Patents

Literature

427results about How to "Eliminate shortcomings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

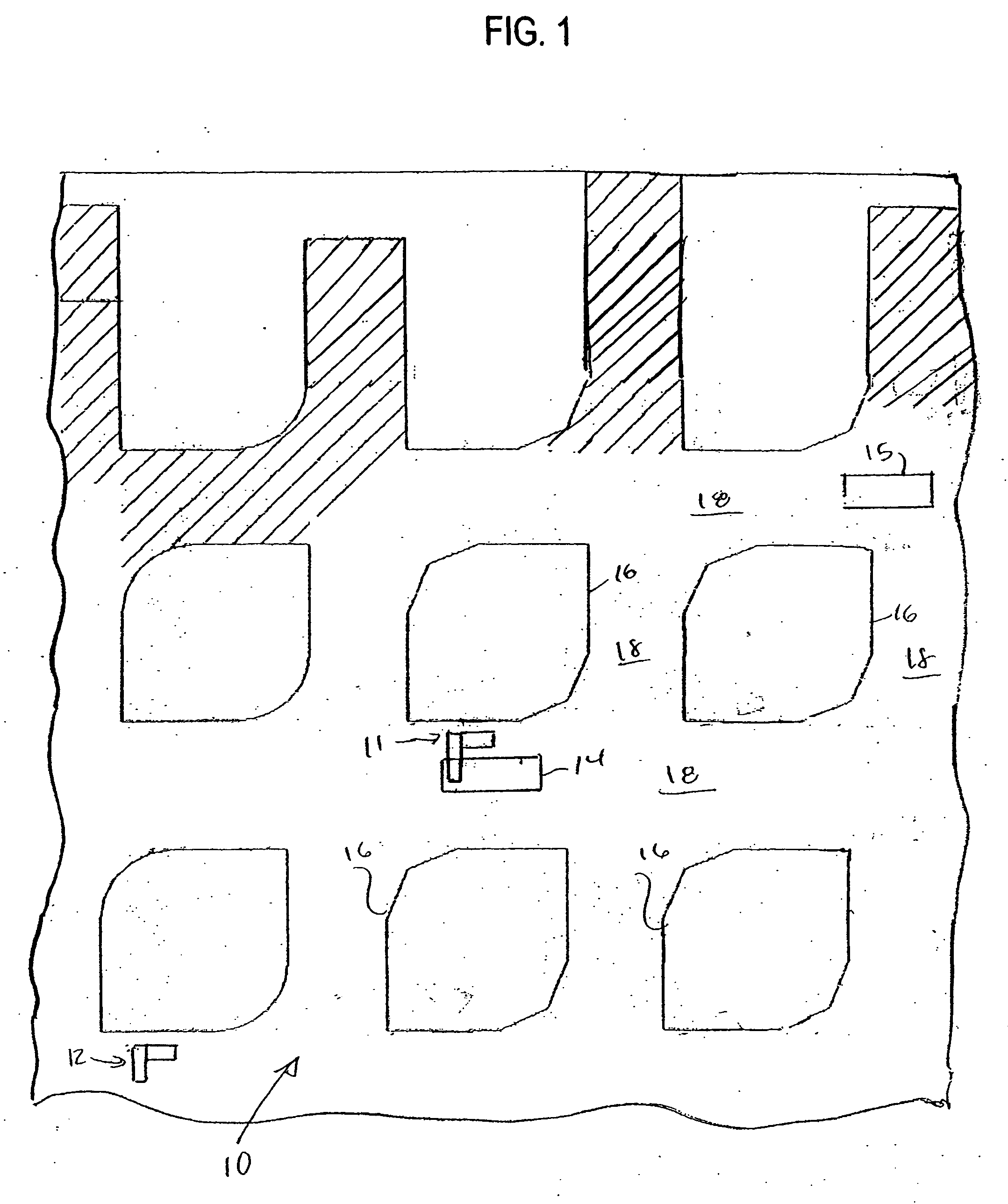

Seamless, maskless lithography system using spatial light modulator

InactiveUS6312134B1Eliminate needImprove processing throughputMirrorsPhotomechanical exposure apparatusRadiation DosagesSpatial light modulator

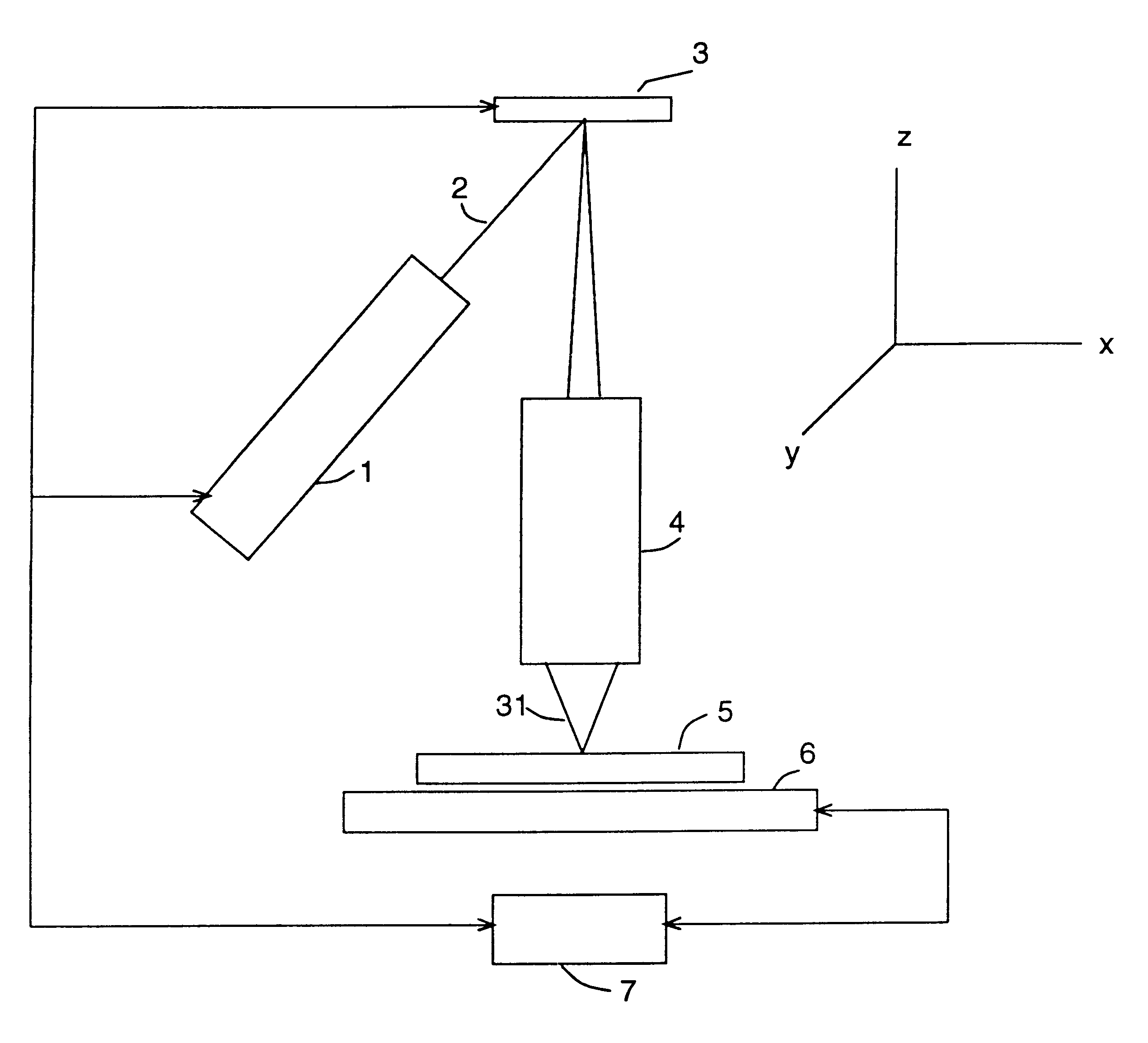

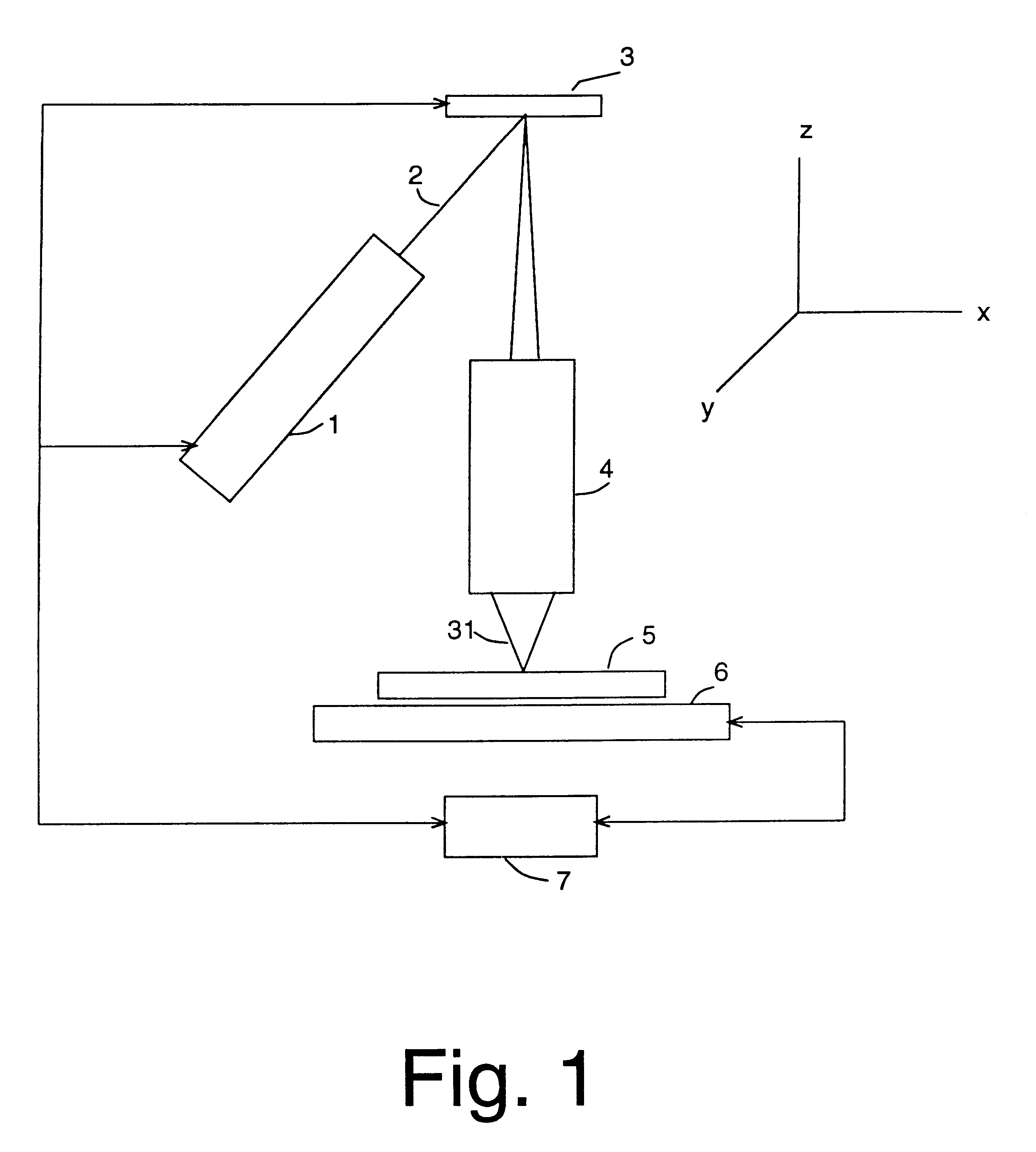

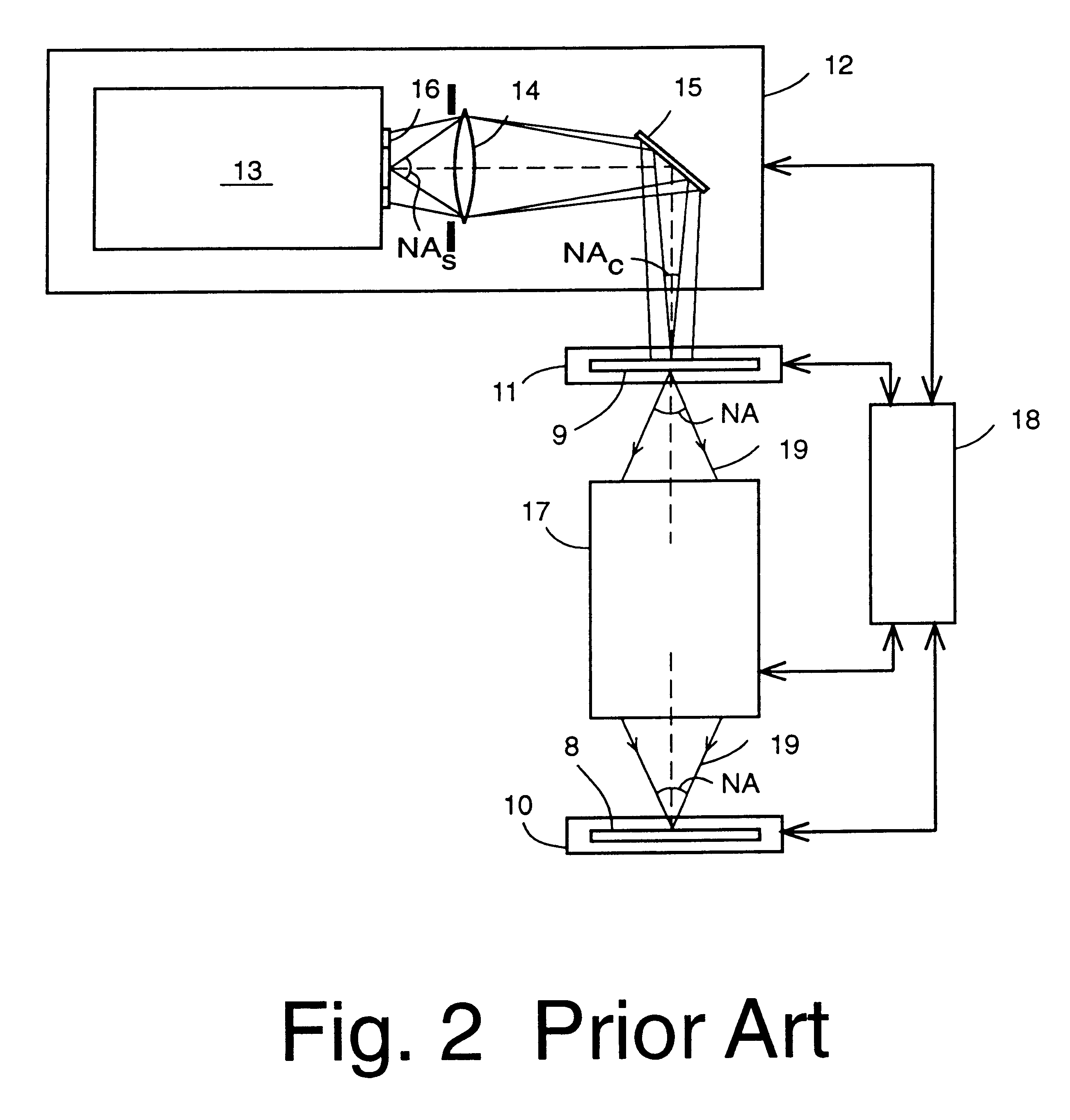

The invention is a seamless projection lithography system that eliminates the need for masks through the use of a programmable Spatial Light Modulator (SLM) with high parallel processing power. Illuminating the SLM with a radiation source (1), which while preferably a pulsed laser may be a shuttered lamp or multiple lasers with alternating synchronization, provides a patterning image of many pixels via a projection system (4) onto a substrate (5). The preferred SLM is a Deformable Micromirror Device (3) for reflective pixel selection using a synchronized pulse laser. An alternative SLM is a Liquid Crystal Light Valve (LCLV) (45) for pass-through pixel selection. Electronic programming enables pixel selection control for error correction of faulty pixel elements. Pixel selection control also provides for negative and positive imaging and for complementary overlapping polygon development for seamless uniform dosage. The invention provides seamless scanning by complementary overlapping scans to equalize radiation dosage, to expose a pattern on a large area substrate (5). The invention is suitable for rapid prototyping, flexible manufacturing, and even mask making.

Owner:ANVIK CORP

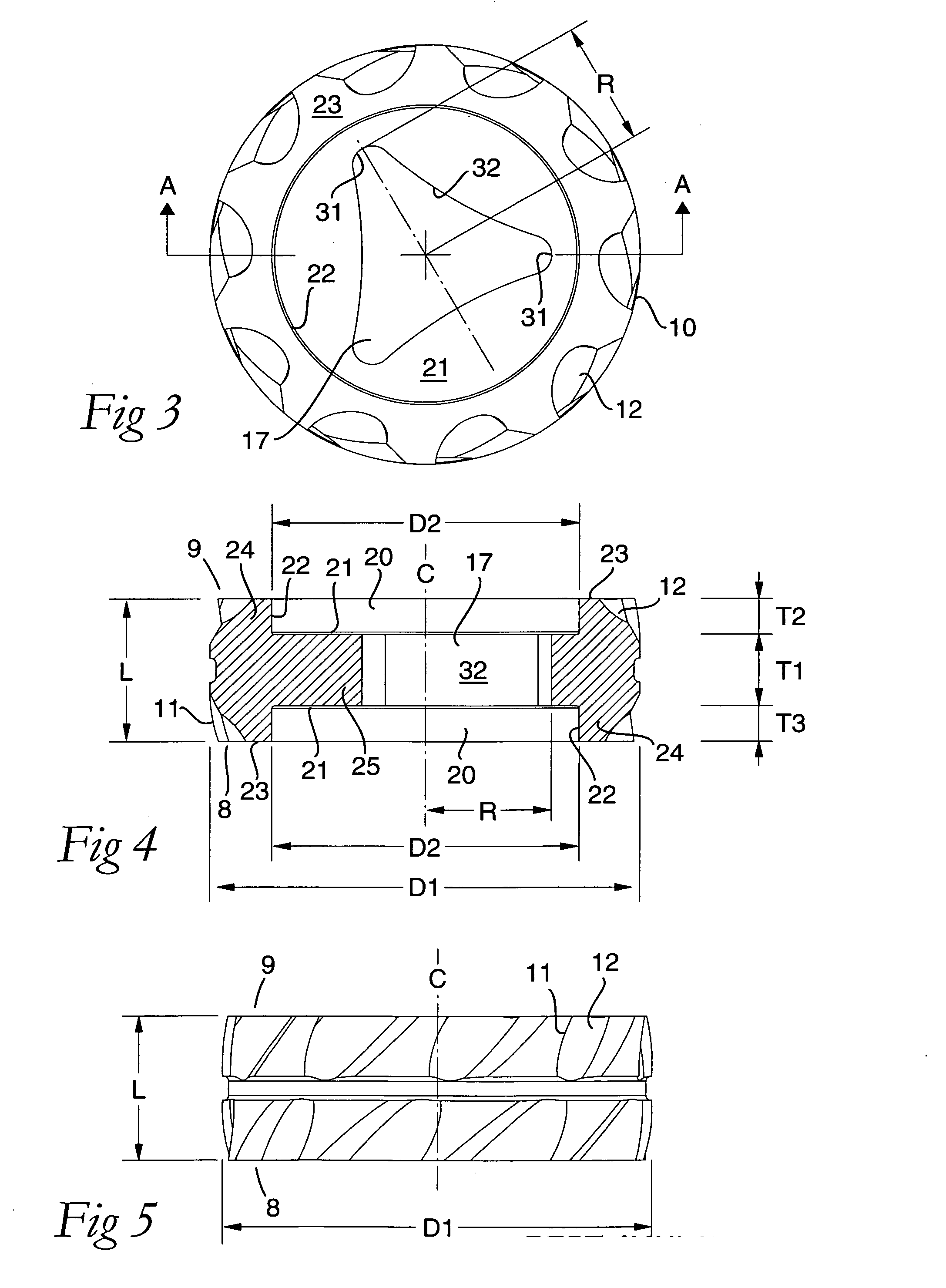

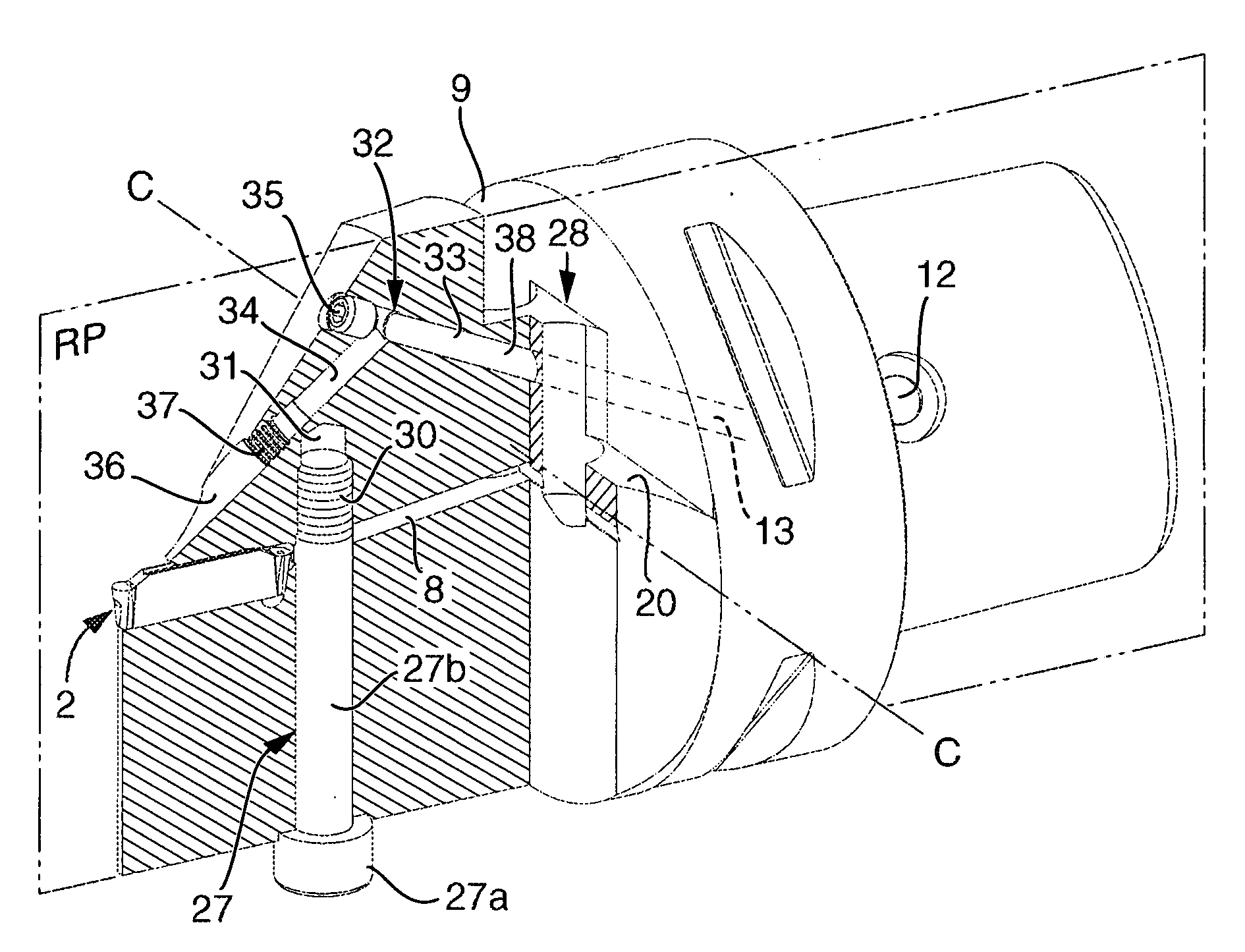

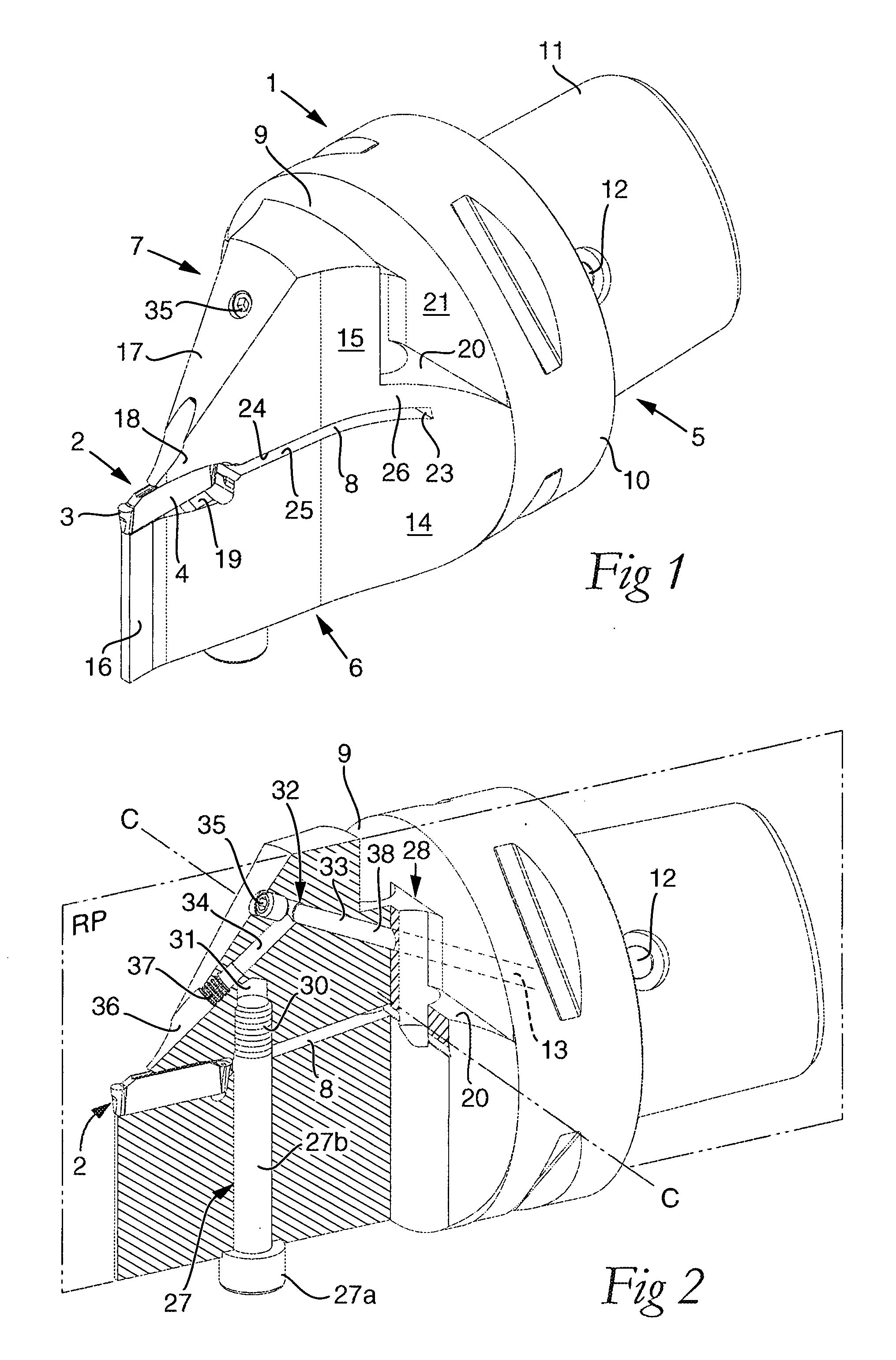

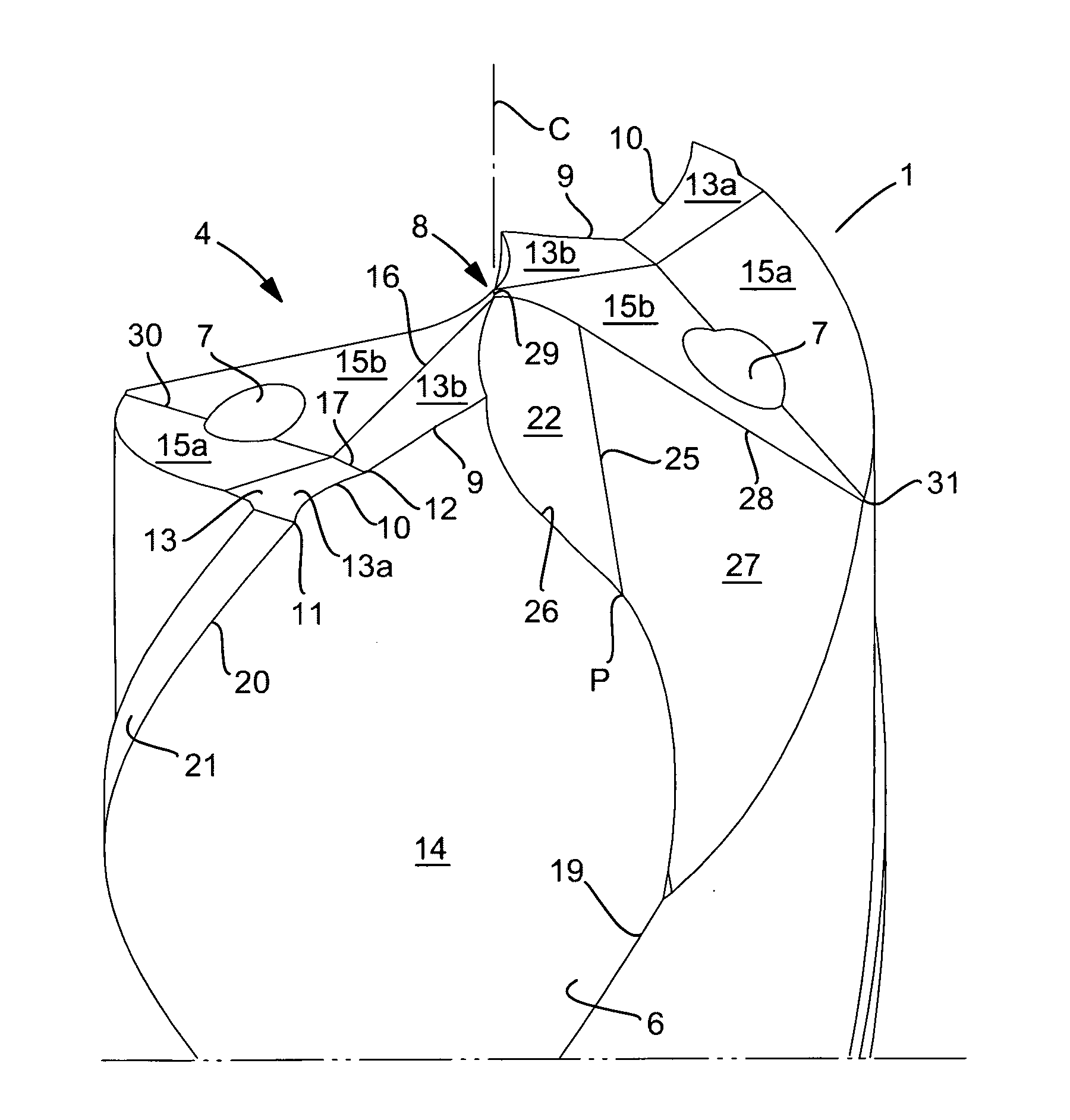

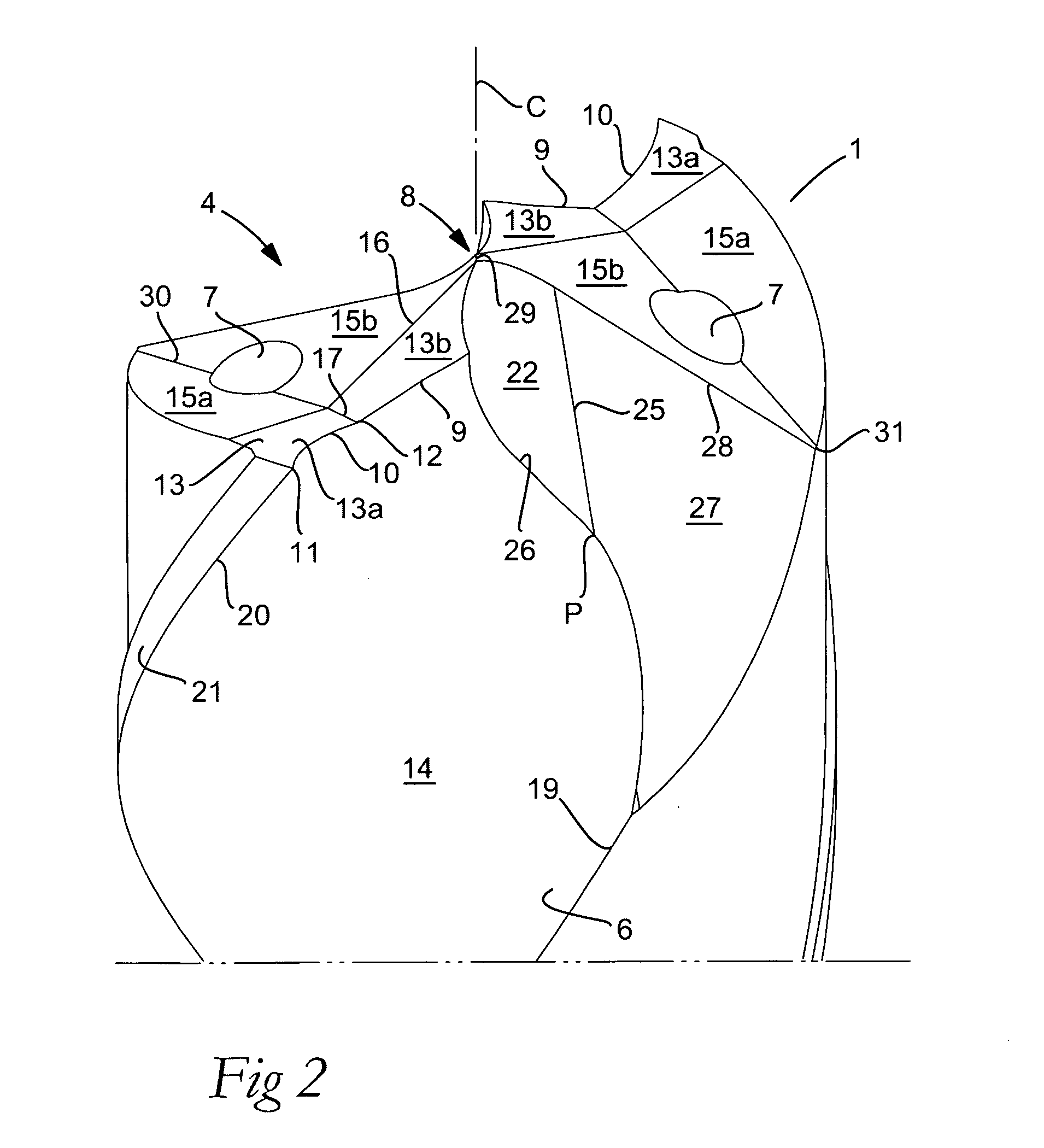

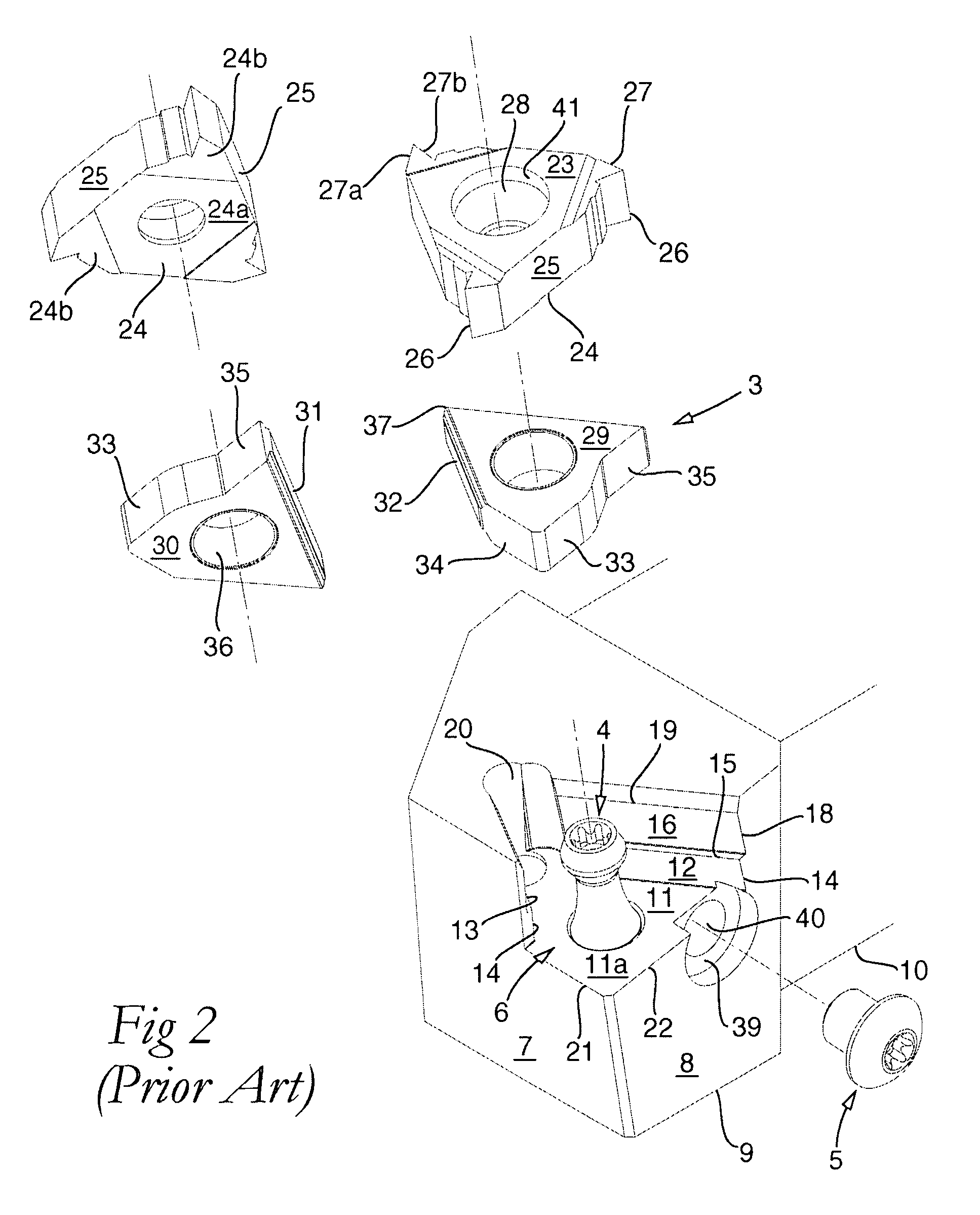

Tool for chip removing machining and having fluid-conducting branch ducts

InactiveUS6595727B2The effect is outstandingManufactured in simple and inexpensiveMilling cuttersTurning toolsEngineeringBranch Duct

Owner:SANDVIK INTELLECTUAL PROPERTY AB

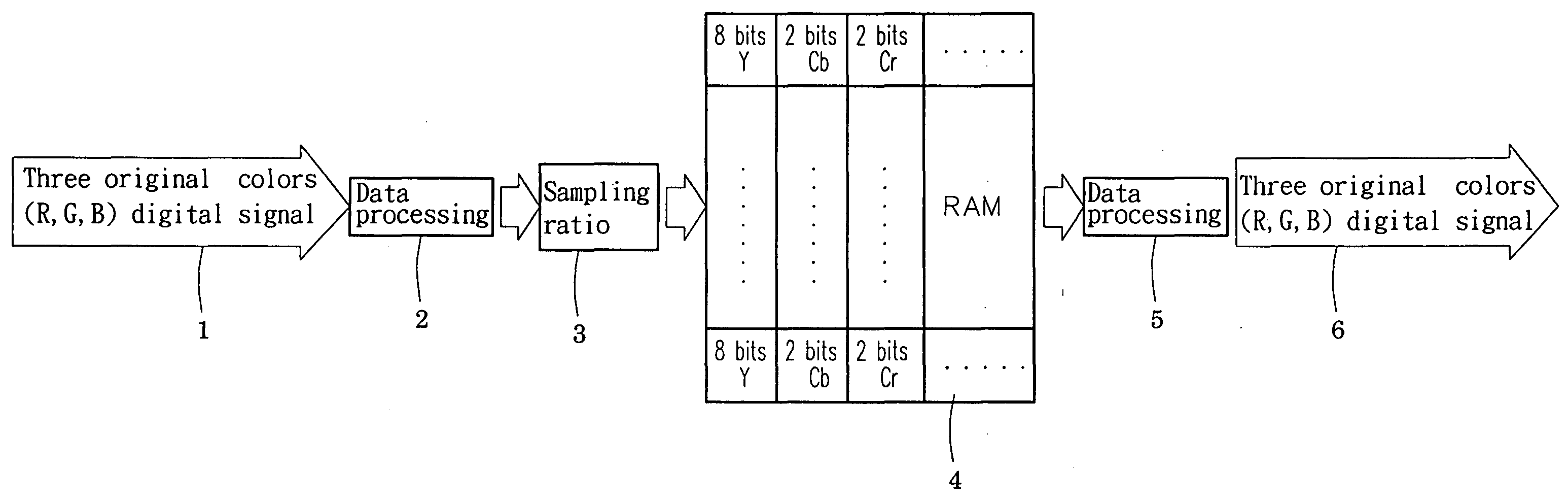

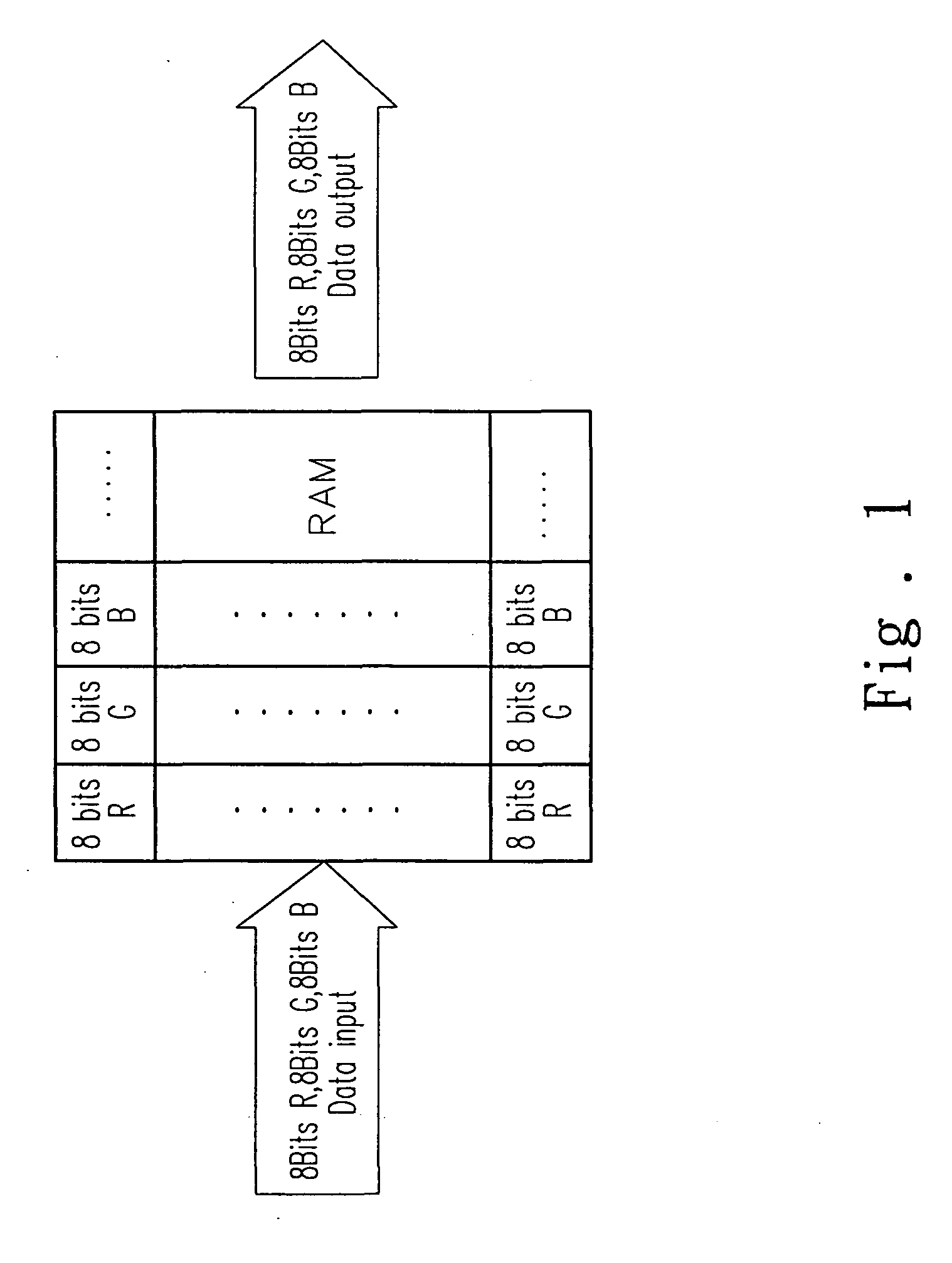

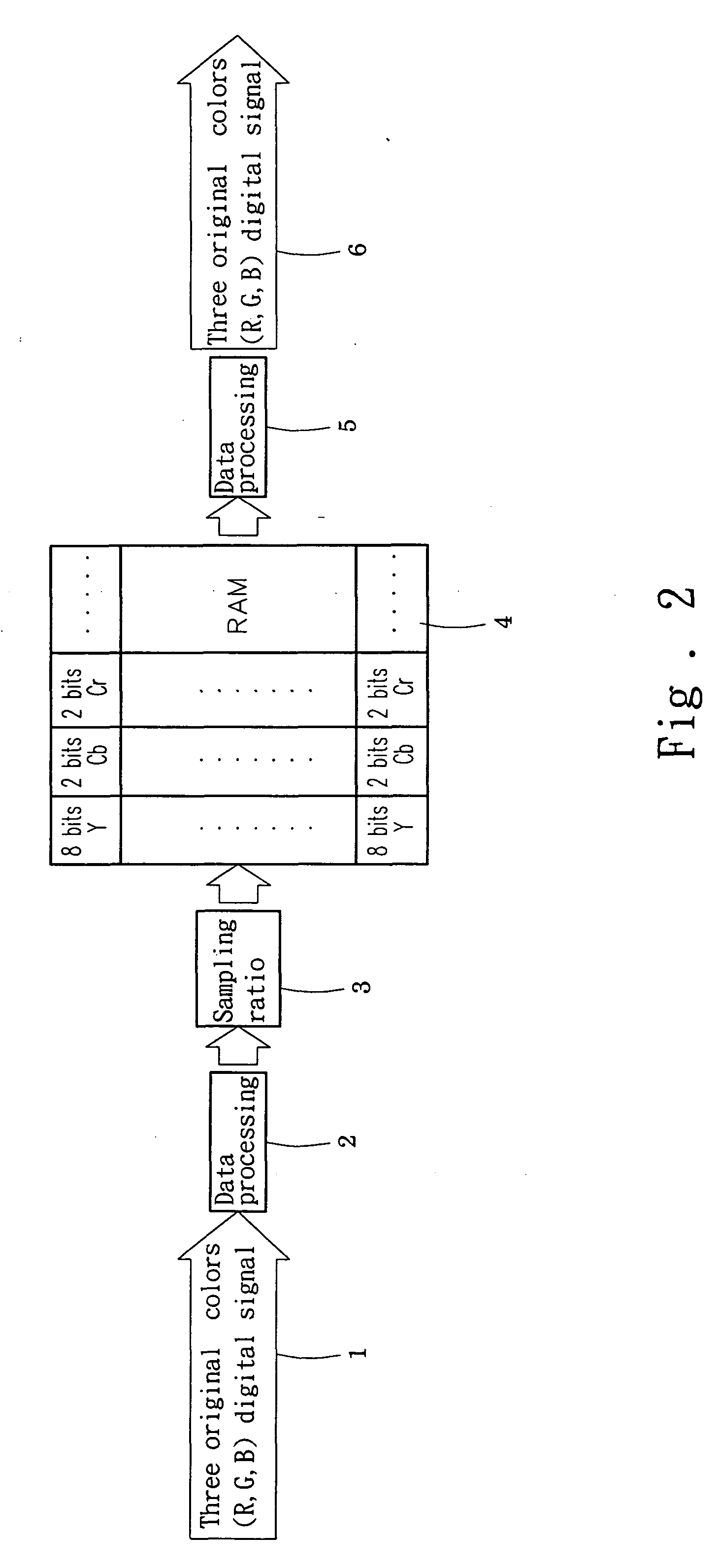

Method for reducing random access memory of IC in display devices

InactiveUS20050024380A1Eliminate shortcomingsReduce RAM spaceCathode-ray tube indicatorsGraphicsRandom access memory

A method for reducing random access memory (RAM) of an IC in display devices includes transforming a digital signal of a graphic data of three original colors (R, G, B) to digital signals of Y:Cb:Cr; taking one sample from two sample ratios of Y:Cb:Cr (4:2:0) or Y:Cb:Cr (4:2:2); storing in the RAM of a driving IC to reduce the RAM usage (with compressible data); then transforming the Y:Cb:Cr signals to three original colors (R, G, B) signal format to output image data, wherein Y represents brightness signal, and Cb and Cr represent color signals.

