Patents

Literature

381 results about "Greatest Diameter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

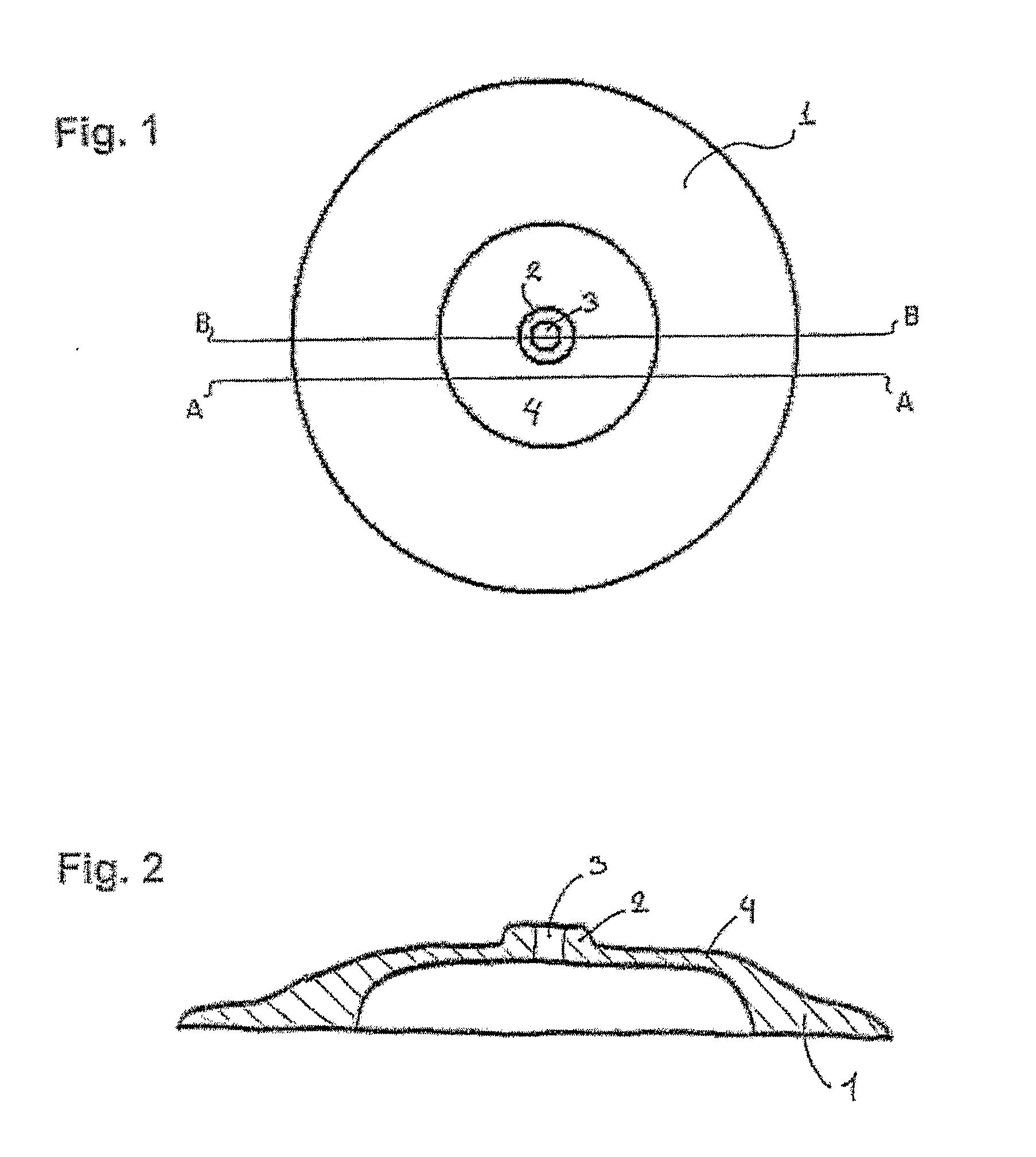

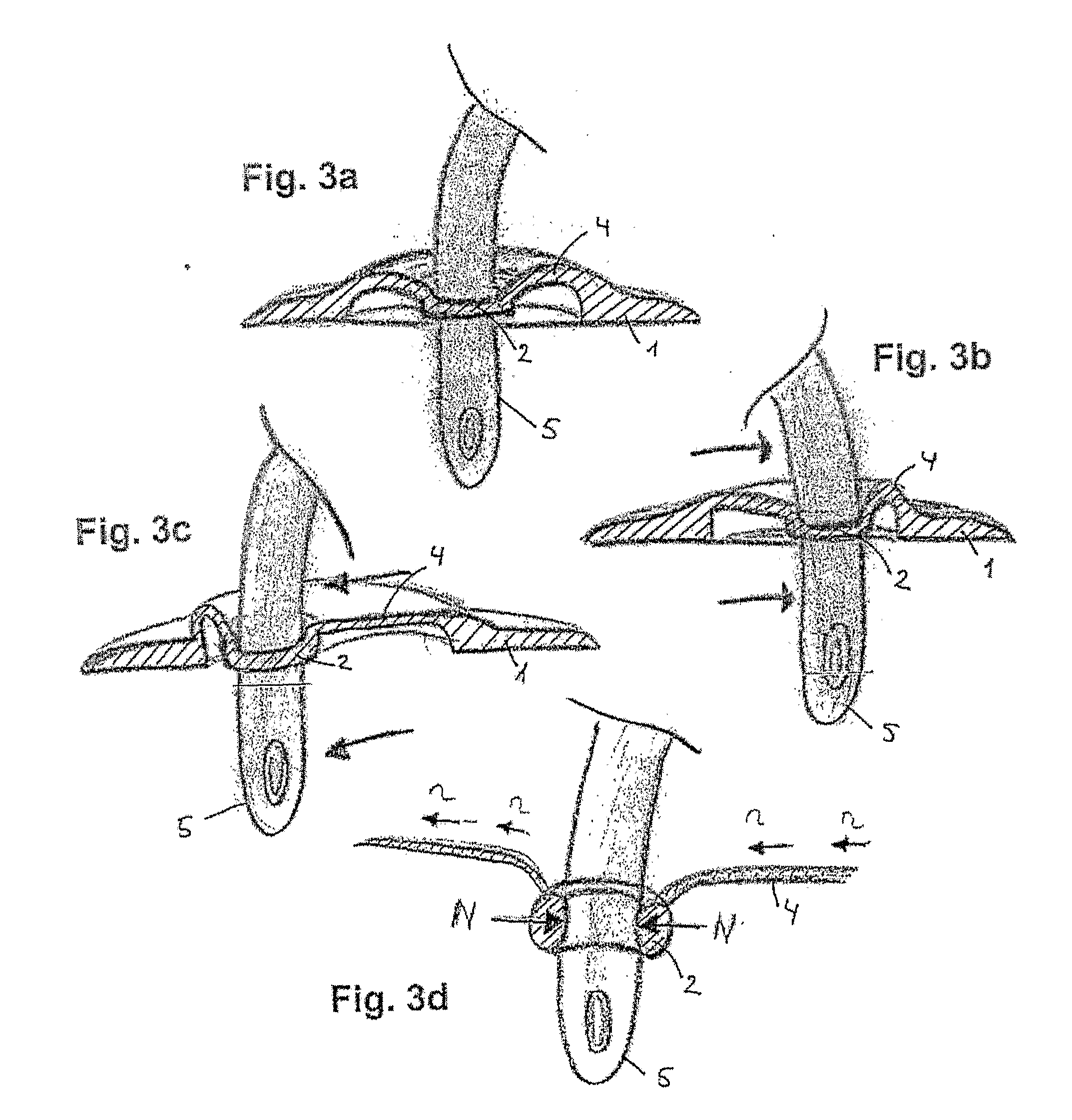

Deformable tools and implants

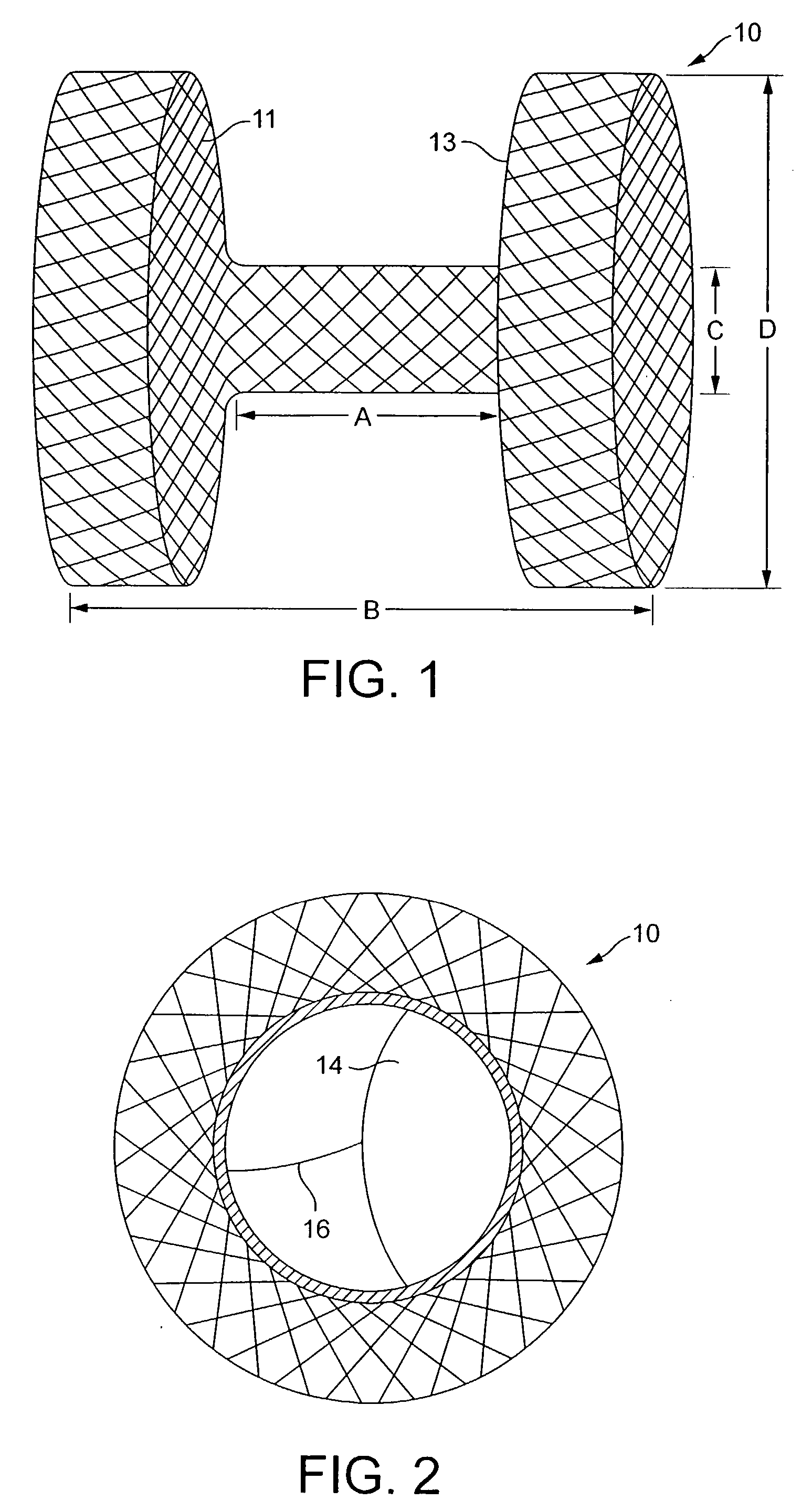

InactiveUS20060271061A1Add dimensionReduce riskDental implantsInternal osteosythesisBiomedical engineeringGreatest Diameter

Owner:ORTHOPHOENIX

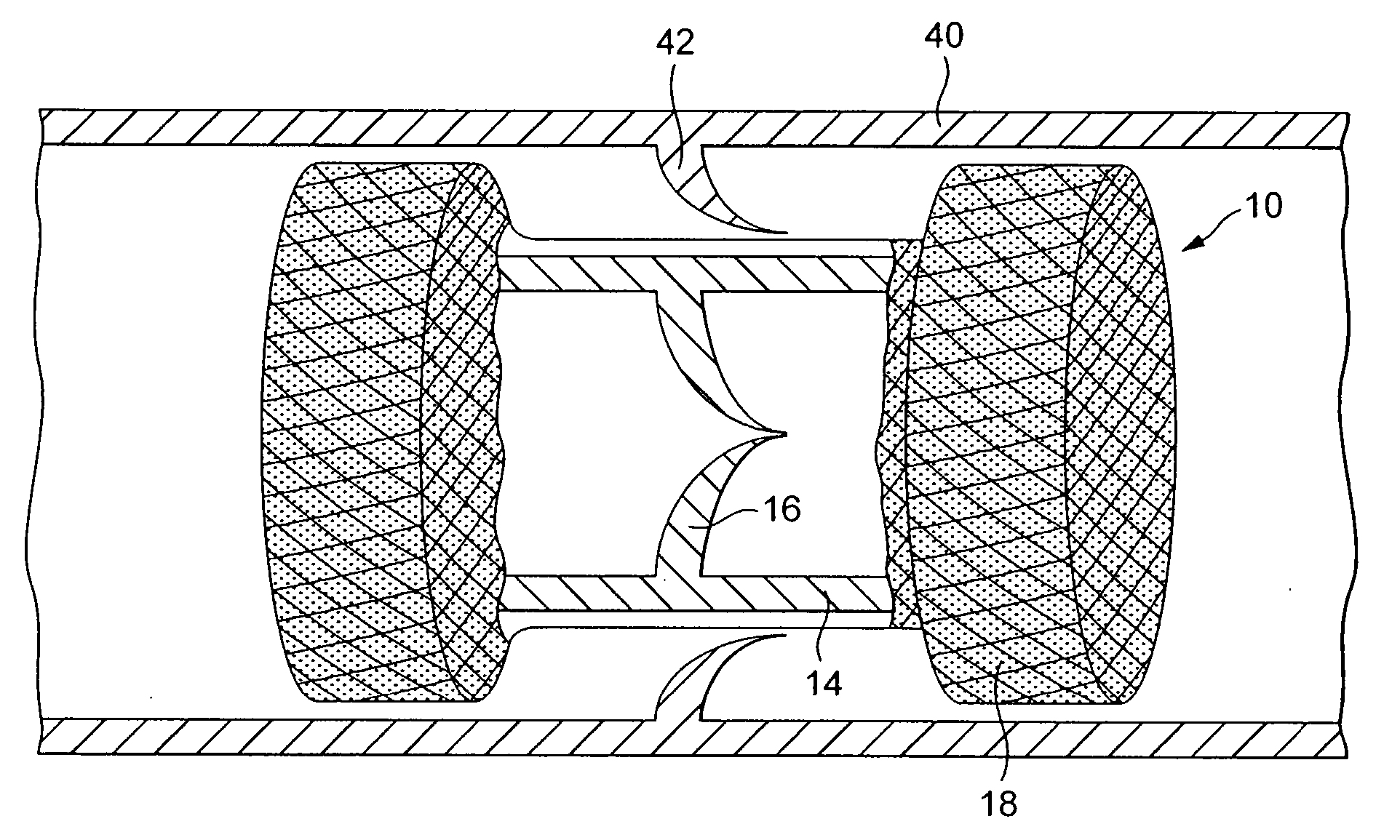

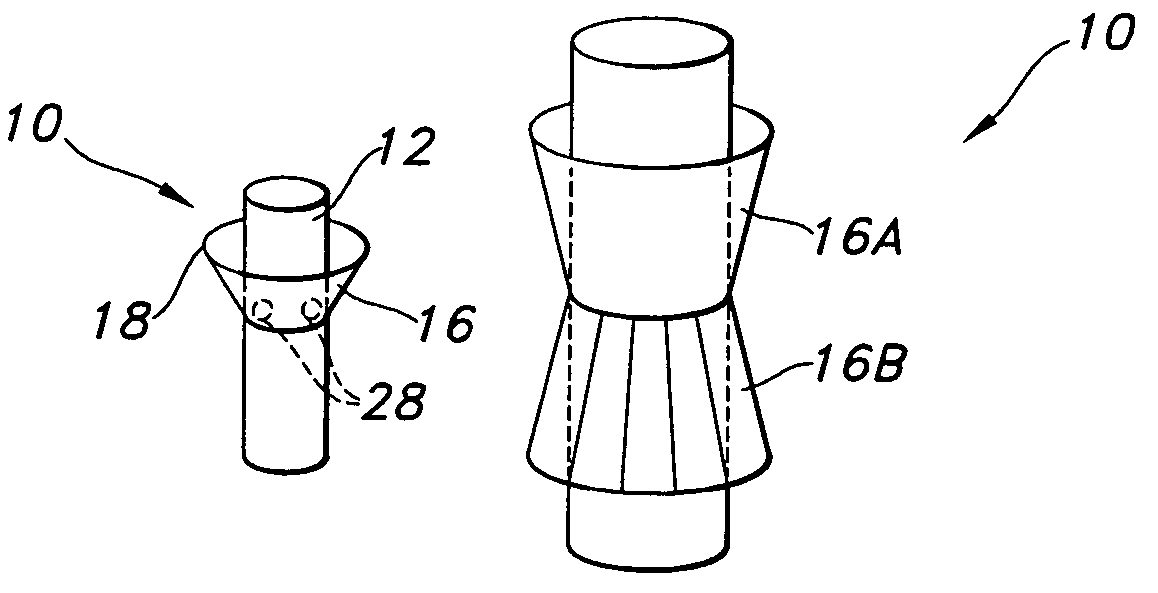

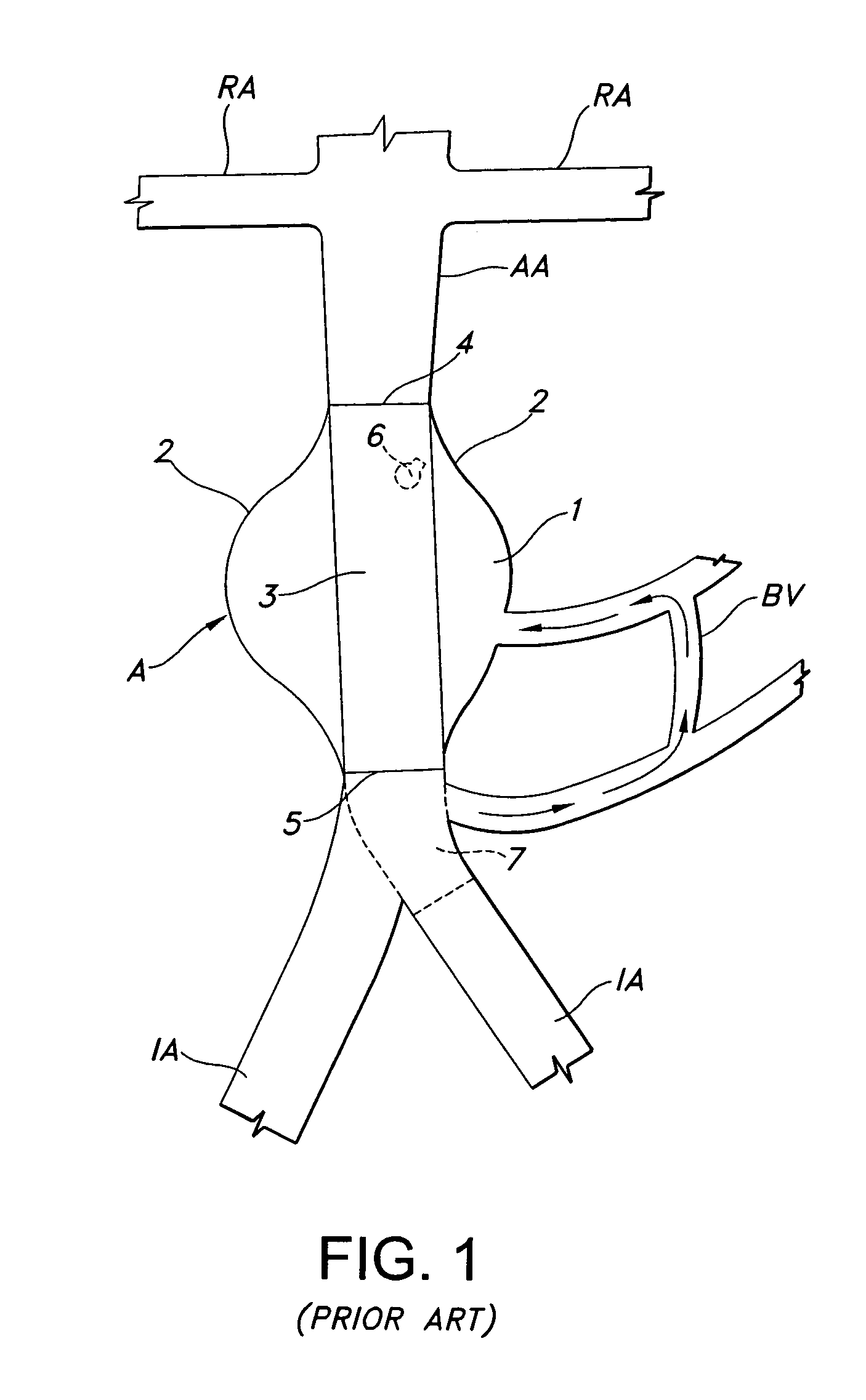

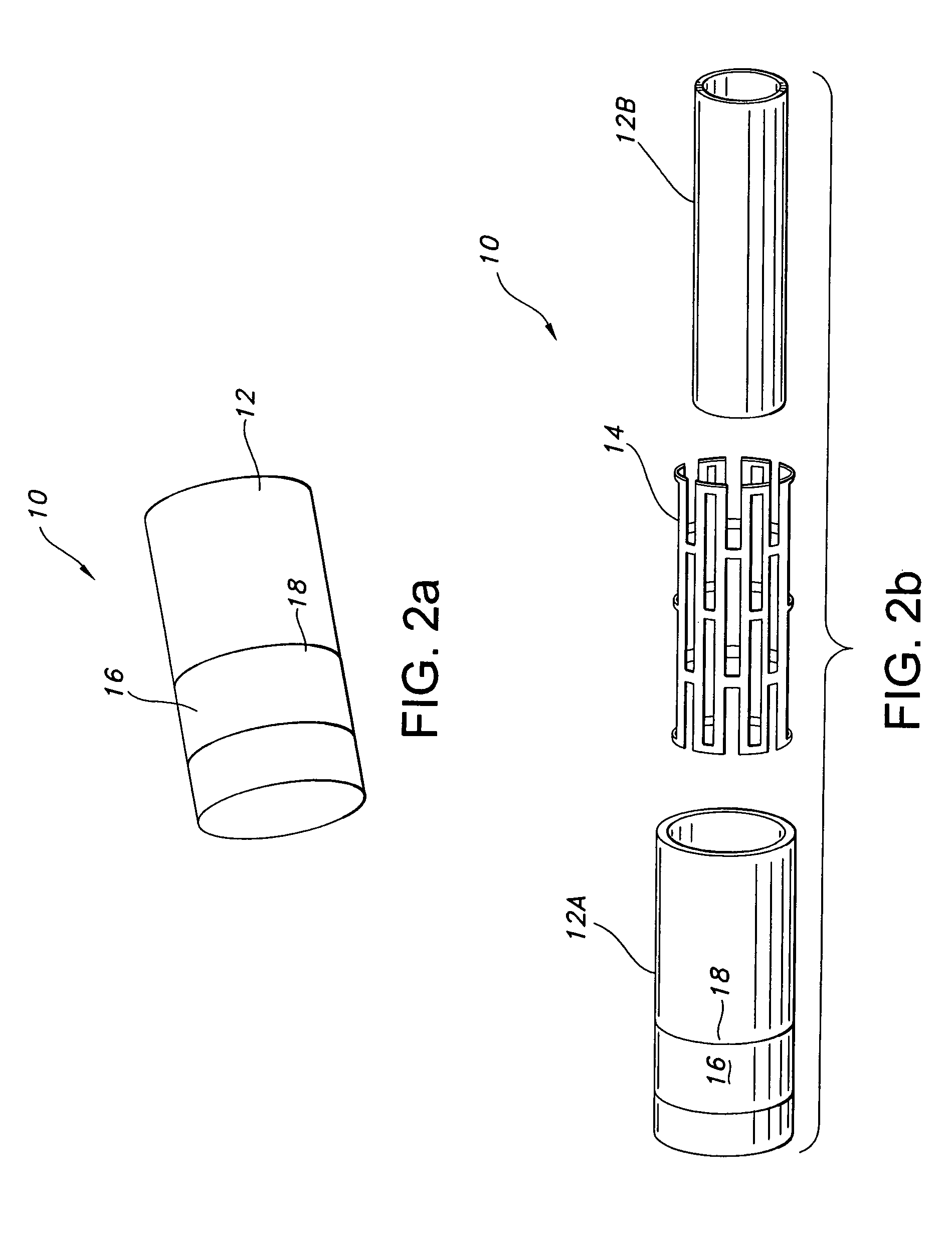

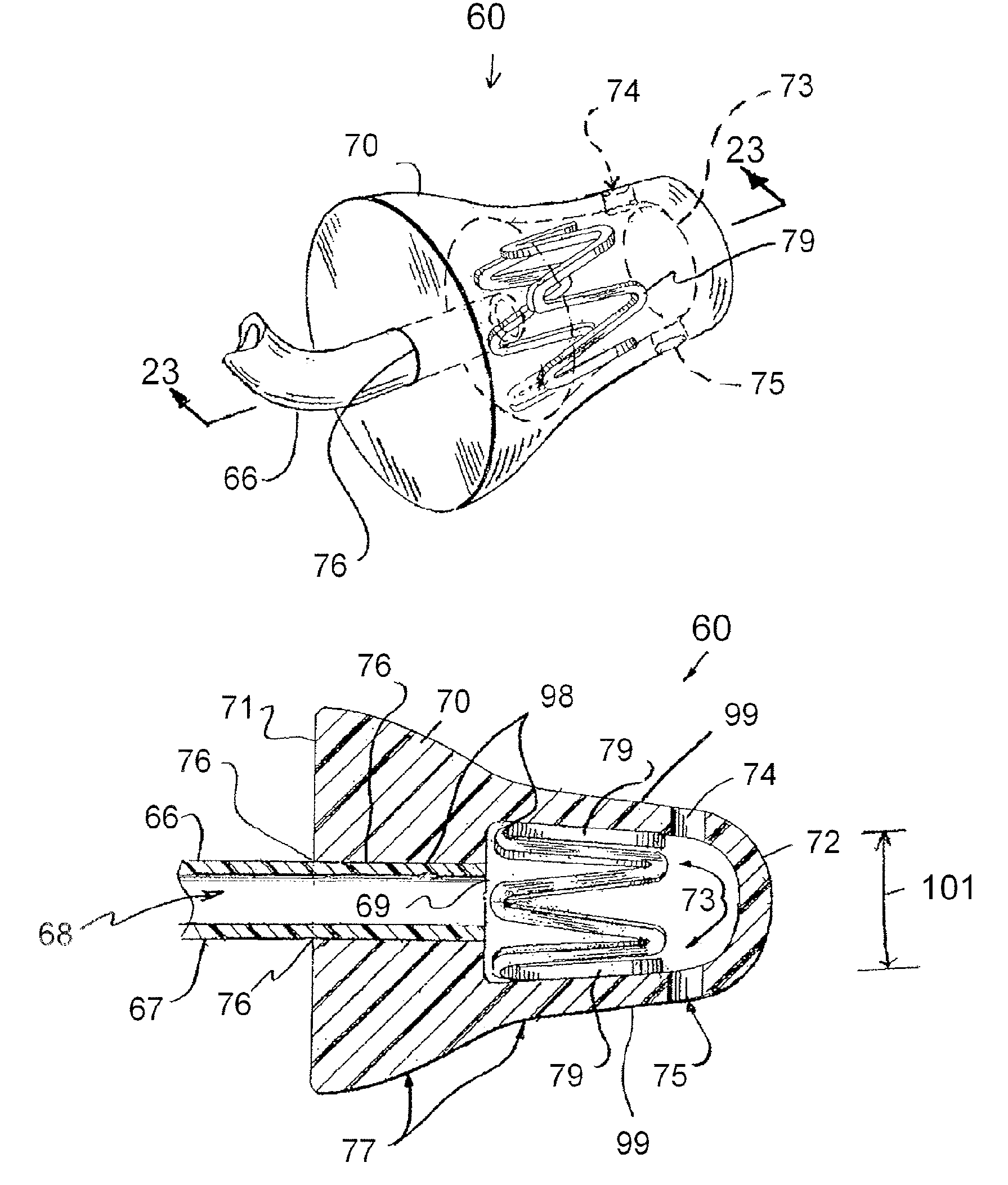

Method And Apparatus For Treatment Of Cardiac Valves

InactiveUS20080015671A1Improve sealingWithout flowVenous valvesBlood vesselsBiomedical engineeringVALVE PORT

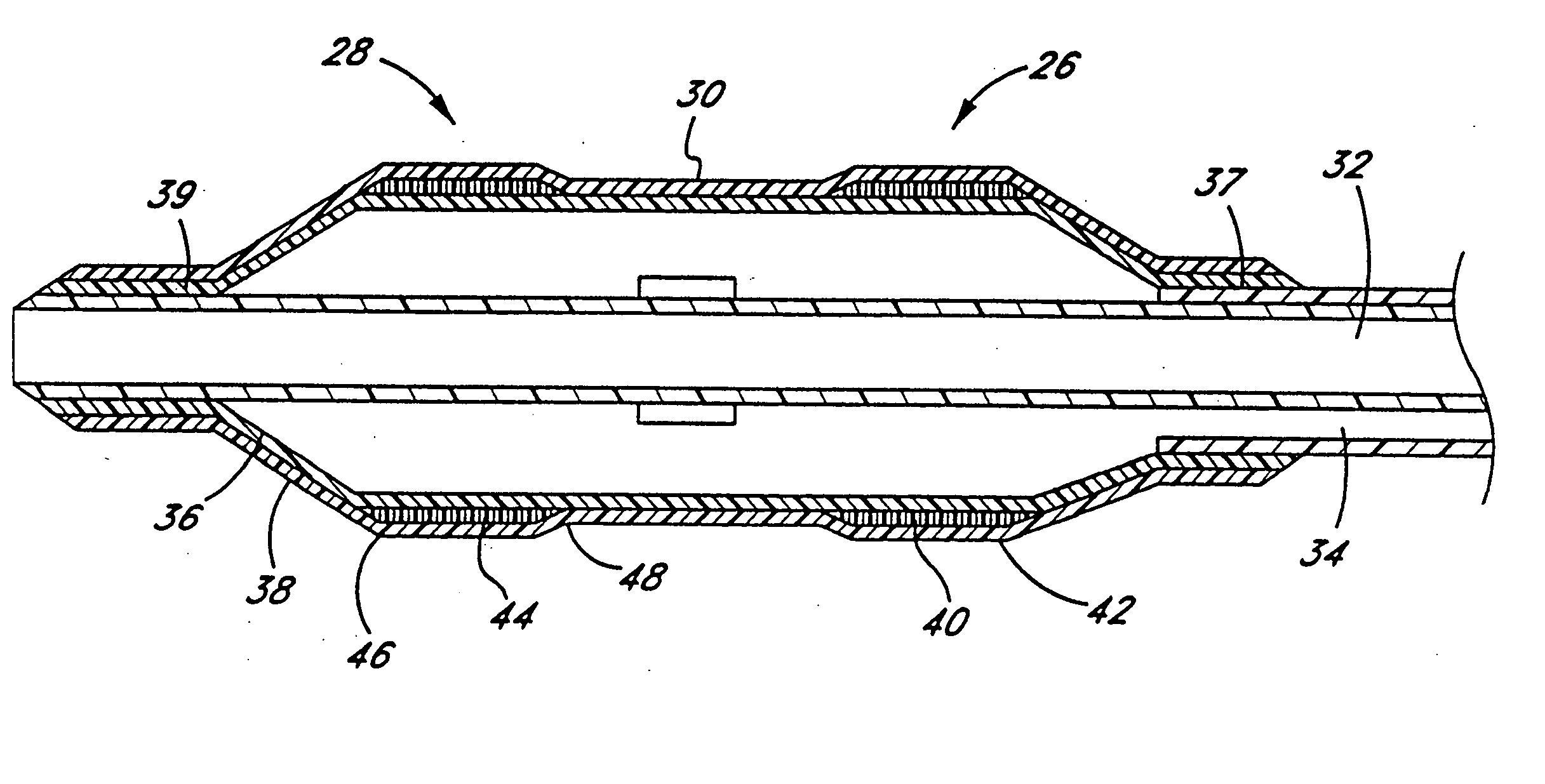

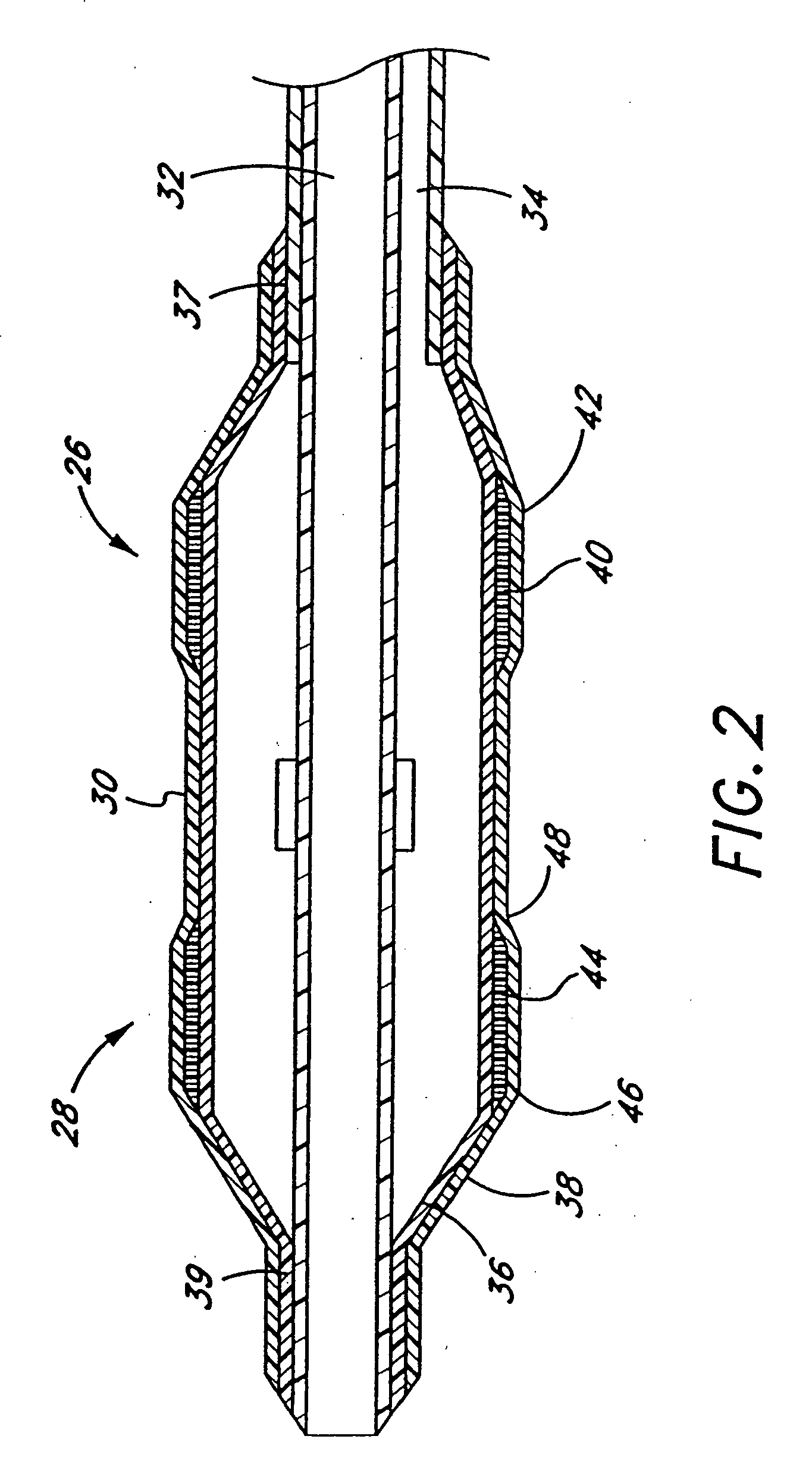

Provided is a method and apparatus for placing a valve (14) in a tubular organ having a greater diameter than the valve, comprising: an expandable tubular adapter (10) having an outer portion with a diameter suitable for contacting the inner walls of the tubular organ, and an inner portion with a diameter suitable for placement of the valve; a valve mounted within the inner portion of the adapter; and a system for placing a valved vascular segment in a tubular organ having a greater inner diameter than the outer diameter of the vascular segment, comprising: an expandable tubular adapter having an outer portion with a diameter suitable for contacting the inner walls of the tubular organ, and an inner portion with a diameter suitable for placement of the valve; an expandable valved vascular segment, expandable to the diameter of the inner portion of the adapter.

