Patents

Literature

66results about How to "Large crystals" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Device and method for growng large diameter 6H-SiC monocrystal with semiconductor property

ActiveCN1554808ALarge crystalsFor the purpose of dopingPolycrystalline material growthFrom condensed vaporsEngineeringSingle crystal

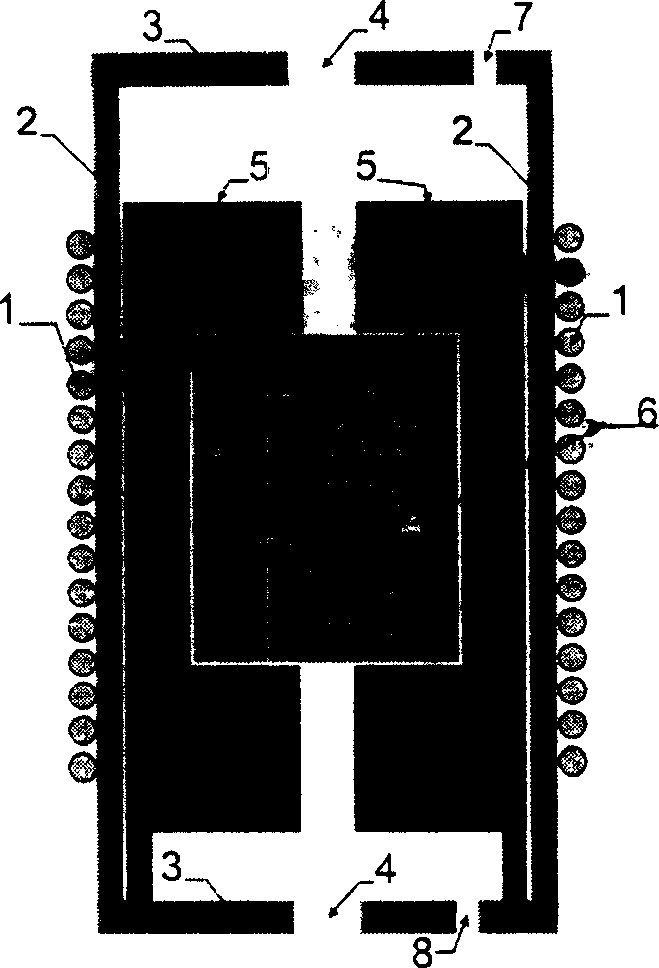

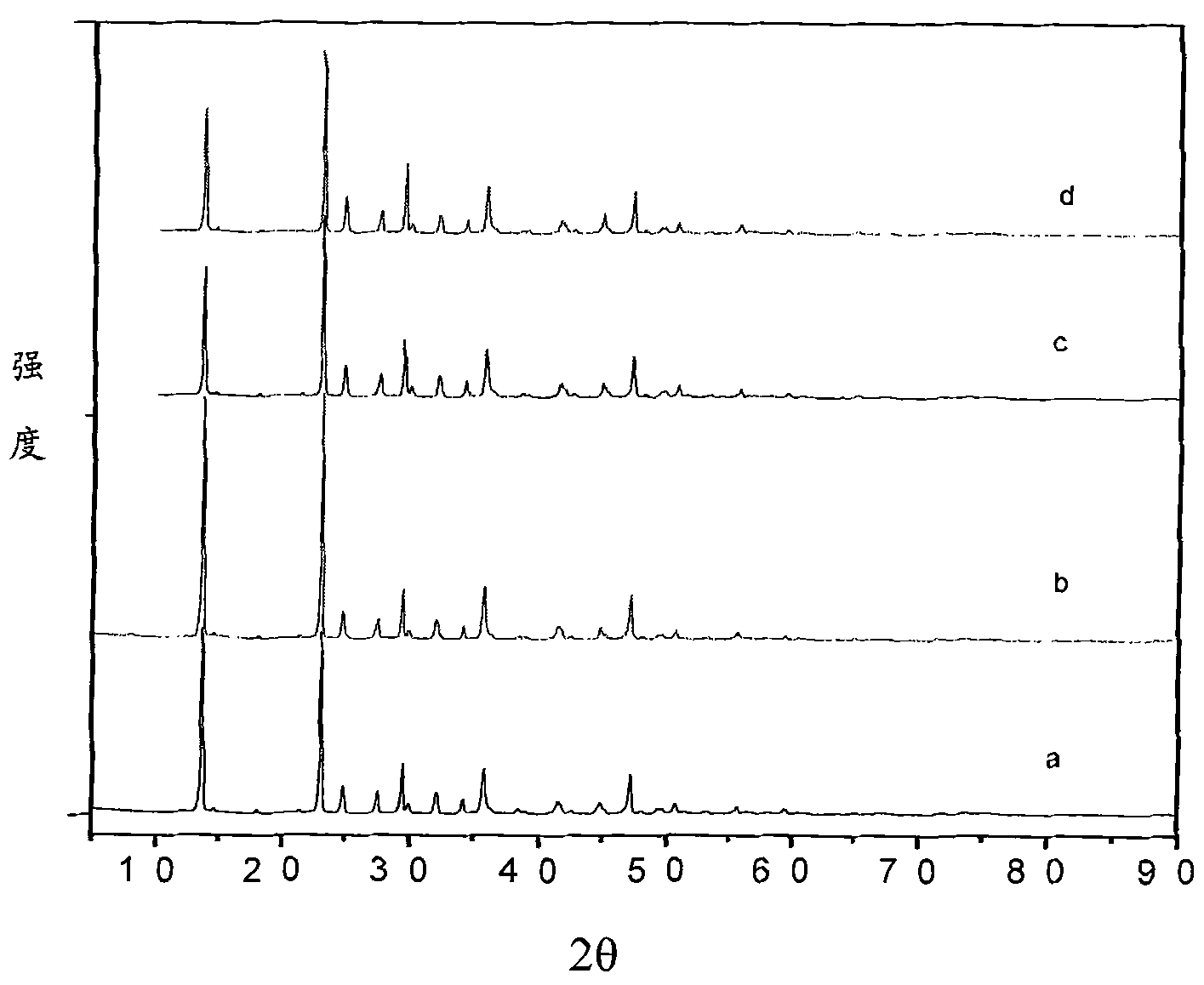

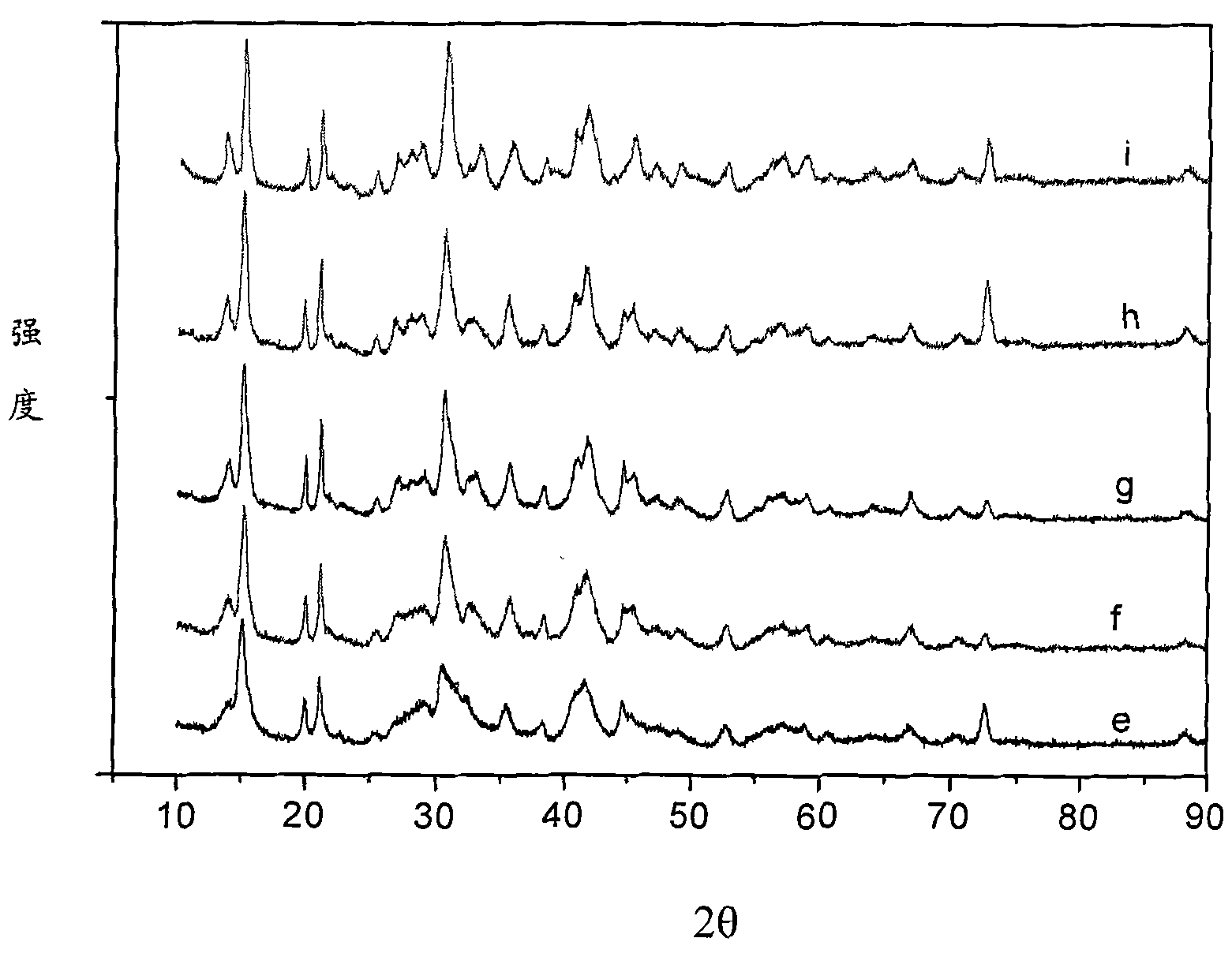

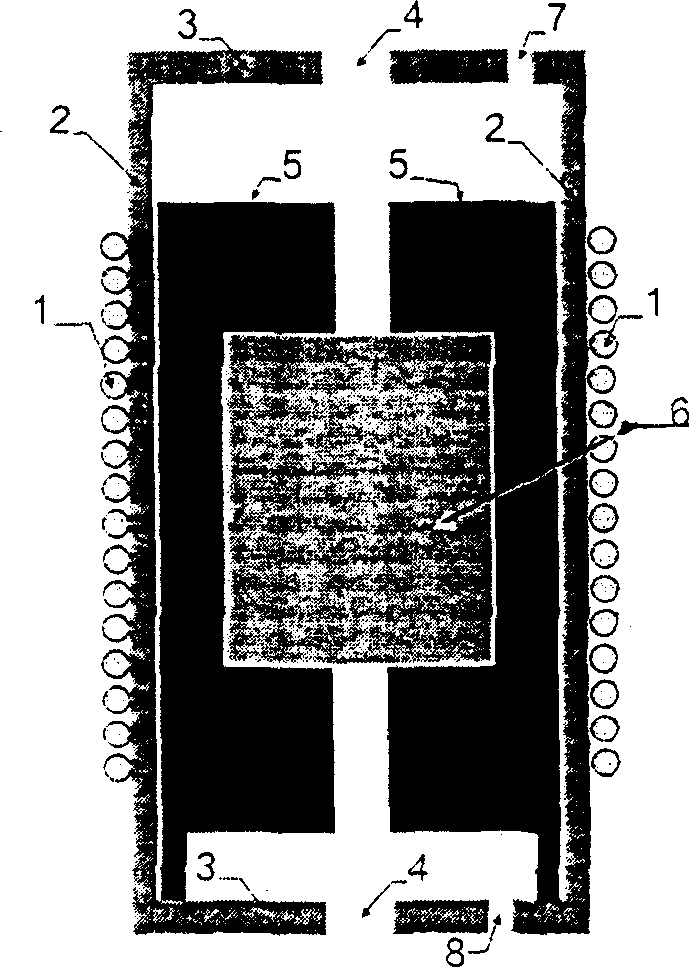

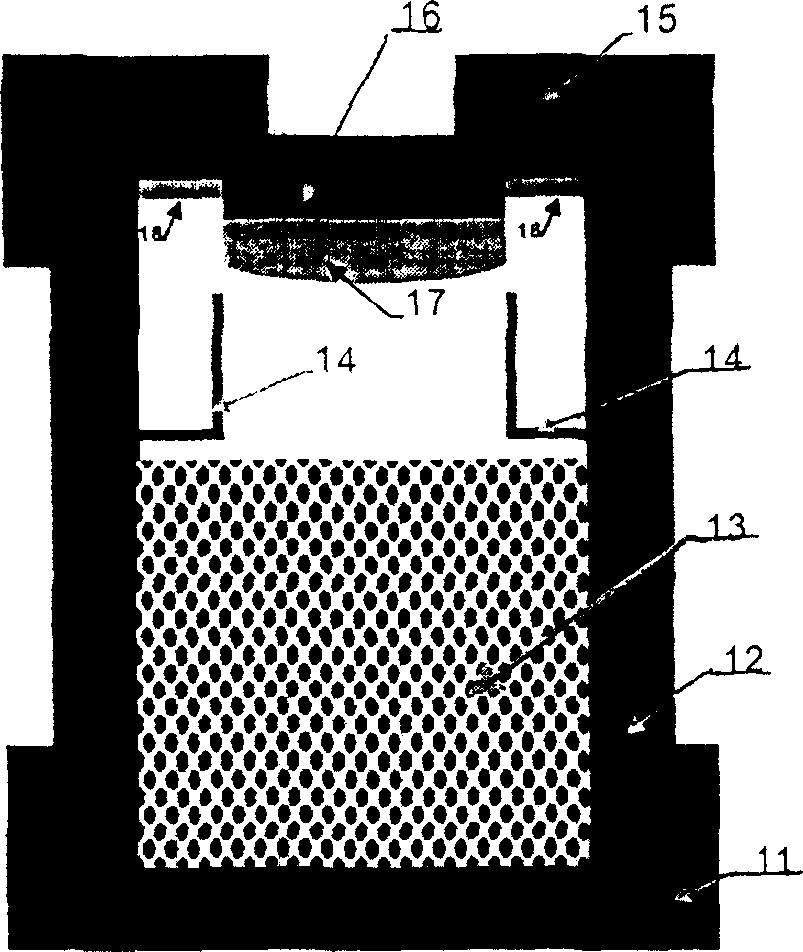

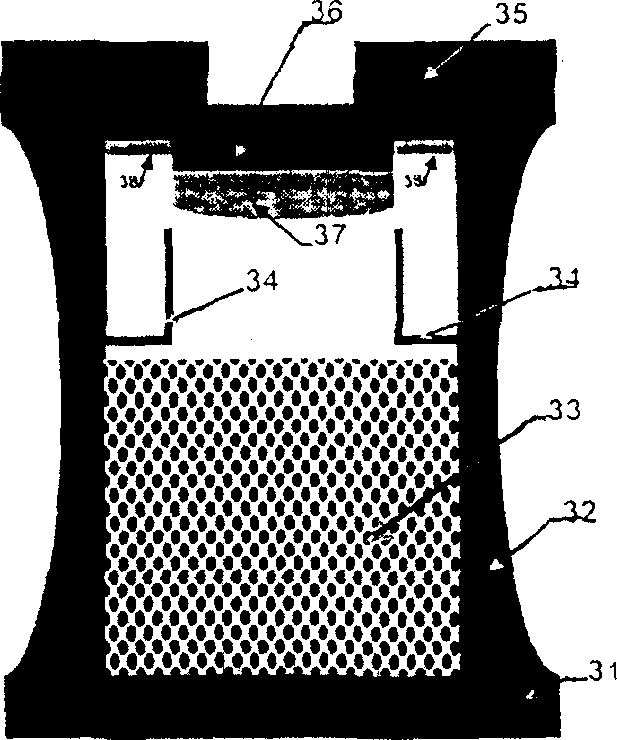

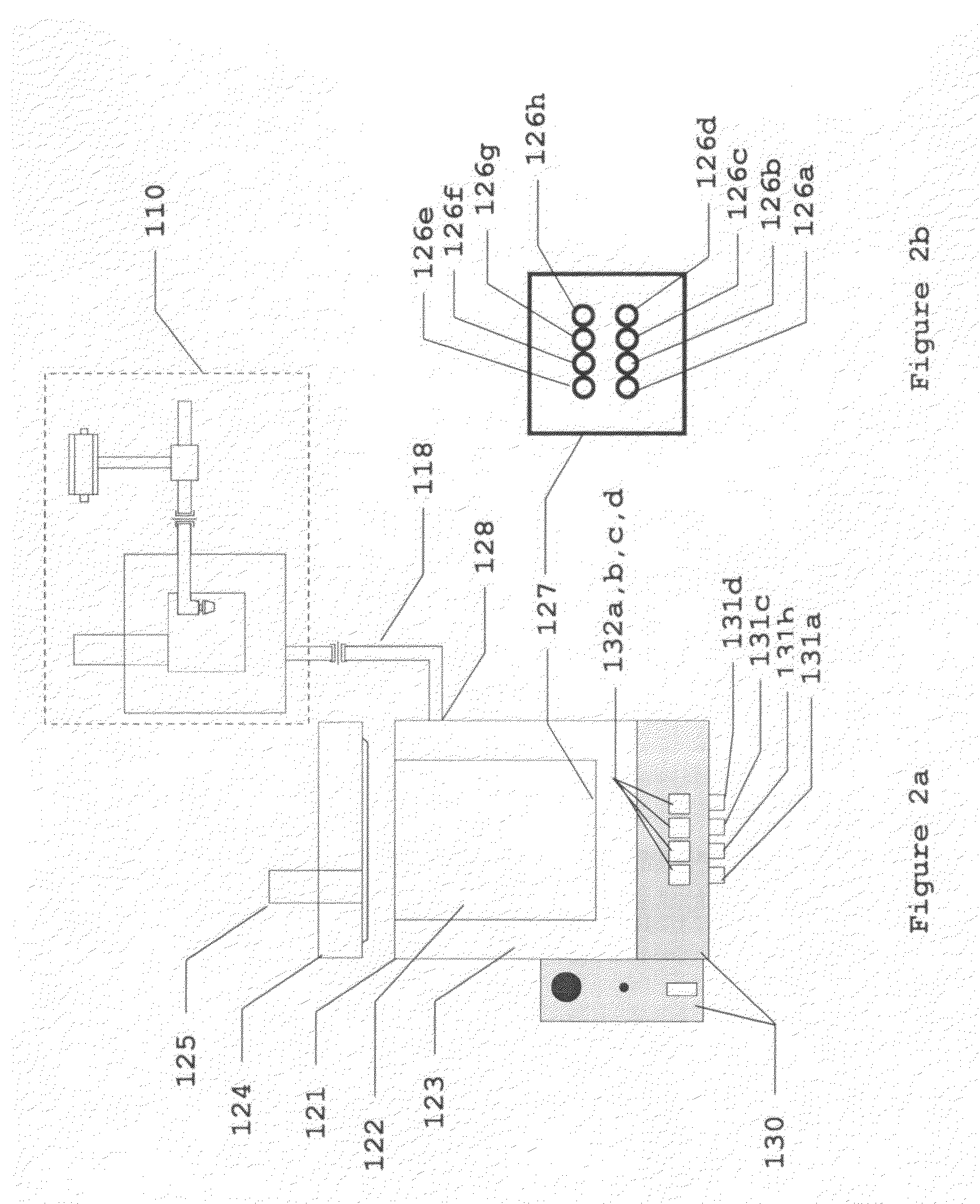

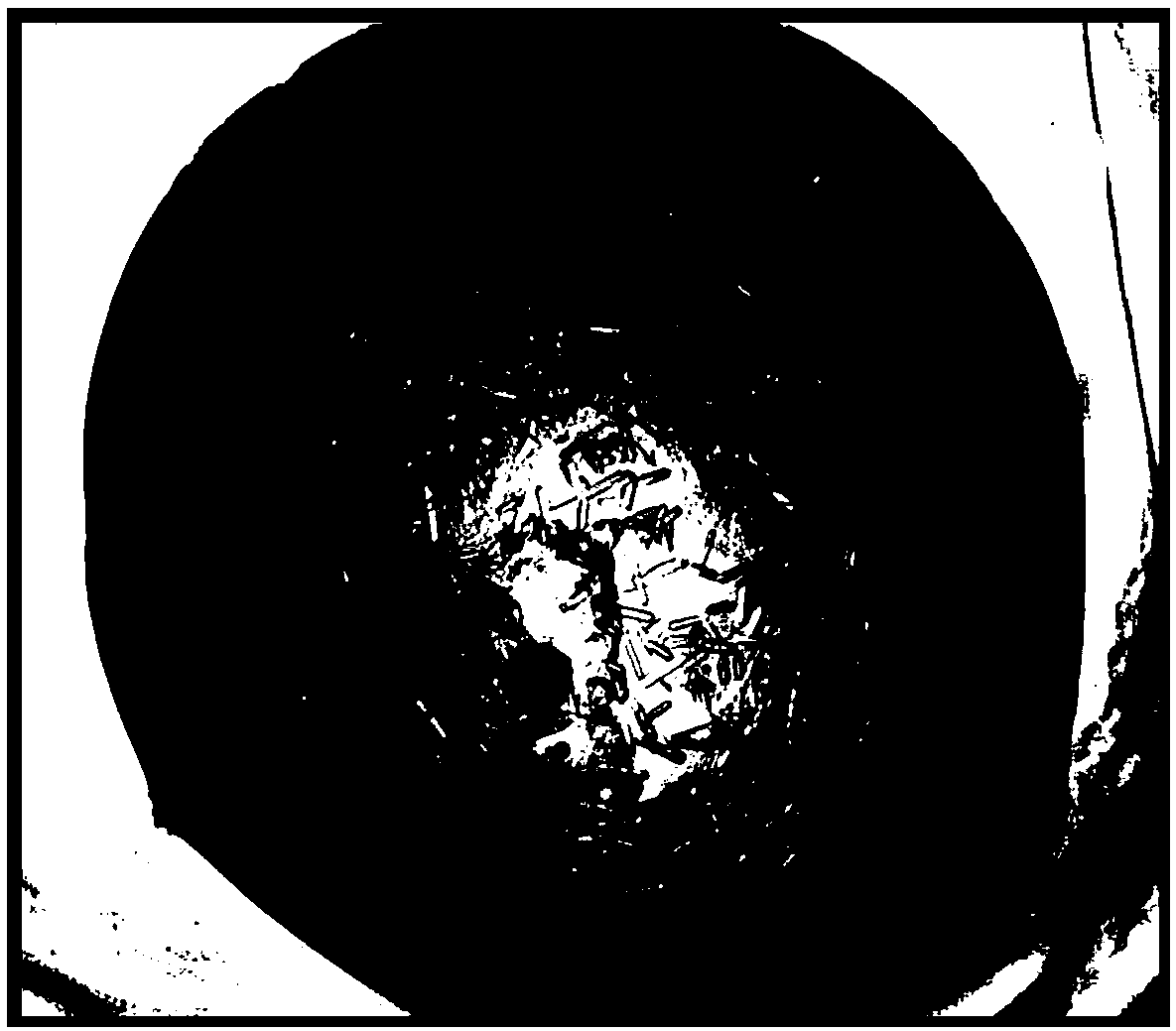

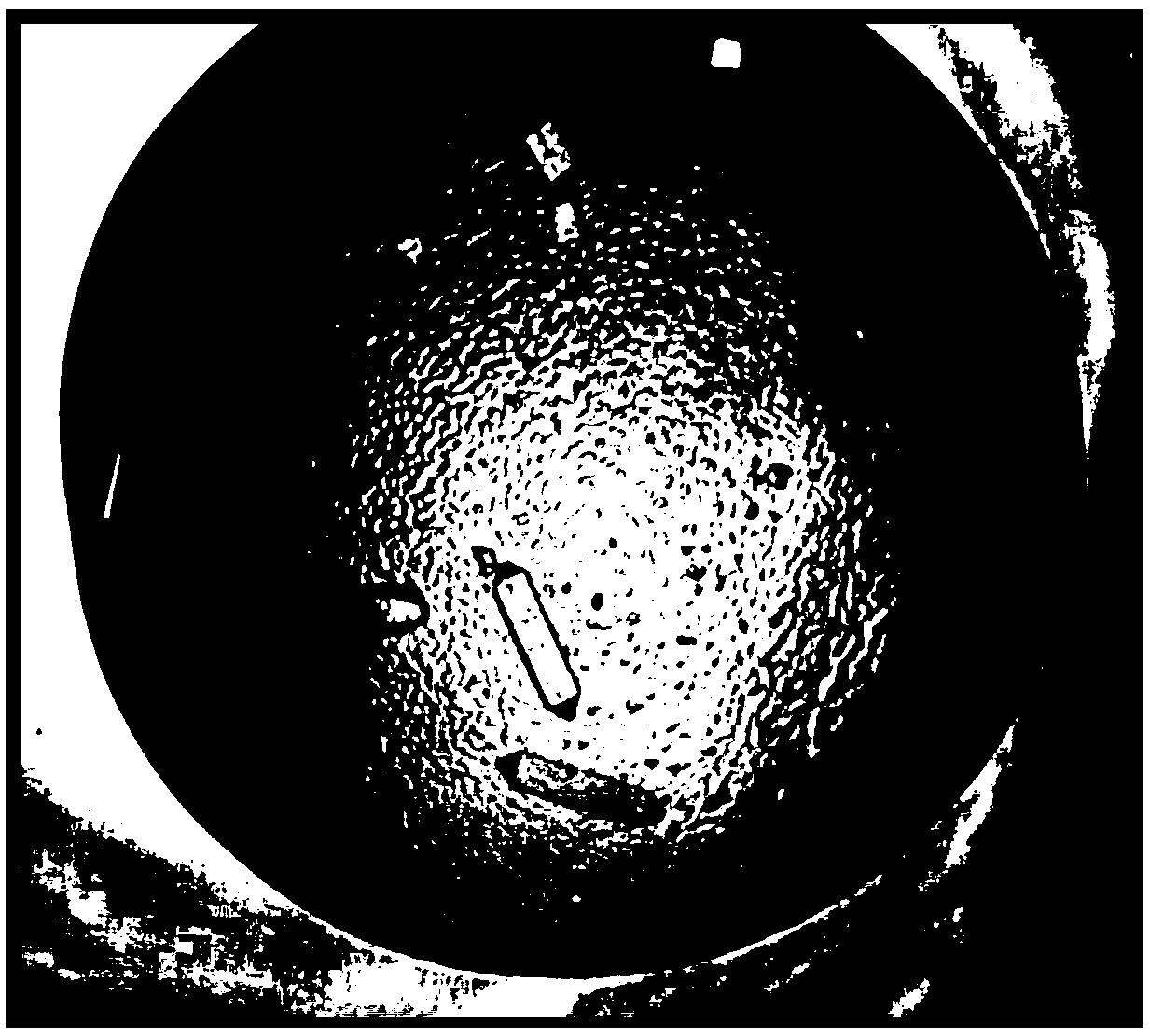

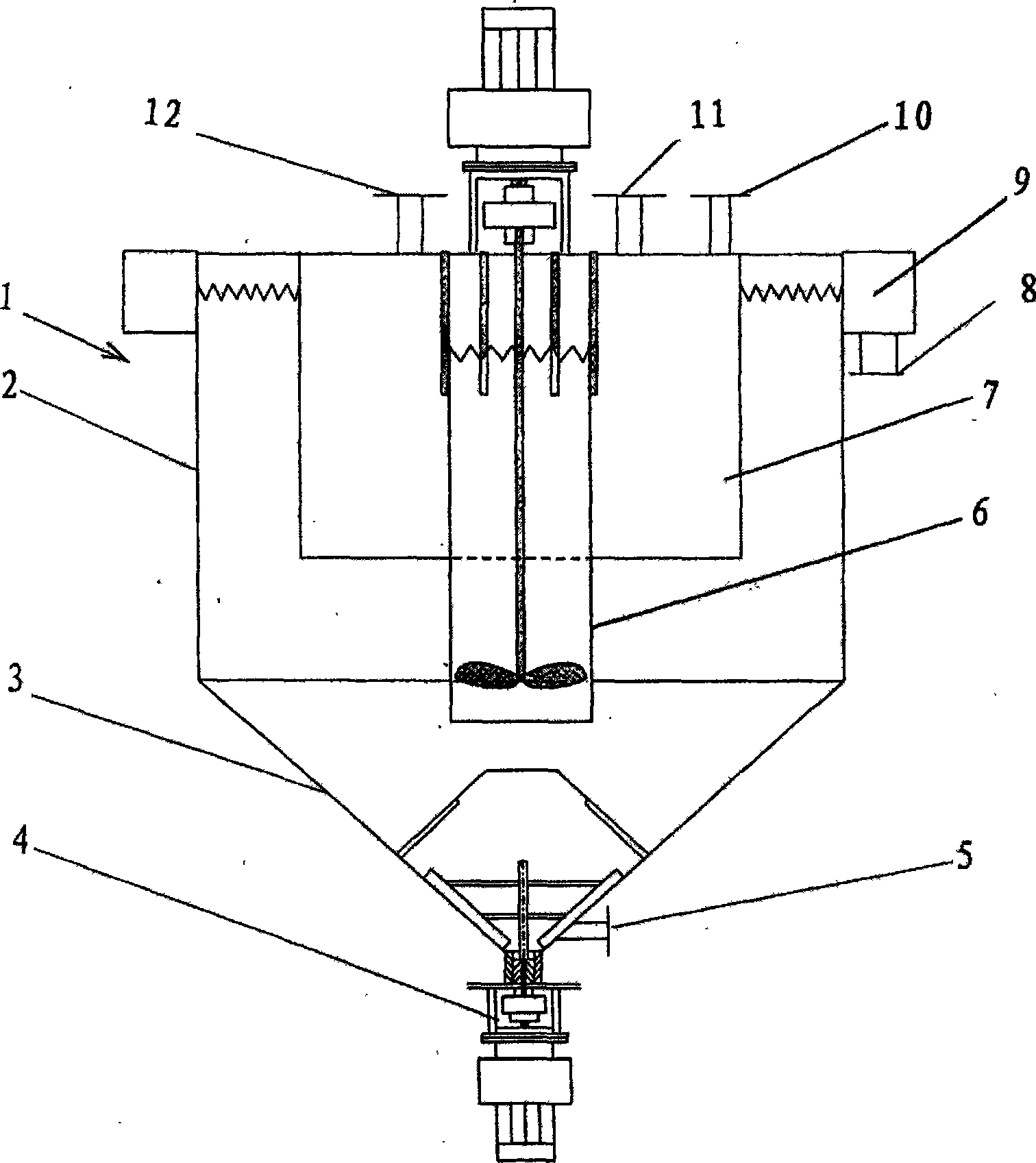

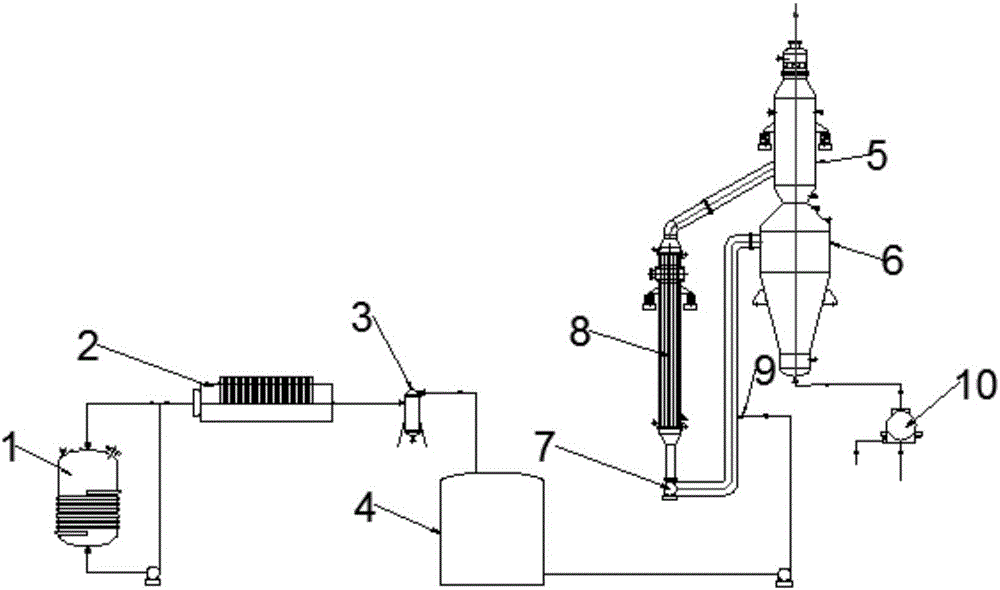

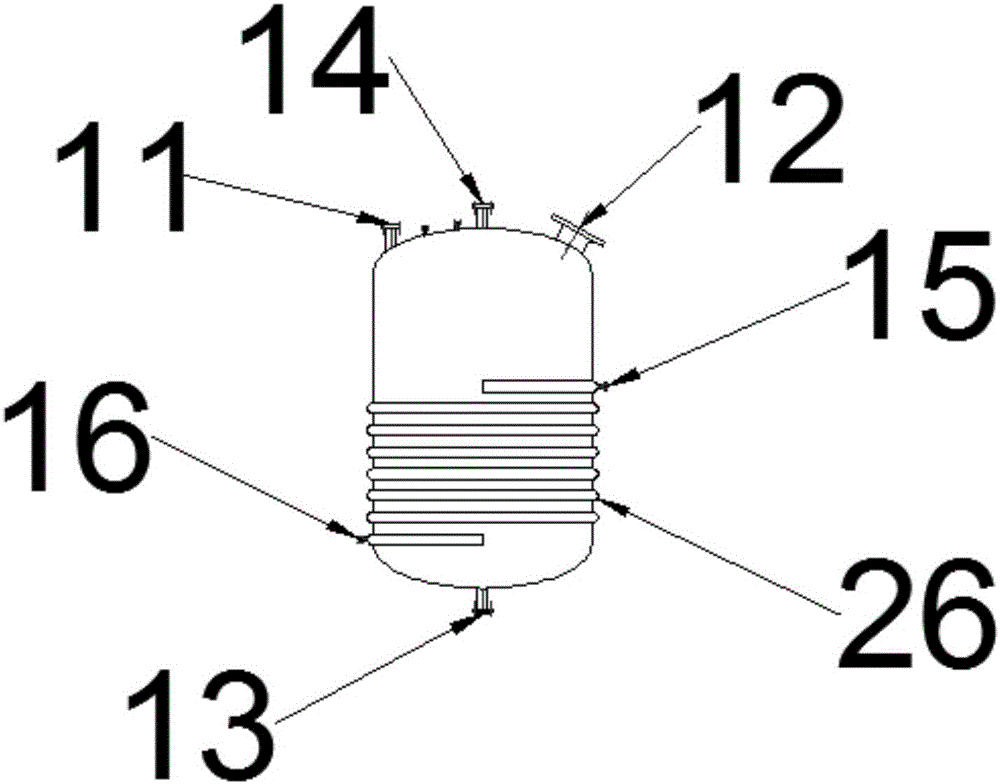

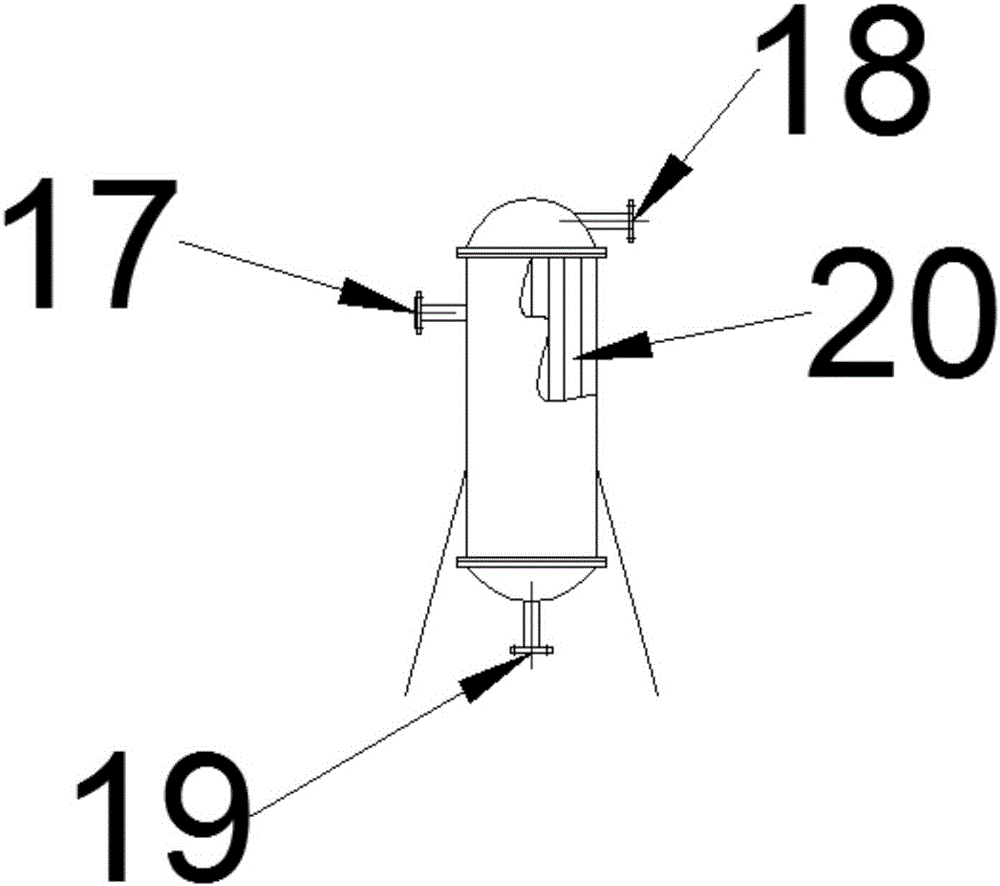

The present invention relates to apparatus and method of growing great diameter 6H-SiC monocrystal with semiconductor characteristic and belongs to the field of crystal growing technology. The apparatus includes growing chamber, water cooler on the side wall of the growing chamber, graphite crucible, heat insulating material, induction heating system, cylindrical vapor guiding plate of Ta inside the crucible, and cylinder. Regulating the position of the crucible relative to the inducing coil can minimize the temperature at the crystal seed inside the crucible and increase the temperature field distribution in the growing direction. Altering the atmosphere composition or material compounding can obtain great diameter SiC monocrystal with n-type, p-type or semi-insulating type semiconductor characteristic. By means of selecting the Si plane of the crystal seed and growing temperature, the crystal form may be controlled and 6H-SiC may be obtained.

