Patents

Literature

216results about How to "Short crystallization time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing epoxide

ActiveCN101348472AShort crystallization timeIncrease productivityOrganic chemistryMolecular sieve catalystsEpoxideLow activity

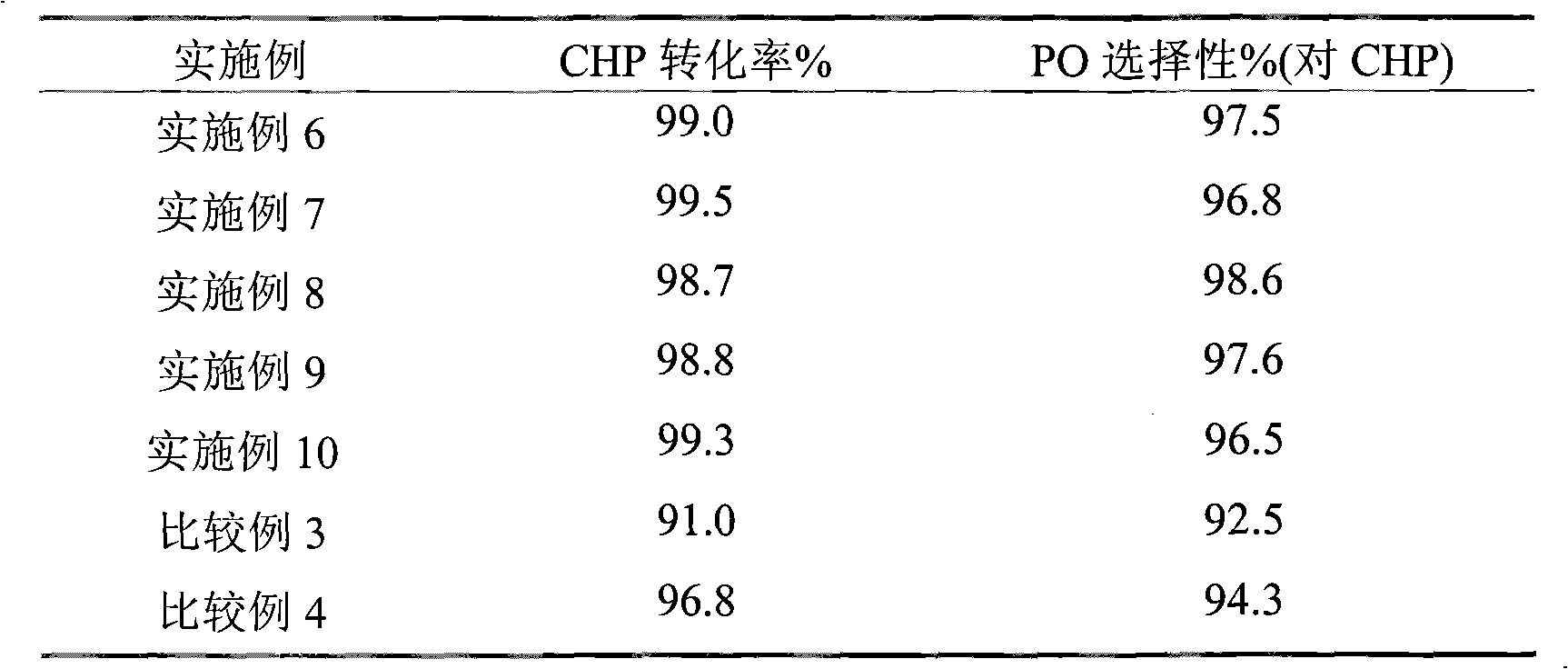

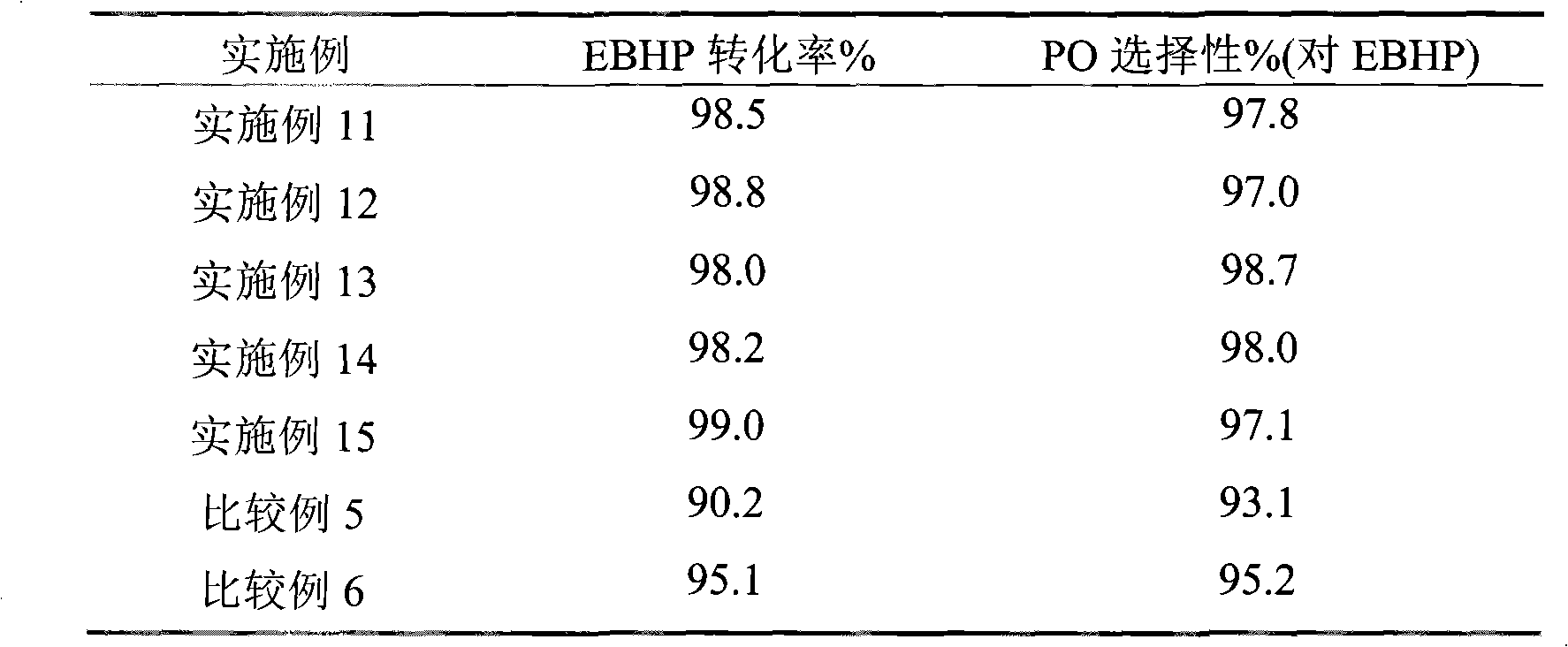

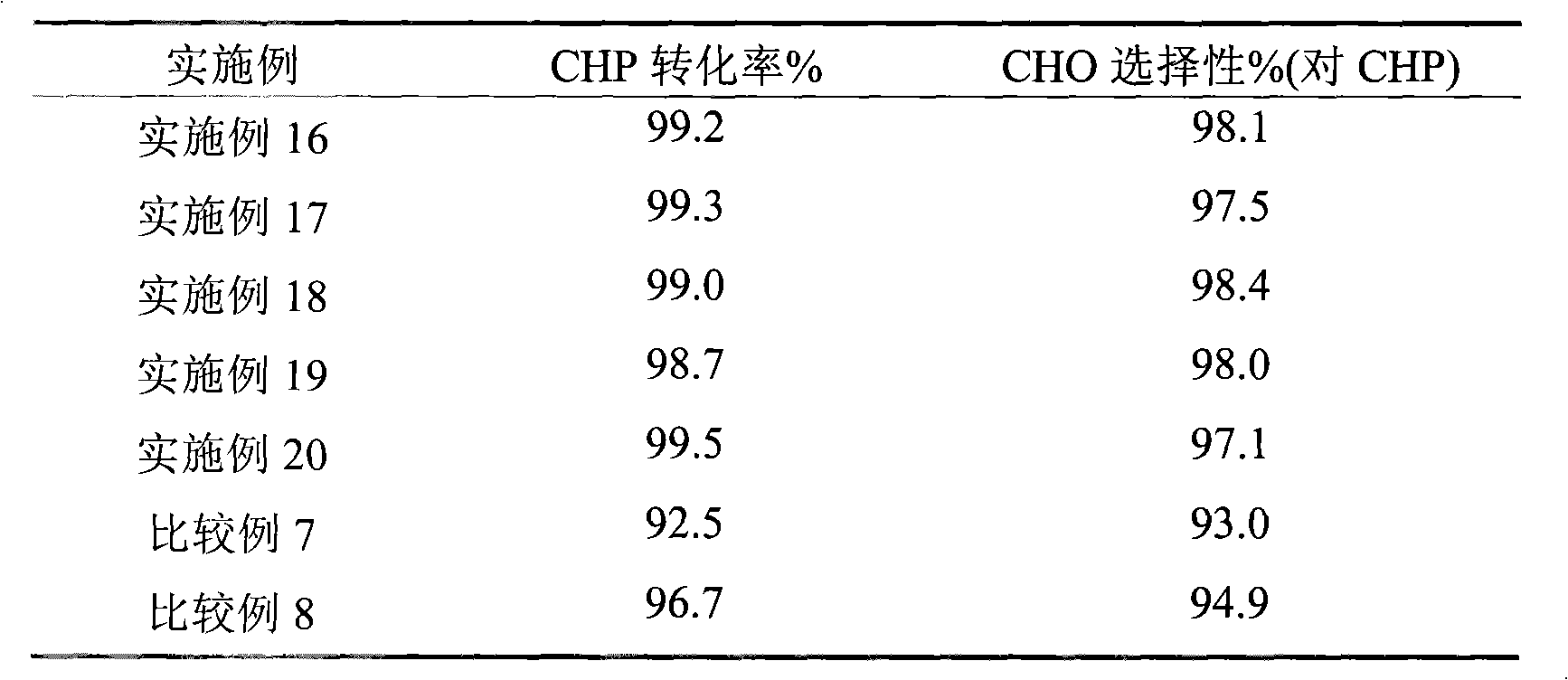

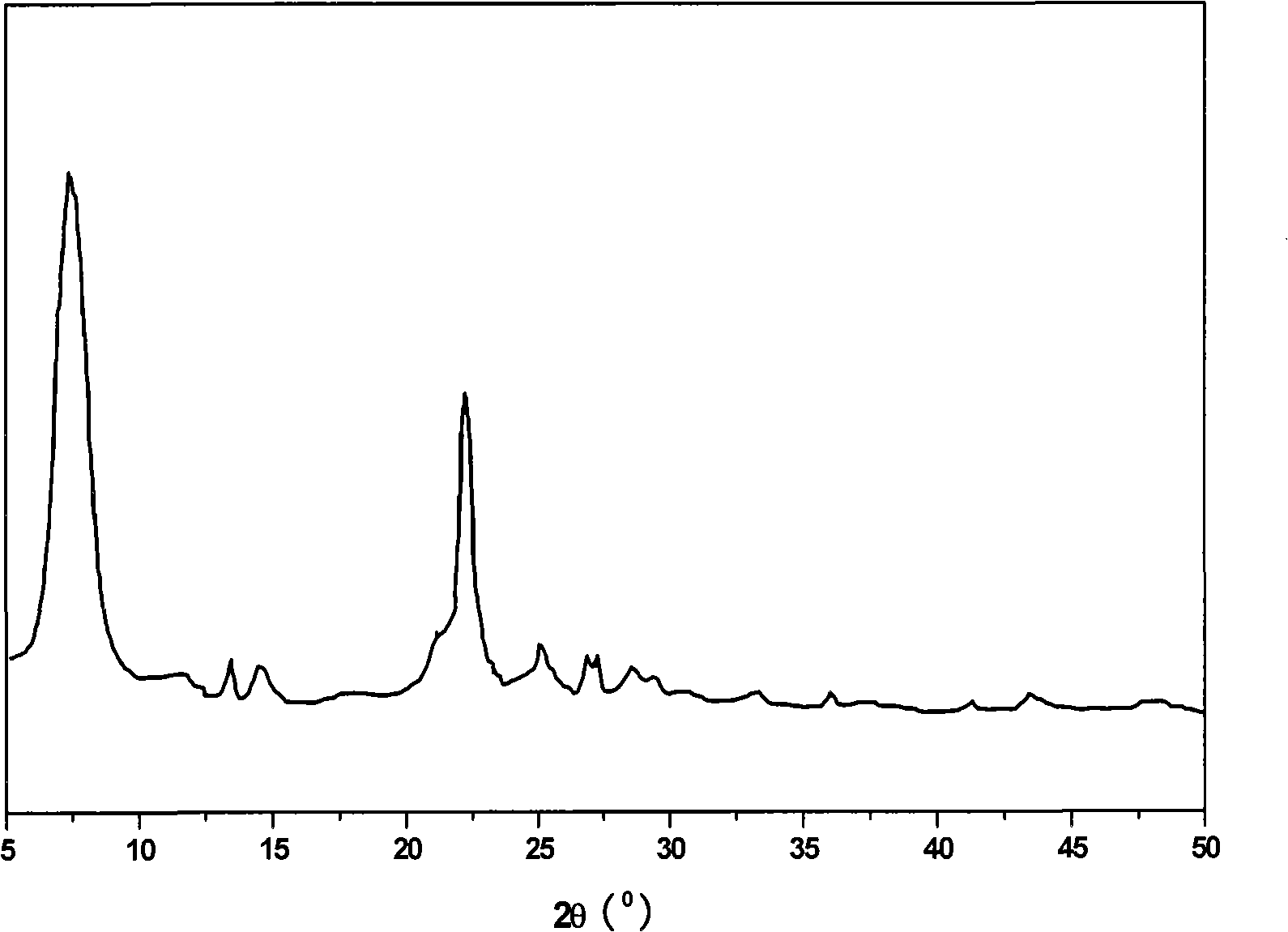

The invention relates to a method for preparing an epoxide and mainly resolves the problems in the prior art such as the low activity of catalysts for production of the epoxide, poor effect of mass transference, and high cost of production. The invention well resolves the problems through adopting the technical proposal which selects cheap organic amine as a template with shorter crystallization time, carries titanium through posterior synthesis in the presence of inertia gas, grafts inorganic titanium to silicon dioxide framework with a hexagonal mesoporous structure to form a substance of active titanium with four coordinating structure, and carries out alkylation treatment to produce a catalyst of the epoxide. The method provided by the invention can be applied to the industrialized production of the epoxide.

