Patents

Literature

329results about "Winding capacitor machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

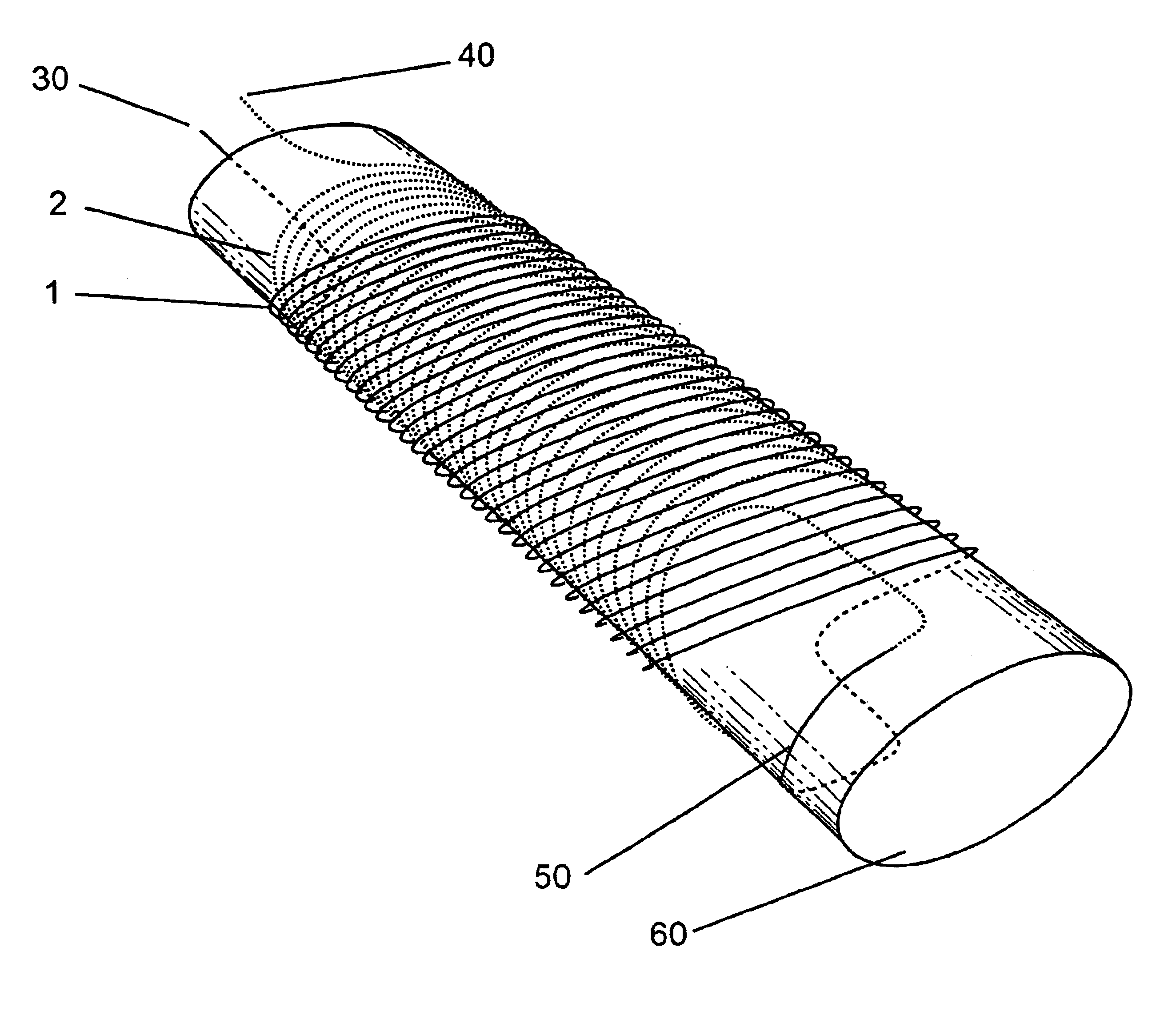

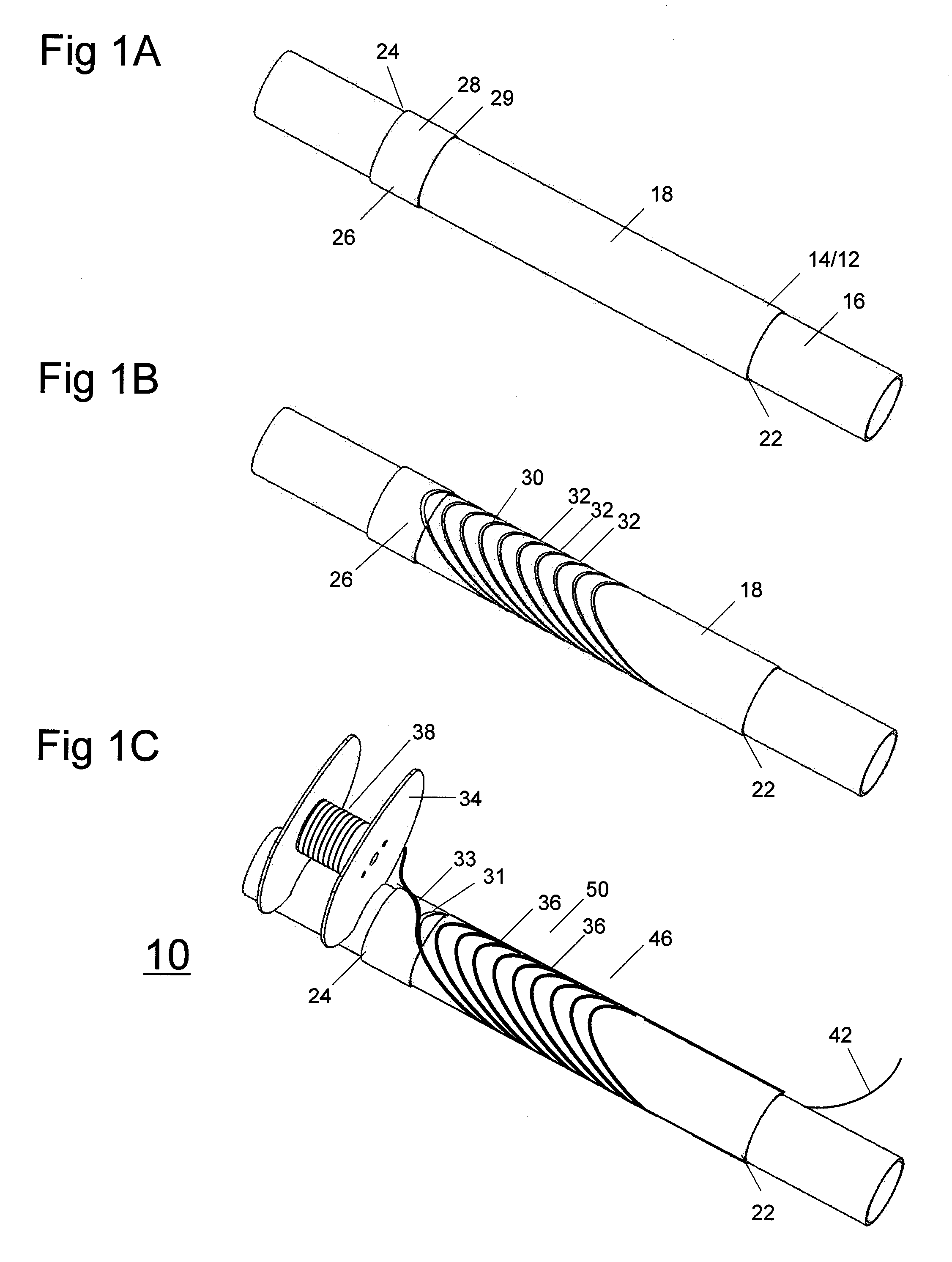

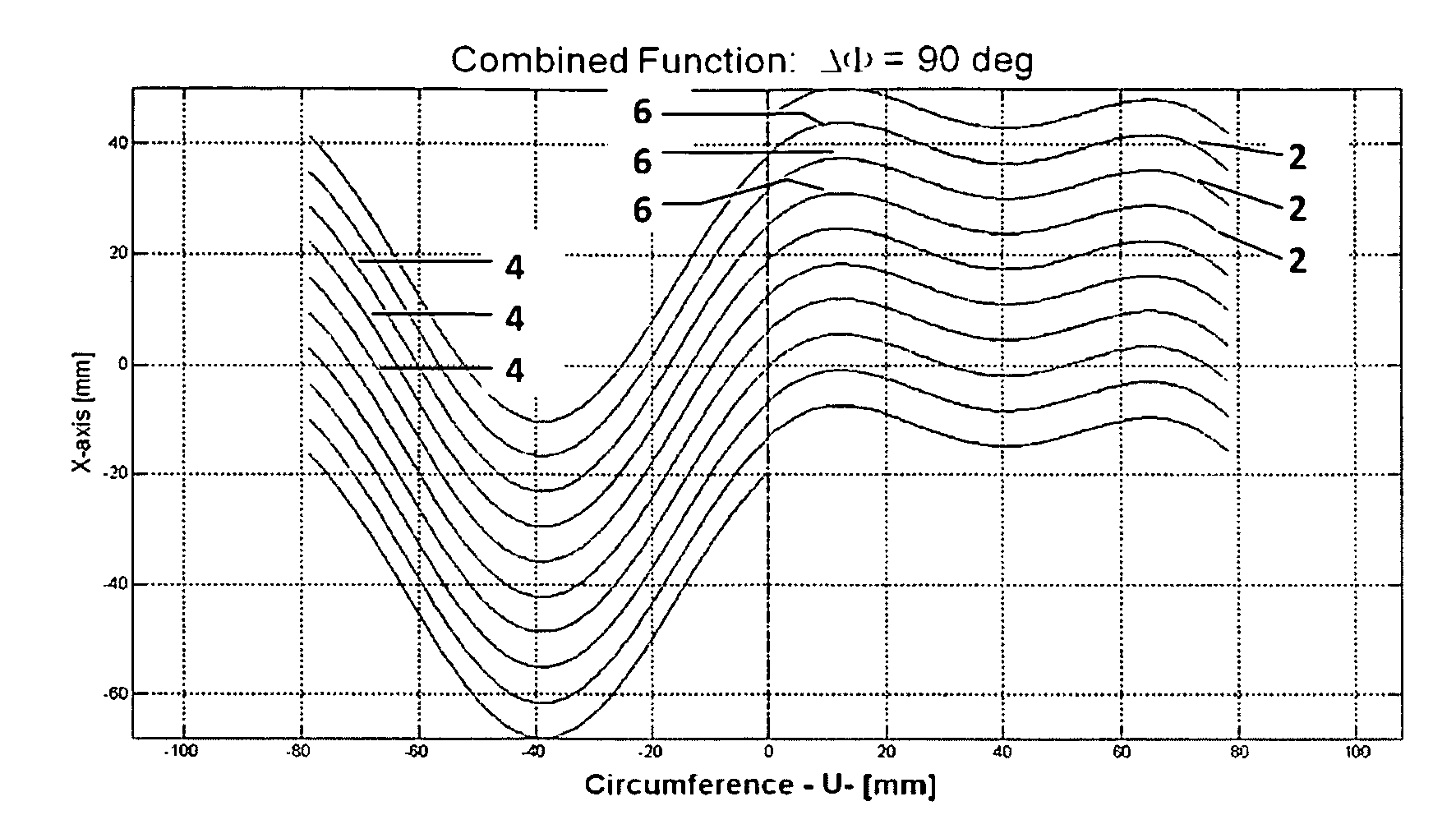

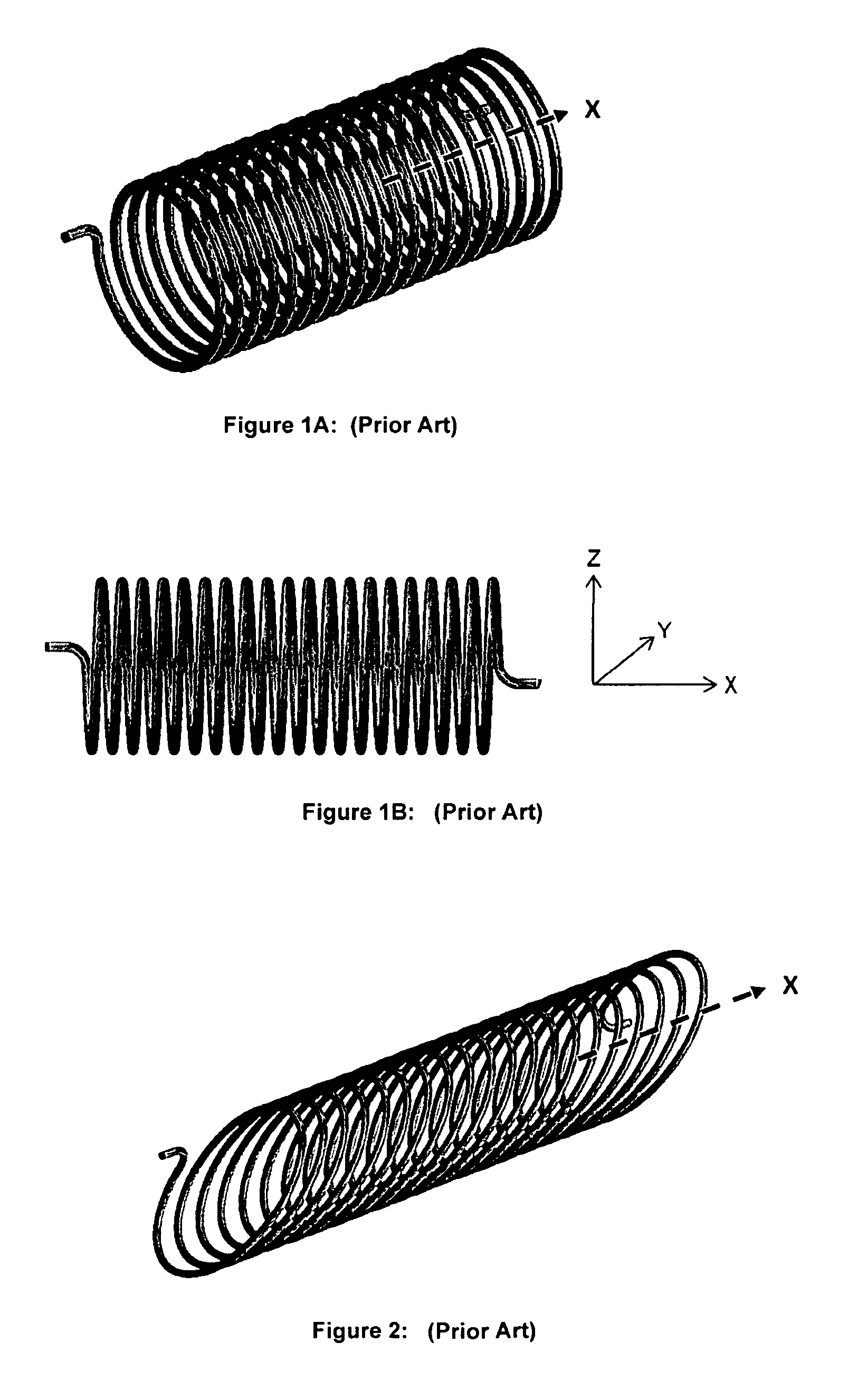

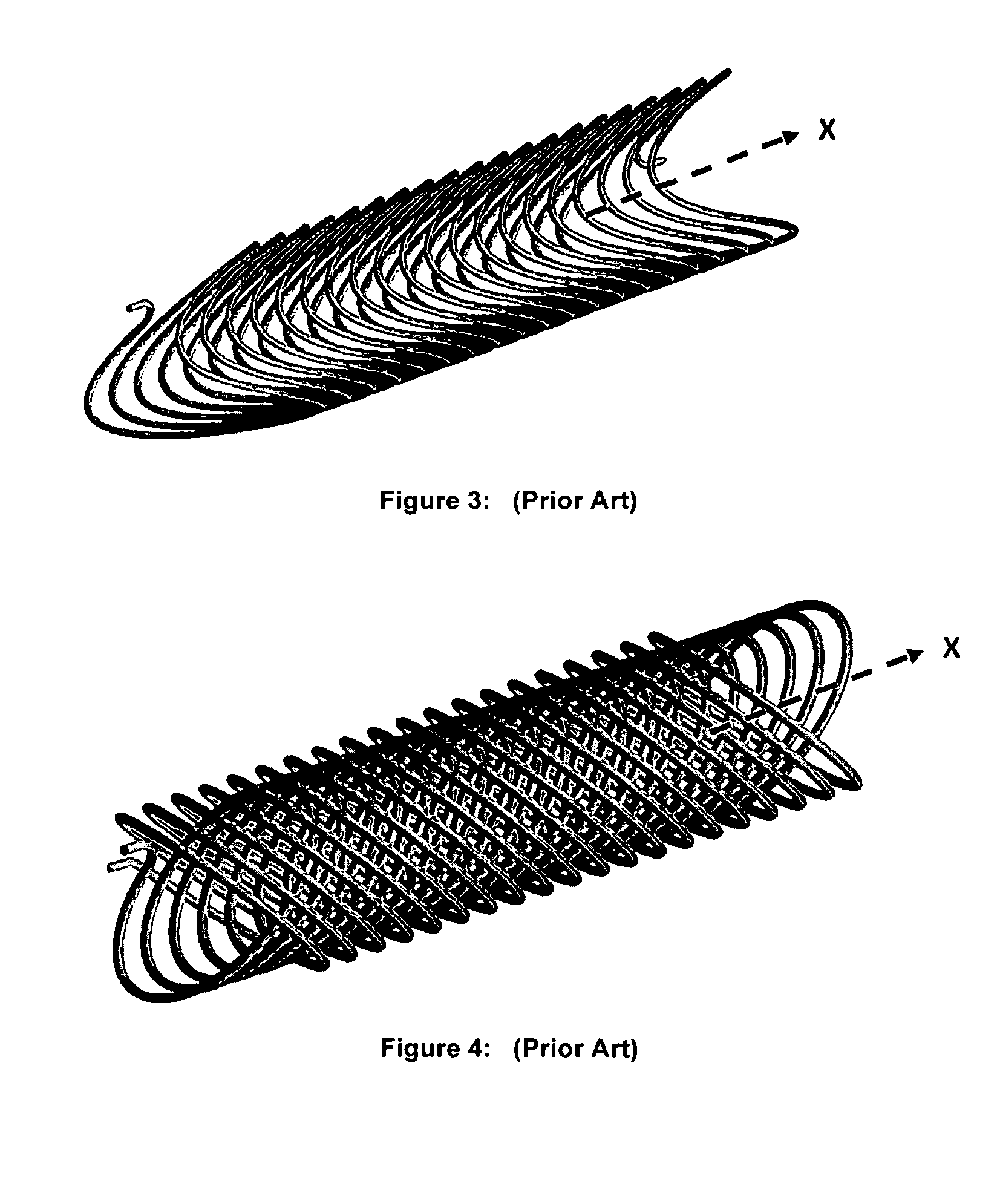

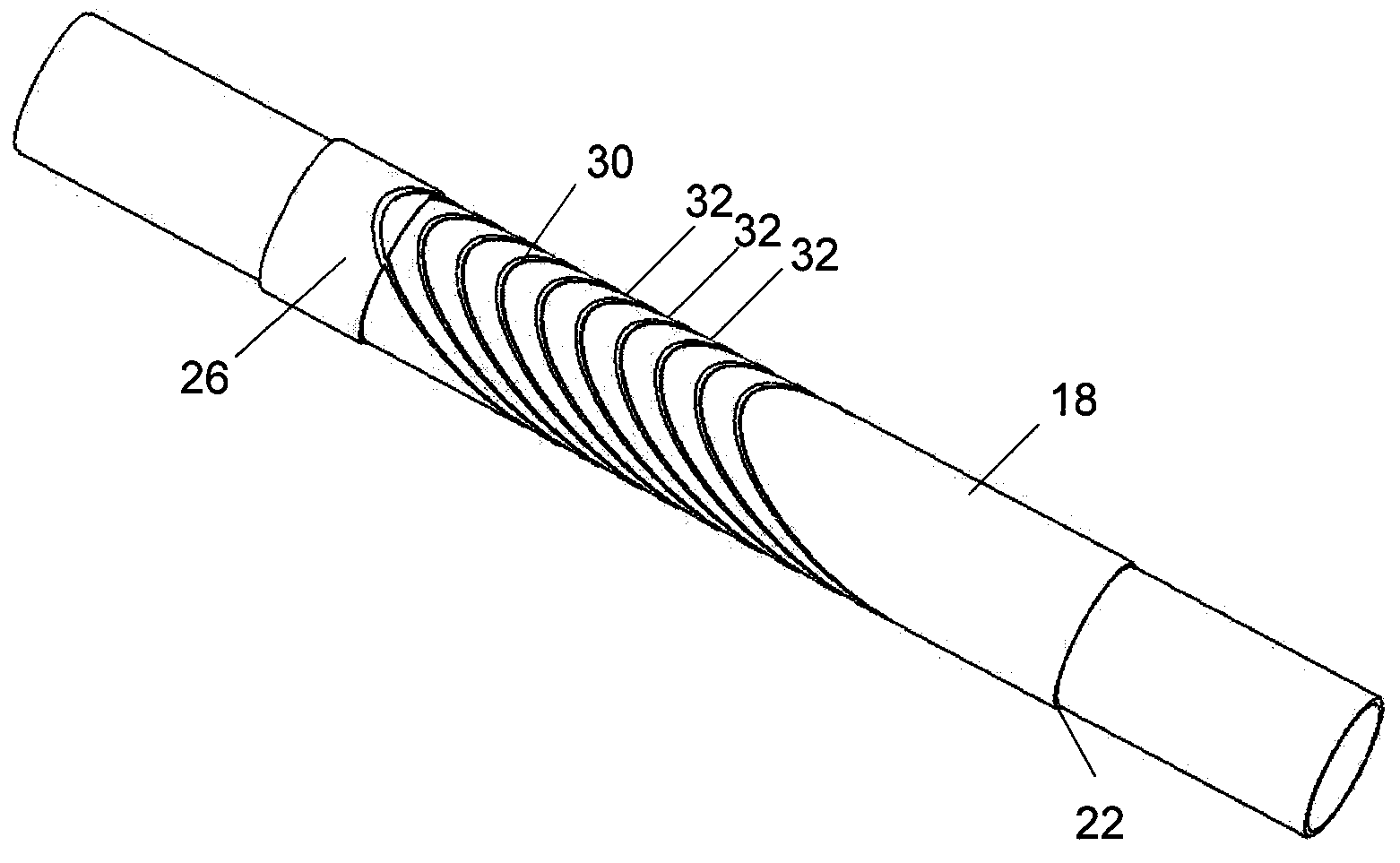

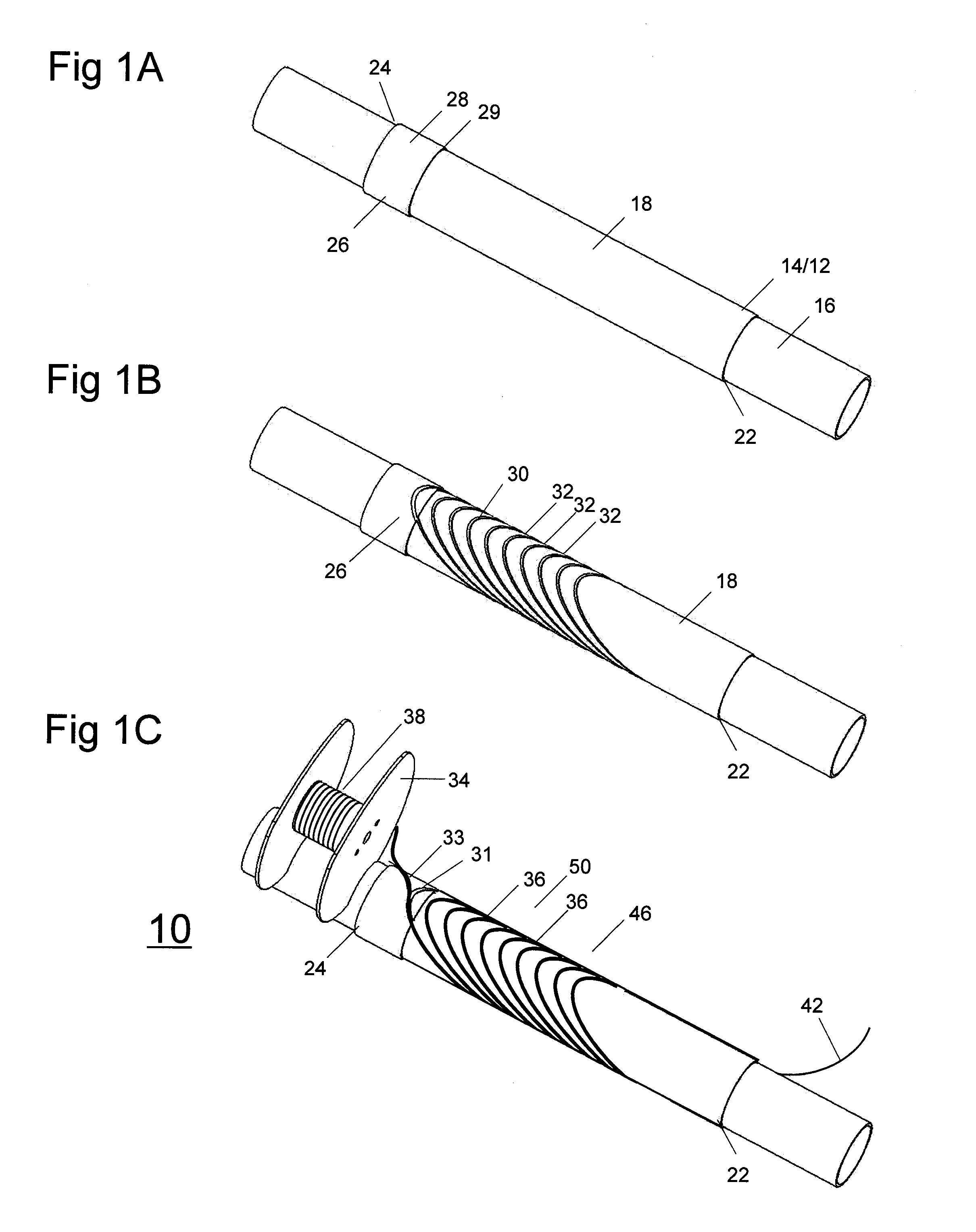

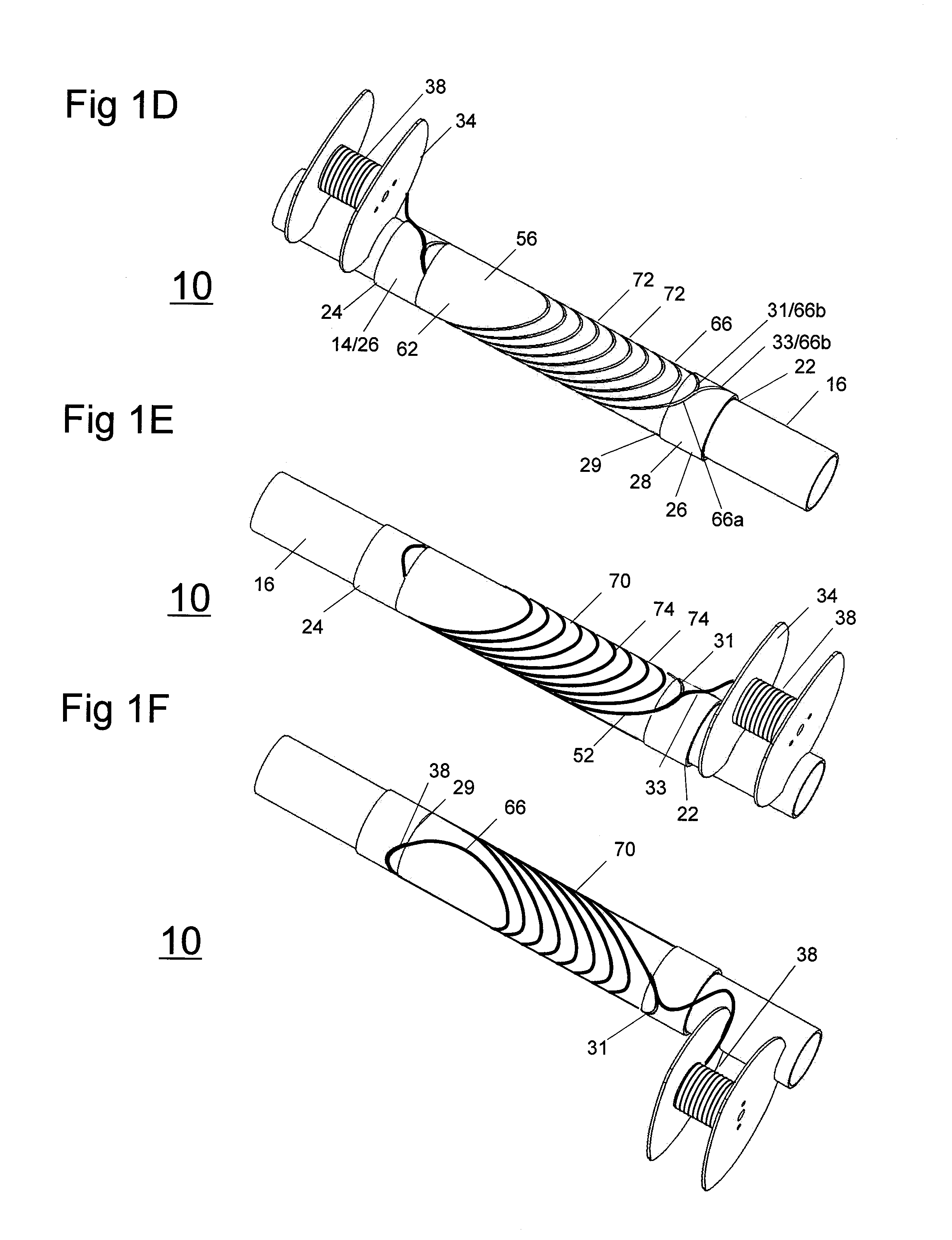

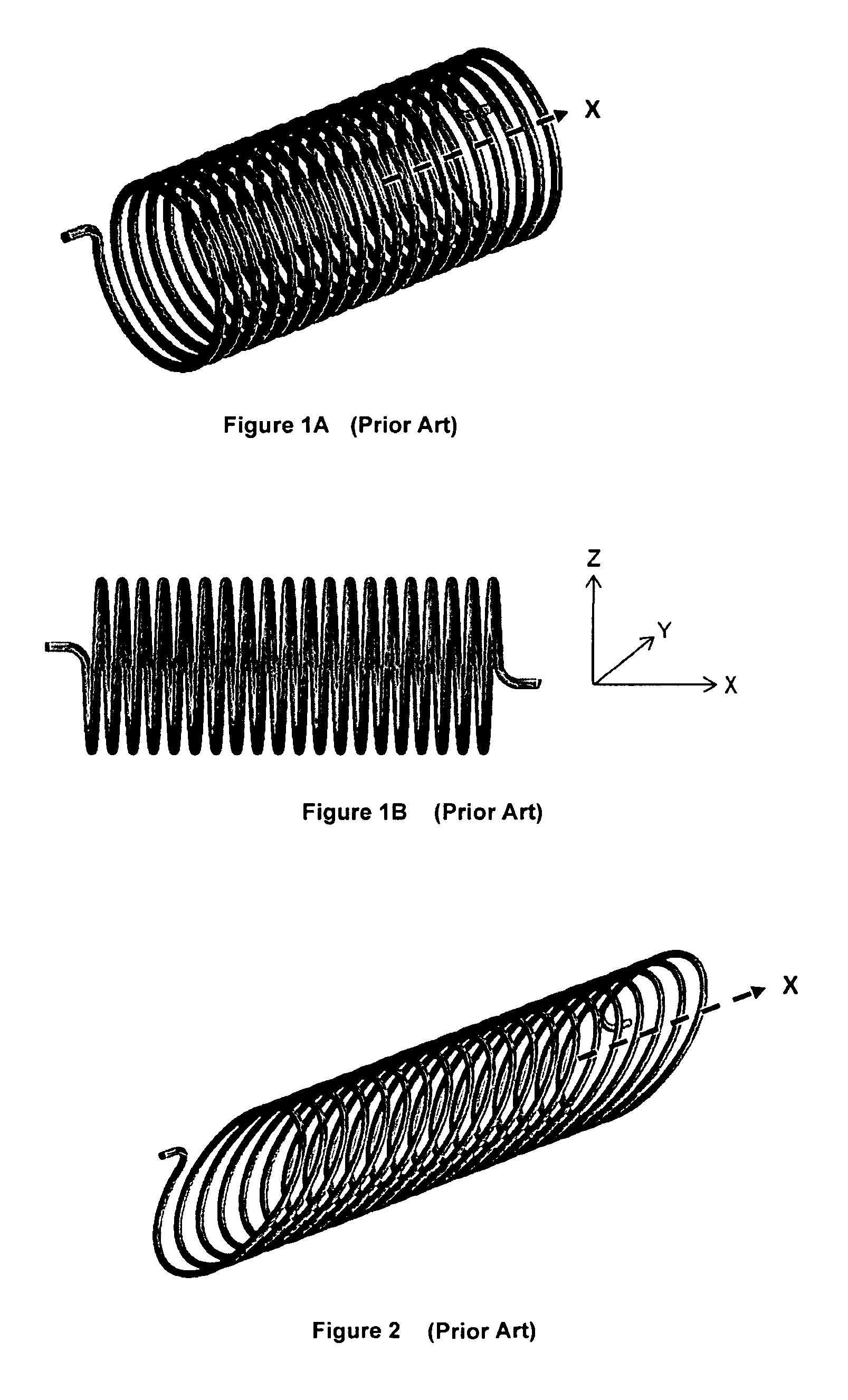

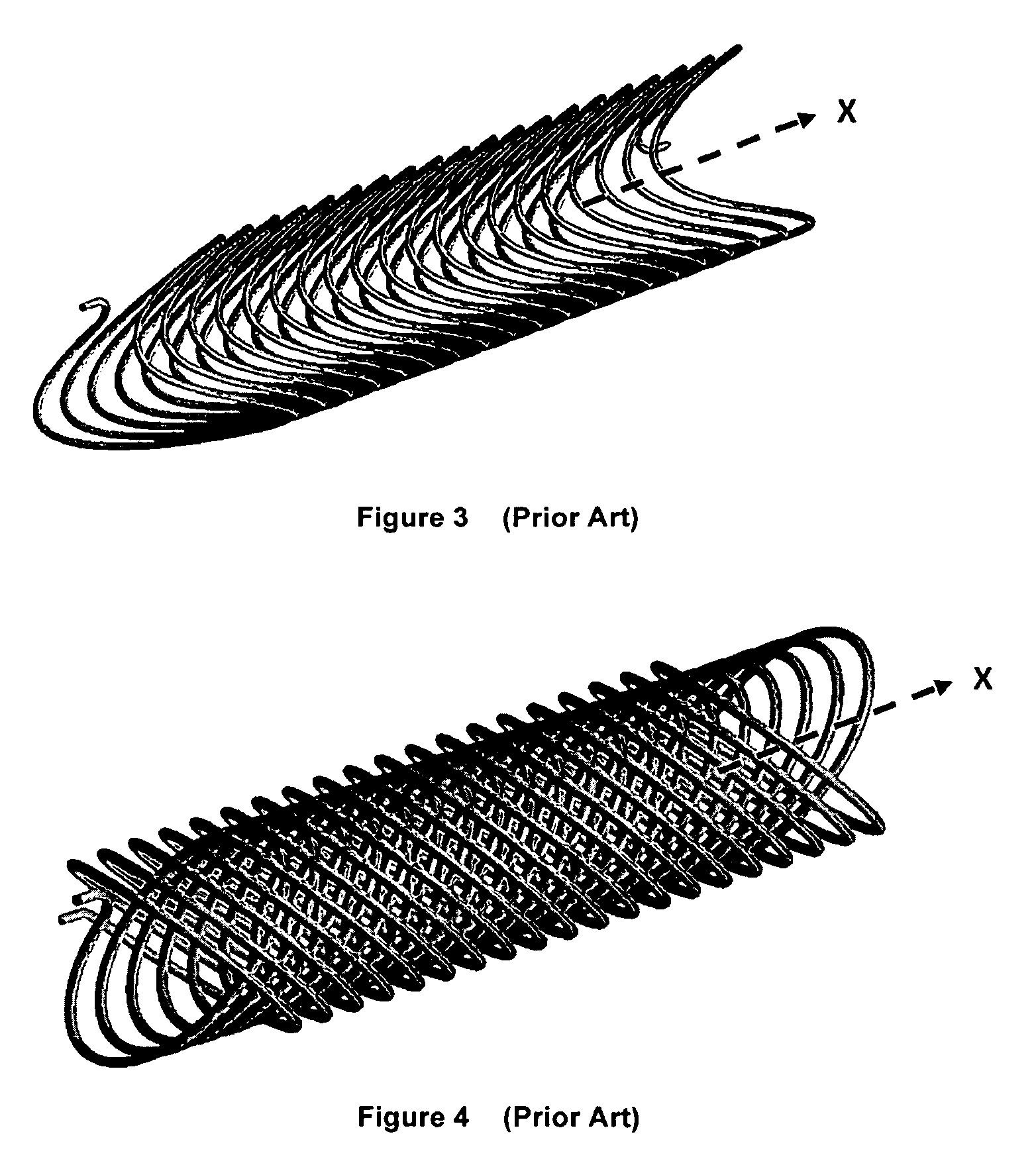

Concentric tilted double-helix dipoles and higher-order multipole magnets

InactiveUS6921042B1Simple processLess costlyElectromagnets without armaturesFilament handlingElectric machineryMagneto hydrodynamic

Concentric tilted double-helix magnets, which embody a simplified design and construction method for production of magnets with very pure field content, are disclosed. The disclosed embodiment of the concentric tilted double-helix dipole magnet has the field quality required for use in accelerator beam steering applications, i.e., higher-order multipoles are reduced to a negligibly small level. Magnets with higher multipole fields can be obtained by using a simple modification of the coil winding procedure. The double-helix coil design is well-suited for winding with superconducting cable or cable-in-conduit conductors and thus is useful for applications that require fields in excess of 2 T. The coil configuration has significant advantages over conventional racetrack coils for accelerators, electrical machinery, and magneto-hydrodynamic thrusting devices.

