Patents

Literature

175results about How to "Improve working efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Conductive adhesive agent and process for manufacturing article using the conductive adhesive agent

ActiveUS20060038304A1Fully curedUniform thicknessSemiconductor/solid-state device detailsConductive materialPolymer scienceFluid viscosity

The present invention provides a conductive adhesive agent capable of being diluted with a solvent to give good coating workability and allowing formation of a conductive joint excellent in both thermal conductivity and electrical conductivity by inhibiting a gas generated when a binder resin is heat-cured after attachment of a part. The conductive adhesive agent according to the present invention is a conductive adhesive agent wherein, based on 100 parts by weight of silver powder having an average particle diameter of micrometers, which is used for a conductive medium, e.g. as a main component, 1 to 10 parts by weight of silver fine particles having an average particle diameter of nanometers is used in combination therewith and 5 to 15 parts by weight of thermosetting resin as a binder resin component and 10 parts or less by weight of solvent for adjustment of a fluid viscosity are blended therein as essential components, and by selection of such a blending ratio, generation of a gas component during heating and curing of the thermosetting resin to prevent formation of voids, and at the same time, fabrication of a conductive joint excellent in thermal conductivity and electrical conductivity is achieved.

Owner:HARIMA CHEM INC +1

Conductive adhesive agent with ultrafine particles

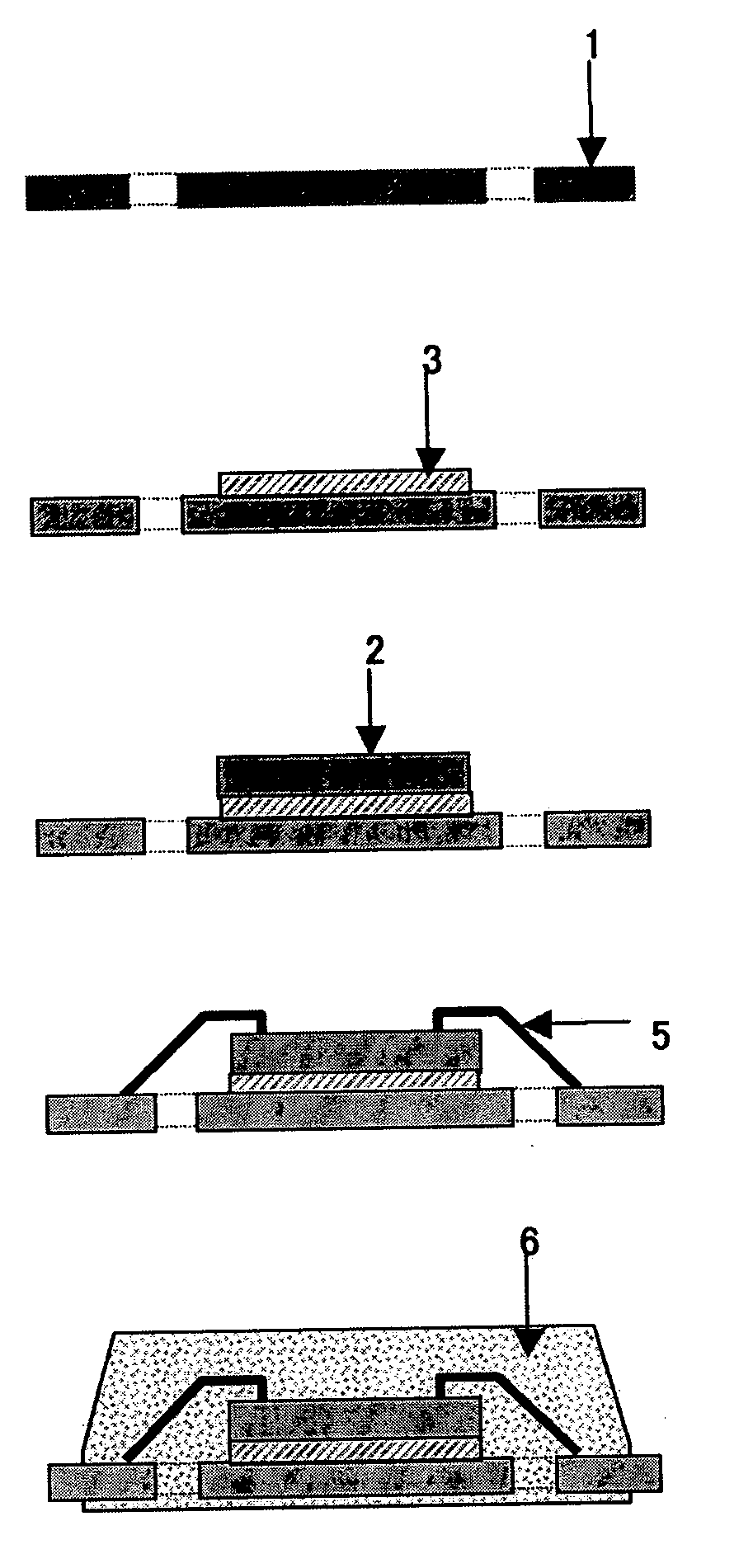

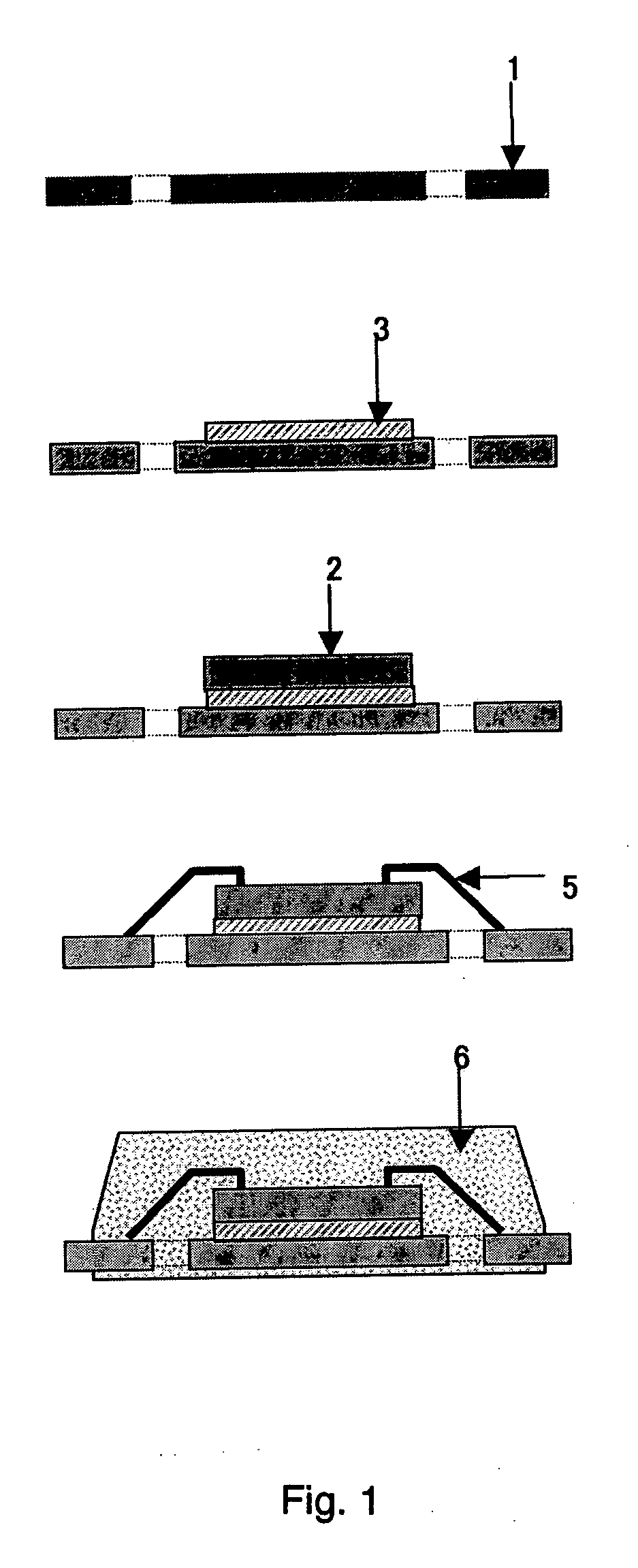

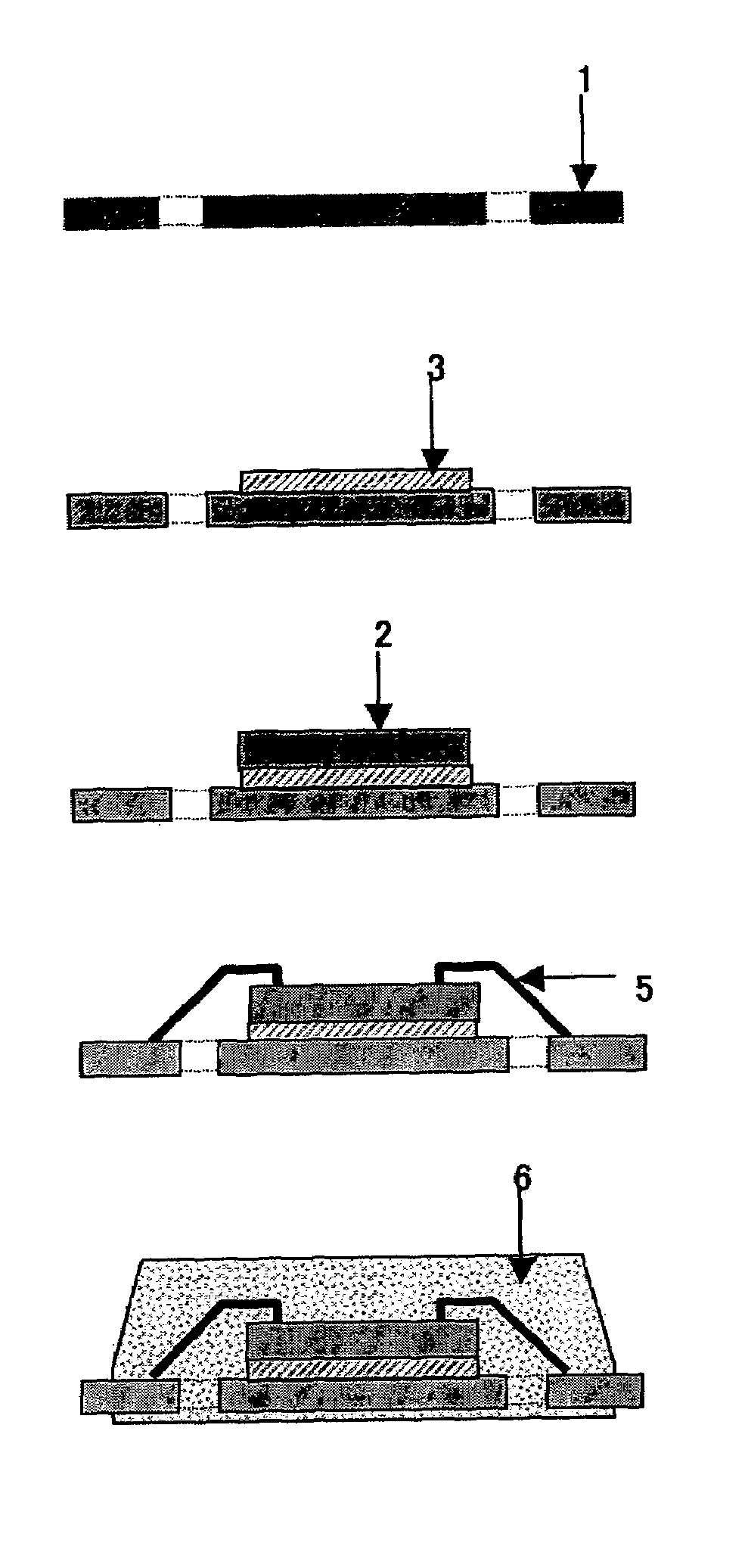

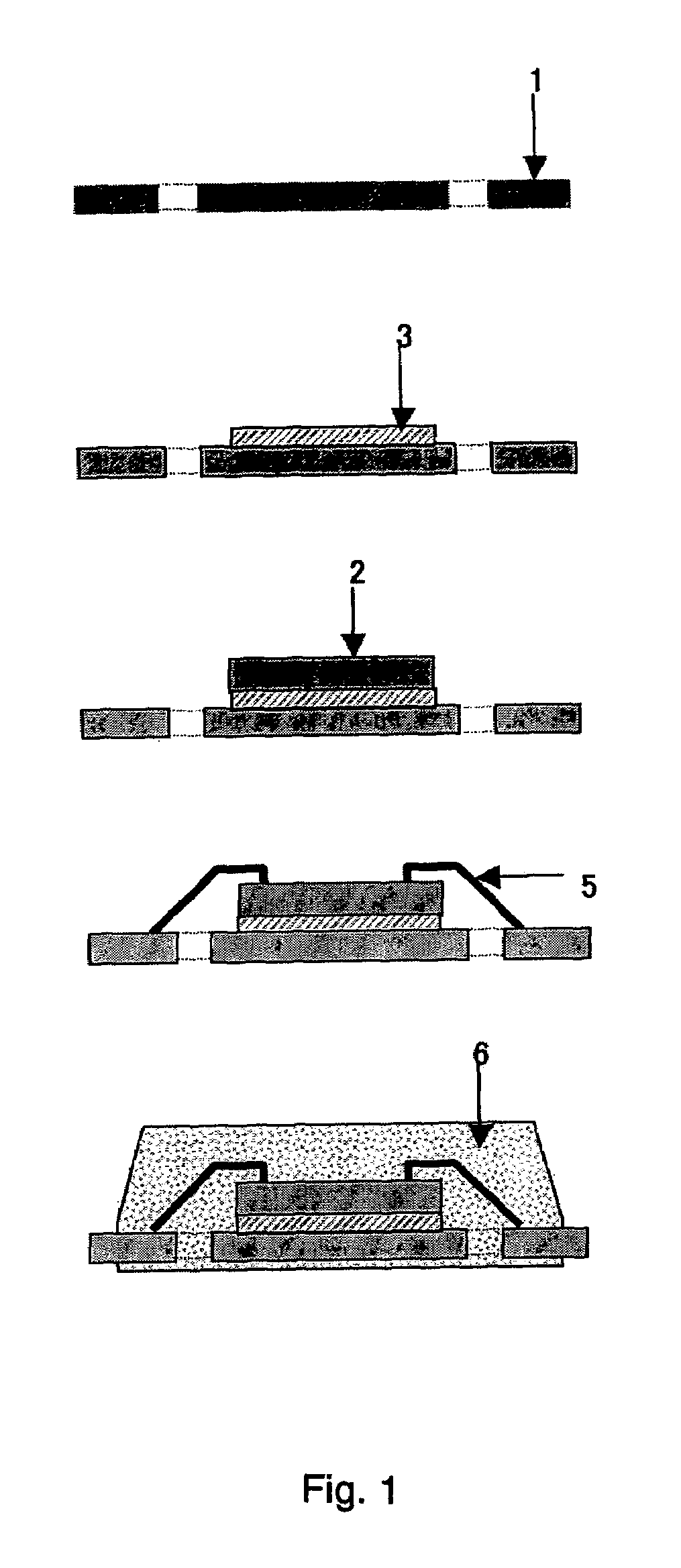

ActiveUS7262511B2Improve working efficiencyUniform and good thermal conductivity propertySemiconductor/solid-state device detailsConductive materialMicrometerFluid viscosity

The present invention provides a conductive adhesive agent capable of being diluted with a solvent to give good coating workability and allowing formation of a conductive joint excellent in both thermal conductivity and electrical conductivity by inhibiting a gas generated when a binder resin is heat-cured after attachment of a part. The conductive adhesive agent according to the present invention is a conductive adhesive agent wherein, based on 100 parts by weight of silver powder having an average particle diameter of micrometers, which is used for a conductive medium, e.g. as a main component, 1 to 10 parts by weight of silver fine particles having an average particle diameter of nanometers is used in combination therewith and 5 to 15 parts by weight of thermosetting resin as a binder resin component and 10 parts or less by weight of solvent for adjustment of a fluid viscosity are blended therein as essential components, and by selection of such a blending ratio, generation of a gas component during heating and curing of the thermosetting resin to prevent formation of voids, and at the same time, fabrication of a conductive joint excellent in thermal conductivity and electrical conductivity is achieved.

Owner:HARIMA CHEM INC +1

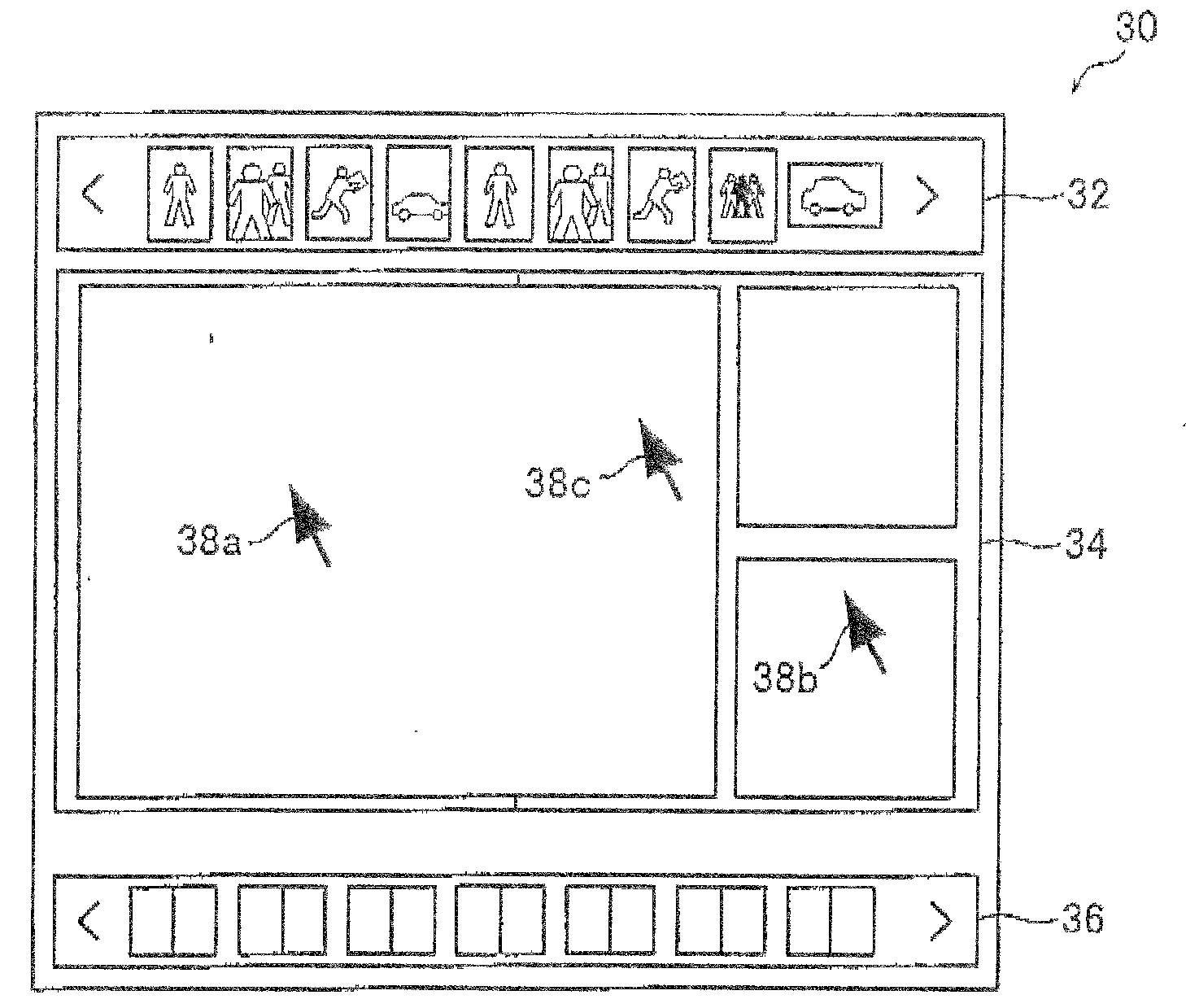

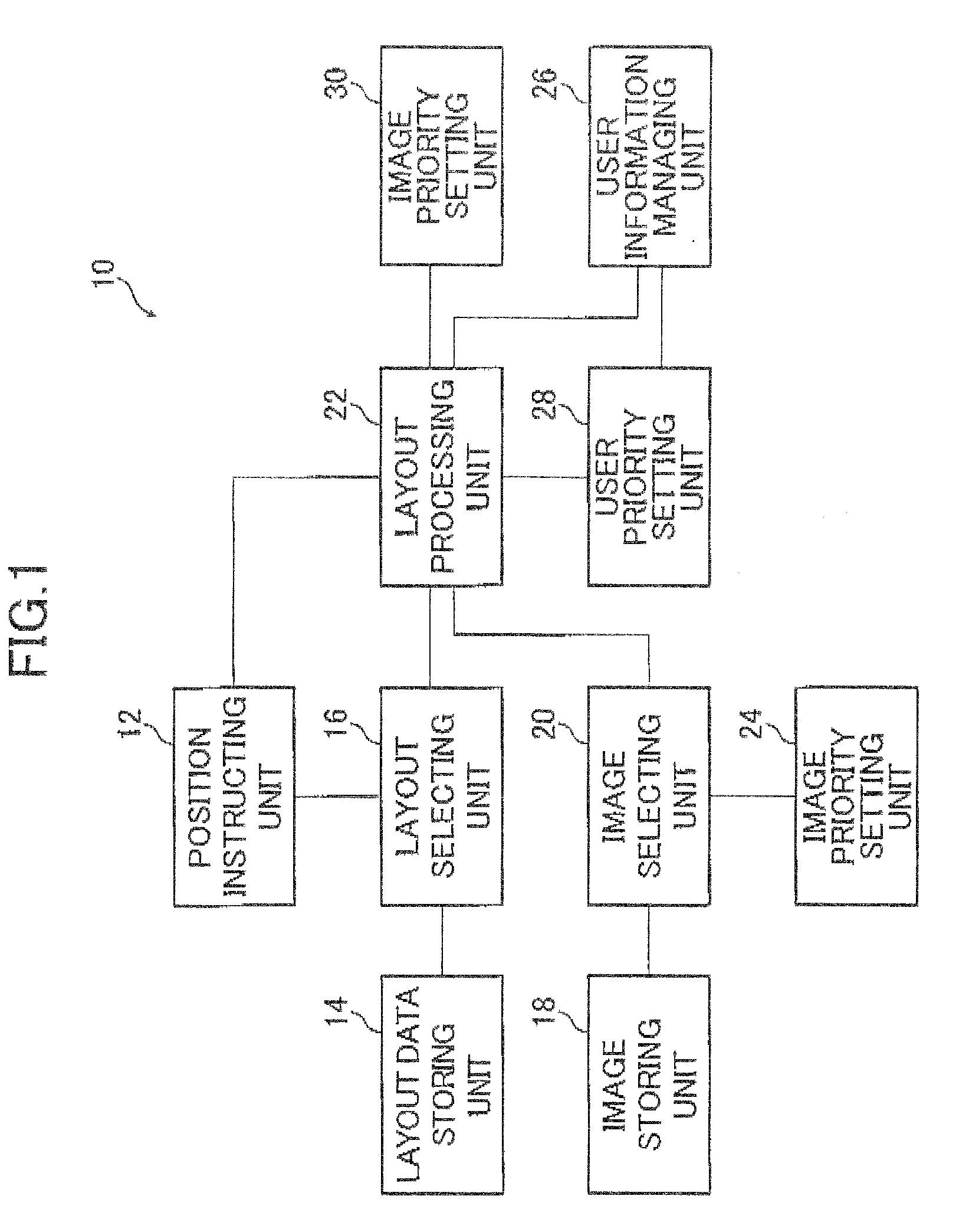

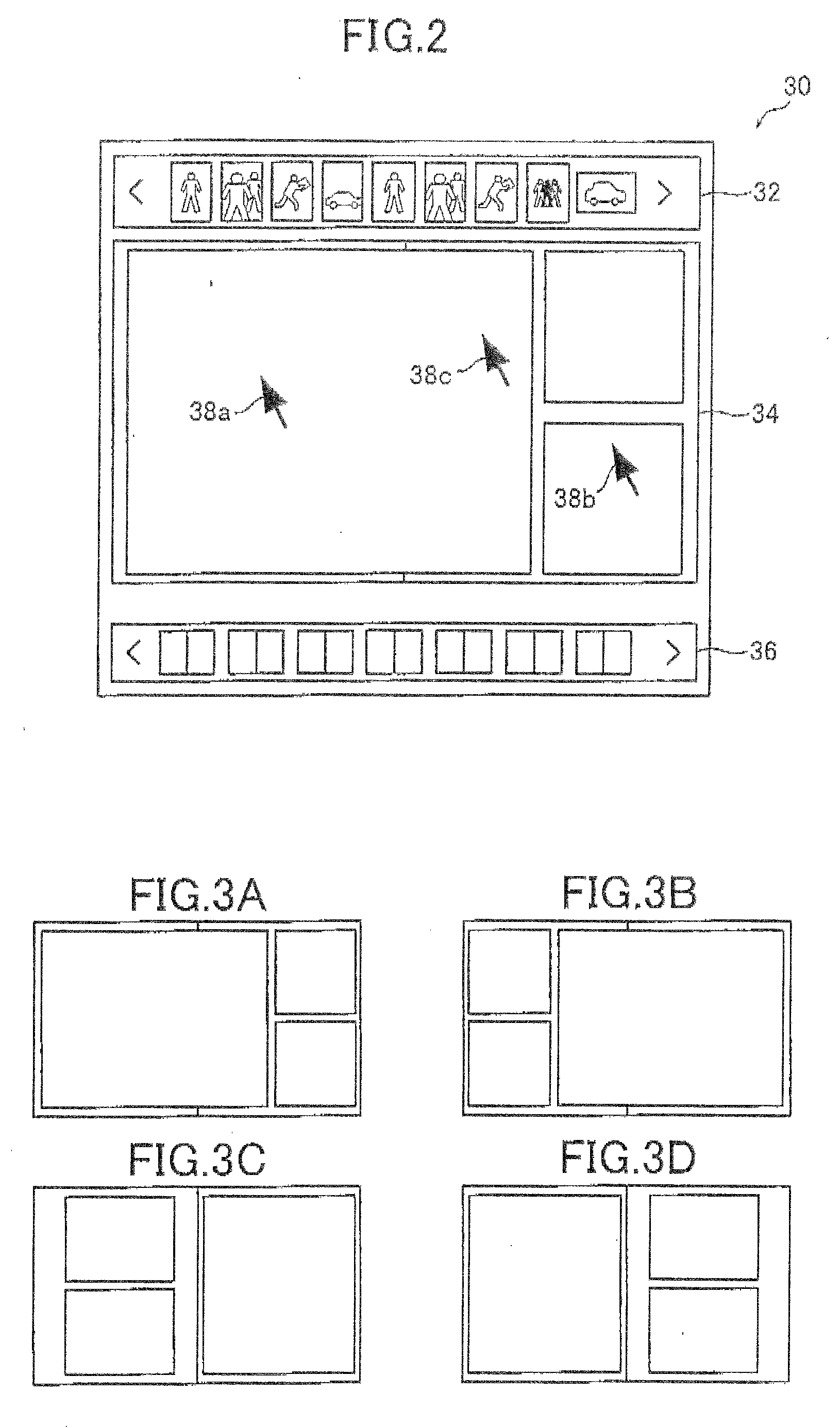

Image layout device, recording medium, and image layout method

ActiveUS20090287996A1Efficient processingHigh user work efficiency2D-image generationCharacter and pattern recognitionData setComputer graphics (images)

The image layout device configured to enable users to lay out images includes a layout data storing unit configured to store layout data sets that specify image arrangement regions for laying out the images, a layout selecting unit configured to automatically select the layout data set from the layout data storing unit based on a number of the users, an image storing unit configured to store images, one or more position instructing unit configured to select an image to be arranged based on the selected layout data set from stored images, and provide an instruction regarding an arrangement location with respect to the layout data set for the selected image and a layout processing unit configured to determine whether or not an instruction from the instructing unit is executable and, if it is executable, arrange the selected image in accordance with the selected layout data set.

Owner:FUJIFILM CORP

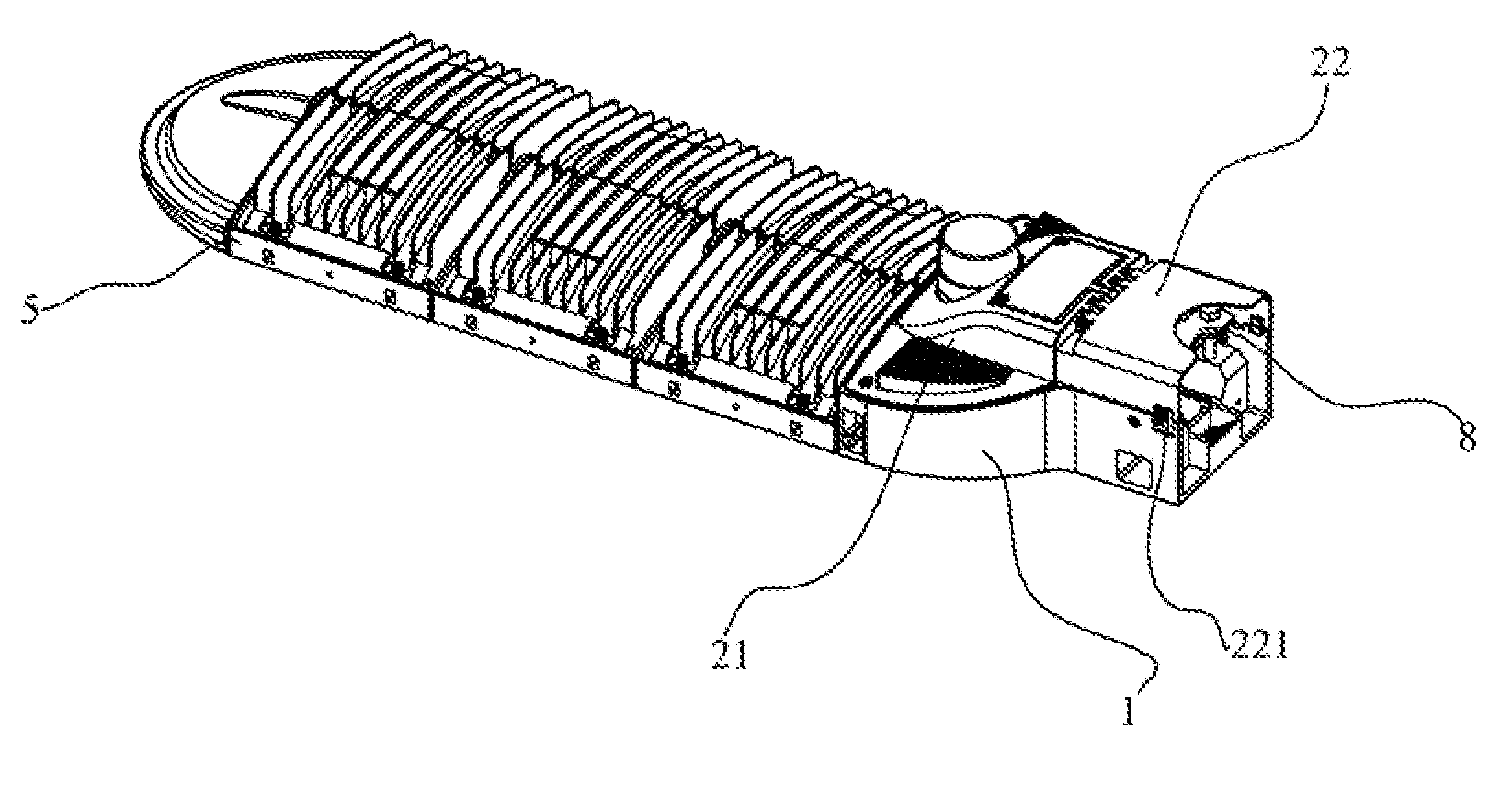

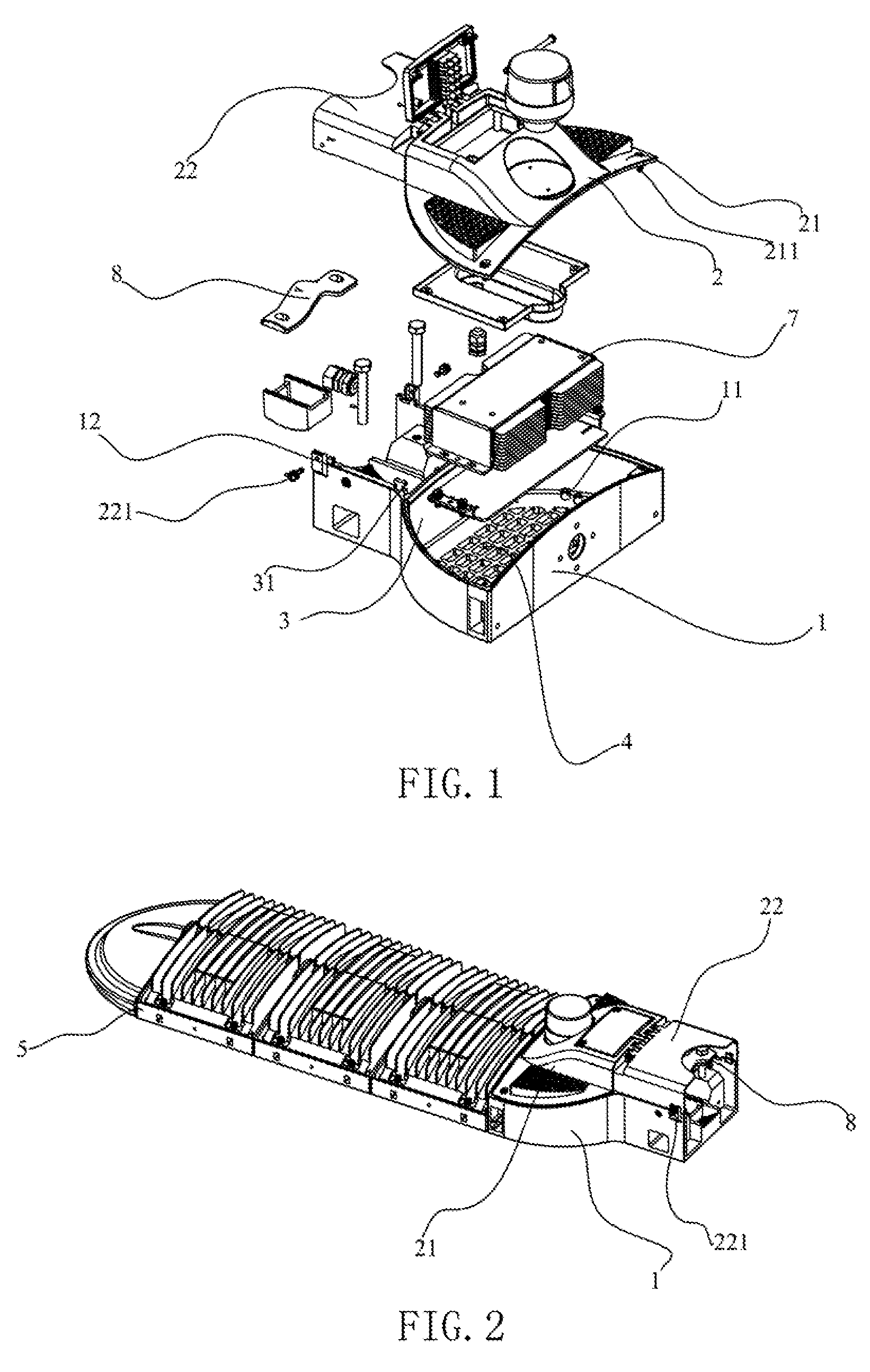

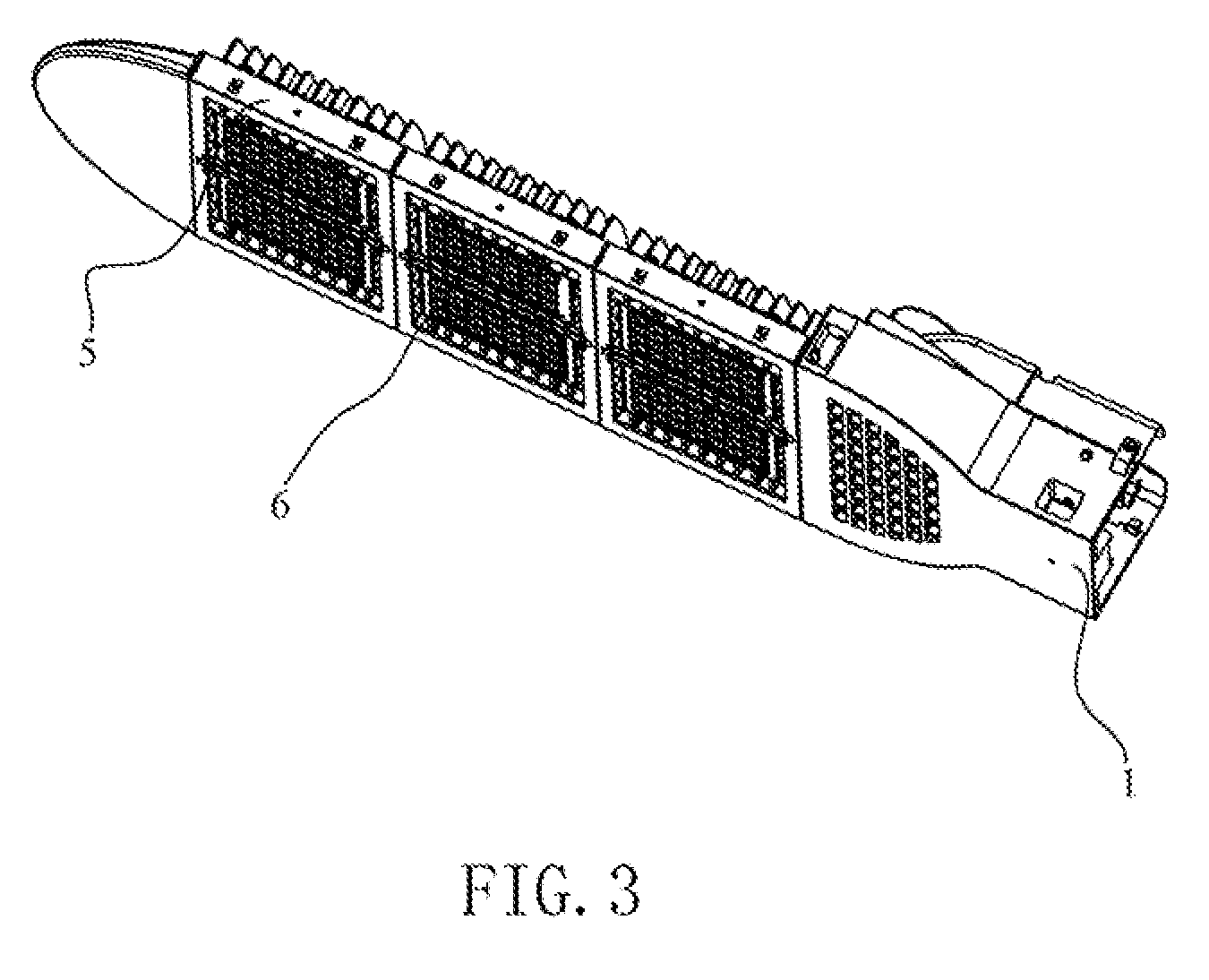

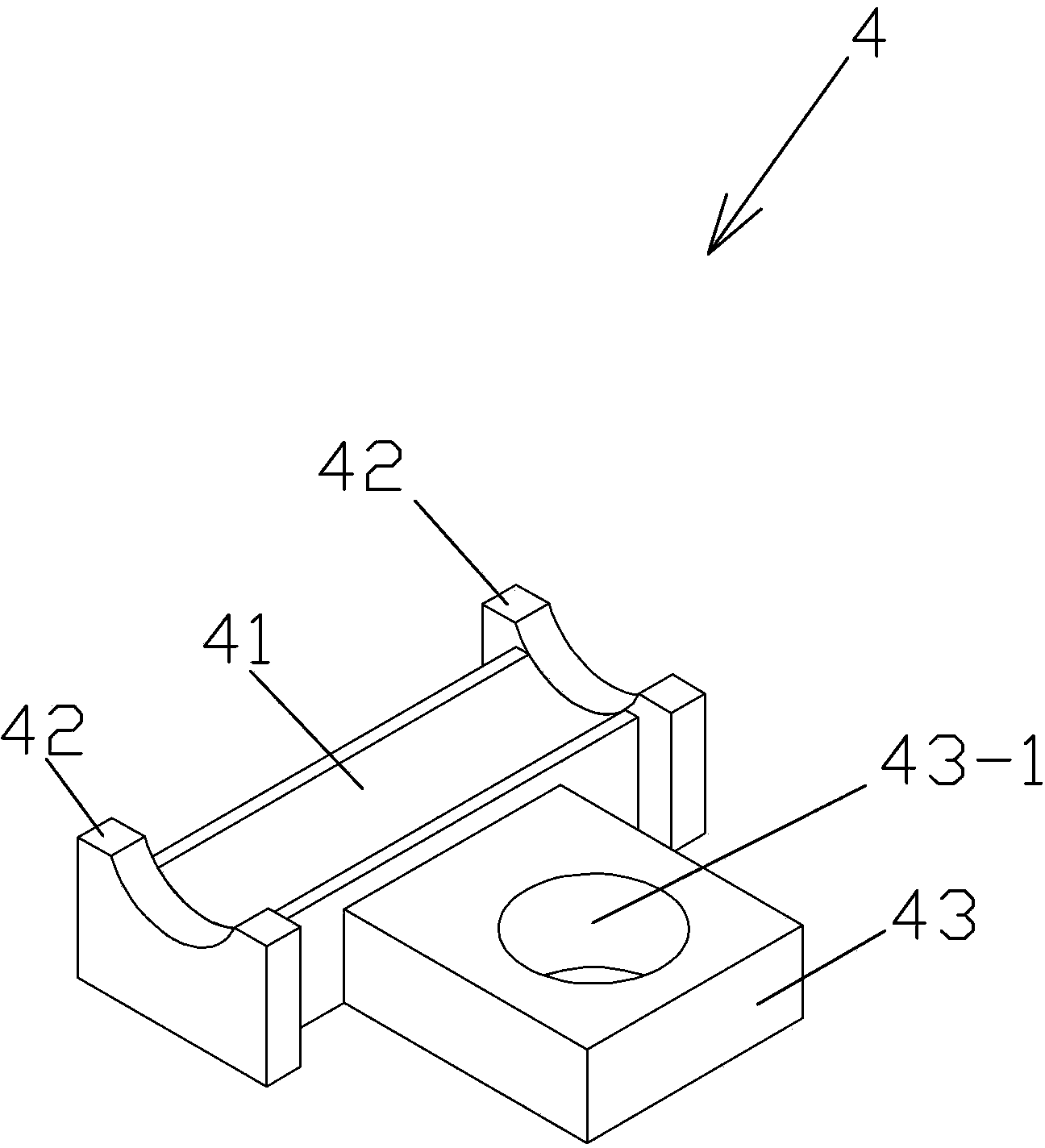

LED streetlamp installation seat and LED streetlamp

InactiveUS20120287654A1Improve working efficiencyLow costNon-electric lightingMechanical apparatusLED lamp

An exemplary LED streetlamp installation seat and an LED lamp both has a seat body (1), which has a first accommodating chamber (11) and a second accommodating chamber (12) the first accommodating chamber (11) being used to accommodate a control device (7) for controlling the LED streetlamp and the second accommodating chamber (12) being used to accommodate a fixing device (8) for installing the LED lamp to a lamp-post; and a cover cap, corresponding to the first and the second accommodating chambers (11, 12), which has a first cap (21) and a second cap (22), the first cap (21) and the second cap (22) being hinge-joined. The first cap (21), corresponding to the first accommodating chamber (11), is detachably connected to the first accommodating chamber (11). The second cap (22), corresponding to the second accommodating chamber (21), is detachably connected to the second accommodating chamber (21).

