Self-learning winding device and method

A winding device and self-learning technology, applied in the direction of assembling battery machines, winding capacitor machines, instruments, etc., can solve problems such as difficult simulation, line speed fluctuation, poor control effect, etc., and achieve the effect of eliminating accumulated errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

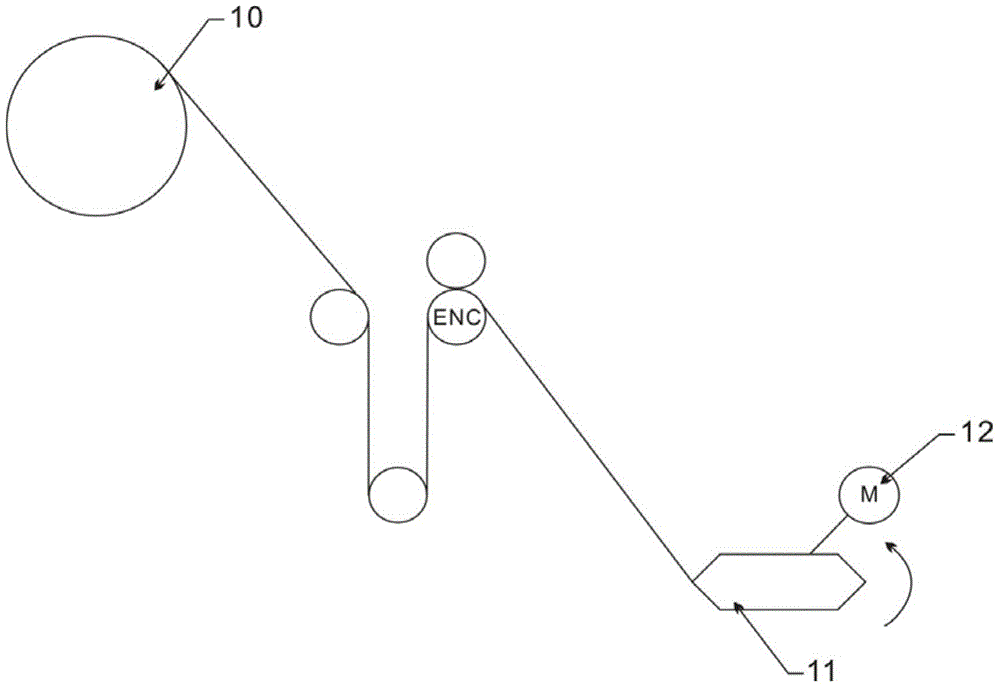

[0049] see figure 1 , The existing battery capacitor winding device mainly consists of a roller 10, a winding needle 11 and a winding needle motor 12.

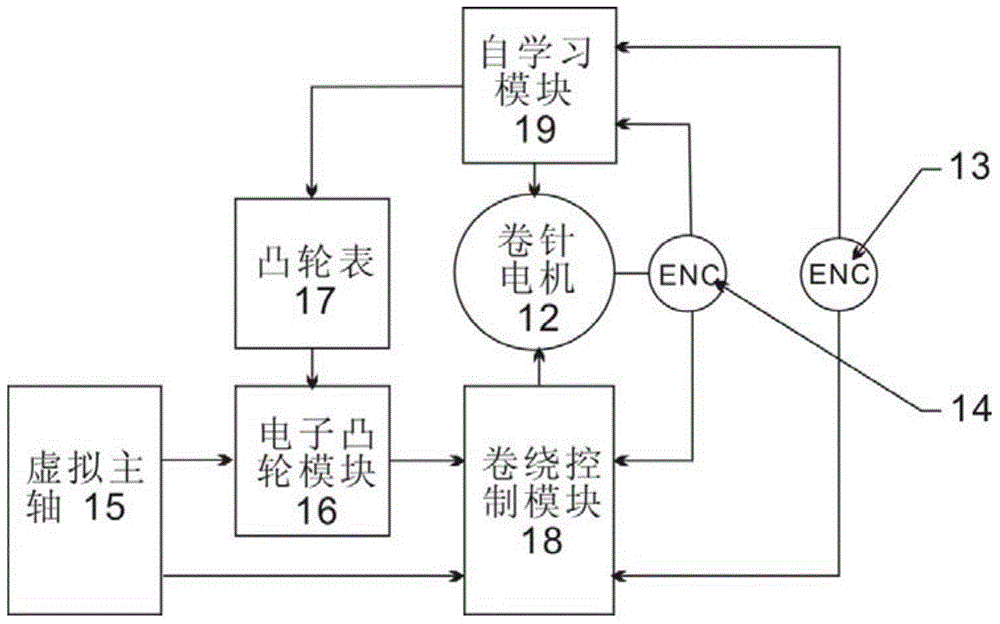

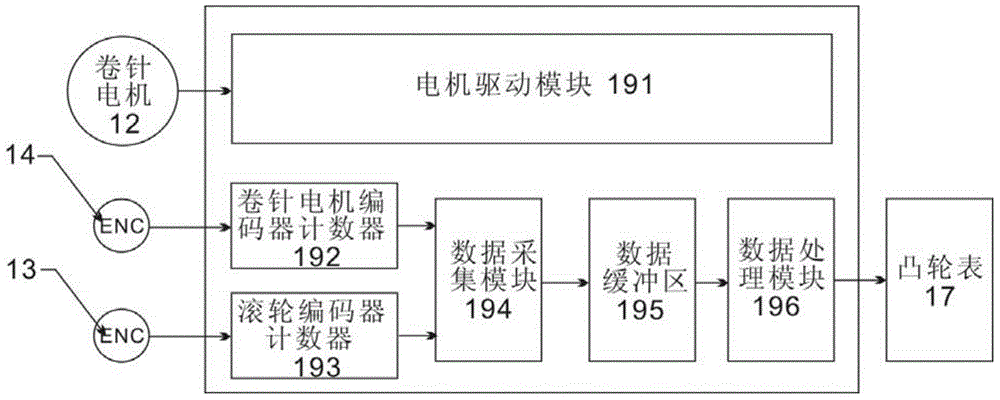

[0050] see figure 2 , the self-learning winding device provided by the present invention includes a roller encoder 13 for recording the movement position of the roller 10, a needle winding motor encoder 14 for recording the movement position of the winding needle 11, a virtual main shaft 15, an electronic cam module 16, Cam table 17, winding control module 18 and self-learning module 19; virtual main shaft 15 is connected with electronic cam module 16, and electronic cam module 16 and virtual main shaft 15 are respectively connected with winding control module 18; winding needle motor encoder 14 and roller The encoders 13 are all connected with the self-learning module 19 and the winding control module 18, and the self-learning module 19 and the winding control module 18 are also connected with the winding needle motor 12; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com