Owner:GOODZEIT CARL L +2

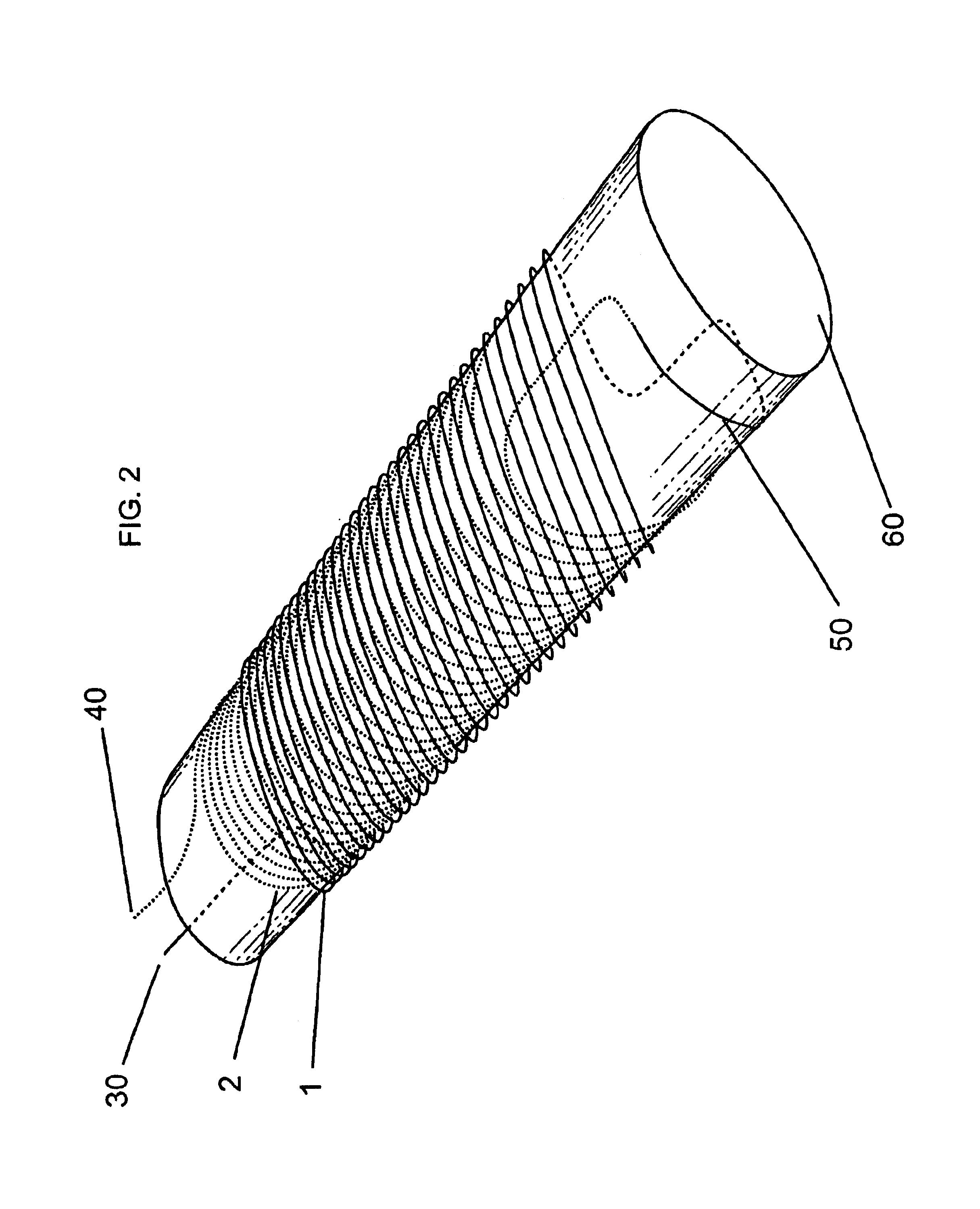

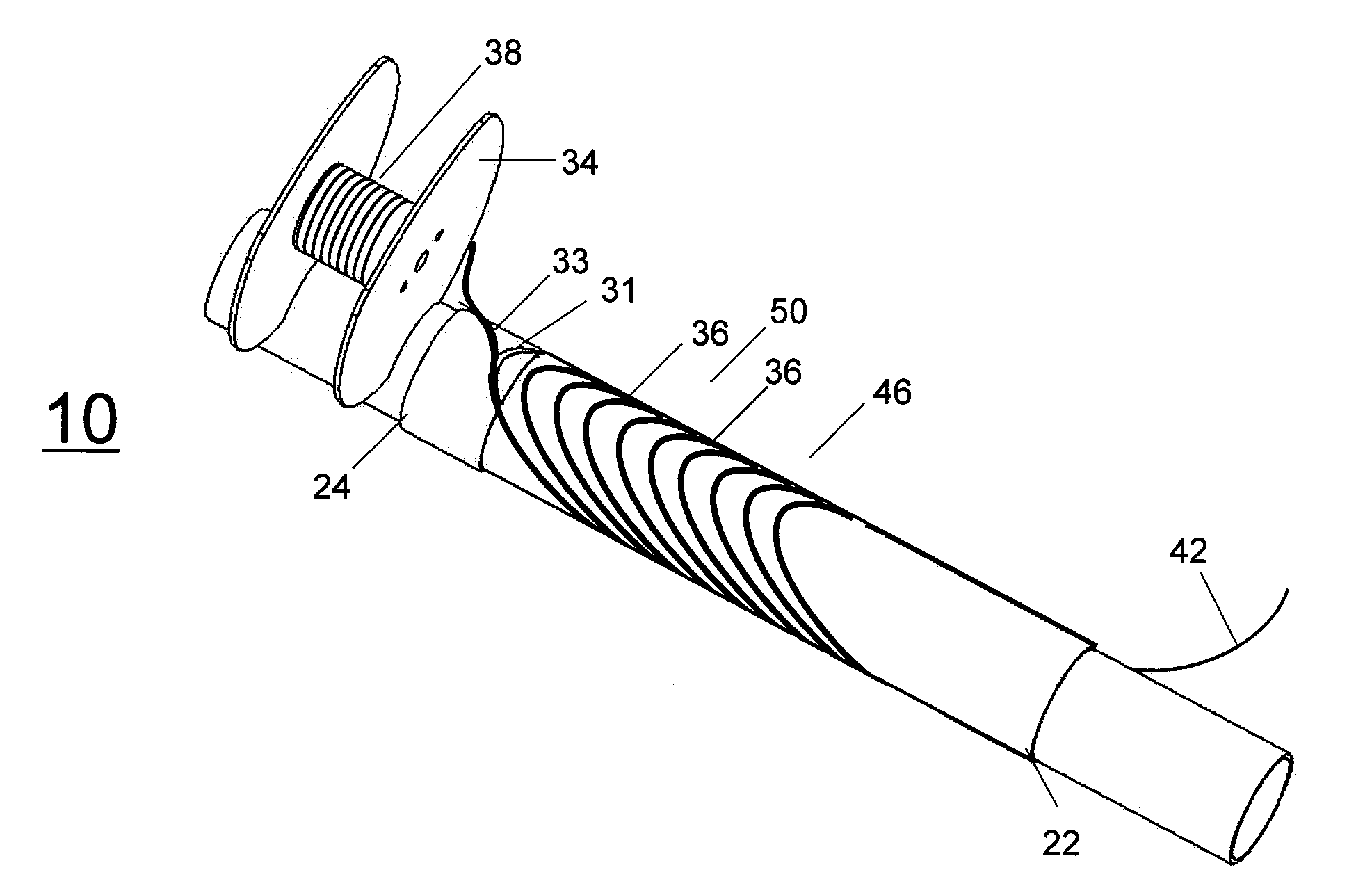

Structure For A Wiring Assembly And Method Suitable For Forming Multiple Coil Rows With Splice Free Conductor

InactiveUS20090251271A1Transformers/inductances coils/windings/connectionsFilament handlingShoulder regionConductive materials

A conductor assembly and method for constructing an assembly of the type which, when conducting current, generates a magnetic field or which, in the presence of a changing magnetic field, induces a voltage. In one embodiment the method includes forming a structure comprising layers of material extending along a first aperture path. The structure includes multiple concentric layer surfaces. A channel is formed in each of the layers of the material and along each of the multiple surfaces. Conductive material is positioned in each channel to provide a spiral configuration. The surfaces of multiple ones of the layers are of tubular shape. The layers of material are sequentially positioned one over another and about an axis along which first and second opposing coil end regions are formed. The layers are formed with a region of a first thickness and a shoulder region. The shoulder region is alternately formed in the sequence at one coil end region or at the other coil end region. Each shoulder region has a greater thickness than the first thickness.

