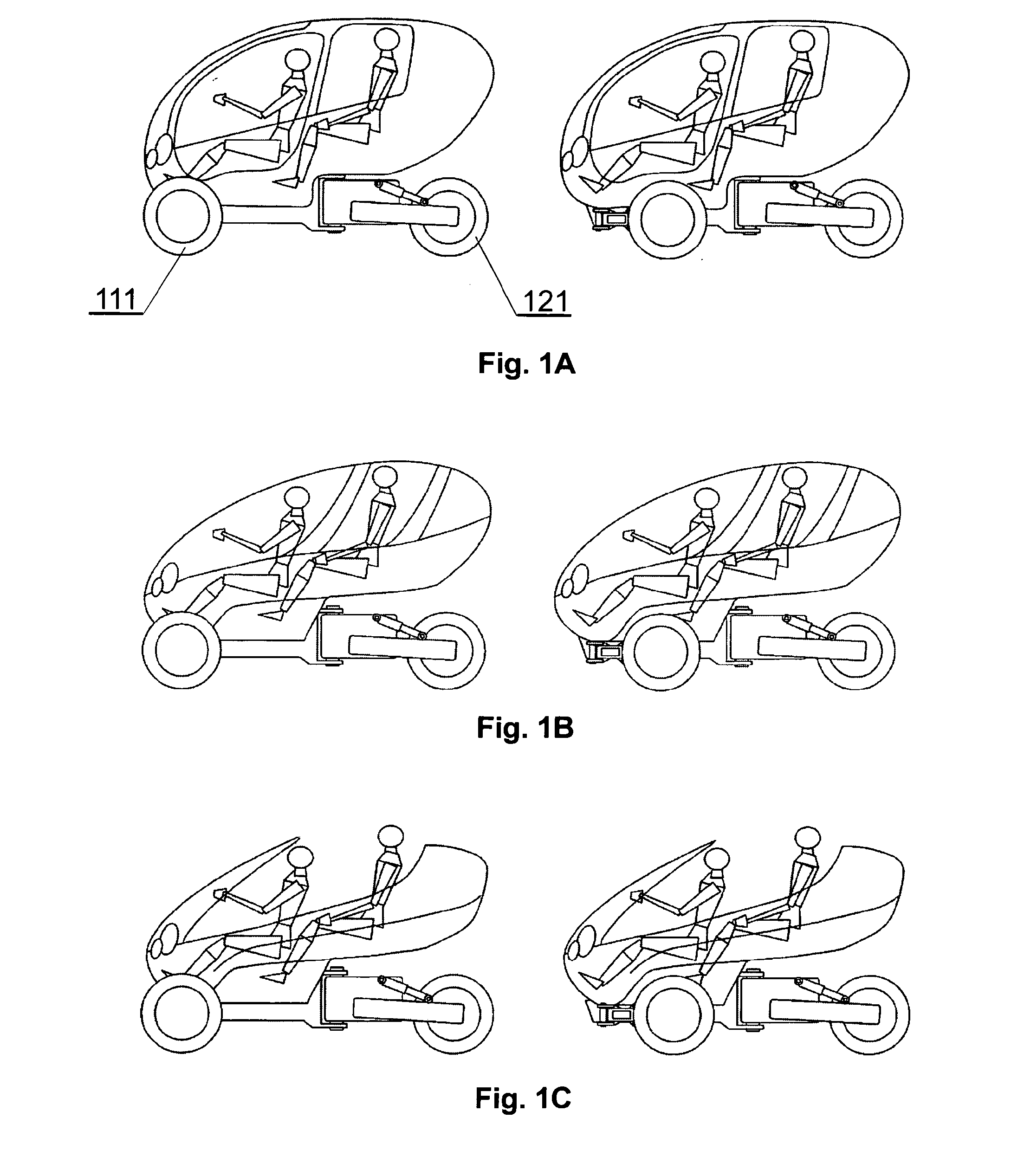

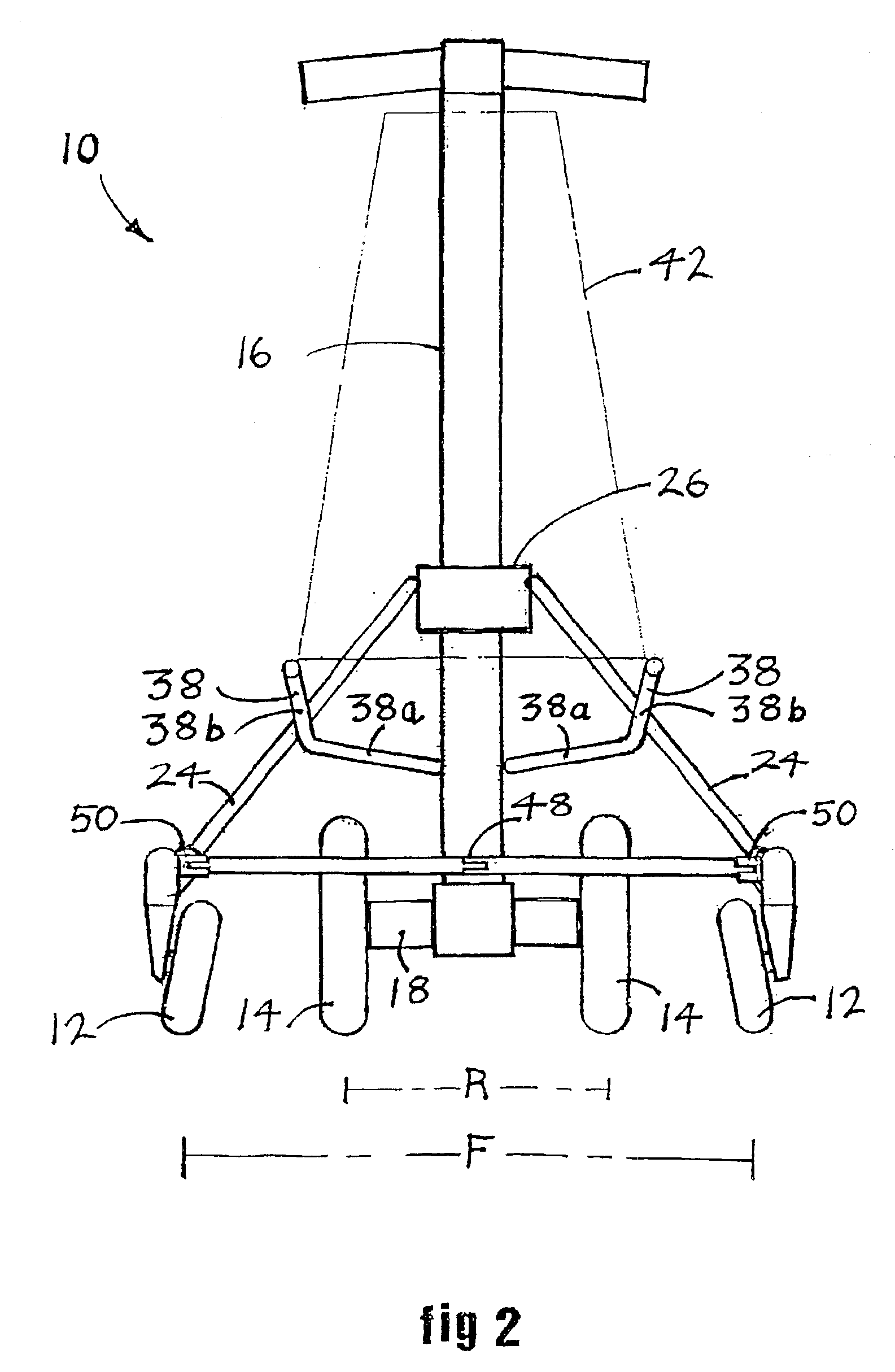

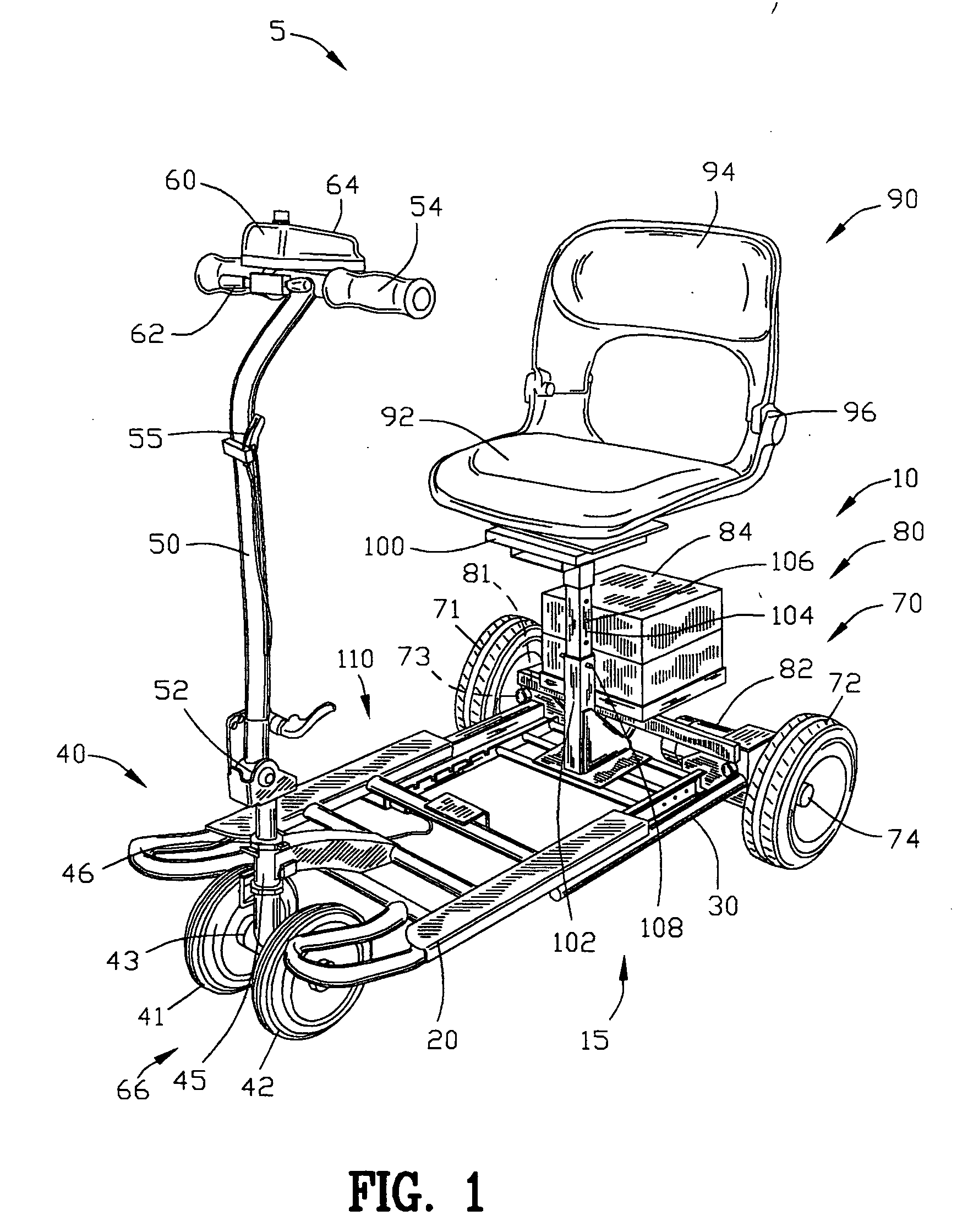

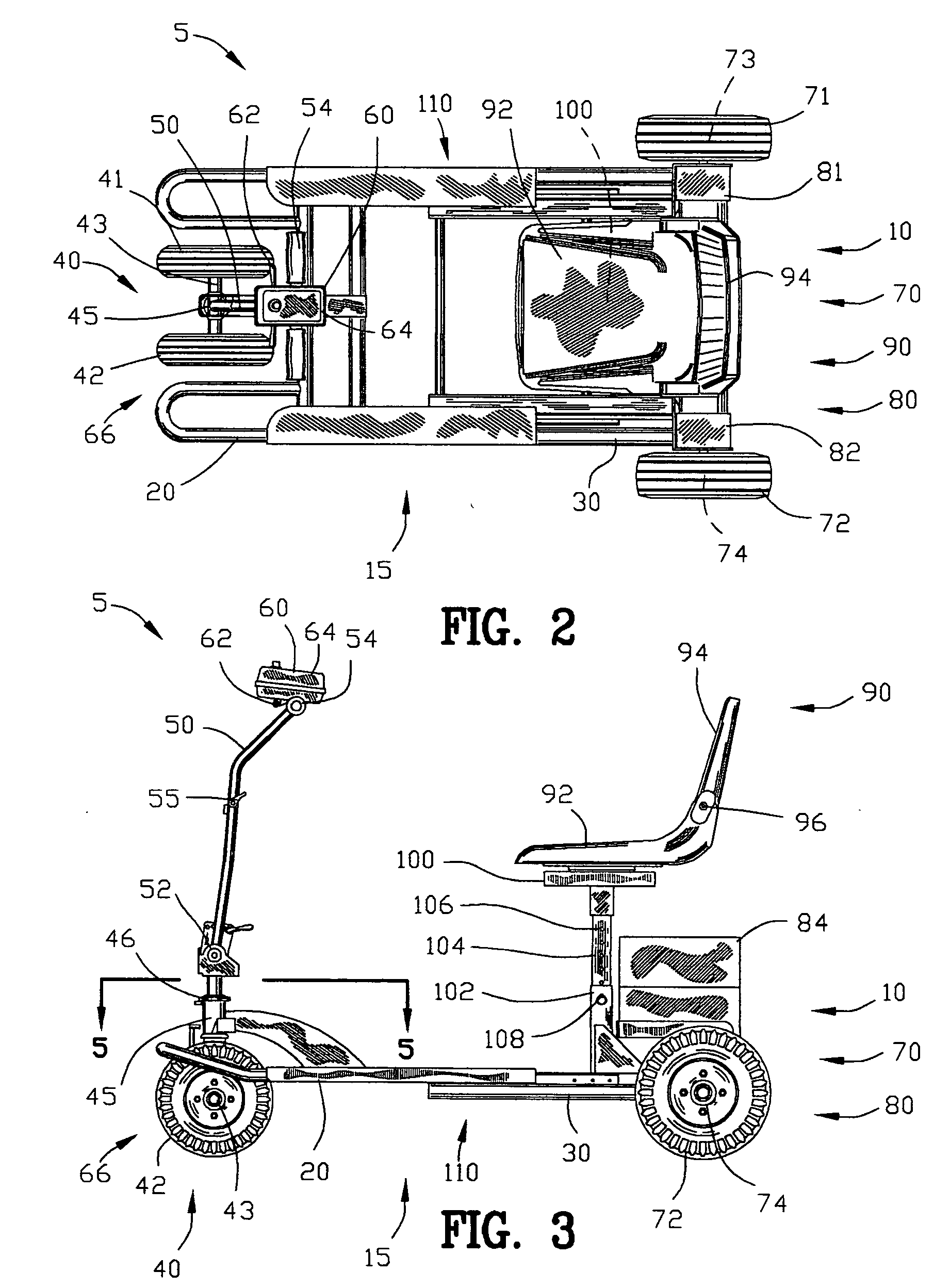

ATV with improved driver positioning and/or multi passenger capacity

InactiveUS6968917B2Safely accommodatedIncrease the wheelbaseCyclesLuggage carriersDriver/operatorEngineering

An all-terrain vehicle (ATV) includes a frame and a pair of front and rear wheels suspended from the frame. A straddle-type seat has a main portion and a secondary portion to accommodate a driver and a passenger. The wheelbase of the ATV is increased in length (compared to conventional ATVs) so as to increase stability and comfort for the driver, and / or to accommodate a passenger behind the driver. The passenger and secondary seat portion are disposed in front of the rear wheel axis and moved closer to the center of the wheelbase. Moreover, the combined center or gravity of the ATV, rider, and passenger is moved closer to the center of the wheelbase to improve stability, comfort and / or safety. The driver and passenger each have sufficient space to actively position themselves without significantly interfering with each other.

Owner:BOMBARDIER RECREATIONAL PROD INC

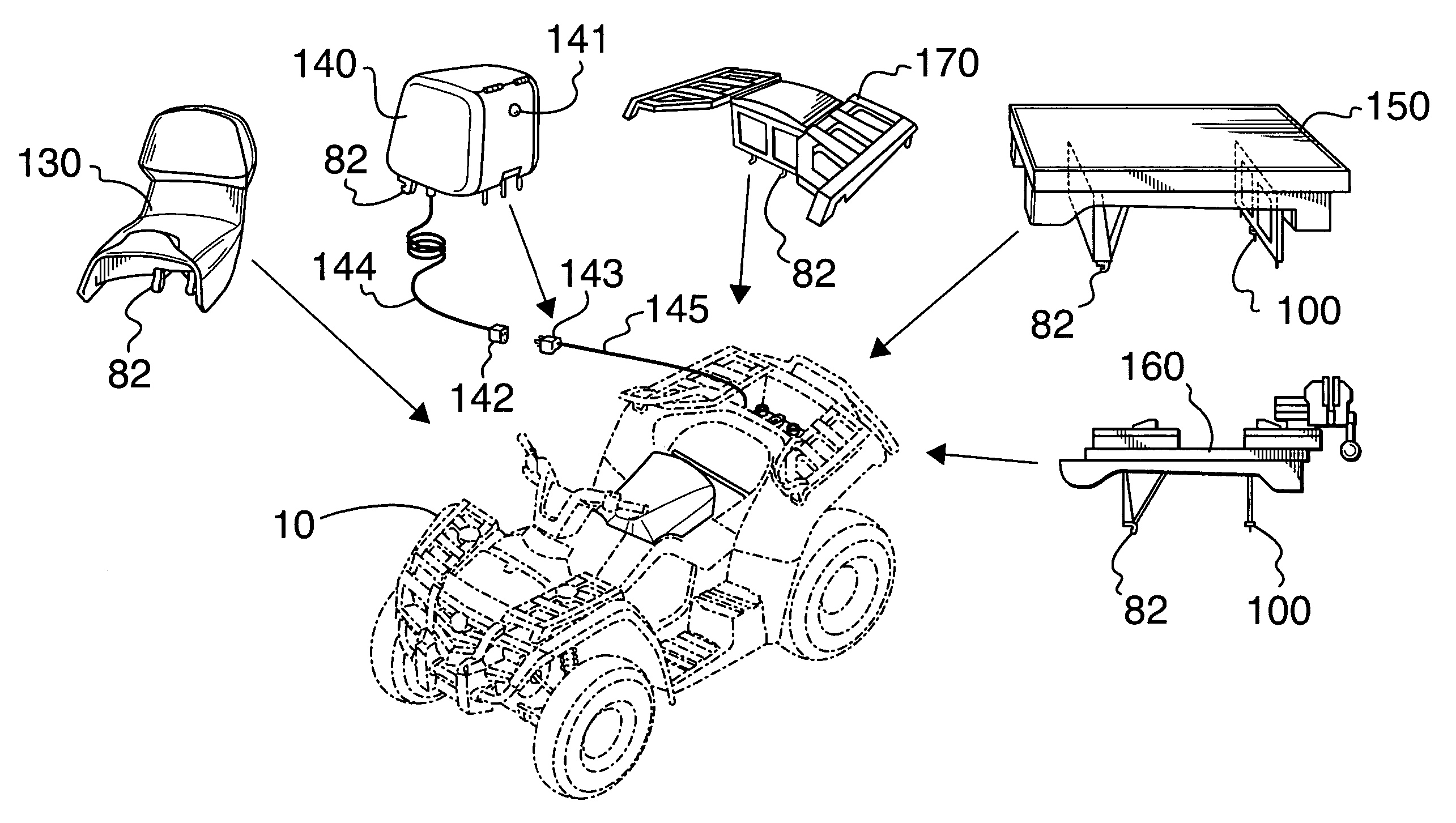

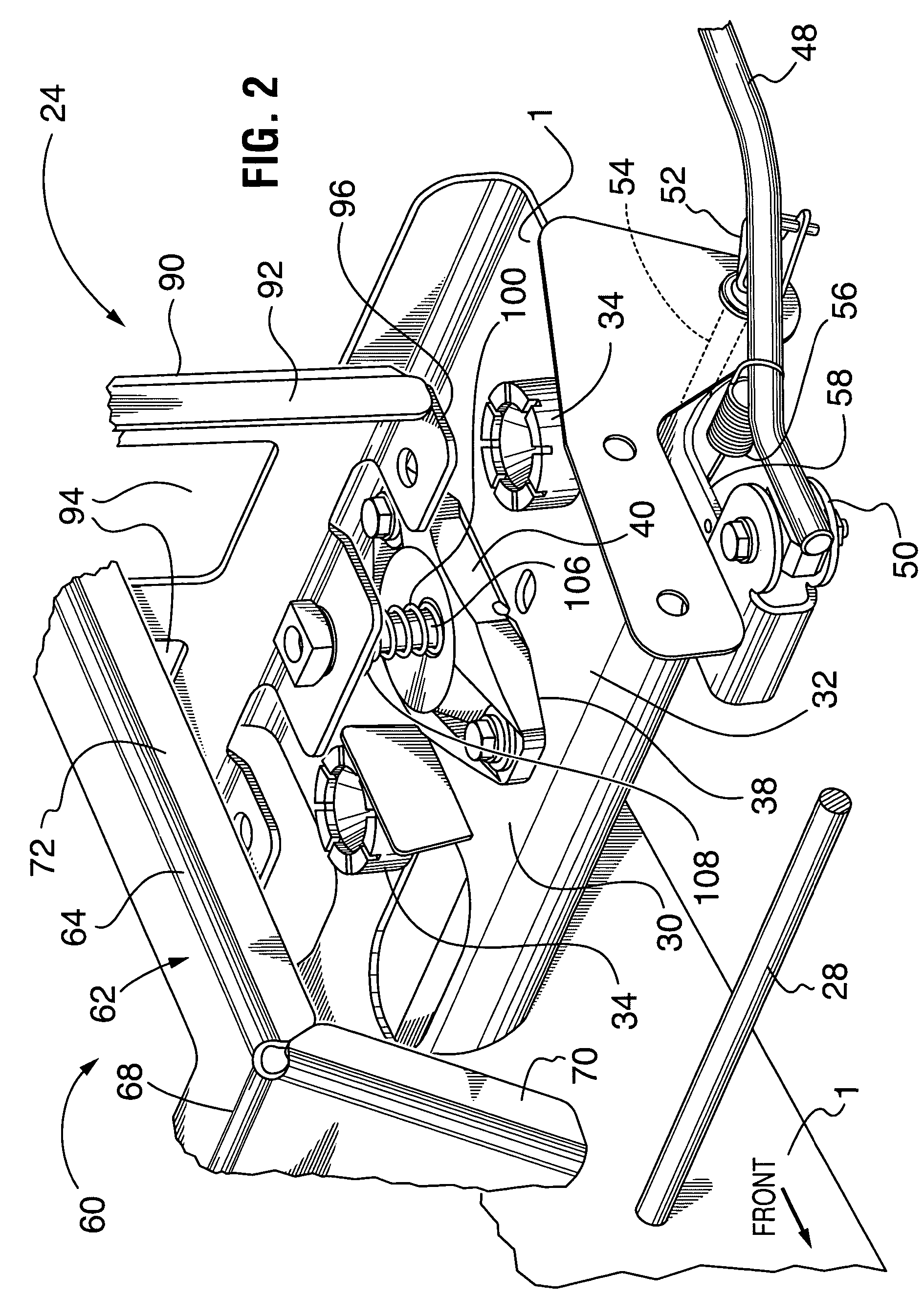

Modular components for an all-terrain vehicle

InactiveUS7377570B2Easy to replaceEasy interchangeCyclesSuperstructure subunitsModularityElectrical connection

An all-terrain vehicle (ATV) with an elongated wheelbase has a rear-mounted receptacle for receiving one of a plurality of interchangeable modular components, such as a passenger seat, a cargo container, a cargo rack, a flatbed or a workbench. The modular component has an electrical connection and a mechanical connector on an underside thereof which has hooks and posts for engaging, respectively, a transverse rod and sockets. A latching mechanism locks the modular component to the rear of the vehicle. Accordingly, the modular component is selectively releasable to easily and quickly interchange one modular component with another.

