Epoxy organosilicone ultraviolet curing coating modified by (methyl) acrylic acid and preparation method thereof

A technology for curing coatings and epoxy curing agents, applied in the field of coatings, can solve the problems of low weather resistance, less photosensitive groups, low water resistance, etc., and achieve good hardness and adhesion, increased crosslinking density, and compatibility. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

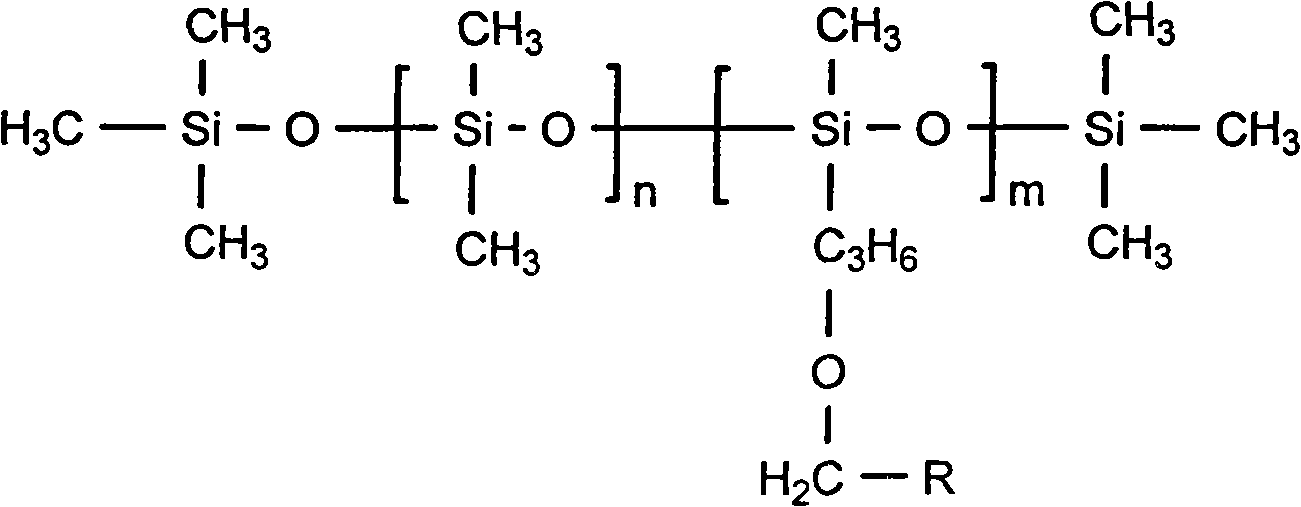

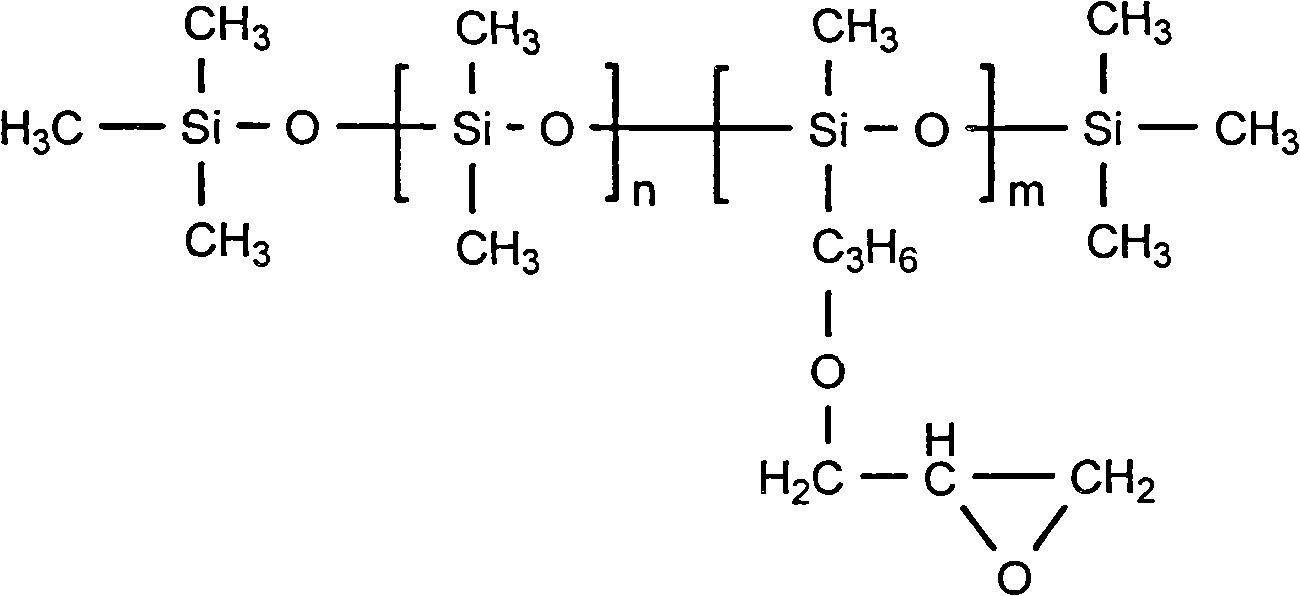

[0039] (1) Synthesis of methacrylic acid modified epoxidized silicone: take 100 parts of epoxidized silicone with an epoxy value of 0.51mol / 100g and put it into a reactor equipped with a stirrer, dropping funnel and thermometer, heat and stir until At 75°C, slowly add dropwise a mixture of 30 parts of methacrylic acid, 0.78 parts of trimethylbenzyl ammonium chloride and 0.22 parts of hydroquinone, and react for 1 hour to obtain methacrylic acid-modified epoxidized silicone;

[0040] (2) Take 100 parts of bisphenol A epoxy resin (epoxy value 0.20) and put it into a reactor equipped with a stirrer, dropping funnel and thermometer, heat and stir to 85°C, slowly add 17 parts of methacrylic acid, three A mixture of 1.3 parts of methyl benzyl ammonium bromide and 0.02 parts of p-hydroxyanisole was heated up to 105 ° C for 5 hours to obtain bisphenol A epoxy methacrylate resin;

[0041] (3) Add 100 parts of methacrylic acid modified epoxy silicone into the container;

[0042] (4) Ad...

Embodiment 2

[0049] (1) Synthesis of acrylic acid modified epoxidized silicone: take 88 parts of epoxidized silicone with an epoxy value of 0.30mol / 100g and put it into a reactor equipped with a stirrer, dropping funnel and thermometer, heat and stir to 80 ℃, slowly drop a mixture of 15 parts of acrylic acid, 0.8 parts of tetrabutylammonium bromide and 0.2 parts of p-methoxyphenol, and react for 1.2 hours to obtain acrylic acid-modified epoxidized silicone;