Owner:ADVANCED MAGNET LAB

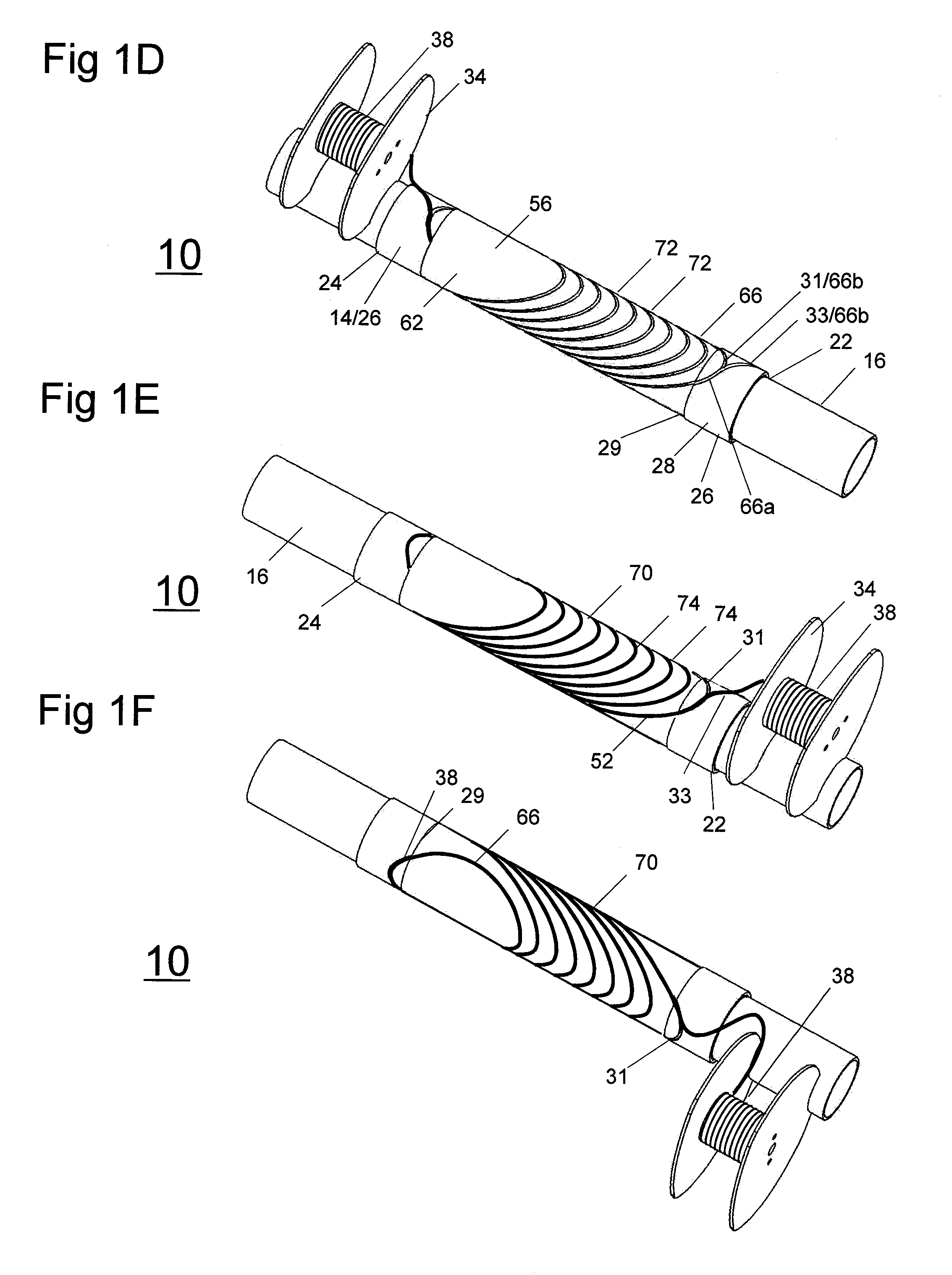

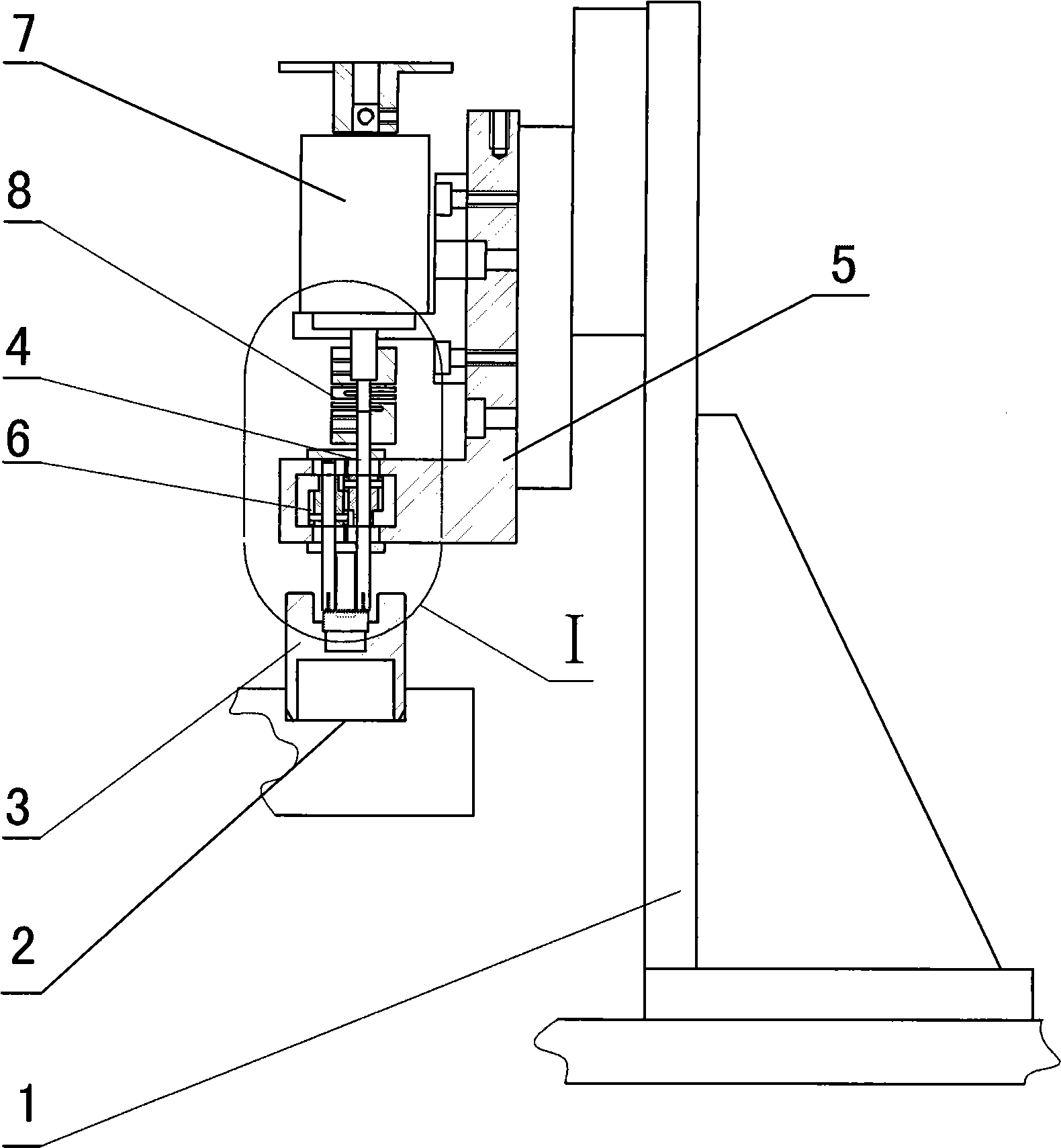

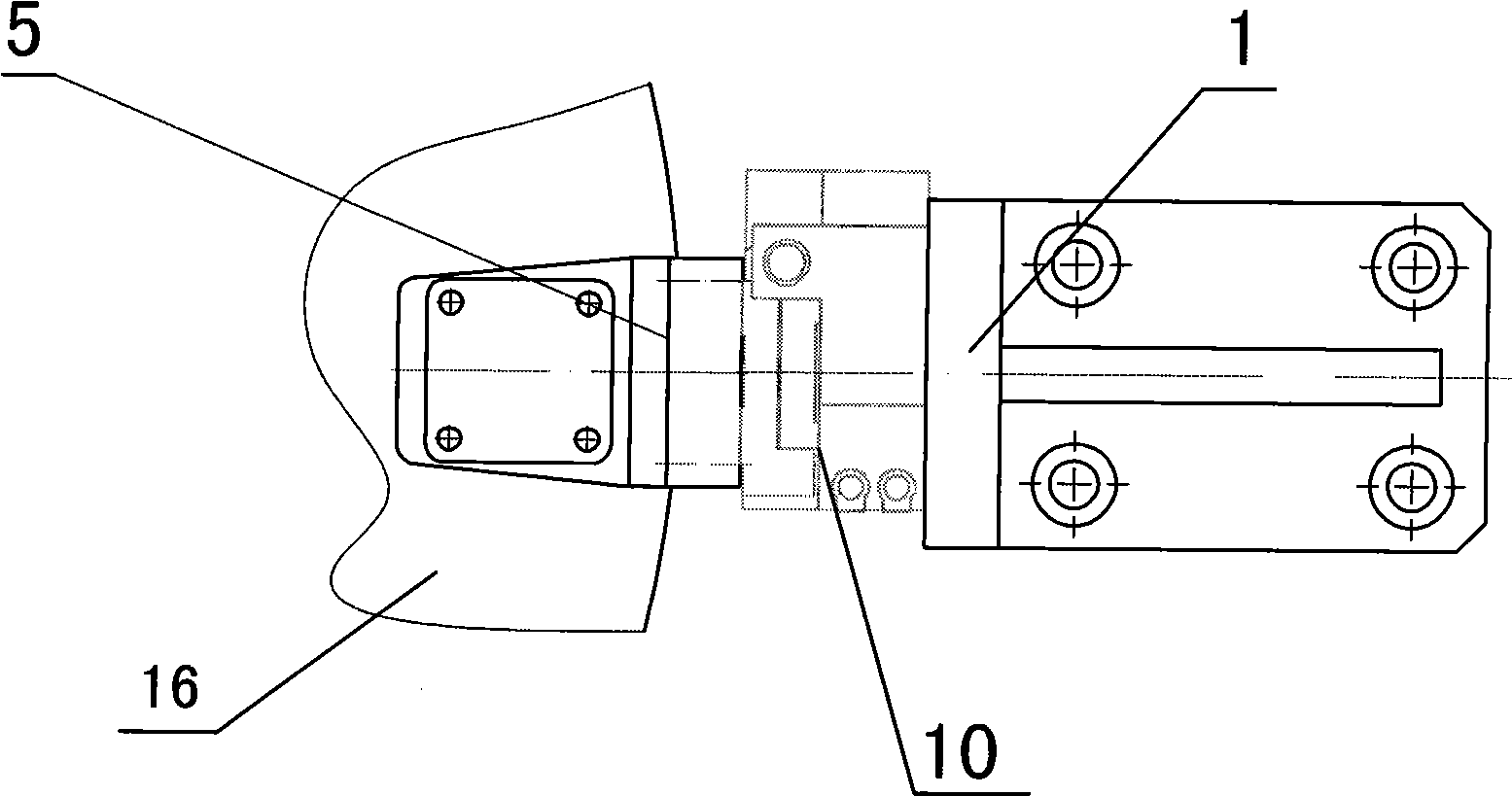

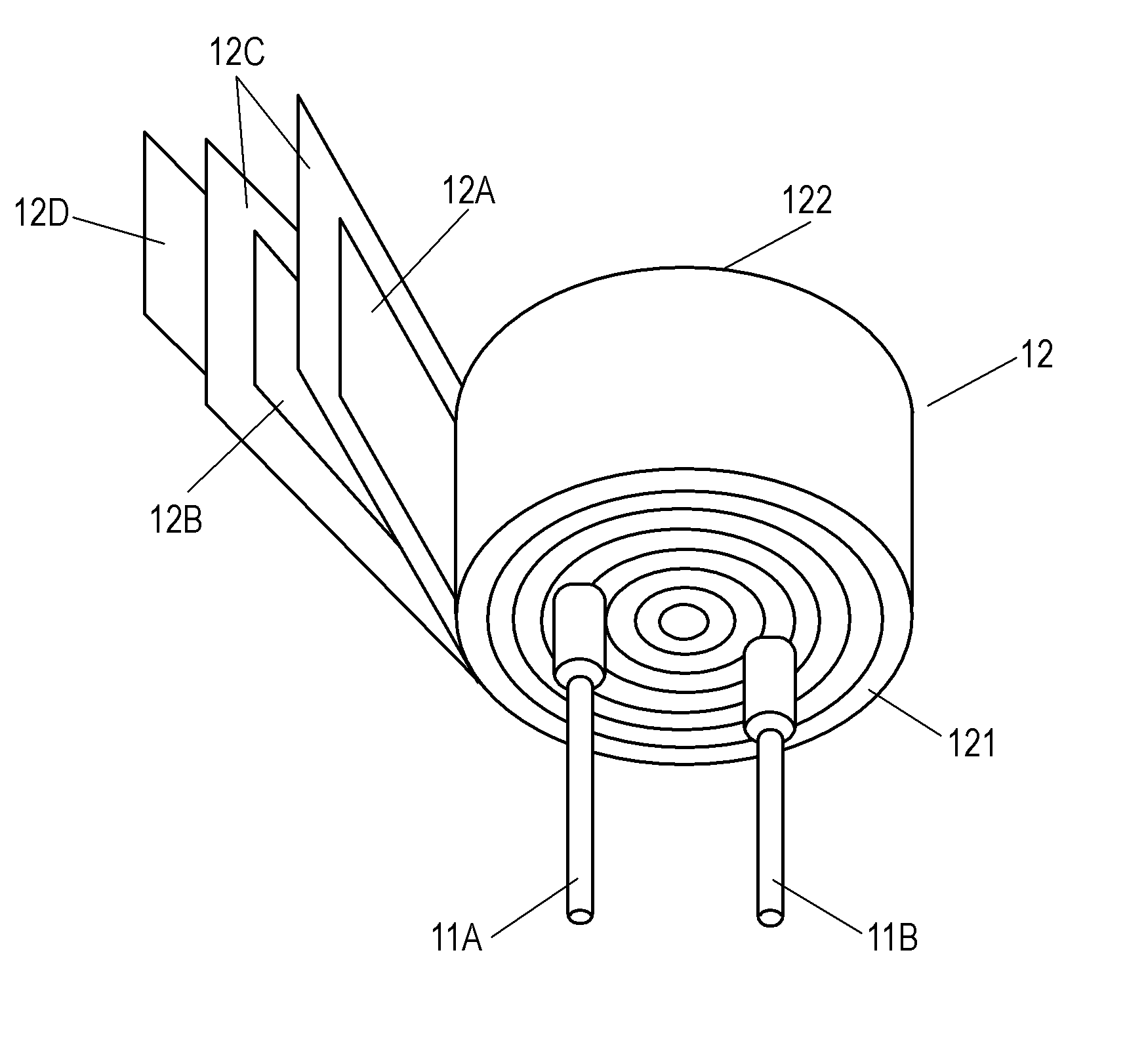

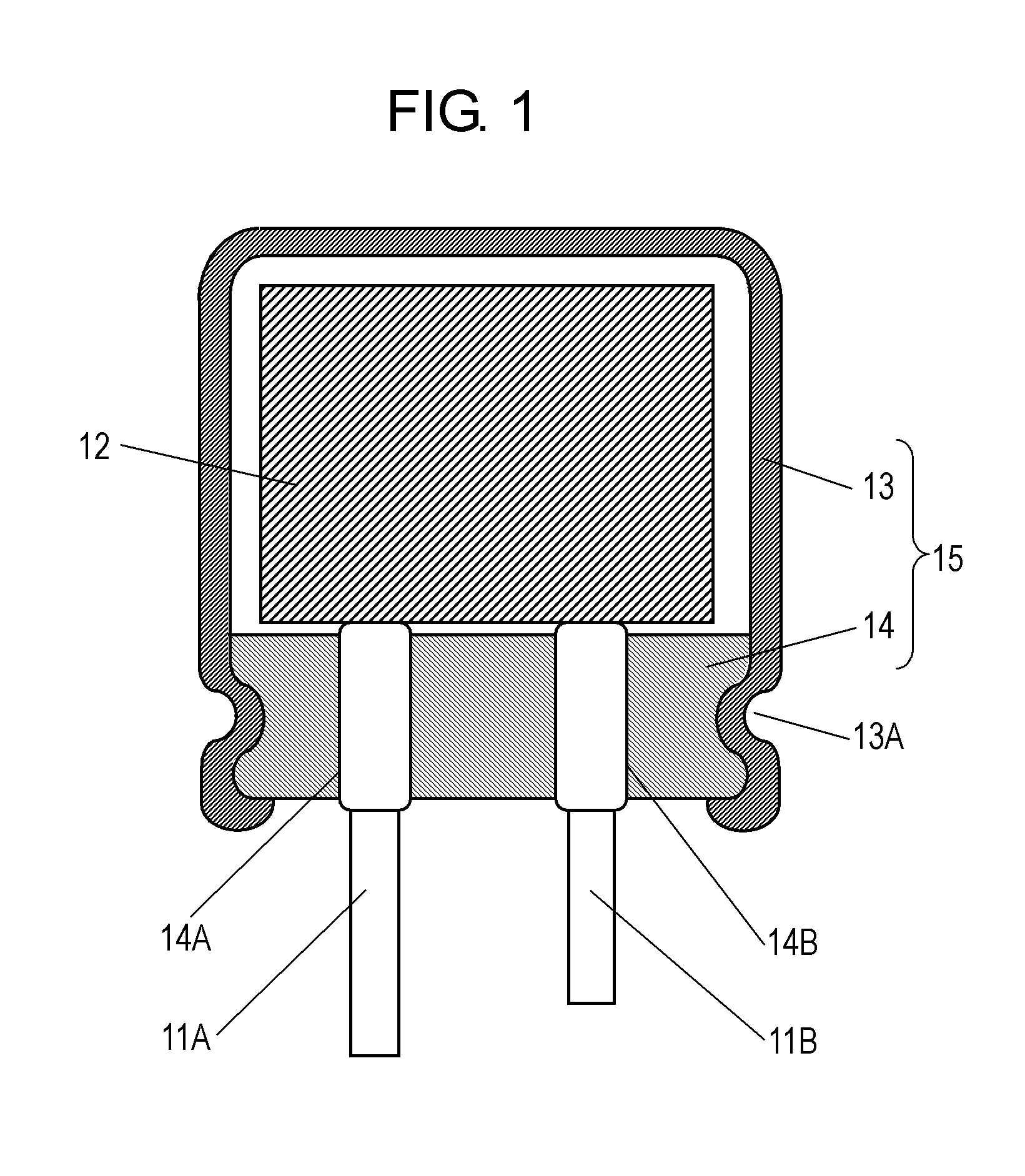

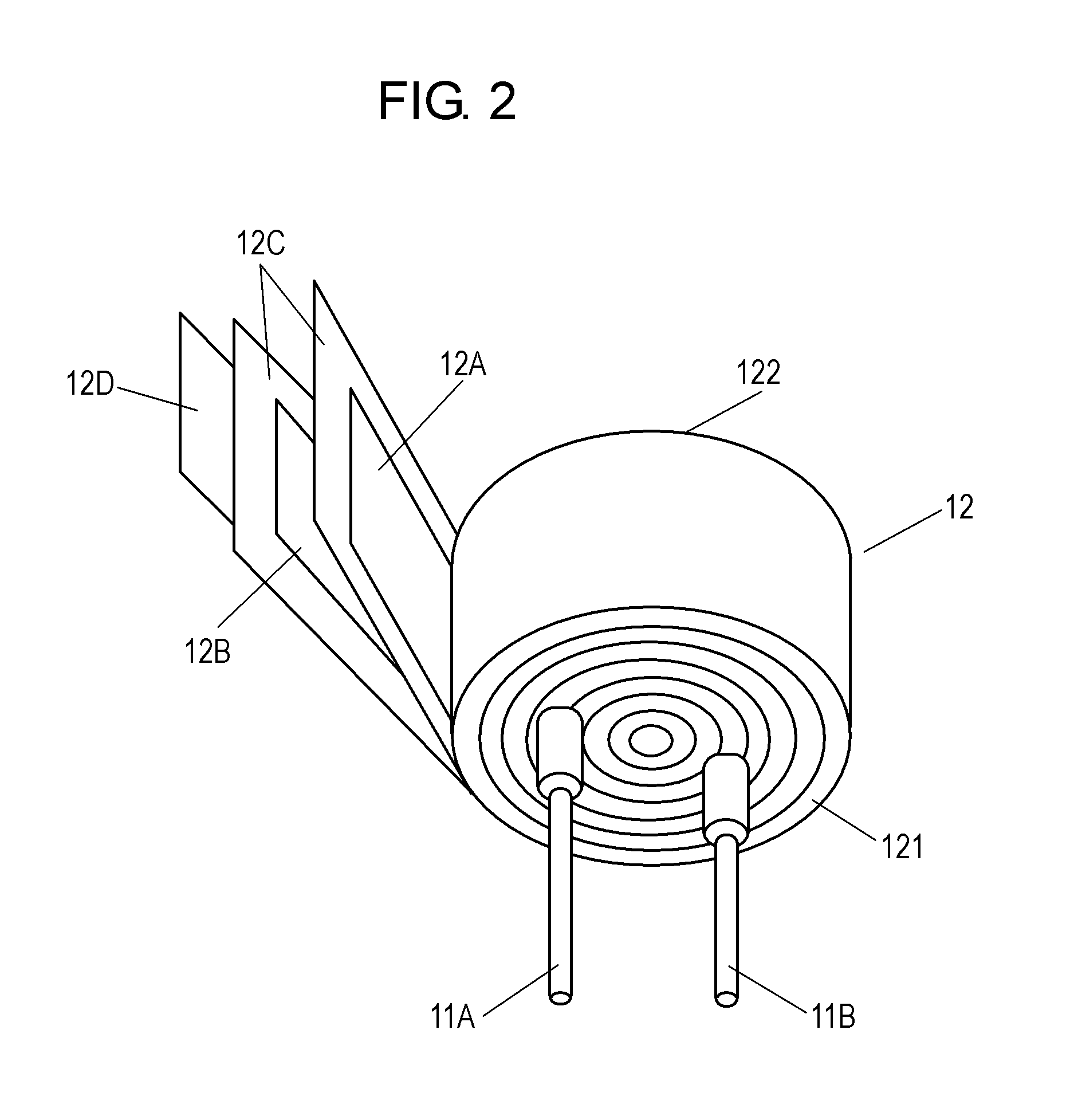

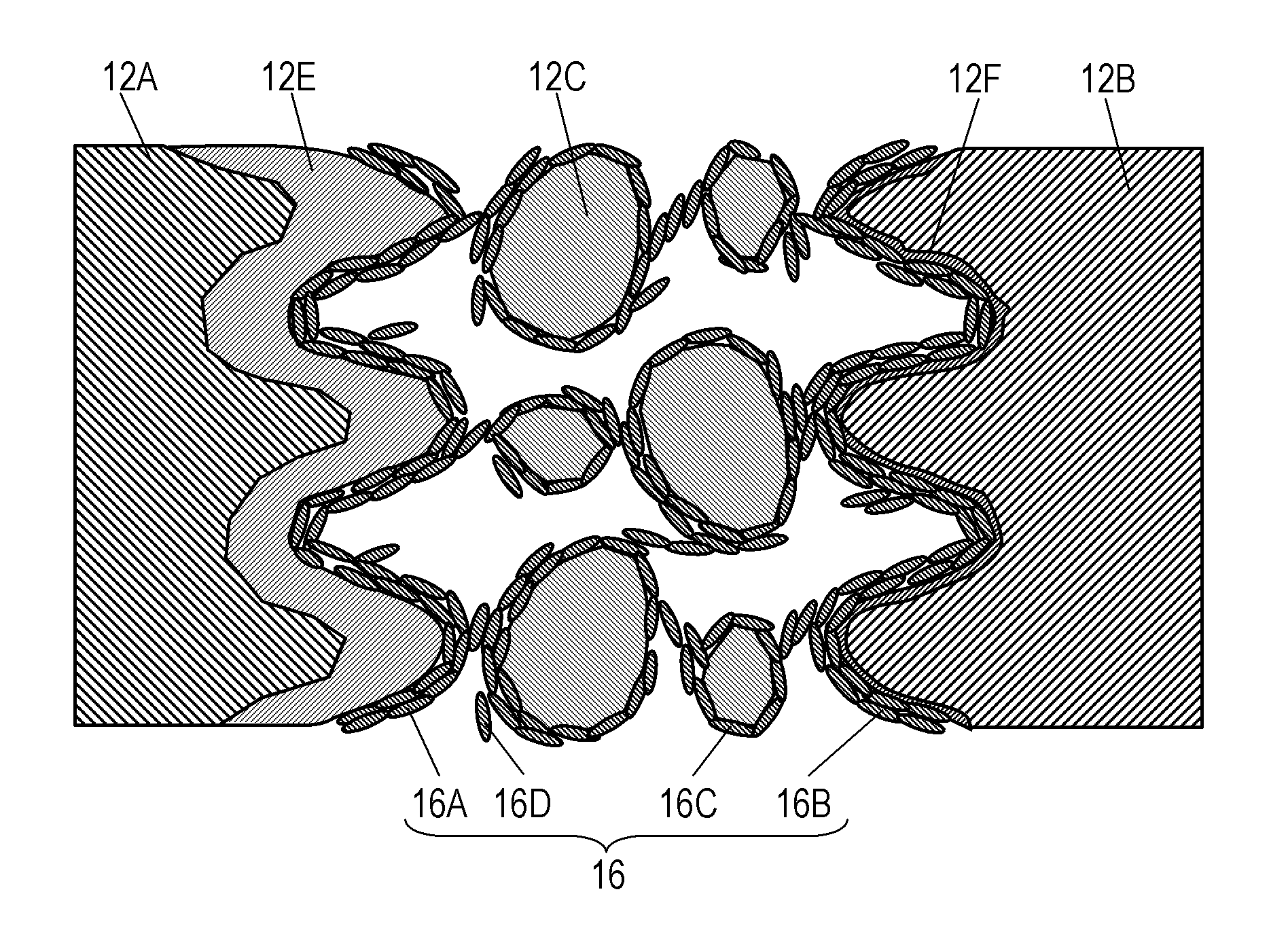

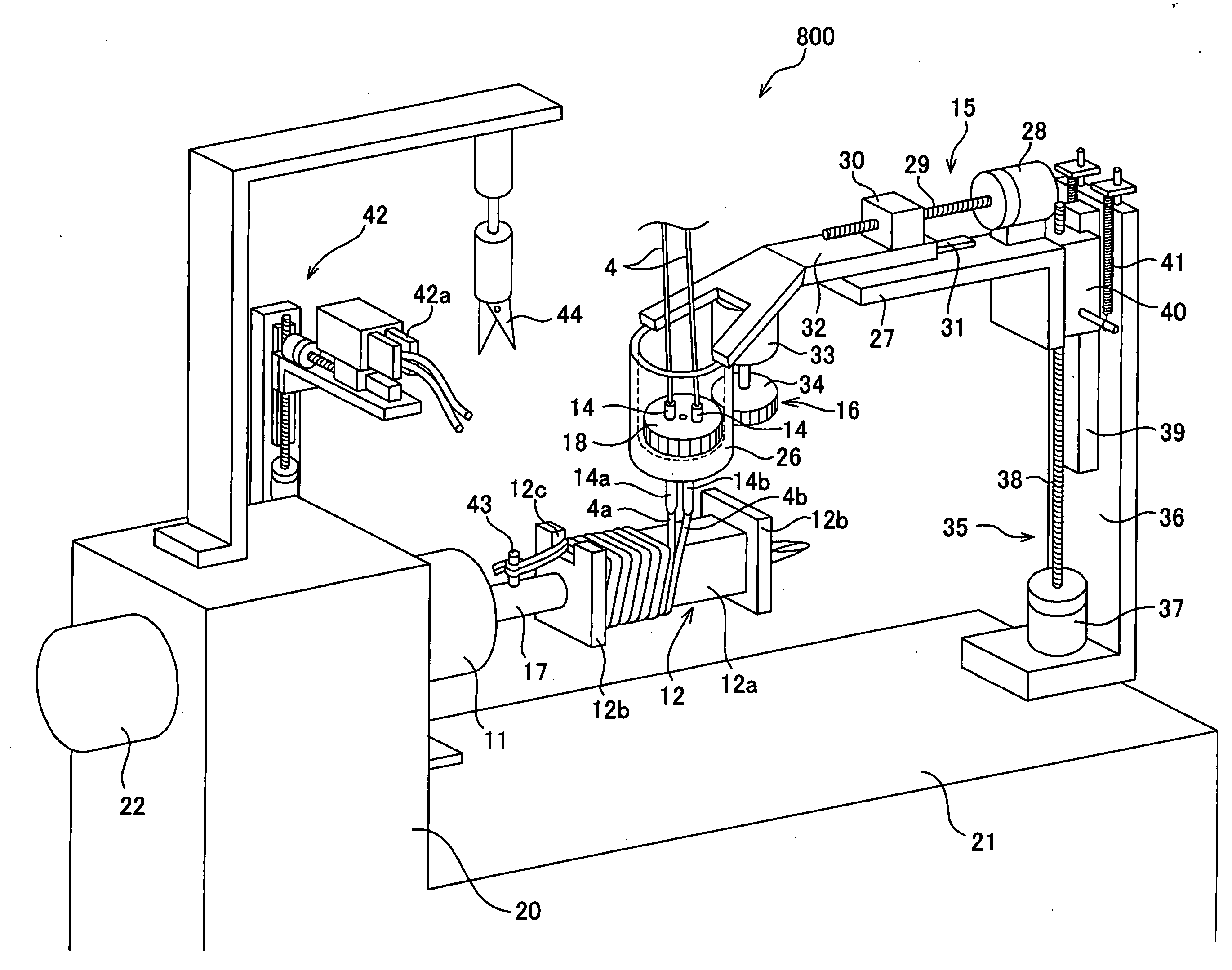

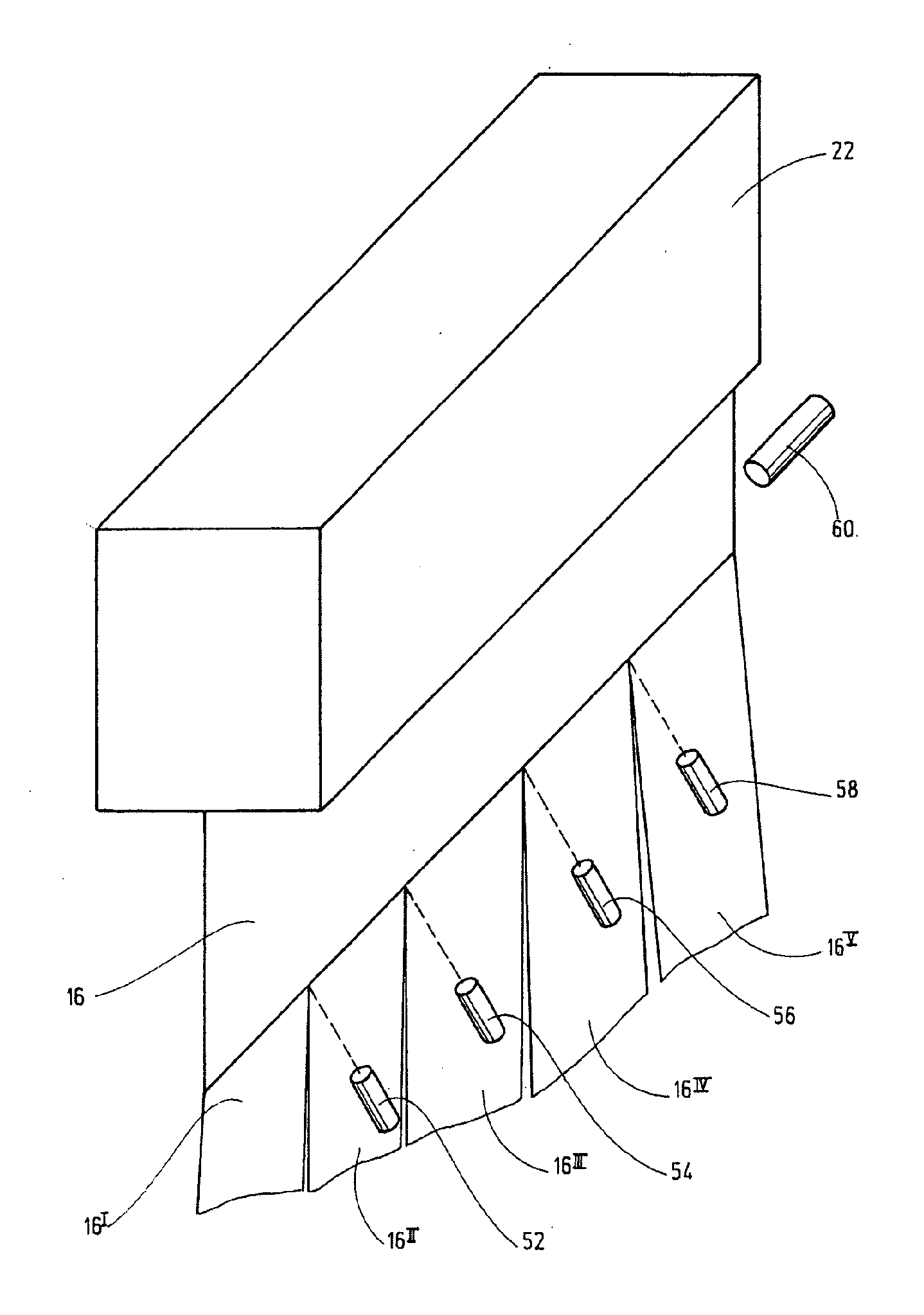

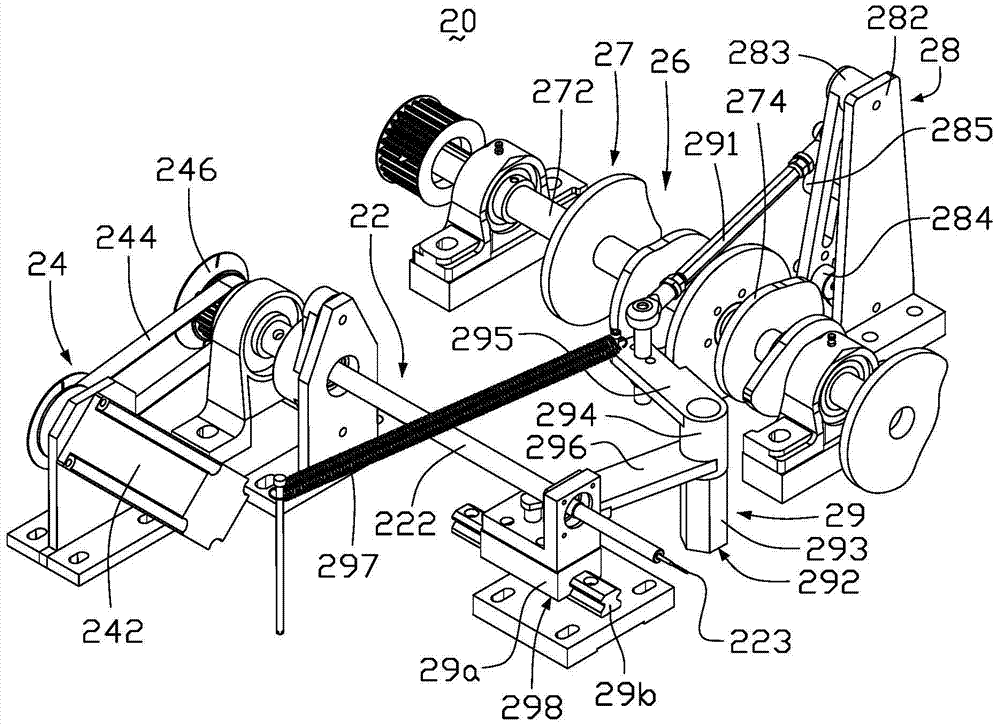

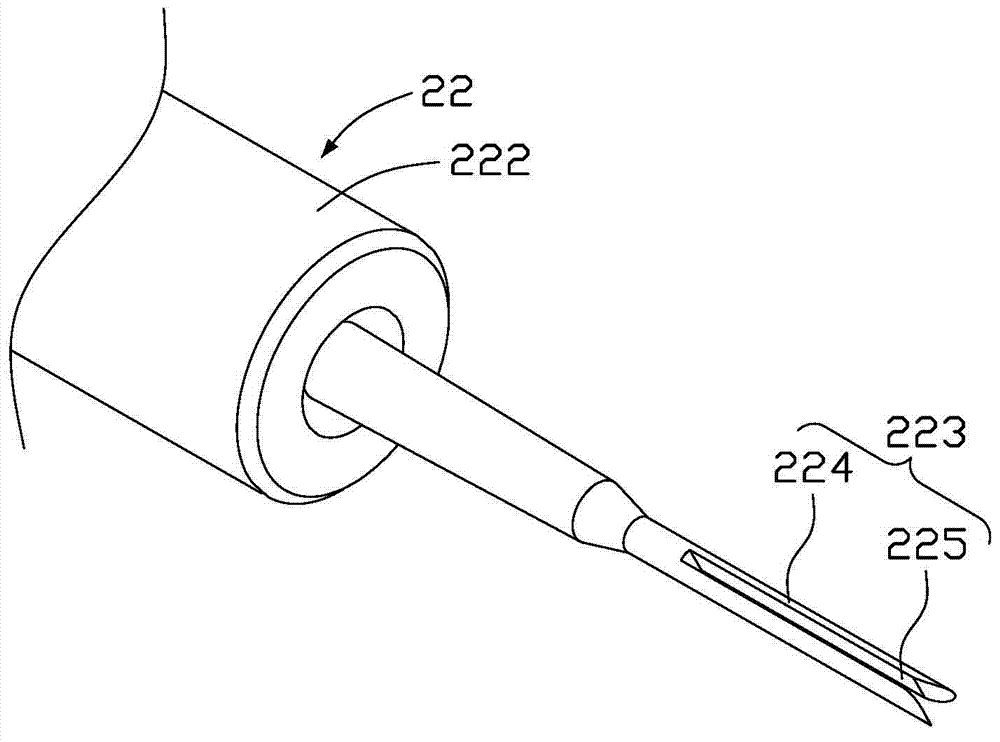

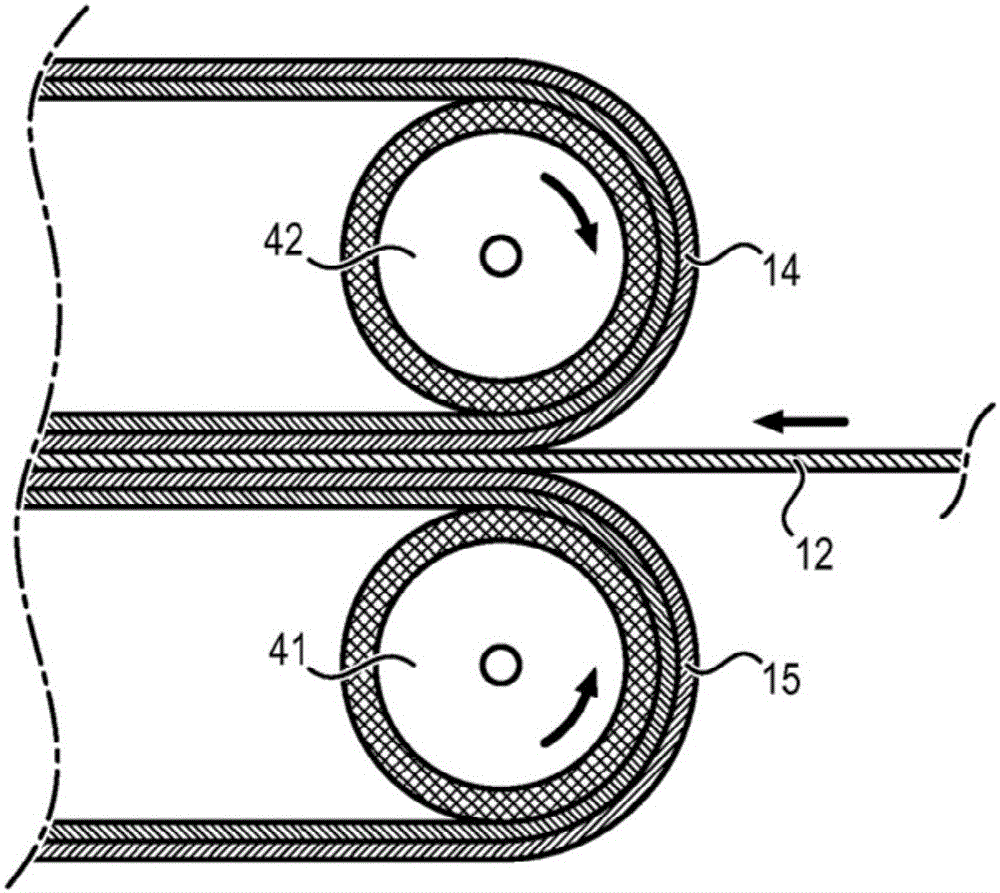

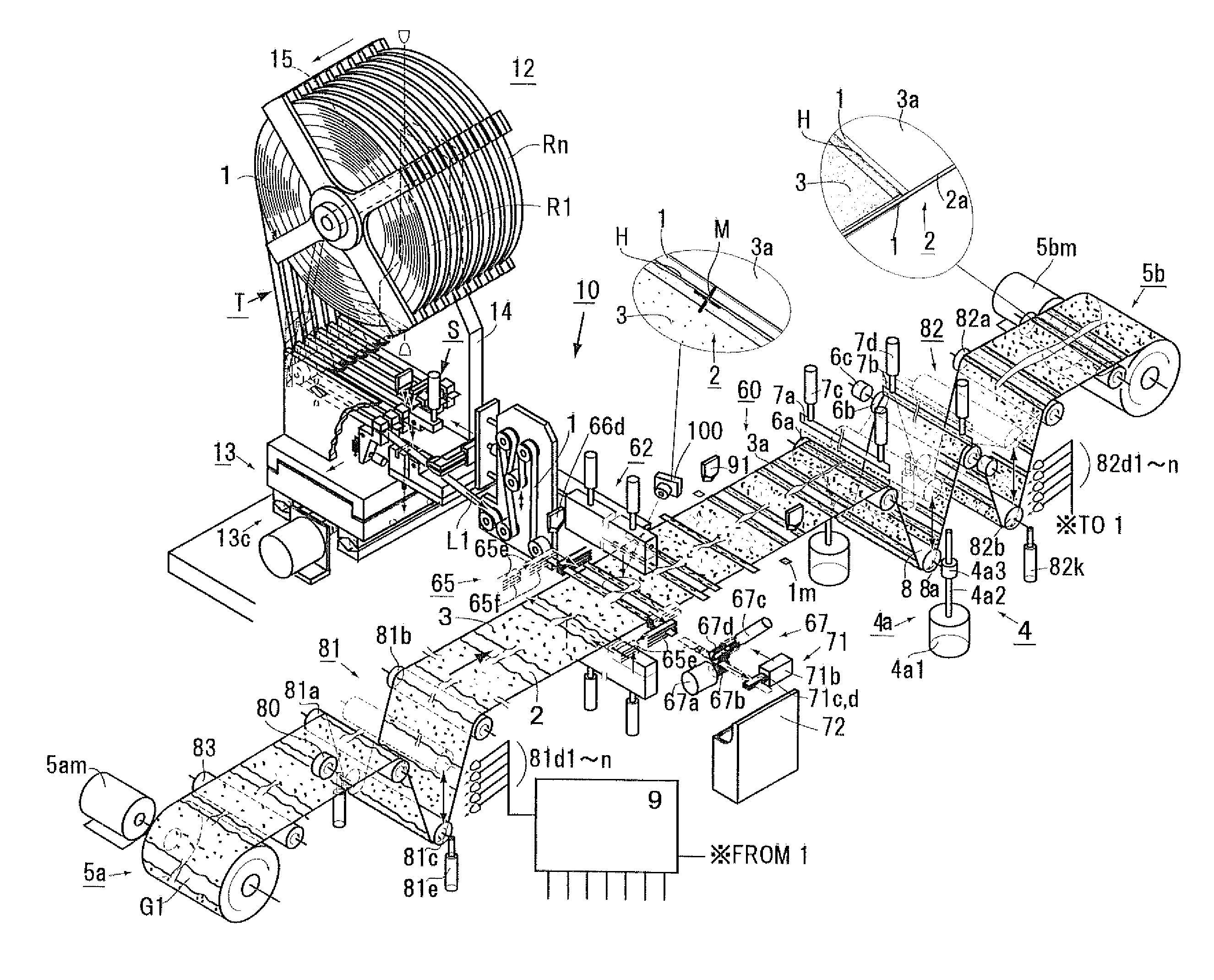

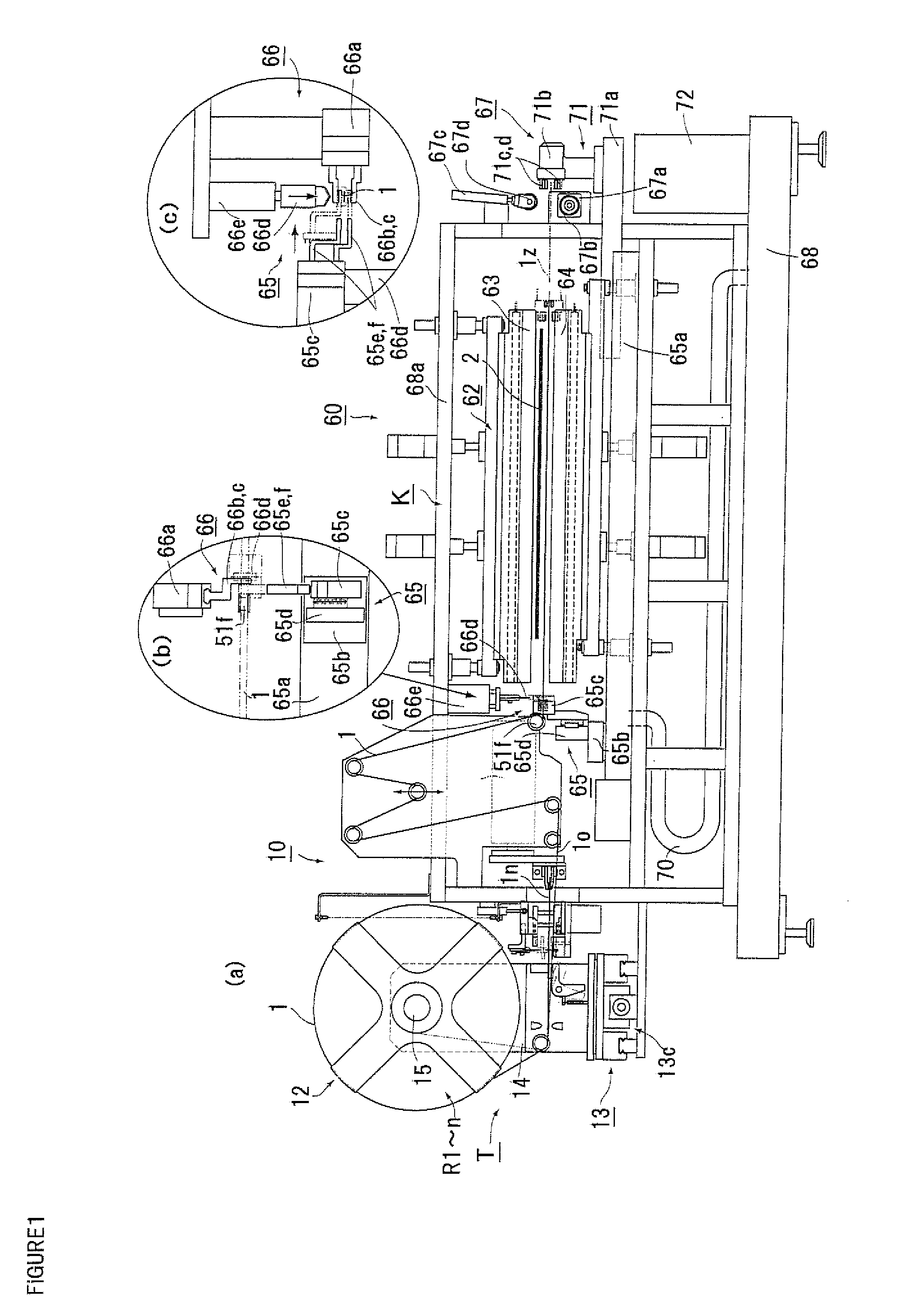

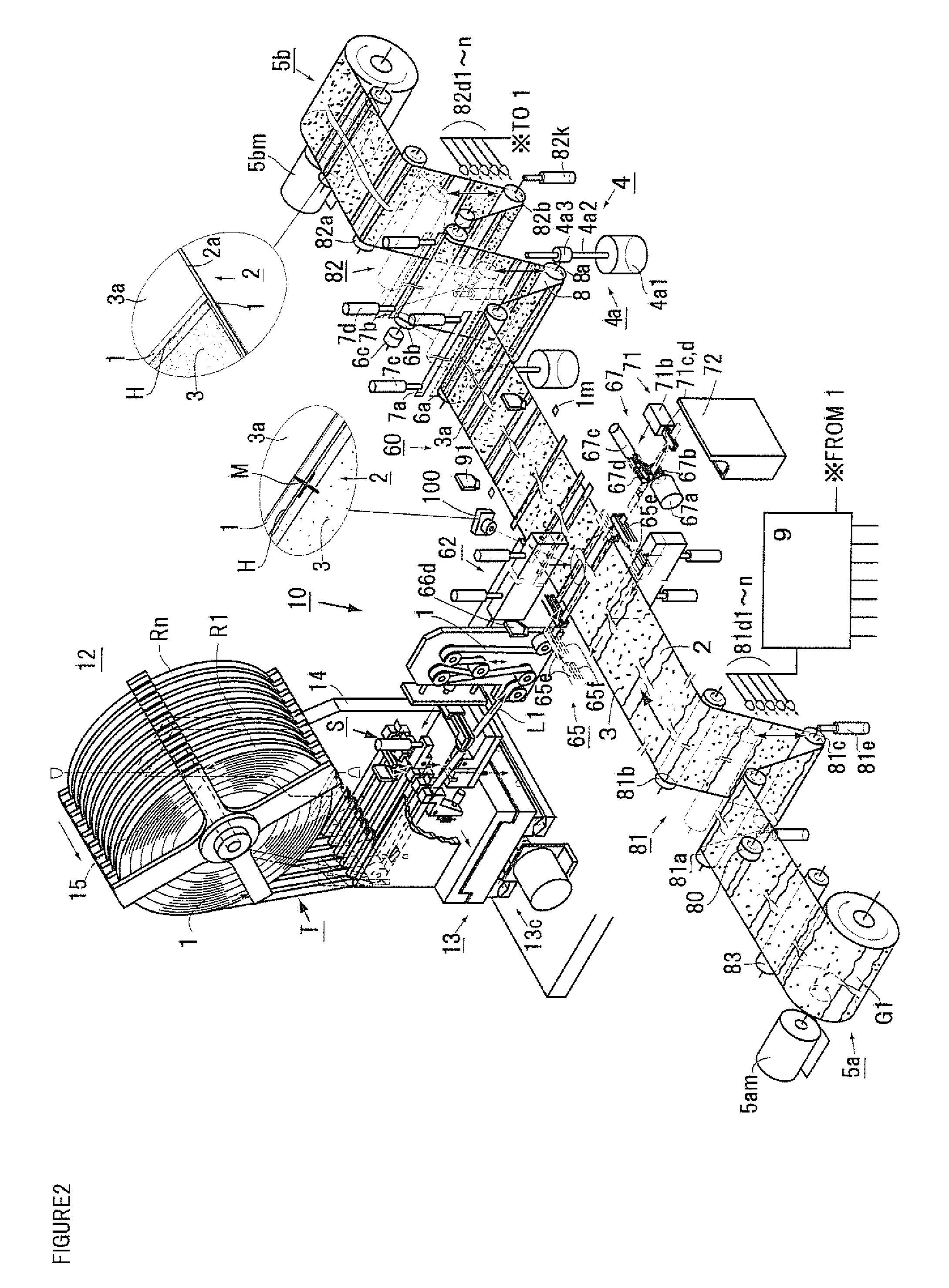

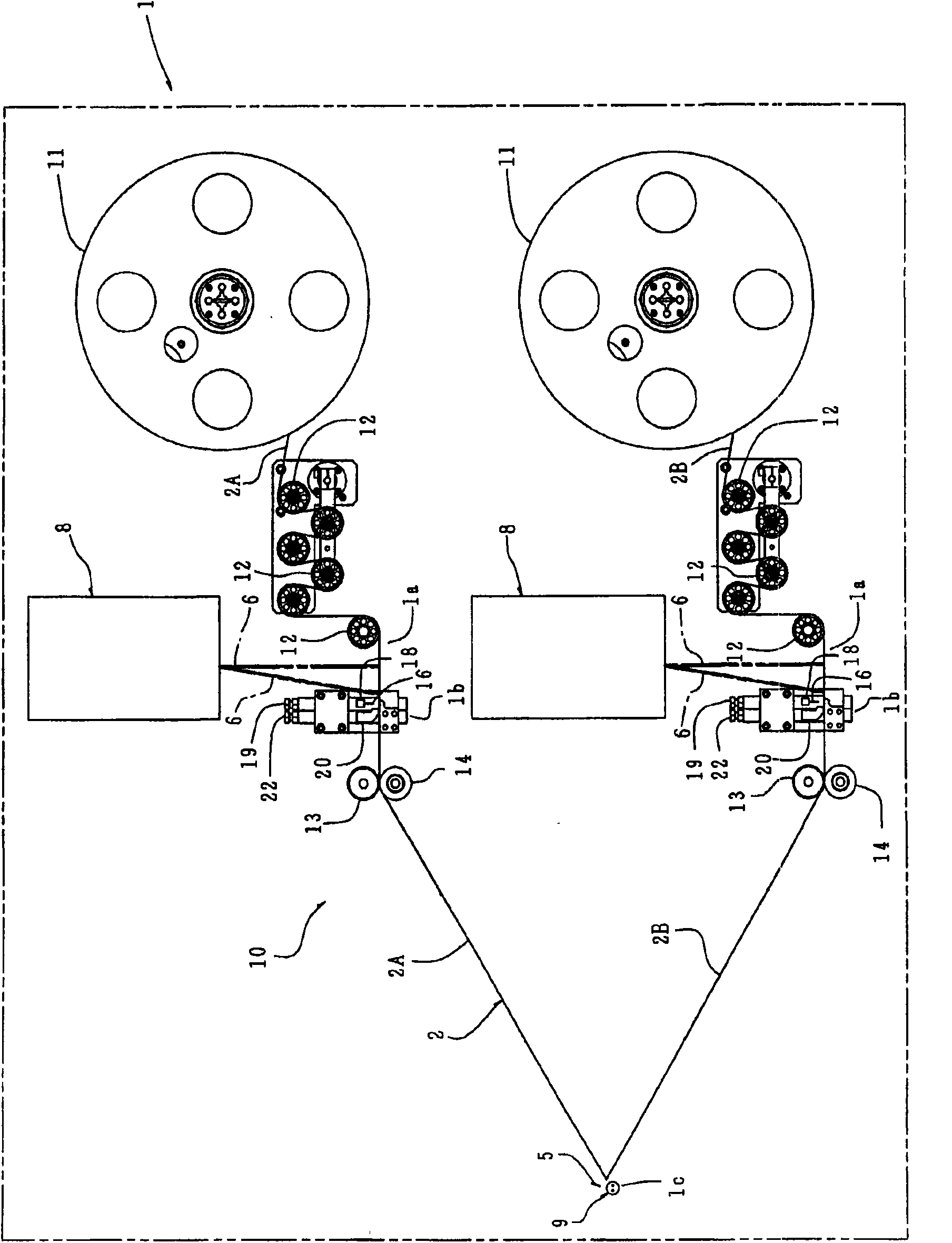

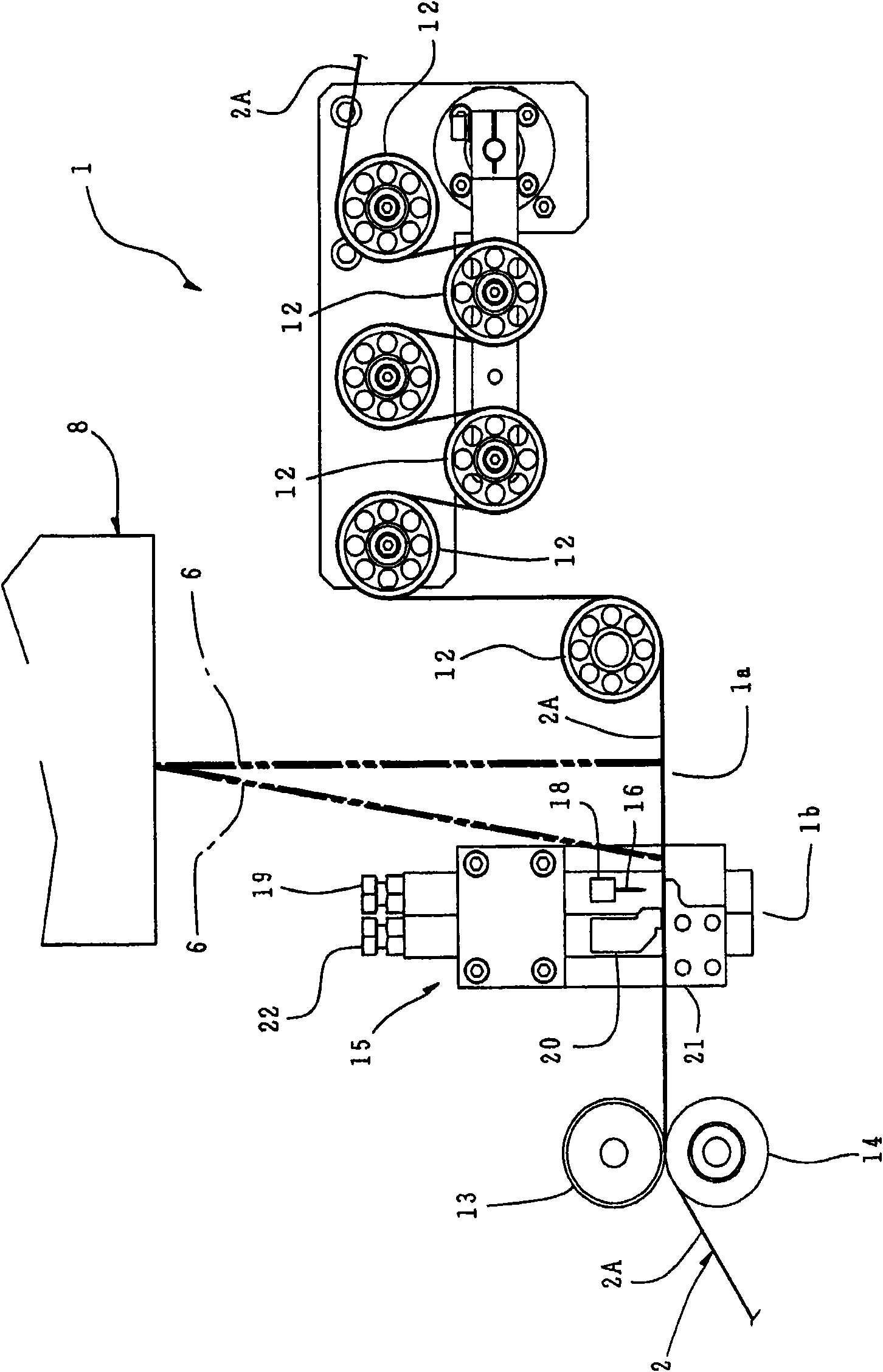

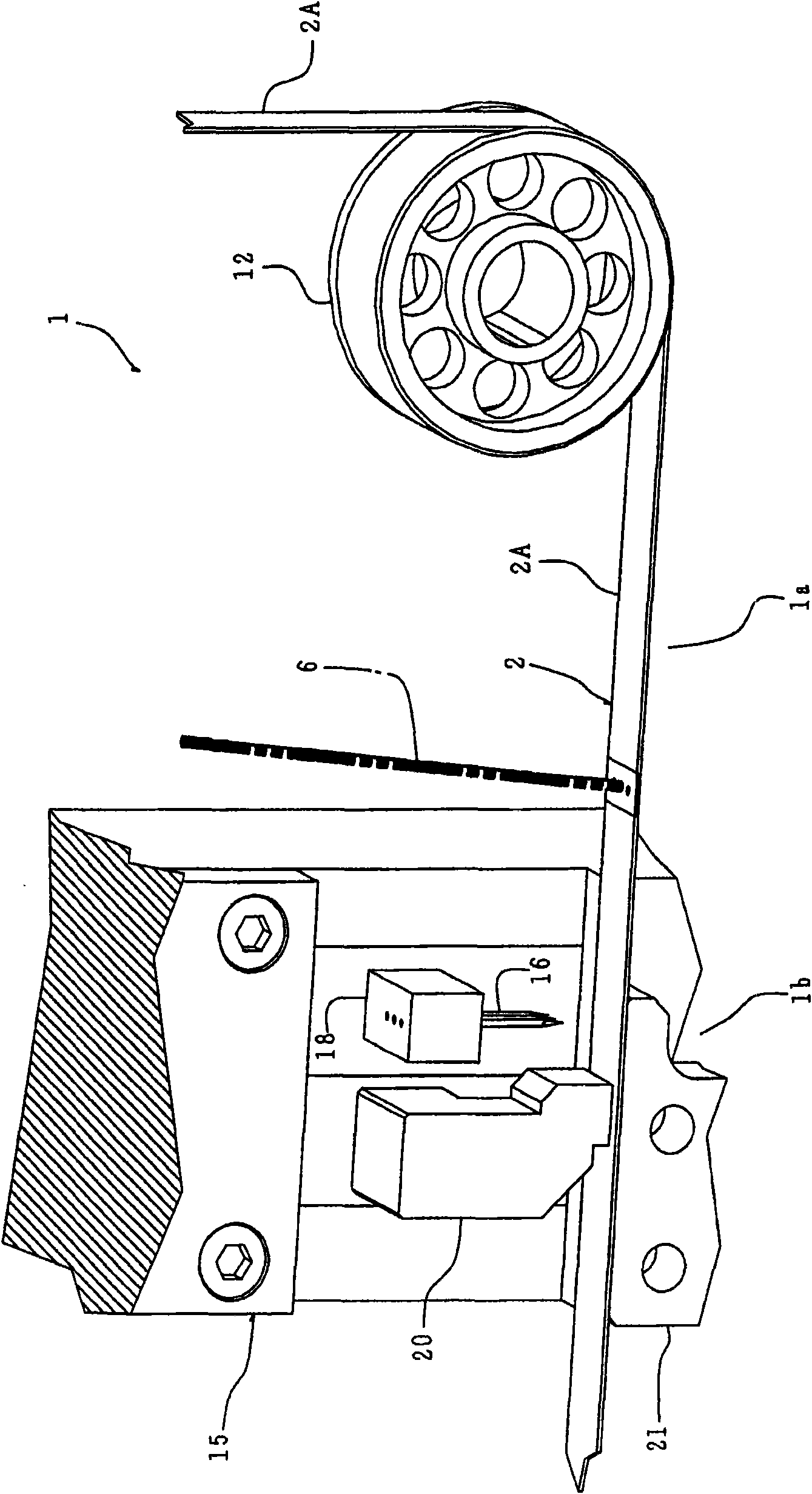

Winding device and winding machine

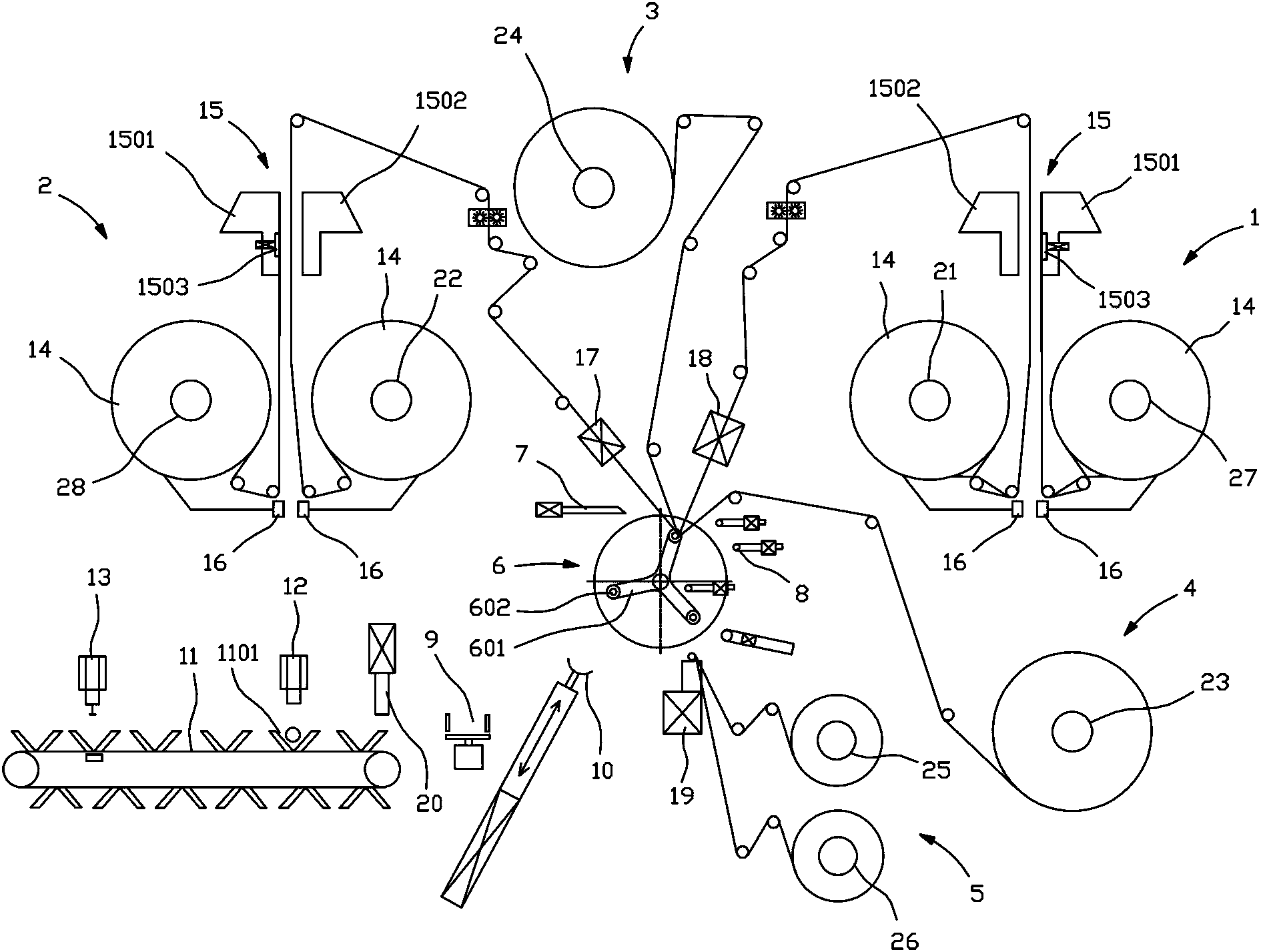

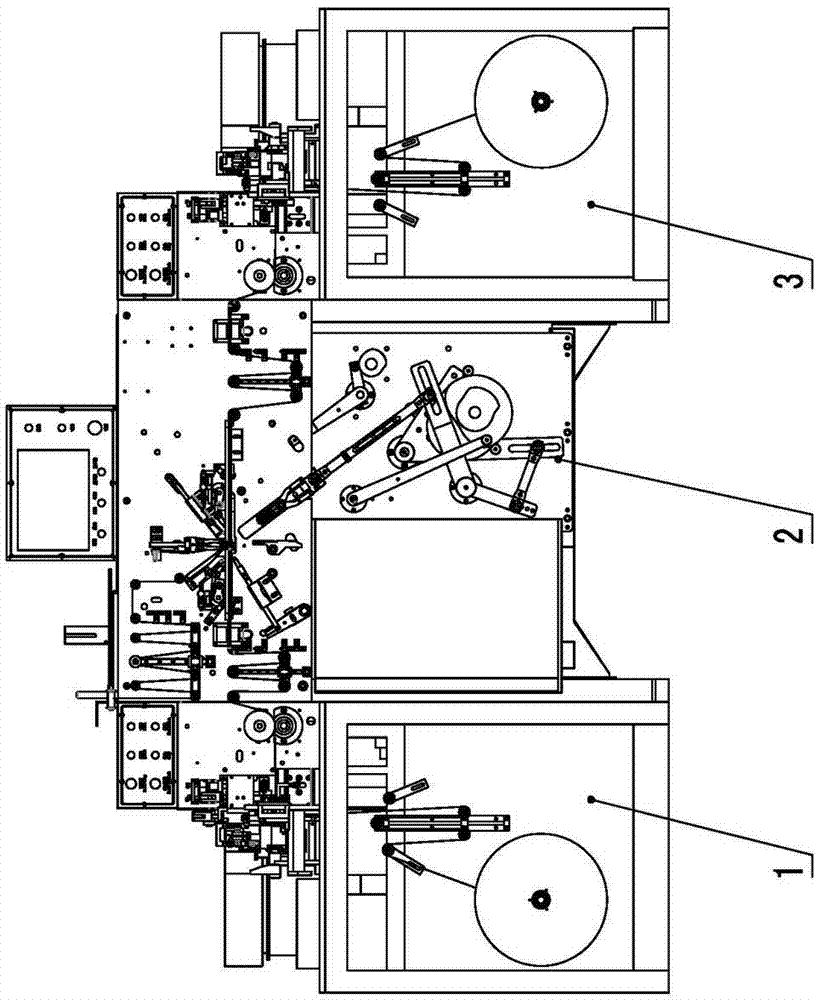

ActiveCN101533698AImprove efficiencyUniform number of turnsWinding capacitor machinesCoils manufactureAutomatic controlInductor

The invention discloses a high-efficiency winding device for winding stubs of electronic elements such as resistors, capacitors, inductors and the like, and a full automatic integrated winding machine. The winding machine comprises a rack (24) and a worktable (13). The worktable (13) is provided with a working turntable (16), the winding device, an upper fixture manipulator (21), a lower fixture