Patents

Literature

701results about How to "Improve notched impact strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

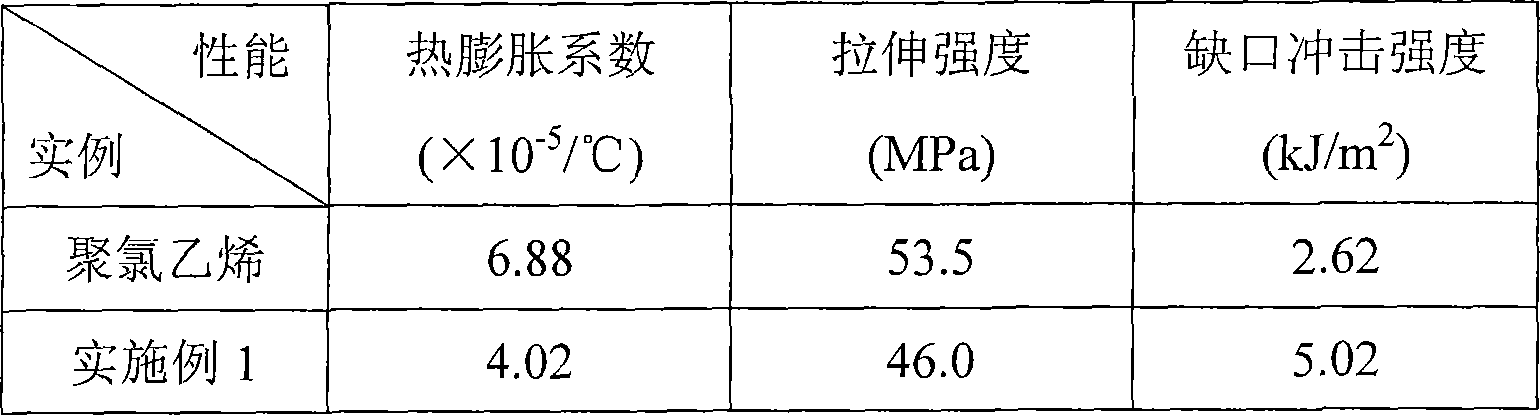

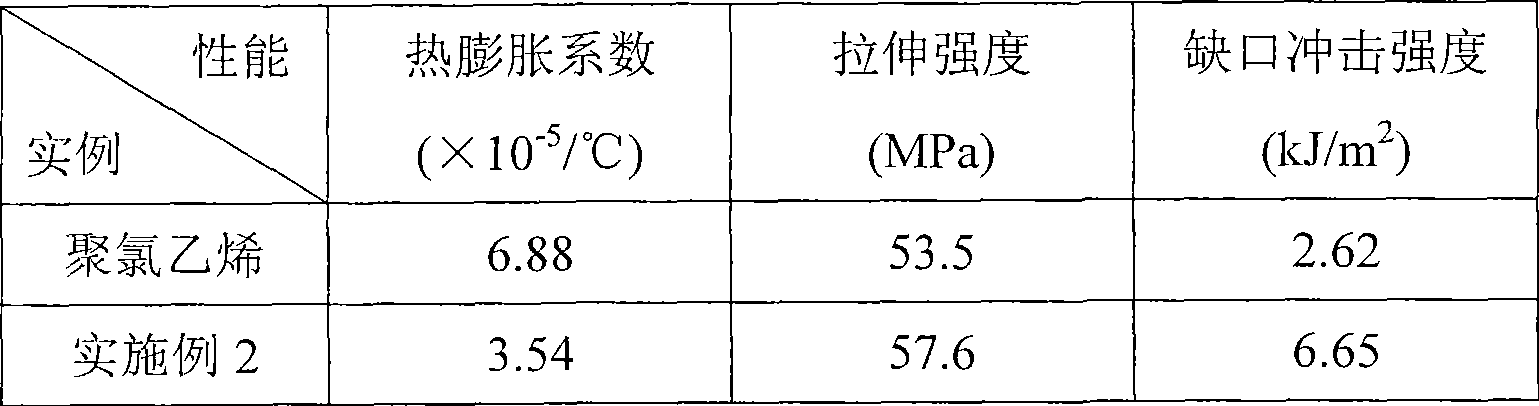

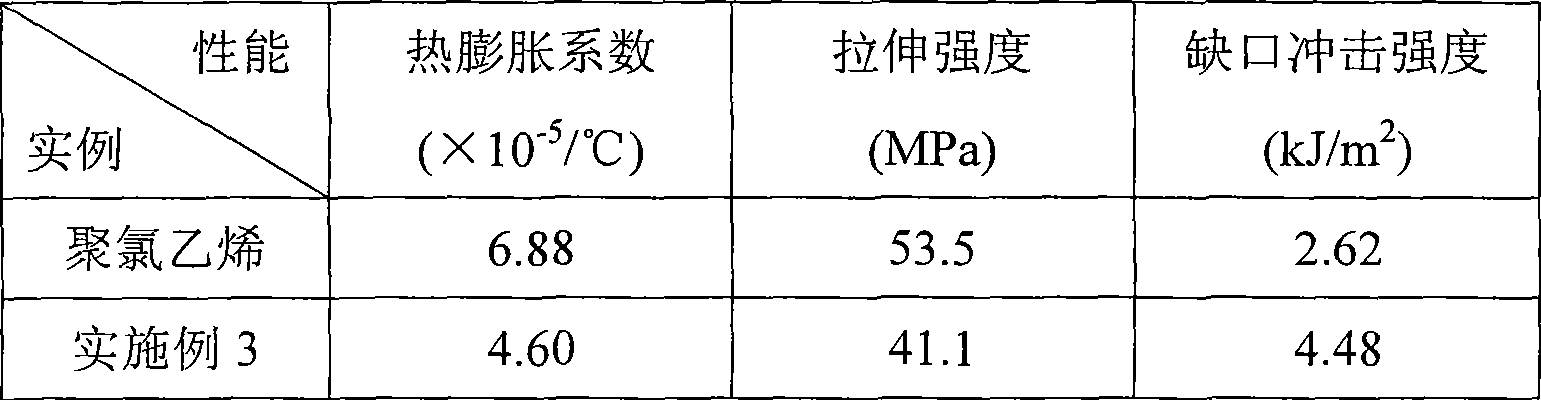

Low-expansion coefficient polyvinyl chloride alloy material and manufacturing method thereof

The invention provides a low-expansion coefficient polyvinyl chloride alloy material and a manufacturing method thereof. The ingredients of raw materials of the alloy material comprise a polyvinyl chloride substrate, a heat-resistant modifier, a heat stabilizer, a lubricator, a filler and a processing agent, and the alloy material is manufactured by a melt blending technique. The processing agent and the filler in the ingredients of the raw materials of the invention are the processing agent that is subjected to modification by a new method and the filler that is subjected to organic treatment, and by means of a mechanochemical reaction, self-plastification, toughening and reinforcement of the PVC can be combined organically to improve compatibility and dispersity of the polyvinyl chloride, the filler and heat-resistant resin, thus settling the problem about the contraction between the improvement of heat expansion performance and heat resistance of the PVC, and processing performance, strength and toughness of the PVC; the polyvinyl chloride engineering plastic with low expansion coefficient, high heat resistance, high strength, high toughness, excellent aging resistance and outstanding processing performance is manufactured; the invention has extensive industrial market prospect and the manufacturing method thereof is simple in technology, convenient in operation and control, stable in quality and high in production efficiency.

Owner:SICHUAN UNIV

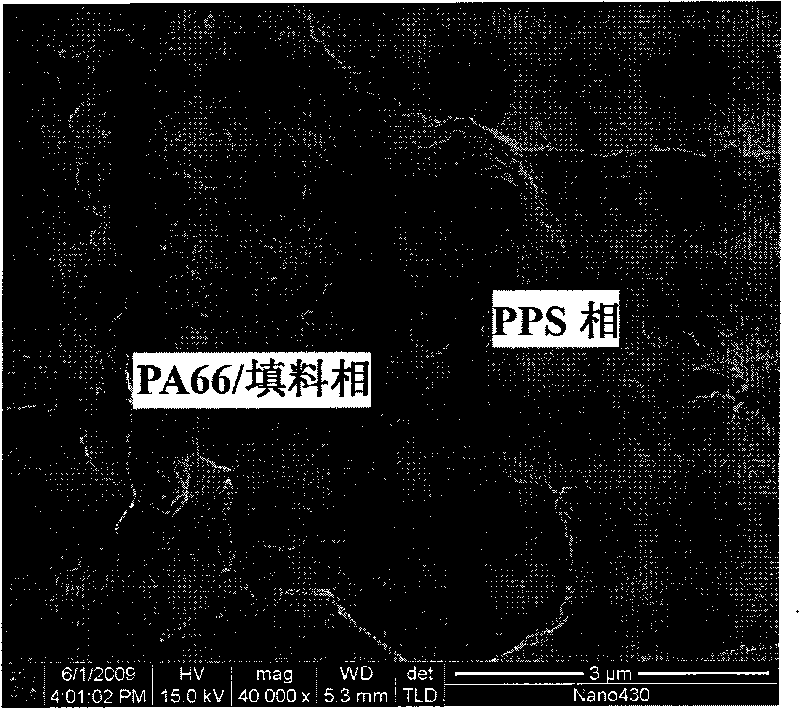

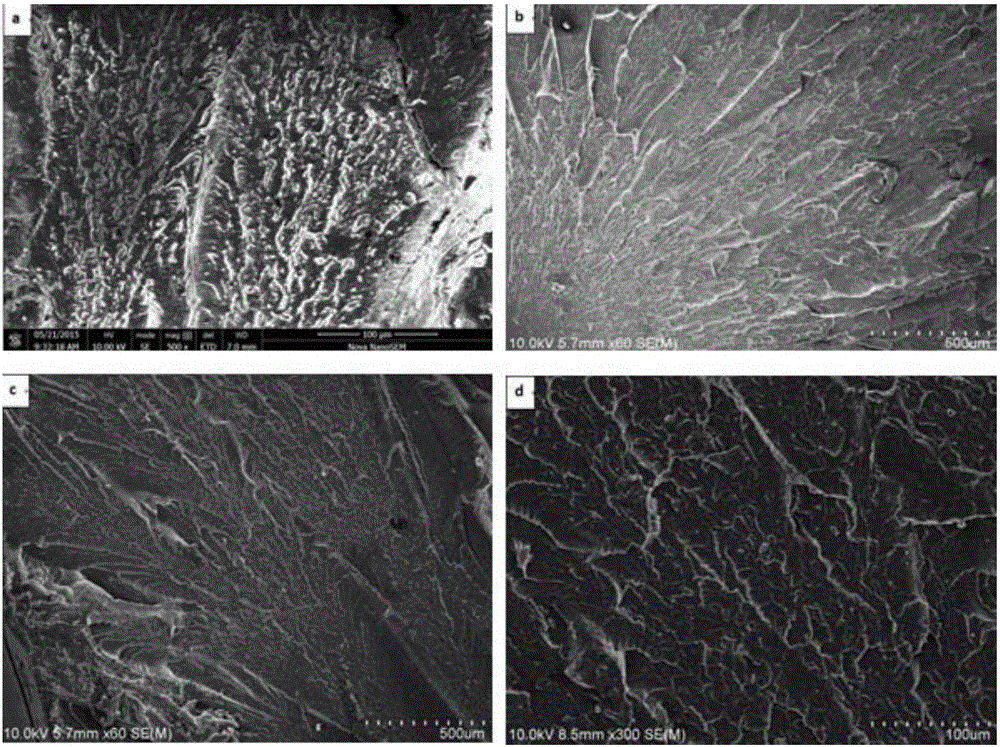

Filling-type thermal-conducting electric-insulating polyphenyl thioether and polyamide blended alloy and preparation method thereof

The invention discloses a filling-type thermal-conducting electric-insulating polyphenyl thioether and polyamide blended alloy and a preparation method thereof. The blended alloy comprises polyphenyl thioether, polyamide, an inorganic thermal-conducting filler, a surface modifier and processing assistants, wherein the polyamide and the polyphenyl thioether form a bicontinuous phase structure, and the inorganic thermal-conducting filler is distributed in the polyamide phase and forms a continuous thermal-conducting network. The preparation method comprises the following three steps: step 1: carrying out the surface modification on the inorganic thermal-conducting filler by using the surface modifier; step 2: mixing the inorganic thermal-conducting filler, the polyamide and the processing assistants by using a high-speed mixer, and extruding the mixture by using a double screw extruder to obtain the thermal-conducting master batch; and step 3: extruding the thermal-conducting master batch, the polyphenyl thioether and the processing assistants for the second time to make granules. The composite material of the invention has good thermal conduction, electrical insulation, mechanical properties and processability. Under the condition of the same amount of the inorganic thermal-conducting filler, compared with the blended alloy phase in which the continuous phase is not formed, the coefficient of thermal conductivity of the composite material in the invention is obviously enhanced.

