Patents

Literature

431results about "Encapsulating capacitors apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

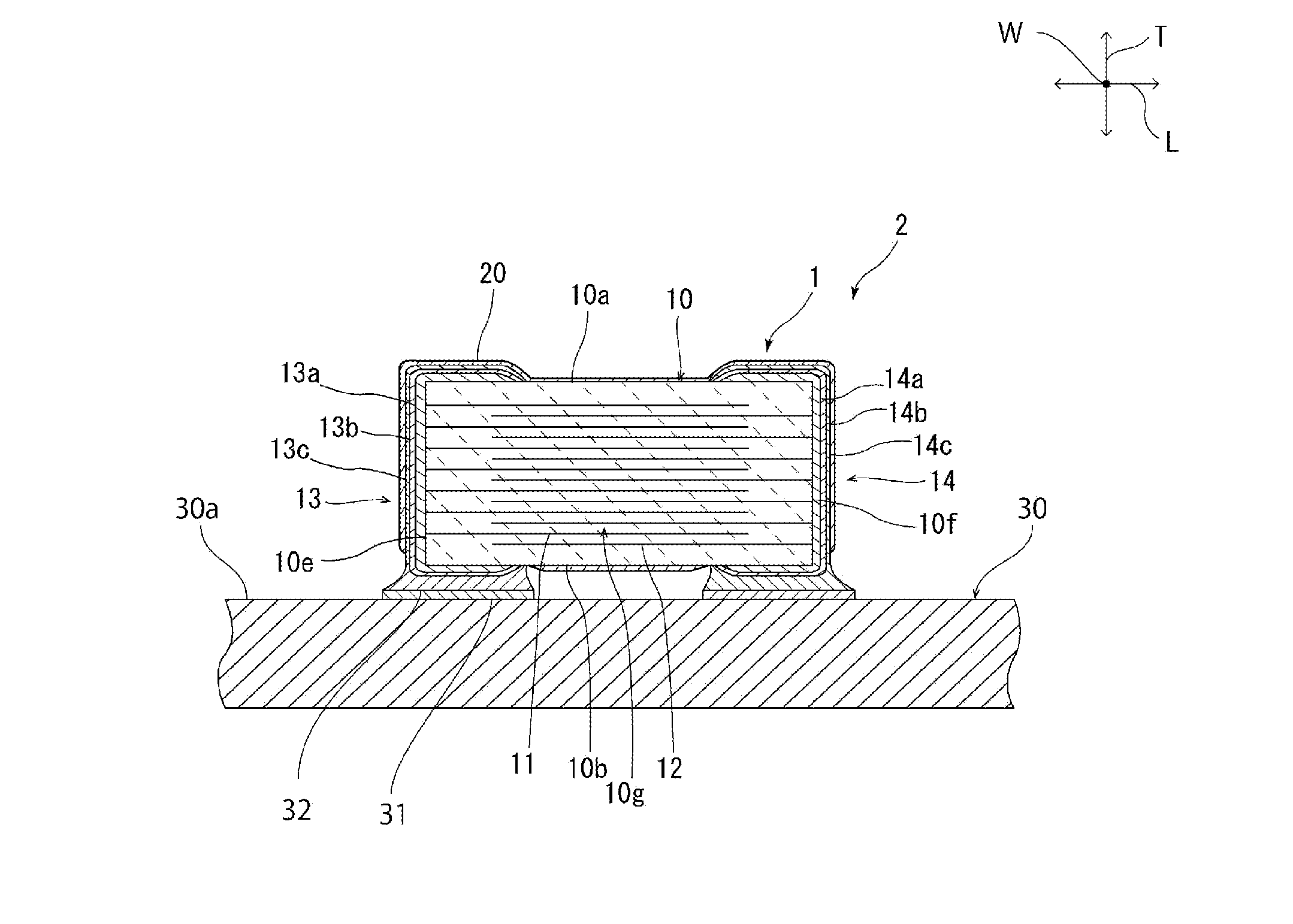

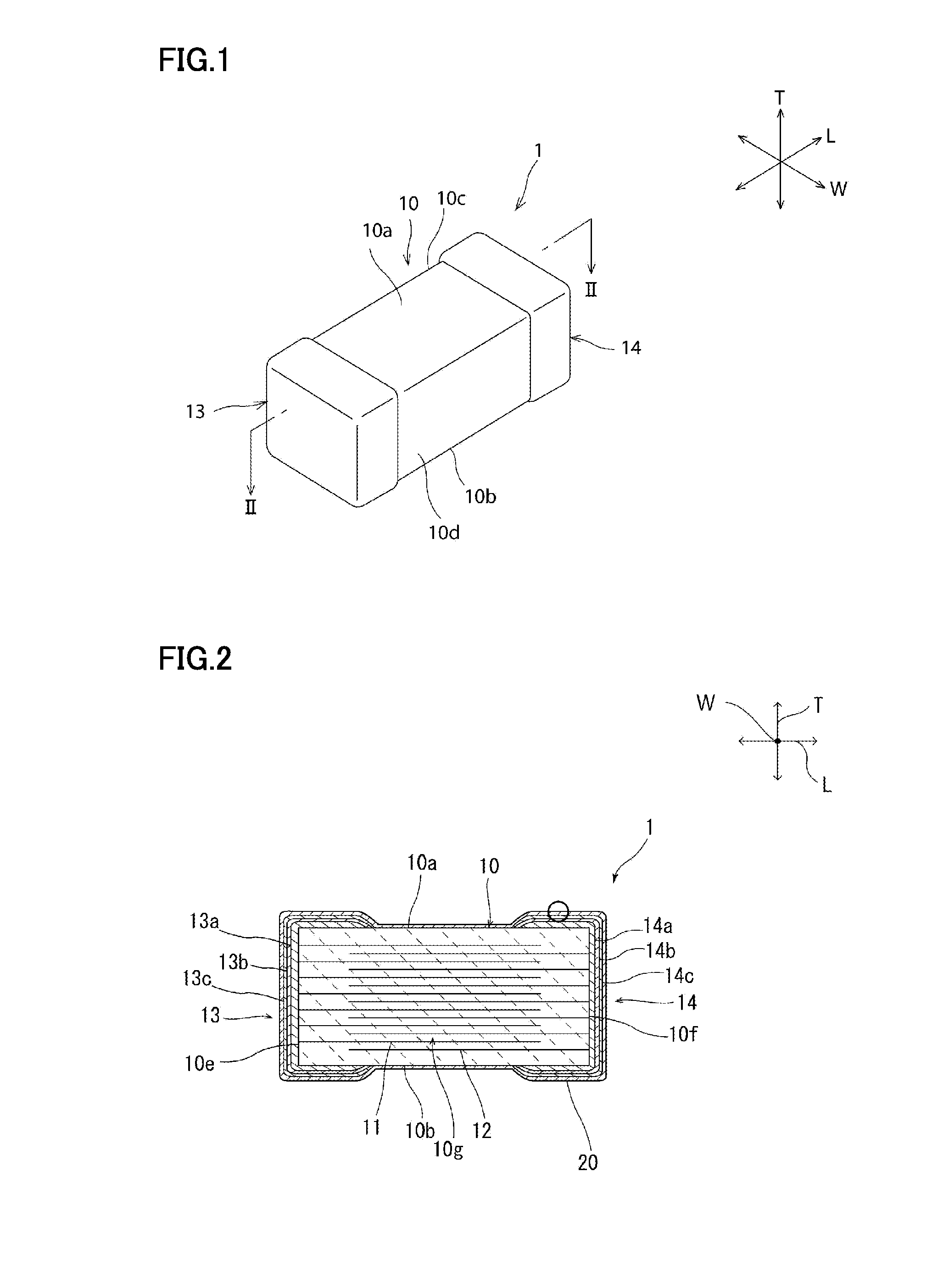

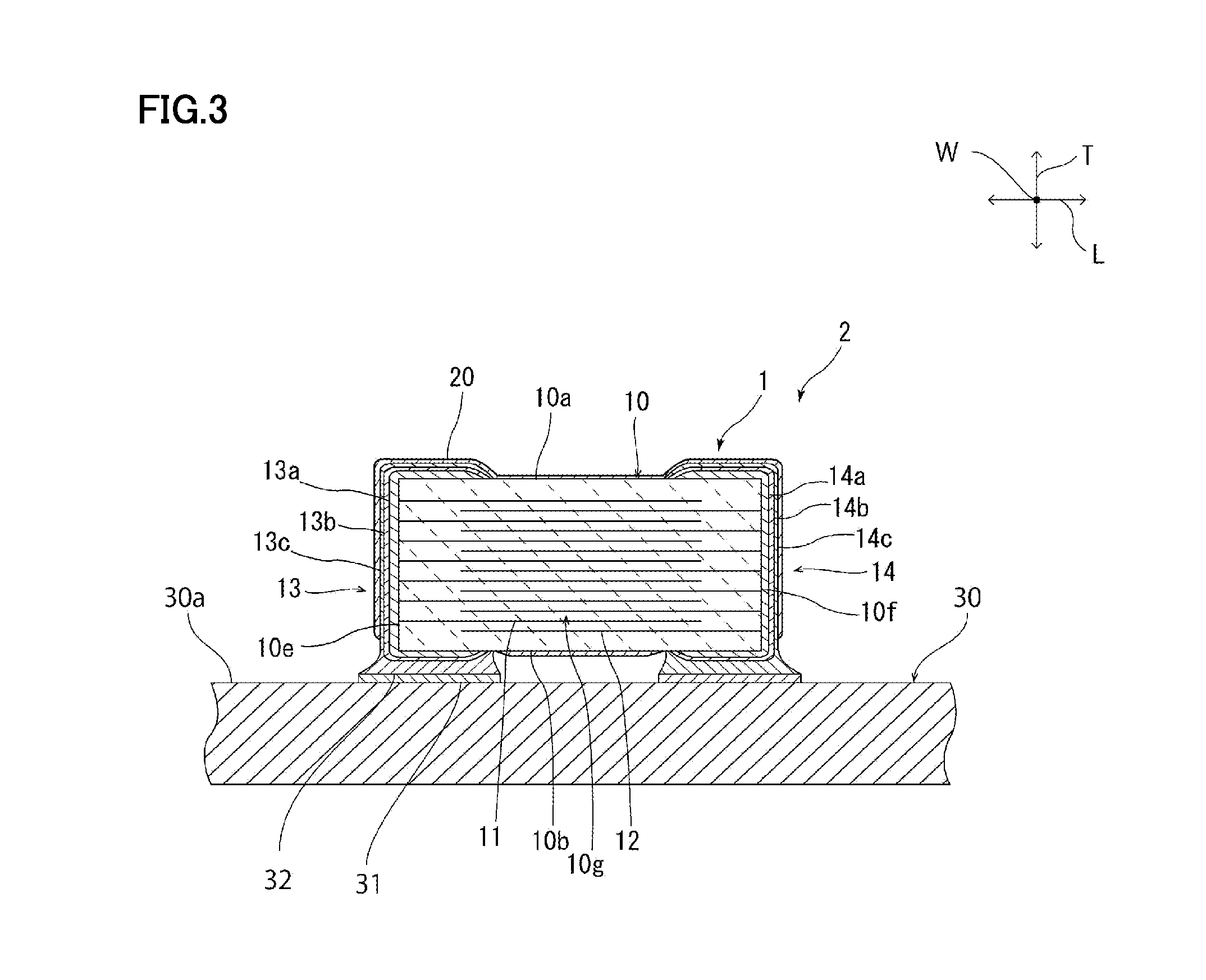

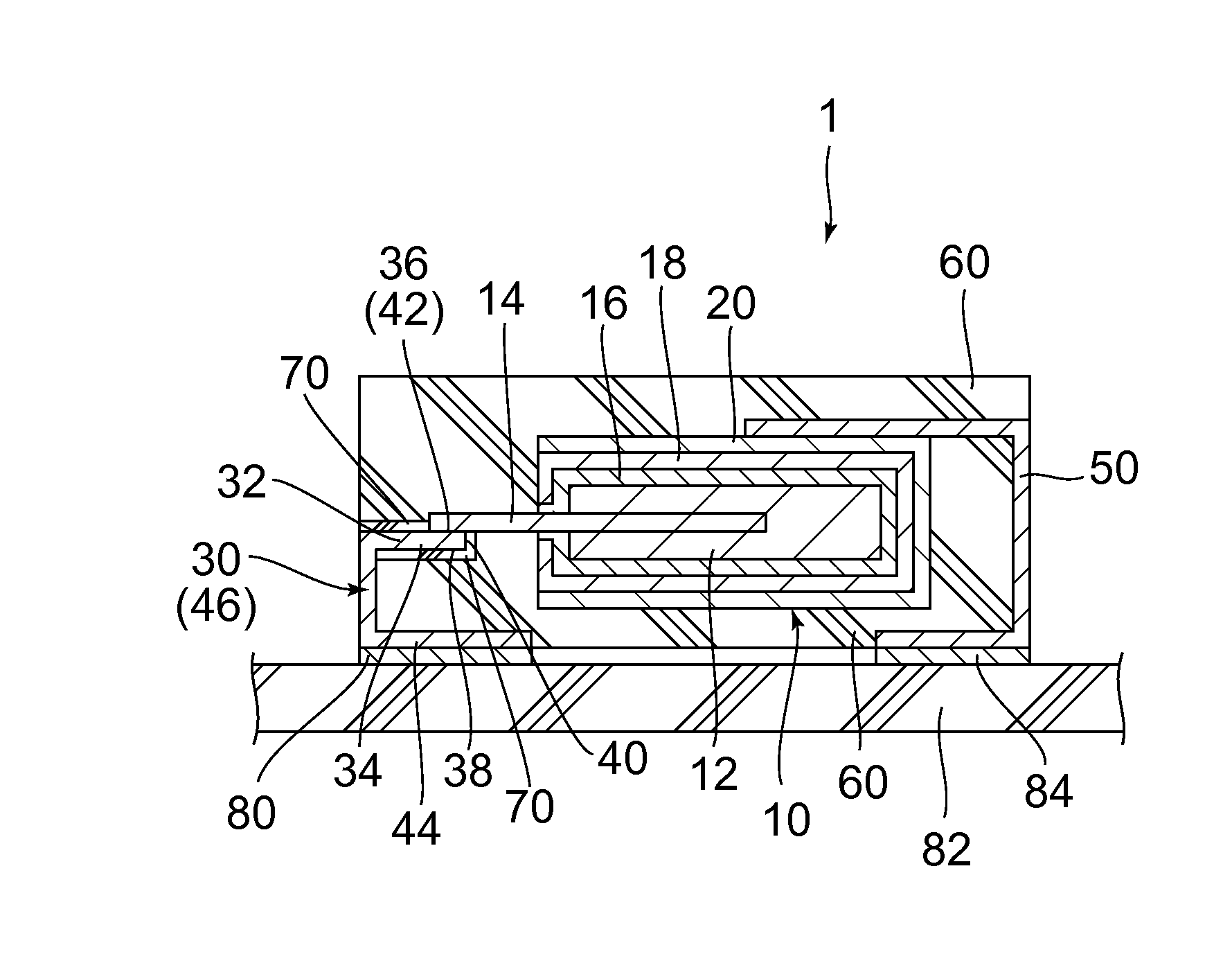

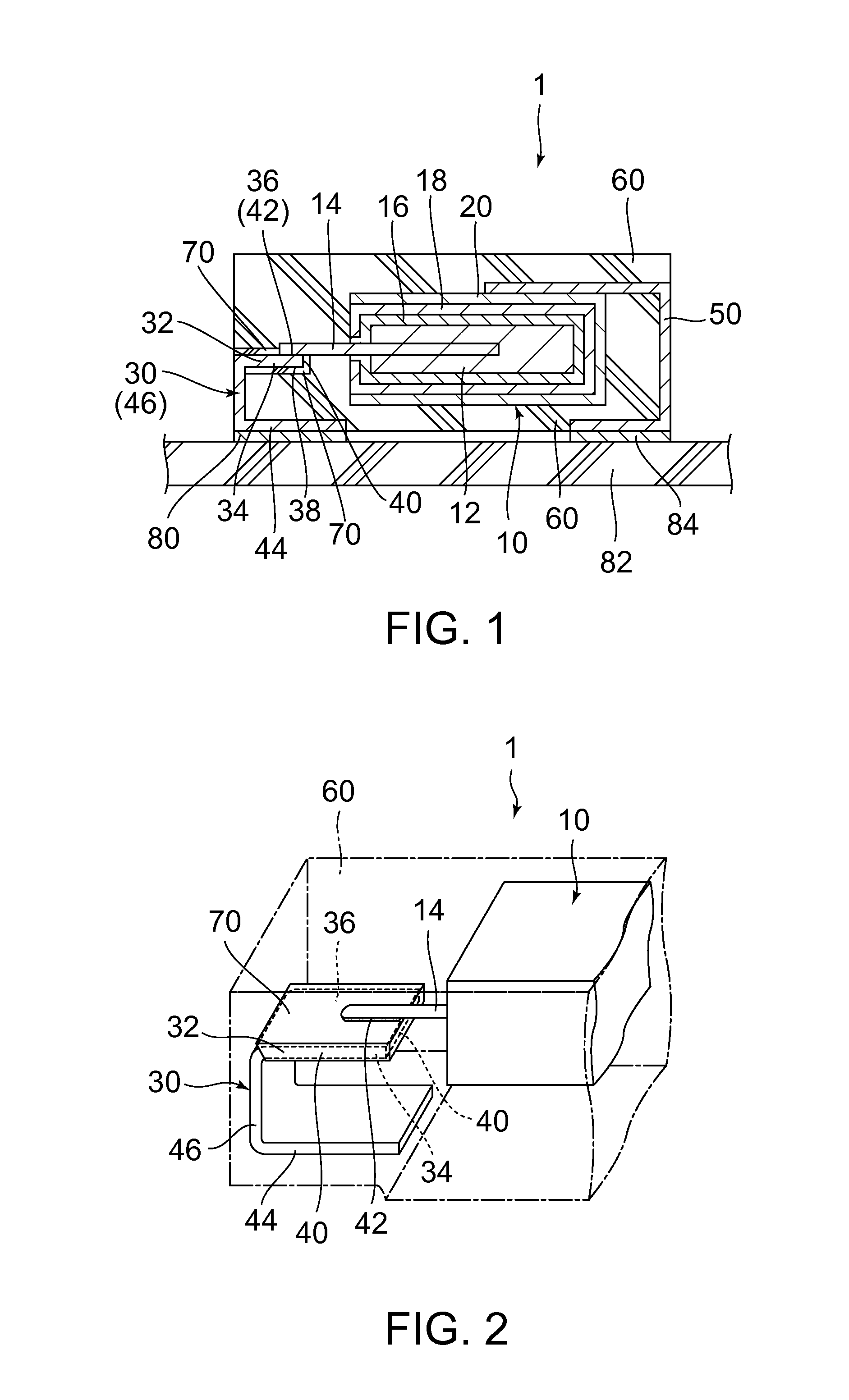

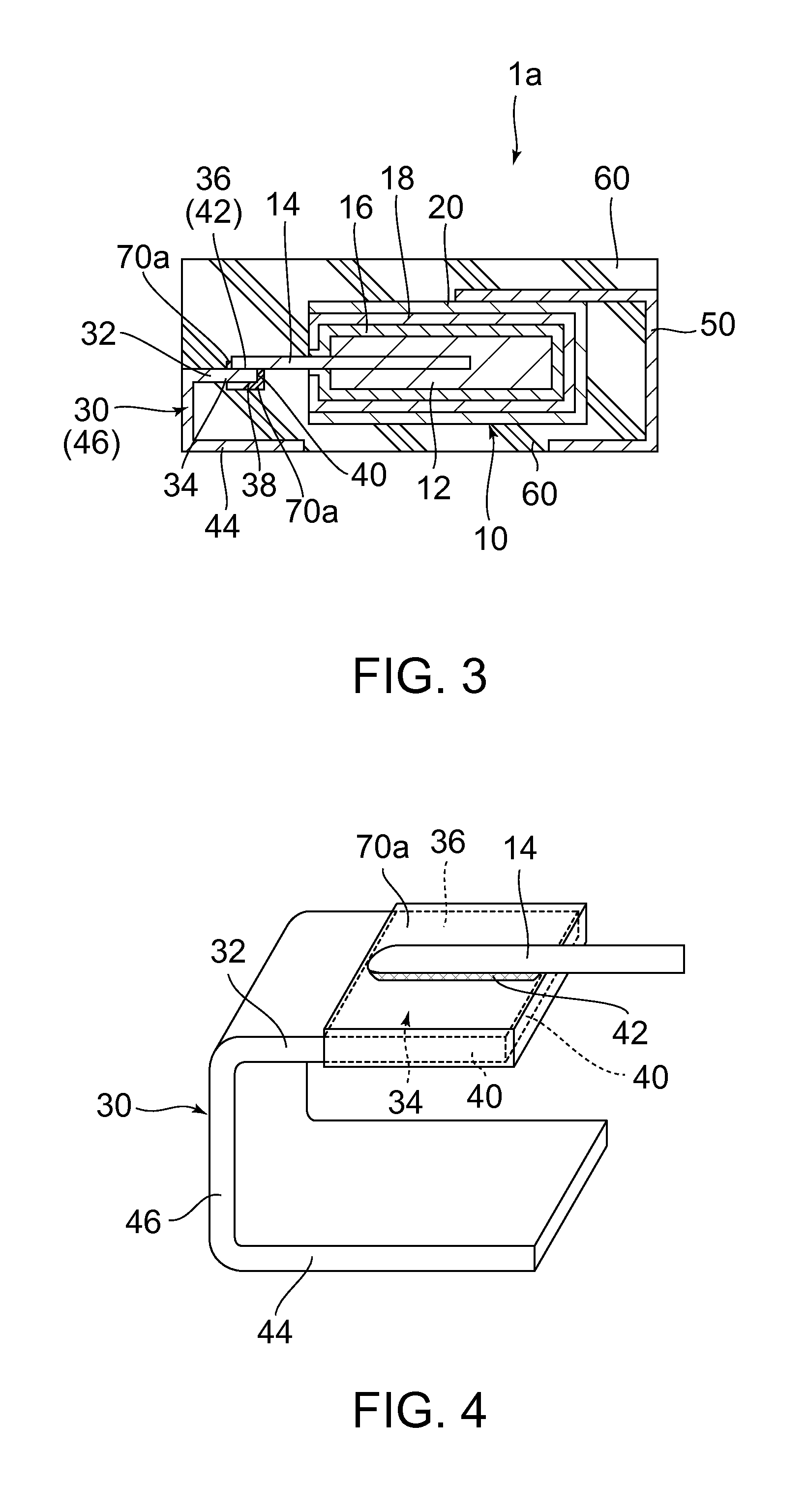

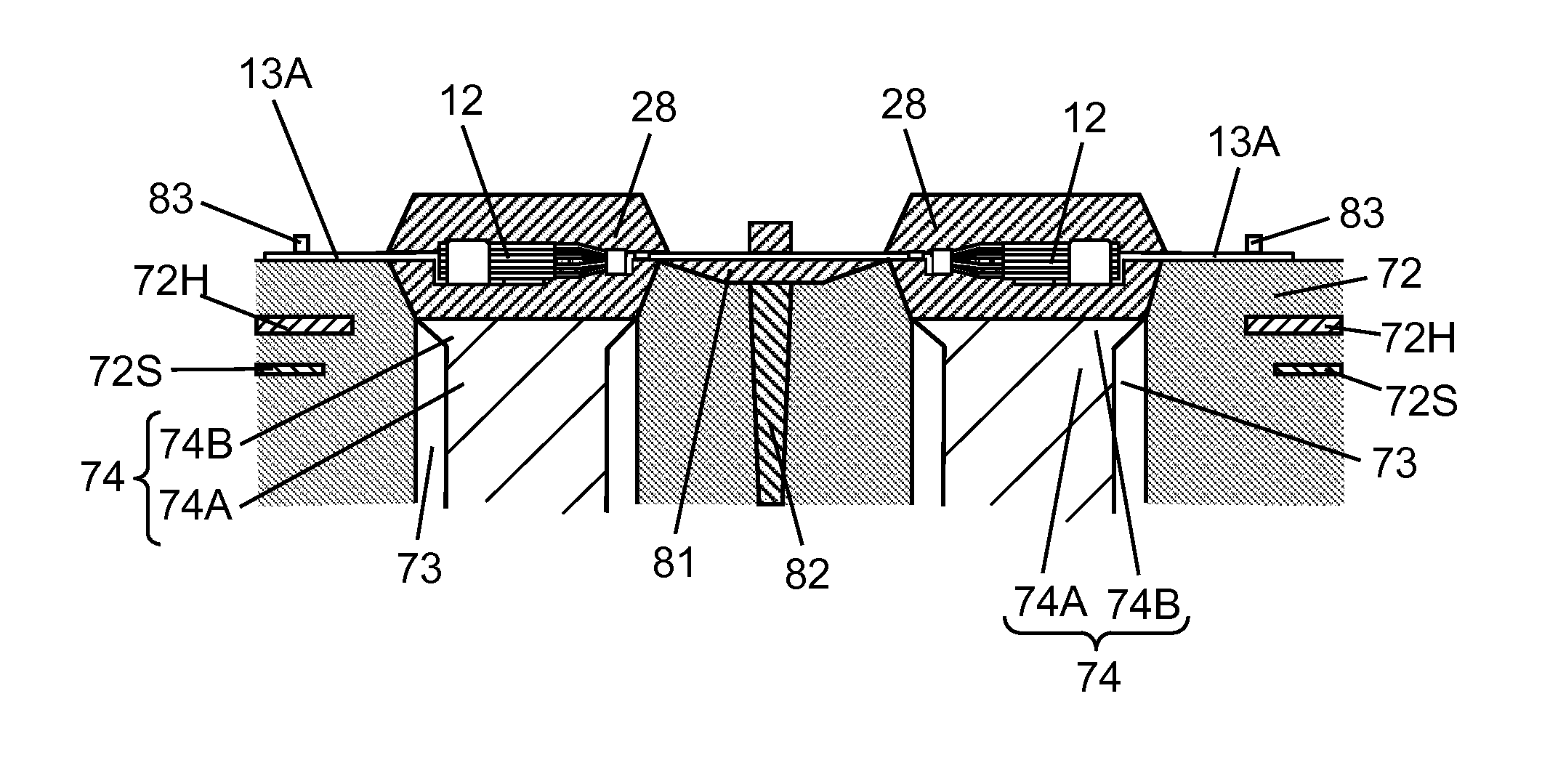

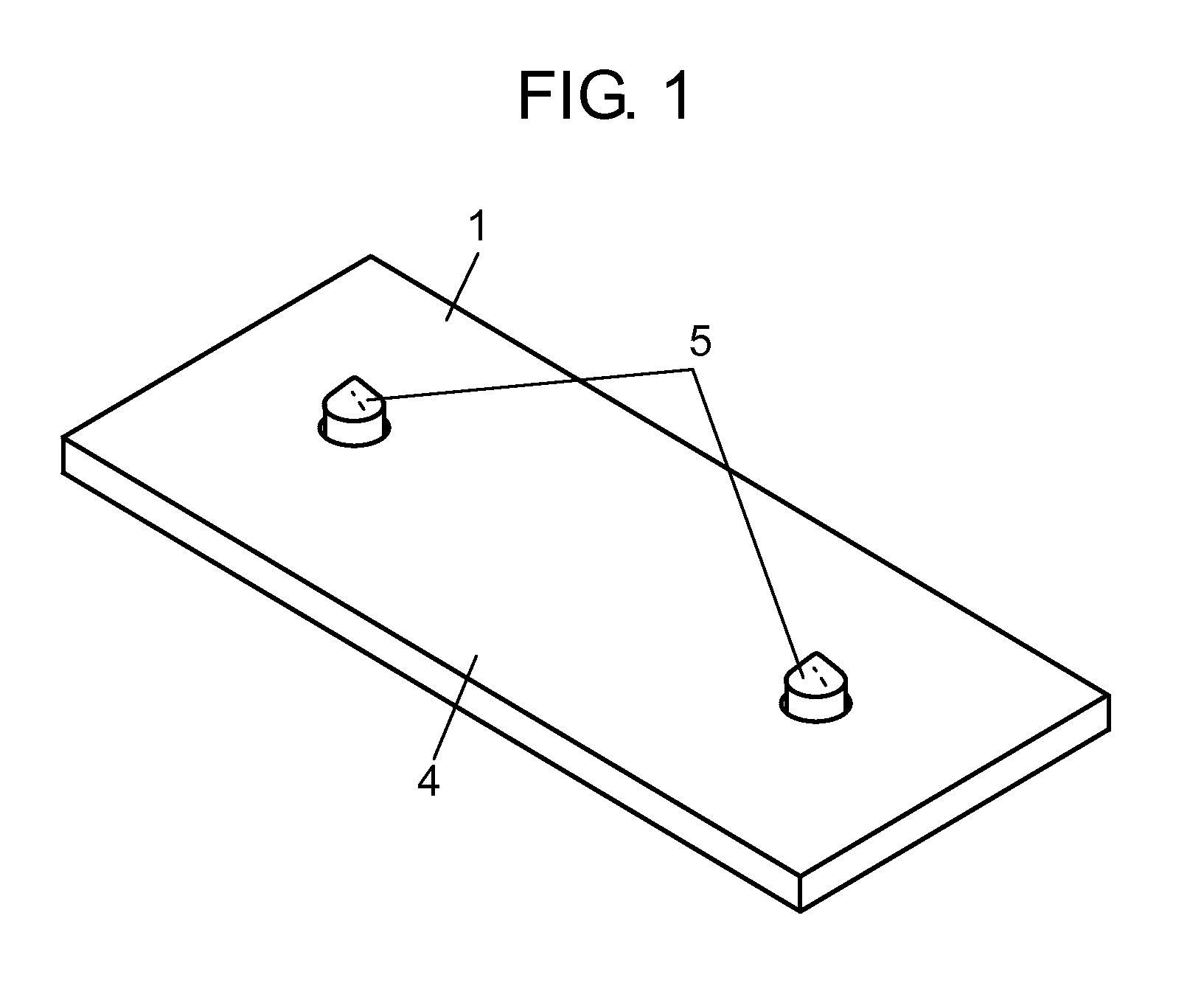

Electronic component, method of manufacturing the same, and mount structure of electronic component

ActiveUS20150287532A1Improve installabilityOccurrence is reduced and preventedFinal product manufacturePrinted circuit manufactureCross-linkEngineering

An electronic component includes a main body, first and second external electrodes, and a water-repellent film. The first and second external electrodes are provided on a portion of a surface of the main body. The water-repellent film is provided on another portion of the surface of the main body and on a surface of the first external electrode. The water-repellent film contains a non-cross-linked silicone resin. An angle of contact of water of about 25° C. with the water-repellent film is not less than about 100° and not greater than about 160°.

Owner:MURATA MFG CO LTD

Manganese Oxide Capacitor for Use in Extreme Environments

ActiveUS20120257329A1Solid electrolytic capacitorsLiquid electrolytic capacitorsGaseous atmosphereManganese oxide

A capacitor assembly for use in high voltage and high temperature environments is provided. More particularly, the capacitor assembly includes a capacitor element containing an anodically oxidized porous, sintered body that is coated with a manganese oxide solid electrolyte. To help facilitate the use of the capacitor assembly in high voltage (e.g., above about 35 volts) and high temperature (e.g., above about 175° C.) applications, the capacitor element is enclosed and hermetically sealed within a housing in the presence of a gaseous atmosphere that contains an inert gas.

