Patents

Literature

596results about How to "Fully cured" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

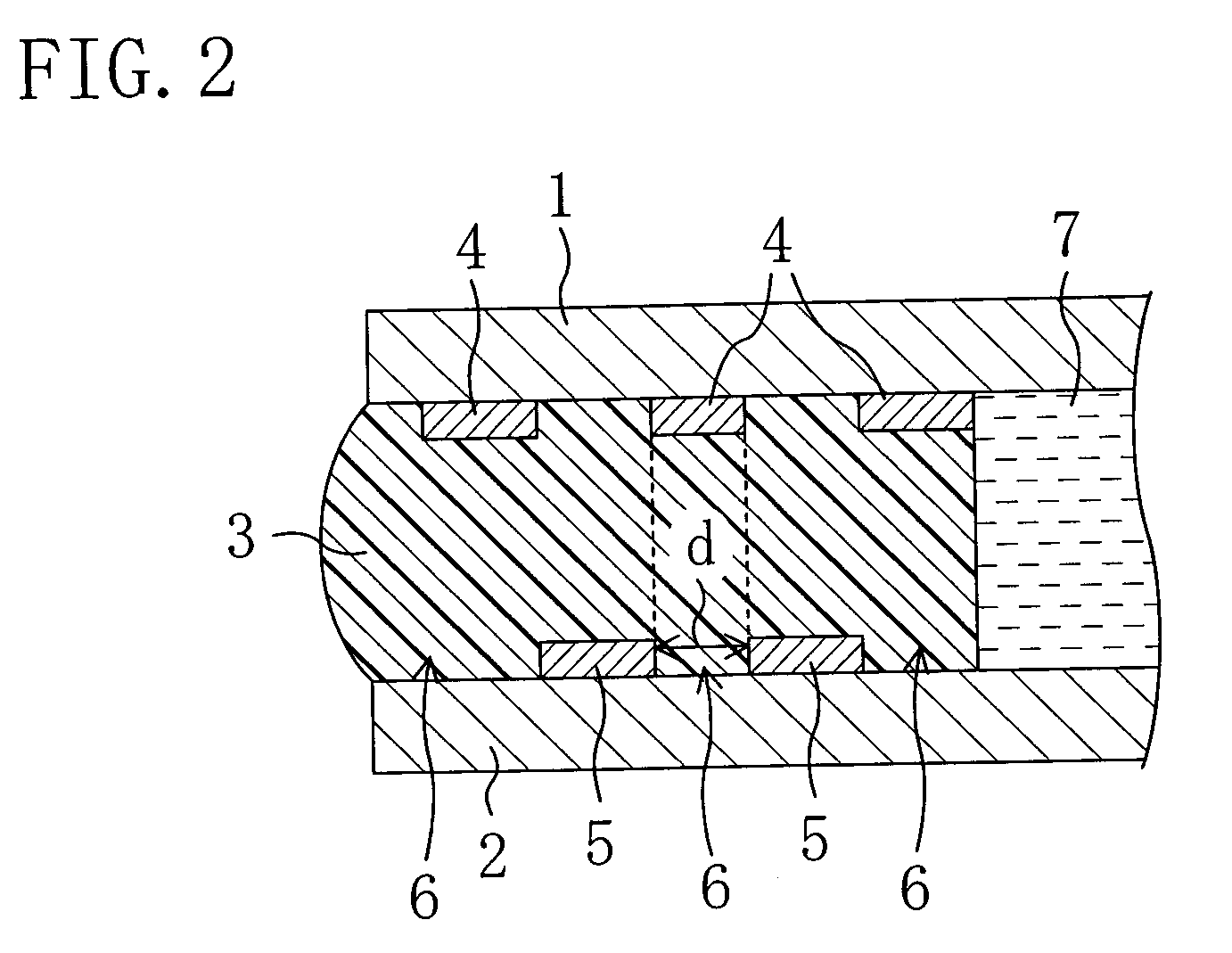

Conductive adhesive agent and process for manufacturing article using the conductive adhesive agent

ActiveUS20060038304A1Fully curedUniform thicknessSemiconductor/solid-state device detailsConductive materialPolymer scienceFluid viscosity

The present invention provides a conductive adhesive agent capable of being diluted with a solvent to give good coating workability and allowing formation of a conductive joint excellent in both thermal conductivity and electrical conductivity by inhibiting a gas generated when a binder resin is heat-cured after attachment of a part. The conductive adhesive agent according to the present invention is a conductive adhesive agent wherein, based on 100 parts by weight of silver powder having an average particle diameter of micrometers, which is used for a conductive medium, e.g. as a main component, 1 to 10 parts by weight of silver fine particles having an average particle diameter of nanometers is used in combination therewith and 5 to 15 parts by weight of thermosetting resin as a binder resin component and 10 parts or less by weight of solvent for adjustment of a fluid viscosity are blended therein as essential components, and by selection of such a blending ratio, generation of a gas component during heating and curing of the thermosetting resin to prevent formation of voids, and at the same time, fabrication of a conductive joint excellent in thermal conductivity and electrical conductivity is achieved.