Owner:SOUTH CHINA UNIV OF TECH

Aliphatic-aromatic copolyester, preparation method and application thereof

ActiveCN101717493AAvoid problems such as affecting performanceEvenly dispersedAdhesivesCarboxylic acid halidesMonomer

The invention provides aliphatic-aromatic copolyester, a preparation method and application thereof. Polymerization monomers comprise a compound selected from aliphatic dibasic acid, and naphthenic base dibasic acid or the ester, the anhydride and the acyl halide thereof, a compound selected from aromatic dibasic acid or the ester, the anhydride and the acyl halide thereof, a compound simultaneously with two functional groups selected from an amino-group, a mercapto group or a hydroxy or a compound of a derivative of the amino-group, the mercapto group or the hydroxyl with an epoxy group and an azepine ring, a compound selected from unsaturated acid with at least one C-C, C-O, C-N or C-S double bond and C-C or C-N triple bond or the ester, the anhydride and the acyl halide thereof and a compound of unsaturated alcohol with at least one C-C double bond or a C-C triple bond or an epoxide thereof. The aliphatic-aromatic copolyester is prepared by carrying out esterification and polycondensation after mixing the polymerization monomers, polymerizing the double bonds and / or the triple bonds on the polymerization monomers under the action of an initiator and then carrying out a graftingand / or coupling reaction.

Owner:HANGZHOU XINFU TECH CO LTD

Halogen-free flame retardant polyamide 6 composition

The invention discloses a halogen-free flame-retardant polyamide 6 composition with high toughness and antistatic property. The composition comprises active magnesium hydrate, organic phosphate oligomer, zinc oxide crystal whisker, a macromolecular compatilizer, a plasticizer and an additive. The active magnesium hydrate and the organic phosphate oligomer are used to improve flame retardance; organic anlistatig and the zinc oxide crystal whisker are used to improve the antistatic property; and the macromolecular compatilizer is used to improve interaction among polyamide, the inorganic magnesium hydrate and the zinc oxide crystal whisker. The flame-retardant polyamide 6 composition has the advantages that compared with a sole magnesium hydrate flame-retardant polyamide 6, the use amount of the magnesium hydrate is reduced to below 50 mass percent; the impact strength of a gap is increased by over 80 percent; the breaking elongation rate is improved by approximately 20 times; the resistivity is reduced by 4 orders of magnitude; the flame retardant performance reaches UL94V-0 level; simultaneously, the toughness is basically maintained at the level of pure polyamide 6; the temperature for thermal deformation is much higher than 65 DEG C of the pure polyamide 6; and the molding shrinkage rate is reduced to 0.6 percent from 1.78 percent of the pure polyamide 6.