Owner:CHINA PETROLEUM & CHEM CORP +1

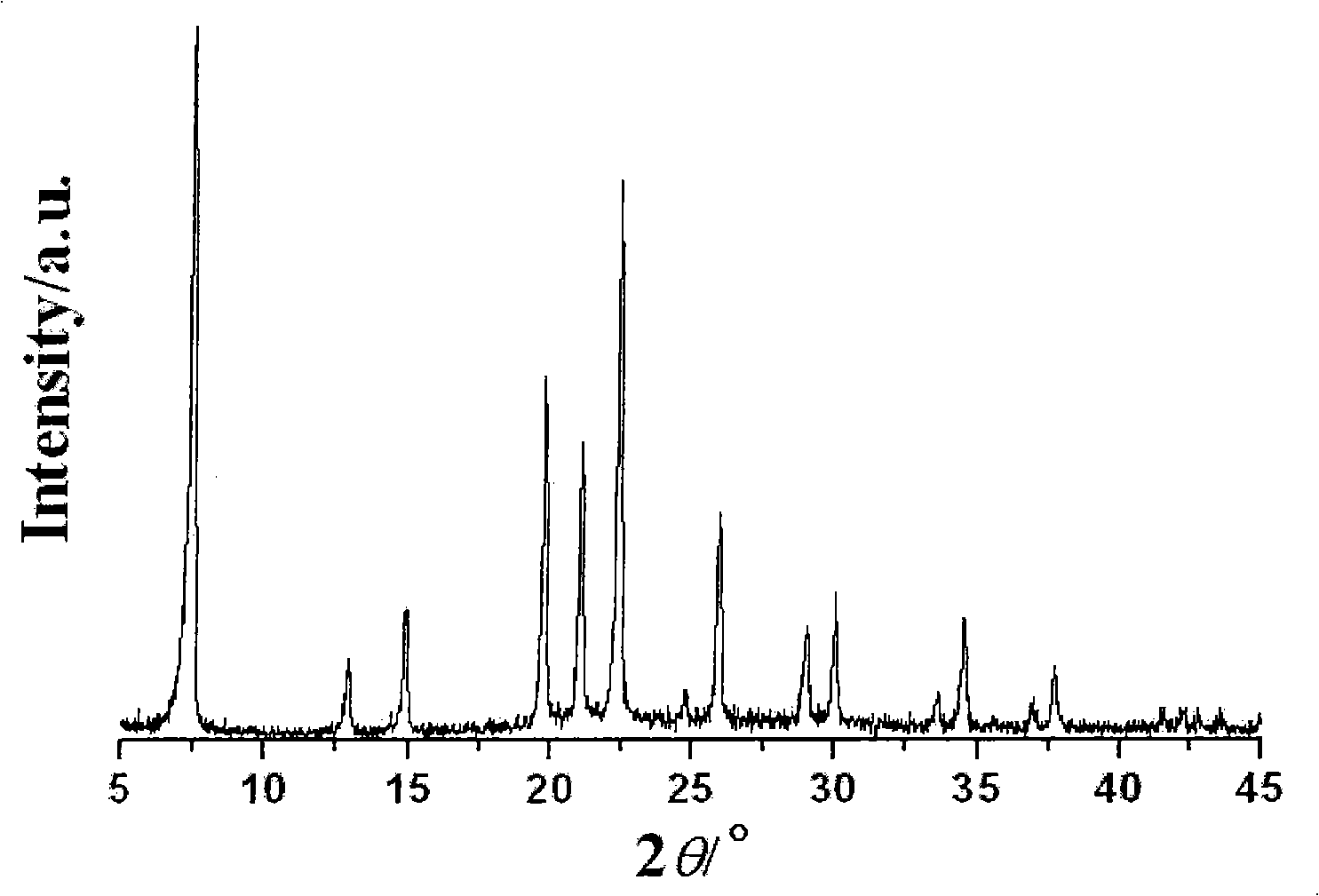

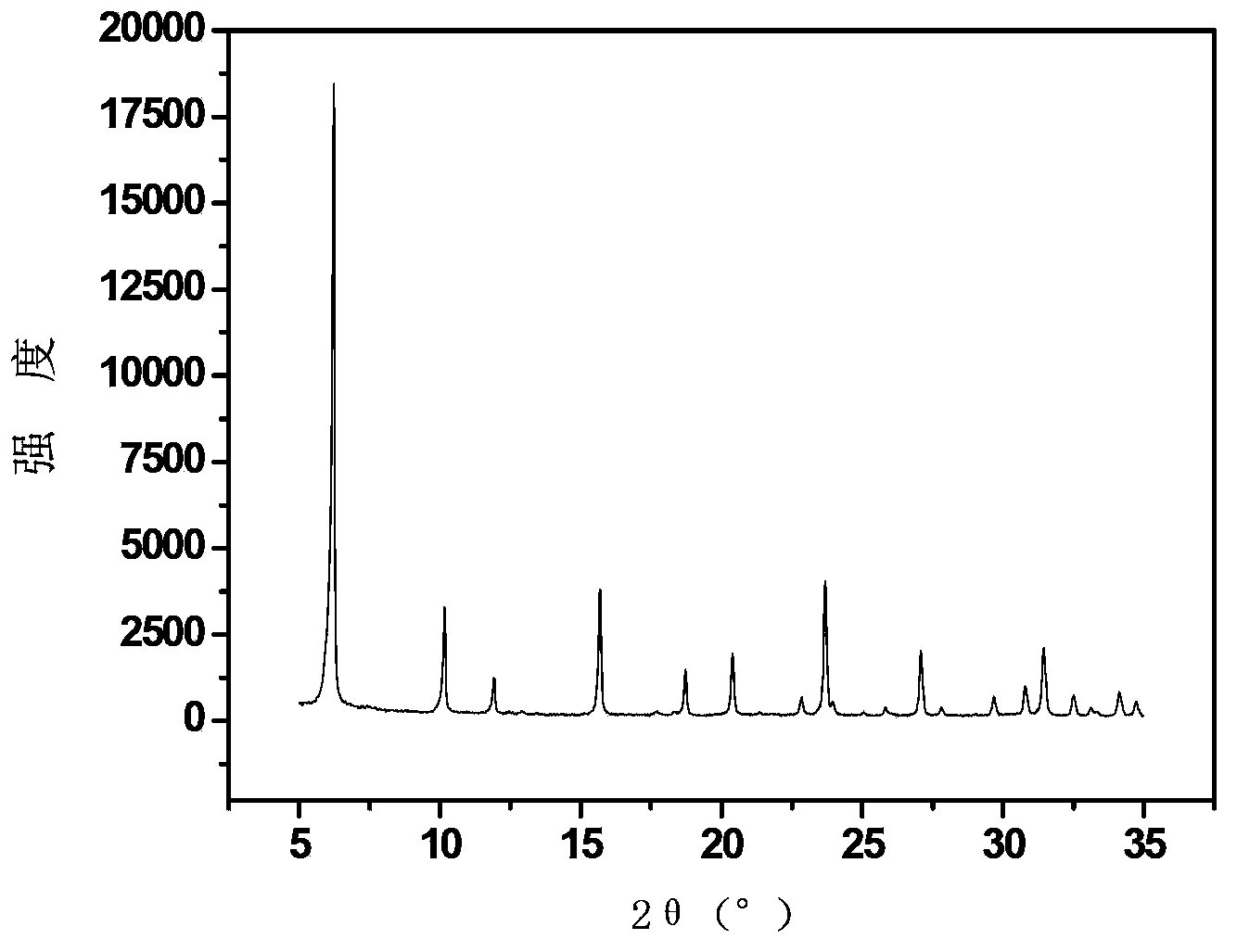

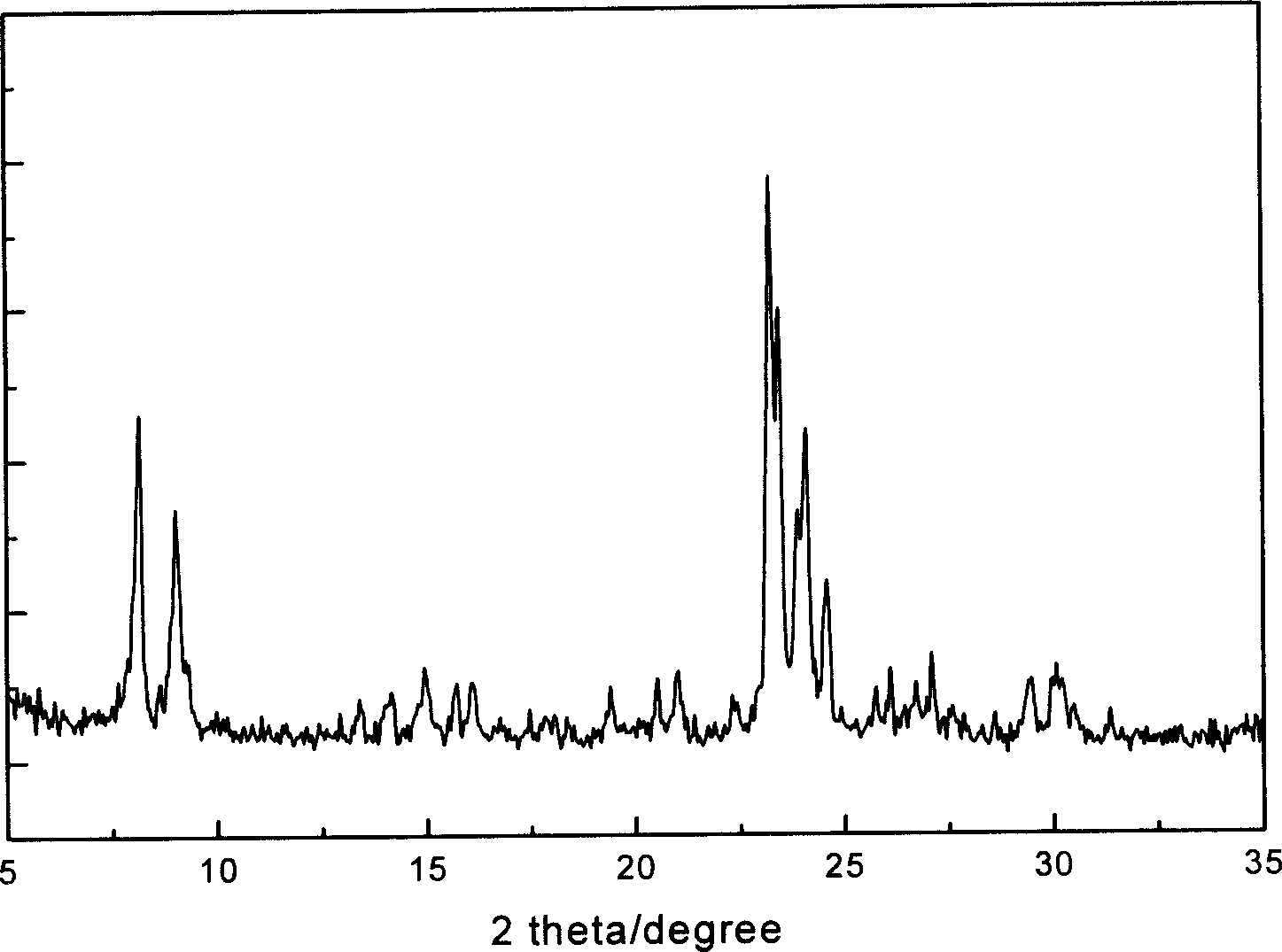

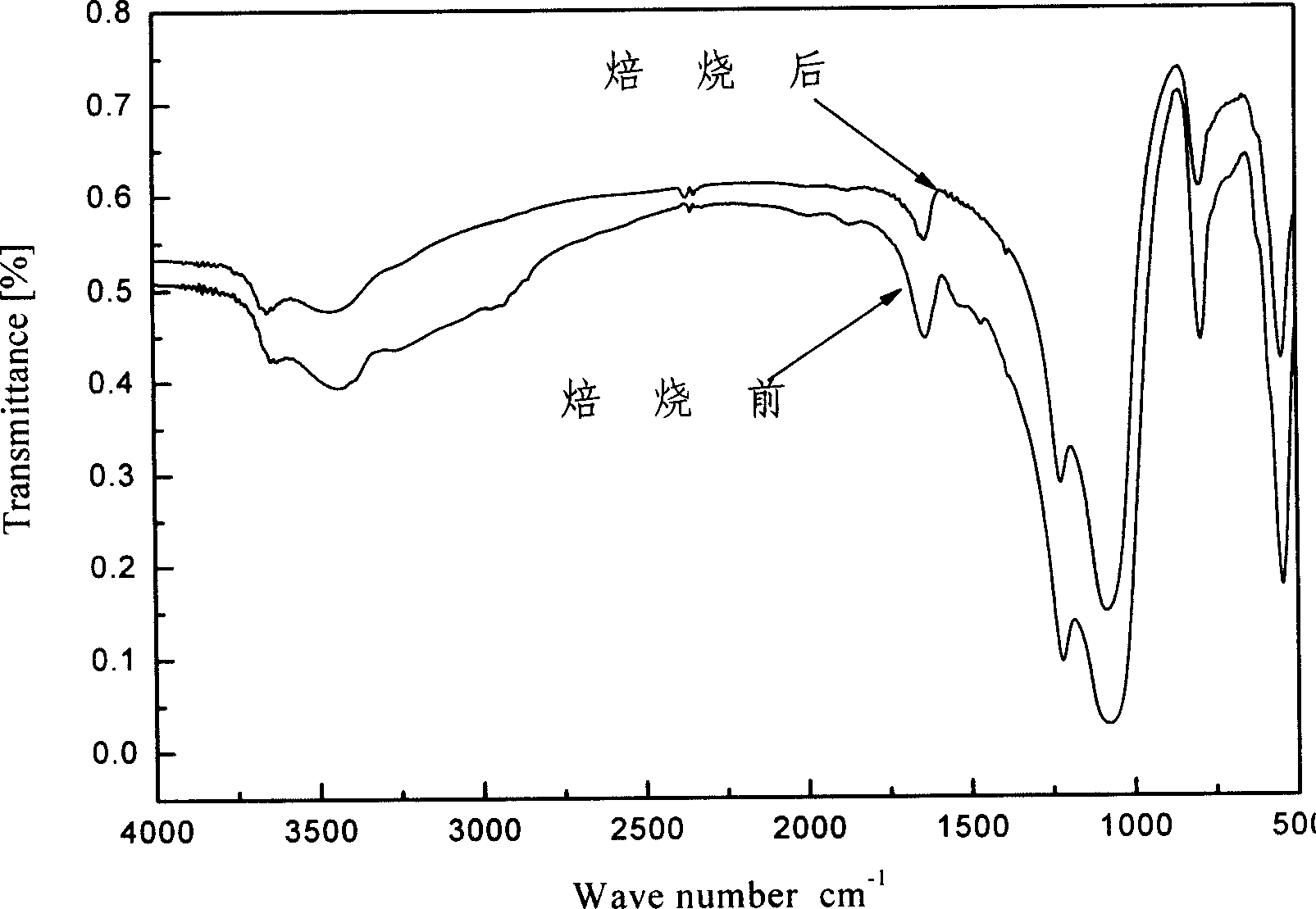

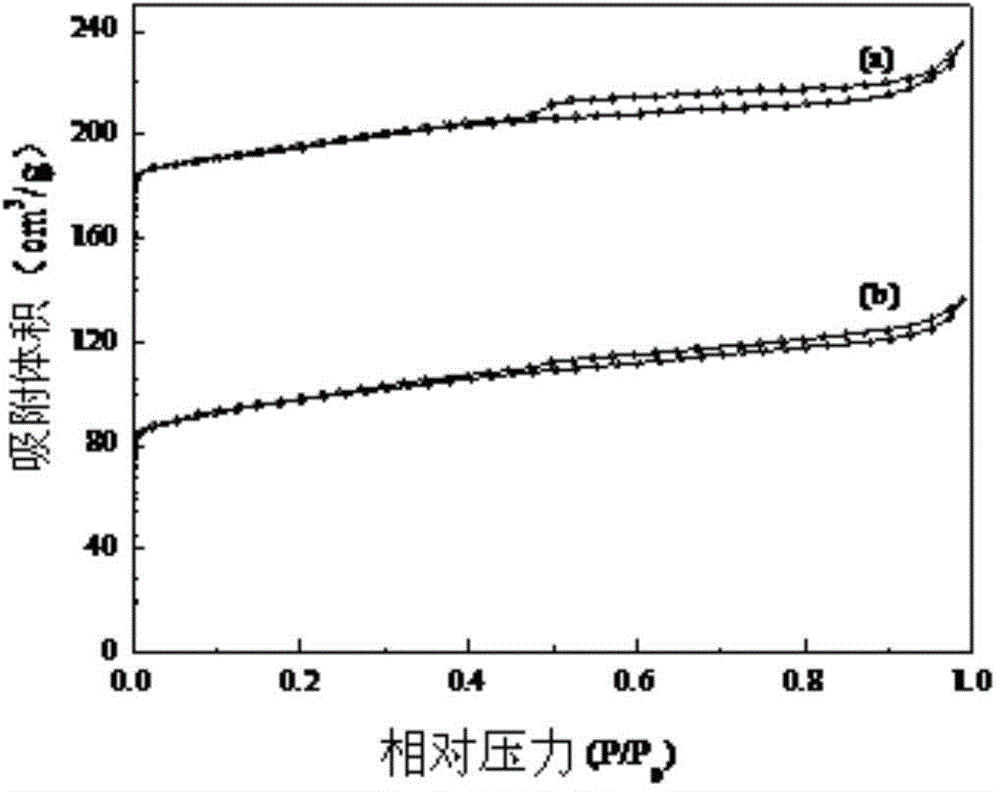

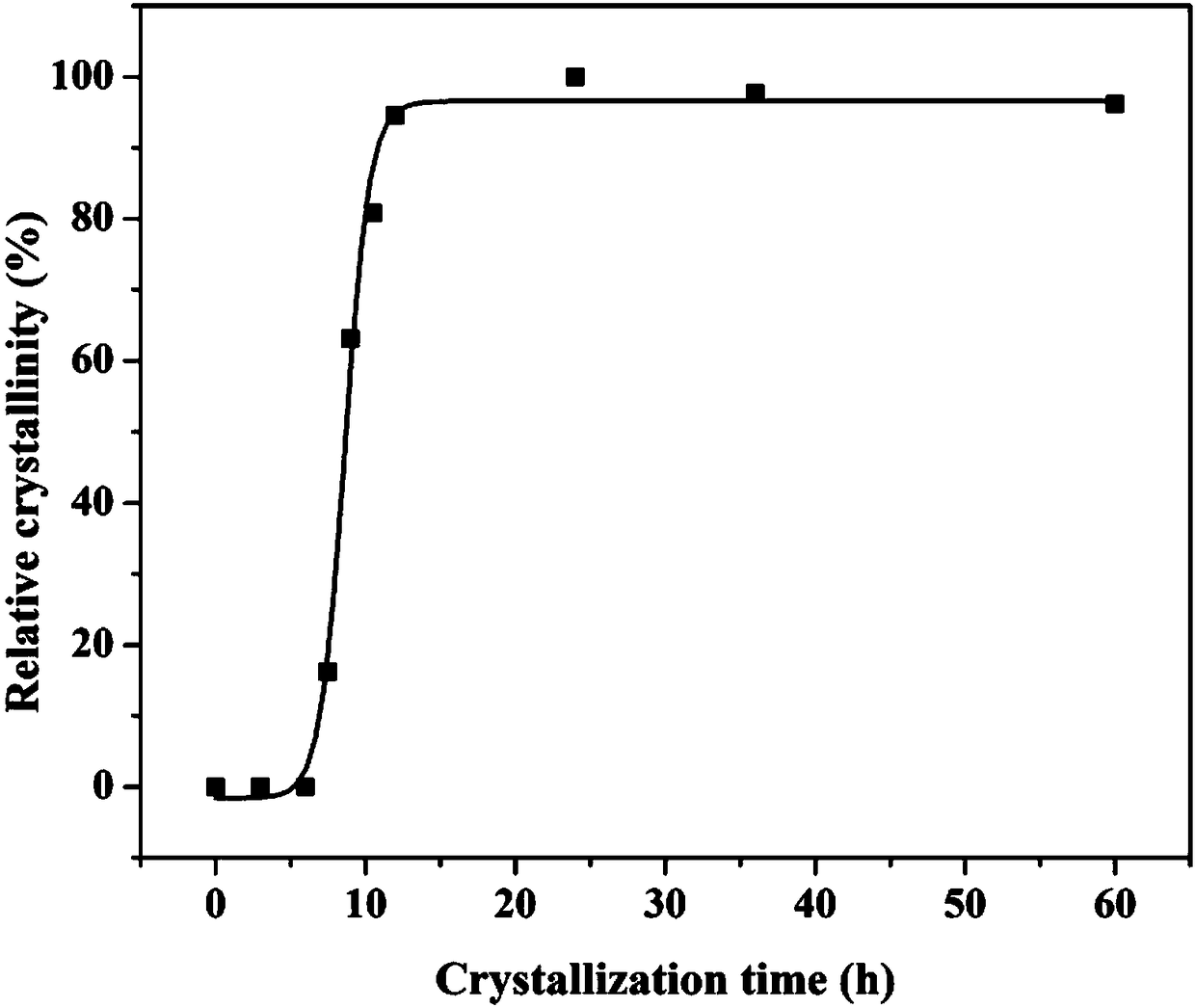

Method for preparing SAPO-34 molecular sieve

InactiveCN101525141AShort crystallization timeHigh crystallinityMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sievePre treatment

The invention discloses a method for preparing SAPO-34 molecular sieve, which is characterized in that Al2O3, P2O5, SiO2, R and H2O which have the mol ratio of 1:0.5-1.02:0.1-0.8:0.32-3:50-200 are mixed together into crystallization liquid and processed by aging treatment at the temperature of 2-110 DEG C for 10-24hr; or the crystallization liquid is processed by ultrasonic treatment at the temperature of 20-90 DEG C for 0.5-1hr, the ultrasonic frequency is 40-60 Hz, and the power is 200-400W. After being pretreated by the technique, the crystallization liquid is crystallized at the temperature of 180-200 DEG C for 18-48hr, and the solid product is washed in a centrifugal way and dried at the temperature of 105-115 DEG C; then, the obtained solid product is calcined at the temperature of 530-560 DEG C for 5-6hr, so that the SAPO-34 molecular sieve is obtained.

Owner:CHENGDU HUIEN FINE CHEM +1

Synthetic method of Ti-beta molecular sieve

ActiveCN101353169AHigh crystallinityLess structural defectsCrystalline aluminosilicate zeolitesMolecular sieveAlcohol

A synthetic method of TI-beta zeolite comprises the steps as follows: (1) silicate ester, titanate ester and butanol are evenly mixed according to the mol ratio that SiO2: TiO2: alcohol equals 1: (0.01-0.05): (4.0-15.0), and then NaOH solution is added for reaction at the room temperature of 120 DEG C, and kanemite is obtained by roasting; (2) the kanemite (counted based on SiO2), a template agent and water are evenly mixed according to the mol ratio that the SiO2: the template agent: the water equals 1: (0.1-1.0): (2.0-8.0) at the temperature of 120-170 DEG C, and crystallized for 2-15 days to obtain raw powder of a titanium silicalite molecular sieve with BEA skeleton structure; (3) the raw powder of the titanium silicalite molecular sieve obtained in the step (2) is washed by acid; and (4) the product washed by acid is roasted to obtain a Ti-beta molecular sieve product. The Ti-beta molecular sieve synthesized by the method in the invention contains little non-skeleton Ti, contains no Al, and is characterized by high relative crystallinity, few structural defects, good thermal stability, and nano crystal grain dimension.