Owner:SHENZHEN BANG BELL ELECTRONICS

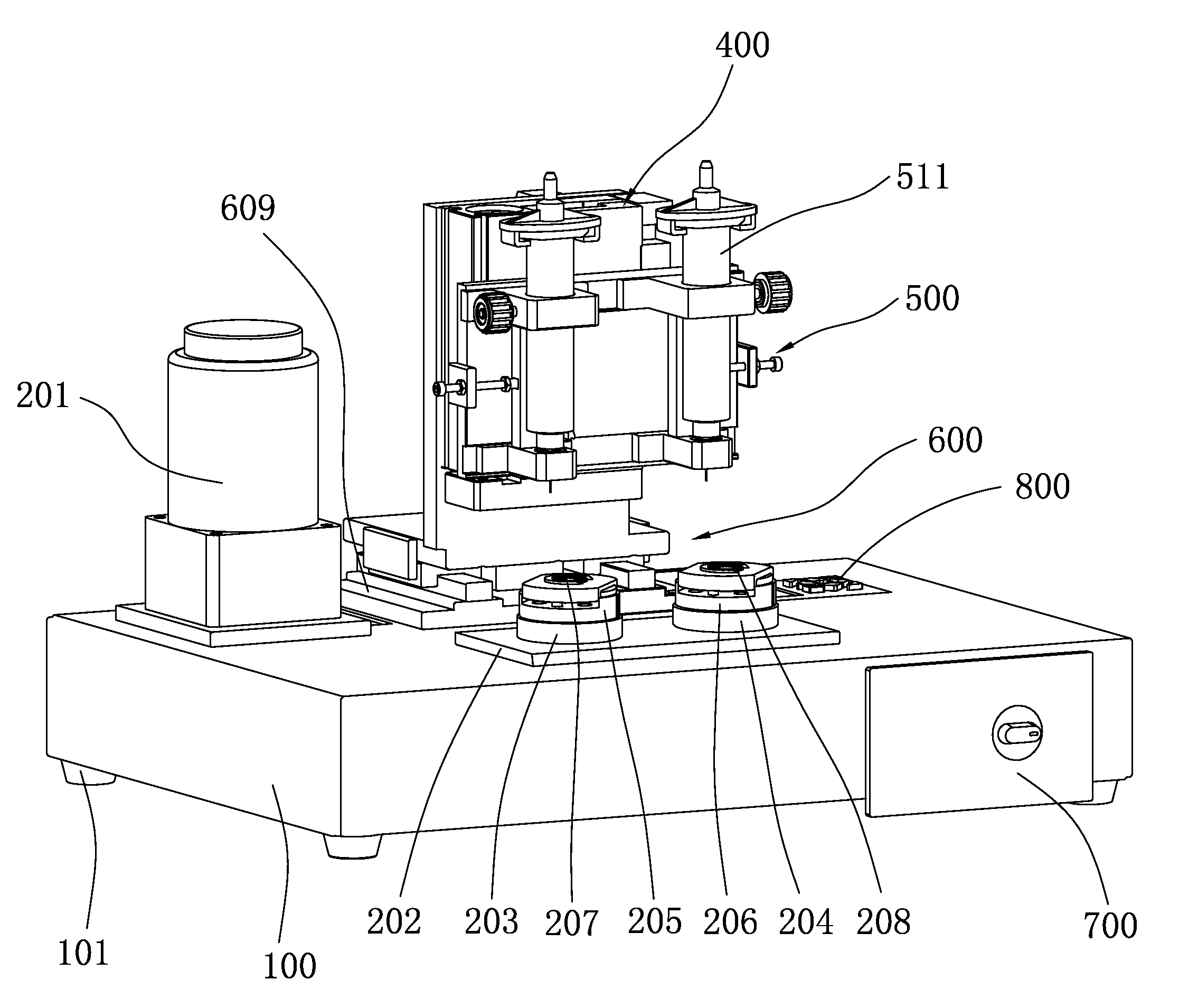

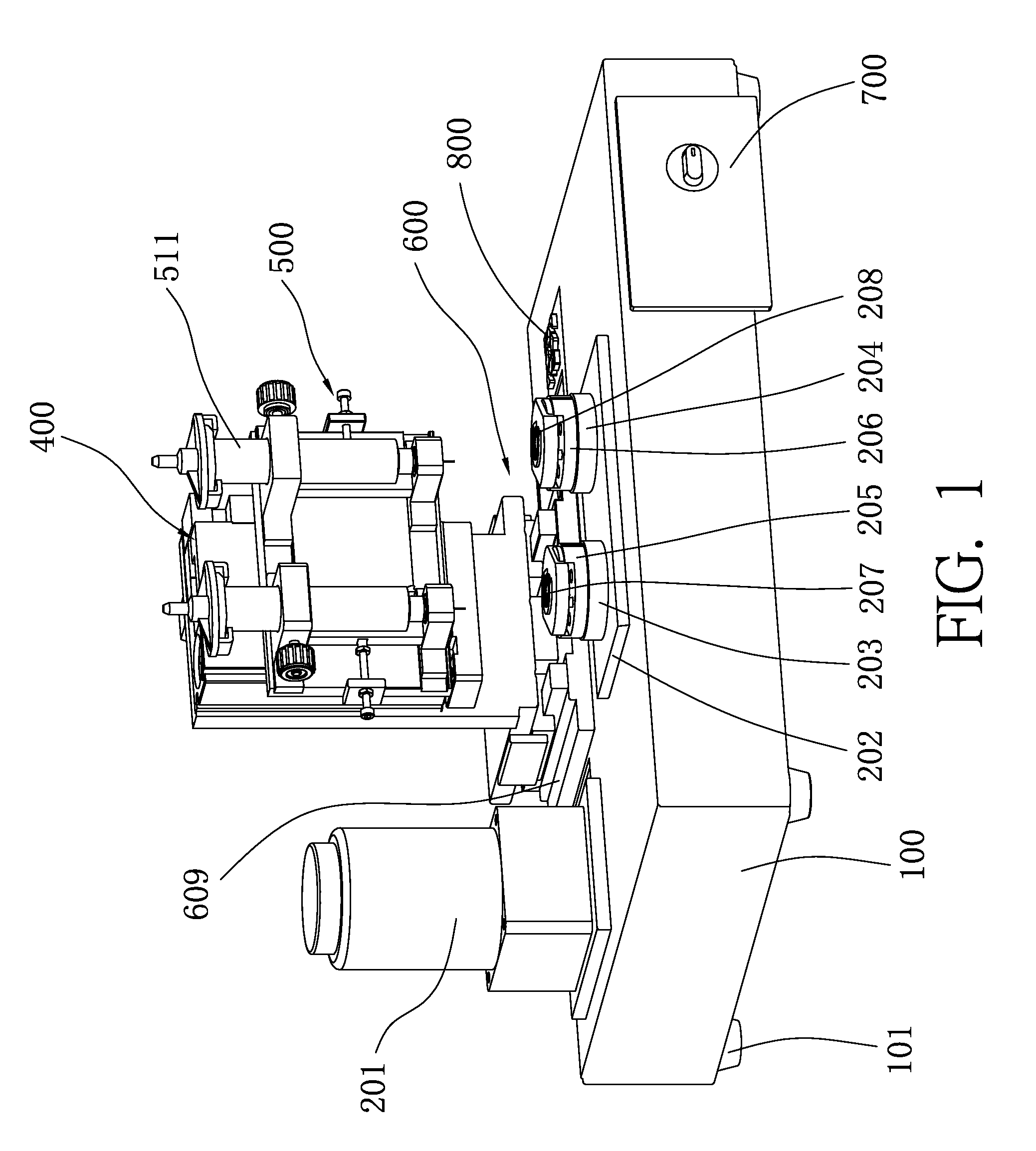

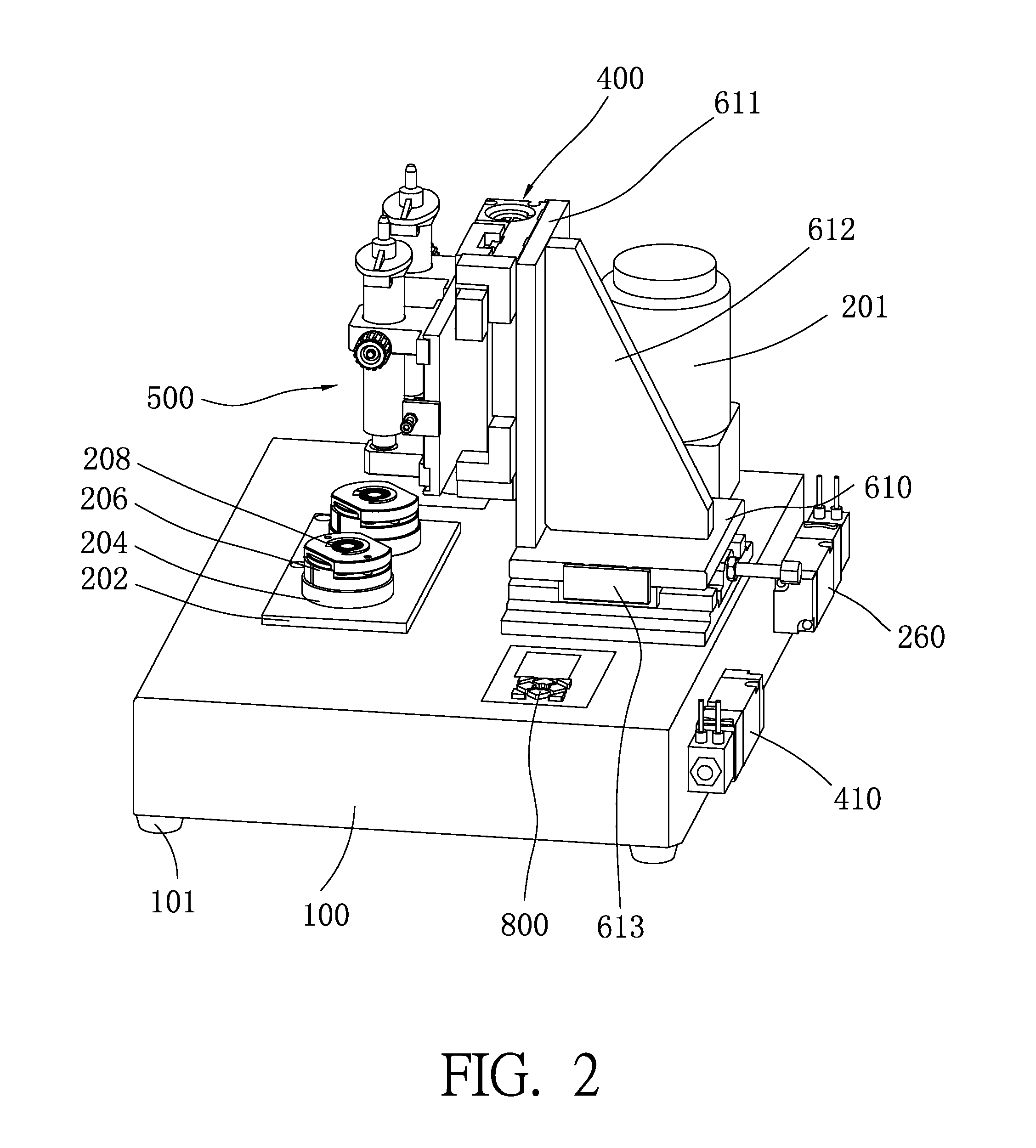

Gluing mechanism

InactiveUS20120031326A1Improve working efficiencyImprove gluing qualityLiquid surface applicatorsManual label dispensersMotor driveEngineering

A gluing mechanism comprising a platform, a plurality of turn tables set on the platform for workpieces, a motor for driving the turn tables and a gluing device firmly set up on the platform. The gluing device comprises a forward assembly, an elevator, a panning assembly and a plurality of glue applicators. The forward assembly is set on the platform and moves along a shorter side of the platform. The elevator is set on the forward assembly and moves relative to the platform vertically. The panning assembly is set on the elevator and moves along a longer side of the platform. The glue applicators are installed on the panning assembly. The motor drives the turn tables simultaneously. The gluing mechanism of the present invention has benefits of simple structure, a high working efficiency and proceeds a precise rotary gluing process to workpieces. Therefore, an excellent gluing quality can be realized.

Owner:CHENG UEI PRECISION IND CO LTD

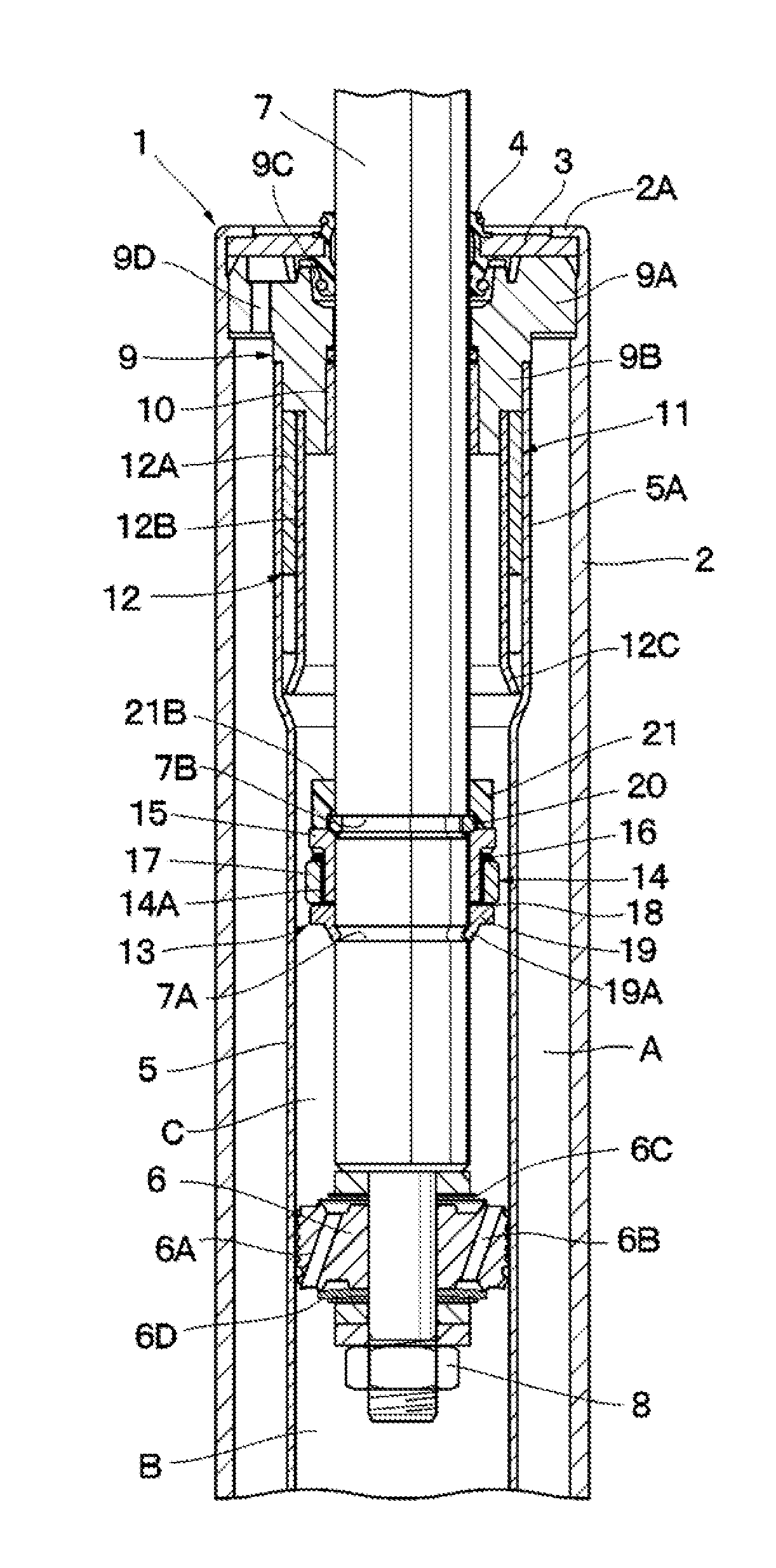

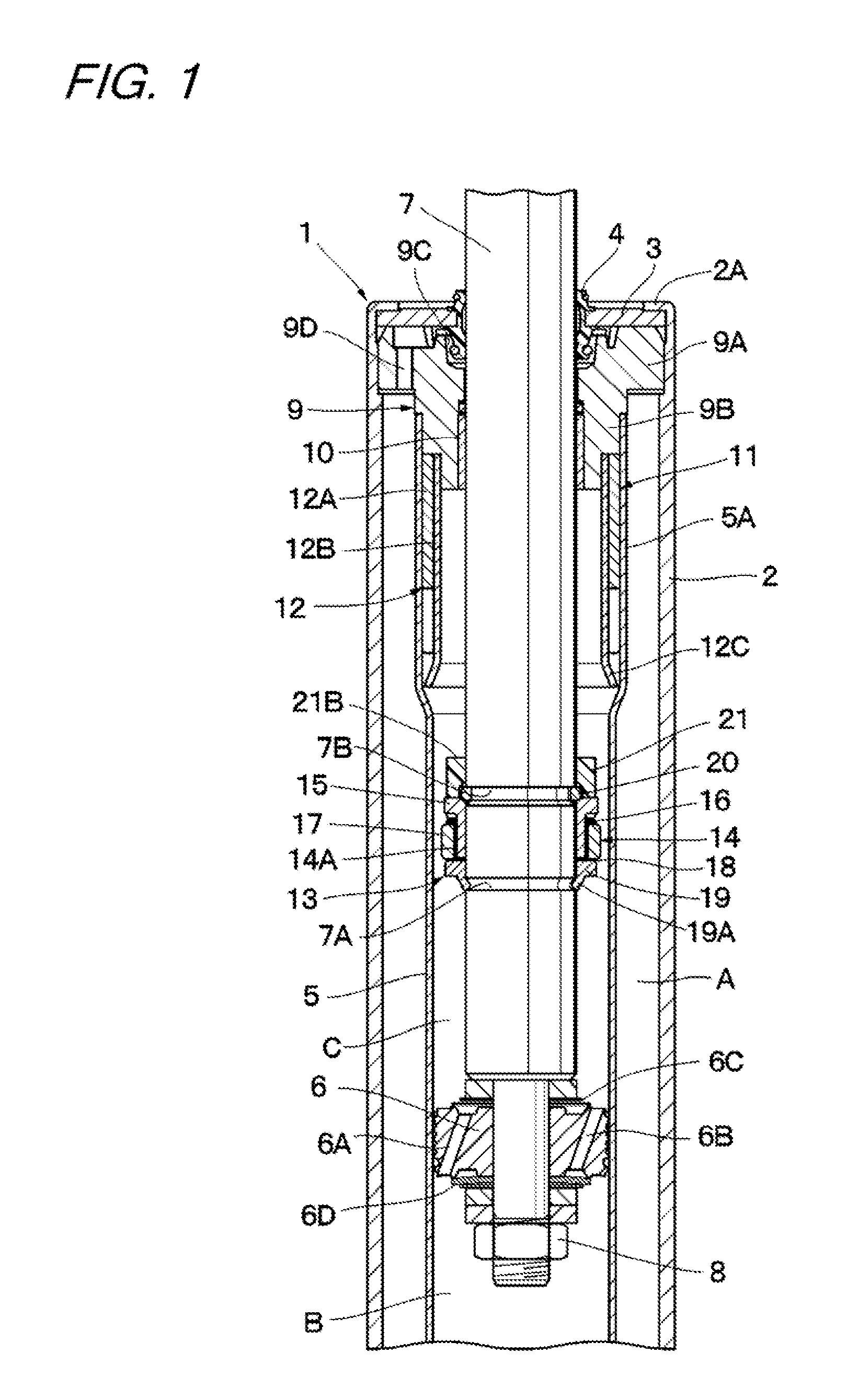

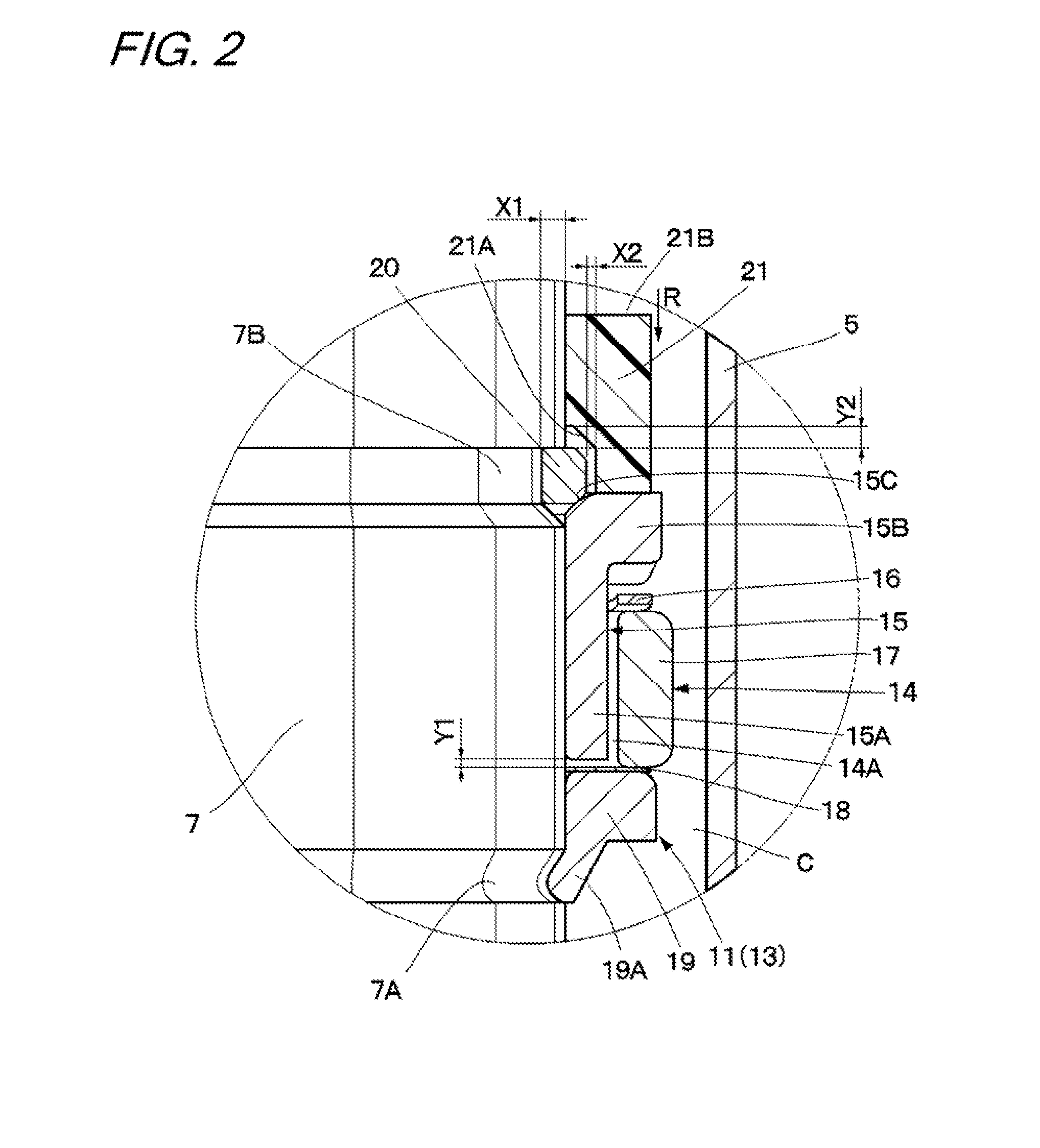

Cylinder device and manufacturing method therefor

InactiveUS20150090548A1High work efficiencyPrevents formationSpringsMetal working apparatusPistonMechanical engineering

A lock piston (13) of a locking mechanism (11) includes a flow path limiting-opening mechanism (14) provided on an outer peripheral side of a piston rod (7), an annular stopper (19) for supporting the flow path limiting-opening mechanism (14) from a piston (6) side, and a restriction ring (20) for restricting a fitting cylindrical body (15) of the flow path limiting-opening mechanism (14) from moving to a rod guide (9) side, the restriction ring (20) being fitted to a second annular groove (7B) of the piston rod (7). The restriction ring (20) is inserted along an outer peripheral side of the piston rod (7) from an upper end side of the piston rod (7), and fitted and fixed into the second annular groove (7B).

Owner:HITACHI AUTOMOTIVE SYST LTD

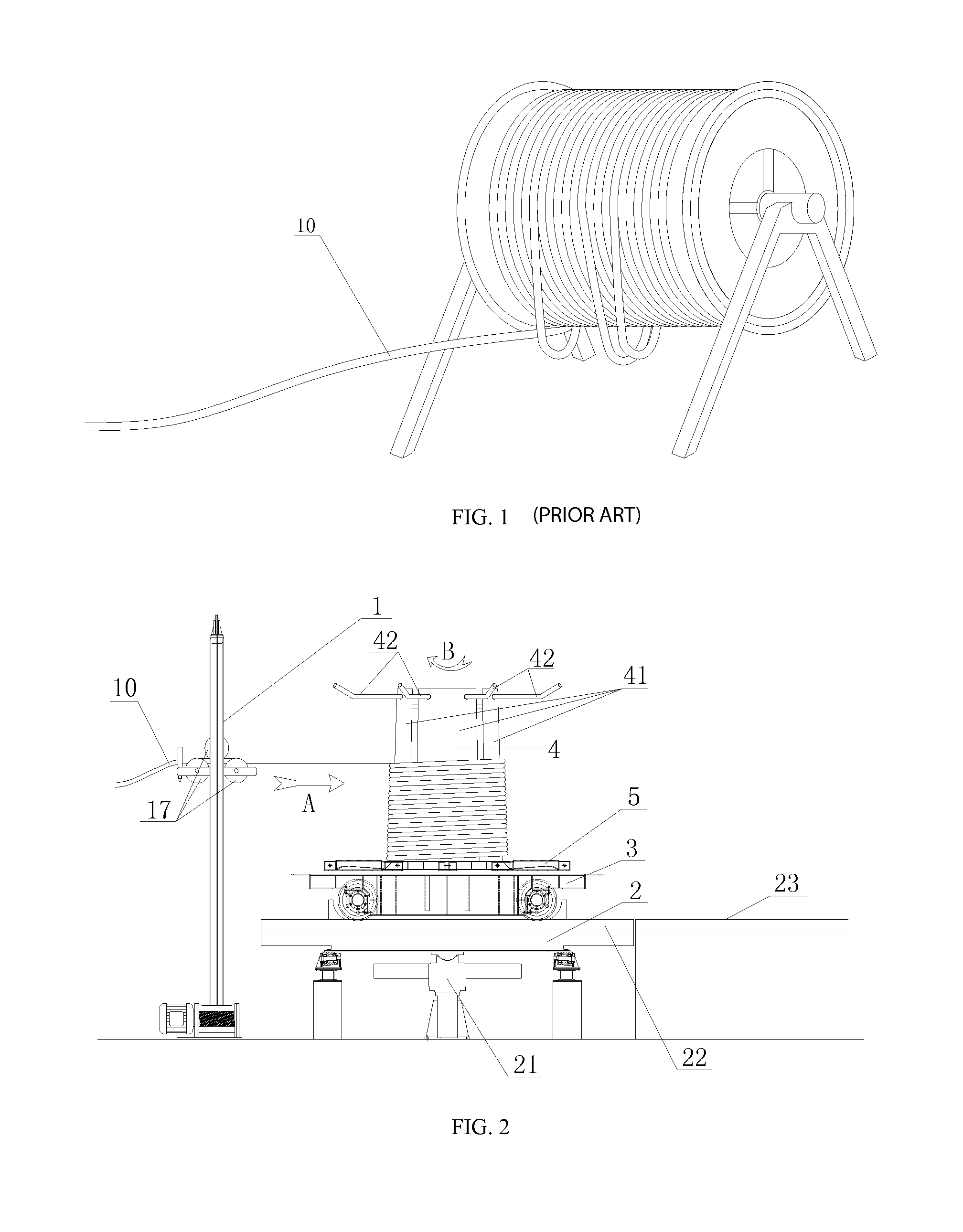

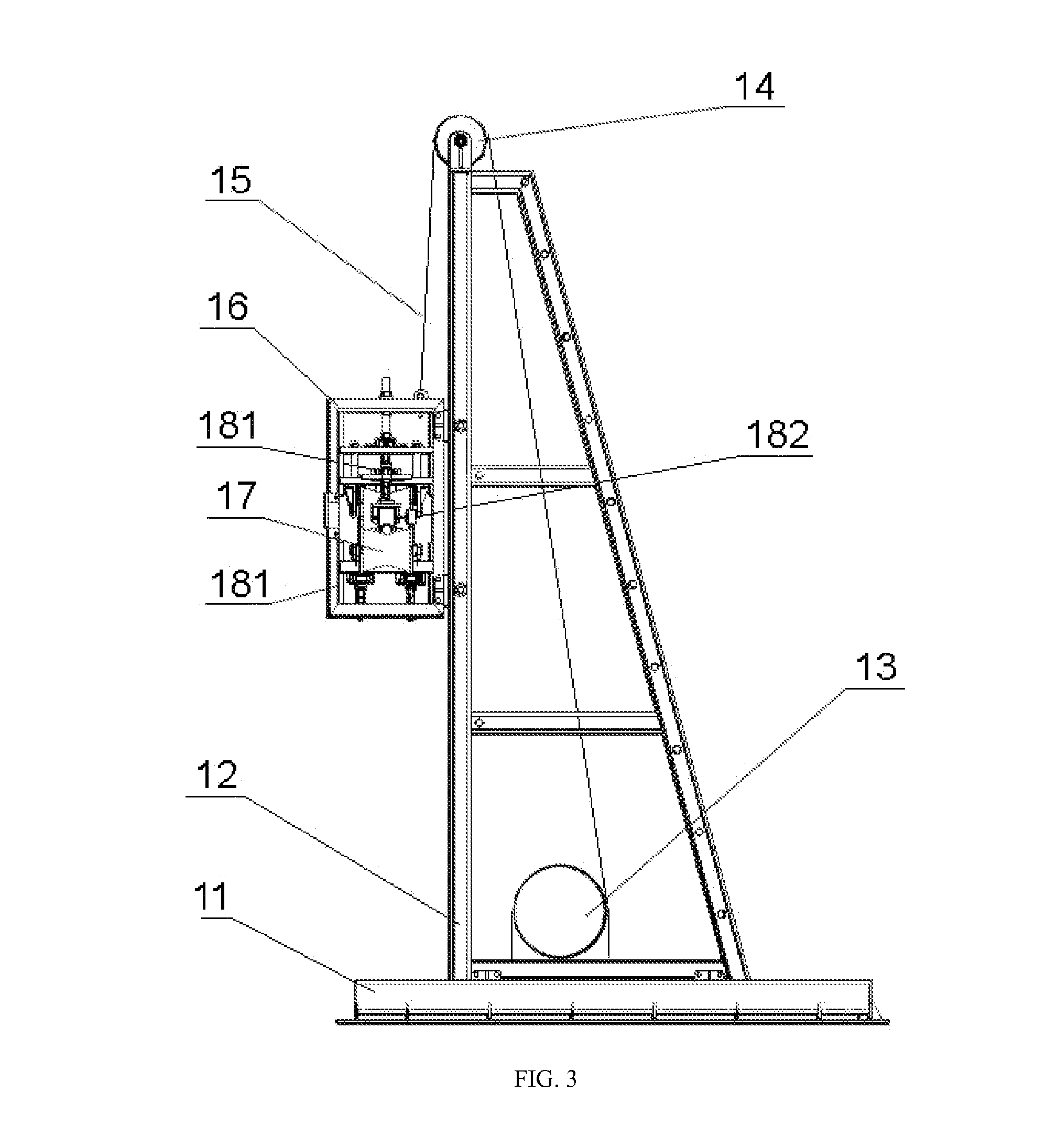

Method for Horizontally Winding and Unwinding a Parallel Wire Strand

InactiveUS20130248638A1Avoid damageAvoid injuryFilament handlingBridge structural detailsMechanical engineeringRotational axis