Owner:HARIMA CHEM INC +1

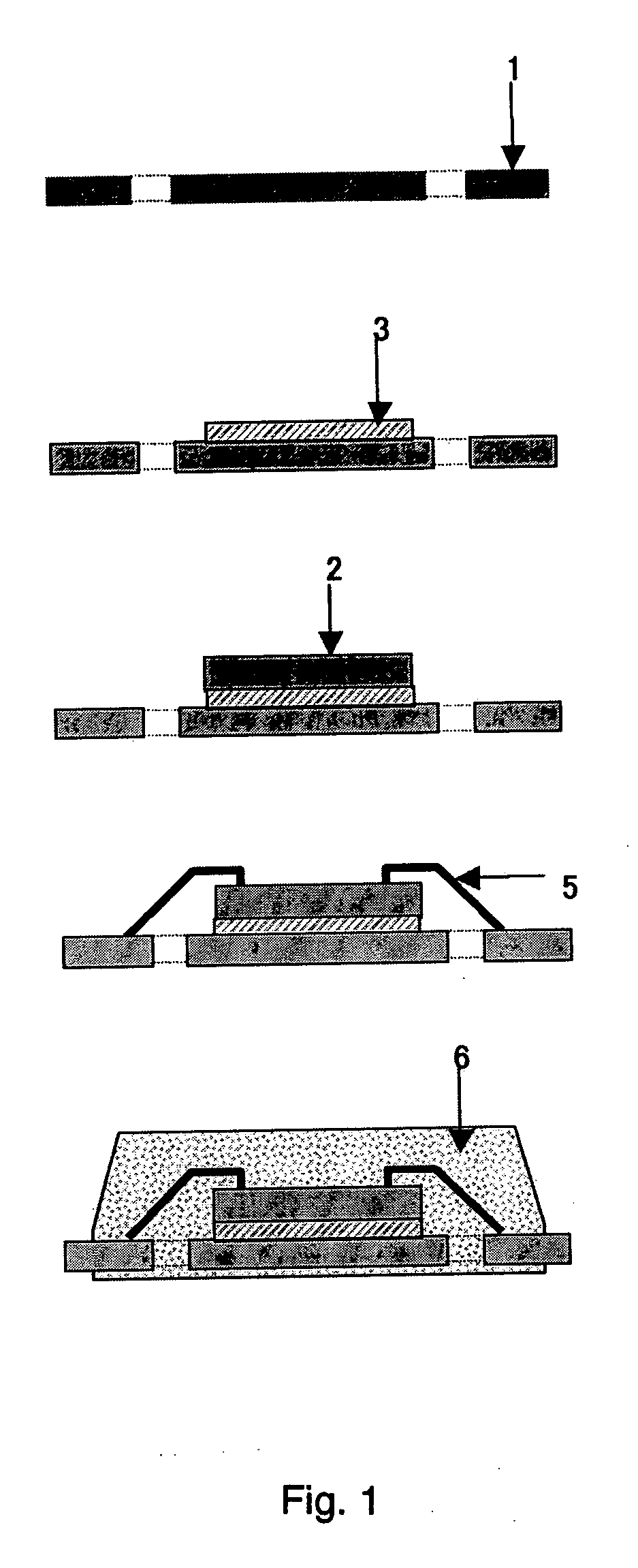

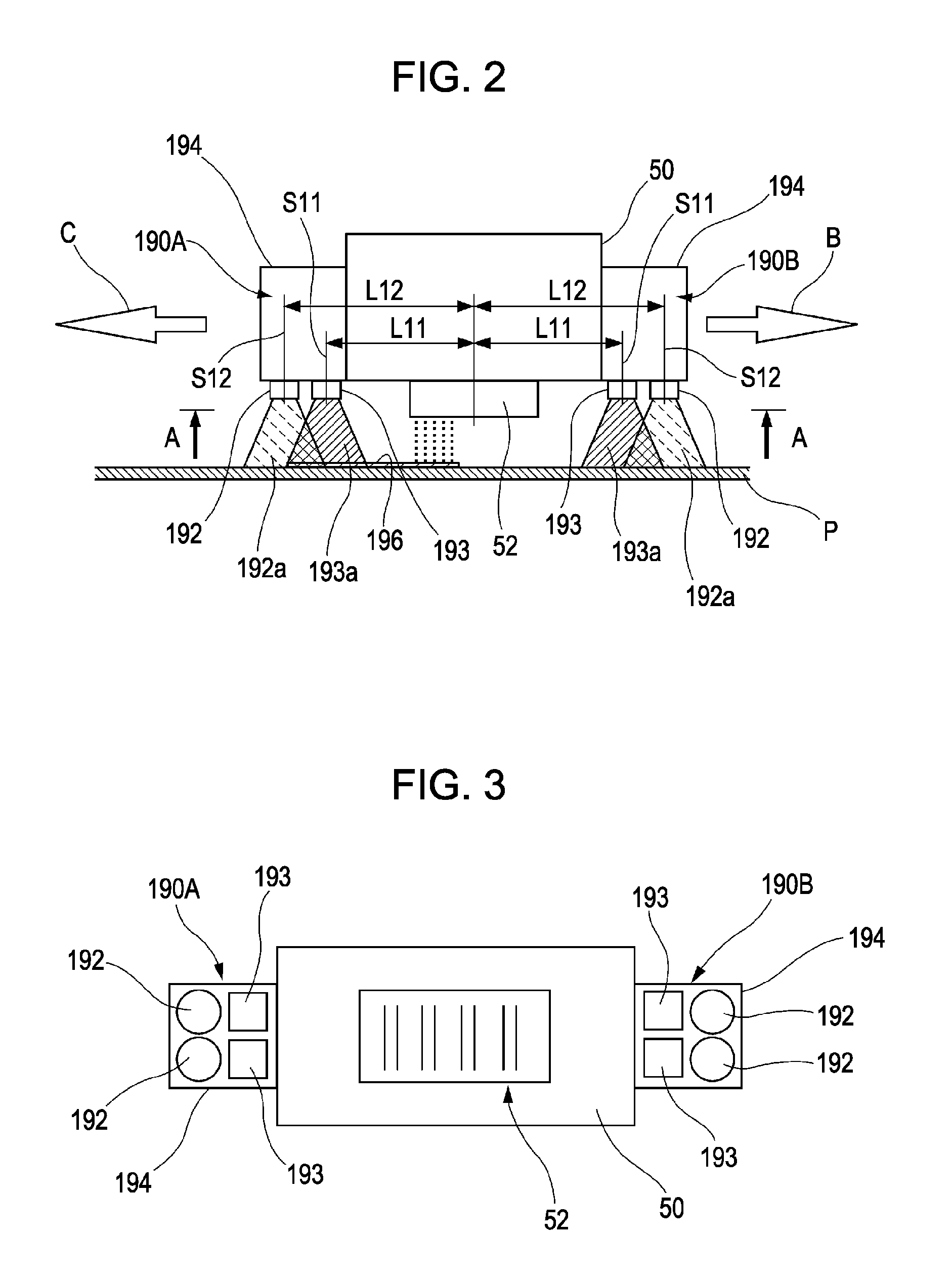

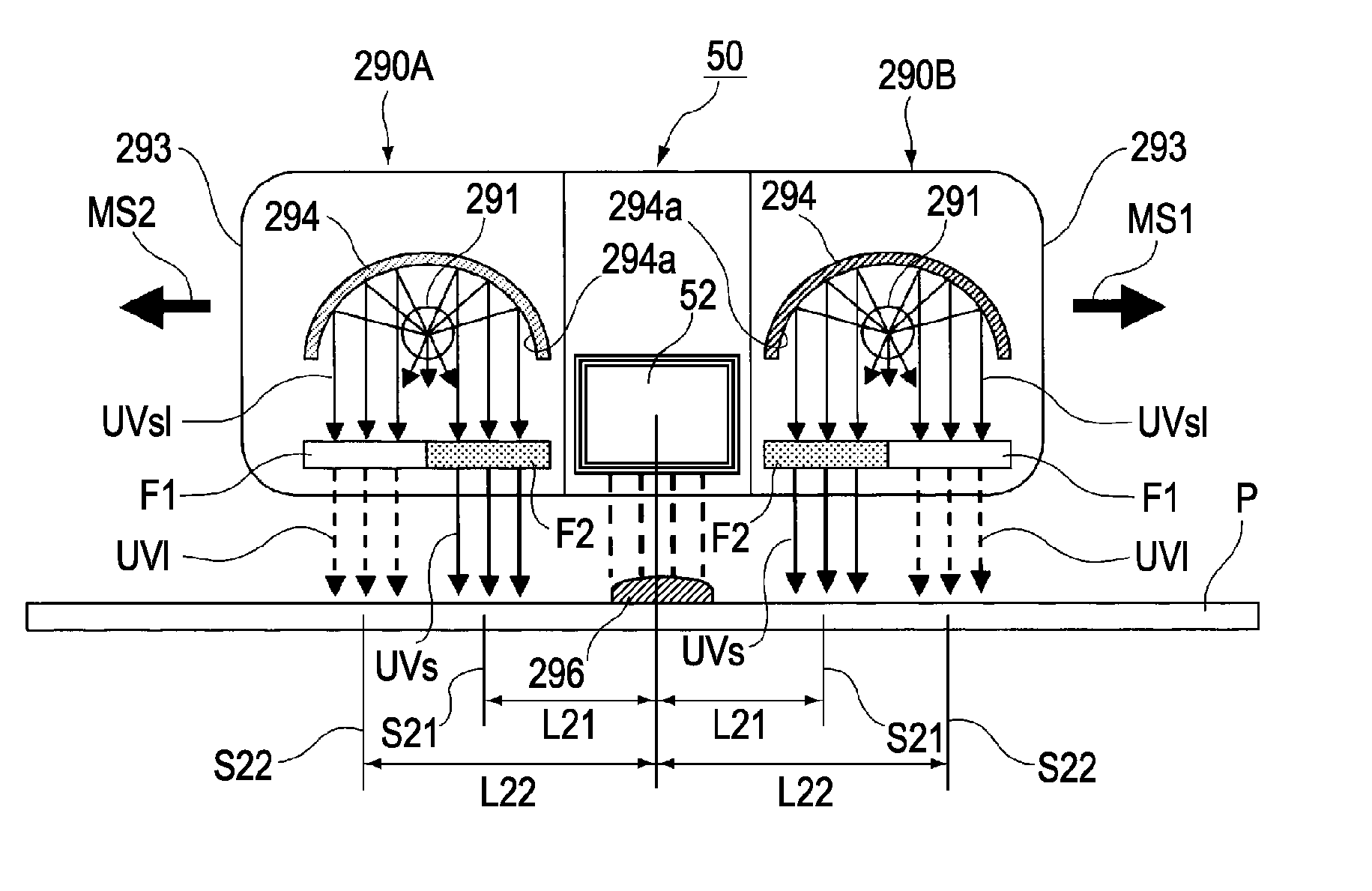

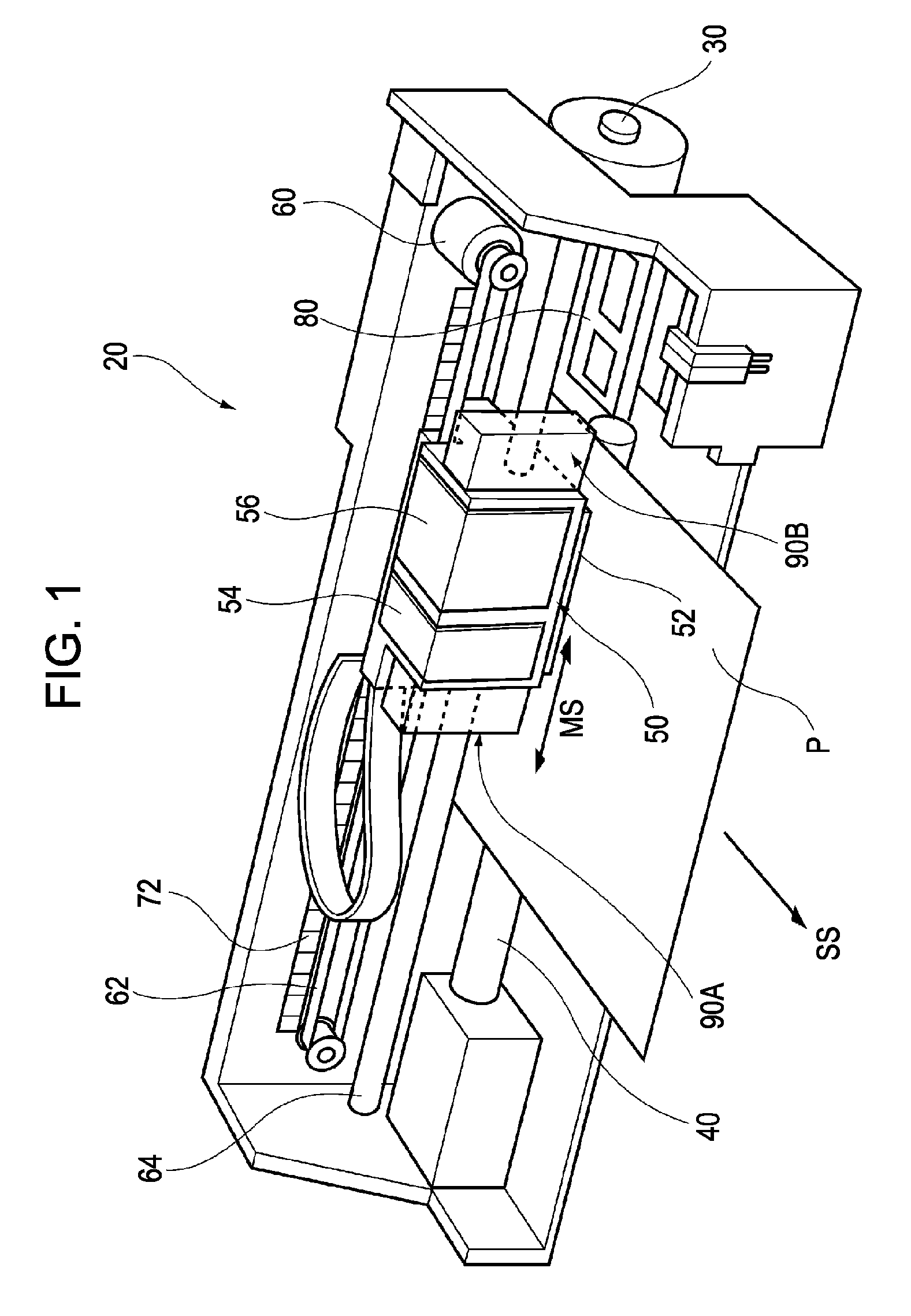

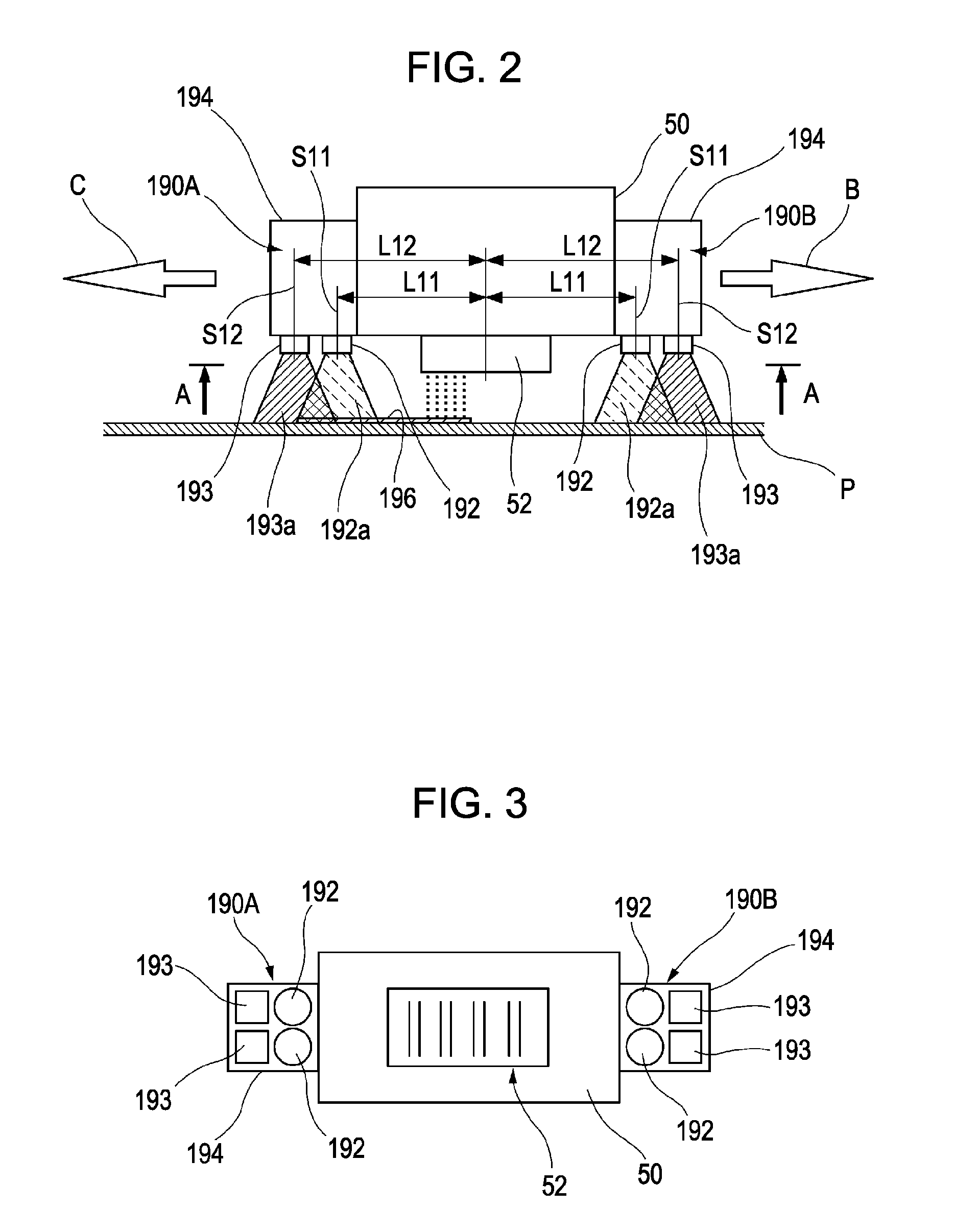

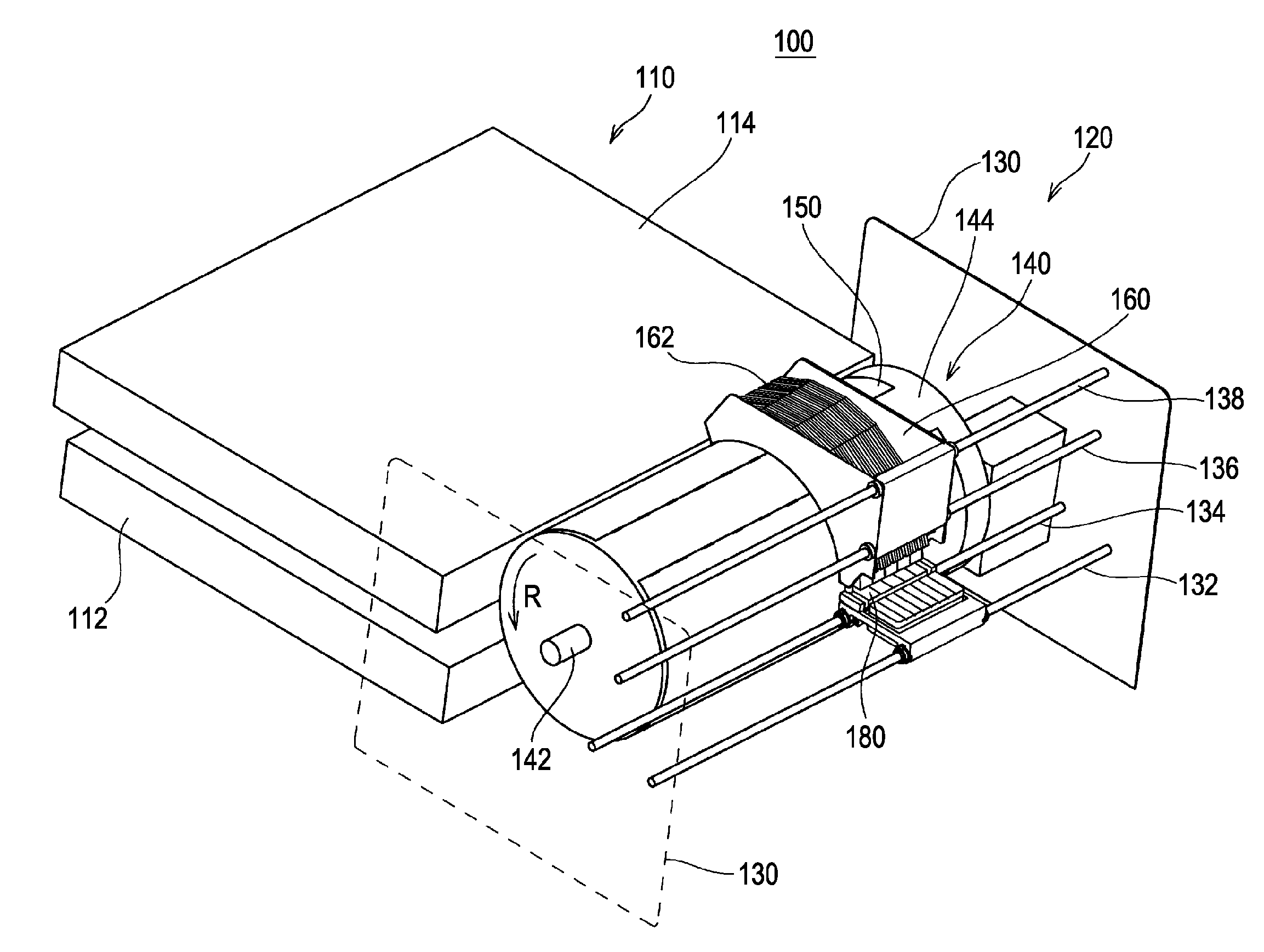

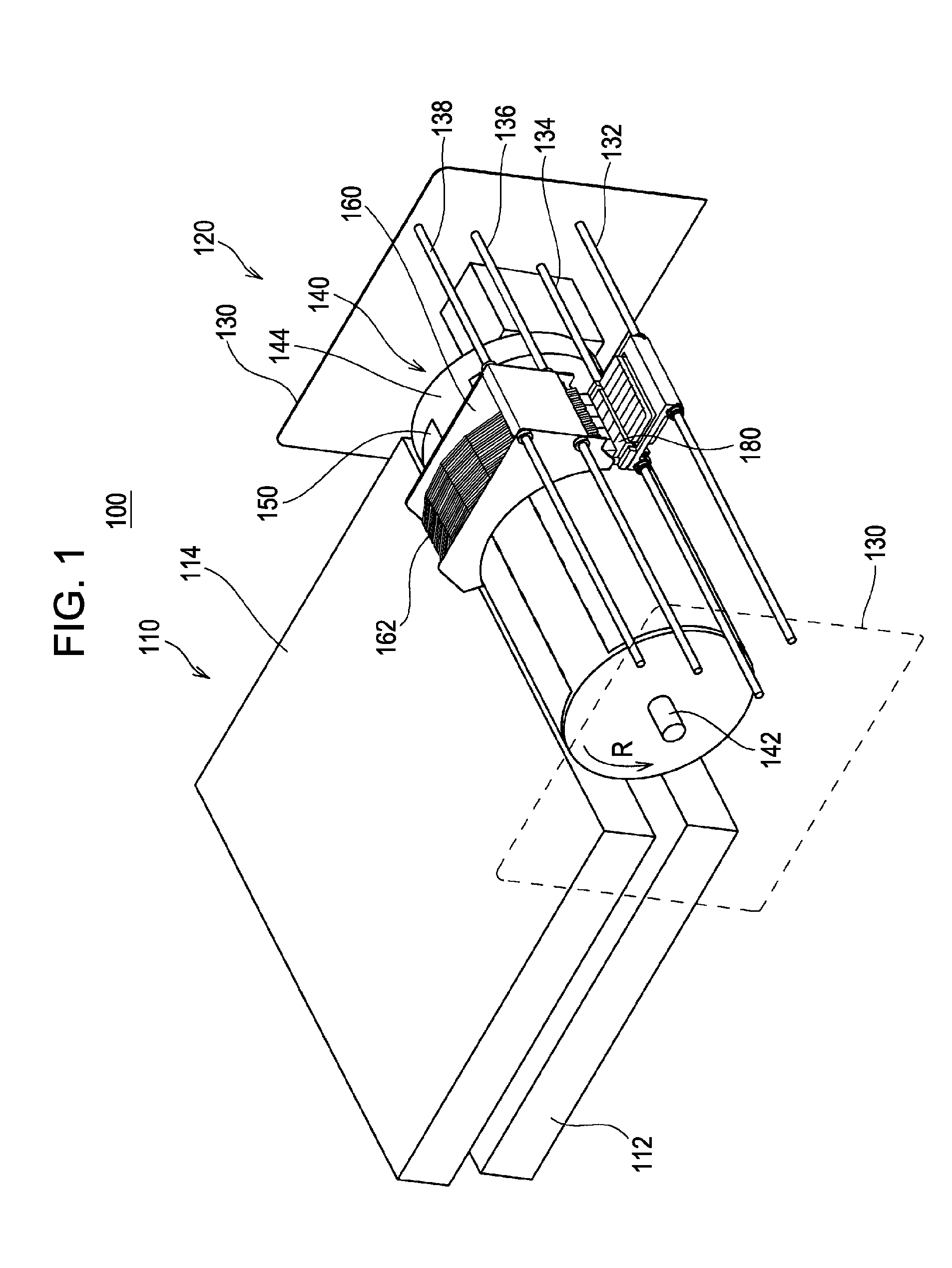

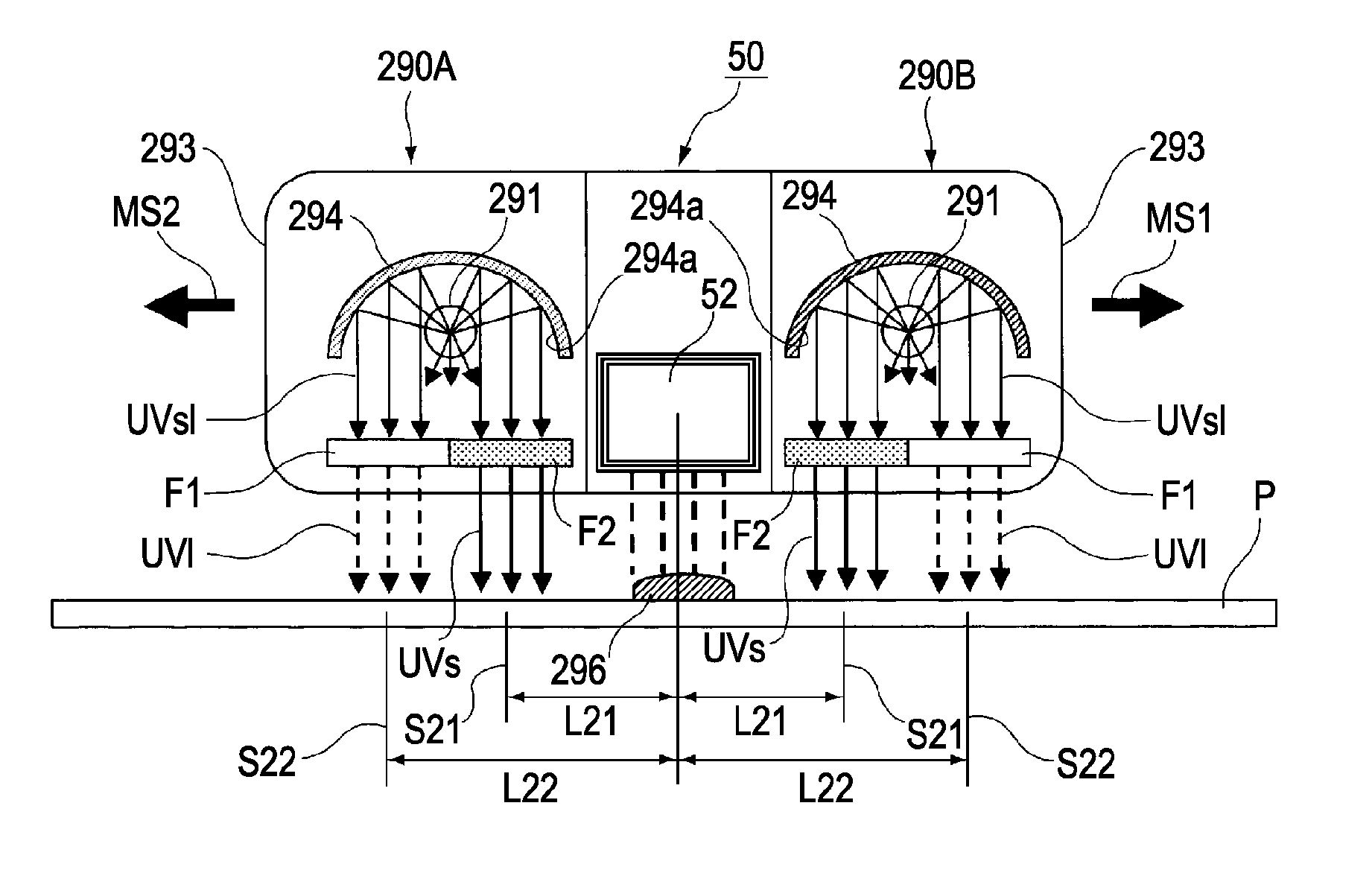

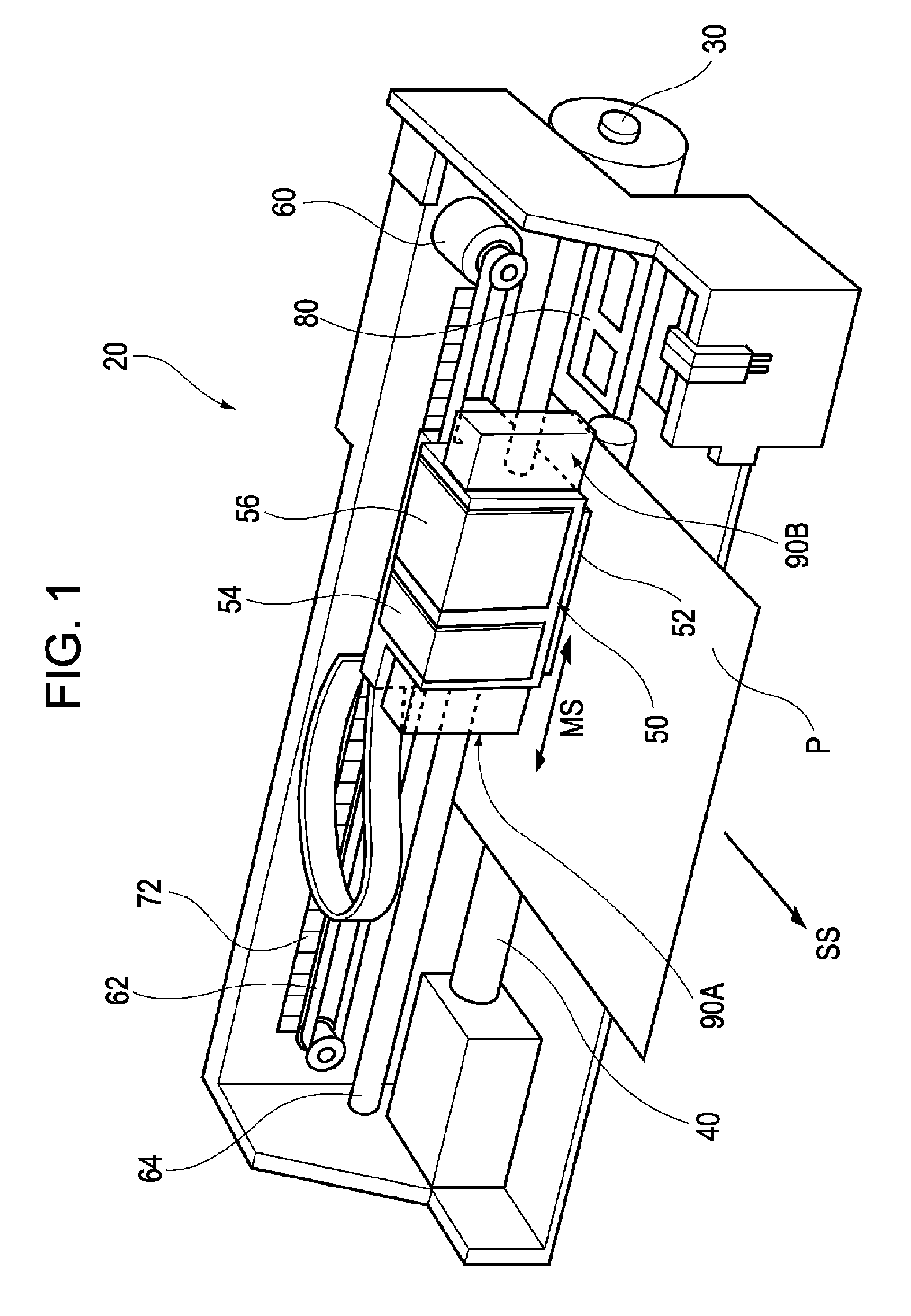

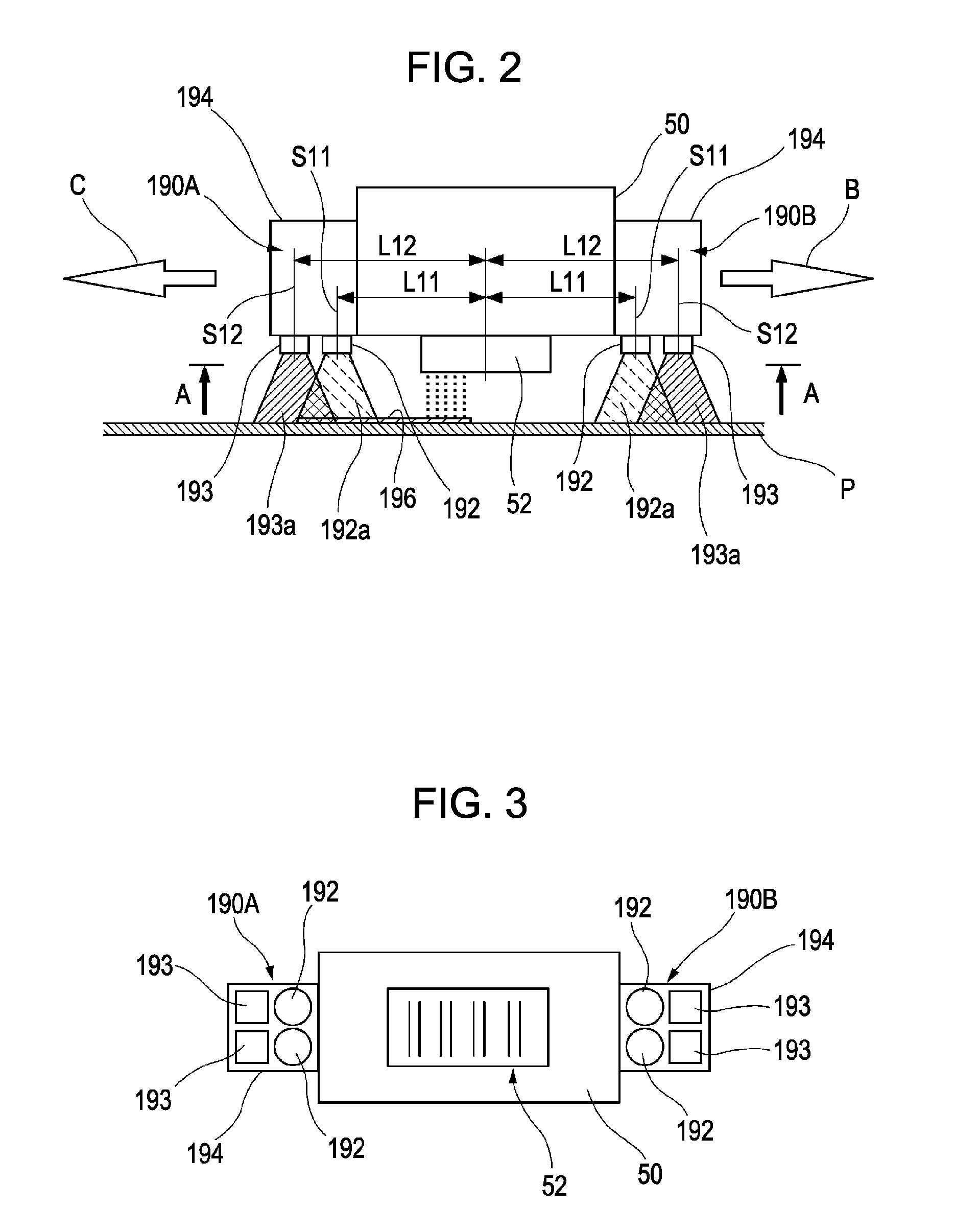

Ultraviolet ray irradiation device, recording apparatus using the ultraviolet ray irradiation device, and recording method

ActiveUS20080174648A1Fully curedRadiation pyrometryX-ray tube with very high currentUltravioletLength wave

Ultraviolet-ray irradiation devices are attached to a carriage having a print head that ejects ultraviolet curable ink, and include a plurality of ultraviolet light sources and that irradiate ultraviolet rays onto an ink coating ejected on a print sheet by a print head. An ultraviolet ray that is irradiated onto the print sheet in the vicinity of the print head has a wavelength longer than an ultraviolet ray that is irradiated onto the print sheet apart from the vicinity of the print head along the moving direction of the carriage. The ultraviolet ray irradiation devices are capable of sufficiently curing ultraviolet curable ink without the problem of only the surface of the ink being cured in a print process (for example a monochrome print process) when the ink coating adhered to the recording medium is relatively thick.

Owner:SEIKO EPSON CORP

Energy-saving type concrete crack repairing agent

The invention discloses an energy-saving type concrete crack repairing agent which comprises the following components in parts by weight: 12-18 parts of sand, 5-10 parts of a quartz powder, 20-35 parts of ordinary portland cement, 10-18 parts of sulphoaluminate cement, 6-12 parts of sodium silicate, 5-9 parts of a polyvinyl acetate emulsion powder, 3-7 parts of silica fume, 7-10 parts of a slag powder, 6-9 parts of fly ash, 8-10 parts of an expansive agent, 0.4-0.6 part of a polycarboxylic acid type high-efficiency water-reducing agent, and 0.2-0.4 part of polypropylene fiber. The concrete repairing agent has high bonding strength, and significantly improves the binding force between a new concrete interface and an old concrete interface; the concrete repairing agent is short in congealing curing time, fast in development of strength after congealing, and suitable for rapid repairing; the concrete repairing agent has the advantages of environmental protection, no toxicity, no smell, harmlessness to human bodies, single-component construction, and no pollution to the environment; and the concrete repairing agent can be used for repairing of concrete cracks, holes, honeycombs and pock marks, and drawing repairing of seams of face bricks and mosaic.

Owner:HUNAN CONSTR ENG GRP COR +1

Epoxy organosilicone ultraviolet curing coating modified by (methyl) acrylic acid and preparation method thereof

ActiveCN101555386AEasy to synthesizeIncrease crosslink densityEpoxy resin coatingsPhotoinitiatorWeather resistance

The invention discloses epoxy organosilicone ultraviolet curing coating modified by (methyl) acrylic acid and a preparation method thereof. The coating comprises epoxy organosilicone modified by (methyl) acrylic acid, an epoxy (methyl) acrylate resin, active diluent, a photoinitiator, an epoxy hardener and an auxiliary agent. The coating not only has the advantages of the epoxy organosilicone modified by (methyl) acrylic acid, has high toughness, weather resistance and water resistance, but also needs no organic solvents in the process of preparing the coating and enjoys simple required curingconditions.

Owner:CHANGXING PHOTOELECTRIC MATERIAL

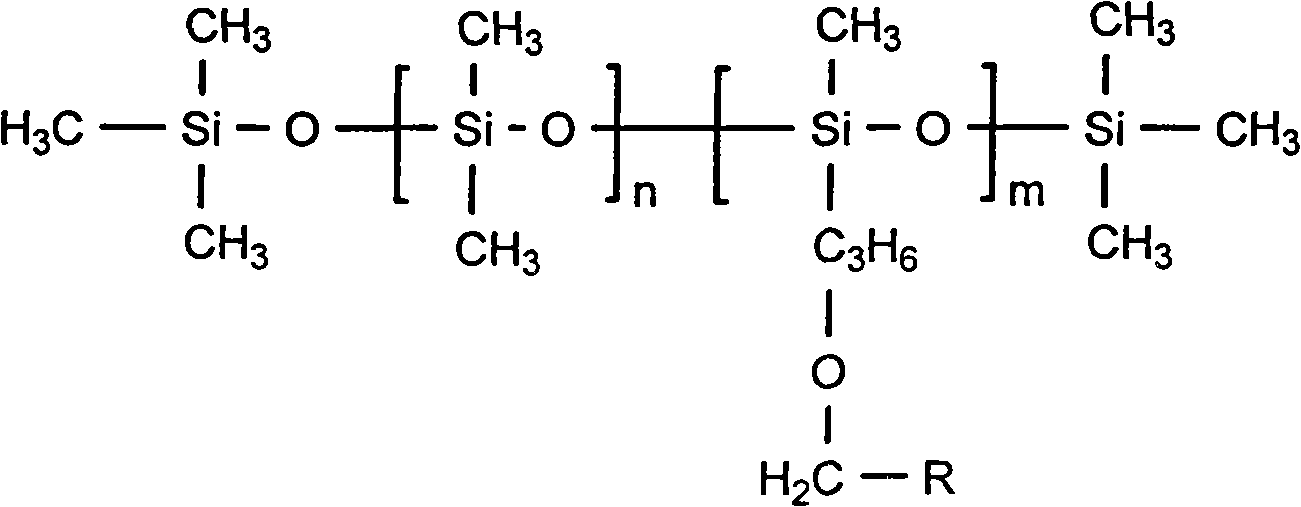

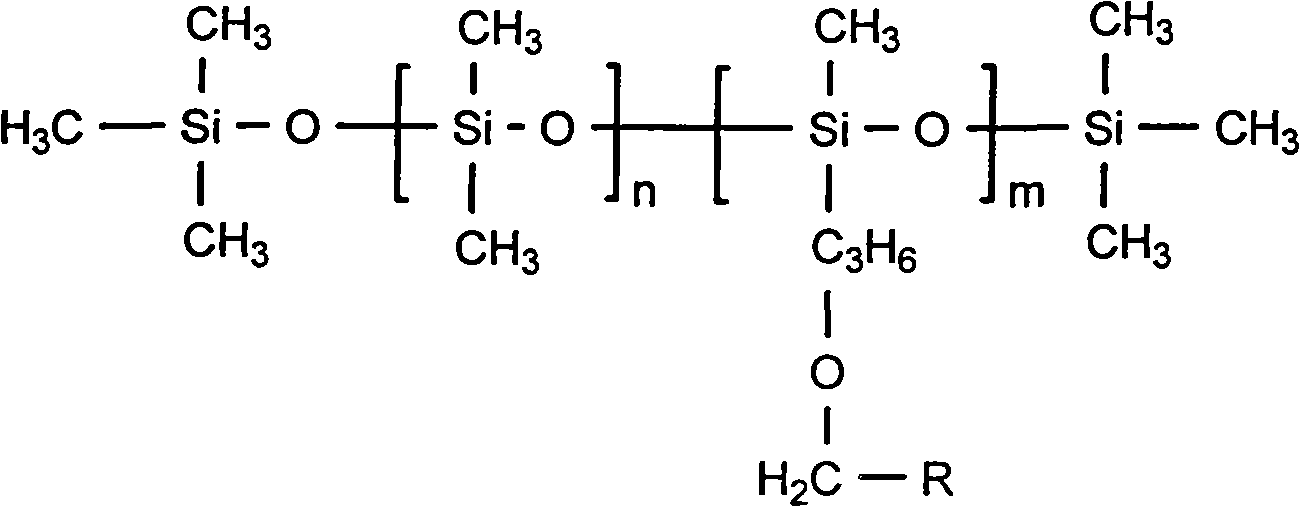

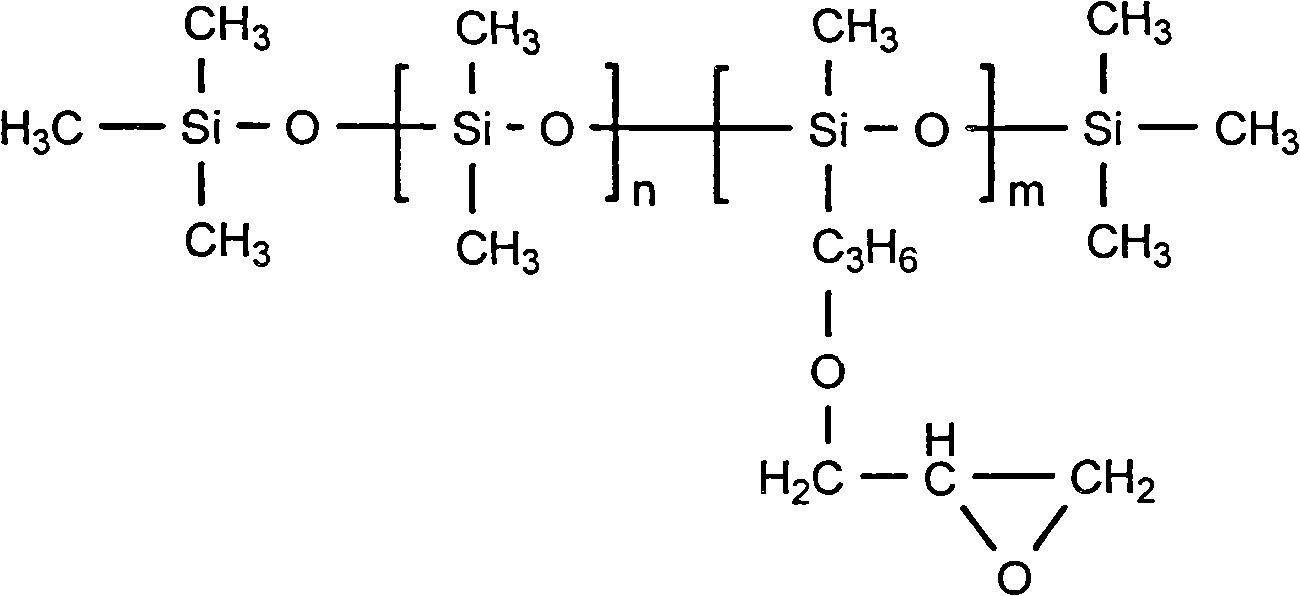

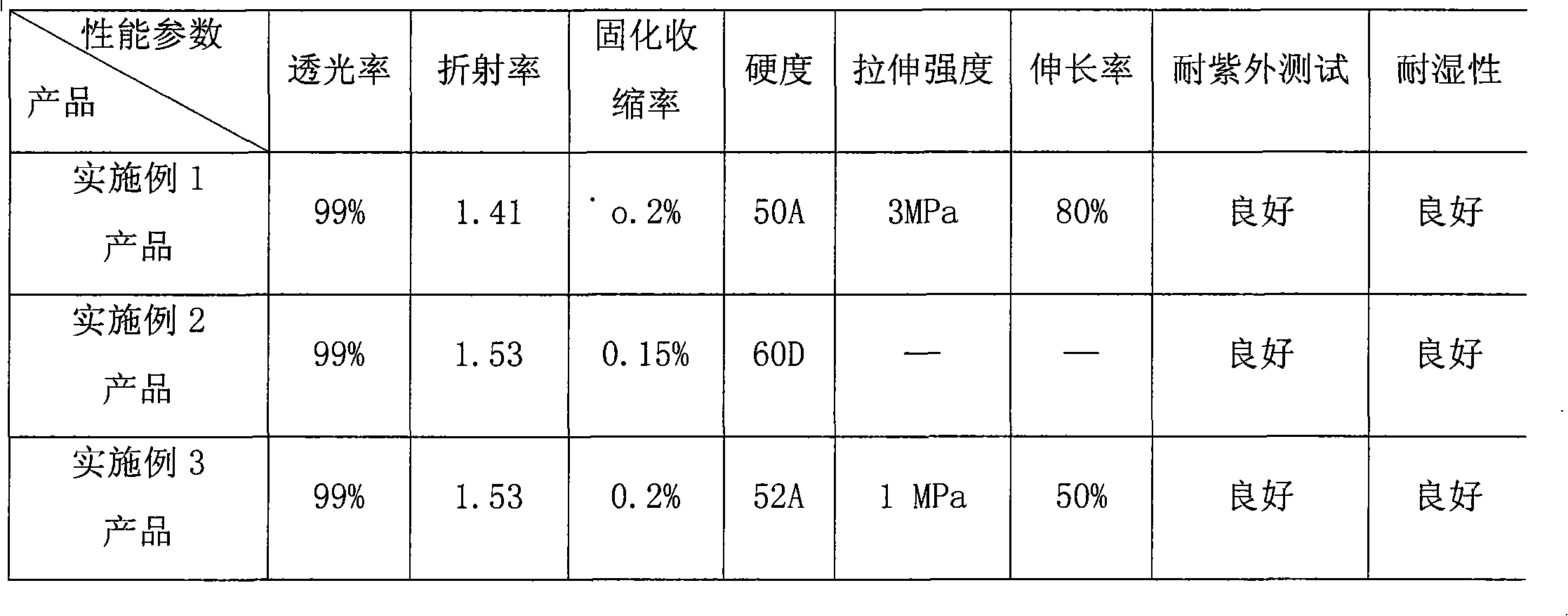

Organ silicon material for encapsulating power-type LED and synthetic method thereof

ActiveCN101608068AFully curedEven distribution of phenyl groupsSemiconductor devicesCross-linkMass ratio

The invention discloses an organ silicon material for encapsulating a power-type LED and a synthetic method thereof. The organ silicon material is mixed with a component A and a component B according to a mass ratio of 1:1 to 1:20, wherein the component A is a mixture of vinyl silicon polymer and a solidify catalyst, and the vinyl silicon polymer comprises vinyl silicon resin and polysiloxane with vinyl; and the component B comprises vinyl hydro silicon resin, poly hydro siloxane and an inhibitor. The organ silicon material has a higher refractive index, high transparency, excellent ultraviolet ageing resistance, good heat ageing resistance, and the like and is an ideal encapsulating material of the power type LED. The invention also discloses a synthetic method of an organ silicon material for encapsulating the power-type LED, the solidification of resin is more complete, and the light transmission and the hardness of the cross-link resin are effectively increased.

