Patents

Literature

113results about How to "Increase material cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

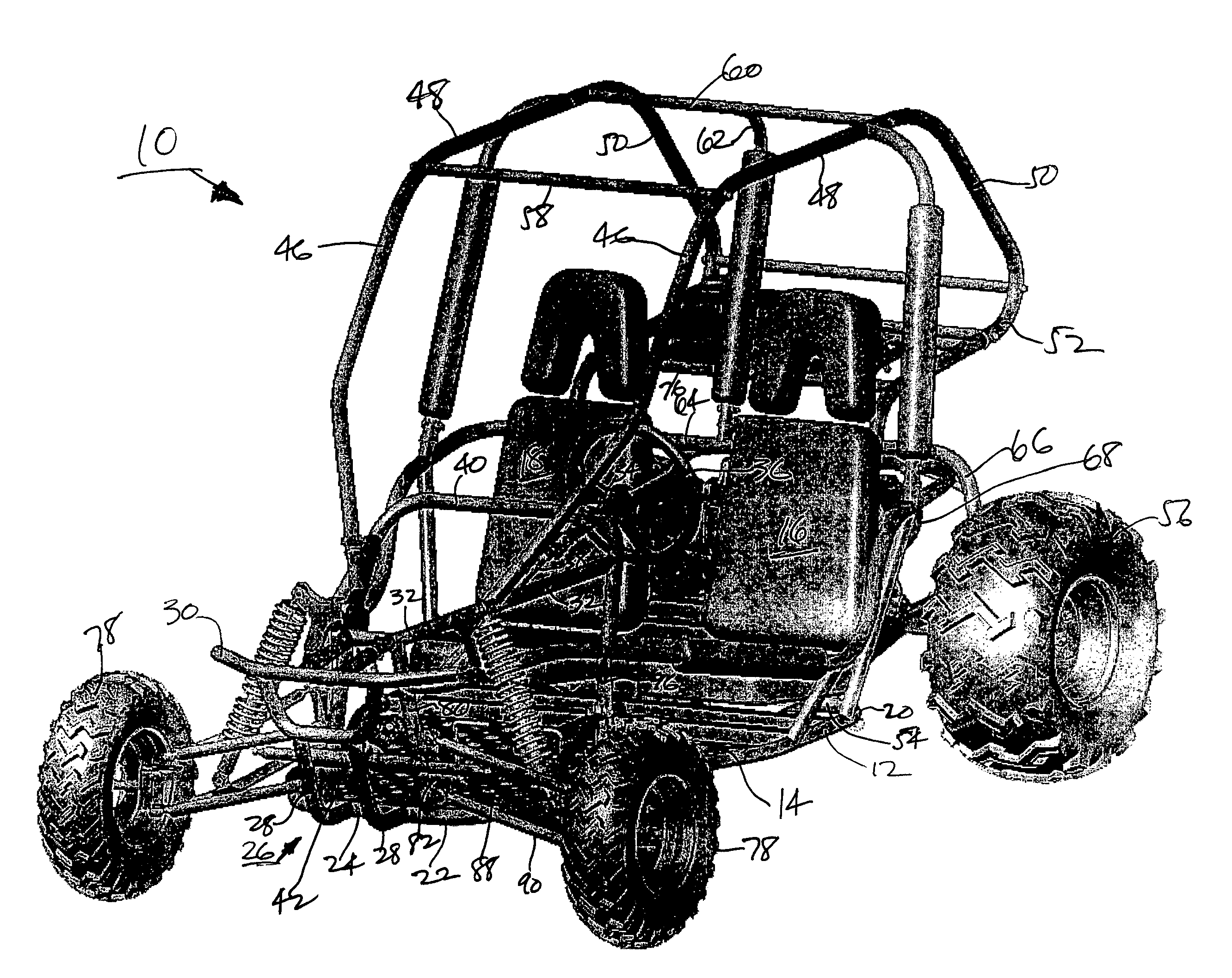

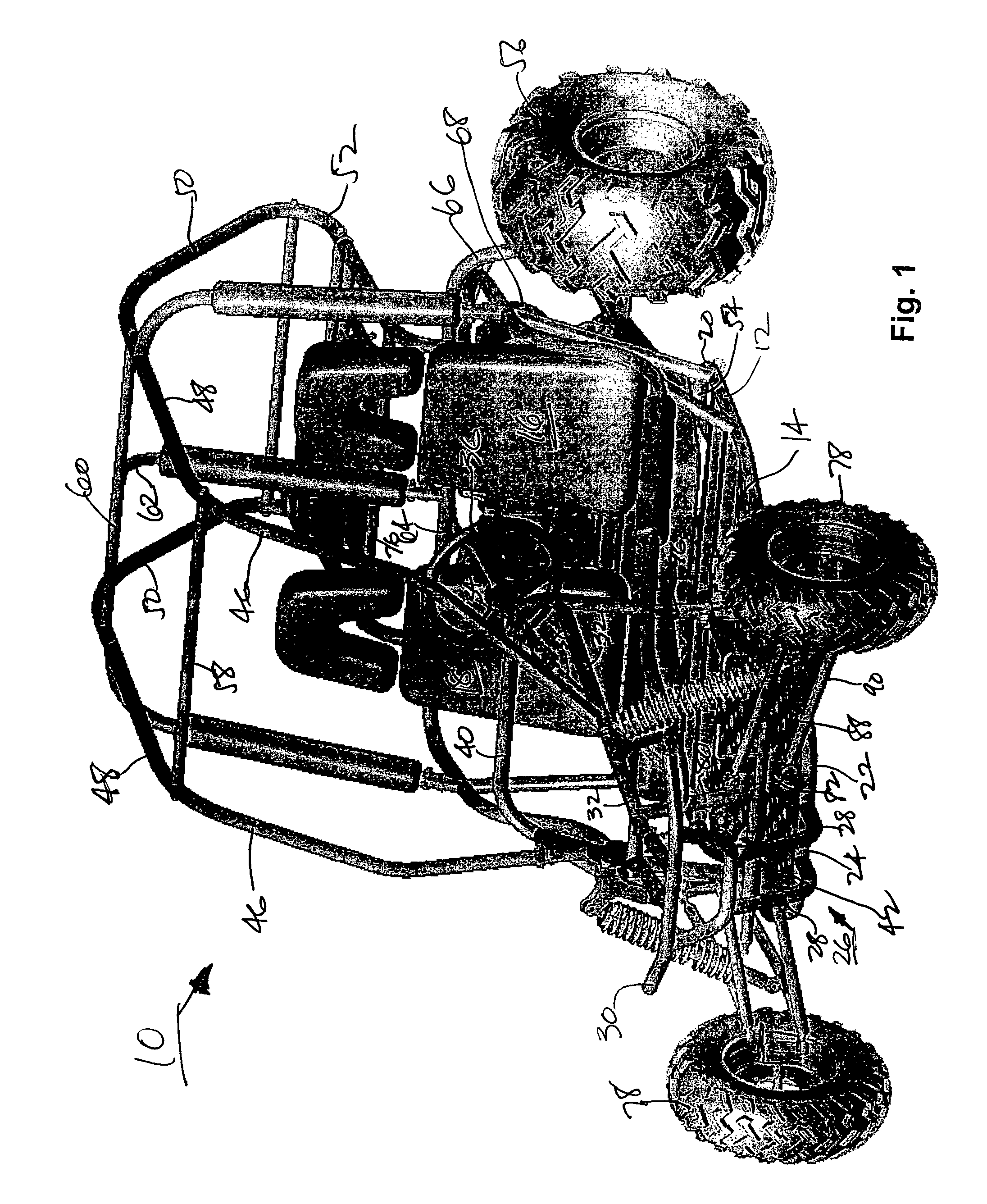

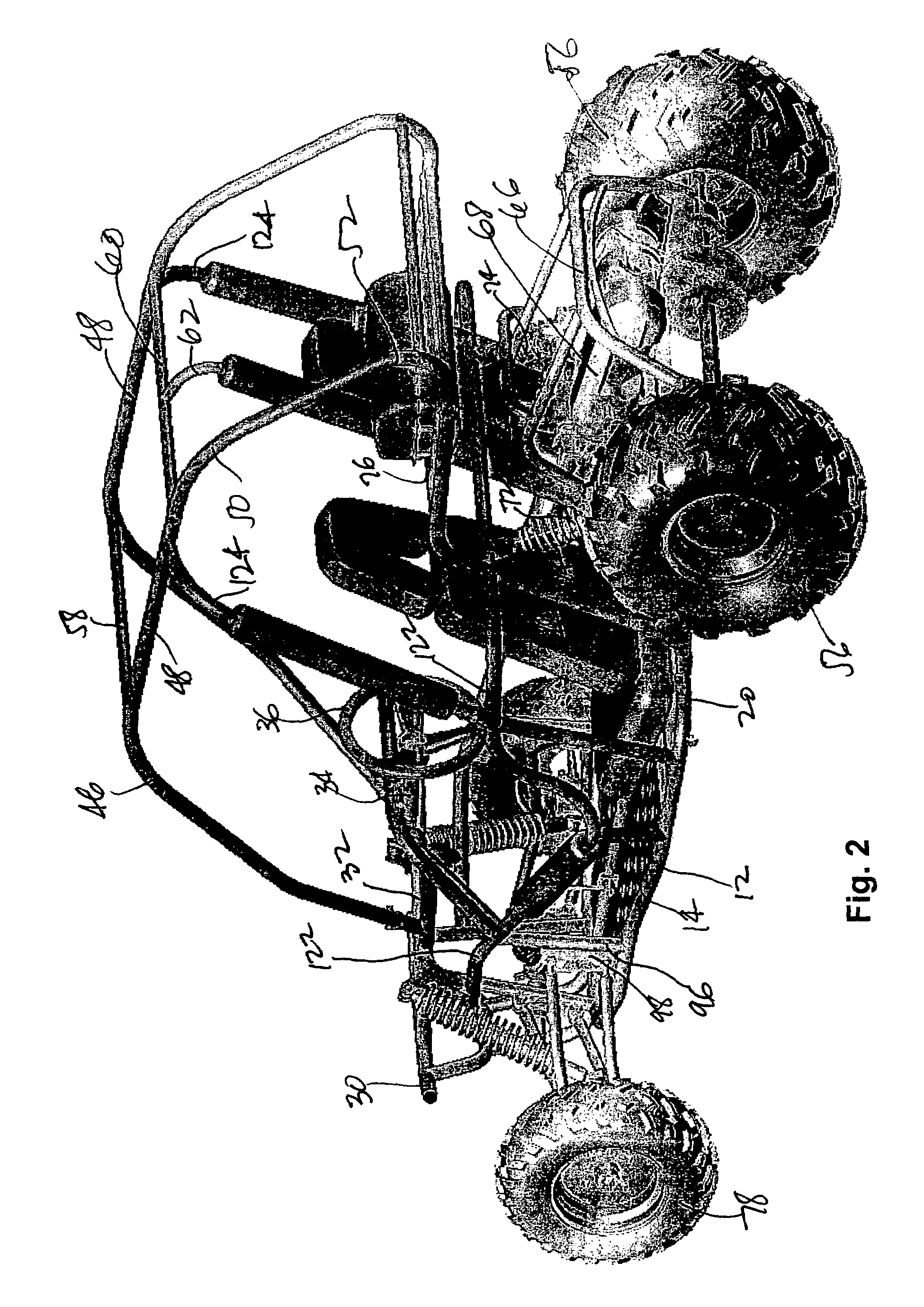

Go-cart

InactiveUS7380805B1Great vertical front wheel travelLong legroomResilient suspensionsPivoted suspension armsTerrainControl arm

A four-wheeled recreational vehicle in the form of a go-cart having an open body without doors or windows. The body is formed from interconnected tubular members to define a chassis and frame. The vehicle includes a front suspension having V-shaped, parallel upper and lower control members including forward and rear control arms. The forward control arms are substantially perpendicular to the chassis centerline and the rear control arms incline inwardly and rearwardly from the front wheels. Greater vertical front wheel travel is provided for improved ride comfort and stability over rough terrain. The accelerator and brake pedals are placed closer to the front wheel pivot axis for greater legroom.

Owner:ASIAN VENTURES

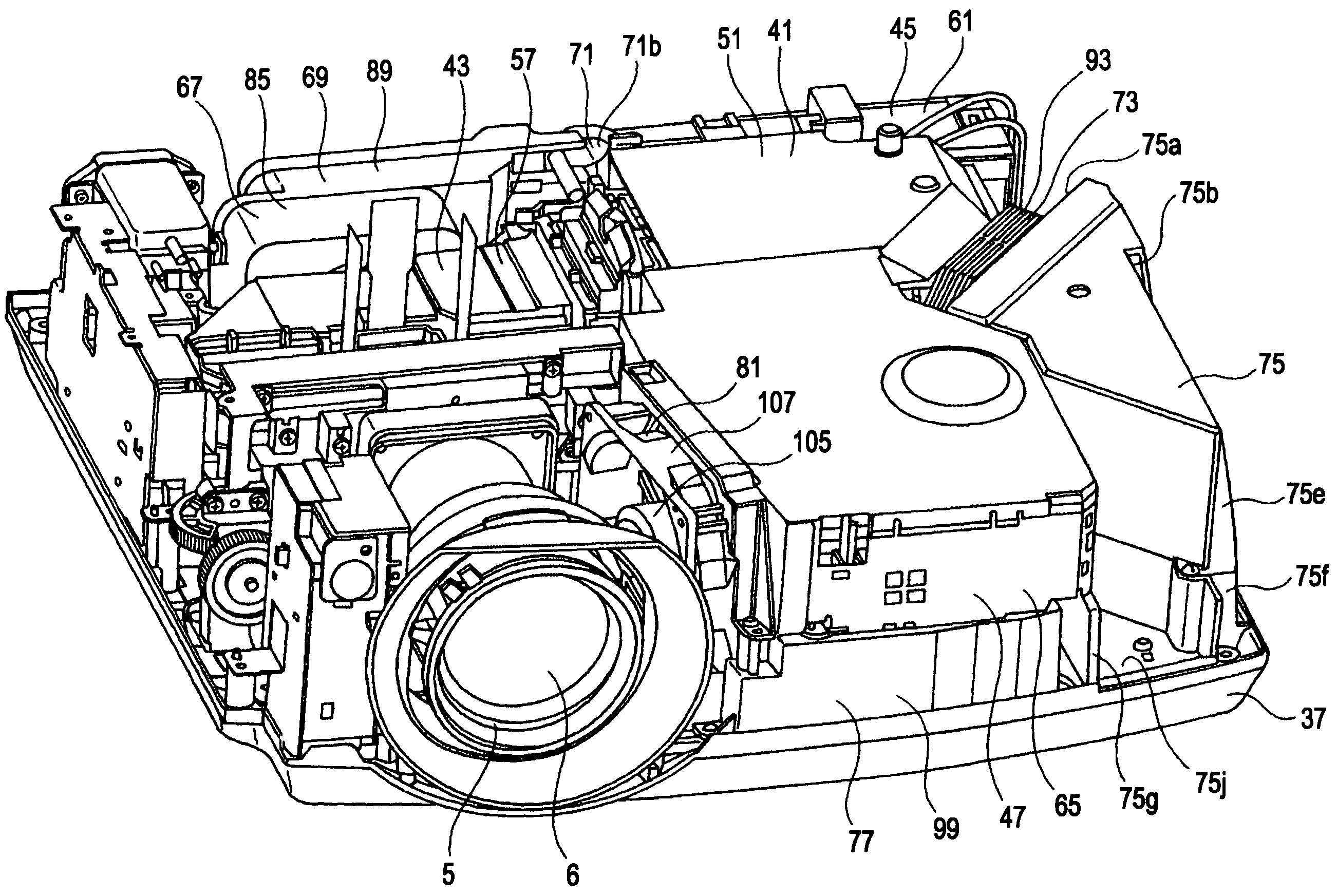

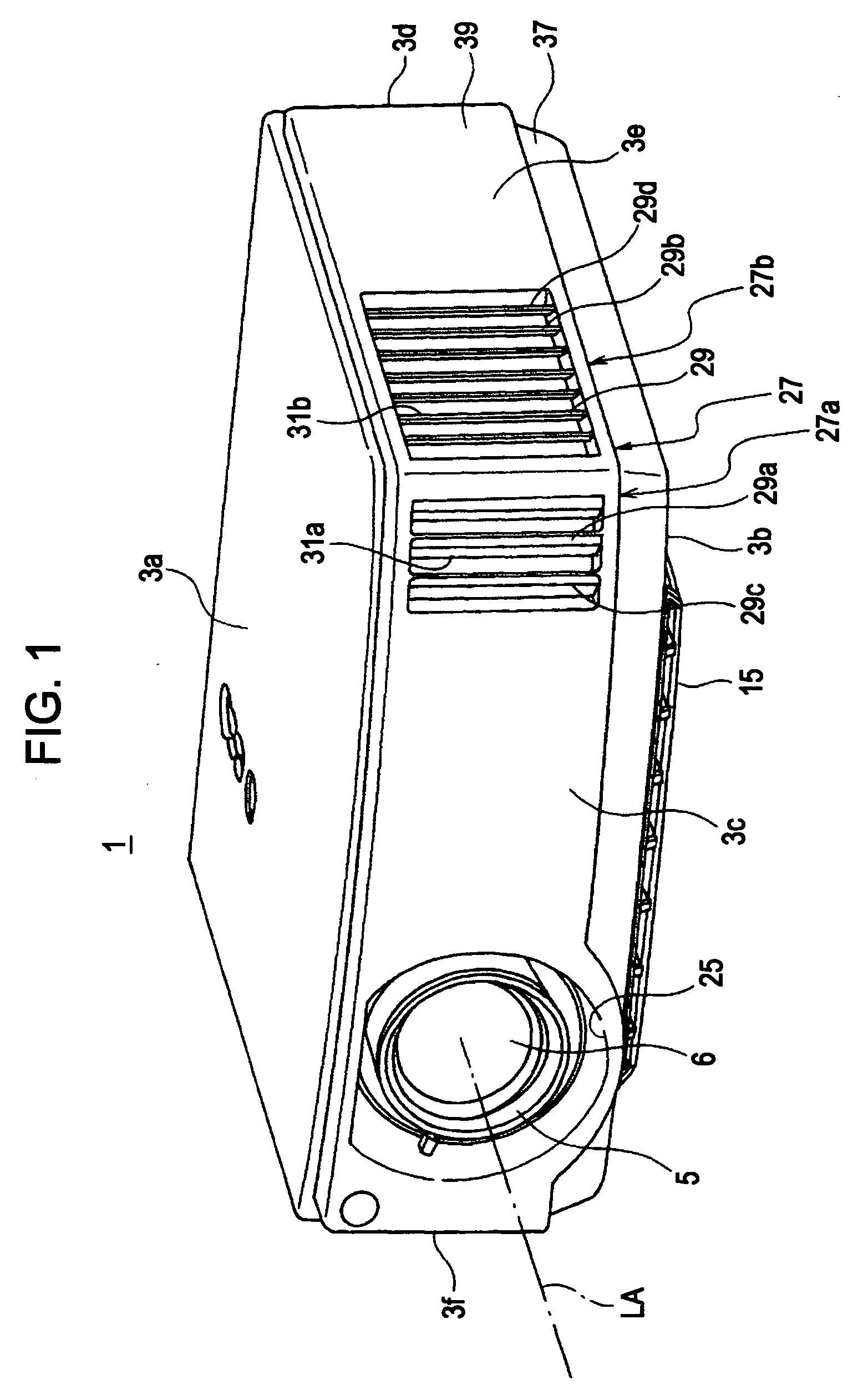

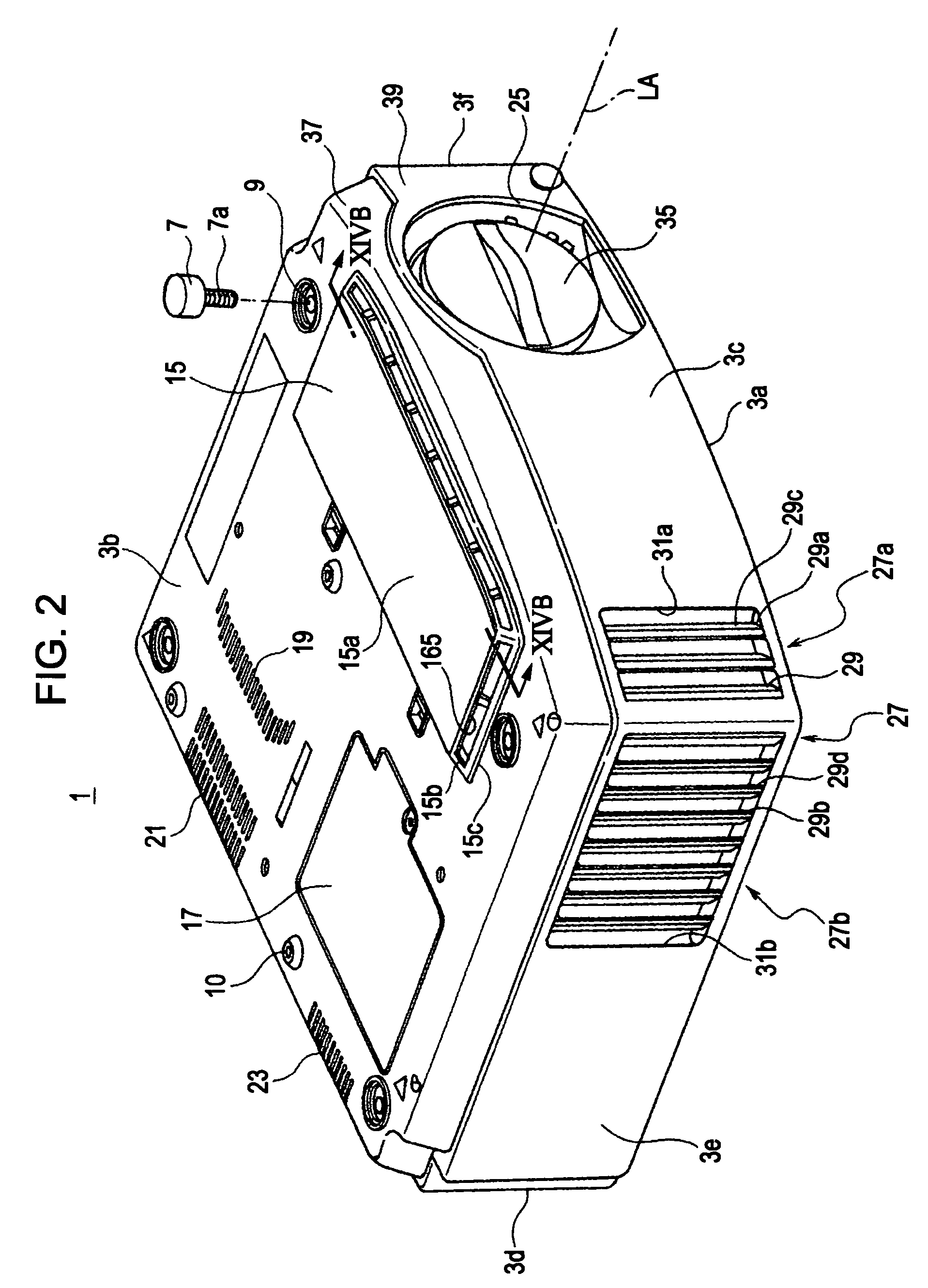

Projection display device

InactiveUS20080252859A1Increase material costIncrease work costsPump componentsProjectorsRotational axisEngineering

A projection display device includes: a housing; a fan disposed within the housing, the fan having a vane portion and a fan case accommodating the vane portion so as to be rotatable; and multiple vibration-proofing members having at least one of elasticity and viscosity, the vibration-proofing members being disposed at multiple positions in the circumferential direction of the perimeter face portion of the fan case surrounding the vane portion around the rotational axis of the vane portion, such that the vibration-proofing members are introduced between the housing and the fan case.

Owner:SONY CORP

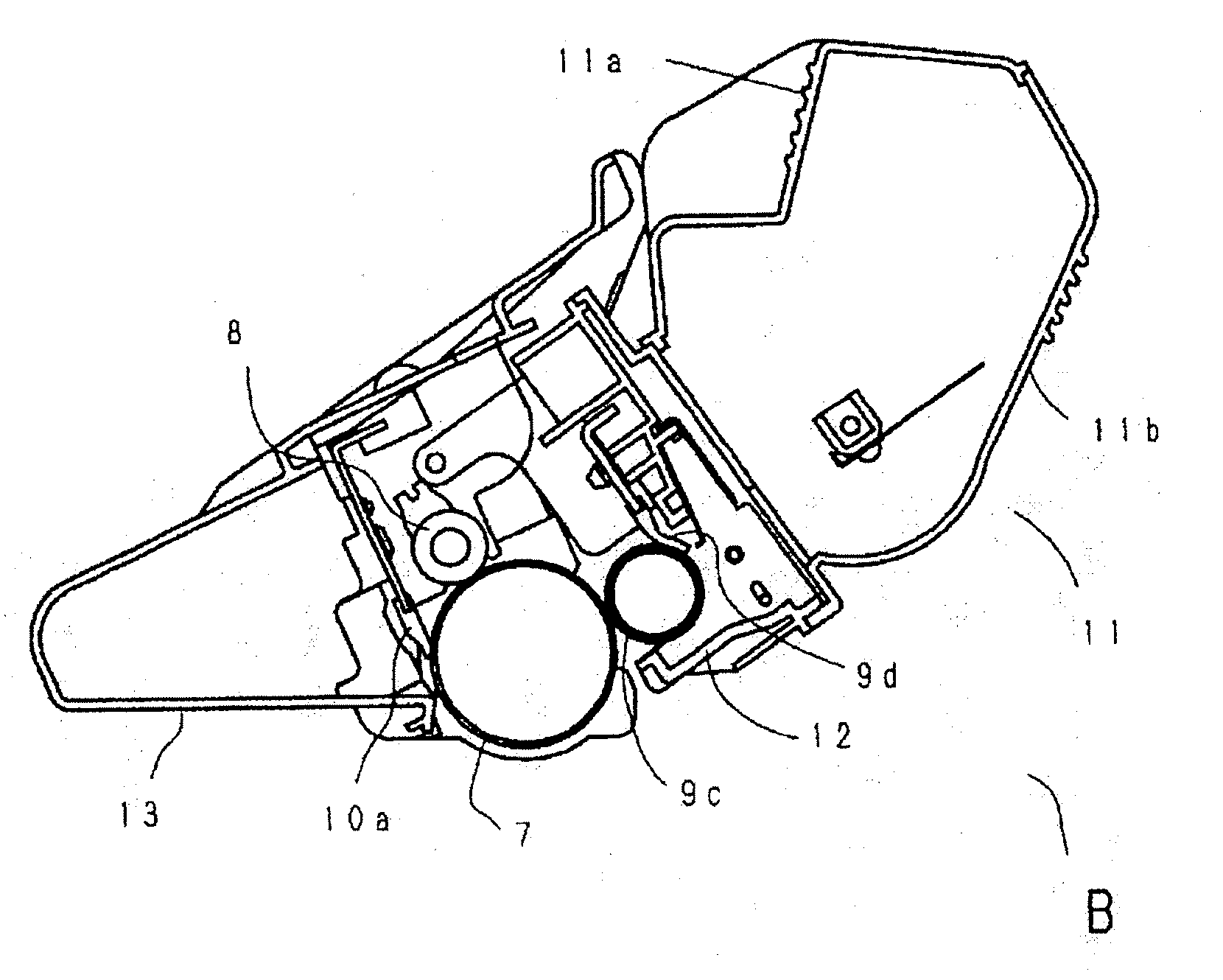

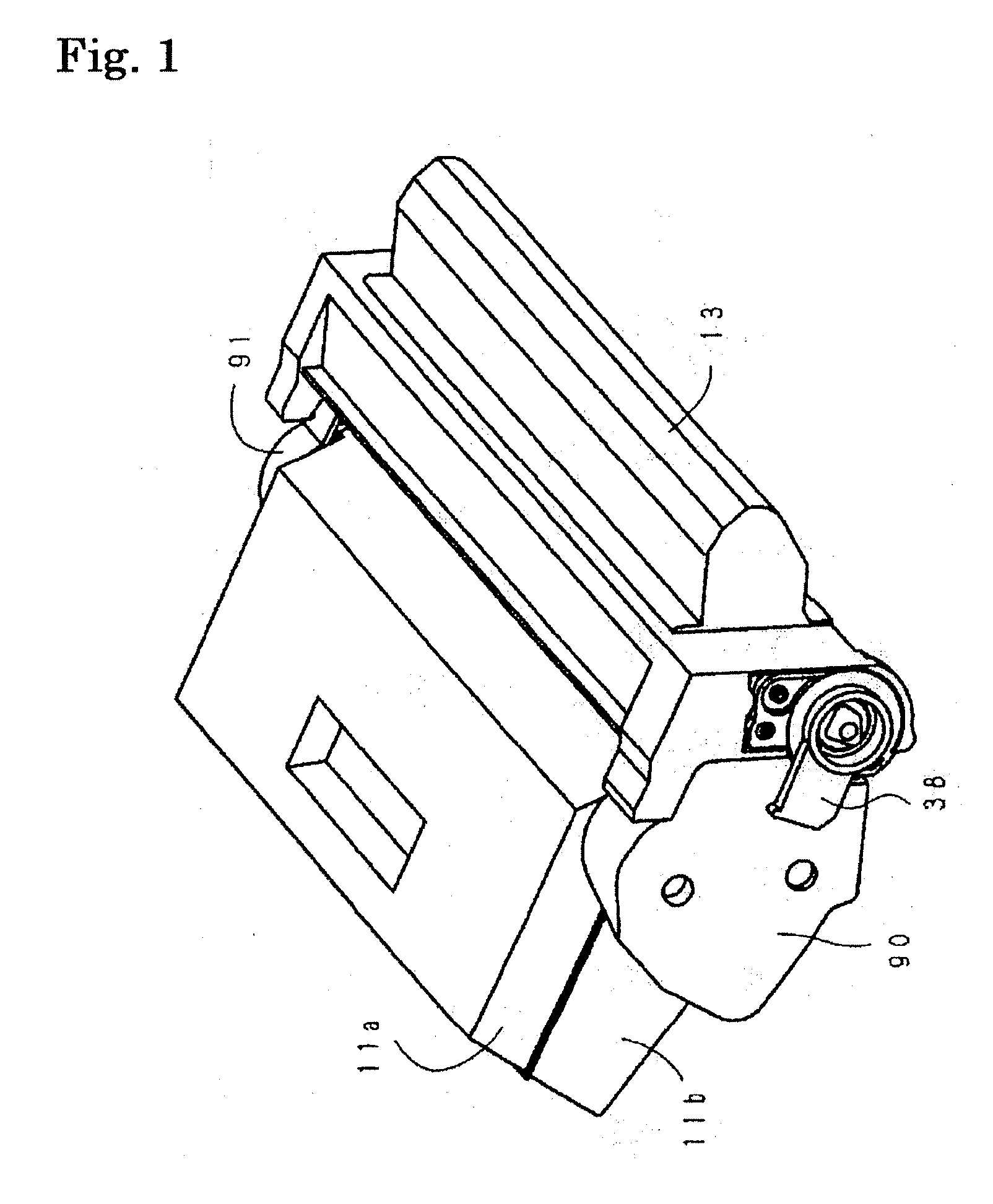

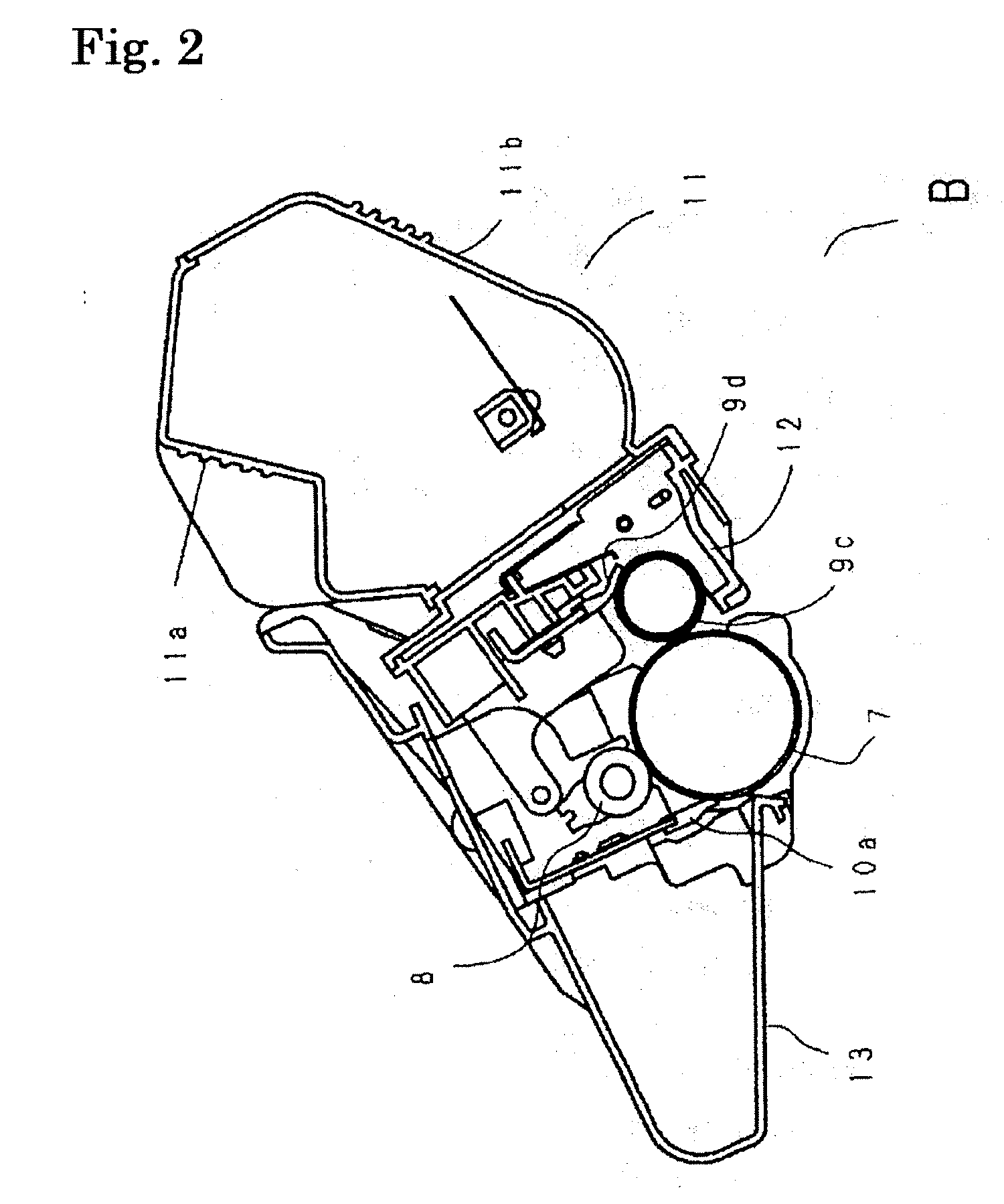

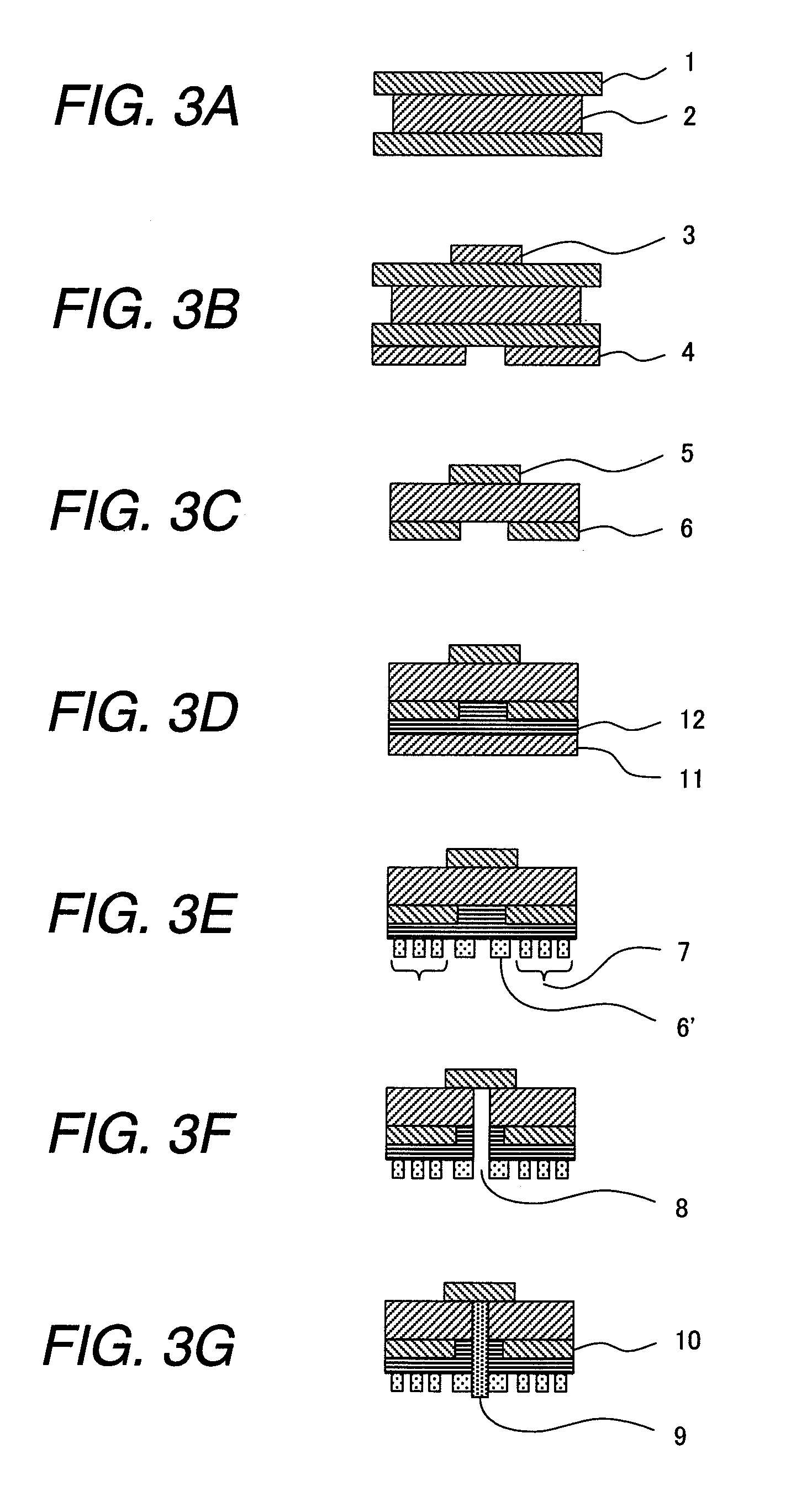

Cartridge and a process for manufacturing a cartridge

InactiveUS20070092291A1Increase costImprove impact resistanceElectrographic processOptical transmittanceEngineering

To provide a cartridge and a toner container each of which does not increase a material cost and is excellent in impact resistance against, for example, a vibration or a fall, the impact resistance being a needed function. The cartridge and the toner container each include a first part molded out of a laser light absorptive styrene resin composition and a second part molded out of a laser light transmissive styrene resin composition, the first part and the second part being joined with each other by laser welding. In each of the cartridge and the toner container, the transmittance of each of the parts is adjusted depending on, for example, the particle size and amount of rubber in each of the styrene resin compositions, or the kind of a flame retardant in each of the compositions.