Owner:BOMBARDIER RECREATIONAL PROD INC

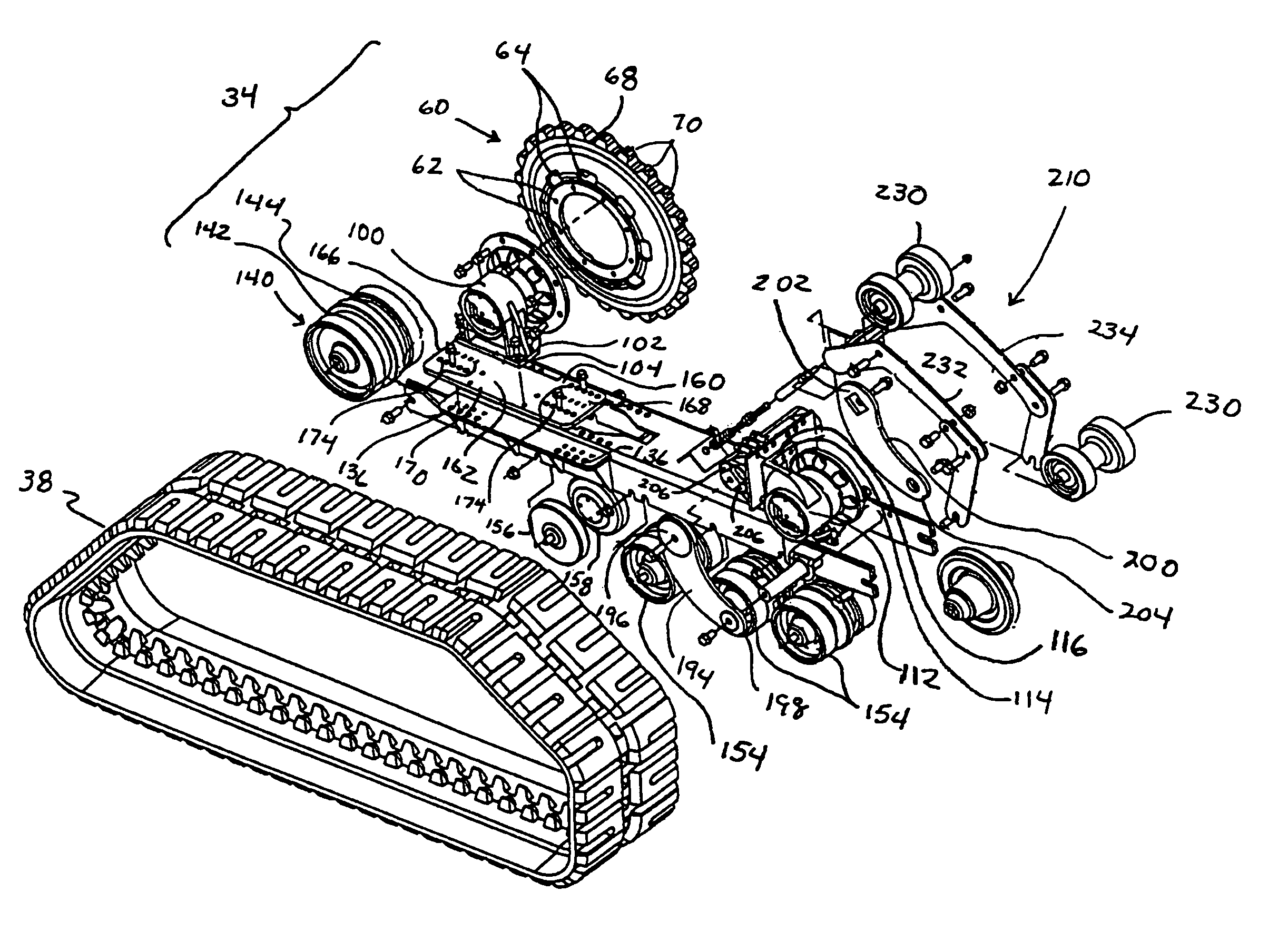

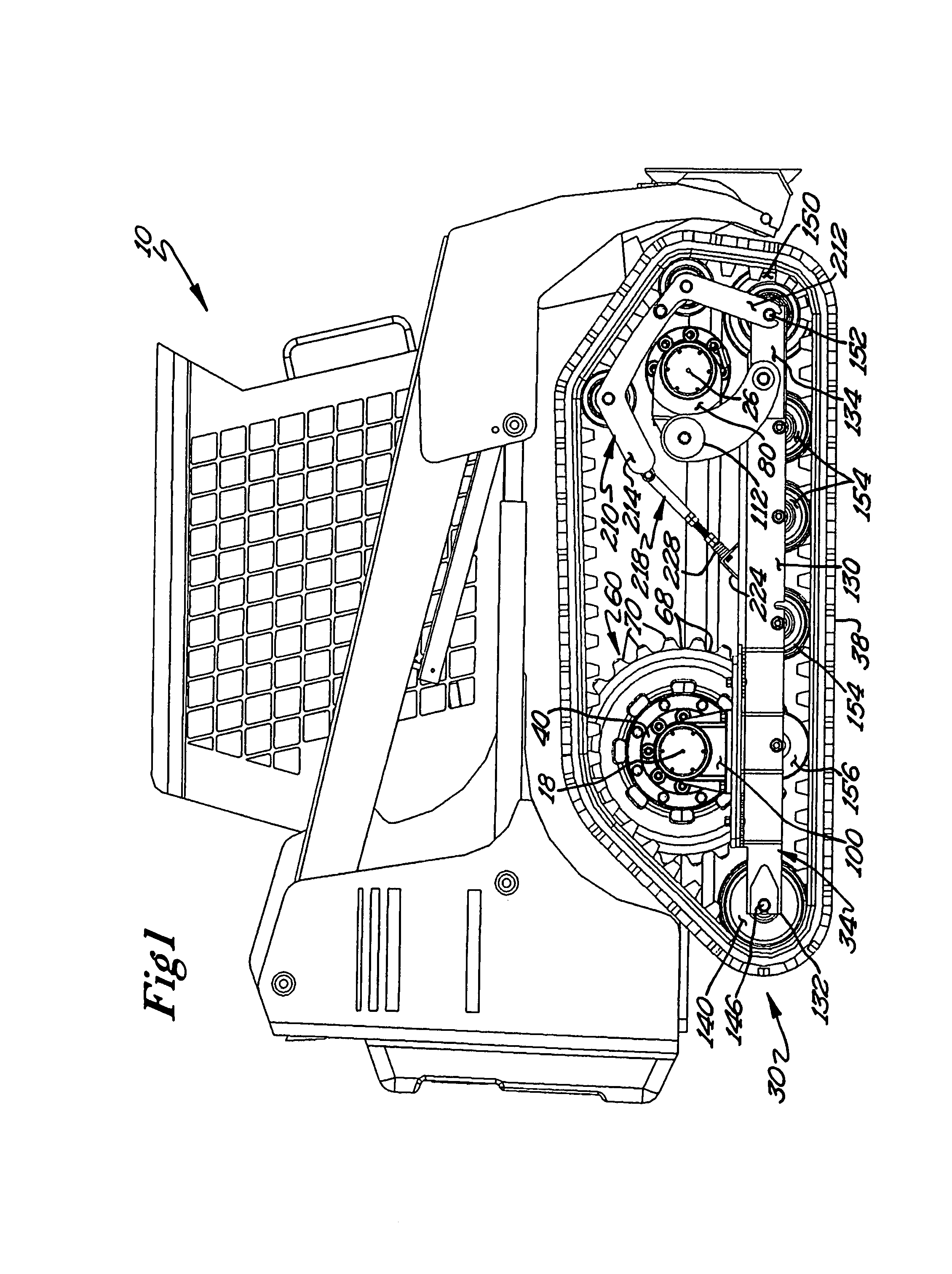

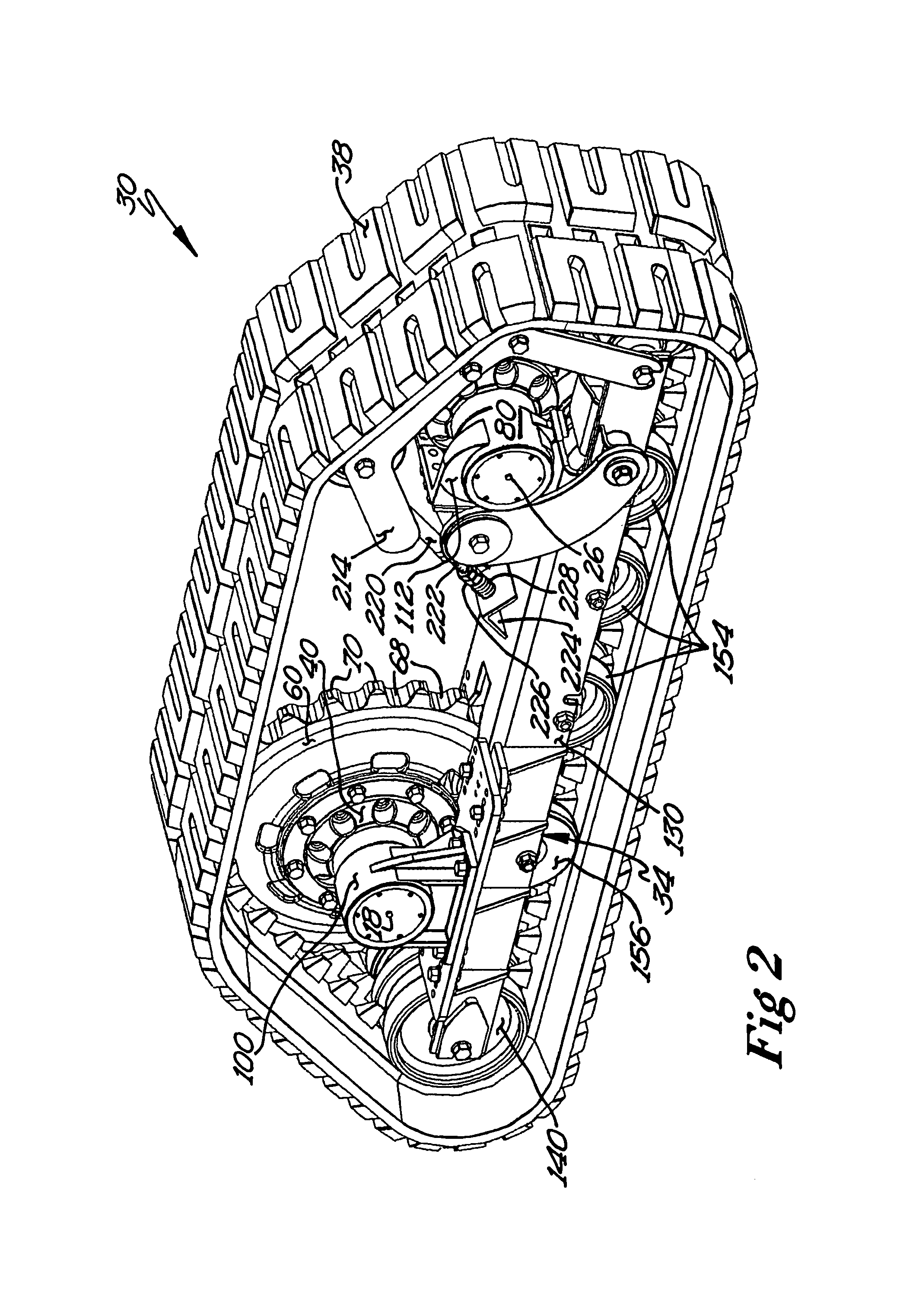

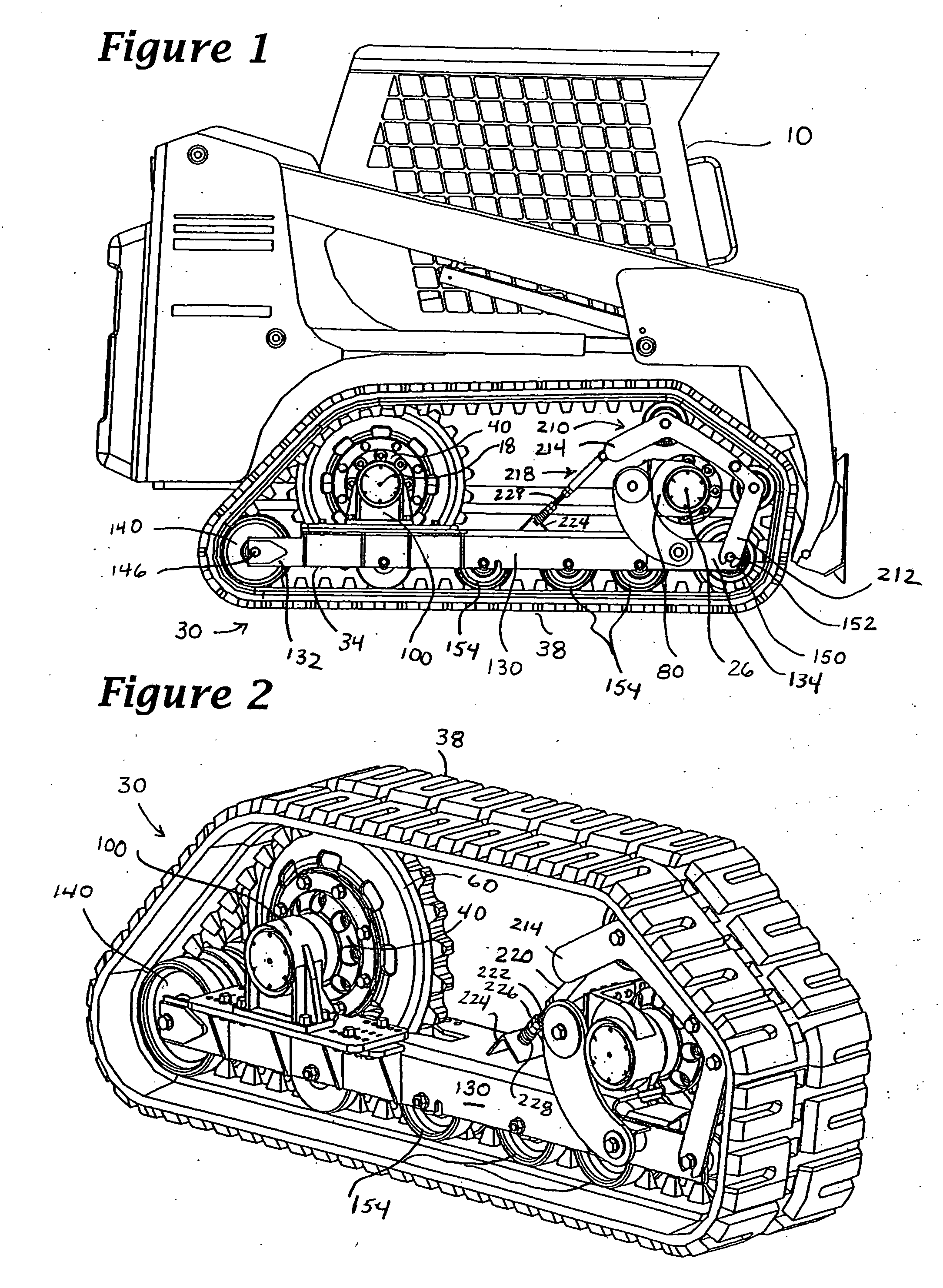

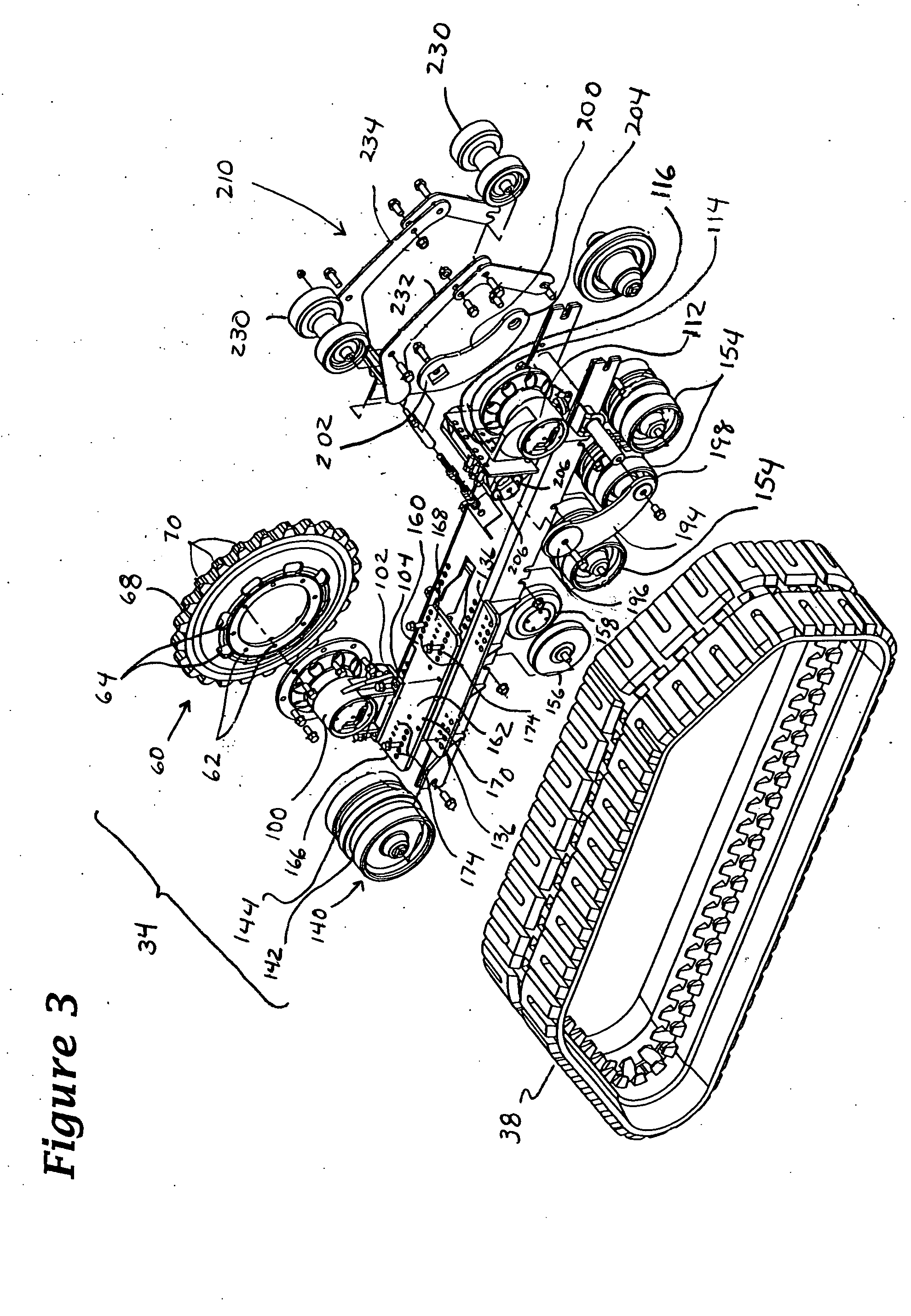

Track assembly

ActiveUS7255184B2Improve stabilityGreat tractionGearingEndless track vehiclesBraced frameEngineering

Owner:ASV HLDG INC

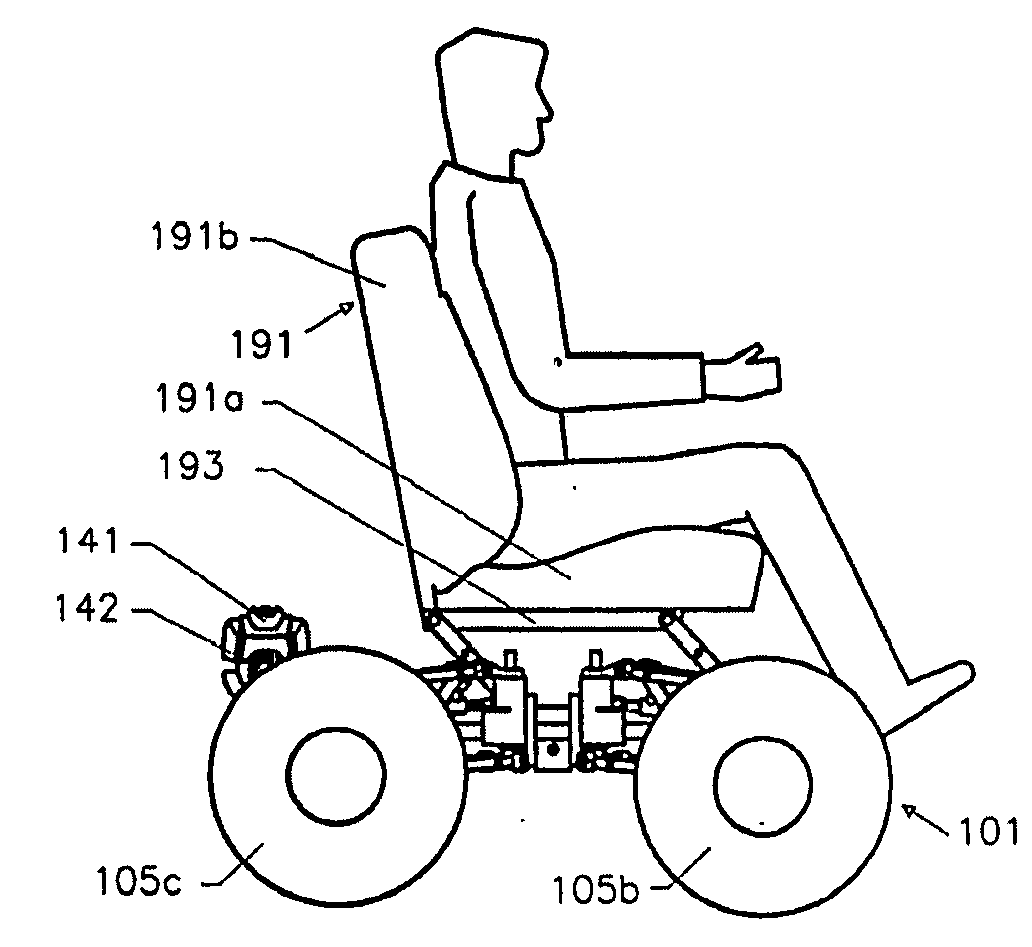

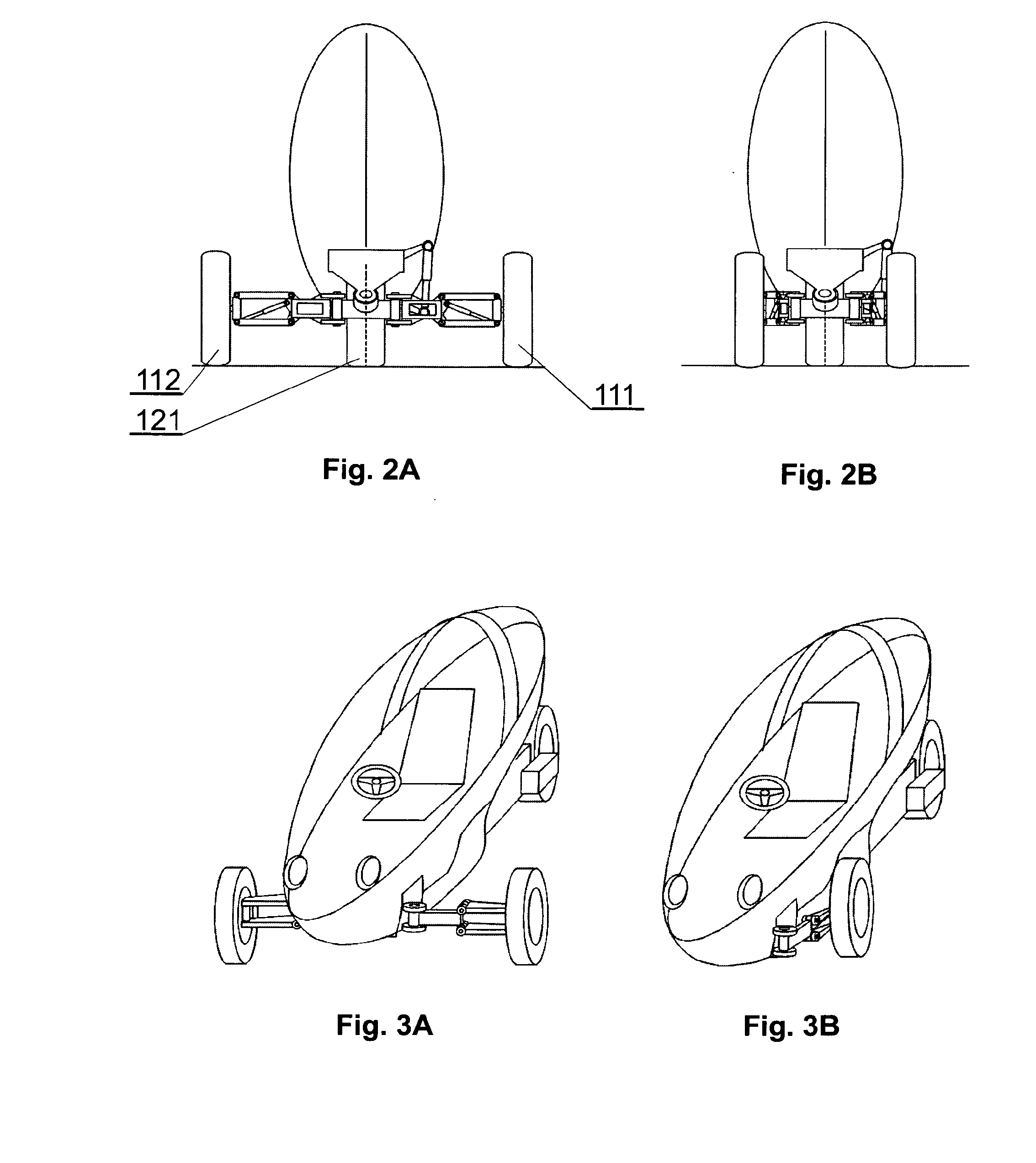

Vehicle

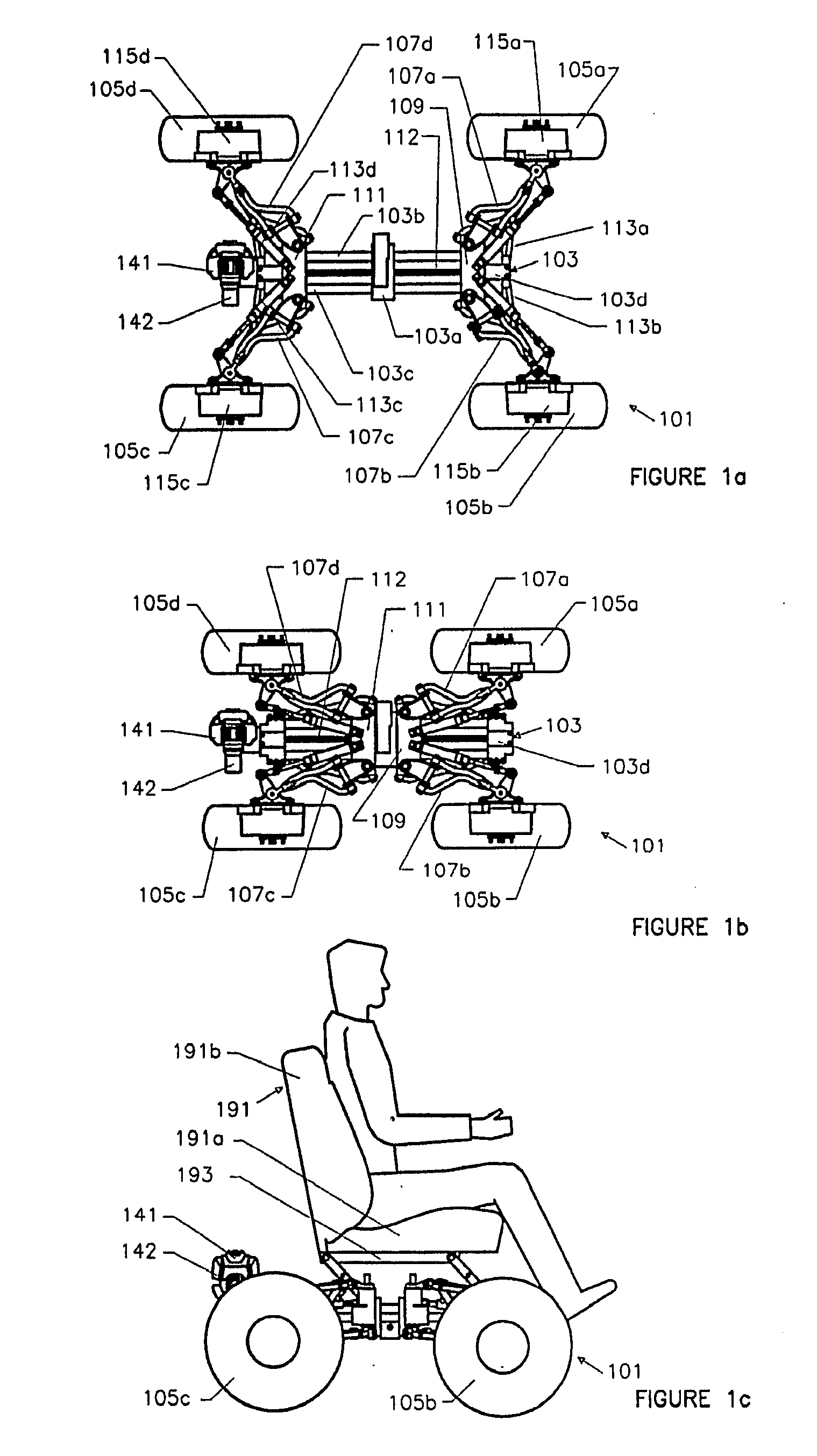

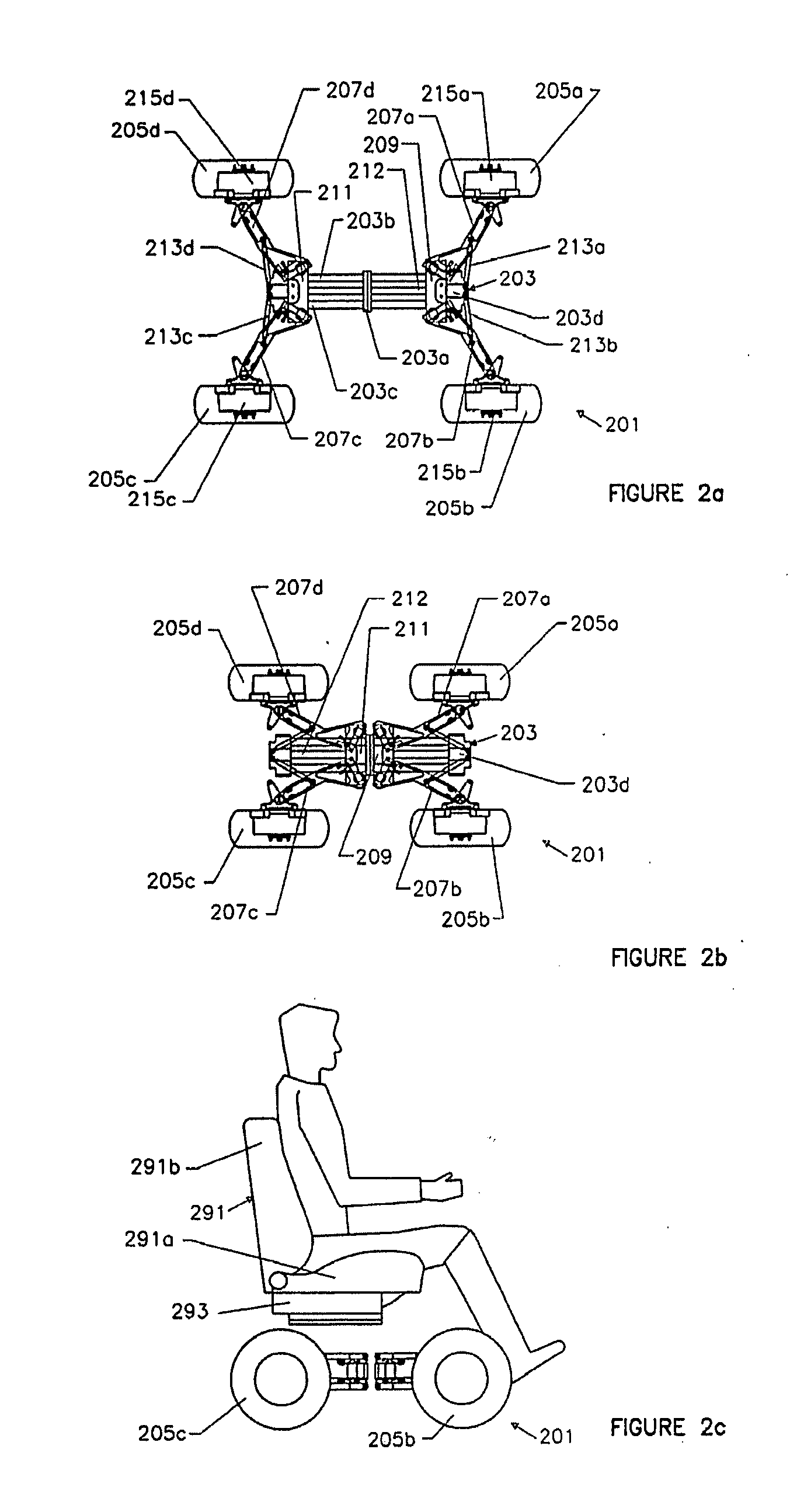

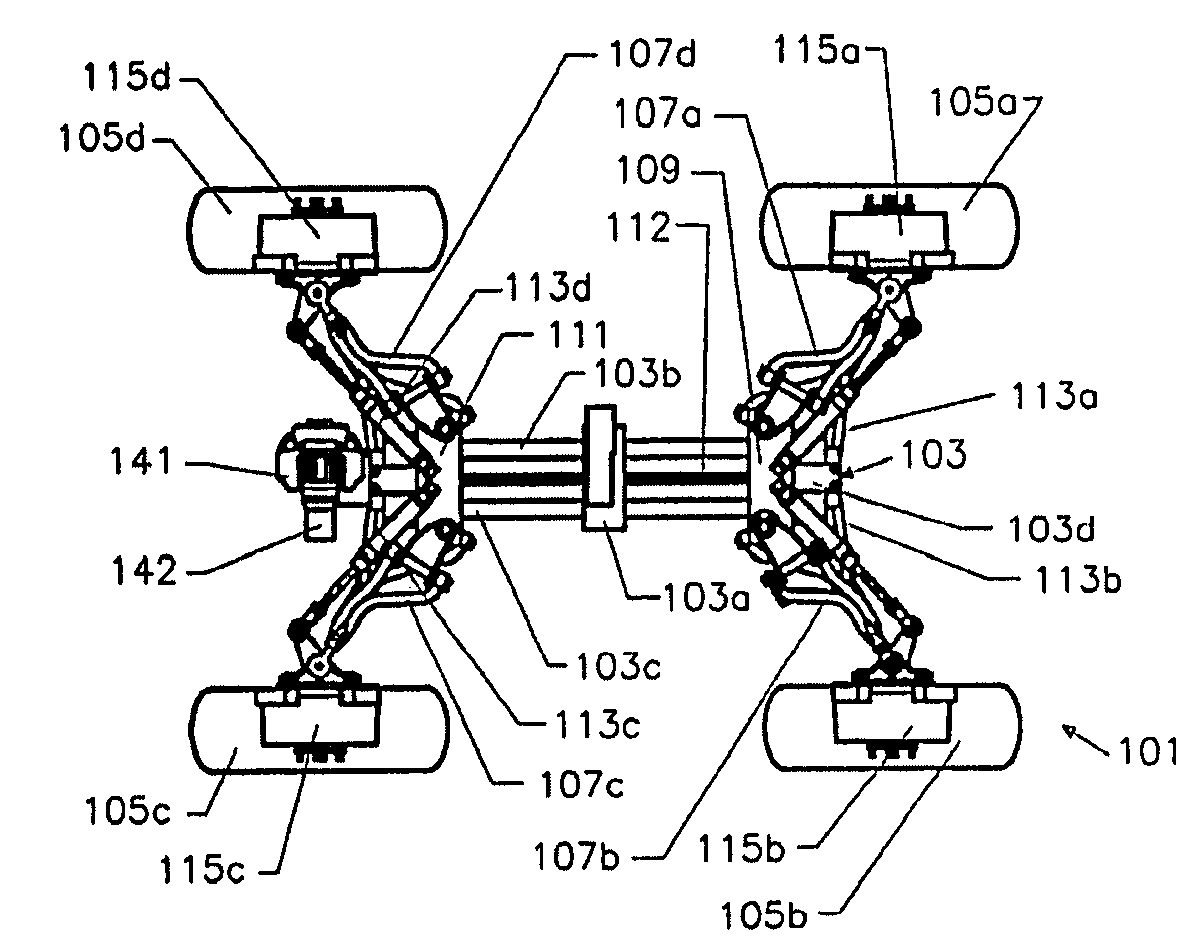

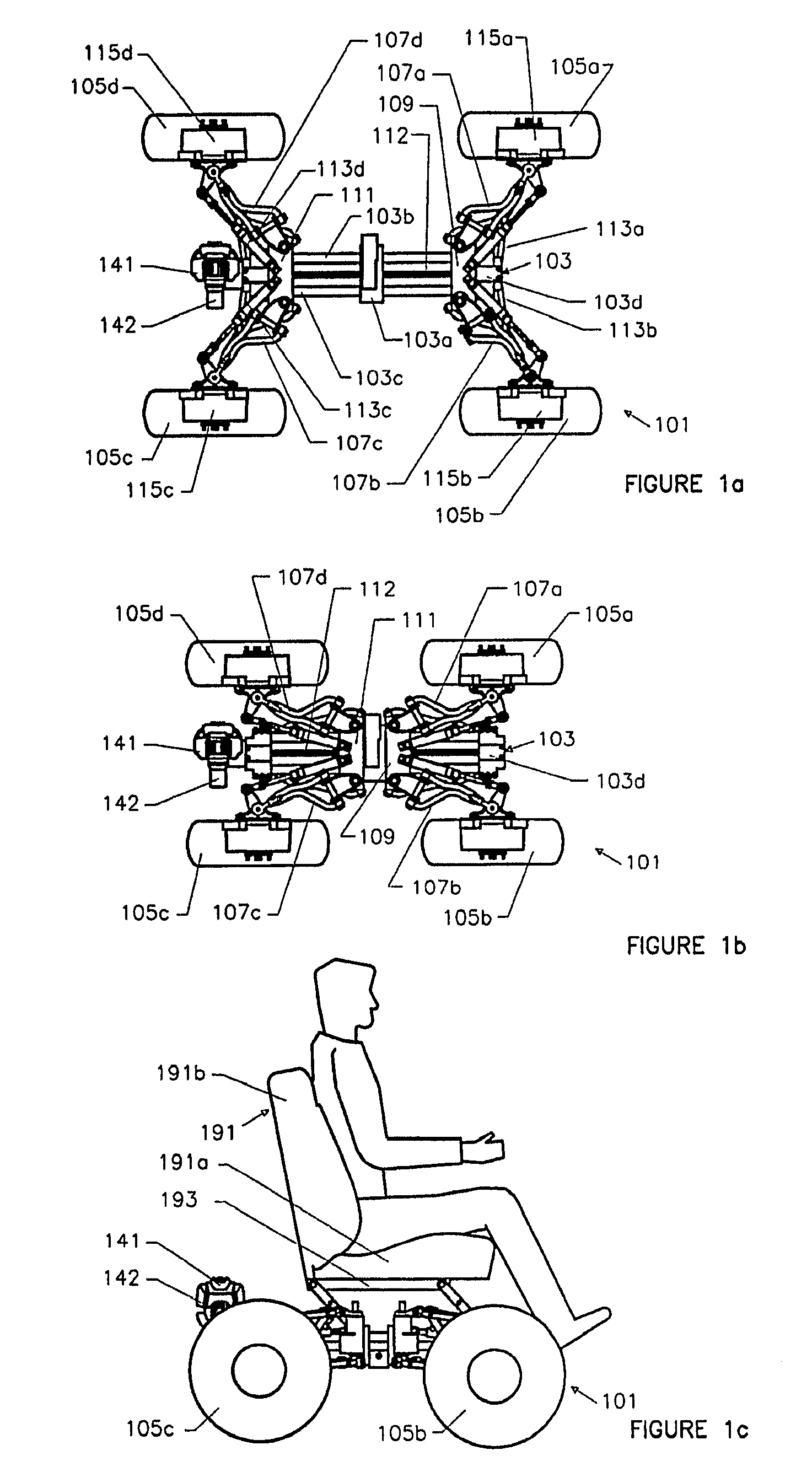

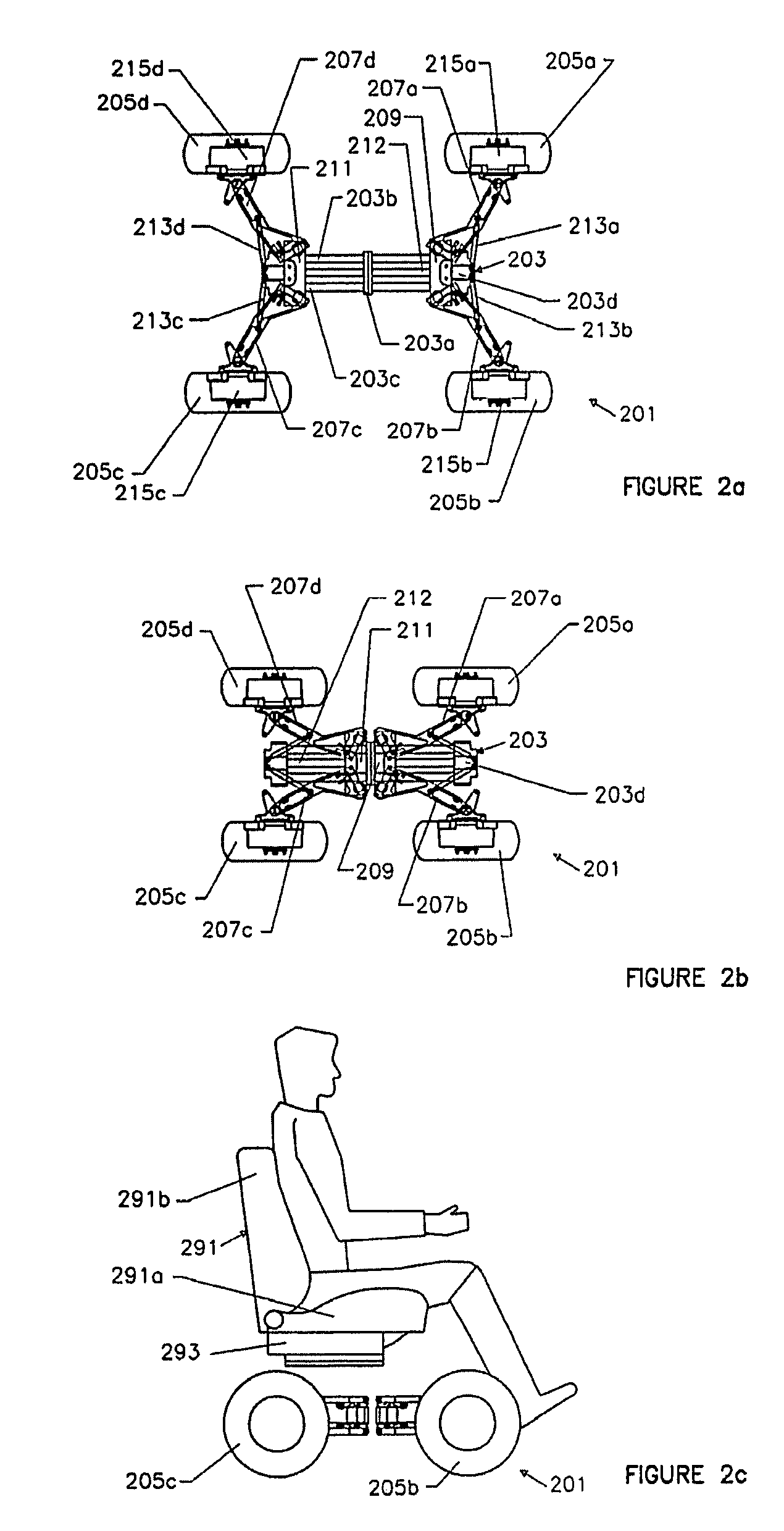

InactiveUS20080190682A1Minimize damageElectric propulsion mountingWheelchairs/patient conveyanceWheelbaseAxle track

A vehicle for transporting a person has a chassis (103) and four wheels (105a, 105b, 150c, 105d) supporting the chassis above a ground surface. The wheels enable the vehicle to move along the ground surface. Each of the four wheels is adjustable in position to enable the wheelbase length and track width of the vehicle to be changed. Each of the wheels is steerable to enable the changes in the wheelbase length and the track width to be effected whether the vehicle is substantially stationary or in motion.