Owner:MEDTRONIC INC

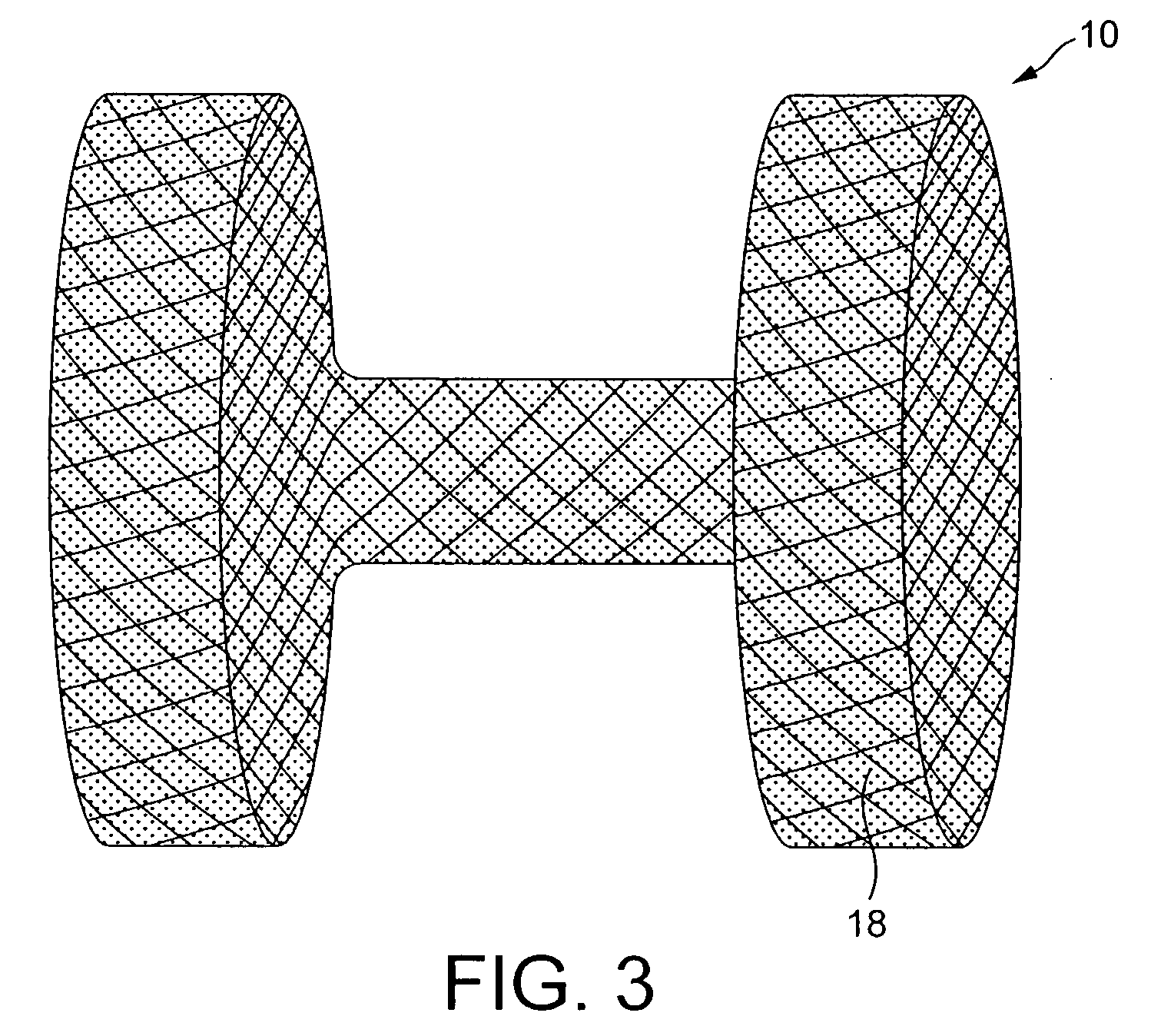

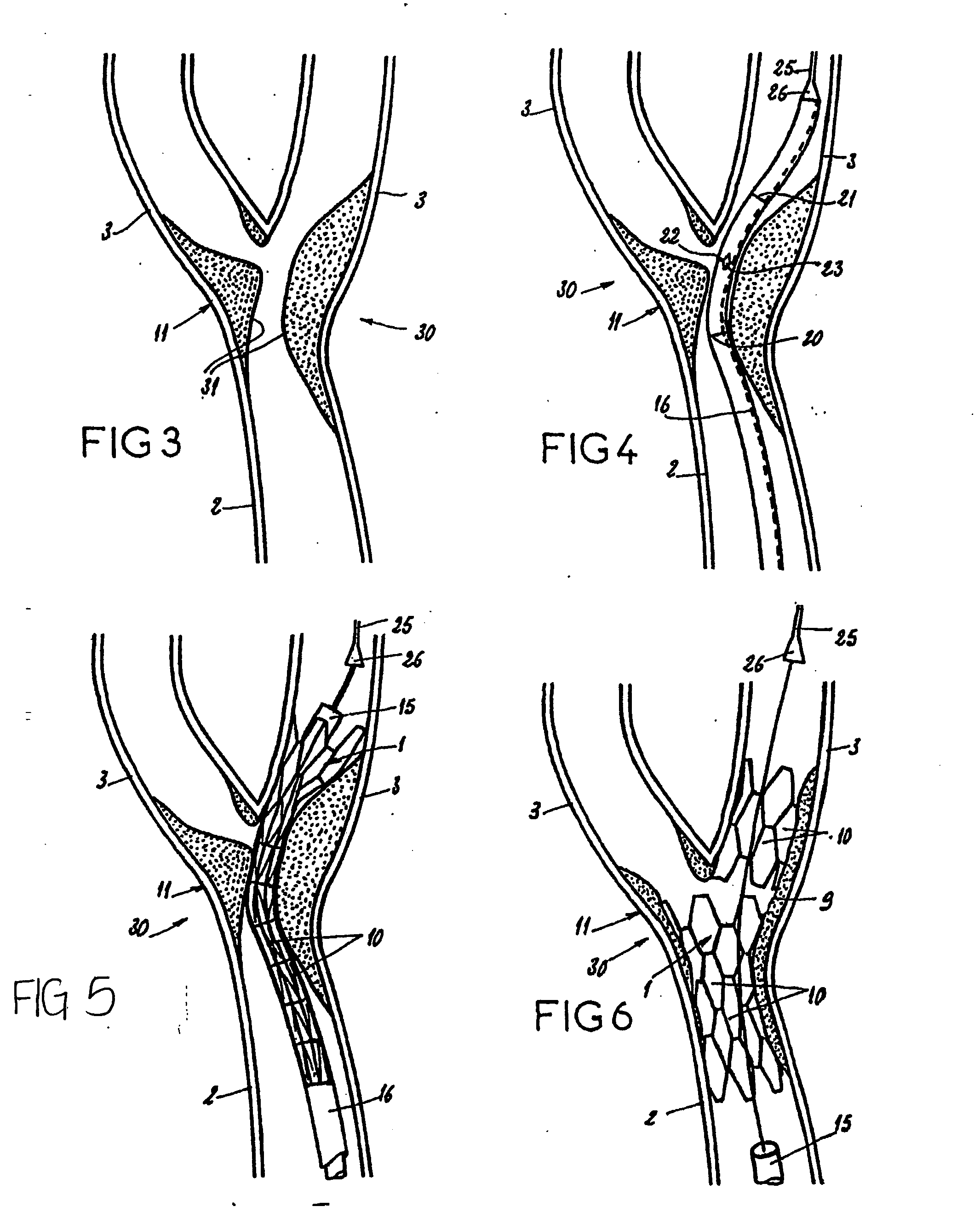

Endoprosthesis for vascular bifurcation

An apparatus for treating an area of bifurcation where a principal body conduit separates into at least two secondary conduits comprises a radially expandable first stent body. The first stent body has a substantially conical shape and a first end having a greater diameter than a second end when fully expanded. The first stent body is preferably shaped to be independent of any other stent bodies, and is free of any means for connecting to any other stent bodies when fully expanded.

Owner:SEGUIN JACQUES +1

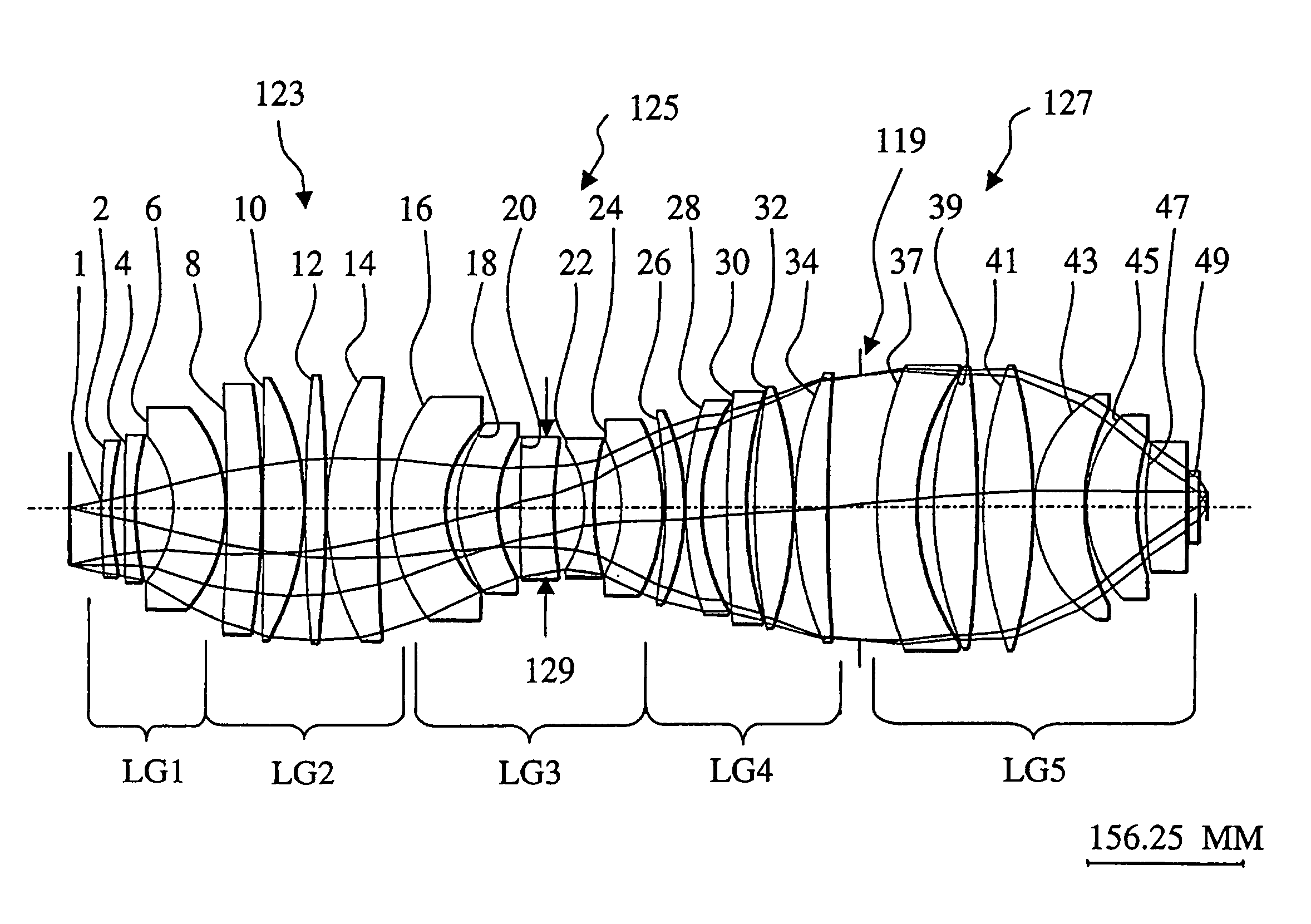

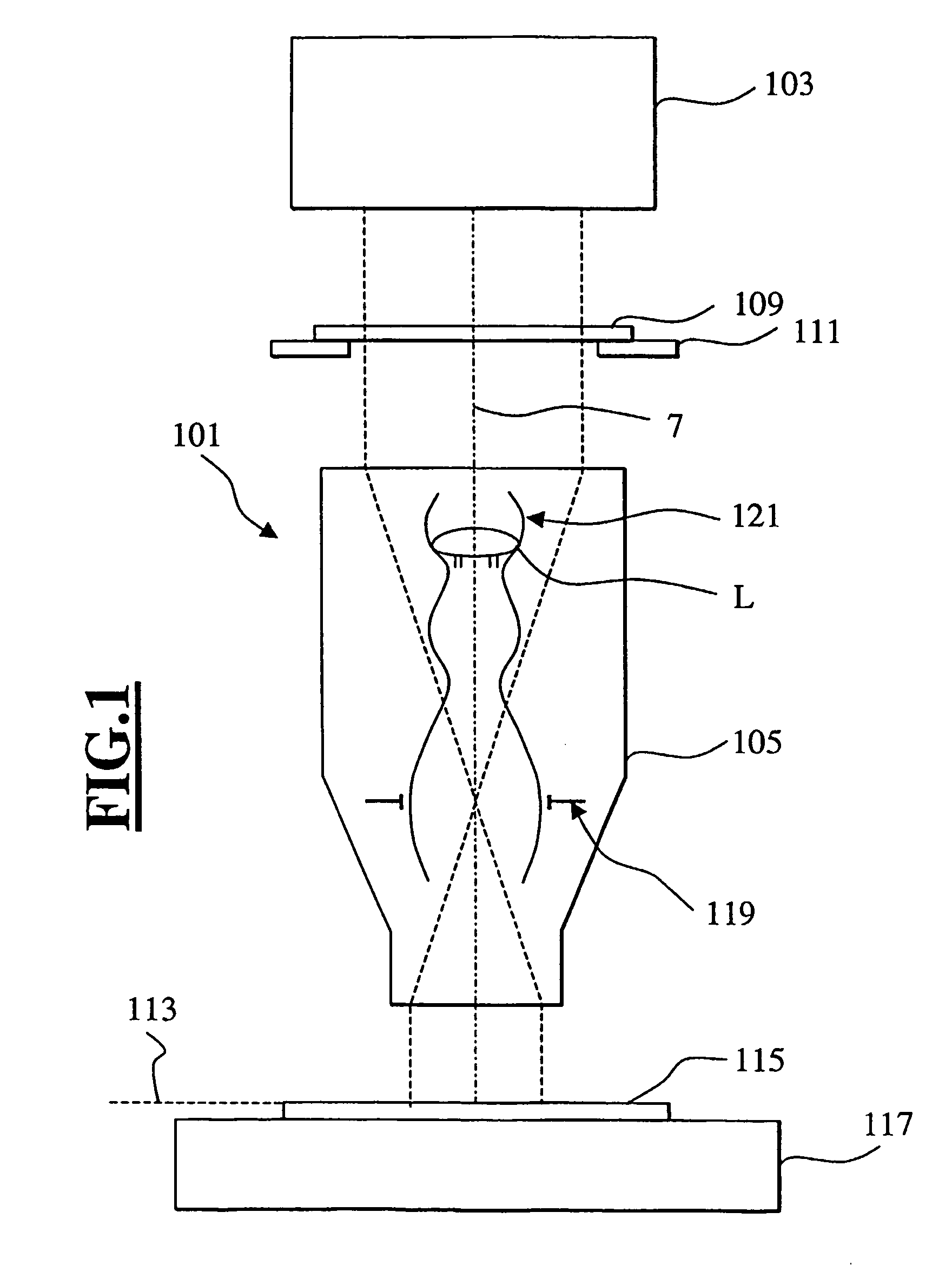

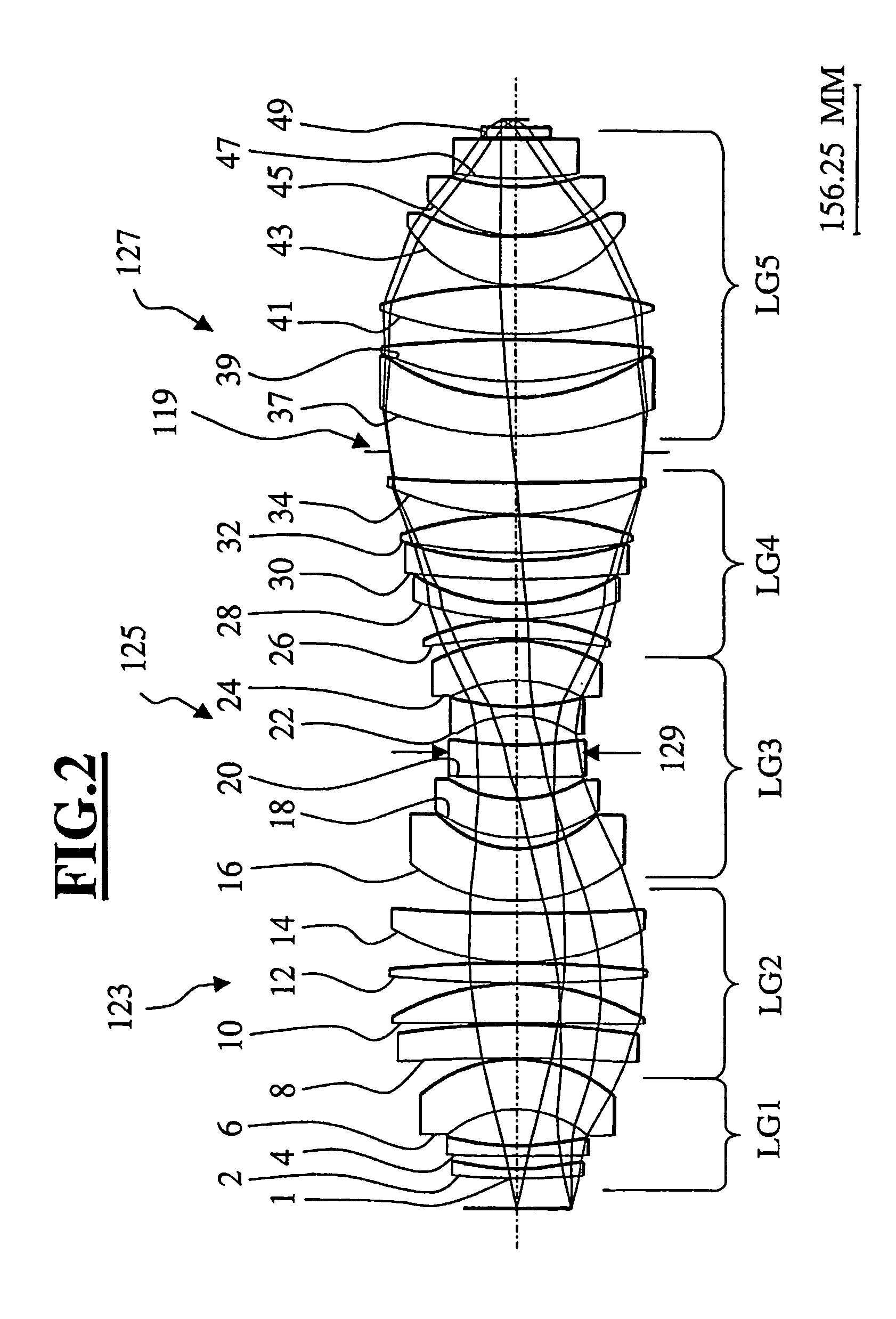

Refractive projection objective

InactiveUS7190527B2Low production costFavorably correctedPhotomechanical exposure apparatusMicrolithography exposure apparatusMaximum diameterSurgery

Owner:CARL ZEISS SMT GMBH

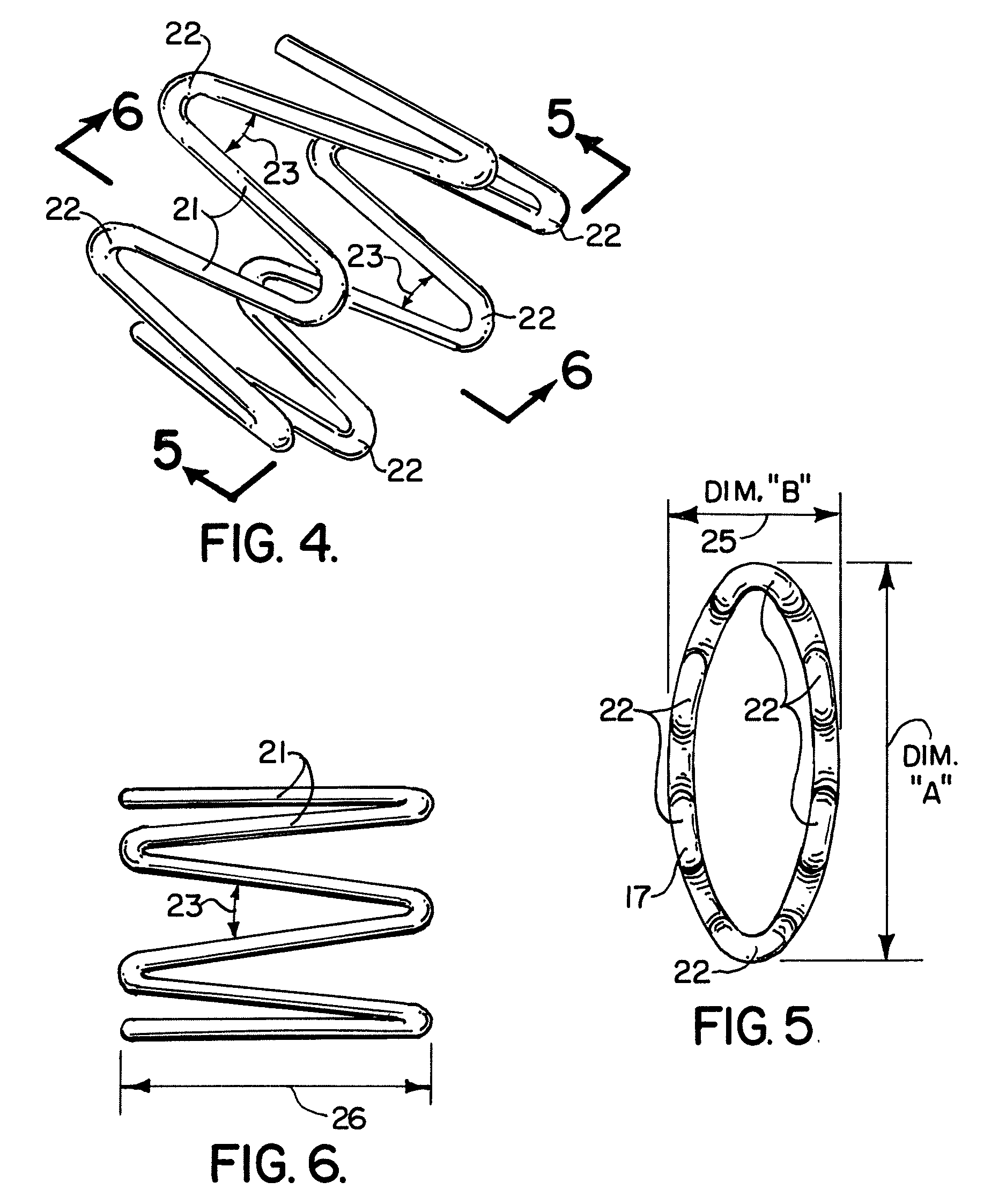

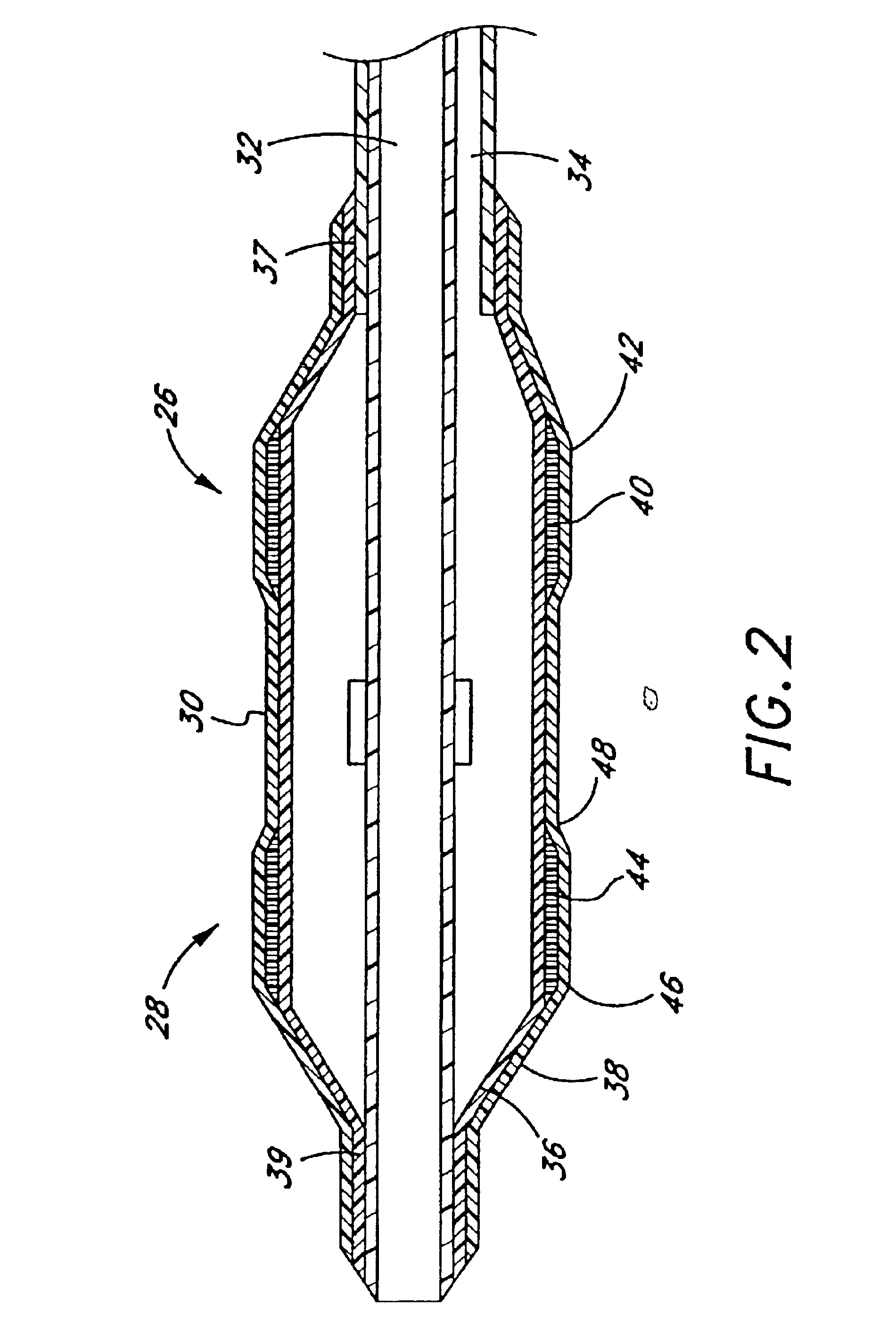

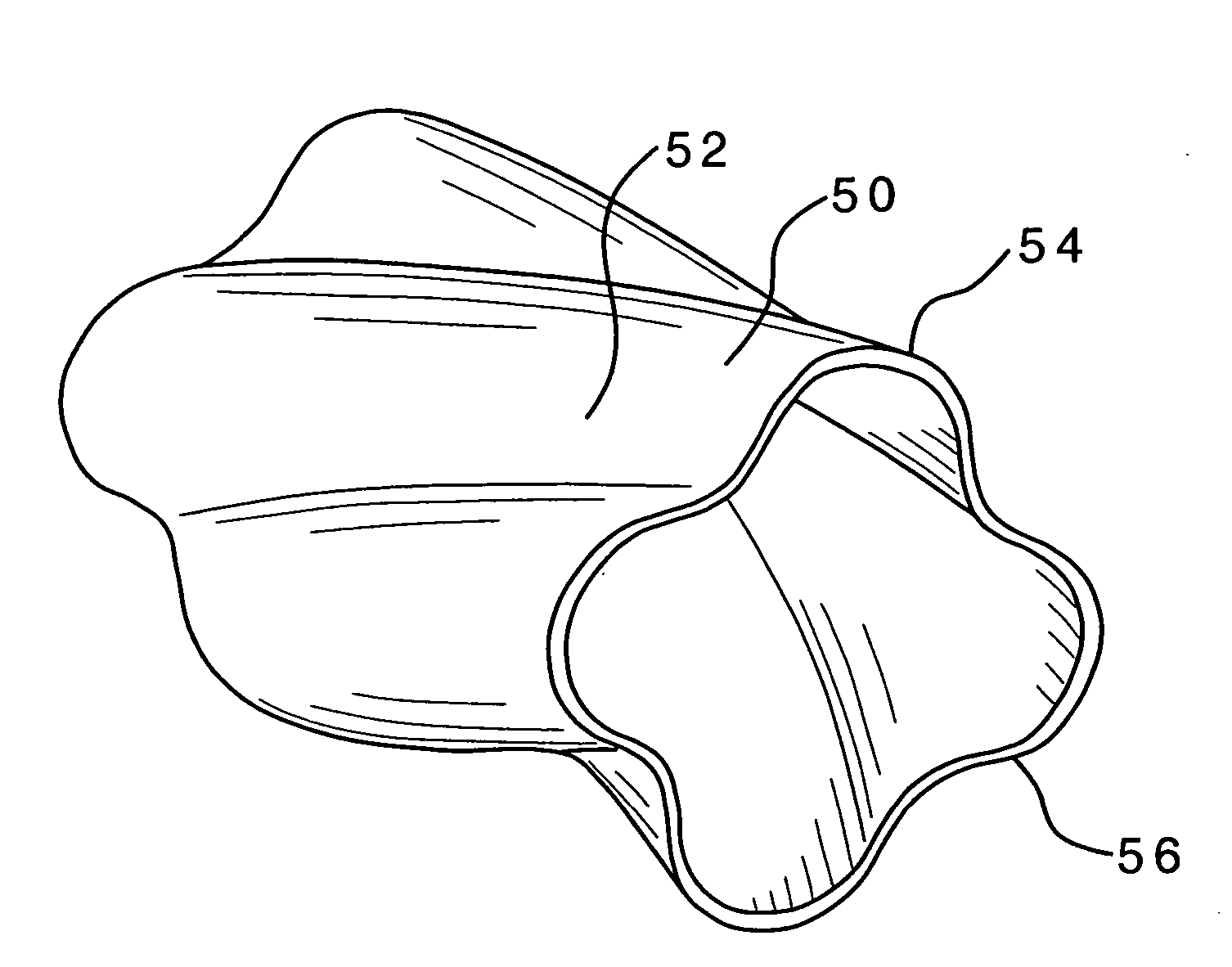

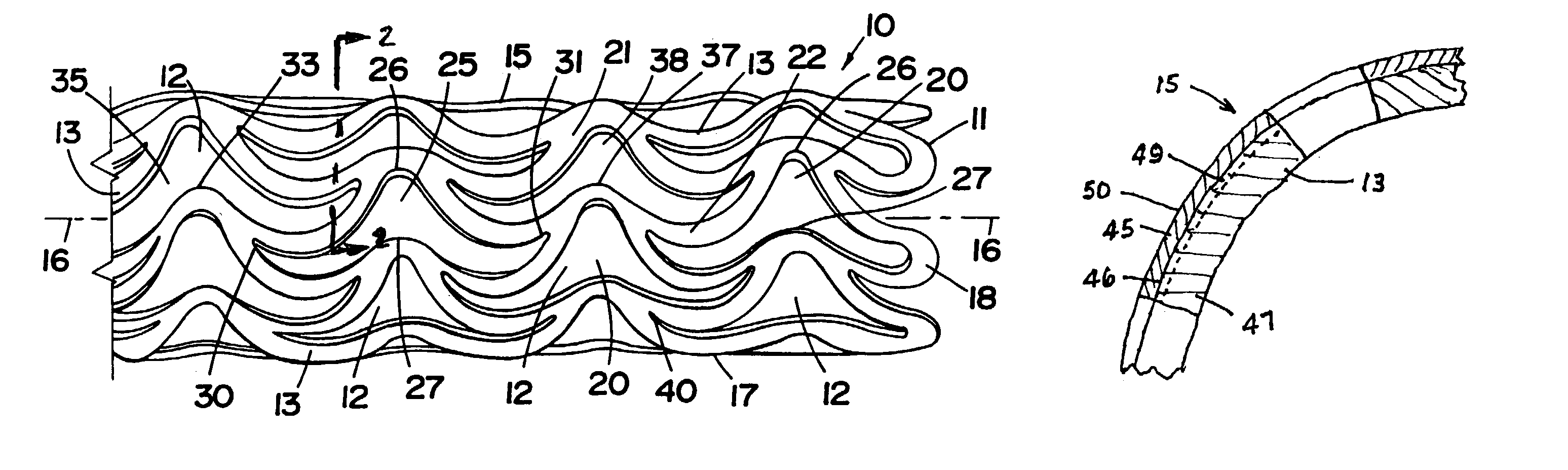

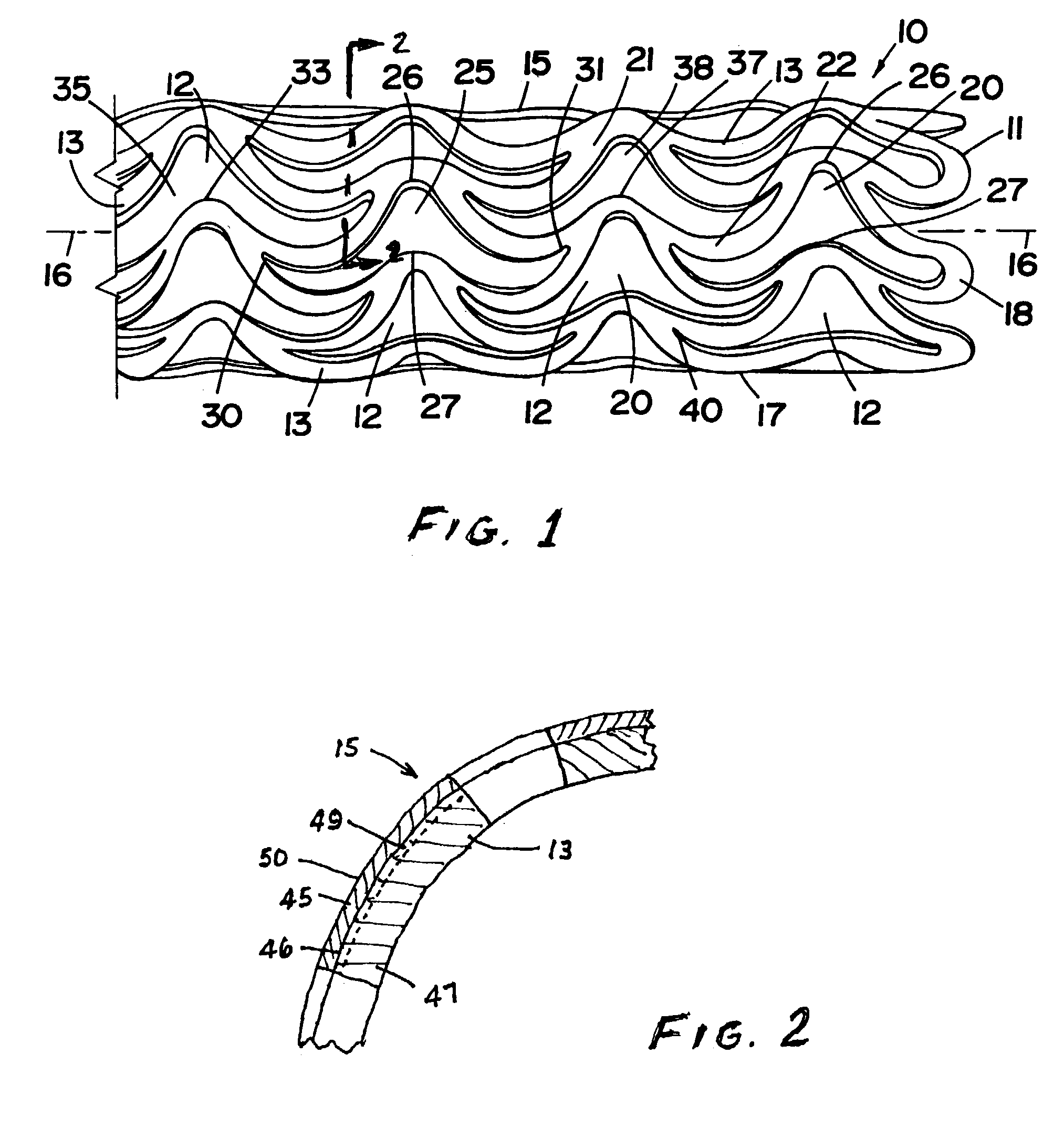

Implantable prosthesis with displaceable skirt

An implantable prosthesis is provided having a radially-expandable tubular body and at least one skirt extending therefrom. The skirt terminates in a peripheral edge, wherein at least portions of the peripheral edge are free and displaceable to a greater diameter of the tubular body. Thus, with the implantable prosthesis being a stent-graft used to treat an aortic aneurysm (e.g., abdominal aortic aneurysm (“AAA”)), the skirt may be used to inhibit Type I endoleaks upon its selective displacement in response to irregular aortic shaping and / or aneurysm neck expansion. The skirt may actively inhibit Type I endoleaks by forming a physical barrier against flow between the tubular body and the aortic wall. In addition, the skirt may passively inhibit endoleak formation by sufficiently restricting blood flow to allow coagulation and clot formation, which would act as a barrier against endoleakage.

Owner:LIFESHIELD SCI

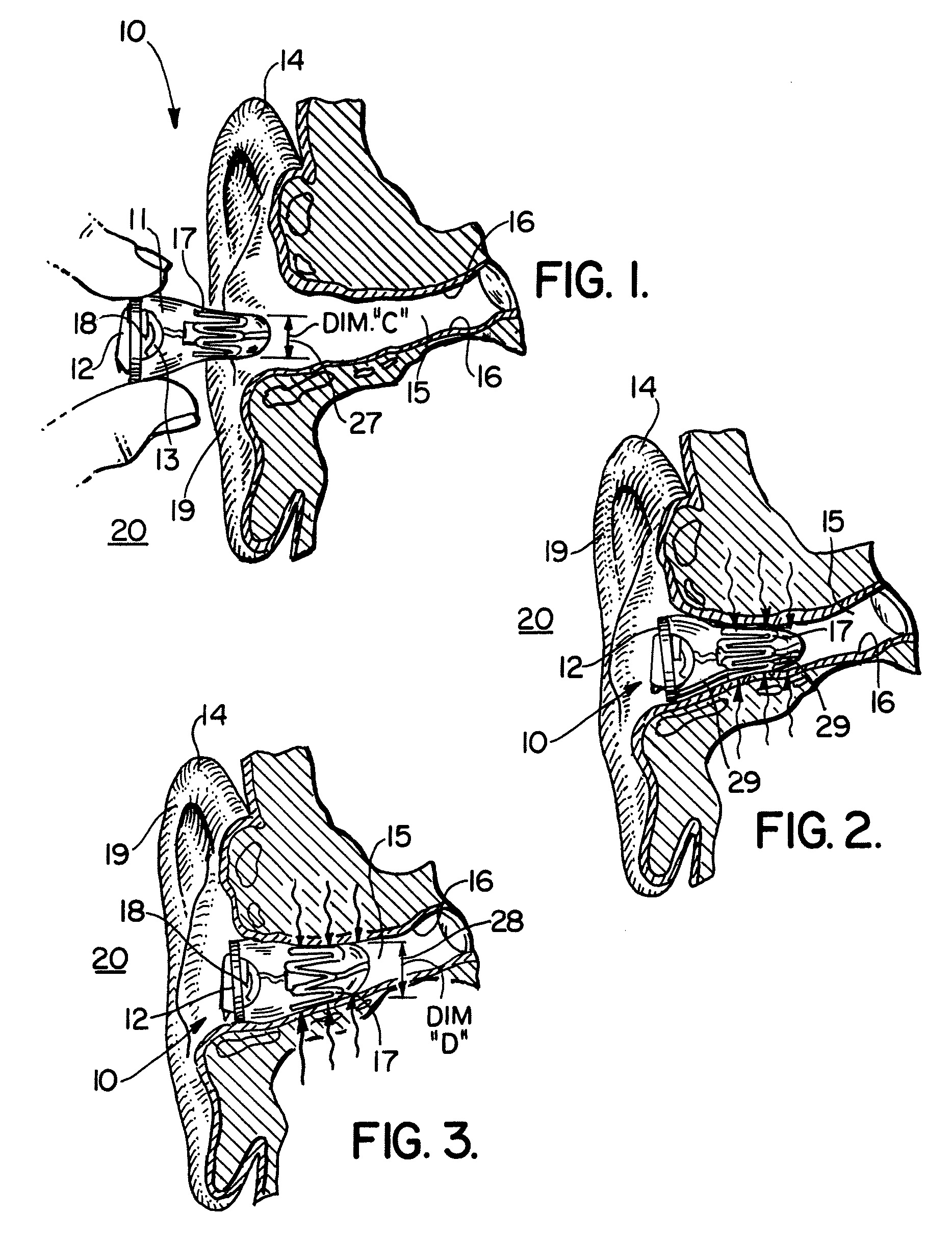

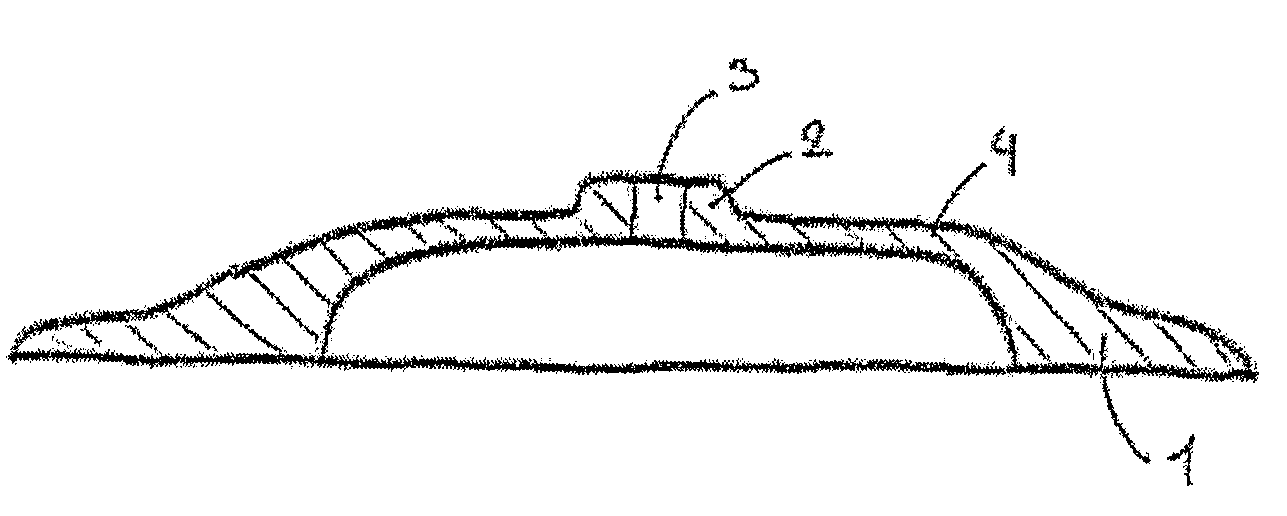

Self forming in-the-ear hearing aid with conical stent

InactiveUS7778434B2Maintain good propertiesReduce leakageEar moulds/tips acoustic sealsEarplugsInsertion stentSelf forming

A hearing aid body is provided that contains electronic hearing aid components and that is attachable to the user's body outside the ear canal. A conduit connects the hearing aid body to the flexible plug. The conduit enables sound emitted by the hearing aid to travel via the conduit to the flexible plug so that the user's able to hear a sound that is amplified by the hearing aid and received by the plug via the conduit. The conduit can be a flexible hollow tube or an electronic conduit that transmit electrical signals between the hearing aid and the plug. A stent embedded in the plug is provided, the stent having a first smaller diameter at a temperature below body temperature and being expandable to a second greater diameter when subjected to the user's body temperature, such as the temperature in the ear canal of a user.

