Crystallization method of sucralose

A sucralose and crystallization technology, applied in the crystallization field of sucralose, can solve the problems of increasing process steps and production costs, increasing the fluidity of sucralose, and high requirements for reaction devices, achieving broad market application prospects and being conducive to industrialization The effect of low production and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

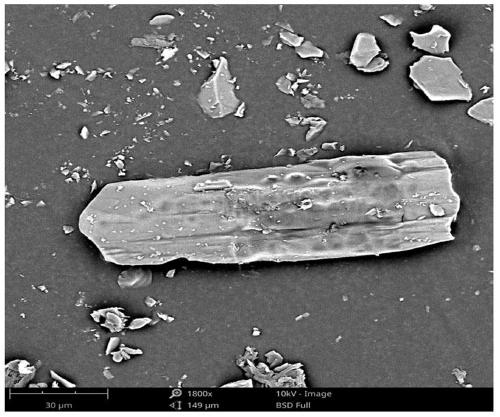

[0026] Add 40 mL of methyl acetate to 20 mL (24 g) of the crude sucralose solution, mix and stir for 4 h at room temperature, filter to remove impurities; add 20 mL of water-methanol mixed solution with a molar ratio of 3:7, heat up to 60°C, and stir to react 6 Hours later, the temperature was lowered to 20 ºC at a rate of 5 ºC per hour; after standing for 2 hours, it was filtered and vacuum-dried to obtain 20.4 g of sucralose crystals, with a crystallization yield of 85.0%, a purity of 98.2%, and an average particle size of 40 mesh. The scanning electron microscope picture of the prepared sucralose crystal is shown in figure 1 .

Embodiment 2

[0028] Add 40 mL of sec-butyl acetate to 20 mL (24 g) of sucralose crude solution, mix and stir for 4 h at room temperature, filter to remove impurities; add 20 mL of water-ethanol mixed solution with a molar ratio of 7:3, heat up to 80 ºC, and stir to react After 2.5 hours, the temperature was lowered to 20 ºC at a rate of 10 ºC per hour; after standing for 2 hours, it was filtered and vacuum-dried to obtain 19.5 g of sucralose crystals. The crystallization yield is 81.25%, the purity is 98.5%, and the average particle size is 45 mesh.

Embodiment 3

[0030] Add 40 mL of ethyl acetate to 20 mL (24 g) of crude sucralose solution, mix and stir for 4 h at room temperature, filter to remove impurities; add 20 mL of water-methanol mixed solution with a molar ratio of 5:5, raise the temperature to 75°C, and stir to react 4 Hours, at a rate of 8 ºC per hour, the temperature was lowered to 20 ºC; after standing for 2 hours, it was filtered and vacuum-dried to obtain 22.1 g of sucralose crystals, with a crystallization yield of 92.08%, a purity of 98.8%, and an average particle size of 38 mesh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com