Vertical shaft construction device and using method thereof

A construction device and shaft technology, which is used in shaft equipment, well sinking, earthwork drilling, etc., can solve the problems of vibration damage of newly poured concrete, increase in supporting materials and supporting costs, poor blasting molding, etc., so as to reduce the overhang of the formwork. The effect of hoisting wire ropes and suspending and stabilizing vehicles, supporting materials and supporting costs, noise and dust control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

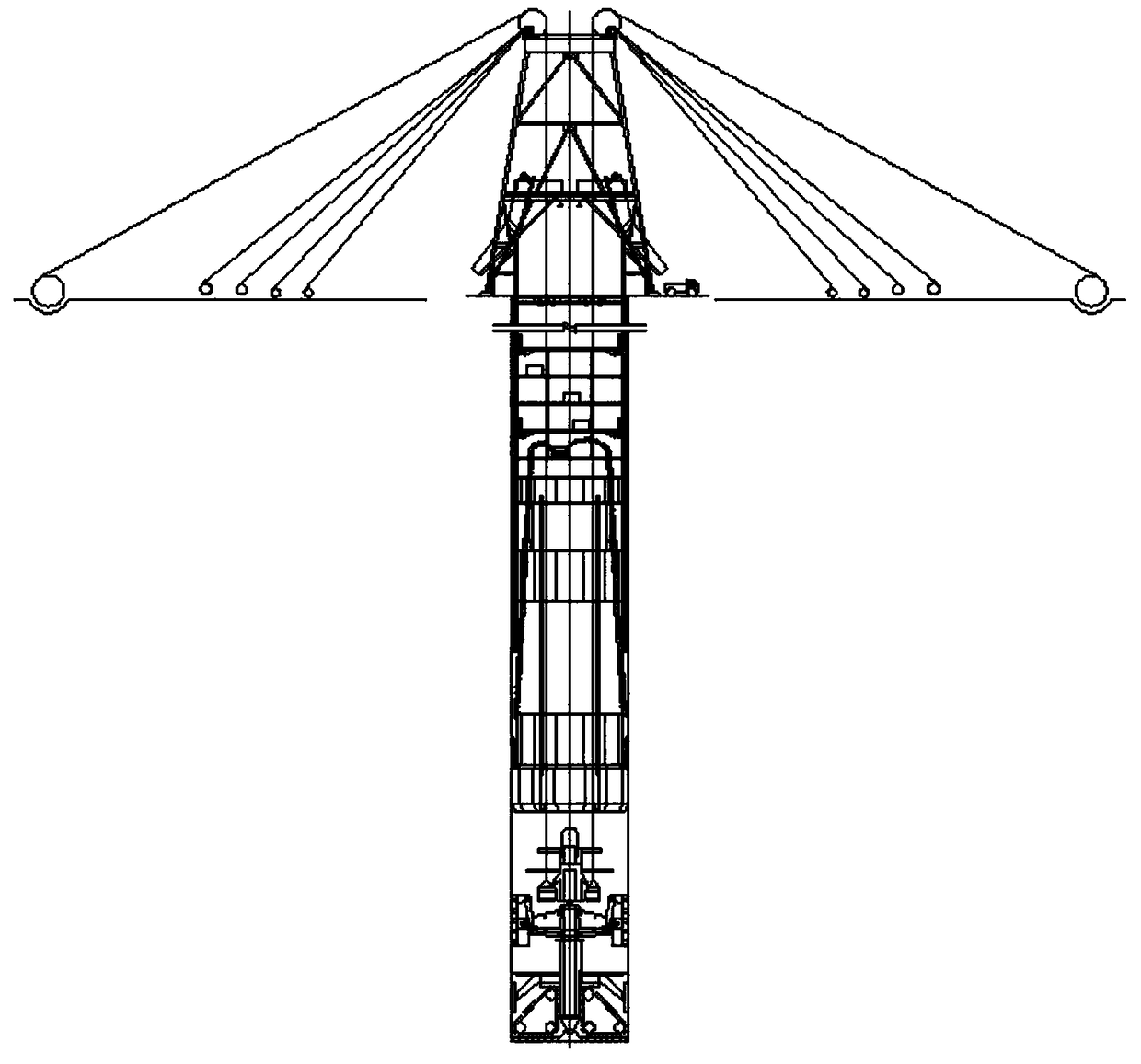

[0047] figure 1 It is an overall structure diagram of the present invention.

