Patents

Literature

603results about How to "Ensure structural safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

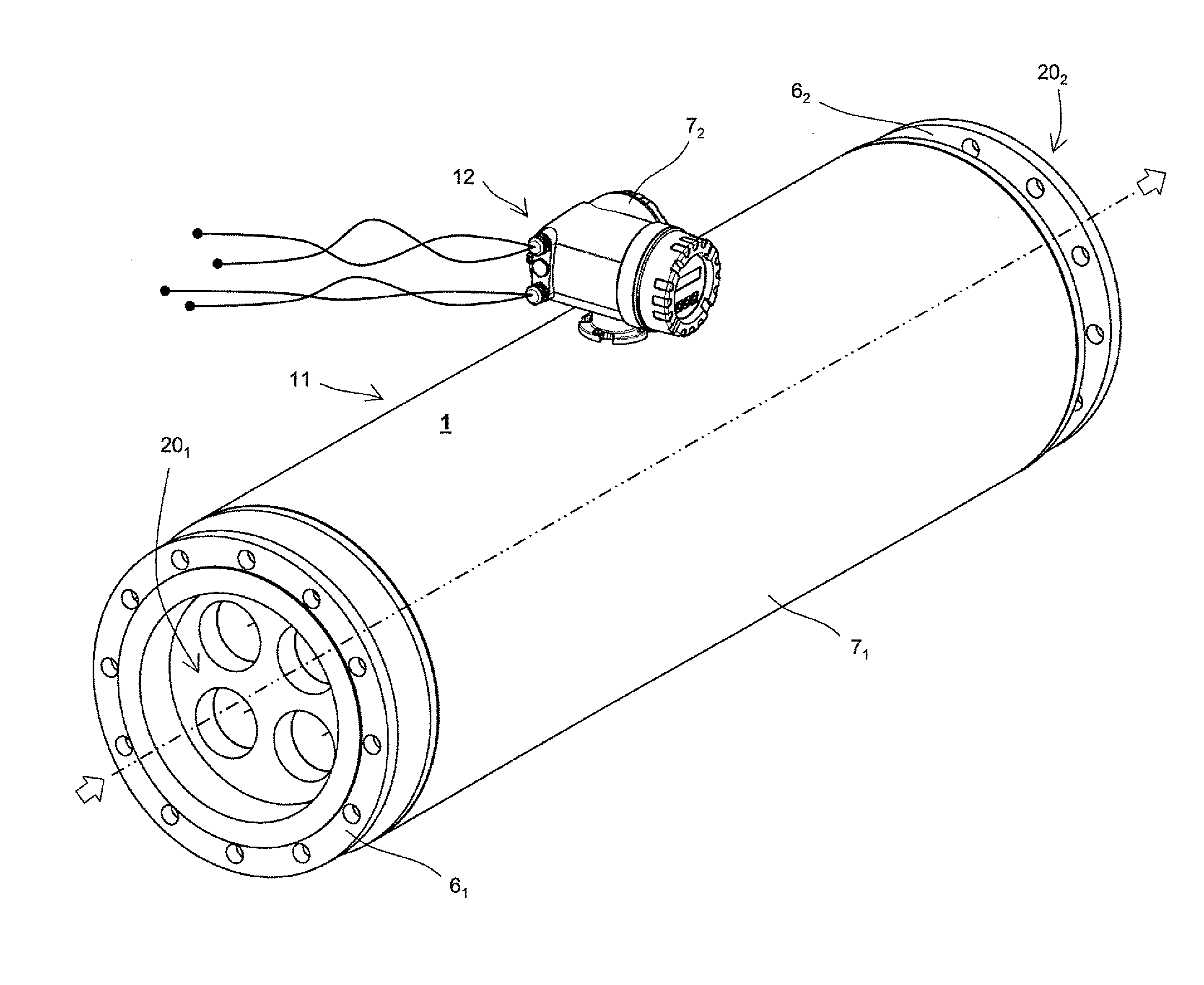

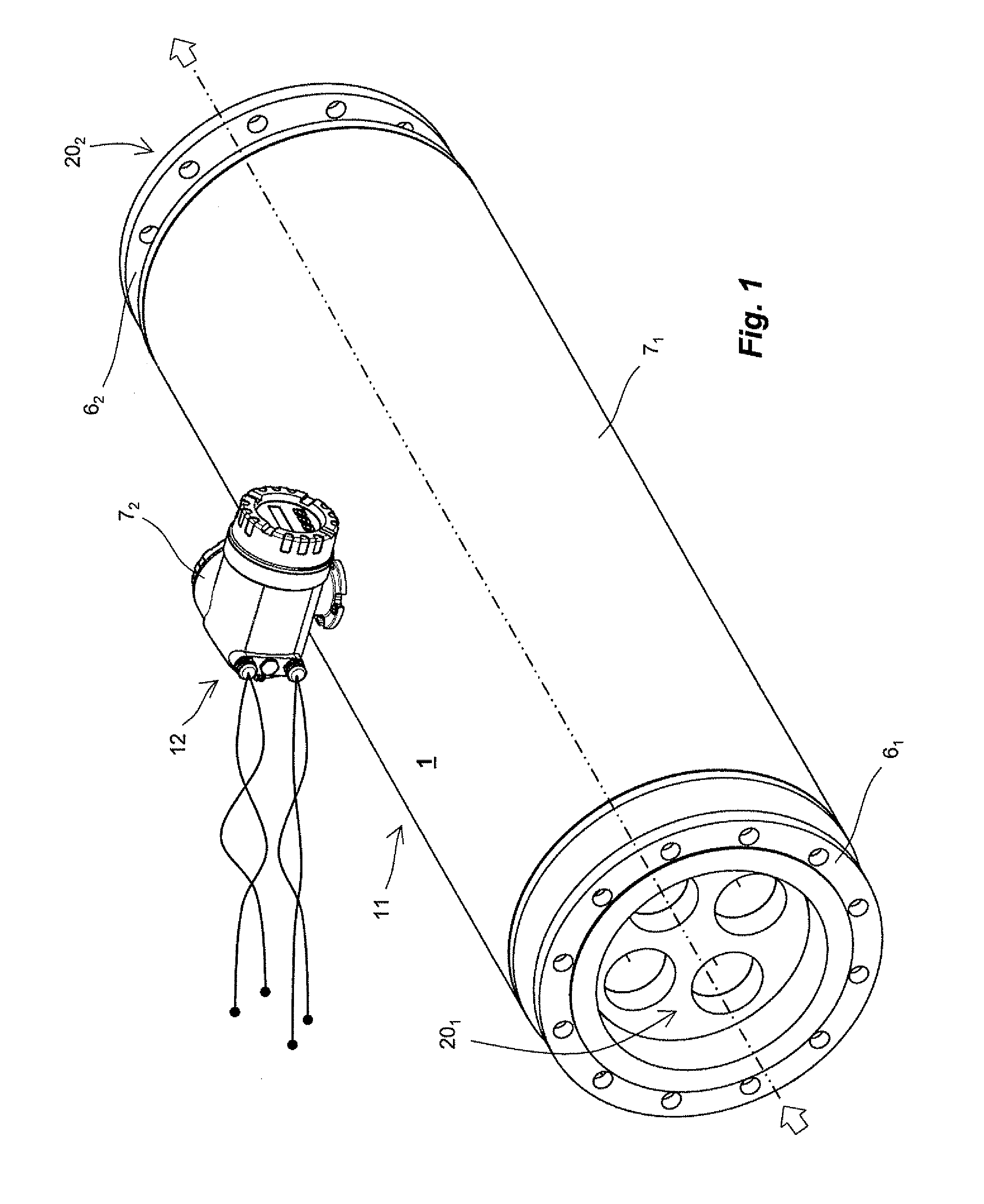

Measuring transducer of vibration-type

ActiveUS20110167907A1Impairs accuracy of measurementMeasurement accuracySpecific gravity using flow propertiesVolume variation compensation/correction apparatusSection planeTransducer

The measuring transducer comprises: a transducer housing, of which an inlet-side, housing end is formed by means of a flow divider including four flow openings spaced, and an outlet-side, formed by means of a flow divider including four flow openings spaced, from one another. A tube arrangement including four curved measuring tubes connected to the flow dividers for guiding flowing medium along flow paths connected in parallel. Each measuring tubes opens with an inlet-side, measuring tube end into one of the flow openings of the flow divider and with an outlet-side, measuring tube end into one the flow openings of the flow divider. The two flow dividers are embodied and arranged in the measuring transducer, so that the tube arrangement extends both between a first and a second of the measuring tubes and between a third and a fourth of the measuring tubes. An imaginary longitudinal-section plane, with respect to which the tube arrangement is mirror symmetric and perpendicular to the imaginary longitudinal-section plane, an imaginary longitudinal-section plane, with respect to which the tube arrangement likewise is mirror symmetric. An electromechanical exciter mechanism of the measuring transducer serves for producing and / or maintaining mechanical oscillations of the four measuring tubes.

Owner:ENDRESS HAUSER FLOWTEC AG

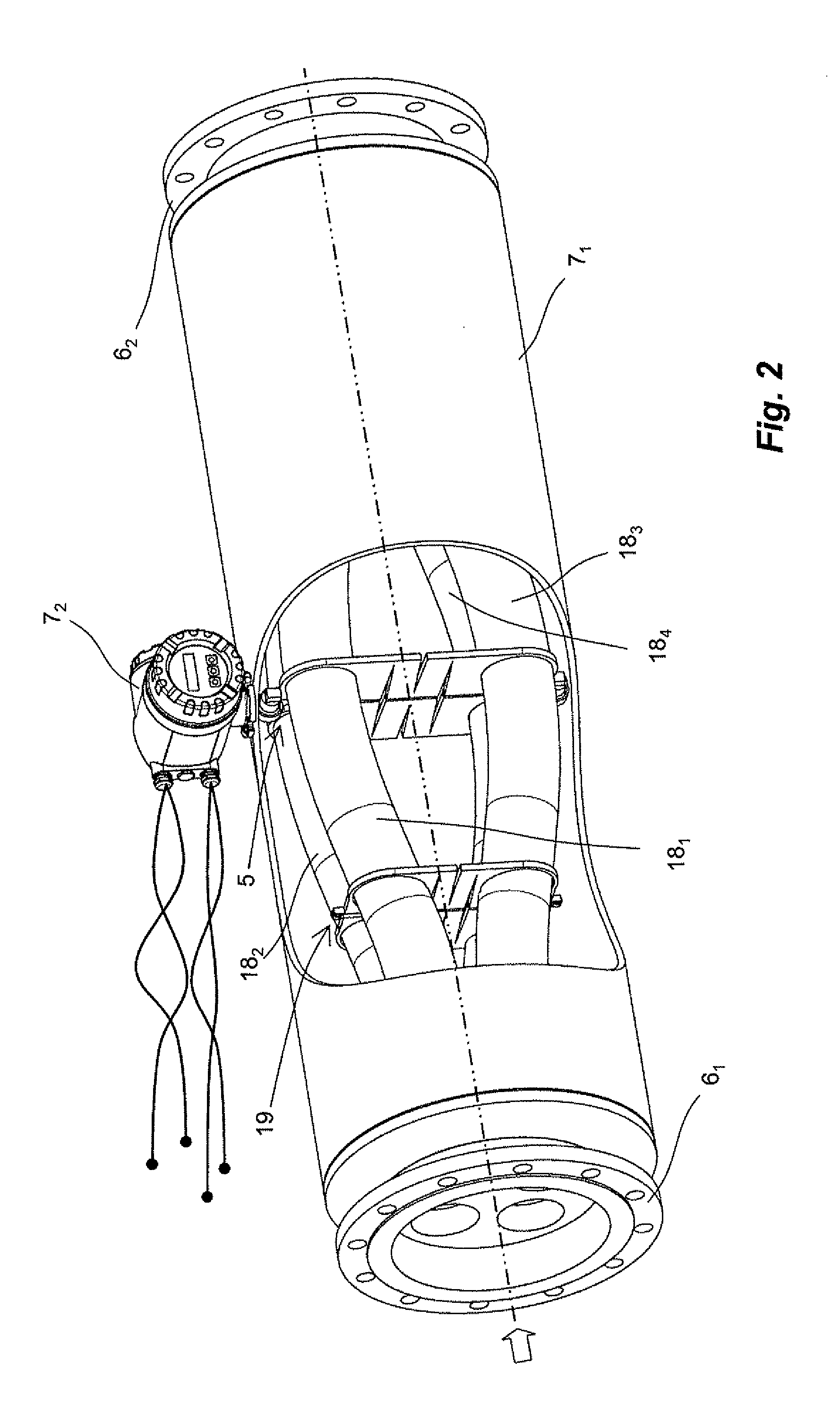

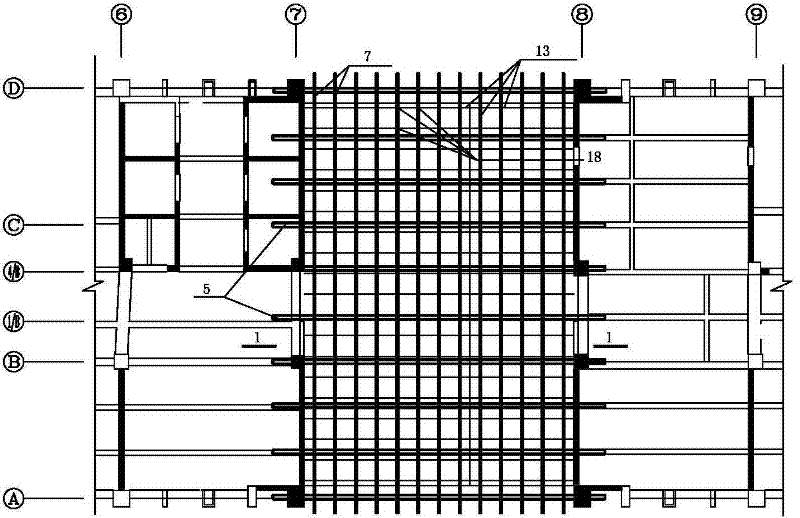

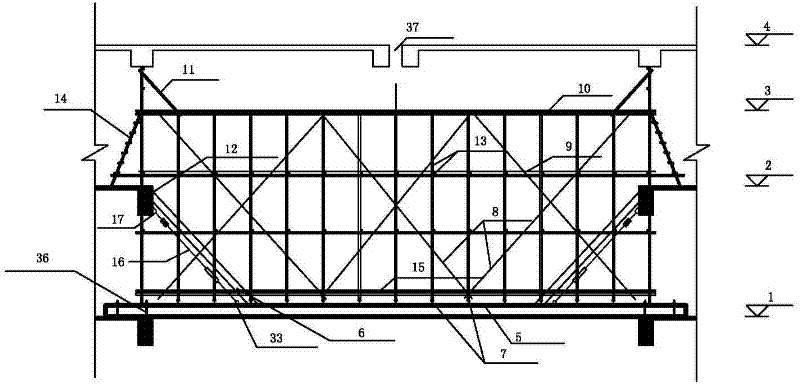

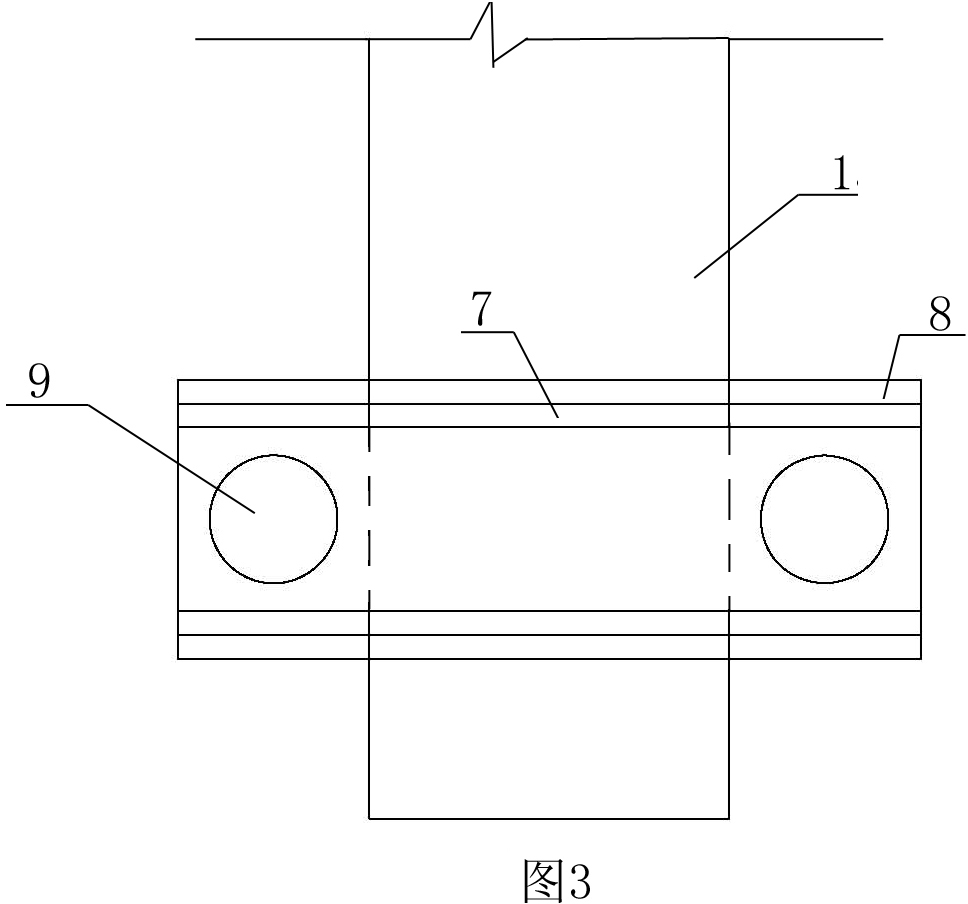

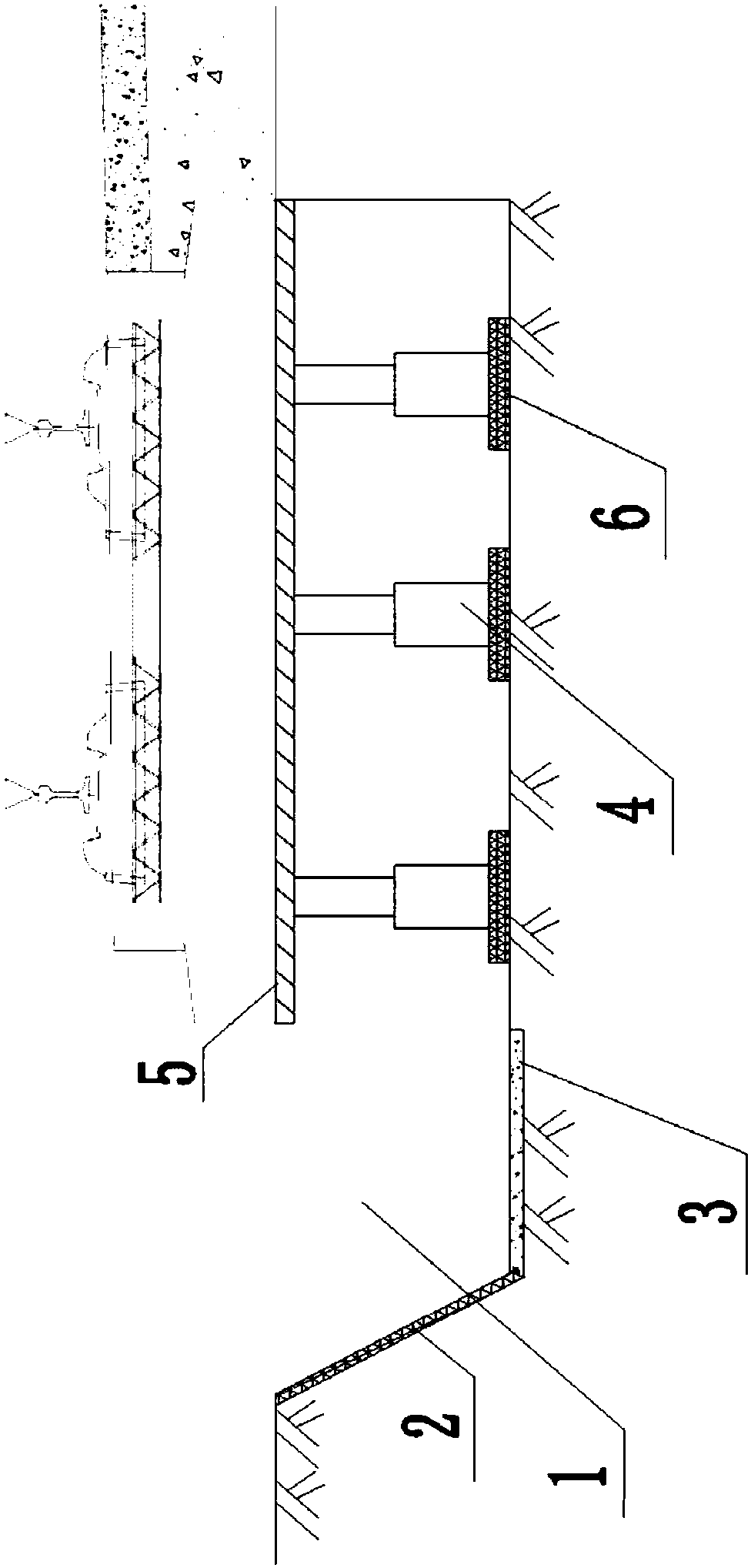

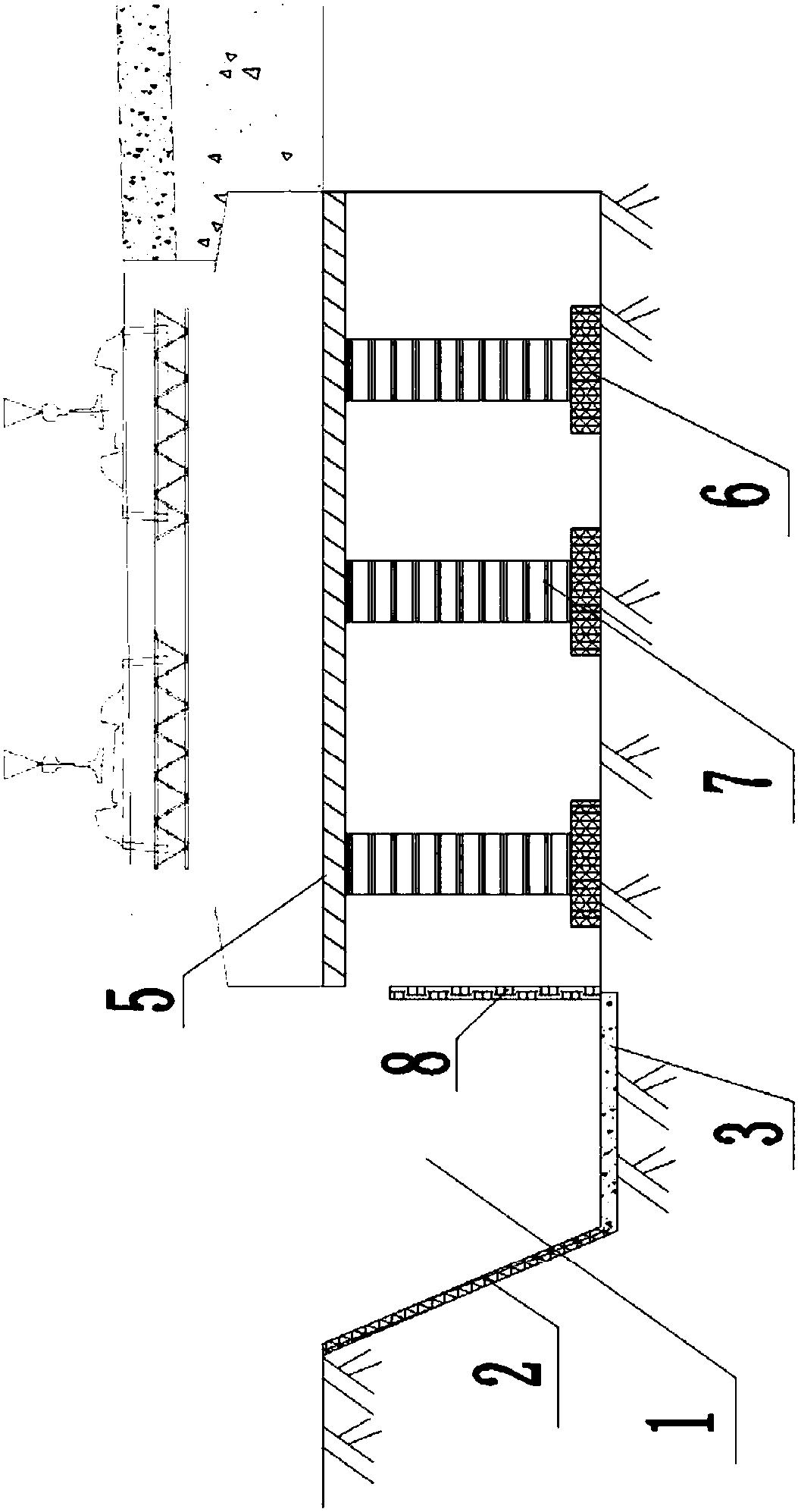

High-altitude long-span overhanging corridor type reinforced concrete structure and construction method

InactiveCN102444203ASave turnover materialsReduce construction costsBuilding material handlingSteel platesReinforced concrete

The invention relates to a high-altitude long-span overhanging corridor type reinforced concrete structure and a construction method, wherein the corridor part is a stiff beam structure; with own bearing capacity of a profile steel, a beam template supporting system is a hung template supporting system in such a manner of fixing a square steel by means of a U-shaped screw and a nut; a floorslab is a self-supporting steel bar truss template which is welded to a pre-embedded steel plate on the stiff beam by means of a pin; and a steel platform is arranged on a corresponding floor at the lower part of the corridor as an operating and safety protection platform for template support construction. The high-altitude long-span overhanging corridor type reinforced concrete structure and the construction method have the advantages that: the template supporting construction method, according to which the operating platform is built from H-steel or profile steel beams, the stiff beam is hung and is self-supported and the floorslab is self-supported, is employed, so that the problem of difficult template supporting of the high-altitude long-span overhanging corridor structure, the revolving materials are greatly saved, the construction cost is reduced, the construction progress is accelerated and the safety is ensured; and the steel plate is pre-embedded on the stiff beam, so that the floor bearing plate is effectively connected with the stiff beam and the floor bearing plate and the stiff beam are capable of acting together to ensure the safety of the structure.

