Method for Horizontally Winding and Unwinding a Parallel Wire Strand

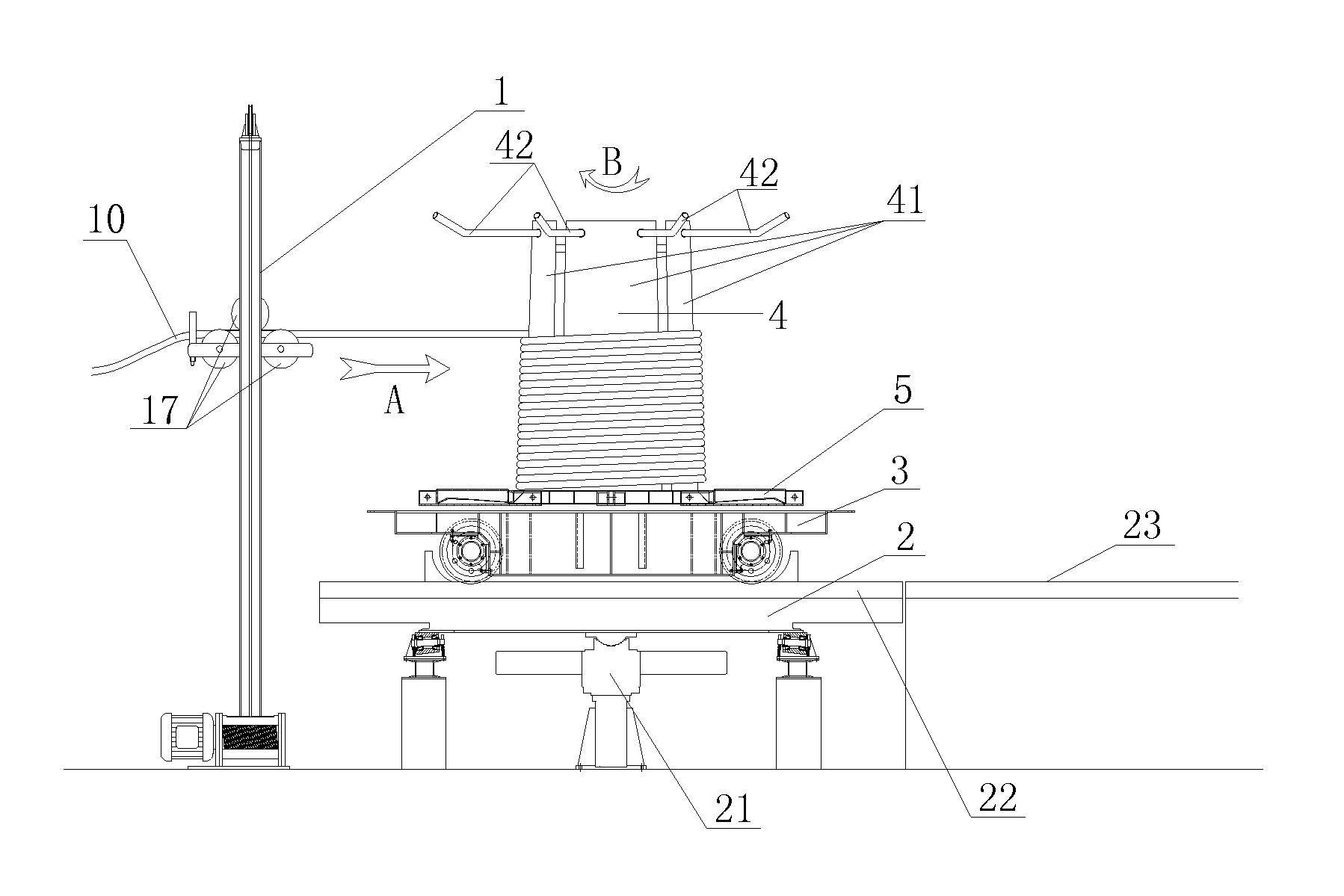

a technology of parallel wire strands and wire strands, which is applied in the direction of bridges, bridge structural details, transportation and packaging, etc., can solve the problems of difficult unwinding of cable strands from steel reels, cable strands giving birth to oval traumas, and loosening of cable strands, so as to avoid cable strand damage or injury or loss, increase the erection benefits and cable strand quality, and reduce labor intensity and operation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