Owner:矽时代材料科技股份有限公司

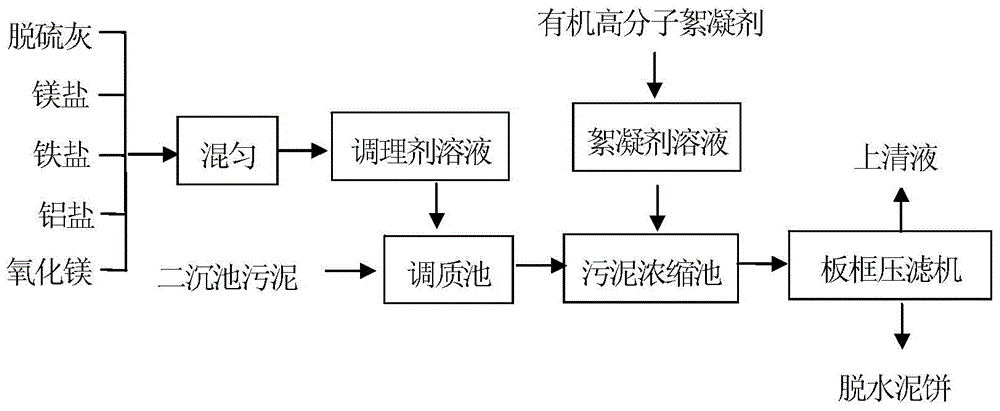

Sludge dewatering conditioning agent and dewatering method thereof

ActiveCN105314815AThe conditioning process is simpleReduce dosageSludge treatment by de-watering/drying/thickeningChemistryIron salts

The present invention discloses a sludge dewatering conditioning agent, which comprises, by weight, 30-70% of desulfurization ash, 5-15% of a magnesium salt, 5-30% of an iron salt, 2-20% of an aluminum salt, and 0.1-15% of magnesium oxide. The invention further provides a dewatering method of the conditioning agent, wherein the dewatering method comprises conditioning agent solution preparing, sludge conditioning, flocculant solution preparing, sludge dewatering and other steps. According to the present invention, the characteristics of wide used raw material source, and low raw material price, low preparation cost and good dewatering effect are provided, the method can be performed through the existing sludge dewatering facility, the implementation process is simple, the stability and the reliability of the sludge dewatering process can be effectively improved, and the sludge dewatering conditioning agent and the dewatering method can be widely used for treatments of various wastewater, sewage and sludge.

Owner:BAOSHAN IRON & STEEL CO LTD +1

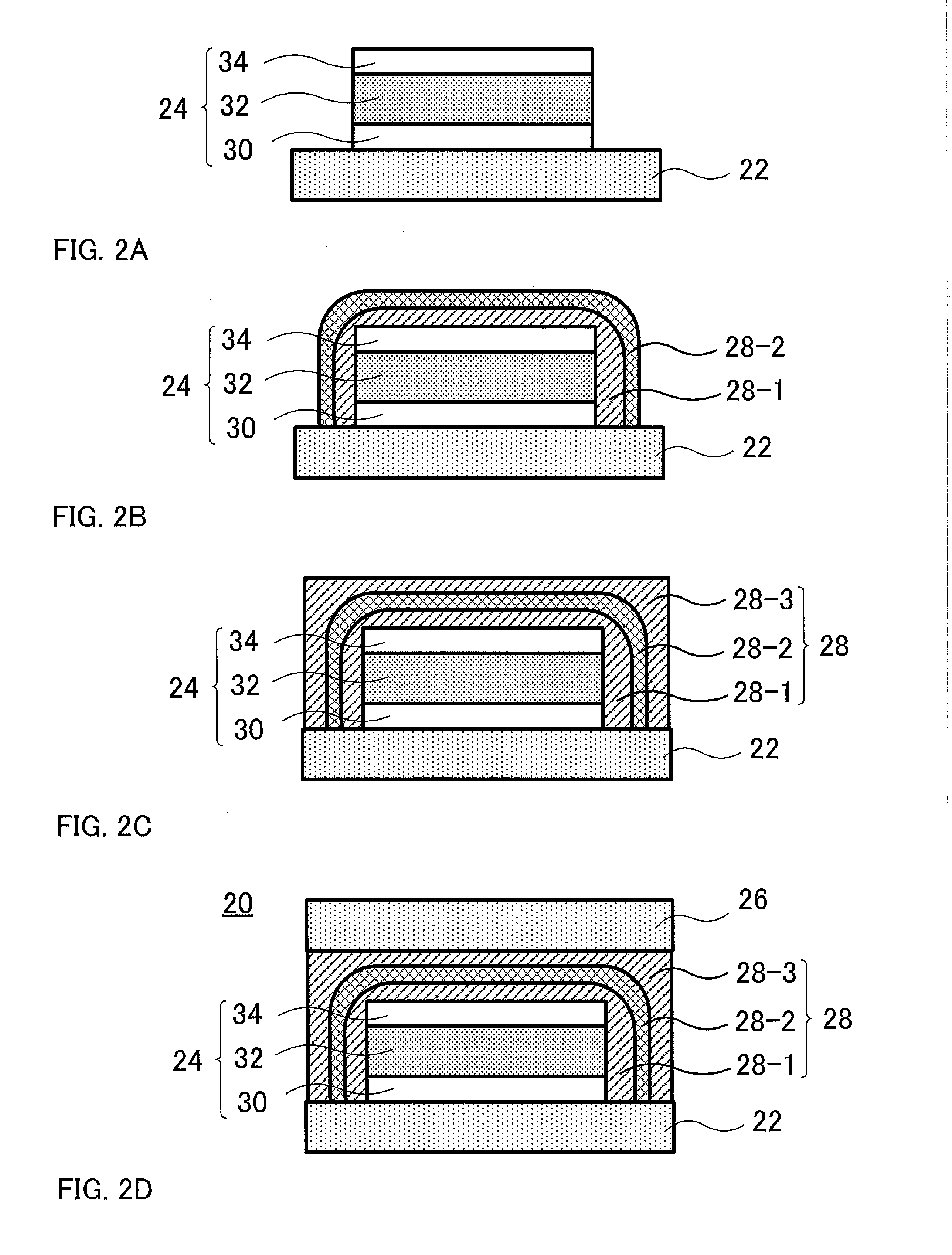

Surface sealing agent for organic el element, organic el device using same, and manufacturing method for same

InactiveUS20140367670A1Fully curedIncrease resistanceSolid-state devicesSemiconductor/solid-state device manufacturingEpoxyQuaternary ammonium ions

The present invention addresses the issue of providing a surface sealing agent which can be cured at low temperatures and which exhibits excellent storage stability. In order to resolve this issue, provided is a surface sealing agent for an organic EL element, the surface sealing agent including an epoxy resin (A) having at least two epoxy groups in a molecule, and a curing accelerator (B) which is a salt of a specific quaternary ammonium ion, wherein 0.1-10 parts by weight of the curing accelerator (B) is contained relative to 100 parts by weight of the surface sealing agent.

