Full-automatic nail joint winding machine and element manufacturing method thereof

A winding machine, fully automatic technology, applied in winding capacitor machines, metal processing, etc., can solve the problems of uneven overlapping of positive and negative aluminum foil, bursting, low efficiency, etc., and achieve the effect of improving production efficiency and reducing the probability of waste products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing:

[0033] The directional terms mentioned in the following embodiments, such as "up, down, left, right" are only referring to the directions of the drawings, therefore, the directional terms are used for illustration and not for limiting the present invention.

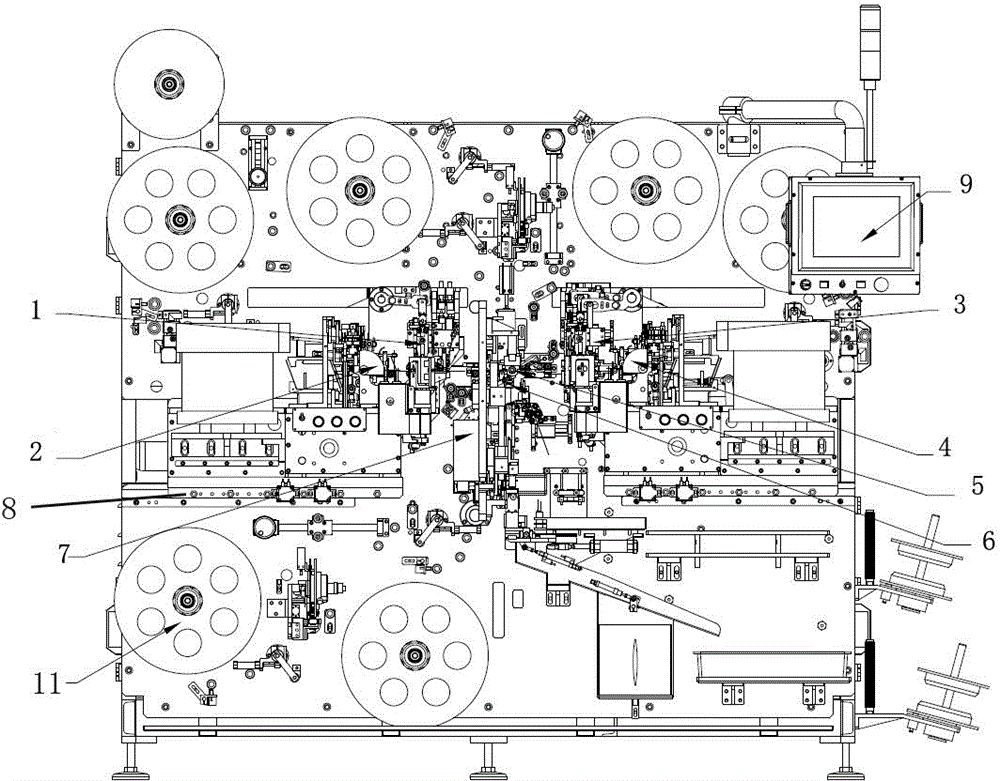

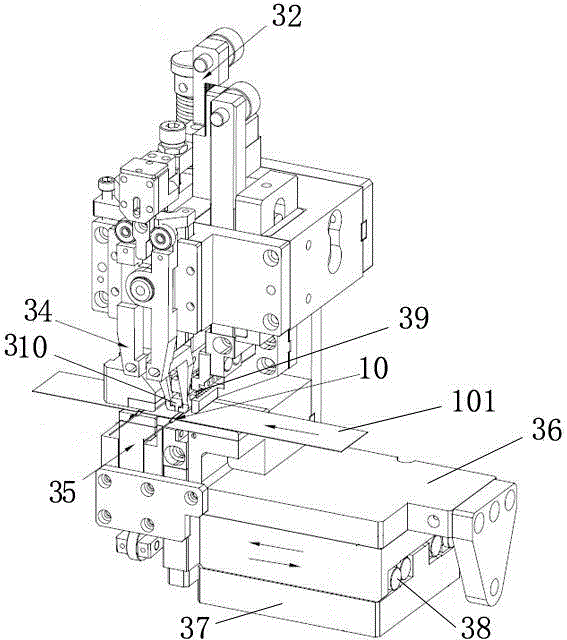

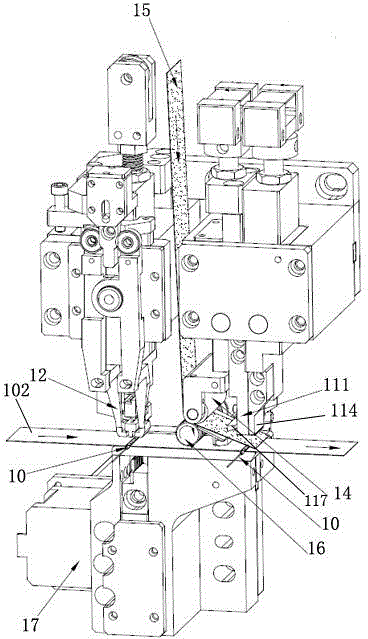

[0034] Such as figure 1 As shown, it includes a winding mechanism 5, a positive nailing machine mold mechanism 3 and a positive nailing mechanism 4 arranged on one side of the winding mechanism 5 in sequence, and a negative nailing machine mold mechanism arranged on the other side of the winding mechanism 5 in sequence 1 and the negative nailing mechanism 2, the element winding adhesive tape mechanism 6 and the element stripping mechanism 7 arranged side by side at the lower end of the winding mechanism 5; Direction selection mechanism 8; the above-mentioned mechanisms are all connected with a control panel circuit 9....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com