Owner:SICC CO LTD

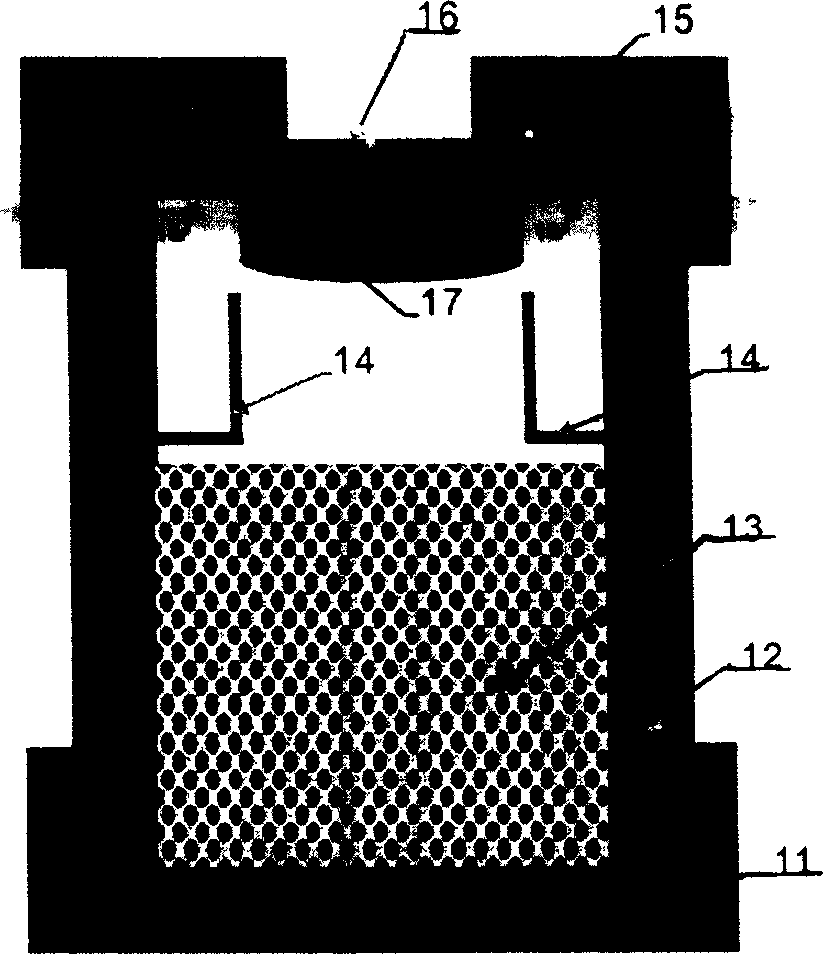

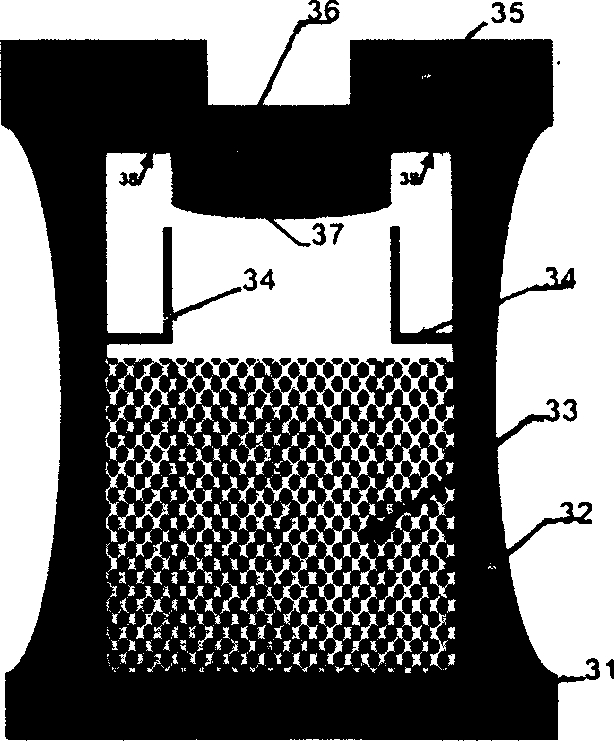

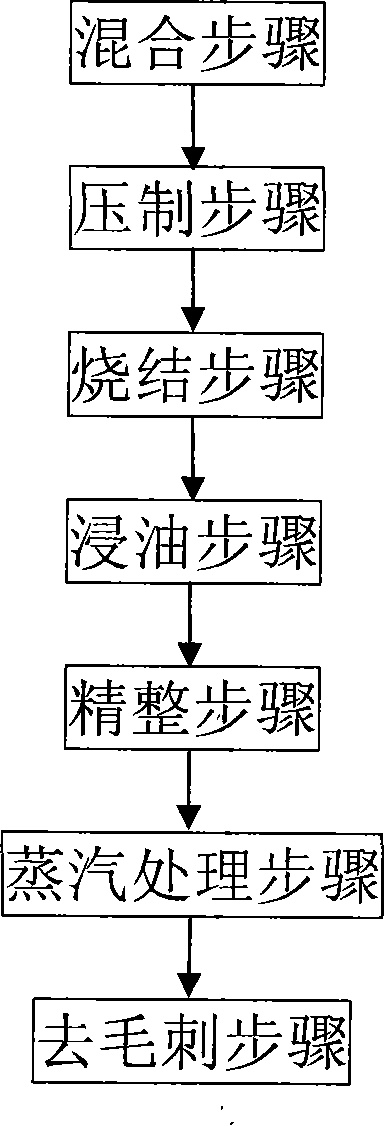

Powder metallurgy technique

The invention provides a powder metallurgic process, which comprises the following steps of: pressing, sintering, soaking in oil, finishing and treating with steaming. In the process steps, iron-based powders are uniformly mixed according to a ratio and are transmitted to a presser; the presser transmits the iron-based powders into a preset product mold and presses to obtain a rough product; the rough product is arranged in a conveying mesh belt, which conveys the rough product to a sintering furnace according to a set speed; air is used for repeated extraction and pressurization in the sintering process, and the temperature of the sintering furnace is adjusted to sinter the rough product to a semi-product; the semi-product is cooled and soaked in engine oil and is subjected to fine correction in a sizing die; the corrected semi-product is subjected to steam treatment to form a rustproof layer and to deburring treatment by shot blasting, vibration and manual deburring. The product has high performance-price ratio, and a dense protection film is formed on the product surface to improve the rustproof performance.

Owner:ZHEJIANG ZHONGPING POWDER METALLURGY

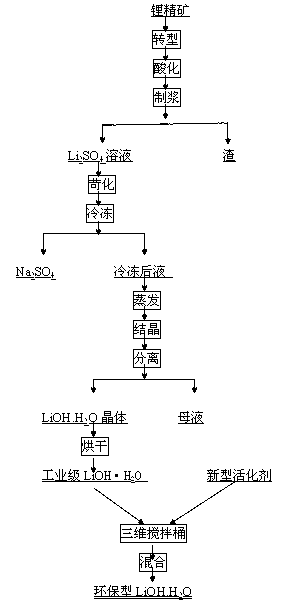

Method for directly producing environment-friendly lithium hydroxide monohydrate from spodumene

ActiveCN102838140AGood liquidityLarge crystalLithium oxides/hydroxidesCycloalkaneLithium hydroxide monohydrate

Owner:SICHUAN GUORUN NEW MATERIAL

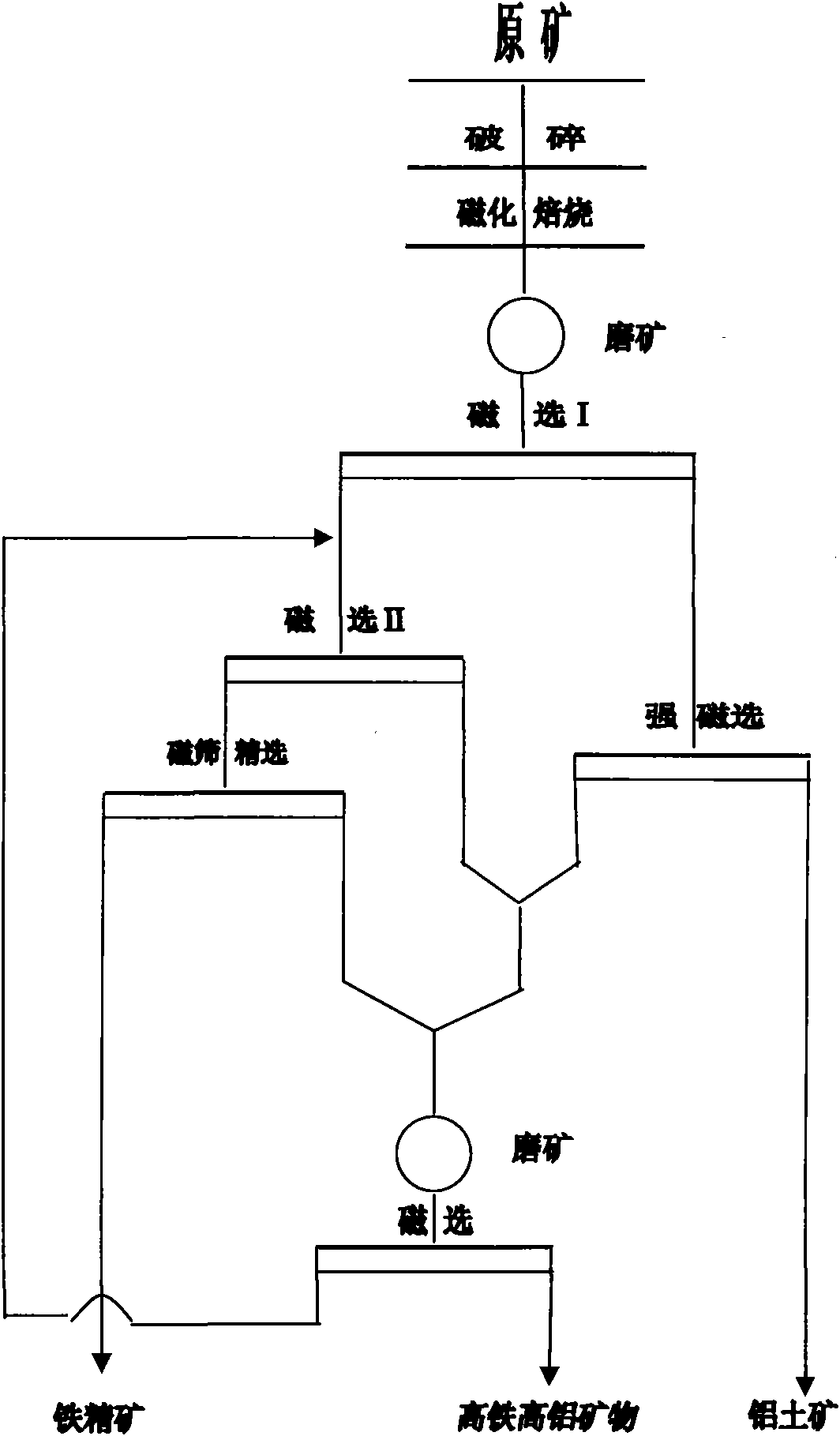

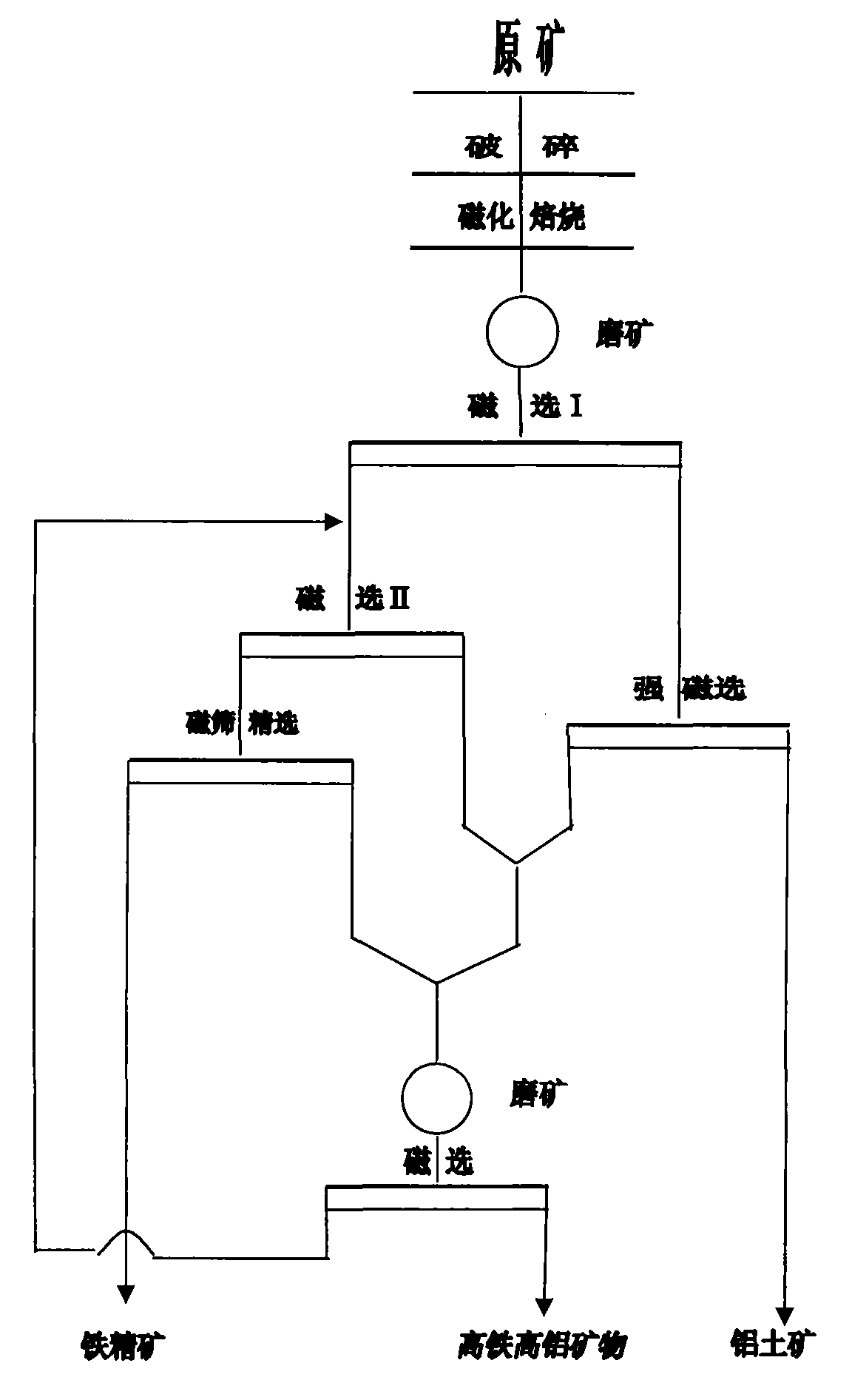

Method for separating aluminum and iron in high-iron bauxite

The invention discloses a method for separating aluminum and iron in high-iron bauxite, which comprises the following steps: (1) breaking high-iron bauxite; (2) carrying out magnetic roasting for the broken high-iron bauxite; (3) milling; and (4), separating the bauxite from iron minerals through weak magnetic separation, and respectively obtaining the bauxite and the iron minerals. Before the high iron bauxite is dissolved out, the magnetic roasting - magnetic separation process is adopted, so that the iron is separated from the bauxite containing high iron through the magnetic roasting - magnetic separation process, and the iron is removed from the bauxite after the magnetic separation through strong magnetic separation so as to obtain qualified bauxite concentrate, so that the high-iron bauxite is utilized well, and the bauxite and the iron minerals can be comprehensively utilized. The invention has the advantages of simple process, low cost, high yield, good product quality, safety and environment protection and the like.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

Preparation method for gold plating on surface of silicon carbide particle reinforced aluminum-based composite material

ActiveCN109371439AUniform crystallizationReduce coating porosityAnodisationLiquid/solution decomposition chemical coatingMicro arc oxidationAluminum matrix composites

The invention relates to a preparation method for a gold plating on the surface of a silicon carbide particle reinforced aluminum-based composite material, and belongs to the technical field of surface engineering. The preparation method comprises the following steps that pretreatment is performed on the silicon carbide particle reinforced aluminum-based composite material; micro-arc oxidation isperformed on the pretreated silicon carbide particle reinforced aluminum-based composite material; surface sensitization, activation and reduction treatment is performed on the material subjected to the micro-arc oxidation; chemical nickel plating is performed on the surface of the material to obtain the material with a nickel layer; and gold plating is performed on the surface of the nickel layerto obtain the gold plating located on the surface of the silicon carbide particle reinforced aluminum-based composite material. According to the preparation method, a ceramic membrane layer is formed, so that the homogenization of chemical properties of an interface of the high-volume-fraction SiCp / Al composite material is realized, it is guaranteed that the subsequent plating is uniform in crystallization, then the porosity of the subsequent plating is reduced, and the compactness of the plating is improved.

Owner:BEIJING SATELLITE MFG FACTORY

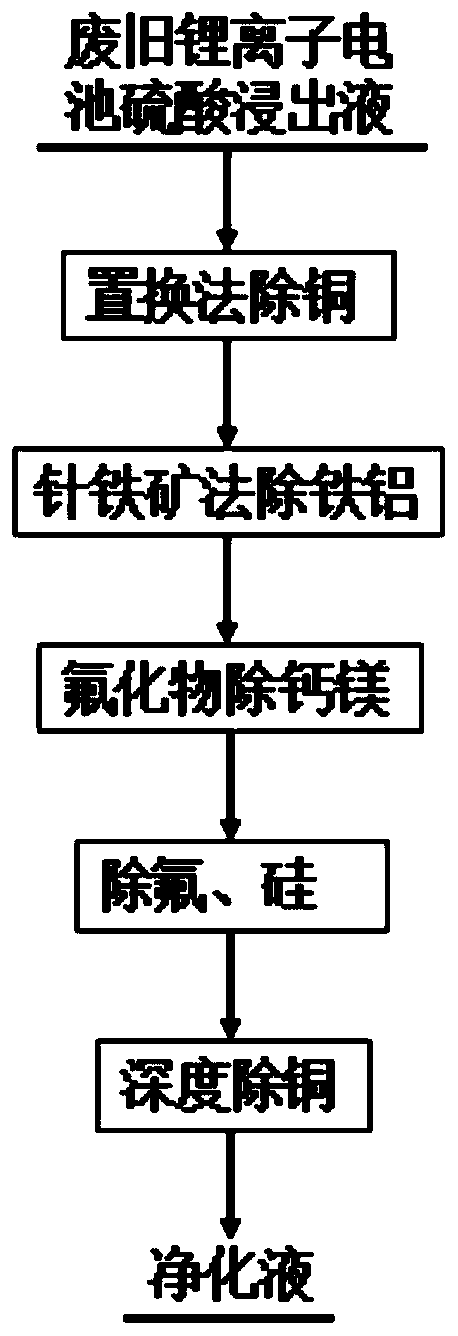

Method for removing impurities from waste battery leachate

The invention relates to a method for removing impurities from waste battery leachate. The method comprises the following steps that iron powder is added, and filtering is carried out after stirring so as to obtain a copper-removed solution; an oxidant is added to obtain a ferrous-removed solution; a small amount of the ferrous-removed solution is taken and diluted to serve as a base solution, theferrous-removed solution and a pH regulator are added, the pH regulator is continuously added after the ferrous-removed solution is completely added, and filtering is carried out after stirring so asto obtain an iron-aluminum-removed solution and iron-aluminum slag; fluoride is added into the iron-aluminum-removed solution, and filtering is carried out after stirring so as to obtain a calcium-magnesium-removed solution; the obtained iron-aluminum slag is added, and filtering is carried out after stirring so as to obtain fluorine-silicon-removed solution and fluorine-silicon-removed iron-aluminum slag; and manganese powder is added into the fluorine-silicon-removed solution, and filtering is carried out after stirring so as to obtain a purified solution. According to the method, the ironpowder is used for replacing and removing copper, and the cost is low; iron and aluminum are removed through a goethite method, and the slag filtering performance is good; fluorine and silicon are removed from the iron-aluminum slag, so that the waste slag is effectively utilized, and the iron-aluminum slag pickling process is reduced; and the copper is deeply removed through the manganese powder,the environment is protected, and the operation is easy.

