Capacitor based on metallized film nano-evaporation technique and preparation process of capacitor

A metallized film and preparation technology, applied in the field of capacitors, can solve the problems of poor capacity stability and weak high current capability, and achieve the effects of preventing water intrusion, suppressing capacity decay, and high self-healing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

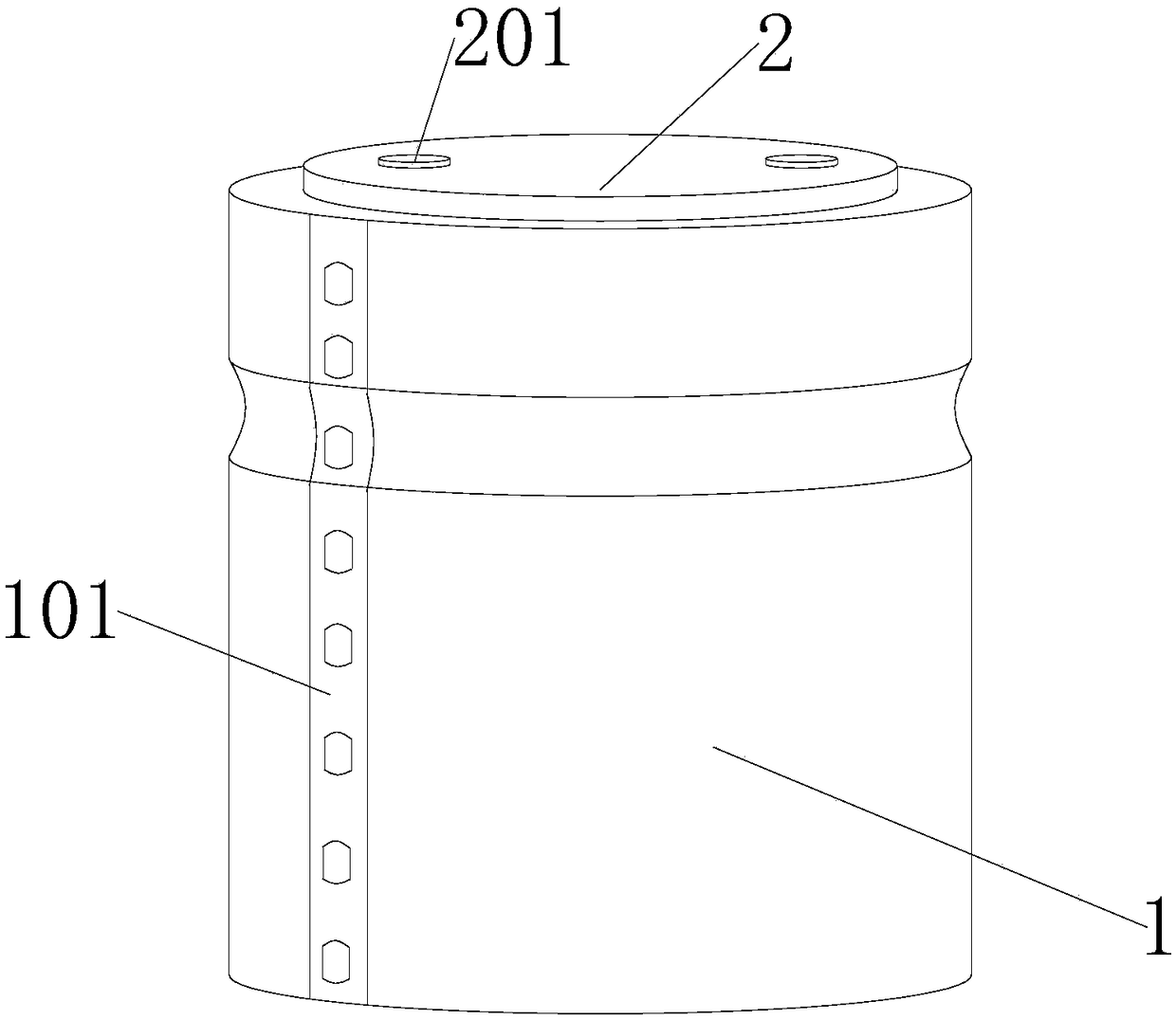

[0048] A capacitor based on nano-evaporation metallized film technology and its preparation process, such as figure 1 As shown, the outer surface of the housing 1 is fixedly connected with a sealing strip 101, and the sealing strip 101 is arranged at the butt joint of the housing 1, and the sealing strip makes the housing structure achieve a hermetic effect, which can prevent the intrusion of moisture from the external environment , thereby reducing air ionization, and can achieve the effect of suppressing capacitor capacity attenuation. The cover plate 2 fixedly connected to the upper part of the housing 1 is used to make the housing 1 achieve a closed environment. Two through holes 201 fixedly connected on the upper surface of the cover plate 2 , for placing the lead wire 202 .