Owner:MITSUI CHEM INC

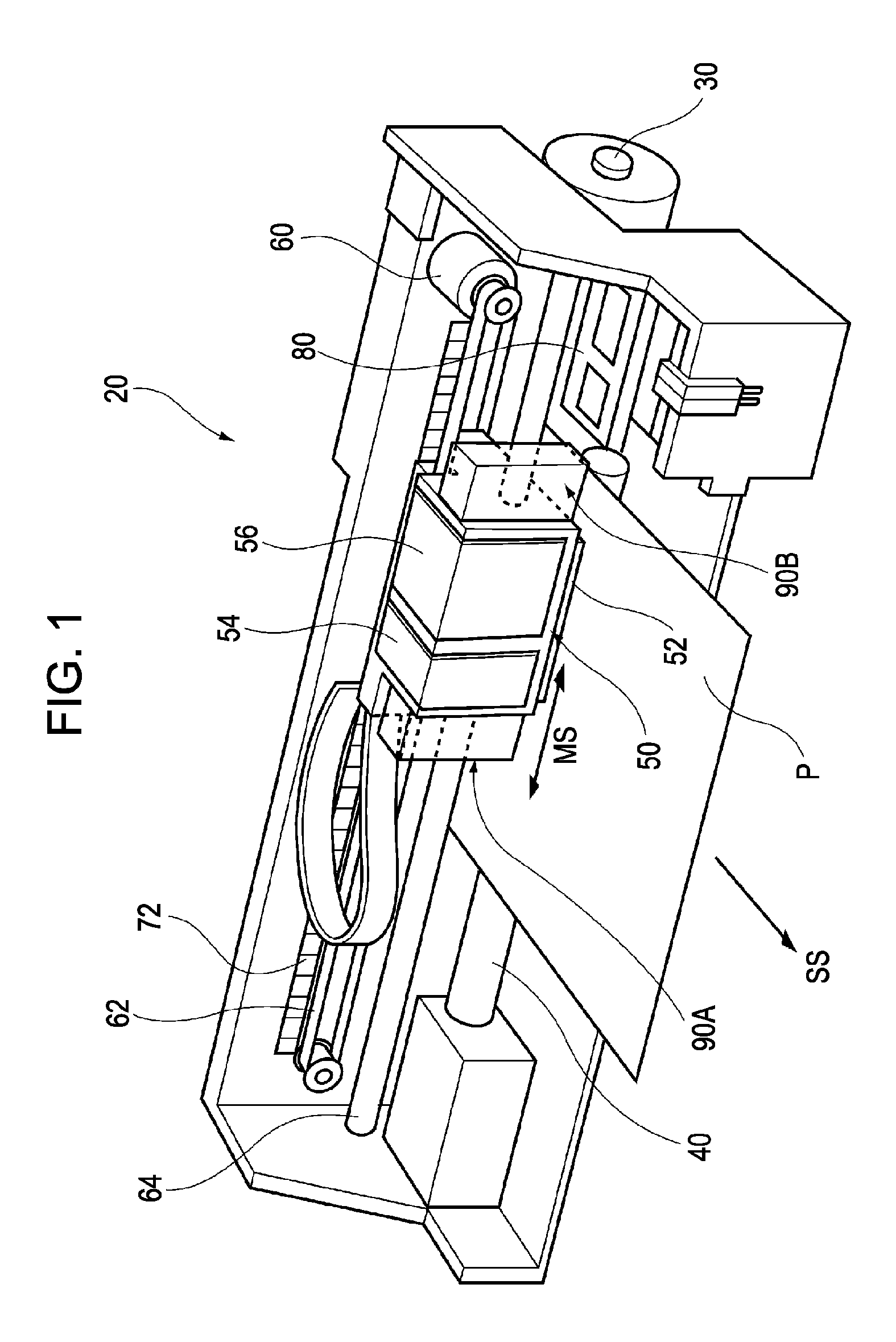

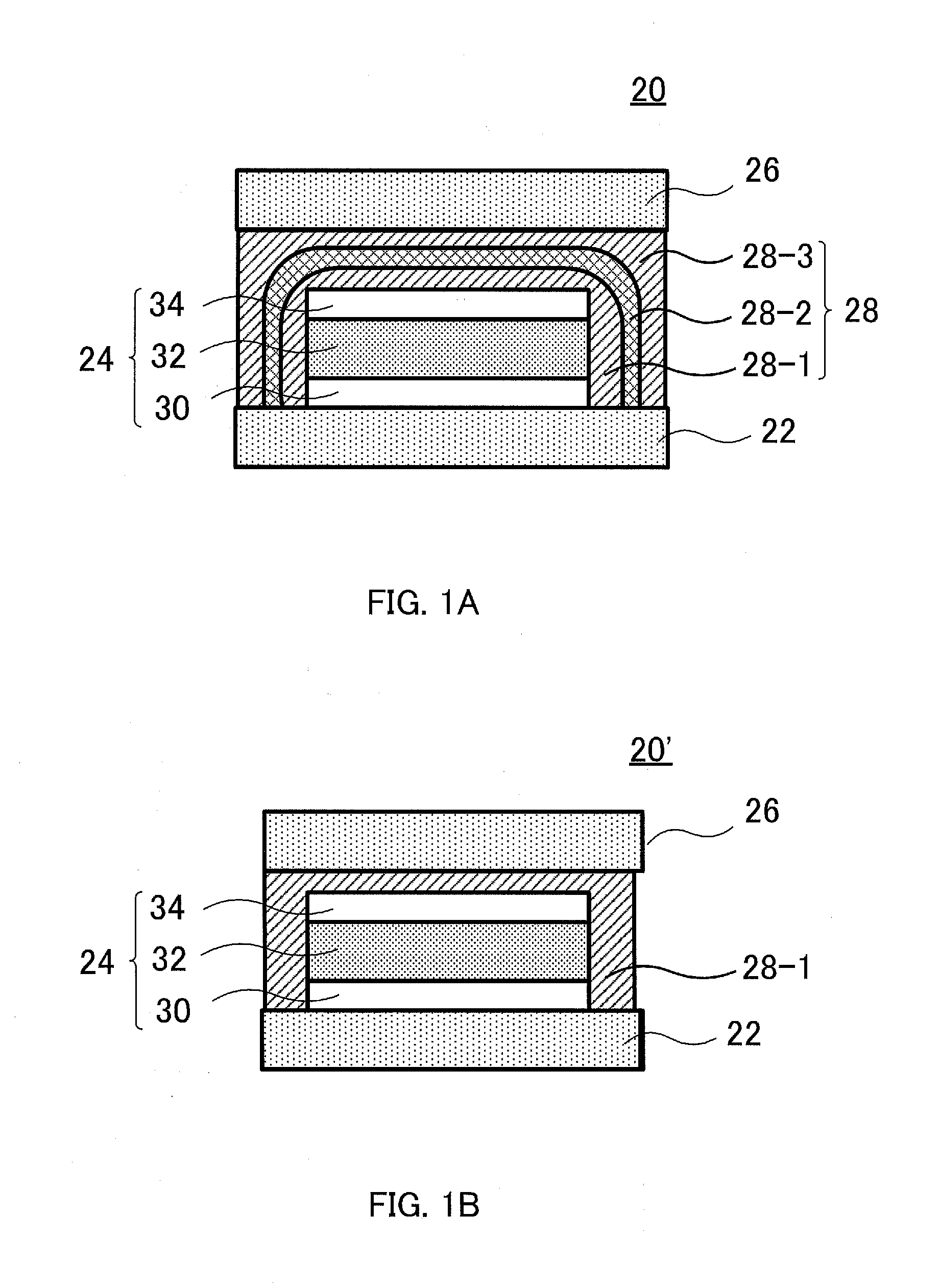

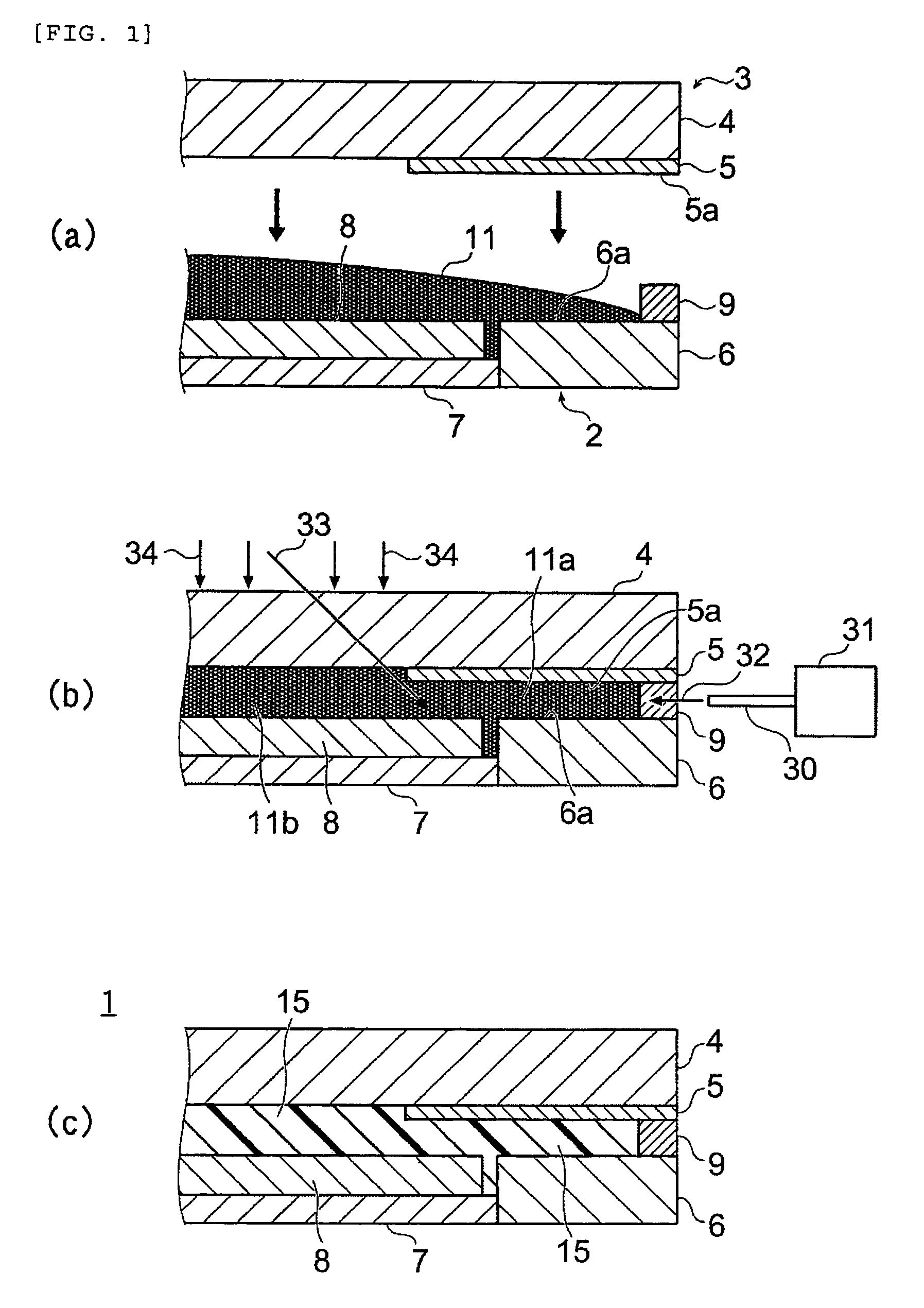

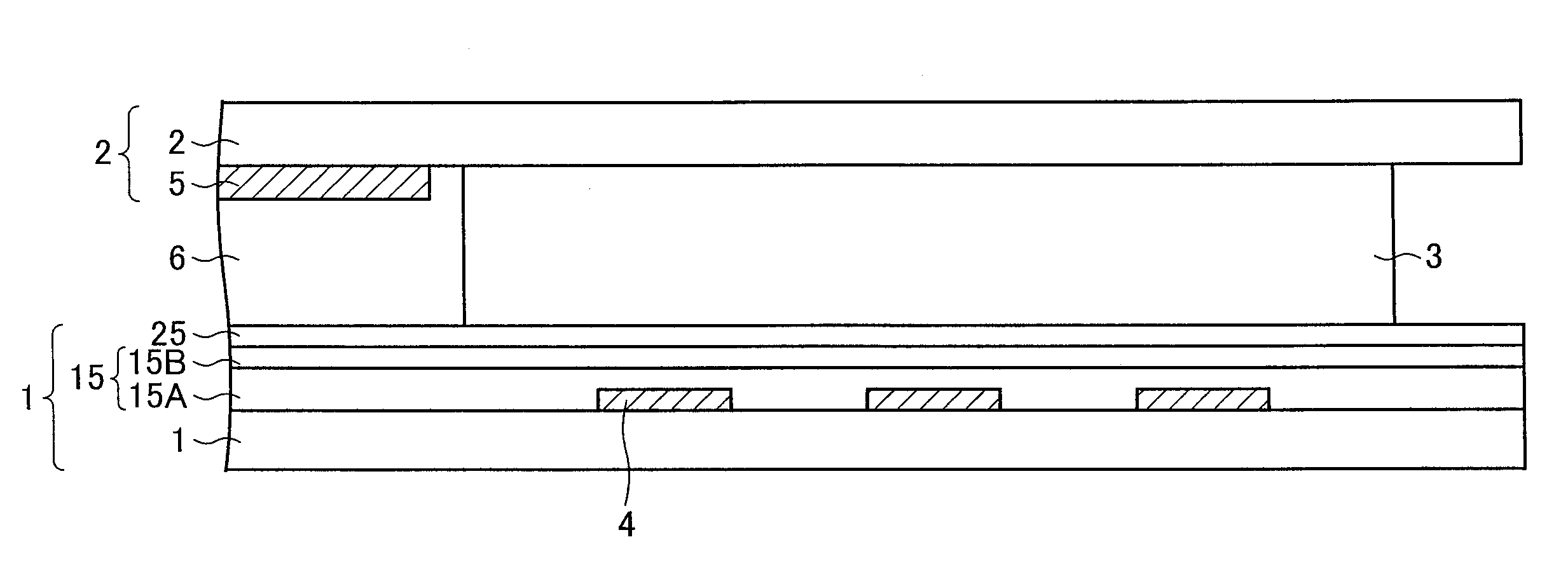

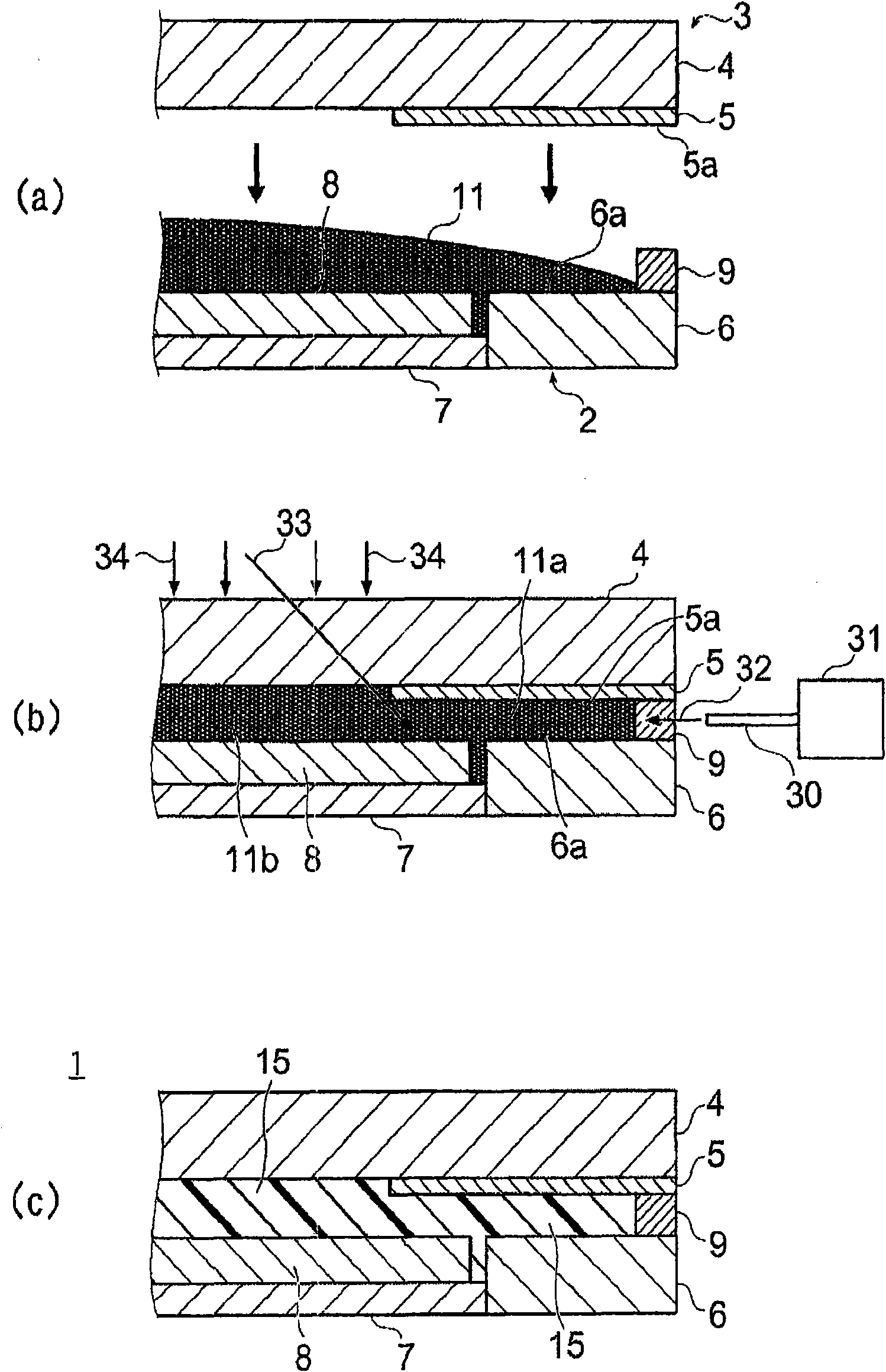

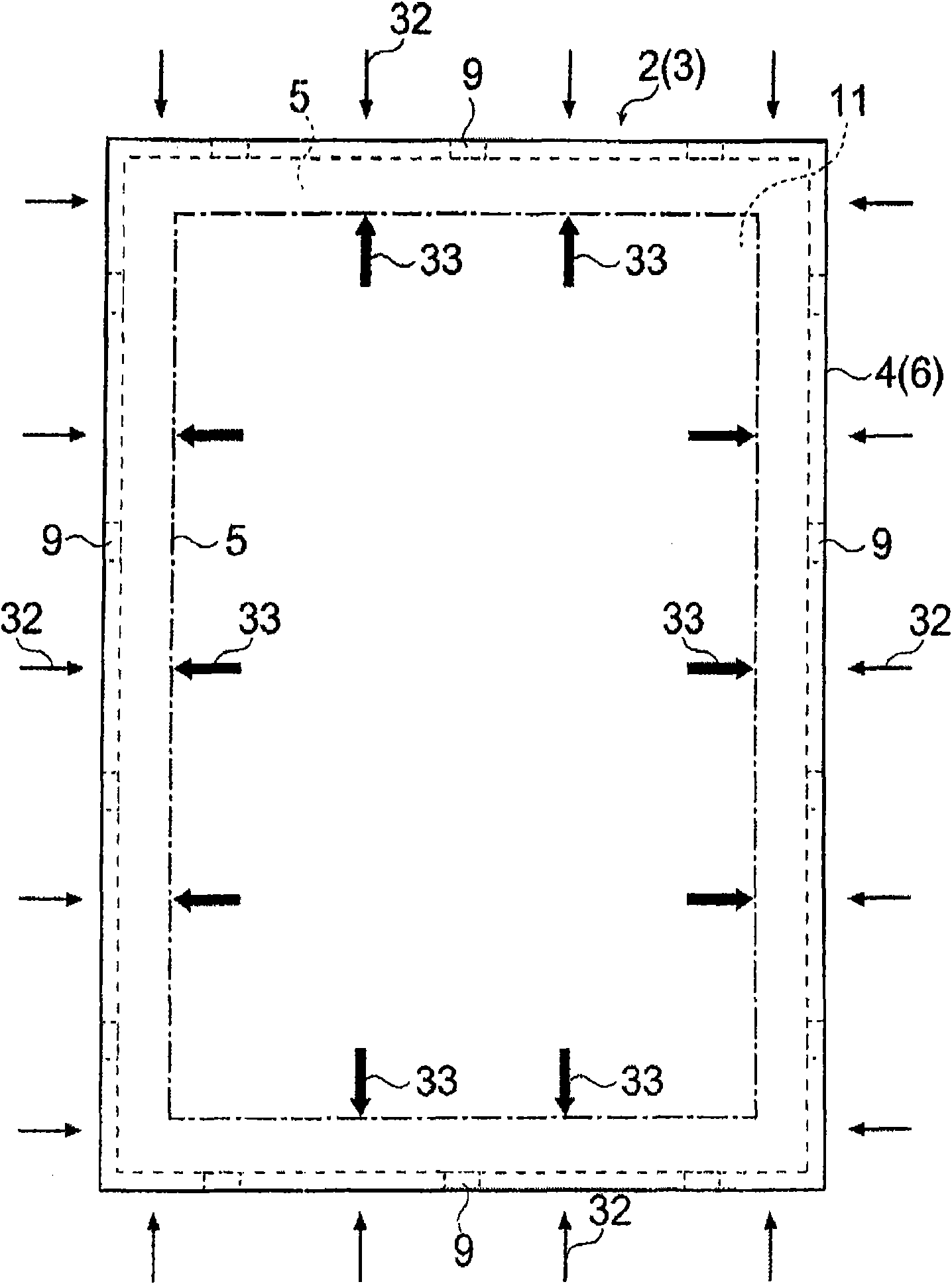

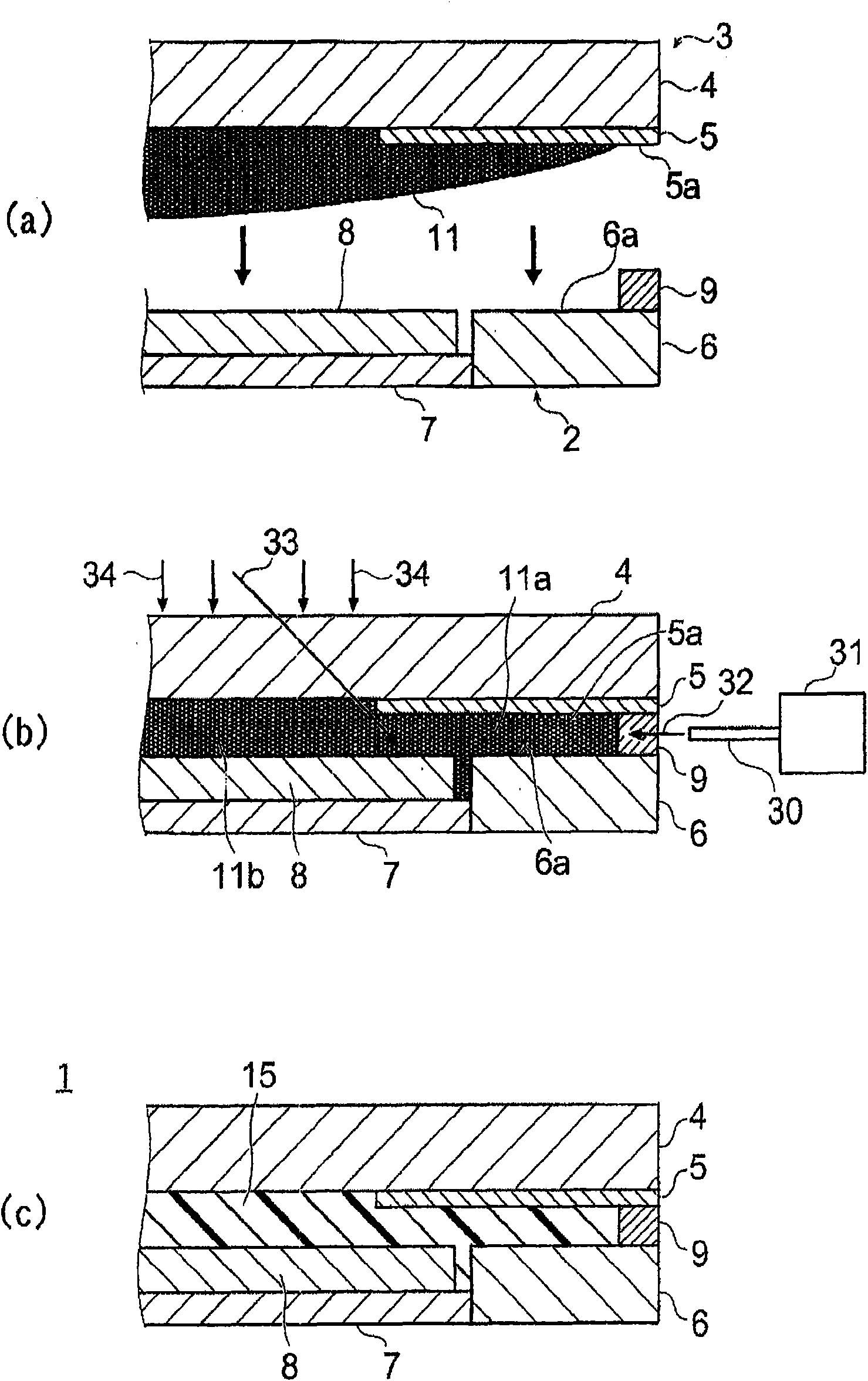

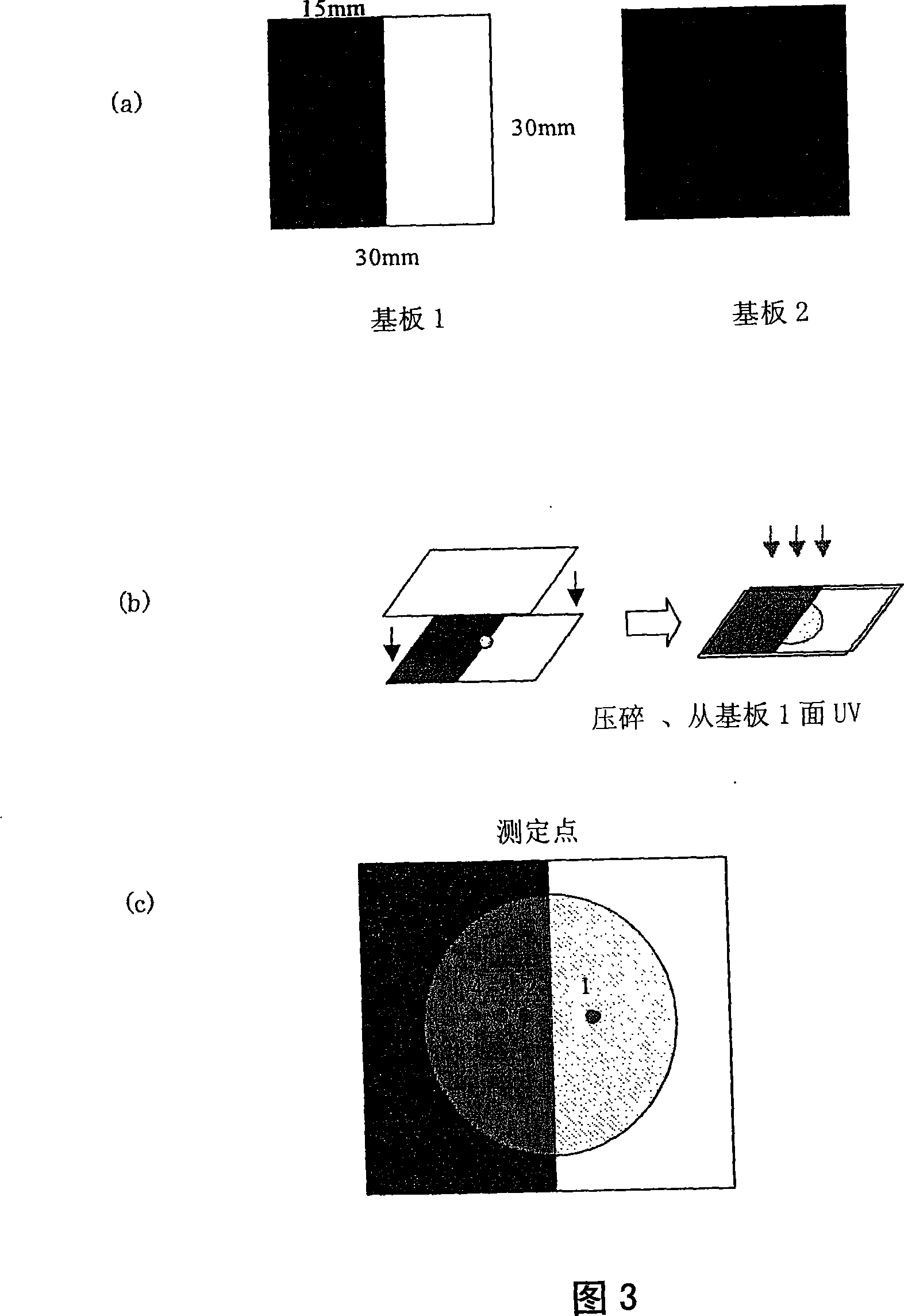

Method for manufacturing image display device

ActiveUS7910033B2Fully curedReduce the amount requiredLiquid crystal compositionsLamination ancillary operationsLiquid-crystal displayTransmittance

A method for manufacturing an image display device includes the step of forming a cured resin layer 15 by interposing a photo-curable resin composition between a base 2 including an image display unit such as a liquid crystal display panel 8 and a light-transmitting protection member 3 including a light-shielding member 5 and then photo-curing the photo-curable resin composition. In this method, a resin composition having a curing shrinkage ratio of 5% or less, yielding a cured product having a storage elastic modulus at 25° C. of 1.0×107 Pa or less, and forming the cured resin layer having a light transmittance of 90% or more in the visible range is used as the photo-curable resin composition.

Owner:DEXERIALS CORP

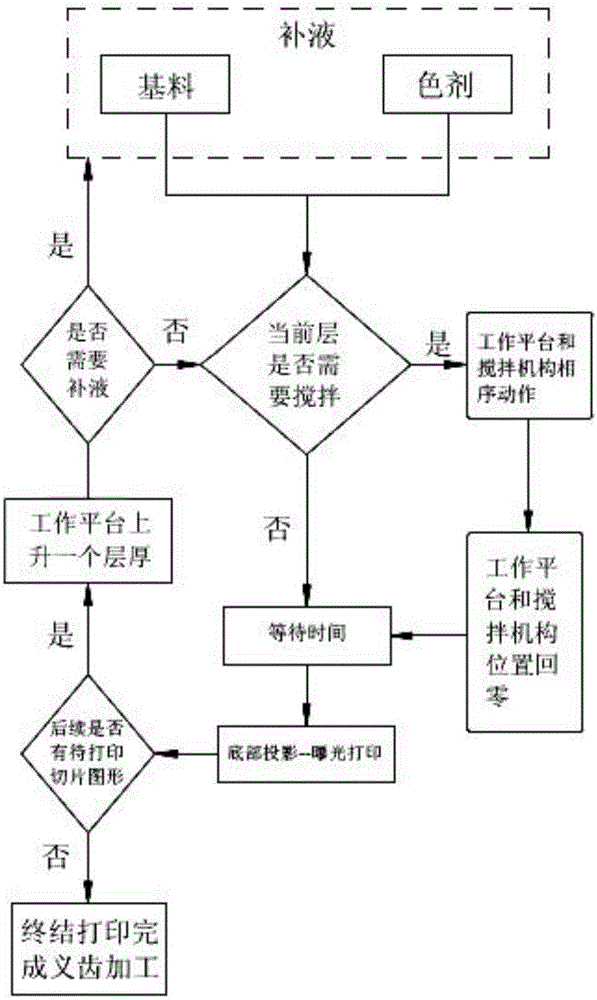

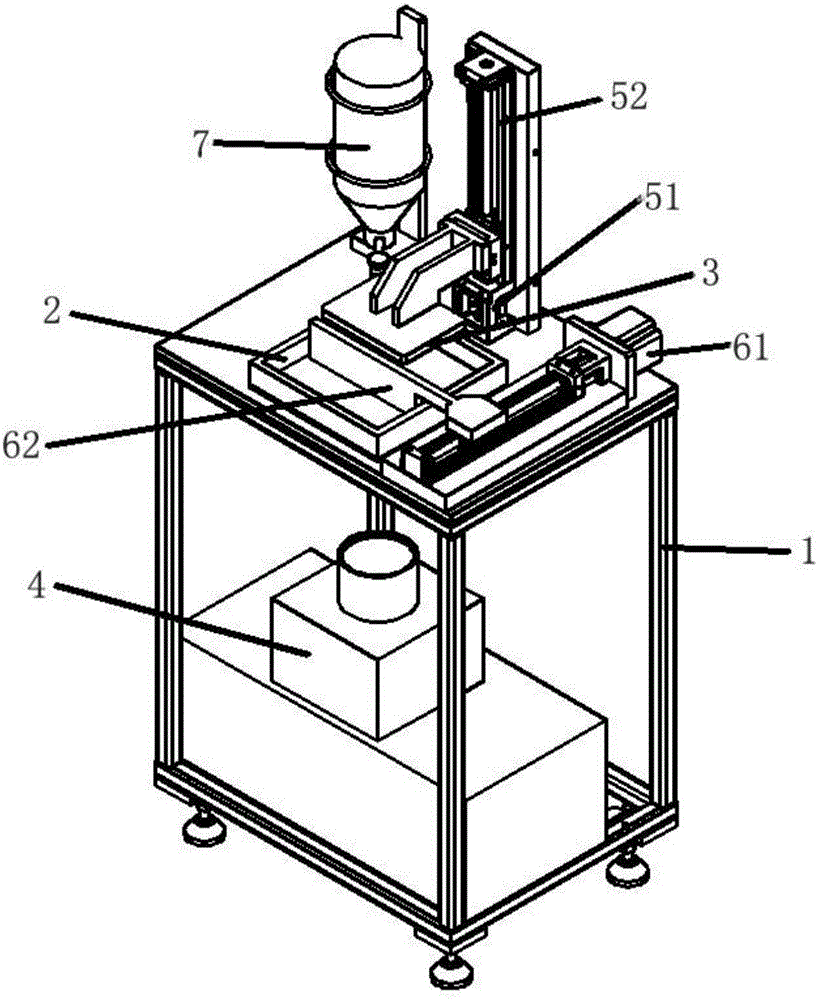

Method and device for ceramic denture 3D printing suitable for light curing molding

ActiveCN106217882AGuaranteed accuracyGuaranteed to mix evenlyAdditive manufacturing apparatusCeramic shaping apparatusData modelLight source

The invention relates to a method and device for ceramic denture 3D printing suitable for light curing molding and belongs to the technical field of tooth making. According to the method, through scanned tooth data and data processing, data of each layer of image after a data model to be printed is sliced are obtained and transmitted to a control system, a liquid supplementing action is controlled through the control system so that the liquid level of a base material can be always kept at the preset height, the base material is configured by photosensitive resin and ceramic powder according to the ratio, and the control system controls completion of stirring of supplemented liquid after liquid supplementing; and a bottom projection manner is adopted for printing, slice images of each layer of image are projected successively, light source exposure is conducted, and curing is completed layer by layer. The method and device have the beneficial effects that the making process is simple, the making efficiency is high, the consumption of materials is low, the making precision is high, and the match is good.

Owner:SHANGHAI UNION TECH

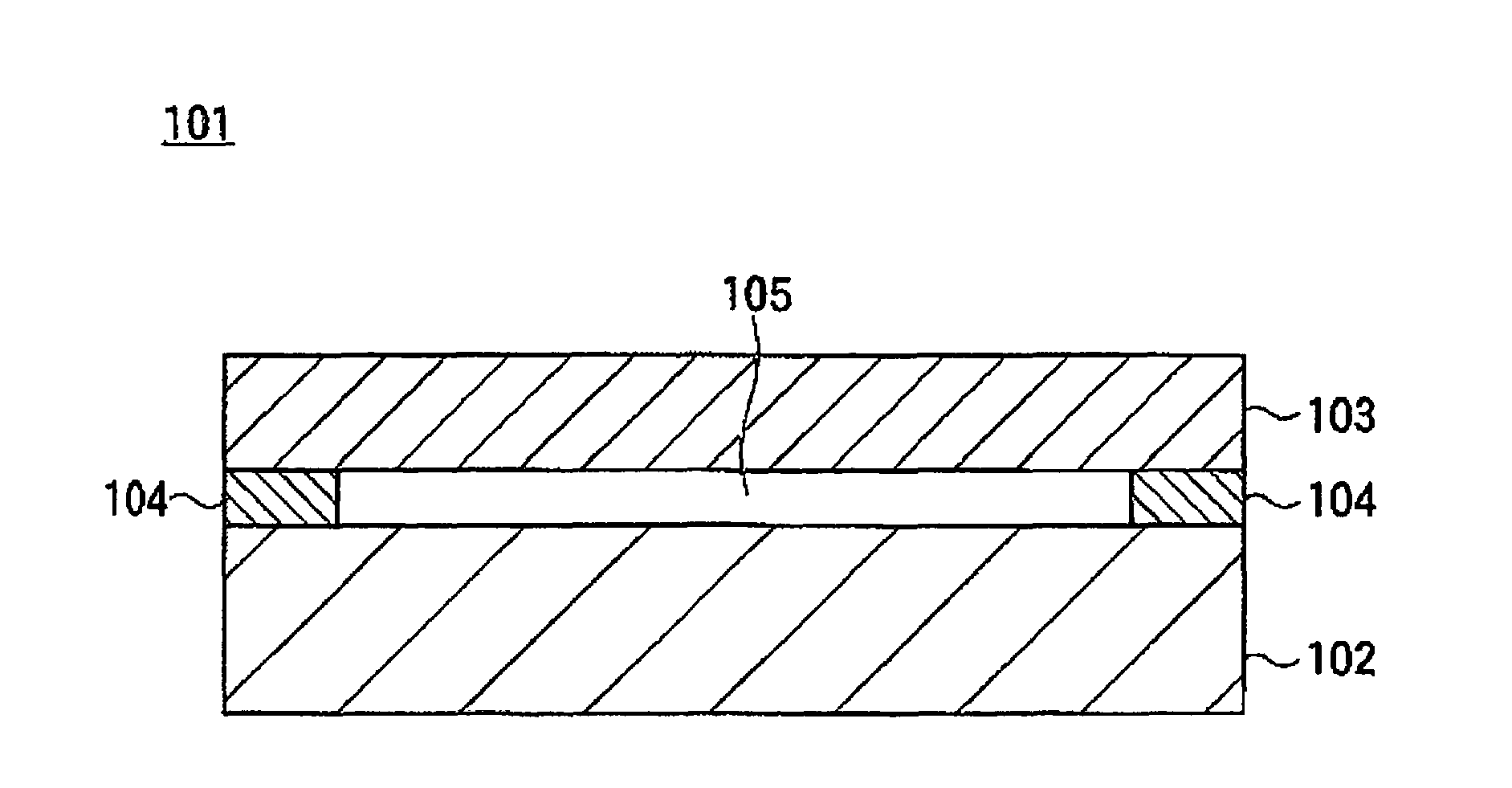

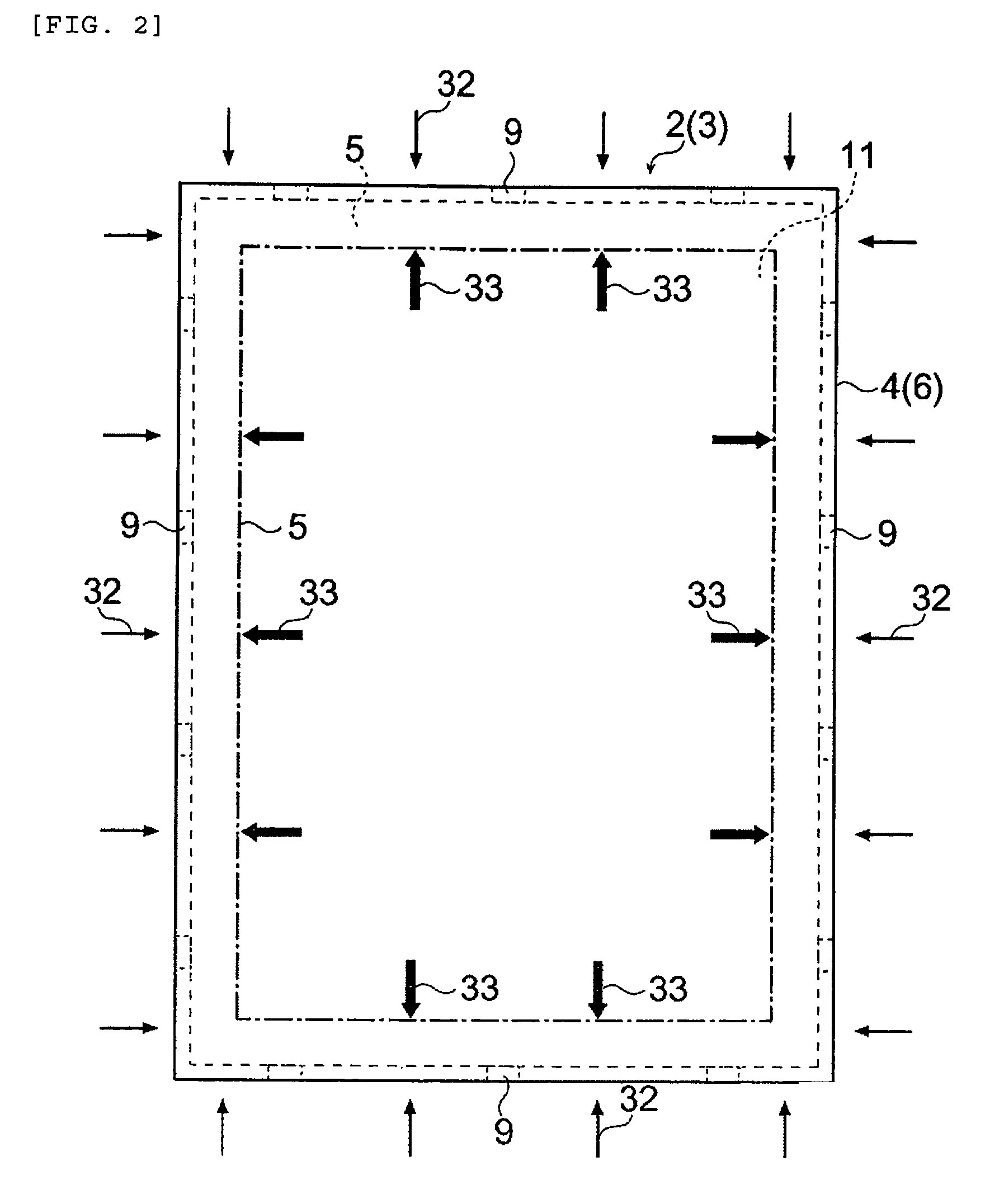

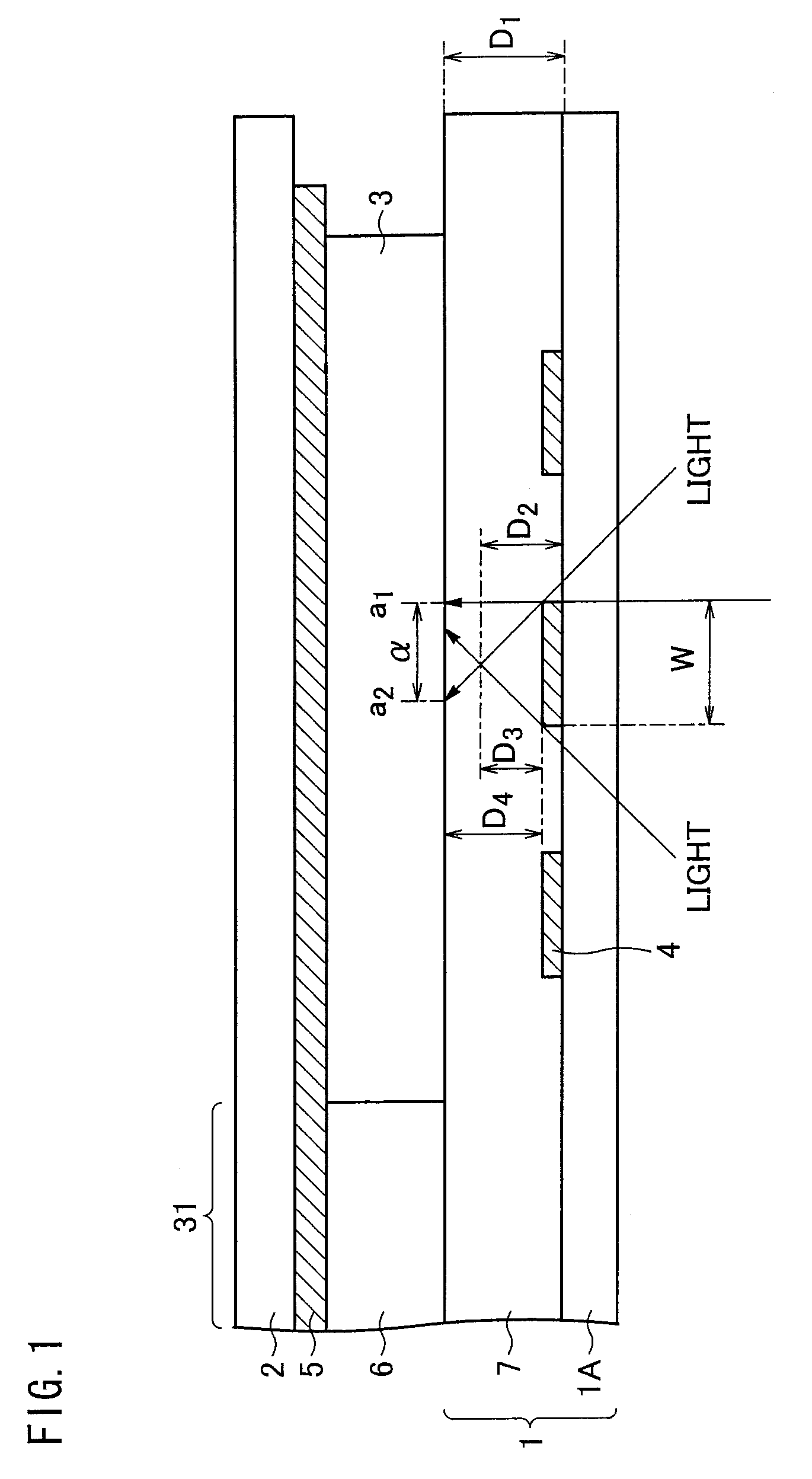

Liquid crystal display device and manufacturing method thereof

InactiveUS20090033846A1Easy curingReduces light irradiation energyNon-linear opticsLiquid-crystal displayMaterials science

In a liquid crystal display device, an array substrate and a CF substrate arranged face to face with each other. A liquid crystal layer is provided between the array substrate and the CF substrate. The array substrate and the CF substrate are bonded together by a sealing member containing a photo curing material. The array substrate has a surface opposed to the CF substrate. Metal wires are provided in the circumferential portion of the opposed surface. A transparent film is disposed between the metal wires and the sealing member.