Owner:KYOCERA AVX COMPONENTS CORP

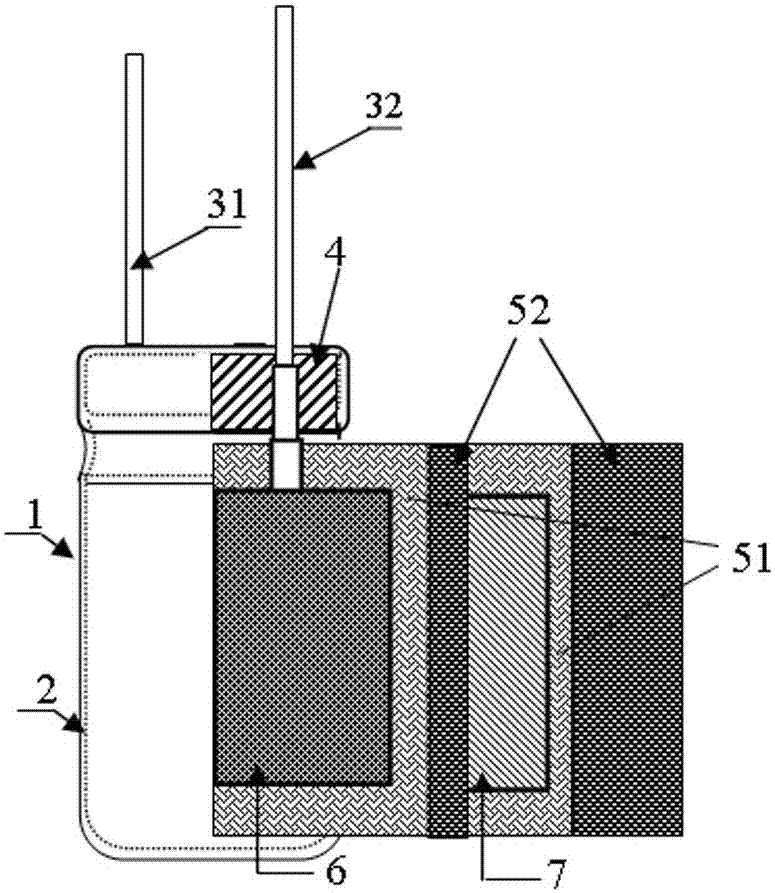

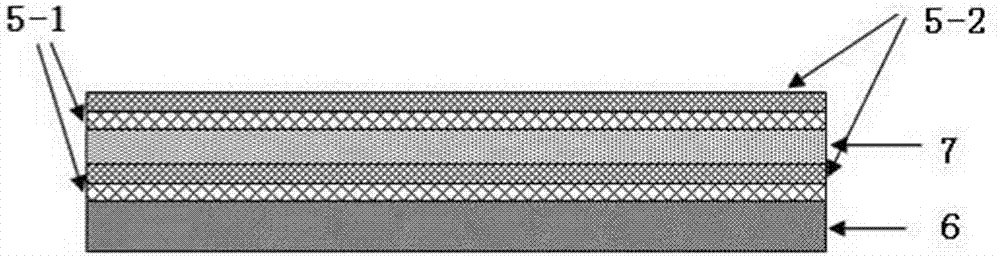

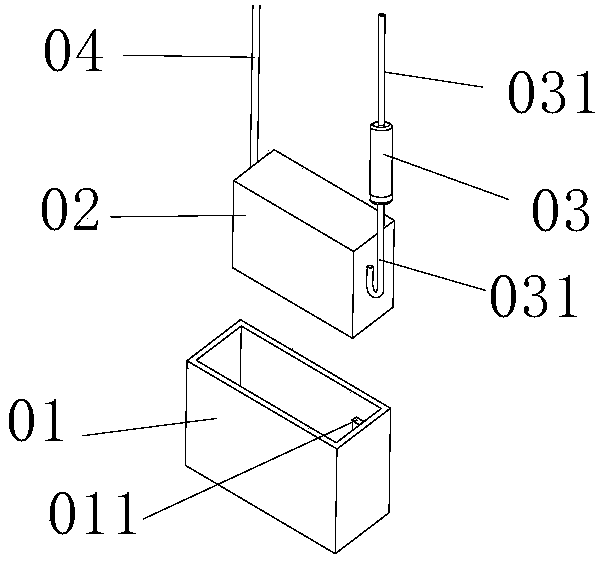

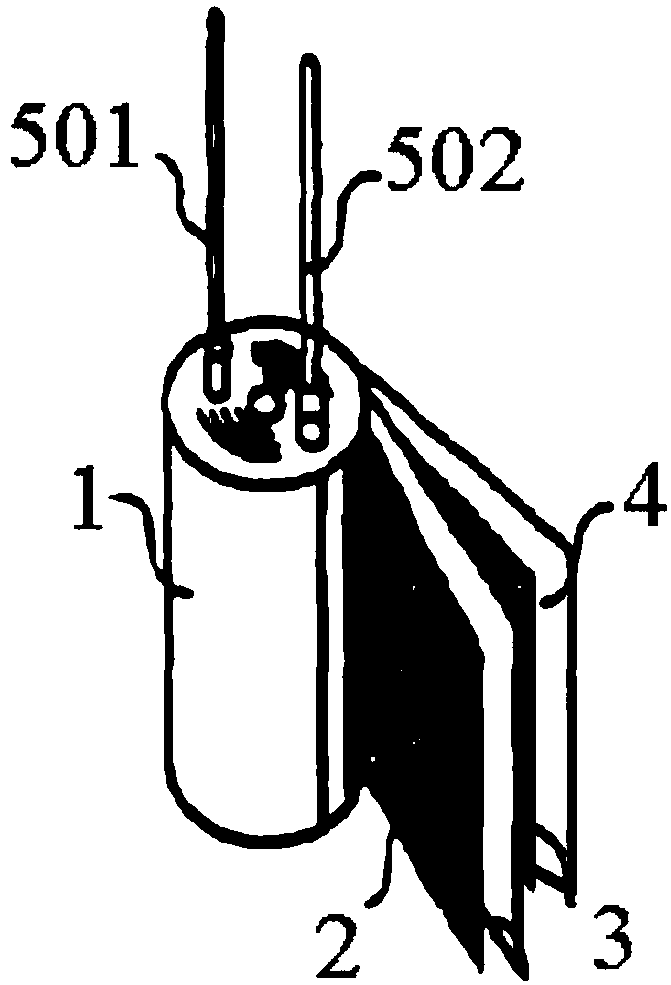

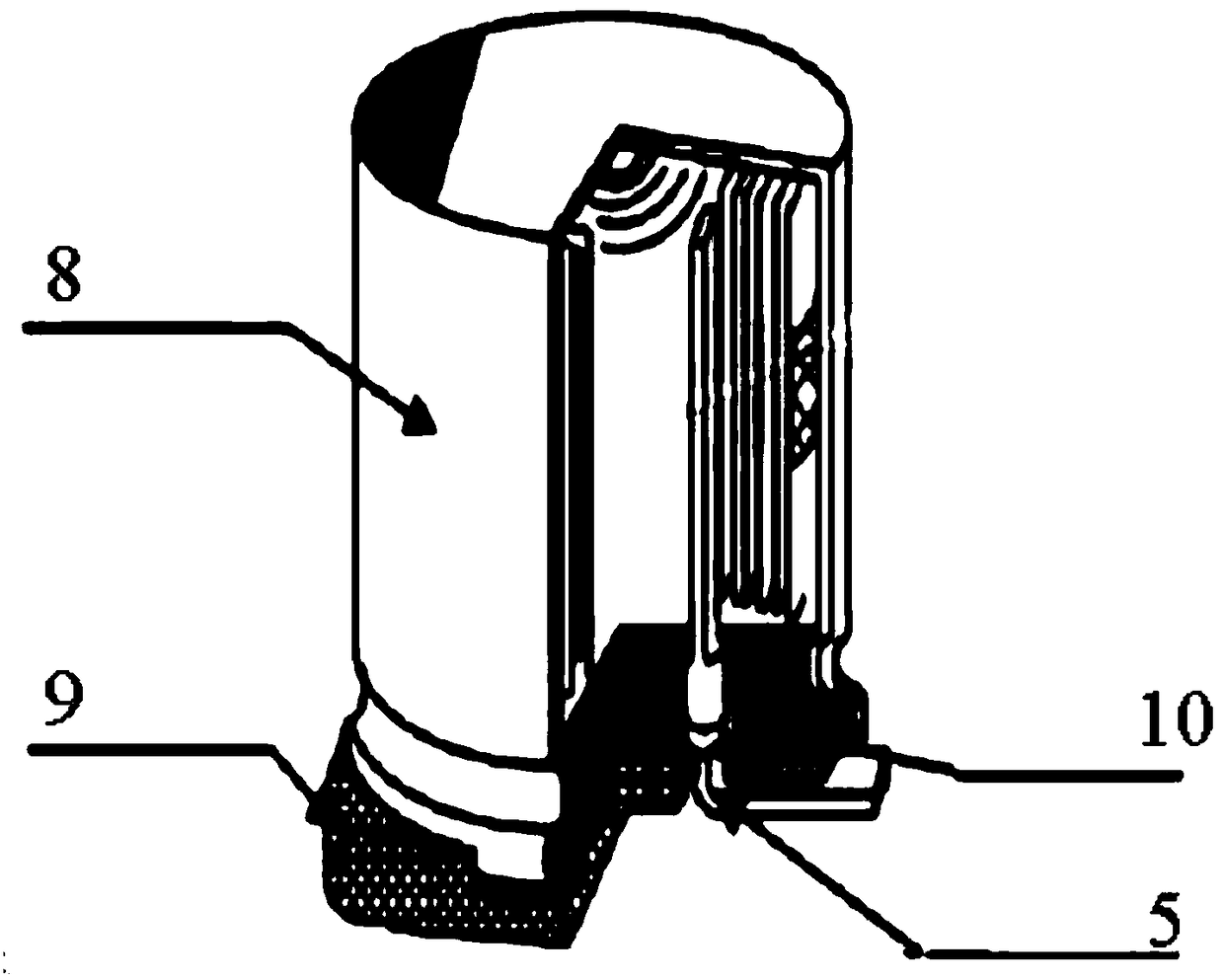

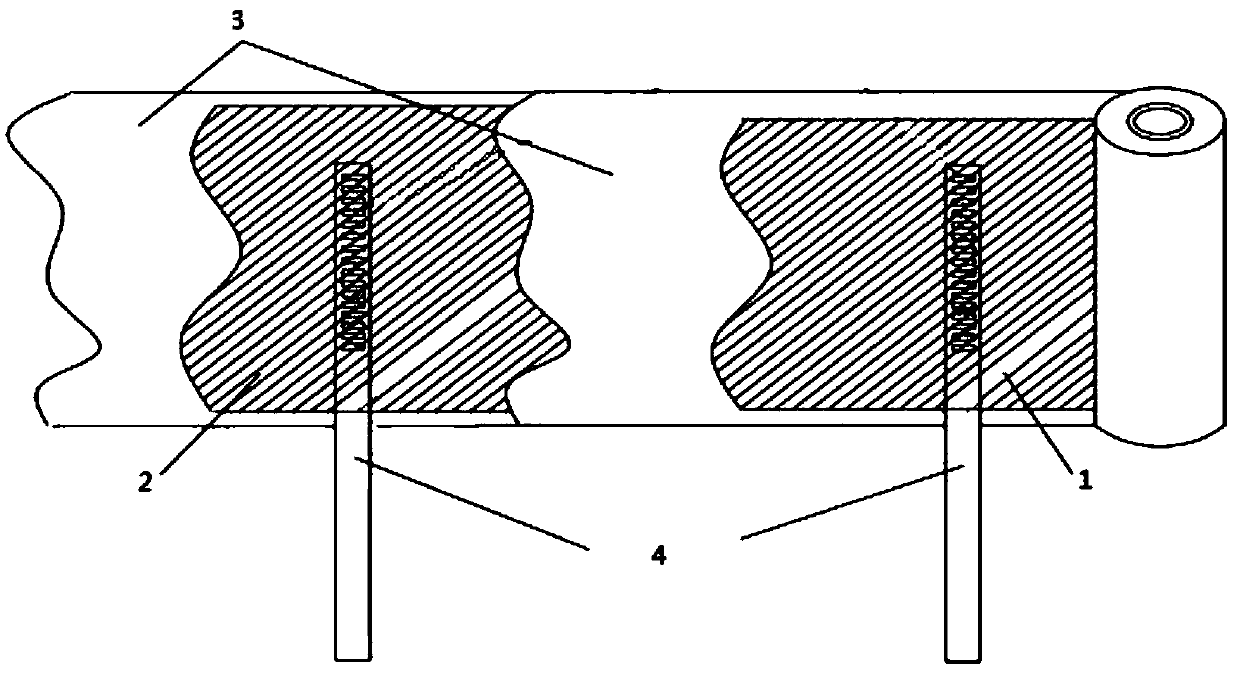

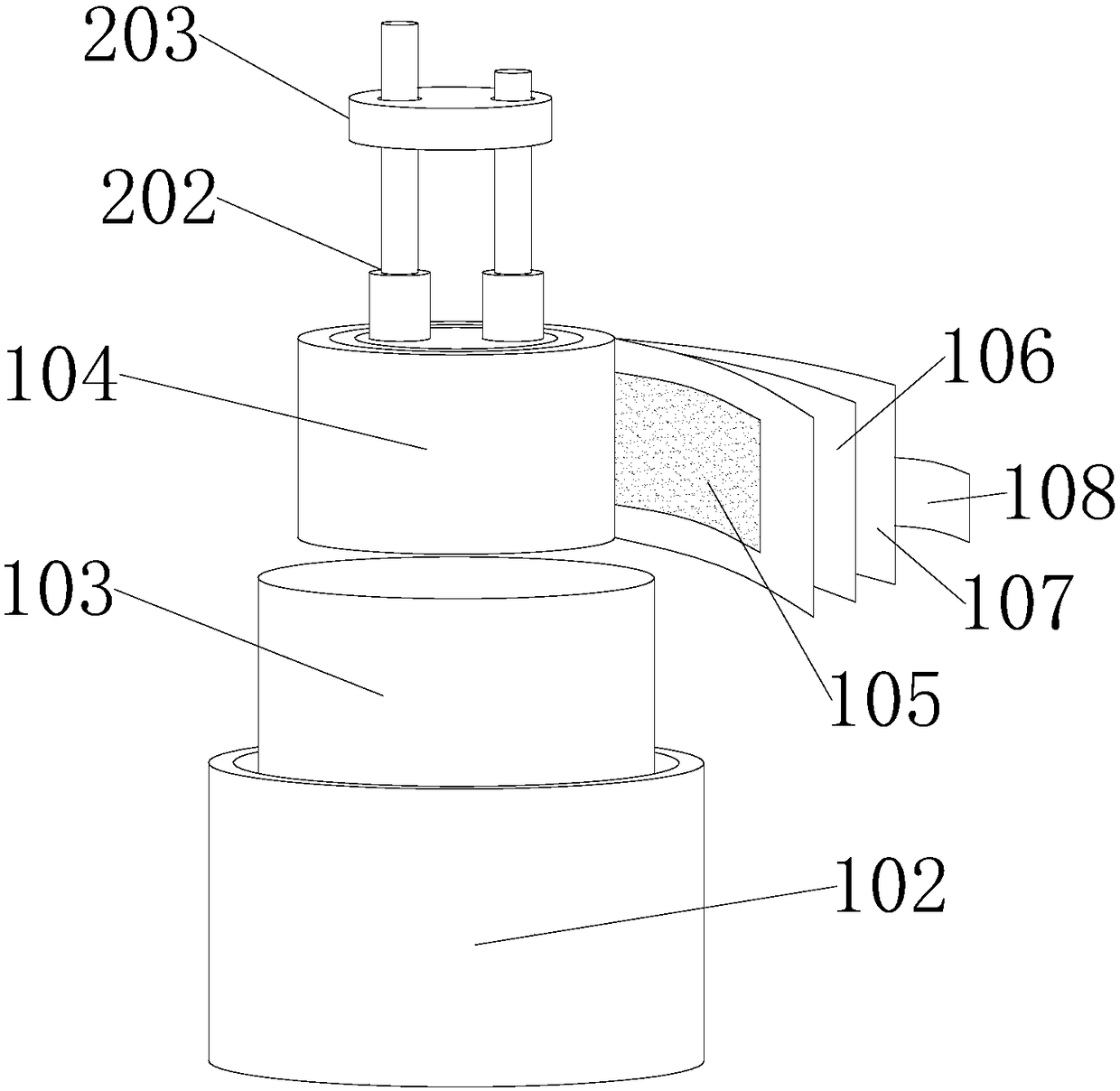

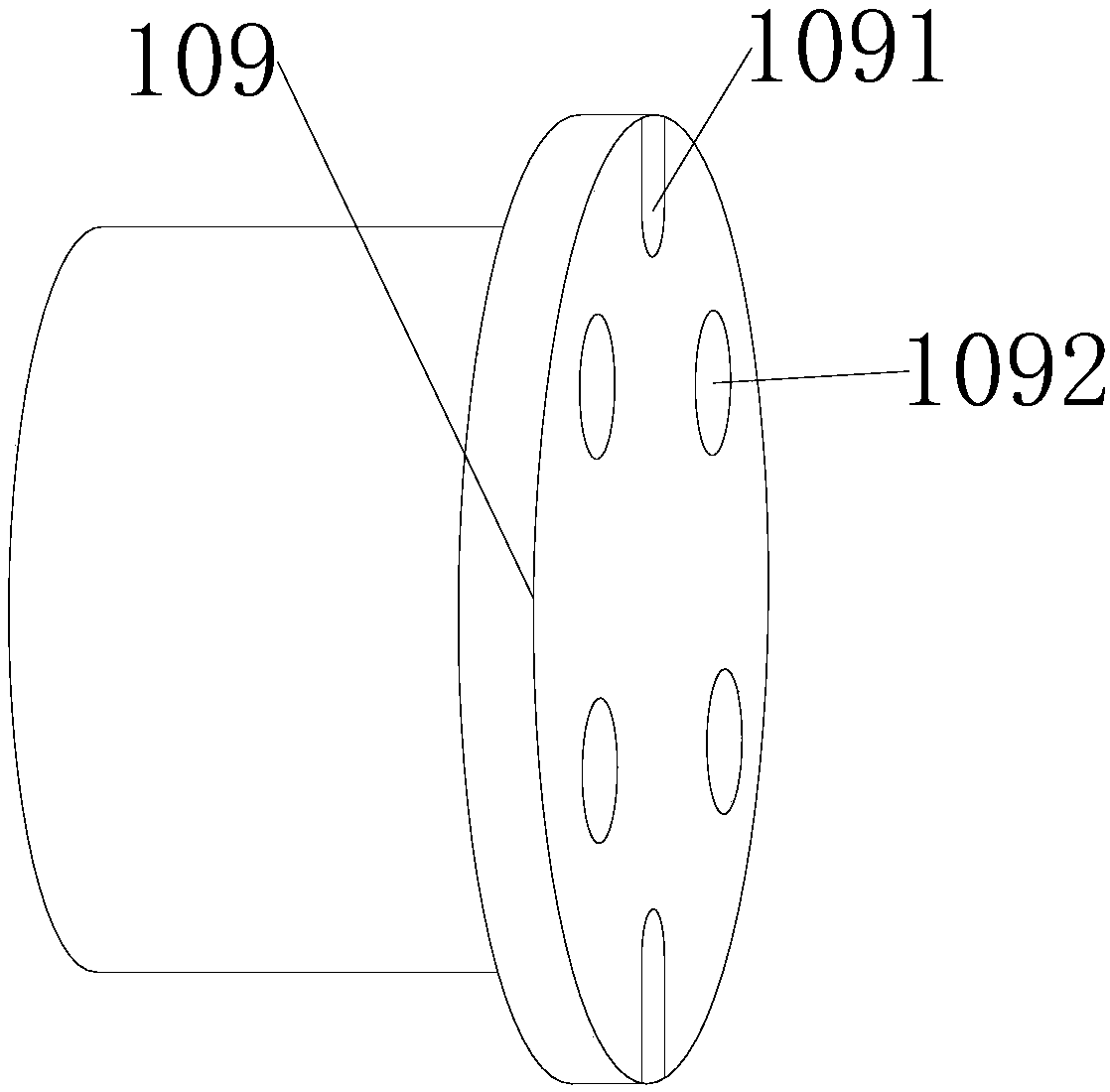

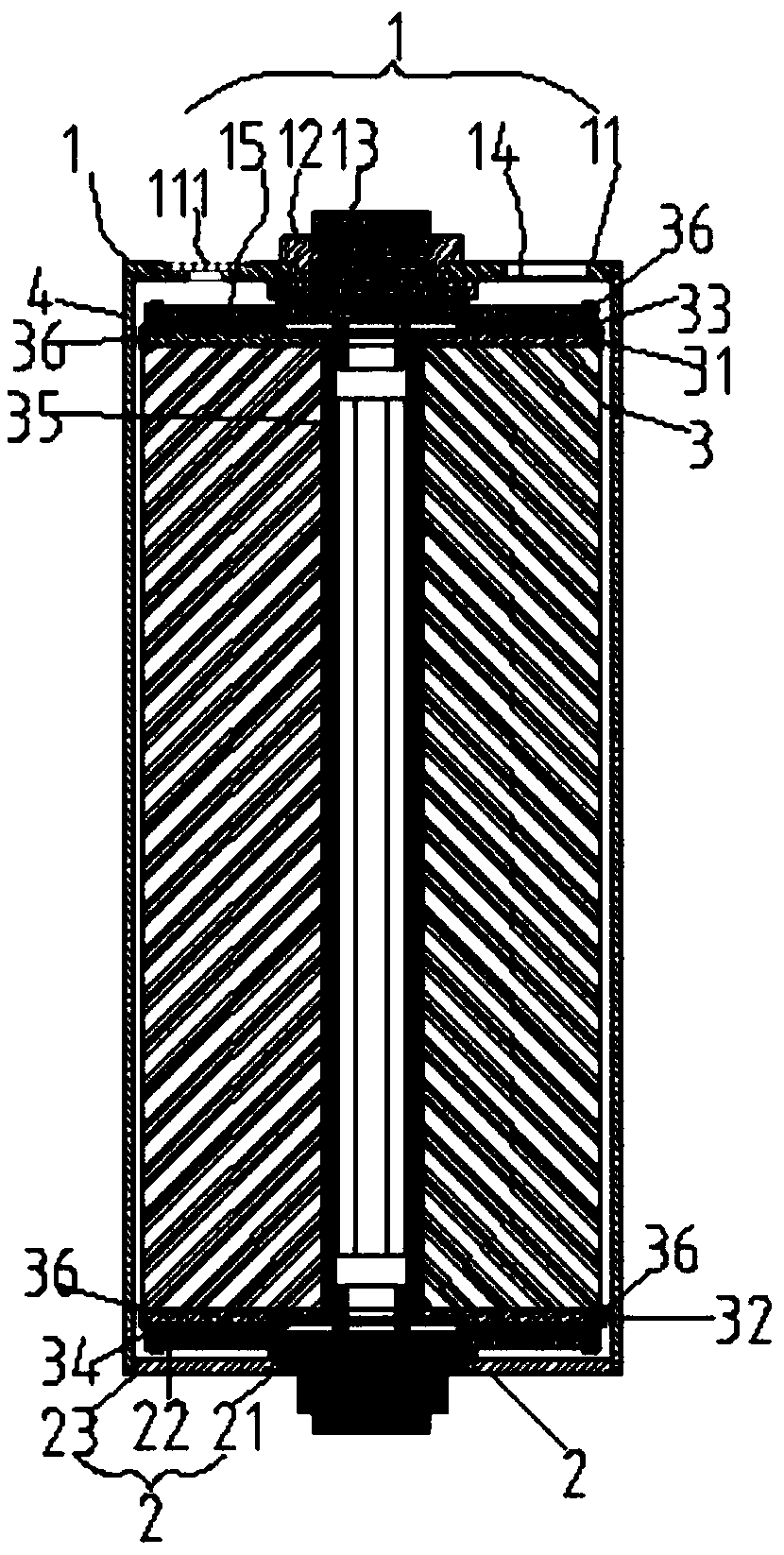

Novel lightning-stroke protection aluminium electrolytic capacitor and preparation method therefor

ActiveCN107195460AImproving the ability to withstand instantaneous high pressureImprove securityCapacitor housing/encapsulationWinding capacitor machinesLightning strokesEngineering

The invention provides a novel lightning-stroke protection aluminium electrolytic capacitor and a preparation method therefor. A core is immersed with an electrolyte with a break-down voltage of 490V or above; the core is formed by a pieces of positive electrode foil, a piece of negative electrode foil and electrolytic paper in an overlapping and winding manner, wherein the electrolytic paper used as a substrate is arranged on the same sides of the negative electrode foil and the positive electrode foil separately; a positive electrode conductive pin in nail joint with the positive electrode foil and a negative electrode conductive pin in nail joint with the negative electrode foil are arranged in a manner of running through a packaging layer; the electrolytic paper comprises inner layer electrolytic paper and outer layer electrolytic paper; the inner layer electrolytic paper is positioned on the inner side of the corresponding negative electrode foil or positive electrode foil; and the inner layer electrolytic paper and outer layer electrolytic paper are consistent in tightness. The overall voltage withstand capacity of the product is improved effectively, and the instantaneous voltage withstand of the aluminium electrolytic capacitor is improved to 2.2KV; and in addition, the aluminium electrolytic capacitor has high impact resistance, high safety and an effect of ensuring the service life.

Owner:ZHAOQING BERYL ELECTRONICS TECH

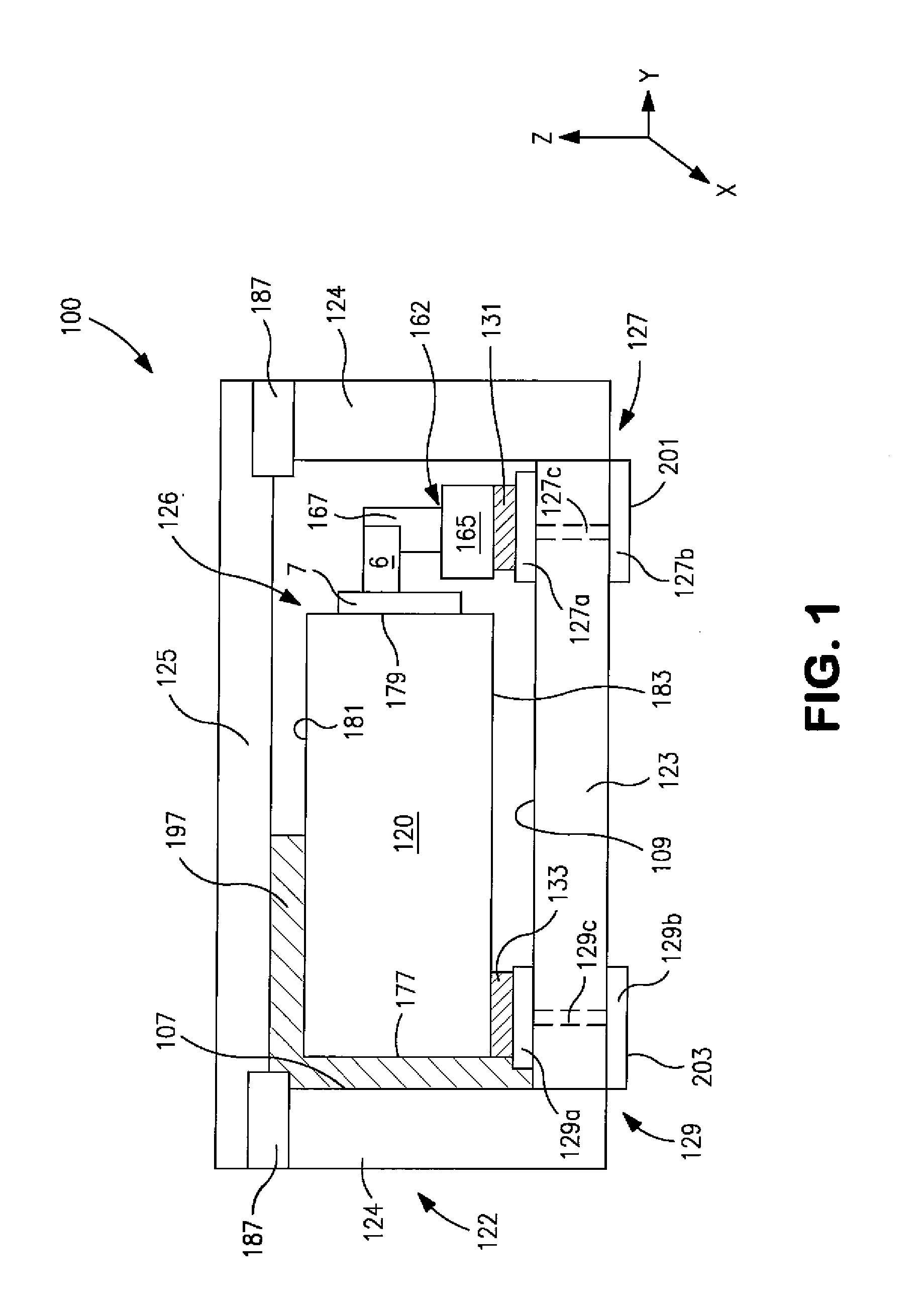

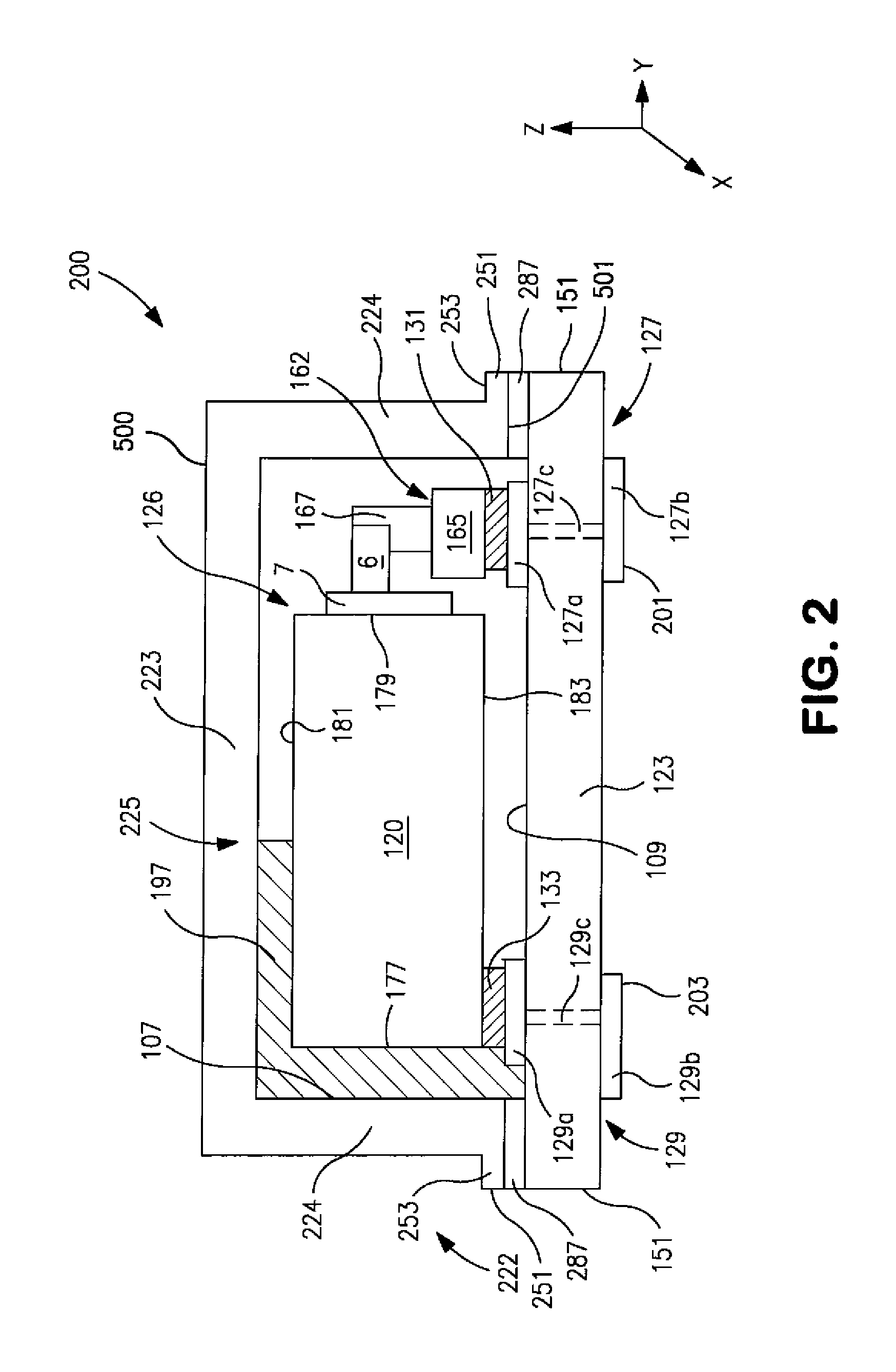

Manganese oxide capacitor for use in extreme environments

ActiveUS8947857B2Solid electrolytic capacitorsLiquid electrolytic capacitorsGaseous atmosphereEngineering

A capacitor assembly for use in high voltage and high temperature environments is provided. More particularly, the capacitor assembly includes a capacitor element containing an anodically oxidized porous, sintered body that is coated with a manganese oxide solid electrolyte. To help facilitate the use of the capacitor assembly in high voltage (e.g., above about 35 volts) and high temperature (e.g., above about 175° C.) applications, the capacitor element is enclosed and hermetically sealed within a housing in the presence of a gaseous atmosphere that contains an inert gas.

Owner:KYOCERA AVX COMPONENTS CORP

Solid Electrolytic Capacitor

ActiveUS20150213961A1Improve moisture resistanceImprove suppression propertiesSolid electrolytic capacitorsLiquid electrolytic capacitorsElectrolysisEngineering

An outer insulation member made of a first resin packs a part of an anode terminal. The packed part of the anode terminal has a predetermined section. All surfaces of the predetermined section consist of a front surface, a back surface and edges connecting between the front surface and the back surface. The front surface includes a connection area. An anode lead wire is connected to the connection area while being not connected to the anode terminal other than the connection area. The all surfaces of the predetermined section are completely covered with a mask layer made of a second resin except for the connection area. The second resin is different from the first resin in at least one of composition thereof, content of an inclusion, size of an inclusion and shape of an inclusion.

Owner:TOKIN CORP +1

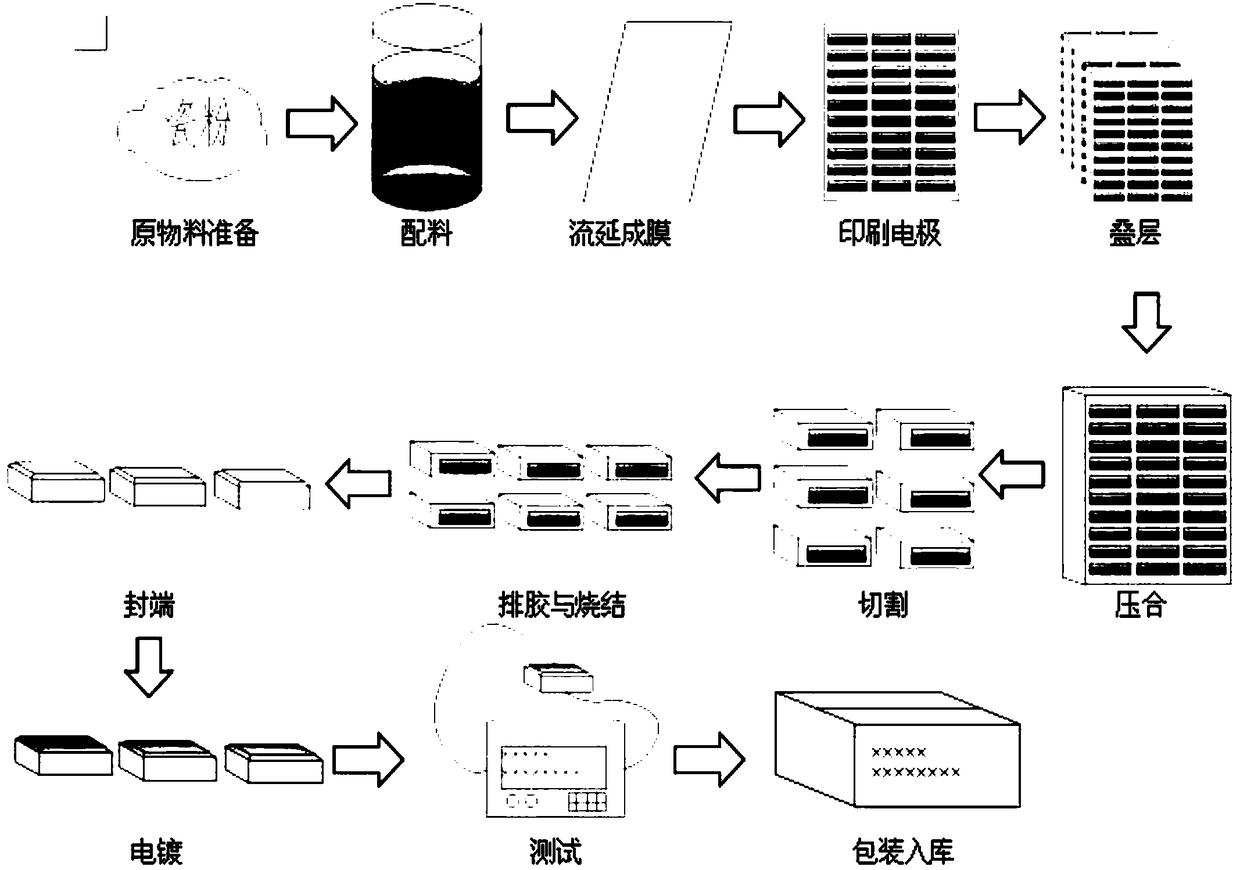

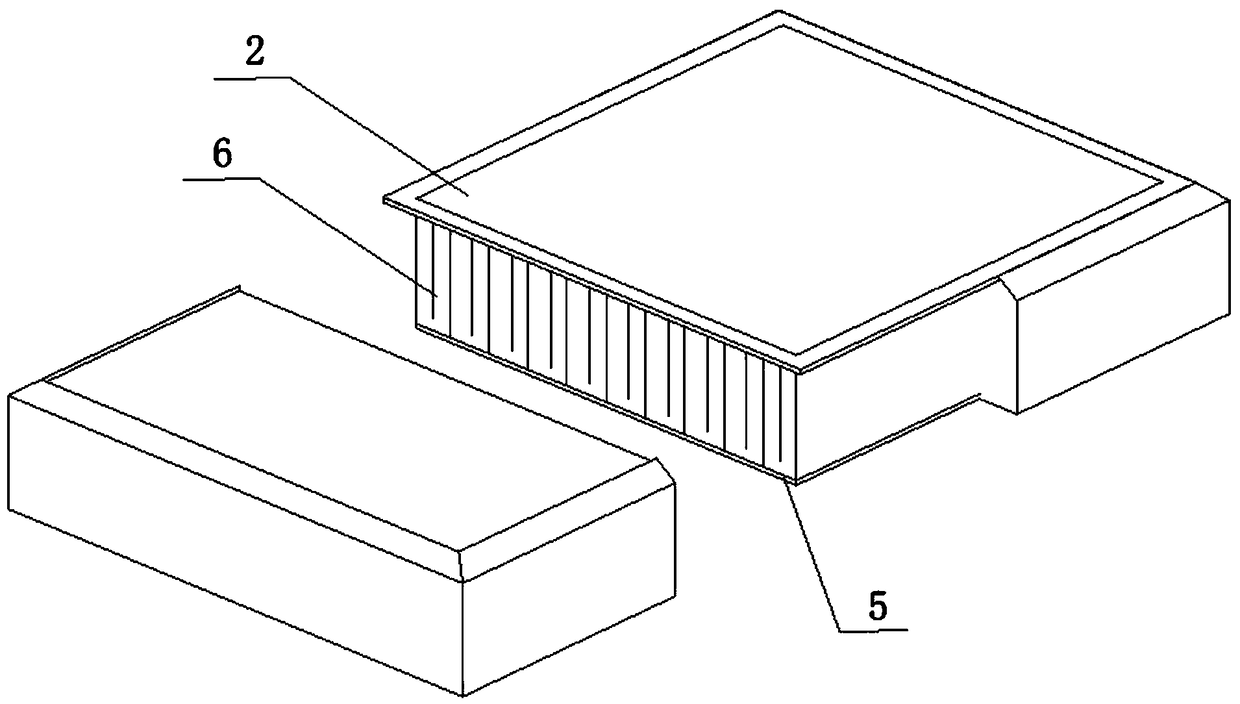

Manufacturing process of vertical ceramic patch capacitor and capacitor product of vertical ceramic patch capacitor

InactiveCN108281283AChange shapeChange electrode directionFixed capacitor electrodesFixed capacitor dielectricCapacitanceMaterials preparation

The invention discloses a manufacturing process of a vertical ceramic patch capacitor and a capacitor product of the vertical ceramic patch capacitor, and belongs to the technical field of microelectronics. The process comprises the steps of material preparation, in which raw materials are mixed according to a proportion; coating, in which a layer of uniform paste thin film is formed from paste bya coating machine; printing, in which internal electrode paste is printed onto a ceramic film by a screen printing plate according to the process requirement; lamination, in which the printed ceramicfilms are laminated to form green blank having different layers; lamination, in which the green blank is loaded in a lamination bag; cutting, in which the laminated large green blank is cut to relatively small blanks; gluing, in which the cut blank blocks are glued; sintering, in which the green blank is sintered to form a ceramic body; chamfering, corners of the product of the capacitor sinteredto form ceramic are chamfered; sealing, in which the product is sealed to form the ceramic body; and sintering, in which the ceramic body is sintered to form the ceramic capacitor. The purpose of changing the shape of the capacitor and the electrode direction is achieved by changing an electrode printing method, a cutting method and a coating process, so that the installation and the applicationof a capacitor in a flat package component can be adapted.

