Waterborne photochromic coating as well as nail polish and decorative material

A technology of photochromic and decorative materials, applied in the field of coatings, can solve problems such as the impact on the environment and human health, achieve complete curing, excellent environmental performance, and promote curing efficiency and curing depth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

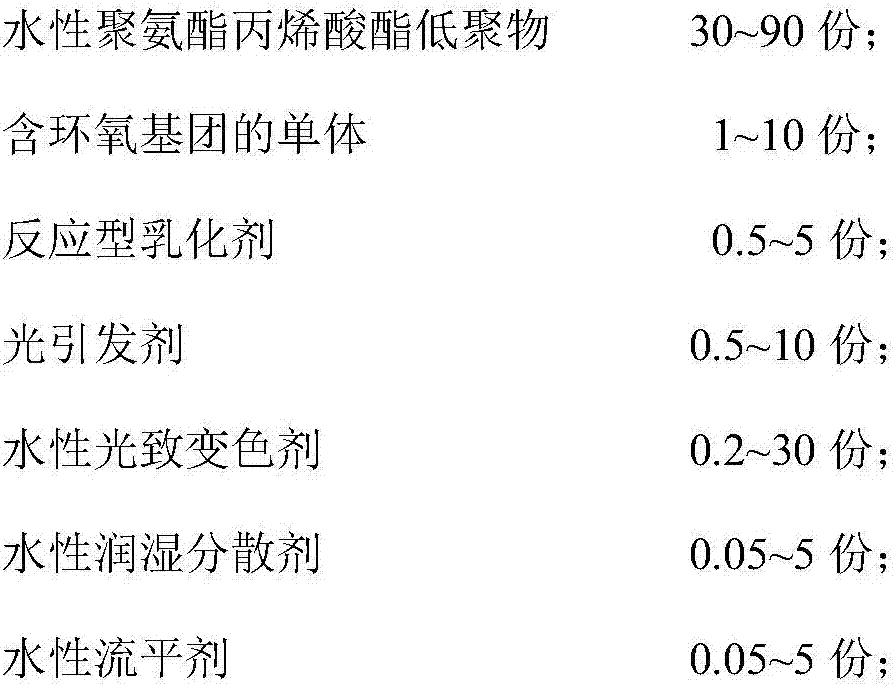

[0068] The present embodiment 1 water-based photochromic coating is made after LED photocuring by the following components by weight:

[0069]

[0070] The preparation method is as follows:

