Rolling device of electrode material

A technology of electrode materials and rolling equipment, applied in electrode manufacturing, battery electrodes, lamination, etc., can solve problems such as not raised

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

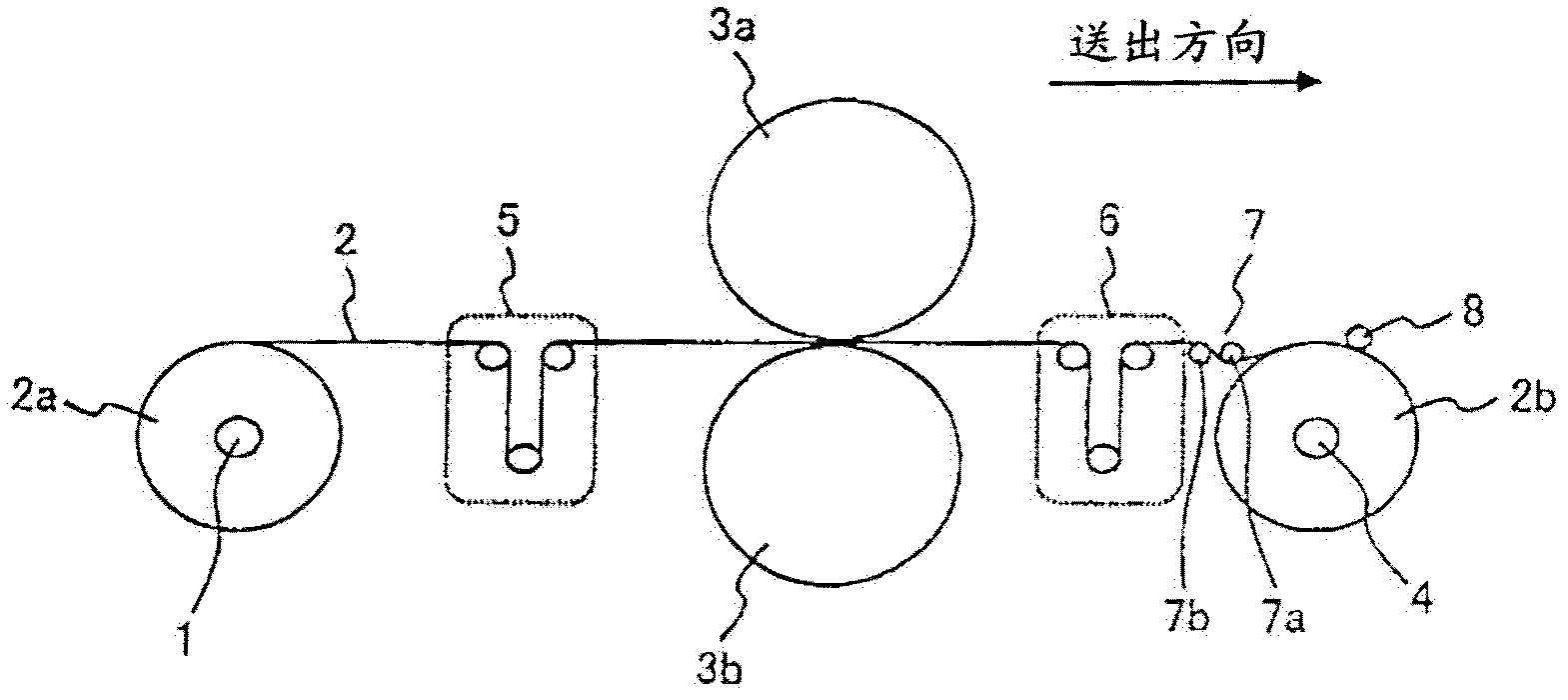

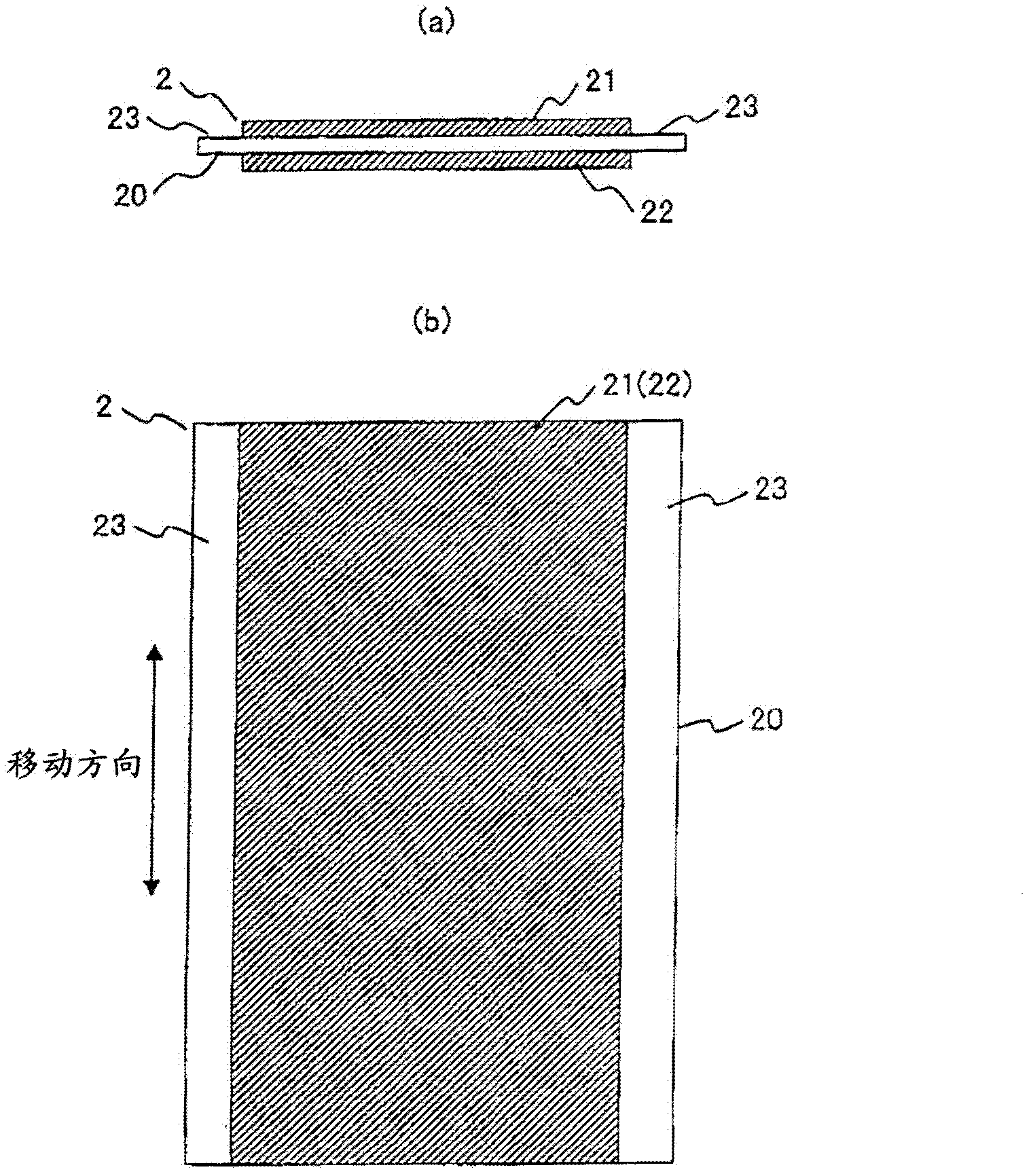

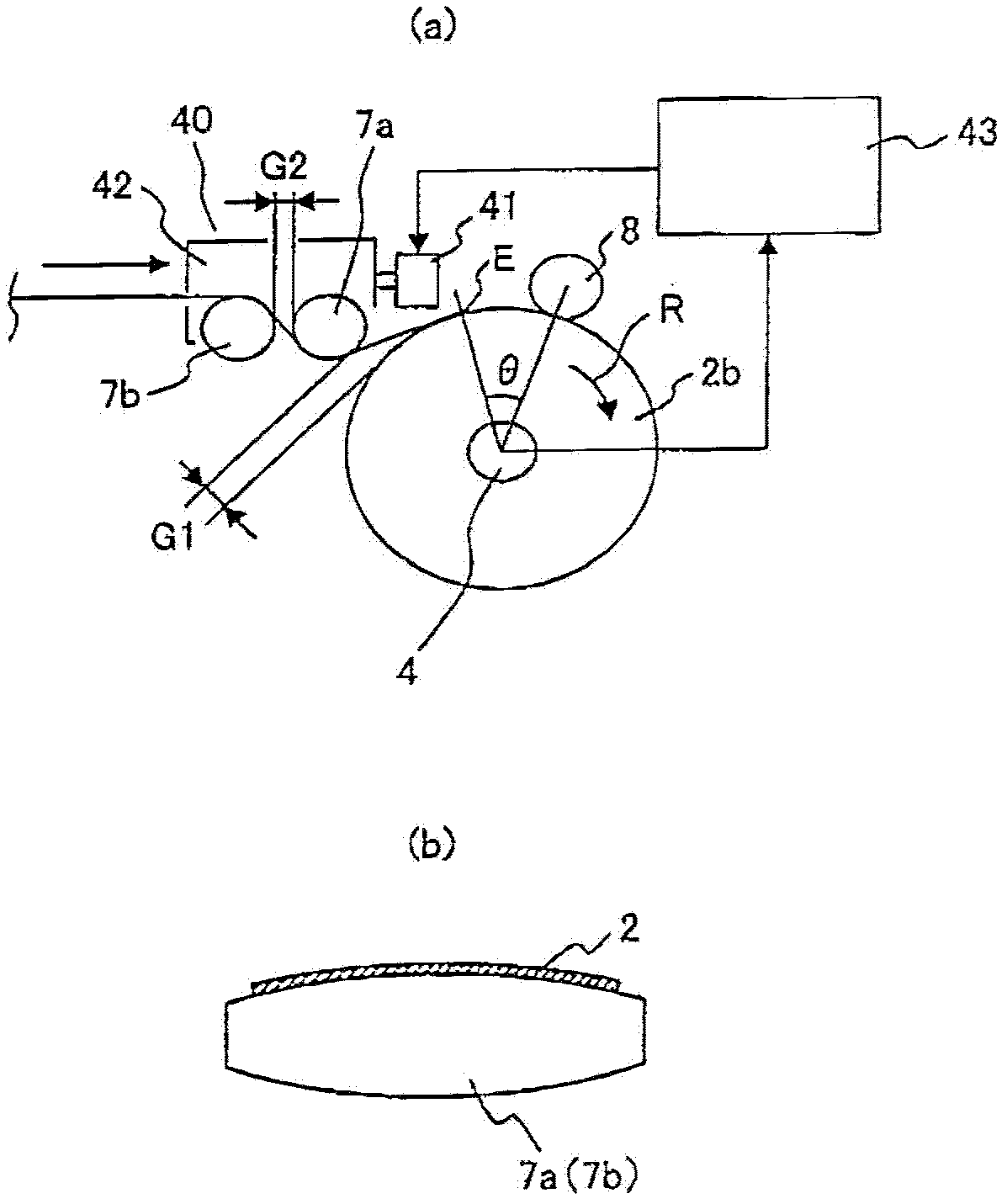

[0027] figure 1 It is a system configuration diagram showing the overall outline of the rolling equipment for electrode materials according to the first embodiment of the present invention. The rolling equipment of this embodiment generally has: an unwinding shaft (uncoiling device) 1 on which an uncoiled roll 2a of the electrode material 2 is wound; rolls (upper pressure roll 3a, lower pressure roll 3b); and a reel (winding device) 4 for winding the compressed electrode material 2 to produce a wound roll 2b. A tension