Glass fiber reinforced co-polypropylene composite material and preparation method of the Glass fiber reinforced co-polypropylene composite material

A technology of copolymerized polypropylene and composite materials, which is applied in the field of glass fiber reinforced polypropylene copolymer and its preparation, can solve the problems of high melt viscosity, poor fluidity, and difficulty in injection molding of glass fiber reinforced polypropylene, and achieves high tensile strength. Tensile yield strength and impact resistance, improved processing fluidity, and the effect of excellent toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

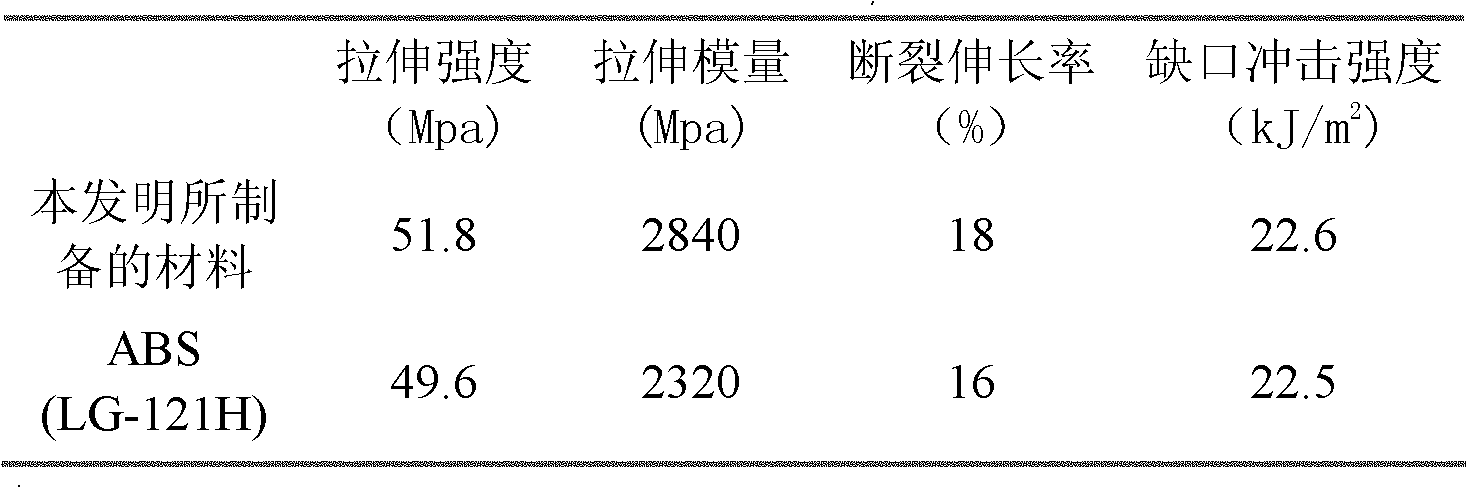

Image

Examples

Embodiment 1

[0035] The notched impact strength of 50 parts of the Izod beam is 50kJ / m 2 1. Block copolymer polypropylene with a melt index of 5g / 10min, 10 parts of polypropylene grafted with maleic anhydride with a graft rate of 0.5%, 2 parts of homopolypropylene with a melt index of 2g / 10min, 0.01 part of diperoxide Cumene, 0.1 part of antioxidant 1010 are mixed evenly together, and the mixed material is added into the twin-screw extruder from the feed port, and 40 parts of surface-treated silane are added from the entrance of the glass fiber above the barrel wall of the screw melting section. Coupling agent-treated glass fiber plied rovings with a single filament diameter of 6 μm are melt-extruded and pelletized at 170-220°C to obtain high-performance glass fiber-reinforced block copolymerized polypropylene composites. After testing, the melt index (200°C, load 2.26Kg) of the material is 35g / 10min, the tensile strength is 89MPa, the elongation at break is 9%, the Young's modulus is 5.3G...

Embodiment 2

[0037]The notched impact strength of 80 parts of the Izod beam is 80kJ / m 2 , a random copolymer polypropylene with a melt index of 0.3g / 10min, 5 parts of polypropylene grafted maleic anhydride with a graft rate of 1%, 5 parts of homopolypropylene with a melt index of 10g / 10min, 0.1 part of peroxidized Benzoyl, 0.05 parts of antioxidant 168 are mixed together evenly, and the mixed material is added into the twin-screw extruder from the feeding port, and 10 parts of surface-treated silane are added from the entrance of the glass fiber above the barrel wall of the screw melting section. Coupling agent-treated glass fiber plied rovings with a single filament diameter of 17 μm are melt-extruded and pelletized at 170-220 ° C to obtain high-performance glass fiber-reinforced block copolymerized polypropylene composites. After testing, the melt index (200°C, load 2.26Kg) of the material is 21g / 10min, the tensile strength is 49MPa, the elongation at break is 35%, the Young's modulus is...

Embodiment 3

[0039] The notched impact strength of 60 parts of the Izod beam is 60kJ / m 2 , a random copolymer polypropylene with a melt index of 3g / 10min, 7 parts of polypropylene grafted maleic anhydride with a graft rate of 0.8%, 8 parts of homopolypropylene with a melt index of 8g / 10min, 0.05 part of benzene peroxide Formyl, 0.1 part of antioxidant 168 mixed with antioxidant 1010 in a ratio of 1:1 is mixed evenly, and the mixed material is added to the twin-screw extruder from the feed port, and at the same time, it is removed from the barrel wall of the screw melting section Add 20 parts of glass fiber plied rovings with silane coupling agent on the surface and a single filament diameter of 10 μm to the entrance of the upper glass fiber, and melt and extrude at 170-220 ° C to obtain high-performance glass fiber reinforcement. Block copolymer polypropylene composites. After testing, the melt index (200°C, load 2.26Kg) of the material is 18g / 10min, the tensile strength is 63MPa, the elo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com