Owner:SHARP KK

Manufacturing process for plugging conductive holes of circuit board with resin

InactiveCN101854778AImprove efficiencyLow costPrinted element electric connection formationEngineeringElectroplating

The invention discloses a manufacturing process for plugging conductive holes of a circuit board with resin, which comprises the following steps: A) carrying out plated through hole and electroplating treatment on a circuit board substrate which is provided with conductive holes; B) carrying out windowing treatment on conductive holes of the circuit board substrate which is electroplated, and adhering a dry film to transfer the printed picture; C) electroplating the conductive holes of the circuit board which is provided with the dry film; D) filling resin into the conductive holes so as to plug the conductive holes, and baking the circuit board at low temperature after the conductive holes are plugged; E) removing the remained resin through polishing way; F) removing the film of the circuit board after being polished; and G) and baking the circuit board at high temperature after the film is removed. The process not only can solve the problem that the air bubbles are easy to produce by directly filling ink or other anti-corrosion materials, but also greatly reduces the polishing difficulty; and during the hole plugging process of the conductive holes of the circuit board, the circuit board is only required to be polished for one time, so not only the efficiency is improved, but also the cost is reduced.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

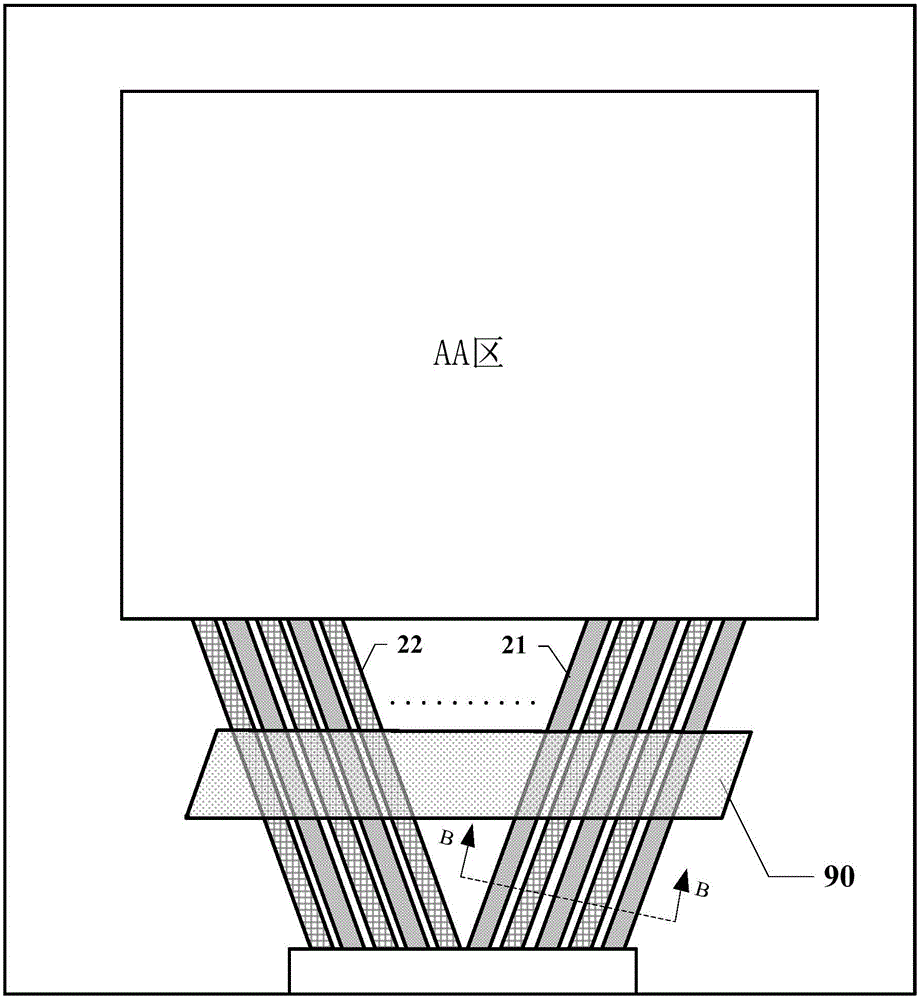

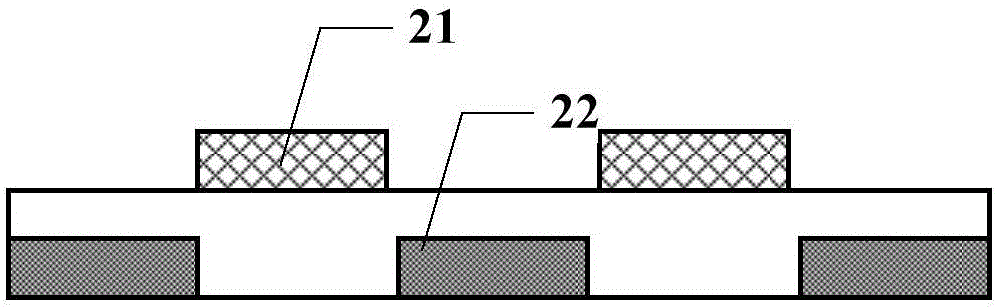

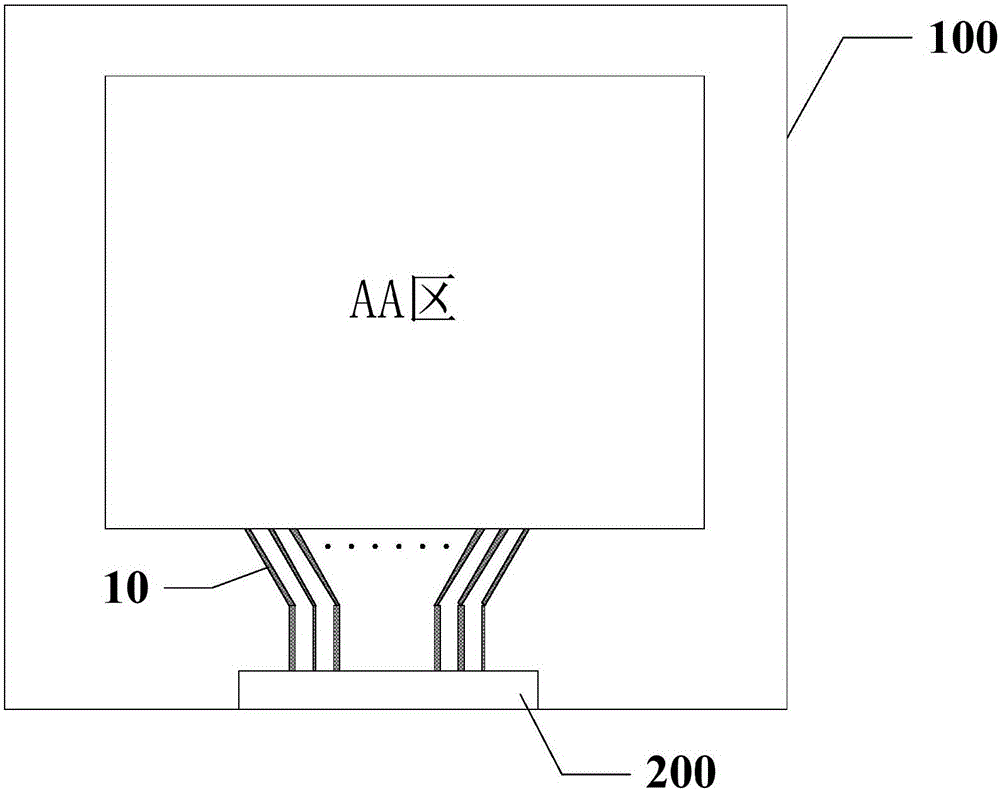

Array substrate, display panel and display device

ActiveCN106647071AReduce coupling interferenceGuaranteed light transmittanceNon-linear opticsInput/output processes for data processingDistributed structureTransmittance

The application discloses an array substrate, a display panel and a display device; the array substrate comprises a fan-out wire walking and distributing structure; the fan-out wire walking and distributing structure comprises a first fan-out walking wire and a second fan-out walking wire; the first fan-out walking wire and the second fan-out walking wire are insulated to each other; the fan-out wire walking and distributing structure at least comprises a front end wire distribution zone, a middle gluing zone and a back end wire distribution zone; the front projections of the parts where the first fan-out walking wire and the second fan-out walking wire are located at the front end wire distribution zone on the plane of the array substrate are not overlapped to each other; the front projections of the parts where the first fan-out walking wire and the second fan-out walking wire are located at the middle gluing zone on the plane of the array substrate are overlapped to each other; the front projections of the parts where the first fan-out walking wire and the second fan-out walking wire are located at the back end wire distribution zone on the plane of the array substrate are not overlapped; the middle gluing zone is used for coating the first sealing glue layer on the array substrate. The manner can guarantee the light transmittance of the gluing zone, so that the sealing glue can be fully cured to avoid liquid crystal leakage.

Owner:SHANGHAI AVIC OPTOELECTRONICS

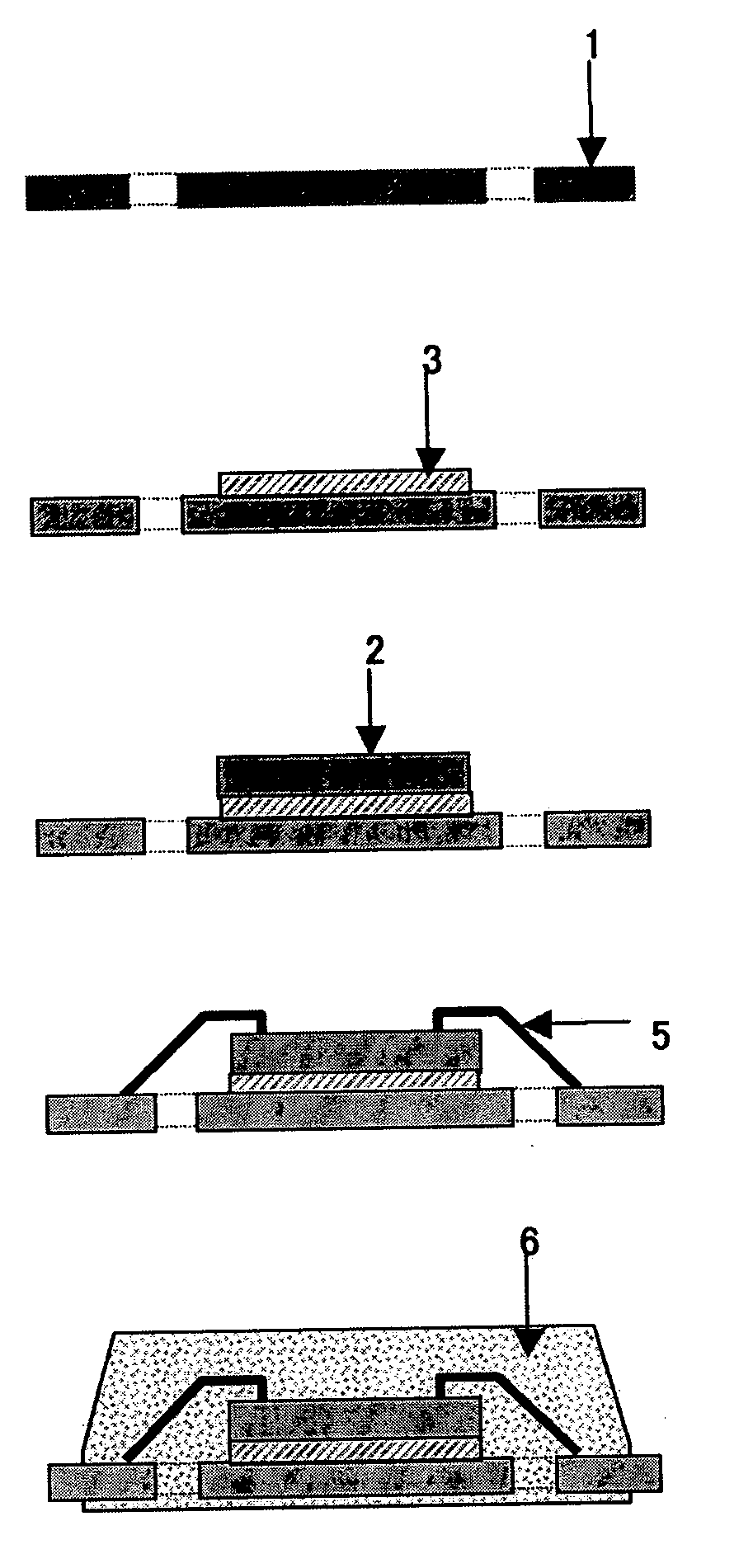

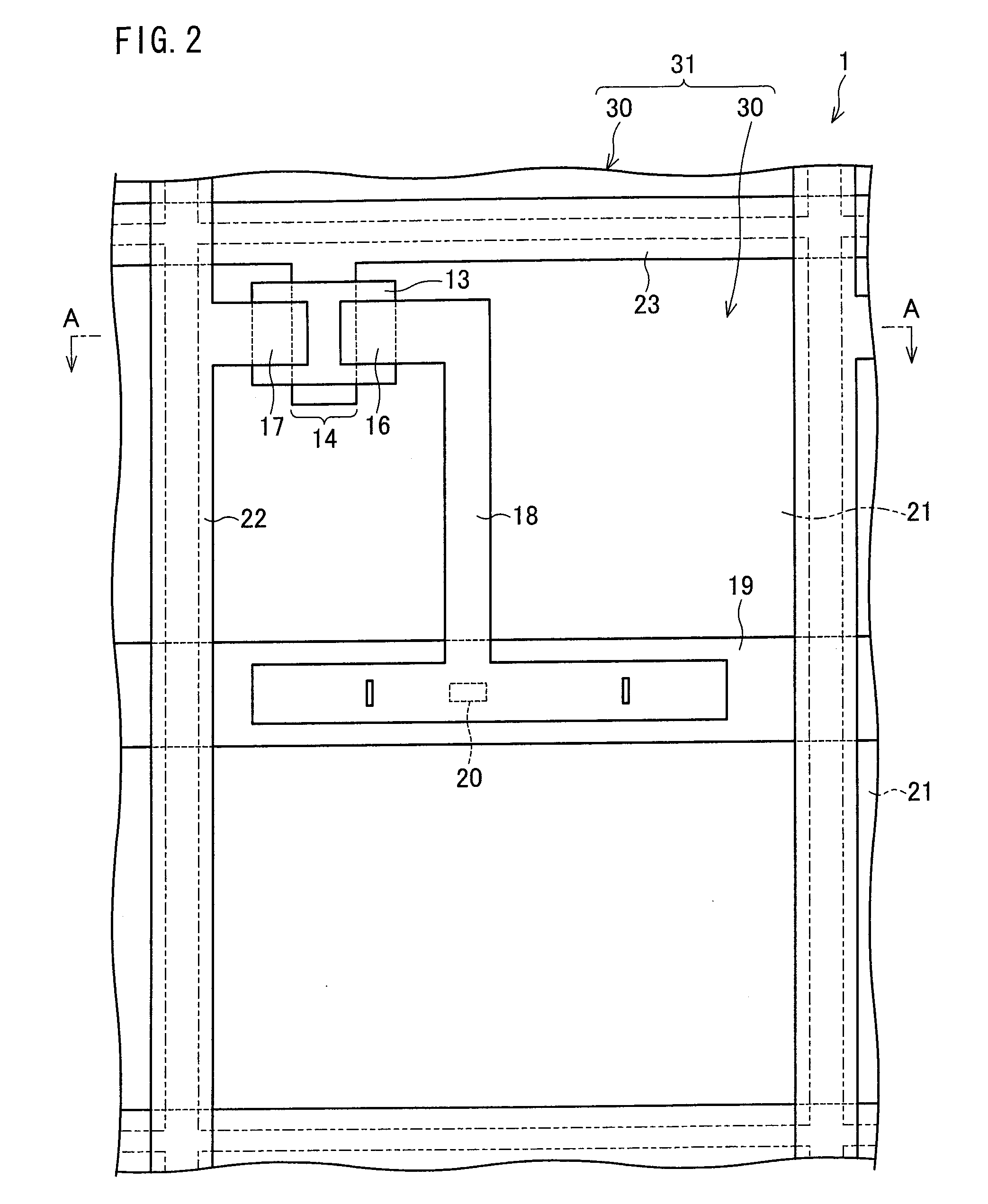

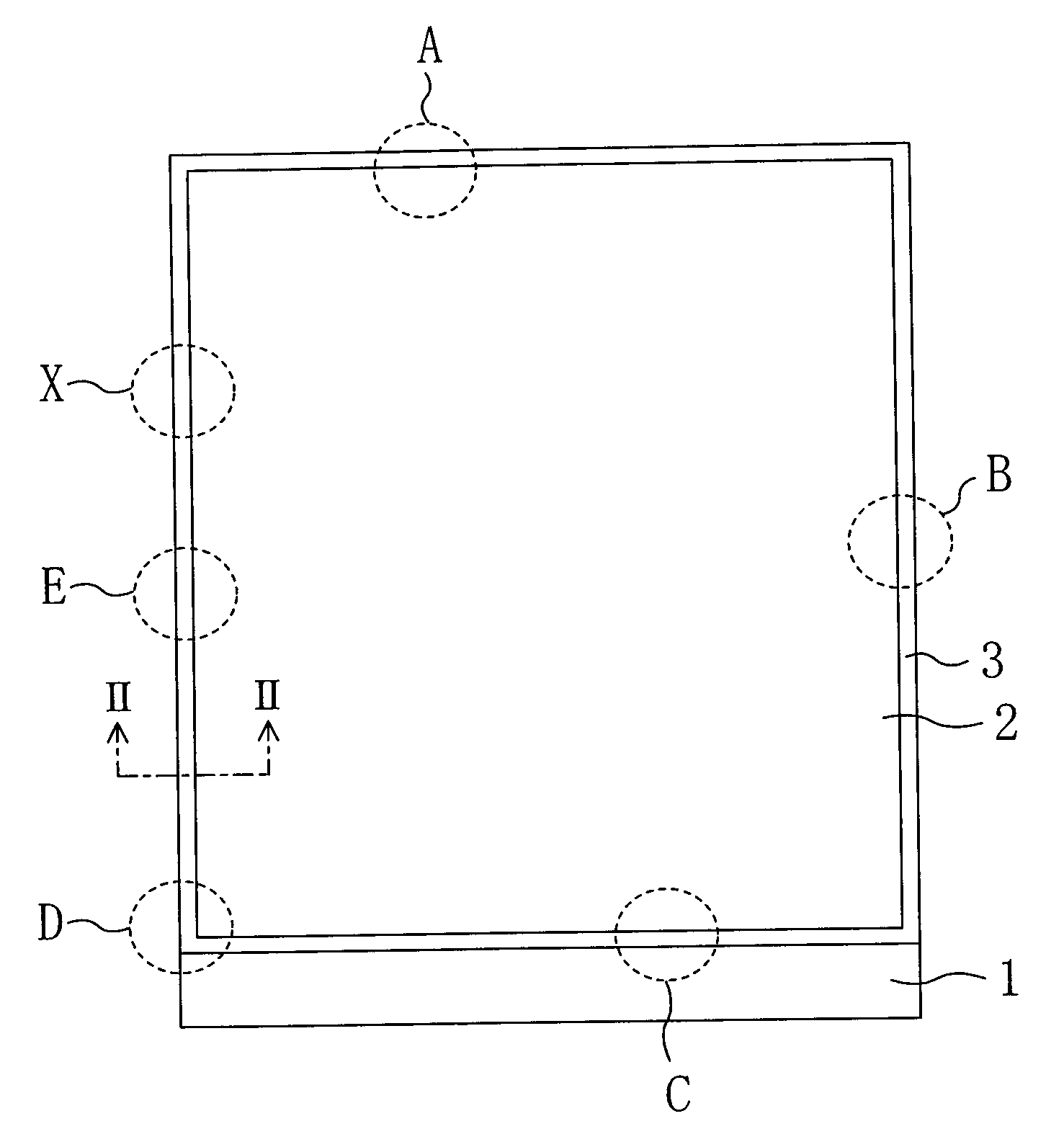

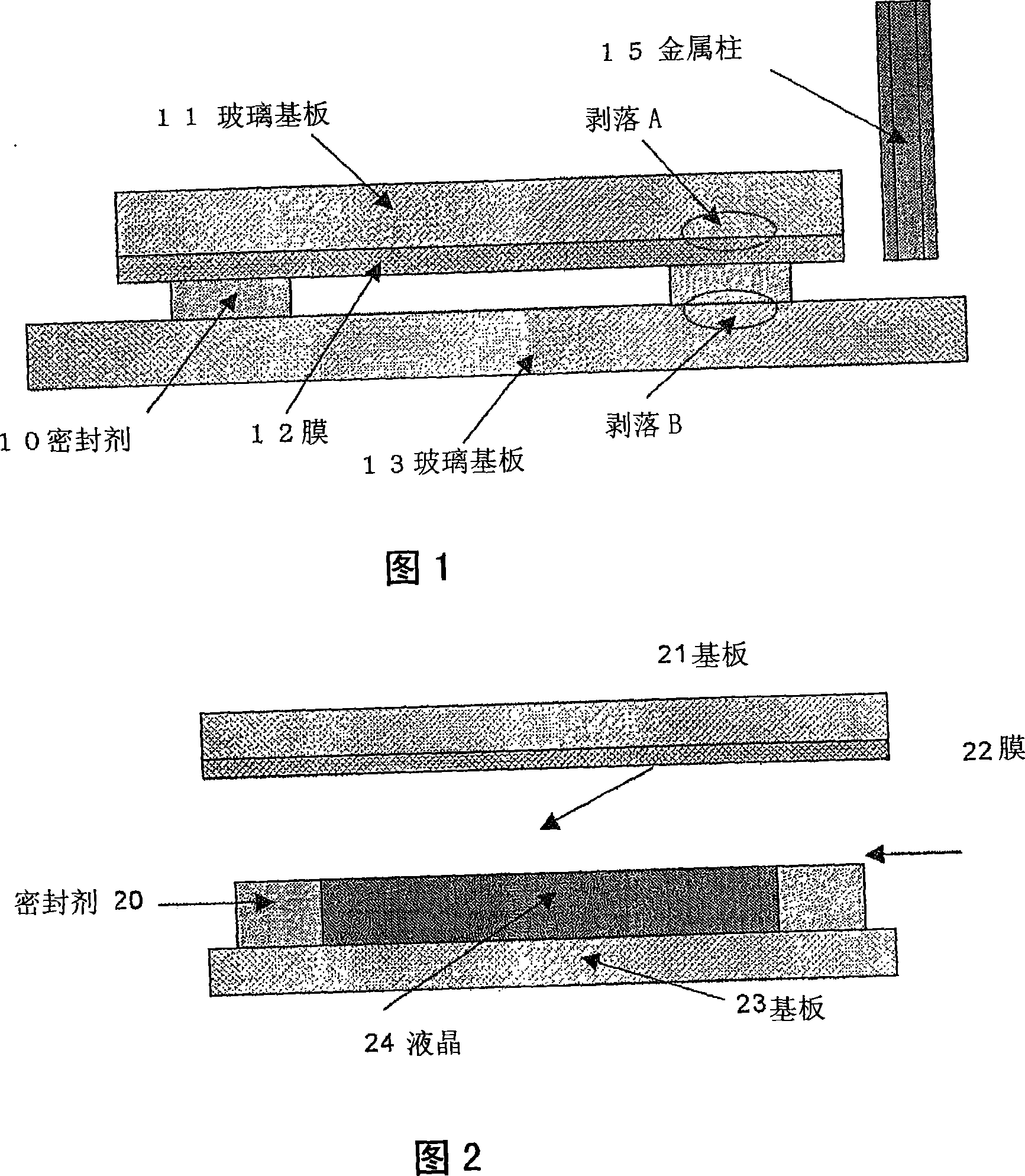

Panel and method for manufacturing the same

InactiveUS20090303427A1Low production costSmall sizeNon-linear opticsIdentification meansLiquid-crystal displayEngineering

A liquid crystal display panel includes a TFT substrate, a color filter (CF) substrate opposed to the TFT substrate, a sealant disposed between the TFT substrate and the CF substrate and disposed between portions of both the substrates located immediately outside display regions thereof, and a liquid crystal layer disposed between the TFT substrate and the CF substrate. The CF substrate is provided with a light-shielding layer at a portion located immediately outside its display region. The light-shielding layer is provided with a slit at a region that coincides with a line on the TFT substrate.

Owner:SHARP KK

Ultraviolet ray irradiation device, recording apparatus using the ultraviolet ray irradiation device, and recording method

ActiveUS20080174649A1Low viscosityFully curedInking apparatusRadiation pyrometryColor printingColor mixing

The ultraviolet ray irradiation devices are attached to a carriage having a print head that ejects the ultraviolet curable ink, and include a plurality of ultraviolet light sources that irradiate ultraviolet rays onto ink coating ejected on a print sheet by the print head. An ultraviolet ray of the ultraviolet light source that irradiates the ultraviolet ray onto the print sheet in the vicinity of the print head has a wavelength shorter than an ultraviolet ray of the ultraviolet light source that irradiates the ultraviolet ray onto the print sheet apart from the vicinity of the print head along the moving direction of the carriage. The ultraviolet ray irradiation device is capable of sufficiently curing a plurality of ultraviolet curable ink adhered on a recording medium without incurring a problem of blurring or color mixing for a multiple-color printing process such as a full-color printing process.The ultraviolet ray irradiation devices are attached to a carriage having a print head that ejects the ultraviolet curable ink, and include a plurality of ultraviolet light sources that irradiate ultraviolet rays onto ink coating ejected on a print sheet by the print head. An ultraviolet ray of the ultraviolet light source that irradiates the ultraviolet ray onto the print sheet in the vicinity of the print head has a wavelength shorter than an ultraviolet ray of the ultraviolet light source that irradiates the ultraviolet ray onto the print sheet apart from the vicinity of the print head along the moving direction of the carriage. The ultraviolet ray irradiation device is capable of sufficiently curing a plurality of ultraviolet curable ink adhered on a recording medium without incurring a problem of blurring or color mixing for a multiple-color printing process such as a full-color printing process.

Owner:SEIKO EPSON CORP

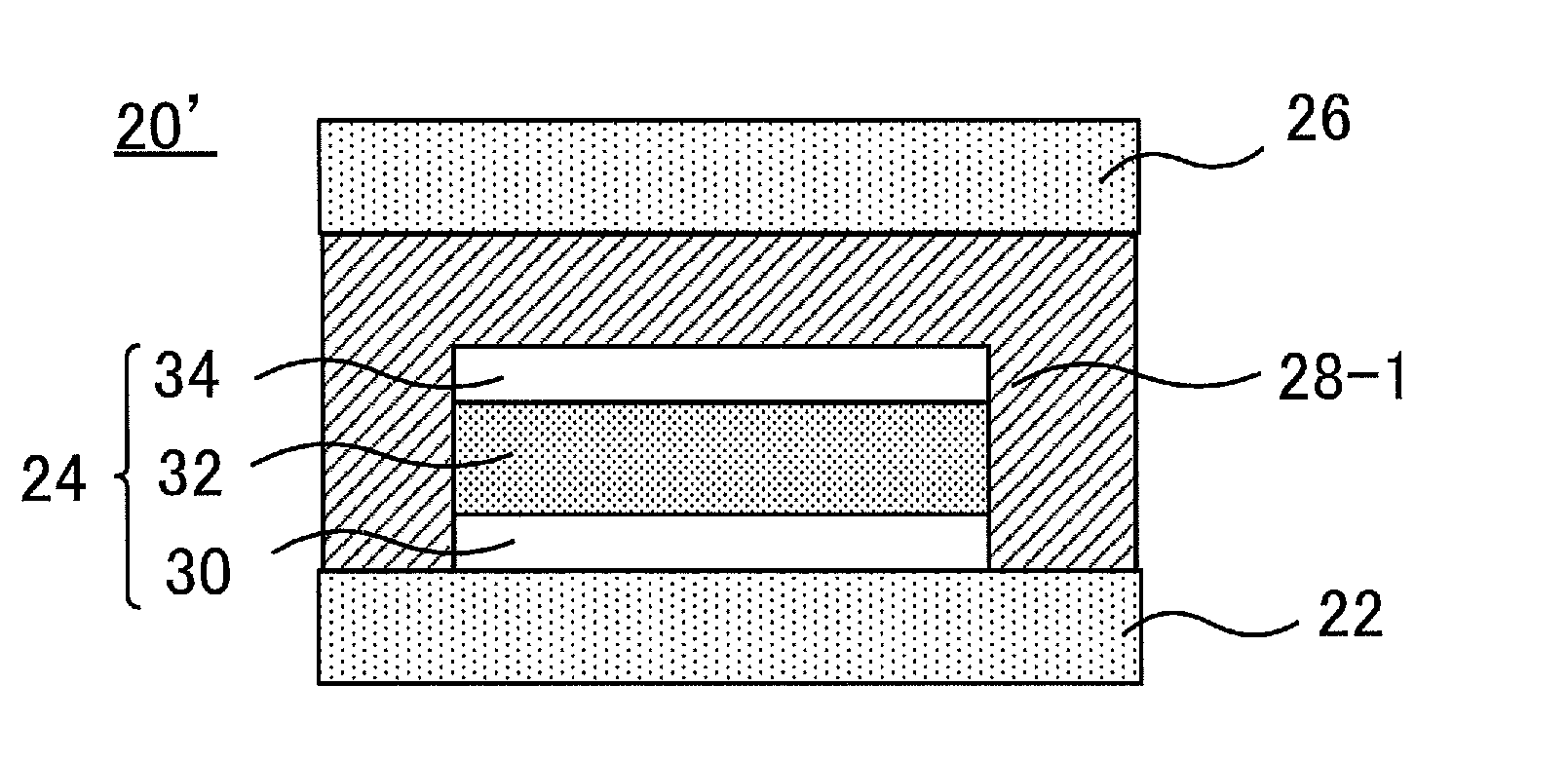

Method for manufacturing image display

ActiveCN101652803APrevent orientation confusionFully curedNon-linear opticsIdentification meansHigh contrastTransmittance

Disclosed is a method for manufacturing an image display (1), which comprises a step wherein a photocurable resin composition (11) is interposed between a base unit (2) having an image display unit such as a liquid crystal display panel (8) and a light-transmitting protective unit (3) having a light-shielding portion (5), and a cured resin layer (15) is formed by photocuring the resin composition(11). In this method, a resin composition having a curing shrinkage rate of not more than 5% and a storage modulus of the cured product at 25 DEG C of not more than 1.0 OE10<7> Pa, which enables to obtain a cured resin layer (15) having a visible light transmittance of not less than 90% is used as the photocurable resin composition (11). The method further comprises a step wherein a curable resincomposition (11a) containing a thermal polymerization initiator is interposed at least between the light-shielding portion (5) and the base unit (2) and then the curable resin composition (11a) is heated. Consequently, the resin in a forming-region of the light-shielding portion (5) is sufficiently cured, while attaining a high-luminance, high-contrast display without having display defects due todeformation of the image display unit (8), during manufacture of the thin image display (1) wherein the resin is interposed between the protective unit (3) having the light-shielding portion (5) andthe image display unit (8).