Owner:GUANGDONG XINHUI MEIDA NYLON

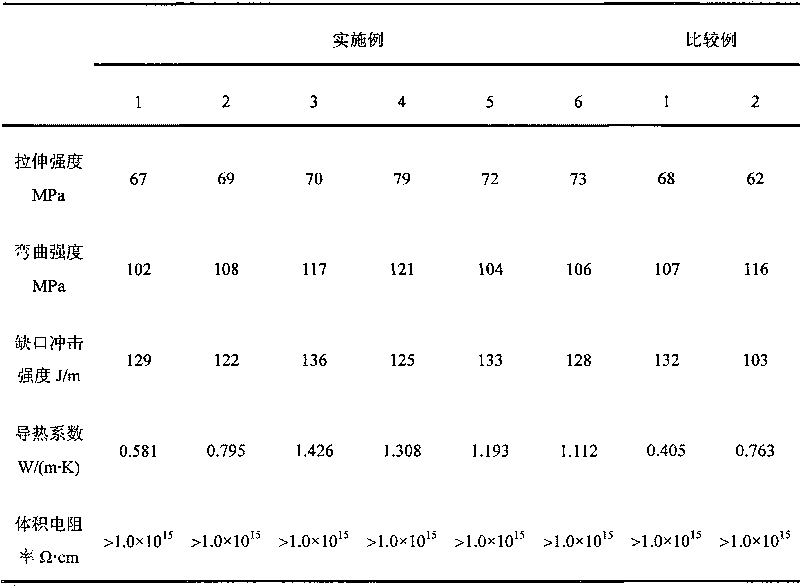

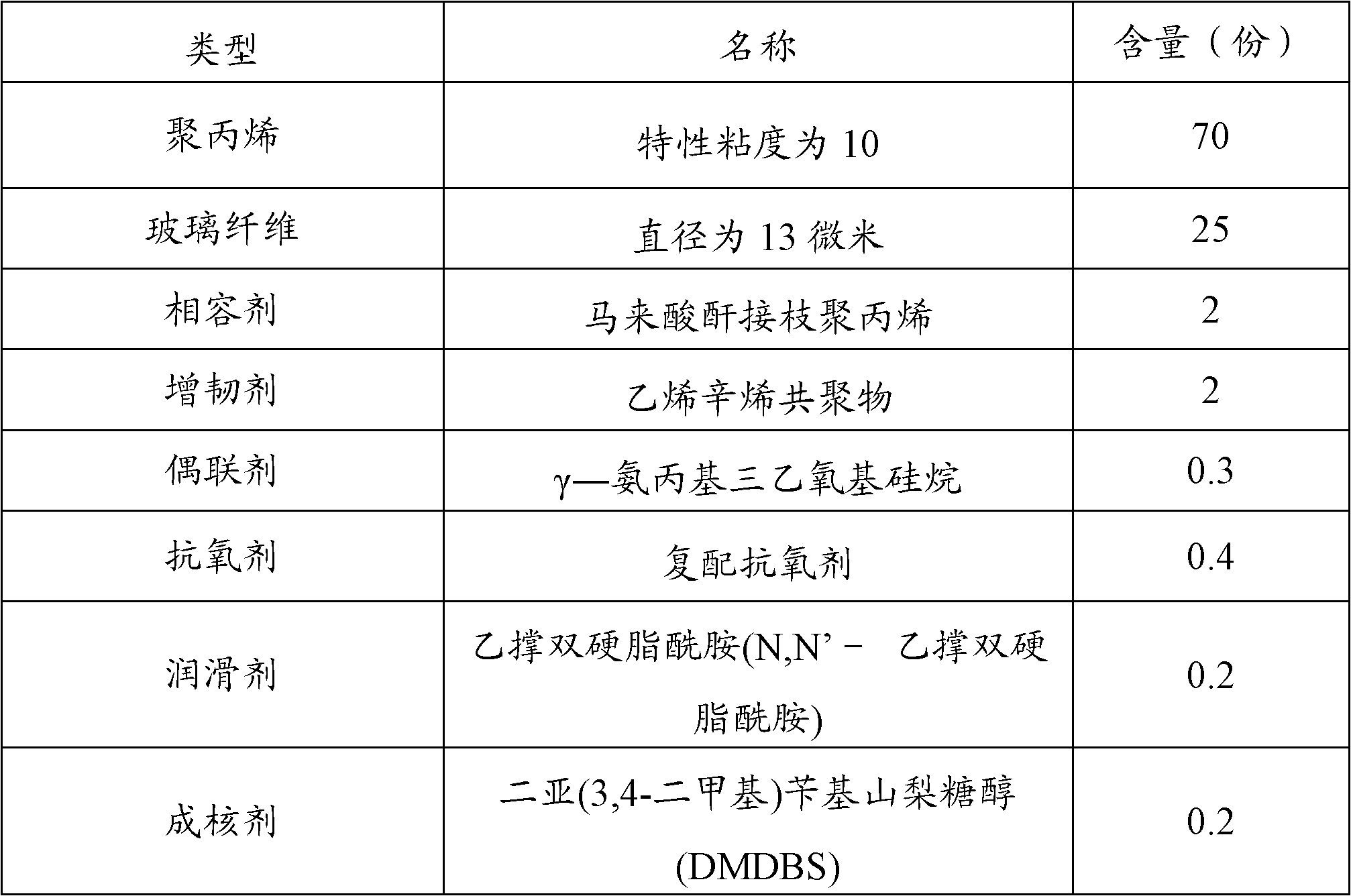

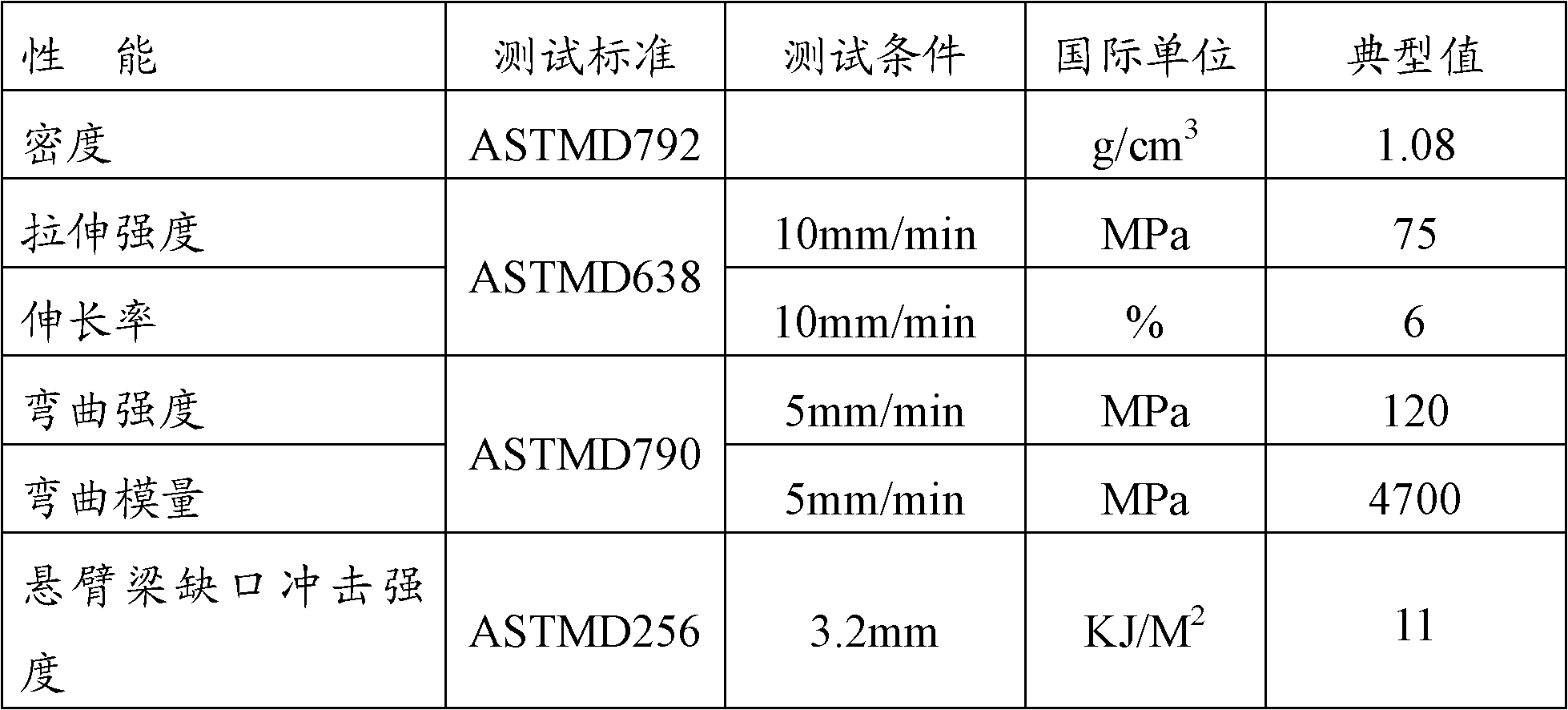

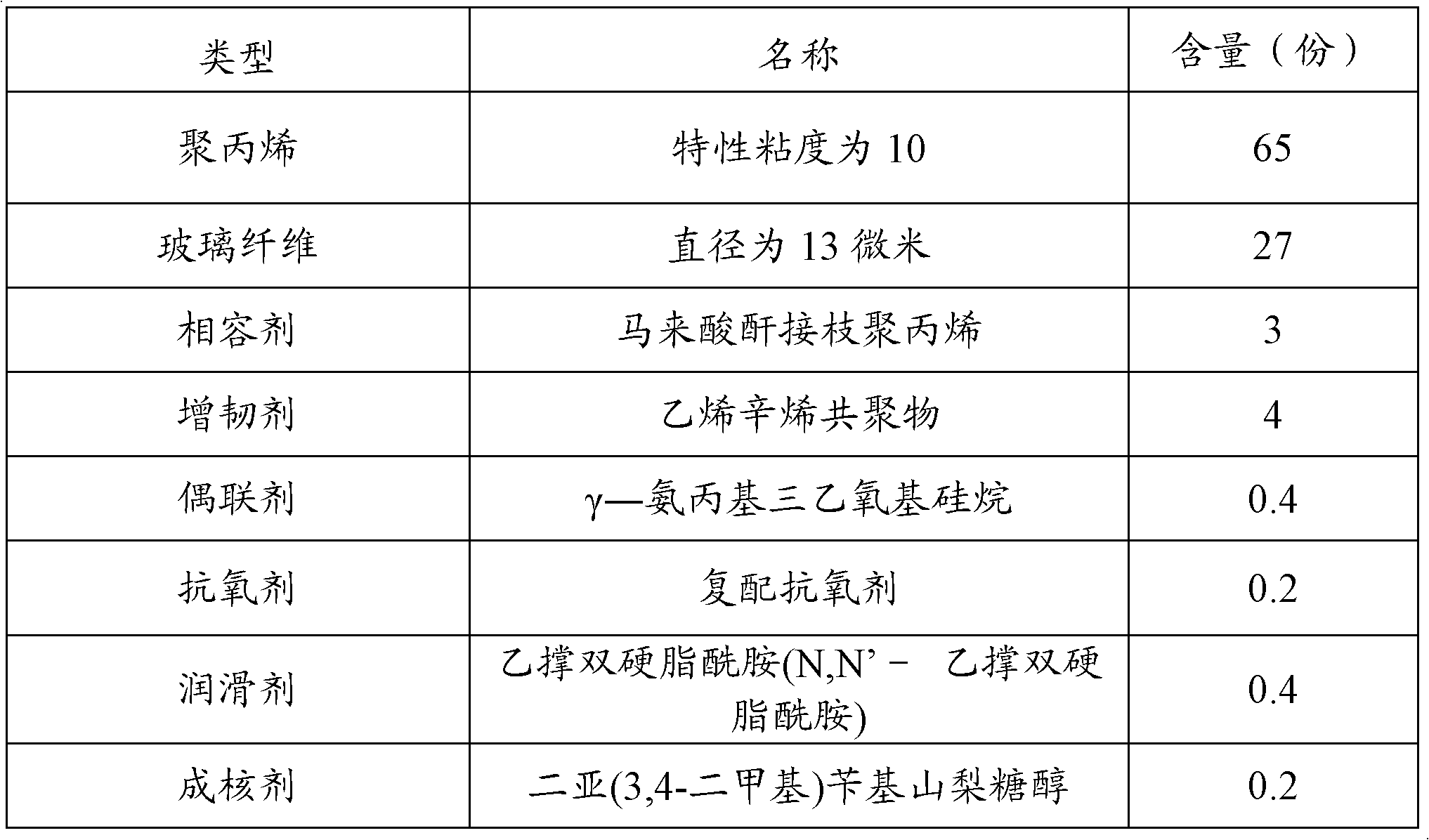

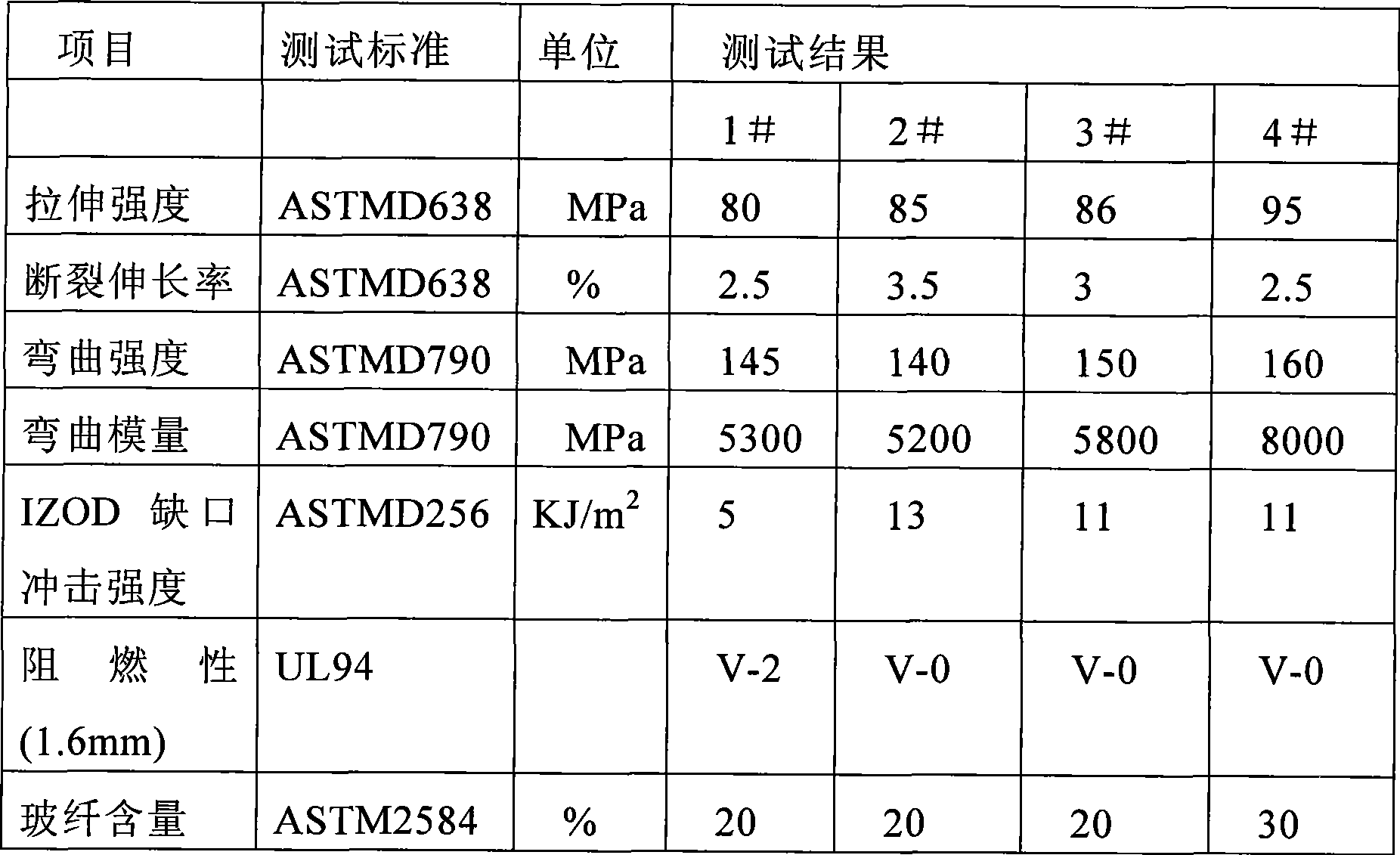

Polypropylene Composite

The invention relates to a polypropylene composite material, which comprises the following components in part by weight: 65 to 70 parts of polypropylene, 25 to 27 parts of glass fibers, 2 to 4 parts of compatilizer, 2 to 4 parts of flexibilizer, 0.2 to 0.4 part of coupling agent, 0.2 to 0.4 part of antioxidant, 0.2 to 0.5 part of lubricant and 0.2 to 0.4 part of nucleator. The polypropylene composite material is high in mechanical strength and creep resistance.

Owner:古道尔工程塑胶(深圳)有限公司 +1

High tenacity halogen-free flame-retardant glass fiber reinforced polycarbonate composition

InactiveCN101469112AImprove mechanical propertiesImprove notched impact strengthPolycarbonateHalogen

The invention relates to a high-tenacity, halogen-free and flame-retardant fiber glass reinforced polycarbonate composition, which comprises the following components by weight portion: 300 to 800 portions of polycarbonate, 100 to 400 portions of fiber glass, 30 to 150 portions of toughening compatilizer, 10 to 100 portions of organosilicon flame retardant, 10 to 150 portions of nano silicic acid inorganic substances, 1 to 10 portions of antioxidant A, 1 to 15 portions of antioxidant B, 1 to 15 portions of coupling agent, and 0 to 20 portions of other assistants. Compared with the prior art, the composition has the characteristics of good processing property, high impact strength, environmental protection due to free halogen and flame retardance, and the like.

