Novel lightning-stroke protection aluminium electrolytic capacitor and preparation method therefor

An aluminum electrolytic capacitor and anti-lightning strike technology, which is applied in the direction of capacitor manufacturing, capacitors, and wire-wound capacitor machines, can solve the problems of poor high-voltage impact resistance, capacitor life failure, and insufficient electrolyte adsorption capacity, etc. Strong impact ability and the effect of improving the withstand voltage ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

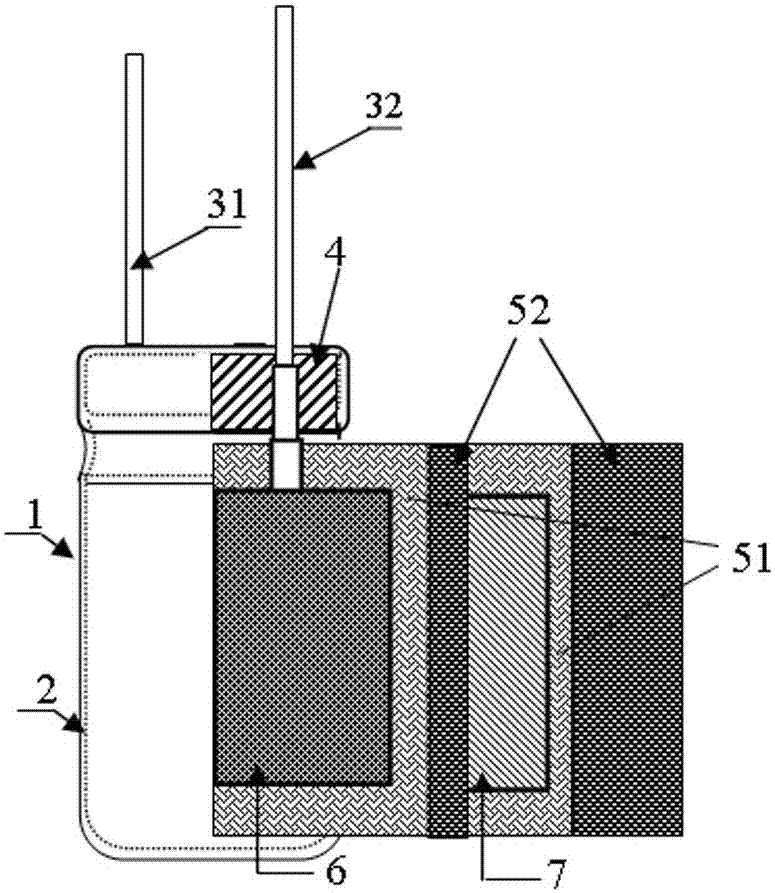

[0031] A new type of anti-lightning aluminum electrolytic capacitor preparation method, the steps are as follows:

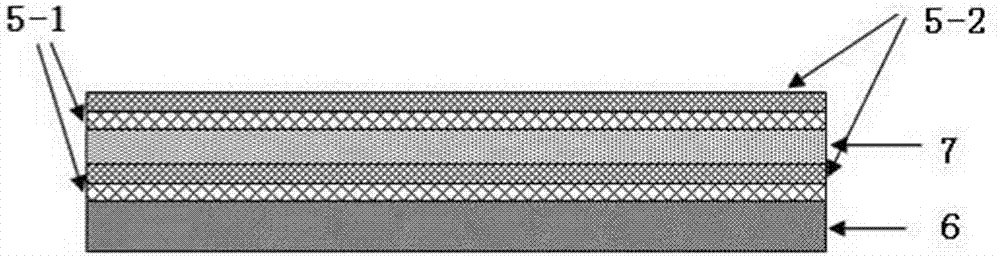

[0032] 1) Cutting, cutting cathode foil, anode foil and electrolytic paper, wherein the electrolytic paper includes an inner layer of electrolytic paper and an outer layer of electrolytic paper, the inner layer of electrolytic paper is located inside the corresponding cathode foil or anode foil, and the inner layer is electrolyzed The tightness of the paper and the outer electrolytic paper are the same;

[0033] 2) Nail, through the encapsulation layer to nail the positive electrode lead pin and the negative electrode lead pin to the anode foil and the cathode foil respectively, and stack the electrolytic paper, cathode foil, and anode foil into electrolytic paper-cathode foil-electrolytic paper-anode foil The layered structure is wound into a core package, wherein the electrolytic paper includes an inner layer of electrolytic paper and an outer layer of electrolytic ...

Embodiment 2

[0046] This embodiment is basically the same as embodiment 1, except that, in this embodiment, the composition of the electrolyte includes: 30% hexanediol, 0.7% pure water, 0.7% ammonium sebacate, and 1.5 ammonium pentapentanoate. %, ammonium isosebacate 5%, p-nitrobenzoic acid 0.52%, hypophosphorous acid 0.9%, citric acid 2%, diethylene glycol 2%.

Embodiment 3

[0048] This embodiment is basically the same as Embodiment 1, except that, in this embodiment, the composition of the electrolyte includes: hexanediol 35%, pure water 1.2%, ammonium sebacate 1.5%, and ammonium pentapentanoate 2.2% , Ammonium isosebacate 8%, p-nitrobenzoic acid 0.70%, hypophosphorous acid 1.5%, citric acid 2%, diethylene glycol 2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com