Owner:CHINA PETROLEUM & CHEM CORP +1

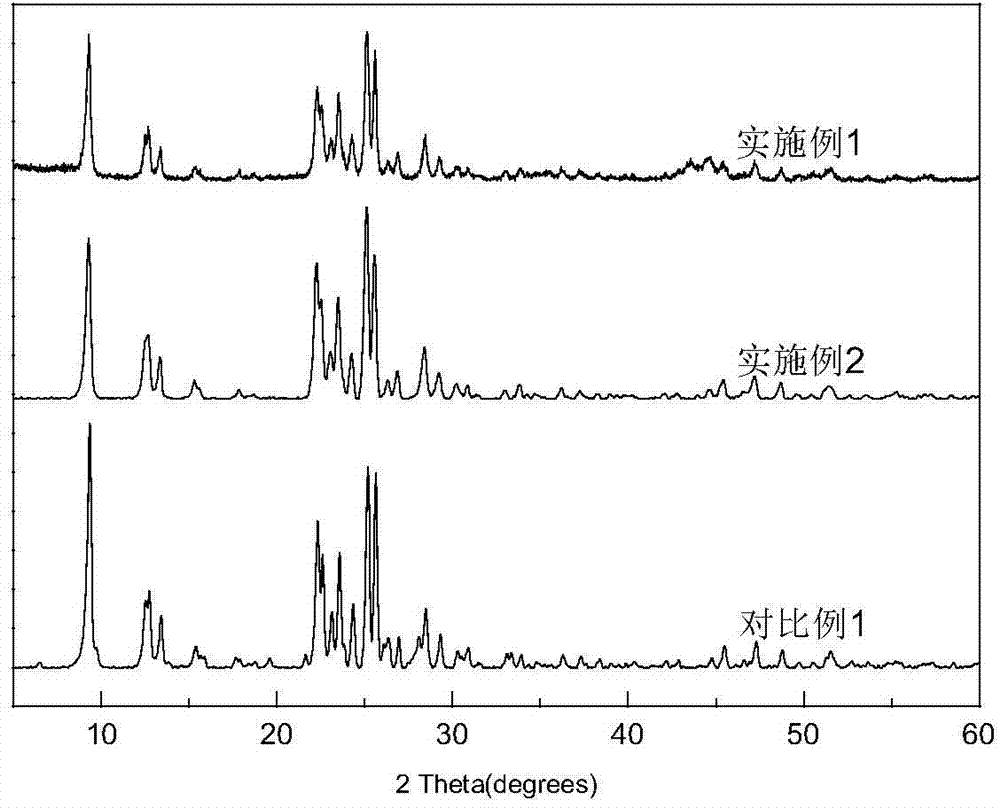

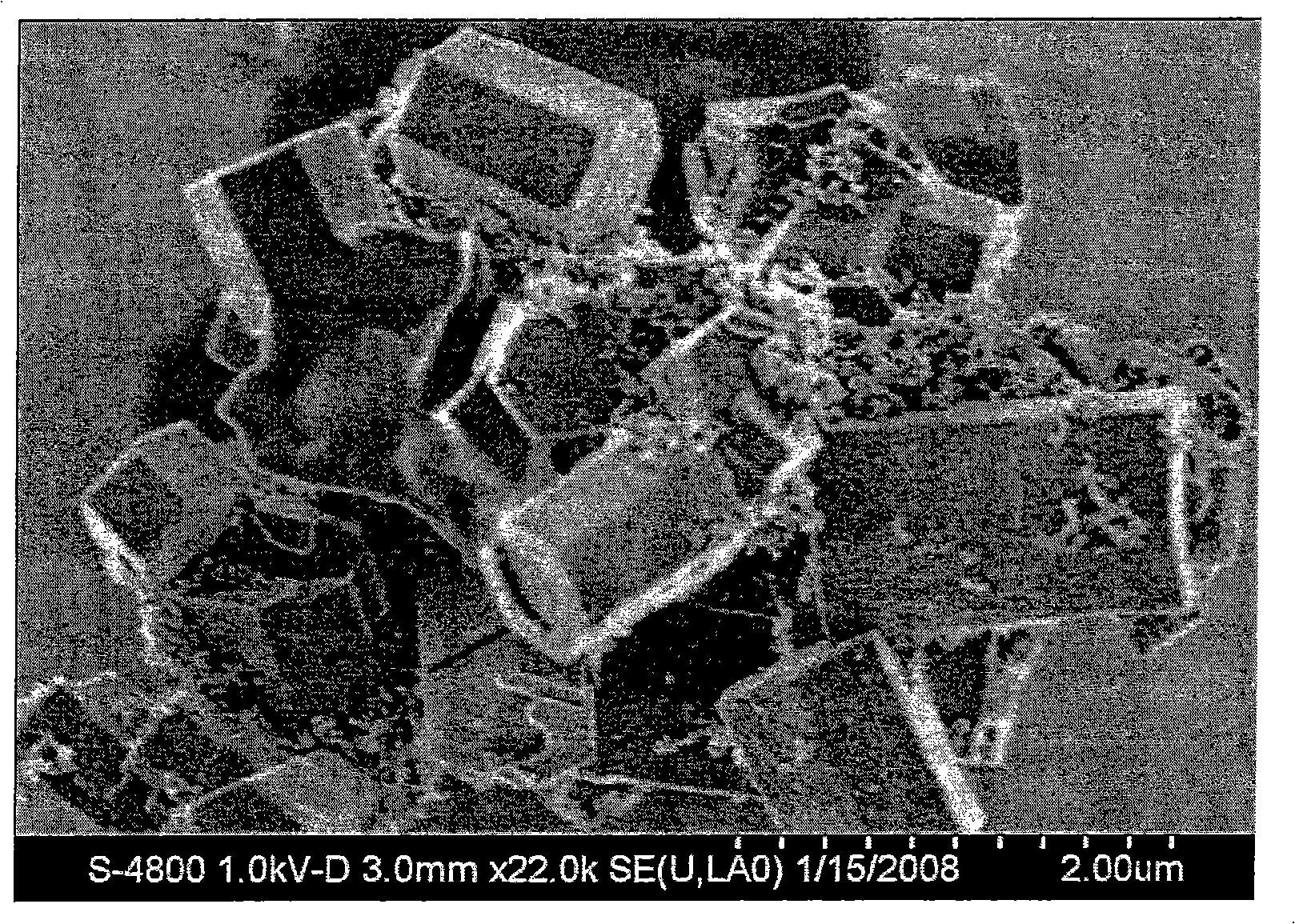

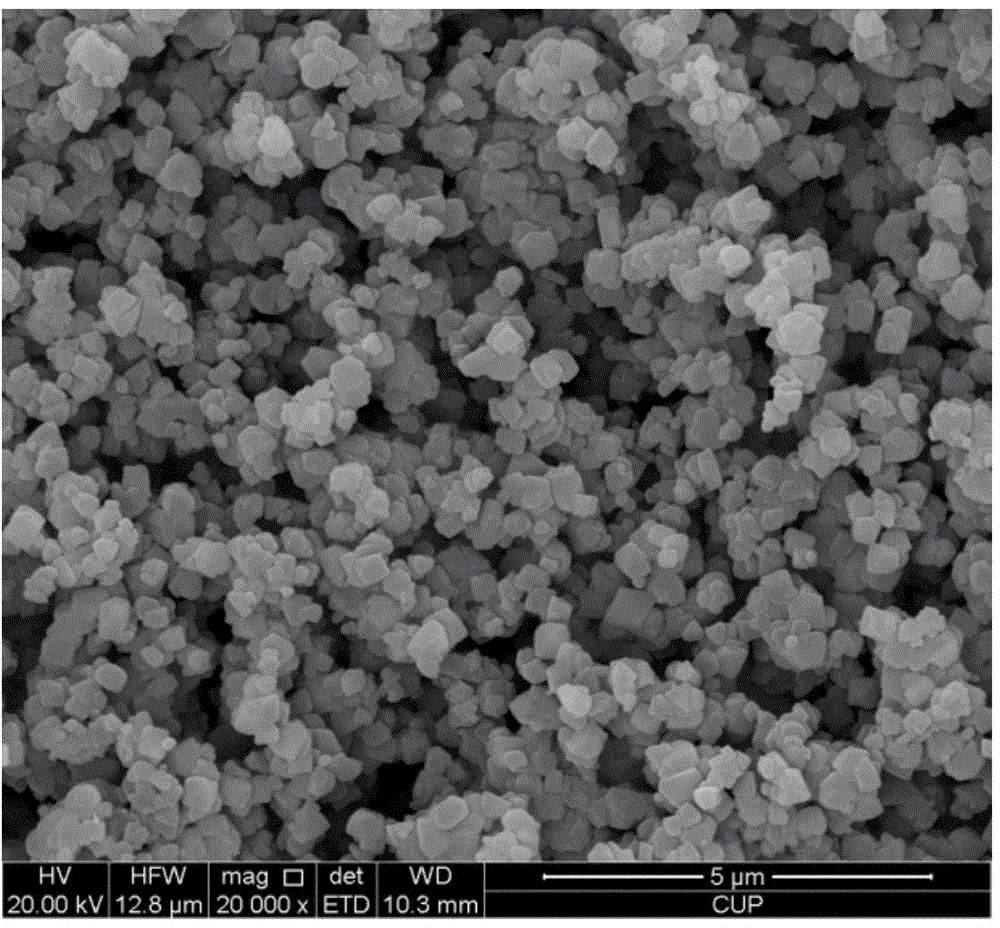

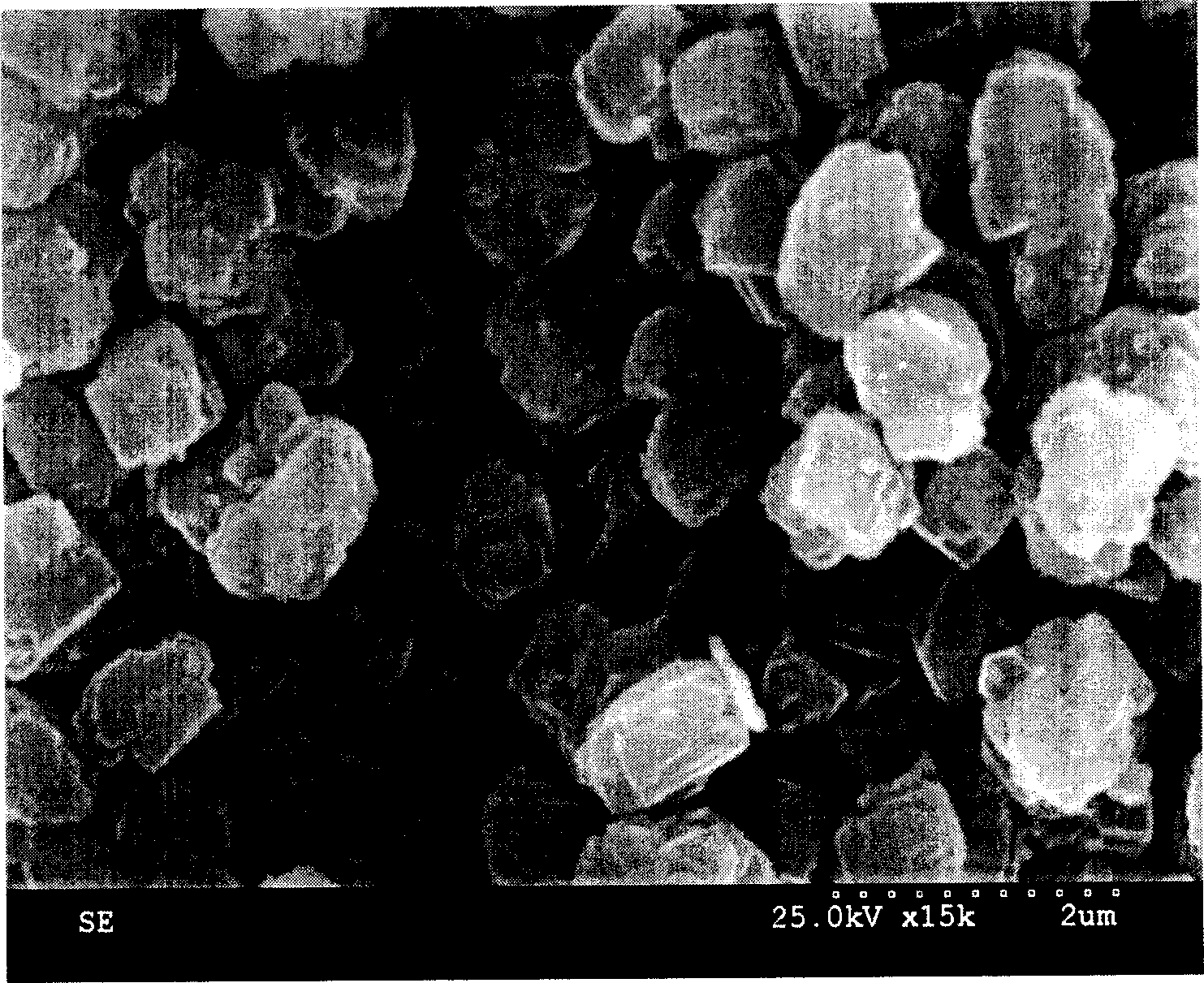

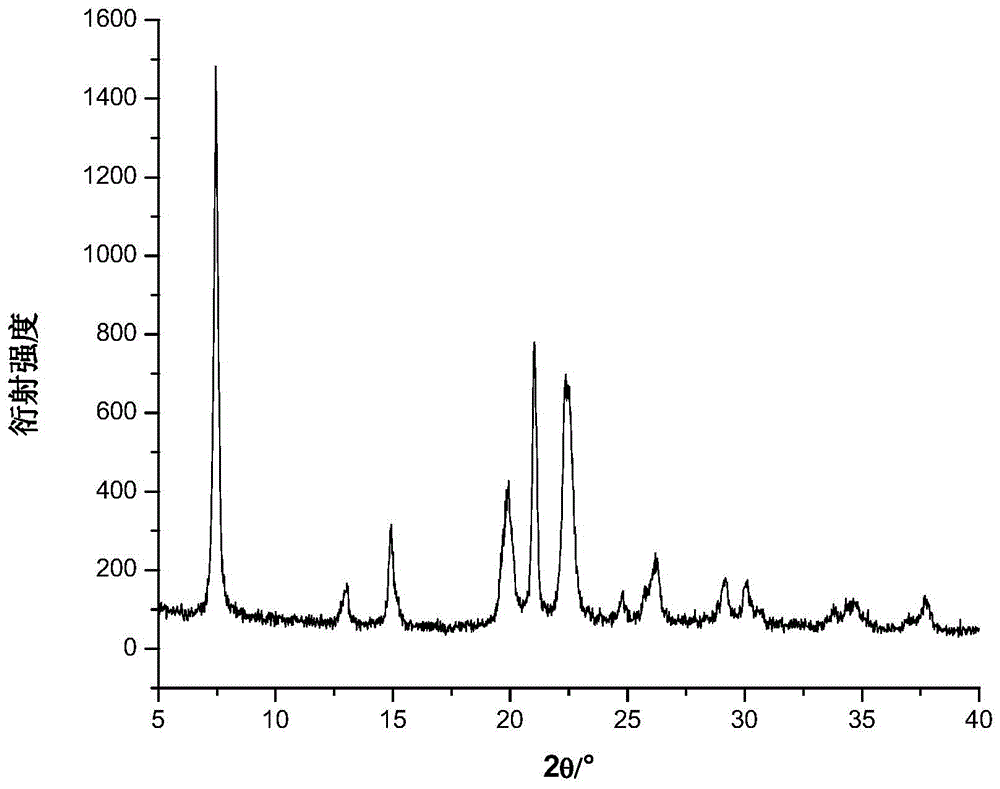

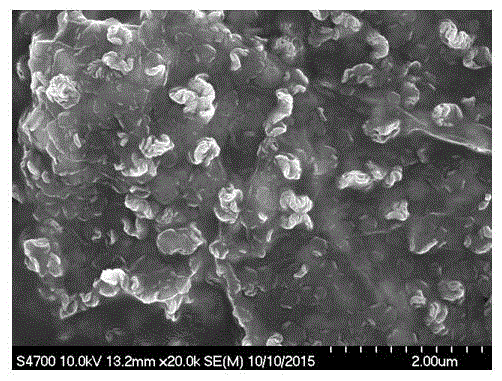

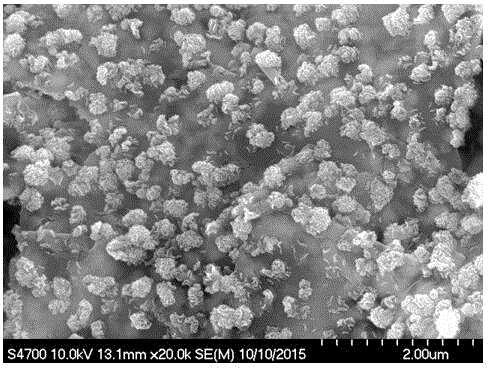

Preparation method of small grain ZSM-35 molecular sieve

ActiveCN104495869ASmall particle sizeHigh crystallinityFerrierite aluminosilicate zeoliteEthylenediamineMolecular sieve

The invention provides a preparation method of a small grain ZSM-35 molecular sieve. The method comprises the following steps: uniformly mixing a silicon source, an aluminum source, an alkaline source, a template and water to obtain a colloid liquid, the molar ratios of which are as follows: SiO2 / Al2O3=18.5-28.6, template / SiO2=0.81-1.25, OH<-> / SiO2=0.03-0.18 and H2O / SiO2=10-26; firstly crystallizing the colloid liquid for 5-30 hours at 15-80 DEG C and then continuously crystallizing for 10-30 hours at 150-200 DEG C; and filtering, washing and drying to obtain the small grain ZSM-35 molecular sieve. According to the preparation method, by using cheap ethidene diamine as the template, the crystallizing process is controlled to synthesize the small grain ZSM-35 molecular sieve by adding seed crystals and crystallizing in two stages, so that the grain size reaches about 0.5 micron at minimum.

Owner:PETROCHINA CO LTD +1

Method for synthesizing SAPO-5 with diethylamine as a template and recovering template

InactiveCN101302015AHigh yieldShort crystallization timeMolecular-sieve and base-exchange phosphatesMolecular-sieve silicoaluminophosphatesMolecular sieveNitrogen

The invention provides a method for synthesizing SAPO-5 by using diethylamine as template and recovering the template of the SAPO-5. The structural formula of the SAPO-5 is represented by aR x (SixAlyPz)O2, wherein, the x, y and z are a molar fraction of Si, a molar fraction of Al and a molar fraction of P respectively, and meet a relation of x+y+z =1; the R is the template; and the a is the mole number of the template, and a is between 0.5 and 2.5. The invention is characterized in that: the template adopts the diethylamine or mixture of nitrogenous organic substances mainly containing the diethylamine ; and the method comprises the following steps of: weighing the template, a silicon source, an aluminium source, a phosphorus source and water according to the mole amount of H2O on a molecular sieve with meshes between 0 and 500; preparing gel through sufficiently mixing and stirring the materials; crystallizing the gel at a temperature of between 160 and 350 DEG C with a reaction time not shorter than 0.1 hour; filtering, washing and drying after complete crystallization, and performing drying under a temperature of between 25 and 120 DEG C; heating up the gel to a temperature not higher than 250 DEG C after molecular sieve synthesis, and condensing and volatilizing diethylamine template which can be reused. The method has the advantages of simple preparation method, low cost and high product yield.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

Method for synthesizing MCM-22 molecular sieve

InactiveCN102040228ALower crystallization temperatureShort crystallization timeCrystalline aluminosilicate zeolitesMolecular sieveBenzene

The invention relates to a method for synthesizing MCM-22 molecular sieve. The method comprises the following steps of: preparing gel consisting of a silicon source, an aluminum source, an organic template agent, halogen compounds, alkali and water; then crystallizing the gel; and performing the traditional steps of filtering, washing, drying and roasting so as to obtain product of the MCM-22 molecular sieve, wherein the organic template agent can be dimethyleneimine, and also can be a mixed template agent composed of the dimethyleneimine and one or more than one of hydrocarbon, organic amine, alcohol and ketone. Compared with the prior art, the method has the advantages of low crystallization temperature, short crystallization time, high yield coefficient of product, high product quality and the like. The MCM-22 molecular sieve produced according to the invention has excellent catalytic performances of catalytic cracking, olefin alkylating, benzene alkylating and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Synthetic method for NaY zeolite with high silica-alumina ratio

ActiveCN104118885AHigh crystallinityMild preparation temperatureFaujasite aluminosilicate zeoliteHigh silicaSilicon

The invention provides a synthetic method for NaY zeolite with a high silica-alumina ratio. The method comprises the main steps: according to the proportioning requirement of a directing agent to uniformly mix a silicon source, an aluminium source and water, and ageing at 15 DEG C-60 DEG C for 0.5-120 h, so as to prepare the directing agent; according to the proportioning requirement of a gel reaction mixture to adding the directing agent and an alkaline solution into a silicone source at 10 DEG C-90 DEG C, stirring for 1 h-80 h, and stirring uniformly to obtain the gel reaction mixture; performing crystallization on the gel reaction mixture at 80-120 DEG C for 10-50 h, and then filtering, washing and drying to prepare NaY zeolite. The method does not employ a template, the preparation of the directing agent is mild in temperature, NaY zeolite with high crystallization degree and the high silica-alumina ratio is synthesized at a relatively short crystallization time. Also the method is capable of replacing conventional production technology without changing current apparatuses for industrial production, and has great important meaning on improving performances of catalytic cracking catalysts.