Owner:浙江城建建设集团有限公司

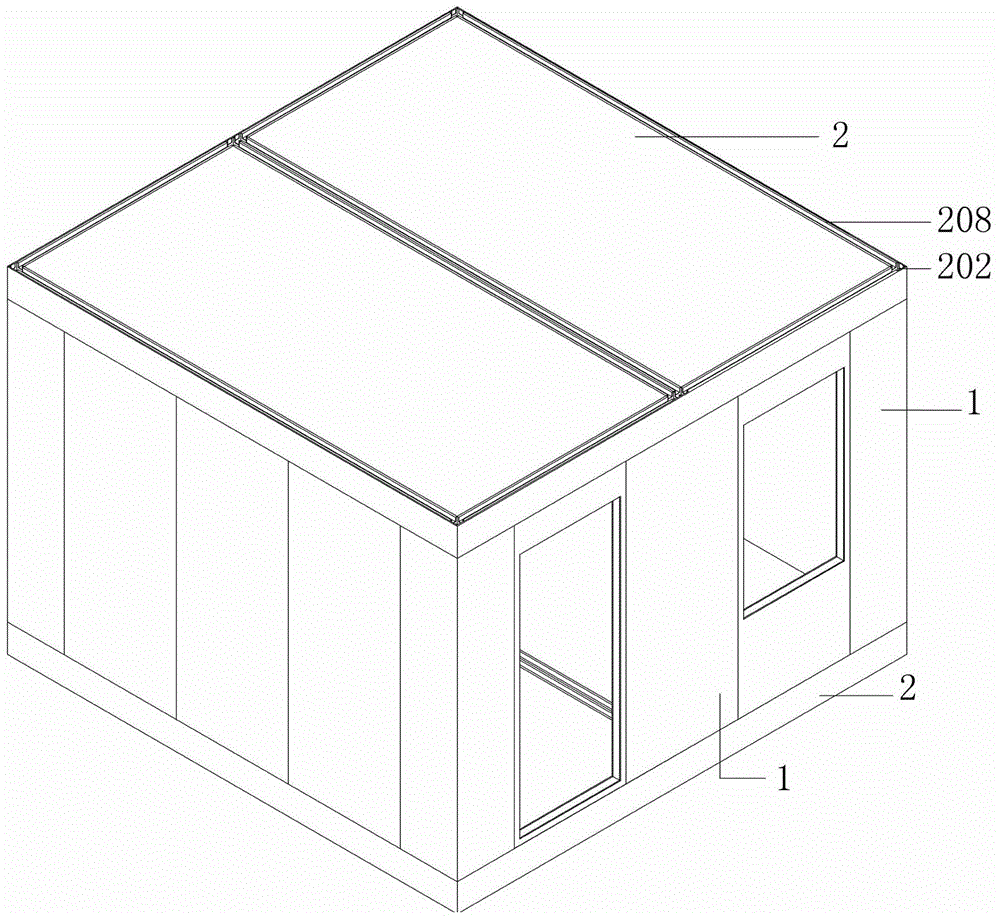

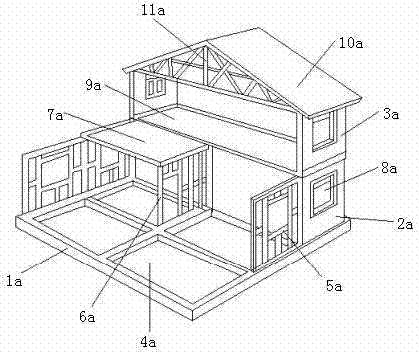

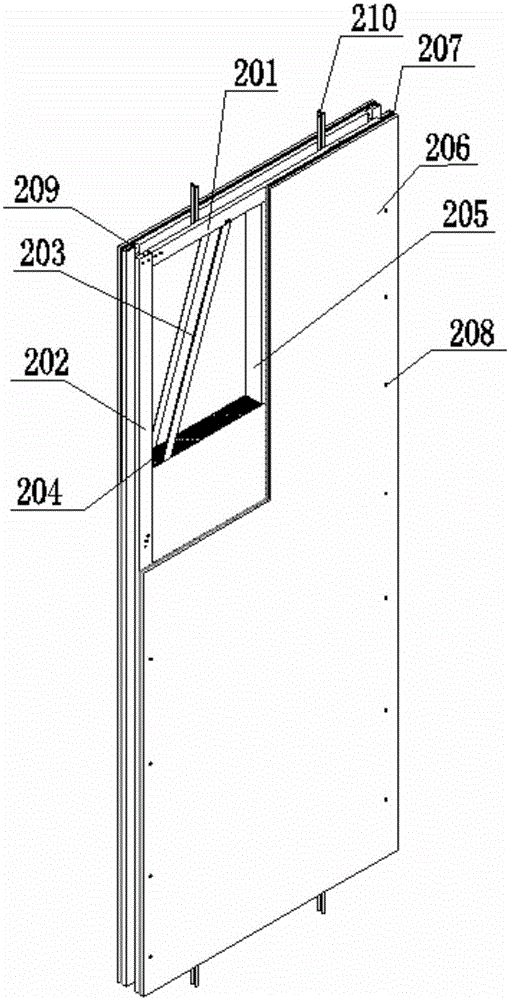

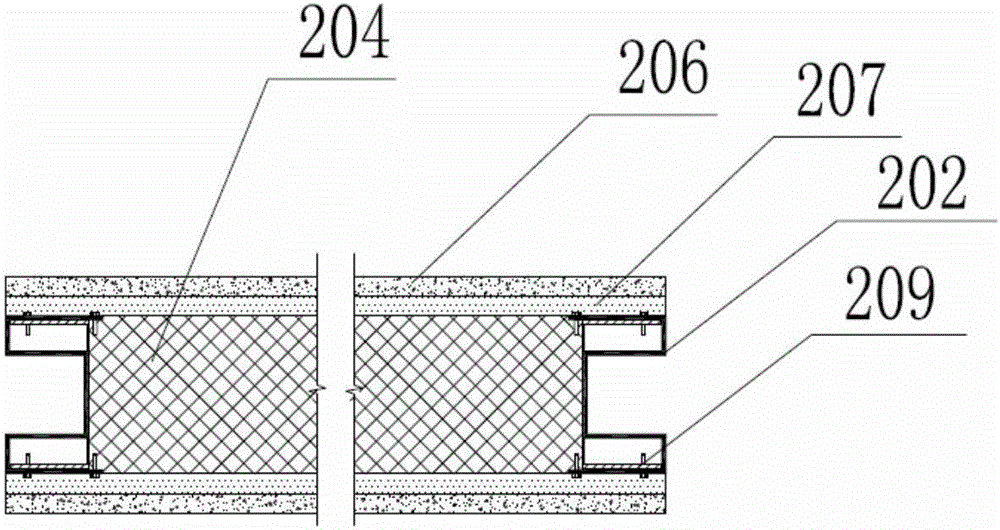

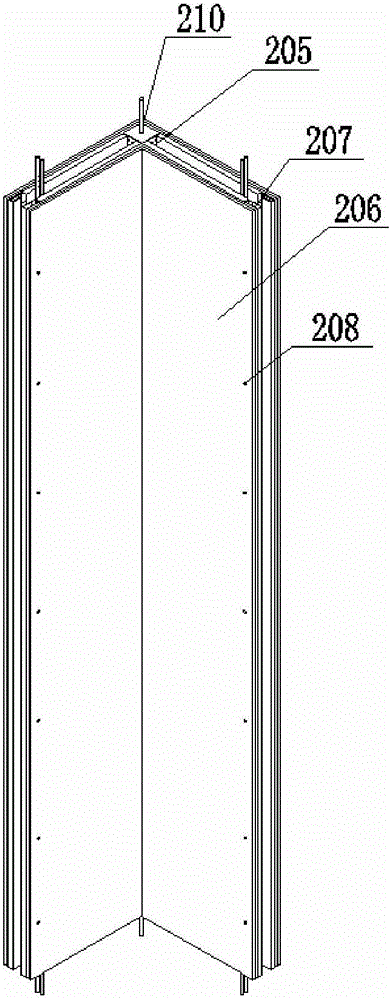

DGC modular fabricated building system and building method thereof

Provided are a DGC modular fabricated building system and a building method thereof. Wallboards are composite boards prefabricated in a factory. Light steel profiles and light steel keels are connected through self-tapping screws. The corners of the light steel profiles with grooves in frames are connected through self-tapping screws and light steel keel connecting pieces. The interiors of the wallboards are filled with heat preservation materials. Pouring layers of modified cement mortar or light aggregate concrete materials are arranged on the outermost sides of the wallboards. Floors are composite boards prefabricated in the factory, and each composite board is a foundation bottom plate or a floorboard or a roof panel of the DGC modular fabricated building system. The wallboards are connected through board connecting pieces, the wallboards and the floors are connected through board connecting pieces, and the floors are connected through board connecting pieces. The DGC modular fabricated building system is simple in structure, convenient to mount and low in cost, the construction period can be saved, and therefore the defects that an existing fabricated building is single in structure, complex in mounting process and high in manpower cost are overcome.

Owner:江苏保力装配式住宅工业有限公司

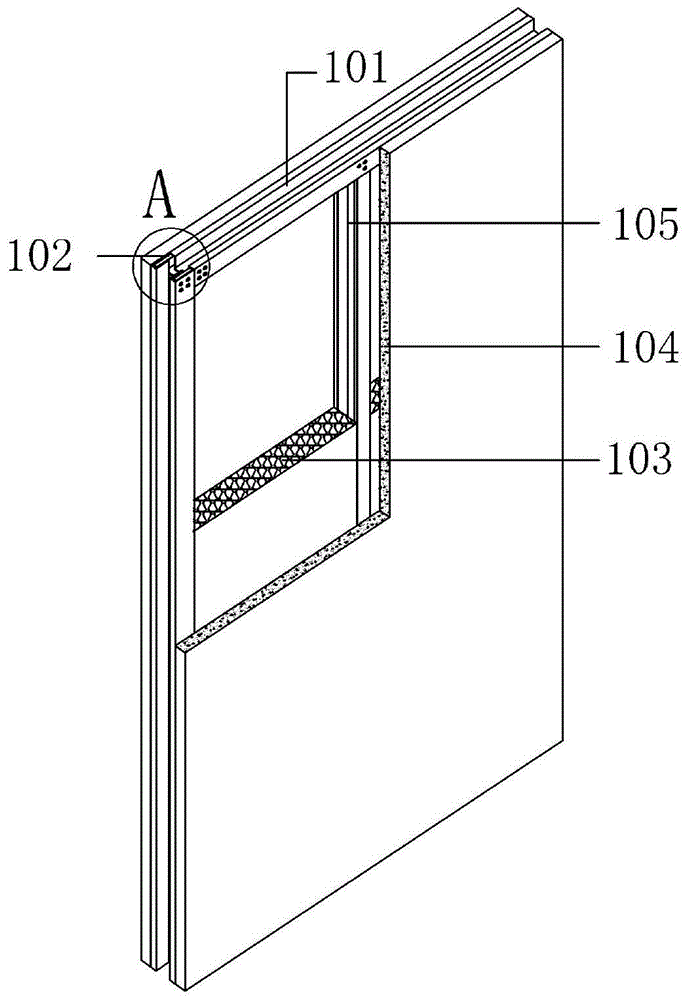

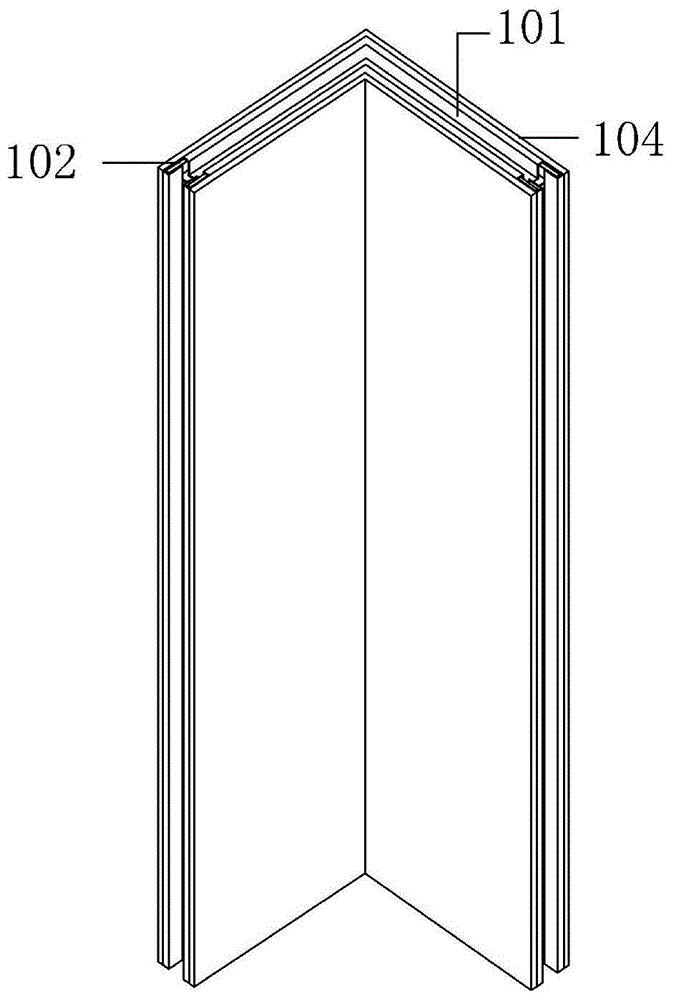

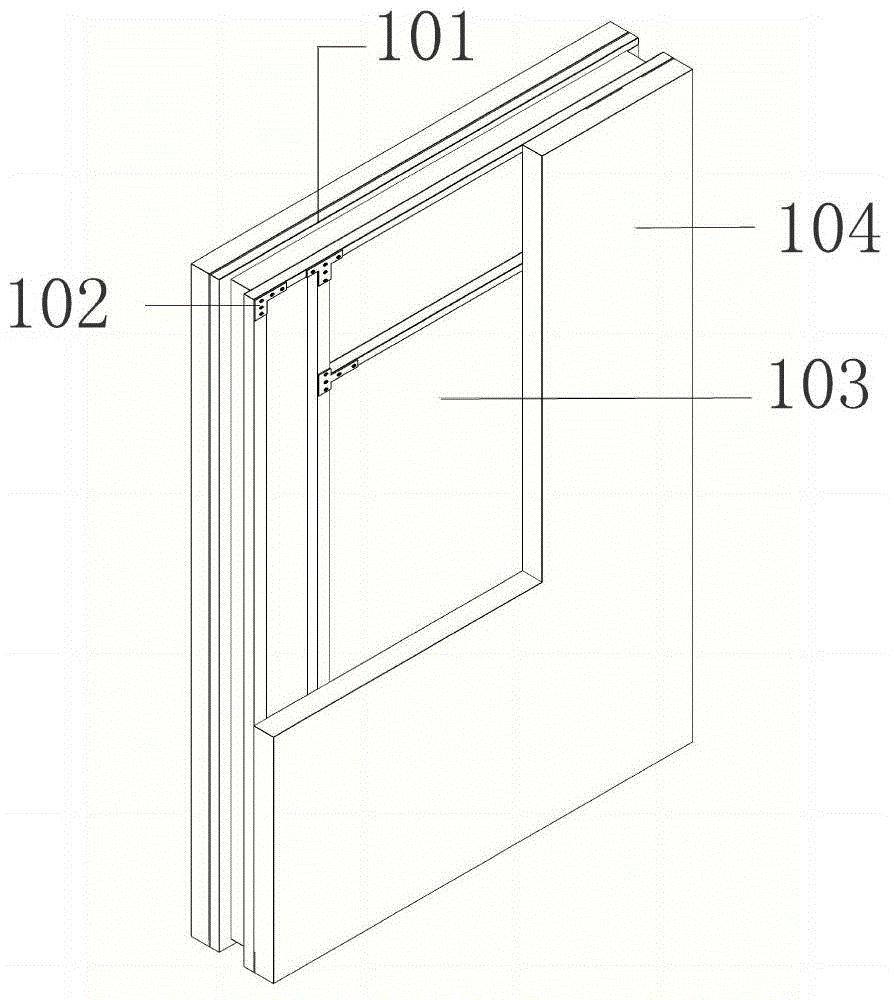

Simply-built green light steel fabricated building and installation method

ActiveCN104947792AImprove prefabrication rateEnsure structural safetyBuilding componentsBuilding material handlingPollutionPrefabrication

The invention provides a simply-built green light steel fabricated building and an installation method. The fabricated building comprises wall plates, main plates, composite frame columns and main connection pieces. The two wall plates are connected by means of the corresponding main connection pieces through self-tapping screws. The composite frame columns and the wall plates are connected by means of the corresponding main connection pieces through self-tapping screws. In the connection process, firstly the main connection pieces abut against the composite frame columns, the self-tapping screws are screwed into the composite frame columns to fix the composite frame columns, the wall plates are then arranged in place, and the main connection pieces are clamped into lateral side grooves of the wall plates. The main boards are connected with the composite frame columns, and body column sleeves of the portions, on the top layers of the main plates, of the composite frame columns are inserted in upwards-exposed tenon columns in a sleeved mode and are then fixed through bolts. By means of the full industrialized prefabrication of the wall plates and the main plates, the prefabrication rate of main components of the building is greatly increased, and therefore the structure safety and quality of the building are better facilitated, site workloads are reduced, the construction environment pollution is reduced, the construction period is shortened, and cost is saved.

Owner:江苏保力装配式住宅工业有限公司

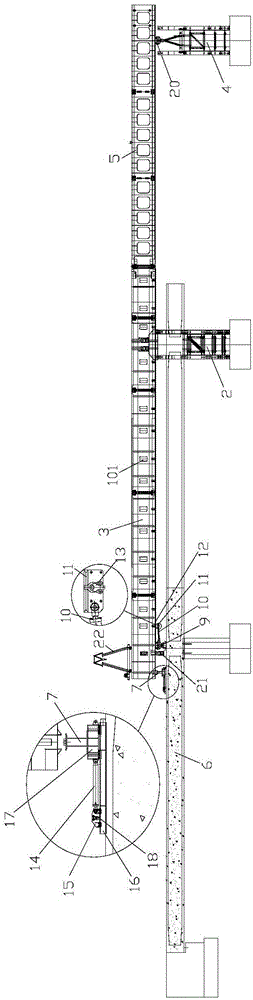

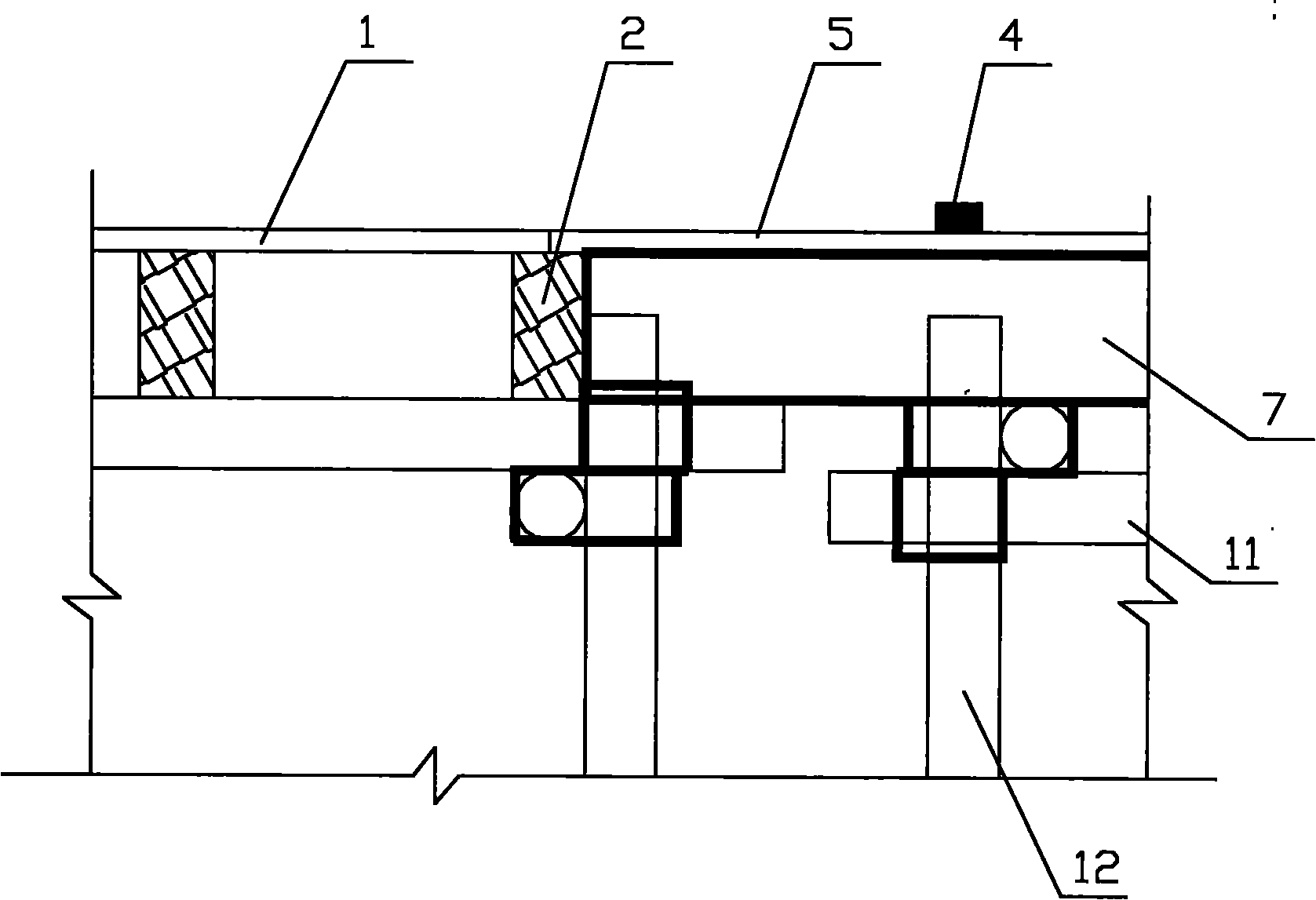

Upward moving type movable formwork for continuous box girder construction

InactiveCN105155423ALow costSpeed up the construction progressBridge erection/assemblyStructural stabilityEngineering

The invention discloses an upward moving type movable formwork for continuous box girder construction. The upward moving type movable formwork comprises a box girder body construction mold, a main beam, a nose beam and a rear sliding beam. The bottom of the box girder body construction mold is unfolded for box girder form removal or the bottom of the box girder body construction mold is closed so that a box girder can be poured. The main beam is supported on a middle supporting leg of the box girder and used for bearing the box girder body construction mold and driving the box girder body construction mold to move in the longitudinal direction of the box girder. The nose beam is supported on a front supporting leg of the box girder and used for guiding the main beam moving in the longitudinal direction of the box girder. The rear sliding beam is supported on the poured molded box girder and used for assisting the main beam in moving in the longitudinal direction of the box girder and being adjusted to be bent in the transverse direction of the box girder. The box girder body construction mold is suspended on the main beam, the nose beam is arranged at the advancing end of the main beam, and the rear sliding beam is arranged at the rear end of the main beam. Whole box girder pouring construction and mold movement are finished on the supporting legs and the poured molded box girder, the box girder body construction mold is opened from the bottom to form a folding span-crossing structure, and therefore the structural stability and safety of the whole formwork are guaranteed.

Owner:CCFEB CIVIL ENG

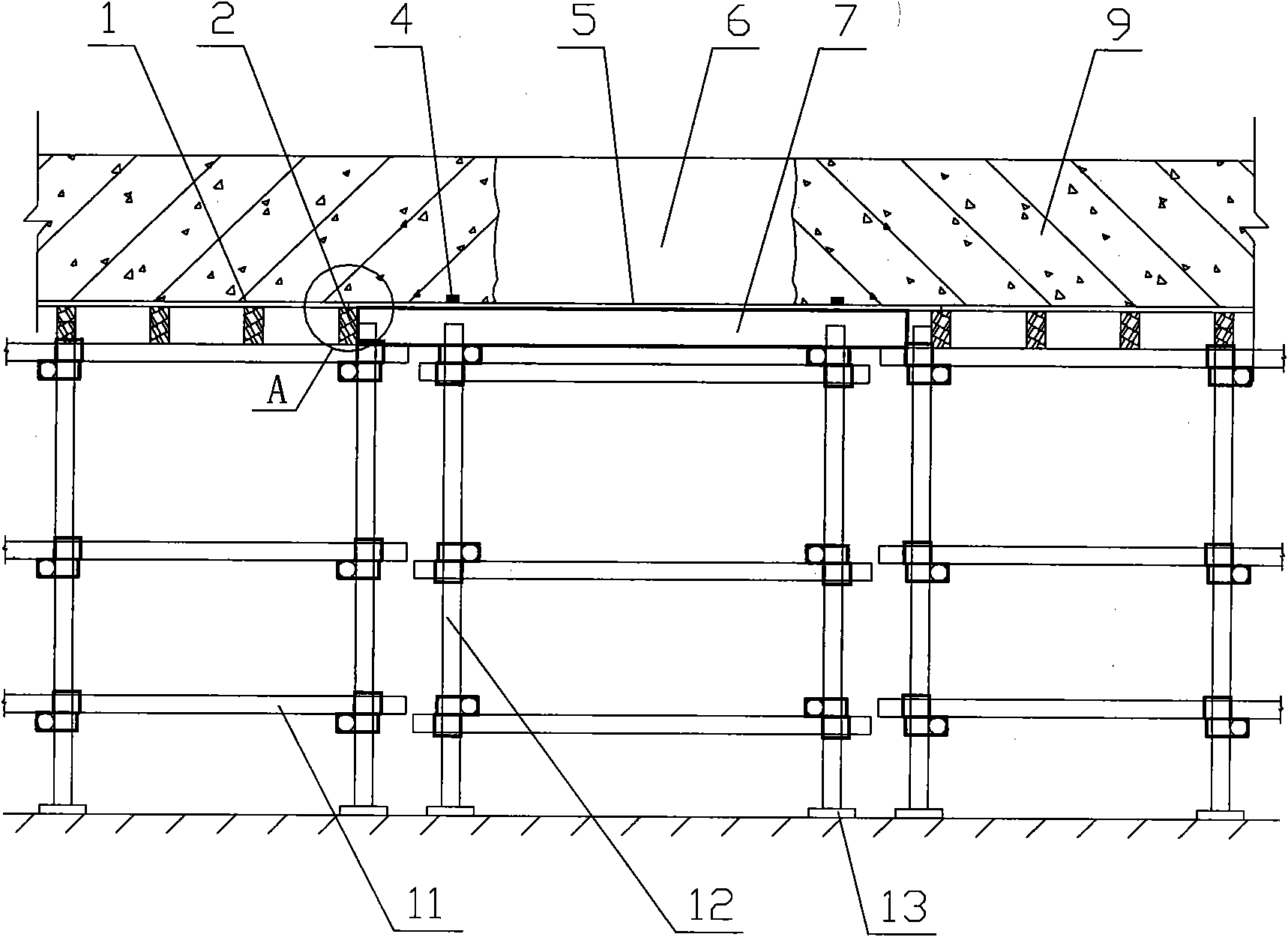

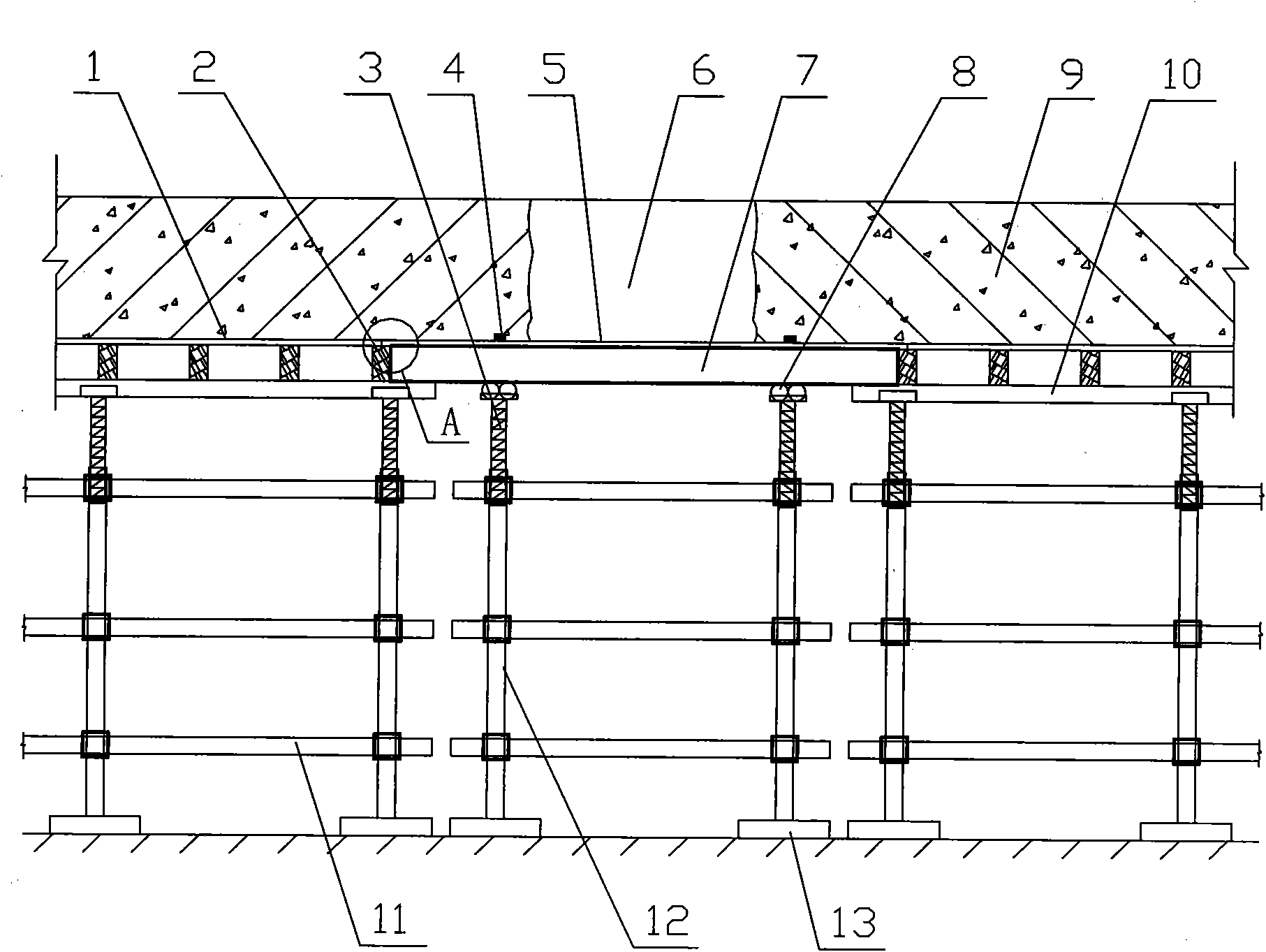

Method for constructing beam plate supporting system having post-cast strip

InactiveCN101871262AEnsure structural safetyEasy to cleanForms/shuttering/falseworksSupporting systemButt joint

The invention discloses a method for constructing a beam plate supporting system having a post-cast strip. The method comprises the following steps: 1) setting up an upright rod and a horizontal rod and forming a supporting bracket, wherein the supporting bracket at the position of the post-cast strip is an independent system, 2) laying a longitudinal secondary keel on the supporting brackets at two sides of the post-cast strip and laying a lateral secondary keel on the supporting bracket at the position of the post-cast strip, and 3) arranging a template at the position of the post-cast strip on the lateral secondary keel, arranging the templates at two sides of the post-cast strip on the longitudinal secondary keel, tightly butt jointing the template at the position of the post-cast strip with the adjacent templates at two sides, and arranging the longitudinal secondary keel under the joint. The post-cast strip of the invention adopts the independent supporting system. After the brackets are arranged, no reconstruction is needed, so the reconstruction for the brackets is avoided and the human labor and materials are saved. The independent supporting system is maintained at the position of the post-cast strip all the time so as to ensure the safety of the post-cast strip.

