AGV composite navigation method based on quick response code and inertia sensor

An inertial sensor and composite navigation technology, applied in the field of automatic guided vehicle path navigation, can solve problems such as high environmental requirements, high cost, and difficult development, achieve high-precision navigation and positioning, eliminate accumulated errors, and reduce the amount of calculation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

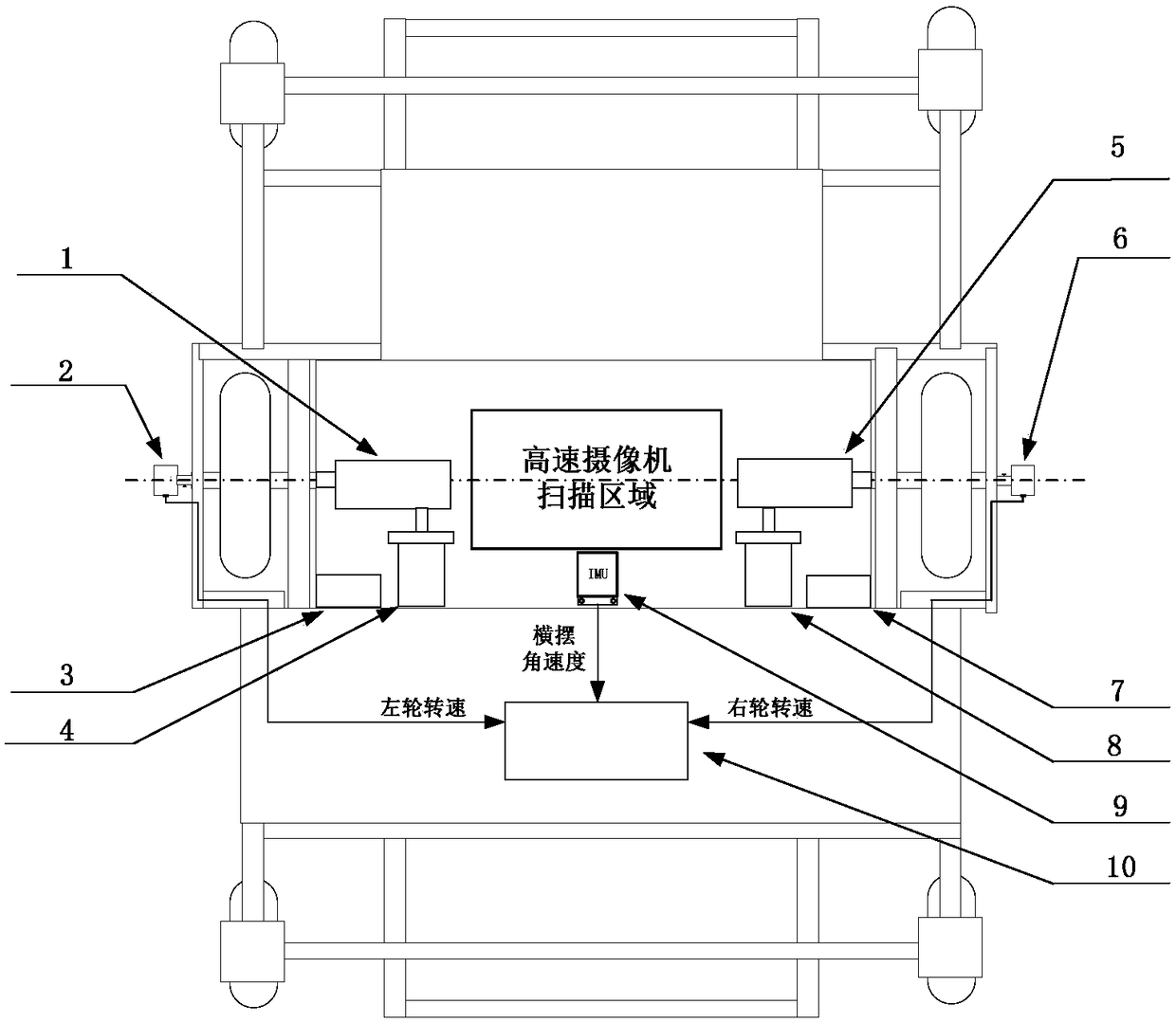

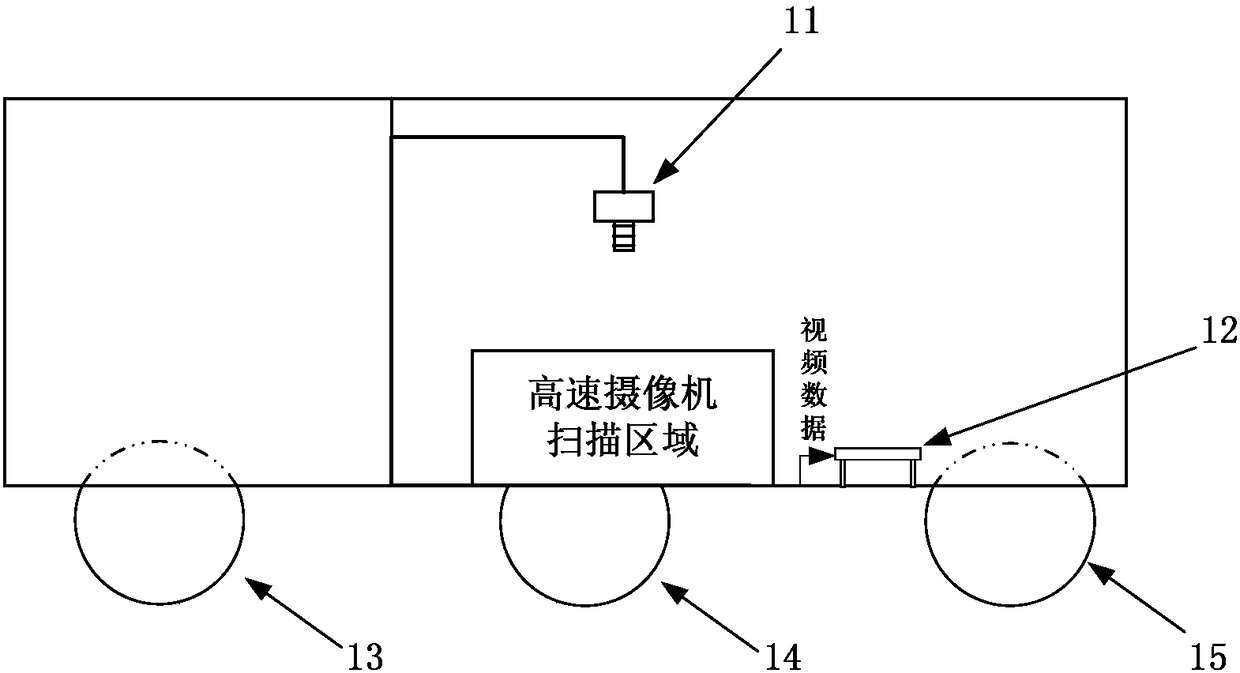

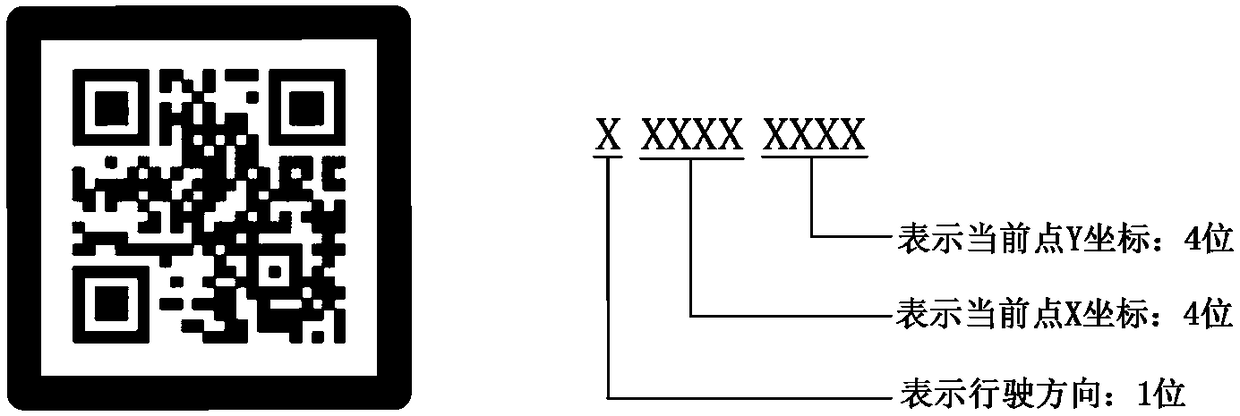

[0058] In this embodiment, an AGV composite navigation method based on two-dimensional codes and inertial sensors is applied in smart factories, smart manufacturing, and smart logistics. In the factory workshop, a grid map of AGV walking space is established through two-dimensional code labels. Two-dimensional The code label contains site location coordinate information and direction information; through the vehicle-mounted industrial high-speed camera to dynamically identify the two-dimensional code frame in the grid map, estimate the longitudinal and lateral distance deviation and direction deviation when the AGV reaches the two-dimensional code label, and calculate the deviation As the initial deviation of inertial navigation between stations, the cumulative error of inertial navigation can be eliminated, and the purpose of precise navigation can be achieved. Specifically, proceed as follows:

[0059] step 1, Figure 1A and Figure 1B Shown is a schematic diagram of the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com