Owner:WINTEK CORP

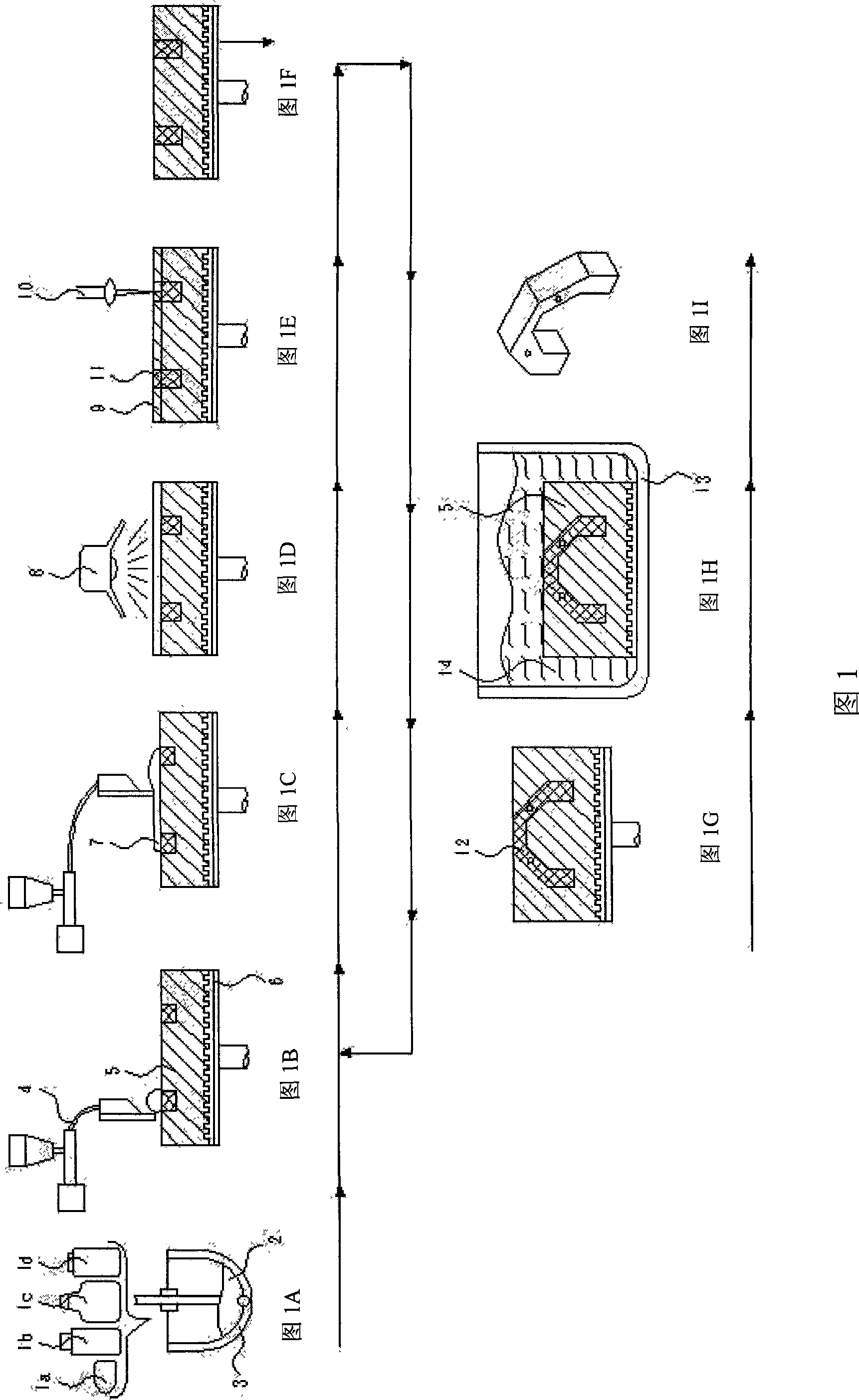

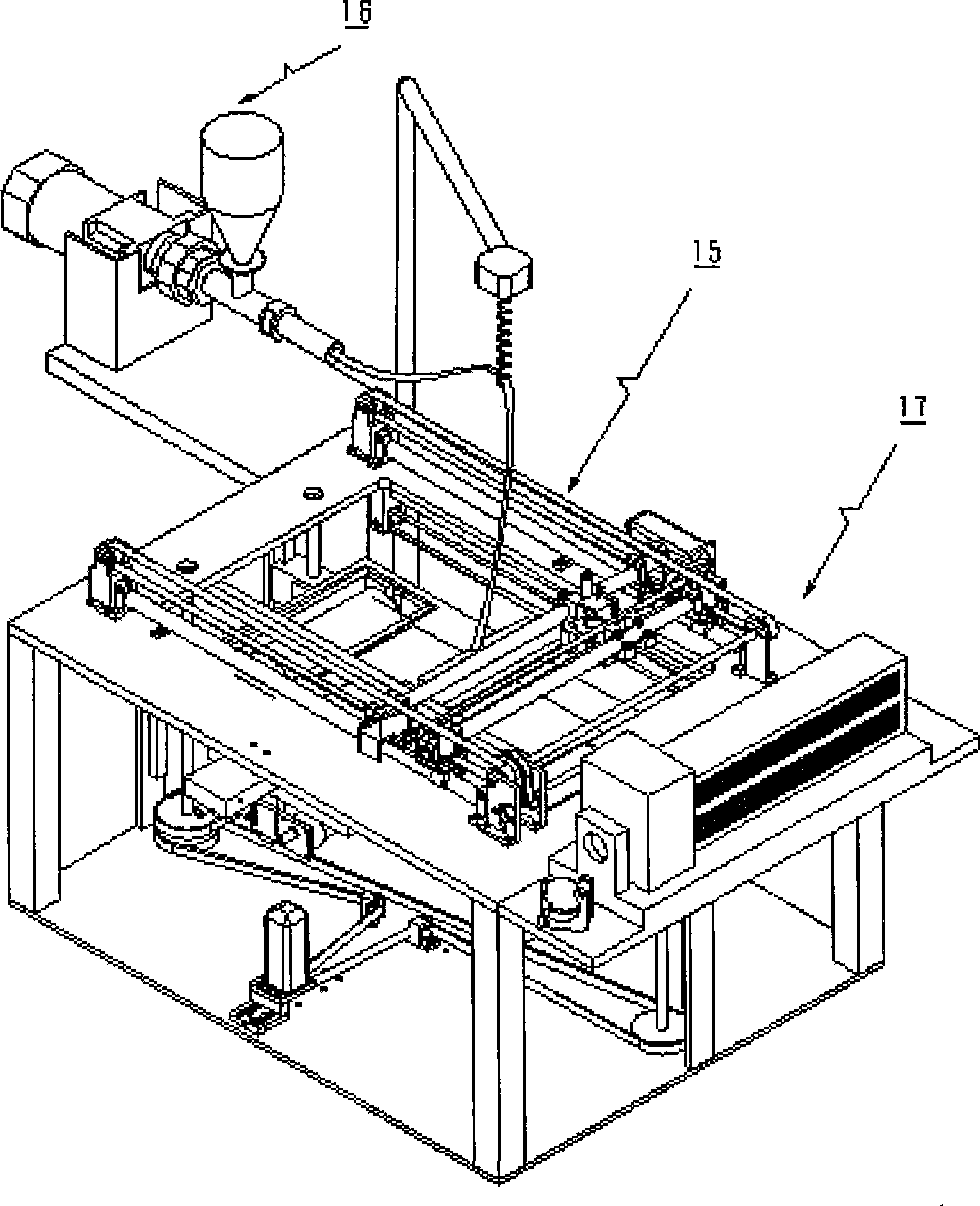

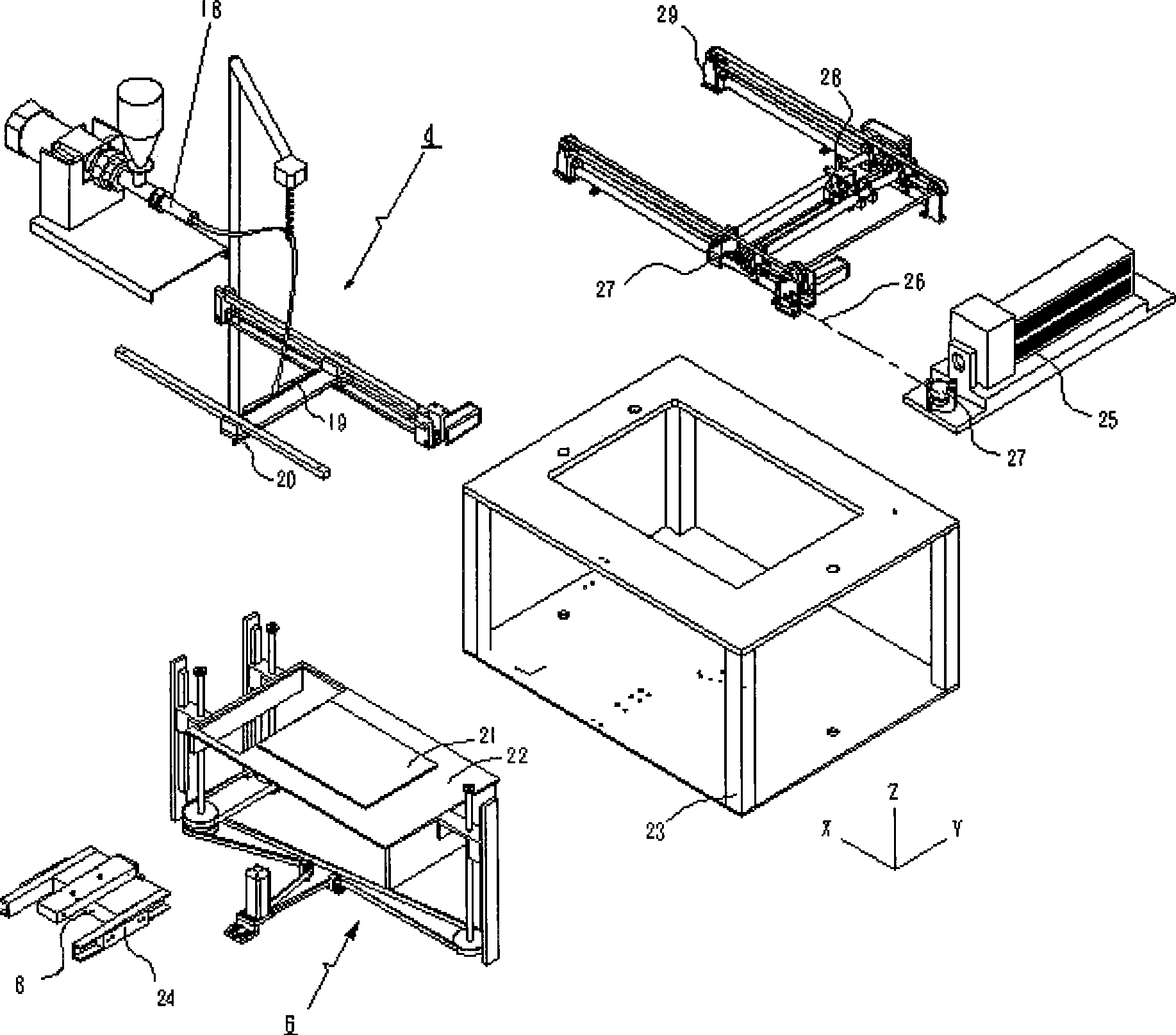

Manufacture method and device of three-dimensional workpiece

InactiveCN101422963AReduce the staircase effectHigh resolutionLiquid surface applicatorsIncreasing energy efficiencySelective laser sinteringAdhesive

The invention provides a method and equipment using organic adhesive mixed solvent and powder to manufacture three-dimensional workpieces. The work principle is as follows: the raw materials are stirred into slurry, which is laid as a green compact thin layer that can disintegrate in disintegrant; the green compact thin layer can form a workpiece thin layer that does not disintegrate in the disintegrant after scanned by an energy beam; in such a cycle, the steps of laying the thin layer and energy beam scanning are repeated, and then the three-dimensional workpiece can be formed; and the disintegant is used for separating the green compact not scanned by the energy beam from the workpiece, thus remaining the needed three-dimensional workpiece. The invention is widely applicable to manufacturing plastic, metallic, ceramic and compound workpieces, can avoid the defects of a selective laser sintering method, can use fine and very thin powder and therefore, can manufacture a finished product which is better than that made in the traditional selective laser sintering method in surface roughness and texture fineness, in addition, through subsequent densified sintering, the metallic and ceramic workpieces can have the strength superior to that in the traditional selective laser sintering method.