Owner:CANON KK

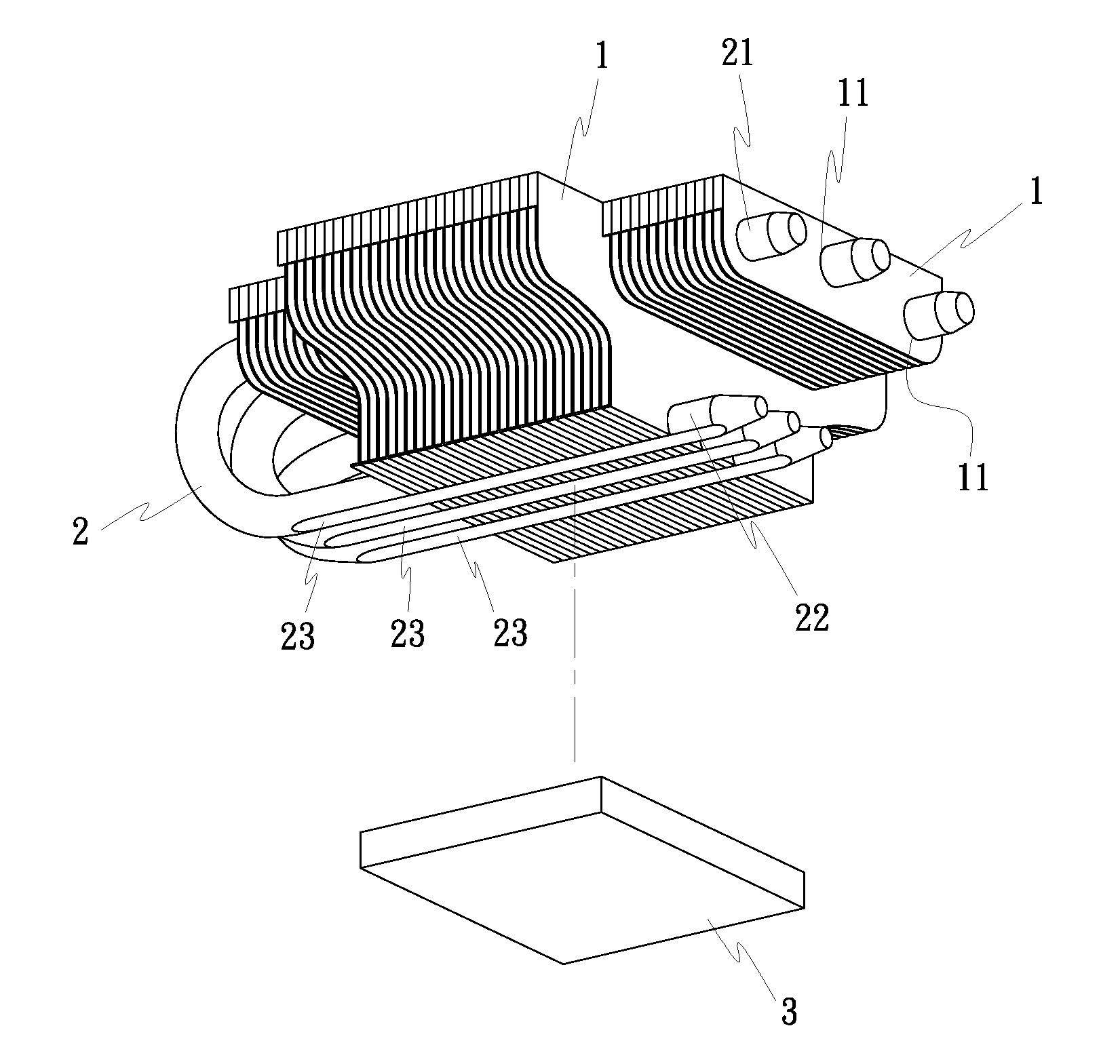

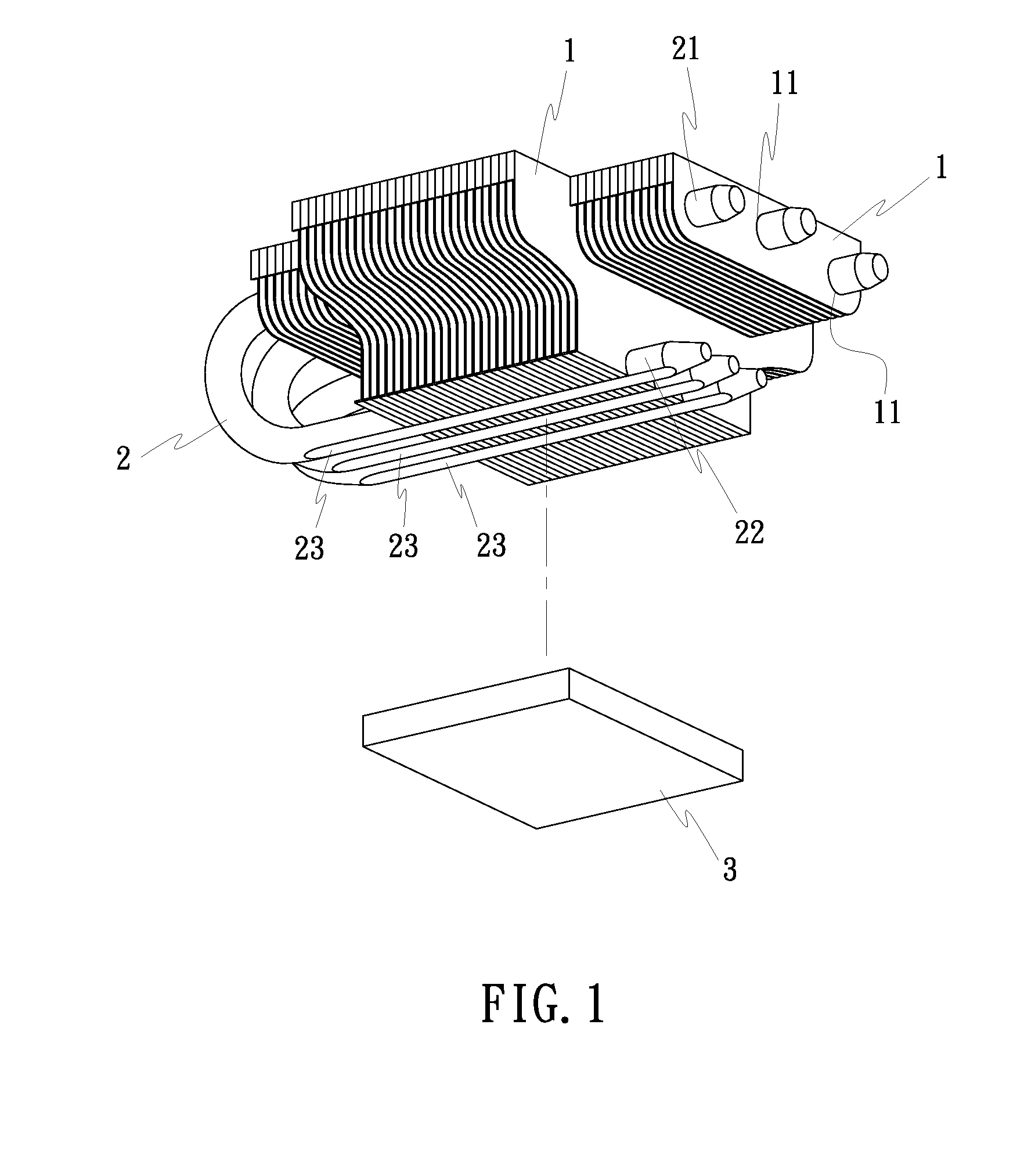

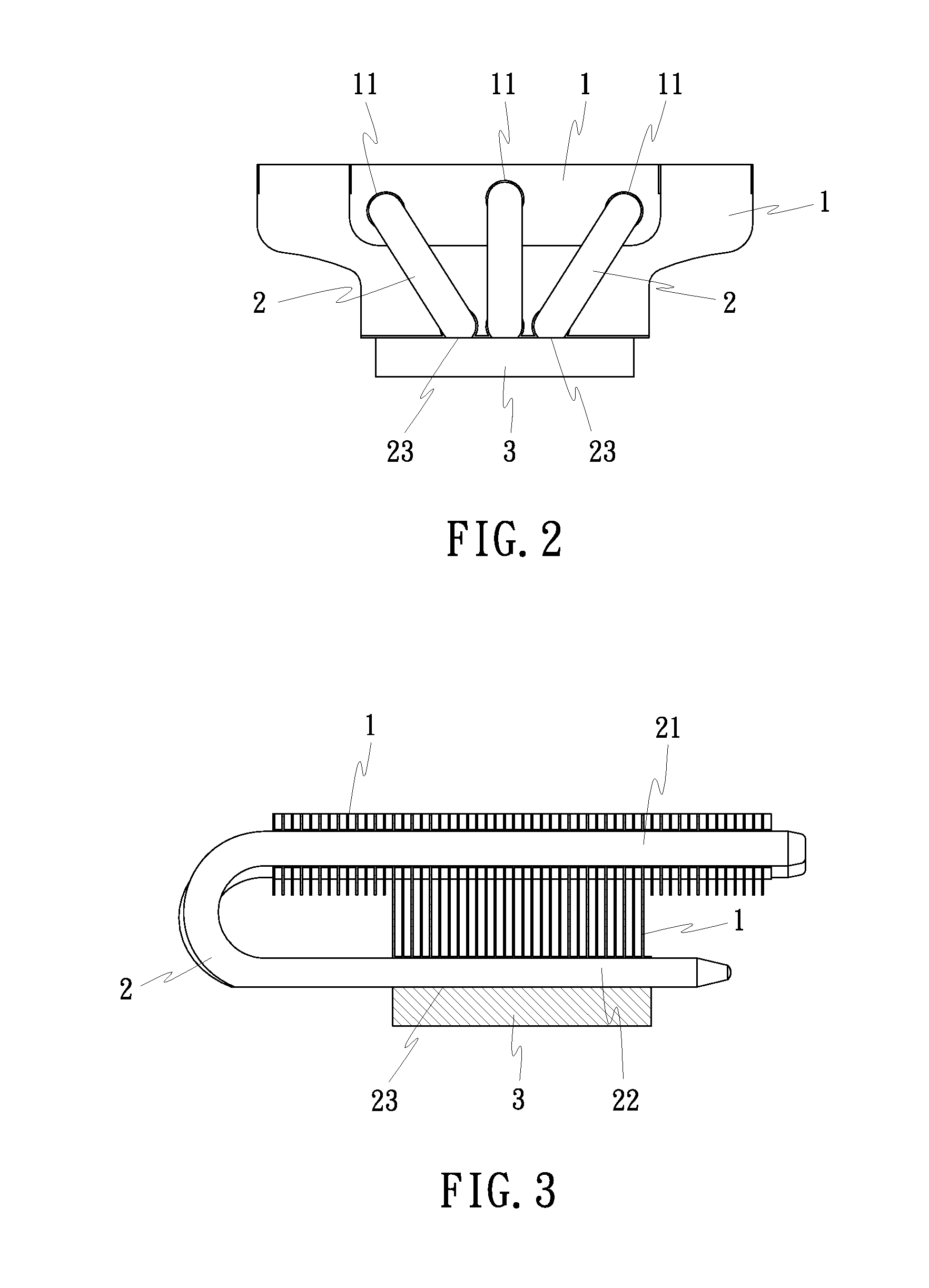

Cooler module without base panel

ActiveUS20090178787A1Dissipate quicklyEliminate useSemiconductor/solid-state device detailsSolid-state devicesEngineeringHeat sink

A light, compact, non-bottom panel type cooler module includes a plurality of radiation fins arranged in a stack, and a plurality of U-shaped heat pipes fastened to the radiation fins to hold the radiation fins in parallel, each U-shaped heat pipe having one or two opposite end pipe sections thereof press-fitted into respective through holes on the radiation fins and a flat bottom surface portion exposed to the outside of the radiation fins for bonding to a semiconductor device for enabling the heat pipes to transport heat from the semiconductor device to the radiation fins for dissipation.

Owner:HUANG TSUNG HSIEN

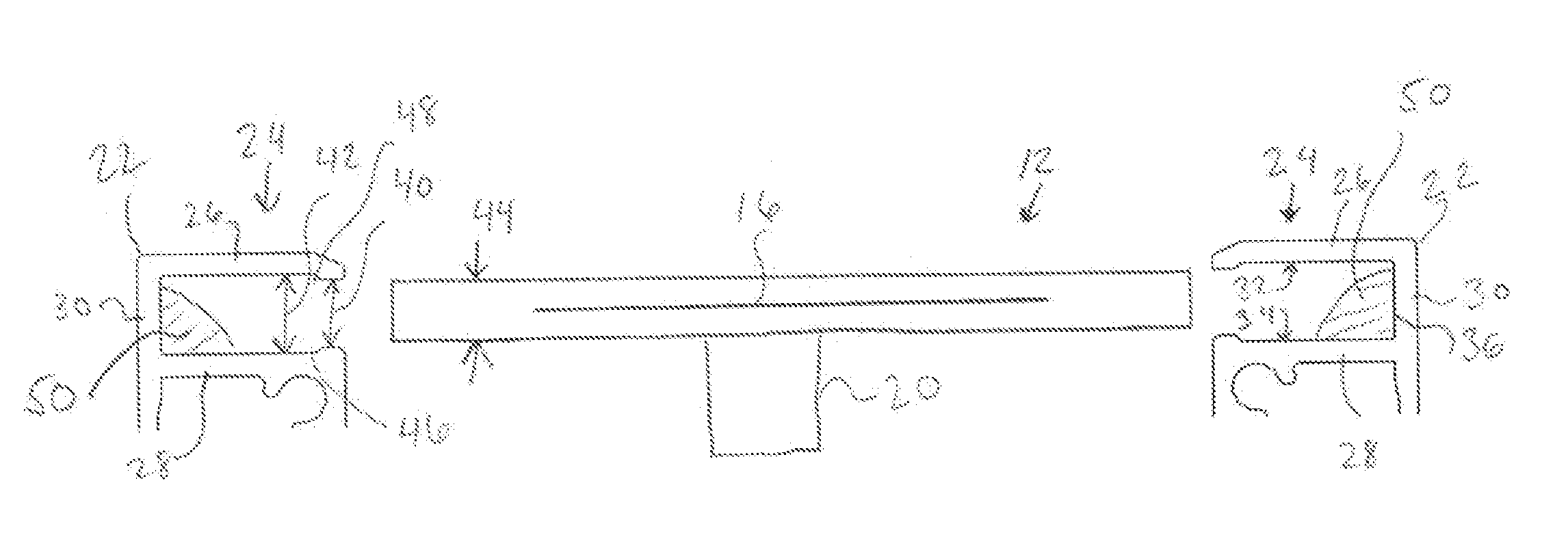

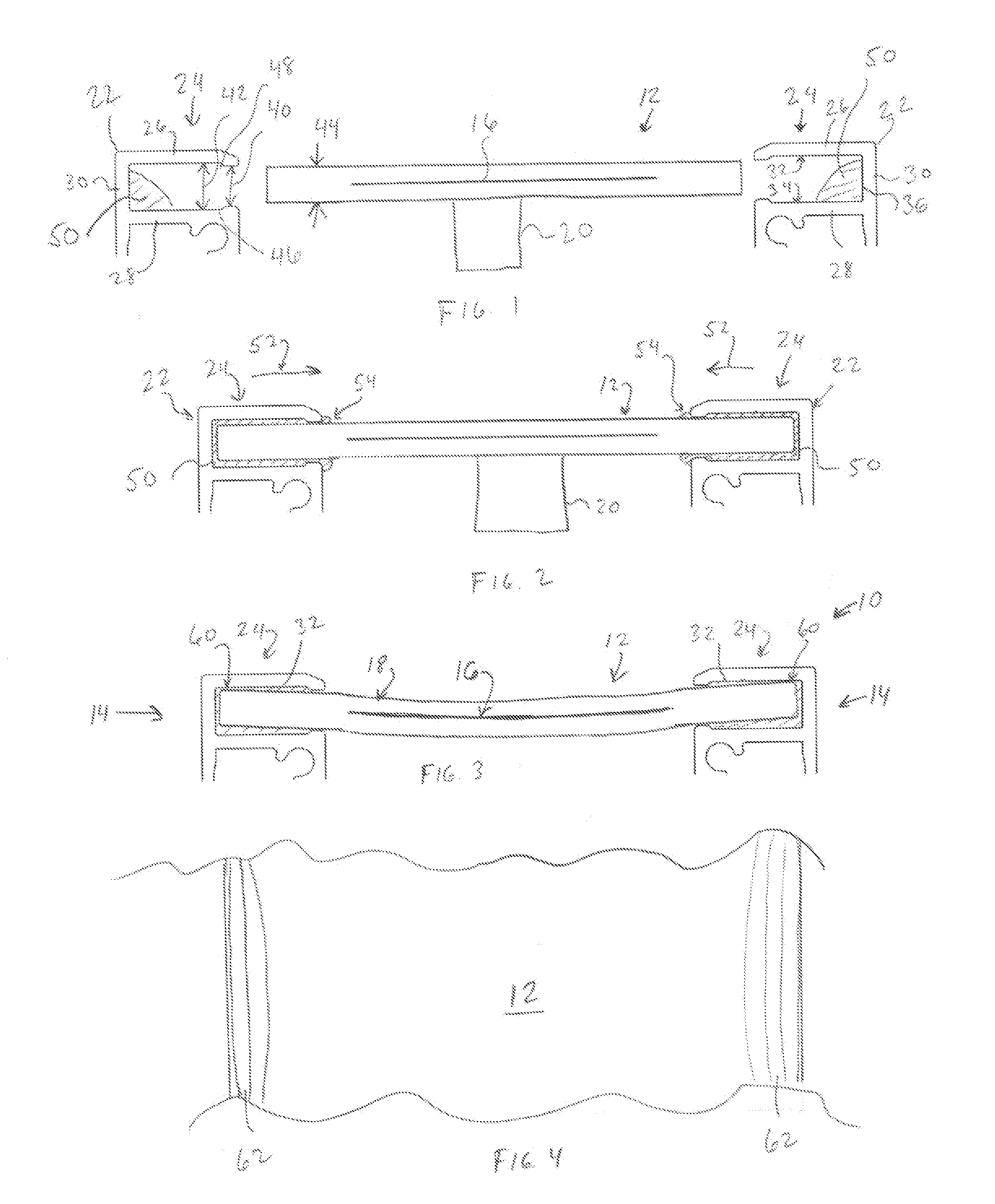

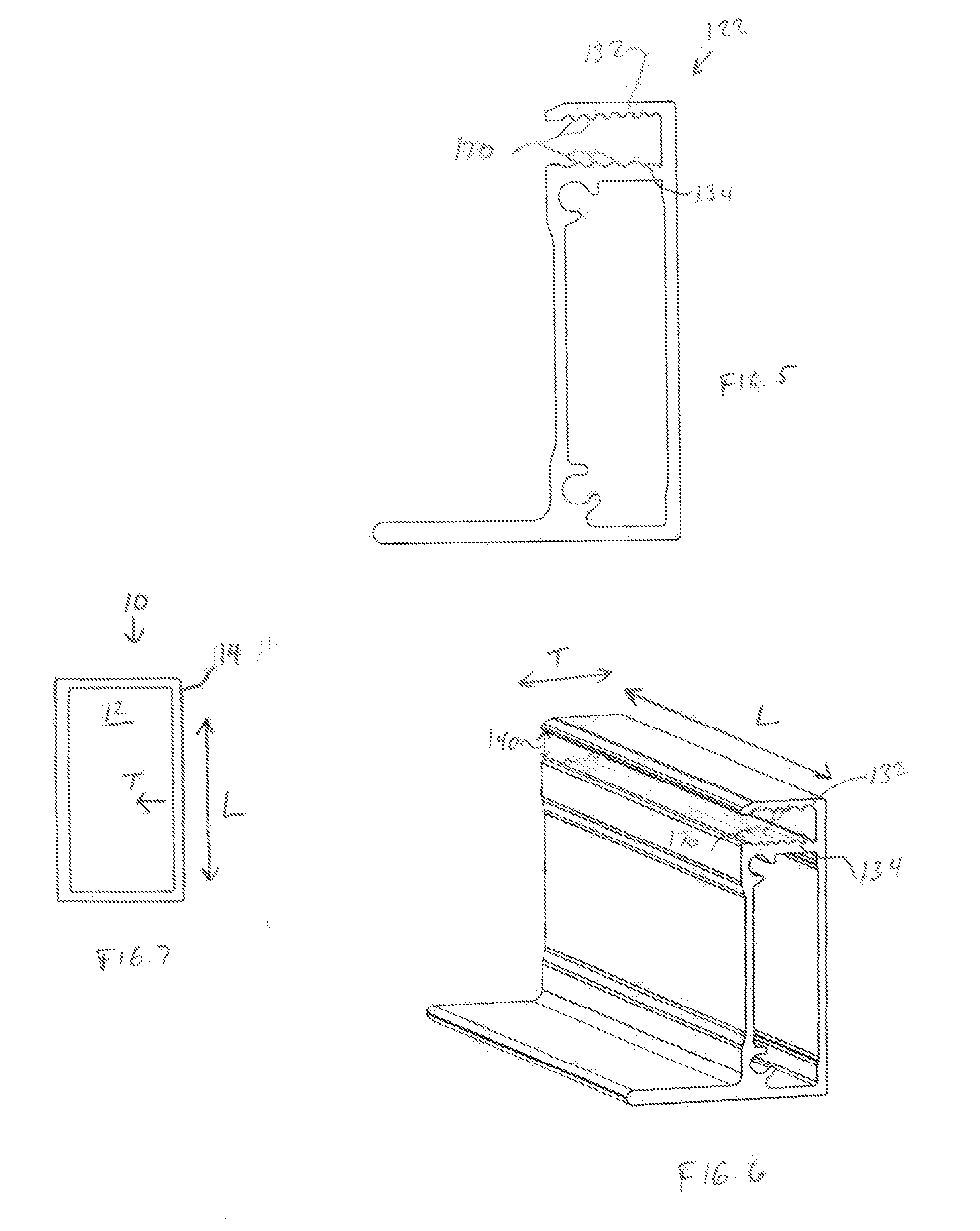

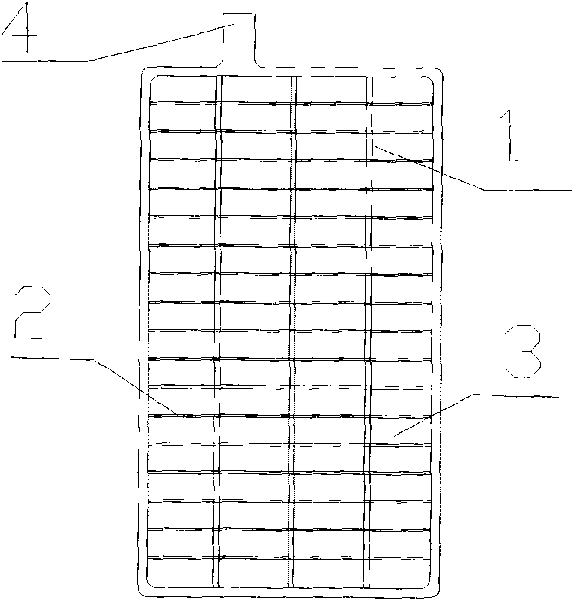

Photovoltaic module frame with improved bondability

InactiveUS20140182661A1Quantity maximizationFail prematurelyPV power plantsPhotovoltaic energy generationEngineeringUltimate tensile strength

A photovoltaic module can be formed with a laminate bonded to frame members. The frame members can extend around the periphery of the laminate. The frame members can include surface features which increase the surface area of the portion of the frame member bonded to the laminate, and thereby improve the bond strength between the frame member and the laminate. Further, the surface features can extend generally longitudinally along the peripheral edges of the laminate, thereby helping to guide a flow of liquid adhesive, during the manufacturing process, along longitudinal direction and thus reduce the amount of adhesive that leaks out onto the laminate during the manufacturing process.

Owner:SUNPOWER CORPORATION

Carburizing steel and steel products manufactured making use of the carburizing steel

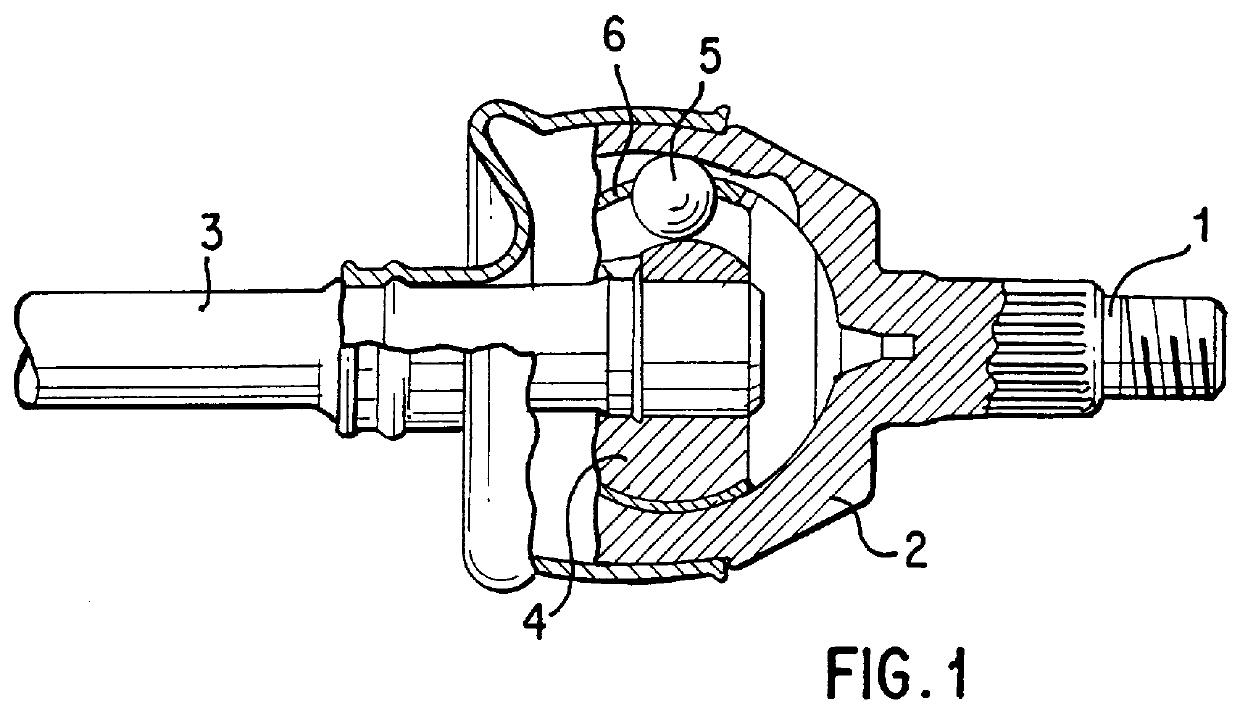

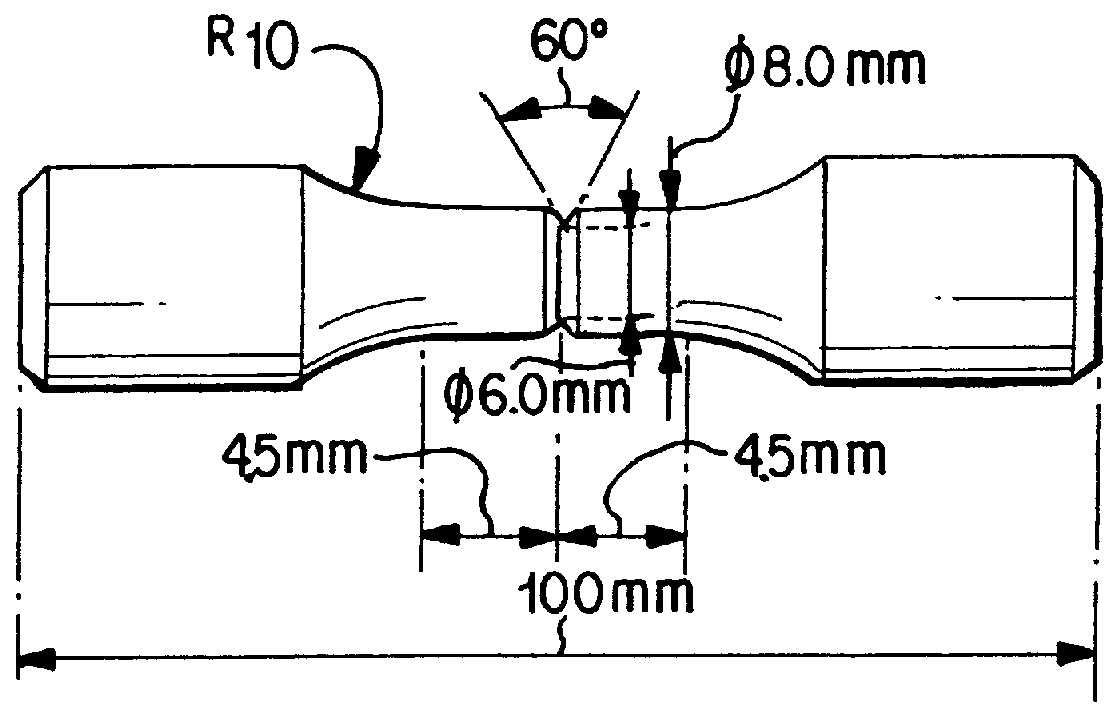

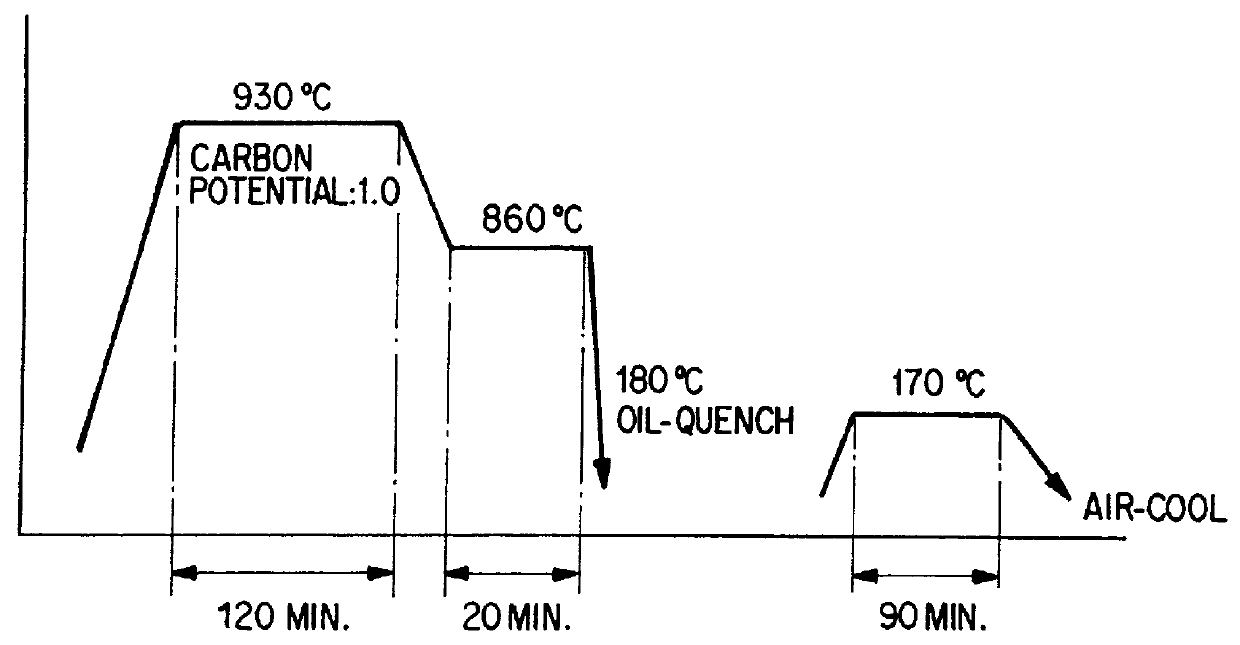

InactiveUS6126897AImproving rolling contact fatigue resistanceHigh strengthYielding couplingSolid state diffusion coatingChemical compositionUniversal joint

A carburizing steel having the following chemical composition: C: 0.1 to 0.25%, Si: 0.2 to 0.4%, Mn: 0.3 to 0.9%, P: 0.02% or less, S: 0.001 to 0.15%, Cr: 0.5 to 0.9%, Mo: 0.15 to 1%, Al: 0.01 to 0.1%, B: 0.0005 to 0.009%, N: less than 0.006%, and the balance of Fe and incidental impurities, wherein % is on a weight basis. Also disclosed are a method for the manufacture of the carburizing steel, parts of constant velocity universal joints for drive shafts made of the carburizing steel, as well as a method for the manufacture of such parts. The carburizing steel may further contain Ni: 0.3-4.0%, and one or more elements selected from the group consisting of Ti, Nb, V and Zr: 0.01-0.3% for each. The parts of constant velocity universal joints for drive shafts are manufactured using the carburizing steel of the present invention as a material. When they are carburized and quenched, they exhibit a surface hardness (Hv) of 650-800, core hardness (Hv) of 250-450, and carburized case depth of 0.2-1.2 mm.