Owner:SHANGHAI PUJIANG CABLE +1

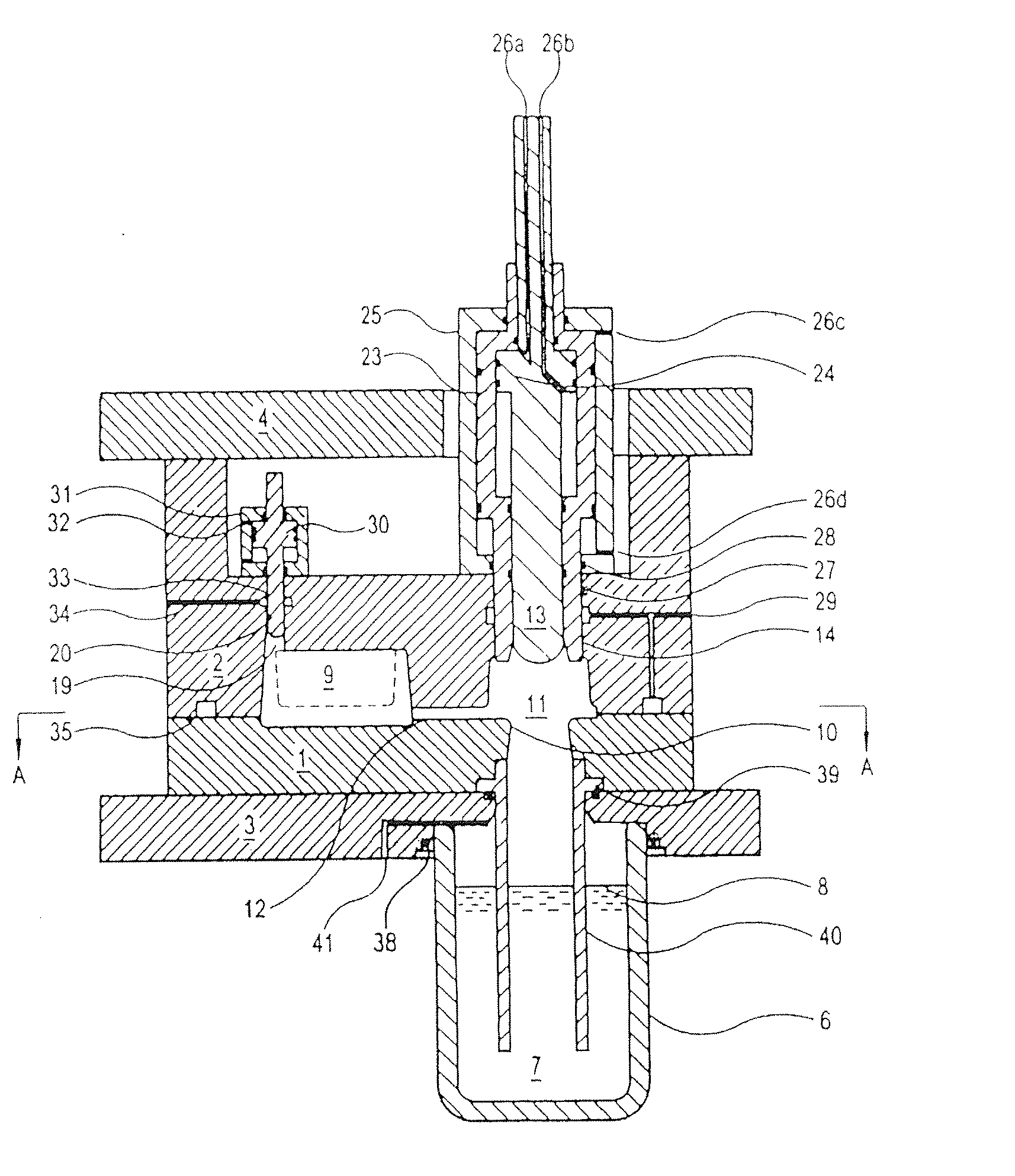

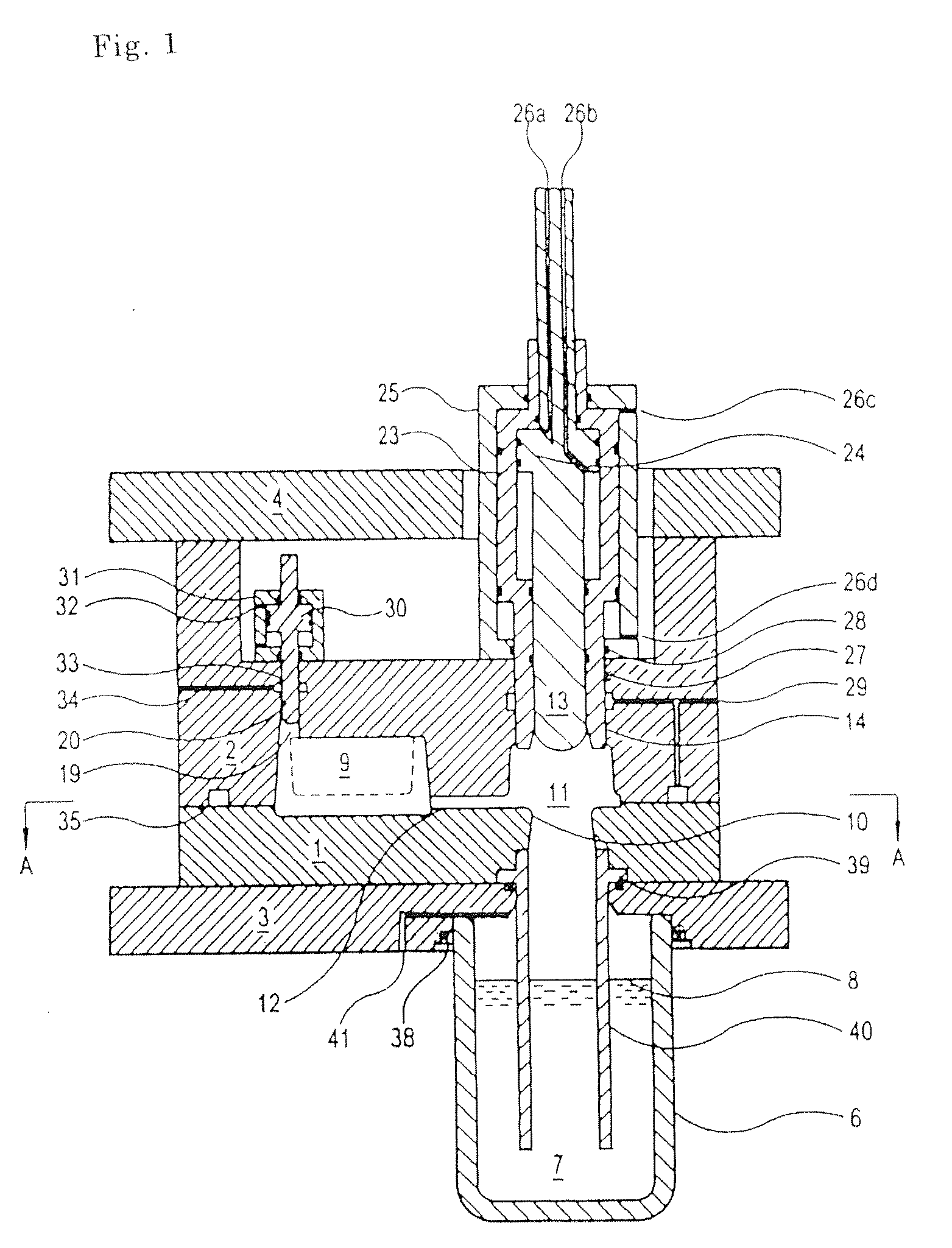

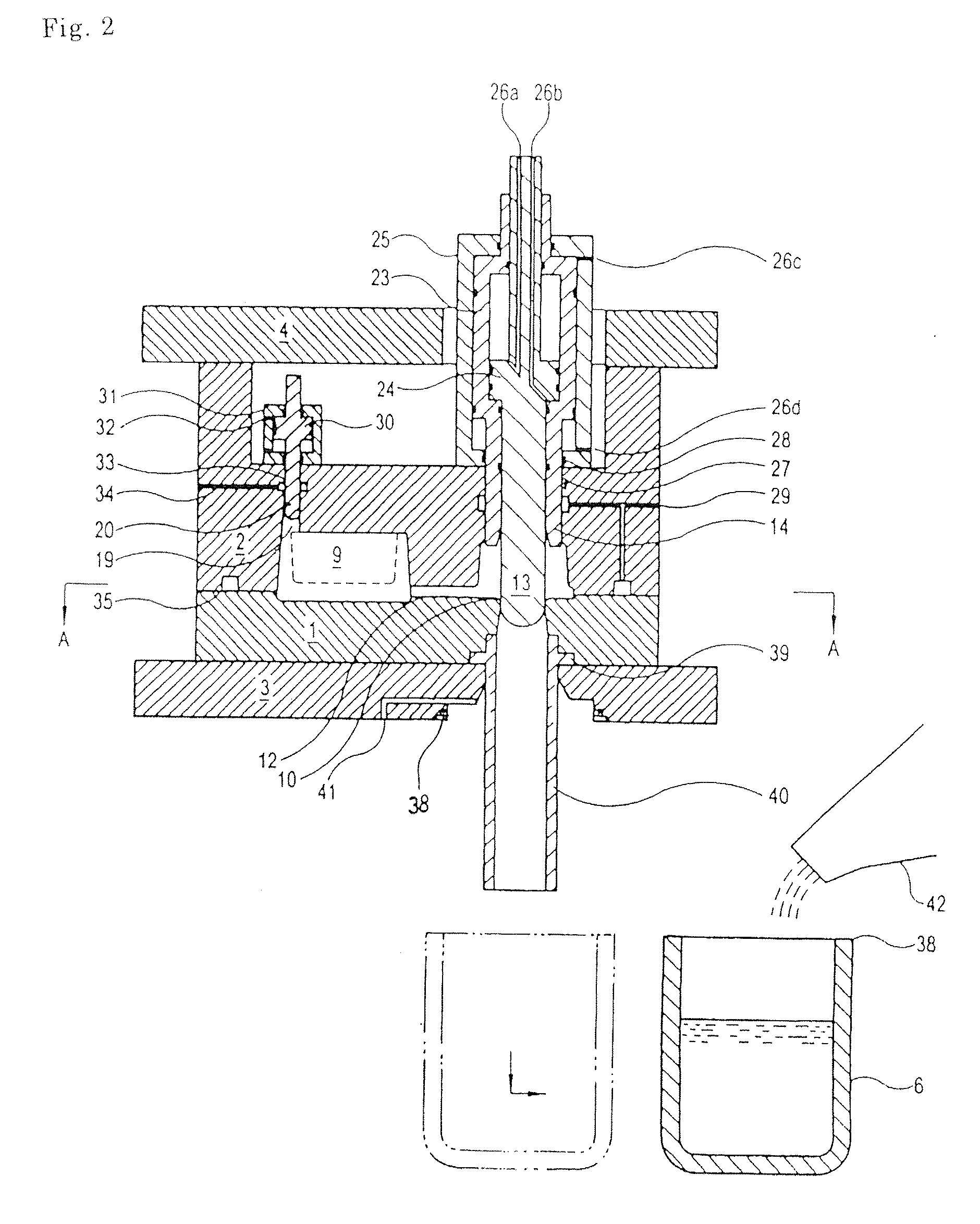

Vertical Casting Apparatus and Vertical Casting Method

The present invention is to provide a vertical casting apparatus capable of easily manufacturing castings without causing shrinkage cavities and entrainment of gas, by filling a molten metal into a mold cavity at a high speed and by effectively pressurizing the molten metal in the closed cavity, which has high work efficiency, ease of maintenance, and a low cost of equipment, and a vertical casting method using the vertical casting apparatus. The vertical casting apparatus is provided with an apparatus body comprising a fixed mold 1 on the lower side and a movable mold 2 on the upper side, a closing means 13 for closing a molten metal in-flow gate 10 formed in the fixed mold 1, and a pressurizing means 20 for pressurizing the molten metal in the closed mold cavity, and a casting means for supplying and filling the molten metal into the mold cavity from the underside. The casting means has a gas-pressurized molten metal pouring ladle 6 attachable to and detachable from the apparatus body.

Owner:KOSEI ALUMINUM

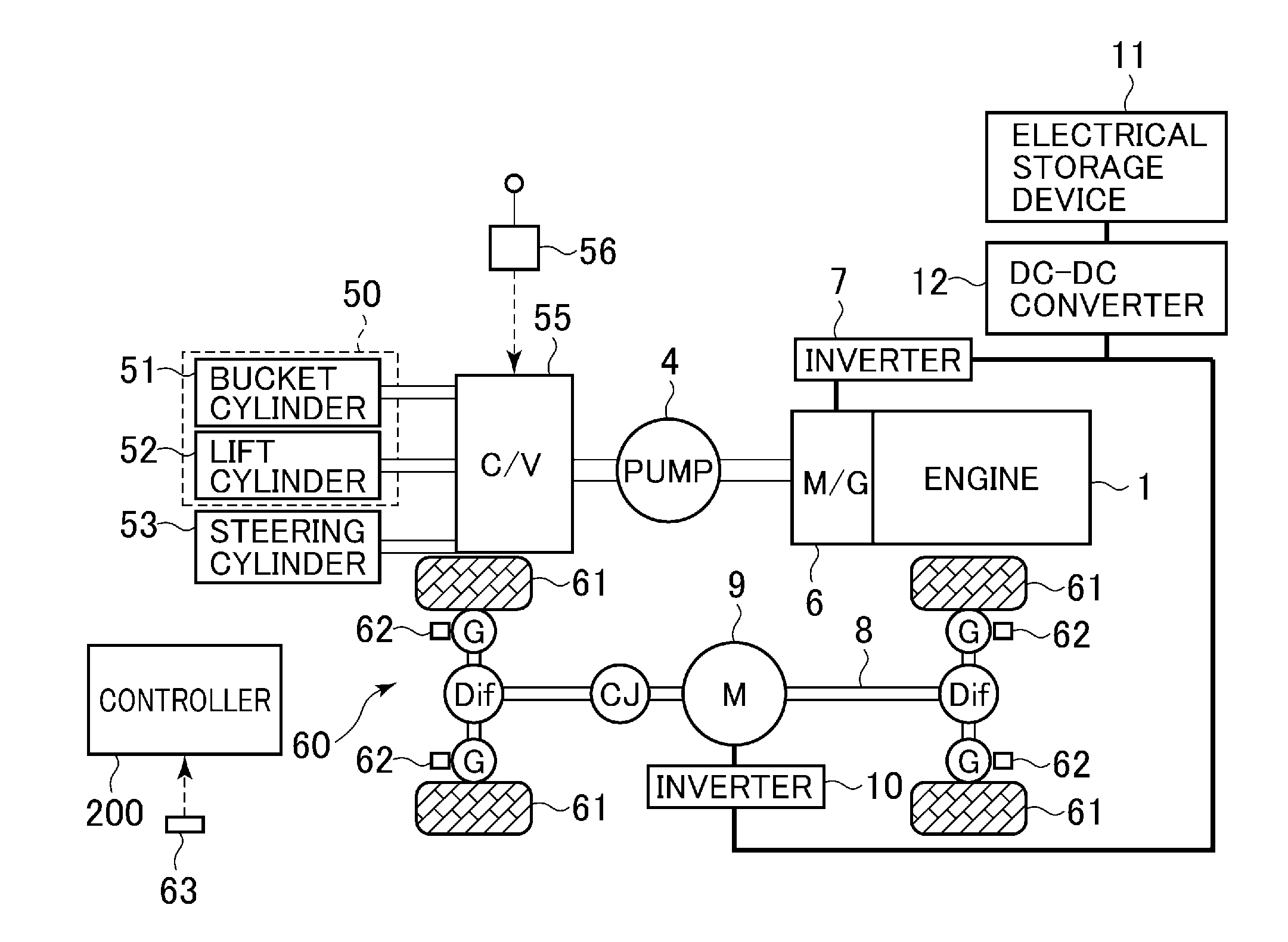

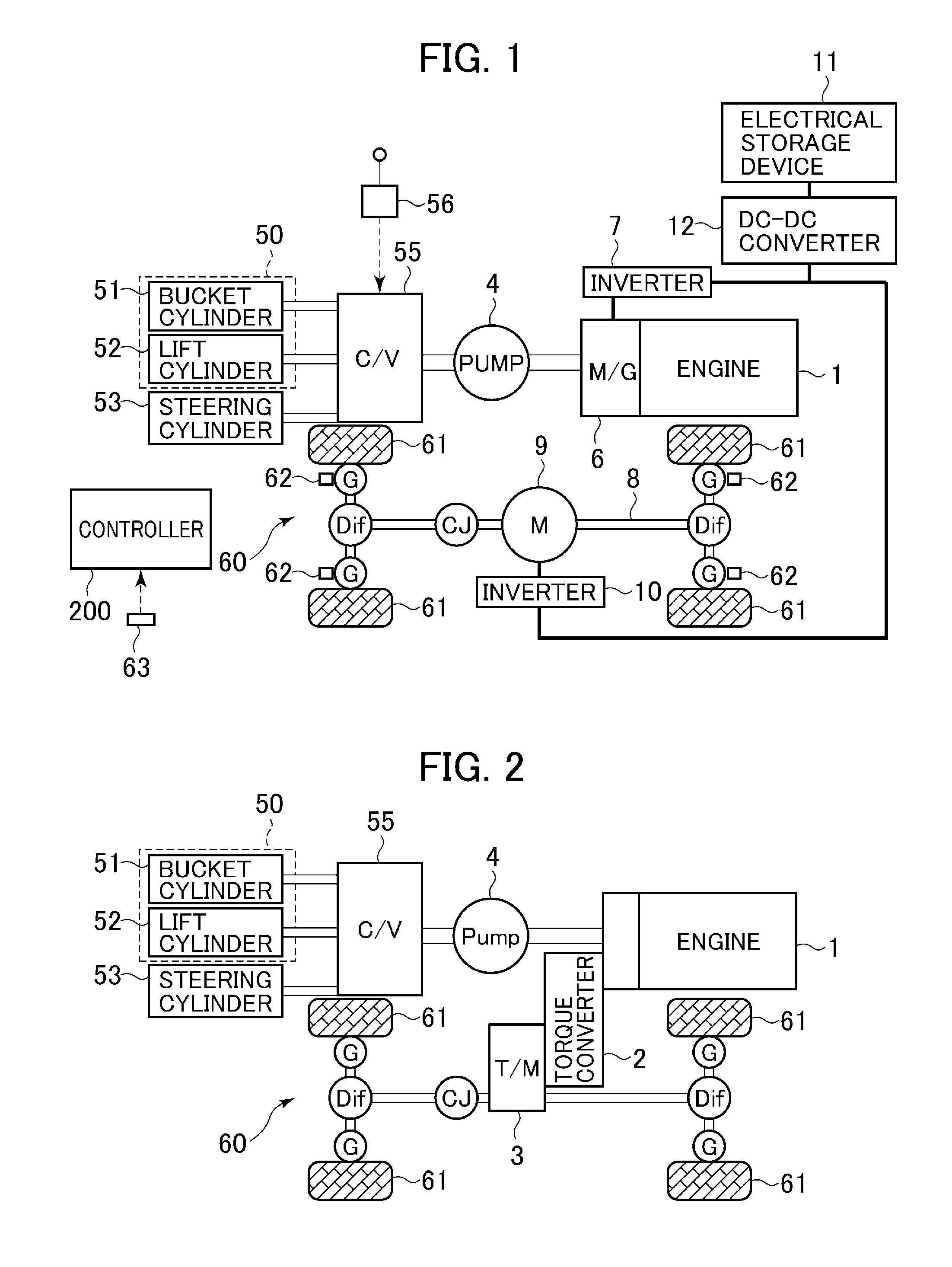

Wheel loader

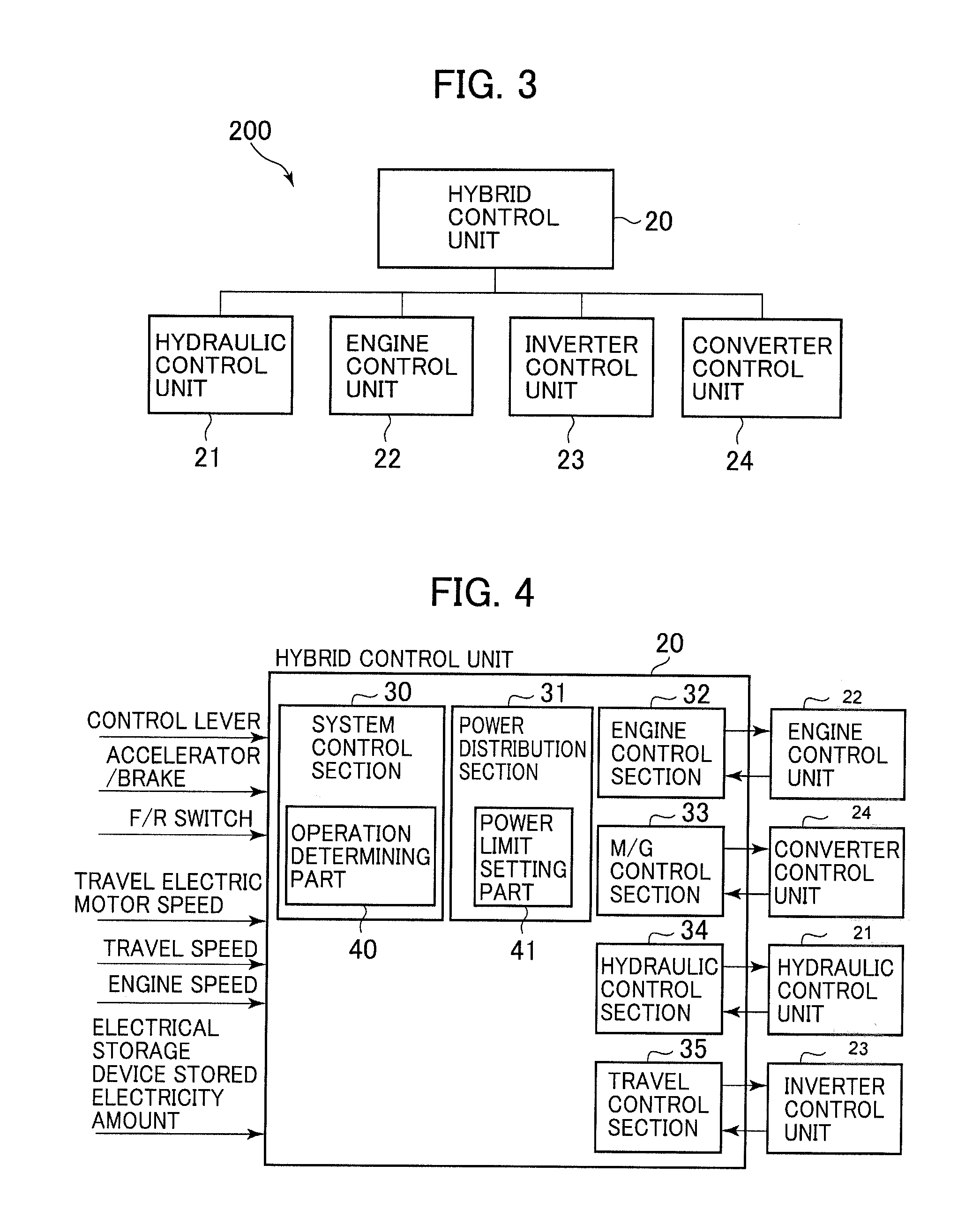

ActiveUS20130317684A1Improve working efficiencyHybrid vehiclesDigital data processing detailsDrive wheelHydraulic pump

A hybrid wheel loader is provided, the hybrid wheel loader achieving high work efficiency even with a short supply of power to be output relative to a vehicle power requirement.The hybrid wheel loader includes a motor generator 6 connected to an engine (1), a hydraulic pump (4) connected to the motor generator, a hydraulic actuator (51, 52, 53) driven by hydraulic oil supplied from the hydraulic pump, a travel electric motor (9) for driving wheels (61), and an electrical storage device (11) connected to each of the motor generator and the electrical storage device via respective inverters (7, 10). When a total requirement power value is greater than a hybrid output upper limit value, either one of a hydraulic requirement power value Pf and a travel requirement power value Prun is limited according to an operation of the wheel loader to thereby set the total requirement power value to a value equal to, or less than, the hybrid output upper limit value.

Owner:NIHON KENKI CO LTD

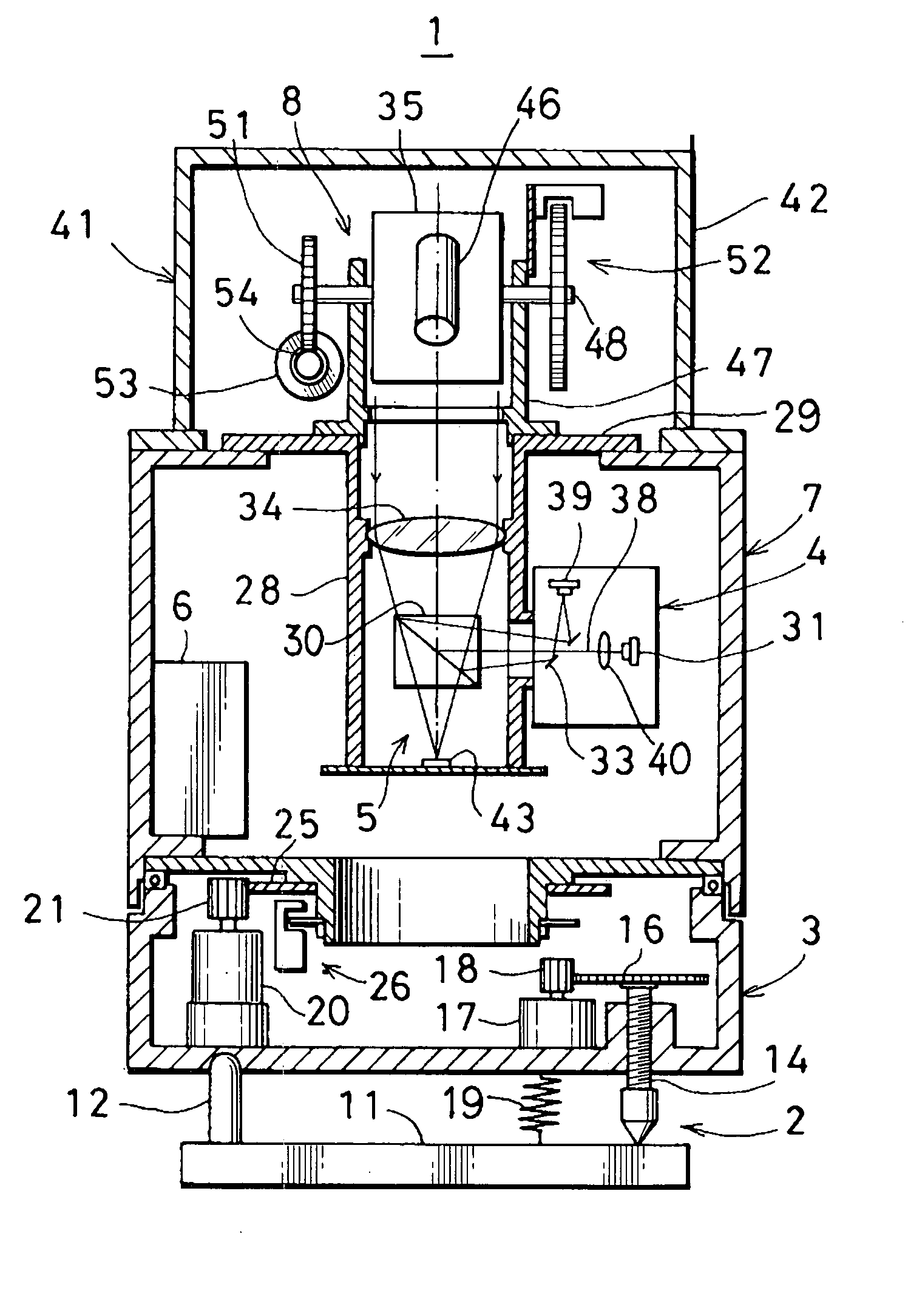

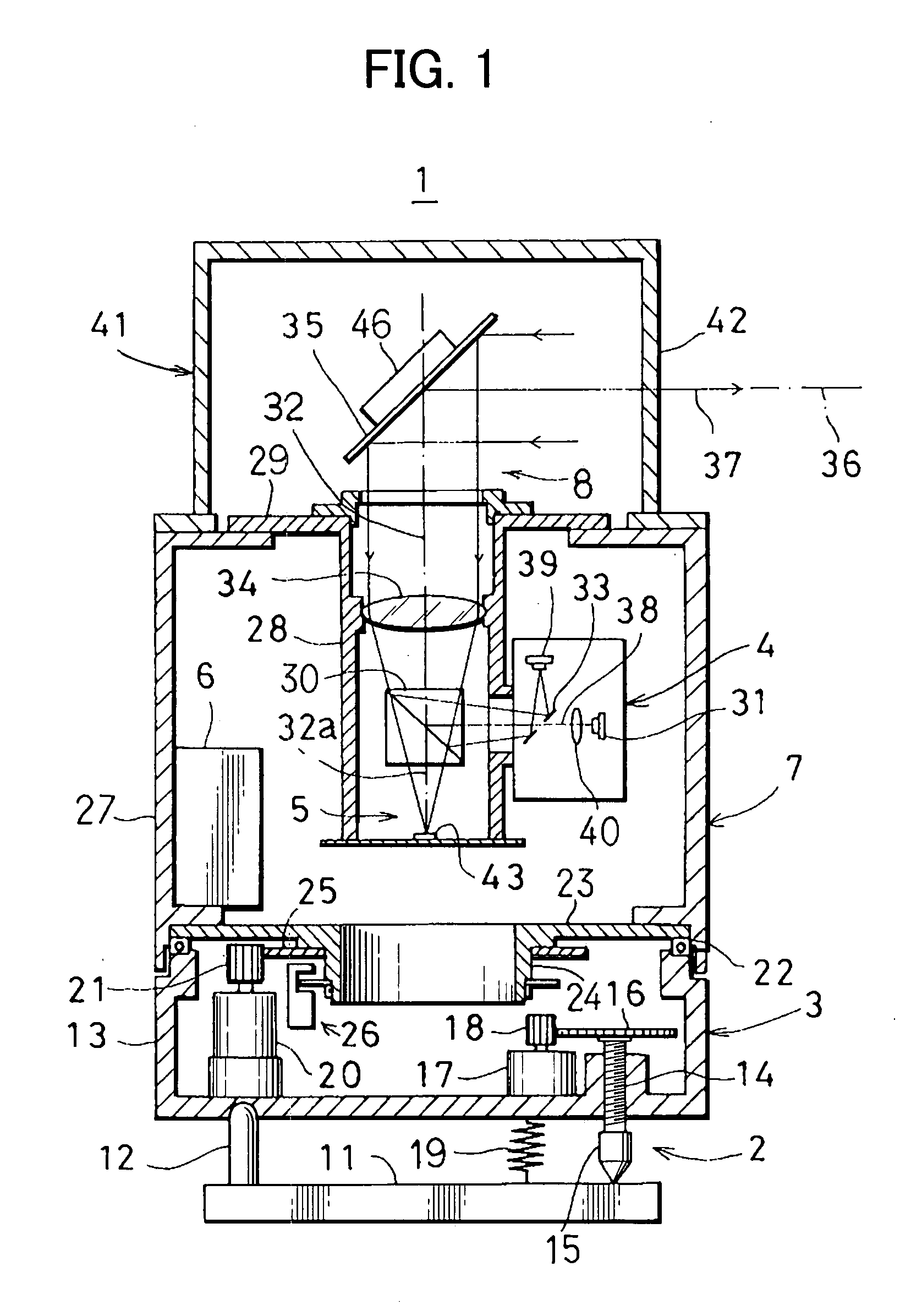

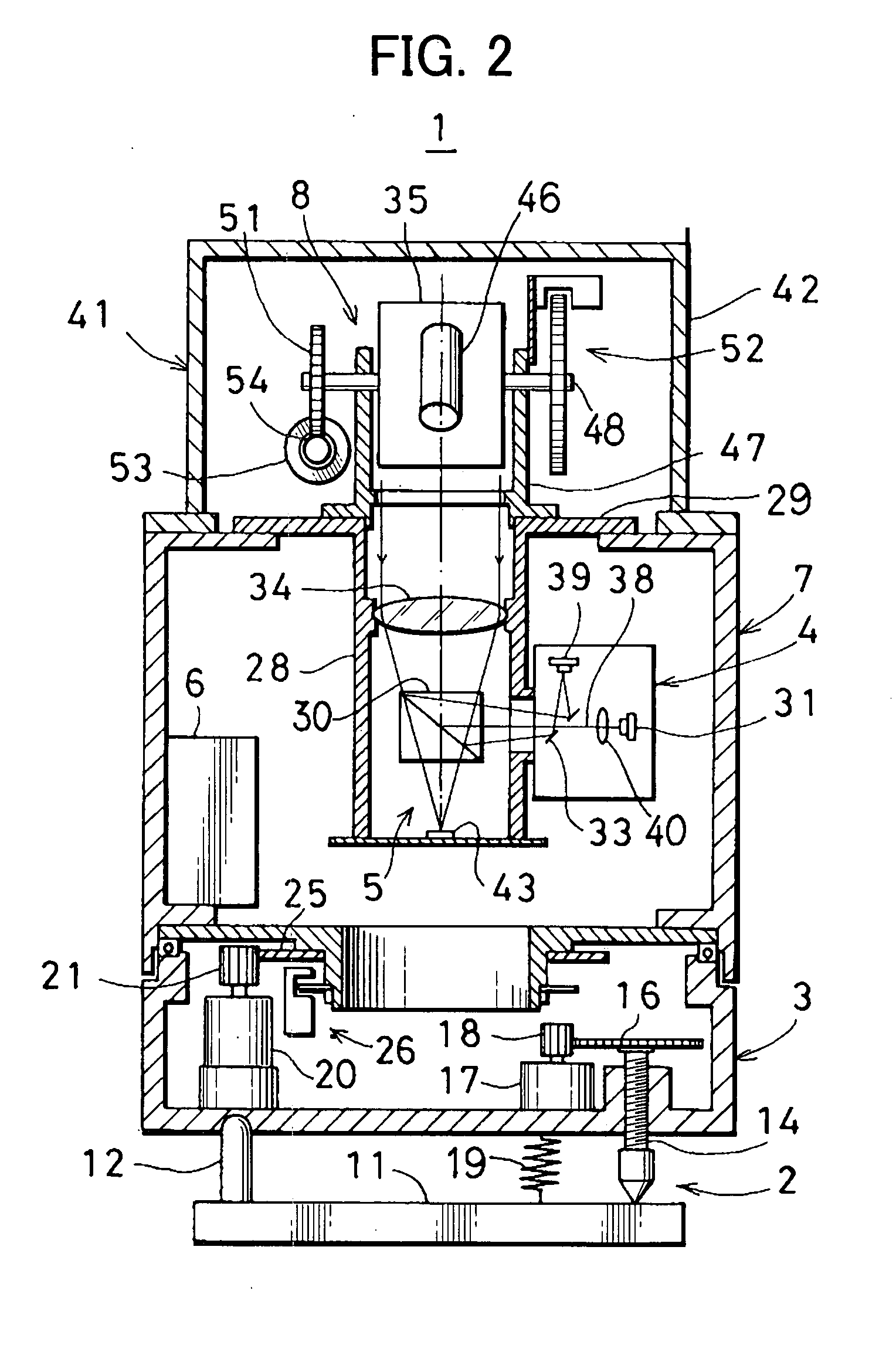

Laser scanner

ActiveUS20080074637A1Improve working efficiencySimple structureAngle measurementOptical rangefindersLaser scanningOptoelectronics

A laser scanner, comprising a mirror rotatably provided, a driving unit for rotating the mirror, a distance measuring unit for projecting a distance measuring light for scanning to a measurement range via the mirror and for obtaining a position data by receiving the reflected distance measuring light via the mirror, a measuring direction observing means for indicating a projecting direction of the distance measuring light, and an operation unit for setting the measurement range by designating at least two measuring directions based on the result of observation of the measuring direction obtained by the measuring direction observing means.

Owner:KK TOPCON

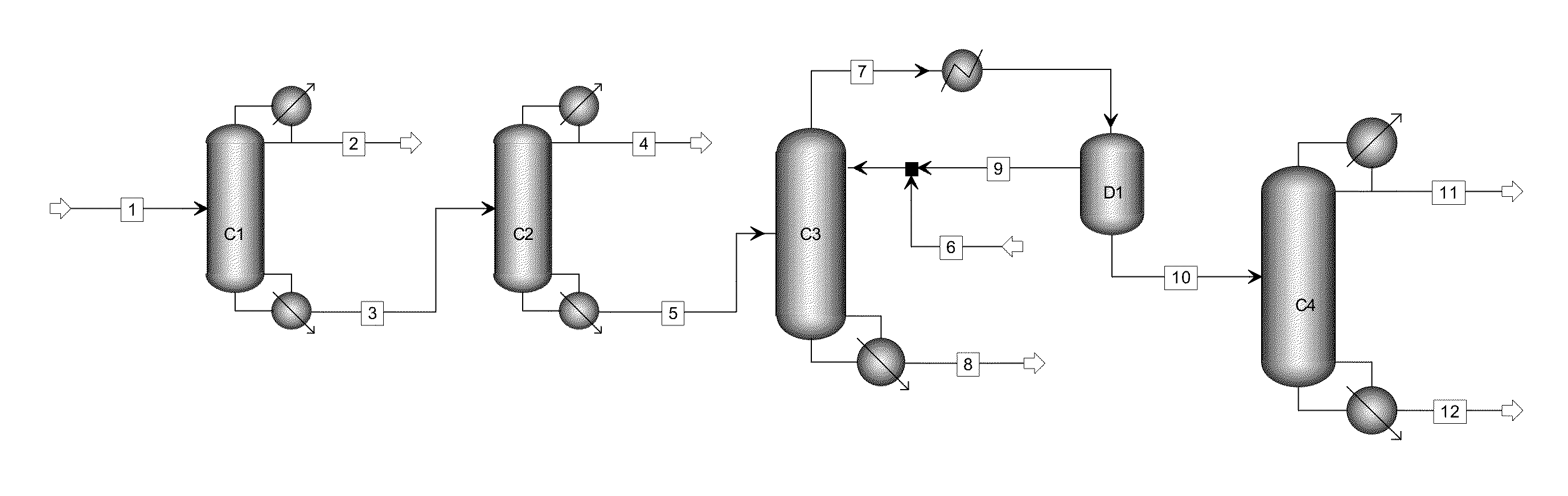

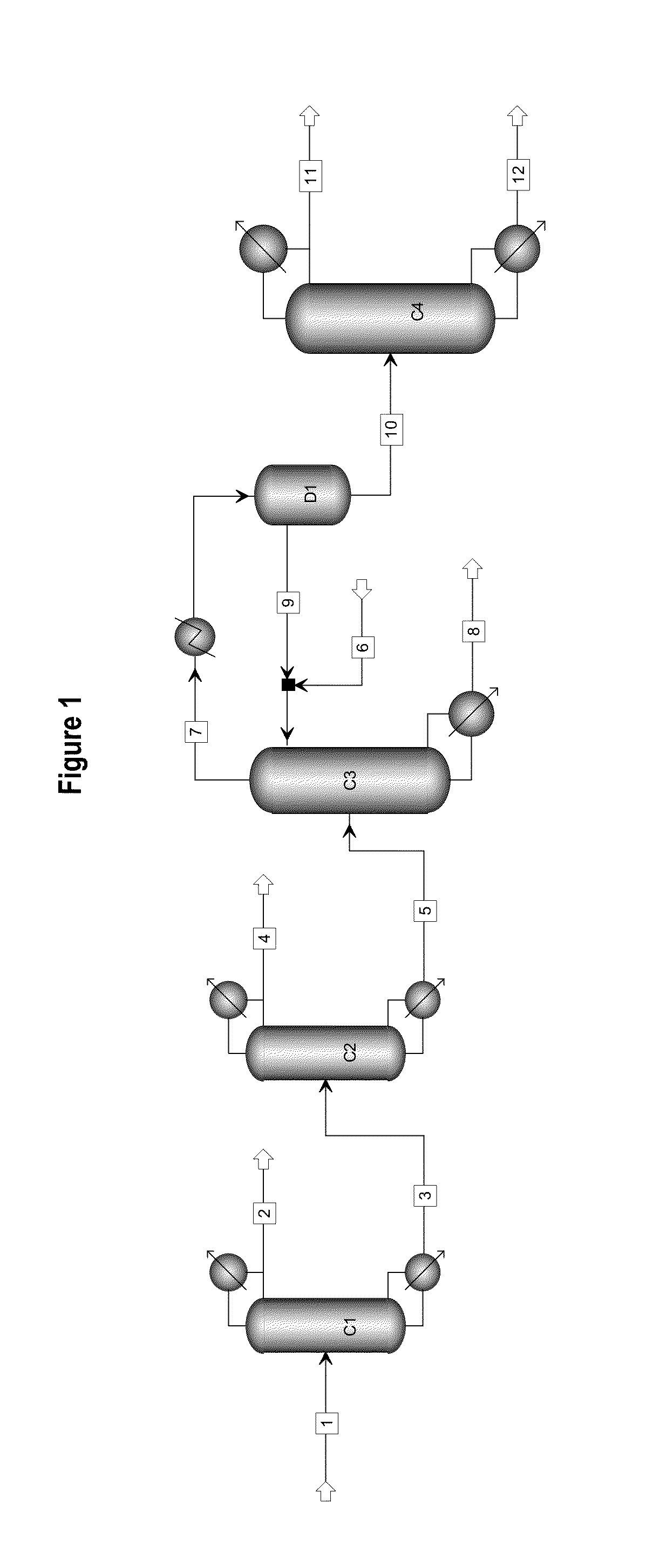

Process for separating ethylene glycol and 1, 2-butanediol

ActiveUS20130284584A1High purityBig investmentOrganic compound preparationHydroxy compound preparationButanediolGlycol synthesis

The present invention relates to a process for separating ethylene glycol and 1,2-butanediol. A material flow containing ethylene glycol and 1,2-butanediol gets into the lower-middle part of the azeotropic rectification column C3 after the light components are removed by the separating columns C1 and C2, wherein the ethylene glycol and the azeotropic agent added from the top of the column form azeotrope which is distilled out from the top of the column and gets into the phase separator D1 after being condensed, the upper phase enriched with azeotropic agent after the phase was separated returns to the top of the column to continue to participate in azeotropy, and the lower phase enriched with ethylene glycol gets into the fourth separating column C4 to be refined to obtain the ethylene glycol product.