Owner:DEXERIALS CORP

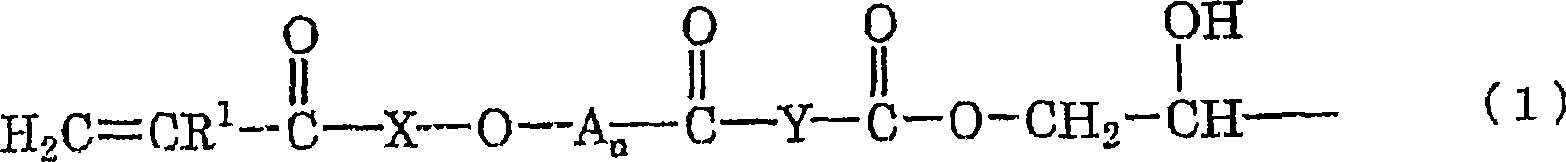

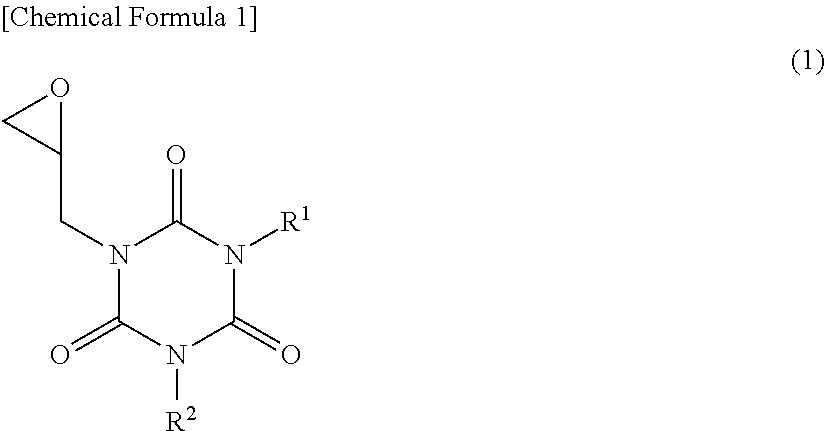

Sealing material for liquid crystal dropping method, vertically conducting material, and liquid crystal display element

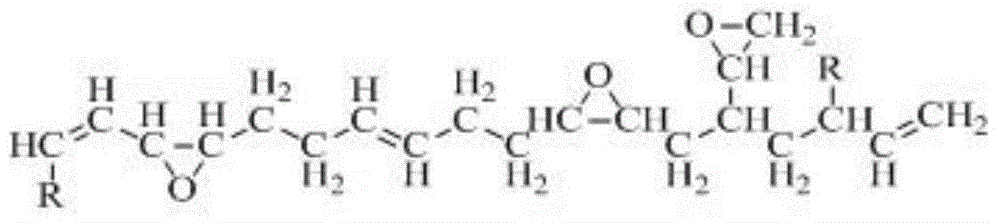

ActiveCN101176033AImprove display qualityImprove reliabilityOther chemical processesNon-linear opticsMeth-Liquid-crystal display

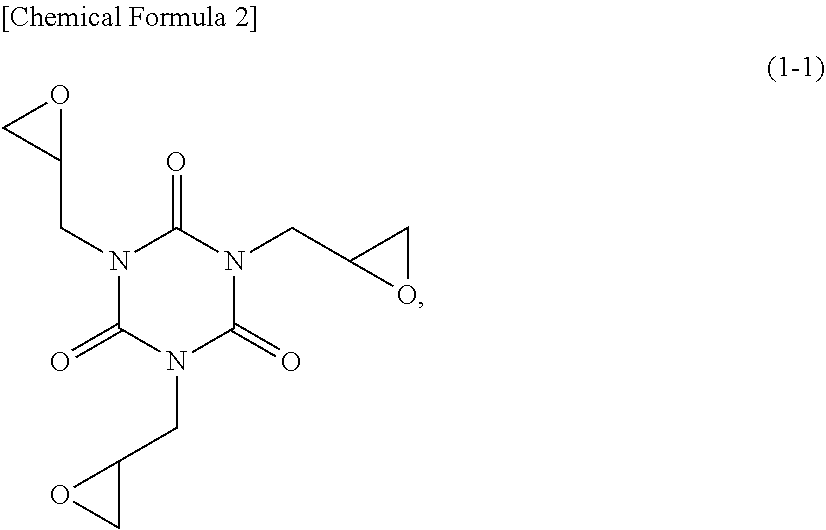

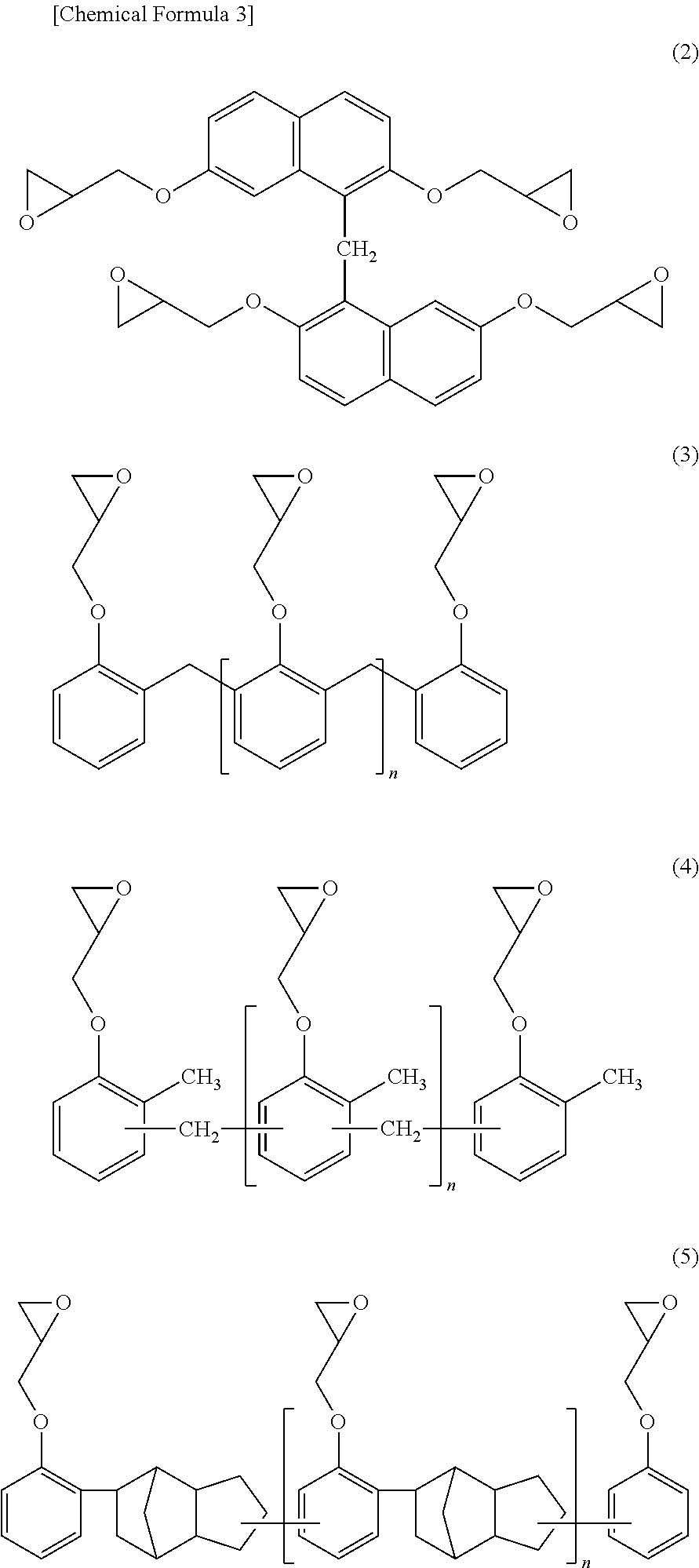

It is an object of the present invention to provide a sealant for a One prop Fill process which hardly causes a peeling phenomenon between the sealant and a substrate in production of liquid crystal display device since the sealant has excellent adhesion to the substrate, and which is most suitable for producing a liquid crystal display device having low color irregularity in liquid crystal display since the sealant does not cause liquid crystal contamination, and relates to a sealant for a One prop Fill process, in which in production of liquid crystal display device by a One prop Fill process, even a portion where light may be not directly irradiated can be adequately cured, a liquid crystal is not deteriorated by ultraviolet light to be irradiated in curing the sealant, and high display quality and high reliability of the liquid crystal display device can be realized, a vertically conducting material, and a liquid crystal display device obtained by using these. The present invention is directed to a sealant for a One prop Fill process, which contains a (meth)acrylate compound having a structure represented by the following general formula (1), 10 to 70% by weight of a curable resin component contained in the sealant being the (meth)acrylate compound. In the general formula (1), R1 represents a hydrogen atom or a methyl group, X represents one species selected from the group expressed by the following chemical formula (2), Y represents one species selected from the group expressed by the following chemical formula (3), A represents a ring opening structure of cyclic lactone, and n has a value of zero or one.

Owner:SEKISUI CHEM CO LTD

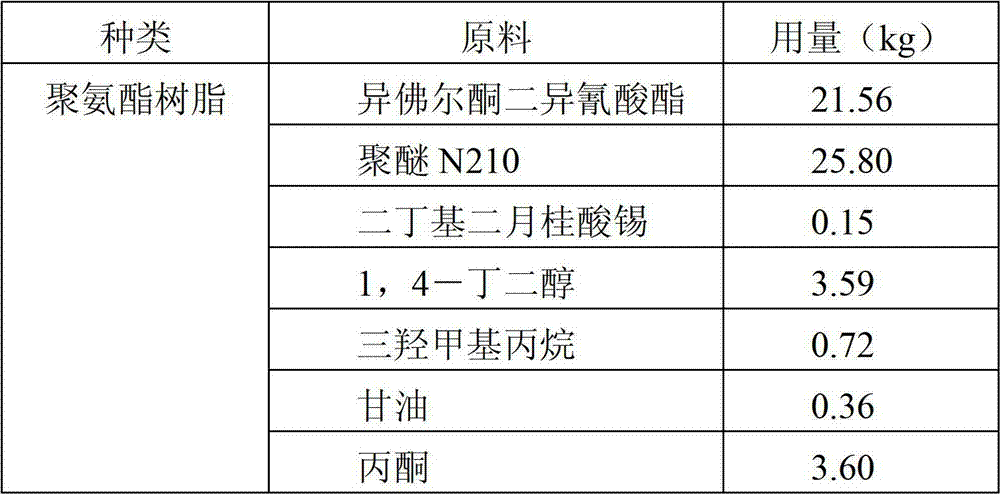

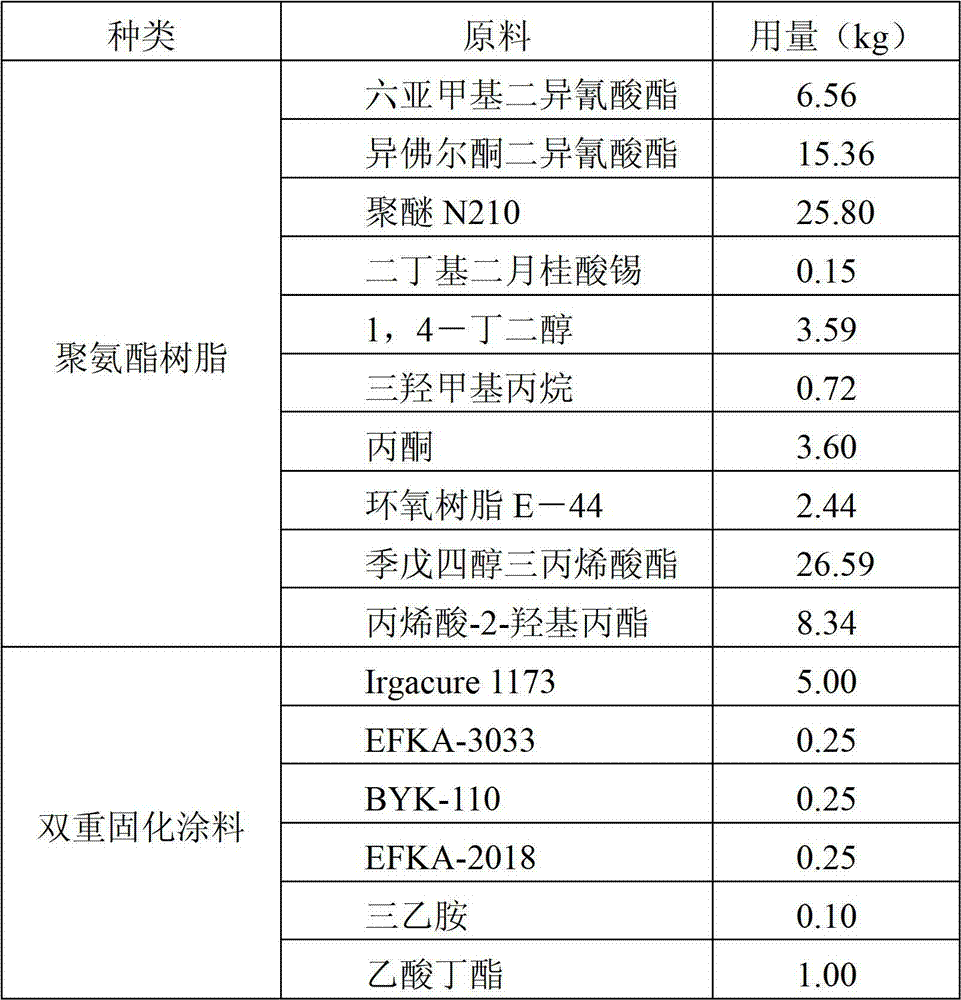

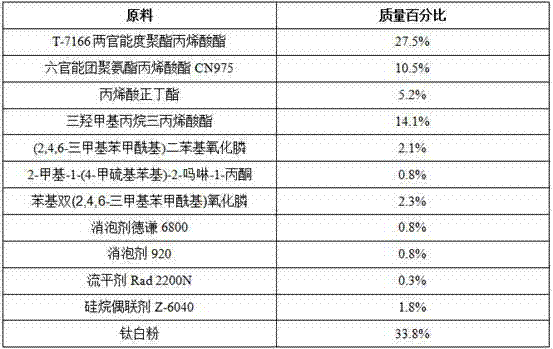

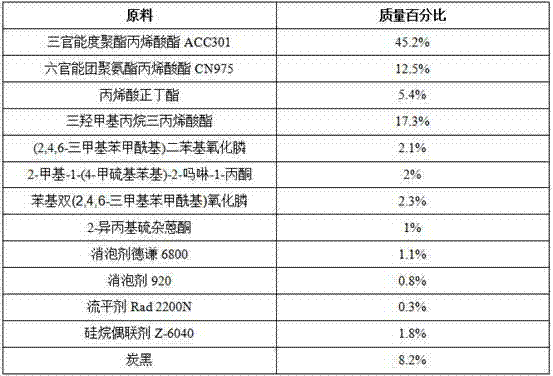

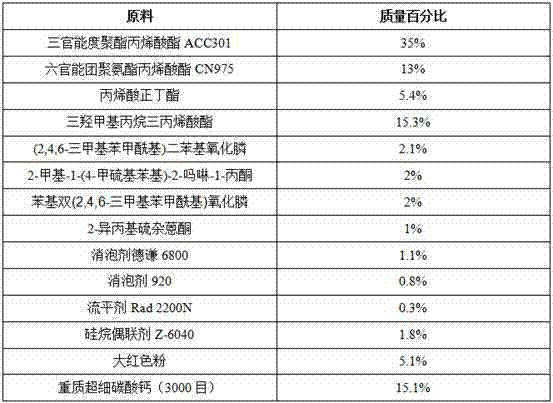

Humidity and ultraviolet dual-cured polyurethane woodware coating and preparation method thereof

The invention discloses humidity and ultraviolet dual-cured polyurethane woodware coating and a preparation method thereof. A synthesis method includes synthesizing initial polyurethane polymer I, polyurethane pre-polymer II, polyurethane pre-polymer III, polyurethane acrylate oligomer and ultraviolet cured woodware coating. The humidity and ultraviolet dual-cured polyurethane woodware coating is mainly prepared by aliphatic diisocyanate, dihydric alcohol pre-polymer, polyhydroxy acid, epoxy resin and hydroxy acrylic ester and the like, and by adding auxiliaries such as photoinitiators, flatting agents, defoamers, substrate wetting agents and catalysts, the ultraviolet cured woodware coating is prepared. The ultraviolet cured woodware coating can form films and be cured under irradiation of ultraviolet, also can be cured by humidity in the air within 5 hours at the room temperature, and has the advantages of high solid, NCO (isocyanate) group content and adhesion force, fine resistance to chemical corrosion, high film coating hardness and fine storage stability and the like, can be used for irregular coating surfaces, hone finished UV (ultraviolet) paint and UV colored paint and the like where cannot be irradiated by the ultraviolet.

Owner:广州常圣新材料科技有限公司

Grinder of bullet train tread cleaner and production method thereof

ActiveCN102432978AAvoid stressAvoid heat cracksOther chemical processesVehicle cleaningIron powderGraphite

The invention provides a grinder of a bullet train tread cleaner, wherein the grinder is made of a composite material; the composite materials comprises modified phenolic resin 6818, iron powder, copper fibres, steel fibres, sepiolite, potassium feldspar, graphite, cryolite and aluminium oxide; the invention further provides a production method of the grinder.

Owner:BEIJING RAILWELD NEW MATERIAL TECH CO LTD +1

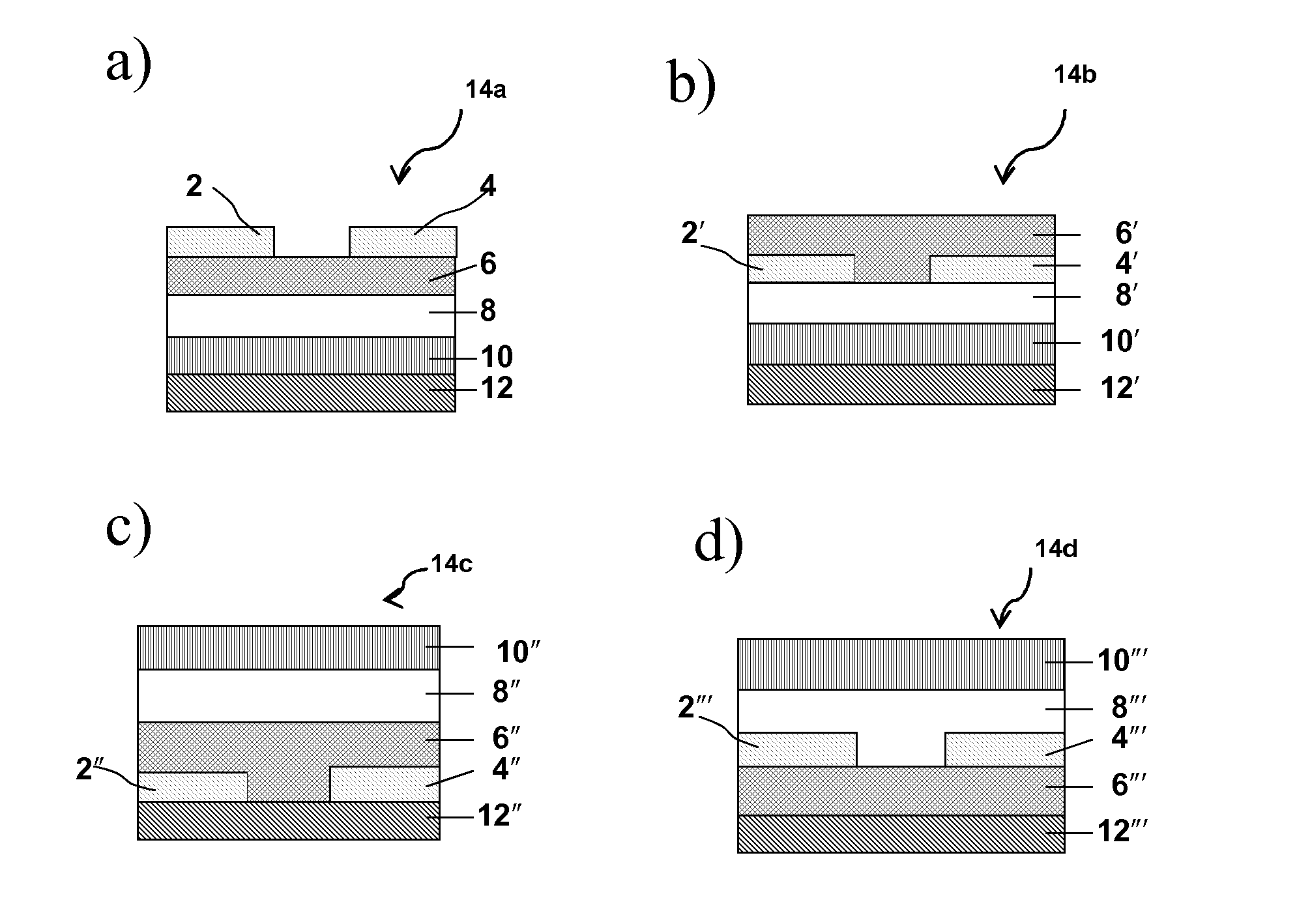

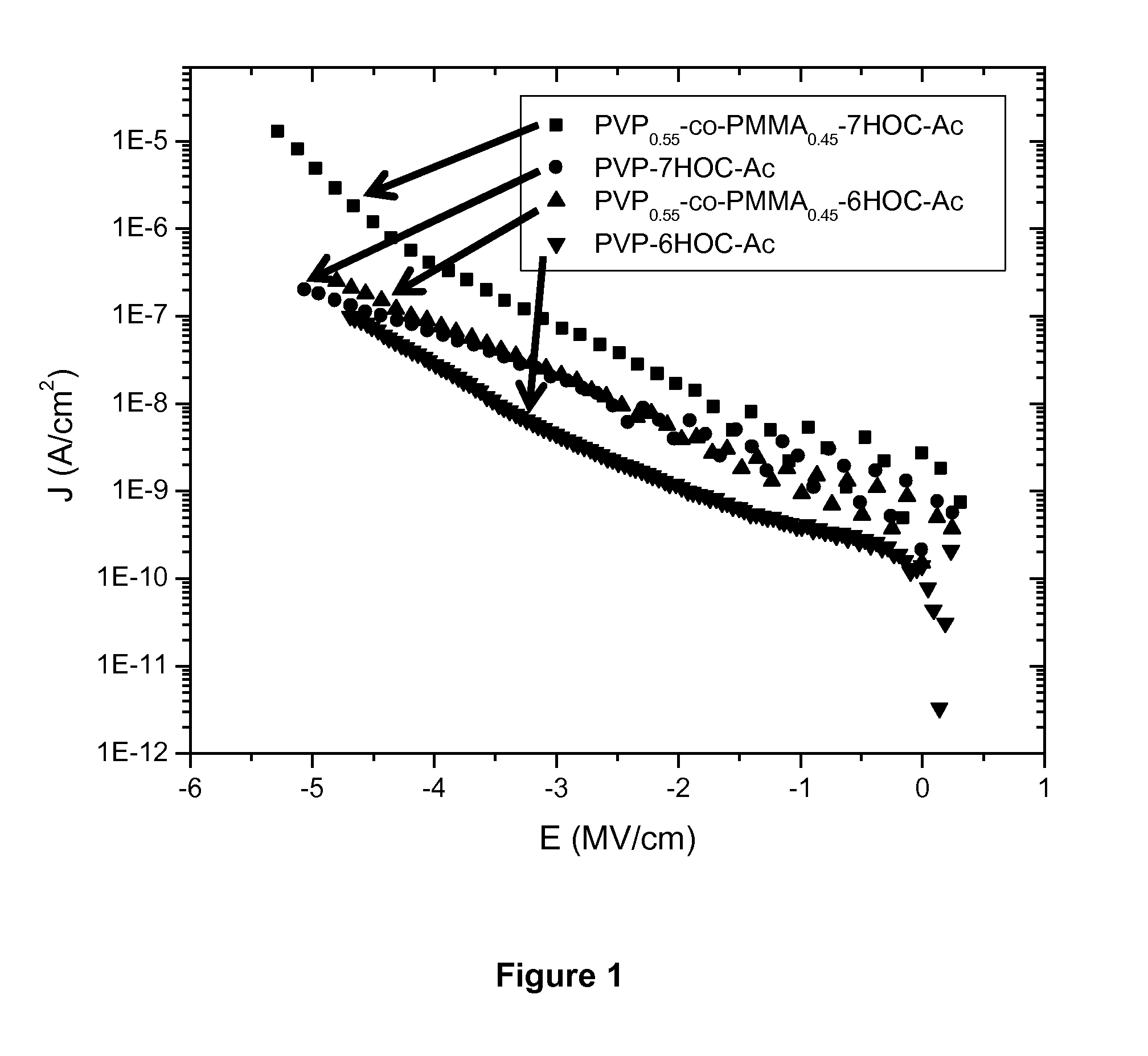

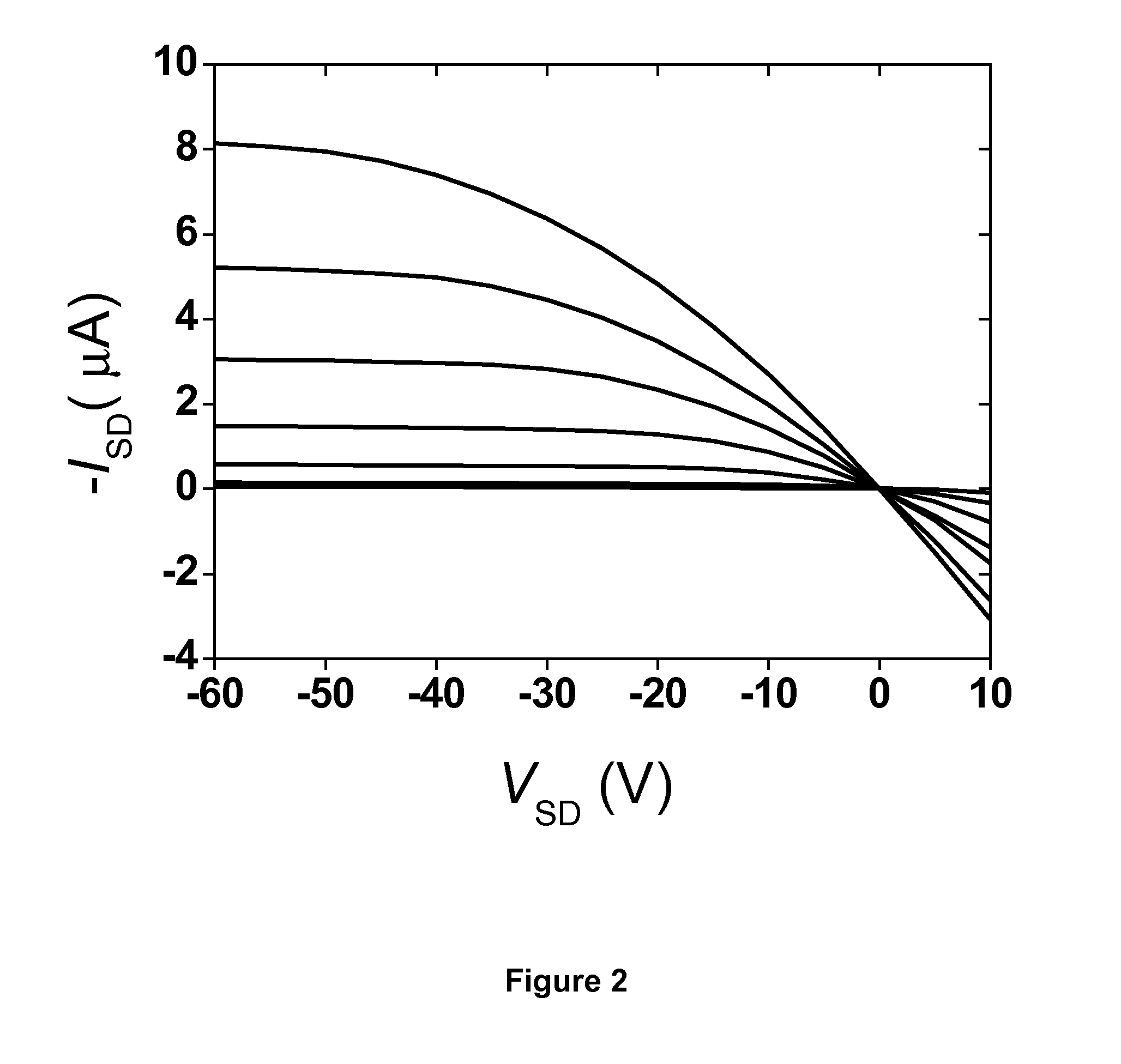

Photocurable polymeric dielectrics and methods of preparation and use thereof

ActiveUS20110215334A1Faster and deep cureEasy to implementTransistorSolid-state devicesDielectricCombinatorial chemistry

Disclosed are polymer-based dielectric compositions (e.g., formulations) and materials (e.g. films) and associated devices. The polymers generally include photocrosslinkable pendant groups; for example, the polymers can include one or more coumarin-containing pendant groups.