Owner:OUKESI INT

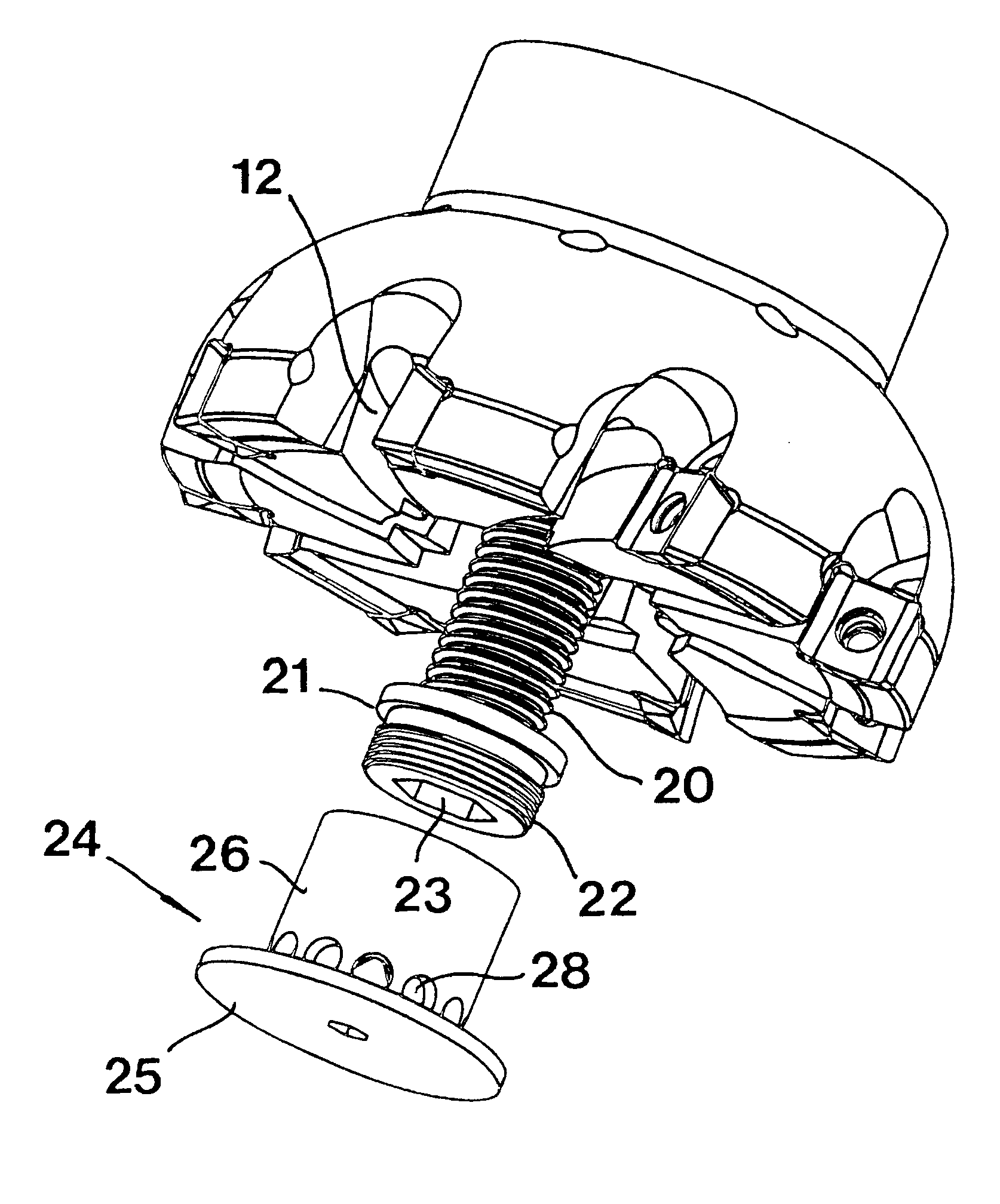

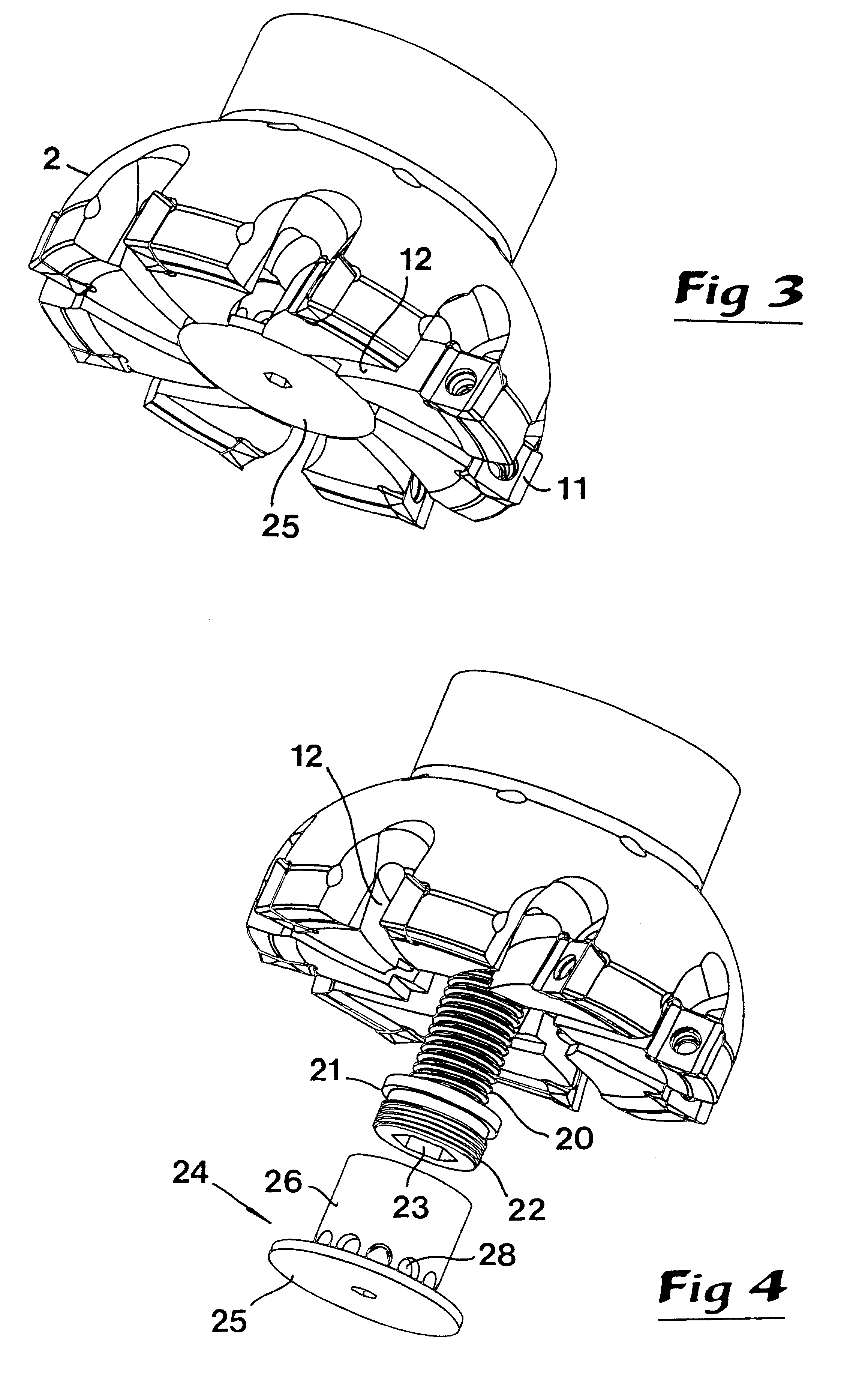

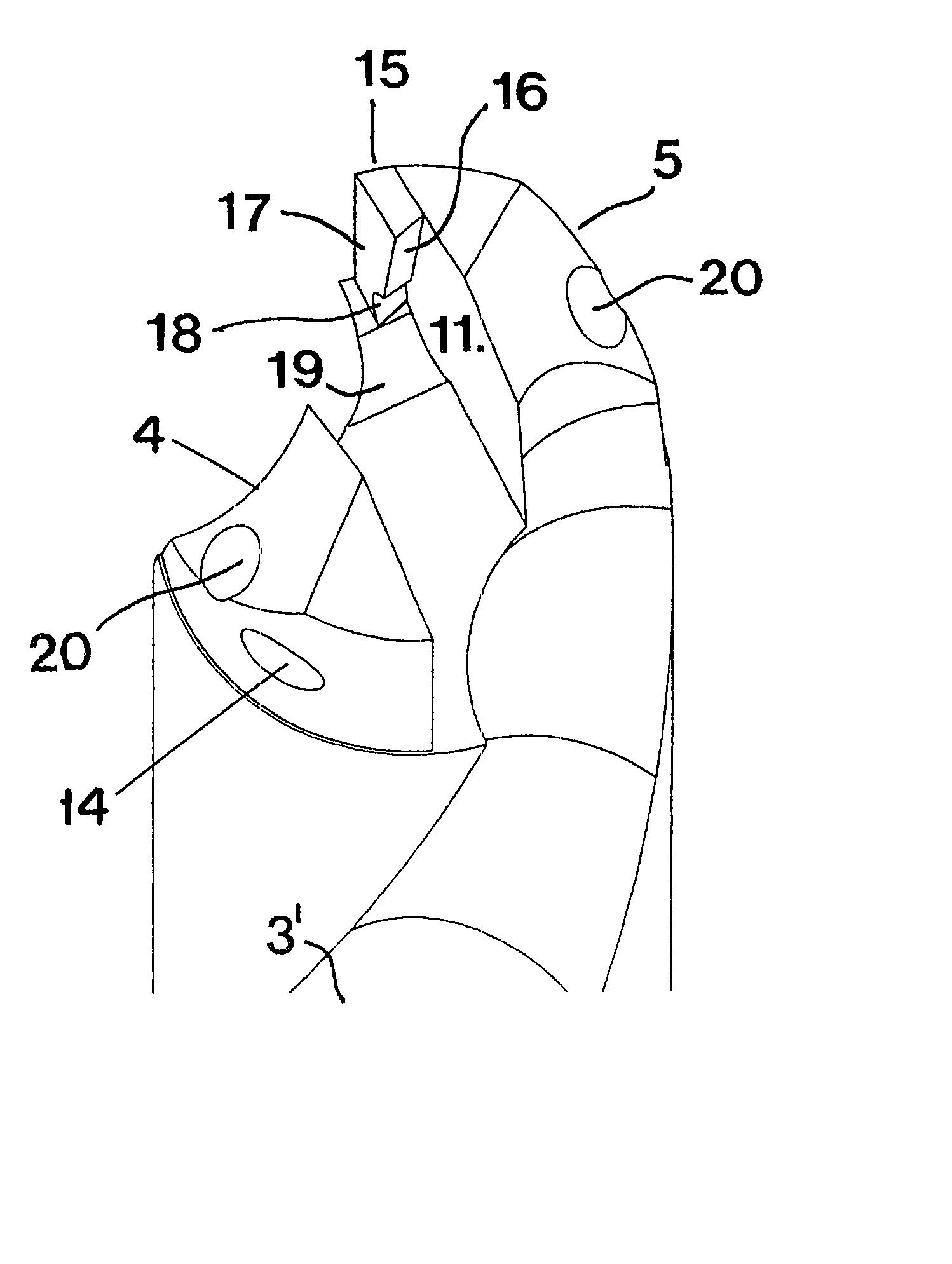

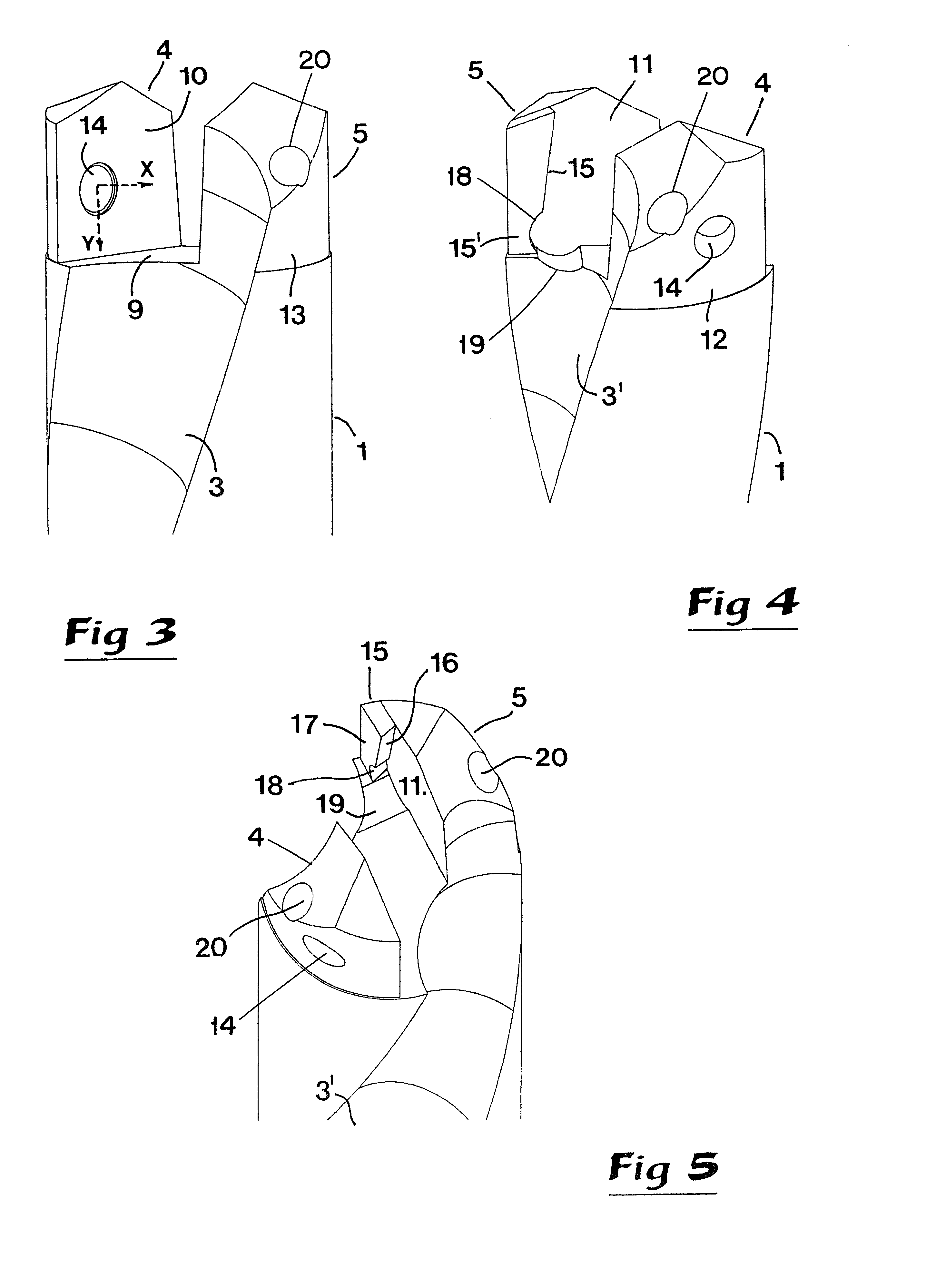

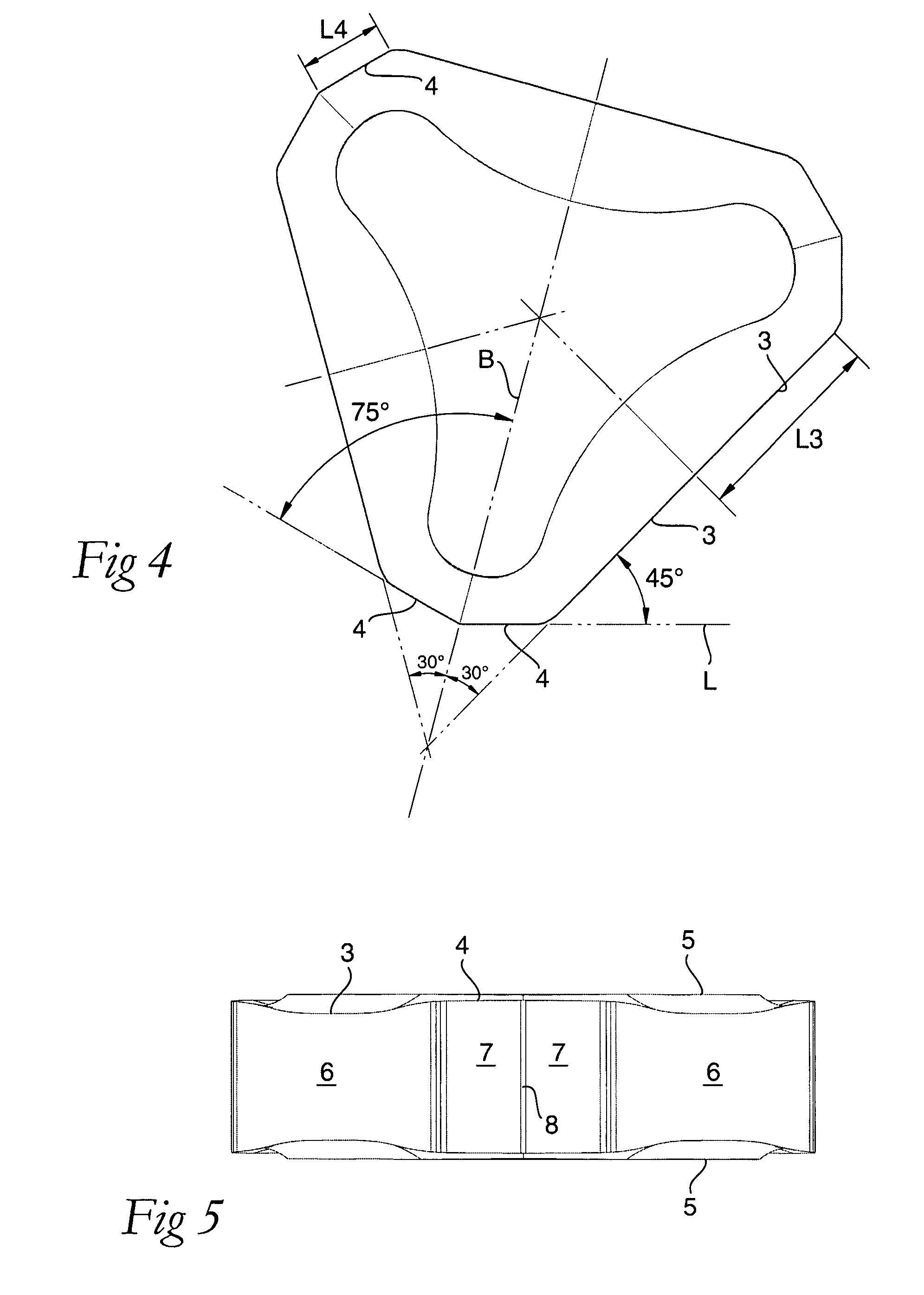

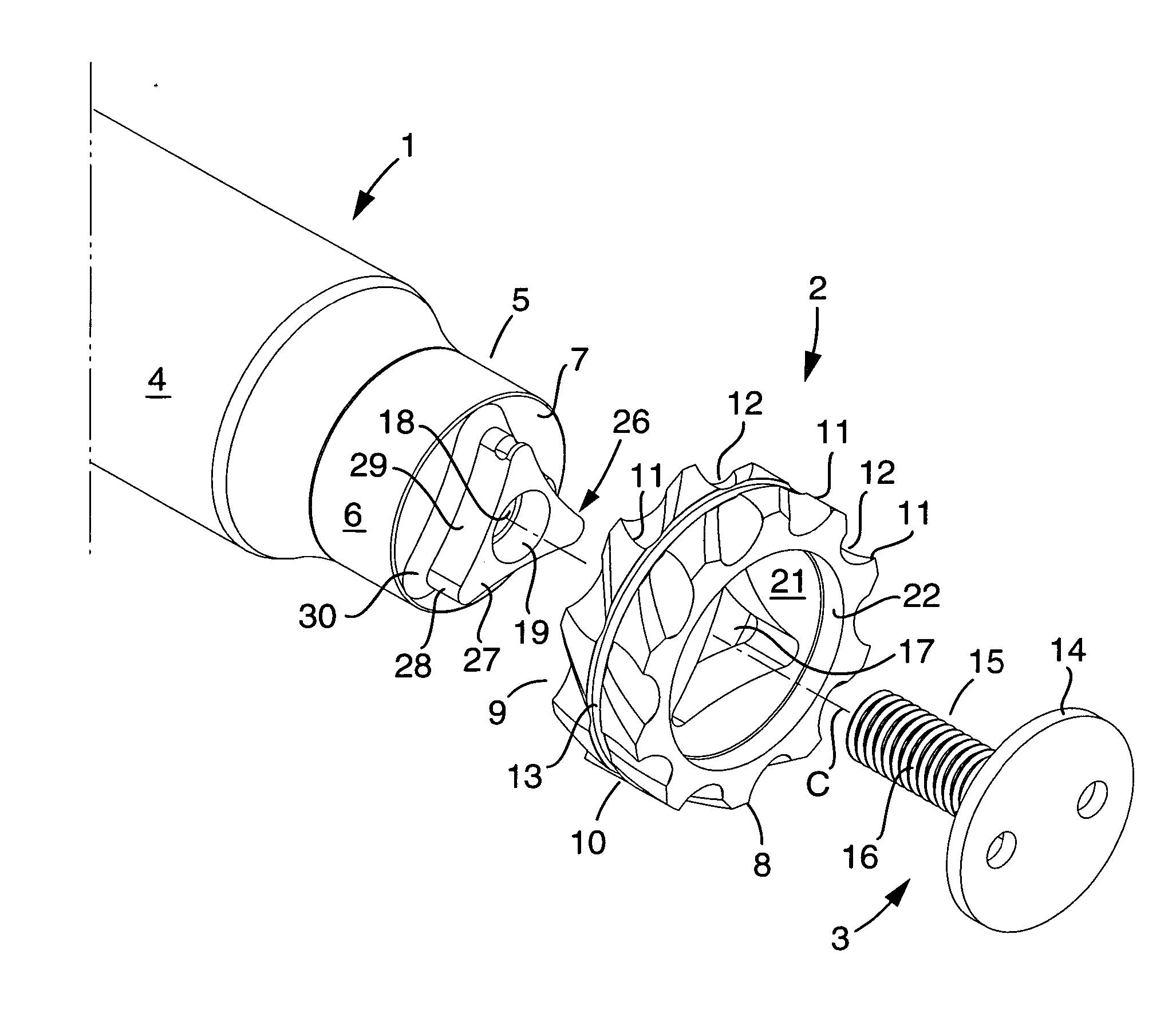

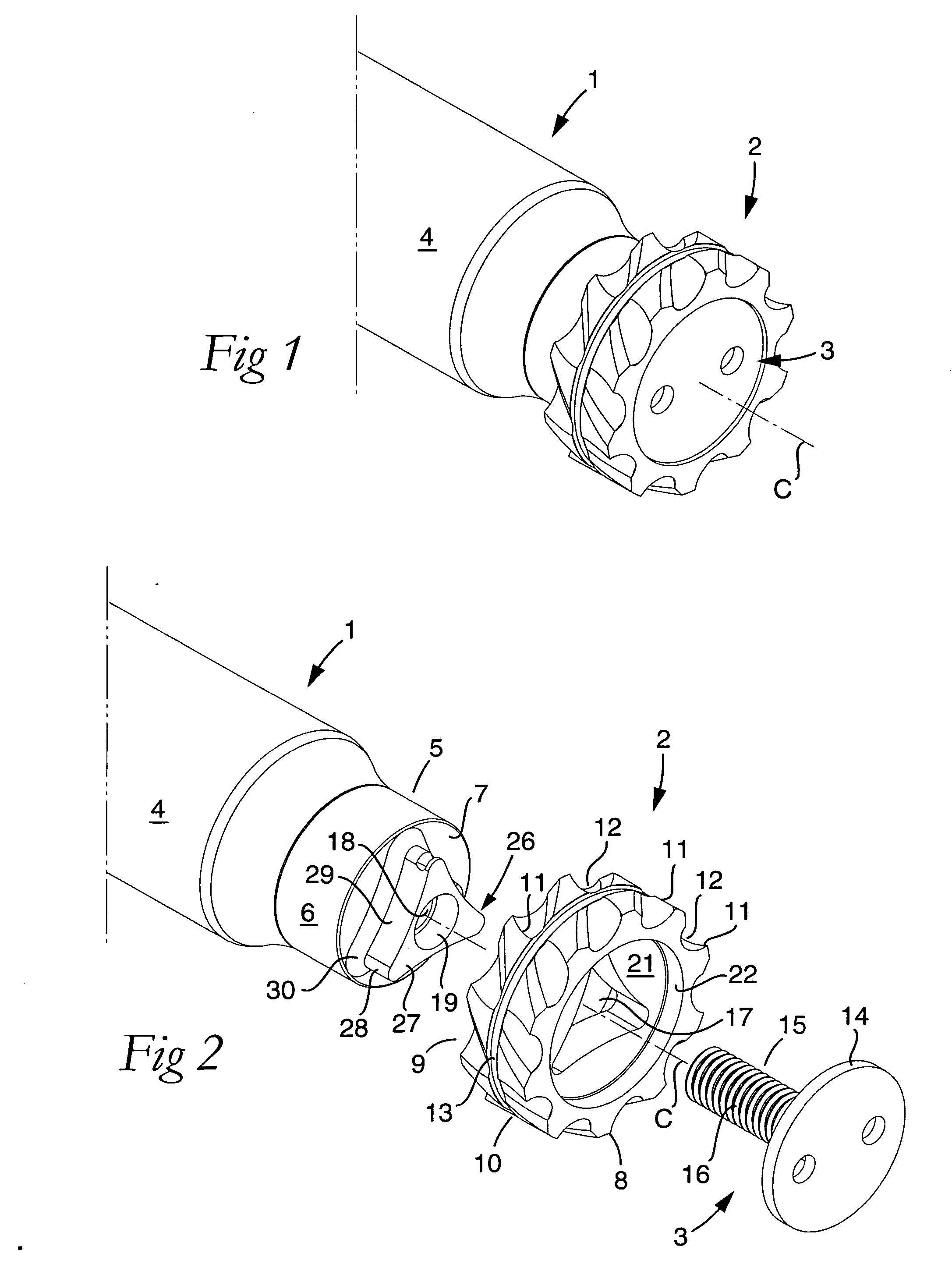

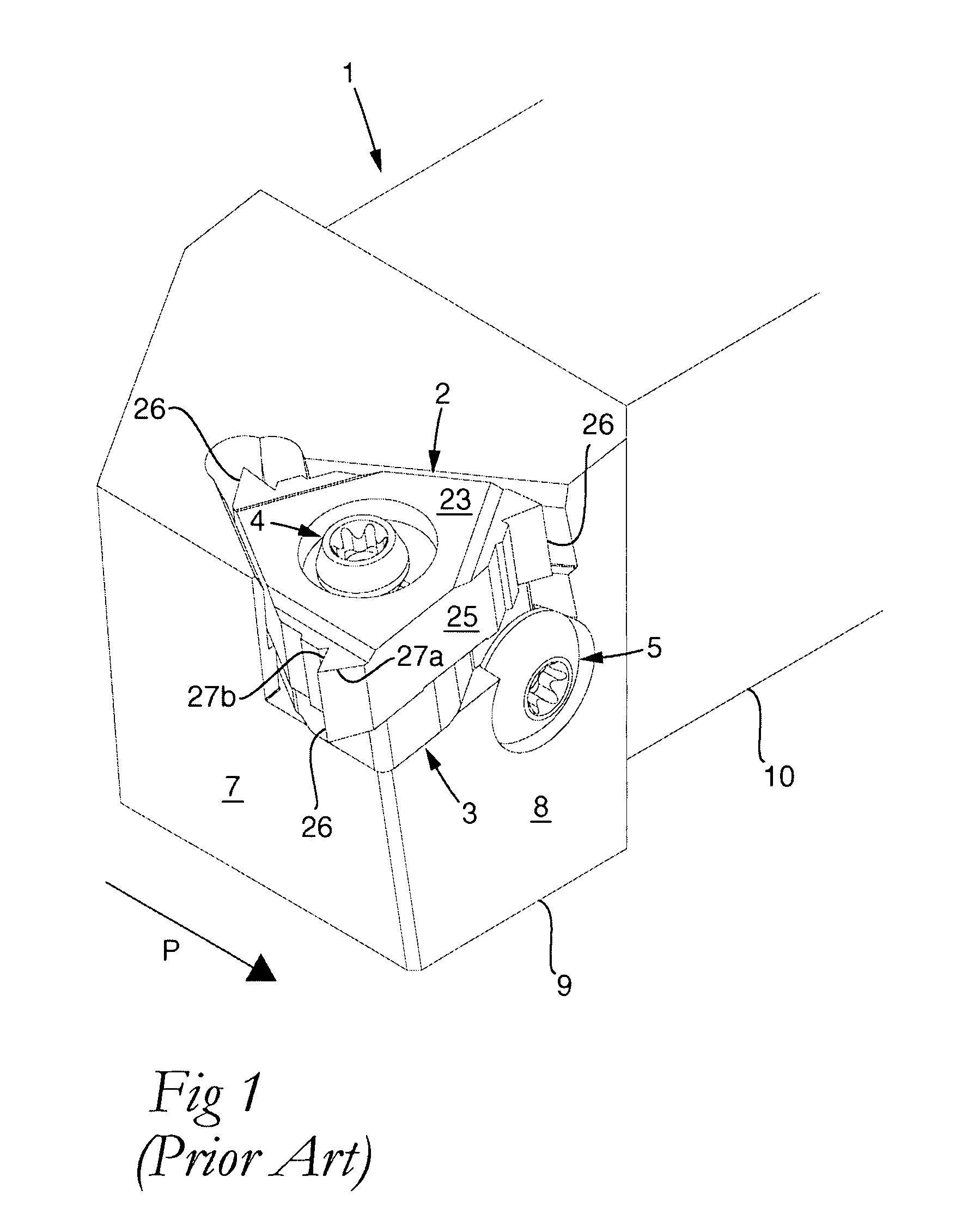

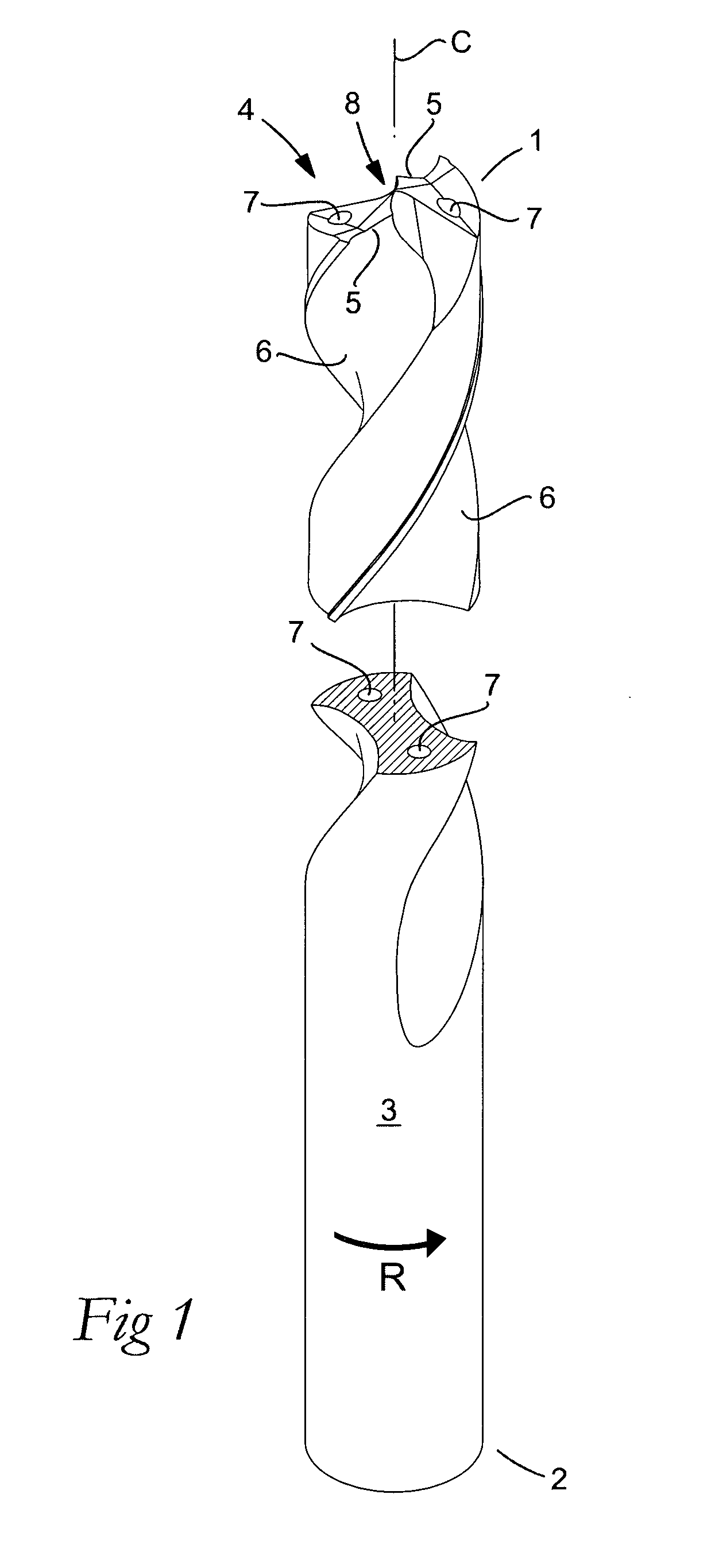

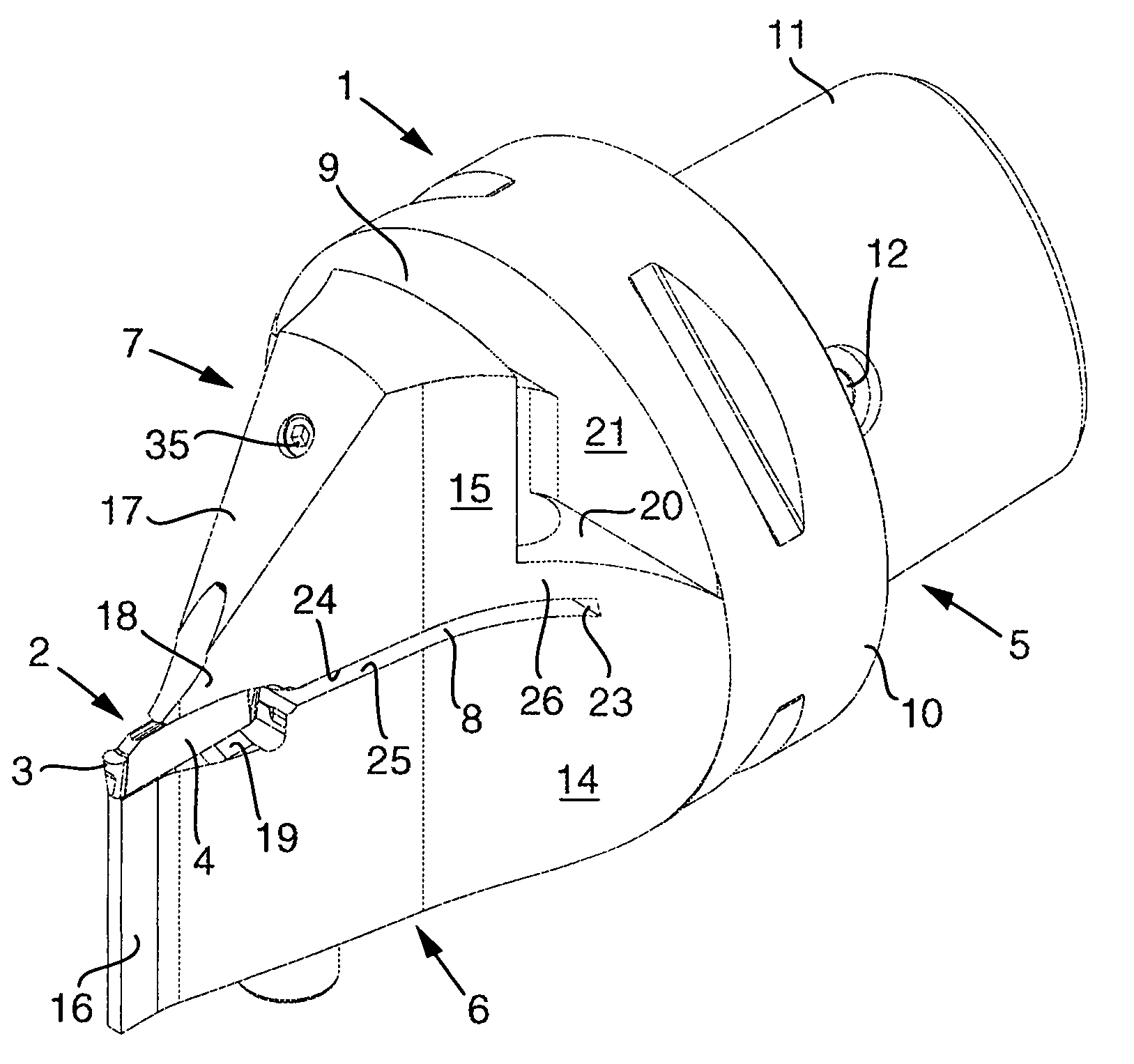

Drilling tool including a shank and a cutting body detachably secured thereto

InactiveUS6481938B2The way is simple and fastImprove cooling effectWood turning toolsTransportation and packagingPre stressPre stressing

A drilling tool includes a shaft having a front end to which a cutting body provided with cutting edges is detachably connected. In the front end of the shaft, a seat is formed which is delimited by spaced-apart protrusions between which there is a bottom surface. In the protrusion, there is a threaded hole for a screw, which when tightened applies pre-stressing forces to the cutting body. On the inside of the opposite protrusion, there is a supporting shoulder against which the cutting body is pressed when the screw is tightened and applies a lateral pre-stressing force to the cutting body. The protrusions are laterally displaced in relation to each other in order to freely expose the screw beside one of the protrusions.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

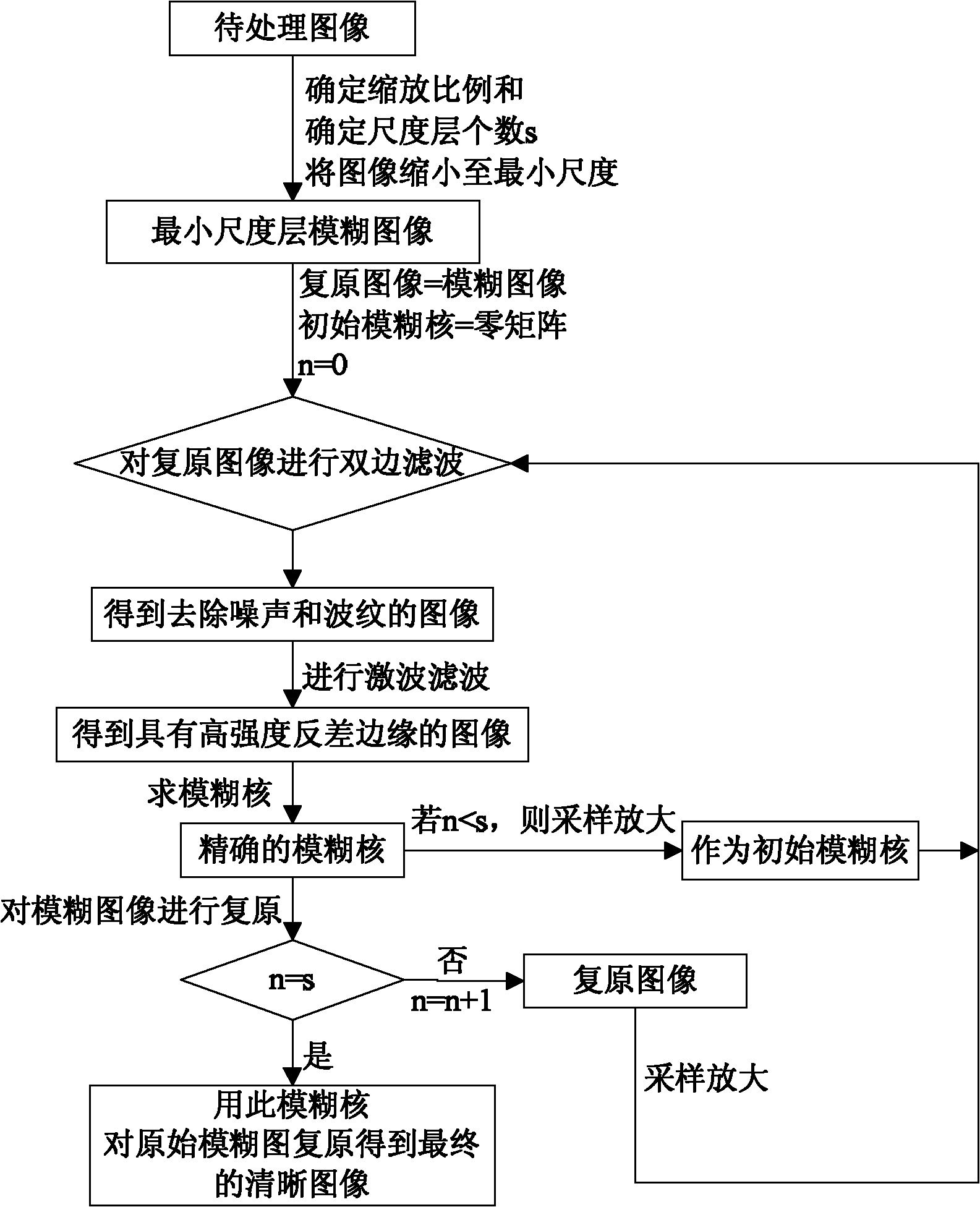

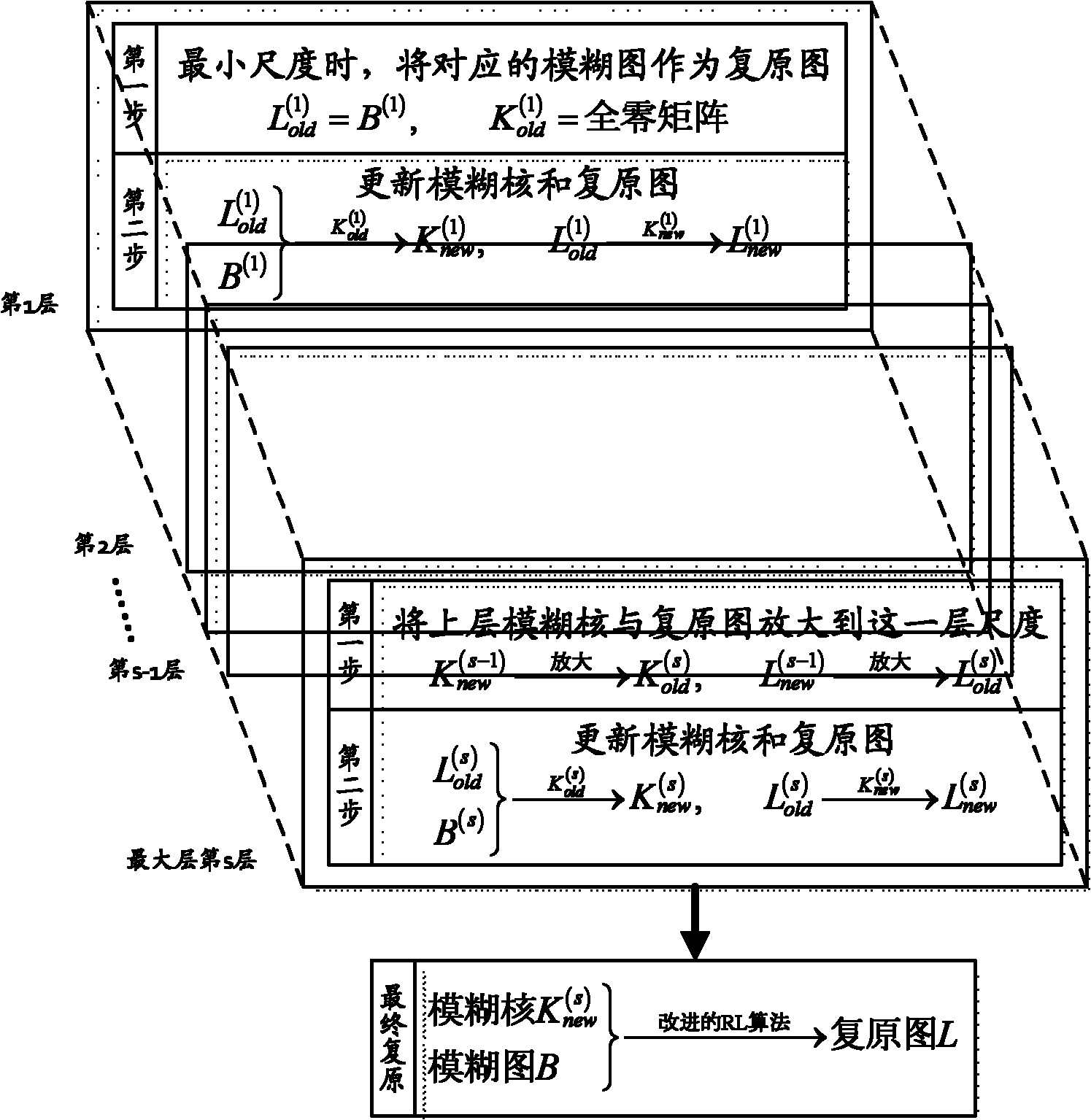

Edge information-based multi-scale blurred image blind restoration method

InactiveCN101930601AEffective convergenceReduce computational complexityImage enhancementShock wavePattern recognition

The invention discloses an edge information-based multi-scale blurred image blind restoration method, which comprises the following steps of: circularly and gradually restoring an image from a small scale layer to a large scale layer, setting self-adaptive parameters at different scales, and processing each scale layer, namely bilaterally filtering the restored image to obtain an image of which the noise and ripple are removed; performing shock wave filtering to obtain an image with high-strength contrast edges; solving the edges, and combining a fuzzy core initial value and a fuzzy graph to obtain an accurate fuzzy core; restoring a fuzzy image at the current scale to obtain a clear restored image by using the solved fuzzy core; sampling and amplifying in the current scale layer to obtain the restored image and a fuzzy core initial value of an adjacent large scale layer, and performing cycle operation on the adjacent large scale layer. The edge information-based multi-scale blurred image blind restoration method can effectively converge various images in different fuzzy degrees, and compared with a general blind restoration method which directly solves the energy minimization, the blurred image blind restoration method has the advantages of low computational complexity and high noise suppression capacity.

Owner:ZHEJIANG UNIV

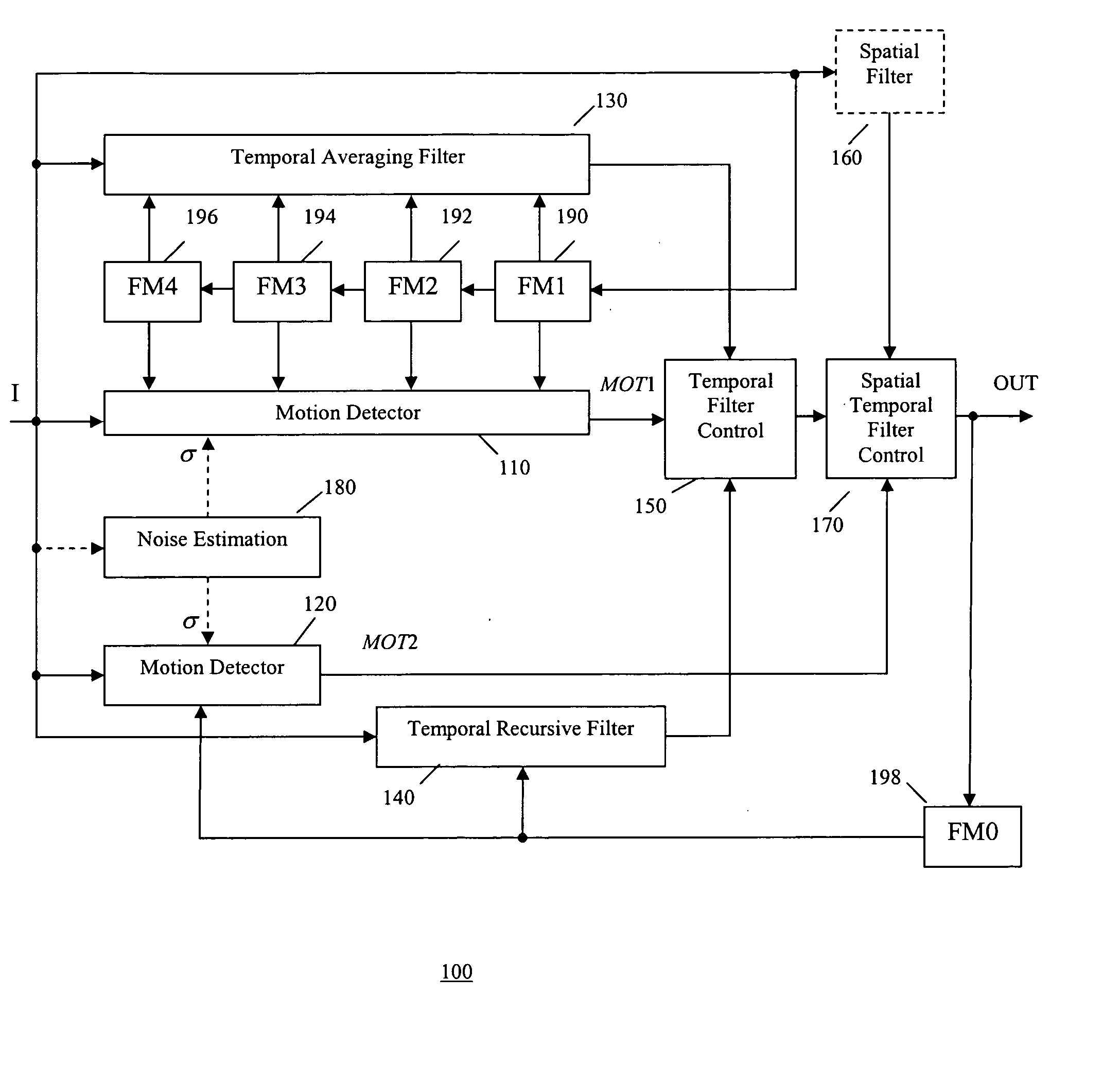

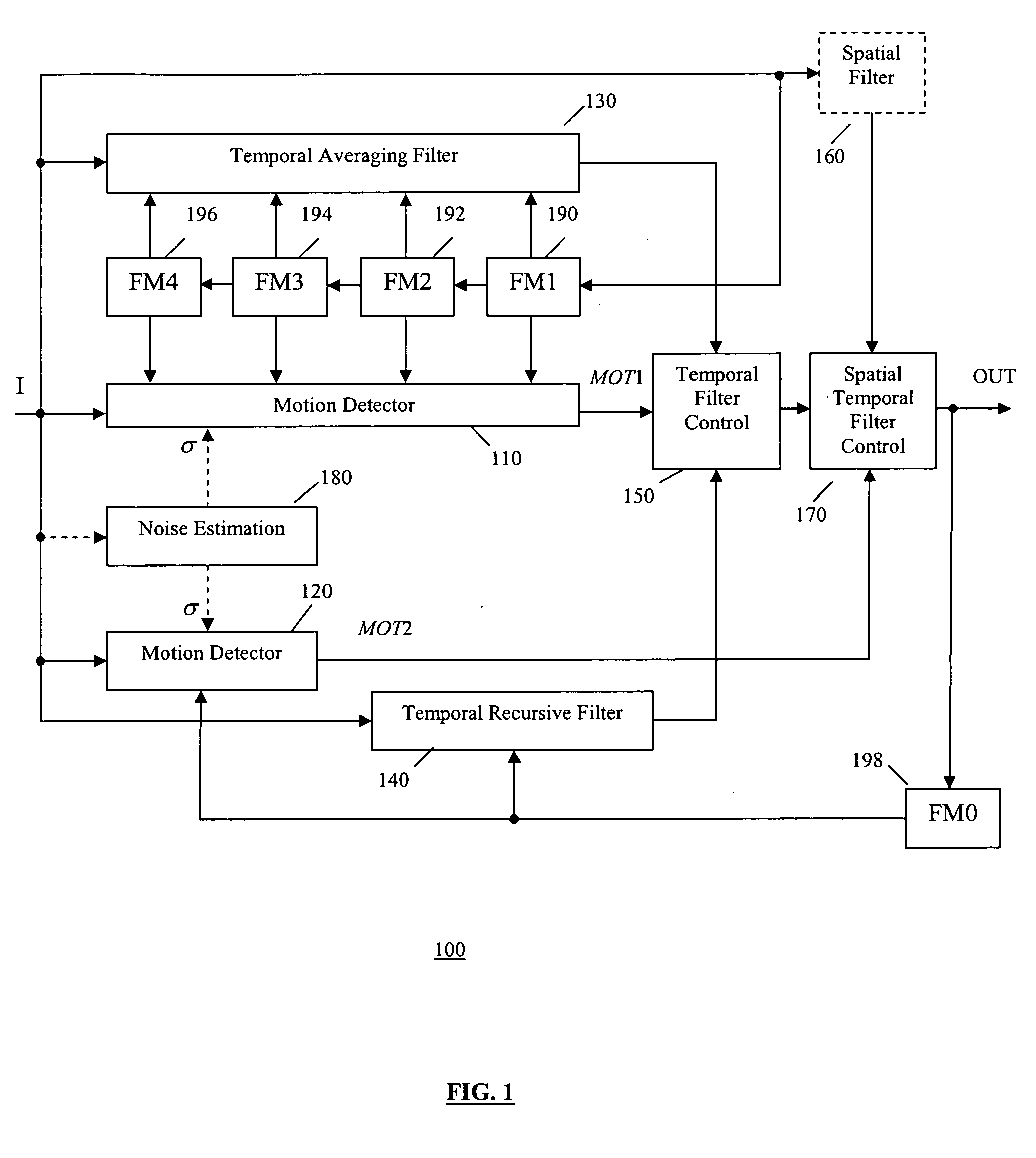

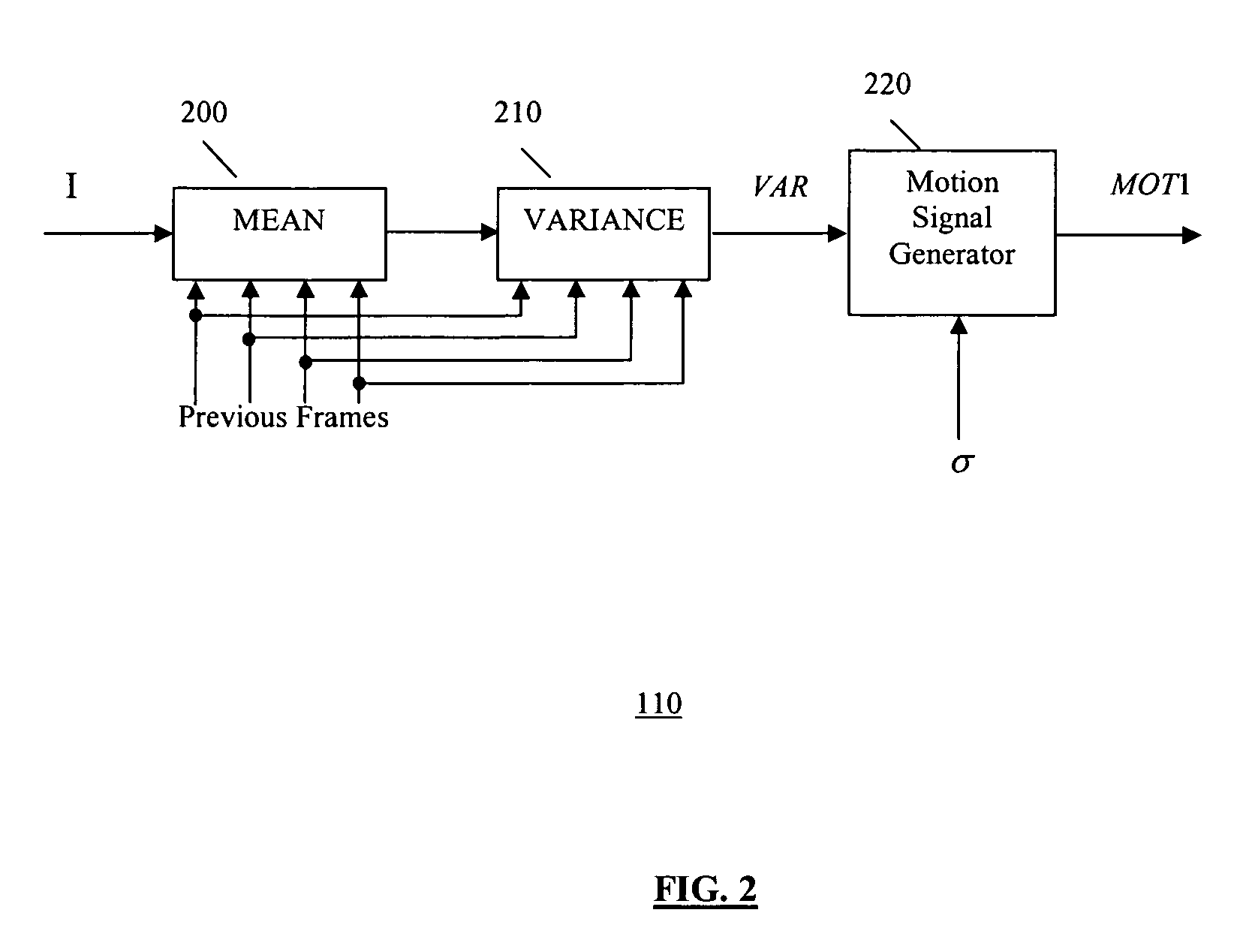

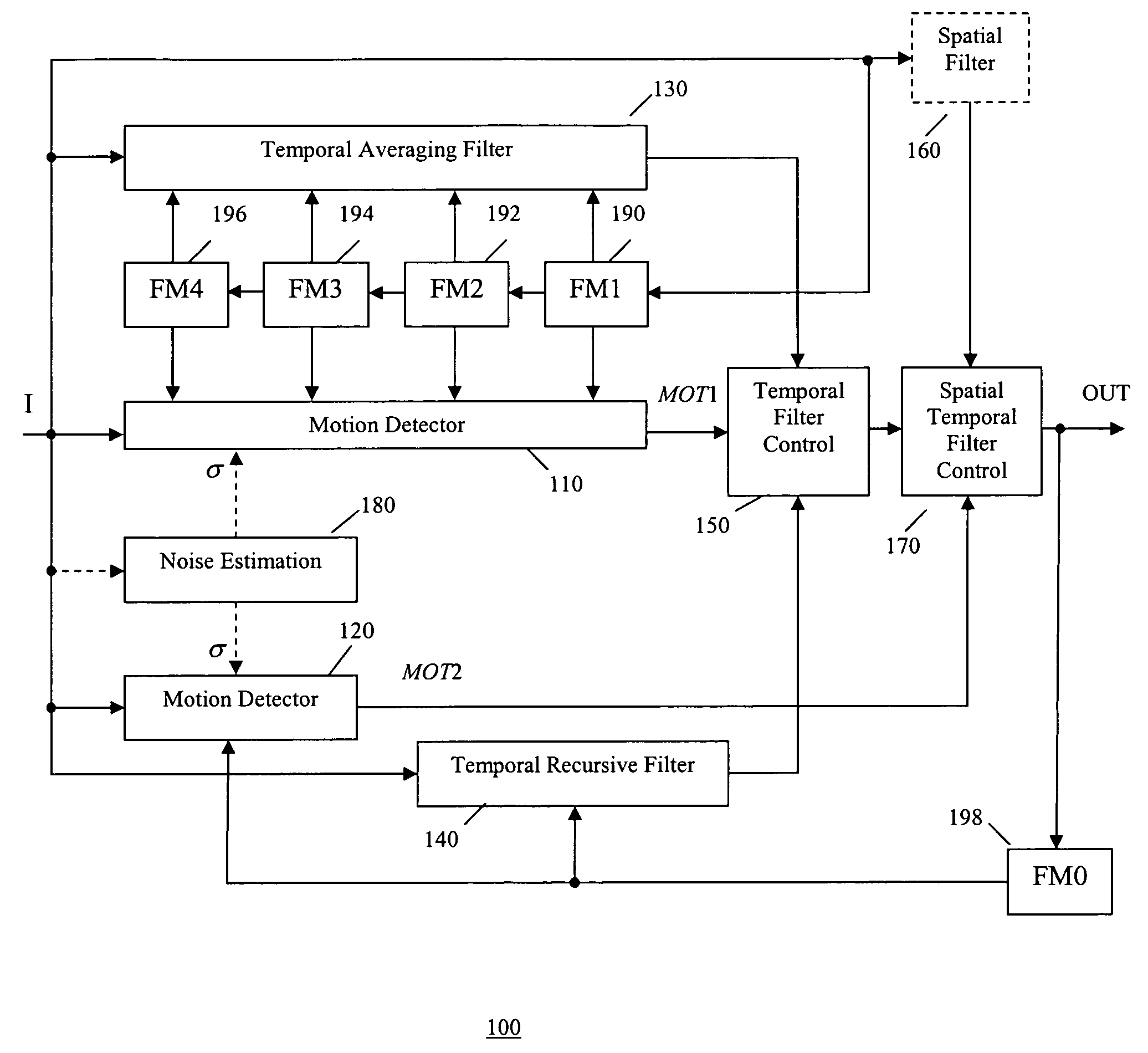

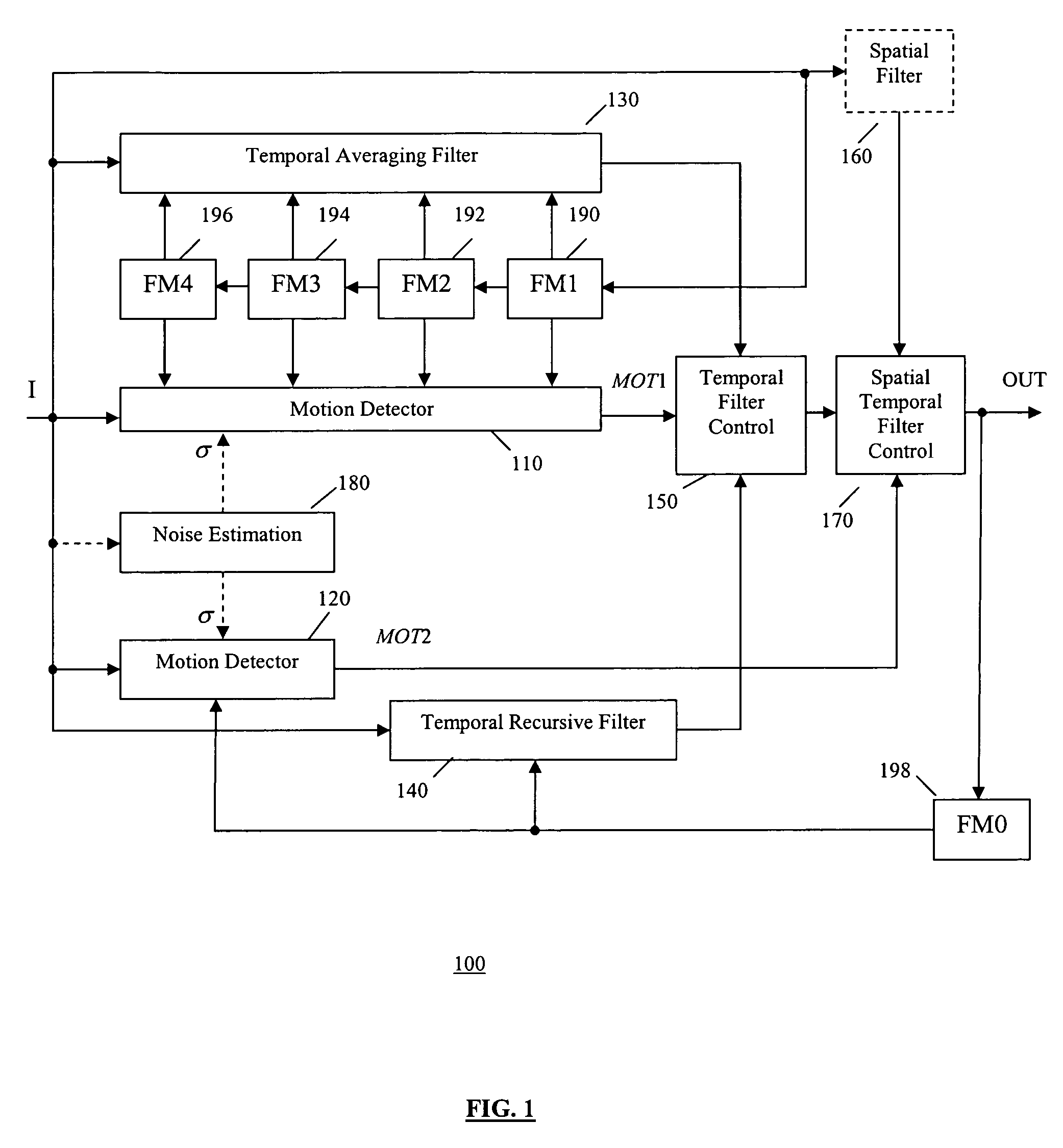

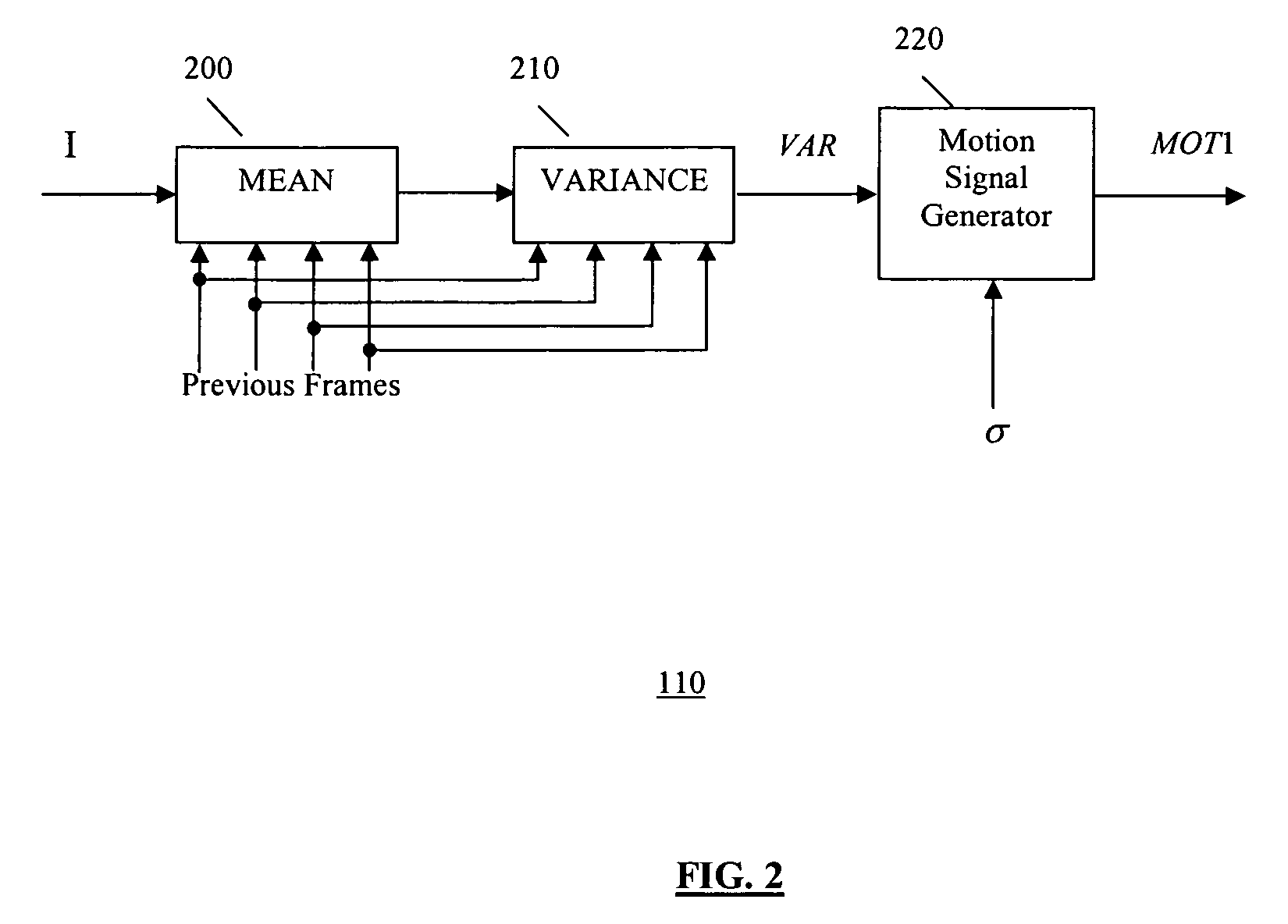

Motion adaptive noise reduction apparatus and method for video signals

InactiveUS20050280739A1Optimal noise reductionIncrease the areaTelevision system detailsImage enhancementPattern recognitionSoft switching

A video noise reduction system for a set of video frames that computes a first motion signal using a current frame and multiple consecutive previous frames, computes a second motion signal using the current frame and the processed preceding frame; computes the multi-frame temporal average of the current frame and multiple consecutive previous frames; computes the recursive average of the current frame and the processed preceding frame; generates a temporal filtered signal by soft switching between the multi-frame temporal average and the recursive average based on the first motion signal; applies a spatial filter to the current frame to generate a spatial filtered signal; and combines the temporal filtered signal and the spatial filtered signal based on the second motion signal to generate a final noise reduced video output signal.