control mechanism 5 for the counter electrode material 2 is provided between the unwinding device 1 (unrolled roll 2a) and the main rolls 3a, 3b. Between the main rolls 3a, 3b and the unwinding device 4 (winding roll 2b), a tension control mechanism 6 and a guide roll mechanism 7 on the winding side (guide rolls 7a, 7b) are provided.

[0028] The guide rollers 7a, 7b are constituted by rollers formed in a convex shape or a true cylindrical shape.

[0029] The...

Embodiment 2

[0052] Figure 4 It is a side view showing the electrode material winding mechanism of the rolling equipment for electrode materials according to the second embodiment of the present invention, Figure 5 express Figure 4 The top view of the electrode material winding mechanism of the embodiment.

[0053] In this embodiment, the main structure of the rolling equipment is the same as that of the first embodiment, and only the differences from the first embodiment will be described here. The same reference numerals as those of the first embodiment denote the same or shared constituent elements.

[0054] In the first embodiment, the adjacent guide roller movement control is performed by calculating the outer diameter D of the winding roller 2 b by the control device 43 , but in this embodiment, the control is performed as follows instead. That is, the guide roller movement control mechanism has the winding coil outer diameter detection sensor 71 which performs movement control...

Embodiment 3

[0058] Figure 7 It is a side view showing the electrode material winding mechanism of the rolling equipment for electrode materials according to the third embodiment of the present invention, Figure 8 express Figure 7 The top view of the electrode material winding mechanism of the embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com