manipulator (18), a charging conveyer belt (17), a cutting device (19), a clamping device (20), a discharging device (22) and the like. The winding device adopts a winding shaft (4) that has a kinking body (12) with the section being semicircle at the tail end to wind the stubs of workpieces. The winding machine realizes the full automatic control over the following process of: charging, cutting off thread ends, clamping by the fixture, installing the fixture, automatic winding, discharging and removing the fixture. The winding device and winding machine are suitable for the batch production of large-scale enterprises and have good market prospect.

Owner:东电化电子(珠海)有限公司

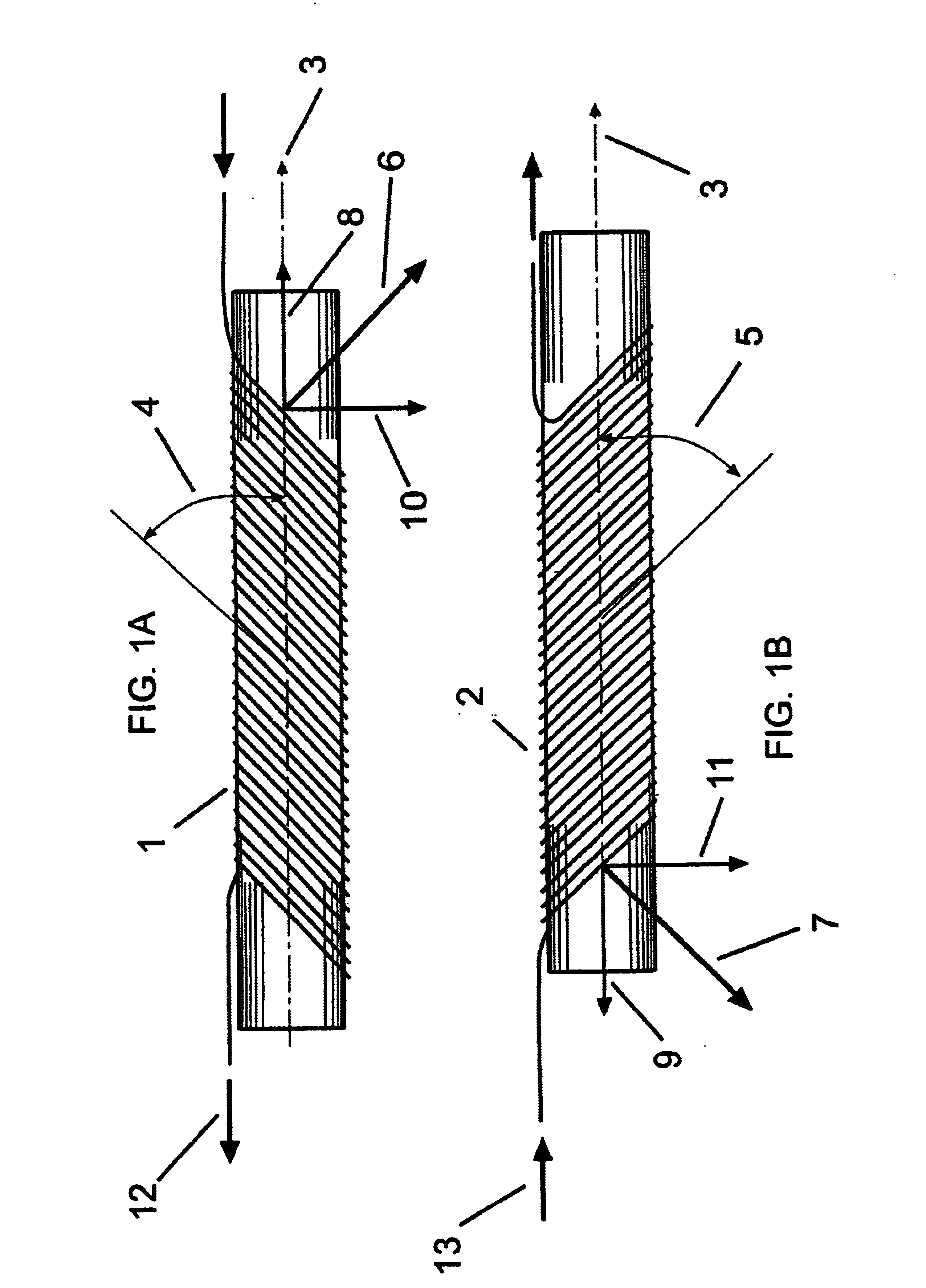

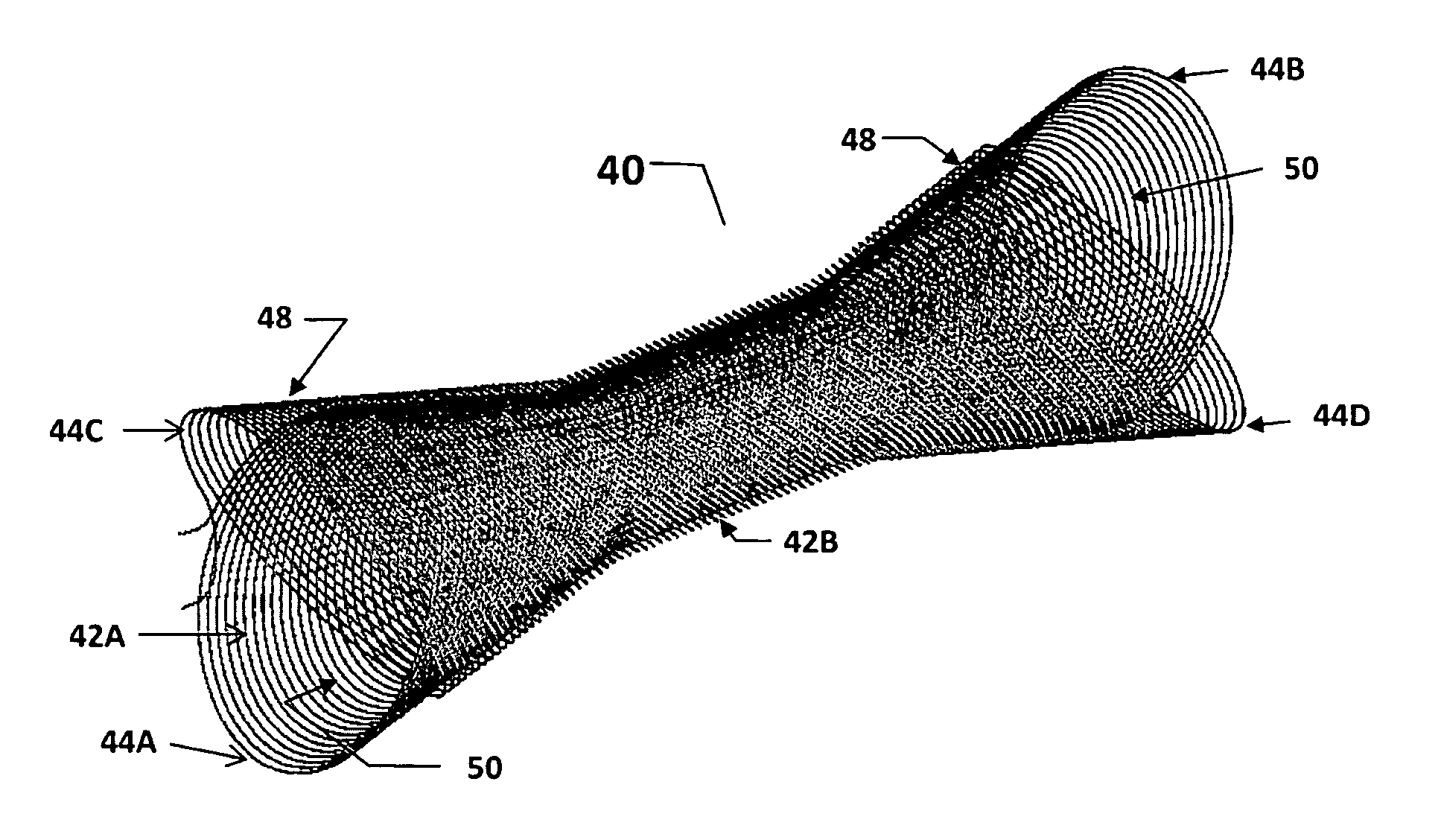

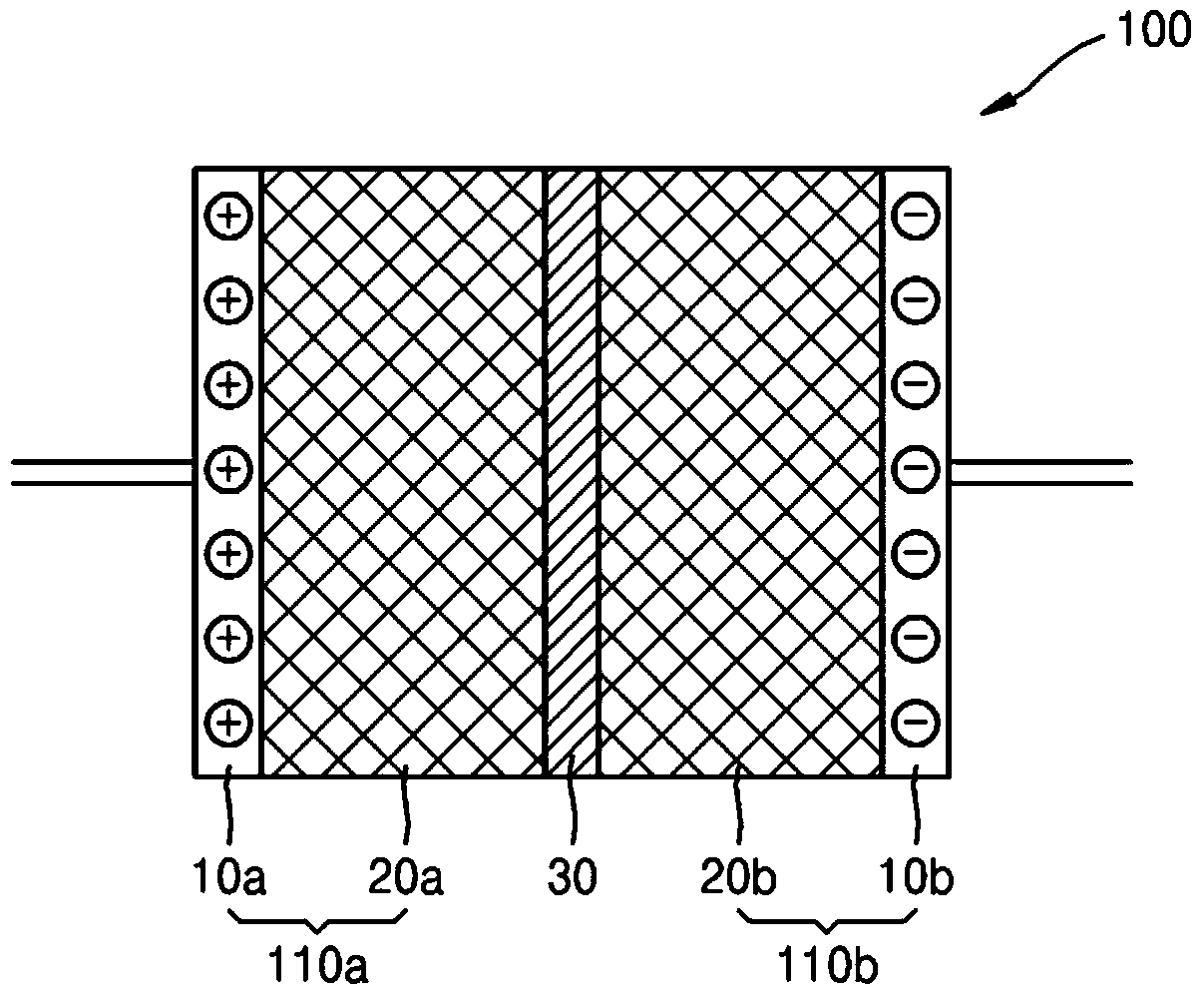

Conductor Assembly Including A Flared Aperture Region

InactiveUS20090085709A1Broaden the fieldAvoid interferenceMagnetic measurementsTransformers/inductances coils/windings/connectionsElectrical conductorVoltage

A conductor assembly of the type which, when conducting current, generates a magnetic field or in which, in the presence of a changing magnetic field, a voltage is induced. A helical wiring pattern is positioned along an axis a radial distance R from the axis. The wiring pattern is formed about an aperture region extending from the axis toward the wiring pattern, the distance R varying along a portion of the axis.