Owner:SAMSUNG ELECTRONICS CO LTD

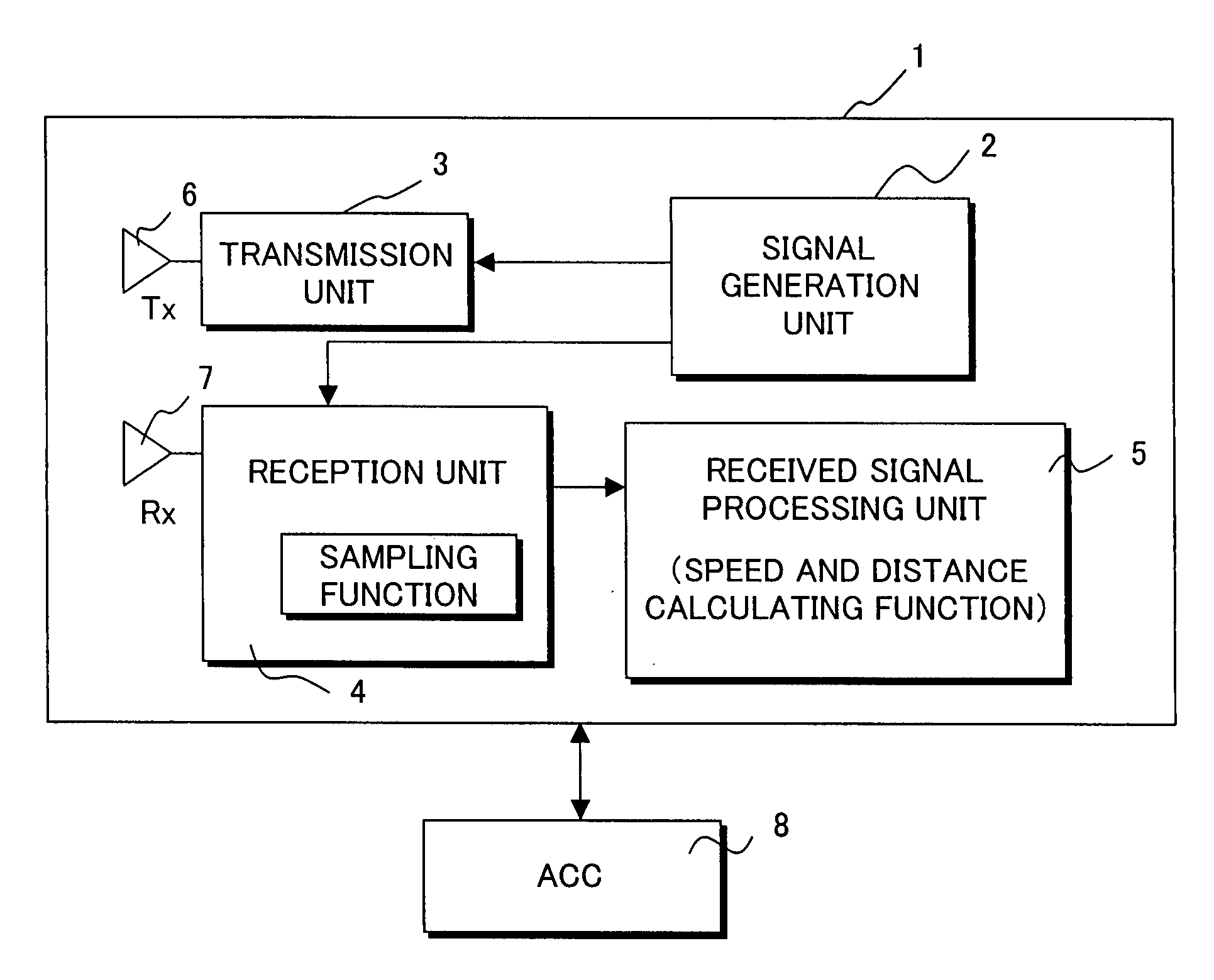

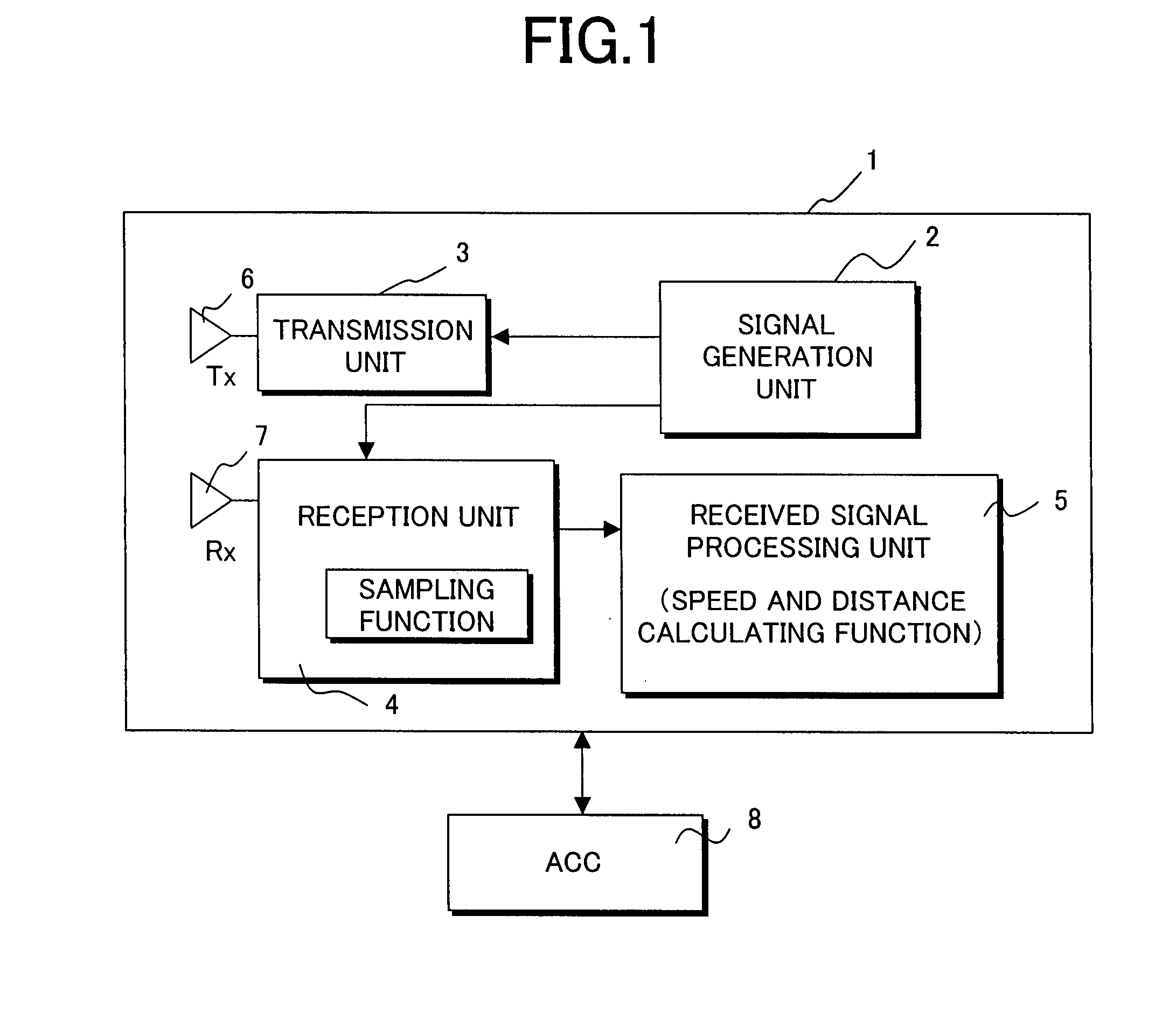

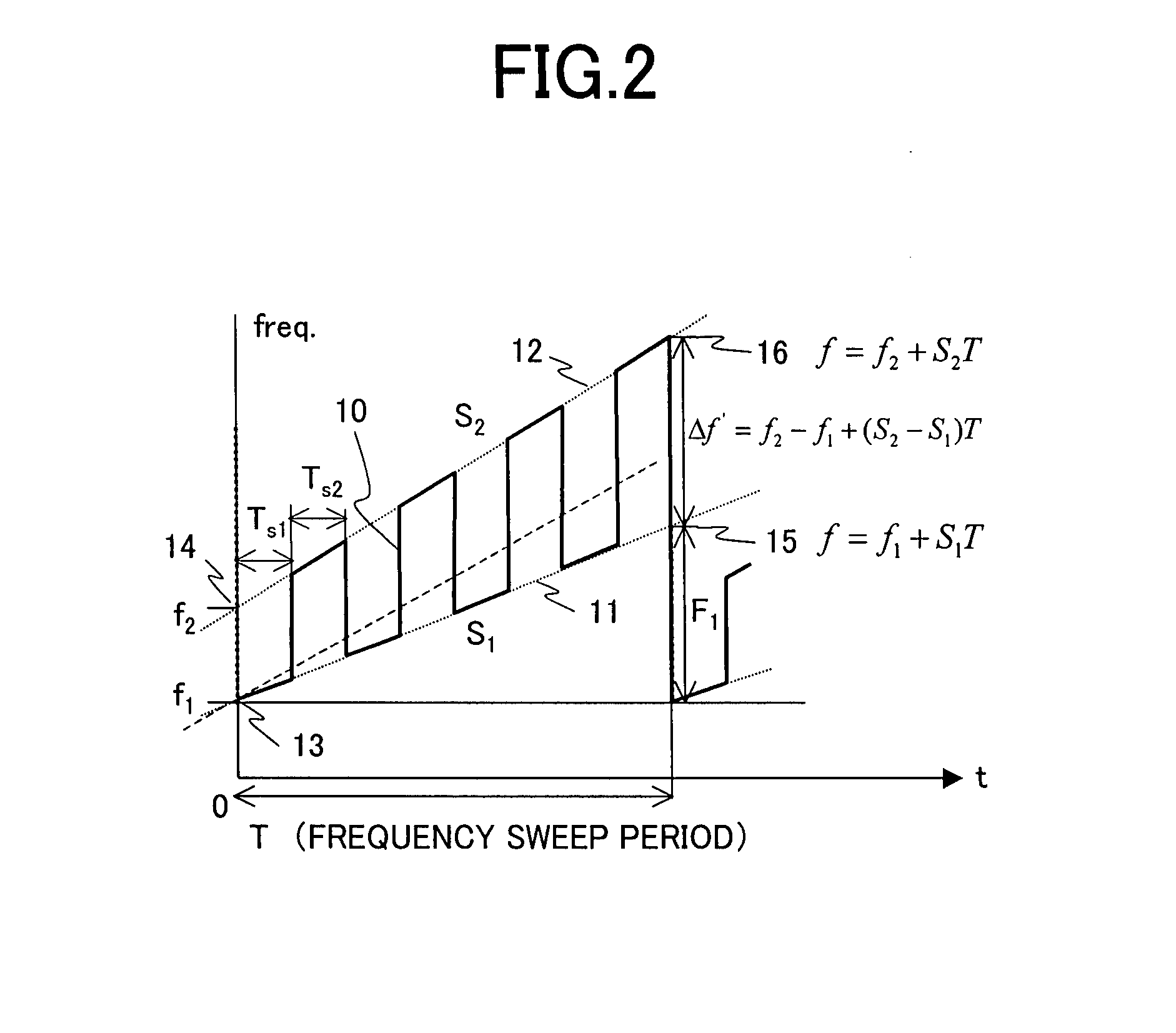

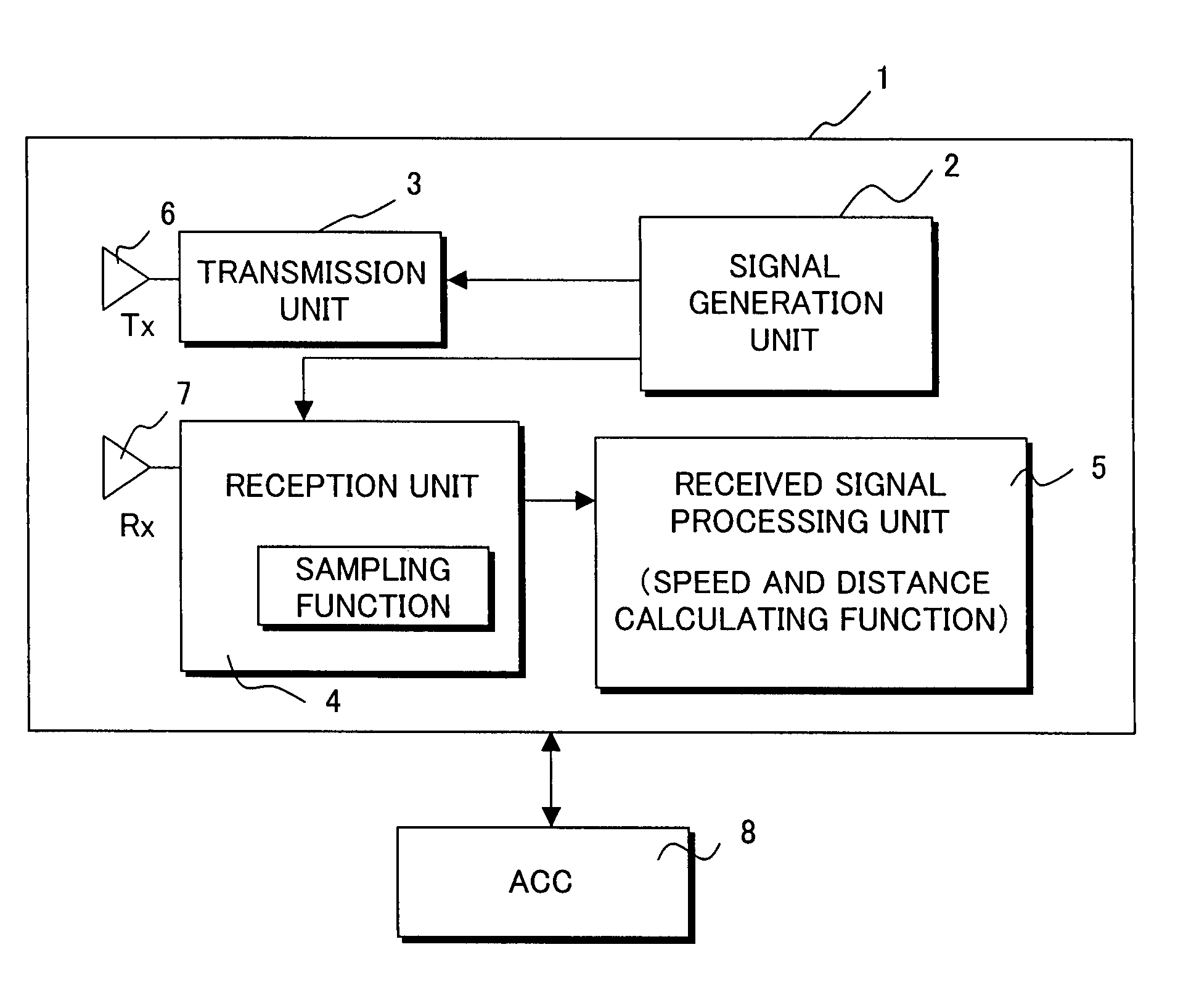

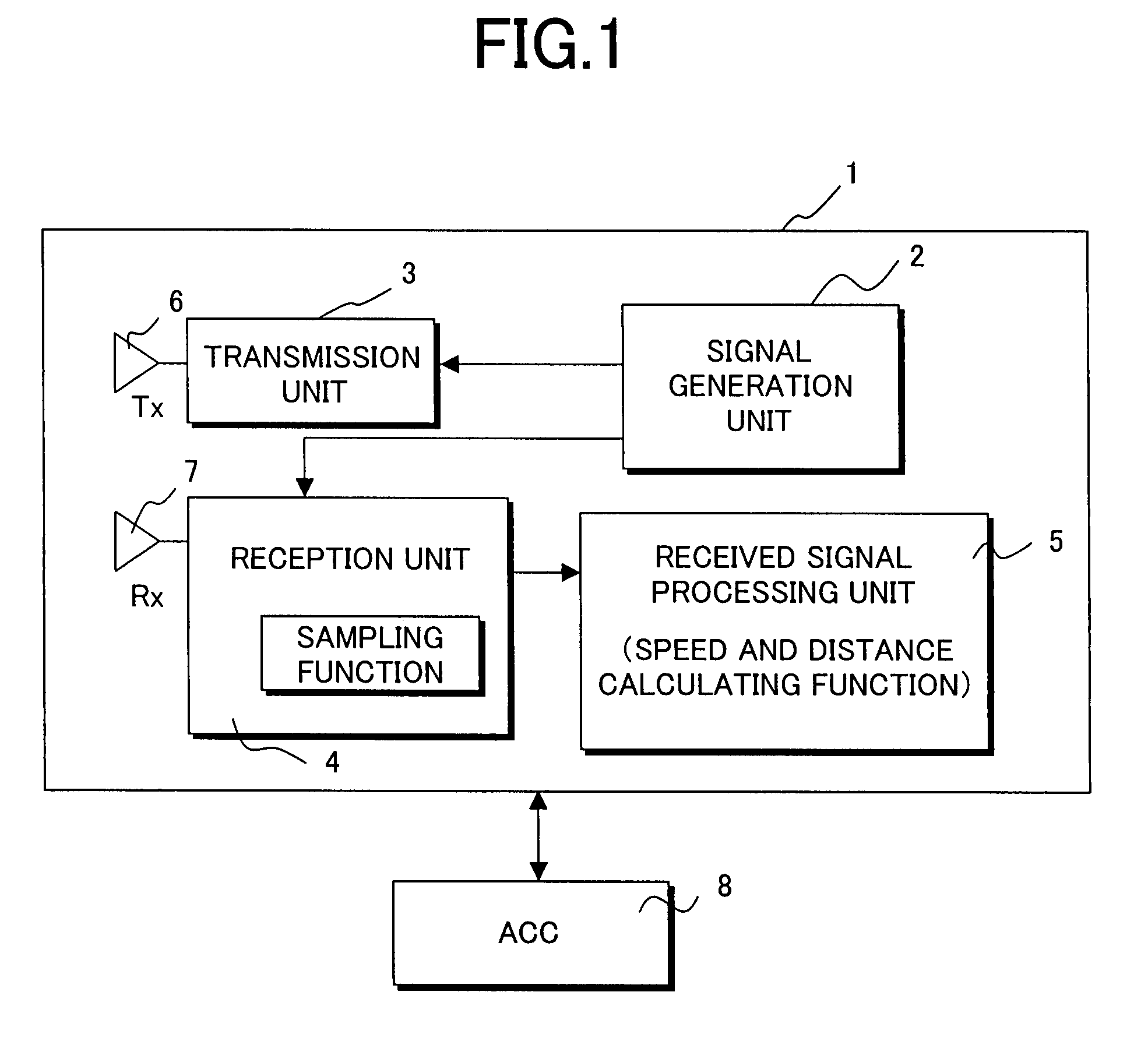

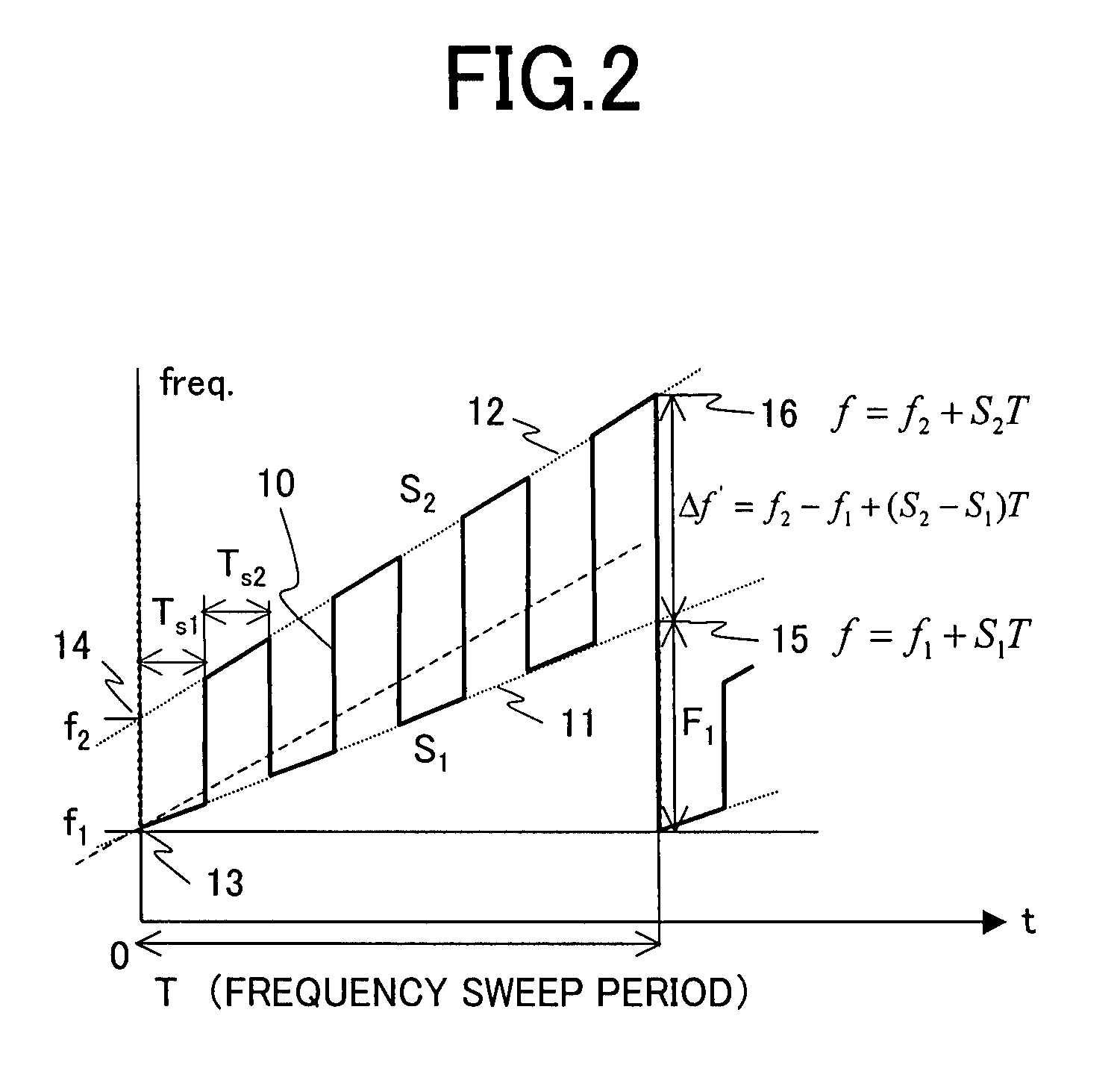

Radar, radio frequency sensor, and radar detection method

InactiveUS20080100500A1Reduce uncertaintyImprove accuracyRadio wave reradiation/reflectionEngineeringRadar detection

In a sensor and a radar for measuring the distance and the moving speed of a target by radiating a radio frequency, particularly a millimeter wave, compatibility between cost reduction and high detection performance has been conventionally a significant problem. In the present invention, the frequency of a transmitted signal changes during a fixed time while performing digitally-frequency-modulation on frequency sweeping straight lines extending, with different slopes relative to the time axis, from plural slightly different initial values serving as starting points, the signal is transmitted after being modulated so as to periodically repeat the sweep time serving as a unit, signal components corresponding to the respective sweeping slopes are digitally sampled, in synchronization with the transmitted modulation signal, from a received signal which is reflected and returned from a target, and the received signal is analyzed.

Owner:HITACHI LTD

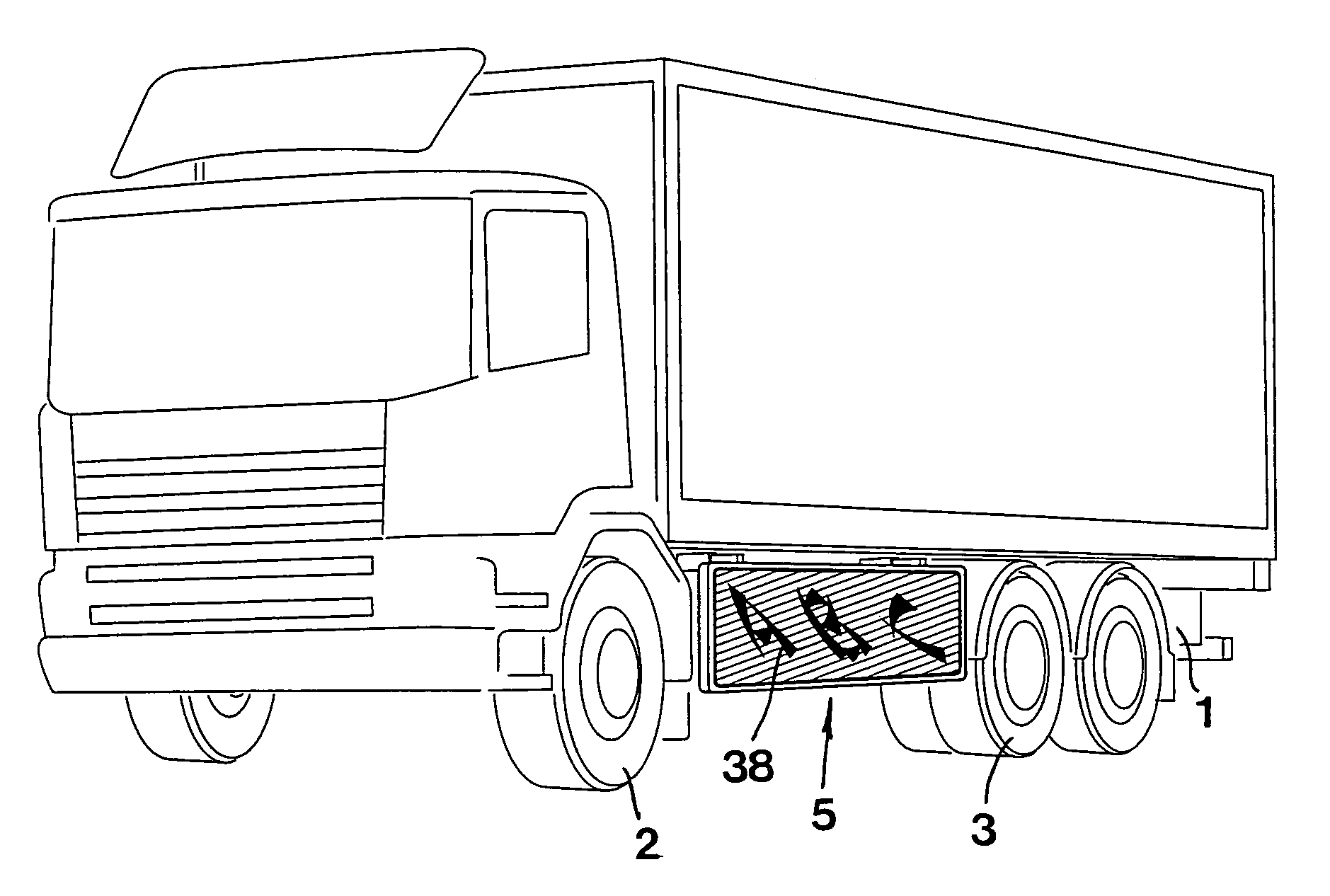

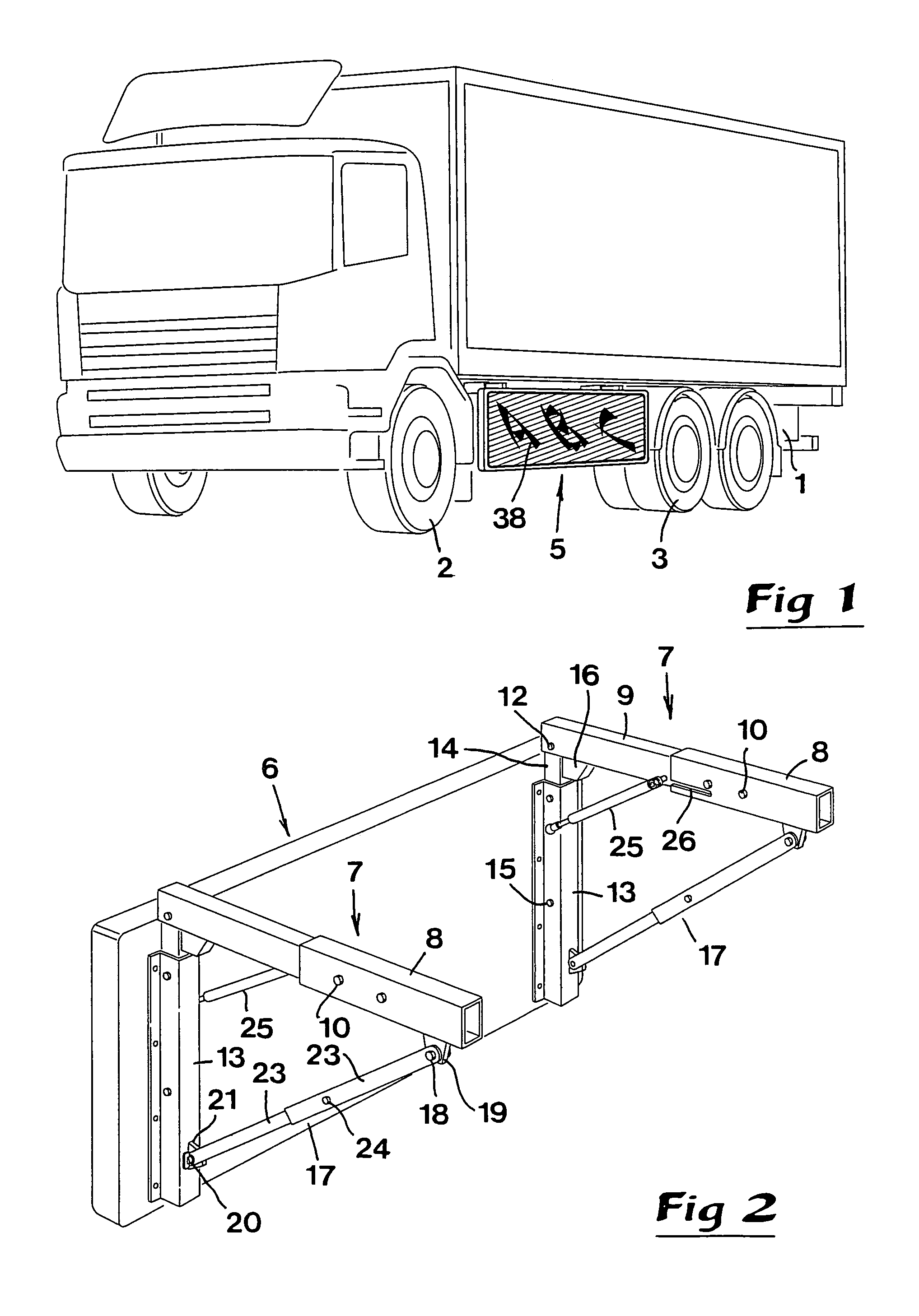

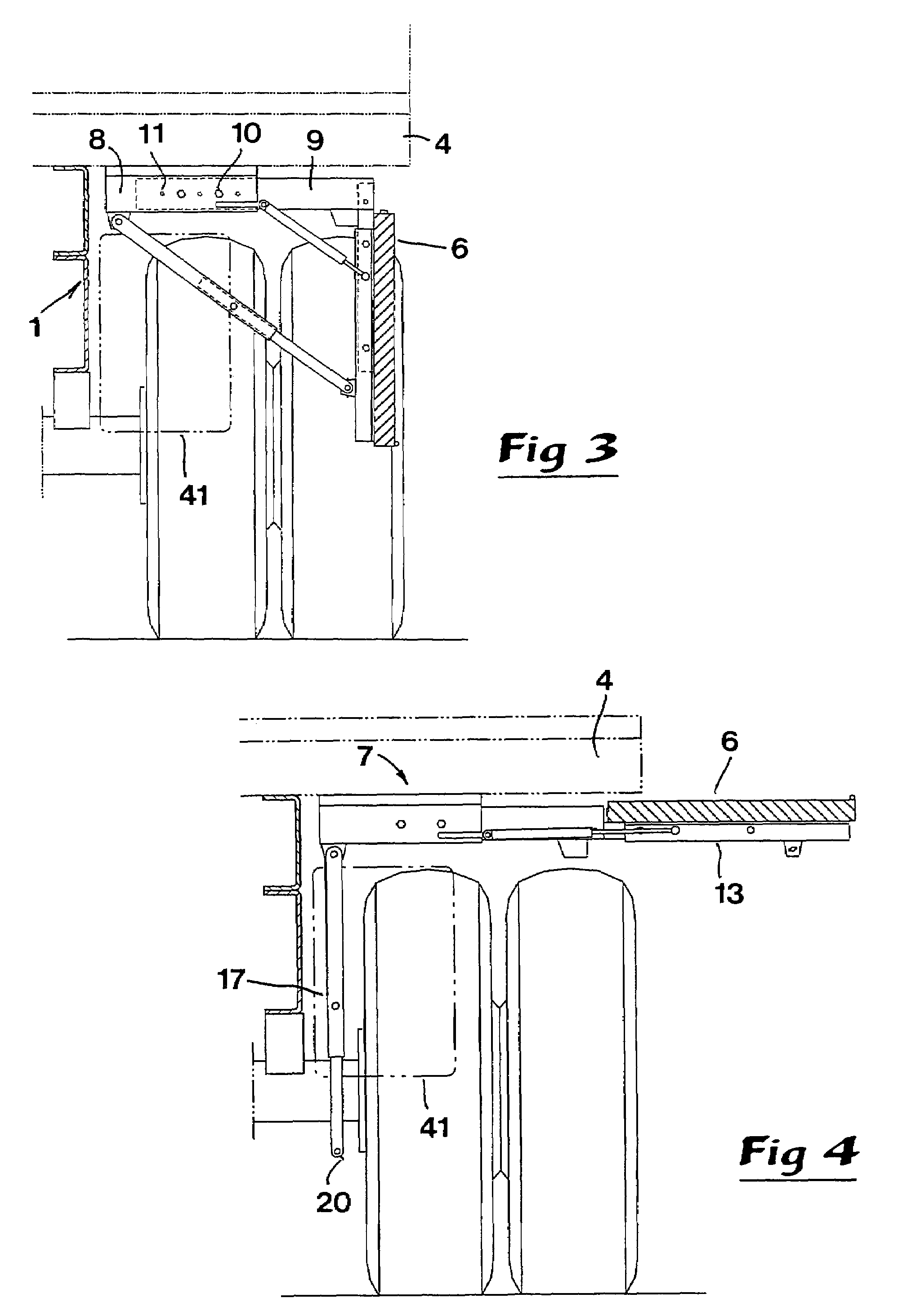

Underrun protection for vehicles

Owner:NORELIUS JAN ERIK

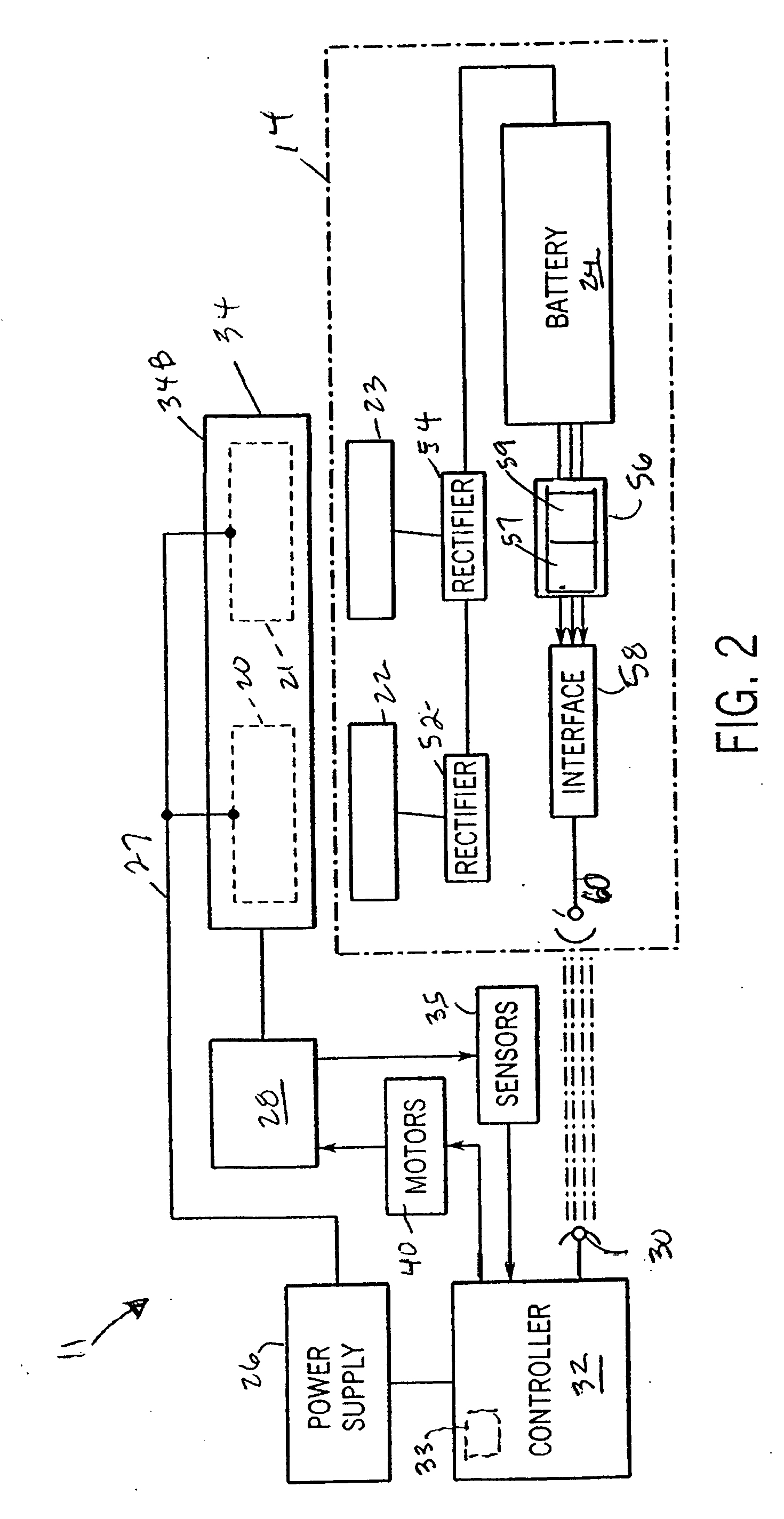

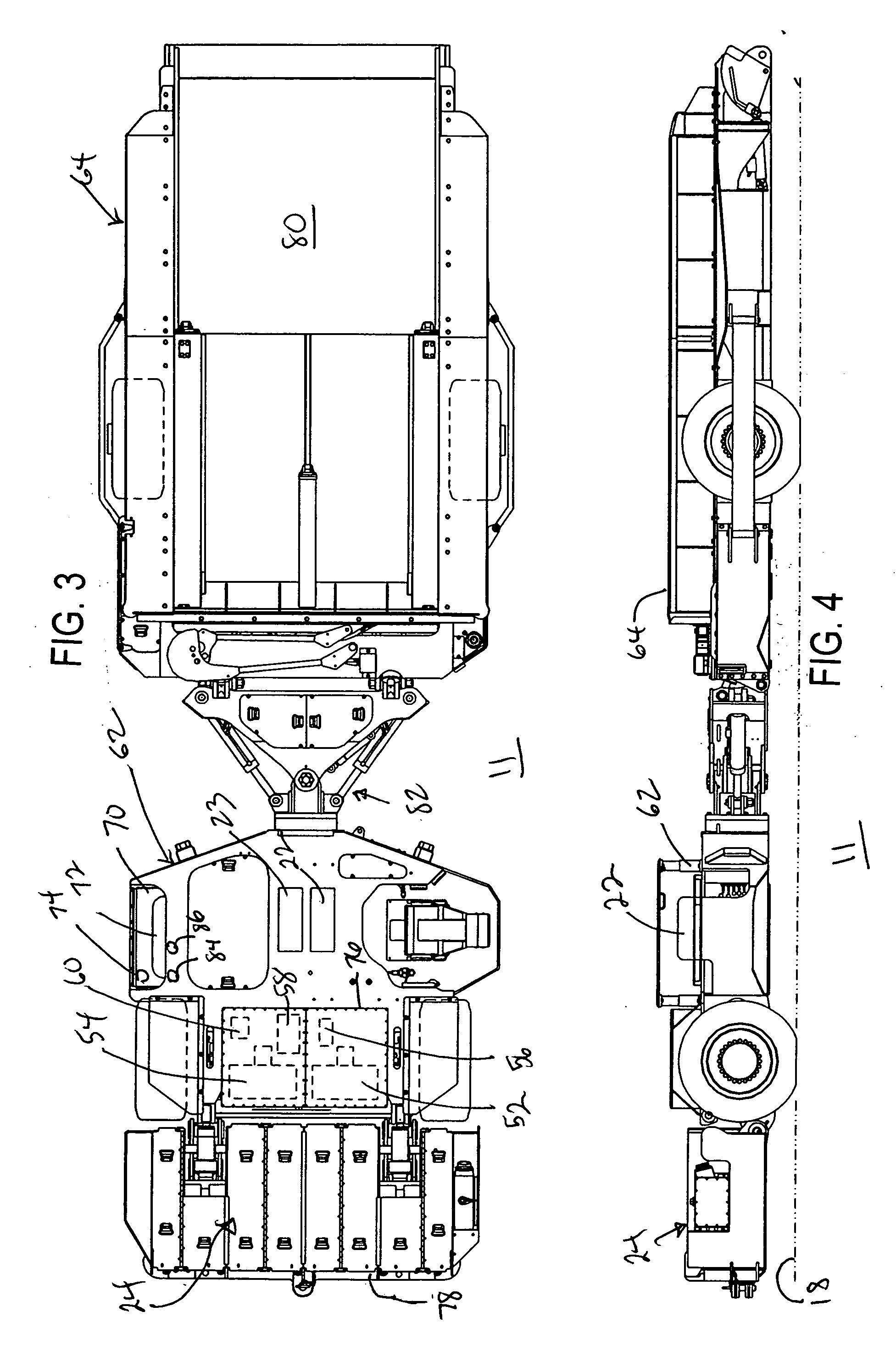

Opportunity charging system for battery powered mining equipment

InactiveUS20060273756A1Change timeFast chargingCharging stationsRailway vehiclesElectric power transmissionBattery charge

An opportunity charging system for a battery-powered, mobile mining machine employs inductive power transfer for transferring battery charging current produced by a rapid charging station to the battery of the machine. An alignment module of the charging station automatically aligns primary coils of the charging station with pick-up coils carried by the machine in response to detection of the presence of the machine at the charging station. The charging station is located along roadways of the mine normally traveled by production equipment.

Owner:JOY MM DELAWARE INC

Motion adaptive noise reduction apparatus and method for video signals

InactiveUS7199838B2Optimal noise reductionIncrease the areaImage enhancementTelevision system detailsPattern recognitionSoft switching

A video noise reduction system for a set of video frames that computes a first motion signal using a current frame and multiple consecutive previous frames, computes a second motion signal using the current frame and the processed preceding frame; computes the multi-frame temporal average of the current frame and multiple consecutive previous frames; computes the recursive average of the current frame and the processed preceding frame; generates a temporal filtered signal by soft switching between the multi-frame temporal average and the recursive average based on the first motion signal; applies a spatial filter to the current frame to generate a spatial filtered signal; and combines the temporal filtered signal and the spatial filtered signal based on the second motion signal to generate a final noise reduced video output signal.