Owner:CHINA PETROCHEMICAL CORP +1

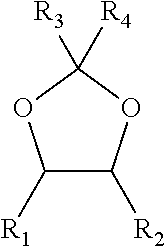

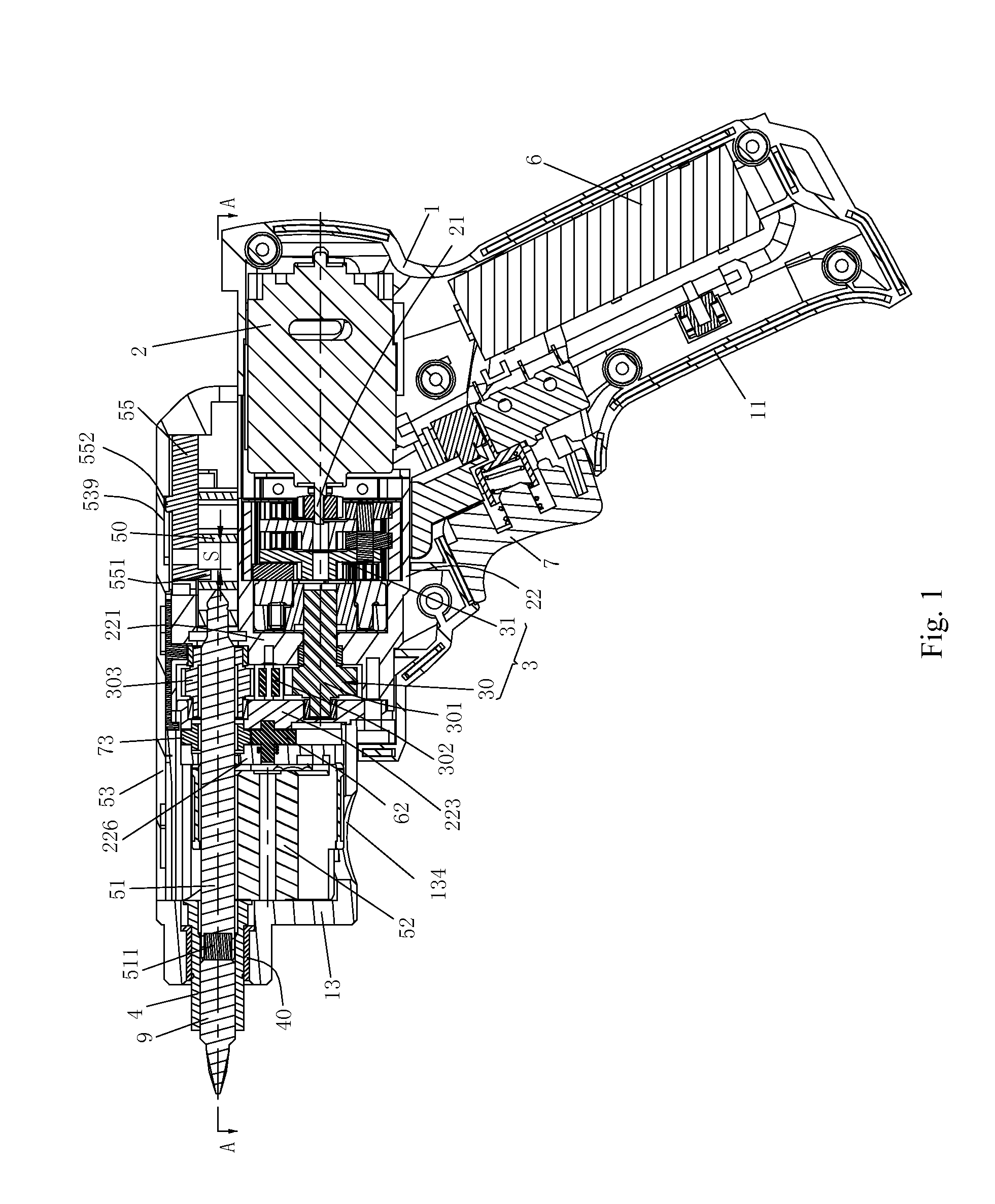

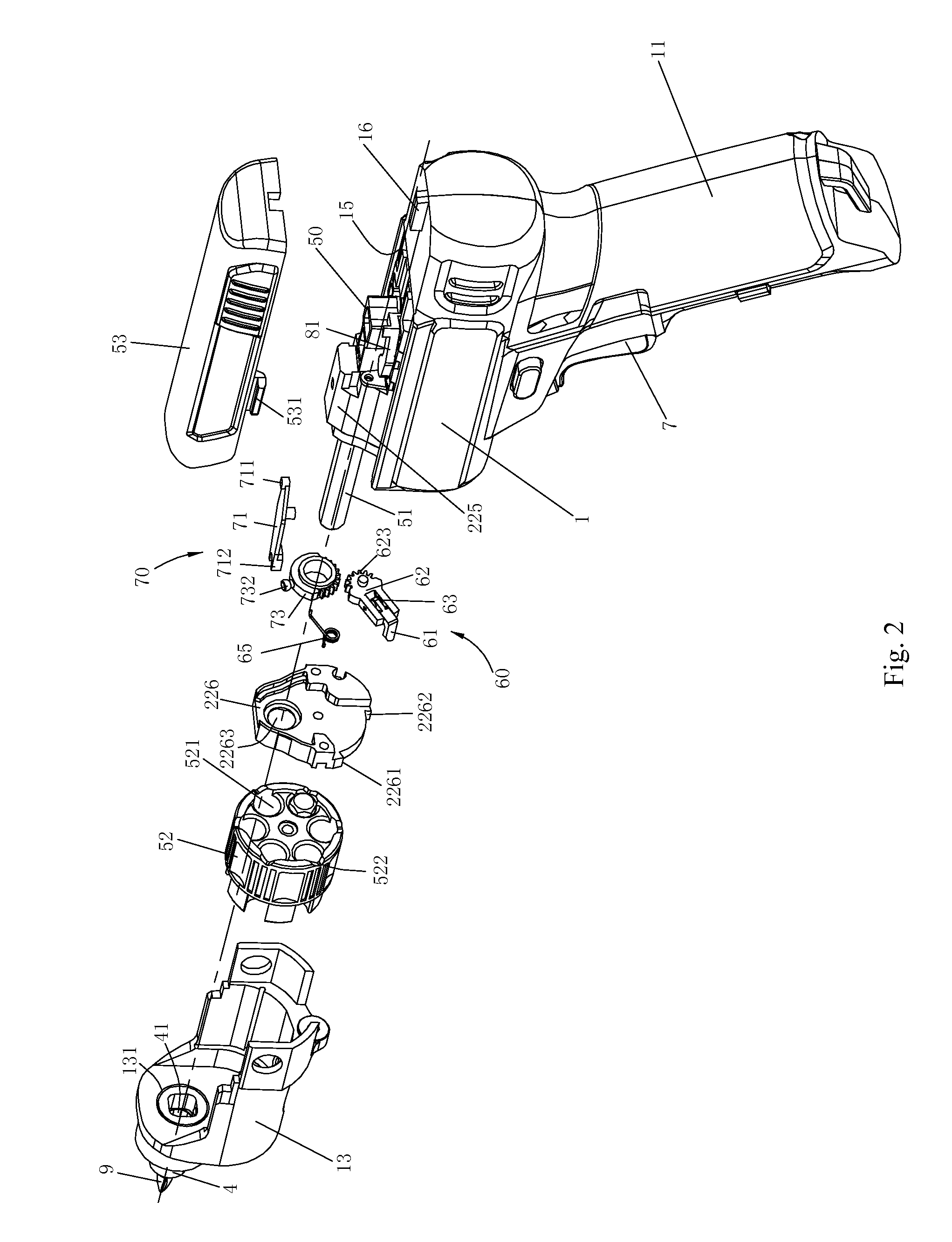

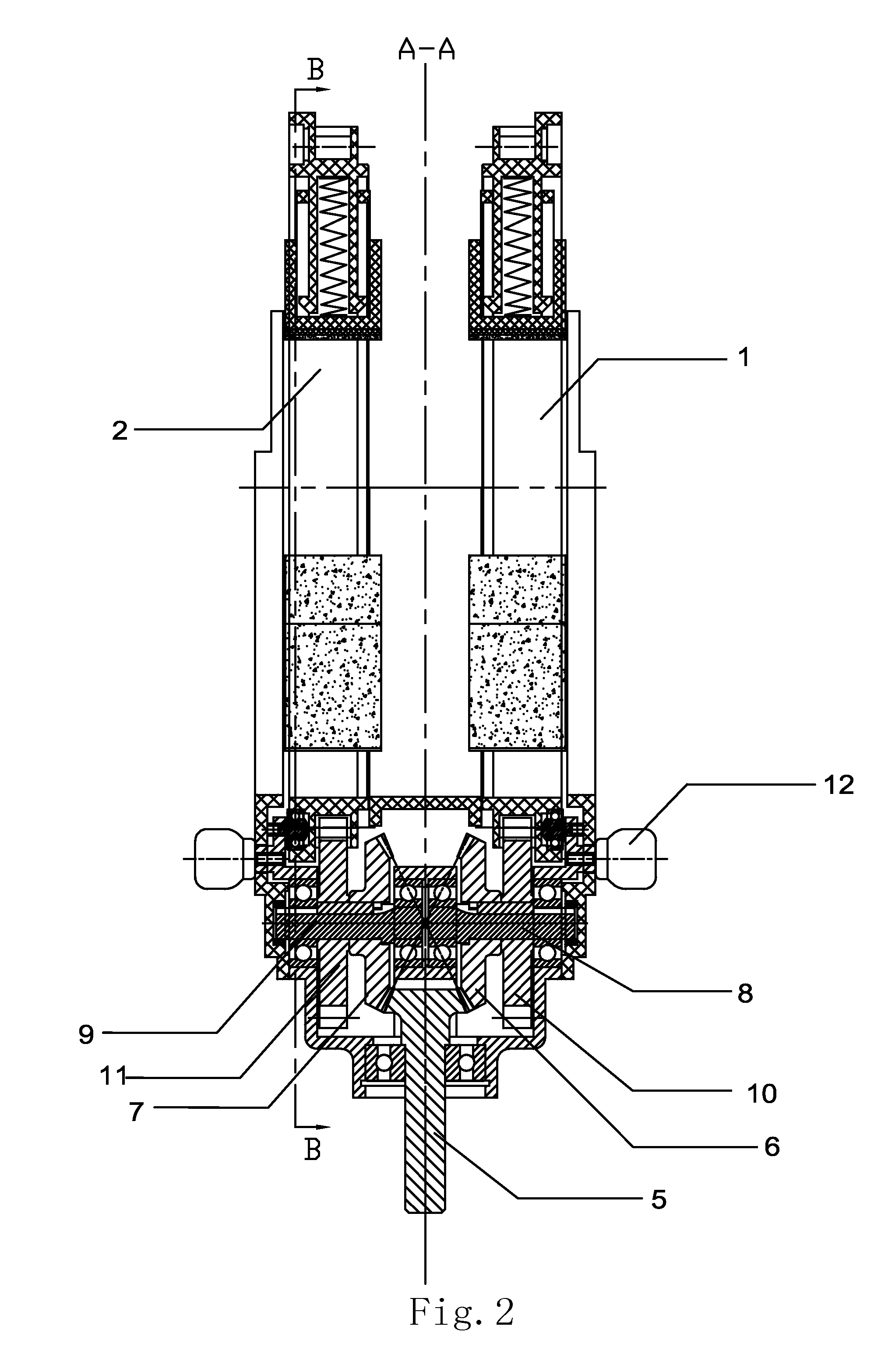

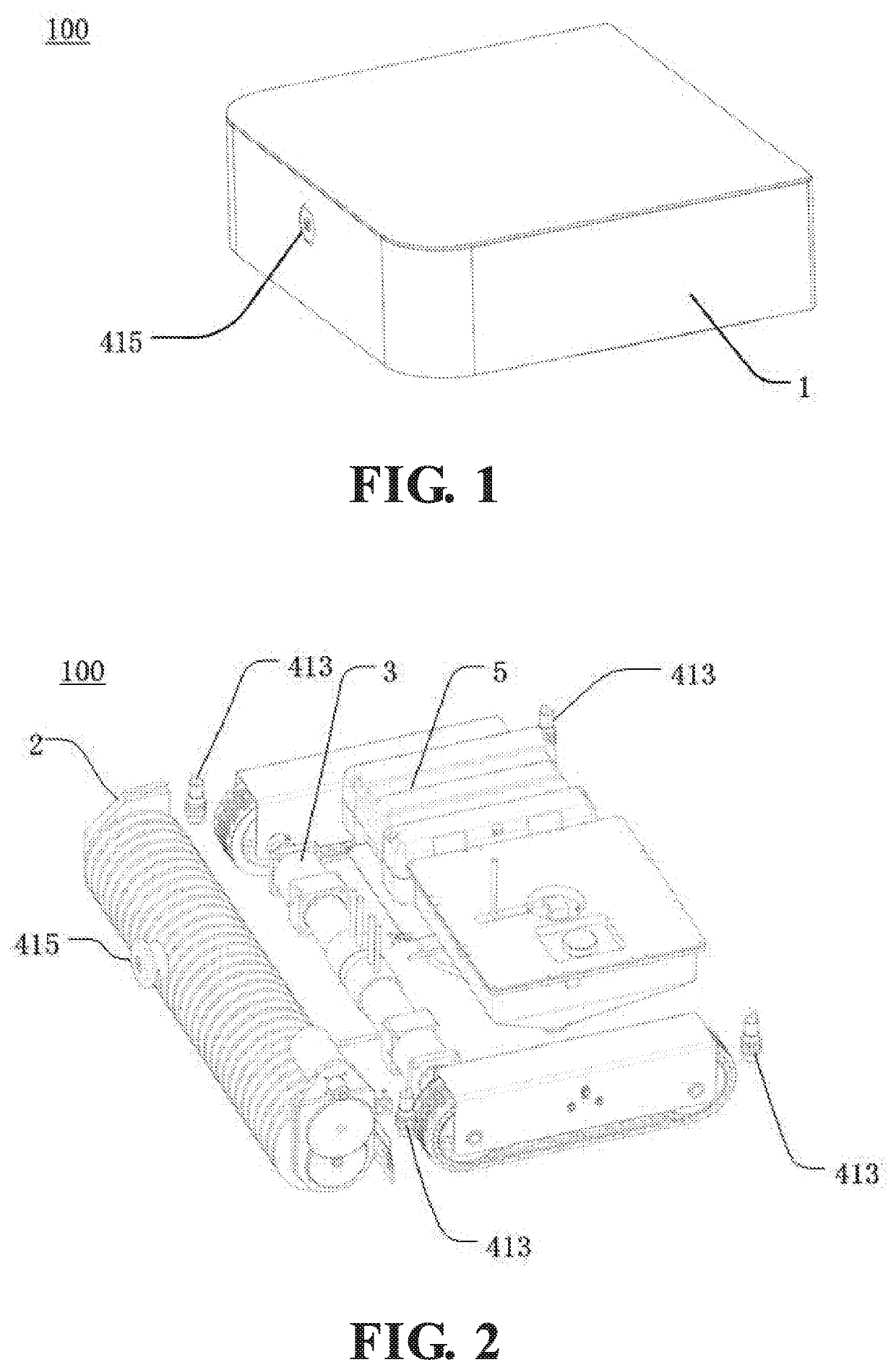

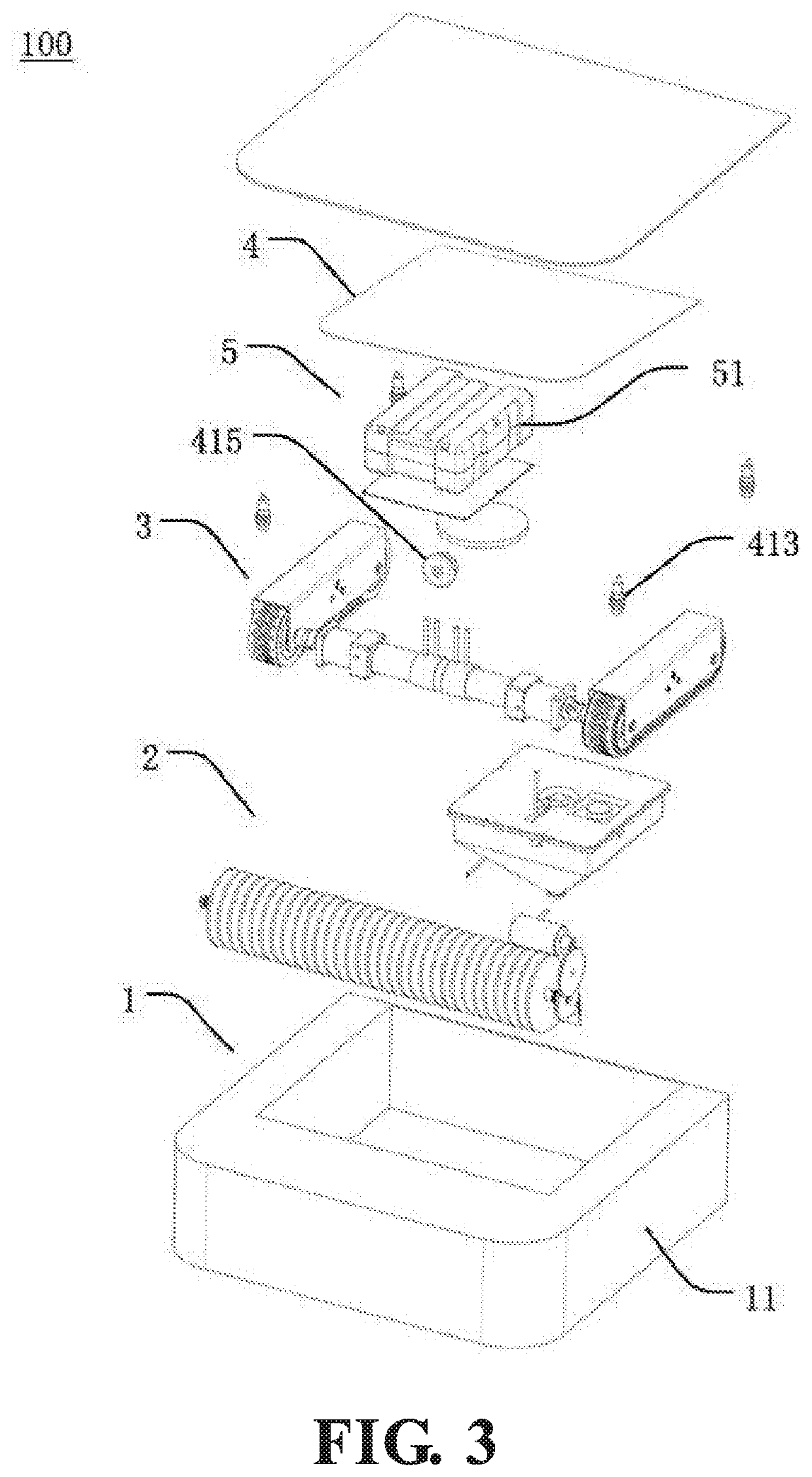

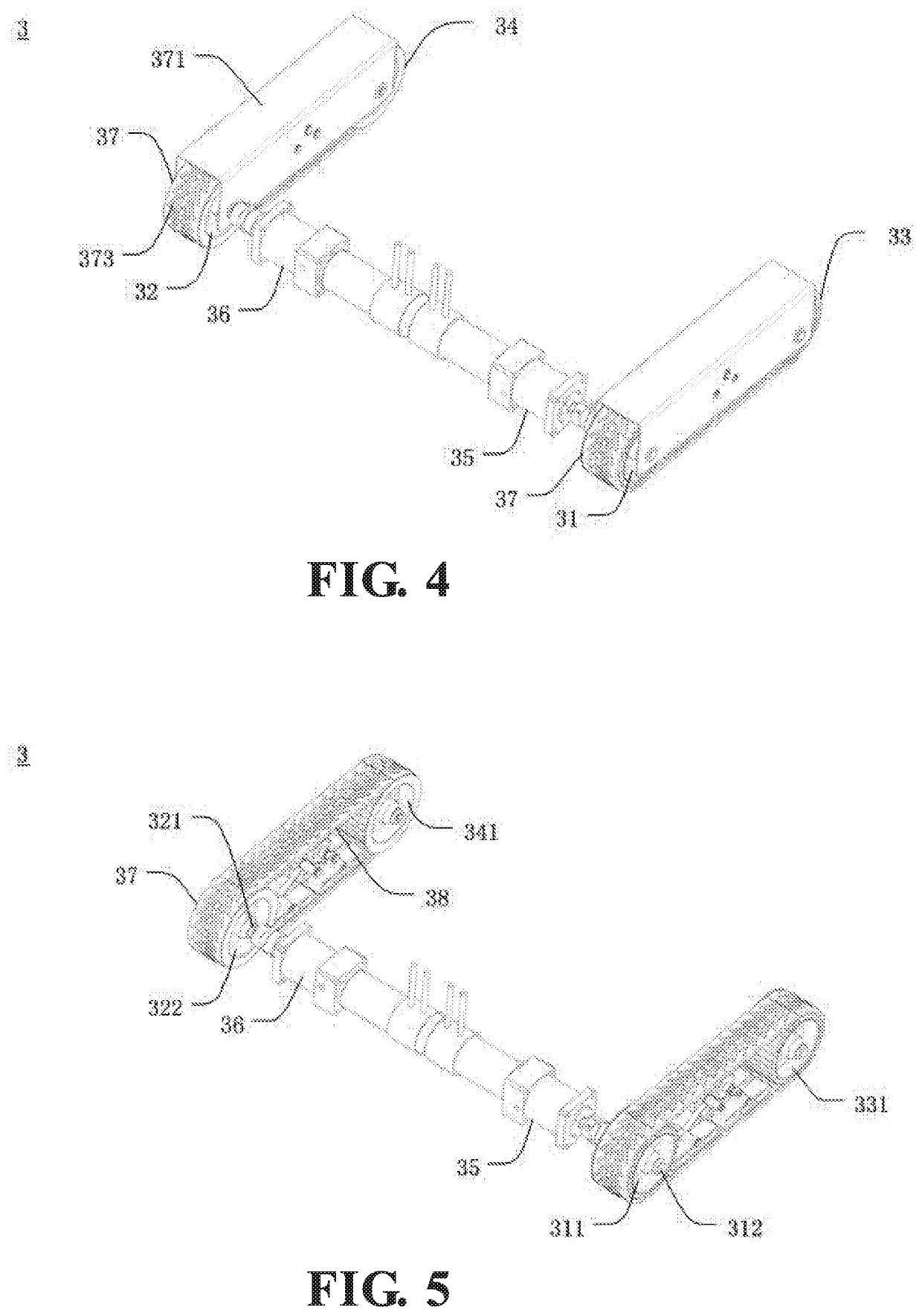

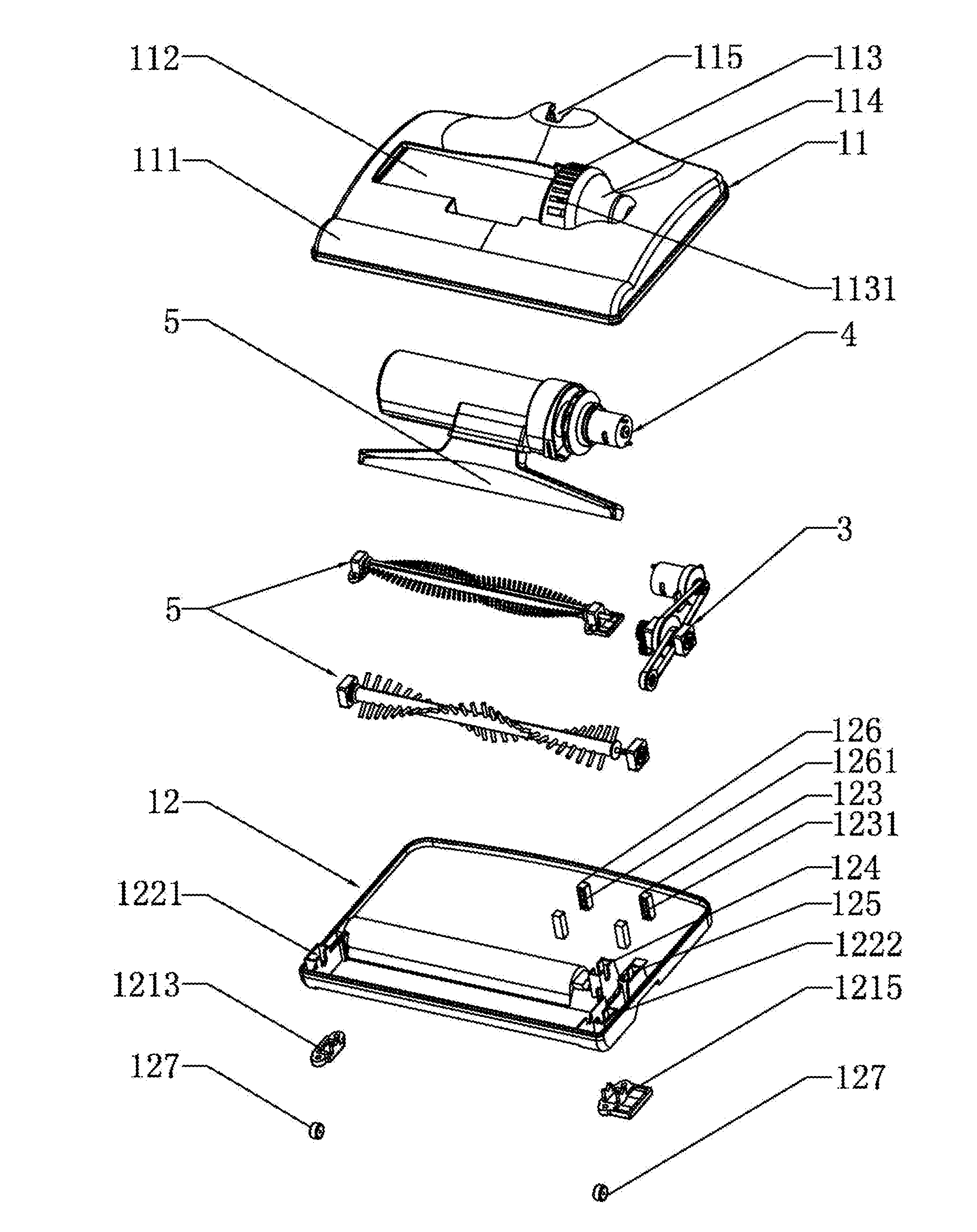

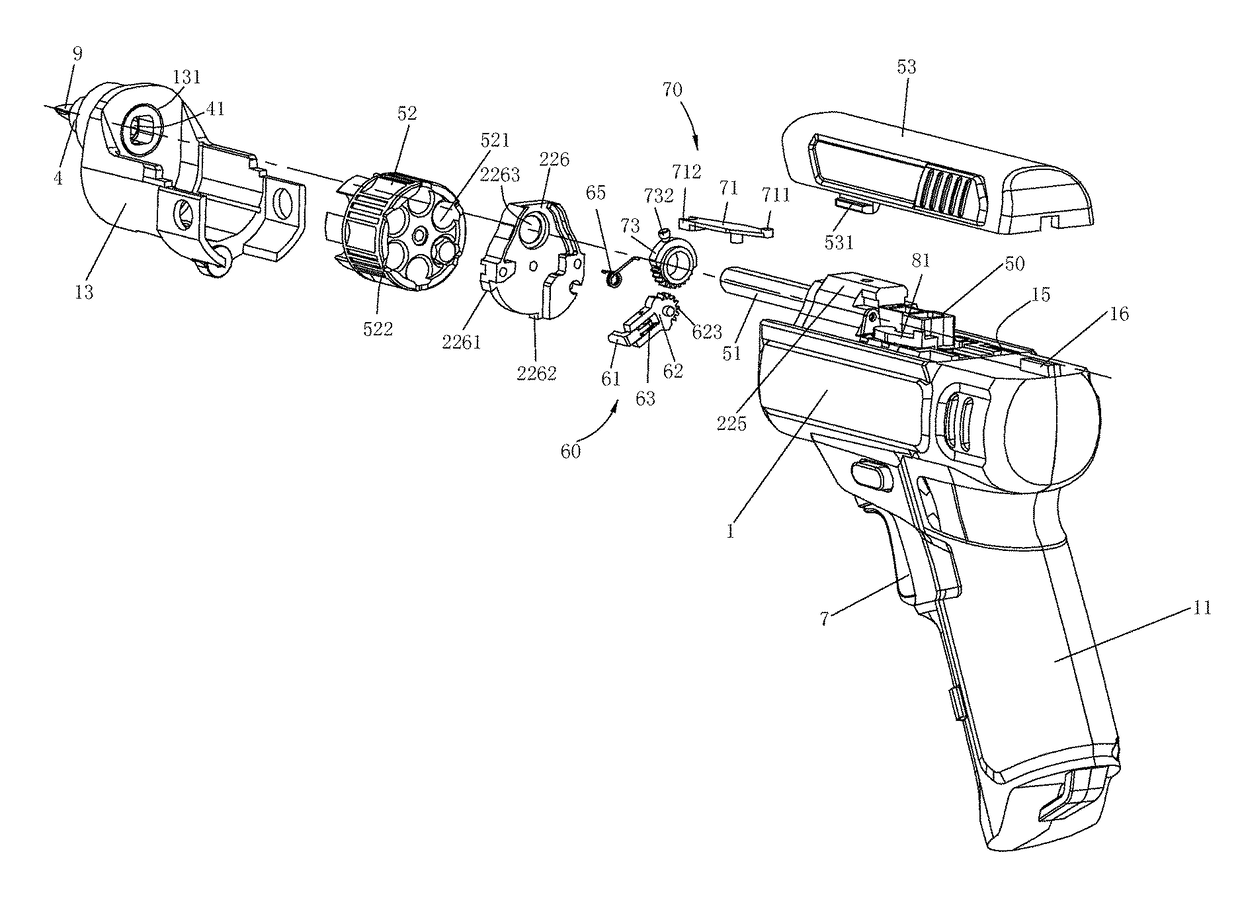

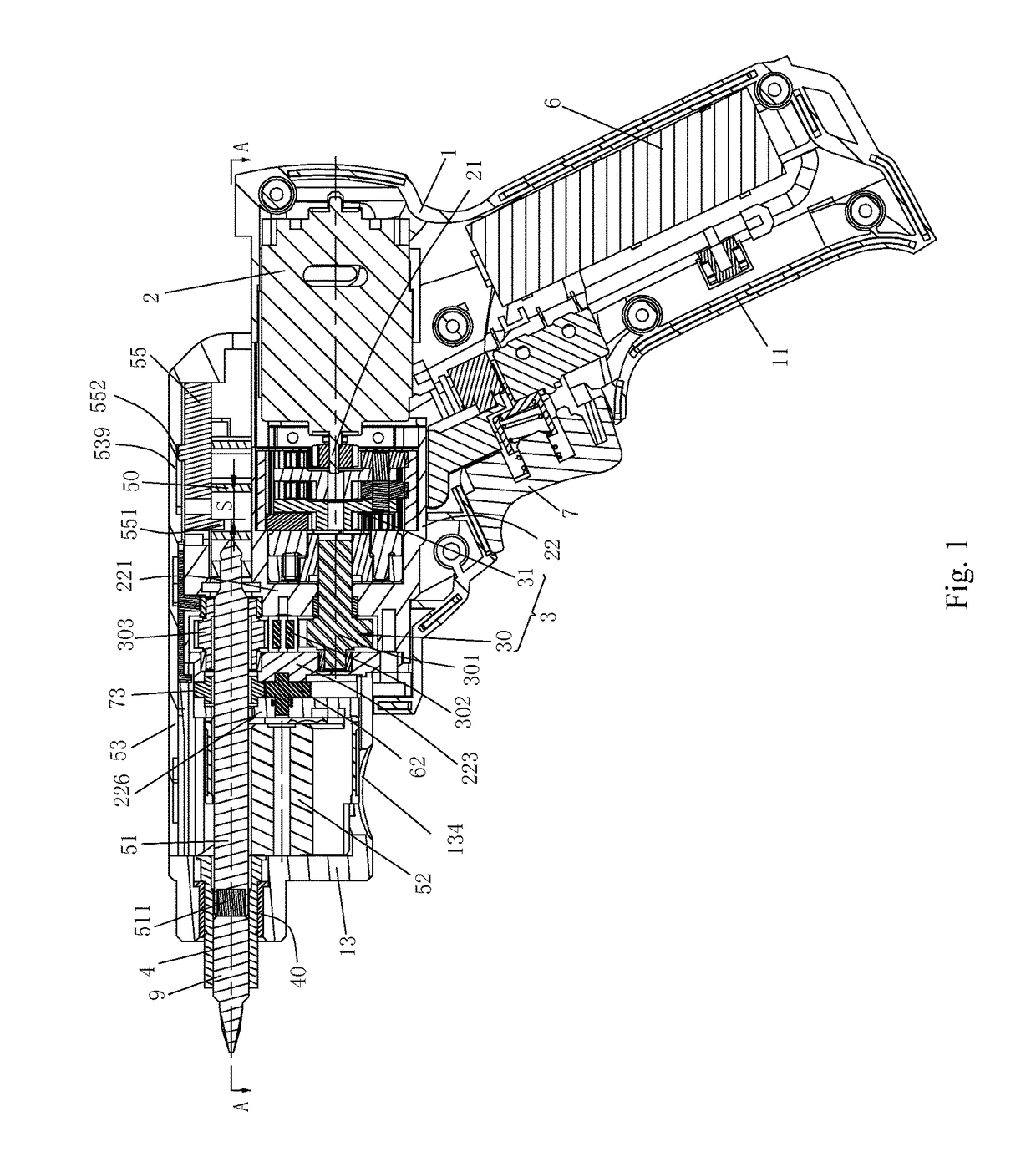

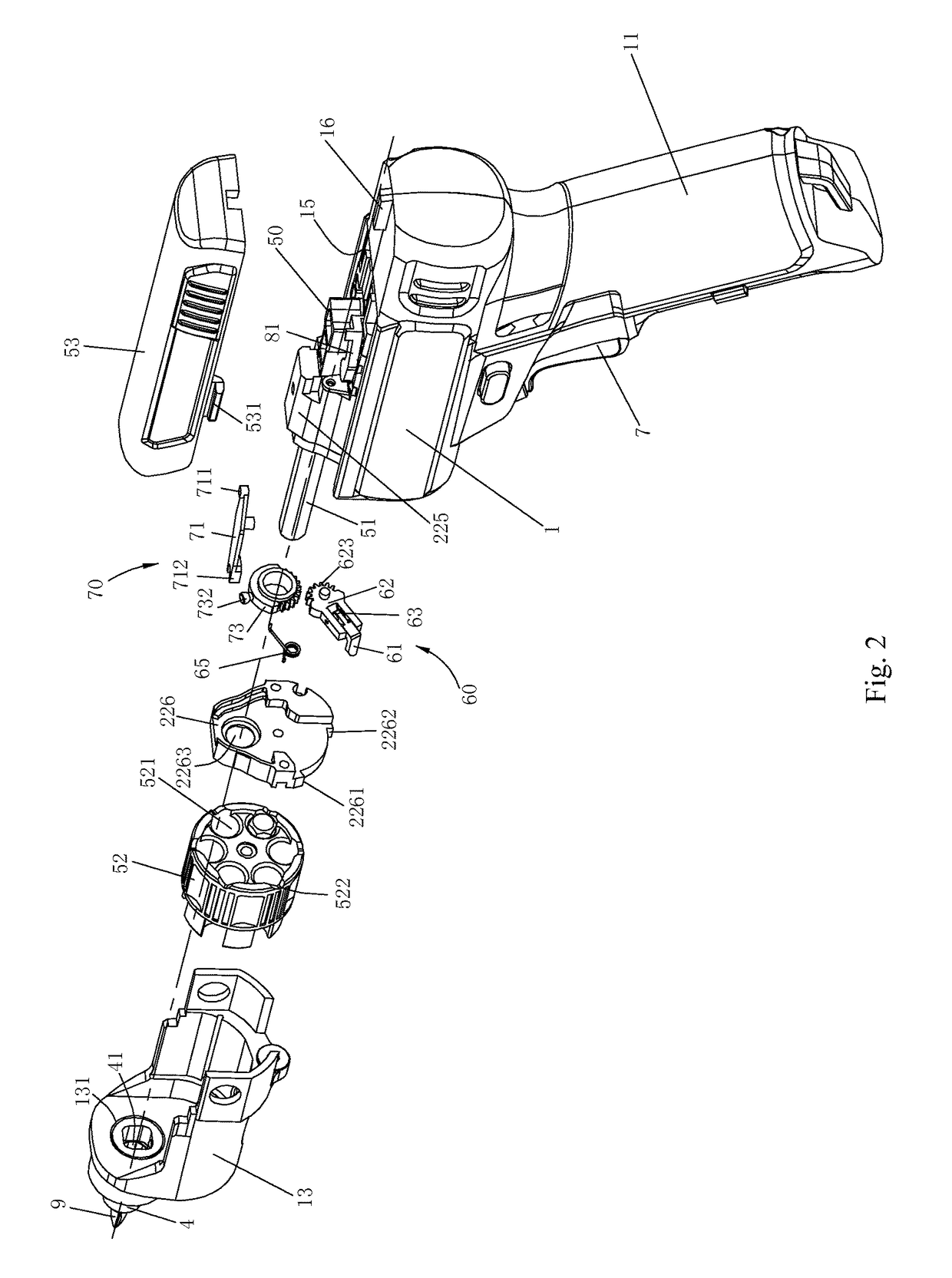

Power tool and operating method for use on the power tool

ActiveUS20140329654A1Simple structureEasy to operateTool changing apparatusPortable power-driven toolsEngineeringPower tool

A power tool, comprising: a housing; a motor being disposed in the housing for outputting rotary power; an output shaft having an accommodating hole in the axial direction for holding a tool bit; a transmission mechanism, being disposed between the motor and the output shaft for transmitting rotary power from the motor to the output shaft; a tool bit supporting being disposed in the housing and including several chambers disposed in parallel for holding the tool bit; a connecting member being disposed in the housing and capable of moving axially between a working position where the connecting member passes through one of the chambers and to accommodate the tool bit in the chamber connect the output shaft, and a release position where the connecting member exits and separates from one of the several chambers; and an operating member is arranged on the housing for controlling the axial movement of the connecting member; the power tool further includes an automatic shifting means for adjusting the position of the tool bit supporting in response to the movement of the operating member, wherein the connecting member moves axially to a position that is separated from one of the several chambers, and the cartridge moves to a position where another chamber is axially corresponding to the output shaft under the action of the automatic shifting means.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

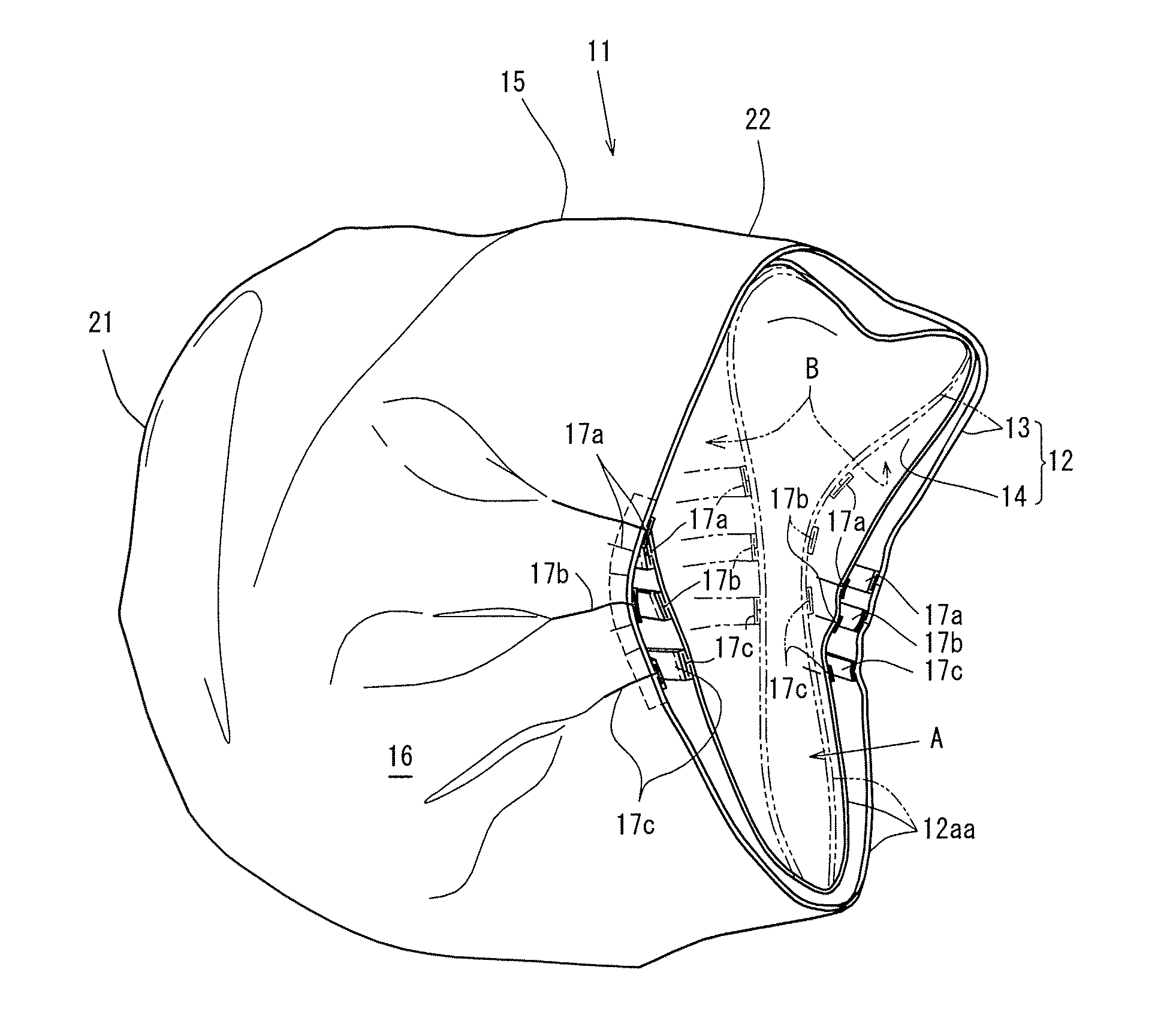

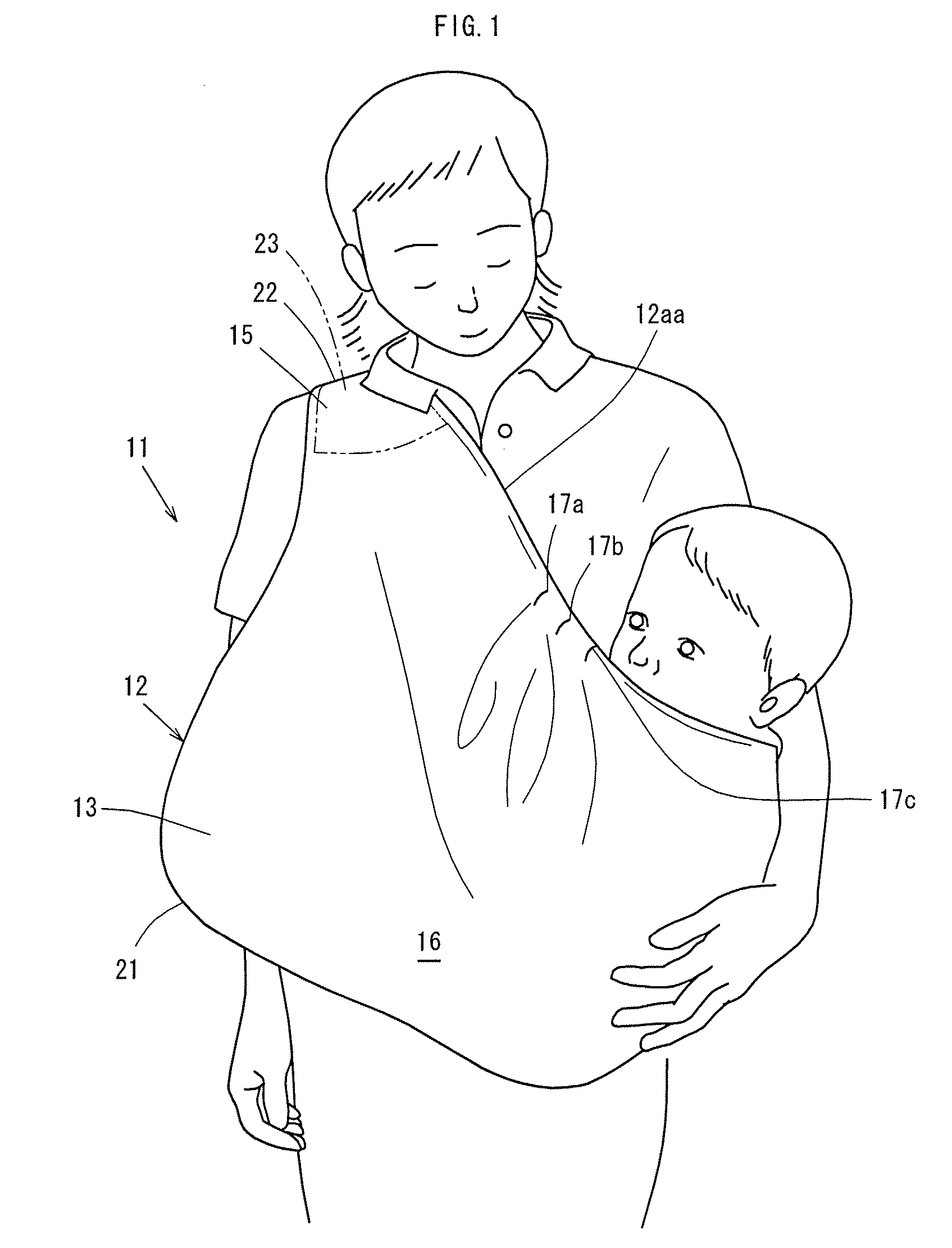

Baby carrier

InactiveUS20070062987A1Low costImprove working efficiencyStretcherWheelchairs/patient conveyanceEngineeringMechanical engineering