[0050](2) Take 100 parts of bisphenol A epoxy resin (epoxy value 0.42) and put it into a reactor equipped with a mixer, dropping funnel and thermometer, heat and stir to 90°C, slowly add 30 parts of acrylic acid, triethyl A mixture of 1.5 parts of benzyl ammonium chloride and 0.05 parts of 2,5-dimethylhydroquinone was heated to 110° C. for 4 hours to obtain bisphenol A epoxy acrylate resin;

[0051] (3) Add 100 parts of acrylic acid modified epoxidized silicone into the container;

[0052] (4) Add 50 parts of bisphenol A type epoxy a...

Embodiment 3

[0059] (1) Synthesis of methacrylic acid-modified epoxidized silicone: Take 100 parts of epoxidized silicone with an epoxy value of 0.12mol / 100g and put it into a reactor equipped with a stirrer, dropping funnel and thermometer, heat and stir To 80°C, slowly add dropwise a mixture of 8 parts of methacrylic acid, 0.8 parts of trimethylbenzyl ammonium bromide and 0.2 parts of p-methoxyphenol, and react for 1.2 hours to obtain methacrylic acid modified epoxidized silicone ;

[0060] (2) Take 100 parts of bisphenol A epoxy resin (epoxy value 0.31) and put it into a reactor equipped with a mixer, a dropping funnel and a thermometer, heat and stir to 80°C, slowly add 22 parts of acrylic acid, tetrabutyl A mixture of 1.1 parts of ammonium bromide and 0.02 parts of p-hydroxyanisole was heated up to 100 ° C for 4.5 hours to obtain bisphenol A epoxy acrylate resin;

[0061] (3) Add 100 parts of methacrylic acid modified epoxy silicone into the container;

[0062] (4) Add 70 parts of b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pencil hardness | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com