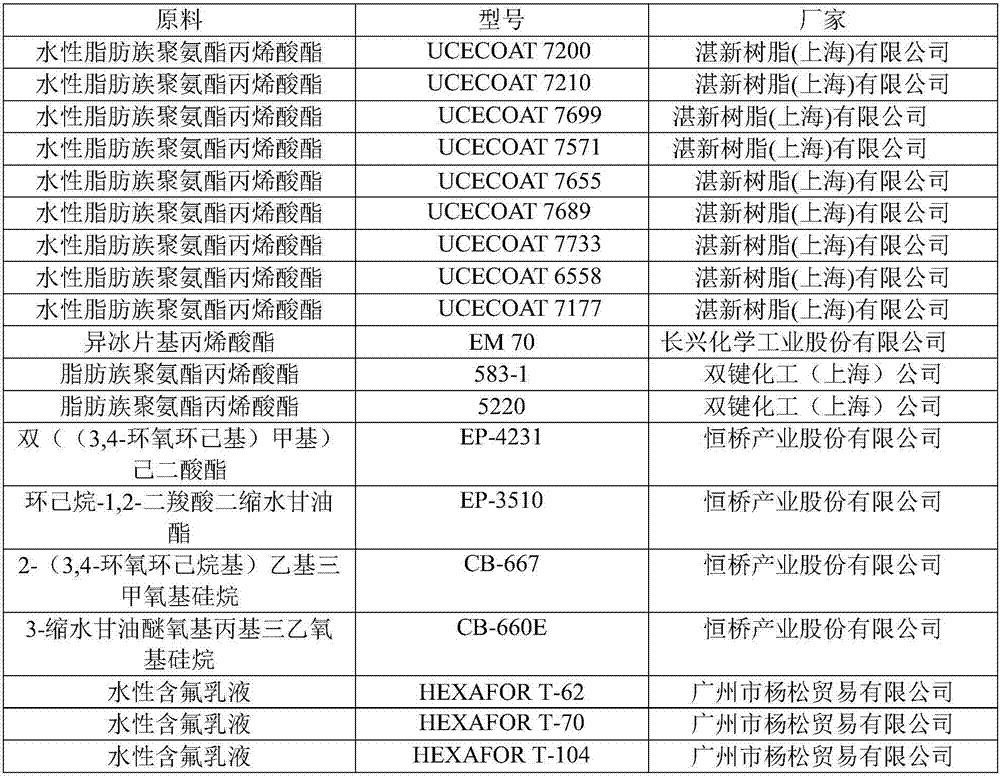

[0071]Add 15 parts of water-based aliphatic urethane acrylate UCECOAT 7200 (Allnex), 15 parts of UCECOAT 7177 water-based aliphatic urethane acrylate (Allnex), and 1 part of deionized water into a mixing bucket with a condenser. Then, under the condition of uniform stirring, add 5 parts of reactive emulsifier ER-20 into the above emulsion system to make it uniformly dispersed in the solvent, stirring at 800r / min for 0.5 hours. Then, add 0.05 parts of dispersant DISPERBYK-180 to make it evenly dispersed in the system. Then, gradually add 0.2 parts of #19 red photosensitive microcapsule powder (Chongyu Co., Ltd.), increase the stirring speed to 1200r / min, and stir for 0.5 hours. Then, add 30 parts of epoxy monomer EP-4231 (Hengqiao Industry), 0.2 part of free radical photoinitiator IRG...

Embodiment 2

[0074] The present embodiment 2 water-based photochromic paint is made after LED photocuring by the following components by weight:

[0075]

[0076] The preparation method is as follows:

[0077] Add 45 parts of water-based aliphatic urethane acrylate UCECOAT 7200 (Allnex), 45 parts of UCECOAT 7177 water-based aliphatic urethane acrylate (Allnex), and 20 parts of deionized water into a mixing tank with a condenser. Then, under the condition of uniform stirring, add 3 parts of reactive emulsifier ER-20 into the above emulsion system to make it evenly dispersed in the solvent, stirring at 800r / min for 0.5 hours. Then, add 5 parts of dispersant DISPERBYK-180 to make it evenly dispersed in the system. Then, gradually add 30 parts of #19 red photosensitive microcapsule powder (Chongyu Co., Ltd.), increase the stirring speed to 1200r / min, and stir for 0.5 hours. Then, add 15 parts of epoxy monomer EP-4231 (Hengqiao Industry), 6.5 parts of free radical photoinitiator IRGACURE 1...

Embodiment 3

[0080] The present embodiment 3 water-based photochromic paint is made after LED photocuring by the following components by weight:

[0081]

[0082] The preparation method is as follows:

[0083] Add 35 parts of water-based aliphatic urethane acrylate UCECOAT 7200 (Allnex), 25 parts of UCECOAT 7177 water-based aliphatic urethane acrylate (Allnex), and 10 parts of deionized water into a mixing tank with a condenser. Then, under the condition of uniform stirring, add 1 part of reactive emulsifier ER-20 into the above emulsion system to make it uniformly dispersed in the solvent, stirring at 800r / min for 0.5 hours. Then, add 0.2 parts of dispersant DISPERBYK-180 to make it evenly dispersed in the system. Then, gradually add 5 parts of #19 red photosensitive microcapsule powder (Chongyu Co., Ltd.), increase the stirring speed to 1200r / min, and stir for 0.5 hours. Then, add 5 parts of epoxy monomer EP-4231 (Hengqiao Industry), 2 parts of free radical type photoinitiator IRGAC...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com