Owner:GENERAL HEARING INSTR

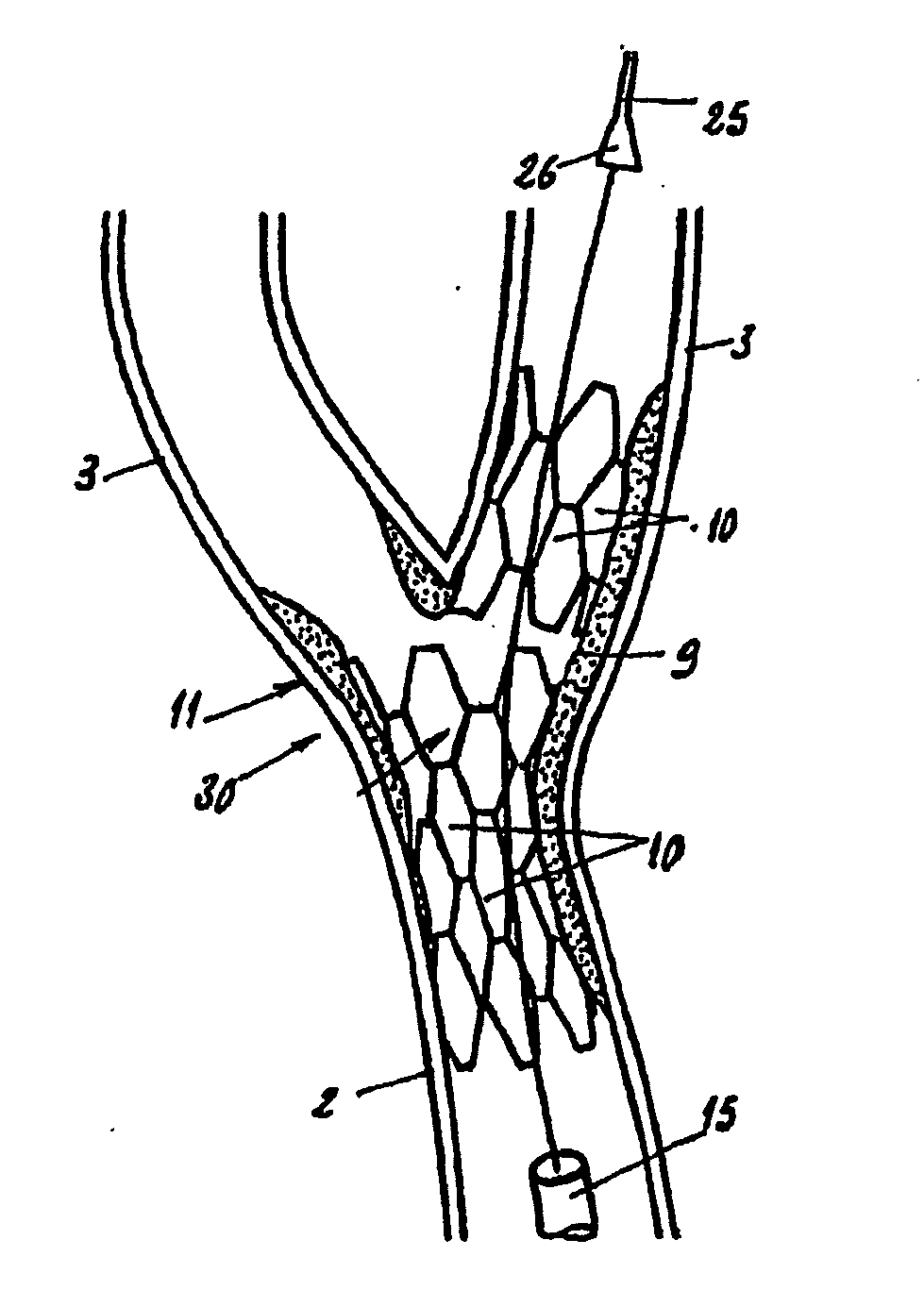

Focalized stent implantation

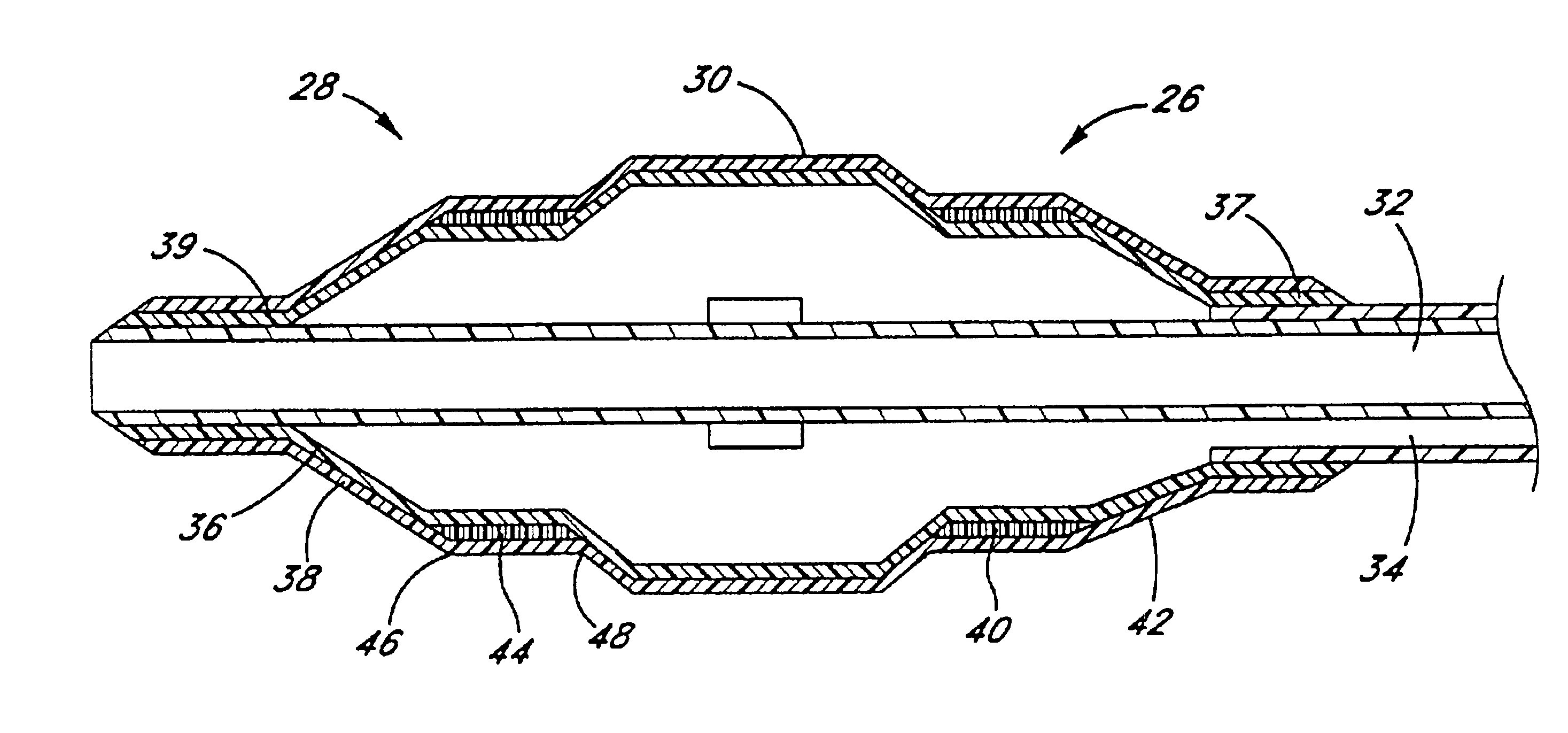

Disclosed is a focal balloon having at least one reference zone and a focal zone. In one embodiment, the reference zone and focal zone are inflatable to a first generally cylindrical profile at a first pressure. At a second, greater pressure, the focal section expands to a second, greater diameter, while the reference zone remains substantially at the first diameter. In an alternate embodiment, the focal zone and the reference zone are inflatable to their respective predetermined diameters at the inflation pressure, in the absence of constricting lesions or anatomical structures. Multiple lobed and drug delivery embodiments are also disclosed.

Owner:RADIANCE MEDICAL SYST

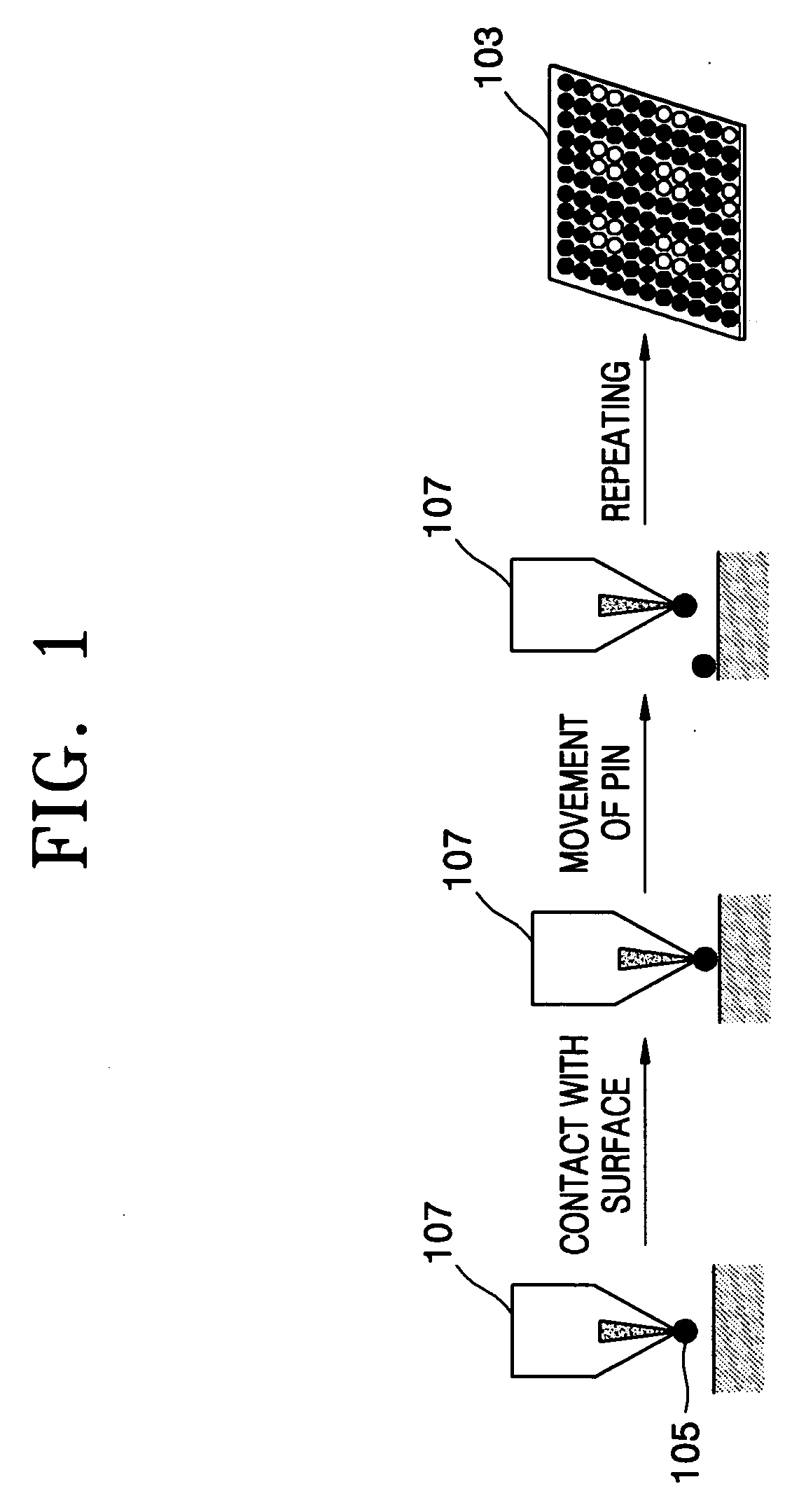

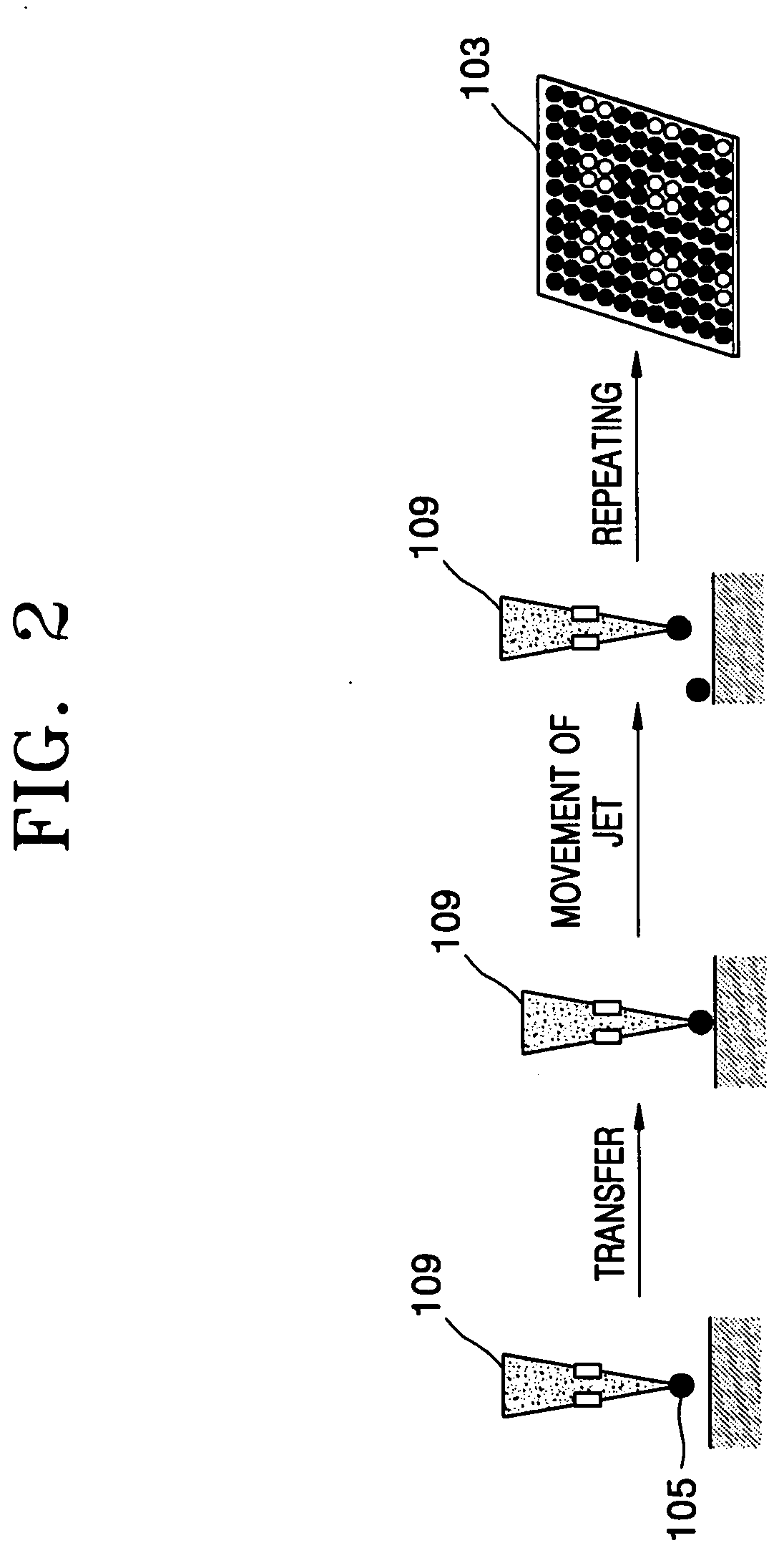

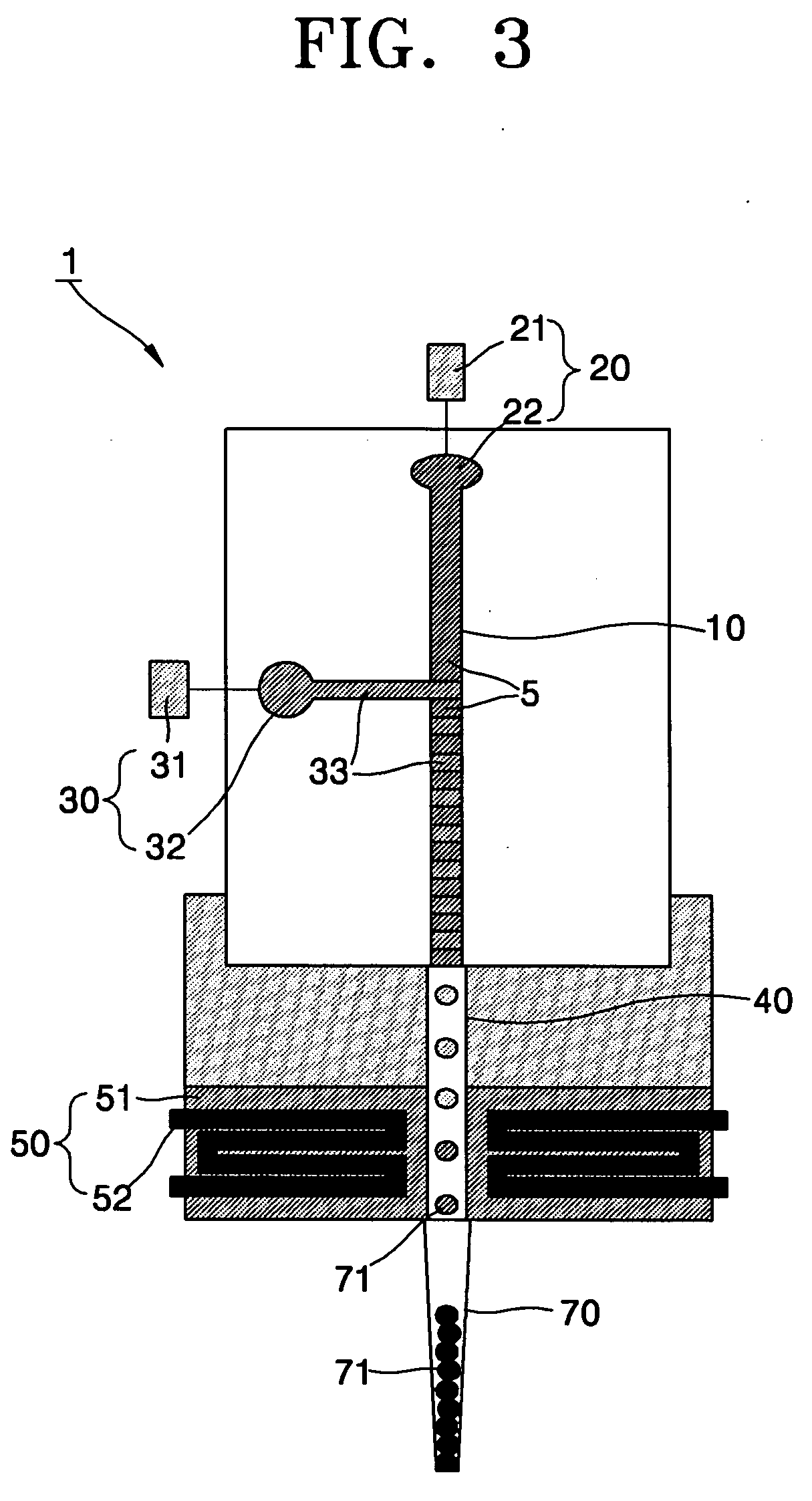

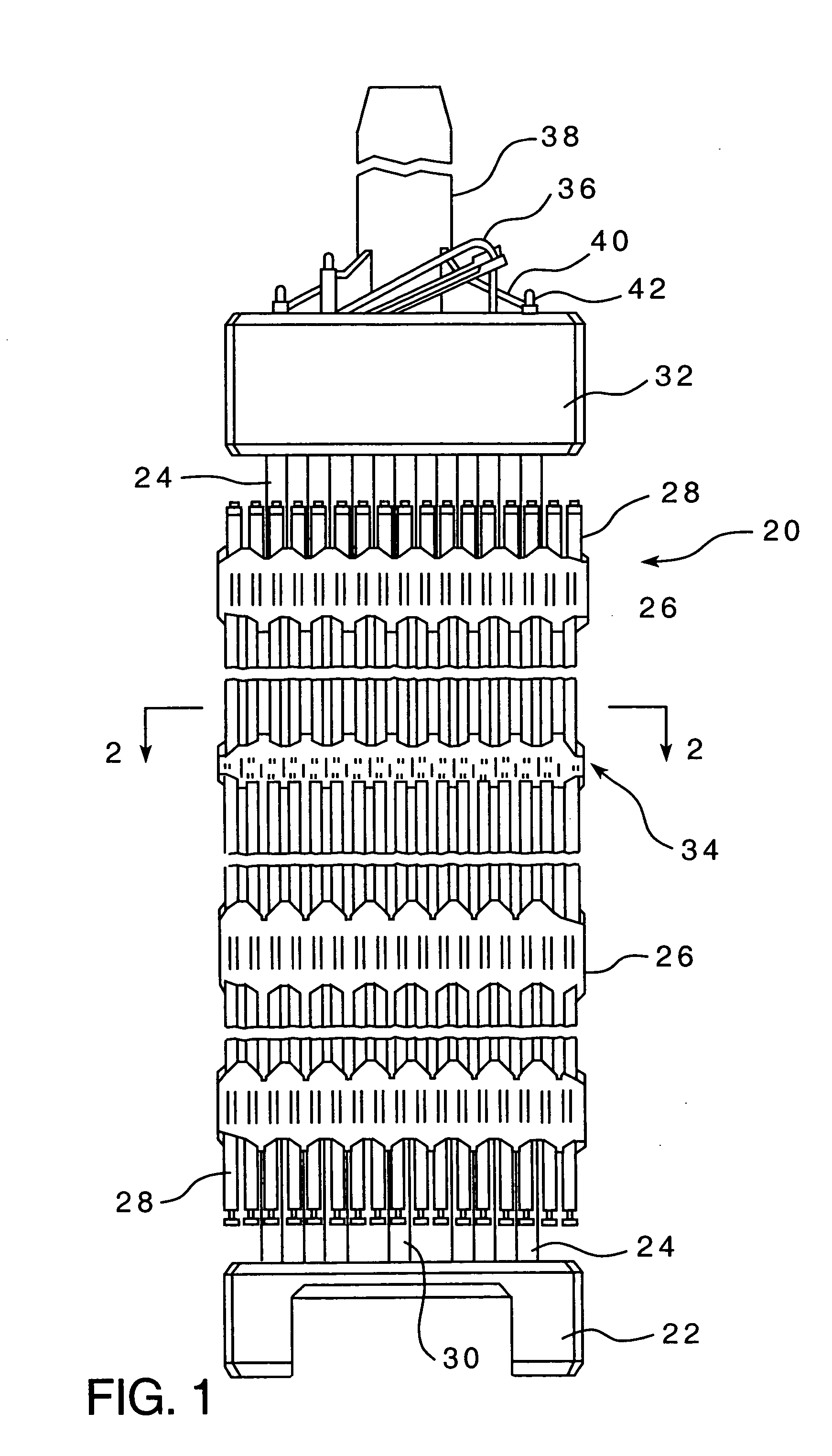

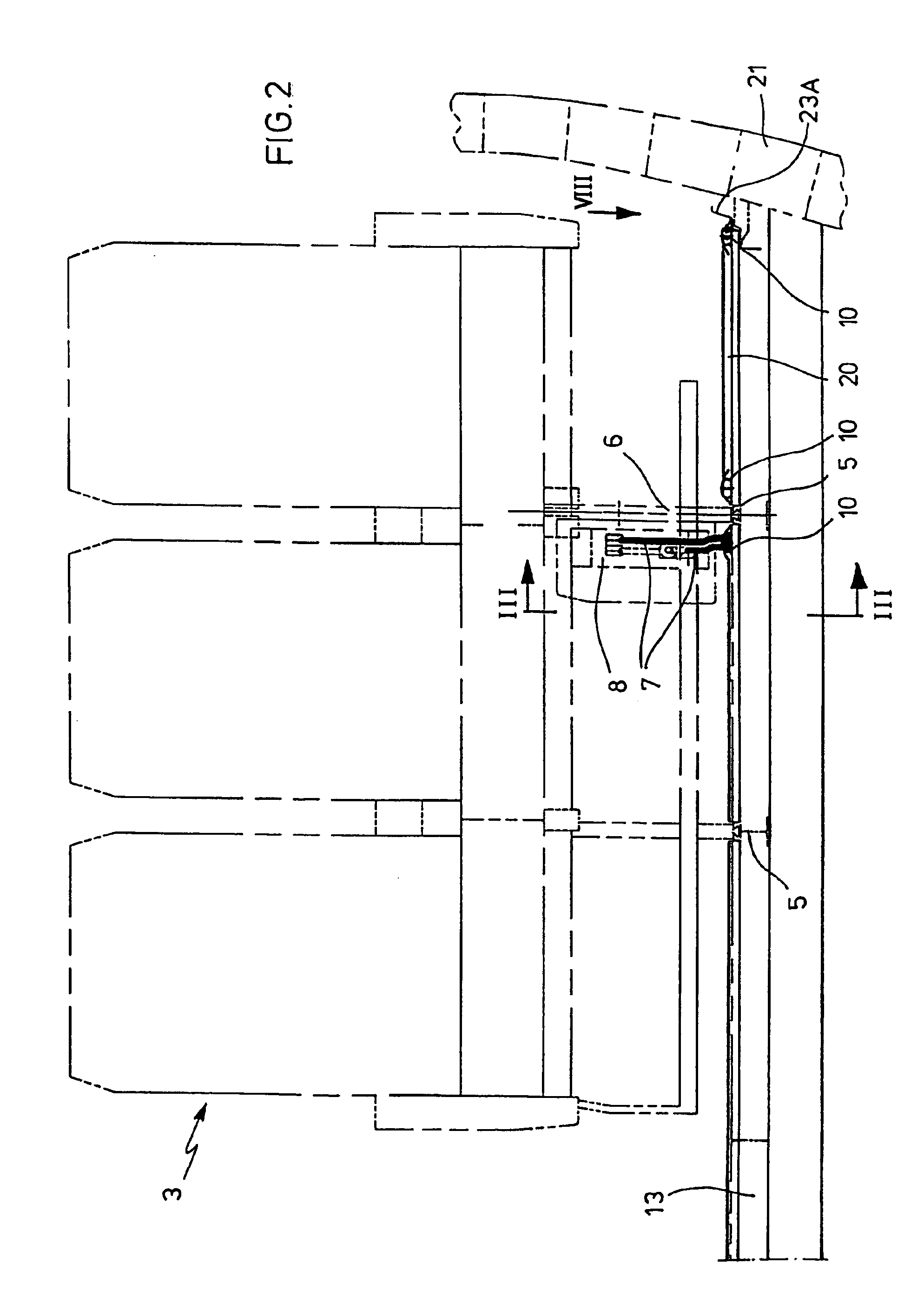

Spotting device for manufacturing DNA microarray and spotting method using the same

InactiveUS20050158755A1Shorten production timeUniform shapeBioreactor/fermenter combinationsMaterial nanotechnologyCross-linkDNA microarray

A spotting device for manufacturing a DNA microarray and a spotting method using the same are provided. The spotting device for dropping and immobilizing a solution of biomolecules, for example nucleic acids such as probe DNA, mRNA, and peptide nucleic acid (PNA), and proteins on a DNA microarray surface to manufacture a DNA microarray, includes a first microchannel with a tube shape; a supplying unit supplying the solution of biomolecules to the first microchannel; a biomolecule solution droplet forming unit cross-linked to the first microchannel and forming biomolecule solution droplets with a predetermined size by periodically jetting a gas toward the biomolecule solution flowing in the first microchannel; a second microchannel linked to the first microchannel and having a greater diameter than the first microchannel; a cooling unit surrounding at least a part of the second microchannel to freeze the biomolecule solution droplets which pass through the second microchannel; and a spotting unit thawing the frozen biomolecule solution droplets and dropping the thawed biomolecule solution droplets on a surface of the DNA microarray. The spotting device can form spots with uniform shape, minimize an effect of temperature on biomolecules, and easily manipulate biomolecules when manufacturing a DNA microarray.

Owner:SAMSUNG ELECTRONICS CO LTD

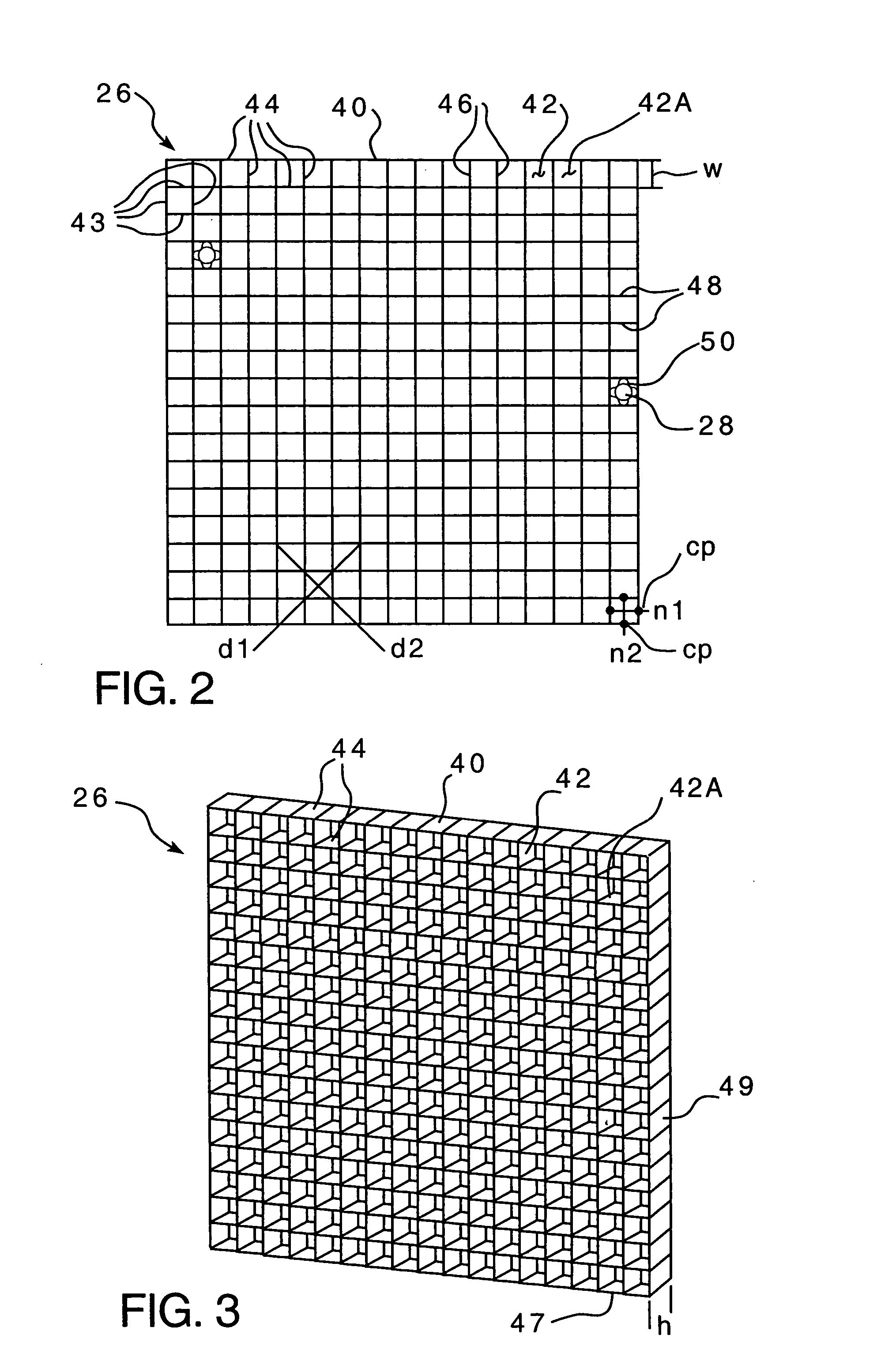

Helically fluted tubular fuel rod support

ActiveUS20060153327A1Minimal pressure dropUniform thicknessNuclear energy generationFuel element assembliesEngineeringCell contact

A support grid for a nuclear fuel assembly, the fuel rod assembly having a generally cylindrical fuel rod with a diameter, wherein the support grid includes a frame assembly having a plurality of generally uniform cells, each the cell having at least one wall and a width and at least one generally cylindrical tubular member having a cell contact portion with a greater diameter and at least one helical fuel rod contact portion with a lesser diameter, the cell contact portion and the fuel rod contact portion joined by a transition portion, the greater diameter being generally equivalent to the cell width, and the lesser diameter being generally equivalent to the fuel rod diameter such that a fuel rod disposed in the tubular member would engage the inner diameter. Wherein the least one tubular member disposed in one cell of the plurality of generally square cells so that the cell contact portion engages the at least one cell sidewall.

Owner:WESTINGHOUSE ELECTRIC CORP

Access Port

An access port for enabling passage of a conduit through a partition wall, said port comprising three portions, a sleeve portion surrounding an aperture for receiving a conduit there through, a flange portion for attachment to the partition wall, said flange portion encircles the sleeve portion and has a greater diameter than the sleeve portion, and a membrane portion connecting the flange portion and the sleeve portion. The port may be suitable for, in a leak-proof manner, passing a catheter or drain tube through the wall of a medical device such as a wound care device or a drainage bag.

Owner:COLOPLAST AS

Telescopic strut for an external fixator

ActiveUS8057474B2Improve usabilityReadily and quickly changed in its lengthInternal osteosythesisJoint implantsExternal fixatorSpherical shaped

A telescopic strut for use with an external fixator includes a tube and a rod, especially a threaded rod being in threaded engagement with the tube. The tube comprises at least one hole for accommodating a ball, the ball having the spherical shape for engagement with the threaded rod. A sleeve is provided on the portion of the tube comprising the hole. The sleeve comprises a non-spherical inner cross-section. The greater diameter of the sleeve has a dimension which is at least the sum of the outer diameter of the threaded rod plus the diameter of an accommodating ball for allowing direct axial movement of the threaded rod against the tube in such a rotational position of the sleeve. The lesser diameter has a dimension to place the ball within the threaded rod for allowing a rotational movement of the threaded rod against the tube.

Owner:STRYKER EURO OPERATIONS HLDG LLC

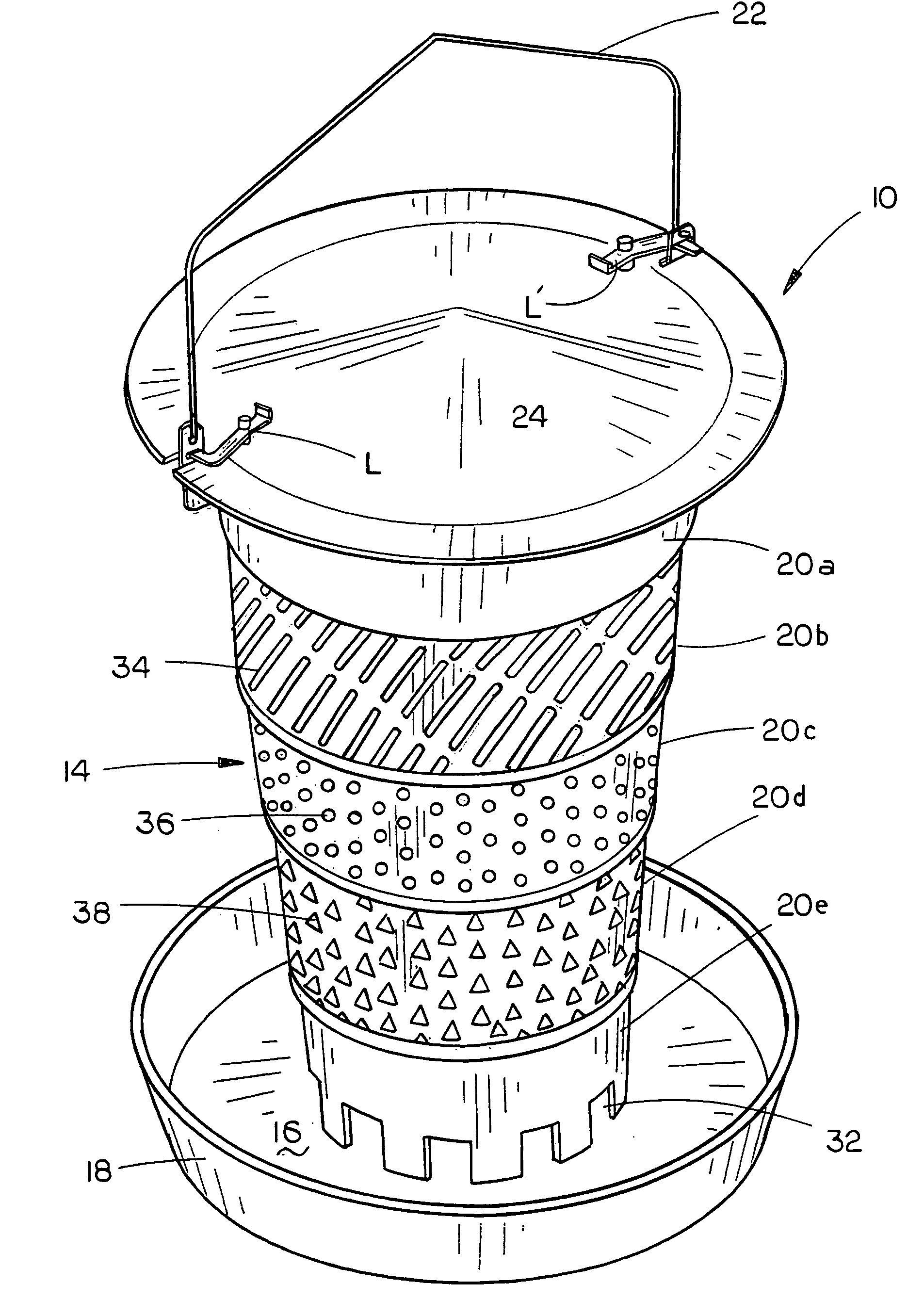

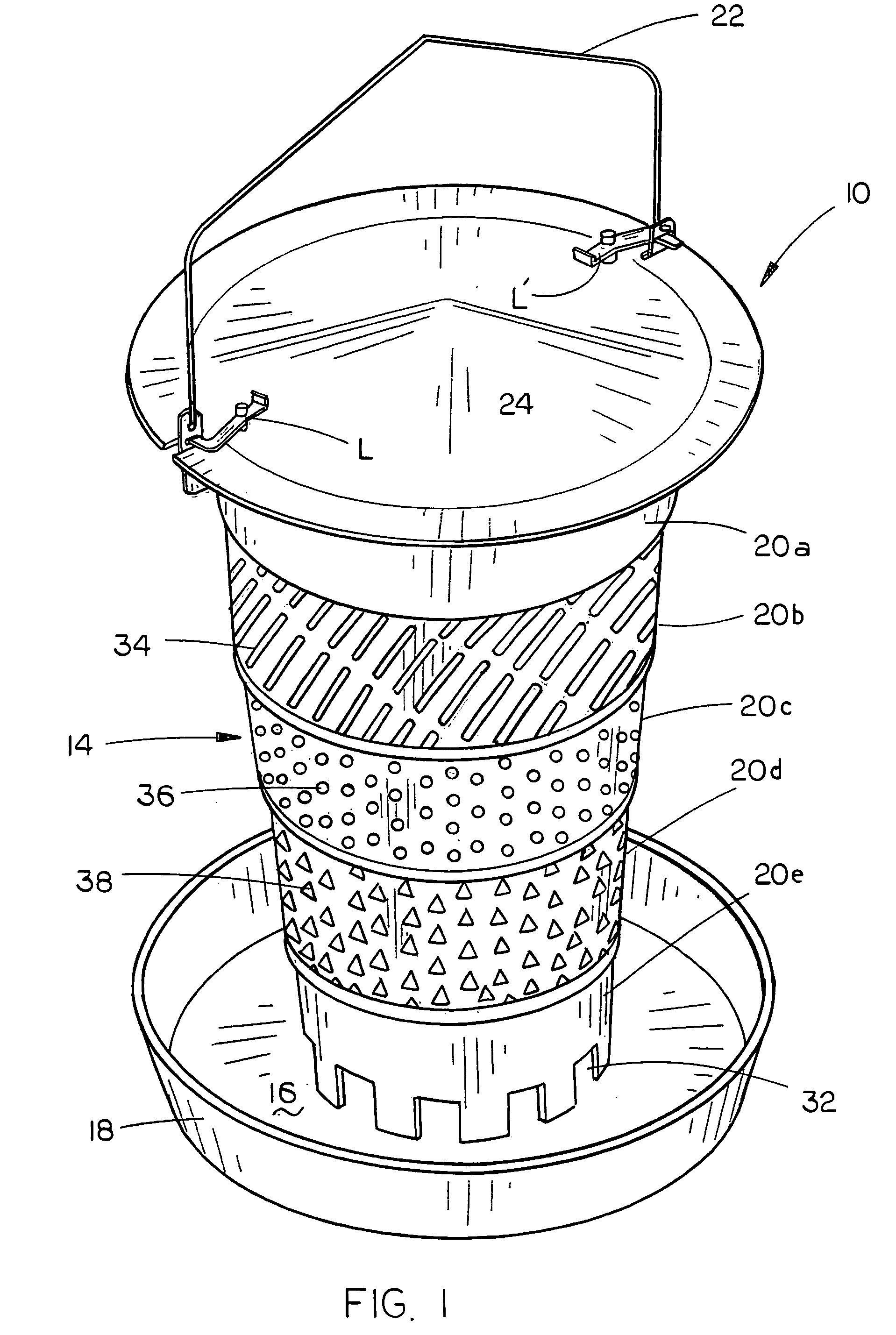

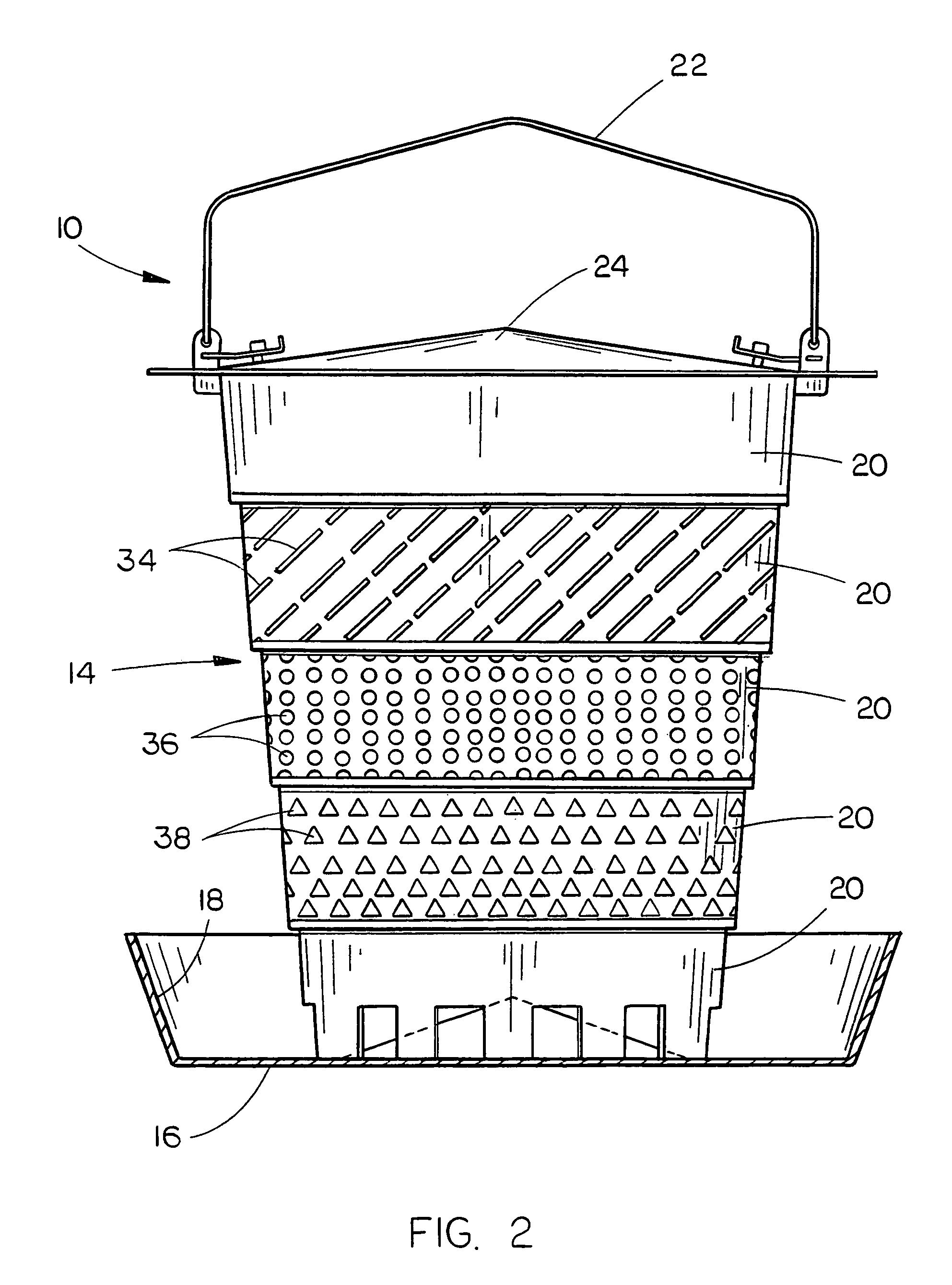

Collapsible feeder

ActiveUS7506611B1Easy to fillEasy to hangAnimal feeding devicesPisciculture and aquariaVisual observationEngineering

A collapsible feeder for birds, squirrels and the like and comprises a feeder body including a base and a rim. A series of hollow body segments of graduated diameters extend upwardly from the base within the rim to form a feeder body. The segment of smallest diameter is joined to the base and has a plurality of feed outlet openings formed therein to enable feed from within the feeder body to pass outwardly therefrom onto the base inwardly of the rim. A feeder lid is provided at the upper end of the segment of greatest diameter when the feeder body is in the extended position. The body segments include structure for yieldably maintaining the feeder in its straight extended position for filling and hanging. At least some of the body segments are comprised of a perforated metal material to enable the visual observation of the feed level within the feeder.

