Electrolytic condenser nail joint coiling high speed machine

A technology of electrolytic capacitors and high-speed machines, applied in winding capacitor machines and other directions, can solve the problems of slow winding speed, inability to automatically cut positive aluminum foil, negative aluminum foil, low efficiency, etc., and achieve the effect of improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

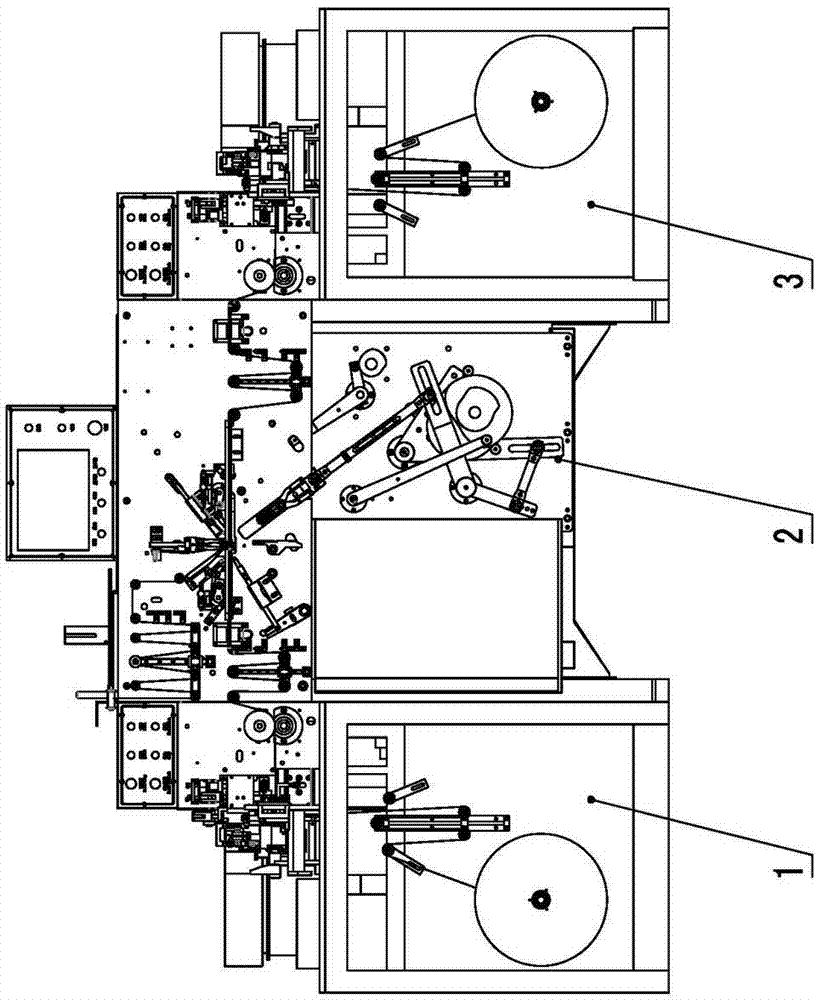

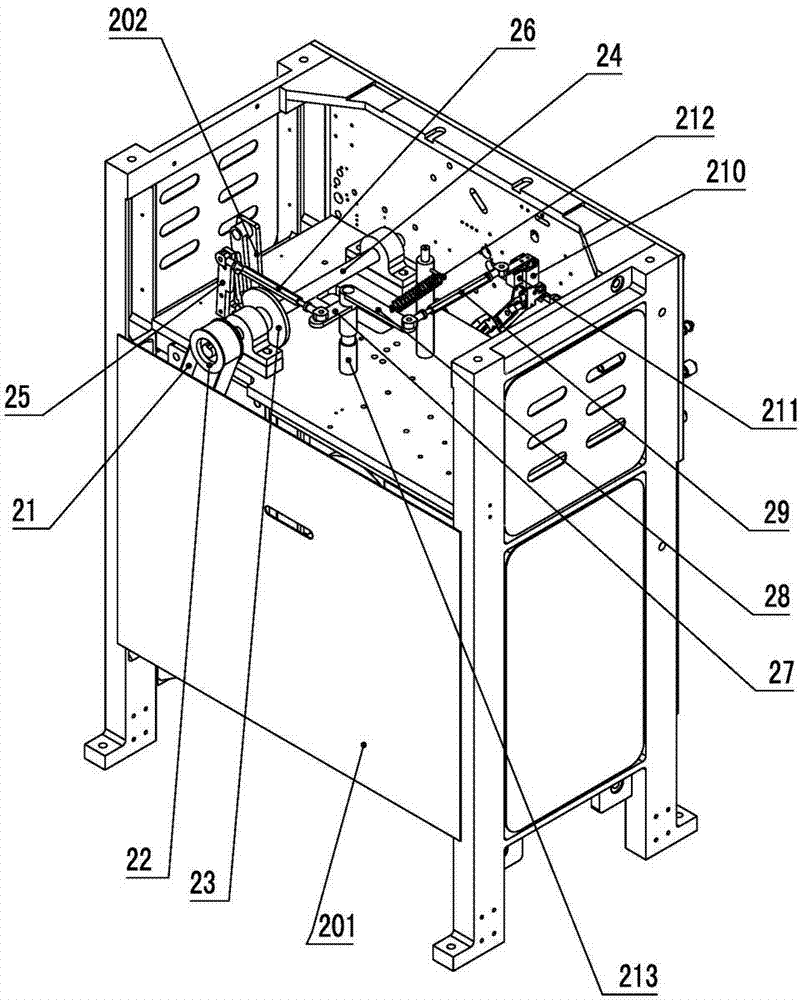

[0016] Figure 1 to Figure 2 The reference numerals in are: positive pole nailing machine 1; winding machine 2; machine base 201; swing arm fixing base 202; conveyor belt 21; The first connecting rod 26; the second swing arm 27; the second connecting rod 28; the third connecting rod 29; scissors 210; guide rail 211; return spring 212; rotating shaft 213;

[0017] Such as Figure 1 to Figure 2 As shown, a high-speed nailing and winding machine for electrolytic capacitors includes a positive nailing machine 1, a negative nailing machine 3, and a winding machine 2 between the positive nailing machine 1 and the negative nailing machine 3, and the winding machine 2 includes a machine base 201 and a winding mechanism for winding the positive aluminum foil delivered by the positive nailer 1 and the negative aluminum foil delivered by the negative na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com