Owner:T-REX

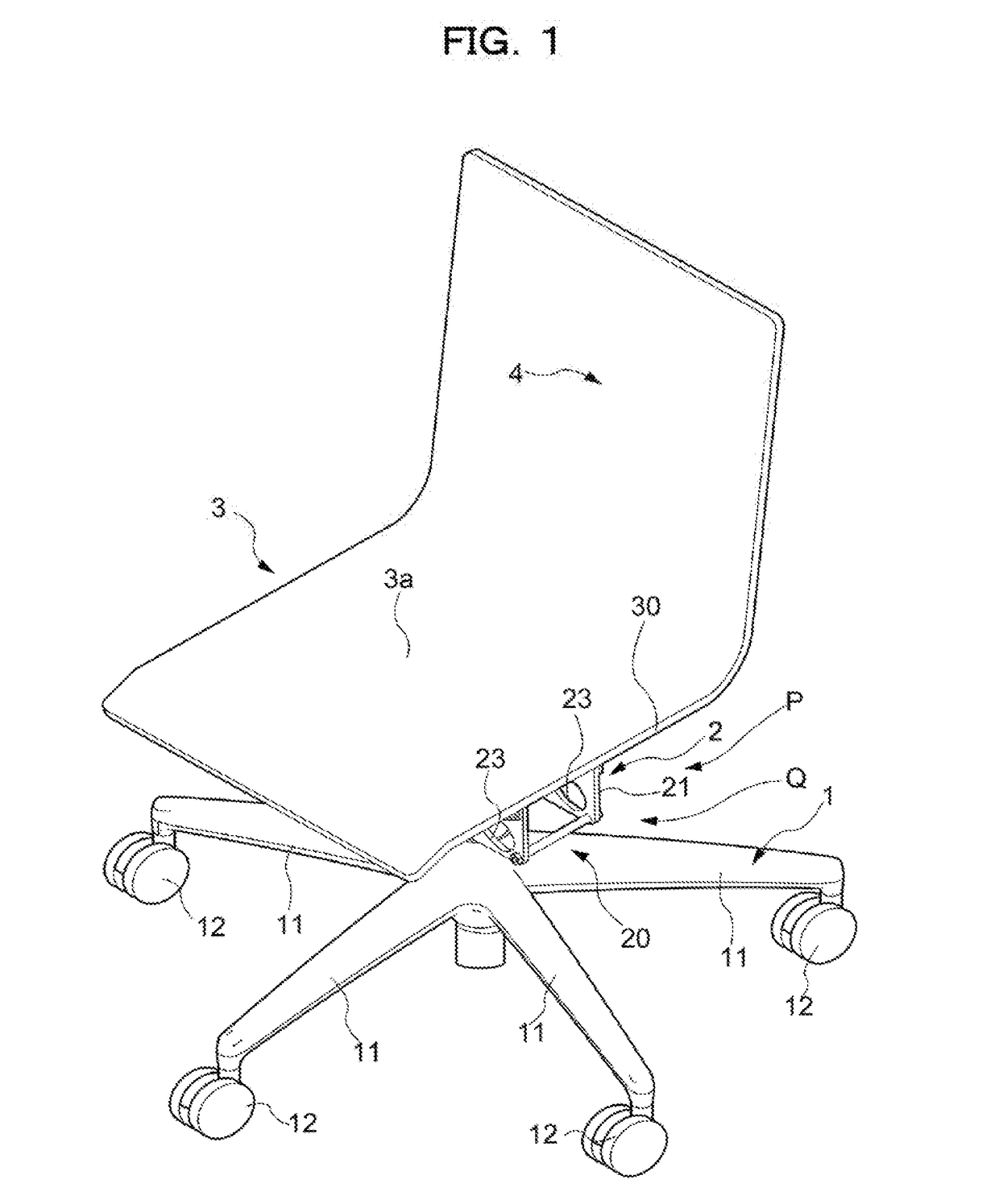

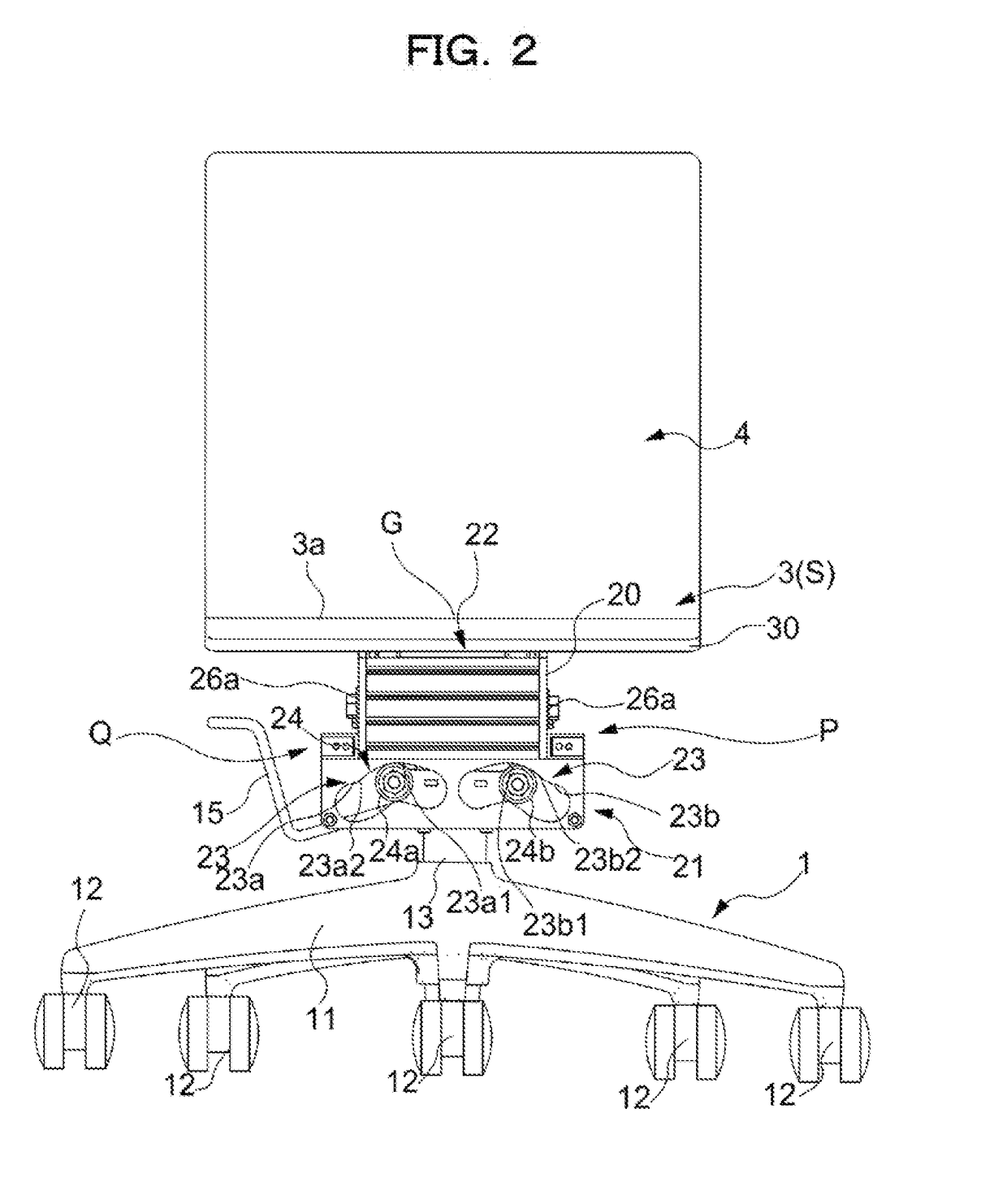

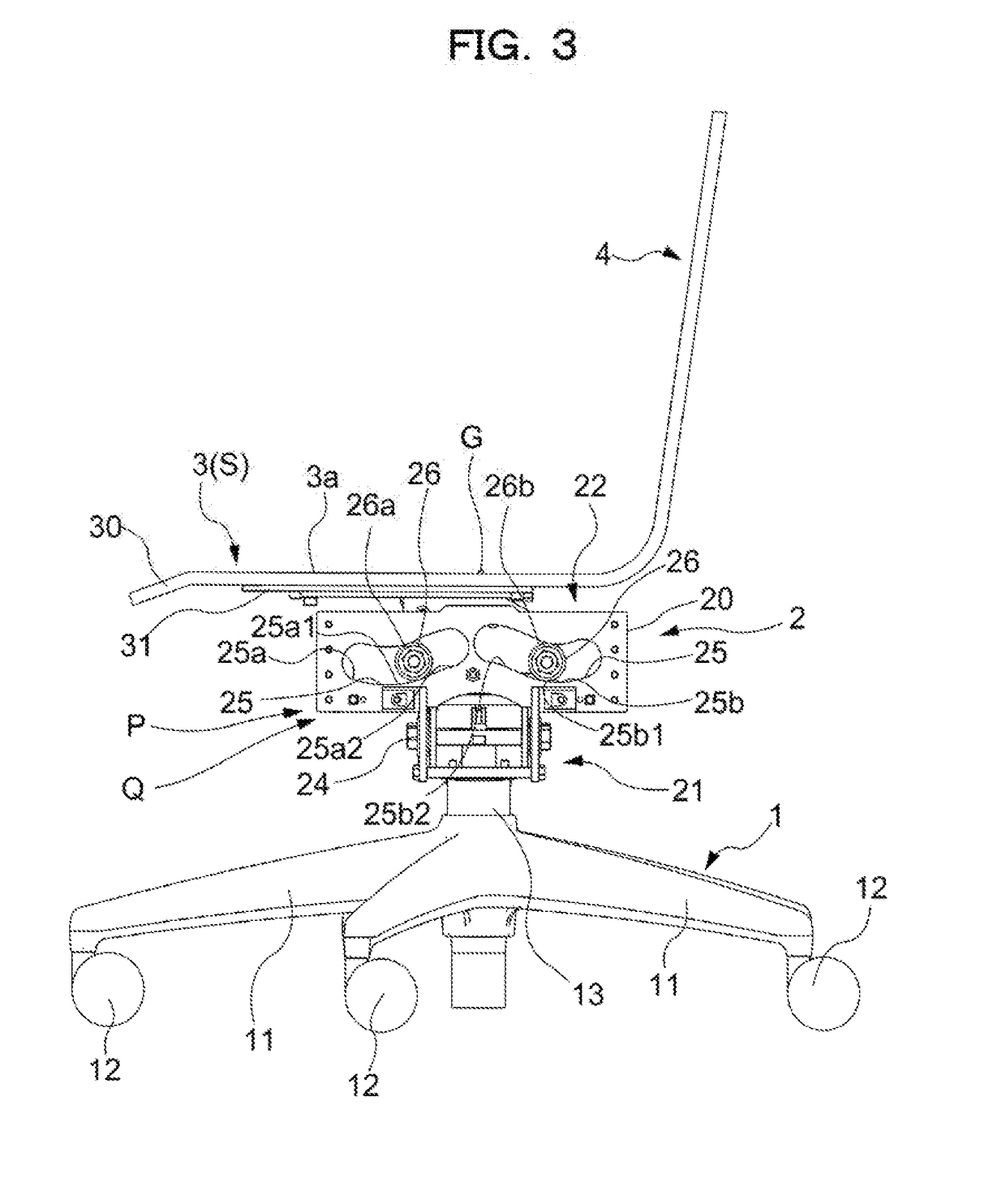

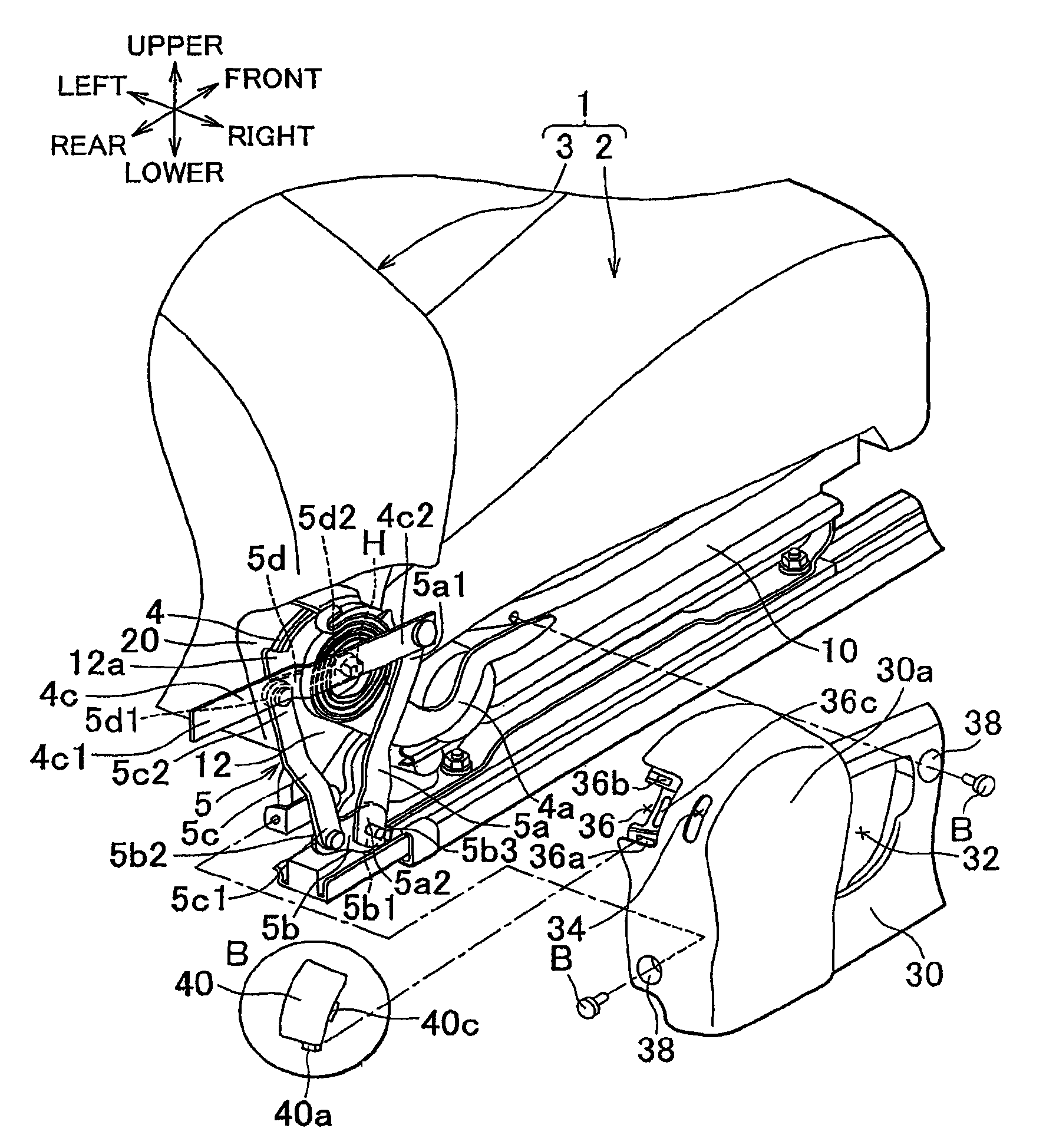

Chair and seat support mechanism

ActiveUS20190045928A1Improve working efficiencyFeel comfortableStoolsAdjustable chairsForce generationGravity center

A chair includes a support mechanism 2 interposed between a leg 1 and a seat 3, wherein the support mechanism 2 is arranged below the seat 3, is configured to each individually and movably support the seat 3, at least at two locations in a front-rear direction and two locations in a left-right direction, along a predetermined trajectory, and the support mechanism 2 includes: a seat inclining mechanism Q or a seat inclining function configured to downwardly incline a tip side in a movement direction of the seat 3 in accordance with movement of the seat 3, and further includes: a center-of-gravity movement mechanism P or a return-force generation mechanism configured to generate a return force in a direction of returning the seat 3 having moved from a reference position (S) in a front-rear or left-right direction, to the reference position (S) by using a center-of-gravity movement.

Owner:KOKUYO CO LTD

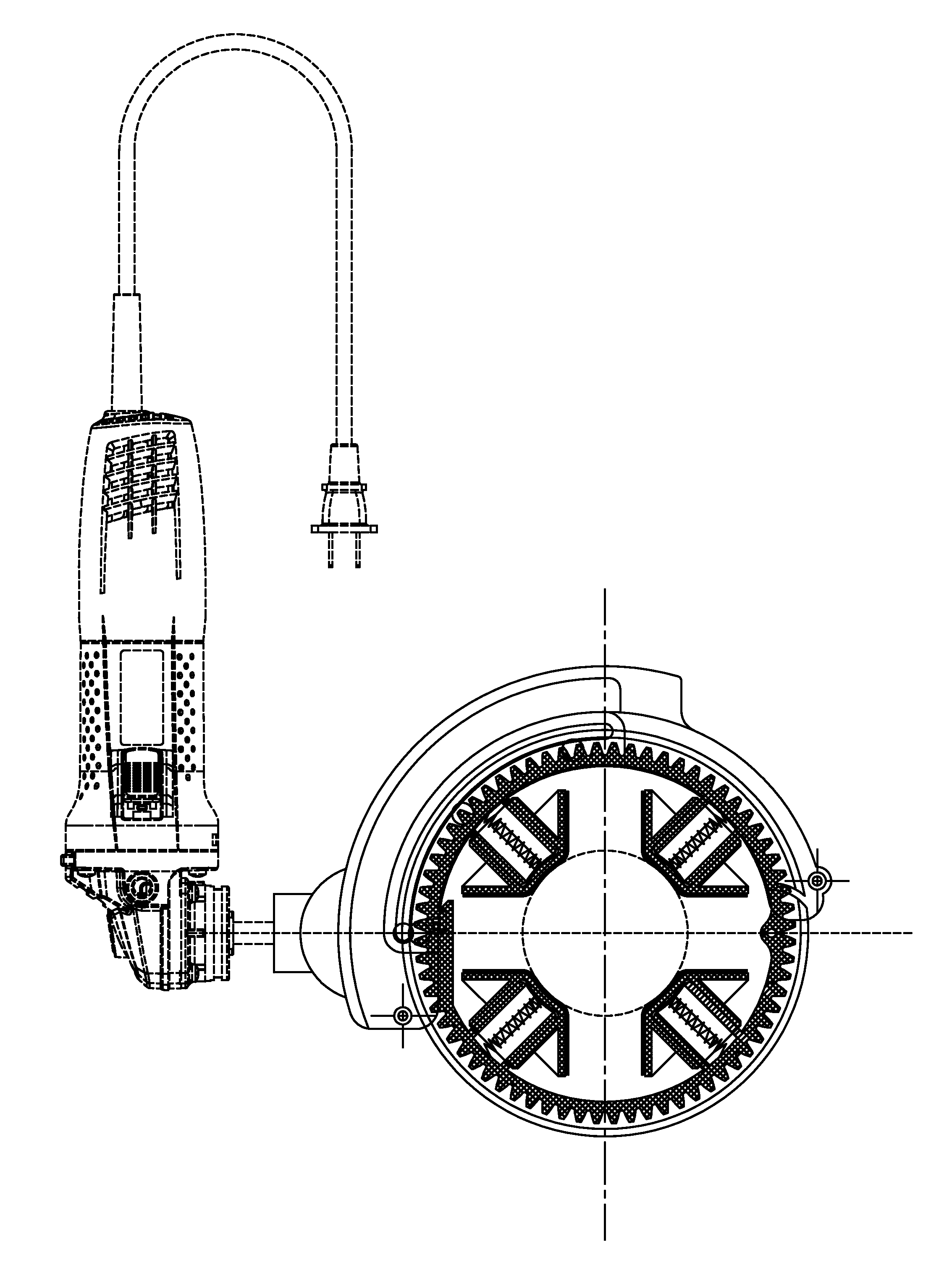

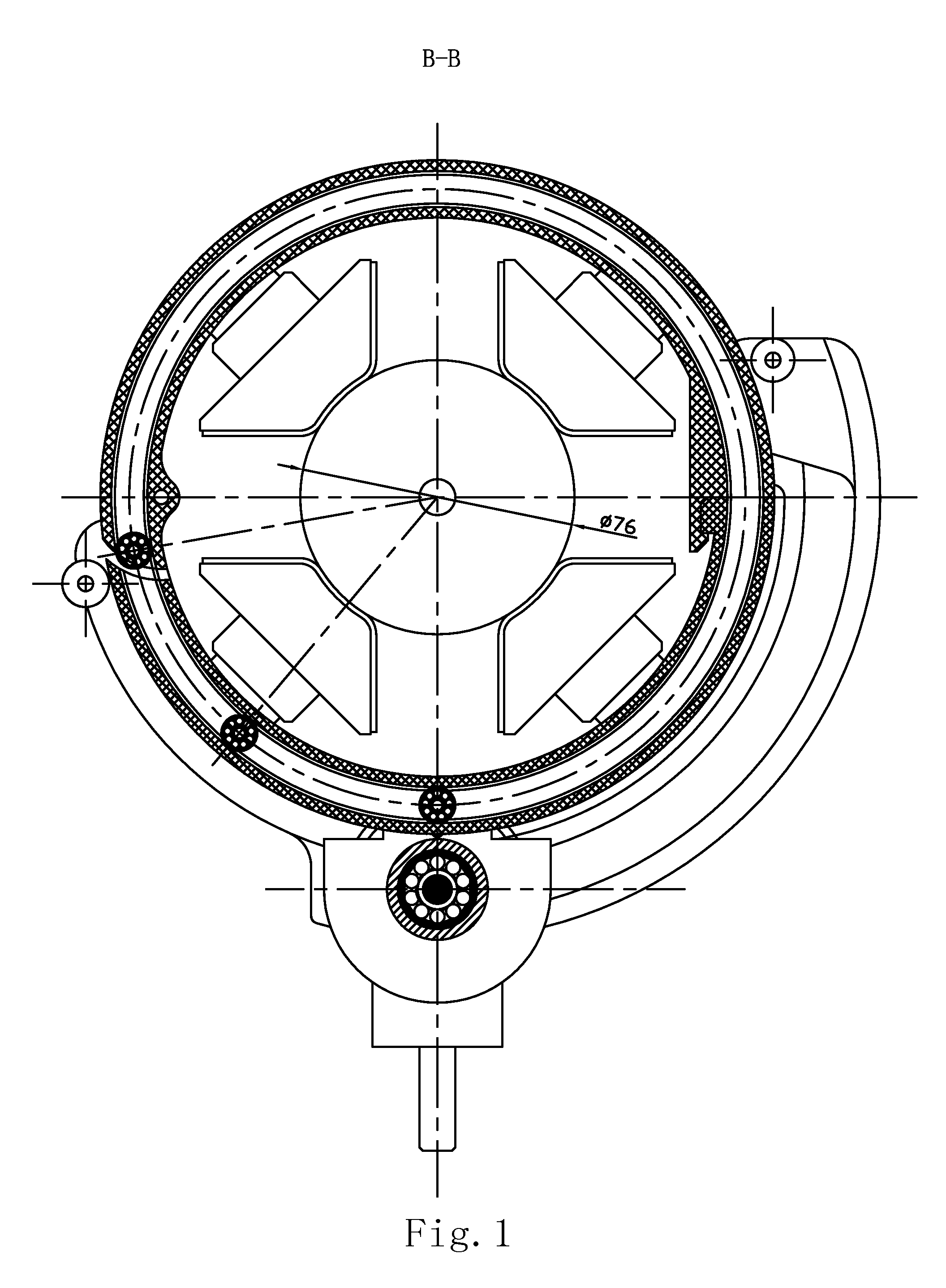

External circular polisher with double polishing wheels

InactiveUS20150183075A1Improve working efficiencyGood effectEdge grinding machinesRevolution surface grinding machinesCircular surfaceElectric motor

An external circular polisher with double polishing wheels includes: a first polishing wheel having a first internal circular surface; a second polishing wheel having a second internal circular surface; a plurality of holders mounted on the first internal circular surface and the second internal circular surface; a plurality of polishing units connected to the holders for polishing a target external circular surface; a driving unit for driving the first polishing wheel and the second polishing wheel; and a supporter for supporting the first polishing wheel and the second polishing wheel. With the foregoing structure, a user can polish a target with two polishing wheels at the same time, and the external circular polisher works stably; the present invention can be driven by a motor of a conventional device for further increasing a scope of application of the external circular polisher with double polishing wheels.

Owner:HAMMER ELECTRIC POWER TOOLS

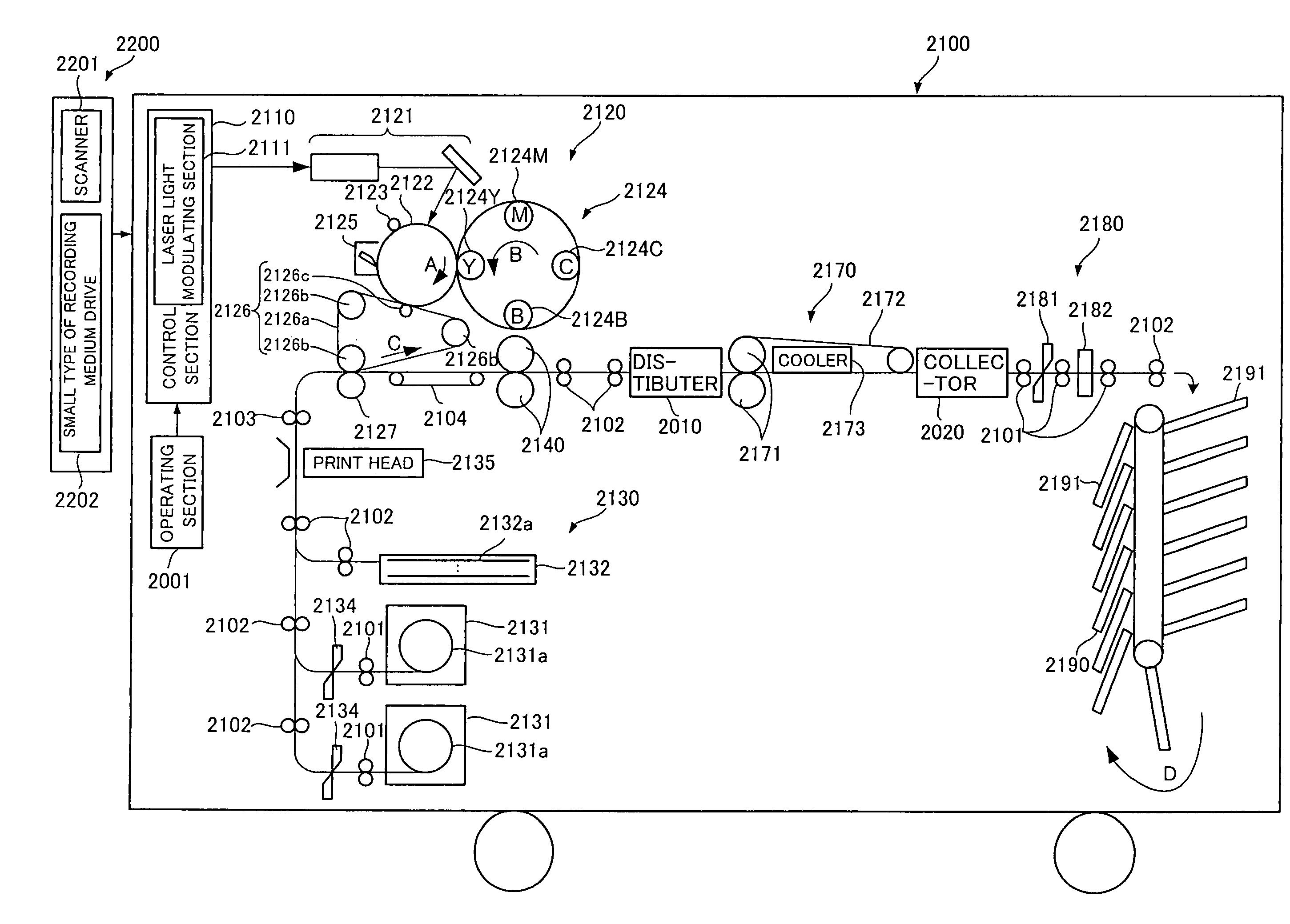

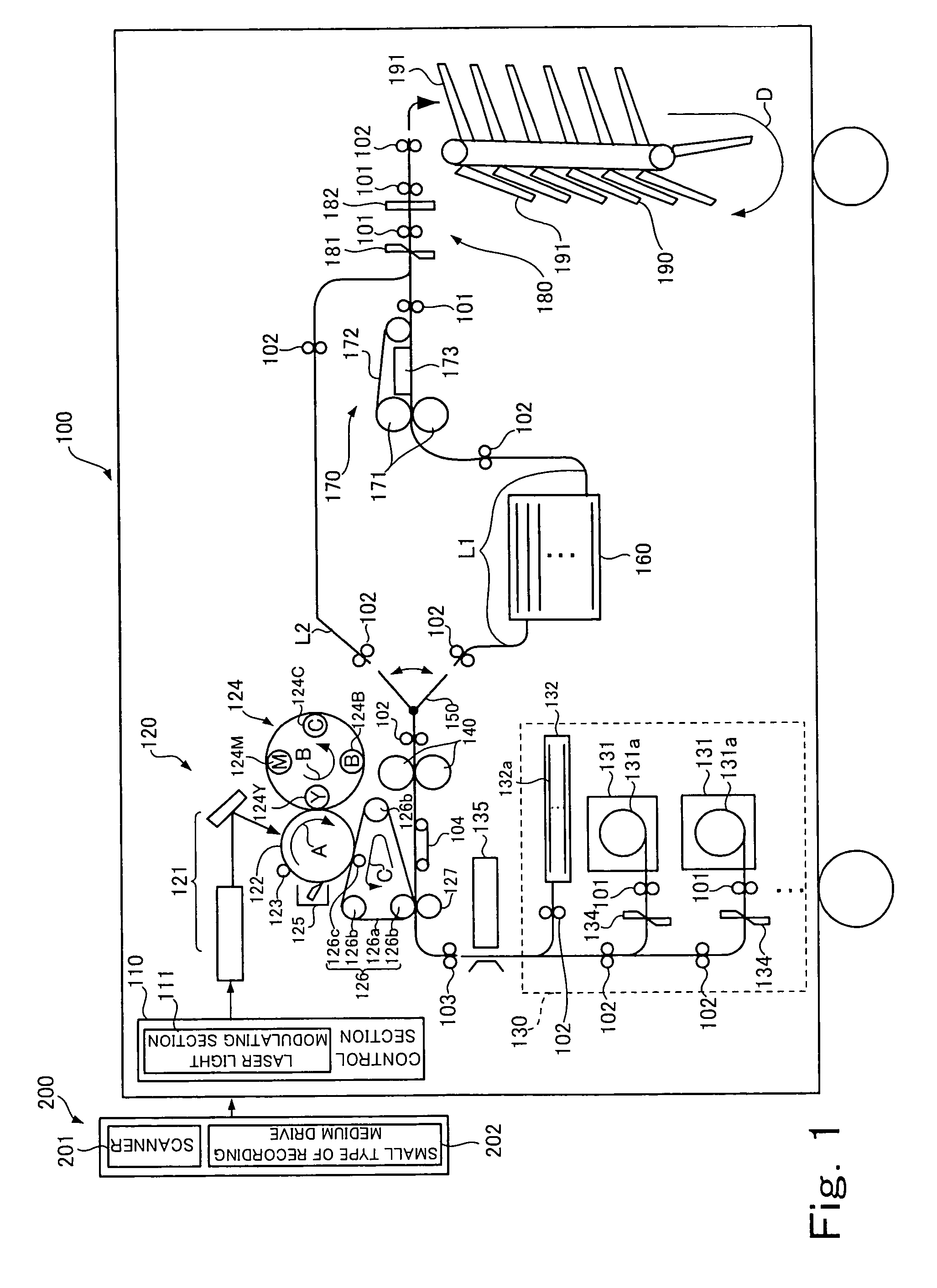

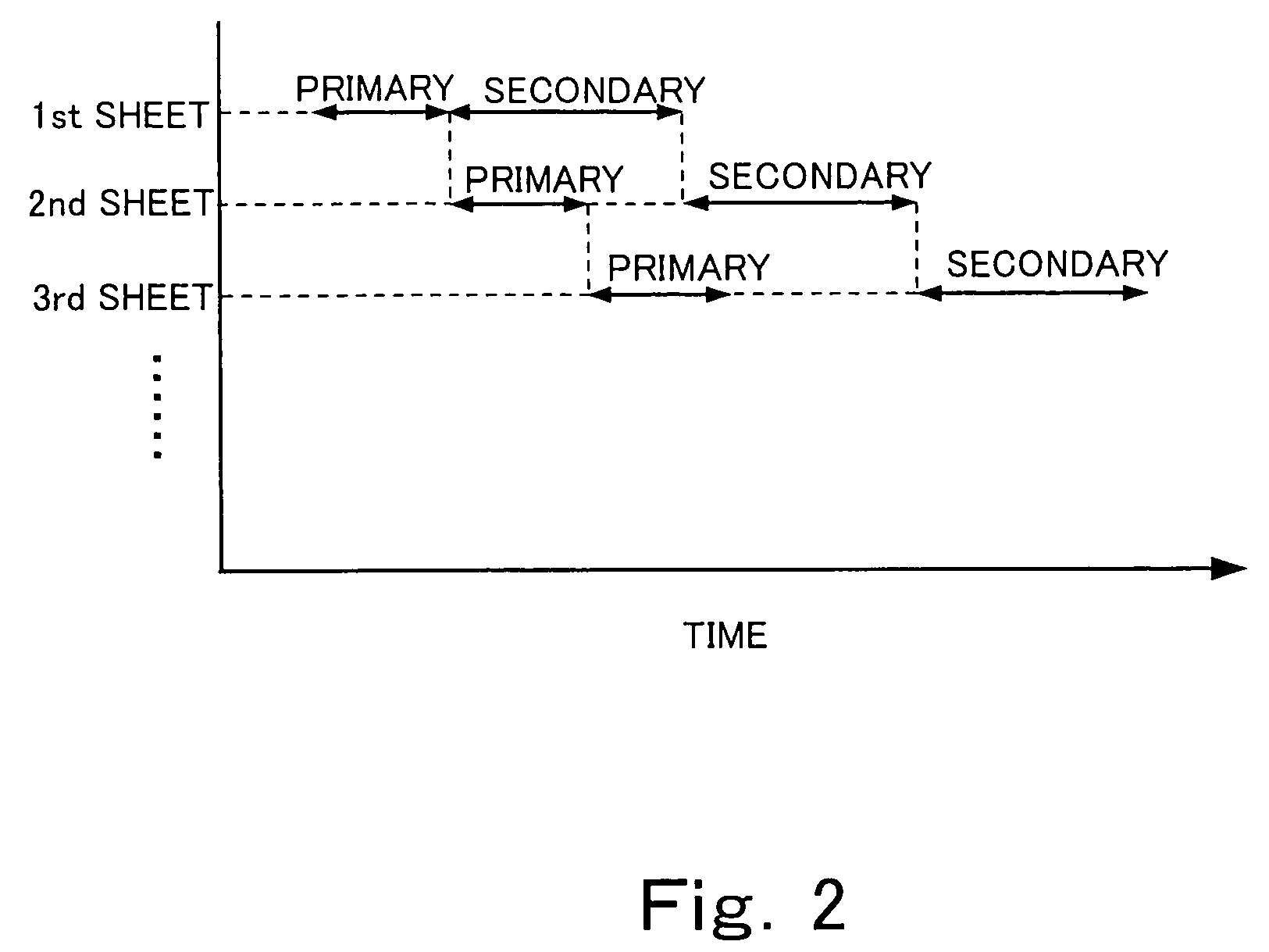

Printer and image forming method providing selectable path for recording medium

InactiveUS7197271B2Improve working efficiencyElectrographic process apparatusLatent imageImage transfer

A printer includes: an image forming section that transfers a toner image onto a sheet-like recording medium conveyed on a conveyance-path, in which an electrostatic latent image is formed on a surface of an image carrier, and the toner image is formed on the surface of the image carrier by causing the electrostatic latent image to absorb toner; a primary fixing section disposed downstream of the image forming section in the conveyance-path and fixing on the recording medium the toner image transferred to the recording medium by the image forming section; a storage section disposed downstream of the primary fixing section in the conveyance-path and storing the recording medium on which the toner image is fixed by the primary fixing section; and a secondary fixing section disposed downstream of the storage section in the conveyance-path and performing a surface processing for the toner image fixed by the primary fixing section.