Owner:PETROCHINA CO LTD +1

Ultralow-expansion coefficient high transparent glass-ceramics and method for producing its product

The present invention relates to a Li2O-Al2O3-SiO2 system ultra-low expansion coefficient high-transparency glass-ceramic and production method of the products. Calculated by weight percentage, the ultra-low expansion coefficient high-transparency glass-ceramic is composed of 3.2 to 4.6 percent of Li2O, 18.0 to 23.6 percent of Al2O3, 64.1 to 69.4 percent of SiO2, 0.3 to 0.8 percent of MgO, 0.8 to 2.5 percent of BaO, 0.3 to 0.8 percent of R2O, 0.01 to 0.4 percent of Y2O3, 1.8 to 2.5 percent of TiO2, 1.6 to 2.4 percent of ZrO2, 1.1 to 1.8 percent of P2O5, 0.6 to 1.5 percent of Sb2O3, 0.3 to 1.0 percent of NaCl and 1.0 to 2.0 percent of NH4NO3. The heat-resistant glass plates and heat-resistant glass products can be manufactured by using the formula and the corresponding forming die. The present invention has the advantages that the production technique is simple, the produced products have low expansion coefficient, good transparency, high thermal impact temperature, high strength, have constant transparency when being used under the temperature of 700 Celsius system for a long time, the products have long service life, etc.

Owner:广东科迪微晶玻璃实业有限公司 +1

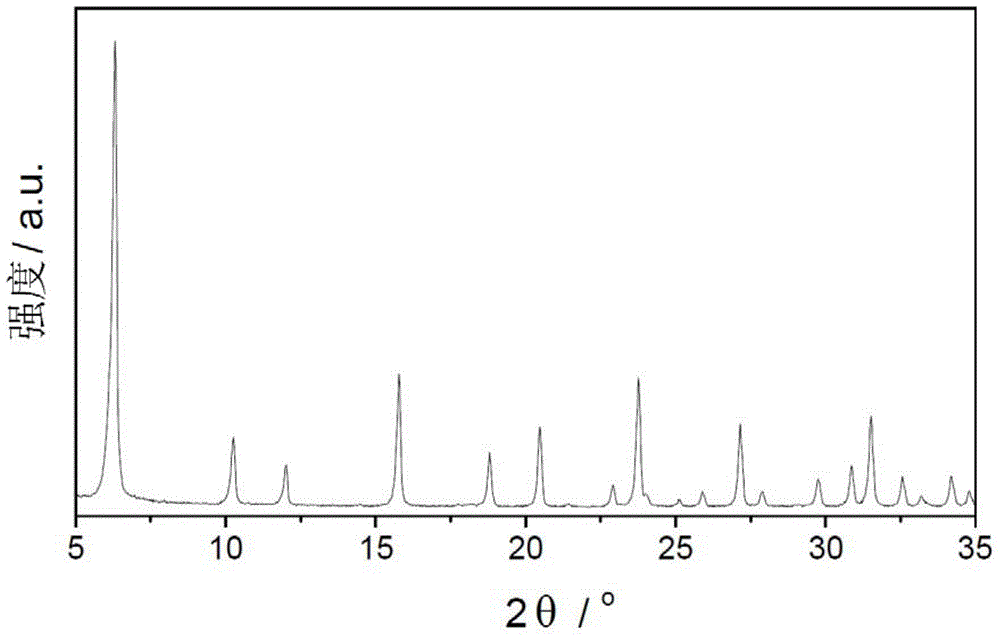

A method of synthesizing a NaY molecular sieve and the synthesized NaY molecular sieve

InactiveCN104692412AEvenly dispersedHigh solid contentFaujasite aluminosilicate zeoliteMolecular sieveFiltration

The invention relates to a method of synthesizing a NaY molecular sieve and the synthesized NaY molecular sieve. The method includes following steps: a step of synthesizing a directing agent, namely a step of subjecting a silicon source and NaOH to mixing pretreatment, adding water and an aluminum source, mixing uniformly and ageing to obtain the directing agent, with the mole ratio of Na2O, Al2O3, SiO2 and H2O being 15-25:1:10-30:250-450; a step of preparing reactive gel, namely a step of adding a solid silicon source into a NaOH solution, pretreating to prepare hydrous silica gel, adding an aluminum source, mixing uniformly, adding the directing agent, stirring and mixing uniformly to obtain flow type solid-like reactive gel, with the total adding mole ratio of the Na2O, the Al2O3, the SiO2 and the H2O being 2-6:1:5.5-10.5:50-150; and a step of crystallizing, performing suction filtration and drying, namely a step of crystallizing the prepared solid-like reactive gel, filtering after crystallization is finished, washing and drying to obtain a product.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Process for high concentration fast synthesis of ZSM-5 molecular sieve

InactiveCN1884075AHigh yieldShort crystallization timeMolecular sieve catalystsPentasil aluminosilicate zeoliteAluminium chlorideHigh concentration

The invention discloses a high-density rapid synthesizing method of ZSM-5 zeolitic molecular sieve, which is characterized by the following: adopting water glass or silicasol as silicon source, and aluminum sulfate, aluminium chloride, aluminum nitrate as aluminum source and short-chain organic amine as mould agent; adding ZSM-5 as seed to crystallize according to normal water-heat synthesizing method. The invention shortens crystallizing time, which reduces manufacturing cost effectively.

Owner:NANKAI UNIV

Synthetic method of MCM-22 (Multiple Chip Module 22) molecular sieve

ActiveCN102040229ALower crystallization temperatureShort crystallization timeCrystalline aluminosilicate zeolitesKetoneAlkylation

The invention relates to a preparation method of an MCM-22 (Multiple Chip Module 22) molecular sieve, which comprises the following steps of: firstly preparing a structure directing agent, and uniformly mixing the structure directing agent with a silicon source, an aluminum source, a boron source or an iron source, an organic template agent and water into glue, wherein the organic template agent can be dimethyleneimine and can also be a mixed template agent comprising the dimethyleneimine and one or more of hydrocarbons, organic amine, alcohols and ketones; and then synthesizing an MCM-22 molecular sieve material through the silicon source, the aluminum source, alkali, the organic template agent and the structure directing agent, carrying out hydrothermal crystallization and obtaining an MCM-22 molecular sieve product through conventional processes of filtering, washing, drying and roasting. The method disclosed by the invention has the main characteristic that the structure directing agent is added into gel, and compared with the prior art, the method disclosed by the invention has the advantages of low crystallization temperature, short crystallization time, high product yield, high product quality and the like. The MCM-22 molecular sieve product disclosed by the invention has excellent catalytic performances, such as catalytic cracking, olefin and benzene alkylation and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Crystallization method for trichlorosucrose

ActiveCN101210034AShort crystallization timeEasy to operateSugar derivativesSugar crystallisationSolubilitySucrose

The invention discloses a crystallization method of trichloro sucrose. The method dissolves a concentrate or a solid that contains the trichloro sucrose in a mixed impregnant. The mixed impregnant contains two impregnant with large difference in boiling points; wherein, the impregnant with a low boiling point has higher solubility to the trichloro sucrose while the impregnant with a high boiling point has lower solubility to the trichloro sucrose. In the condition of proper temperature and vacuum degree, the impregnant is concentrated and crystals of the trichloro sucrose are separated when the impregnant with low boiling point volatilizes and finished product of trichloro sucrose crystals is obtained through filtering and desiccation after being settled. The method has the advantages of low production cost, high production yield, mild condition, stable quality and simple equipment, etc.

Owner:JK SUCRALOSE

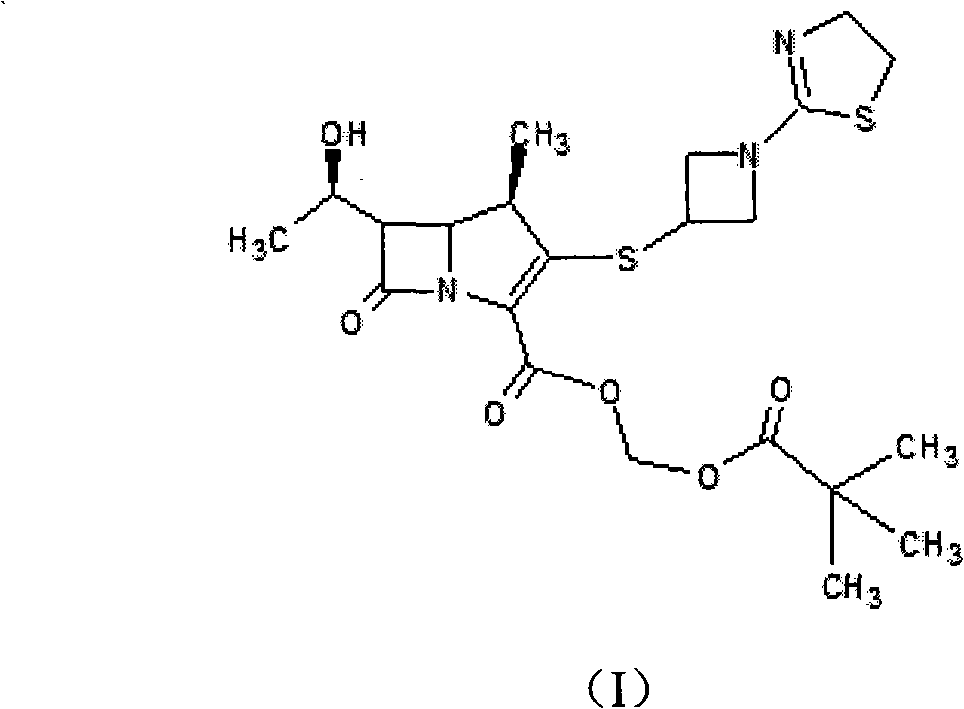

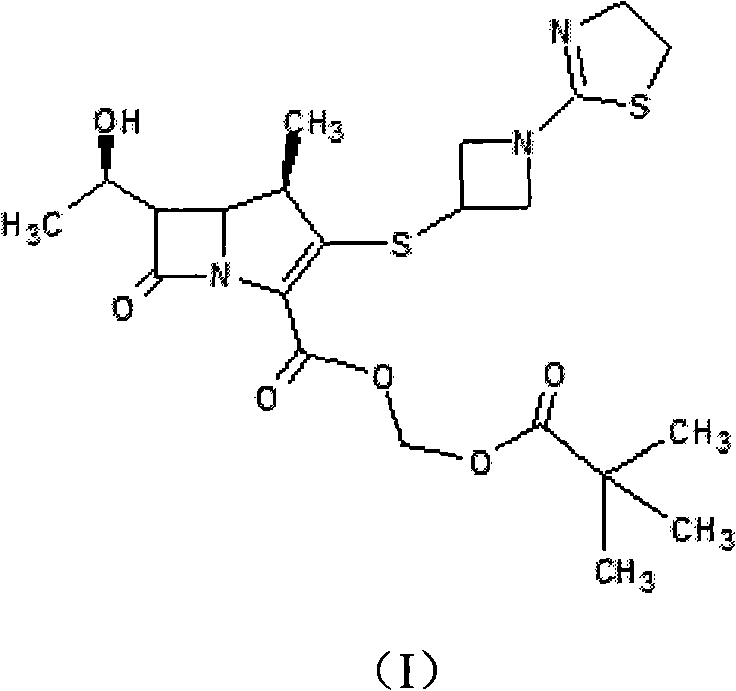

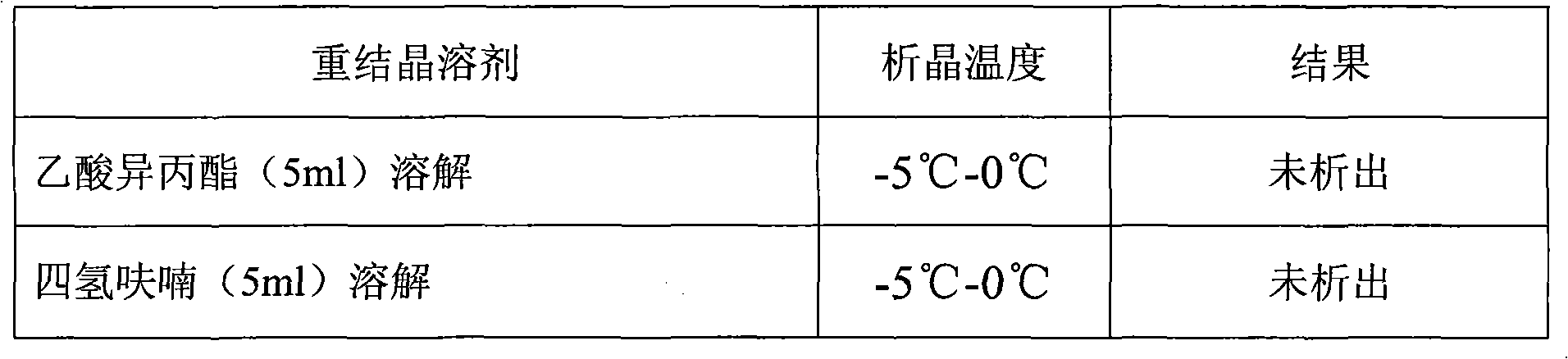

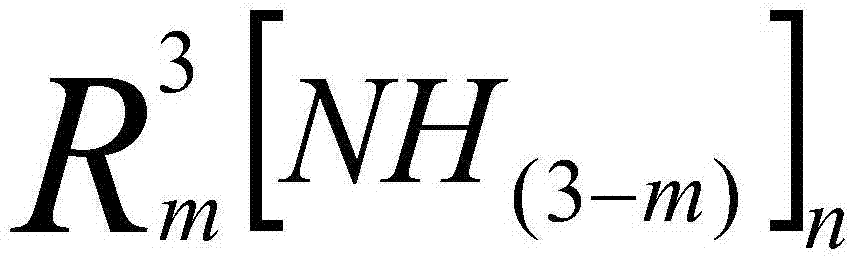

A kind of recrystallization refining method of tipipenem ester

InactiveCN102276611AEasy to operateShort crystallization timeOrganic chemistryIsopropyl etherDrugs preparations

The invention discloses a method for purifying tebipenem by recrystallizing. Acetone and isopropyl ether are adopted as recrystallizing solvents, the operation is simple, heating or cooling equipment is not required, crystallization is realized at room temperature, crystallization time is short, and recrystallization yield is high and over 75 percent, so that the method is suitable for industrialproduction, the recrystallized product has short melting range, high purity which is over 99.9 percent by virtue of HPLC (high performance liquid chromatography) detection, and can be used as a raw material medicament in accordance with requirements to prepare a medicinal preparation for safe administration of patients.