Owner:ADVANCED MAGNET LAB

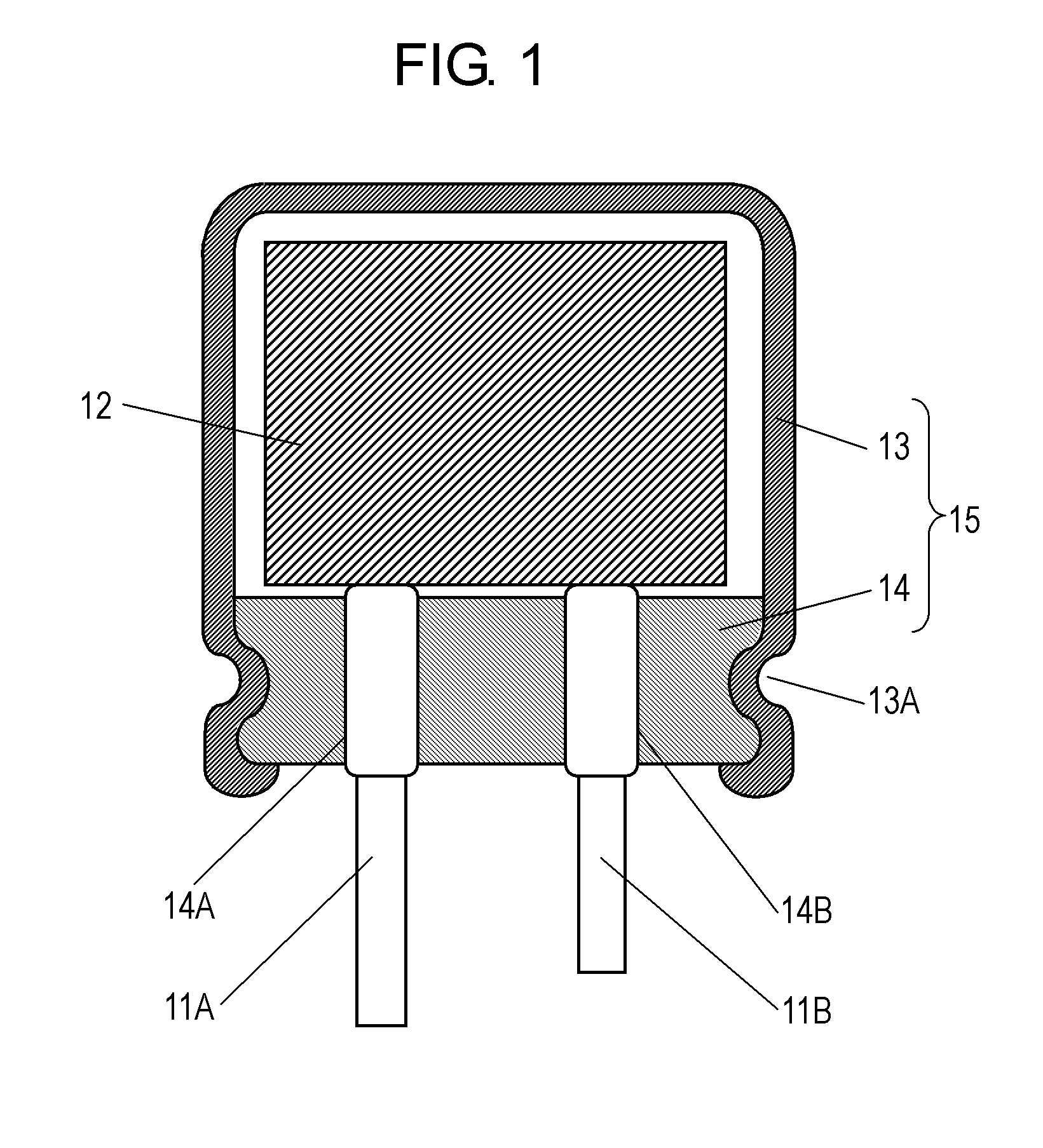

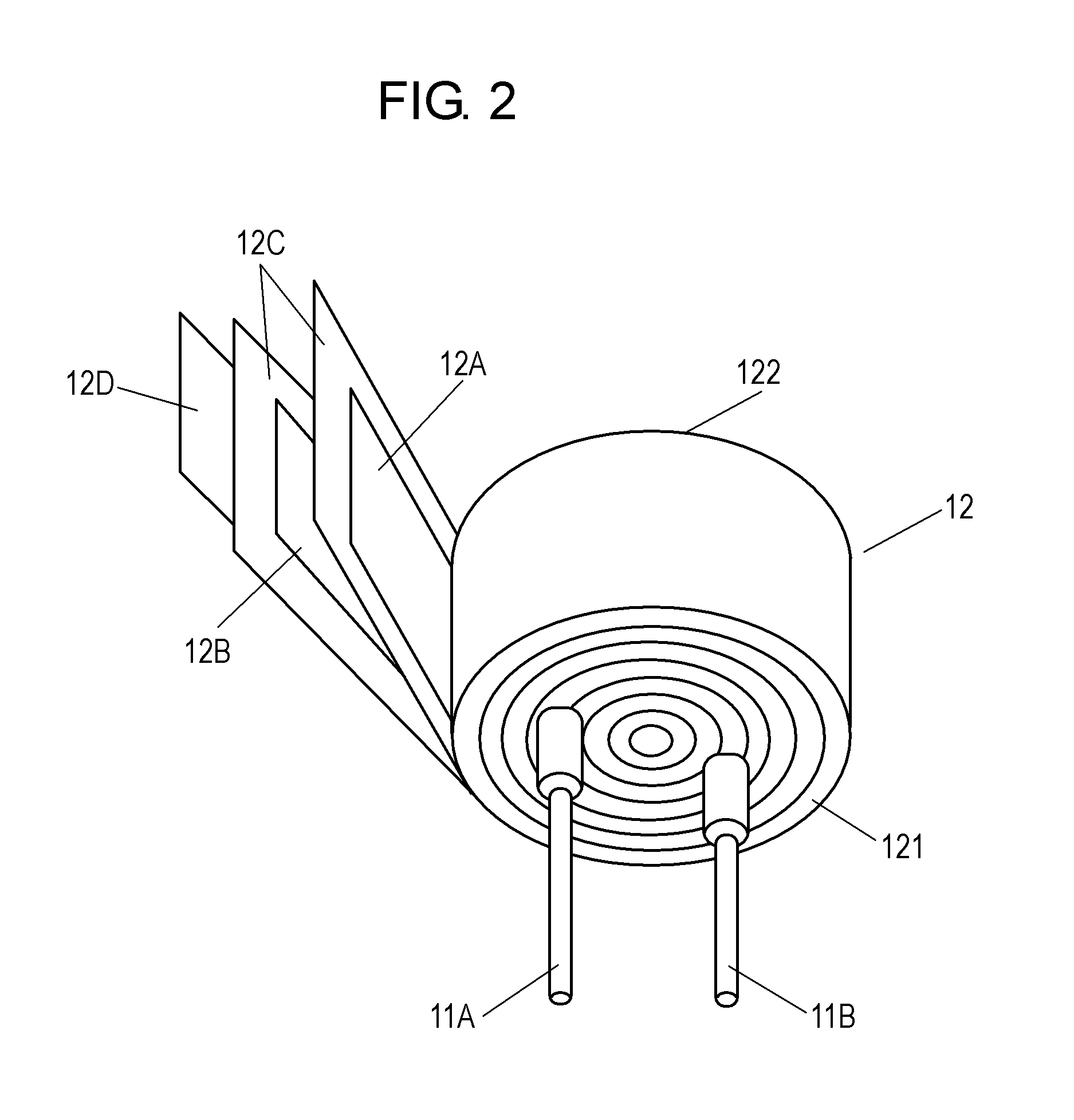

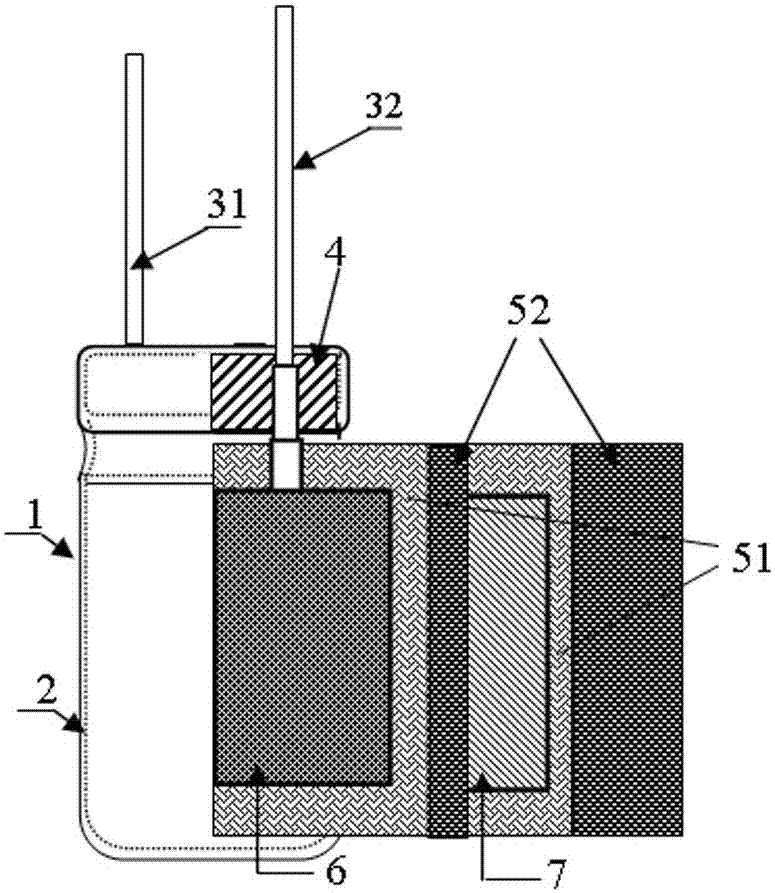

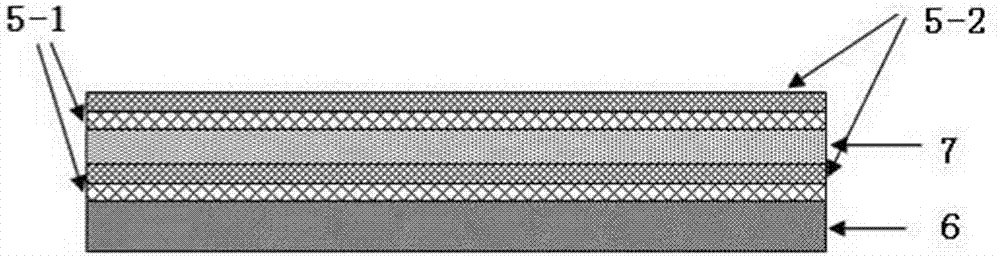

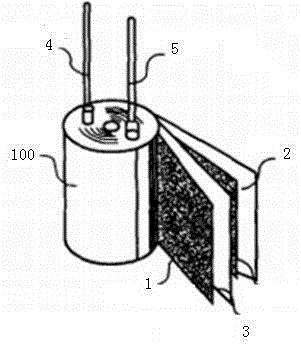

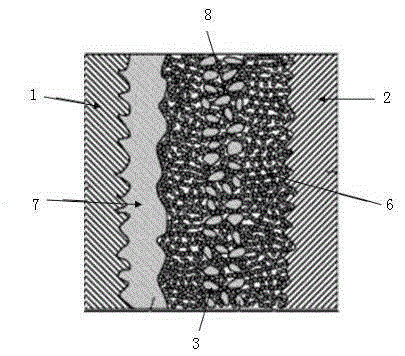

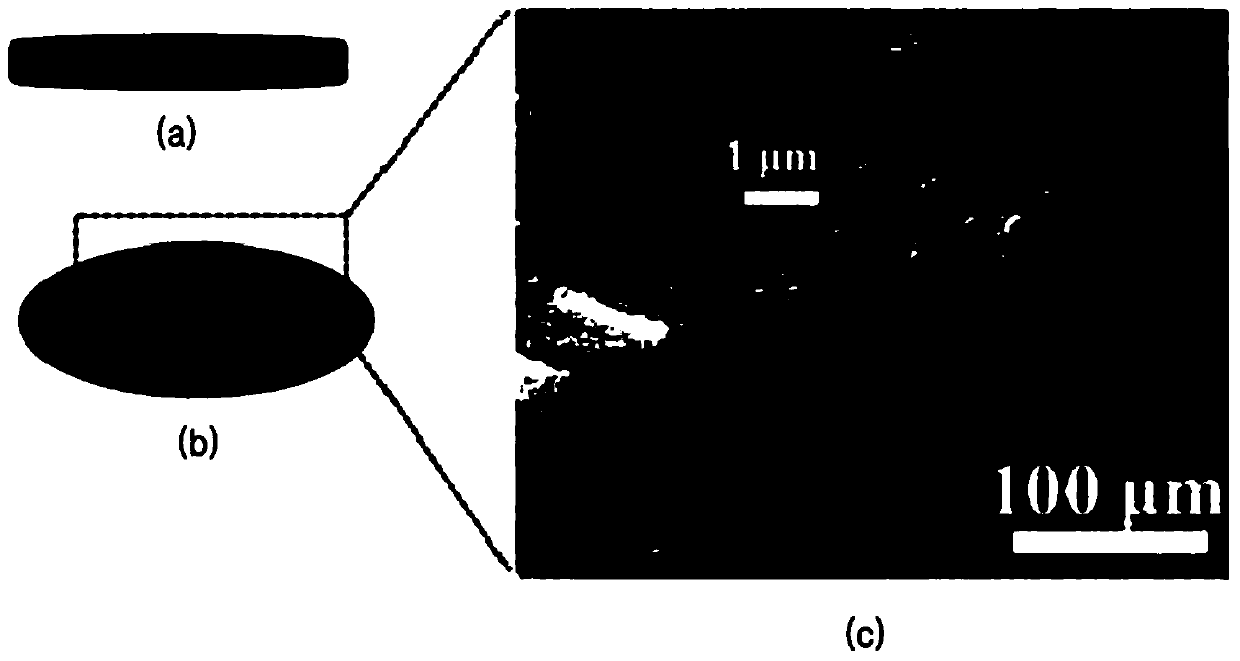

Electrolytic capacitor and method of manufacturing the same

ActiveUS20130027847A1Avoid damageIncrease probabilityHybrid capacitor separatorsHybrid capacitor electrolytesElectrolysisConductive polymer

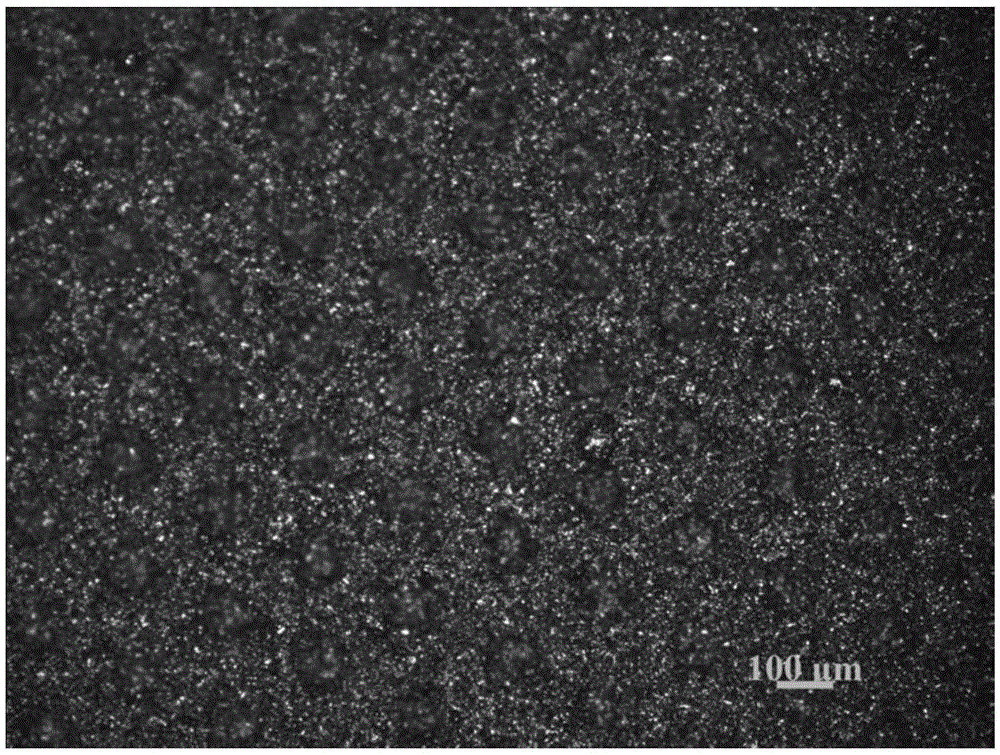

An electrolytic capacitor includes a capacitor element and an electrolyte solution impregnated into the capacitor element. The capacitor element includes an anode foil, cathode foil, separator, and a solid electrolytic layer. The anode foil has a dielectric layer on its surface, and the cathode foil confronts the anode foil. The separator is interposed between the anode foil and the cathode foil. The solid electrolytic layer is formed on the surfaces of the anode foil, cathode foil, and separator as an aggregate of fine particles of conductive polymer. The separator has an air-tightness not greater than 2.0 s / 100 ml. Sizes of the fine particles measure not greater than 100 nm in diameter, and the fine particles are contained in an amount ranging from 0.3 mg / cm2 to 1.2 mg / cm2 converted to amounts per unit area of the anode foil.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Electrolytic capacitor and method of manufacturing the same

ActiveUS8767377B2Avoid damageIncrease probabilityHybrid capacitor separatorsHybrid capacitor electrolytesPrillElectrolysis

An electrolytic capacitor includes a capacitor element and an electrolyte solution impregnated into the capacitor element. The capacitor element includes an anode foil, cathode foil, separator, and a solid electrolytic layer. The anode foil has a dielectric layer on its surface, and the cathode foil confronts the anode foil. The separator is interposed between the anode foil and the cathode foil. The solid electrolytic layer is formed on the surfaces of the anode foil, cathode foil, and separator as an aggregate of fine particles of conductive polymer. The separator has an air-tightness not greater than 2.0 s / 100 ml. Sizes of the fine particles measure not greater than 100 nm in diameter, and the fine particles are contained in an amount ranging from 0.3 mg / cm2 to 1.2 mg / cm2 converted to amounts per unit area of the anode foil.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

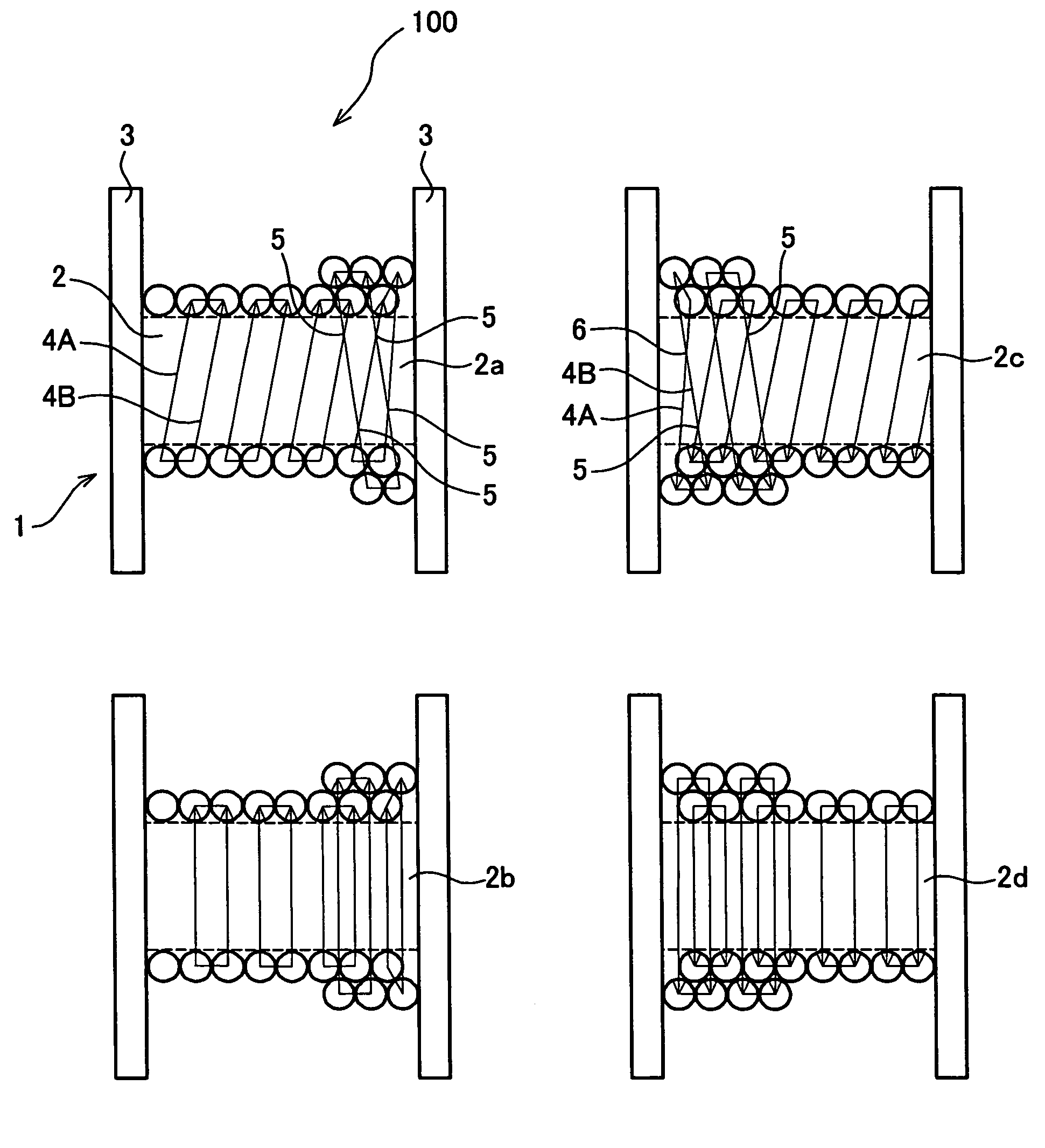

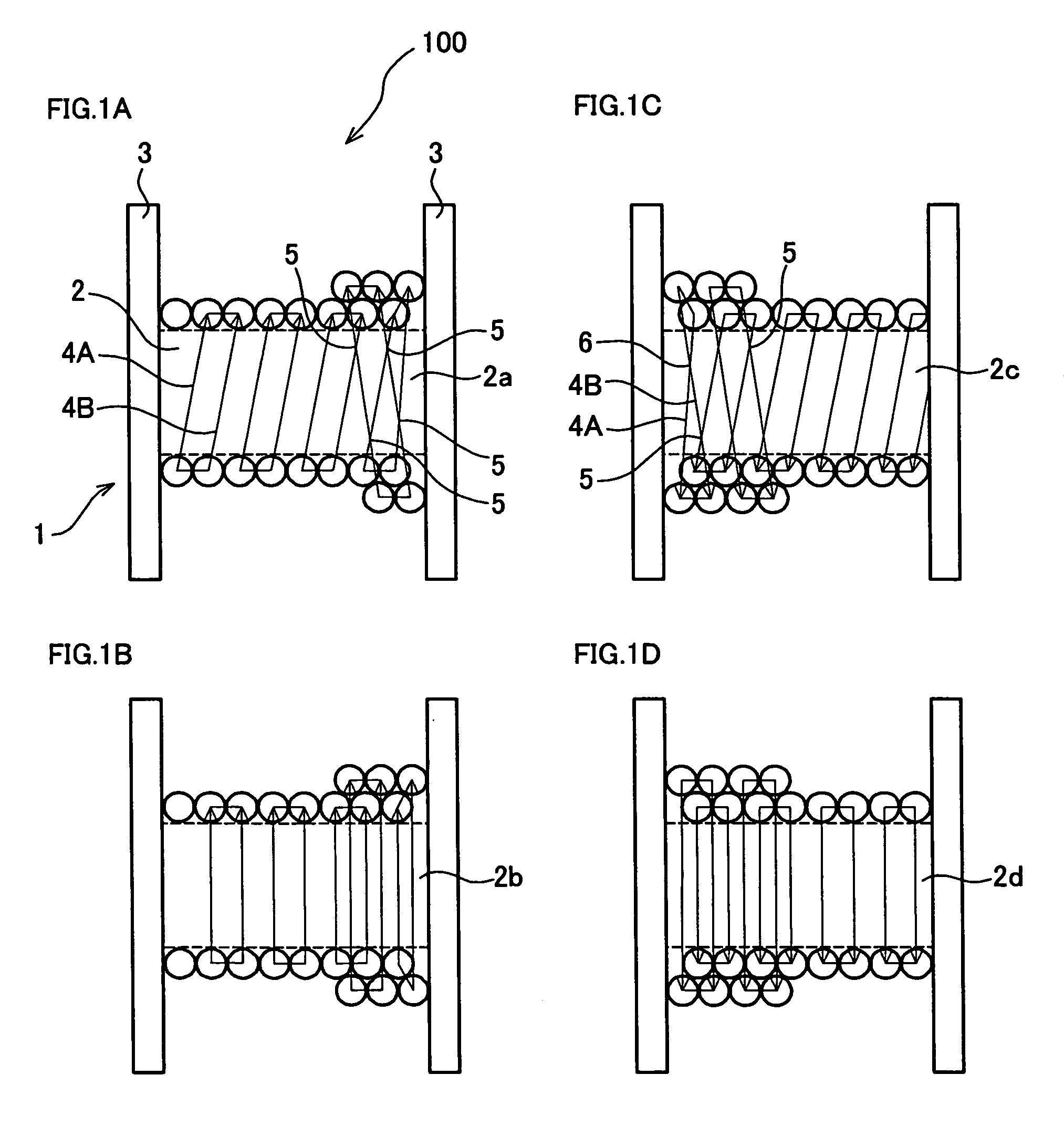

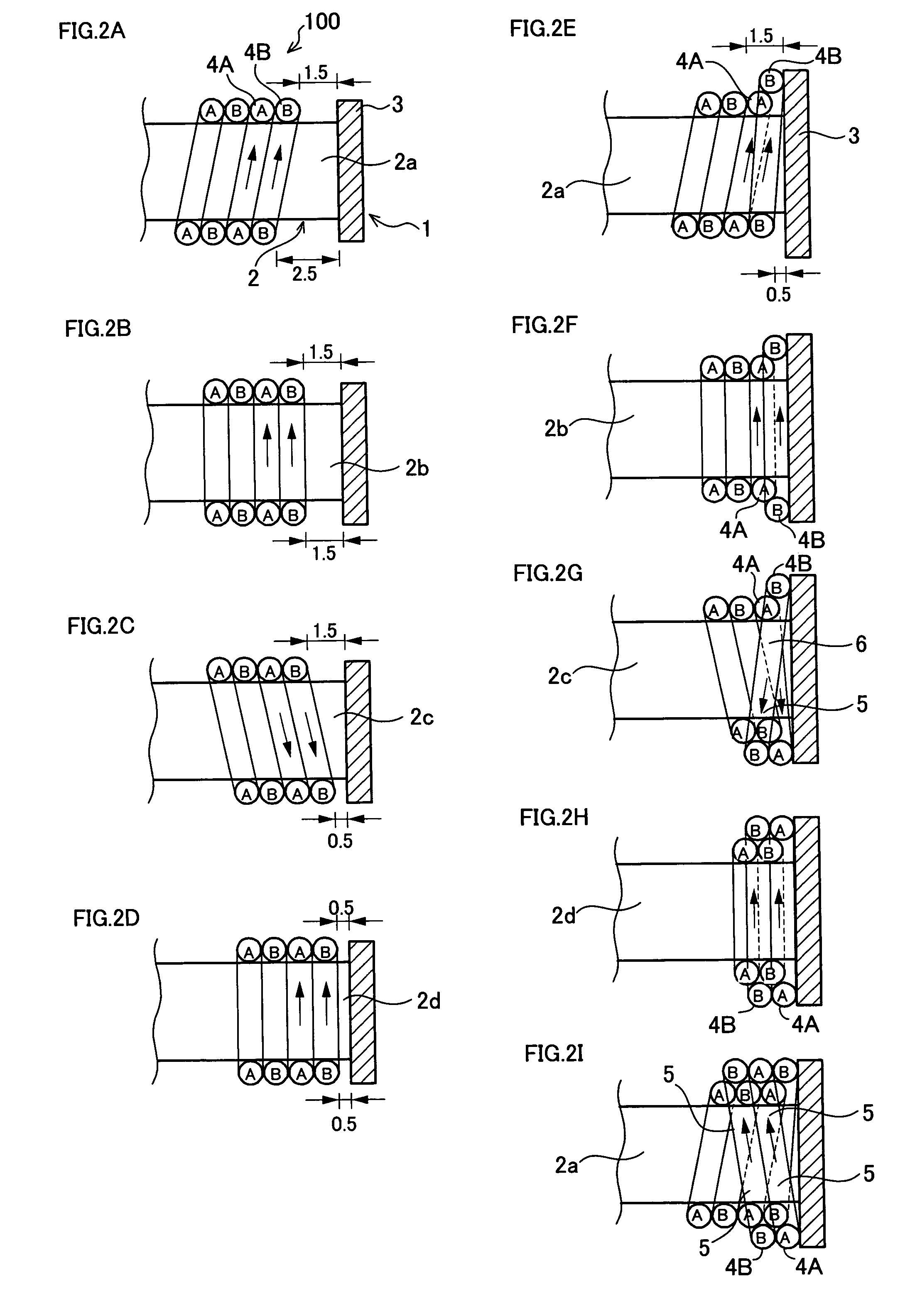

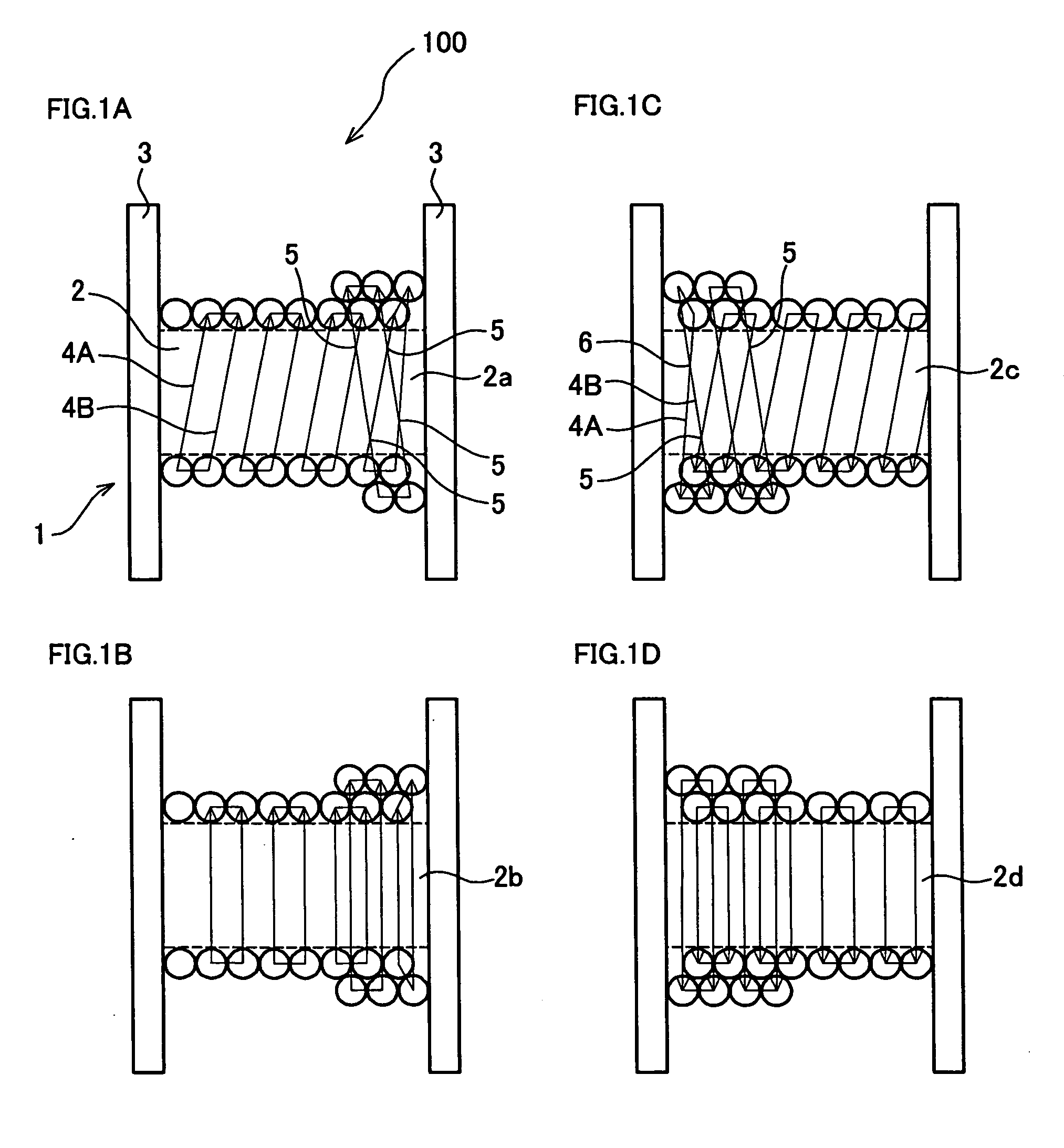

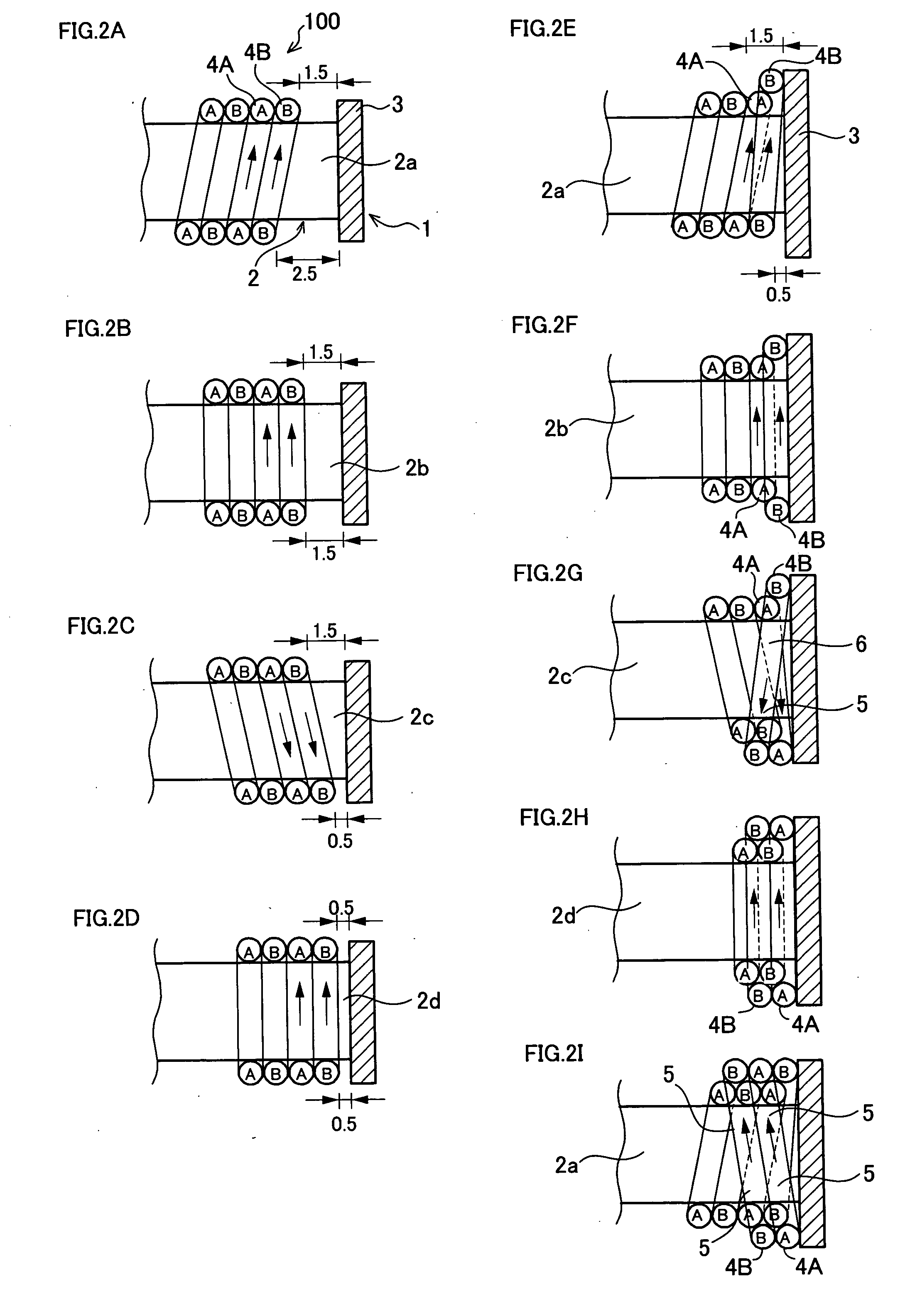

Multilayer coil, winding method of same, and winding apparatus of same

Owner:NITTOKU ENG CO LTD

Wiring Assembly And Method For Positioning Conductor In A Channel Having A Flat Surface Portion

A conductor assembly and method for constructing an assembly of the type which, when conducting current, generates a magnetic field or which, in the presence of a changing magnetic field, induces a voltage. In one embodiment the method includes providing a first insulative layer having a curved surface along which a conductor segment may be positioned, and forming a channel in the insulative layer, which defines a first conductor path. The channel includes first and second opposing channel surfaces each extending from the surface of the insulative layer into the insulative layer and a third channel surface extending between the first and second channel surfaces. Each of the first and second channel surfaces includes a substantially flat surface portion with the surface portion of the first channel surface parallel with the surface portion of the second channel surface. A first segment of conductor is placed in the channel.