Owner:FUJIFILM HLDG CORP +1

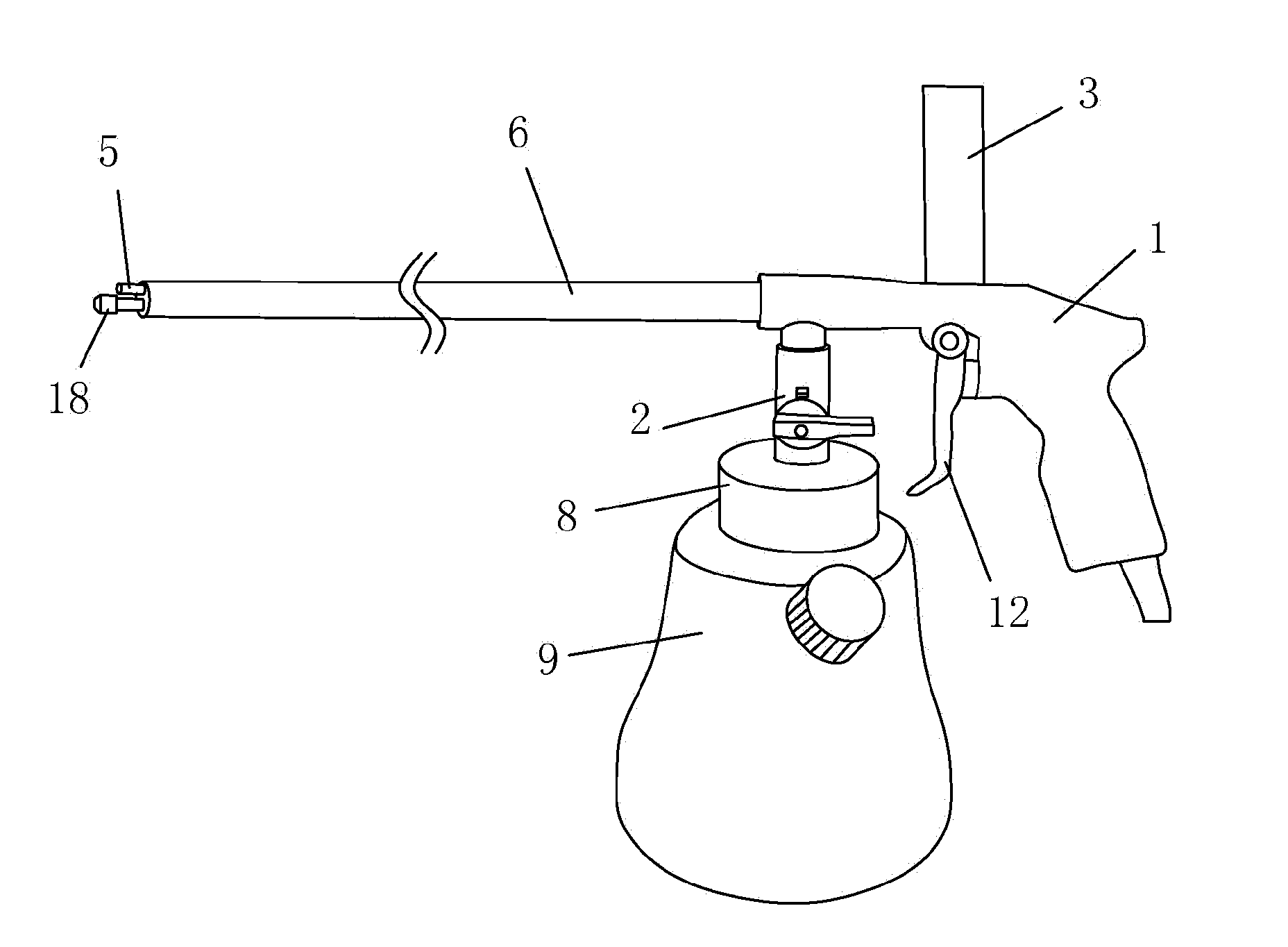

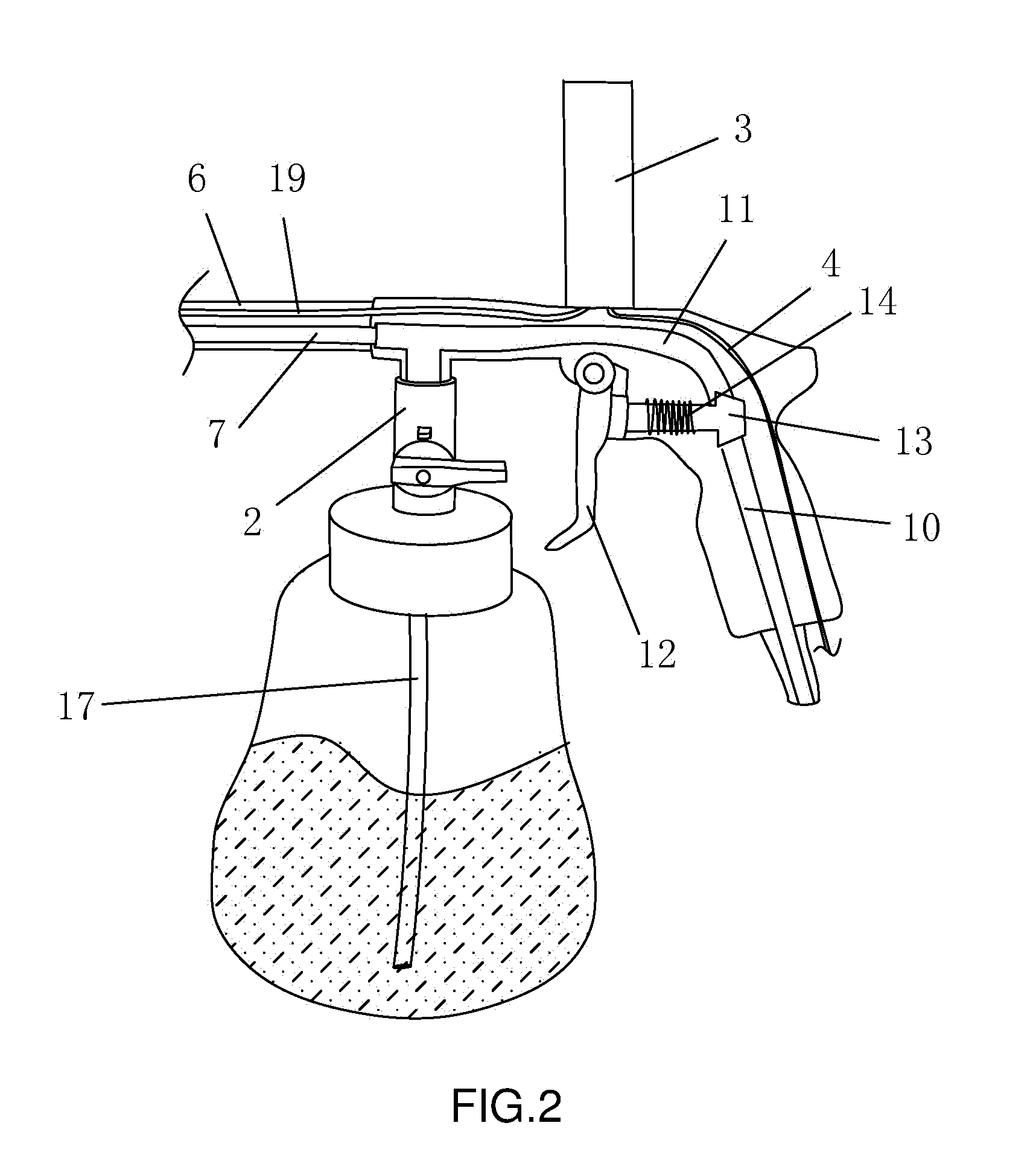

Portable visual cleaning device

InactiveUS20160296980A1Simple structureGuaranteed uptimeCapsClosure capsInlet channelTransmission channel

A portable visual cleaning device having a gun, an air / liquid switching valve, an endoscope display, an endoscope probe, an endoscope wire, a flexible pipe, a liquid outlet pipe and a liquid storage bottle: an air inlet channel and an air transmission channel are provided in the gun; a liquid pumping port and a liquid outlet port in communication with the air transmission channel are arranged on one end of the gun; the liquid pumping port of the gun is connected to a bottle cap of the liquid storage bottle via the air / liquid switching valve; one end of the liquid outlet pipe is connected to the air transmission channel, and the other end of the liquid outlet pipe is provided with a nozzle; the flexible pipe is sheathed on the liquid outlet pipe and the endoscope wire.

Owner:ZHENG JUNMING

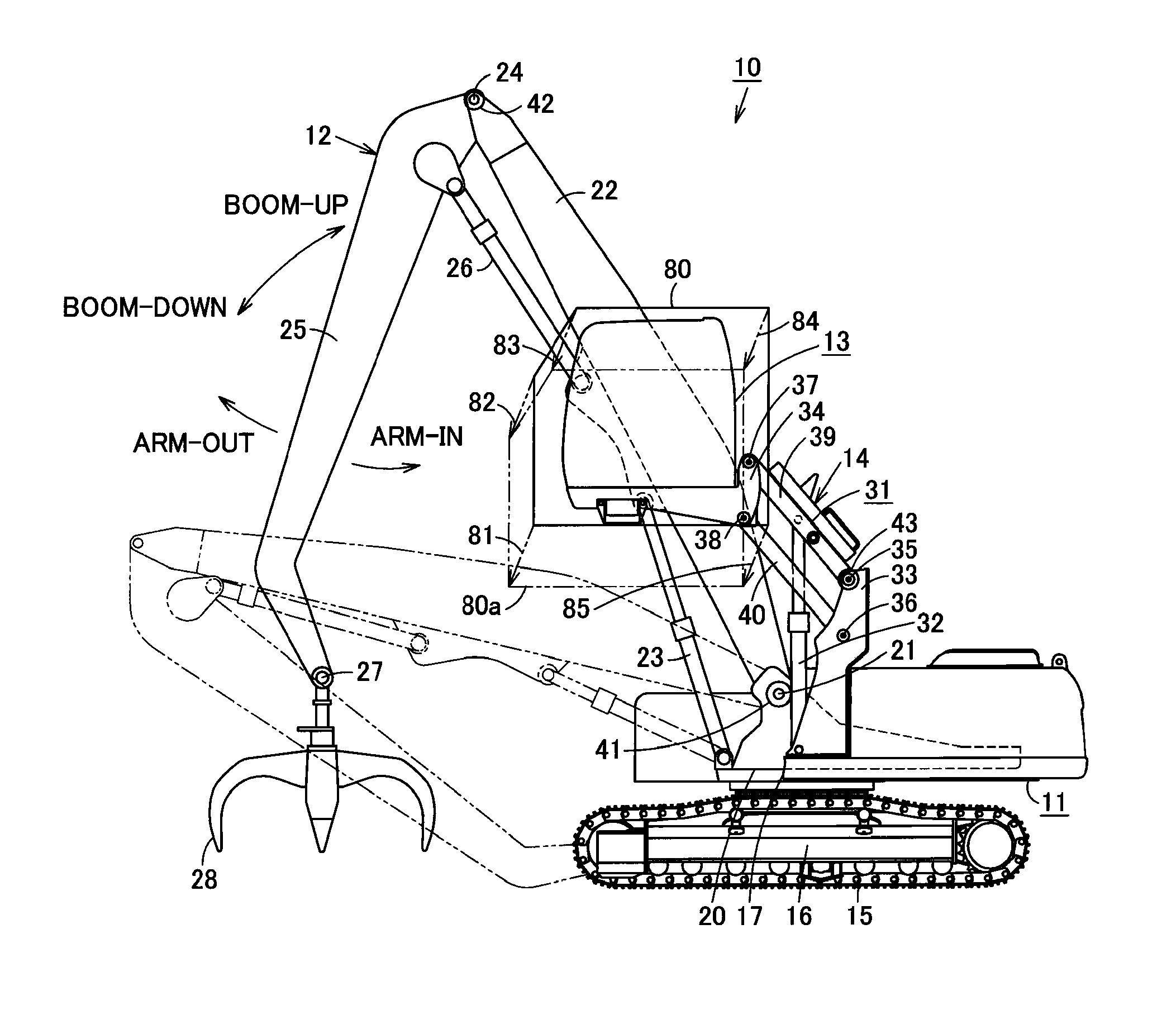

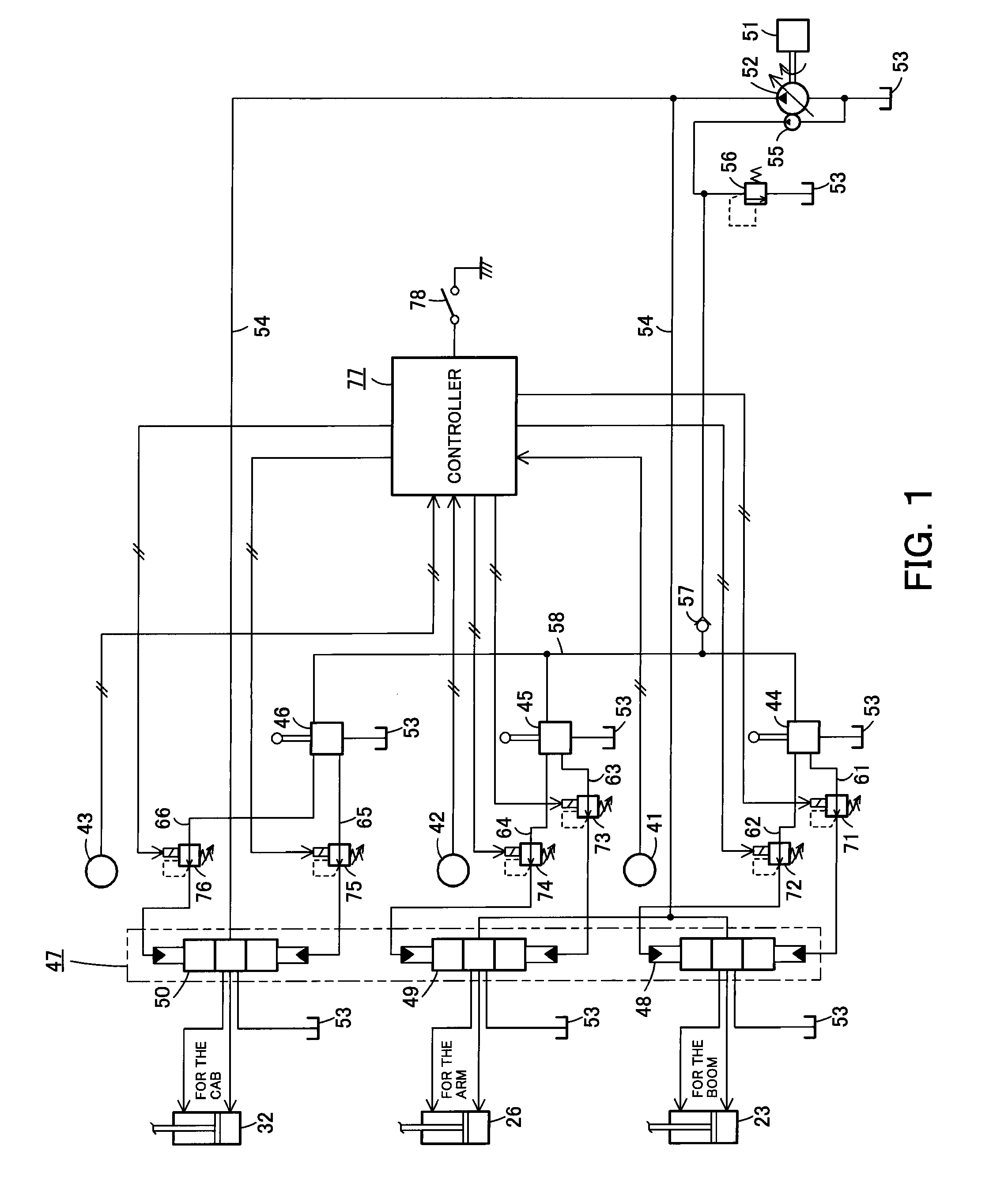

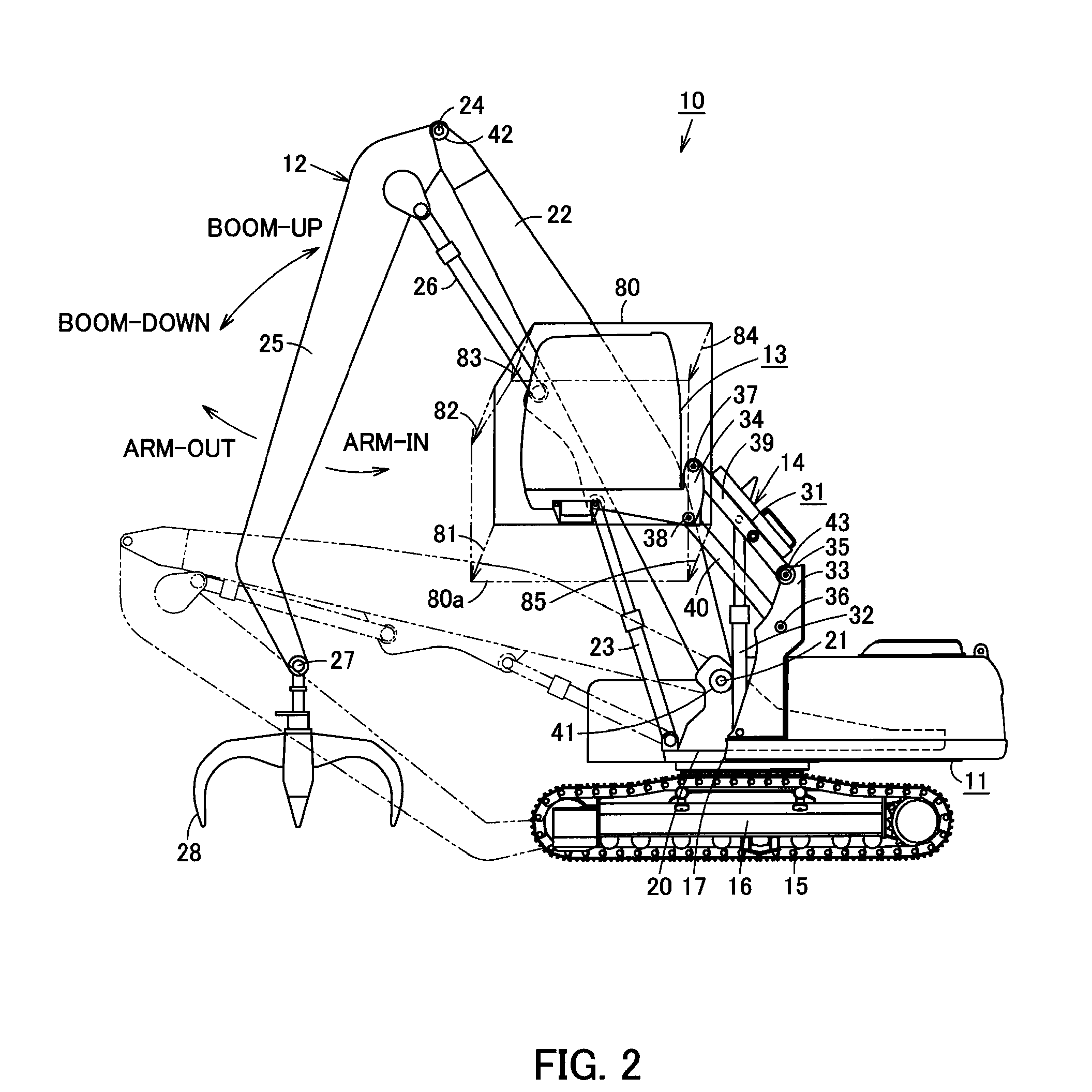

Interference prevention control device of work machine

InactiveUS20110004379A1Operation efficiency can be improvedRun at high speedAnalogue computers for trafficMechanical machines/dredgersEngineeringControl valves

The present invention provides an interference prevention control device of a work machine, wherein the interference prevention control device is capable of preventing interference between the cab and a tool of the work equipment regardless of whether either one of the cab or the work equipment is moved while the other is being operated, and thereby improving operation efficiency of the work machine. With regard to a work machine provided with a movable cab, a cab position sensor for detecting a cab position, as well as a boom angle sensor and an arm angle sensor for detecting a position of a tool at the distal end of the work equipment, are connected to a controller. Solenoid-operated directional control valves for limiting the movement of a boom cylinder and an arm cylinder for operating the work equipment are disposed in pressure passages of a pilot-operated control valve, and the solenoids of the solenoid-operated directional control valves are connected to the controller. The controller computes moving vectors based on the position of the cab detected by the cab position sensor and the moving speed of the cab determined by differentiation, predicts the cab position where the cab should be after a prescribed time, and controls the boom cylinder and the arm cylinder by means of the solenoid-operated directional control valves so as to prevent interference between the predicted cab position and the tool position.

Owner:CATEPILLAR SARL

Determining method and control method for straight running of robot on slope plane

ActiveUS20200012291A1Improve working efficiencyWork at highProgramme-controlled manipulatorAutomatic obstacle detectionSimulationStraight path

An objective of the present invention is to provide a method for determining and controlling a robot to move straightly on a sloping plane to solve a technical issue that a deviation of a conventional robot from a predetermined straight path is difficult to detect when the robot moves on a sloping plane and cannot be corrected, and moving on the straight path is difficult to guarantee.

Owner:SUZHOU RADIANT PHOTOVOLTAIC TECH

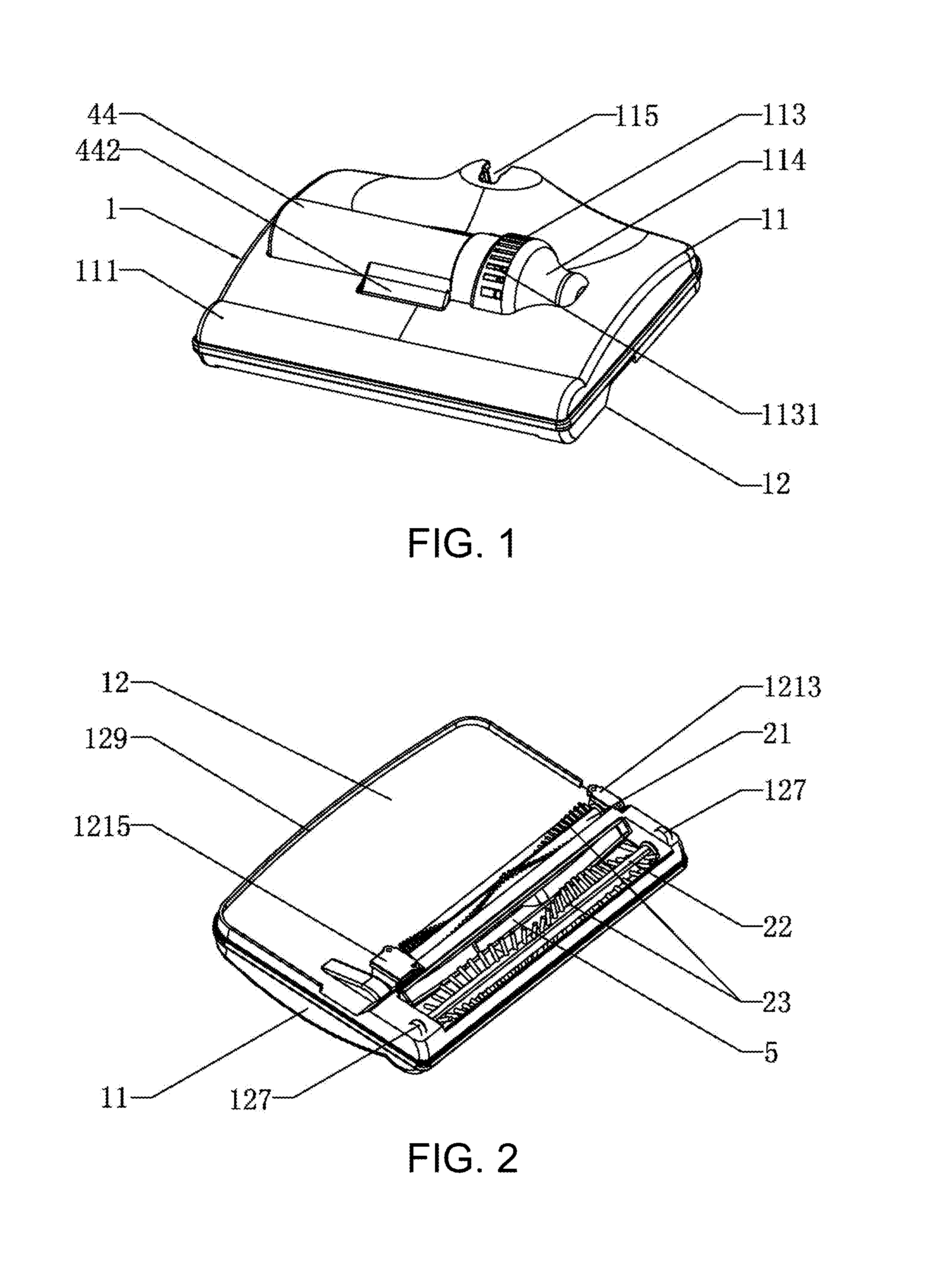

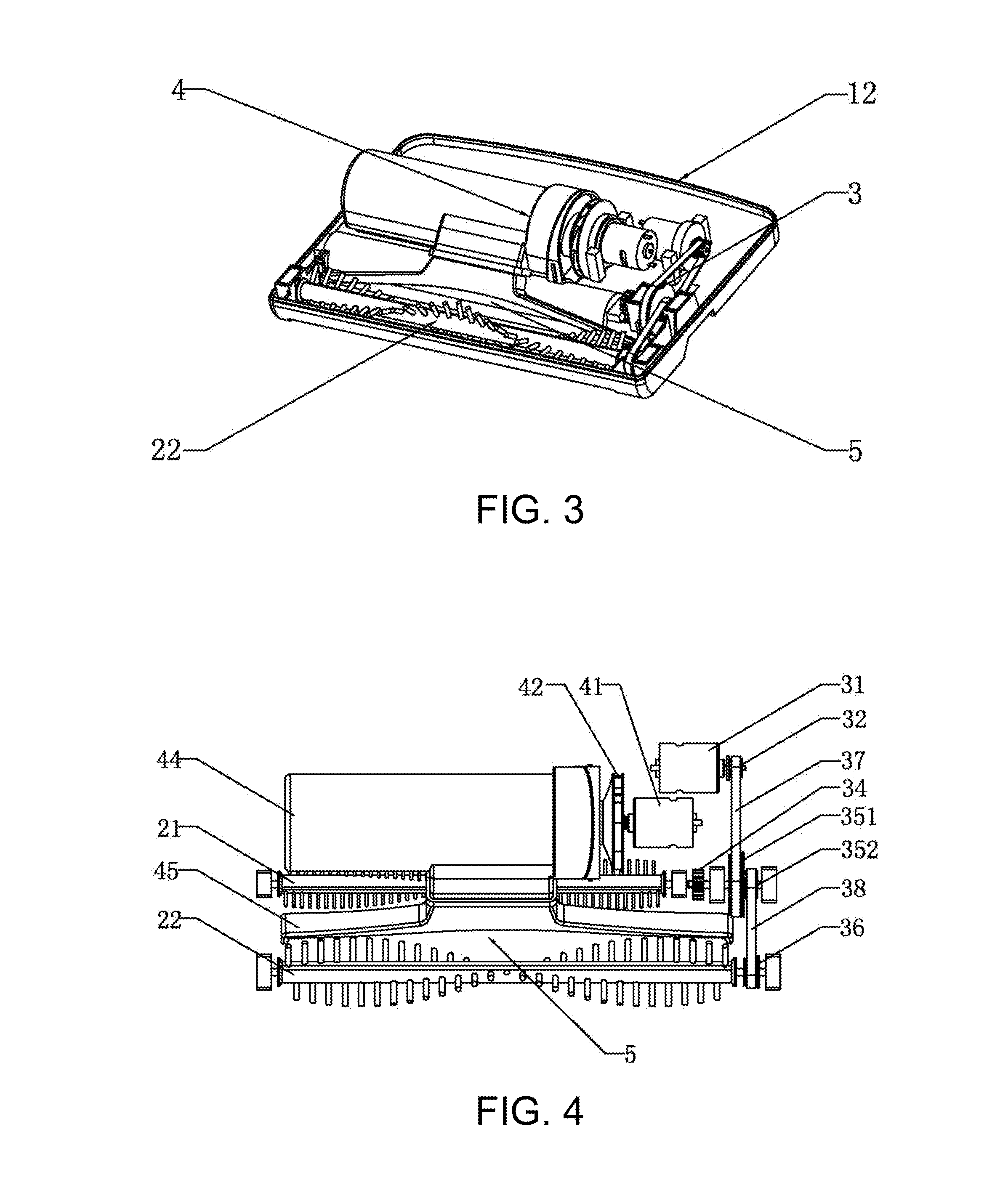

Cleaning appliance

InactiveUS20160198918A1Improve working efficiencyQuick effectCleaning filter meansSuction filtersEngineeringDust collector

The present invention relates to the technical field of cleaning, in particular to a cleaning appliance, which comprises a cleaning appliance body. The cleaning appliance body includes a housing, two brush rollers disposed at the bottom of the housing, a drive mechanism disposed in the housing and configured to drive the two brush rollers to rotate, and a dust collector disposed on the housing; a suction port of the dust collector is disposed between the two brush rollers; and both rotation directions of the two brush rollers direct towards the suction port. The cleaning appliance provided by the present invention adopts a combined structure of the two brush rollers and the dust collector; both rotation directions of the two brush rollers direct towards the suction port; dust, particulate waste or flocks are gathered; the waste is sucked into the dust collector through the suction port between the two brush rollers.

Owner:DONGGUAN PHEATON ELECTRONICS TECH

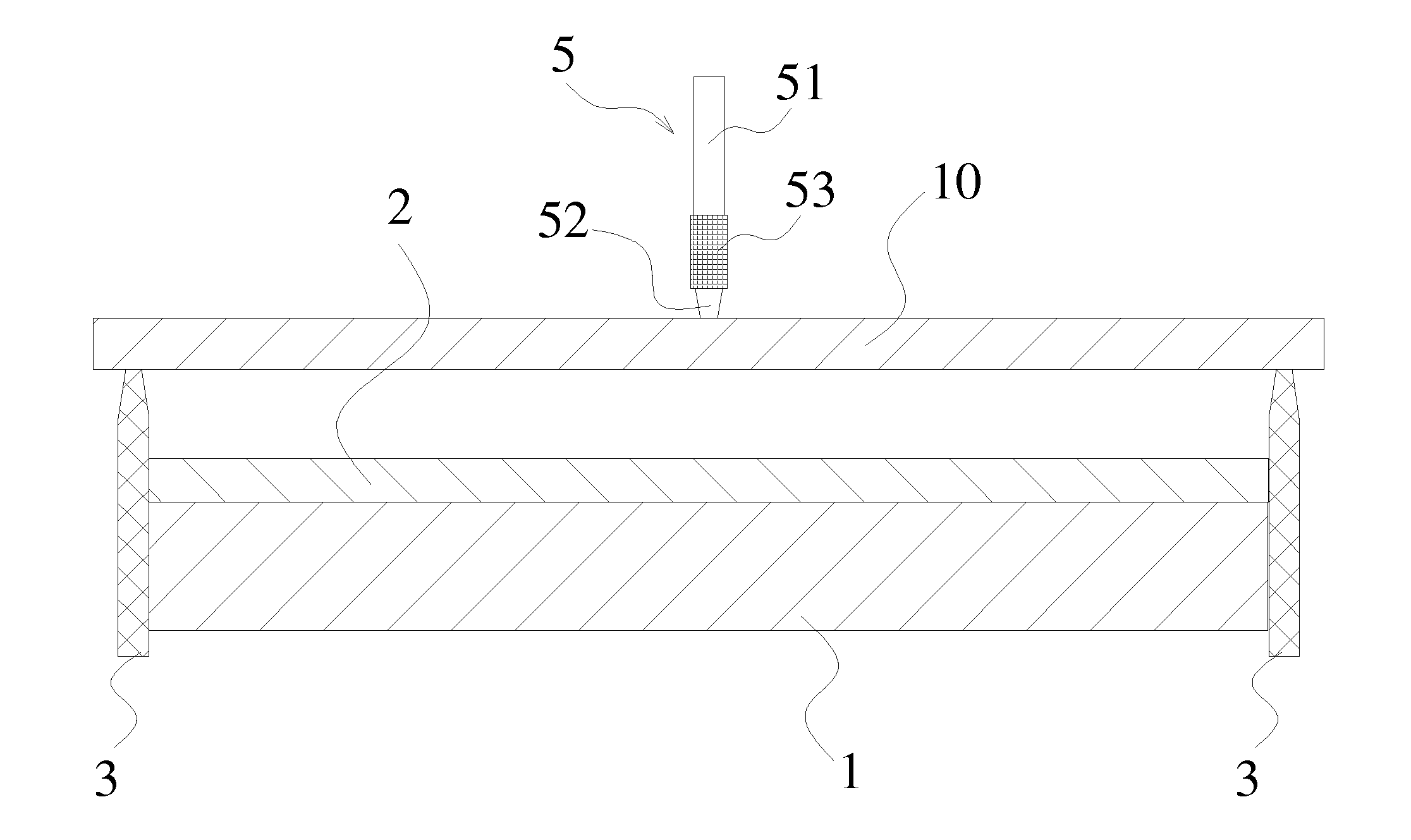

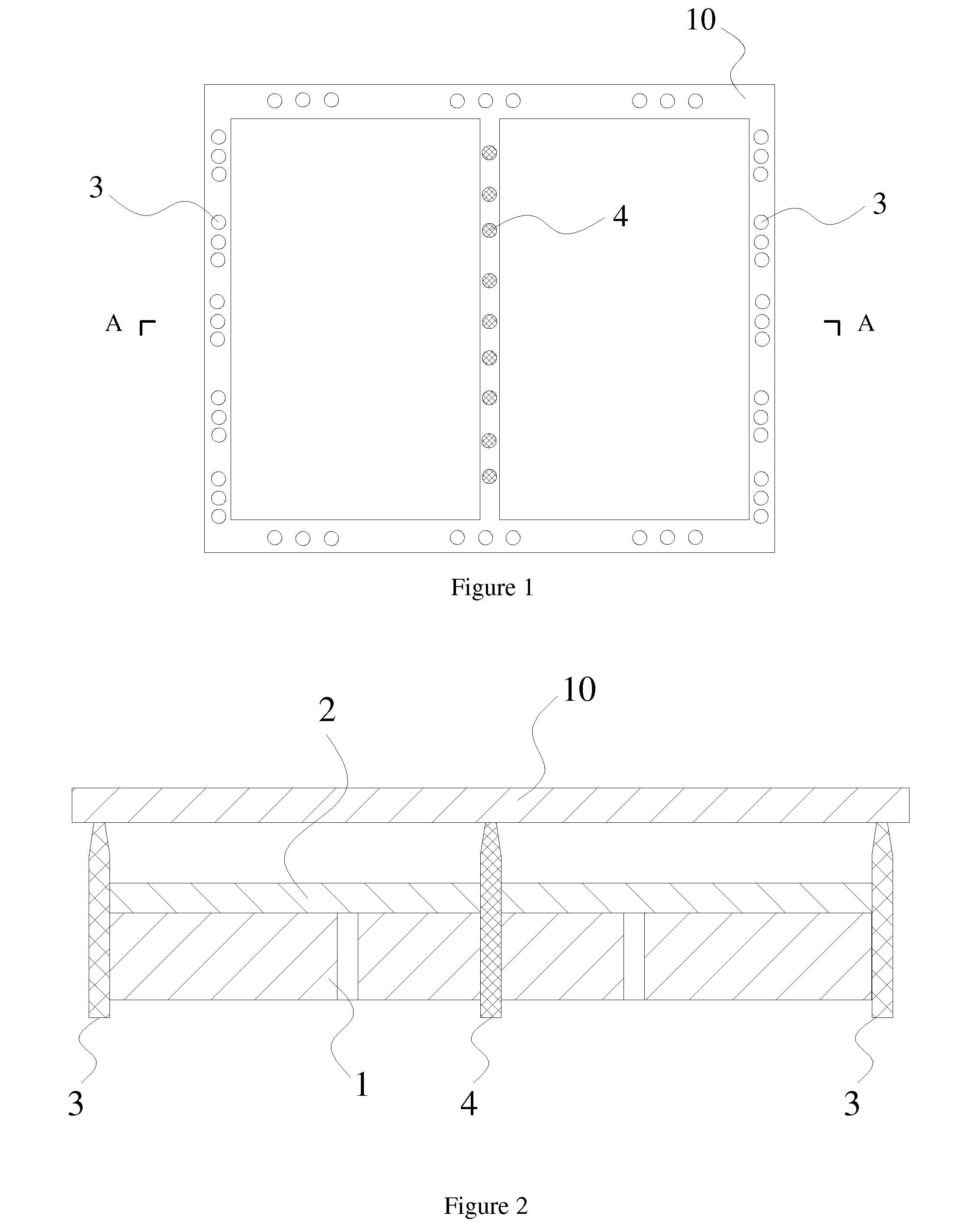

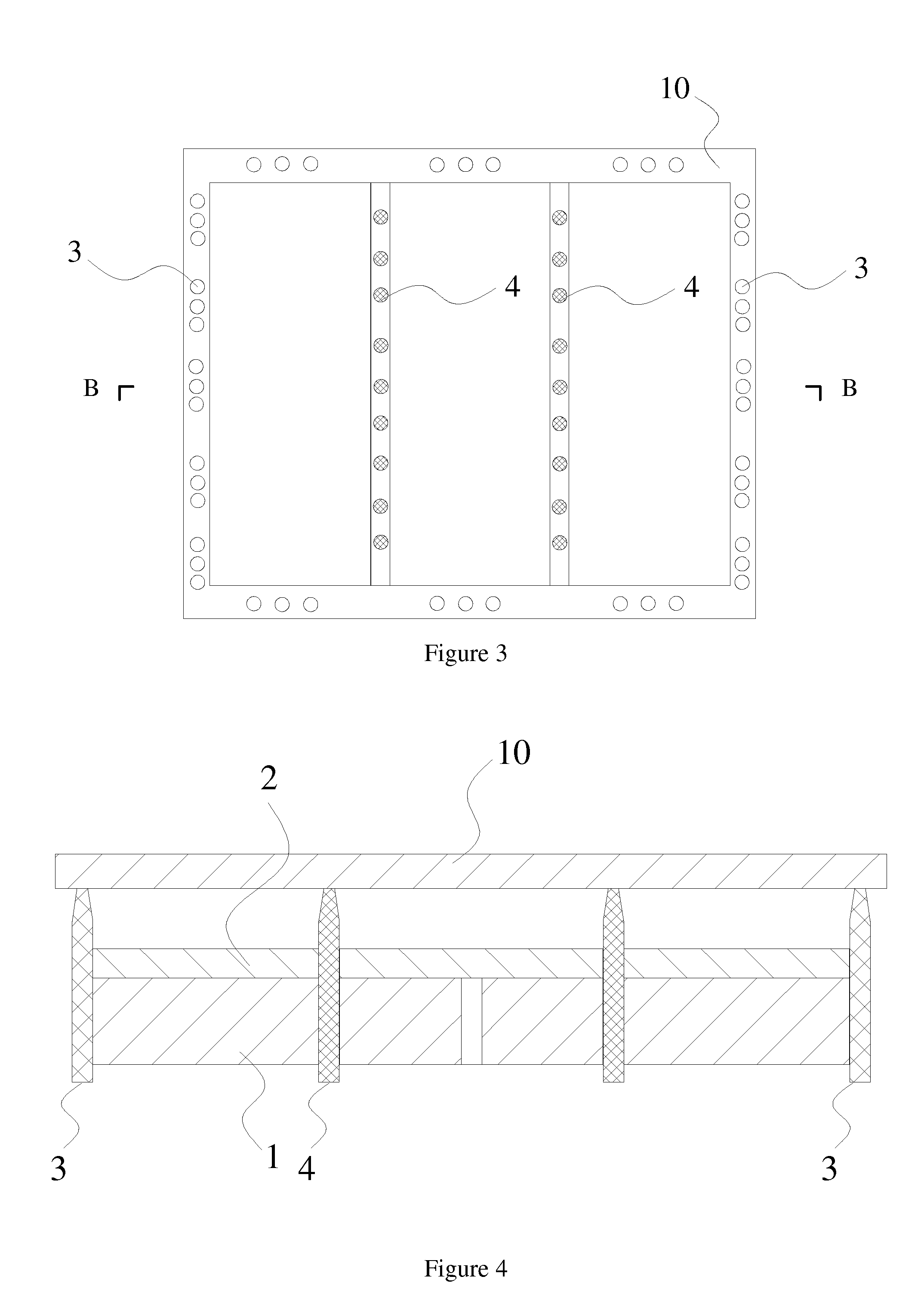

Lift mechanism for a glass substrate in an exposure machine

ActiveUS20140286735A1Good integralityConducive to uniform temperatureWork holdersLifting framesEngineering

A lift mechanism for a glass substrate in an exposure machine is provided, which comprises a base, a lift platform mounted on the top of the base and used to lift the glass substrate, lift bars mounted on the perimeter of the base, and at least one adsorbing devices mounted above the glass substrate; the lift bars are used to lift the perimeter of the glass substrate; each of the adsorbing devices is used to adsorb the upper surface of the substrate and able to move along the vertical direction and the horizontal direction. The lift mechanism for the glass substrate comprises a lift platform, and it has good integrality and uniform temperature, which is benefit for the HVA optically aligning of the glass substrate. Furthermore, the switch between the two-part lift method and the three-part lift method will be simple and with high working efficiency.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