Owner:HEFEI GENIUS NEW MATERIALS

Halogen-free flame retardant polyphenyl ether/polystyrene alloy material and preparation method thereof

The invention discloses a halogen-free flame retardant polyphenyl ether / polystyrene alloy material. The material comprises the following components by weight: 37-90 parts of polyphenyl ether, 10-50 parts of polystyrene, 5-20 parts of a flame retardant, 0.2-0.5 parts of an antioxidant and 5.1-35.1 parts of an assistant. The invention also discloses a preparation method of the halogen-free flame retardant polyphenyl ether / polystyrene alloy material. The PPO / PS alloy material provided by the invention has advantages of excellent property, low cost and energy saving, and can realize steel substitution by plastic. The added halogen-free flame retardant endows the alloy with good flame retardancy, is friendly to the environment, and does not cause secondary pollution. Besides, the material forming process is simple, and saves processing cost. Further, a section bar produced from the PPO / PS alloy material has wide application, and can be used for parts in special electronic and electrical appliances and large equipment, due to the advantages of good flame resistance, corrosion resistance, insulation, good strength and toughness, light resistance and light weight.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

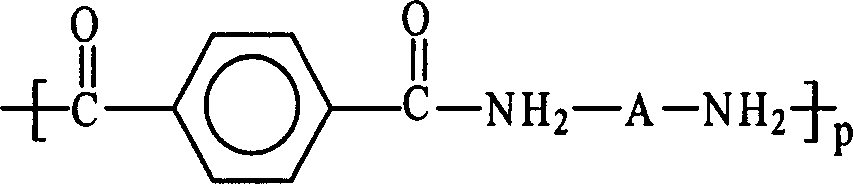

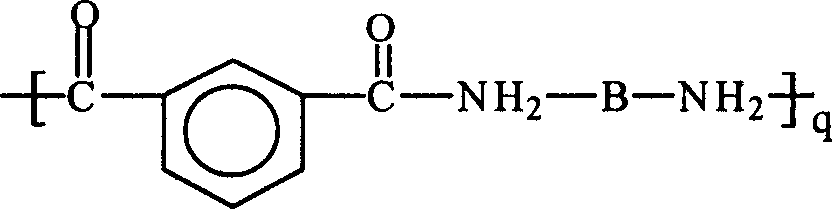

High-toughness semi-aromatic nylon and its preparation method

A high-toughness semi-aromatic nylon is disclosed, which has high tension strength (40 MPa), elongation for break (6%), bending modulus (3000 MPa) and Izod notch impact strength (100 J / m). Its preparing process is also disclosed, which features that the nylon resin with long carbon chain is also used as one of its raw materials.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

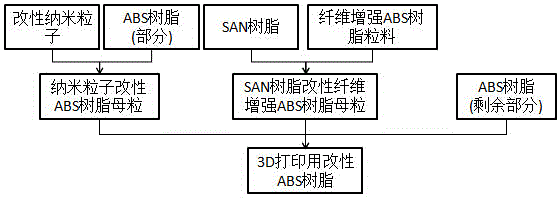

Modified ABS resin for 3D printing as well as preparation method of modified ABS resin

The invention provides modified ABS resin for 3D printing as well as a preparation method of the modified ABS resin. The modified ABS resin for 3D printing provided by the invention is prepared from the following components in percentage by weight: 40-85% of ABS resin, 1-10% of modified nanoparticles, 10-40% of SAN resin and 4-30% of fiber enhanced ABS resin aggregates. The modified ABS resin for 3D printing prepared by the invention has relatively good toughness and mechanical property and is suitable for most FDM moulded 3D printers in the market, so that edge warping in the printing process can be effectively reduced.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

Random-copolymerization polypropylene toughening modified material and preparation method thereof

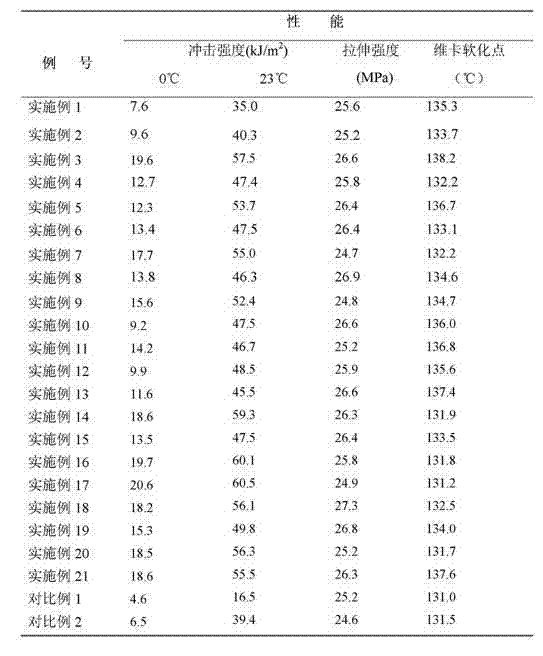

The invention discloses a random-copolymerization polypropylene toughening modified material which is formed by carrying out melt blending modification on the following components in parts by weight: 100 parts of random-copolymerization polypropylene, 0-15 parts of polypropylene homopolymer, 5-20 parts of ethylene copolymer, 2.5-12 parts of modifying master batch and 0.1-0.4 part of antioxidant. The tensile strength of the material is 24.7-27.3MPa, the notch impact strength at 23 DEG C is 35.0-60.5 kJ / m<2>, the notch impact strength at 0 DEG C is 7.6-20.6 kJ / m<2>, and the Vicat softening point is 131.2-138.2 DEG C. The invention also discloses a preparation method of the random-copolymerization polypropylene toughening modified material. The random-copolymerization polypropylene toughening modified material disclosed by the invention has favorable rigidity / toughness balance performance and heat resistance, can be widely used in the industries of construction materials, furniture, automobiles, electric appliances, electronics, electric appliances and the like, and can be used for preparing various profiles, tubes, films, sheets, plates, injection molding parts and the like. Besides, the preparation method is simple, can shorten the molding processing time, and can also lower the energy consumption and the production cost, thereby having high practicality.

Owner:SICHUAN UNIV

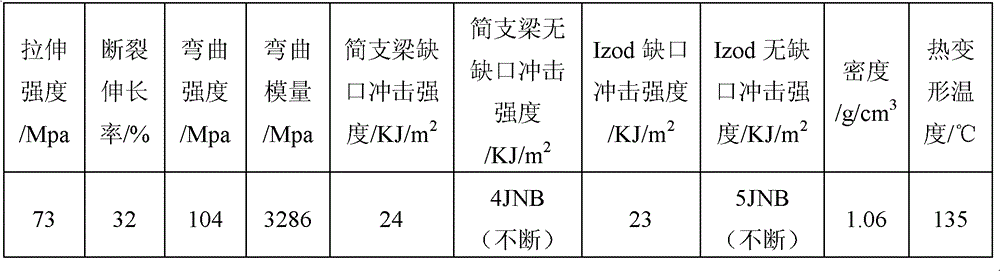

Low-dielectric laser direct structuring composite material suitable for 5G communication and preparation method thereof

ActiveCN110655792ALow dielectric constantHigh heat distortion temperatureChemical platingFire retardant

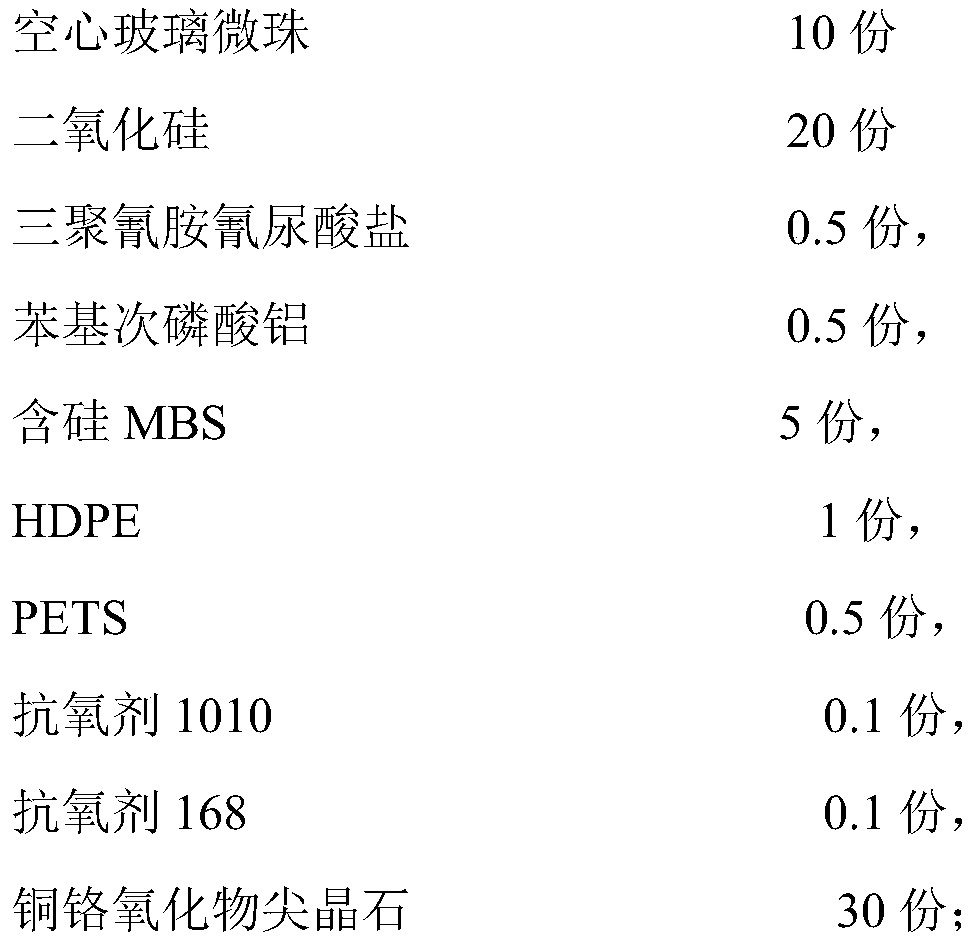

The invention relates to a low-dielectric laser direct structuring composite material suitable for 5G communication. The composite material is composed of the following components in parts by weight:52 to 86 parts of base resin, 0 to 30 parts of glass fibers, 10 to 30 parts of a filling agent, 1 to 9 parts of a flame retardant, 4 to 15 parts of a toughening agent, 0.1 to 1 part of a lubricating agent, 0.2 to 1 part of an antioxidant and 10 to 30 parts of a laser sensitive additive. A preparation method of the composite material comprises the steps that a twin-screw extruder is used for processing, the melt extrusion temperature is 250-380 DEG C, and the screw rotating speed is 150-300 rpm / min. The composite material has low dielectric property, so that improvement of the transmission speed of 5G communication millimeter wave signals is facilitated, the signal delay is reduced, and the signal loss is reduced; the composite material has the LDS processing capacity, can be rapidly prepared in a small size and a large number, can be subjected to batch laser etching and chemical plating to form a metal connecting circuit, and is an optimal solution of a 5G plastic antenna oscillator material.