Owner:HUNAN BRUNP RECYCLING TECH +2

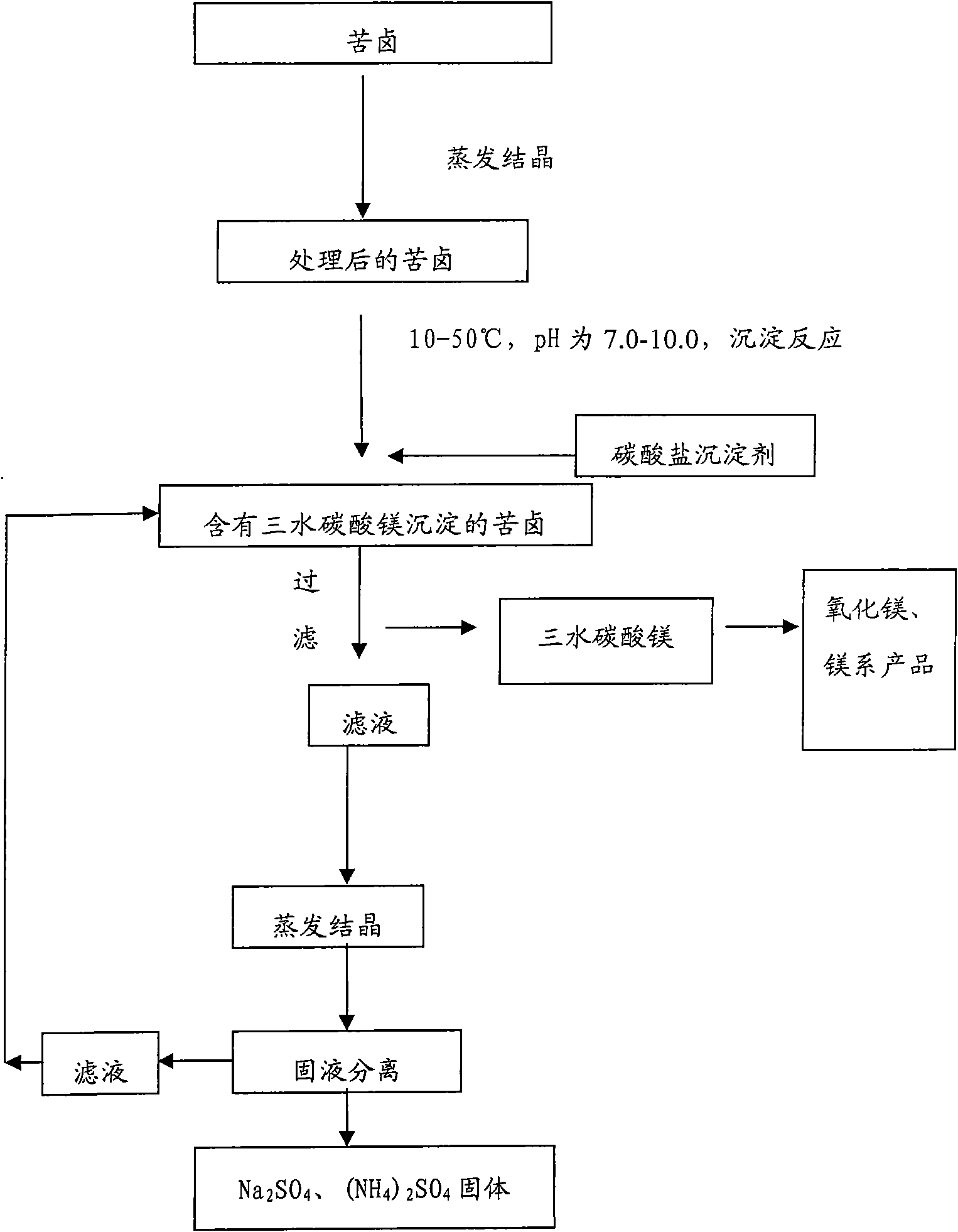

Preparation method of magnesium oxide by using bittern and carbonate

The present invention provides a preparation method of magnesium oxide by using bittern and carbonate, comprising the following steps: a. evaporating the bittern for crystallization to remove the sodium salt and sylvine; b. adding a precipitant into the processed bittern at the temperature of 10 to 50 DEG C, reacting at the temperature to obtain the bittern containing the sediment of trihydrate magnesium carbonate, keeping the pH value of 7.0 to 10.0 during the addition of the precipitant, the molar ratio of the precipitant and the magnesium ions is between 1:1.1 to 1:1.2, and the precipitant is carbonate solution or carbonate solid; c. filtering the obtained bittern containing the sediment of trihydrate magnesium carbonate; d. calcining the solid sediment of step c to obtain the magnesium oxide. By the process of the invention, the solid sediment of trihydrate magnesium carbonate obtained in step c has the purity of 99.0%, and the magnesium oxide obtained in step d has the purity of 99.4%.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Device and method for growng large diameter 6H-SiC monocrystal with semiconductor property

ActiveCN1282770CLarge crystalsFor the purpose of dopingPolycrystalline material growthFrom condensed vaporsCrystal growthSemiconductor properties

The invention relates to a device and method for growing 6H-SiC single crystal with semiconductor characteristics, belonging to the technical field of crystal growth. The device includes a water cooling device for the growth chamber and its side wall, a graphite crucible, insulation materials and an induction heating system. The crucible has a built-in cylindrical gas phase deflector made of Ta, and the side is a cylinder with a curved outer wall. The shape of the curve can be a rectangle. or arc. By adjusting the position of the crucible relative to the induction coil, the temperature at the seed crystal inside the crucible is the lowest, and the growth direction has a large gradient temperature field distribution; the distribution of the radial isotherms on the crystal growth surface is approximately parallel, the center is the lowest, and the edge is the highest , so as to ensure that the diameter of the crystal continues to expand. By changing the atmosphere composition or raw material ratio, etc., a large-diameter SiC single crystal with semiconductor characteristics of n-type, p-type or semi-insulating type can be obtained. The polytype of the crystal is controlled by selecting the Si surface of the seed crystal and the growth temperature, and then 6H-SiC is obtained. The invention is used for the growth of large-diameter 6H-SiC single crystal in the semiconductor device industry.

Owner:SICC CO LTD

Freeze-dried preparation moisture control method and application thereof

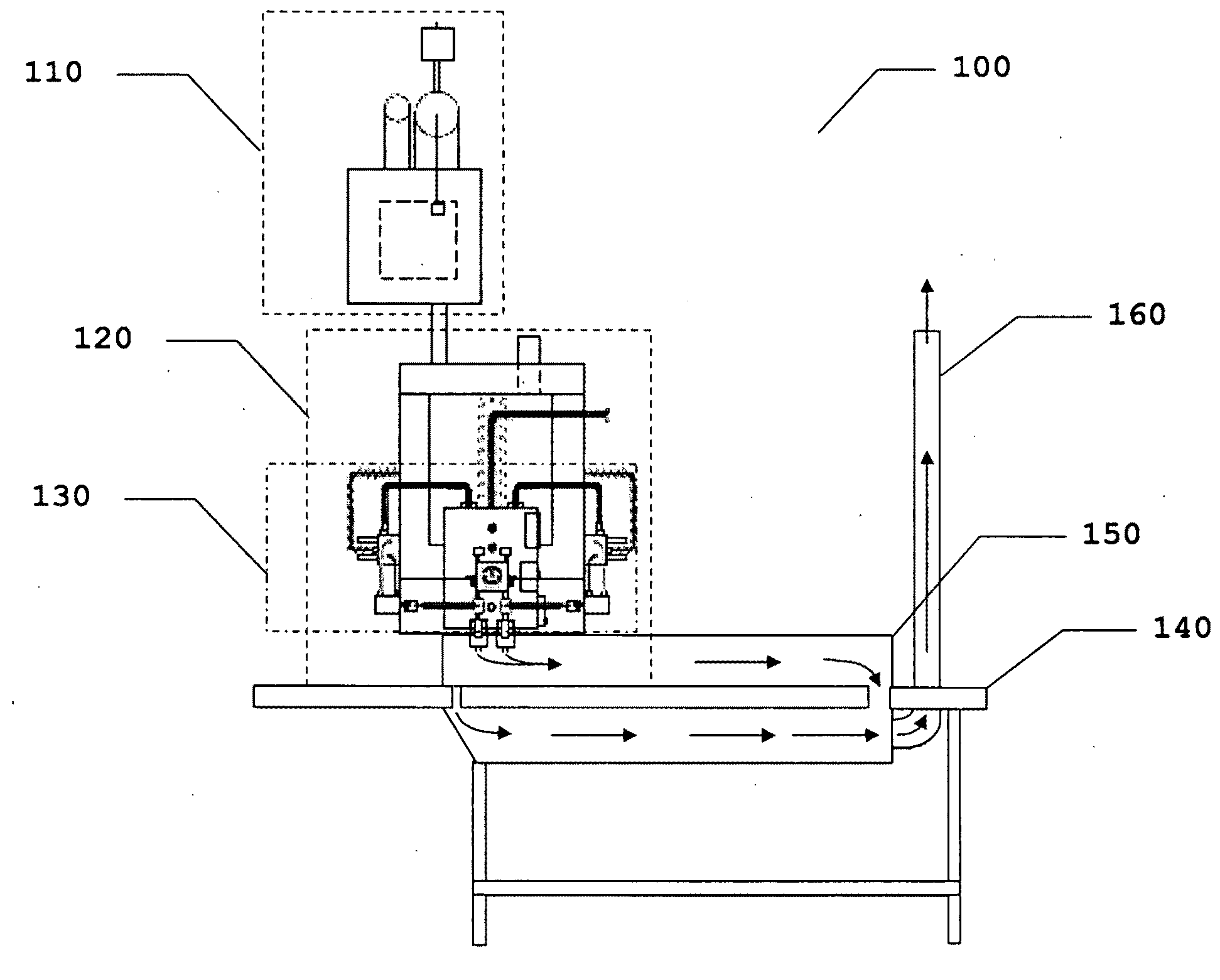

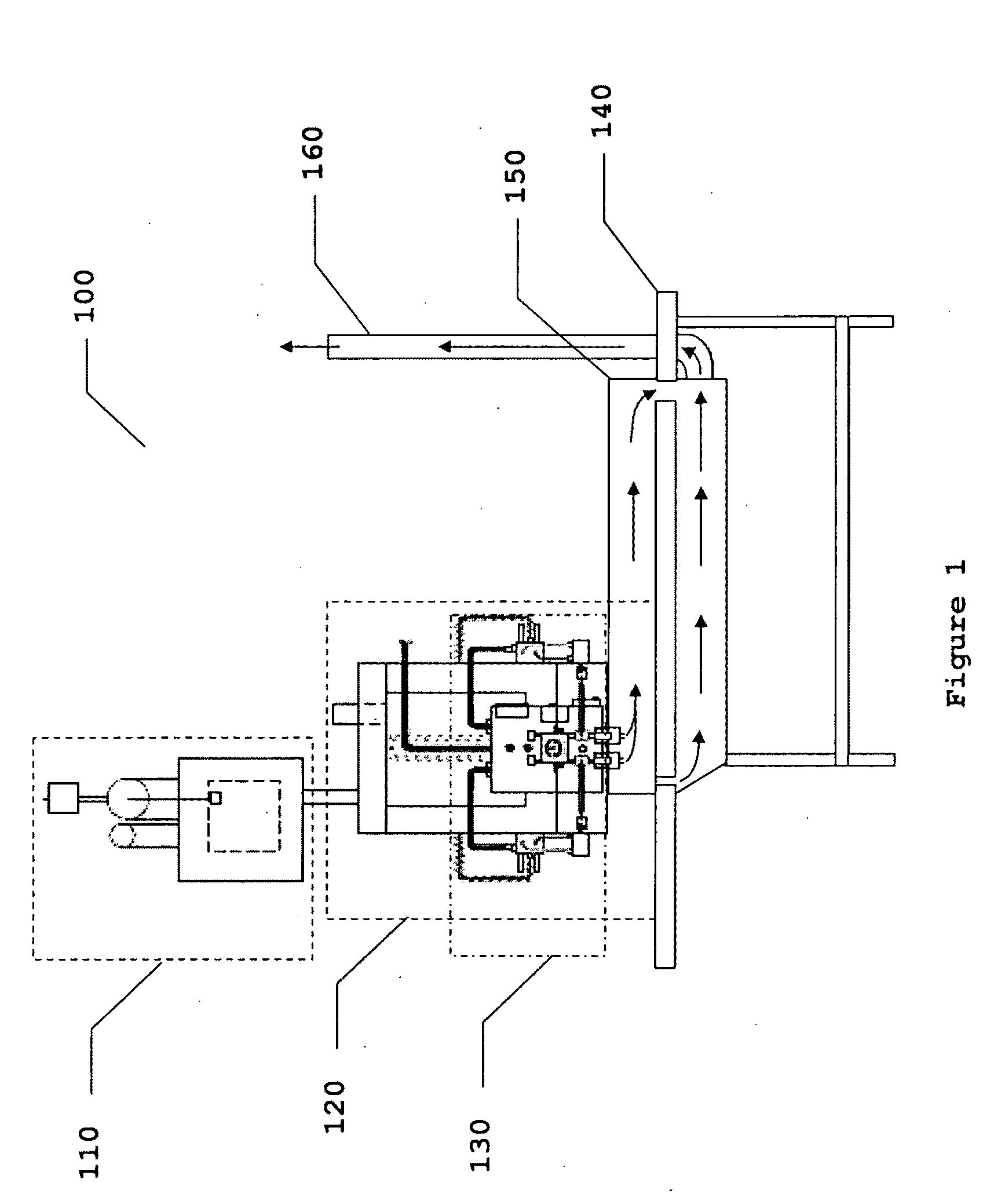

ActiveCN112361726ALarge crystalsUniform size distributionOrganic active ingredientsPowder deliveryMoistureMaterials science

The invention relates to a freeze-dried preparation moisture control method and application thereof, and belongs to the technical field of preparation of freeze-dried preparations. The freeze-dried preparation with low impurity content and low moisture content is obtained by controlling various operation parameters of the cooling speed, the annealing temperature, the annealing frequency, the sublimation drying temperature and the sublimation drying vacuum degree in the pre-freezing process of the preparation, and the method solves the problems of high moisture content, poor stability in the storage period, short expiration date and the like of the final product of the freeze-dried preparation.

Owner:NKD PHARMA CO LTD

Ultrafast food freezing equipment by direct contact with dosed liquid nitrogen

InactiveUS20100139293A1Promote rapid formationPromote crystallizationFruit and vegetables preservationLighting and heating apparatusPhysical spaceOxygen

The invention is related to an ultrafast freezing equipment for food contained in a packing with multiple cavities, for public sale, by applying a liquid nitrogen trickle, in an amount enough to produce an ultrafast freezing of food. Liquid nitrogen is dispensed from a container at atmospheric pressure, vacuum isolated, through a plurality of nozzles, by gravity, into the center of the upper surface for each cavity, producing short-time immersion in the individual cavity. Nitrogen gas produced is used to make a practically oxygen-free atmosphere, cold enough to maintain the freezing process after dispensing. The process diminish the amount of liquid nitrogen required as compared to other freezing processes, as well as personnel, facilities and physical space needed for install and operate it, reducing the associated costs.

Owner:MACCISE SADE YAMIL ADIV +1

Method for producing cistofuran large particle crystal

The invention relates to a method for producing large-grained nitrofurantoin crystals, and belongs to the field of chemical synthesis. The invention adopts a technical proposal which comprises: placing a crude product of nitrofurantoin formed by the condensation of raw materials of 5-nitrofurfural diacetate and 1-aminohydantoin, and DMF of which the weight is two times of that of the crude product of the nitrofurantion in a retort, heating the mixture to between 85 and 90 DEG C, stirring the mixture, maintaining the temperature for 10 minutes, stirring the mixture, opening a clamping sleeve, cooling the retort by cooling water for 80 to 90 minutes to between 30 and 35 DEG C, stopping stirring, standing the retort for 2.5 to 3 hours to less than 2 DEG C below zero, casting material, and washing the material with 95 percent ethanol to obtain odorless DMF. Nitrofurantoin crystals prepared by the process are larger and the granularity of 95 percent of the products is more than 80 meshes, so the process facilitates filtration and separation and contributes to the reduction of production cost.

Owner:SHANDONG FANGXING SCI & TECH DEV

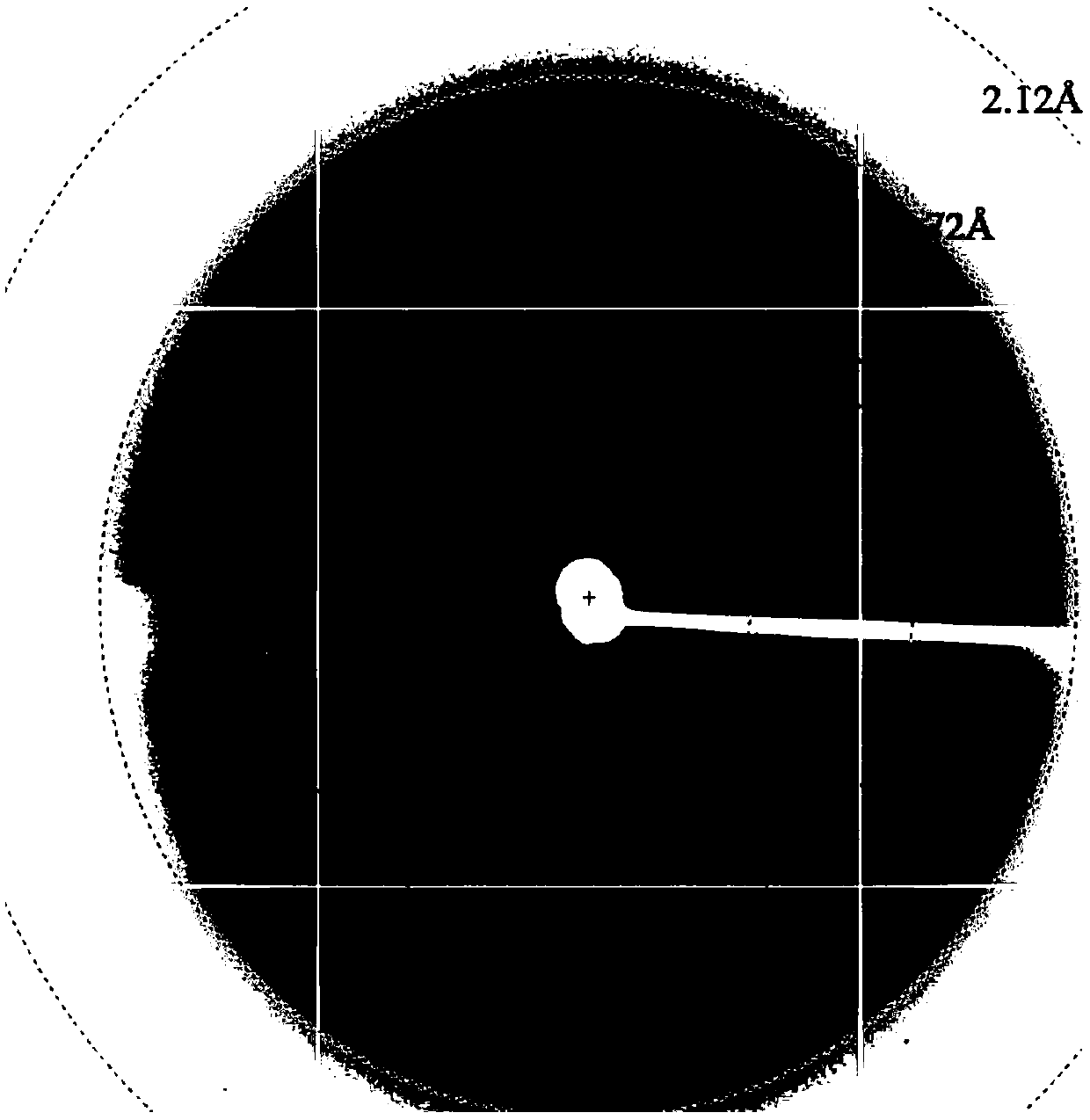

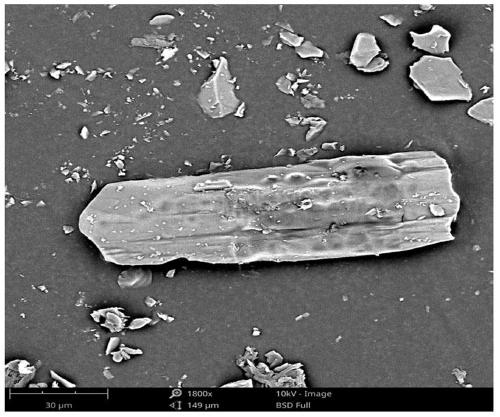

Preparation method and crystallization method of oryza sativa receptor protein RGA5A_S

InactiveCN110498847ALarge crystalsQuality improvementFrom normal temperature solutionsPeptide preparation methodsProtein targetChromatography column

The invention discloses a preparation method and crystallization method of oryza sativa receptor protein RGA5A_S. The preparation method of the protein RGA5A_S comprises the steps of expressing the oryza sativa receptor protein RGA5A_S through a prokaryotic expression system, performing thalli splitting, and enabling splitting supernatant to sequentially pass through an affinity chromatography column and a molecular sieve chromatography column so as to obtain purified target protein finally. In accordance with the characteristic that the protein RGA5A_S contains a metal ion structural domain,during recombinant strain induced shaking culture, 100 [mu] M of Zn<2+> is added to a culture medium, so that the stability of the protein is improved. The invention also provides the crystallizationmethod of the protein RGA5A_S. The protein crystallization condition is screened and optimized by a shot gun method and a 9-window method, so that crystals obtained from the protein RGA5A_S under thecondition of 0.18-0.22M of NH4NO3 and 18%-22% of PEG3350 are large, good in quality and high in resolution. The method is good in repeatability.