Owner:ZHONGTIAN CONSTR GROUP

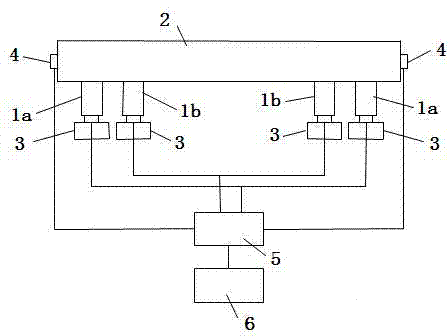

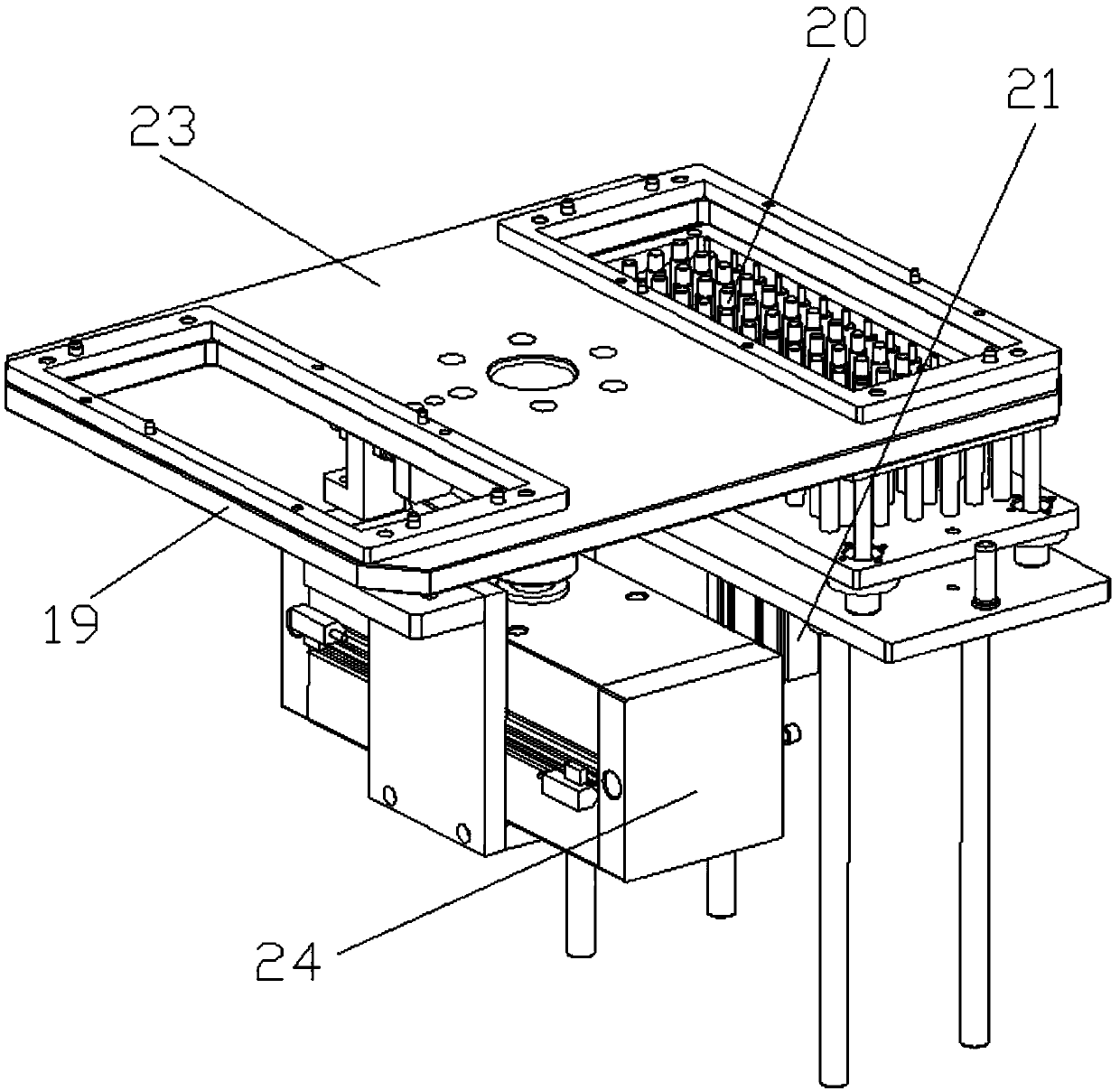

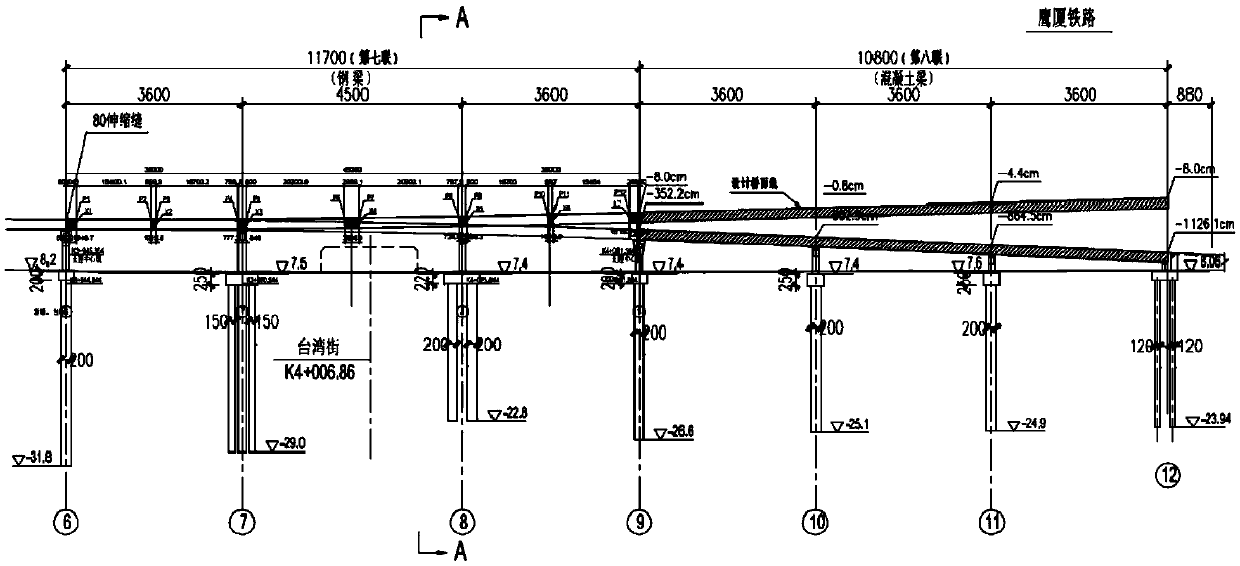

Slope-variable proportional alternate jacking construction method for continuous beam bridges

ActiveCN103205940AEliminate compressionEliminate height differenceBridge erection/assemblyBridge strengtheningHydraulic pumpContinuous beam

The invention discloses a slope-variable proportional alternate jacking construction method for continuous beam bridges. The slope-variable proportional alternate jacking construction method includes setting two groups of jacks capable of actively applying jacking force at the bottom of a bridge structure corresponding to fronts and backs of a pier and an abutment; enabling a control panel to control a hydraulic pump station to drive the two groups of jacks to carry out slope-variable proportional alternate jacking; and plugging temporary steel support cushion blocks at bottoms of one group of jacks when the other group of jacks performs jacking so as to eliminate height differences among various support points. The slope-variable proportional alternate jacking construction method has the advantages that the safety of the bridge structure is effectively guaranteed in a jacking procedure; and the requirement on a design gesture of an existing beam is met by the continuous slope-variable proportional alternate jacking method, and accordingly the purpose of modifying an existing bridge is achieved.

Owner:CHENGDU CONSTR ENG GROUP CORP

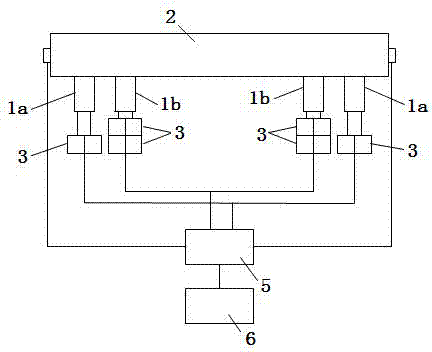

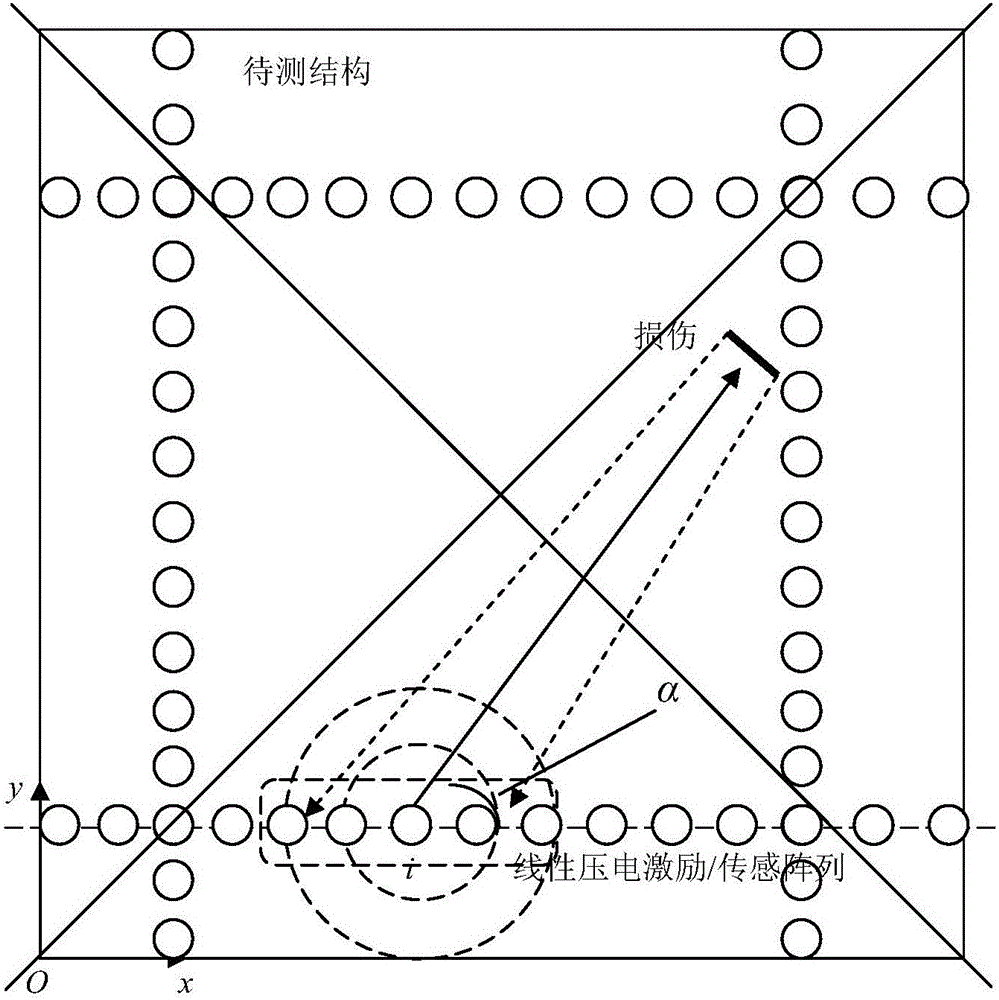

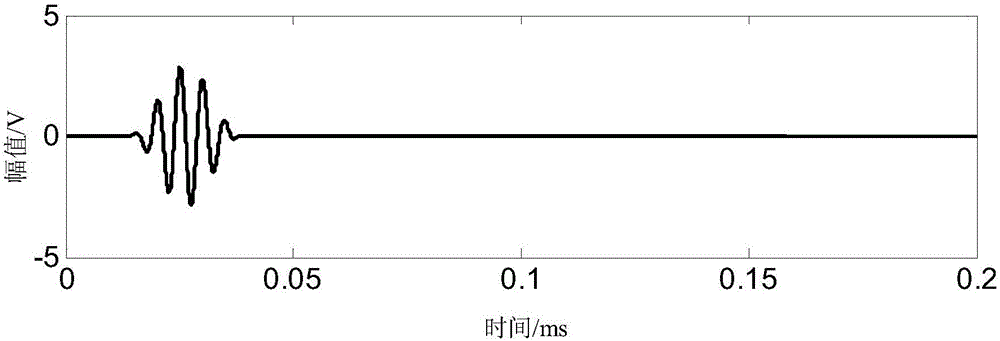

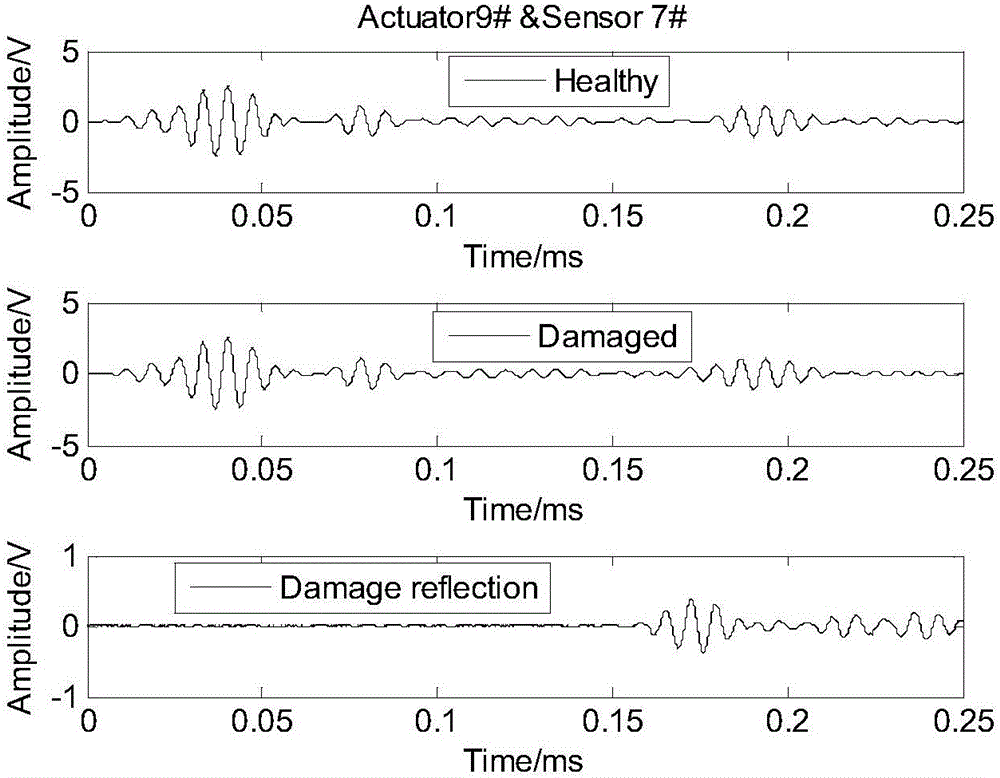

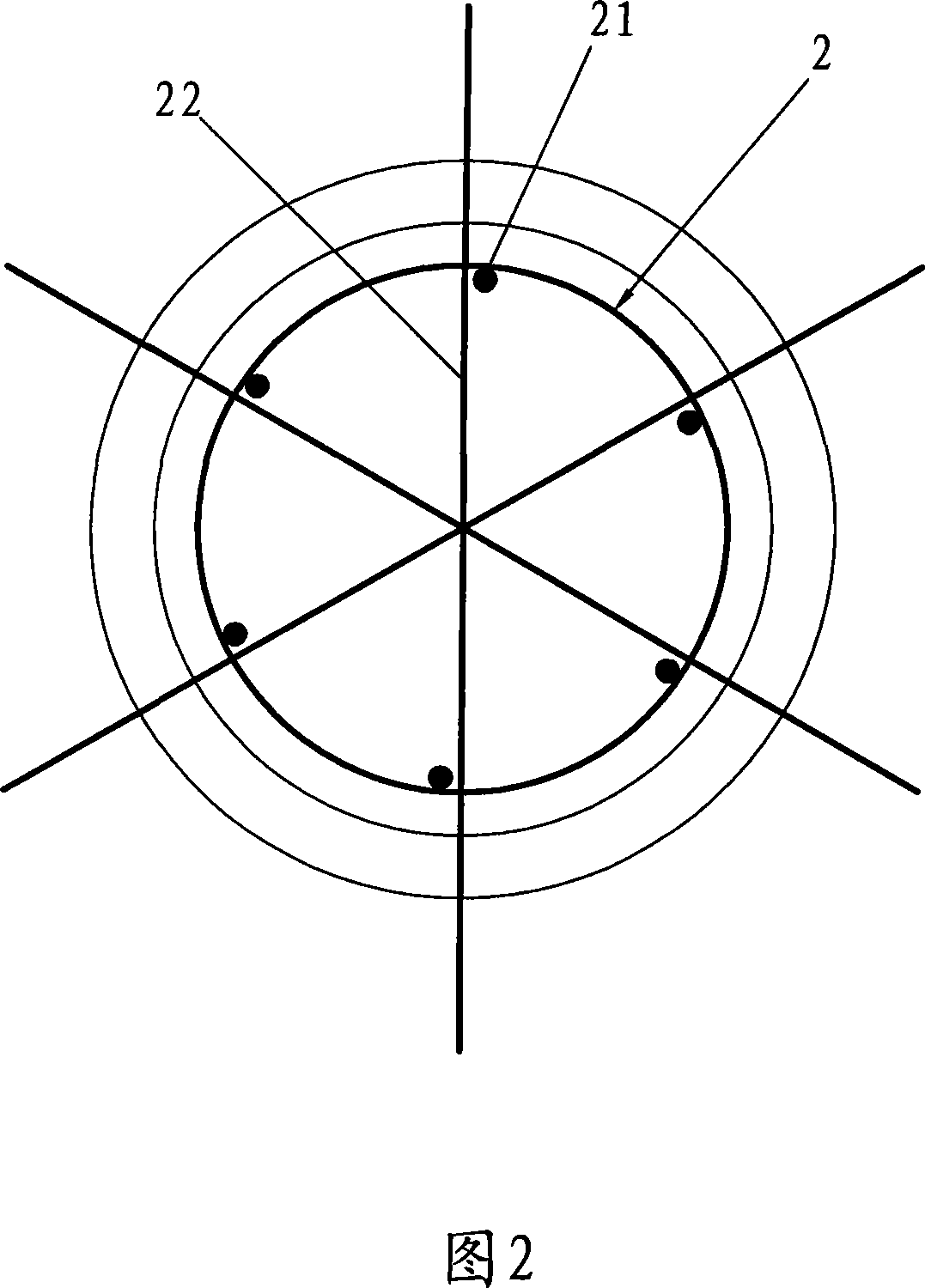

Active monitoring and evaluating method for directional damage of engineering structure

ActiveCN105784853AClear representationSignificant interference suppressionProcessing detected response signalAssessment methodsActive monitoring

The invention discloses an active monitoring and evaluating method for directional damage of an engineering structure.The active monitoring and evaluating method includes the steps that multiple linear piezoelectric actuating / sensing arrays are arranged around regions, to be detected, on the structure to be detected so that the regions of the whole structure to be detected can be covered after the scanning and monitoring ranges of all the arrays are combined; Lamb wave standard response signals of all actuating / sensing channels of all the arrays in a healthy state of the structure and Lamb wave response signals in a damaged state are collected and subjected to subtraction to extract damage scattered signals; according to coherence between the damage scattered signals and phases thereof, damage direction information and the position of a main actuator are obtained through calculation, directional damage is imaged to obtain damage position and length, and then the health condition of the structure to be monitored is analyzed and judged.By means of the method, monitoring accuracy of direction damage such as cracks and structural fracture can be improved, and structural safety is guaranteed.

Owner:南京协鼎网络技术有限公司

Seperator coated with electrolyte-miscible polymer and electrochemical device using the same

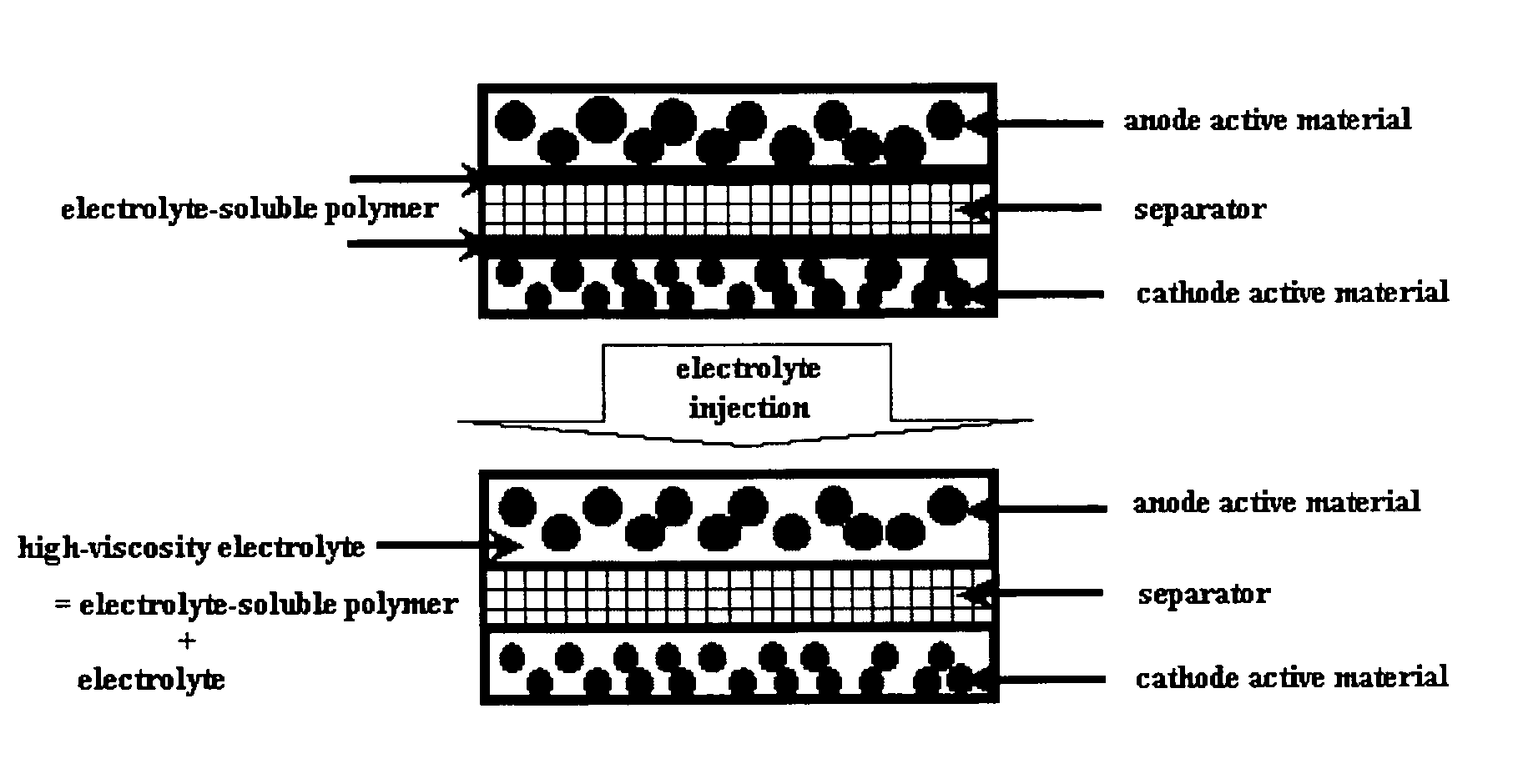

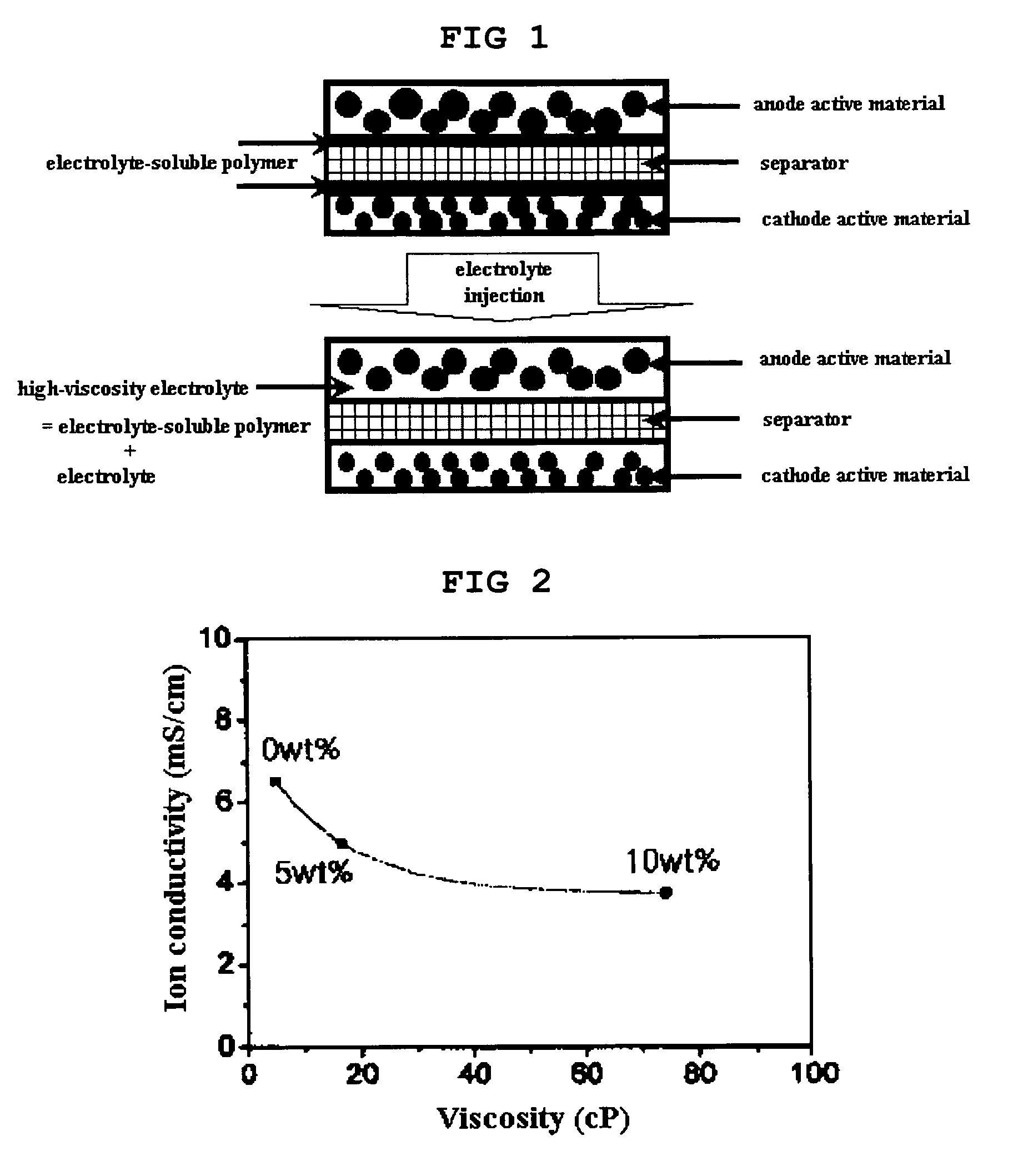

InactiveUS20070054184A1Improve battery safetyInhibit deteriorationCell seperators/membranes/diaphragms/spacersFinal product manufactureLithiumElectrochemistry

The present invention provides a separator in which an electrolyte-soluble polymer, which is soluble in liquid electrolyte, is coated on one or both surfaces of the separator, as well as an electrochemical device including the separator. Also, the present invention provides a method for producing an electrochemical device, comprising the steps of: (a) coating an electrolyte-soluble polymer, which is soluble in liquid electrolyte, on one or both surfaces of a separator; (b) interposing the separator produced in the step (a) between a cathode and an anode so as to assemble an electrochemical device; and (c) injecting a liquid electrolyte into the electrochemical device produced in the step (b). The electrochemical device, such as a lithium secondary battery, produced by the inventive method, has an improved safety while deterioration in the battery performance is minimized.