Owner:中广核高新核材科技(苏州)有限公司

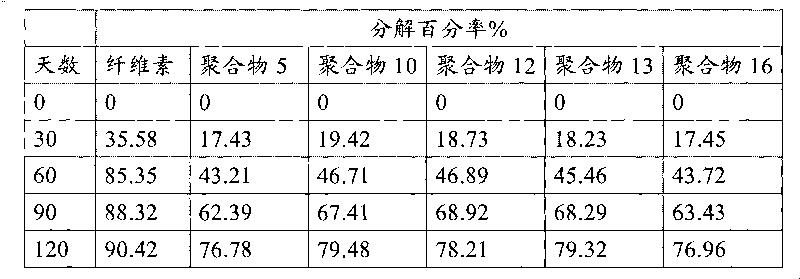

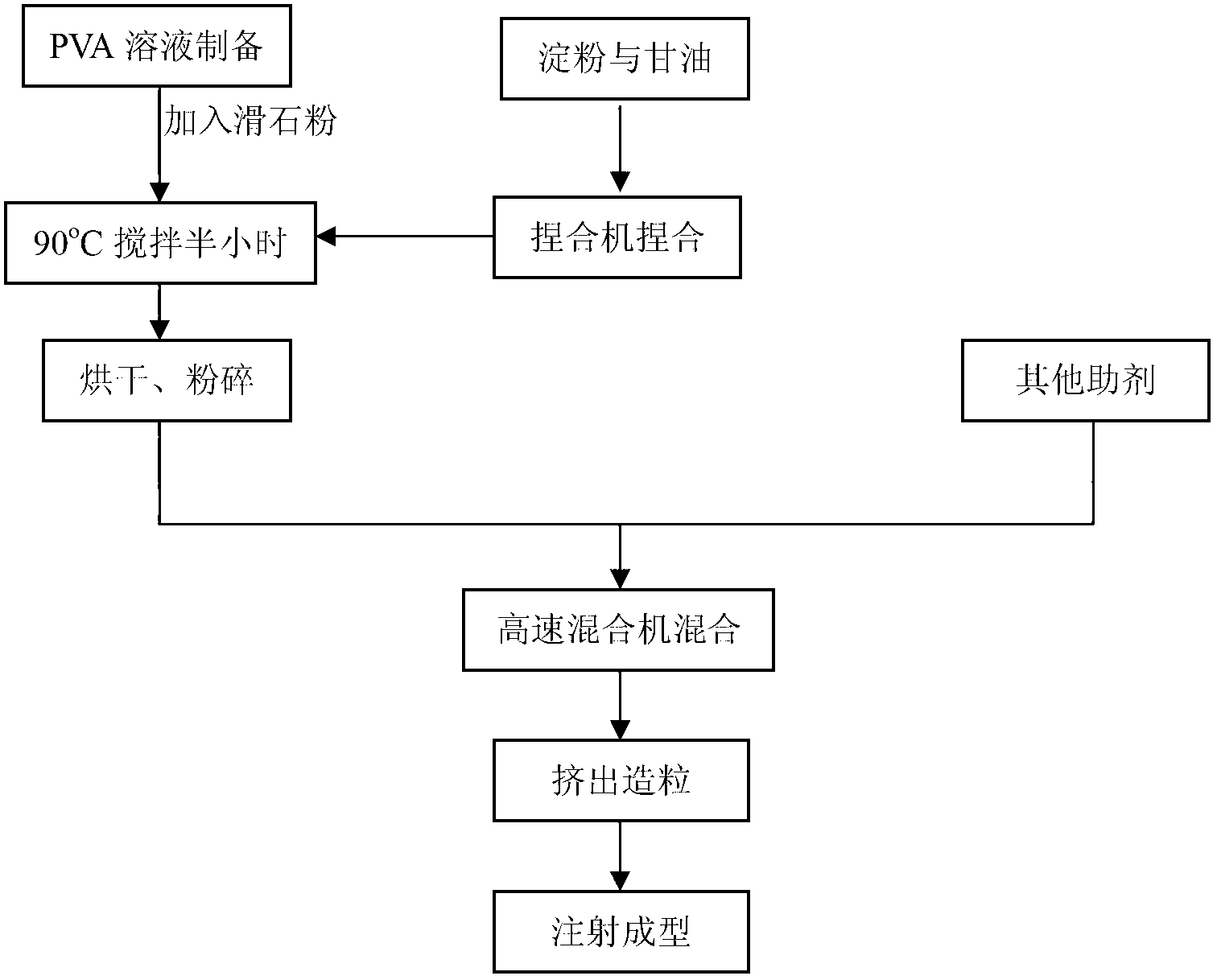

All-degradable thermoplastic starch/polylactic acid blend material and preparation method thereof

The invention relates to a thermoplastic starch / polylactic acid blend material and a preparation method thereof. The thermoplastic starch / polylactic acid blend material is prepared from 40-84% of starch, 8-51% of polylactic acid, 0.2-8% of polyvinyl alcohol, 1-10% of toughener, 0.1-2% of lubricant, 5-30% of plasticizer, 0.1-5% of preservative and 1-10% of inorganic filler. The starch is modified to prepare the thermoplastic starch with excellent properties, the polyvinyl alcohol solution is utilized to pretreat the inorganic filler and thermoplastic starch, and the mixture is subjected to extrusion and granulation by a double screw extruder, and subjected to injection molding to obtain the thermoplastic starch / polylactic acid blend material. The thermoplastic starch / polylactic acid blend material has the advantages of low cost and pollution-free production process, and is all-degradable. The cantilever notch impact strength of the prepared material is 3.5-6.4 KJ / m<2>, the tensile strength is 19-60 MPa, the bending strength is 63-110 MPa, the heat-deformation temperature is 75.5-88.3 DEG C, and the weight loss rate after three-month degradation reaches higher than 90%.

Owner:EAST CHINA UNIV OF SCI & TECH

Polyphenylene oxide/polystyrene blend alloy material, its preparation method and application

Belonging to the technical field of high polymer materials, the invention discloses a polyphenylene oxide / polystyrene blend alloy material, its preparation method and application. The polyphenylene oxide / polystyrene blend alloy material provided in the invention is prepared from the following components by weight: 36-90 parts of polyphenylene oxide, 10-50 parts of polystyrene, 0.2-0.7 part of a lubricant, 0.2-0.5 part of an antioxidant and 7.1-46.1 parts of an assistant. The preparation method of the polyphenylene oxide / polystyrene blend alloy material consists of the steps of: weighing 36-90 parts of polyphenylene oxide, 10-50 parts of polystyrene, 0.2-0.7 part of the lubricant, 0.2-0.5 part of the antioxidant and 7.1-46.1 parts of the assistant, mixing them uniformly at a high speed by a high-speed mixing machine, then pouring the mixture into a screw extruder, and carrying out strand pelletizing by the screw extruder, thus obtaining the product. The invention also discloses application of the polyphenylene oxide / polystyrene blend alloy material as an extrusion type profile material. The polyphenylene oxide / polystyrene blend alloy material provided in the invention can reduce cost and save energy, and realizes the purpose of substituting plastics for steel.

Owner:上海事升新材料有限公司

Nucleocapsid structure polyvinyl chloride impact modifier, and its preparing method and use

InactiveCN1743371AImprove toughening efficiencyImprove the interface binding forceElastomerCross-link

Owner:HEBEI UNIV OF TECH

PPO/PA alloy material with high impact resistance, and preparation method thereof

The invention discloses a PPO / PA alloy material with high impact resistance, and a preparation method thereof, wherein the PPO / PA alloy material comprises, by weight, 30-70 parts of a PPO resin, 30-70parts of a PA resin, 3-10 parts of a compatibilizer, 5-15 parts of a toughening agent, and 0.1-1 part of an antioxidant. According to the present invention, the PPO / PA alloy obtained by blending PPOand PA integrates the unique advantages of PPO and PA, wherein the unique advantages comprise excellent heat resistance, excellent processing property, excellent dimensional stability and high notchedimpact strength; and the PPO / PA material with high impact resistance is extremely focused at home and abroad, especially in the vehicle industry, and the modified PPO / PA alloy can easily process larger-size parts through injection molding and can provide good impact resistance.

Owner:SHANGHAI PRET COMPOSITES +4

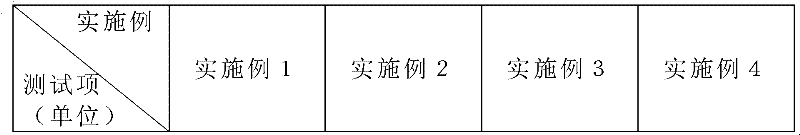

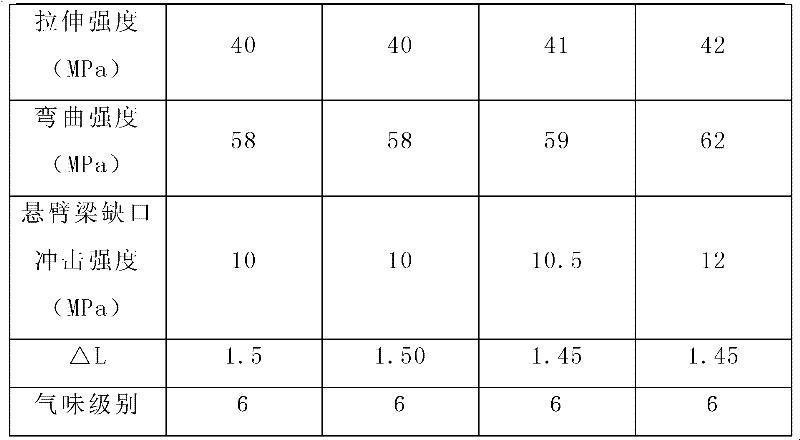

Low-odor scraping-resistant polypropylene material and preparation method thereof

The invention relates to a low-odor scraping-resistant polypropylene material and a preparation method of the low-odor scraping-resistant polypropylene material and belongs to the technical field of polypropylene materials. In order to solve the technical problems that the odor of the polypropylene material in the prior art is difficult to eliminate, the odor can be eliminated only through aiming at a certain single ingredient, the scraping resistance is poor, and the production cost is high when fluorine-containing polymers are adopted for production. The invention provides the low-odor scraping-resistant polypropylene material and also provides the preparation method of the polypropylene material, wherein the polypropylene material comprises acrylic resin, nanometer silicon dioxide, ultra-fine talcum powder, odor eliminating agents, disperse lubricating agents, antioxidants and hindered amine light stabilizers, the method comprises material mixing and squeezing granulation steps, and the low-odor scraping-resistant polypropylene material is obtained. The polypropylene material provided by the invention has the advantages of low odor and scraping resistance. The product obtained from the material has the advantage that the performance such as tensile strength, bending strength, cantilever beam notch impact strength and delta L is high. The method has the advantages that the process is simple, the operation is easy, raw materials are easy to obtain, and the industrial production is favorably realized.

Owner:浙江明江新材料科技股份有限公司

Biodegradable material and preparation method and application thereof

The invention relates to the field of biodegradable materials, in particular to a biodegradable material and a preparation method and application thereof. The biodegradable material at least comprises the following components in parts by weight: 100 parts of a carrier, 10-50 parts of a bio-based material, 5-20 parts of a compatilizer, 1-12 parts of a photodegradation agent, 5-20 parts of a filler and 0.01-5 parts of an aid, wherein the carrier is polyolefin resin; the bio-based material is any one or more of starch and natural plant fibers; the compatilizer is a mixture of glycidyl methacrylate and modified cyclodextrin, wherein the mass ratio of glycidyl methacrylate to modified cyclodextrin is 1:(0.1-1); the photodegradation agent is any one or more of anatase TiO2, a benzophenone compound, a transition metal compound or complex and rare earth carboxylate; and the aid is any one or more of an initiator, a plasticizer, a slipping agent, a dispersant and styrene.