Owner:WOODSTREAM CORP

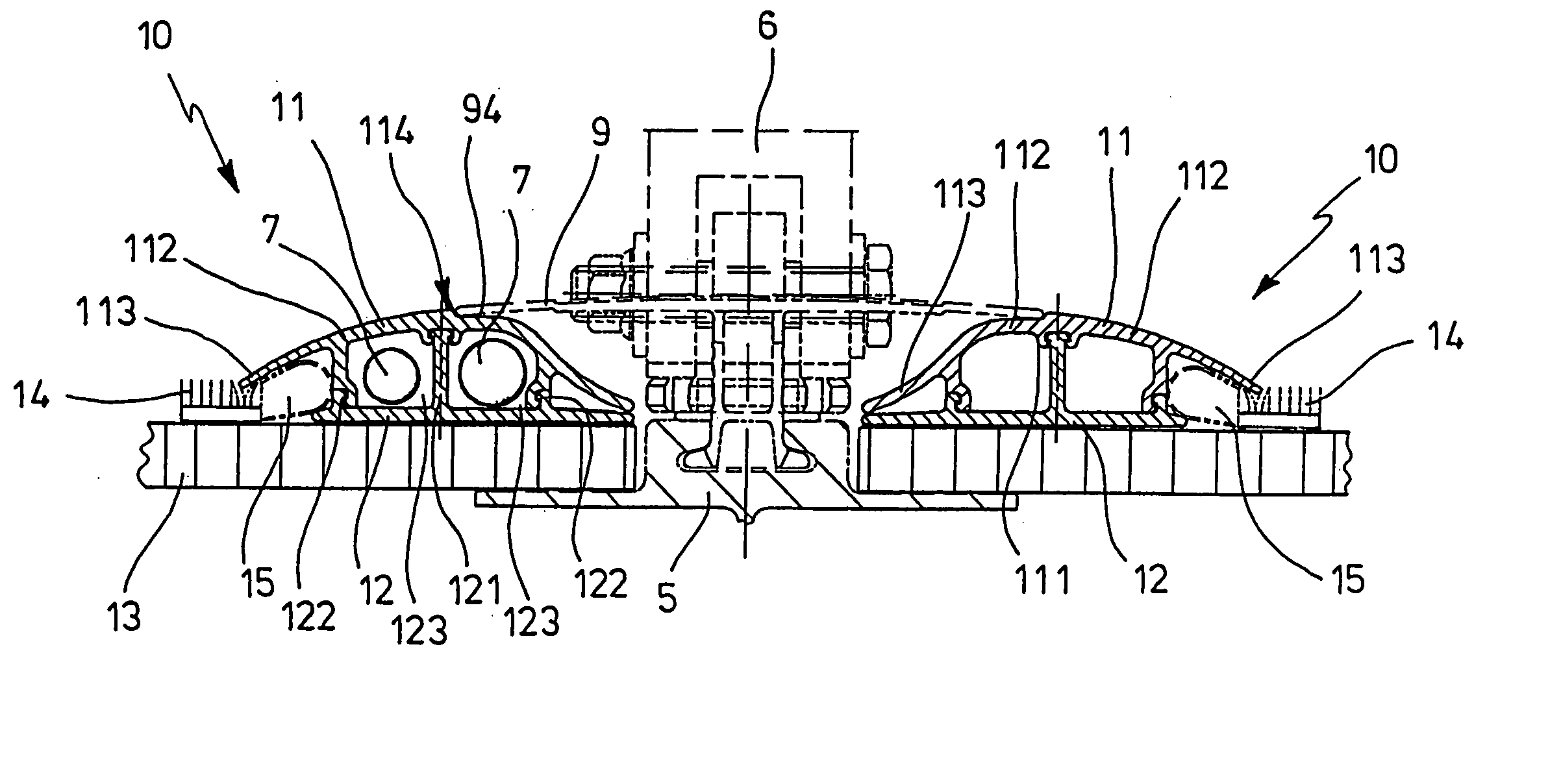

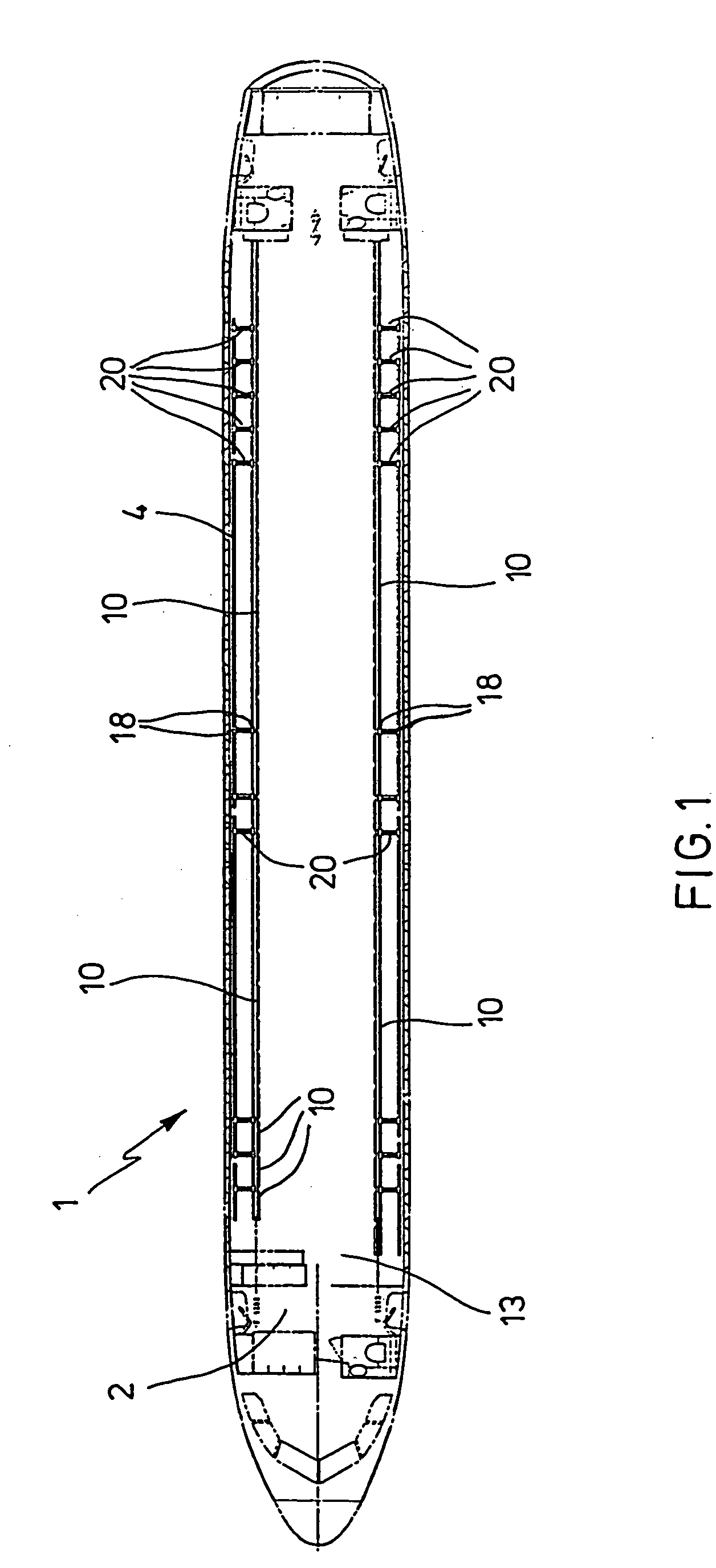

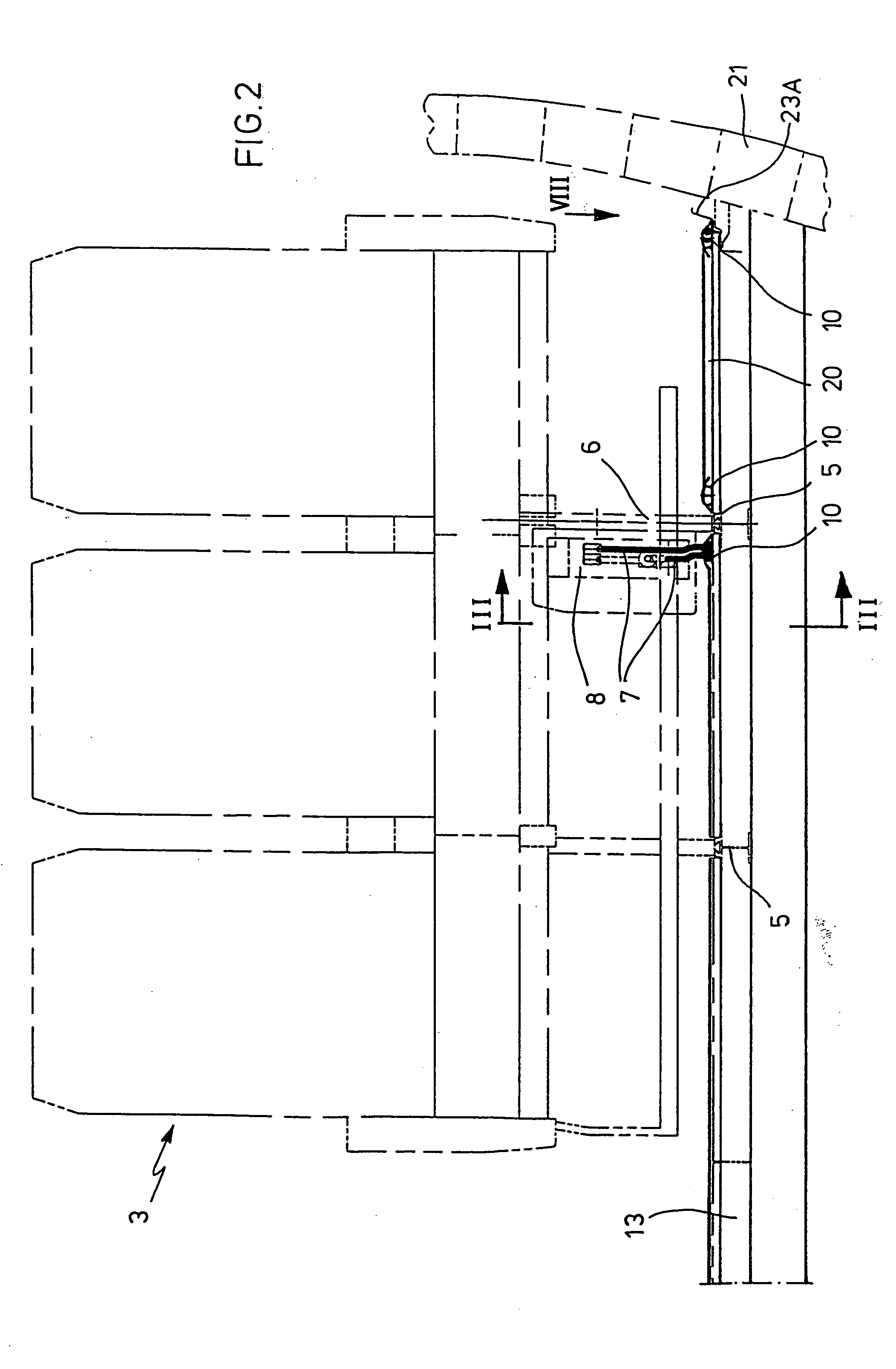

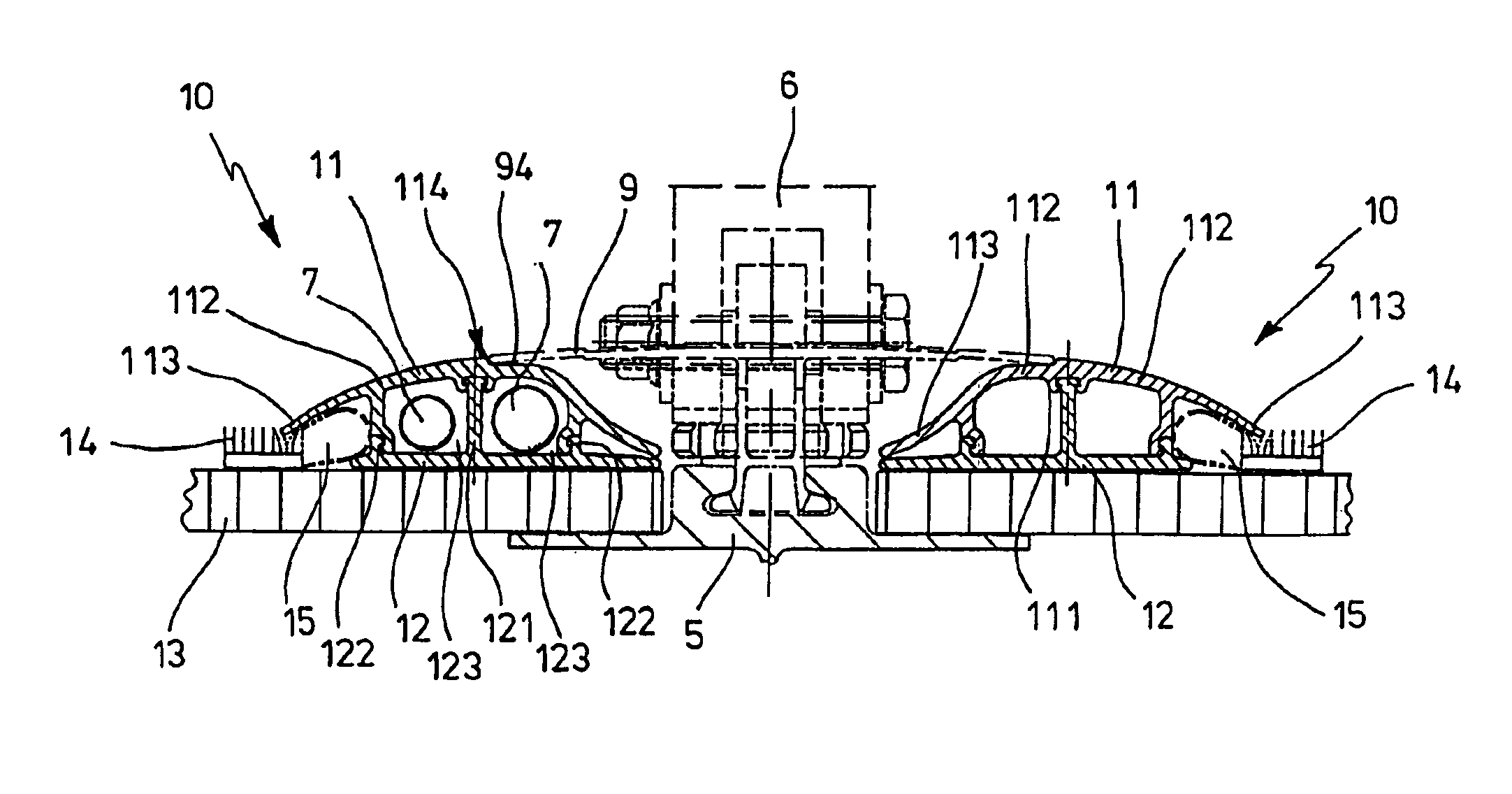

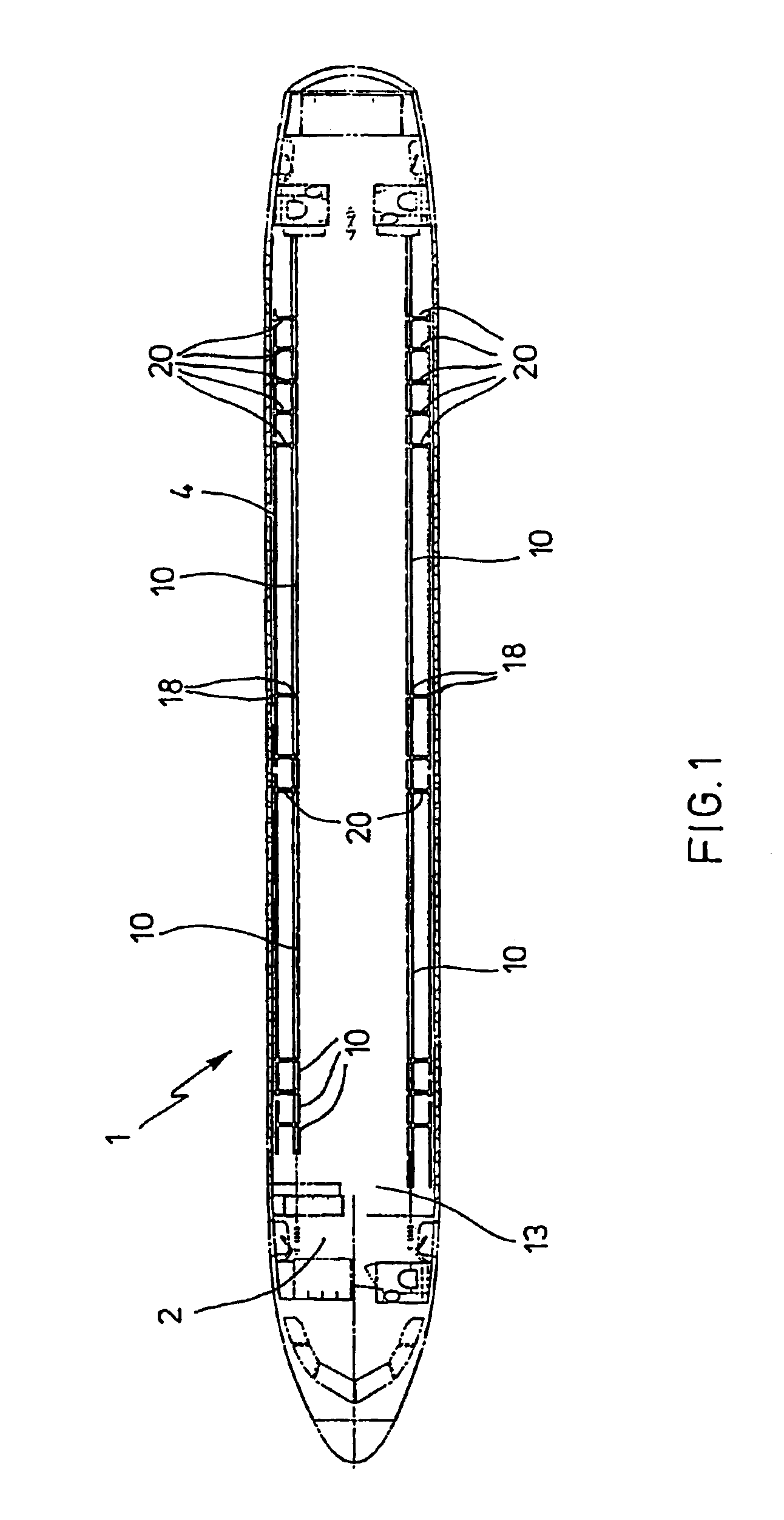

Arrangement for laying cables in the floor area of a passenger transport aircraft

ActiveUS20040129445A1Minimal complexityMinimal effortPipe supportsClosed circuit television systemsNacelleEngineering

A conduit system for laying cables along the floor of a passenger cabin of an aircraft includes longitudinal and transverse cable guide elements respectively forming cable channels, and cable branch junctions at intersections of the longitudinal and transverse guide elements. Each guide element includes a lower part secured to the cabin floor, and an upper part secured (e.g. snap fitted) onto the lower part to cover the cable channel. The cable branch junction includes a lower section secured to the floor and covered by an upper section, and allows the cables to continue straight through the junction or to be deflected by 90° or by 180°. With this arrangement, a greater number and greater diameter of cables can be laid out with a minimal installation effort. The components of the system are easily adaptable to any required installation layout, while providing a continuous covered protected enclosure for the cables.

Owner:AIRBUS OPERATIONS GMBH

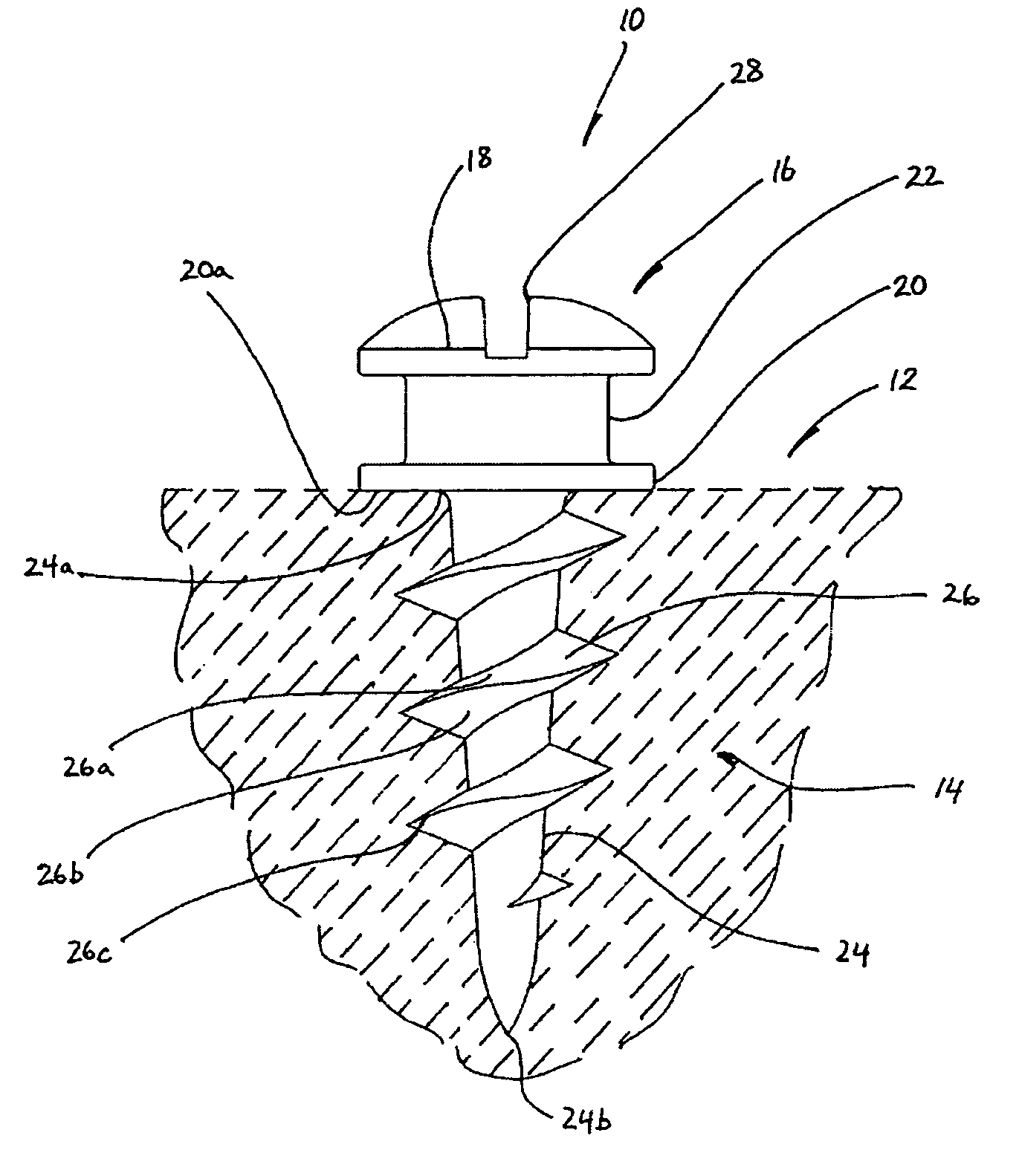

Supporting device

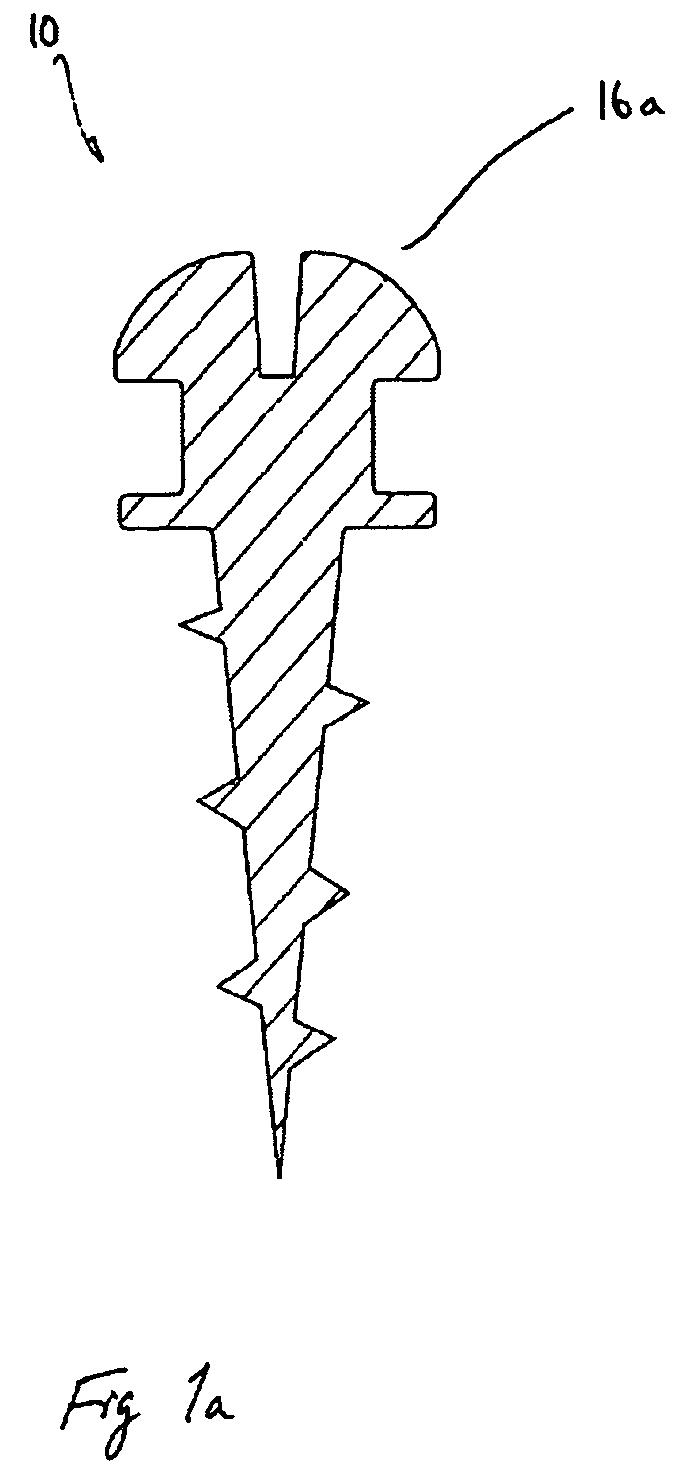

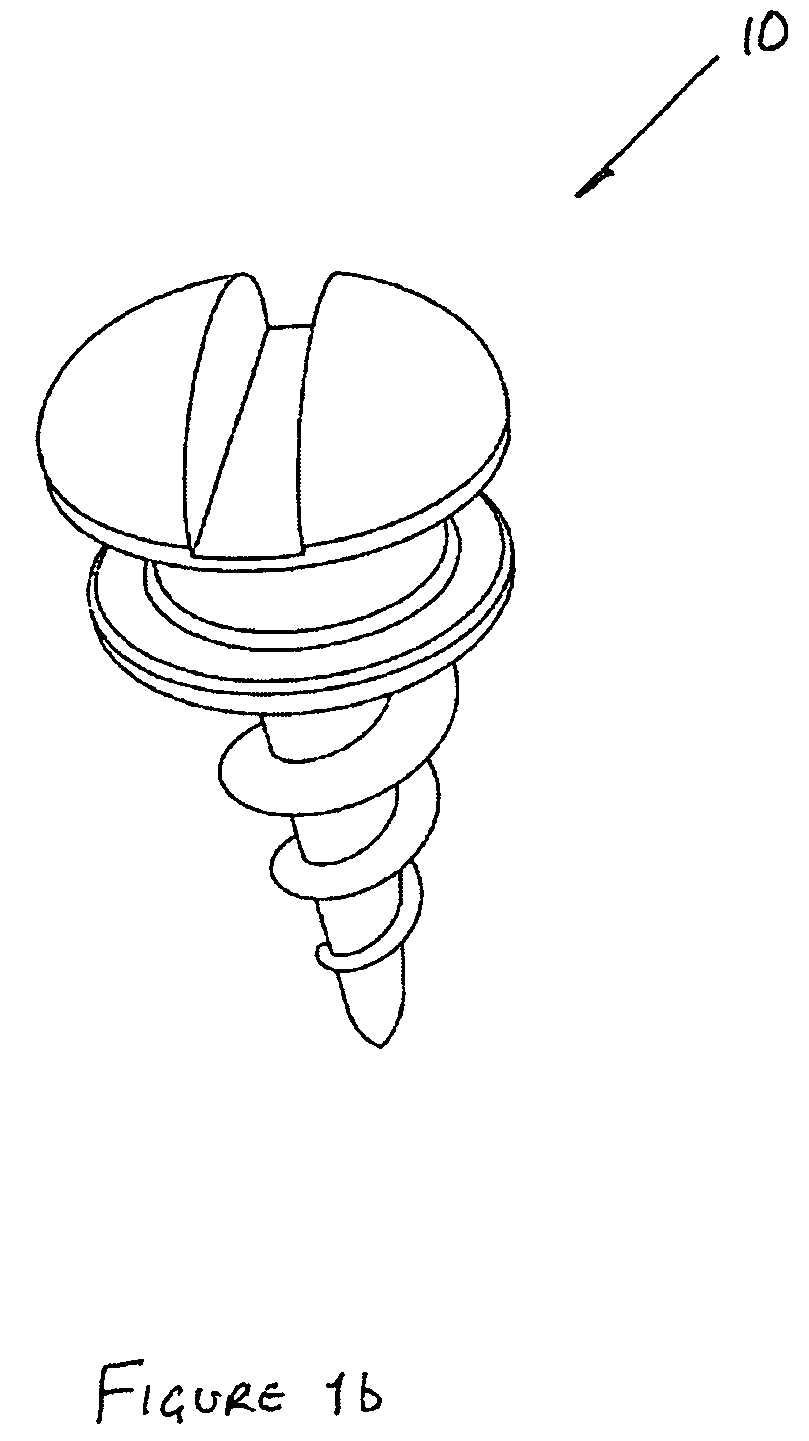

A device for supporting an article on a structure. The support device includes an elongate body with a head at one end, a neck, a shoulder flange, and an elongate threaded shank with threads extending therefrom. The head and / or neck may be arranged to engage the article, and the shoulder flange has a surface for engaging a corresponding surface of the structure. The elongate shank portion anchors the support device at a target site on the structure and tapers from a greatest diameter proximate to the shoulder flange to a pointed end. The initial taper is at a lesser angle to the longitudinal axis of the elongate body to a point where the angle increases, before which the threads may terminate.

Owner:ANNE MARIE SEDGWICK +1

Metal stent with surface layer of noble metal oxide and method of fabrication

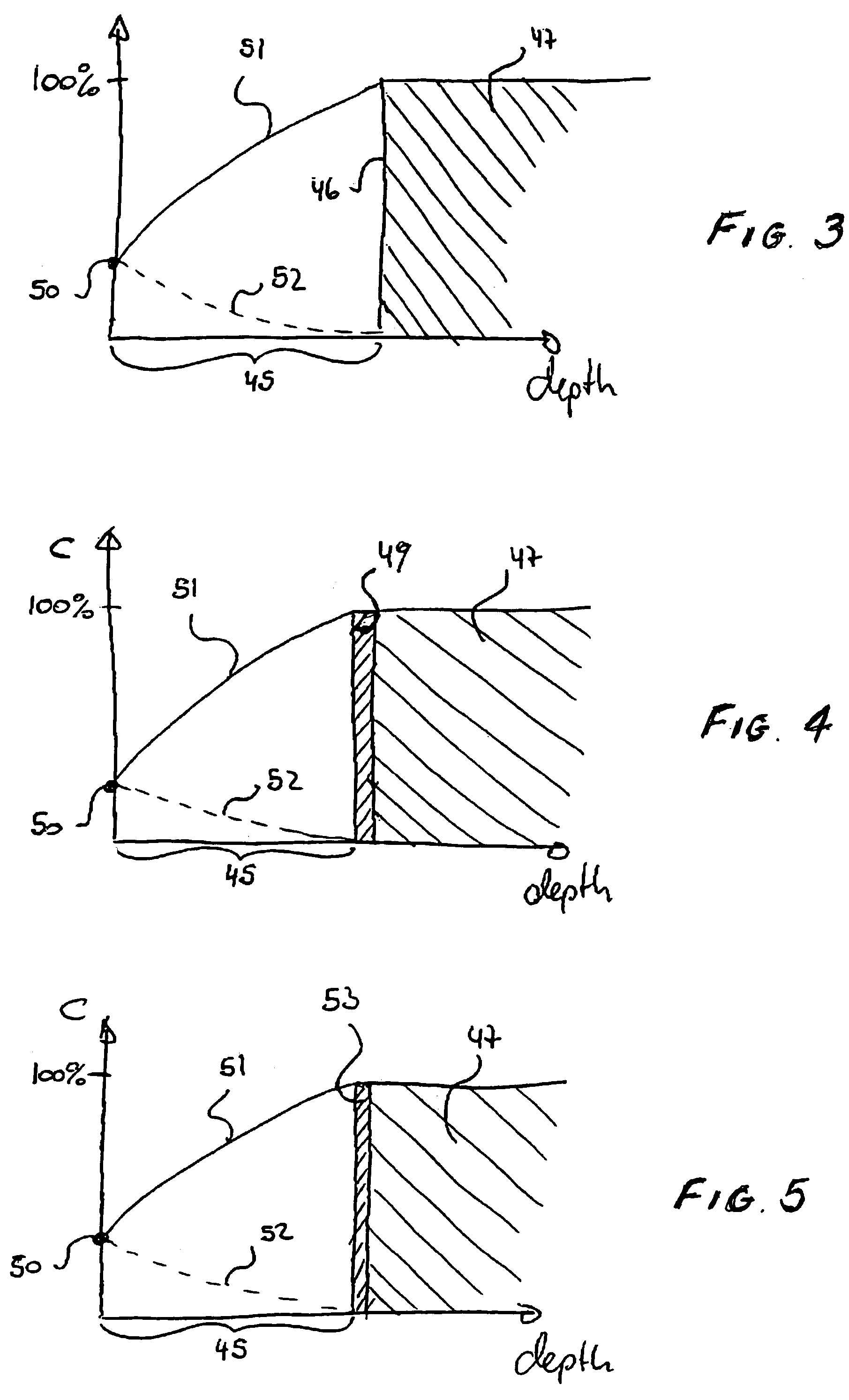

In a process for producing a biocompatible stent, a tubular substrate of the stent adapted for diametric expansion has a layer of a noble metal oxide formed over at least the outer surface of greater diameter of the substrate, the substrate being composed of a metal or an alloy thereof that is non-noble or less-noble than the layer's noble metal. An interface region adapted to prevent corrosion and to provide a firm bond between the surface of the substrate and the noble metal oxide layer is established, at least in part, by forming the noble metal oxide layer with a progressively varying concentration of noble metal-to-oxide with depth of the layer such that a surface of pure noble metal and negligible oxide of the layer is in closest proximity to the surface of the substrate. In one embodiment of the process, the interface region is established by forming the surface of pure noble metal and negligible oxide thereof in direct contact with the metal or alloy of the substrate surface. In another, the interface region is established by first creating an oxide of the substrate metal or alloy thereof at the substrate surface, and then forming the noble metal oxide layer as above, but in contact with the substrate metal or alloy oxide. Alternatively, the noble metal oxide layer has no progressively varying concentration but simply overlies an oxide of the substrate metal or alloy.

