Pile foundation underpinning method for building foundation adjacent to deep foundation pit

A technology for buildings and deep foundation pits, which is applied in construction, foundation structure engineering, and foundation structure repair. It can solve the problems of shallow depth of underpinning piles, low construction efficiency, and low bearing capacity, and achieve high construction efficiency. The effect of small deformation of the factory building and high bearing capacity of single piles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

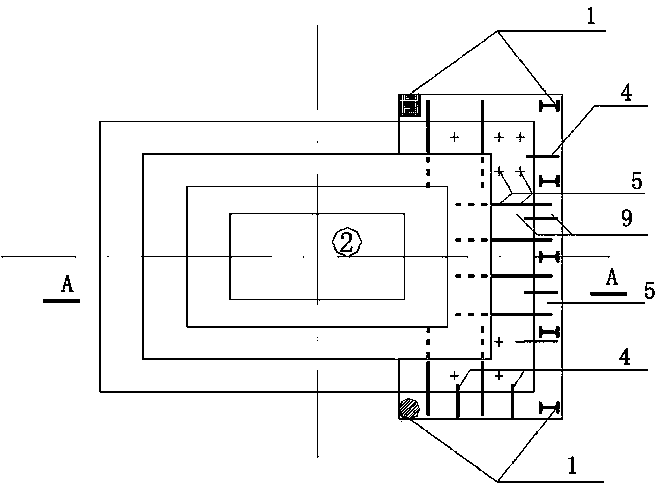

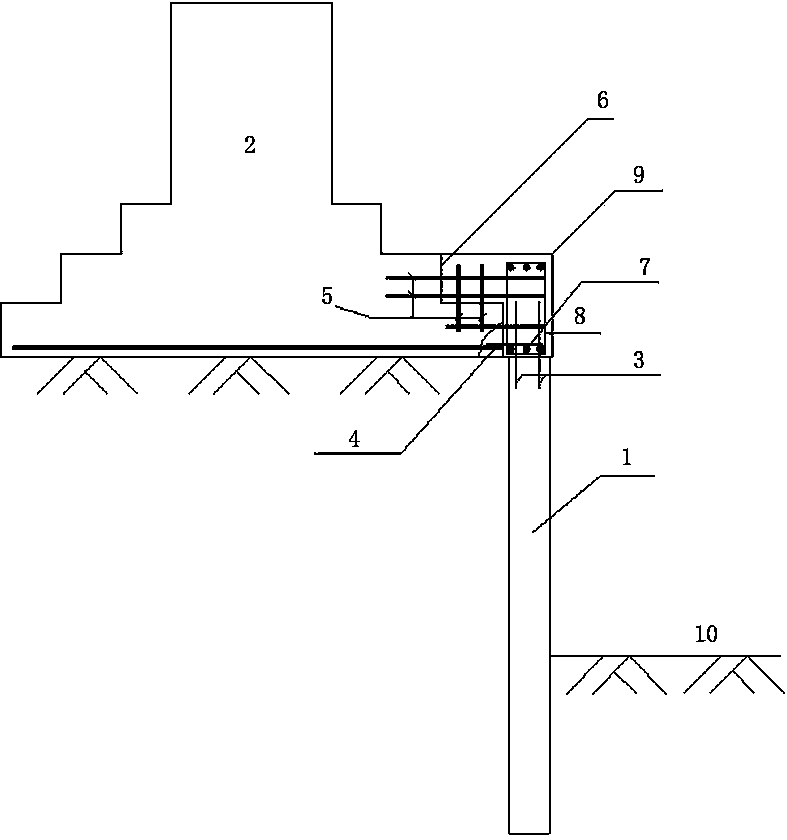

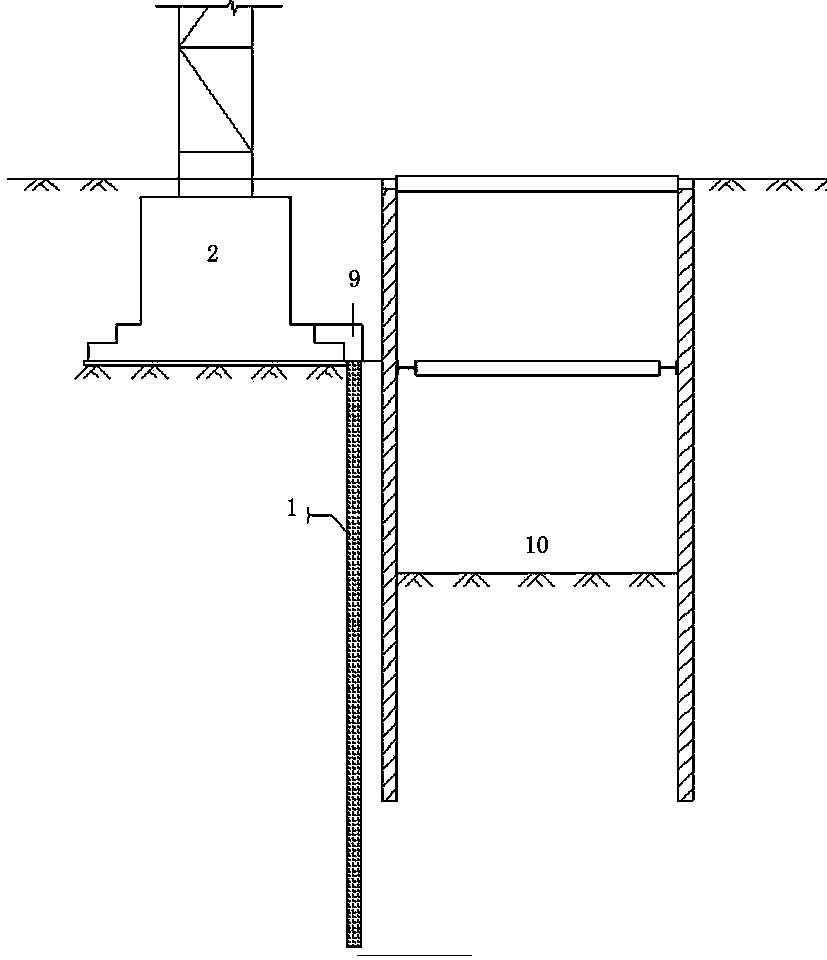

[0074] 1. The 3# cold line project of Shanxi Taigang Stainless Steel Co., Ltd. Cold Rolling Plant, which was constructed in 2004, is located in a 27m span, 12m column spacing, and 20m high single-story steel structure workshop. The 75-ton bridge crane is in normal operation and the workshop column foundation -5.0m, natural foundation. The depth of the 3# cold line degreasing pit foundation pit is -10.5m, the distance between the foundation of the plant column and the foundation pit is 0.5m, 3m, and the height difference is 3.1m, 5.5m; due to the close distance between the deep foundation pit and the building foundation, direct excavation will cause The bottom soil subsides.

[0075] The owner requires that corresponding measures be taken in the construction of deep foundation pits to ensure the safety of the factory building structure. After many researches and expert demonstrations, the construction plan adopts the present invention. Accurately position and set out the pile ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com