Owner:SHANDONG DIYI ELECTRONICS SCI & TECH

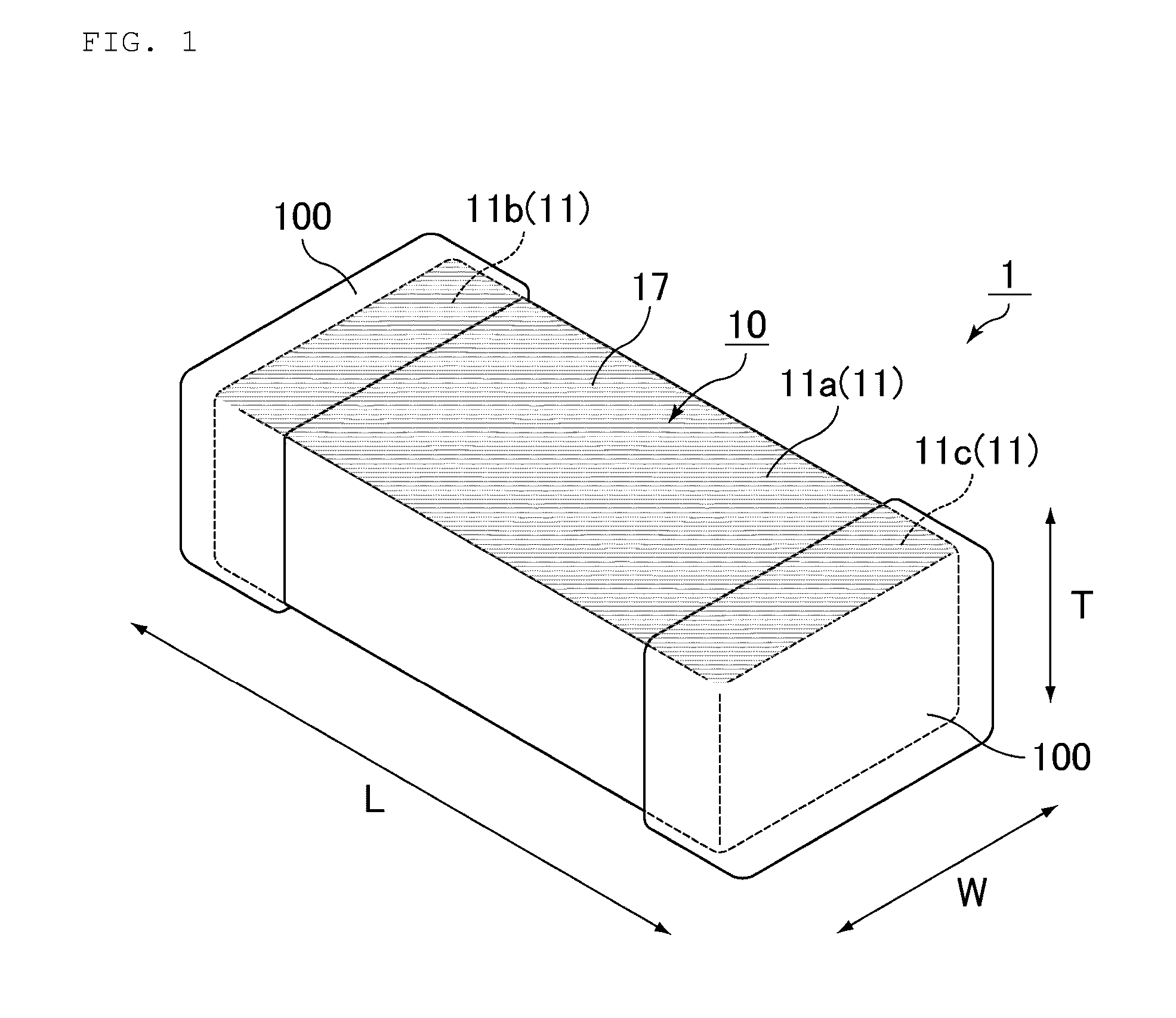

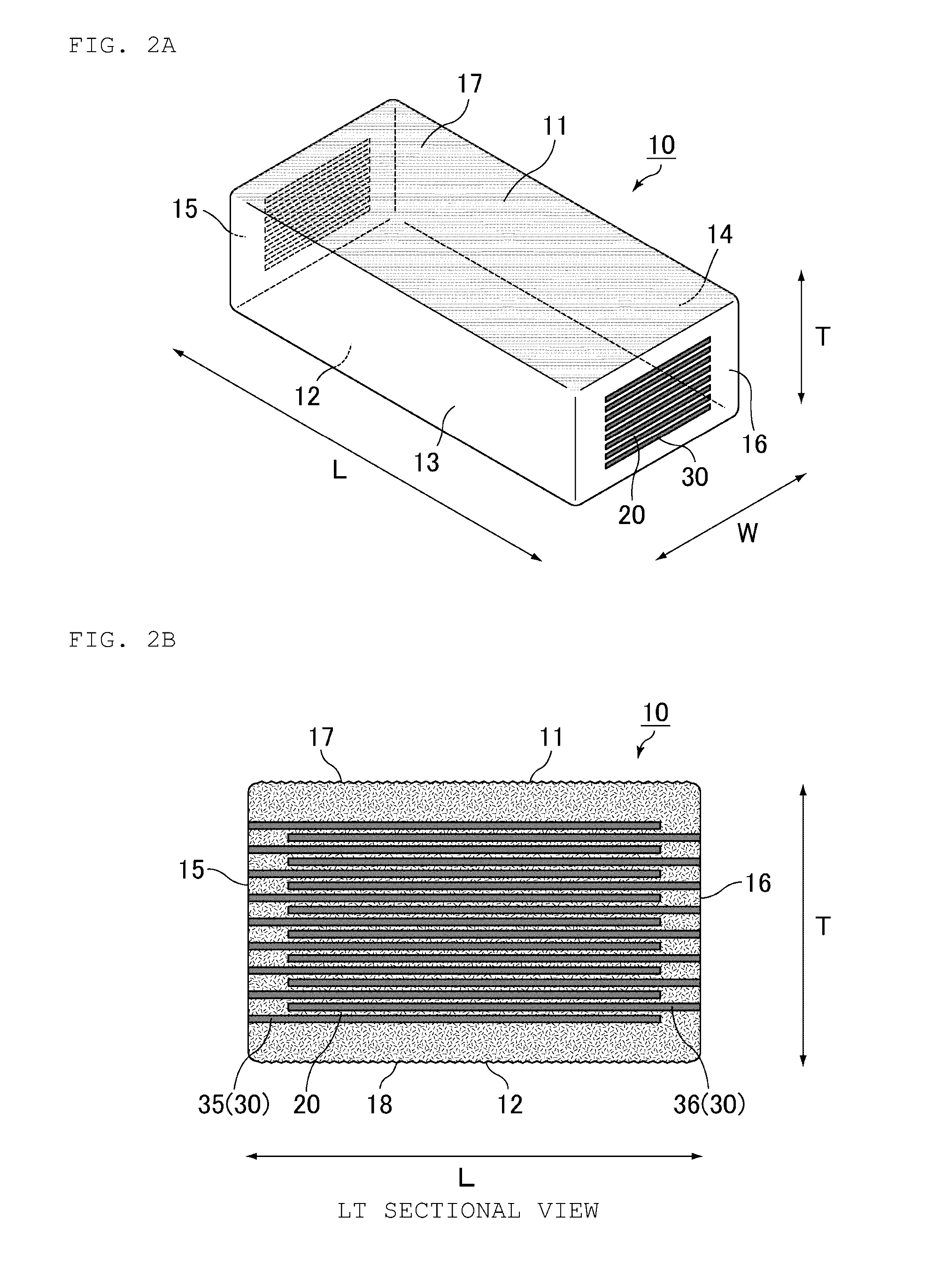

Method of manufacturing ceramic electronic component, and ceramic electronic component

ActiveUS20170040112A1Good effectFacilitates through-hole connectionFixed capacitor electrodesFixed capacitor dielectricMetallurgyElectronic component

A method of manufacturing a ceramic electronic component including a main body including a first principal surface and a second principal surface opposite to each other, and a first external electrode and a second external electrode provided on a portion of a surface of the main body, includes providing a plurality of recesses in a first principal surface of a laminated block including a ceramic material and an organic substance by relatively moving the laminated block and a protrusion surface including a protrusion, in a direction along the first principal surface of the laminated block with the protrusion surface being in contact with a first principal surface of the laminated block, obtaining a chip by cutting the laminated block including the recesses, and obtaining the main body by firing the chip.