Owner:ADVANCED MAGNET LAB

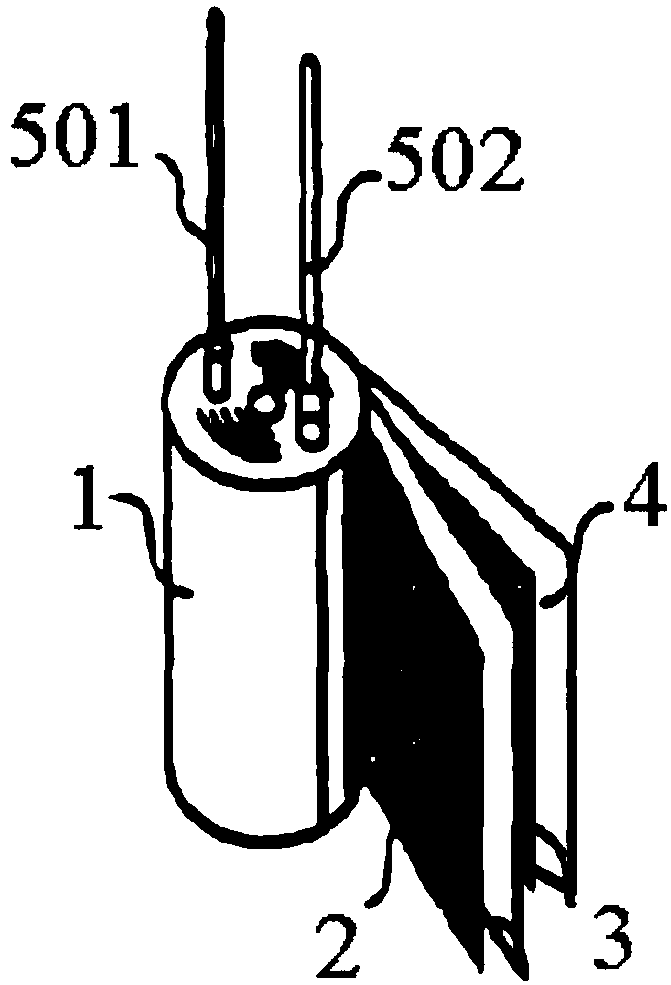

Novel lightning-stroke protection aluminium electrolytic capacitor and preparation method therefor

ActiveCN107195460AImproving the ability to withstand instantaneous high pressureImprove securityCapacitor housing/encapsulationWinding capacitor machinesLightning strokesEngineering

The invention provides a novel lightning-stroke protection aluminium electrolytic capacitor and a preparation method therefor. A core is immersed with an electrolyte with a break-down voltage of 490V or above; the core is formed by a pieces of positive electrode foil, a piece of negative electrode foil and electrolytic paper in an overlapping and winding manner, wherein the electrolytic paper used as a substrate is arranged on the same sides of the negative electrode foil and the positive electrode foil separately; a positive electrode conductive pin in nail joint with the positive electrode foil and a negative electrode conductive pin in nail joint with the negative electrode foil are arranged in a manner of running through a packaging layer; the electrolytic paper comprises inner layer electrolytic paper and outer layer electrolytic paper; the inner layer electrolytic paper is positioned on the inner side of the corresponding negative electrode foil or positive electrode foil; and the inner layer electrolytic paper and outer layer electrolytic paper are consistent in tightness. The overall voltage withstand capacity of the product is improved effectively, and the instantaneous voltage withstand of the aluminium electrolytic capacitor is improved to 2.2KV; and in addition, the aluminium electrolytic capacitor has high impact resistance, high safety and an effect of ensuring the service life.

Owner:ZHAOQING BERYL ELECTRONICS TECH

Multilayer coil, winding method of same, and winding apparatus of same

Owner:NITTOKU ENG CO LTD

Capacitor and method of making same

ActiveUS20110317329A1High breakdown strengthIncrease energy densityLamination ancillary operationsFixed capacitor dielectricAlkali metal oxideOverflow downdraw method

A capacitor having a dielectric consisting of a glass layer with an alkali metal oxide content of at most 2 wt % and a thickness of at most 50 μm is provided. The capacitor includes at least two metal layers which are separated by the glass layer. The glass layer is preferably produced by a down-draw method or by an overflow down-draw fusion method.

Owner:SCHOTT AG

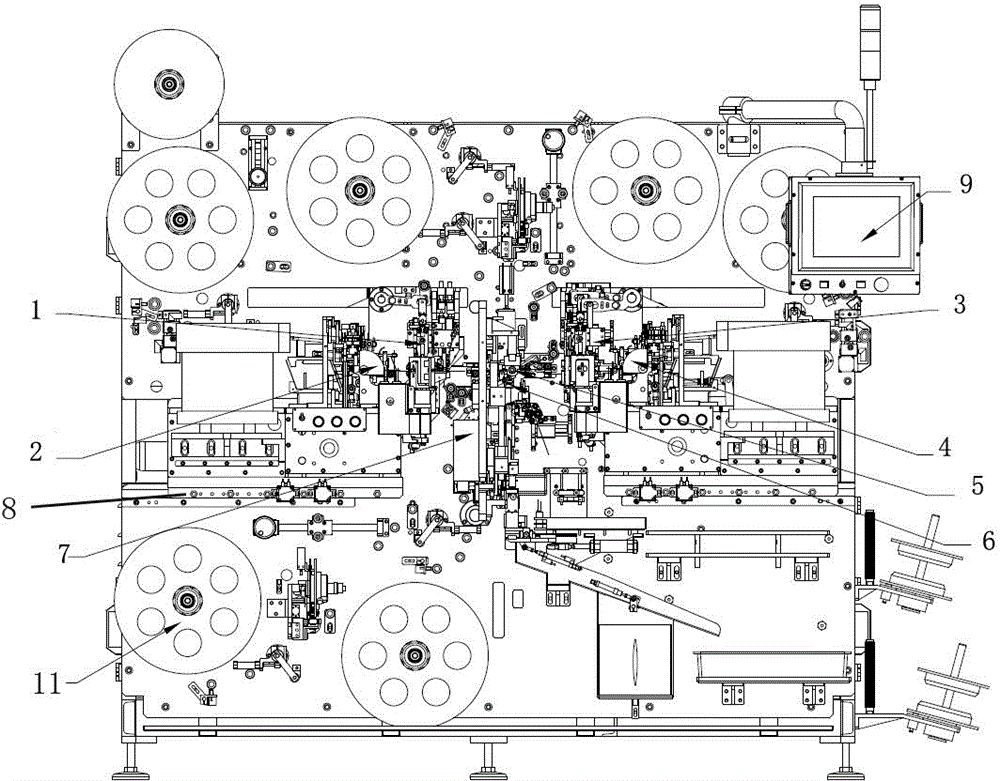

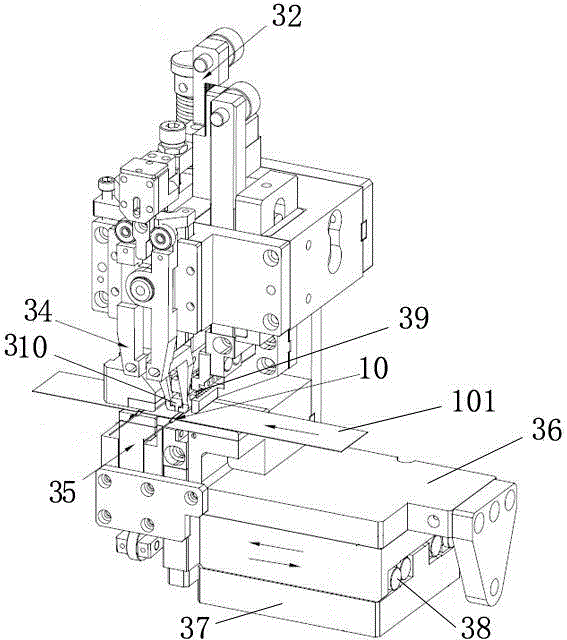

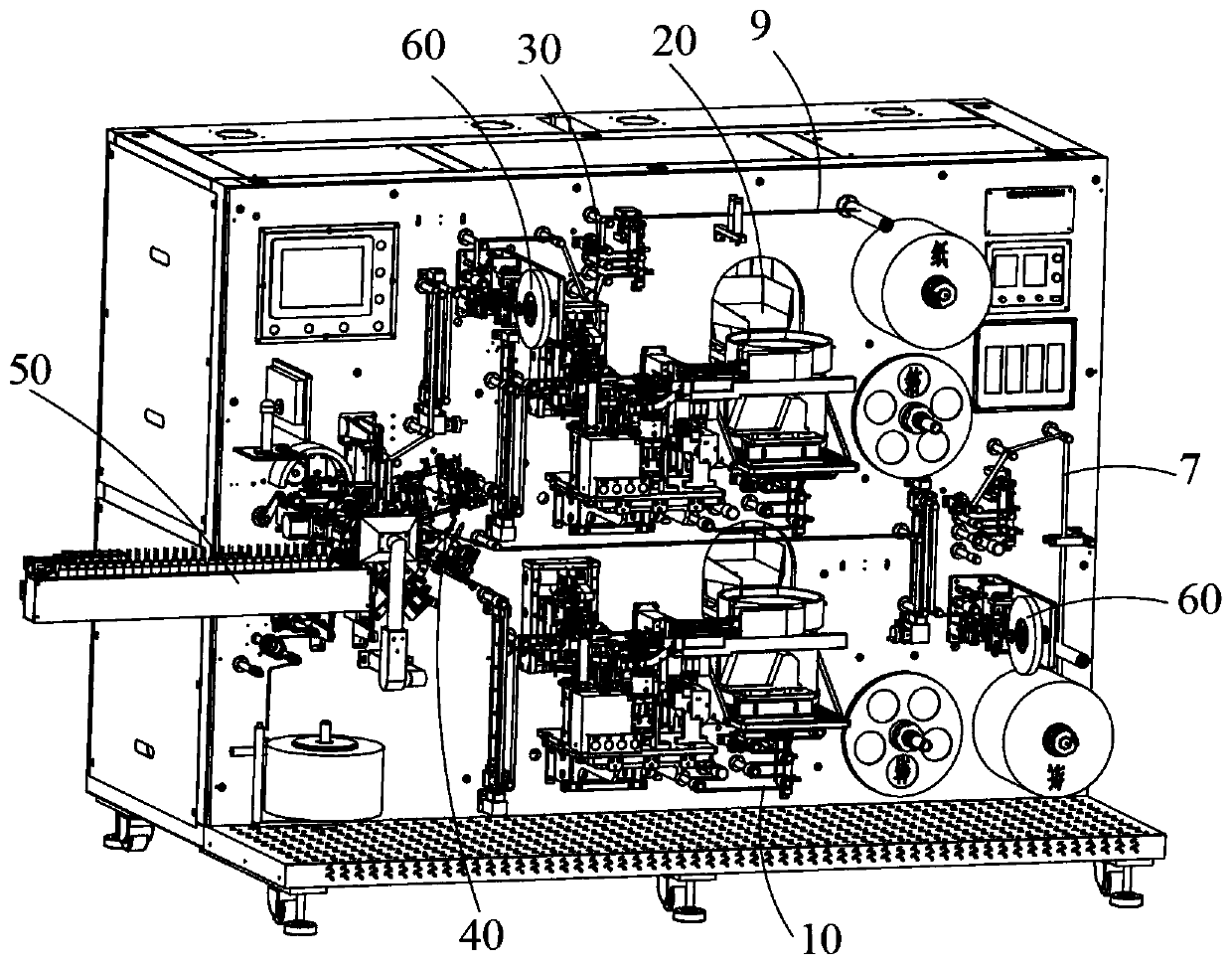

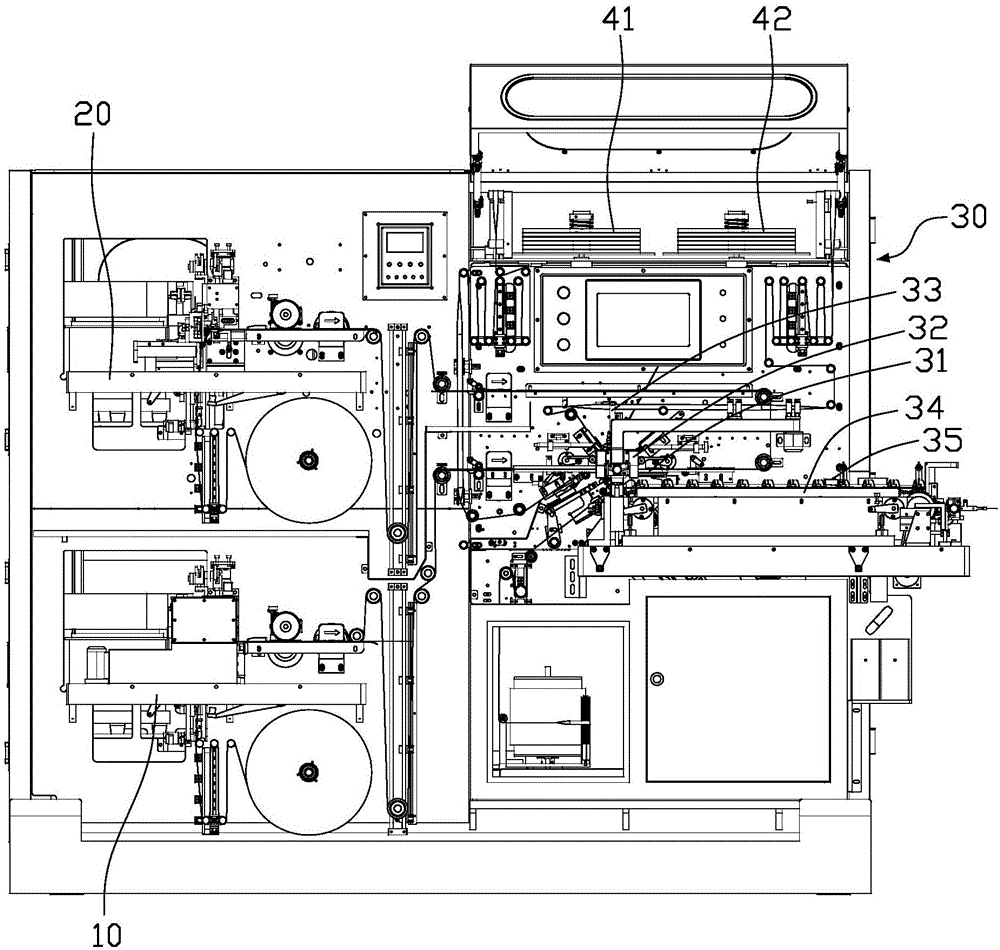

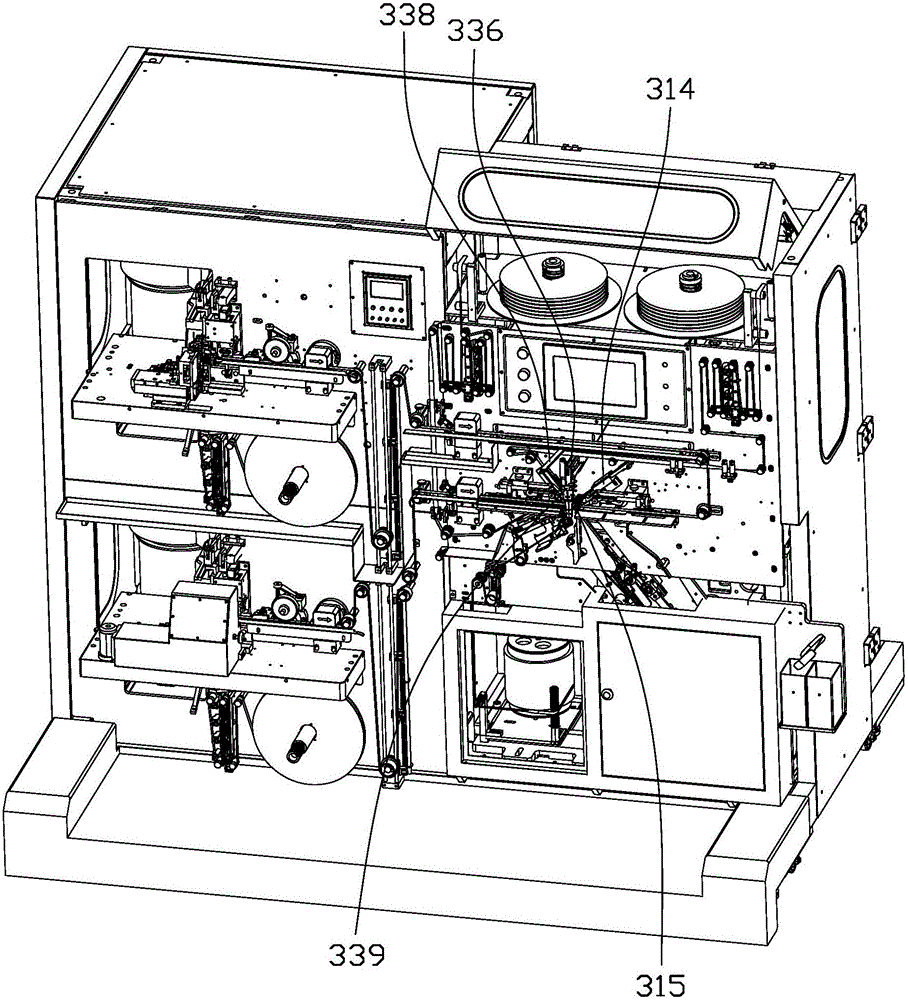

Full-automatic nail joint winding machine and element manufacturing method thereof

ActiveCN104658772ALarge capacityReduce chanceWinding capacitor machinesMetal working apparatusWinding machineRejection rate

The invention discloses a full-automatic nail joint winding machine and an element manufacturing method thereof, and particularly relates to the field of mechanical manufacturing for full-automatic manufacture of elements. The full-automatic nail joint winding machine comprises a winding mechanism, a positive nail machine mould mechanism, a positive nail joint mechanism, a negative nail machine mould mechanism, a negative nail joint mechanism, an element winding tape adhesion mechanism and an element returning mechanism, wherein the positive nail machine mould mechanism and the positive nail joint mechanism are arranged on one side of the winding mechanism in sequence; the negative nail machine mould mechanism and the negative nail joint mechanism are arranged on the other side of the winding mechanism in sequence; the element winding tape adhesion mechanism and the element returning mechanism are arranged at the lower end of the winding mechanism in parallel; the positive nail joint mechanism and the negative nail joint mechanism are respectively connected with an eccentric guide pin automatic direction choosing mechanism; all the mechanisms are connected with a control panel circuit. According to the full-automatic nail joint winding machine and the element manufacturing method, the element production efficiency is greatly improved, the rejection rate is reduced and the overlapping degree of aluminum foils with different requirements can be satisfied.

Owner:东莞和宏机械有限公司

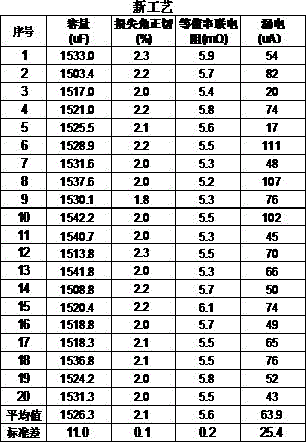

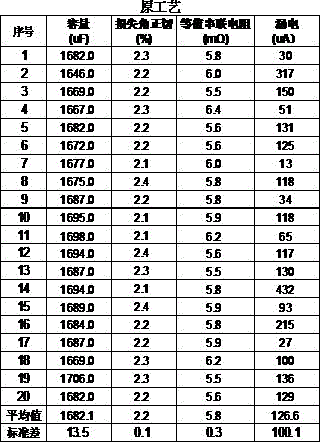

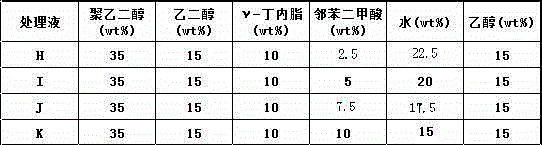

Method for producing low leakage winding type solid electrolytic capacitor

The invention provides a method for producing a low leakage winding type solid electrolytic capacitor. The method comprises the following steps: step 1), cutting; and step 2), element preparation: performing formation, drying, pretreatment, monomer impregnation, oxidizer impregnation, polymerization, assembly and aging on a core package; performing formation, and immersing the core package after winding into a formation electrolyte to electrify, wherein the electrifying voltage is the withstand voltage of an anode foil, and the formation electrolyte is the aqueous solution of ammonium dihydrogen phosphate; and performing pretreatment: immersing the core package into a mending agent, drying the core package, and after that, forming a layer of insulating film which is less than or equal to 20nm on an aluminum foil surface. Compared with the previous products, the method of the invention does not require a high temperature of 230 to 300 DEG C after mending an oxide film by a formation process, thus the damage to the oxide film is less; and besides, the pretreatment is added before impregnating the monomer, an ultra-thin insulating film covering the surface of the aluminum foil can be formed, so that the defects of the oxide film can be further reduced, therefore, the leakage of solid electrolytic capacitor products produced by the invention is 20% to 50% smaller than that of ordinary products.

Owner:YIYANG AIHUA FUXIAN ELECTRONICS

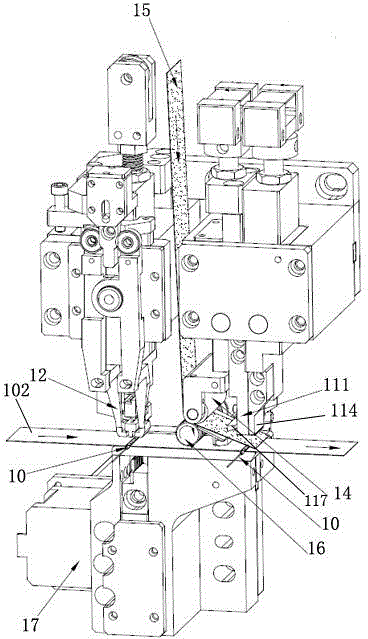

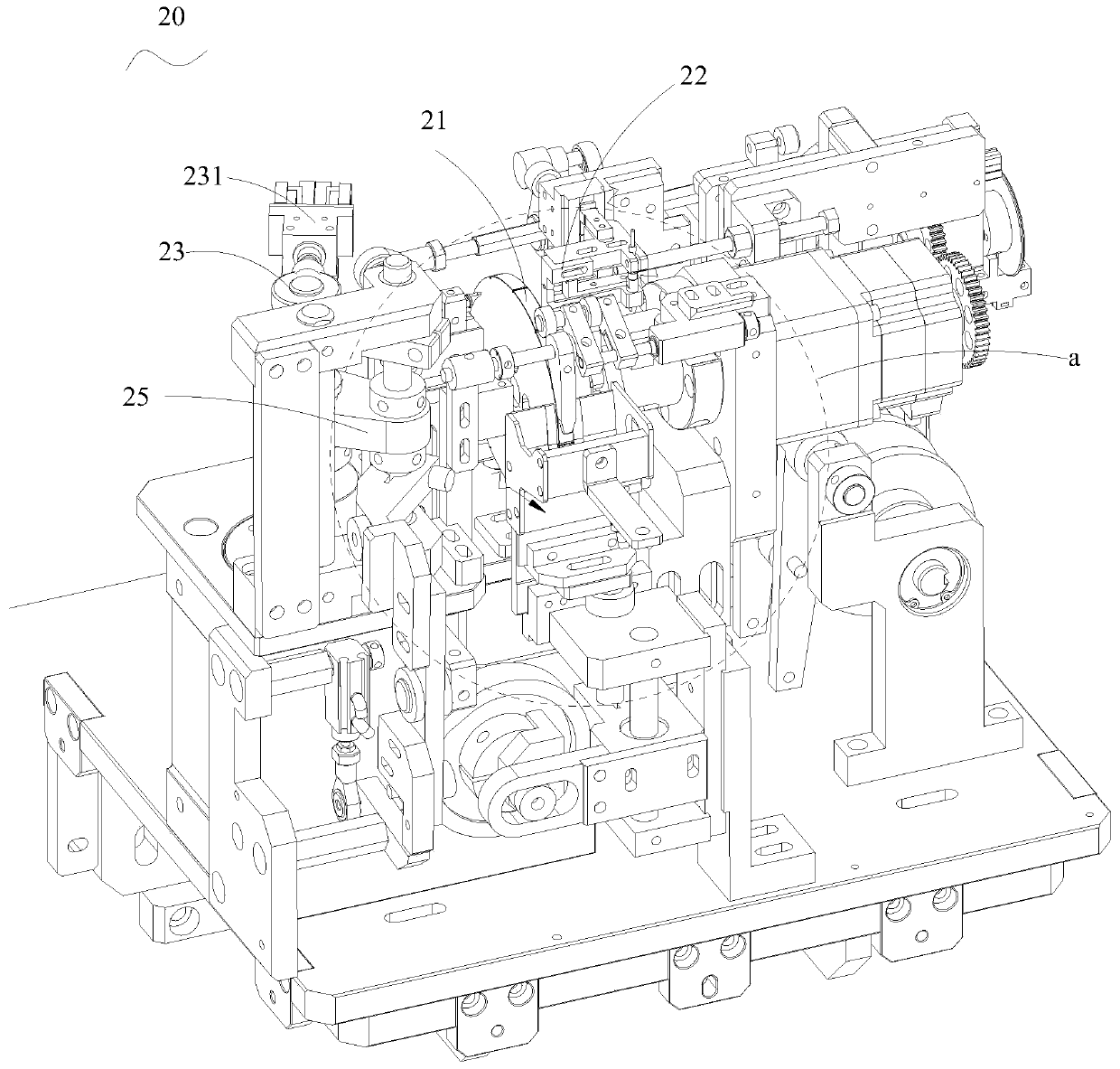

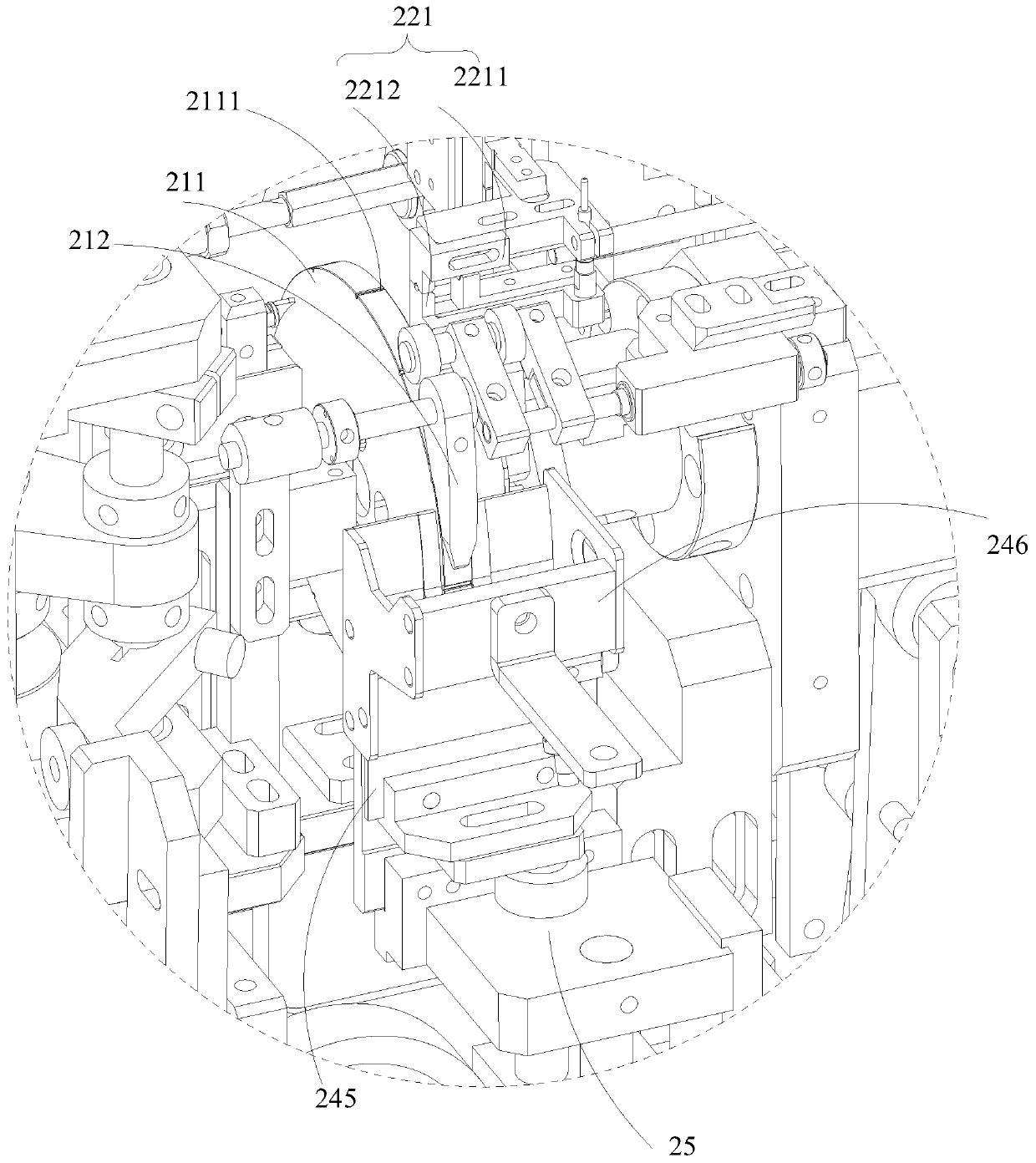

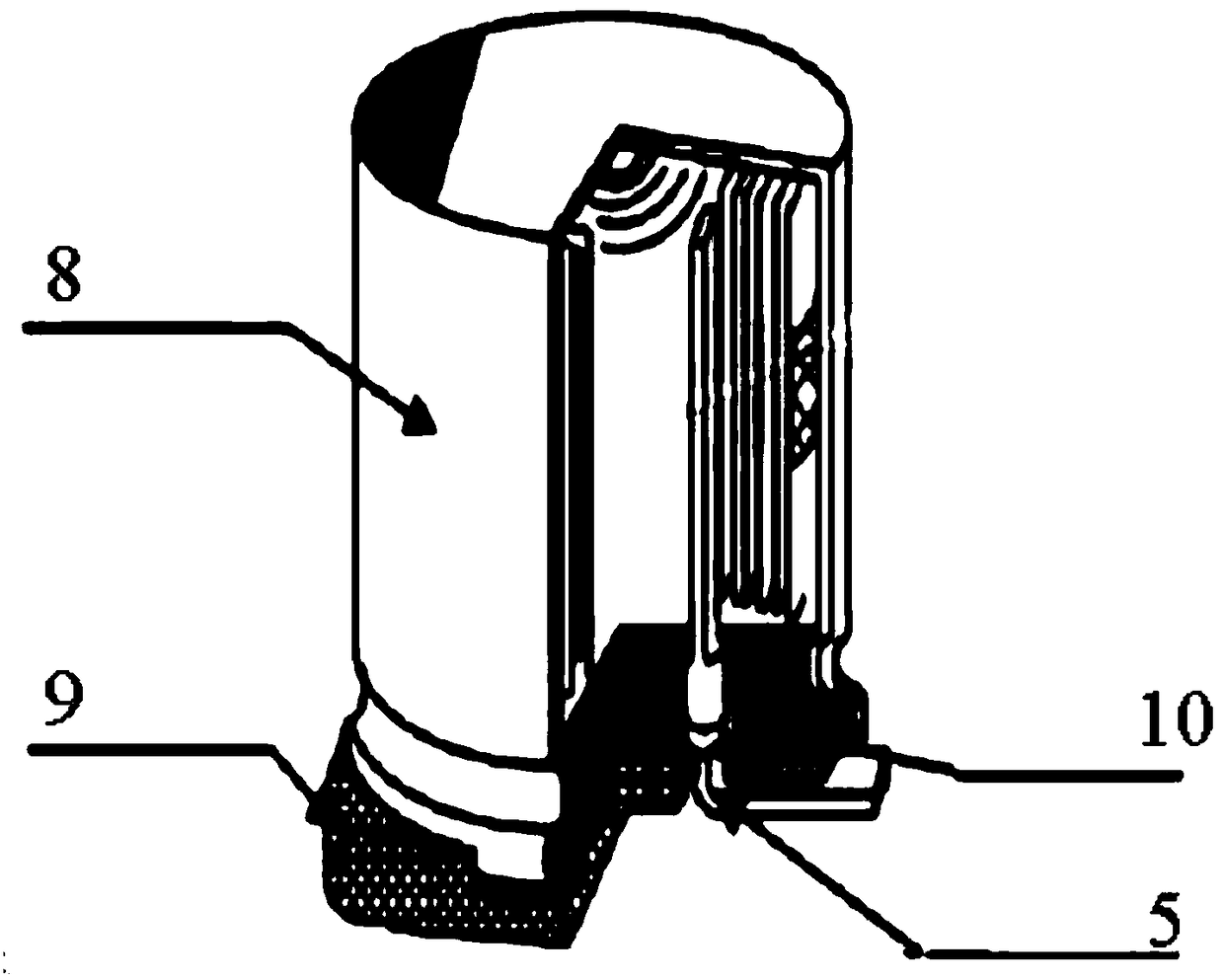

Capacitor element winding device and capacitor element winding method

The invention discloses a capacitor element winding device which comprises a first rolling needle shaft, a second rolling needle shaft, a first driving mechanism and a second driving mechanism. The first rolling needle shaft and the second rolling needle shaft are coaxial and are oppositely arranged. The end, close to the second rolling needle shaft, of the first rolling needle shaft is provided with a first rolling needle facing the second rolling needle shaft, the end, close to the first rolling needle shaft, of the second rolling needle shaft is provided with a second rolling needle facing the first rolling needle shaft, and the first rolling needle and the second rolling needle get close to each other and are used for forming a capacitor element in a winding mode. The first driving mechanism drives the first rolling needle shaft and the second rolling needle shaft to rotate synchronously, and the second driving mechanism drives the first rolling needle shaft and the second rolling needle shaft to get close to each other or get away from each other. Capacitor element deformation caused when the capacitor element winding device conduct needle drawing can be avoided, gaps between aluminum foil of the capacitor element are reduced, the quality of a capacitor element product is improved, and material waste is reduced. The invention further relates to a capacitor element winding method.