Owner:MAHY GRAHAM JOHN +2

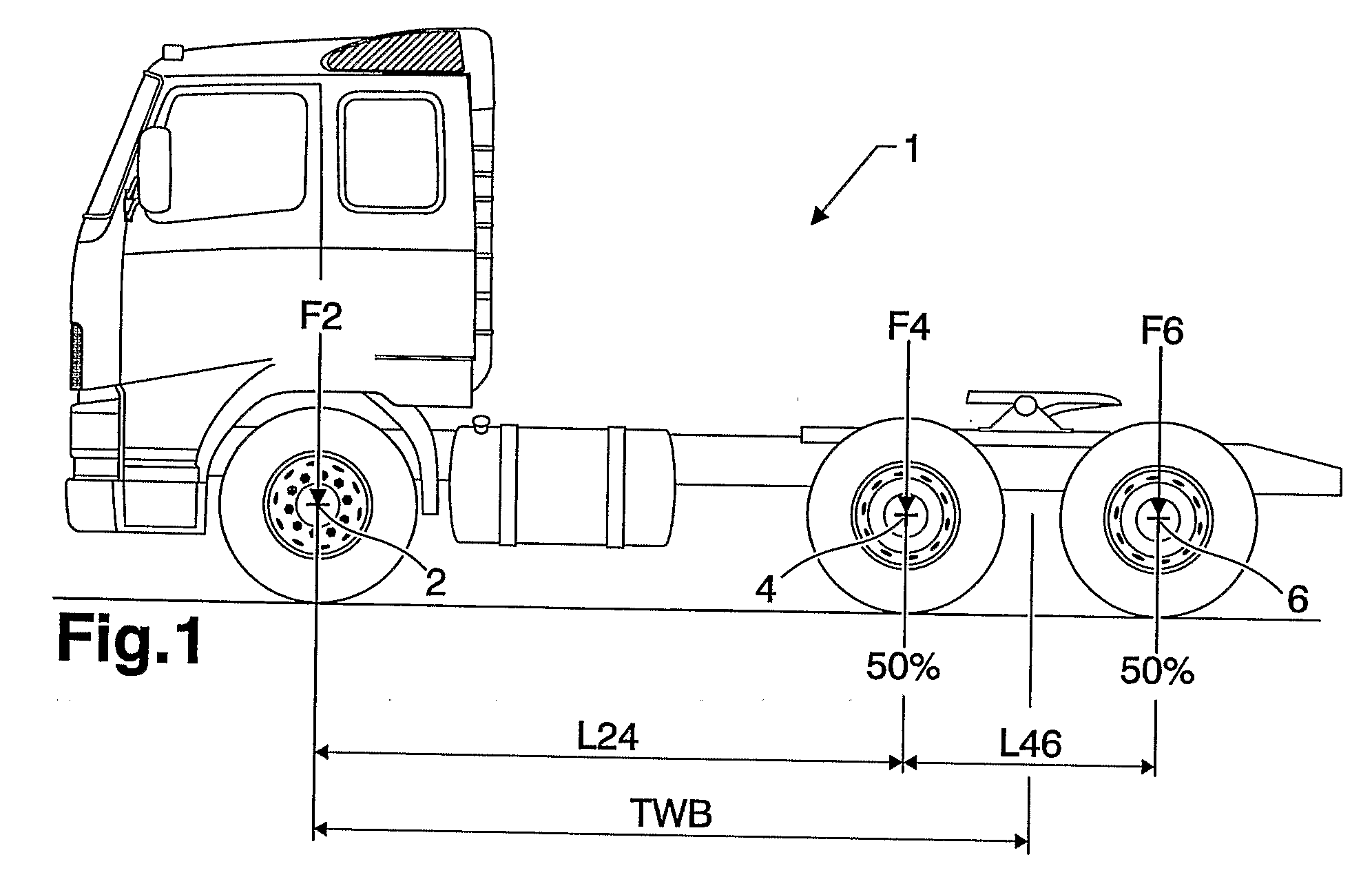

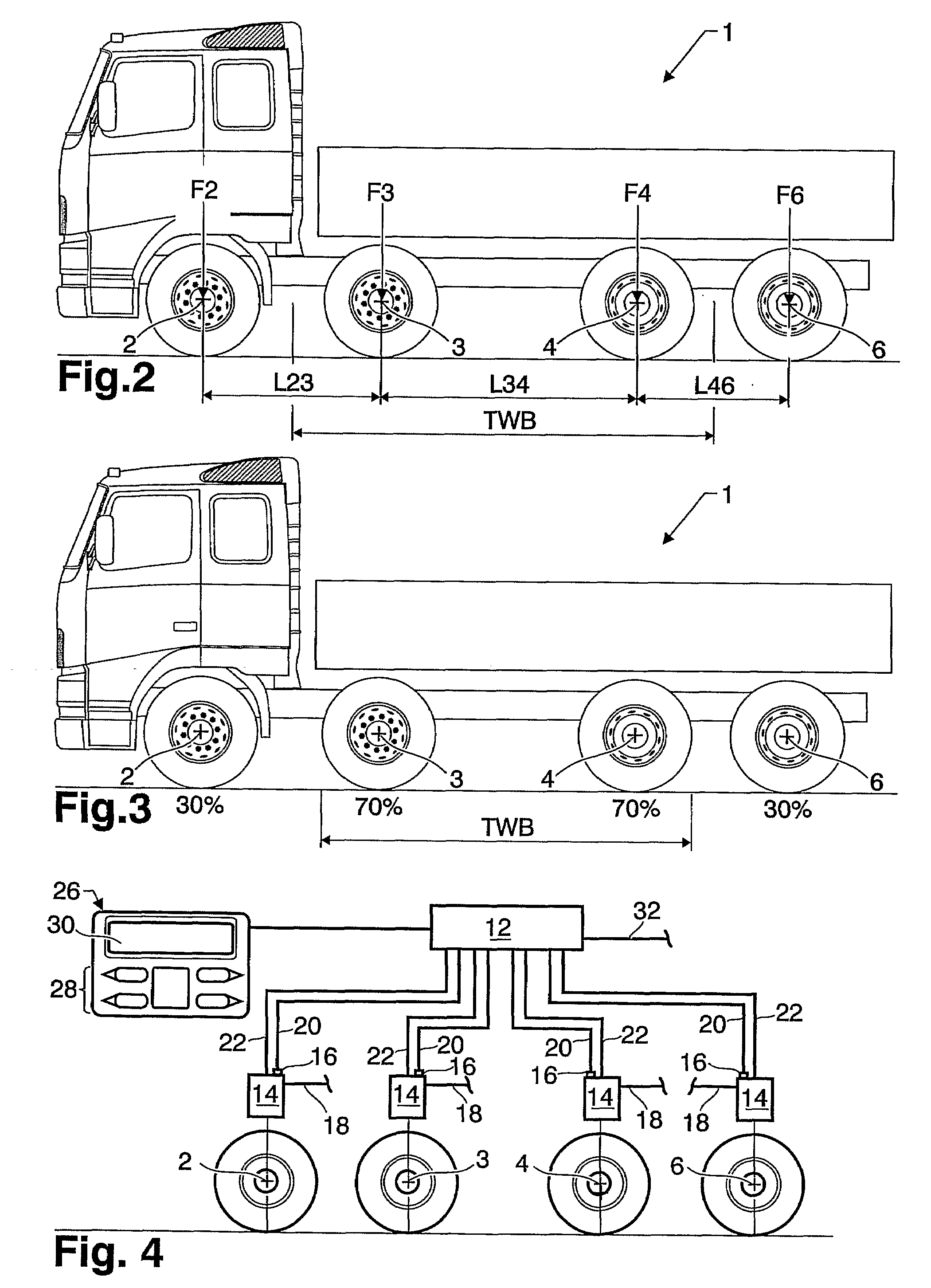

System and Method for Controlling the Axle Load Split Ratio on a Vehicle With Two Front Axles

InactiveUS20080269986A1Risk minimizationImprove vehicle handlingDigital data processing detailsAnimal undercarriagesMobile vehicleAdjustable stiffness

A system is provided for controlling the load split between the axles and thereby the theoretical wheelbase of a vehicle having two front axles being suspended in suspension units at least some of which have springs with adjustable stiffness. A method for controlling the load split between the axles and to a motor vehicle including such a system and / or by use of such a method is also disclosed.

Owner:VOLVO LASTVAGNAR AB

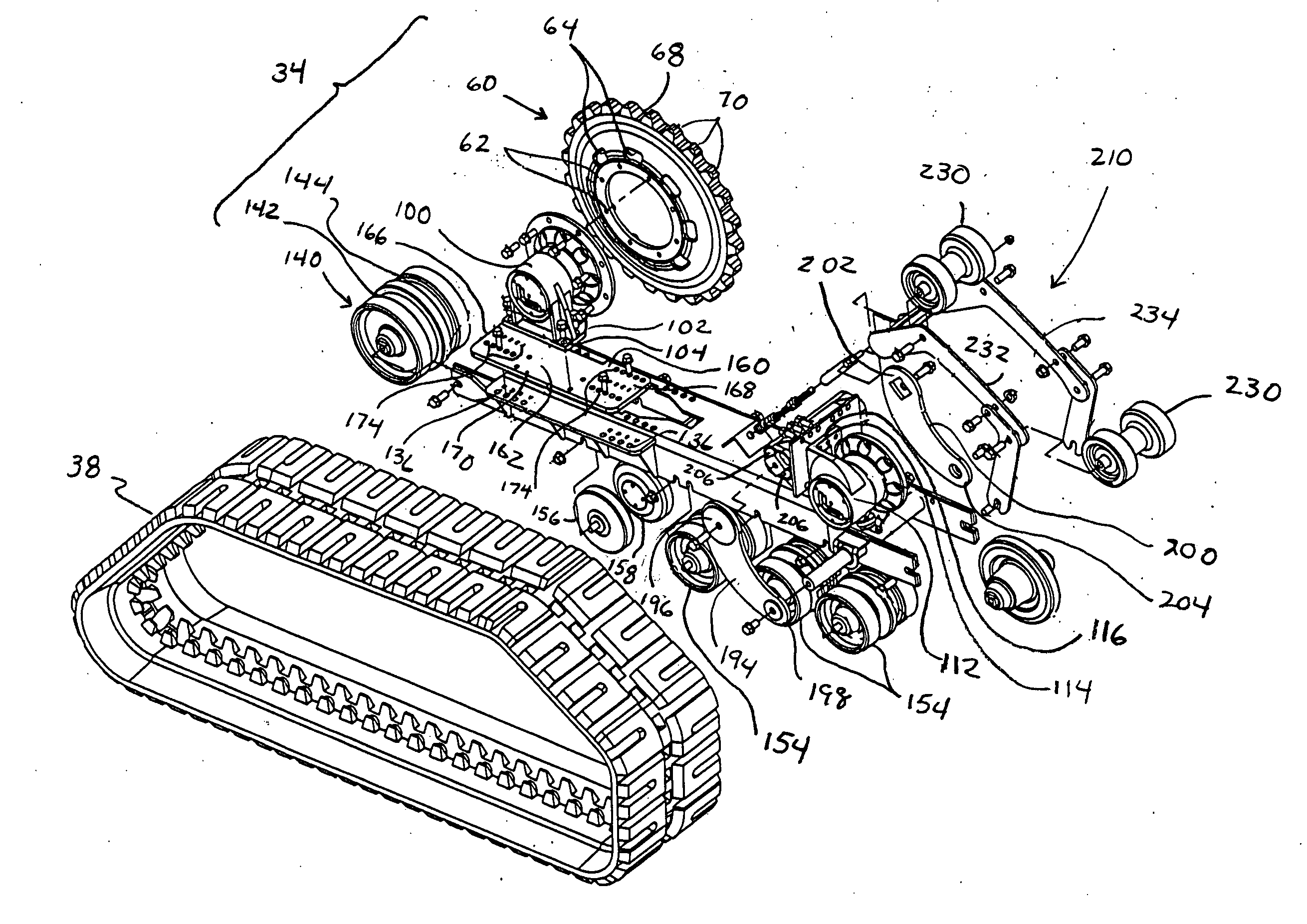

Track assembly

ActiveUS20050145422A1Improve stabilityGreat tractionGearingEndless track vehiclesBraced frameEngineering

A track assembly having first and second hub assemblies that are operatively connected to a support frame by first and second attachment members, respectively. The first and second attachment members include resilient or movable mounts that are configured so that the track assembly can be attached to vehicles whose axles or wheel flanges are misaligned or have irregular rotational movement such as runout or wobble. The attachment members may be adjustably positioned relative to the support frame to accommodate vehicles having different wheelbase lengths and axle lengths. An endless track encircles the first and second hub assemblies, and the support frame, and is drivingly engaged by one of the hub assemblies. First and second rollers, which define the longitudinal extent of the endless track, are positioned at either end of the support frame. A tensioning member, with at least one upper idler roller, positions the endless track so that it is spaced from one of the hub assemblies in a spaced relation. The track assembly increases traction and stability by providing a vehicle with an independent front suspension, a larger footprint, and a longer wheelbase. In use, each track assembly is bolted onto wheel flanges of a vehicle using existing wheel lugs and nuts.

Owner:ASV HLDG INC

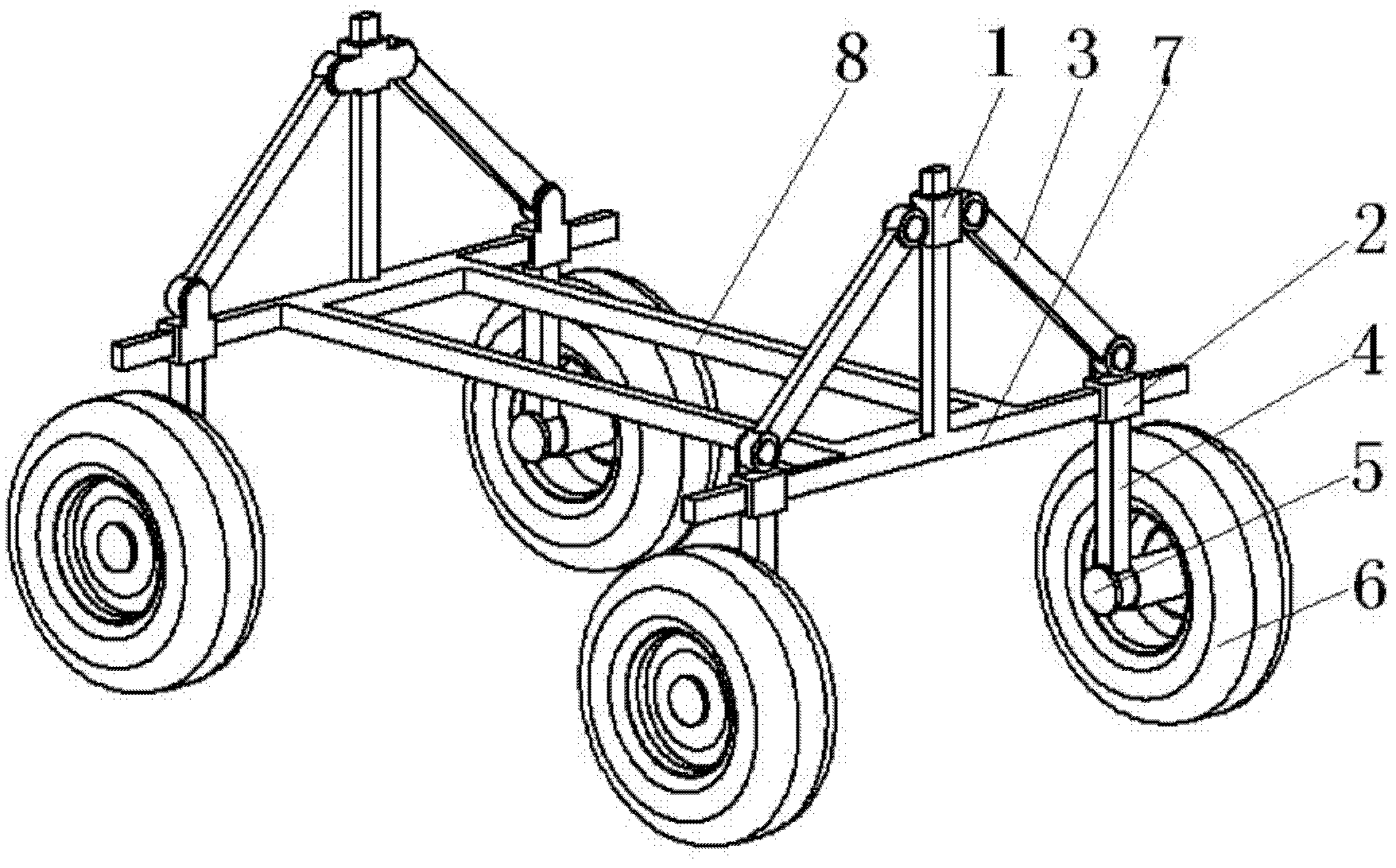

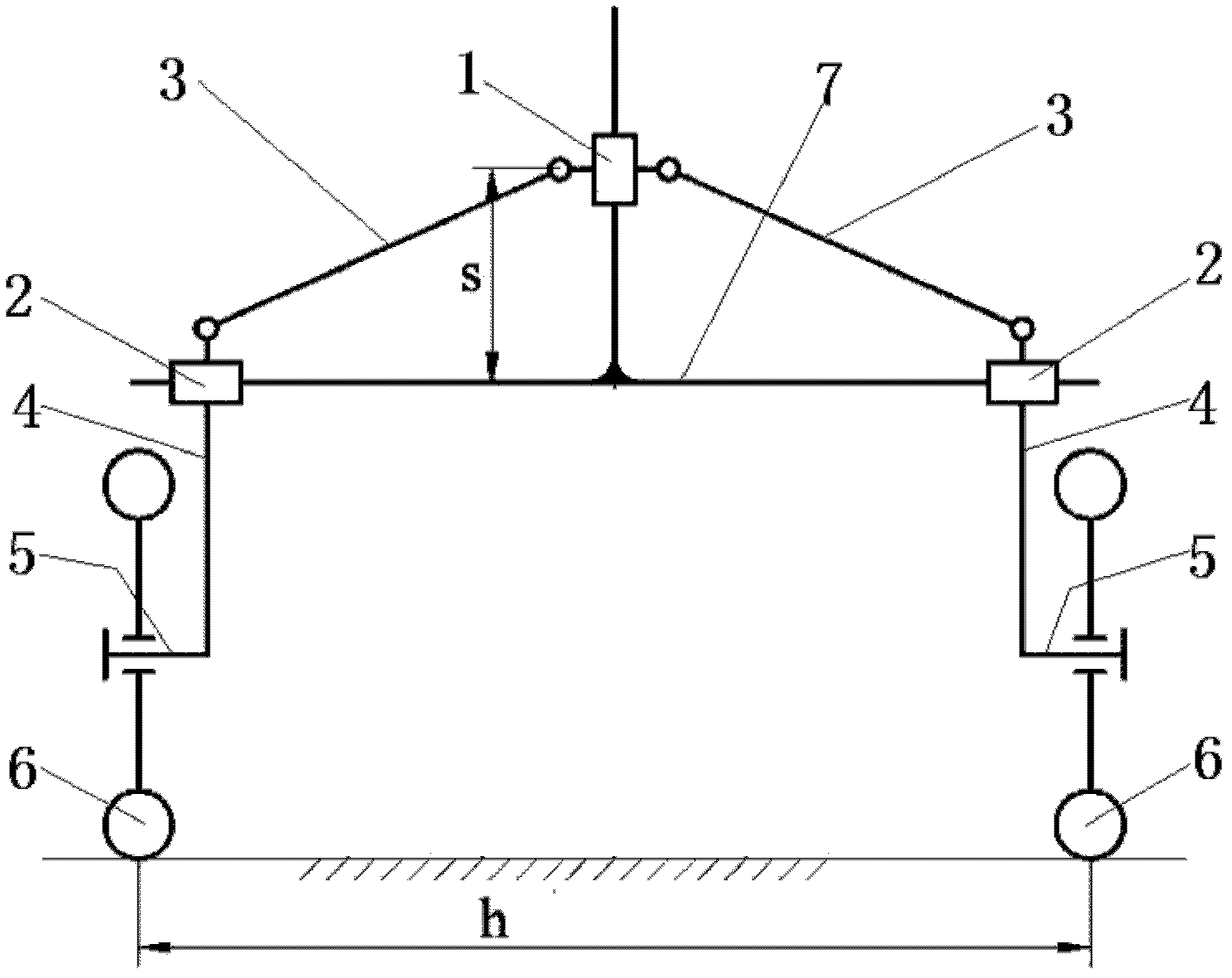

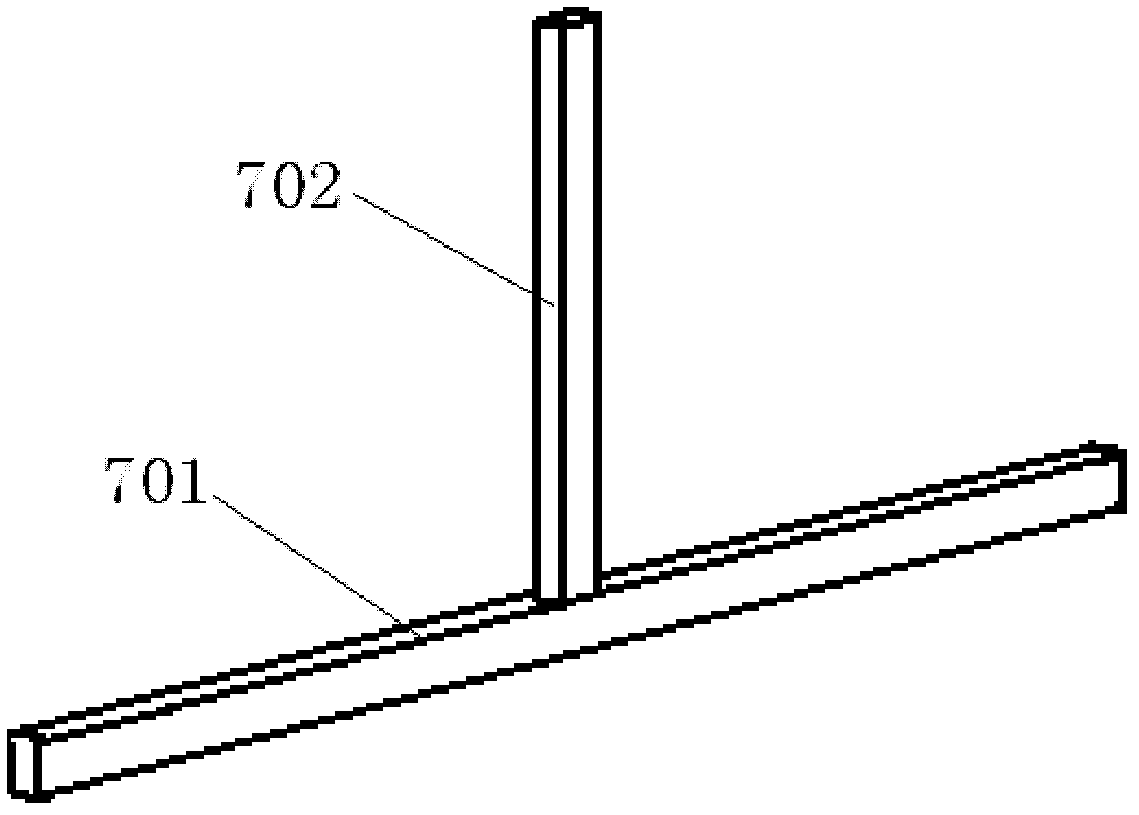

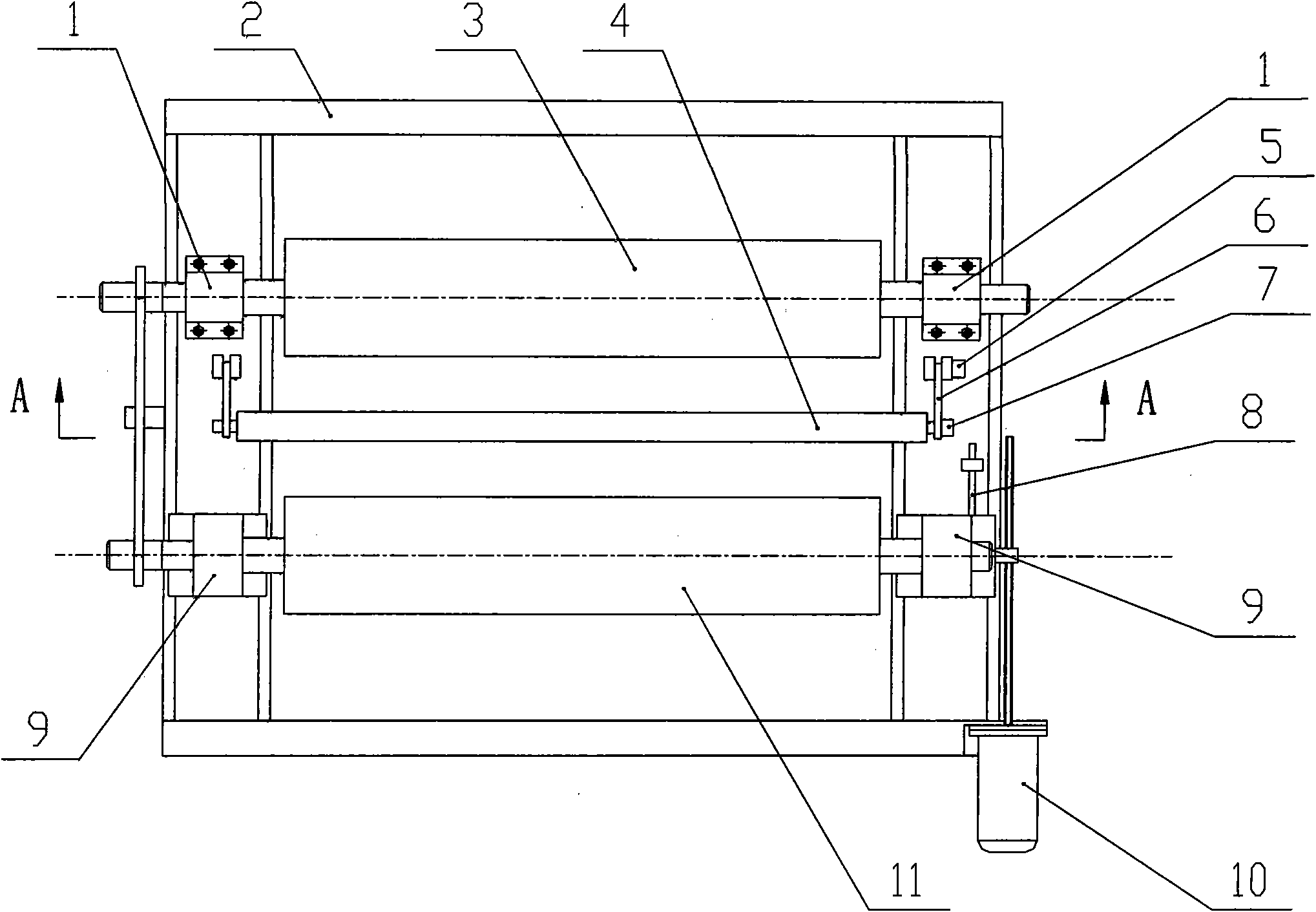

Wheel track adjustable agricultural vehicle chassis

InactiveCN102514626AAdapt to the requirements of mechanized operationsRealize centralized controlUnderstructuresVehicle frameAgricultural engineering

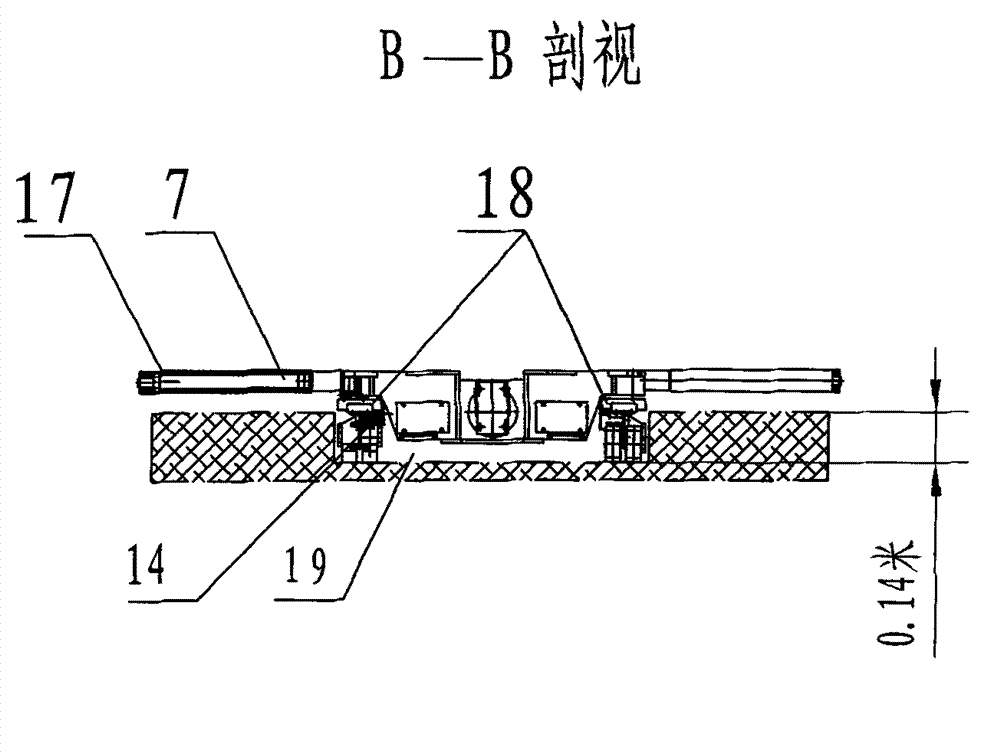

The invention belongs to the technical field of vehicle chassis, and relates to a wheel track adjustable agricultural vehicle chassis. Two groups of agricultural vehicle wheel track adjusting devices share a longitudinal center plane of a vehicle and are arranged in a front-and-back mode on a frame according to a wheel base of wheels; and the two groups of wheel track adjusting devices are respectively fixedly connected with front and back ends of the frame through a horizontal rail of a support to form the wheel track adjustable agricultural vehicle chassis. Each group of agricultural vehicle wheel track adjusting device consists of a driving slider, driven sliders, connecting rods, supporting rods, wheel axles, wheels and a frame; distances between driving sliders and horizontal rails in the front and back agricultural vehicle wheel track adjusting devices are synchronously changed and kept equal by external driving power, and distances of wheels and the longitudinal center plane ofthe vehicle are symmetrically changed, so that the stepless adjustment of the wheel track of the agricultural vehicle chassis is realized and requirements on mechanical operation for crops in different row spacing are met. The wheel track adjustable agricultural vehicle chassis is suitable for field management mechanical operation in a growth period of crops.