Owner:SUMITOMO METAL IND LTD +1

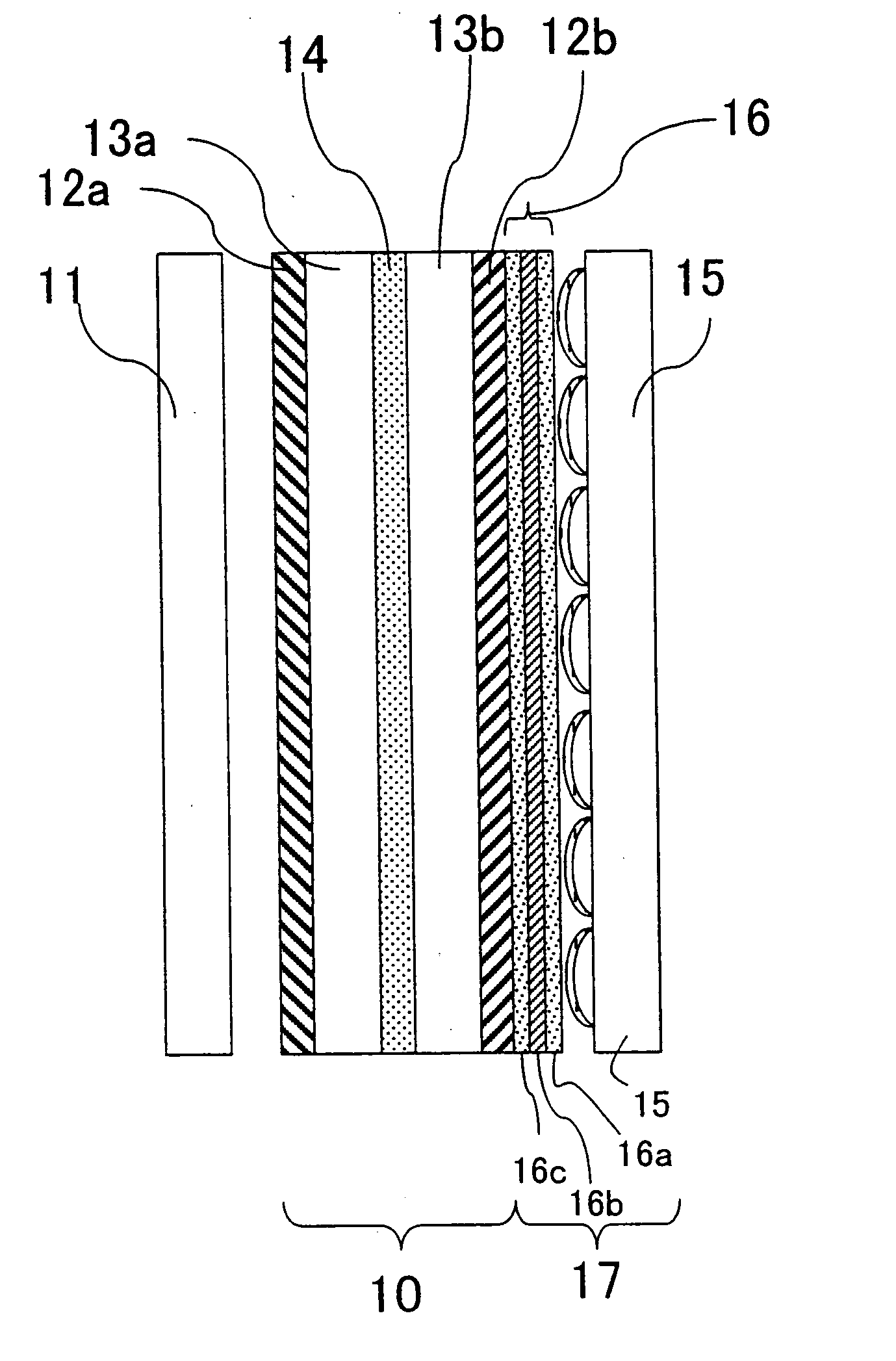

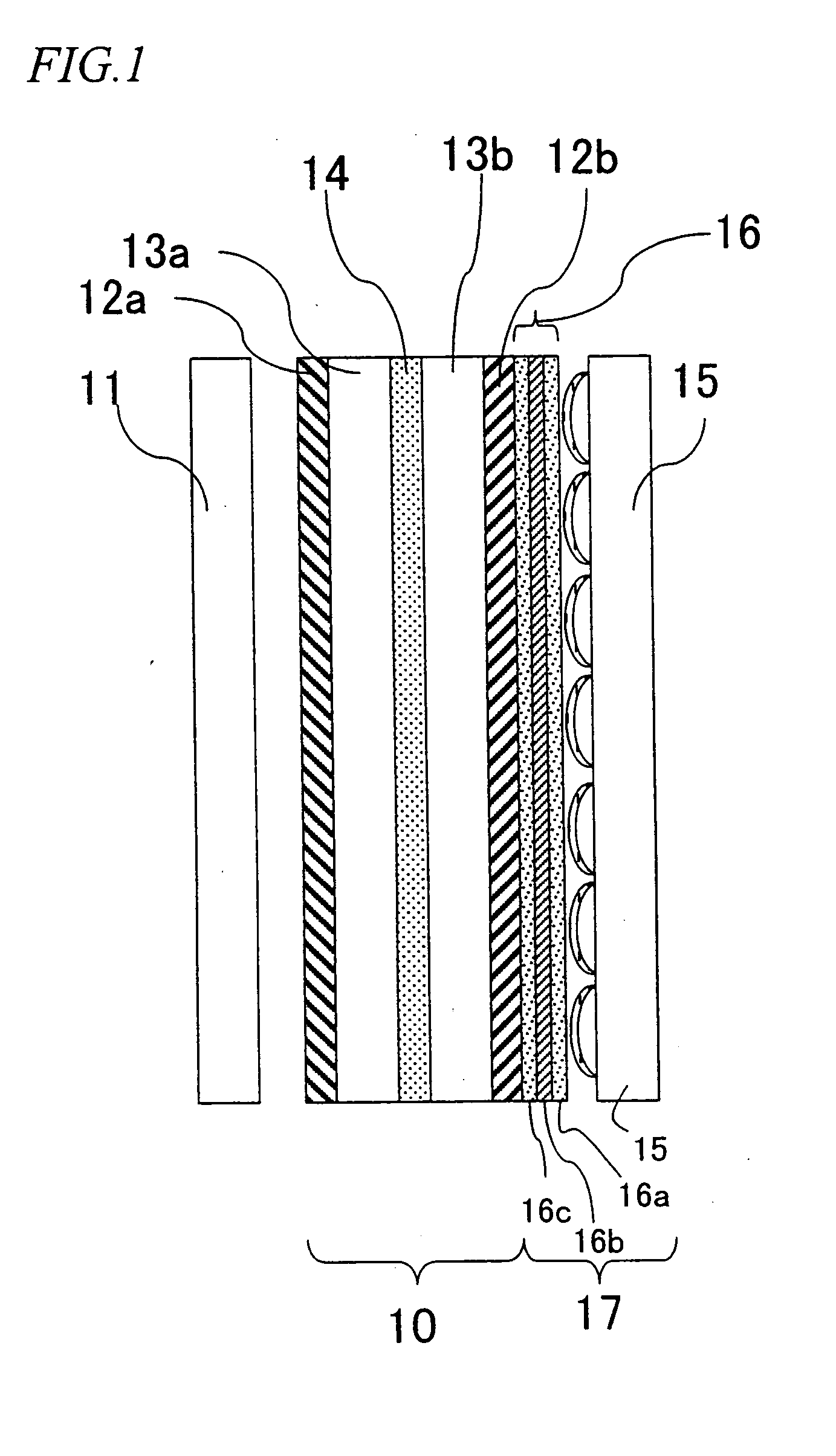

Method for fabricating a laminate film, laminate film, and method for fabricating a display device

InactiveUS20050003108A1Good adhesionEasily fixed togetherLiquid crystal compositionsDiffusing elementsLiquid-crystal displayDisplay device

Adhesive layers are formed on the two opposing surfaces of a transparent support. At least one of the adhesive layers is made of a material of which the cured state may be changed. The adhesive layer is irradiated with light and a lens sheet is then pressed against the adhesive layer. The adhesive layer is cured. In this illustrative way, a laminate film of the lens sheet fixed to the transparent support via the adhesive layer may be obtained. The laminate film may be bonded to a polarizing plate on the viewer's side of a liquid crystal display element via the other adhesive layer.

Owner:SHARP KK

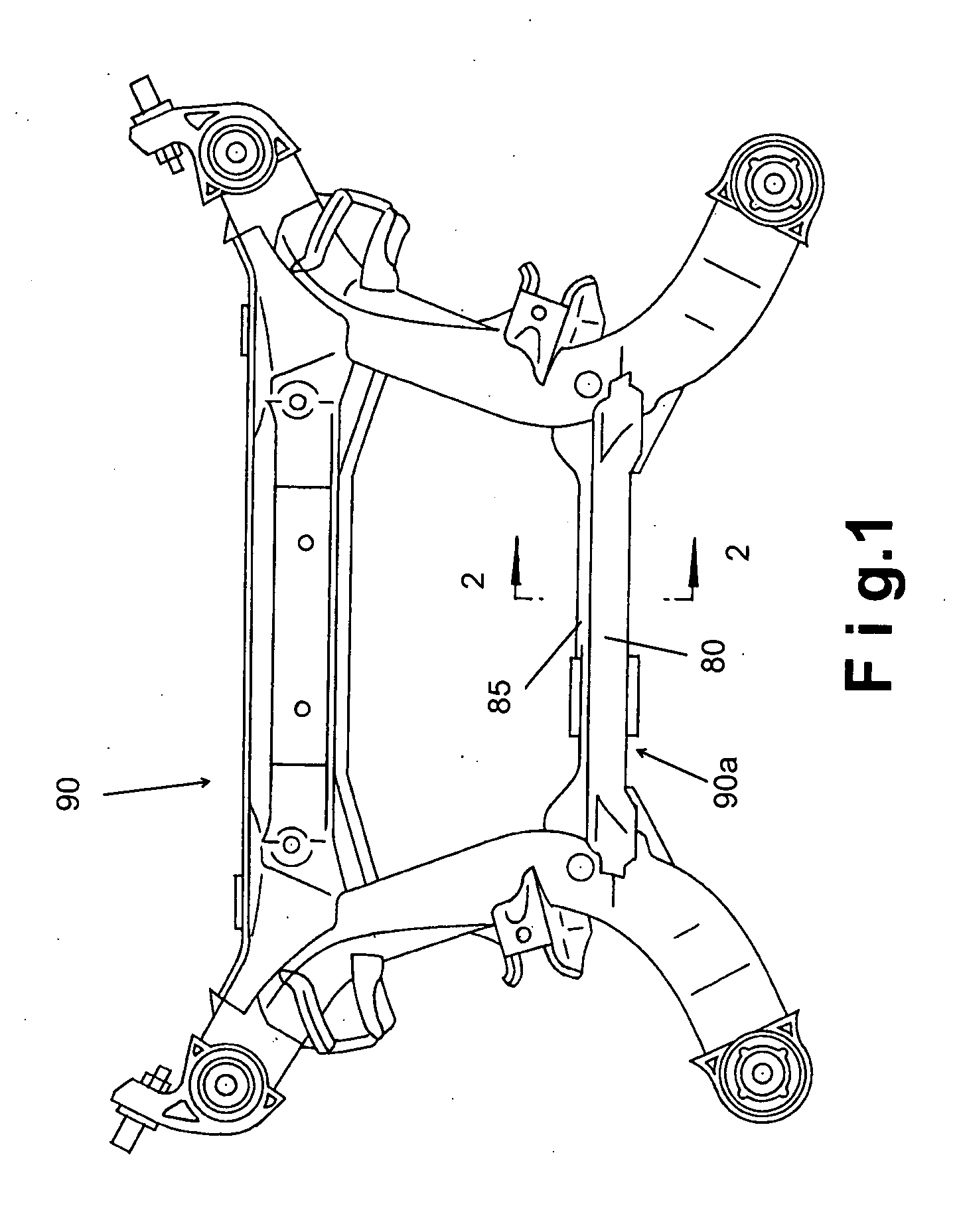

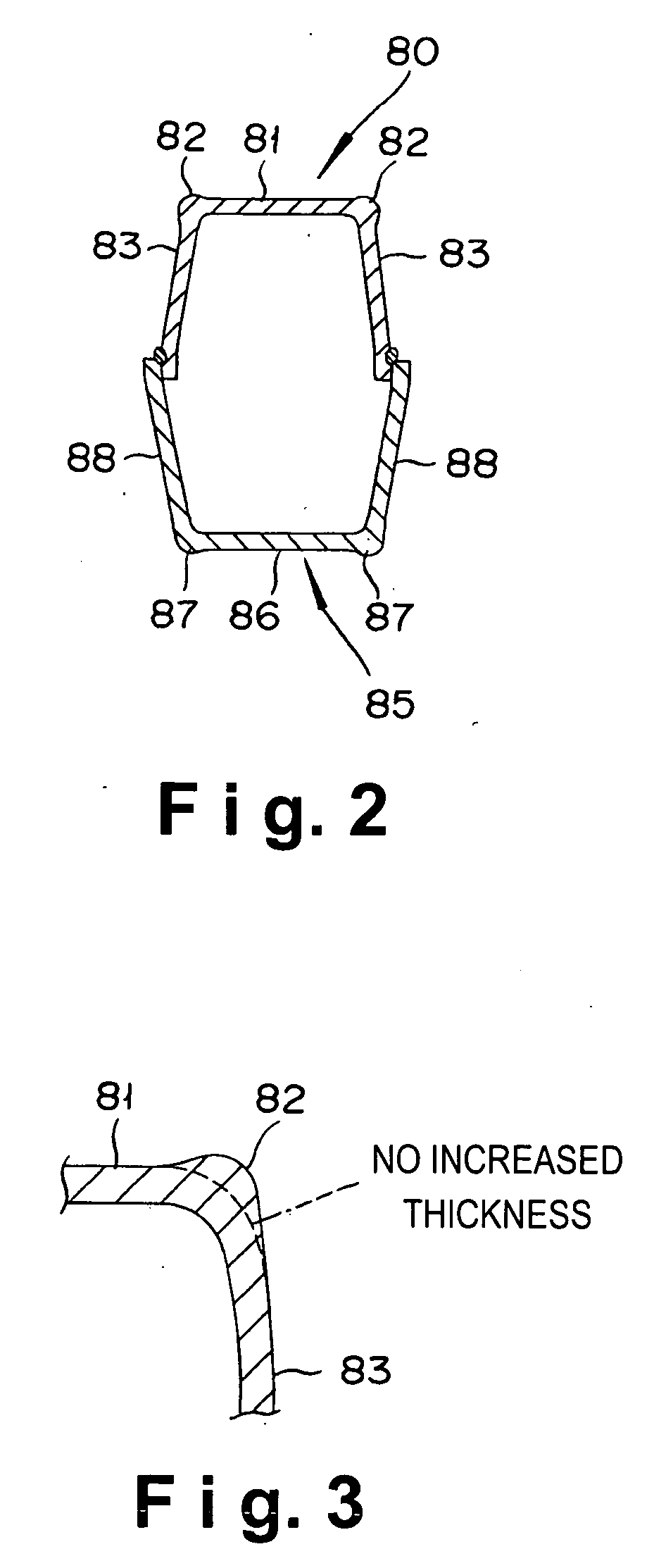

Press-formed member having corner portion, press-formed member manufacturing apparatus and press-formed member manufacturing method

InactiveUS20070125149A1Increase production capacityReduce thicknessForging/hammering/pressing machinesVehicle componentsManufactured apparatusMechanical engineering

A press-formed member includes a first wall with a first thickness, a second wall with a second thickness, and a first corner portion. The first corner portion is disposed between the first and second walls, with the first corner portion having an increased thickness formed by pressure-forming such that the increased thickness of the first corner portion is larger than the first and second thicknesses of the first and second walls adjacent to the first corner portion. In a manufacturing method for the press-formed member, a preliminary body structure to be deformed is provided, and the thickness of the first corner portion of the preliminary body structure is increased by applying pressure to the preliminary body structure.

Owner:NISSAN MOTOR CO LTD

Method for manufacturing coke

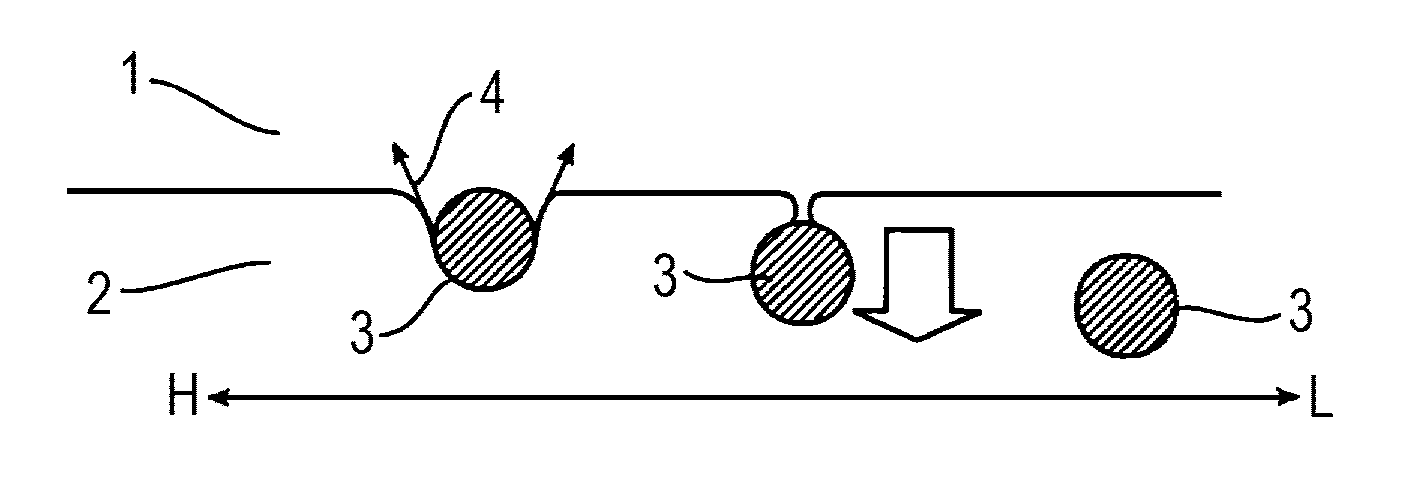

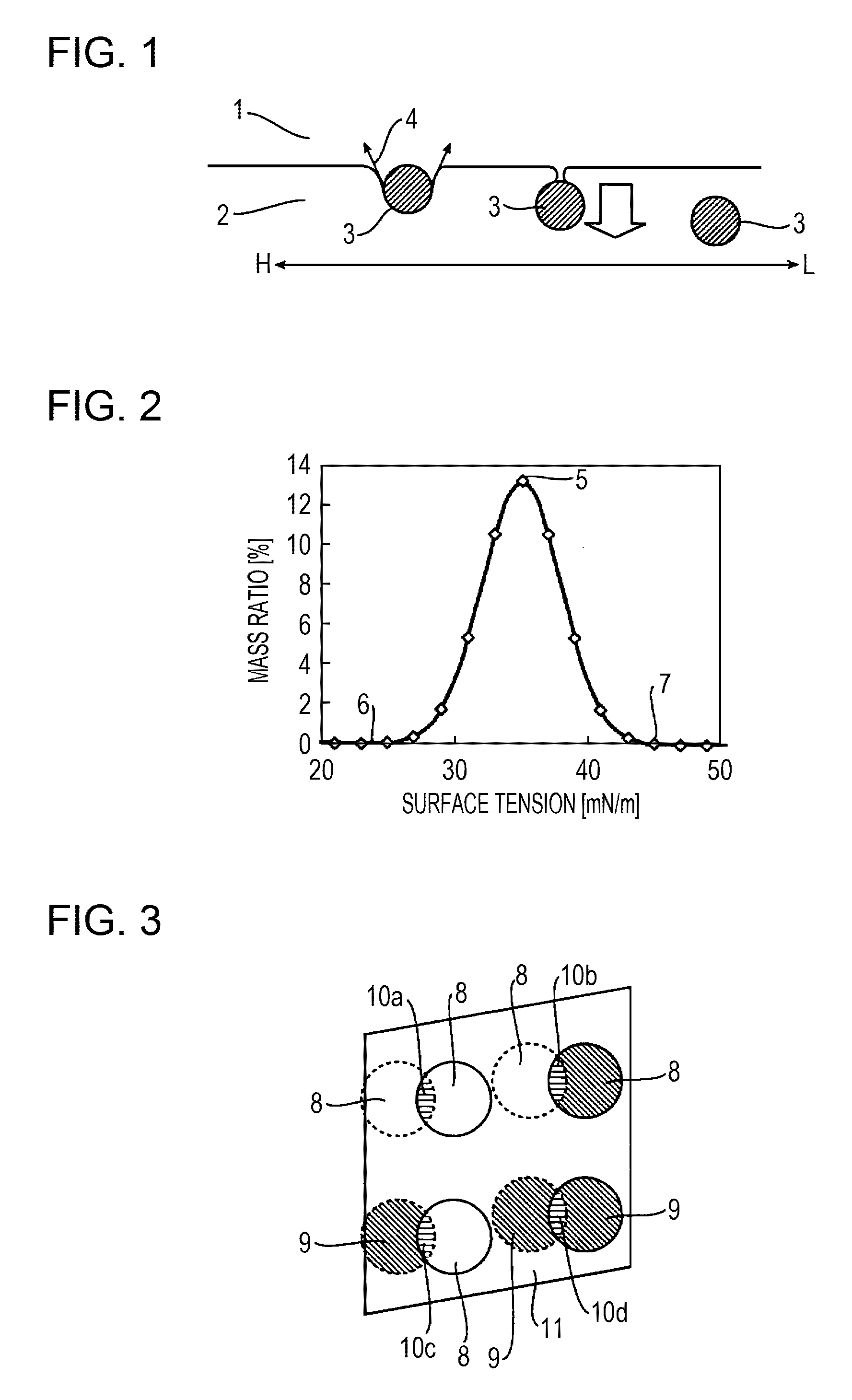

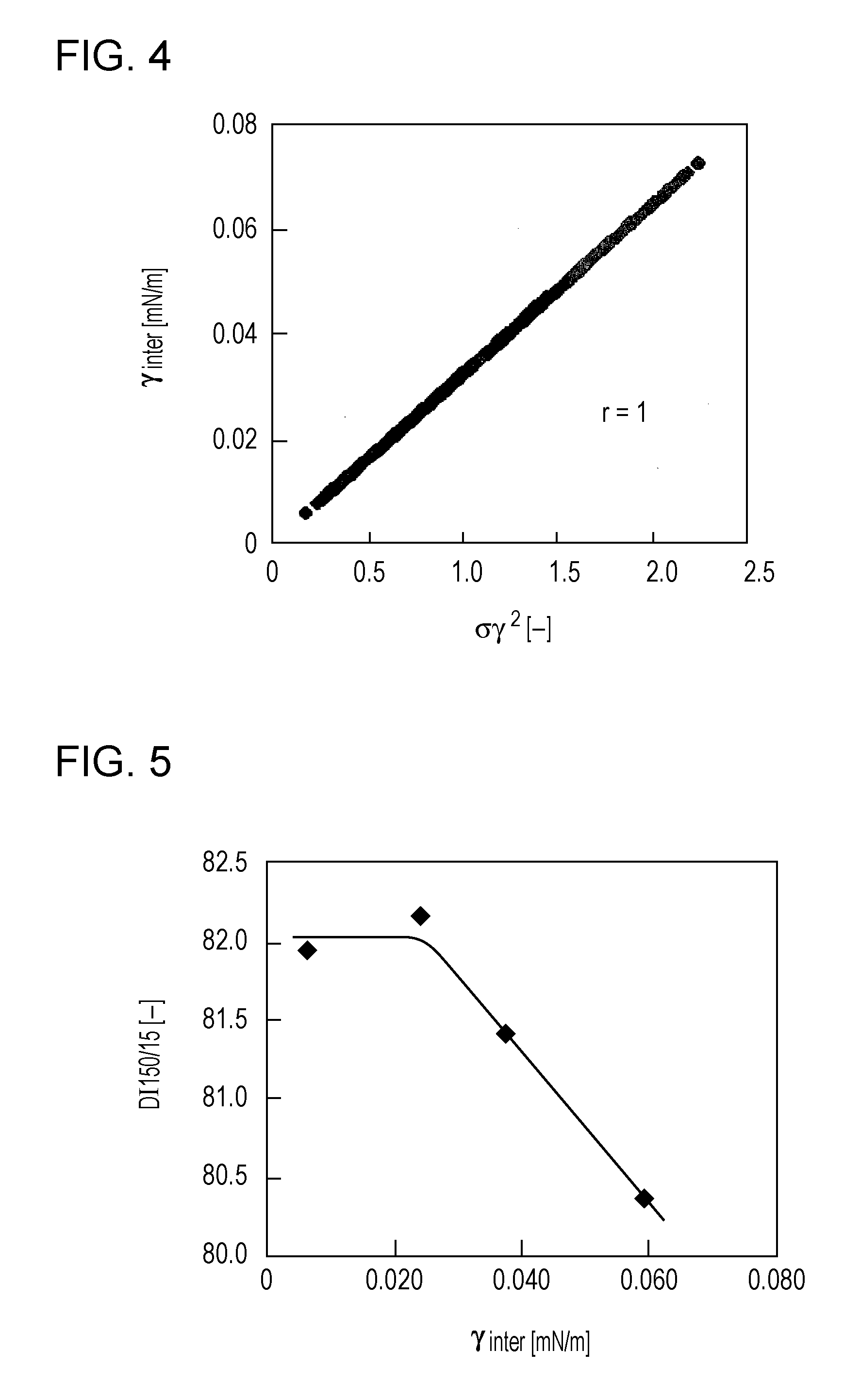

ActiveUS9463980B2Simple materialIncrease material costSolid fuelsCarbon preparation/purificationCokeCarbonization

Coke is manufactured by blending two or more kinds of coal to form a coal blend and by carbonizing the coal blend. Interfacial tension among coal kinds is used as a control index for determining the blending ratio of each coal when forming the coal blend. It is possible to increase the strength of coke without increasing the material cost of a coal blend.