Owner:MURATA MFG CO LTD

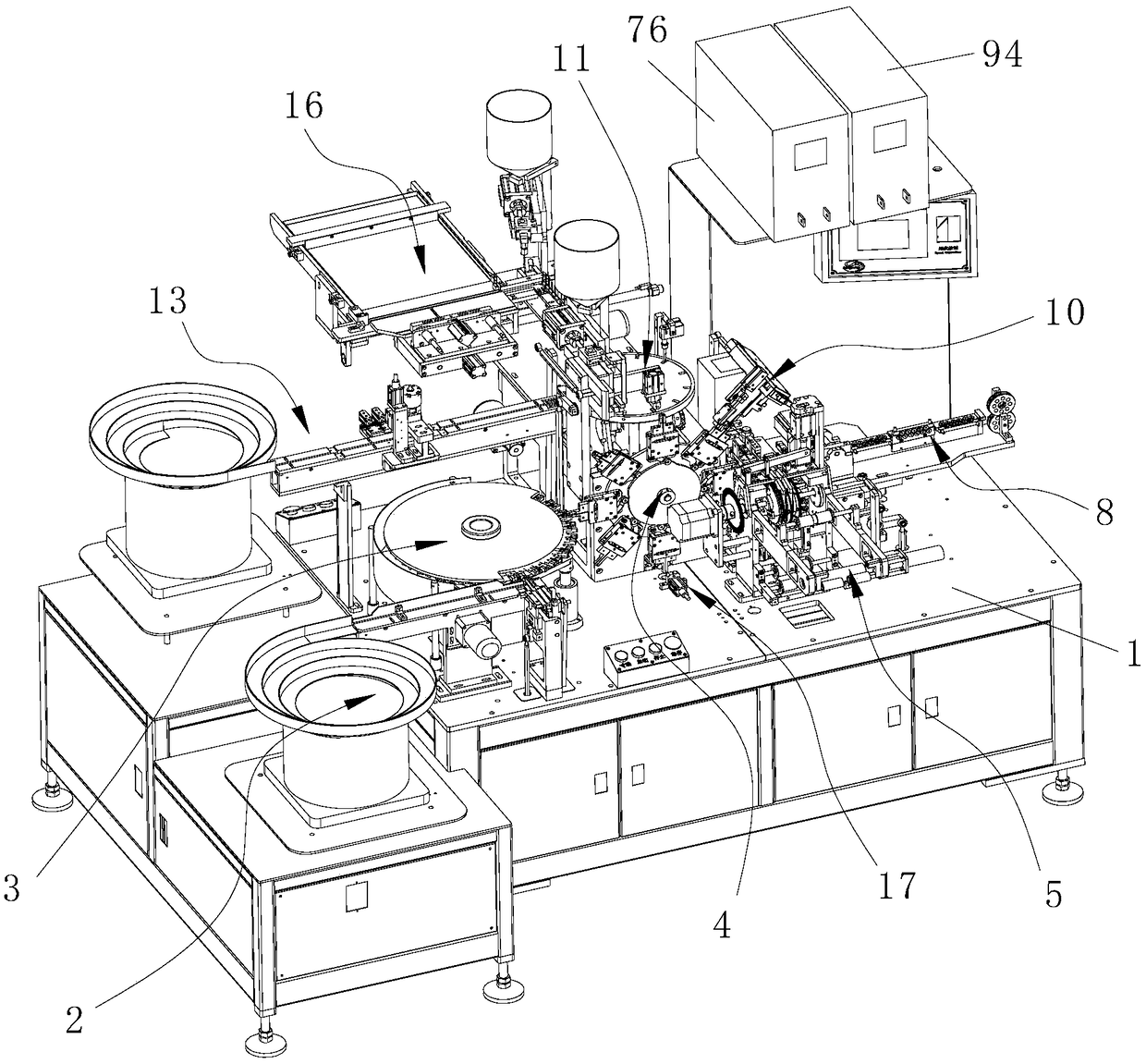

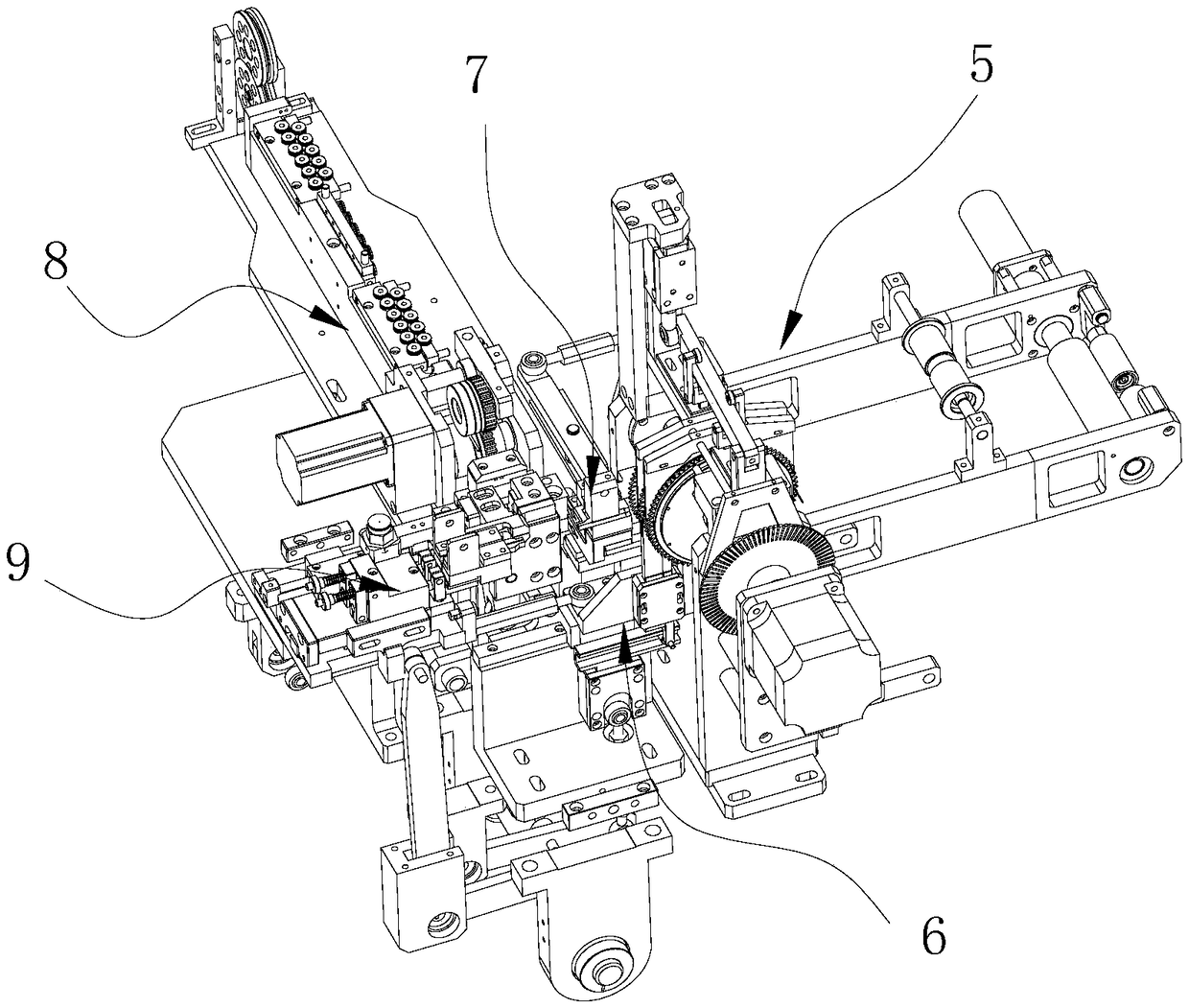

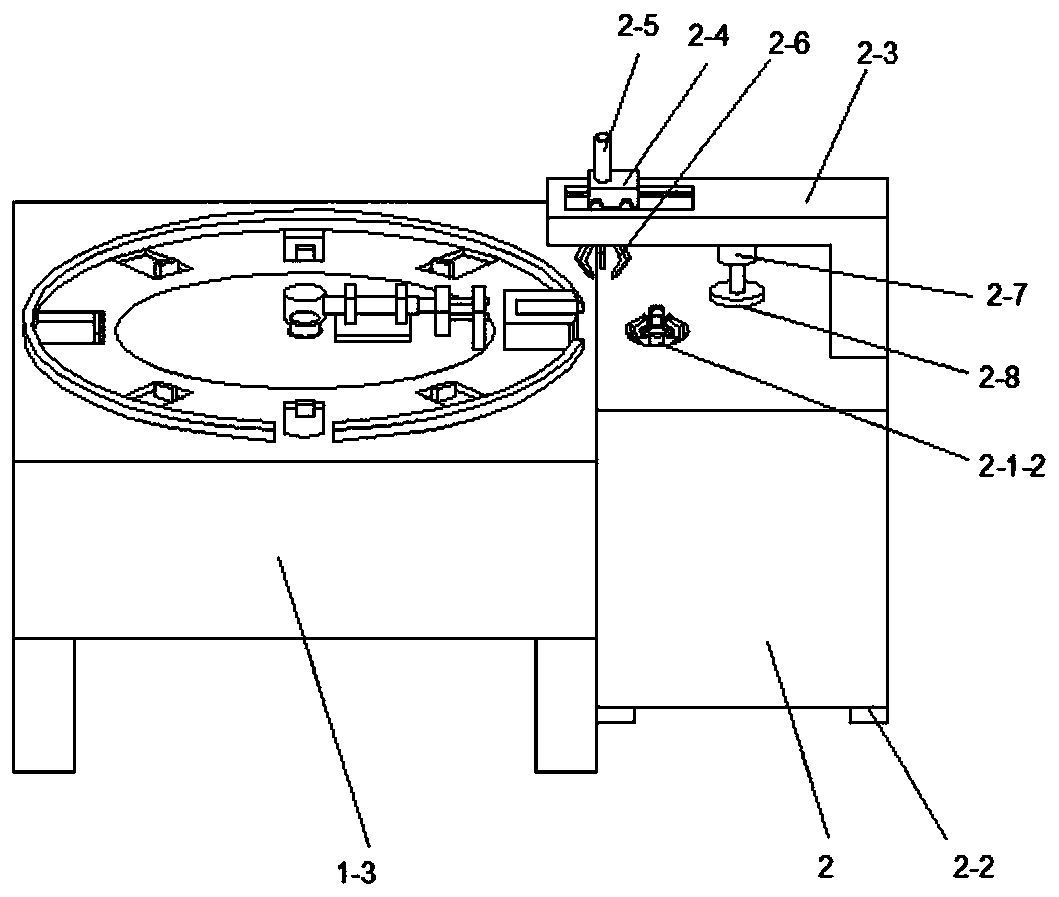

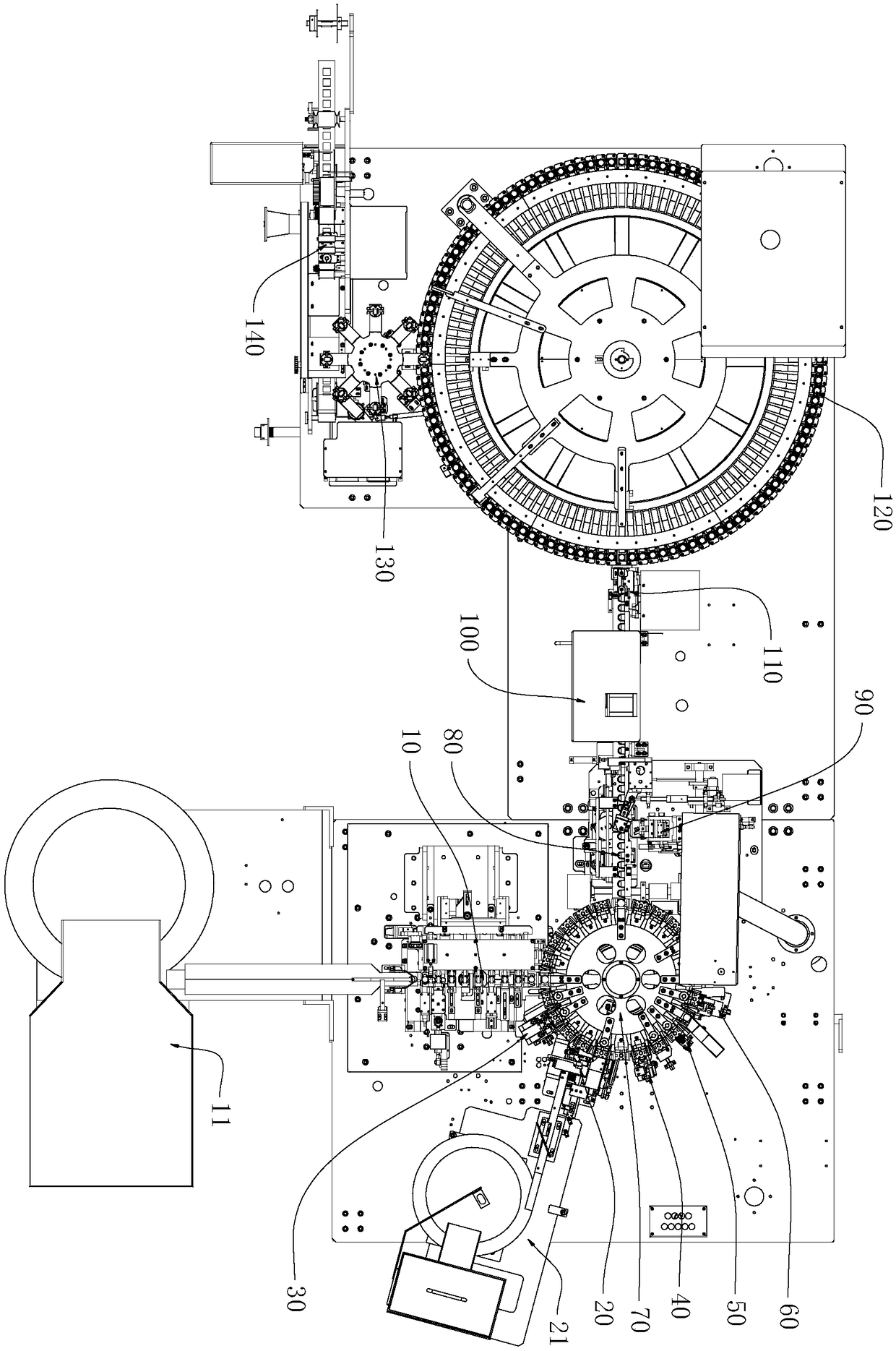

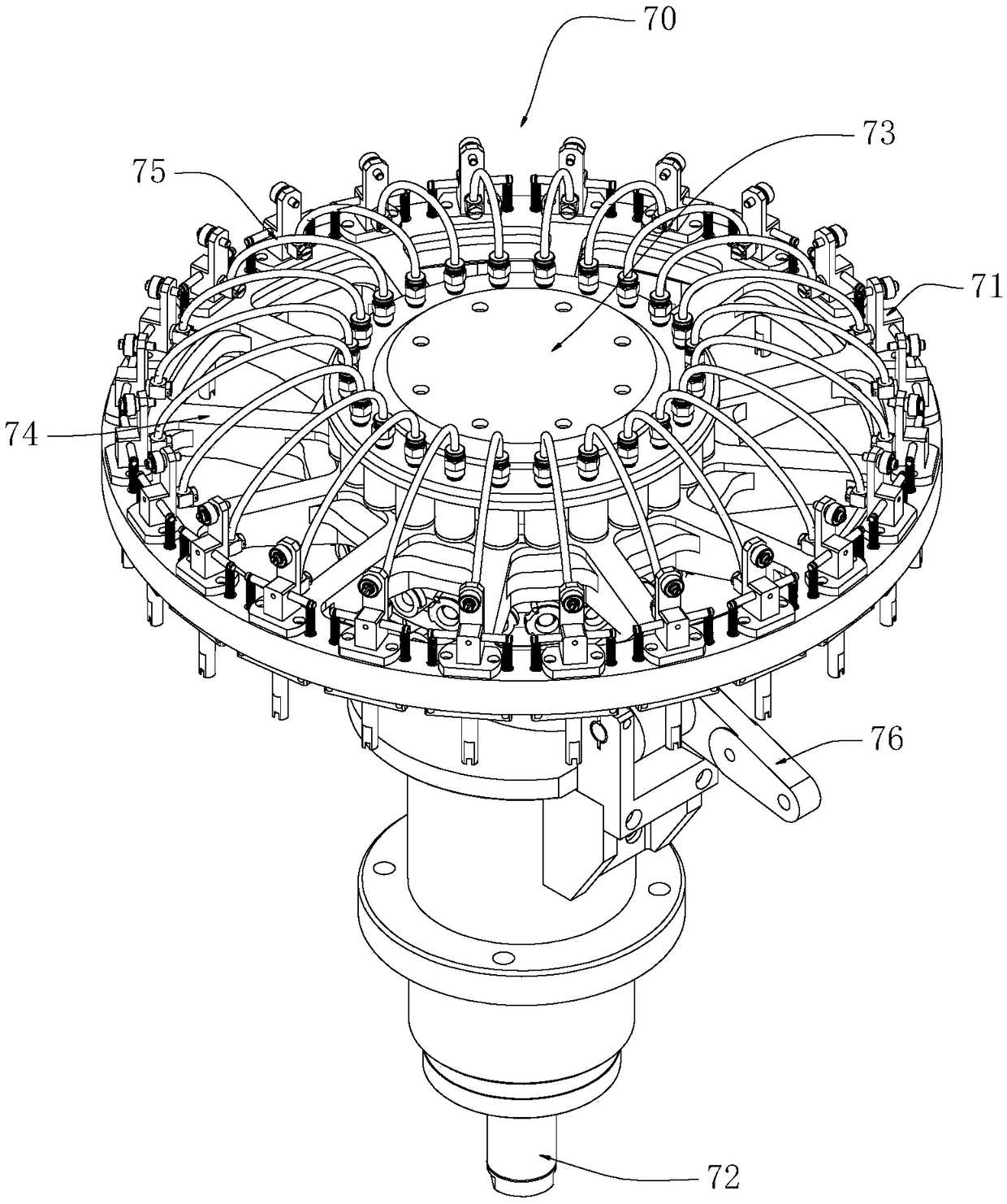

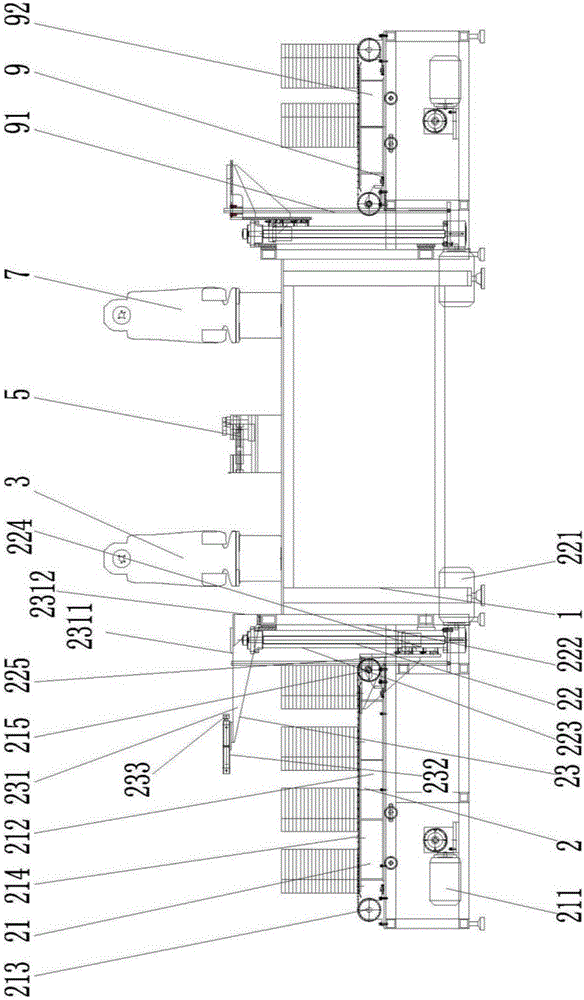

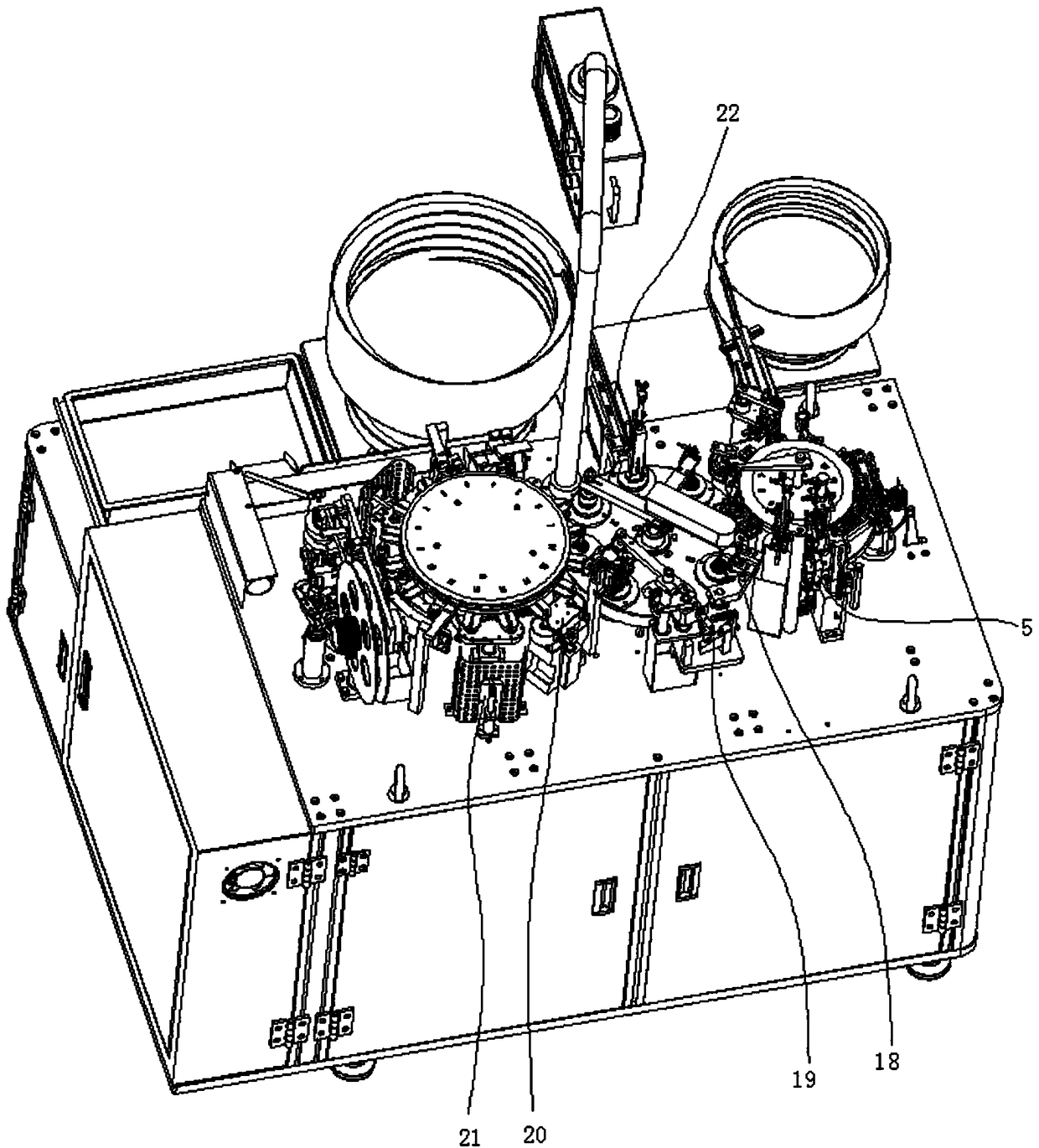

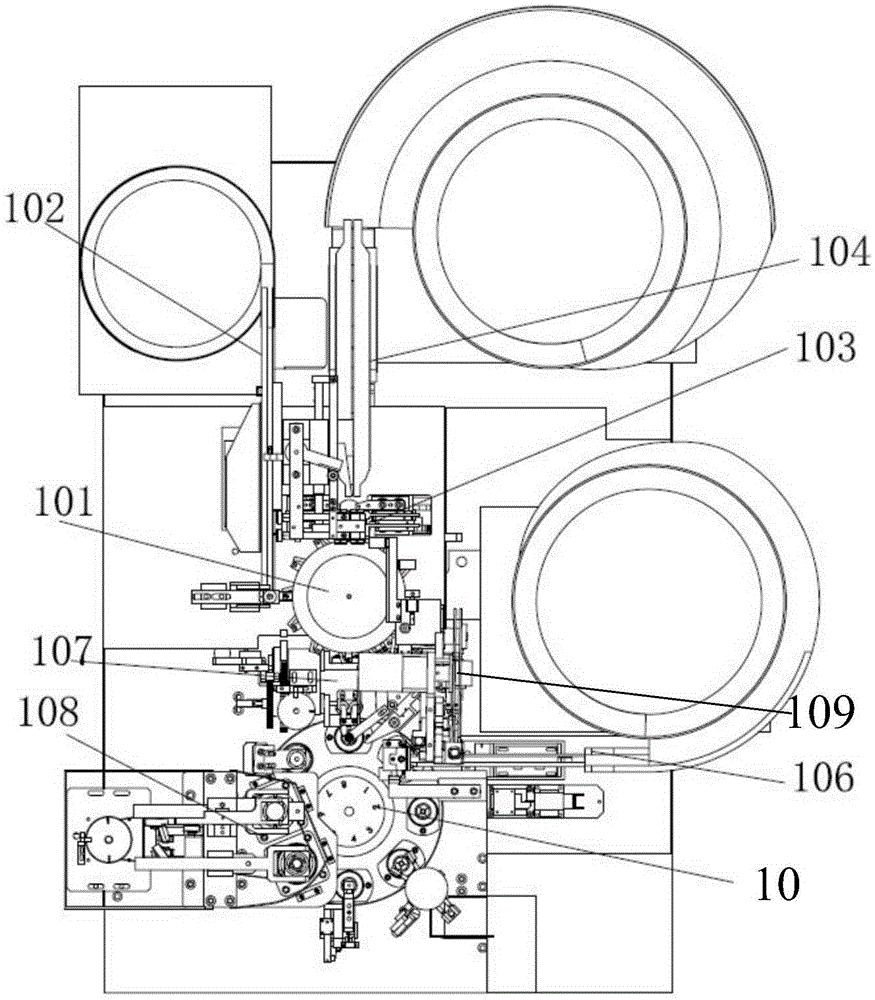

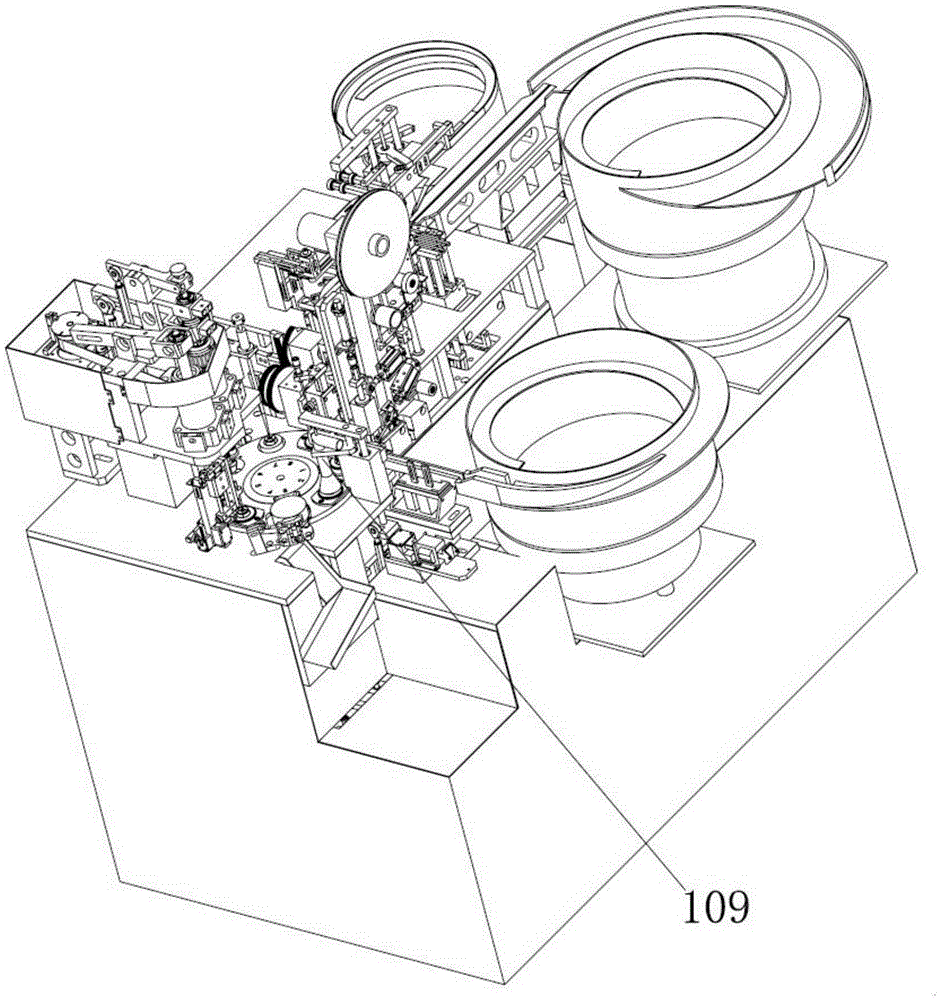

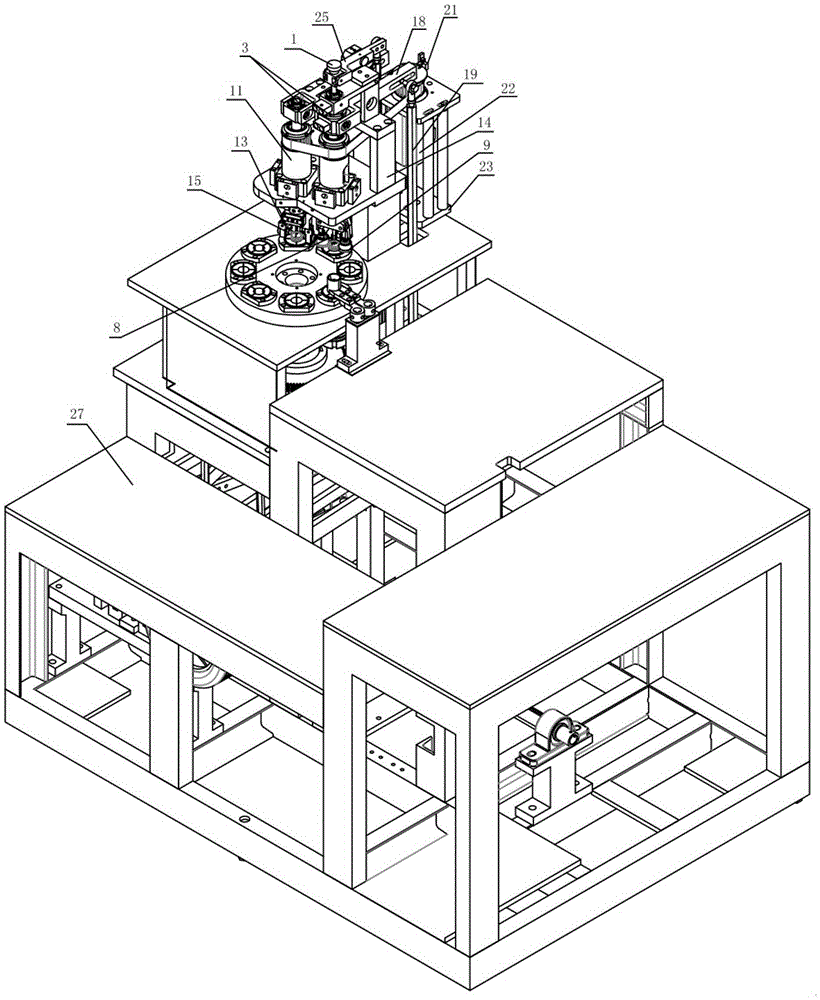

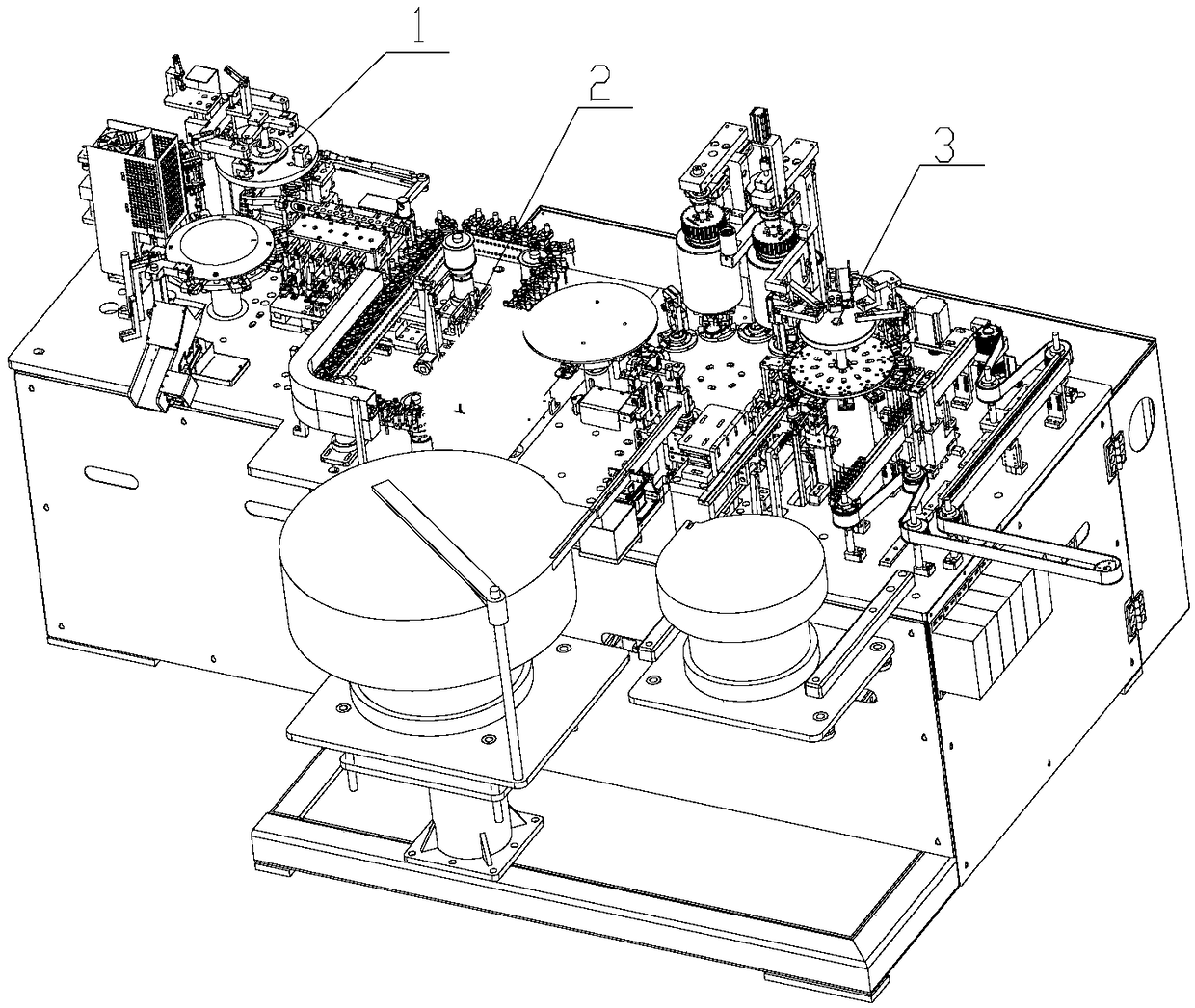

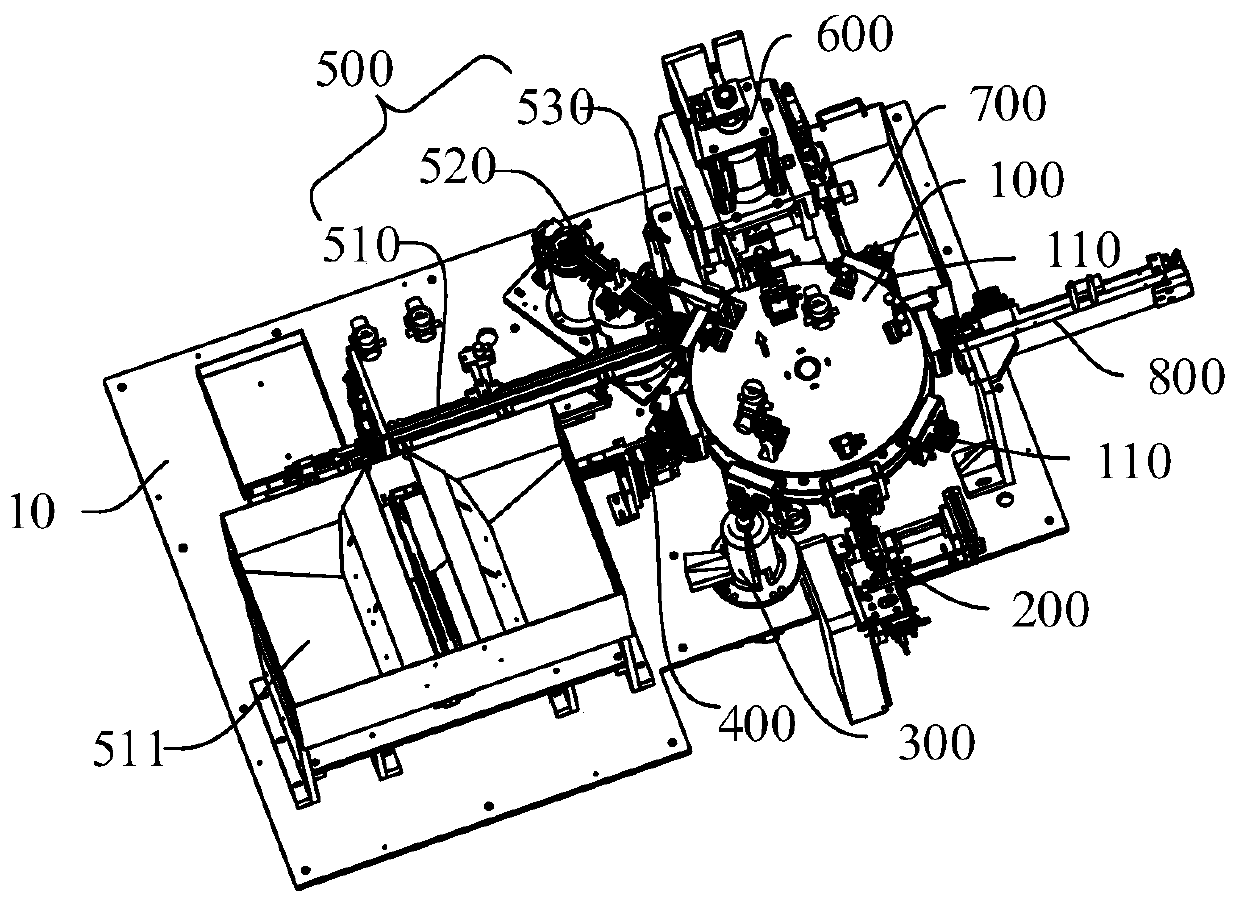

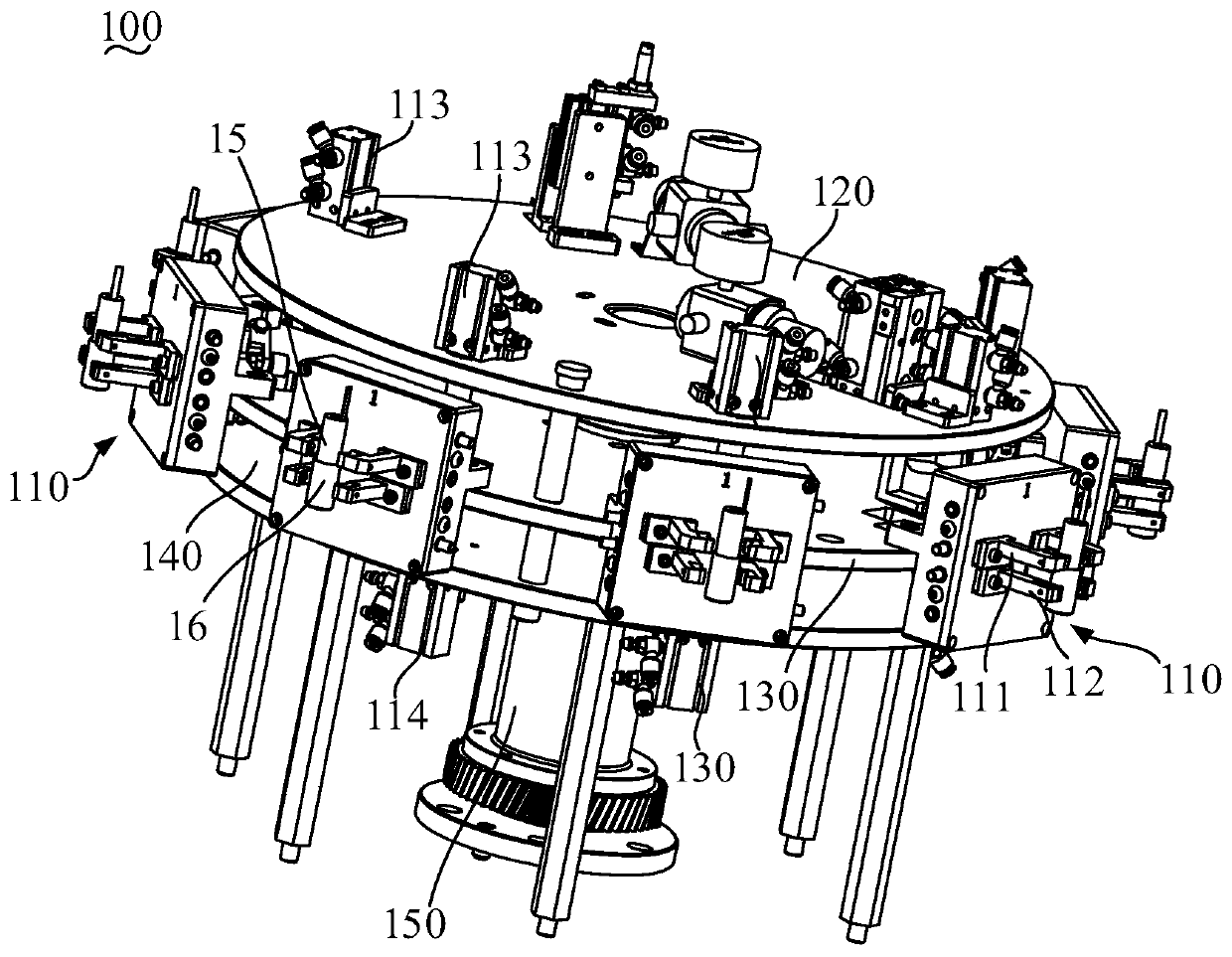

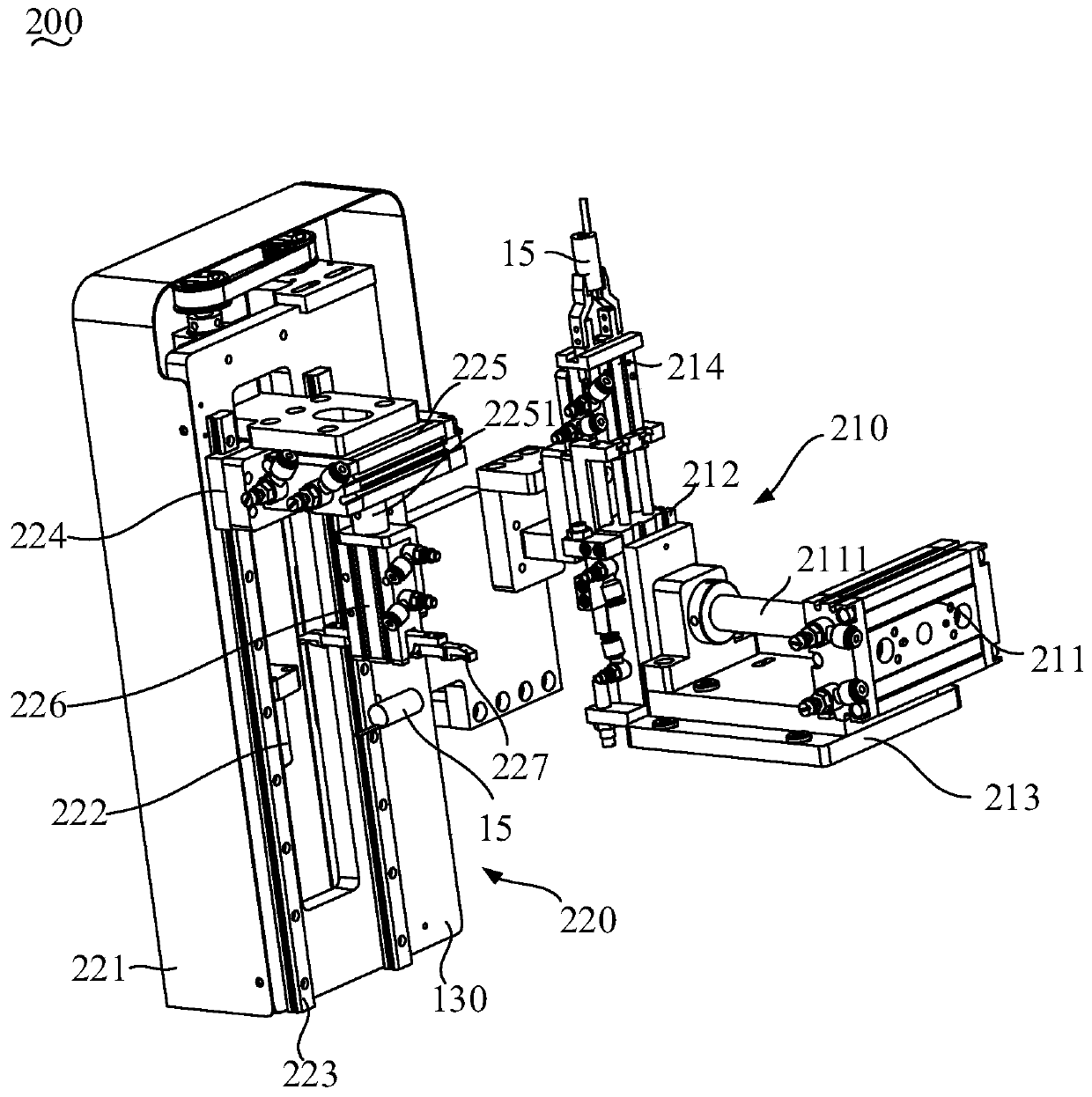

RC capacitor automatic assembly machine

PendingCN109494083AMass productionIncrease productivityEncapsulating capacitors apparatusCapacitanceEngineering

The present invention discloses a RC capacitor automatic assembly machine. The RC capacitor automatic assembly machine comprises a rack, a capacitor element feed mechanism, a rotary table element enabling distribution mechanism, an element table material clamp running mechanism, a resistance dismounting and mounting thread cutting mechanism, a resistance clamping feed mechanism, a resistance welding mechanism, a pin cutting feed mechanism, a pin welding mechanism, a twisted foot mechanism, a material shifting plug shell mechanism, an assembly table running mechanism, a capacitor housing feed mechanism, a glue injection mechanism, an assembly table discharge and setting mechanism and a capacitor receiving mechanism. The RC capacitor automatic assembly machine can automatically weld a capacitor element and a resistor and pins and can assemble the capacitor element and a resistor and pins in the capacitor housing for package so that the RC capacitor automatic assembly machine is high in production efficiency, saves time and labor, is stable and reliable to run, reduces the production cost, can improve the product production quality and the percent of pass, can achieve a series of automatic work such as automatic loading, enabling, welding, twist of bottom, shell plugging, glue injection and material receiving and can meet large-scale production of enterprises.

Owner:湖南宏邦自动化设备有限公司

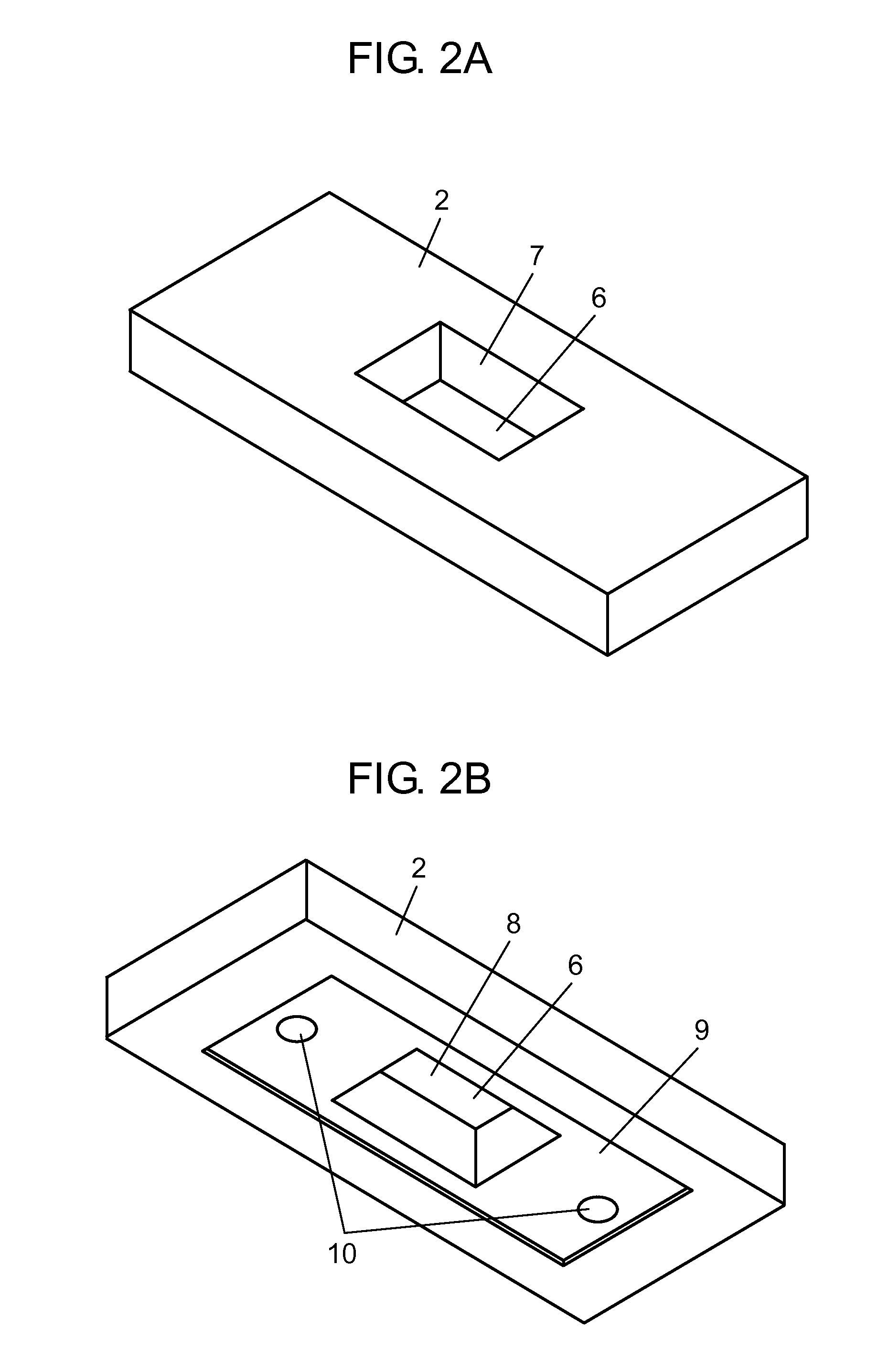

Method of manufacturing resin molded electronic component (as amended)

InactiveUS20110127694A1Increase production capacityImprove reliabilitySolid electrolytic capacitorsFixed capacitor housing/encapsulationElectronic componentViscosity

A method of manufacturing a resin molded electronic component using a first mold having a cavity with an open top surface and a second mold combined with the first mold on top includes the following steps: (A) inserting a element of the electronic component and a liquid resin precursor into the cavity of the first mold, the liquid resin precursor having viscosity of 10 Pa·s or lower at 40° C.; (B) arranging the second mold such that the element and the resin precursor are sandwiched after the step (A); and (C) pressing the element and the resin precursor between the first mold and the second mold, and curing the resin precursor by heat from the second mold after the step (B). A temperature of the second mold is set to be higher than that of the first mold.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Manufacturing method for semi-solid aluminum electrolytic capacitor

InactiveCN108538650AImprove wettabilityGood restorativeCapacitor electrolytes/absorbentsWinding capacitor machinesCapacitanceConductive polymer

The invention proposes a manufacturing method for a semi-solid aluminum electrolytic capacitor, and relates to the technical field of aluminum electrolytic capacitors. The method comprises the following steps: S100, the making of an element; S200, a first impregnation stage, wherein the element is impregnated into a liquid at the stage; S300, a second impregnation stage, wherein the element is impregnated with a conductive polymer monomer, an oxidant and dispersion liquid at the stage; S400, a third impregnation stage, at which the element is impregnated with a treatment liquid; S500, a fourthimpregnation stage, at which the element is impregnated with an electrolyte; S600, the packaging of the element which is subjected to the fourth impregnation stage into an aluminum shell. In the invention, a mixed aluminum electrolytic capacitor (the semi-solid aluminum electrolytic capacitor) which contains the three materials (a conductive solid layer, treating fluid and the electrolyte) and isformed by the conductive polymers is disposed in the capacitor element. The semi-solid aluminum electrolytic capacitor has the characteristics of high reliability, high capacity, high ripple currentresistance and the like, has the function of promoting the repair of the defect portion of an oxide film of anode foil, and can suppress the occurrence of a short circuit fault.

Owner:CAPXON ELECTRONIC (SHENZHEN) CO LTD

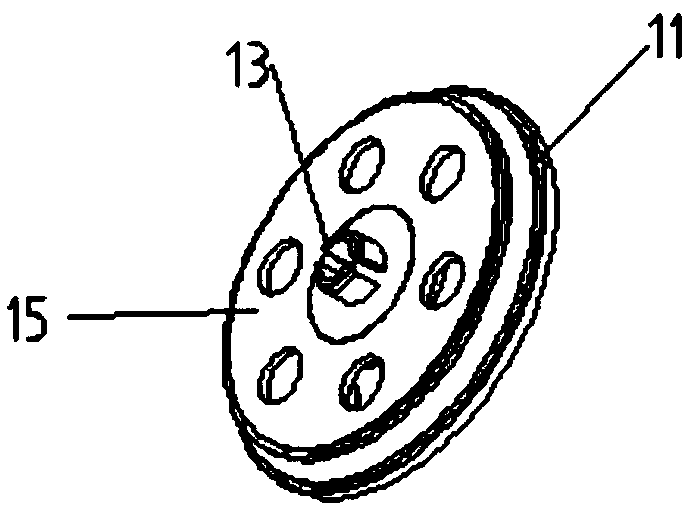

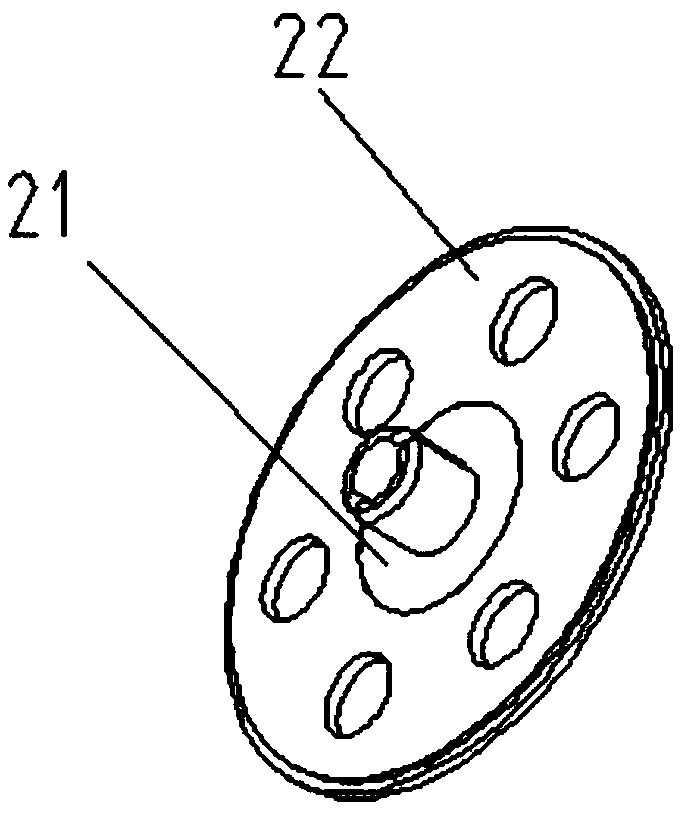

Molding tool for processing nano super capacitor battery

PendingCN110534359AEasy accessImprove the flexibility of useEncapsulating capacitors apparatusCapacitanceEngineering

The invention provides a molding tool for processing a nano super capacitor battery. The molding tool comprises a turntable device, a roller groove device and a clamping device. The turntable device comprises a turntable base, a turntable base post, a fixed disk, a center post, a push rod, a push rod bracket, a push block, a bracket block, an ejector rod, a rotating disk, a turntable motor, a turntable gear, a limit gear and a conveying part. The roller groove device is arranged on one side of the turntable device. The roller groove device comprises a roller groove table, a roller groove tablepost, a roller groove bracket, a clamp claw motor, an electric push rod, a clamping mechanism, a hob motor, a hob, a support rod, a telescopic cylinder, a telescopic rod, a bearing seat, a support rod, a support rod gear, a gear casing, a casing support, a clamping transmission motor and a clamping transmission gear. The clamping device is arranged inside the roller groove table. The top end of the clamping device protrudes out of the top of the roller groove table through a roller groove table through hole. The molding tool provided by the invention can realize the processes of conveying, clamping and roller groove of a battery casing body, has a reasonable structure, uses battery casing bodies of different sizes for processing, and has the advantage of flexible use.