Owner:SAMSUNG ELECTRONICS CO LTD

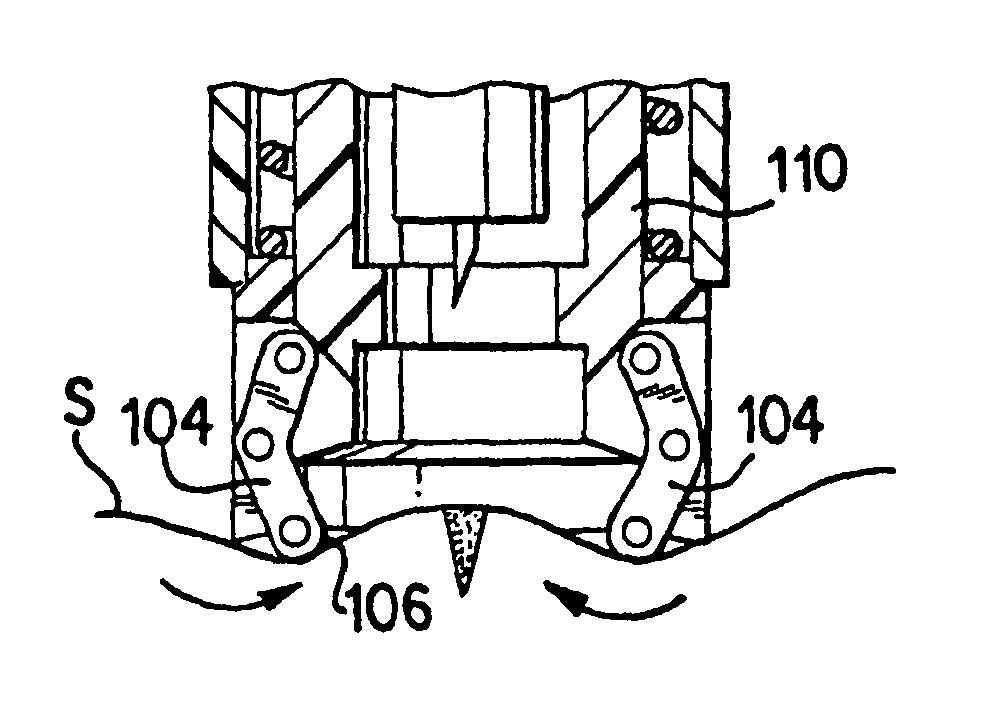

Methods and apparatus for expressing body fluid from an incision

A sample of a body fluid such as blood or interstitial fluid is obtained from a body by lancing a portion of a user's skin, preferably in an area other than a finger tip, to form an incision. After the needle has been removed from the incision, a force is applied to depress the skin in a manner forming a ring of depressed body tissue in surrounding relationship to the incision, causing the incision to bulge and the sides of the incision to open, whereby body fluid is forced out through the opening of the incision. A stimulator member is mounted to an end of a lancet-carrying housing for applying the force. The stimulator member can be movable relative to the housing, and can be either heated or vibrated to promote movement of the body fluid.

Owner:ROCHE DIABETES CARE INC

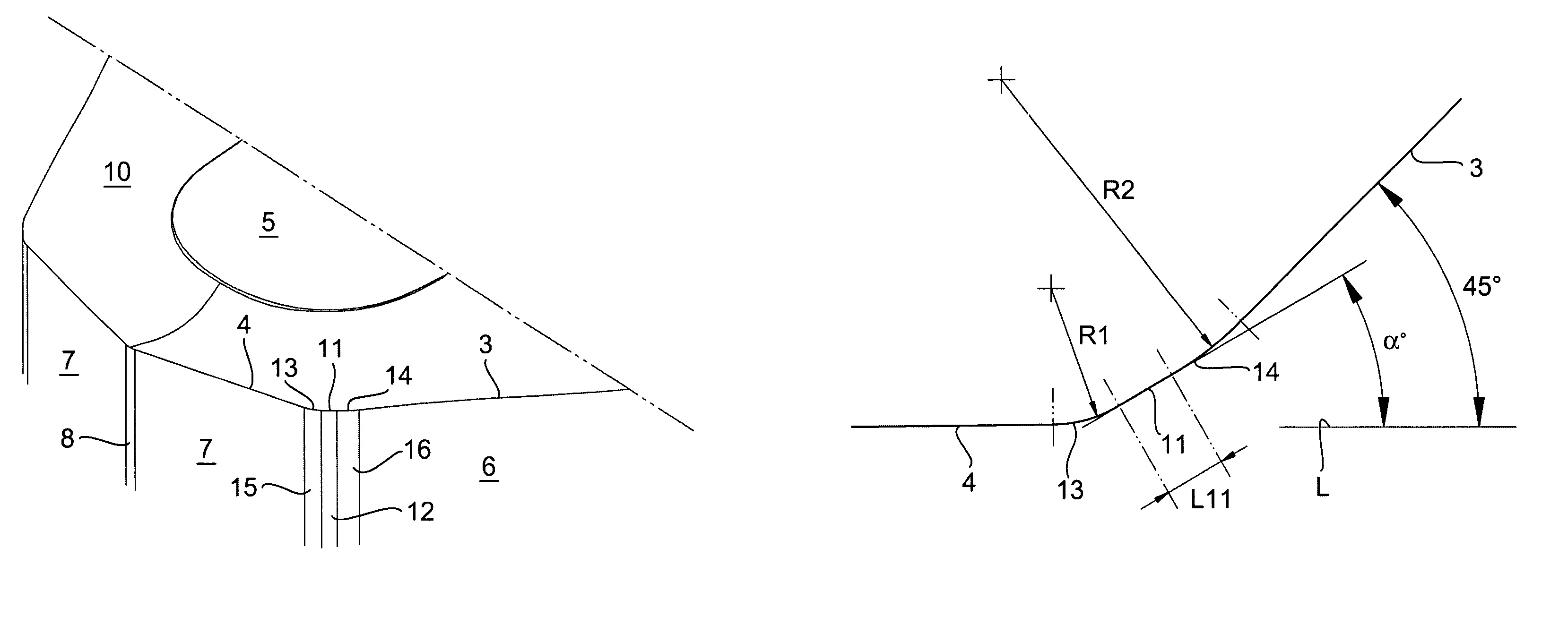

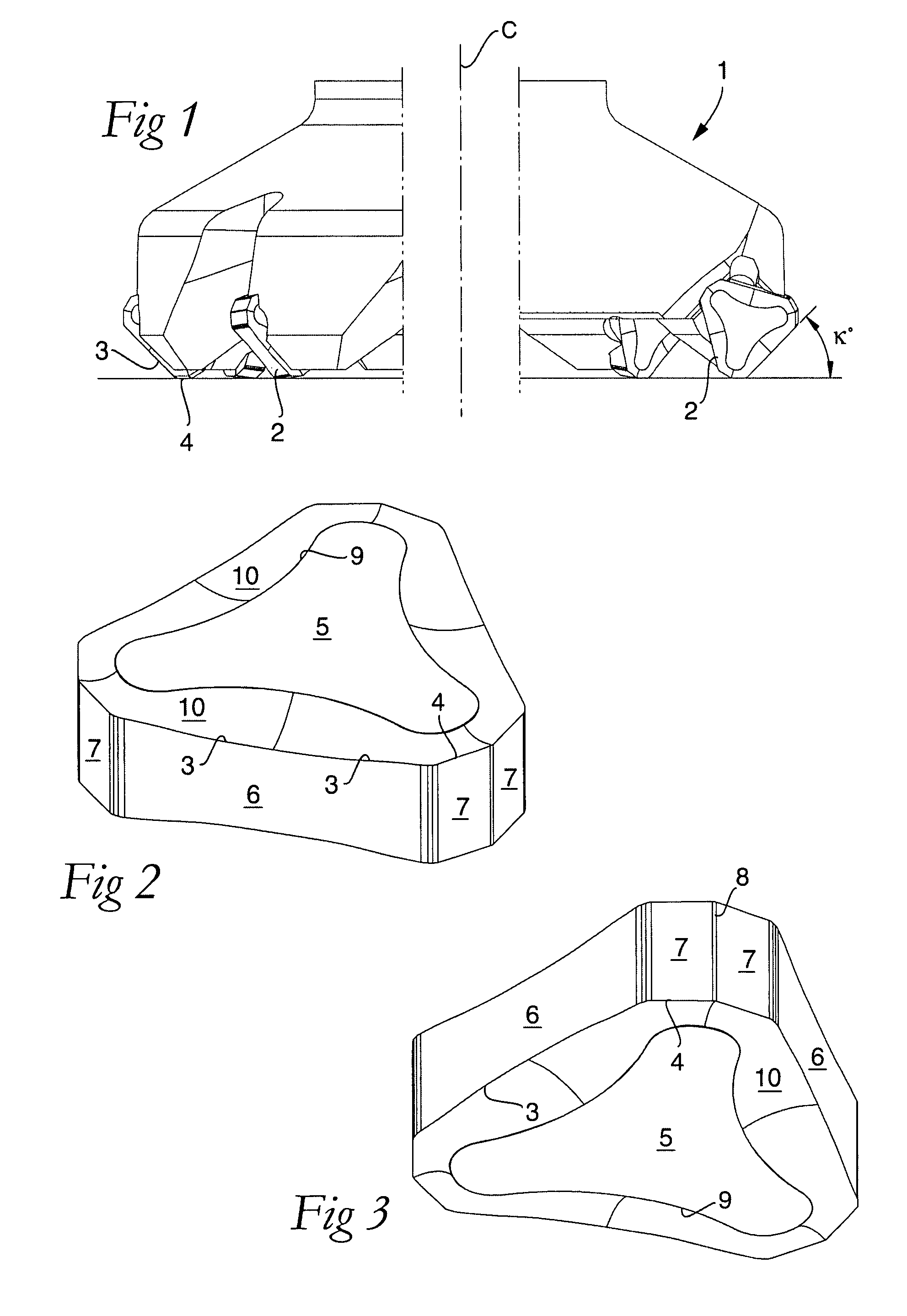

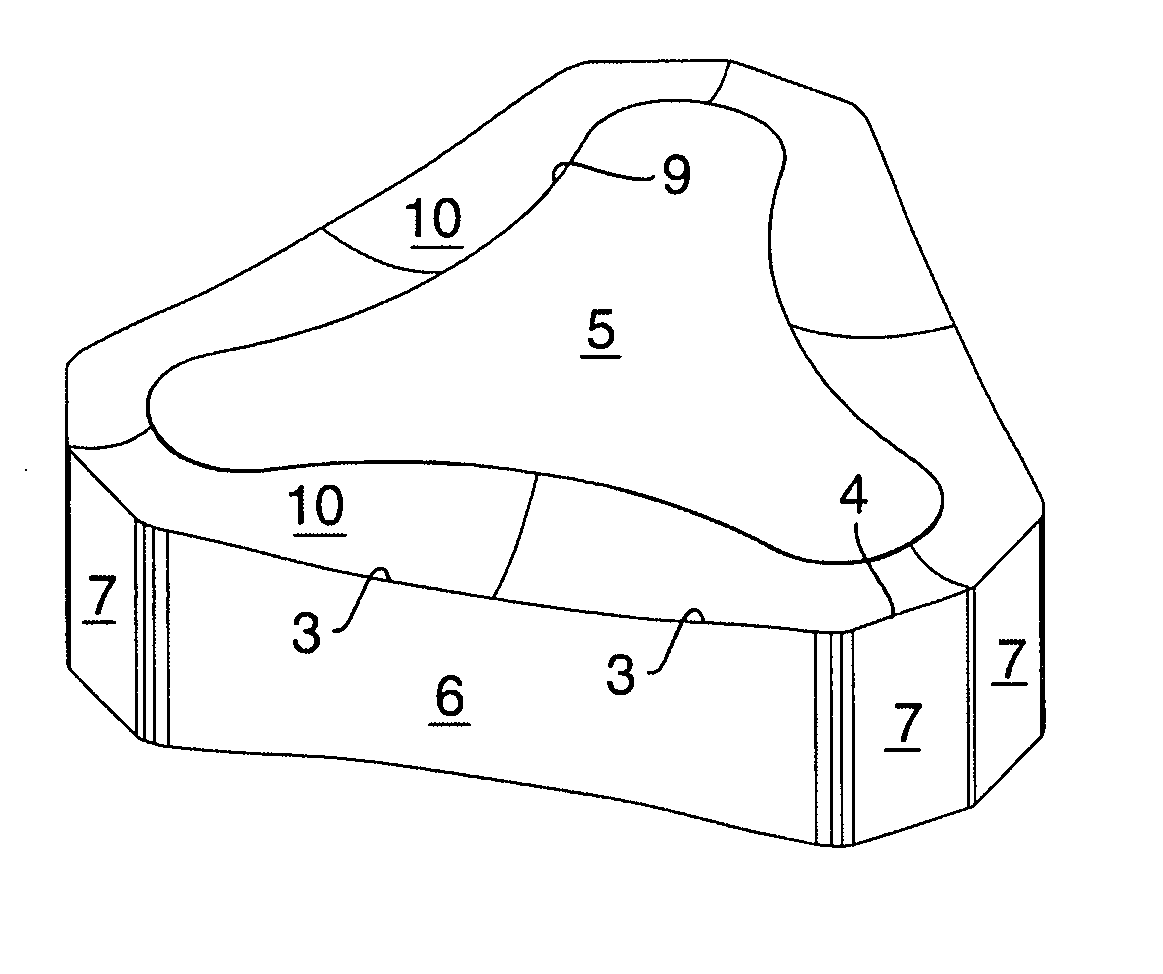

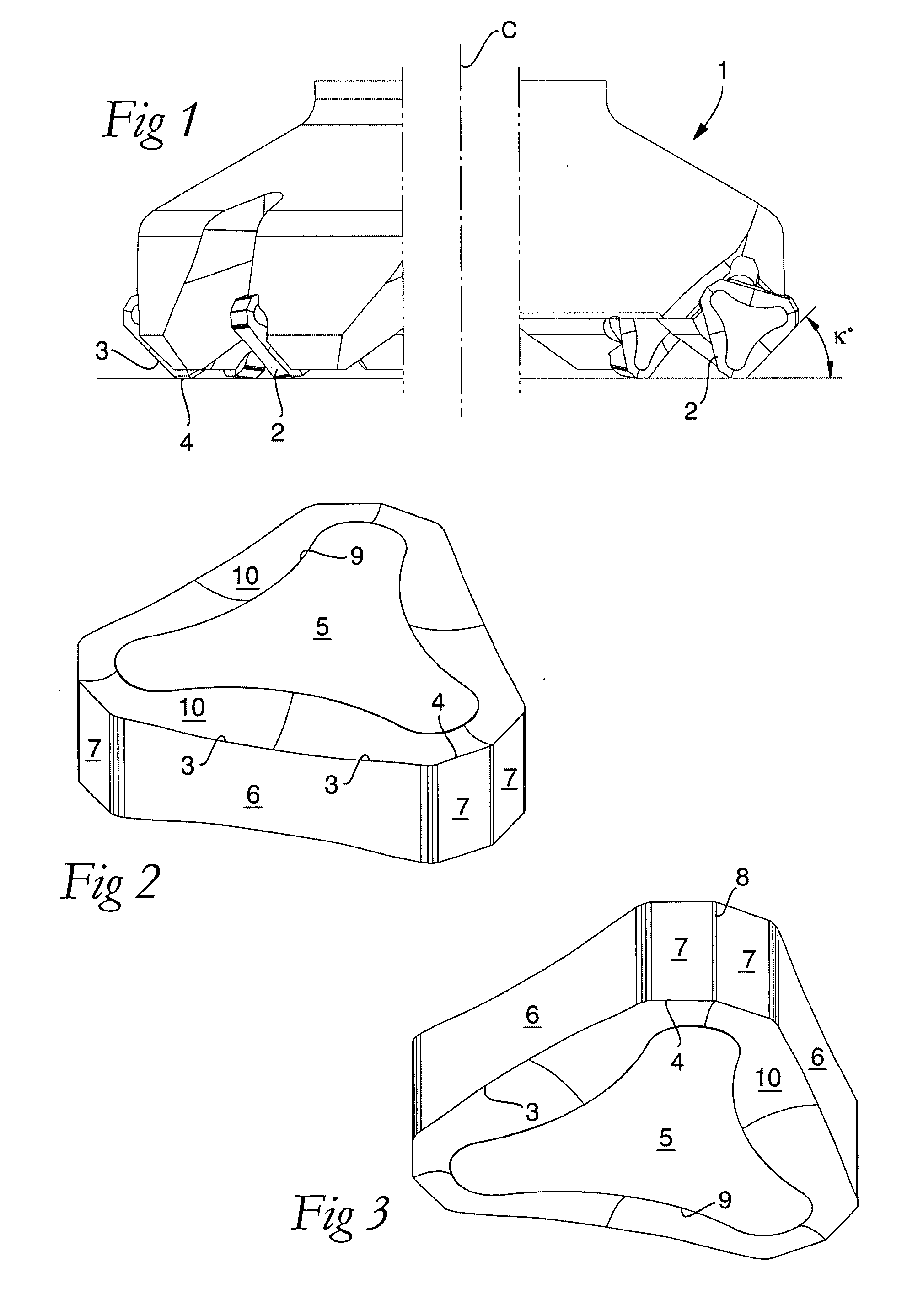

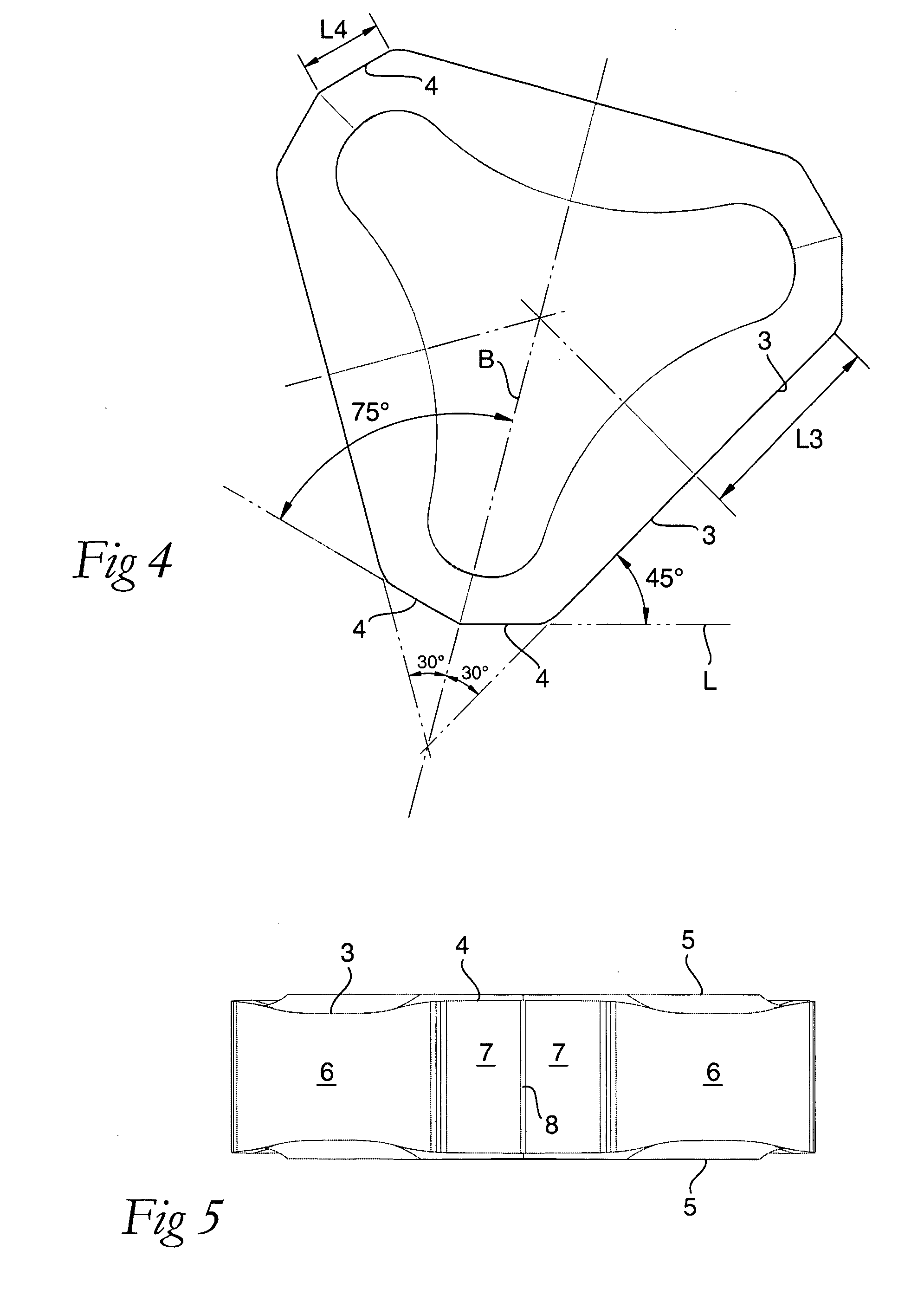

Face milling insert

ActiveUS7547164B2High surface finishEasy to useTransportation and packagingMilling cuttersStructural engineeringEngineering

A face-milling insert, including a chip-removing main cutting edge adjacent to a first clearance surface, and a surface-wiping secondary edge adjacent to a second clearance surface, the main cutting edge forming an angle of 45° with an imaginary straight line in the extension of the secondary edge. Adjacent to a third clearance surface, an intermediate cutting edge is formed between the main cutting edge and the secondary edge, the intermediate cutting edge being shorter than the main cutting edge and forming an angle within a range of 20-40° with the extension line. The intermediate cutting edge transforms into the adjacent edges via arched part edges adjacent to convex clearance surfaces.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

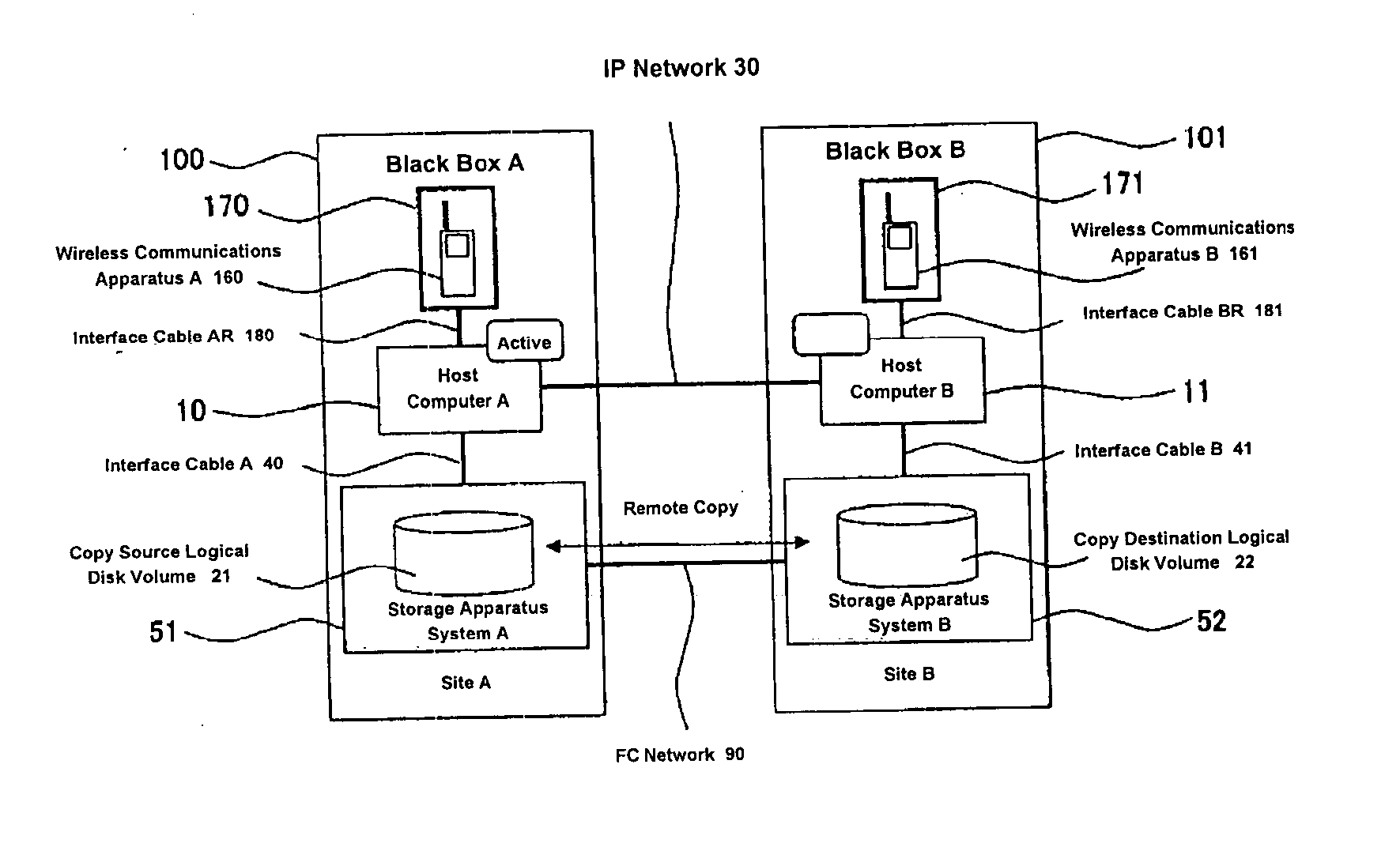

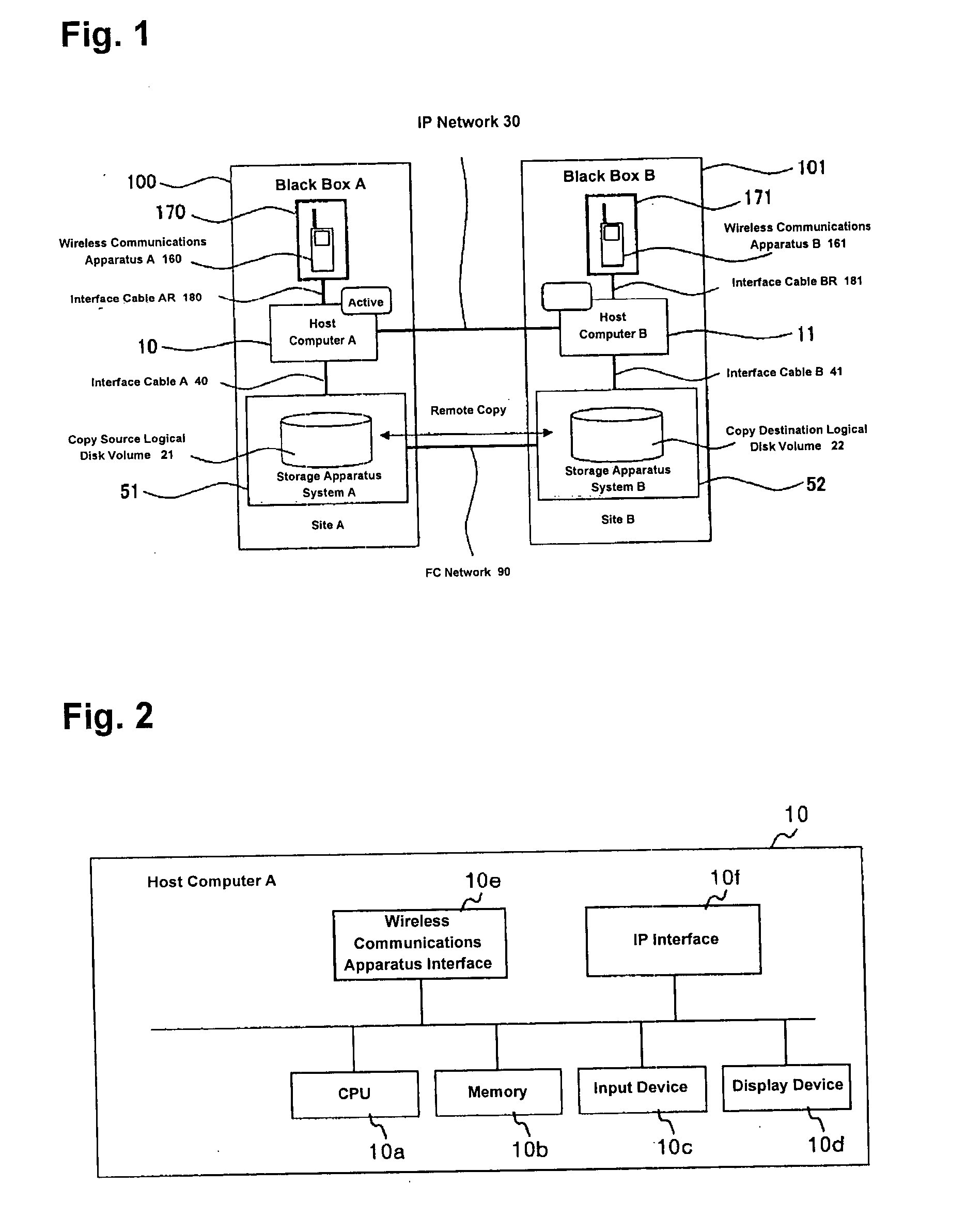

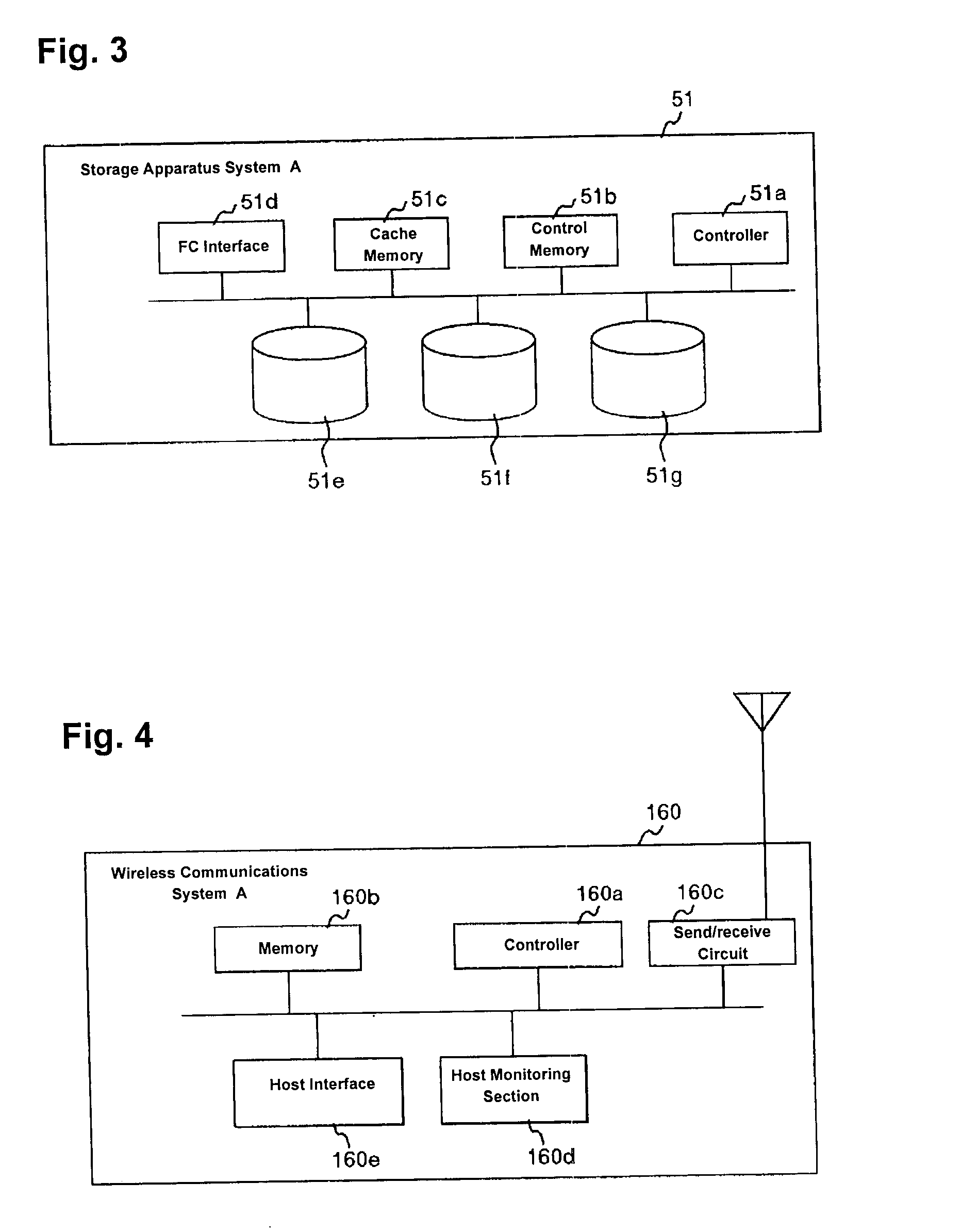

Cluster computing system and its failover method

InactiveUS20050005001A1Eliminate shortcomingsImprove system reliabilityDigital computer detailsTransmissionFailoverActive systems

A cluster computing system includes an active system and a standby system connected via wire networks. The active system and the standby system each has a wireless communications apparatus, such that when all of the wire networks connecting the active system with the standby system are disconnected, the wireless communications apparatus of the active system reports the standby system of the failure of the active system using its wireless communications capability with the wireless communications apparatus of the standby system. The report includes the verification ID of the active system, and the standby system begins operation upon receiving a packet containing the verification ID.

Owner:HITACHI LTD

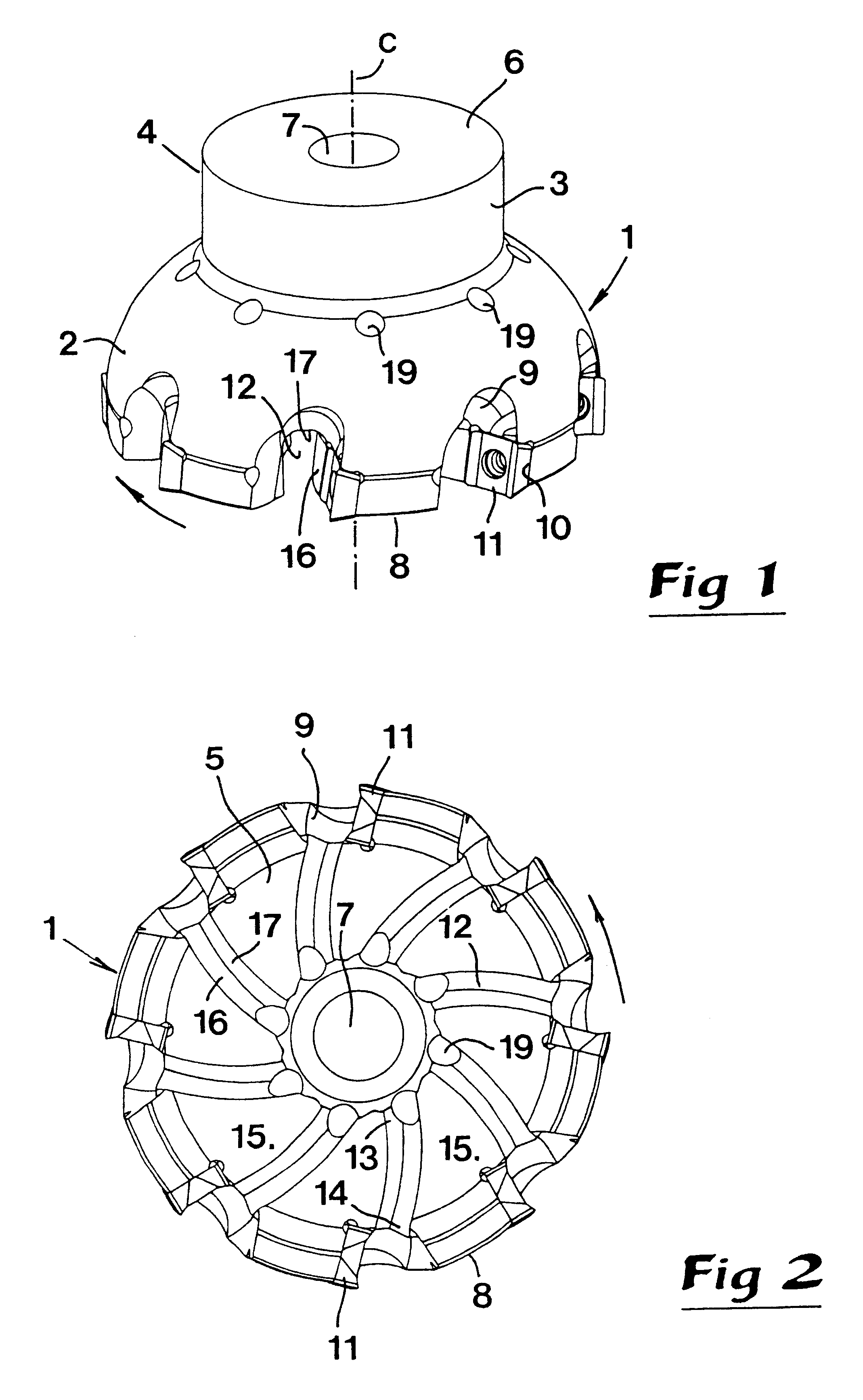

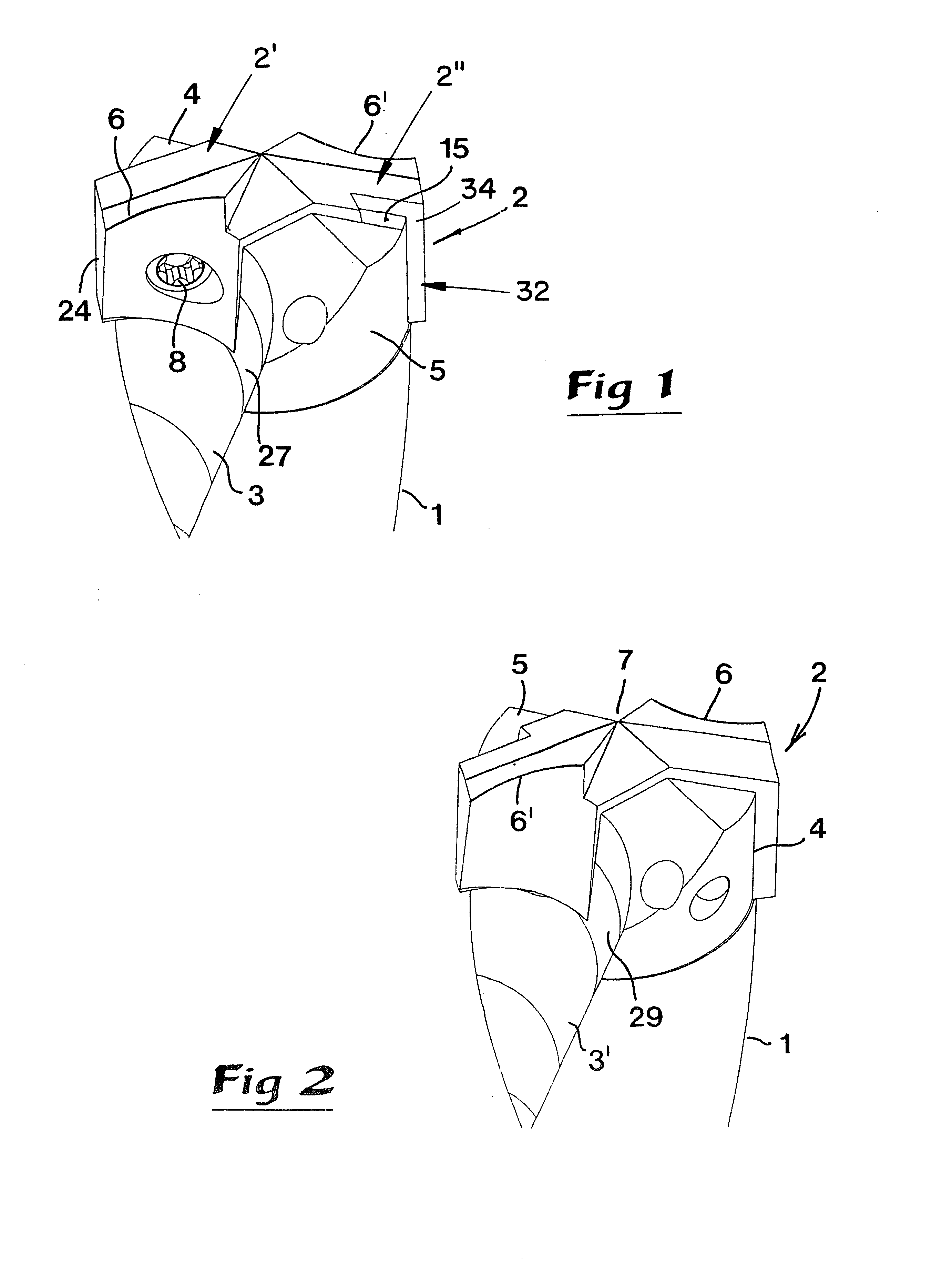

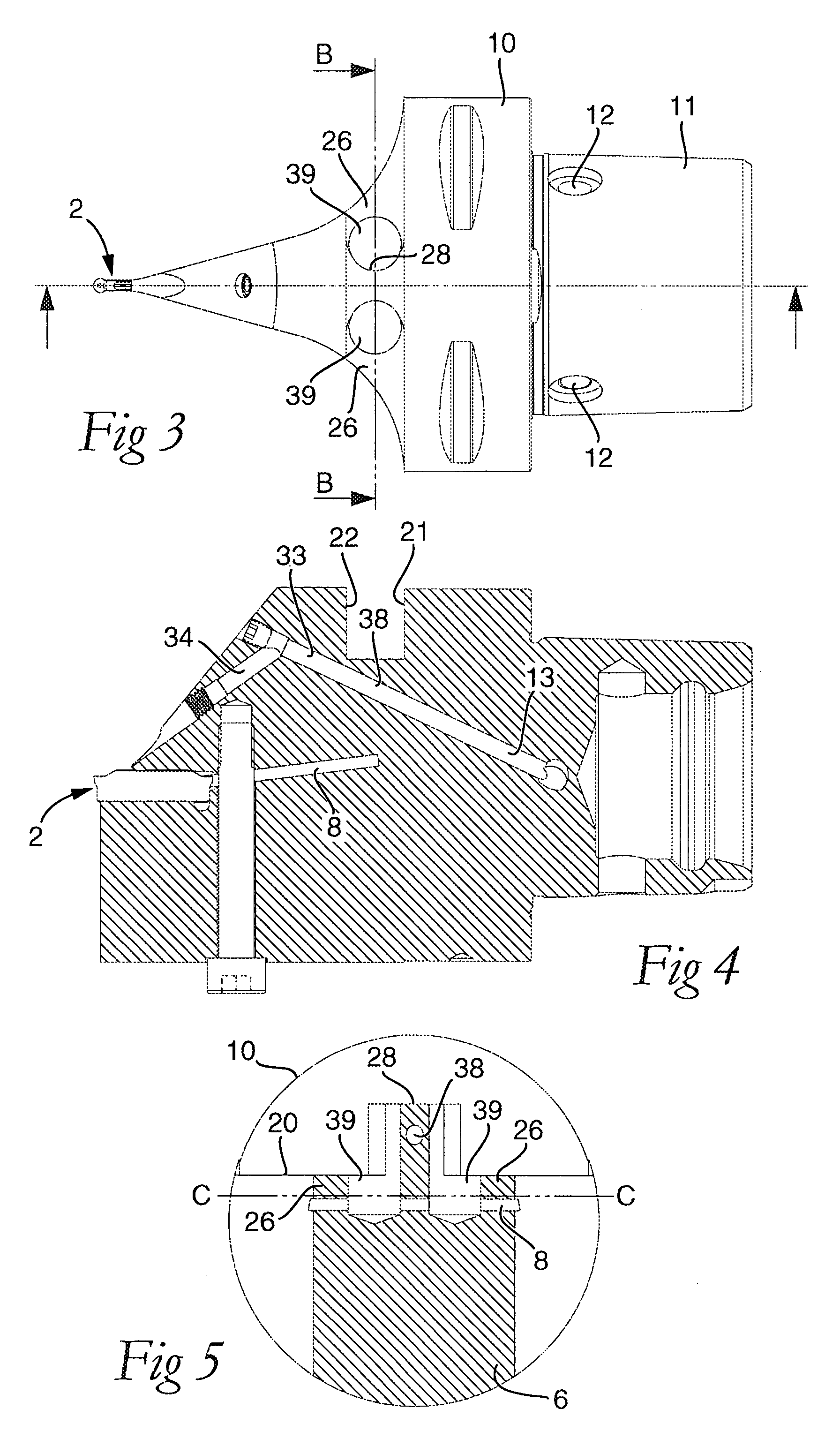

Milling cutter head and a milling cutter tool

InactiveUS20070081873A1Large formatEliminate shortcomingsMilling cuttersAttachable milling devicesFluteTool bit

