An electric transformer with improved cooling system

A technology of coil device and choke coil, which is applied in the direction of transformer/inductor coil/winding/connection, transformer/inductor parts, transformer/inductor magnetic core, etc., can solve the problem of cost and achieve low eddy current loss, Improved rotational symmetry and less noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

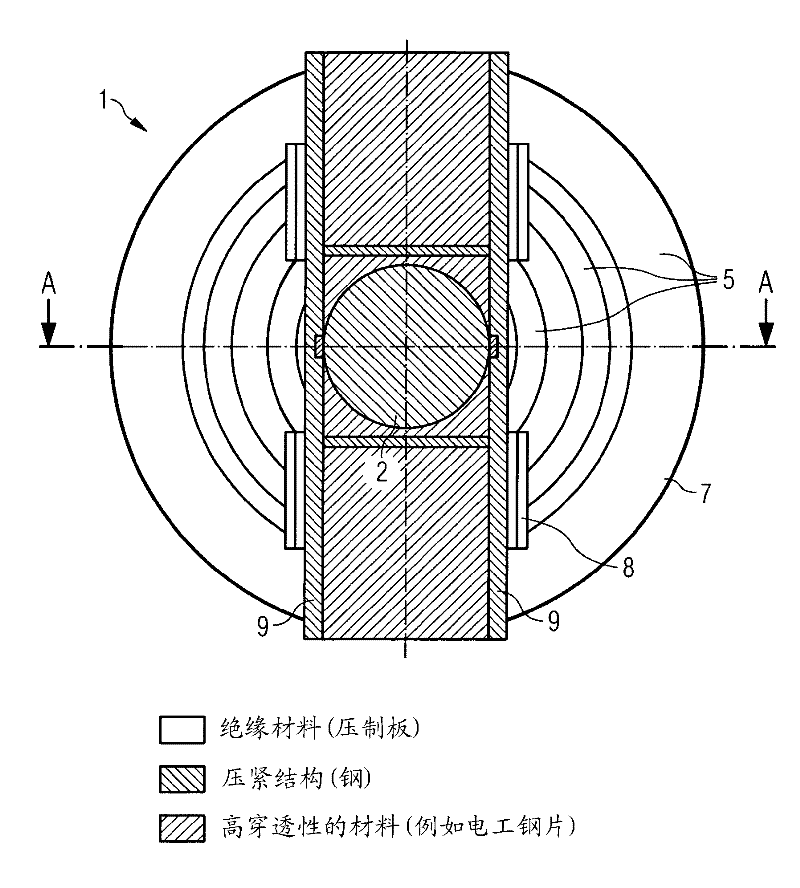

[0036] figure 1 The transformer 1 is shown in the region of a transformer leg 2 which carries a multipart coil 5 . The individual sections of the coil 5 are arranged concentrically around the leg axis 4 . A bearing and clamping device 8 formed of insulating material (press span) is pressed onto the pressure ring 7 . The bearing and clamping device 8 is supported on the yoke pressure plate 9 . Transformer leg 2 is composed of highly penetrating electrical steel sheets.

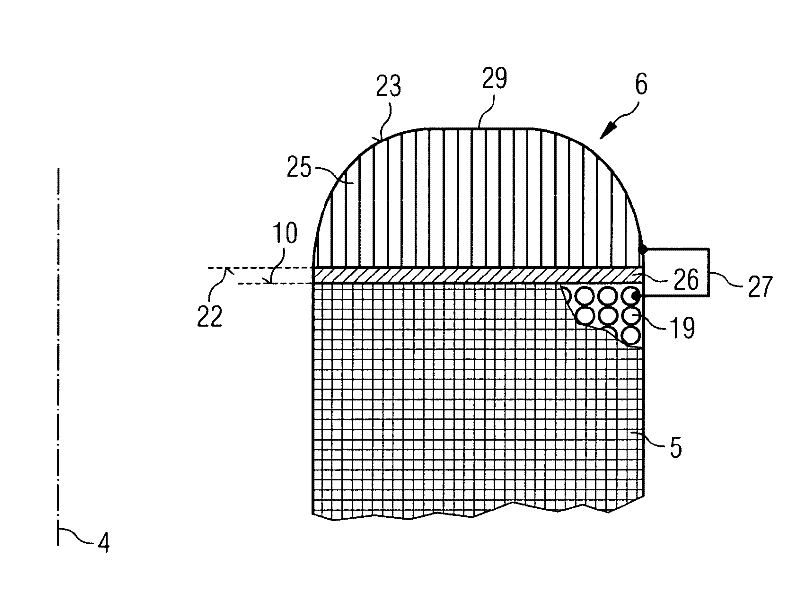

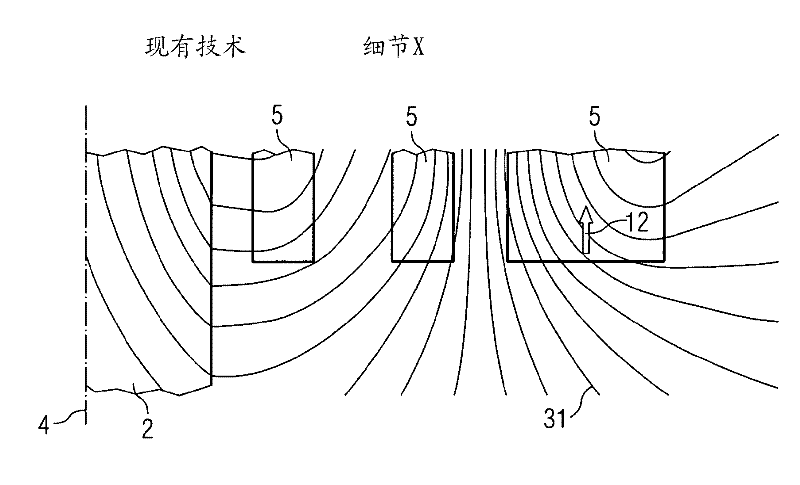

[0037] figure 2 The schematic diagram shows the basis of figure 1Sectional view of line A-A. The bearing and clamping device 8 presses the individual coils 5 in the axial direction (direction of the leg axis 4 ). In this case, coil covers 6 , which are respectively arranged on the end faces of the coil elements 5 , lie in the magnetic flux. As will be explained in more detail below in the exemplary embodiment, the coil cover 6 on the one hand brings about a deflection of the magnetic flux in the end reg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com