Owner:LG CHEM LTD

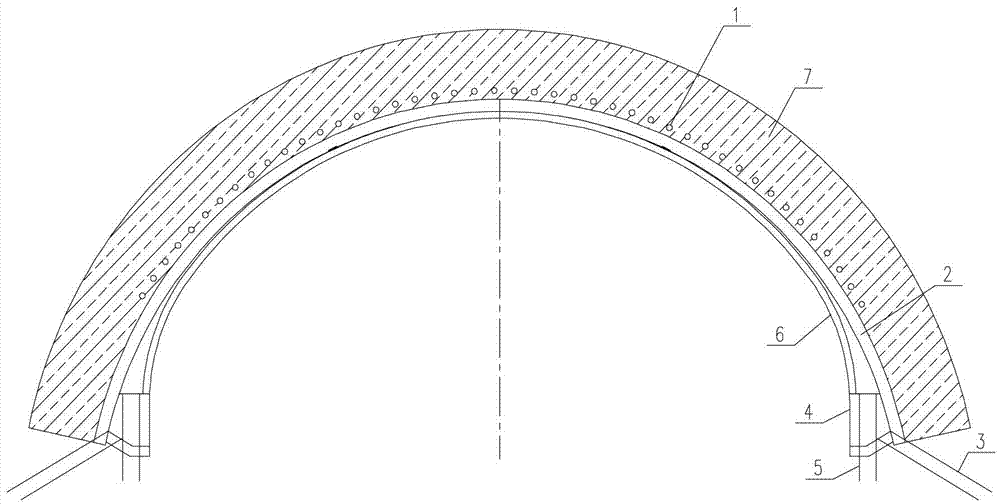

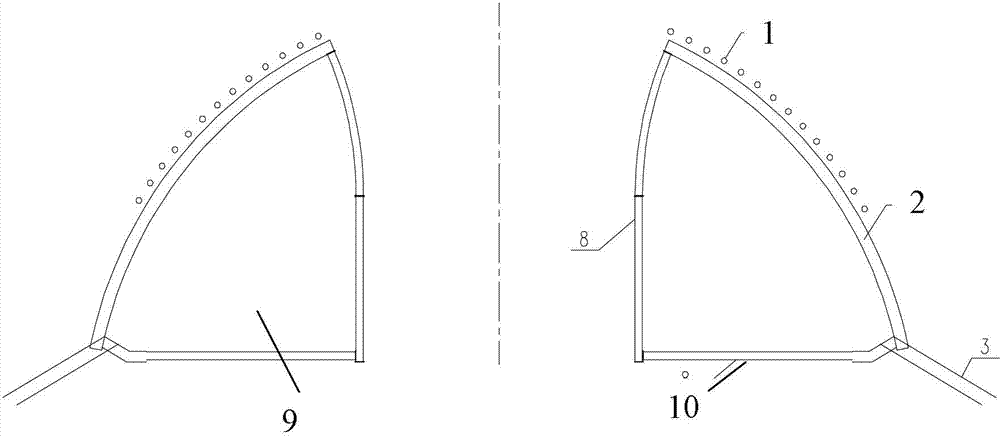

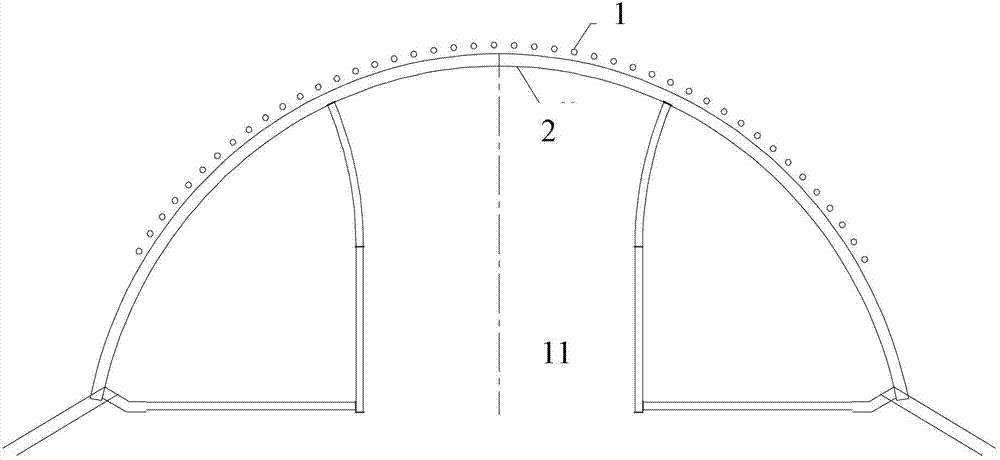

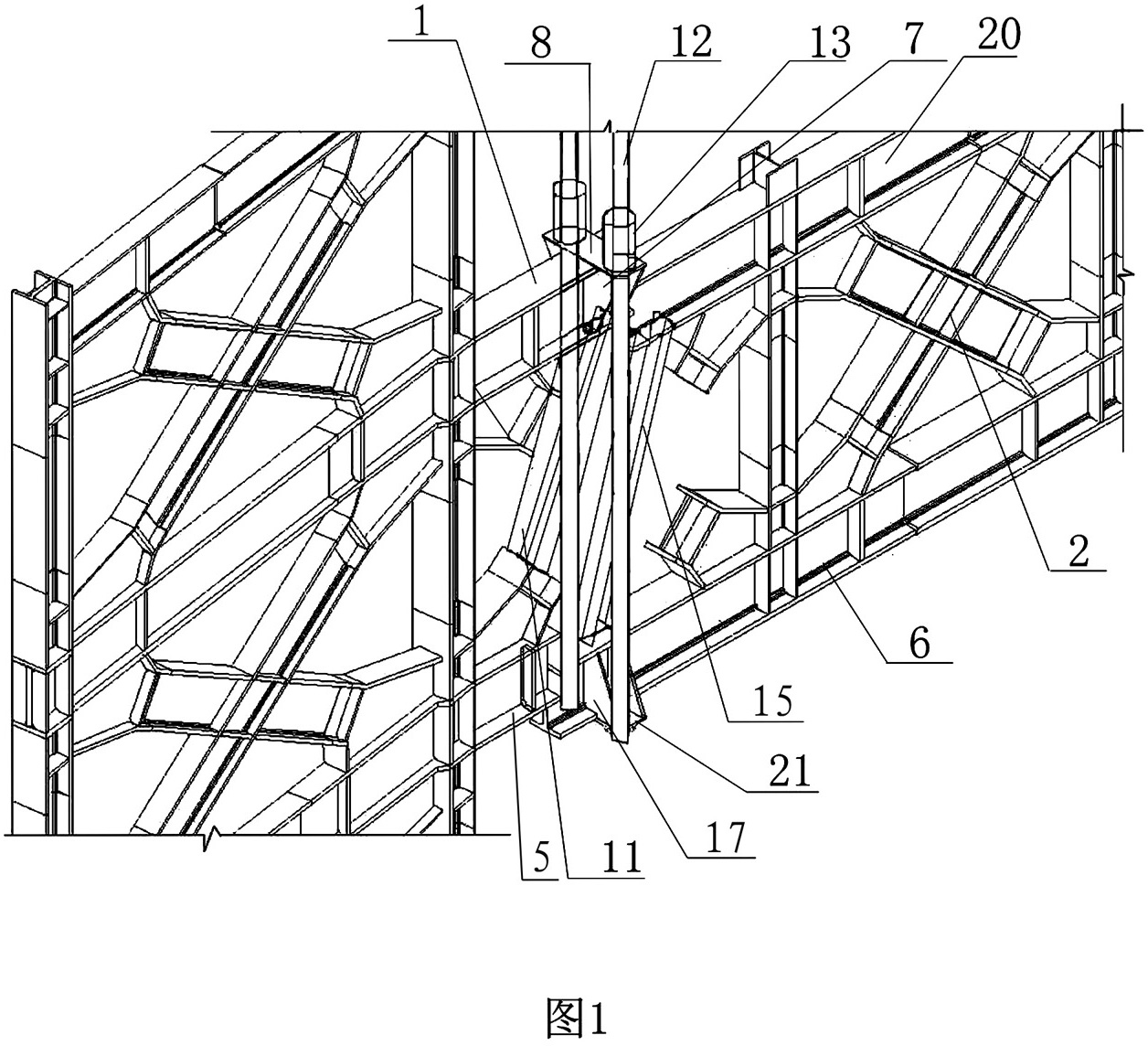

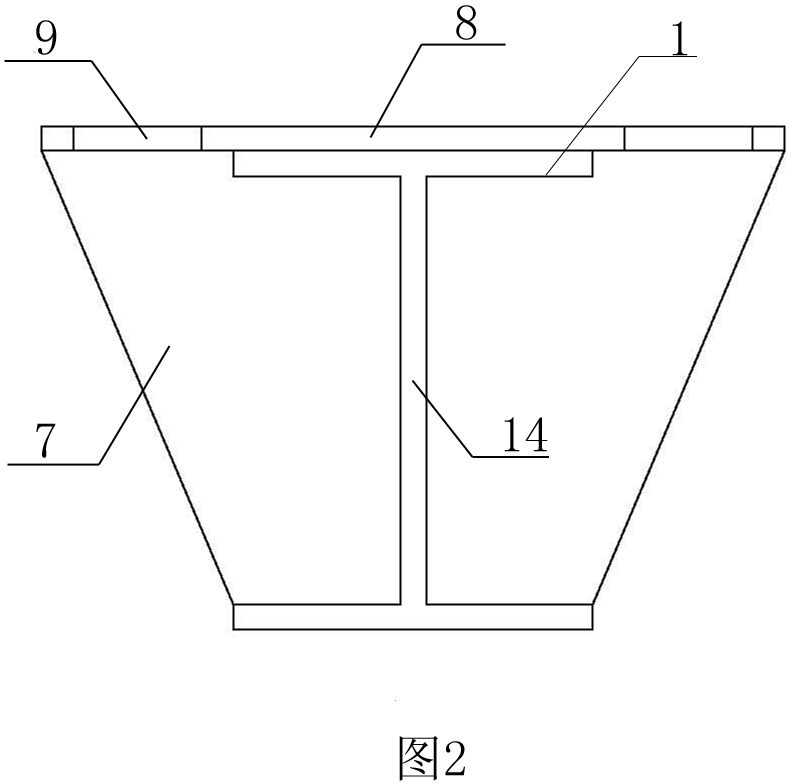

Long-span tunnel overlapping carrying arch structure for upper-soft and lower-hard stratum and construction method thereof

InactiveCN102758642ASimple structureImprove mechanical performanceUnderground chambersCarrying capacityLong span

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

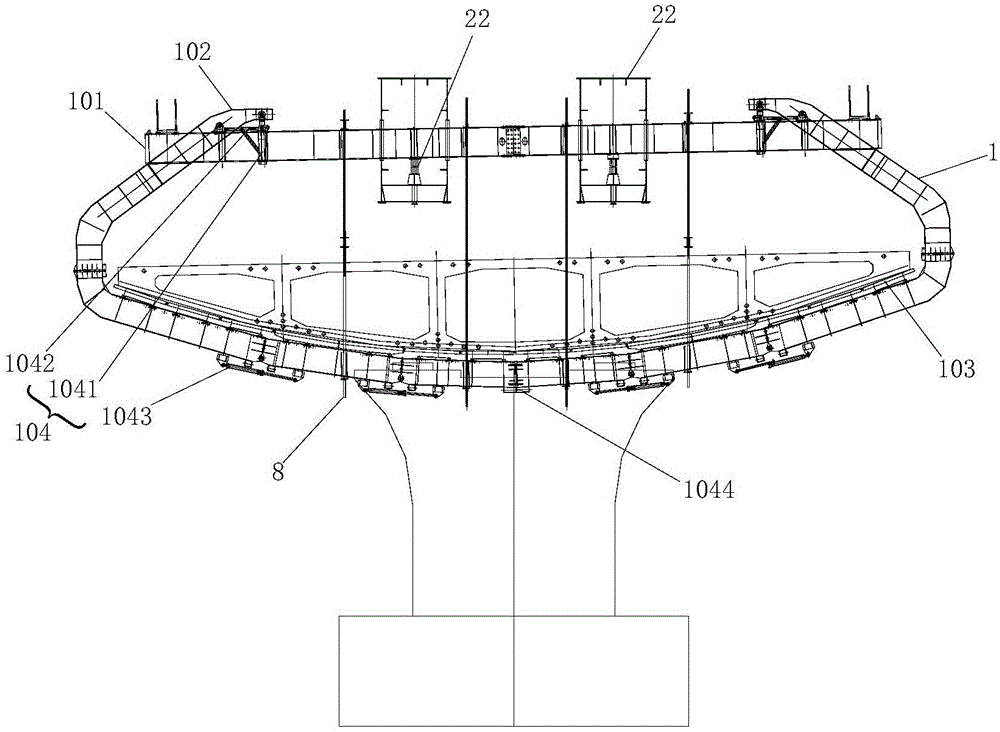

High-rise long-span door type truss integral lifting device and construction method thereof

InactiveCN102071814ASimple structureEasy to implementBuilding repairsLifting devicesEngineeringLong span

The invention relates to a high-rise long-span door type truss integral lifting device and a construction method thereof. The device comprises a run-through jack, a steel strand and an anchoring structure, wherein the anchoring structure consists of an upper anchoring structure which is fixed on an arranged upper truss bracket and a lower anchoring structure which is fixed on a lifted truss; the run-through jack is fixed on the upper anchoring structure and is symmetric on the two sides of the arranged upper truss bracket; and the run-through jack and the steel strand integrally lift the lifted truss to a position which is flush with the arranged upper truss bracket. A whole-course dynamic stress monitoring mode is adopted for monitoring while the integral lifting is performed by a lifting unit. In auxiliary measures of the method, an operating scaffold for ground assembly and an overhung scaffold at a lifting point position are only required to be erected, so the measures are extremely few; and the integral lifting process is controlled by a jack travel control computer; and the conventional measurement monitoring and the stress strain monitoring are performed, so the construction safety and the structural safety are guaranteed. The device can be widely applied to door type truss integral lifting construction.

Owner:THE THIRD CONSTR ENG CO LTD OF CHINA CONSTR SECOND ENG BUREAU

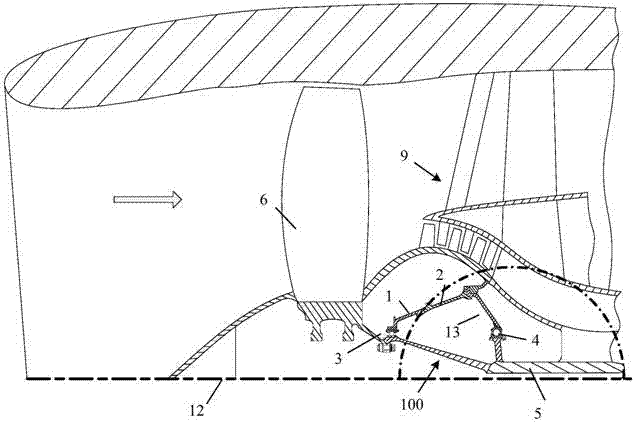

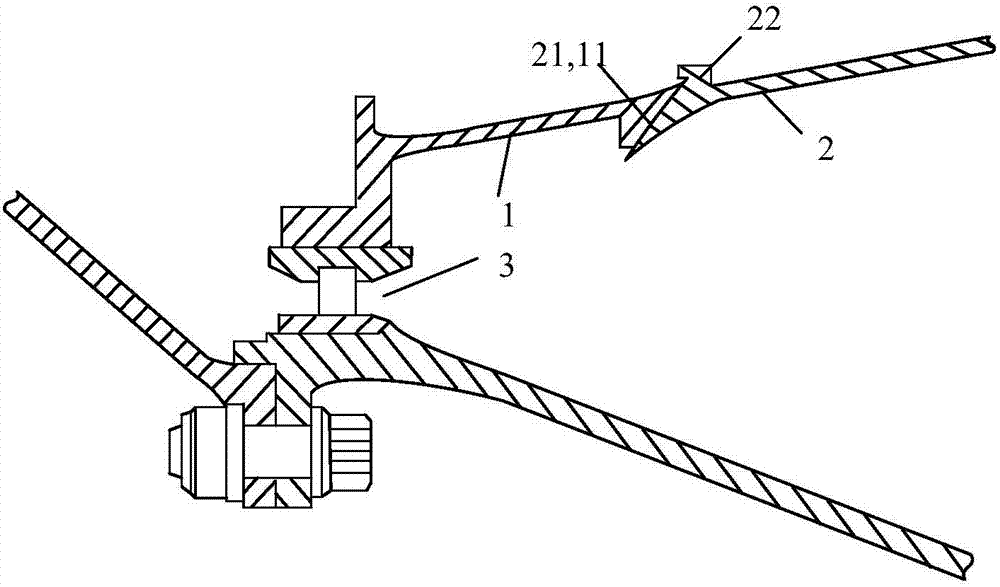

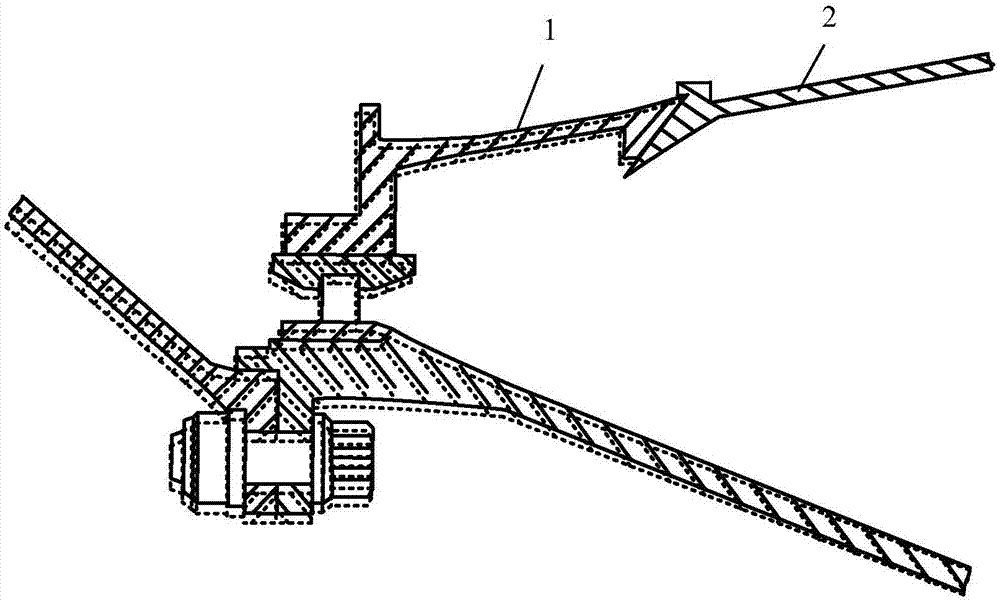

Aircraft engine and fusing method of aircraft engine under loads caused by FOB (fan blade off)

ActiveCN107237655AImprove structural design flexibilityEnsure structural safetyEngine manufactureEngine fuctionsAviationFan blade

The invention provides a fusing structure and method of an aircraft engine under loads caused by FOB (fan blade off). The aircraft engine comprises a fan rotor, a stator piece intermediate case, a first bearing, a second bearing, a first supporting conical arm and a second supporting wall, wherein the fan rotor is supported by the first bearing and the second bearing, the first bearing is supported on the stator piece intermediate case through the first supporting conical arm, and the second bearing is supported on the stator piece intermediate case through the second supporting wall. The first supporting conical arm is of a thin-wall annular structure and comprises an upper conical arm body and a lower conical arm body. The upper conical arm body is provided with an upper combining surface. The lower conical arm body is provided with a lower combining surface. One of the upper combining surface and the lower combining surface is a concave spherical surface, and the other one is a convex spherical surface. The upper combining surface and the lower combining surface are complementary and are welded into the fusing structure with the strength lower than that of a parent material. The spherical center of the fusing structure is located at the axis of the fan rotor.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

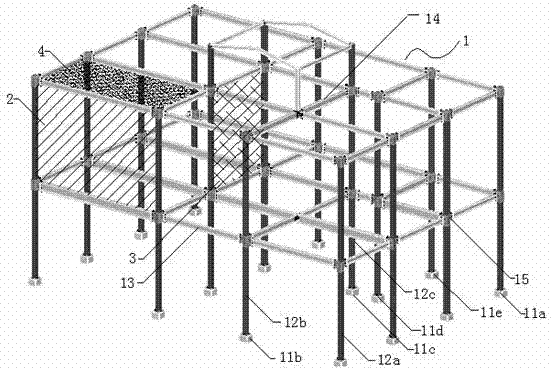

Light-weight steel structure house and construction method thereof

ActiveCN106948472AFast adjustmentEasy to adjustFloorsFoundation engineeringNoise reductionUltimate tensile strength

The invention relates to a light-weight steel structure house and a construction method thereof. The light-weight steel structure house comprises a house frame, double-layer outer wall plates, inner wall plates and lightweight floor plates. The house frame comprises a foundation, supporting upright columns, truss beams and cross sleeve connecting pieces; the supporting upright columns comprise four corner supporting upright columns, a plurality of outer supporting upright columns and a plurality of inner supporting upright columns; each supporting upright column is of an I-shaped steel structure; and the supporting upright columns are mounted on the foundation in mutually-parallel mode. The double-layer outer wall plates are arranged between every two adjacent outer supporting upright columns or between the adjacent corner supporting upright columns and the outer supporting upright columns. The inner wall plates are arranged between every two adjacent inner supporting upright columns or between the adjacent inner supporting upright columns and the outer supporting upright columns. The lightweight floor plates are parallelly arranged between every two adjacent truss beams. The light-weight steel structure house and the construction method thereof have the advantages that by means of the house frame, the double-layer outer wall plates, the inner wall plates and the lightweight floor plates and adjustment of connection of all the structures, the house is convenient for correction, effective heat dissipation and noise reduction are achieved, and meanwhile the overall strength of the house is guaranteed.

Owner:西藏藏建科技股份有限公司

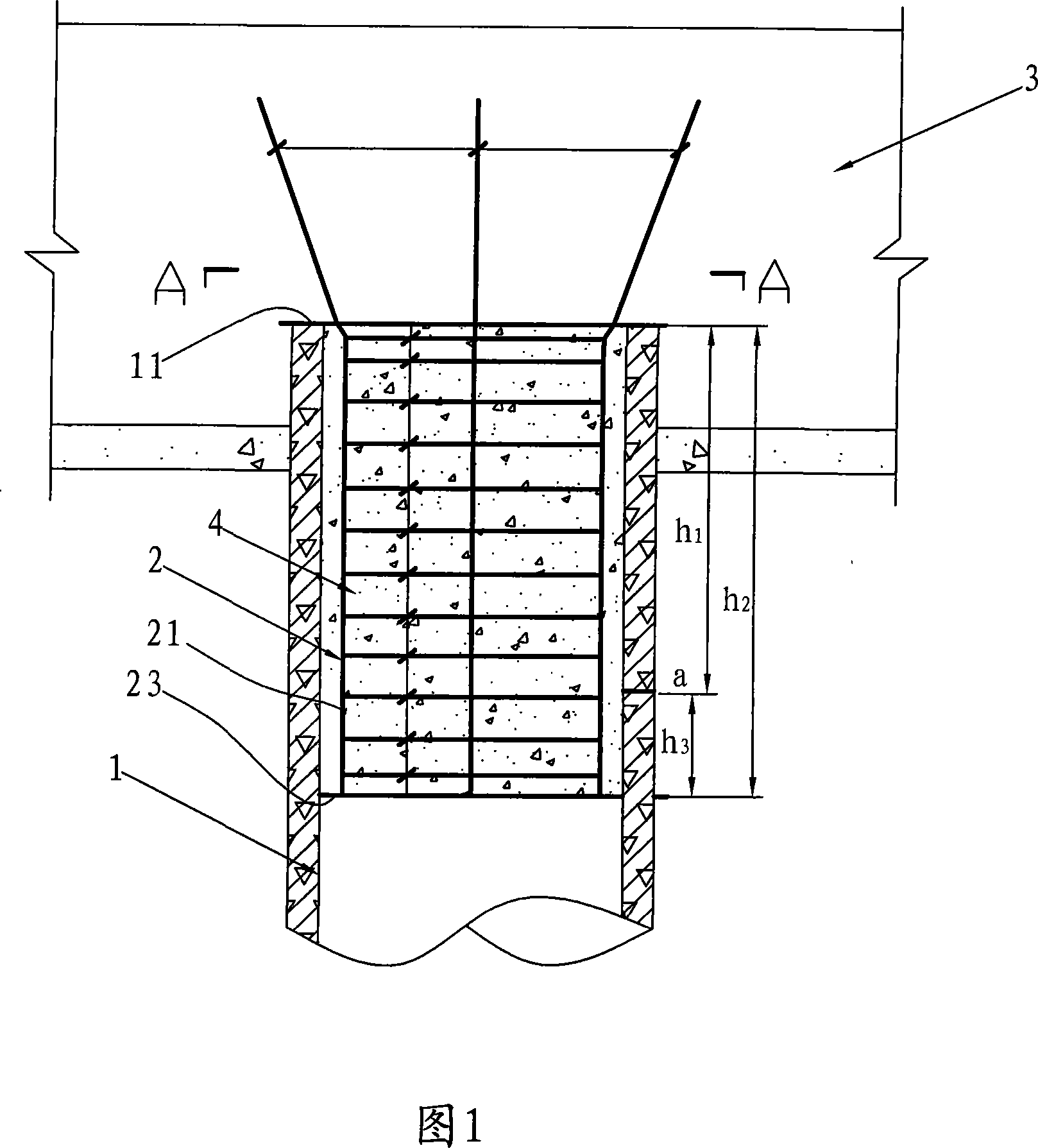

Fastening method of post-treating pipe pile break with pre-stress pipe pile construction

InactiveCN101220593AEnsure structural safetyDoes not affect constructionBulkheads/pilesPre stressPre stressing

The invention relates to a reinforcing method for dealing with the rupture of a pipe pile after the construction of the prestressed pipe pile. The procedures are as following: (1) the position of the rupture of the prestressed pipe pile is detected first; (2) the laitance on the inner wall of the pipe pile is cleared; (3) a reinforced skeleton frame is put into the pipe pile and the reinforced skeleton extends to the position three meters under the pipe pile from the pile top; (4) concrete under pile level is poured into the pipe pile, and the strength grade is not smaller than C30; (5) after the condensation of the concrete, the reinforced skeleton frame is led to be fixed with the reinforced steel in a cushion cap, and further the reinforced technique of the rupture of the pipe pile is finished. The reinforcing method of the invention can ensure the safety of the structure and does not affect the construction of the next working procedure; besides, the invention has the advantages of convenient construction, short constructing period, low cost and good effect.