Owner:深圳万乐药业有限公司

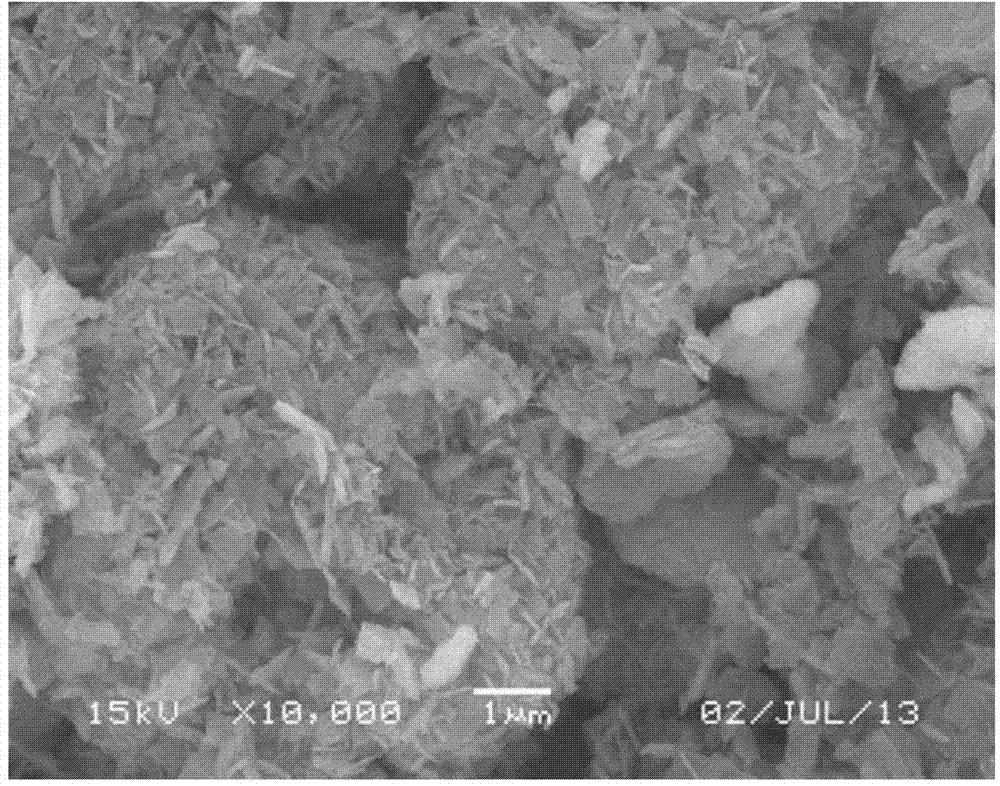

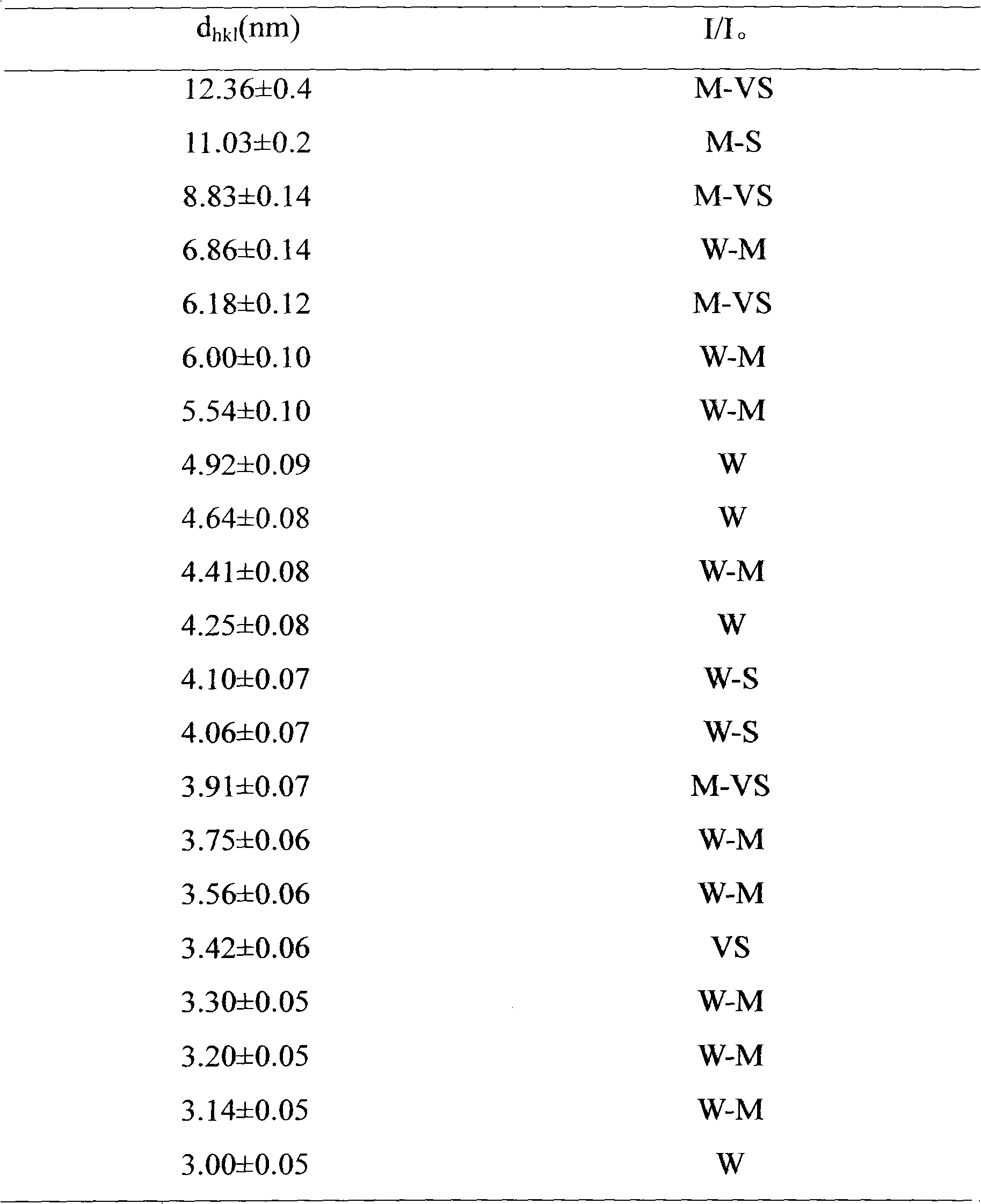

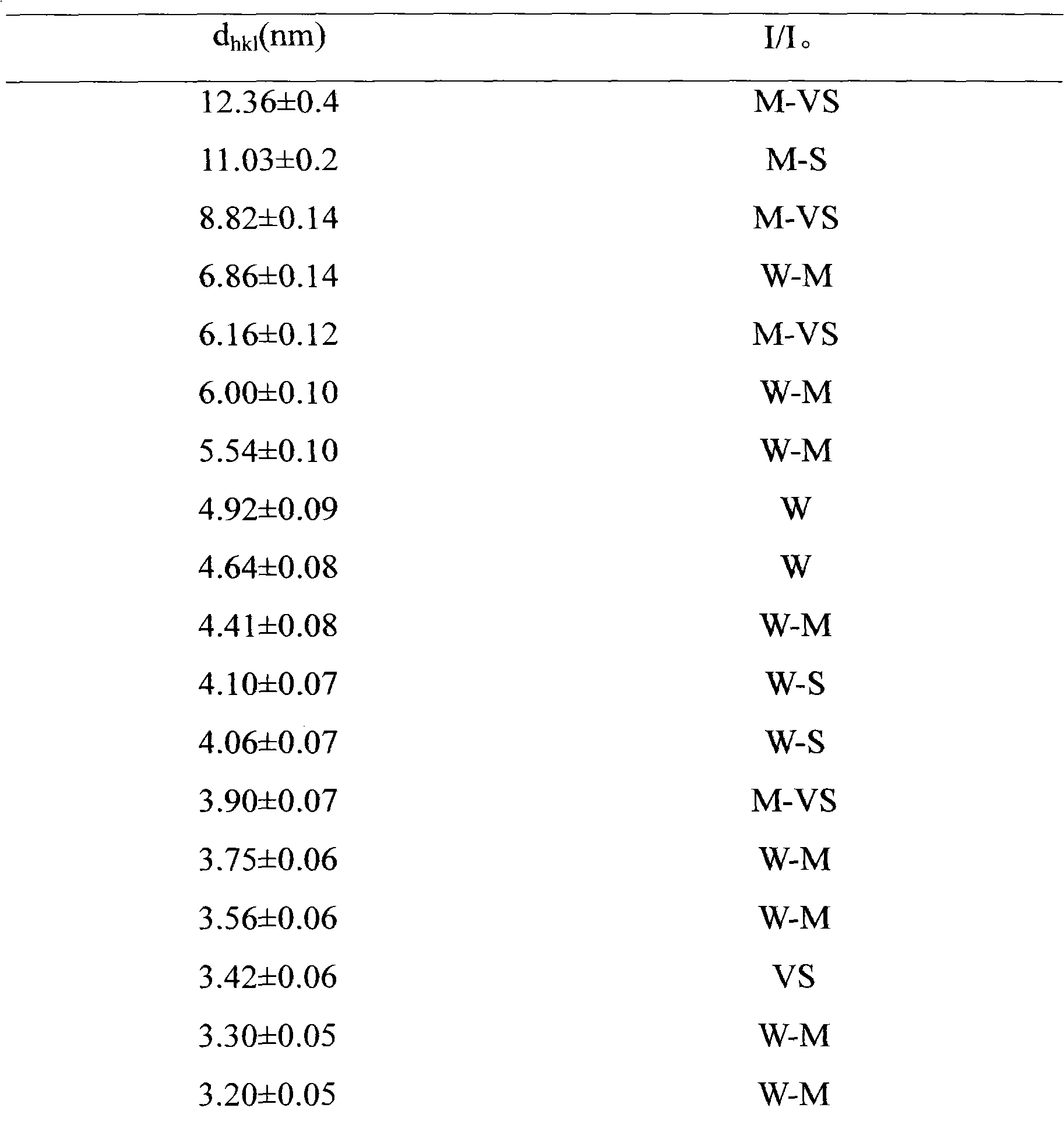

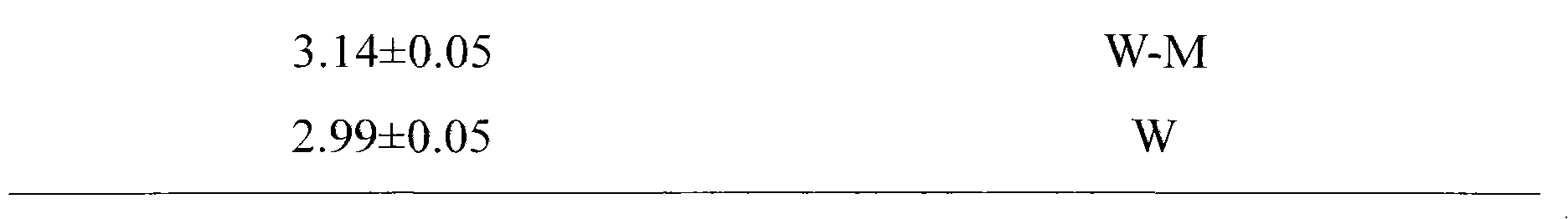

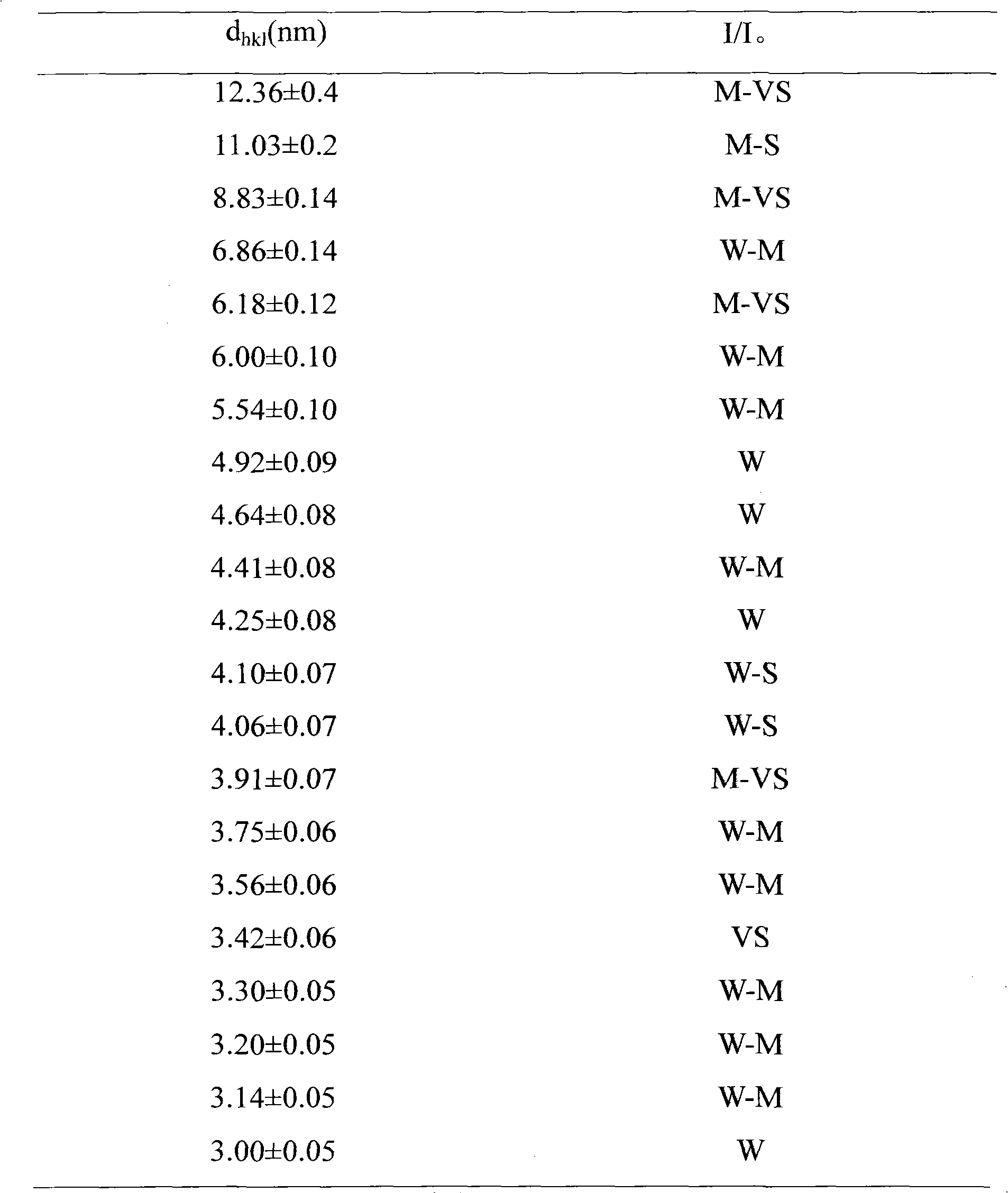

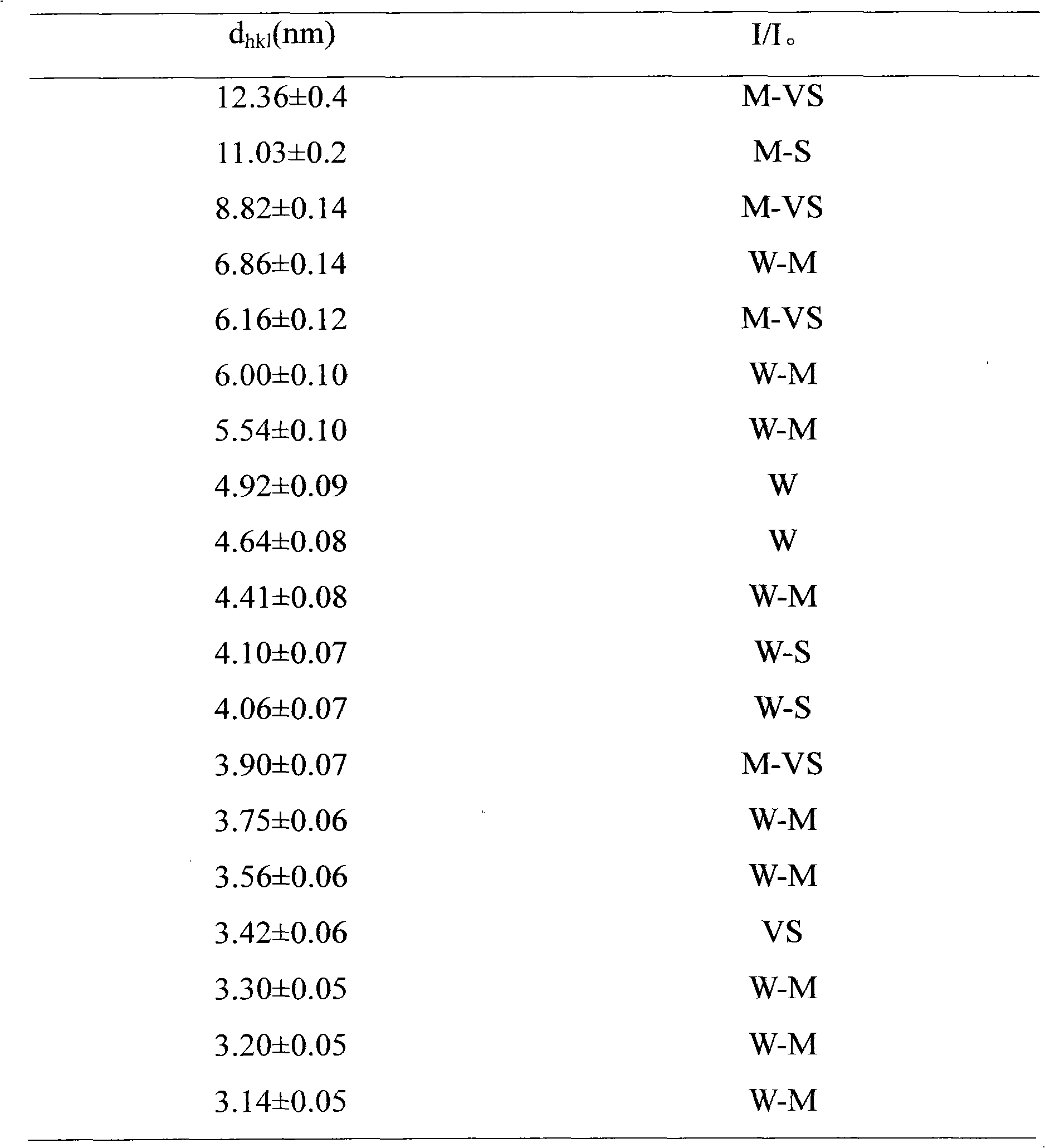

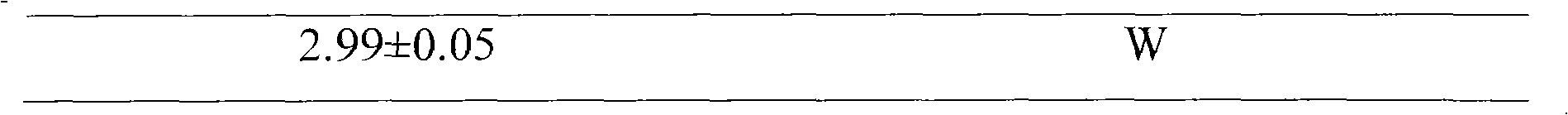

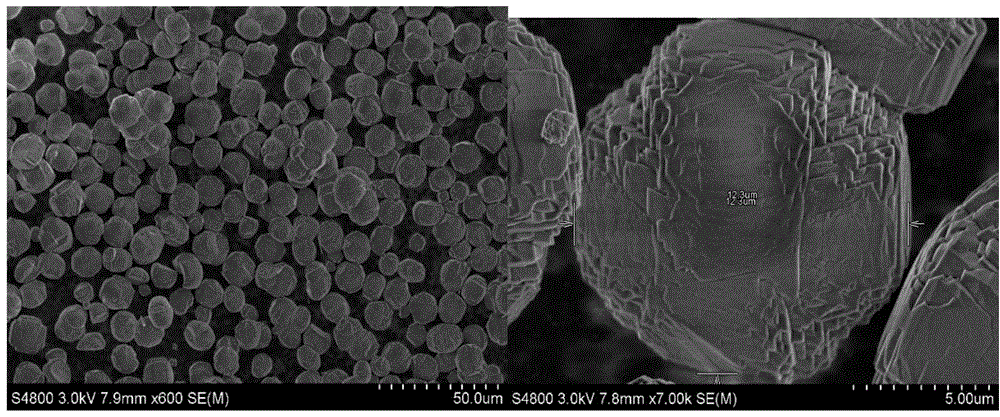

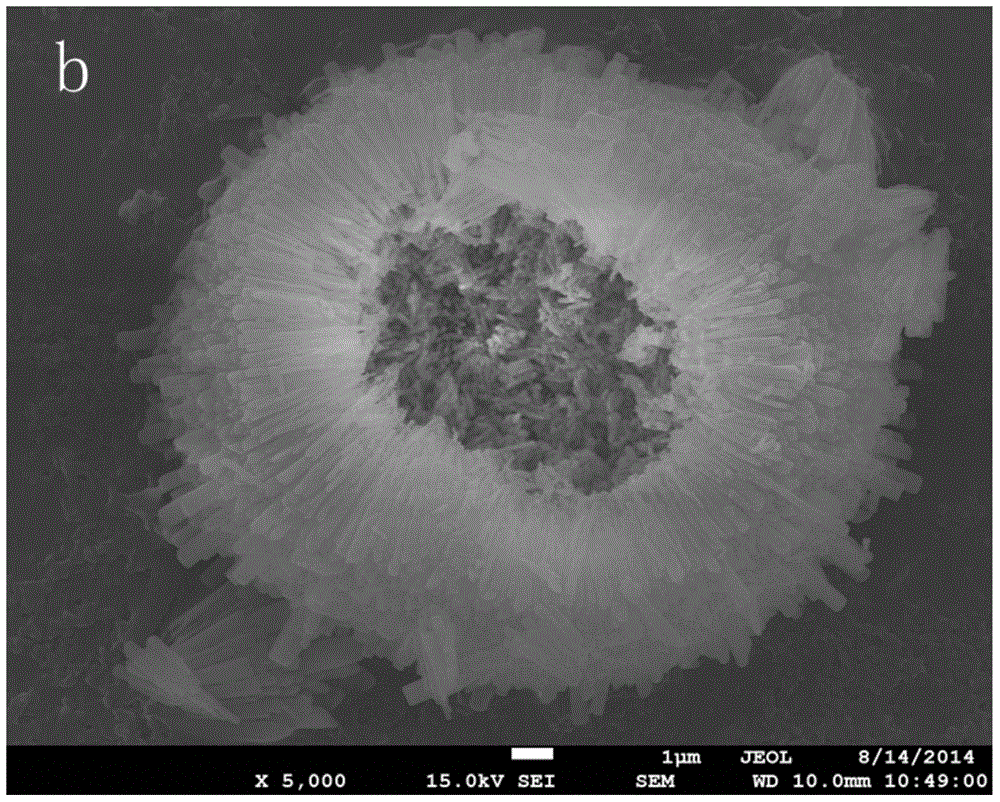

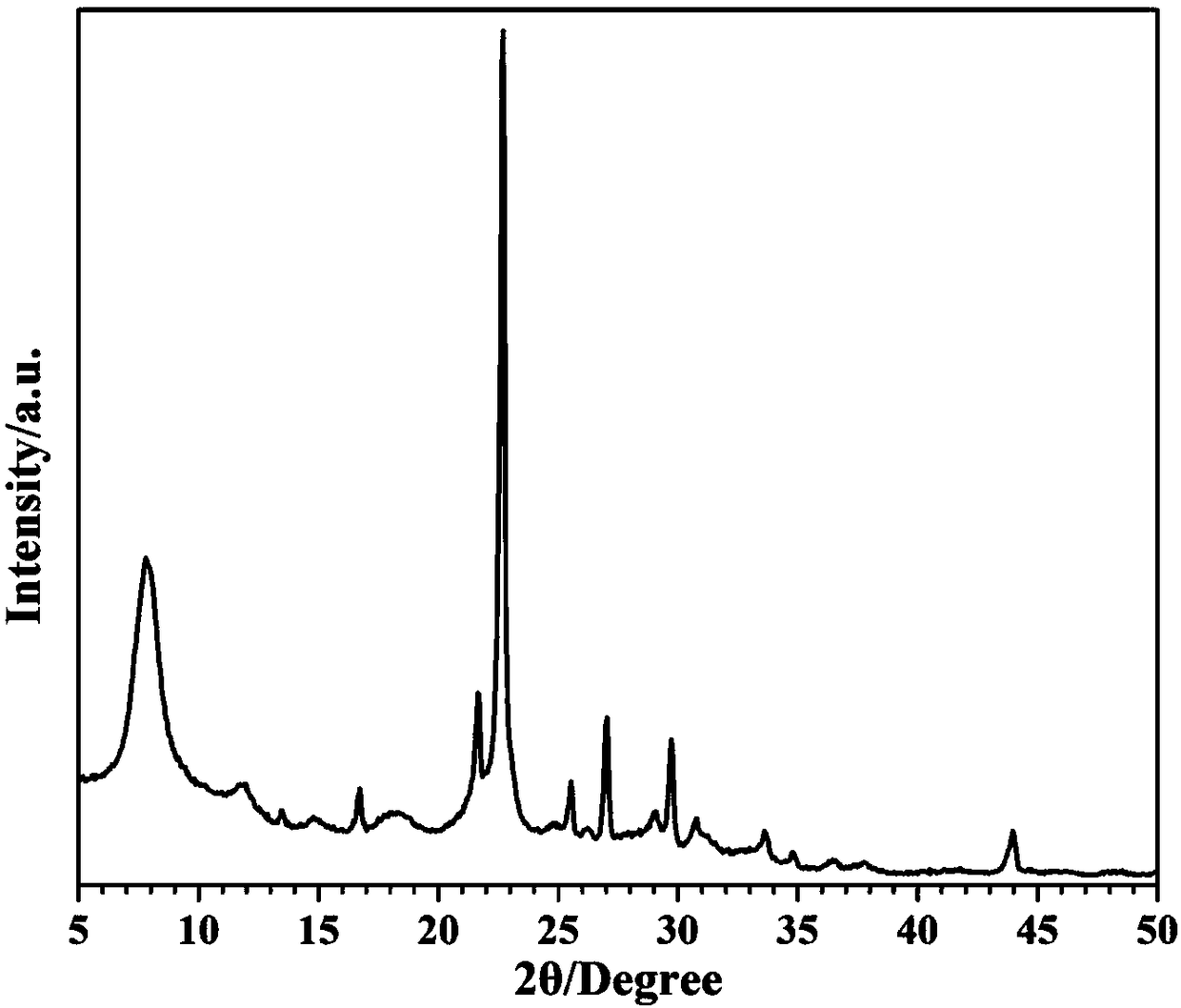

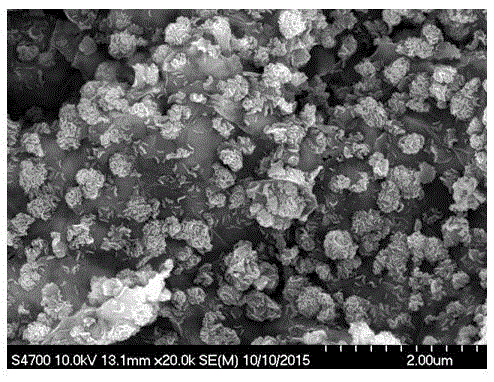

Preparation method of titanium-silicate molecular sieve having large particle size