Owner:CHINA AGRI UNIV

Vehicle having variable track

ActiveUS20130062133A1Increase widthSteering linkagesUnderstructuresEngineeringAutomotive engineering

Owner:JAXA NETWORKS

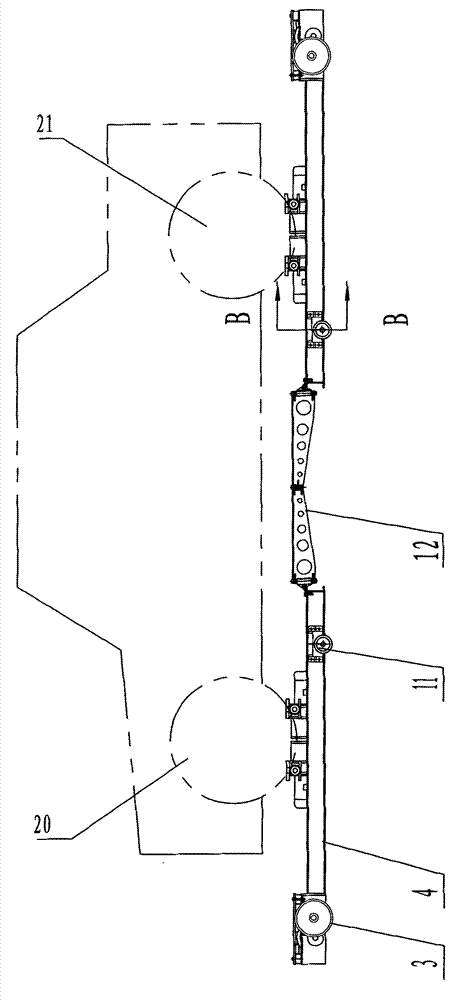

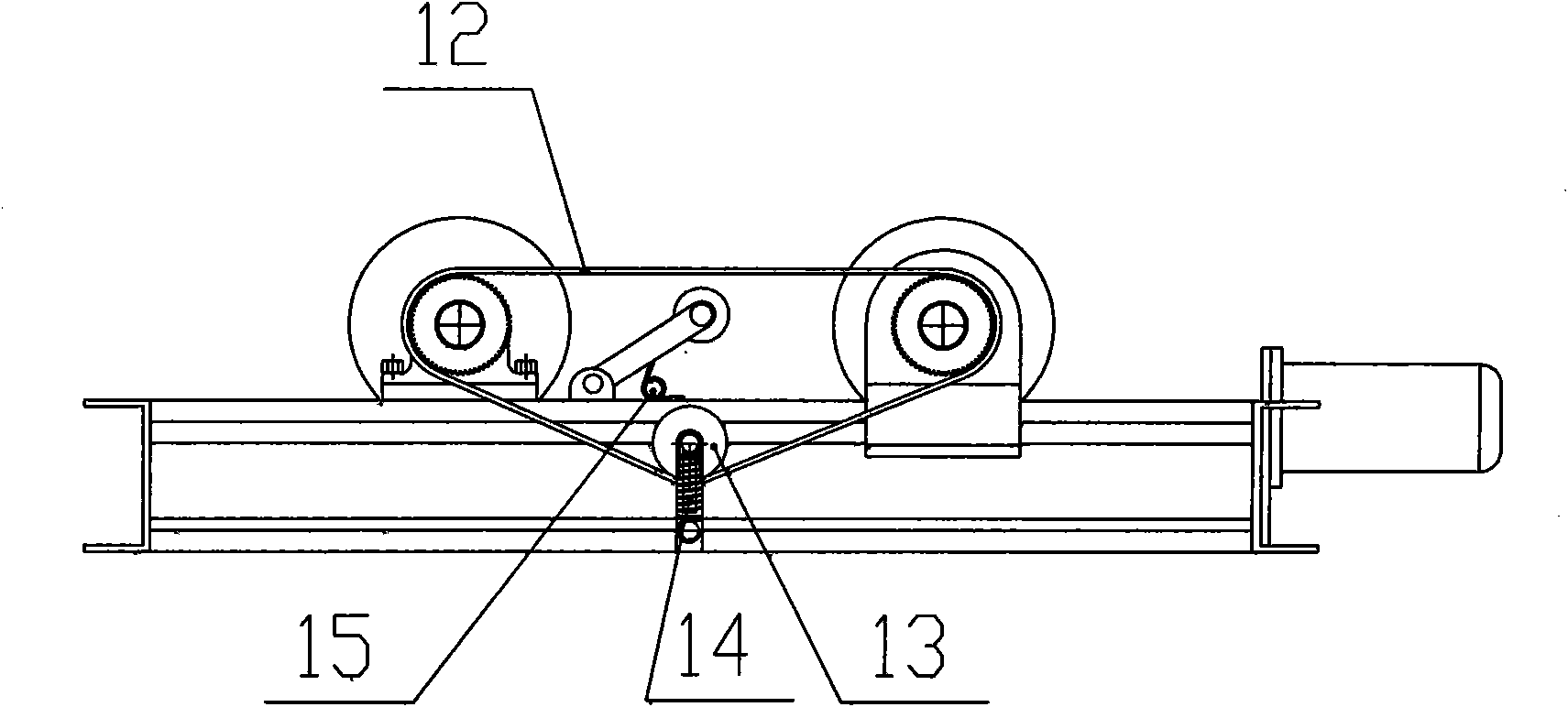

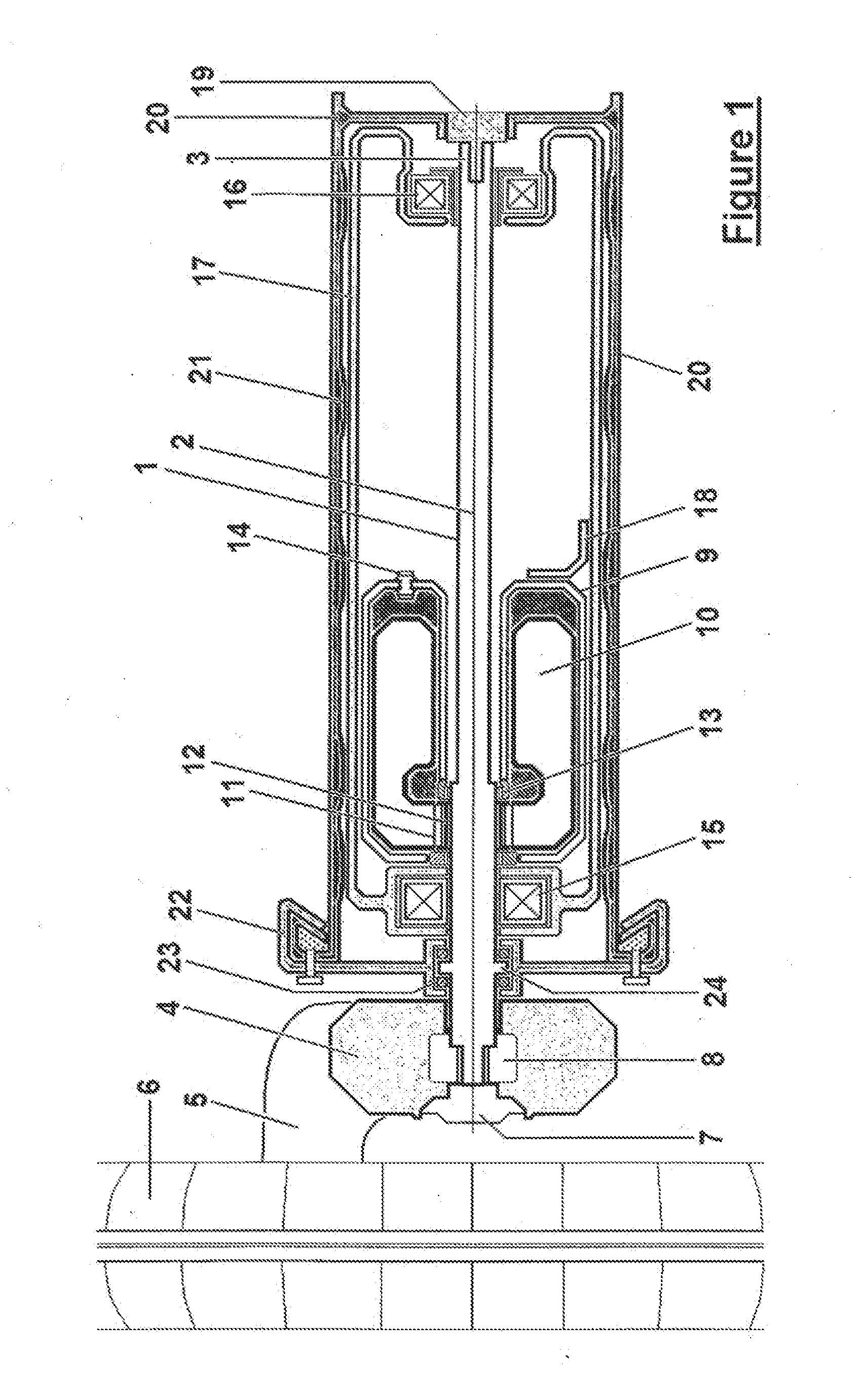

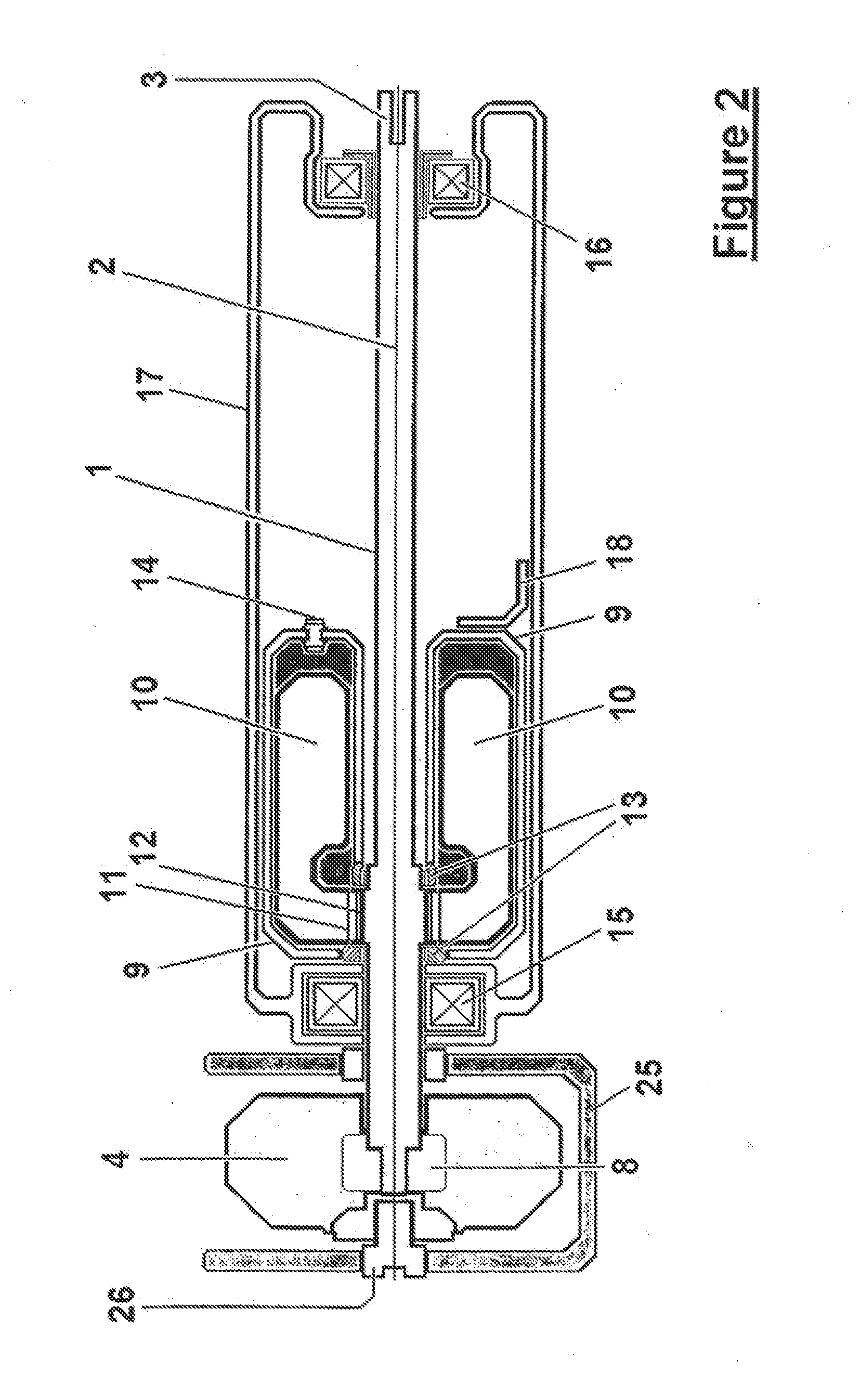

Longitudinal shifting carrier for cars

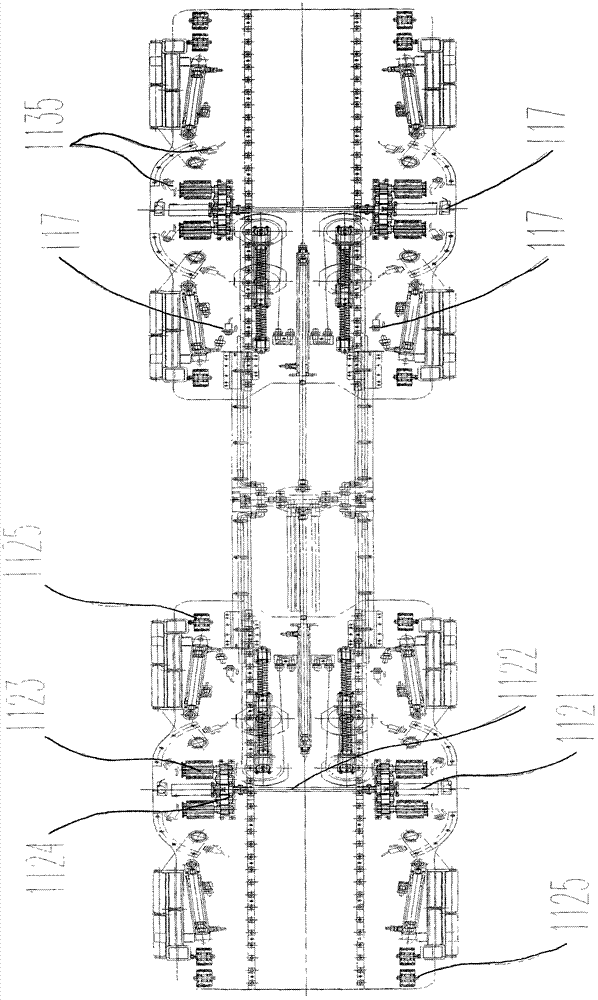

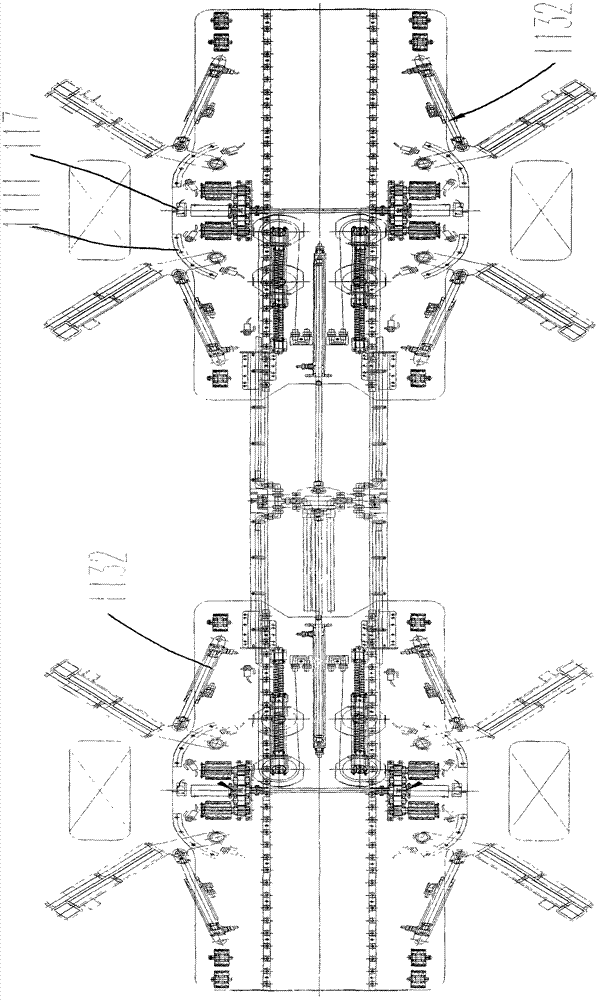

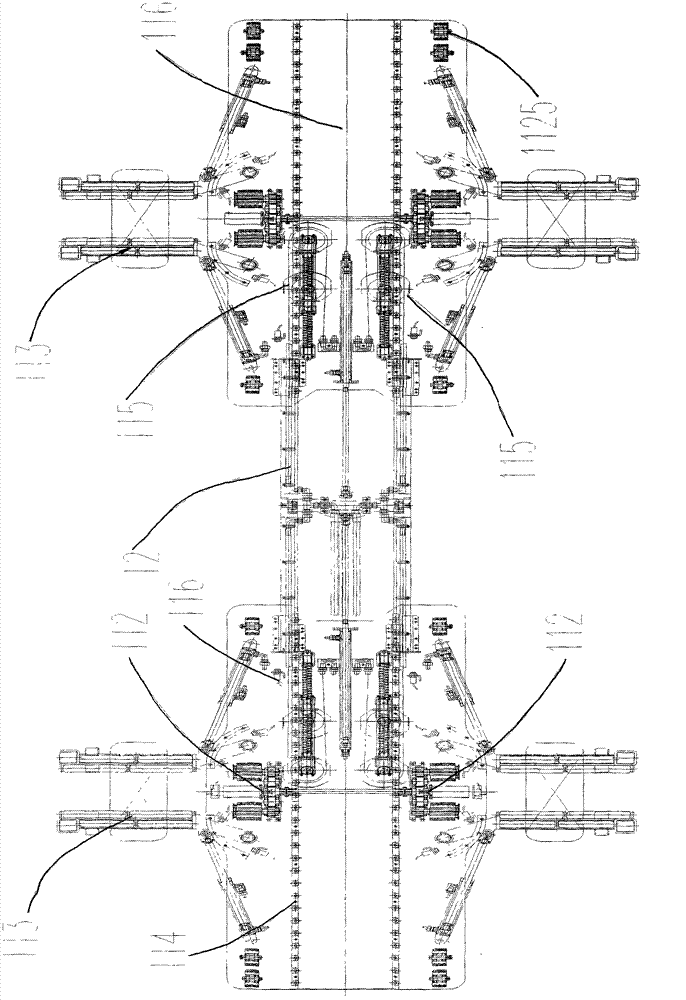

The invention relates to a longitudinal shifting carrier for cars and relates to the technical field of parking and carrying equipment for garages. The longitudinal shifting carrier for cars comprises a front trolley and a rear trolley. The two rear trolleys are integrally connected through moving chains. A travel mechanism of each trolley comprises two drive wheels, two driven wheels, a motor and a reducer of the motor. Two left pairs of wheel clamping arm mechanisms and two right pairs of wheel clamping arm mechanisms are further disposed on each trolley and are used for clamping four tiers of a car placed on track grooves. Each trolley is also provided with a synchronous wheel-clamping lifting mechanism. The defects in the prior art are overcome. The longitudinal shifting carrier for cars has the advantages of simple structure, stability in car shifting, high reliability, small occupied area, convenience and flexibility in operation, durability, low manufacturing cost and the like. The longitudinal shifting carrier for cars is adaptable to various cars different in type, axle distance and wheel thread. The longitudinal shifting carrier for cars is used for carrying, storing and parking cars, and is especially applicable to intersection systems of large mechanical stereo garages.

Owner:北京宏地车港科技有限公司

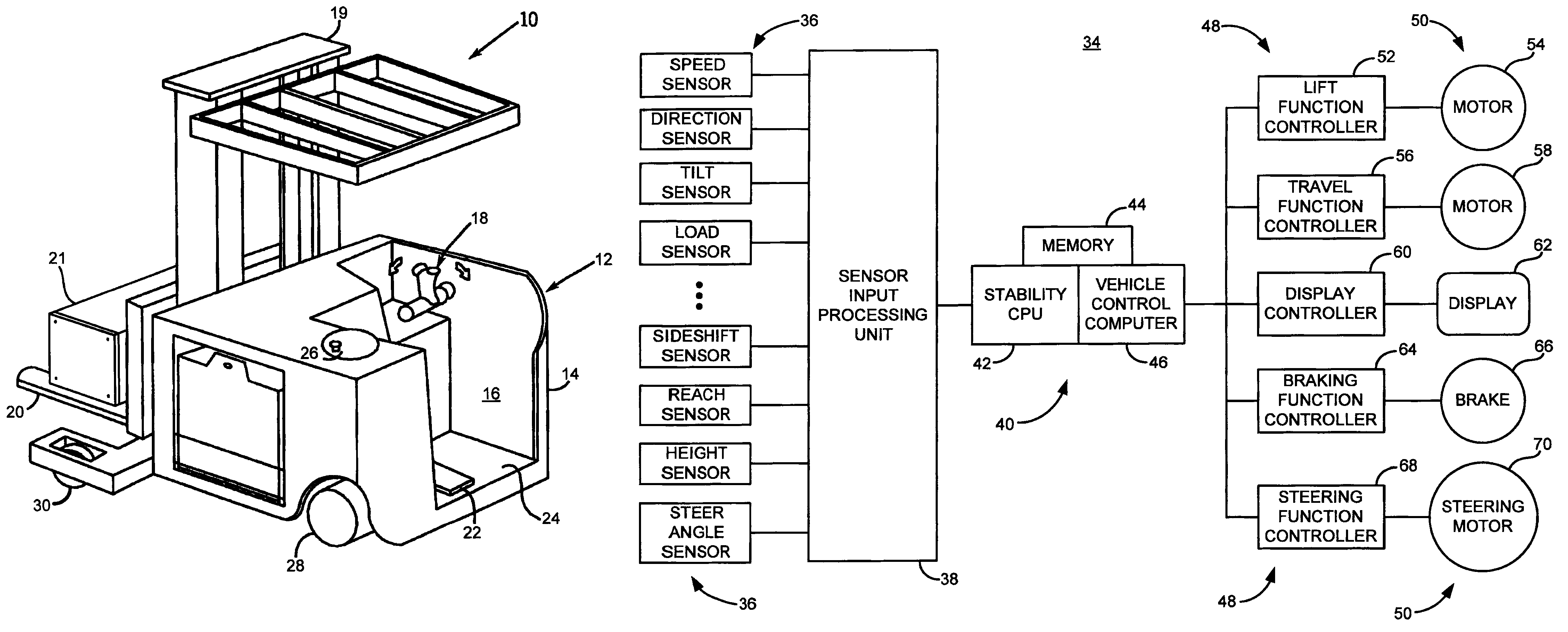

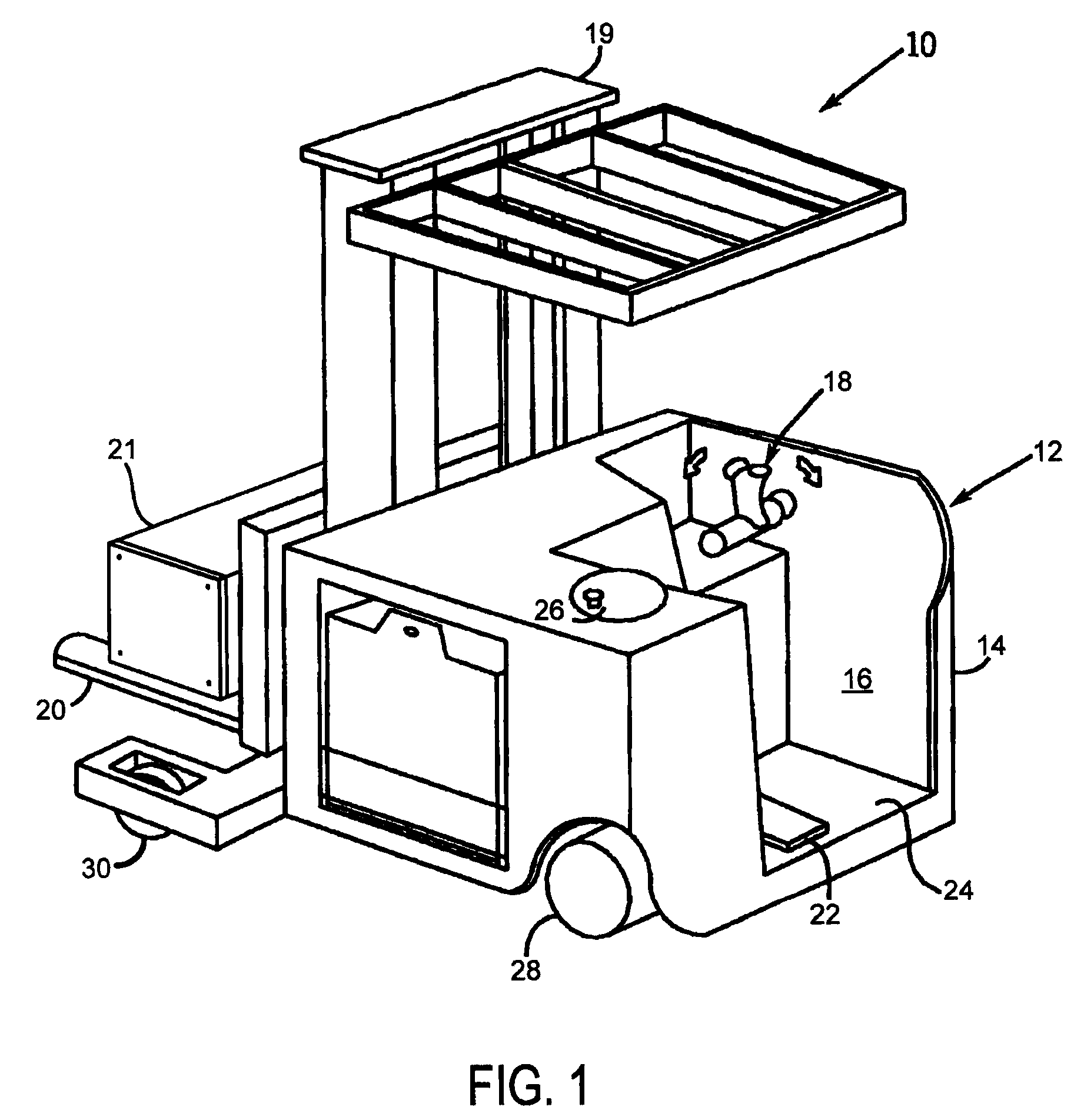

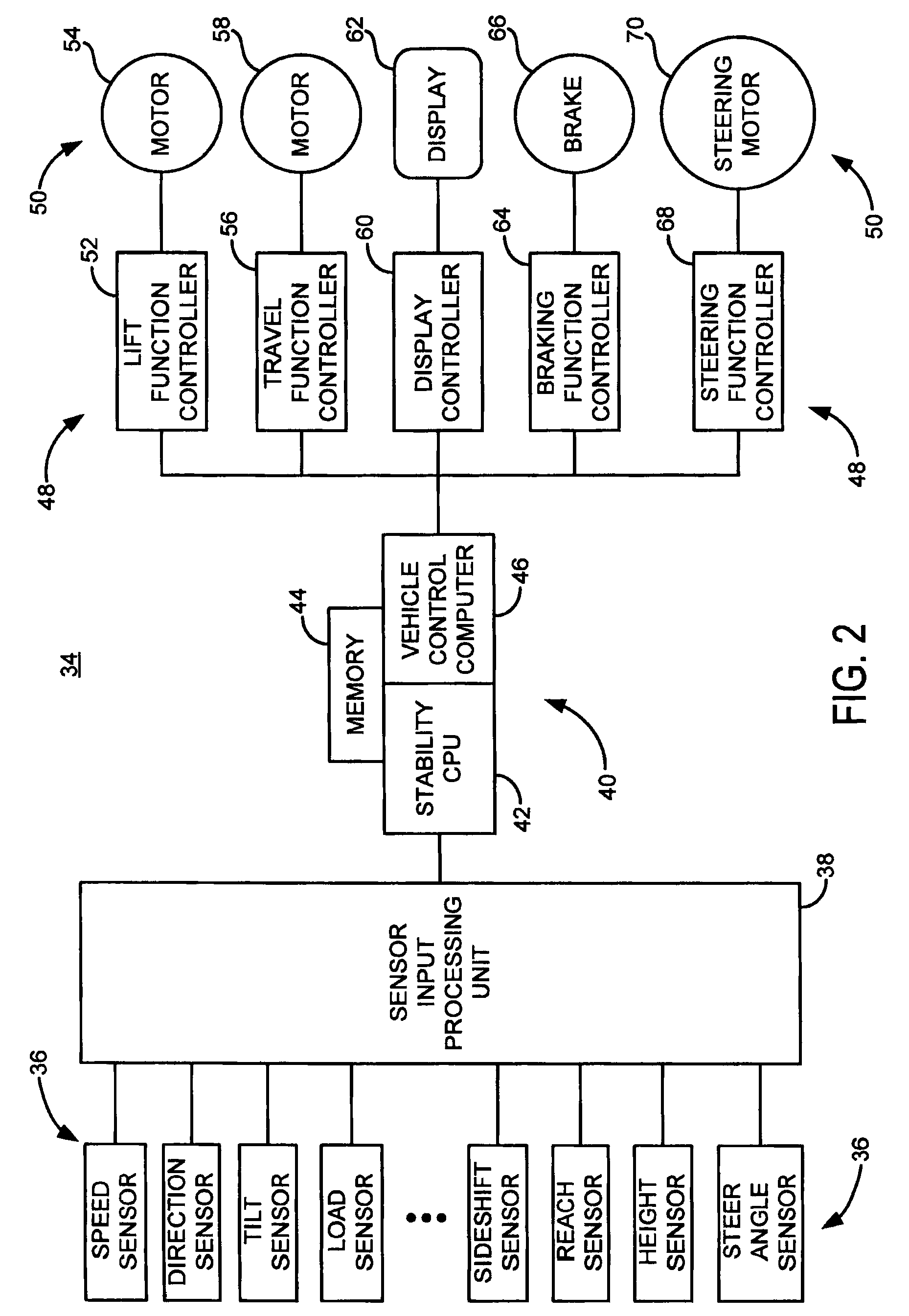

System and method for dynamically maintaining the stability of a material handling vehicle having a vertical lift

ActiveUS8140228B2Improve material stabilityMaintain dynamic stabilitySafety devices for lifting equipmentsAnalogue computers for trafficWheelbaseMaintaining vehicles

Owner:RAYMOND LTD

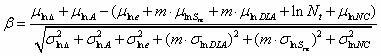

Probabilistic finite element method (PFEM)-based steel-bridge fatigue reliability evaluation method

ActiveCN102384856ALow costShorten the evaluation cycleStructural/machines measurementStatistical analysisElement analysis

The invention relates to a probabilistic finite element method (PFEM)-based steel-bride fatigue reliability evaluation method, in particular to a fatigue reliability evaluation method by combining dynamic weighing data (WIM) of a car and the analysis of the PFEM, which aims at solving the problems that the bridge structure health monitoring cost is higher and the stress measuring point distribution is limited, and utilizes the real WIM data to statistically analyze car load and establishes a probabilistic distribution model of a car type, road distribution, axle weight and wheel-base. Finite element method analysis software is used for establishing a numeric model of a bridge. A probabilistic finite element program is compiled, stress amplitude and stress cyclic quantity of a key part under the random car load effect are extracted through the sampling, loading and finite element analysis to be statistically counted. The fatigue reliability calculation is performed according to the statistical result, and the reliability attenuation trend of the evaluated part in the subsequent application process is predicted. By adopting the method, a feasible analysis tool is provided for the fine fatigue evaluation of complicated steel-bridge details.