Owner:HIDETAKA NANO TECH CO LTD

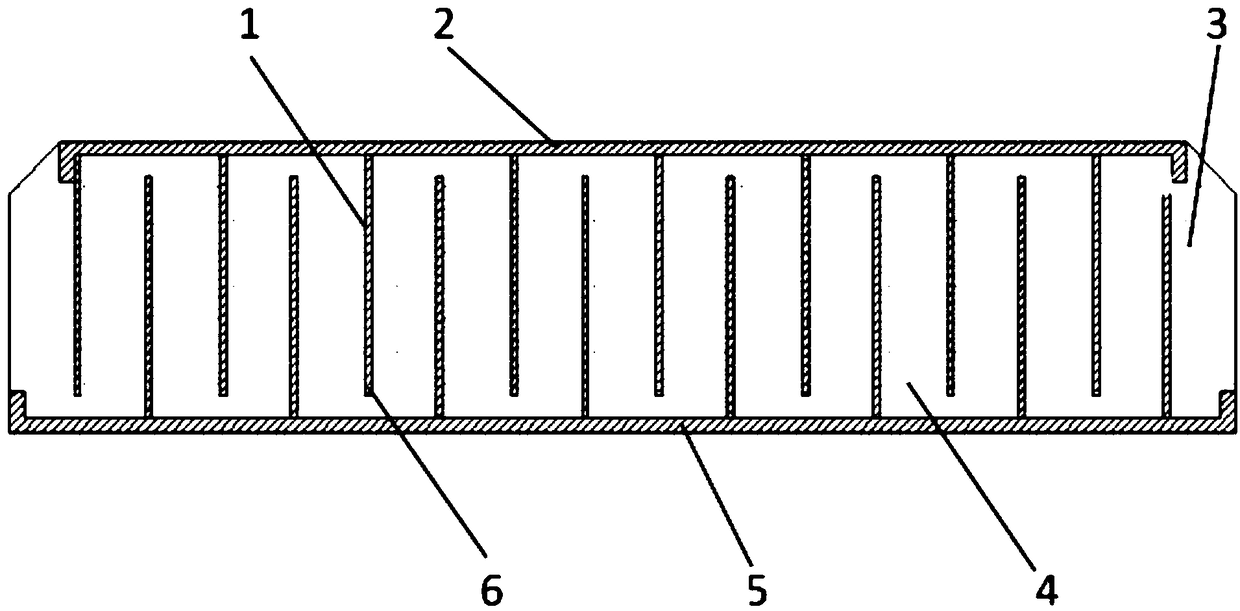

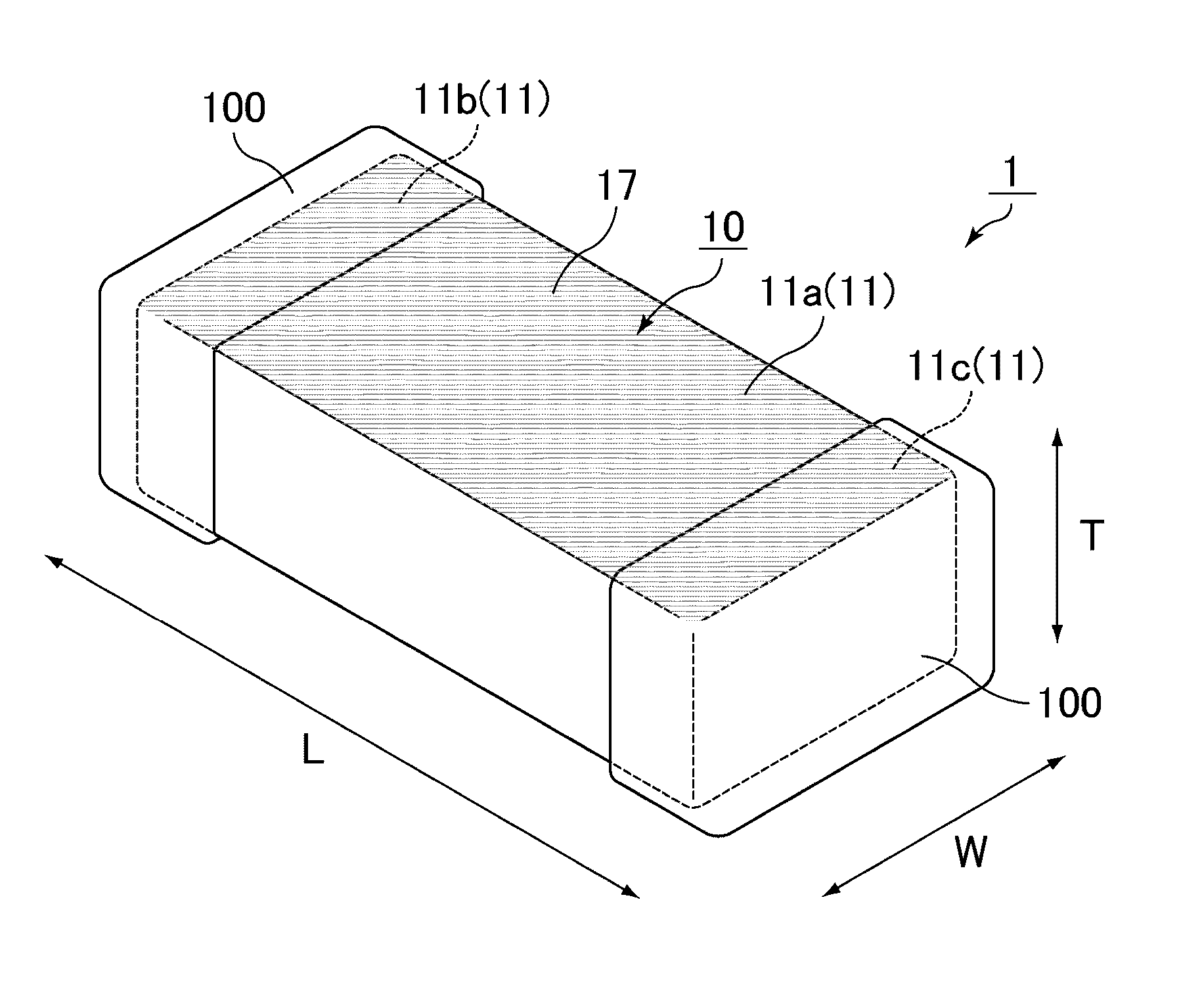

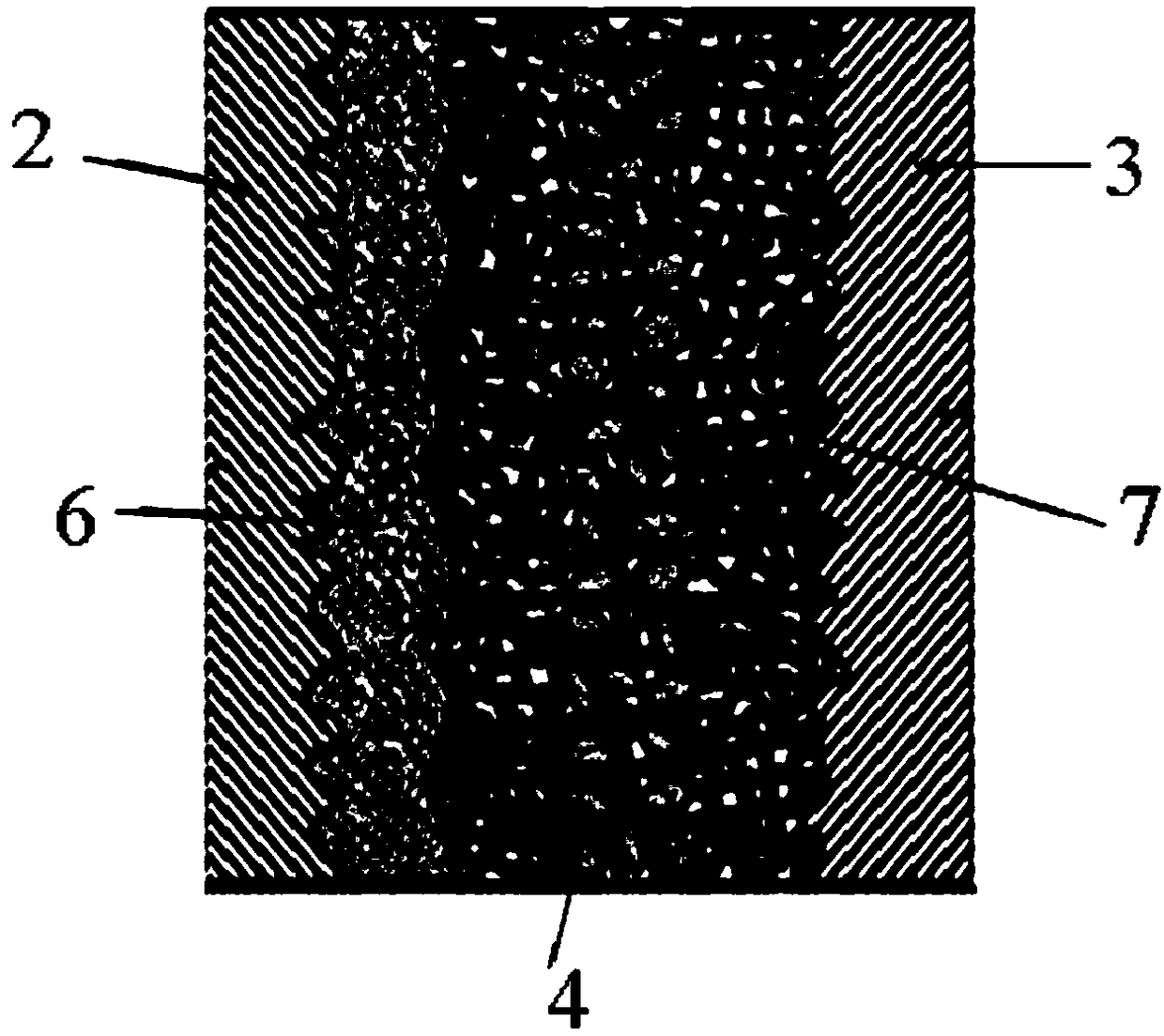

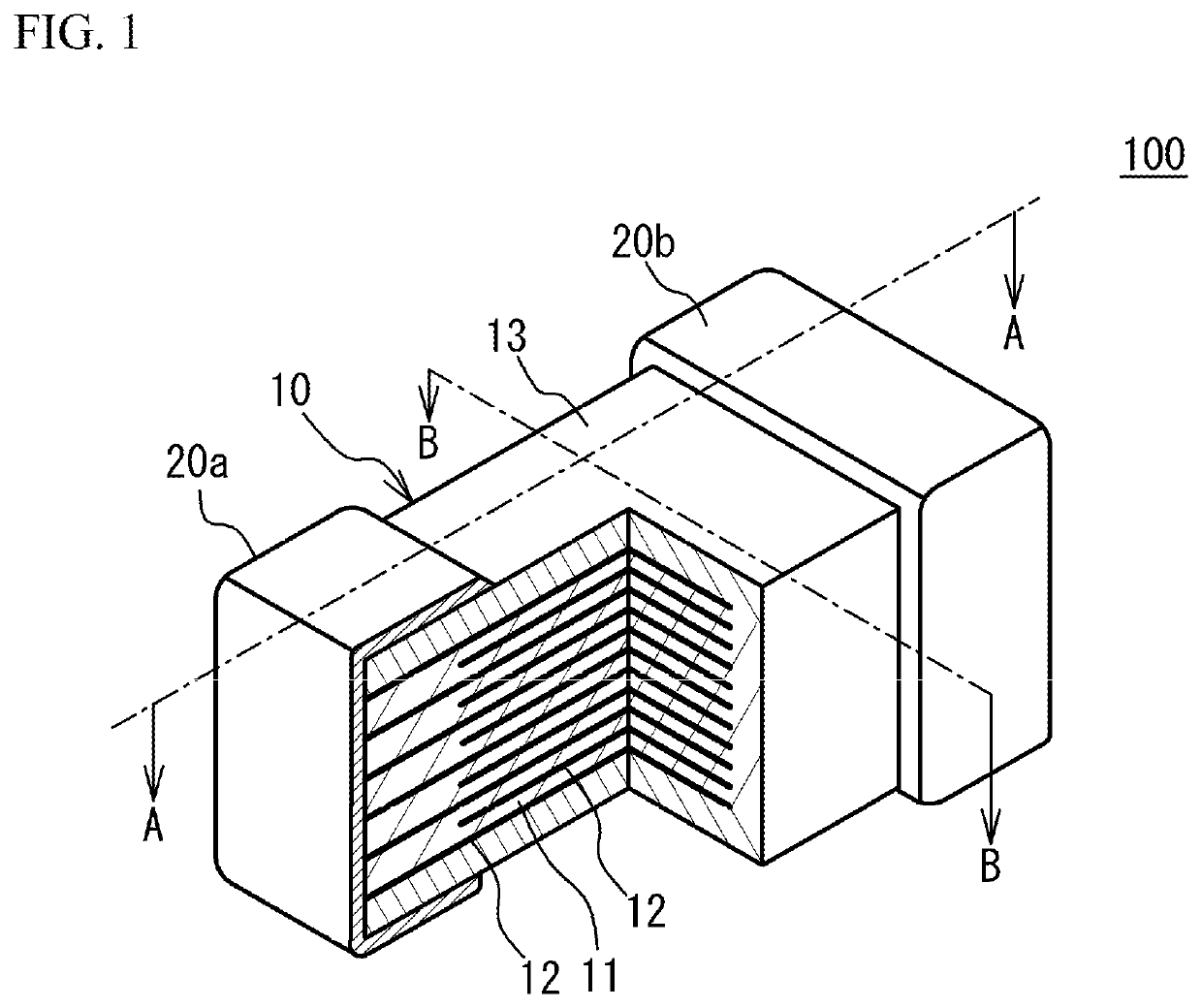

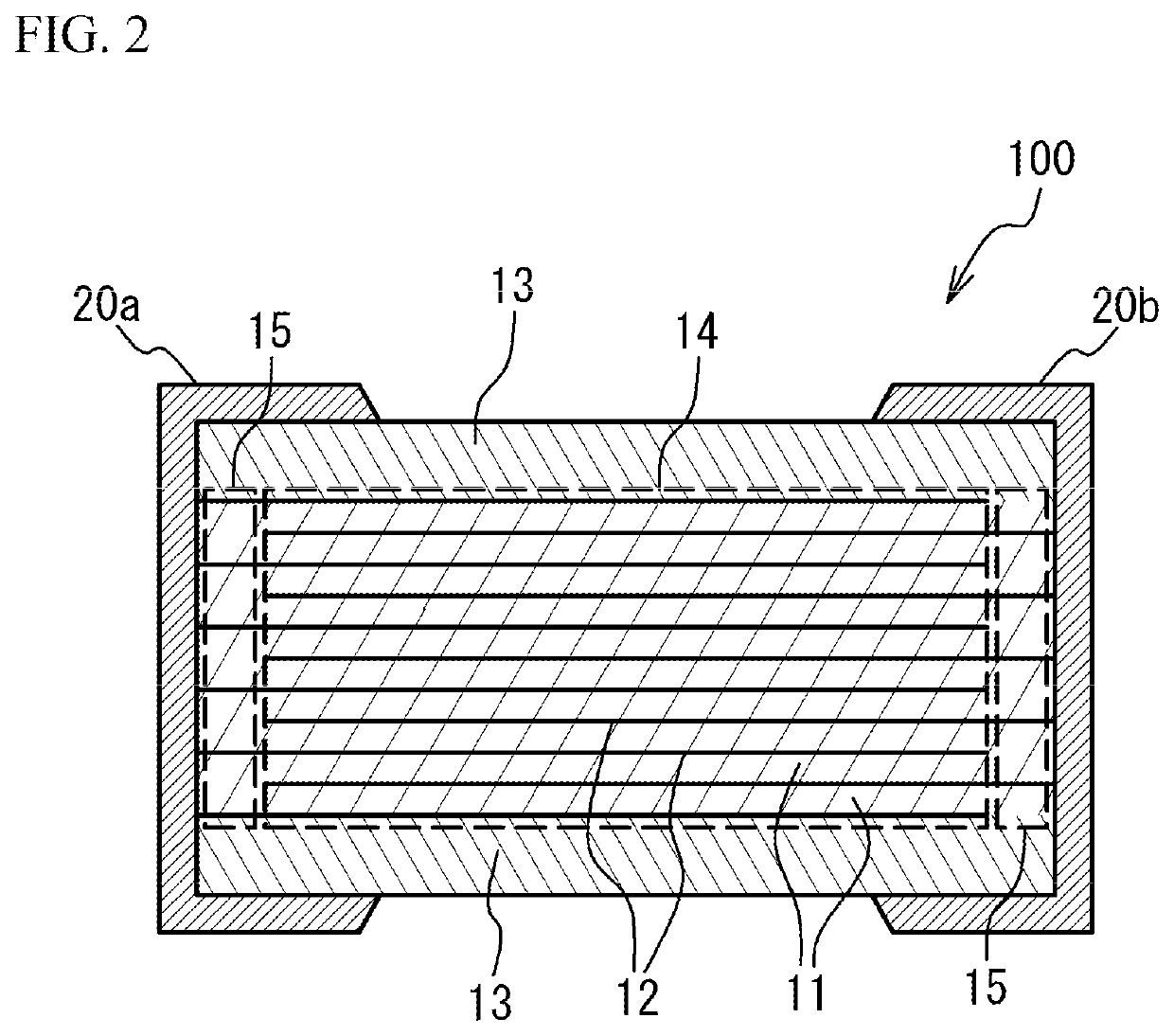

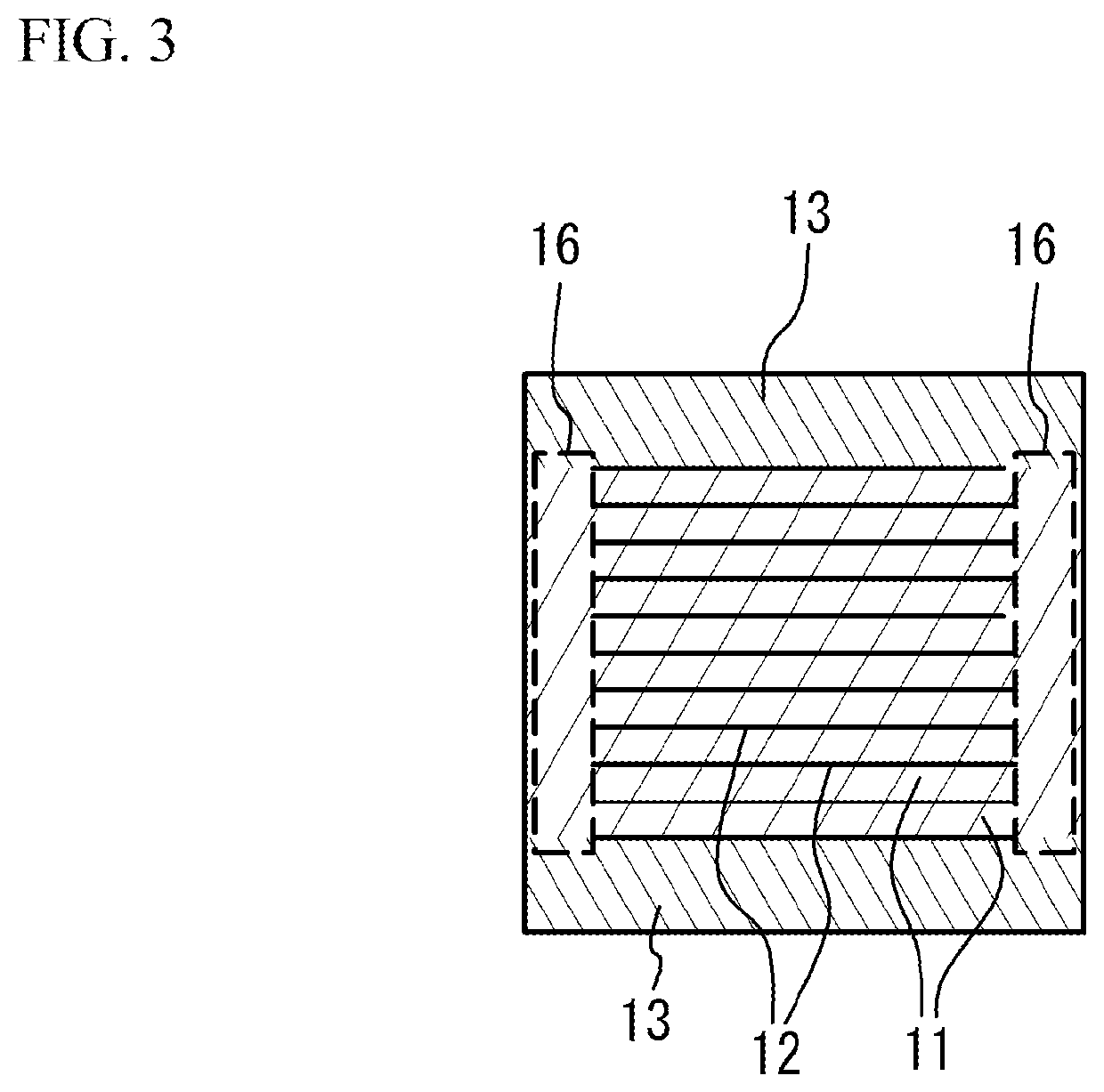

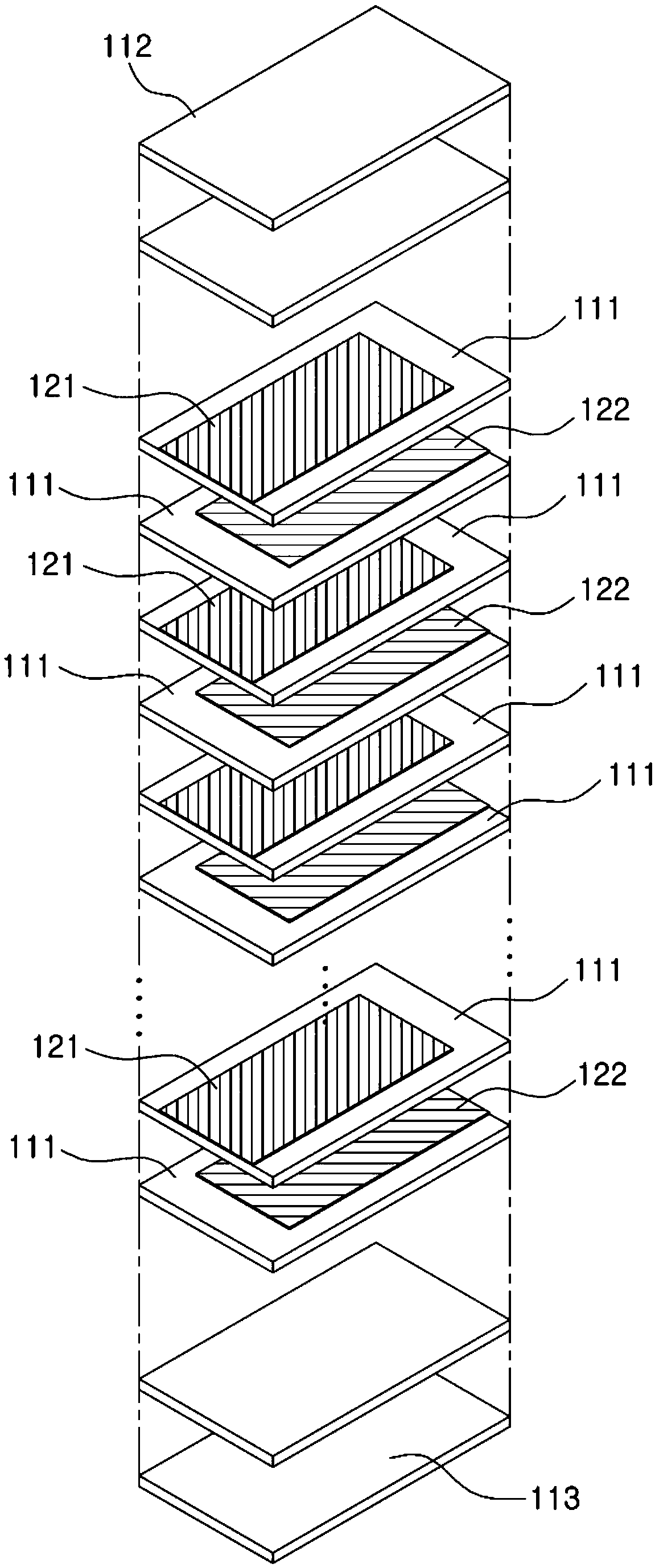

Multilayer ceramic capacitor

ActiveUS10672558B2InhibitionFixed capacitor electrodesFixed capacitor dielectricCapacitanceCeramic capacitor

A multilayer ceramic capacitor includes: a multilayer structure in which each of ceramic dielectric layers and each of internal electrode layers are alternately stacked, the plurality of internal electrode layers being alternately exposed to a first edge face and a second edge face of the multilayer structure, wherein: a region in which a set of internal electrode layers exposed to the first edge face of the multilayer structure face with another set of internal electrode layers exposed to the second edge face of the multilayer structure is a capacity region; at least a part of the circumference region around the capacity region has a protective region of which an average grain diameter of a main component ceramic is larger than that of the capacity region and of which a concentration of a donor element in the main component ceramic is larger than that of the capacity region.

Owner:TAIYO YUDEN KK

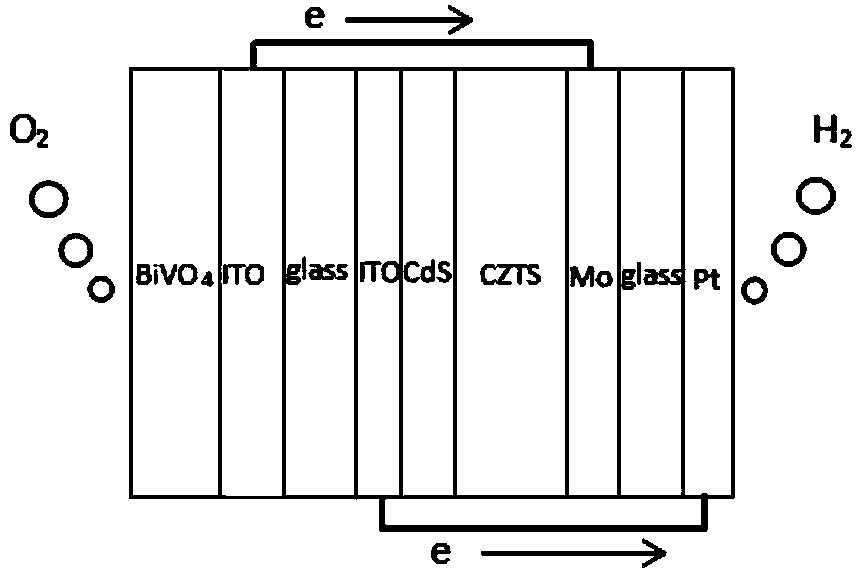

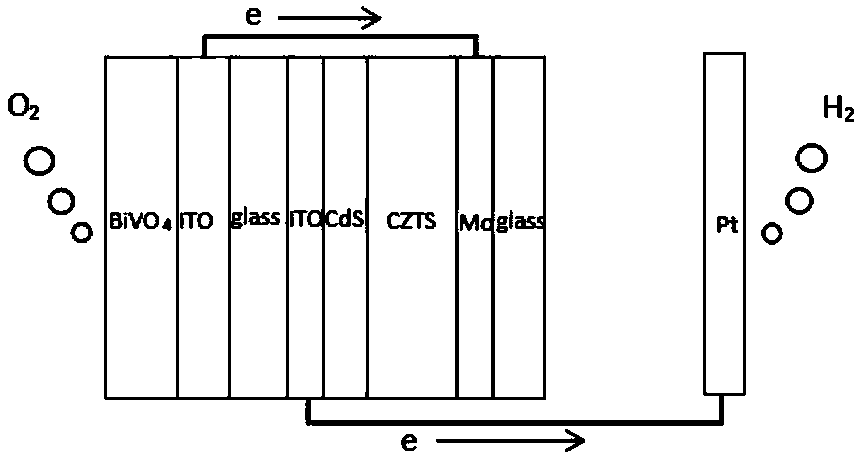

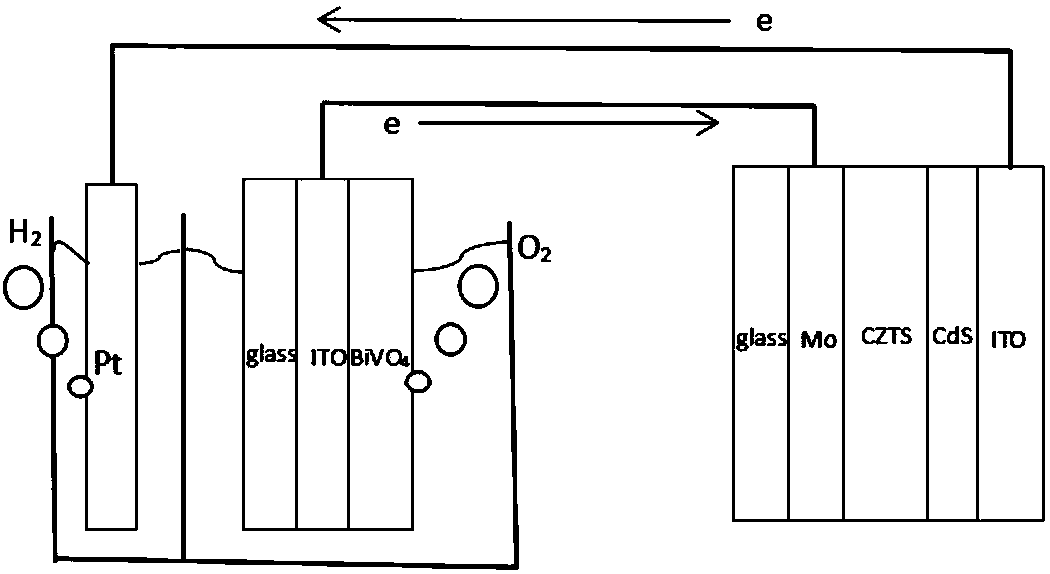

Sunshine water decomposition hydrogen generation microelectronic device and preparation method thereof

ActiveCN108335911ALight-sensitive devicesFinal product manufactureExternal biasPhotocatalytic water splitting

The invention relates to a sunshine water decomposition hydrogen generation microelectronic device and a preparation method thereof. The sunshine water decomposition hydrogen generation microelectronic device comprises a CZTS solar cell, a BiVO<4> photo anode, a wire and a Pt sheet, wherein the CZTS solar cell, the BiVO<4> photo anode and the Pt sheet are connected through the wire to realize thesemiconductor device without external bias voltage and with a series structure for performing hydrogen making through photocatalytic water splitting; without an extra power supply, sunshine is utilized directly to realize automatic hydrogen making through photocatalytic water splitting, so that all source of the hydrogen energy is sunshine; and the sunshine direct power generation is stable, toxic-free, low in cost of raw materials, and real cleaning, low-cost, environmental protection and environment friendly hydrogen making can be realized, and the produced hydrogen renewable.

Owner:SOUTH CHINA NORMAL UNIVERSITY

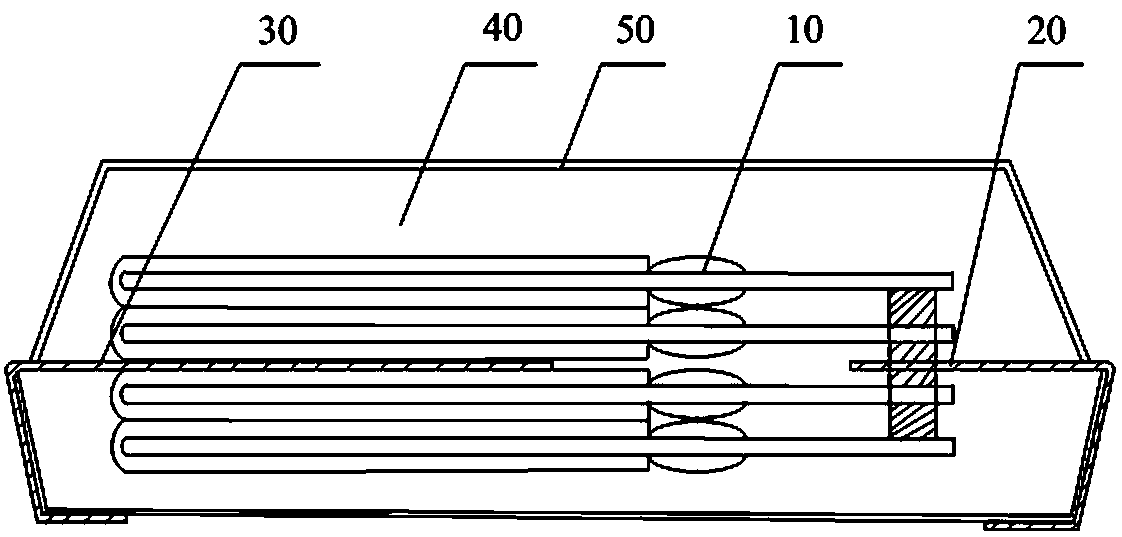

Aluminum electrolytic capacitor and manufacturing method thereof

ActiveCN109616327ALow costShorten the lengthLiquid electrolytic capacitorsWinding capacitor machinesElectrolysisBreakdown rate

The invention provides an aluminum electrolytic capacitor. A basic structure of the aluminum electrolytic capacitor is of a foil-type winding structure and is fabricated by winding a positive electrode foil corroded to form an oxide film, a corroded negative electrode foil and electrolyte paper partitioned between the positive electrode foil and the negative electrode foil to form a core pack, immersing the core pack in an electrolyte, riveting a cover plate and sealing in an aluminum shell. The length of the positive electrode foil is reduced, the winding number of the aluminum electrolytic capacitor can be reduced after winding is completed, so that the volume of the aluminum electrolytic capacitor can be reduced; compared with electrolyte paper selecting general thickness and general density in the prior art, the volume of the aluminum electrolytic capacitor formed by winding can be reduced after winding is completed, the breakdown rate of the aluminum electrolytic capacitor is reduced, meanwhile, the oxidization time of the positive electrode foil during oxidization can be reduced, the efficiency is improved, and the cost is reduced.

Owner:横店集团东磁有限公司

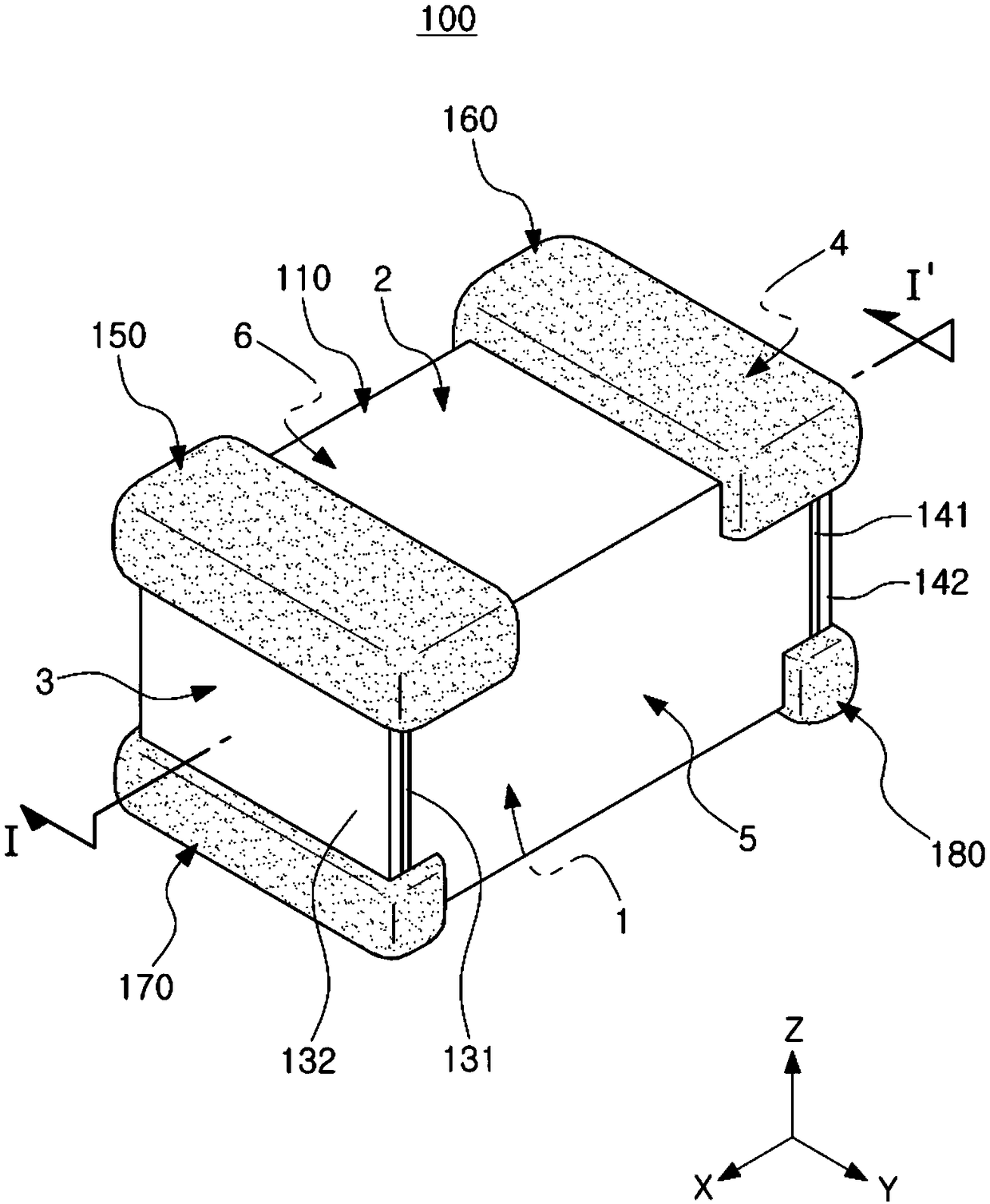

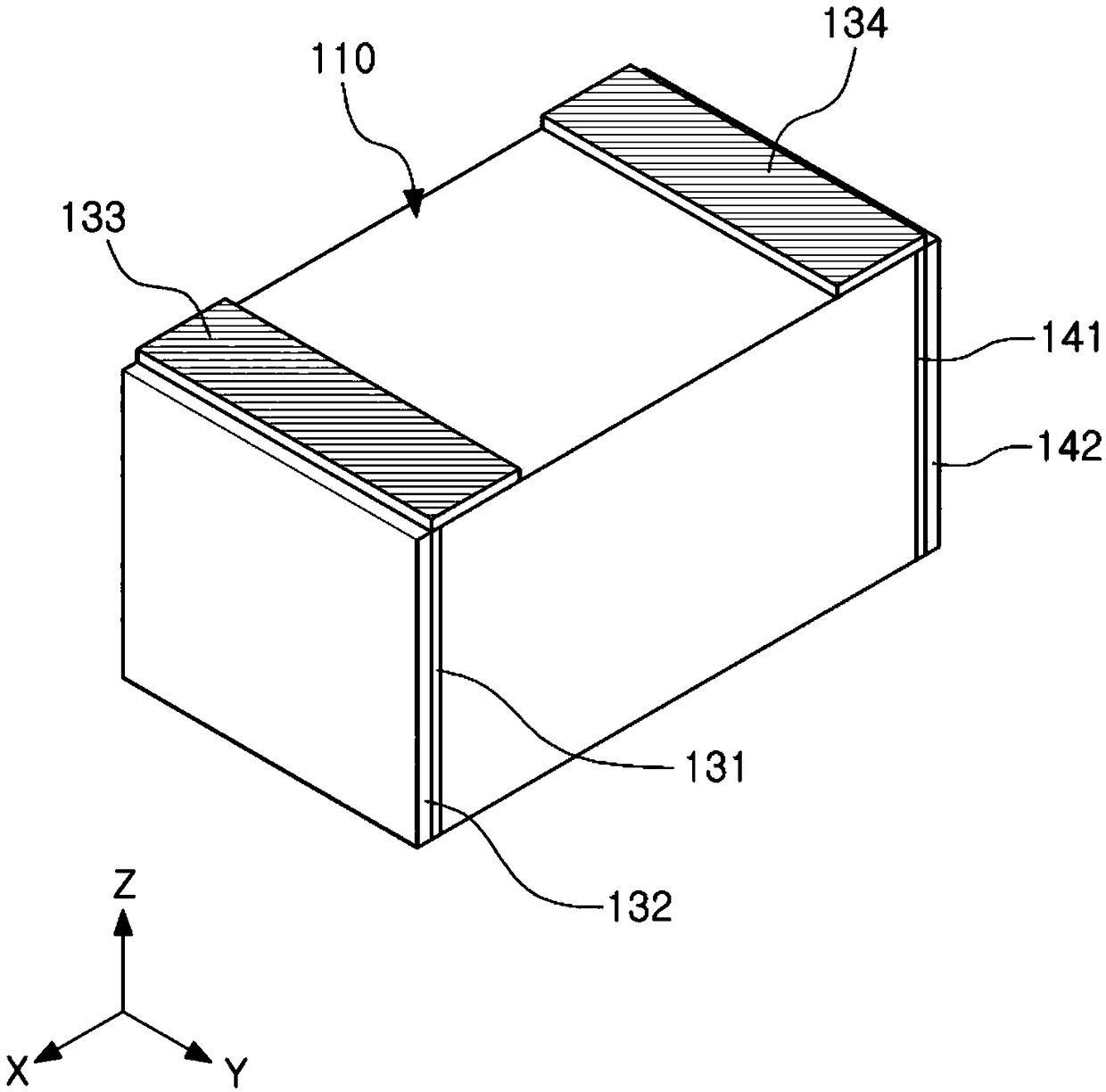

Capacitor component and method of manufacturing the same

The invention provides a capacitor component and method of manufacturing the same. The capacitor component includes a body including first and second internal electrodes alternately disposed with respective dielectric layers interposed therebetween to be exposed to the third and fourth surfaces of the body, respectively; first and second conductive layers covering the third and fourth surfaces andconnected to the first and second internal electrodes, respectively; first and second insulating layers covering the first and second conductive layers, respectively; first and second band portions spaced apart from each other on the second surface of the body; first and second external electrodes covering a portion of the first and second band portions and the first insulating layer, respectively; and third and fourth external electrodes covering a portion of the first and second insulating layers and a portion of the first surface of the body, respectively.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Capacitor based on metallized film nano-evaporation technique and preparation process of capacitor

InactiveCN108538578AImprove surge current capabilityReduce contact lossThin/thick film capacitorStacked capacitorsCapacitanceEvaporation

The invention discloses a capacitor based on a metallized film nano-evaporation technique and a preparation process of the capacitor, and belongs to the field of capacitors. The technical scheme is characterized in that the capacitor comprises a casing, a cover plate and a capacitor core, wherein the capacitor core comprises a metallized polypropylene film which is tightly attached to the outer surface of the capacitor core, and the metallized polypropylene film is of a double-layer and double-side structure; the upper part of the casing is fixedly connected with the cover plate, the capacitorcore is embedded in the casing, heat-shrinkable tubing is tightly attached to the inner wall of the casing, and an aluminum shell is connected in the heat-shrinkable tubing in a penetration manner. According to the capacitor based on the metallized film nano-evaporation technique and the preparation process of the capacitor, surge current resistance of the capacitor can be improved by the metallized polypropylene film, and contact loss is reduced, so that open circuit or substantially reduced capacity of the capacitor can be avoided.