A milling cutter head in the form of a body, which has an external envelope surface having a rotationally symmetrical basic shape in respect of a central axis, and includes a plurality of peripherally spaced-apart cutting edges and chip flutes. The cutter head includes two axially spaced-apart ends in which hollow spaces open, which are arranged to receive male elements included in a basic body, and are spaced-apart by a partition wall in which a through hole is formed. The through hole mouths in bottom surfaces in the hollow spaces. The cross-section area of each individual hollow space, in a plane perpendicular to the center axis, amounts to at least 25% of the total cross-section area of the body, as defined by the greatest diameter of the envelope surface.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

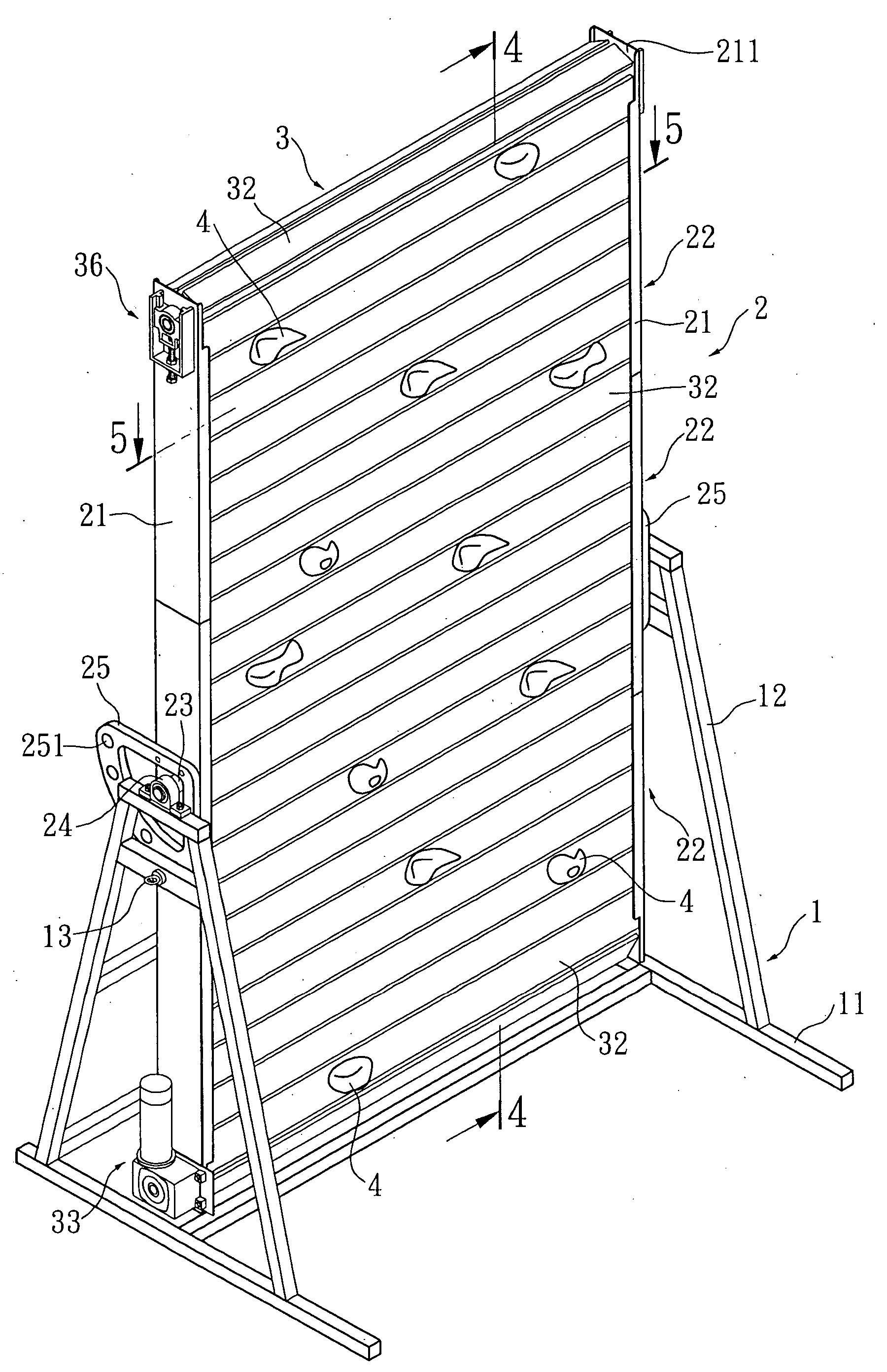

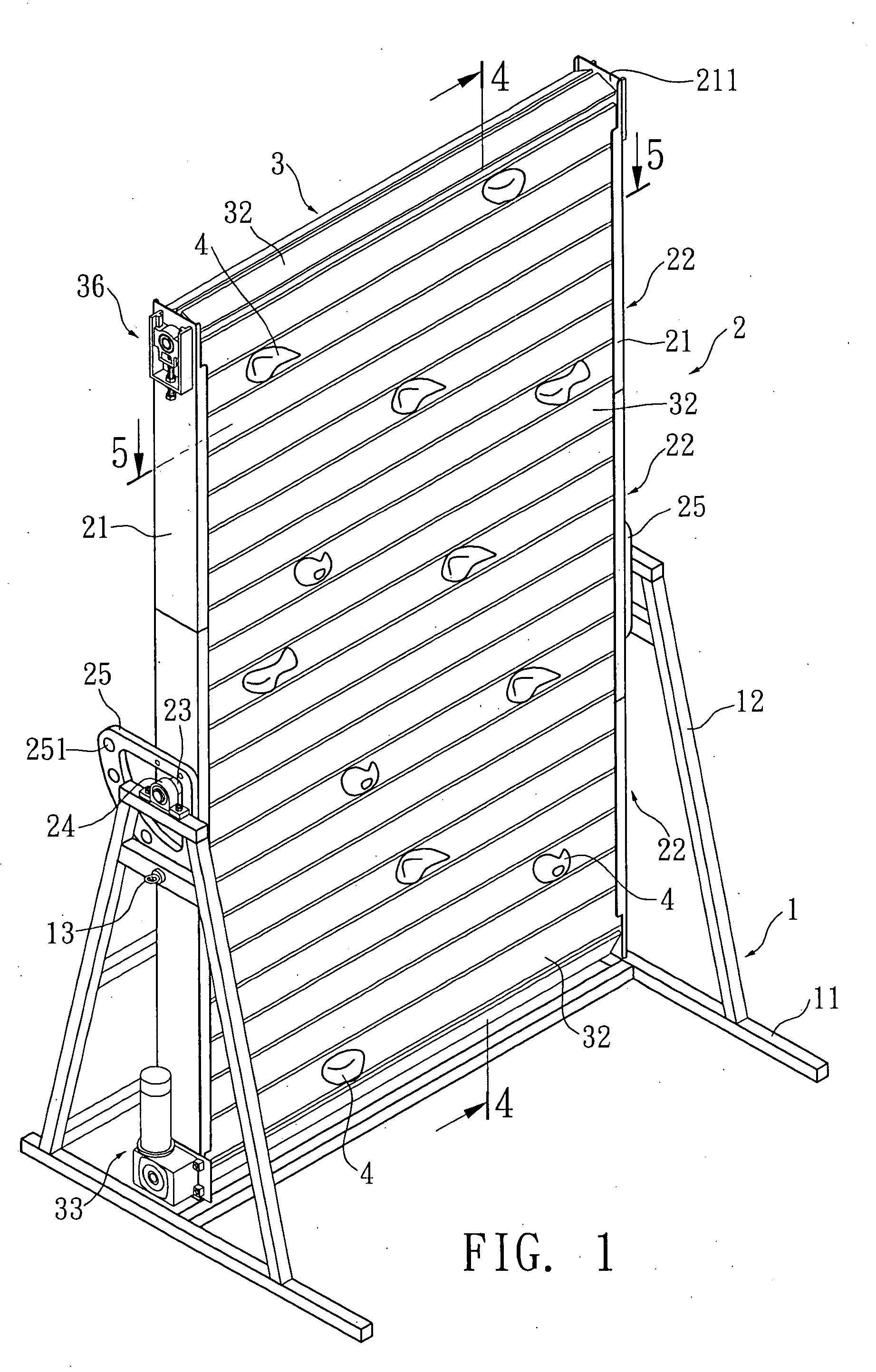

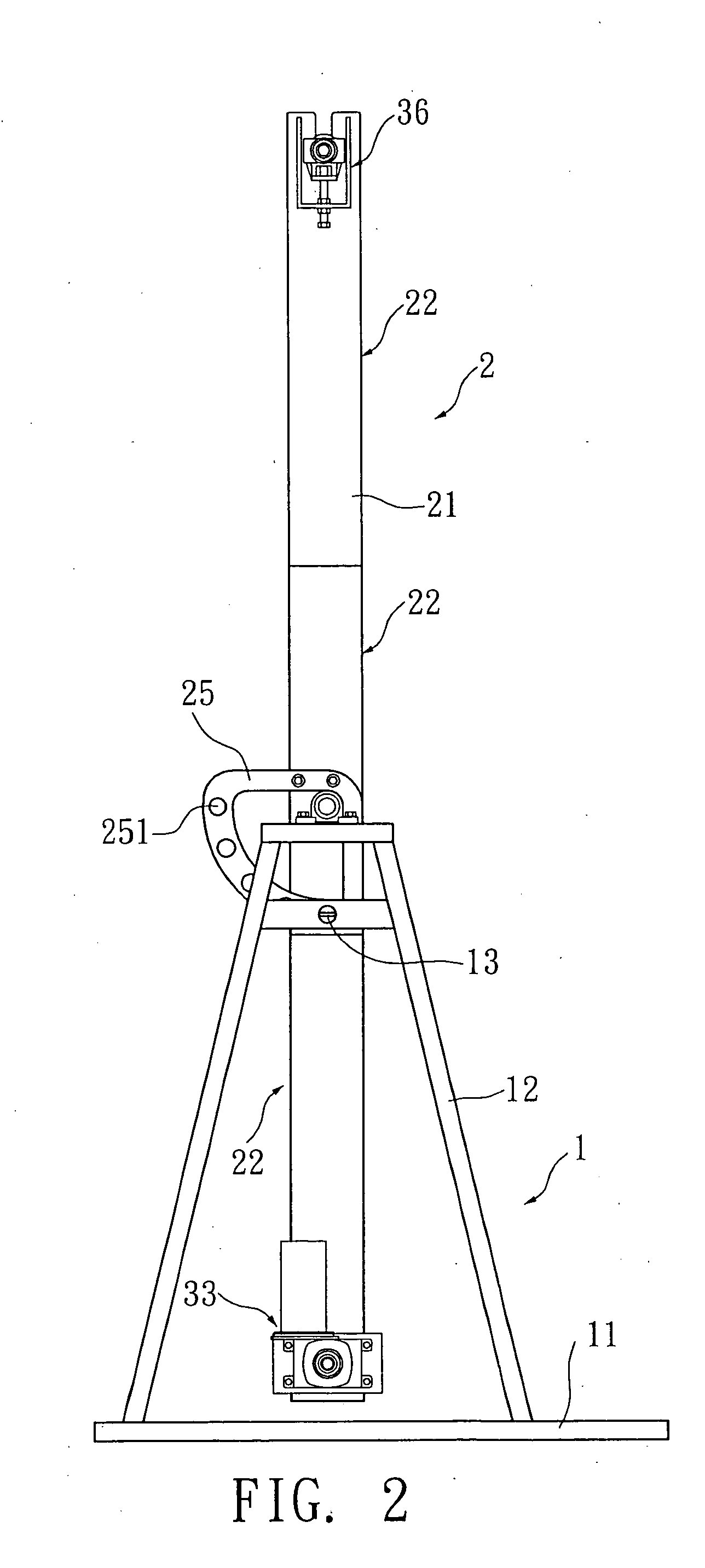

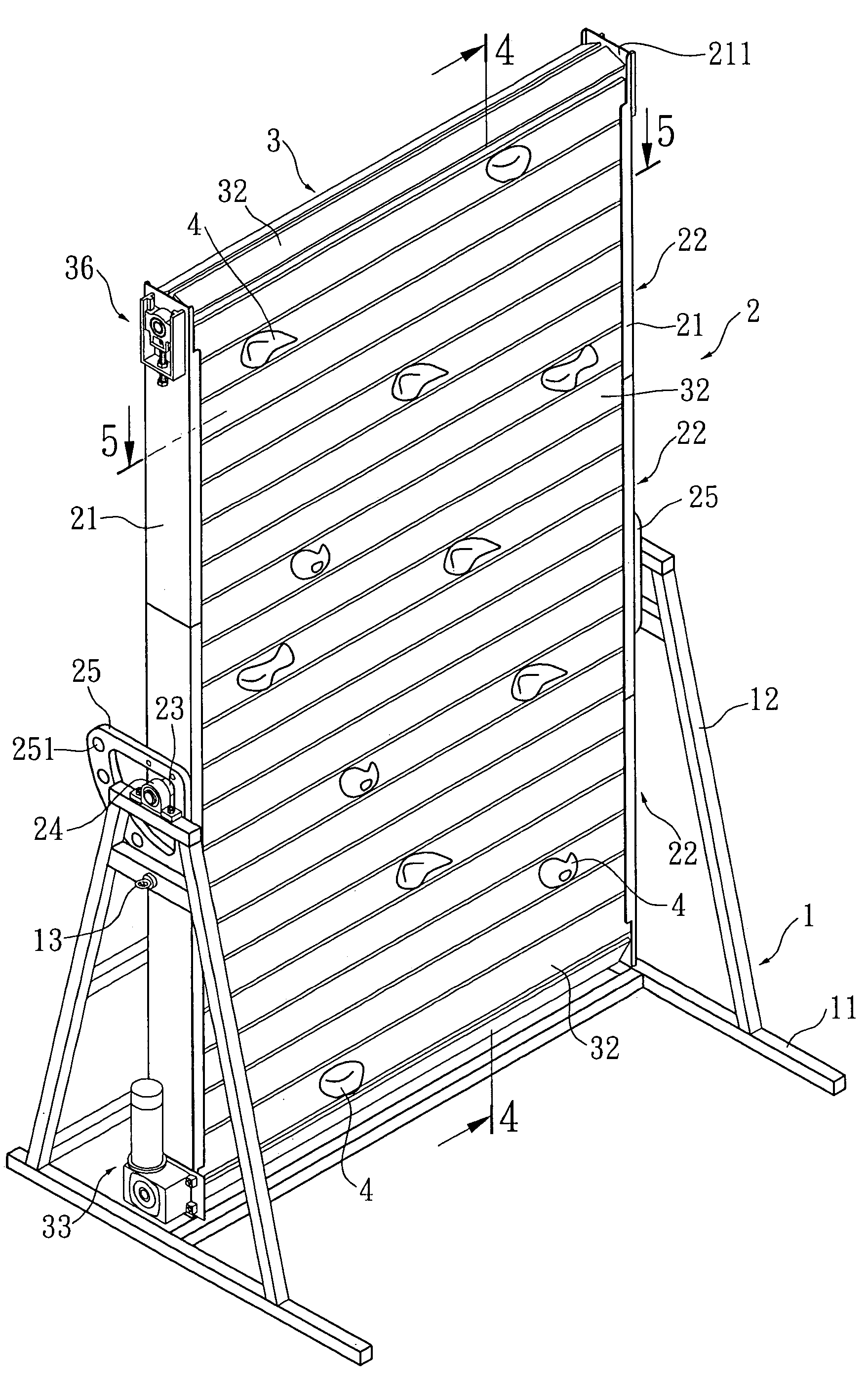

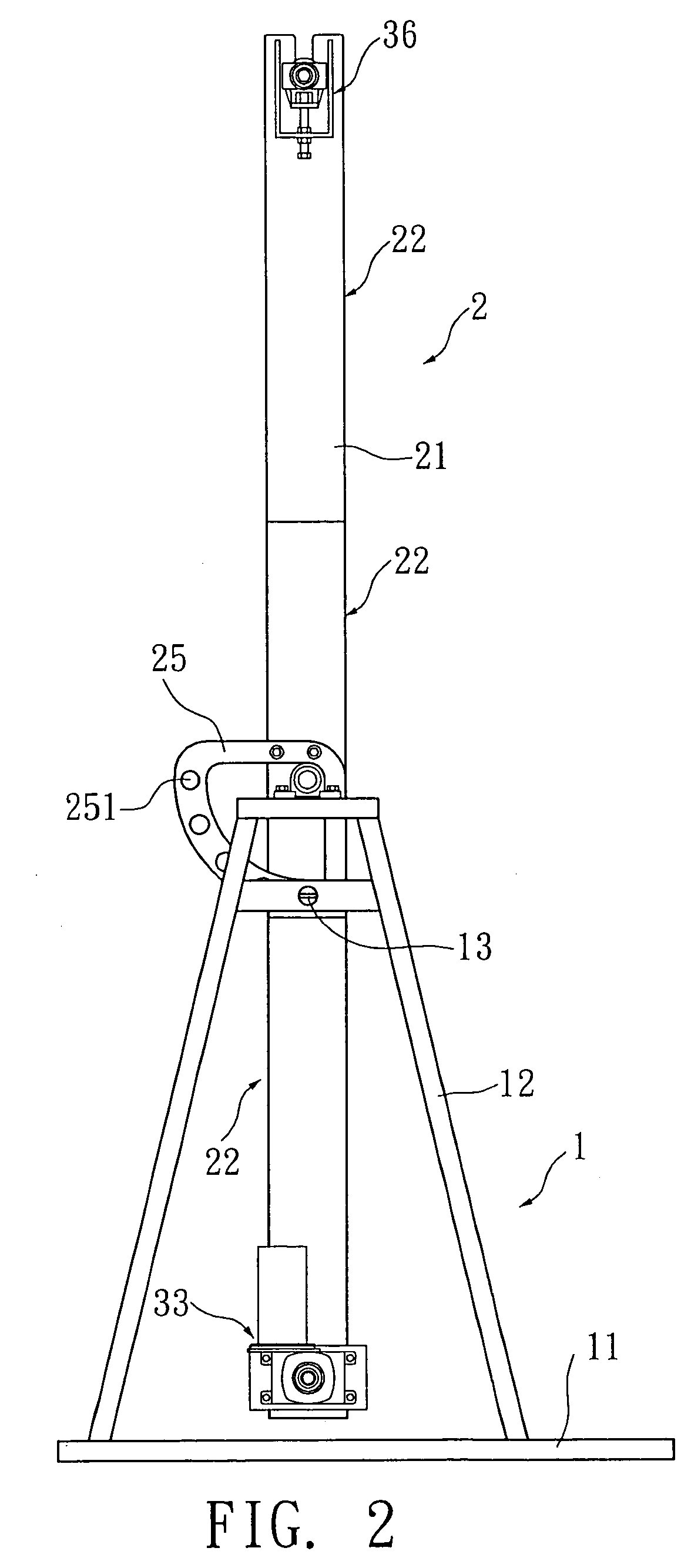

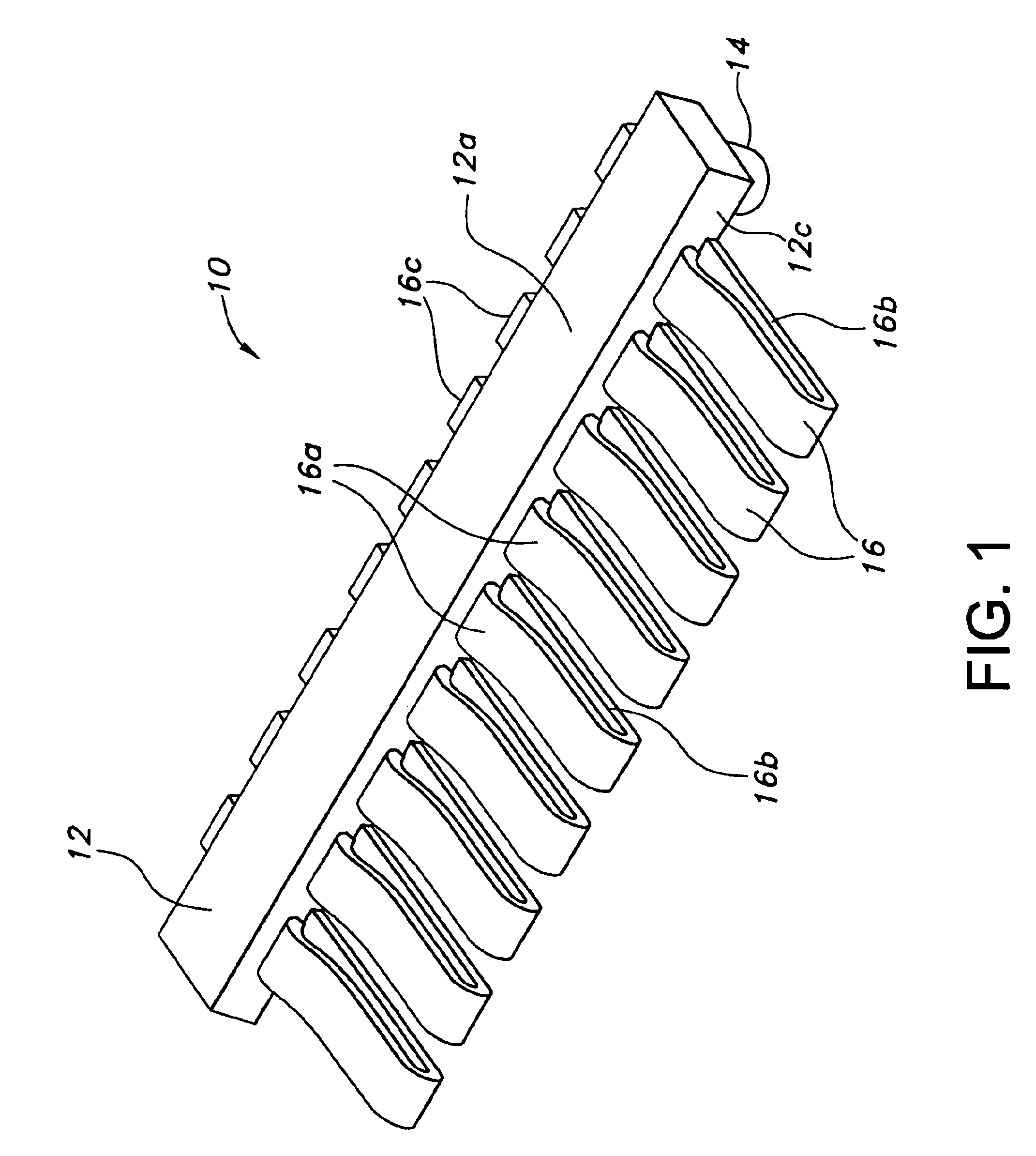

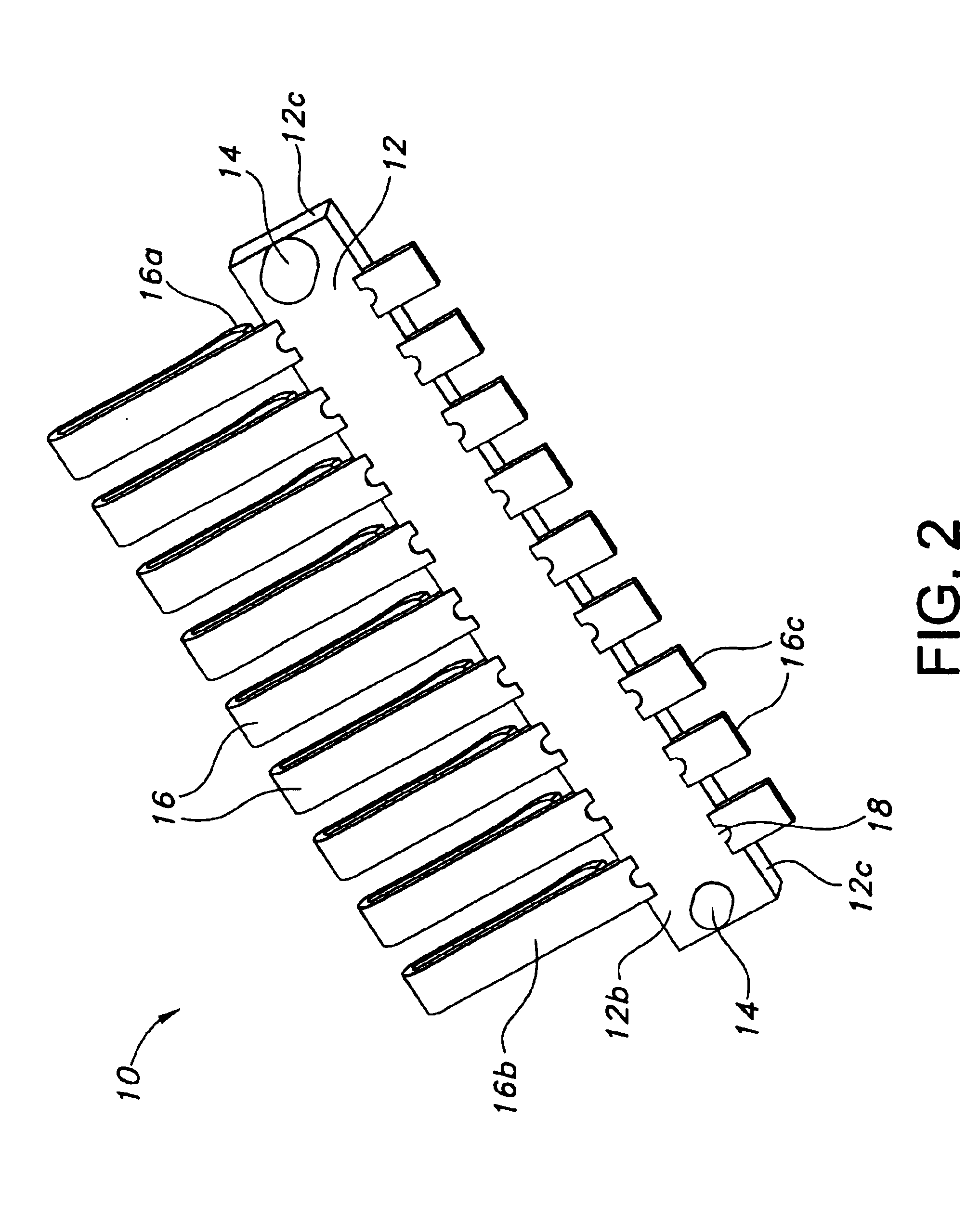

Rock climbing apparatus

A rock climbing apparatus including a support stand on which a main body frame is mounted. The main body frame has two lateral columns, several transverse support beams and several longitudinal support columns built between the lateral columns to serve as a support skeleton. A rotary mechanism is arranged in the main body frame, including at least two chains in parallel to the length of the main body frame, multiple transverse slats in parallel to the width of the main body frame and a power supply for driving the chains to circularly revolve. The longitudinal support columns of the main body frame are arranged in a position where the chains are positioned. Each longitudinal support column has a rib rail, whereby the link shafts of the chains are slidably leant on the rib rail. The transverse slats are fixed on the chains and immediately adjacent to each other. The chains are positioned near the middle of the transverse slats. The transverse slats can circularly revolve along the lateral columns. Several rocks are locked on one face of each transverse slat distal from the chains for a user to climb.

Owner:WU YU FENG

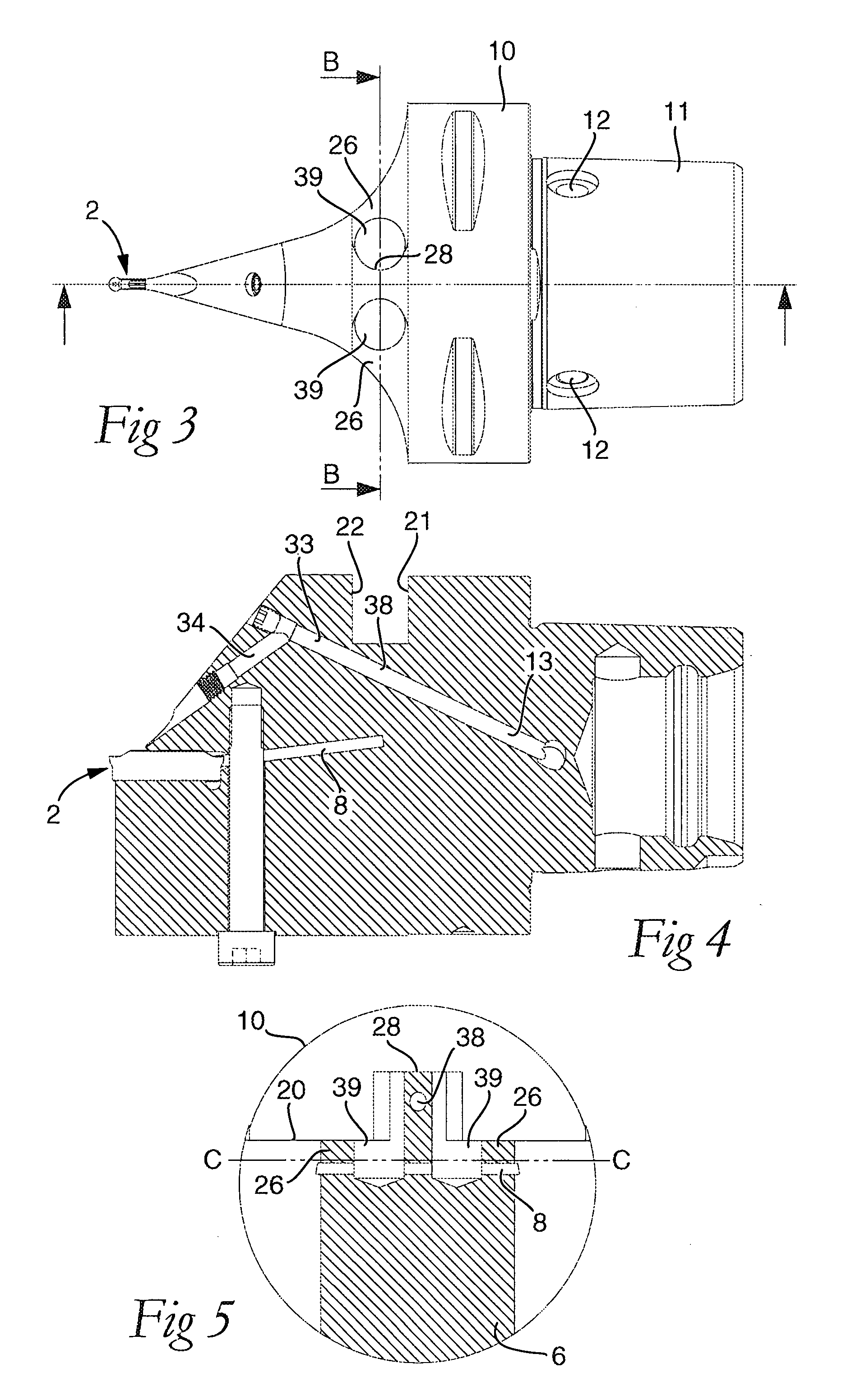

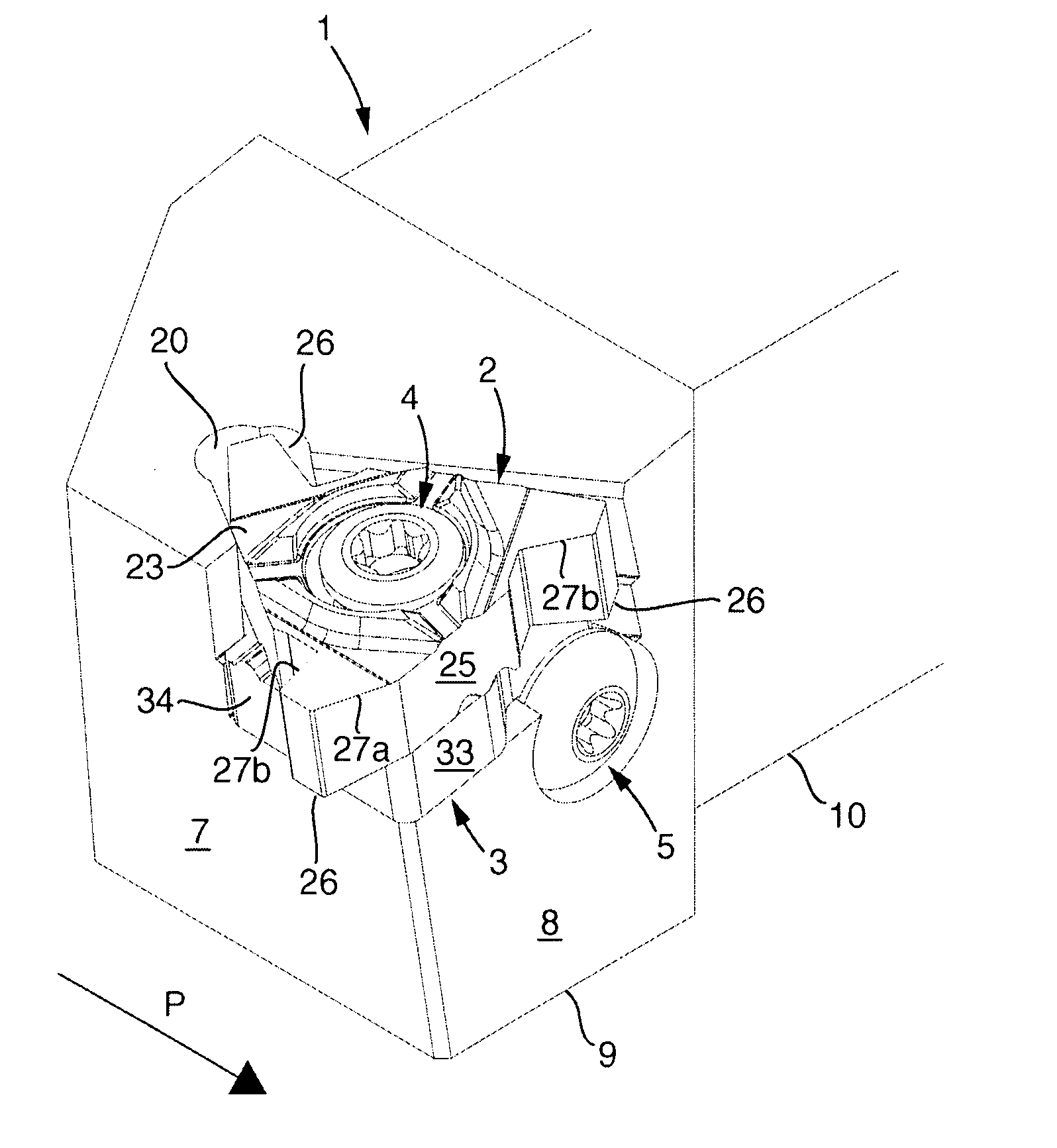

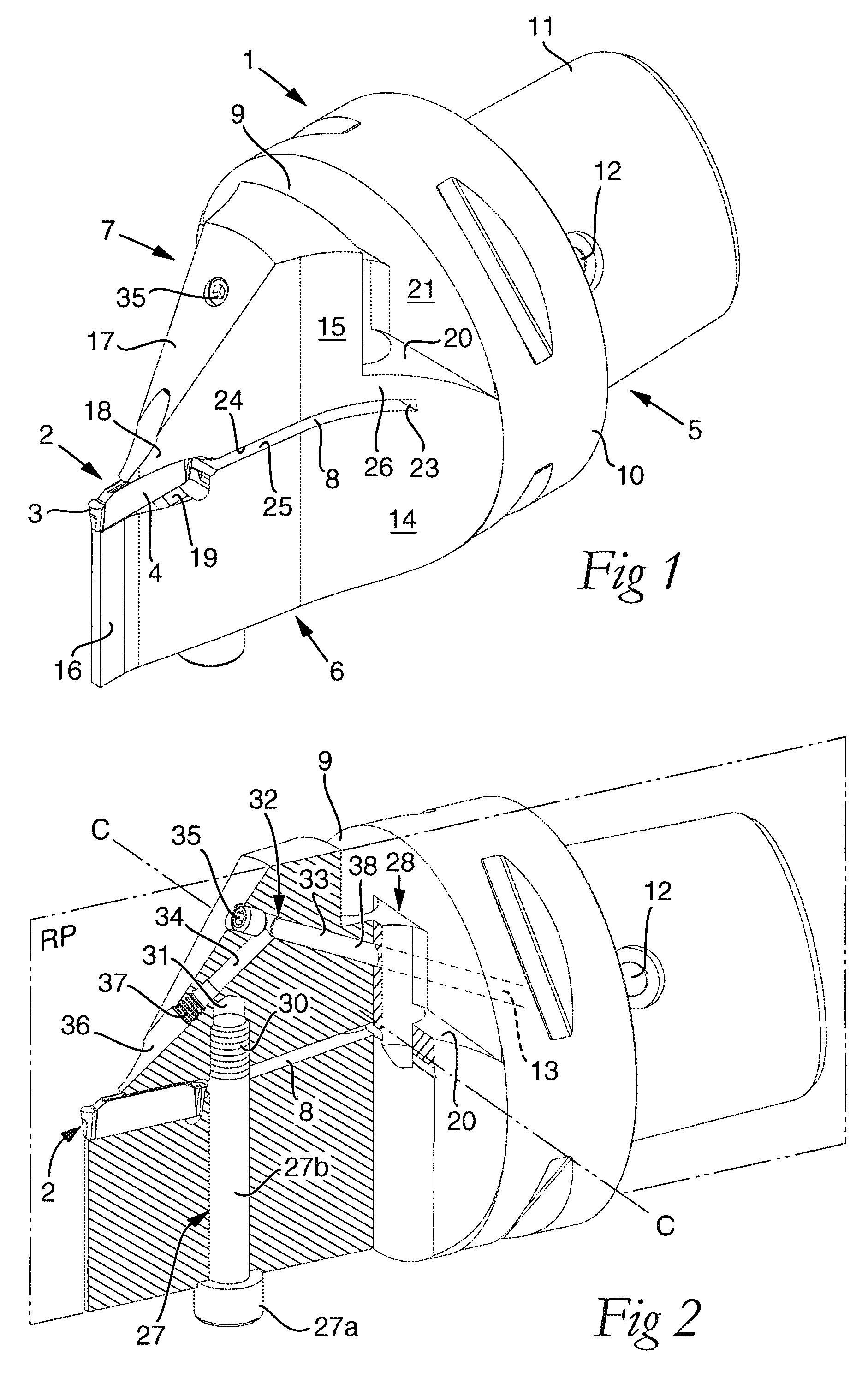

Tool for chip removing machining and a basic body therefor

InactiveUS20080131215A1Sufficient strainAccurate precisionCutting insertsTurning toolsMechanical engineering

A tool for chip removing machining, including a replaceable cutting insert and a basic body. The basic body includes a rear fixing part, a front supporting part having an insert seat, and a tightening part situated over the support part, and spaced-apart from the front supporting part by a first gap and from the rear fixing part by a second gap. The tightening part is connected to the basic body via a joint. The joint is formed of at least one elastically resilient material portion and has an axis around which the tightening part is pivoted in order to press the cutting insert against the insert seat by a front finger. The rear fixing part includes an internal channel for feed of a fluid in the forward direction through the basic body. The internal channel extends into a second channel inside the tightening part via a channel section that is entirely or partly housed in a bridge which, like the joint, is formed of the material in the basic body, and which bridges one of the first and second gaps.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