Owner:SOUTHEAST UNIV

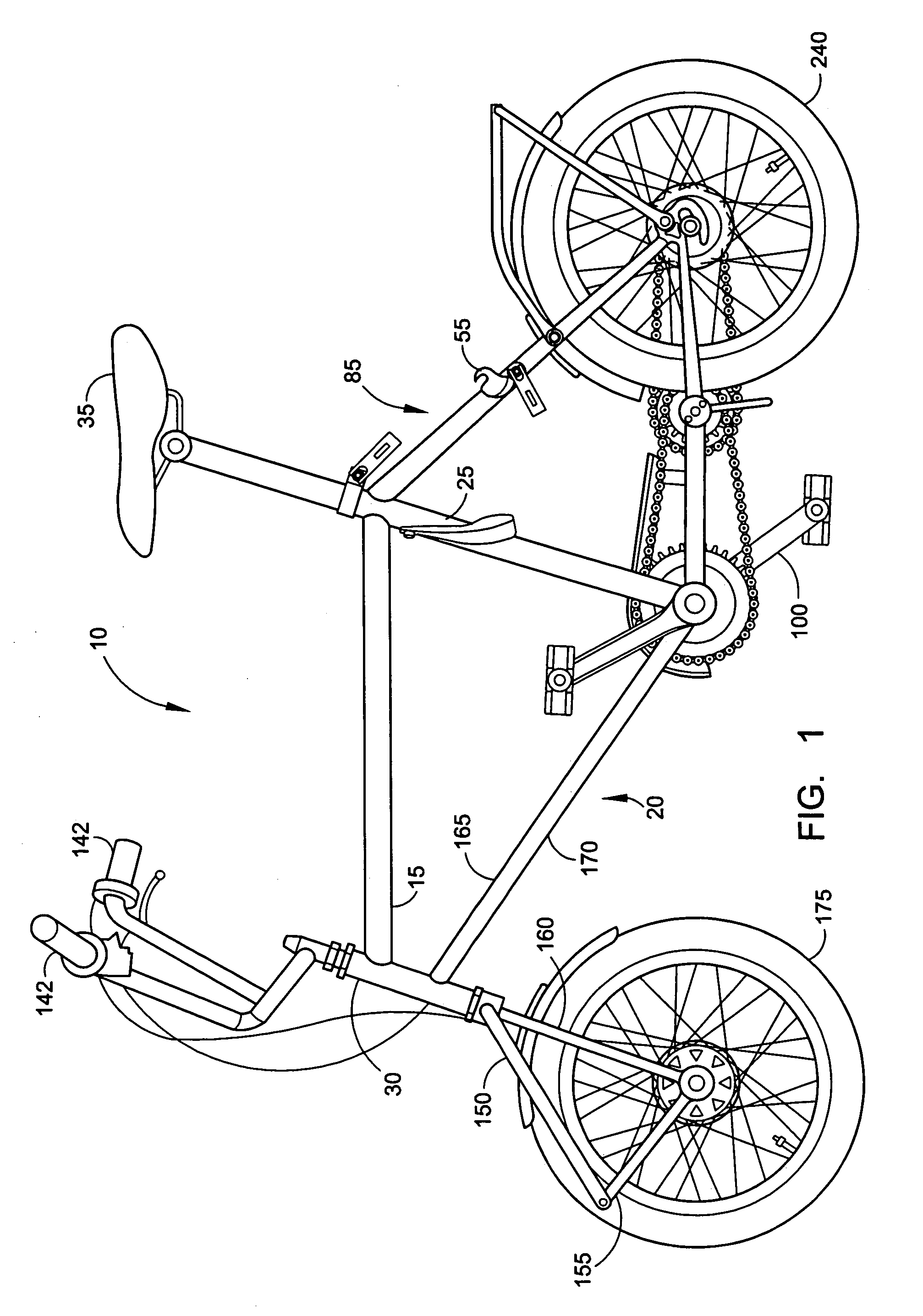

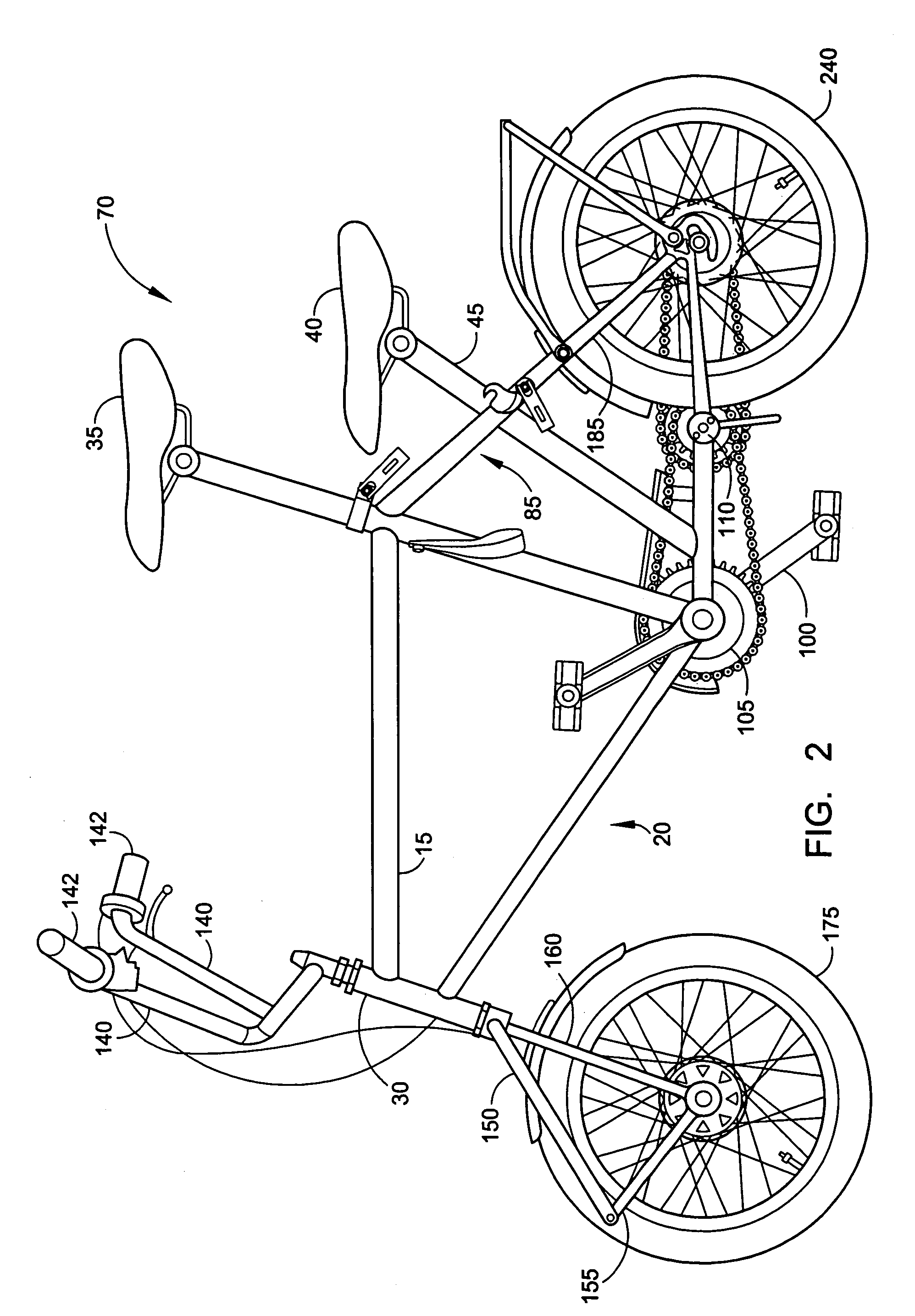

Folding bicycle

InactiveUS7229089B2Small sizePromote ergonomic riding characteristics of a non-folding bicyclePassenger cyclesWheel based transmissionSubject matterEngineering

Owner:STUDIO MODERNA SA

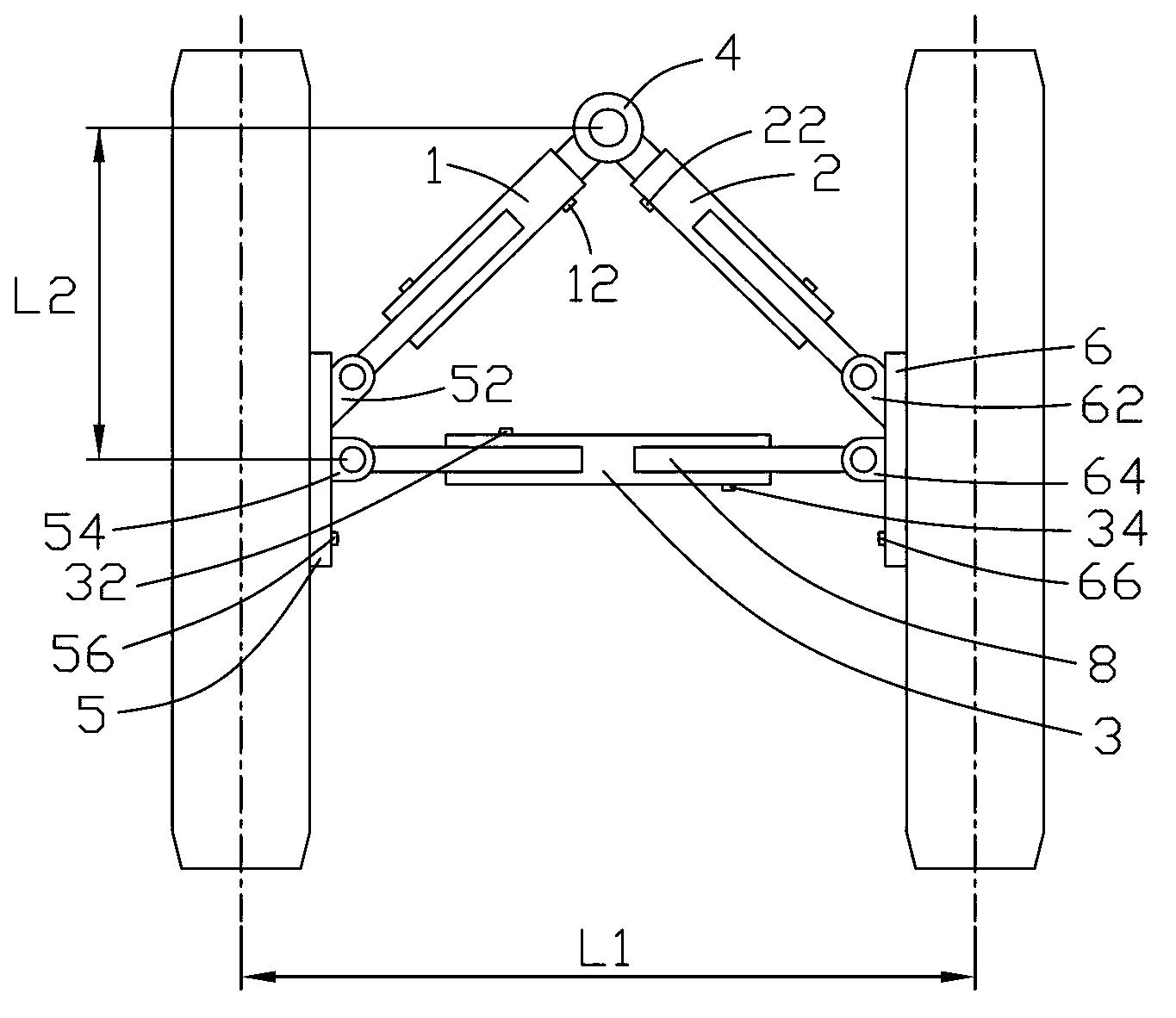

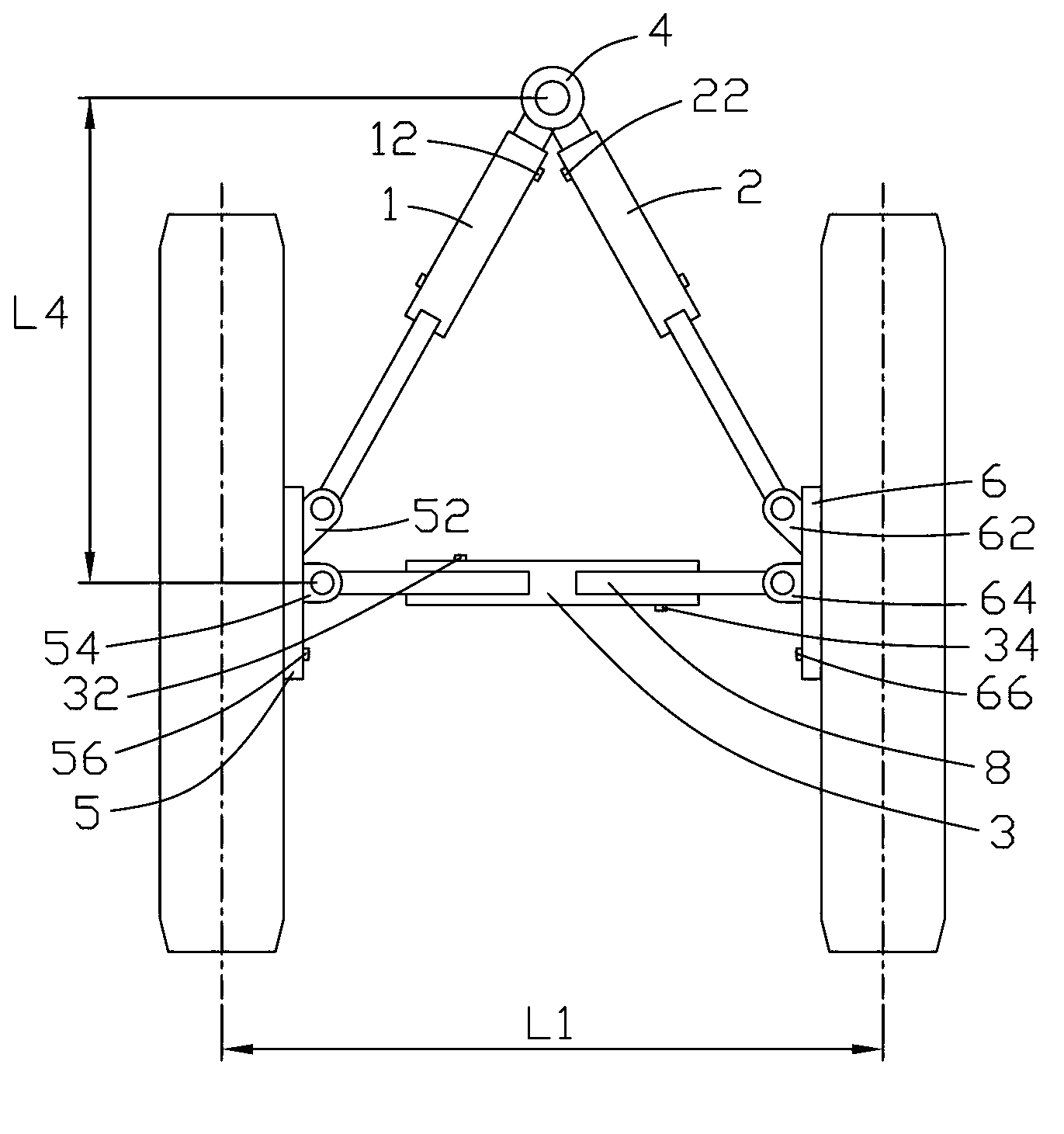

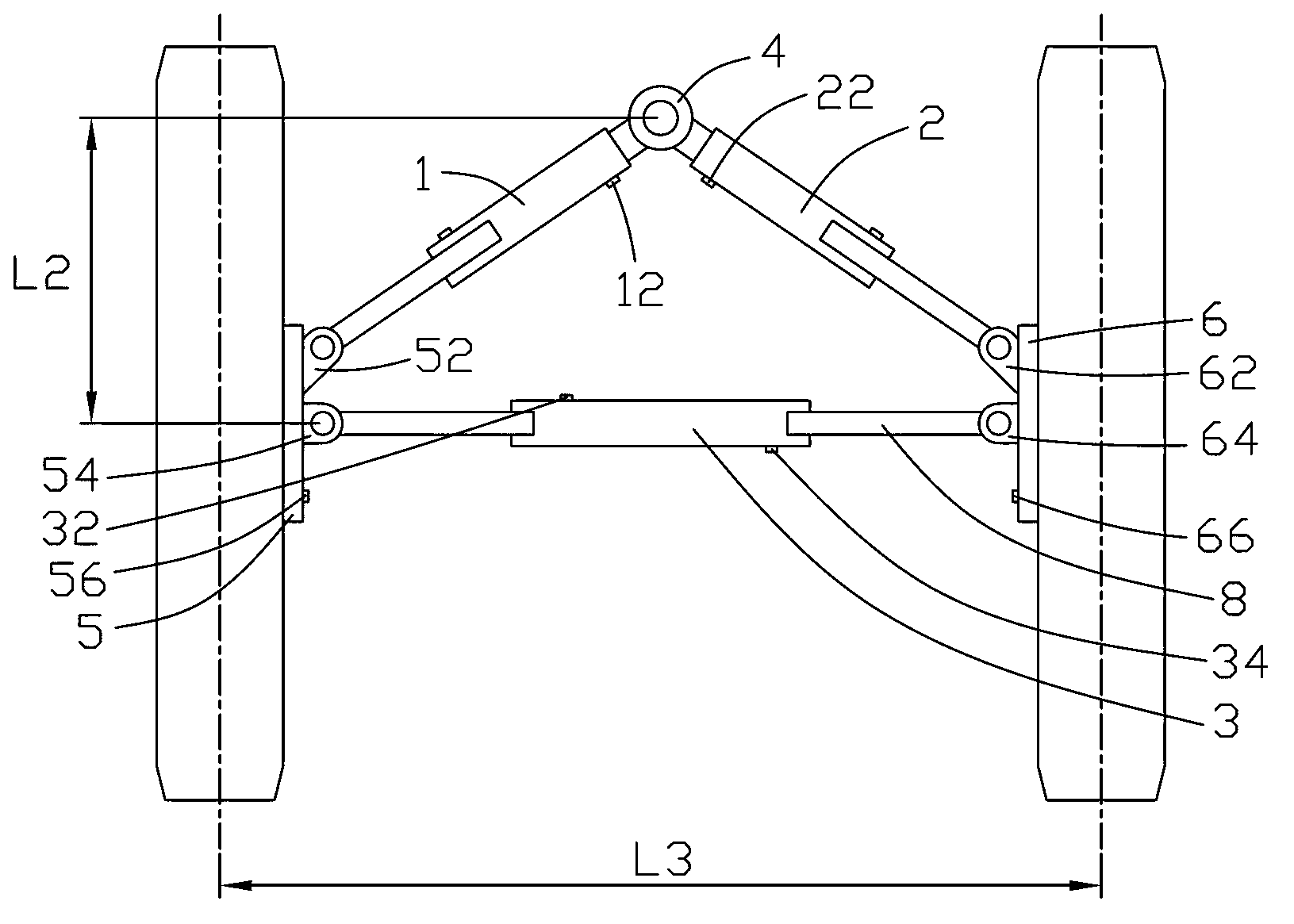

Telescopic device and vehicle provided with same

ActiveCN103231625AExpanded ability to adapt to road conditionsImprove driving stabilityAxle unitsEngineeringMechanical engineering

The invention provides a telescopic device which comprises a first telescoping mechanism, a second telescoping mechanism, a horizontal telescoping mechanism, a mounting seat, a first mounting board and a second mounting board, wherein a first end of the first telescoping mechanism and a first end of the second telescoping mechanism are hinged with the mounting seat respectively; a second end of the first telescoping mechanism and a second end of the second telescoping mechanism are hinged with the first mounting board and the second mounting board respectively; and a first end and a second end of the horizontal telescoping mechanism are hinged with the first mounting board and the second mounting board respectively. The invention further provides a vehicle provided with the telescopic device. With the adoption of the telescopic device and the vehicle, the wheelbase and the tread of the vehicle can be adjusted respectively or simultaneously.

Owner:HANGZHOU BRANCH ZHEJIANG GEELY AUTOMOBILE RES INST +2

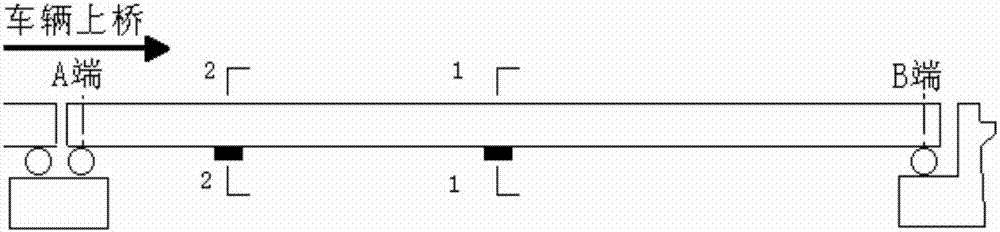

Rapid bridge detection method based on influence lines

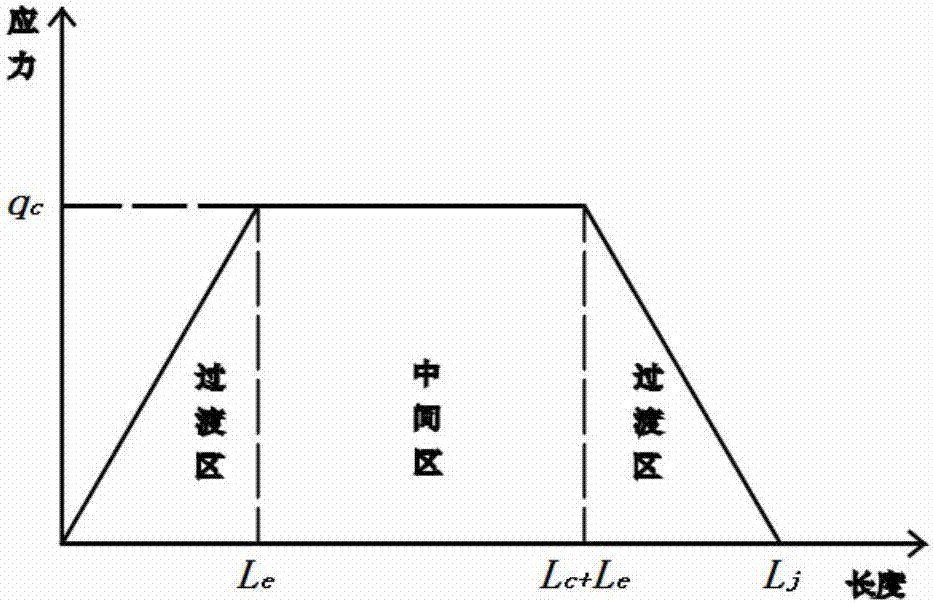

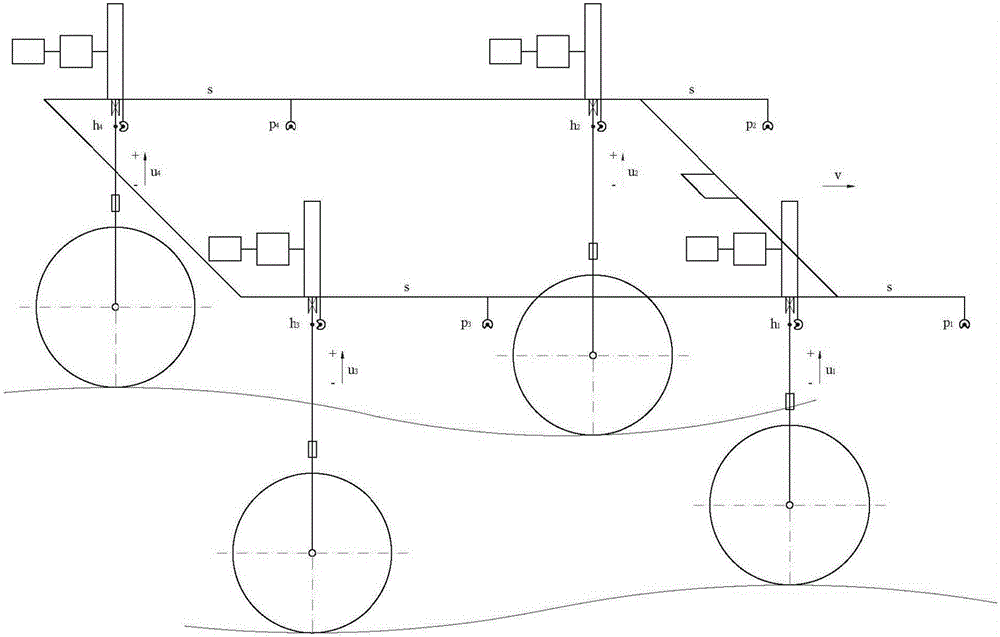

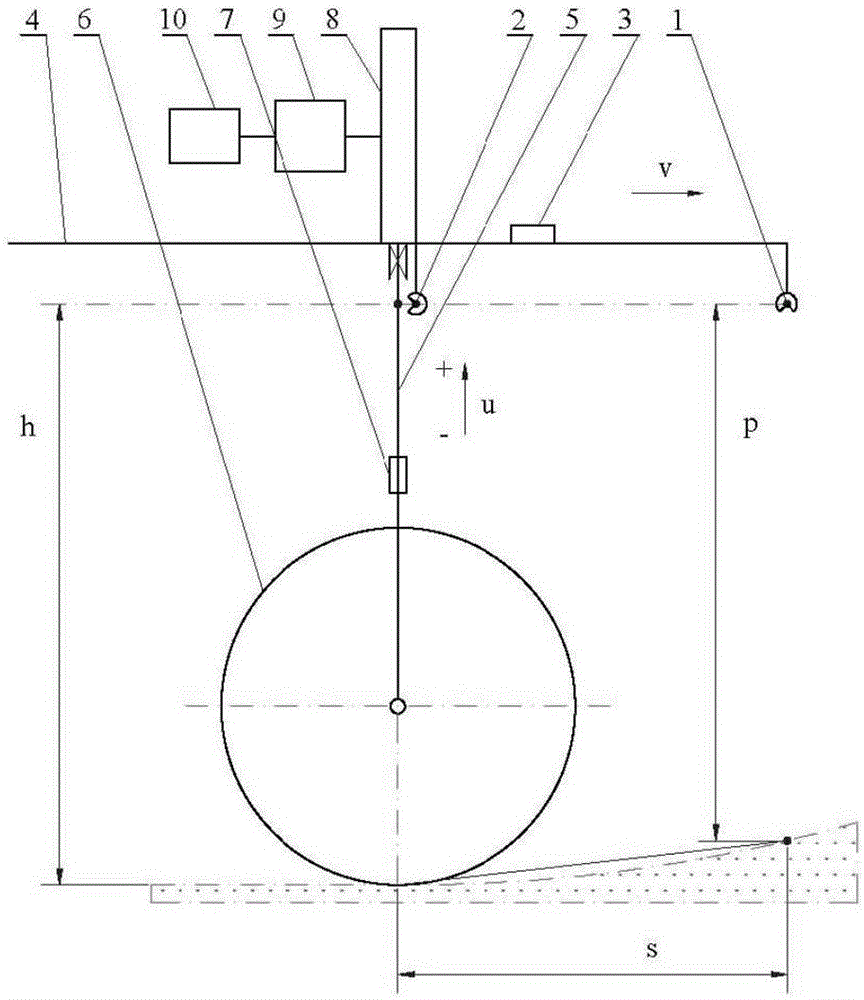

ActiveCN107132011AImprove measurement and calculation accuracyQuick checkInformaticsSpecial data processing applicationsInfluence lineSpecific function

The invention relates to a rapid bridge detection method, which belongs to the technical field of civil engineering application. Firstly, a loading test vehicle with known axle load and wheelbase is adopted for loading to measure response of a test point; then, a method of adopting a specific function (piecewise polynomial and sine wave stacking) to fit the dynamic response of the test point is adopted to extract influence line information of the bridge; a tire-pavement stress distribution emprical formula is introduced to build a tire-pavement contact force trapezoid distribution model; in combination of the actual influence line information and the vehicle tire-pavement contact force distribution model, a linear superposition method is adopted to reconstruct bridge test point response information under different vehicle load combination effects, and thus, rapid bridge detection based on the influence lines is realized. Based on few driving tests on a single vehicle, the actual influence line information can be acquired rapidly and accurately, the bridge response information under different static load combination working conditions is reconstructed, rapid bridge detection is achieved, and the defects that the existing bridge detection method is long in consumed time, high in economic cost and long in traffic block time can be solved.