Owner:SHENZHEN CHENGJIE INTELLIGENT EQUIP CO LTD

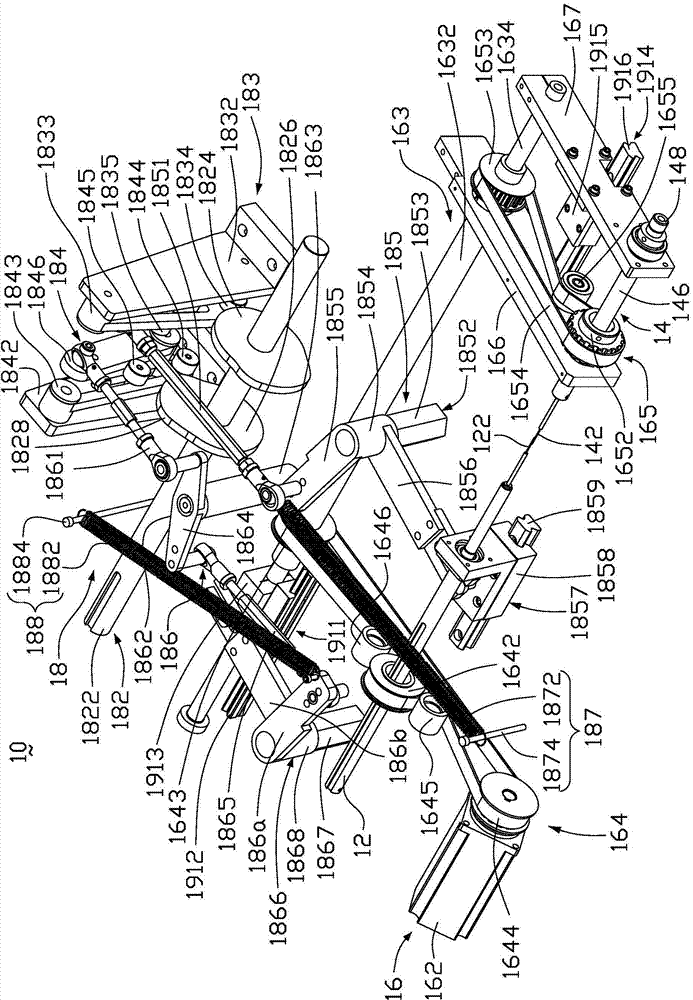

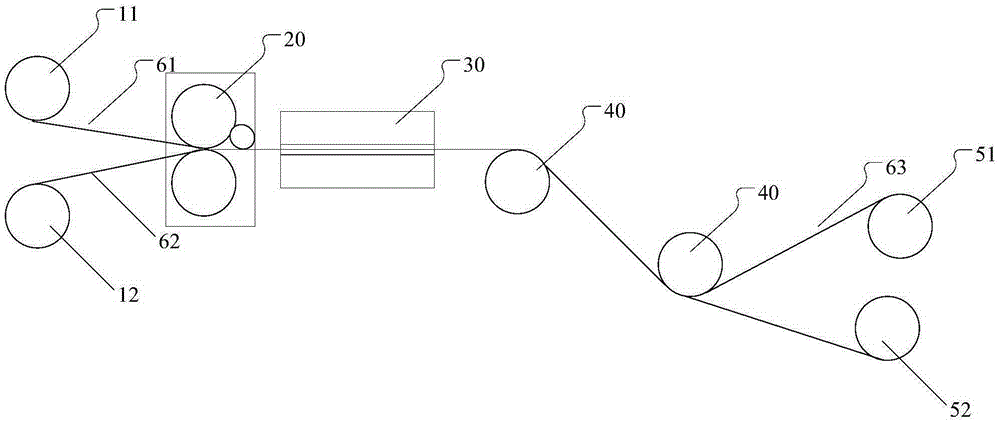

Fully automatic nailing and winding integrated machine

ActiveCN110140189AAvoid errorsImprove hole position accuracyWinding capacitor machinesTerminal applying apparatusWinding machineEngineering

The invention relates to the technical field of capacitor preparation, in particular to a fully automatic nailing and winding integrated machine. The automatic nailing and winding integrated machine comprises a foil conveying mechanism, a needle conveying mechanism, a nailing mechanism, a winding mechanism and a cutting mechanism, and the nailing mechanism only needs to move the mold assembly to be movable in the first direction And the movement of the molds on the mold assembly in the second direction can complete the nailing of the guide pins and the foil strips without changing the positionof the foil strips, omitting the foil-rolling wheel, and avoiding the foil-feeding wheel during the transmission process The error caused by the change of the tension improves the precision of the hole position of the first nailing hole and the second nailing hole, ensures the quality of the nailing, and improves the yield of the automatic nailing and winding machine.

Owner:SHENZHEN CHENGJIE INTELLIGENT EQUIP CO LTD

Conductor assembly including a flared aperture region

InactiveUS7880578B2Avoid interferenceMagnetic measurementsTransformers/inductances coils/windings/connectionsPower flowElectrical conductor

A conductor assembly of the type which, when conducting current, generates a magnetic field or in which, in the presence of a changing magnetic field, a voltage is induced. A helical wiring pattern is positioned along an axis a radial distance R from the axis. The wiring pattern is formed about an aperture region extending from the axis toward the wiring pattern, the distance R varying along a portion of the axis.

Owner:ADVANCED MAGNET LAB

Manufacturing method of solid-state electrolytic capacitor

InactiveCN105405661AHigh voltageIncrease capacitySolid electrolytic capacitorsWinding capacitor machinesCapacitanceSolid state electrolyte

The invention provides a manufacturing method of a solid-state electrolytic capacitor, and relates to the technical field of electrolytic capacitors. The method comprises the following steps: S100, manufacturing an element; S200, at a first impregnation stage, impregnating the element with a forming liquid to repair oxide scales caused by cutting and nail coiling on a front foil surface of the element; S300, at a second impregnation stage, impregnating the element with a conducting polymer dispersion liquid; S400, at a third impregnation stage, impregnating the element with a treatment liquid; and S500, packaging the element undergoing the third impregnation stage into an aluminum shell. Through adoption of the method, the development of the dispersion liquid is effectively avoided; the production period is shortened; and the cost is reduced. The treatment liquid and solid-state electrolytes such as conducting polymers are used together, so that the solid-state electrolytic capacitor having the characteristics of high voltage, high capacity, low impedance, small leakage current and the like is obtained. Meanwhile, the high treatment liquid has a function of facilitating repair of positive electrode foil oxide scale defects, so that the situation of short circuit can be restrained.

Owner:CAPXON ELECTRONIC (SHENZHEN) CO LTD

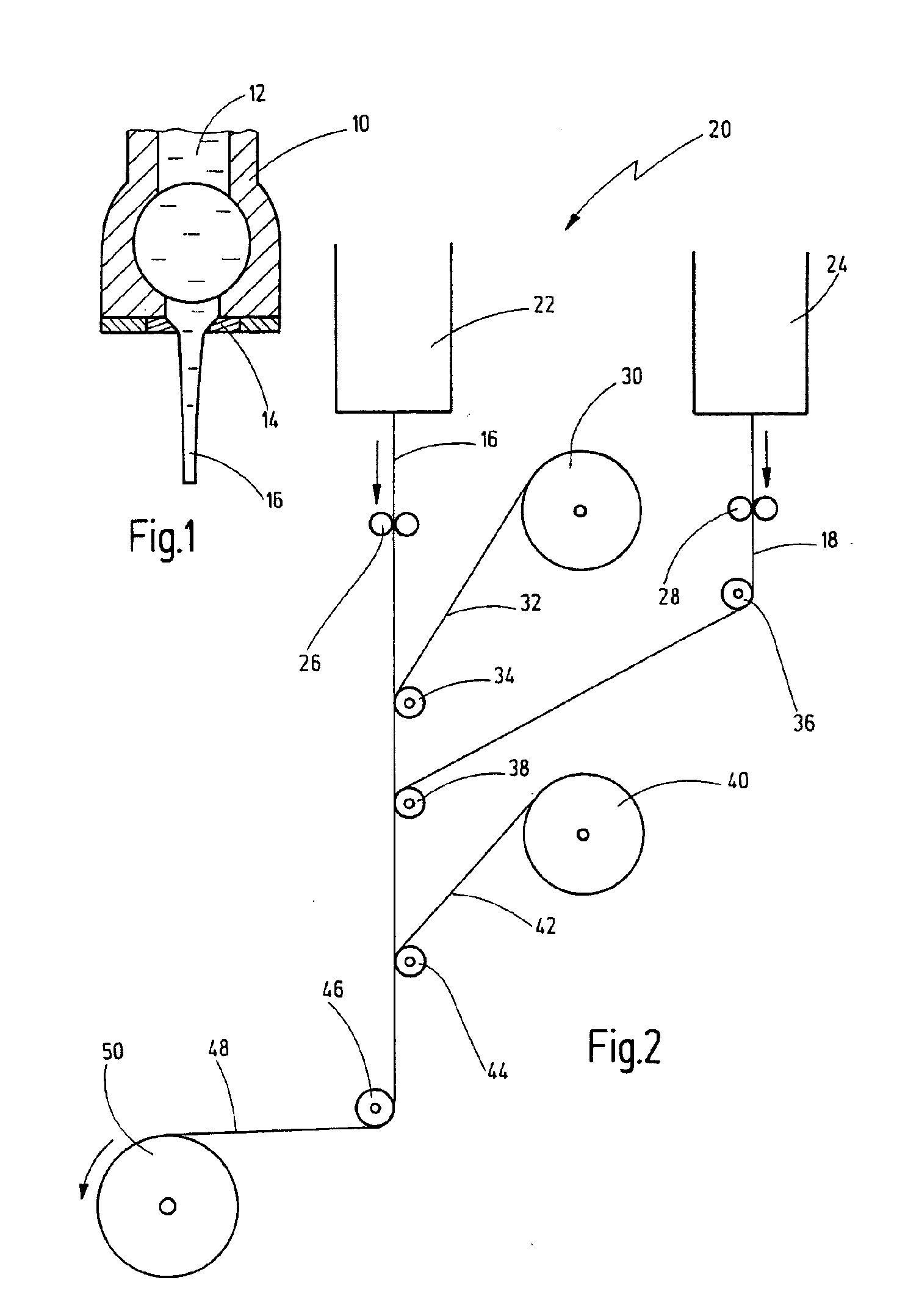

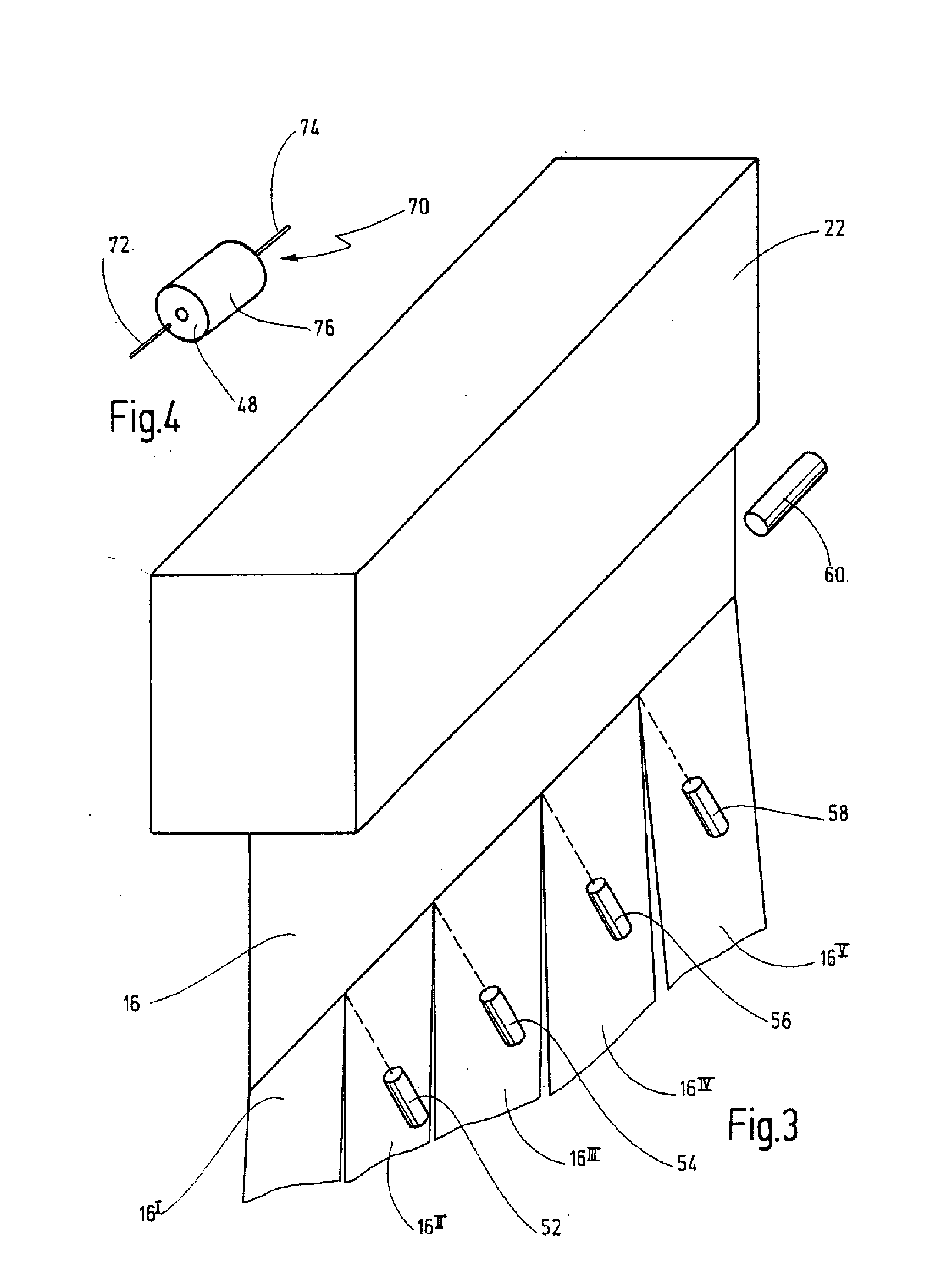

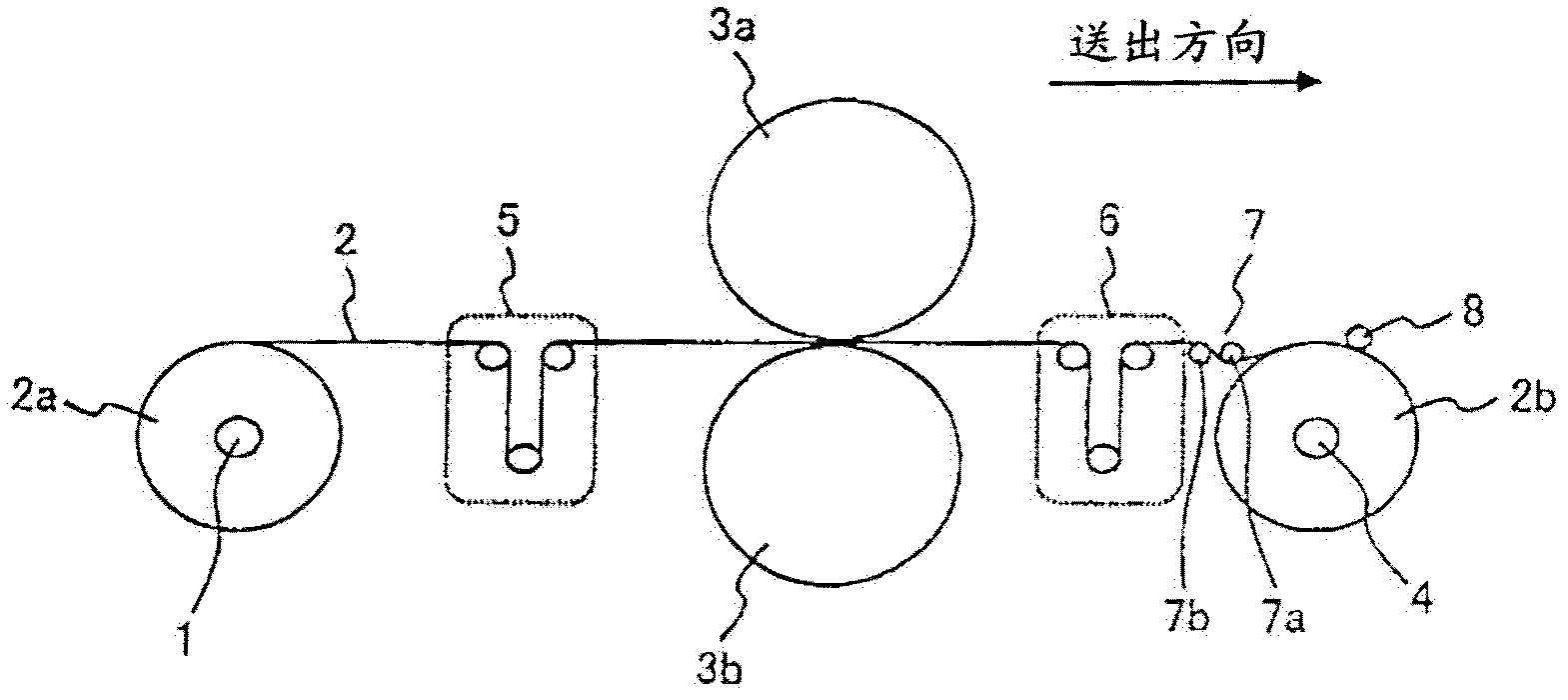

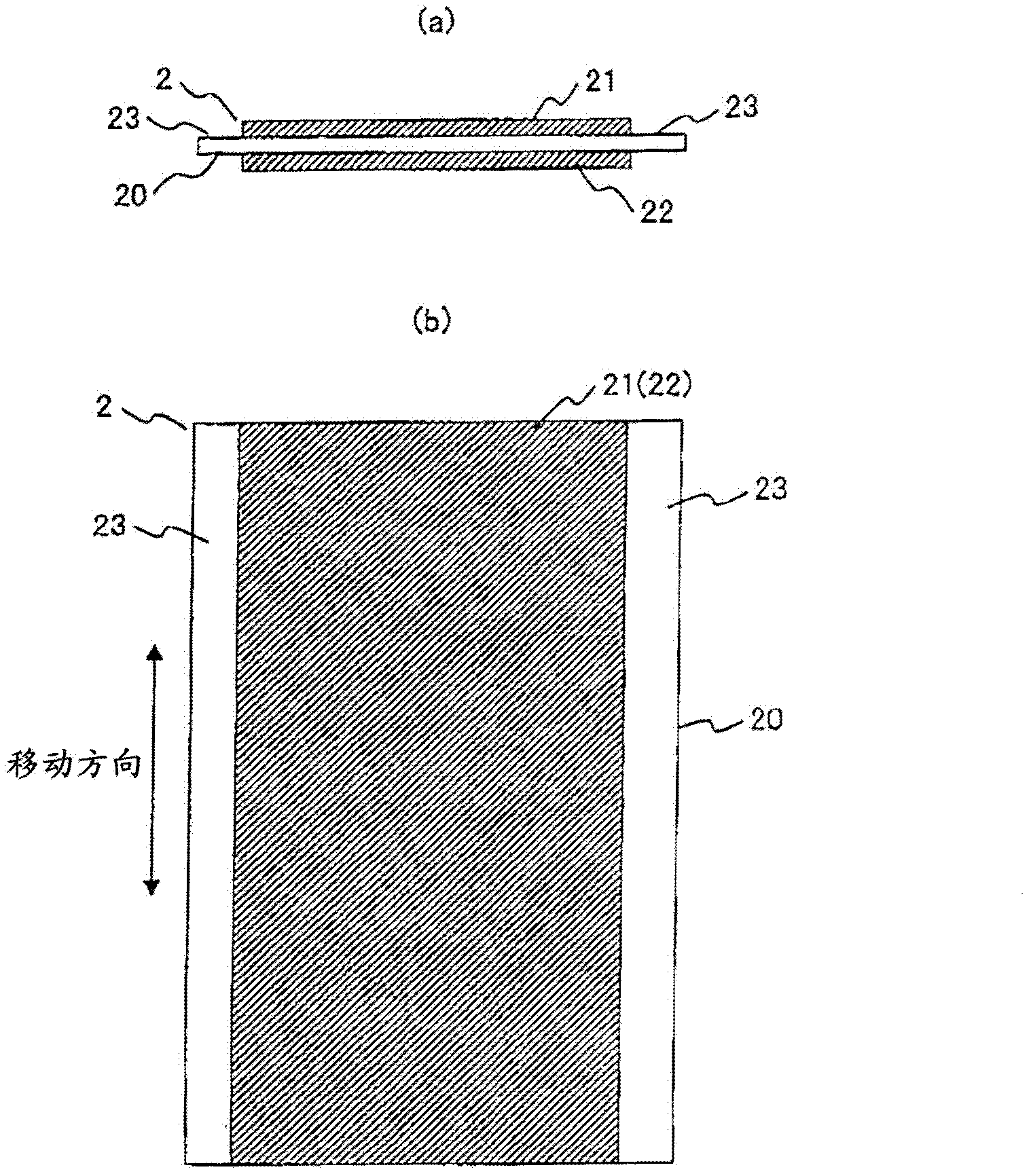

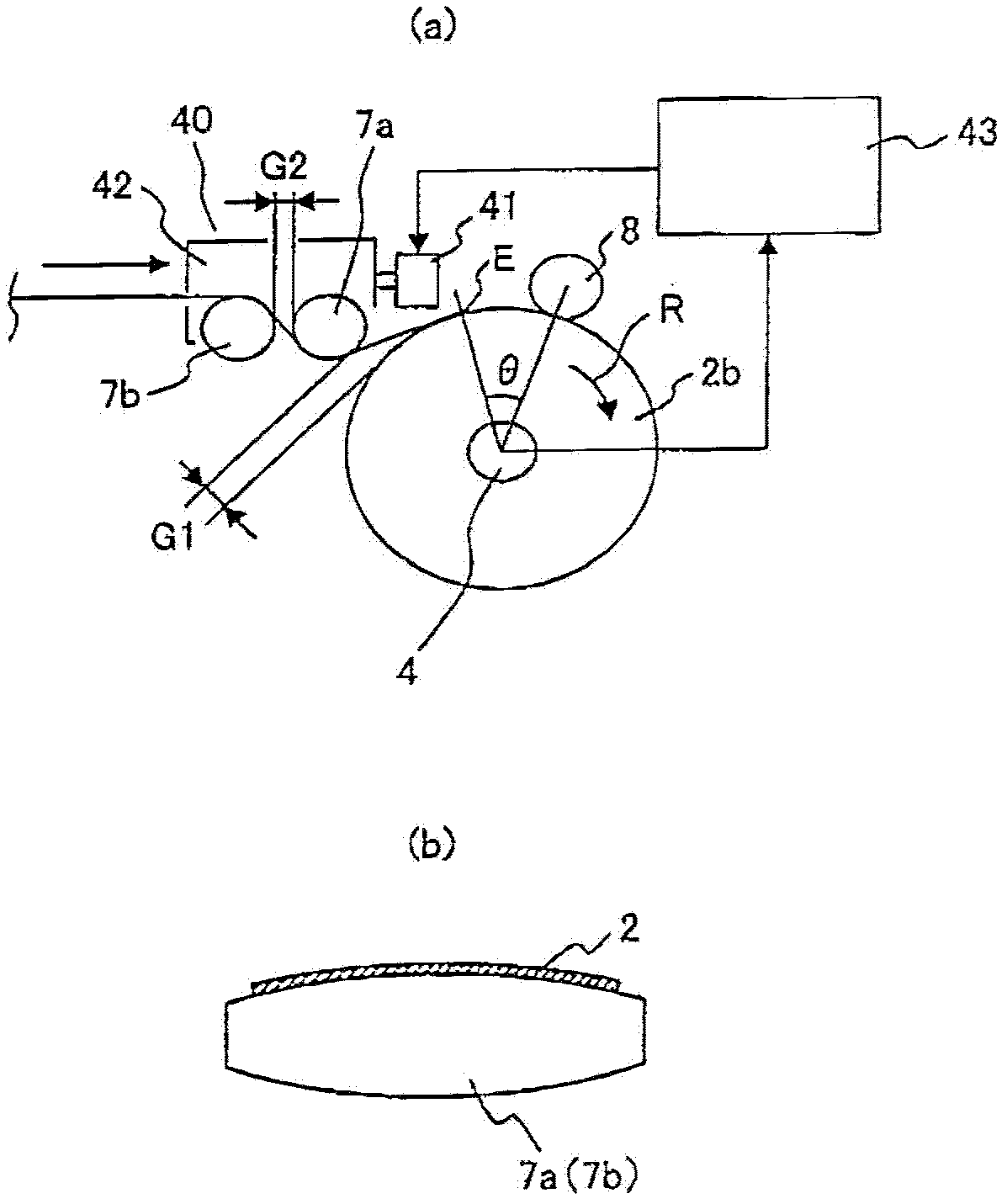

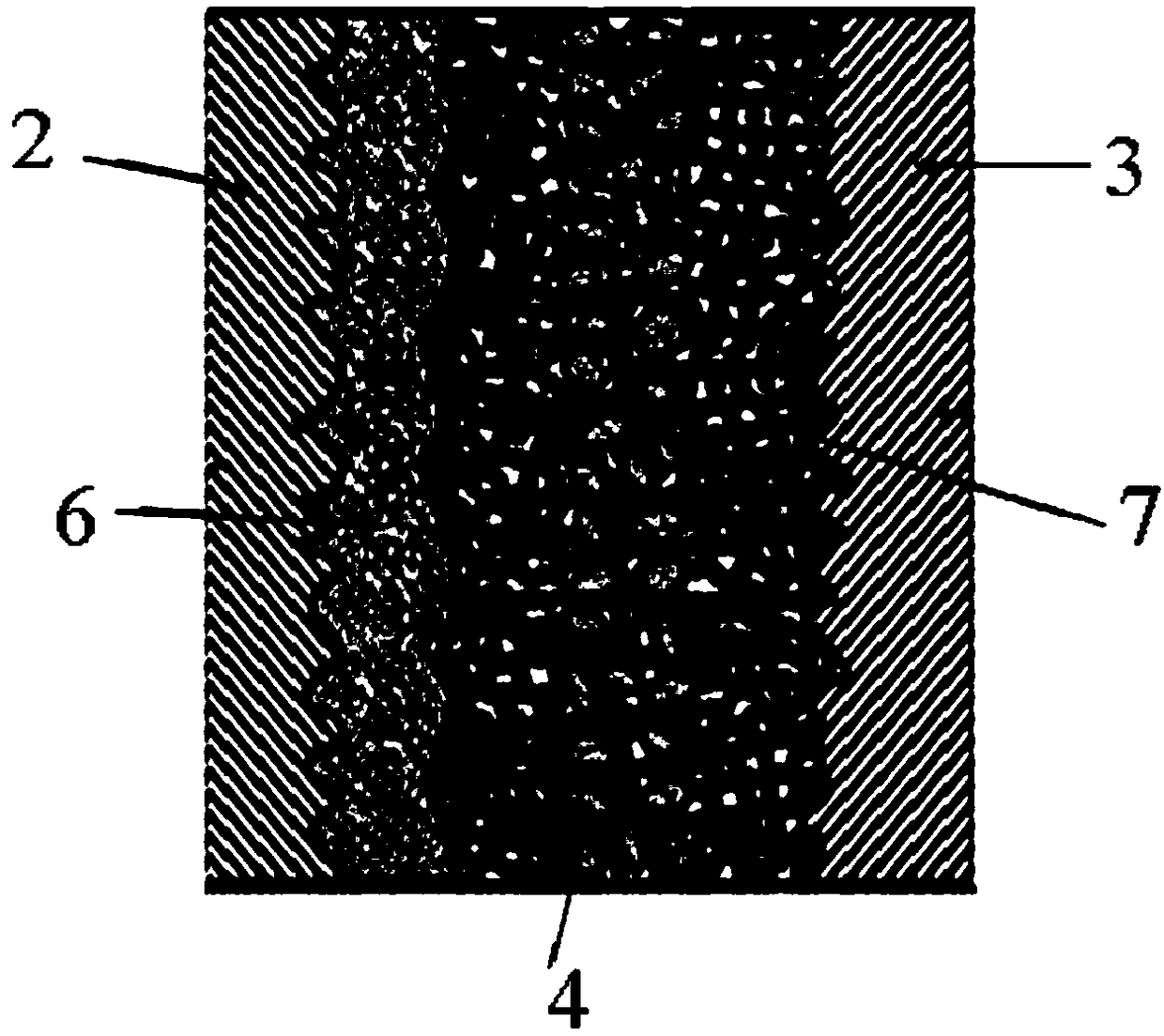

Rolling device of electrode material

The invention provides a rolling device of a wrinkle-prevention mechanism of an electrode material corresponding to the thin-film of the base material foil of the strip-shaped electrode material and high speed of the rolling speed of the electrode material. The rolling device can be sued to convey, compact, process and wind the electrode material (2) with active matters coated on the surface of the base body material. The rolling device is provided with a pressurizing roller (7a, 7b) processing the electrode material into the predetermined thickness; a winding device (4) used for winding the compacted electrode material into the winded winds (2b). Guide roller (7a) adjacent to winding device is disposed between an output side of the pressurizing roller and winding device, and disposed on an inner side of the winded winds (2b) to reach the largest outer diameter. The adjacent guide roller 7a can be movably controlled, so that the interval G1 between the adjacent guide roller 7a and the winded winds (2b) can be remained the predetermined value during the winding process.

Owner:HITACHI ENG & SERVICES CO LTD

Device and method for winding and forming of cells

The invention discloses a device and a method for winding and forming of cells. A rotating tower is provided with three rotating arms, each rotating arm is provided with a core shaft, a negative electrode belt, a second membrane, a positive electrode belt and a first membrane are sequentially conveyed to one core shaft and wound to form one cell, and the cells are continuously wound around the core shafts of the three rotating arms sequentially through rotation of the rotating tower. According to the device and the method, the production process of the cells is simple, the production efficiency is high, and the equipment cost is low.

Owner:NINGBO CRRC NEW ENERGY TECH CO LTD

Electrolytic condenser nail joint coiling high speed machine

The invention provides an electrolytic capacitor nail joint reeling high speed machine which comprises an anode nail machine, a cathode nail machine as well as a reeling machine positioned between the anode nail machine and the cathode nail machine, wherein the reeling machine comprises a frame, a winding mechanism for reeling anode aluminum foil transferred by the anode nail machine and cathode aluminum foil transferred by the cathode nail machine, and a cutting-off mechanism for cutting off the anode aluminum foil and the cathode aluminum foil, the cutting-off mechanism comprises a driving motor, a tape driving mechanism connected with the driving motor, a cam mechanism connected with the tape driving mechanism, a link mechanism connected with the cam mechanism, and a pair of scissors, which is connected with the link mechanism, and the pair of scissors and the frame are in a sliding pair. The electrolytic capacitor nail joint reeling high speed machine provided by the invention has the benefits as follows: the driving motor drives the cam mechanism through the tape driving mechanism so as to switch rotating motion into pendulum motion of the link mechanism, and then the pair of scissors is driven to carry out linear feed along the frame so as to cut off the anode aluminum foil and the cathode aluminum foil automatically. Therefore, the efficiency is improved.