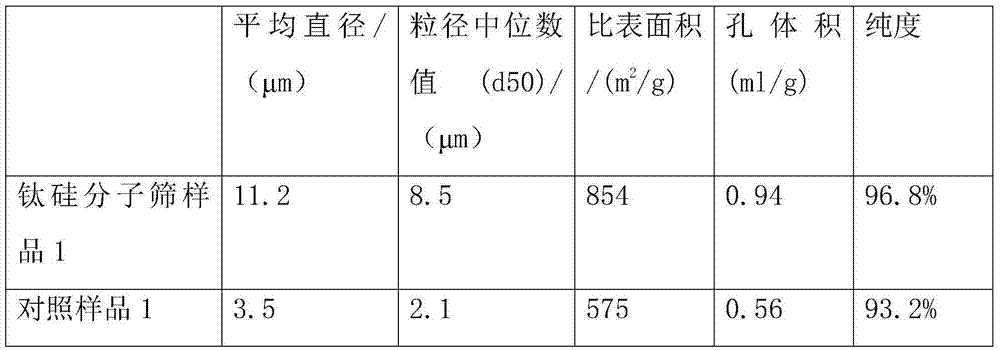

ActiveCN104495867ASolving Recycling ProblemsShort crystallization timeCrystalline aluminosilicate zeolitesMolecular sieveInorganic Chemical

The invention discloses a preparation method of a titanium-silicate molecular sieve having large particle size and belongs to the technical field of inorganic chemical synthesis. The preparation method comprises the following steps of synthesizing a crystalline material; introducing the crystalline material into a mixed solution comprising an inorganic silicon source, an inorganic titanium source, an organic template agent and water, controlling pH by virtue of an alkaline source, carrying out hydrothermal crystallization, filtering, washing, drying and calcining to obtain the titanium-silicate molecular sieve. By the preparation method, the deficiencies of the prior art are overcome and by the prepared titanium-silicate molecular sieve, the problem that titanium-silicate molecular sieve having small particle size is difficult to be separated from the product and recovered in the industry can be well solved. The titanium-silicate molecular sieve prepared by the preparation method, which is disclosed by the invention has the advantages that the average particle size is greater than 5mu m or more, the crystallization time is short, the product is high in purity, the method has good repeatability, the operation is simple and feasible and the process is easy to control.

Owner:ZHEJIANG JINHUA NEW MATERIALS

Chalcogenide devices and materials having reduced germanium or telluruim content

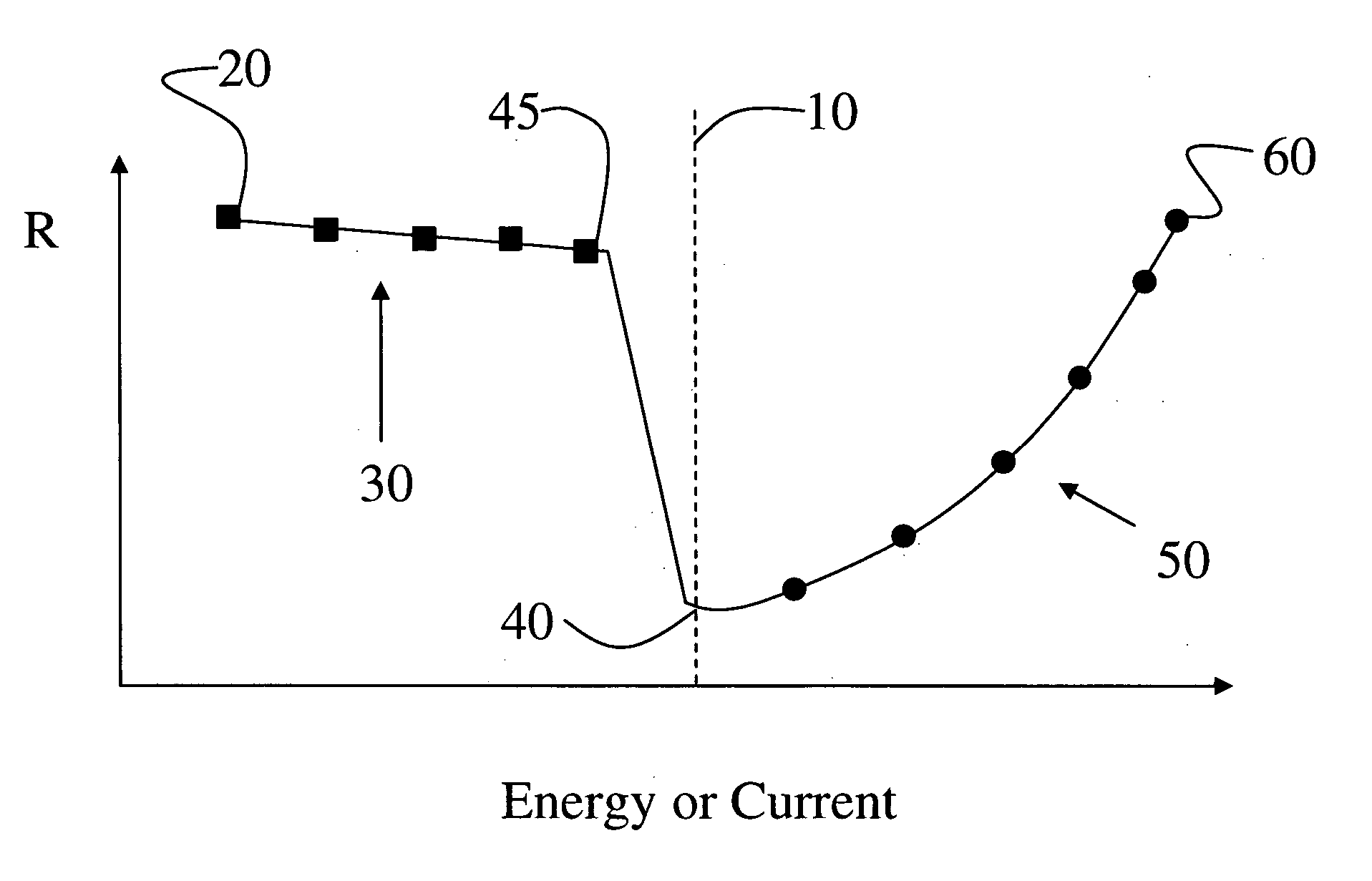

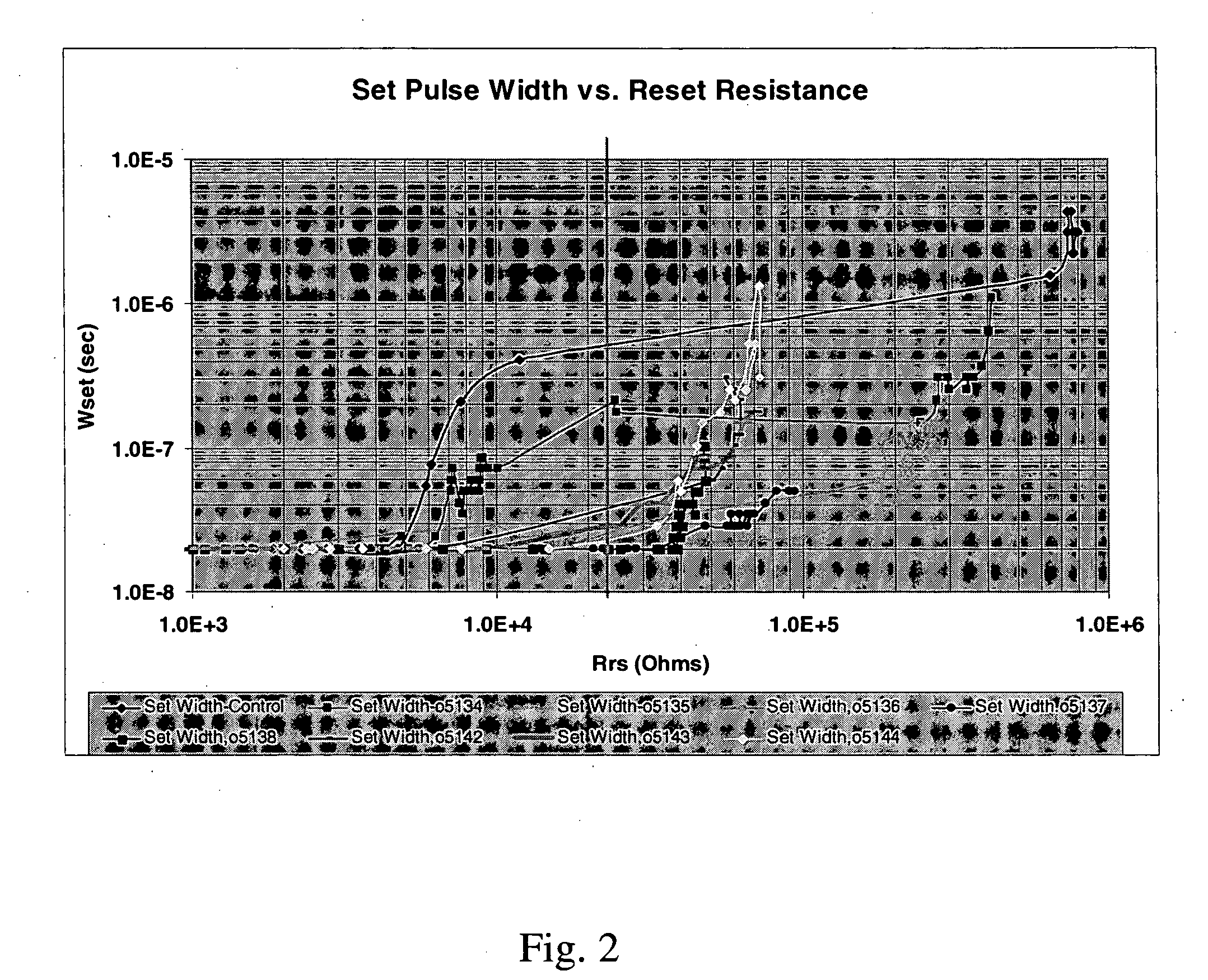

ActiveUS20070034851A1Favorable formation characteristicShort crystallization timeBulk negative resistance effect devicesHigh resistanceSulfur

A chalcogenide material and chalcogenide memory device exhibiting fast operation (short set pulse times) over an extended range of reset state resistances. Electrical devices containing the instant chalcogenide materials permit rapid transformations from the reset state to the set state for reset and set states having a high resistance ratio. The instant devices thus provide for high resistance contrast and improved readability of memory states while preserving fast operational speeds for the device. The chalcogenide materials include materials comprising Ge, Sb and Te in which the Ge and / or Te content is lean relative to the commonly used Ge2Sb2Te5 chalcogenide composition. In one embodiment, the atomic concentration of Ge is between 11% and 22%, the atomic concentration of Sb is between 22% and 65%, and the atomic concentration of Te is between 28% and 55%. In a preferred embodiment, the atomic concentration of Ge is between 15% and 18%, the atomic concentration of Sb is between 32% and 35%, and the atomic concentration of Te is between 48% and 51%.

Owner:OVONYX MEMORY TECH LLC

Preparation method for SCR catalyst for purifying oxynitride in motor vehicle exhaust

InactiveCN105833899ASmooth coating processImprove stabilityGas treatmentInternal combustion piston enginesCrystallizationSSZ-13

The invention discloses a preparation method for an SCR catalyst for purifying oxynitride in motor vehicle exhaust .The preparation method includes the steps of preparation of an SSZ-13 molecular sieve, preparation of a Cu-SSZ-13 catalyst and preparation of an integrated SCR catalyst .The preparation method is simple, production cost is lowered, SSZ-13 crystallization time is short, crystallization is relatively pure, HN3-SCR catalytic activity is high, and the purification rate of oxynitride in motor vehicle exhaust is high.

Owner:ZHEJIANG FORSOL ENERGY

Method for gathering/recovering VE (Vitamins E), squalene and polyunsaturated fatty acids from deodorized distillate of plant oil

ActiveCN103483305AShort crystallization timeReduce lossesFatty acids production/refiningCrystallisation purification/separationSolventSterol

The invention discloses a method for gathering / recovering VE (Vitamins E), squalene and polyunsaturated fatty acids from the deodorized distillate of plant oil. Specifically, the method comprises the following steps: adopting urea and a solvent as addition agents; mixing the addition agents with the distillate so as to dissolve the addition agents in the distillate; carrying out flexible packaging, vacuum degassing and sealing; applying a super high pressure for quickly crystallizing and agglomerating saturated fatty acids, monounsaturated fatty acids, fatty hydrocarbons, sterols and the like in the distillate; adsorbing a large quantity of impurities with an inclusion compound; carrying out pressure filtering and separating to obtain filter residue and filtrate; removing the solvent from the filtrate to obtain the VE, squalene and polyunsaturated fatty acids with high concentration. According to the method, the recovery rates of the VE, squalene and polyunsaturated fatty acids are all more than 80%, and neutral oil can be reserved.

Owner:潘见

Method for preparing molecular sieve ZSM-5

InactiveCN102001679ASimple processUniform temperaturePentasil aluminosilicate zeoliteProduction rateGranularity

The invention relates to a method for preparing a molecular sieve ZSM-5 by preparing a precursor glue solution, crystallizing, filtering, drying and roasting. The invention adopts two crystallization methods, one method comprises the following steps of: directly illuminating the precursor glue solution in a sealed container by adopting a microwave field, and crystallizing by utilizing the coaction of the microwave effect and the autogenous hydrothermal pressure of the glue solution; and the other method comprises the following steps of: heating the precursor glue solution in the sealed container by adopting saturated steam for crystallization treatment, wherein the heating and the crystallization treatment can be simultaneously carried out in the microwave field. The saturated steam for the crystallization treatment is crystallized at 170-180 DEG C for 1-6h, 1-10 percent by weight of inoculating seeds are added after aging the precursor glue solution and before crystallizing the precursor glue solution which is prepared by adopting a template-free preparation method. The method of the invention has the following advantages of simple and practical process and uniform temperature in the crystallization process, obtains the molecular sieve with high crystallinity, pure crystal phase, controllable grain size, wider range and short crystallization time, can improve the production efficiency, decrease the cost and save energy.

Owner:YUEYANG YITIAN CHEM

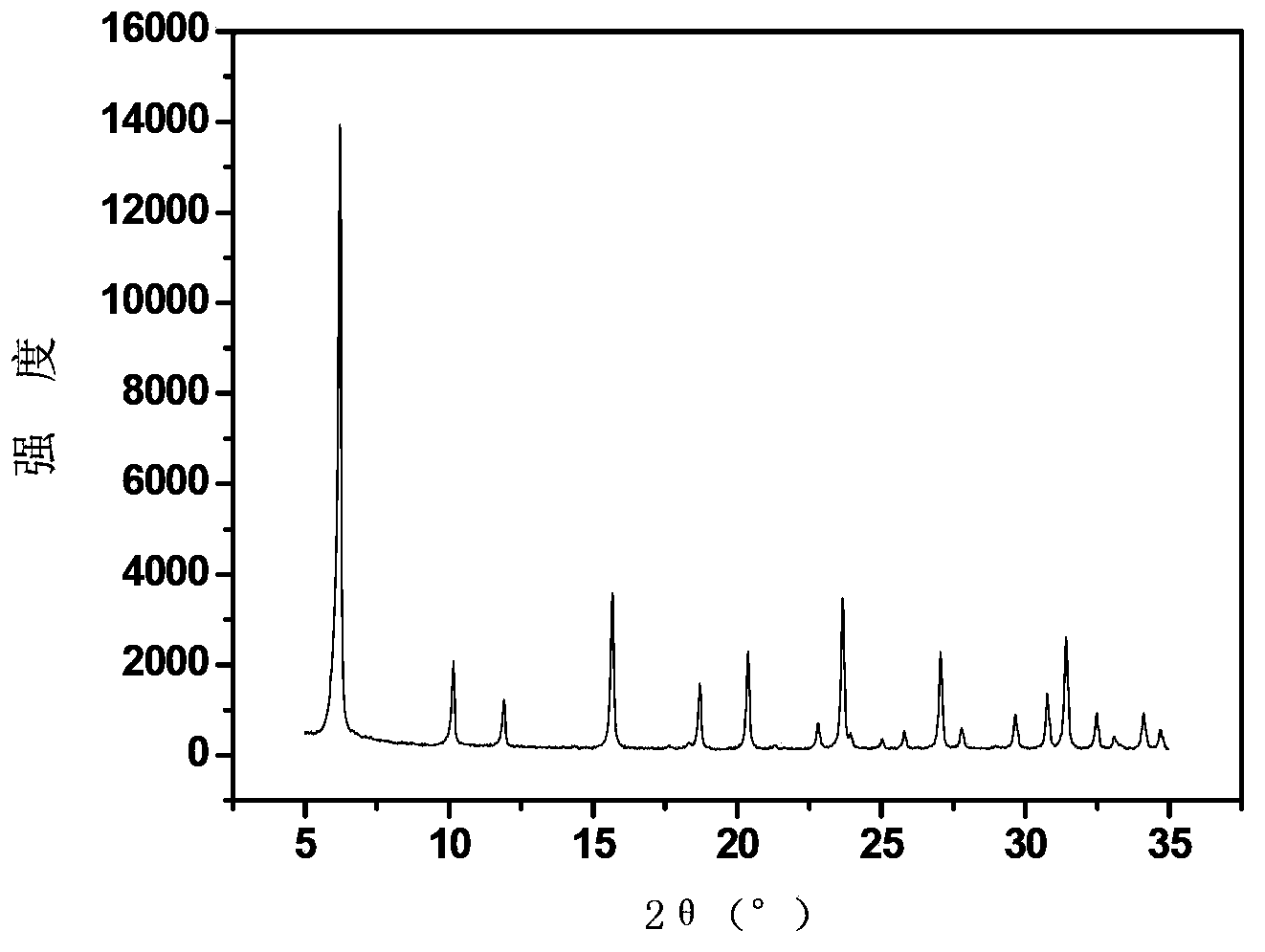

Method for synthesizing NaY molecular sieve

The invention relates to a method for synthesizing a NaY molecular sieve, which comprises the steps of synthesizing director reagents, synthesizing gel, crystallizing and reclaiming. The method is characterized in that an additive is introduced in the process of synthesizing the gel or crystallizing, wherein the weight ratio of the additive to Al2O3 in the gel is 0.1-3:1, and the additive selects from one or more of ethanol with ester or hydrolyzing degree not more than 70 percent. The method does not need to change the prior flow and equipment for synthesizing the NaY molecular sieve, has shorter crystallizing time, can synthesize the NaY molecular sieve with silicon-aluminum ratio more than 5.5.