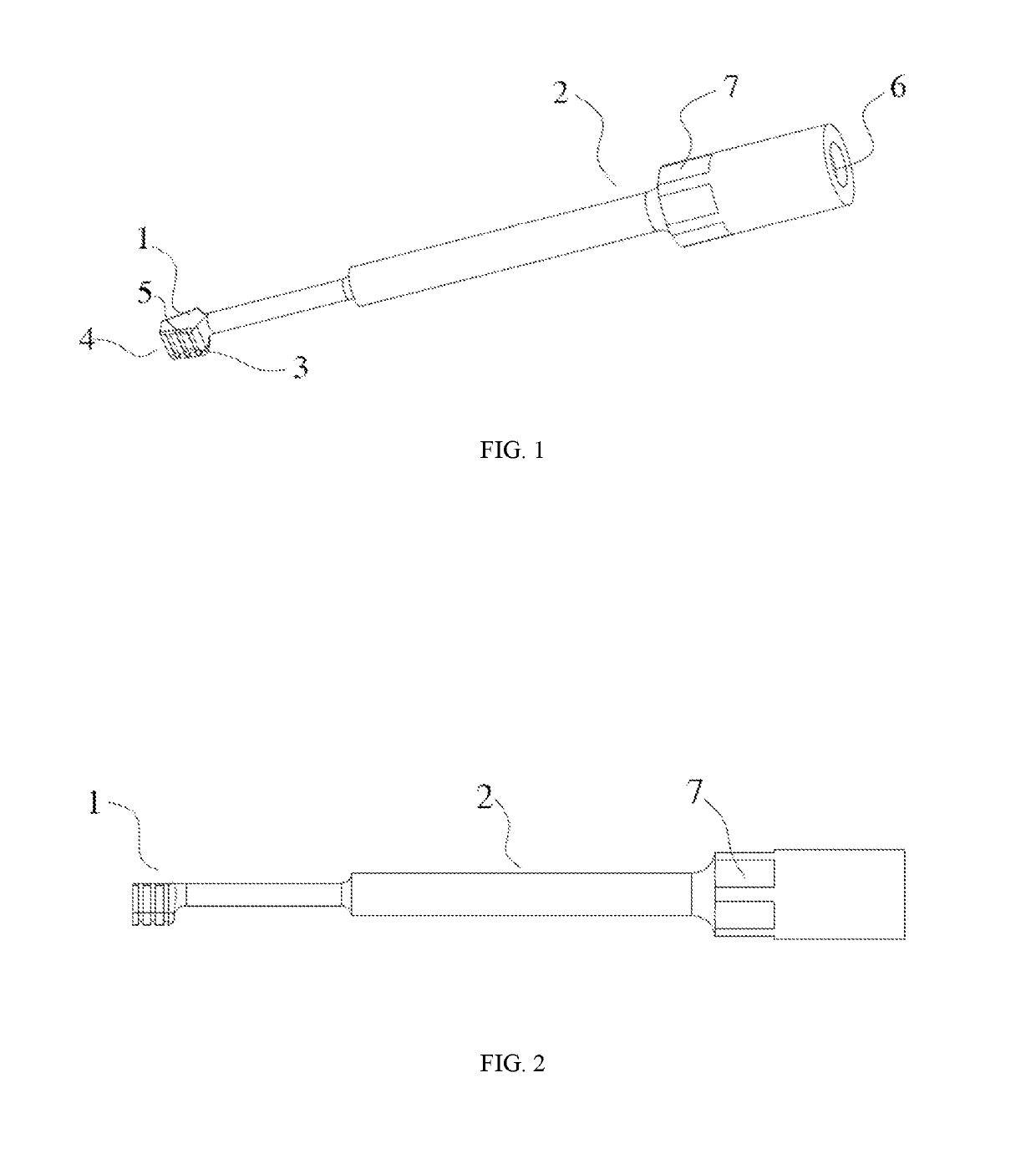

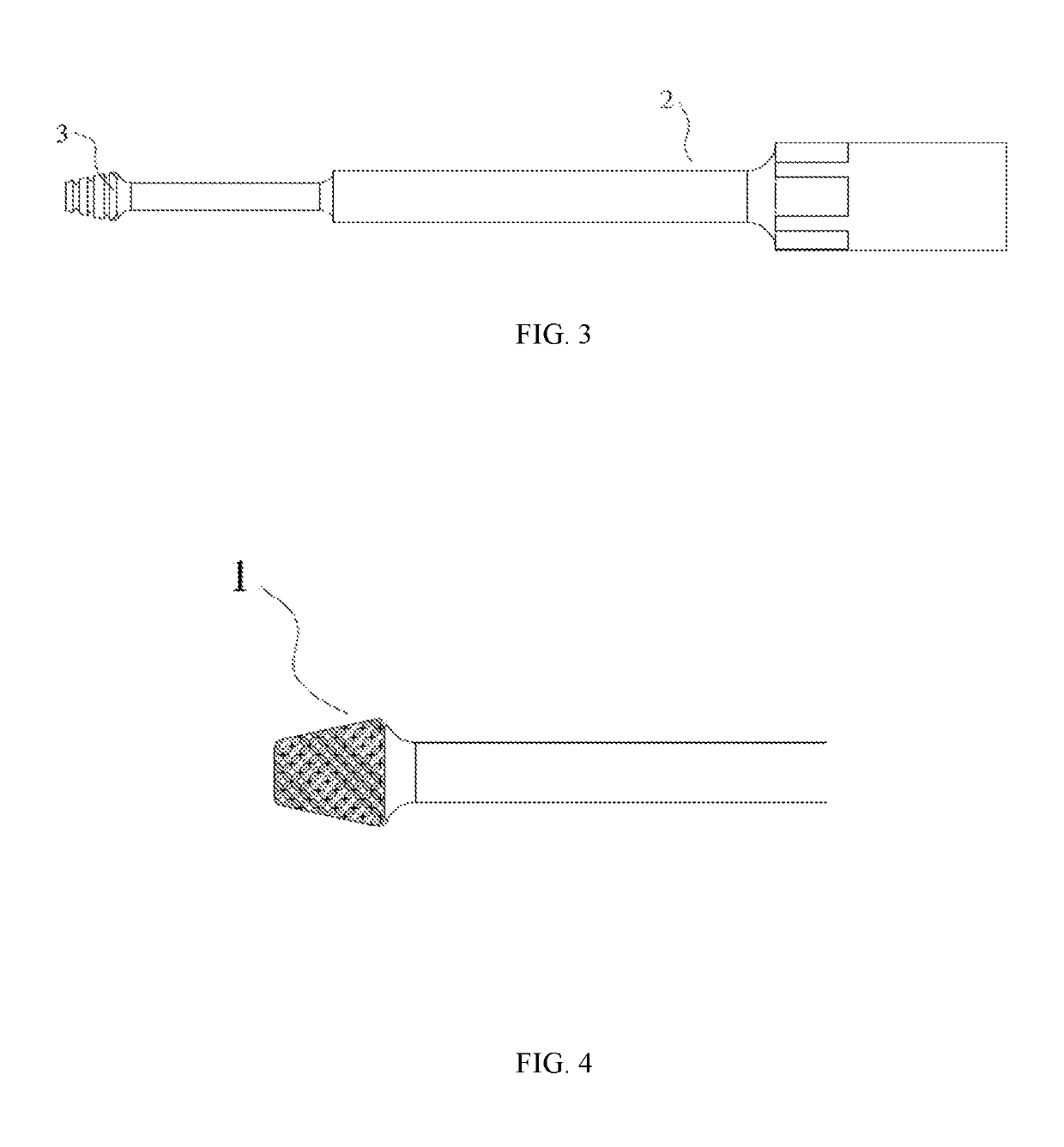

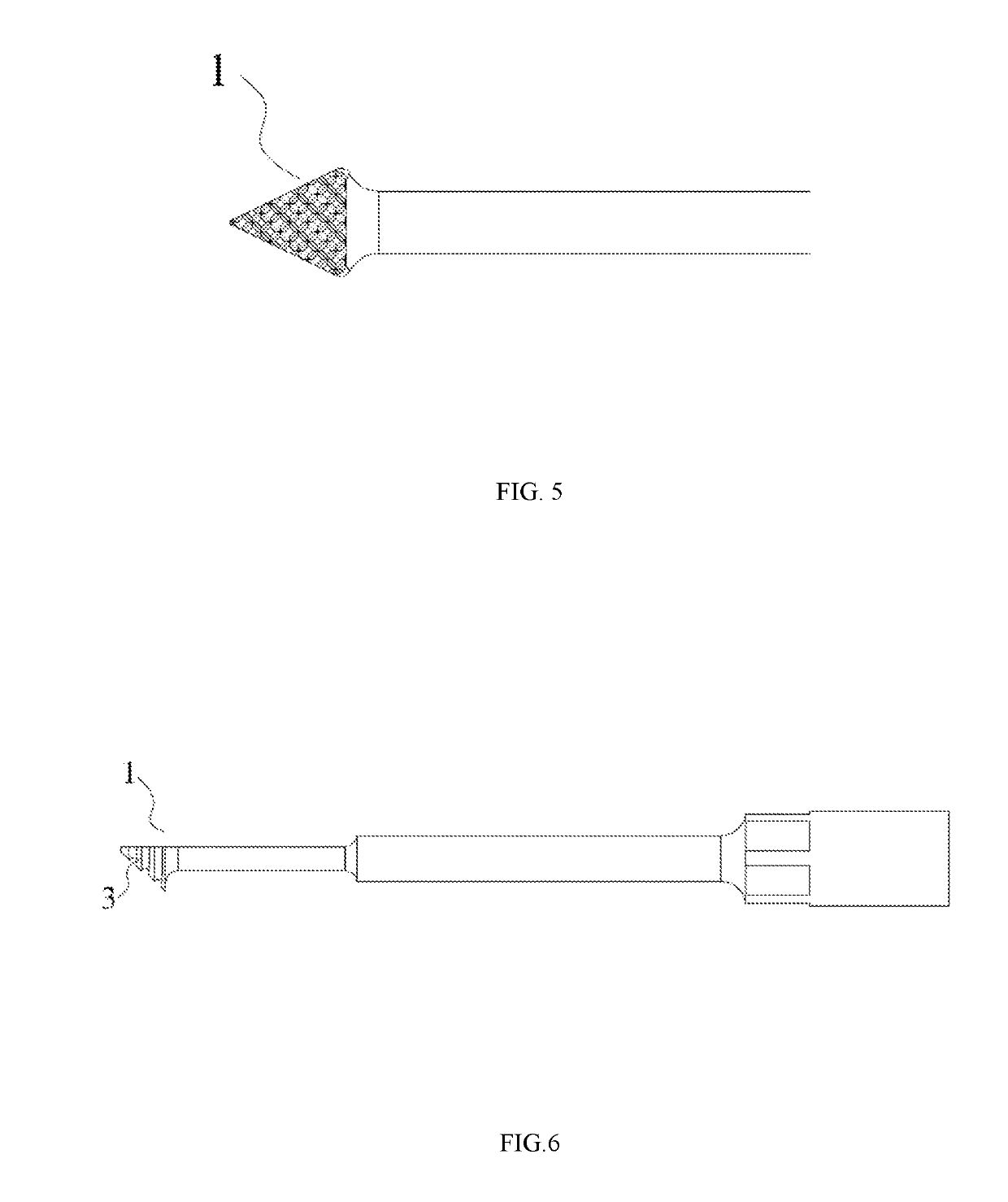

Tool bit for an ultrasonic osteotome

InactiveUS20190110799A1Convenient operationFacilitates focusing energySurgerySmooth surfaceEngineering

Disclosed is a tool bit for an ultrasonic osteotome comprising a grinding portion at a front end of the tool bit, and an arbor with one end connected to the grinding portion and the other end connected with a transducer for an ultrasonic osteotome. The grinding portion has a tapered shape dwindling from a rear end toward a front end thereof and is connected with the arbor at the rear end thereof. A plurality of grinding grooves are provided on a bottom surface and side surfaces of the grinding portion, and a front surface of the grinding portion is a smooth surface. The tool bit has a tapered shape, which is small in structure, simple and flexible for operation, and convenient in use. When the tool bit is used for a surgery, ultrasonic energy is concentrated at a tip end, and a surgical window has a large field of view.

Owner:JIANGSU SMTP TECH CO LTD

Low-density neutral paper

InactiveUS7611606B2Increase coverageIncrease in sizeCalcium/strontium/barium carbonatesPigmenting treatmentPrecipitated calcium carbonateLow density

The present invention provides a low-density neutral paper offering excellent opacity, opacity after printing and other advantageous printability properties despite high bulk, by containing, as a filler, precipitated calcium carbonate-silica composite having an average particle size of 30 μm or less and produced by neutralizing a mixture of precipitated calcium carbonate and alkaline silicate to pH 7 to 9, wherein the ratio of precipitated calcium carbonate to silica (precipitated calcium carbonate / silica) is 30 / 70 to 70 / 30 in solid content by weight and the surface of precipitated calcium carbonate particles is covered with silica. In particular, the present invention provides a low-density printing paper, or an electrophotographic transfer paper offering excellent stiffness and copier suitability, by means of adjusting the filler content in paper to a range of 1 to 25 solid content percent by weight, or provides a neutral newsprinting paper by means of adjusting the filler content in paper to a range of 0.1 to 25 solid content percent by weight.

Owner:NIPPON PAPER IND CO LTD

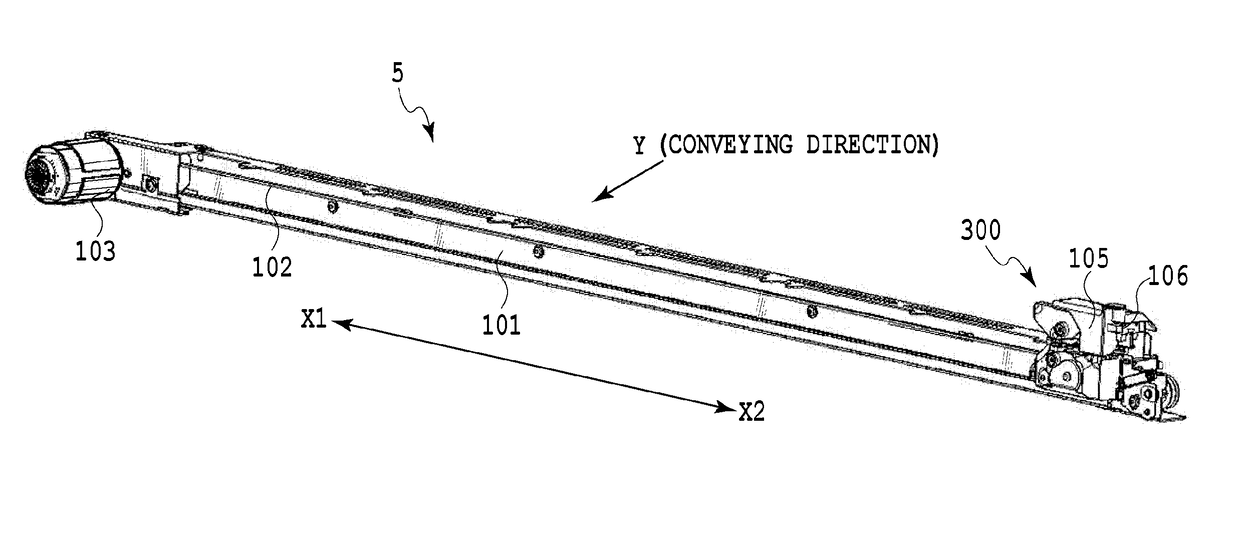

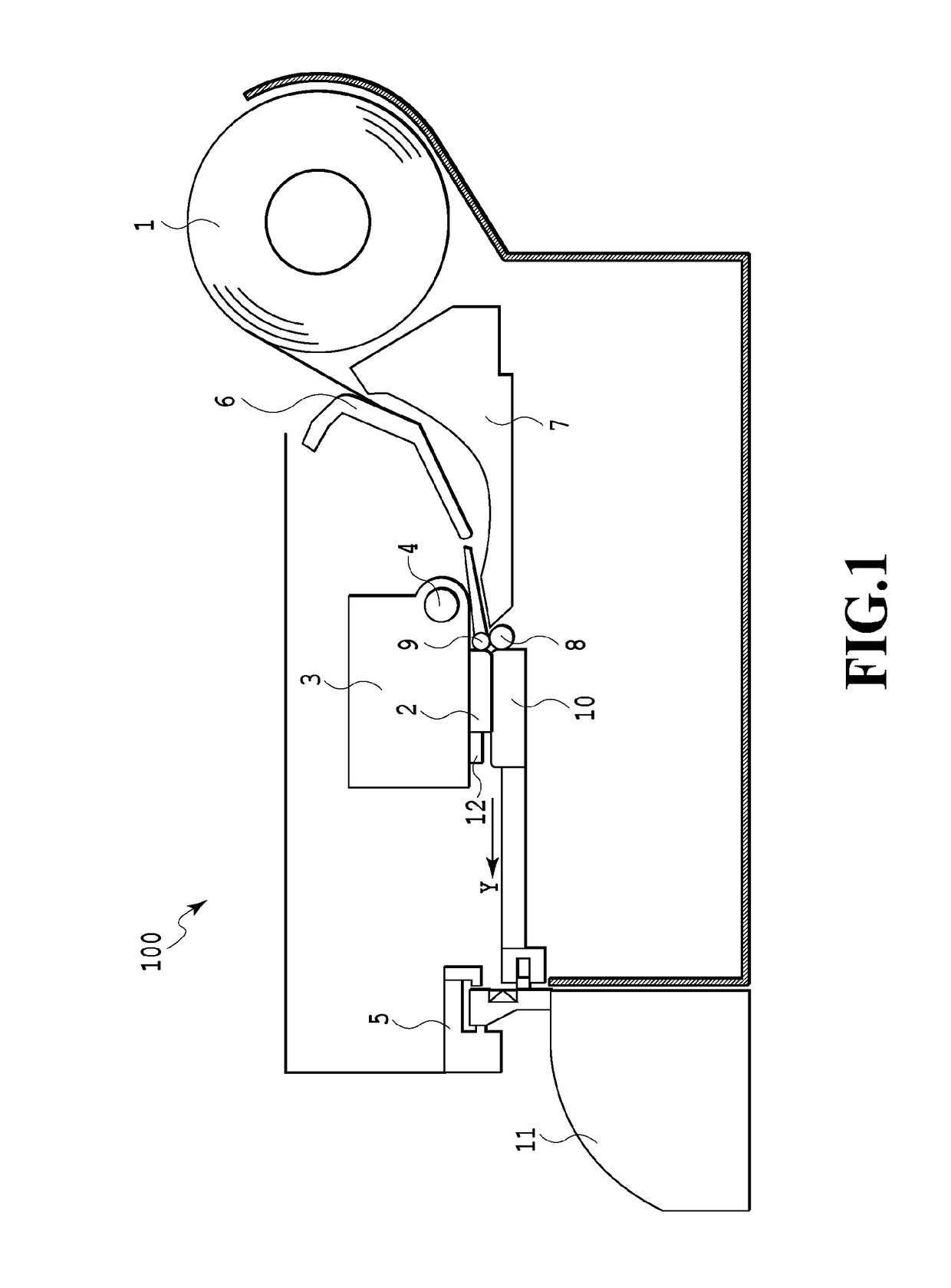

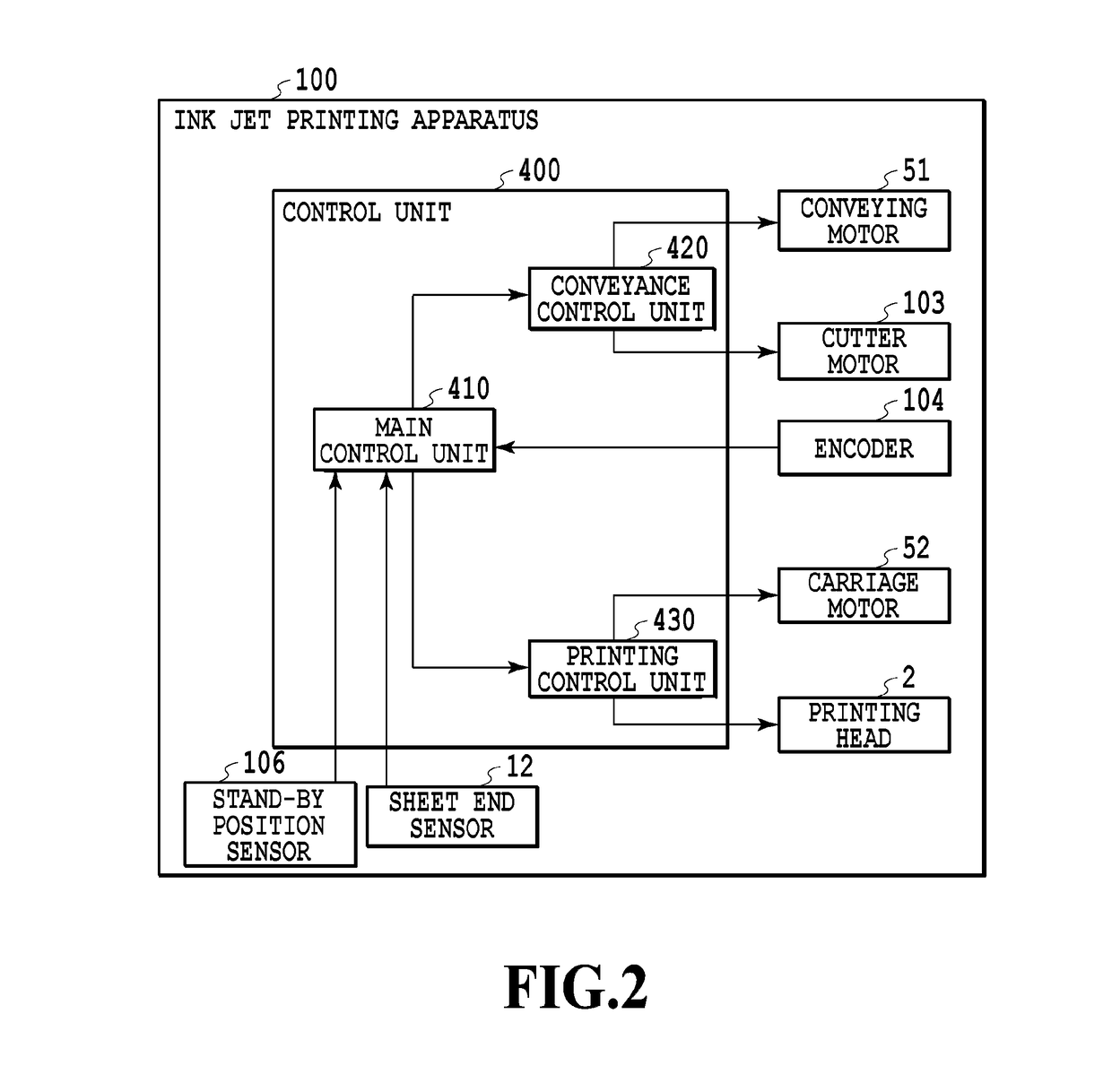

Cutting apparatus and printing apparatus

ActiveUS20170087890A1Improve working efficiencyHigh positioning accuracyOther printing apparatusMetal working apparatusEngineeringMechanical engineering

A cutter unit is attached to a carriage in a predetermined direction, the carriage moving in a cutting direction of a sheet. A first set of first fitting sections and a second set of second fitting sections are provided as groups of fitting sections provided at positions, which face each other, on the carriage and the cutter unit. The first fitting sections and the second fitting sections each of which are fitted to each other in a predetermined direction. When the cutter unit is attached to the carriage, the fitting of the first fitting sections starts before the fitting of the second fitting sections.

Owner:CANON KK

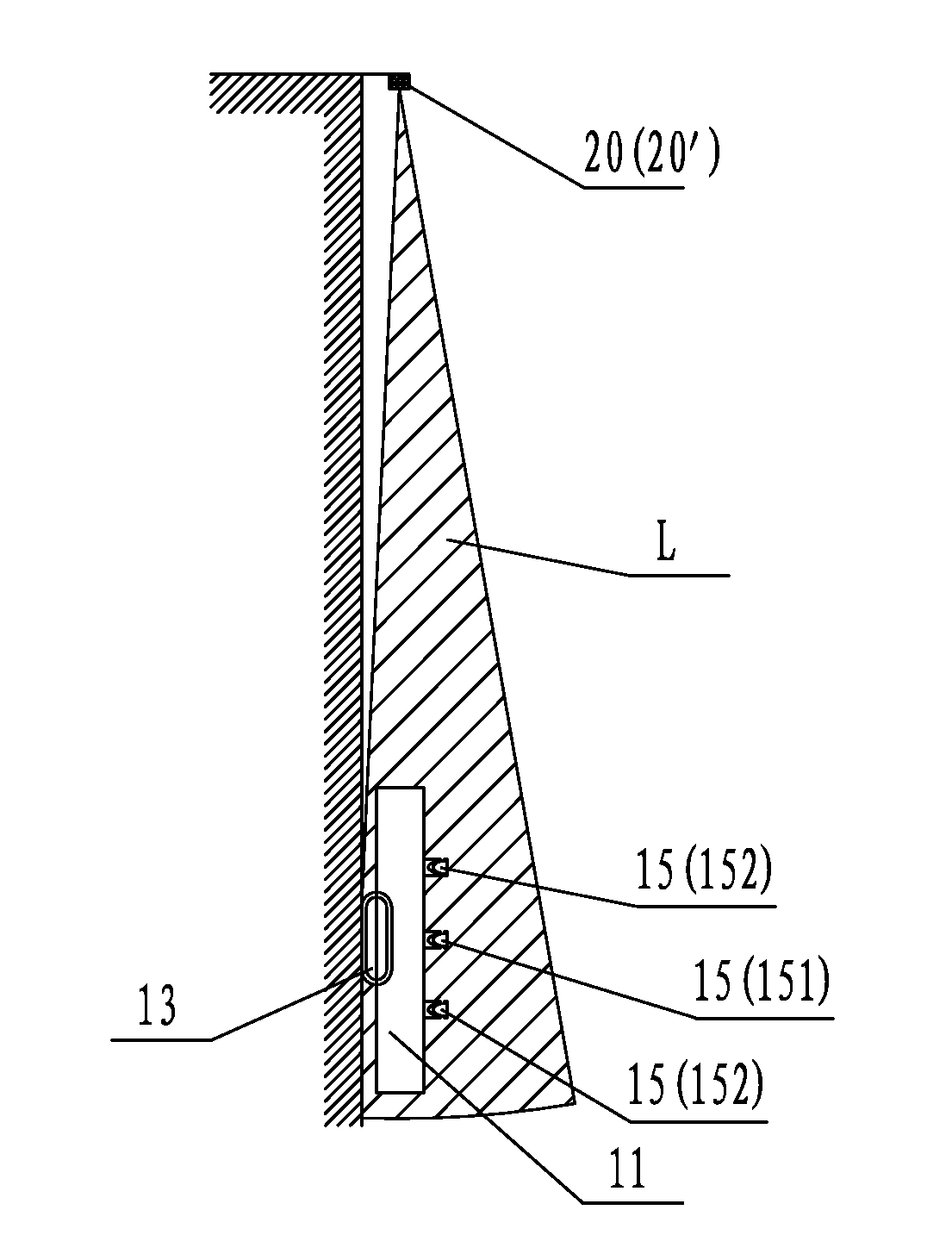

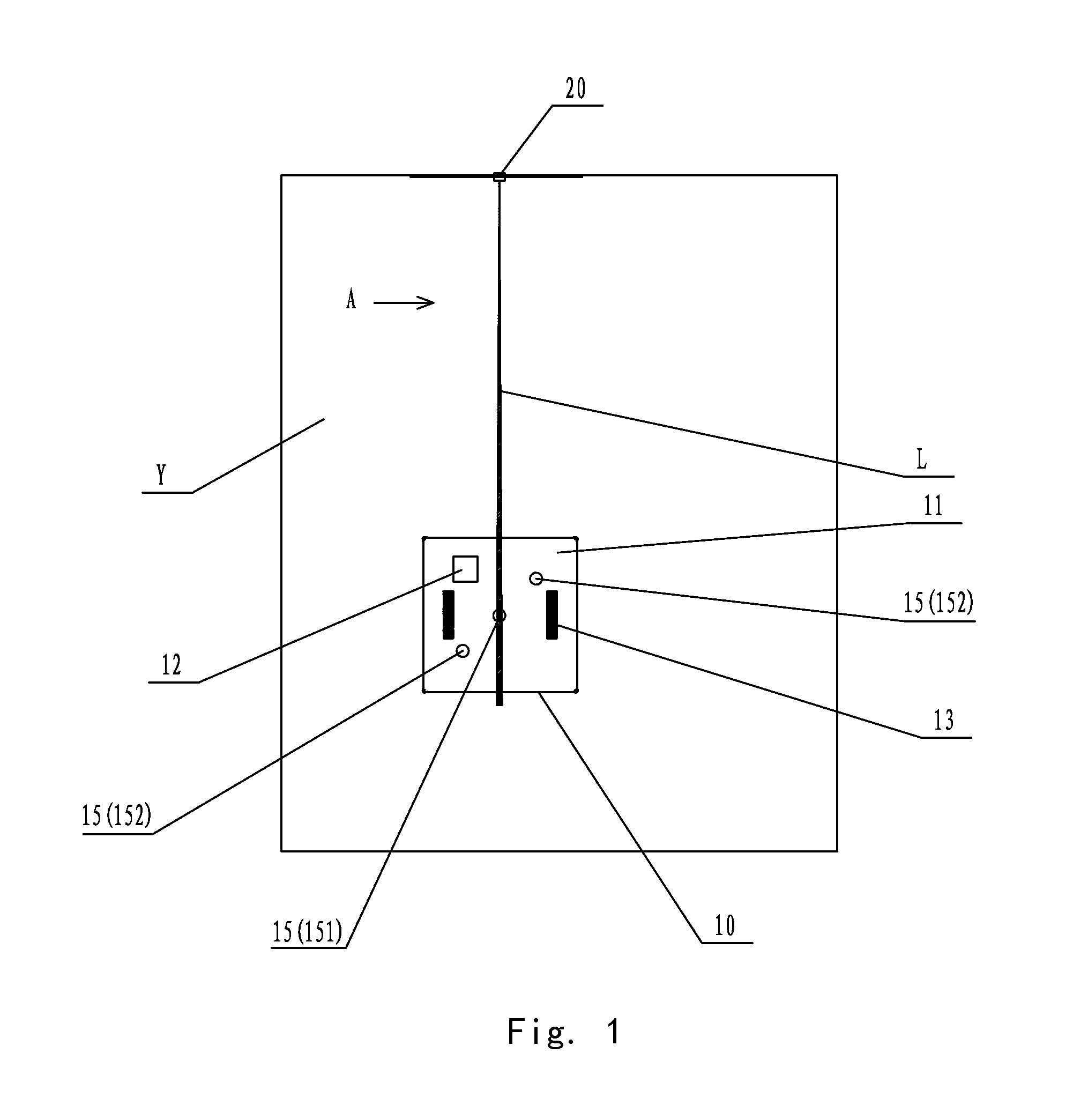

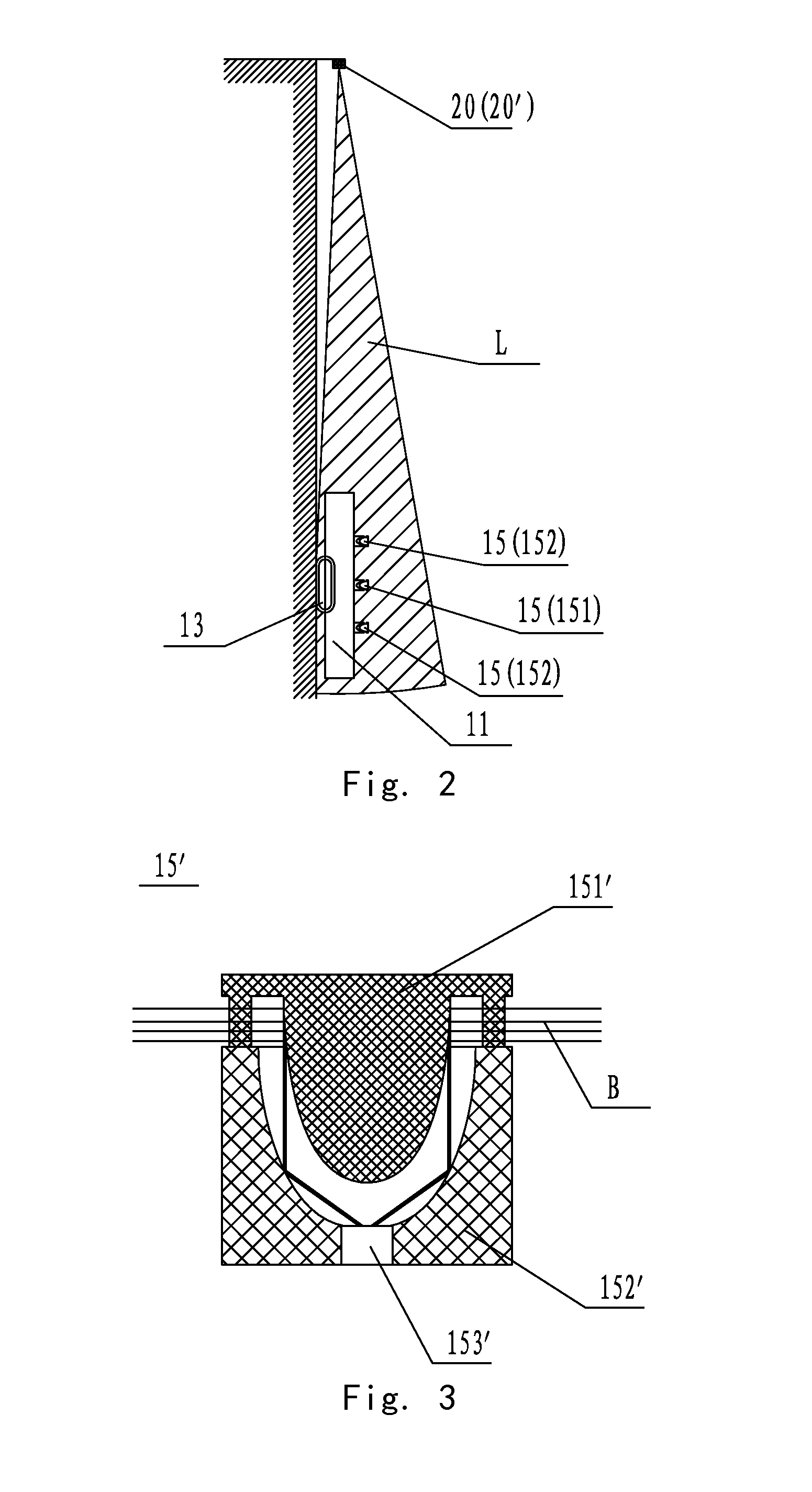

Self-Mobile Robot Laser-Guided Travel Operating System and Control Method Therefor

InactiveUS20160082595A1Concentrating performanceCompact structureProgramme controlAutomatic obstacle detectionOperational systemRemote control

A laser-guided walking operation system for a self-moving robot comprising a self-moving robot (10) and a laser beam transmitter (20). A control mechanism (12) and a walking mechanism (13) are arranged on a machine body (11) of the self-moving robot. The laser beam transmitter (20) is arranged at an edge of an operation area of the self-moving robot. A laser receiver (15) is arranged correspondingly on the machine body (11). The control mechanism controls the walking mechanism so that the self-moving robot performs walking operation along a linear path guided by a laser beam signal transmitted by the laser beam transmitter within the operation region. A control method of the system is: transmitting a laser signal, by a laser beam transmitter arranged at an edge of the self-moving robot operation region; when the laser receiver provided on the machine body of the self-moving robot receives the laser signal, according to the guidance of the laser signal, a control mechanism of the self-moving robot controls a walking mechanism of the self-moving robot to perform walking operation along a linear path within the operation region. The present invention allows for remote control of the robot and is high in work efficiency.