Owner:CHANGXING YOUCHANG ELECTRONICS

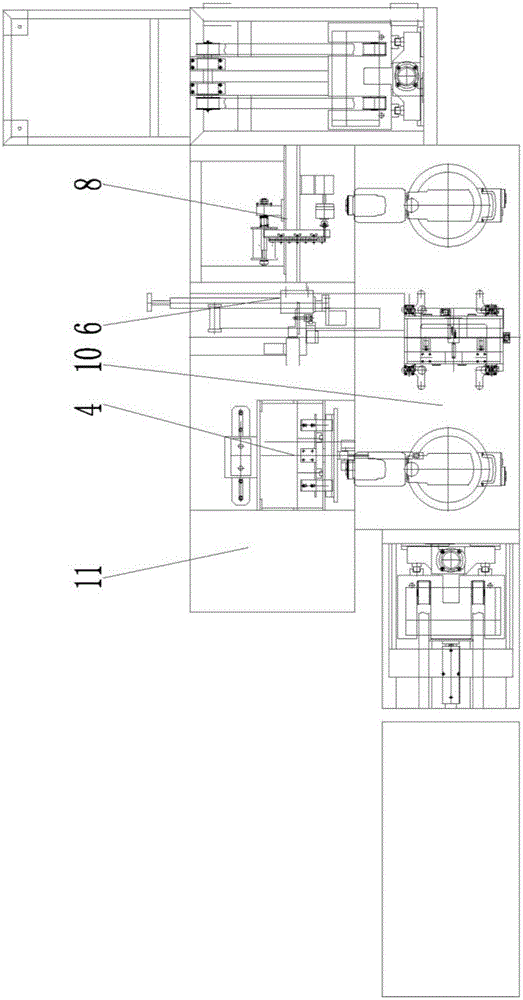

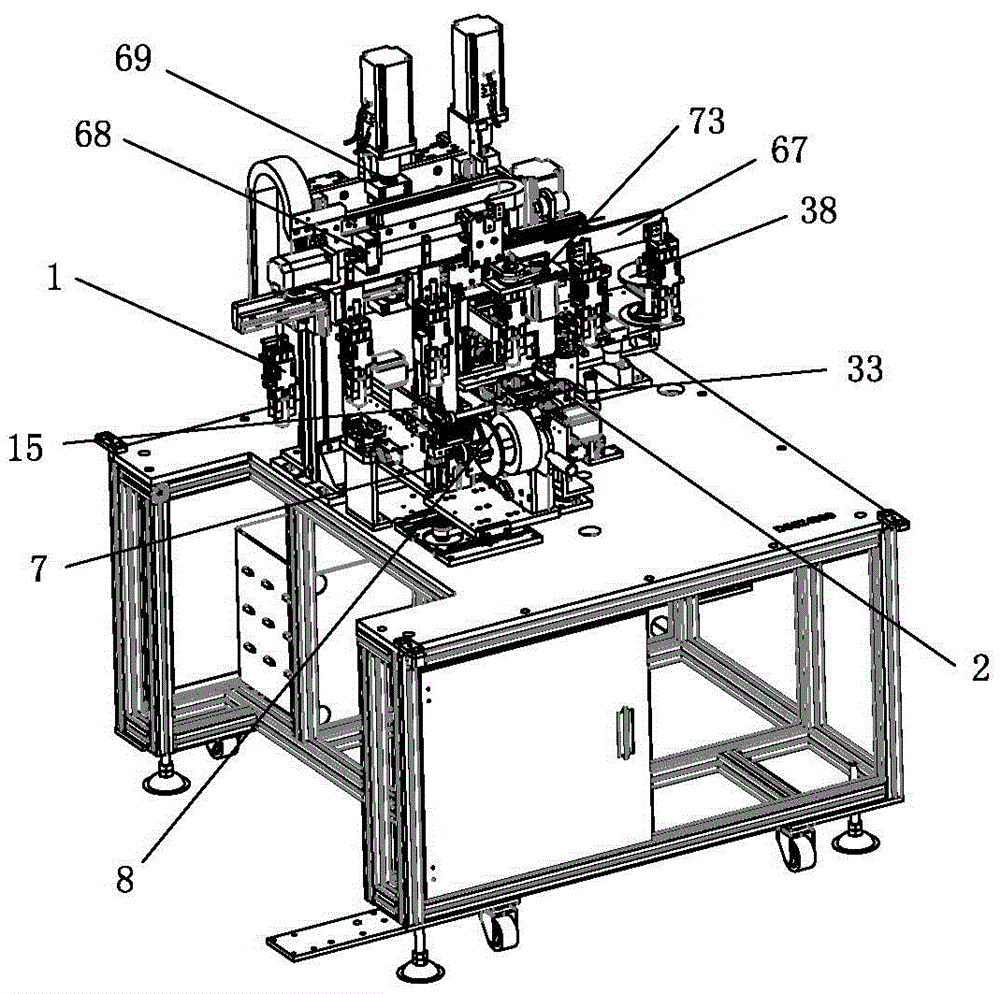

Fully automatic capacitor seat plate assembly test packaging machine

PendingCN109509642ARealize fully automatic seat panel assembly testImplement packagingEncapsulating capacitors apparatusEngineeringTransfer mechanism

The invention discloses a fully automatic capacitor seat plate assembly test packaging machine. The packaging machine includes a frame, a feeding mechanism, a rotating multi-station vacuum conveying mechanism, a printing and conveying mechanism, a printing mechanism, a charging test mechanism, a rotating switching mechanism and a packaging mechanism, wherein the rotating multi-station vacuum conveying mechanism is provided with multiple vacuum suction devices, the feeding mechanism is at a feeding station and is docked with the vacuum suction devices, an upper seat plate mechanism is arrangedat an upper seat plate station, the printing and conveying mechanism is arranged at a printing transfer station, one end of the printing and conveying mechanism is docked with the vacuum suction devices, the other end is docked with the printing transfer mechanism, a printing and switching mechanism is connected between the printing and conveying mechanism and the charging test mechanism, and therotating switching mechanism is arranged between the charging test mechanism and the packaging mechanism. The packaging machine is advantaged in that the partial mechanical structure is employed by each part, overall working efficiency is high, the stability is good, the guided conveying or vacuum adsorption conveying structure is employed, products are not directly clamped, the products bear small force, and the quality is easy to guarantee.

Owner:ZHUHAI HIGRAND ELECTRONICS TECH

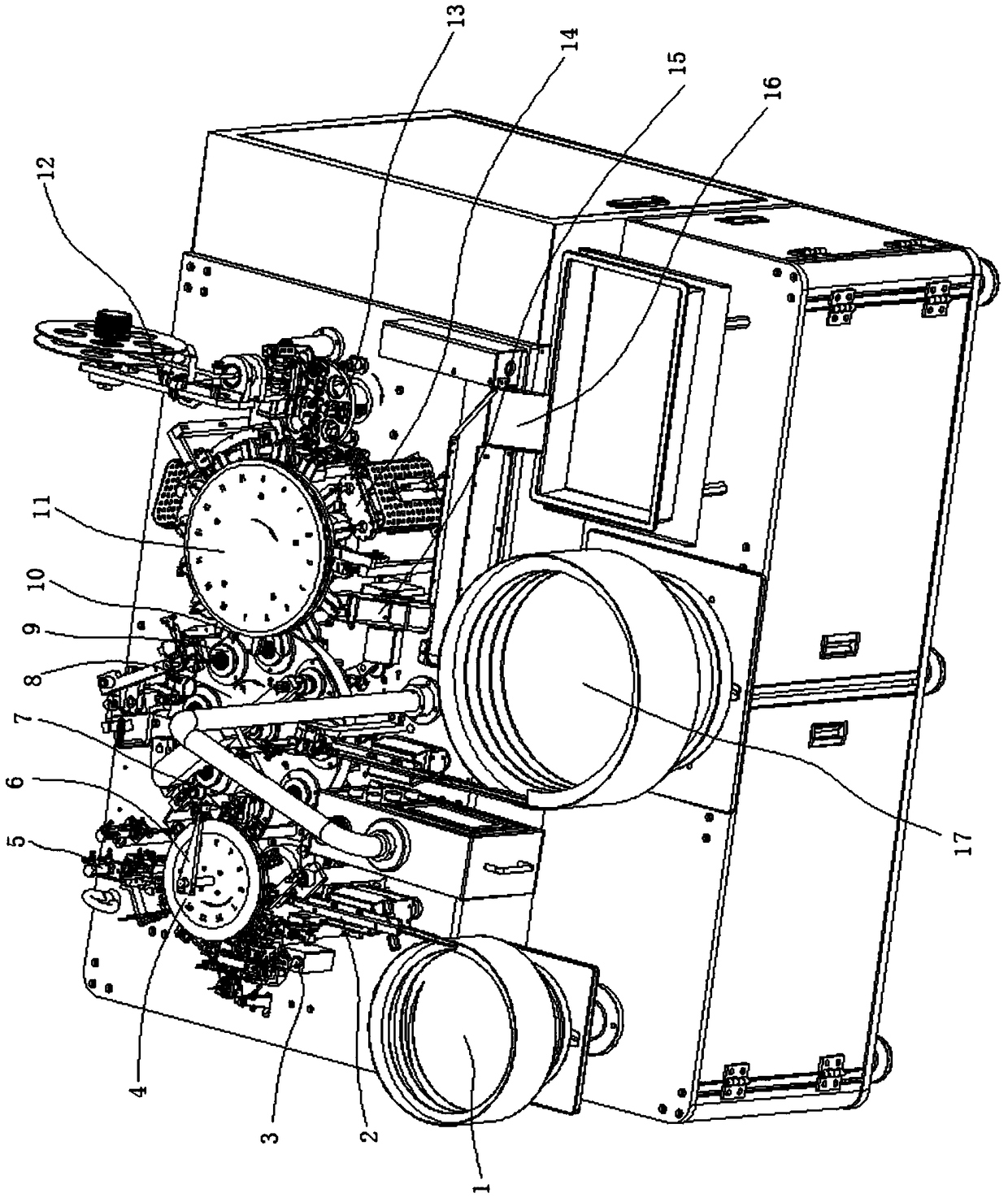

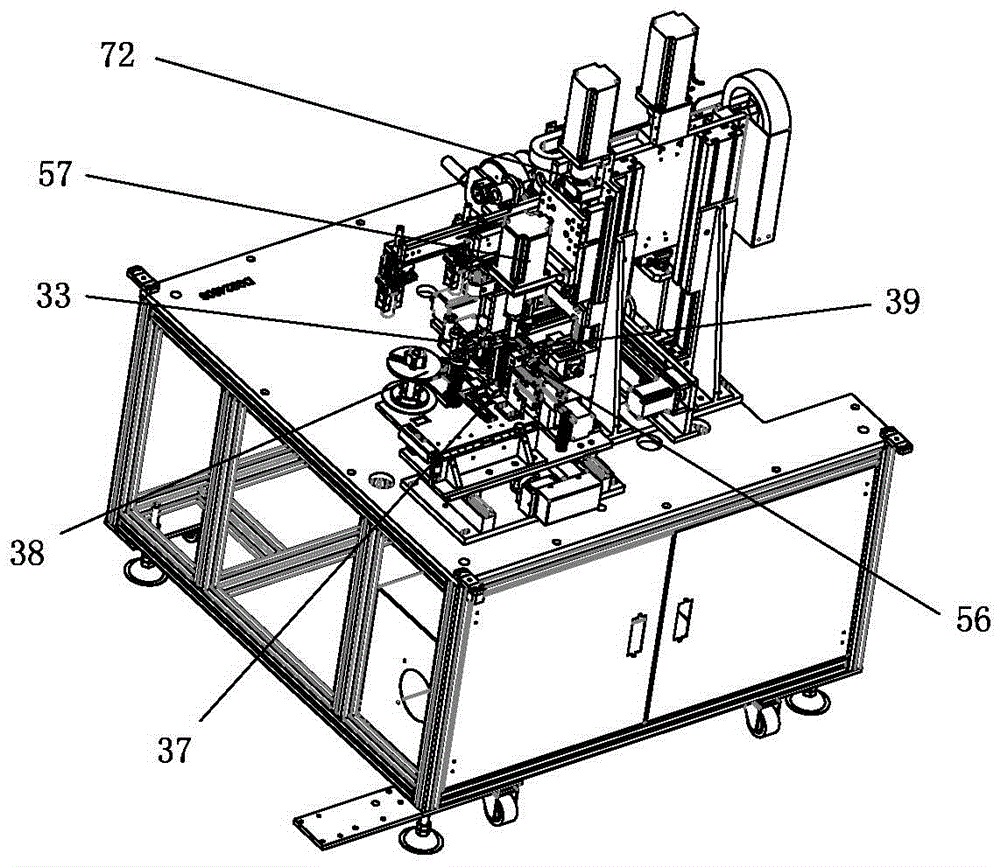

Automatic coating machine for capacitor components

ActiveCN106449184AImprove work efficiencyRealize automatic feeding processEncapsulating capacitors apparatusCapacitanceEngineering

The invention relates to an automatic coating machine for capacitor components. The coating machine comprises a feed mechanism, a first manipulator, an assembly table, a coating table, an adhesive tape bonding device, a second manipulator, an inner fuse making machine and a material receiving mechanism, wherein the feed mechanism conveys a capacitor core pile to a working area of the first manipulator when working; the first manipulator clamps one capacitor core and puts the capacitor core on the assembly table; the assembly table coats the capacitor core with a coating box; the first manipulator conveys the capacitor core to the coating table from the assembly table; the coating table locates the capacitor core; the second manipulator puts a fuse on the capacitor core on the coating table; the adhesive tape bonding device coats the capacitor core with an adhesive tape; the second manipulator conveys the manufactured capacitor components to the material receiving mechanism; and the material receiving mechanism stacks and recycles the capacitor components. According to the automatic coating machine, automatic completing of the processes of producing the fuses in the capacitor components, coating and binding the cores and like is achieved, so that the work efficiency is greatly improved.

Owner:SHAANXI AEROSPACE ELECTROMECHANICAL ENVIRONMENTAL ENG DESIGNING INST CO LTD

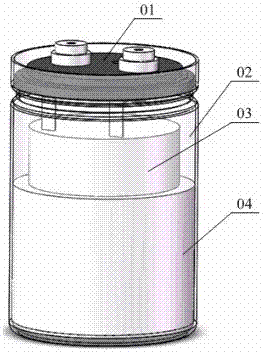

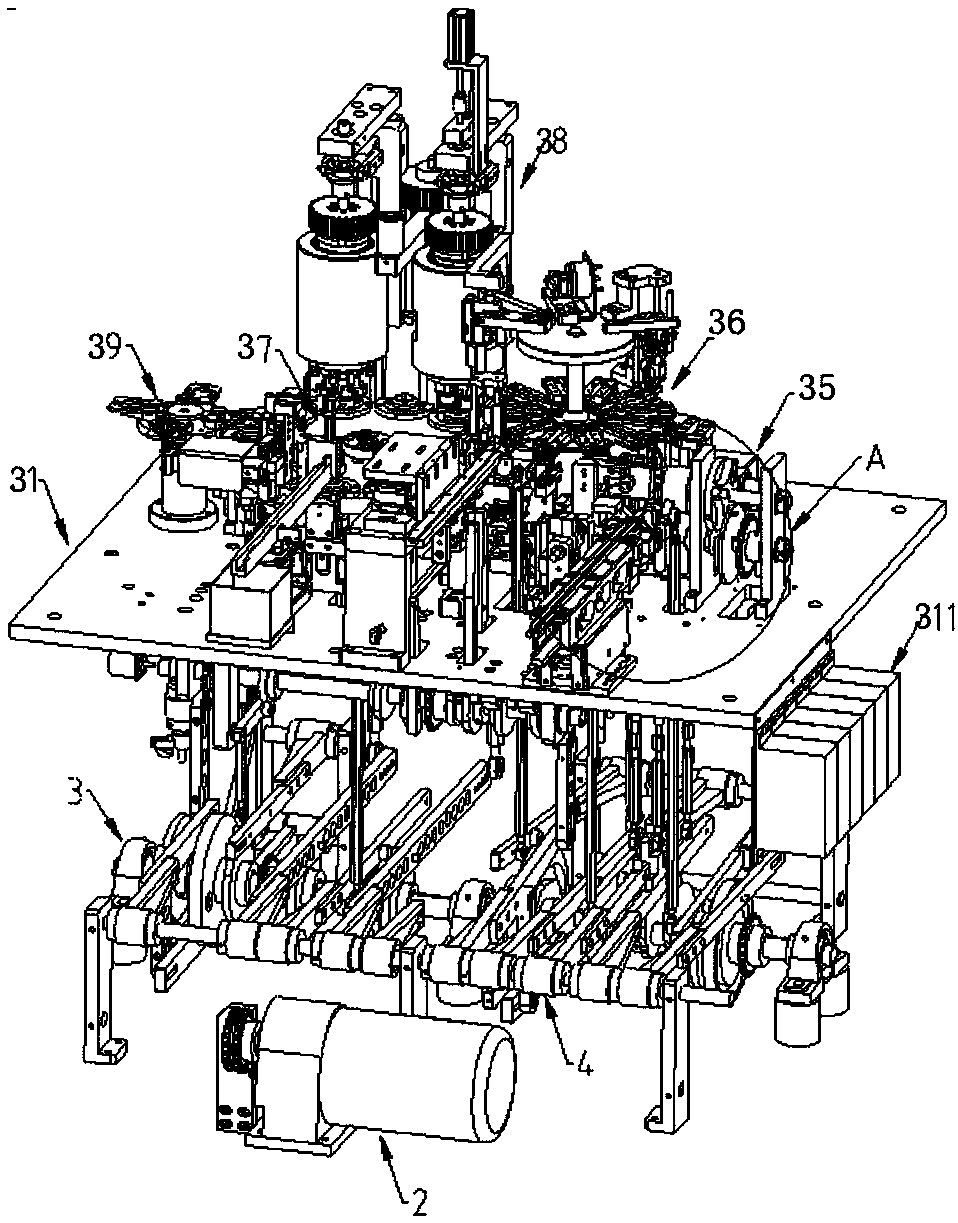

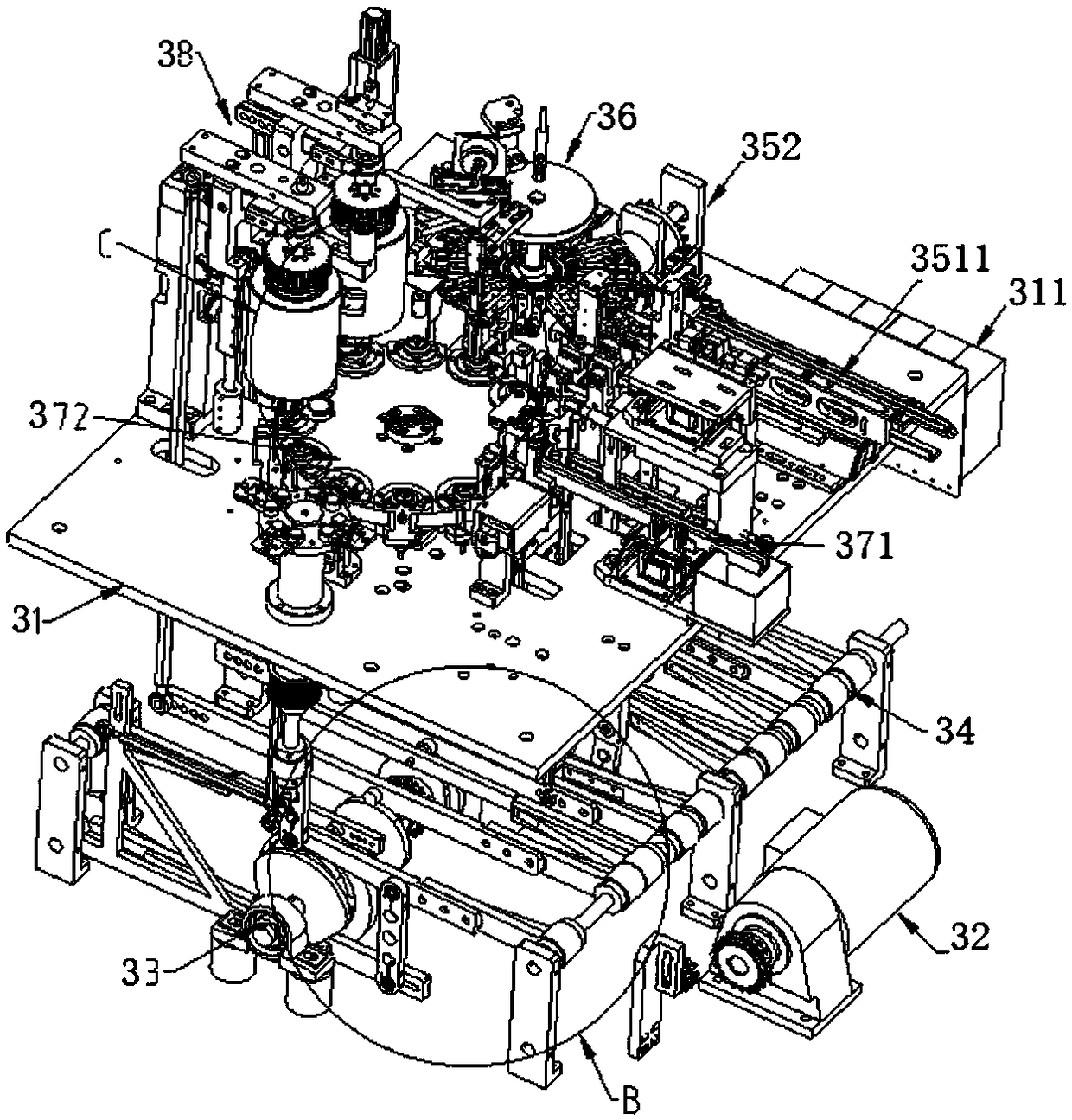

Assembling and sleeving integrated machine for manufacturing capacitors

ActiveCN108064408AAutomate operationCompact structureEncapsulating capacitors apparatusAluminiumEngineering

The invention relates to an assembling and sleeving integrated machine for manufacturing capacitors, and relates to the technical field of capacitor production equipment. The machine comprises an assembling part and a rubber hose sleeving part; the assembling part assembles an element, rubber particles and an aluminum shell into a capacitor bare product, the rubber hose sleeving part comprises a bare product conveying device, a sleeving and clamping group disc, a cleaning device, a drying device, a rubberizing device, a heating device, and a receiving device; and the bare product conveying device conveys the capacitor bare product of the assembling part in the sleeving and clamping group of the sleeving clamping group disc. The sleeving and clamping group disc rotates and the capacitor bare products in the sleeving and clamping group are sequentially brought to the cleaning device, the drying device, the rubberizing device and the heating device for cleaning, drying, sleeving with rubber hose and heating. The receiving device collects the capacitor products heated by the heating device on the sleeving and clamping group disc. The machine can realize the assembly of the capacitor bare products and the operation of the rubber hose sleeving of the capacitor bare products, and the whole process can realize automatic operation, the structure is compact, and the occupied space is small.

Owner:SHENZHEN CHENGJIE INTELLIGENT EQUIP CO LTD

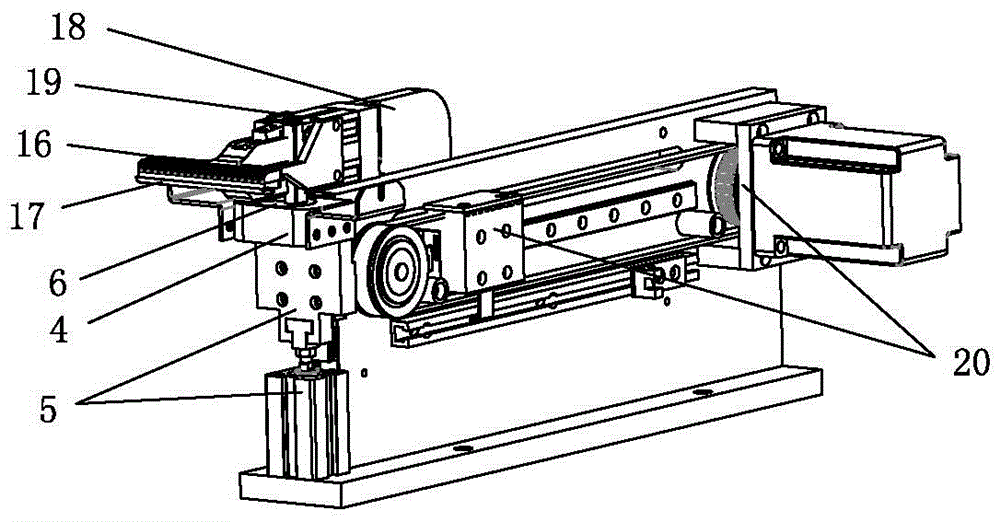

Capacitor gummed paper machine

ActiveCN107527753AIncrease productivityGood quality laggingEncapsulating capacitors apparatusCapacitanceProcess engineering

The present invention relates to the gummed paper device technology field, especially to a capacitor gummed paper machine. The machine comprises a feed mechanism configured to convey a capacitor to be processed, a top gumming mechanism configured to perform gumming of the top of the capacitor and a body gumming mechanism arranged at the discharge end of the feed mechanism and configured to perform gumming of the curved surface of the capacitor. The feed mechanism comprises a plurality of alternatively arranged manipulators configured to clamp the capacitor to be processed and a feed driving device configured to drive a plurality of manipulators to perform left-right or up-down movement; the top gumming mechanism comprises a first gummed paper feed device configured to convey and cut off the gummed paper and a sleeving module configured to sleeve the top of the capacitor, and the first gummed paper feed device and the sleeving module are arranged below two adjacent manipulators; and the top gumming mechanism further comprises a rotation driving module configured to drive the manipulators arranged above the sleeving module to rotate relatively to the sleeving module. The capacitor gummed paper machine can complete the gumming work of the top of the capacitor and the curved surface of the capacitor body at the same time, the production efficiency is high, and the gumming quality is good.

Owner:东莞市展荣电子设备有限公司

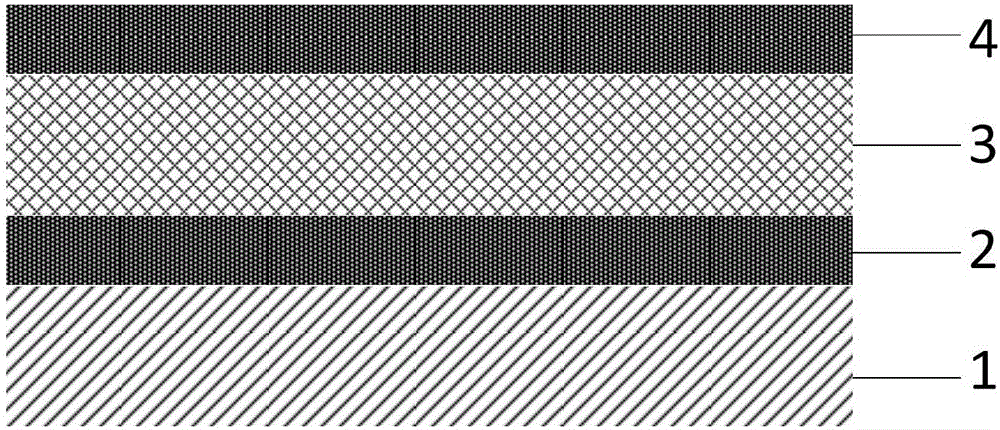

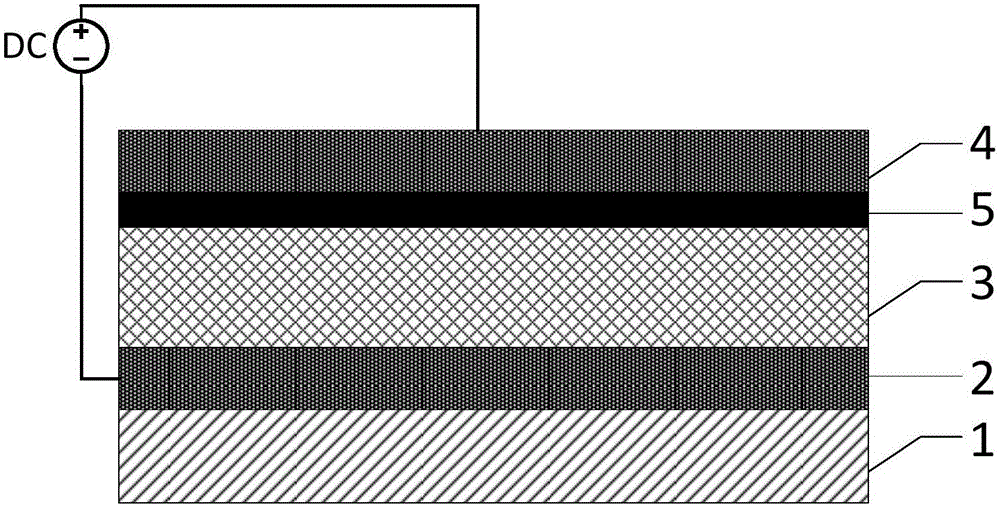

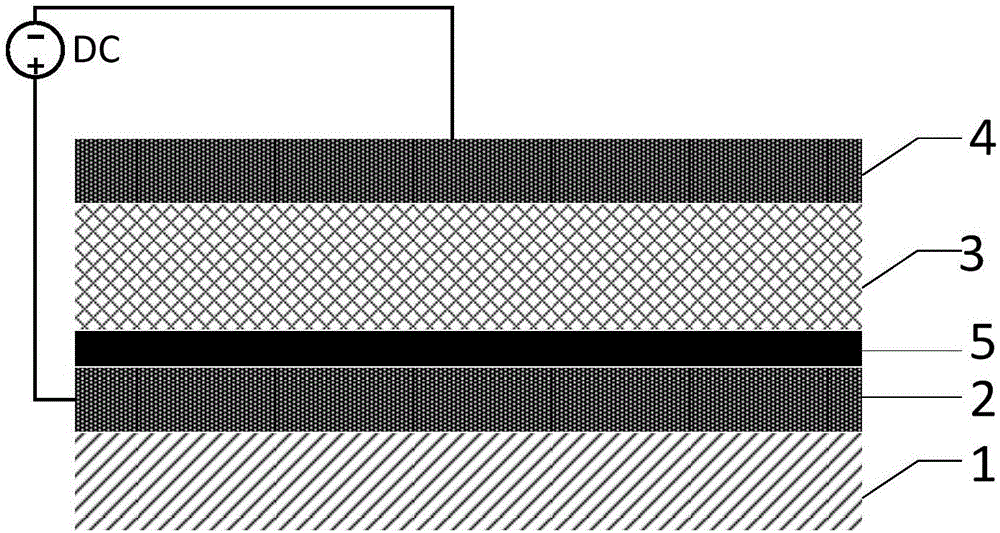

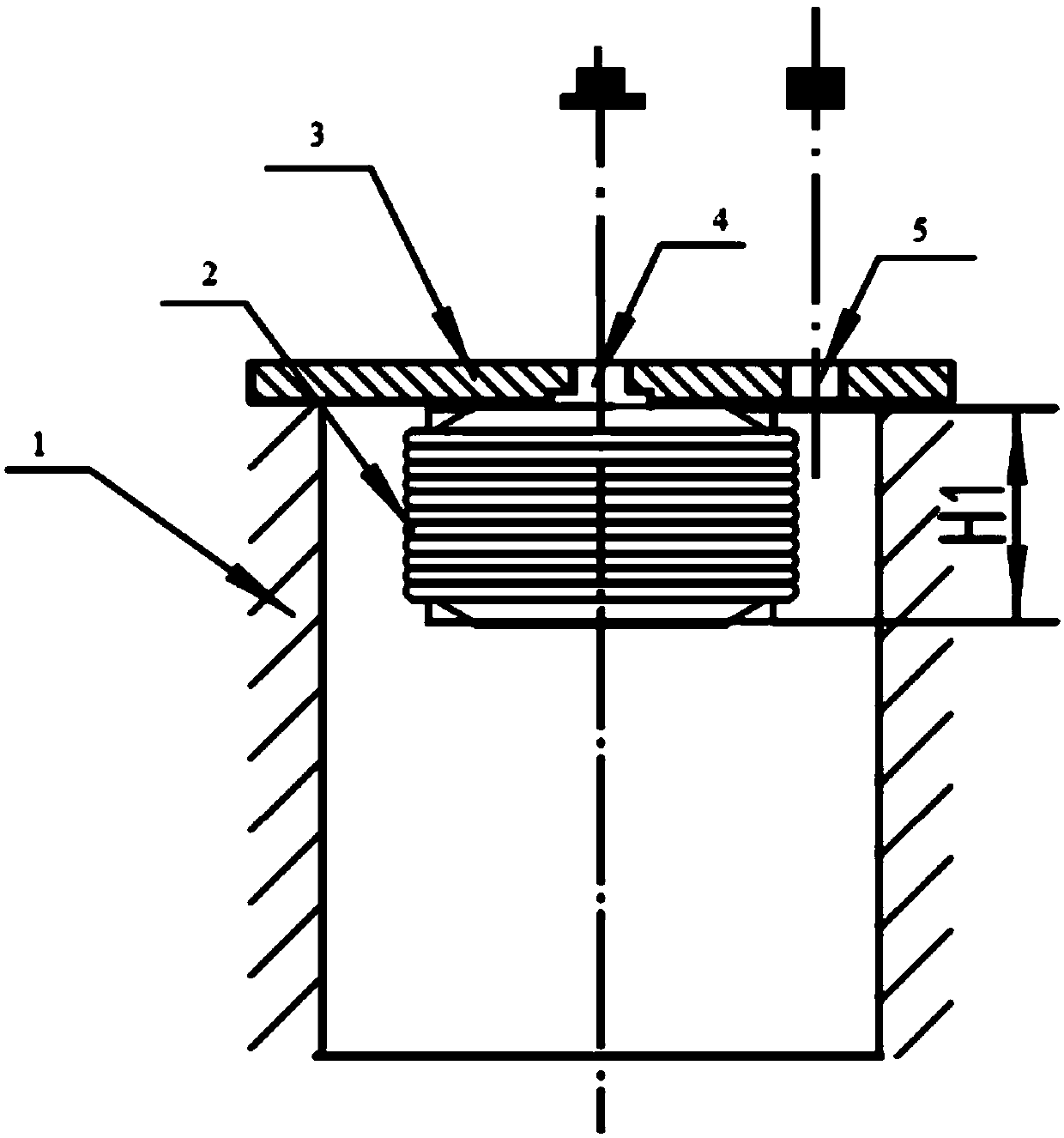

High-energy storage density solid-state dielectric capacitor and preparation method thereof

InactiveCN106710878AUniform textureGood electrical propertiesThin/thick film capacitorFixed capacitor dielectricDielectricHigh energy

The invention relates to a high-energy storage density solid-state dielectric capacitor and a preparation method thereof. The capacitor comprises a substrate, a lower electrode, an aluminum oxide / titanium dioxide composite dielectric film and an upper electrode which are sequentially arranged from bottom to top, wherein the lower electrode coats the substrate; the aluminum oxide / titanium dioxide composite dielectric film is located between the upper electrode and the lower electrode; and the upper electrode and the lower electrode are valve metal films with anodic oxidation capacity. Compared with the prior art, the high-energy storage density solid-state dielectric capacitor has the advantages of being easy to produce, wide in application range, high in energy storage density, safe and reliable and the like.