Owner:CHINA PETROLEUM & CHEM CORP +1

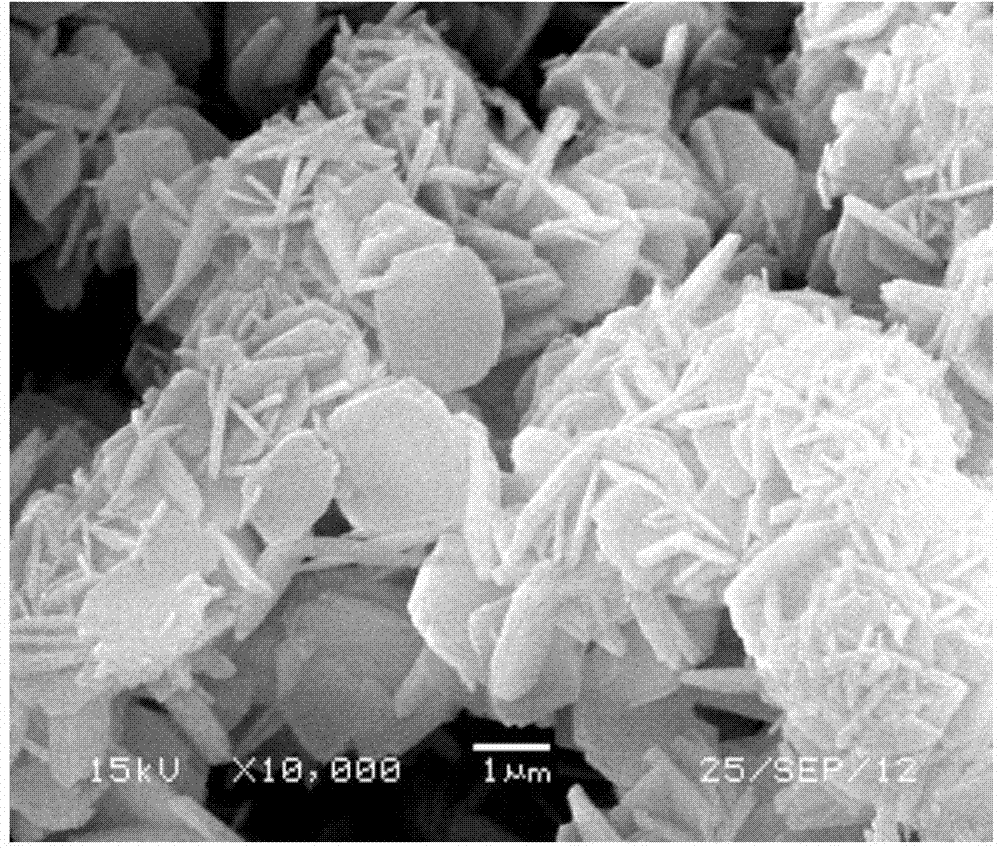

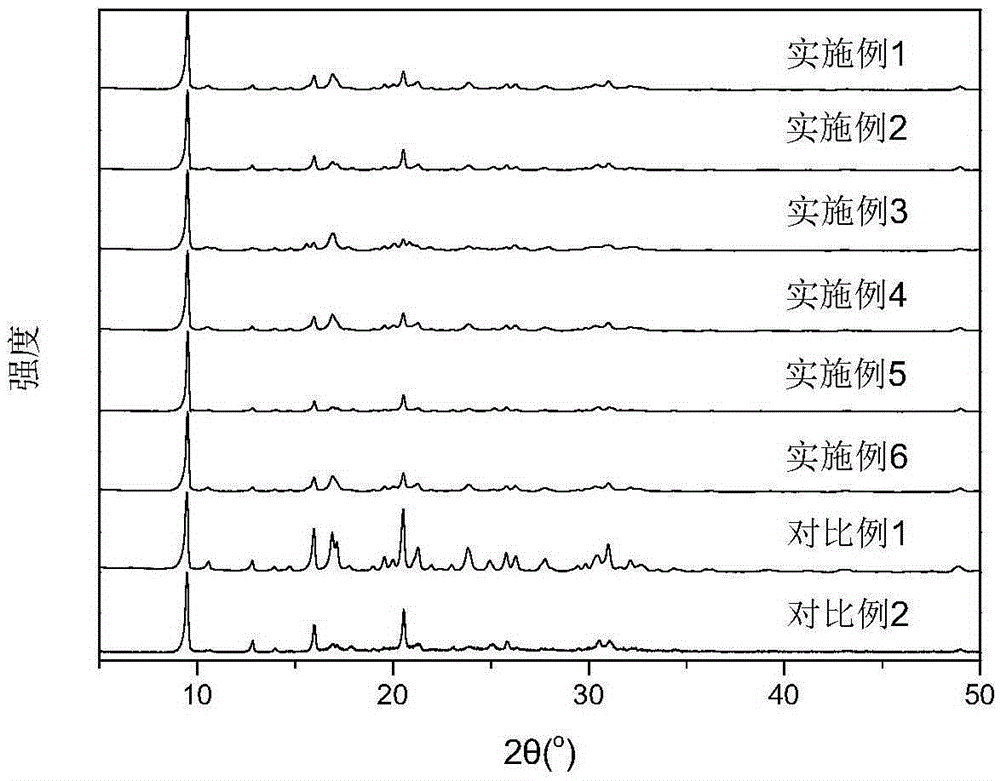

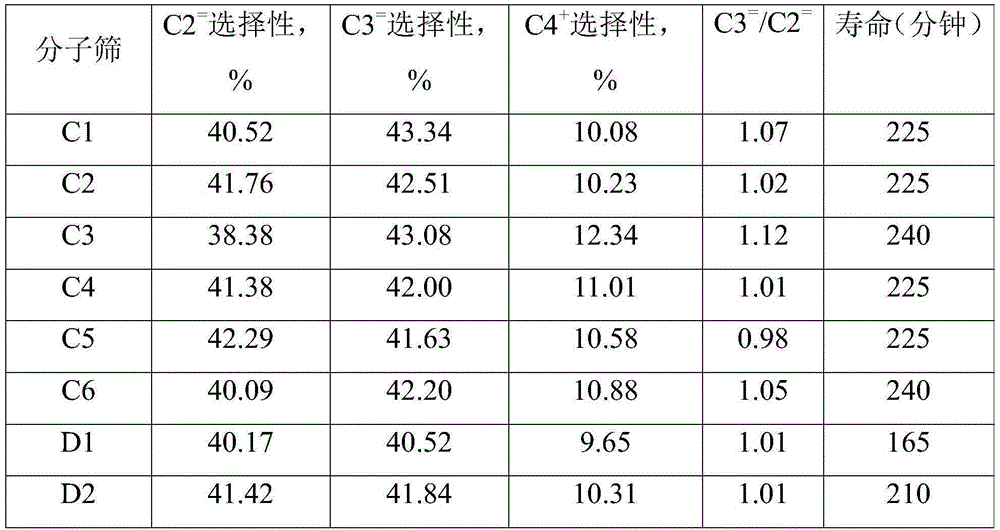

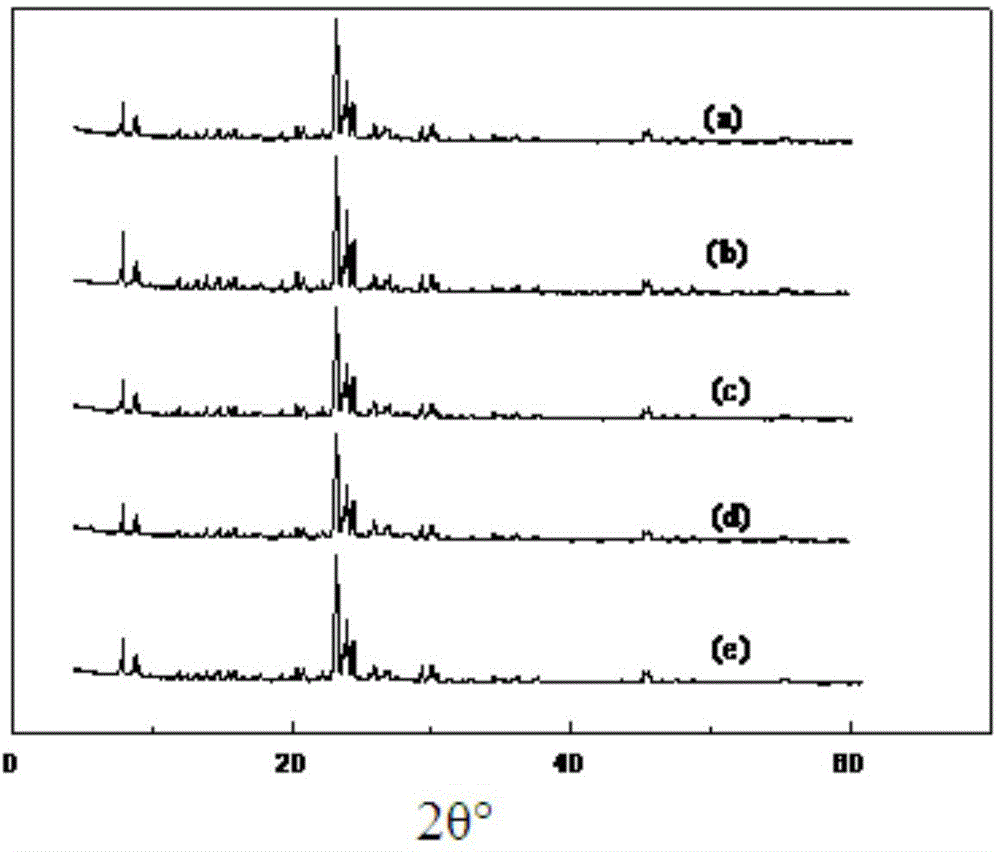

Double-micropore SAPO (silicoaluminophosphate)-34/SAPO-18 composite molecular sieve, and preparation method and application thereof

ActiveCN106564912AImprove composite effectImprove pore structureMolecular-sieve and base-exchange phosphatesMolecular sieveOxygen compound

The invention relates to the field of molecular sieves, and particularly provides a double-micropore SAPO (silicoaluminophosphate)-34 / SAPO-18 composite molecular sieve, and a preparation method thereof. The method comprises the following steps of: (1) carrying out pre-crystallization on a raw material mixture A used for synthesizing SAPO-34 to obtain pre-crystallized liquid S1 which does not contain solids, and carrying out pre-crystallization on a raw material mixture B used for synthesizing SAPO-18 to obtain pre-crystallized liquid S2 which does not contain solids; and (2) mixing the pre-crystallized liquid S1 and the pre-crystallized liquid S2, carrying out crystallization, separating the solids from crystallized liquid, and carrying out roasting after drying is carried out or drying is not carried out. The invention also discloses the application of the double-micropore SAPO-34 / SAPO-18 composite molecular sieve in low carbon olefins prepared from organic oxygen-containing compounds. The ratio of the molecular sieve SAPO-34 to the molecular sieve SAPO-18 is adjustable, when the double-micropore SAPO-34 / SAPO-18 composite molecular sieve is applied to the industrial production of the low carbon olefins prepared from organic oxygen-containing compounds, an ethylene-propylene ratio in the product is adjustable, and the catalytic activity of the molecular sieve is high.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Method for ultrasonically crystallizing rebaudiosideA

InactiveCN101812096AHigh purityShort crystallization timeSugar derivativesSugar derivatives preparationSolventChemistry

The invention discloses a method for ultrasonically crystallizing rebaudiosideA, which comprises the following steps of: charging stevioside and dissolvent according to the quality volume ratio (kg:L) of 1:4-10; stirring, charging and heating to be the temperature of 40-80 DEG C; constantly keeping the temperature at 30-90 minutes; fast reducing the temperature to be 10-25 DEG C with the velocity of 5-15 DEG C per minute; sequentially statically crystallizing and recrystallizing for 3-12 hours, wherein the ultrasonic wave is adopted to perform auxiliary crystallizing and recrystallizing during statically putting; stirring and performing the ultrasonic wave for 5-15 minutes every 30-90 minutes; and performing solid-liquid separation, dissolution in a washing way, membrane separation, reduced pressure distillation and spray drying to the recrystallized crystalloid to obtain the high-purity rebaudiosideA. The method has the crystallizing time of only 6-24 hours, the rebaudiosideA yield which is more than 75%, even crystallizing grains, and the rebaudiosideA purity which reaches up to be more than 95%, meets the standards of American FDA, can be produced on a large scale, and has obvious effect.

Owner:GANZHOU JULONG HIGH TECH INDAL

Method of quickly synthesizing super fine 4A zeolite

InactiveCN1597517ASmall granularityNarrow particle size distributionAluminosilicate zeolite type-AGranularitySodium aluminate

A process for quickly synthesizing superfine 4A zeolite includes such steps as dissolving Si source in the solution of sodium hydroxide to obtain solution of sodium silicate, dissolving Al source in the solution of sodium hydroxide to obtain solution of sodium aluminate, adding inorganic sodium salt to said solution of sodium aluminate, stirring, adding the solution of sodium silicate, regulating pH greater than II, stirring to become colloid, heating, crystallizing, filtering water washing and drying at 100-300 deg.C.

Owner:CHINA RES INST OF DAILY CHEM IND

Preparation method of total-silicon molecular sieve Silicalite-1 having high hydrogen bond silicon hydroxyl content

InactiveCN106032278AIncrease contentReduce contentMolecular-sieve and base-exchange compoundsMolecular sievePhysical chemistry

The invention relates to a preparation method of a total-silicon molecular sieve Silicalite-1 having the high hydrogen bond silicon hydroxyl content. The preparation method comprises: (1) mixing a silicon source, a templating agent and water, stirring into a gel, and adjusting the pH value of the gel to 7.5-11.5; and (2) crystallizing the gel of the step (1), washing the crystallized product, separating, and calcining to obtain the total-silicon molecular sieve Silicalite-1, wherein the crystallization comprises the two crystallization processes, the first crystallization process comprises that the crystallization is performed for 1-10 h at a temperature of 60-120 DEG C, and the second crystallization process comprises that the crystallization is performed for 3-24 h after the temperature is increased to 150-200 DEG C. According to the present invention, the total-silicon molecular sieve Silicalite-1 prepared by the preparation method has the high hydrogen bond silicon hydroxyl content, and further maintains high crystallinity, good thermal stability, and good hydrothermal stability of the molecular sieve.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

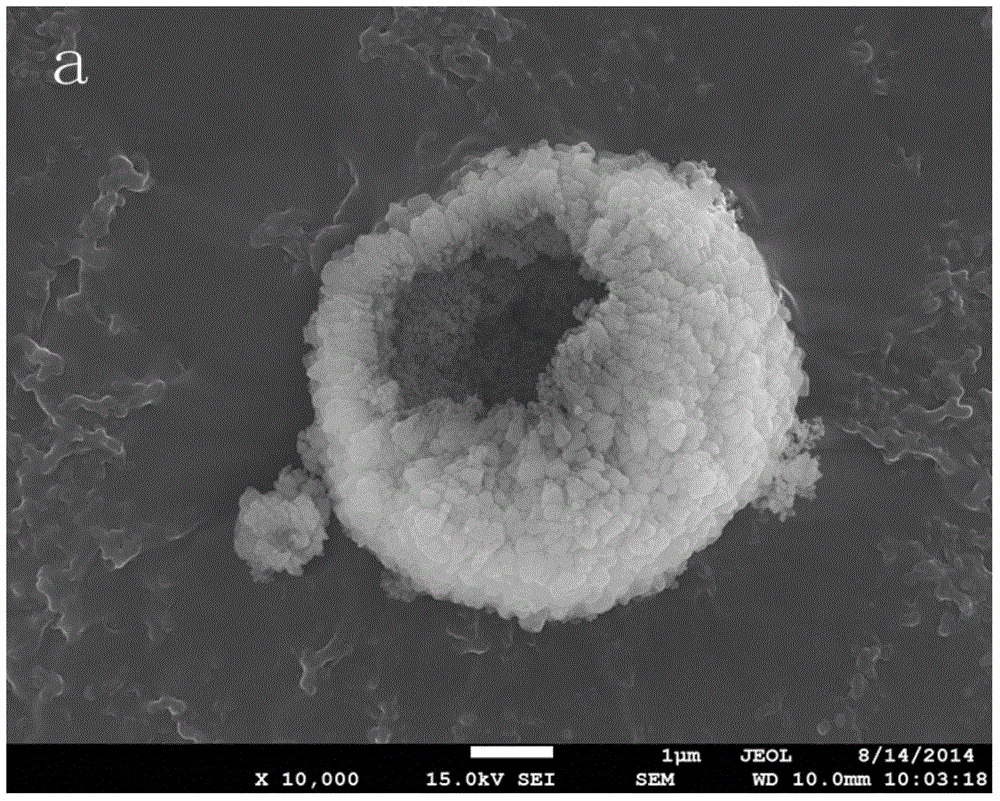

Hollow AFI type molecular sieve and preparation method thereof

ActiveCN104944434ASimple processEasy to operateMolecular-sieve and base-exchange phosphatesMolecular-sieve silicoaluminophosphatesMolecular sieveDiffusion

The invention discloses a hollow AFI type molecular sieve and a preparation method thereof. The molecular sieve is a hollow crystallization product which is prepared by mixing ionic liquid, an aluminum source, a phosphorus source, a fluorine source, water and a template agent, then performing reaction to prepare a molecular sieve synthetic gel, and then performing crystallization on the molecular sieve synthetic gel, wherein the mole ratio of the ionic liquid to the aluminum source (calculated in Al2O3) to the phosphorus source (calculated in P2O5) to the fluorine source (calculated in F) to the water to the template agent is (5-50):1:(1.8-4):(0-0.5):(0-10):(0.5-4). According to the hollow AFI type molecular sieve disclosed by the invention, the use amount of each raw material can be reasonably adjusted by introducing the ionic liquid into an aluminum phosphate molecular sieve synthetic system, the morphology of an aluminum phosphate molecular sieve is effectively changed, and an obvious hollow structure is synthesized; and the hollow AFI type molecular sieve is used as a catalyst carrier and is beneficial for diffusion of reactants and products, thereby significantly improving the conversion rate of catalytic reaction.

