Quickly molded high density polyethylene composition and preparation method thereof

A high-density polyethylene and composition technology, applied in the field of polymer materials, can solve the problems of high price and high production cost, and achieve the effects of short crystallization time, fast forming speed, and easy forming and processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

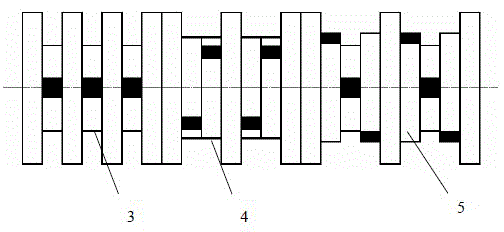

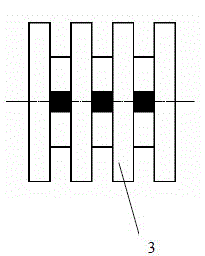

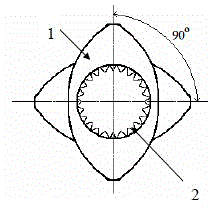

Image

Examples

Embodiment 1

[0035]The melt mass flow rate (21.6Kg) of polyethylene A is 9.5g / 10min, and the density is 0.945g / cm 3 ; The melt mass flow rate (21.6Kg) of polyethylene B is 2.1 g / 10min, and the density is 0.950g / cm 3 , the weight average molecular weight is 450,000, the comonomer is butene, and the molar ratio of butene to ethylene is 0.005.

[0036] The preparation method of the additive masterbatch is: adding absolute ethanol to the rare earth coupling agent for dilution, the mass ratio of the rare earth coupling agent and absolute ethanol is 1:5, stirring at high speed in a mixer for 3 minutes, and diluting the nano calcium carbonate and The rare earth coupling agent with a mass ratio of 100:6 was added to the high-speed mixer and mixed for 3 minutes, then the high-speed mixer was heated to 80°C~100°C and mixed for 5 minutes.

[0037] Mix superfine talcum powder and polyethylene wax with a mass ratio of 100:3 in a high-speed mixer for 5 minutes.

[0038] Mix low-density polyethylene, n...

Embodiment 2

[0041] The melt mass flow rate (21.6Kg) of polyethylene A is 8.5g / 10min, and the density is 0.947g / cm 3 ; The melt mass flow rate (21.6Kg) of polyethylene B is 2.3 g / 10min, and the density is 0.951g / cm 3 , the weight average molecular weight is 550,000, the comonomer is propylene, and the molar ratio of propylene to ethylene is 0.01.

[0042] The preparation method of the additive masterbatch is: adding acetone to the silane coupling agent for dilution, the mass ratio of the silane coupling agent to acetone is 1:3, stirring at high speed in a mixer for 1 min, and coupling the nano-calcium carbonate with the diluted silane The mass ratio of the agent is 100:4, add to the high-speed mixer and mix for 5 minutes, then heat the high-speed mixer to 80°C-100°C and mix for 5 minutes.

[0043] Mix superfine talcum powder and polyethylene wax with a mass ratio of 100:3 in a high-speed mixer for 10 minutes.

[0044] Mix low-density polyethylene, nano-calcium carbonate, and ultra-fine t...

Embodiment 3

[0047] The melt mass flow rate (21.6Kg) of polyethylene A is 10.0g / 10min, and the density is 0.943g / cm 3 ; The melt mass flow rate (21.6Kg) of polyethylene B is 2.5 g / 10min, and the density is 0.955g / cm 3 , the weight average molecular weight is 400,000, the comonomer is propylene, and the molar ratio of propylene to ethylene is 0.02.

[0048] The preparation method of the additive masterbatch is: add acetone to the titanate coupling agent to dilute, the mass ratio of the titanate coupling agent to acetone is 1:5, stir in a mixer at high speed for 1min, and dilute the nano-calcium carbonate and The titanate coupling agent in the mass ratio of 100:6 was added to the high-speed mixer and mixed for 5 minutes, and then the high-speed mixer was heated to 80°C-100°C and mixed for 3 minutes.

[0049] Mix superfine talcum powder and oxidized polyethylene wax with a mass ratio of 100:3 in a high-speed mixer for 3 minutes.

[0050] Mix low-density polyethylene, nano-calcium carbonate,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com