Owner:BOSTON SCI SCIMED INC

Focalized intraluminal balloons

Owner:CROCKER MICHAEL +1

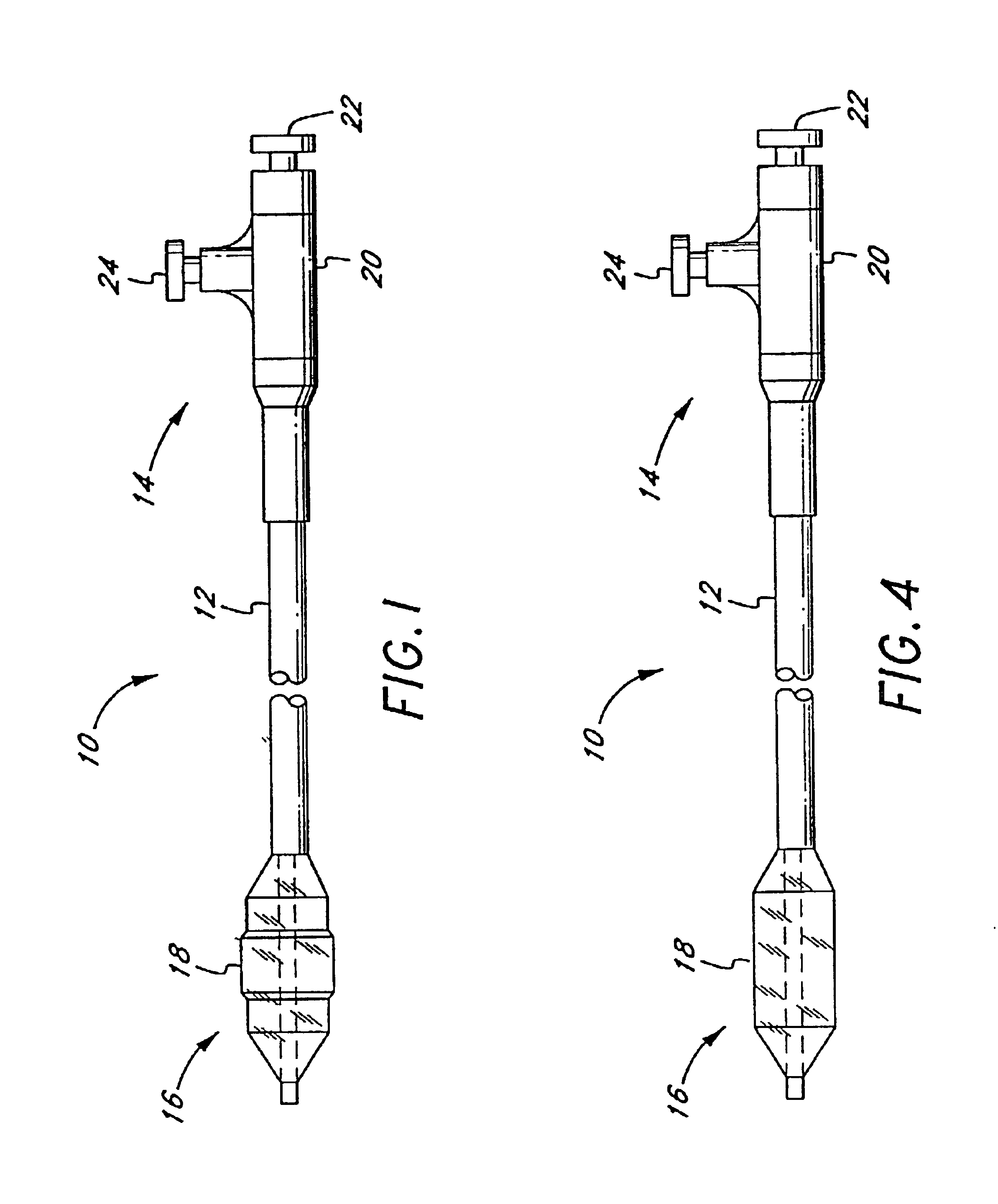

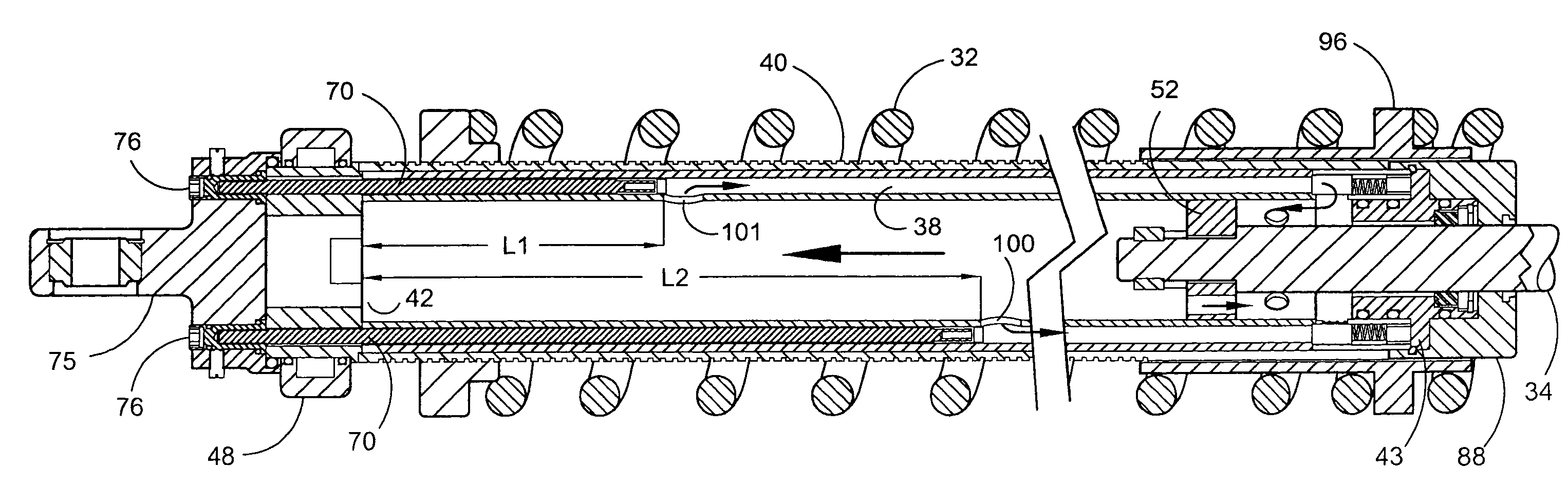

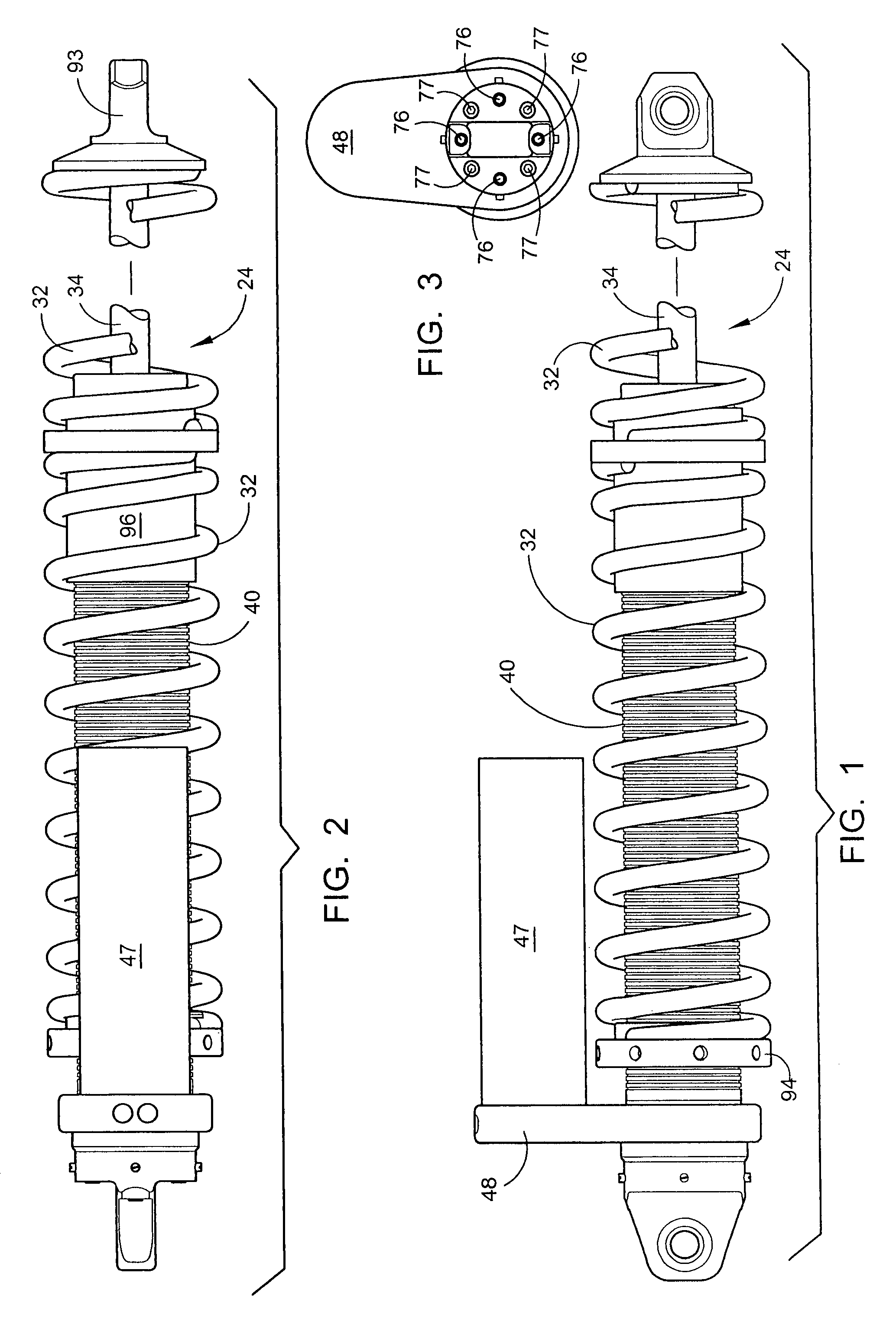

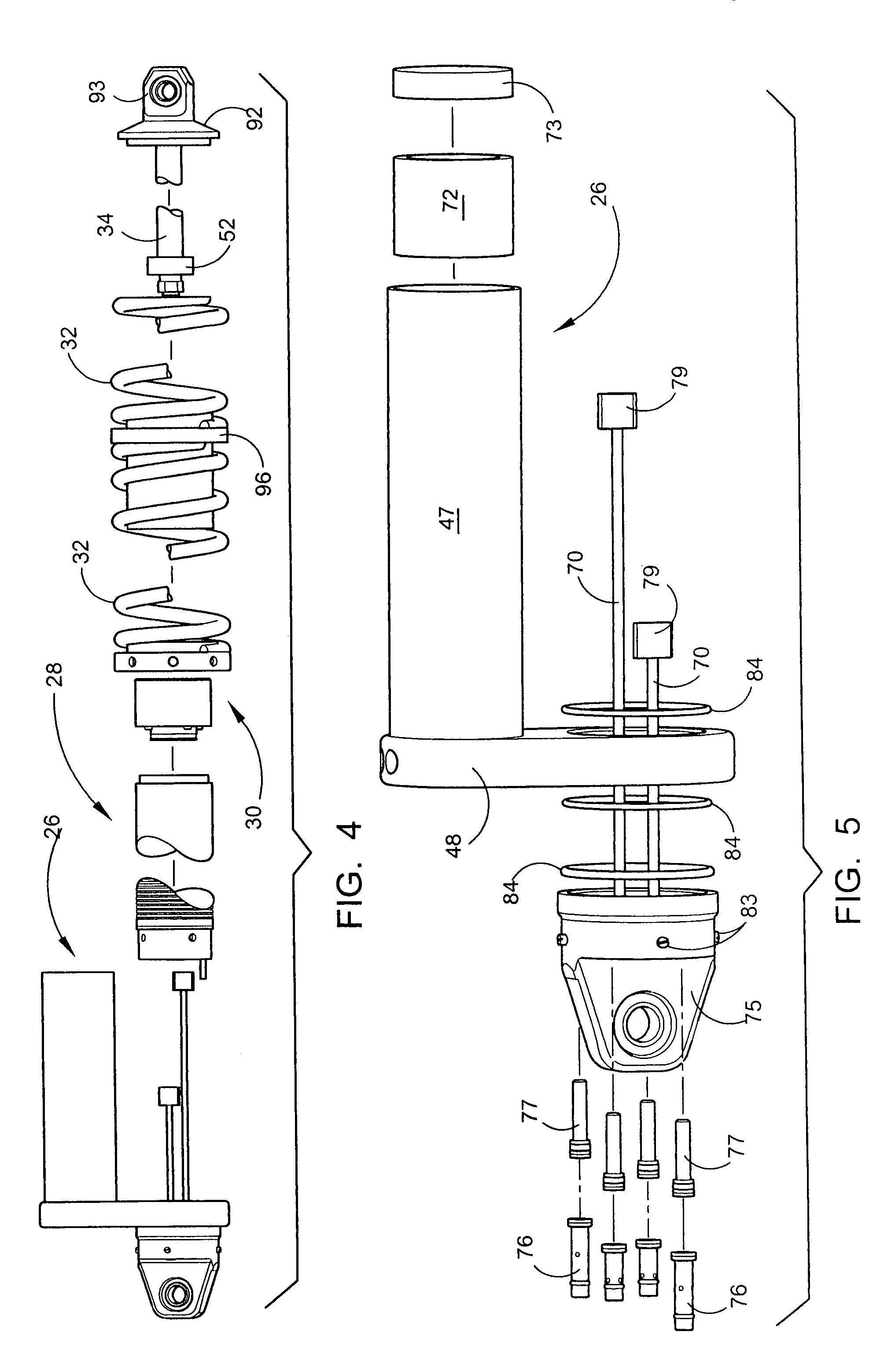

Externally adjustable internal bypass shock absorber

ActiveUS7270222B1Characteristic variesReduce the overall diameterSpringsShock absorbersReciprocating motionCoil spring

A shock absorber that combines both the suspension function and the shock absorbing function in one unit. It has an elongated shock body filled with hydraulic fluid and a piston mounted on a piston rod that reciprocally travels within the shock body. The shock body is telescopically received in a bypass cylinder body having a greater diameter that produces an annular chamber between the outer surface of the shock body and the inner surface of the bypass cylinder body. A coil spring is mounted on the outside surface of the bypass cylinder body to provide a suspension function by the shock absorber. A plurality of bypass tubes are associated with longitudinally spaced ports in the shock body. Adjuster rods are telescopically received inside the respective bypass tubes for controlling whether the individual ports are closed, partially open, or fully open. These adjuster rods would be manipulated externally of the shock absorber assembly.