Owner:东莞市桦业土木基础工程有限公司

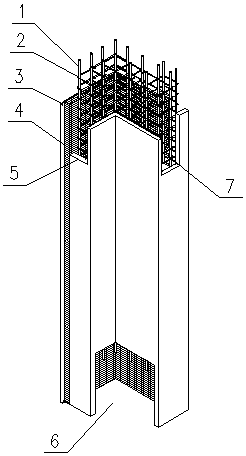

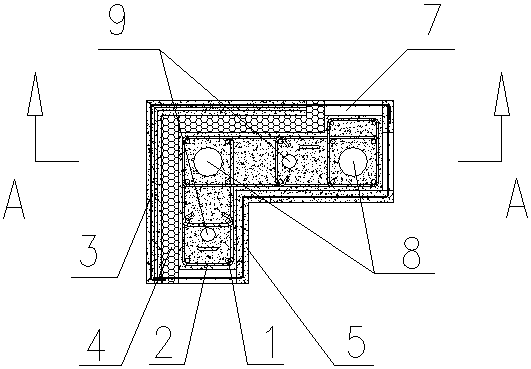

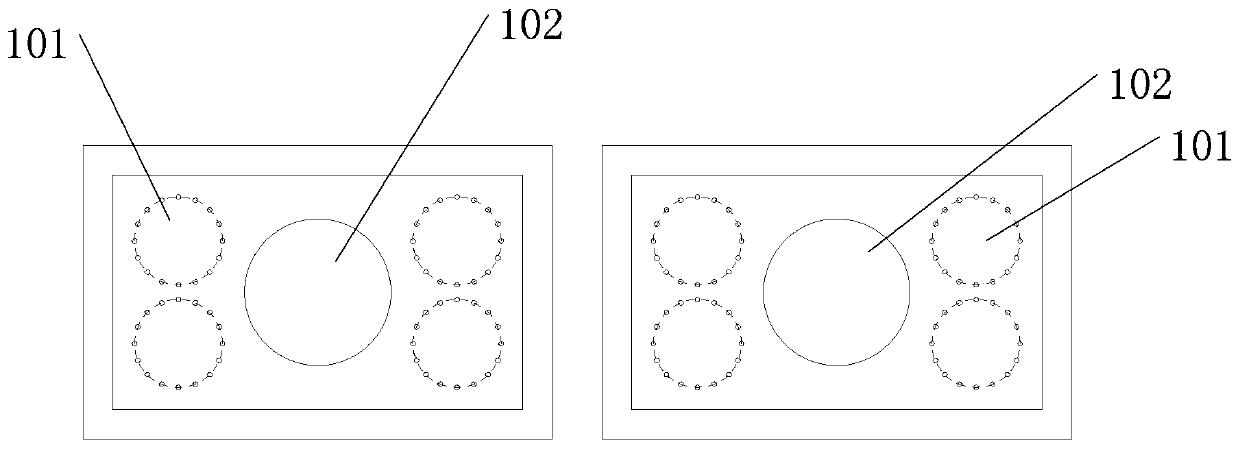

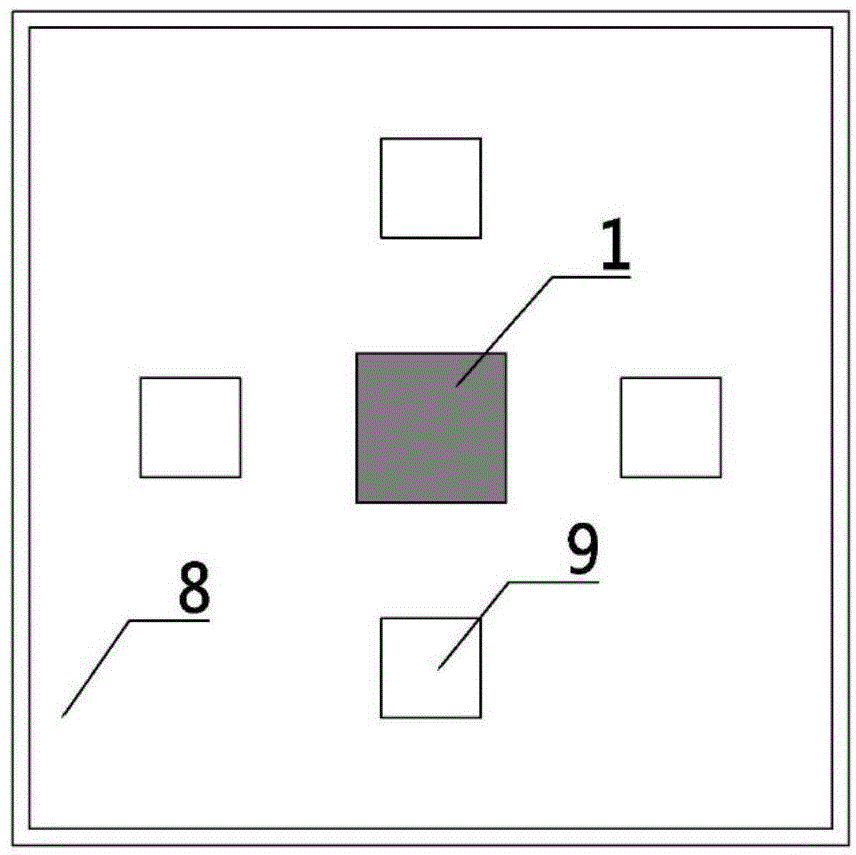

Prefabricated cold-formed thin-walled steel plate column structure tenon and mortise connection system and construction method thereof

InactiveCN107795013AImprove prefabrication rateEnsure structural safetyStrutsPillarsCold formedHouse building

The invention relates to a prefabricated cold-formed thin-walled steel plate column structure tenon and mortise connection system and a construction method thereof, and belongs to the technical fieldof structural engineering. Single-hole columns, double-hole columns, three-hole columns and four-hole columns are support columns of the system. A floor module is the main structure of the system. Theconnection mode between the floor and the columns is the connection mode between the support columns and the main structure of the system. The single-hole columns and the double-hole columns are respectively arranged at joint connection support parts at the bottom of the floor module. The three-hole columns are arranged at corner support parts at the bottom of the floor module. The four-hole columns are located at center cross support parts at the bottom of the floor module. Through the method of optimizing the light steel plate column structure system by implanting beam-column joints in thefloor, the structure is allowed to bear the force more reasonably, the consumption of building materials and the amount of construction work at a construction site are greatly reduced, and a rapid green construction is truly realized. The whole building is sturdy and durable, thermal-insulating, lightweight, energy-saving, environmentally friendly, suitable for all kinds of housing construction and highly applicable, and will bring good economic and social benefits.

Owner:谢志强 +1

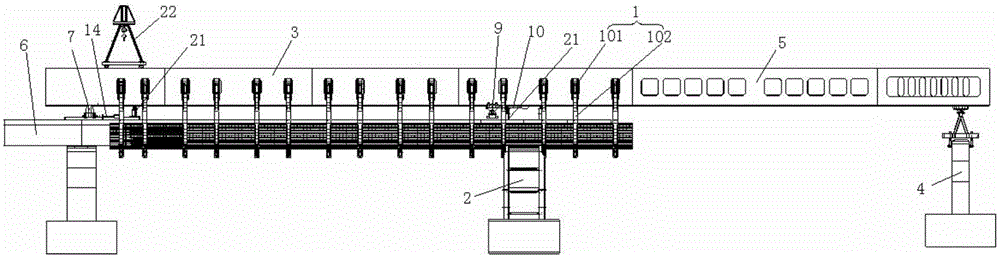

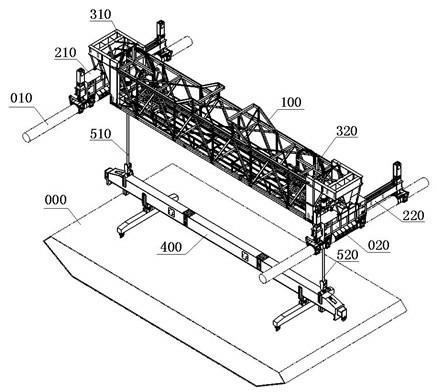

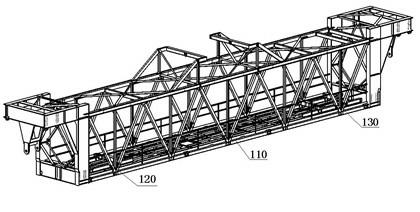

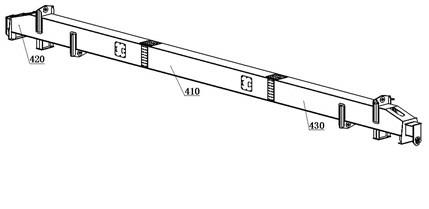

Propelled hydraulic cable carrying crane

InactiveCN102153022AEnsure structural safetyWalk fastLoad-engaging girdersSuspension bridgeControl systemEngineering

The invention discloses a propelled hydraulic cable carrying crane which comprises a power system, a control system and a mechanical executing mechanism, wherein the mechanical executing mechanism mainly comprises a main truss (100), walking type propelling systems (210 and 220) installed at both ends of the main truss, two sets of hydraulic lifting systems (310 and 320) installed on the main truss and a shoulder pole beam (400); the main truss and the shoulder pole beam both adopt length changeable structures; and the hydraulic lifting systems (310 and 320) comprise synchronous stepping continuous lifting jacks and continuous lifting steel strands (510 and 520). The whole crane realizes walking type propelling on a cable by controlling actions of a walking frame and a sliding end beam so as to alternately bear and alternately walk without additional traction equipment and manual disassembly, assembly and conveying of accessories at high altitude, such as clamping cables, hoops, and the like, and the invention has the advantages of high walking speed, high sliding resistance and high safety.

Owner:SOUTHWEST JIAOTONG UNIV +1

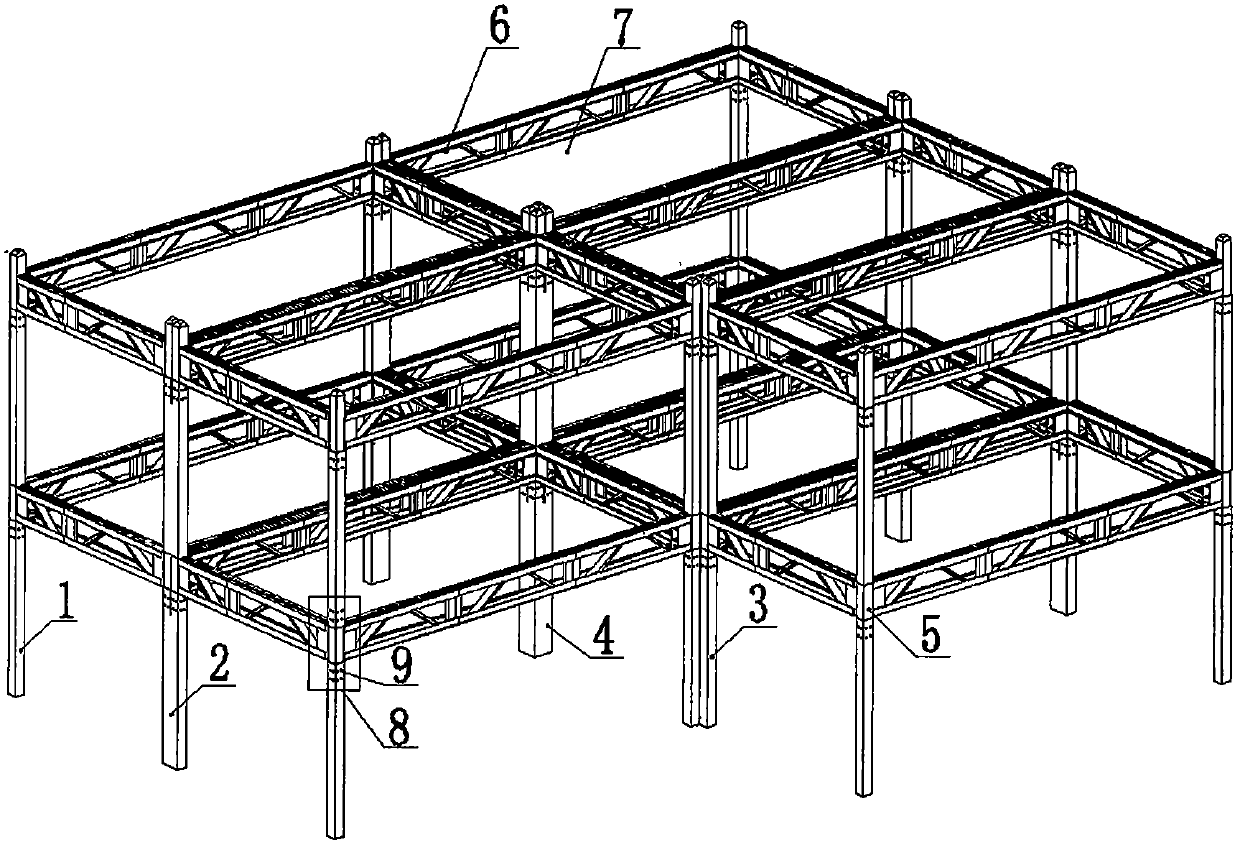

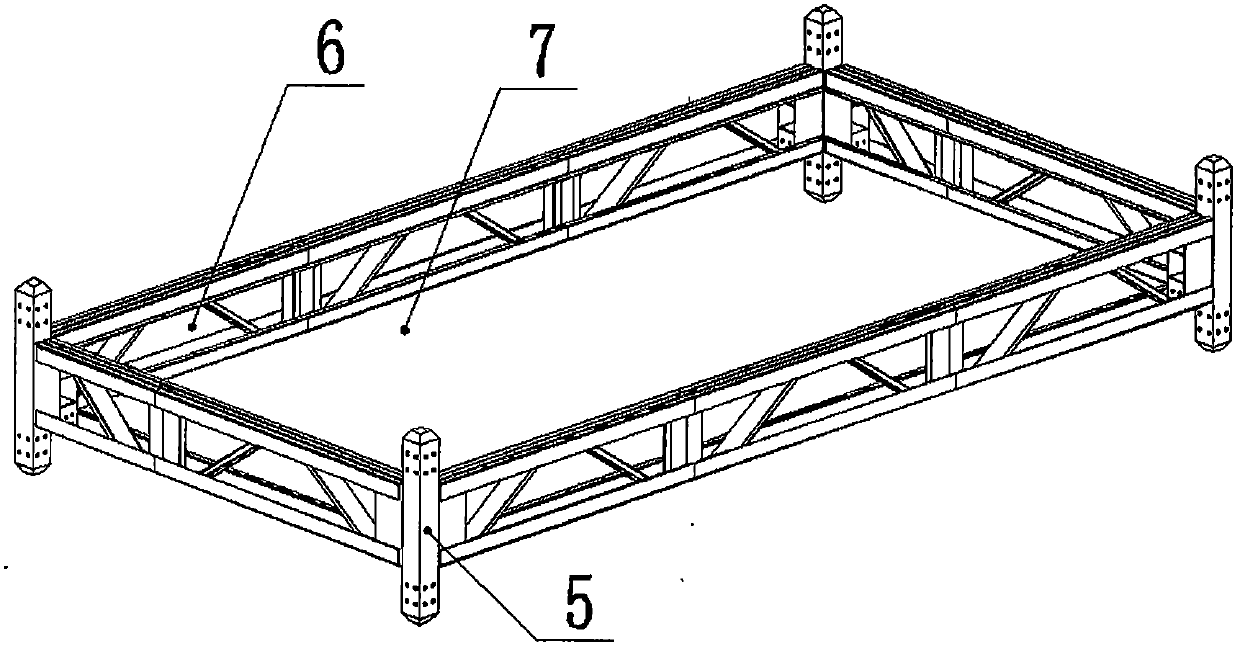

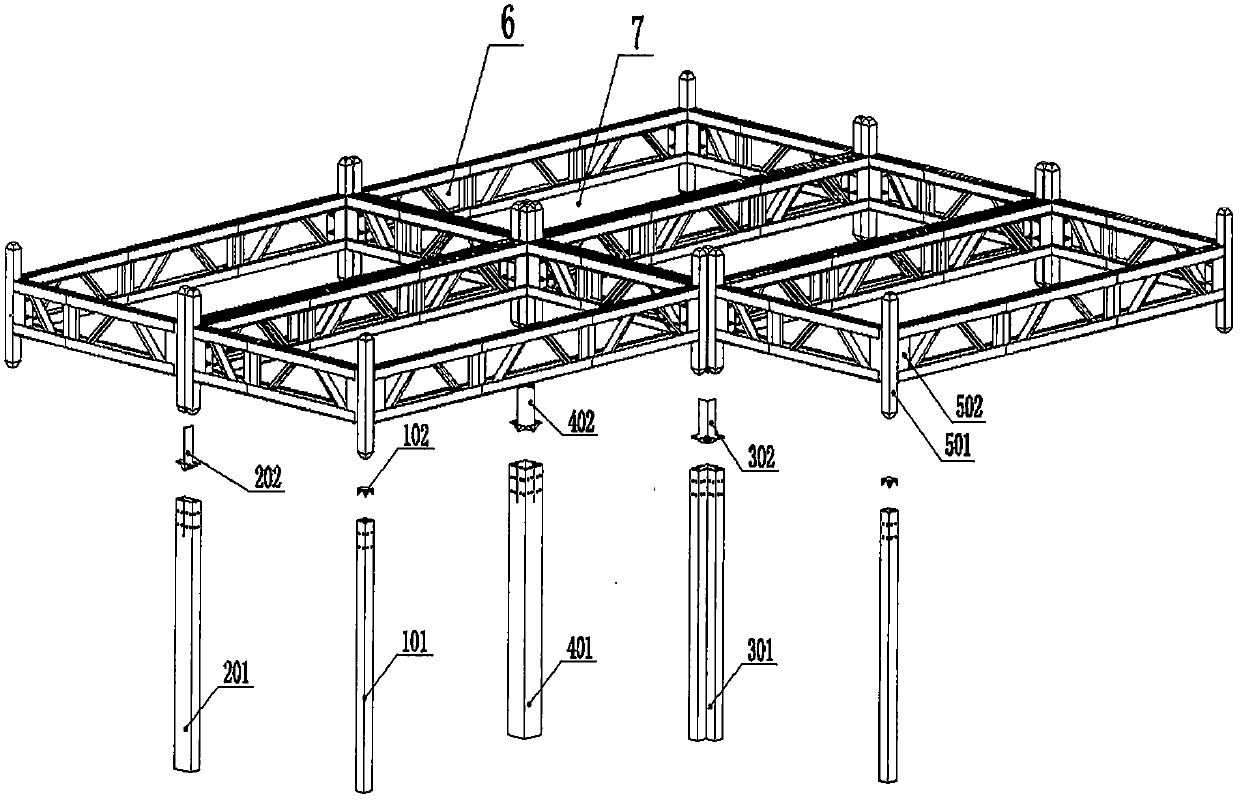

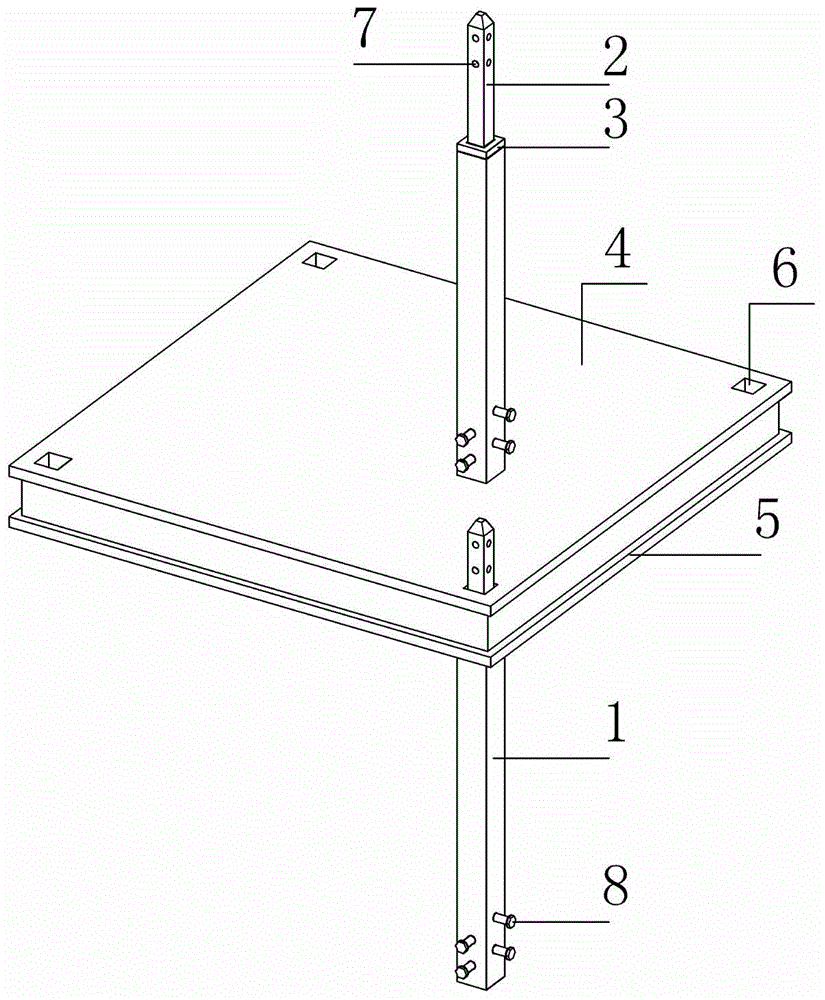

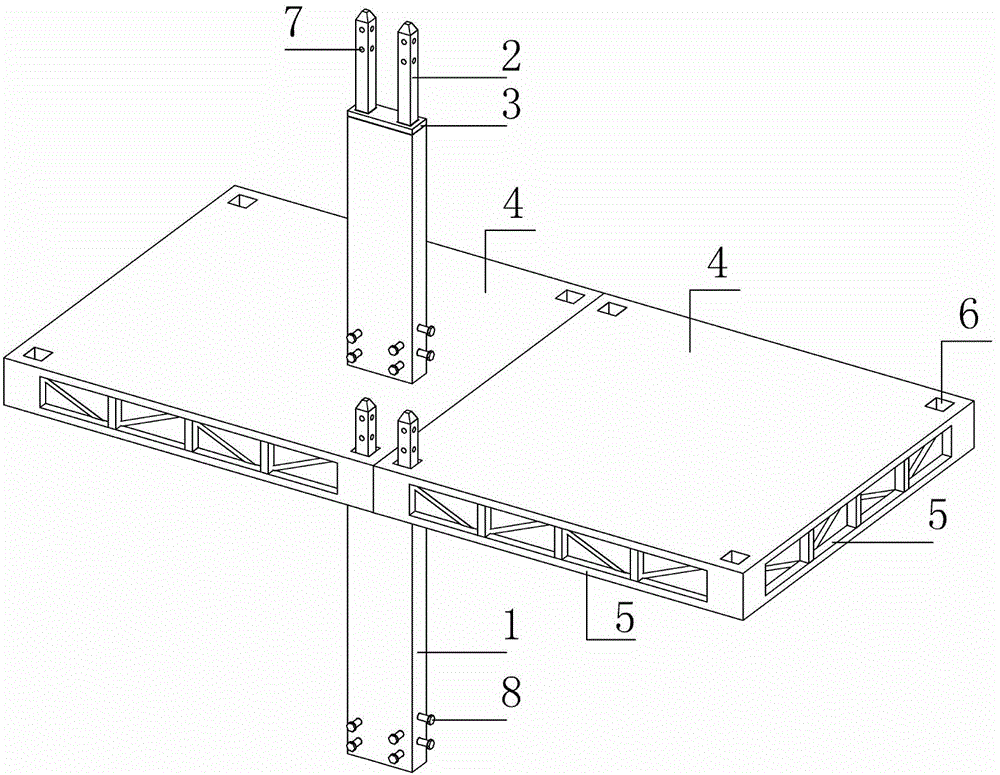

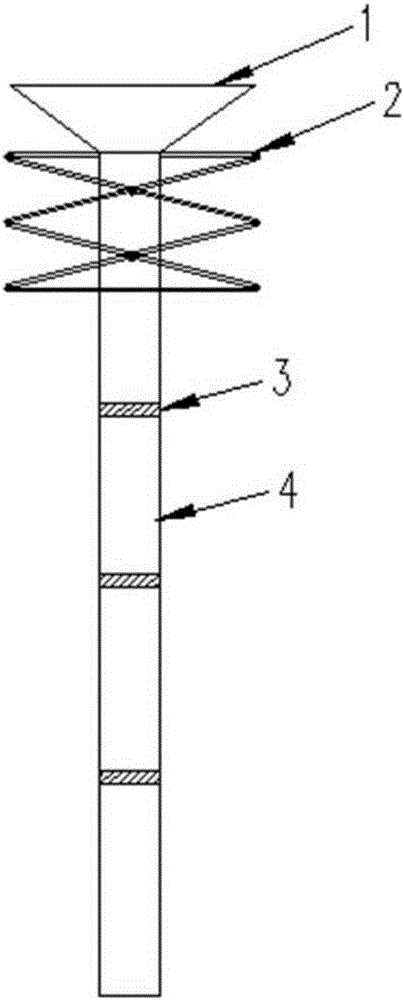

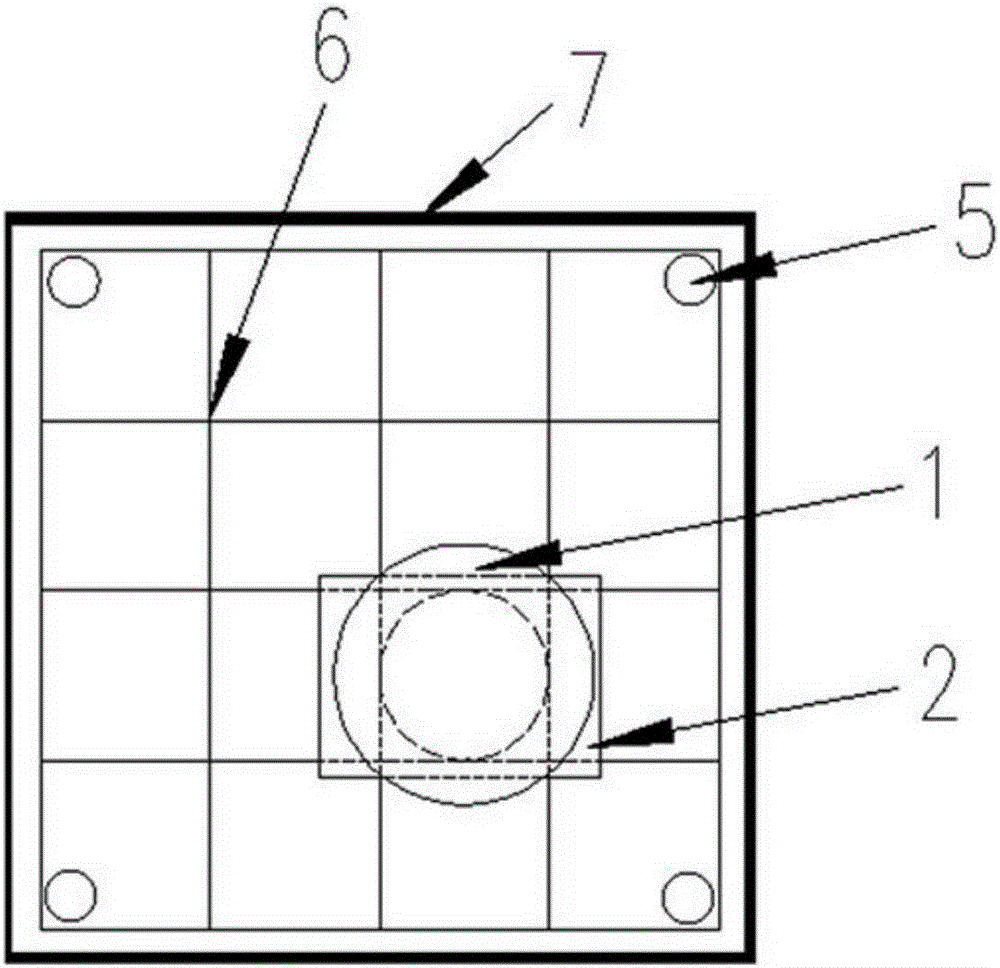

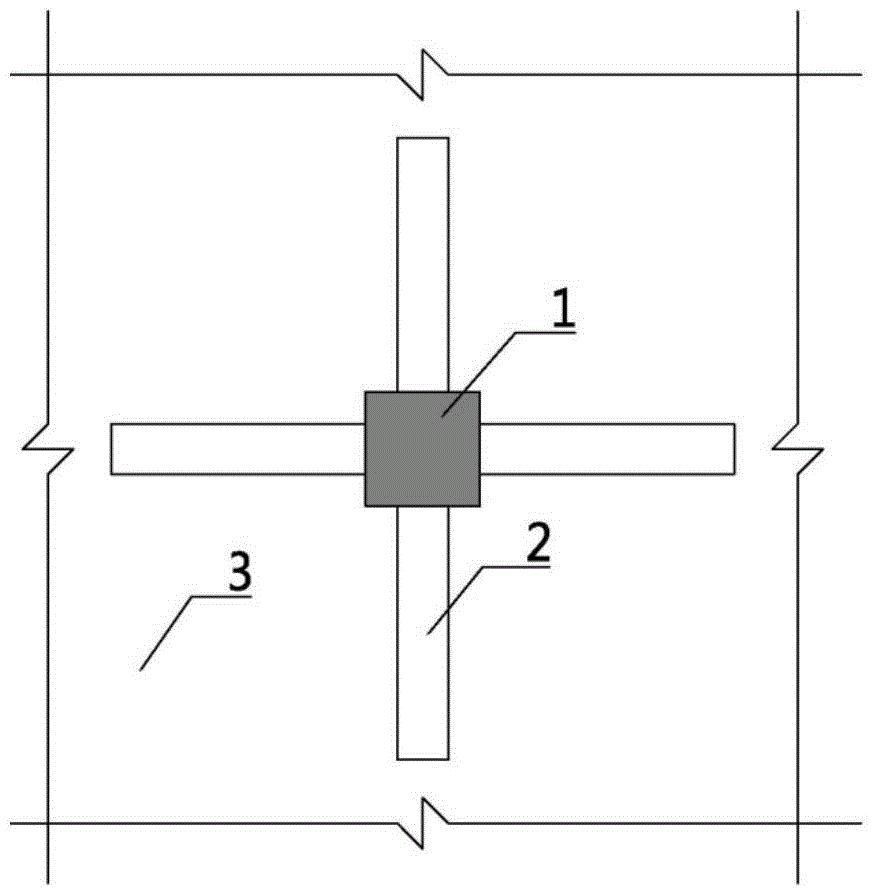

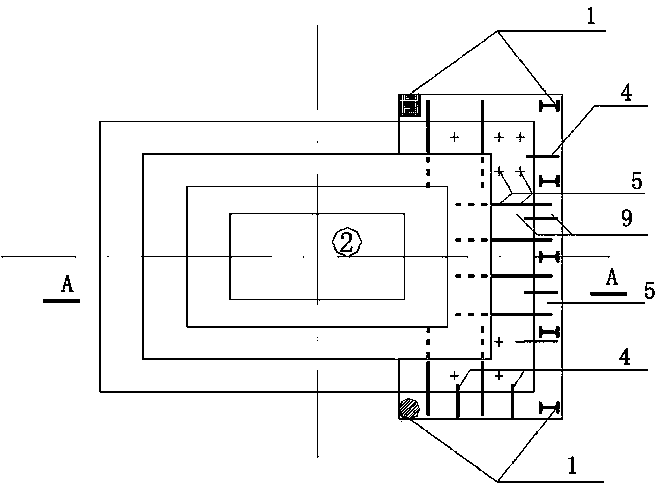

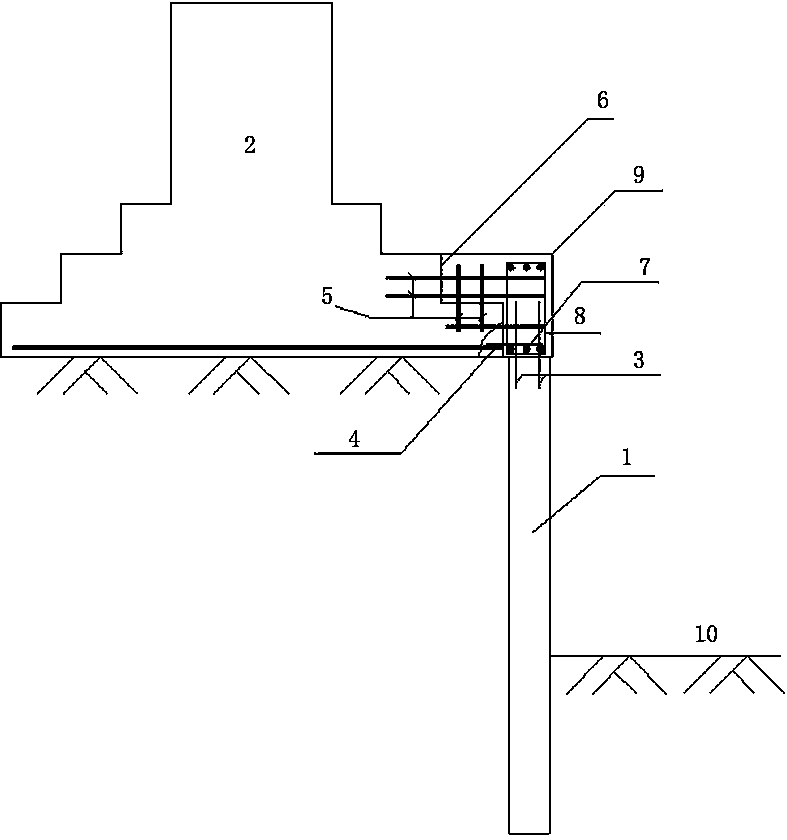

Prefabricated slab and column mortise and tenon type connecting joint and installation method