Owner:TONGJI UNIV

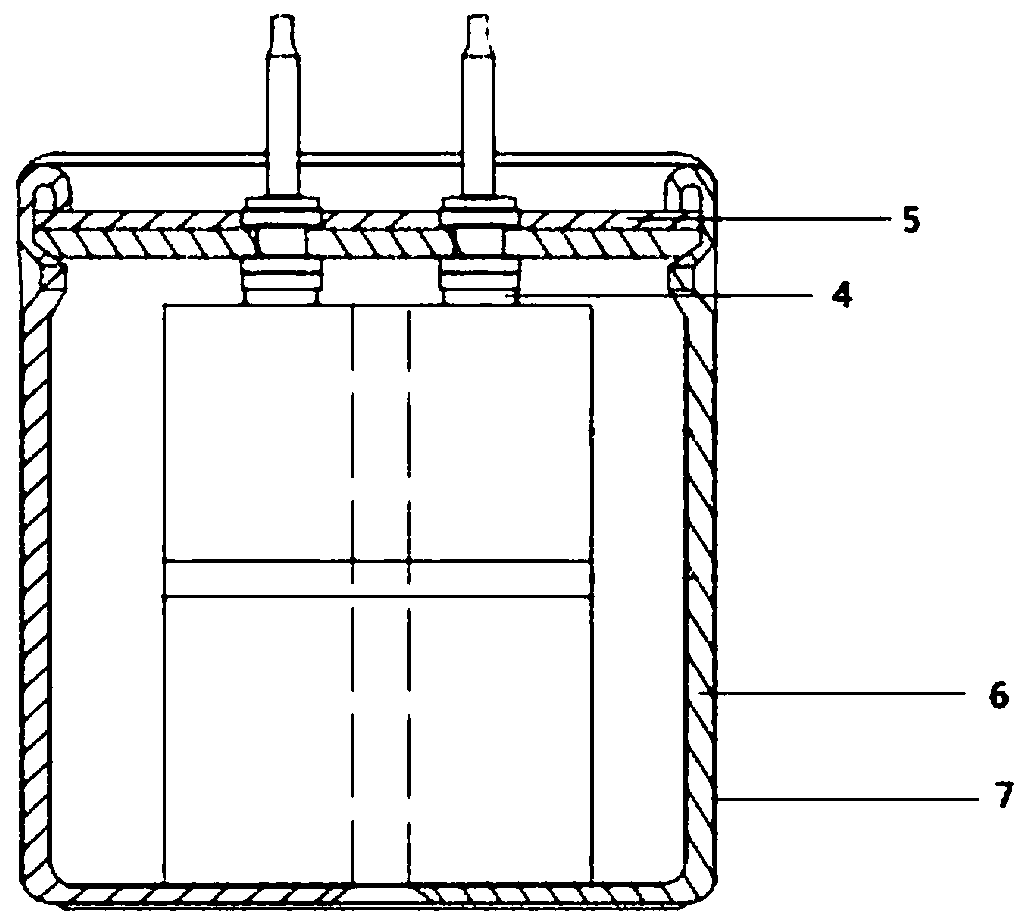

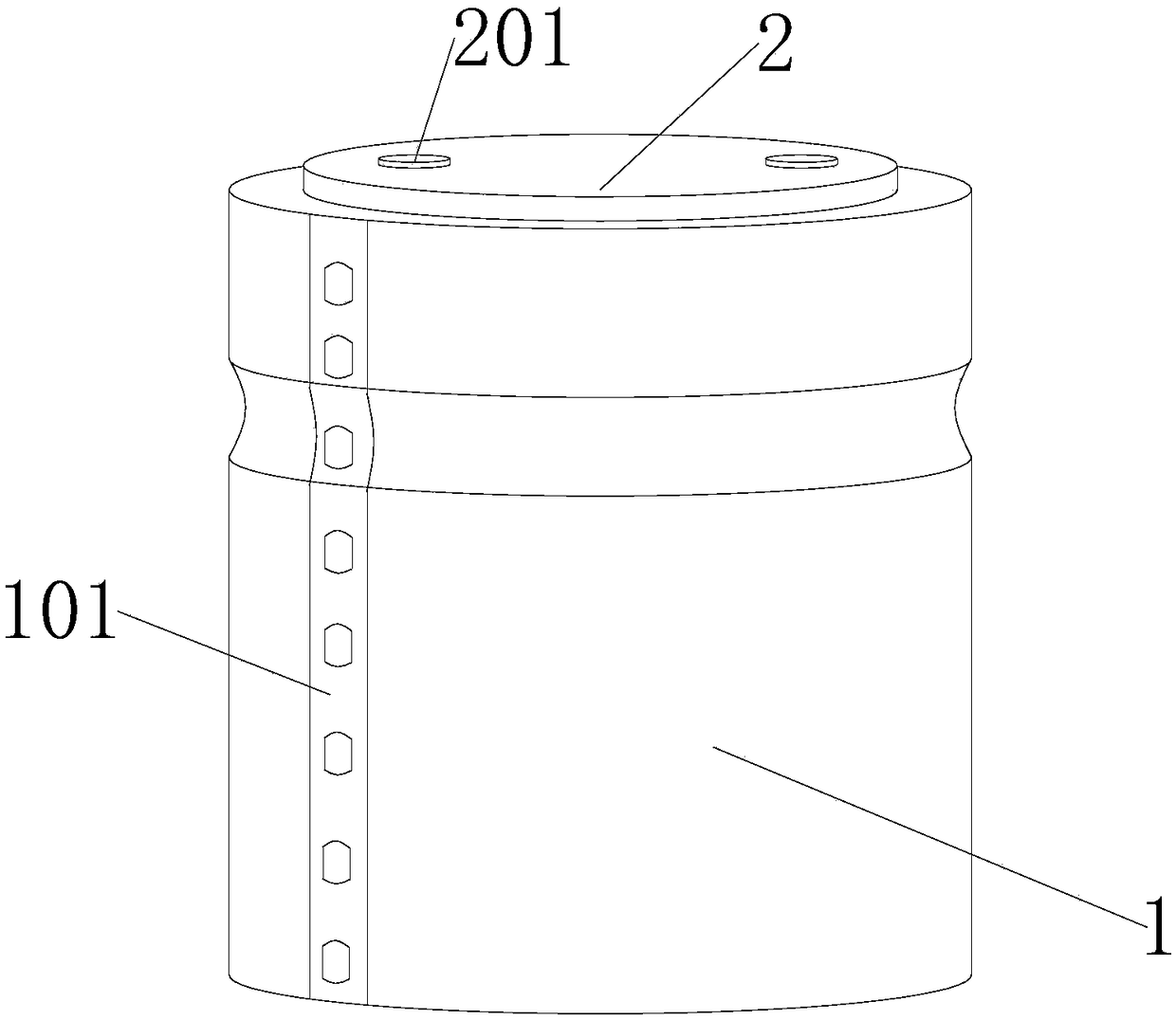

Capacitor device, manufacturing process thereof and capacitor voltage transformer

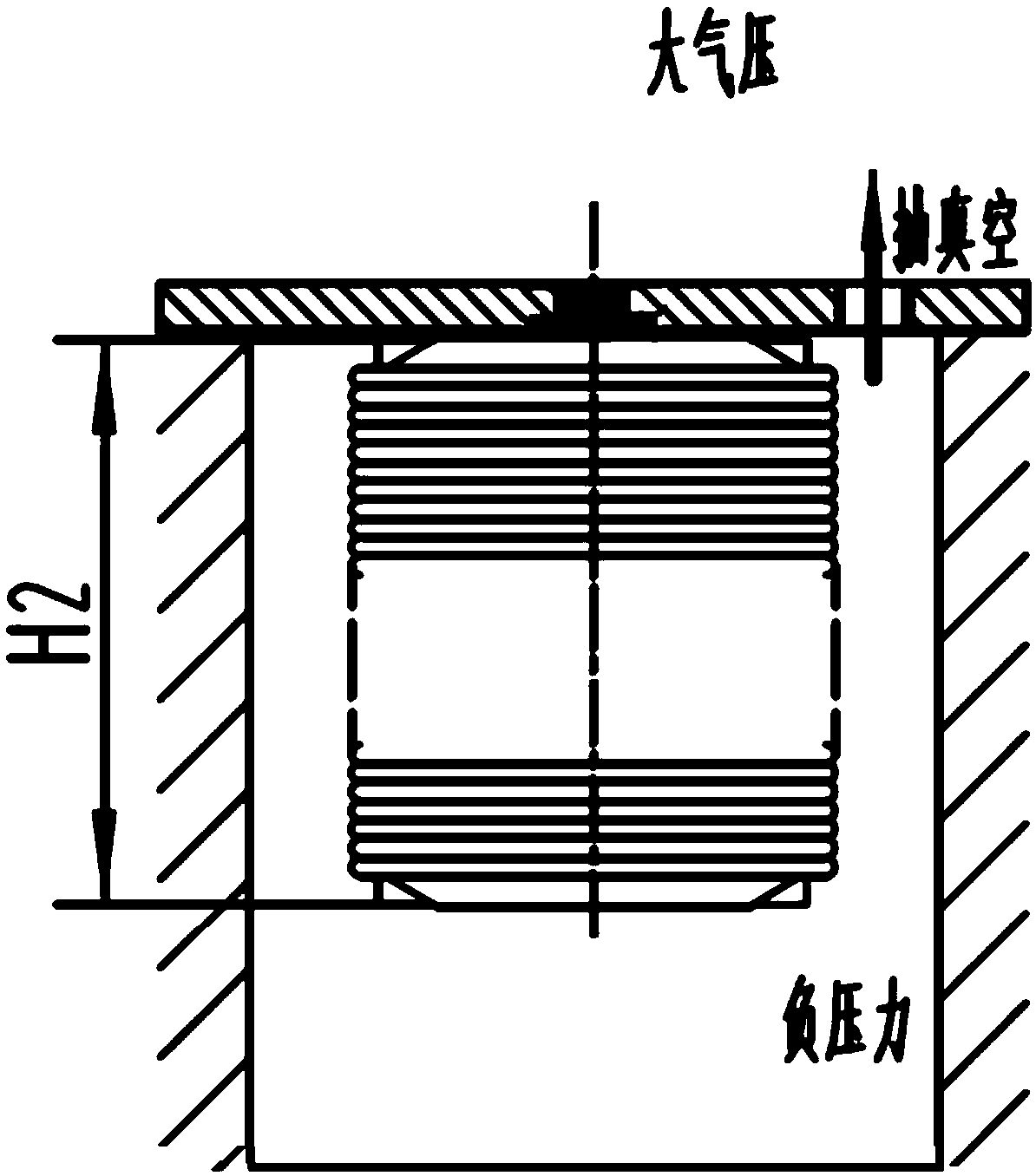

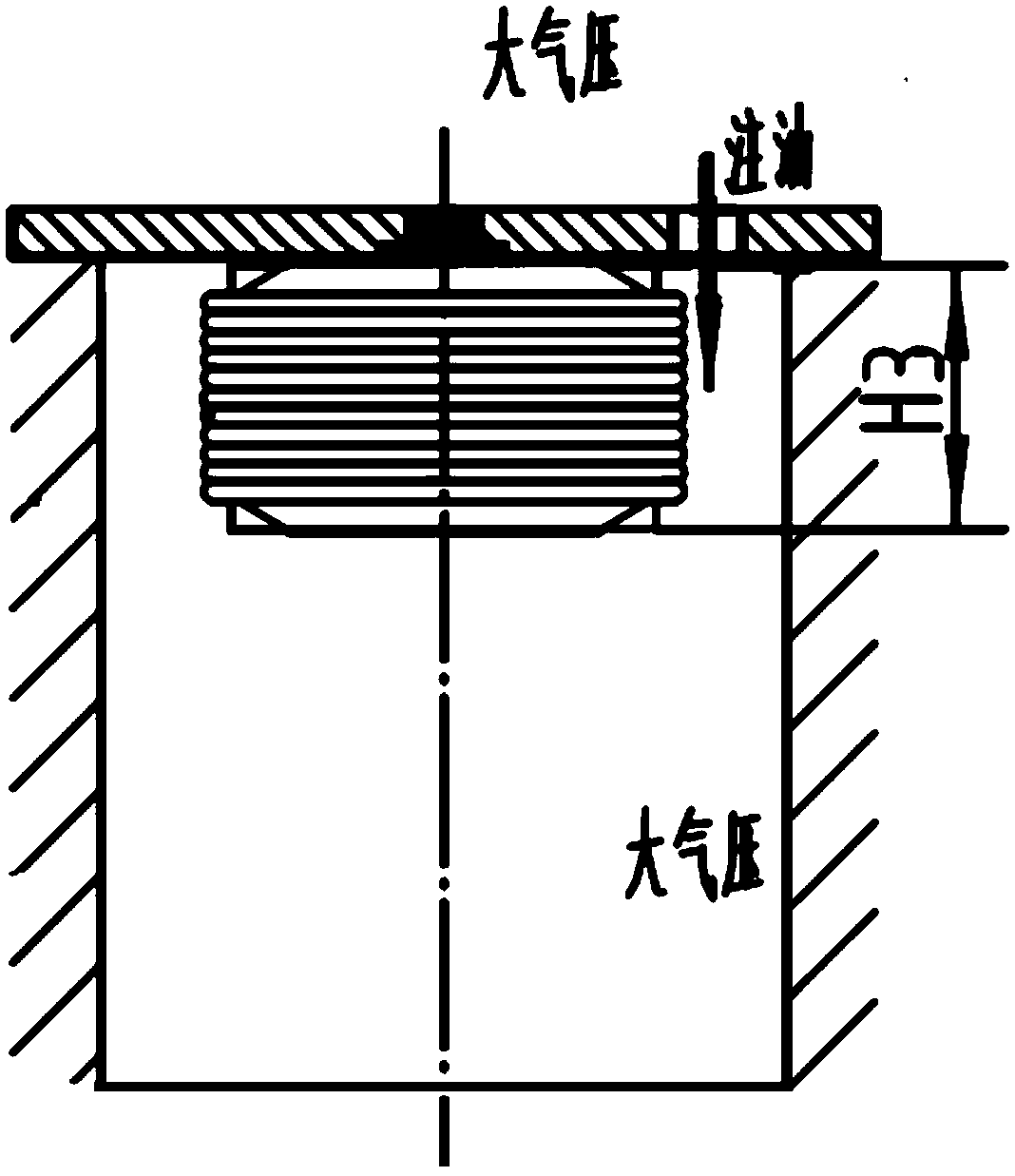

InactiveCN109616337ASmall expansion elongationAvoid burst damageEncapsulating capacitors apparatusCapacitanceVacuum pumping

The invention discloses a capacitor device, a manufacturing process thereof and a capacitor voltage transformer provided with the capacitor device. The manufacturing process of the capacitor device comprises the following steps: forming a closed space by the inner wall of a barrel-shaped shell, the inner wall of a cover plate and the outer wall of an expander, wherein the top opening of the barrel-shaped shell is covered with the cover plate, a first through hole is formed in the expander, the expander is arranged inside the barrel-shaped shell to be connected with the cover plate, right now,the expander is a closed component and is in a natural non-expansion state or in a contraction state after a part of gas (or all gas) is extruded; carrying out vacuum-pumping treatment on the closed space; closing the closed space after oil is injected into the closed space; pumping air into the expander so that pressure inside the closed space reaches a preset positive pressure value, and then closing the expander to form the closed component. In the manufacturing process of the capacitor device, the expander can be installed firstly, then the technical treating process of vacuum pumping, oilinjection, pressurization and the like is completed at one time, the manufacturing procedure is less, and the expander is unlikely to damage.

Owner:XIAN XD POWER CAPACITOR CO LTD +1

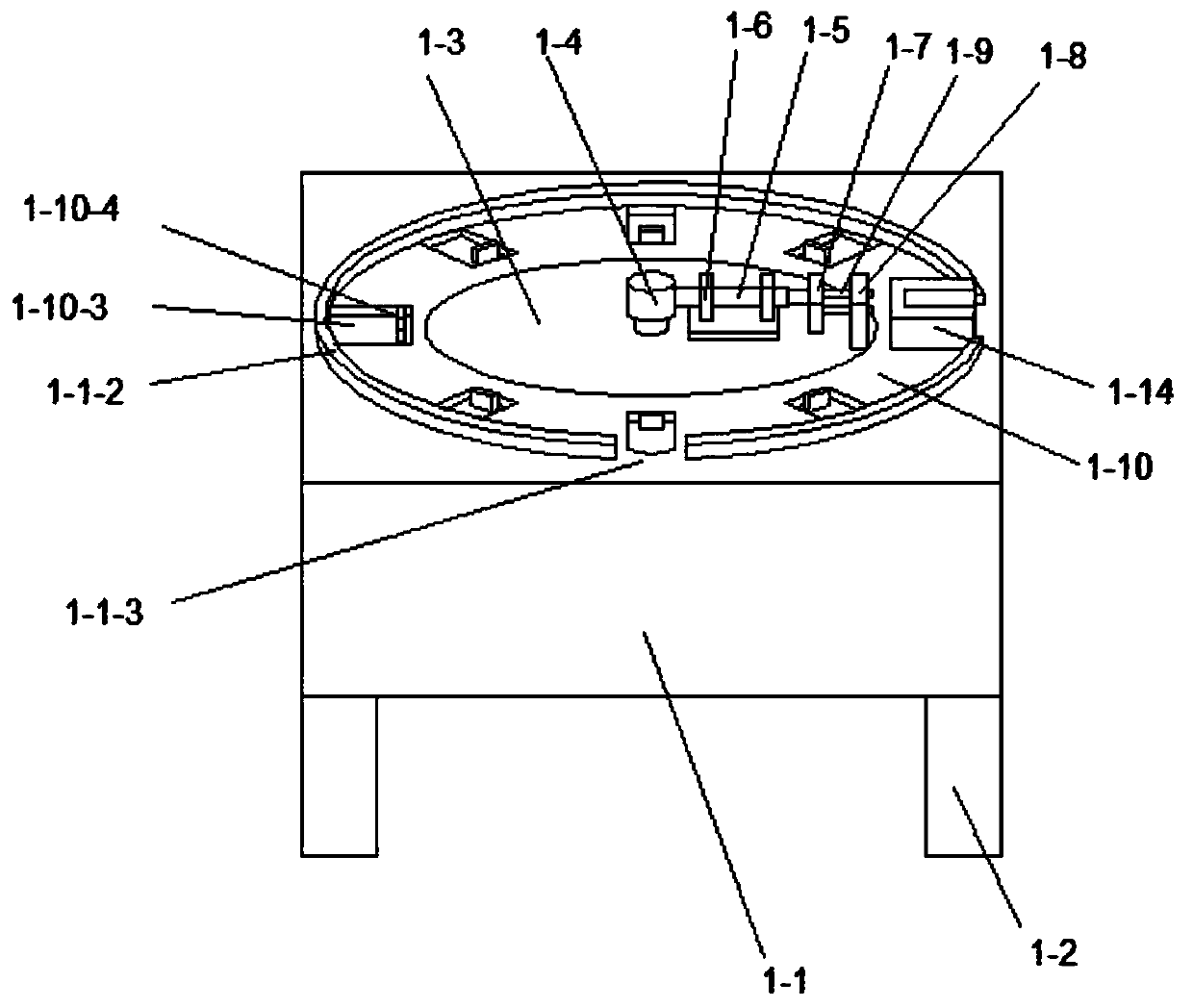

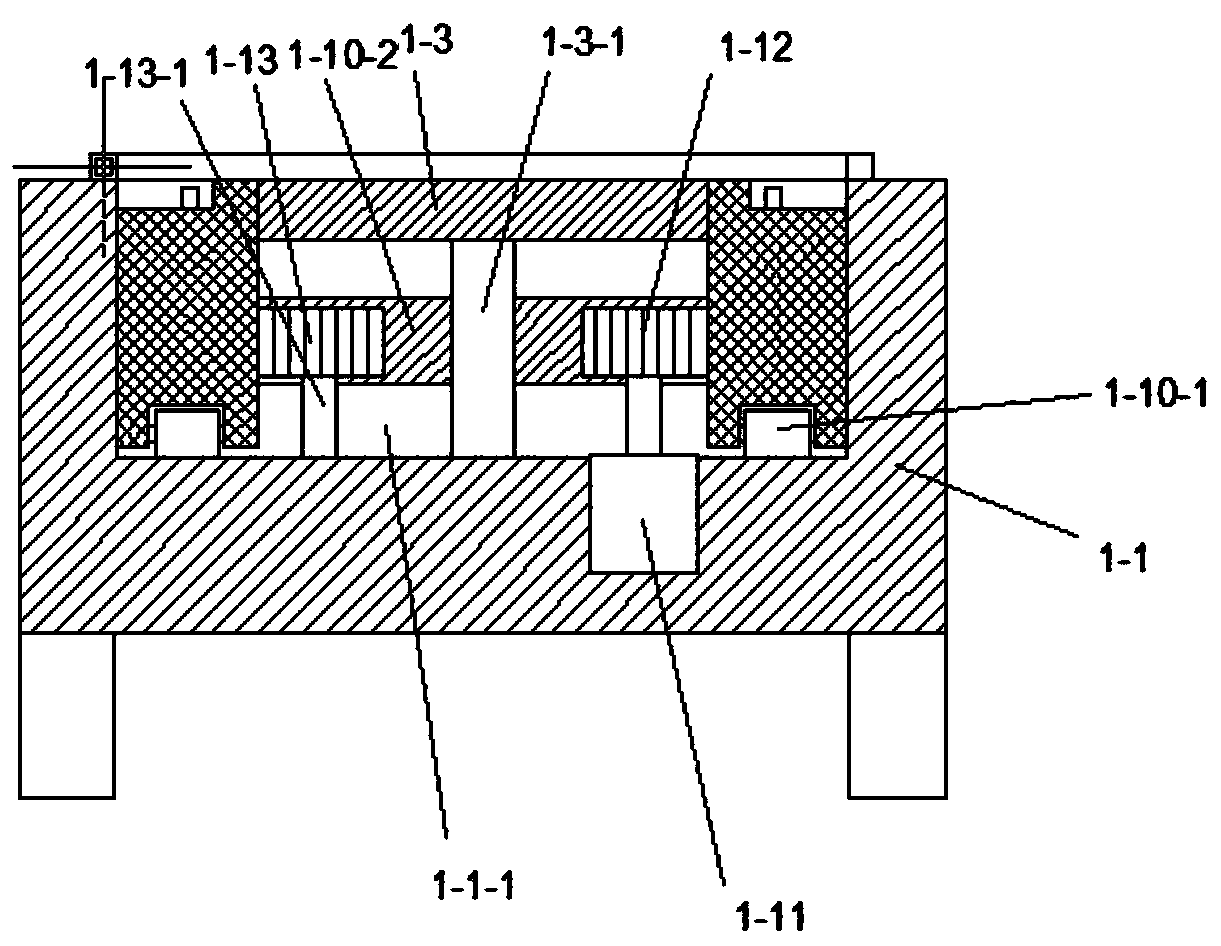

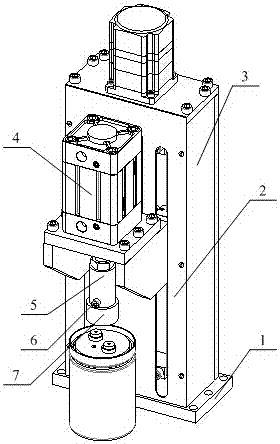

Fully automatic assembly device

ActiveCN105428094AReduce wasteAvoid wastingEncapsulating capacitors apparatusEngineeringElectronic component

The present invention relates to the field of electronic component processing, and particularly relate to a fully automatic assembly device. The device comprises a material disc which is provided with multiple clamp heads, a rubber plug feeding device which delivers a rubber plug to the material disc, a core package installation device which installs a core package for the rubber plug on the material disc, a core package feeding device which delivers the core package for the core package installation device, a multiple-position clamp head disc which is provided with multiple aluminum shell clamp heads, an aluminum shell feeding device which delivers the aluminum shell to the multiple-position clamp head disc, an overturn feeding clamp device which transfers an preliminarily assembled electronic component into the aluminum shell on the multiple-position clamp head disc, and a sealing waist girdling device. According to the fully automatic assembly device, the out-of-position phenomenon of a waist girdling seal can be avoided, the waste of materials is reduced, the production efficiency is improved, the product quality is improved, an overhigh product or a product with an unflat bottom surface is prevented, a product damage due to collision and clamping by a clamp is prevented, and the collision and damage phenomena of the electronic component in falling can be avoided.

Owner:SHENZHEN XINGCHUANG JIA TECH

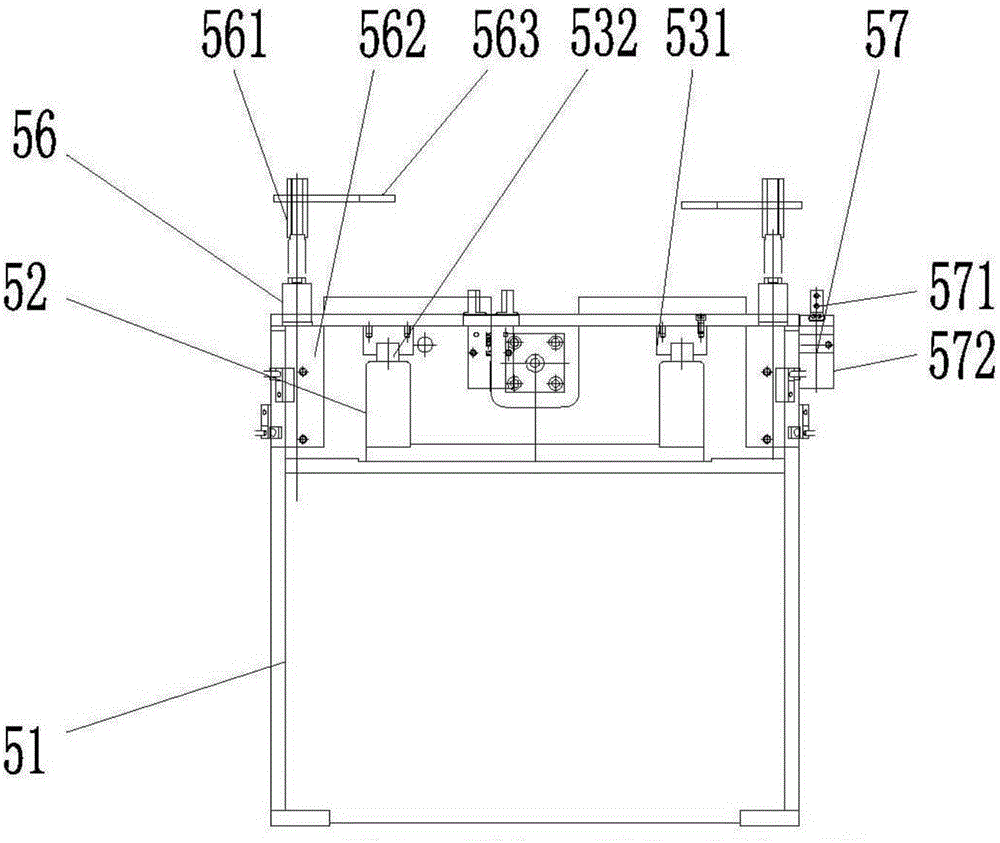

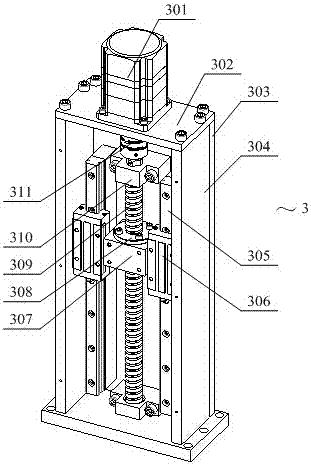

Automatic pre-pressing mechanism applicable to multi-specification capacitor cover plates

ActiveCN106876172AReduce stressRealize automatic preloadingEncapsulating capacitors apparatusEngineeringMechanical engineering

The invention discloses an automatic pre-pressing mechanism applicable to multi-specification capacitor cover plates. The automatic pre-pressing mechanism comprises a bottom plate, a protective cover, a linear lifting assembly, a pre-pressing air cylinder assembly, a connecting shaft, a locking screw and a pre-pressing die, wherein the bottom plate is used for fixing and mounting the linear lifting assembly; the protective cover is used for performing sealing and dust preventing on the linear lifting assembly; the linear lifting assembly is fixedly mounted on the bottom plate, and used for controlling up and down movement of the pre-pressing air cylinder assembly and the pre-pressing die; the pre-pressing air cylinder assembly is used for controlling the pre-pressing die to automatically pre-press multi-specification cover plates; one end of the connecting shaft is connected with a piston rod of a pre-pressing air cylinder while the other end is connected with the pre-pressing die; the locking screw is used for tightly locking the pre-pressing die on the connecting shaft; and the pre-pressing die comprises a pre-pressing shaft and a pre-pressing main body. The automatic pre-pressing mechanism is simple in structure, convenient to use, high in cover plate pre-pressing stability and capable of realizing automatic pre-pressing on the cover plates of different specifications.

Owner:NANTONG HICON ELECTRONICS

Aluminum electrolytic capacitor assembly, cleaning and sleeve integrating machine

The invention relates to the technical field of aluminum electrolytic capacitor processing, in particular to an aluminum electrolytic capacitor assembly, cleaning and bushing integrated machine. The aluminum electrolytic capacitor assembly, cleaning and sleeving machine comprises an assembly machine, an ultrasonic cleaning machine and a sleeving machine which are connected in turn. The invention can realize the automatic production process of assembling the core cladding, the aluminum shell and the leather head (colloidal particles) together, carrying out ultrasonic cleaning, and heat shrinkage of the sleeve, replacing manual operation, and improving the production efficiency.

Owner:东莞市卓劲电子机械有限公司

Large-capacity super-capacitor and preparation method therefor

PendingCN108682568ASolve the problem of high current conductionIncrease diversion areaElectrolytic capacitorsEncapsulating capacitors apparatusCapacitanceElectrical polarity

The invention discloses a large-capacity super-capacitor, and the super-capacitor comprises a negative top cover assembly, a positive top cover assembly, a battery cell and a housing. The negative topcover assembly and the positive top cover assembly are welded and fixed on two ends of the battery cell, and the housing sleeves the battery cell. Two ends of the housing are respectively fixedly connected with the negative top cover assembly and the positive top cover assembly, and the negative top cover assembly includes a negative adapter piece and a negative pole welded and fixed at the center of the surface of the negative adapter piece. The negative pole is electrically connected with the negative adapter piece, and an insulating plastic layer is disposed at the periphery of the outer surface of a side wall of the negative pole, wherein the exterior of the insulating plastic layer is fixedly sleeved by a negative top cover piece. The super-capacitor solves a problem of large-currentconduction of a large-capacity super-capacitor, and there are the positive and negative electrode lugs with opposite polarities at the two ends of the battery cell and the corresponding current collecting pieces, the mandrels and insulating cement, and the positive and negative electrode lugs of the battery cell make area contact with the current collecting pieces, thereby greatly increasing thecurrent guiding areas of the charging and discharging of the battery cell, and enabling the battery cell to have the performances of large-current charging and discharging.