Owner:ECOVACS COMML ROBOTICS CO LTD

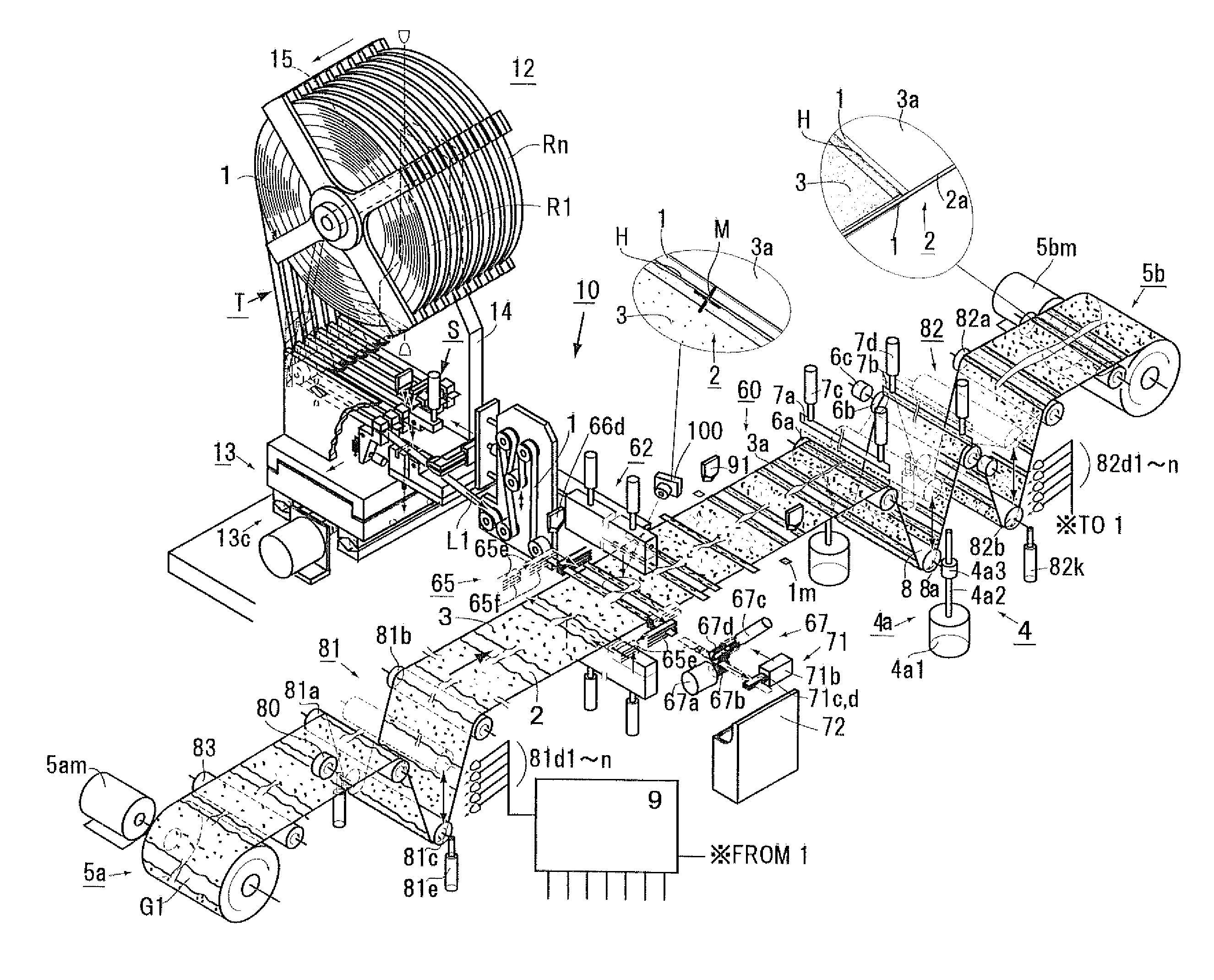

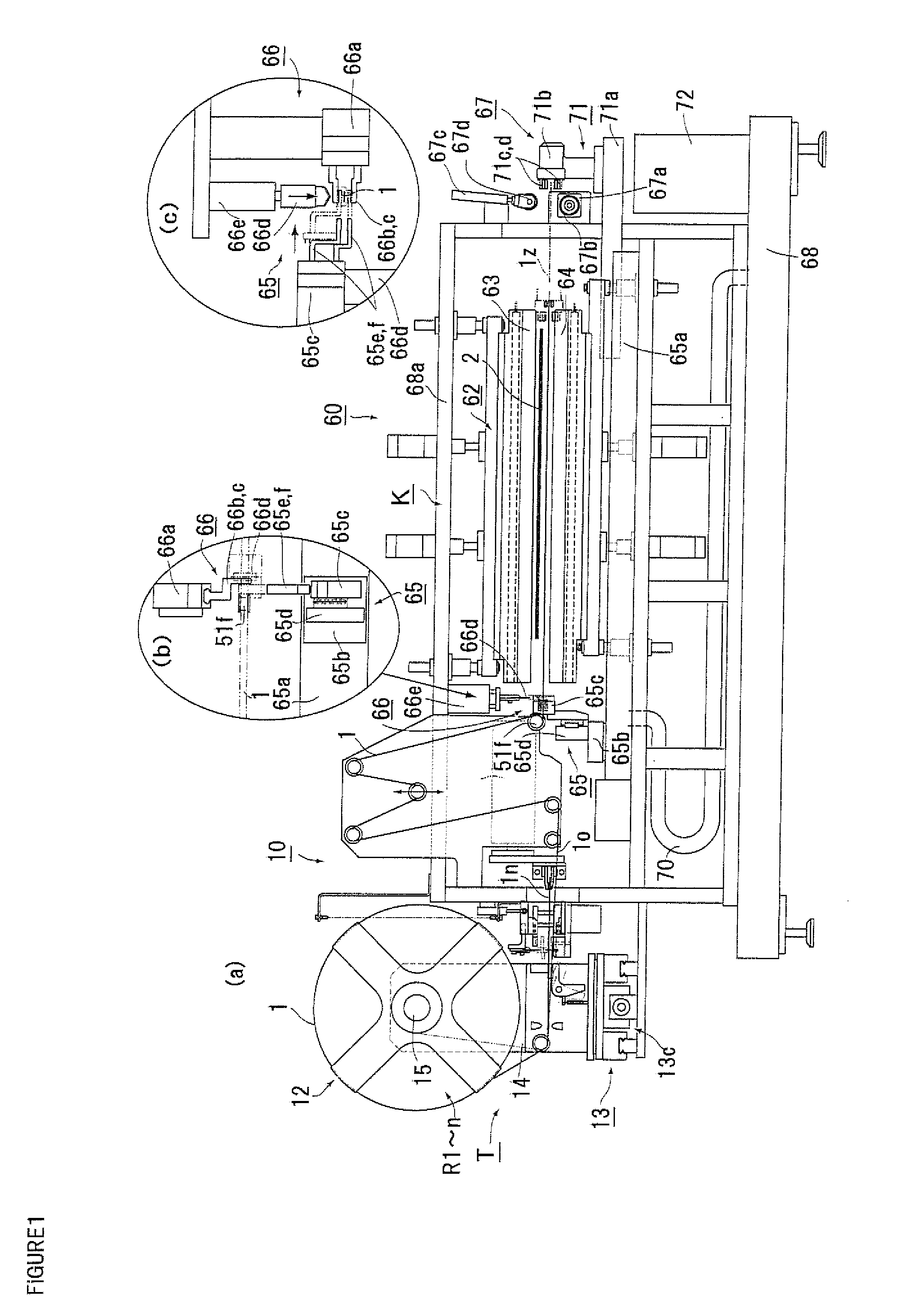

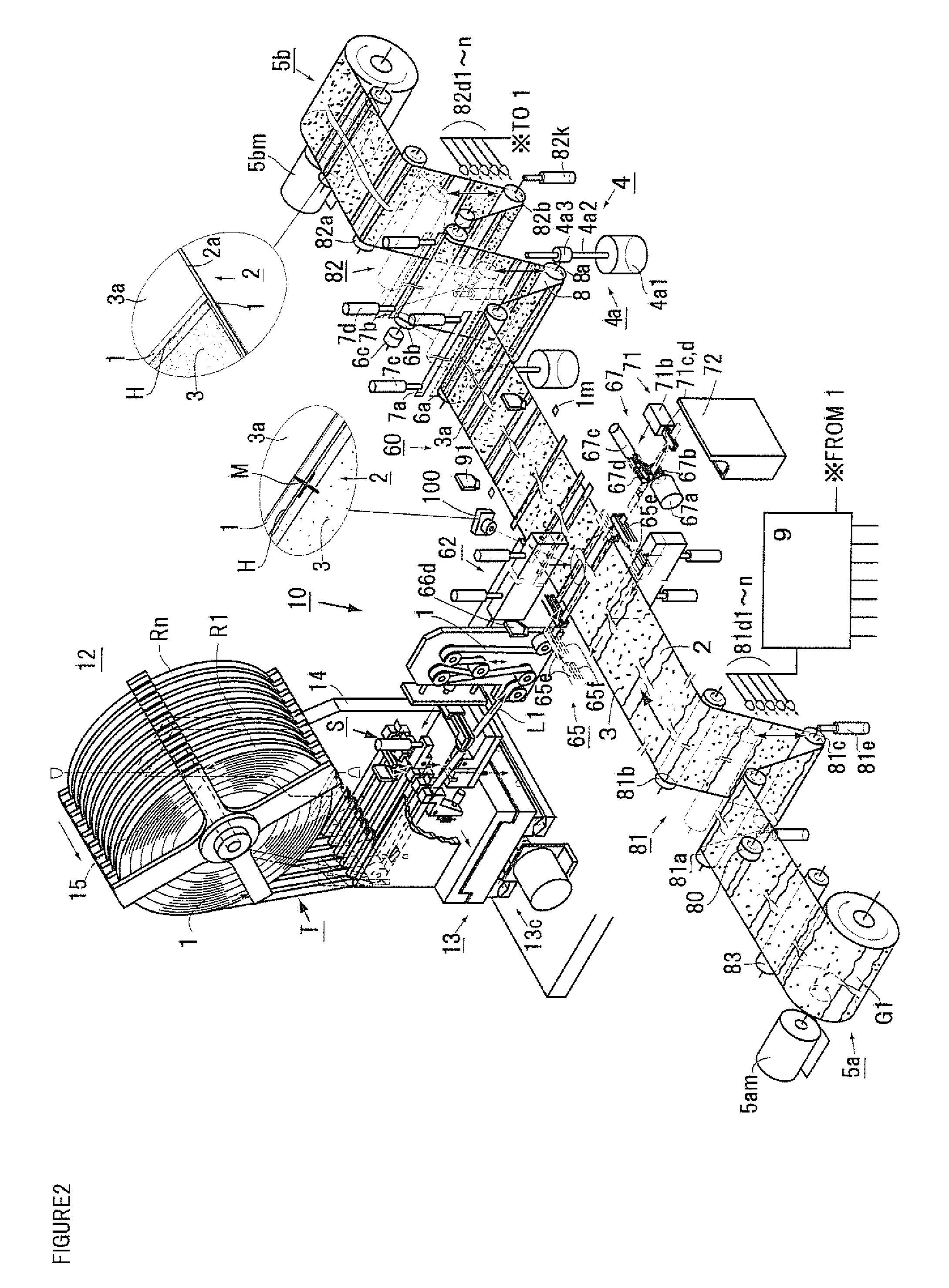

Original fabric pitch feed mechanism of original fabric manufacturing device for electrochemical element

ActiveUS20120222819A1Prevent reversalIncrease speedFinal product manufactureWinding capacitor machinesProcess regionMechanical engineering

Provided is a pitch feed mechanism which is capable of performing an accurate, high-speed pitch feed of an original fabric having unevenness on a surface thereof in a sticking operation of an insulating tape. The original fabric pitch feed mechanism that is provided on a downstream side of an insulating tape sticking process region in a long original fabric, and performs the pitch feeding of the original fabric in one direction in accordance with a boundary part, the original fabric pitch feed mechanism being characterized by comprising a feed side roller, an original fabric take-up side roller, a feed side contact and separate member, a take-up side contact and separate member, and a pitch feed roller, which is disposed between the feed side roller and the original fabric take-up side roller, and pulls out, when the feed side contact and separate member is separated from the feed side roller, and the take-up side contact and separate member is in contact with the original fabric take-up side roller to fix the original fabric with the original fabric disposed therebetween, the original fabric by a predetermined size from the feed side roller side by pressing the original fabric that is extended between the feed side roller and the original fabric take-up side roller.

Owner:O M C

Power tool and operating method for use on the power tool

ActiveUS9833884B2Easy to operateImprove working efficiencyTool changing apparatusPortable power-driven toolsEngineeringPower tool

A power tool, comprising: a housing; a motor being disposed in the housing for outputting rotary power; an output shaft having an accommodating hole in the axial direction for holding a tool bit; a transmission mechanism, being disposed between the motor and the output shaft for transmitting rotary power from the motor to the output shaft; a tool bit supporting being disposed in the housing and including several chambers disposed in parallel for holding the tool bit; a connecting member being disposed in the housing and capable of moving axially between a working position where the connecting member passes through one of the chambers and to accommodate the tool bit in the chamber connect the output shaft, and a release position where the connecting member exits and separates from one of the several chambers; and an operating member is arranged on the housing for controlling the axial movement of the connecting member; the power tool further includes an automatic shifting means for adjusting the position of the tool bit supporting in response to the movement of the operating member, wherein the connecting member moves axially to a position that is separated from one of the several chambers, and the cartridge moves to a position where another chamber is axially corresponding to the output shaft under the action of the automatic shifting means.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

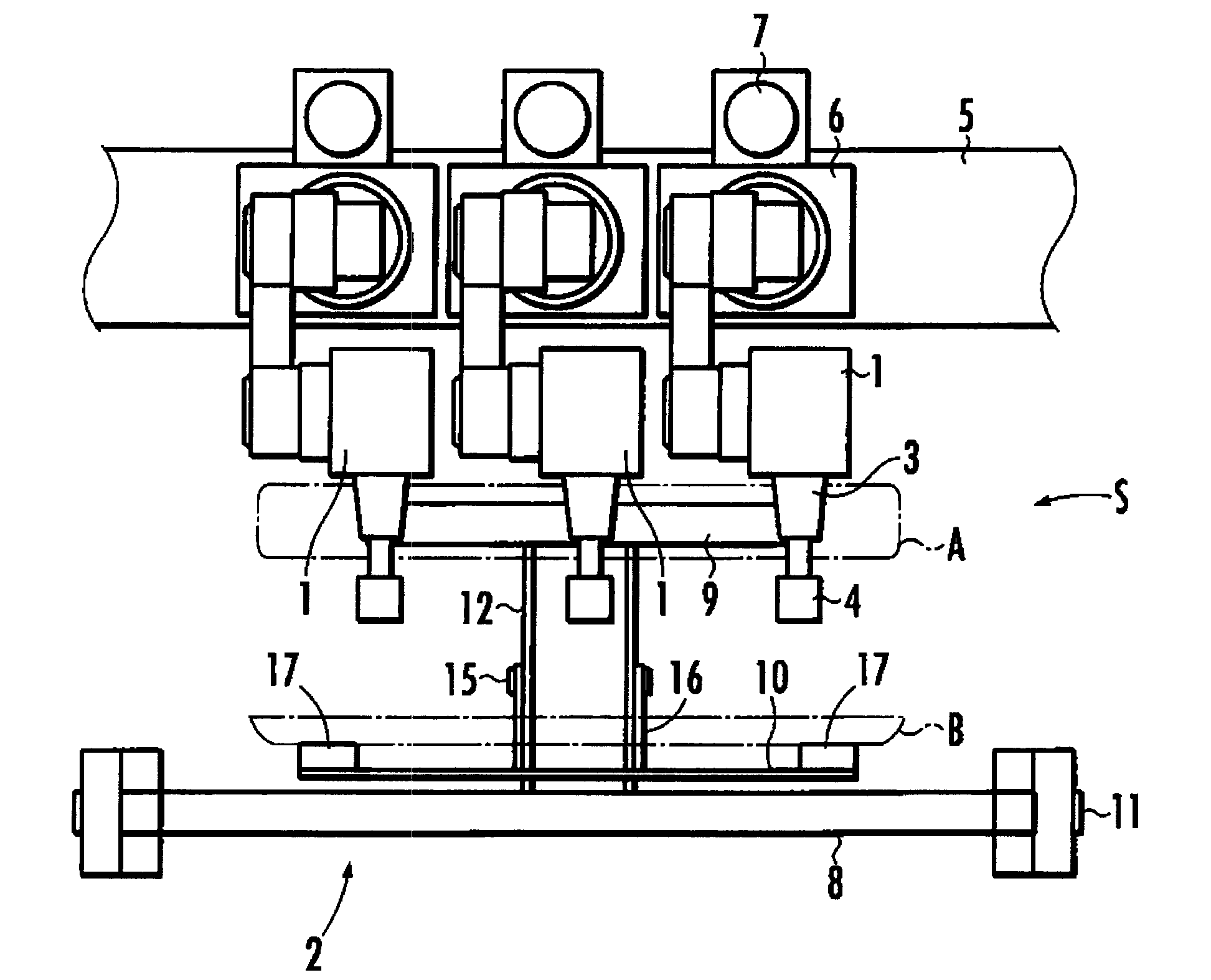

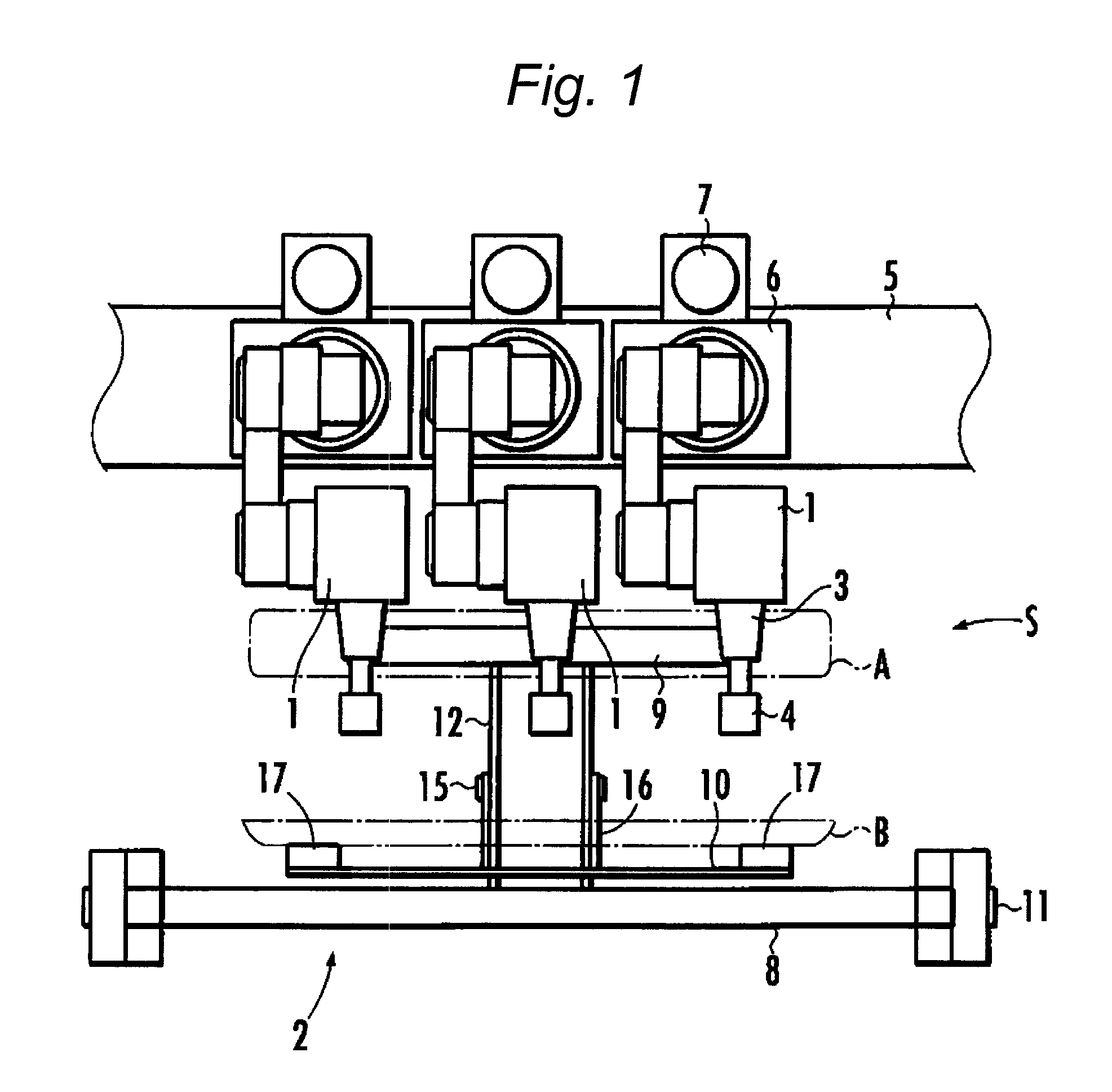

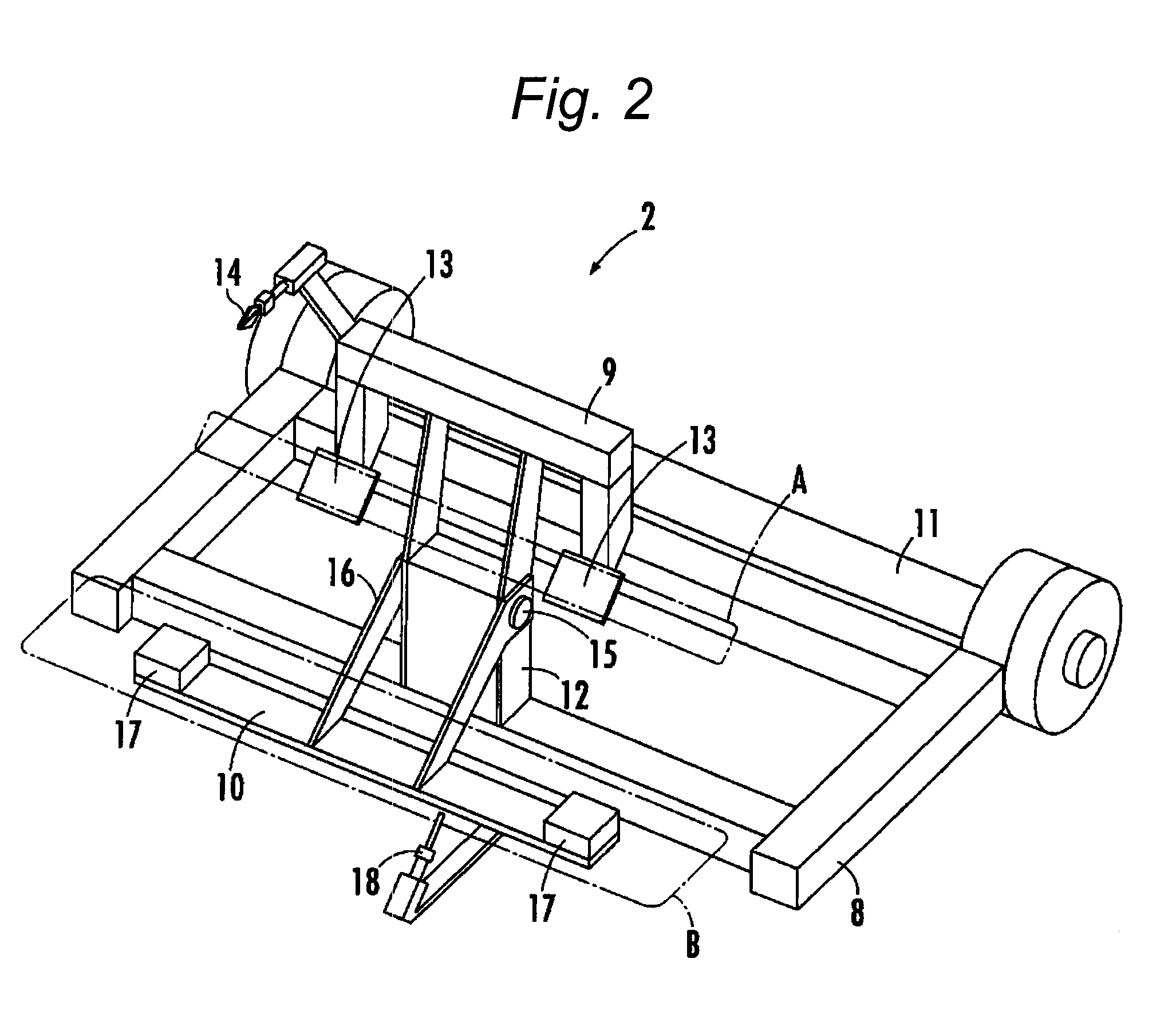

Assembling method and apparatus for assembly, and assembling method and apparatus for workpiece

ActiveUS8312611B2Low costImprove working efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWork unit

A first holding frame of a component holding unit is allowed to hold a plurality of components composing a first assembly and a second holding frame of the component holding unit is allowed to hold a plurality of components composing a second assembly which is to be mounted on the first assembly. The first assembly held onto the first holding frame and the second assembly held onto the second holding frame are assembled by an assembly work unit. The second holding frame is allowed to reciprocate towards the first holding frame to pass the second assembly from the second holding, frame to the first holding frame. Thereafter, the first assembly and the second assembly which are held onto the first holding frame are assembled and coupled together by the assembly work unit.

Owner:HONDA MOTOR CO LTD

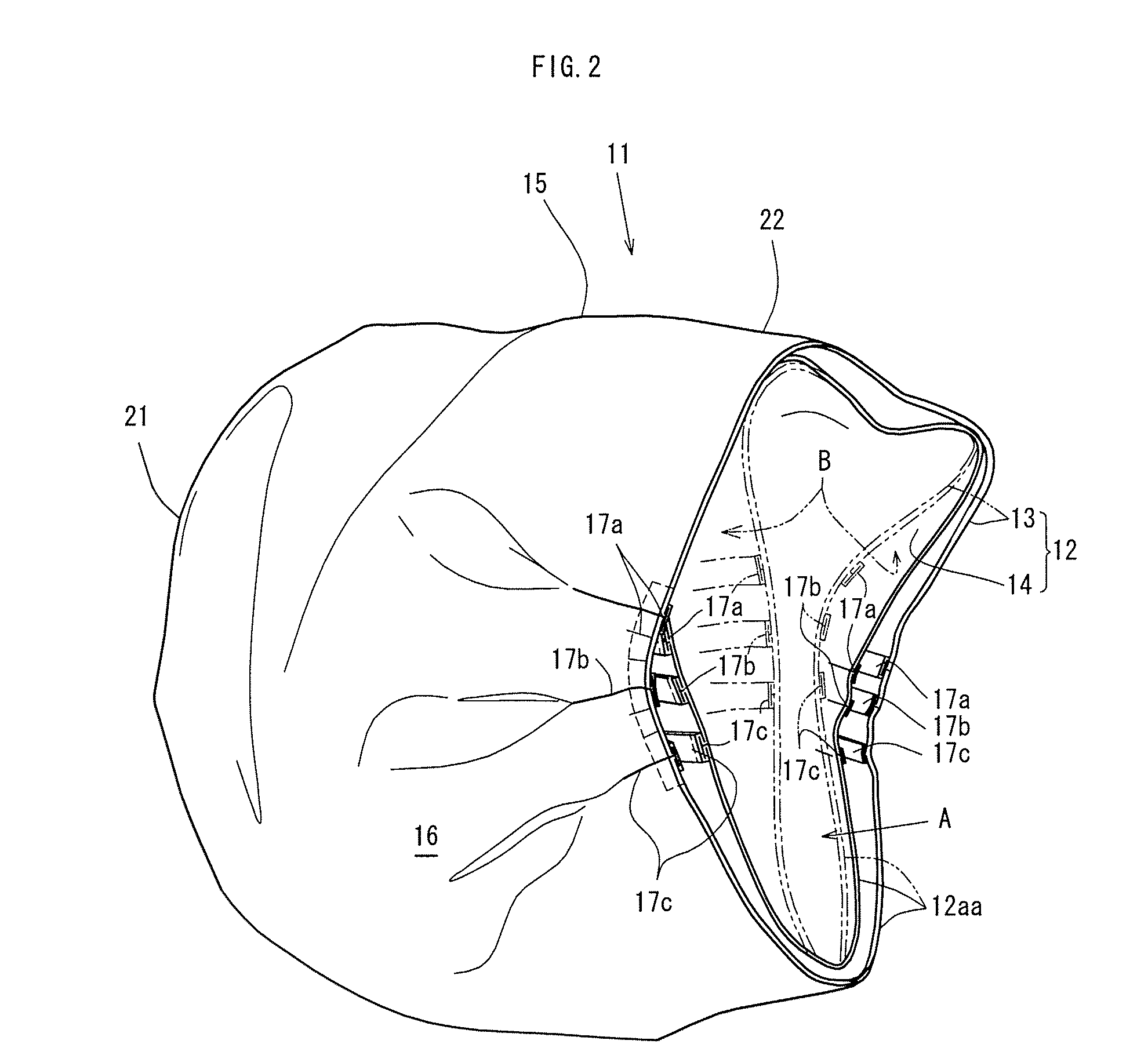

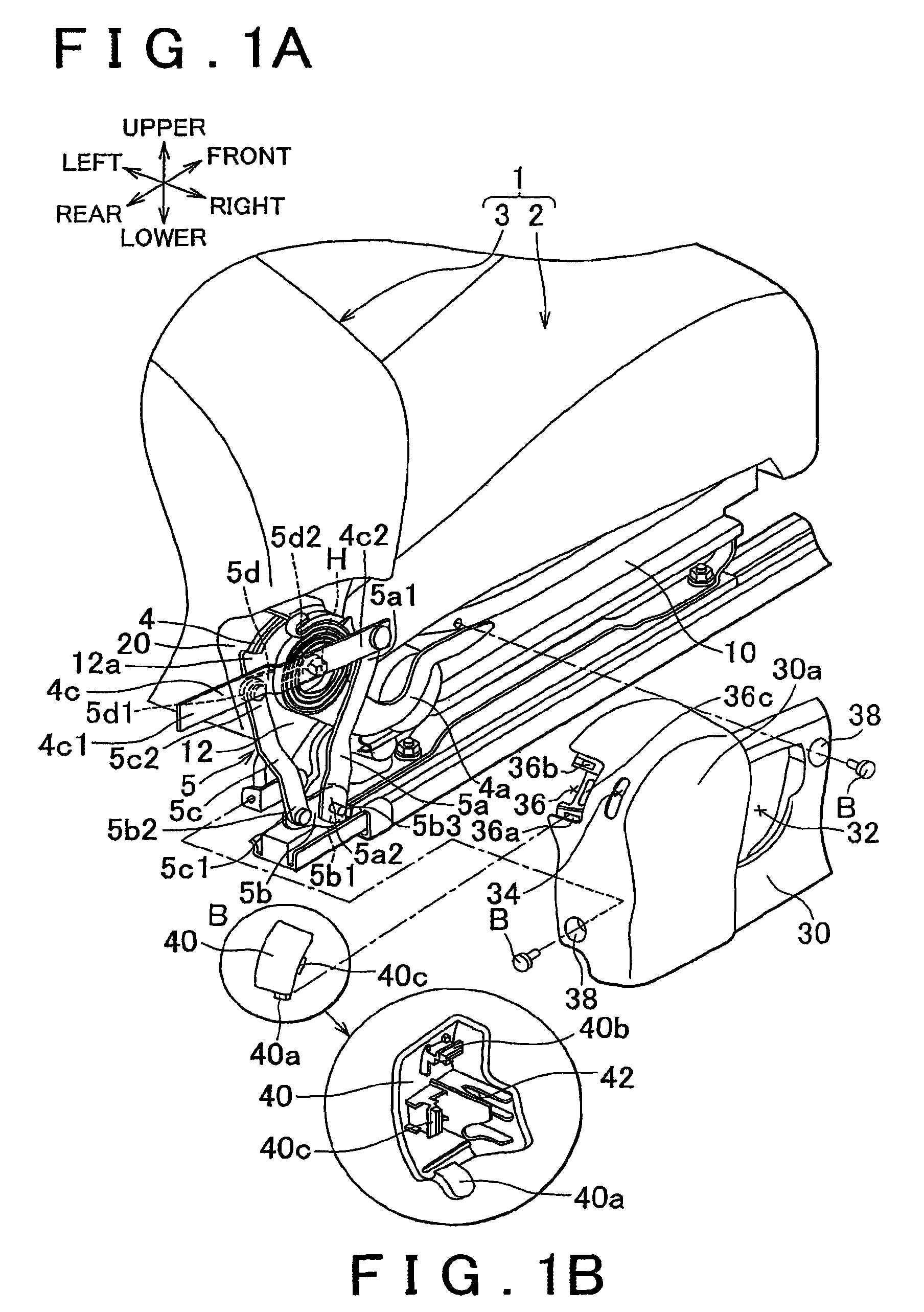

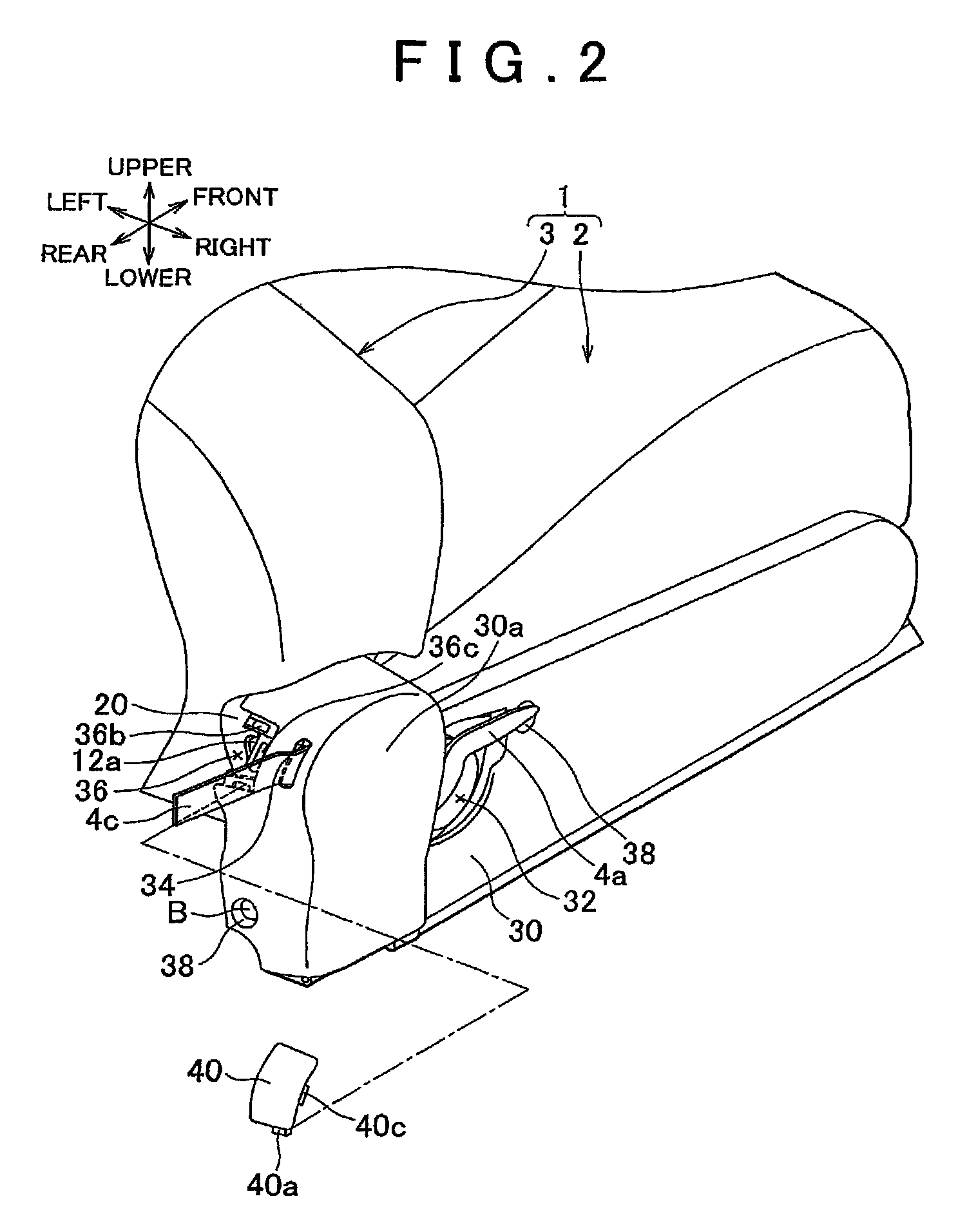

Vehicle seat

Owner:TOYOTA BOSHOKU KK

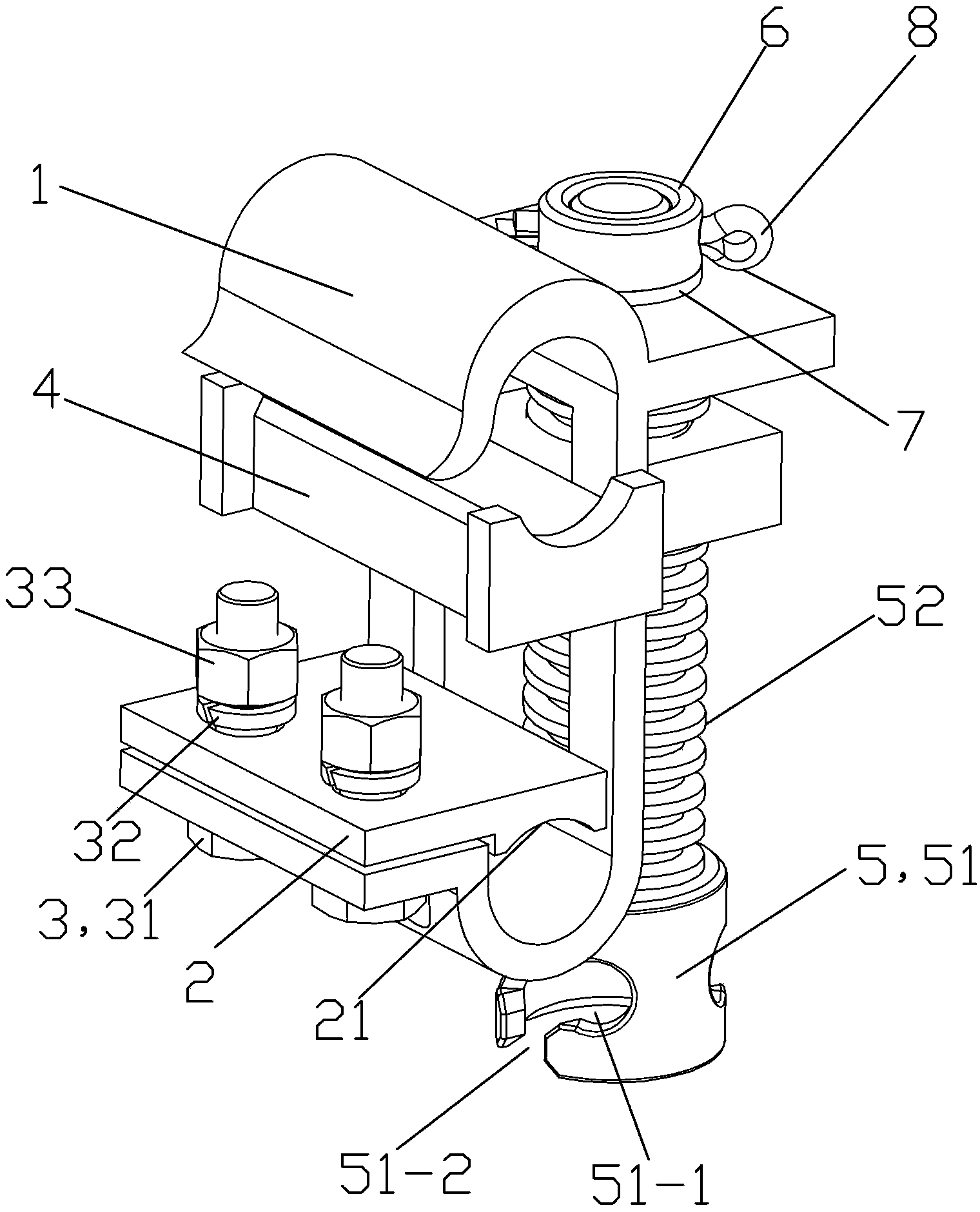

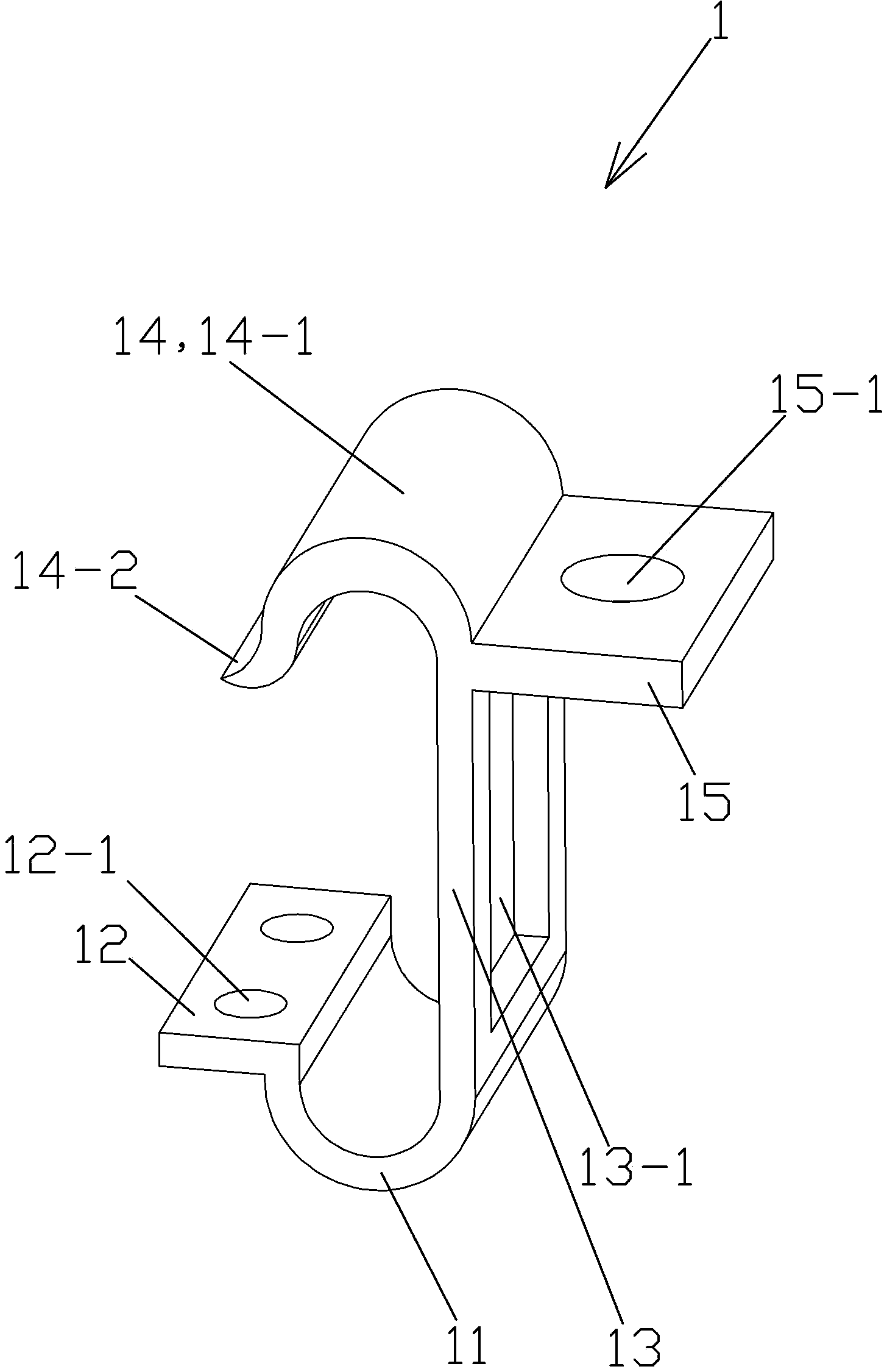

Ground potential operation non-bearing connection wire clamp

ActiveCN103457214ASimple structureLow costOverhead installationApparatus for overhead lines/cablesInterference fitEngineering

The invention provides a ground potential operation non-bearing connection wire clamp. The ground potential operation non-bearing connection wire clamp comprises a wire clamp body, a drainage wire pressing plate, bolted connection assemblies, a bus fastener, a driving screw, a guide sleeve, a sliding sleeve and a shaft pin. The drainage wire pressing plate is in bolted connection with the wire clamp body through the bolted connection assemblies, the bus fastener is in threaded connection with the driving screw, and the sliding sleeve is fixedly installed on a connecting lug plate through a connecting through hole of the connecting lug plate of the wire clamp body in a vertical interference fit mode. The inner wall of the guide sleeve and the upper end of a thread driving column of the driving screw are in threaded connection and then connected in a pin joint mode through the shaft pin. The outer wall of the guide sleeve and the inner wall of the sliding sleeve can be connected in a sleeved and vertical sliding mode. The ground potential operation non-bearing connection wire clamp is simple in structure, low in cost, convenient to mount and demount, and high in working efficiency and applicability, time and labor are saved, construction can be directly conducted under the power-outage-free condition, and unnecessary economic and social losses caused by power outage construction can be effectively avoided.

Owner:JIANGSU ELECTRIC POWER CO +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com