Owner:JFE STEEL CORP

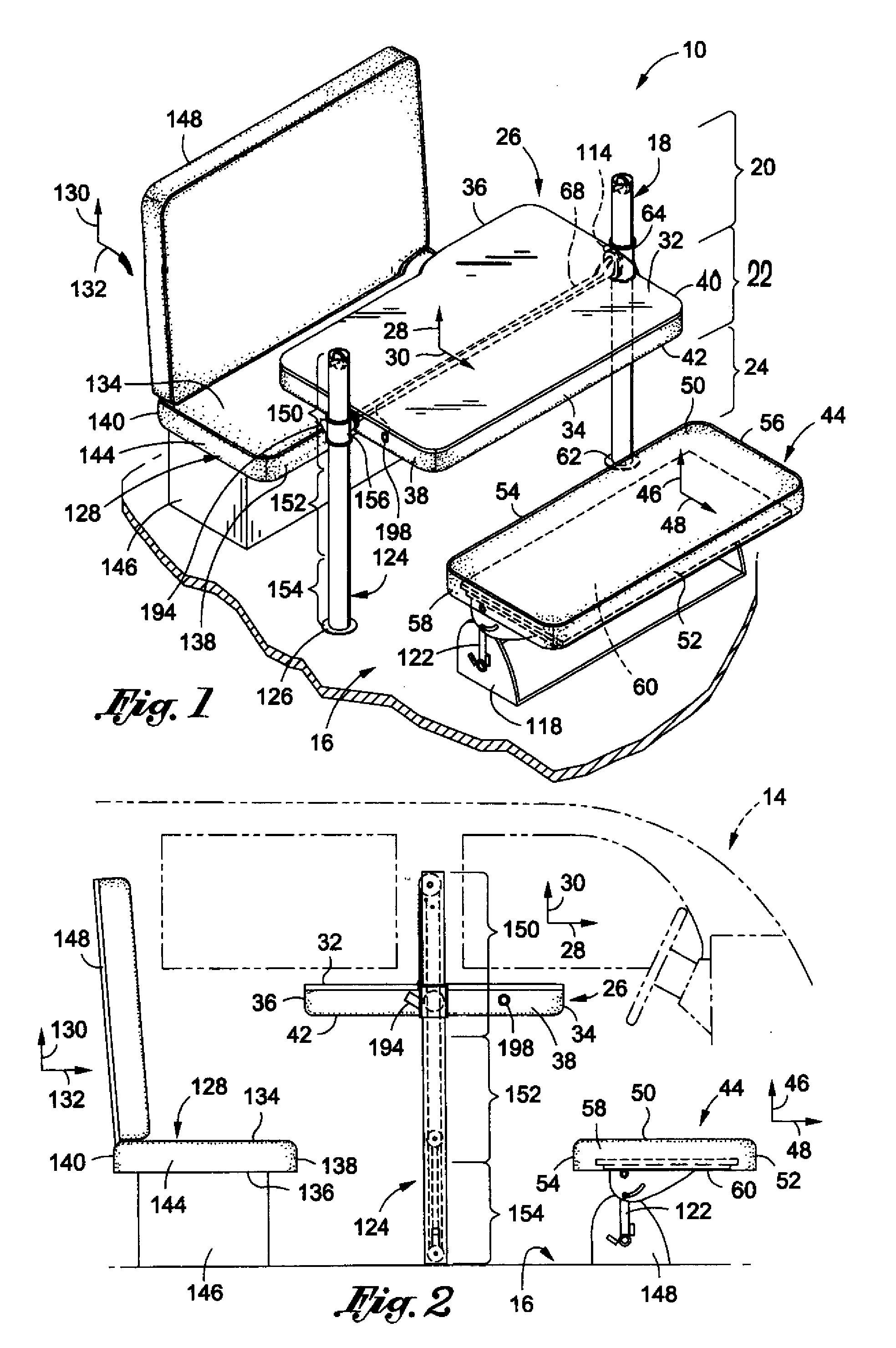

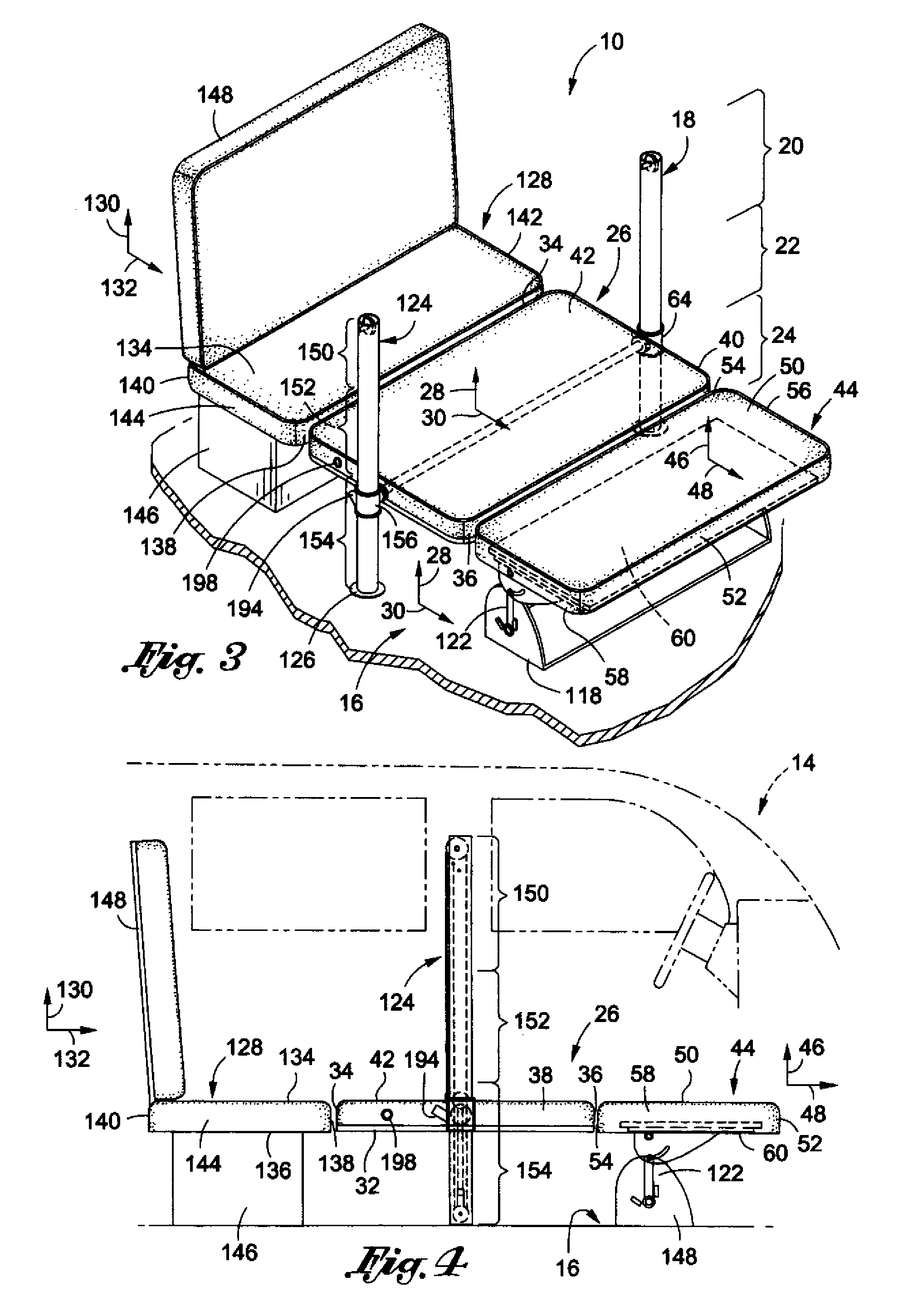

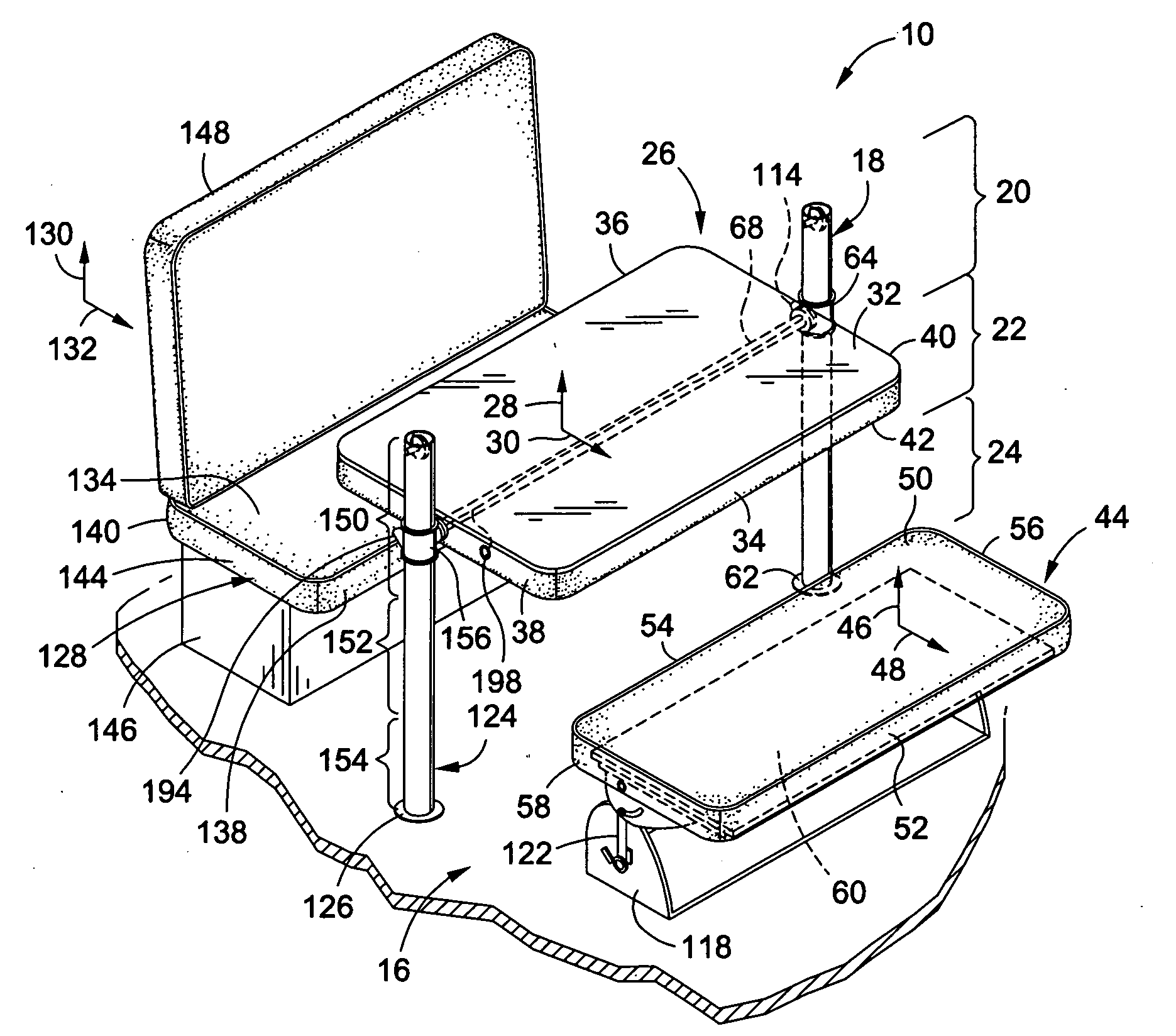

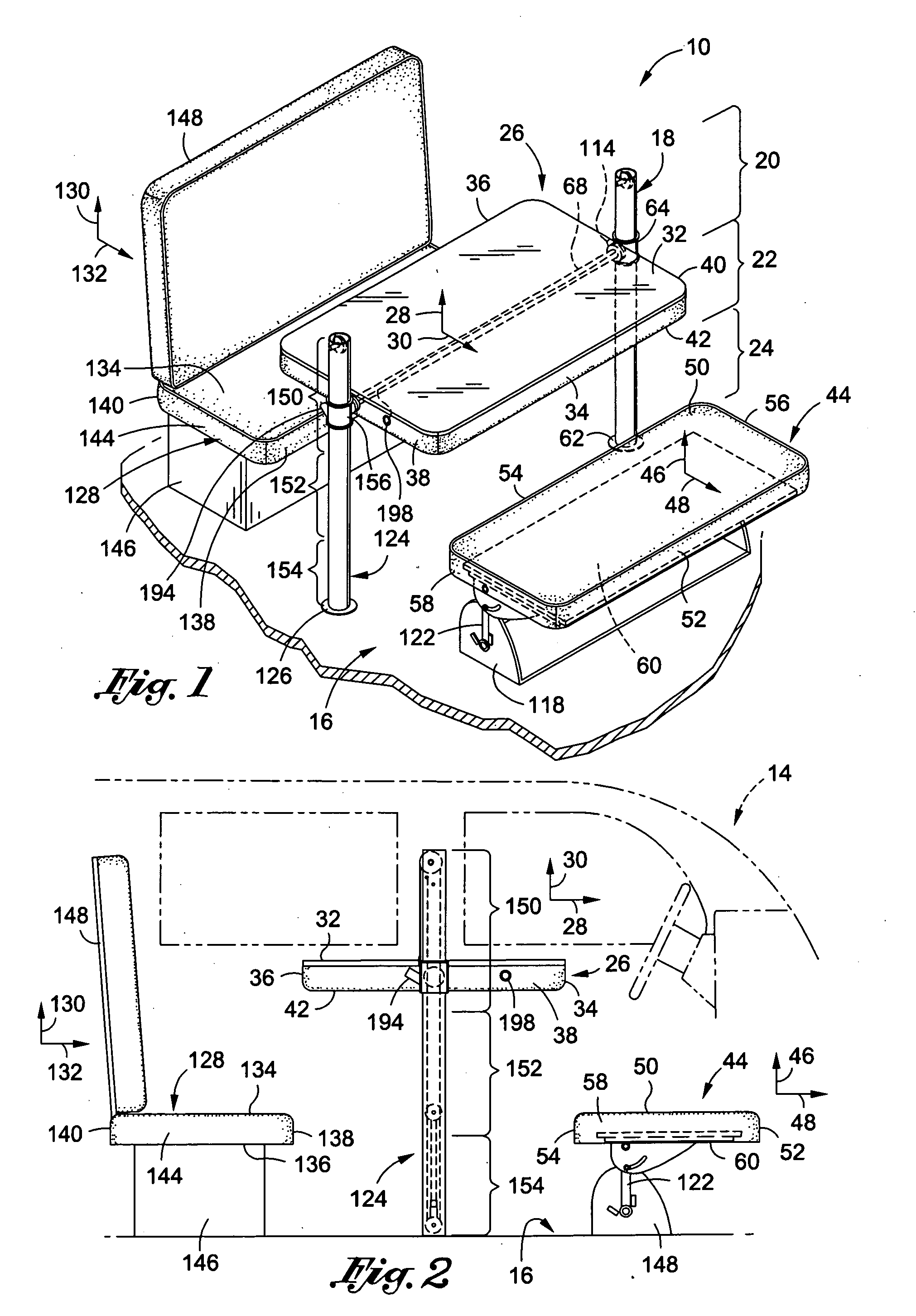

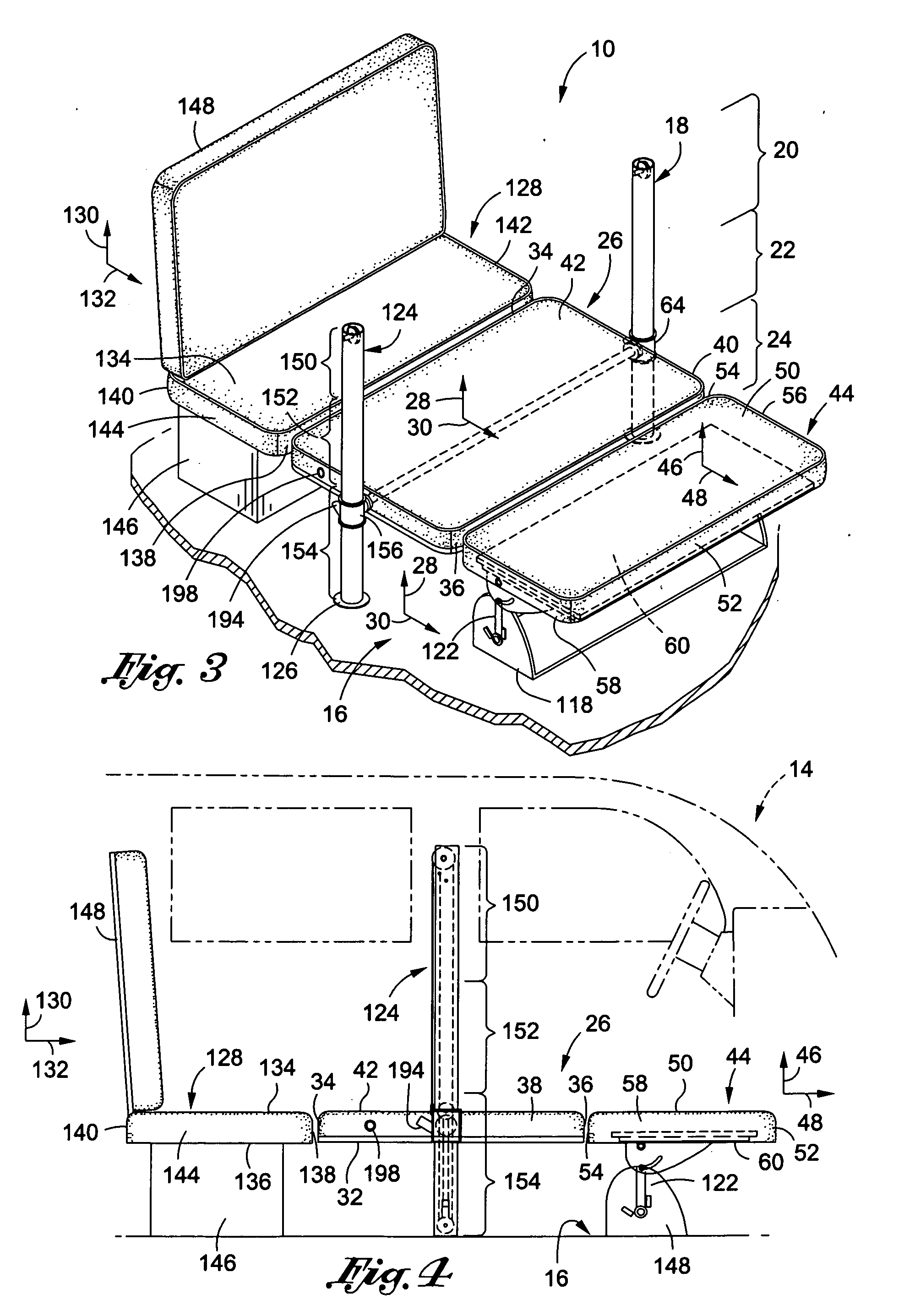

Multipurpose vehicle furniture system

InactiveUS20100201163A1Increase expensesExtension of timeVehicle seatsConvertible furnitureDriver/operatorEngineering

A multipurpose vehicle furniture system for use proximate to a vehicle driver's seat, the system comprising: a first post having a first post first end, a first post body, and a first post second end mountable to the floor of the vehicle; a primary support having a primary support longitudinal axis generally perpendicular to a primary support lateral axis, a primary support top surface, a primary support bottom surface, a primary support first longitudinal side rotatably and slidably engageable to the first post, a primary support second longitudinal side, a primary support first lateral side, and a primary support second lateral side, the primary support disposable in a first position, a second position, a third position, and a fourth position; a primary support rod; and a second support adjacent to the primary support with the primary support in the second position and the third position.

Owner:DUNKEL PETER LAWRENCE

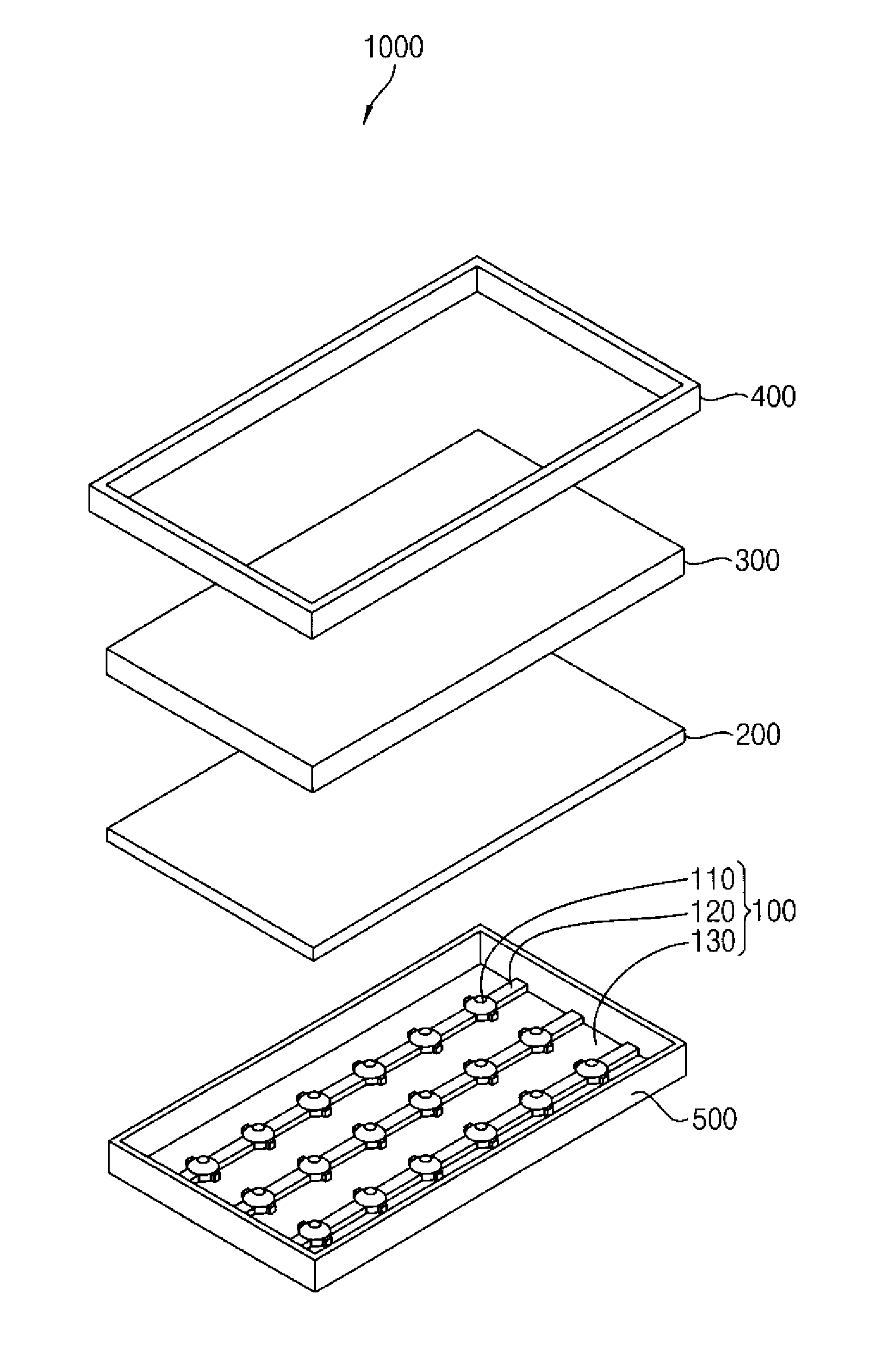

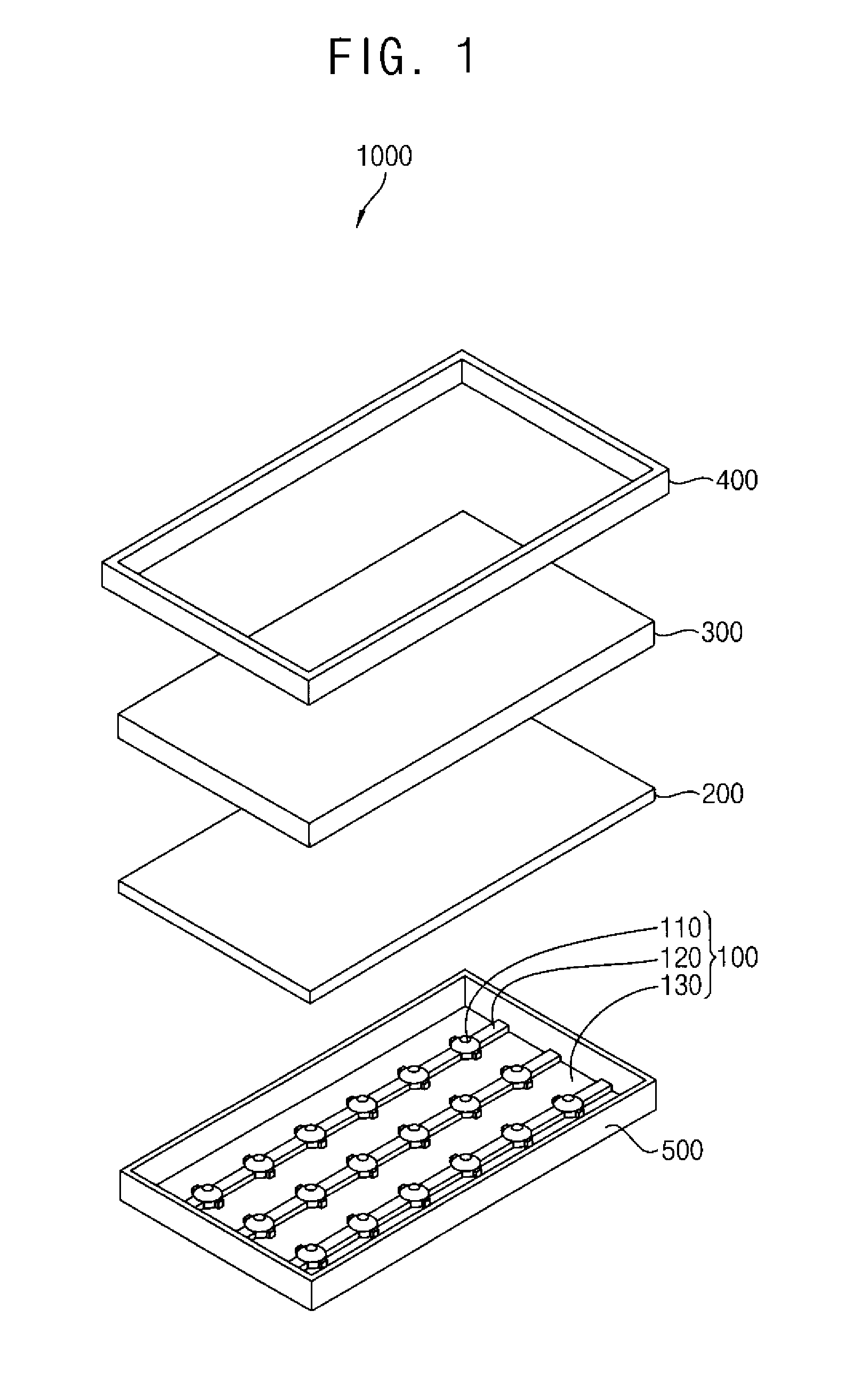

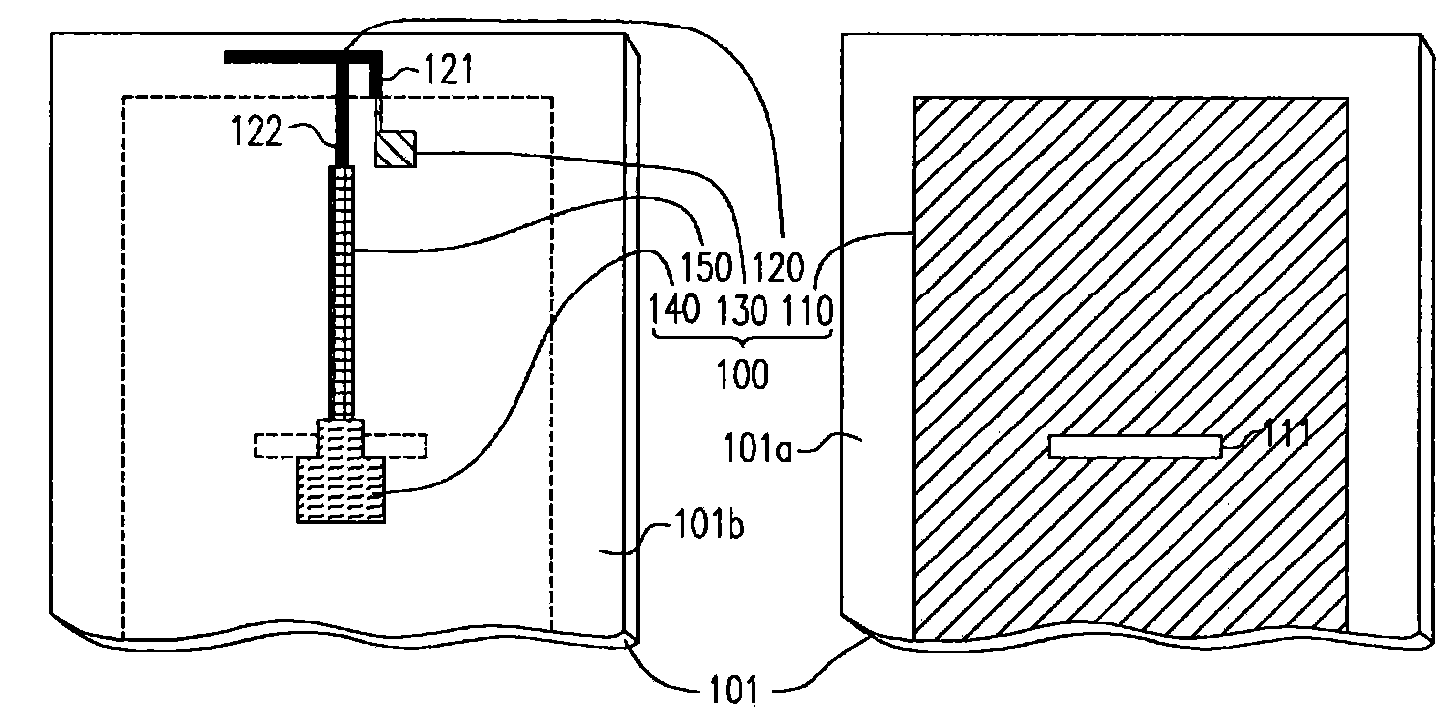

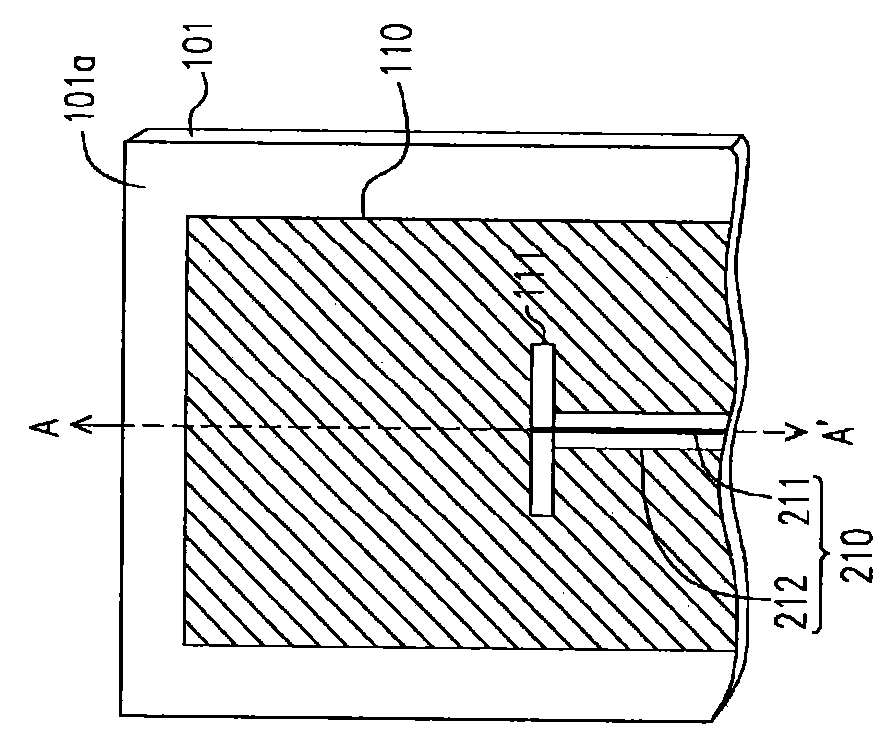

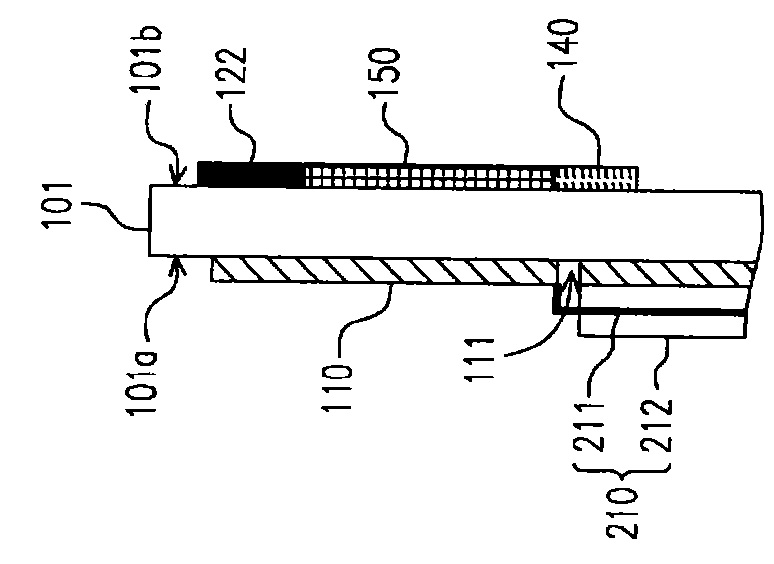

Lens, backlight assembly and display apparatus having the same

ActiveUS20130148333A1Increase material costReduce assemblyCondensersIlluminated signsBiomedical engineering

A lens includes an upper flat surface having a first outer diameter, a bottom surface having a second outer diameter and a third inner diameter, an external curved surface which connects the upper flat surface and the bottom surface, and an inner curved surface which protrudes toward the upper flat surface from the bottom surface at the third inner diameter.

Owner:SAMSUNG DISPLAY CO LTD

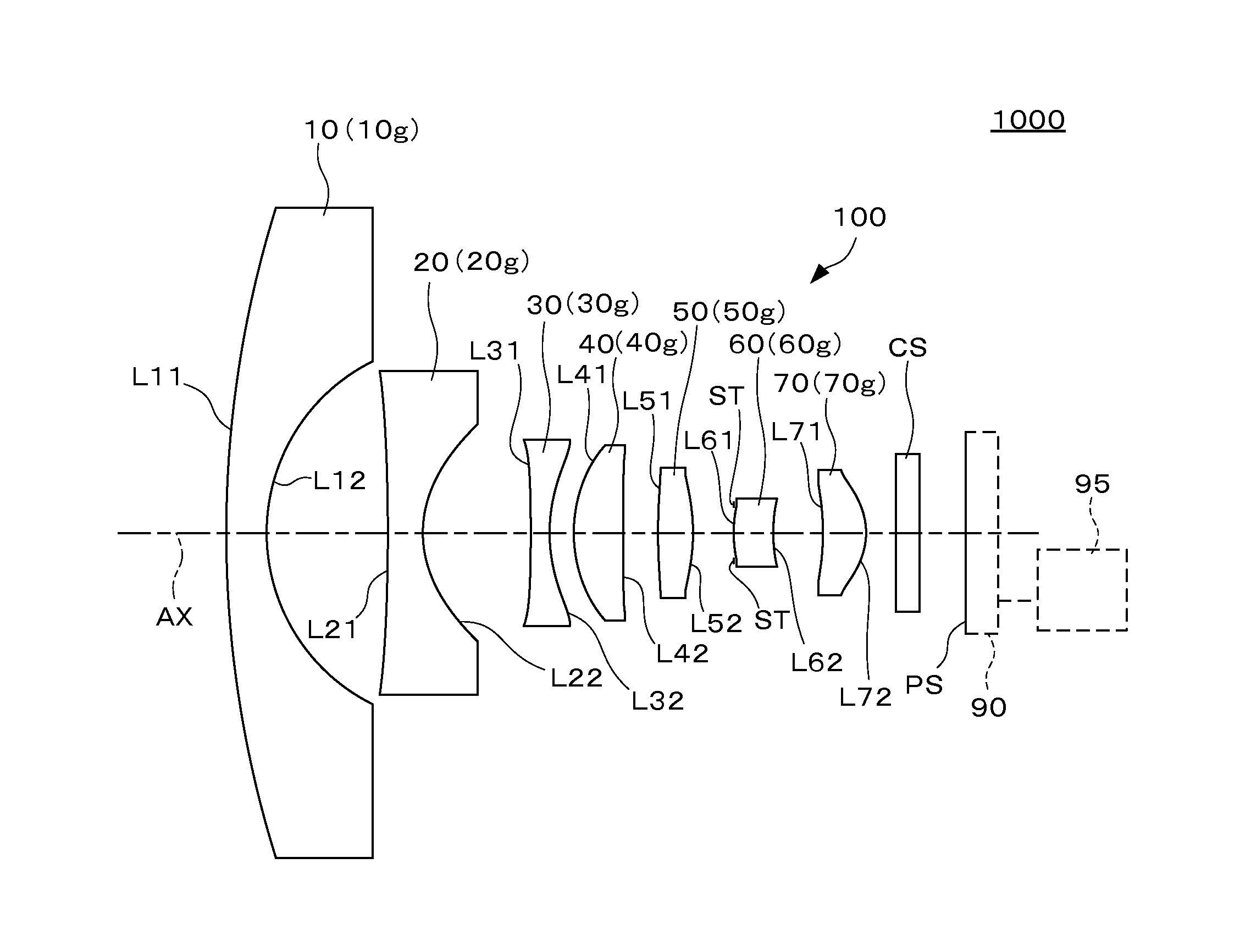

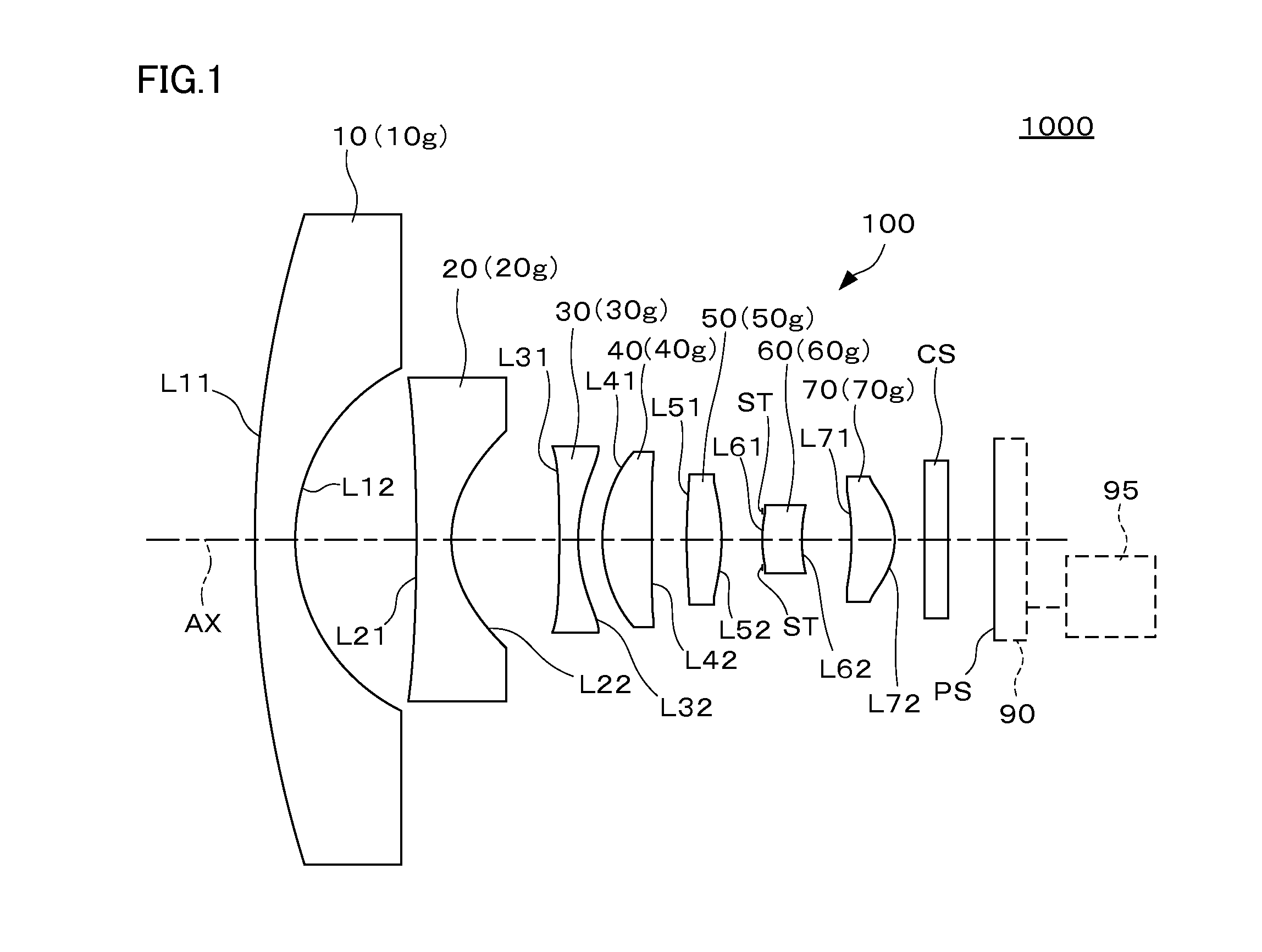

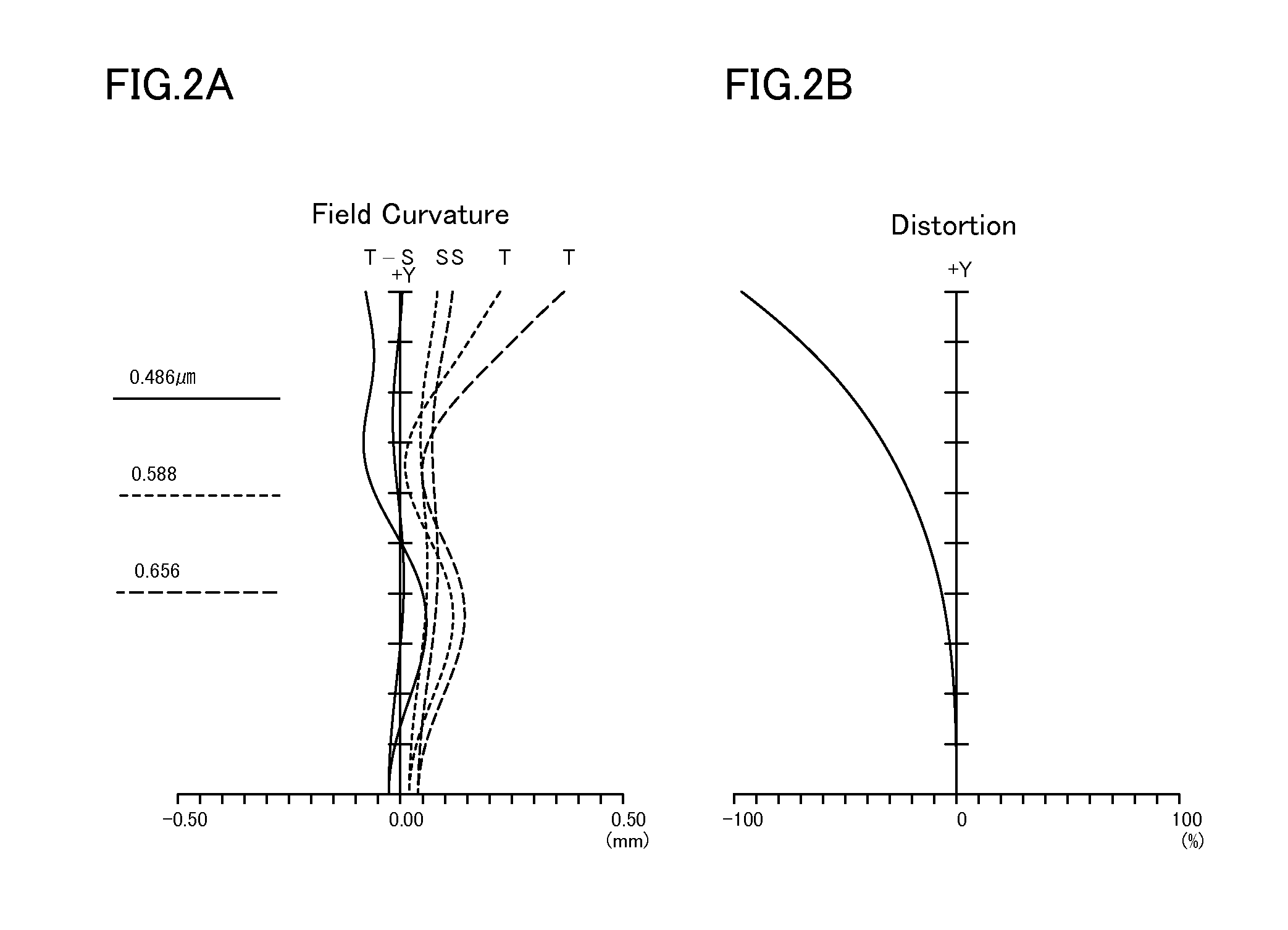

Imaging optical system and imaging equipment

ActiveUS20140293100A1Low costIncrease material costTelevision system detailsTelevision system scanning detailsProduction rateSolid-state

There are provided an imaging optical system and imaging equipment, which are compatible with a solid-state imaging device having a size of ½ inches or less and which include an optical system having a small size and lightness in weight and also having an excellent mass productivity and a low cost while keeping optical performance at a wide field angle, for example, at a total angle of view of 80 degrees or more. When predetermined conditions are satisfied for a plurality of lenses constituting the imaging optical system, the absolute value of power of each lens group is suppressed to be small, and thus the generation of aberration is suppressed and a preferable aberration is obtained.