Owner:FLEXTERRA INC

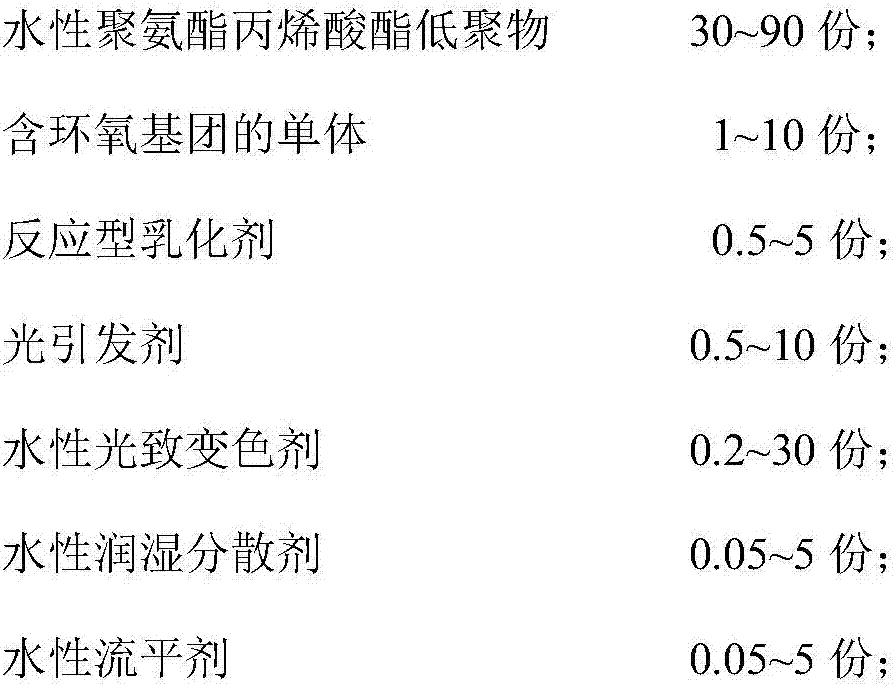

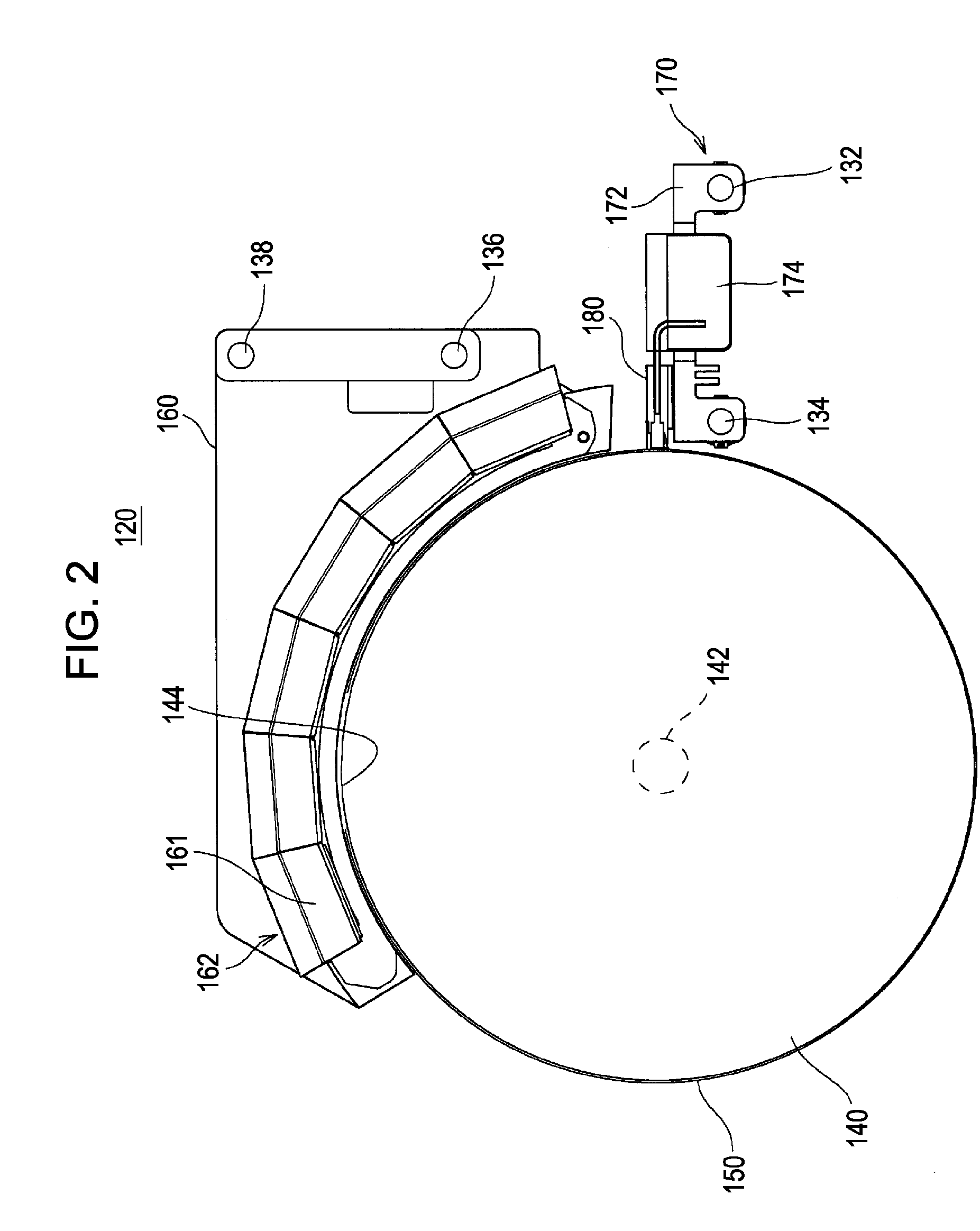

Waterborne photochromic coating as well as nail polish and decorative material

ActiveCN107325603ASolve the problem of slow curing speed and low efficiencyFully curedCosmetic preparationsAntifouling/underwater paintsOligomerSolvent

The invention discloses a waterborne photochromic coating as well as nail polish and a decorative material. The waterborne photochromic coating is prepared from the following components in parts by weight: 30 to 90 parts of a waterborne polyurethane acrylate oligomer, 1 to 10 parts of an epoxy group-containing monomer, 0.5 to 5 parts of a reactive emulsifier, 0.5 to 10 parts of a photoinitiator, 0.2 to 30 parts of a waterborne photochromic agent, 0.5 to 5 parts of a waterborne wetting dispersant, 0.05 to 5 parts of a waterborne flatting agent and 1 to 20 parts of deionized water. The waterborne photochromic coating disclosed by the invention has the advantages that the problems of low curing speed and low efficiency of a heat curable photochromic coating, and the problem that a large amount of solvents or volatile monomers are used in a UV (ultraviolet) photochromic coating are solved; the waterborne photochromic coating is suitable for coating various plastic substrates or nail, and has relatively-high industrial production benefits and a good application prospect.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

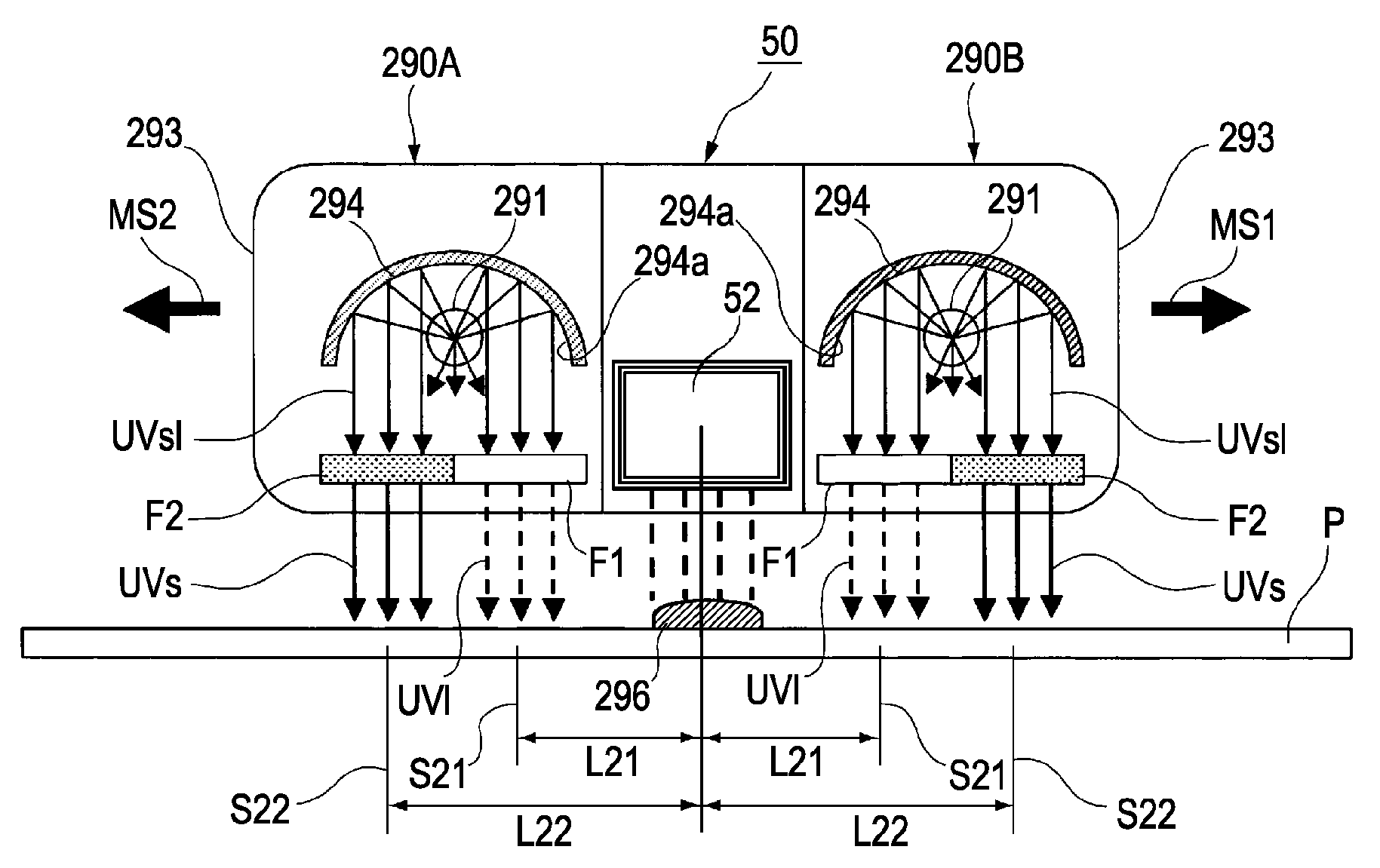

Recording apparatus and liquid ejecting apparatus

InactiveUS20080225100A1Improve throughputQuality improvementInking apparatusMeasurement apparatus componentsUV curingUltraviolet

A recording apparatus includes a support drum which rotates while supporting a recording medium on a support surface thereof. A guide shaft of the recording apparatus is spaced apart from the support surface by a predetermined distance and extends in parallel to a direction perpendicular to a rotation direction of the support drum. A carriage which is guided by the guide shaft is reciprocally moved along the support surface. A recording head mounted on the carriage ejects an ultraviolet curing ink toward the recording medium. An ultraviolet ray irradiation unit irradiates ultraviolet rays to the ultraviolet curing inks which are ejected from the recording head. In operation, the carriage is moved along the guide shaft so as to form an image formed by the ultraviolet curing ink and a coat ink over the overall surface of the recording medium supported by the support drum.

Owner:SEIKO EPSON CORP

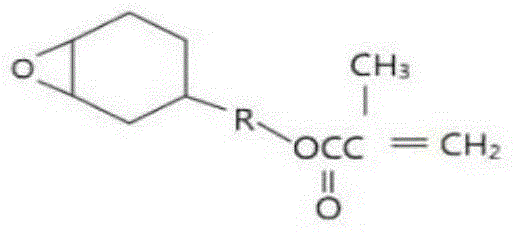

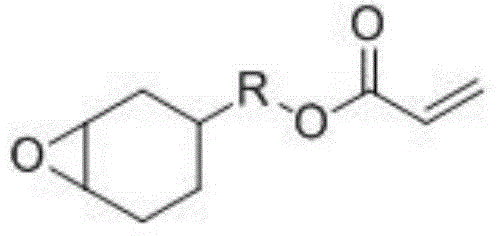

Ultraviolet-heat dual curing optical adhesive containing epoxidized polybutadiene resin

ActiveCN104449419ASynergistic priming effect is goodIncrease the polymerization rateOrganic non-macromolecular adhesivePolyolefinFast tempo

The invention belongs to the technical field of adhesives, and particularly relates to an ultraviolet-heat dual curing optical adhesive containing epoxidized polybutadiene resin. The ultraviolet-heat dual curing optical adhesive comprises the following components in percentage by weight: 14.5%-45% of epoxidized polybutadiene resin, 10%-40% of alicyclic epoxy modified resin, 5%-15% of polyolefin liquid rubber, 25.5%-35% of an acrylic ester reactive diluent, 2.4%-3.4% of a free radical photoinitiator, 0.1%-0.2% of a cationic photoinitiator and 2%-2.5% of a peroxide initiating curing agent. The optical adhesive disclosed by the invention is relatively completely solidified at a shaded part, a dark adhesive layer part or a thick adhesive layer part, has excellent optical properties such as high refractive index and high transmittance after being solidified, has the advantages of shock resistance, low yellowing coefficient, low haze, low shrinking percentage, easiness in repairing and good flexibility, meets the requirements of optical, physical and chemical properties of display devices, and is suitable for fast-tempo and high-efficiency production processes.

Owner:信泰永合(烟台)新材料有限公司

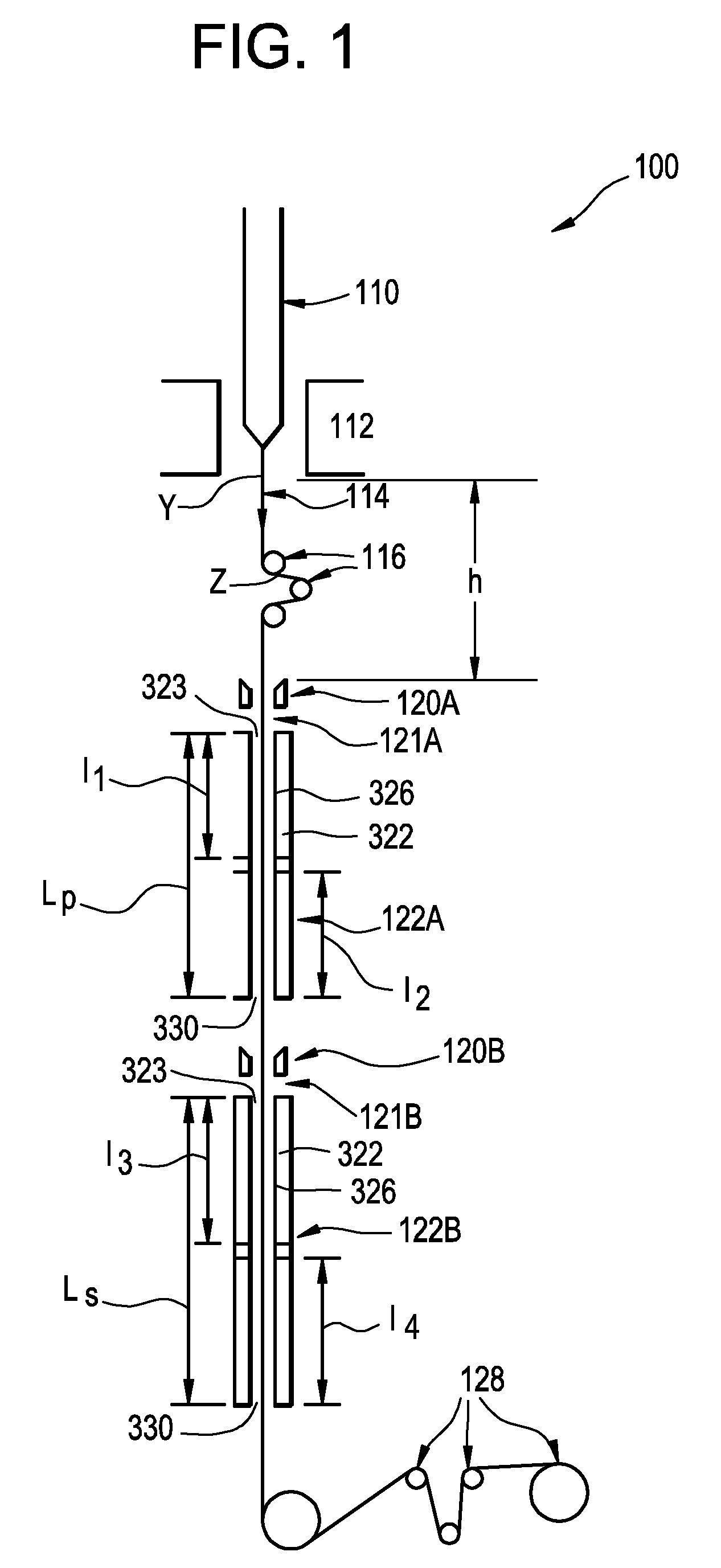

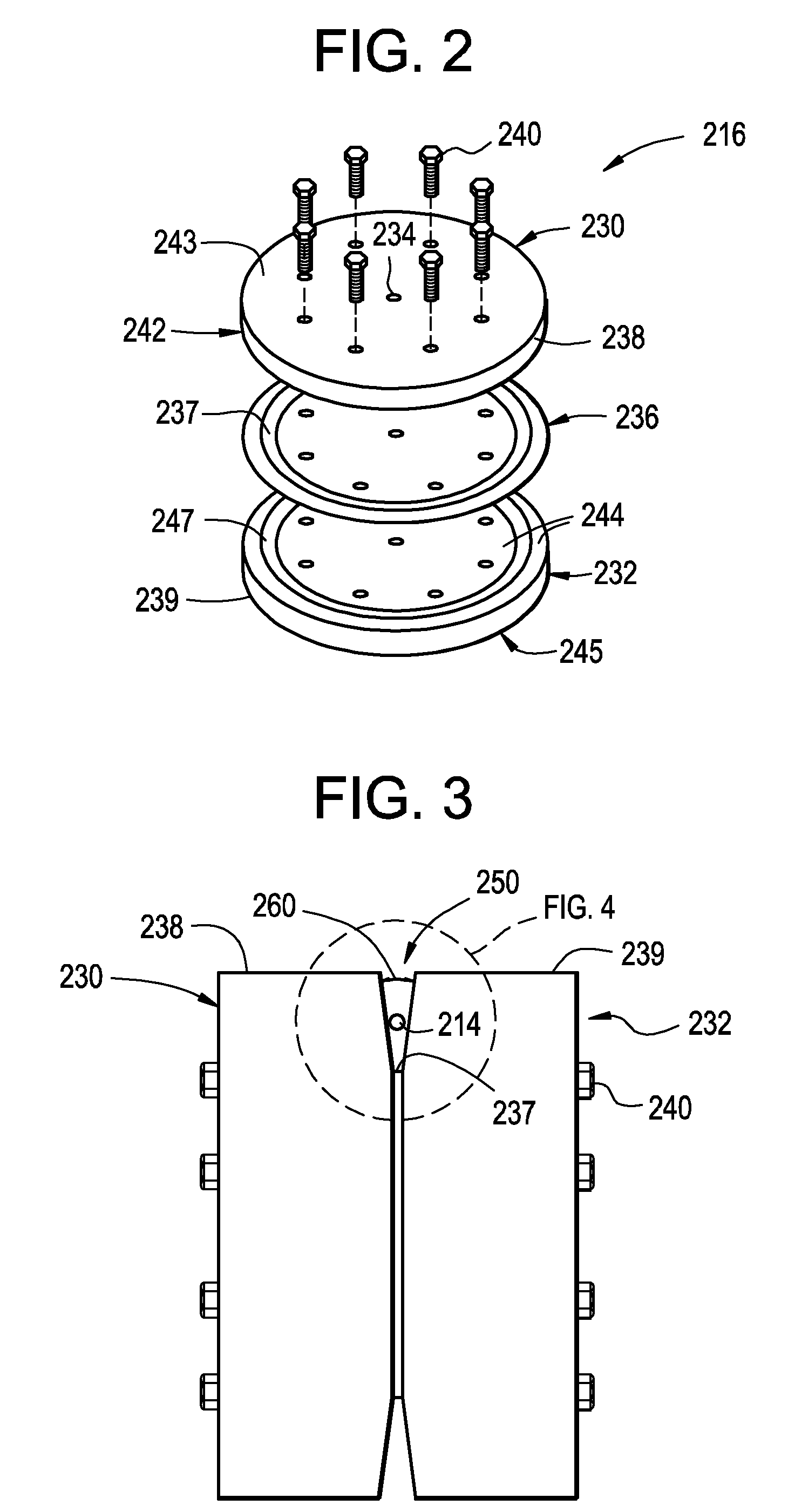

Fiber Cure with Extended Irradiators

ActiveUS20090139269A1Reduce defectsIncrease speedGlass fibre drawing apparatusRotary drum furnacesFiberFirst pathway

A method for producing an optical fiber that includes a method for producing an optical fiber, said method comprising: (i) drawing a bare optical fiber from a preform along a first pathway at a rate of at least 10 m / sec; (ii) contacting said bare optical fiber with a region of fluid in a fluid bearing and redirecting said bare optical fiber along a second pathway as said bare optical fiber is drawn across said region of fluid cushion; (iii) coating the bare optical fiber; and (iv) irradiating said coated fiber in at least one irradiation zone to at least partially cure said coating, while subjecting the optical fiber to UV light.

Owner:CORNING INC

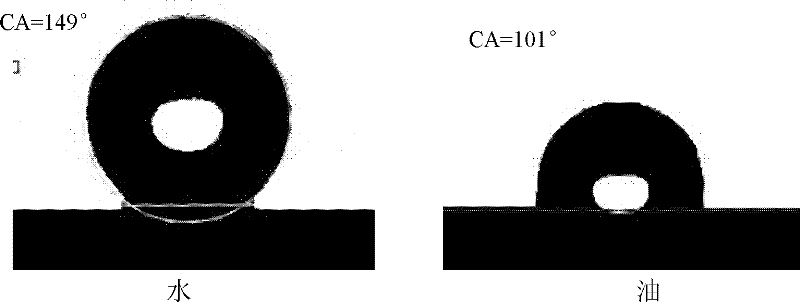

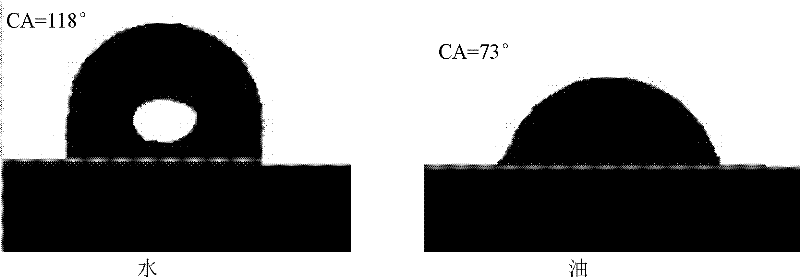

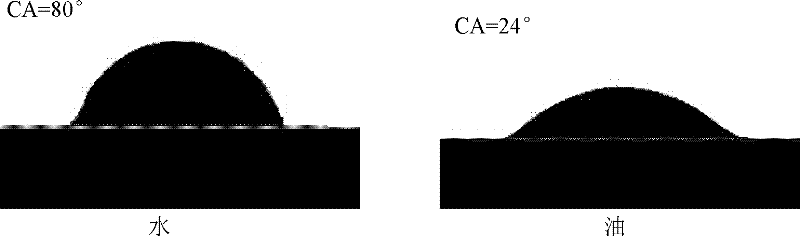

Hydrophobic olephobic epoxy paint and its preparation and application method

InactiveCN102229777ALow costFix compatibility issuesPretreated surfacesEpoxy resin coatingsEpoxyMass ratio

The invention provides a hydrophobic olephobic epoxy paint and its preparation and application method. The paint is prepared by mixing the following raw materials according to the mass ratio of epoxy paint for color coding: fluorine-silicon copolymer: a mixed solvent: nanometer silica: a curing agent = 1.0 : 0.005-0.12 : 0.5-3.0 : 0-0.30 : 0.01-0.25. An epoxy coating formed by the paint has a microscopic rough structure, overcomes the disadvantage of poor compatibility of an epoxy paint modified by a fluorine-silicon material, and has a water contact angle of 149 degrees and an oil contact angle of 101 degrees, being an epoxy coating with strong hydrophobicity and olephobicity.