Owner:CHINA AGRI UNIV

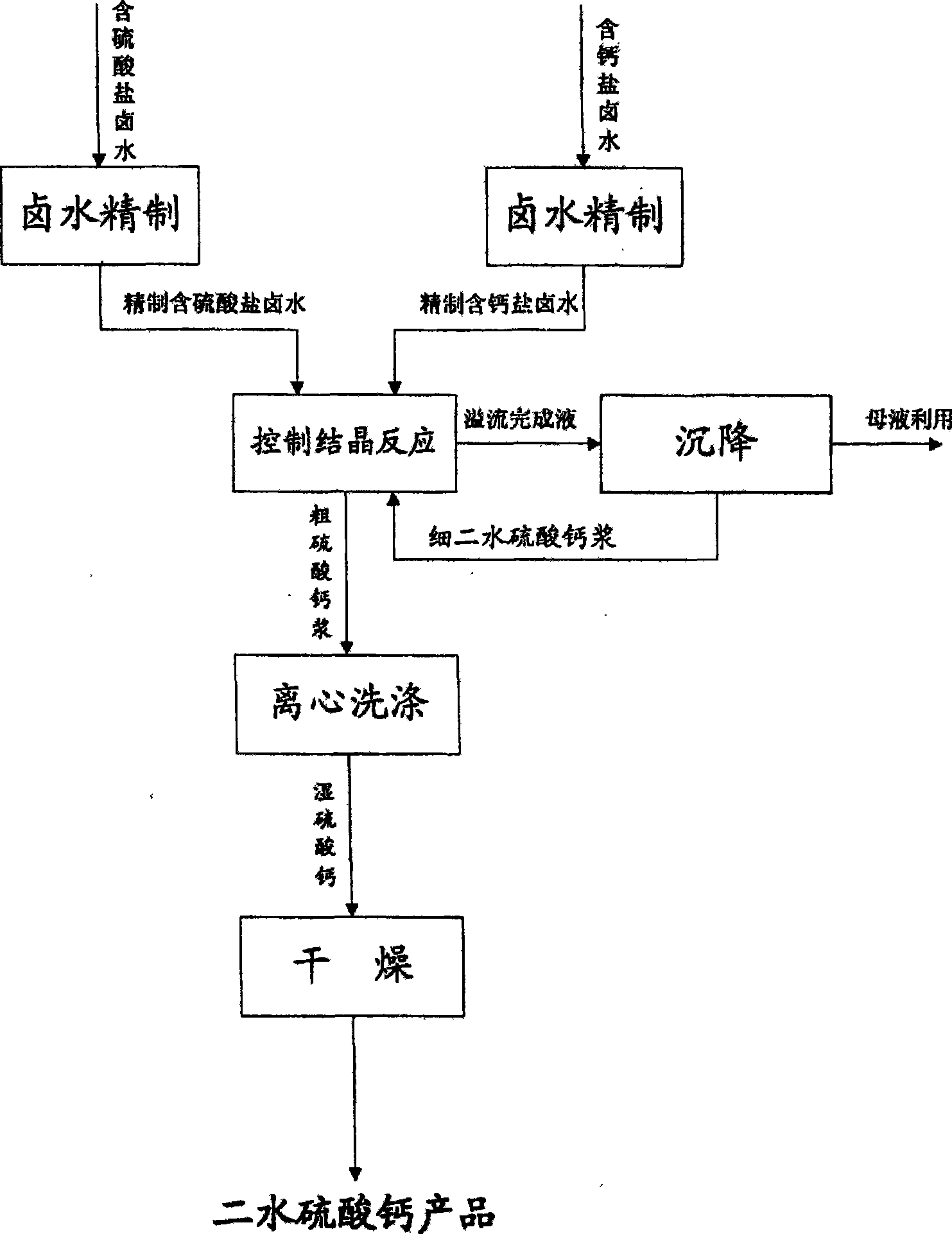

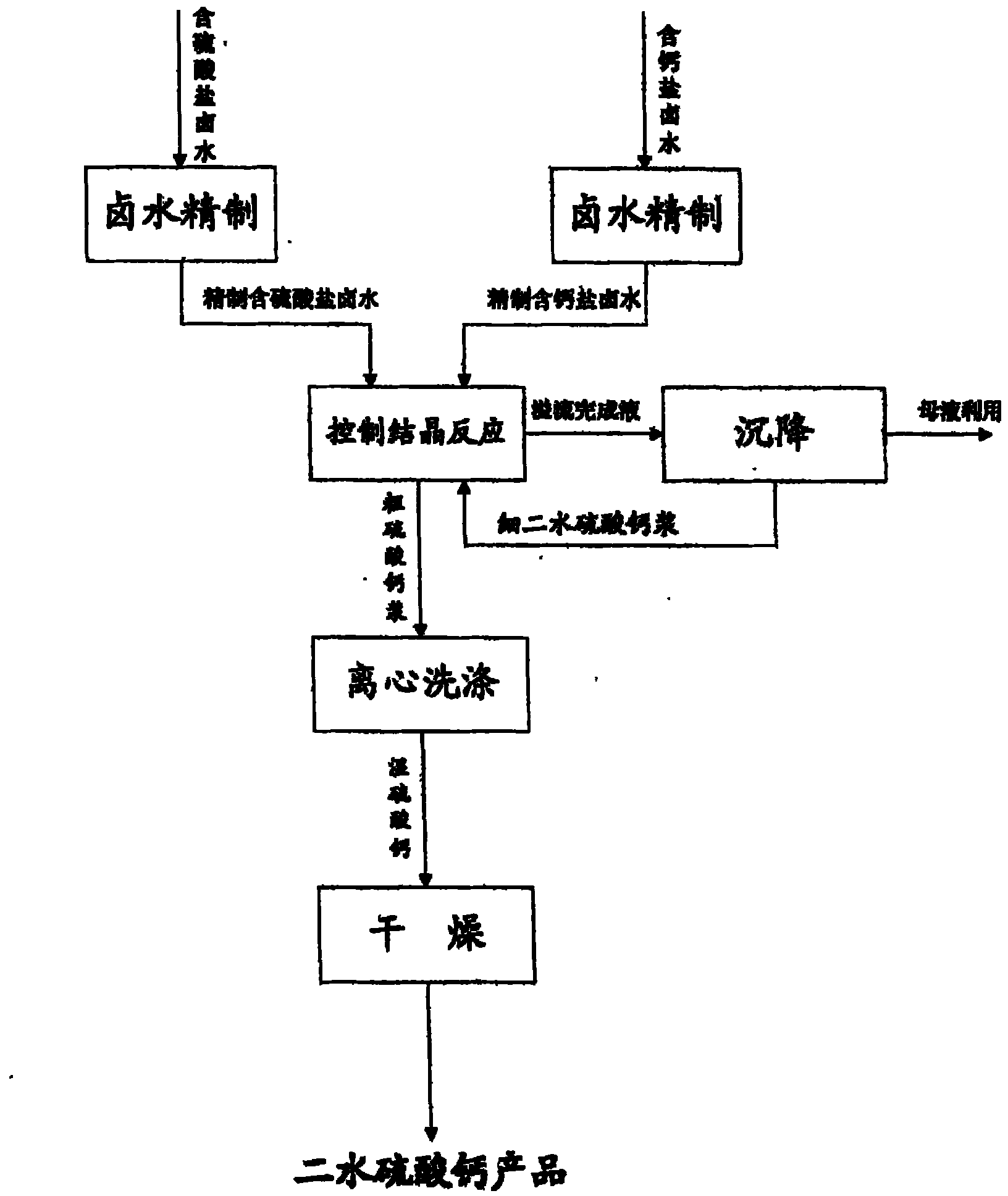

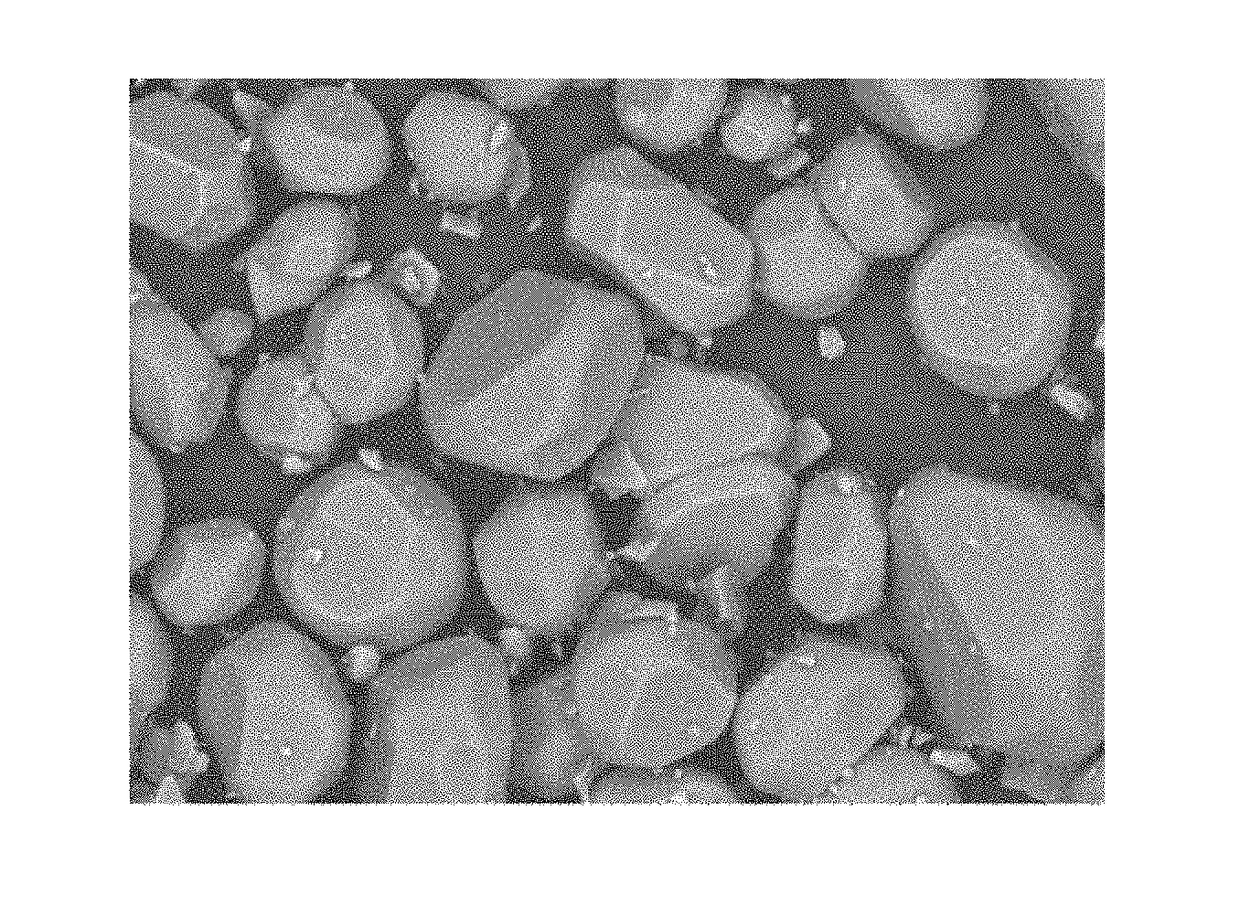

Method for preparing calcium sulphate with sulfate containing bittern and calcium containing bittern

ActiveCN101367538BReduce supersaturationLarge crystalsCalcium/strontium/barium sulfatesSulfate radicalsPhysical chemistry

The invention relates to a method for preparing the calcium sulfate with the sulfate-contained brine and the calcium-salt-contained brine; the two refined brines in a crystallization control reactor are uniformly and consecutively mixed with the cycling liquid inside a cycling lifting device to form dihydrate calcium sulfate crystal with large grain diameter; the dehydrate calcium sulfate crystalis centrifugally washed and dried to prepare the product of the high-purity dehydrate calcium sulfate. The flow rate of the refined sulfate-contained brine that is continuously added in a reaction crystallization barrel is determined according to the ratio between the flow rate of the refined sulfate-contained brine and the flow rate of the cycling liquid in the cycling lifting device in the reactor of 1:10 to 1:30. The flow rate of the refined calcium-salt-contained brine that is consecutively added is determined according to the mol ratio of 1:1 between the sulfate radical ion and the calcium ion in the refined sulfate-contained brine and the calcium-salt-contained brine.

Owner:TIANJIN SEA WATER DESALINATION & COMPLEX UTILIZATION INST STATE OCEANOGRAPHI

Preparation method of ceramic membrane support

A preparation method of a ceramic membrane support is disclosed. Take aluminium hydroxide, produced through a carbon decomposing process by a sintering method, as a raw material, pre-sinter the aluminium hydroxide, and obtain a low-temperature alumina product A; add a first amount of mineralizer into the product A, grind after calcining the added product A, and obtain a α-alumina product B; mix the product B with Al2O3.nH2O, calcine after adding a second amount of mineralizer into the mixed product B, and obtain a α-alumina product C; grind, scatter and grade the calcined and heat-preserved α-alumina product C, and obtain polyhedral alumina powders; mix the polyhedral alumina powders, water, humectant and dispersant and then sinter, and finally obtain the porous alumina support. The prepared support is easy to be sintered, is high in alumina purity, is good in corrosion resistance, and is improved in porosity and flux.