Owner:SASAYA TOSHIHIRO

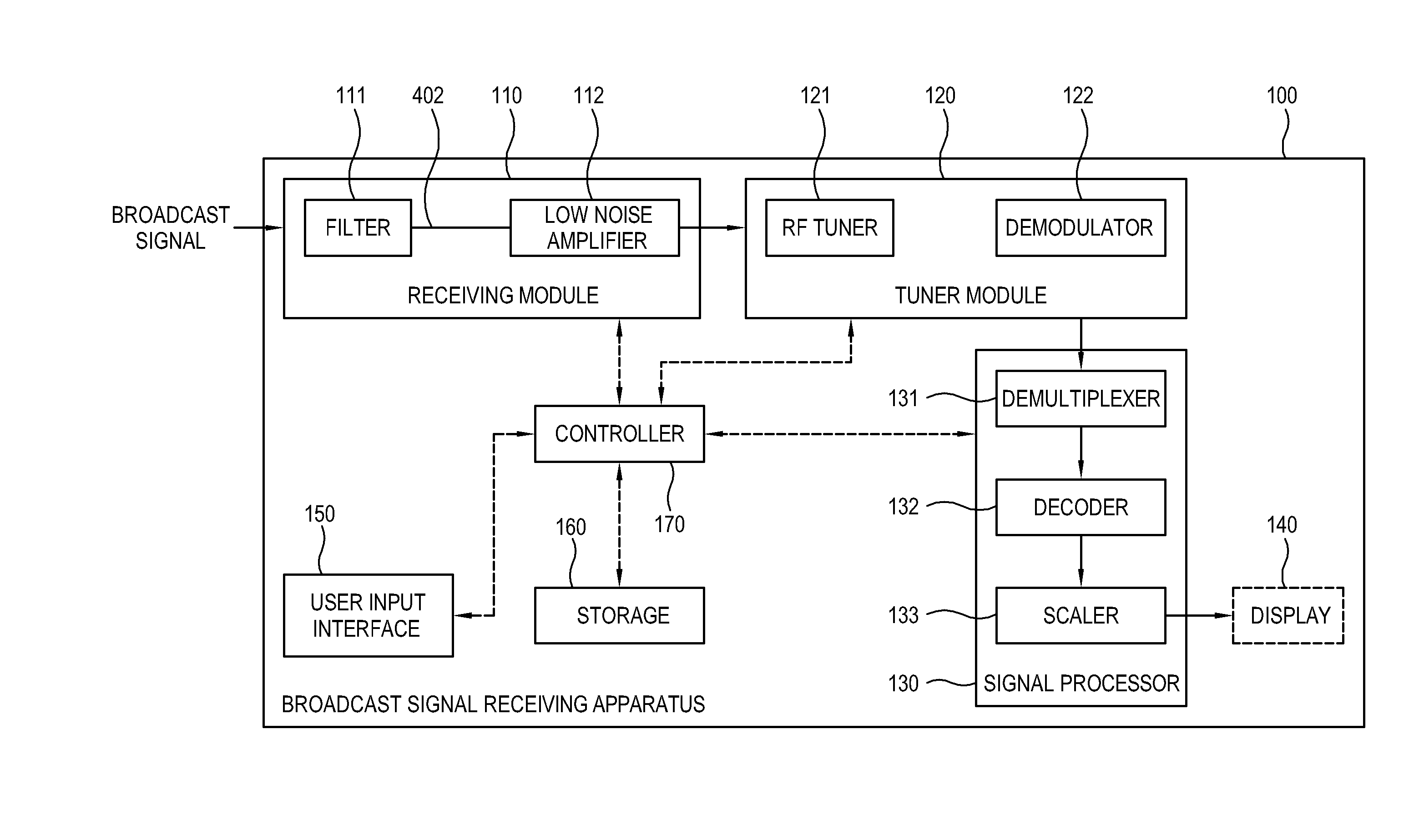

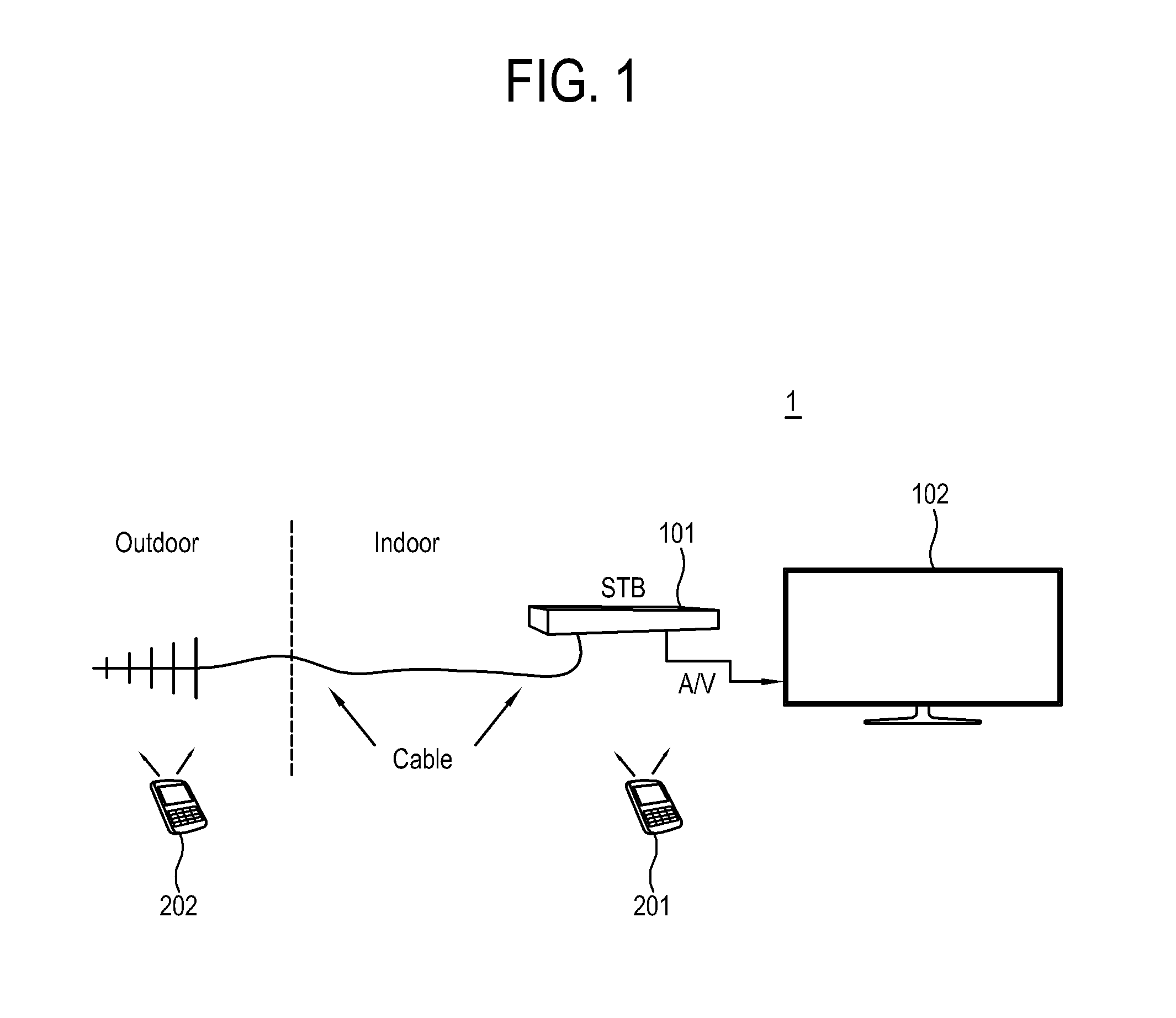

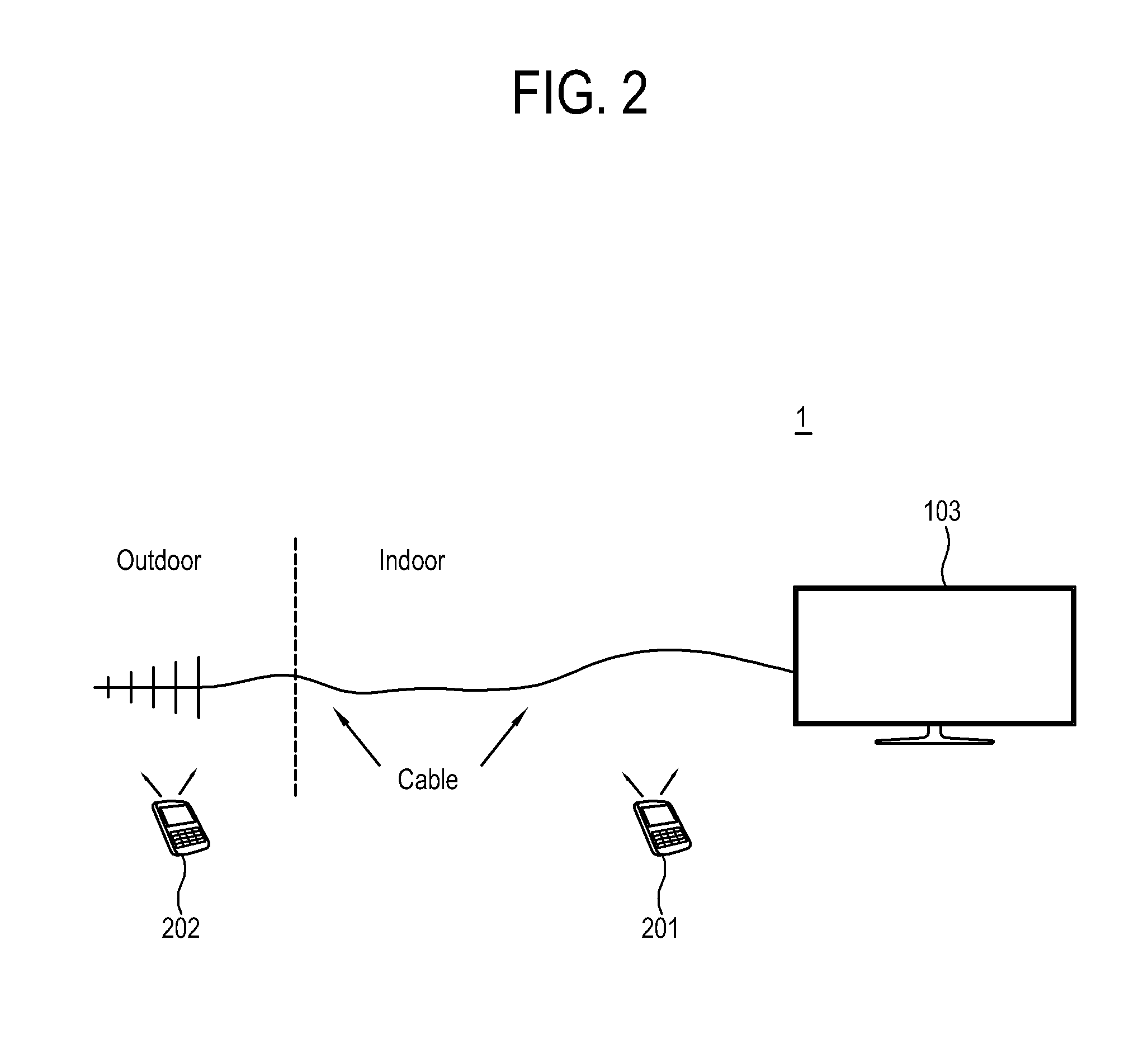

Broadcast signal receiving apparatus and multi-layer printed circuit board

InactiveUS20160365882A1Increase material costReduce distortion problemsTransmissionTransmission linePrinted circuit board

A broadcast signal receiving apparatus, including a multi-layer printed circuit board comprising a transmission line configured to connect with at least one component mounted on the multi-layer printed circuit board, the at least one component being configured to process a broadcast signal received from an outside of the apparatus through a cable, wherein a signal line for receiving the broadcast signal is at least partially provided on an inner layer of the multi-layer printed circuit board.

Owner:SAMSUNG ELECTRONICS CO LTD

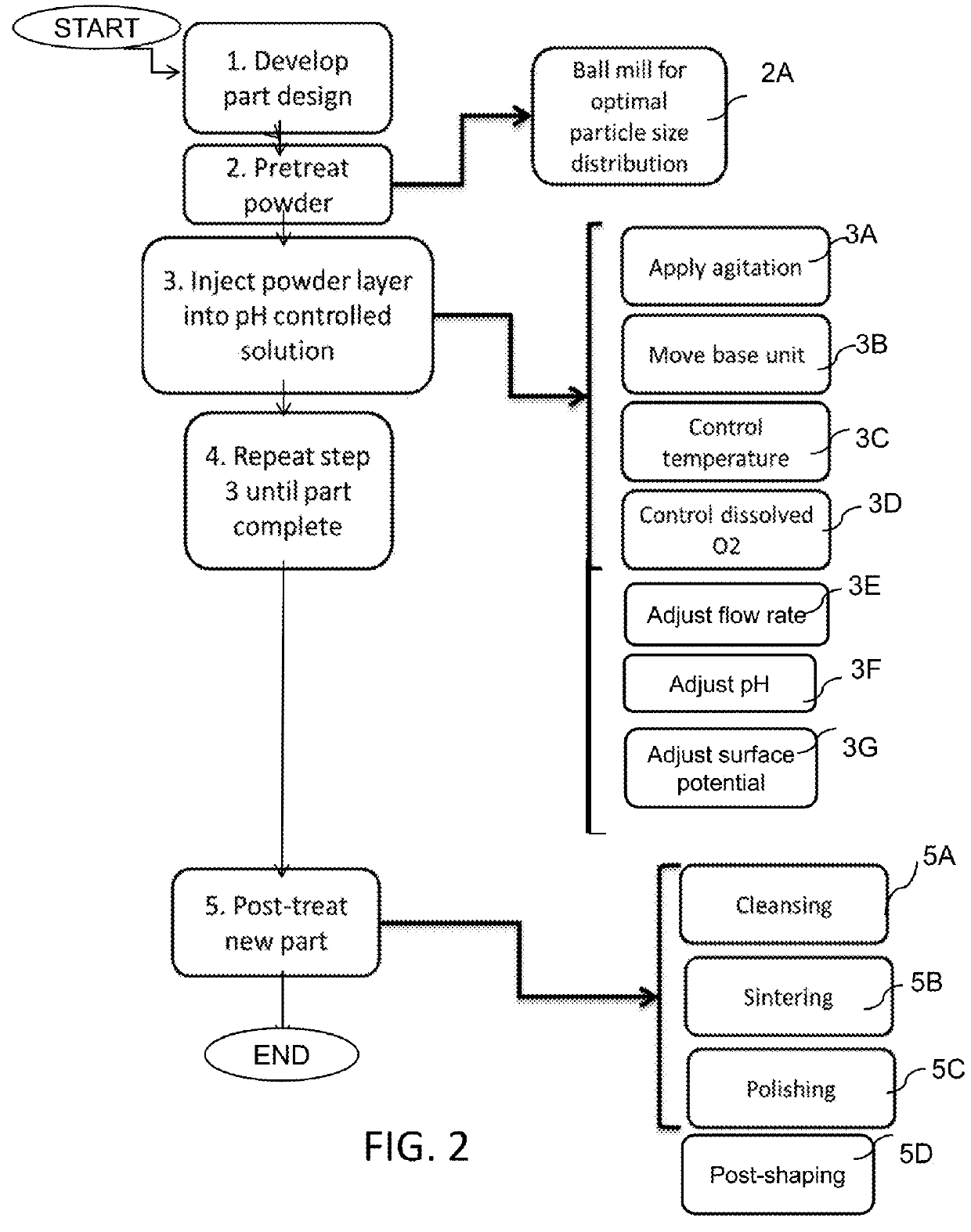

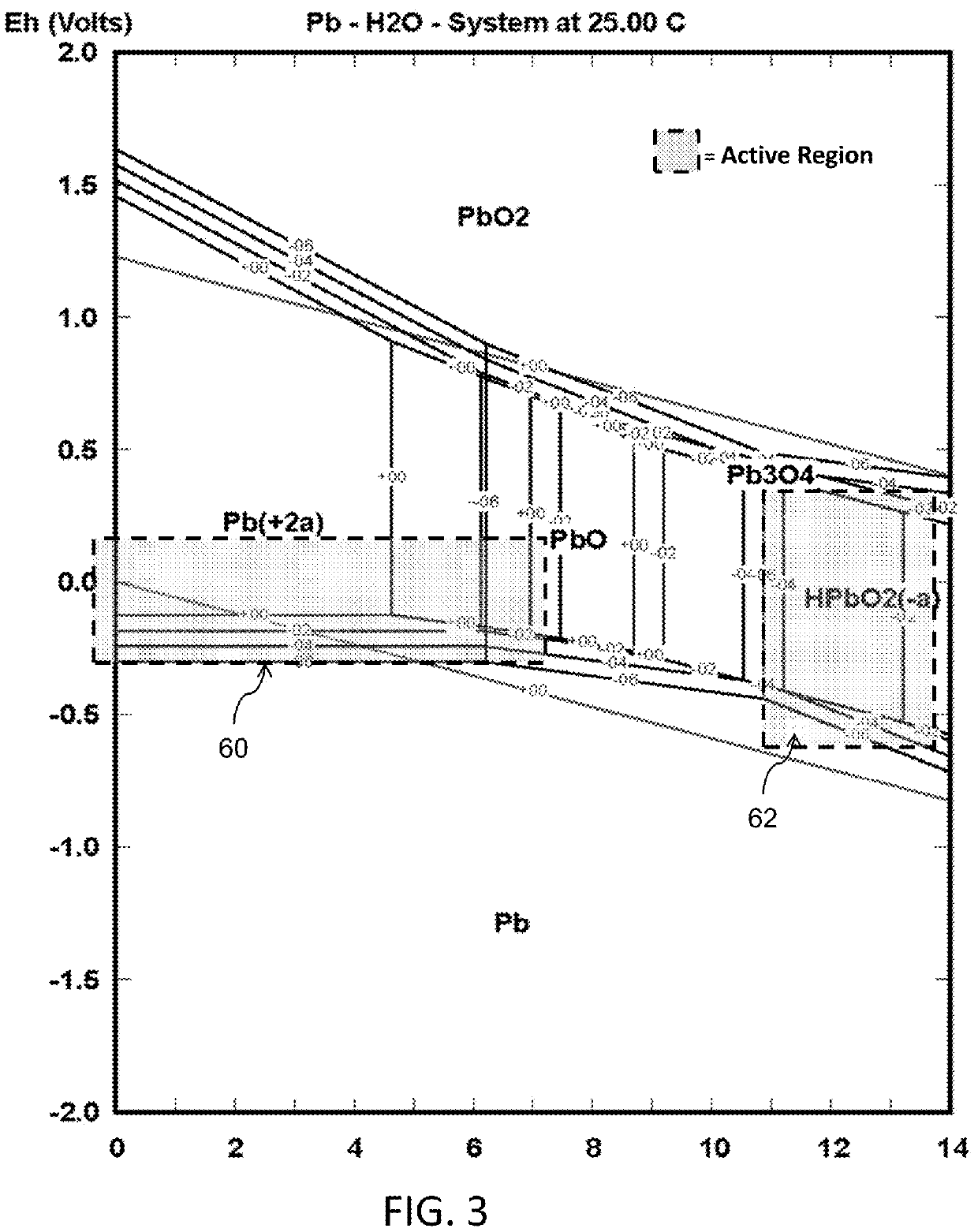

Method for additive manufacturing using pH and potential controlled powder solidification

ActiveUS9248501B1Increase material costTransportation and packagingMetal-working apparatusMetal particleDissolution

A powder consolidation method and apparatus make use of corrosion processes occurring on surfaces of metal particles to consolidate a metal-containing powder into a formed body. The method includes contacting metal particles with an acidic or basic liquid at a pH and potential at which dissolution of metal from the particles and reduction of soluble metal-containing ions to metal on surfaces of the particles can co-occur, such that the metal powder agglomerates to form a body.

Owner:UNITED STATES OF AMERICA

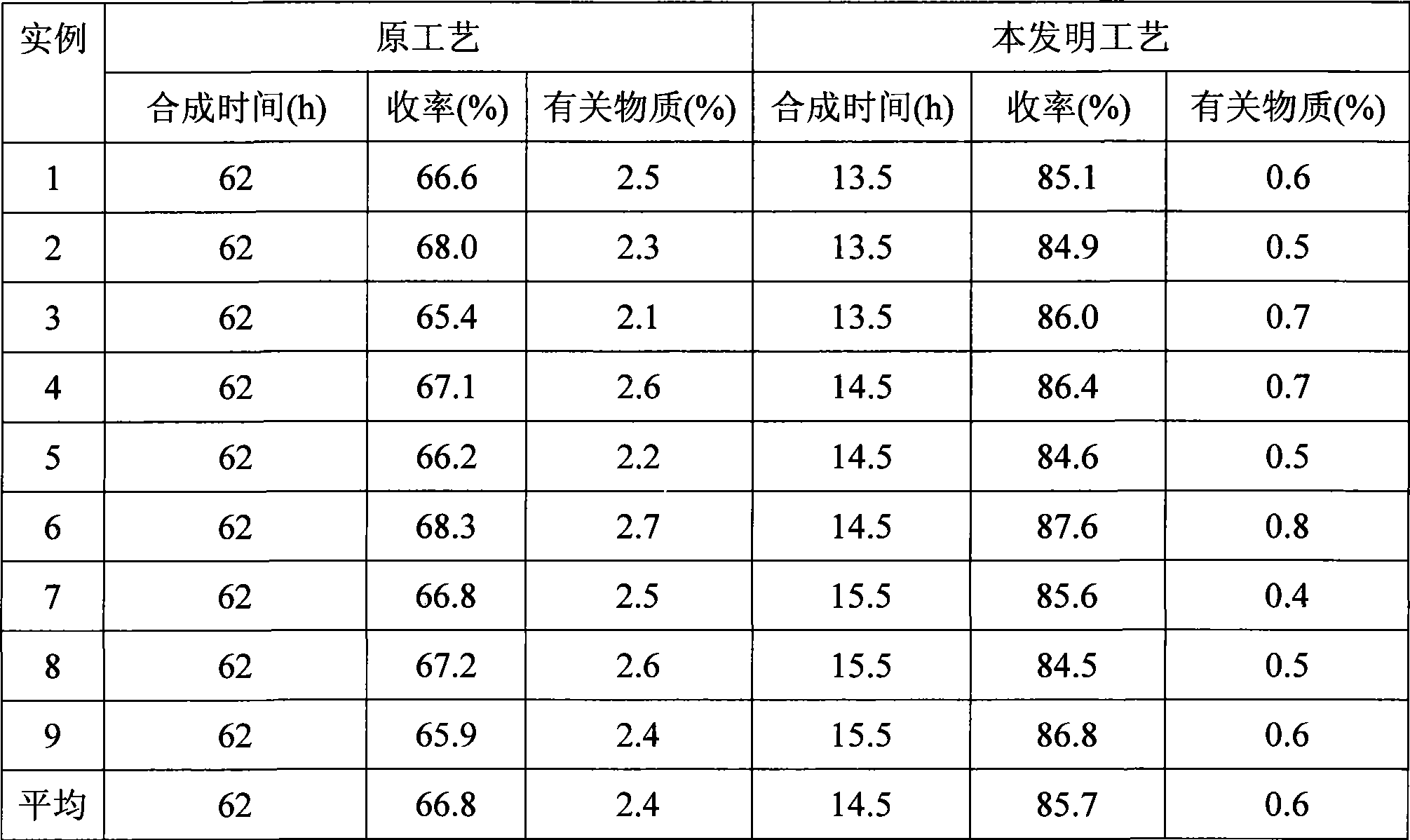

Preparation of aceglutamide

ActiveCN101434559AIncrease labor costIncrease material costOrganic compound preparationCarboxylic acid amides preparationAlcoholFiltration

The invention provides a preparation method of acetylglutamine, which includes the steps of acylation neutralization reaction, refining, drying and the like. Based on the original technology, the preparation method saves the technological processes of drying, heating and dissolving crude products. After neutralization reaction, filtration and the preparation of the crude products, alcohol is directly used for dissolving crystals and an end product is obtained by drying. The preparation method is simple, and has low cost, high product yield and good quality. All indicators are fully consistent with the existing quality standards; therefore, the preparation method is applicable to industrialized production.

Owner:SHANGHAI ZHAOHUI PHARMA +1

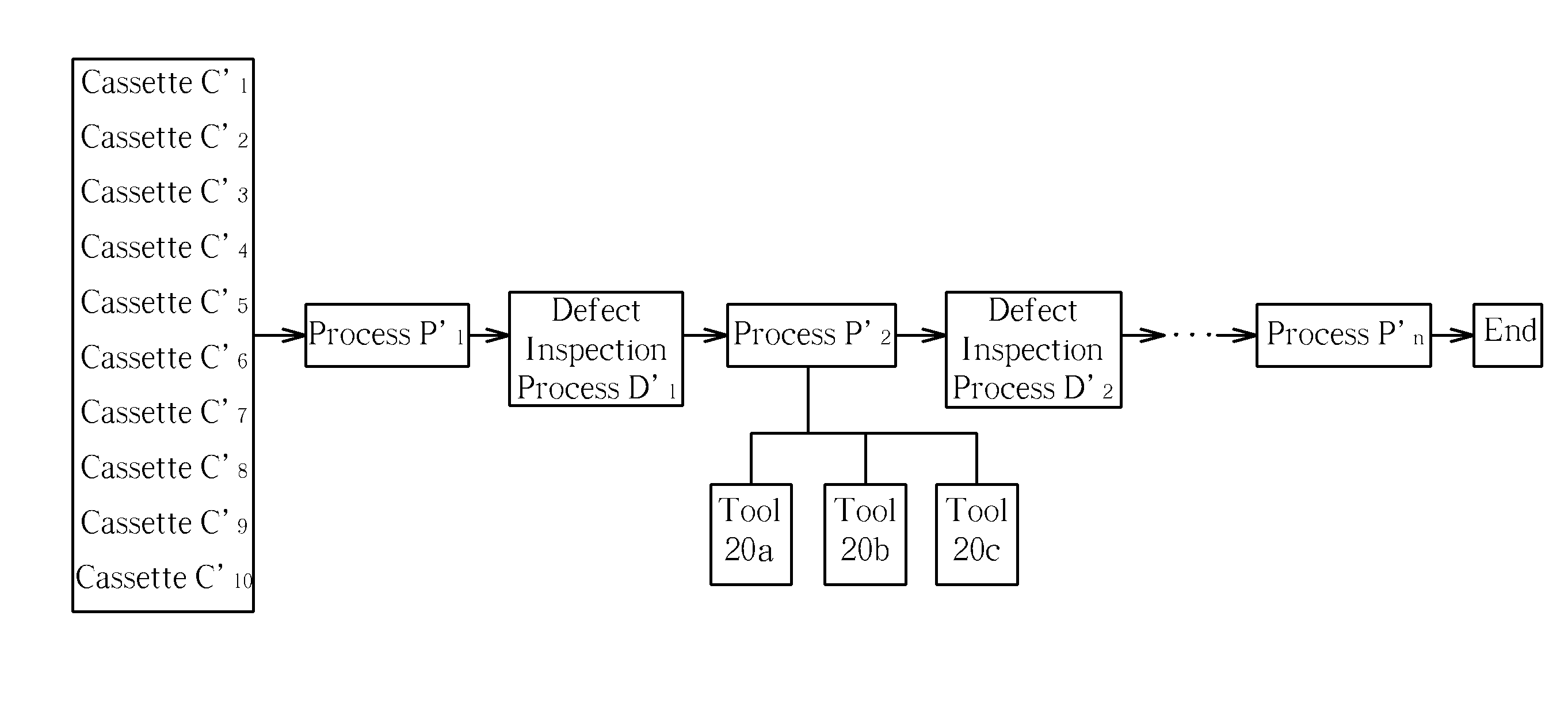

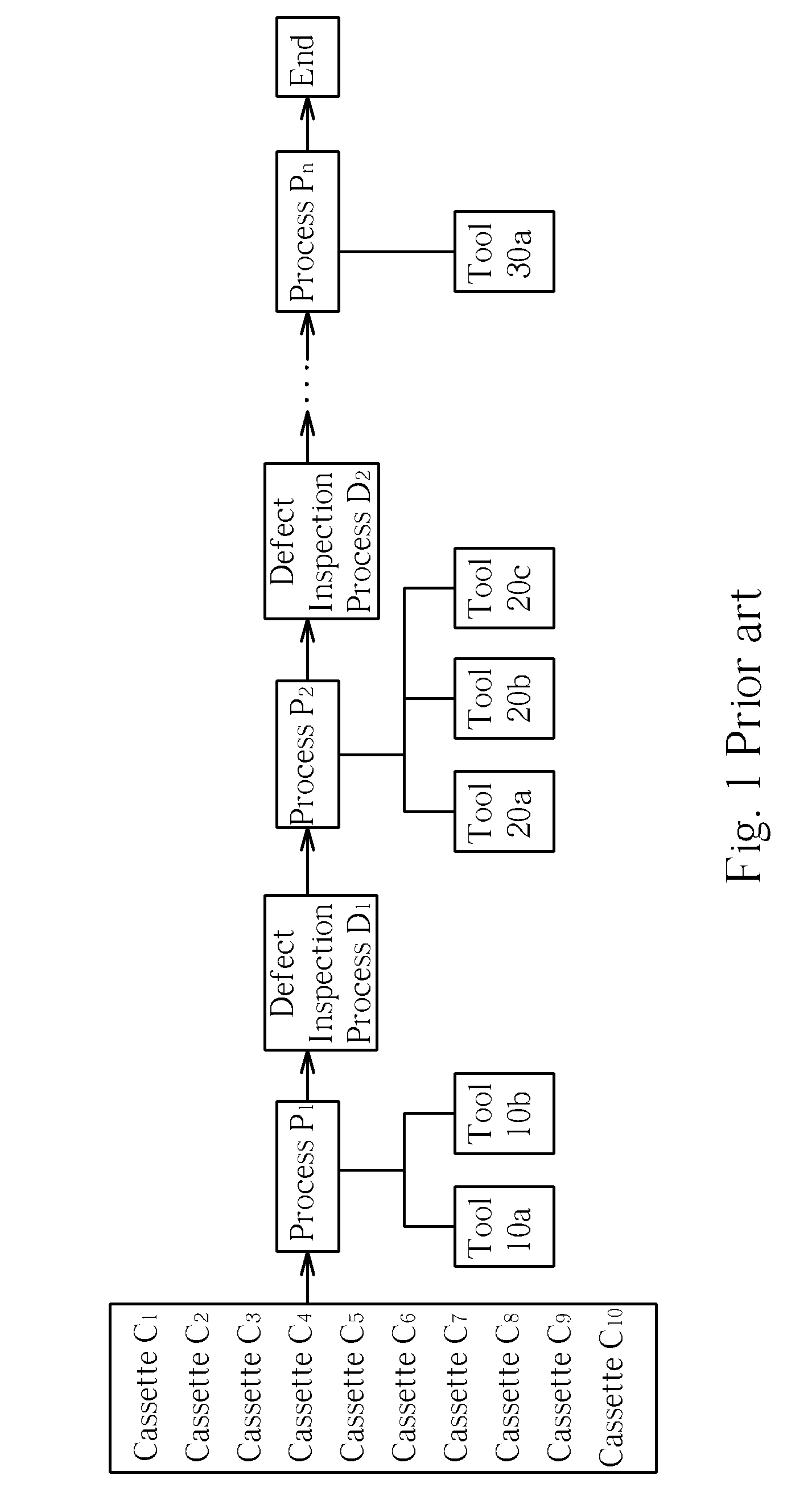

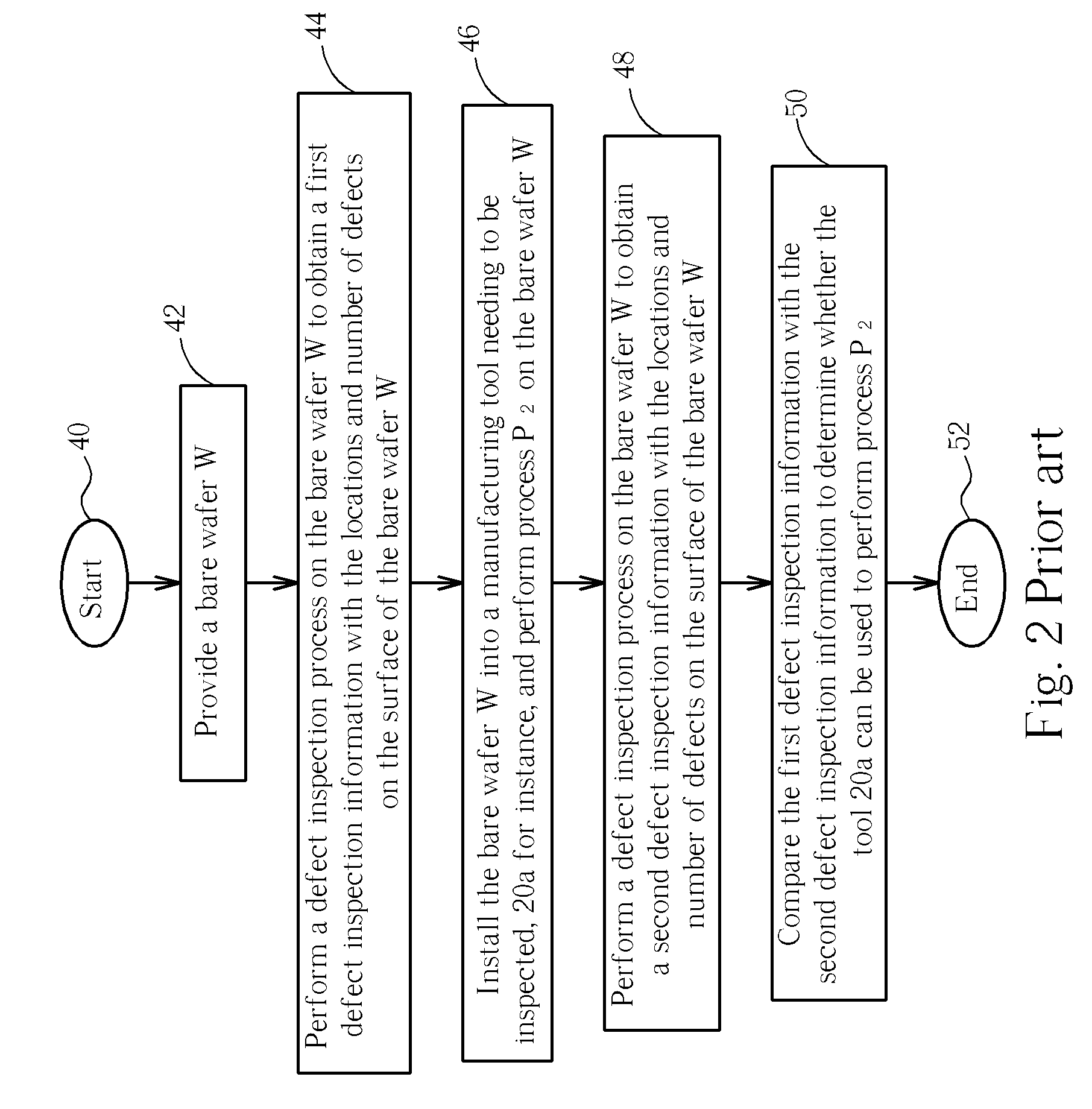

Method of defect inspection

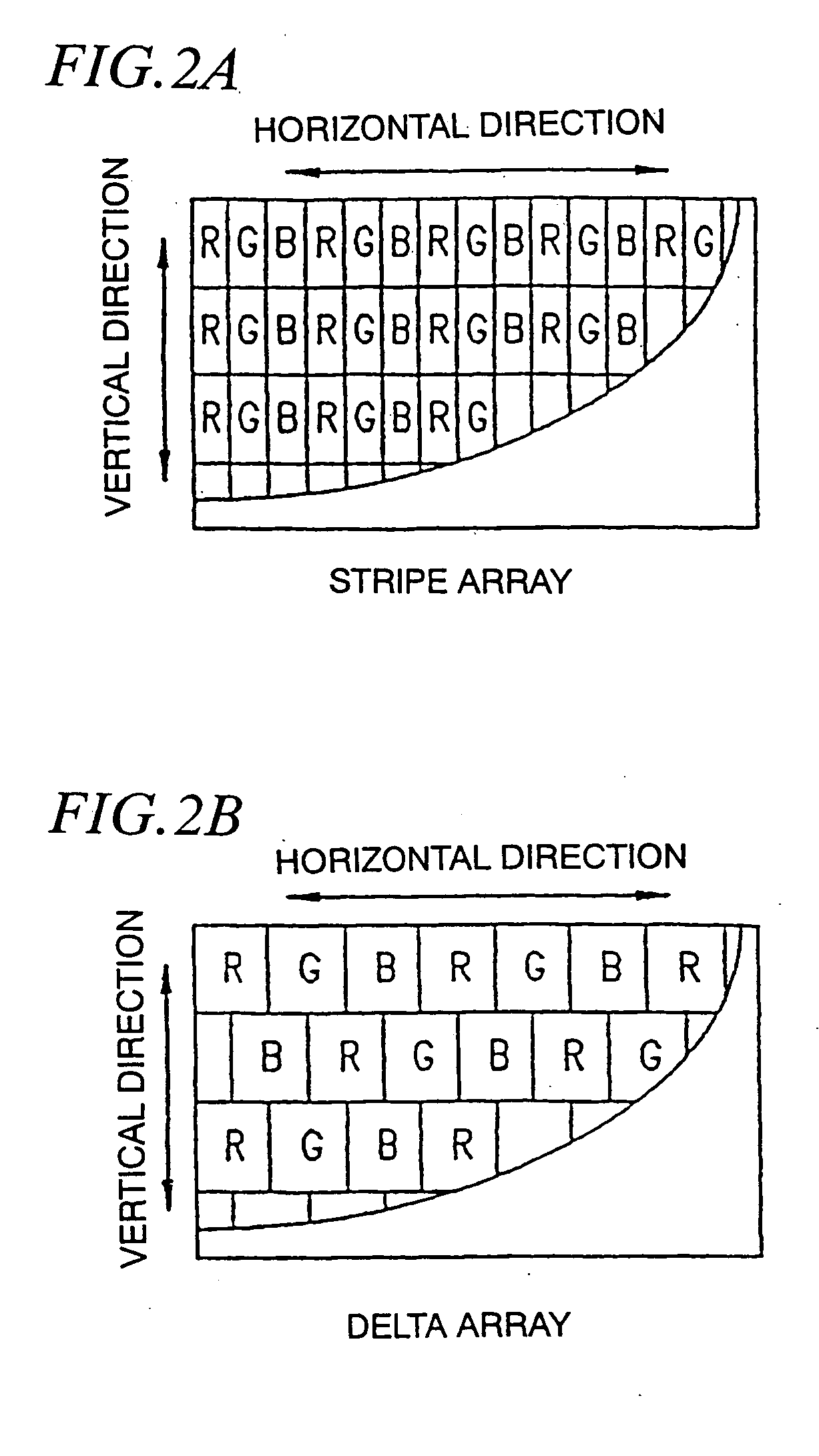

ActiveUS20050248756A1Quick responseAvoid redundancySemiconductor/solid-state device testing/measurementMaterial analysis by optical meansEngineeringMechanical engineering

A plurality of cassettes, each having a plurality of wafers respectively having a first defect information, is selected. Each of the cassettes is then assigned to a corresponding tool having at least one reaction chamber, and the wafers are substantially equally assigned to the reaction chambers. A first process is then performed on each of the wafers in the reaction chamber. Finally, a first defect inspection process is performed on each of the wafers.

