Apparatus and method for preparing sodium hyposulfite through purifying coking desulphurization waste liquid salt extraction filter residues used as raw material

A technology of coking desulfurization waste liquid and sodium thiosulfate, which is applied in the direction of thiosulfate/dithionite/polythionite, etc., which can solve the problems of difficult control of the reaction process, difficulty in meeting industrial production, pollution and waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

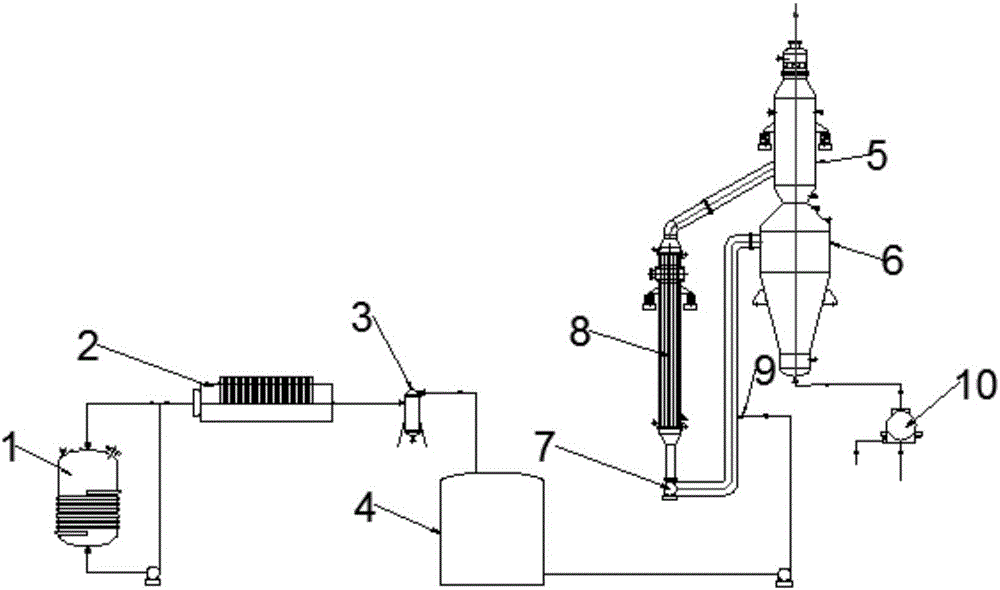

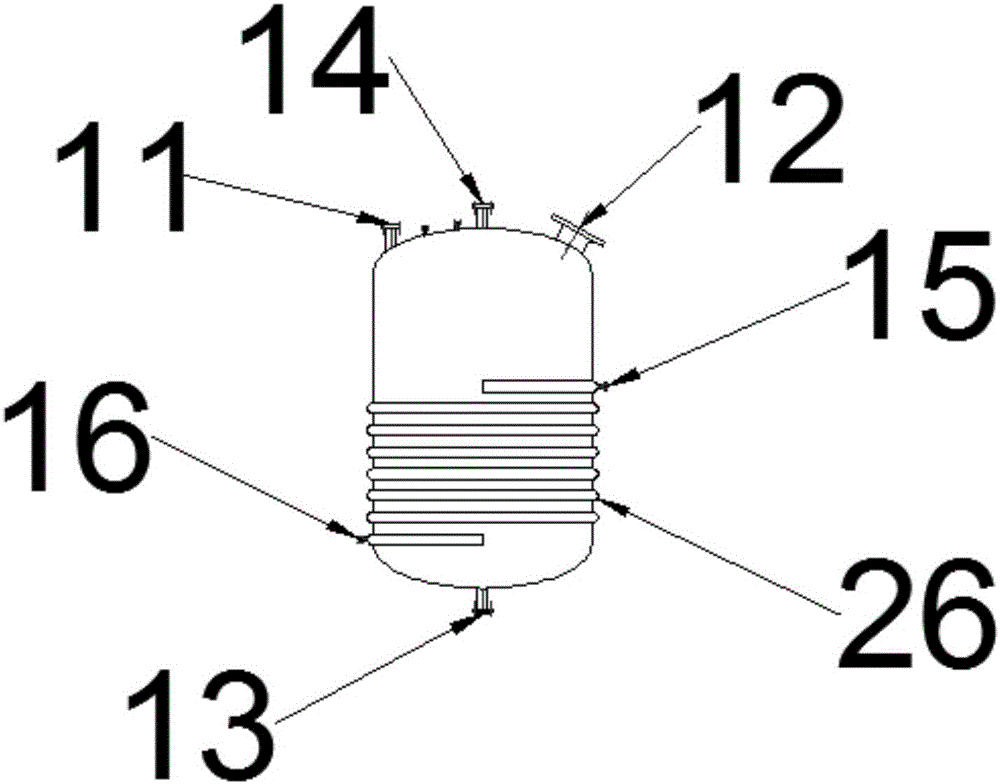

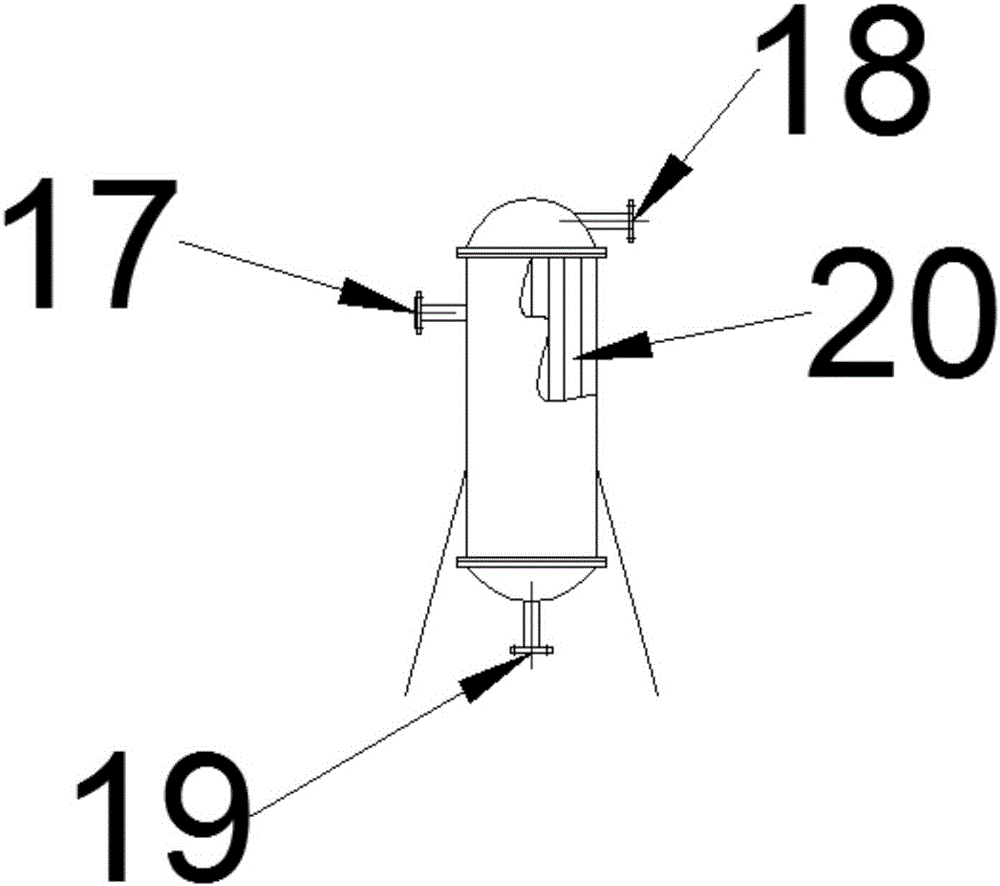

[0031] In this embodiment, the device for purifying sodium thiosulfate with coking desulfurization waste liquid extracting salt and extracting filter residue as raw material, such as figure 1 As shown, it includes a dissolution kettle 1, a plate and frame filter 2, a precision filter 3, an Oslo evaporation crystallizer group and a centrifuge 10 connected in sequence by pipelines. Such as figure 2 As shown, the upper part of the dissolution kettle 1 includes a liquid phase feed port 11, a solid phase feed port 12 and a self-circulation feed port 14. It has a steam inlet 15, a steam condensate outlet 16 at the lower part, and a solution outlet 13 at the bottom. Such as image 3 As shown, the upper part of the side wall of the precision filter 3 has a precision filter inlet 17, the top has a precision filter outlet 18, the bottom has a sewage outlet 19, and the inside has a filter element 20. Such as Figure 4 As shown, the Oslo evaporative crystallizer group includes a sepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com