Ground potential operation non-bearing connection wire clamp

A non-load-bearing, continuous line technology, applied in the direction of electrical components, cable installation, overhead lines/cable equipment, etc., can solve the increasingly high requirements for power quality and power supply reliability of distribution lines, difficult operations, To avoid unnecessary economic and social losses, to facilitate installation and disassembly, and to facilitate installation and construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

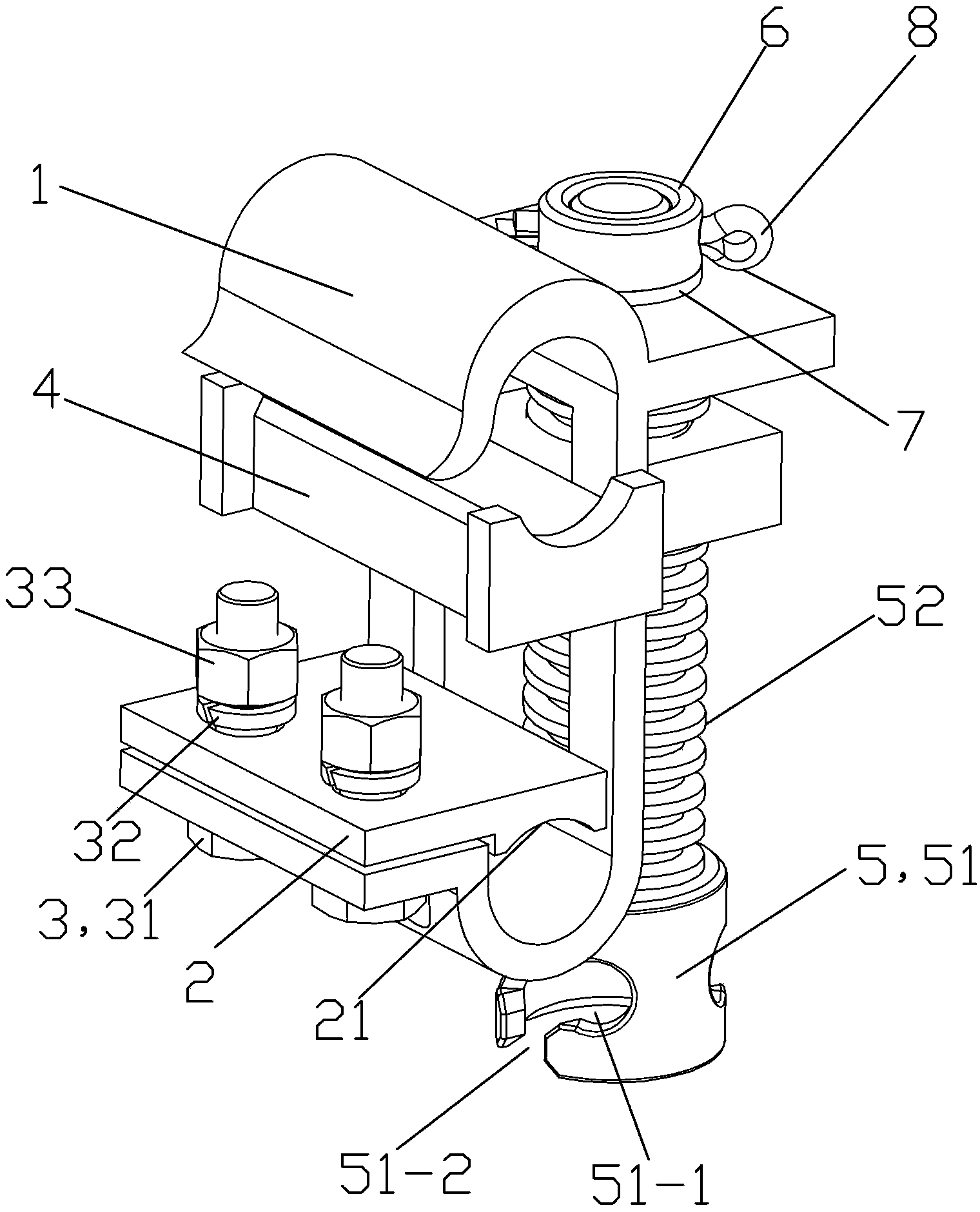

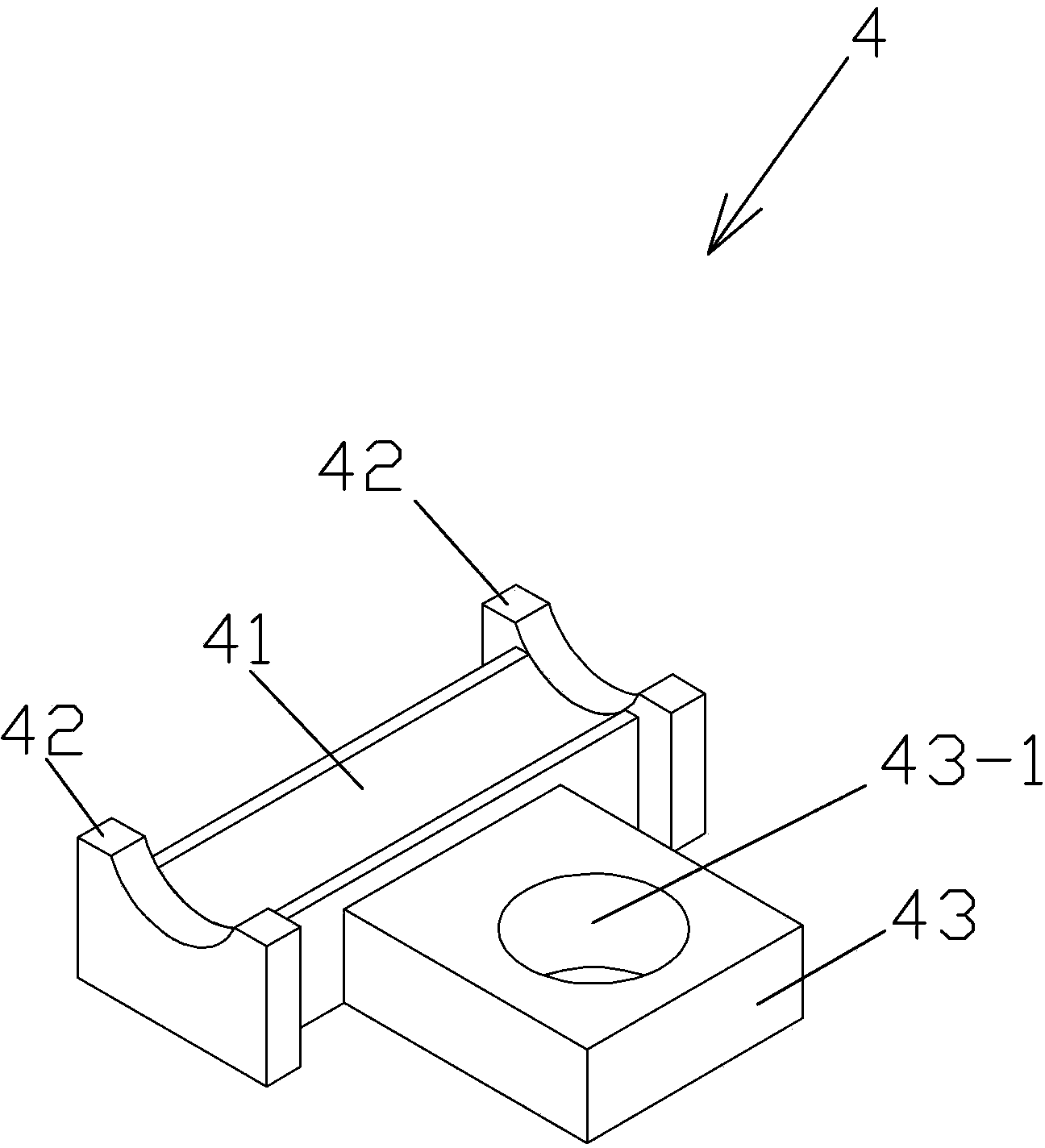

[0032] See Figure 1 to Figure 3 , the ground potential operation non-load-bearing connection clamp of this embodiment is mainly composed of a clamp main body 1, a drain line pressure plate 2, a bolt connection assembly 3, a busbar fastener 4, a driving screw 5, a guide sleeve 6, a sliding sleeve 7 and Shaft pin 8 forms.