Owner:ZHENGZHOU UNIV

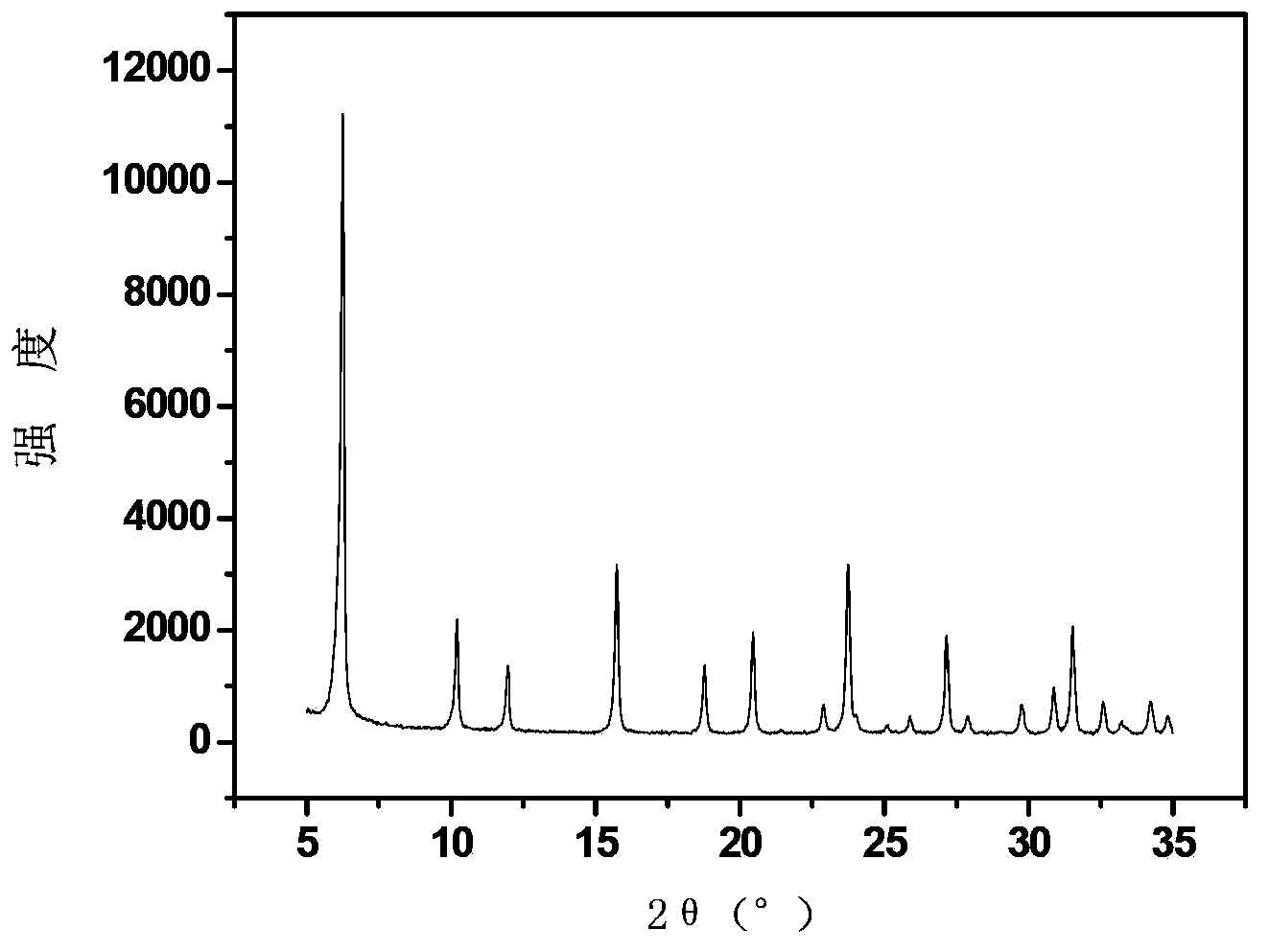

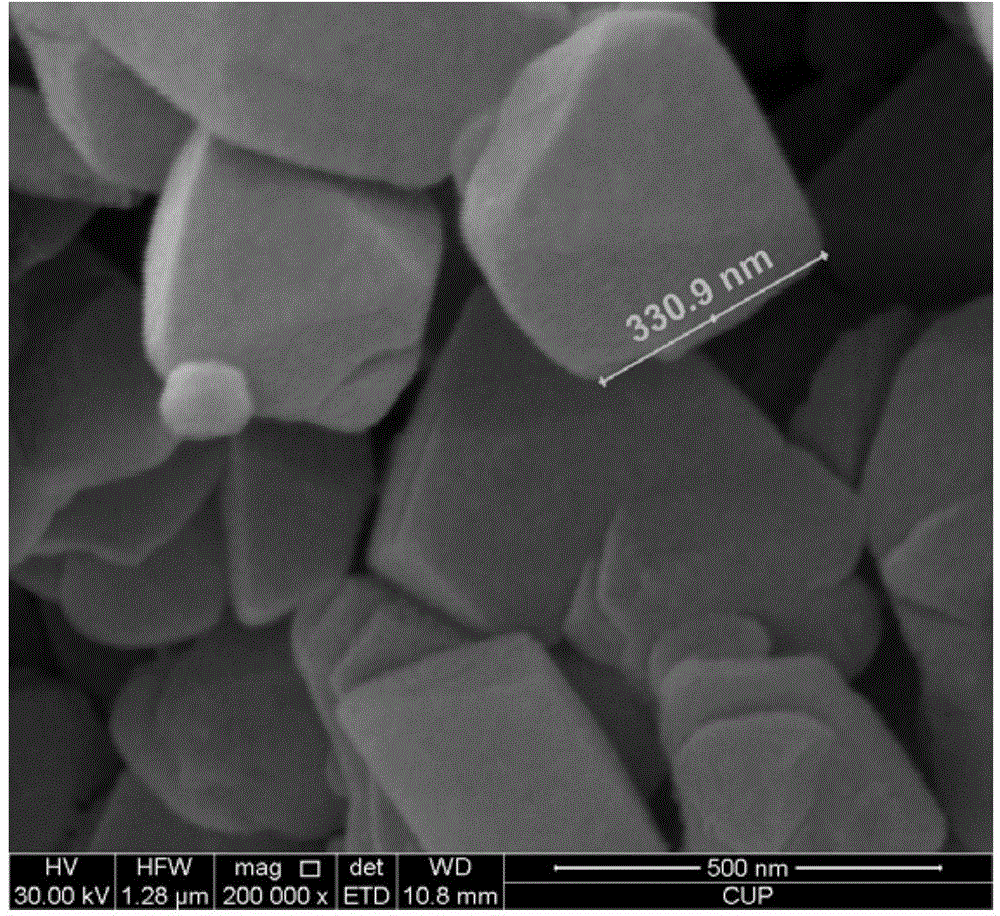

Method for synthesizing fine grain NaY molecular sieve

ActiveCN101468802ASmall particle sizeShort crystallization timeFaujasite aluminosilicate zeoliteMolecular sieveReagent

The invention relates to a method for synthesizing a NaY molecular sieve, which comprises the steps of synthesizing director reagents, synthesizing gel and crystallizing. The method is characterized in that the mol composition of the director reagent is (10-30)Na2O:Al2O3:(0.1-8) SiO2:(150-380)H2O. The method can synthesize the small crystal grain NaY molecular sieve with the grain diameter of between 150 and 350nm.

Owner:CHINA PETROLEUM & CHEM CORP +1

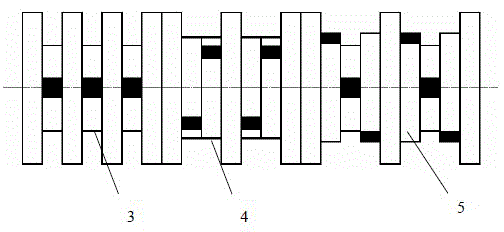

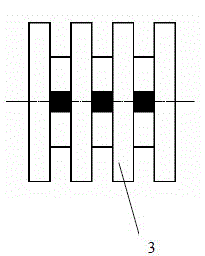

Quickly molded high density polyethylene composition and preparation method thereof

ActiveCN104558747AFast crystallization temperatureRapid prototyping High crystallization temperatureMasterbatchPolymer science

The invention relates to a quickly molded high density polyethylene composition and a preparation method thereof and belongs to the technical field of macromolecular materials. The composition is characterized by being prepared from polyethylene A and polyethylene B with different densities and melt quality flow rates by adding an additive masterbatch to blend and granulate, wherein the composition is prepared from the following components in parts by weight: 75-90 parts of polyethylene A, preferably 80-85 parts, 10-25 parts of polyethylene B, preferably 15-20 parts, and 0.06-0.15 part of the additive masterbatch, and the additive masterbatch is a mixed extrudate of low density polyethylene, nano calcium carbonate and talc powder in a mass ratio of 3: 2: 1. During granulation, three groups of matching kneading blocks with different included angles are used to extrude and granulate at 210-220 DEG C. The composition provided by the invention is high in crystallization temperature and short in crystallization time, the product is fast in molding speed during production and good in dimensional stability, and the components are relatively low in price.

Owner:CHINA PETROLEUM & CHEM CORP

Method for promoting Beta molecular sieve synthesis

InactiveCN108217684AShort crystallization timeLower crystallization temperatureMolecular sieve catalystsMolecular-sieve and base-exchange compoundsMolecular sieveTert-Butylamine

The invention provides a method for promoting Beta molecular sieve synthesis. According to the method, a silicon source, an aluminum source, inorganic alkali, a microporous template agent and crystalgrowth promoters R are sufficiently mixed; the obtained gel is subjected to short-time hydrothermal crystallization for fast preparing a Beta molecular sieve. The synthesized product is formed by stacking and connecting primary nanometer particles; the primary particle diameter is 10 to 30nm; the synthesis process is fast; the materials can be directly crystallized for 10 to 60 hours at the propertemperature; the crystal growth promoters are 2-pyrrolidone, N-methyl-2-pyrrolidone, N-ethyl-2-pyrrolidone or N-isopropyl-2-pyrrolidone or a mixture of the 2-pyrrolidone, N-methyl-2-pyrrolidone, N-ethyl-2-pyrrolidone, N-isopropyl-2-pyrrolidone. The cheap crystal growth promoters are used for fast preparing the Beta molecular sieve by a one-step method; the conventional crystal seed method is replaced for fast obtaining the Beta molecular sieve; the method belongs to the economic and fast Beta molecular sieve obtaining method. In addition, the prepared Beta molecular sieve also has the excellent catalyst performance; high isobutene conversion rate and tert-butylamine selectivity are shown in the isobutene amination reaction.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation method of nickel hydroxide/graphene composite material for nickel-metal hydride battery positive pole

ActiveCN105591087AImprove electrochemical utilizationBuffer volume expansionCell electrodesGastight accumulatorsFiltrationMass ratio

The invention discloses a preparation method of a nickel hydroxide / graphene composite material for a nickel-metal hydride battery positive pole, and belongs to the technical field of nickel-metal hydride battery pole materials. The method comprises the steps that graphite oxide is used as a raw material to be pressed into 1 mg / mL suspension liquid, nickel nitrate of different masses is added into the suspension liquid, the mass ratio of graphite oxide to nickel hydroxide in the composite material is 1:5 or 1:9 or 1:13, the suspension liquid with the nickel nitrate added is subjected to ultrasonic wave dispersion, then urea is dropwise added into the suspension liquid, the mixture is transferred into a three-mouth flask after being stirred, then the three-mouth flask is placed into an Apex normal-pressure micro wave reaction synthesizer for a reaction, then vacuum filtration is carried out, the product is washed with deionized water and absolute ethyl alcohol to be neutral, vacuum drying is carried out, and therefore the nickel hydroxide / graphene composite material is prepared. The preparation method has the advantages that the temperature gradient is small, the reaction speed is high, heating is uniform, crystallization time is short and the yield is high, and the preparation method is applicable to large-scale commercialized production.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

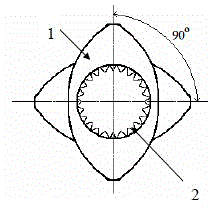

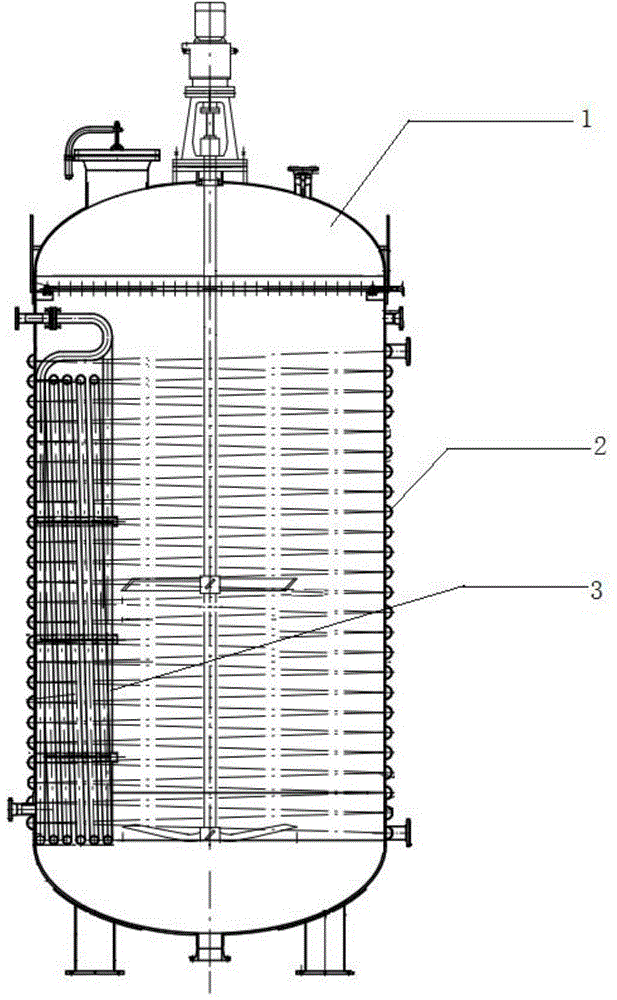

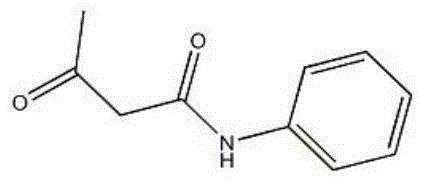

Crystallization method of N-acetoacetanilide type compounds

ActiveCN104370767AShort crystallization timeIncrease productivityOrganic compound preparationCarboxylic acid amide separation/purificationAnilineAcetoacetanilide

The invention relates to the field of synthesis of N-acetoacetanilide type compounds, and in particular relates to a crystallization method of N-acetoacetanilide. According to the crystallization method, gradient cooling is performed on materials by introducing a condensation medium into a cooling tube of a reaction kettle. The crystallization method disclosed by the invention is short in crystallization time, simple in operation step, capable of achieving automation and standardization and capable of improving the yield and purity of products, the particle sizes of product crystals are uniform and consistent, the phenomenon of agglomeration is further reduced, and the agglomeration time is greatly prolonged.

Owner:青岛海湾集团有限公司

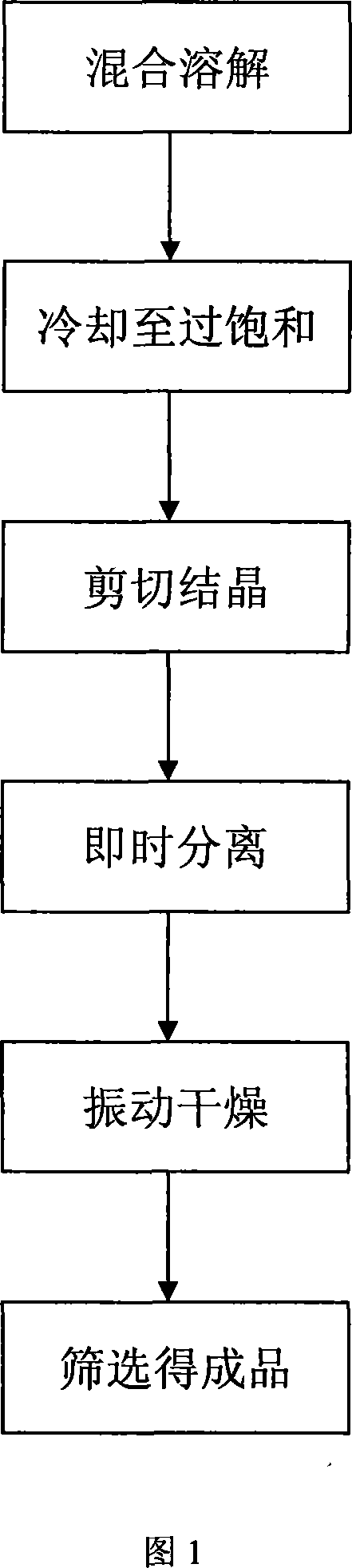

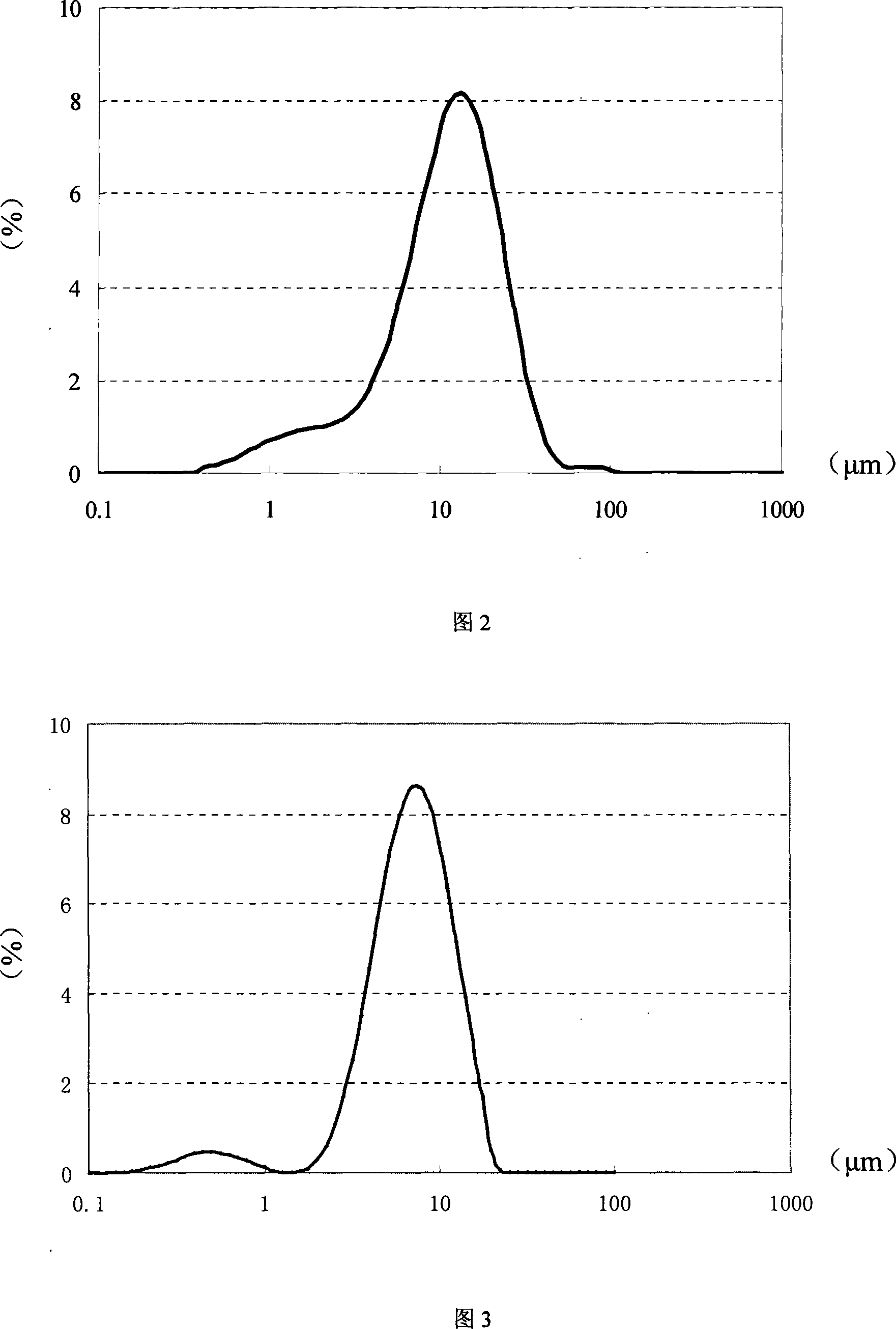

Method for preparing high shearing force microcrystal lactose

ActiveCN101239996AEasy to controlConcentrated particle size distributionSugar derivativesPharmaceutical delivery mechanismDispersityMechanical crushing

The invention discloses a high shearing force preparation of microcrystalline lactin, including steps of: (1) mixing solid lactin and water with a certain proportion, stiring and heating until the latin is fully dissolved; (2) cooling the latin solution to a predetermined temperature to obain hypersaturate solution of latin; (3) turn on a shear in a crystallizer, to stimulate crystallization of the solution by high shear force; (4) fast separating latin crystal from mother liquid by continuous centrifuge; (5) drying obtained latin crystal; (6) product of microcrystalline lactin is obtained by screening. The invention not only stimulate crystallization of mother liquid by shearing force, in order to realize control of the crystal forming process, and obtain product with centralized grain-size distribution, but also avoids mechanical crushing in the preparation, so that crystal structure is protected, and generation of non-crystal granular is also avoided. Further, the invention combines centrifugal and vibrating drying, thus crystal exhibit excellent fluidity and dispersity, and crystallization time is short.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com