Polycarbonate composite material and preparation method thereof

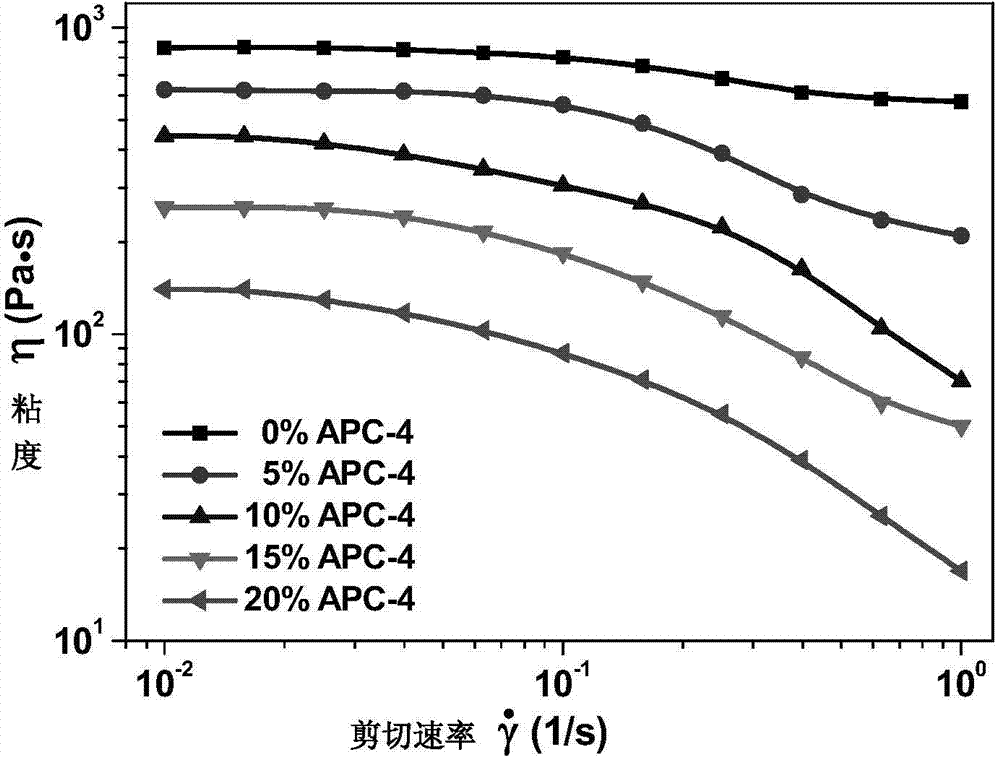

A polycarbonate and composite material technology, applied in the field of polymer materials, can solve the problems of difficulty in simultaneously improving PC processing fluidity and notched impact strength, increasing material complexity and cost, and poor notched impact strength, etc. And the effect of flexible adjustment of molecular weight, viscosity reduction, and improved processing fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Embodiment 1, prepare polycarbonate composite material

[0060] Polycarbonate composites were prepared according to the following steps:

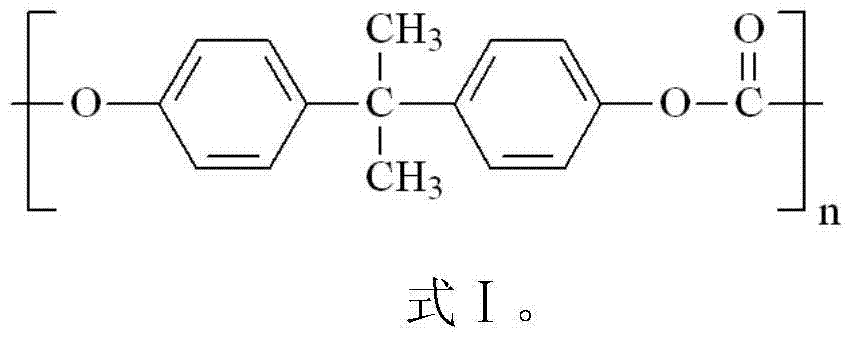

[0061] (1) Dry the linear bisphenol A type aromatic polycarbonate resin (trade name PC2200R, weight average molecular weight is 22000g / mol) at 100°C for 20 hours, polybutylene carbonate (weight average molecular weight is 85000g / mol) Dry at 60°C for 24 hours.