Owner:SHANDONG GUIYUAN ADVANCED CERAMICS

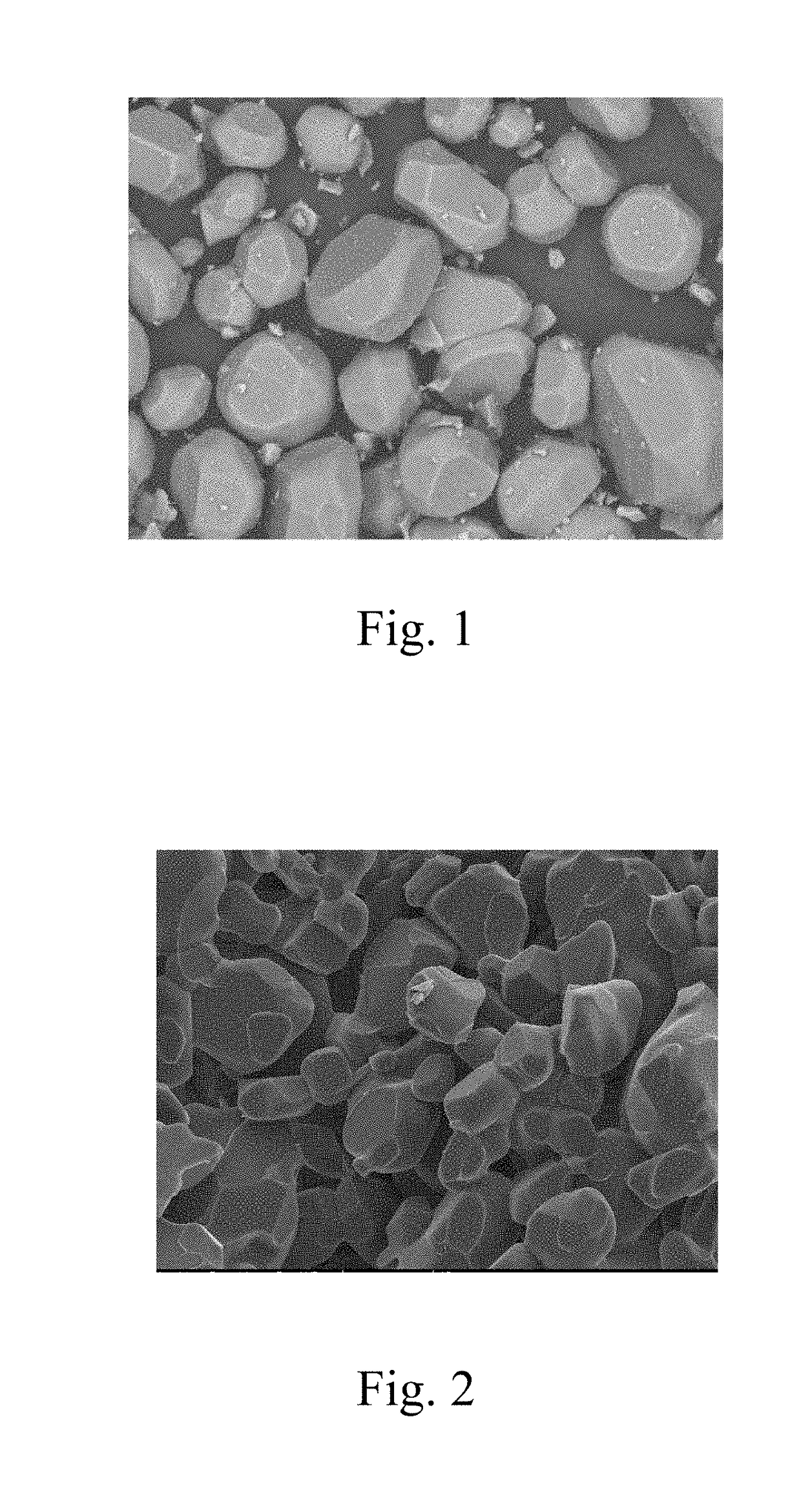

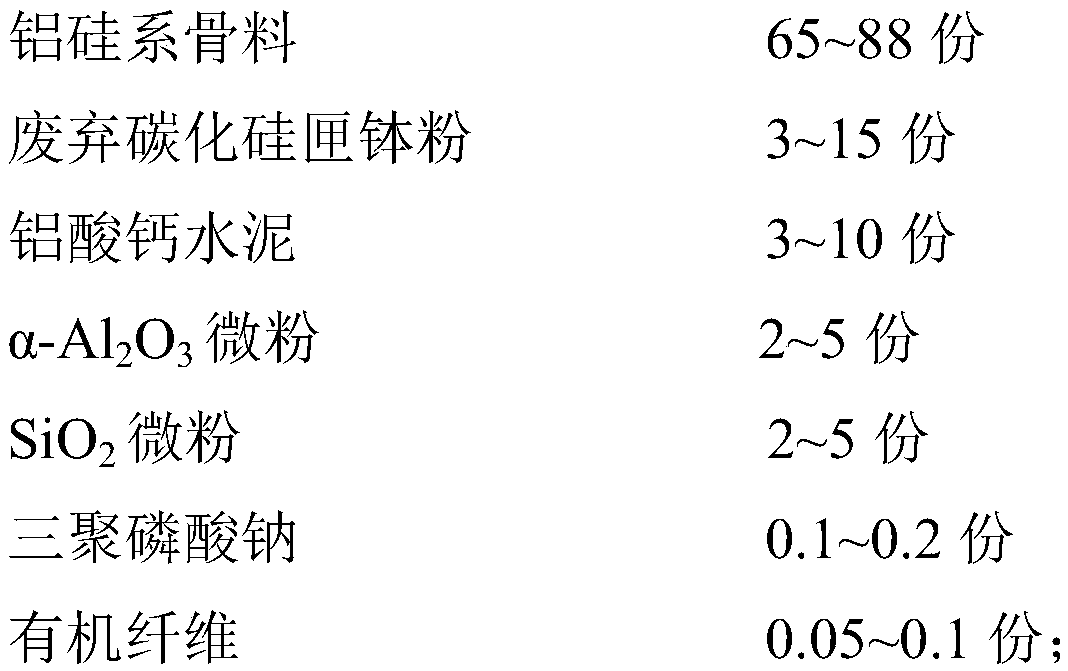

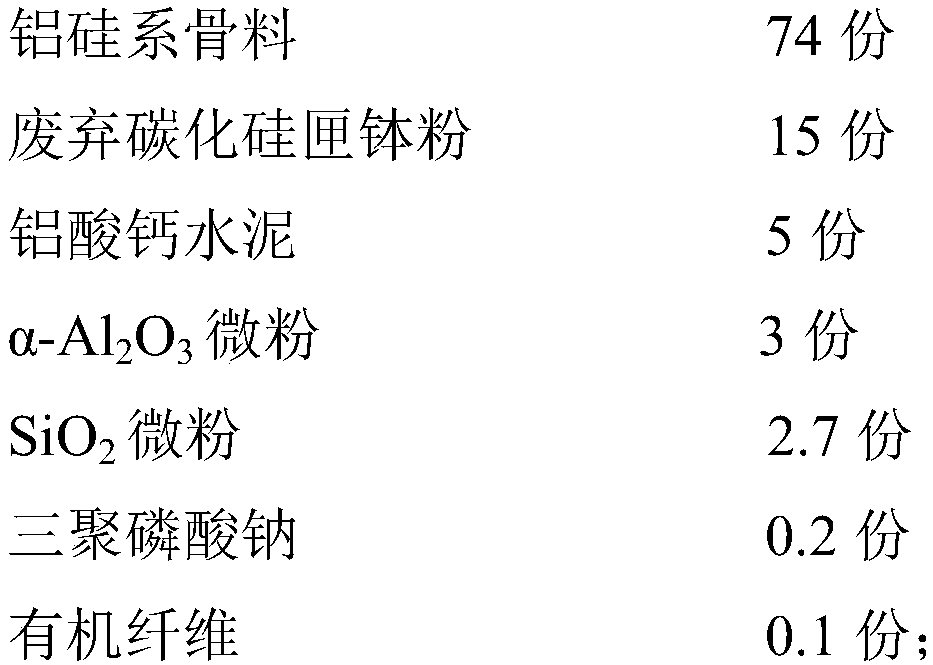

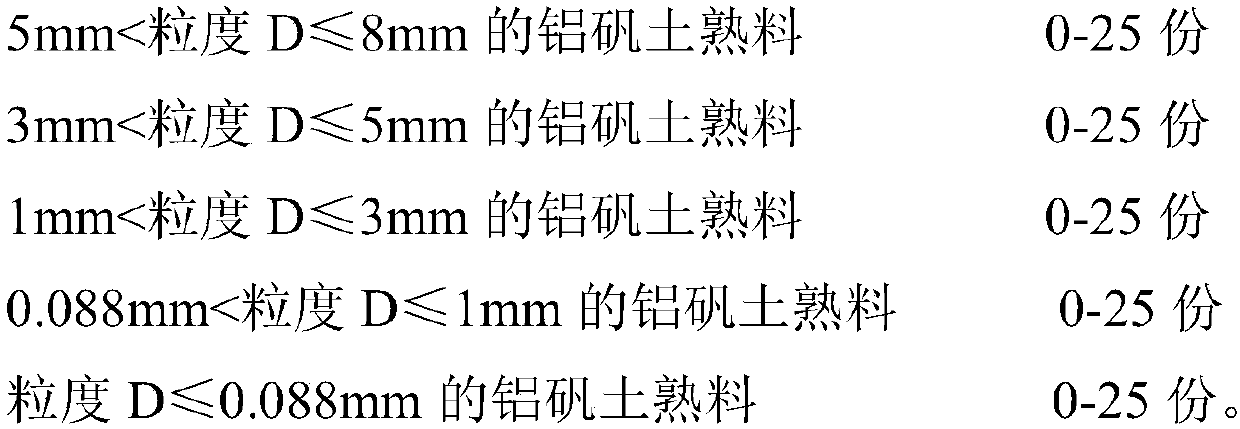

Aluminum silicon carbide castable for hot metal bottles and preparation method thereof

The invention discloses an aluminum silicon carbide castable for hot metal bottles and a preparation method thereof. The aluminum silicon carbide castable for hot metal bottles is prepared from the following raw materials by weight: 65-88 parts of aluminum-silicon aggregate, 3-15 parts of waste silicon carbide sagger powder, 3-10 parts of calcium aluminate cement, 2-5 parts of alpha-Al2O3 micropowder, 2-5 parts of SiO2 micropowder, 0.1-0.2 part of sodium tripolyphosphate, and 0.05-0.1 part of organic fiber. The aluminum-silicon aggregate is selected from one or more of clay clinker, mullite and bauxite clinker. The waste silicon carbide sagger powder is prepared by crushing waste silicon carbide sagger and performing fine grinding treatment. The aluminum silicon carbide castable for hot metal bottles provided by the invention contains waste silicon carbide sagger powder, thus not only reducing the manufacturing cost, but also improving the compactness, sinterability and iron slag resistance of the castable.

Owner:WUGANG REFRACTORY CO LTD

Novel lead-acid storage battery negative electrode lead paste and preparation method thereof

InactiveCN108807984AIncrease capacityImprove low temperature (-18°C) capacityLead-acid accumulatorsCell electrodesFiberGraphite

The invention discloses a novel lead-acid storage battery negative electrode lead paste and a preparation method thereof. The lead paste is prepared from 84-86% of lead powder, 6-8% of sulfuric acid,0.05-0.15% of conductive fiber, 0.1-1.0% of induline base N, 0.05-0.10% of graphite, 0.3-0.5% of humic acid, 0.5-3% of barium stearate and the balance of deionized water. The negative electrode lead paste prepared by the preparation method provided by the invention significantly reduces phenomena of the difficulty in passivation of a negative electrode, falling, softening, and shedding too early,and also significantly reduces a phenomenon of non-uniform distribution of active material particles on a negative electrode plate; the initial capacity and the battery capacity of a battery preparedfrom the negative electrode lead paste are improved to a certain extent, so that the cycle life of the battery is prolonged.

Owner:HENAN CHAOWEI POWER SUPPLY

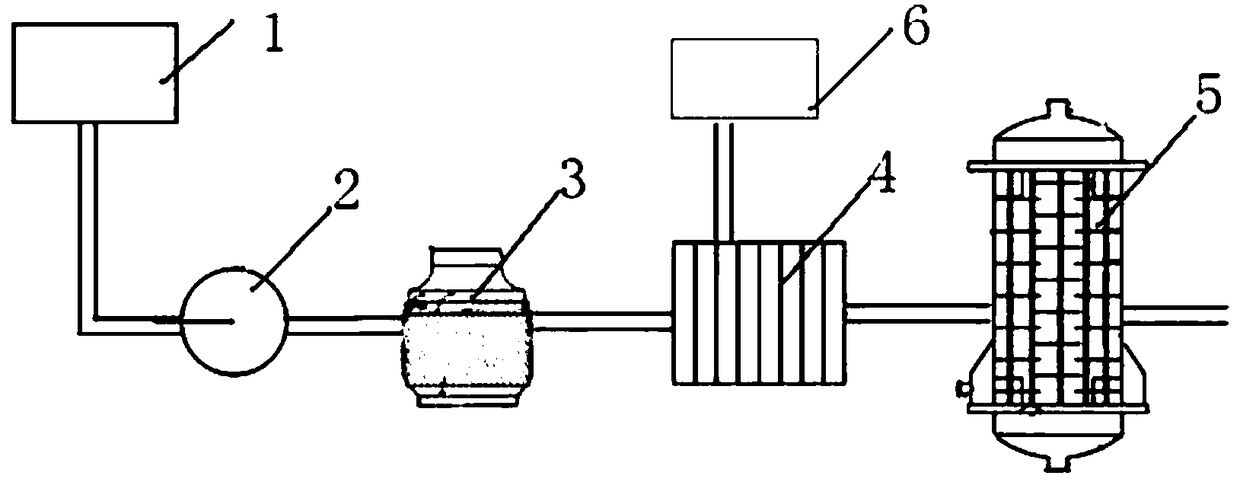

Apparatus and method for preparing sodium hyposulfite through purifying coking desulphurization waste liquid salt extraction filter residues used as raw material

InactiveCN105819406ALarge crystalsRealize resource utilizationThiosulfates/dithionites/polythionitesFiltrationEvaporation

A device and method for purifying sodium thiosulfate by using coking desulfurization waste liquid salt extraction and filter residue as raw material, the device includes a dissolution kettle, a plate and frame filter, a precision filter, an evaporation crystallizer and a centrifugal machine. The present invention uses coking desulfurization waste liquid salt extraction filter residue as raw material, dissolves, plate and frame filter, precision filter, crystallizes in Oslo cooling crystallizer, and centrifugally separates the product sodium thiosulfate. Compared with other methods for preparing sodium thiosulfate, the present invention not only has easy-to-obtain raw materials, simple process, energy-saving, larger crystal particles of the product sodium thiosulfate, but also realizes resource utilization of extraction filter residue, low cost and environmental protection.

Owner:BEIJING FUHAITIAN ENVIRONMENTAL SCI & TECH CO LTD

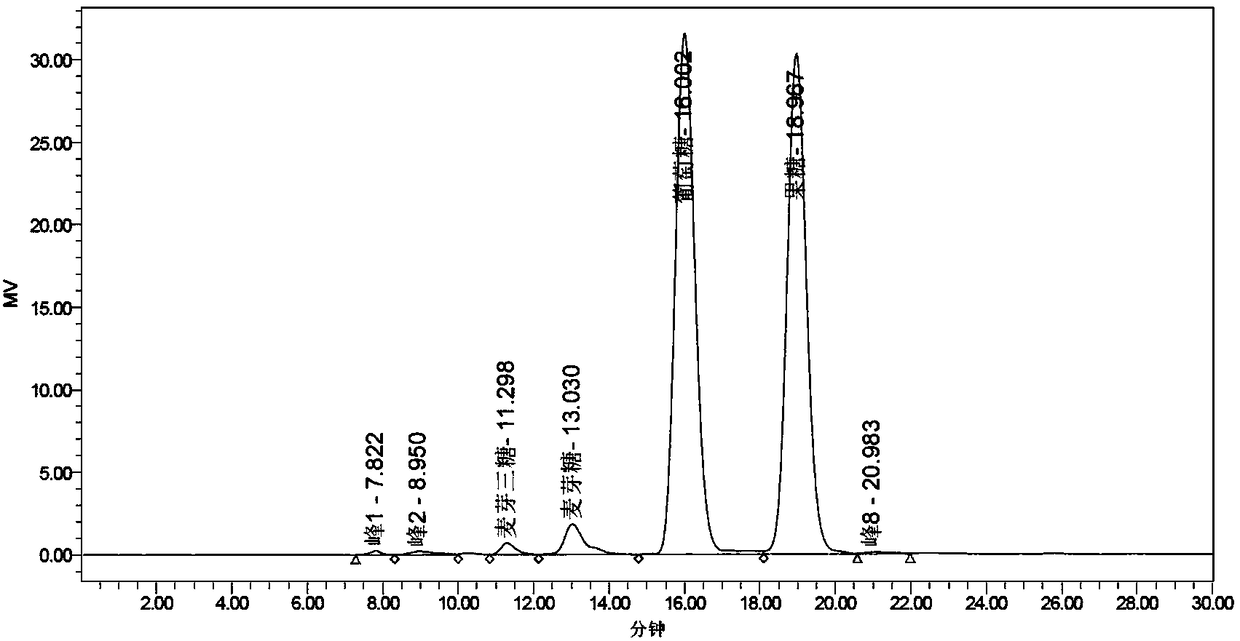

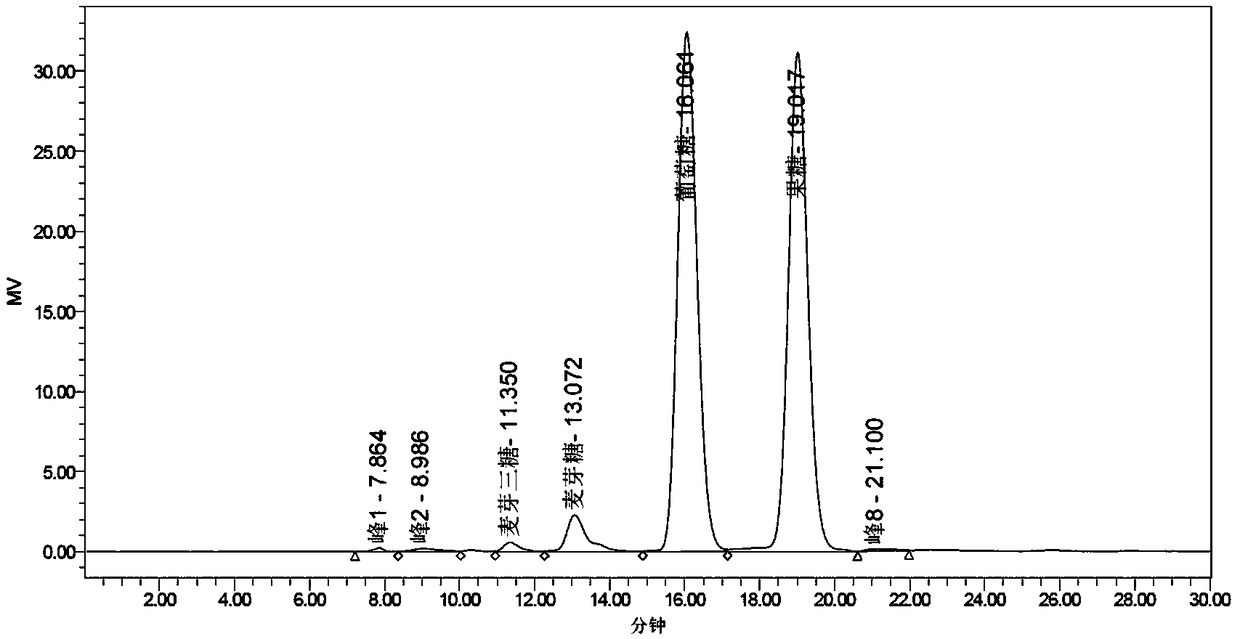

Method for delaying crystallization of high fructose syrup

InactiveCN108300813AImprove solubilityPrevent crystallizationFructose productionGlucose productionSolubilityHigh fructose

The invention belongs to the technical field of storage of sugars and particularly relates to a method for delaying crystallization of high fructose syrup. The method for delaying crystallization of the high fructose syrup is characterized in that finished product high fructose syrup is heated and then cooled. The method has the benefits as follows: with the adoption of the method, the finished product high fructose syrup is firstly heated to a certain temperature and then cooled to a specific temperature, the method adopts a process designed according to the characteristics of the high fructose syrup, so that the high fructose syrup has increased solubility after being heated and cooled, and the condition that use and sales of the high fructose syrup are affected due to crystallization ofthe high fructose syrup at the low temperature is effectively prevented.

Owner:SHANDONG SCENTS JIANYUAN BIO TECH

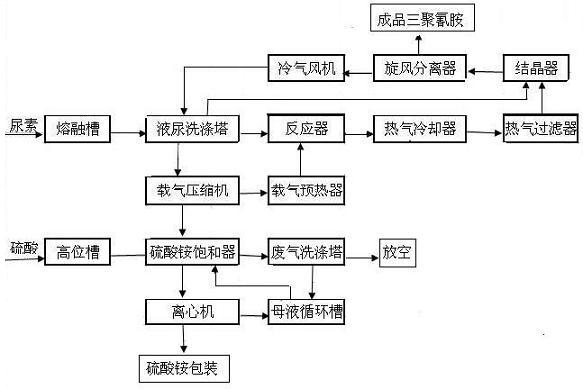

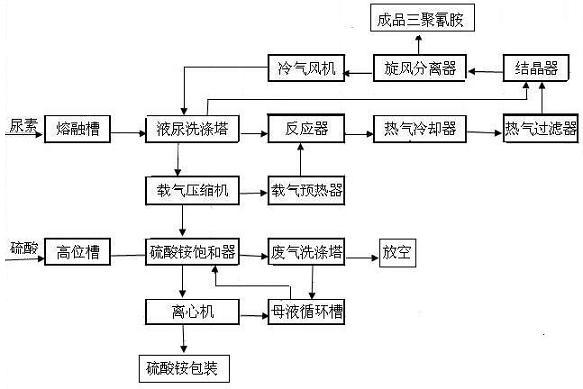

Process for coproducing melamine and ammonium sulfate

InactiveCN102584731ALarge crystalsQuality improvementOrganic chemistryAmmonia compoundsCold airFluidized bed

The invention relates to a process for coproducing melamine and ammonium sulfate. The process comprises the following steps of: melting urea serving as a raw material in a urea fusion tank to form liquid urea, conveying the liquid urea into a reactor by a liquid urea washing tower, filtering reacted gas to remove impurities, condensing melamine to form a solid by a crystallizer, and conveying the solid into a cyclone separator for a finished product along with the mixed gas, discharging, cooling and packaging to obtain the melamine; and pressurizing tail gas exhausted from the top of the cyclone separator by a cold air fan to enter the liquid urea washing tower, and dividing the tail gas into three paths, wherein the first path of tail gas is pressurized by a gas carrying compressor, is used as fluidized bed carrier gas and enters the reactor; a second path of tail gas returns to the crystallizer circularly to be used as quenching gas; the third path of tail gas is separated from the gas carrying compressor, enters an ammonium sulfate saturator and reacts with sulfuric acid to generate an ammonium sulfate crystal, and the ammonium sulfate crystal is separated by a centrifugal machine to obtain an ammonium sulfate finished product; and an ammonium sulfate mother solution returns to a mother solution circulating tank to be recycled. The ammonium sulfate is large in crystalline particles, and the process is simple, easy to operate and environment-friendly, and has an obvious economic benefit.

Owner:NANTONG ZIXIN IND

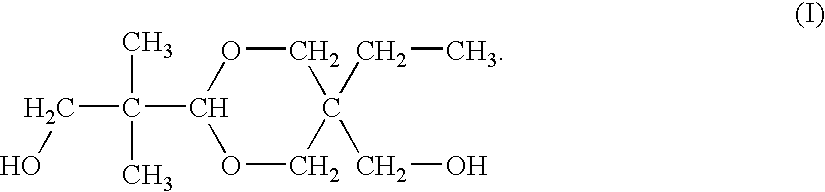

Process of producing dioxane glycol

ActiveUS20070078271A1High purityImprove thermal stabilityOrganic chemistryReaction temperatureTrimethylolpropane

A process of producing 2-(5-ethyl-5-hydroxymethyl-1,3-dioxane-2-yl)-2-methylpropane-1-ol (DOG) by the acetalization of hydroxypivalaldehyde with trimethylolpropane in water in the presence of an acid catalyst and optional seed crystals. DOG crystals having an increased particle size and containing the trans isomer in a high content are produced by the process in which the reaction temperature, pH of the reaction system and concentration of DOG to be produced in the reaction system are controlled.