Owner:POWERCHIP SEMICON MFG CORP

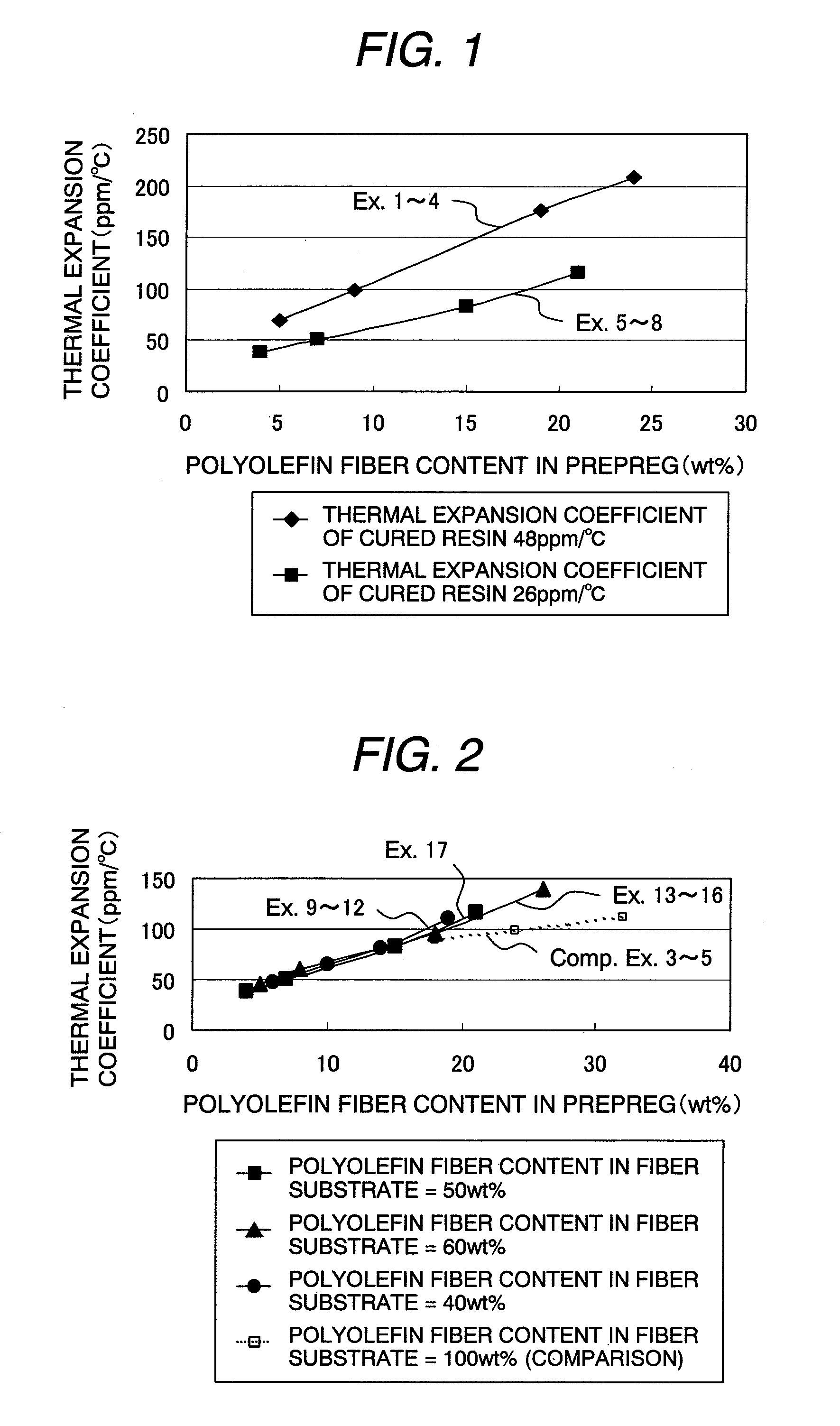

Prepreg and its application products for low thermal expansion and low dielectric tangent

ActiveUS20090178832A1Reduction factorIncrease material costSynthetic resin layered productsPrinted circuit manufactureGlass fiberPolyolefin

A prepreg comprising composite woven cloth or non-woven cloth composed of glass fiber and polyolefin fiber that are a main part of the cloth and a thermosetting resin composition that gives a cured product having a low thermal expansion coefficient, wherein the thermal expansion coefficient of the cured resin composition at 50 to 100 ° C. is 50 ppm / ° C. or less. A printed circuit board, multi layered circuit board, and electronic part are disclosed.

Owner:HITACHI CHEM CO LTD

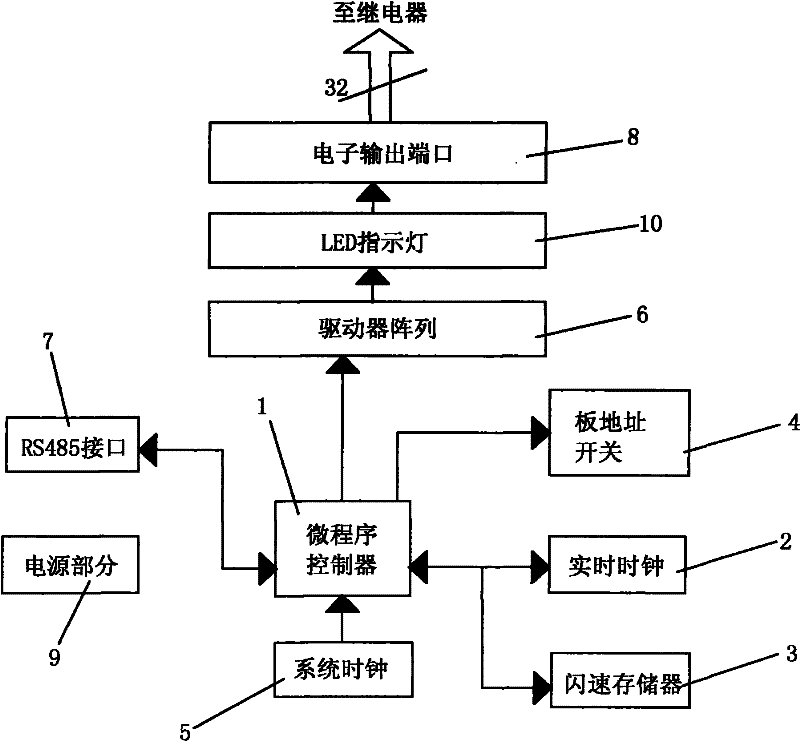

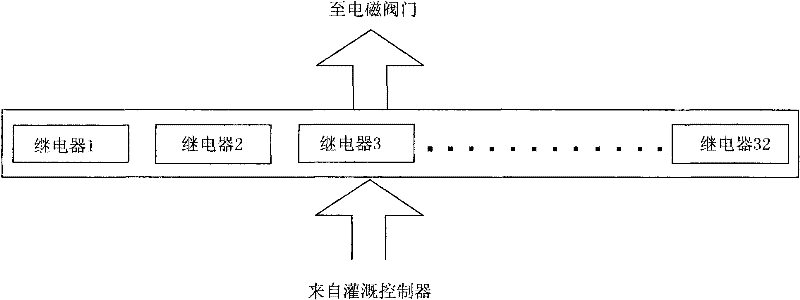

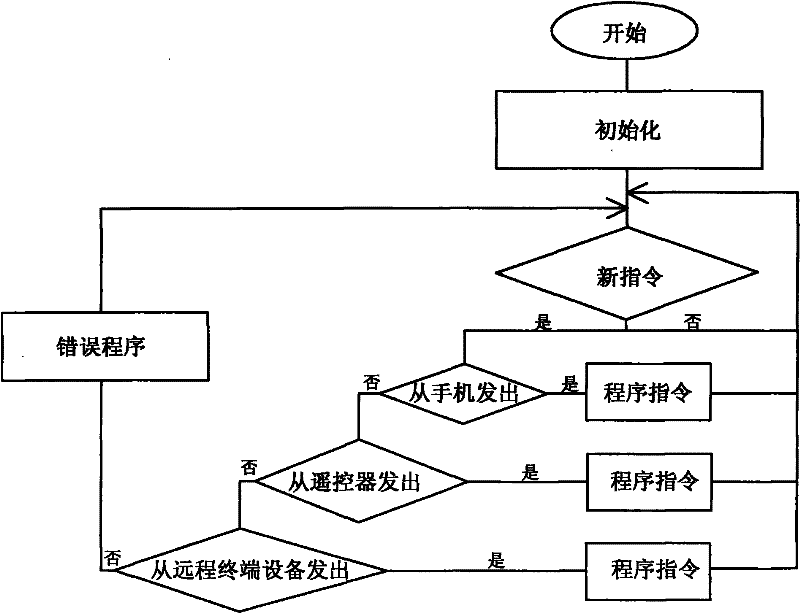

Satellite irrigation system controller

InactiveCN102200767AAvoid wastingStrong targetingWatering devicesCultivating equipmentsWireless controlEngineering

The invention relates to a remote irrigation control system, more particularly to a satellite irrigation system controller with wireless control. The controller includes three parts: power, central control, and signal output. The central control part is a microprogram control unit, and an output terminal of the microprogram control unit is connected with a board address switch and a driver array. The driver array is output to a relay board through an electronic output terminal. The input port and output port of the microprogram control unit are connected with an RS485 interference as well as a real-time clock and a flash memory, and the power part provides direct-current power supply of 12V for the microprogram control unit. The satellite irrigation system controller provided in the invention has a function of directly sending a digital controlled signal to unlatch or close an electromagnetic valve for normal irrigation one by one or selectively. Therefore, pertinency for irrigation is stronger, so that the waste of precious water resource is avoided. Meanwhile, increase of manual labor and material resources brought about by cable laying can be avoided, so that the cost is substantially reduced.

Owner:SHENZHEN CSC LANDSCAPE ENG & DESIGN

Integrated molding safety helmet and method for producing the same

The invention provides an integral safety helmet. A precasting hard outer helmet is directly injected with poly-long particles to form a soft inner helmet through heating and pressurizing, and both helmets are integrally formed and closely and firmly jointed into the safety helmet without gap. The making steps of the integral safety helmet comprise: sheathing a formed shell of the hard outer helmet onto an upper mould; matching the upper mould and a lower mould according to the sequence, heating the moulds to soften the outer helmet made of compound materials, pressurizing the outer helmet to discharge redundant resin in the outer helmet made of the compound materials, ejecting, foaming, pressurizing and cooling the poly-long particles in an inner concave cavity of the matched moulds after reducing the temperature and cooling, and then demoulding to make the soft inner helmet integrally formed in the hard outer helmet.

Owner:王泽平

Method for preparing low-turbidity instant tea

InactiveCN102228104ATo achieve clarity and transparencyReduced service lifeTea extractionAdditive ingredientUltrafiltration

The invention discloses a method for preparing low-turbidity instant tea. The method comprises the following steps of: adding a solvent into tea and extracting, and performing solid-liquid separation to obtain tea extracting solution; cooling the tea extracting solution to below 80 DEG C, adding aqueous solution of polyacrylamide, and fully mixing uniformly; and performing solid-liquid separation on mixed liquid, concentrating obtained clear liquid, sterilizing, and drying to obtain an instant tea product which is clarified and perfectly clear and has less bitter taste and of which the turbidity is less than or equal to 50NTU. Raw materials of the low-turbidity instant tea can be various kinds of tea such as greet tea, oolong tea or black tea and the like, so the source of the raw materials is rich and the raw materials are easy to obtain. In the method, the low-turbidity instant tea product which is clarified and perfectly clear and has less bitter taste and better mouthfeel and of which the turbidity is less than 50NTU is obtained by adding the polyacrylamide to flocculate insoluble ingredients in the tea extracting solution and synchronously remove partial macromolecular ester catechins with heavier bitter taste, and not using commonly used filtration processes such as ultrafiltration, membrane filtration and the like. The process is simple; and the method is easy to operate and is suitable for industrialized large-scale production.

Owner:南京融点食品科技有限公司

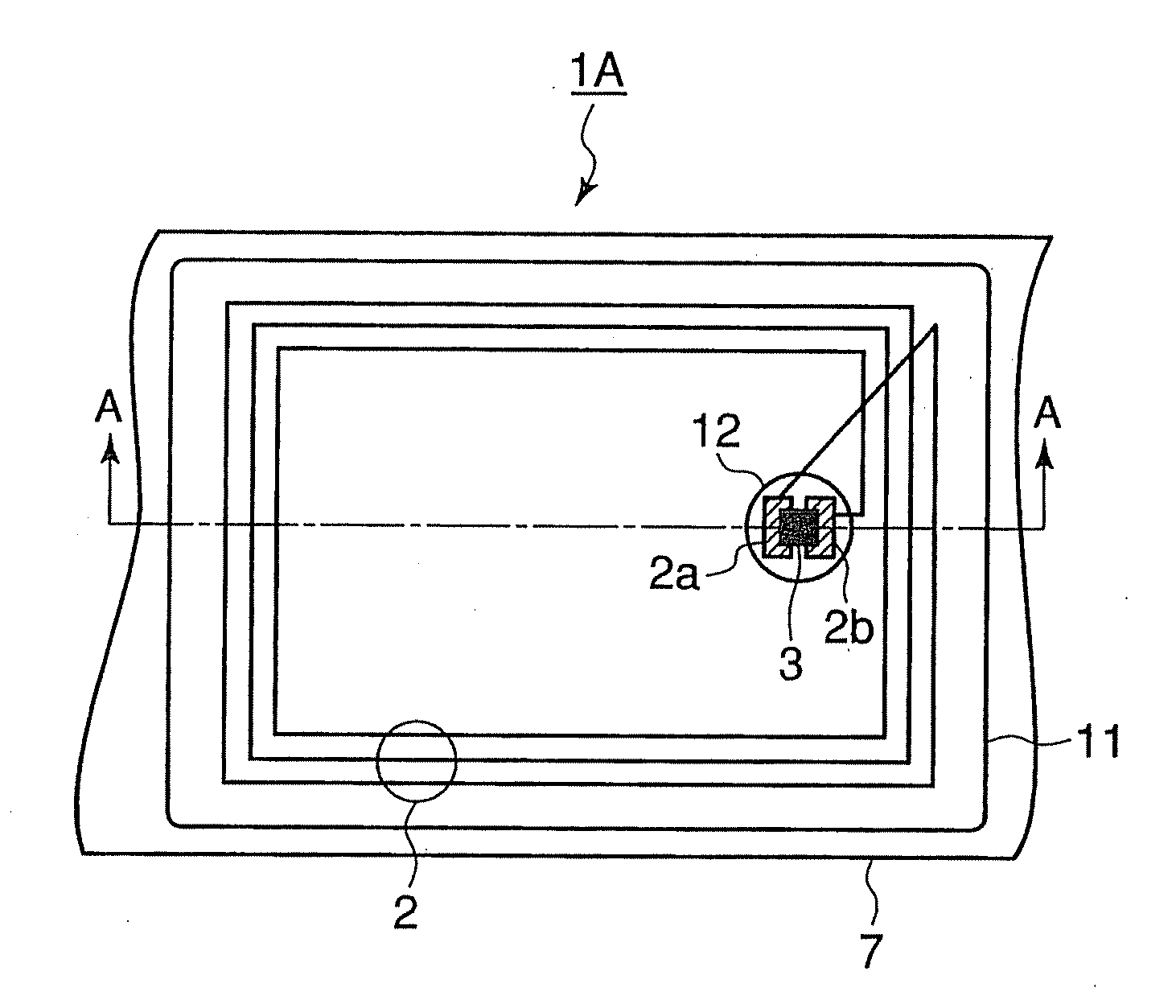

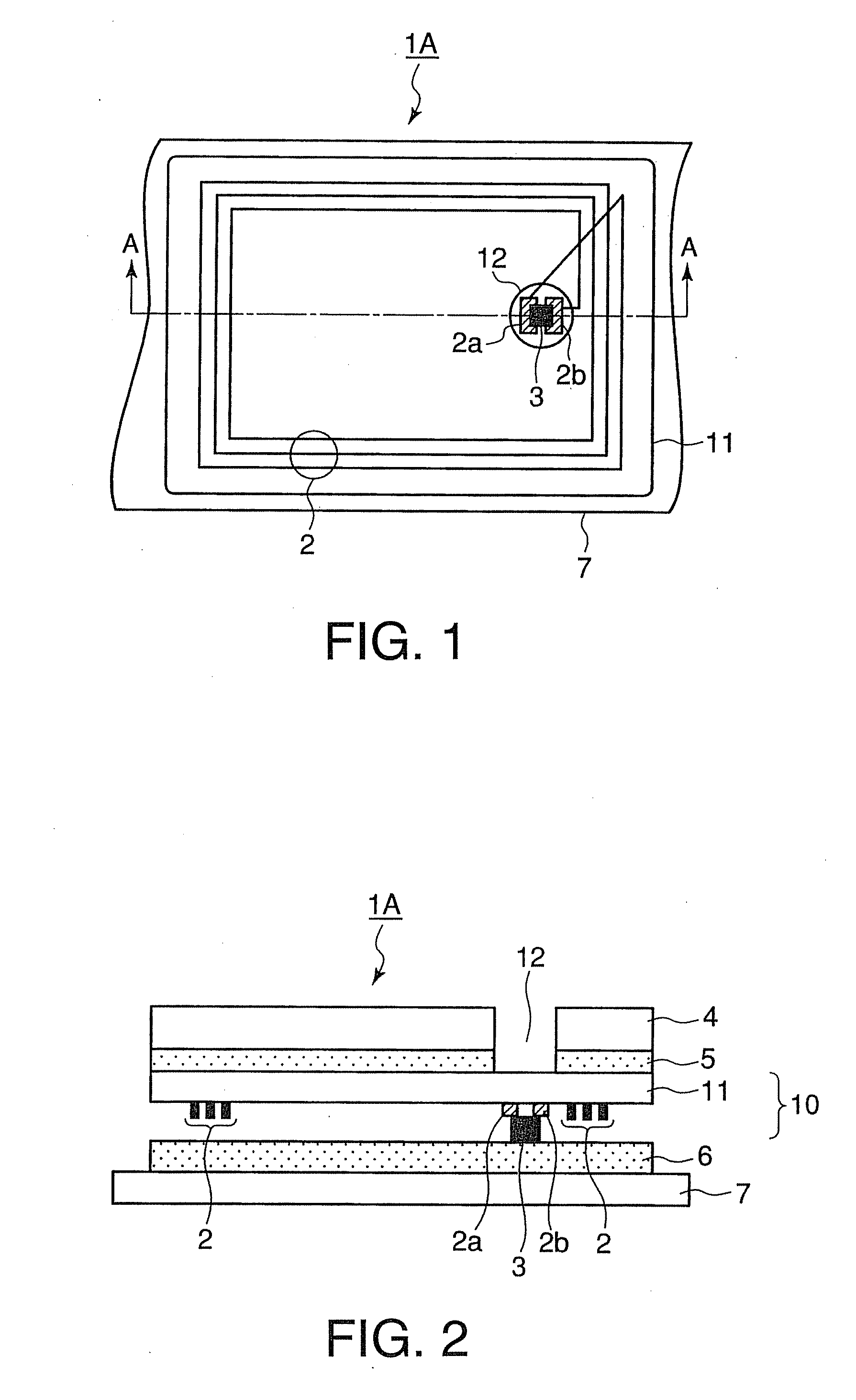

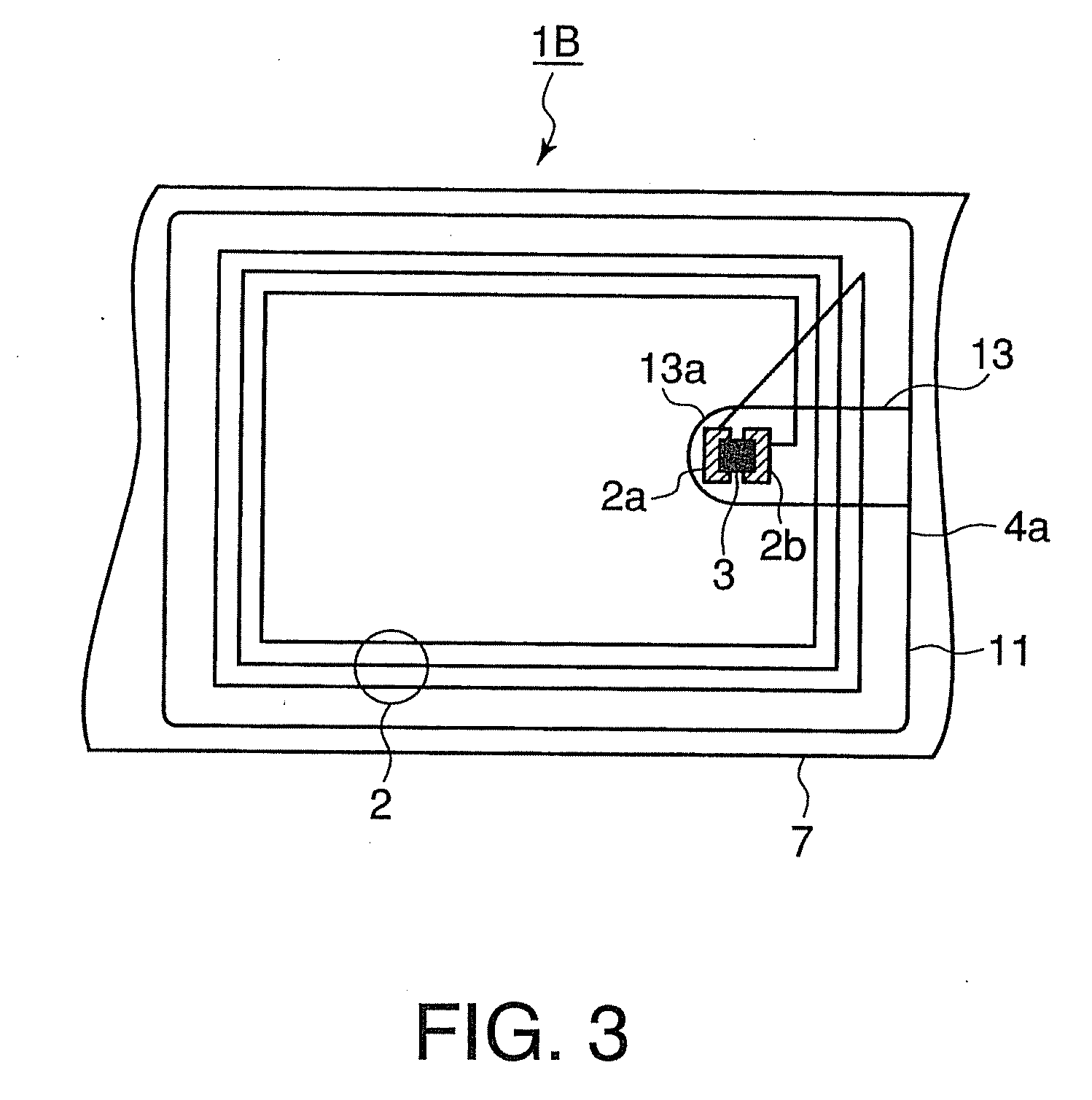

IC tag label

ActiveUS20090303011A1Avoid thickeningIncrease material costLamination ancillary operationsLaminationEngineeringElectrical and Electronics engineering

An IC tag label 1A includes an inlet substrate 11; an IC chip protection sheet 4 which is mounted on one surface of the inlet substrate 11; and an antenna pattern 2 and an IC chip 3 which are mounted on the other surface of the inlet substrate. An adhesive layer is mounted on the other surface of the inlet substrate 11 to cover the antenna pattern 2 and IC chip 3. An opening, which serves as a clearance for the IC chip 3, is formed in a portion of the IC chip protection sheet 4, the portion corresponding to the IC chip 3.

Owner:DAI NIPPON PRINTING CO LTD

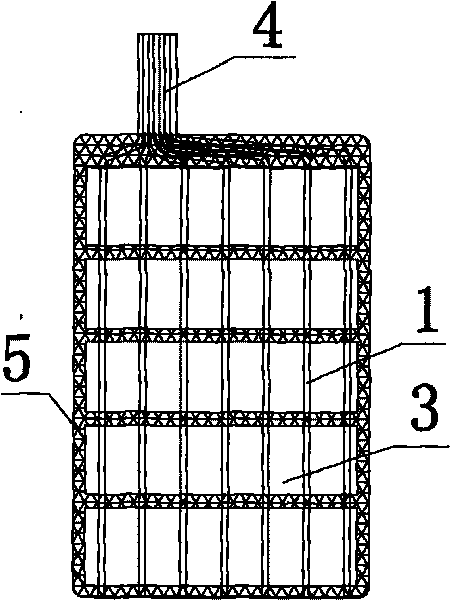

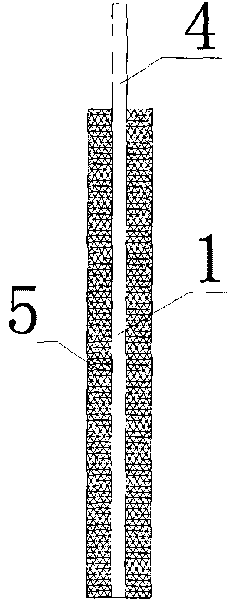

Hybrid current collector used for lead storage batteries

InactiveCN101694878AReduce weightWidely meet the needs of useElectrode carriers/collectorsCell component detailsElectricityEngineering

The invention discloses a hybrid current collector used for lead storage batteries, which is characterized in that the hybrid current collector comprises at least one conducting framework and a shaping framework, the conducting framework is molded in a hybrid form, the shaping framework is manufactured by lightweight hard materials, and the hybrid current collector is a grid plate with hollow grids or a plate-shaped current collector without grids. The hybrid process of the conducting framework and the shaping framework includes injection molding and joggle fixing molding, wherein the injection molding utilizes thermal plastic and cold extrusion or uses cement concrete, the joggle fixing comprises steps of utilizing the lightweight hard material to manufacture a substrate module which is used as the shaping framework and then joggling and fixing the shaping framework with the conducting framework which is designed as a coupling module. The conducting framework of the current collector can extend to form an integrated lead electrode or is electrically fixedly connected with a split lead electrode. The polar plate manufactured by utilizing the current collector is light in weight, high in specific energy, simple in manufacture and low in material cost.

Owner:东莞恒量新能源科技有限公司 +1

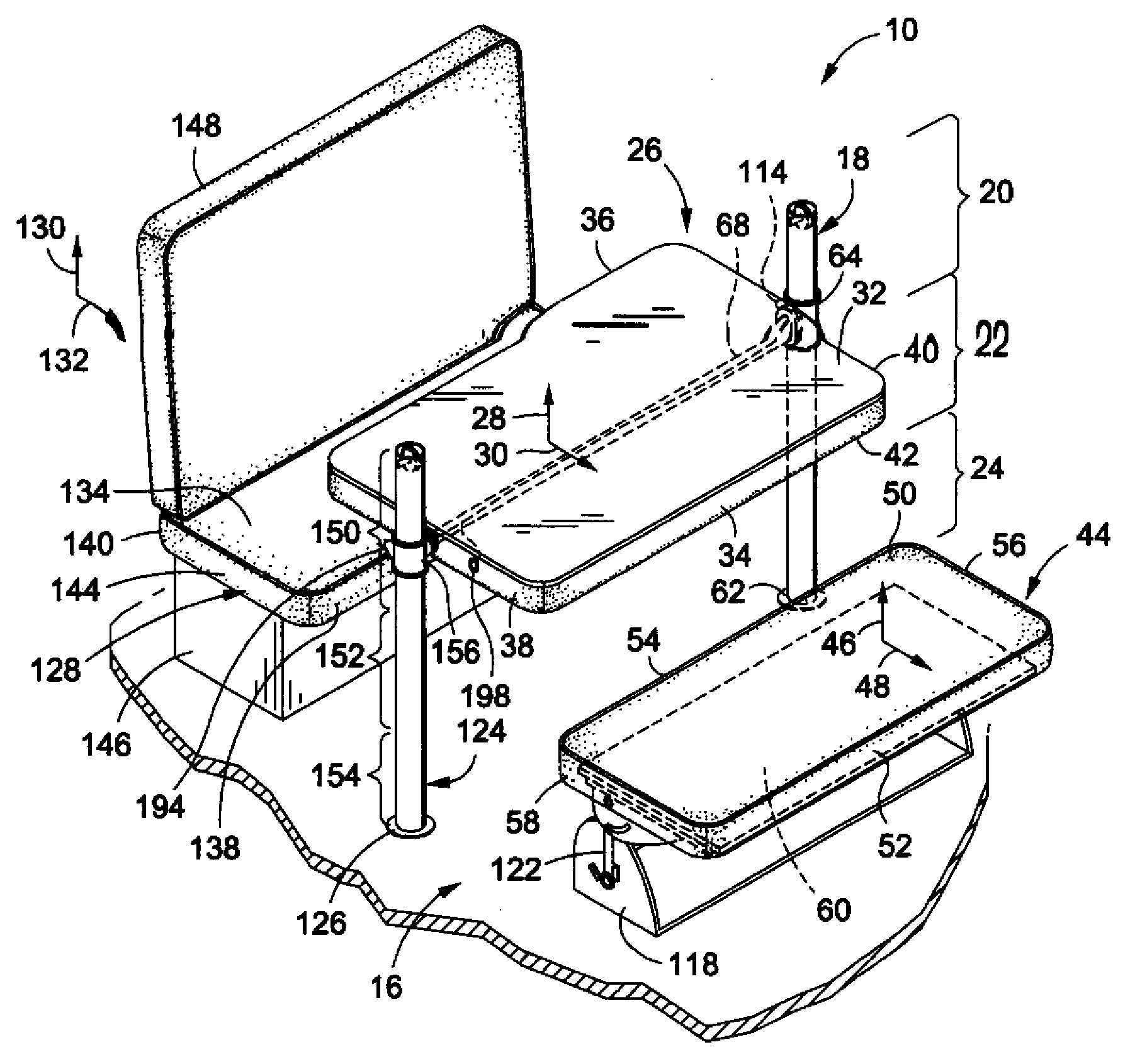

Multi purpose vehicle furniture system

InactiveUS20100171344A1Increase expensesExtension of timeVehicle seatsBenchesDriver/operatorEngineering

A vehicle furniture system for use proximate to a vehicle driver's seat, the system comprising: a first post having a first post first end, a first post body, and a first post second end mountable to the floor of the vehicle; a primary support having a primary support longitudinal axis generally perpendicular to a primary support lateral axis, a primary support top surface, a primary support bottom surface, a primary support first longitudinal side rotatably and slidably engageable to the first post, a primary support second longitudinal side, a primary support first lateral side, and a primary support second lateral side, the primary support disposable in a first position, a second position, a third position, and a fourth position; a primary support rod; and a second support adjacent to the primary support with the primary support in the second position and the third position.