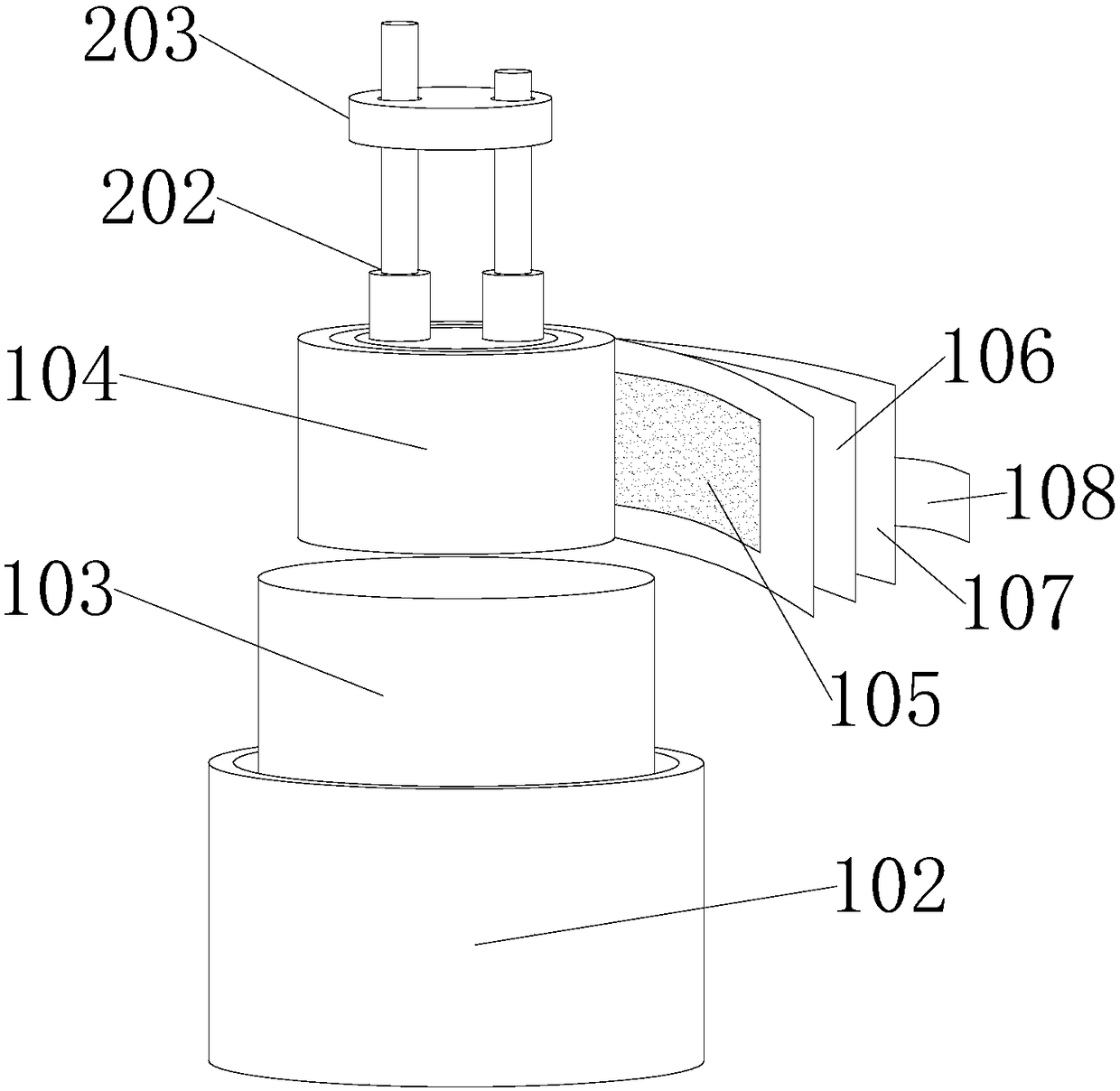

[0049] In the invention, such as figure 2 As shown, the inner wall of the housing 1 is closely attached to the heat-shrinkable sleeve 102, and the interior of the heat-shrinkable sleeve 102 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com