Owner:AYMAR BRANDON

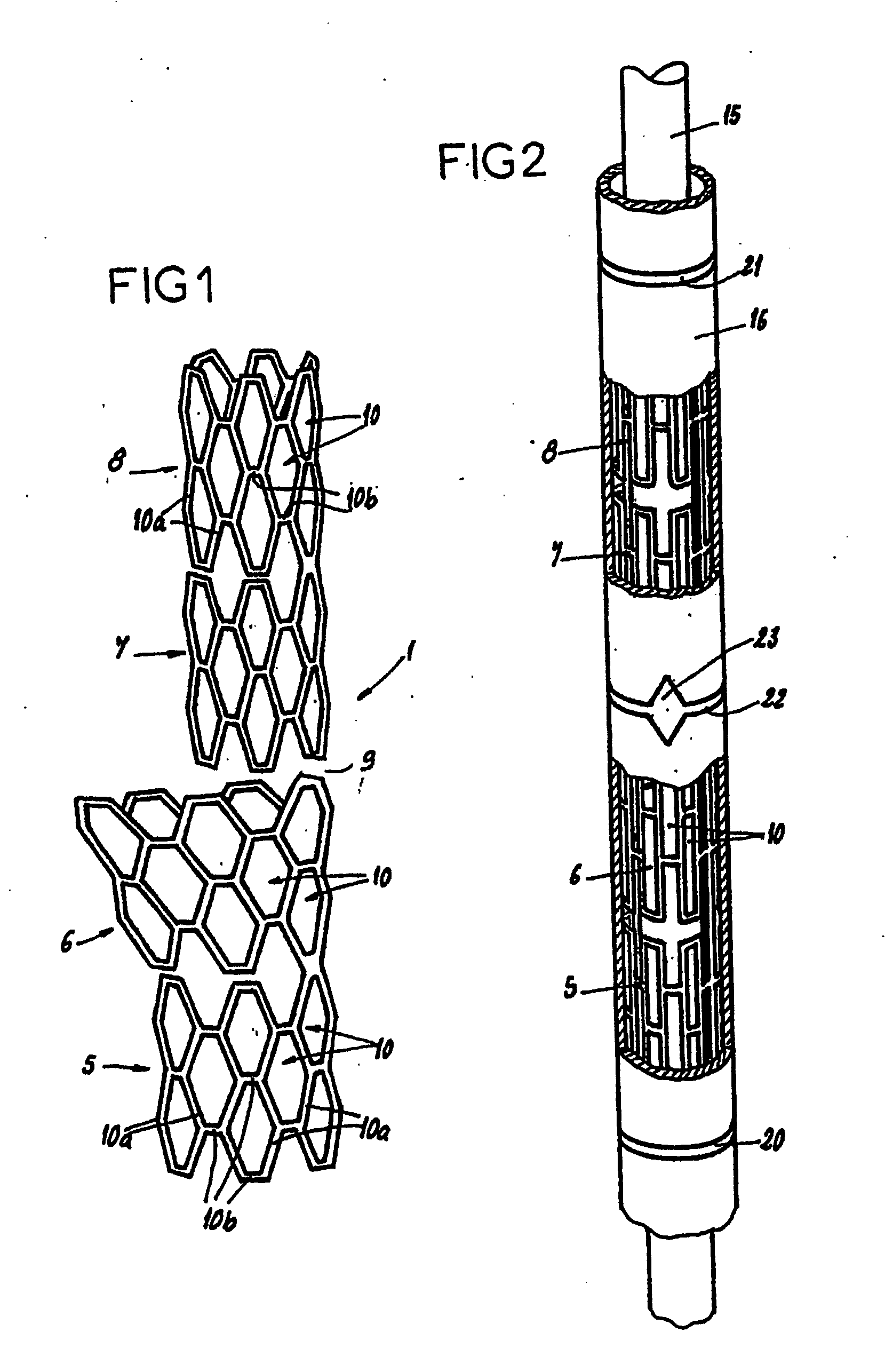

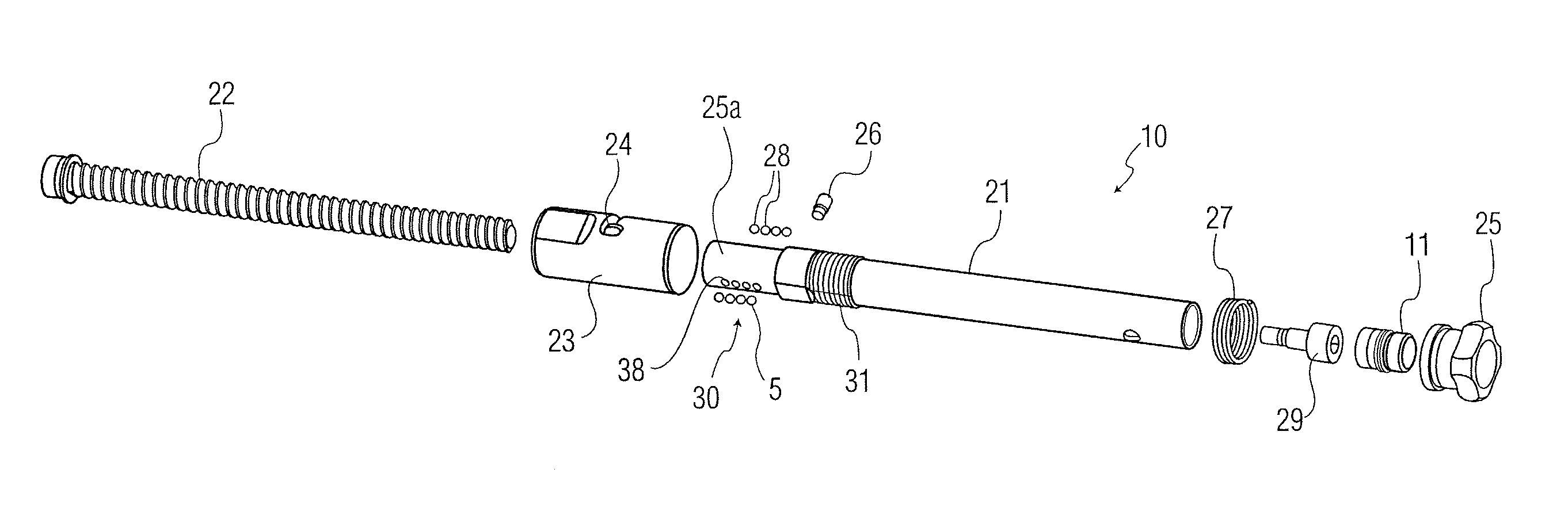

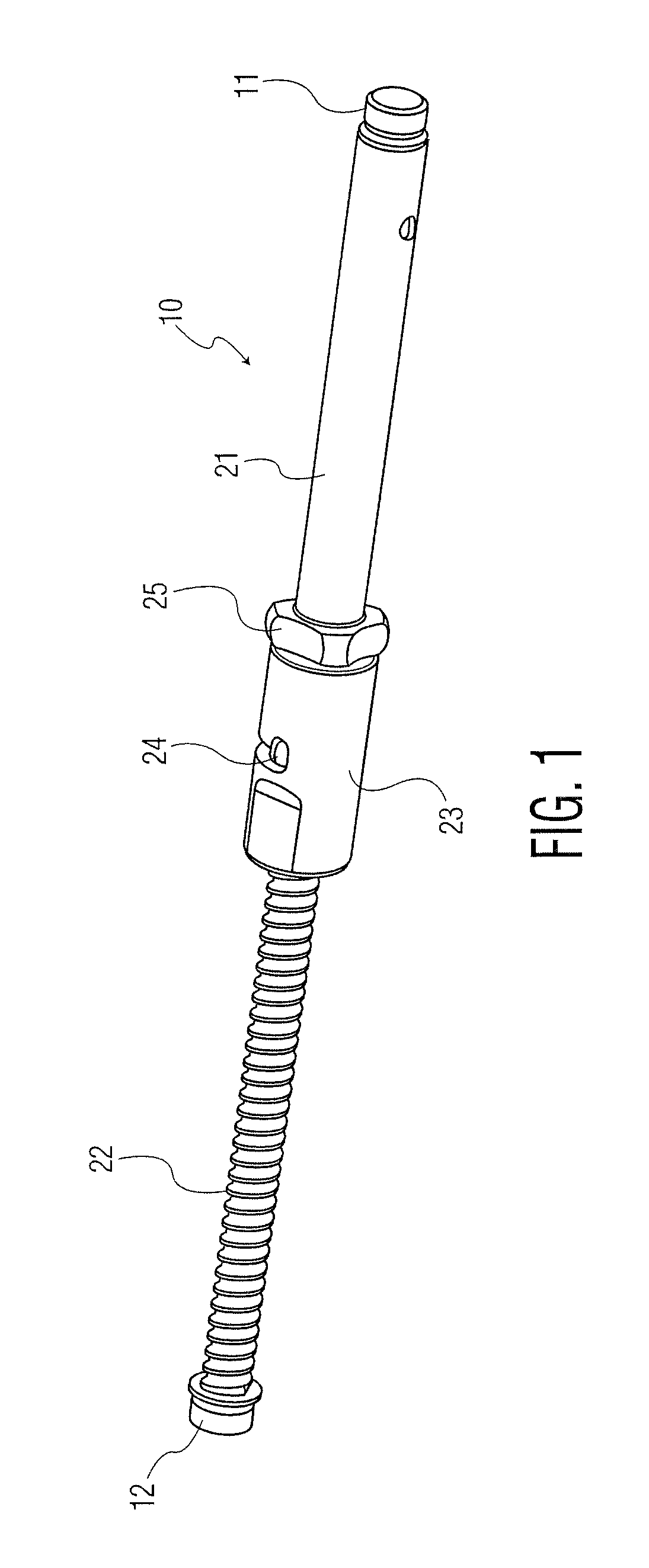

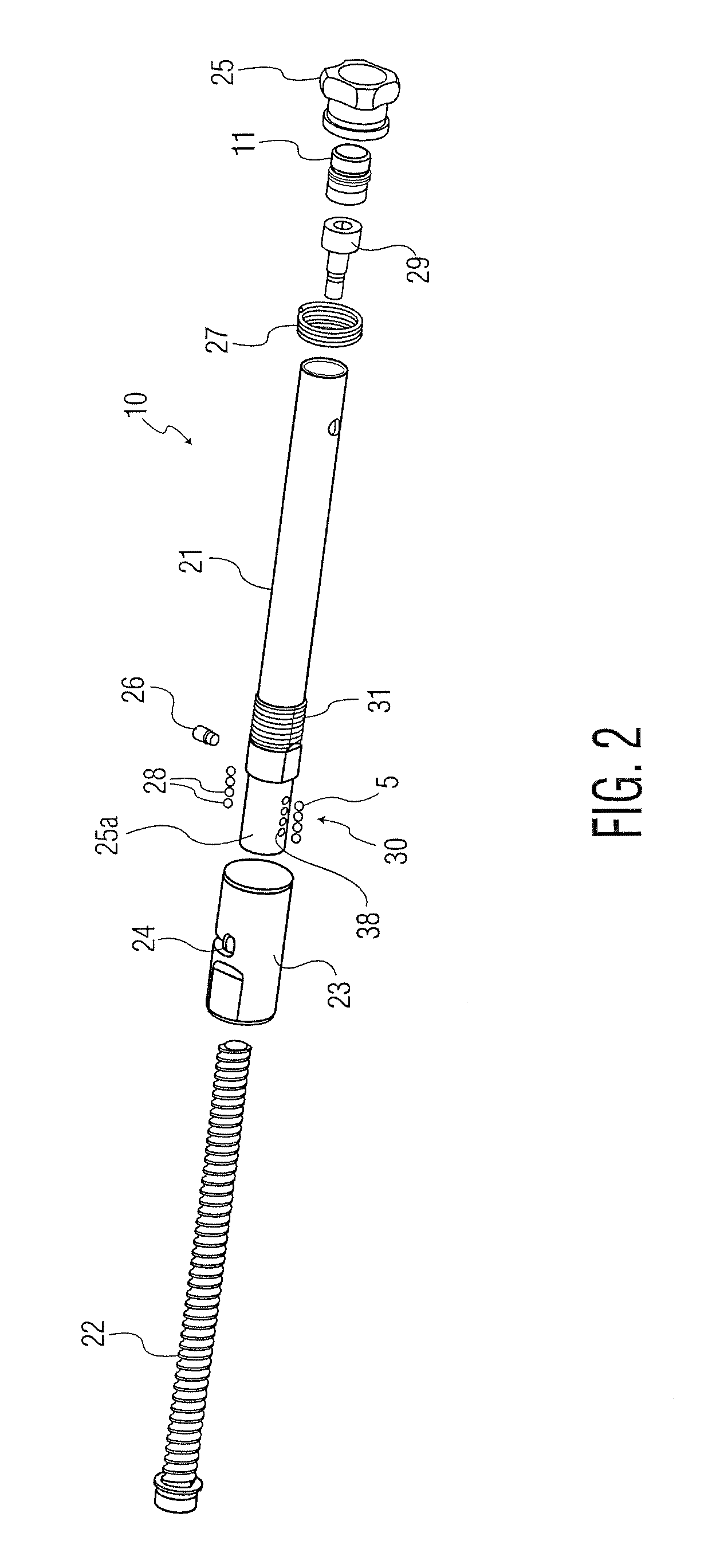

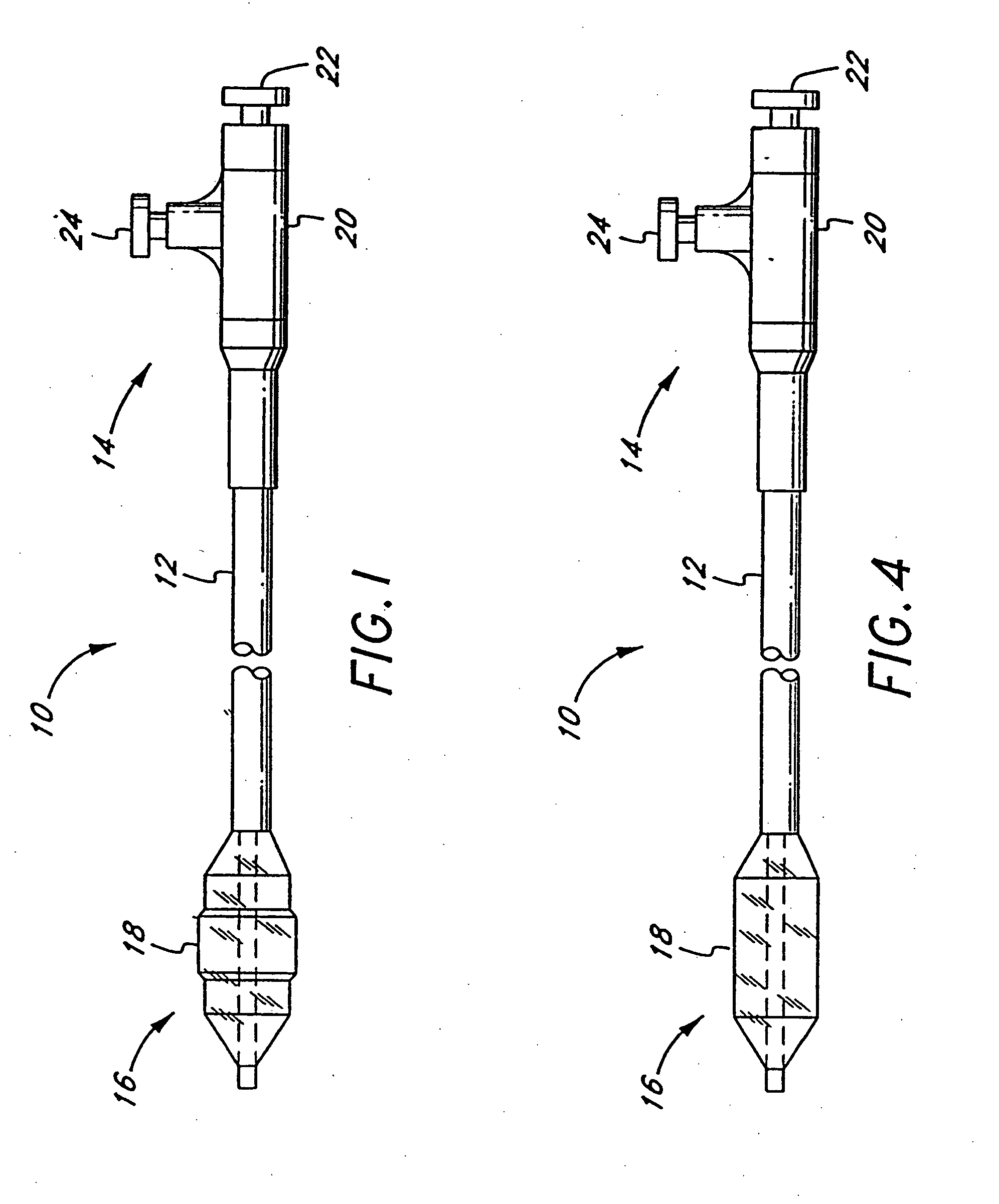

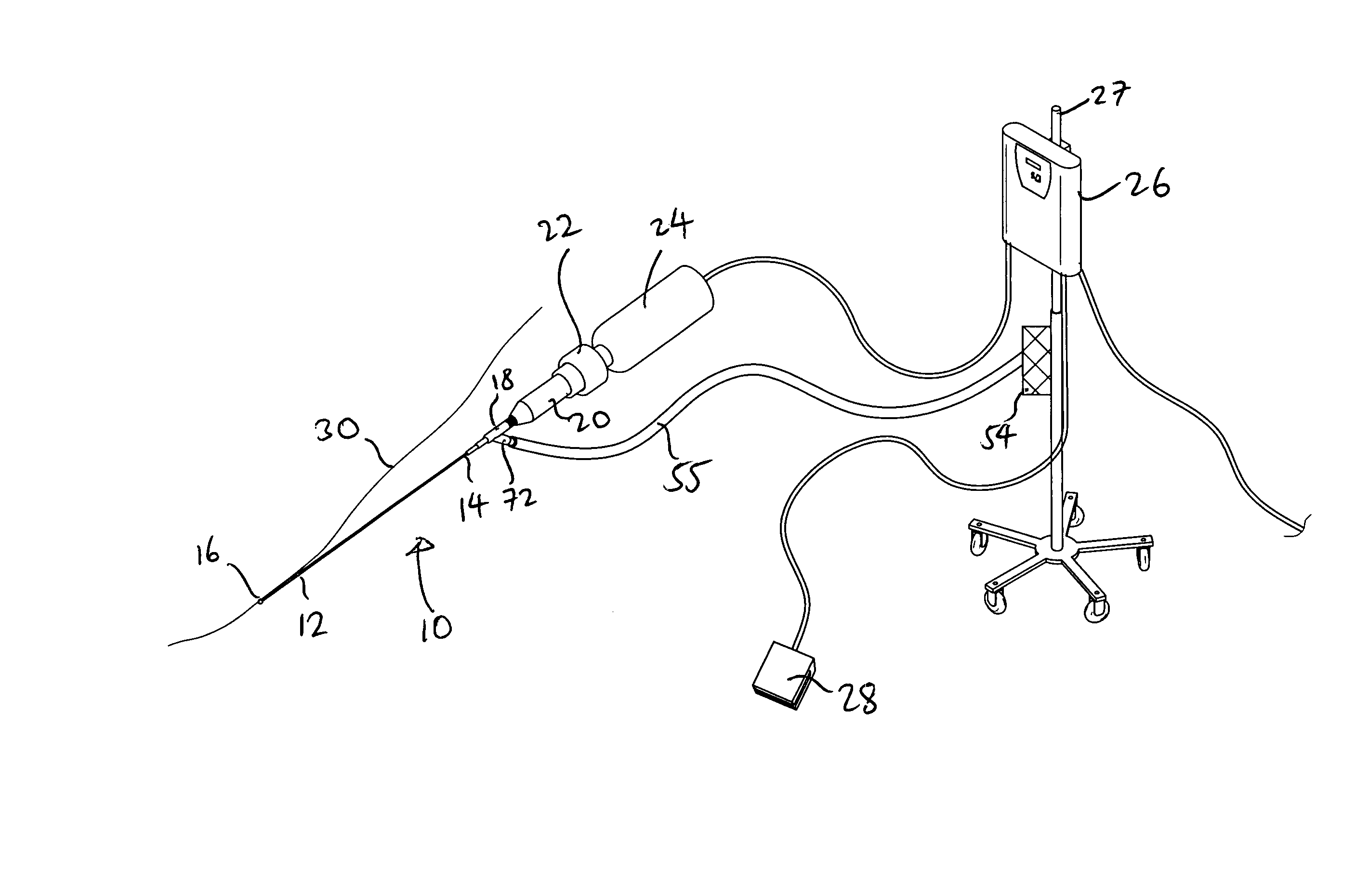

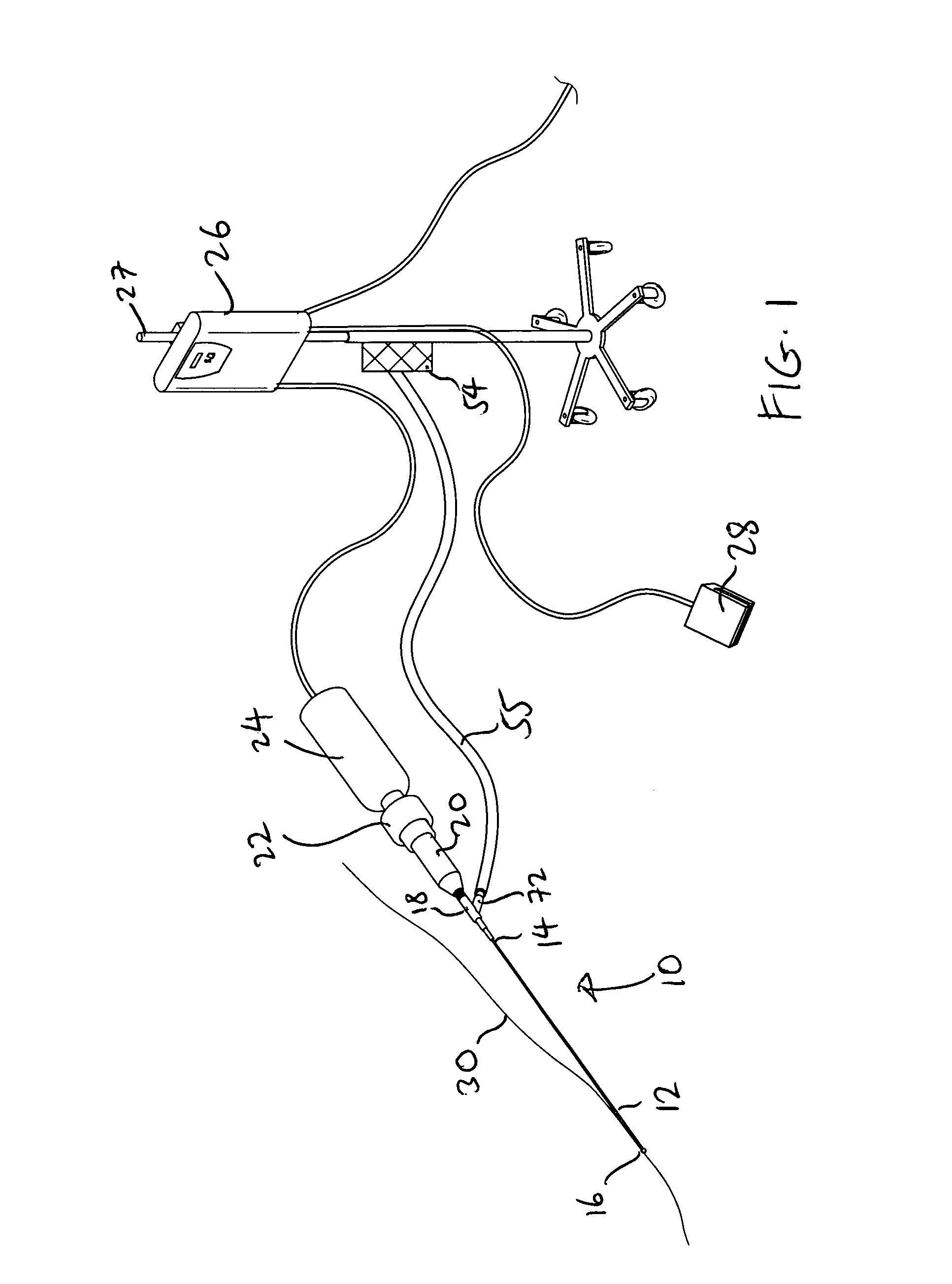

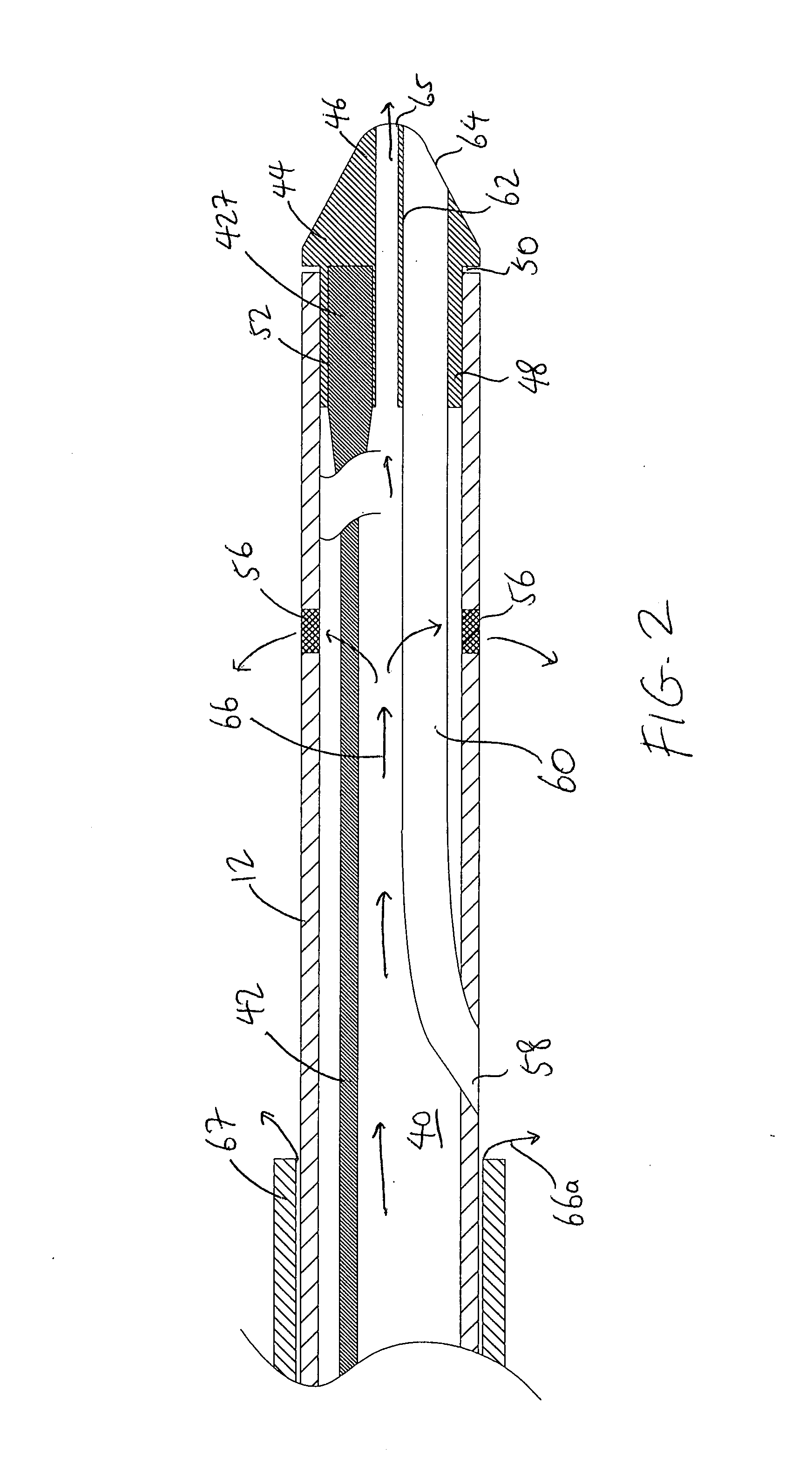

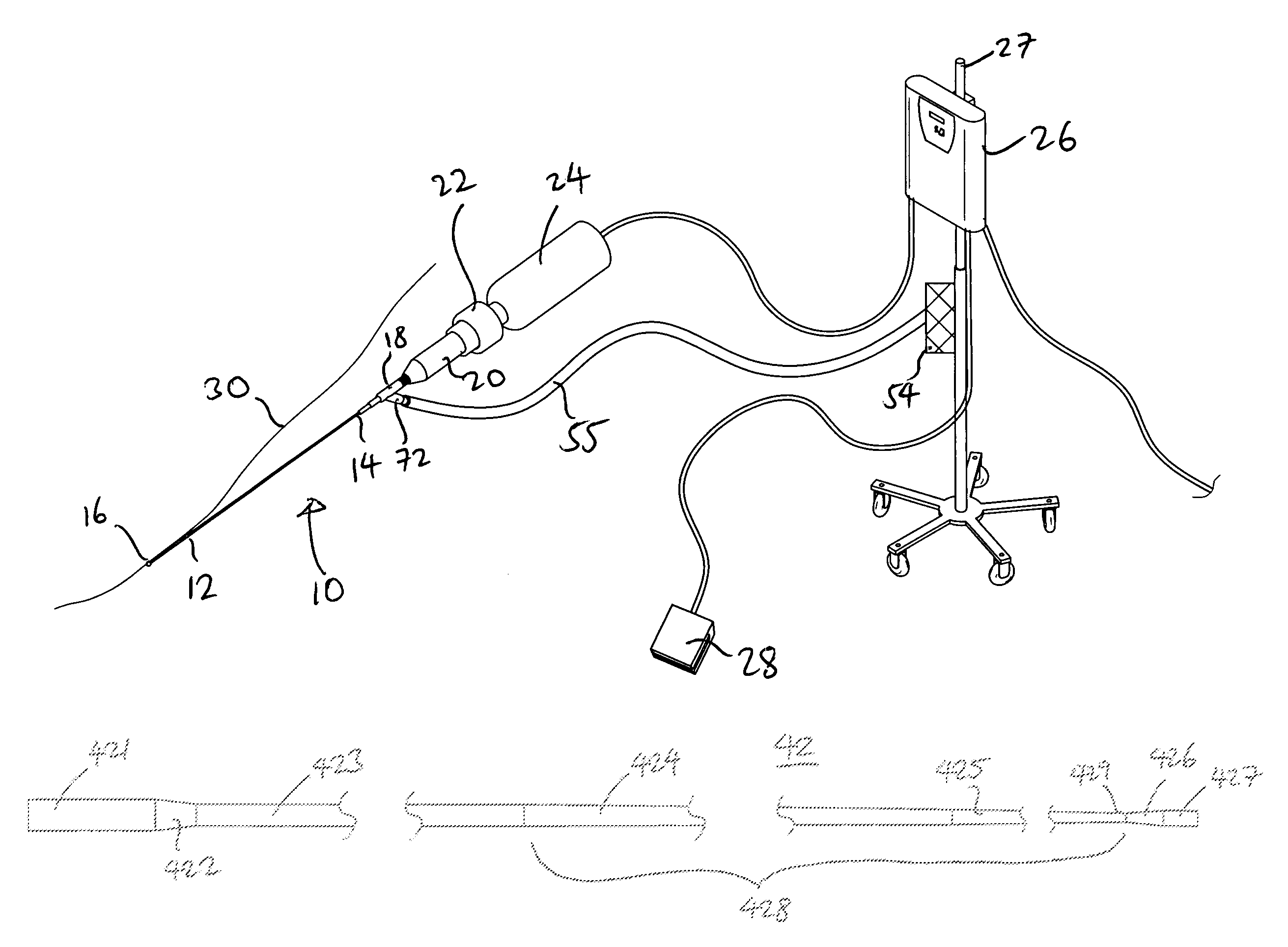

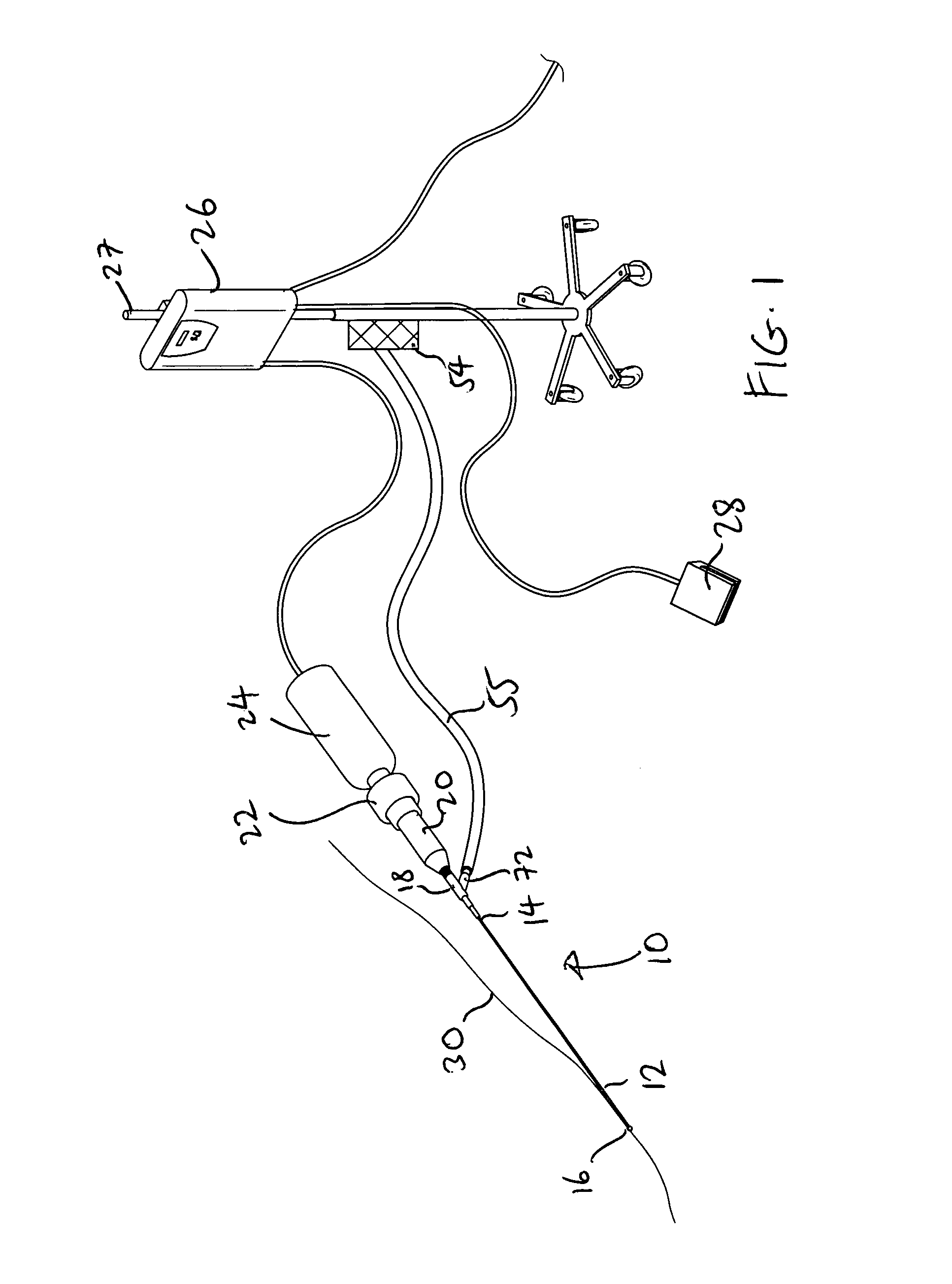

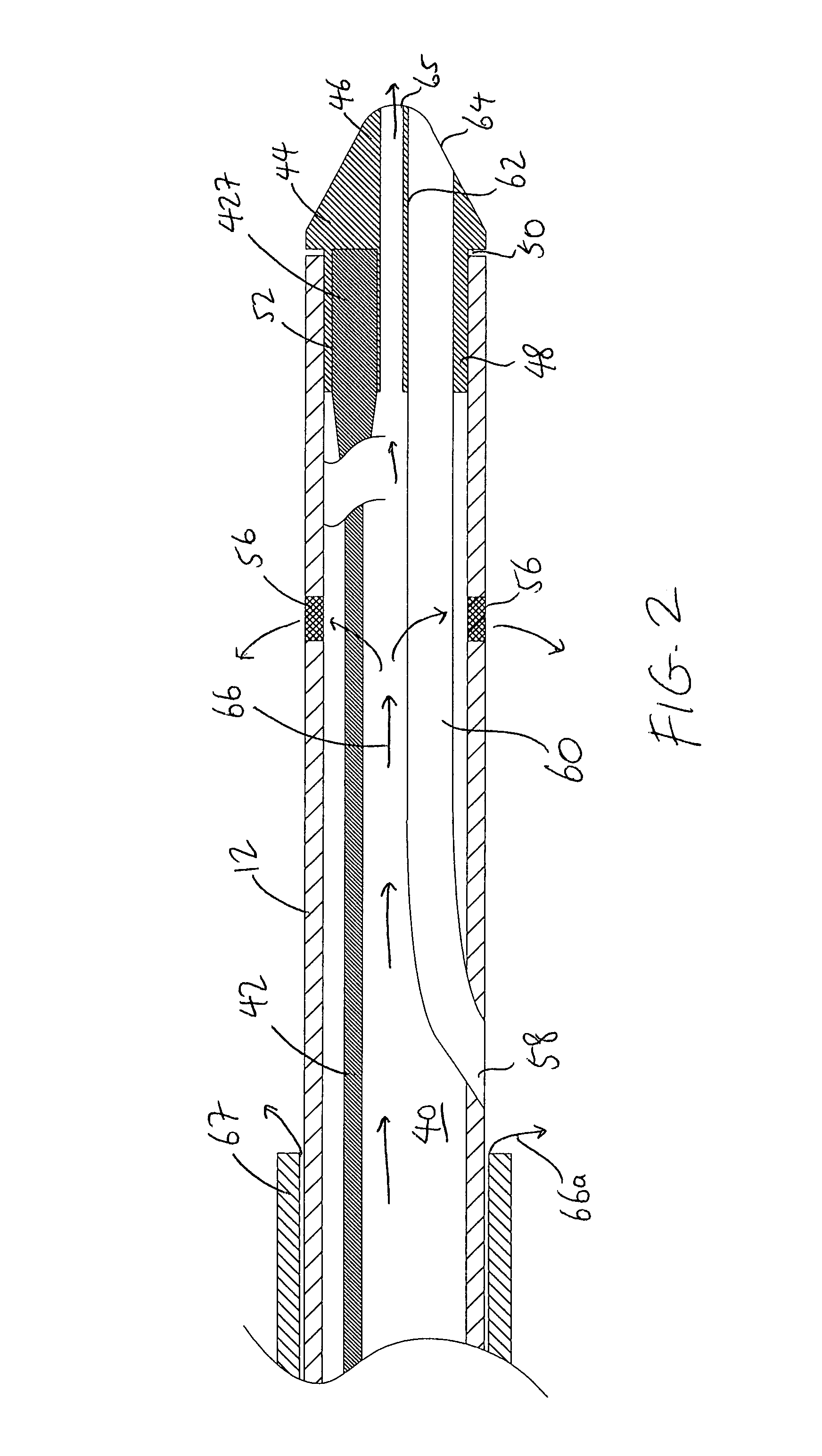

Therapeutic ultrasound system

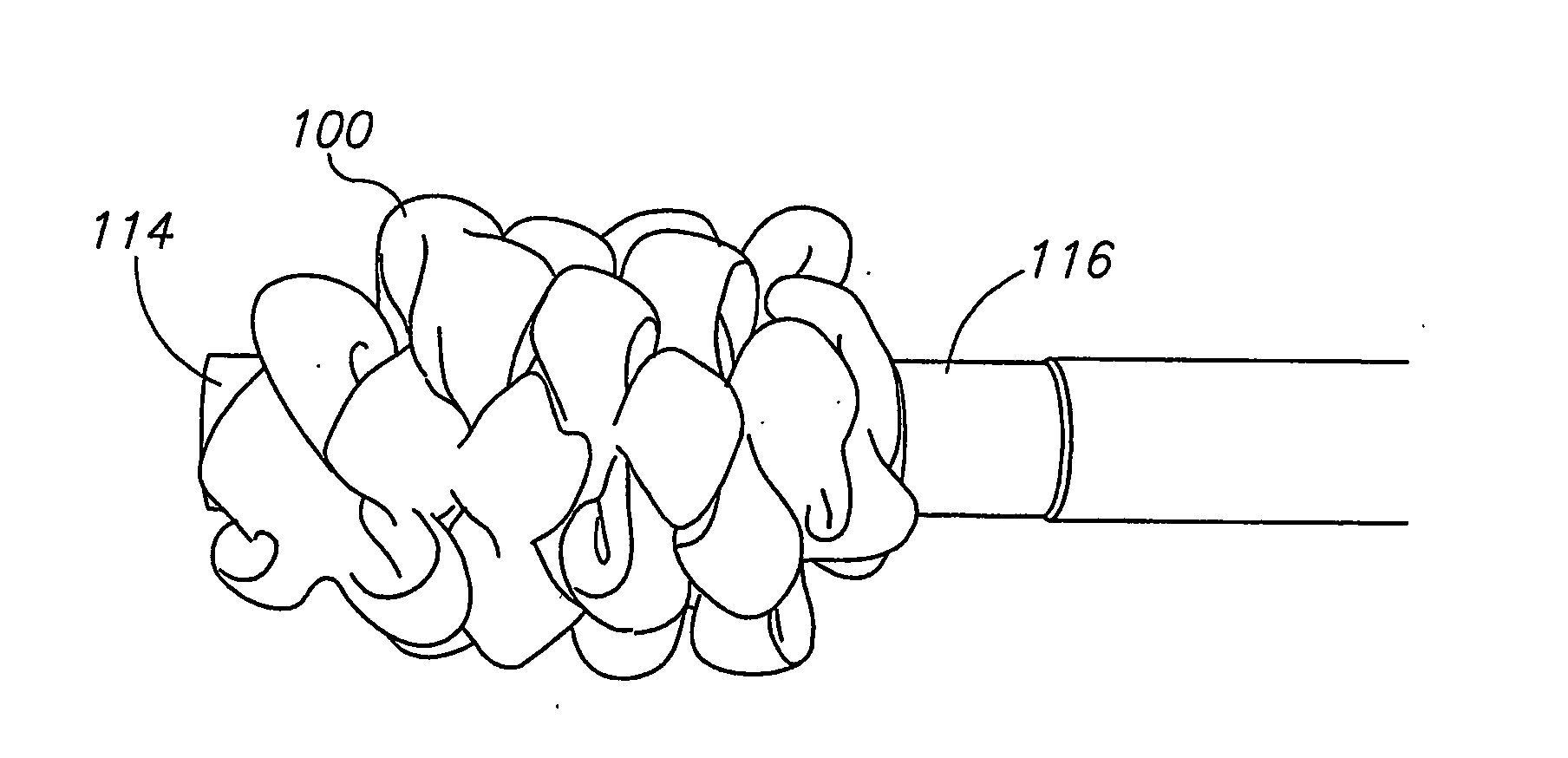

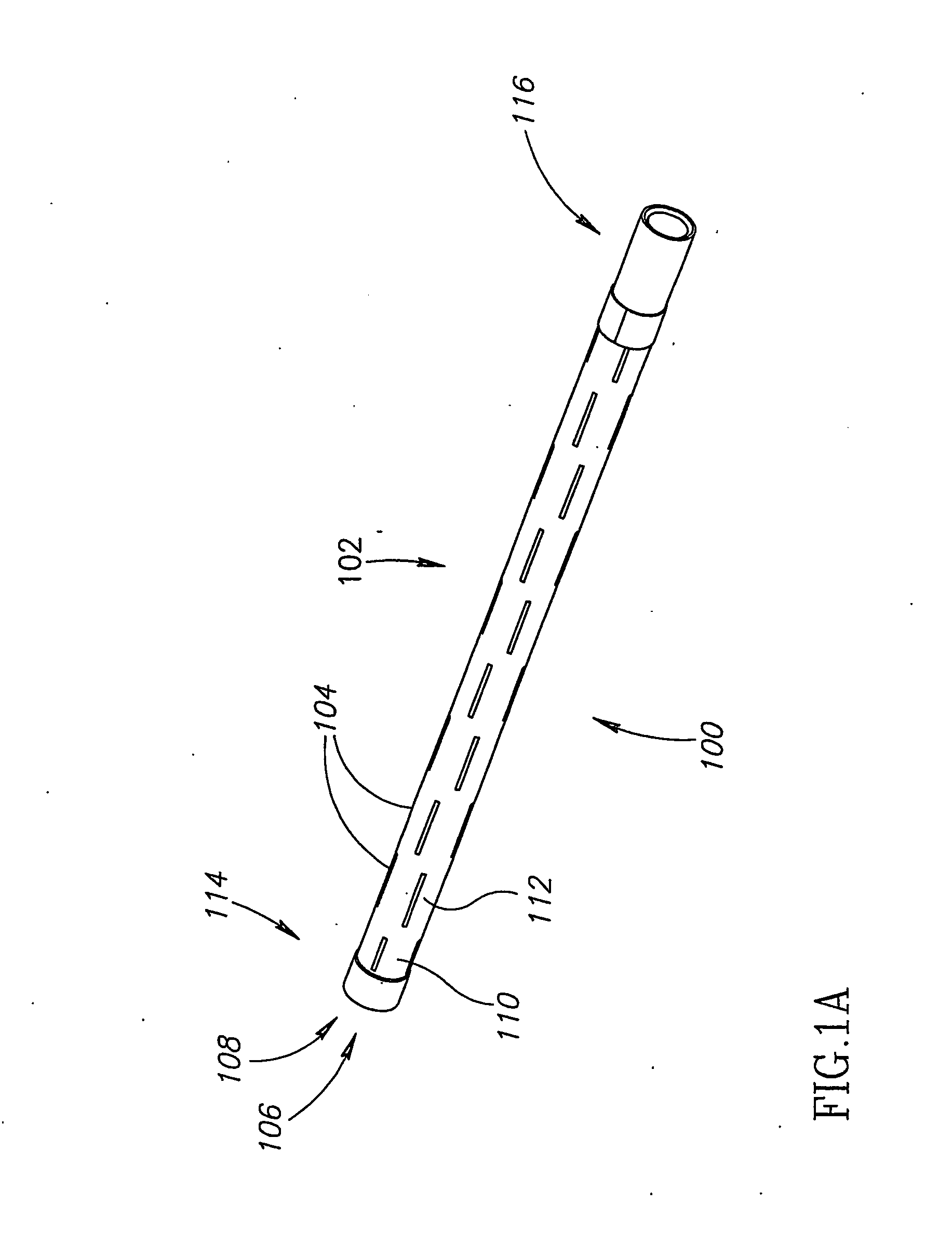

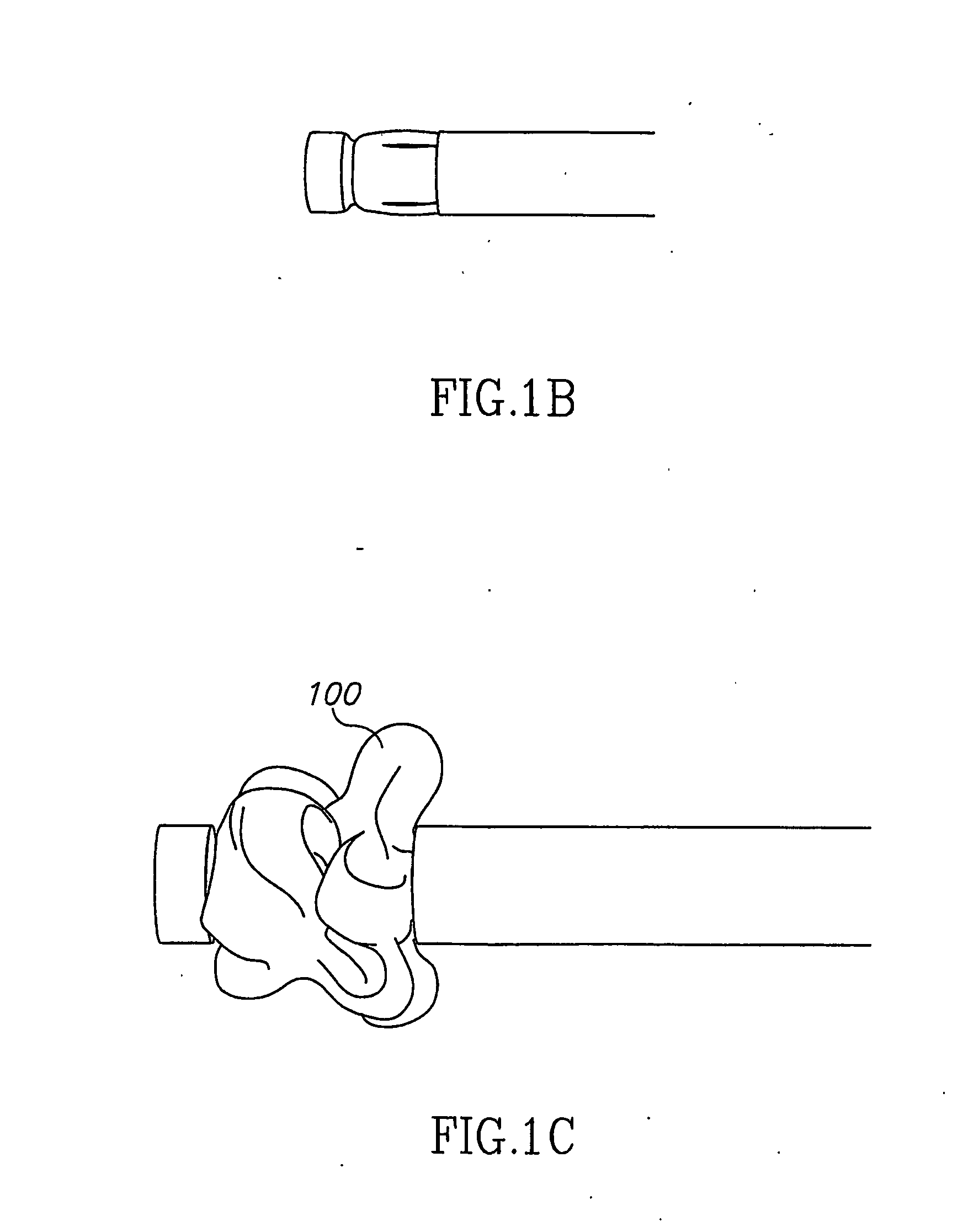

ActiveUS20070239027A1Way of increaseUltrasonic/sonic/infrasonic diagnosticsSurgeryAcoustic transmission lineTherapeutic ultrasound

An ultrasound system has a catheter including an elongate flexible catheter body having at least one lumen extending longitudinally therethrough. An ultrasound transmission wire extends longitudinally through the lumen of the catheter body, and has a proximal region, a distal region, and an intermediate region between the proximal region and the distal region. A sonic connector is connected to the proximal region of the ultrasound transmission wire, and a distal head is positioned at the distal end of the catheter body and coupled to the distal region of the ultrasound transmission wire. The proximal region of the ultrasound transmission wire has a larger diameter than the intermediate region, the intermediate region is continuously tapered with a progressively decreasing diameter from its proximal end to its distal end, and the distal region has a greater diameter than the distal end of the intermediate region.

Owner:FLOWCARDIA

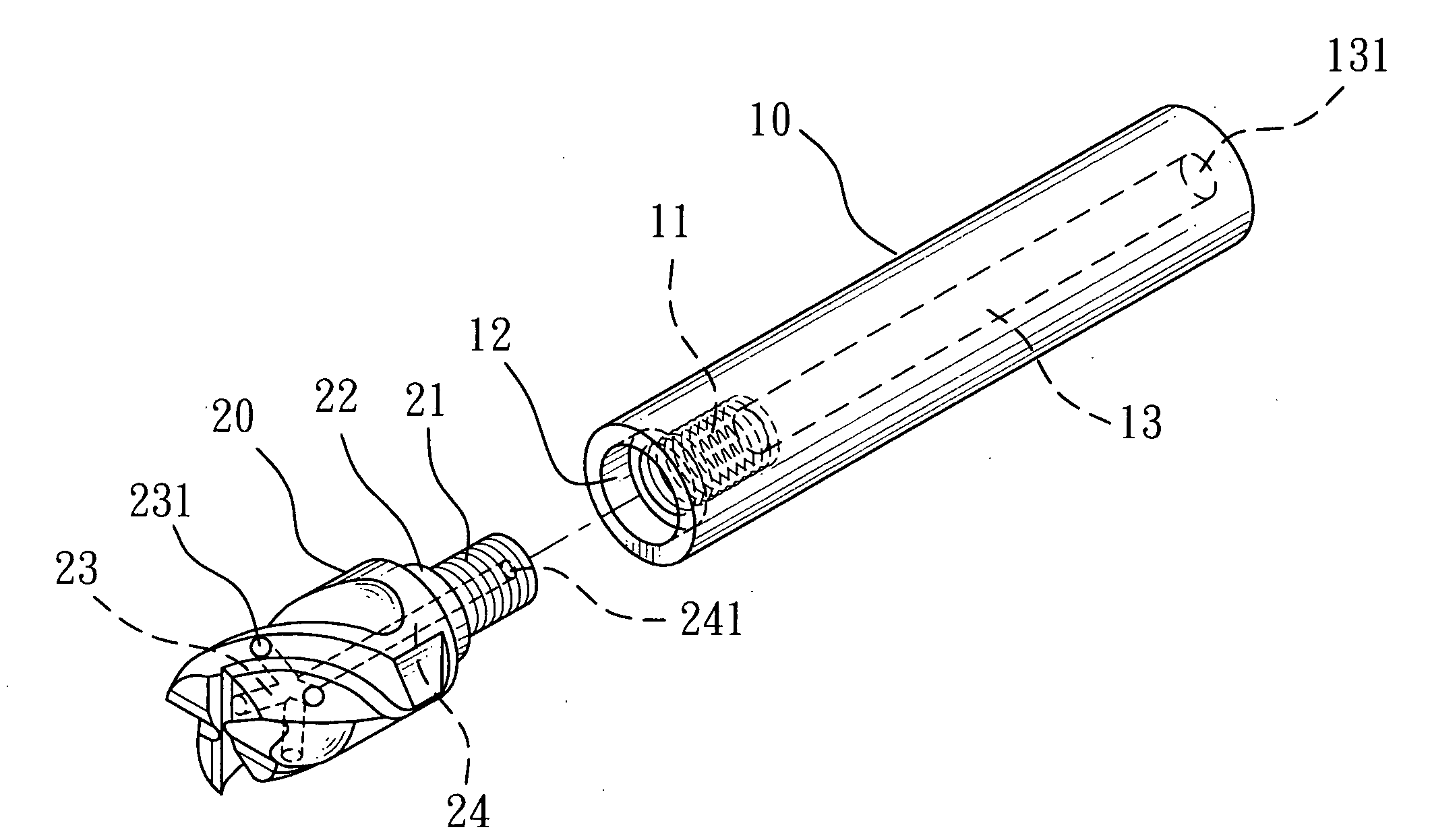

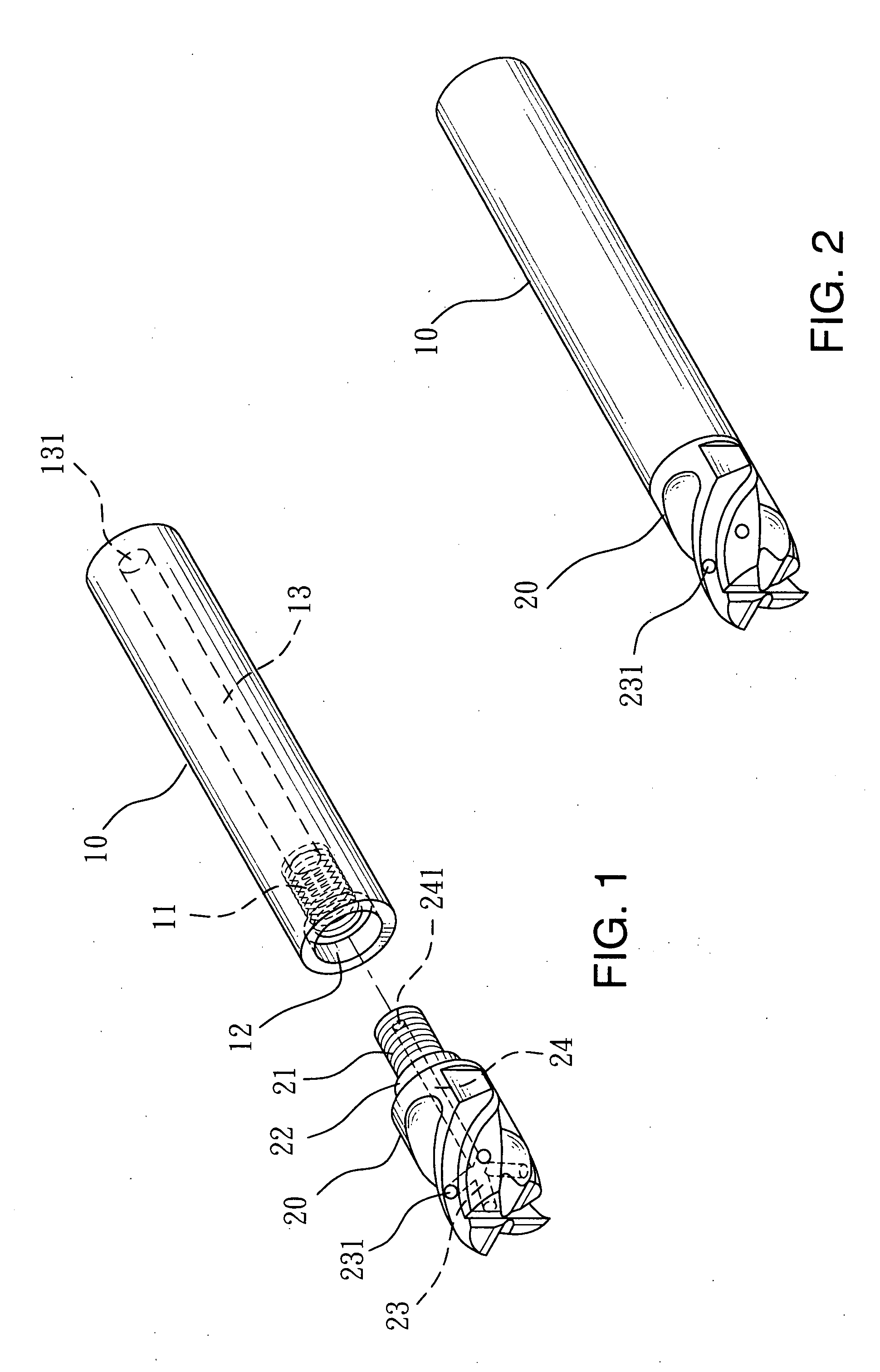

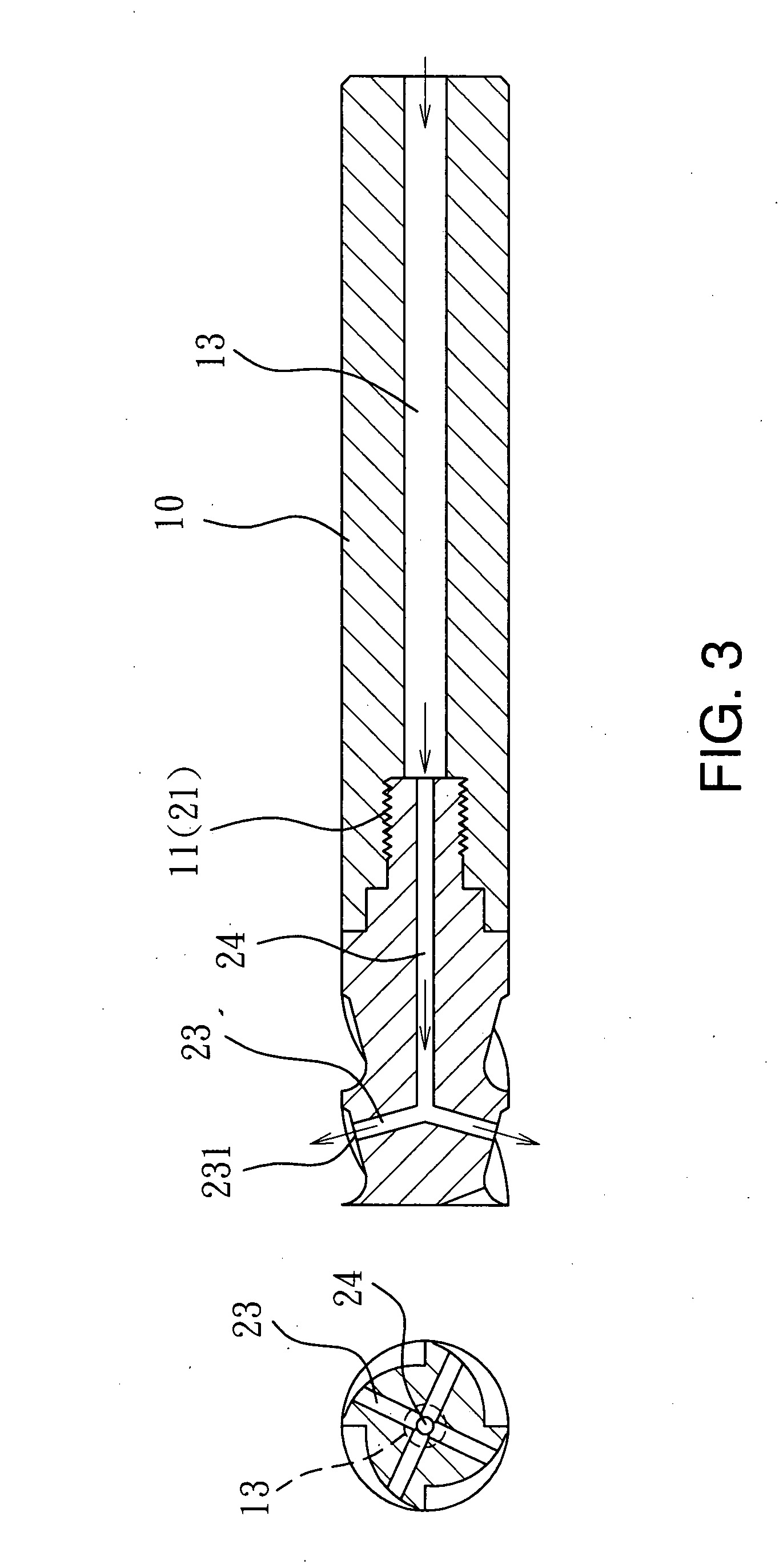

Tungsten steel cutter

InactiveUS20090142150A1Overcomes shortcomingAvoid accumulationWood turning toolsTransportation and packagingWater dischargeCoupling

A tungsten steel cutter which is lower cost to use and can increase fabrication efficiency and improve quality mainly includes a shank and a bit screwing at a front end of the shank. Both are made of tungsten steel and formed in an integrated fashion. The shank has a screw hole at the front end and a coupling trough formed at the front end of the screw hole. The bit has a screw bar extended from the bottom end thereof and a coupling neck at the front section of the screw bar. The coupling trough is formed at a depth same as the height of the coupling neck and the coupling trough and the coupling neck are formed at the same size. The bit and the shank have respectively a water discharge passage and a water drawing passage, and a water intake passage that communicate with each other. The water intake passage is formed at a greater diameter than the water discharge passage and water drawing passage. Thus when the bit and the shank are screwed together, in addition to screw coupling of the screw hole and the screw bar, the coupling trough and the coupling neck also form a tight coupling to minimize gaps that might otherwise happen between them like the conventional ones do. The water discharge passage and water intake passage provide cooling effect for cutting fluid and prevent debris from accumulating on the bit and affecting cutting quality. The invention provides a two-section coupling that can save the cost and improve steadiness and fabrication efficiency of precision tools.

Owner:DHF PRECISION TOOL TRADING

Arrangement for laying cables in the floor area of a passenger transport aircraft

InactiveUS6875916B2Minimal complexityMinimal effortPipe supportsElectrical apparatusNacelleElectric cables

A conduit system for laying cables along the floor of a passenger cabin of an aircraft includes longitudinal and transverse cable guide elements respectively forming cable channels, and cable branch junctions at intersections of the longitudinal and transverse guide elements. Each guide element includes a lower part secured to the cabin floor, and an upper part secured (e.g. snap fitted) onto the lower part to cover the cable channel. The cable branch junction includes a lower section secured to the floor and covered by an upper section, and allows the cables to continue straight through the junction or to be deflected by 90° or by 180°. With this arrangement, a greater number and greater diameter of cables can be laid out with a minimal installation effort. The components of the system are easily adaptable to any required installation layout, while providing a continuous covered protected enclosure for the cables.