Owner:MITSUBISHI GAS CHEM CO INC

Antibacterial agent containing copper, silver and zinc antibacterial metal ions, and preparation method thereof

InactiveCN101884338BImprove antibacterial propertiesImprove efficiencyBiocideDisinfectantsCopper nitrateZinc nitrate

The invention discloses a preparation method for an antibacterial agent containing copper, silver and zinc antibacterial metal ions. The method comprises the following steps of: (1), levigating, crushing and processing epidesmine to 550 to 600 meshes; (2), acidulating each gram of epidesmine with 40ml of 0.1M hydrochloric acid, reacting the epidesmine and 20 percent of sodium chloride at a constant temperature for 2 hours with maintaining and stirring, standing the reaction product, washing the reaction product until the reaction product is neutral, and drying the reaction product; and (3), sequentially adding 1g of sodic zeolite, 5ml of 0.1M copper nitrate, 5ml of 0.1M zinc nitrate and 10ml of 0.1M silver nitrate into modified sodic zeolite, performing a reaction at a constant temperature for 2 to 3 hours with maintaining and stirring, standing the reaction product, washing the reaction product until the reaction product is neutral, and drying the reaction product to obtain the antibacterial agent. The epidesmine antibacterial agent has the advantages of strong antibiosis, high efficiency, heat resistance, good stability, high safety, good long-term effectiveness, wide antibacterial range and the like. Bacteria have no medicament resistance to the epidesmine antibacterial agent; the antibacterial effect is over 95 percent; and the cost is low.

Owner:GUANGXI NORMAL UNIV

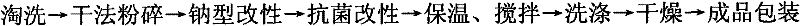

Method for recovering antioxidant 300 from efficient solvent oil mother liquor

InactiveCN111662218AShort crystallization timeMany crystalsOrganic chemistryOrganic compound preparationProcess engineeringSolvent

The invention belongs to the technical field of chemical engineering, and particularly relates to a method for recovering an antioxidant 300 in efficient solvent oil mother liquor. The recovery methodof the antioxidant 300 in the efficient solvent oil mother liquor comprises the following steps of: (1) mother liquor concentration: carrying out reduced pressure distillation and concentration on the mother liquor containing the antioxidant 300 to evaporate No.200 solvent oil of which the volume is 30-60% of the total volume of the mother liquor; (2) cooling of the concentrated solution: introducing chilled water into a jacket of a recovery kettle, putting the concentrated solution with the temperature of 130-140 DEG C into the recovery kettle, and stirring until the temperature of the concentrated solution is 50-80 DEG C; (3) crystallization: adding n-hexane accounting for 10%-20% of the volume of the concentrated solution into the recovery kettle, continuously stirring until the temperature is -10 DEG C to -5 DEG C, and then stirring for 2-3 hours; and (4) standing and centrifuging: stopping stirring, standing, and then centrifuging to obtain the antioxidant 300. The method is short in crystallization time, high in recovery efficiency, low in centrifugal difficulty and high in operation safety.

Owner:淄博万科化工有限公司

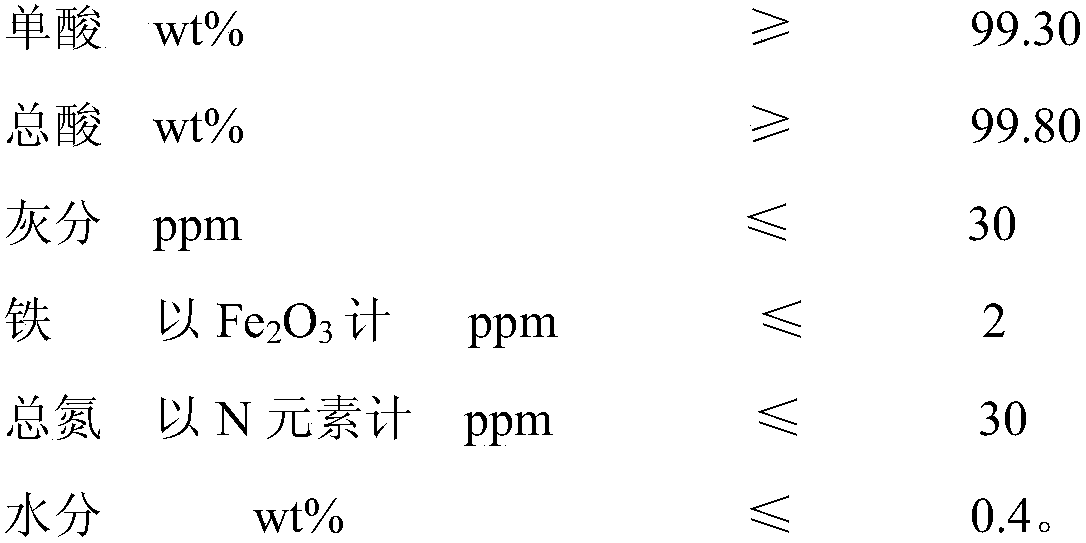

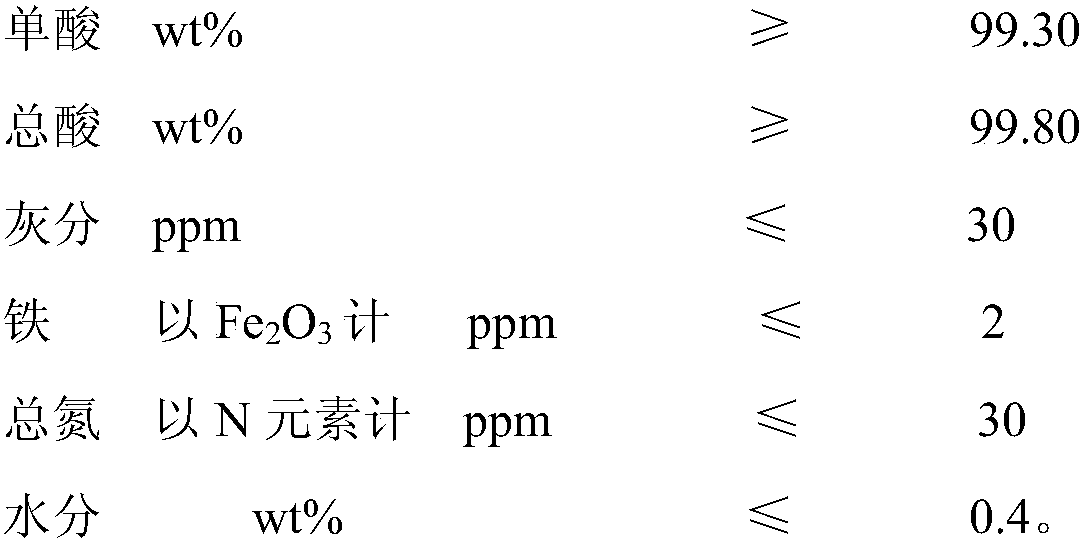

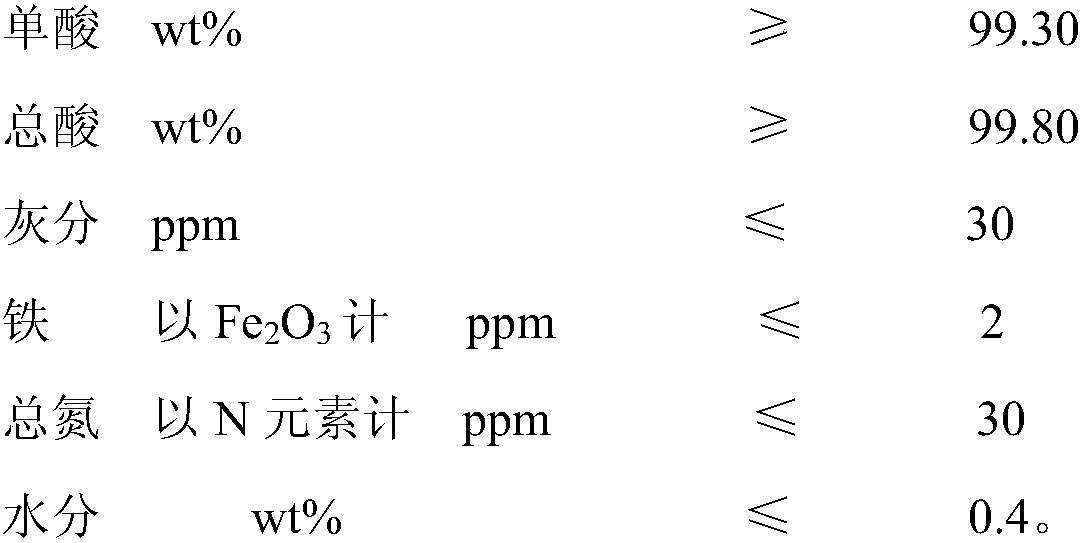

Refining and purifying method of dodecanedioic acid

InactiveCN108084015AHigh yieldHigh purityCarboxylic compound separation/purificationIon contentTotal nitrogen

The invention relates to a refining and purifying method of dodecanedioic acid. The method is characterized in that the moisture content of a crude dodecane material is controlled to be lower than orequal to 1.0 wt% and the content of an acetic acid solvent is higher than or equal to 95.0wt%; three-section gradient cooling is adopted in a crystallization process, and inducing seed crystals are added after second-section cooling to induce crystallization; crystallized filter cakes are firstly eluted with acetic acid, then eluted with water and subjected to centrifugal filtration; then, the filter cakes are washed with water at the environment temperature; the acetic acid solvent produced in the refining process is completely recovered with an azeotropic distillation method to be recycled;a washing solution and mother liquor produced in the refining process are completely recovered and recycled. The refining and purifying method of dodecanedioic acid has high product yield, lower refining cost and high purity. The refined and purified dodecanedioic acid has the total acid content of 99.90%, the monomer acid content of 99.45%, the total nitrogen of 6 ppm, the iron ion content of 0.5ppm, the ash content lower than or equal to 10 ppm, the moisture content lower than or equal to 0.10% and the comprehensive yield of purification of 98.64%. All quality technical indexes meet the user requirement.

Owner:ZIBO GUANGTONG CHEM

Solder and insulation container welded by means of same

ActiveCN111545950AActive connectionLarge crystalsWelding/cutting media/materialsSoldering mediaComposite materialTitanium

The present invention relates to a solder and an insulation container welded by means of same. The solder comprises, in percentage by weight, 5% of zirconium, 9% of nickel, 78% of titanium, and 8% ofcopper. The insulation container comprises a titanium material liner and a stainless steel housing made of SUS304 stainless steel; a welding cavity is formed between the liner and the housing after assembly; the solder as described above is used for vacuum brazing; and the connection of the liner and the housing is implemented after welding. The present invention can implement the welding connection between the titanium liner and the stainless steel housing of the insulation container, is high in tensile strength of welded parts thereof and excellent in compactness, guarantees the quality of the insulation container, and prolongs the service life thereof.

Owner:浙江库尔仕科技有限公司

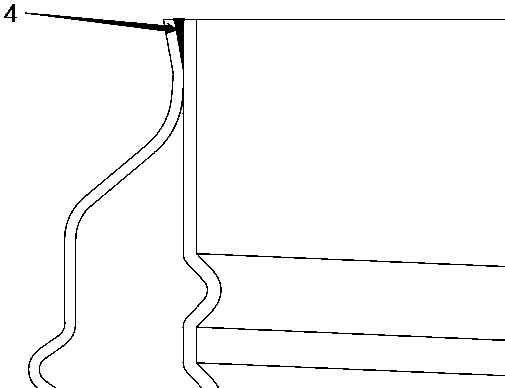

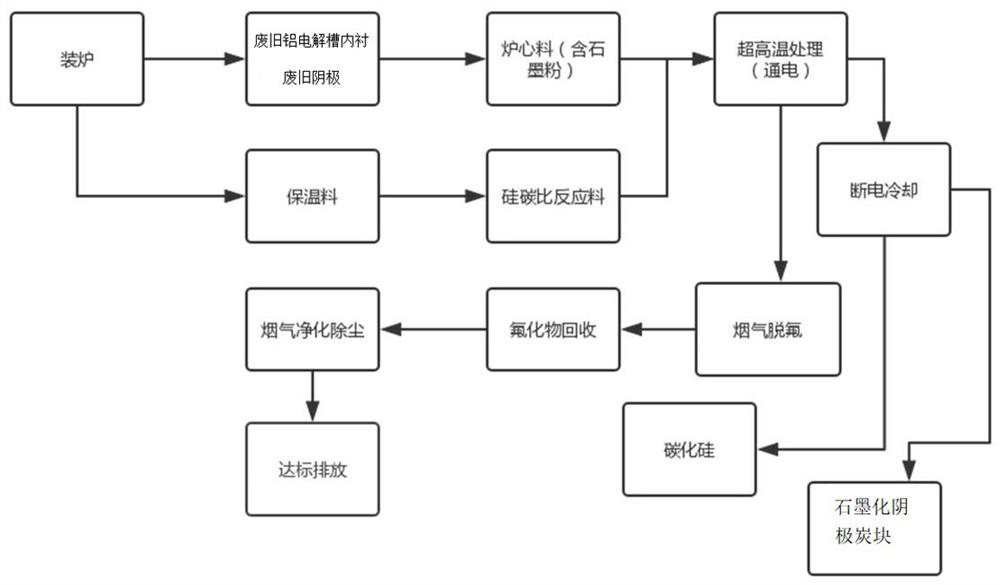

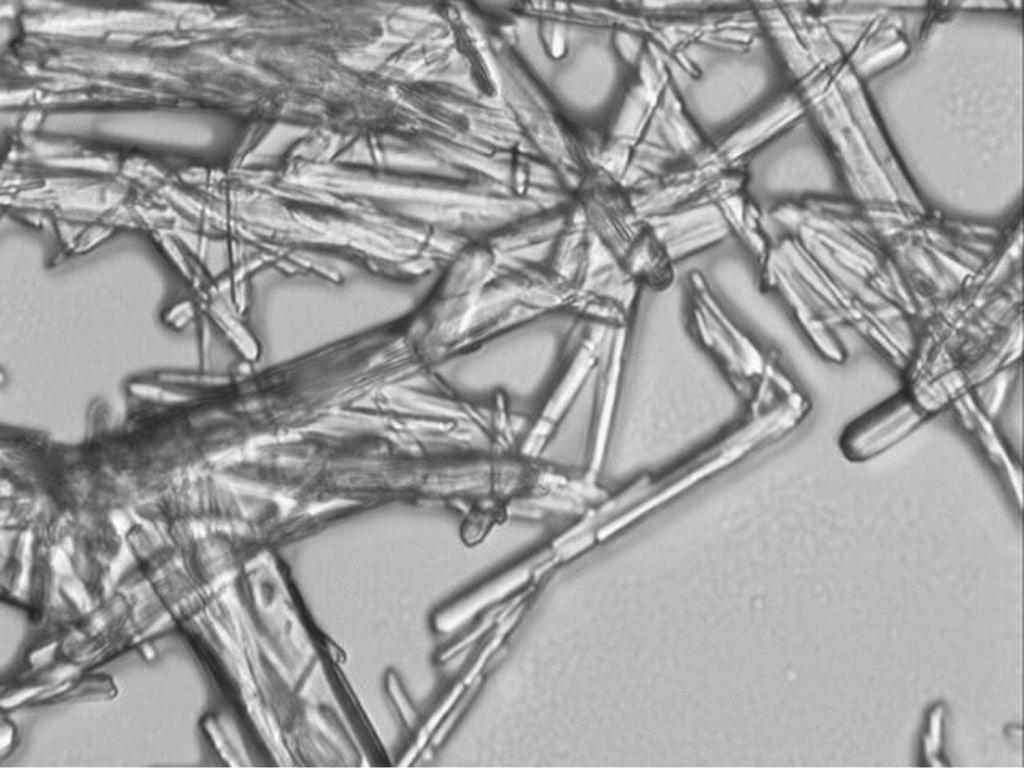

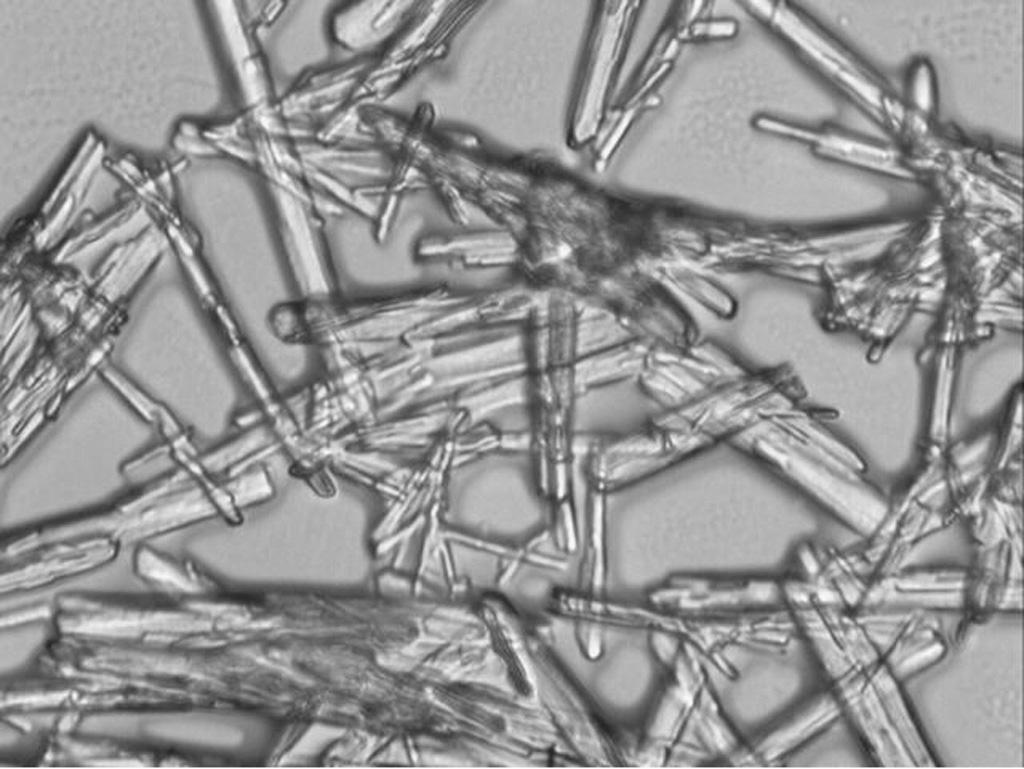

Harmless and efficient resource recovery method for waste aluminum electrolysis cell linings and waste cathodes

InactiveCN113461003AComplete dischargeThermal vibration frequency increasesSilicon carbideAluminium electrolysisHazardous substance

The invention belongs to the technical field of chemical engineering, and particularly relates to a harmless and efficient resource recovery method for waste electrolytic cell linings and waste cathodes. The method comprises the following steps: charging crushed waste electrolytic cell lining blocks, waste cathode blocks, a furnace core material, a heat preservation material and a carbon-silicon ratio reaction material into a direct-current resistance furnace, electrifying the direct-current resistance furnace, conducting heating to 2800-3000 DEG C, carrying out anaerobic combustion for 35-38 hours, conducting cooling for 144 hours, and conducting discharging to obtain silicon carbide blocks and graphitized cathode carbon blocks; and subjecting fluoride flue gas generated in the anaerobic combustion process of the direct-current resistance furnace to defluorination and dust removal treatment. The ultrahigh-temperature anaerobic combustion process and the defluorination recovery process are adopted, toxic components in the waste electrolytic cell lining can be completely discharged and subjected to innocent treatment, and meanwhile other impurities and harmful substances are discharged together.