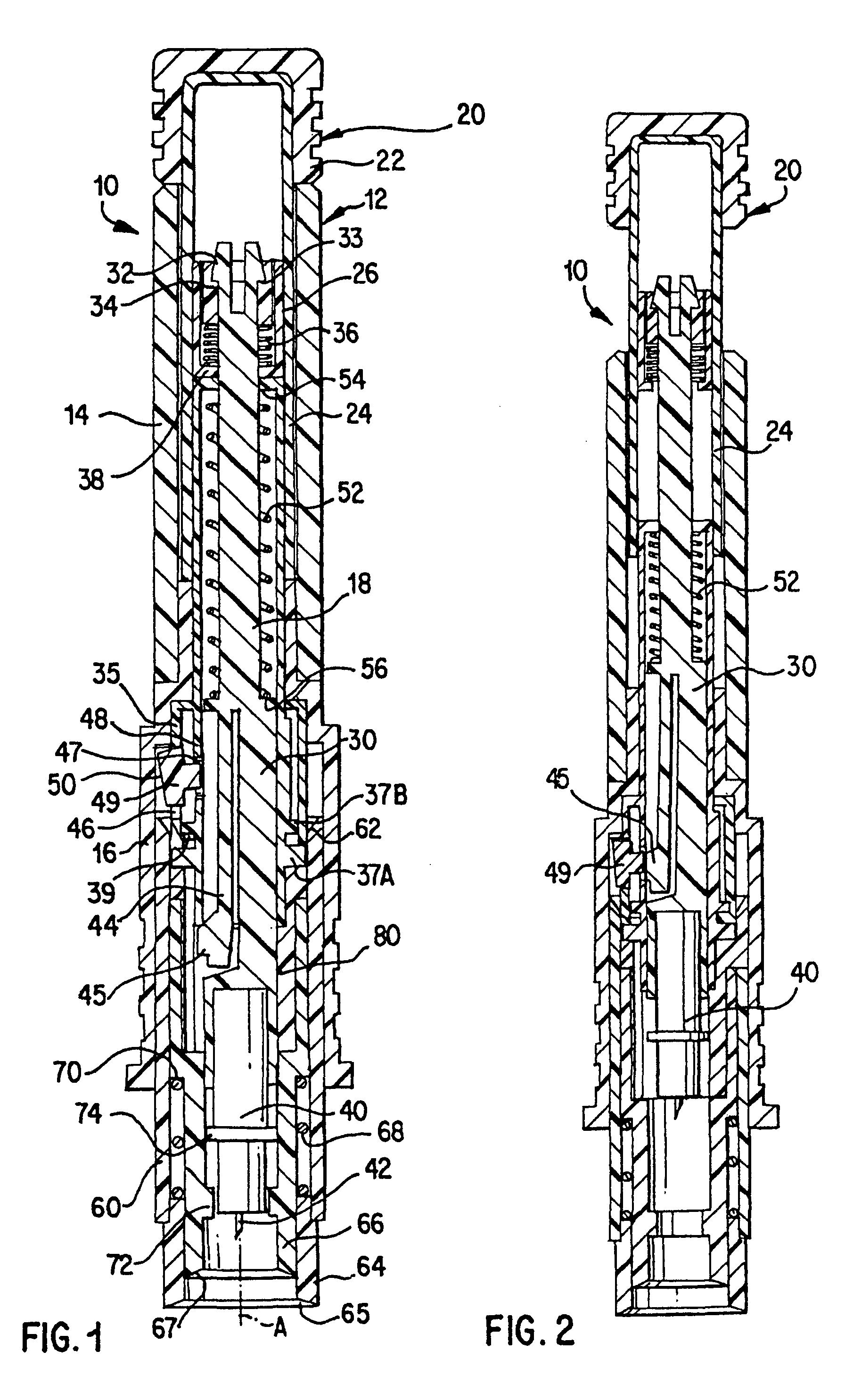

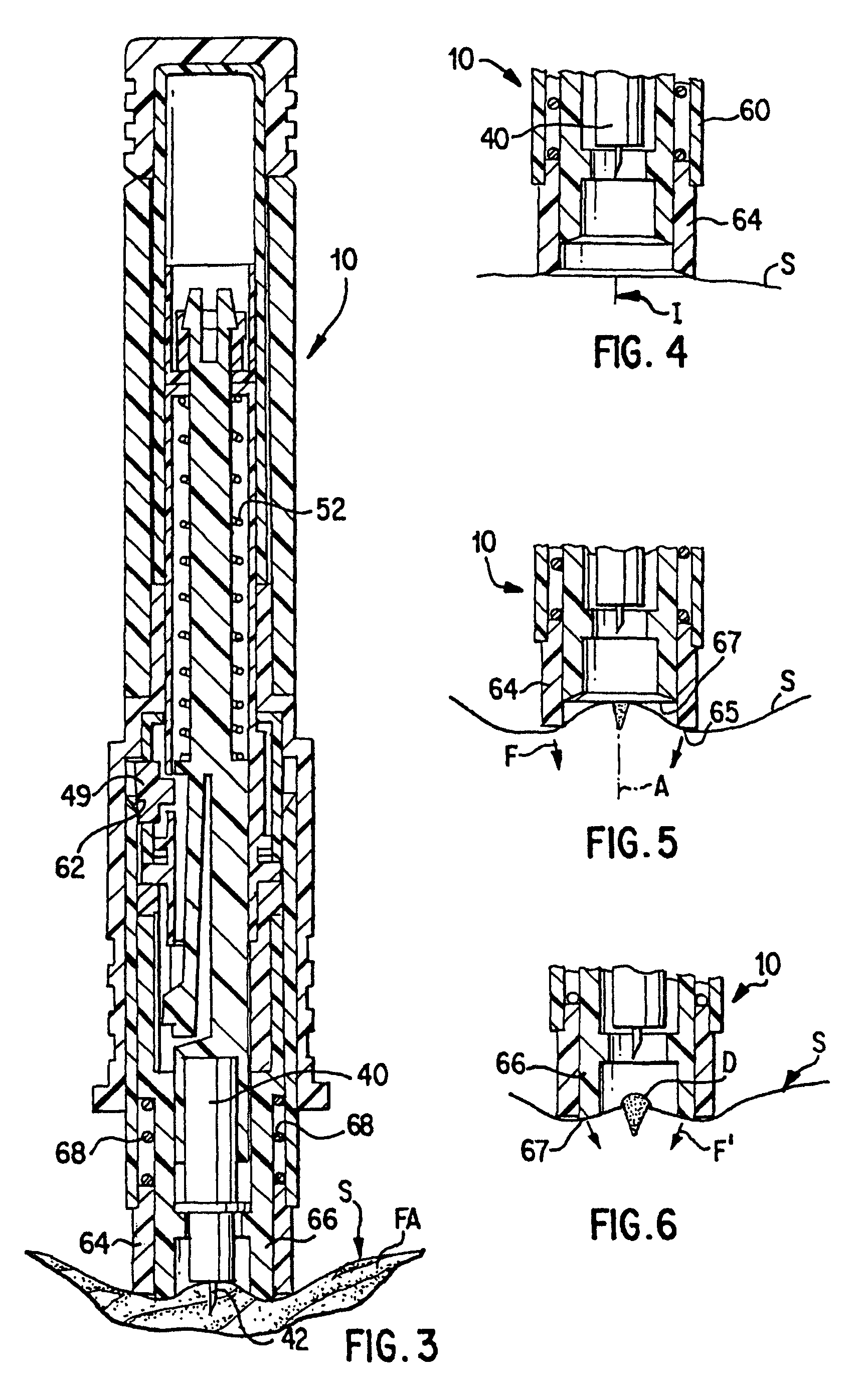

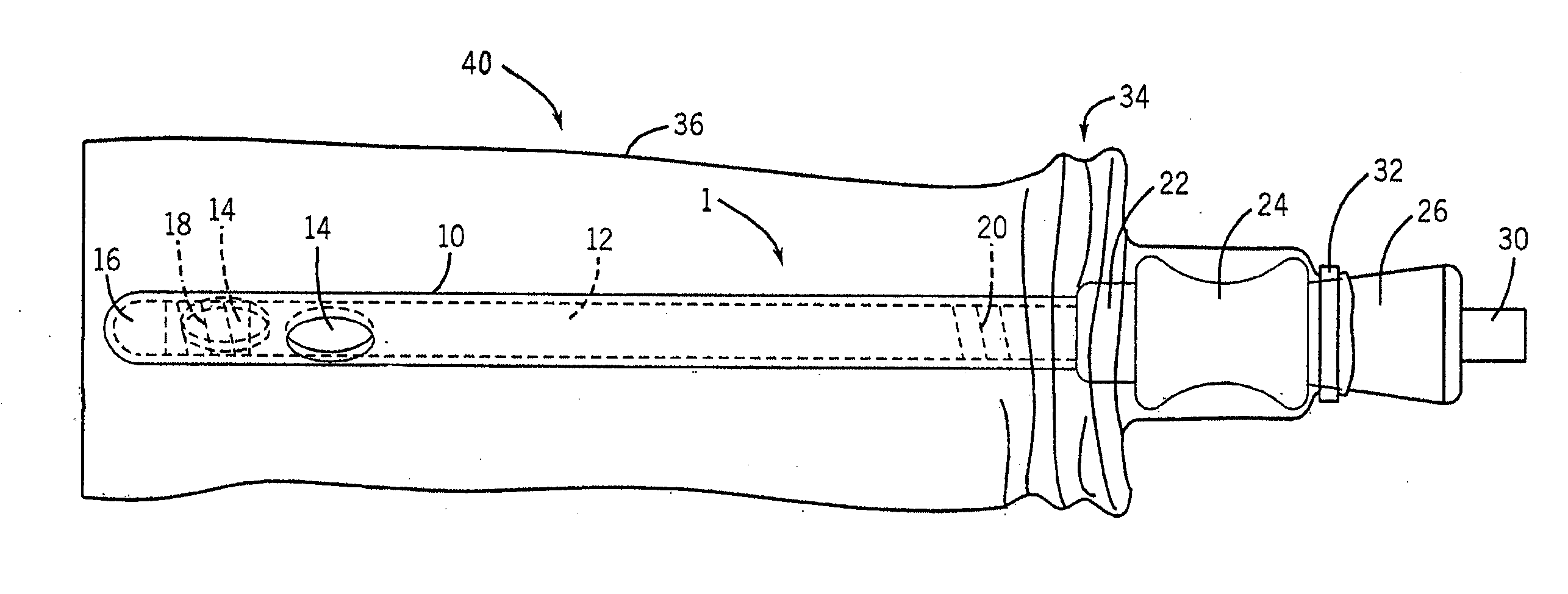

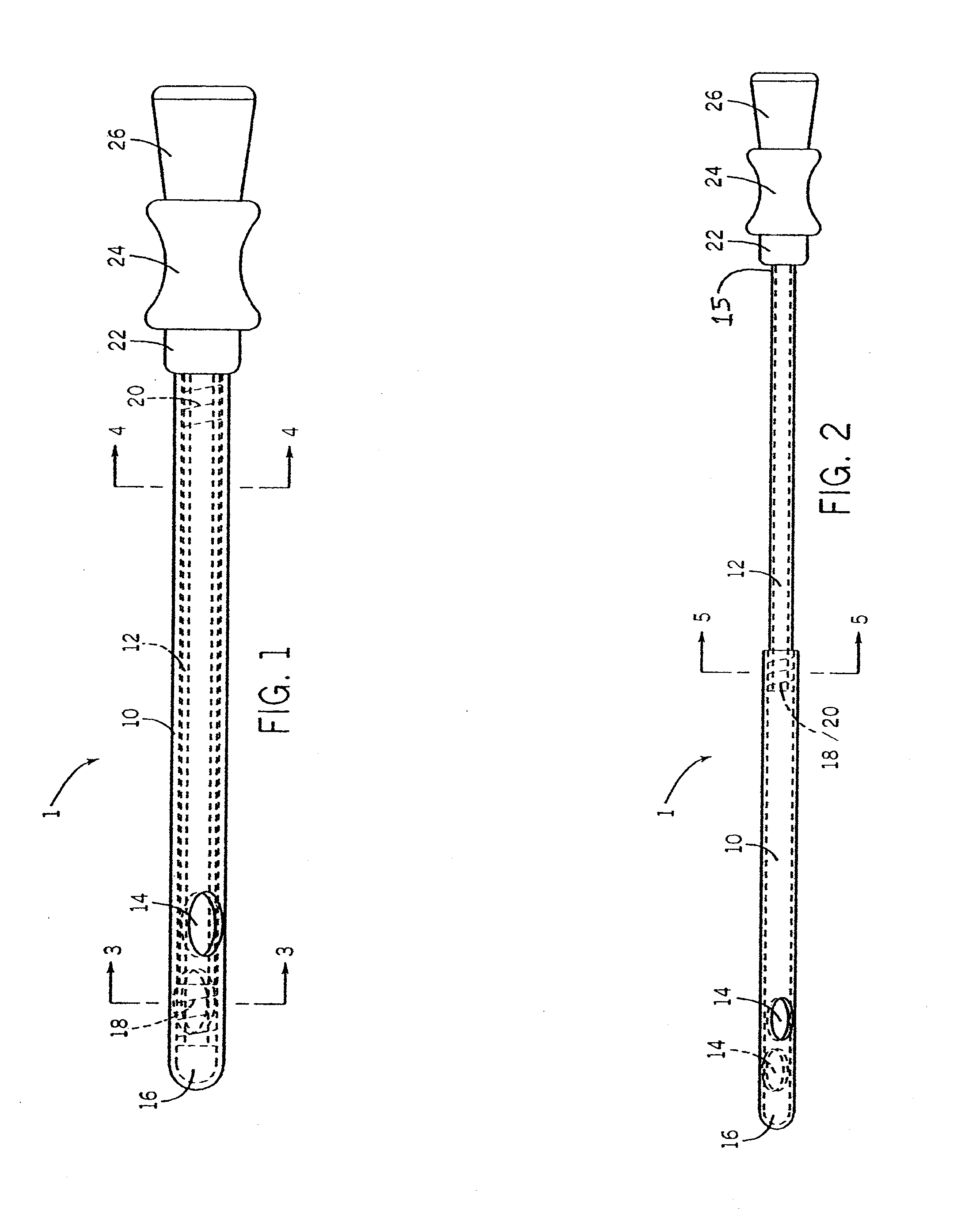

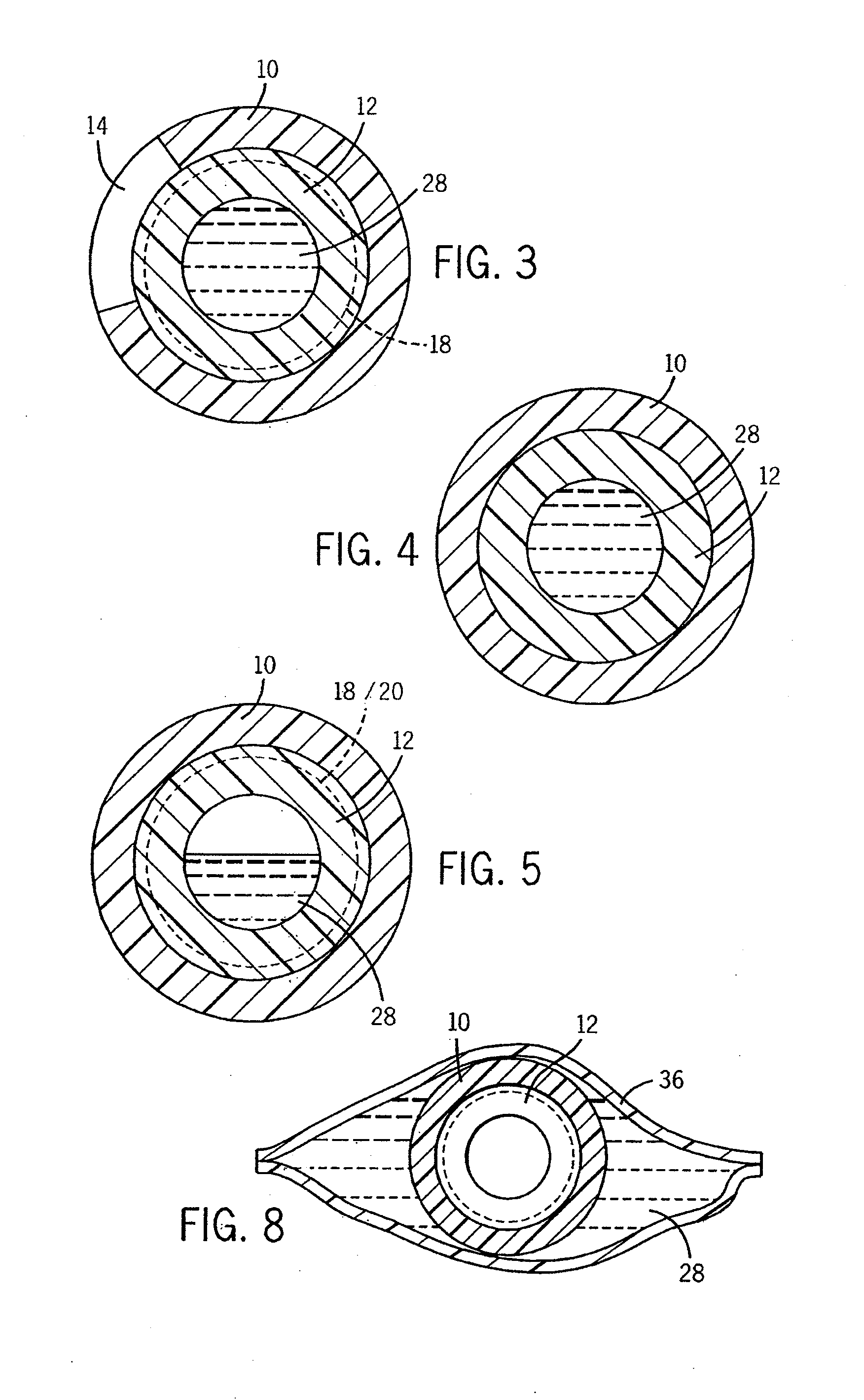

Catheter Having Internal Hydrating Fluid Storage and/or Catheter Package Using the Same and Method of Making and/or Using the Same

A catheter assembly (1) includes an inner member (12) having a proximal end (15), a distal end (13), and a lumen configured to store a hydrating fluid (28) An outer member (10) has a proximal end (19), a distal end (16), and a lumen configured to receive therein a portion of the inner member (12) The outer member (10) is movable relative to the inner member (12) at least one of between a first position (FIG. 1) preventing fluid (28) from passing out of the at least one drainage opening (14) from within the lumen of the inner member (12) and a second position (FIG. 2) allowing fluid (28) to pass out of the at least one drainage opening (14) from within the lumen of the inner member (12).

Owner:CR BARD INC

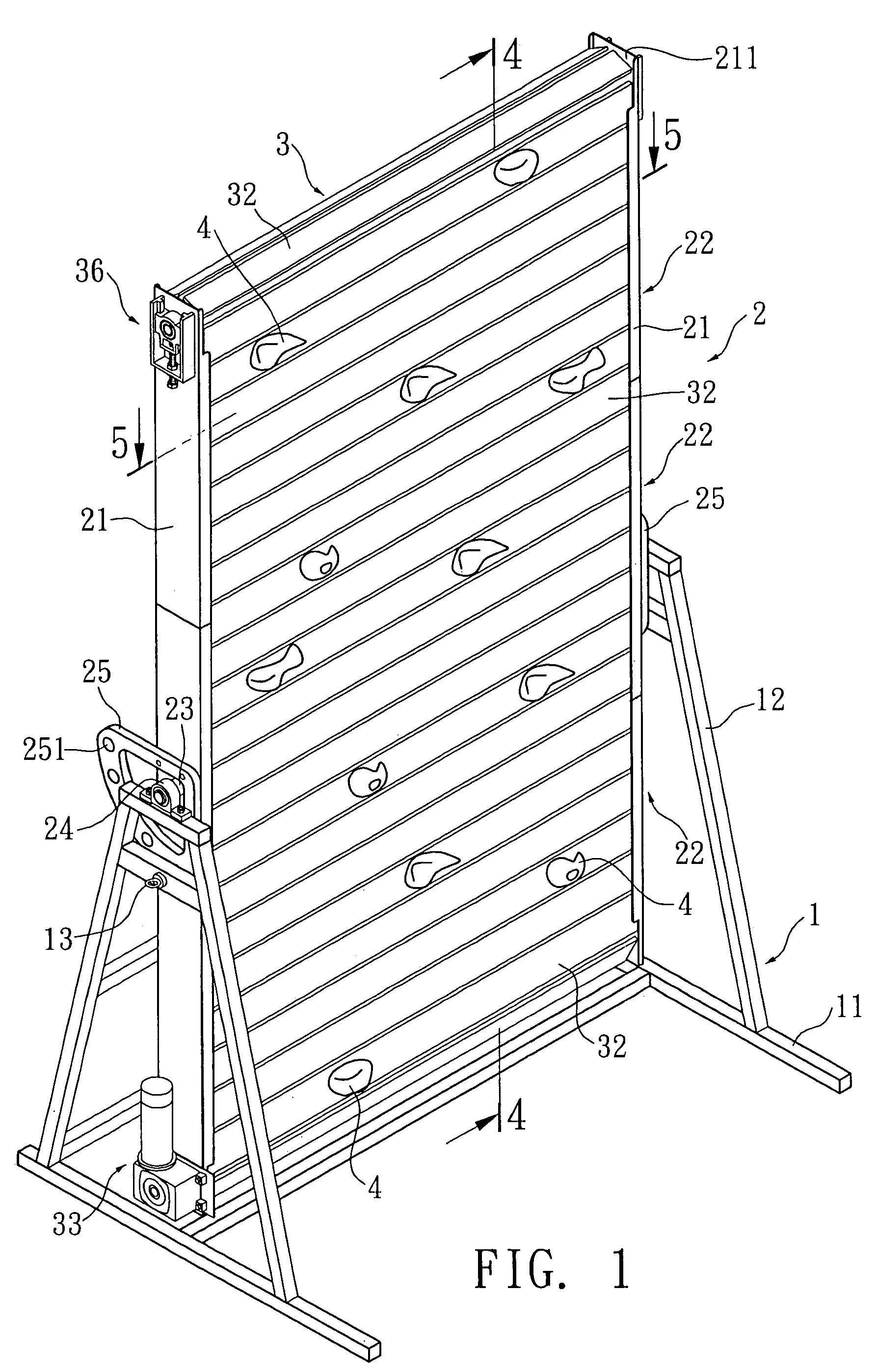

Rock climbing apparatus

A rock climbing apparatus including a support stand on which a main body frame is mounted. The main body frame has two lateral columns, several transverse support beams and several longitudinal support columns built between the lateral columns to serve as a support skeleton. A rotary mechanism is arranged in the main body frame, including at least two chains in parallel to the length of the main body frame, multiple transverse slats in parallel to the width of the main body frame and a power supply for driving the chains to circularly revolve. The longitudinal support columns of the main body frame are arranged in a position where the chains are positioned. Each longitudinal support column has a rib rail, whereby the link shafts of the chains are slidably leant on the rib rail. The transverse slats are fixed on the chains and immediately adjacent to each other. The chains are positioned near the middle of the transverse slats. The transverse slats can circularly revolve along the lateral columns. Several rocks are locked on one face of each transverse slat distal from the chains for a user to climb.

Owner:WU YU FENG

Face milling insert

ActiveUS20070297865A1Good surface finishLong service lifeTransportation and packagingMilling cuttersSwarfStructural engineering

A face-milling insert, including a chip-removing main cutting edge adjacent to a first clearance surface, and a surface-wiping secondary edge adjacent to a second clearance surface, the main cutting edge forming an angle of 45° with an imaginary straight line in the extension of the secondary edge. Adjacent to a third clearance surface, an intermediate cutting edge is formed between the main cutting edge and the secondary edge, the intermediate cutting edge being shorter than the main cutting edge and forming an angle within a range of 20-40° with the extension line. The intermediate cutting edge transforms into the adjacent edges via arched part edges adjacent to convex clearance surfaces.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

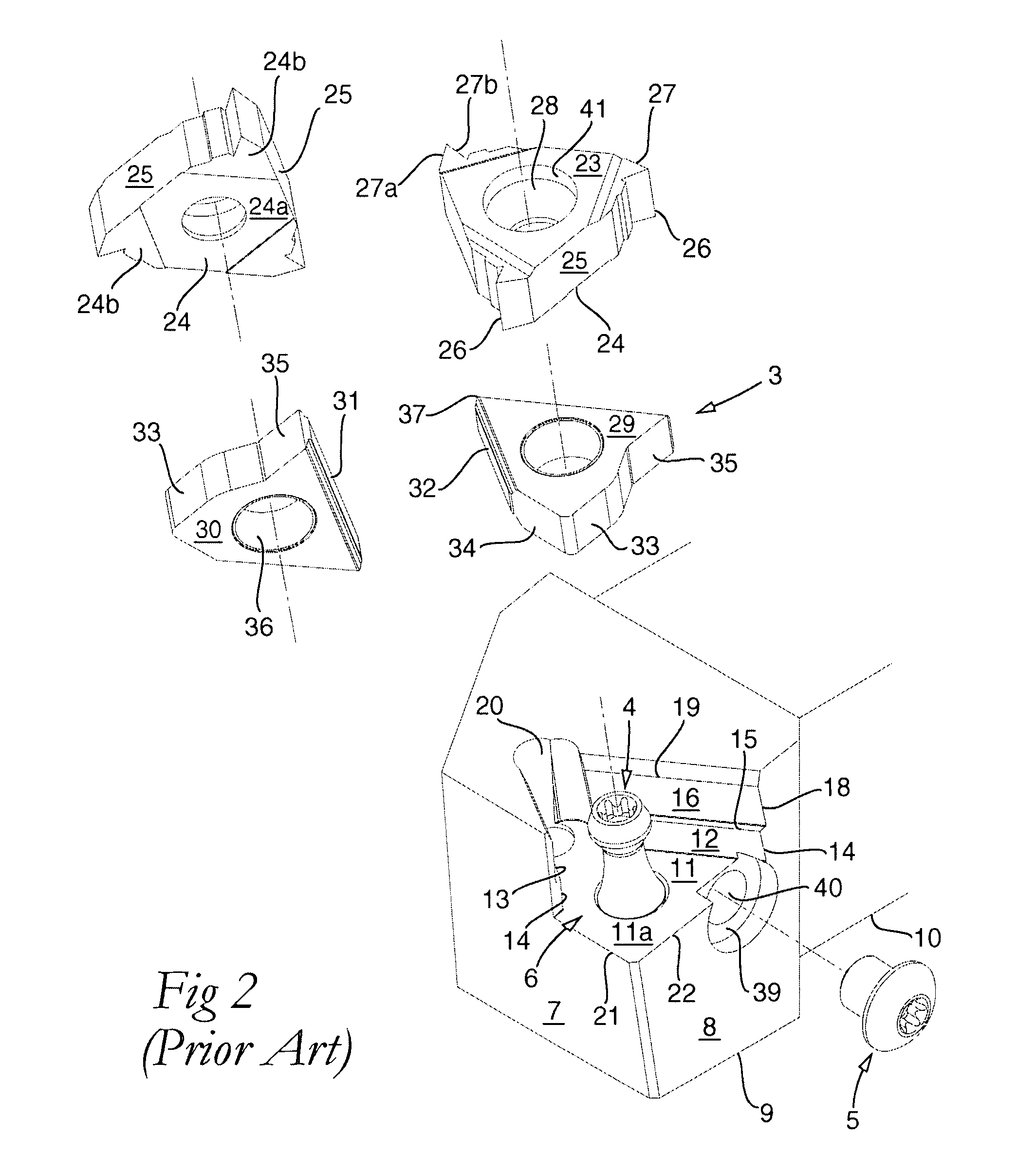

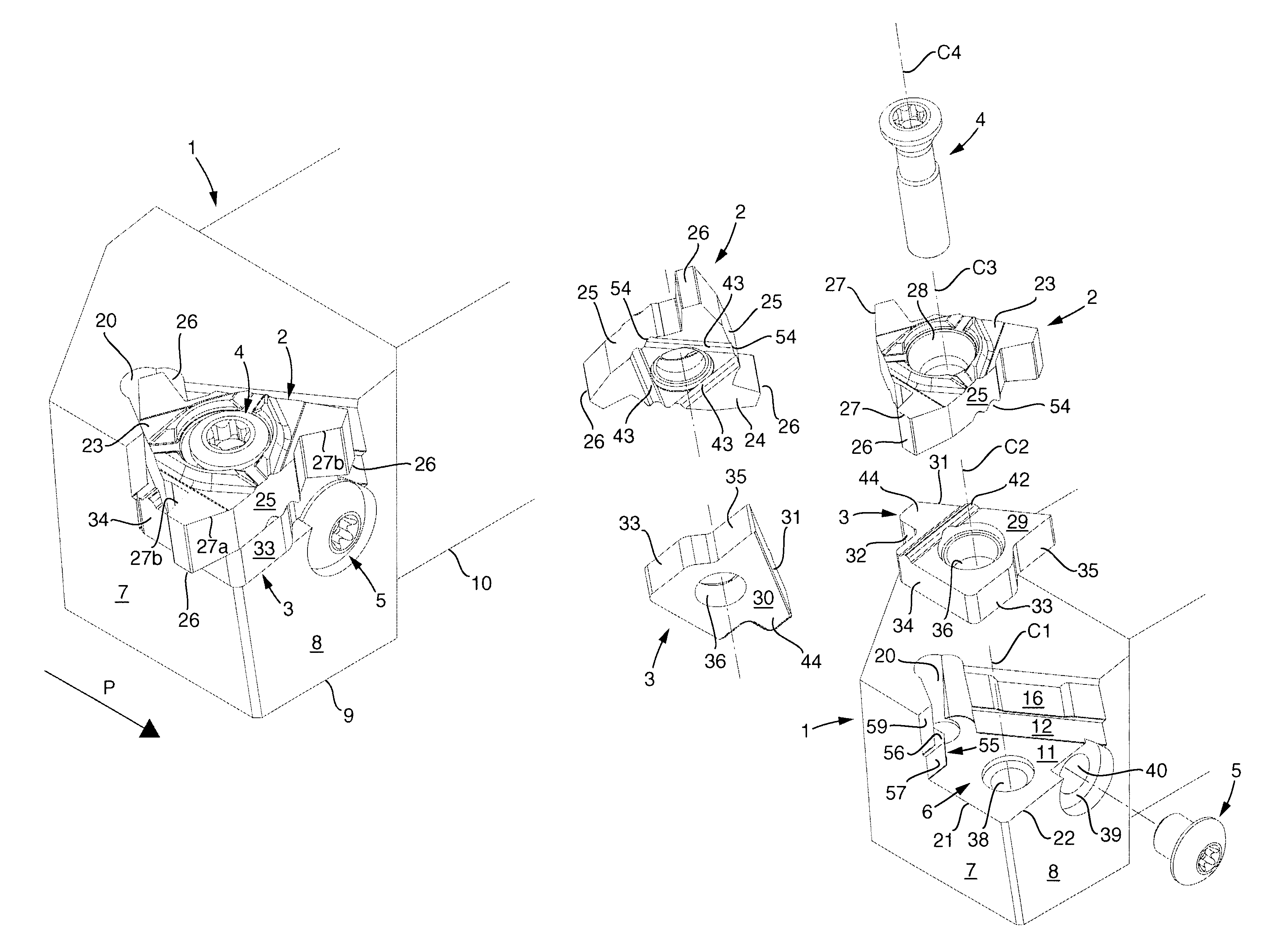

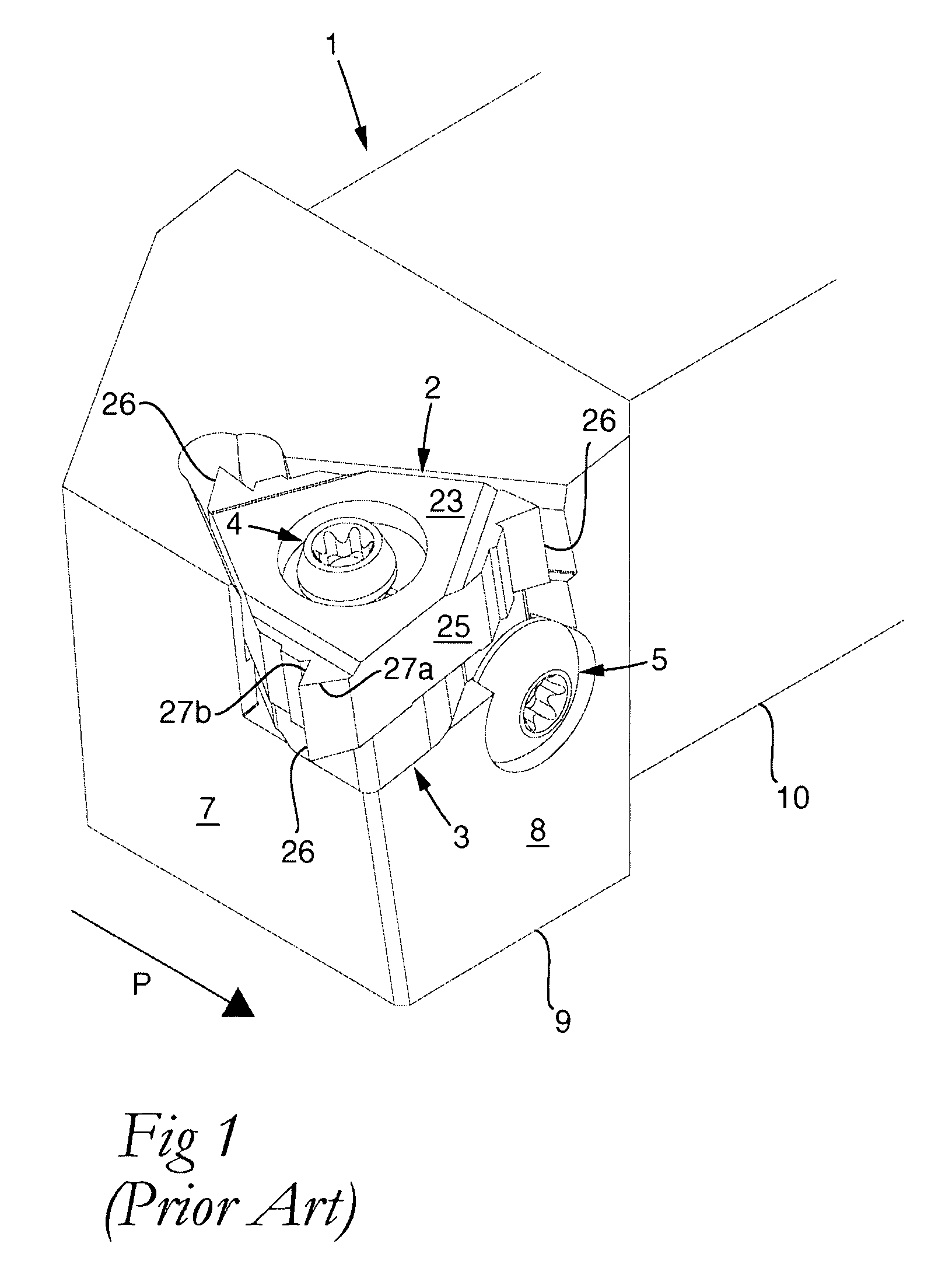

Turning tool, and a basic body and a shim plate for a turning tool

ActiveUS20080152441A1Eliminate shortcomingsThread cutting toolsCutting insertsIsoetes triquetraAcute angle

A turning tool including a basic body having a pocket, a shim plate mounted in the pocket, and an indexable turning insert mounted in the pocket. The pocket opens in a front surface and in a side surface of the basic body, and accommodates two spaces spaced-apart level-wise, a lower space housing the shim plate and delimited by a bottom surface and two side support surfaces, which form an acute angle with each other, one of which is a primary side support surface and the other one a secondary side support surface, and an upper space housing the turning insert. The shim plate includes an upperside and an underside between which a pair of primary and secondary contact surfaces extend, which form an acute angle with each other and are urged against the primary and secondary side support surfaces in the pocket, as well as a pair of inactive surfaces extend in the form of an outer end surface and an outer side limiting surface, which together delimit a supporting corner section of the shim plate. The turning insert has a triangular basic shape and includes an upperside, an underside resting against the upperside of the shim plate, and three side surfaces that are situated in a first imaginary, equilateral triangle and therefore converge in pairs at an angle of 60° toward corners in which cutting edges are included. First and second tightening elements are arranged to detachably fix the shim plate and the turning insert individually. The secondary side support surface of the pocket is formed on a lug having a top surface situated under the turning insert. Respective acute angles (ε, γ) between the primary and secondary side support surfaces of the pocket, and the primary and secondary contact surfaces of the shim plate, are smaller than 60°. The underside of the turning insert and the upperside of the shim plate are engaged with each other via an interface that includes female-like and male-like engagement members, which are in engagement with each other to prevent turning of the turning insert.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Radar, radio frequency sensor, and radar detection method

InactiveUS7786927B2Low costPerformance demandRadio wave reradiation/reflectionRadar detectionMillimetre wave

In a sensor and a radar for measuring the distance and the moving speed of a target by radiating a radio frequency, particularly a millimeter wave, compatibility between cost reduction and high detection performance has been conventionally a significant problem. In the present invention, the frequency of a transmitted signal changes during a fixed time while performing digitally-frequency-modulation on frequency sweeping straight lines extending, with different slopes relative to the time axis, from plural slightly different initial values serving as starting points, the signal is transmitted after being modulated so as to periodically repeat the sweep time serving as a unit, signal components corresponding to the respective sweeping slopes are digitally sampled, in synchronization with the transmitted modulation signal, from a received signal which is reflected and returned from a target, and the received signal is analyzed.

Owner:HITACHI LTD

Drill body

ActiveUS20090279965A1Moderate cutting forceReliable alignmentWood turning toolsTransportation and packagingEngineeringDrill

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Tool for chip removing machining and a basic body therefor

InactiveUS7568864B2Accurate precisionImproved cooling and chip-forming capacityCutting insertsTurning toolsEngineeringMechanical engineering

A tool for chip removing machining, including a replaceable cutting insert and a basic body. The basic body includes a rear fixing part, a front supporting part having an insert seat, and a tightening part situated over the support part, and spaced-apart from the front supporting part by a first gap and from the rear fixing part by a second gap. The tightening part is connected to the basic body via a joint. The joint is formed of at least one elastically resilient material portion and has an axis around which the tightening part is pivoted in order to press the cutting insert against the insert seat by a front finger. The rear fixing part includes an internal channel for feed of a fluid in the forward direction through the basic body. The internal channel extends into a second channel inside the tightening part via a channel section that is entirely or partly housed in a bridge which, like the joint, is formed of the material in the basic body, and which bridges one of the first and second gaps.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

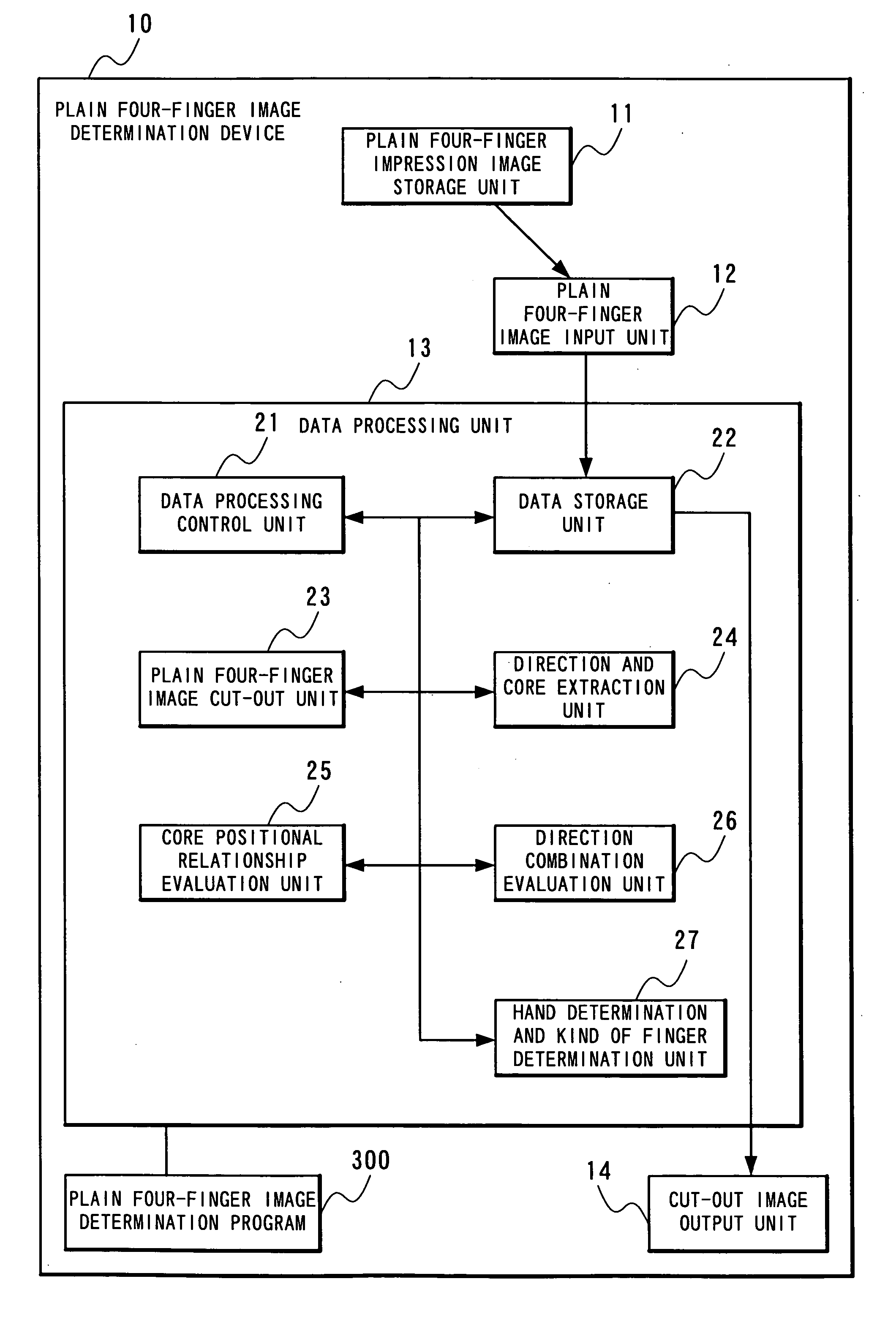

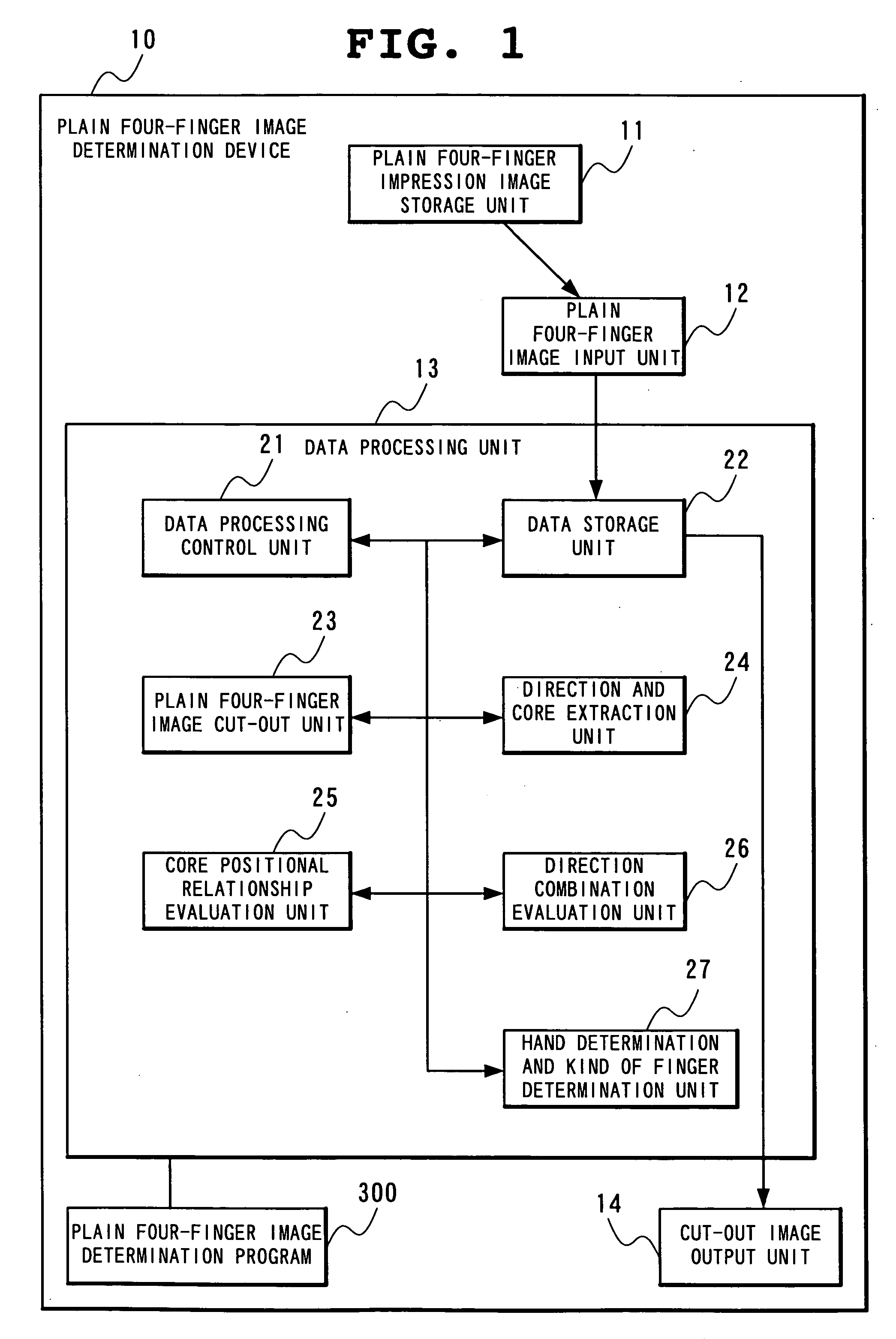

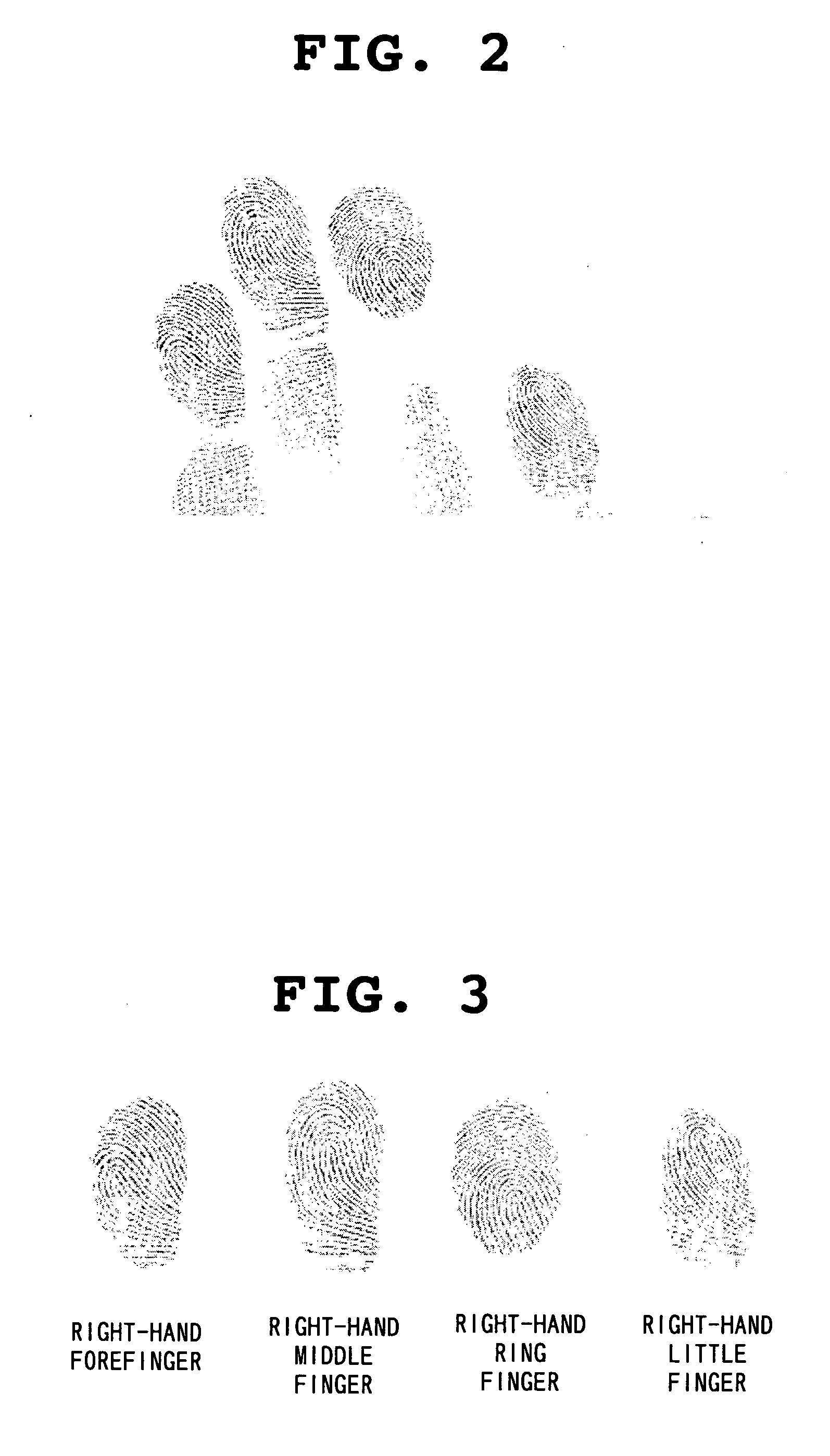

Plain four-finger image determination device, plain four-finger image determination method and plain four-finger determination program

InactiveUS20060067566A1Accurate measurementEliminate shortcomingsCharacter and pattern recognitionFingerprintHand parts

The plain four-finger image determination device includes a cut-out unit which cuts out a fingerprint image of each finger from a plain four-finger image, an extraction unit which extracts a core of a fingerprint from each cut-out fingerprint image and a ridge line direction in the vicinity of the core of the fingerprint, an evaluation unit which makes hand determination and determination of a kind of finger based on a relationship of heights of cores of the fingerprints in the respective fingers, an evaluation unit which makes hand determination and determination of a kind of finger based on a combination of tendencies of ridge line directions each determined for each fingerprint of each finger, and a determination unit which makes ultimate hand determination and determination of a kind of finger based on confidence obtained by merging confidences of both the determination results.

