Sunshine water decomposition hydrogen generation microelectronic device and preparation method thereof

A technology for microelectronic devices and water production of hydrogen, applied in electrolytic capacitors, capacitor manufacturing, capacitors, etc., can solve the problems of low hydrogen production efficiency, corrosion, and low utilization rate of visible light.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

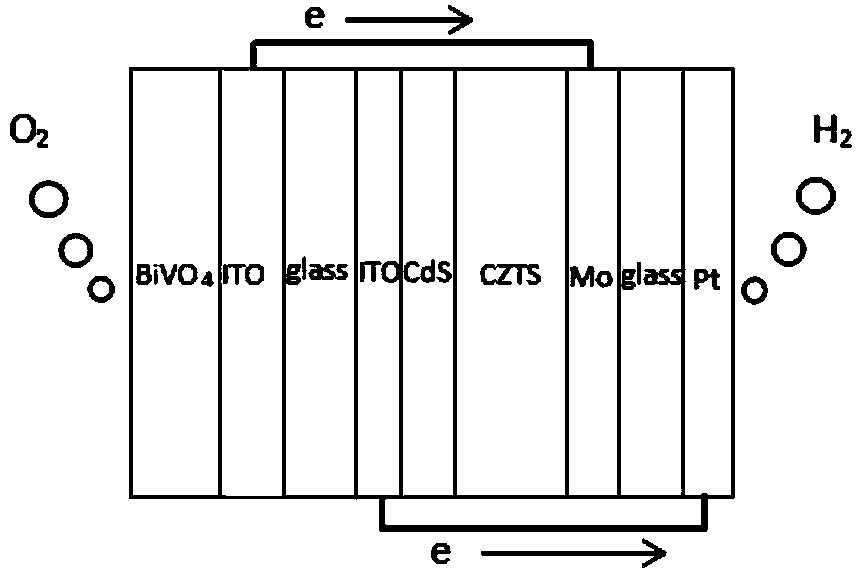

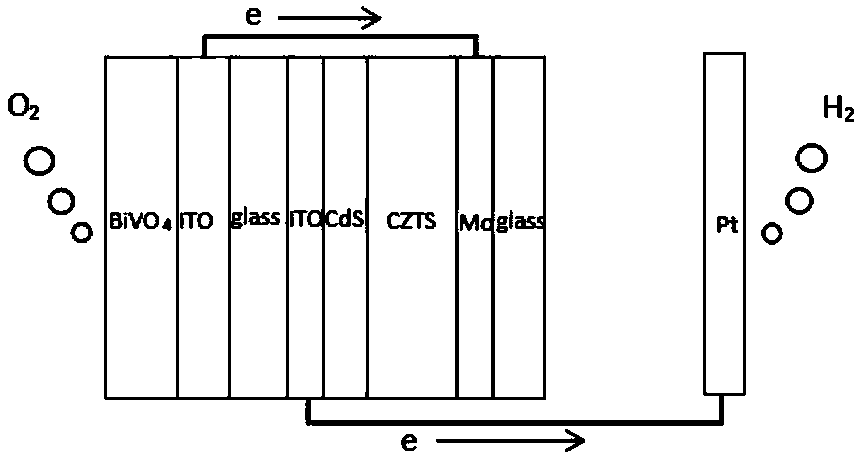

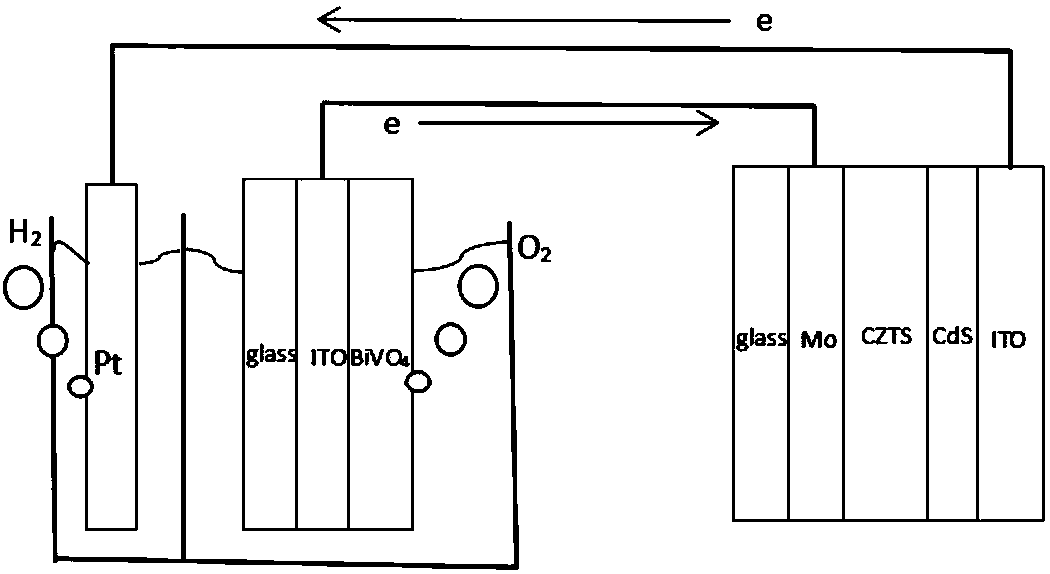

[0027] Hereinafter, the present invention will be described in further detail with reference to the accompanying drawings.

[0028] The preparation of CZTS solar cell, it comprises,

[0029] The preparation method of CZTS absorption layer in CZTS solar cell:

[0030] CZTS films were prepared by electrodeposition followed by sulfuration annealing. An electrochemical workstation was used for electrodeposition, and the electrode system used was a three-electrode device consisting of an Ag / AgCl reference electrode, a Pt counter electrode, and a working electrode on a molybdenum-coated glass substrate. Concretely comprise following preparation steps:

[0031] First, deposit the copper layer, the deposition potential of the copper layer is -0.3V~-0.5V (relative to the Ag / AgCl reference electrode), and the electroplating solution is 0.03mol / L~0.06mol / L CuSO 4 ·5H 2 O, prepared from 0.01mol / L~0.03mol / L citric acid and 0.03mol / L~0.06mol / L sodium citrate.

[0032] Carry out the dep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com