Owner:CENT SOUTH UNIV

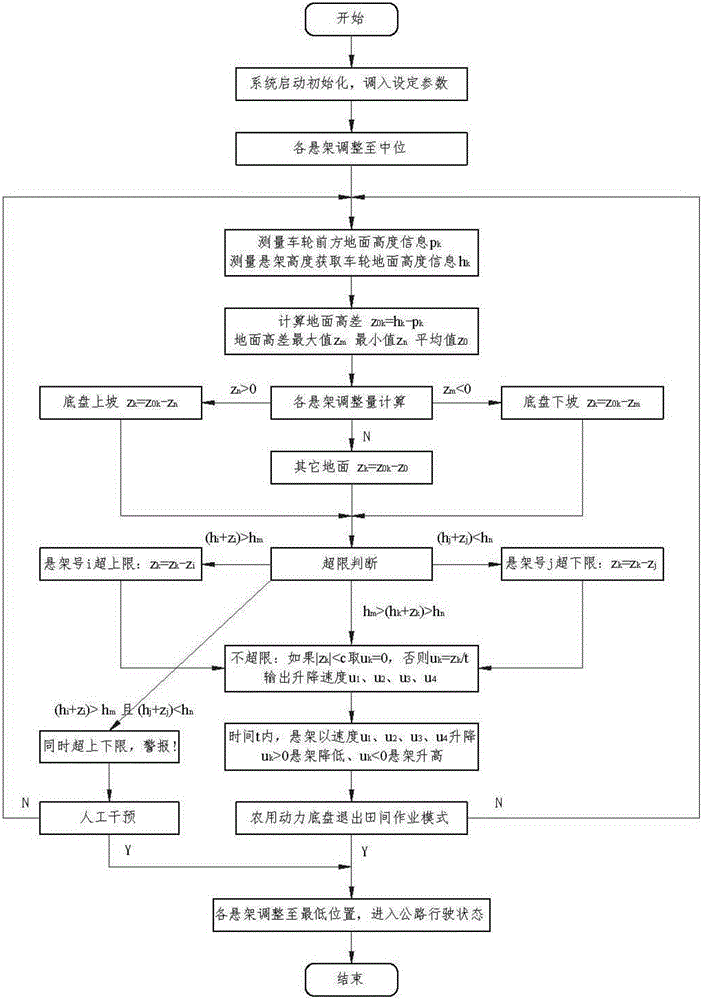

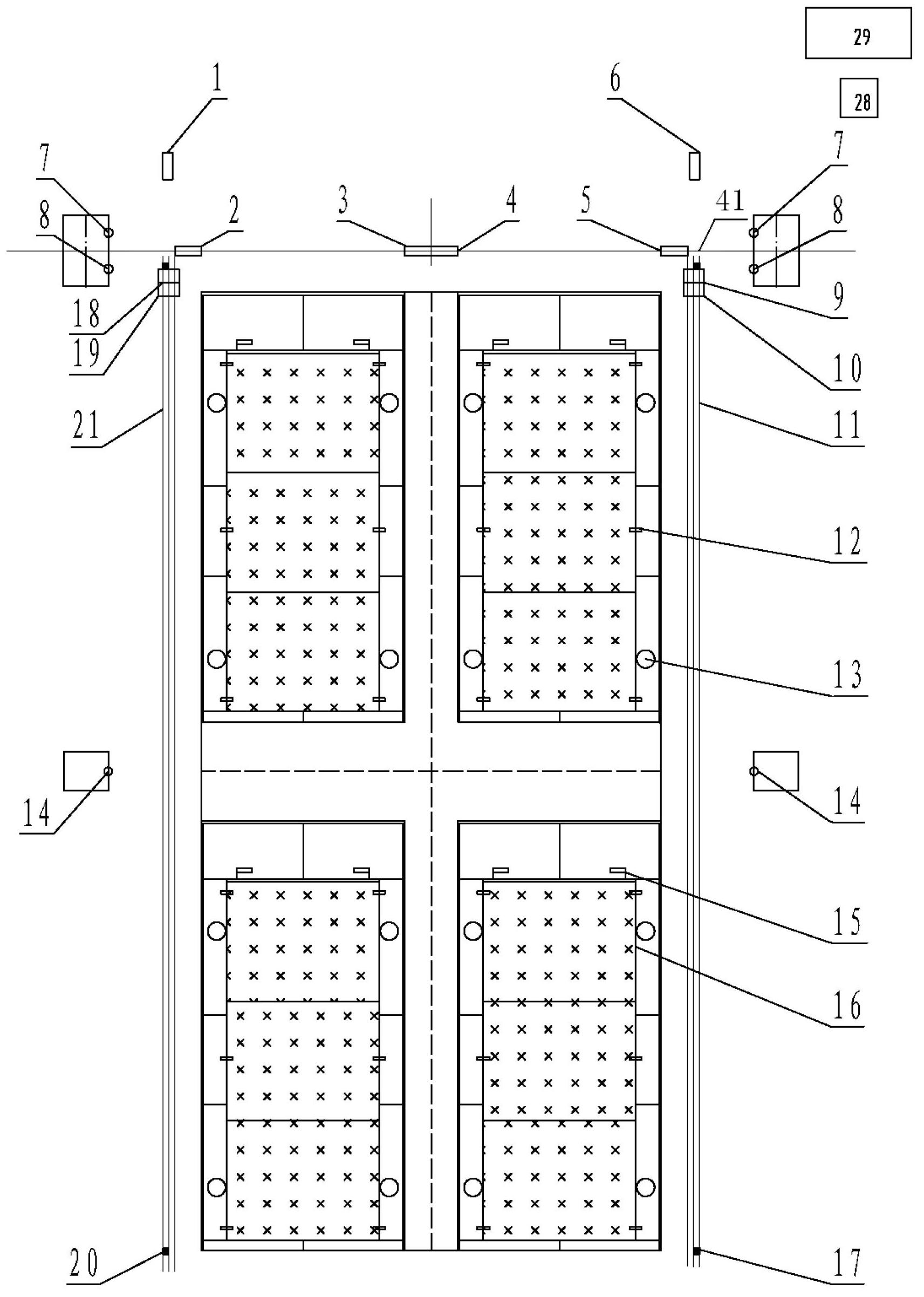

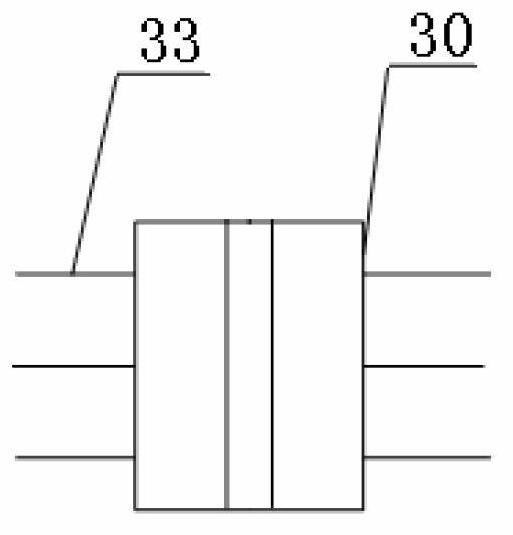

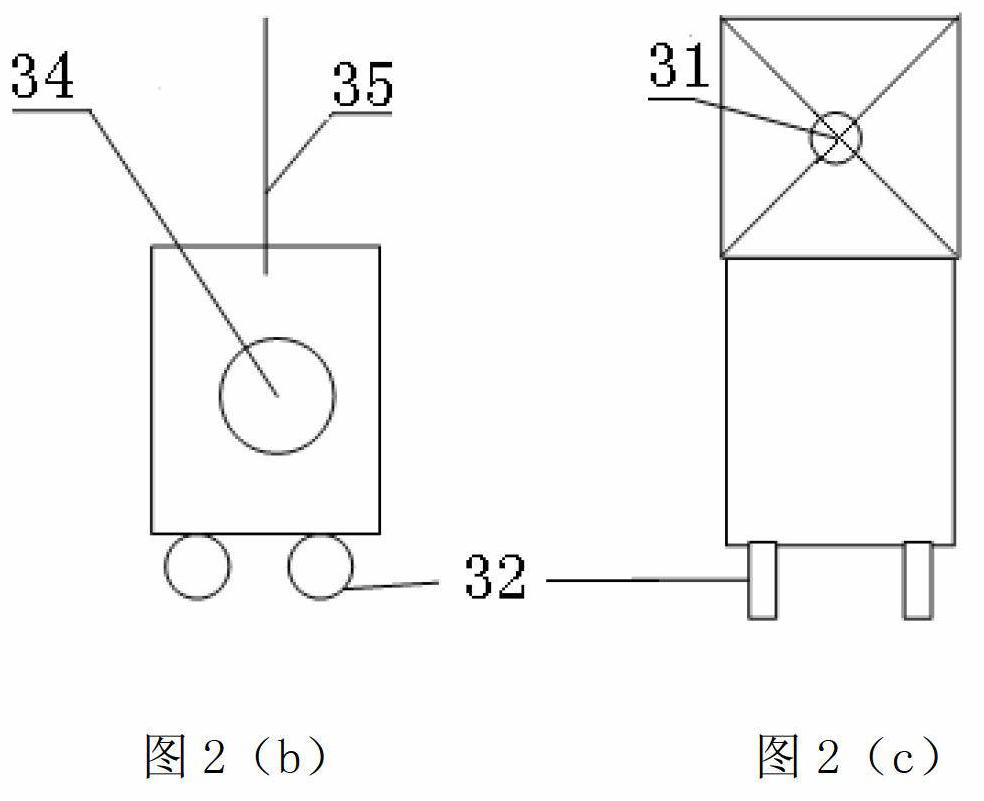

Leveling system and leveling method for agricultural power chassis

ActiveCN106427451ASatisfy plant protectionMeet the harvestAgricultural vehiclesResilient suspensionsTerrainVehicle frame

The invention discloses a leveling system and a leveling method for an agricultural power chassis, and belongs to the technical field of vehicle chassis. The leveling system for an agricultural power chassis comprises a distance measuring sensor, a position sensor, a central processor, a vehicle frame, suspensions and wheels; four groups of the suspensions are mounted on the vehicle frame in bilateral symmetry according to the given wheelbase and wheel track, and the lower ends of the suspensions are connected with the wheels; the information of terrain height in front of the wheels is measured by the distance measuring sensor; the heights of the suspensions are measured by the position sensor to obtain the wheel-terrain height information; calculation and analysis are carried out by the central processor; the suspensions are driven by a servo motor and the heights of the suspensions are adjusted in real time; and the wheels actively contour the ground, so that dynamic leveling of the vehicle body during traveling and operation of the agricultural power chassis is achieved.

Owner:CHINA AGRI UNIV

Braking process-based dynamic automobile gravity position detector and method

InactiveCN102692297AQuick measurementAccurate measurementStatic/dynamic balance measurementTraffic accidentData acquisition

The invention relates to braking process-based dynamic automobile gravity position detector and a method. The device consists of an axle weight, a braking force detector, an axle base measuring device, a wheel base measuring device and a data collection processing system; dynamic gravity detection algorithm is obtained by derivation on the basis of braking process, the device is applied to collect axle weight and braking force signals, axle base signals and wheel base signals, thus being capable of calculating the position of the automotive gravity. Based on the automotive gravity position calculation method, sideslip and rolling-over of vehicles can be analyzed to calculate limiting values of sideslip and rolling-over of vehicles under different road conditions and give out early-warning information to avoid occurrence of traffic accidents. The invention can be widely applied in safety driving control process of various vehicles.

Owner:JILIN UNIV

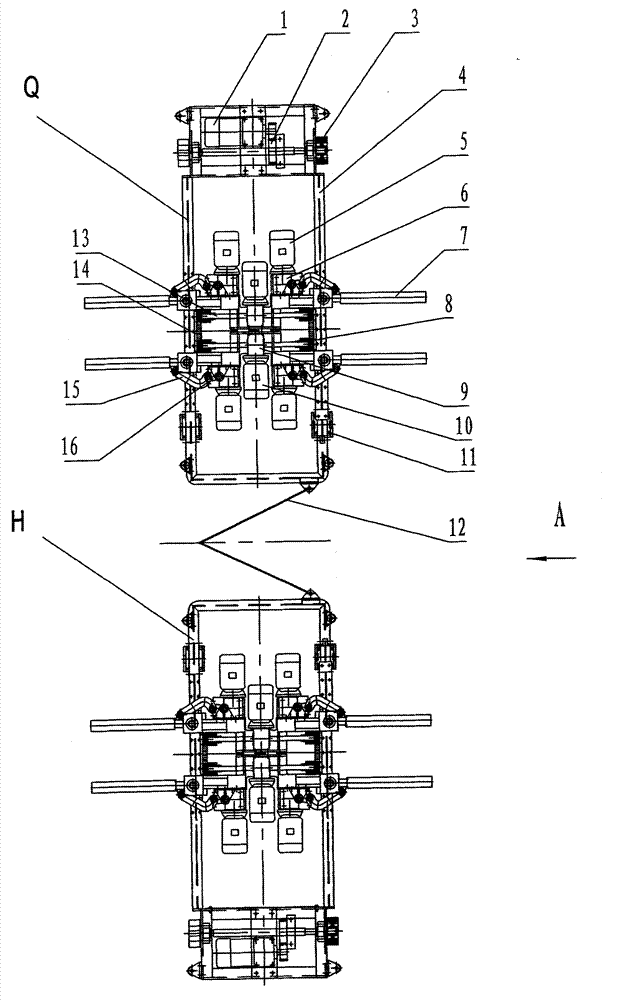

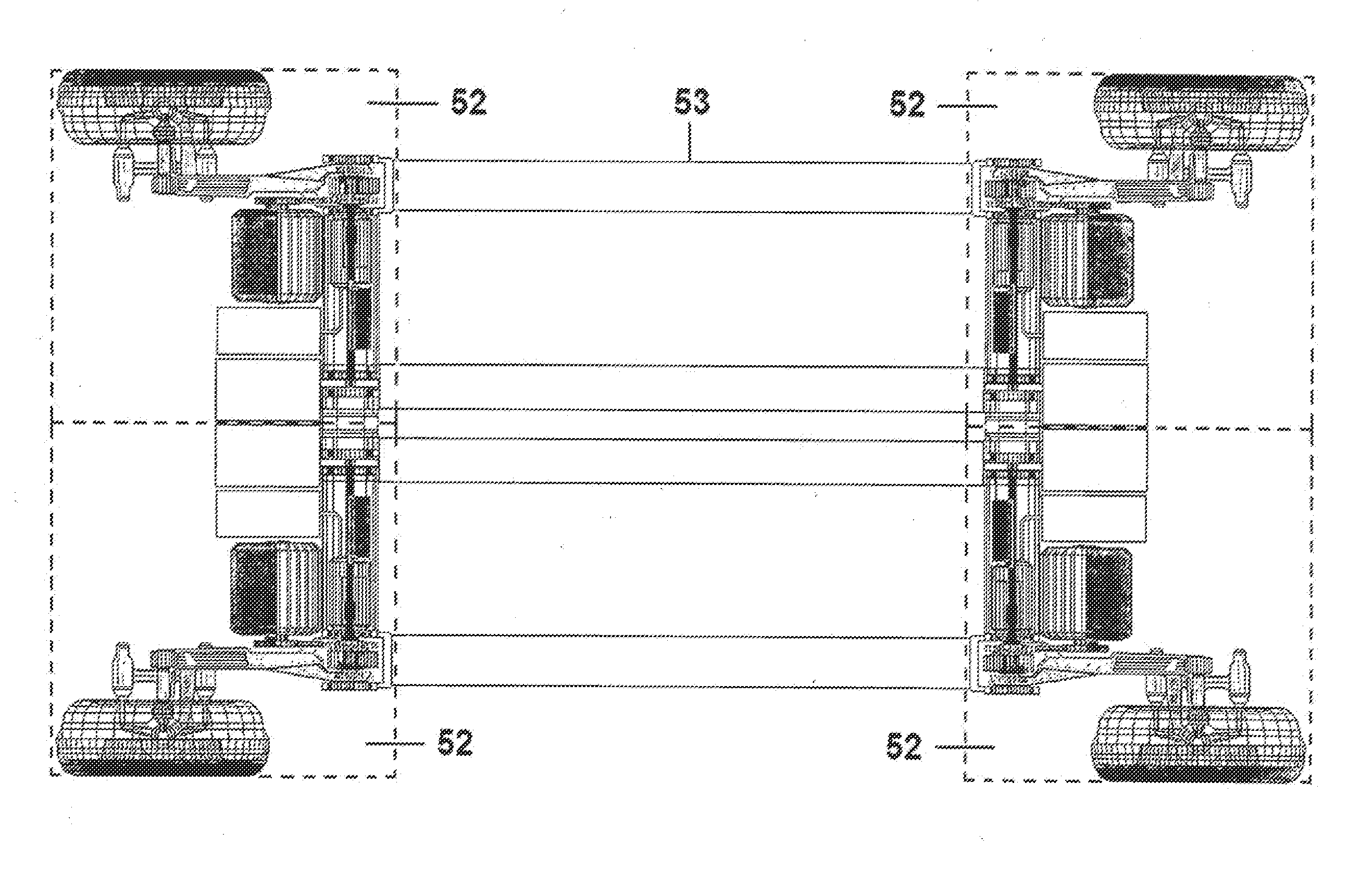

Handling robot and mechanical three-dimensional garage using the handling robot

The invention relates to a handling robot, in particular to an intelligent mechanical three-dimensional garage using clamping tires of the handling robot to lift cars (or similar goods) and carry out front-back bi-directional carrying-depositing actions. The mechanical three-dimensional garage consists of a handling robot, a car storage place, a carrier, a loading platform, and a platform rail. The handling robot includes two moving trolleys in front and back sides, a retractable device is arranged between trolleys. The moving trolley comprises a trolley rack, a moving mechanism, clamping arms, a steering wheel assembly and an oil-way circuit slewing mechanism. According to the handling robot and a mechanical three-dimensional garage using the handling robot, problems of depositing cars in limited space are solved, automatic positioning of tires of cars with different wheelbases is flexibly realized, and the front-back bi-directional carrying-depositing actions are achieved. Besides, a moving drive mechanism can be independently installed on the loading platform to suitable for a flat mobile type parking system, and a lifting mechanism can be installed on the loading platform with the moving mechanism to suitable for an aisle-stacking parking garage, so as to realize three-dimensional movement of objects.

Owner:SHENZHEN YEEFUNG AUTOMATION TECH CO LTD

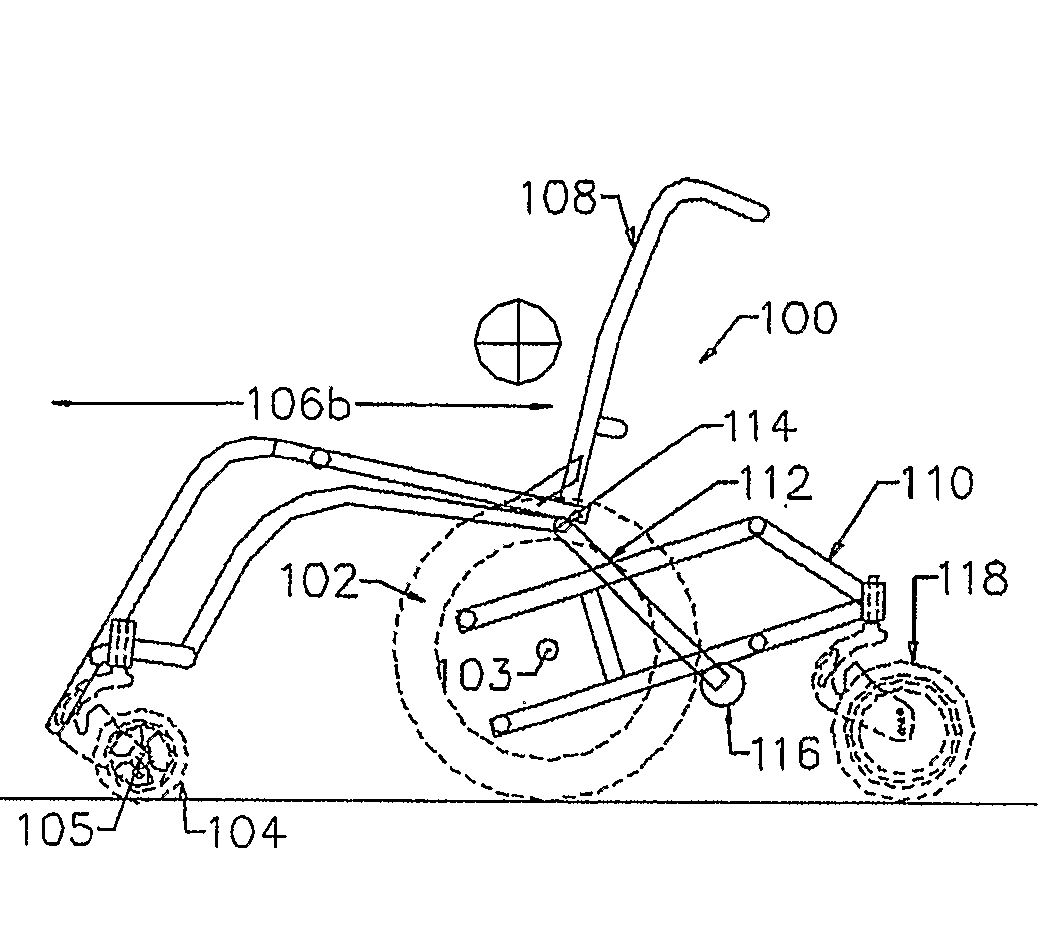

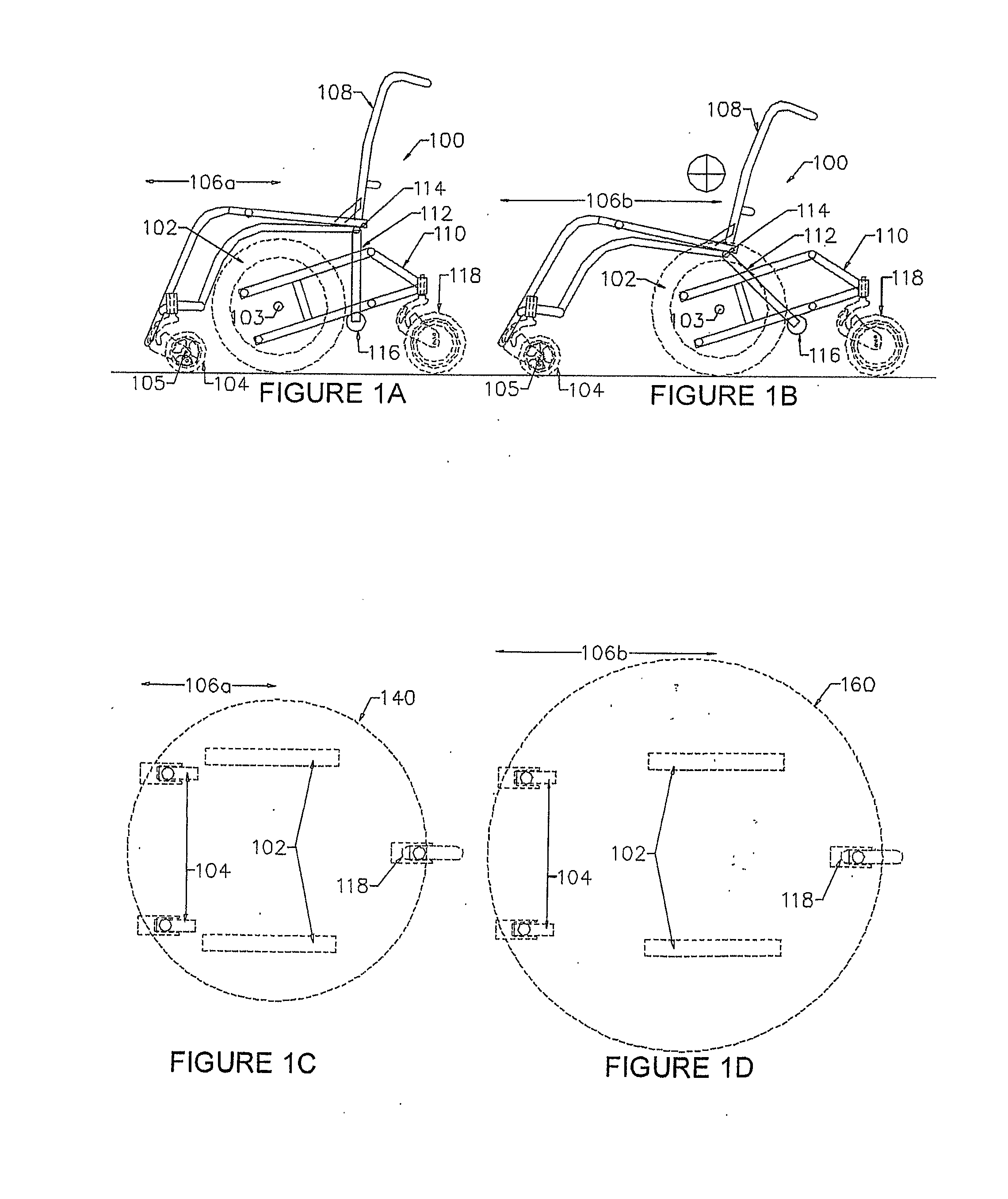

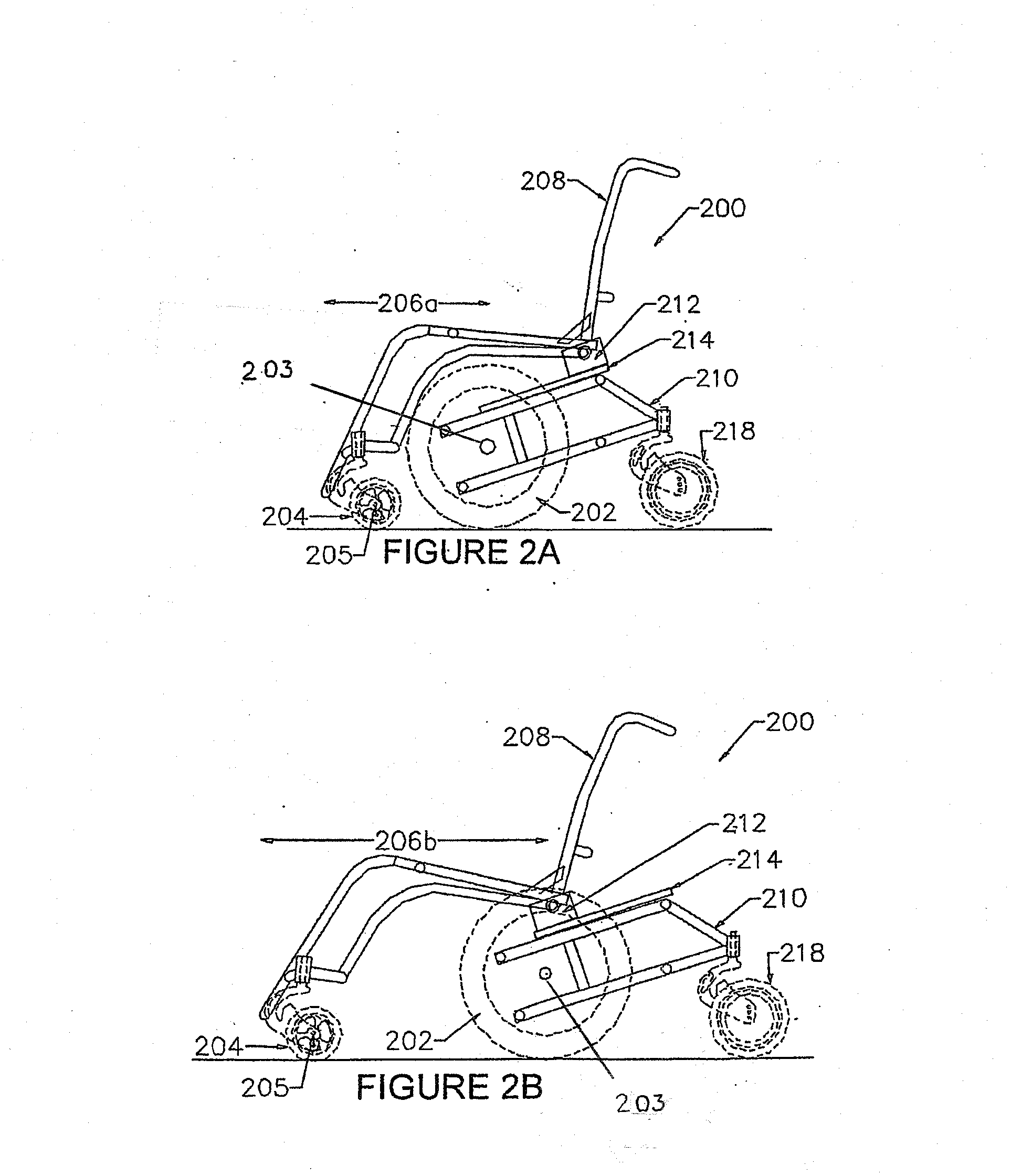

Vehicle

InactiveUS7717210B2Minimize damageElectric propulsion mountingWheelchairs/patient conveyanceEngineeringWheelbase

A vehicle for transporting a person has a chassis (103) and four wheels (105a, 105b, 150c, 105d) supporting the chassis above a ground surface. The wheels enable the vehicle to move along the ground surface. Each of the four wheels is adjustable in position to enable the wheelbase length and track width of the vehicle to be changed. Each of the wheels is steerable to enable the changes in the wheelbase length and the track width to be effected whether the vehicle is substantially stationary or in motion.

