Slotting and milling process for vane of integral vane wheel

An integral impeller and processing method technology, applied in milling cutters, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult interference between workpieces and tools, prolong cutting time, reduce processing efficiency, etc., and achieve easy guarantee of processing quality. The effect of improving machining efficiency and increasing cutting amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

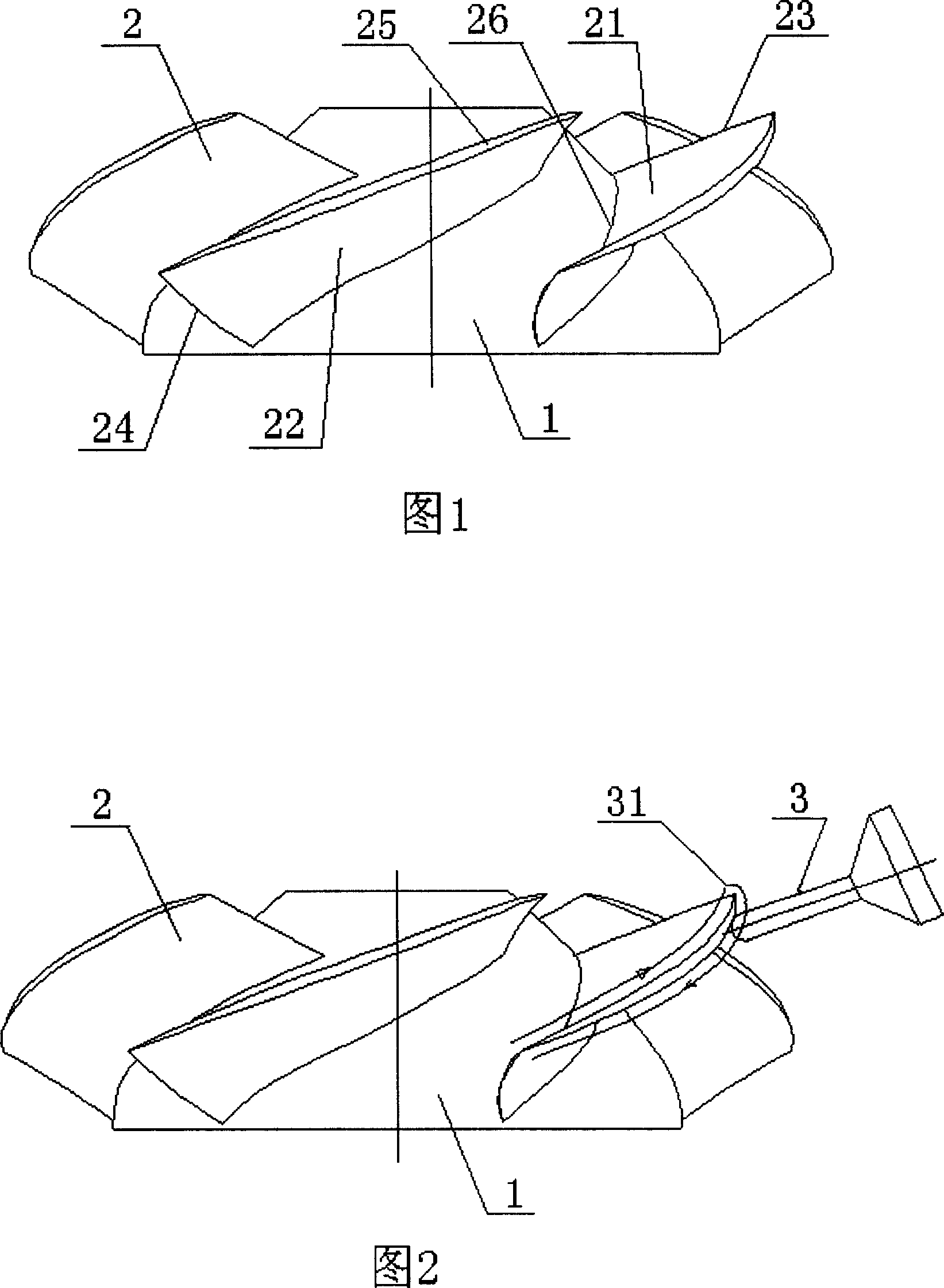

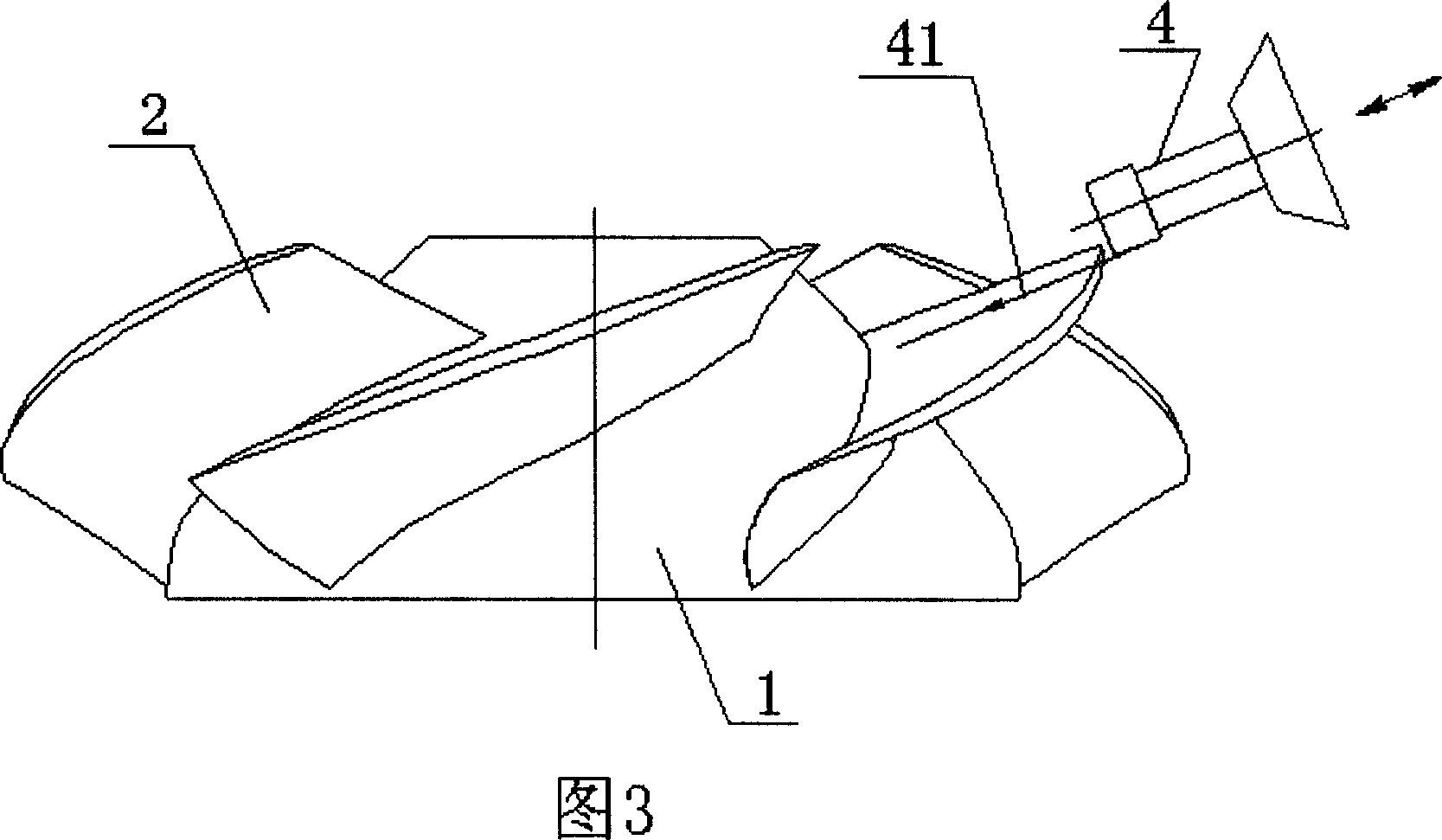

Embodiment 1

[0020] The free-form surface blade 2 of the axial-flow integral impeller is processed by the method of the present invention. The material of the impeller is ultra-low carbon duplex stainless steel, the maximum diameter of the impeller is 800-1000 mm, and the maximum height of the blade 2 is 240-260 mm. Processing is carried out on a five-coordinate CNC machining machine. The creation of the plunge milling cutter processing method and the generation of the program include the following steps:

[0021] 1 Establish the solid model of the impeller in the UG NX2.0 / CAD module.

[0022] 1.1 According to the design points given by the design drawings, connect the points of the same section with NURB splines (Non-Uniform Rational B-splines) to form a closed curve, and perform smoothing treatment.

[0023] The points given in the design drawings are the discrete points on the section of the blade 2. In order to generate the free-form surface of the blade 2, these points must be fitted...

Embodiment 2

[0047] Adopt ball cutter processing method and the inventive method to process and compare above-mentioned same integral impeller blade 2: adopt ball cutter processing earlier, the processing cycle of every integral impeller blade is about 17 days (20 hours every day), about 340 hours altogether; After adopting plunge milling cutter to process by the method of the present invention, the manufacturing cycle of every integral impeller blade is about 7 days, about 140 hours. The processing efficiency of the method of the invention is more than 2 times higher than that of the ball cutter processing, and the precision of the produced integral impeller product is greatly improved, and the quality is stably controlled, which fully meets the needs of large-diameter, high-precision impeller product processing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com