Method for producing low leakage winding type solid electrolytic capacitor

A technology of solid electrolytic capacitors and production methods, applied in the direction of wire-wound capacitor machines, etc., can solve the problems of insufficient monomer polymerization, poor product characteristics, low efficiency, etc., achieve the effect of small leakage and reduce oxide film defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

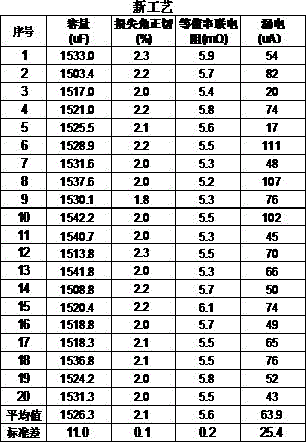

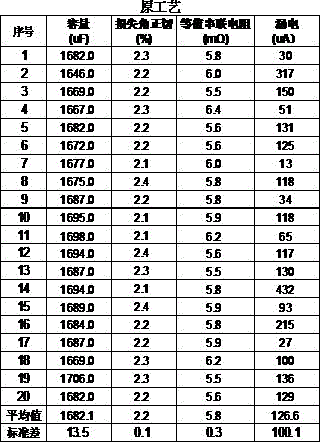

Examples

Embodiment

[0020] A method for producing a low-leakage winding solid electrolytic capacitor, comprising the following steps: 1) cutting, cutting the anode foil, cathode foil and electrolytic paper into a specified width;

[0021] 2) Element preparation, the positive guide pin is riveted on the anode aluminum foil, the negative guide pin is riveted on the cathode aluminum foil, the electrolytic paper is sandwiched between the anode foil and the cathode foil, and the core package is formed, dried, pretreated, impregnated with a single Body, impregnation oxidant, polymerization, assembly, aging; chemical formation, immerse the core package after winding in the chemical formation electrolyte for electrification, the electrification voltage is the withstand voltage of the anode foil; the formation electrolyte is an aqueous solution of ammonium dihydrogen phosphate, Its mass fraction is 0.4%, conductivity is 2.1μS / cm, and pH value is 3.2. The formation temperature is 70°C, and the formation ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com