Owner:DUNKEL PETER L

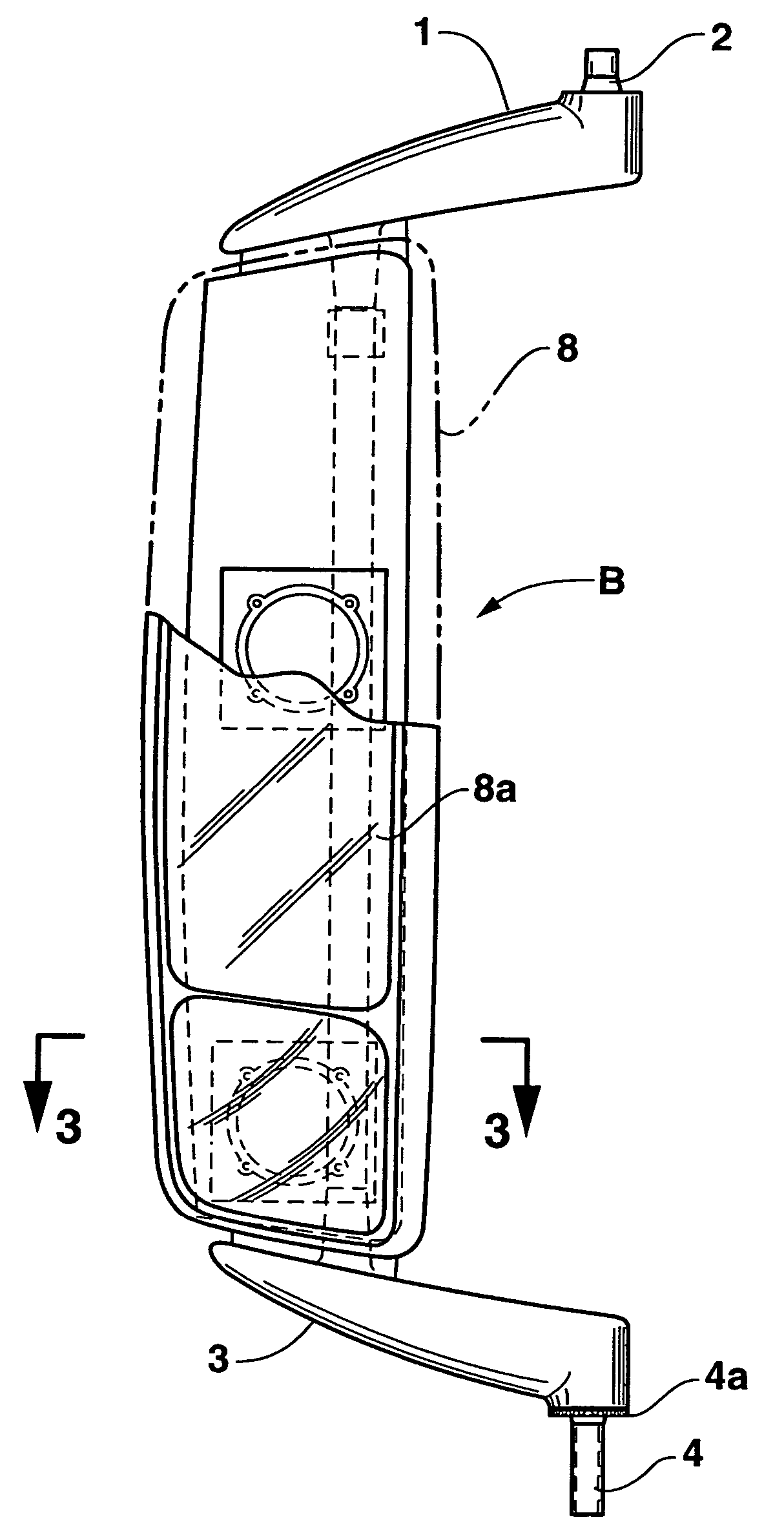

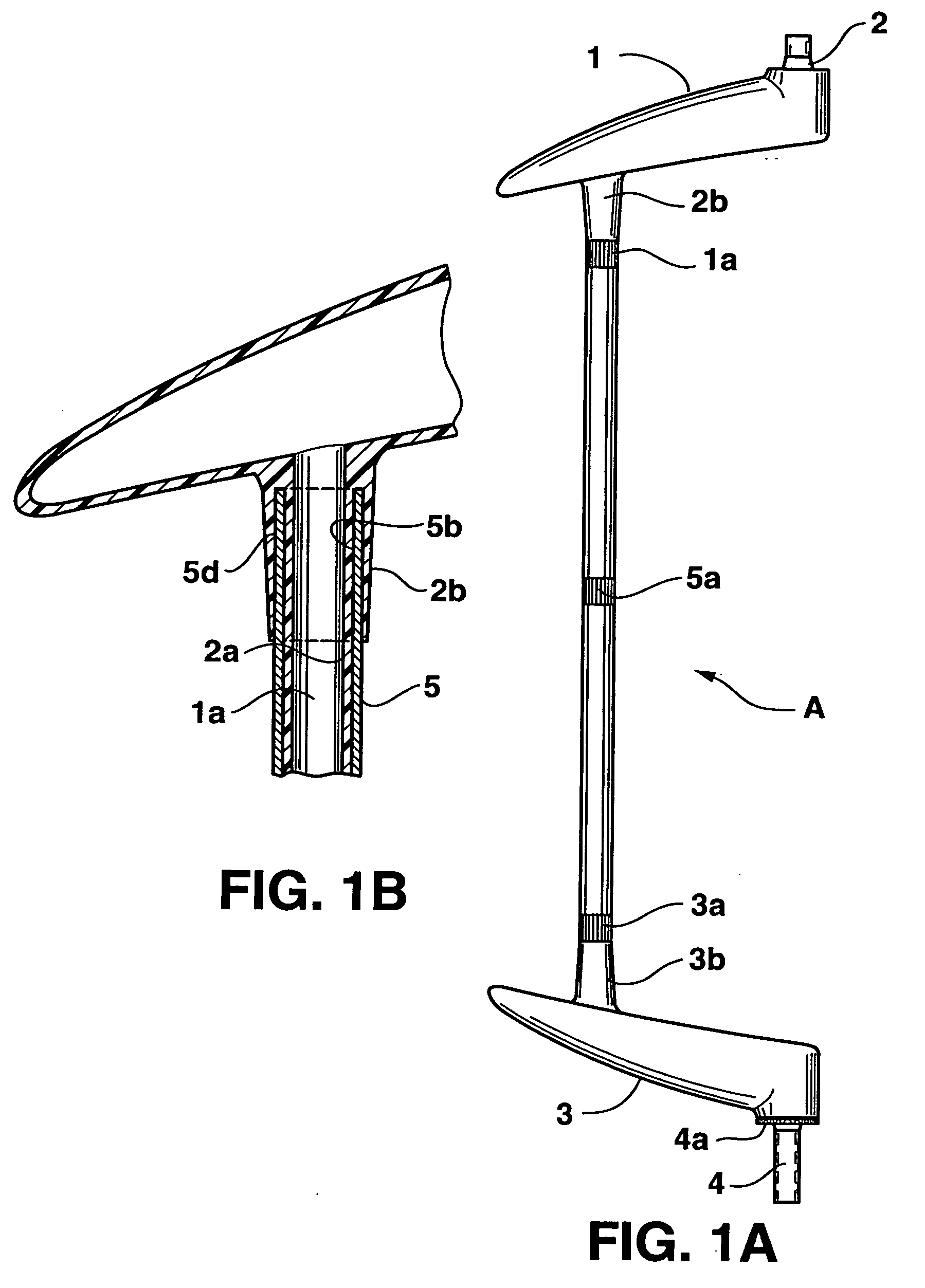

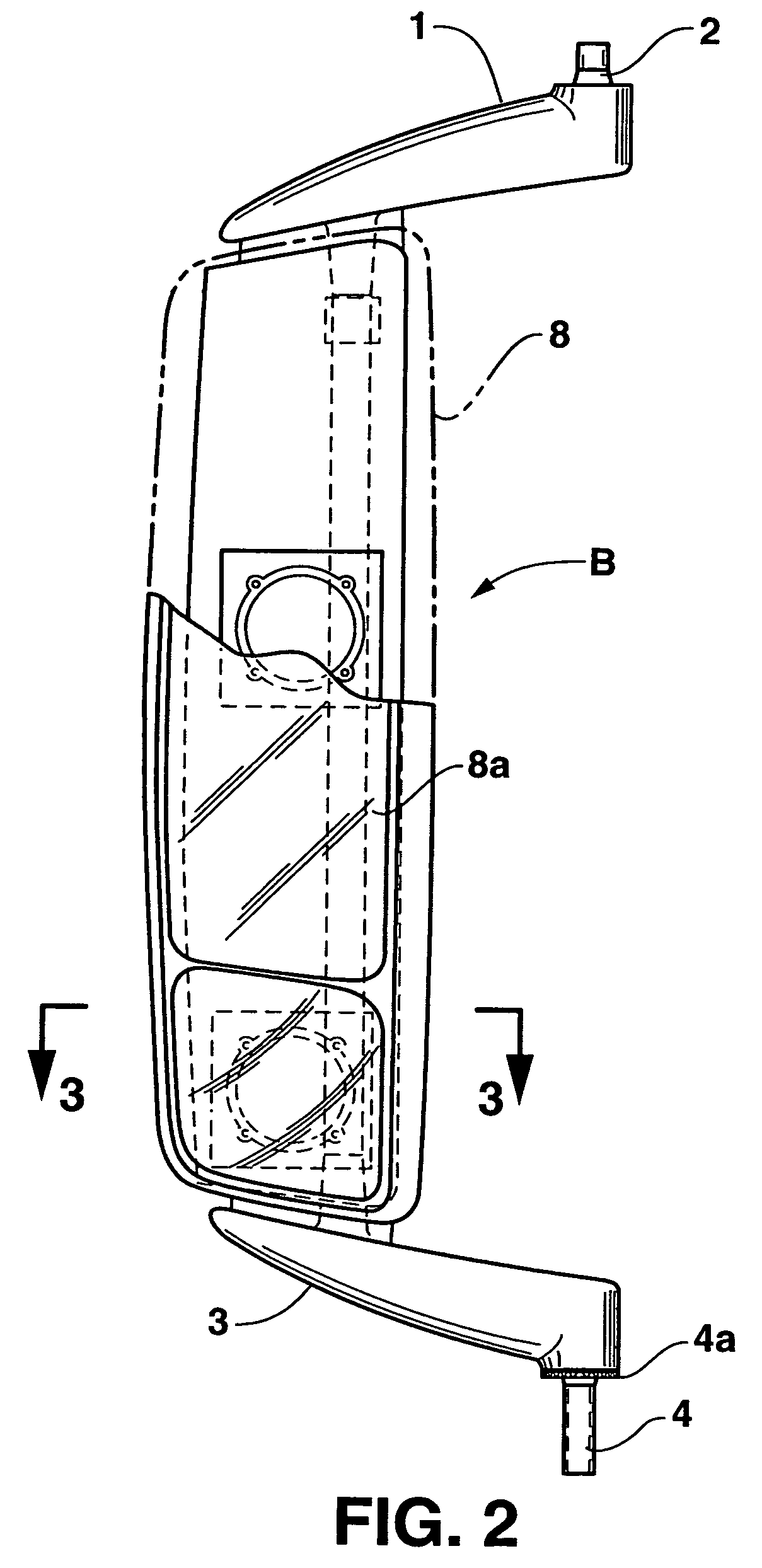

Support arm for vehicle mirror

ActiveUS20050122605A1Improve stabilityImprove overall utilizationPicture framesDomestic mirrorsWing mirrorMechanical engineering

A support arm for a vehicle mirror having at least one mirror head with a mirror pane which includes an upper holding arm (1) made of plastic with an anchoring element (2) for mounting on a vehicle, and a lower holding arm (3) made of plastic with an anchoring element (4) at the bottom for mounting on a vehicle. A one-piece base (6) includes a metal tube (5) whose top or, as the case may be, bottom end is securely connected with the upper and lower holding arm, respectively. The base can also be built in the form of a base plate. In this case, the base has a removable positioning wedge (7) that can be removed from the base to change the angle of at least one mirror pane and / or mirror head carried by the base. The positioning wedge is attached to provide an exterior driver-side rear view mirror, and is removed to provide a passenger-side rear view mirror.

Owner:LANG MEKRA NORTH AMERICA LLC

Panel antenna and wireless communication device

ActiveCN101656350ALow costIncrease material costRadiating elements structural formsResonant antennasCouplingTransmission zeros

The invention relates to a panel antenna and a wireless communication device, in particular to a panel antenna without a through hole structure. The panel antenna is arranged on a plate. The plate is provided with a first surface and a second surface. The panel antenna comprises a metal layer, an antenna body, a stepped impedance element, a coupling element and a matching element. The metal layeris arranged on the first surface and is provided with a groove body for exposing the first surface. The antenna body, the stepped impedance element, the coupling element and the matching element are arranged on the second surface. Apart from a feed-in end of the antenna body, the antenna body corresponds to the periphery of the metal layer. The stepped impedance element and the matching element correspond to the metal layer, while the coupling element corresponds to the groove body. The matching element is electrically connected between the coupling element and the feed-in end of the antenna body to be used as impedance match. The stepped impedance element is electrically connected with a grounding terminal of the antenna body and has a transmission zero point in a radio-frequency range operated by the antenna body.

Owner:ASUSTEK COMPUTER INC

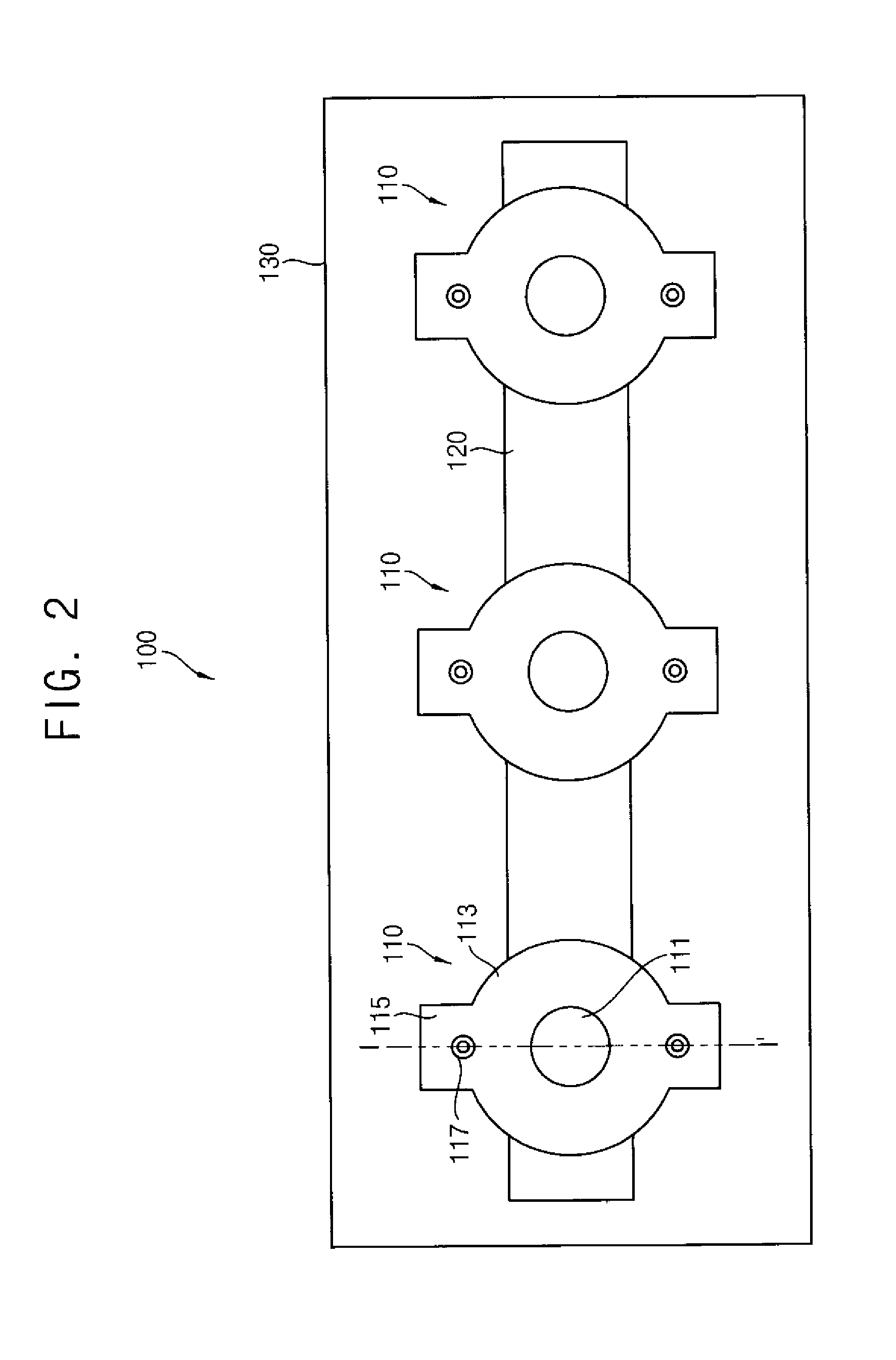

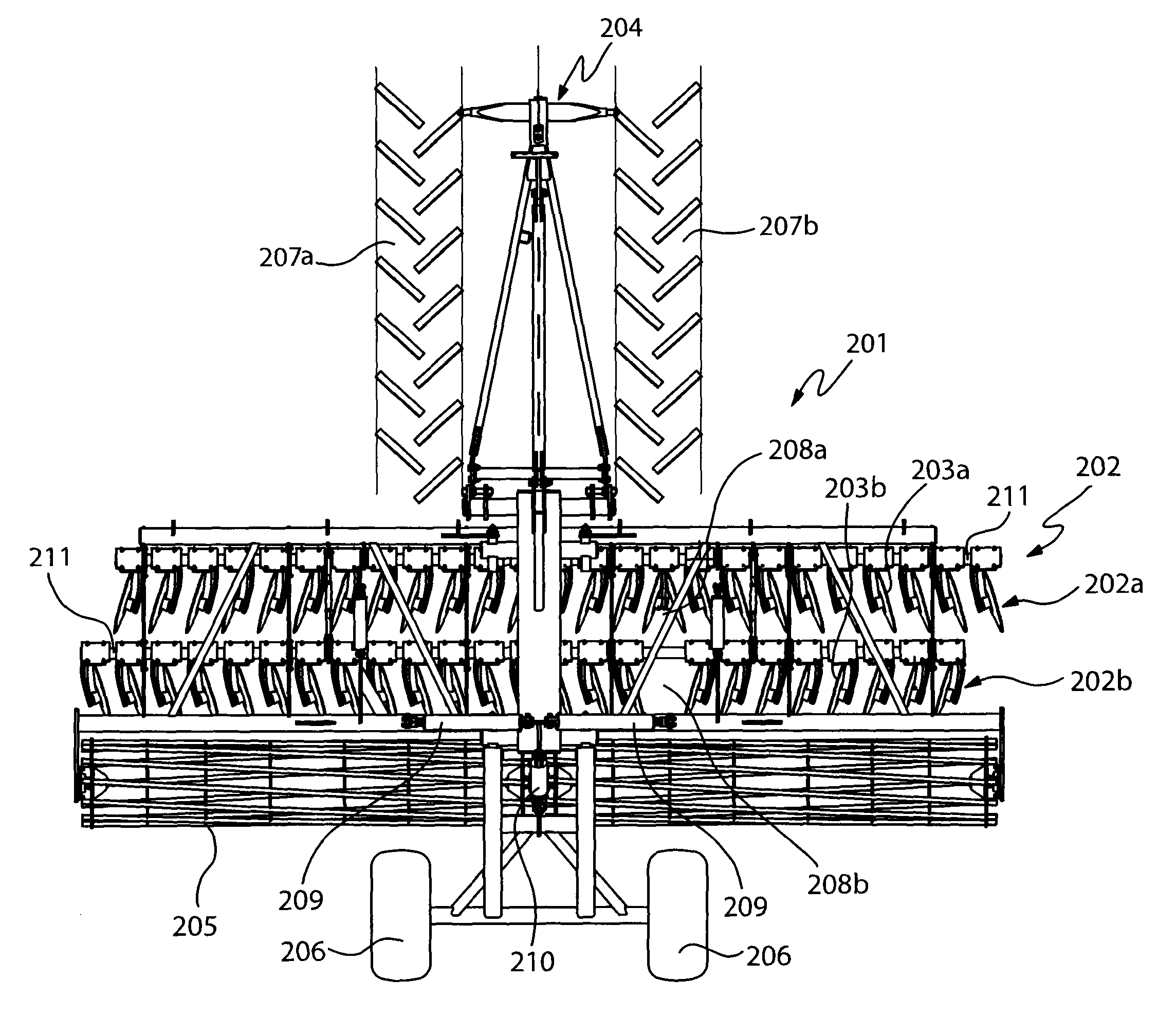

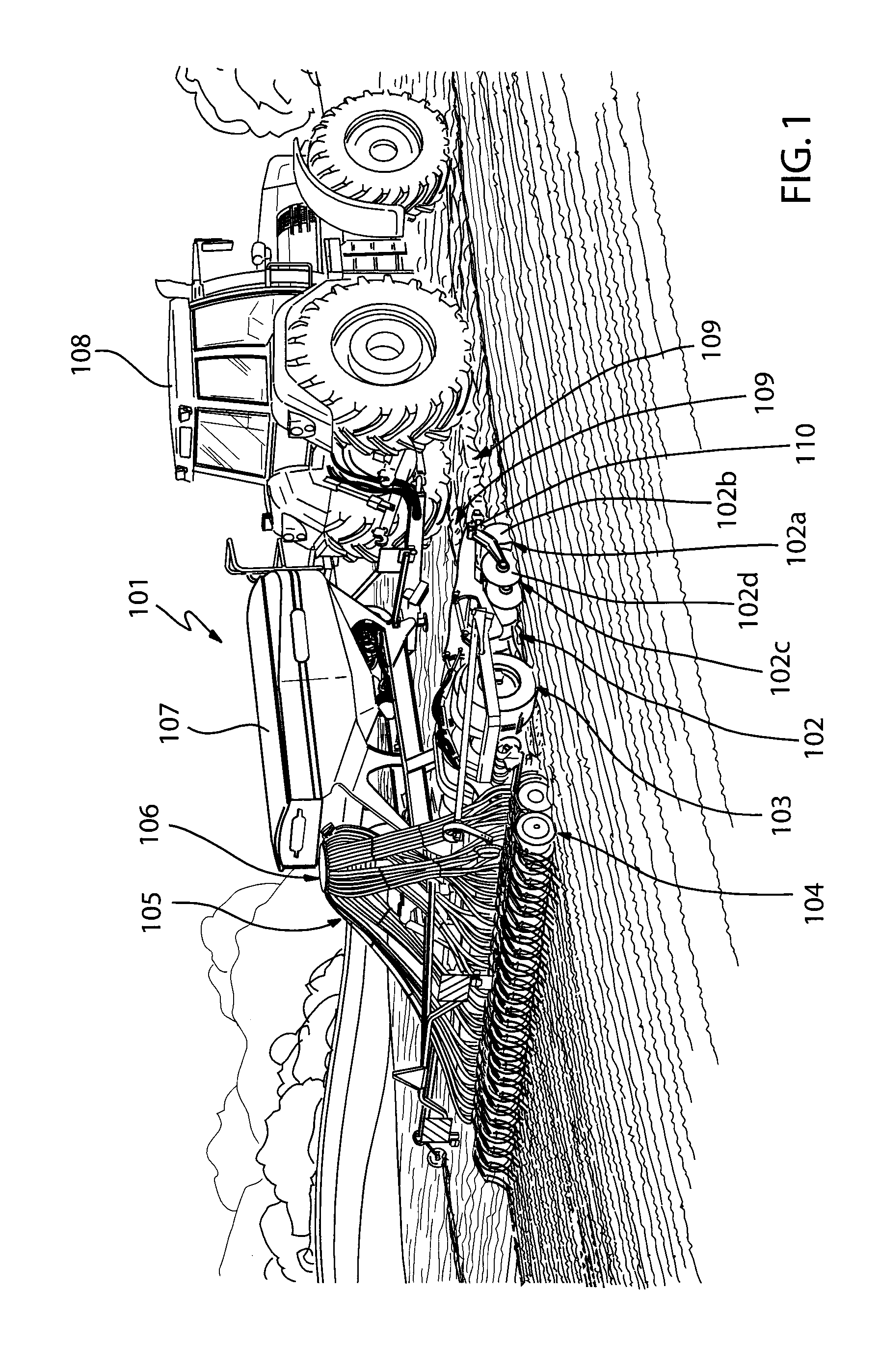

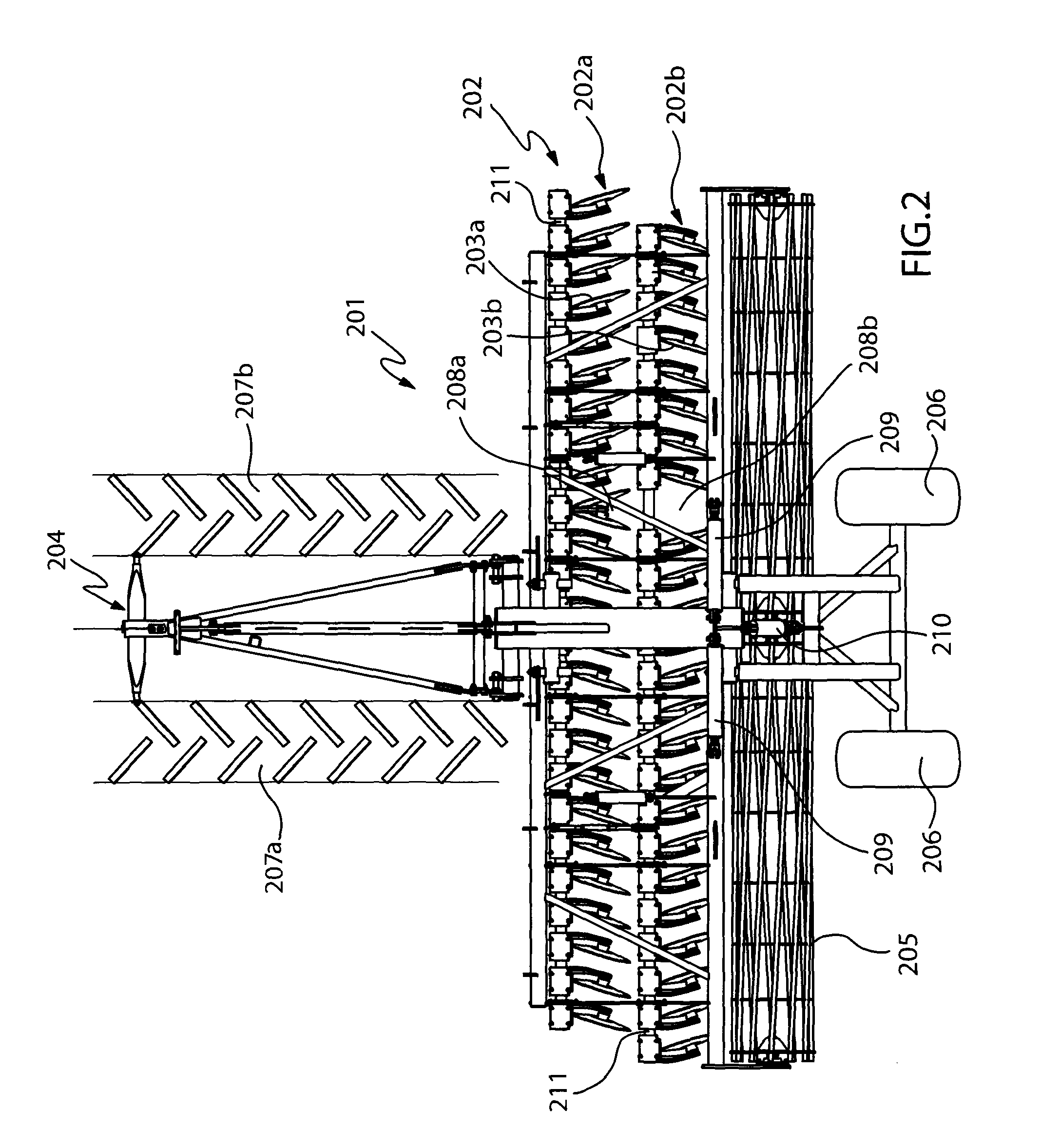

Cultivator with two rows of discs in direction of travel

ActiveUS8997886B2Function increaseOptimizationSoil loosening devicesSoil-working equipmentsIndustrial engineeringOptical disc

An agricultural machine (101; 201; 301) comprising two mainly parallel, in the direction of travel, cross-running disc implement rows (102a, 102c; 202a, 202b; 304a, 304b), wherein the orientation of the disc implements (102b, 102d; 203a, 203b; 302a, 302b) contained in the mentioned disc implement rows is arranged so that the fore row (102a; 202a; 304a) has disc implements that are mounted on a frame beam (110; 211; 303) and that are angled outwards and backwards towards the sides of the machine and in a dividing line mainly parallel to the direction of travel of the machine form a first point of change (208a, 304c), and the rear row (102c, 202b; 304b) has disc implements (102d; 203b; 302b) that are mounted on a frame beam (110; 211; 303) and that are angled inwards and backwards from the sides of the machine and in the dividing line form a second point of change (208b, 304a), wherein the fore row is adapted to throw soil from the first point of change outwards towards the sides of the machine and the other row is adapted to throw soil from the sides of the machine inwards towards the second point of change. The dividing line with the first point of change (208a, 304c), and with the second point of change (208b, 304) is arranged at a predetermined distance from the centre line of the machine (101; 201; 301) across the direction of travel.