Owner:AIRBUS OPERATIONS GMBH

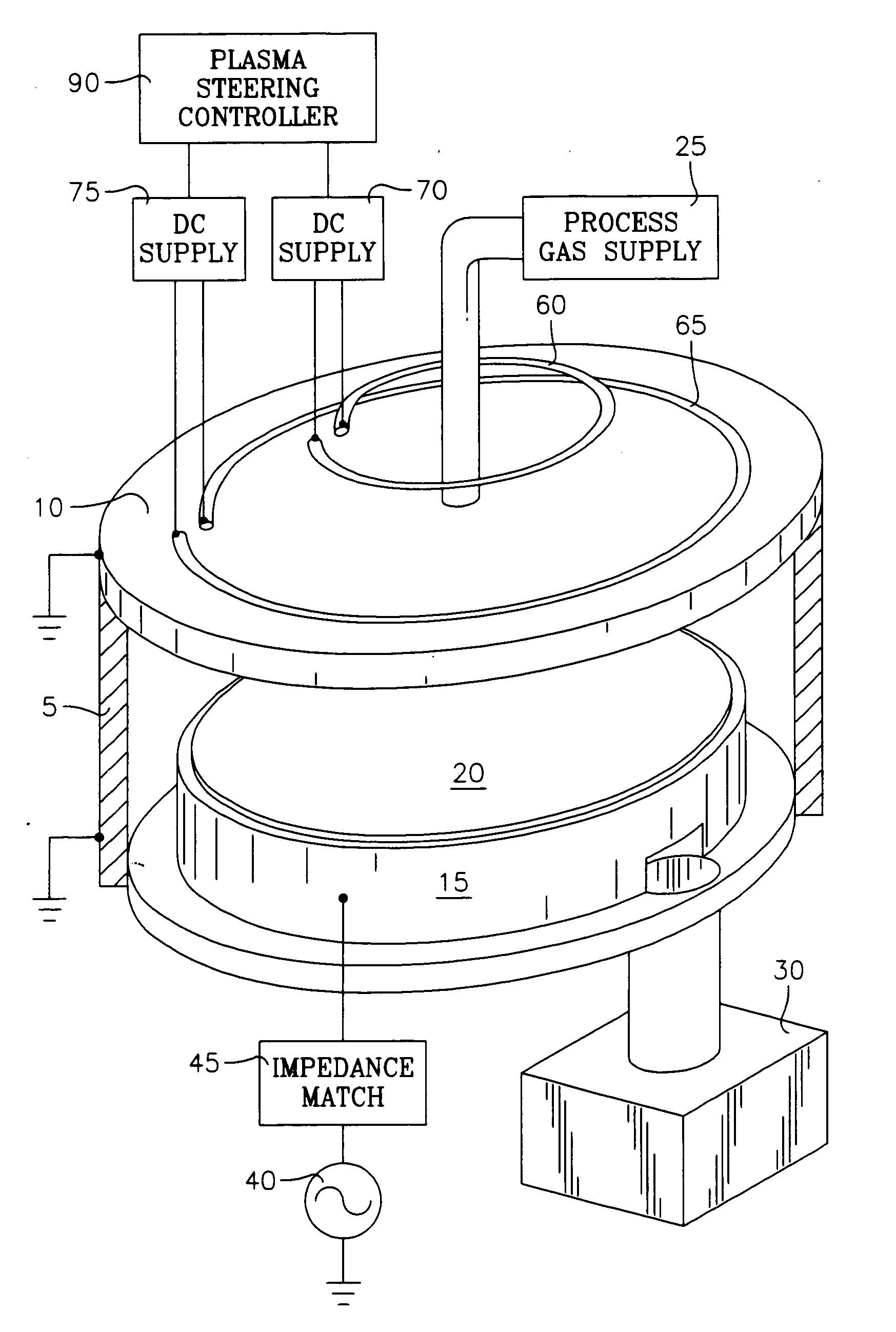

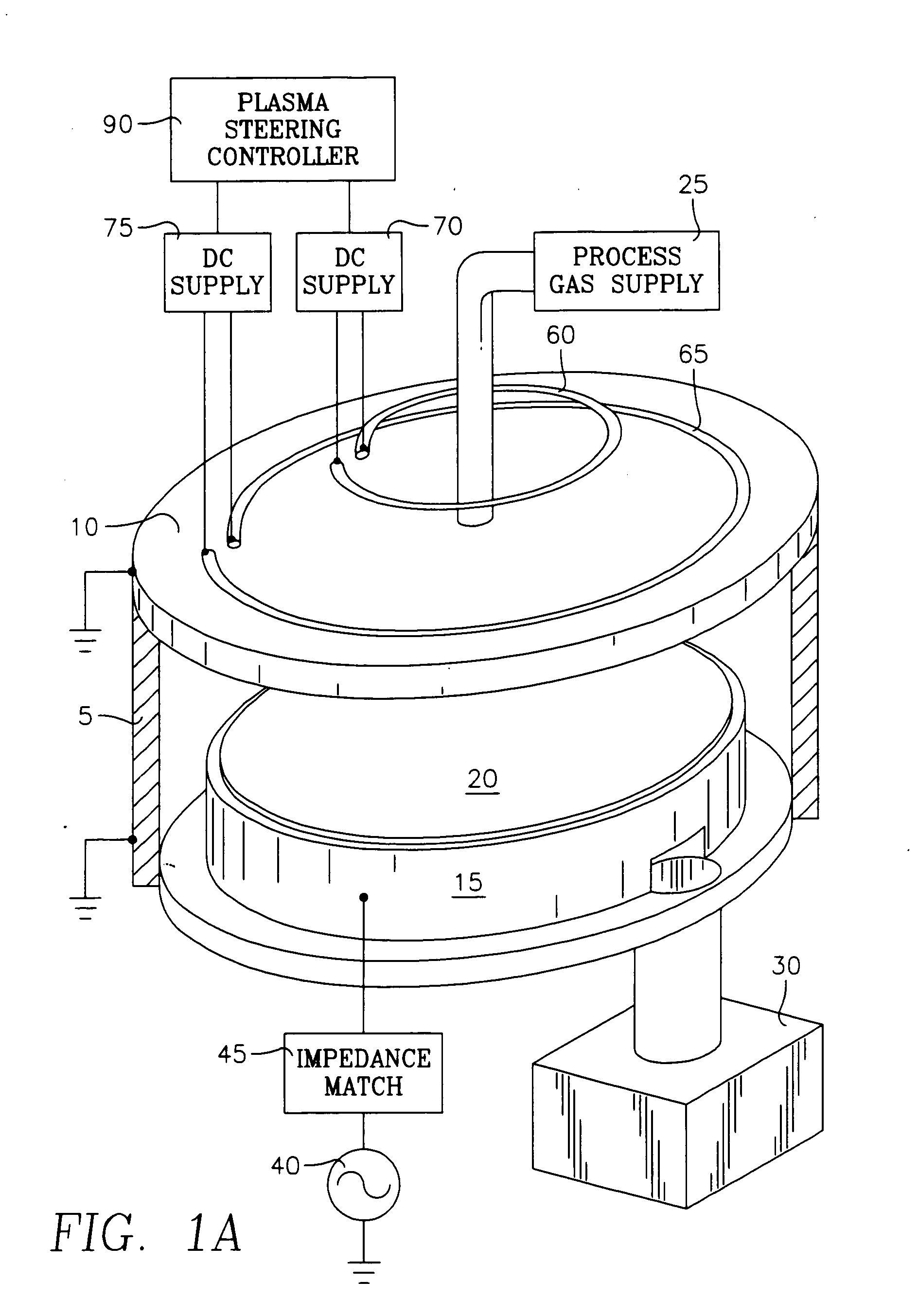

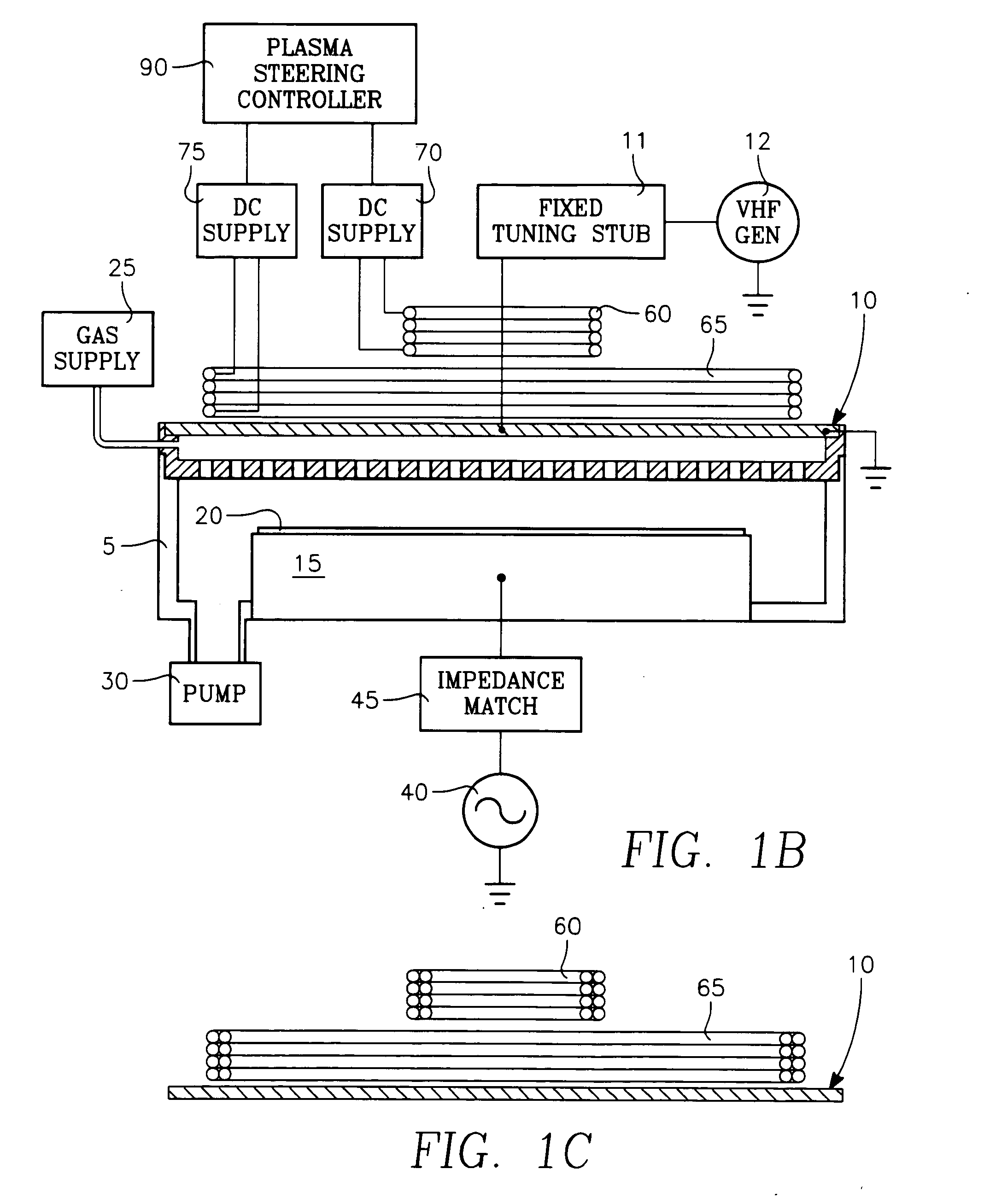

Plasma reactor with minimal D.C. coils for cusp, solenoid and mirror fields for plasma uniformity and device damage reduction

ActiveUS20050167051A1Increase ion densityImproving device damage resultElectric discharge tubesDecorative surface effectsVacuum chamberPlasma reactor

A plasma reactor for processing a workpiece, includes a vacuum chamber defined by a sidewall and ceiling, and a workpiece support pedestal having a workpiece support surface in the chamber and facing the ceiling and including a cathode electrode. An RF power generator is coupled to the cathode electrode. Plasma distribution is controlled by an external annular inner electromagnet in a first plane overlying the workpiece support surface, an external annular outer electromagnet in a second plane overlying the workpiece support surface and having a greater diameter than the inner electromagnet, and an external annular bottom electromagnet in a third plane underlying the workpiece support surface. D.C. current supplies are connected to respective ones of the inner, outer and bottom electromagnets.

Owner:APPLIED MATERIALS INC

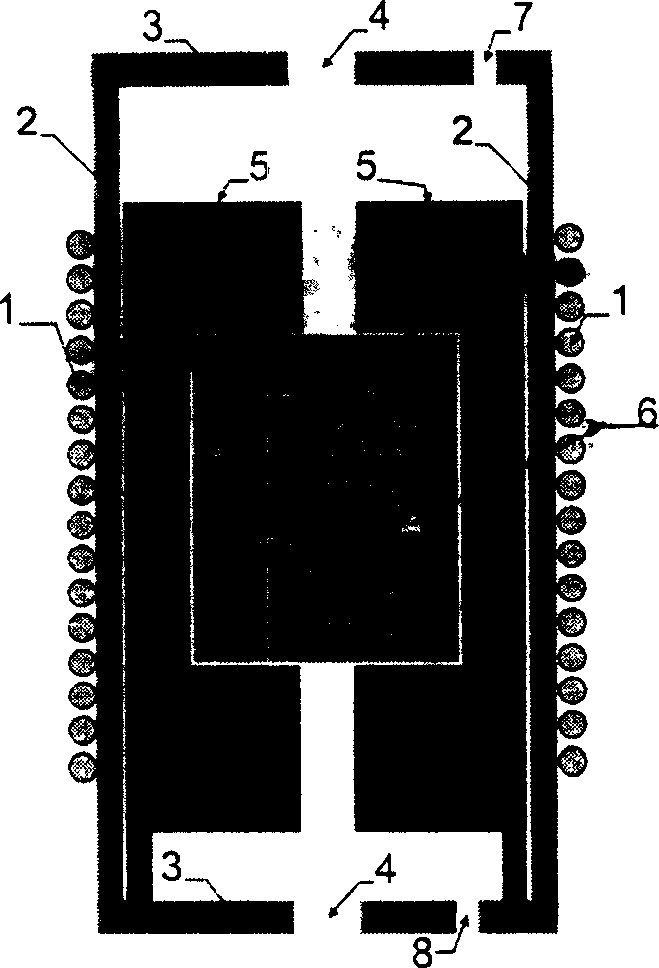

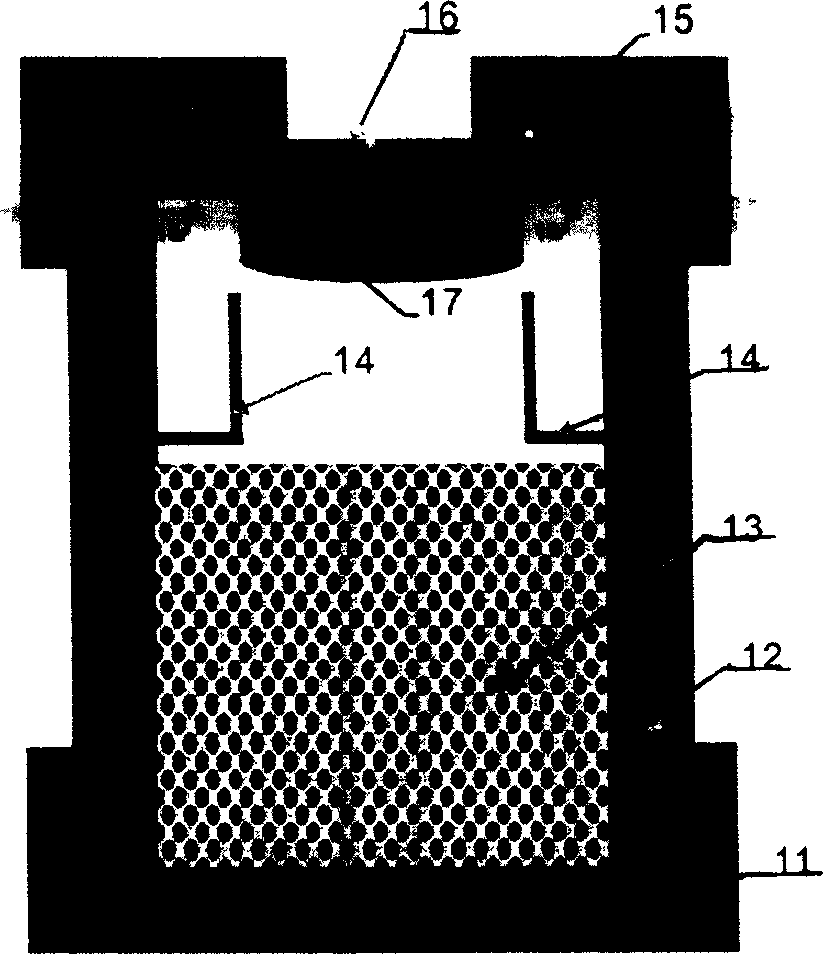

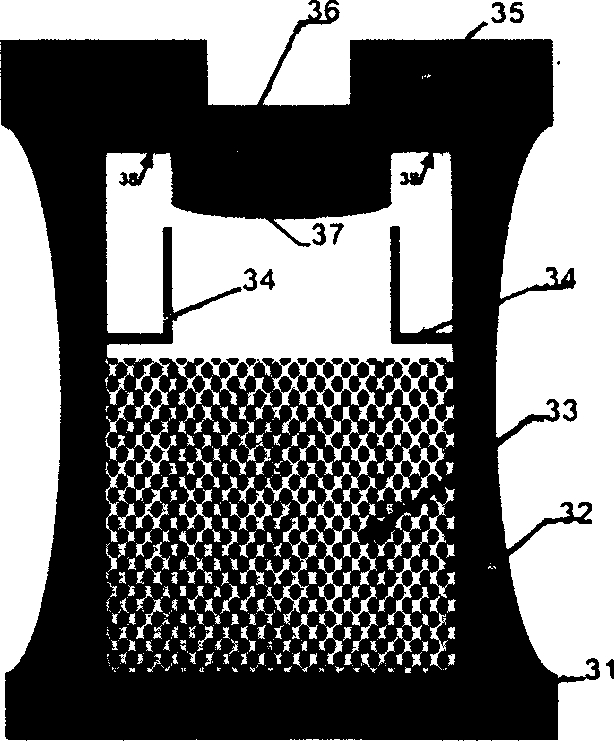

Device and method for growng large diameter 6H-SiC monocrystal with semiconductor property

ActiveCN1554808ALarge crystalsFor the purpose of dopingPolycrystalline material growthFrom condensed vaporsEngineeringSingle crystal

The present invention relates to apparatus and method of growing great diameter 6H-SiC monocrystal with semiconductor characteristic and belongs to the field of crystal growing technology. The apparatus includes growing chamber, water cooler on the side wall of the growing chamber, graphite crucible, heat insulating material, induction heating system, cylindrical vapor guiding plate of Ta inside the crucible, and cylinder. Regulating the position of the crucible relative to the inducing coil can minimize the temperature at the crystal seed inside the crucible and increase the temperature field distribution in the growing direction. Altering the atmosphere composition or material compounding can obtain great diameter SiC monocrystal with n-type, p-type or semi-insulating type semiconductor characteristic. By means of selecting the Si plane of the crystal seed and growing temperature, the crystal form may be controlled and 6H-SiC may be obtained.

Owner:SICC CO LTD

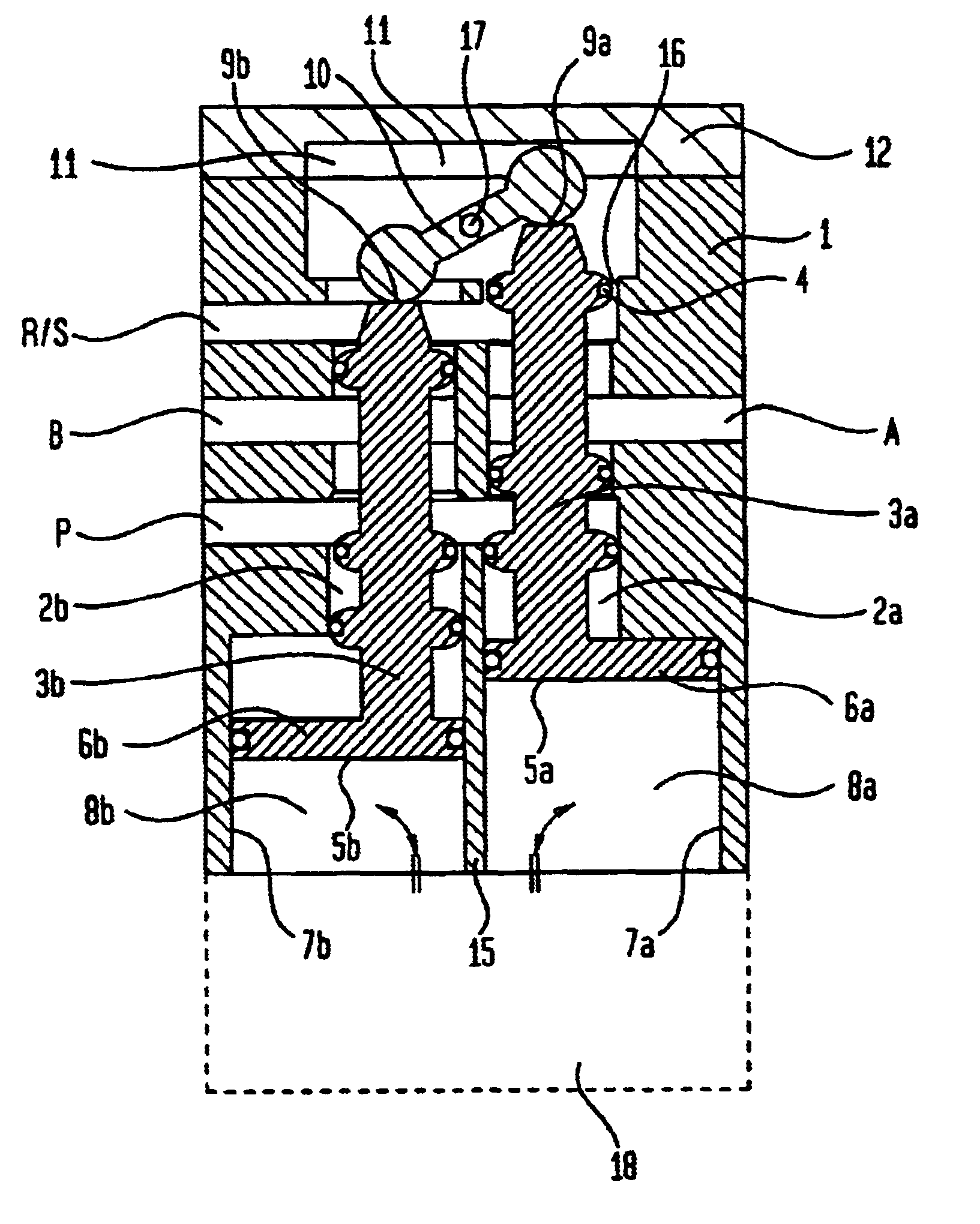

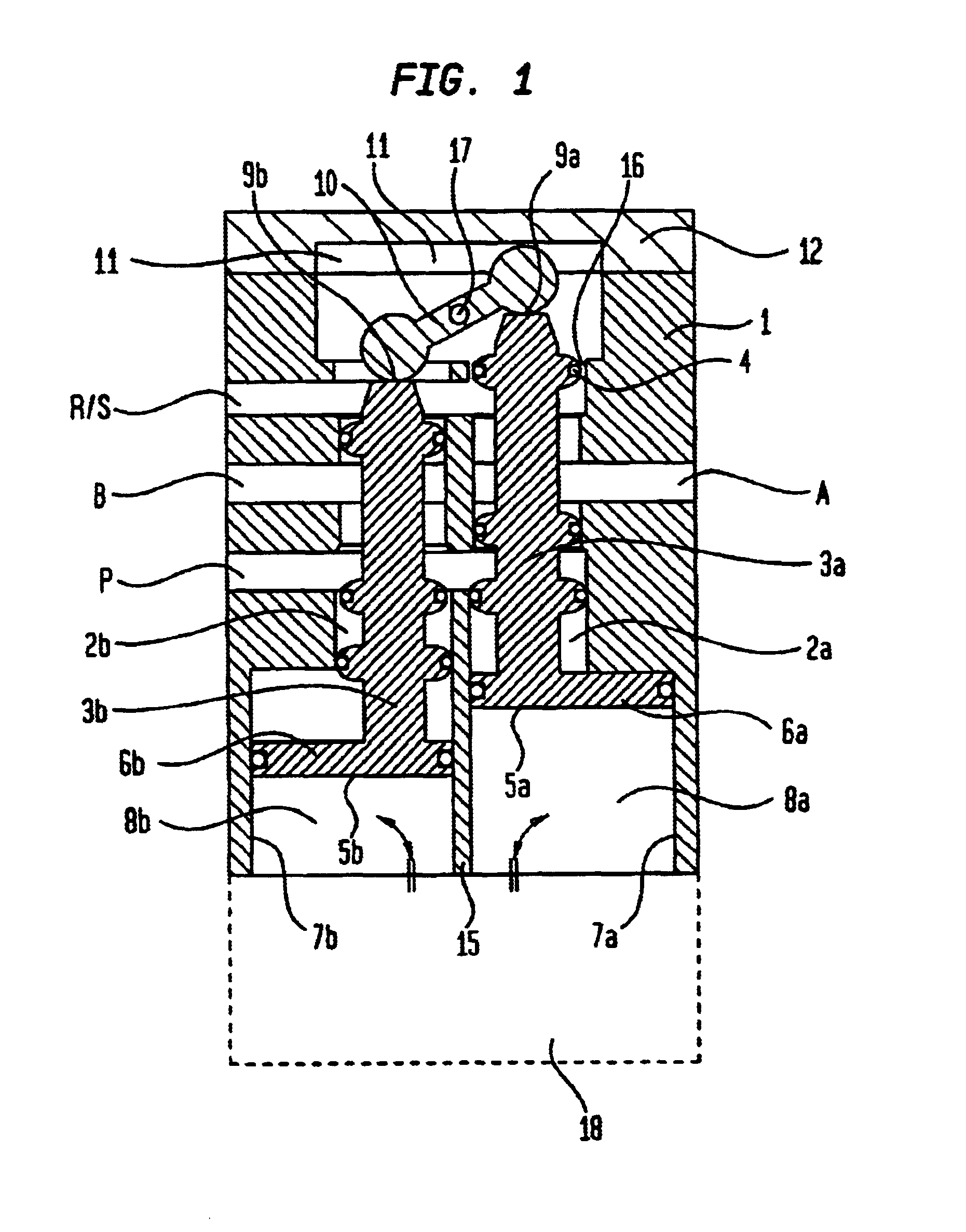

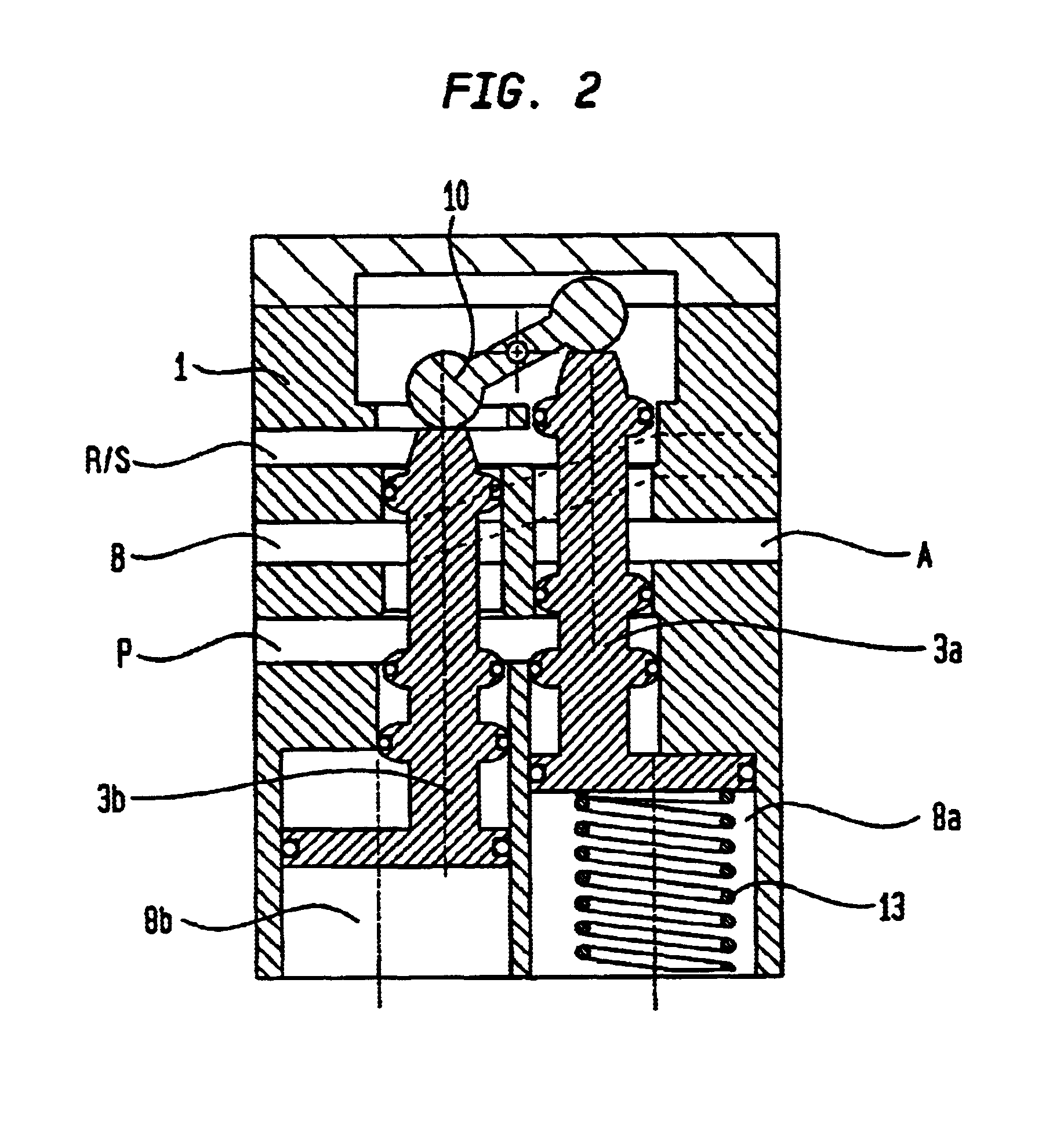

Multiway valve for switching a flow of fluid under pressure with parallel disposition of valve bores, and valve assembly kit

InactiveUS6688332B2Eliminate needCompact configurationFluid-pressure actuator safetyOperating means/releasing devices for valvesCouplingEngineering

A multiway valve for controlling a flow of fluid under pressure, includes a valve housing having fluid ports and a plurality of bores in side-by-side parallel disposition substantially at a same level. Each bore is configured for accommodation of a valve spools which are sealed in the bores against the valve housing. The spools have opposite first and second end faces, and include portions of greater diameter and portions of smaller diameter. Acting on the first end face of the spools is an actuation unit for moving the spools in a longitudinal direction to thereby direct a flow of fluid under pressure between the ports, whereas a mechanical coupling mechanism, which is secured to the valve housing, interacts with the second end faces of the spools.

Owner:AB REXROTH MECMAN

Therapeutic ultrasound system

ActiveUS9282984B2Way of increaseUltrasonic/sonic/infrasonic diagnosticsSurgeryTherapeutic ultrasoundGreatest Diameter

An ultrasound system has a catheter including an elongate flexible catheter body having at least one lumen extending longitudinally therethrough. An ultrasound transmission wire extends longitudinally through the lumen of the catheter body, and has a proximal region, a distal region, and an intermediate region between the proximal region and the distal region. A sonic connector is connected to the proximal region of the ultrasound transmission wire, and a distal head is positioned at the distal end of the catheter body and coupled to the distal region of the ultrasound transmission wire. The proximal region of the ultrasound transmission wire has a larger diameter than the intermediate region, the intermediate region is continuously tapered with a progressively decreasing diameter from its proximal end to its distal end, and the distal region has a greater diameter than the distal end of the intermediate region.

Owner:FLOWCARDIA

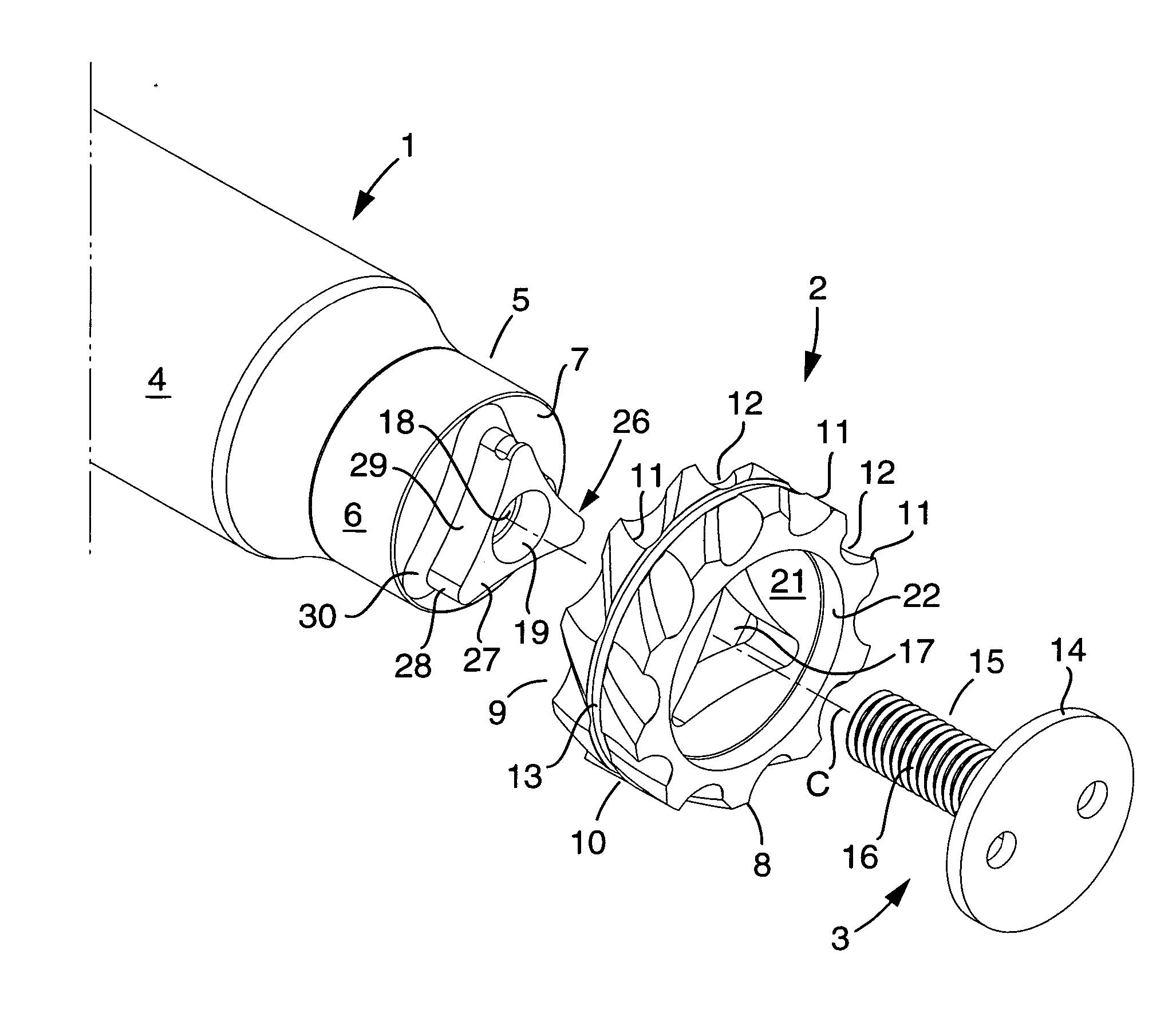

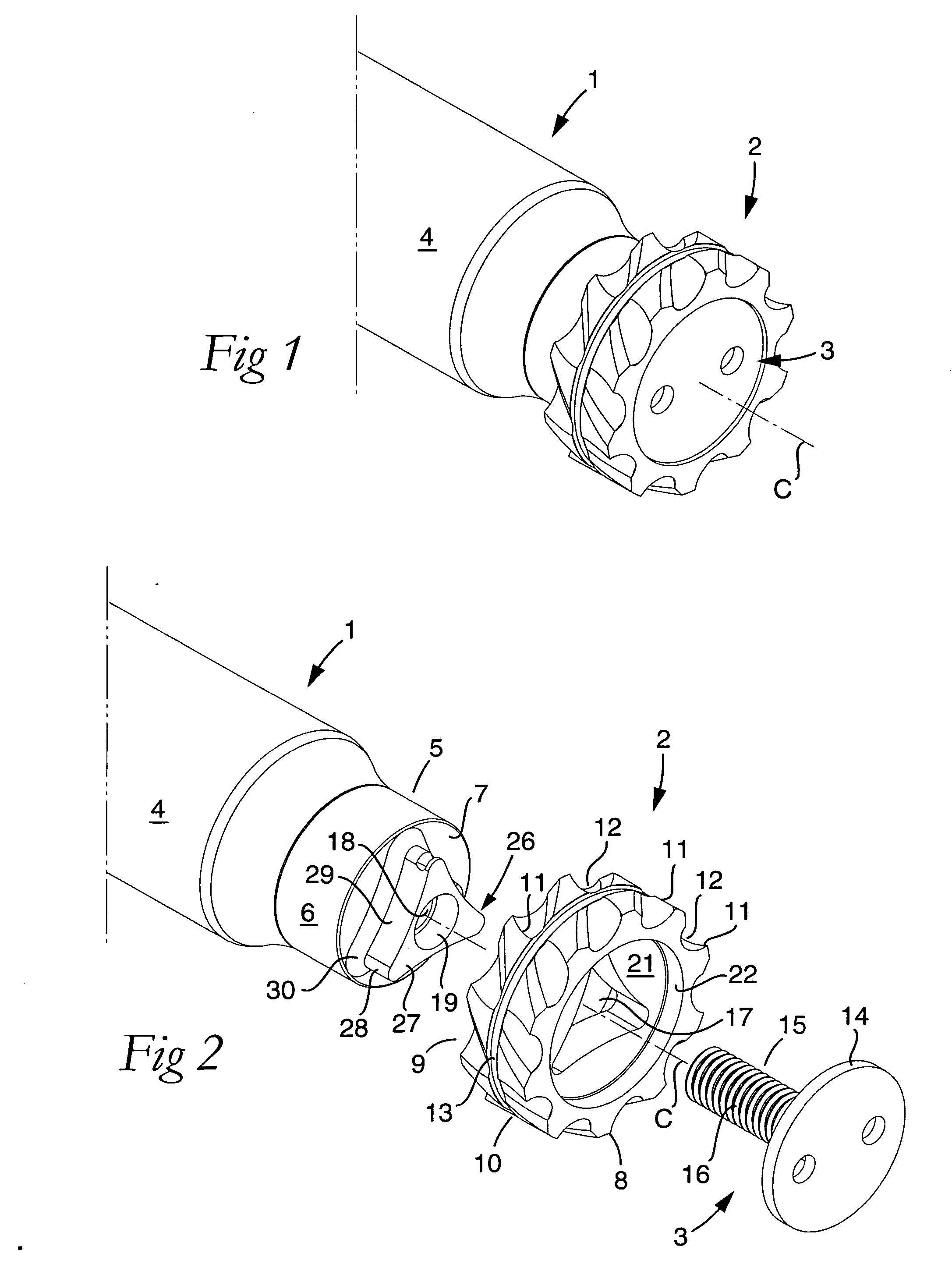

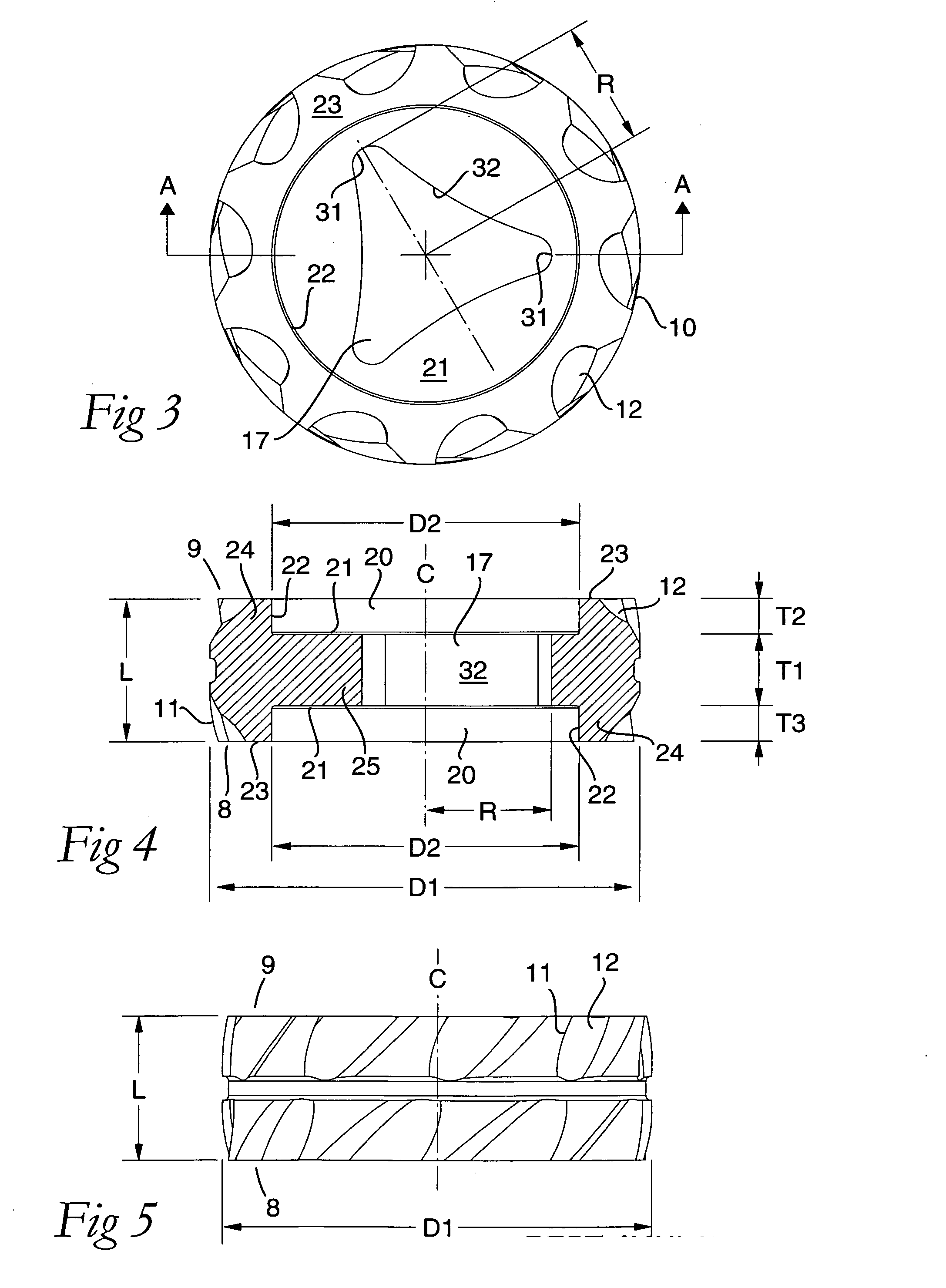

Milling cutter head and a milling cutter tool

InactiveUS20070081873A1Large formatEliminate shortcomingsMilling cuttersAttachable milling devicesFluteTool bit