Owner:浙江苏达山新材料有限公司

Modified environment-friendly polyolefin material and preparation method thereof

InactiveCN101531788AIn line with the general direction of environmental protectionImprove performancePolyolefinAntioxidant

The invention discloses a modified environment-friendly polyolefin material which comprises components with the following weight percentages: 40 percent to 70 percent of vegetable fiber, 20 percent to 50 percent of polyolefin resin, 3 percent to 8 percent of coupling agent, 3 percent to 10 percent of nano calcium carbonate, 3 percent to 5 percent of polypropylene oxide wax and 0.3 percent to 0.5 percent of antioxidant. The preparation method comprises the following steps of: preparing materials, mixing the materials at high speed, granulating and drying for later use. The polyolefin material can not only be biochemically degraded in nature, but also can be chemically degraded by chemical fertilizers, is in accord with the general orientation of environmental protection, fully meets the requirements of European ROHS, reaches the toy safety standard of EN71 / ASTM 963, contains no heavy metal, toxic elements or chemical substances damaging the ozone layer, and has the advantages of ultraviolet (UV) radiation resistance, mechanical performance against thermal and cold shocks and excellent pigmenting property.

Owner:鹏马环保塑料有限公司

Method for producing plastic pipe fitting with insert made from polyphenylene sulfide alloy material

The invention relates to a method for making a plastic pipe with an insert made from a PPS alloy material. Materials such as PPS, nylon, etc. are treated with steps of blending, extrusion, strip stretching, cooling, pelletizing, homogenization, injection molding, etc. so as to obtain the plastic pipe with the insert made from the PPS alloy material. The making method of the invention has simple and easy technique; the alloy material has the advantages of small specific weight, good heat and corrosion resistance as well as good dimensional stability; in addition, the obtained pipe has good sealing, high notched impact strength, etc. The plastic pipe provided by the invention has wide range of application and can be applicable to water supply and drainage systems and drinking water pipe systems, gas transmission systems and industrial pipe systems, heating systems and agricultural pipe systems.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS +1

Method for preparing plastic pipe fitting from polyethylene terephthalate (PET) bottle reclaimed material

InactiveCN101781446AGood compatibilityImproved injection processabilityRigid pipesPolyethylene terephthalate glycolEngineering

The invention relates to a method for preparing a plastic pipe fitting from a PET bottle reclaimed material, which comprises the following steps: taking 63-74 parts by weight of the PET bottle reclaimed material and 22-32 parts by weight of m-LLDPE as raw materials, adding 2-4 parts by weight of compatilizer, 0.6-1.2 parts by weight of lanthanum oxide and 0.5-1.0 part by weight of antioxidant 1010, pulverizing, mixing at high speed, extruding and pelleting by a twin screw, and injection molding to process the pipe fitting. The compatilizer is prepared by mixing an ethylene-acrylic acid copolymer and an ethylene-octylene copolymer in proportion by weight of 1:0.5-0.9. Compared with the pipe fittings manufactured from unmodified PET bottle reclaimed materials, the pipe fitting prepared by the method has the advantages that the notch impact strength is improved by 45%-55%, the compression resilience rate is improved by 22%-26%, and the rate of finished products of injection pipe fittings is improved by 18-23%; and the pipe fitting has the characteristics of high anti-impact strength, good pressure resistance, lustrous surface, low cost and the like, and is suitable for drainage and sewage pipe fittings in municipal works and water-saving irrigation pipe fittings in agriculture.

Owner:FUJIAN NORMAL UNIV

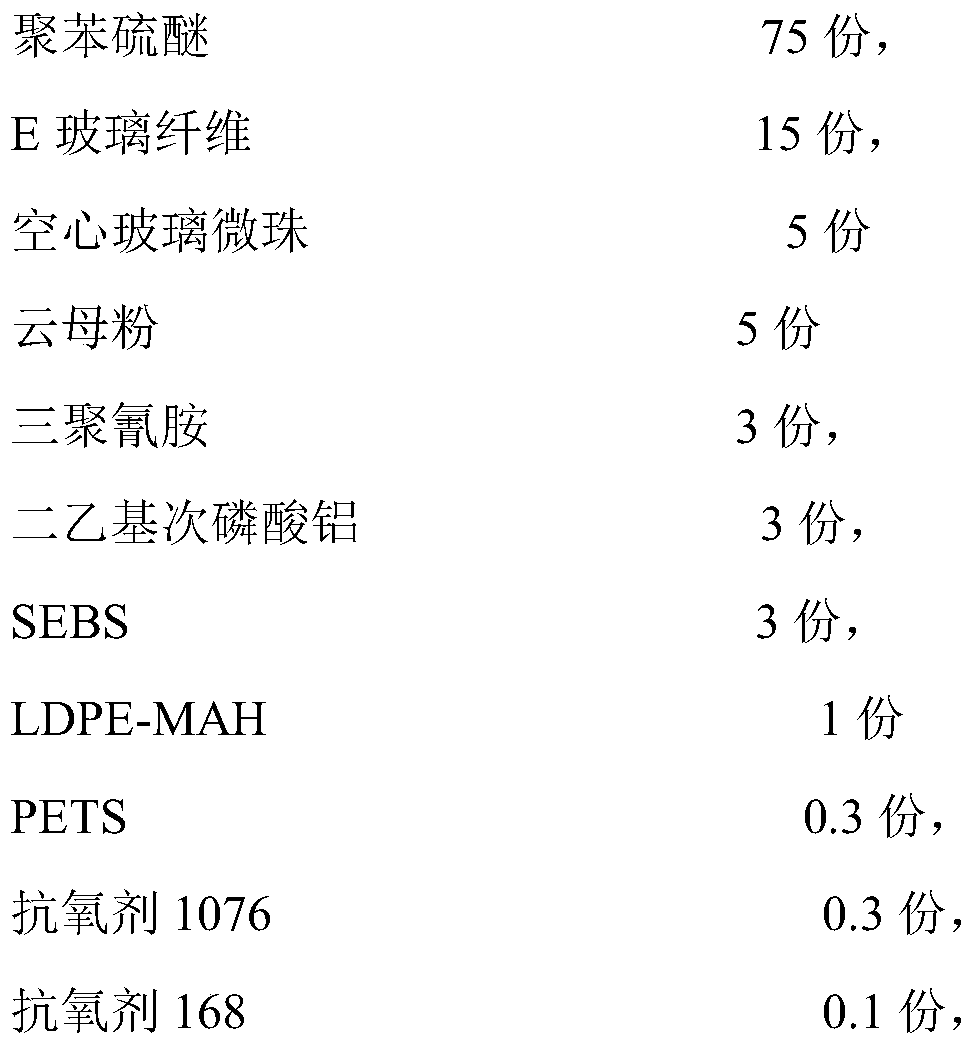

Fiberglass enhanced polyphenyl thioether/polyphenylether composite material and preparation method thereof

The invention discloses a fiberglass enhanced polyphenyl thioether / polyphenylether composite material and a preparation method thereof. The composite material is mainly prepared by the following raw materials: polyphenyl thioether, polyphenylether, fiberglass, mineral filler, a compatibility agent, an antioxidant and a processing aid. The preparation method of the fiberglass enhanced polyphenyl thioether / polyphenylether composite material comprises the following steps of: (a) firstly, respectively blasting and drying polyphenyl thioether resin and polyphenylether resin; (b) weighting the polyphenyl thioether resin and the polyphenylether resin which are dried, the mineral filler, the compatibility agent, the antioxidant and the processing aid; (c) mixing the dry materials in the step (b) to obtain a compound; and (d) adding the compound in the step (c) and the fiberglass to a double screw extruder for melt blending and pelleting. The fiberglass enhanced polyphenyl thioether / polyphenylether composite material can unconspicuously lower the temperature-resistant level and the rigidity of the polyphenyl thioether resin, further improve the molding accuracy of the polyphenyl thioether resin and decrease the cost.

Owner:SHENZHEN KEJU NEW MATERIAL

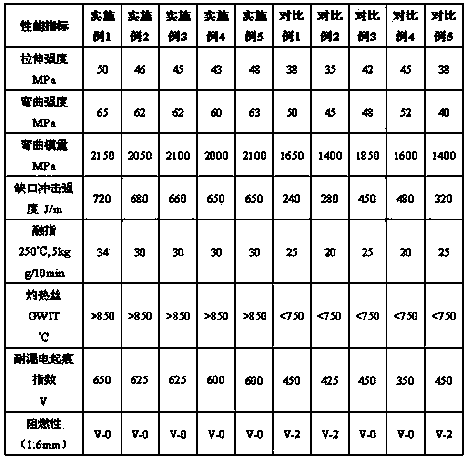

High-glowing-filament high-CTI (comparative tracking index) super-tough flame-retardant PBT/PC (polybutylene terephthalate/polycarbonate) alloy material and preparation method thereof

The invention relates to a high-glowing-filament high-CTI (comparative tracking index) super-tough flame-retardant PBT / PC (polybutylene terephthalate / polycarbonate) alloy material and a preparation method thereof. The material is prepared from the following raw materials in parts by weight: 15-70 parts of PBT, 10-25 parts of PC, 10-25 parts of compound toughener, 5-20 parts of bromine flame retardant, 3-10 parts of phosphorus-nitrogen flame retardant, 2-5 parts of inorganic flame-retardant synergistic agent, 0.1-0.5 part of ester exchange inhibitor, 0.1-0.5 part of anti-dripping agent PTFE (polytetrafluoroethylene), 0.1-0.5 part of lubricant and 0.1-0.5 part of antioxidant. The PBT / PC alloy material has excellent comprehensive properties; and the ASTM (American Society for Testing and Materials) notch impact strength is greater than 600 J / m, the flame retardancy reaches UL94V-0, the glowing filament temperature GWIT is greater than 850 DEG C, and the CTI is greater than 600V, thereby greatly widening the application range of the PBT / PC alloy material.

Owner:上海日之升科技有限公司

Graphene modified PA6 composite and preparation method thereof

The invention discloses a graphene modified PA6 composite. The graphene modified PA6 composite is prepared from the following components in parts by weight: 100 parts of PA6 resin, 0.02-0.6 part of modified graphene carbon materials, 0.2-0.6 part of an antioxidant and 1.0-5.0 parts of a compatibilizer, wherein the modified graphene carbon materials are modified graphene, modified graphene oxide, or a mixture of the modified graphene and modified graphene oxide. A preparation method of the graphene modified PA6 composite disclosed by the invention comprises the following steps of firstly preparing the modified graphene and the modified graphene oxide, and then premixing the modified graphene and the modified graphene oxide with PA6 composites in a certain proportion. Through the adoption of the method, the modified graphene and the modified graphene oxide can be uniformly dispersed in the PA6 composite, the mechanical properties of the PA6 composite can be obviously improved, besides, the heat stability of the composite is improved, and the water absorption of the composite can also be reduced.