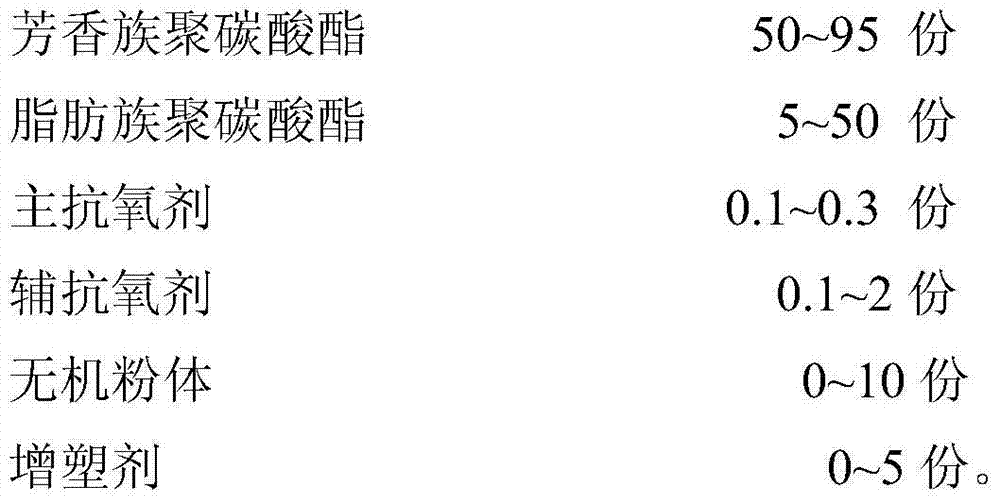

[0062] (2) In a high-speed stirrer, mix aromatic polycarbonate resin, aliphatic polycarbonate, primary antioxidant, secondary antioxidant and plasticizer according to the following proportions, in parts by weight, each The composition of the components is as follows:

[0063]

[0064] (3) Melting and extruding through a twin-screw extruder to prepare a polycarbonate composite material. Among them, the temperature and screw speed of each section of the twin-screw extruder are set as follows:

[0065] The temperature of the first and second stages is 240°C, the temperatur...

Embodiment 2

[0067] Embodiment 2, prepare polycarbonate composite material

[0068] Polycarbonate composites were prepared according to the following steps:

[0069] (1) Dry the linear bisphenol A type aromatic polycarbonate resin (the weight average molecular weight is 22000g / mol) at 110°C for 20 hours, polybutylene carbonate (the weight average molecular weight is 85000g / mol) at 80°C Let dry for 24 hours.

[0070] (2) In a high-speed stirrer, mix aromatic polycarbonate resin, aliphatic polycarbonate, primary antioxidant, secondary antioxidant and inorganic powder (with a particle size of 2 to 3 μm) uniformly in the following ratio , in parts by weight, each component is composed as follows:

[0071]

[0072] (3) Melting and extruding through a twin-screw extruder to prepare a polycarbonate composite material. Among them, the temperature settings of each section of the twin-screw extruder are as follows:

[0073] The temperature of the first and second stages is 220°C, the temperat...

Embodiment 3

[0075] Embodiment 3, prepare polycarbonate composite material

[0076] Polycarbonate composites were prepared according to the following steps:

[0077] (1) Dry the linear bisphenol A type aromatic polycarbonate resin (the weight average molecular weight is 22000g / mol) at 100°C for 20 hours, and dry polybutylene carbonate (the weight average molecular weight is 85000g / mol) at 70°C Let dry for 24 hours.

[0078] (2) In a high-speed mixer, mix aromatic polycarbonate resin, aliphatic polycarbonate, primary antioxidant, secondary antioxidant, inorganic powder (with a particle size of 4 to 5 μm) and plasticizer as follows Said ratio is mixed evenly, and in parts by weight, each component is composed as follows:

[0079]

[0080]

[0081] (3) Melting and extruding through a twin-screw extruder to prepare a polycarbonate composite material. Among them, the temperature settings of each section of the twin-screw extruder are as follows:

[0082] The temperature of the first a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com