ActiveCN104947803AEnsure structural safetyGuaranteed structural qualityBuilding material handlingFloor slabMortise and tenon

The invention discloses a prefabricated slab and column mortise and tenon type connecting joint and an installation method. The connecting joint comprises a composite frame column, a floor slab and a high-strength bolt. A column end sealing plate is welded to the top end of a column body, and the bottom end of a column tenon is welded to the column end sealing plate. Frame beams on the periphery are structural steel or structural steel combination trusses. Tenon holes are hollow steel members connected with the frame beams, the cross section shape of the tenon holes is the same as that of the column tenon, and the cross sections of the tenon holes are larger than the cross section of the column tenon but small than the cross section of a body of the composite frame column. Composite frame columns and floor slabs are sequentially connected and fixed through bolt holes and high-strength bolts. By means of tenon and mortise type connection of slabs and columns prefabricated in a factory, the structure form and the installation mode are greatly simplified, the structural safety and quality of a building can be guaranteed better, the field workload is reduced, the construction environment pollution is reduced, the construction period is shortened, and cost is saved.

Owner:江苏保力装配式住宅工业有限公司

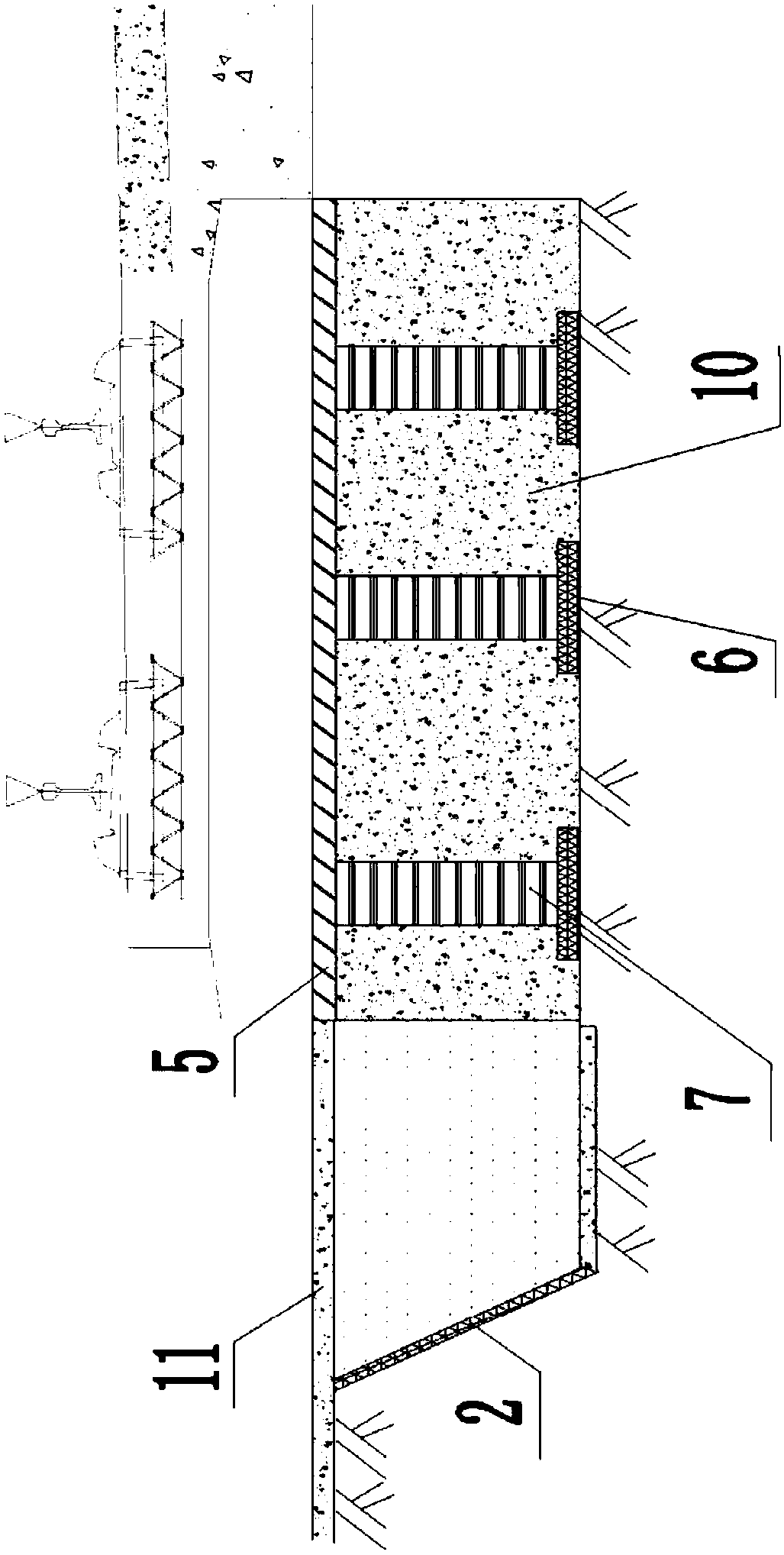

Cast-in-place superposed formwork integrated structure of prefabricated building and construction method

The invention relates to a cast-in-place superposed formwork integrated structure of a prefabricated building and a construction method and belongs to the field of building engineering. The structurecomprises shear wall members, superposed column members, superposed beam members, superimposed slab members, inner partition members, peripheral guard wall members, stair members and balcony members.The members are connected through sleeve grouting and then connected into a whole by grouting concrete from grouting holes, so that the cast-in-place superposed formwork integrated structure of the prefabricated building is formed. The integrated structure is used for constructing the prefabricated building; all nodes of the building have the same performance as cast-in-place nodes; and the prefabricated building has the same integrity as cast-in-place building and excellent shock resistance, water resistance and sound insulation performance.

Owner:江西万盟建筑科技有限公司

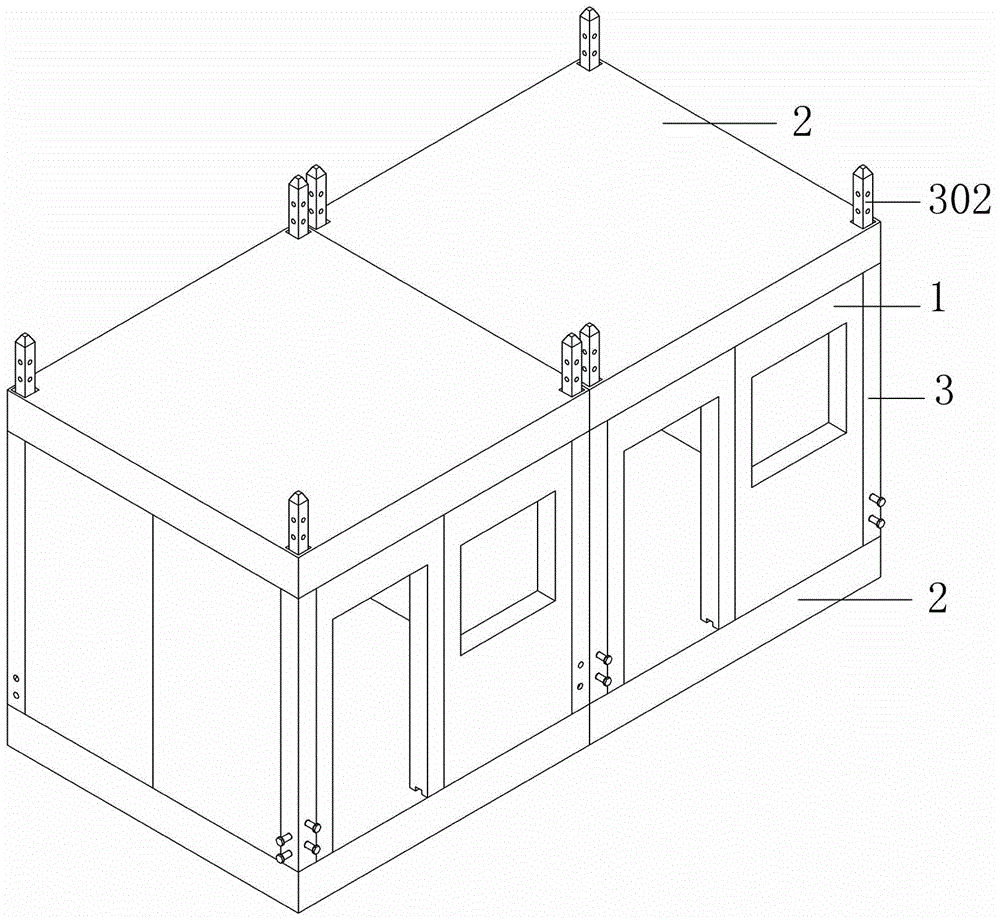

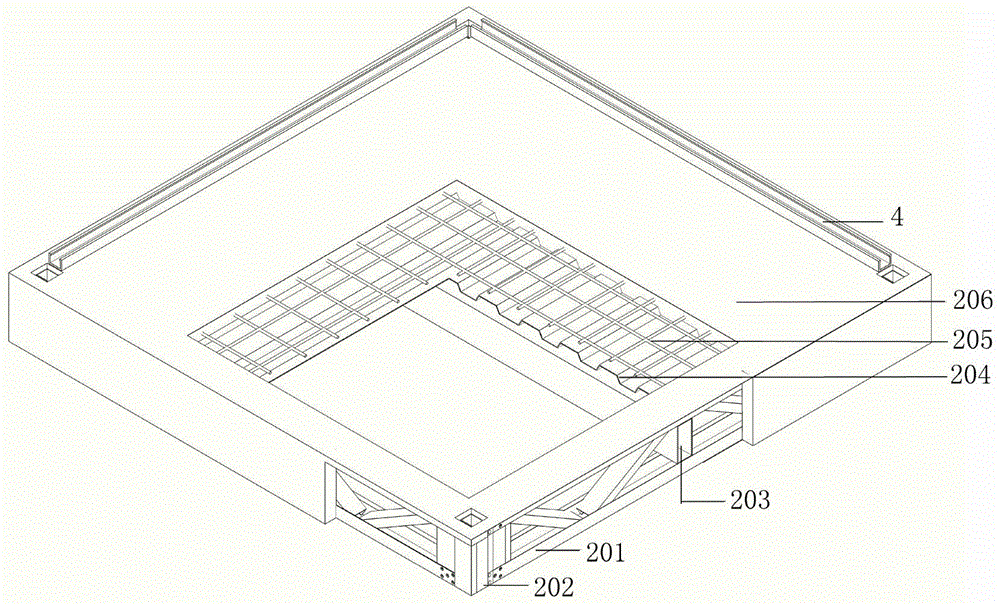

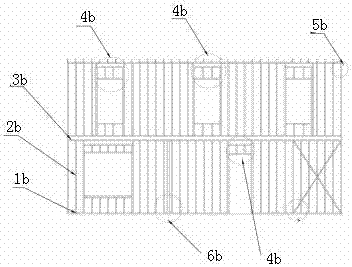

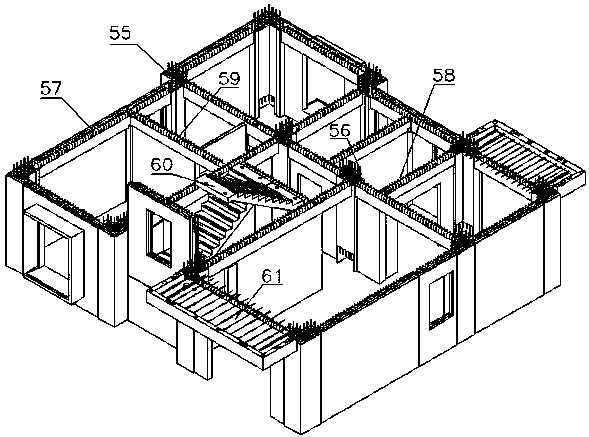

DGC board-type assembled house system and construction method and manufacturing method thereof

InactiveCN105804233AImprove prefabrication rateEnsure structural safetyWallsFloorsModular compositionInsulation layer

The invention discloses a DGC board-type assembled house system and a construction and a manufacturing method thereof. A basic unit of the system is formed by floor slabs and wallboards which are combined and assembled in a modularized manner; the wallboards are prefabricated composite boards, each wallboard mainly consists of a light-steel frame, a peripheral guard board, a sandwich insulation layer, a heat insulating layer and turnbuckles, and different wallboard standard modules such as in-line wallboards, L-shaped wallboards, T-shaped wallboards and cross-shaped wallboards are adopted and freely combined; the floor slabs are prefabricated composite boards, the floor slabs are used as foundation slabs, floor slabs or roof slabs of the DGC board-type assembled house system, and vertical connection between the floor slabs and the wallboards in the system consists of combined connection of lateral connection of horizontal M-shaped steel, M-shaped chord members and square steel pipes through tapping screws and vertical connection of the turnbuckles in trusses. According to the DGC board-type assembled house system and the construction method and the manufacturing method thereof, the structure is simple, the construction speed is fast, the construction period is reduced, the cost is low, and the defects of single structure, complex installation process and high labor cost of the existing assembled house structure can be overcome.

Owner:江苏保力自动化科技有限公司

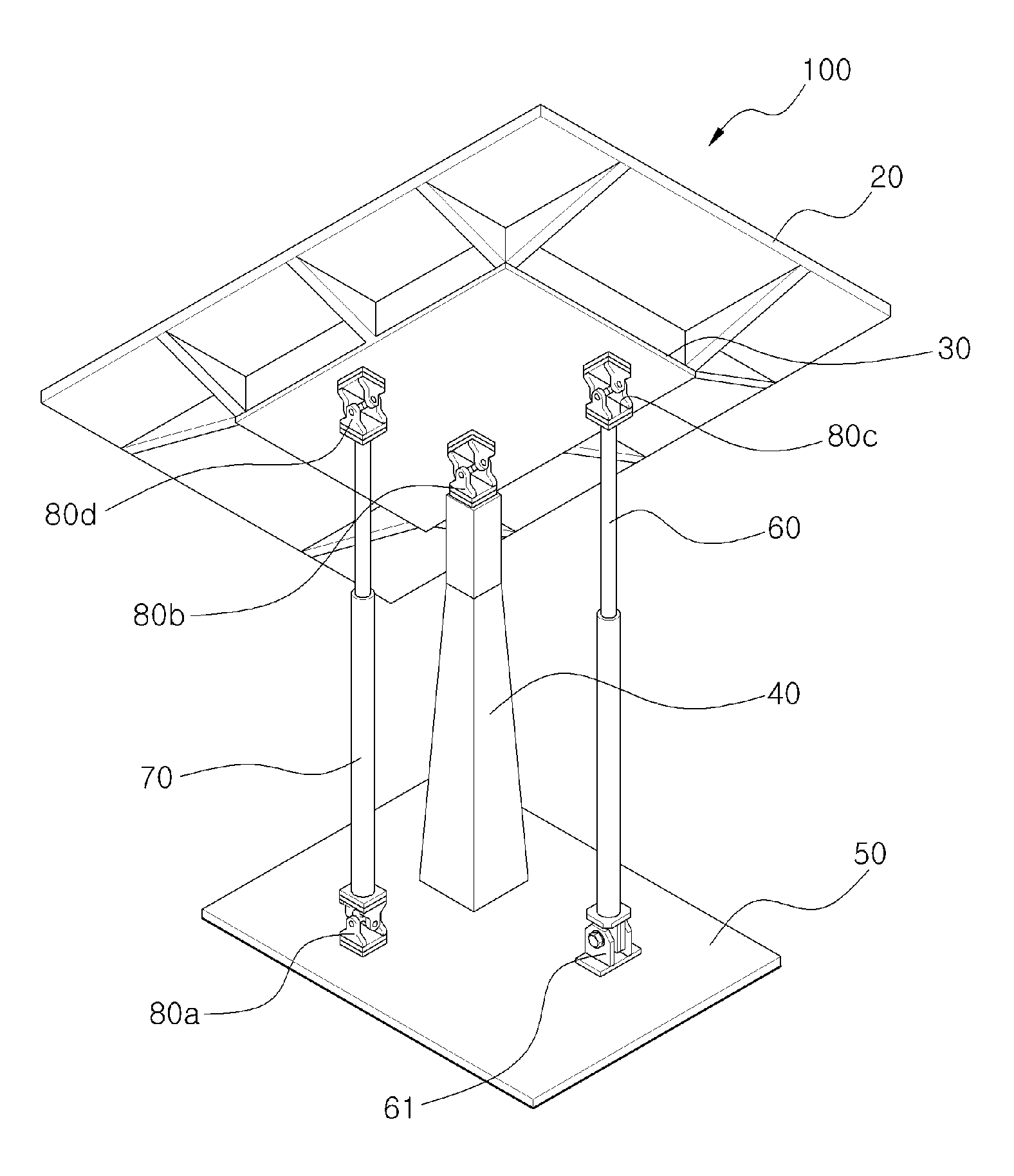

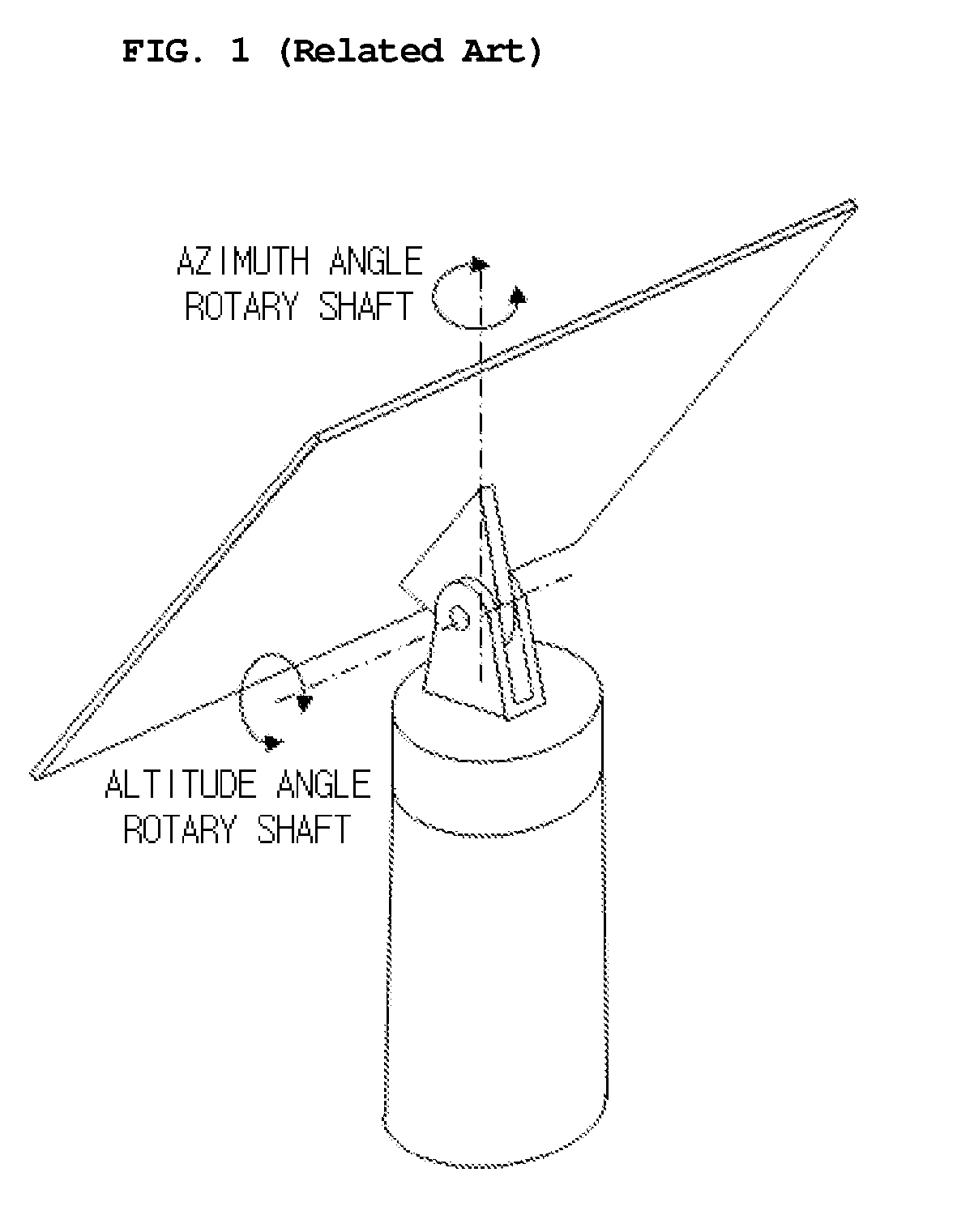

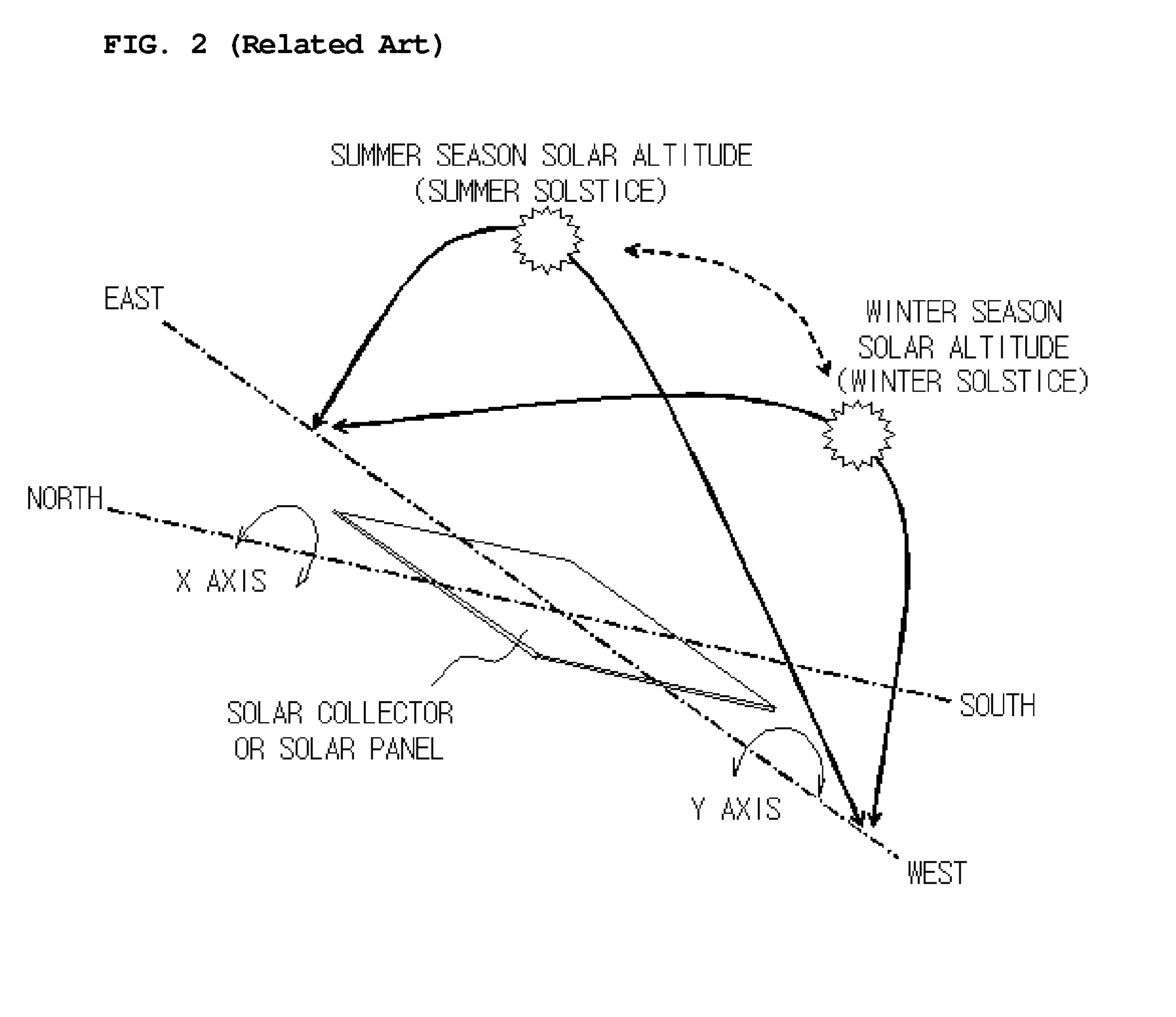

Solar tracker for photovoltaic power generation

InactiveUS20140069481A1Small diurnal changeConsumes driving powerPhotovoltaic supportsSolar heating energySolsticeSolar tracker

A solar tracker is provided to fix an altitude angle until the altitude of the sun secedes from a predetermined range after matching the altitude through once driving of one shaft that tracks the altitude angle and to drive only the other shaft that tracks an east-west azimuth angle in daily repetition in a state where the altitude angle of the sun, which is repeatedly changed according to seasons of the year in the range of the winter solstice having the lowest altitude angle and the summer solstice having the highest altitude angle, has an extremely small diurnal change, whereas the azimuth angle of the sun is repeatedly changed in one direction, that is, from sunup to sundown, in a day. Accordingly, consumption of firm power of a driving unit for tracking the sun can be minimized, and the operating and management costs of the device can be reduced.

