Easy-to-form heat-resistant polyethylene composition

A technology of heat-resistant polyethylene and composition, which is applied in the field of easy-to-form heat-resistant polyethylene composition, can solve the problems of unstable performance of the prepared composition, complicated components and preparation process, high cost of nucleating agent, etc., and achieve good resistance High pressure performance, high flexibility, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

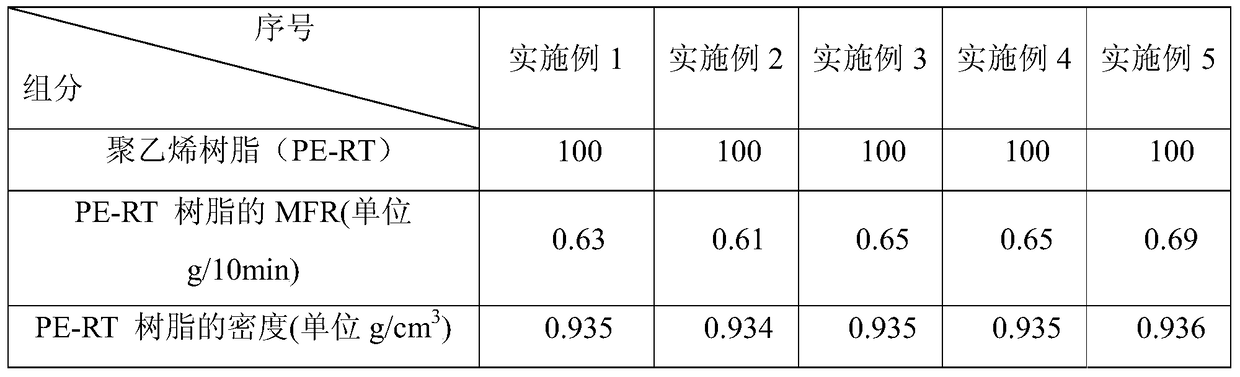

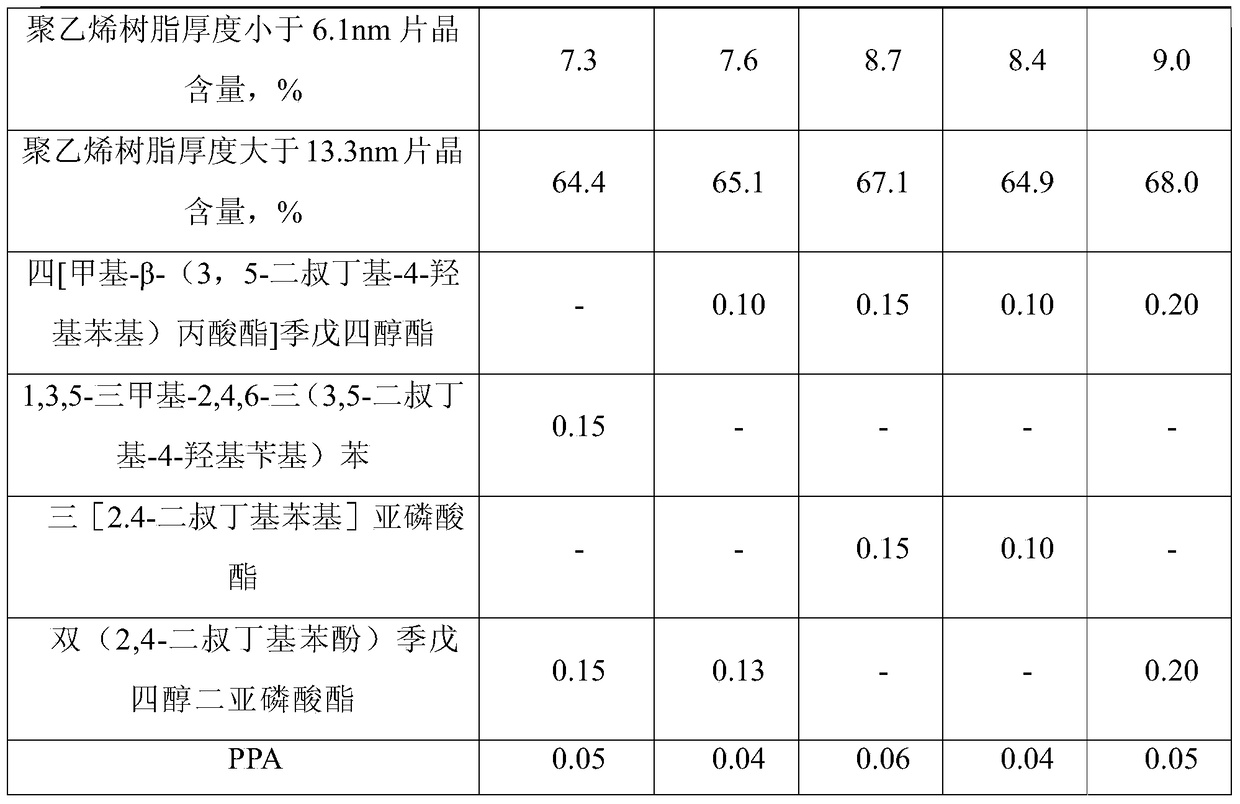

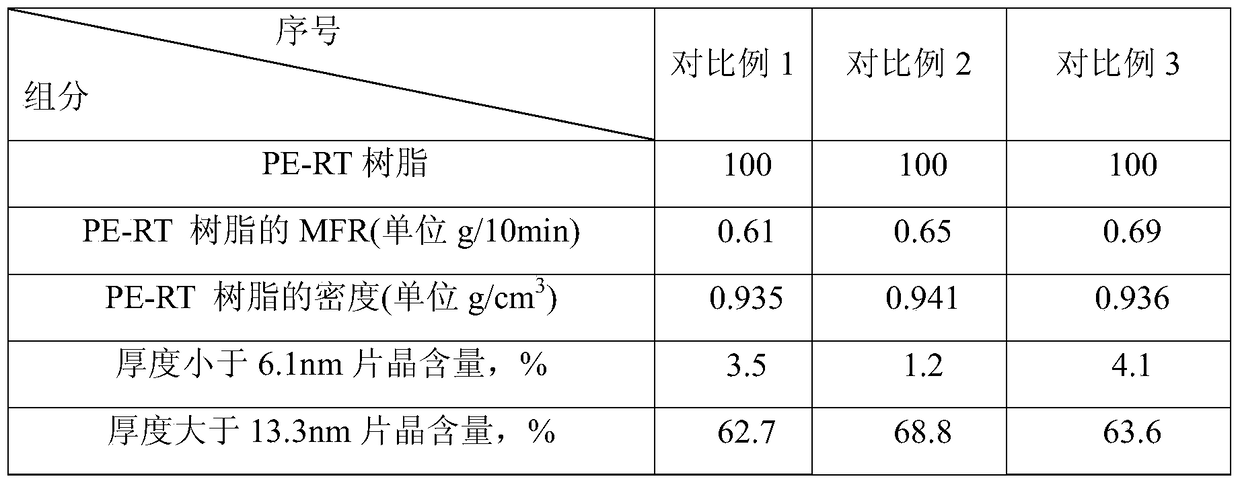

[0024] Table 1 shows the proportioning components of the polyethylene resin composition used in hot water pipes in Examples 1-5.

[0025] Table 1 The polyethylene resin composition table of embodiment 1-5 hot water pipeline (by weight)

[0026]

[0027]

[0028] "-" in the table means not added.

[0029] The preparation method of embodiment 1-5 is:

[0030] a) Put the polyethylene resin, antioxidant and processing aid into a high-speed mixer and mix them with a stirring speed of 1200 rpm, a stirring time of 10 minutes, and a stirring temperature lower than 40°C;

[0031] b) Add the homogeneously mixed materials into a twin-screw extruder for melting, plasticizing, extruding, and granulating. The screw length-to-diameter ratio is 35:1, and the processing temperature is 220°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com