Owner:NEC CORP

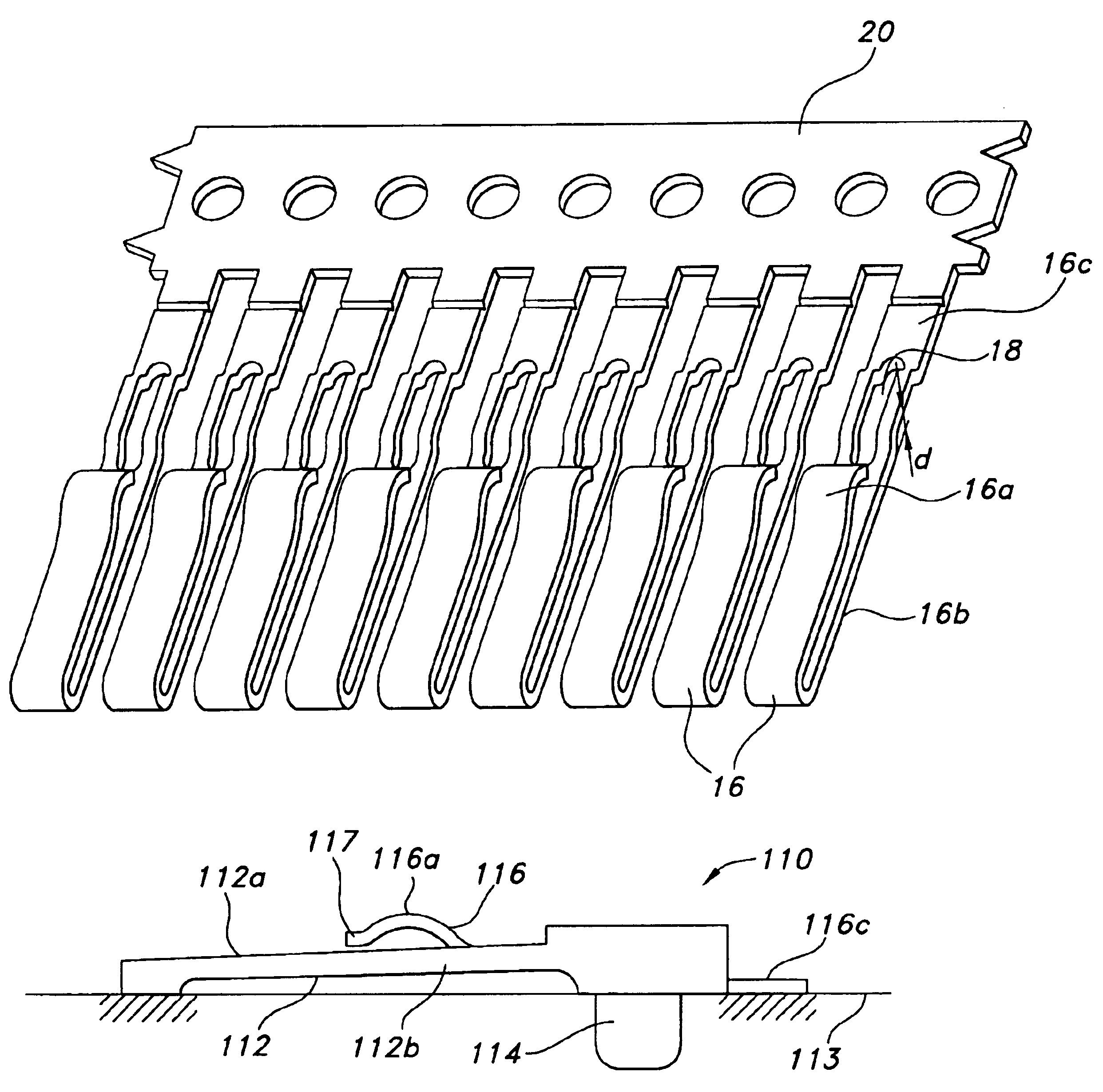

LCD connector for printed circuit boards

InactiveUS6855013B2Easy to optimizeInexpensively moldedElectric discharge tubesCoupling contact membersContact freeContact pressure

An electrical connector for establishing electrical connection between a conductive portion of an LCD display and conductive elements of a printed circuit board comprises a substantially planar insulative connector housing and a plurality of electrical contacts supported thereby. Each contact includes a deflectable spring-like portion for resilient engagement with the LCD display and a tail portion for conductive engagement with the printed circuit board. Each contact further includes therebetween a mid-section secured to the insulative housing. The contacts are supported in the housing in laterally spaced disposition with respect to each other, and are adapted to provide sufficient normal forces to maintain sufficient mechanical and electrical connection between the connector and each of an LCD display and a printed circuit board. Contact free ends may be captured in a slot in the housing and the housing may include a flexible extent to provide increased contact pressure upon mating.

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

Turning tool, and a basic body and a shim plate for a turning tool

A turning tool including a basic body having a pocket, a shim plate mounted in the pocket, and an indexable turning insert mounted in the pocket. The pocket opens in a front surface and in a side surface of the basic body, and accommodates two spaces spaced-apart level-wise, a lower space housing the shim plate and delimited by a bottom surface and two side support surfaces, which form an acute angle with each other, one of which is a primary side support surface and the other one a secondary side support surface, and an upper space housing the turning insert. The shim plate includes an upperside and an underside between which a pair of primary and secondary contact surfaces extend, which form an acute angle with each other and are urged against the primary and secondary side support surfaces in the pocket, as well as a pair of inactive surfaces extend in the form of an outer end surface and an outer side limiting surface, which together delimit a supporting corner section of the shim plate. The turning insert has a triangular basic shape and includes an upperside, an underside resting against the upperside of the shim plate, and three side surfaces that are situated in a first imaginary, equilateral triangle and therefore converge in pairs at an angle of 60° toward corners in which cutting edges are included. First and second tightening elements are arranged to detachably fix the shim plate and the turning insert individually. The secondary side support surface of the pocket is formed on a lug having a top surface situated under the turning insert. Respective acute angles (ε, γ) between the primary and secondary side support surfaces of the pocket, and the primary and secondary contact surfaces of the shim plate, are smaller than 60°. The underside of the turning insert and the upperside of the shim plate are engaged with each other via an interface that includes female-like and male-like engagement members, which are in engagement with each other to prevent turning of the turning insert.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

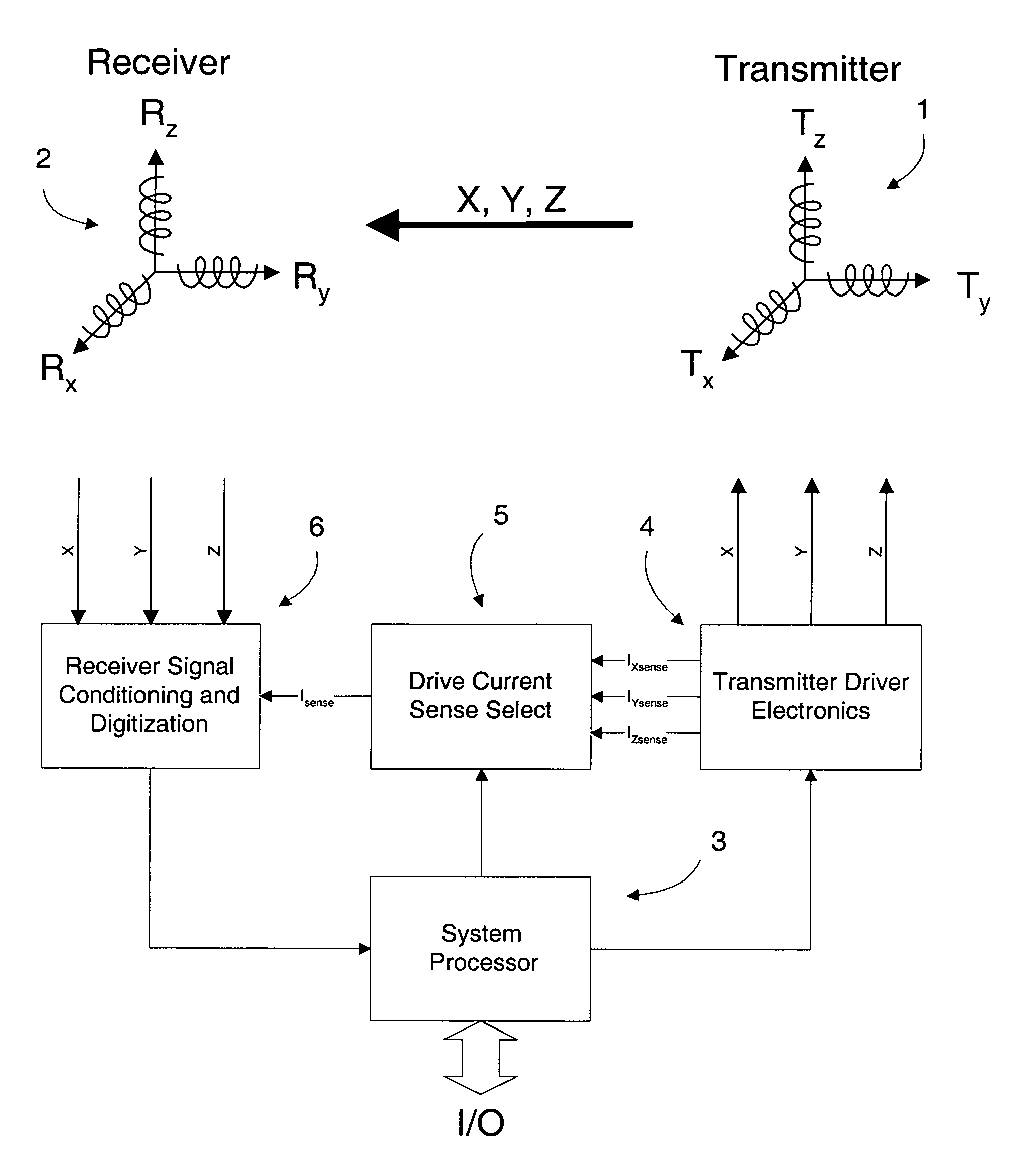

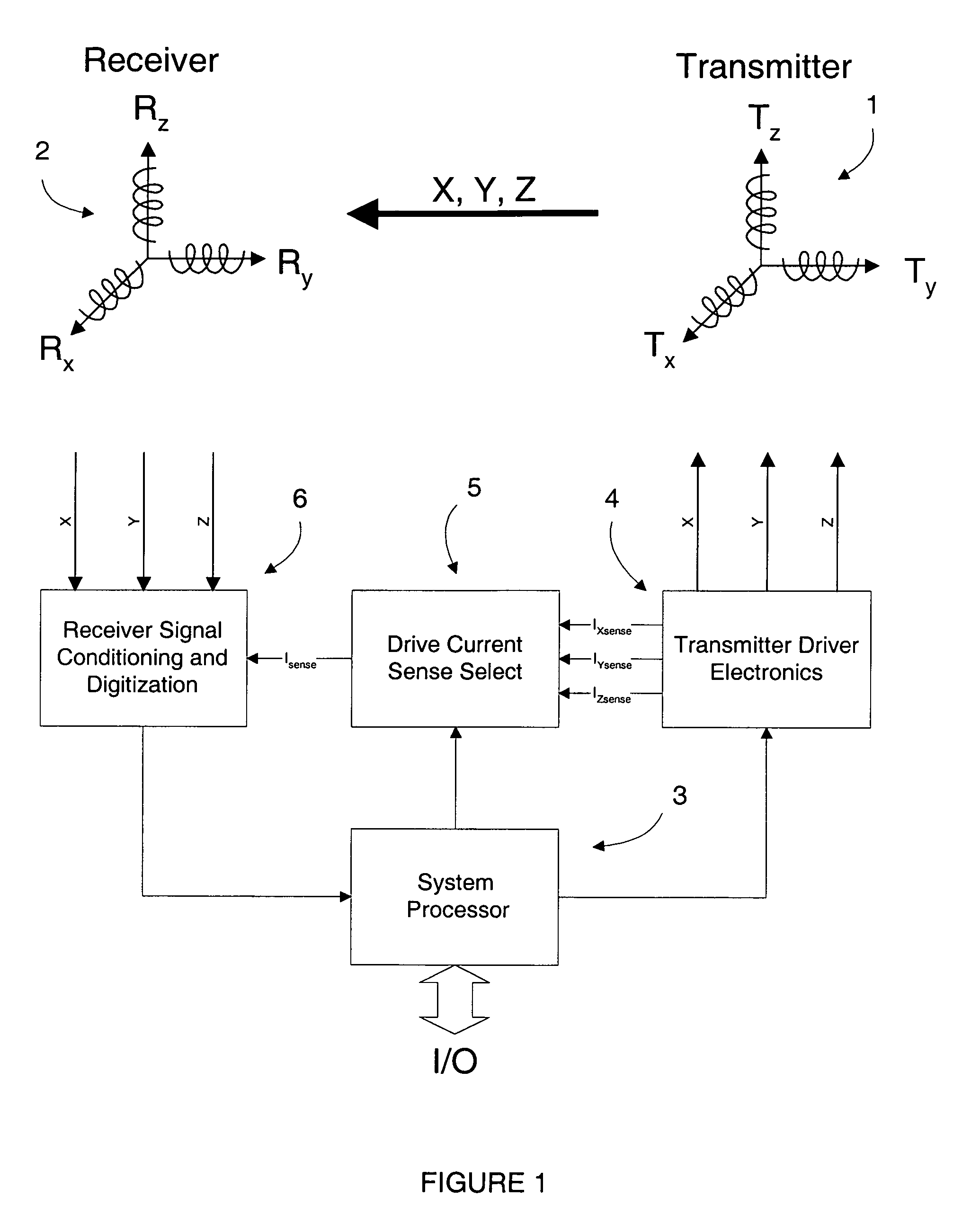

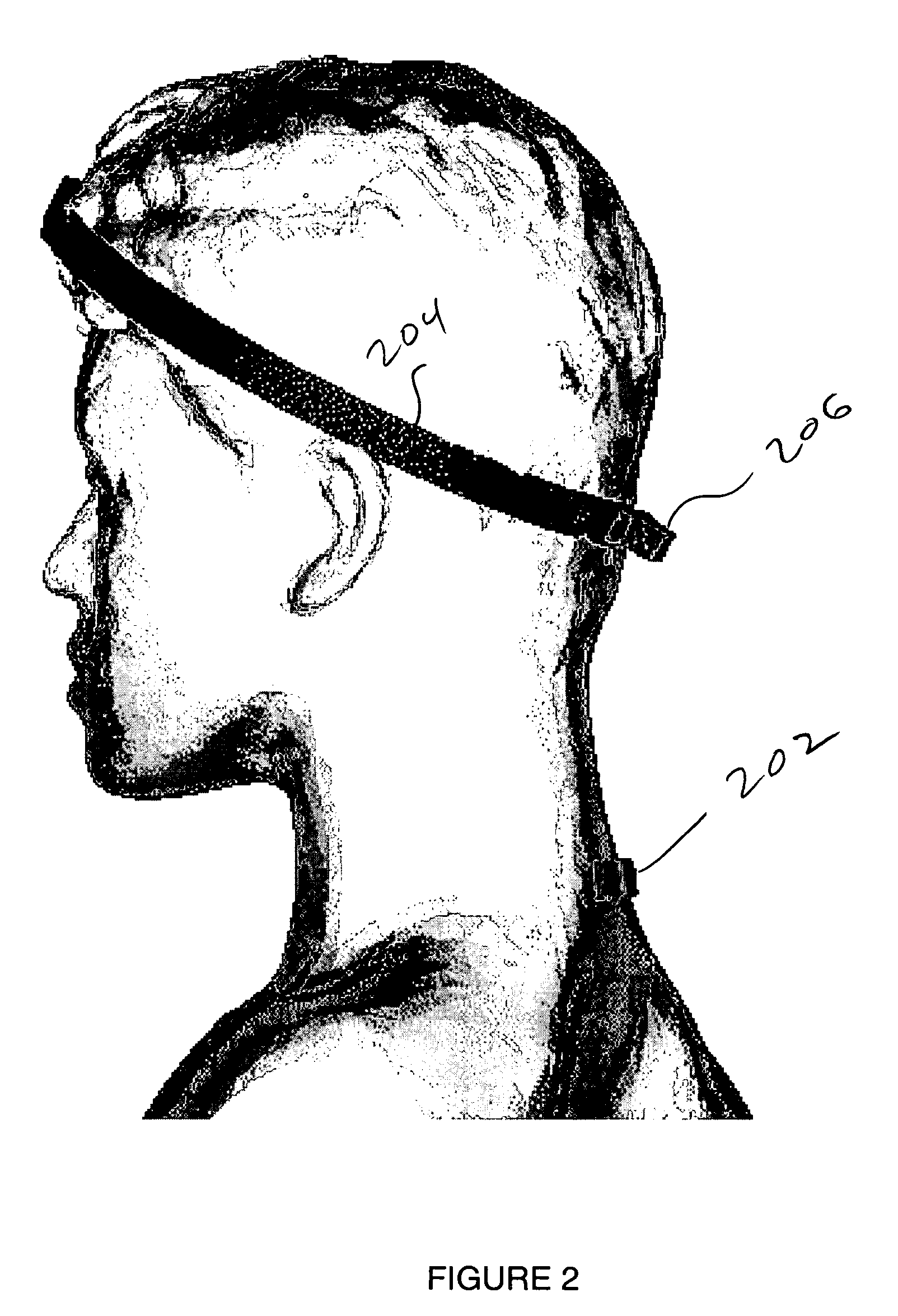

Head-mounted pointing and control device

ActiveUS7710395B2Avoid collectingEliminate shortcomingsCathode-ray tube indicatorsInput/output processes for data processingHead movementsJoystick

A magnetic tracker system for use on an operator's head makes “mouse” / cursor movements on a screen similar to that of the classic computer “mouse” / track ball / touchpad / joystick. Only head movements are used as opposed to lifting a hand from the keyboard for making such moves. The new “mouse” avoids interrupting the hands from their position on the keyboard and has no moving mechanical parts that become clogged and that need a special surface (mouse pad) or special surface measurements (optical mouse).

Owner:ALKEN INC DBA POLHEMUS

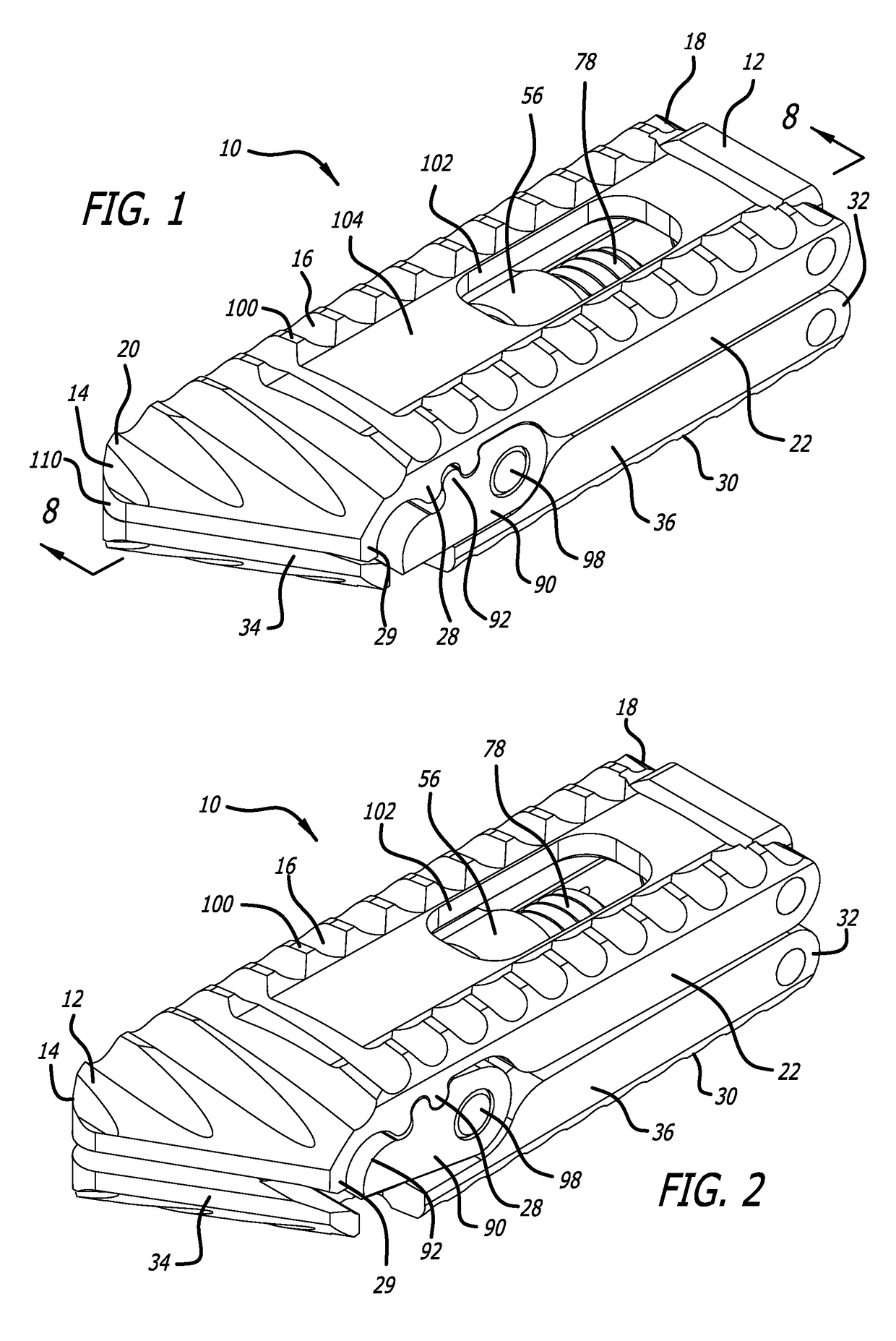

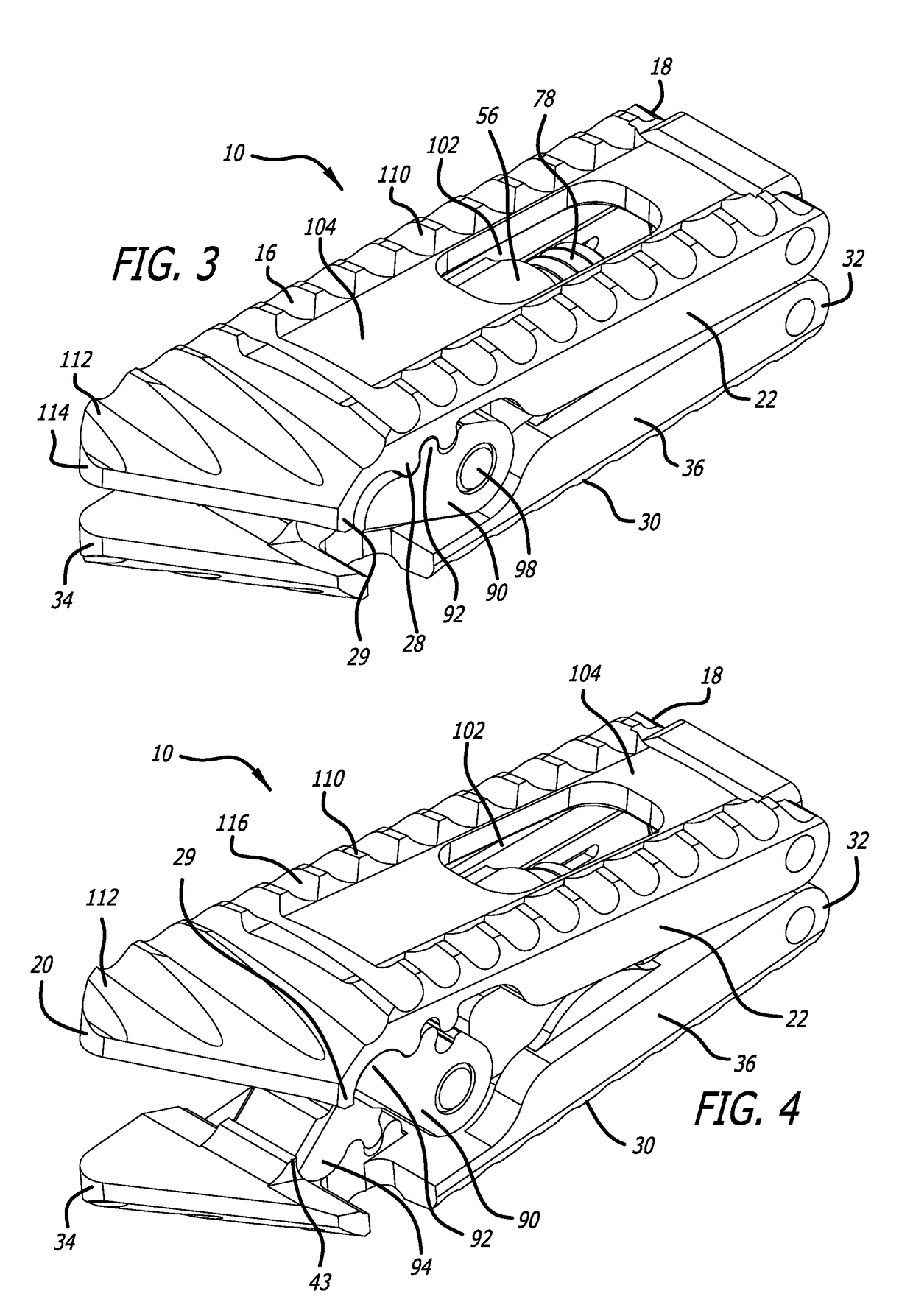

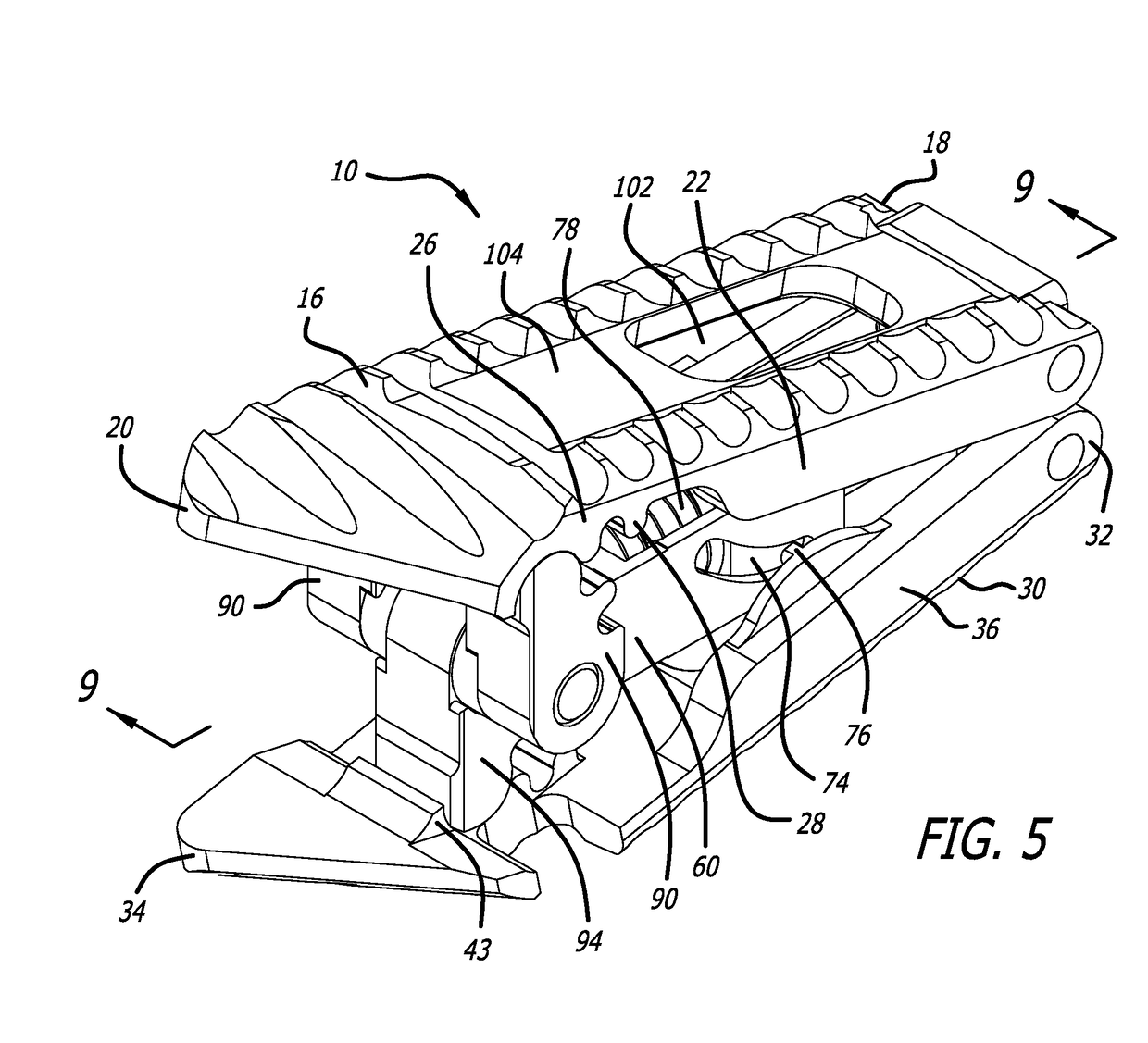

Geared cam expandable interbody implant and method of implanting same

A geared cam expandable spinal implant. Rotational motion of a rotating portion is translated into linear motion of a yoke, which moves geared cams at the distal end of the implant to mate with, and walk along, teeth of corresponding racks. The walking of the gear cam teeth along the rack teeth creates a regular rate of implant expansion, reduces initial excessive expansion force applied to the implant, and provides fine adjustment of the expansion rate and force.

Owner:WARSAW ORTHOPEDIC INC

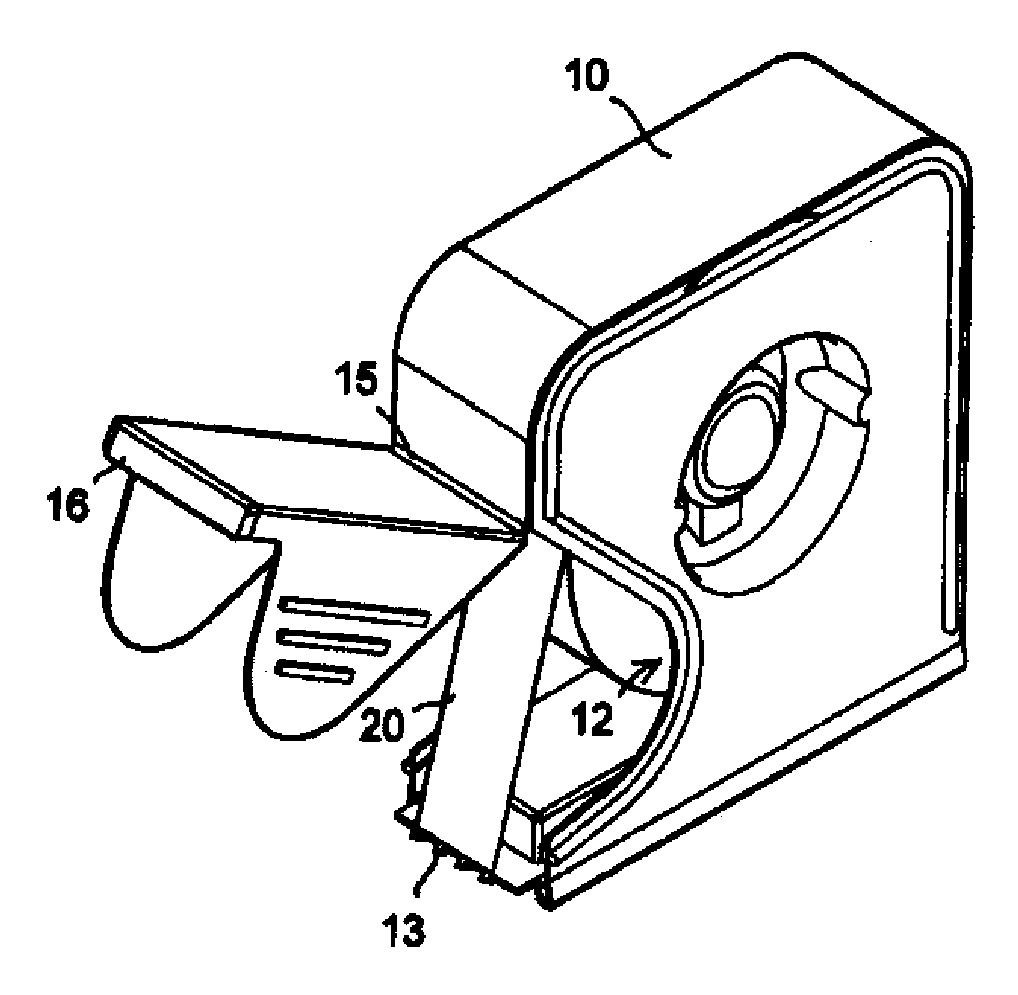

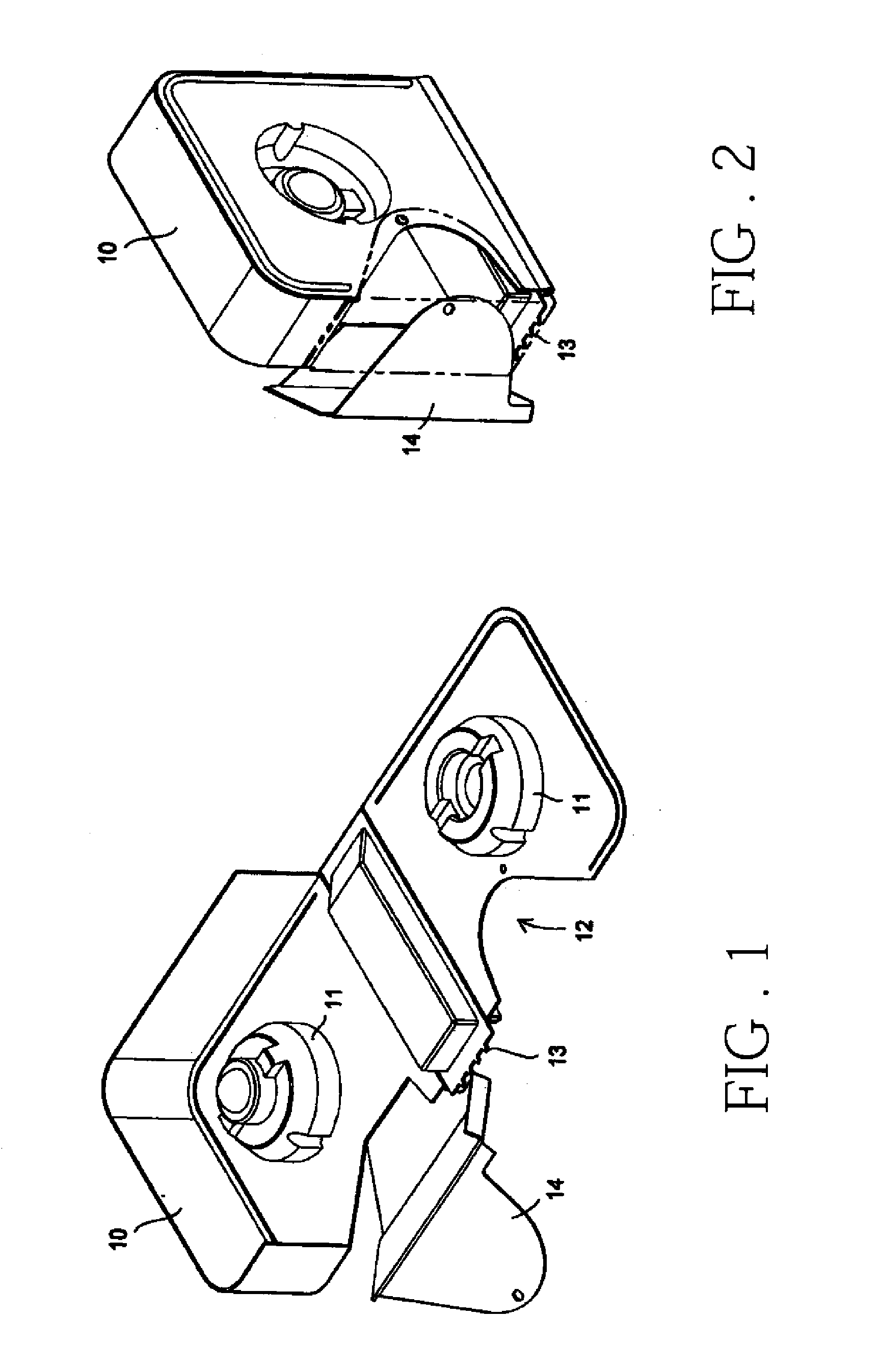

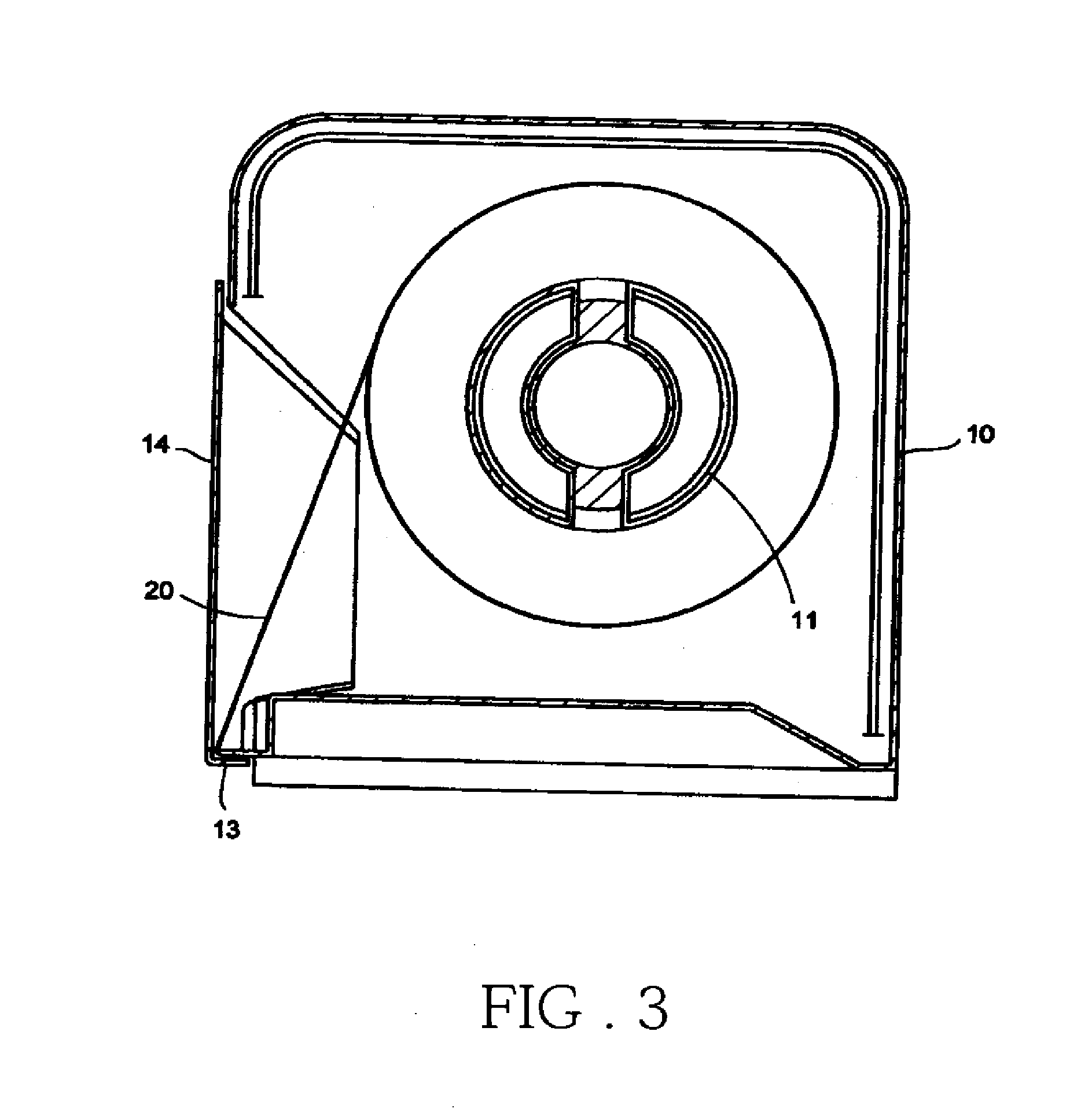

Adhesive tape dispenser

InactiveUS20090230163A1Eliminate shortcomingsEasy and convenient accessMetal working apparatusArticle deliveryAdhesive beltEngineering

The tape dispenser completely conceals its tape roll in a tightly closed housing. A removable cover extended from a major side or a top side of the tape dispenser's body is provided. At least a major side of the tape dispenser's body has a curved recession. As such, when the cover is opened, a section of the adhesive tape and a cutting edge at a front edge of a bottom side of the tape dispenser's body is exposed in a front opening and the recession for easy and convenient access. As such, the tape dispenser provides higher degrees of sanitation and safety than the conventional tape dispensers.

Owner:CHUN NIEN PLASTIC LED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com