Fastening method of post-treating pipe pile break with pre-stress pipe pile construction

A technology of prestressed pipe piles and pipe piles, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as troubles, original pile deviation, and weakened soil compaction effect around piles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

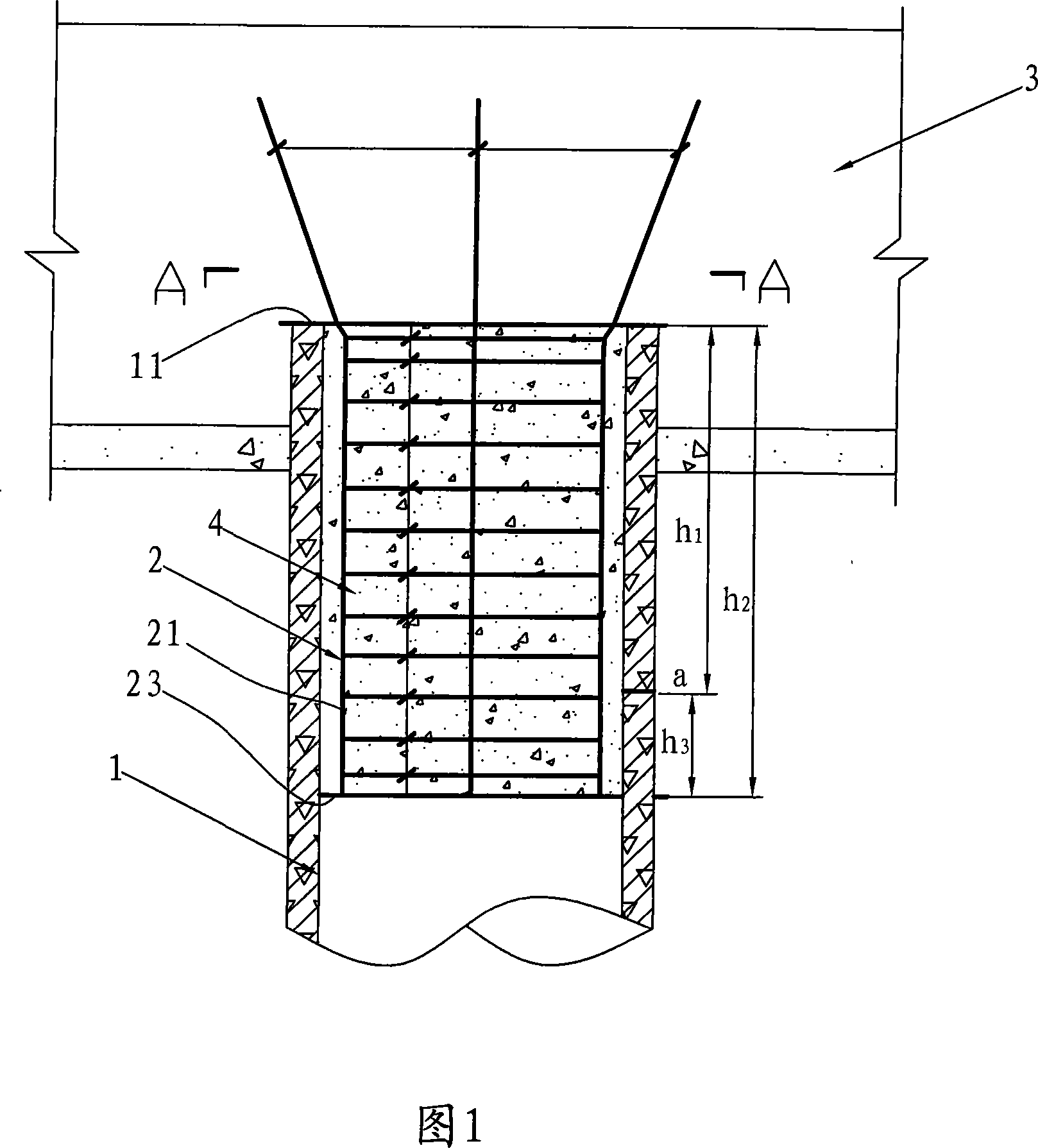

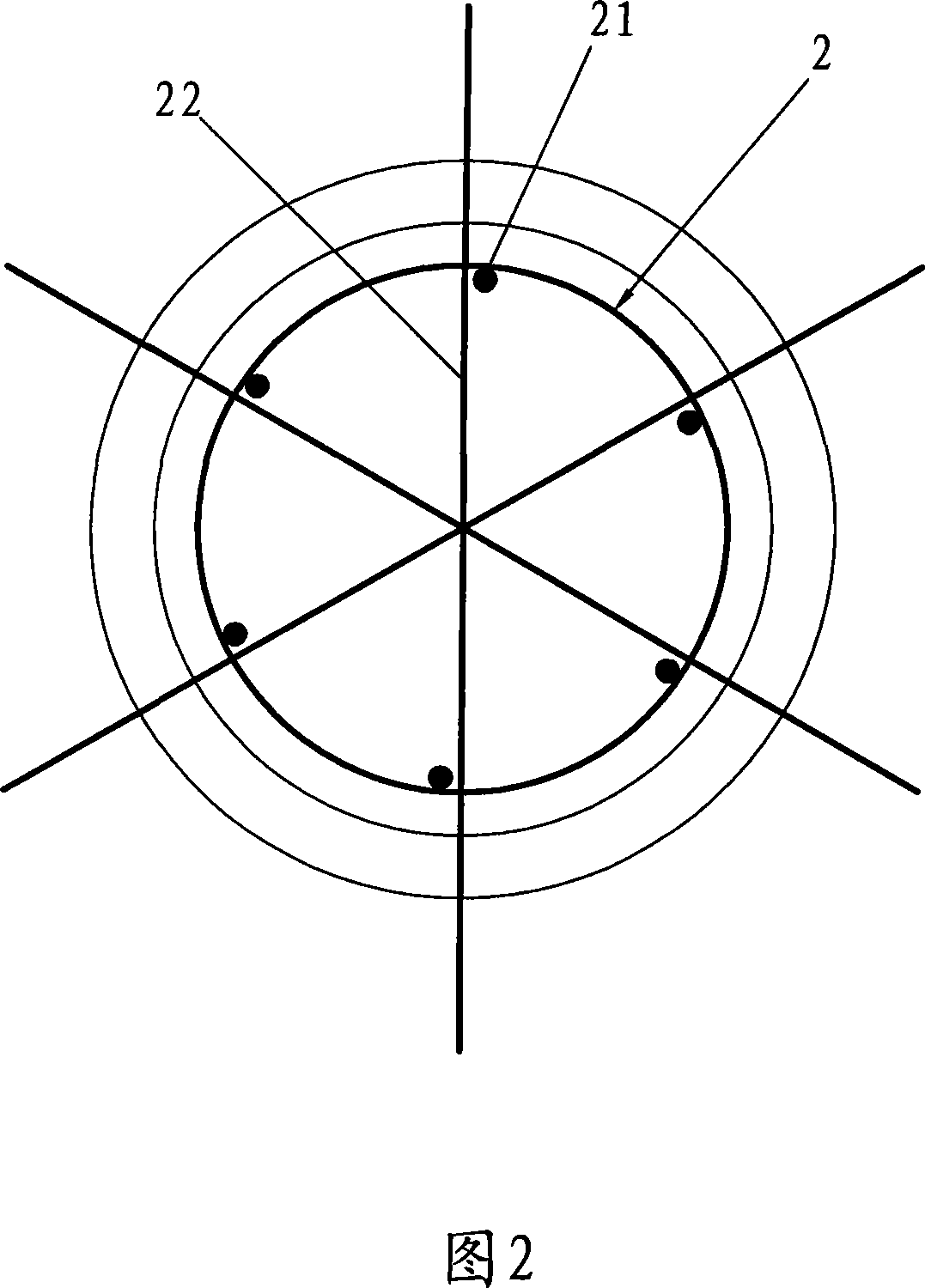

[0023] The present invention will be further described below with reference to the drawings and specific embodiments.

[0024] As shown in Figure 1 and Figure 2, a reinforcement method for treating the fracture of the prestressed pipe pile after construction, the steps are as follows:

[0025] (1) First detect the fracture position a of the prestressed pipe pile 1, for example, the depth at point a is h 1 The detection can be carried out by high or low strain measurement method.

[0026] (2) The floating slurry on the inner wall of the pipe pile 1 is cleaned, and the inner wall is coated with cement paste or concrete interface agent or micro-expansion concrete to improve the integrity of the subsequent pouring concrete and the pipe pile body concrete.

[0027] (3) Prepare a plurality of steel bars 2, the overall height of the steel bars 2 is calculated according to the position a of the pipe pile fracture, such as the depth h of the above-mentioned fracture position a 1 Calculated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com