Owner:HEBEI UNIV OF TECH

Method for preparing branching type water-based epoxy curing agent

The invention discloses a branched waterborne epoxy curing agent and a preparation method thereof: monoepoxy compound is firstly used for carrying out the end-blocking reaction of one end of aliphatic polyamine or aromatic polyamine or the aliphatic polyamine or the aromatic polyamine which undergoes the chain extension by polyether alcohol diglycidyl ether or polyether epoxy resin, and primary amine hydrogen at the other end of the polyamine is simultaneously maintained. Then, novolac epoxy resin or novolac epoxy resin solution is dipped in the solution of the intermediate product of the reaction for carrying out the branching reaction; after that, distilled water solution of monoatomic organic acid is dripped in adduct after the branching for carrying out the salt forming dispersion reaction; and the branched waterborne epoxy curing agent is finally prepared. When in use of the branched waterborne epoxy curing agent of the invention and waterborne epoxy resin component, the branched waterborne epoxy curing agent has the advantages of low viscosity and long application period; and the cured product can overcome the shortcoming of brittle performance of the ordinary epoxy resin material on the premise of keeping good heat resistance.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

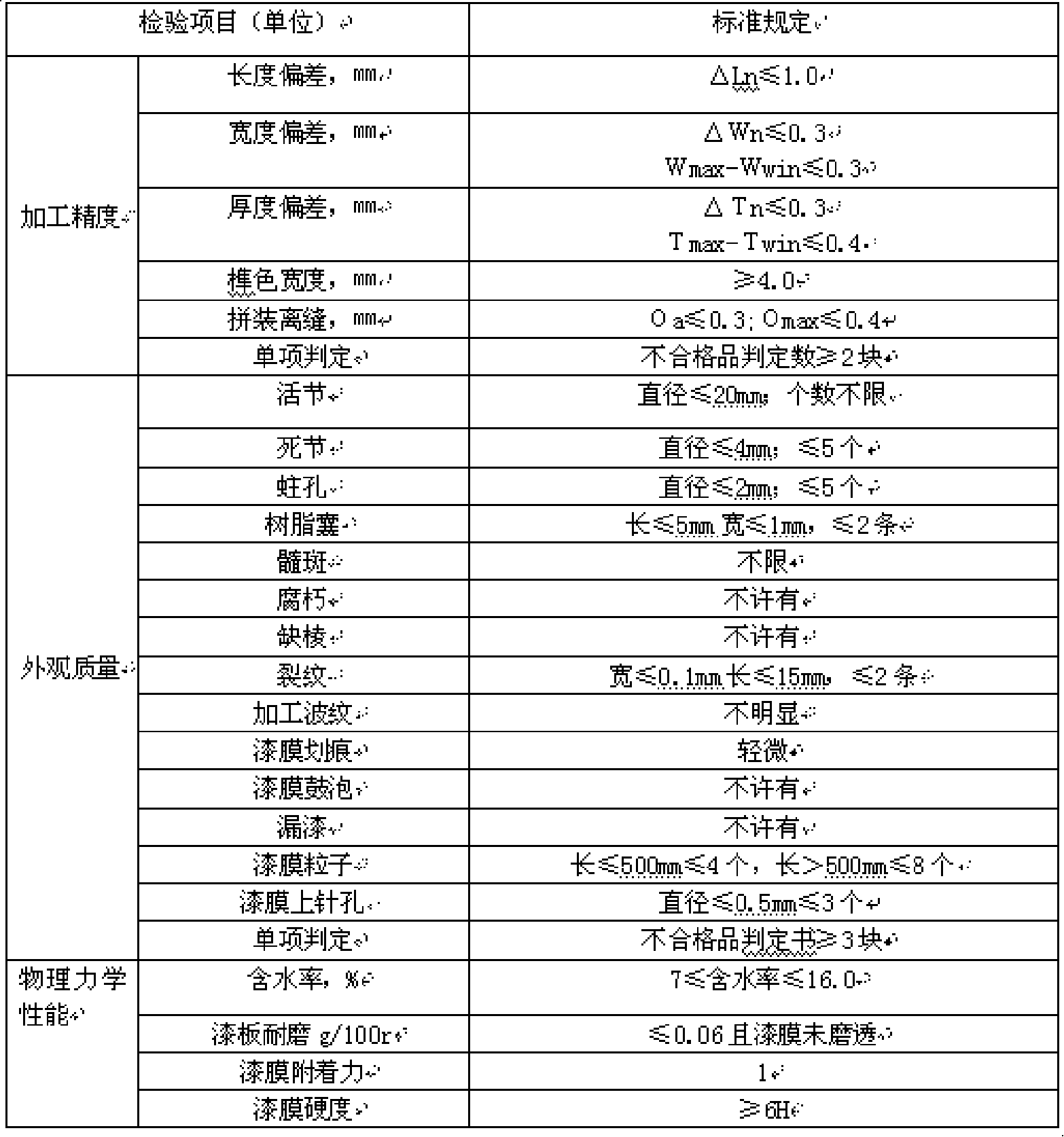

Method for producing wooden floor with platinum crystal surface

InactiveCN101301764ASolve the problem of insufficient adhesionIncrease pressureLiquid surface applicatorsWood treatment detailsPlatinumLacquer

The invention discloses a production method for a platinum crystal face wood floor, which comprises the production steps as follows: drying and curing of floor blank, blank processing, primer and paint painting. The invention adopts a vertical-lubrication penetration roller spraying technique, carries out the pre-heating disposal, drying disposal, balance disposal, humidifying treatment, temperature reduction kiln outgoing and curing to the floor blank, then processes the blank and paints the primer; the paint is then coated by adopting eight-bottom and four-surface so as to gain a finished product. The platinum crystal face wood floor prepared by the invention has the advantages that the paint adhesion of the tree with high grease (oil) content is improved; the floor has ultra-strong adhesion from the interior of the wood to the surface; a production process of eight-bottom and four-surface is adopted to combine an elastic, abration and friction resistance environmental protection paint; therefore, the surface filling of the floor is saturated, clear and natural, the chamfers are smoother and the wood floor is more scraping- resistant and wear-resistant; the one-off qualification rate of the product is improved and achieves 99.5 percent, thus improving the quality of the product.

Owner:浙江上臣家居科技有限公司

Ultraviolet ray irradiation device, recording apparatus using the ultraviolet ray irradiation device, and recording method

ActiveUS7794076B2Fully curedInking apparatusOther printing apparatusColor printingUltraviolet lights

The ultraviolet ray irradiation devices are attached to a carriage having a print head that ejects the ultraviolet curable ink, and include a plurality of ultraviolet light sources that irradiate ultraviolet rays onto ink coating ejected on a print sheet by the print head. An ultraviolet ray of the ultraviolet light source that irradiates the ultraviolet ray onto the print sheet in the vicinity of the print head has a wavelength shorter than an ultraviolet ray of the ultraviolet light source that irradiates the ultraviolet ray onto the print sheet apart from the vicinity of the print head along the moving direction of the carriage. The ultraviolet ray irradiation device is capable of sufficiently curing a plurality of ultraviolet curable ink adhered on a recording medium without incurring a problem of blurring or color mixing for a multiple-color printing process such as a full-color printing process.

Owner:SEIKO EPSON CORP

LED-UV photocurable screen printing halogen-free glass ink

The invention discloses an LED-UV photocurable screen printing halogen-free glass ink. The LED-UV photocurable screen printing halogen-free glass ink is prepared from the following raw materials in percentage by mass: 30-70% of multi-functional group polyester acrylate, 10-30% of urethane acrylate, 10-40% of functional acrylate monomer, 3-10% of photoinitiator, 1-3% of defoamer, 0.1-1.5% of flatting agent, 1-5% of adhesion promoter, 3-8% of organic pigment and 4-50% of inorganic pigment. The invention also discloses a preparation method of the ink. The preparation method comprises the steps of blending, grinding and dispersing, and filtering. Compared with the existing inks, the LED-UV photocurable screen printing halogen-free glass ink is energy-saving, environment-friendly, and high in performance; the operation area needed during printing is relatively small.

Owner:广州市尤特新材料有限公司

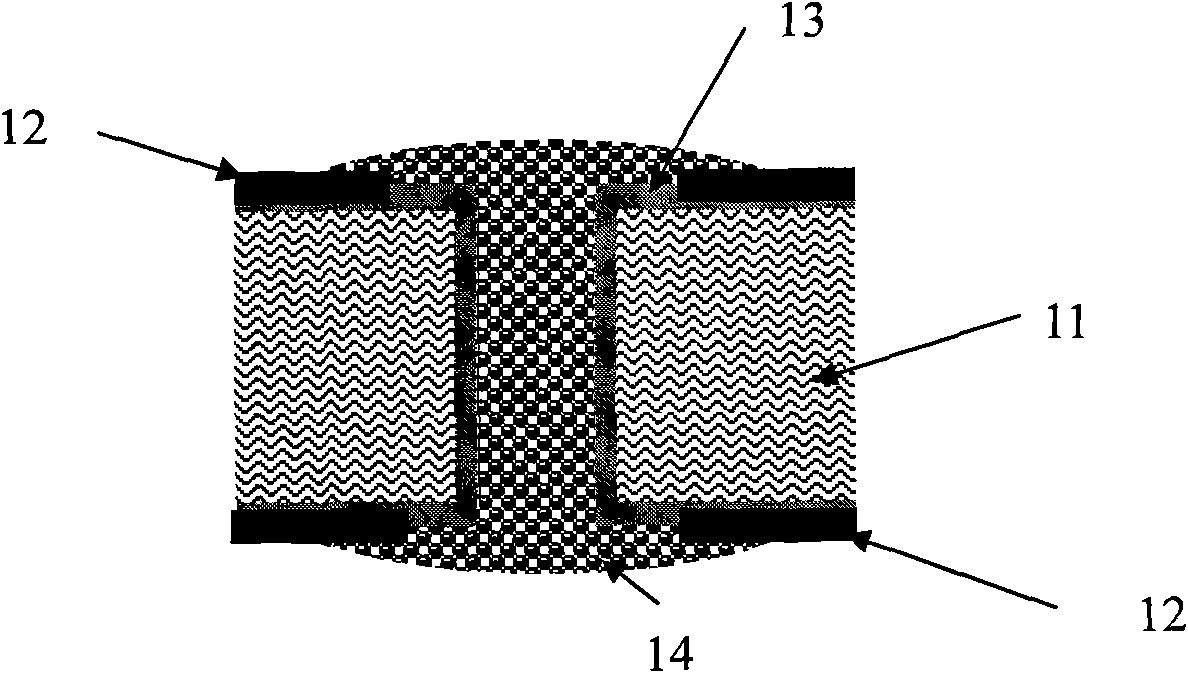

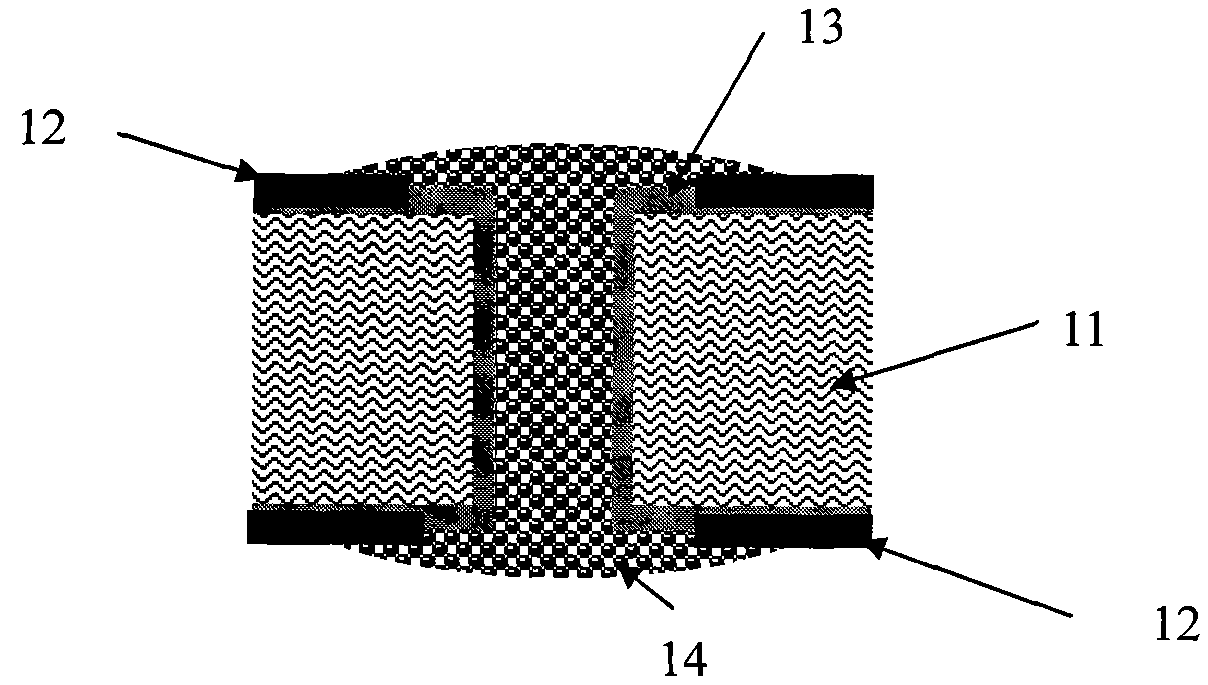

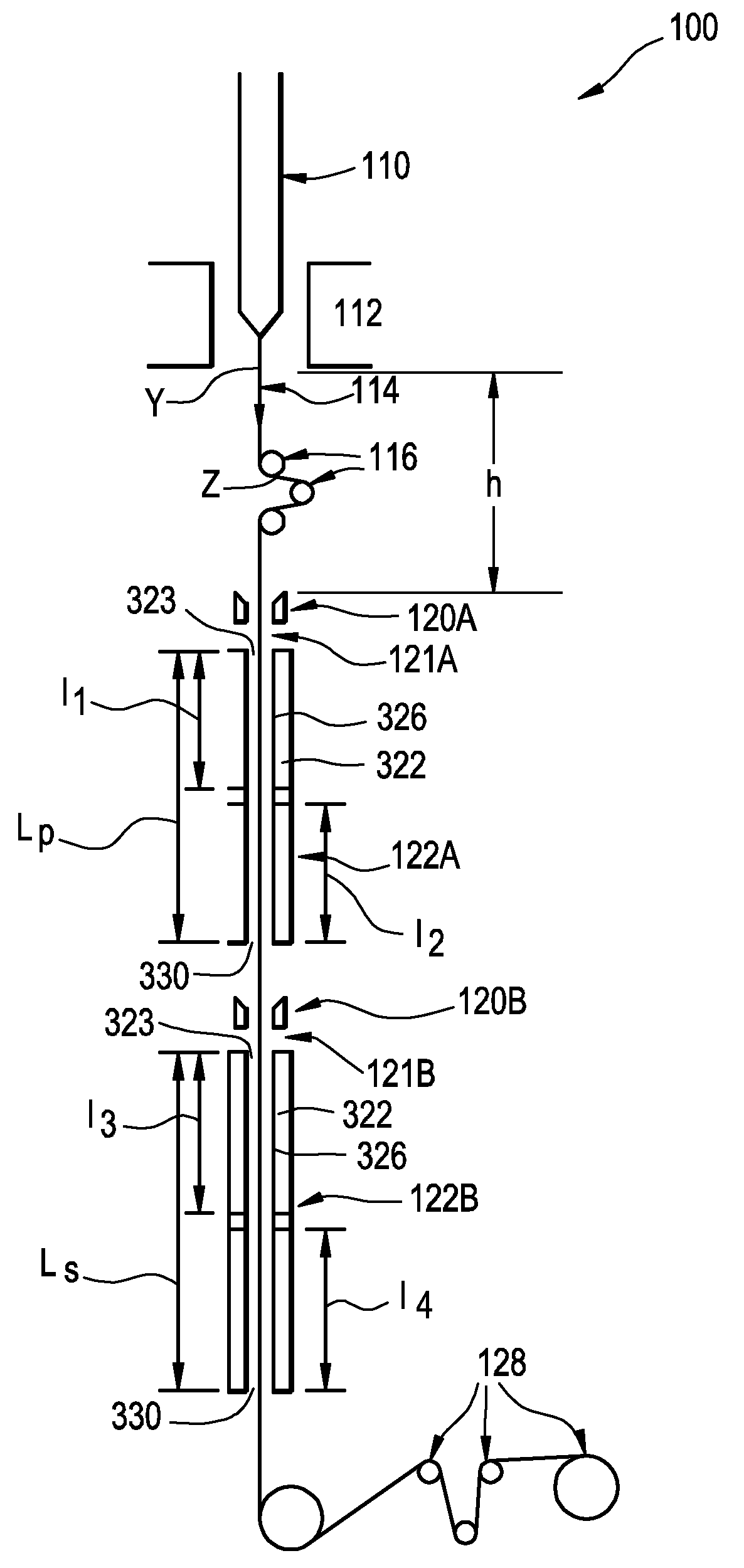

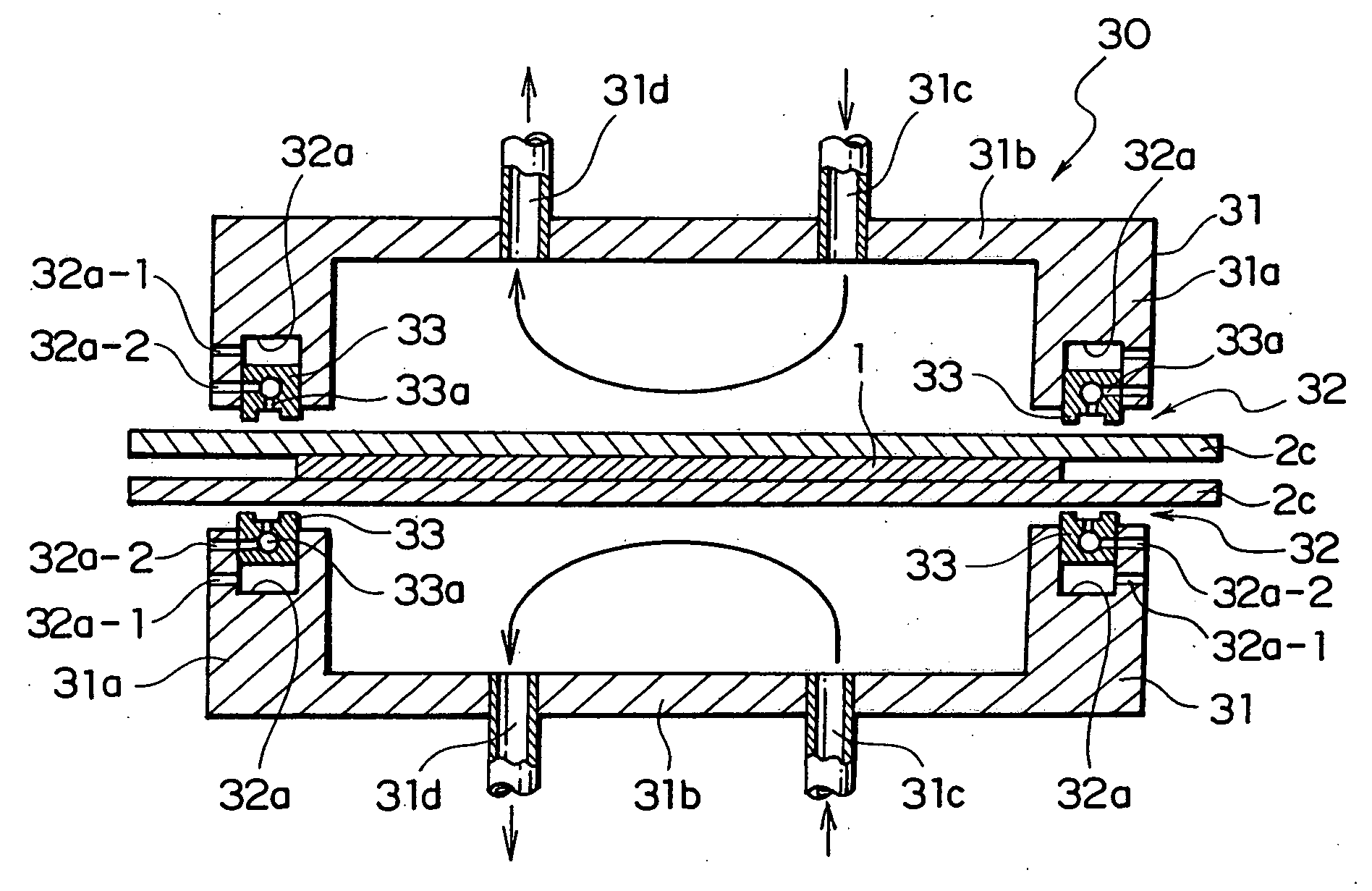

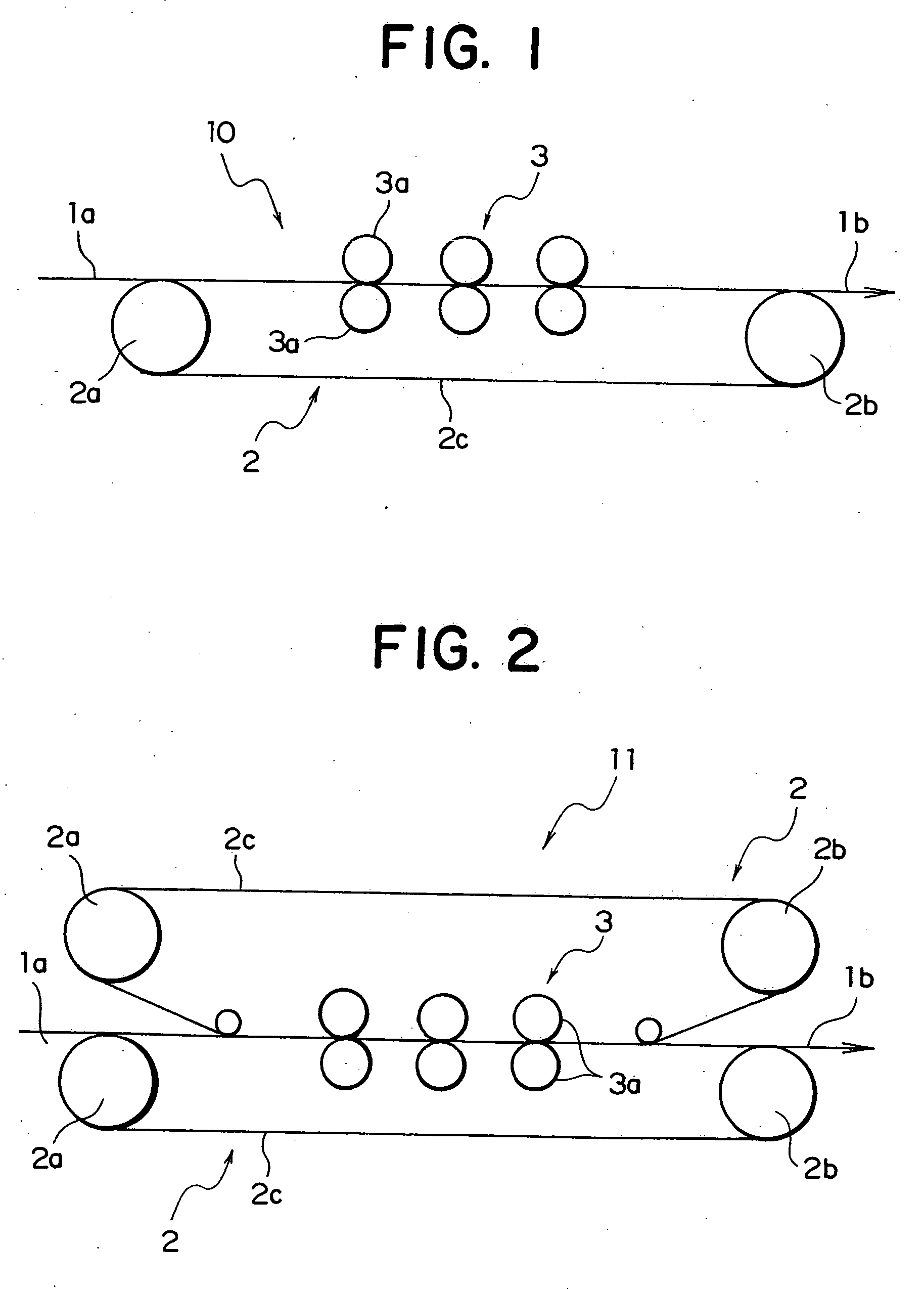

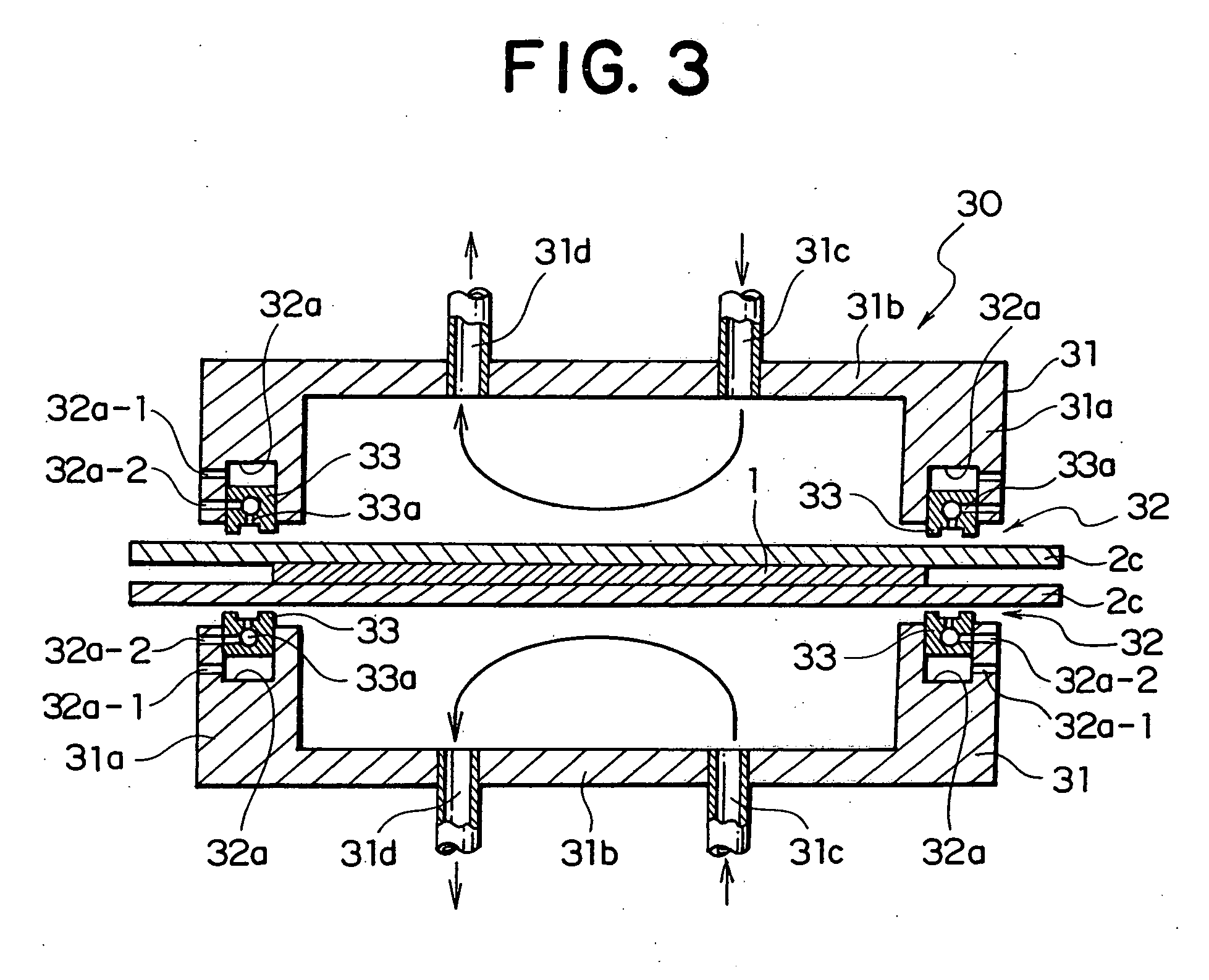

Apparatus and method for manufacturing resin-impregnated cured sheet, and apparatus and method for manufacturing carbonaceous material sheet

InactiveUS20040227265A1Control thicknessFully curedMouldsDough-sheeters/rolling-machines/rolling-pinsFiberCarbonization

An object of the present invention is to provide an apparatus and a method for manufacturing a windable carbonaceous material sheet, which is obtained by continuously curing a long uncured fiber sheet which is obtained by using short fibers to make paper and which contains uncured resin to produce a resin-impregnated cured sheet, and then continuously carbonizing it, and its production process. For the object, a long uncured fiber sheet (1a) is conveyed by conveyance means which is equipped with one rotation belt set (2) comprising a drive roll (2a), a follower roll (2b), and an endless belt (2c) which is put on and around these rolls (2a, 2b). A resin-impregnated cured sheet (1b) is produced by heating and pressurizing the uncured fiber sheet (1a) by resin curing means (3) which is arranged so as to nip the uncured fiber sheet through the endless belt (2c). Further, the resin-impregnated cured sheet is continuously conveyed in a horizontal direction, and then is carbonized by the apparatus for manufacturing a carbonaceous material sheet which is equipped with a carbonization treatment chamber for carbonizing a carbonizing material and guide rolls which are provided in the carbonization treatment chamber, so that a carbonaceous material sheet is continuously produced. Then, this is wound up. Accordingly, production efficiency is remarkably improved, and its handling property and conveying property are excellent.

Owner:MITSUBISHI RAYON CO LTD

Soldering paste flux and soldering paste

InactiveUS20140083567A1Storage stability be excellentExcellent durabilityWelding/cutting media/materialsSoldering mediaPrepolymerSolder paste

The present invention relates to a soldering paste flux, and the soldering paste flux includes (A) a thermosetting prepolymer, (B) a polyfunctional epoxy monomer or oligomer having three or more functional groups in a molecule, (C) a carboxylic acid having a melting point of 80 to 170° C., and (D) a cyanate ester having two or more cyanato groups in a molecule.

Owner:HARIMA CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com