Owner:甘肃嘉润合环保科技有限公司

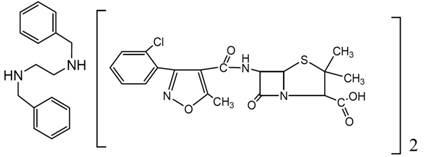

Preparation method of chlorazol benzathine benzylpenicillin

ActiveCN102690277AReduce storageReduce embeddingOrganic compound preparationAmino compound preparationInjectable SuspensionBenzyl-EDTA

The invention relates to a preparation method of chlorazol benzathine benzylpenicillin, which comprises the following steps of: (a) measuring and taking the following materials of 1.0g of cloxacillin sodium, 2.0-10.0ml of water and 0.5-10.0ml of buffer agent according to the mass volume ratio to prepare solution A; (b) measuring and the taking the following materials of 1.0g of N, N'-DBED, 2.0-10.0ml of water and 1.0-10.0ml of buffer agent according to the mass volume ration to prepare solution B; (c) adding 15-30 percent of the total amount of the solution A into the solution B, reacting under a stirring state to generate crystal, and growing the crystal for 10-30 minutes; and flowing the rest solution A into the solution B within 30 minutes, and carrying out salt forming reaction to obtain chlorazol benzathine injectable suspension; and (d) filtering, washing, leaching, and vacuum drying at 50-80 DEG C to obtain the product. Stable degree of supersaturation is kept during the reaction, and the nucleus formation caused by outbreak of the product is effectively controlled, so that the product quality can be improved.

Owner:NORTH CHINA PHARM GRP SEMISYNTECH CO LTD

Medicine water suspended emulsion containing rebamipide and preparation method of medicine water suspended emulsion

The invention provides medicine water suspended emulsion containing rebamipide and povidone, wherein rebamipide fine particles dispersed in the water suspended emulsion can maintain a stable dispersed state and can not get together; besides, the invention also provides a method for preparing the medicine water suspended emulsion containing rebamipide and povidone, and the method for preparing the medicine water suspended emulsion comprises the step of mixing povidone and sodium salt compound with rebamipide.

Owner:NANJING HUAWE MEDICINE TECH DEV

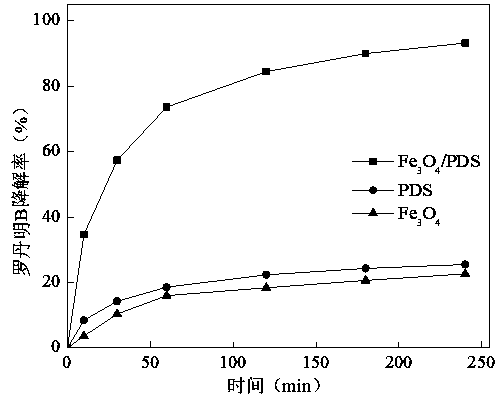

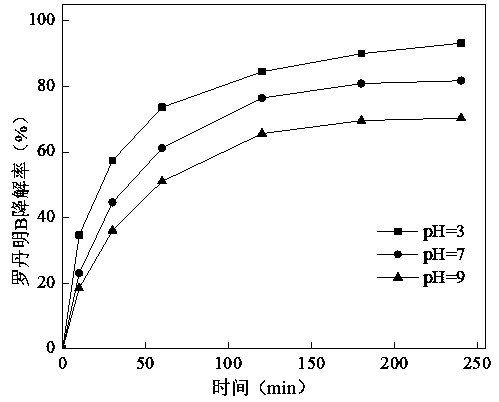

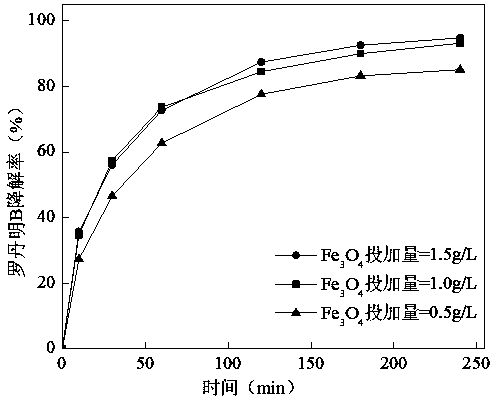

Persulfate activating method

InactiveCN109928482AAdsorptiveImprove adsorption capacityWater contaminantsWater/sewage treatment by oxidationPotential toxicityPersulfate

The invention provides a persulfate activating method. A homogeneous system is generally adopted for common transition metal activation, secondary pollution is prone to being caused due to the fact that metal ions are dissolved in water, meanwhile, the catalysis activity of the homogenous system is largely affected by pH values, and the homogenous system cannot be recycled and has potential toxicity. Fe3O4 which is a non-homogenous Fenton reaction catalyst excellent in performance is adopted, activation of persulfate and degradation of pollutants occur on the surface of the Fe3O4, contact between generated SO4<->. and Fe<2+> in the Fe3O4 can be effectively reduced, the probability of side reaction is lowered, and it is ensured that the utilization rate of persulfate is high; and secondarypollution caused by a large amount of iron ions dissolved in water is avoided.

Owner:CHANGZHOU UNIV

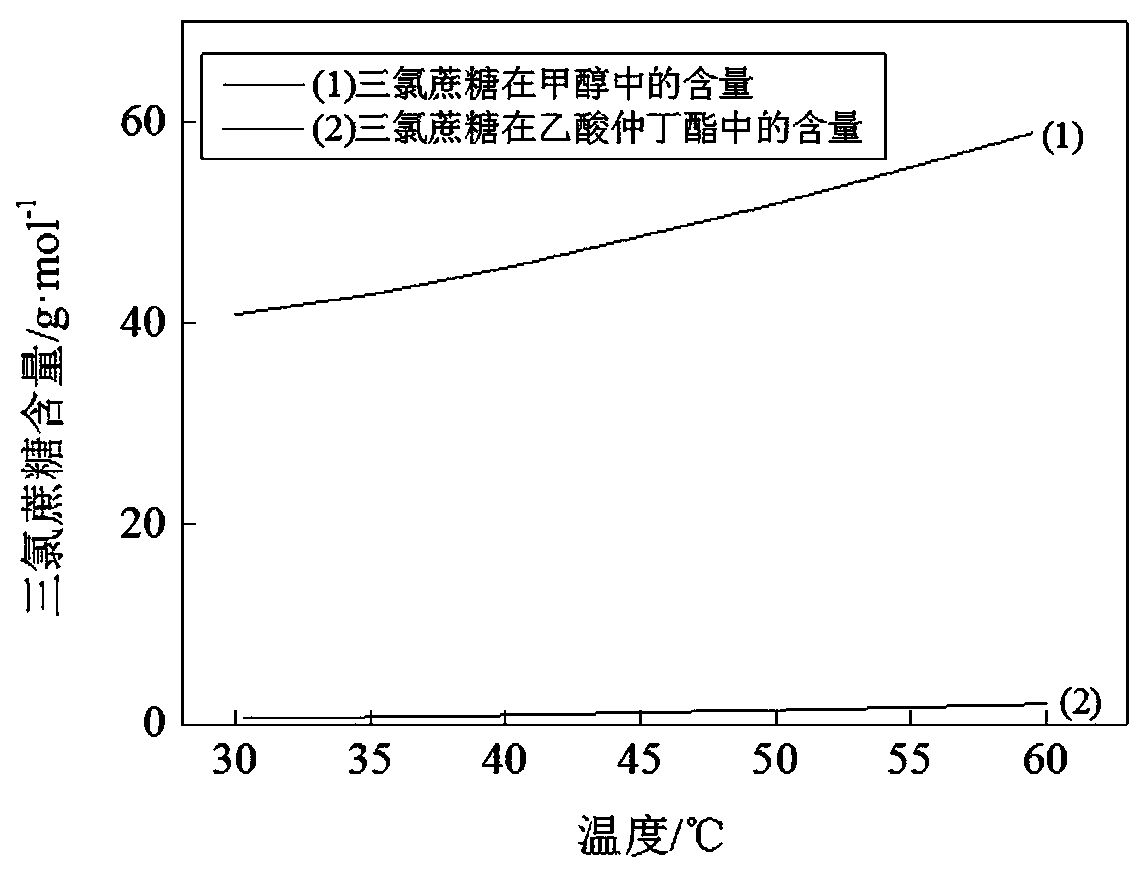

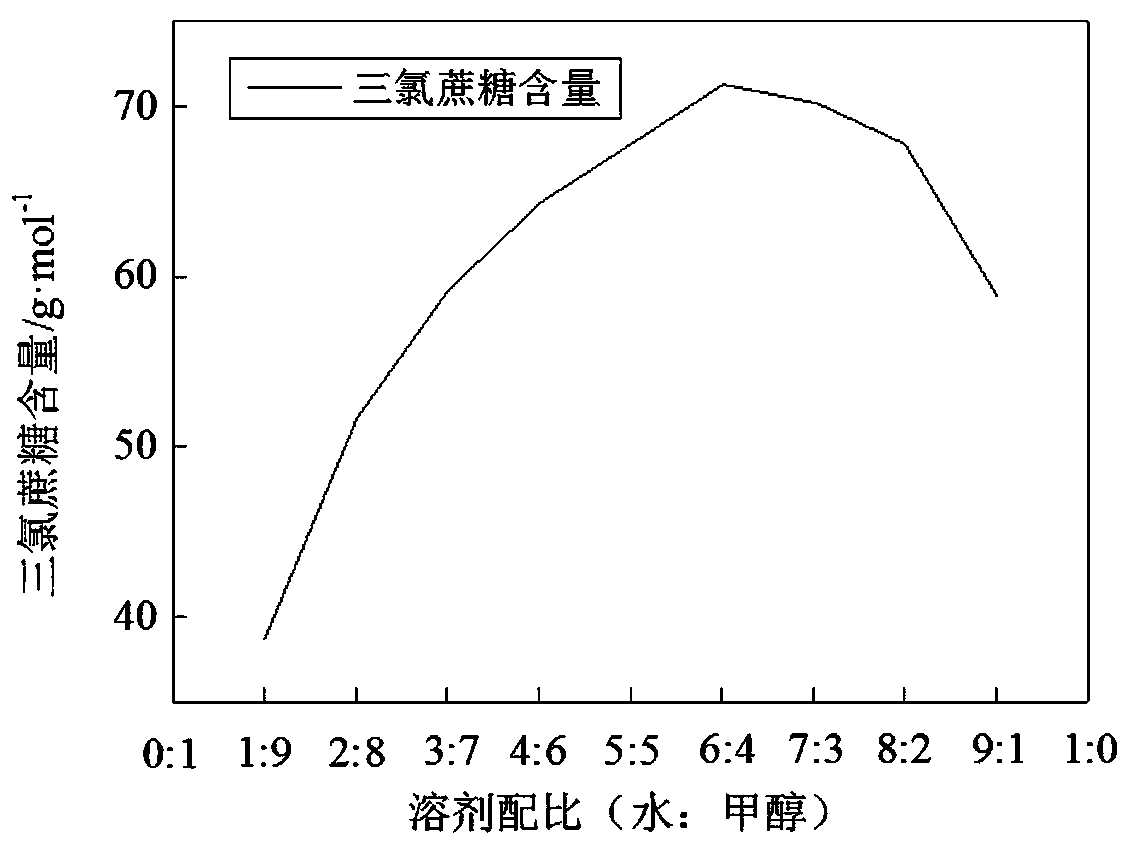

Crystallization method of sucralose

InactiveCN109762030ACrystallization process conditions are simpleMild crystallization process conditionsSugar derivativesSugar derivatives preparationFiltrationSolvent

The invention discloses a crystallization method of sucralose. The crystallization method comprises the following steps that a pure solvent and a crude sucralose solution are mixed and stirred, impurities are removed through filtration, and a crude sucralose raw material is obtained; a mixed solvent is added into the crude sucralose raw material, heating stirring is conducted for a reaction for awhile, and cooling is conducted at a certain speed; after cooling, standing is conducted, and after filtration, sucralose crystals are obtained. The crystallization process conditions are simple and mild, the crystallization time is short, the production cost is low, industrial production is facilitated, the purity of the sucralose obtained by using the method is high, the particles of the crystalare large, and the crystallization method has a wide market application prospect.

Owner:FUZHOU UNIV

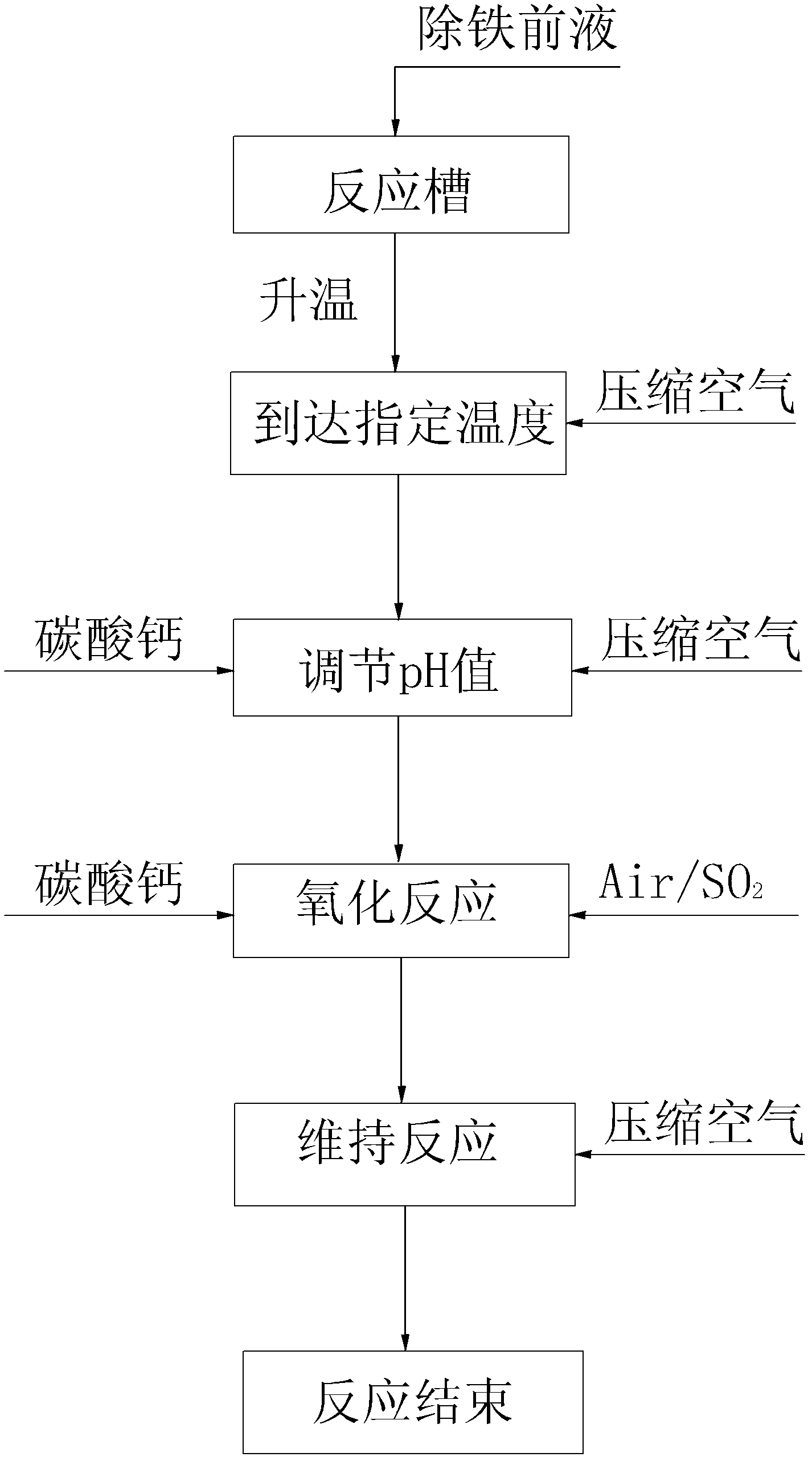

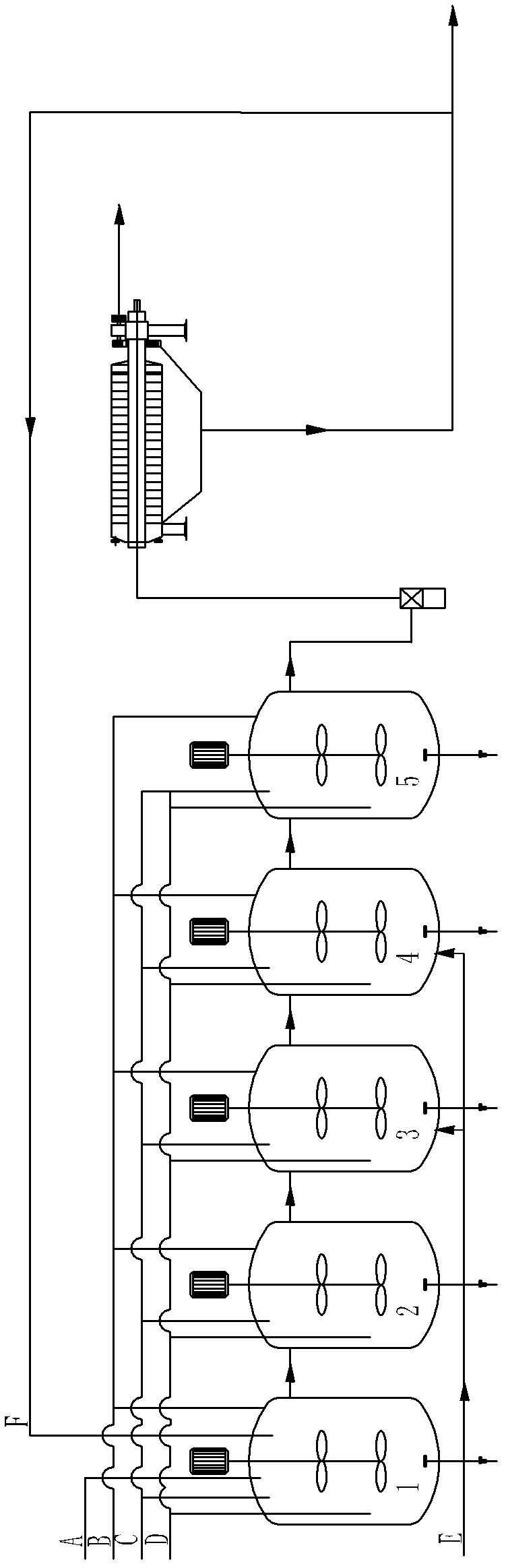

Method for low-temperature deironing by using mixed gas of air and sulfur dioxide (SO2)

ActiveCN102634662BImprove filtering effectLow costProcess efficiency improvementGoethiteOxidizing agent

The invention relates to a process for low-temperature deironing by using mixed gas of air and sulfur dioxide (SO2) for an ore leaching solution in the metallurgy industry. At present, a plurality of deironing methods are available in wet metallurgy, wherein a goethite deironing method has the widest application range in the wet metallurgy, however, oxidant accessories are limited in supply and the production cost is relatively high. The method disclosed by the invention is characterized by comprising the steps: firstly, adjusting the pH value of a solution ahead of deironing by using calciumcarbonate and continuously introducing the air; and then introducing the mixed gas of the air and the SO2 for oxidization, and continuously adjusting the pH value by using the calcium carbonate for neutralization to realize the deironing. According to the method, a derioning effect is guaranteed, the mixed gas of the air and the SO2 is taken as an oxidant, a high-temperature condition is not required and the advantage of low cost is achieved.

Owner:ZHEJIANG HUAYOU COBALT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com