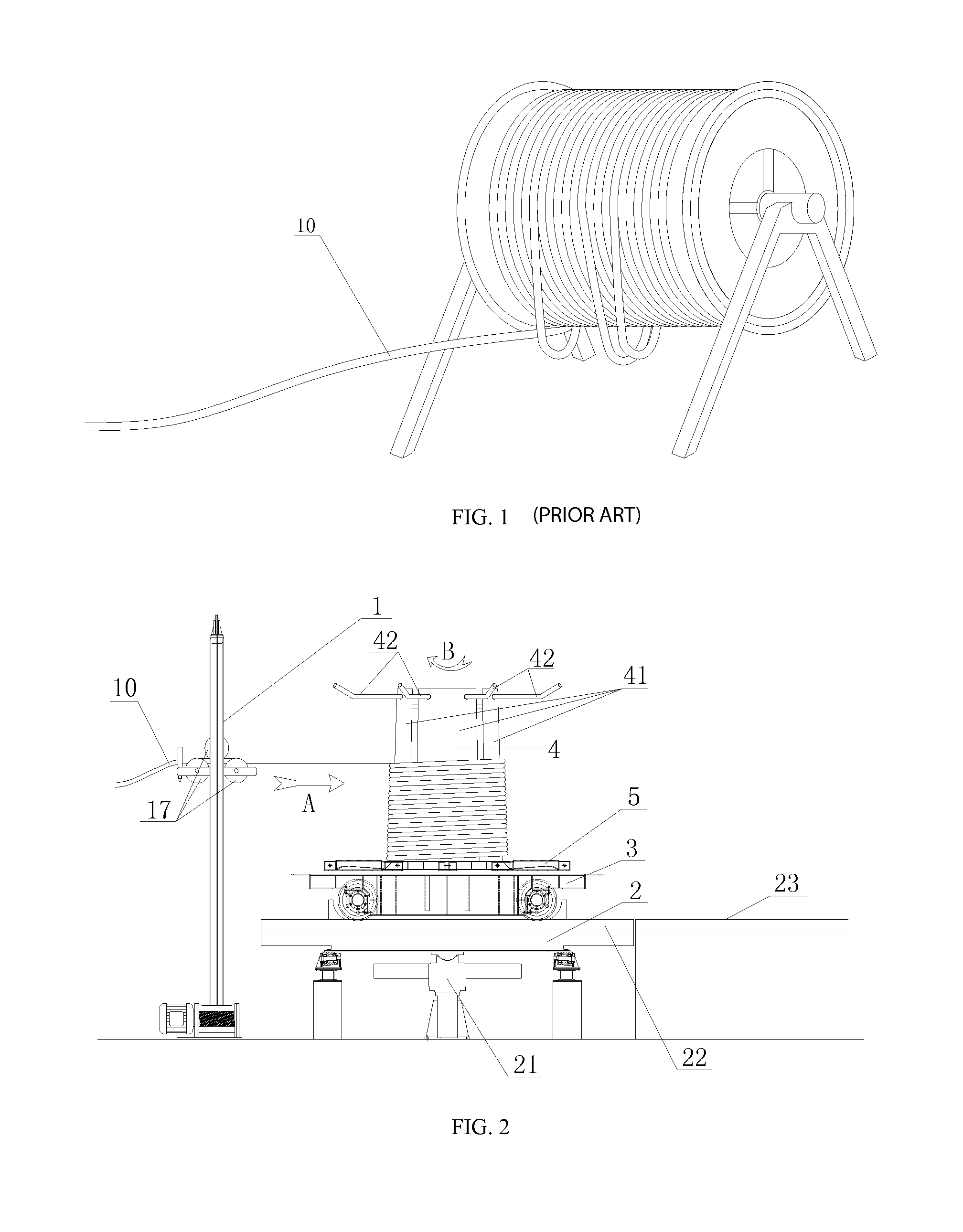

[0029]A method for horizontally winding and horizontally unwinding a parallel wire strand upon a base of a cable reel for transport, storage or installation, a parallel wire strand made up of a plurality of tightly adjacent vertically and horizontally arranged parallel wires, the strand including at least a leading end fitting securing the ends of the wires together, comprising the steps of:

[0030](a) Performing the winding operation, the operation procedure is as follows:

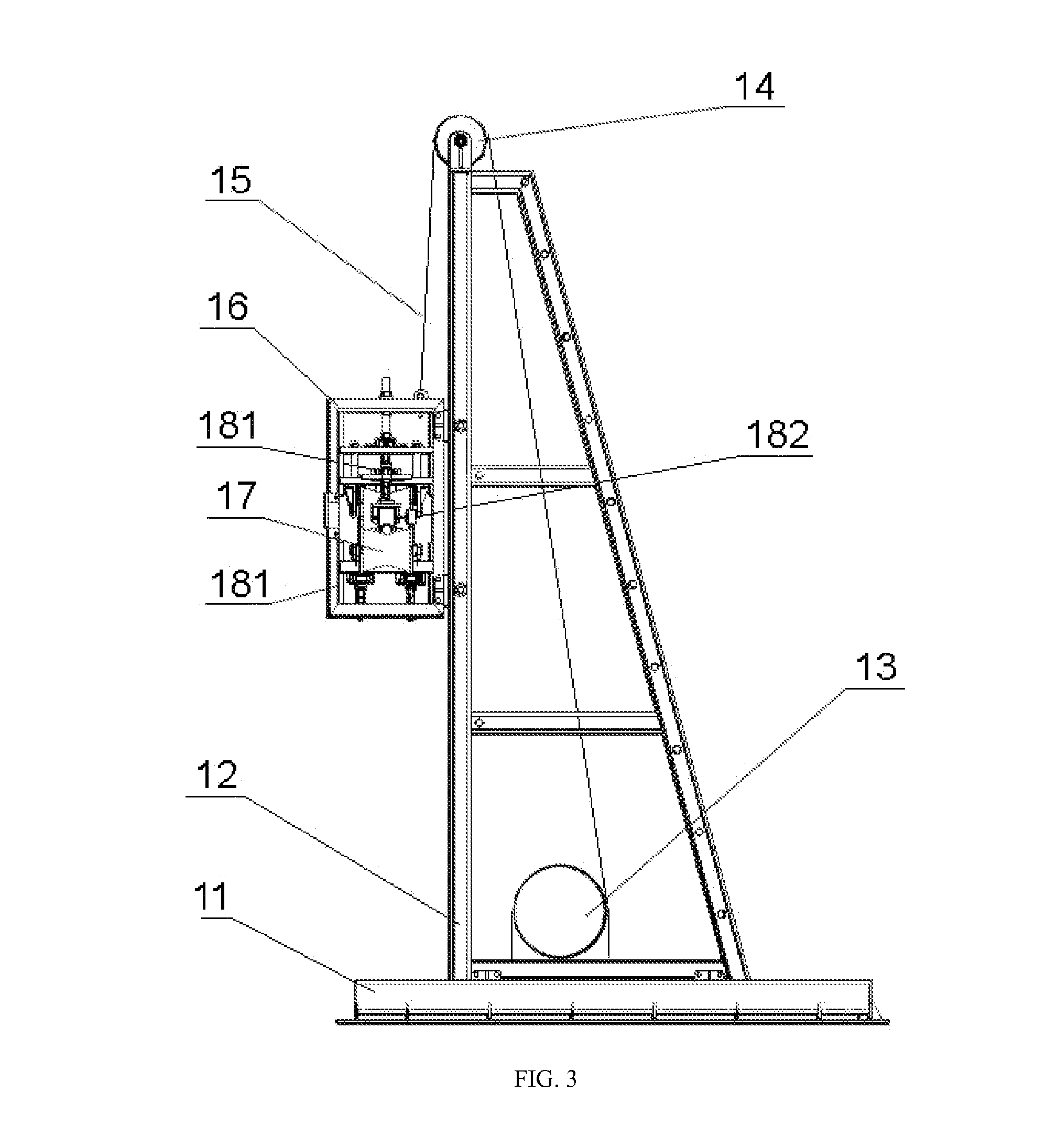

[0031]As shown in FIG. 2, fix the guide frame 1 on the ground, the guide frame 1 is composed by the base 11, support frame 12, electric hoist 13, fixed pulley 14, steel wire rope 15, lifting mechanism 16, roller 17, the pressure sensor 181, speed encoder 182, altimeter encoder 183 and limit roller 19 as shown in FIGS. 3 and 4. Fix the base 1 on the ground and fix the support frame 12 and electric hoist 13 on the base 1. A fixed pulley 14 is equipped at the top of the support frame 12, also a steel wire rope 15 which...

embodiment 2

[0043]It is a method for horizontally winding and horizontally unwinding a parallel wire strand. The method includes winding strand and unwinding strand operations. During the winding strand the container 4 is composed by 6 support plates 41 and the top support rod 42. The six support plates 41 are aligned uniformly in the ring shape. There is a gap between the adjacent support plates 41, and the gap length is 100 percent of the width of support plate 41. The rest structure and method are the same to embodiment 1.

embodiment 3

[0044]It is a method for horizontally winding and horizontally unwinding a parallel wire strand. The method includes winding strand and unwinding strand operations. During the winding strand the container 4 is composed by 10 support plates 41 and the top support rod 42. The ten support plates 41 are aligned uniformly in the ring shape. There is a gap between the adjacent support plates 41, and the gap length is 80 percent of the width of support plate 41. The rest structure and method are the same to embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com