Implantable devices using rechargeable zero-volt technology lithium-ion batteries

a technology of lithium-ion batteries and implantable devices, which is applied in the field of implantable pulse generators, can solve the problems of limited battery life, not all of the features of one device, and no one can teach the use of rechargeable zero-volt technology batteries within the implanted portion of the system, so as to ensure the safe and reliable operation of the system, simple connection, and high volumetric and gravimetric energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041]The following description is of the best mode presently contemplated for carrying out the invention. This description is not to be taken in a limiting sense, but is made merely for the purpose of describing the general principles of the invention. The scope of the invention should be determined with reference to the claims.

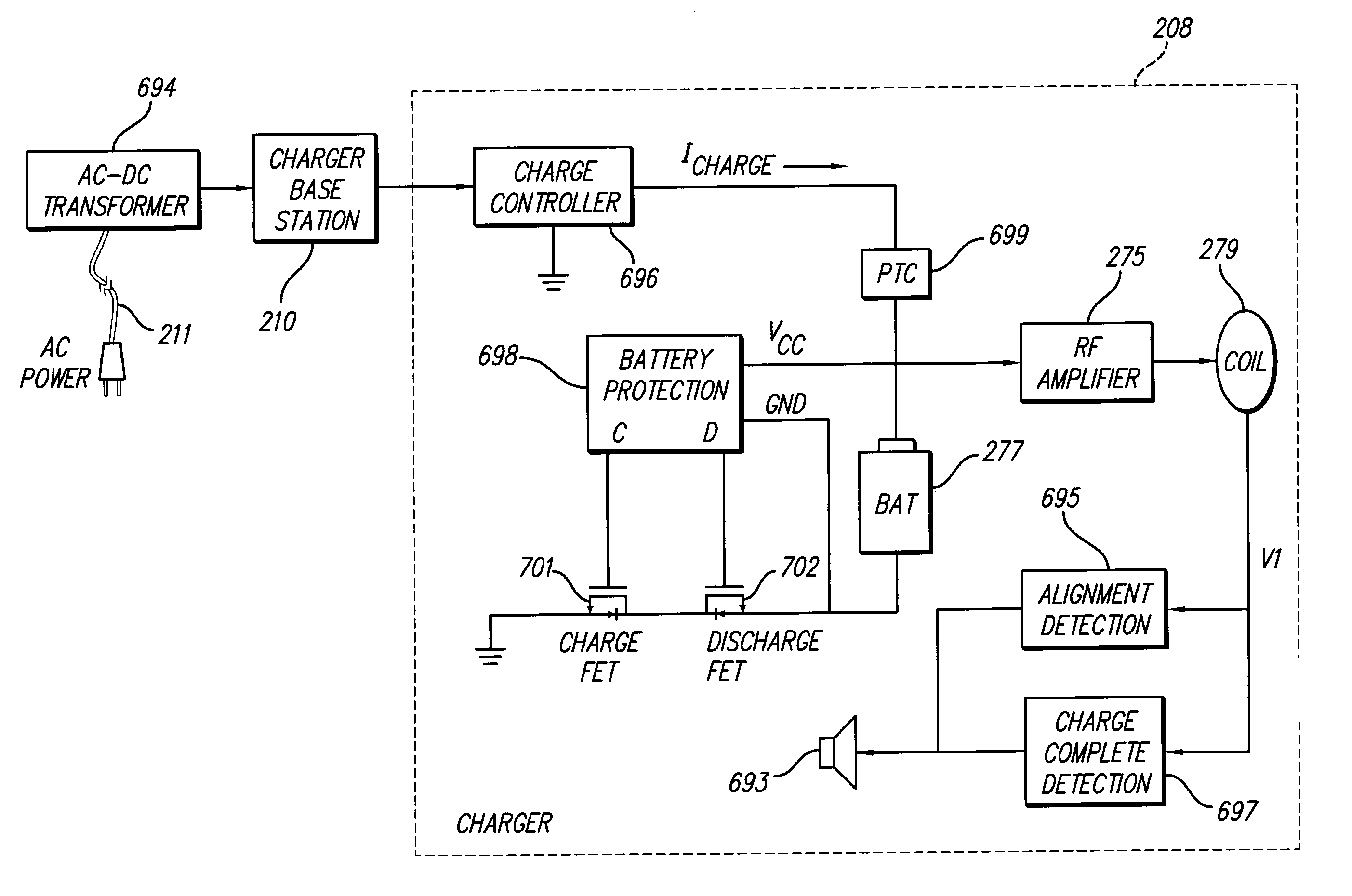

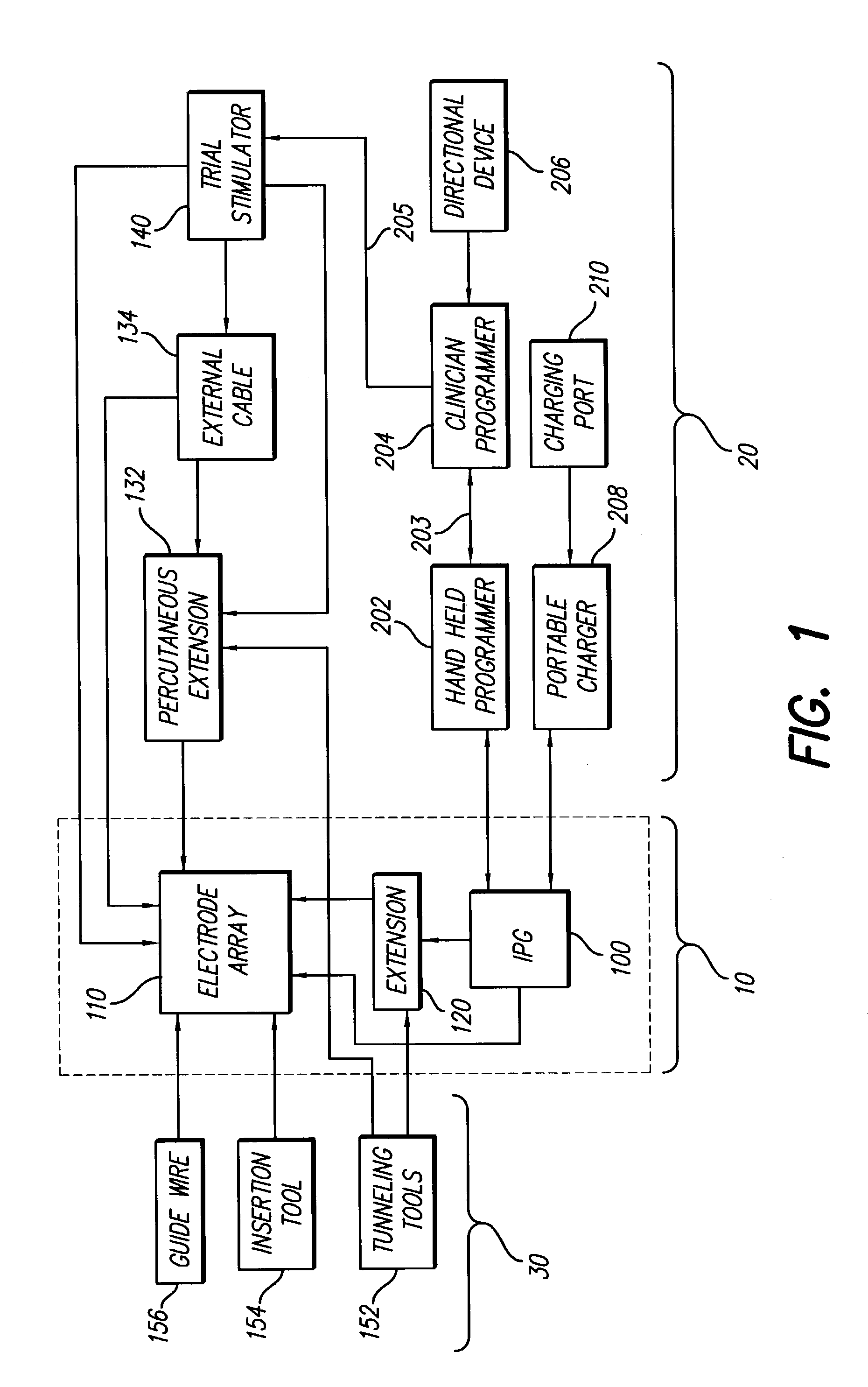

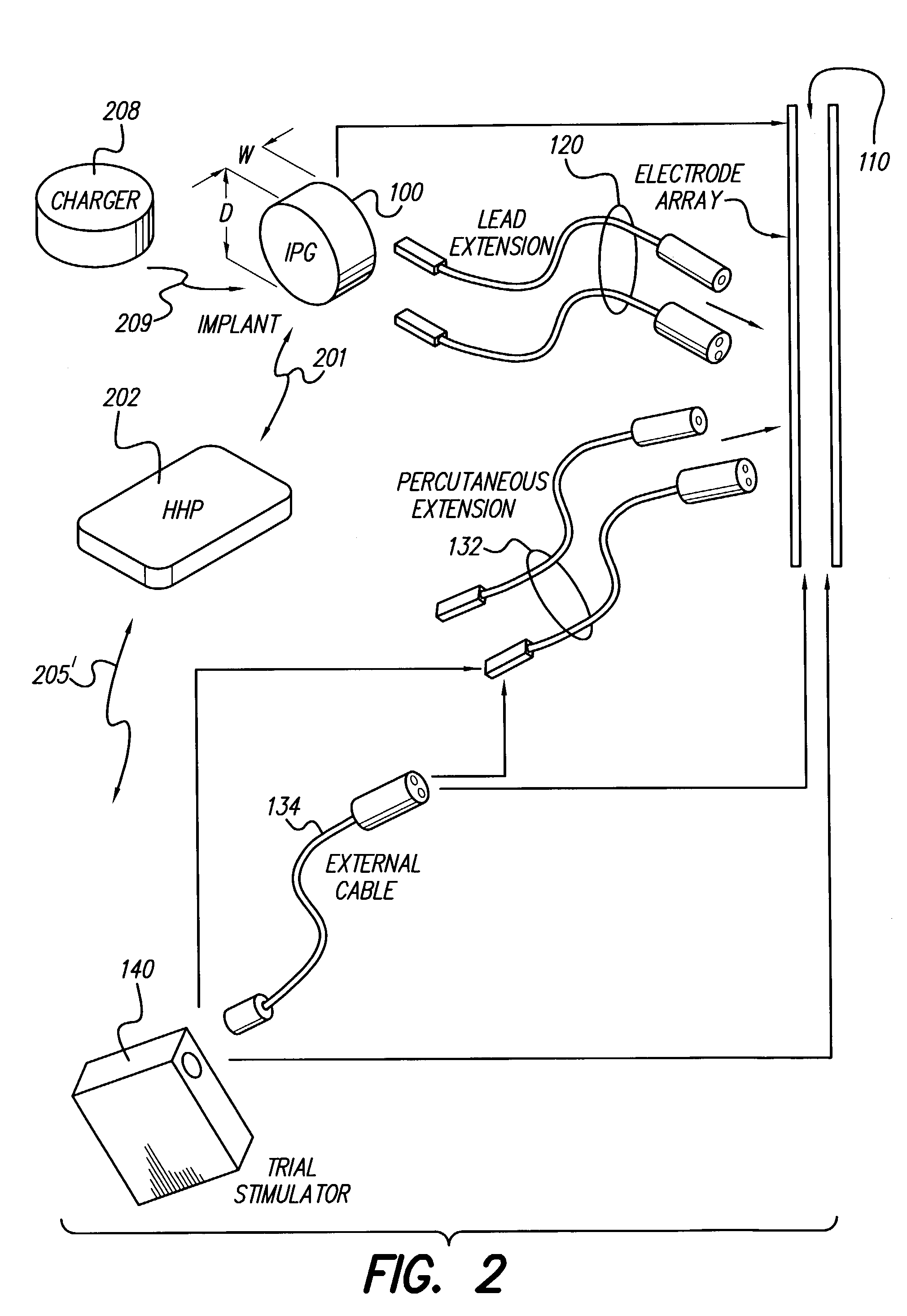

[0042]At the outset, it is noted that the present invention may be used with an implantable pulse generator (IPG), or similar electrical stimulator and / or electrical sensor, that may be used as a component of numerous different types of stimulation systems. The description that follows relates to use of the invention within a spinal cord stimulation (SCS) system. However, it is to be understood that the invention is not so limited. Rather, the invention may be used with any type of implantable electrical circuitry that could benefit from deriving its operating power from a rechargeable battery.

[0043]Further, while the invention is described in connection wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com