Owner:SHENZHEN CHENGJIE INTELLIGENT EQUIP CO LTD

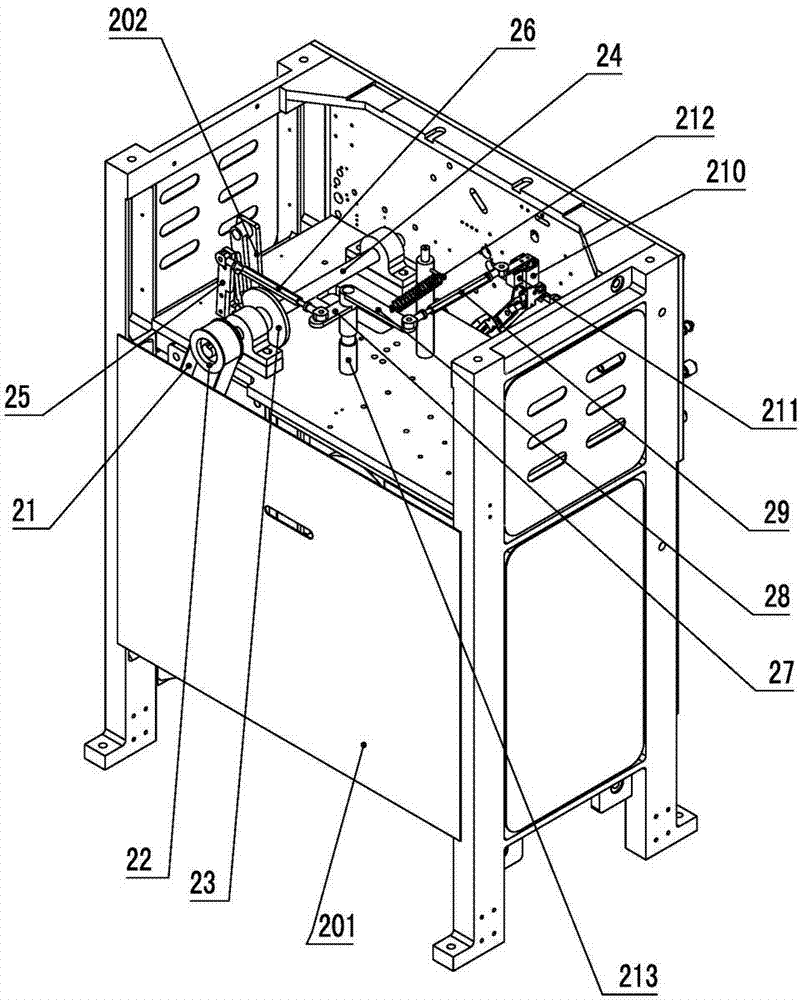

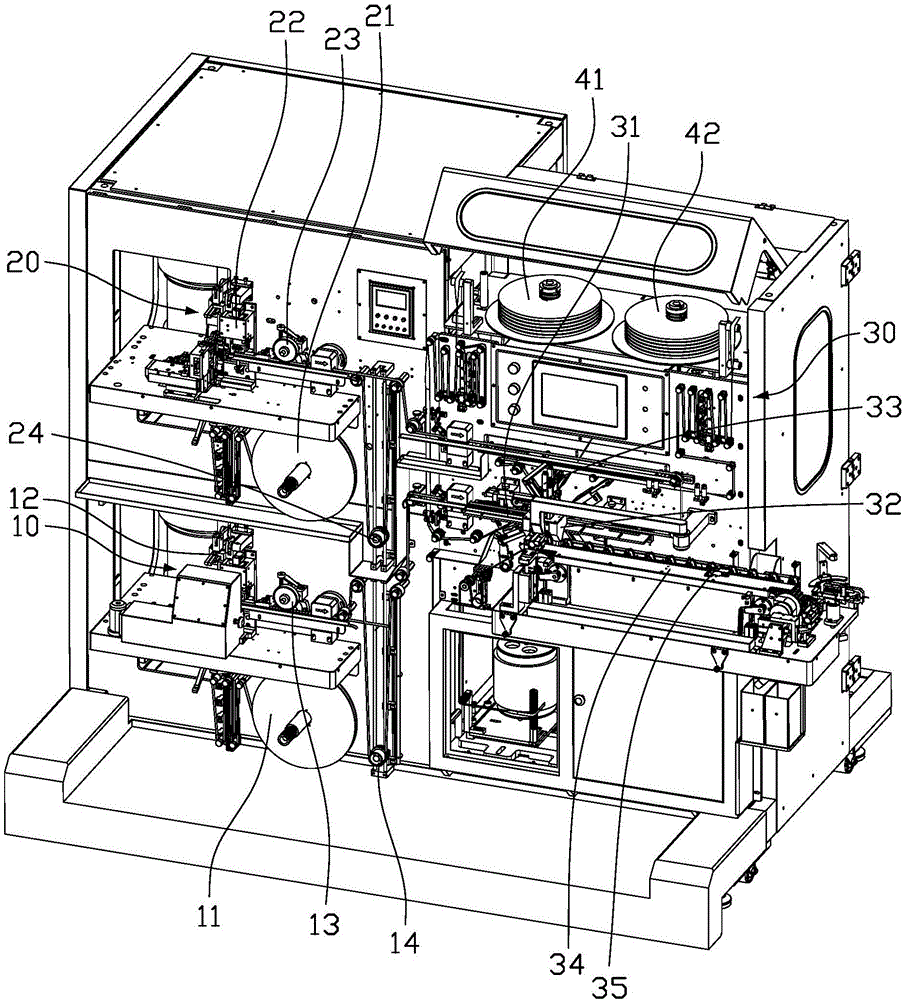

Nailing and winding integrated machine for producing electrolytic capacitor

ActiveCN106373791ACompact structureSmall footprintWinding capacitor machinesEngineeringElectrolytic capacitor

A nailing and winding integrated machine for producing an electrolytic capacitor comprises a winder as well as an anode nailing device and a cathode nailing device placed in the same side of the winder. The anode nailing device is placed over or under the cathode nailing device, and comprises an anode foil disk, a first nailing mechanism and a first foil drawing mechanism arranged successively; the cathode nailing device comprises a cathode foil disk, a second nailing mechanism and a second foil drawing mechanism arranged successively; the winder comprises a winding mechanism which is used to wind and glue an anode foil, a cathode foil and electrolytic paper; the first foil drawing mechanism draws the anode foil from the anode foil disk and nails the anode foil via the first nailing mechanism; the second foil drawing mechanism draws the cathode foil from the cathode foil disk and nails the anode foil via the second nailing mechanism; the nailed anode and cathode foils are transmitted to the winder via corresponding foil conveying wheels and wound and glued with the electrolytic paper to obtain a capacitor element. The nailing and winding integrated machine is compact in structure, small in occupation space and convenient to operate.

Owner:SHENZHEN CHENGJIE INTELLIGENT EQUIP CO LTD

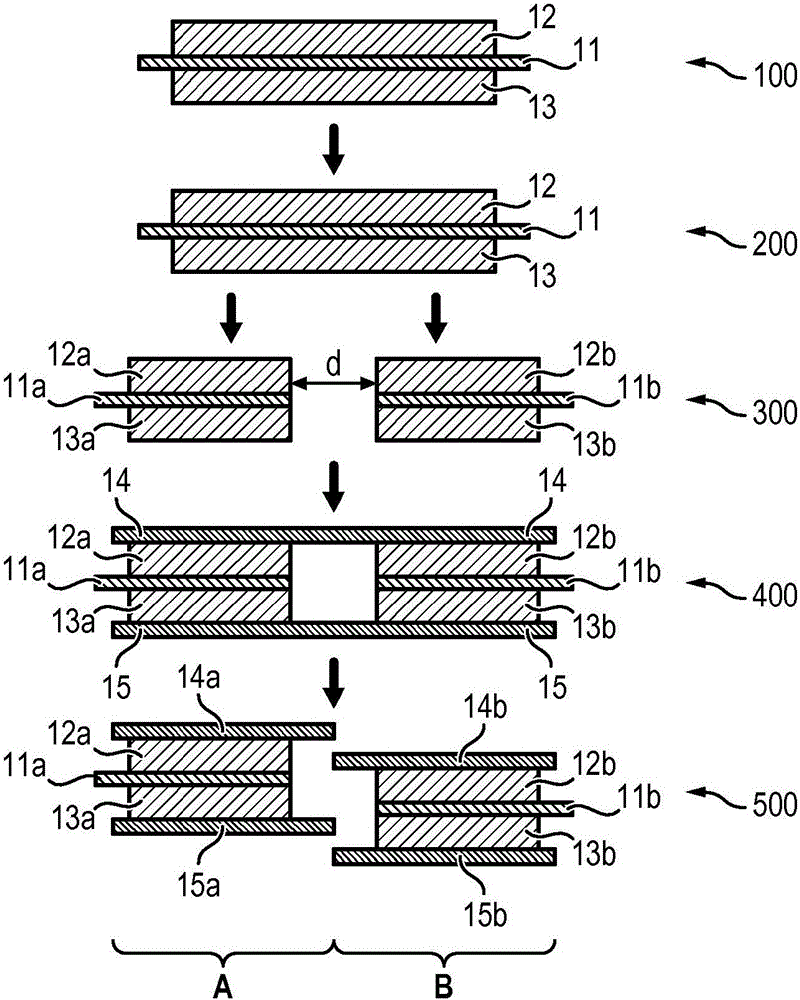

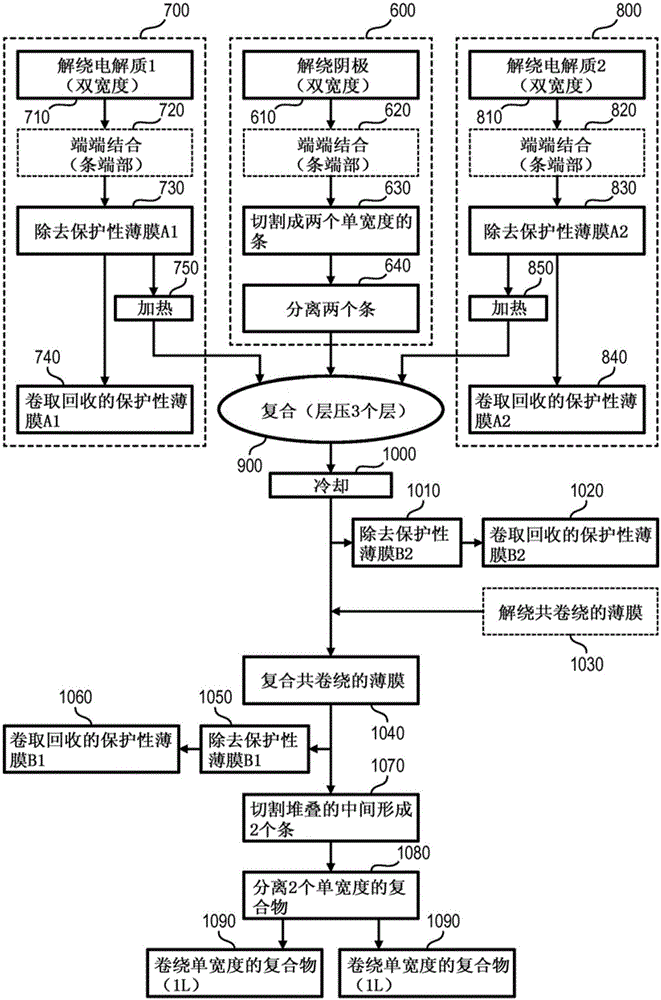

Device for separating at least two adjacent strands of material and system including such device

InactiveCN105164036AImproved bonding qualityElectrode manufacturing processesAssembling battery machinesClassical mechanicsStructural engineering

The invention relates to a device (30) for separating at least two strands of material (12a, 12b) from the cutting of a strip of material moving continuously, characterized in that the device includes a spreader (32, 33) for spreading the strands of material apart in a transverse direction (v) extending in the movement plane (P2) of the strands of material, perpendicularly to the movement direction of said strands of material.

Owner:BLUE SOLUTIONS

Electrode structure, electrode, power device and method for manufacturing the same

Owner:SAMSUNG ELECTRONICS CO LTD +1

Manufacturing method for anti-electromagnetic interference thin-film capacitor

InactiveCN104465092AIncrease contact areaImprove bindingThin/thick film capacitorStacked capacitorsEpoxyHigh current density

The invention discloses a manufacturing method for an anti-electromagnetic interference thin-film capacitor. The method comprises the steps of (1) thin-film metallization, wherein polypropylene thin films are adopted as base films, zinc and aluminum are used as evaporation materials, the method for thickening the edge of a metallization layer is adopted, the sheet resistance of the edge portion ranges from 1 omega / square to 2 omega / square, and the internal sheet resistance ranges from 6 omega / square to 10 omega / square; (2) winding and forming, wherein the metallization polypropylene thin films and a metallization electrode form a capacitor core in a non-inductive winding mode, the space ranging from 0.6 mm to 0.75 mm is formed between the two thin films during winding, series connection is achieved inside the core, and then forming is carried out; (3) metal spraying, wherein a metal alloy layer is sprayed on the end face of the core, pure zinc materials are selected as a bottoming, and then zinc-tin alloy lines are sprayed; (4) enabling; (5) welding assembly and epoxy resin encapsulation; (6) testing. According to the manufacturing method for the anti-electromagnetic interference thin-film capacitor, the obtained thin-film capacitor can bear high current density and pulse current, and is high in voltage resistance and good in dielectric property.

Owner:TONGLING CITY START ELECTRONICS MFG

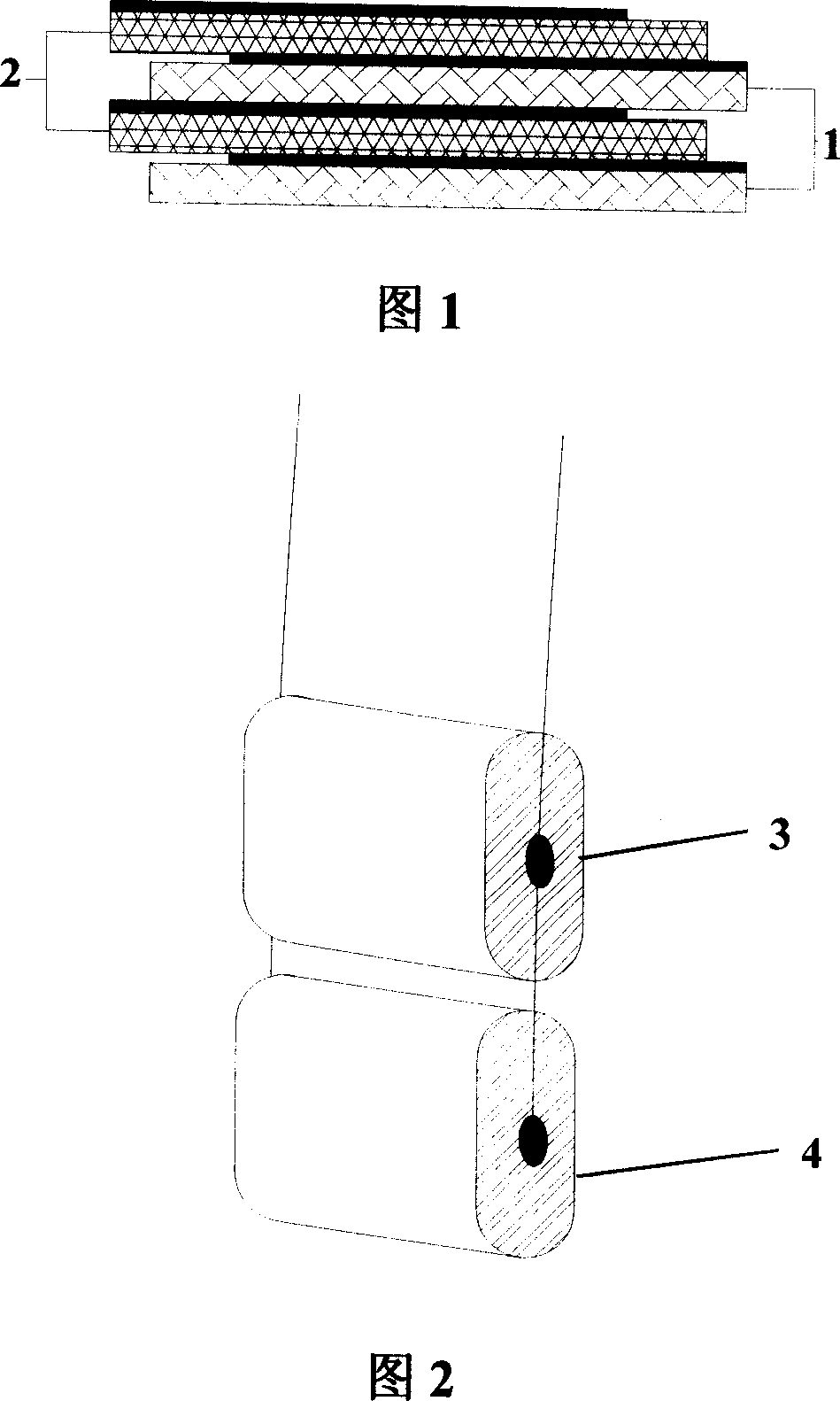

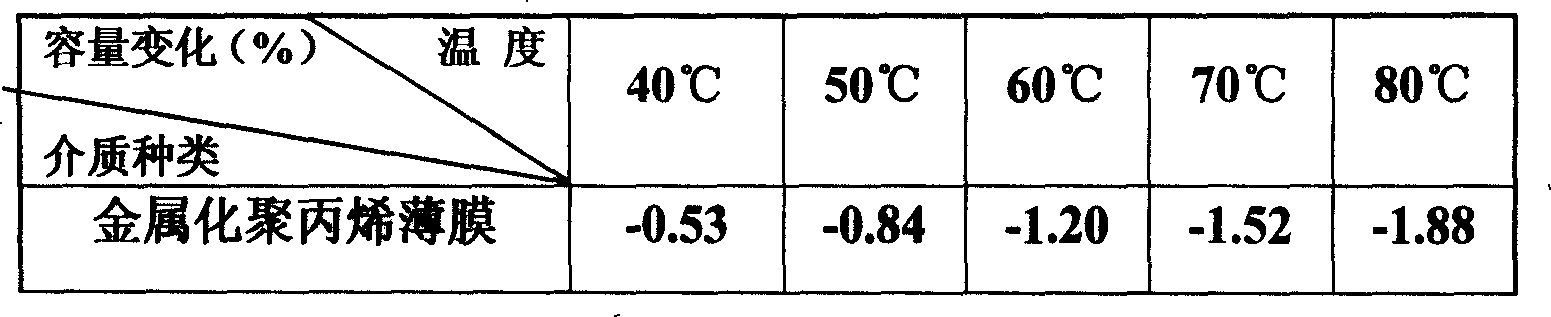

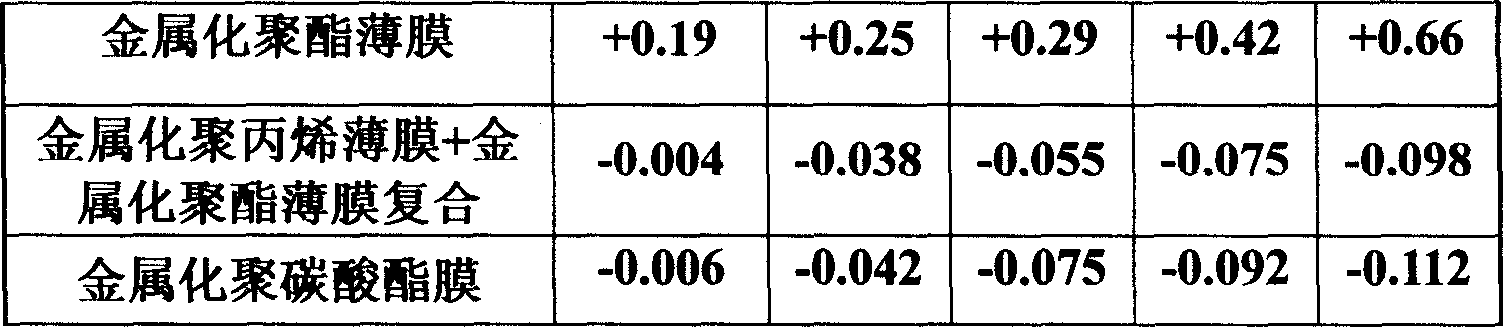

Capacitor with good capacity-temperature stabilization and its preparing method

InactiveCN101026036ALow costIncrease capacityThin/thick film capacitorFixed capacitor dielectricPolyesterHost material

This invention relates to a compound dielectric capacitor, in which, its main body is a core formed by a metalized polymer film and a metalized polypropylene film and the capacitor is made by internal parallel winding and winding outer parallel method,which can solve the problem that the production process of PC, the main material of current metalized PC capacitors will pollute environment and stabilize the volume of capacitors under different temperatures.

Owner:SHANGHAI HAOYE CAPACITORS

Original fabric pitch feed mechanism of original fabric manufacturing device for electrochemical element

ActiveUS20120222819A1Prevent reversalIncrease speedFinal product manufactureWinding capacitor machinesProcess regionMechanical engineering

Provided is a pitch feed mechanism which is capable of performing an accurate, high-speed pitch feed of an original fabric having unevenness on a surface thereof in a sticking operation of an insulating tape. The original fabric pitch feed mechanism that is provided on a downstream side of an insulating tape sticking process region in a long original fabric, and performs the pitch feeding of the original fabric in one direction in accordance with a boundary part, the original fabric pitch feed mechanism being characterized by comprising a feed side roller, an original fabric take-up side roller, a feed side contact and separate member, a take-up side contact and separate member, and a pitch feed roller, which is disposed between the feed side roller and the original fabric take-up side roller, and pulls out, when the feed side contact and separate member is separated from the feed side roller, and the take-up side contact and separate member is in contact with the original fabric take-up side roller to fix the original fabric with the original fabric disposed therebetween, the original fabric by a predetermined size from the feed side roller side by pressing the original fabric that is extended between the feed side roller and the original fabric take-up side roller.

Owner:O M C

Manufacturing method for semi-solid aluminum electrolytic capacitor

InactiveCN108538650AImprove wettabilityGood restorativeCapacitor electrolytes/absorbentsWinding capacitor machinesCapacitanceConductive polymer

The invention proposes a manufacturing method for a semi-solid aluminum electrolytic capacitor, and relates to the technical field of aluminum electrolytic capacitors. The method comprises the following steps: S100, the making of an element; S200, a first impregnation stage, wherein the element is impregnated into a liquid at the stage; S300, a second impregnation stage, wherein the element is impregnated with a conductive polymer monomer, an oxidant and dispersion liquid at the stage; S400, a third impregnation stage, at which the element is impregnated with a treatment liquid; S500, a fourthimpregnation stage, at which the element is impregnated with an electrolyte; S600, the packaging of the element which is subjected to the fourth impregnation stage into an aluminum shell. In the invention, a mixed aluminum electrolytic capacitor (the semi-solid aluminum electrolytic capacitor) which contains the three materials (a conductive solid layer, treating fluid and the electrolyte) and isformed by the conductive polymers is disposed in the capacitor element. The semi-solid aluminum electrolytic capacitor has the characteristics of high reliability, high capacity, high ripple currentresistance and the like, has the function of promoting the repair of the defect portion of an oxide film of anode foil, and can suppress the occurrence of a short circuit fault.

Owner:CAPXON ELECTRONIC (SHENZHEN) CO LTD

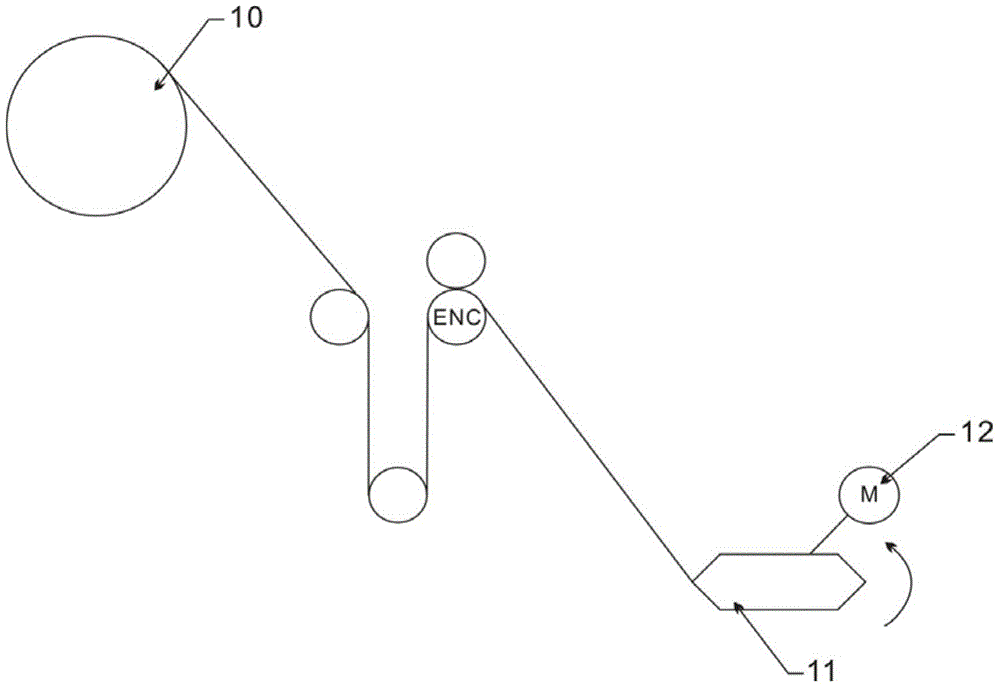

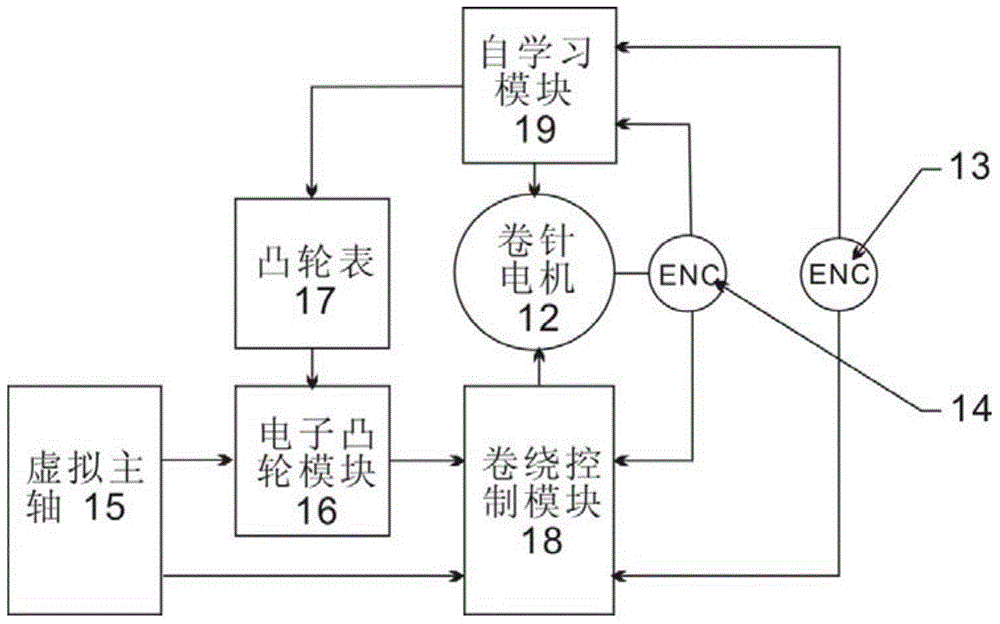

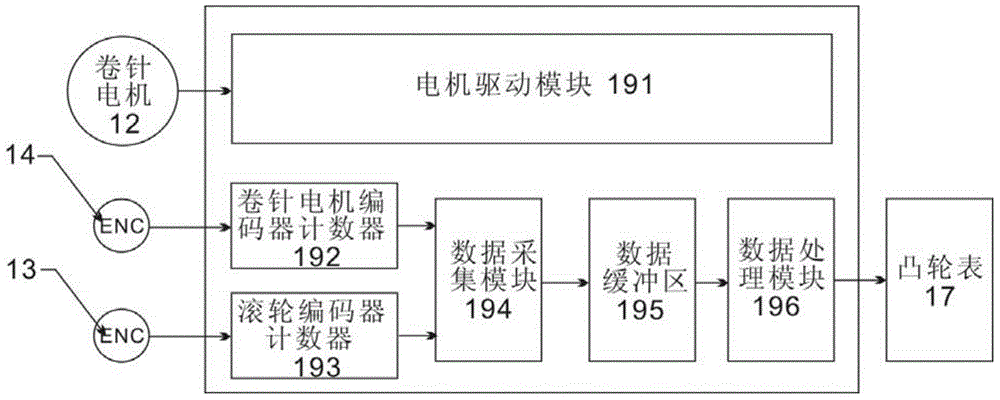

Self-learning winding device and method

ActiveCN104600348ASpeed fluctuations can be adjustedEliminate cumulative errorsAssembling battery machinesSimulator controlComputer moduleEngineering

The invention provides a self-learning winding device and a self-learning winding method. The device comprises a roller encoder used for recording the motion position of a roller, a winding needle motor encoder used for recording the motion position of a winding needle, a virtual main shaft, an electronic cam module, a cam meter, a winding control module and a self-learning module, wherein the virtual main shaft is connected with the electronic cam module; the electronic cam module and the virtual main shaft are respectively connected with the winding control module; the winding needle motor encoder and the roller encoder are connected with the self-learning module and the winding control module; the self-learning module and the winding control module are connected with a winding needle motor; the self-learning module is connected with the cam meter; and the cam meter is connected with the electronic cam module. According to the self-learning winding device provided by the invention, the actual linear velocity and target linear velocity can be acquired for performing PI operation on the basis of executing a cam curve, linear velocity fluctuation caused by reasons such as non-uniform material thickness and middle inserted pole pieces can be adjusted, and the accumulated error is eliminated.

Owner:SHENZHEN VMMORE CONTROL TECH

Production method and device of electronic components

InactiveCN101677034ALower resistanceForm easily and preciselyHybrid capacitor electrodesCapacitor terminalsOptoelectronicsElectrolytic capacitor

The present invention relates to a production method and device of electronic components. The invention provides a production method of electronic components and a device thereof, in particular provide a production method and devices for winding type electronic components (particularly electrolytic capacitors), wherein the traditional tools are replaced and a laser radiation device is used to radiate the laser to an electrode foil, in order to isolate and remove an etching layer or a coating layer from the electrode foil, and holes are formed in the electrode foil, then a groove is formed in ahorizontal side facing to the electrode foil. According to the invention, it is possible to optionally set the shape of the electrode foil from which the etching layer or the coating layer is removed, and to optionally set the shapes of the holes and the groove. As a result, it is possible to expand a contacting area between a joint of the lead wire terminal and metal of the electrode foil.

Owner:JCC ENG

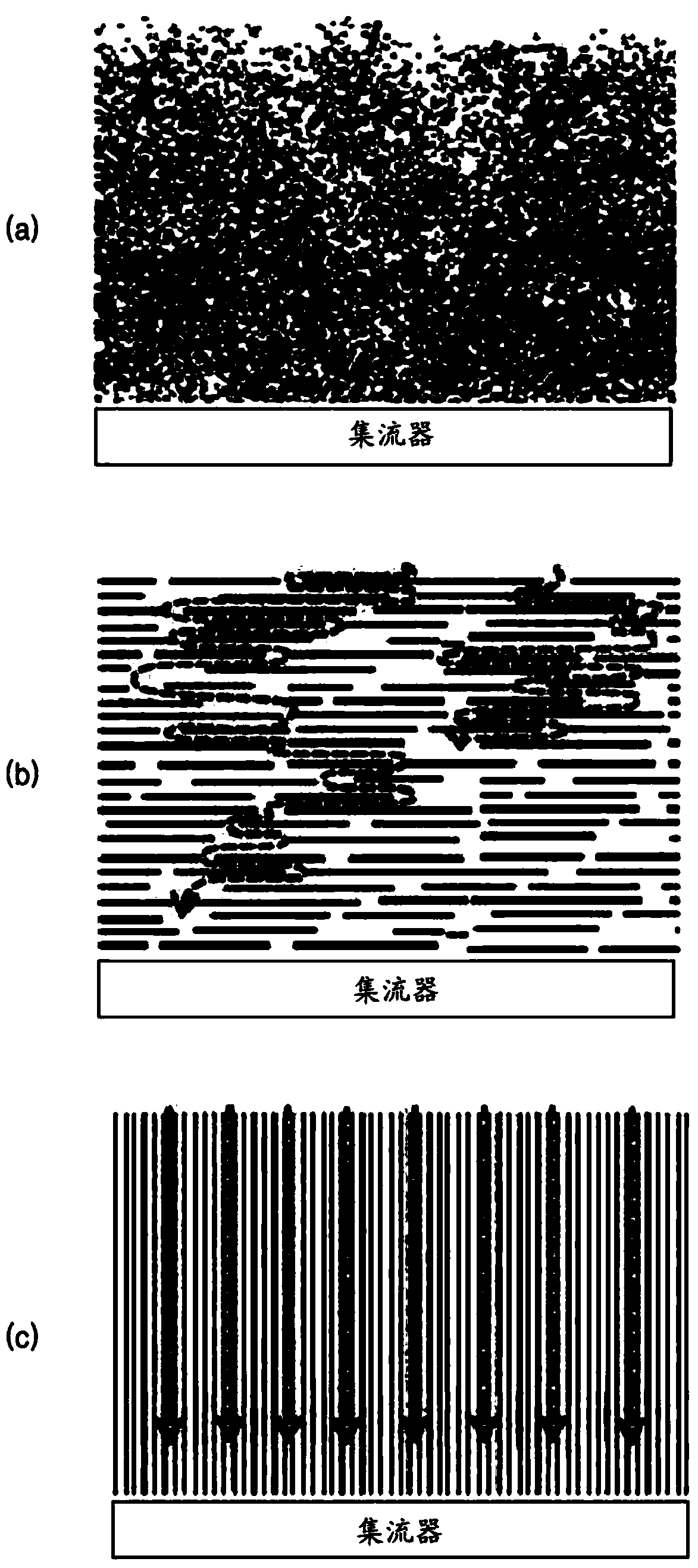

Preparation method of electrode, and apparatus

InactiveCN105355449AWon't leakHybrid capacitor electrodesWinding capacitor machinesPolyethylene glycolAlclad

The invention provides a preparation method of an electrode. An electrode is obtained by coating a current collector having penetrating holes with slurry, and a flexible substrate is adhered to the back side of the current collector when the first side of the electrode is coated. The flexible substrate is a copper foil, or an aluminium foil, or a polyethylene or polypropylene or polyethylene glycol terephthalate film. The thickness of the flexible substrate is 5-20[Mu]m. The opening ratio of the penetrating holes of the current collector is 2%-30%.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com