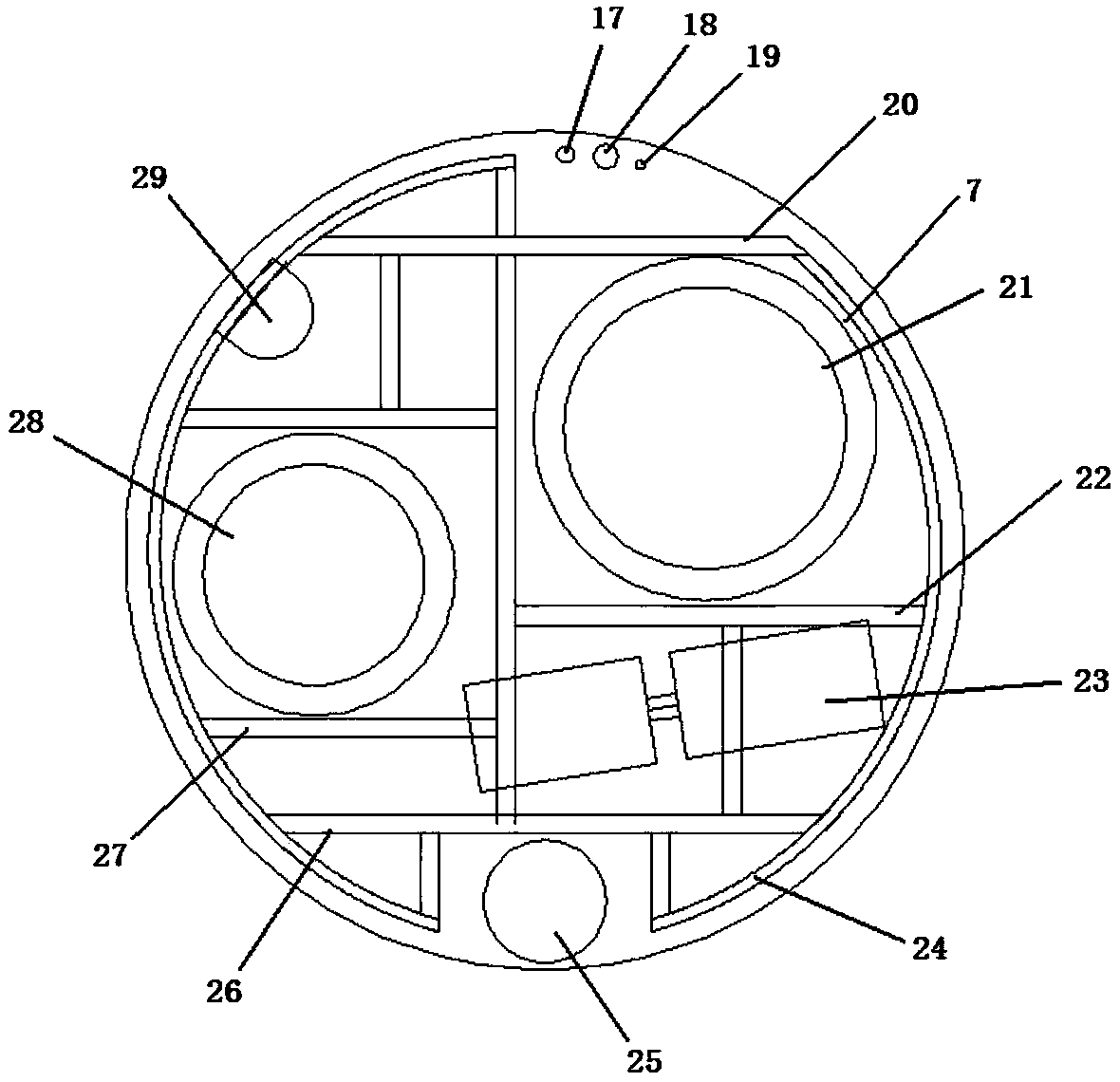

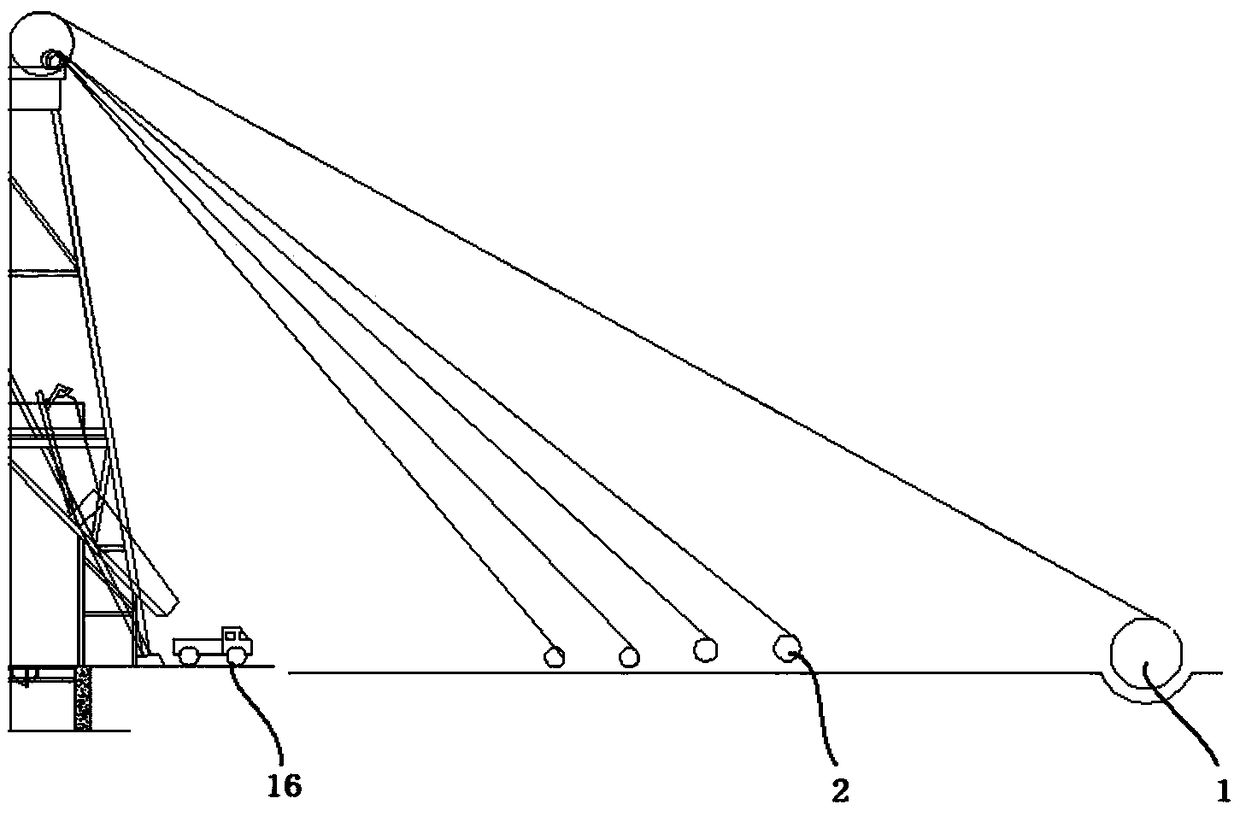

[0048] Such as image 3 , Figure 4 , Figure 5 As shown, a vertical shaft construction device includes a hoist 1, a sinking winch 2, a sinking derrick 3, a sky wheel platform 4, a gangue turning platform 5, a sealing plate 6, and a hanging plate 7. The hanging plate 7 is provided with a supply Electric equipment 11, hydraulic control equipment 12, drainage equipment 13, ash separator 14, and ash separator 14 is provided with ash conveying pipe 15. Such as Figure 6As shown, the bottom of the suspension plate 7 is provided with a non-suspension stepping type seamless formwork 8; the non-suspension stepping type seamless formwork 8 includes an upper support shoe 81, a straight formwork 1 83, a straight formwork 2 84, and a lower support shoe 86, The upper support shoe 81 and the straight formwork one 83 are connected through the stepping oil cylinder 82, the upper support shoe 81 is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com