A milling cutter head in the form of a body, which has an external envelope surface having a rotationally symmetrical basic shape in respect of a central axis, and includes a plurality of peripherally spaced-apart cutting edges and chip flutes. The cutter head includes two axially spaced-apart ends in which hollow spaces open, which are arranged to receive male elements included in a basic body, and are spaced-apart by a partition wall in which a through hole is formed. The through hole mouths in bottom surfaces in the hollow spaces. The cross-section area of each individual hollow space, in a plane perpendicular to the center axis, amounts to at least 25% of the total cross-section area of the body, as defined by the greatest diameter of the envelope surface.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

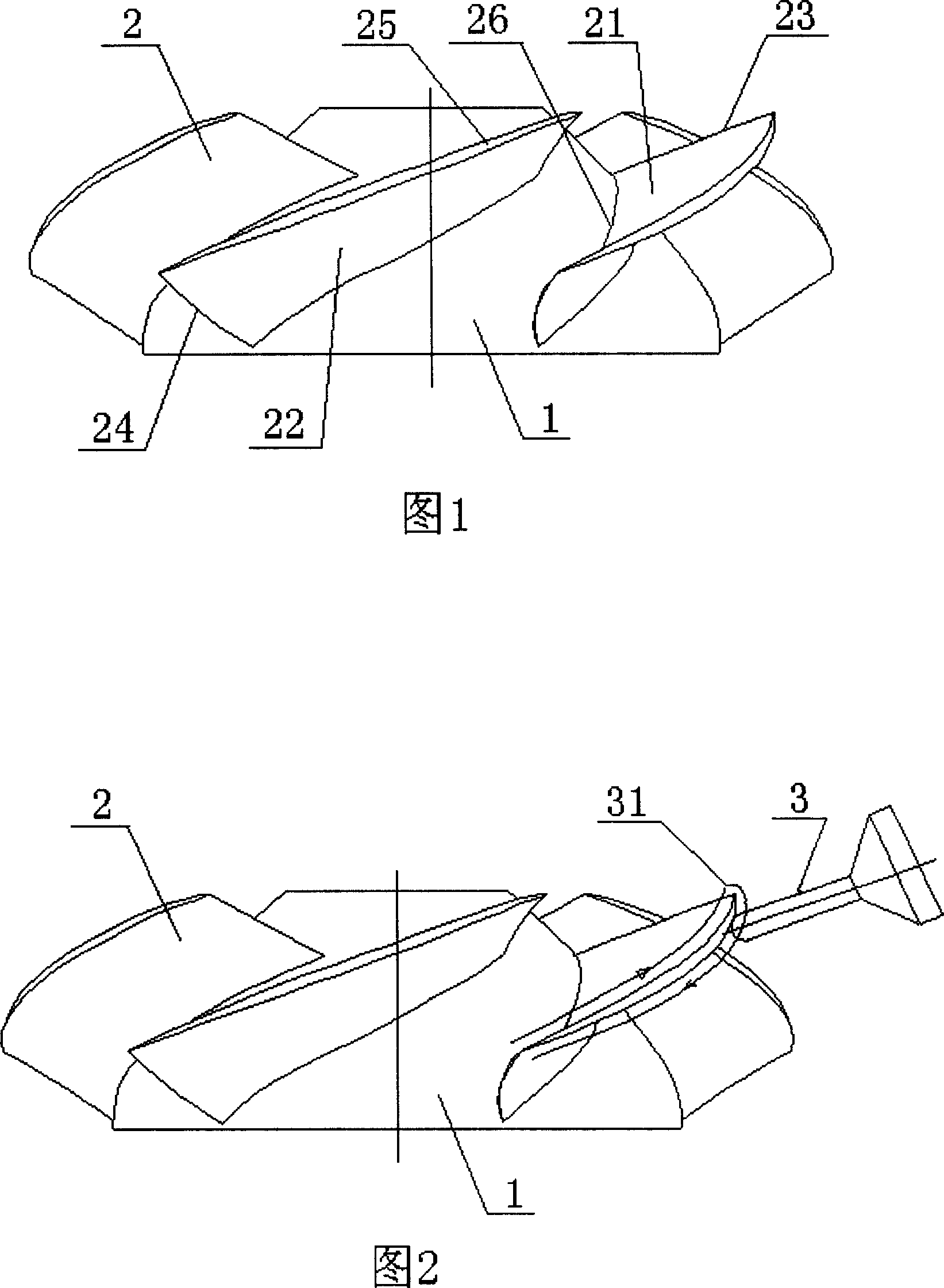

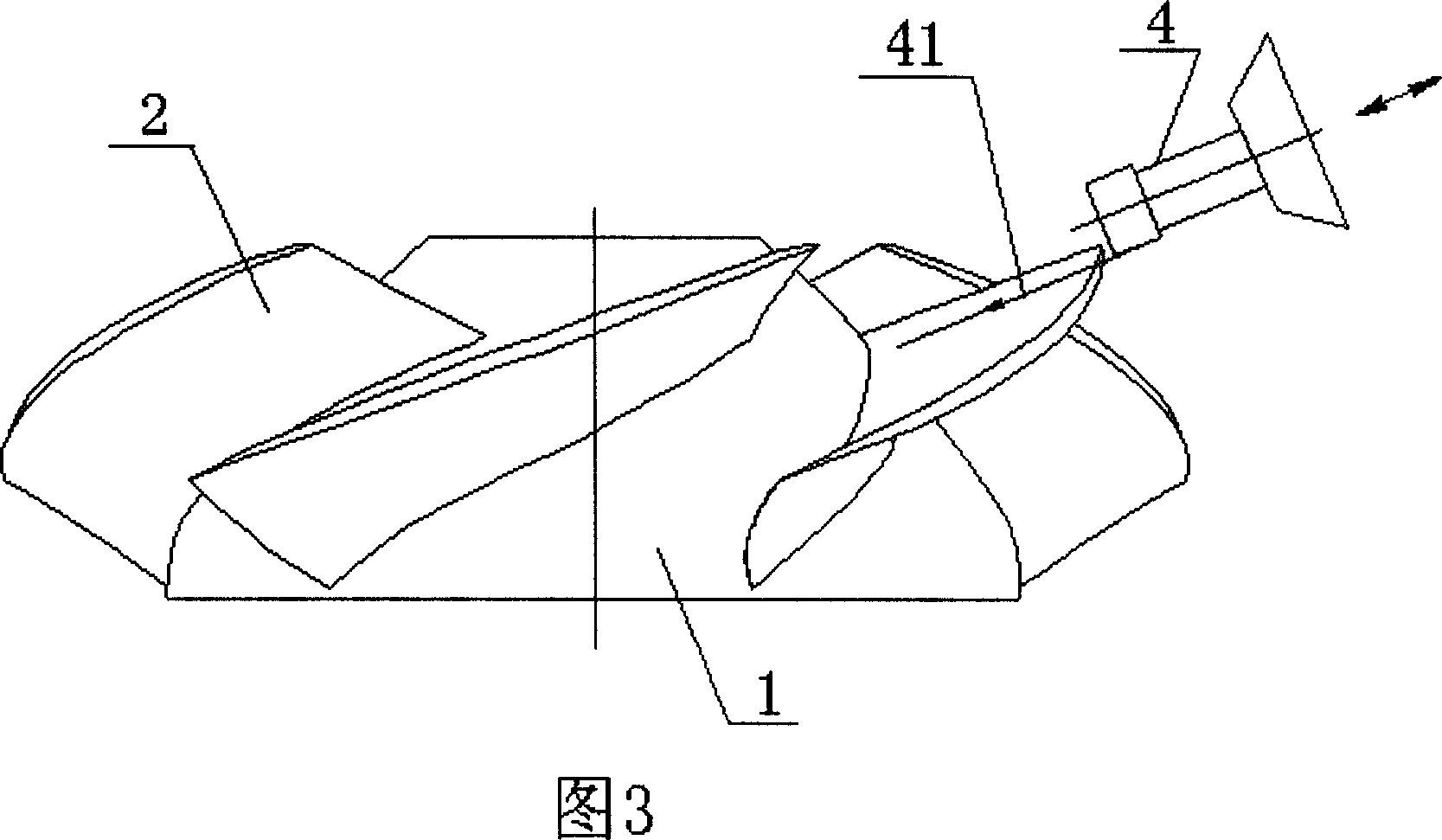

Slotting and milling process for vane of integral vane wheel

InactiveCN1986127ASmall radial componentSmall amount of deformationMilling cuttersImpellerNumerical control

The slotting and milling cutter process for vane of integral vane wheel is completed in a numerically controlled machine tool with slotting and milling cutter advancing in the radial direction of the vane wheel and axial direction of the cutter. It has small radial force component caused by cutting, less vibration of the workpiece and the cutter, smooth cutting, small and controllable vane deformation, high machining quality and high machining efficiency. The present invention can meet the requirement of machining great diameter and high precision vane wheel product.

Owner:WUHAN MARINE MACHINERY PLANT

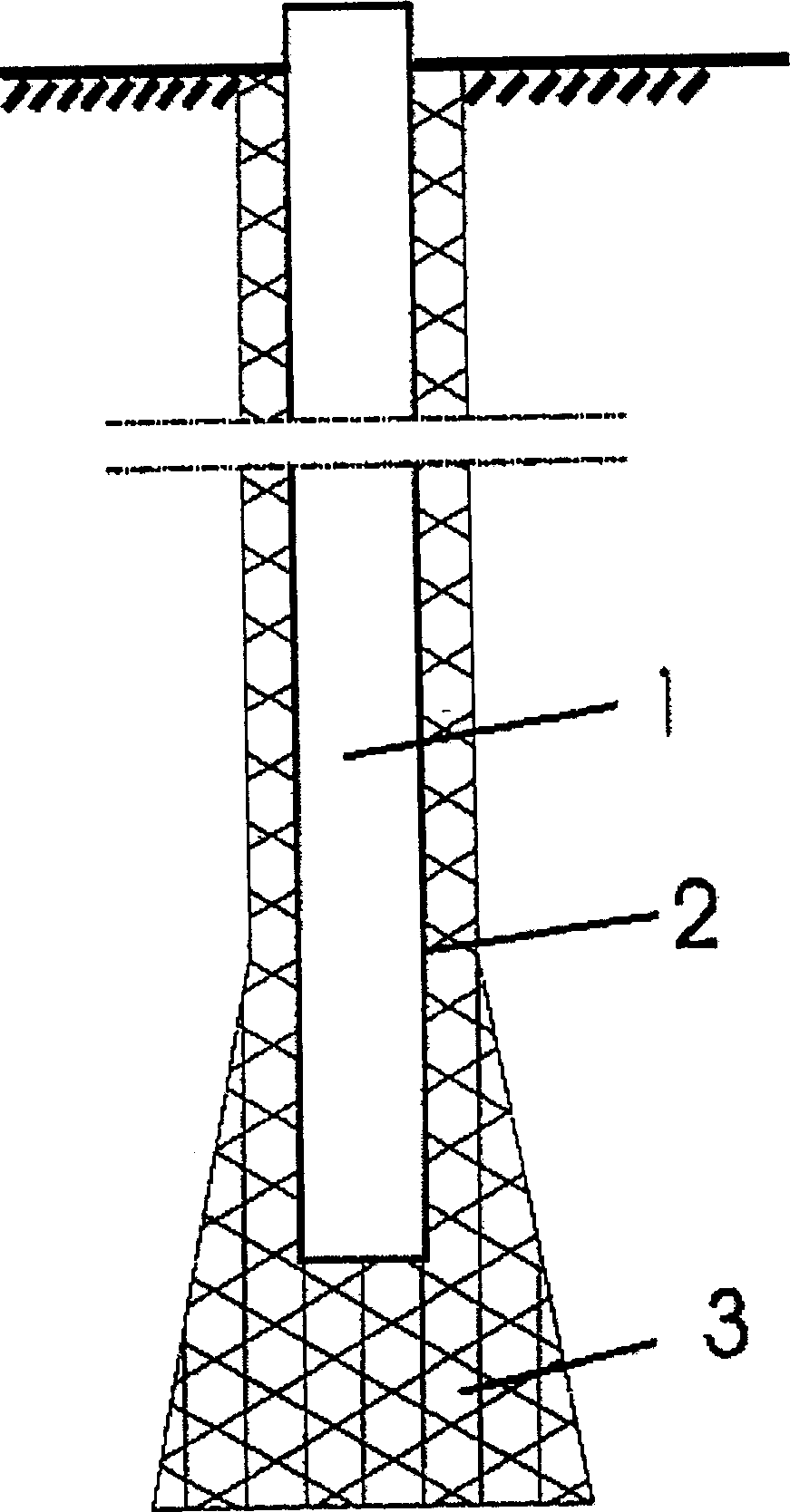

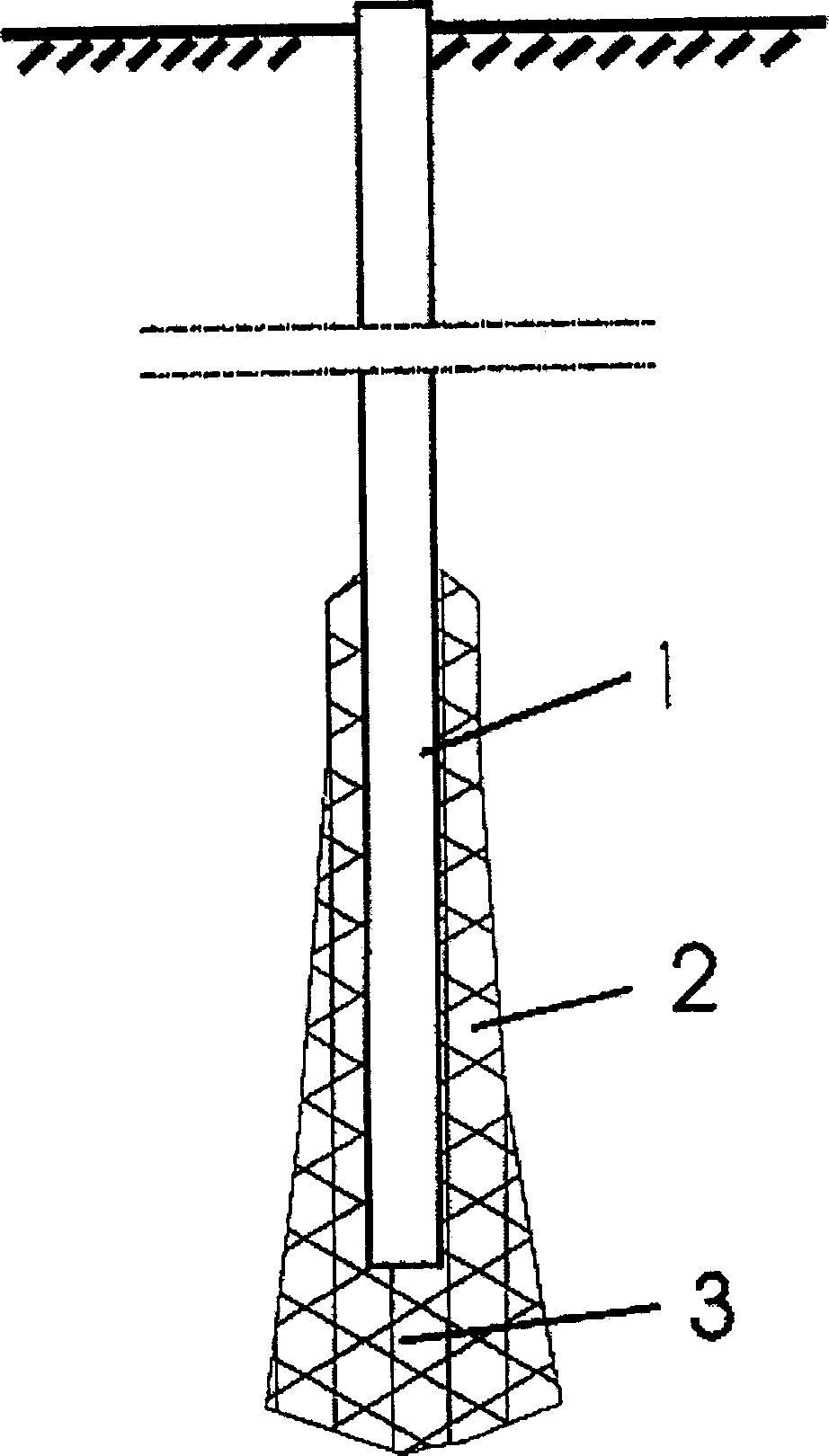

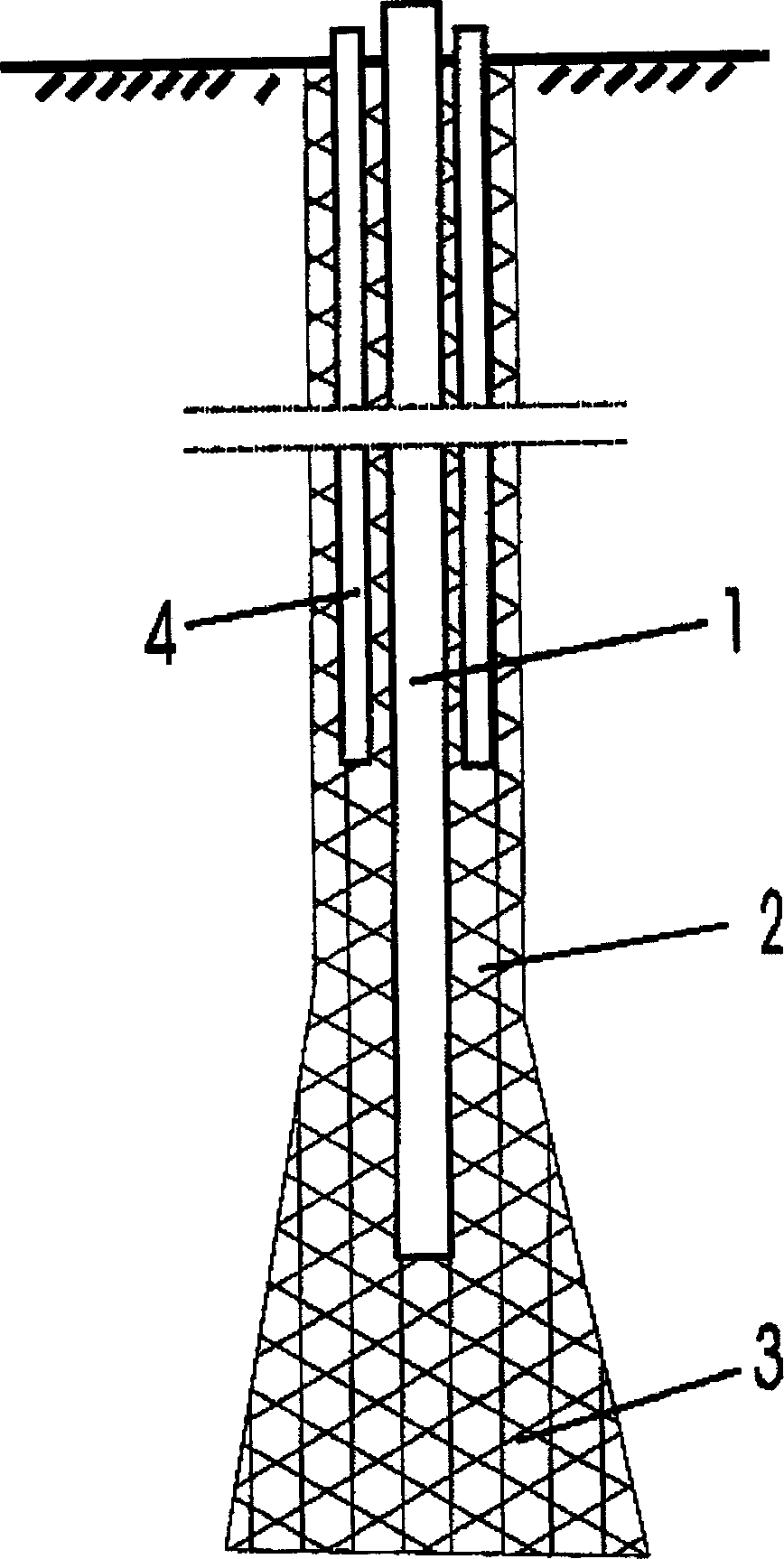

High-pressure rotary spraying and core inserting process to form pedestal pile

InactiveCN1441124AHigh strengthIncrease loading capacityBulkheads/pilesBridge engineeringReinforced concrete

The present invention relates to high-pressure rotary spraying and core inserting process to form pedestal pipe. The pedestal pile consists of core pile, column and pile depestal. The cylindrical or turned frustum-shaped core pile may be prefabricated reinforced concrete pile, in-situ deposited pile or other pile in different cross section shapes. The pile pedestal below the core pile has diameter greater than that of the core pile. The column has circular, semi-circular of fan-shaped cross section. There may be several auxiliary core piles around the main solid or hollow core pile and several rings in relatively great diameter around the column. The present invention has reasonable design, compact structure, high friction resistance, and wide application in building engineering, bridge engineering, civil engineering, water engineering, etc.

Owner:雷玉华

Great diameter SiC monocrystal cutting method

ActiveCN1739927ARealize continuous cuttingReduce lossesMetal working apparatusWire cuttingSingle crystal

The great diameter SiC monocrystal cutting method belongs to crystal material processing technology. SiC monocrystal is cut by means of diamond wire cutting machine with cutting wire of 150-450 micron diameter and coated with diamond grains. The diamond wire cutting wire in high speed reciprocation cuts great diameter SiC monocrystal. The present invention has the following advantages: capacity of cutting SiC monocrystal of size ove 2 in, less cutting loss, shallow cutting trace, less damage to cut chip, capacity of cutting chip with thickness as small as 200 micron, saving in cost, homogeneous thickness and less deformation of the cut chip, and simple cutting process.

Owner:SICC CO LTD

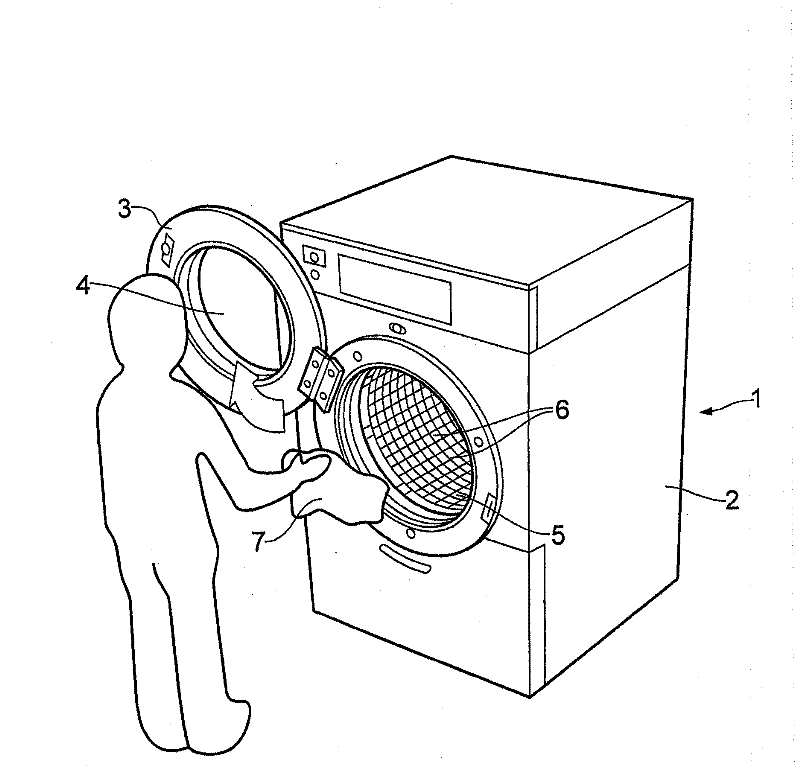

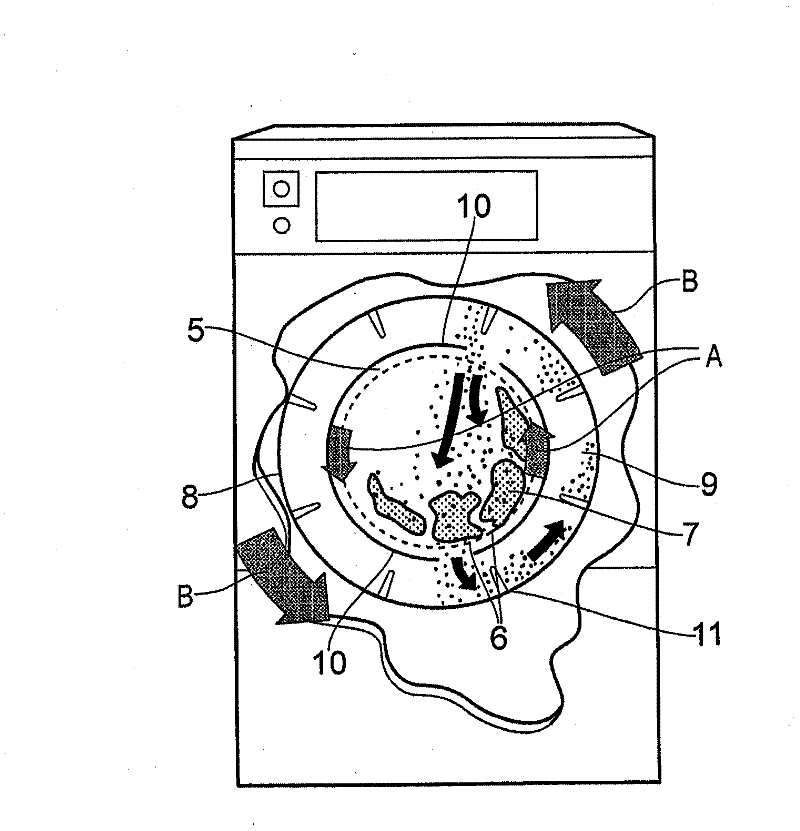

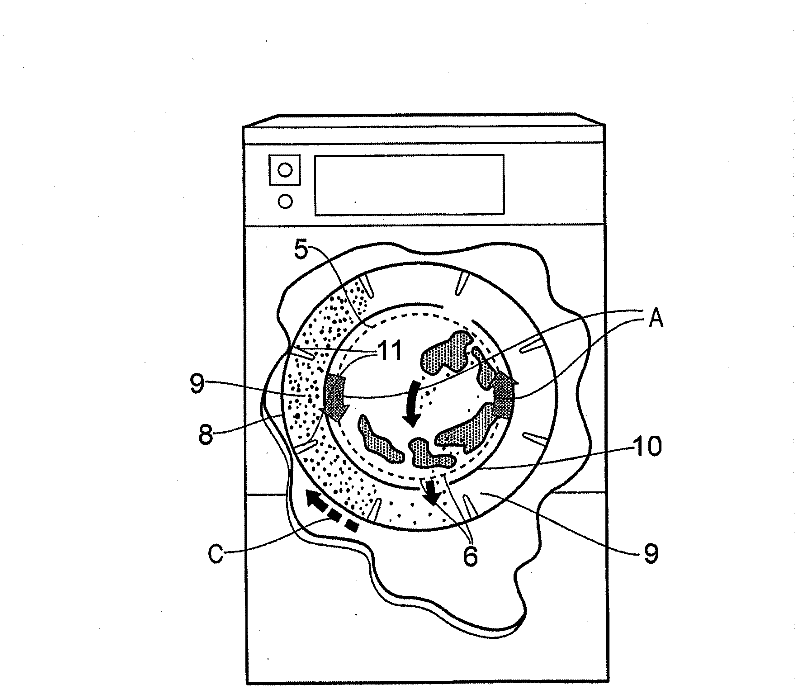

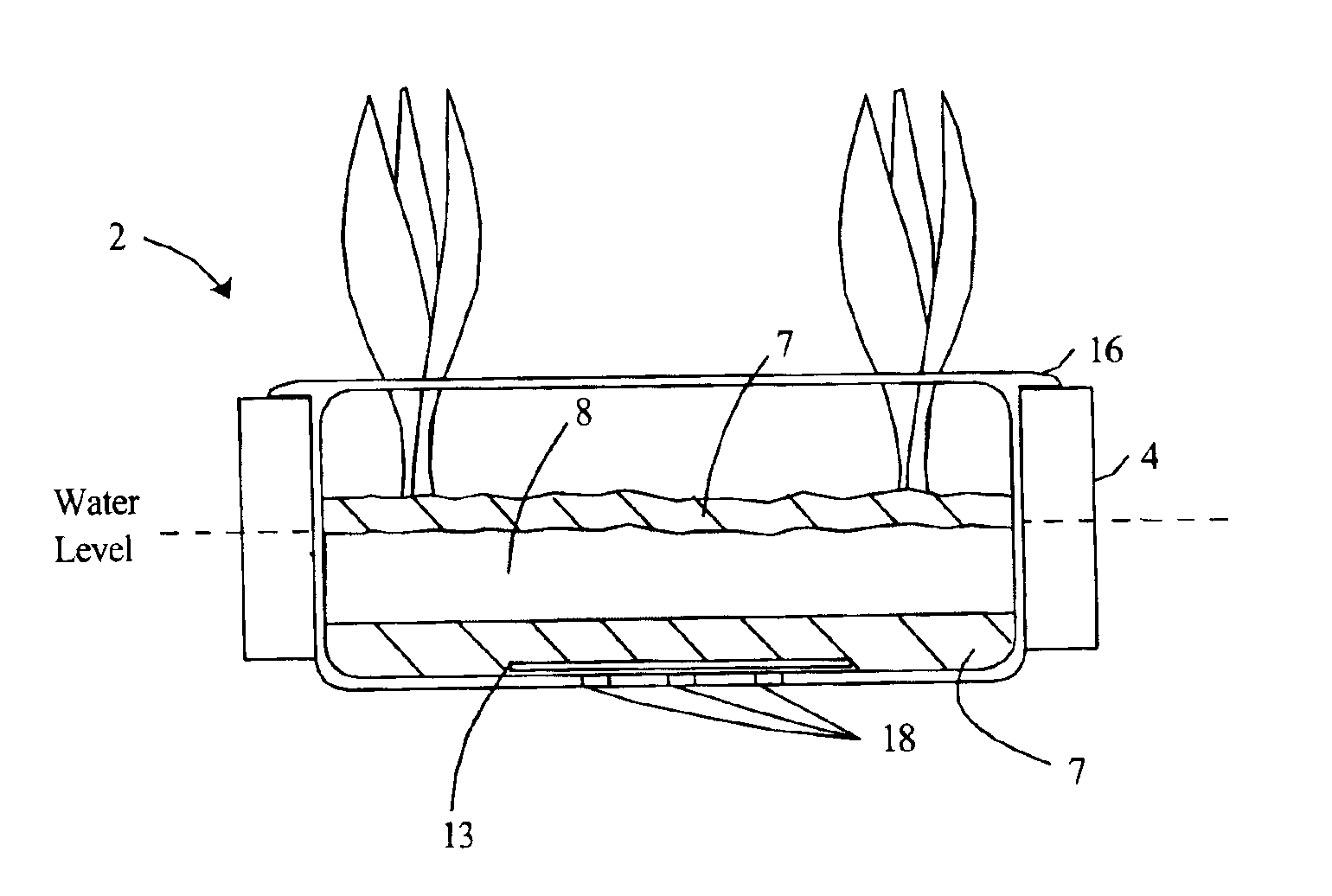

Cleaning apparatus

InactiveCN102317534ADoes not cause disposal problemsOther washing machinesTextiles and paperParticulatesOrganic solvent

The invention provides an apparatus and method for use in the cleaning of soiled substrates, the apparatus comprising a casing which contains a rotatably mounted cylindrical cage concentrically located within a rotatably mounted cylindrical drum having a greater diameter than the basket, wherein the cage and the drum are concentrically located within a stationary cylindrical drum having a greater diameter than the rotatably mounted drum, wherein the casing includes access means, allowing access to the interior of the cylindrical basket, and wherein the rotatably mounted cylindrical cage and the rotatably mounted cylindrical drum are adapted to rotate independently. The method involves cleaning the soiled substrate by treatment of the moistened substrate with a formulation comprising solid particulate cleaning material, the formulation being free of organic solvents, and the method being carried out using the apparatus of the invention, and the apparatus and method find particular application in the cleaning of textile fabrics.

Owner:XEROS LTD

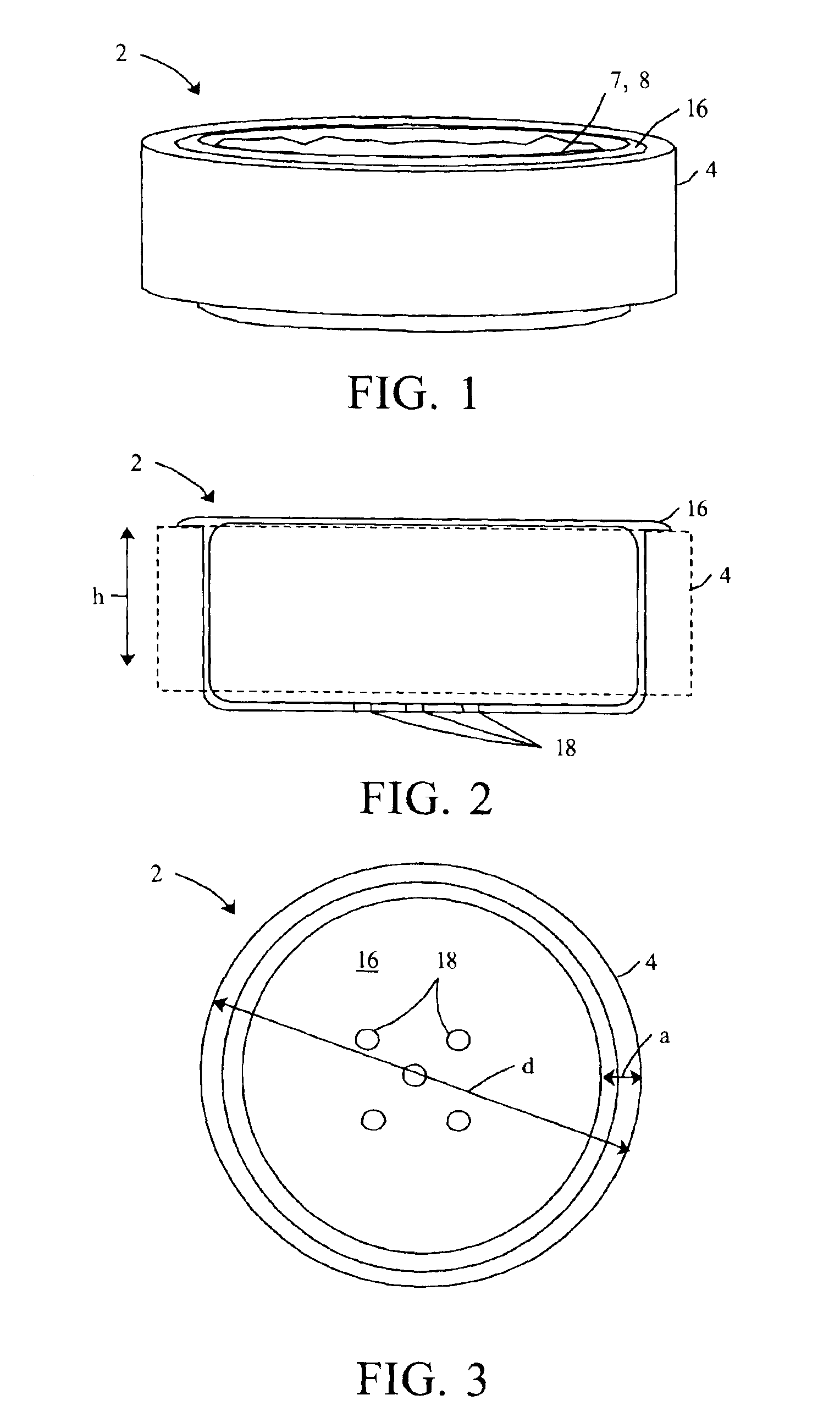

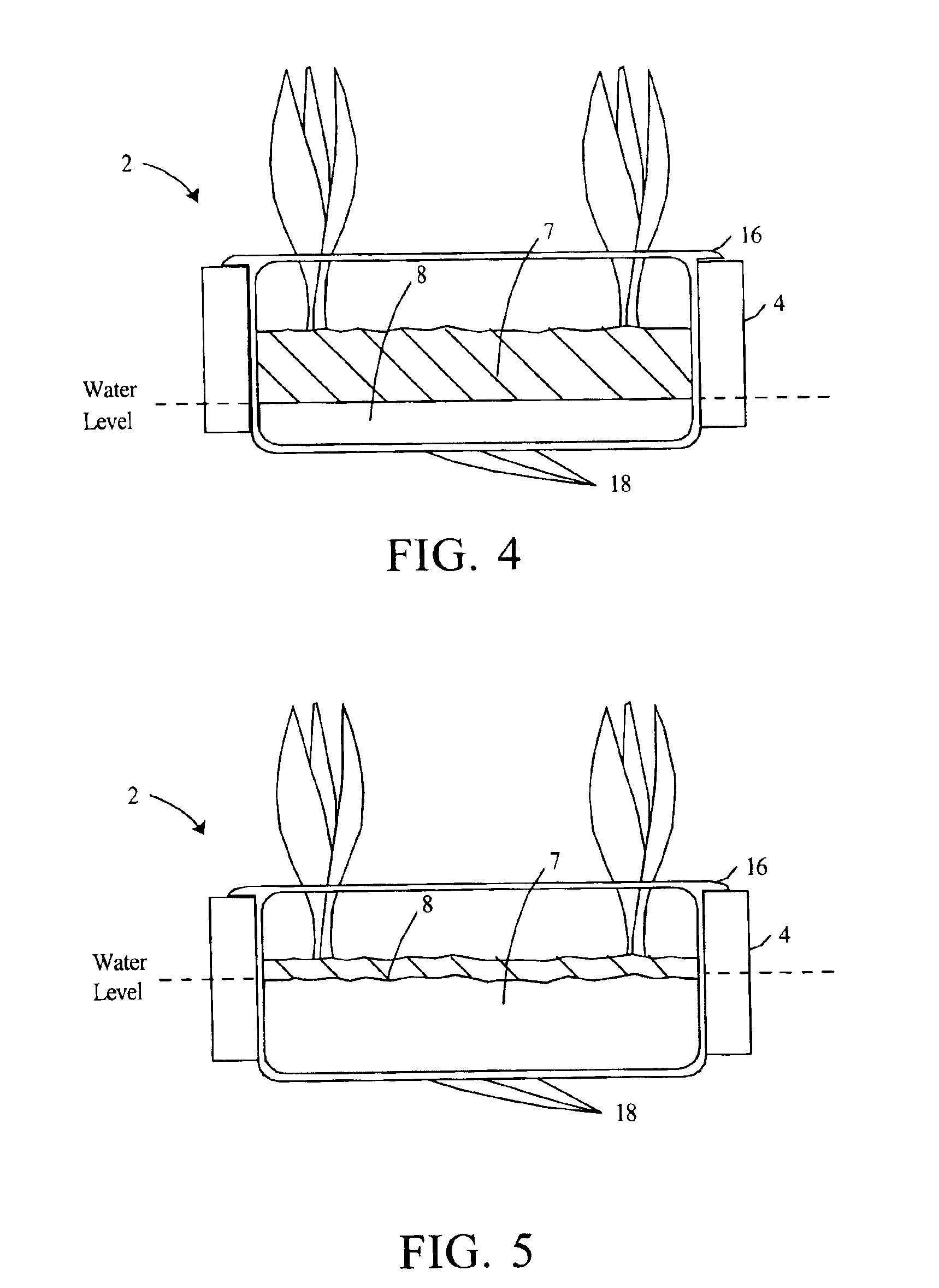

Floating island planting system

InactiveUS6918206B2Resists tippingImprove stabilityCultivating equipmentsReceptacle cultivationSeederPotting soil

An improved floating island planting system comprising a float ring formed as a circular walled member of closed-cell polyethylene foam, and a garden planter formed in a bowl configuration with a collar of greater diameter than the float ring. The bowl of the garden planter is dimensioned for nesting in the float ring, the planter is defined by a plurality of holes through the closed bottom. A fill mix comprising a combination of clay and potting soil resides in the planter. An alternate embodiment is shown in which the planting system is integrally formed from an open-ended circular collar section that is heat sealed to a conforming circular base section.

Owner:SCHUCK RICHARD J

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com