Owner:VADERSTAD HLDG

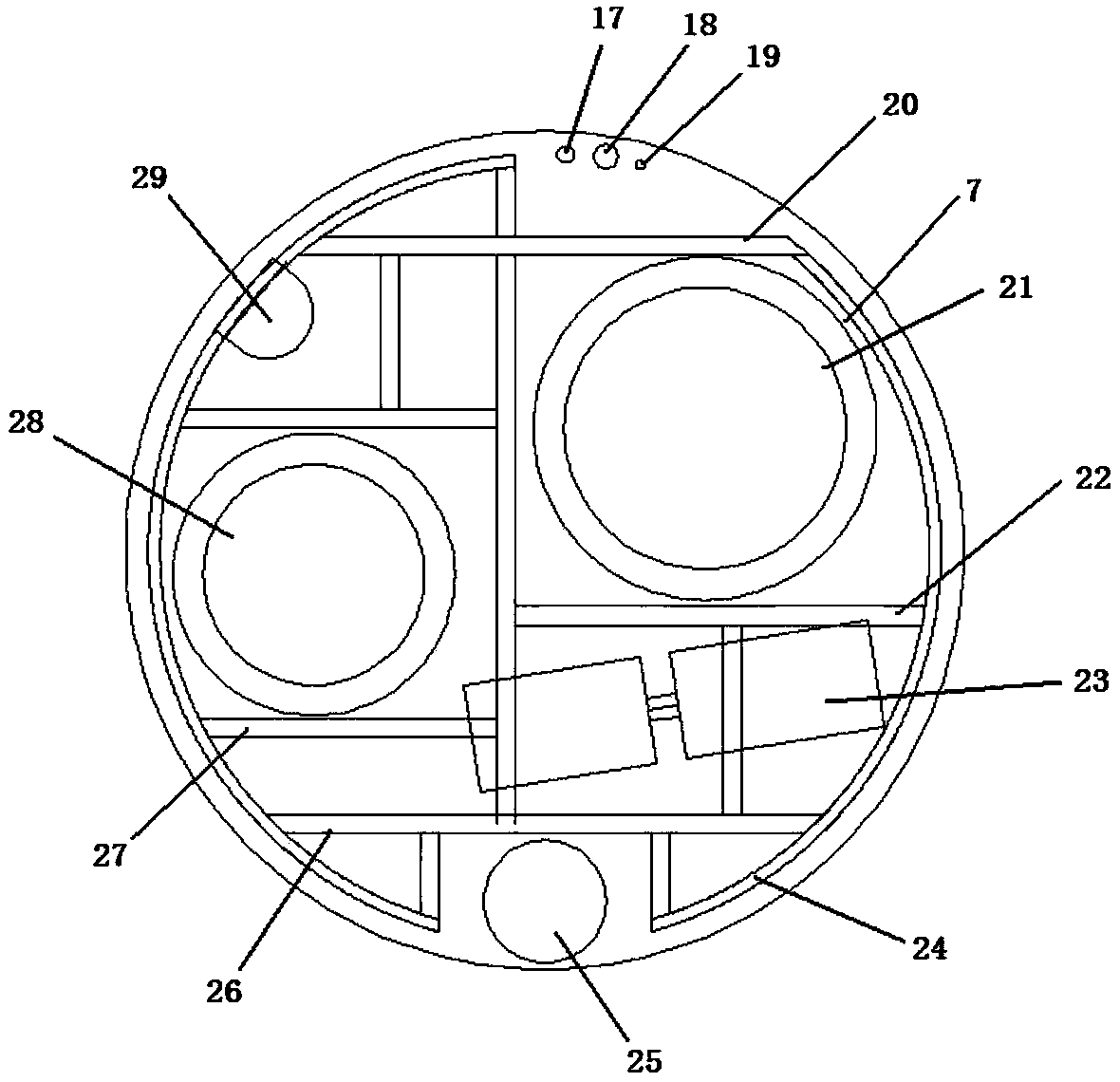

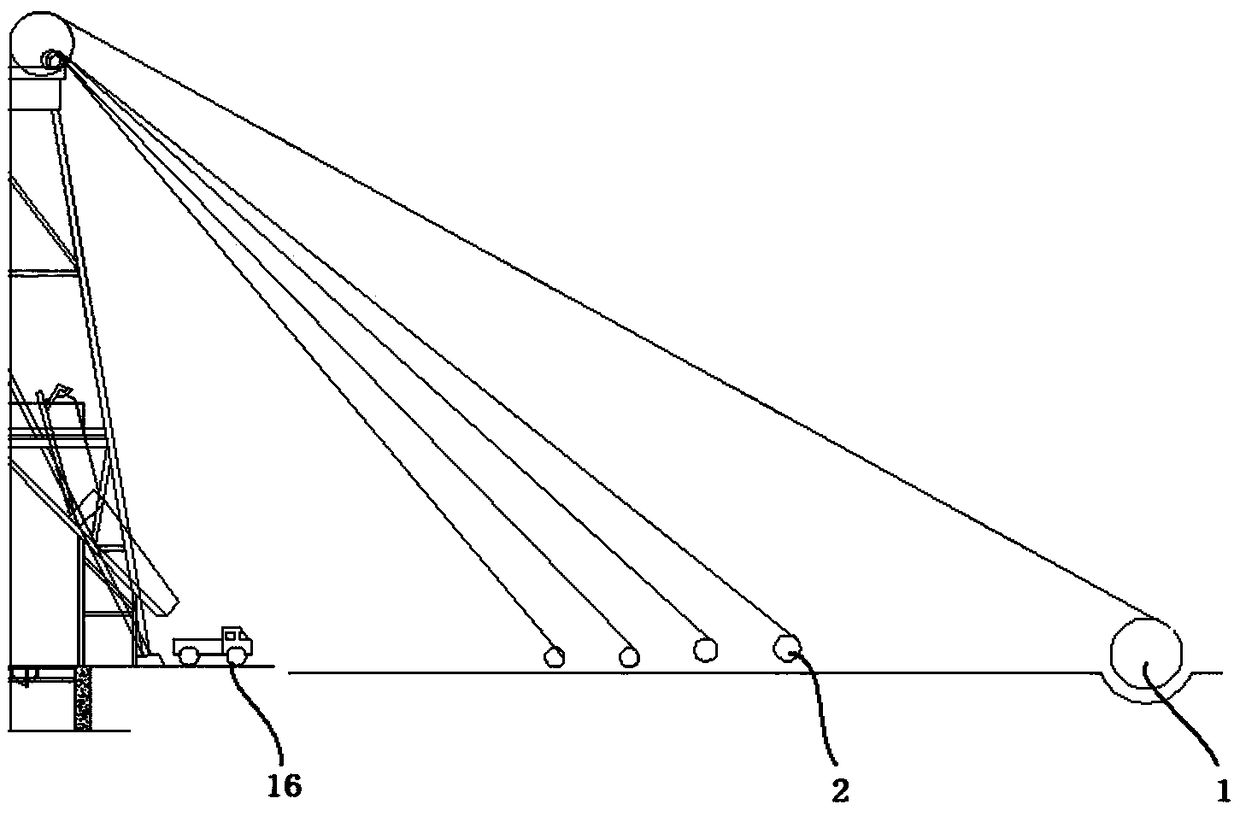

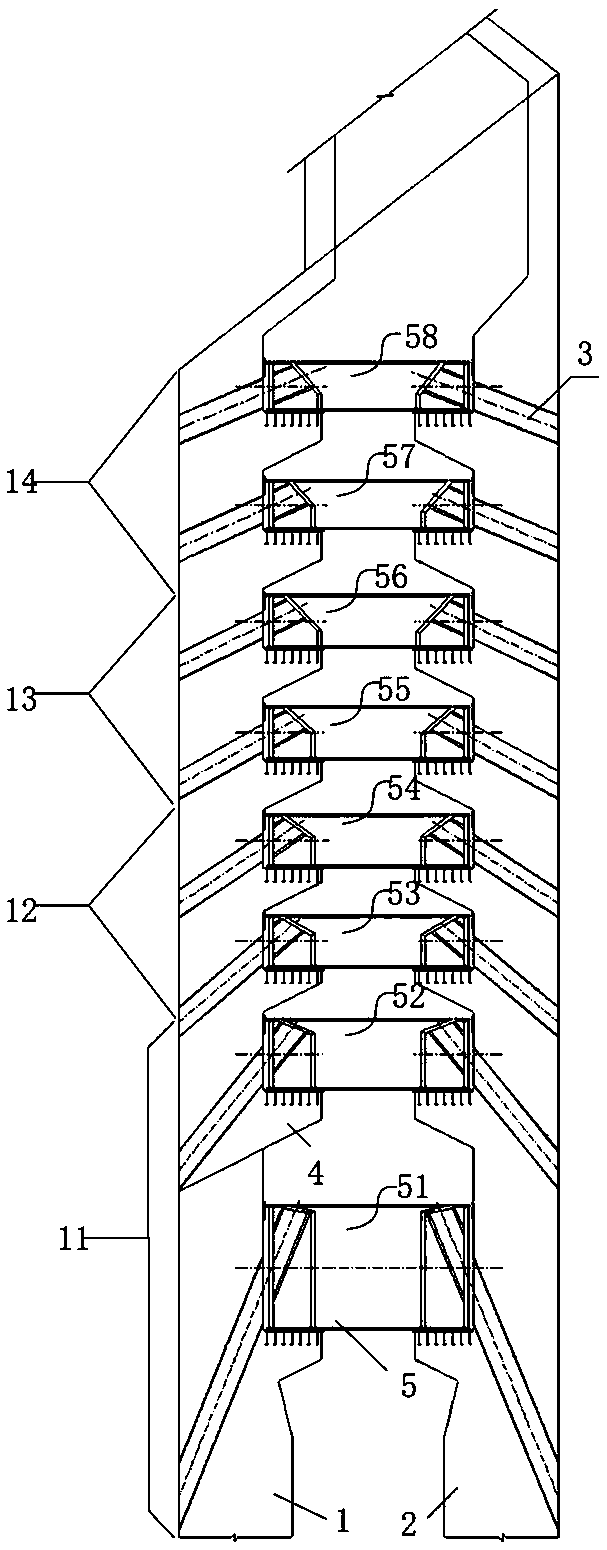

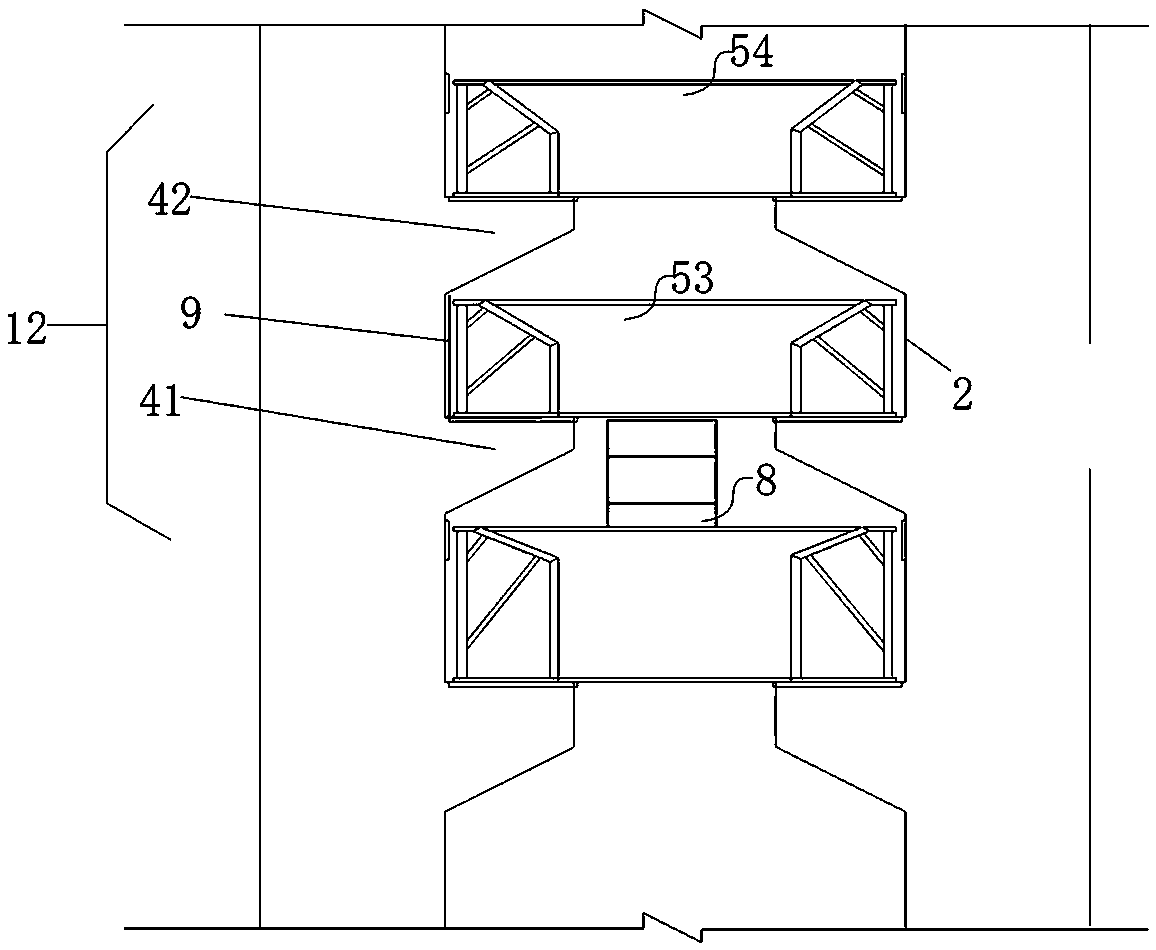

Vertical shaft construction device and using method thereof

The invention discloses a vertical shaft construction device which comprises a hoist, shaft sinking winches, a shaft sinking headframe, a head sheave platform, gangue turning platforms, an opening sealing disc and a hanging scaffold. Power supply and distribution equipment, hydraulic control equipment, water drainage equipment and an ash splitter are arranged on the hanging scaffold, and ash slipping pipes are arranged on the ash splitter. Suspension-free stepping-type seamless formworks are arranged below the hanging scaffold and each comprise an upper supporting shoe, a first straight formwork body, a second straight formwork body and a lower supporting shoe; the upper supporting shoes and the first straight formwork bodies are connected through stepping oil cylinders; the upper supporting shoes is connected with the lower supporting shoes through steel wire ropes; and edge feet are arranged between the second straight formwork bodies and the lower supporting shoes. A vertical shafttunneling machine is arranged below the suspension-free stepping-type seamless formworks. The full-section vertical shaft tunneling machine is adopted for tunneling and slag discharge, complete mechanization is achieved, the suspension-free stepping-type seamless formworks are adopted to achieve tunneling and building parallel operation of the vertical shaft, the number of construction labor hoursis reduced, and the construction efficiency is improved.

Owner:CHINA COAL NO 5 CONSTR +1

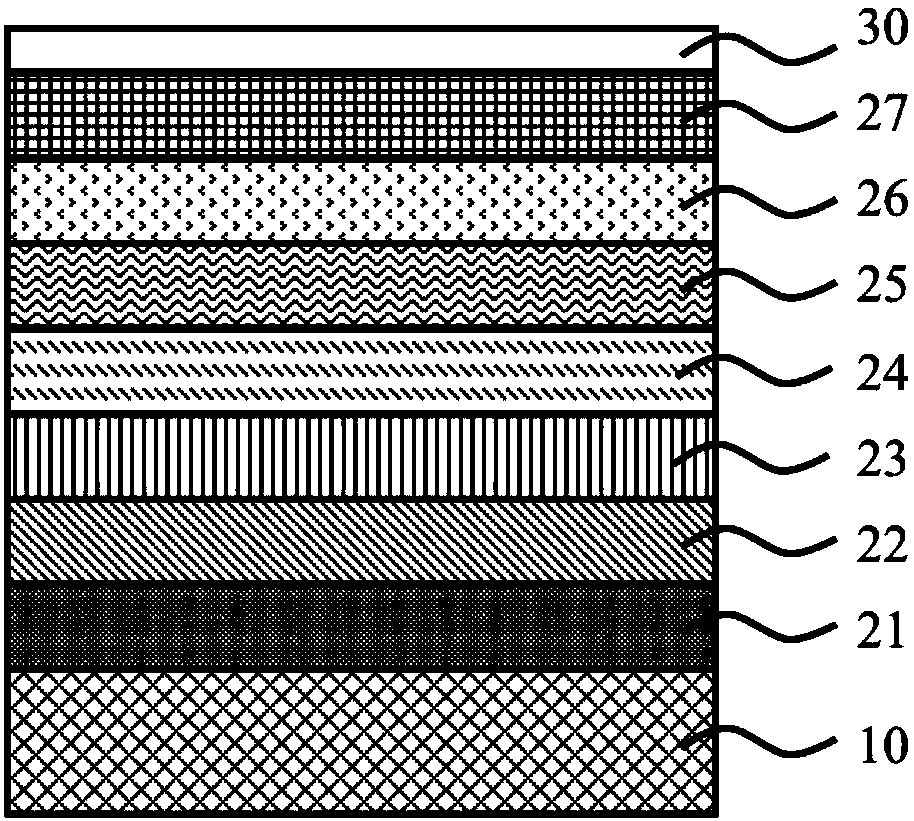

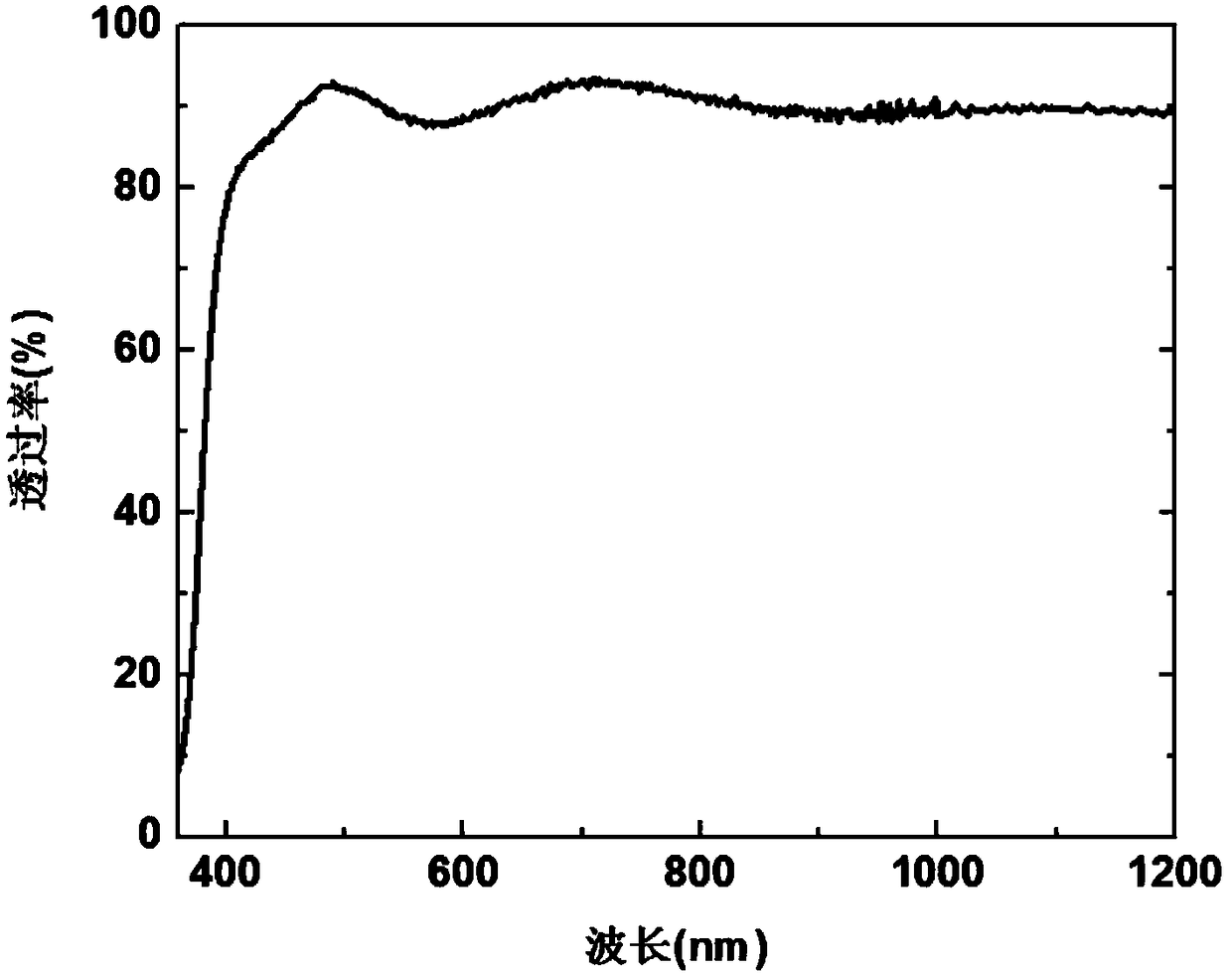

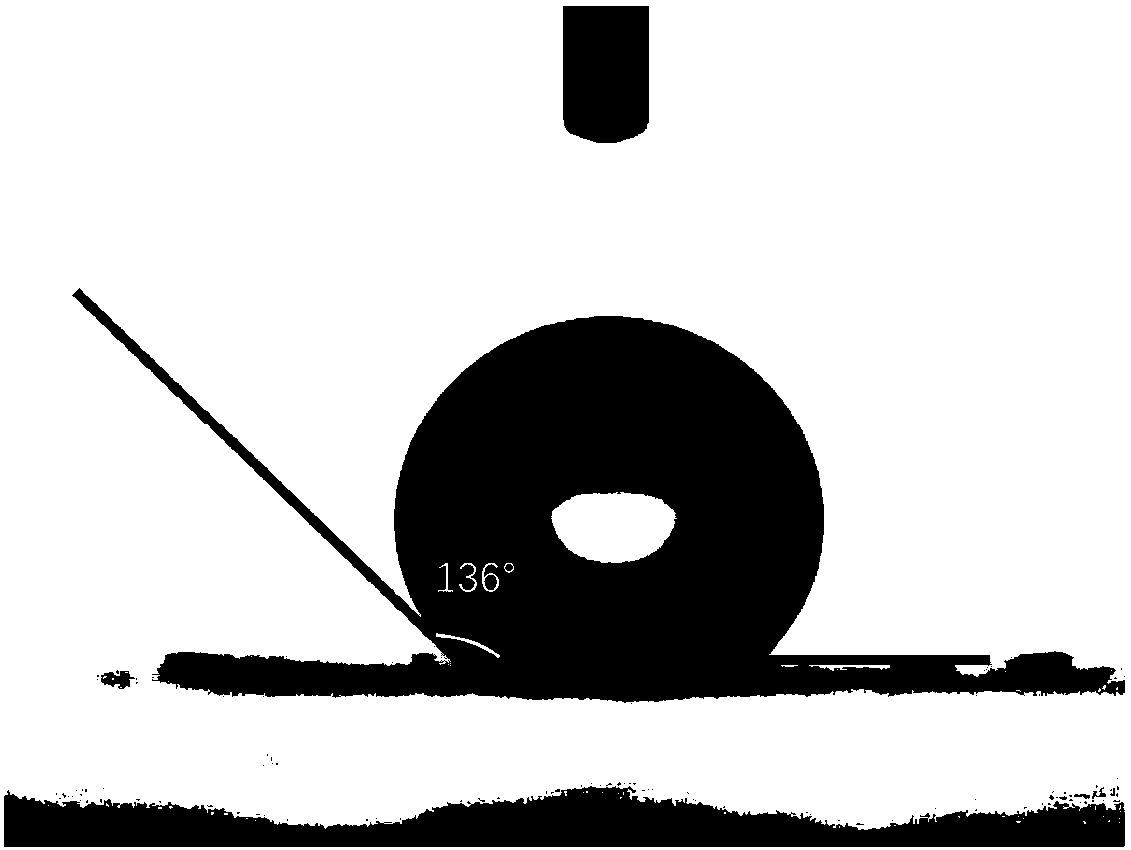

Photovoltaic glass antireflection film

The invention discloses a photovoltaic glass antireflection film. The photovoltaic glass antireflection film comprises a glass substrate and an antireflection film which is compounded on the surface of the glass substrate; the glass substrate is figured glass or ultra-white low-iron glass; the antireflection film is a multilayer film which is prepared by physical vapour deposition; the multilayerfilm is overlapped on the surface of the glass substrate in sequence from inside to outside, wherein the first layer is an Al2O3 coating layer, the second layer is a SiO2 coating layer, the third layer is an Al2O3 coating layer, the fourth layer is a TiO2 coating layer, the fifth layer is a SiO2 coating layer, the sixth layer is a TiO2 coating layer, and the seventh layer is a SiO2 coating layer;the photovoltaic glass antireflection film has a transmission increasing effect in the wavelength range of 300 to 1,200 nanometers without obviously increasing the length of a physical vapour deposition coating production line, materials and production cost; under the condition of single-sided coating, the average transmission rate is higher than 94 percent in the wavelength range of 360 to 1,200nanometers; the observed colour neutrality is good under a vertical incidence condition; compared with a chemically coated antireflection film, the photovoltaic glass antireflection film is closer tothe original colour of ultra-white glass, and has good compatibility with a subsequent glass tempering process.

Owner:宁波纳诺特新材料科技有限公司

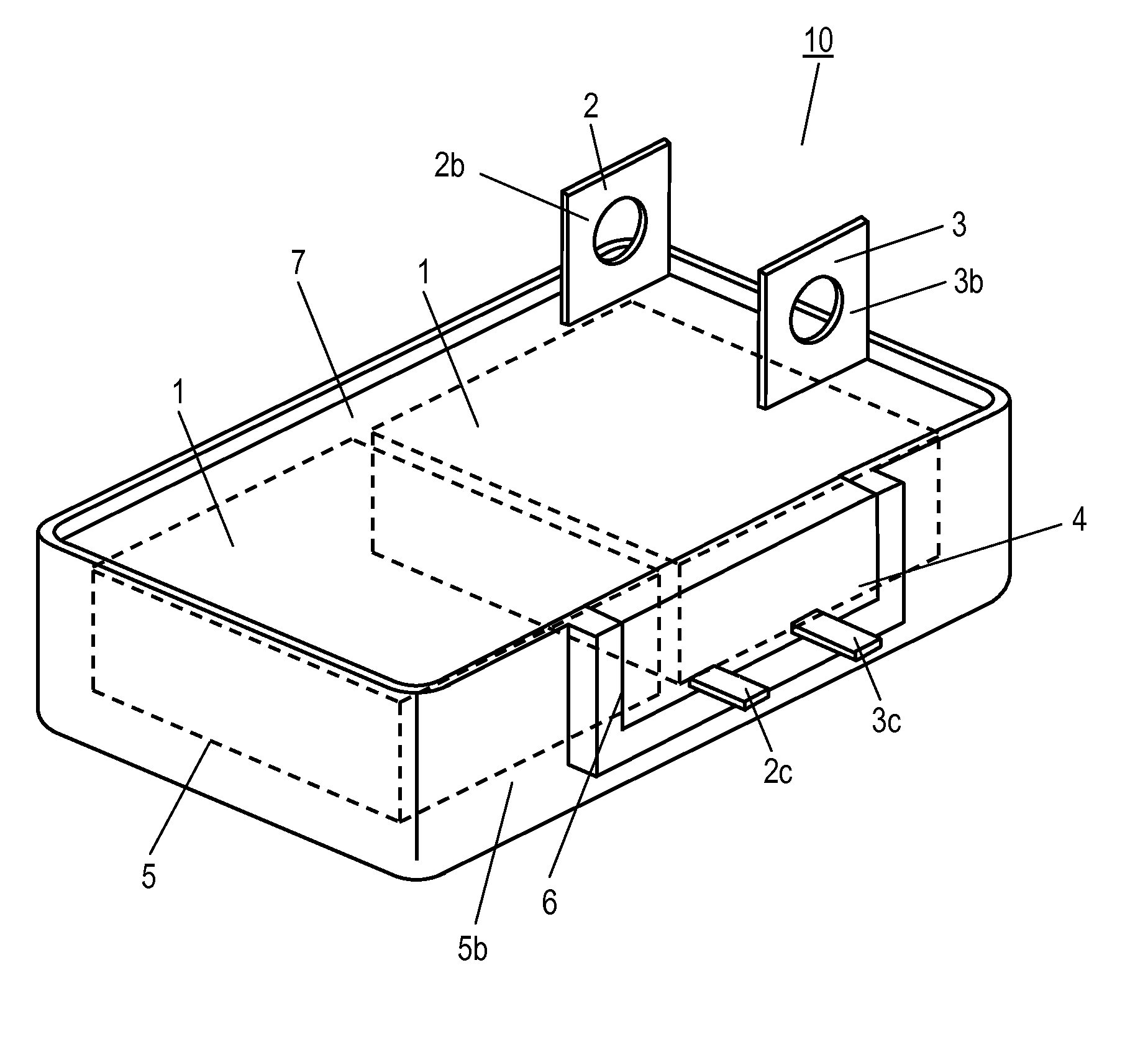

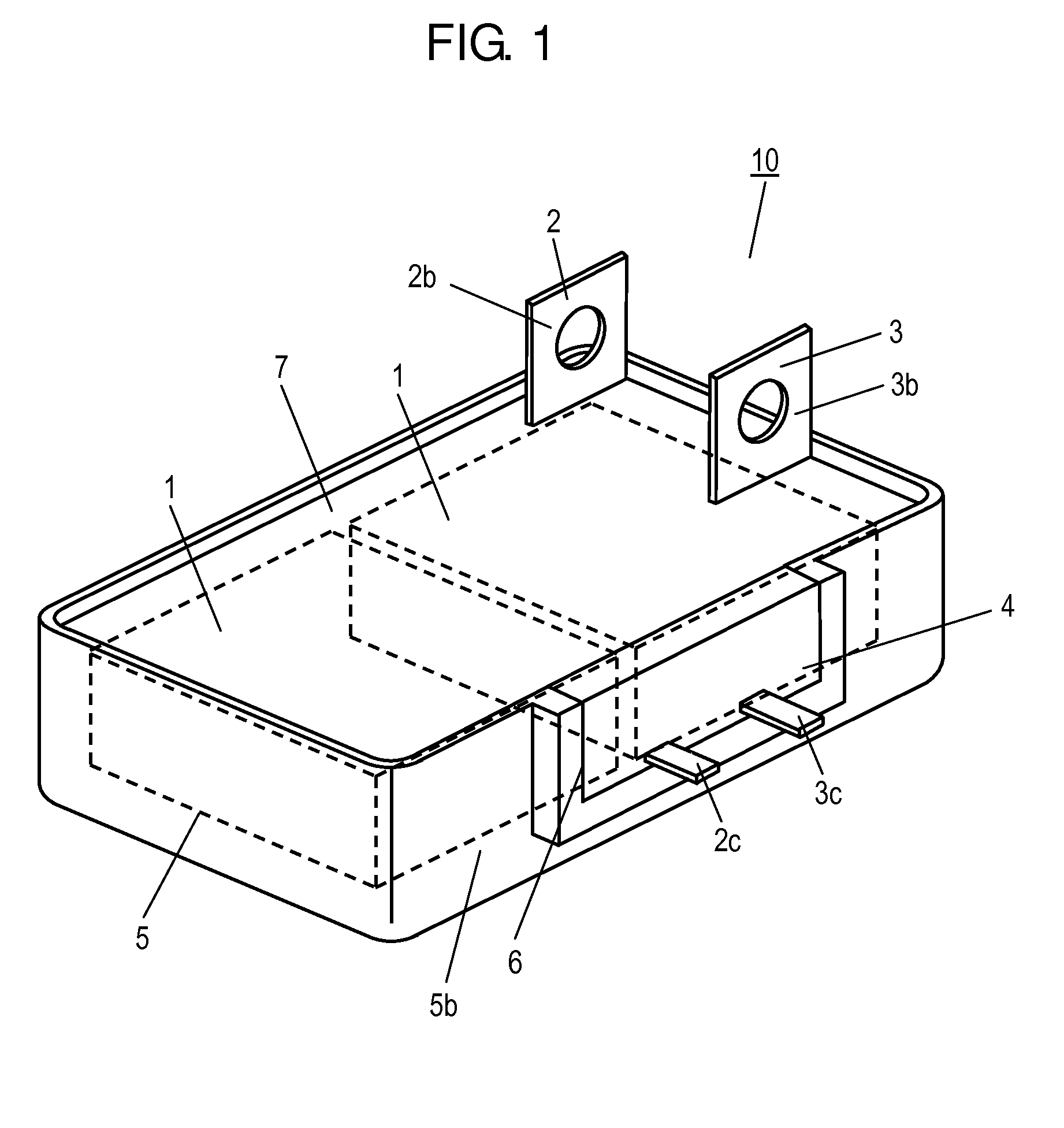

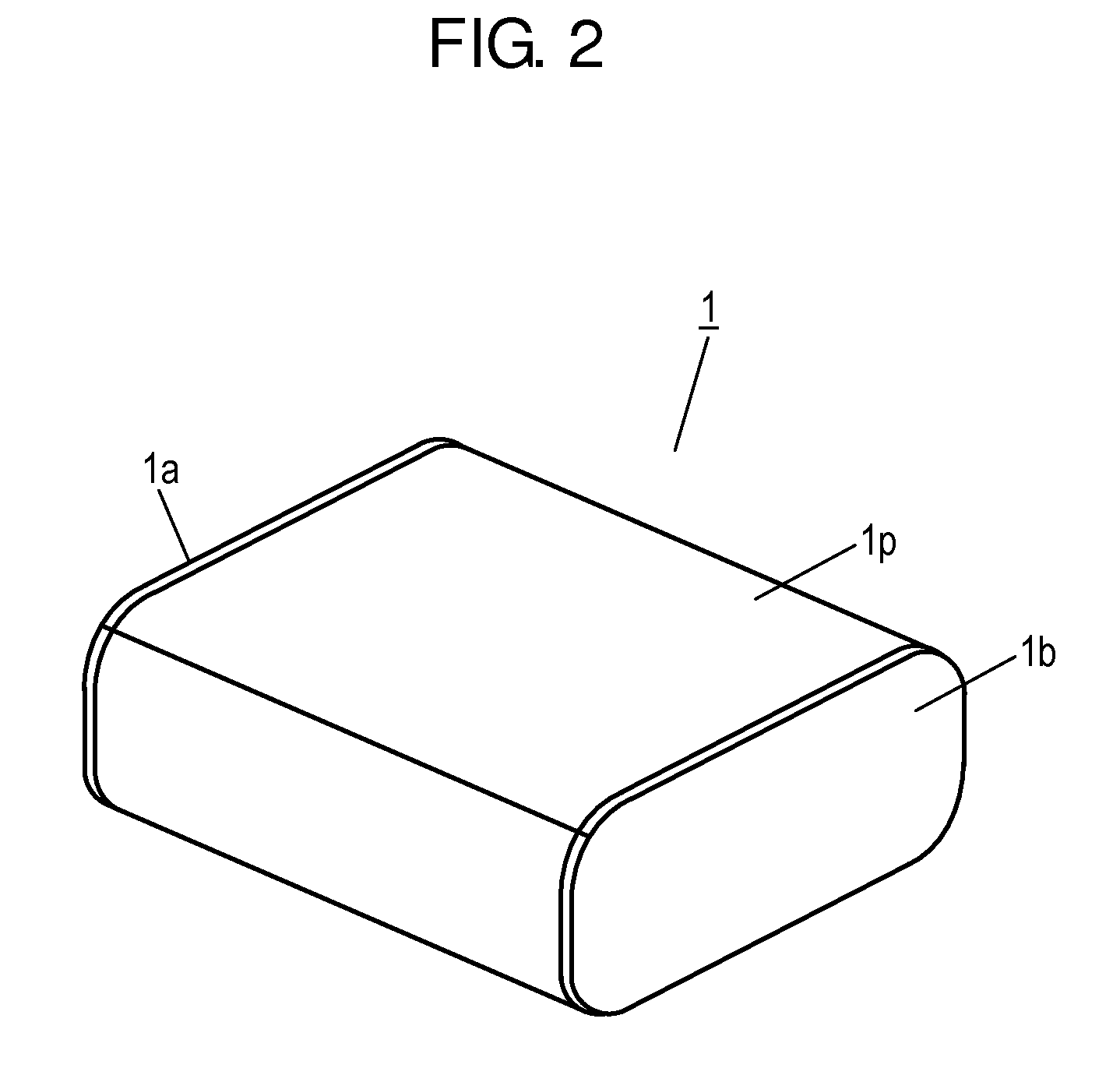

Case-mold-type capacitor and method for producing same

ActiveUS20150348710A1High dimensional accuracyIncrease material costFixed capacitor electrodesFixed capacitor dielectricEngineeringCapacitor

A case-mold-type capacitor includes a capacitor element, first and second bus bars connected to the first and second electrodes of the capacitor element, a case accommodating the capacitor element and the first and second bus bars, and a mold resin filling the case therein. The case has a cutaway portion provided therein. A sealing plate joined to the case so as to seal the cutaway portion. The first and second bus bars pass through the sealing plate and are fixed to the sealing plate. The case-mold-type capacitor improves dimensional accuracy between terminal portions of the first and second bus bars without increasing material cost, and has high reliability.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

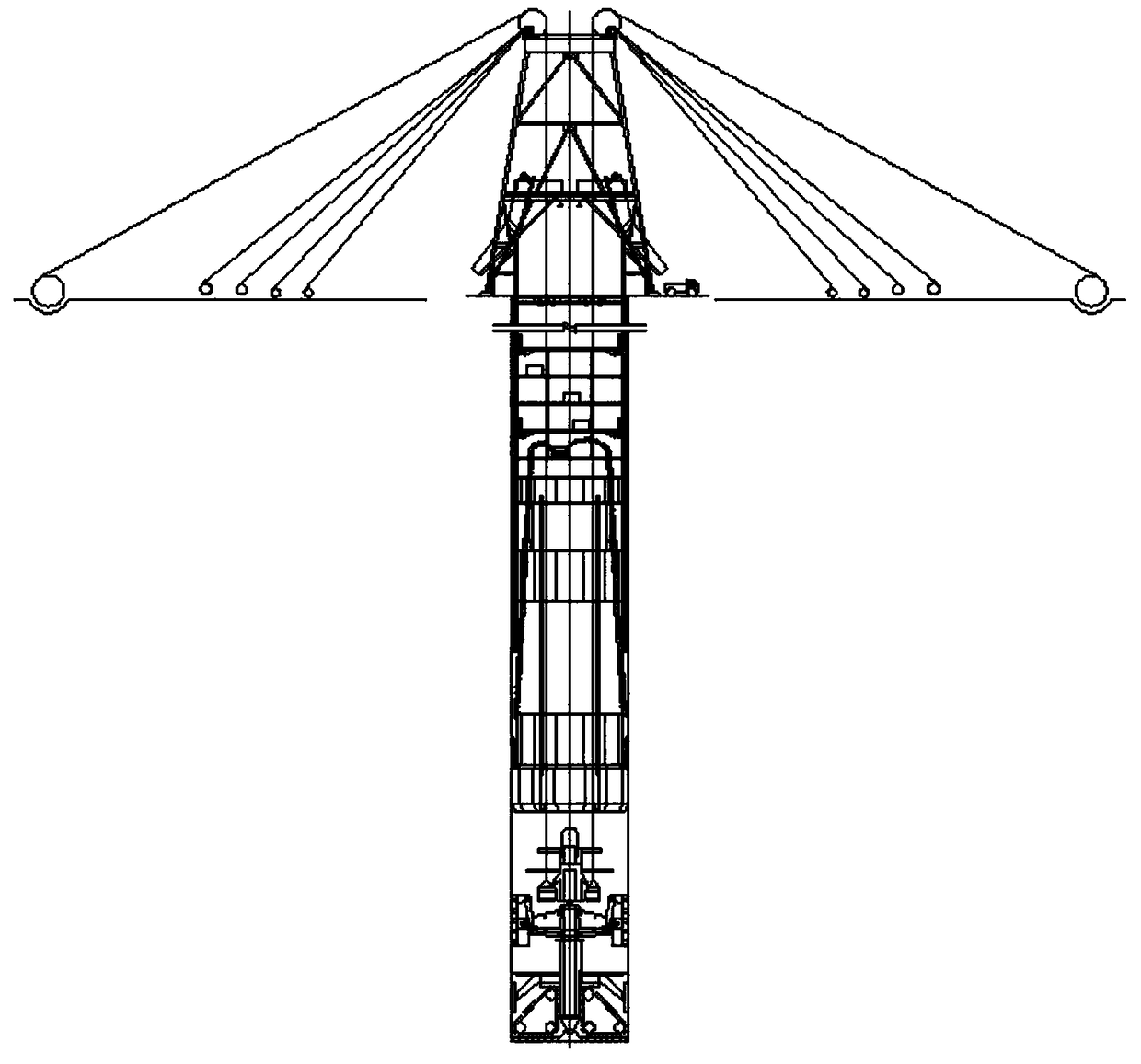

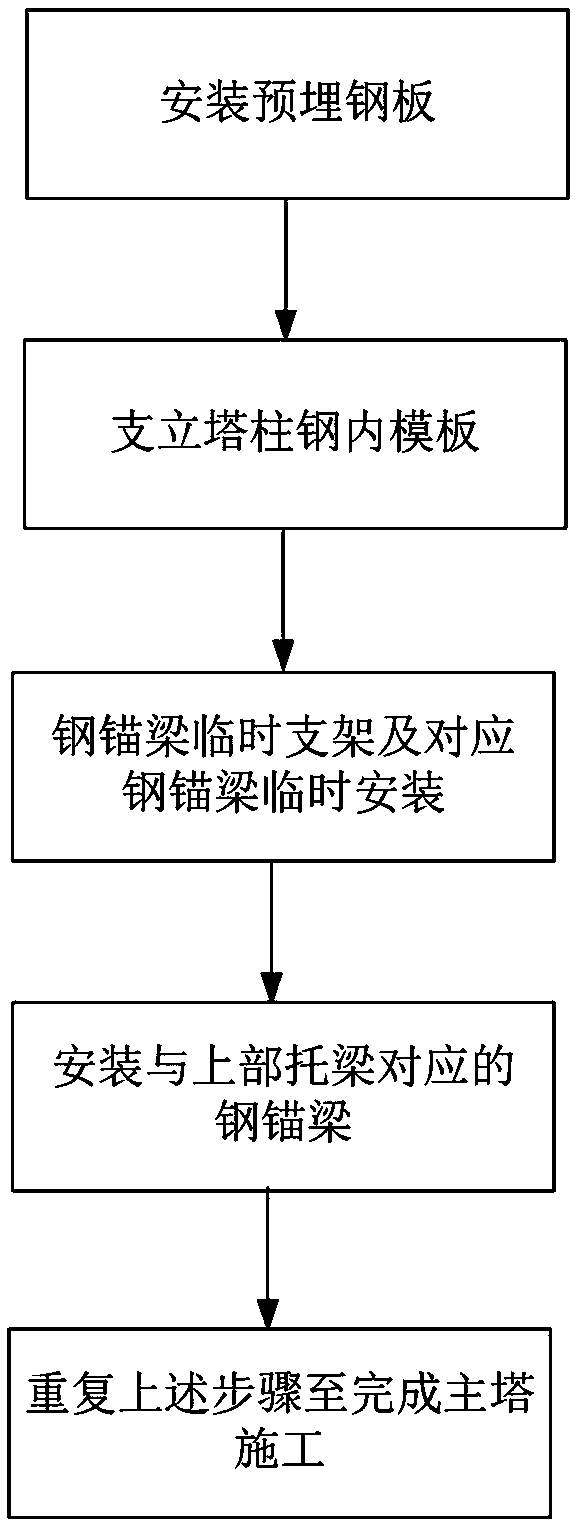

Construction system and construction method for cable-stayed bridge main tower and steel anchor beams

PendingCN108316150AReduce the number of section constructionReduce wasteCable-stayed bridgeBridge erection/assemblyCable stayedJoist

The invention discloses a construction system and a construction method for a cable-stayed bridge main tower and steel anchor beams. The construction method for the cable-stayed bridge main tower andthe steel anchor beams comprises the following steps of step 1, mounting embedded steel plates and arranging the embedded steel plates on the top surface of a beam bracket; step 2, arranging a tower column steel internal template between the top surface of a lower supporting beam and the bottom surface of an upper supporting beam; step 3, mounting the lower part of a steel anchor beam temporary bracket on an existing building platform surface or a finished steel anchor beam top plate; and mounting a steel anchor beam corresponding to the lower supporting beam on the steel anchor beam temporarybracket before segmental concrete pouring of the main tower; and step 4, welding the steel anchor beam corresponding to the lower supporting beam with the embedded steel plate into place; and then mounting a steel anchor beam corresponding to the upper supporting beam and welding the steel anchor beam corresponding to the upper supporting beam with the corresponding embedded steel plate. According to the construction method for the cable-stayed bridge main tower and the steel anchor beams, as the mounting construction of the steel anchor beams is integrated into the construction of a tower column structure, the segmental construction frequency of the tower column is reduced, the method is beneficial for controlling the internal quality and appearance quality of the tower column structure,the construction period is reduced and material waste is reduced.

Owner:BEIJING URBAN CONSTR ROAD & BRIDGE GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com