Manufacturing method of solid-state electrolytic capacitor

A technology of solid electrolytic capacitors and manufacturing methods, which is applied in the direction of solid electrolytic capacitors, electrolytic capacitors, capacitors, etc., which can solve the problems of weak repair ability of positive oxide film defects, high cost of dispersion liquid research and development, cumbersome production process, etc., to achieve increased capacity Extraction rate, solution to insufficient withstand voltage, and high-capacity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

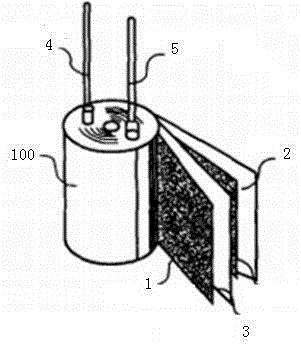

[0039] This embodiment includes the following steps:

[0040] A1. To make the element, cut the positive foil, negative foil and electrolytic paper according to the designed size through a nailing machine, then rivet the positive guide pin and the negative guide pin on the positive foil and the negative foil respectively, and then clip the positive foil and the negative foil The electrolytic paper is wound into a circle, and finally the outer periphery of the circle is wrapped with high-temperature-resistant insulating tape to fix it to form a prime;

[0041] A2. The first impregnation stage. In this stage, the element is impregnated with the high-pressure formation solution of the boric acid system. By applying a voltage of 400V to the guide wire and a current density of 0.05mA / pcs, the oxide film defects on the surface of the positive foil caused by cutting and nailing will be eliminated. Department for repair;

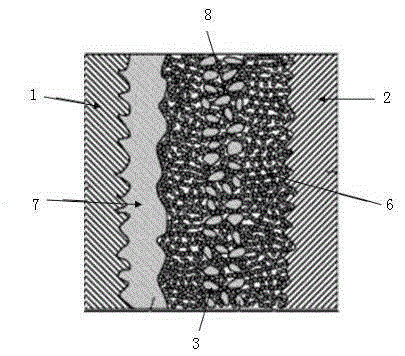

[0042] A3. The second impregnation stage. At this stage, the e...

Embodiment 2

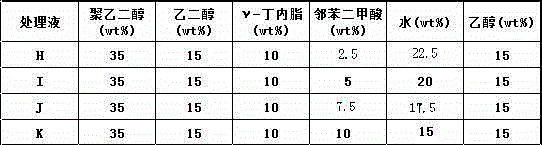

[0047] The steps and principles of this embodiment are basically the same as those of Embodiment 1, except that the treatment liquid used in step A4 is the treatment liquid B in this embodiment, which includes polyethylene with a molecular weight of 600 Diol, calculated by weight percentage, polyethylene glycol (PEG) 35%, ethylene glycol (EG) 15%, γ-butyrolactone 10% (GBL), ethanol 15%, water 20% and phthalic acid 5%.

Embodiment 3

[0049] The steps and principles of this embodiment are basically the same as those of Embodiment 1, except that the treatment liquid used in step A4 is the treatment liquid C, which includes polyethylene glycol with a molecular weight of 1000. Diol, calculated by weight percentage, polyethylene glycol (PEG) 35%, ethylene glycol (EG) 15%, γ-butyrolactone 10% (GBL), ethanol 15%, water 20% and phthalic acid 5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com