SiC JBS cellular structure and preparation method thereof

A cell and graphic technology, applied in the field of SiCJBS cell structure and preparation, can solve the problem of unbalanced leakage current and anti-surge current ability, achieve improved anti-surge current ability, wide application range, and increase inrush current Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

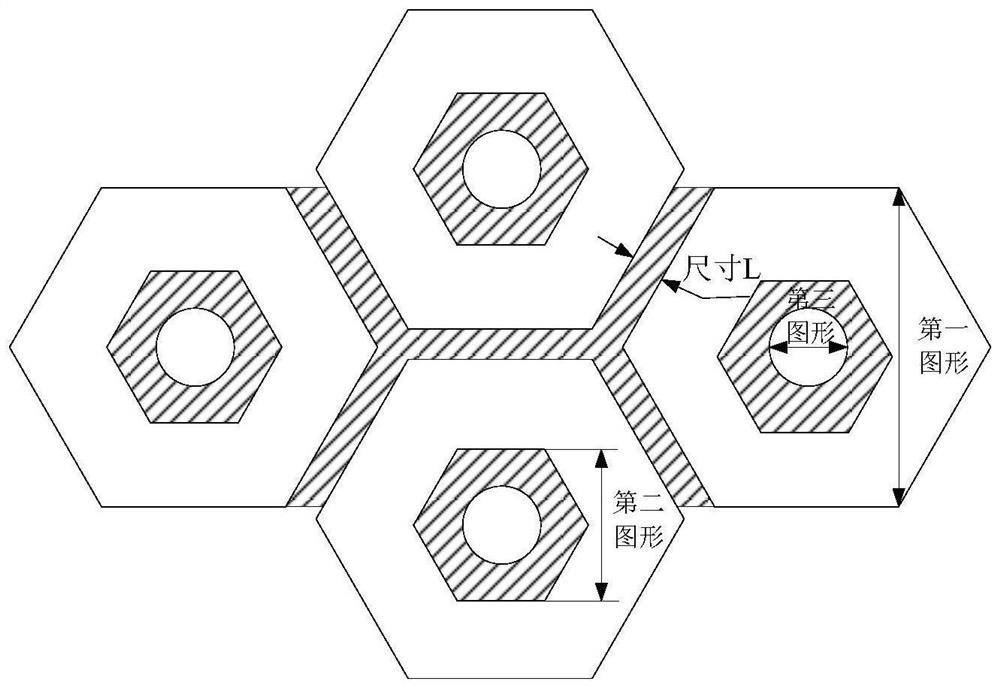

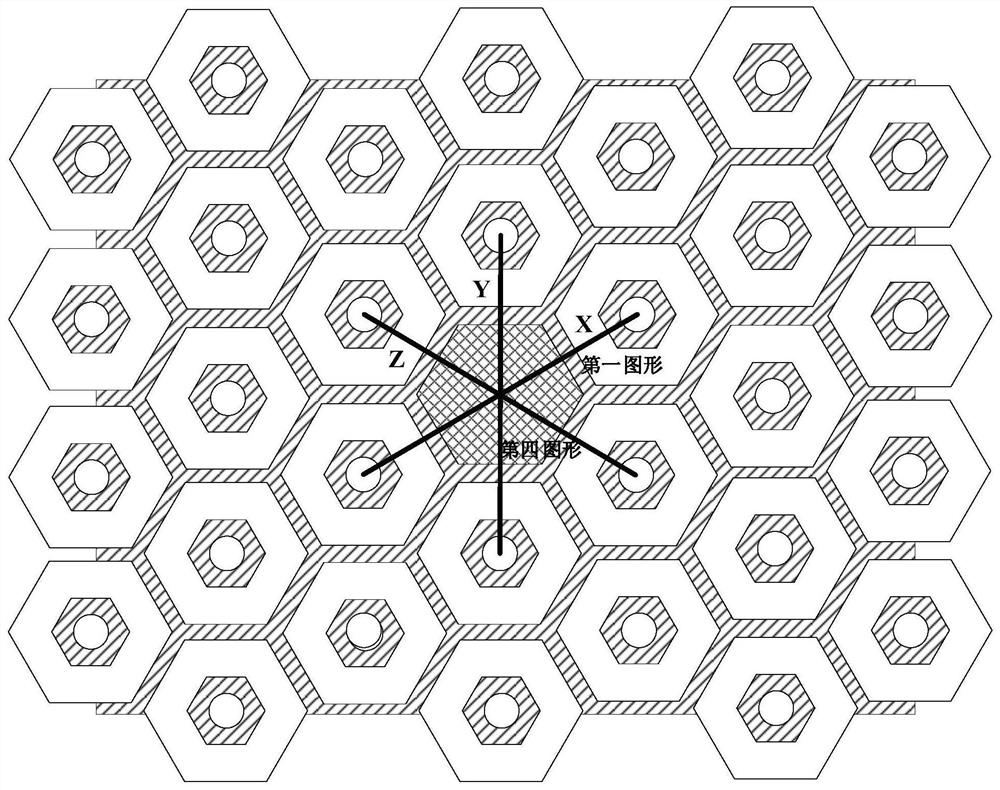

[0058] A SiC JBS cell structure of the present invention includes the following steps: first, deposit an oxide layer on the SiC epitaxial layer to form an implanted masking region; then, carry out photolithography of cell patterns on the oxide layer, such as figure 1 As shown, the first cell and the second cell; the periphery of the second cell is arranged with several first cells; the cross section of the filling area of the first cell is the third figure from the inside to the outside, the first The second figure, the first figure; the area type corresponds to SBD area, P+ area, SBD area or P+ area, SBD area, P+ area in turn; the cross section of the filled area of the second cell is the fourth figure, and the area type is P-type doped region; the first figure is a regular hexagon, the second figure is a regular hexagon, the third figure is a circle or a regular hexagon, and the fourth figure is a regular hexagon. The geometric size of the first figure in the cell is 25u...

Embodiment 2

[0062] A SiC JBS cell structure of the present invention includes the following steps: first, deposit an oxide layer on the SiC epitaxial layer to form an implanted masking region; then, carry out photolithography of cell patterns on the oxide layer, such as figure 1 As shown, the first cell and the second cell; the periphery of the second cell is arranged with several first cells; the cross section of the filling area of the first cell is the third figure from the inside to the outside, the first The second figure, the first figure; the area type corresponds to SBD area, P+ area, SBD area or P+ area, SBD area, P+ area in turn, the cross section of the filled area of the second cell is the fourth figure, and the area type is P-type doped region; the first figure is a regular hexagon, the second figure is a regular hexagon, the third figure is a circle or a regular hexagon, and the fourth figure is a regular hexagon. The geometric size of the first figure in the cell is 100...

Embodiment 3

[0064] A SiC JBS cell structure of the present invention includes the following steps: first, deposit an oxide layer on the SiC epitaxial layer to form an implanted masking region; then, carry out photolithography of cell patterns on the oxide layer, such as figure 1 As shown, the first cell and the second cell; the periphery of the second cell is arranged with several first cells; the cross section of the filling area of the first cell is the third figure from the inside to the outside, the first The second figure, the first figure; the area type corresponds to SBD area, P+ area, SBD area or P+ area, SBD area, P+ area in turn, the cross section of the filled area of the second cell is the fourth figure, and the area type is P-type doped region; the first figure is a regular hexagon, the second figure is a regular hexagon, the third figure is a circle or a regular hexagon, and the fourth figure is a regular hexagon. The geometric dimension L of the first figure in the cell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com