Owner:HYPER

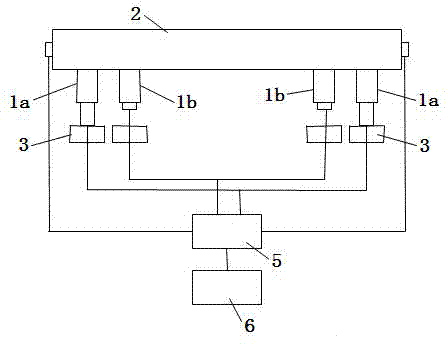

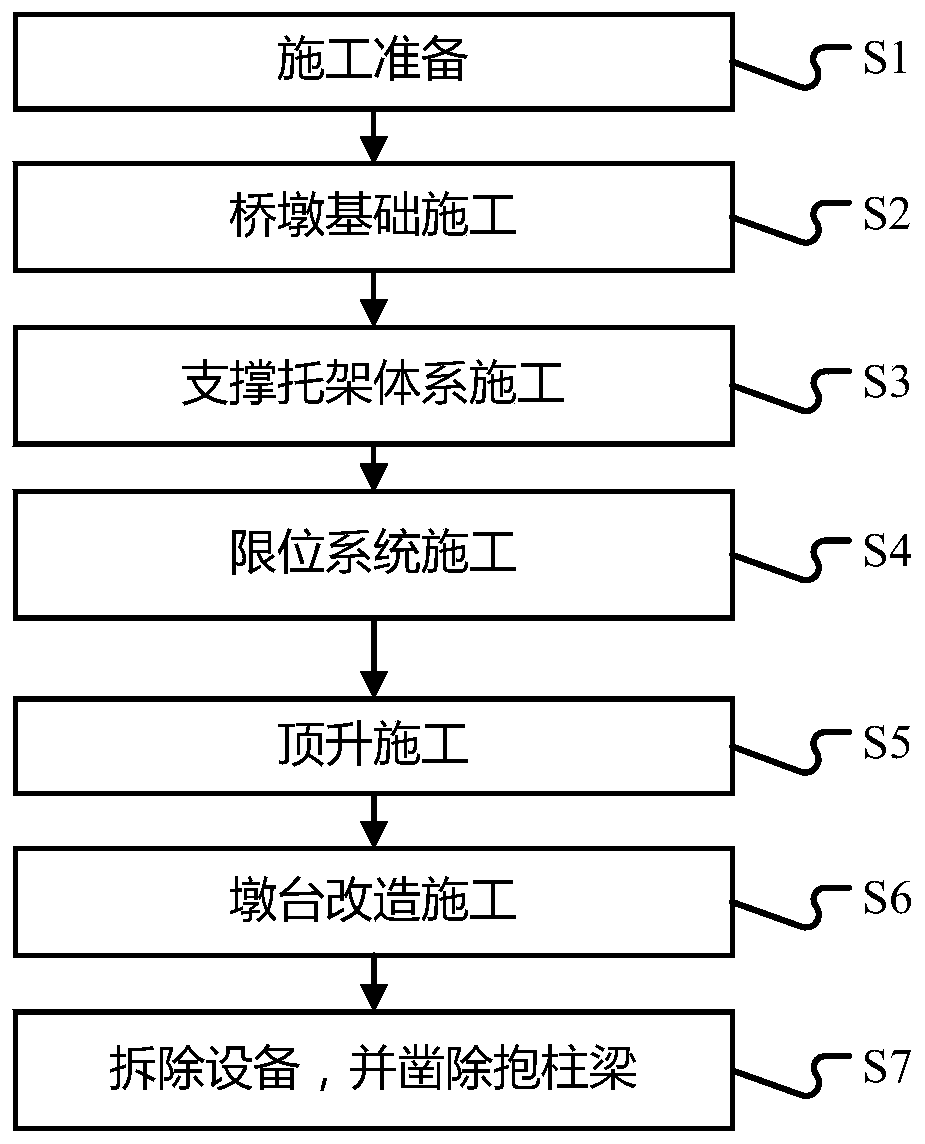

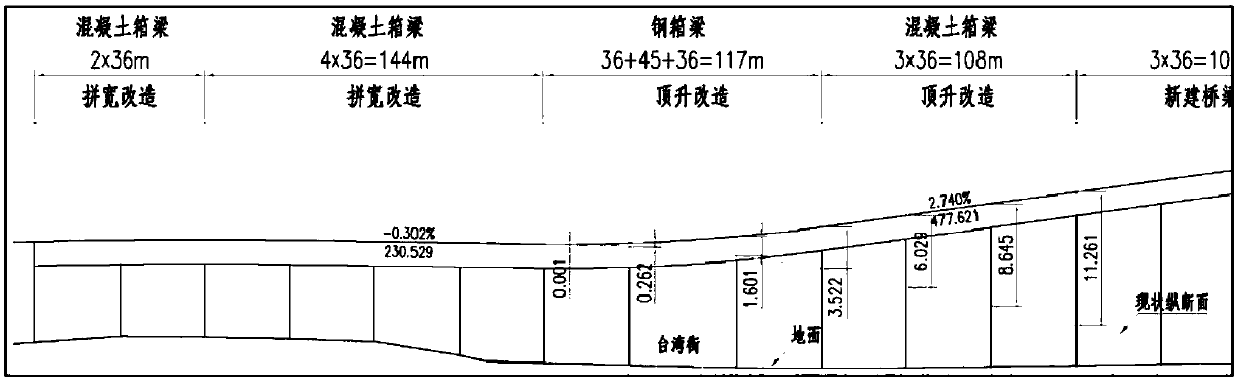

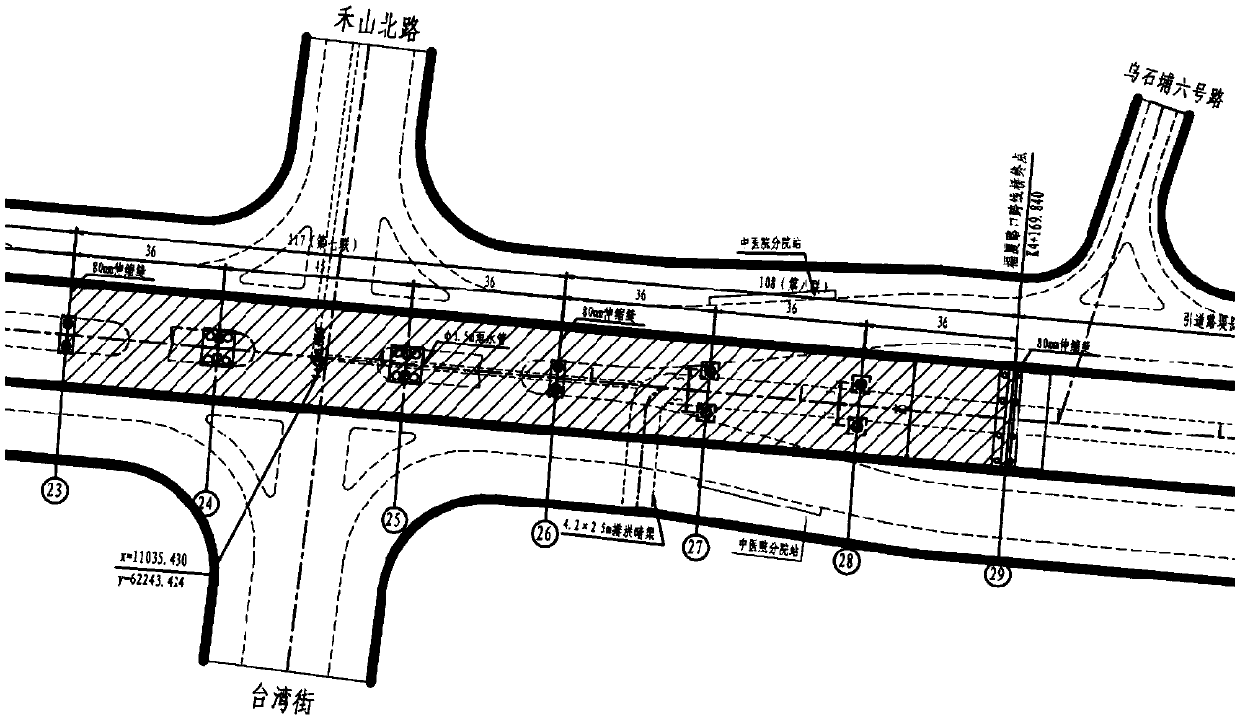

Integral synchronous jacking transformation method of overpass railway flyover

InactiveCN110700117AAlternate jacking for continuous operation safe and controllableSo as not to damageBridge structural detailsBridge erection/assemblySupporting systemArchitectural engineering

The invention provides an integral synchronous jacking transformation method of an overpass railway flyover. Jacks are jacked alternately, continuous operation can be achieved, and safety and controllability are achieved. Due to the fact that alternate jacking is adopted for jacking, in the jacking process of alternate jacking, the beam body is in the state that the two sets of jacks are alternately supported, when the two sets of jacks are alternately supported, the displacement of the beam body is in the controllable state, in each set of supporting state, the compression amount of the supporting system is hardly changed, and therefore the internal force of the beam body is hardly changed. In the operation mode, the displacement of the beam body is continuously in a controlled state fromthe beginning of jacking to the end of jacking. The pressure of each jack is continuously monitored, so that it can be ensured that the beam body can be prevented from being damaged in the jacking process, and the whole bridge jacking system is also in a safe and controllable state. The method is suitable for a series of projects which need to be integrally lifted for construction due to insufficient clearance under the existing flyover, navigation or other conditions.

Owner:CHINA RAILWAY 14TH CONSTR BUREAU GRP 4TH ENG

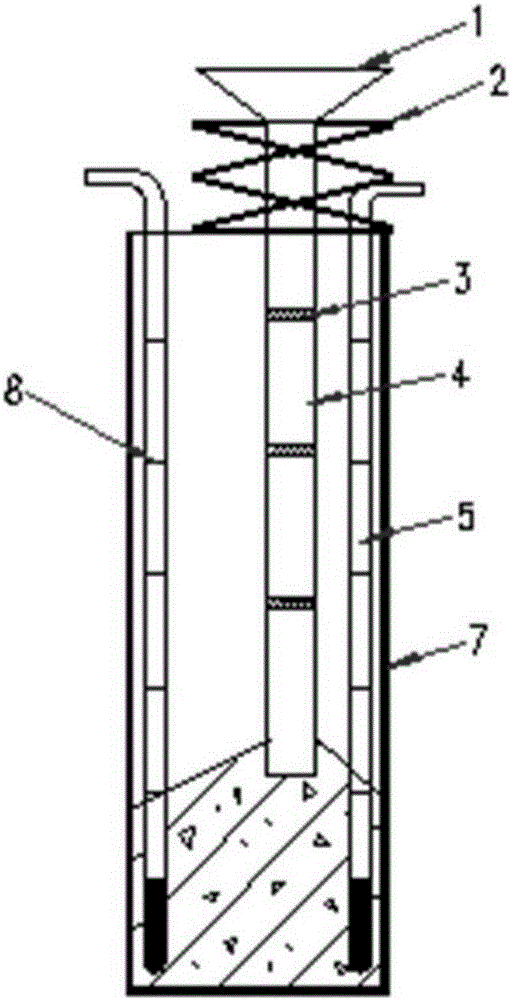

Device and method for one-time pouring molding of ultra-high concrete column

InactiveCN105350777AEnsure structural safetyGuaranteed structural qualityBuilding material handlingReinforced concreteHoneycomb

The invention discloses a device and method for one-time pouring molding of an ultra-high concrete column. The device comprises a guiding device arranged in an ultra-high concrete column formwork. The guiding device comprises a collecting hopper, a scissor fork lifting mechanism, guiding pipe connecting mechanisms and a guiding pipe. The collecting hopper is arranged on the top of the guiding pipe, the guiding pipe is divided into multiple sections with the equal length, the sections are connected through the guiding pipe connecting mechanisms, the lower portion of the collecting hopper is sleeved with the scissor fork type lifting mechanism for lifting the guiding pipe, multiple vibrating rods for vibrating and densifying concrete are arranged between hoops on the edges of the formwork, multiple sections of scale marks are arranged on the vibrating rods, and the length of each section of scale mark is equal to that of each section of guiding pipe. Coincidence and integrity with the concrete are guaranteed, the honeycomb and scale phenomenon caused by the fact that vibration is not in place is avoided, the structural safety and appearance quality of one-time molding of the ultra-high reinforced concrete structure column are guaranteed accordingly, appearance attractiveness is improved, and the construction period is shortened.

Owner:CHINA FIRST METALLURGICAL GROUP

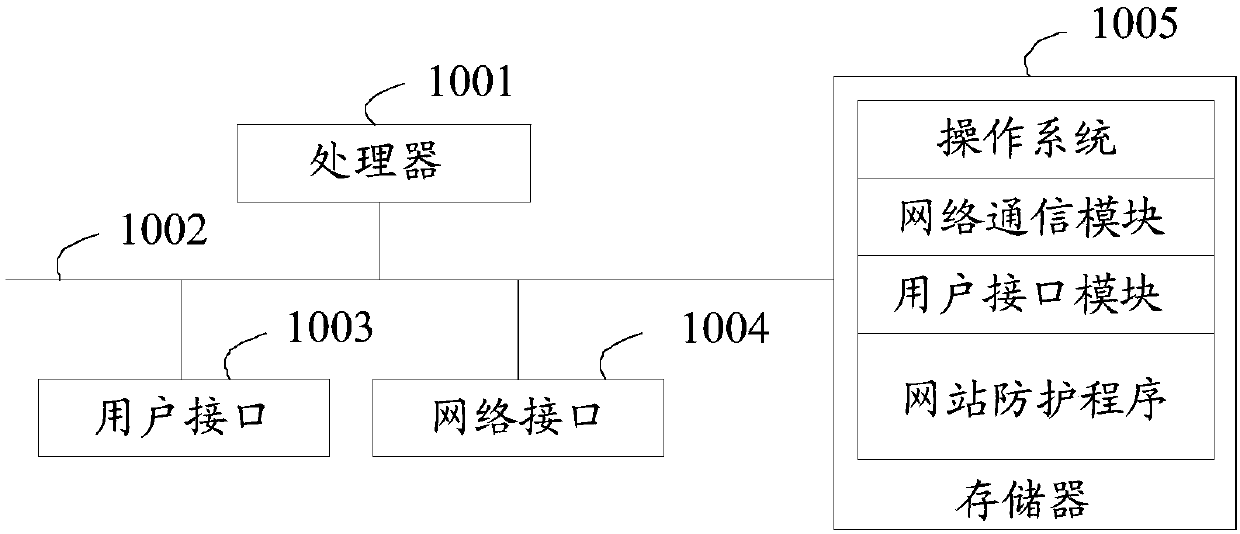

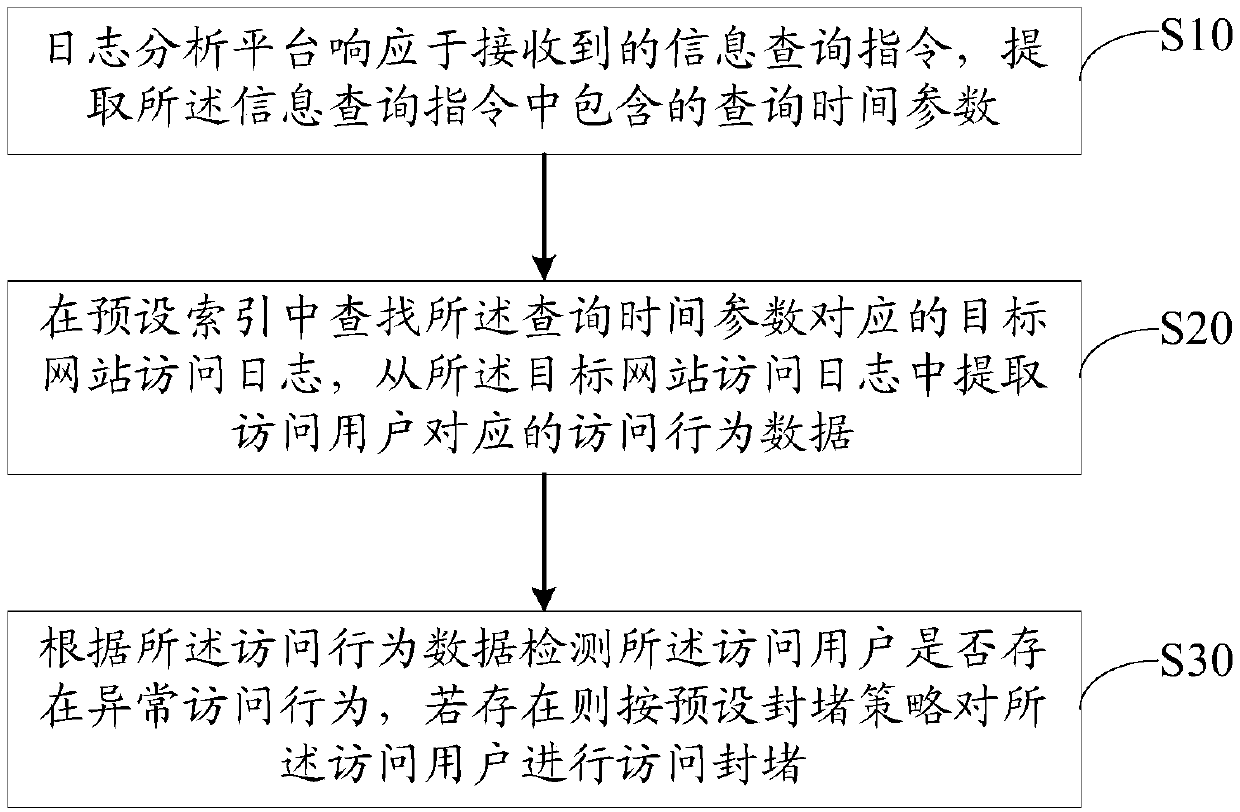

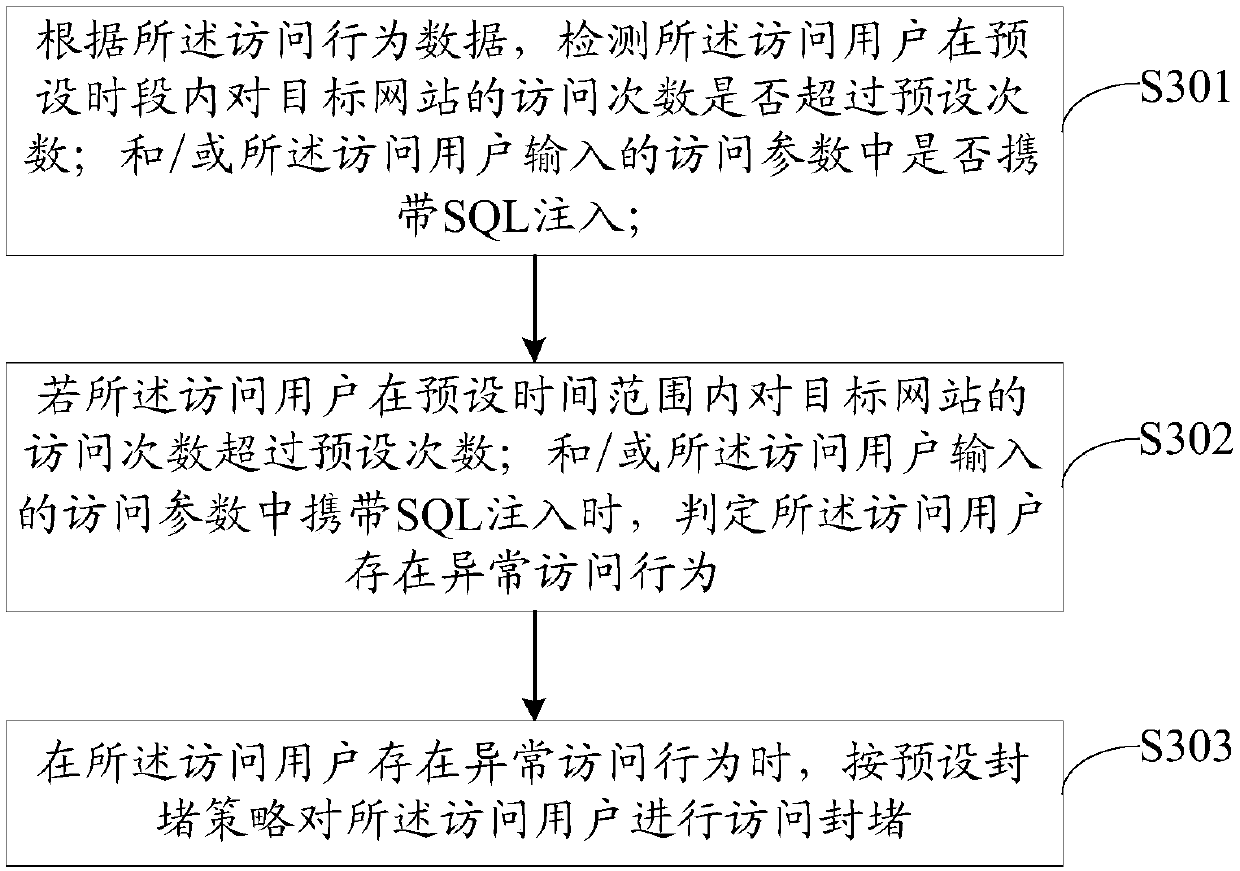

Website protection method, website protection device, website protection equipment and storage medium

ActiveCN109688097AIncrease flexibilityImprove adaptabilityTransmissionInternet privacyInformation security

The invention discloses a website protection method, a website protection device, website protection equipment and a storage medium. The method comprises the following steps: responding to a receivedinformation query instruction by a log analysis platform, and extracting a query time parameter contained in the information query instruction; in preset indexes, looking for a target website access log corresponding to the query time parameter, and extracting access behavior data corresponding to an access user from the target website access log; and according to the access behavior data, detecting whether the access user has abnormal access behaviors, and if yes, performing access blocking on the access user according to a preset blocking strategy. The log analysis platform judges whether auser access is an abnormal access or not according to the access behavior data of the user, so that the situations that a normal access request is mistakenly reported as access rules or firewall strategies are made and an abnormal access request is fail to report are avoided, website protection flexibility and anti-intrusion capability are improved, and information security of a website as well asstructural safety are guaranteed.

Owner:PING AN TECH (SHENZHEN) CO LTD

Treatment method for ballastless track roadbed arching

ActiveCN108951307AAvoid destructionEnsure structural safetyTrack maintainenceCrushed stoneRisk stroke

The invention relates to the field of railway roadbed engineering, in particular to a treatment method for a ballastless track roadbed arching disaster. The disaster is treated in the way that firstly, concrete of an arching section sealing layer on one side or two sides of a road shoulder is broken, a working groove is excavated downwards, and waterproof treatment is conducted on the groove bottom; then, foundation bed padding below a supporting layer is excavated, adjustable supporting devices are used for supporting after excavation is conducted, and a crossbeam and cushion blocks are arranged at the upper ends and the lower ends of the adjustable supporting devices; after excavation is finished, the elevation of track slabs is reduced through reduction of the height or the stroke of the adjustable supporting devices, then simple supports are used for replacing the adjustable supporting devices, and finally a packing material is poured; and the working groove is tamped and filled with graded broken stones layer by layer, and the sealing layer is repaired through concrete. The elevation of the track slabs is recovered to the original designed elevation, and the smoothness of a line is recovered. The provided method has the beneficial effects that construction is convenient and quick, economic cost is low, railway normal operation is not affected, and therefore the method is more practical.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

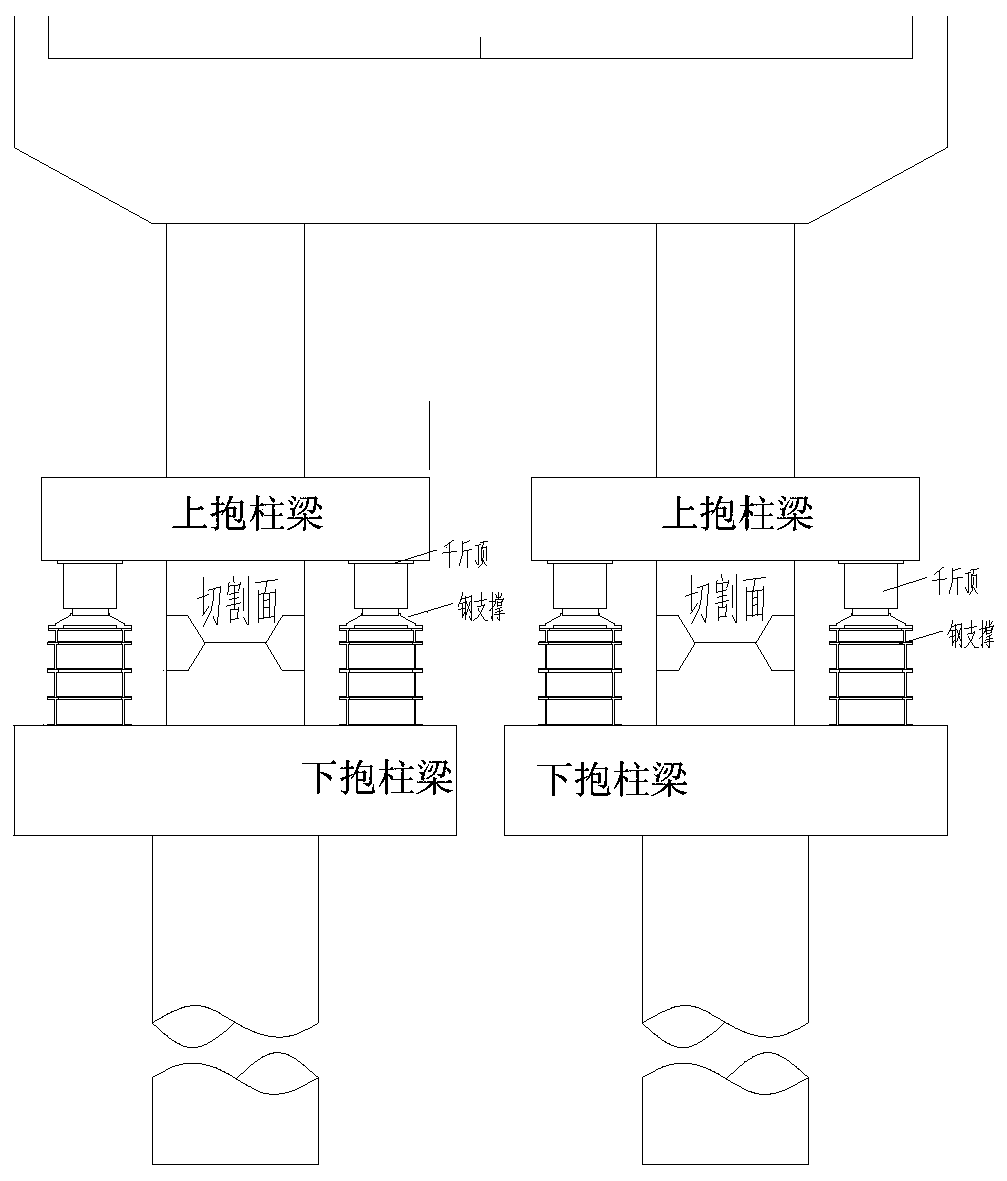

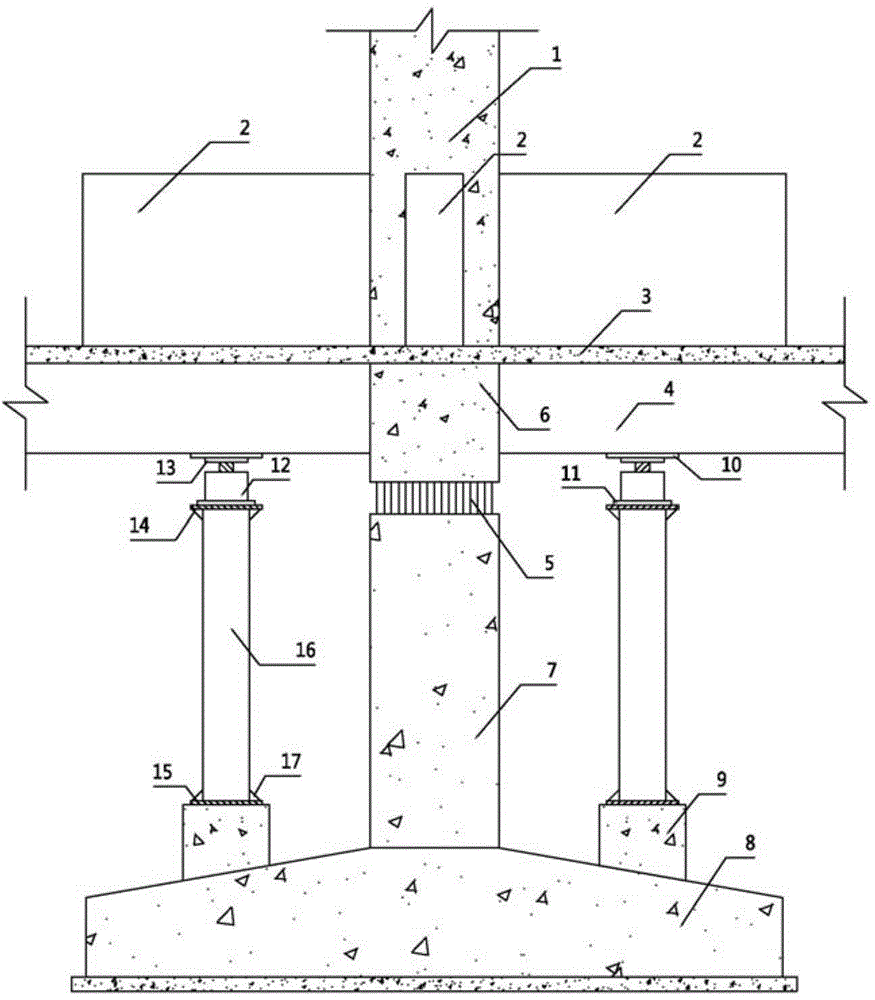

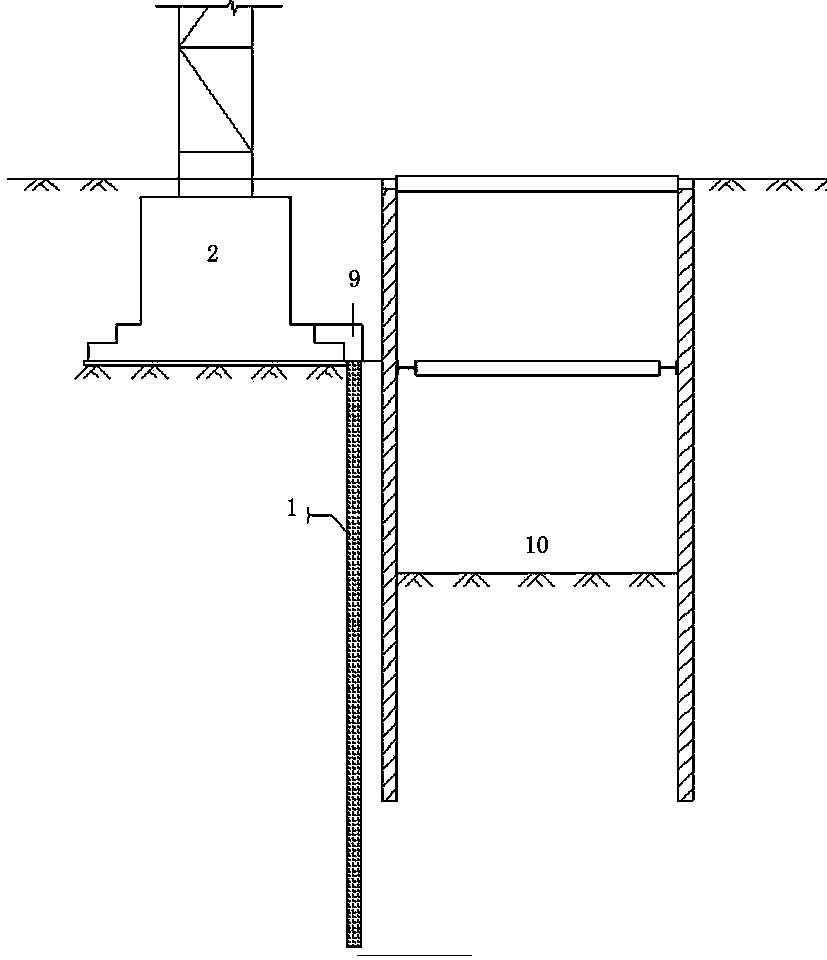

Overall replacement system for original building shock-insulation support and construction method