Owner:MAHY GRAHAM JOHN +2

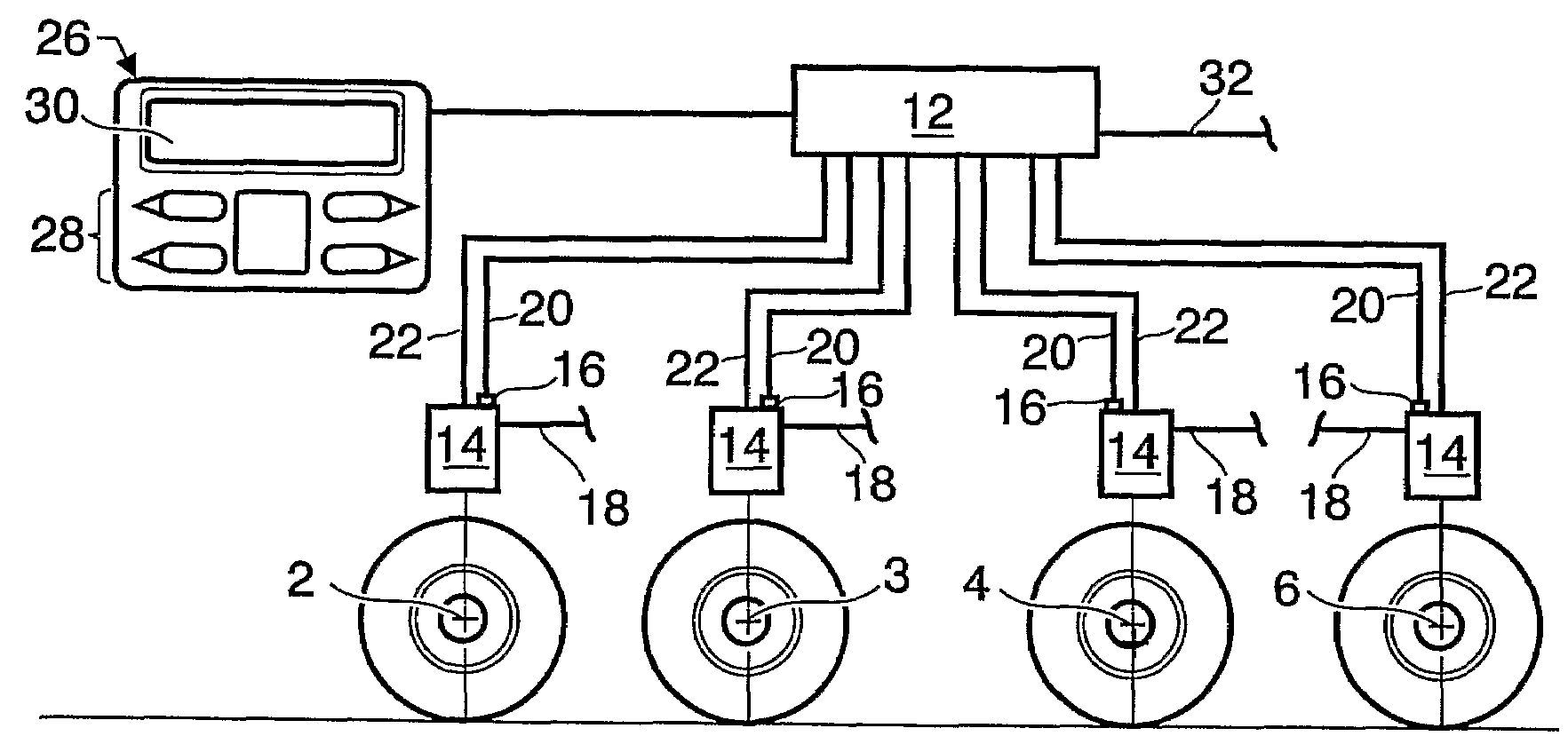

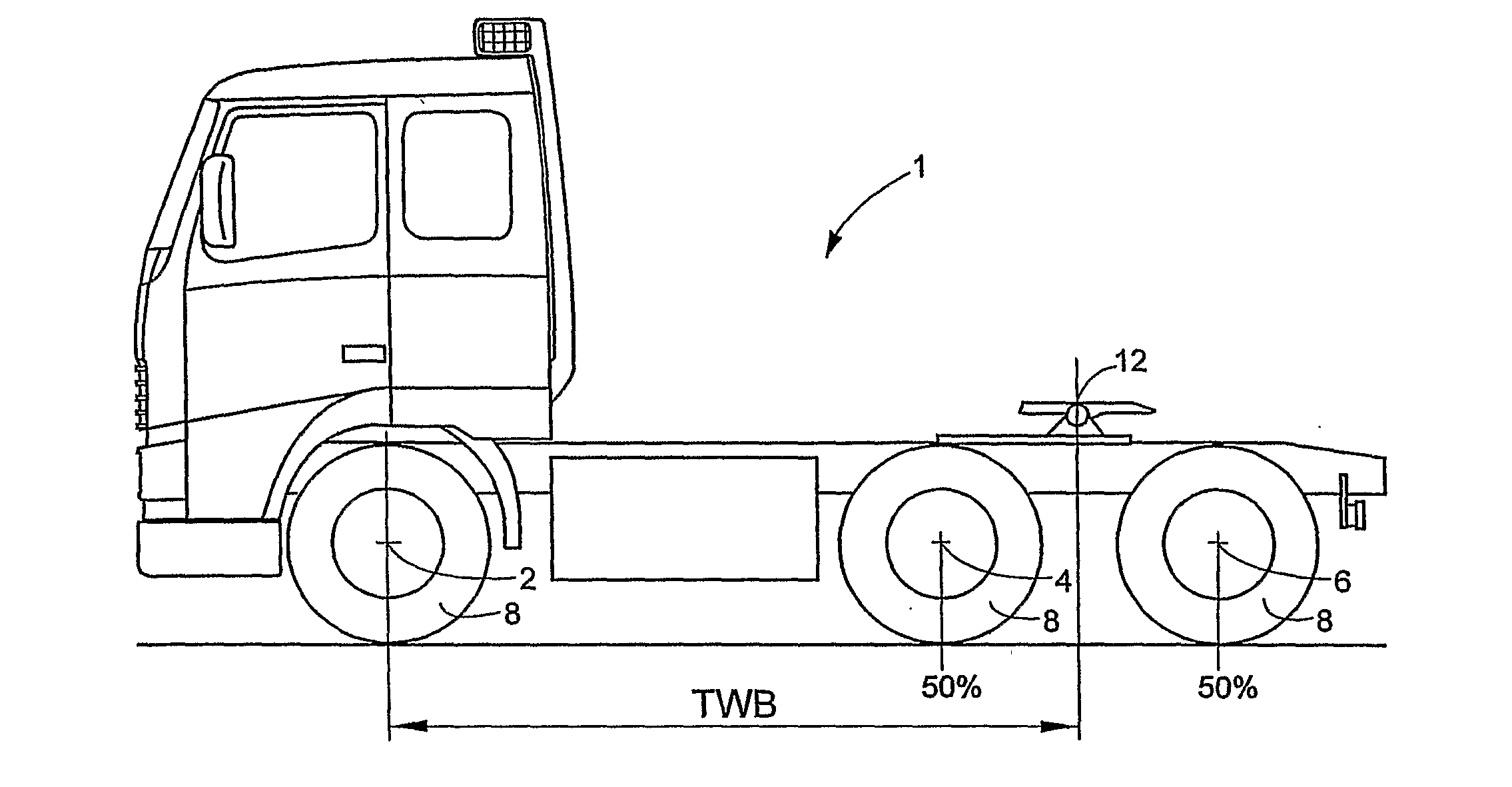

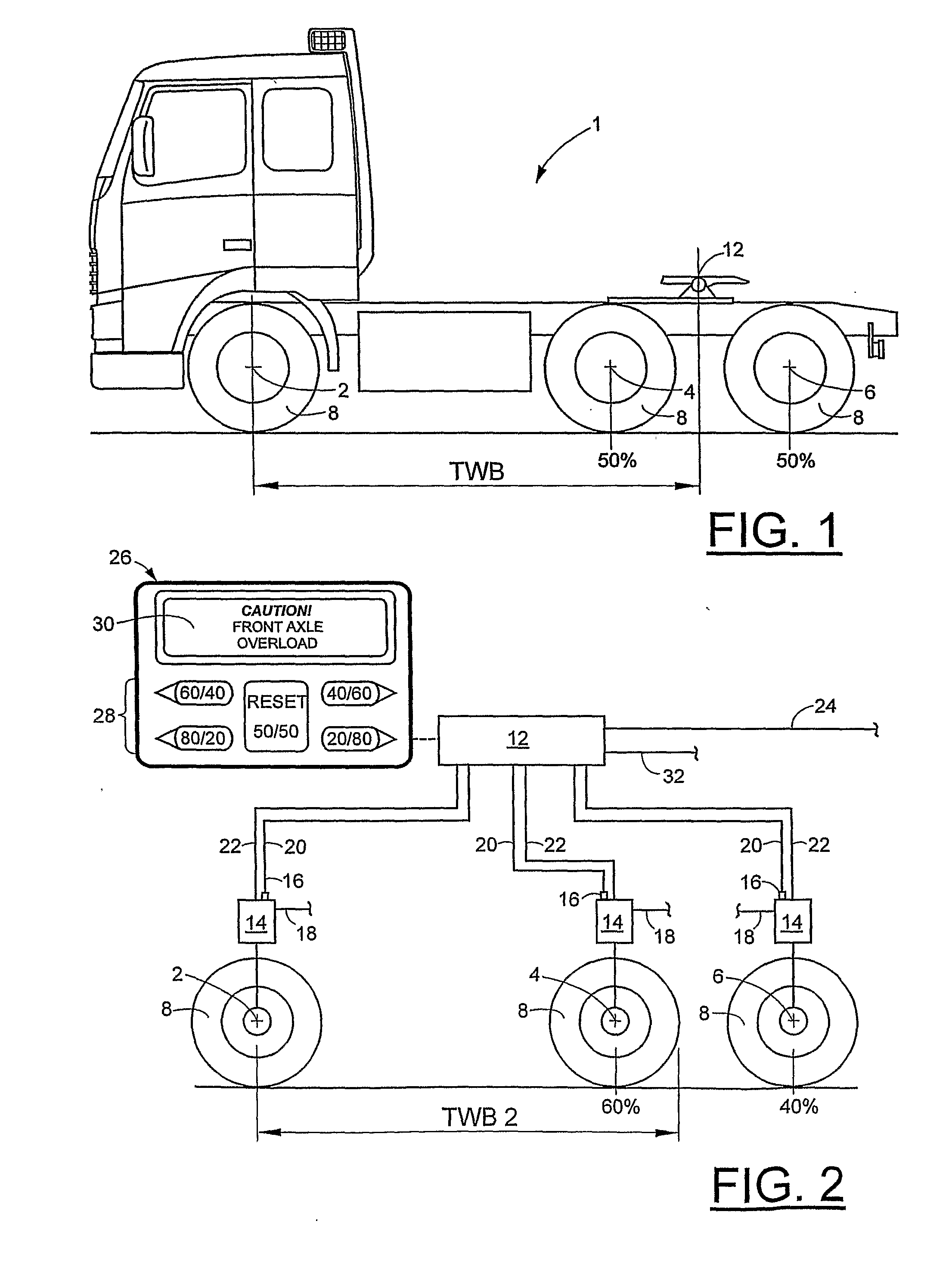

Axle load control system and a wheel base adjustment system

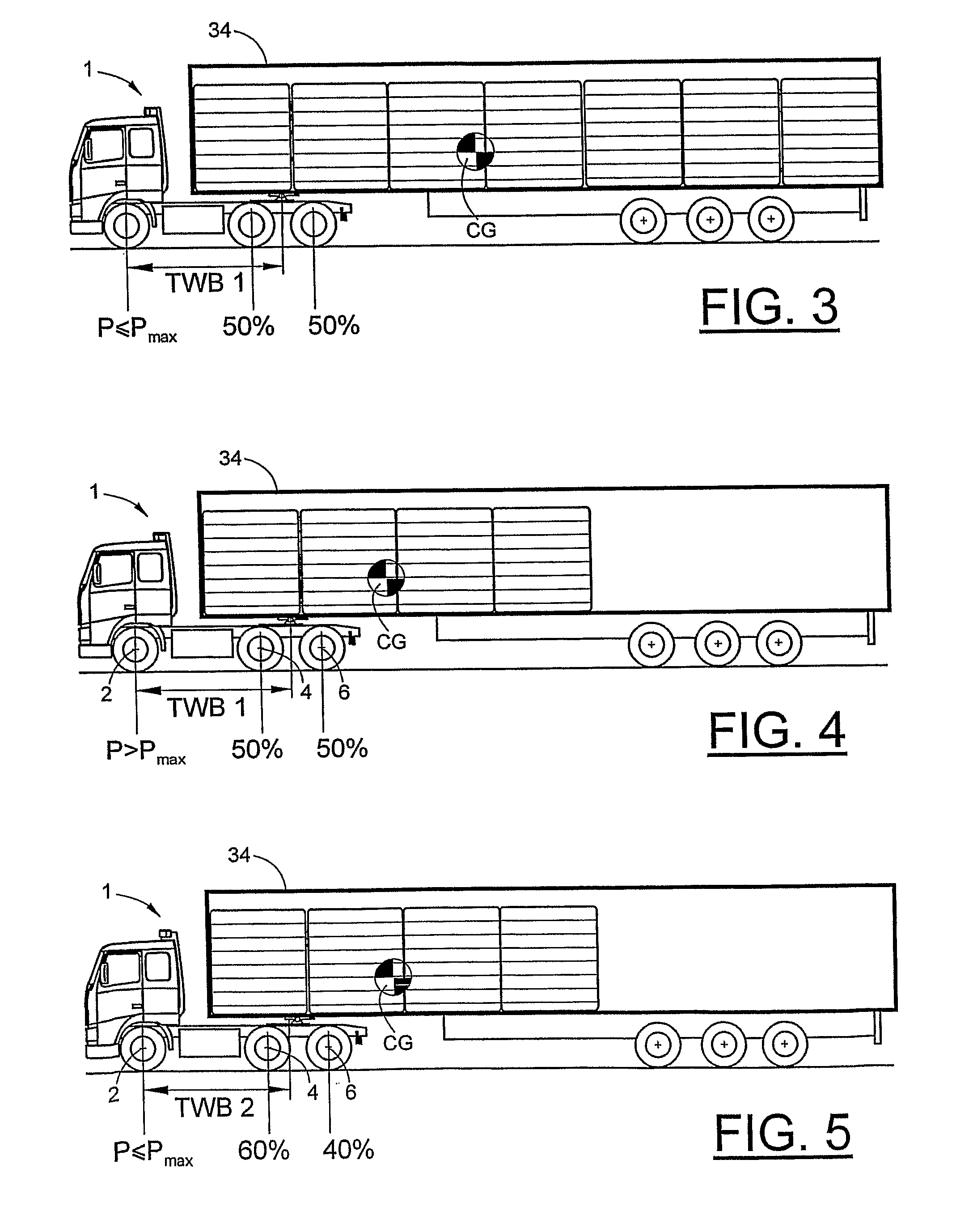

InactiveUS20070296173A1Tractor-trailer combinationsResilient suspensionsDriver/operatorControl system

An axle load control system and method for a load-carrying truck having a front axle and two or more rear axles is provided. The system includes a wheel suspension system with a suspension control processor, a load sensor arranged at each of the axles for detecting one or more load indication parameters, the load sensor providing the parameters to the suspension control processor which translates the parameters into actual axle load values for the individual axles. The control processor is arranged to compare the actual axle load values with a predefined maximum allowable axle load value for each axle, and to control—or indicate to a driver the need to control—the wheel suspension system so as to effect an individual adjustment of the suspension characteristics for each axle in such a way that excess axle load on an overloaded axle is transferred to one or more of the remaining axles, thereby adjusting the theoretical wheelbase of the truck.

Owner:VOLVO LASTVAGNAR AB

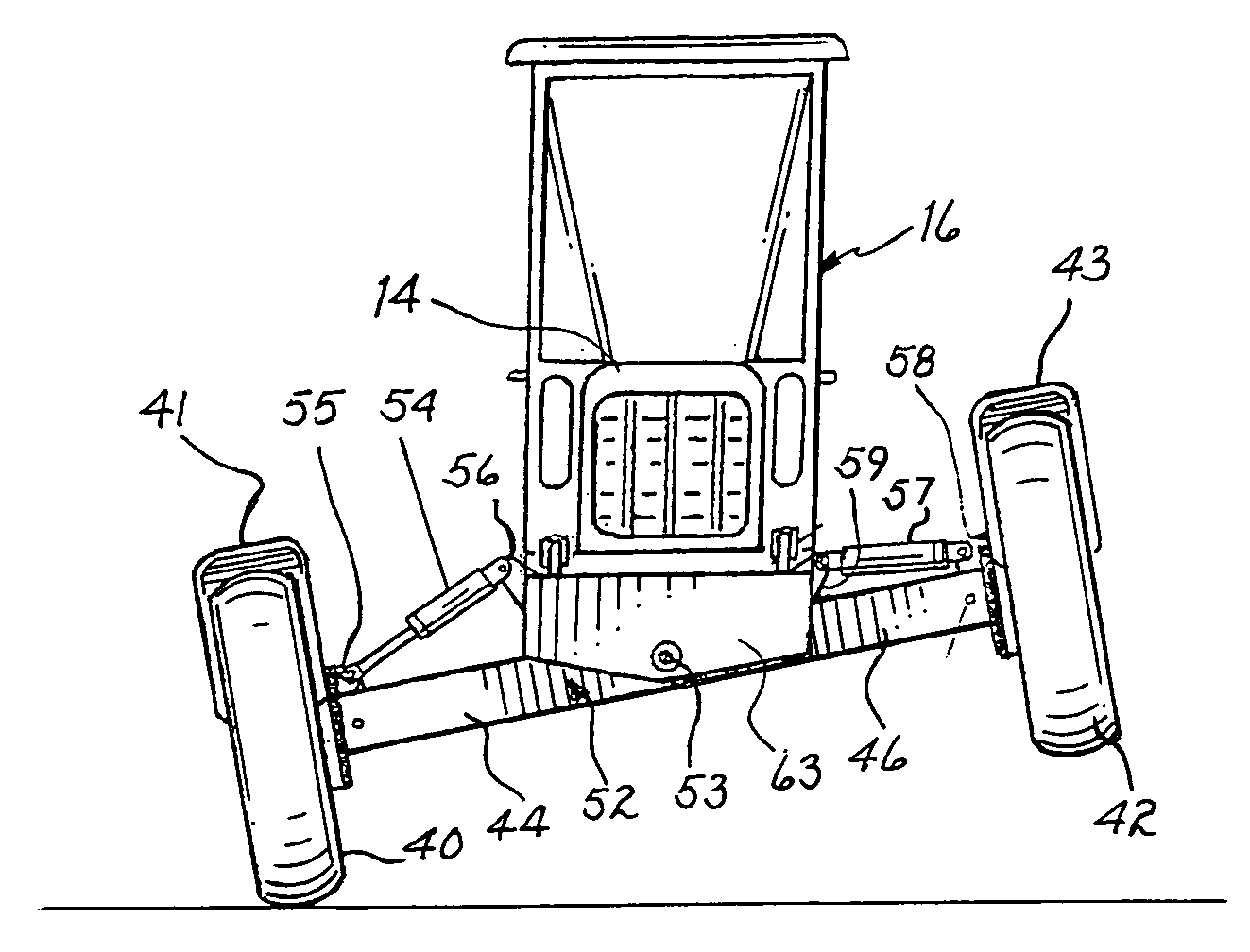

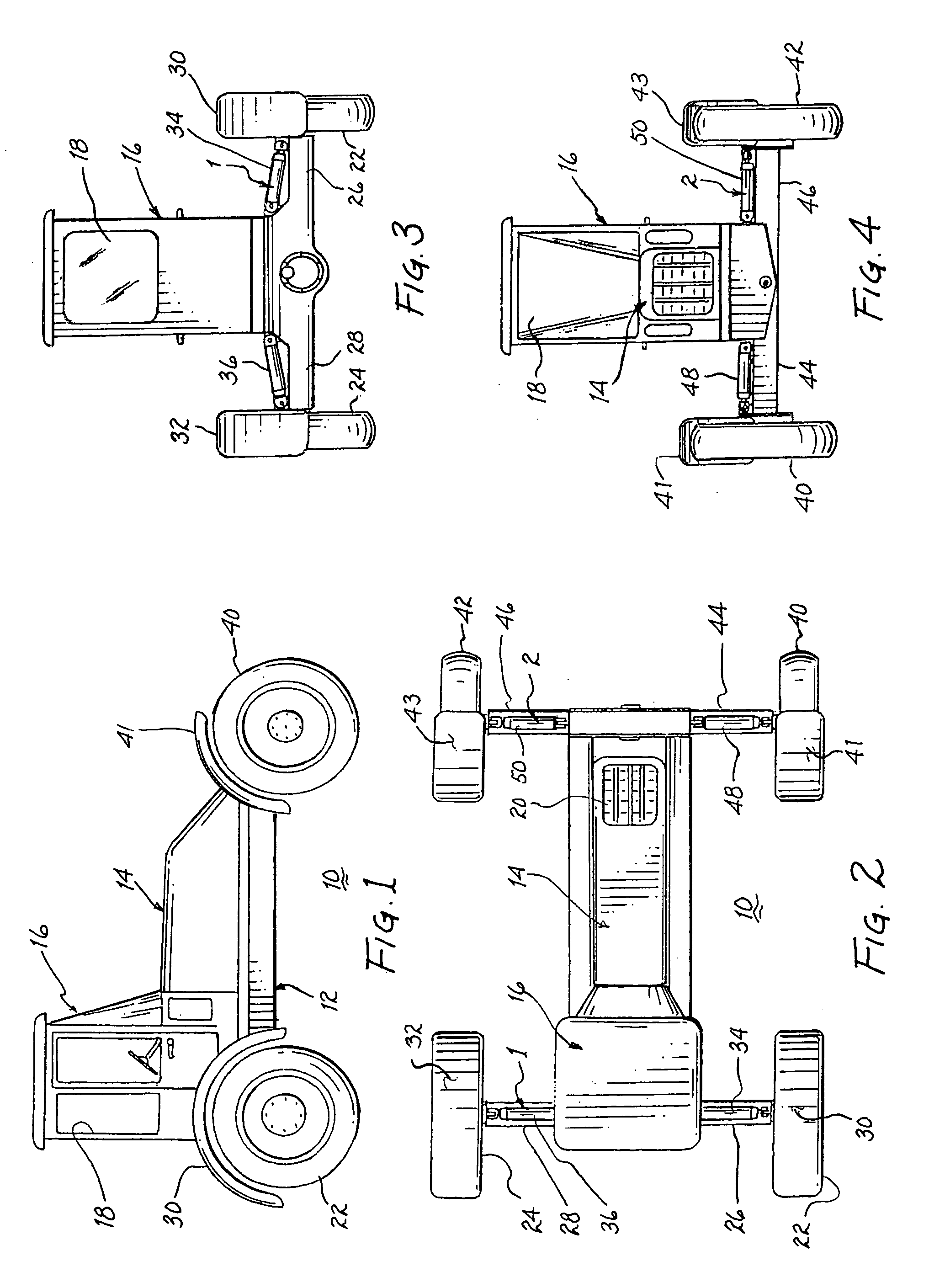

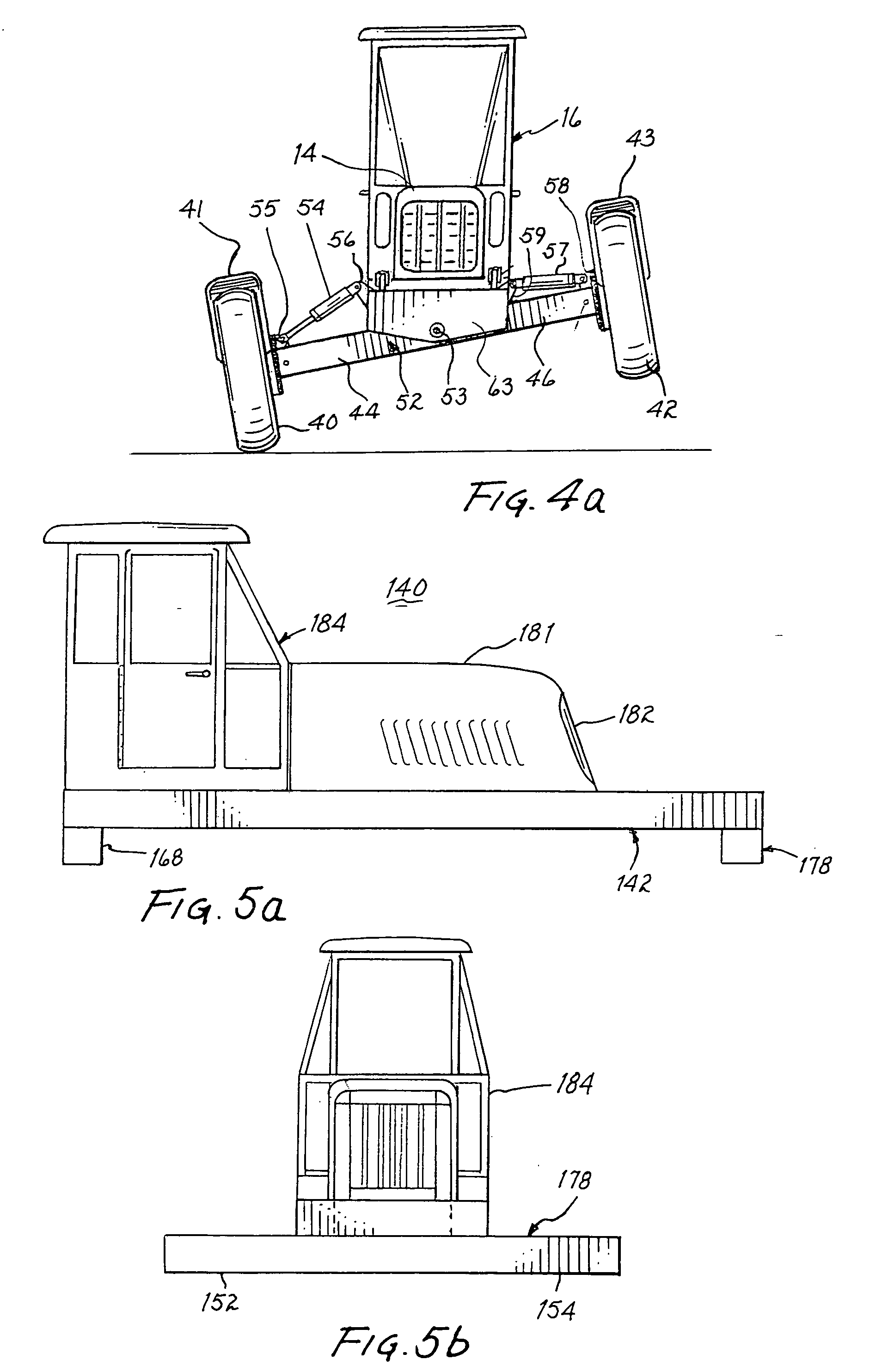

Multi-configurable tractor

InactiveUS20050189730A1Great distanceTotal lengthCarriage/perambulator accessoriesVehicle body-frame connectionsDrive shaftCentre of rotation

A tractor includes a motor, transmission, drive shaft and rear differential for driving the rear axles mounted on a main tubular frame of a variable configuration. Forwardly extendable telescoping tubular frame members are actuated by respective rams to selectively increase the wheel base between the front and rear wheels. The front and rear telescoping tubes supporting each of the wheels are selectively extendable to significantly increase the wheel width of the tractor; the axles for the rear wheels are commensurately extendable. A toolbar dependingly supported from the main frame in front of the cab permits the operator to view the operation of attached implements while driving. The toolbar may include a row guide causing the toolbar to move laterally as necessary to follow a row and the toolbar is connected to the steering mechanism to control the direction of travel of the tractor. The front wheels are pivotally mounted on the corresponding telescoping tubes to provide sufficient clearance to permit near 180° pivotal movement. The steering mechanism is capable of pivoting each front wheel through an angle of about 180° and establishes an appropriate geometric relationship between the front wheels to permit the tractor to turn about any center of rotation intersected by the common axis of rotation of the rear axle, including pivoting about either rear wheel, while maintaining the axis of rotation of each front wheel in intercepting relationship with the center of rotation. Moreover, the turn radius at the end of a row is minimal and can be further reduced by temporarily reducing the length of the frame. Various implements, including a toolbar, can be readily attached directly to the tubular frame at any location intermediate the front and rear axles, as necessary.