Owner:THE SIXTH ELEMENT CHANGZHOU MATERIALS TECH

Method for preparing impact modifier of polyvinyl chloride in new type structure of hud

InactiveCN1916046AImprove toughening efficiencyImprove the interface binding forceElastomerResin matrix

This invention relates to a method for preparing polyvinyl chloride impact modifier with core / shell structure. The method comprises: utilizing acrylate monomer as the raw material, performing seed emulsion polymerization by semi-continuous adding the raw material to obtain crosslinked polymer latex with elastomer core / transition layer structure, adding vinyl chloride monomer and other monomers into the high-pressure kettle, and performing emulsion polymerization to obtain polyvinyl chloride impact modifier with core / shell structure. The impact modifier has polyvinyl chloride as the shell, thus can improve the compatibility with polyvinyl chloride resin matrix when blending, and effectively exert the functions of polyacrylate elastomer core and functional groups. The impact modifier can improve the impact property, weathering resistance and heat stability of polyvinyl chloride materials. Besides, the cost of the impact modifier is lower than that of polyacrylate impact modifier, thus can increase the added value of polyvinyl chloride resin and broaden the applications of polyvinyl chloride resin.

Owner:HEBEI UNIV OF TECH

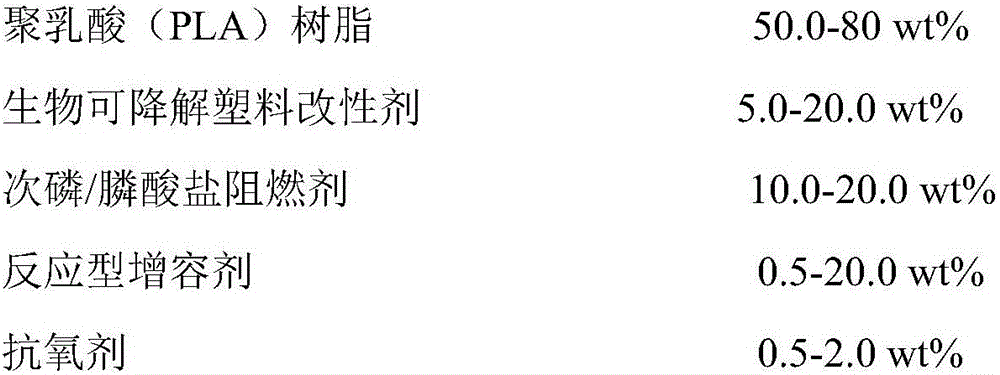

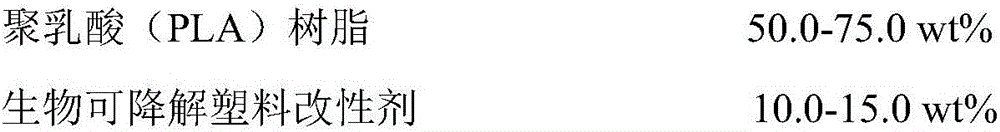

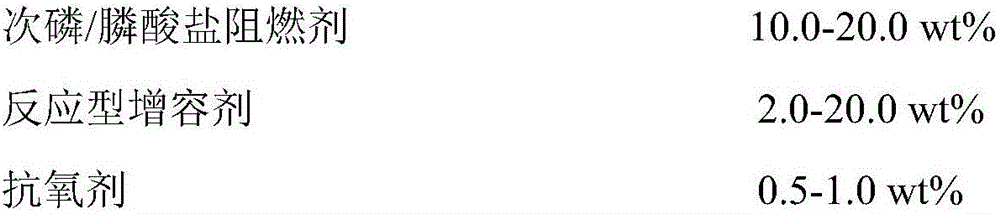

Halogen-free flame retardant polylactic acid toughening modification composite material and preparing method thereof

InactiveCN105694405AGood flame retardant performanceExcellent toughness and elongation at breakBiodegradable plasticAntioxidant

The invention discloses a halogen-free flame retardant polylactic acid toughening modification composite material.The composite material is mainly composed of 50.0-80 wt% of polylactic acid, 5.0-20.0 wt% of biodegradable plastic, 10.0-20.0 wt% of phosphorus based flame retardant, 0.5-20.0 wt% of reactive compatibilizer and 0.2-1.0 wt% of antioxidant.Hypophosphite and phosphonate with different ratios are taken as the flame retardant to achieve flame retarding of polylactic acid, polylactic acid is toughened through a bio-based elastomer, a reactive polymer is added to serve as the reactive compatibilizer, and the halogen-free flame retardant biodegradable polylactic acid toughening modification composite material is prepared through melting reaction and blending.The composite material has excellent flame retarding property, elongation at break and toughness.The biodegradable halogen-free flame retardant polylactic acid toughening modification composite material is efficient and low in toxicity and is an environment-friendly biodegradable flame retardant plastic.The composite material has excellent flame retarding property and mechanical property and can be used in the fields such as packaging, film, textile and automobiles.

Owner:QINGDAO UNIV OF SCI & TECH

Glass fiber reinforced co-polypropylene composite material and preparation method of the Glass fiber reinforced co-polypropylene composite material

InactiveCN102181100AHigh tensile yield strength and impact resistanceGood rigidityMaleic anhydrideThin walled

The invention discloses a glass fiber reinforced co-polypropylene composite material and a preparation method of the glass fiber reinforced co-polypropylene composite material. The preparation method includes the steps as follows: uniformly mixing co-polypropylene, polypropylene grafted with maleic anhydride, homopolymerized polypropylene organic peroxide initiator, and antioxidant in proportion;adding the mixture in a double-screw extruder and simultaneously adding glass fiber strand roving; and conducting melt extrusion for granulation at the temperature of 170-220 DEG C, thus obtaining the glass fiber reinforced co-polypropylene composite material, wherein the melt index of the obtained composite material is 18-35g / 10min, the tensile strength is 49-89 Mpa, the breaking elongation is 9-35%, the Young modulus is 2.3-5.3GPa and the notch impact strength is 10-33kJ / m2. The glass fiber reinforced co-polypropylene composite material provided by the invention has not only outstanding strength, modulus, and impact resisting and heat resisting properties, but also excellent processing flow property, and can injection-mold and form thin-wall products with attractive appearance and complex shape; and the glass fiber reinforced co-polypropylene composite material has the characteristics of being light in weight and cheap in cost can substitute for engineering plastics such as expensive ABS (Acrylonitrile Butadiene Styrene) and nylon.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD +1