Owner:江西中汽瑞华新能源科技有限公司

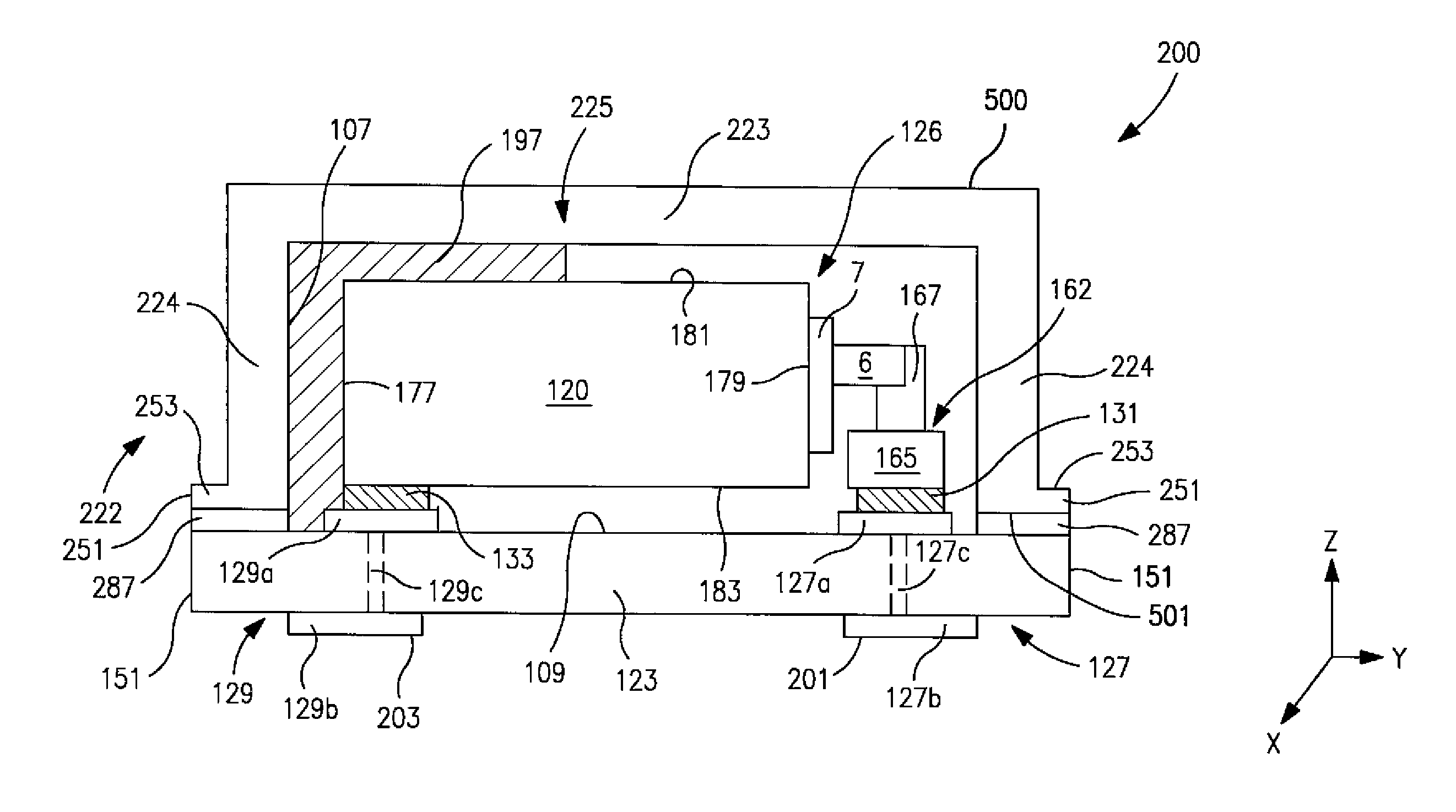

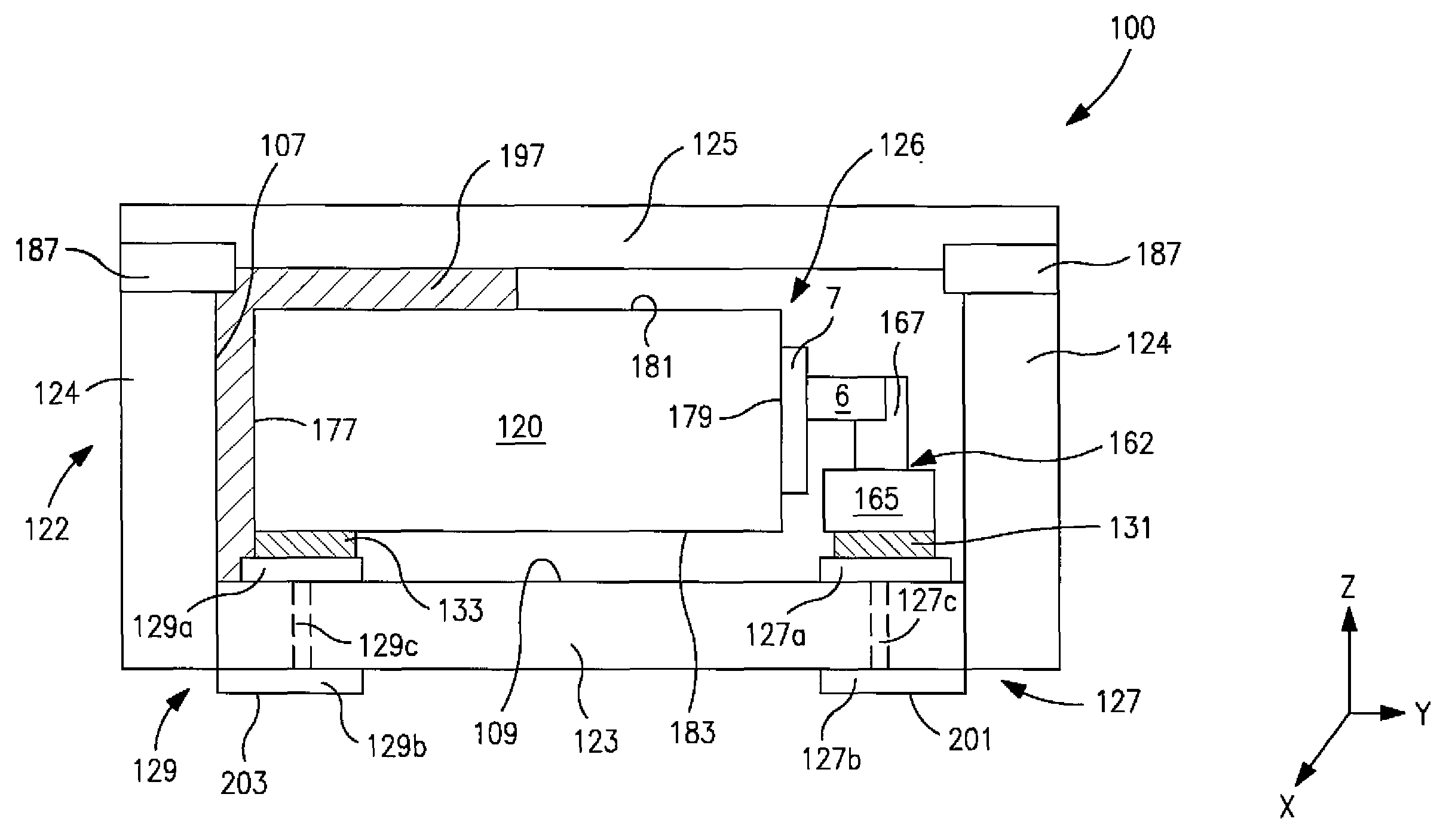

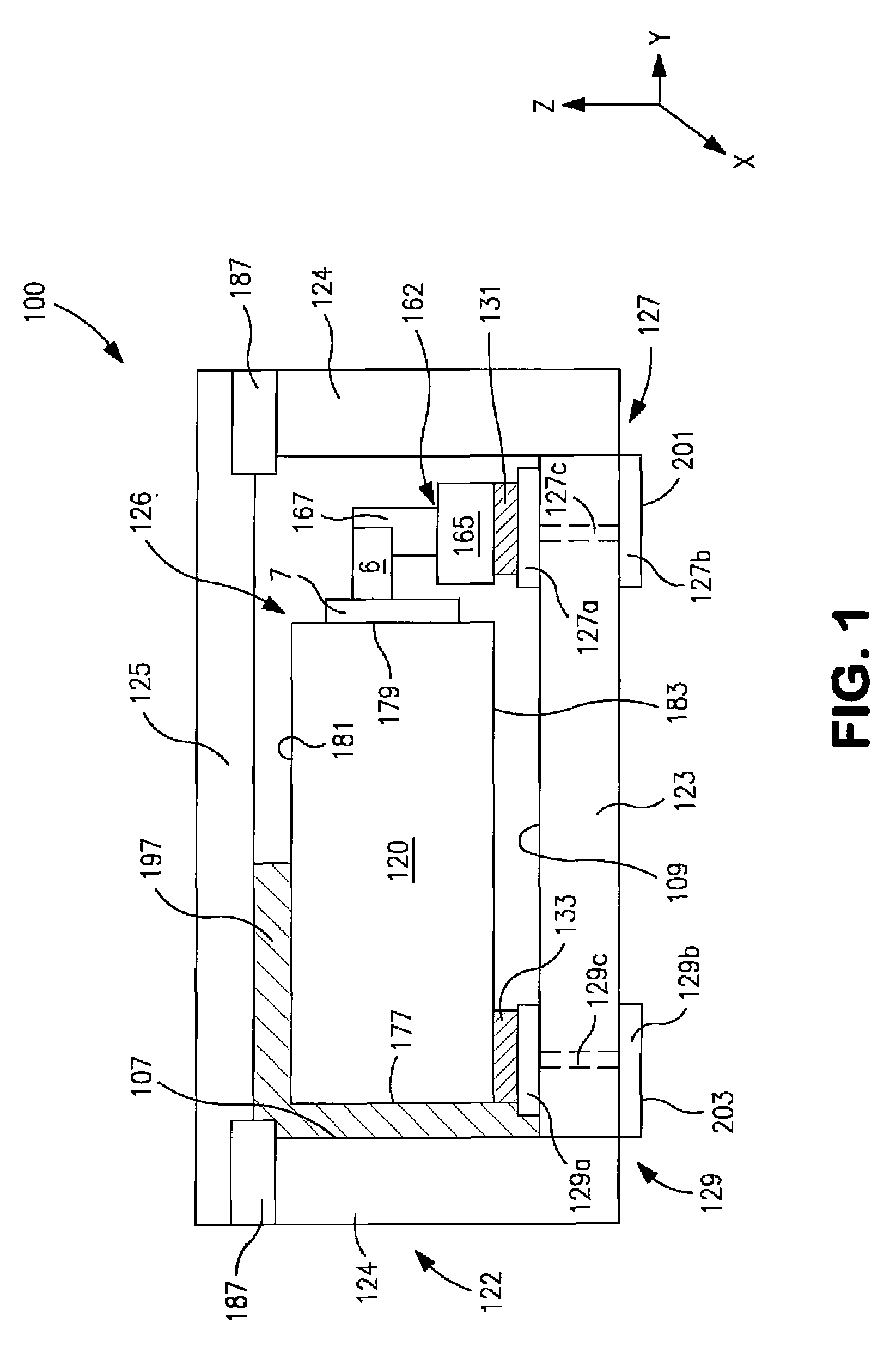

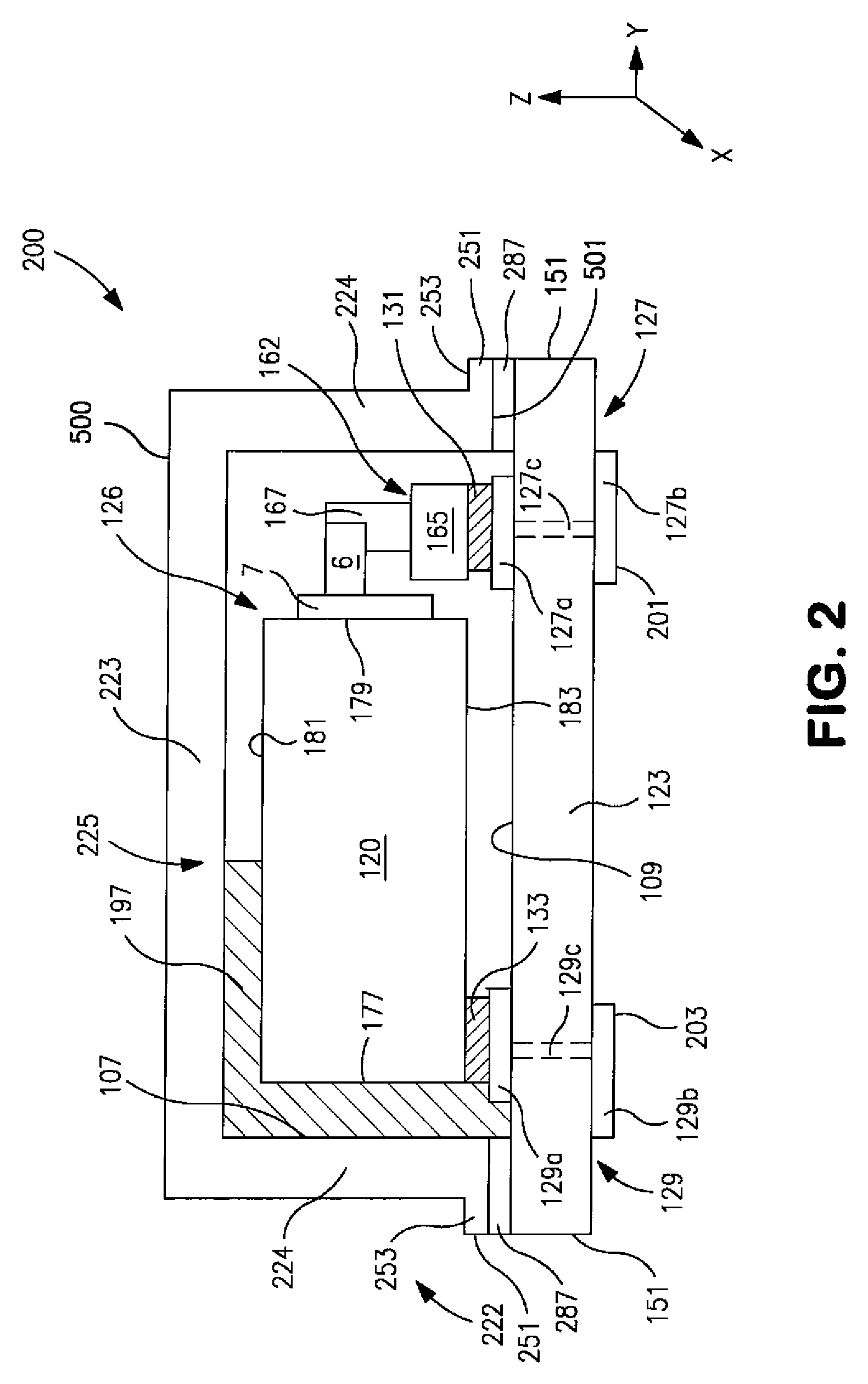

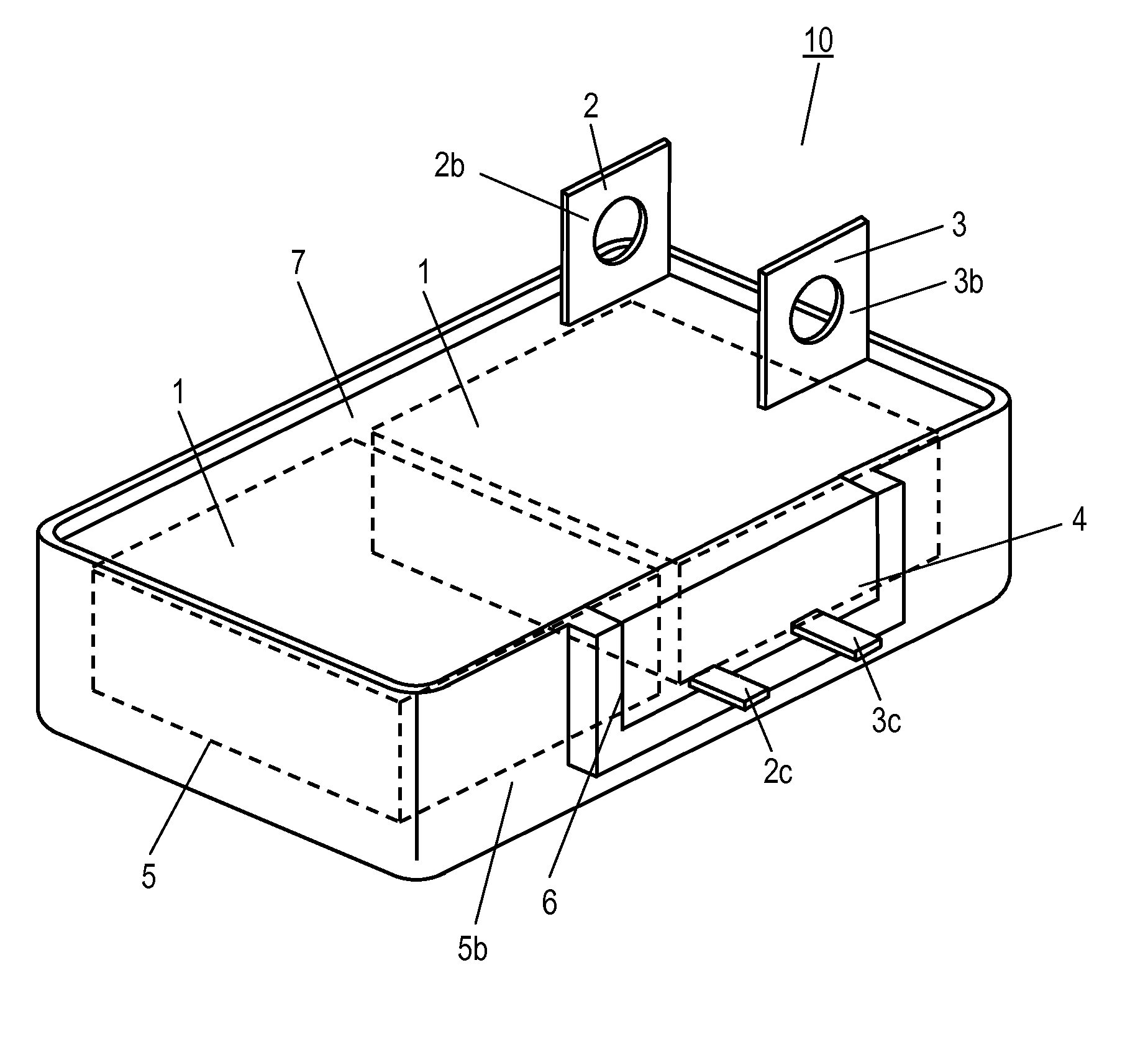

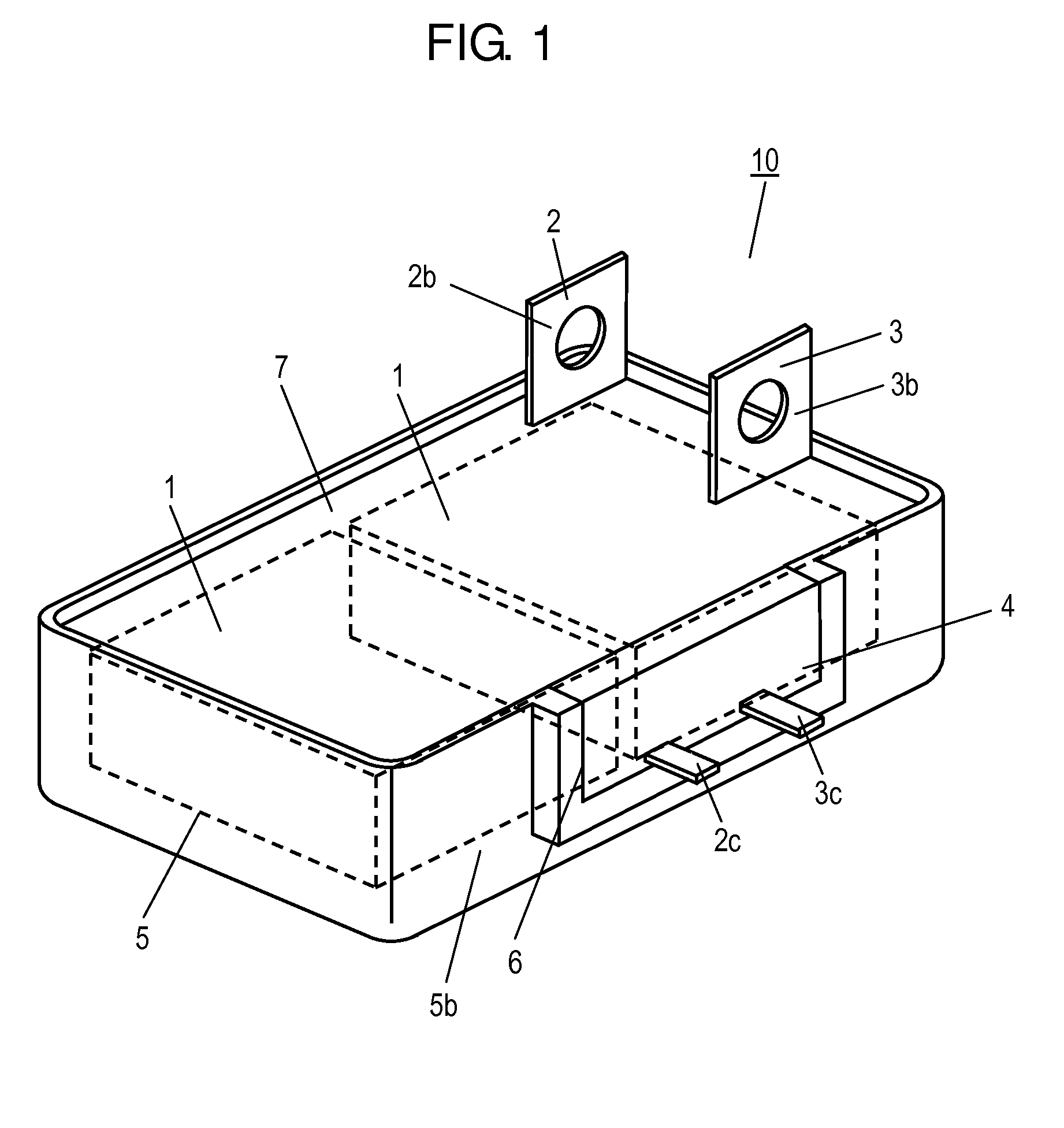

Case-mold-type capacitor and method for producing same

ActiveUS20150348710A1High dimensional accuracyIncrease material costFixed capacitor electrodesFixed capacitor dielectricEngineeringCapacitor

A case-mold-type capacitor includes a capacitor element, first and second bus bars connected to the first and second electrodes of the capacitor element, a case accommodating the capacitor element and the first and second bus bars, and a mold resin filling the case therein. The case has a cutaway portion provided therein. A sealing plate joined to the case so as to seal the cutaway portion. The first and second bus bars pass through the sealing plate and are fixed to the sealing plate. The case-mold-type capacitor improves dimensional accuracy between terminal portions of the first and second bus bars without increasing material cost, and has high reliability.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

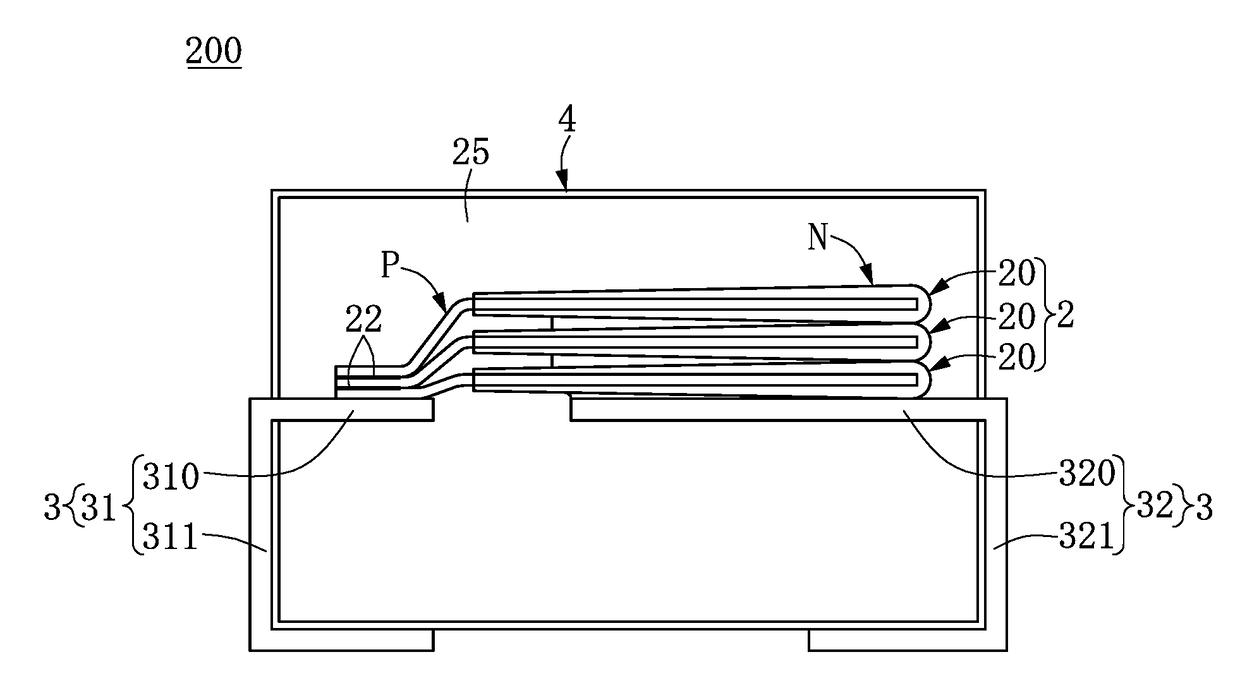

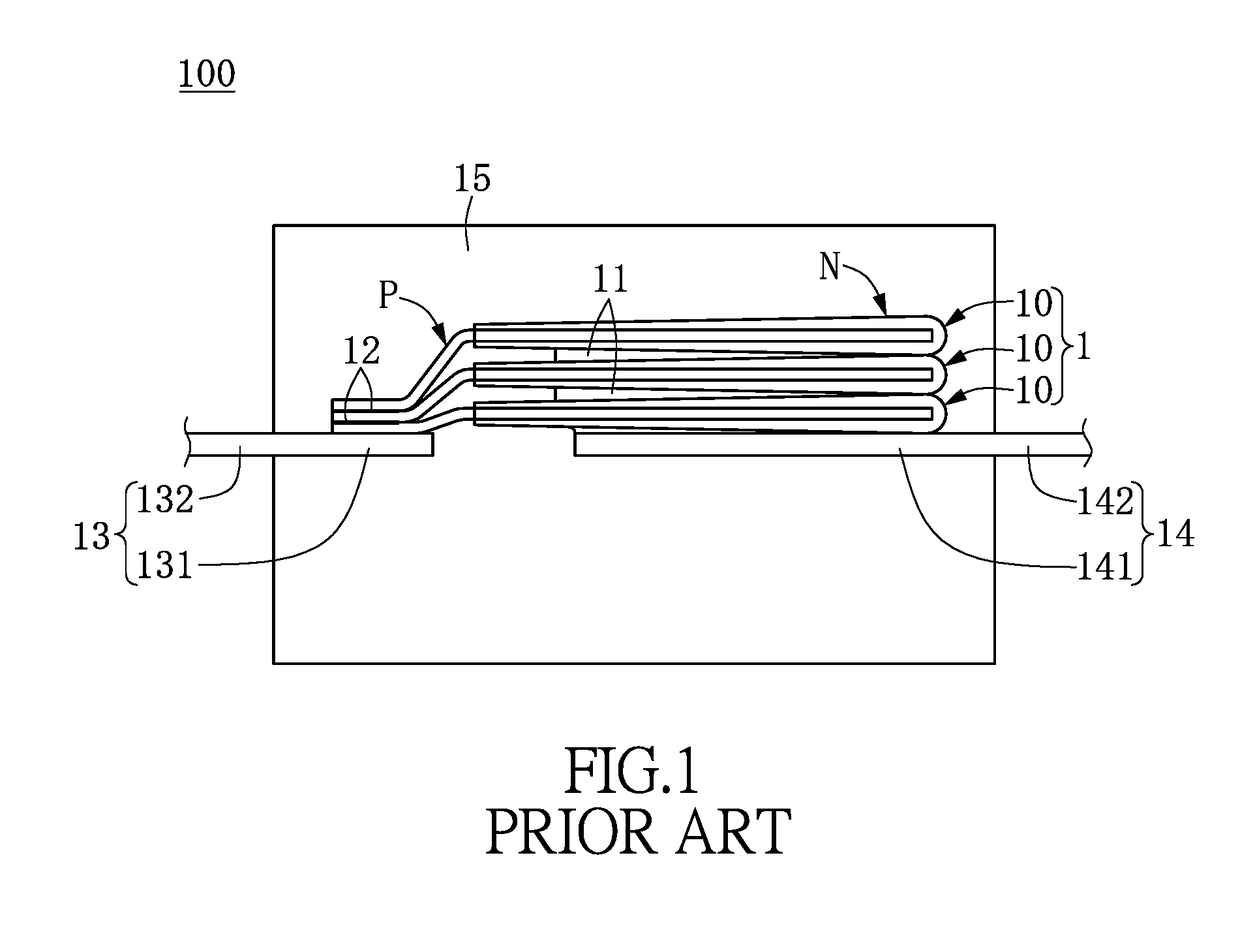

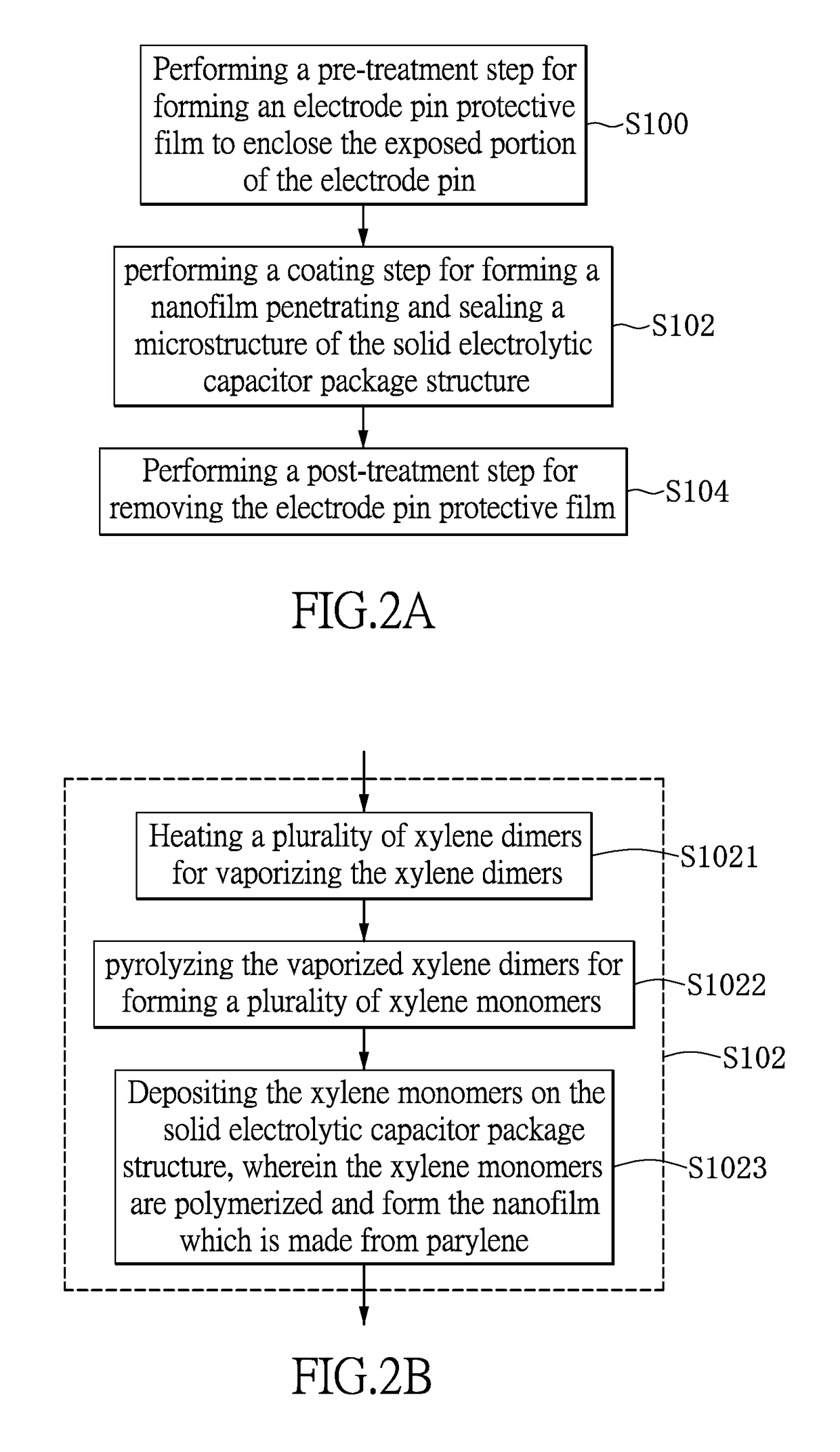

Solid electrolytic capacitor package structure and method of manufacturing the same

ActiveUS20170110256A1Improve propertiesExtended service lifeSolid electrolytic capacitorsCapacitor housing/encapsulationEngineeringElectrolytic capacitor

The instant disclosure provides a solid electrolytic capacitor package structure and method of manufacturing the same. The solid electrolytic capacitor package structure includes a capacitor assembly, at least one electrode pin and a package body enclosing the capacitor assembly and the electrode pin. The electrode pin includes an embedded portion enclosed by the package body and an exposed portion positioned outside the package body. The method of manufacturing the solid electrolytic capacitor package structure includes a protection step including forming a protecting film on the exposed portion; a coating step including depositing a nanomaterial on the solid electrolytic capacitor package structure to form a nanofilm, wherein the nanomaterial penetrates into defects of the solid electrolytic capacitor package structure; and a deprotection step including removing the protecting film. The instant disclosure provides improved air-tight and water-tight properties of the solid electrolytic capacitor package structure, thereby increasing the lifetime thereof.

Owner:APAQ TECH

Cell shell inserting machine

PendingCN110676077ANo manual operationIncrease productivityEncapsulating capacitors apparatusEngineeringMechanical engineering

The invention discloses a cell shell inserting machine which comprises a fixing device, a feeding device, a cell shell inserting device and a discharging device. The fixing device is used for fixing the cell and the shell. The feeding device is used for transferring the cell and the shell to the fixing device. The cell shell inserting device is used for pressing the cell on the fixing device intothe shell. The discharging device is used for taking down the cell pressed into the shell and the shell from the fixing device. The cell can be automatically placed on the fixing device through the feeding device, the cell can be automatically pressed into the shell through the cell shell inserting device, the cell and the shell can be automatically taken from the fixing device through the discharging device, and the cell shell inserting machine can automatically complete the whole process from feeding to processing and blanking without manual operation and has high production efficiency.

Owner:SHENZHEN CHENGJIE INTELLIGENT EQUIP CO LTD

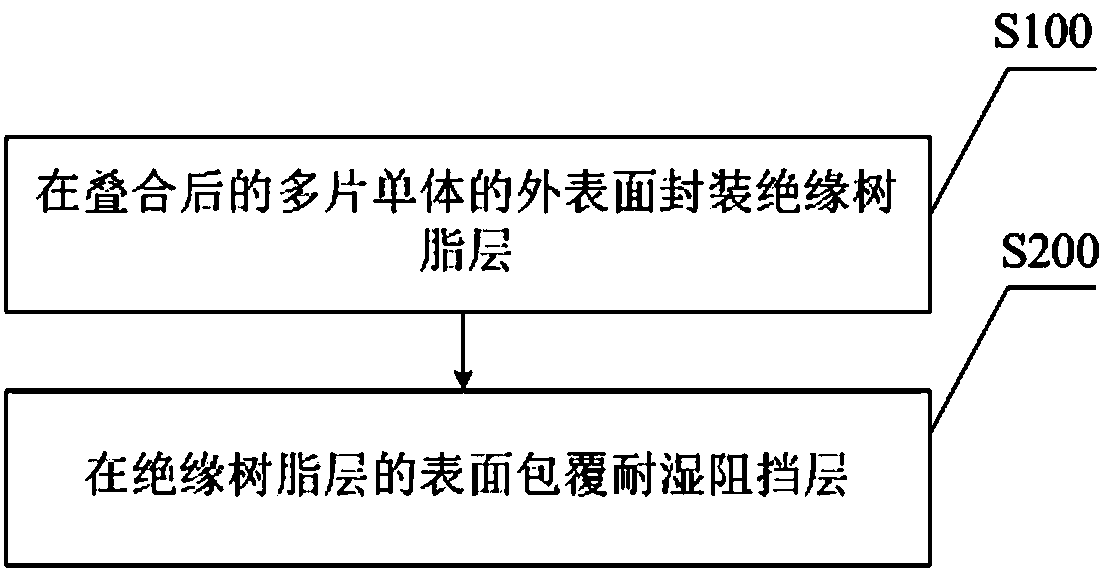

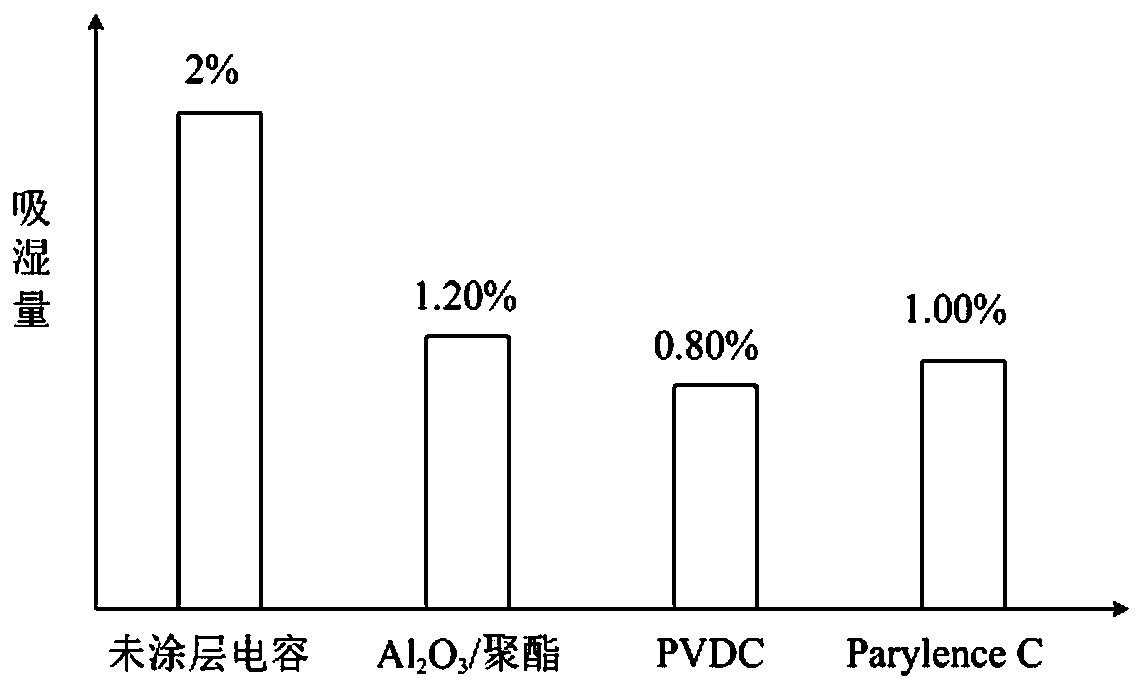

Humidity-resistant laminated solid-state aluminium electrolytic capacitor and manufacturing method thereof

PendingCN108766771AImprove high temperature and high humidity performanceImprove qualitySolid electrolytic capacitorsCapacitor housing/encapsulationElectrolysisMoisture permeability

The invention discloses a humidity-resistant laminated solid-state aluminium electrolytic capacitor and a manufacturing method thereof. The humidity-resistant laminated solid-state aluminium electrolytic capacitor comprises a plurality of stacked single slices, and a positive lead-out terminal and a negative lead-out terminal electrically connected to the stacked single slices; wherein each singleslice comprises a positive end, a negative end and a shielding glue between the positive end and the negative end; the negative ends of each single slice are connected together and connected with thenegative lead-out terminal; the positive ends of each single slice are connected together and connected with the positive lead-out terminal; the outer surface of stacked plurality of single slices isencapsulated with an insulating resin layer; and the outer surface of the insulating resin layer is coated with a moisture-resistant barrier layer for water resisting, wherein the moisture permeability coefficient of the moisture-resistant barrier layer is lower than that of the insulating resin layer. The humidity-resistant laminated solid-state aluminium electrolytic capacitor and the manufacturing method provided by the invention can effectively reduce the equivalent series resistance and leakage current of the laminated solid-state aluminium electrolytic capacitor and improve the productquality.

Owner:YIYANG AIHUA FUXIAN ELECTRONICS

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com