Owner:WHITE TRUST THE DEBRA ARLENE GLAD

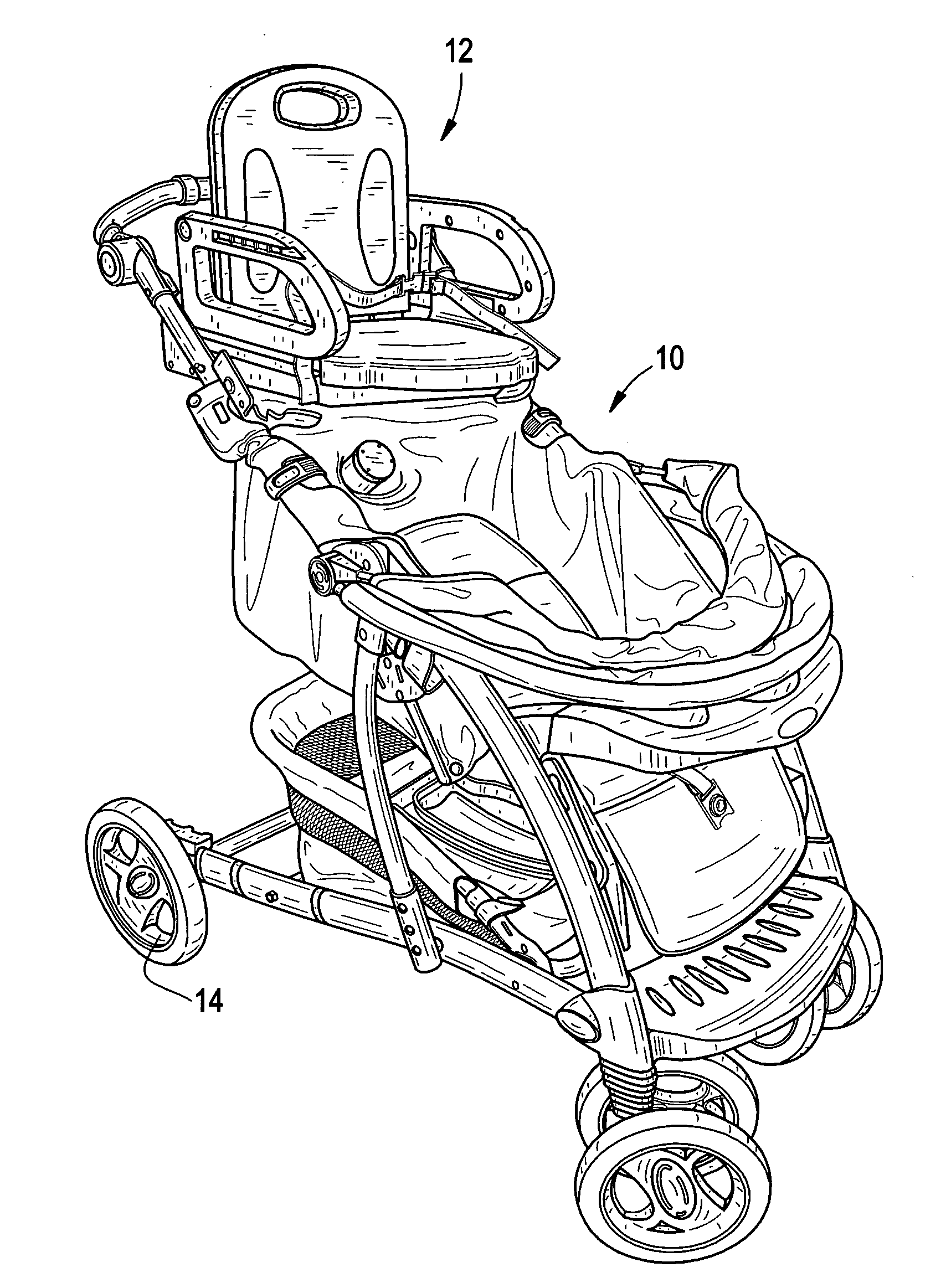

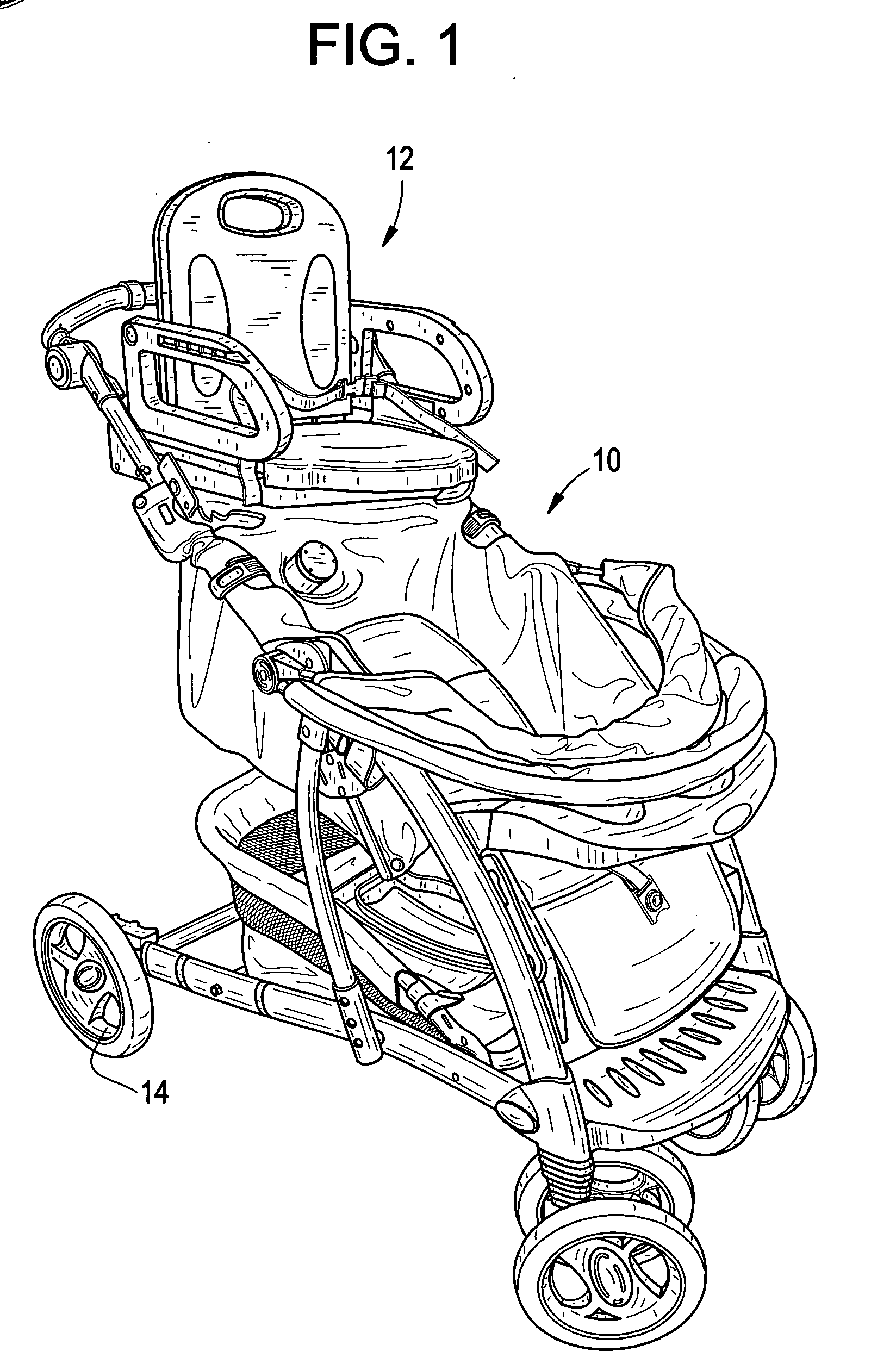

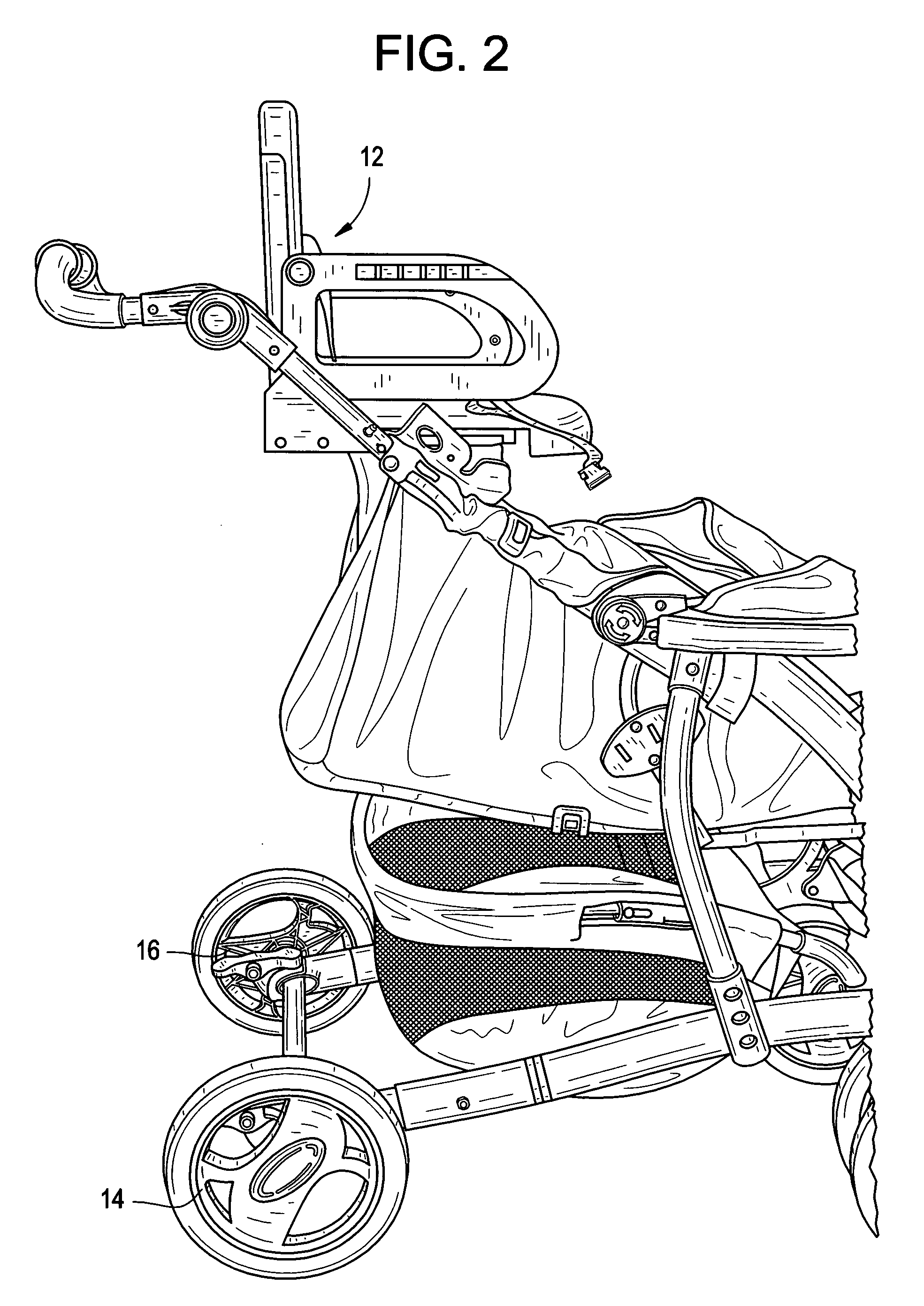

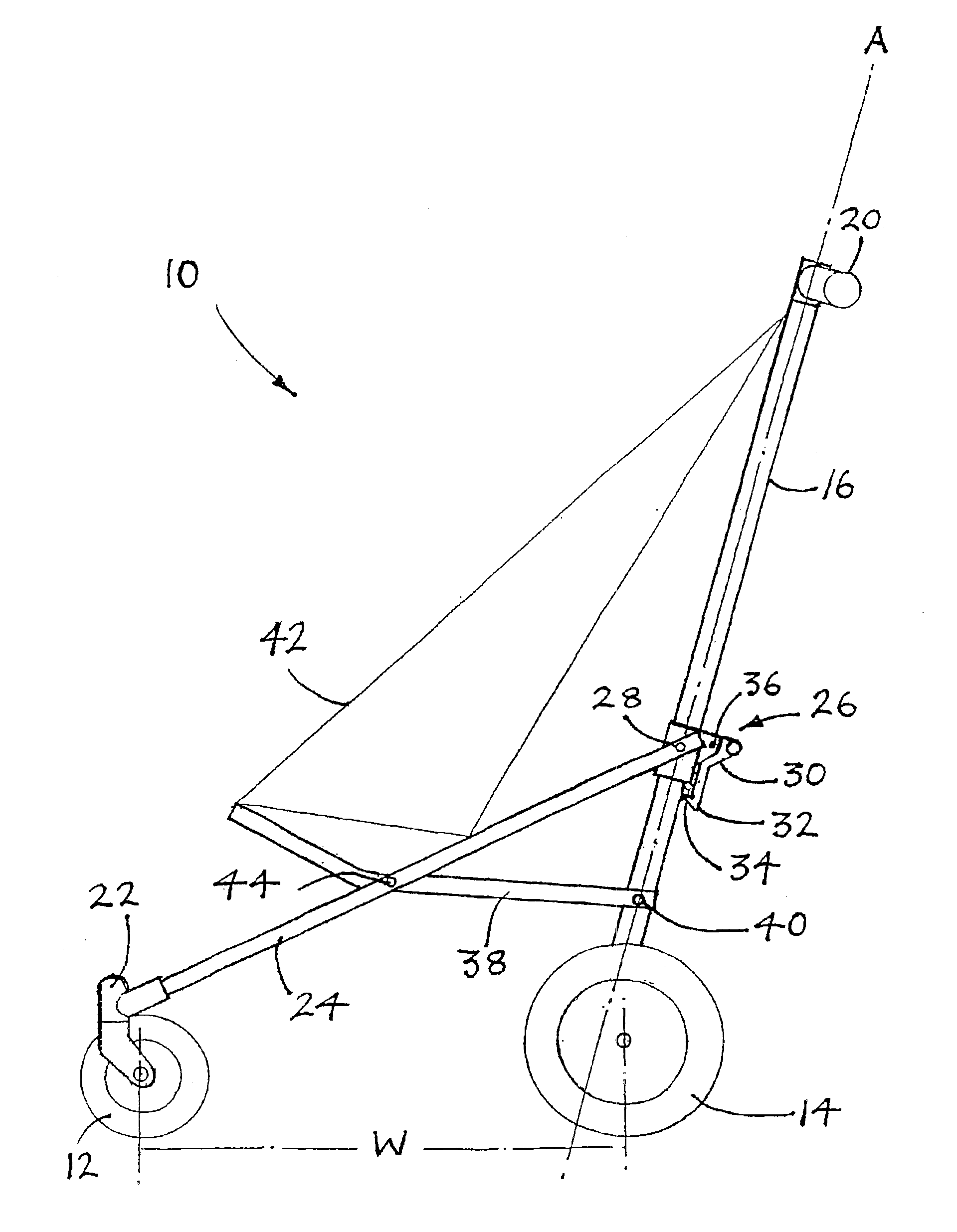

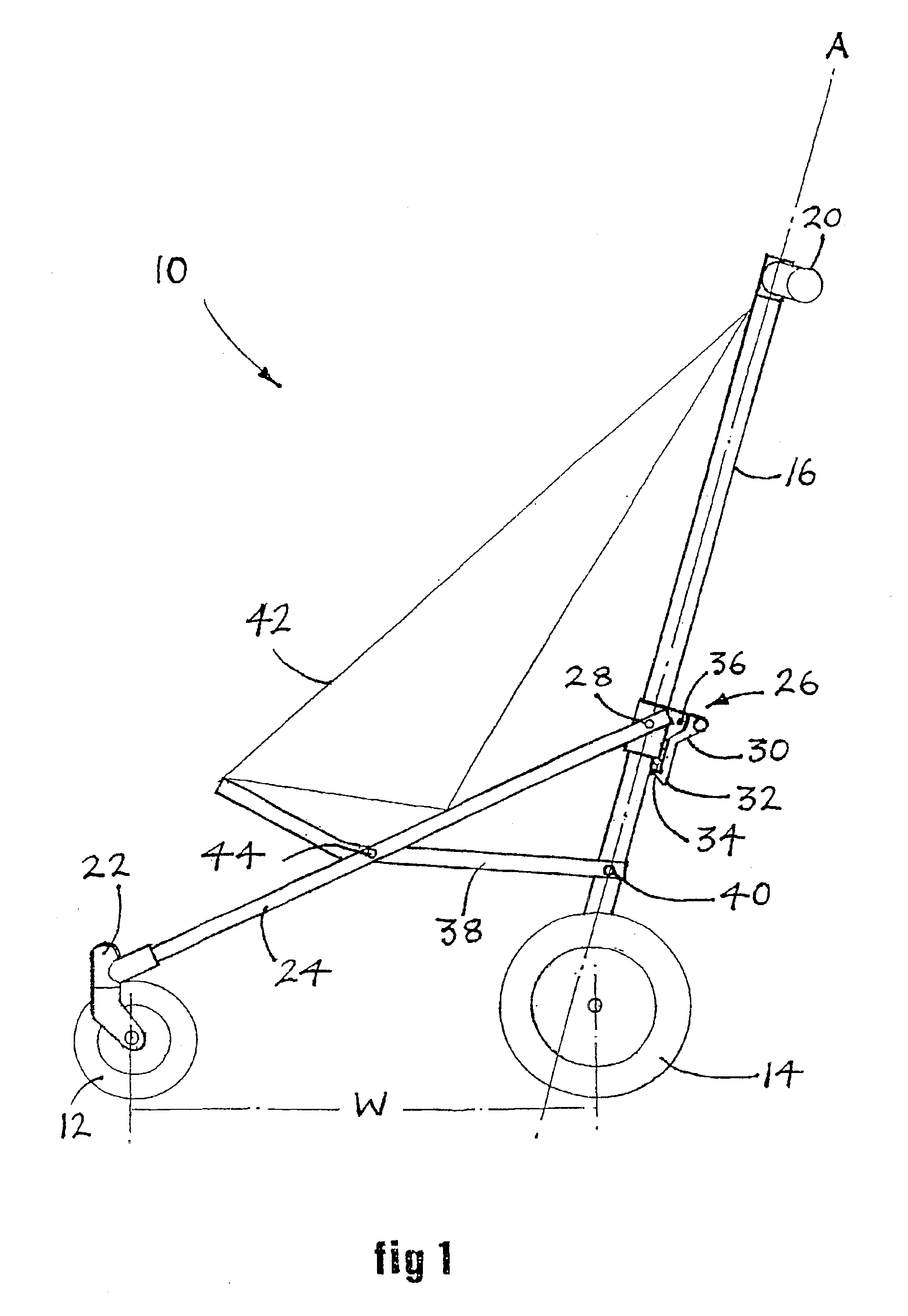

Child stroller construction

InactiveUS20070108710A1Eliminate shortcomingsGuaranteed smooth progressCarriage/perambulator accessoriesCaregiver personInstability

A child stroller is provided which obviates the shortcomings of the prior art by providing a safe and effective positioning site for an auxiliary seat, which seat is so positioned at the upper reaches of the stroller handle as to place the child in close interacting proximity to the parent or other caregiver. The optionally removable seat is reversible so that the child may face either forward or rearward. An extended wheelbase protects the stroller against instability and tipping when the seat is emplaced at the handle.

Owner:PENNISI RICKY C +1

Collapsible pushchair/carrier

A collapsible pushchair / carrier has wheels at the front and back. An upstanding spine extends between the rear wheels and handles. A lockable slider assembly can be moved up and down the spine. The front wheels are supported by wheel assemblies connected by pivotable support legs to the slider assembly. Beneath the slider assembly there are pivot joints linked to cranked support arms pivotably connected to the support legs. A foldable transverse strut extends between the front wheel assemblies. A seat is mounted to the ends of the arms remote from the pivot joints to the legs and the spine. The slider assembly can be moved between two operating positions. In one position, the pushchair is operative with the wheels defining a wheelbase between the front and rear wheels and front and rear wheel tracks between the front and rear wheels respectively. In the other position the pushchair is stowed and collapsed with the legs and arms alongside the spine and the front wheels within the rear wheel track. The now folded strut rests on a floor surface to support the stowed pushchair in an upstanding position. In moving between the stowed and operative positions the front wheel assemblies splay outwardly.

Owner:MICRALITE IP LTD

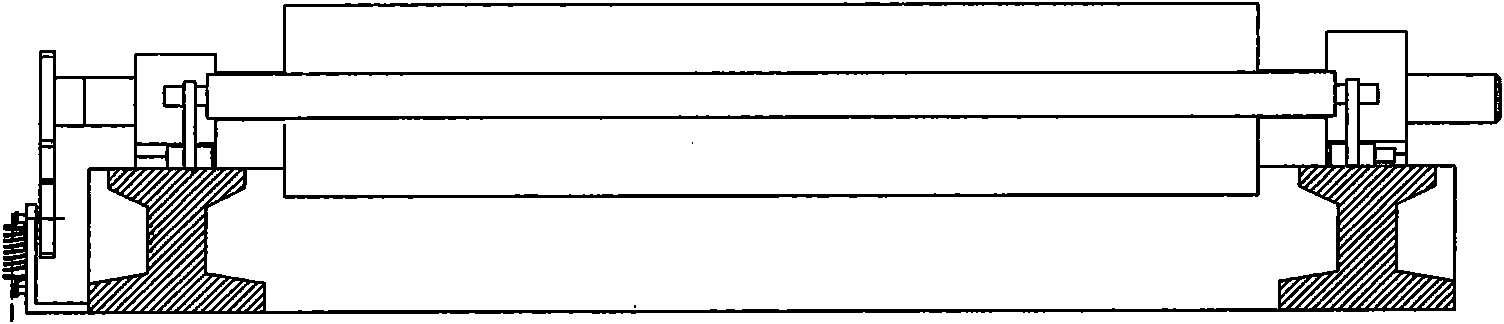

Adjustable-axle distance roller device

InactiveCN101886981AEasy to drive outRealize automatic adjustmentWork measurementTesting/calibration of speed/acceleration/shock measurement devicesAdhesion coefficientDistance detection

The invention discloses an adjustable-axle distance roller device, which comprises a machine frame, a primary roller, a secondary roller, a tire diameter detection device, a roller axle-distance detection and regulation device, a transmission device and a tensioning mechanism. When the device is used, vehicle detection equipment, such as braking detection platforms, chassis dynamometers and speedometer calibration consoles, can realize the automatic adjustment of the axle distance of rollers, the requirements for the longitudinal positioning of tires of different diameters and the adjustment of an adhesive force in a detection process are met, the detection accuracy and efficiency are improved, and the range of vehicles detected is enlarged; a wheel lifting mechanism is not required to be arranged between the primary and secondary rollers; and the adhesive force can be regulated by changing the sum of the supporting forces applied by the rollers onto the wheels in a normal direction so as to realize the simulation of different adhesion coefficients.

Owner:SHANDONG JIAOTONG UNIV

Dual Mode Wheelchair

InactiveUS20080054596A1Reduce the possibilitySmall distanceCarriage/perambulator accessoriesWheelchairs/patient conveyanceTravel modeWheelchair

A dual mode wheelchair (300) providing both a manoeuvrable indoor mode and a travel mode. The wheelchair (300) comprises fore wheels (104) mounted on a fore axis (105) and rear wheels (102) mounted on a rear axis (103). A distance between the fore axis (105) and the rear axis (103) defines a wheelbase of the wheelchair (300). The wheelbase is alterable between a short wheelbase providing a manoeuvrable mode of the wheelchair (300) and a long wheelbase providing a travel mode of the wheelchair (300). The wheelchair (300) further provides a lowered centre of gravity and a reclining position in the travel mode to provide improved stability and occupant security.

Owner:JOHANSON NOMINEES

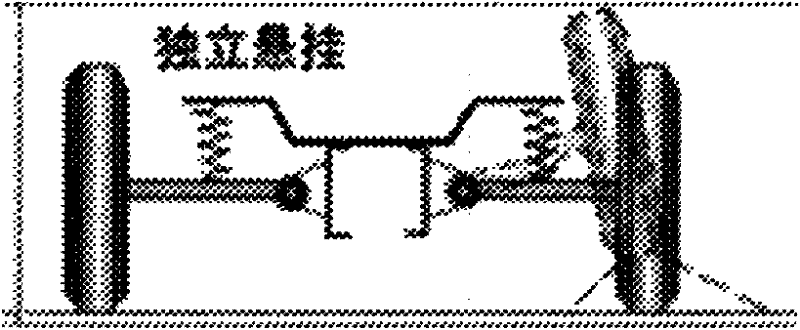

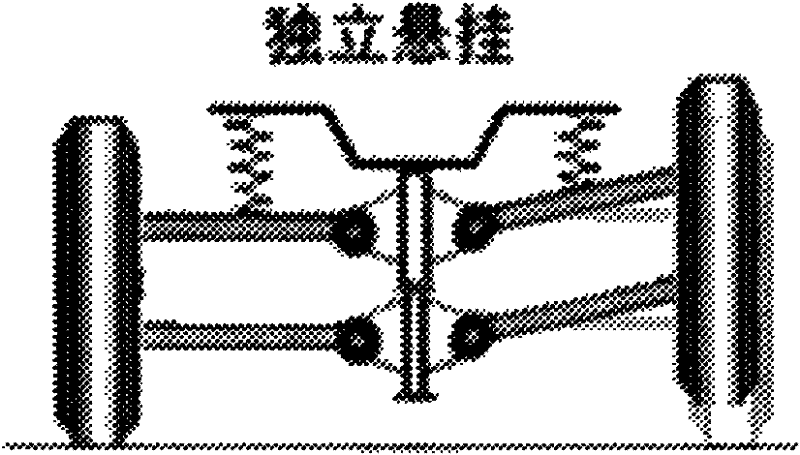

Self compensation floating swing arm independent suspension system

ActiveCN102363408AIdeal handlingIdealized securityInterconnection systemsResilient suspensionsAnti-roll barCamber angle

The invention provides a self compensation floating swing arm independent suspension system, comprising a self compensation floating swing arm independent suspension device and a centrifugal force control scissors-type anti-roll bar device. The two mechanisms can be used in combination or independently and are applicable to both front wheels and rear wheels. The self compensation floating swing arm independent suspension system guarantees that wheels perform line bounce along a vertical direction of a car body on various kinds of road surfaces when a car runs at a low speed or at a high speed or makes turns and guarantees maximum contact area between the wheels and the road surfaces, with the parameters of king pin angle, toe-in angle, camber angle, wheel track, and axle base being maintained the same as original parameters; and, when the car makes turns, the centrifugal force control scissors-type anti-roll bar device works automatically, offsets a roll force with a force equal to the roll force in magnitude and opposite to the roll force in direction, and enables the car body to lower automatically, thereby improving anti-roll capacity and realizing idealization of controllability, safety, stability and comfort of the car. The self compensation floating swing arm independent suspension system has a simple structure, excellent performance, and low cost, and is easy to realize.

Owner:侯贺

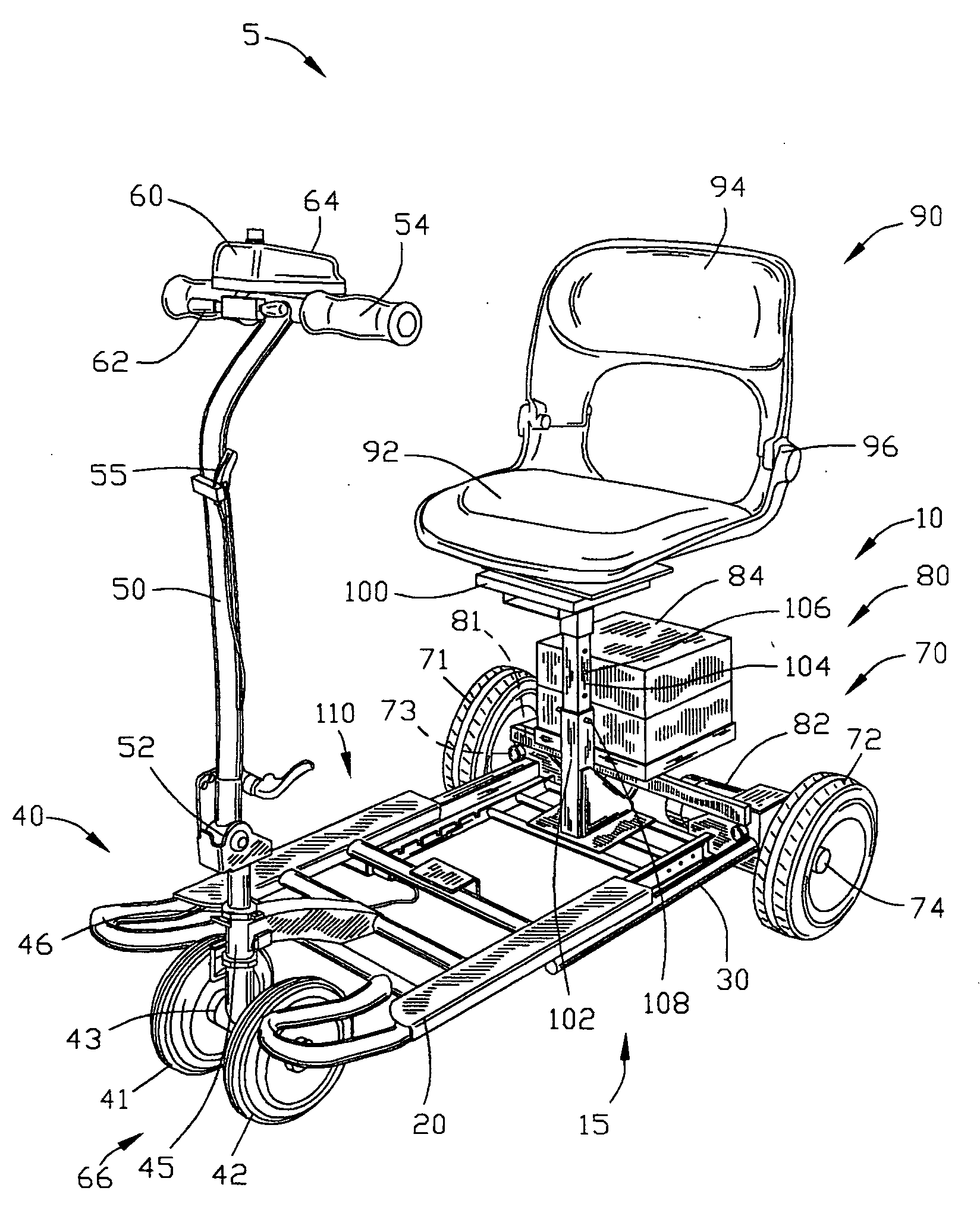

Vehicle with improved turning

InactiveUS20050151334A1Shorten speedIncreased turnCyclesCarriage/perambulator with multiple axesDrive wheelElectric machinery

A vehicle is disclosed having a reduced turning radius comprising a directional wheel assembly for turning the vehicle and a drive wheel assembly for driving the vehicle. The drive wheel assembly has a first and a second drive wheel independently driven by a first and a second motor through a control circuit. A counter-rotation circuit counter-rotates the first and second drive wheels upon a major turning position of the directional wheel assembly to enhance the turning of the vehicle. A reducing circuit reduces the speed of the motors upon a minor turning position of the directional wheel assembly. The vehicle may include a slide mechanism for providing a reduced wheelbase to further reduce the turning radius of the vehicle. One embodiment of the invention includes an improved steering device for controlling the directional wheel assembly.

Owner:ELECTRIC MOBILITY

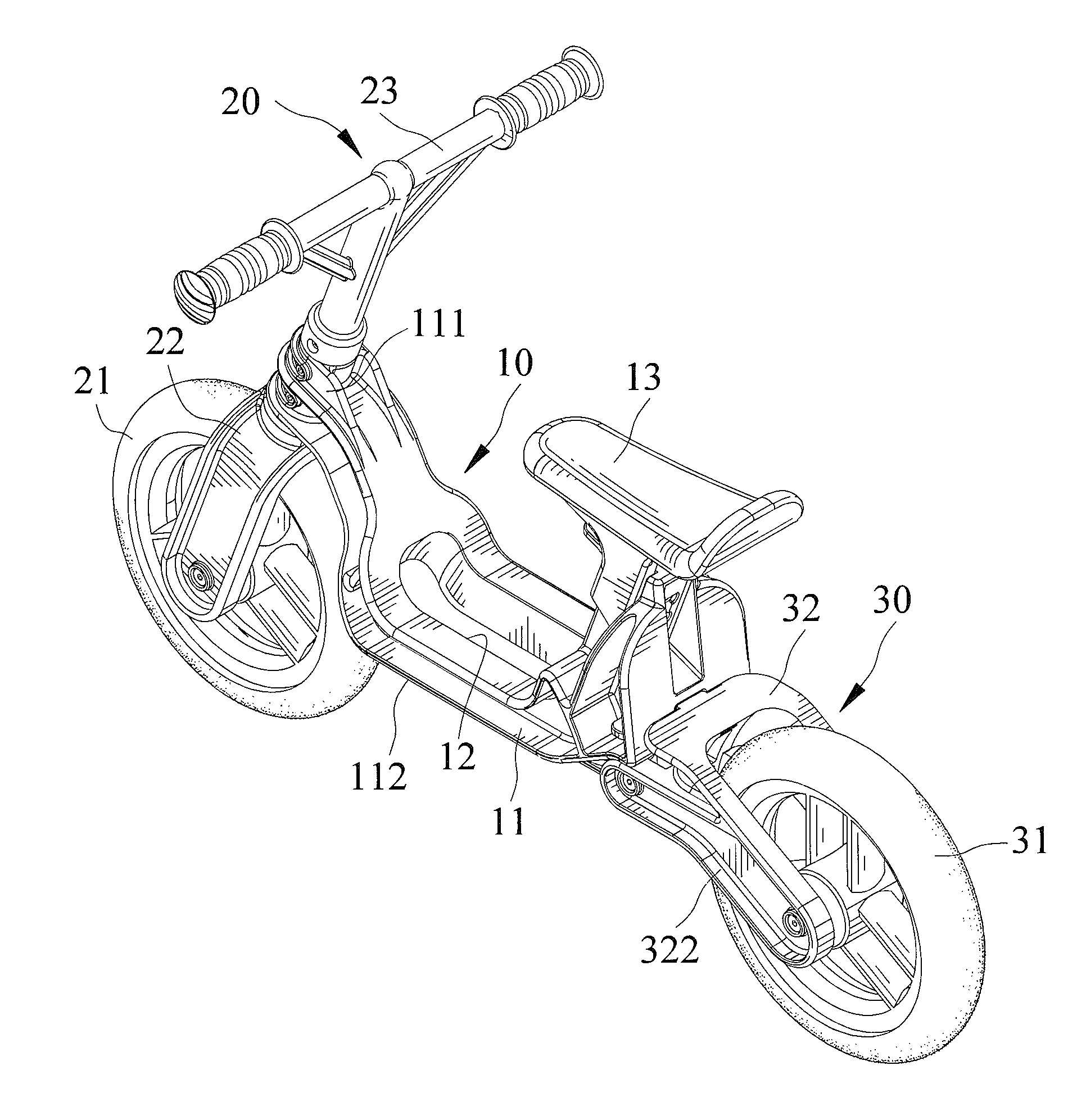

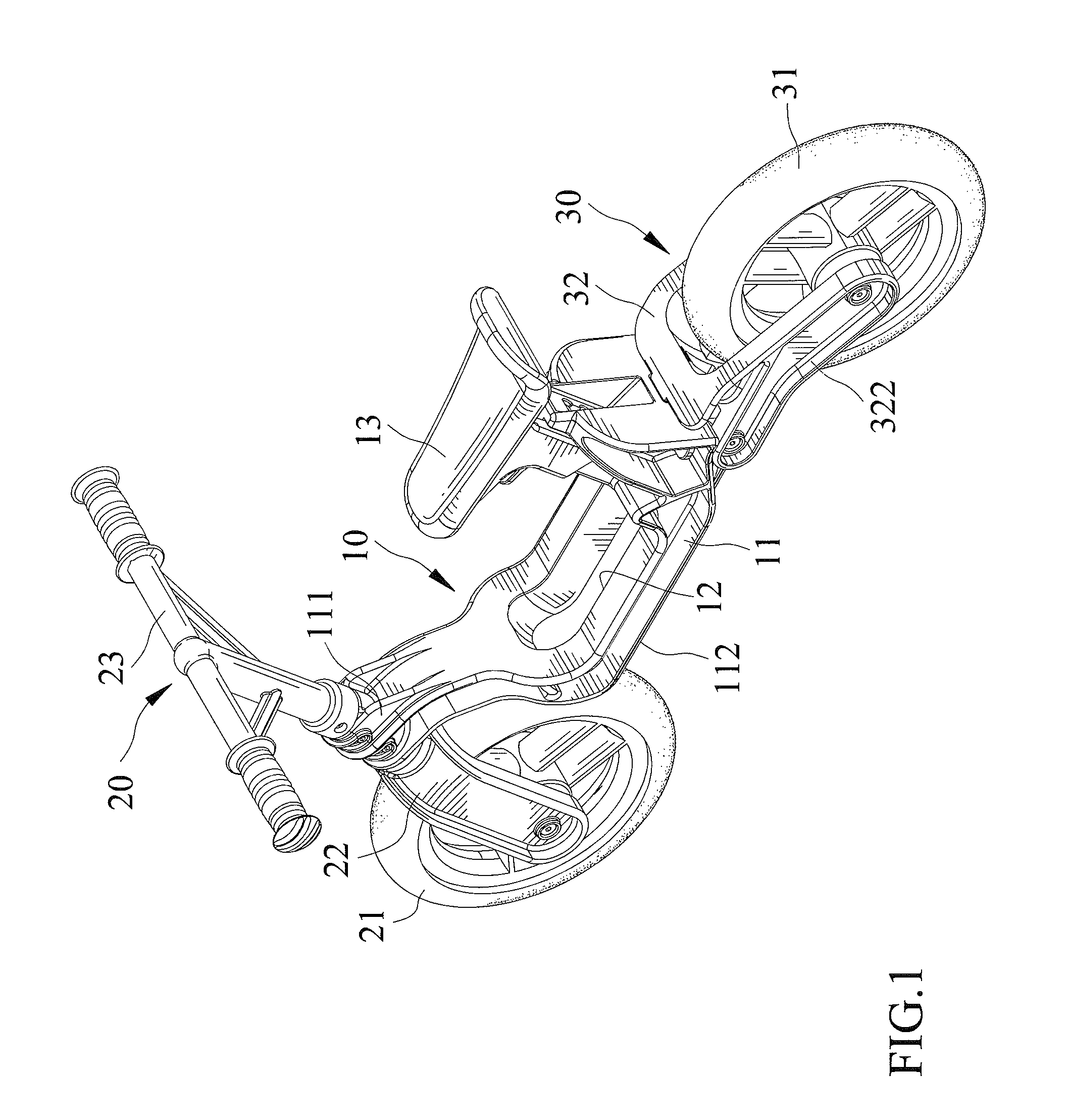

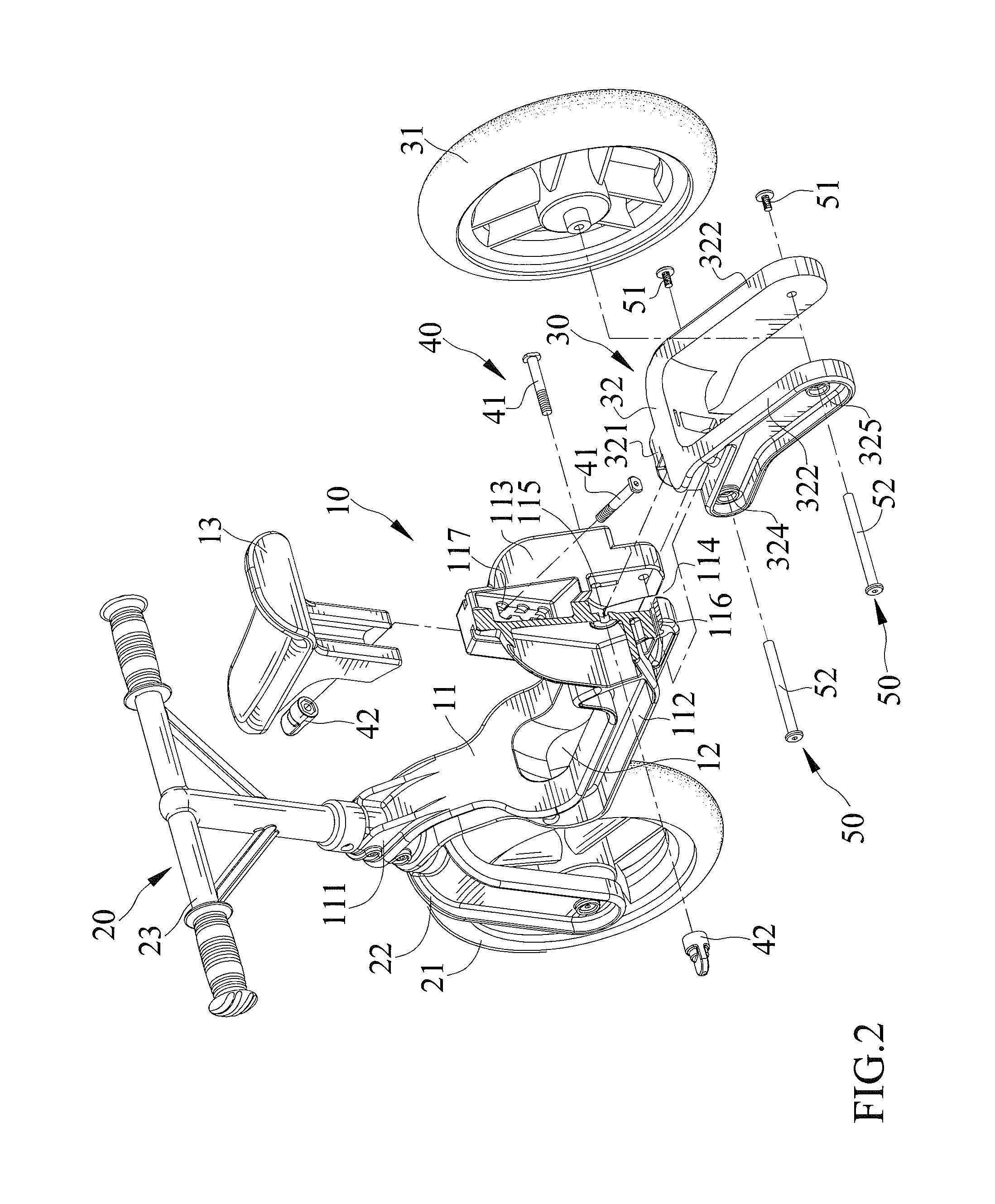

Folding balance bike

A folding balance bike includes a frame, a front wheel assembly pivotally mounted on one end of the frame, and a rear wheel assembly pivotally mounted on the other end of the frame opposite to the front wheel assembly. The front wheel assembly is pivotable with respect to the frame to steer the folding balance bike. The rear wheel assembly is pivotable with respect to and able to be received into the frame to adjust a wheelbase of the folding balance bike to cause the folding balance bike to be operable between an operative state and a stored state.

Owner:CHEN WANG CHUAN

Parametric chassis system for vehicles, comprising four suspension elements, incorporating a lateral torsion bar and co-axial damper unit, in a box-module, that allows central location of heavy items, such as batteries

ActiveUS20110109052A1Improve structural rigidityCost-effectiveUnderstructuresMotor depositionFuel cellsSelf adaptive

A chassis system and a suspension module for vehicles having wheel subsystems incorporates a lateral torsion bar and a co-axial enveloping damper unit, featuring active-adaptive suspension characteristics. Pre-fabricated suspension modules are situated inside respective box-structures, connected via wheelbase and track members, allowing the storage of heavy elements (e.g., batteries or fuel-cells) at the chassis. The robust and self-carrying chassis is enhanced, using upper body members, in terms of structural rigidity, for a given wheelbase, achieving high impact-energy absorbtion. The suspension arms incorporate upper and lower members, articulation, connect internally or externally to the suspension module, and transmit drive and brake forces to the wheels. The suspension module, box-structure, torsion-bar / damper unit, drive and transmission unit, suspension arm and steer module, featuring asymmetrical steer characteristics, can be reproduced on each corner of the chassis, featuring electronic control without mechanical connection (steer by wire), constituting the chassis of the vehicle.

Owner:HATZIKAKIDIS DIMITRIOS A

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com