The invention relates to an overall replacement system for an original building shock-insulation support and a construction method. According to an overall replacement system structure, four temporary small foundations fall on a structural foundation and are evenly distributed on the periphery of the shock-insulation support, a section steel column is placed on each temporary small foundation, a steel cushion plate is placed on the top of each section steel column, a jack is placed on each steel cushion plate, another steel cushion block is placed on each jack, each another steel cushion block makes contact with the beam bottom, and it is guaranteed that a stress system is safe and reliable; one oil pressure pump is connected with the four jacks; four reversed beams are evenly distributed on the periphery of a beam column joint of an upper supporting pier of the shock-insulation support. In the replacement process of the shock-insulation support, jacking supporting, monitoring and high-pressure water lossless jet cutting are selected to be performed, and it is guaranteed that the construction process is safe, controllable, efficient, environmentally friendly, easy and fast.

Owner:THE SECOND CONSTR ENG CO LTD OF CHINA CONSTR THIRD ENG BUREAU +3

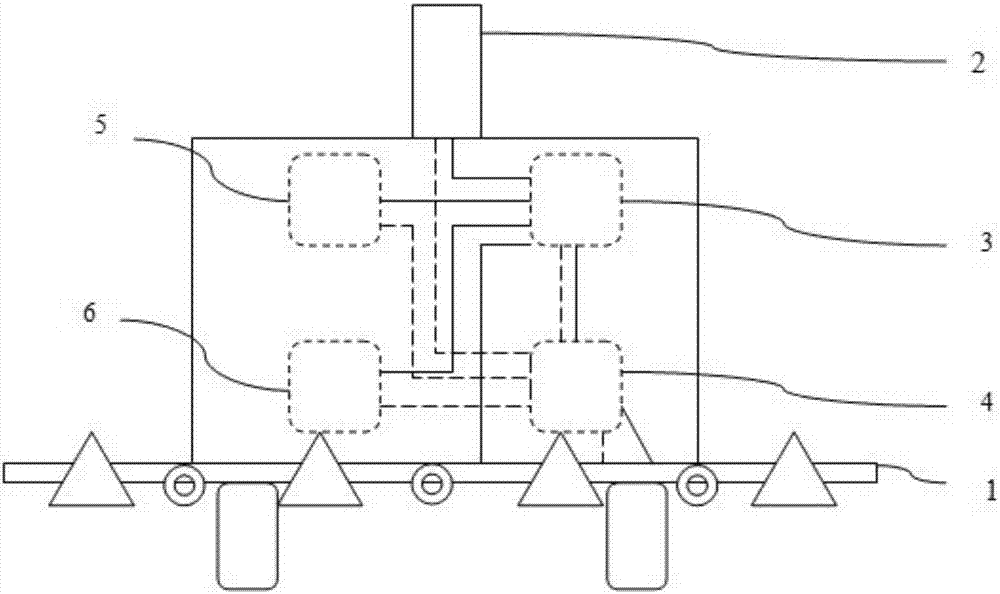

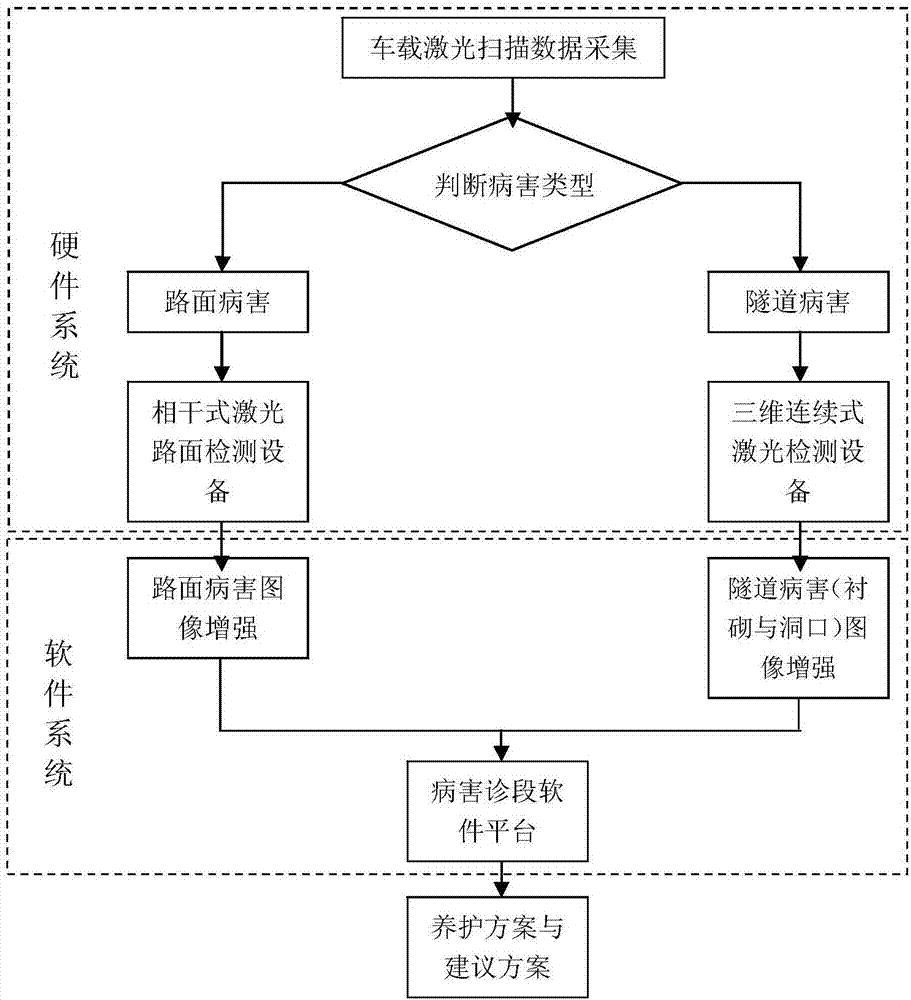

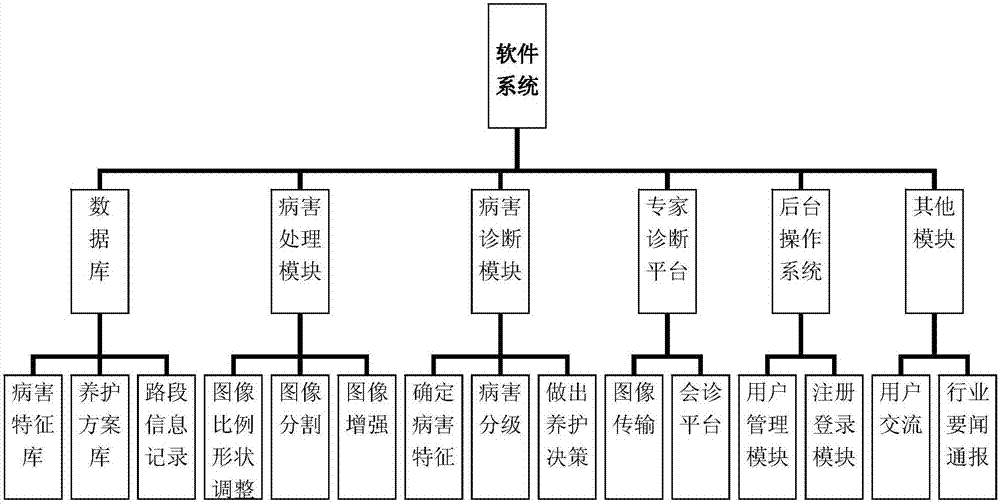

Highway pavement, tunnel distress diagnosis system based on computer image processing

InactiveCN106997588AEnsure structural safetyEnsure driving safetyImage enhancementImage analysisRoad surfaceComputer image

The invention discloses a highway pavement, tunnel distress diagnosis system based on computer image processing. The highway pavement, tunnel distress diagnosis system comprises a hardware part and a software part. The hardware part comprises coherent type laser pavement detection equipment, three-dimensional continuous type laser detection equipment, a main control computer unit, a data recording storage unit, an electrical unit, and an environment guarantee unit. The software part comprises a highway tunnel distress information database, a distress processing module, a distress diagnosis module, an expert diagnosis platform, a backstage operation system, and other modules. After various function and performance debugging, the software part is proved to be provided with a highway pavement, tunnel distress diagnosis-related image processing function, a distress diagnosis function, an expert on-line diagnosis function, and a function of proposing a maintenance scheme and a suggested scheme, and is capable of providing a data, information, process, result integration highway pavement, tunnel distress detection mechanism. Highway, tunnel structural safety and driving safety are guaranteed, tedious work of engineering technicians is reduced, and a significant meaning is provided for environmental protection, reduction of soil and water loss, and reduction of maintenance costs.

Owner:NORTHEAST FORESTRY UNIVERSITY

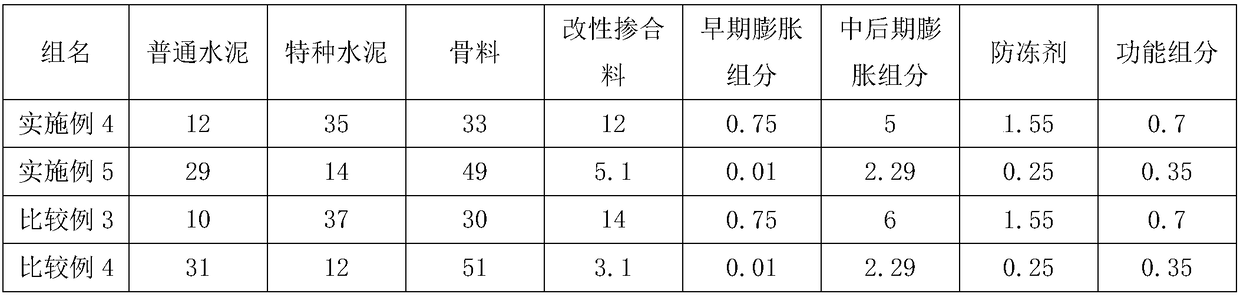

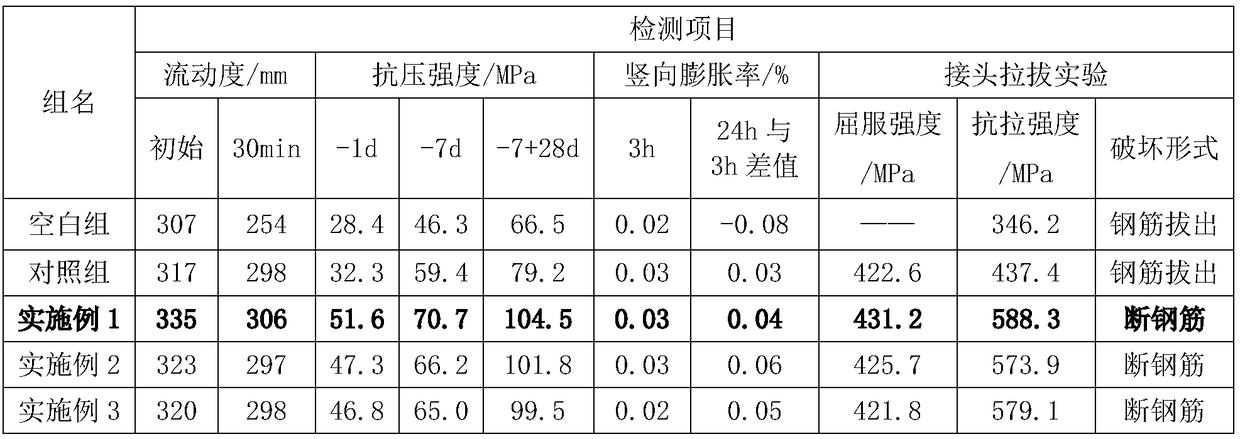

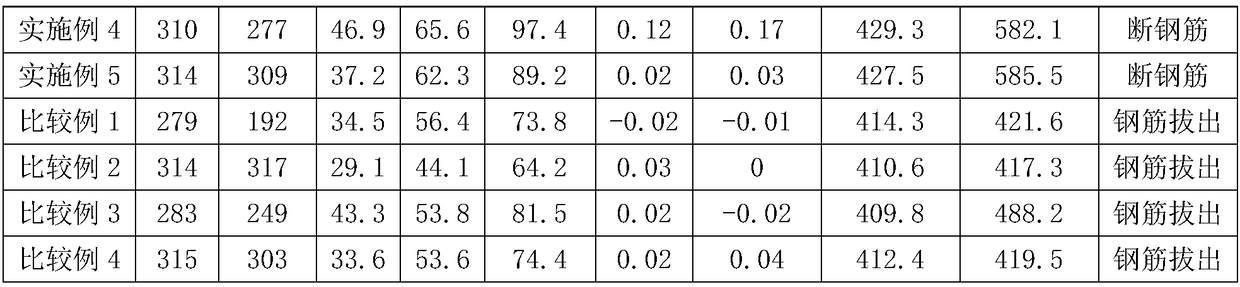

Sleeve grouting material for negative temperature reinforcing steel bar connection and preparation method thereof

The invention relates to a sleeve grouting material for negative temperature reinforcing steel bar connection, wherein the sleeve grouting material comprises 12-29% of ordinary cement, 14-35% of special cement, 33-49% of an aggregate, 5-12% of a modification admixture, 0.01-0.075% of an early expansion component, 2-5% of a middle-later expansion component, 0.25-1.55% of an antifreeze agent and 0.35-0.7% of a function component according to the weight percentage. The modification admixture comprises an organosilane coupling agent, modified nano-silica and ultra-fine slag powder; the modified nano-silica is prepared by soaking nano-silica in a potassium hydroxide and / or sodium hydroxide saturated solution at room temperature, carrying out ultrasonic dispersion and mixing, then filtering, taking a filter residue, drying the filter residue, keeping the temperature constant at high temperature for 8 h, and then dropping to room temperature. The grouting material has good fluidity when beingmixed with 0 DEG C water at the temperature of -10 DEG C, is directly maintained for 1 d and 7 d at the temperature of -10 DEG C, then is maintained for 7 d at the temperature of -10 DEG C and then is transferred to 20 DEG C water and maintained for 28 d; the physical properties of the grouting material at all ages of maintenance at the temperature of -10 DEG C are better than those of conventional grouting materials; the grouting material, a mould and apparatus are not needed to be heated or insulated, so the cost is effectively reduced and the efficiency is improved.

Owner:WUHAN YUANJIN BUILDING MATERIALS TECH CO LTD

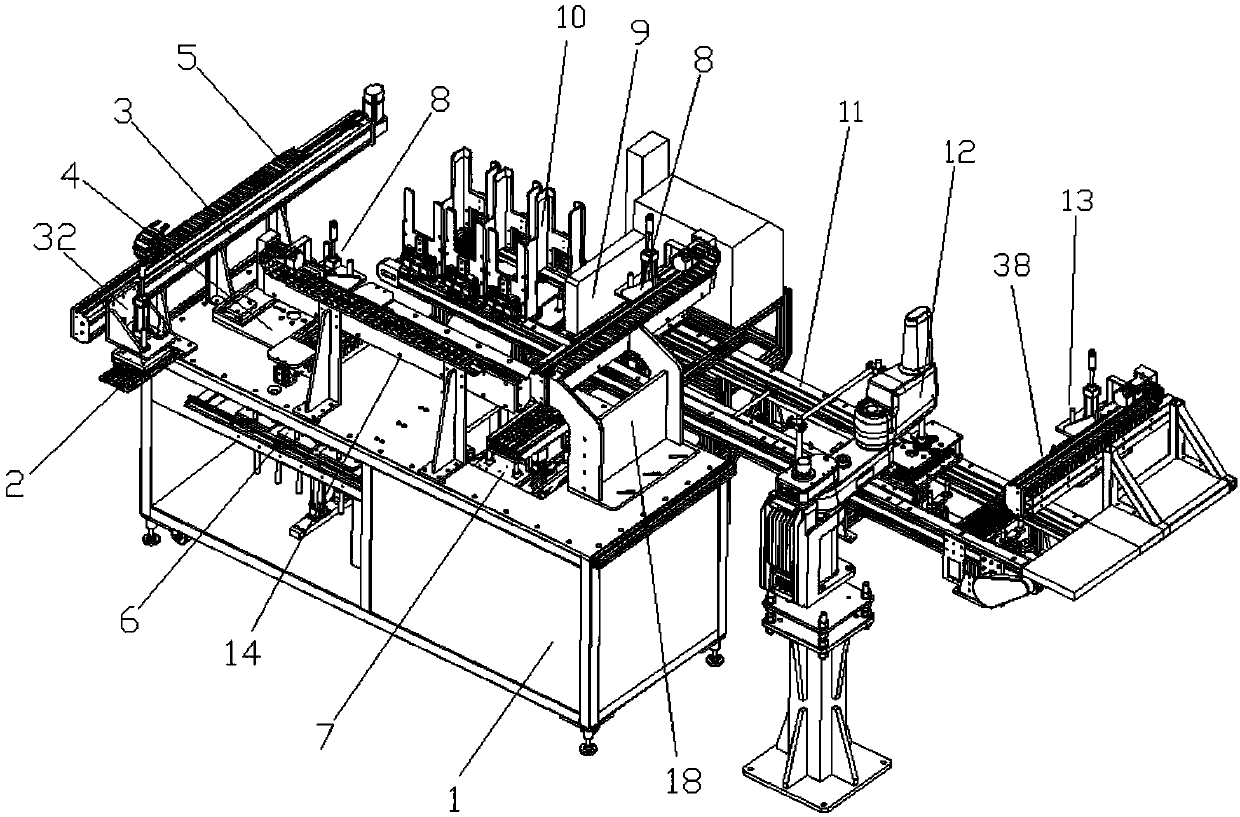

Full-automatic keyboard disassembling and cleaning machine

ActiveCN107737774ARealize fully automatic disassemblyImprove processing efficiencyCleaning using gasesSortingEngineeringManipulator

The invention discloses a full-automatic keyboard disassembling and cleaning machine. The machine comprises a control box, wherein a feeding device, a rotating disc device and a keycap detaching device and a keycap falling device are arranged on the table surface of the control box in sequence from one end to the other end; the feeding device comprises a feeding manipulator arranged on a first electric guide rail; a second electric guide rail is arranged between the keycap detaching device and the keycap falling device; a movable conveying manipulator is arranged on the second electric guide rail; an optical detector is arranged at the rear end of the control box; a third electric guide rail is arranged between the optical detector and the keycap falling device; the conveying manipulator is further arranged on the third electric guide rail; a conveyor belt is arranged below the optical detector; a stacking device is arranged at one end of the conveyor belt, and a dust collecting deviceand a discharging device are arranged at the other end; the discharging device comprises a fourth electric guide rail arranged above the conveyor belt; and a discharging manipulator is arranged on the fourth electric guide rail. The full-automatic keyboard disassembling and cleaning machine can realize full-automatic disassembling, cleaning and sorting of keyboards, thereby being high in automation degree and processing efficiency.

Owner:平邑县经发企业服务有限公司

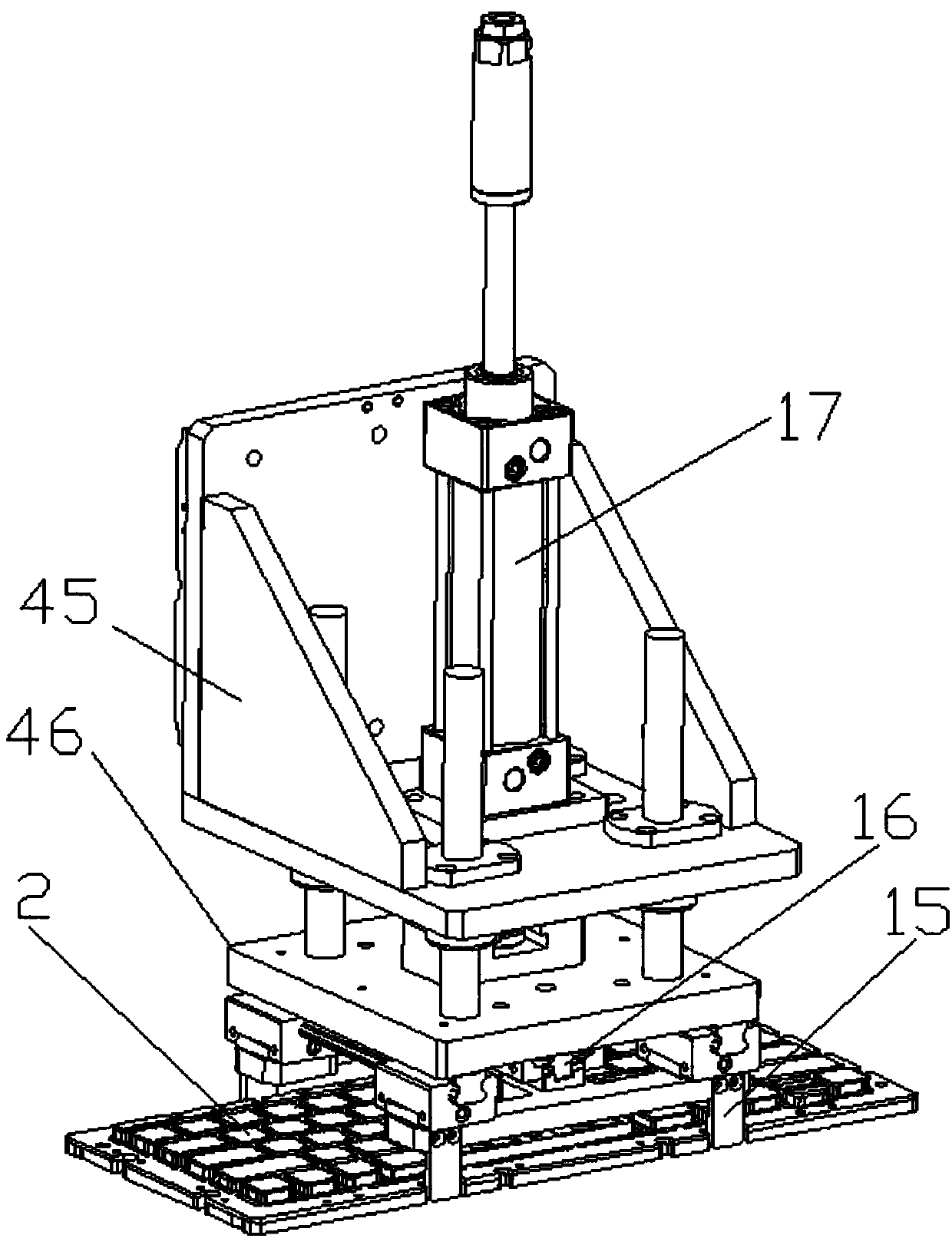

Multi-span box girder integral ultrahigh alternate jacking construction system and method

InactiveCN105507168AGuaranteed construction periodReduce building energy consumptionBridge erection/assemblyBridge strengtheningEcological environmentBuilding energy

The invention discloses a multi-span box girder integral ultrahigh alternate jacking construction system and method. By controlling two groups of jacks capable of positively applying a jacking force, after jacking of one group of jacks is finished, the jacking force of the group of jacks is uniformly linearly transferred to the second group of jacks for performing alternate continuous jacking operation. The overpass bridge ultrahigh alternate jacking construction solution can ensure that during jacking, a bridge structure is safe, the jacking precision and a line type after the whole bridge fall down meet design demands, a construction period is ensured, building energy consumption is reduced and an urban ecological environment is met.

Owner:CCCC THIRD HARBOR ENG +2

Pile foundation underpinning method for building foundation adjacent to deep foundation pit

ActiveCN104179204AMeet bending resistanceMeet punching resistanceFoundation repairArchitectural engineeringShear resistance

The invention relates to the technical field of civil engineering foundation reinforcing of industrial and civil construction projects, in particular to a pile foundation underpinning method for a building foundation adjacent to a deep foundation pit. The method includes the steps of firstly, investigating and designing, to be more specific, investigating the existing building, selecting foundation underpinning pile types according to building foundation size, buried depth, distance between the building foundation and the deep foundation pit and the depth of the deep foundation pit, calculating to determine the required length and number of foundation underpinning piles according to bearing capacity, allowing the foundation underpinning piles to exceed the depth of the bottom of the deep foundation pit, and completing ring beam design; secondly, pressing the piles at the edges of the building foundation; thirdly, performing pile foundation underpinning on the building foundation. The method has the advantages that the building foundation satisfies the requirements of bending resistance, punching resistance and shearing resistance by the aid of pile foundation underpinning, natural foundation bearing of the building foundation is changed into pile foundation bearing, additional load of the building foundation to the deep foundation pit is lowered greatly, sedimentation and horizontal displacement of the building foundation adjacent to the deep foundation pit are solved, and factory building safety is guaranteed.

Owner:山西钢铁建设(集团)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com