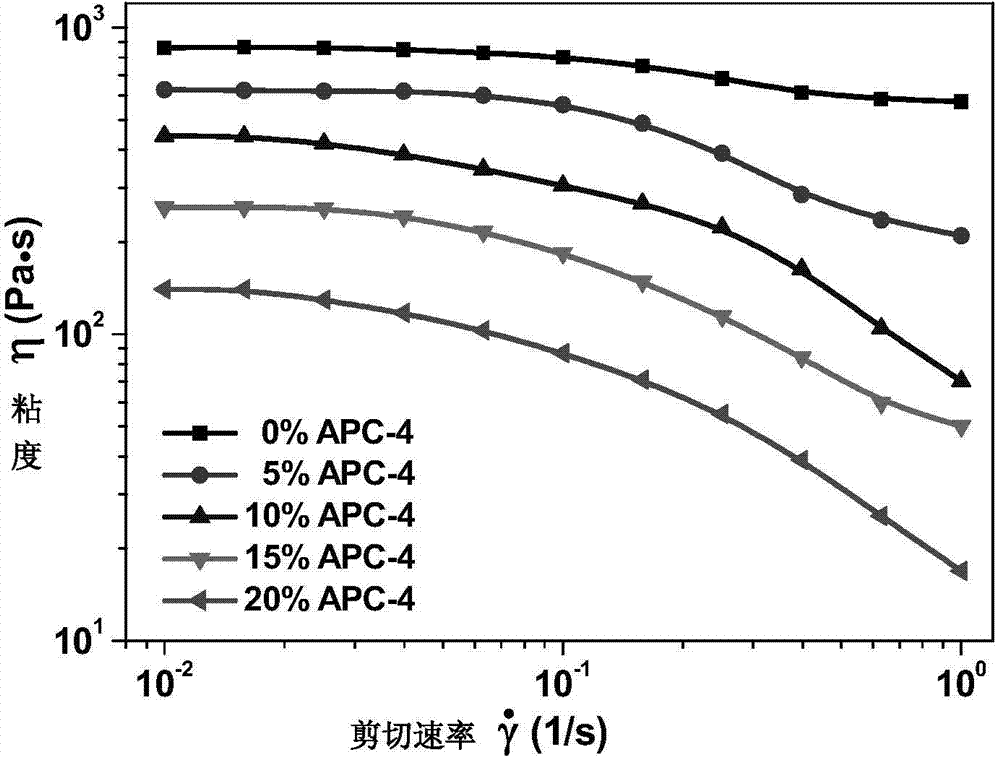

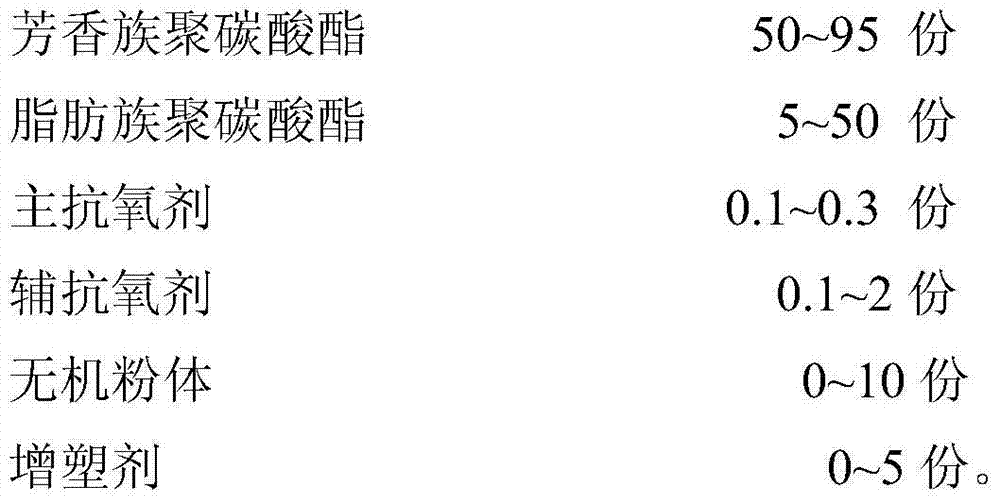

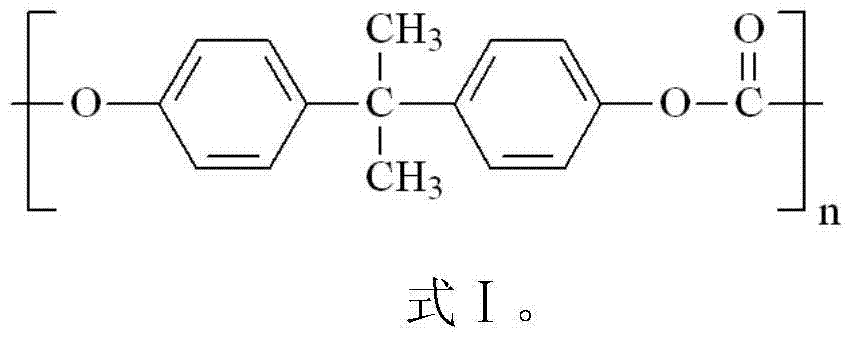

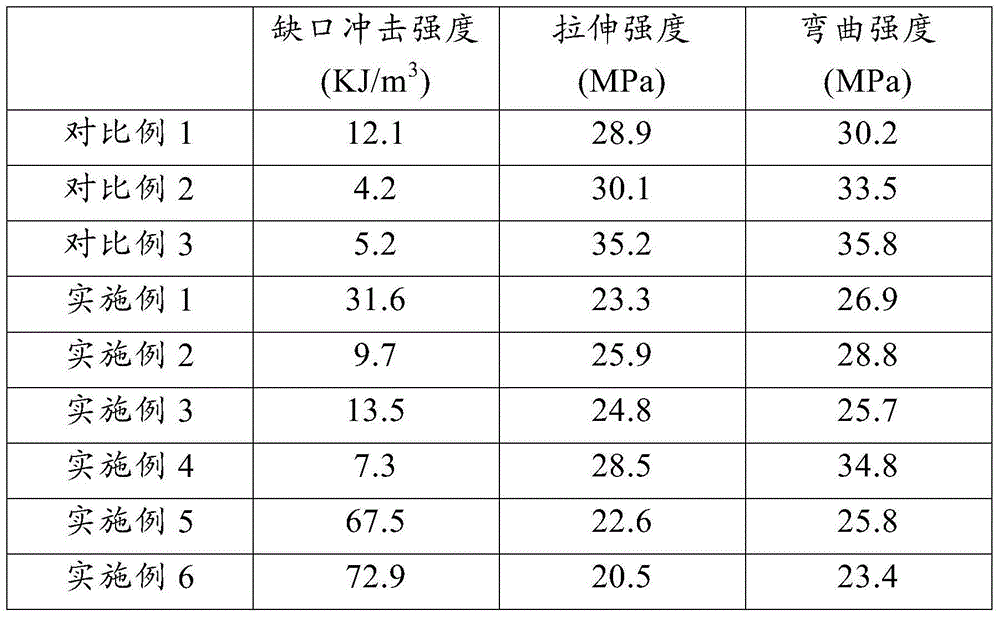

Polycarbonate composite material and preparation method thereof

The invention discloses a polycarbonate composite material and a preparation method thereof. The polycarbonate composite material is composed of the following components in parts by weight: 50-95 parts of aromatic polycarbonate, 5-50 parts of fatty group polycarbonate, 0.1-0.3 part of main antioxidant, 0.1-2 parts of auxiliary antioxidant, 0-10 parts of inorganic powder and 0-5 parts of plasticizer. The preparation method comprises the following steps: 1) respectively drying the aromatic polycarbonate and fatty group polycarbonate at 50-120 DEG C for 4-30 hours; 2) mixing the components; and 3) carrying out melt extrusion on the mixture in the step (2) through a double screw extruder, and granulating. Under the condition of not adding any compatilizer or elastomer, the polycarbonate composite material has the advantages of high notch impact strength and favorable processing flowability, and is partially biodegradable. The fatty group polycarbonate has flexible and adjustable chemical structure and molecular weight, and can be prepared into a series of polycarbonate composite materials according to practical application demands.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Polyropylene composite material and preparation method thereof

InactiveCN104974418AImprove notched impact strengthHigh strengthPolypropylene compositesPolymer science

The invention discloses a polypropylene composite material and a preparation method thereof, wherein the material includes, by weight, (a) 40-85% of polypropylene resin, (b) 5-30% of a toughening agent, (c) 5-40% of a filling material, (d) 0.1-1% of a composite antioxidant, and (e) 0.1-1% of a processing aid. The preparation method includes the steps of (1) weighing the material according to the weight ratio of 40-85% of the polypropylene resin, 5-30% of the toughening agent, 5-40% of the inorganic material, 0.1-1% of the composite antioxidant, and 0.1-1% of the processing aid; (2) mixing the raw materials in a high-speed mixer uniformly; and (3) performing extrusion in a double-screw extruder to obtain a blended substance. The polypropylene composite material is excellent in anti-impact performance, is high in toughness at normal and low temperatures, is excellent in notch impact strength and is excellent in heat resistance and rigidity.

Owner:SINOPEC YANGZI PETROCHEM +1

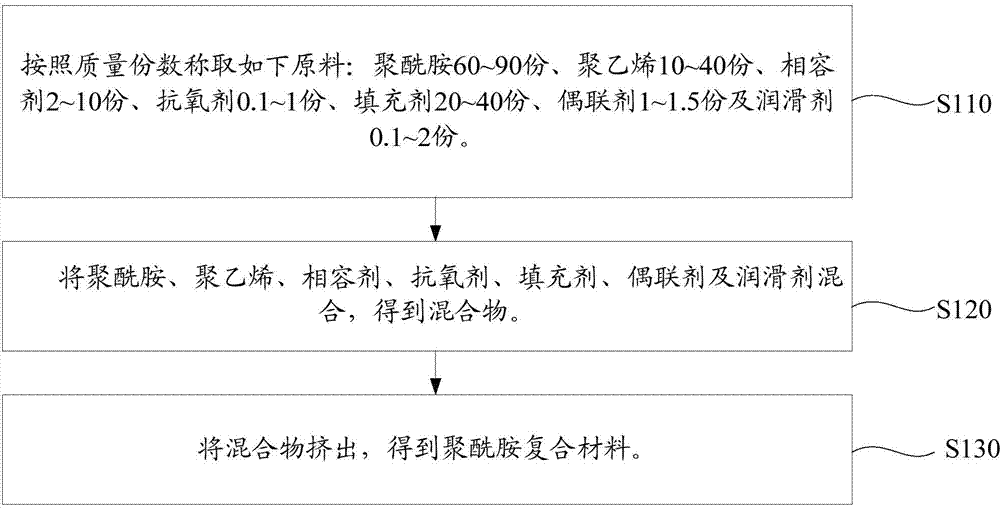

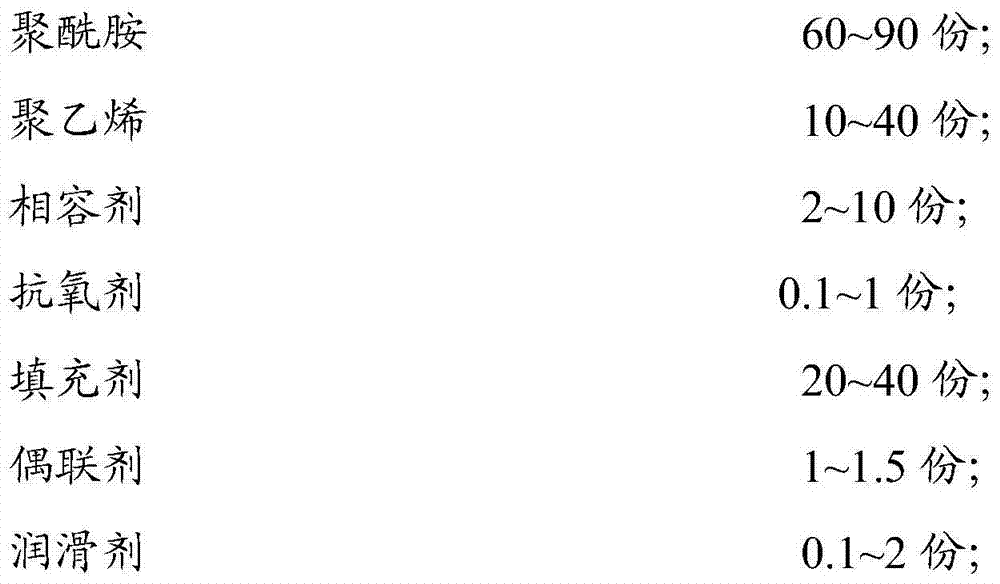

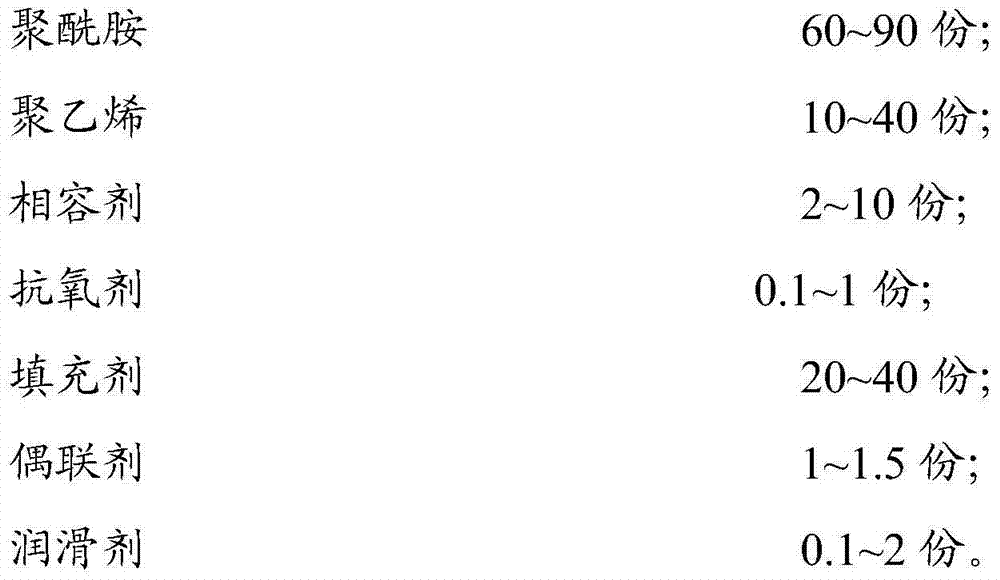

Polyamide composite material and preparation method thereof

The invention relates to a polyamide composite material and a preparation method thereof. The polyamide composite material comprises the following raw materials in parts by weight: 60-90 parts of polyamide, 10-40 parts of polyethylene, 2-10 parts of a compatilizer, 0.1-10 parts of an antioxidizer, 20-40 parts of a filling agent, 1-1.5 parts of a coupling agent, and 0.1-2 parts of a lubricating agent, wherein the filling agent is a glass microsphere and alkali-free glass fibre. The polyamide composite material has better mechanical property and wear-resisting property.

Owner:SHENZHEN XINGSHENGDI NEW MATERIALS

Formaldehyde-free film adhesive and method for manufacturing veneer board and homodromous laminated material

ActiveCN102181239AHigh bonding strengthLabor savingNon-macromolecular adhesive additivesWood veneer joiningLow-density polyethyleneGraphite

The invention relates to a formaldehyde-free film adhesive and a method for manufacturing a veneer board and a homodromous laminated material with multiple advantages by using the formaldehyde-free film adhesive. The veneer board with multiple advantages cannot be manufactured by using the conventional film adhesive. The formaldehyde-free film adhesive comprises 80 weight parts of high-density polyethylene, 20 weight parts of low-density polyethylene, 0.1 to 0.4 weight part of antioxidant and 1 to 1.5 weight parts of graphite powder or graphite master batch. The invention also relates to the method for manufacturing the veneer board and the homodromous laminated material. By using the formaldehyde-free film adhesive and the related method, the veneer board and the homodromous laminated material with multiple advantages such as high waterproof property, high elongation at break, high notch impact strength, ageing resistance and the like can be manufactured and can substitute raw wood in various occasions so as to save the forest resource.

Owner:JIANGMEN DINGSHI ADHESIVE INDAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com