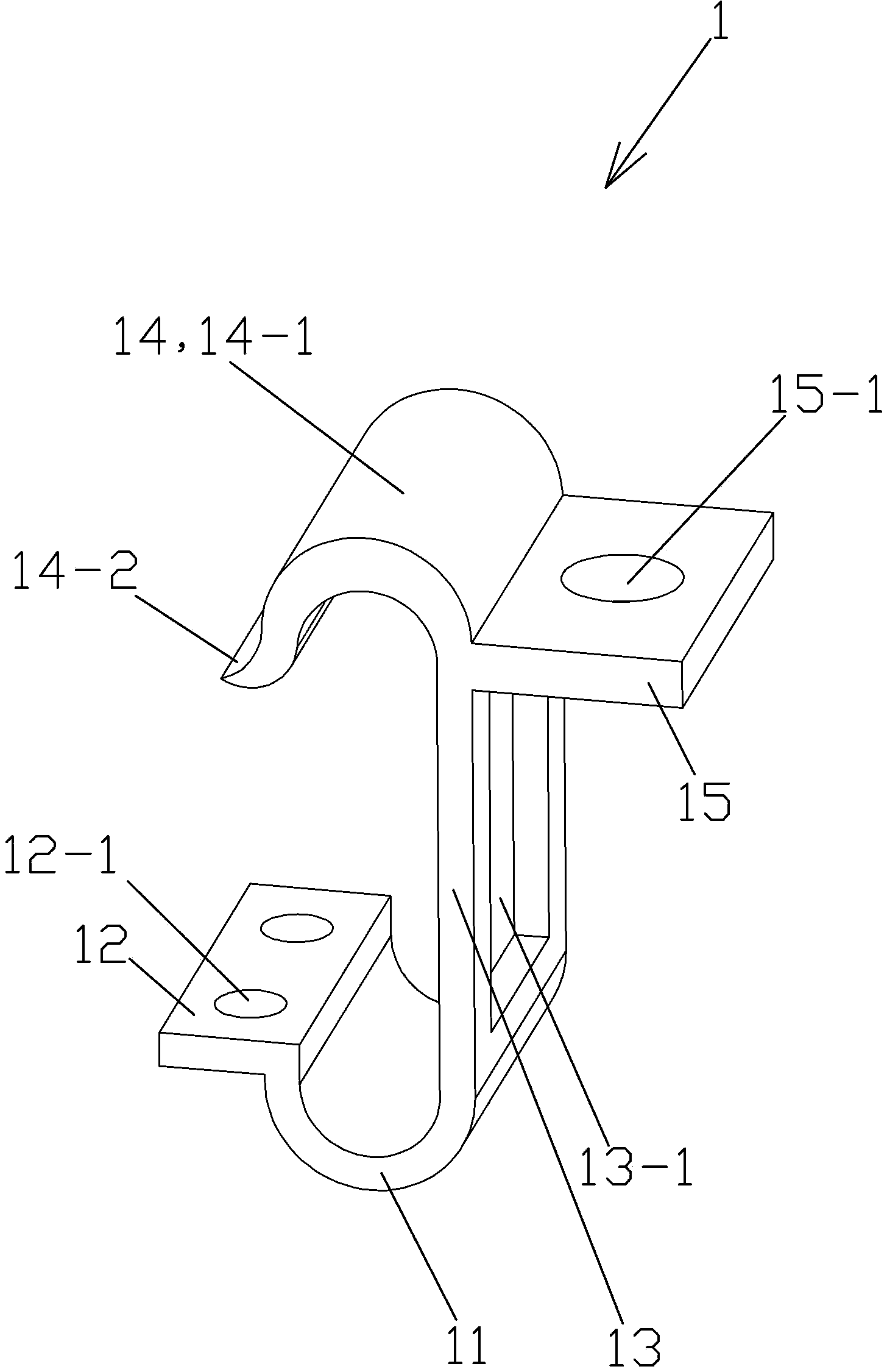

[0033] See figure 2 , The clamp main body 1 is an integral piece made of aluminum alloy. The clamp main body 1 is integrally composed of a drain wire mounting part 11 , a drain wire pressing plate connecting part 12 , an intermediate connecting part 13 , a bus bar clamping part 14 and a connecting ear plate 15 .

[0034] The drain wire installation part 11 is an arc-shaped plate body protruding downward. The drain line clamping plate connecting portion 12 is a rectangular plate body part arranged horizontally, and the draining wire clamping plate connecting portion 12 is provided with 2 circular through-holes up and down, as the bolt holes 12-1 for insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com